Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

904results about "Modelling/simulations for control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

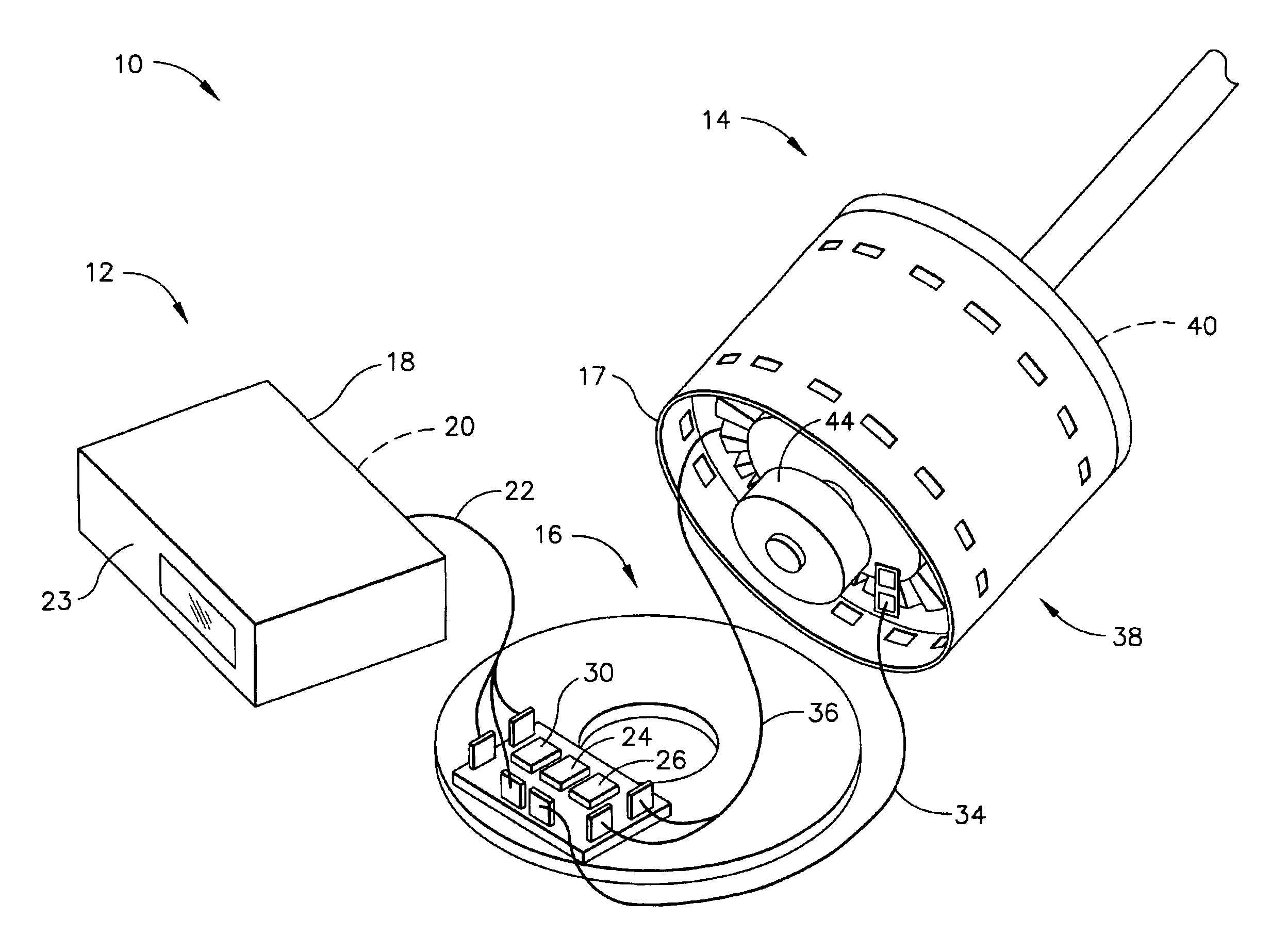

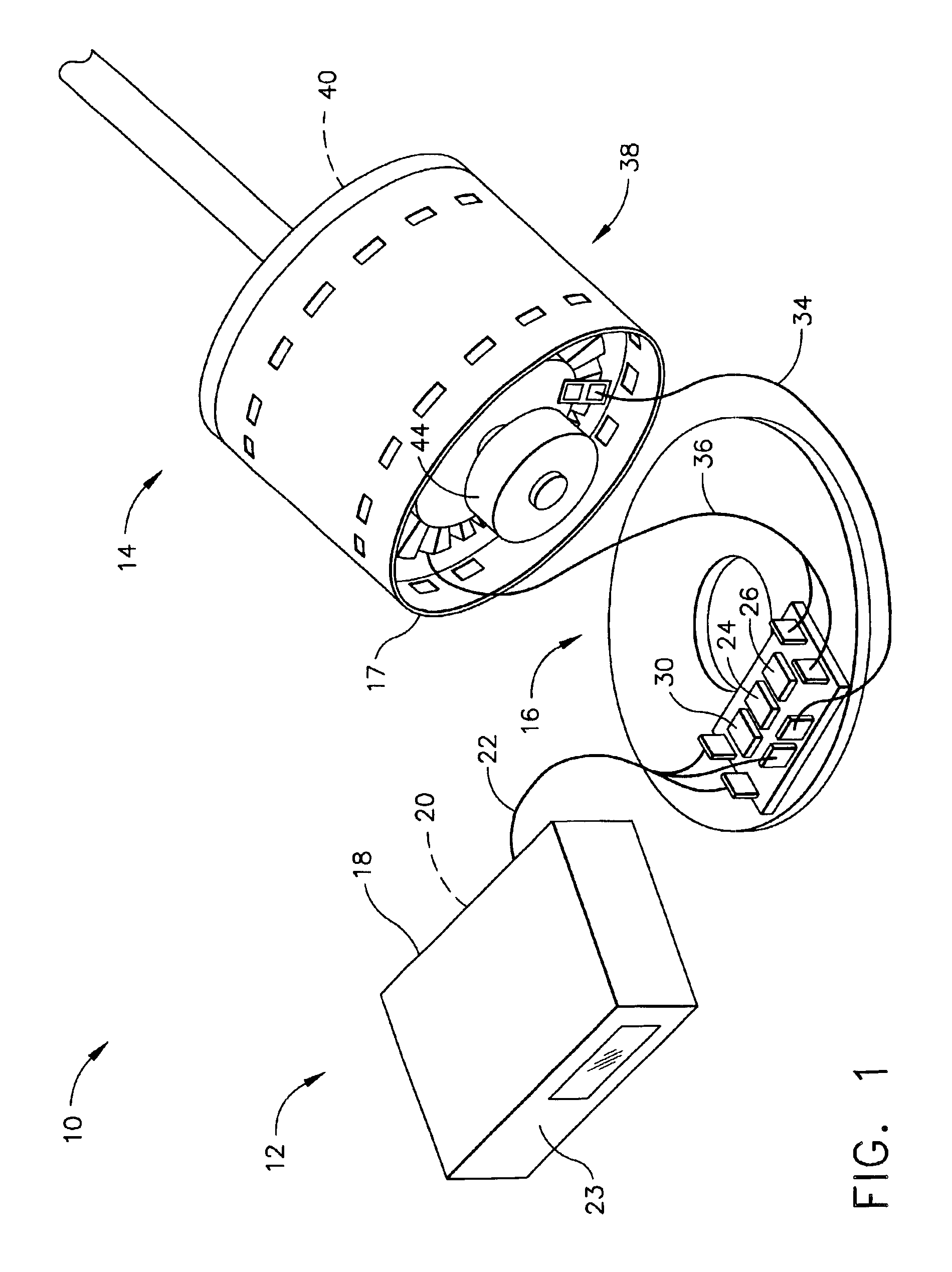

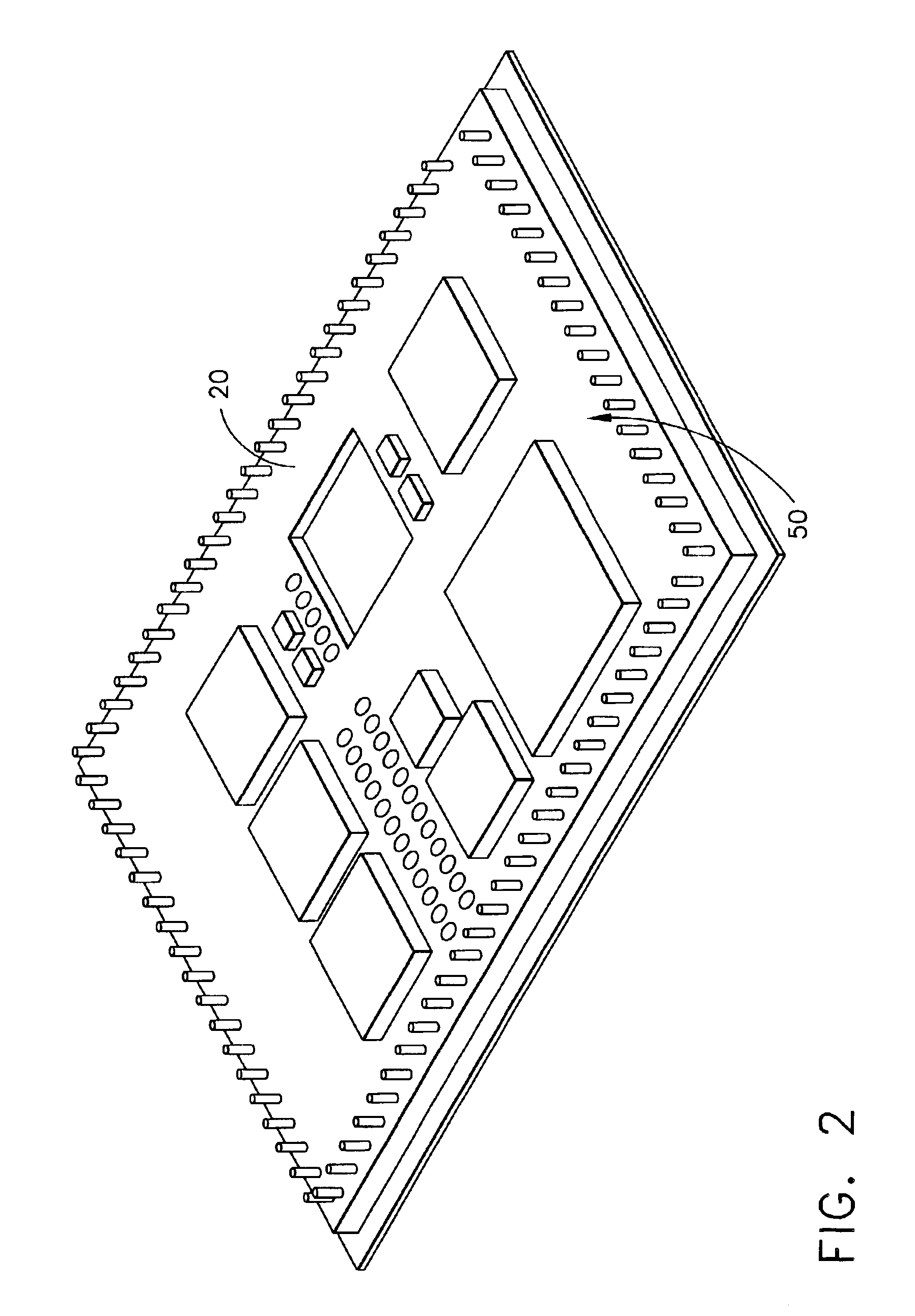

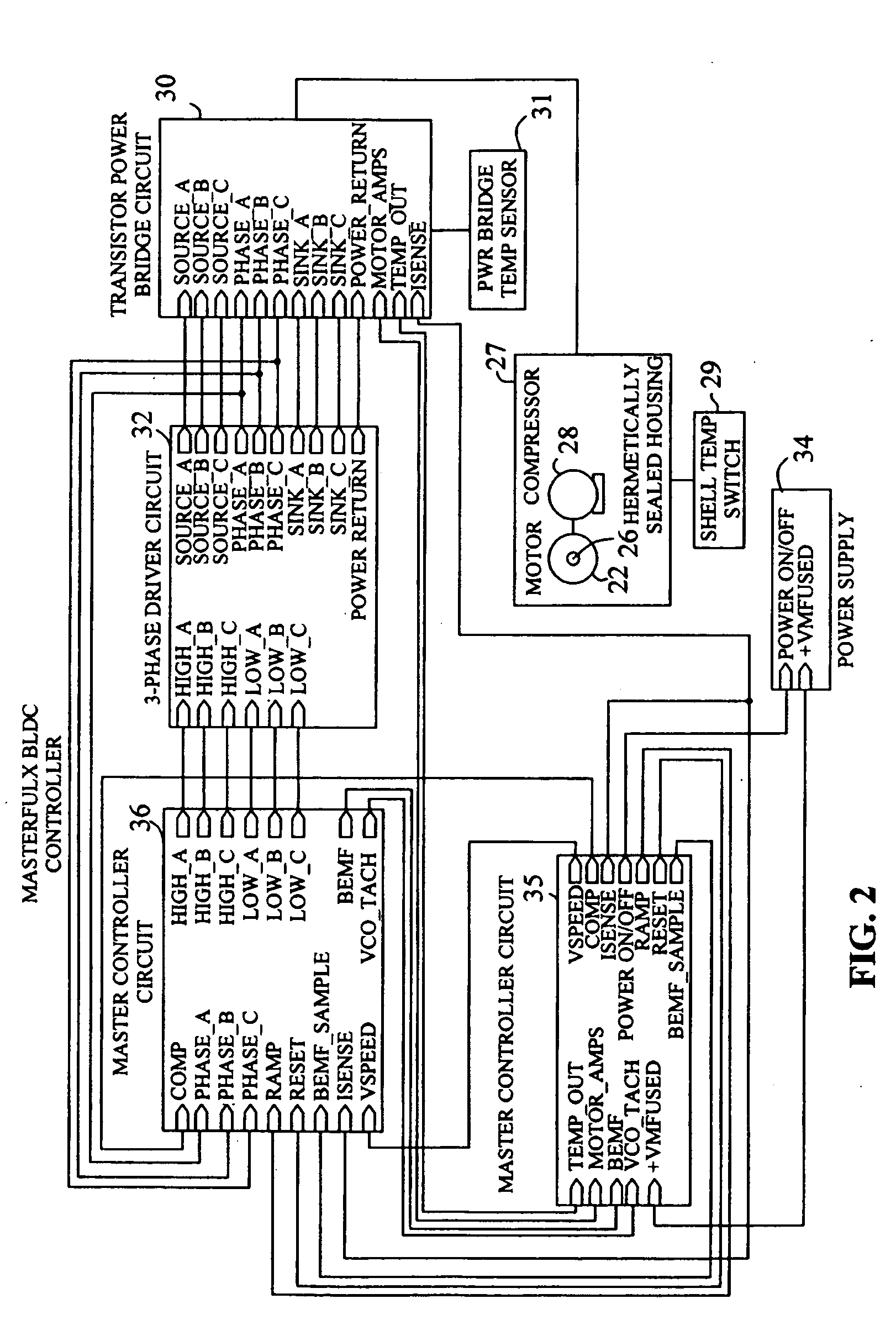

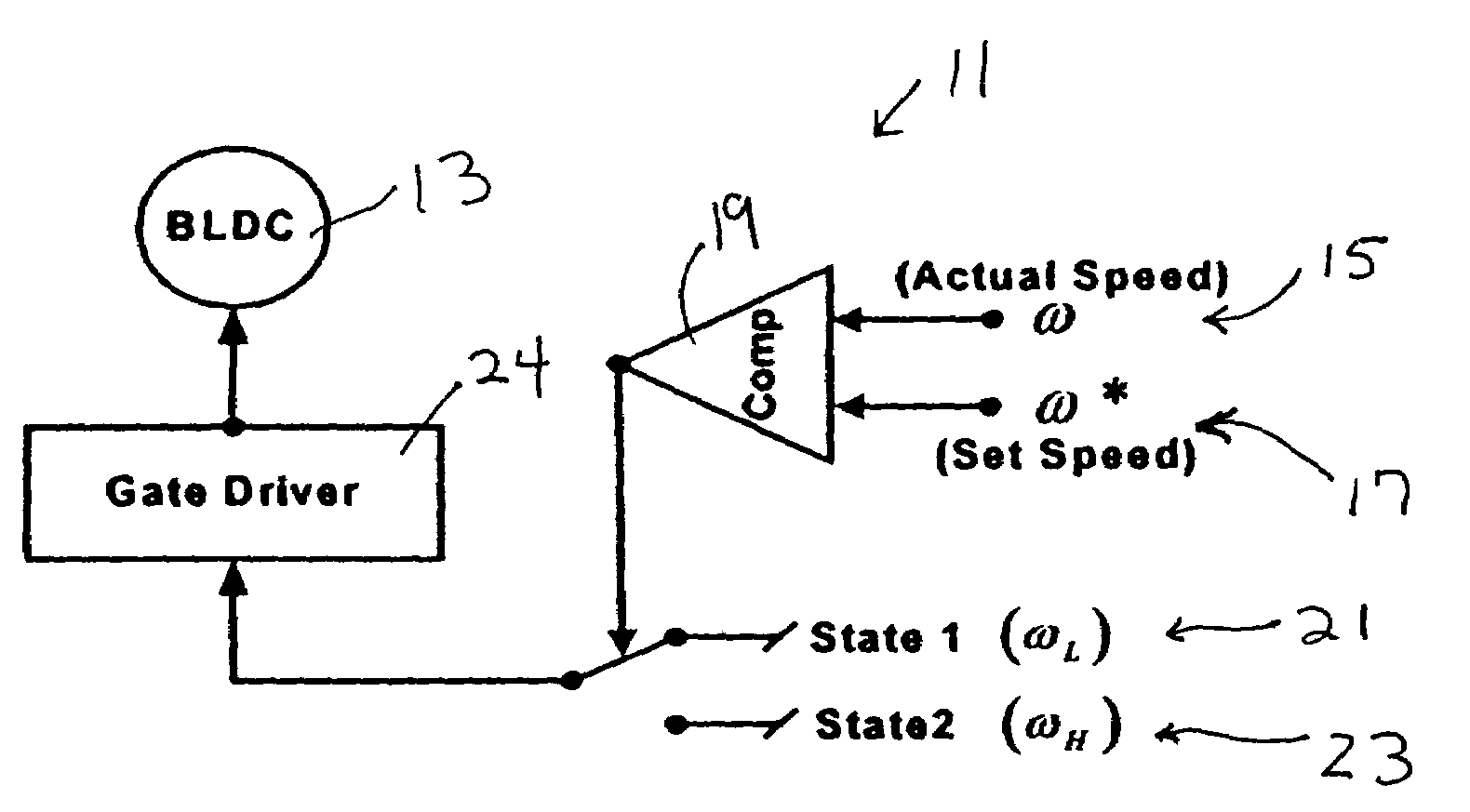

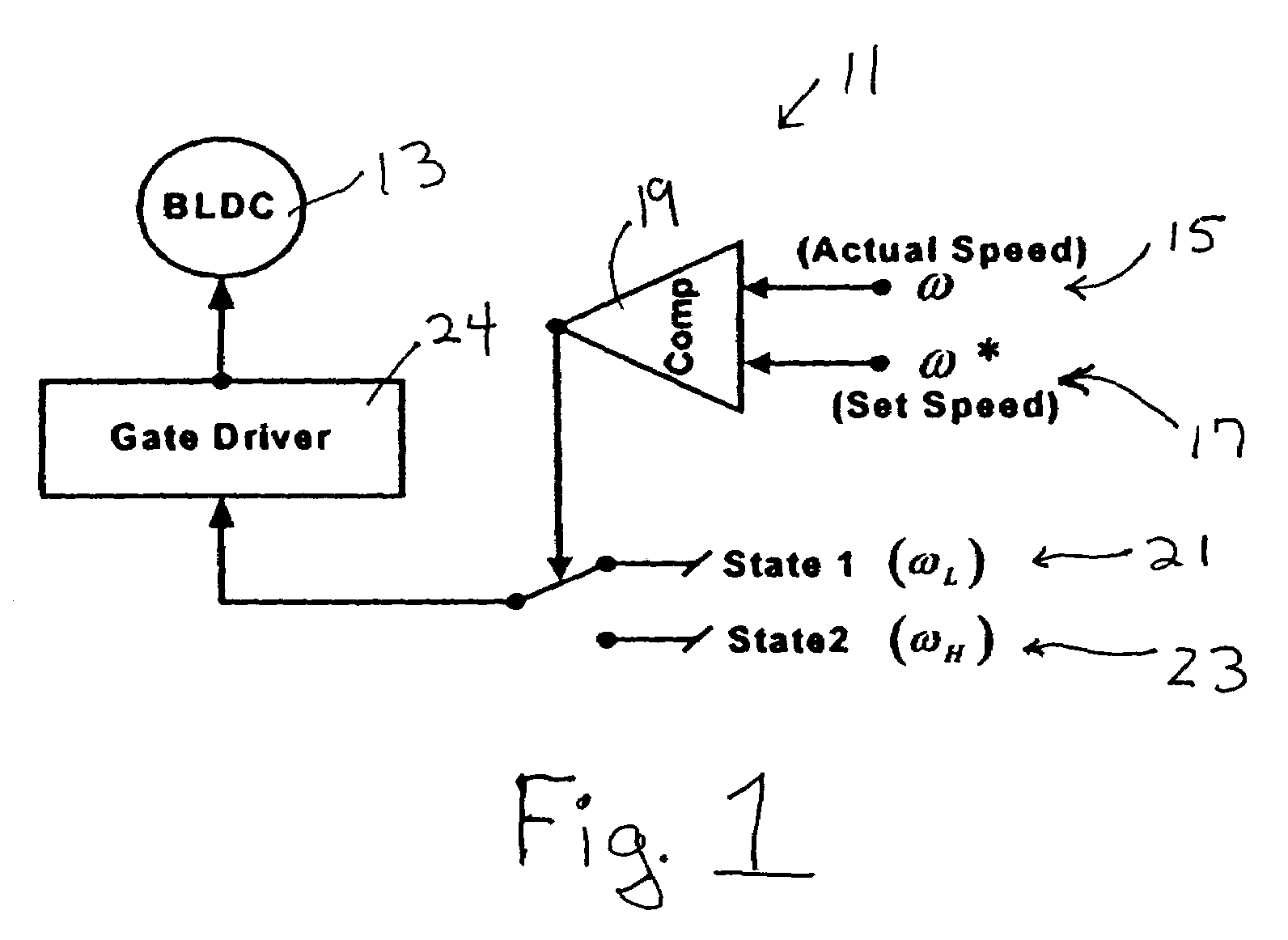

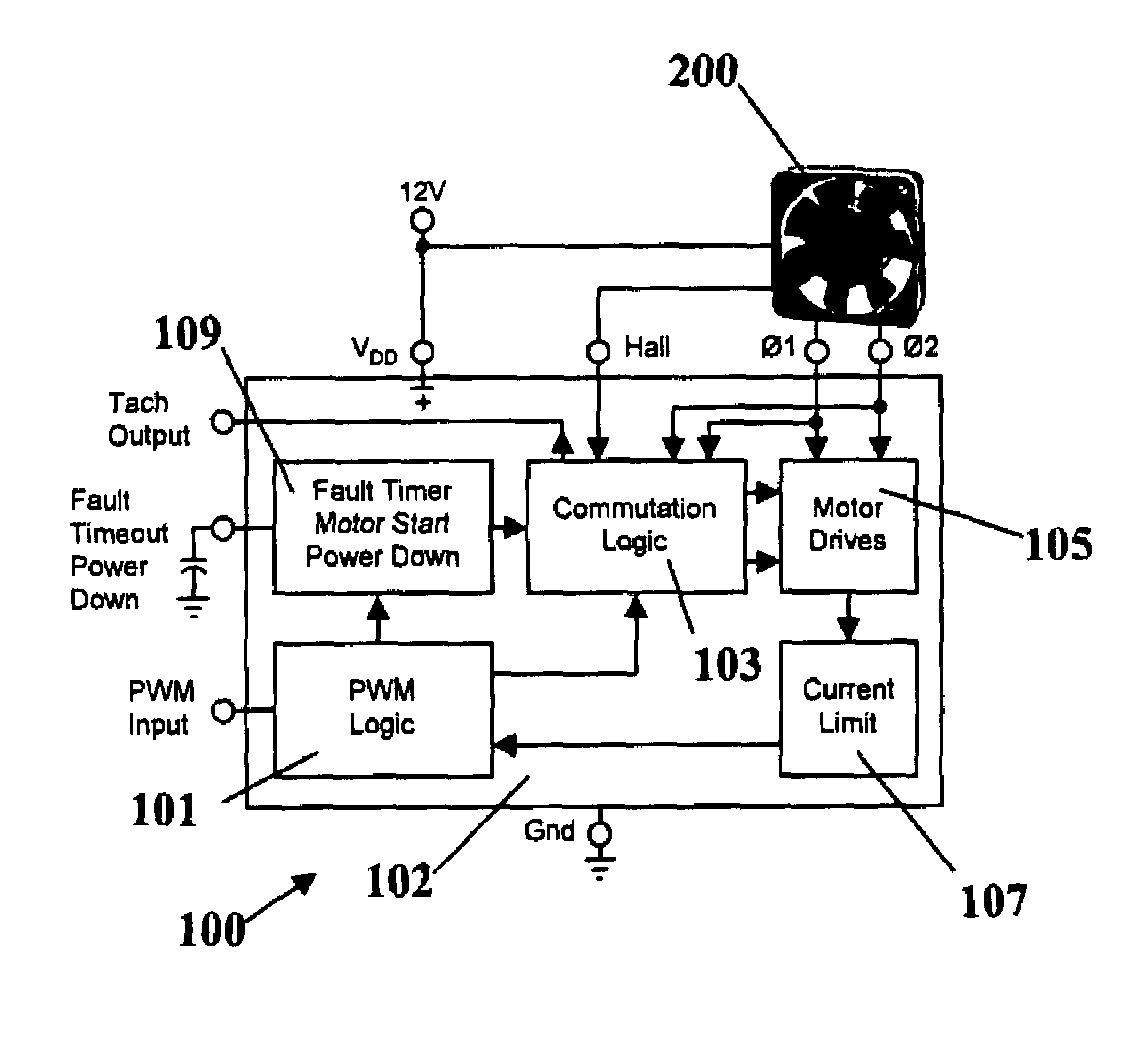

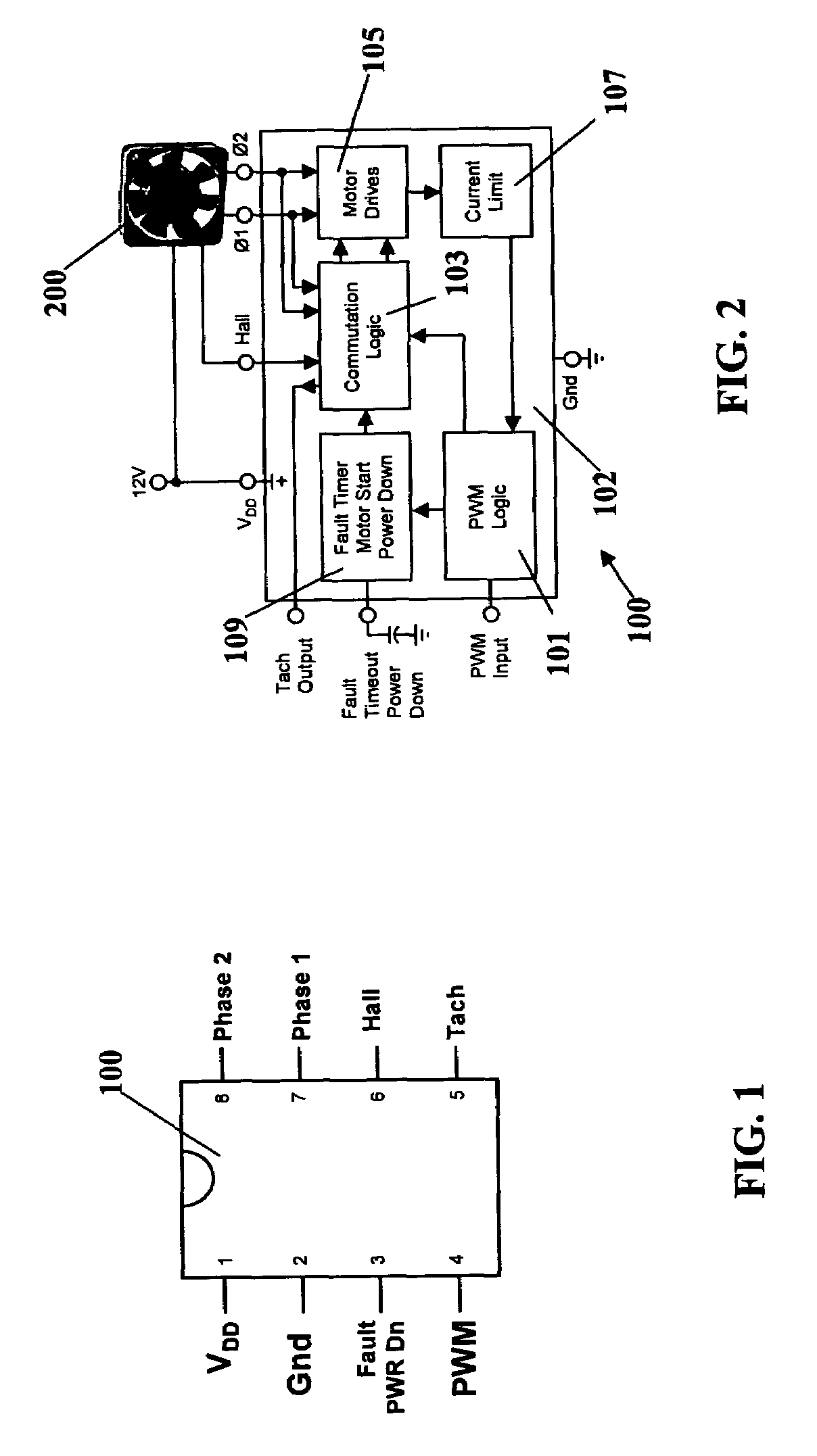

Method and apparatus for controlling electronically commutated motor operating characteristics

InactiveUS6895176B2Operation controlSingle-phase induction motor startersAC motor controlBrushless motorsControl electronics

A permanent magnet DC brushless motor control assembly permits a user to select the permanent magnet DC brushless motor operating characteristics by selecting appropriate control circuits to interface with the motor. The assembly includes a permanent magnet DC brushless motor, a commutator electrically coupled to the motor, and at least one control module electrically coupled to the commutator, to control operating characteristics of the permanent magnet DC brushless motor.

