Piston with pin bore lubrication features

a technology of lubrication features and pin bores, which is applied in the direction of trunk pistons, lubrication elements, and lubricating devices, etc., can solve the problems of reduced bearing area of pin bores, increased load between pin bores and wrist pins, and complicated piston manufacture, etc., to achieve enhanced load capacity of pin bores having lubrication features, maximum load capacity of pin bores, and high performance demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

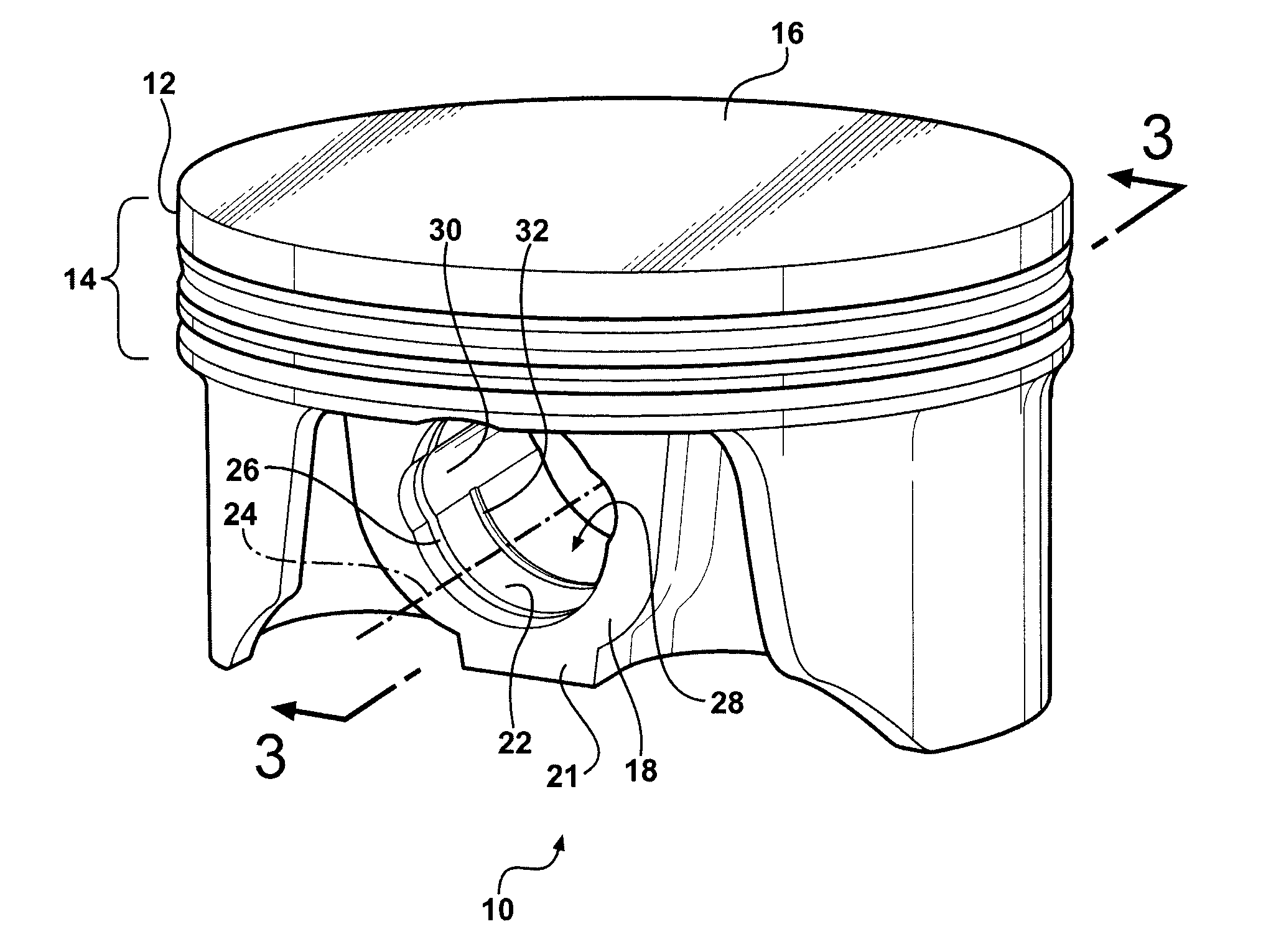

