Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about "Mixing/kneading with rollers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

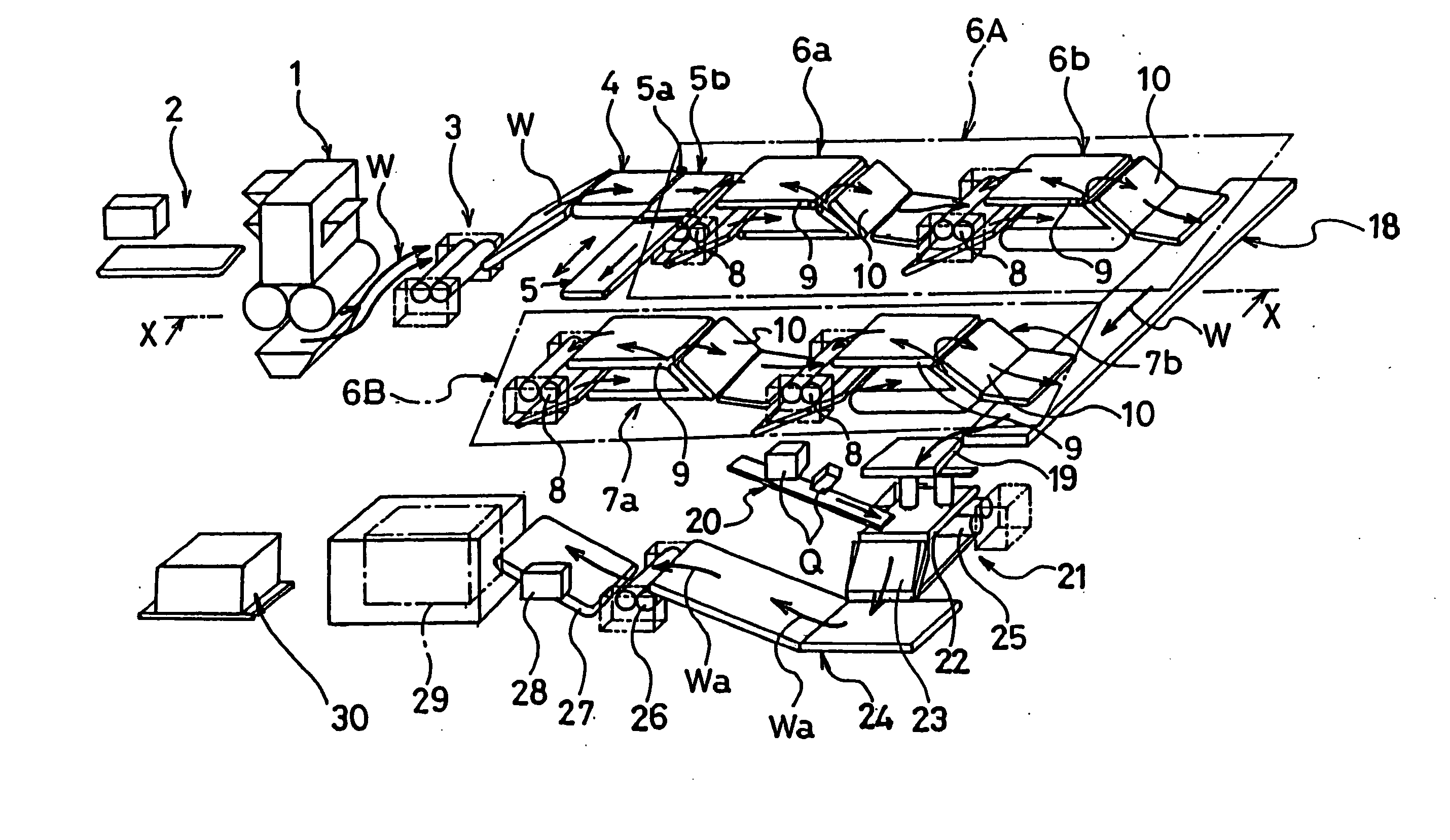

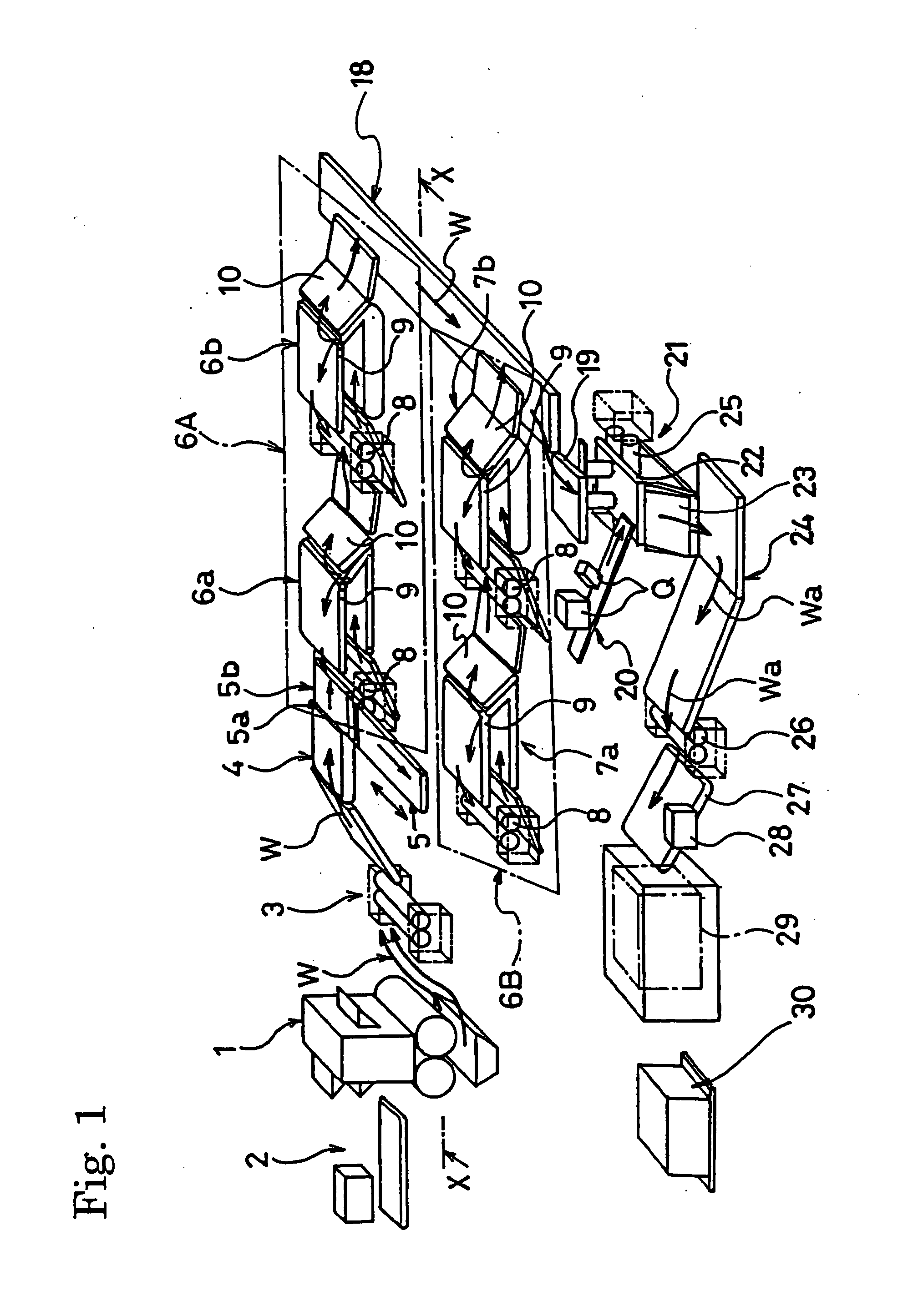

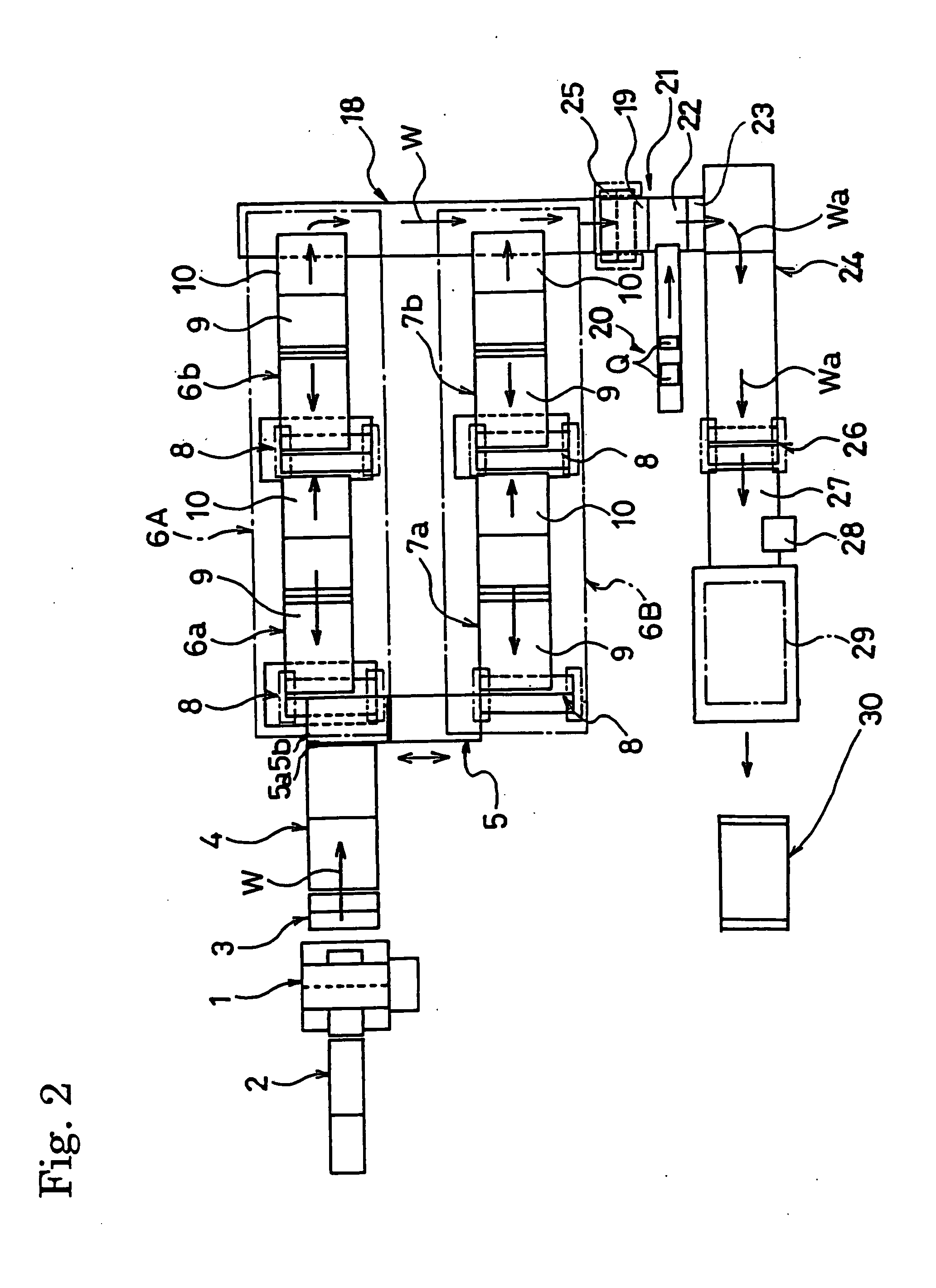

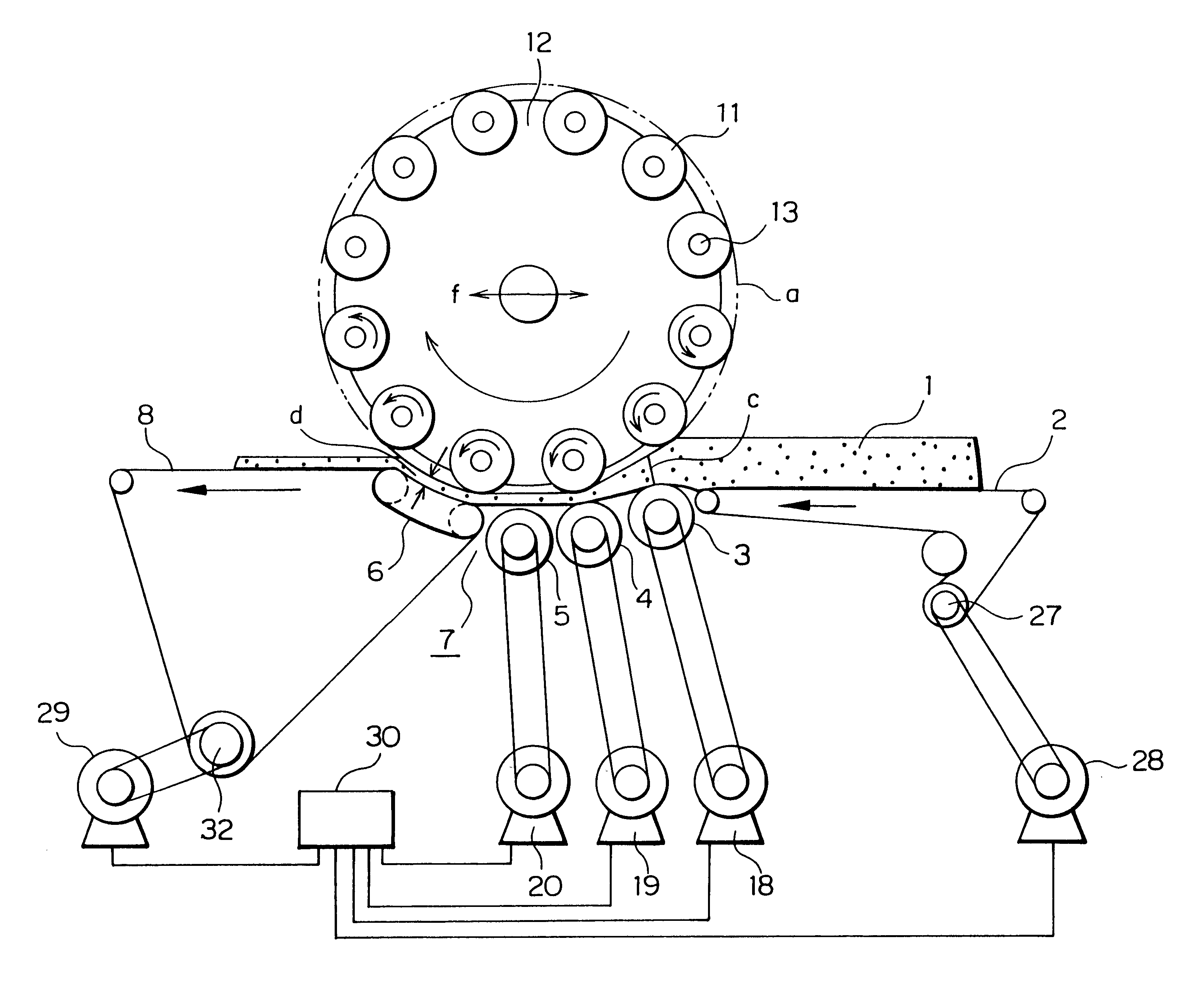

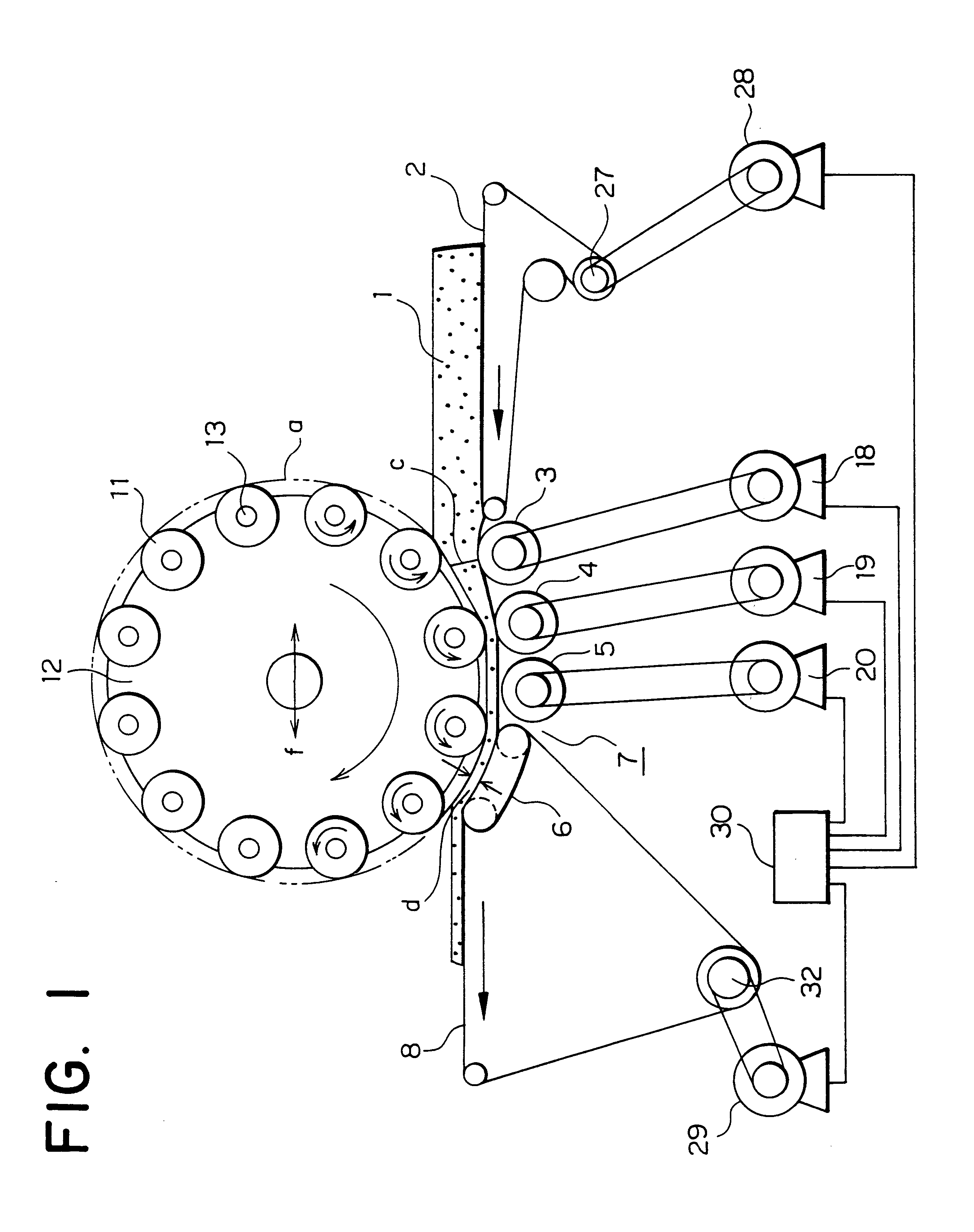

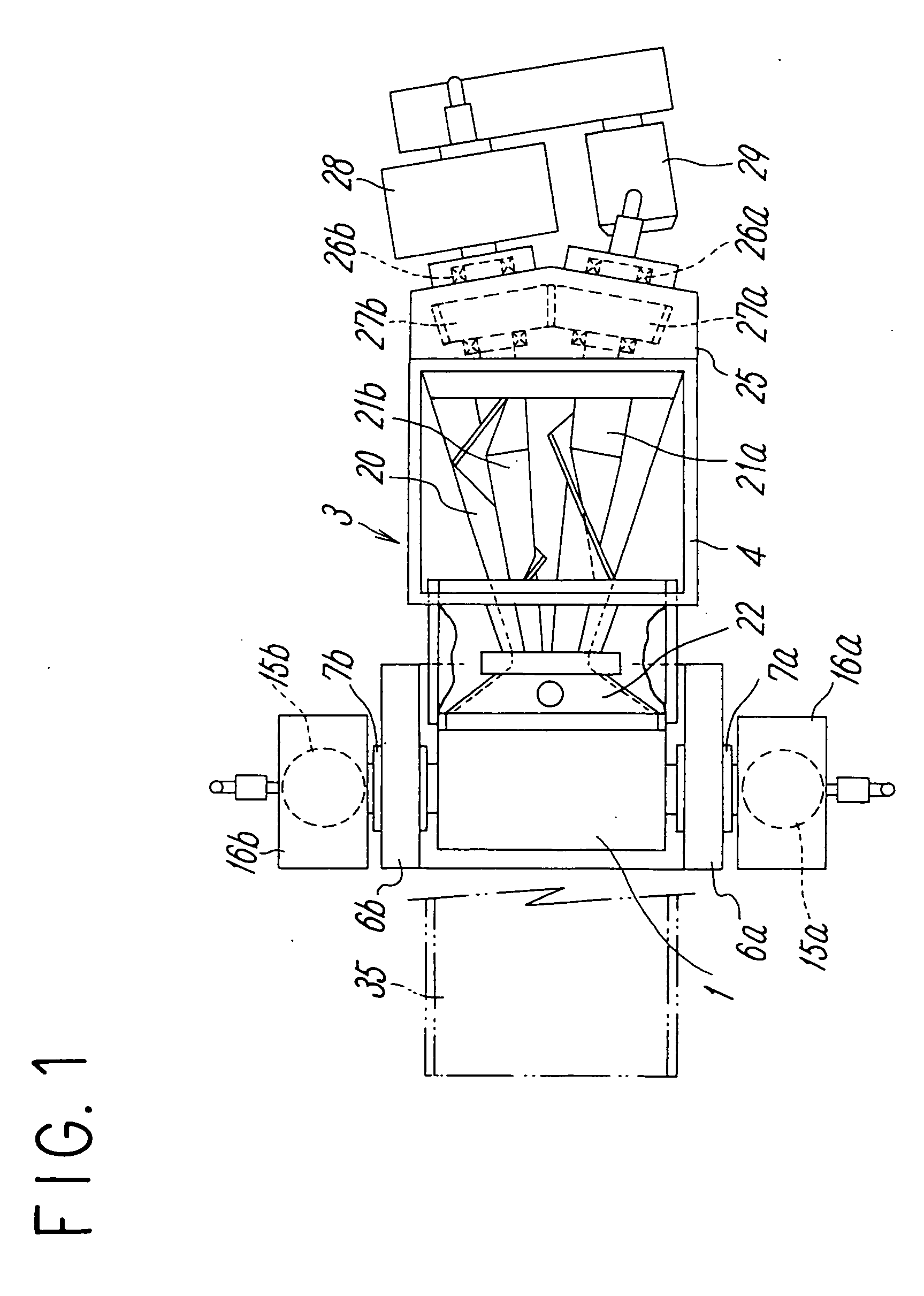

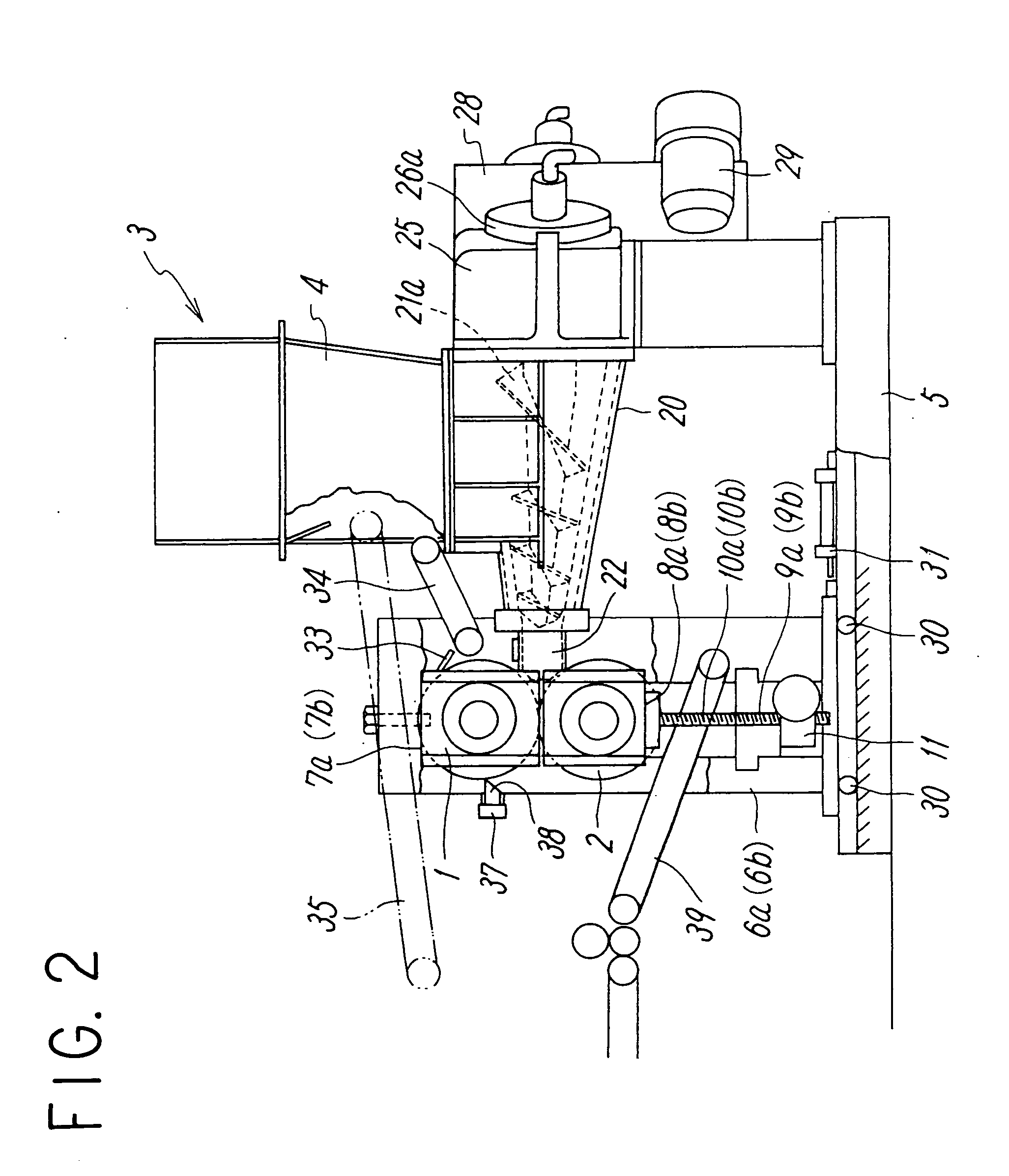

Apparatus for and Method of Kneading Rubber Material

InactiveUS20090238027A1Reduce energy lossLow viscosityDischarging apparatusMixing operation control apparatusRubber materialVulcanization

Disclosed are: an apparatus for kneading a rubber material which continuously performs a series of processes which are kneading a rubber material with a non-vulcanization compounding agent at the beginning, kneading it with a vulcanization compounding agent, and finally obtaining final kneaded rubber; and a kneading method using this kneading apparatus. Preparatory kneaded rubber having been kneaded in one internal mixer is selectively fed, by a distribution conveyor, to a group of kneading lines where at least two kneading lines are provided to be arranged side by side. Each of the kneading line consists of a plurality of open roll mixers serially connected with each other. Intermediate kneaded rubber resulted in having a target viscosity after having been kneaded in the group of kneading lines is kneaded with a vulcanization compounding agent, whereby final kneaded rubber is obtained.