Owner:REGAL BELOIT AMERICA

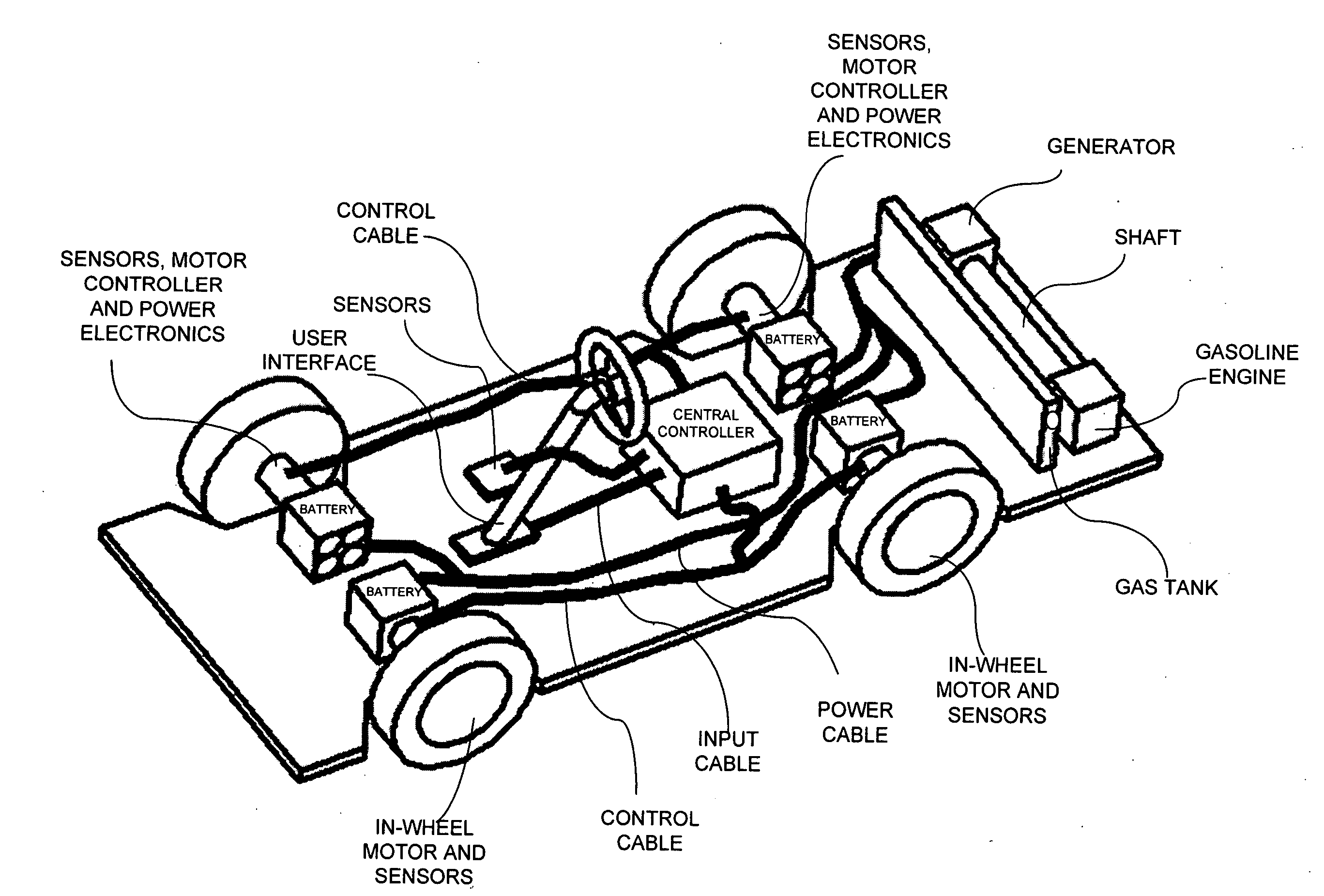

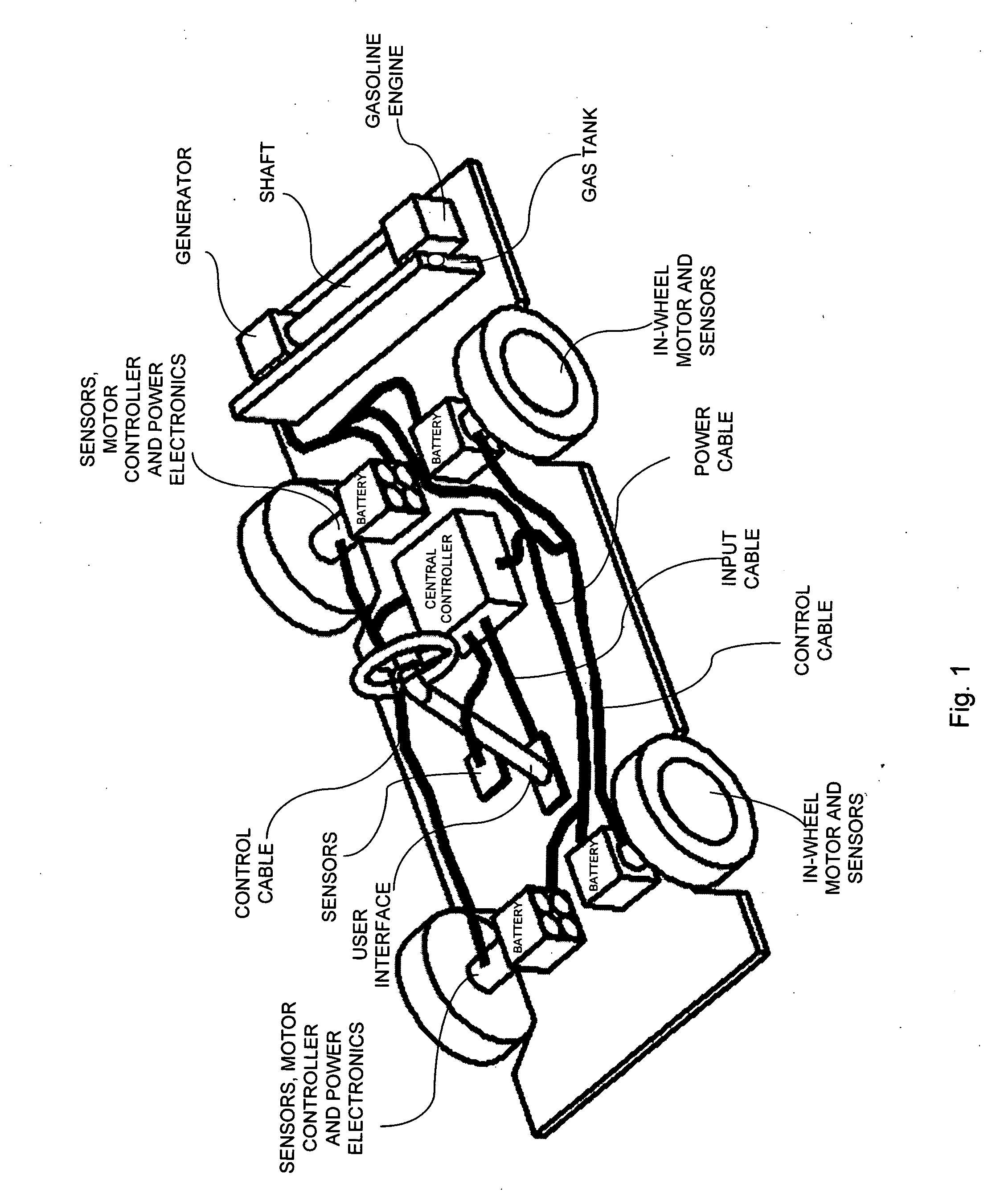

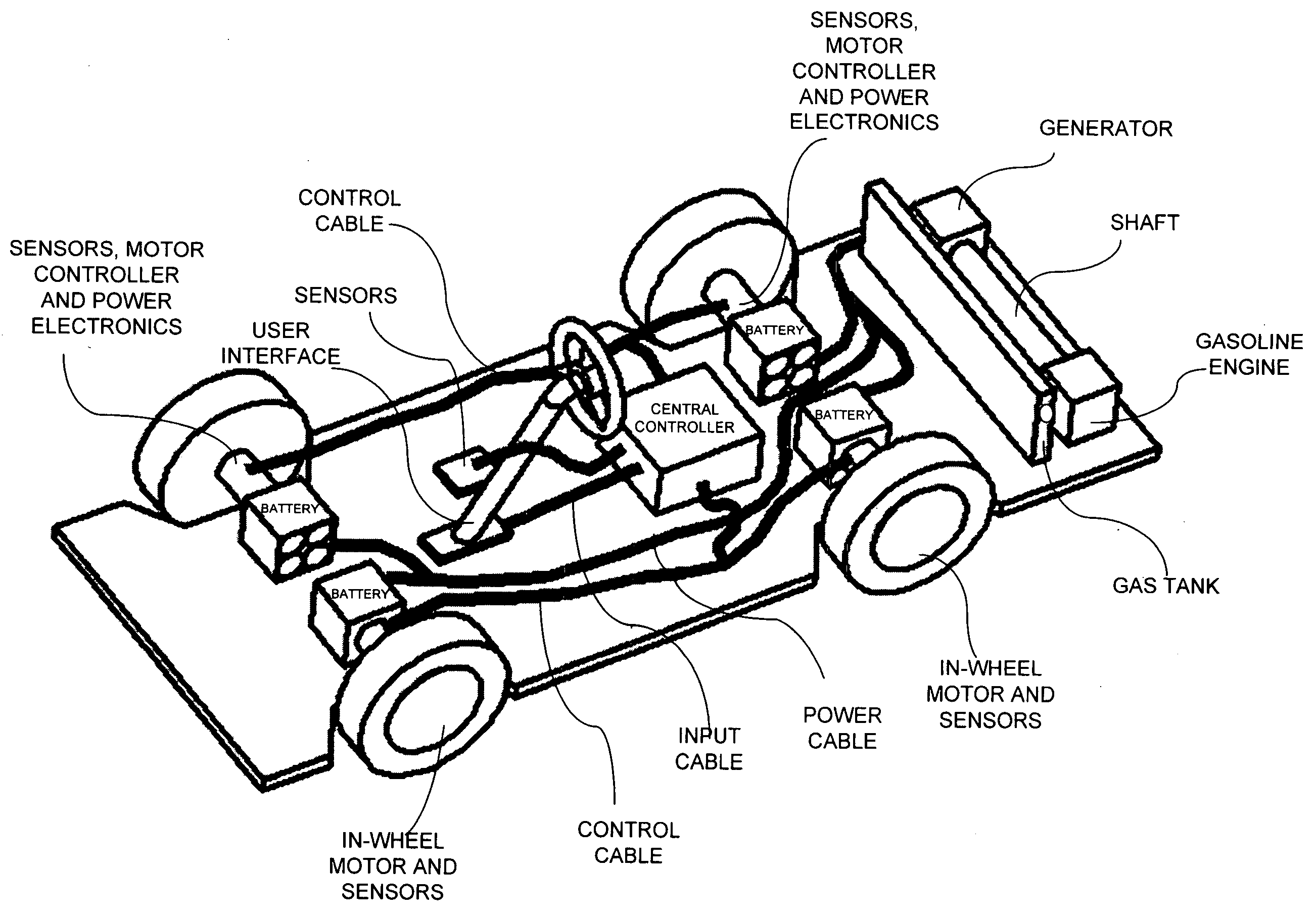

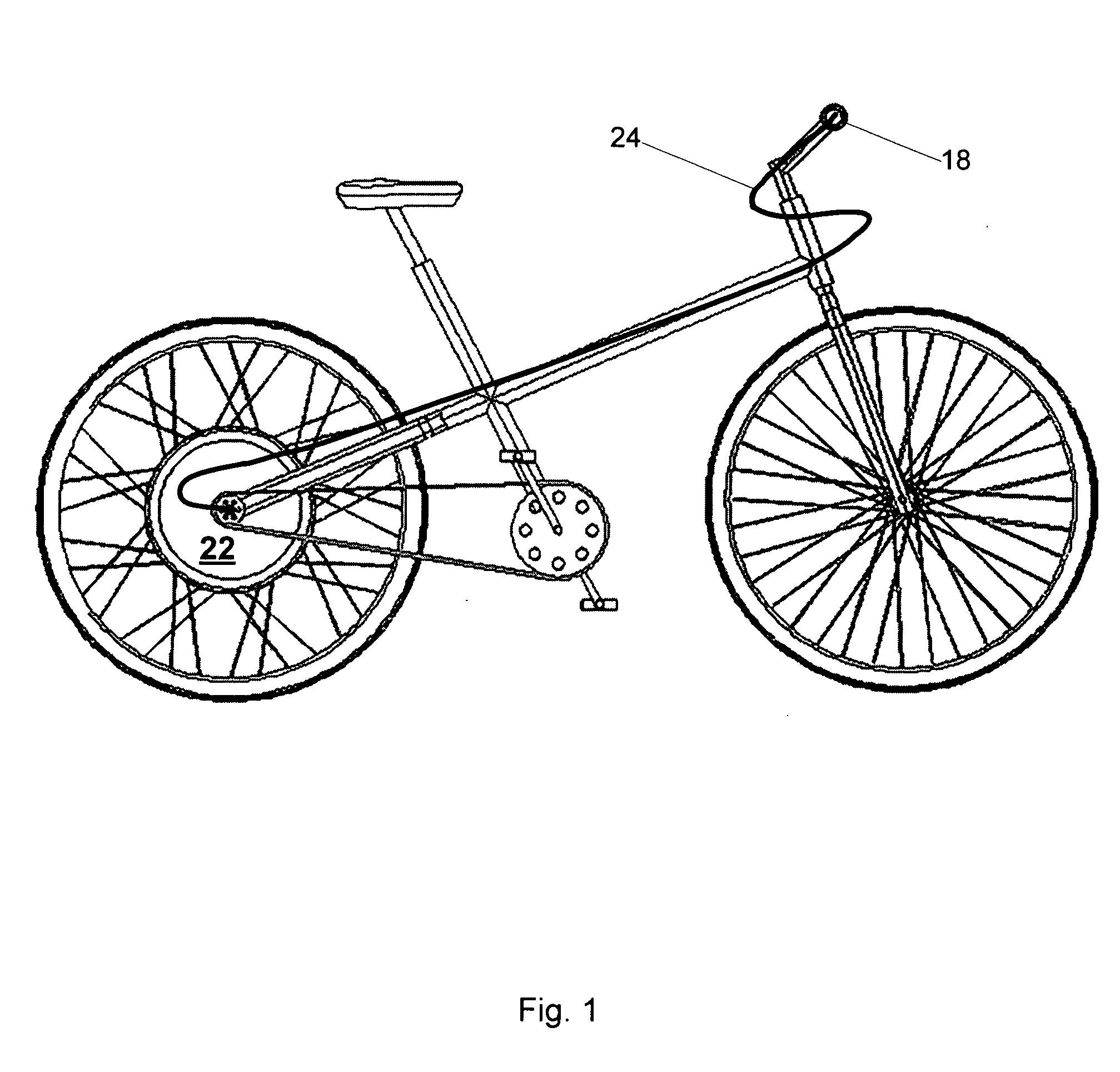

Adaptive electric car

InactiveUS20050052080A1Eliminate electromagneticEliminate electrical interferenceRailway vehiclesAc-dc conversionGasolineMotor control

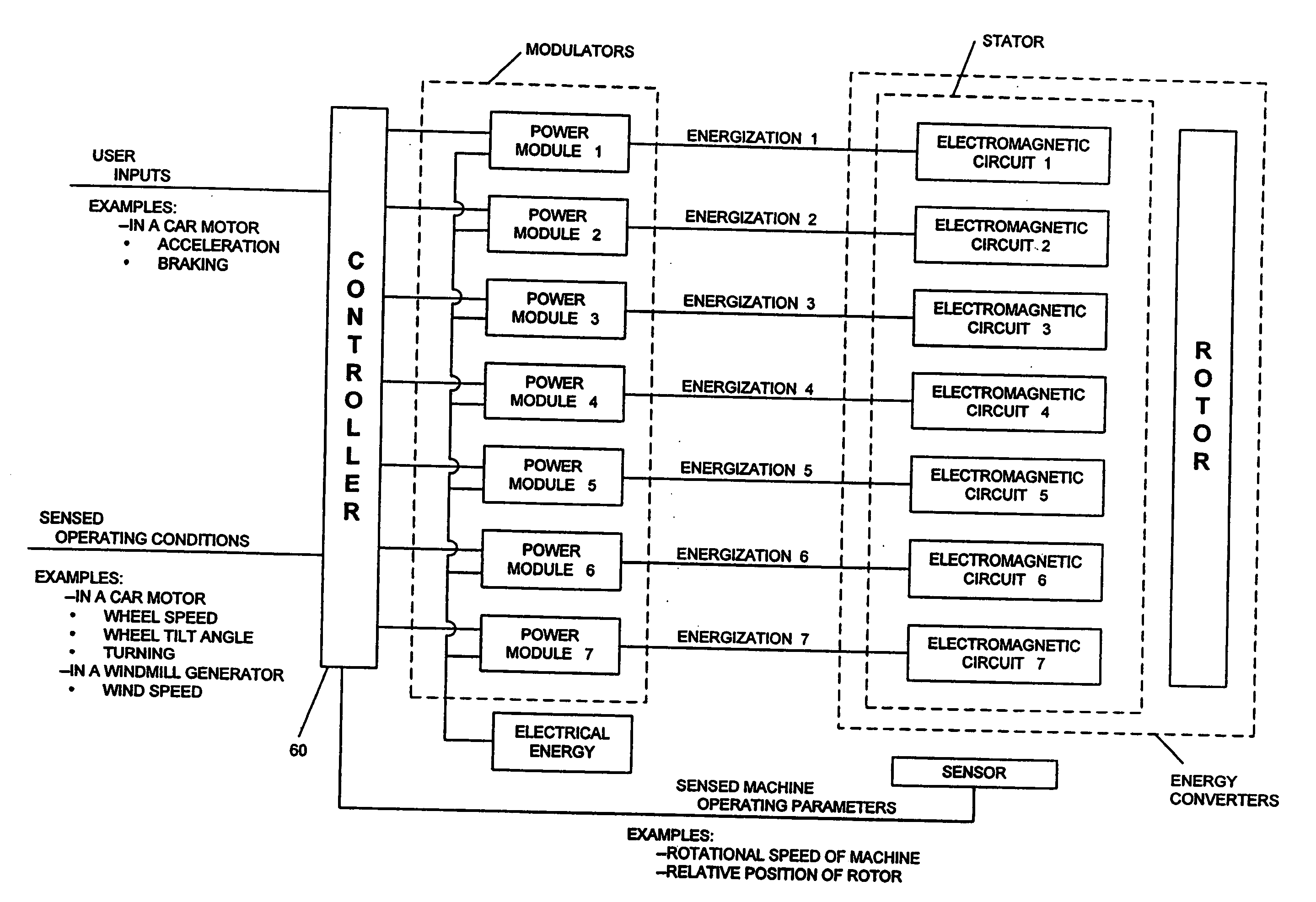

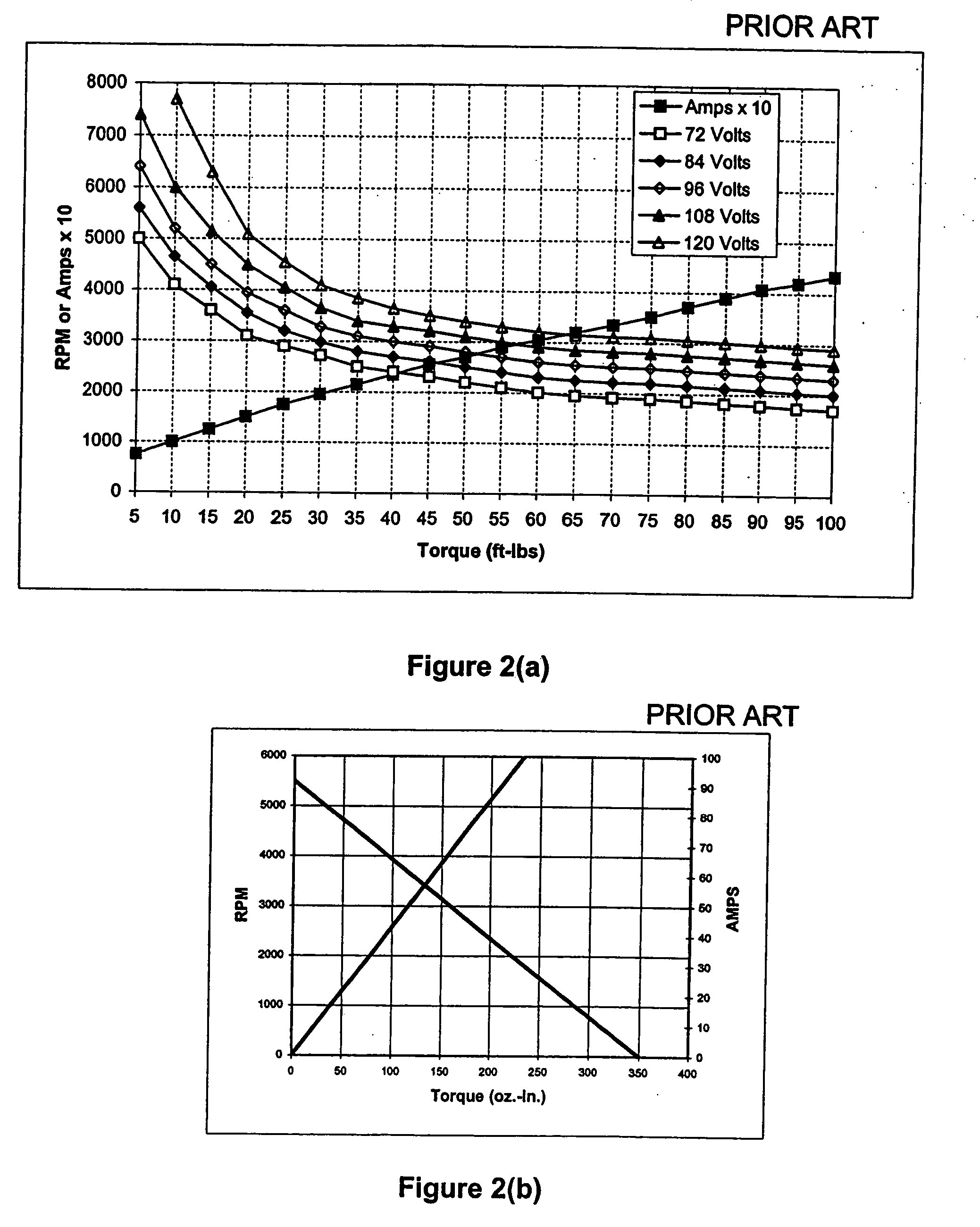

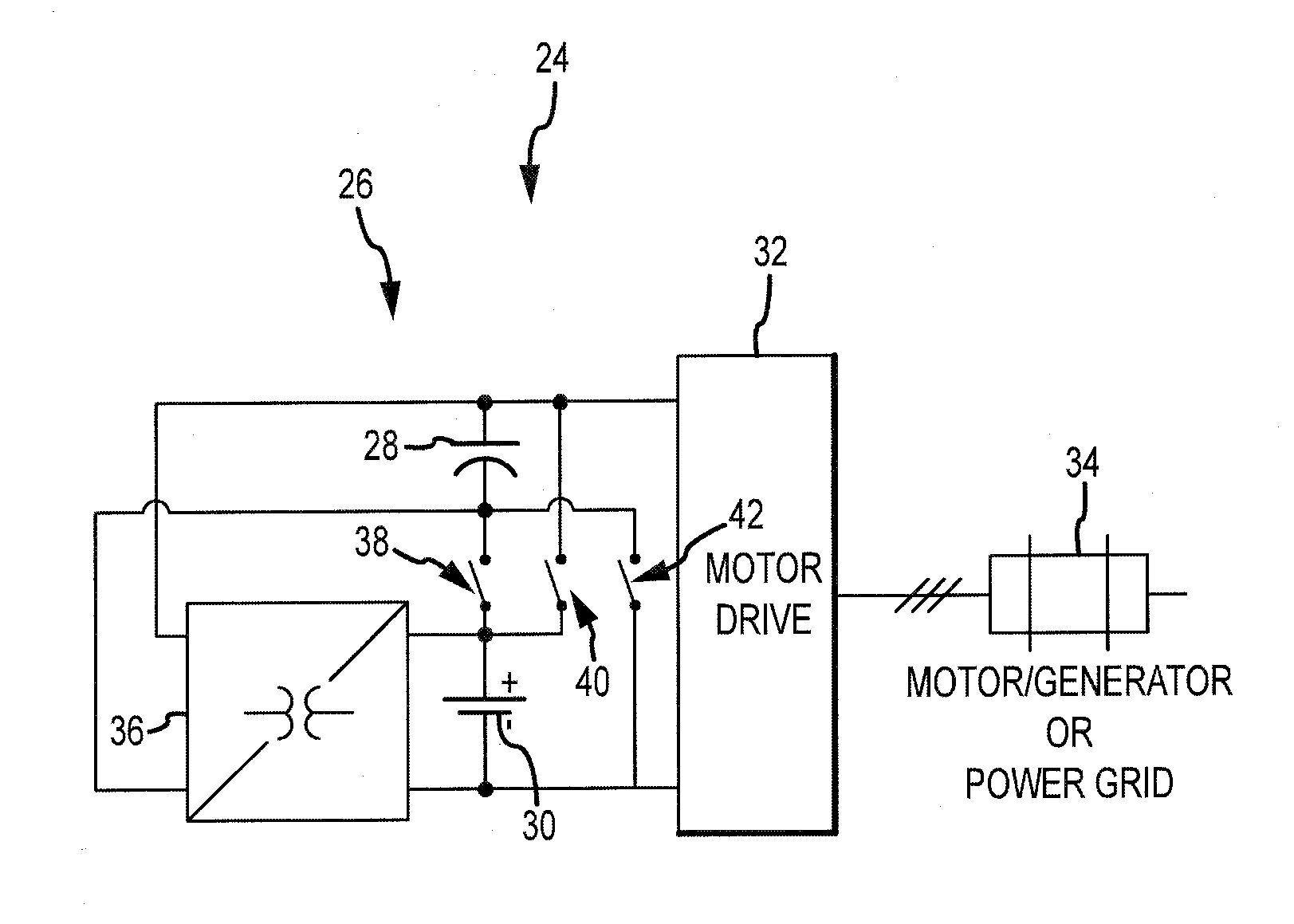

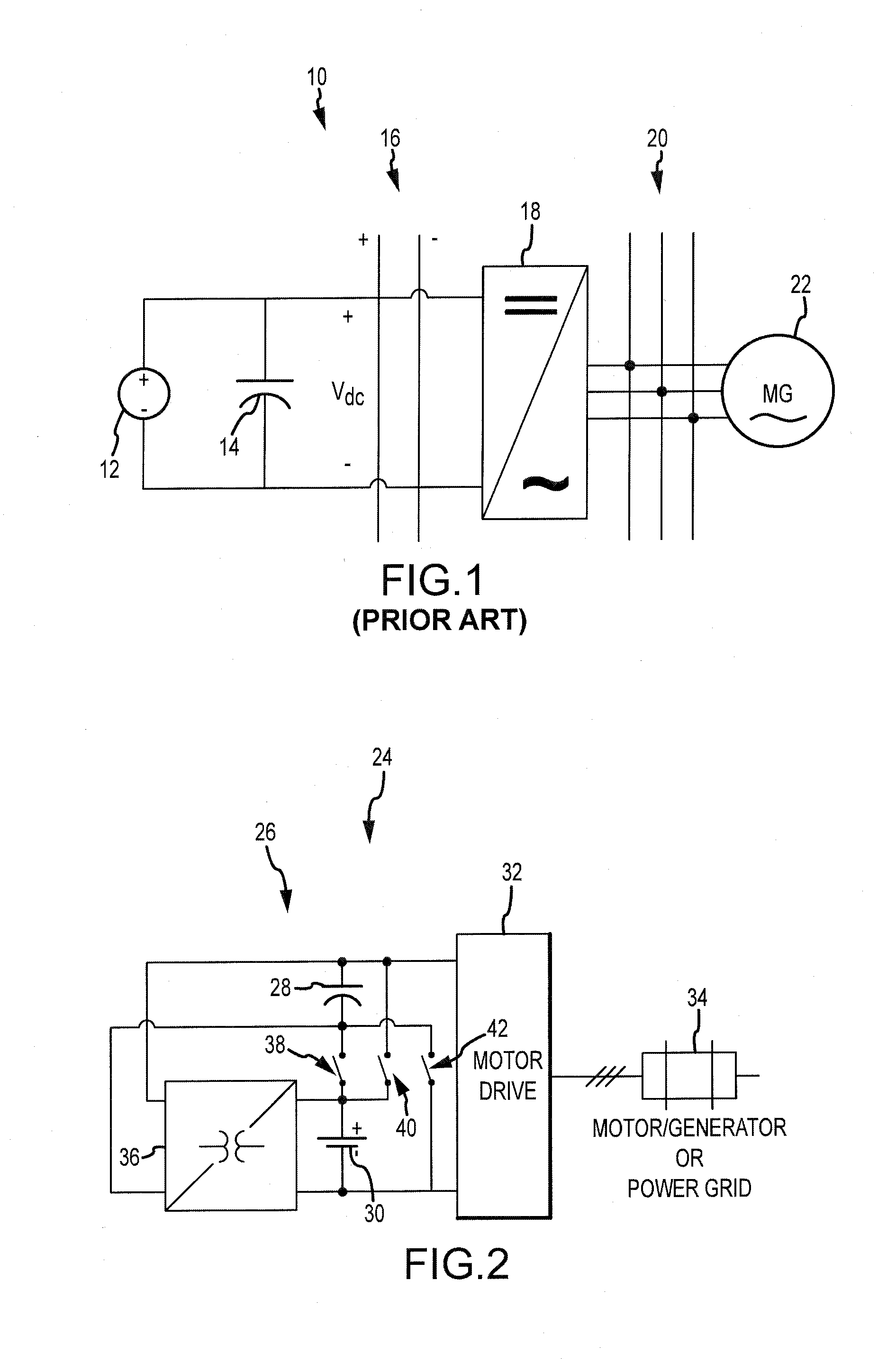

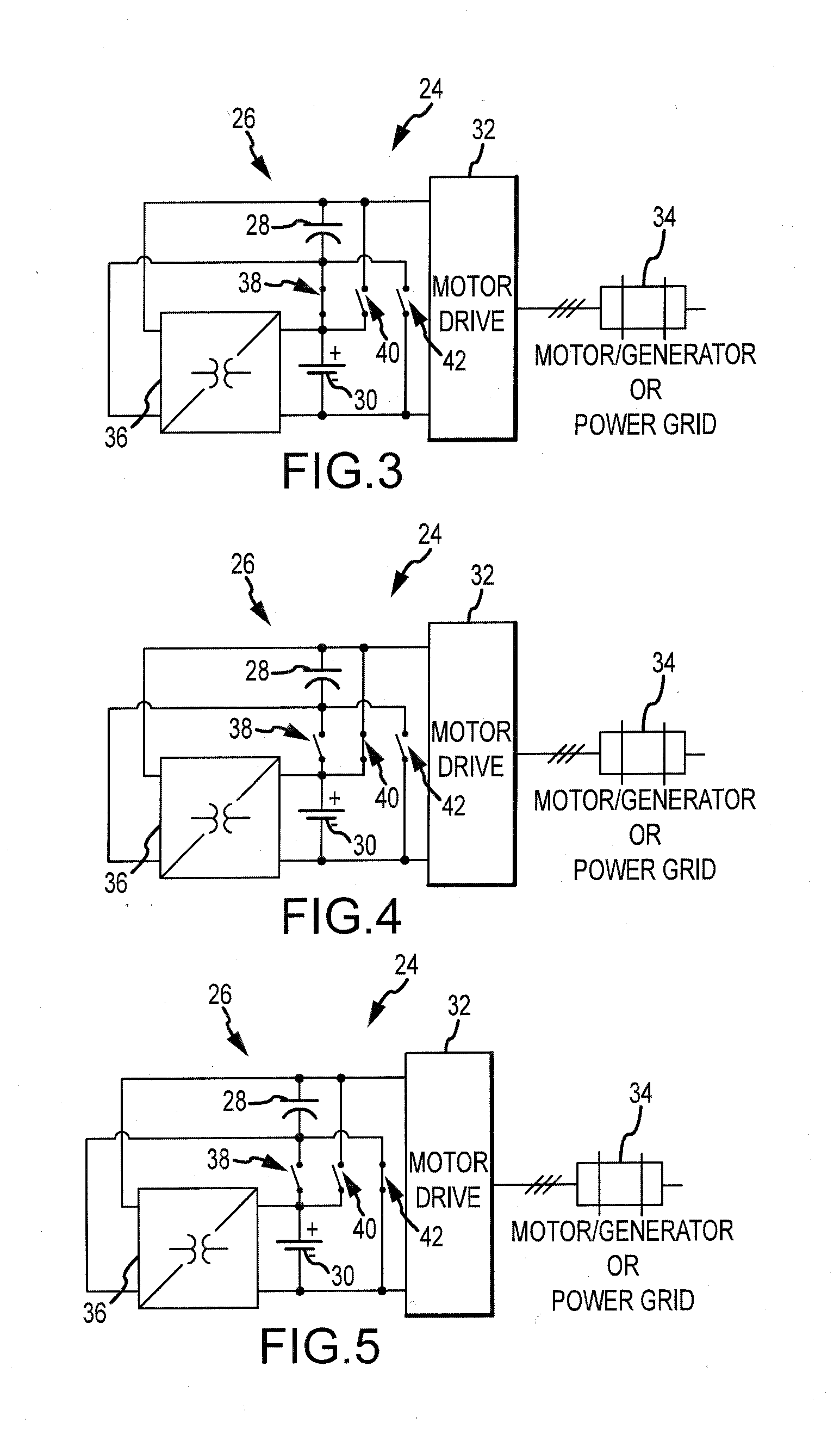

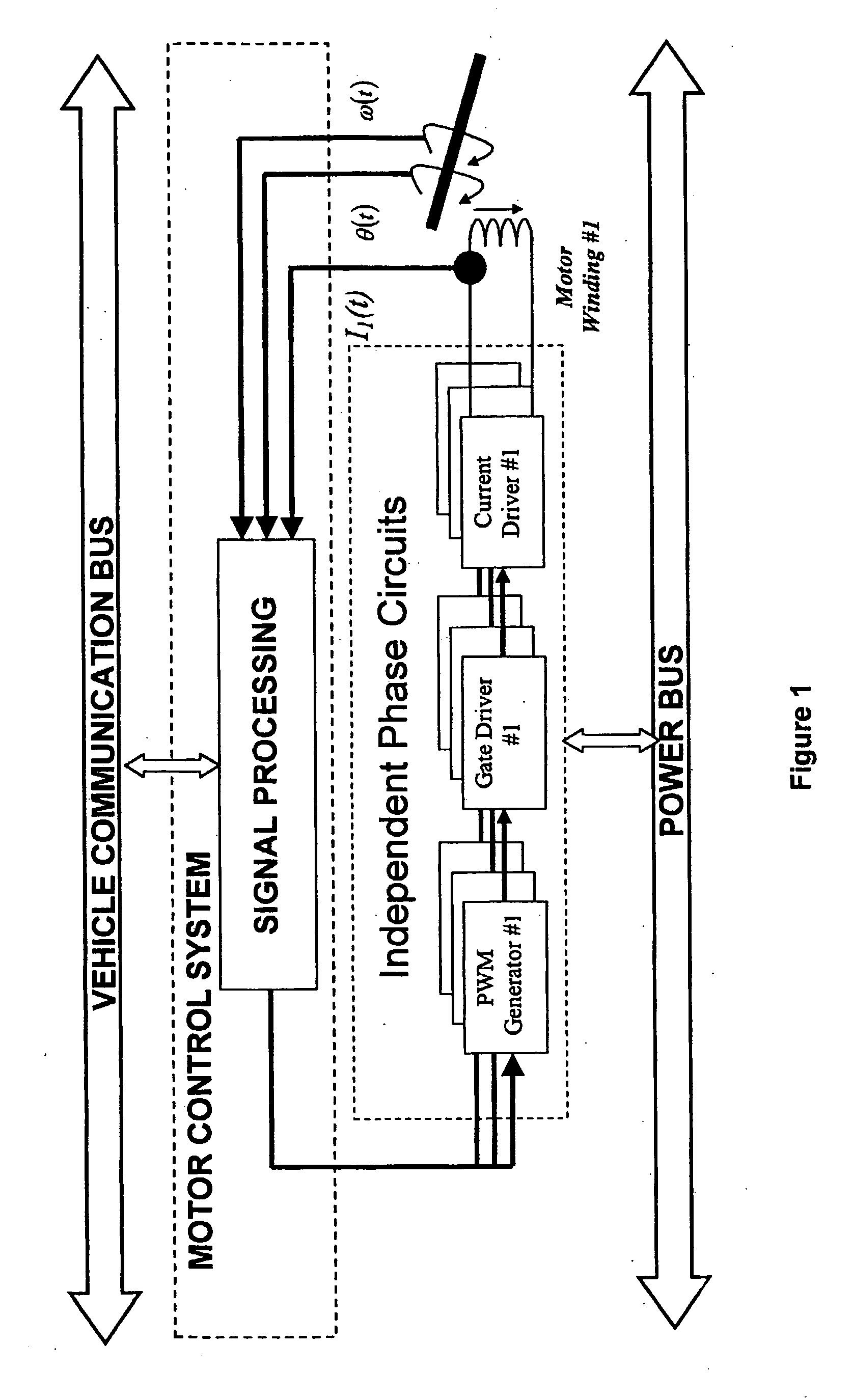

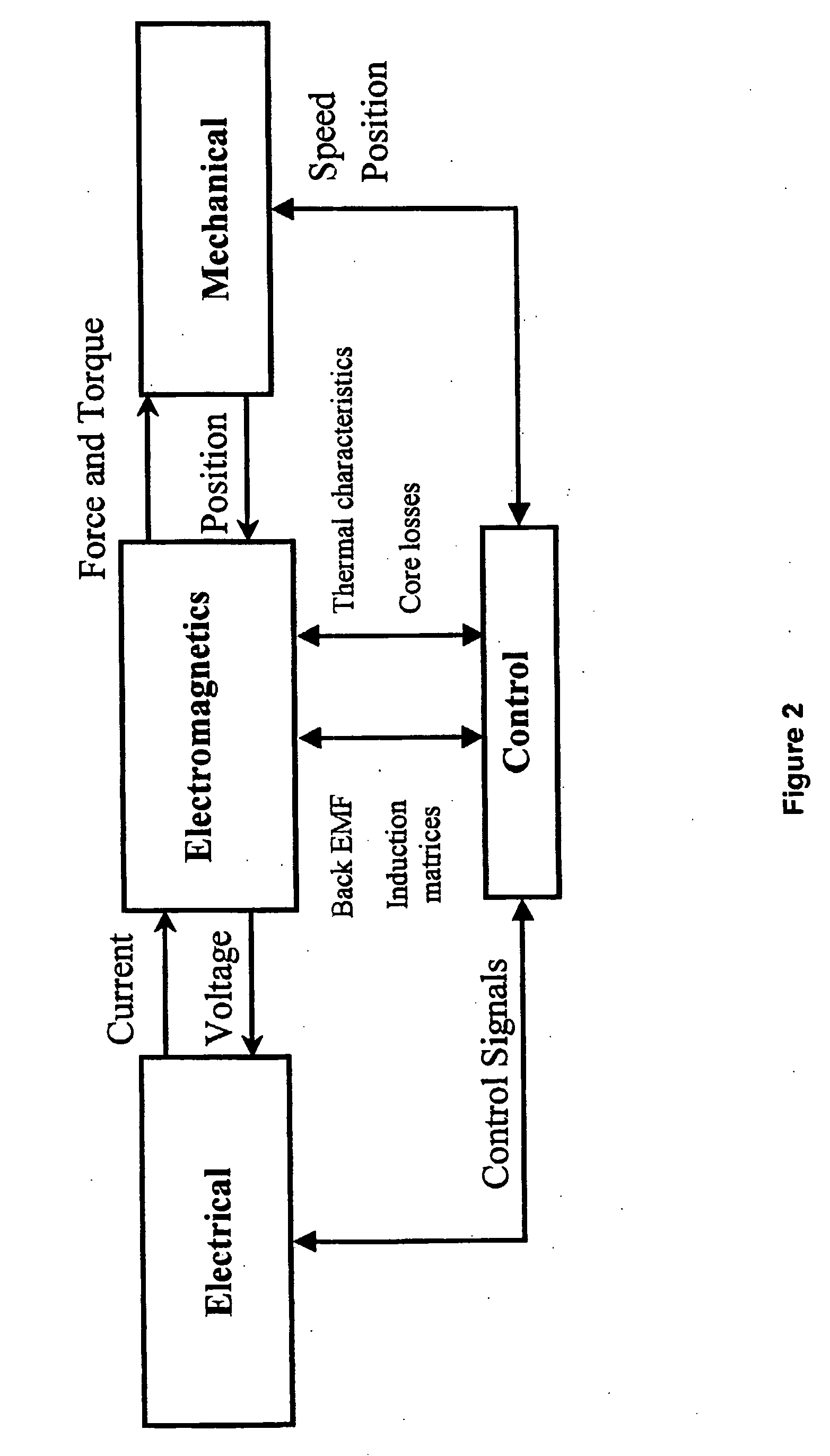

An adaptive electric car or other vehicle with potentially better performance—power, efficiency, range—than a gasoline vehicle, at a competitive cost. The motor control system can dynamically adapt to the vehicle's operating conditions (starting, accelerating, turning, braking, cruising at high speeds) and other inputs and parameters. That consistently provides better performance. Isolating the vehicle's motor or generator electromagnetic circuits allows effective control of more independent parameters. That gives great freedom to optimize. Adaptive motors and generators for an electric vehicle are cheaper, smaller, lighter, more powerful, and more efficient than conventional designs. An electric vehicle with in-wheel adaptive motors delivers high power with low unsprung mass and high torque and power-density. Total energy management of the vehicles entire electrical system allows for large-scale optimization. An adaptive architecture improves performance of a wide variety of vehicles, particularly those that need optimal efficiency over a range of operating conditions.