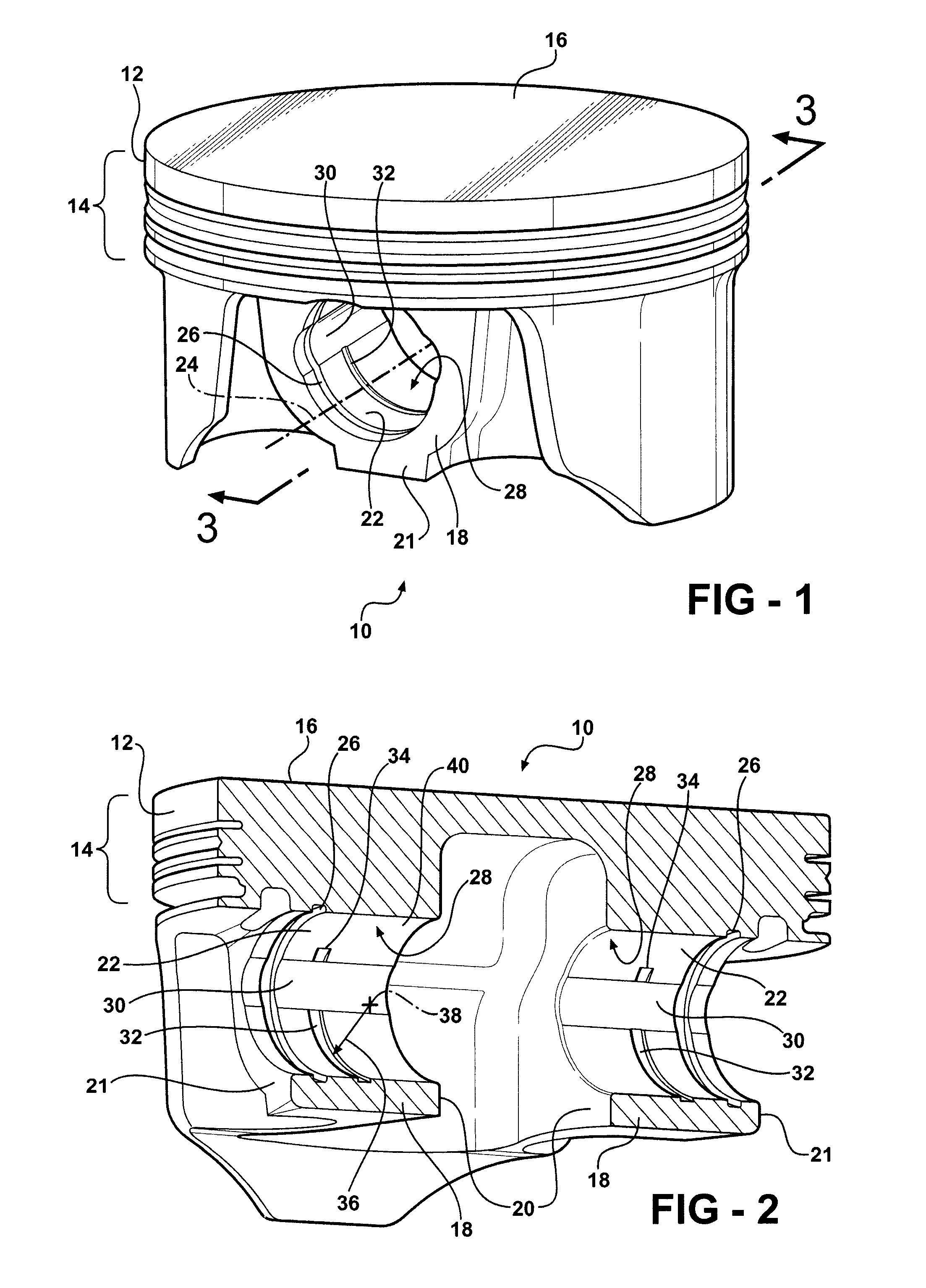

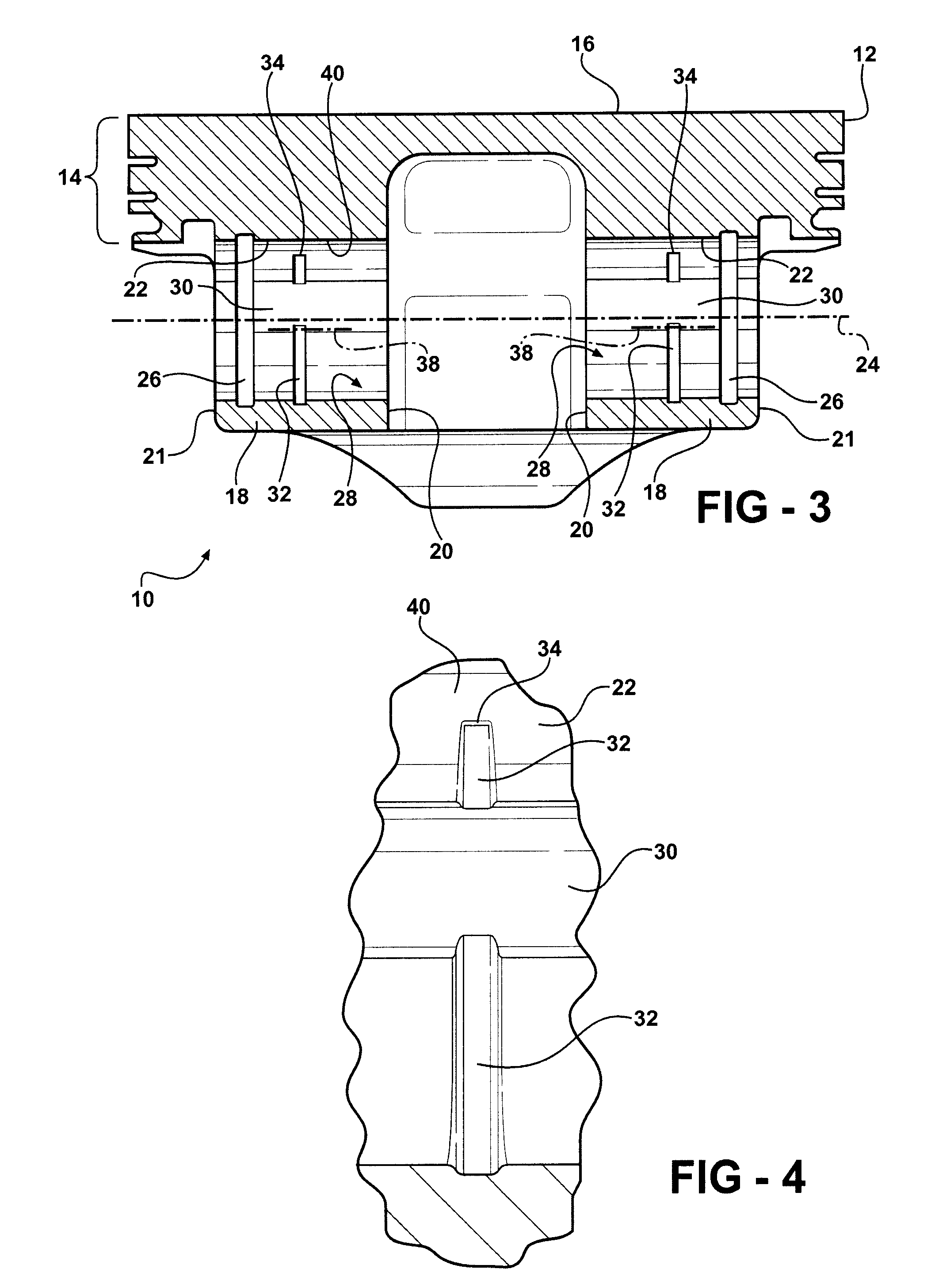

[0018]Referring in more detail to the drawings, FIG. 1 illustrates piston 10 for use in high performance engines, such as those used in racing vehicles and boats, for example. The piston 10 has a crown 12 with an annular outer ring belt 14 extending downwardly from an upper surface 16 and a pair of pin bosses 18 depending from the crown 12. The pin bosses 18 have generally planar inner and outer faces 20, 21, respectively. The inner faces 20 are spaced laterally from one another sufficiently to receive a small end of a connecting rod (not shown) therebetween. The pin bosses 18 have pin bores 22 axially aligned with one another along a central axis 24, wherein the pin bores 22 are sized for receipt of a wrist pin (not shown) to couple the piston 10 to the connecting rod. The pin bores 22 preferably have annular grooves 26 adjacent the outer faces 21 for receipt of snap rings (not shown) to facilitate maintaining the wrist pin in its assembled state. The pin bores 22 have bearing surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com