Owner:YOKOHAMA RUBBER CO LTD

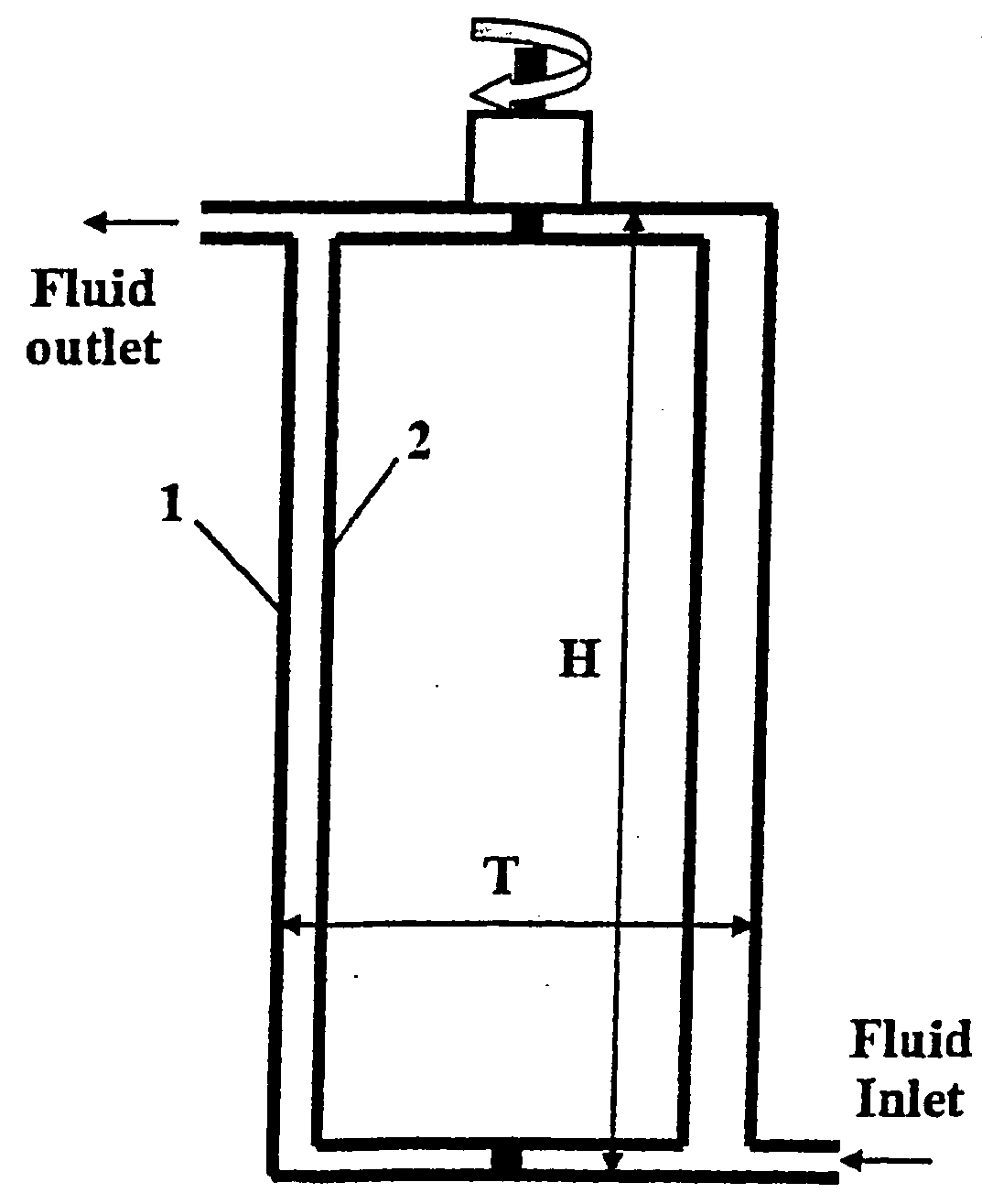

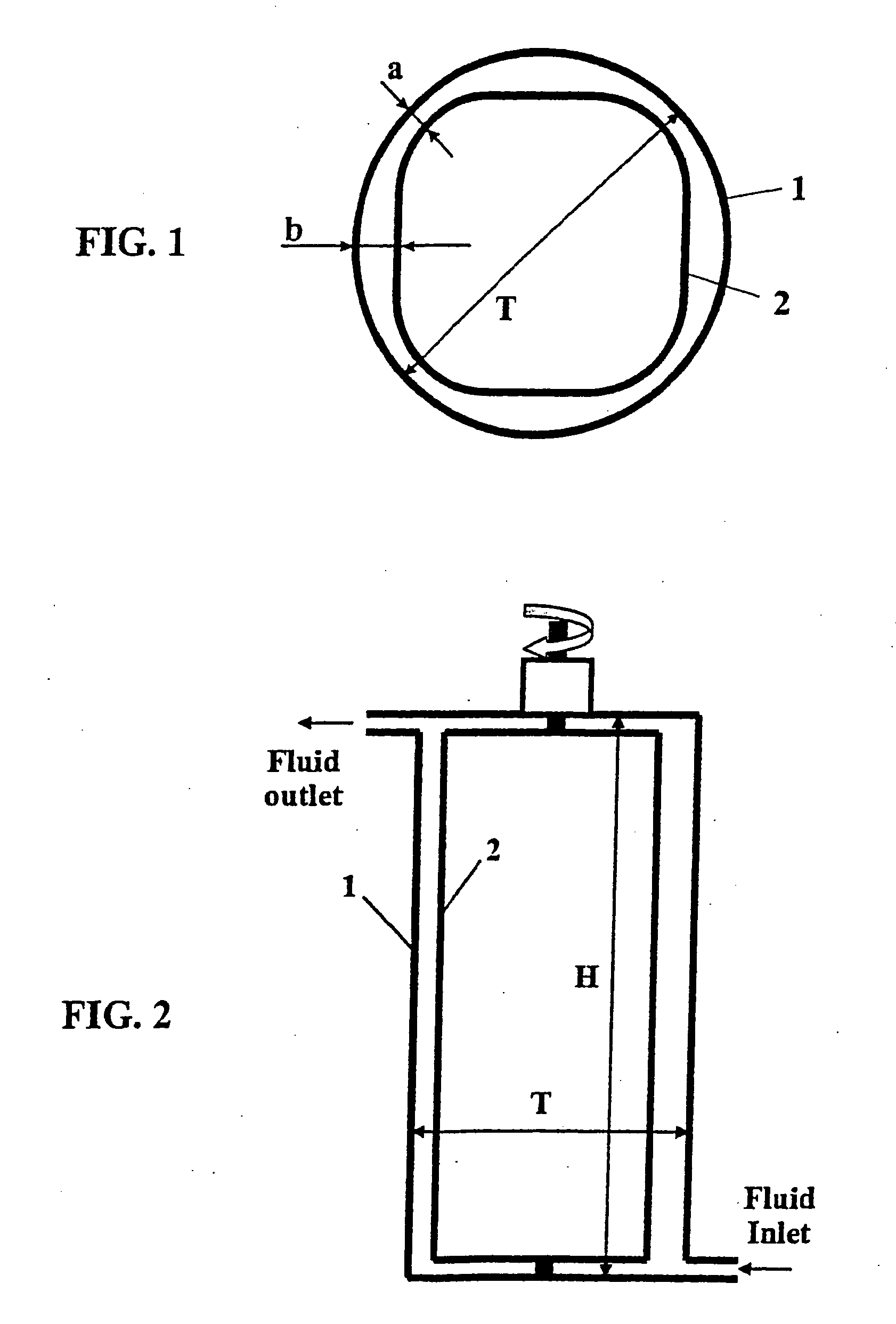

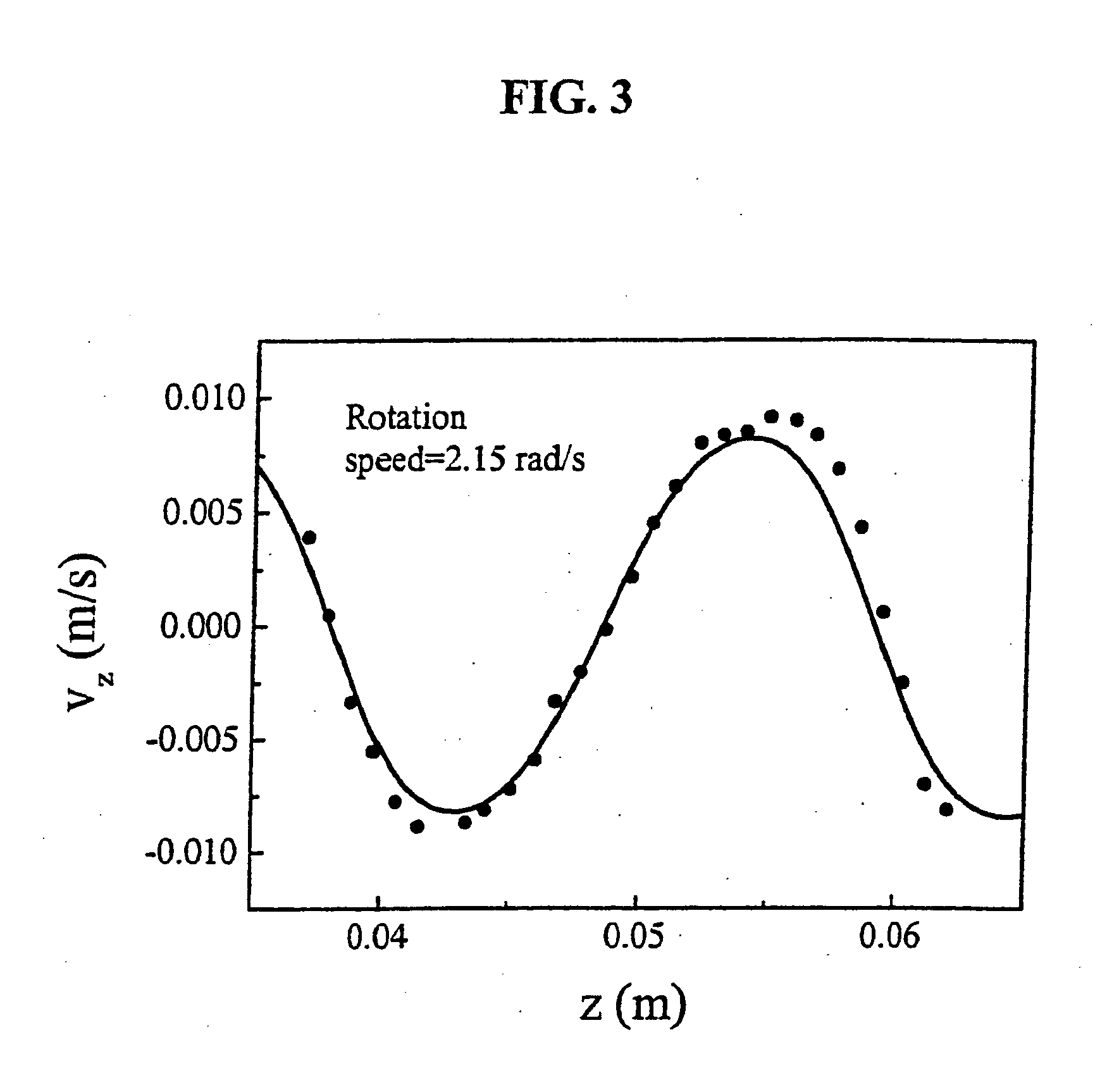

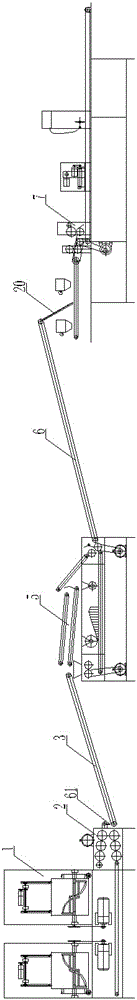

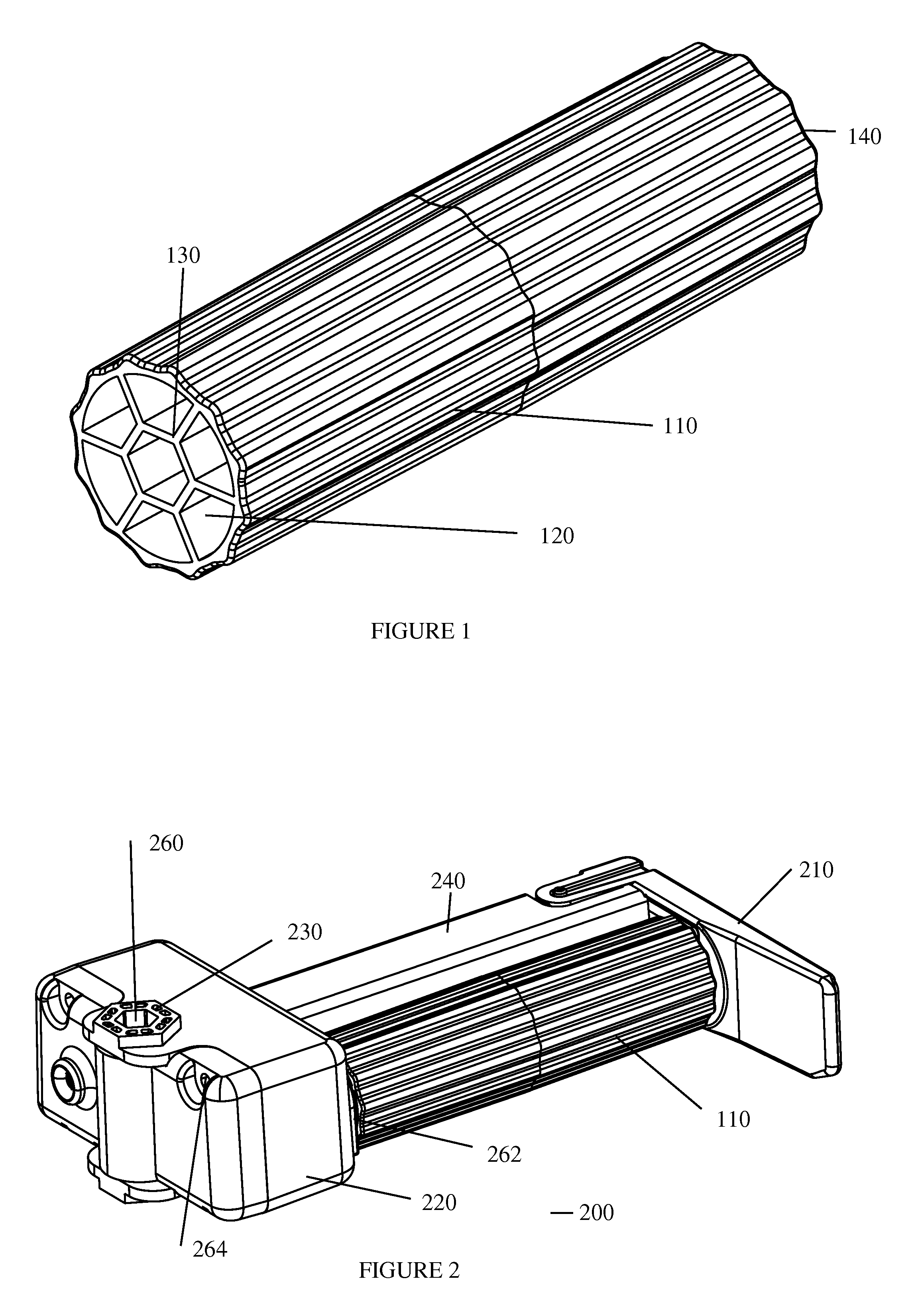

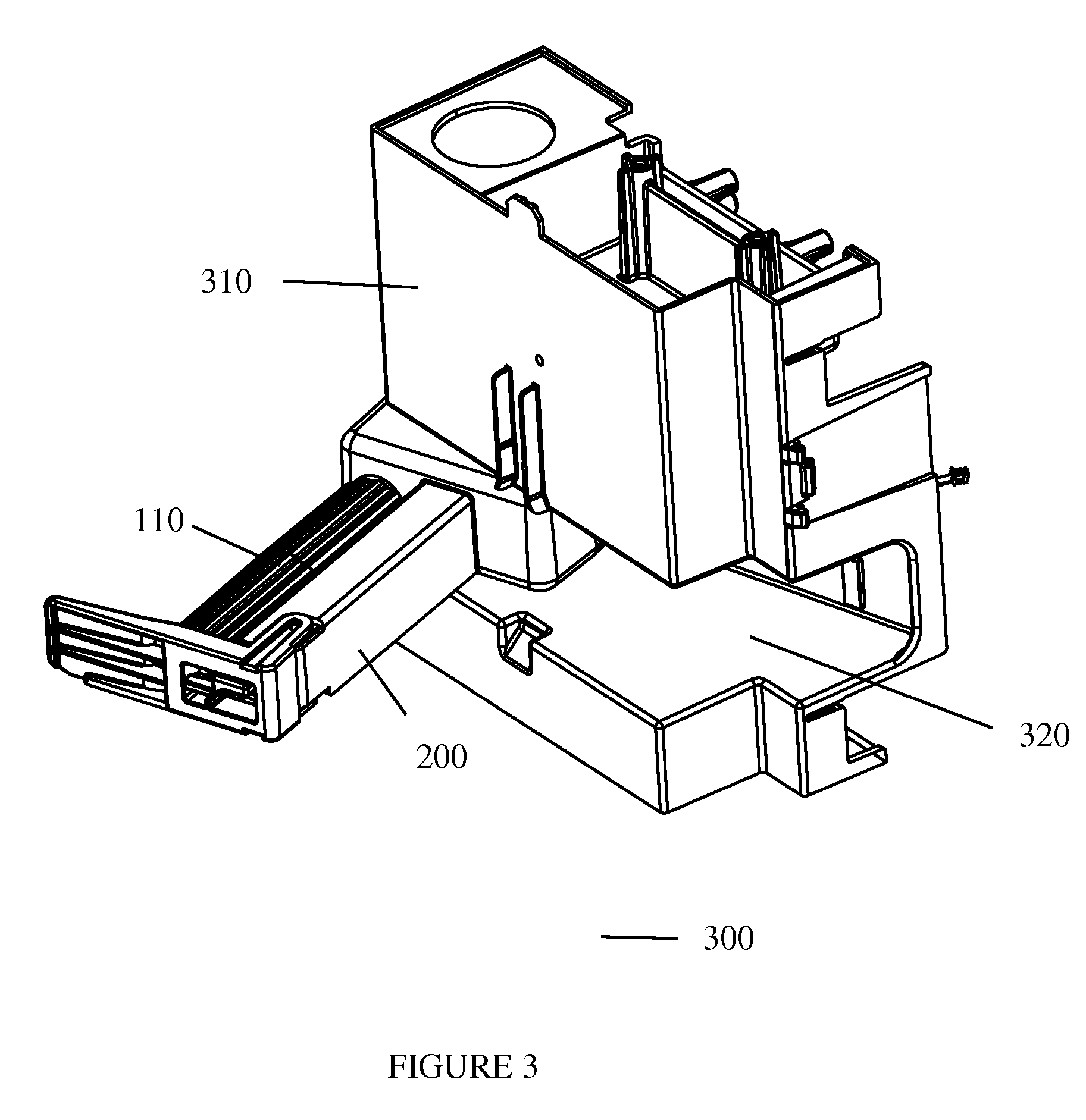

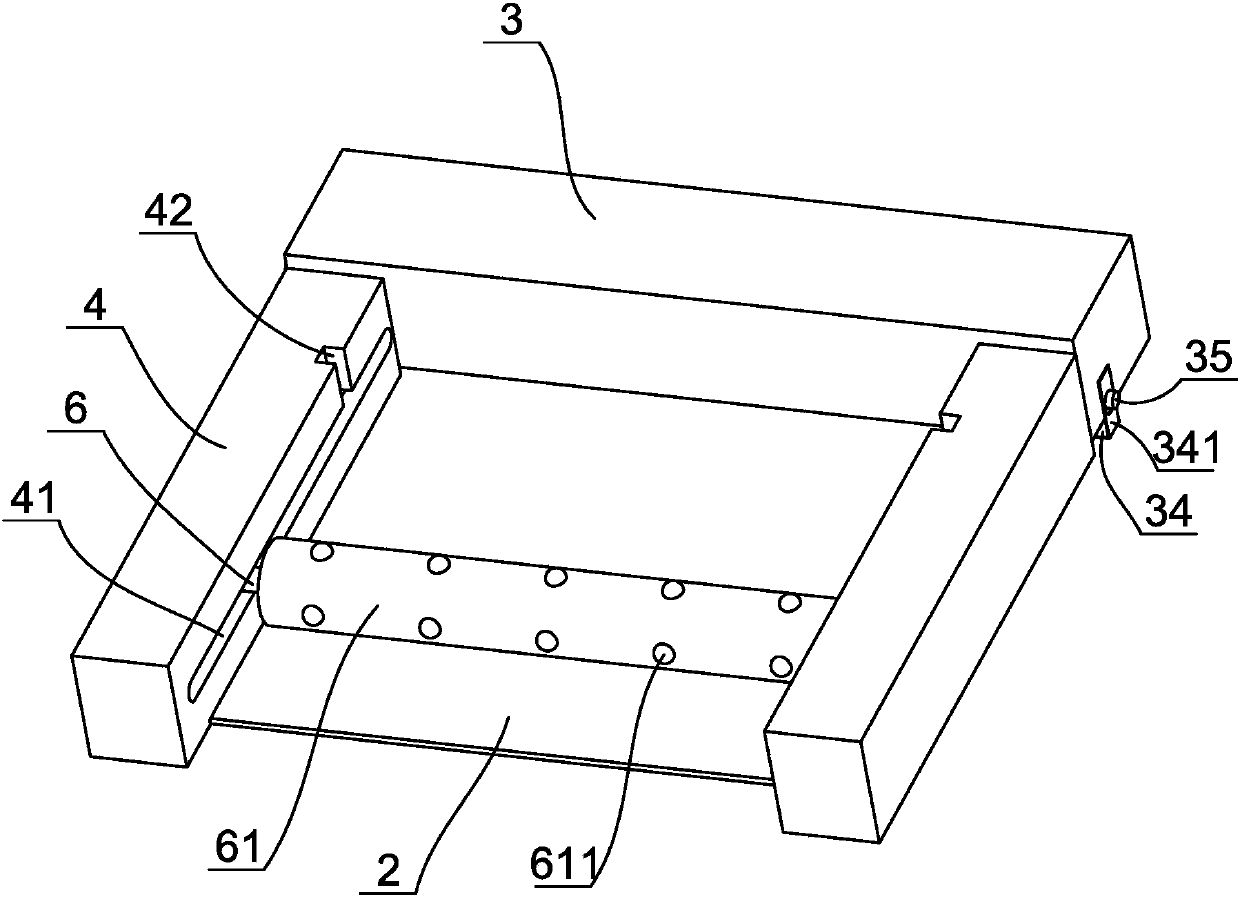

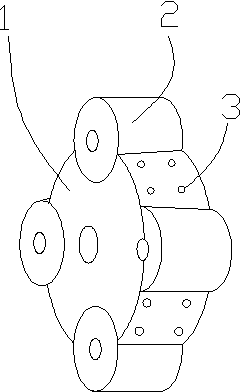

Rotating Stirring Device with Substantially Narrow Distribution of Energy Dissipation Rate

InactiveUS20080226513A1Rotary stirring mixersTransportation and packagingShear rateVolumetric Mass Density

A rotating stirring device for generating substantially narrow distribution of energy dissipation rate and avoiding presence of Taylor vortices is disclosed. The device includes an outer member (1) such as a cylinder with cross-section of circular shape and an inner member (2) with cross-section of equilateral or inequilateral polygon shape with curved cusps. The inner member is preferably concentrically placed within the outer cylinder and rotates. Such device is particularly advantageous as a reactor or mixer for processes where chemical and physical properties are sensitive to the variations in the shear rate and for processes that involve fragile components. The device can be also used to replace Taylor Couette device for the purposes of improving mass transfer and of avoiding separate of components in the gap in the case of presence of differences in density among components.