Owner:BLUWAV SYST LLC

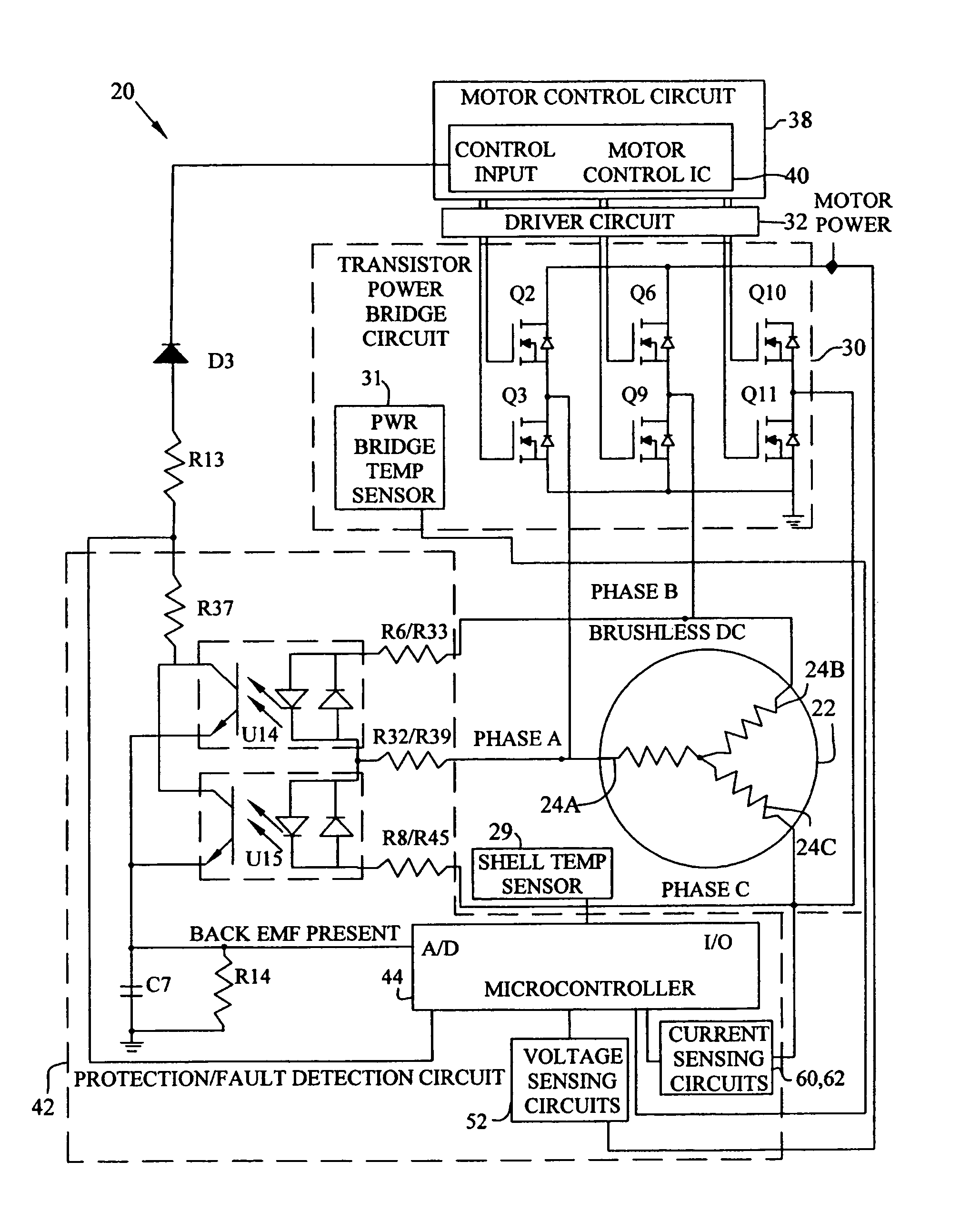

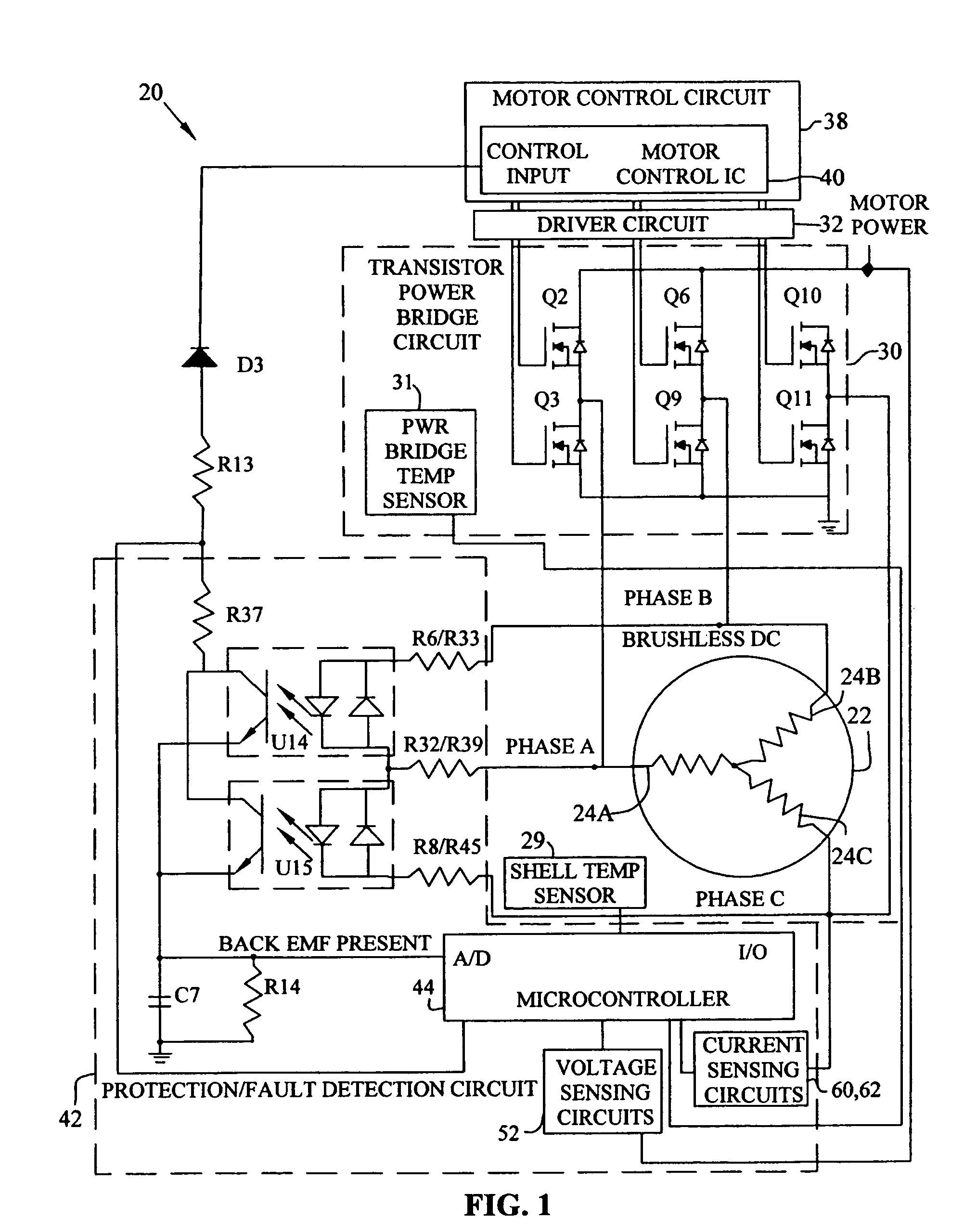

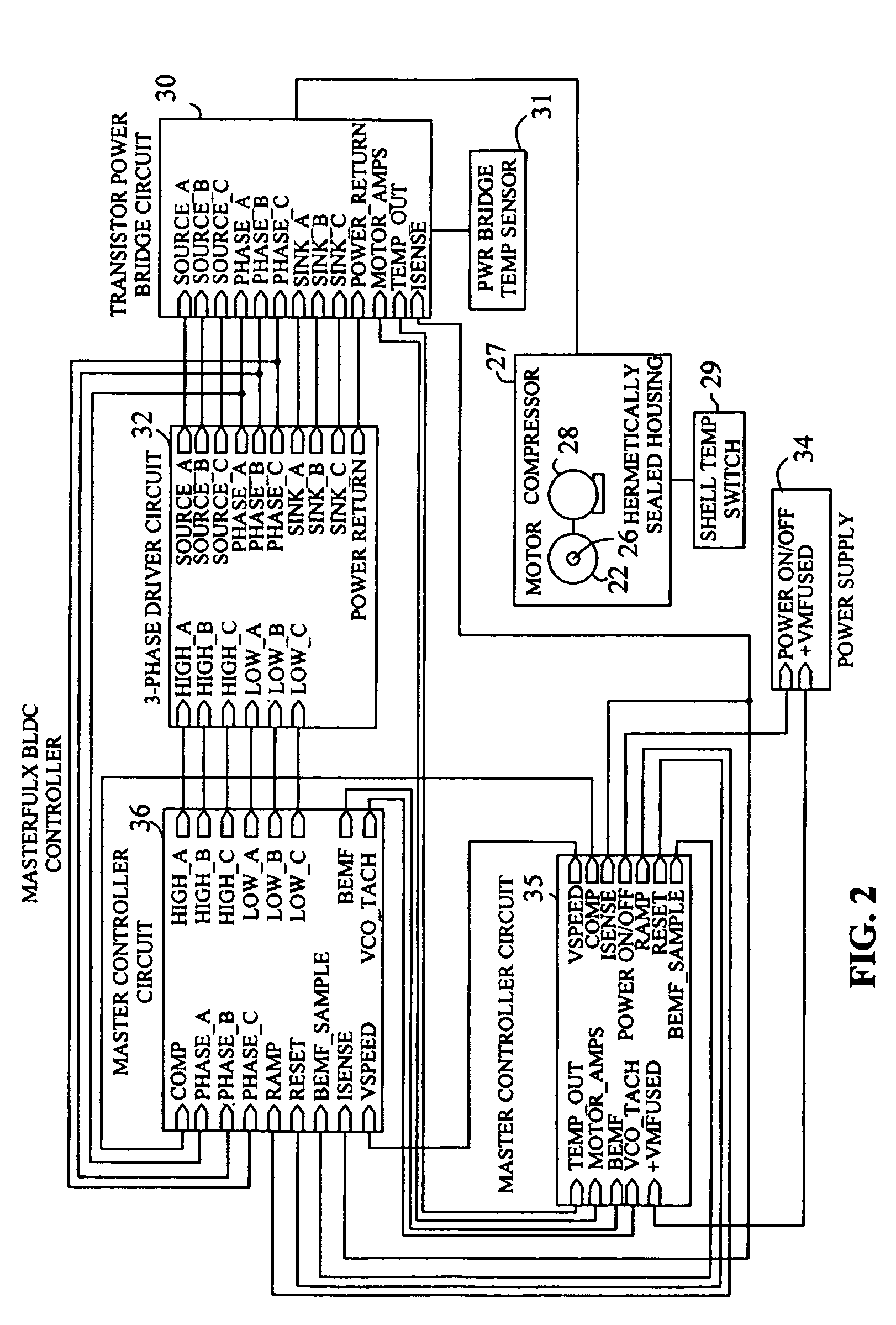

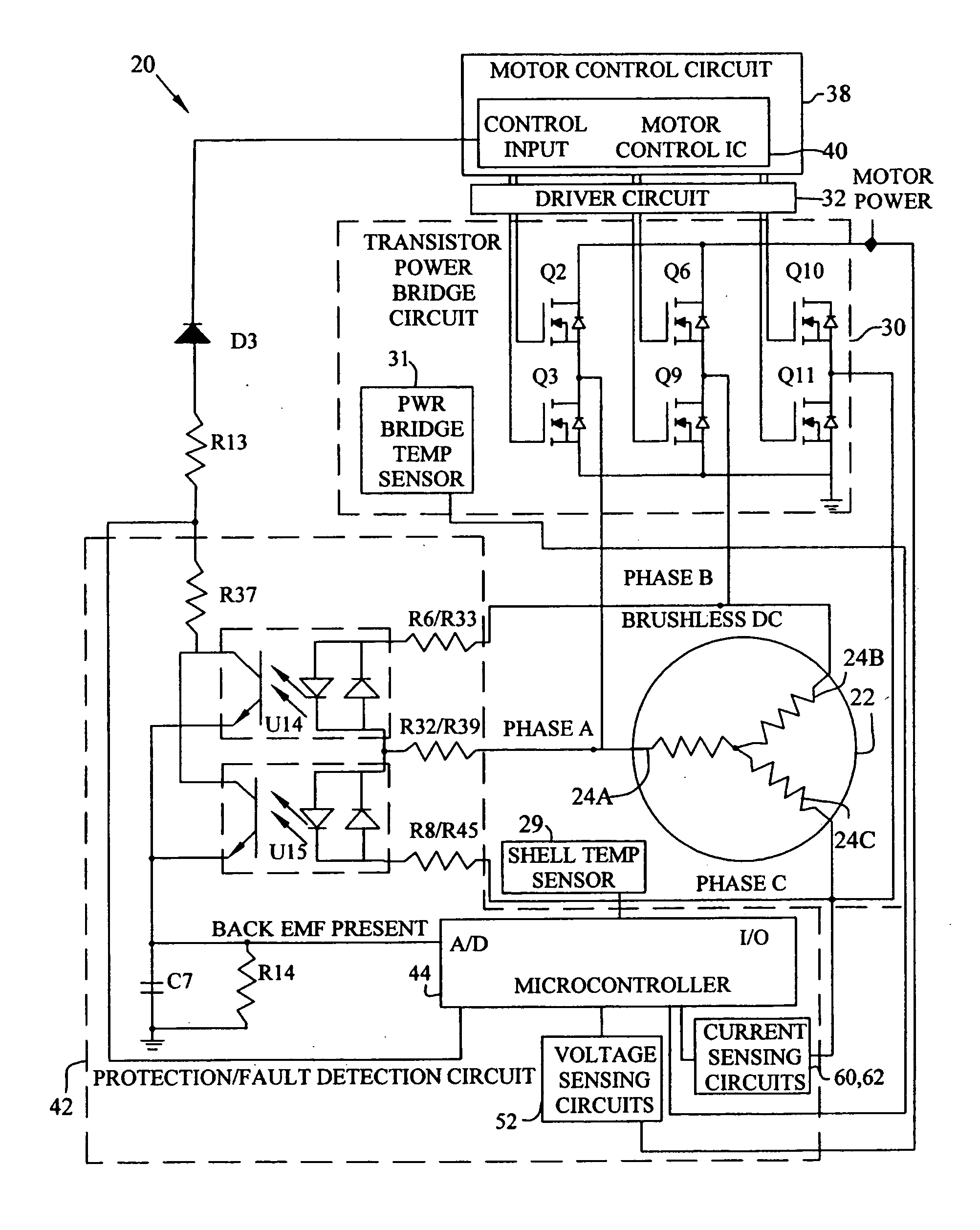

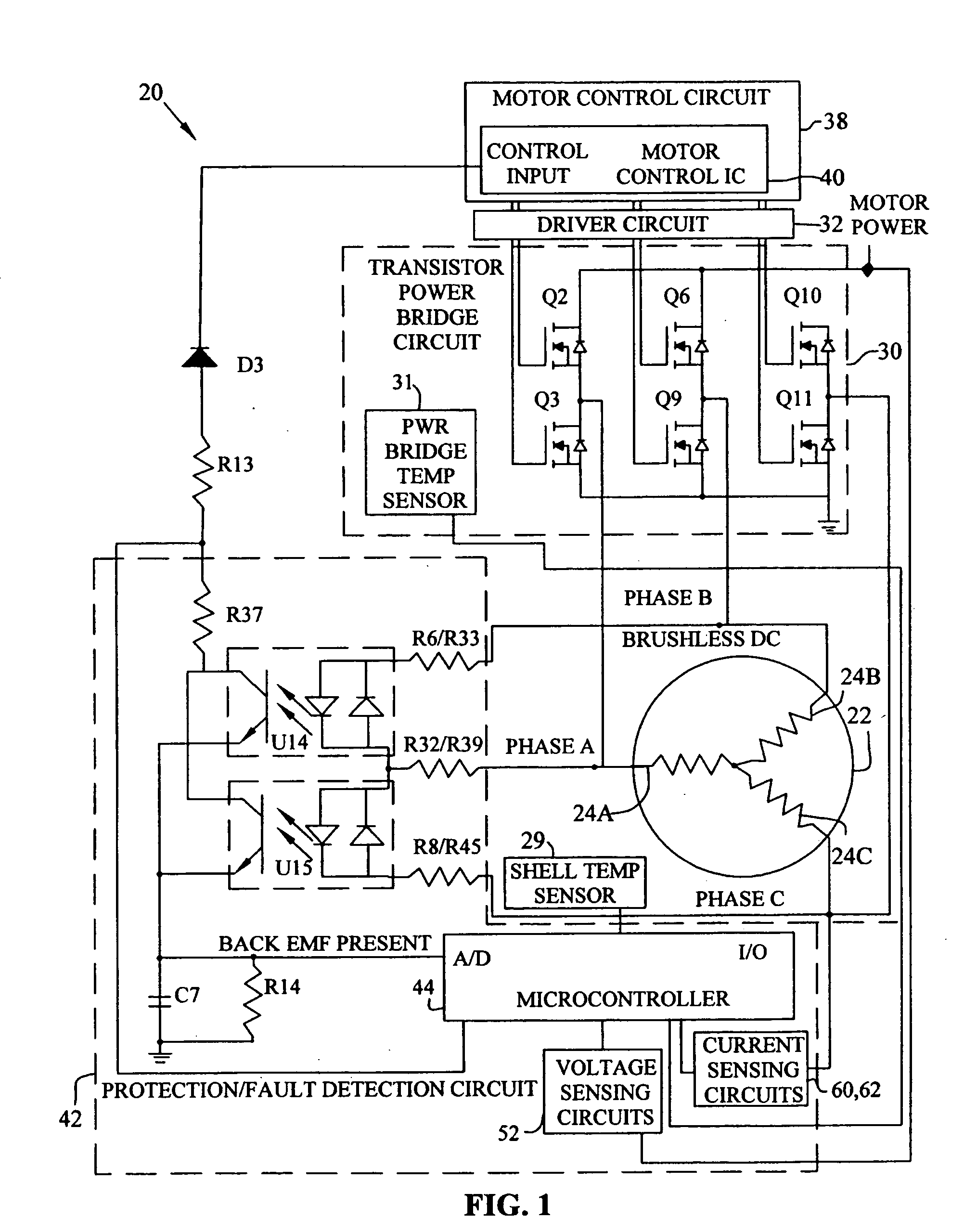

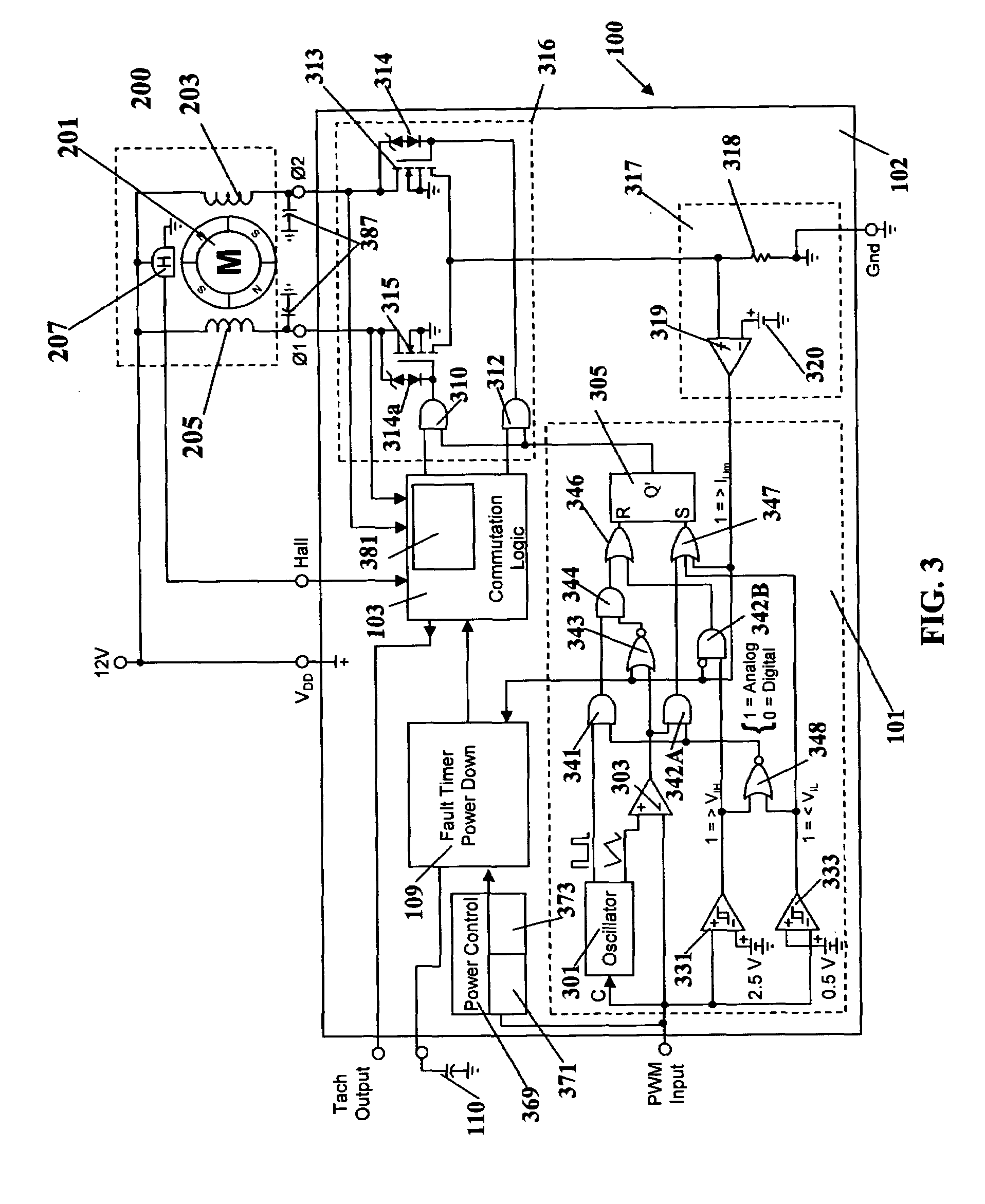

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS7042180B2Simple control methodEasily interfaceCommutation monitoringAC motor controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS20050029976A1Easy to modifyEasily interfaceCommutation monitoringDC motor speed/torque controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

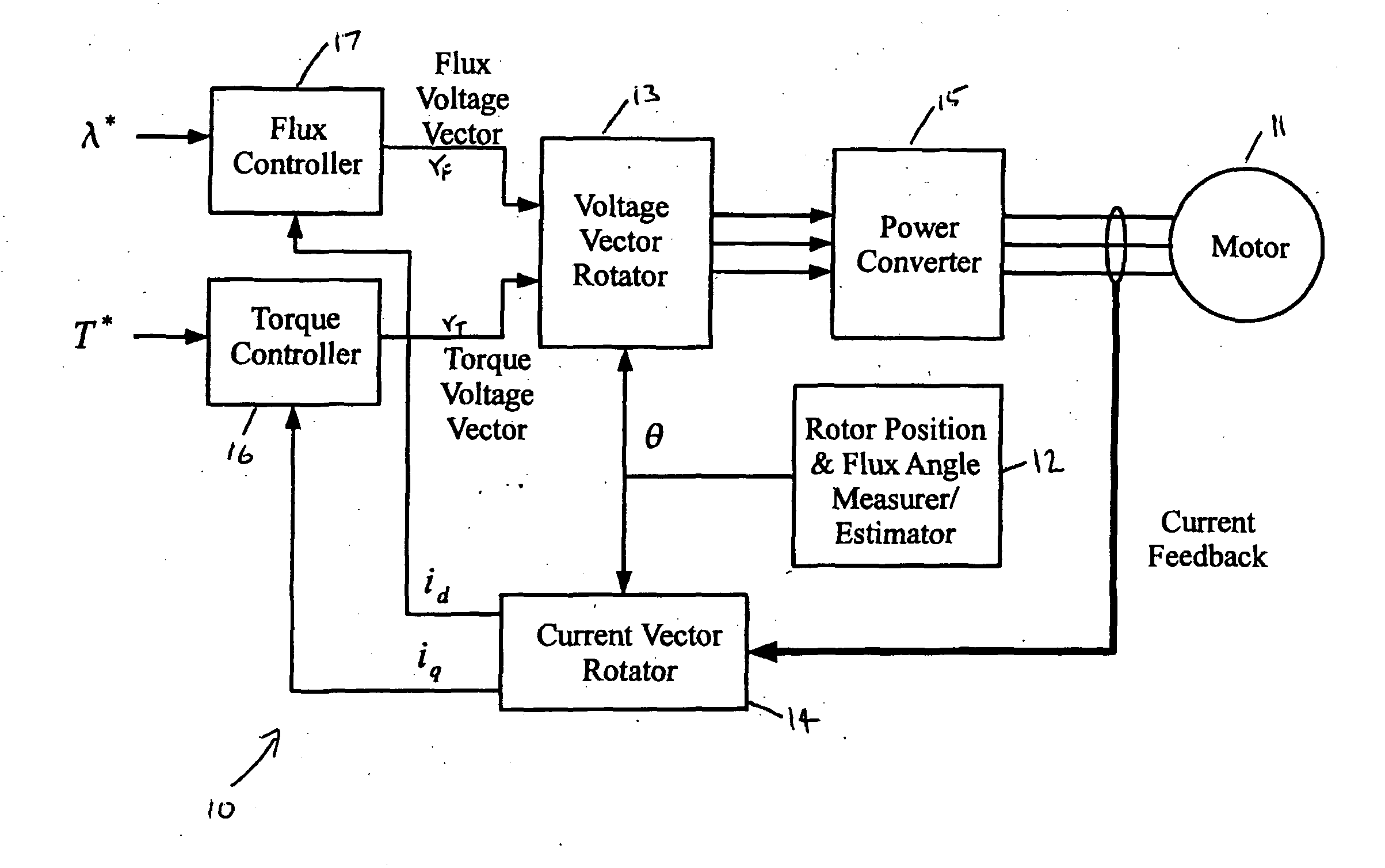

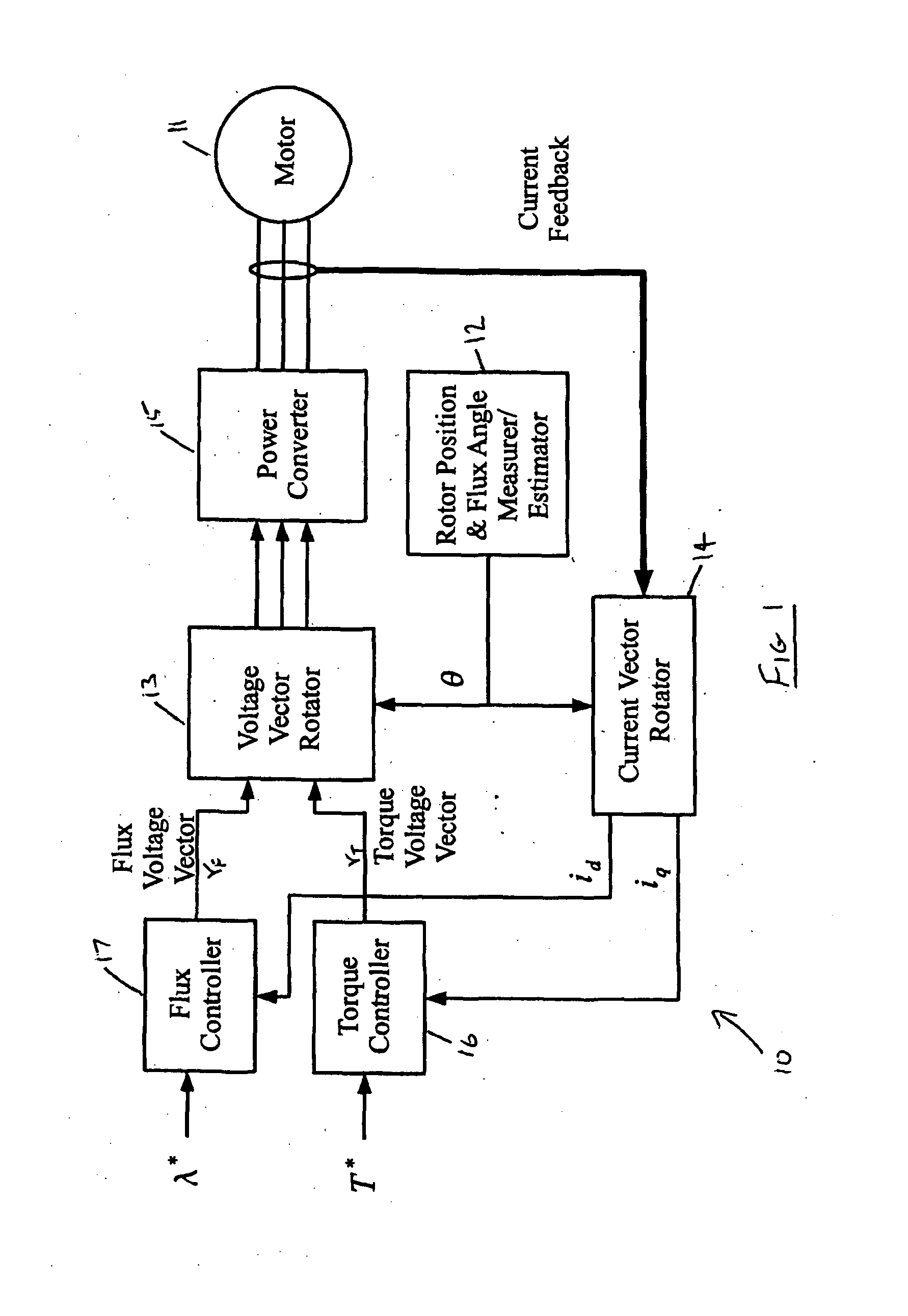

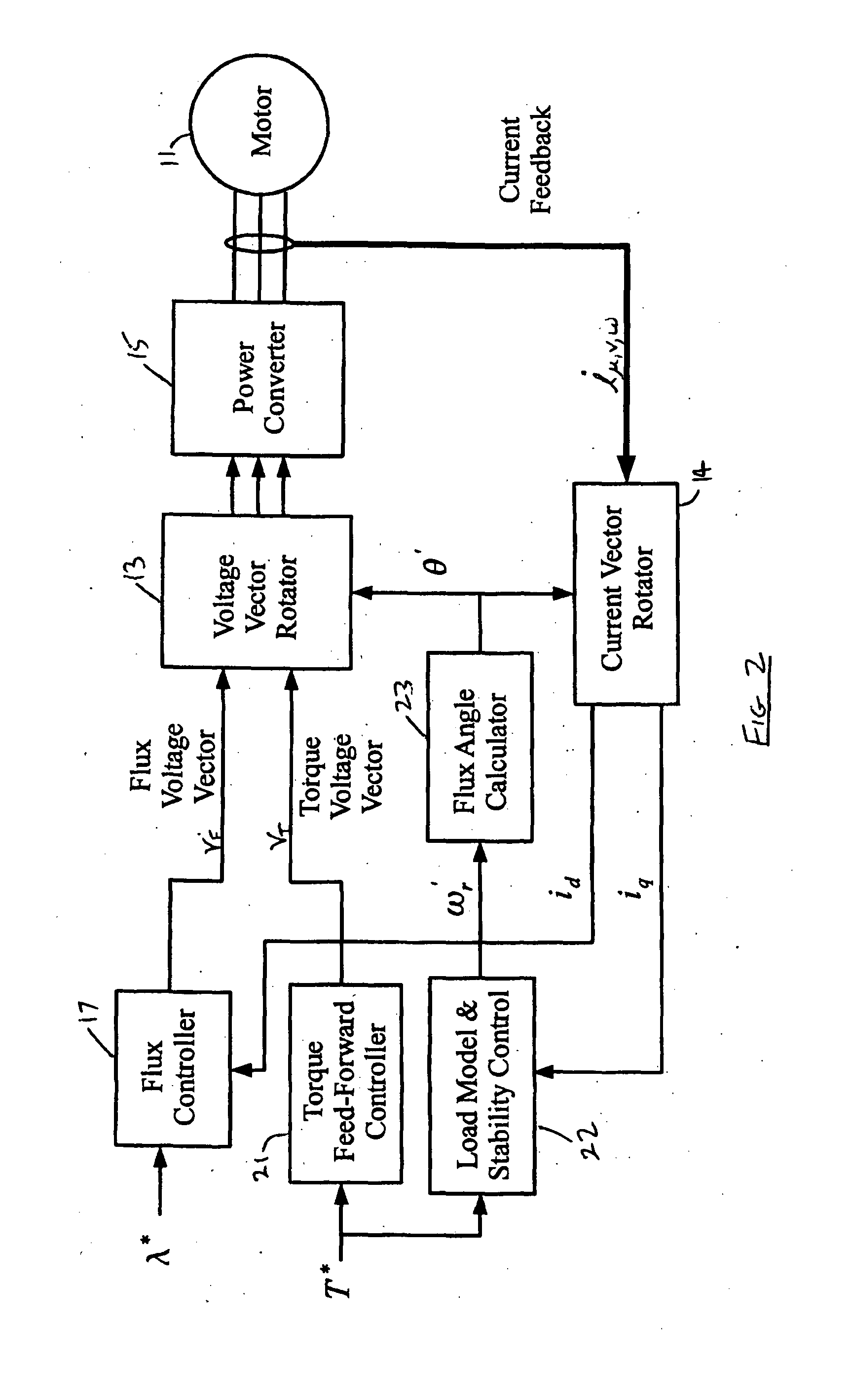

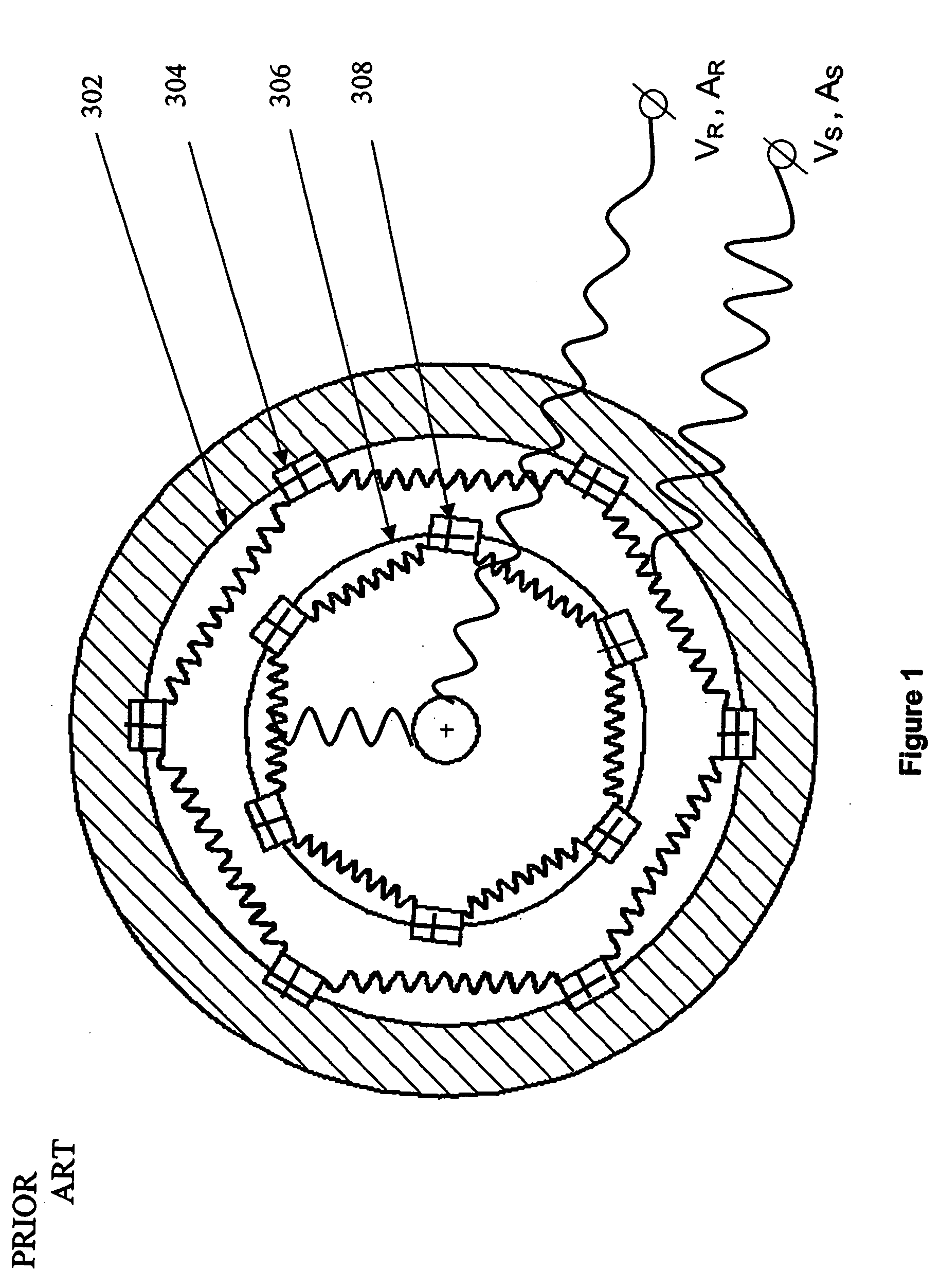

Sensorless ac motor controller

ActiveUS20130221885A1Control changesImprove stabilityCommutation monitoringMotor/generator/converter stoppersMotor speedVoltage vector

A controller for an AC electric motor, includes a Feed Forward Torque Controller and a load model. The Torque controller directly derives a torque related component of applied motor voltages from a signal representing a torque command input T* and at least one motor parameter. The load model derives a motor speed value including a model of motor speed behaviour of the AC electric motor to provide an output signal which represents the motor speed of the AC electric motor. This motor speed output signal is used in determining a frequency of rotation of an applied motor voltage vector. Where an input to the load model is the signal representing the torque command input T*, the load model uses the signal representing the torque command T*, at least over a part of an operating speed range of the AC motor which includes zero speed, to determine the motor speed output signal.

