Automatic lubrication system

a lubrication system and automatic technology, applied in the direction of manual lubrication, machines/engines, distribution equipment, etc., can solve the problems of reducing the longevity of industrial machines and their structures, increasing wear on these elements, and reducing pin li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

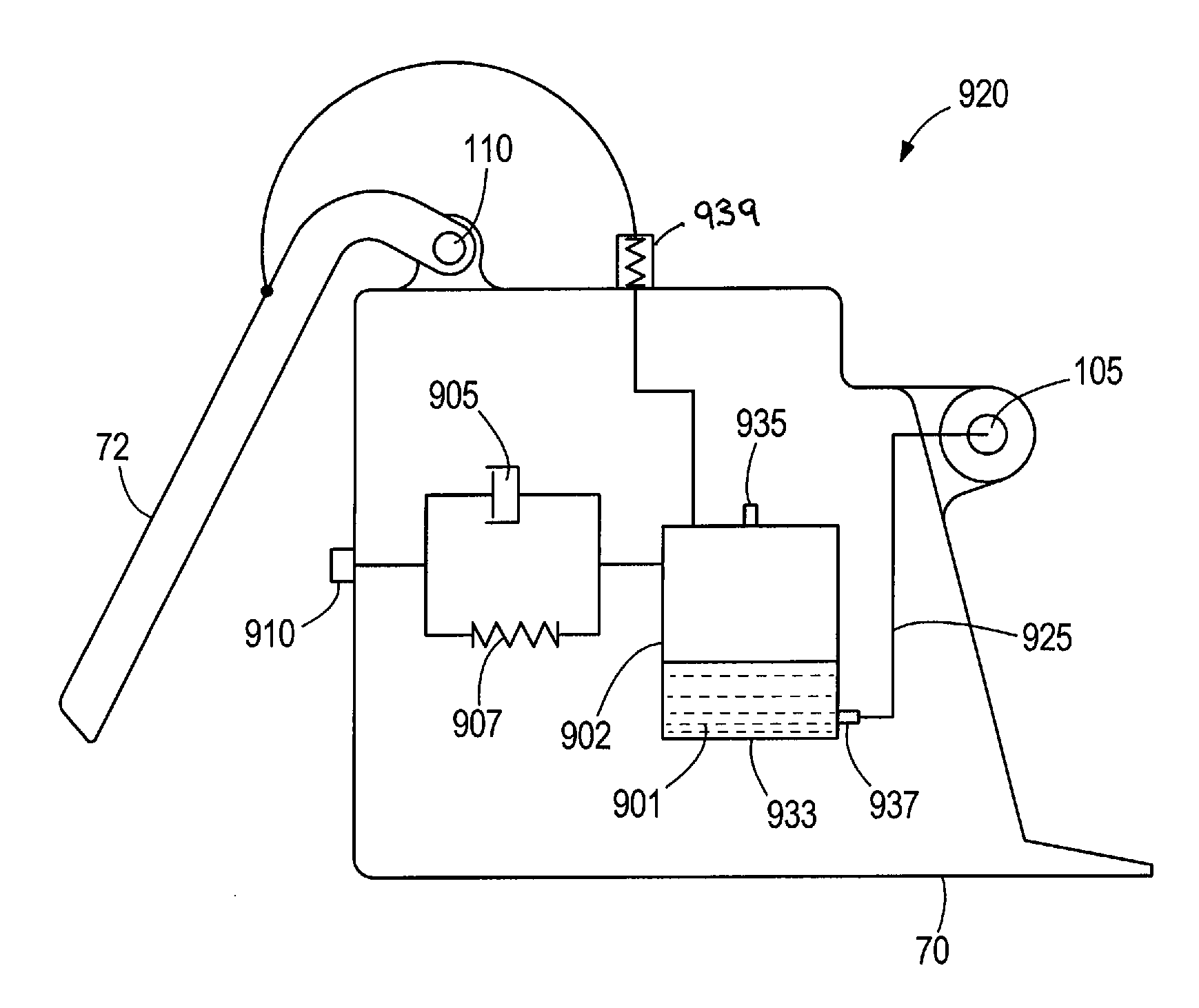

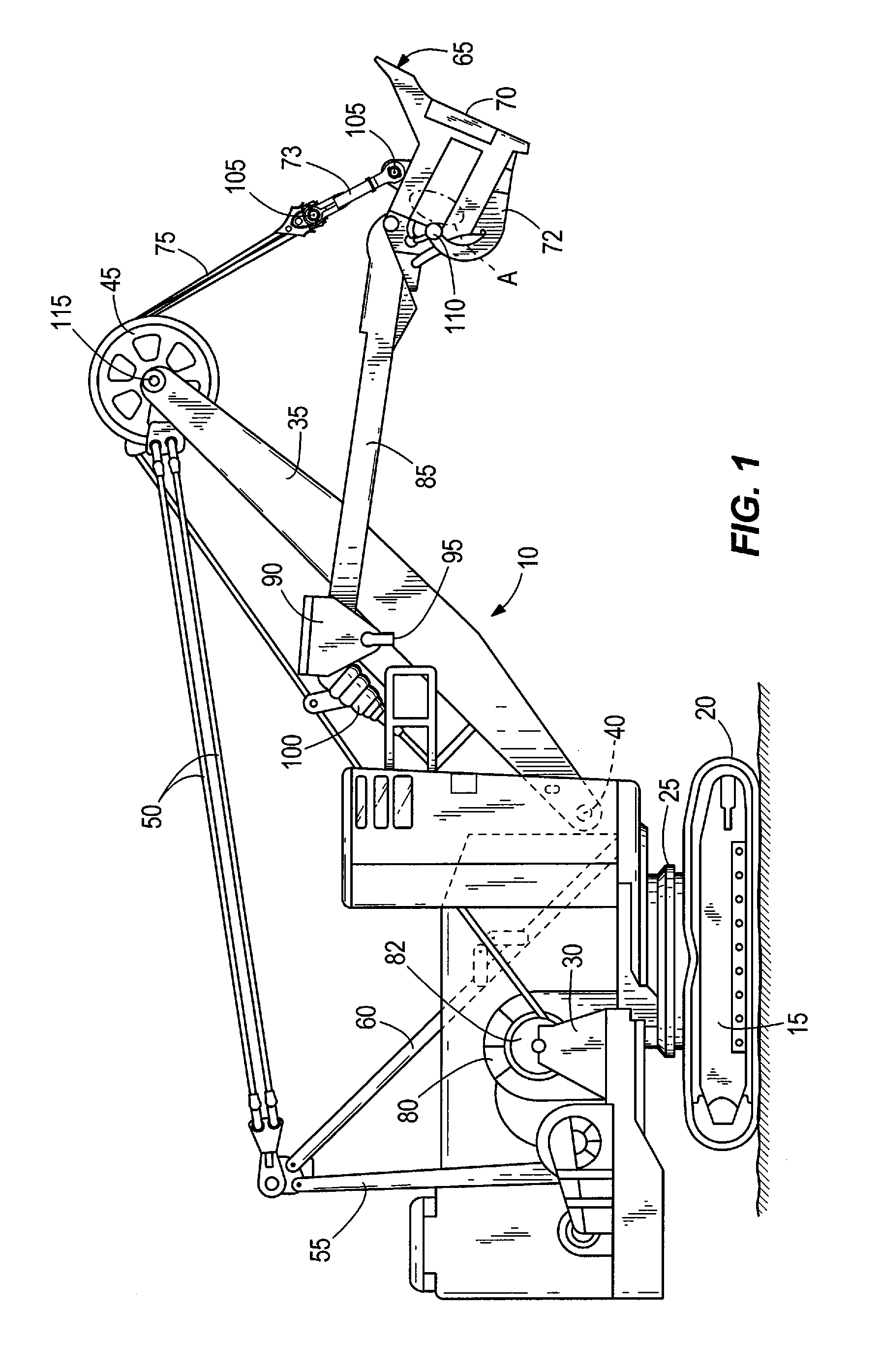

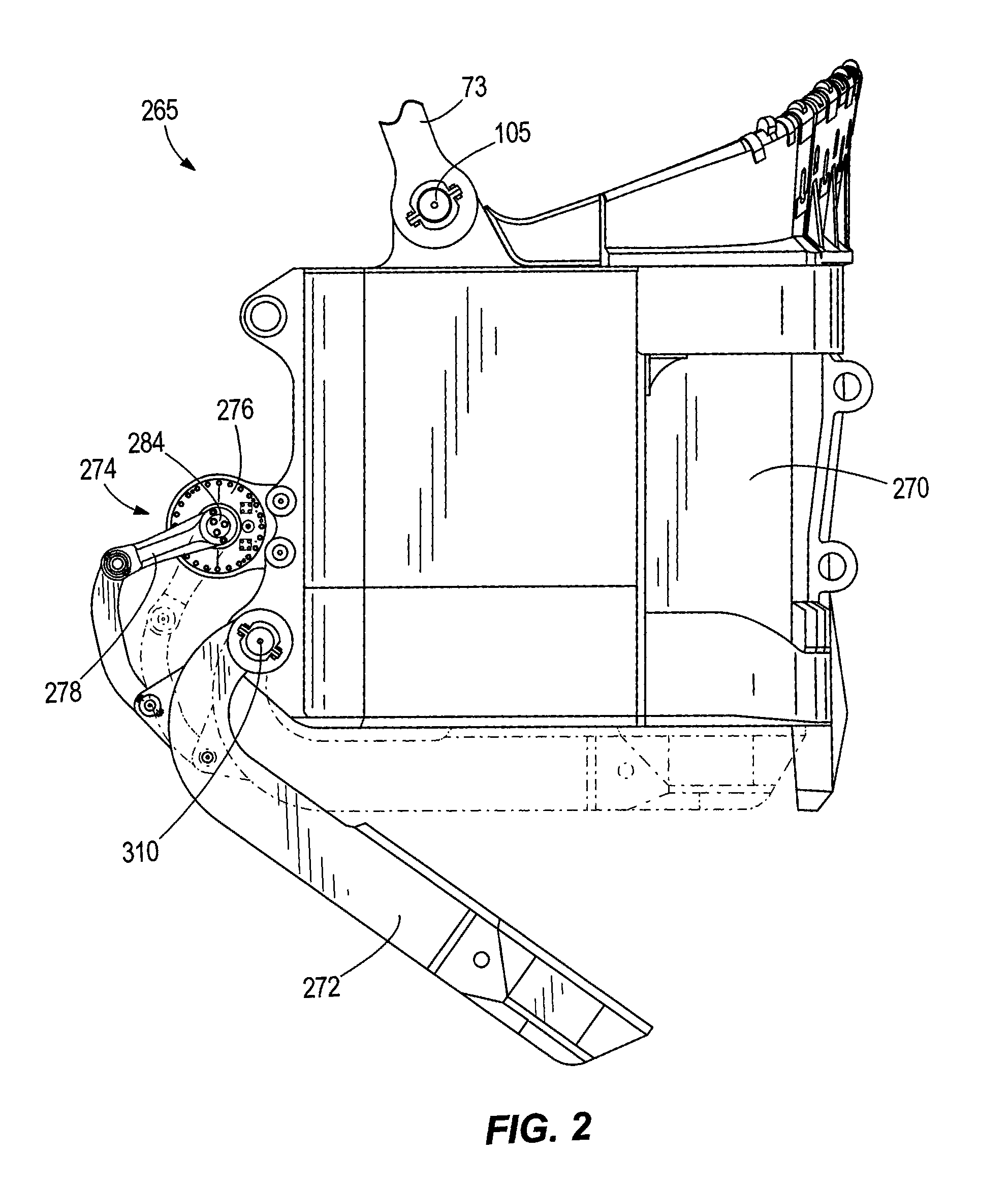

[0018]FIGS. 1-7 illustrate various structural elements that benefit from the automatic lubrication systems described herein. While a shovel and dippers are illustrated, the automatic lubrication systems described herein are applicable to a variety of different industrial machines and industrial machine mechanical components.

[0019]FIG. 1 illustrates a mining shovel 10 that includes a mobile base 15, drive tracks 20, a turntable 25, a revolving frame 30, a boom 35, a lower end 40 (also called a boom foot), tension cables 50, a gantry tension member 55, a gantry compression member 60, a dipper 65 including a dipper body 70 and a dipper door 72, a bail 73, a hoist rope 75, a winch drum 80, an electric motor 82, a dipper handle 85, a saddle block 90, a pivot point 95 (e.g., a shipper shaft), a transmission unit 100 (also called a crowd drive), a bail pin 105, a dipper door pin 110, and a boom point pin 115.

[0020]The mobile base 15 is supported by the drive tracks 20. The mobile base 15 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com