Owner:ETH ZZURICH

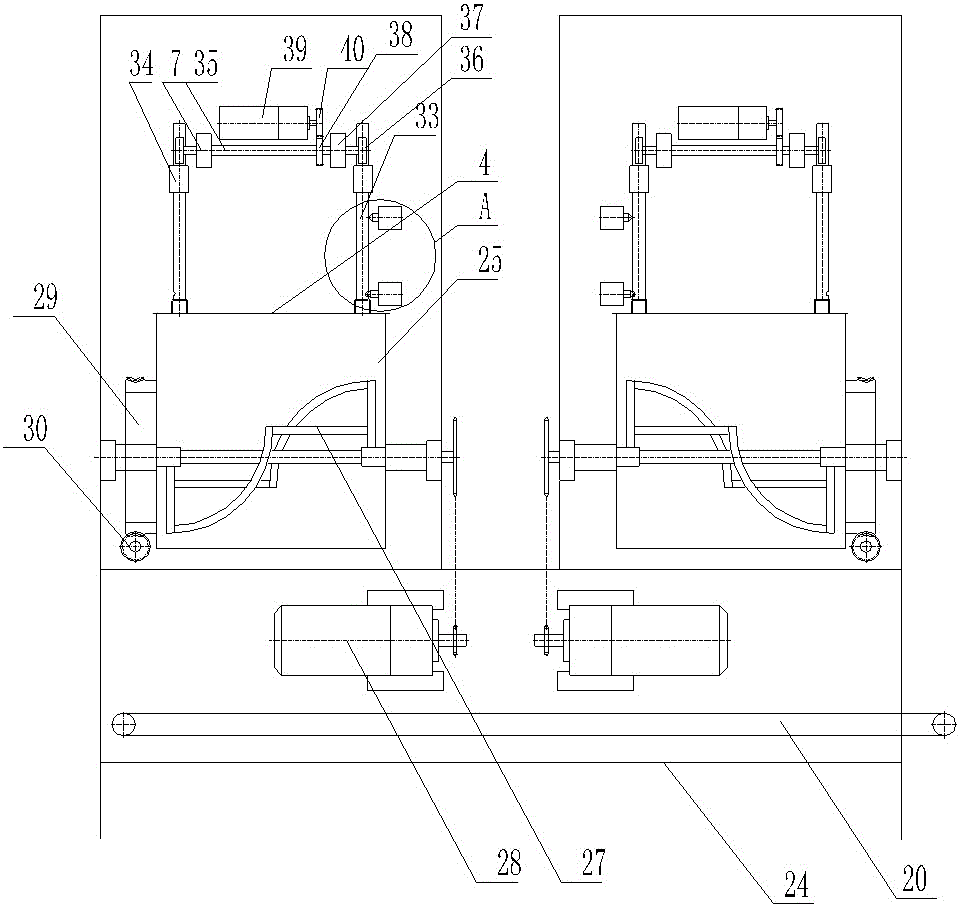

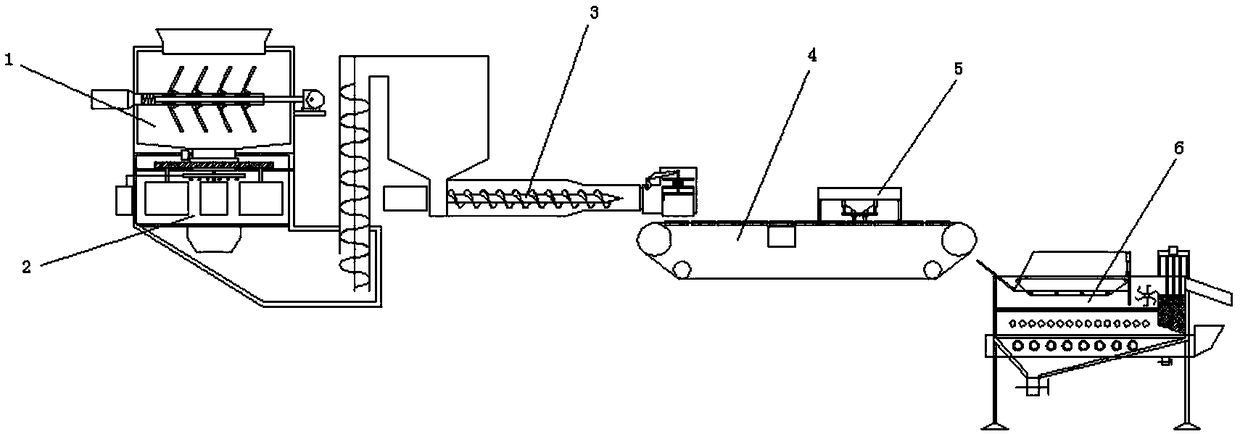

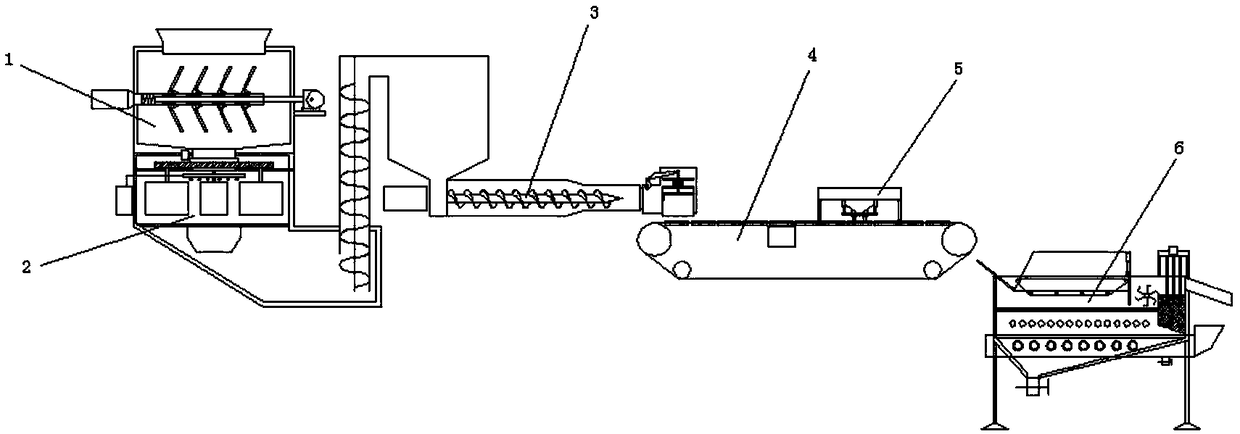

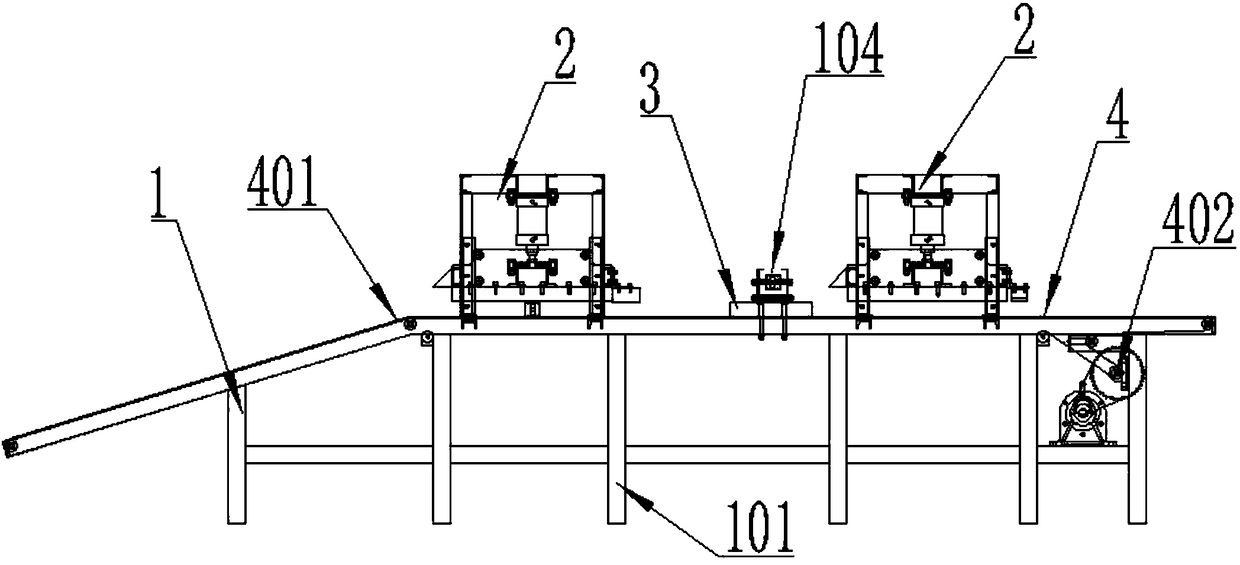

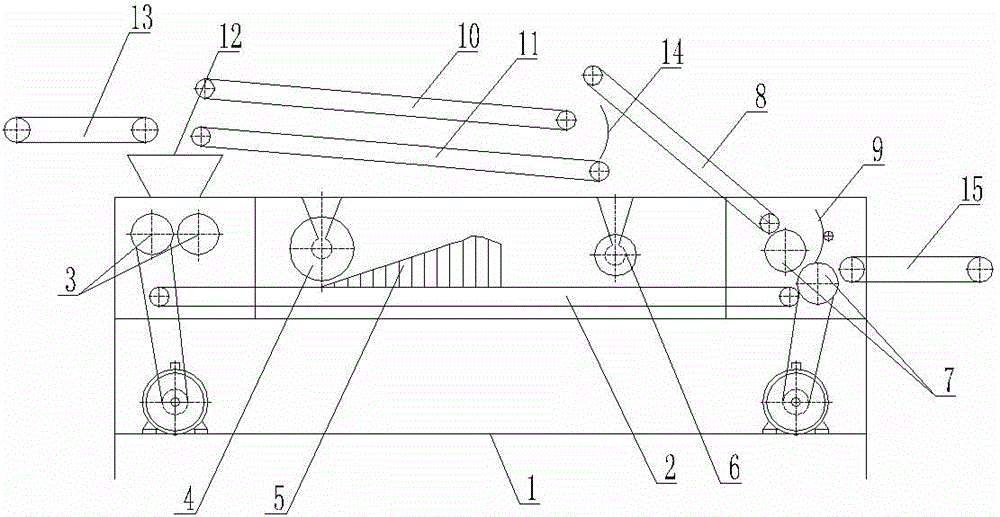

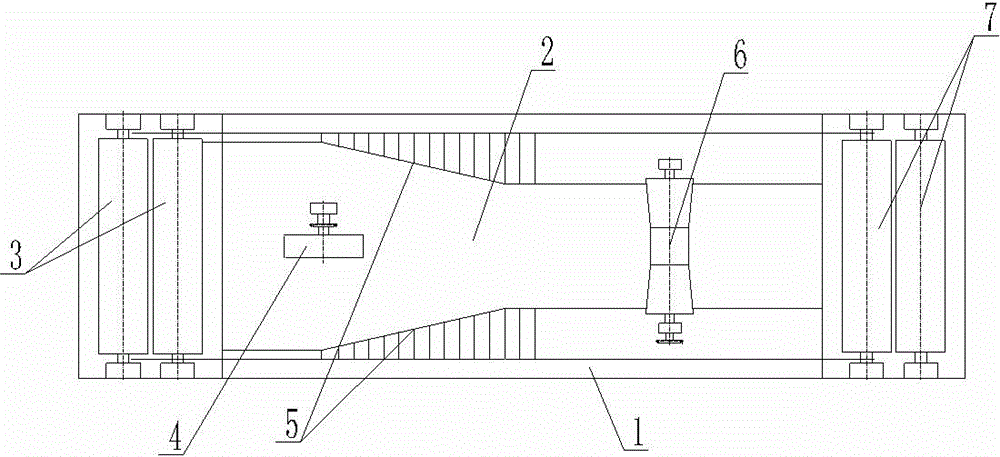

Efficient fully-automatic semi-finished stewed noodle production line

ActiveCN105053104AGood kneading qualityFully automatedMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsReciprocating motionTransverse fracture

The invention discloses an efficient fully-automatic semi-finished stewed noodle production line. The front end of the longitudinal fracture conveying device of the novel double-head fully-automatic cycle dough kneading machine of the production line is provided with a first pair of dough kneading rollers, a longitudinal fracture synchronizing wheel is arranged above the longitudinal fracture conveying device, two sides of the longitudinal fracture conveying device are provided with longitudinal fracture rotating plates inwardly continuously folding to central portions, a longitudinal fracture burdening pressure roller is arranged above the longitudinal fracture conveying device, the rear end of the longitudinal fracture conveying device is provided with a second pair of dough kneading rollers, the second pair of the dough kneading rollers is provided with an obliquely arranged conveying device, a guiding plate is arranged behind the second pair of the dough kneading rollers, the frame of the machine is provided with a transverse fracture one-layer conveying device capable of moving back and forth, a transverse fracture two-layer conveying device is arranged directly below the transverse fracture one-layer conveying device, and the rear end of the transverse fracture two-layer conveying device is connected with the first pair of tough kneading rollers. Dough from the dough kneading machine is automatically sent to the double-head fully-automatic cycle dough kneading machine and is automatically kneaded in a cycle manner in the double-head fully-automatic cycle dough kneading machine, and the kneaded dough is automatically sent to a semi-finished stewed noodle forming machine to realize fully-automatic production of semi-finished stewed noodles.