Owner:HUNTER GREGORY PETER

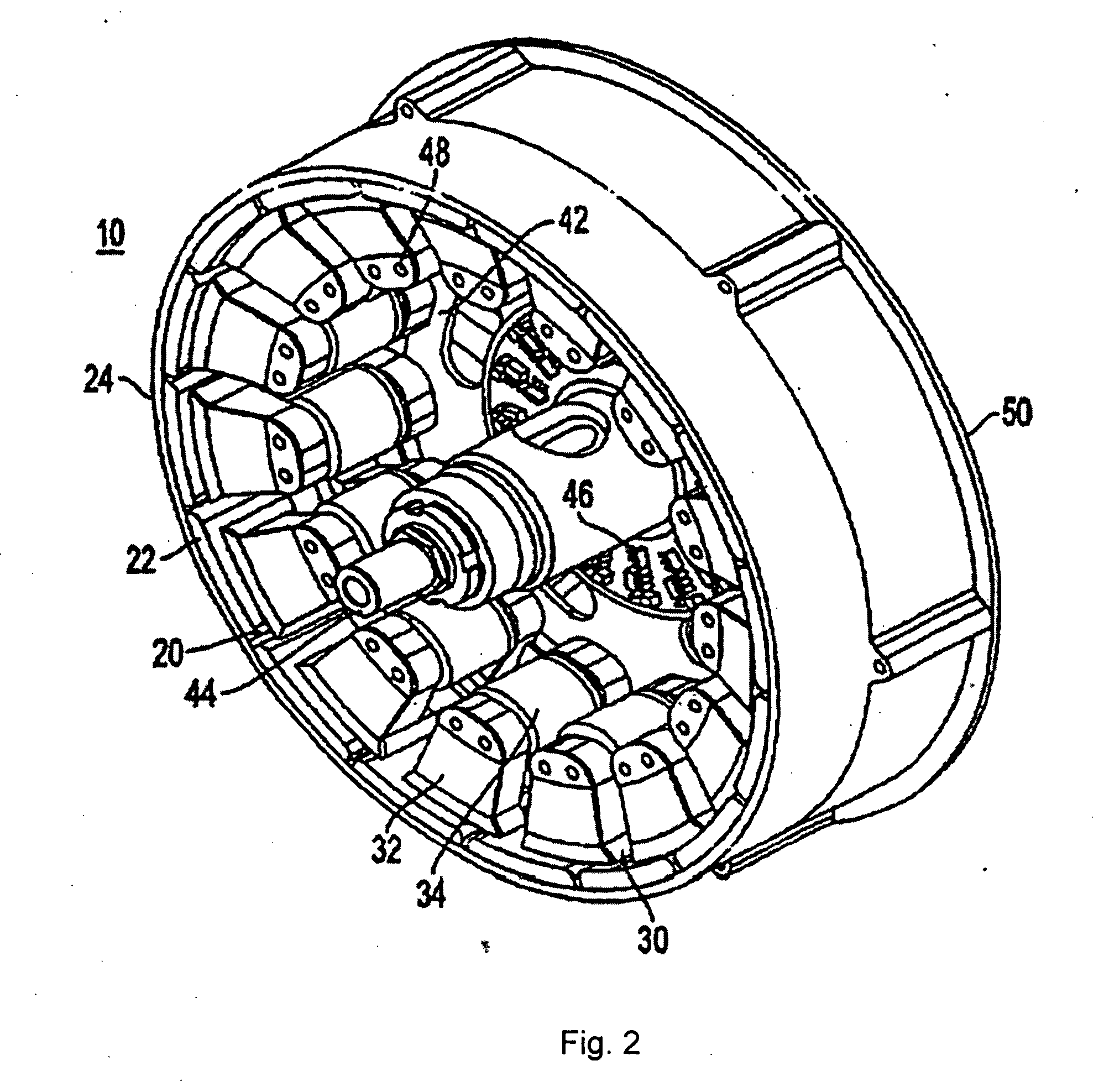

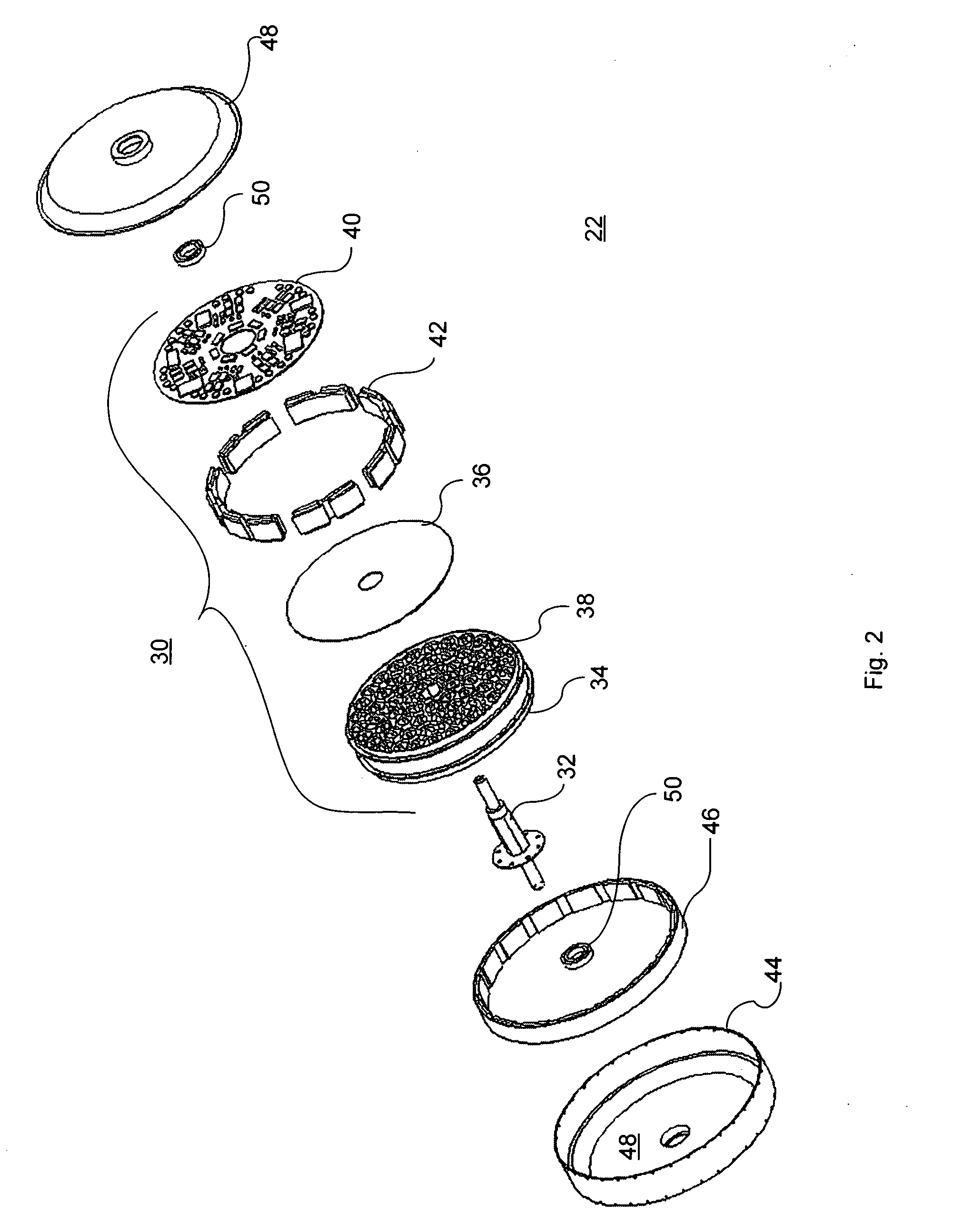

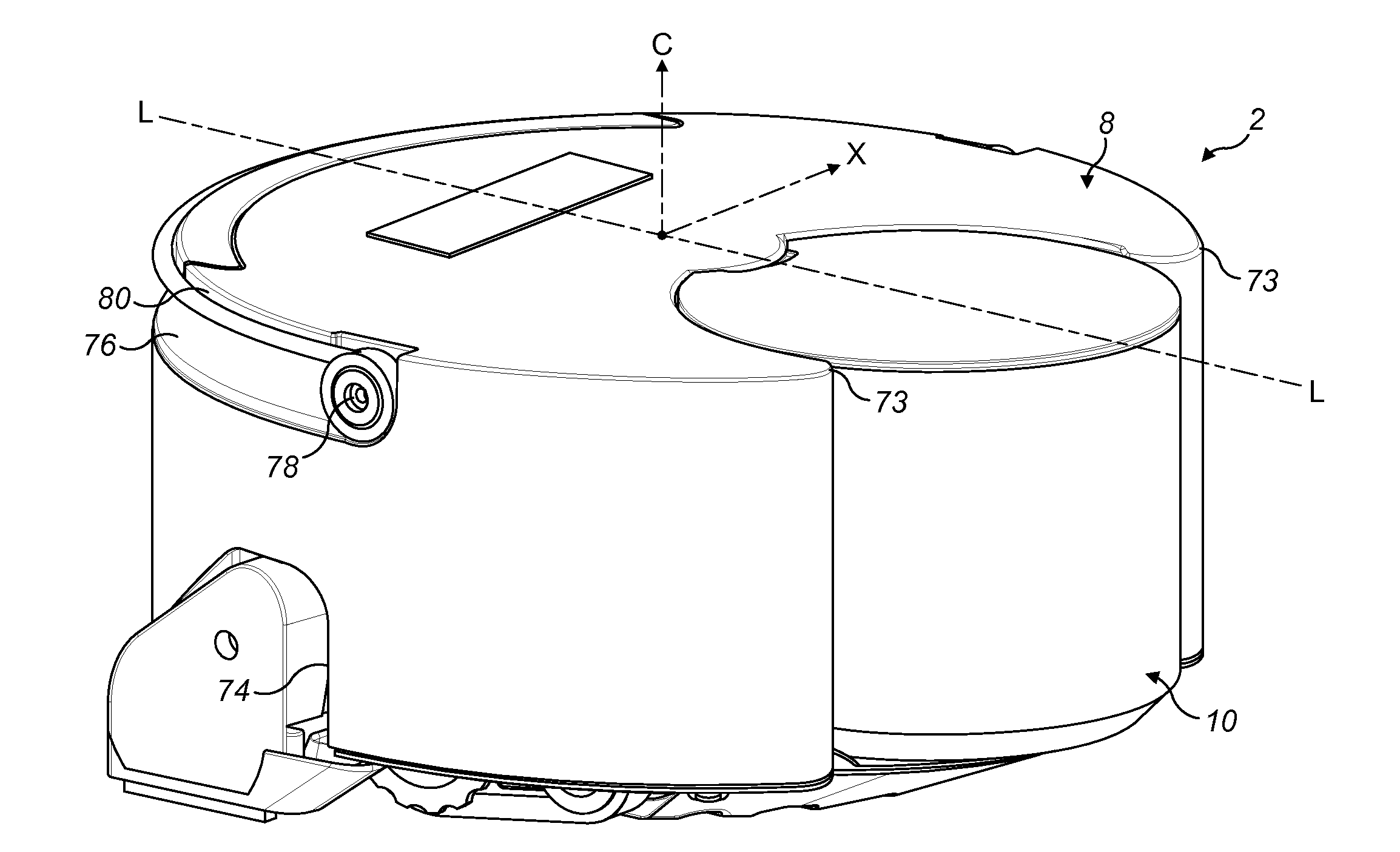

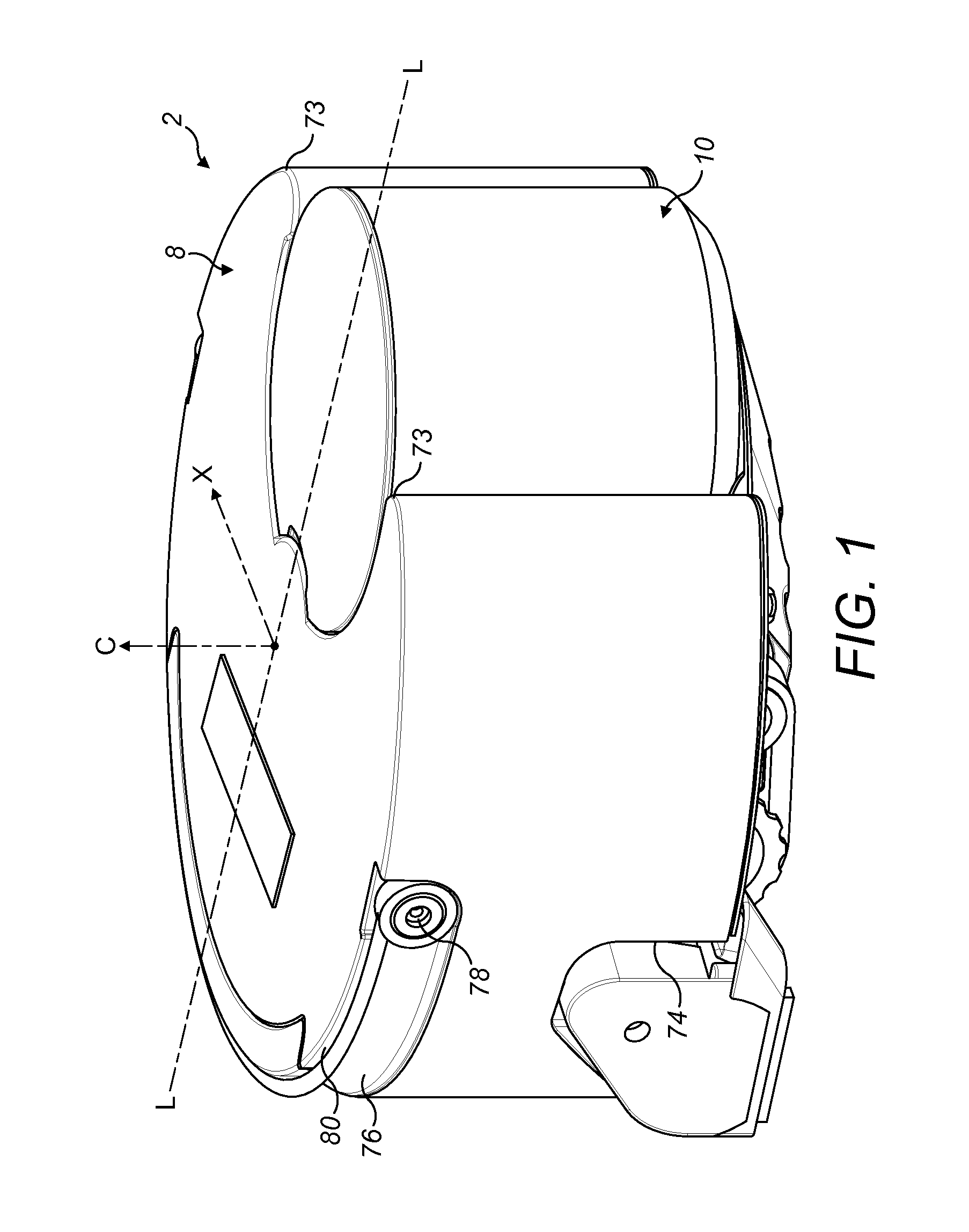

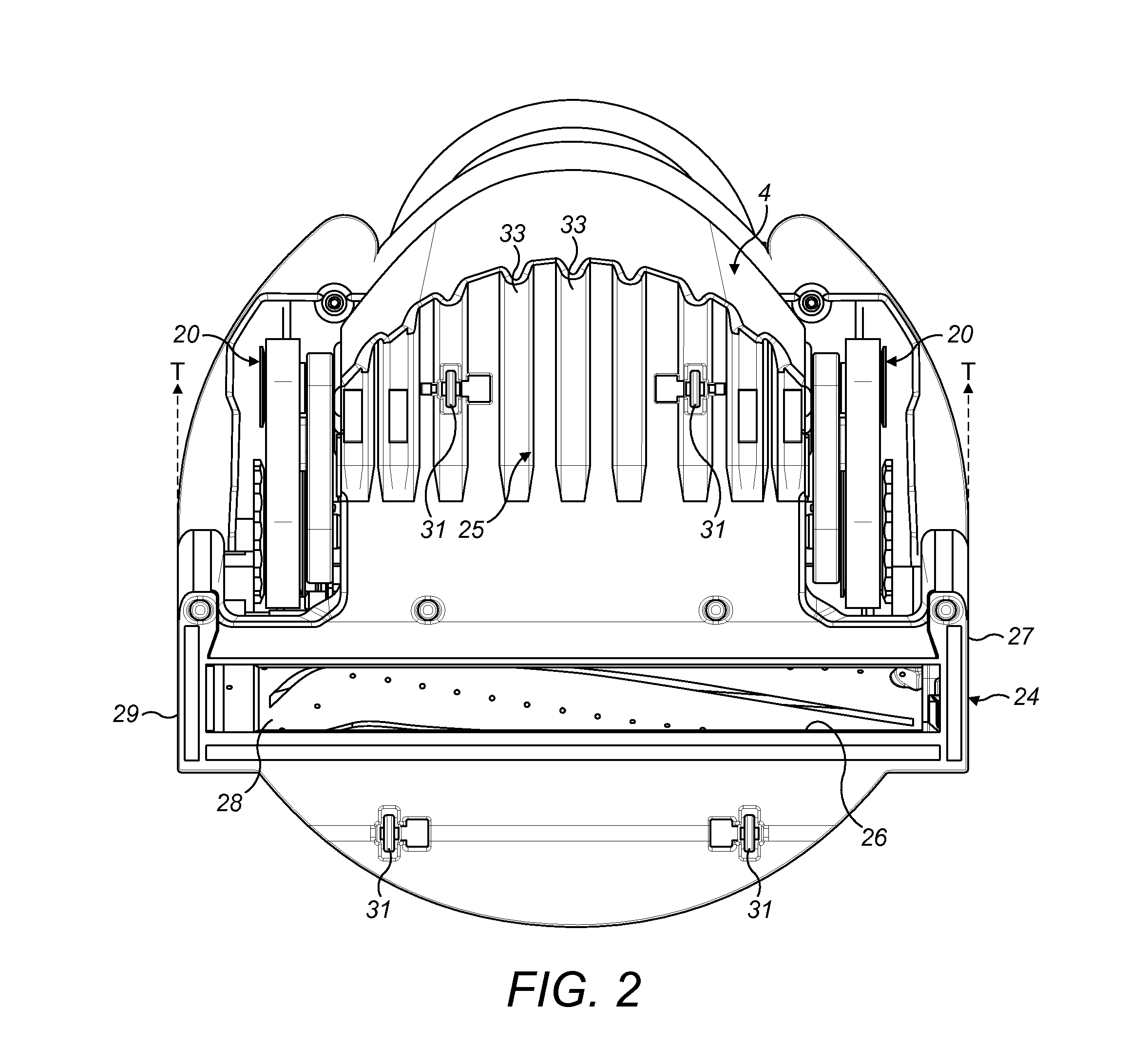

In-wheel electric motors

InactiveUS20050045392A1Simple eleganceImprove efficiencyVehicular energy storageMechanical energy handlingLow voltageControl system

Improved in-wheel, near-wheel and direct-drive electric motors for cars and other vehicles. This motor can be cheaper, lighter, more powerful, more efficient, and more reliable than other direct-drive motors. Its high torque-density and high performance allow it to produce the same peak power as heavier, bigger motors. That helps greatly with the handling issues caused by too much unsprung mass. The motor control system can adapt to the vehicle's operating conditions (like starting, accelerating, turning, braking, and cruising at high speeds). That provides better performance. The motor's low-voltage, low-current design helps reduce heat and weight and leads to lower motor cost. The motor can still operate with some faults, offering “get home” capability. It offers all the benefits of in-wheel motors: efficiency, compactness, direct traction control, quiet, simple driveline. And it adds to those benefits, while reducing or eliminating the drawbacks other in-wheel motors.

Owner:BLUWAV SYST LLC

Adaptive electric motors and generators providing improved performance and efficiency

InactiveUS20050184689A1Induced currentLow reliabilityMagnetic circuitVehicular energy storageElectric vehicleHigher Power

An adaptive architecture for electric motors, generators and other electric machines. An adaptive electric machine provides optimal performance by dynamically adapting its controls to changes in user inputs, machine operating conditions and machine operating parameters. Isolating the machine's electromagnetic circuits allows effective control of more independent machine parameters, enabling greater freedom to optimize and providing adaptive motors and generators that are cheaper, smaller, lighter, more powerful, and more efficient than conventional designs. An electric vehicle with in-wheel adaptive motors enables delivery of higher power with lower unsprung mass, giving better torque-density. The motor control system can adapt to the vehicle's operating conditions, including starting, accelerating, turning, braking, and cruising at high speeds, thereby consistently providing higher efficiency. A wind powered adaptive generator can adapt to changing wind conditions, consistently providing optimal performance. An adaptive architecture may improve performance in a wide variety of electric machine applications, particularly those requiring optimal efficiency over a range of operating conditions.

Owner:BLUWAV SYST LLC

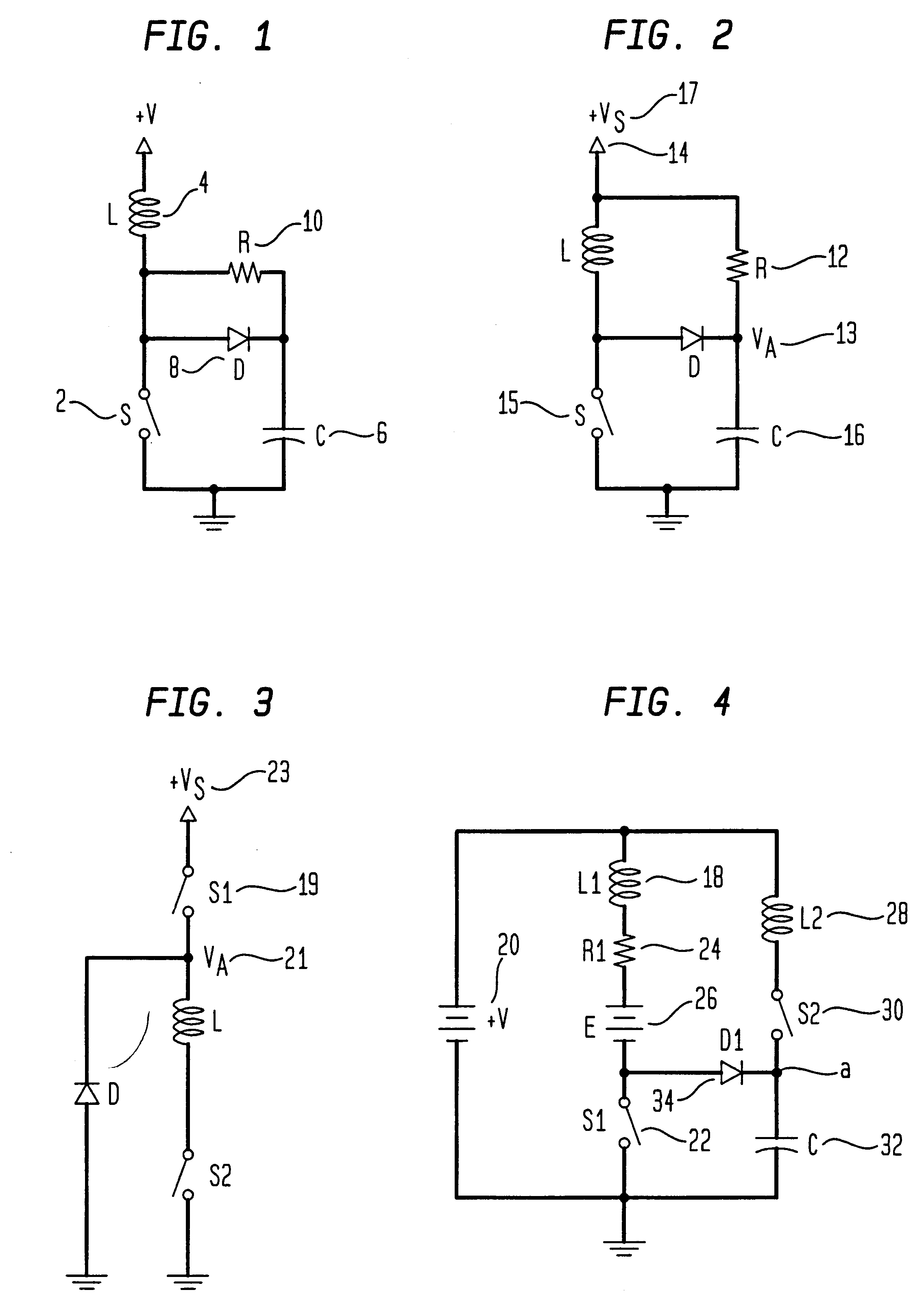

Actively controlled regenerative snubber for unipolar brushless DC motors

InactiveUS6166500AAC motor controlDC motor speed/torque controlConducted electromagnetic interferenceEngineering

An actively controlled regenerative snubber configuration for use in unipolar brushless direct current motors comprises a first inductor, a first switch and a capacitor, all of which are connected in series to a positive voltage supply and in parallel with a second inductor and a second switch. The regenerative snubber is used to maintain constant voltage across the switches to prevent braking of the motor through conduction of motor back EMF and to return excess energy stored in the motor phase coils to the positive voltage supply. The return of energy to the positive rail is done in a manner so as to minimize conducted electromagnetic interference at the power leads.

Owner:SIEMENS CANADA LTD

Method of energy and power management in dynamic power systems with ultra-capacitors (super capacitors)

InactiveUS20140084817A1Maximizes captureMinimize main power supply sizeElectric power distributionEnergy efficient board measuresElectric power systemSupercapacitor

A power management system includes an ultracapacitor and a charge shuttle including a power converter. The charge shuttle may be coupled with the ultracapacitor and may be configured to be coupled with a load. The charge shuttle can be configured to monitor one or more parameters of the load and the ultracapacitor, and to control energy flow between the load and the ultracapacitor based on or according to monitored parameters. The system may also include a battery or other rechargeable energy storage element.

Owner:EATON CORP

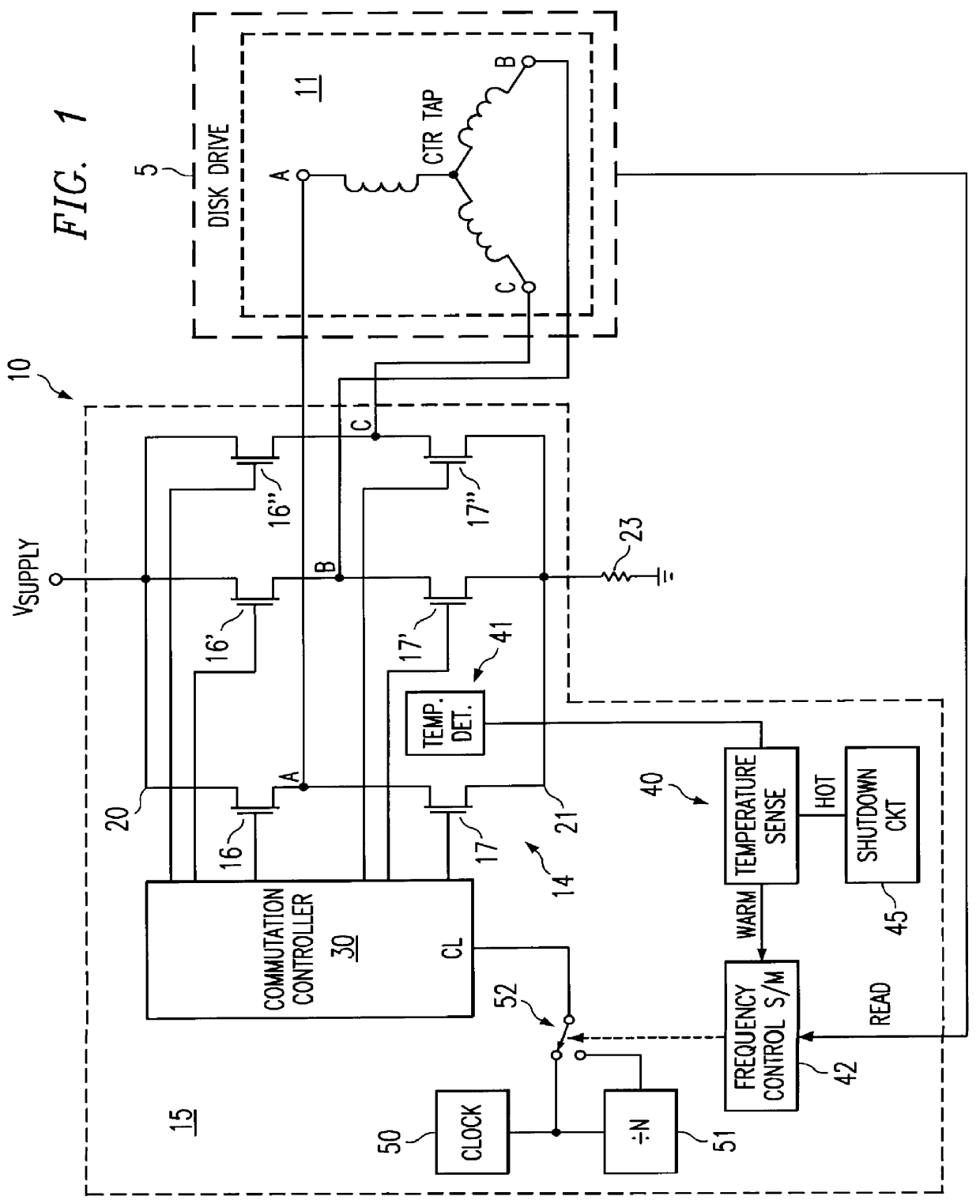

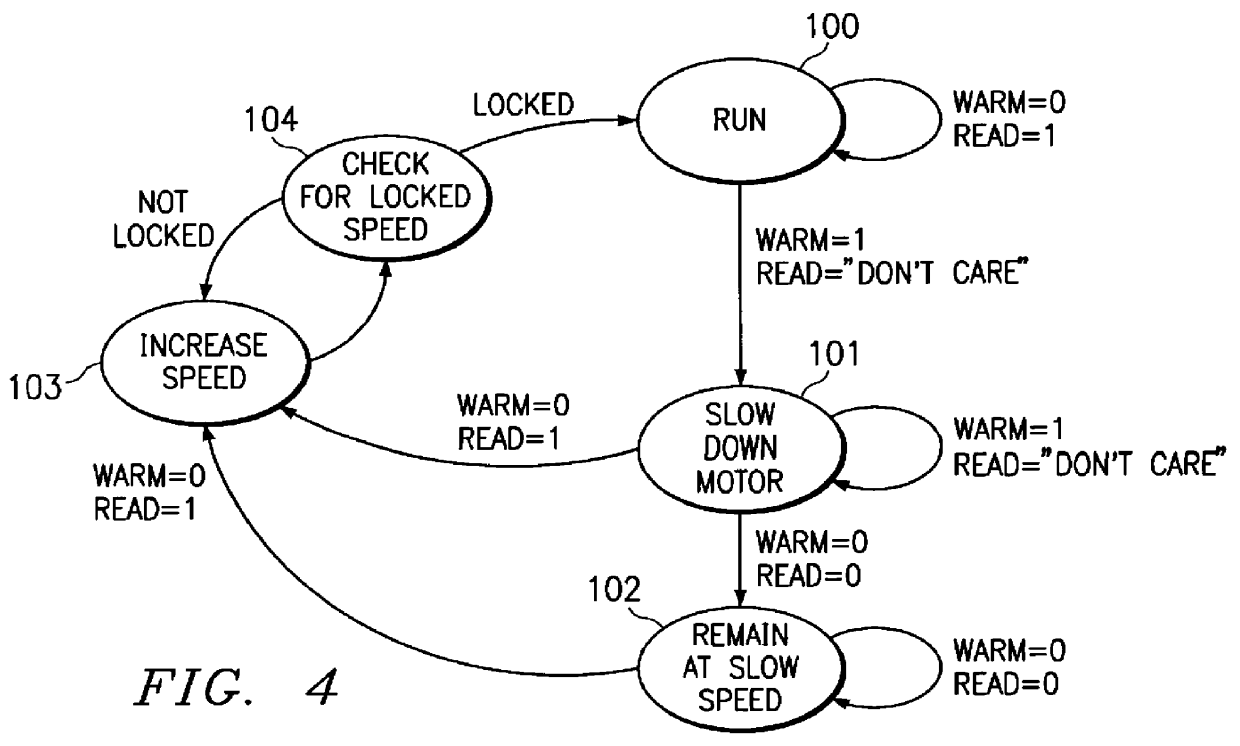

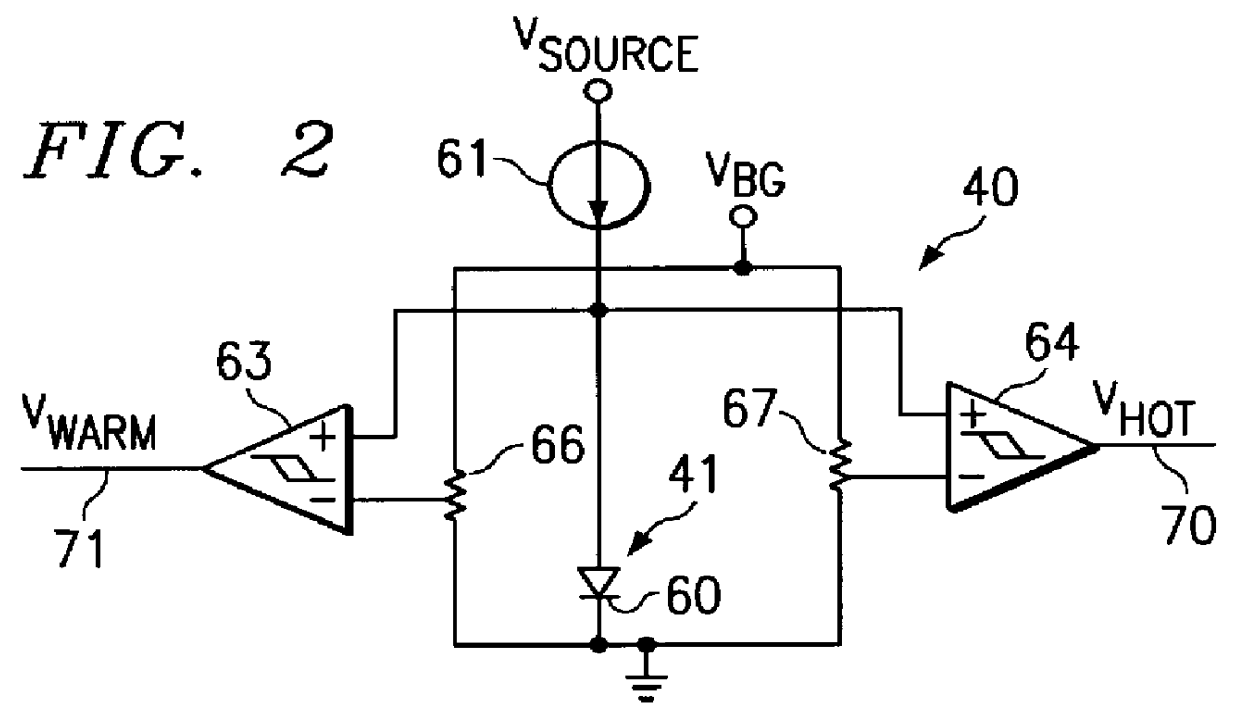

Overtemperature warning cycle in operation of polyphase DC motors

A method and integrated circuit for providing drive signals to a polyphase dc motor. The integrated circuit is fabricated on a semiconductor substrate for providing drive signals to a polyphase dc motor. The circuit includes a coil drive circuit for connection to drive coils of the motor to selectively supply drive currents thereto in a predetermined sequence. A sequencer circuit commutatively selects the drive coils to which the drive currents are selectively supplied, and a motor, speed controlling circuit controls the speed of the motor by controlling the speed of commutation. A temperature sensing element, such as a diode, is fabricated in the substrate to indicate the temperature of the substrate, and a temperature measuring circuit is connected to the temperature sensing element and to the motor speed controlling circuit to operate the motor speed controlling circuit to slow the speed of the motor when the temperature of the substrate exceeds a first predetermined temperature. If desired, temperature measuring circuit can include a circuit for measuring a second temperature higher than the first predetermined temperature to operate a shut down circuit to turn off the motor if the substrate temperature is too high.