Owner:王朝民

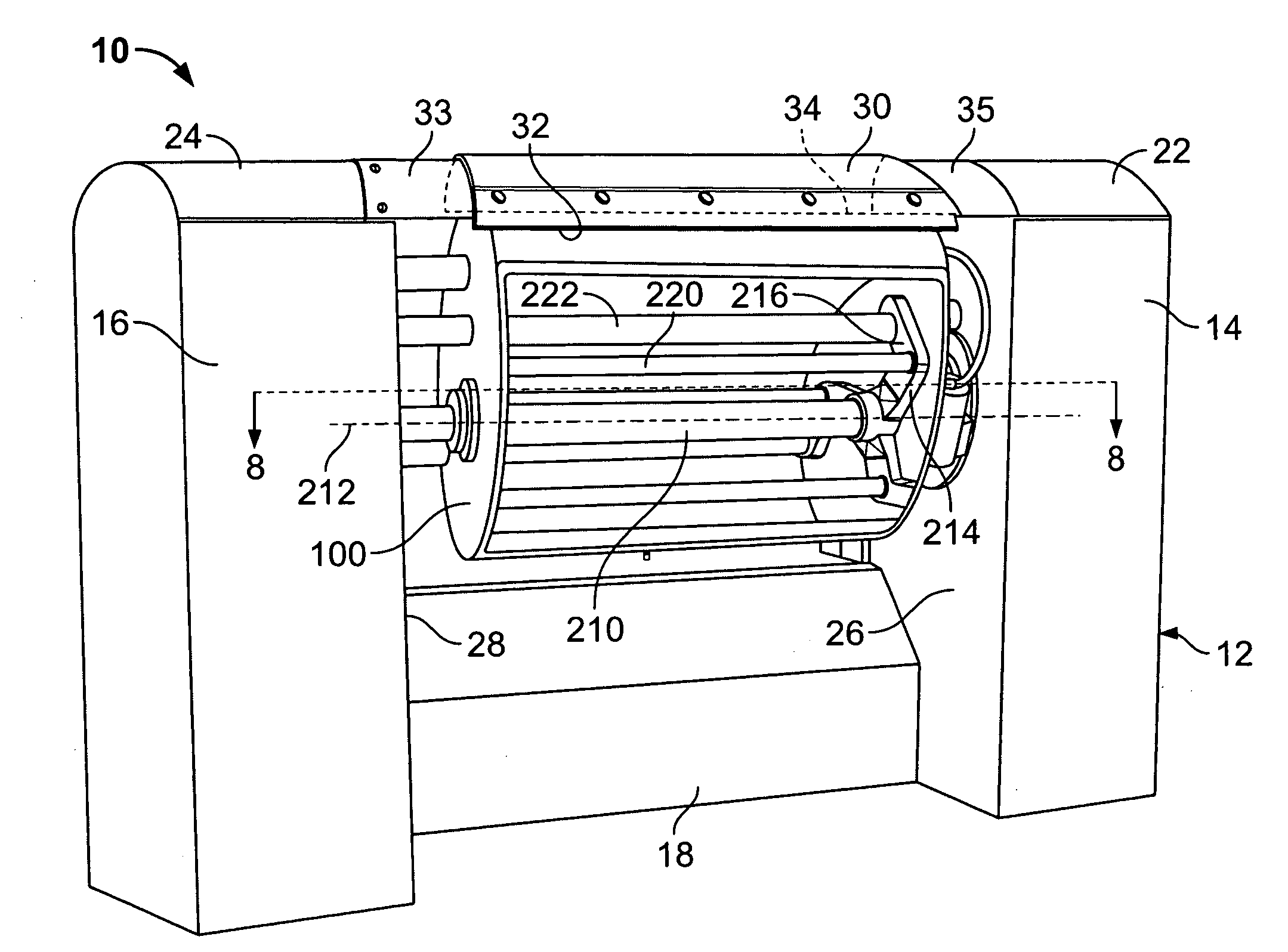

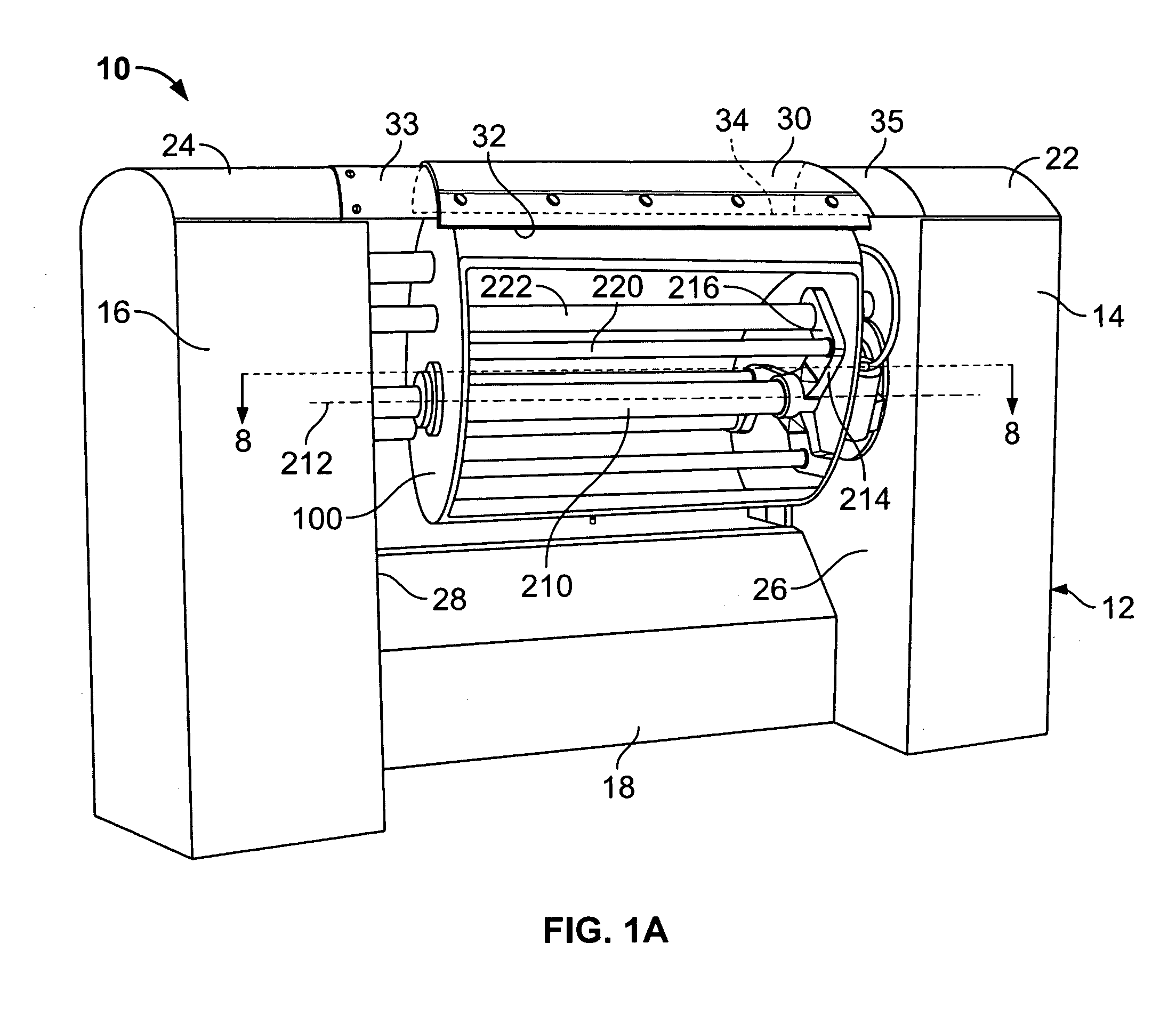

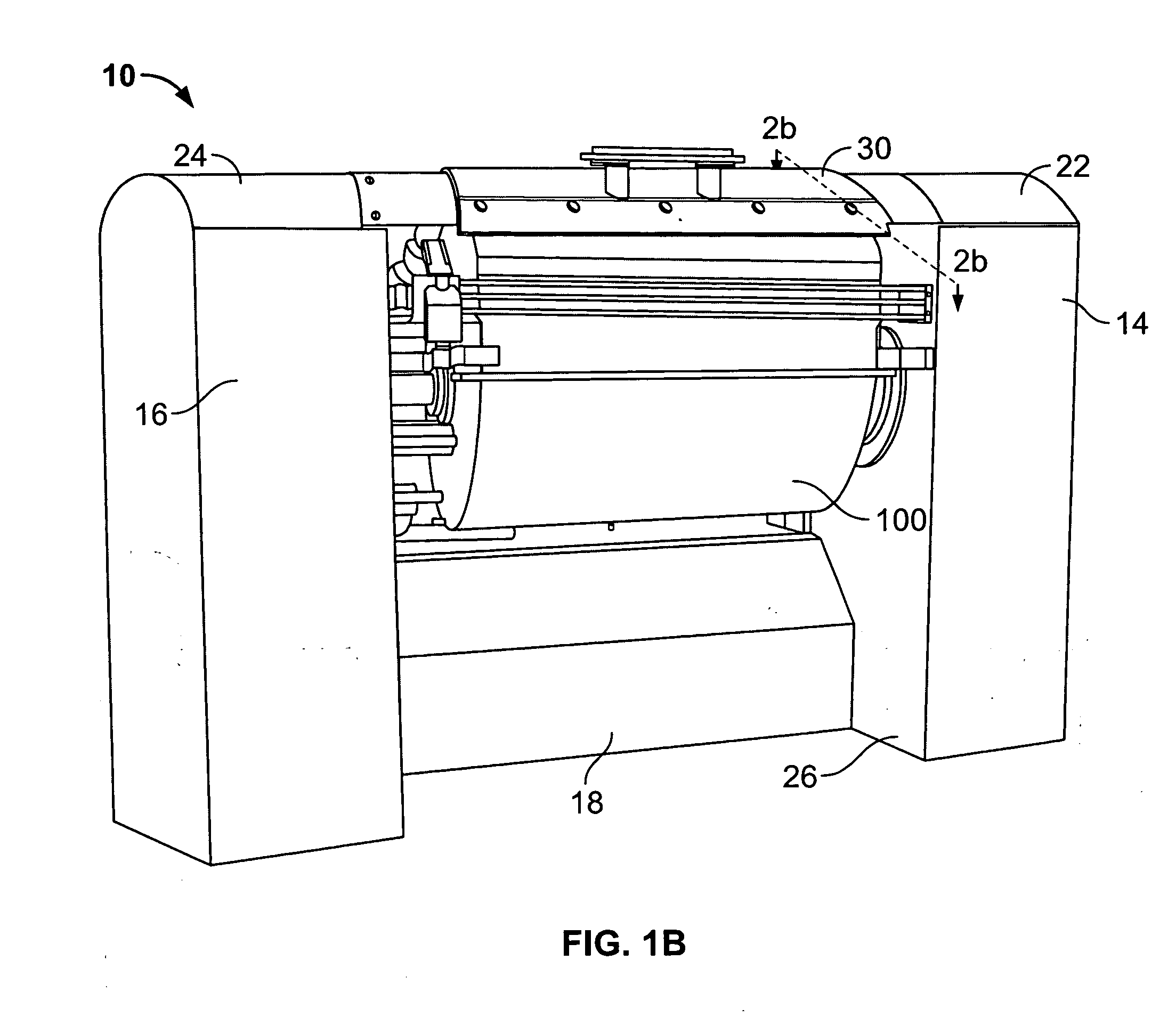

Method and apparatus for mixing dough

InactiveUS20080151682A1Improved efficiency and effectivenessCooling effectRotary stirring mixersTransportation and packagingAir cycleEngineering

The invention provides an apparatus and method for improved mixing of yeast-raised and yeast-raised type dough. The device and method keep the dough cool by an improved structure and method for circulating coolant around a jacketed bowl, and by circulating cooled air through the spinning agitator roller bars. Better aeration of the dough and faster mixing time are achieved along with full water and flour absorption, and reduced operating temperatures by controlling placing of the agitator driveshaft in a carefully defined region. Finally, the invention provides a wiper for wiping the lip of the bowl to keep it clean of dough and to insure a proper seal along the bowl lip when a resilient, expandable bowl seal is used, and it provides a pneumatic seal for securely sealing the mix ingredients in the bowl during mixing.