Owner:STMICROELECTRONICS SRL

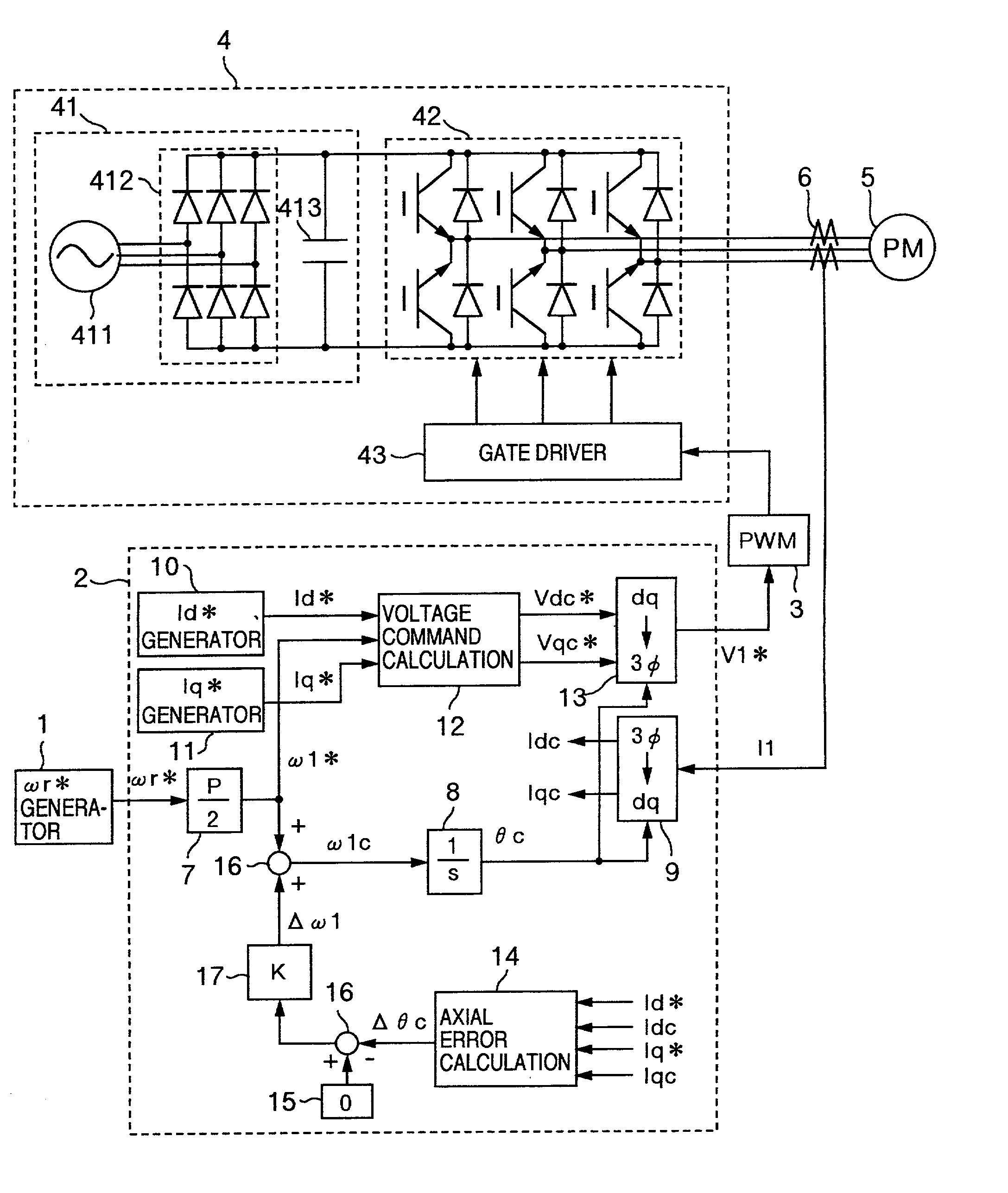

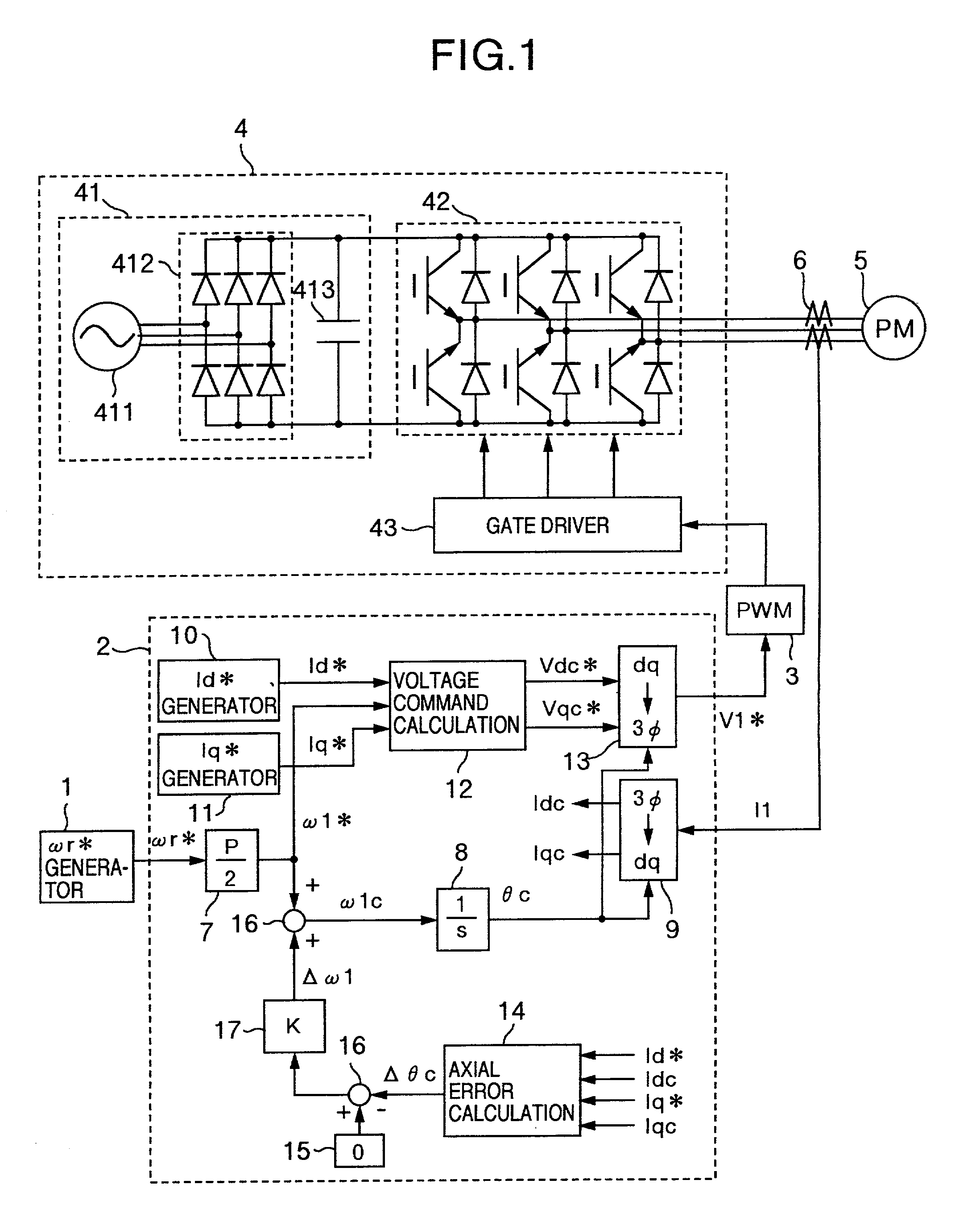

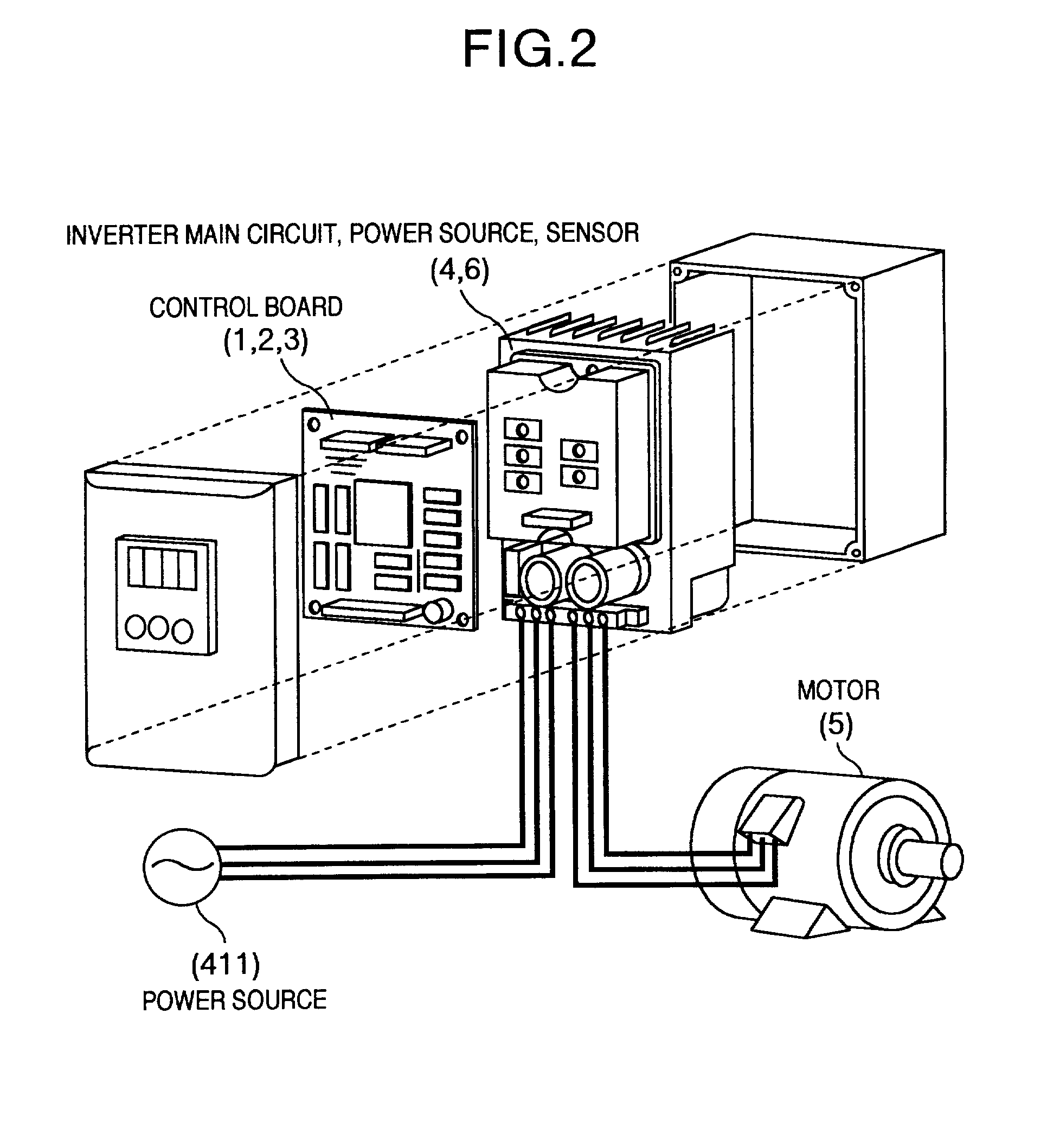

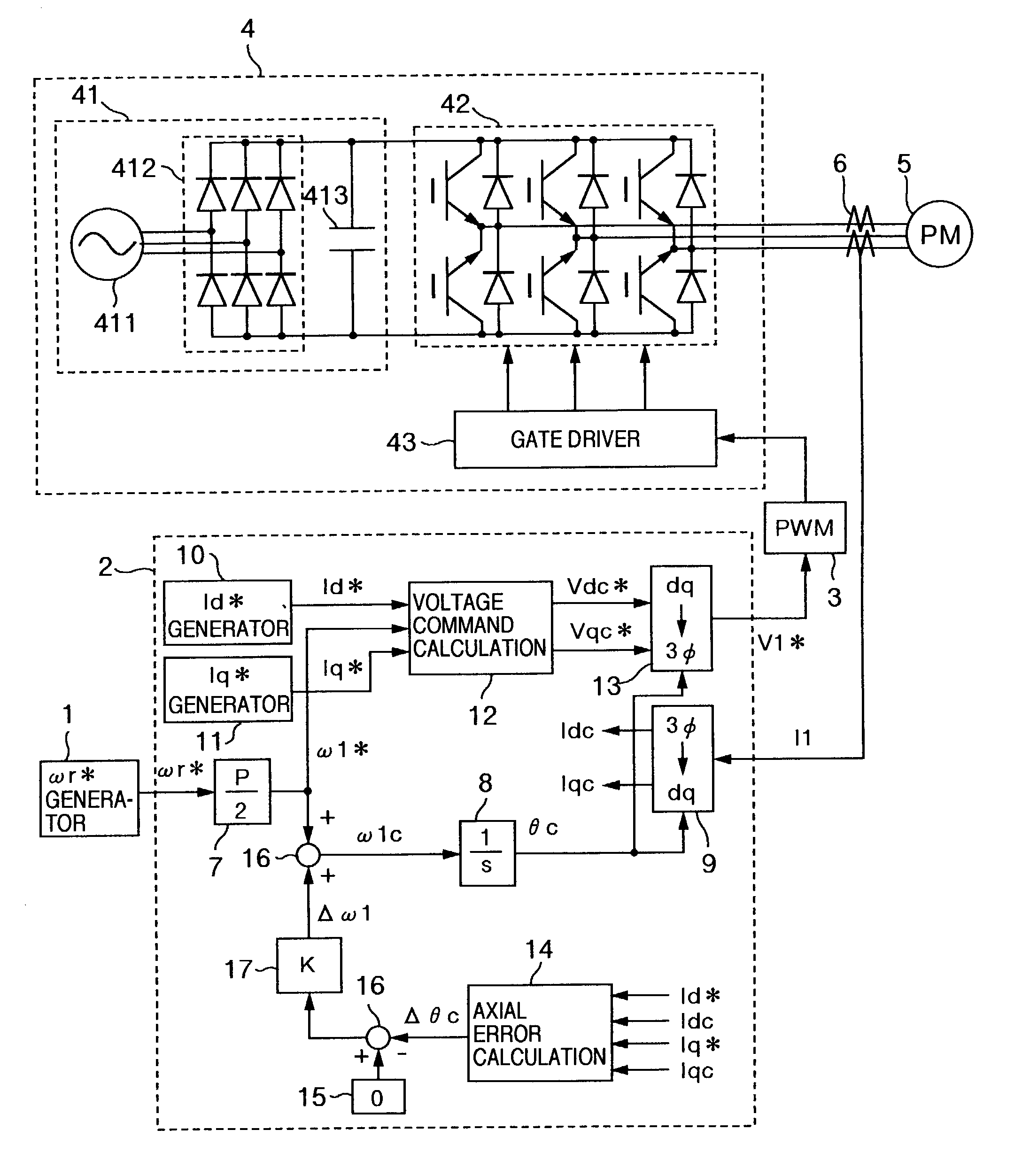

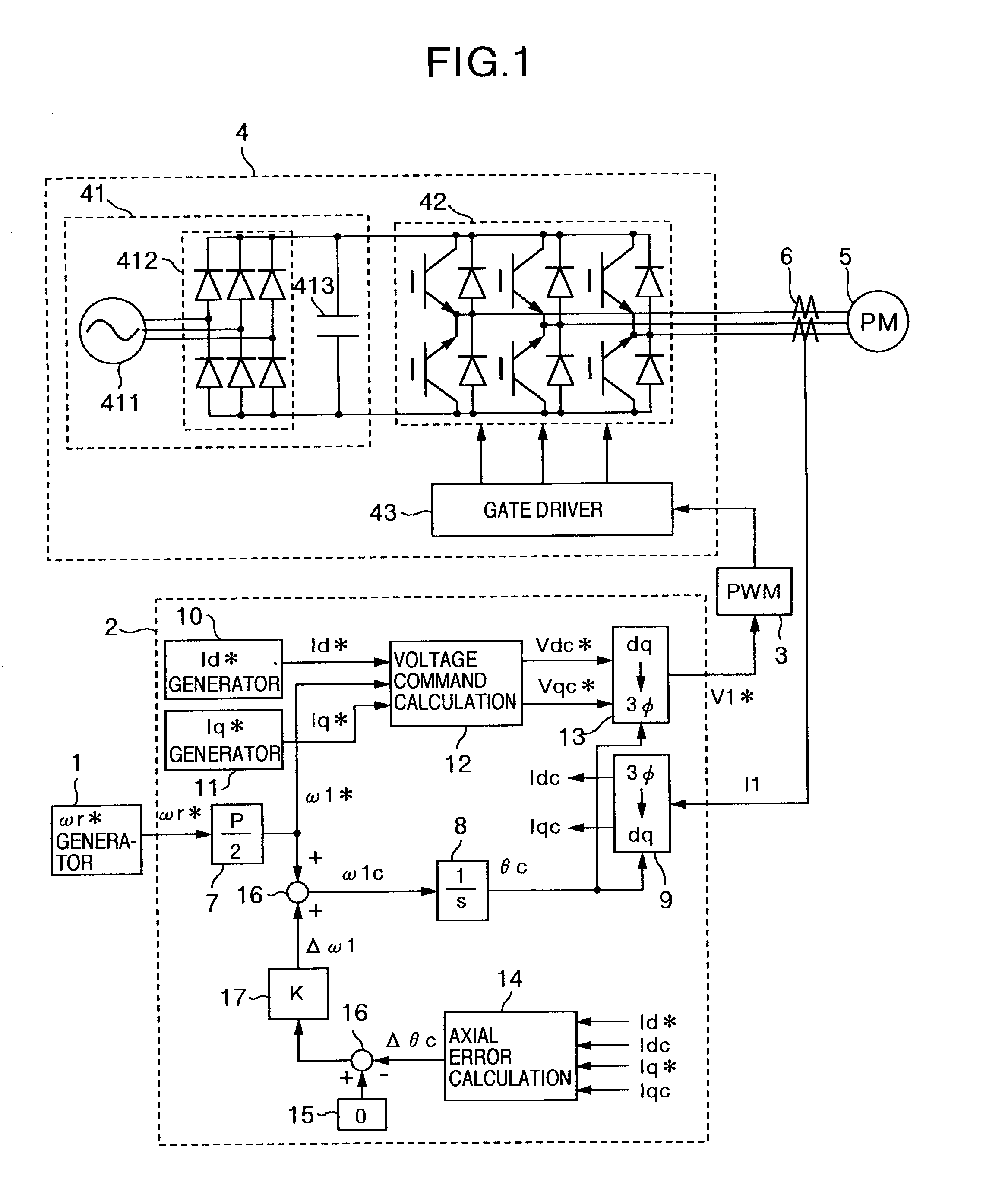

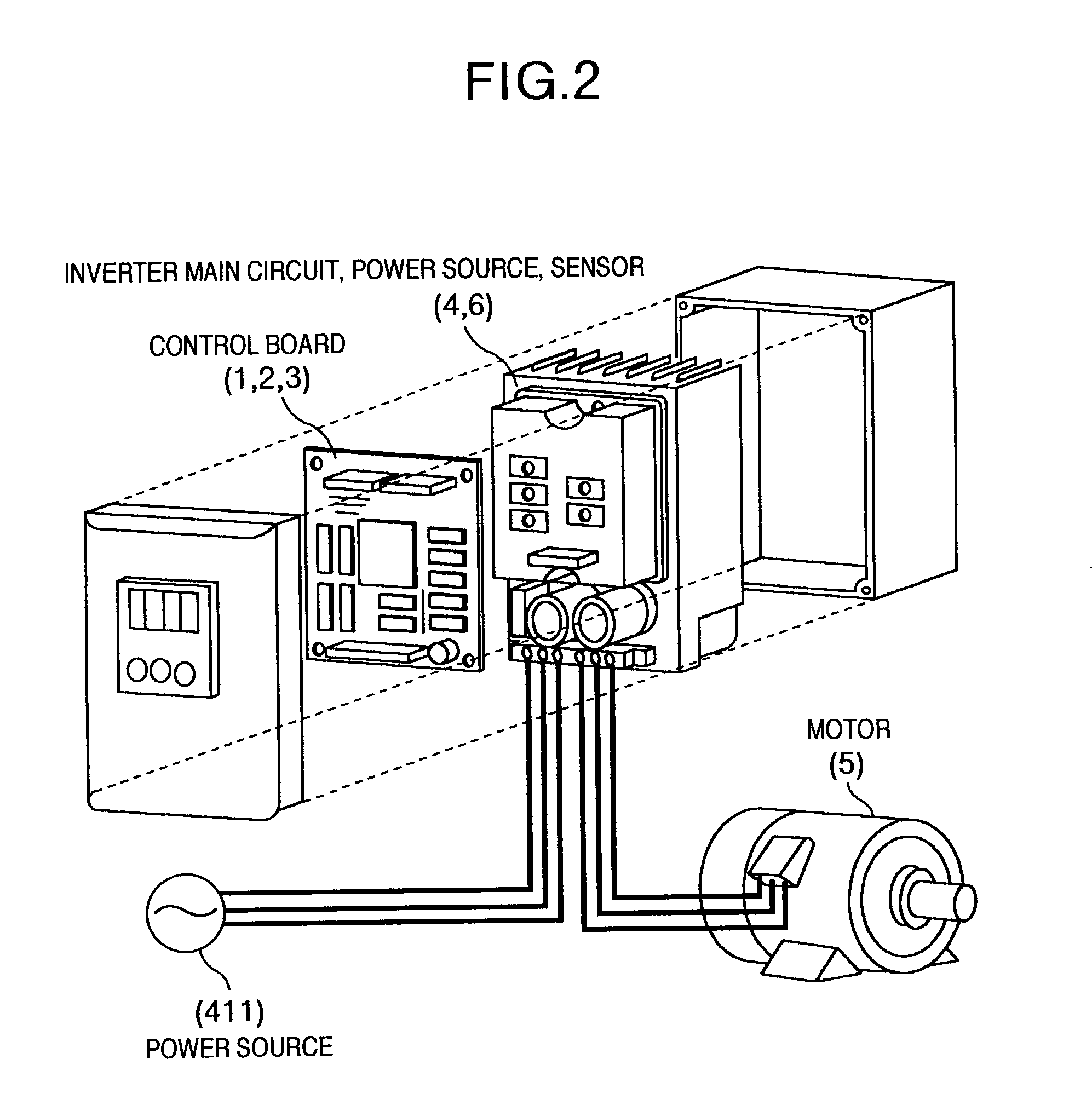

Synchronous motor driving system

InactiveUS20030052640A1DC motor speed/torque controlSynchronous motors startersSynchronous motorMagnetic poles

Axial error calculation unit is provided for estimating an axial error DELTAtheta between a d-q axis and a dc-qc axis by using Ld, Lq, Ke, Id*, Iq*, Idc and Iqc in a range of all rotational speeds except zero of a rotational speed command of a synchronous motor, Ld denoting an inductance on a magnetic pole axis d of the synchronous motor, Lq an inductance on a q axis orthogonal to the magnetic pole axis d, Ke a generated power constant of the motor, Id* a current command of the d axis, Iq* a current command on a q axis, Idc a detected current value on an assumed dc axis on control, and Iqc a detected current value on an assumed qc axis orthogonal to the assumed dc axis. Irrespective of presence of saliency, position sensorless control can be achieved in a wide range a low to high speed zone.

Owner:HITACHI LTD

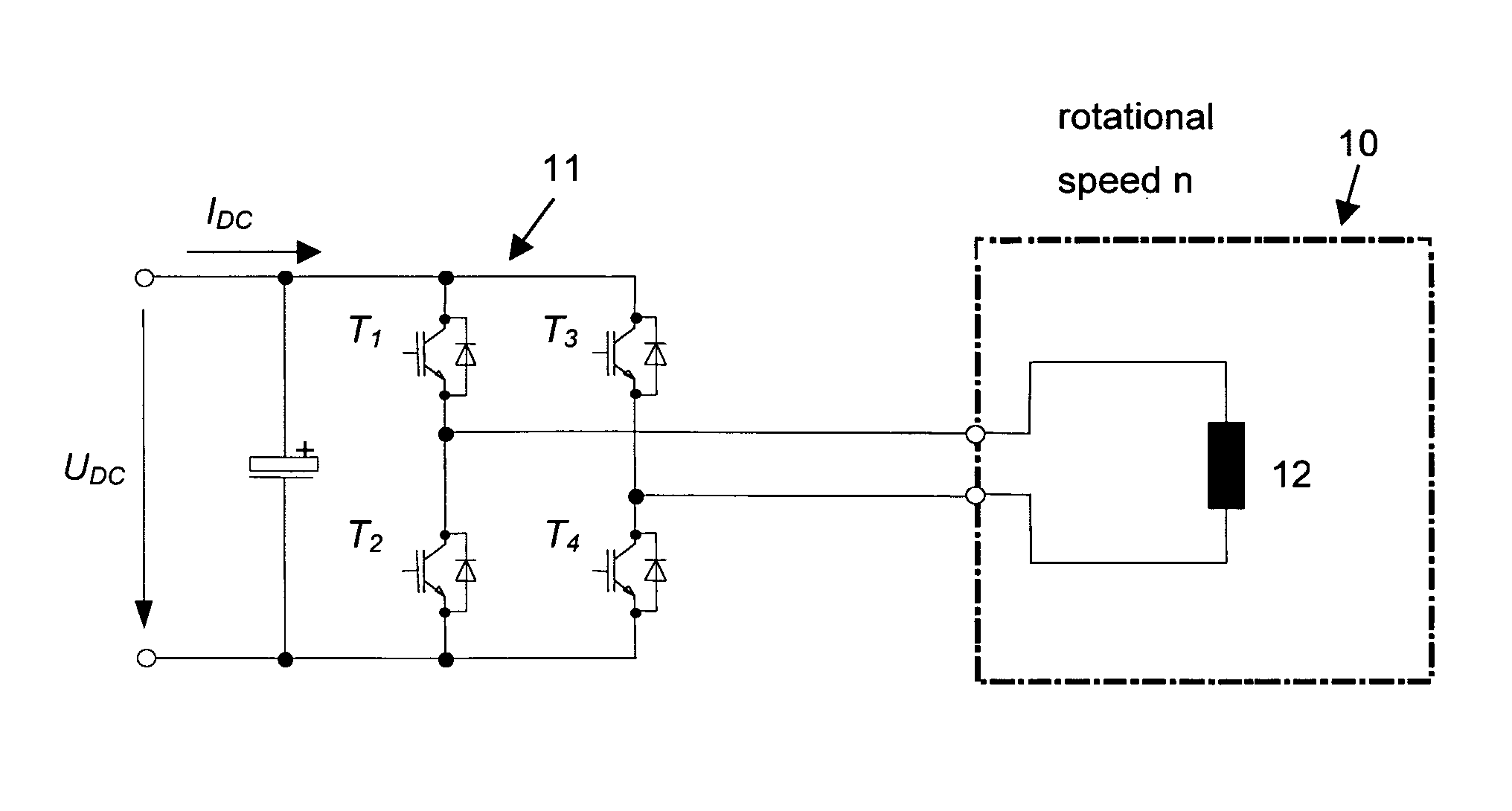

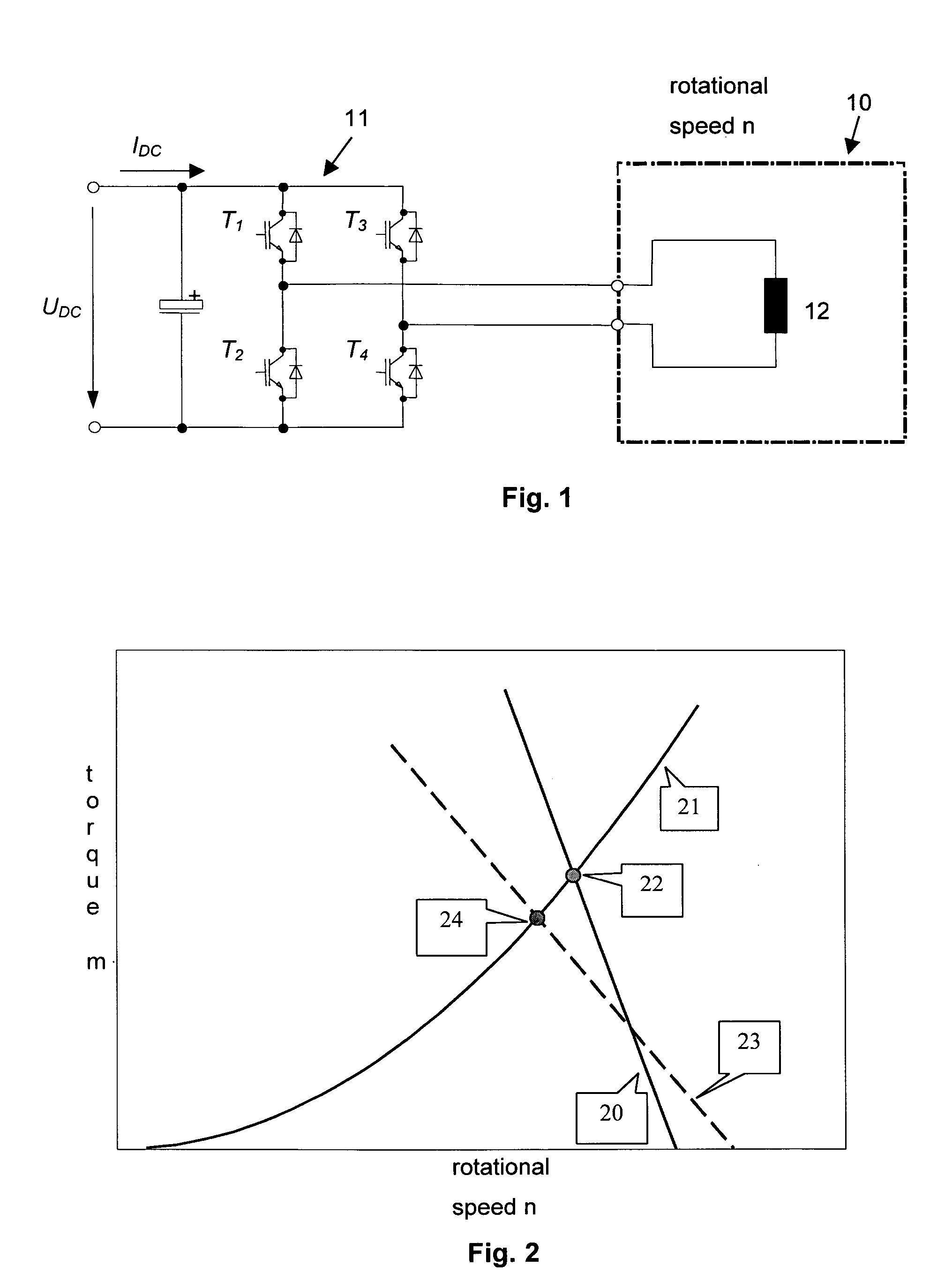

Method for optimizing the efficiency of a motor operated under a load

InactiveUS20050141887A1Low costMore compactDC motor speed/torque controlAC motor controlMotor controlElectric motor

The invention relates to a method to optimize the efficiency of a motor operated under a load having an essentially quadratic characteristic curve, the motor being connected to a motor control with whose aid at least one free motor parameter w can be changed to influence the efficiency. According to the invention, the rotational speed n and the input power PE are determined and the motor parameter w is adjusted to a value at which the value E representing the quotient of the cube of the rotational speed n and the input power PE attains a maximum.

Owner:MINEBEA CO LTD

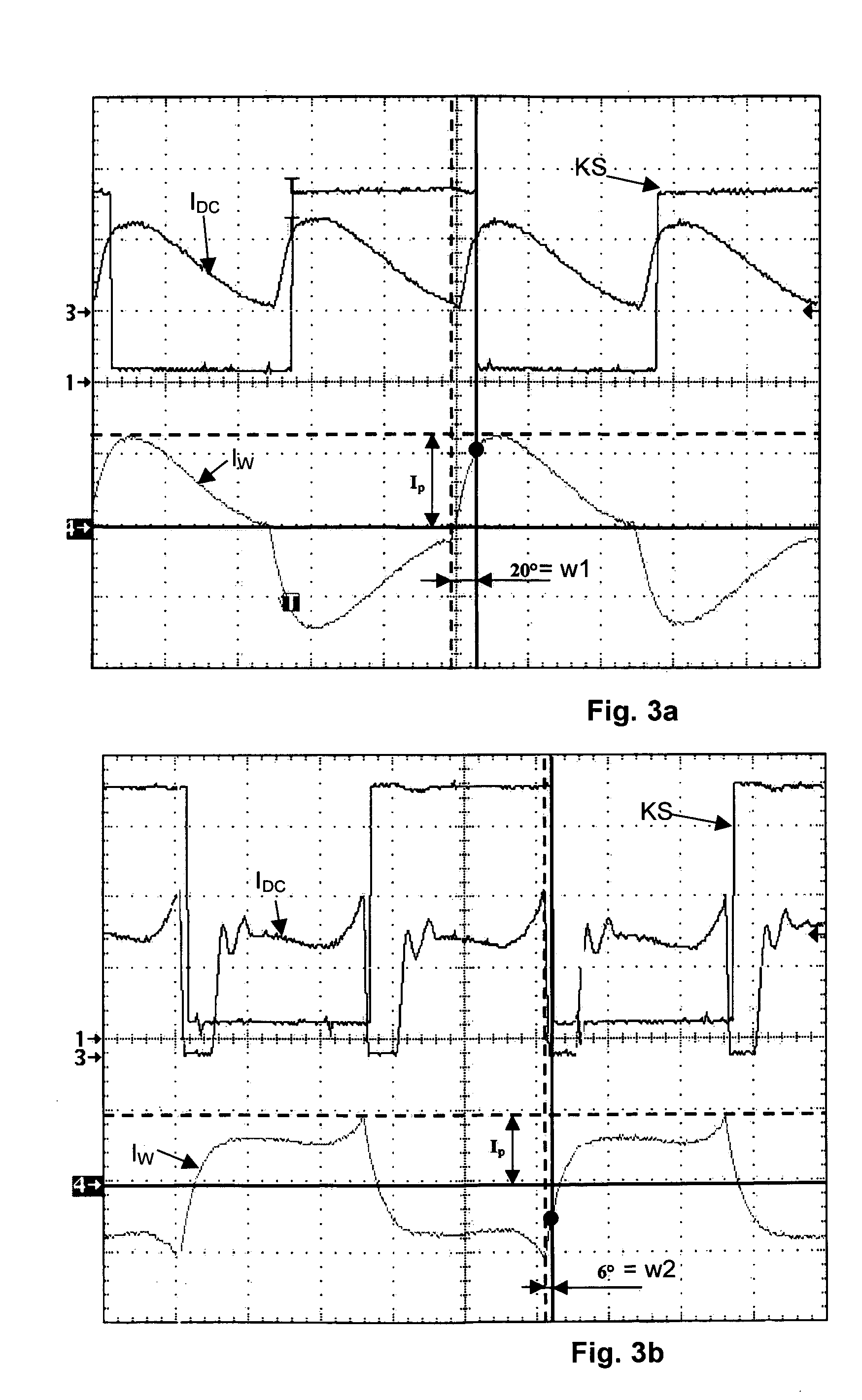

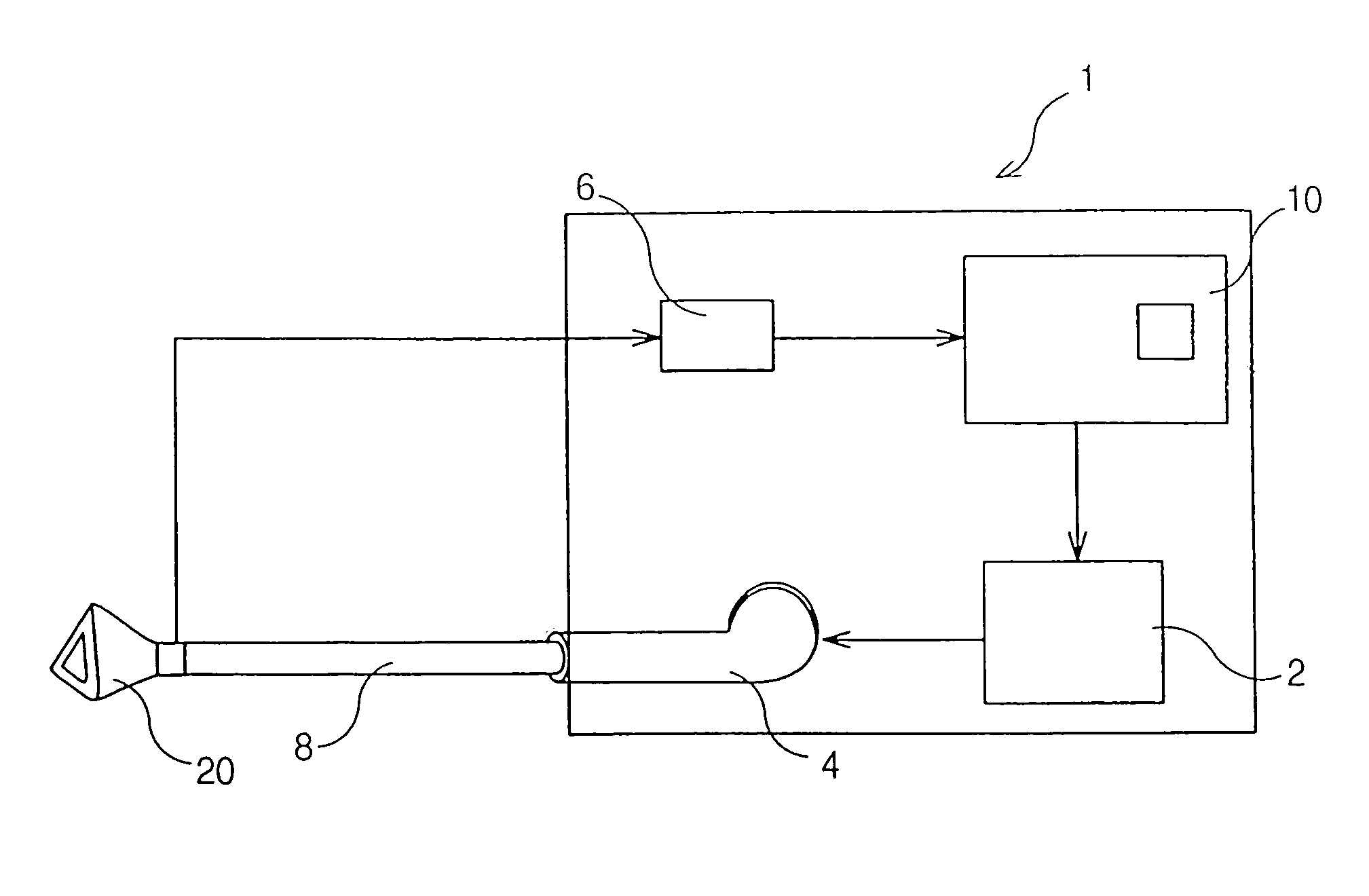

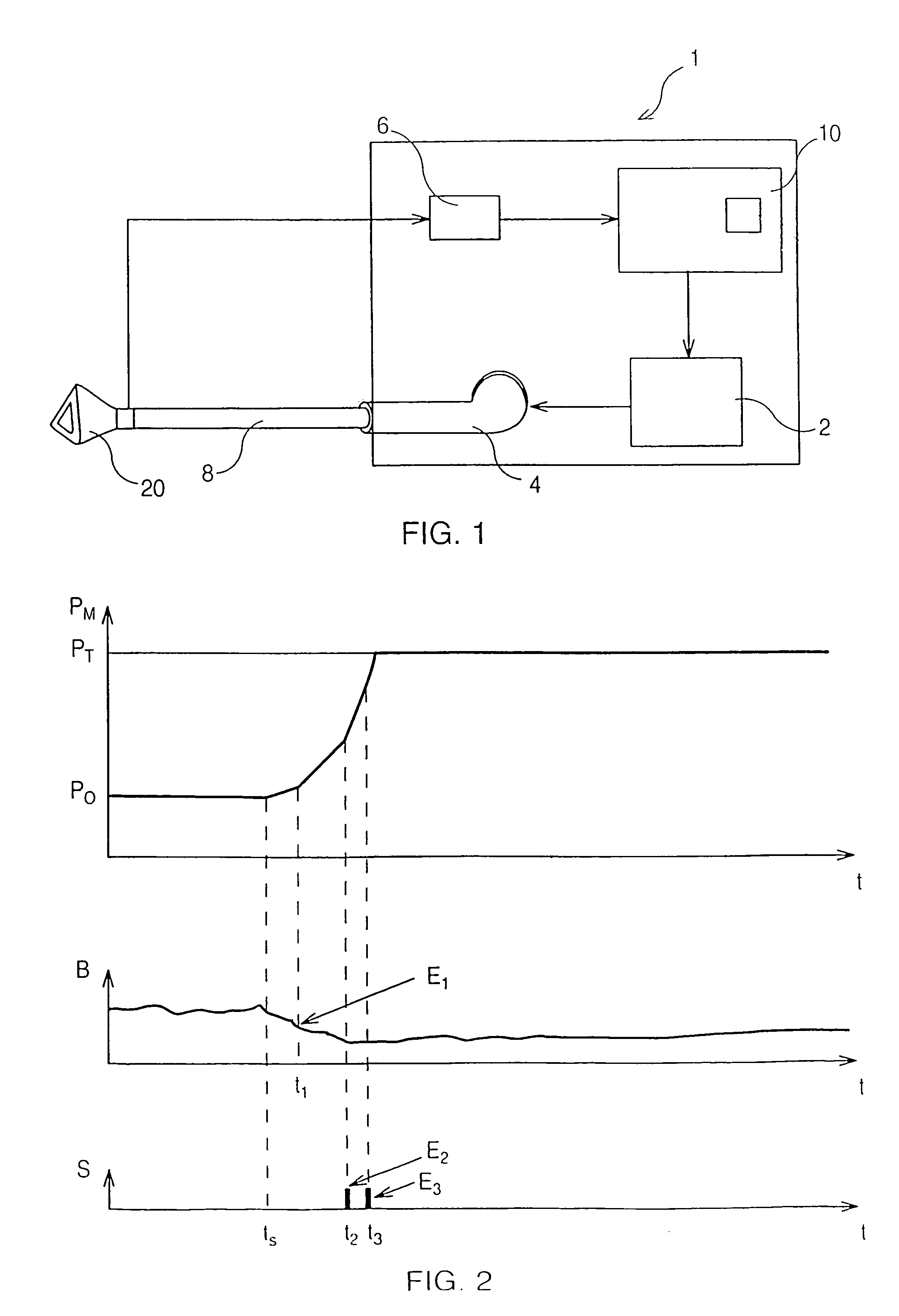

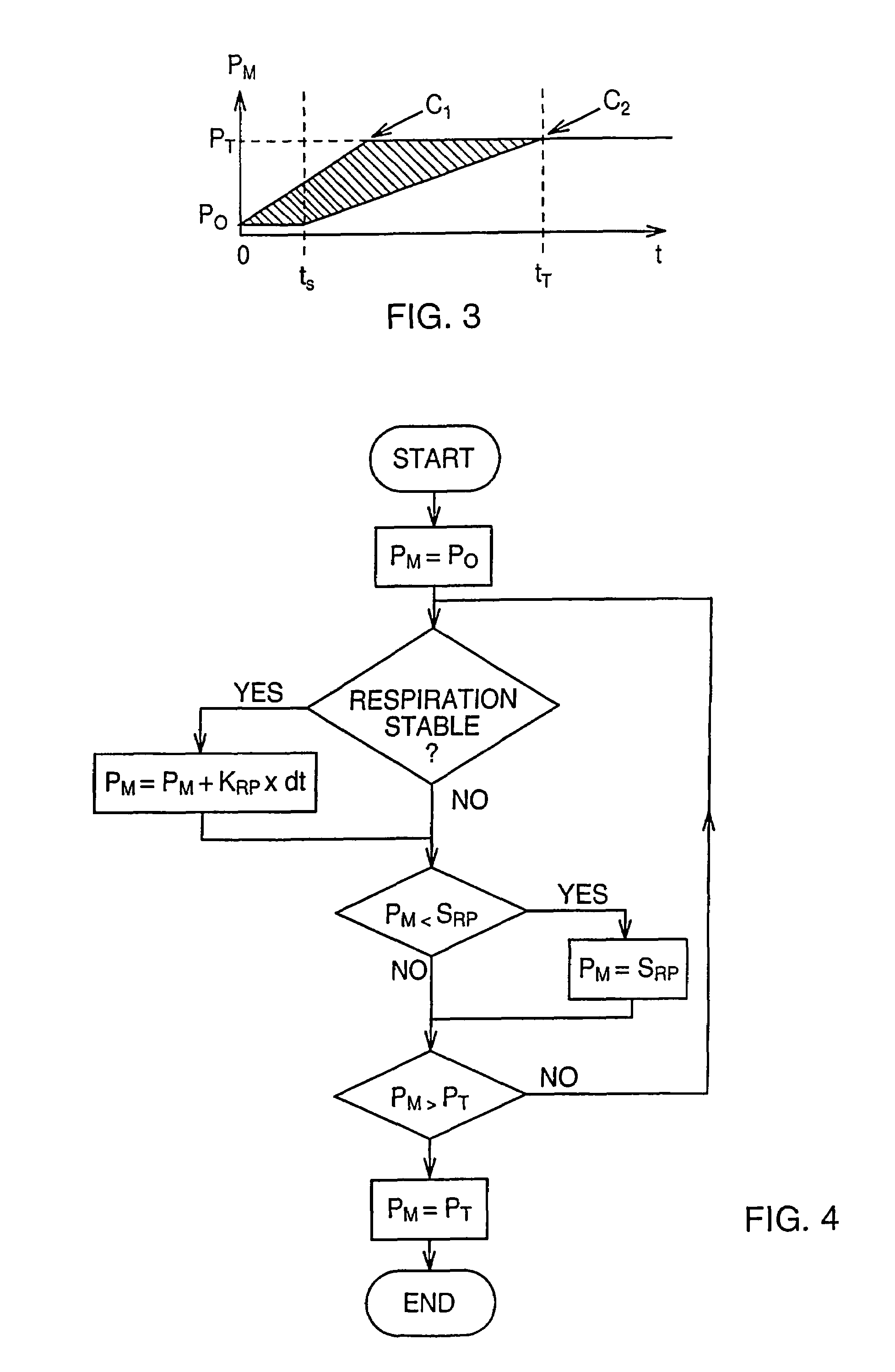

Apparatus to assist a patient's breathing with a variable ramp period to rise to treatment pressure

ActiveUS7500481B2RespiratorsOperating means/releasing devices for valvesPressure riseComputer module

An apparatus (1) to assist a patient's respiration by delivering air to a patient through a mask (20), including a ramp module (10) connected to a control unit (2) to provide the control unit with a pressure value PM at mask (20), so that when apparatus (1) starts functioning, the pressure progressively rises until it reaches a treatment pressure PTi, the apparatus further including a comparator connected to ramp module (10), at least one device for detecting the patient's breathing parameters and sending them to the comparator, so that the comparator can determine whether an event (E1, E2 or E3) occurs in patient's breathing and to send the corresponding data to ramp module (10) which provides control unit (2) with a pressure value PM that will speed up with respect of time, so that the pressure rise at patient's mask (20) is accelerated.

Owner:KONINKLJIJKE PHILIPS NV

Method for self-adjusting control parameters of speed ring of permanent magnet synchronous motor based on fractional orders

ActiveCN103124158ATake full advantage of memory featuresImprove robustnessVector control systemsDynamo-electric converter controlPattern search algorithmPermanent magnet synchronous motor

The invention discloses a method for self-adjusting control parameters of a speed ring of a permanent magnet synchronous motor based on fractional orders. An integer-order proportional integral (PI) controller in an alternating current servo system of the permanent magnet synchronous motor is replaced by a fractional-order PI controller, parameters of the fractional-order PI controller are automatically adjusted, and the alternating current servo system of the permanent magnet synchronous motor can be controlled. The method specifically comprises the following steps of: firstly, acquiring current and speed signals of the alternating current servo system; secondly, identifying a speed ring controlled object model of a permanent magnet synchronous motor servo system according to the acquired signals, and identifying the parameters of the model; and finally, optimally adjusting the control parameters, and thus obtaining optimal control parameters. According to the method, the original integer-order PI controller is replaced by the fractional-order PI controller, and the parameters of the controller are automatically adjusted; the parameters of the controller are optimized by using a pattern search algorithm; and the adjusted parameters of the controller are high in robust, high in anti-disturbance capacity and high in control accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

Synchronous motor driving system and sensorless control method for a synchronous motor

InactiveUS20030057912A1Synchronous motors startersDC motor speed/torque controlSynchronous motorMagnetic poles

Axial error calculation unit is provided for estimating an axial error DELTAtheta between a d-q axis and a dc-qc axis by using Ld, Lq, Ke, Id*, Iq*, Idc and Iqc in a range of all rotational speeds except zero of a rotational speed command of a synchronous motor, Ld denoting an inductance on a magnetic pole axis d of the synchronous motor, Lq an inductance on a q axis orthogonal to the magnetic pole axis d, Ke a generated power constant of the motor, Id* a current command of the d axis, Iq* a current command on a q axis, Idc a detected current value on an assumed dc axis on control, and Iqc a detected current value on an assumed qc axis orthogonal to the assumed dc axis. Irrespective of presence of saliency, position sensorless control can be achieved in a wide range a low to high speed zone.

Owner:HITACHI LTD

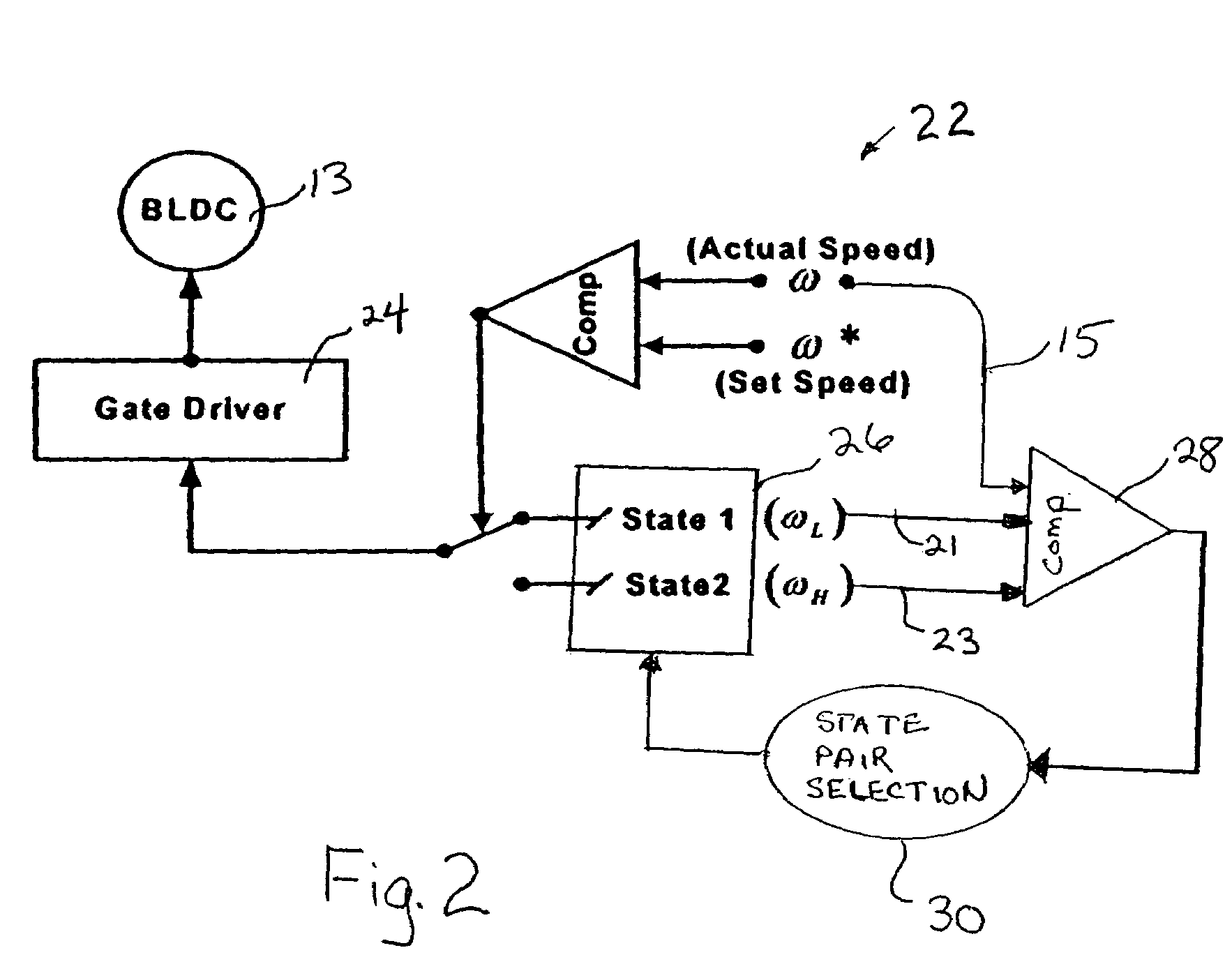

Digital control of motor drives

ActiveUS7193385B2Low costEasy to implementAC motor controlDC motor speed/torque controlMotor driveElectric machine

A digital controller is easily implemented for variable speed or torque control of an electric motor or generator by using a comparator to determine a choice of control state outputs.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

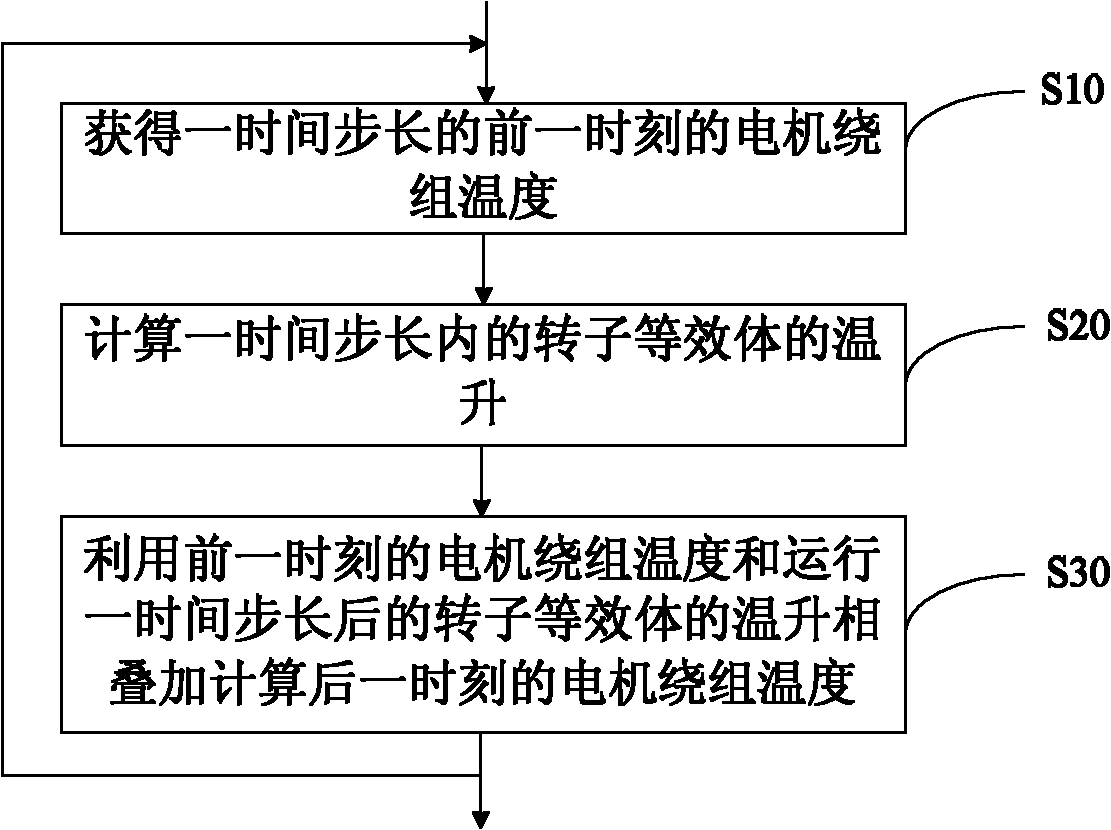

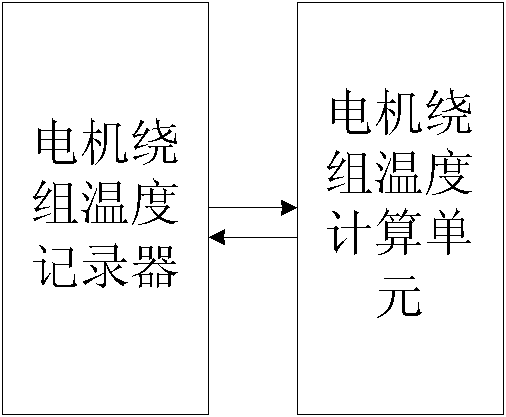

Electric motor, electric motor winding temperature detection method and device as well as electric motor winding thermal protection method and device

ActiveCN102156000ARealize real-time monitoringFully reflect the effect of temperature riseThermometer detailsTemperature measurement in motorsElectric machineEngineering

The invention discloses an electric motor, an electric motor winding temperature detection method and device as well as an electric motor winding thermal protection method and device. The electric motor winding temperature detection method comprises the following steps: acquiring the electric motor winding temperature at the previous moment; then calculating temperature rise of a rotor equivalentbody after operating for one time step; and finally calculating the electric motor winding temperature at the next moment by superimposing the electric motor winding temperature at the previous moment with the temperature rise of the rotor equivalent body after operating for one time step. According to the electric motor winding temperature detection method, the electric motor winding temperatureis monitored in real time; the performance of the electric motor is exerted; and the sensitivity of the electric motor is improved.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

Air moving appliance with on-board diagnostics

ActiveUS20140312813A1Flow of airReliablySynchronous motors startersAC motor controlControl systemMotor load

An air moving appliance comprising an electric motor coupled to a fan, a control system for controlling the motor, the control system including monitoring means configured to monitor a motor load parameter; memory means configured to store a predetermined reference motor load parameter value; compensating means that determines a compensated reference motor load parameter value based on the predetermined reference motor load parameter value and a set of ambient environment input conditions; comparison means configured to compare the motor load parameter and the compensated reference motor load parameter value and trigger an operational event based on the result of the comparison. The invention also relates to a method of controlling an air moving appliance.

Owner:DYSON TECH LTD

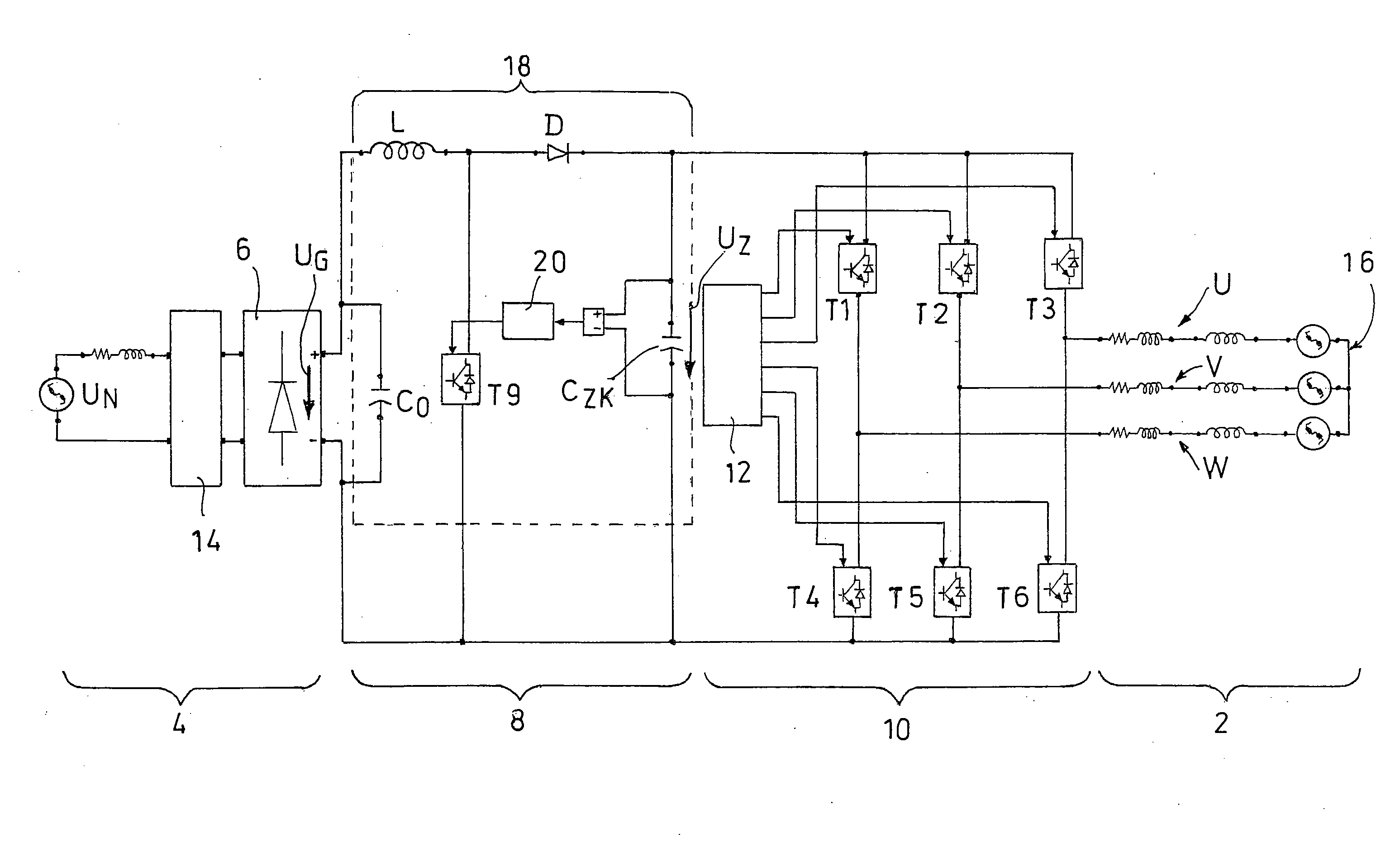

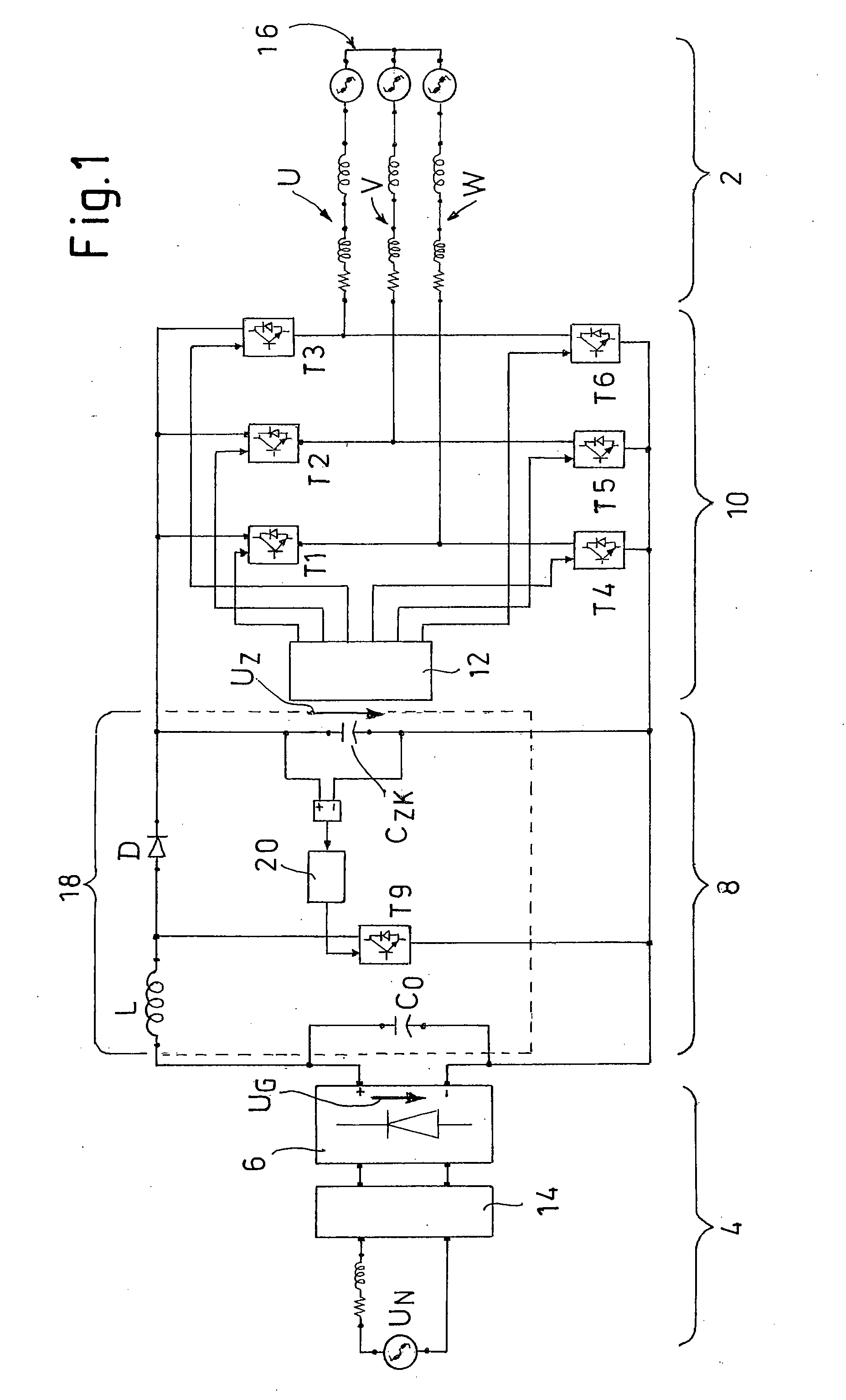

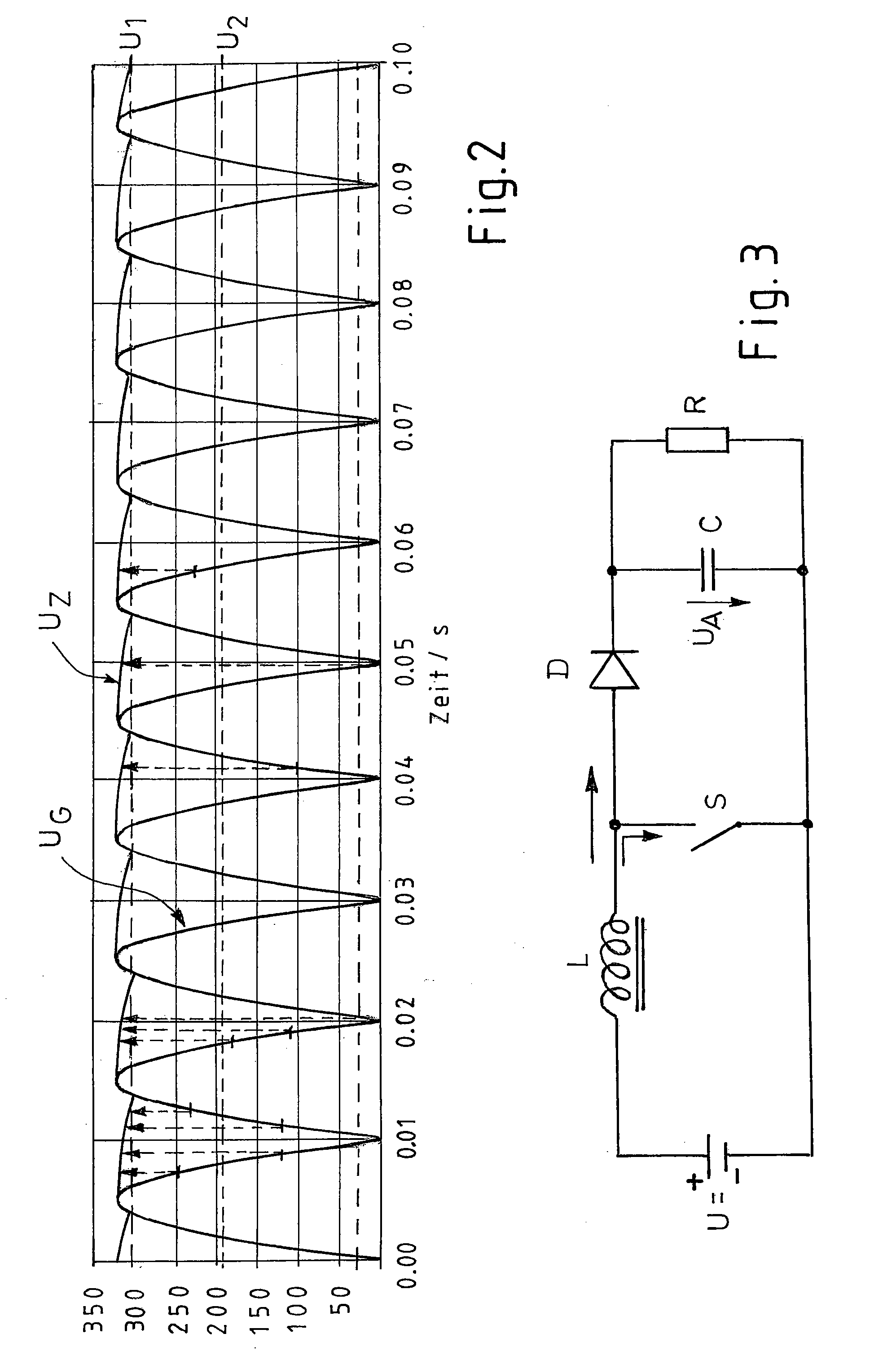

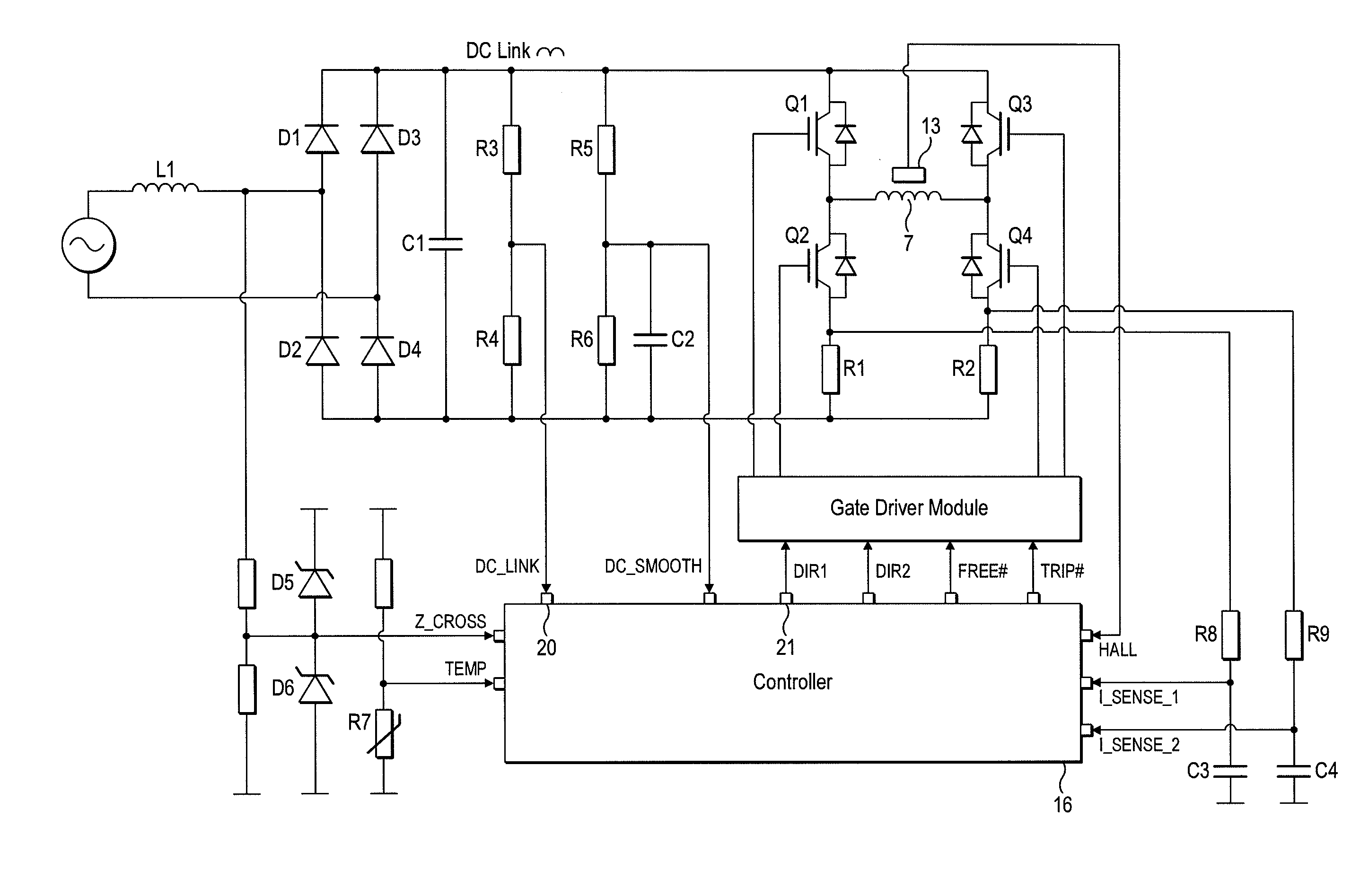

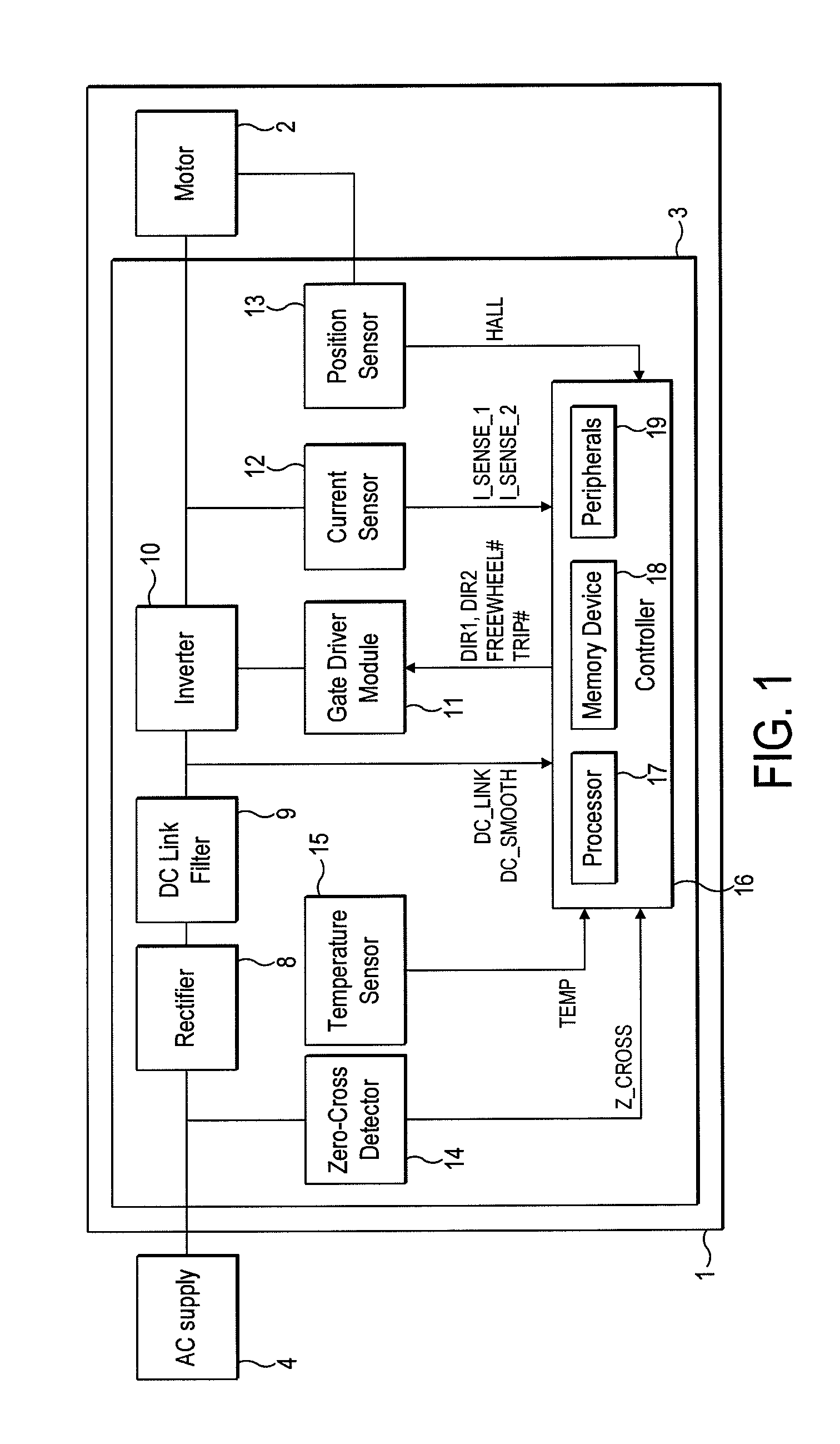

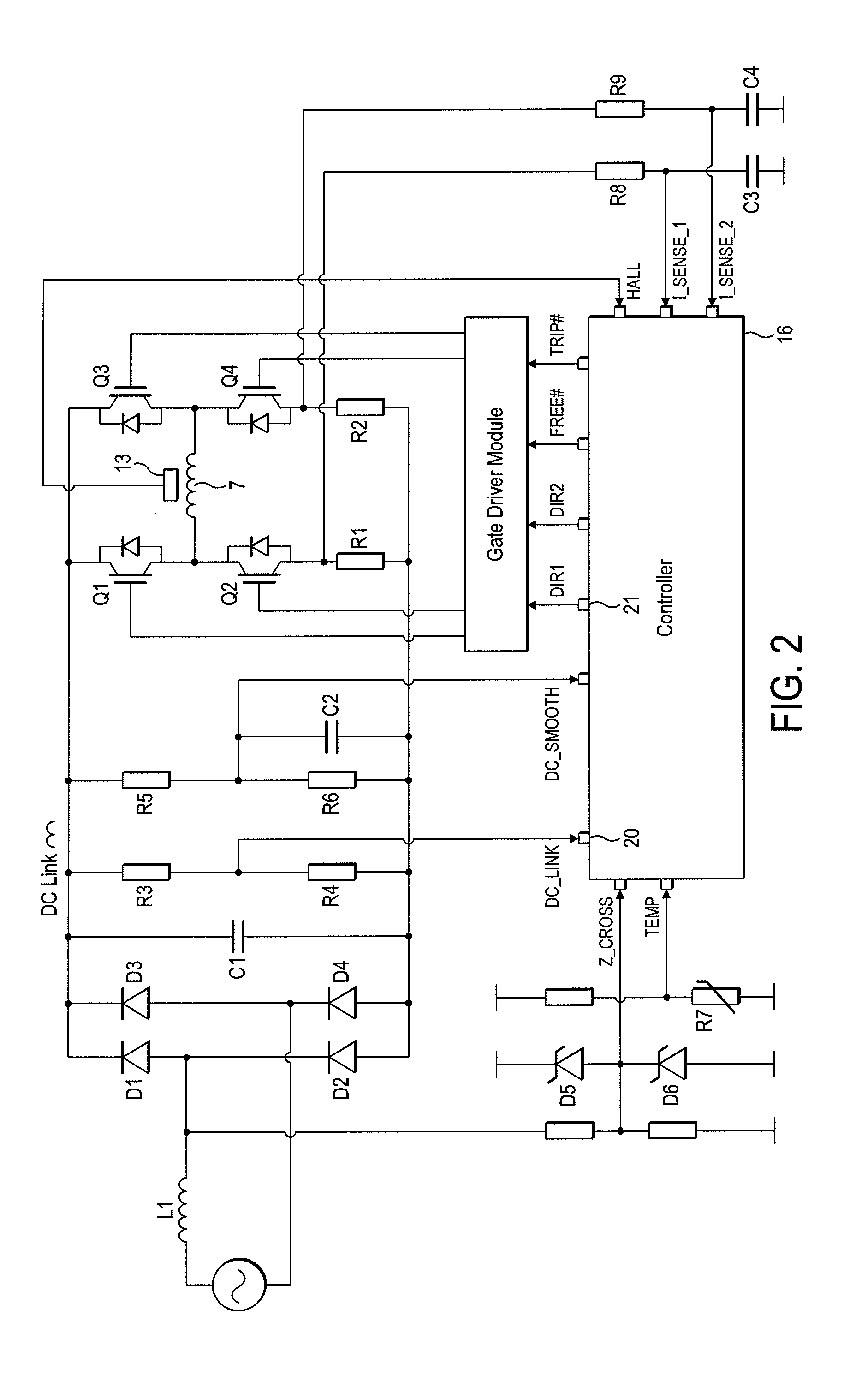

Procedures and Control System to Control a Brushless Electric Motor

ActiveUS20100315027A1Constant voltageSufficient voltageSynchronous motors startersAC motor controlBoost chopperControl system

The present invention relates to a method and a control system for driving a three-strand brushless, electronically commutated electric motor (2), wherein a line AC voltage (UN) is rectified and fed via a slim DC link (8) with minimum DC link reactance as a DC link voltage (UZ) to an inverter (10) that can be driven to supply and commutate the electric motor (2). A pulsating DC voltage (UG) initially generated by rectifying the line AC voltage (UN) is dynamically increased with respect to its instantaneous values by a step-up chopper (18) in such a manner that the resulting DC link voltage (UZ) with a reduced ripple always lies above a defined limit voltage (U18 / U1) over time. The control system consists of a network rectifier (6), a downstream slim DC link (8) with minimum DC link reactance and a controllable inverter (10) that can be supplied via the DC link and driven to commutate the electric motor (2). A step-up chopper (18) is integrated therein with a controller (20) designed in such a manner that, the pulsating DC voltage (UG) rectified by the network rectifier (6) is dynamically increased with respect to its instantaneous values in such a manner that the resulting DC link voltage (UZ) with a reduced ripple always lies above a defined limit voltage (U20 / U1) over time. Stray inductances (Ls1-Ls3) of the motor winding heads present in the electric motor (2) are used as inductor (L) for the step-up chopper (18).

Owner:EBM PAPST MULFINGEN GMBH & CO KG

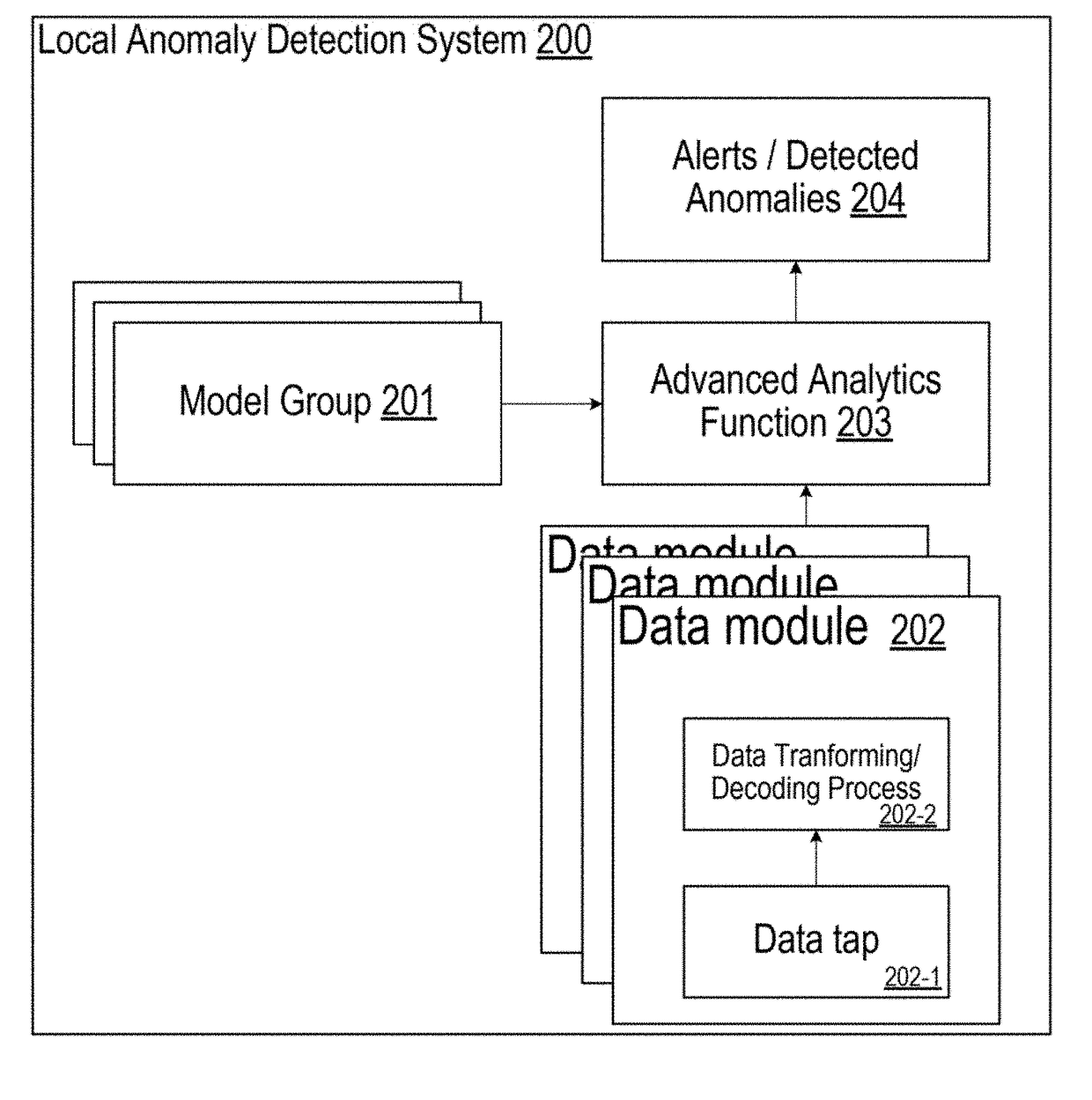

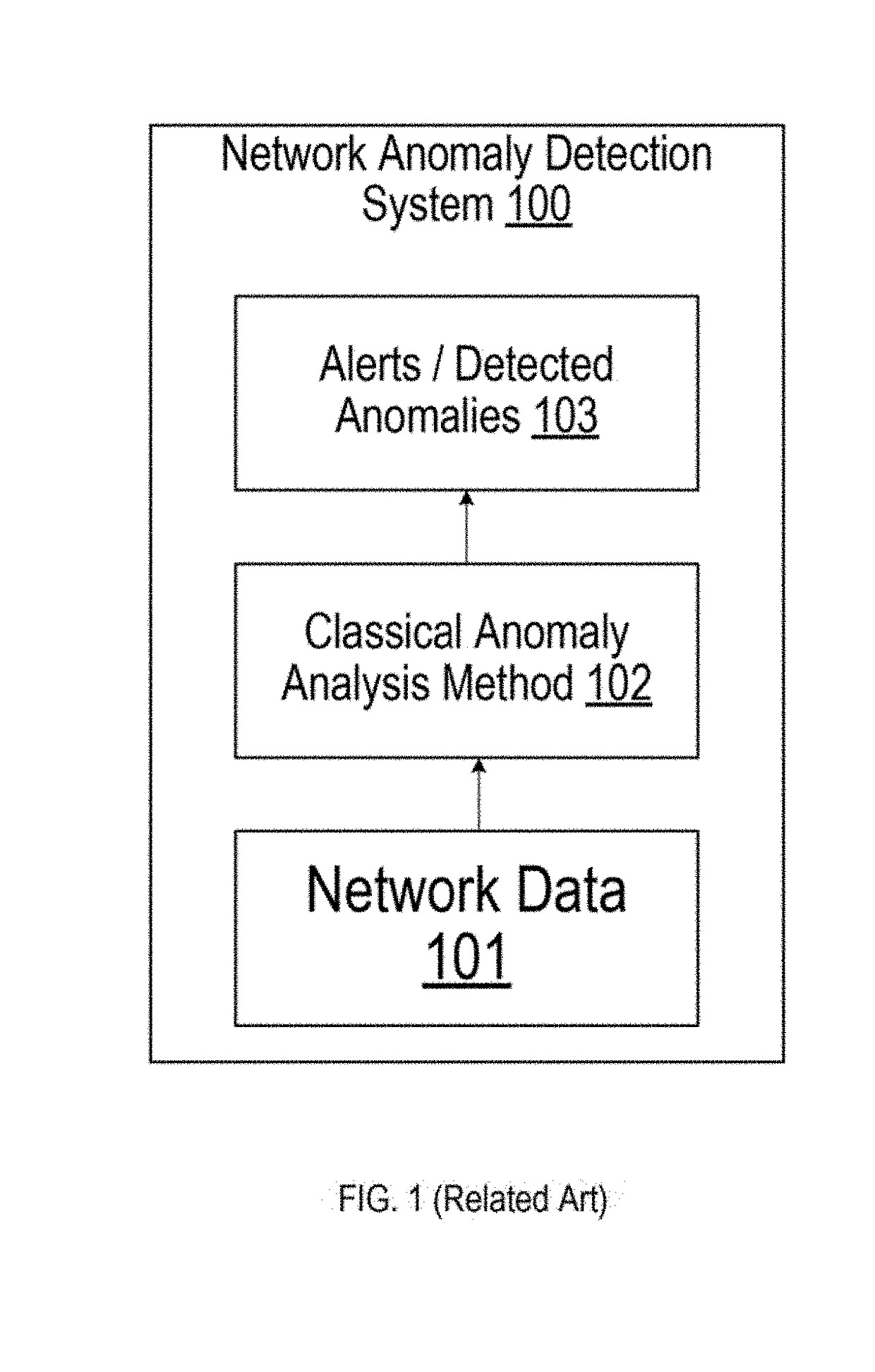

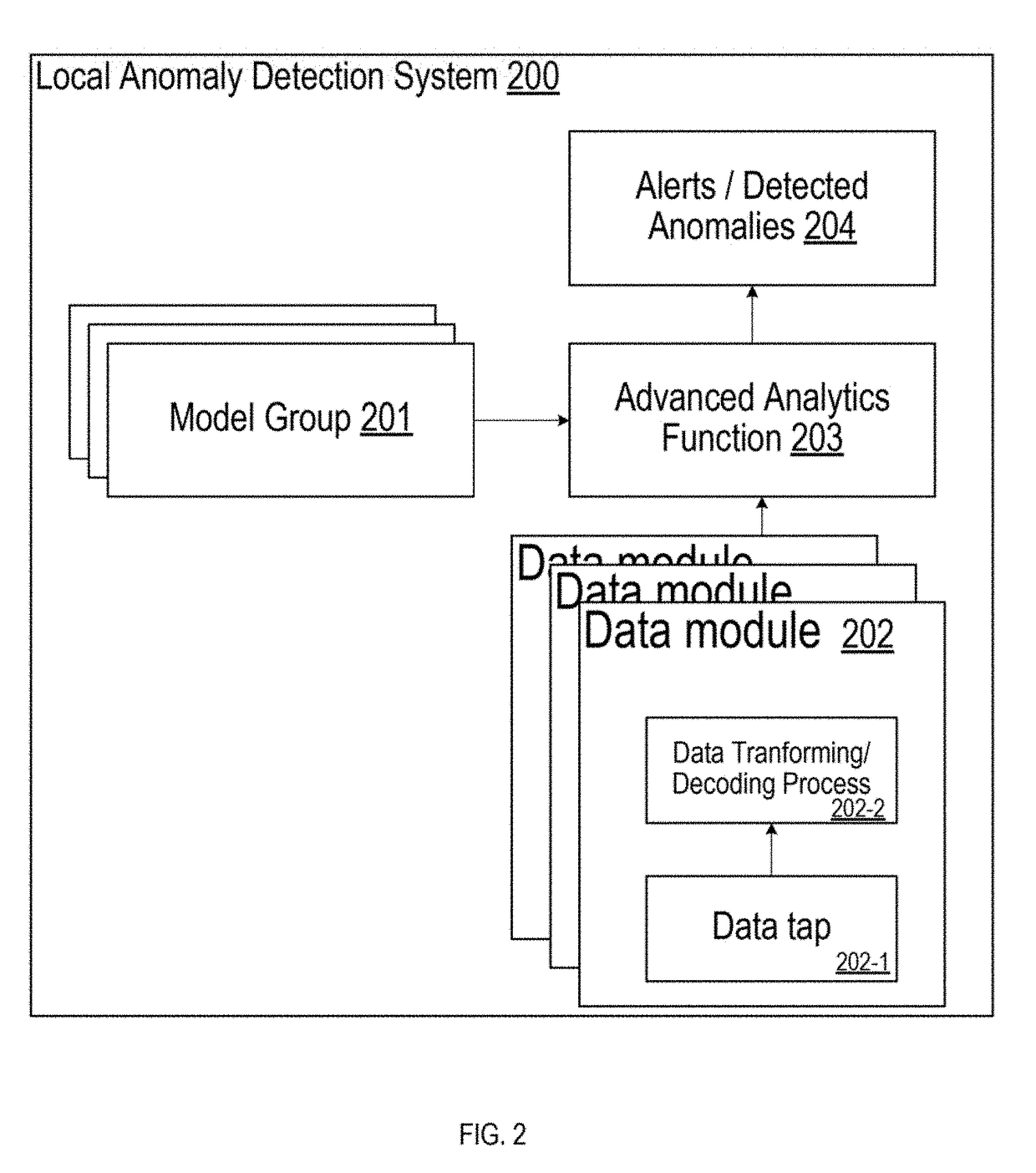

Cooperative cloud-edge vehicle anomaly detection

ActiveUS20180255082A1AC motor controlRegistering/indicating working of vehiclesAnomaly detectionNetwork data

Example implementations of the present disclosure are directed to systems and methods directed to increasing the accuracy and speed that anomalous and malicious network data can be identified within a vehicle. Through the utilization of example implementations described herein, the security of the vehicle can be increased and the risk of a vehicle's internal systems being compromised and property being damaged can be reduced.

Owner:HITACHI LTD

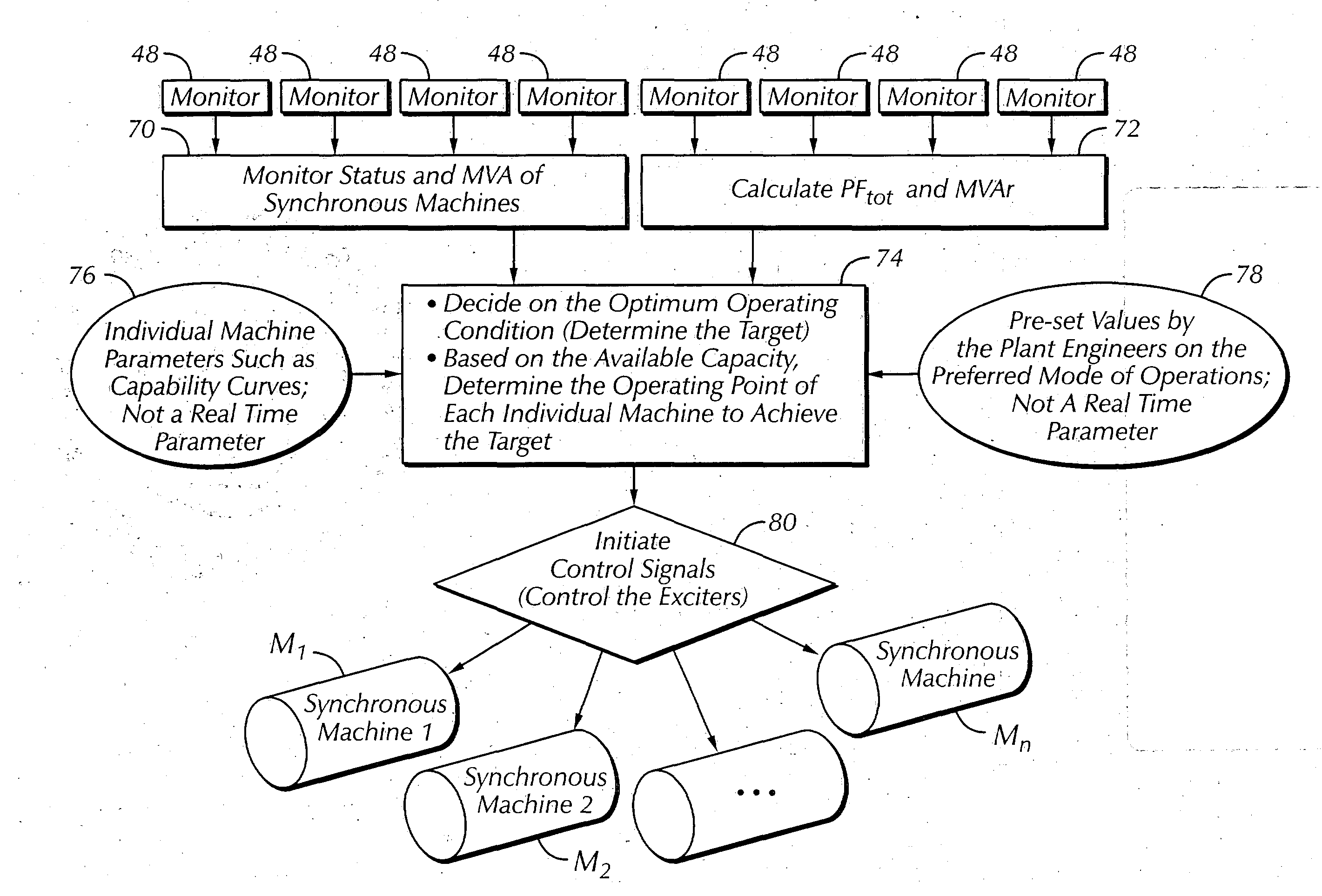

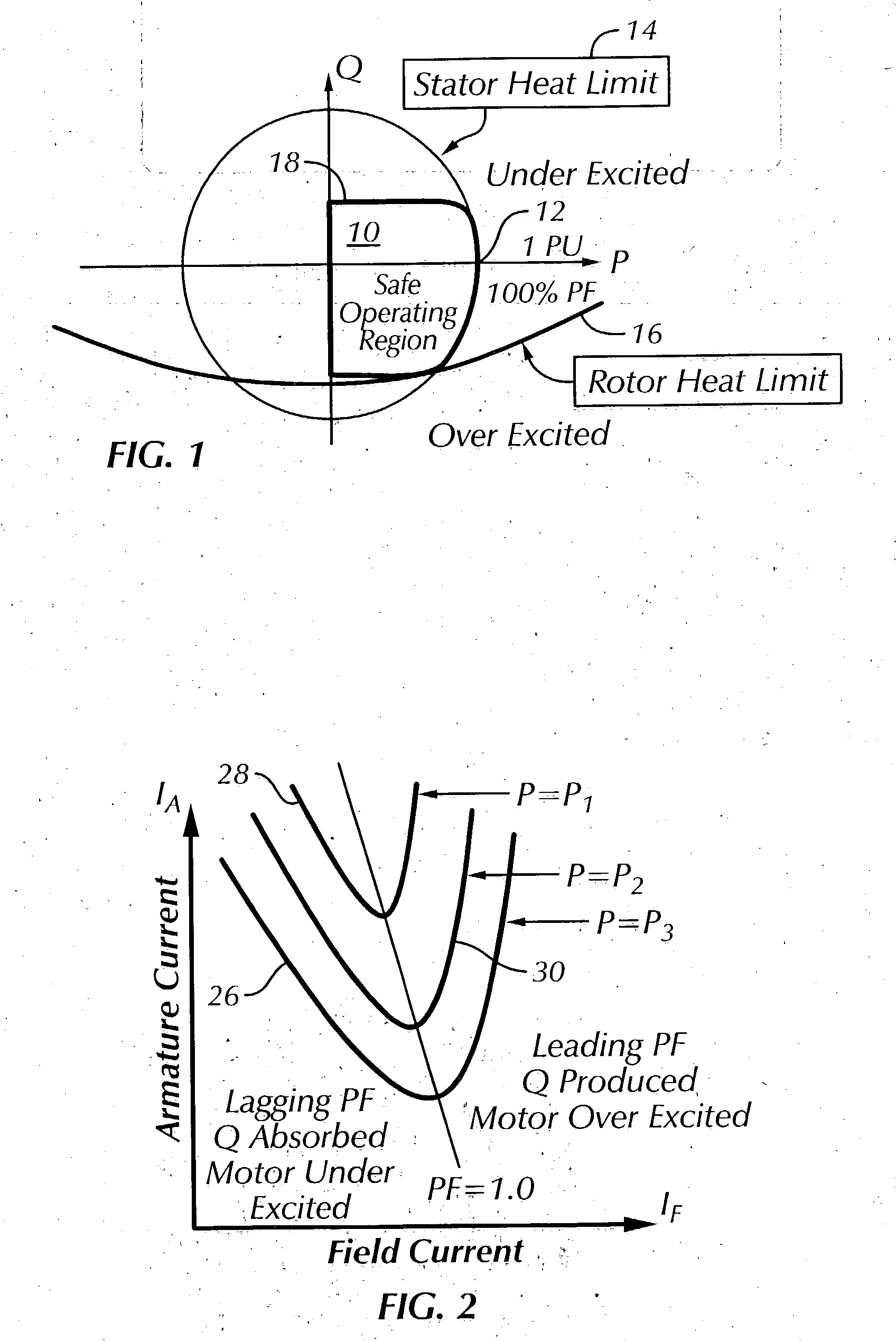

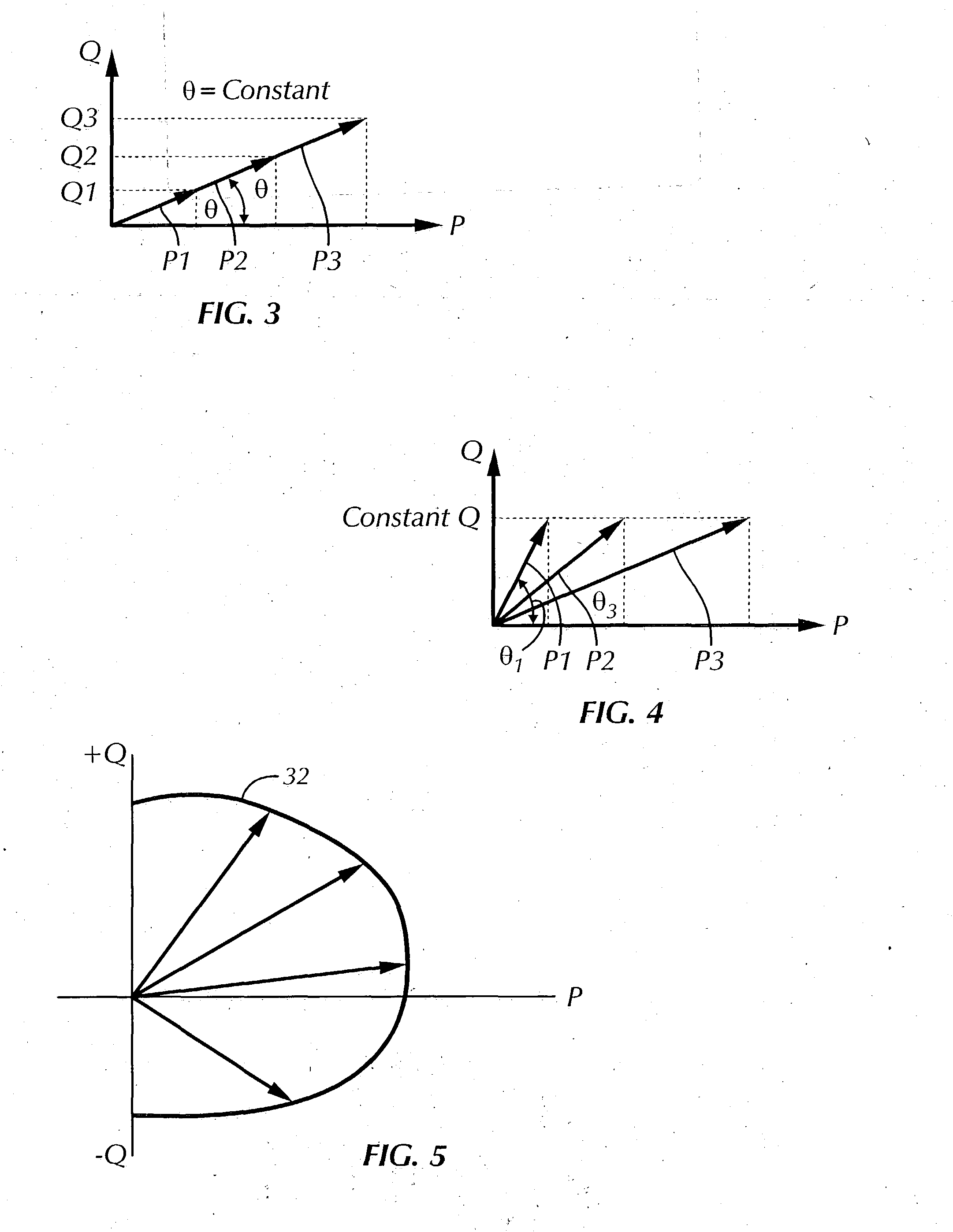

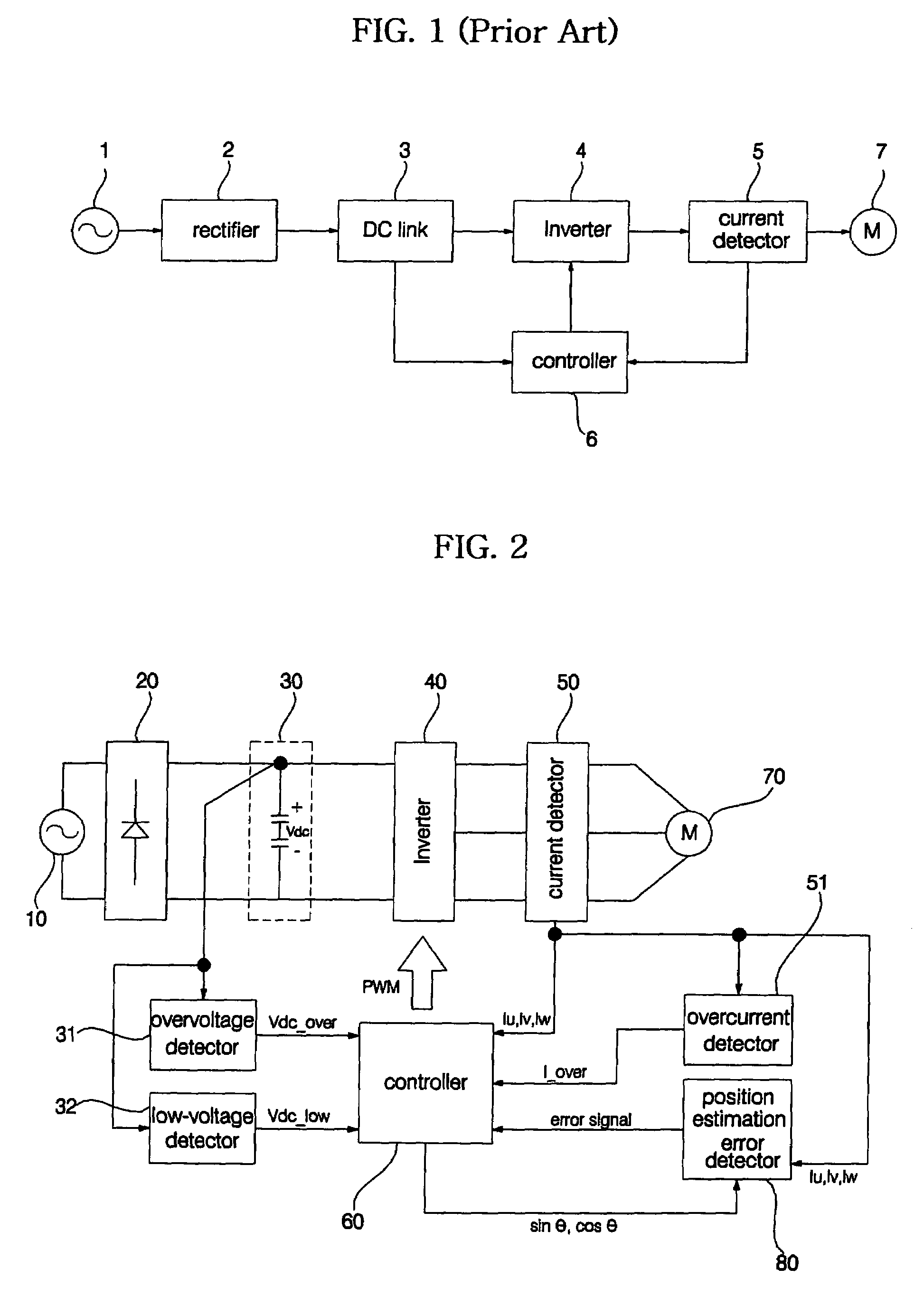

Reactive power optimization with adaptive excitation control

ActiveUS20040260488A1Increase stiffnessVoltage drop can be limitedSynchronous motors startersAC motor controlConstant powerOperating point

Reactive power (VAR) consumption in a power plant or facility having synchronous machines is adaptively controlled in an automated manner. Electrical parameters of the plant are dynamically monitored during plant operation, and the overall plant power system is brought to an optimum operating point under control of a microprocessor-based power measurement system. The microprocessor-based power measurement system adaptively changes the excitation system of synchronous machines in the plant based on results of monitoring. The excitation systems of the synchronous machines may be adjusted to be constant bus voltage, constant reactive power, or constant power factor, according to optimum system performance requirements. The power measurement system also assists in avoiding problems in voltage regulation during increased load demand conditions, such as when starting large electrical motors or energizing large transformers in the system.

Owner:SAUDI ARABIAN OIL CO

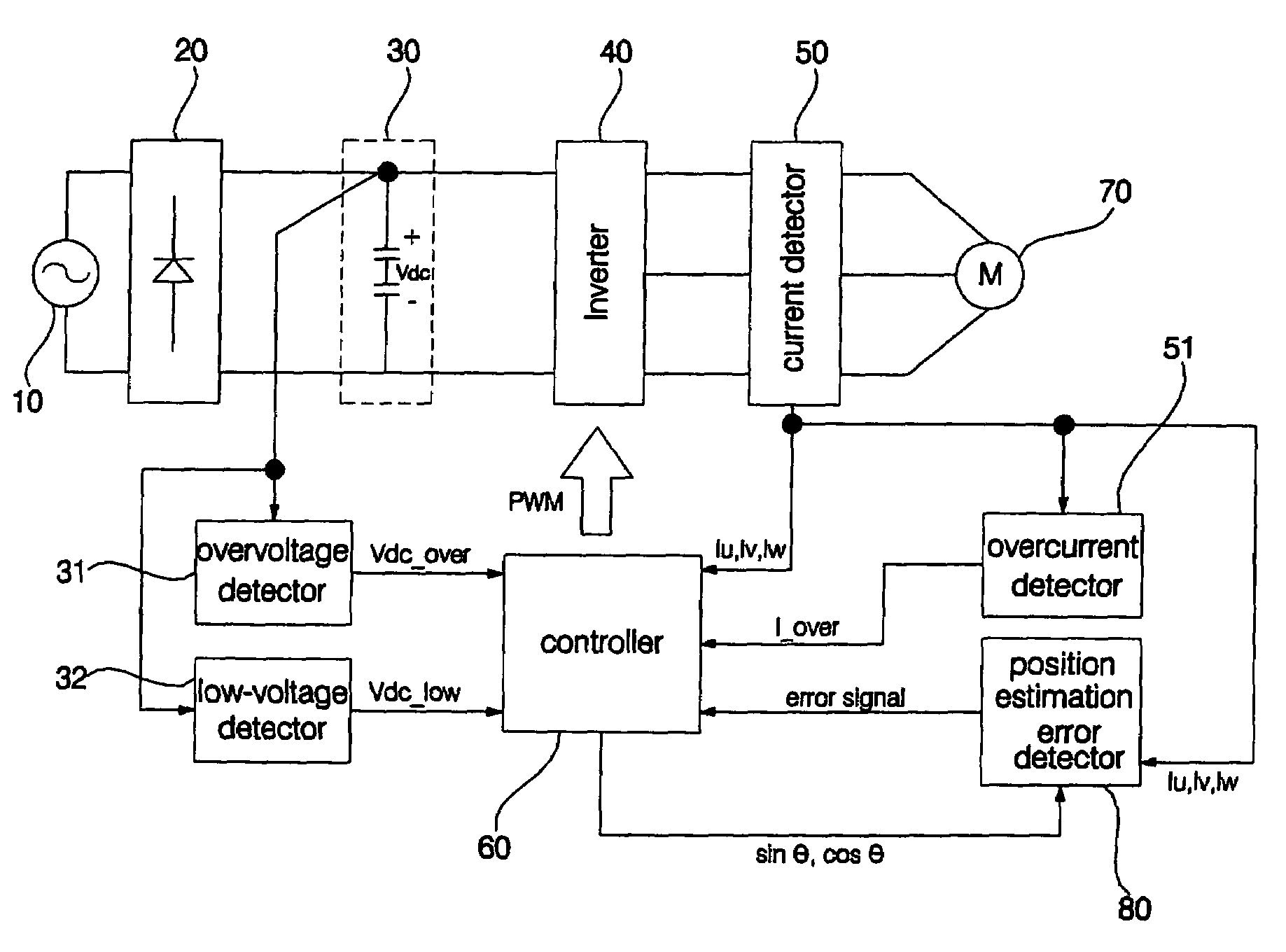

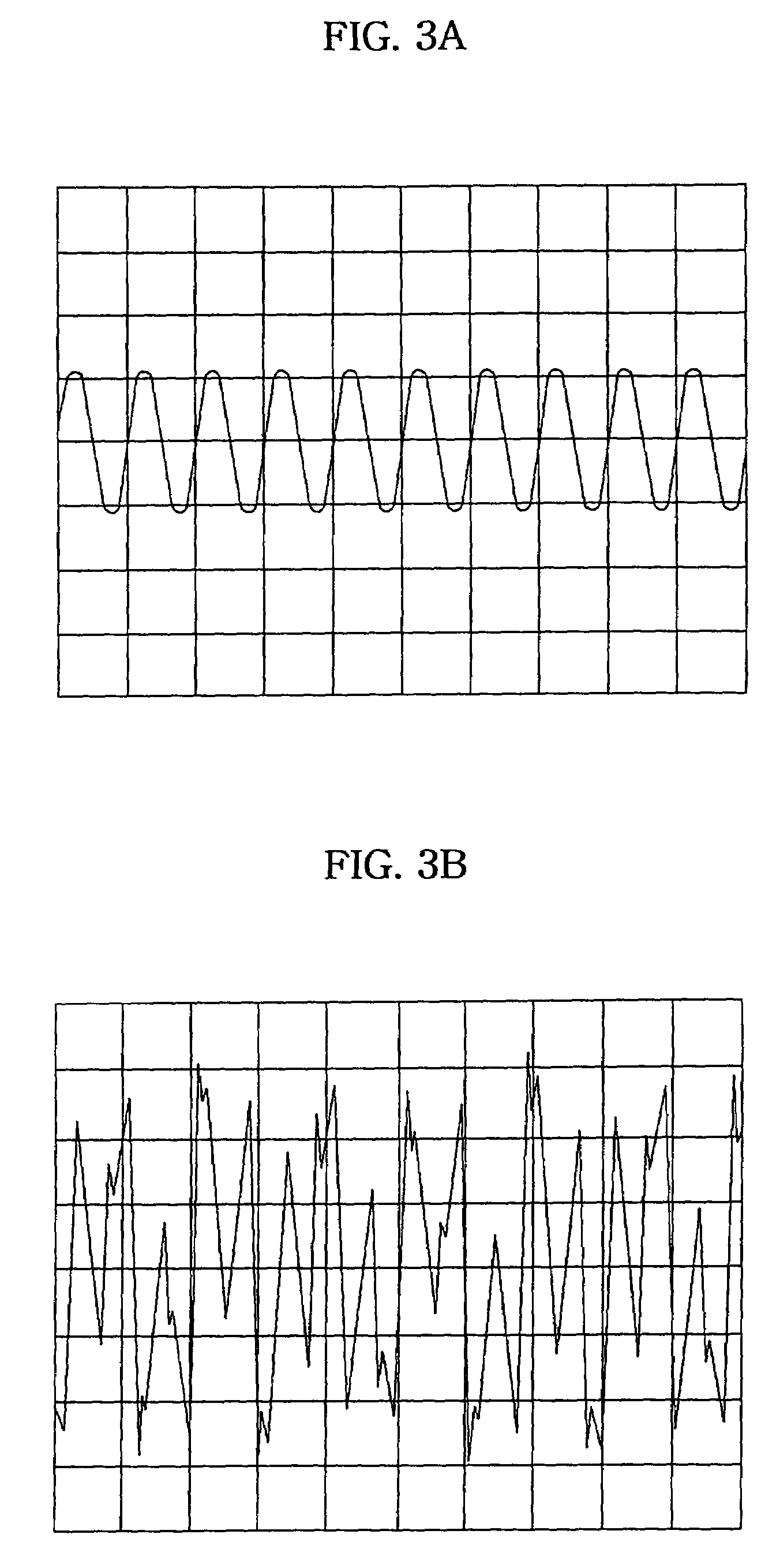

Sensorless motor drive apparatus and method for protecting and controlling the same

A sensorless motor drive apparatus and a method for protecting and controlling the same. The sensorless motor drive apparatus includes a unit for determining the presence or absence of a position estimation error of a rotor contained in a motor using a current value applied to the motor and a position estimation angle of the rotor. Therefore, the sensorless motor drive apparatus determines the presence or absence of the position estimation error of the rotor without using a sensor, so that it reduces production costs, prevents the motor from generating a faulty operation, and prevents a compressor including the motor from being damaged.

Owner:LG ELECTRONICS INC

High torque starting method for high power alternating current (AC) servo driver

ActiveCN102497141ASolve the speed problemSolve problems such as vibratioModelling/simulations for controlStarter arrangementsHigher PowerHigh torque

The invention belongs to the technical field of a servo driver, in particular to a high torque starting method for the servo driver. The aim of the invention is to solve the problem of serious influence on the control accuracy of a servo system due to executive mechanism vibration caused by disturbed torque in the starting process of an alternating current (AC) permanent-magnet servo motor. The technical scheme provided by the invention comprises the following steps of: firstly, establishing a simulation model of the servo driver in MATLAB according to the hardware circuit of the servo driver; secondly, acquiring a proportion integration differentiation (PID) value according to a multi-model control method based on pattern recognition; and finally, acquiring a control signal by a space vector pulse width modulation (SVPWM) method according to the acquired PID value to drive the servo motor and realize the startup of the servo driver. Based on a correction and control technology for current and position deviation in the starting process of the servo driver, the method is effective and rapid and can weaken the ripple wave torque generated by countering electromotive force of the motor and stator current harmonic, improve the low speed stability and control the accuracy.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

Software-based adaptive control system for electric motors and generators

InactiveUS20050046375A1Increase torqueImprove efficiencyElectric motor speed/torque regulationVehicular energy storageElectric machineUser input

A control system for motors, generators and other electric machines that improves machine performance by dynamically adapting to changes. These changes may be in user inputs, machine operating conditions and / or machine operating parameters. The control system can take advantage of more independent machine parameters. That gives greater freedom to optimize and allows motors and generators to perform better than bigger, heavier machines, particularly more efficiently. The control system is software-based. So standard interfaces allow the control system to be improved and updated without changing hardware. This adaptive control system improves performance in a wide variety of motor and generator applications, particularly those that need high efficiency over varying conditions.

Owner:BLUWAV SYST LLC

Actively controlled regenerative snubber for unipolar brushless DC motors

InactiveUS6630805B2Motor/generator/converter stoppersSynchronous motors startersConducted electromagnetic interferenceEngineering

An actively controlled regenerative snubber configuration for use in unipolar brushless direct current motors comprises a first inductor, a first switch and a capacitor, all of which are connected in series to a positive voltage supply and in parallel with a second inductor and a second switch. The regenerative snubber is used to maintain constant voltage across the switches to prevent braking of the motor through conduction of motor back EMF and to return excess energy stored in the motor phase coils to the positive voltage supply. The return of energy to the positive rail is done in a manner so as to minimize conducted electromagnetic interference at the power leads.

Owner:SIEMENS VDO AUTOMOTIVE INC

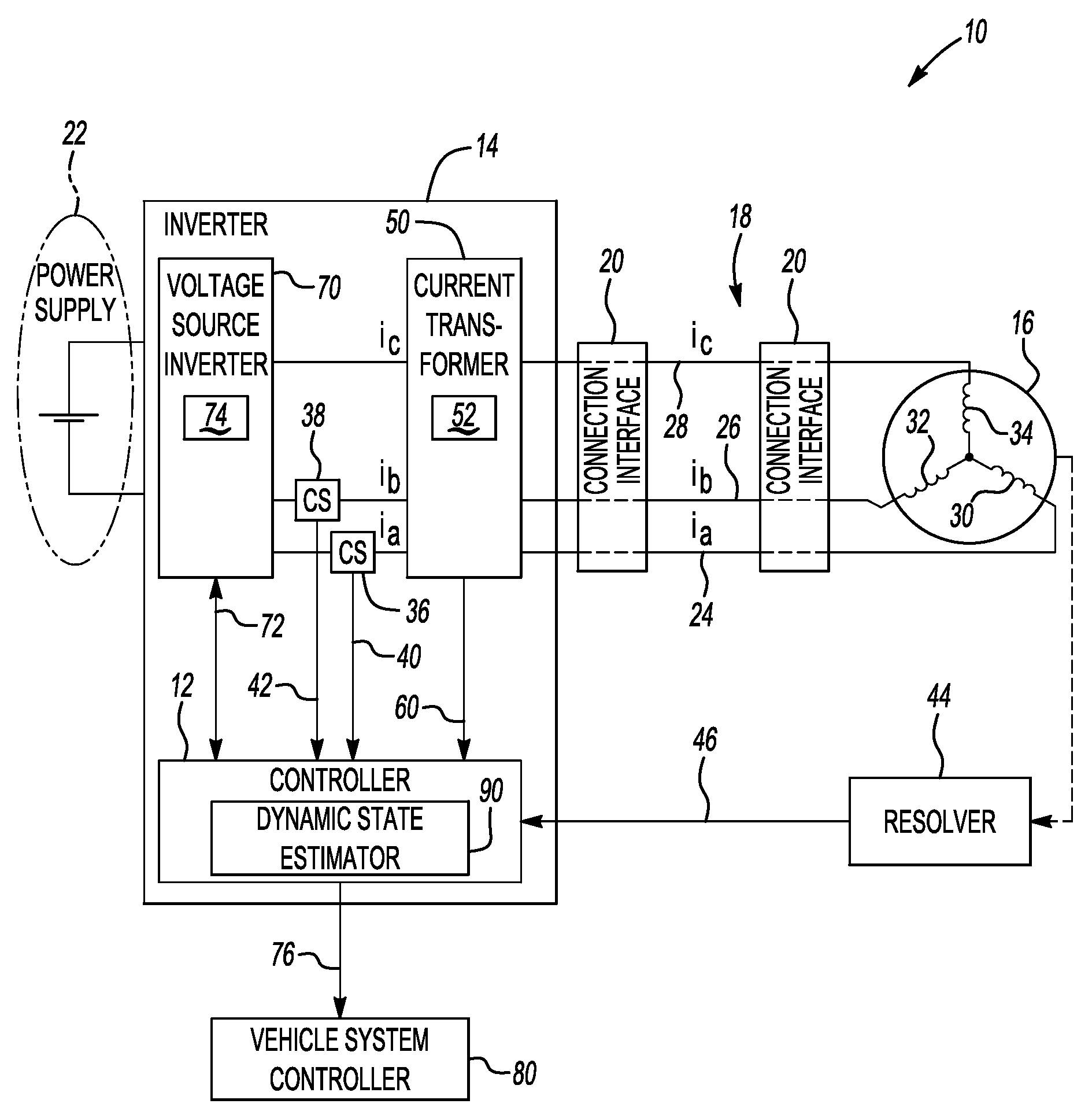

Electric drive system for an automotive vehicle

An electric drive system in an automotive vehicle includes a controller for determining a condition of the electric drive system. The electric drive system includes only two current sensors and a common-mode current transformer. In response to the current sensors and the common-mode current transformer, the controller determines the condition of the electric drive system. The condition of the electric drive system may depend on a condition of an electrical connection between a drive system inverter and a motor in the electric drive system as well as a calculated amount of error in the electric drive system. In addition, the controller may control various operations of the electric drive system, which may or may not depend on the condition of the electric drive system.

Owner:FORD GLOBAL TECH LLC

Controller for a brushless motor

InactiveUS20110257791A1Reduce the possibilityPrecise positioningDC motor speed/torque controlSynchronous motors startersBrushless motorsProcessor register

A controller for a brushless motor that includes a processor, a first timer, a second timer, a compare register, a comparator, an input, and one or more outputs. The processor starts the first timer in response to a signal at the input. The first timer then generates an interrupt after a first period. In response to the interrupt, the processor generates a first control signal at the outputs. The processor also loads the compare register and starts the second timer in response to either the input signal or the interrupt. The comparator then generates a second control signal at the outputs when the second timer and the compare register correspond. Additionally, a motor system that includes the controller.

Owner:DYSON TECH LTD

Controller arrangement with adaptive non-overlapping commutation

A PWM controller for a direct current brushless motor comprising first and second windings includes a motor drive circuit receiving pulse width modulation control signals to drive the first and the second windings; and a control circuit having inputs coupled to the first and second windings to control a pulse width modulation control circuit such that pulse width modulated control signals are provided to the motor drive circuit only when the voltage across the first and second windings are at a predetermined level.

Owner:OL SECURITY LIABILITY CO

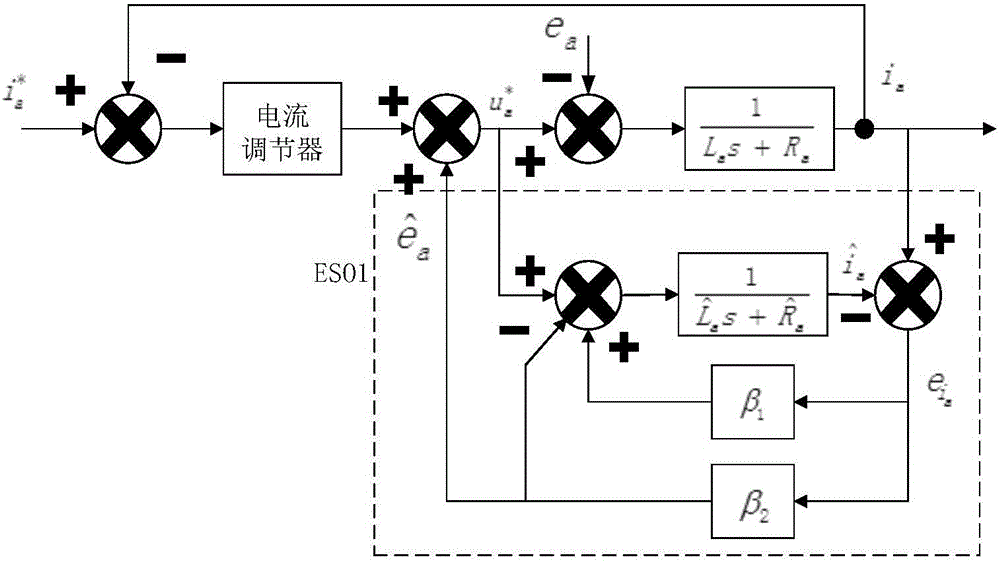

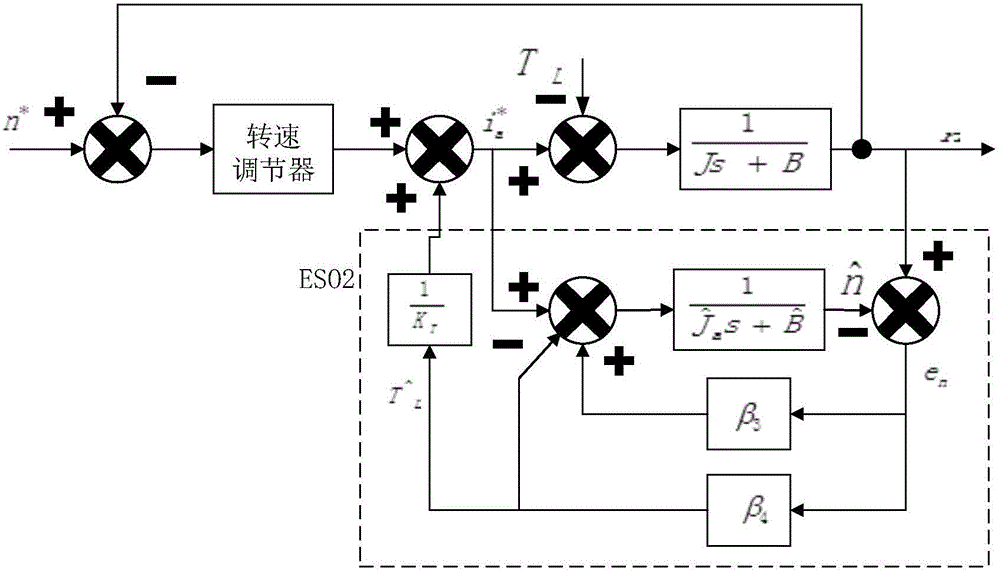

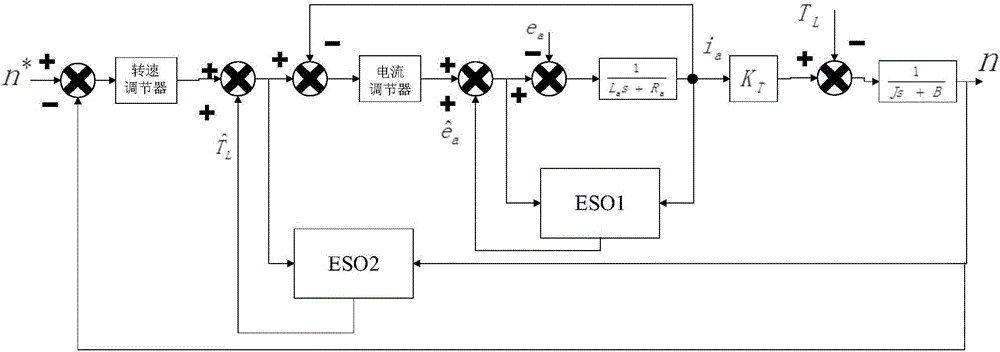

Servo control strategy and system for simultaneously eliminating counter potential and load torque disturbance

ActiveCN106533299AOvercome inaccuraciesImprove static performanceVector control systemsDynamo-electric converter controlLoad torqueEngineering

The invention discloses a servo control strategy and system for simultaneously eliminating a counter potential and load torque disturbance. Based on a nominal model of an armature winding, total disturbance of an electrical part is estimated according to voltages externally applied to two ends of an armature and a detection value of an armature current, and the disturbance is offset by a feedforward compensation part; the residual disturbance of the counter potential is eliminated by combining feedback and adjustment of the armature current; an inner ring of the system is built by a combination step of feedforward control for eliminating electrical total disturbance and current feedback control; based on a nominal mode of a transmission system, the total disturbance of a mechanical part is determined according to the armature current and actual rotational speed information, and the disturbance is offset by the feedforward compensation part; by combining feedback and adjustment of the rotational speed, the residual disturbance of the load torque is eliminated; and an outer ring of the system is built by the combination step of feedforward control for eliminating mechanical total disturbance and rotational speed feedback control. By the servo control strategy, the disturbance of two different time scales is eliminated, and the interference resistant capability and the dynamic and static performance of the servo system are greatly improved.

Owner:SHANDONG UNIV

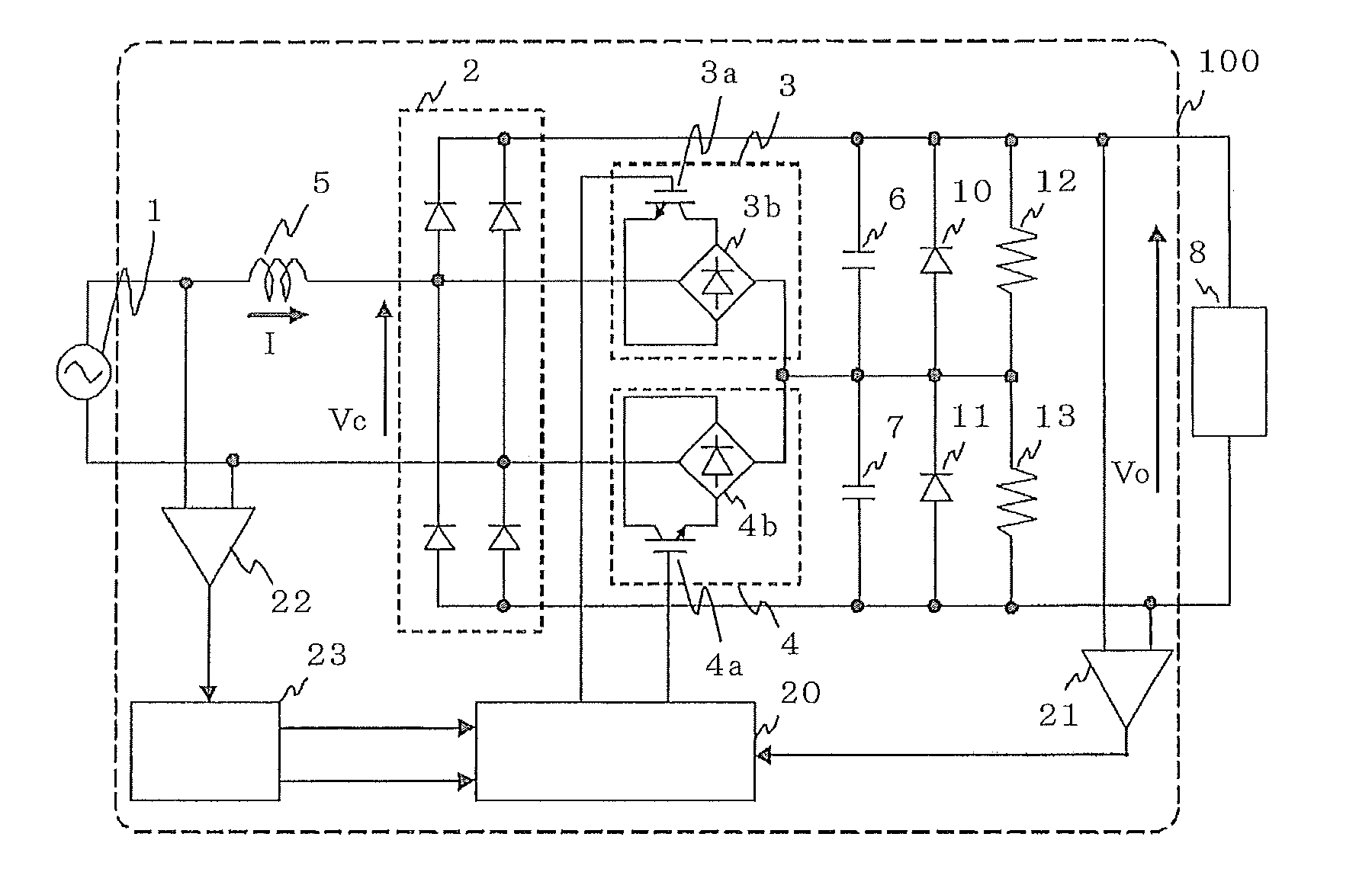

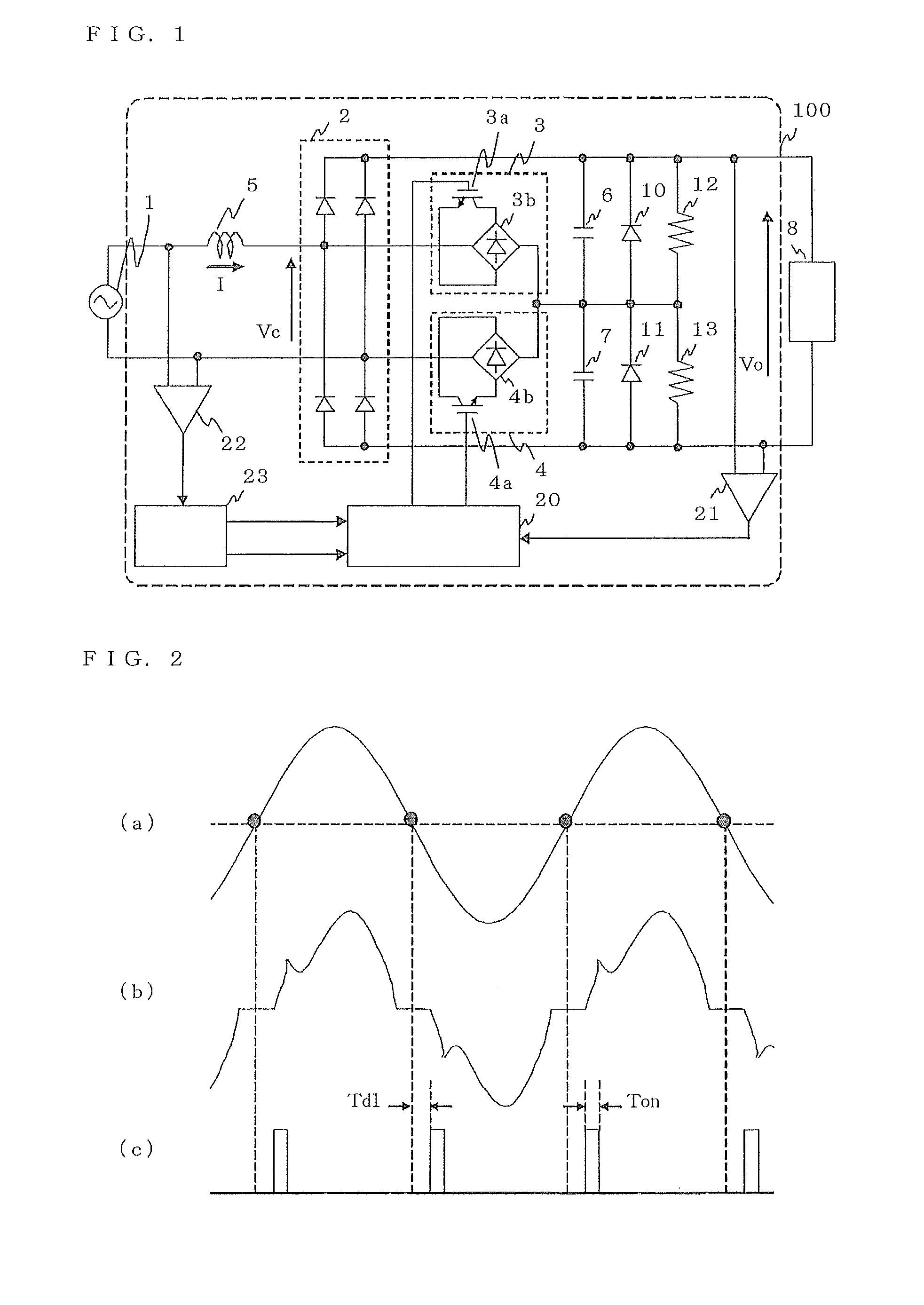

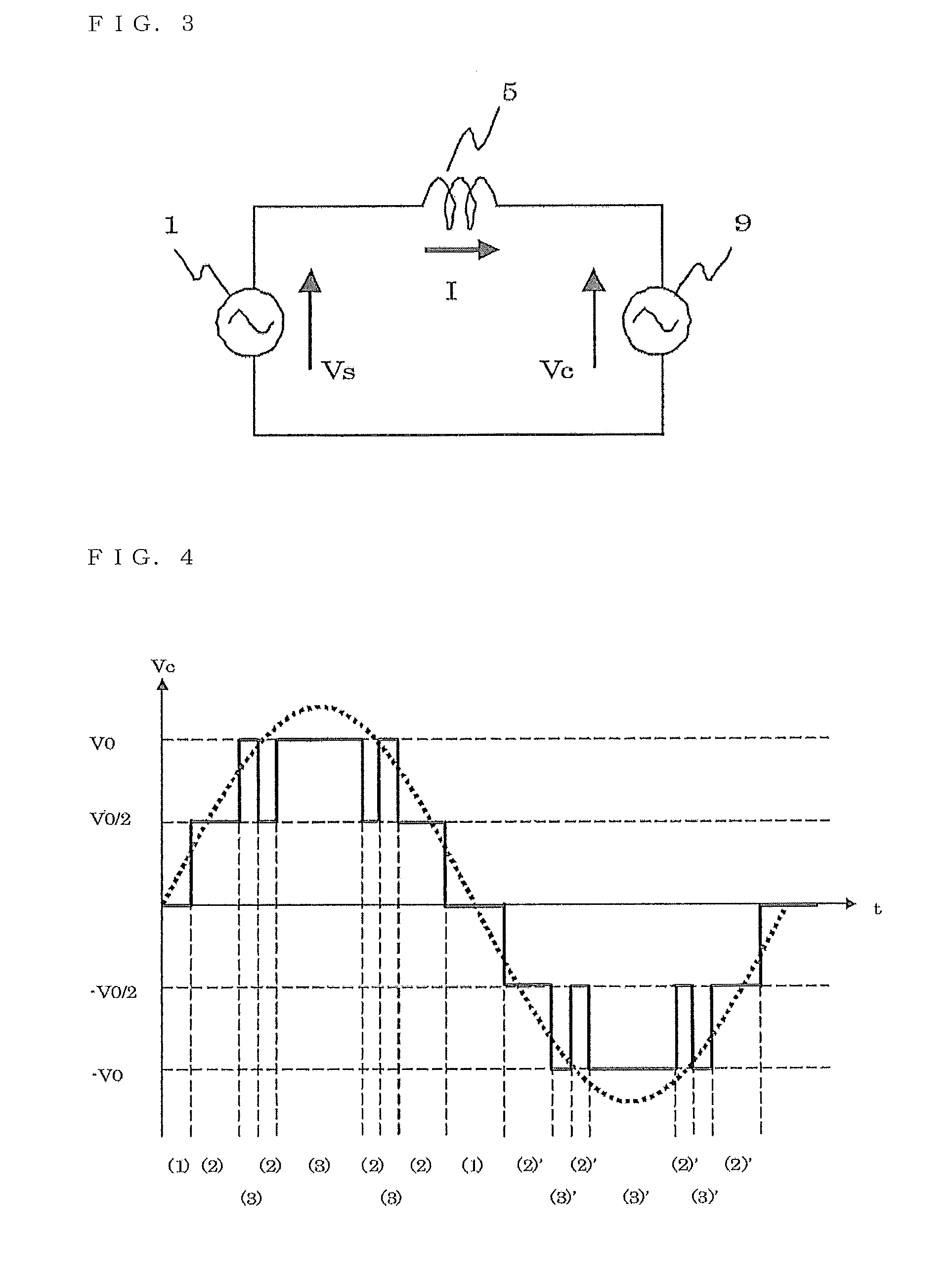

Ac-dc converter, method of controlling the same, motor driver, compressor driver, air-conditioner, and heat pump type water heater

ActiveUS20110101898A1Practical to useLow costMotor/generator/converter stoppersDC motor speed/torque controlCapacitorHeat pump

A rectifier connected with an AC source through a reactor, a plurality of capacitors connected in series between output terminals of the rectifier, first switching means connected between one input terminal of the rectifier and a connection point of a plurality of capacitors, second switching means connected between the other input terminal of the rectifier and the connection point of a plurality of capacitors, and a plurality of diodes connected with the plurality of capacitors in inverse-parallel are provided.

Owner:MITSUBISHI ELECTRIC CORP

Popular searches

Multiple motor speed/torque control Rotary current collector Field or armature current control Starter details Dynamo-electric machines Electronic commutators Polyphase induction motor starter Electric energy management Synchronous machines with stationary armatures and rotating magnets Electric propulsion

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com