Owner:CMC AMERICA CORP

Apparatus for stretching bread dough

InactiveUS6257861B1Uniform thicknessHigh viscosityDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringMechanical engineering

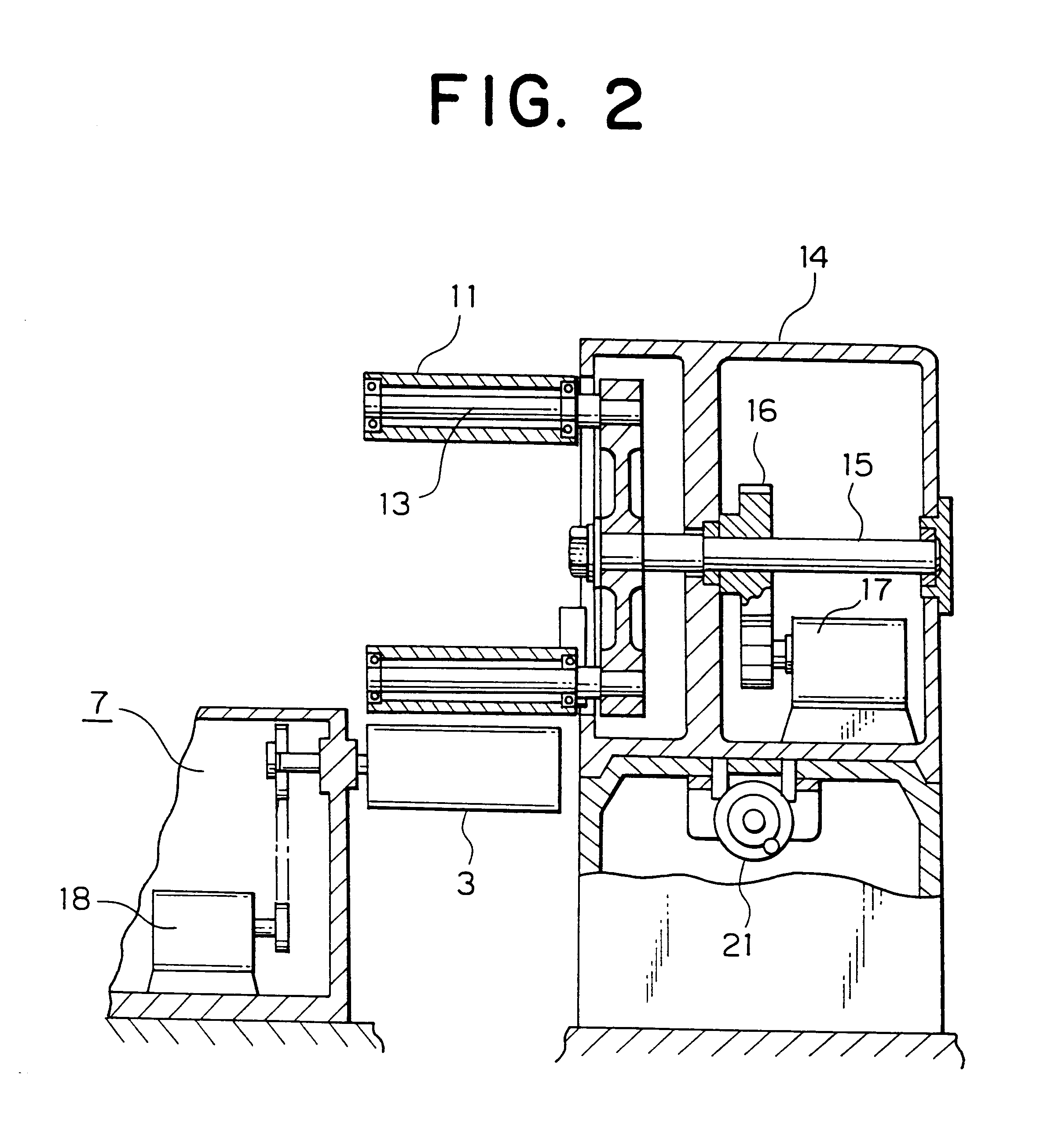

An apparatus is provided for stretching bread dough and the like comprising a rotating member that includes a plurality of planetary rollers that revolve along a circular orbit, a conveying device provided below said rotating member such that a first gap is provided, said first gap gradually decreasing from an inlet to an outlet for the bread dough, said conveying device including a plurality of rollers adapted so that the speed at which each roller rotates gradually increases from said inlet to the outlet for bread dough, and an arcuate plate provided below the rotating member and downstream of the plurality of rollers such that a second gap in which the bread dough is pressed by the plurality of rollers.

Owner:RHEON AUTOMATIC MASCH CO LTD

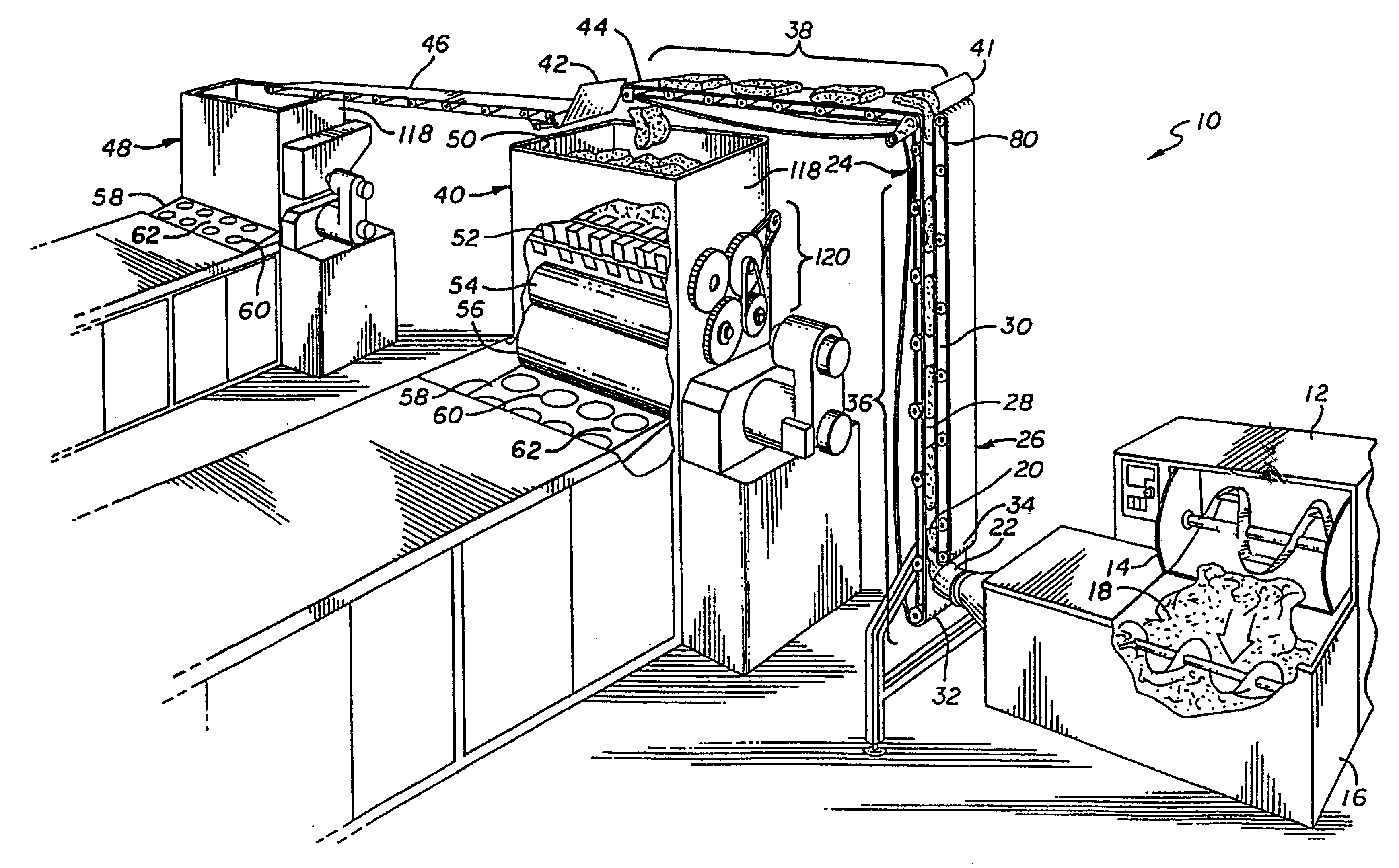

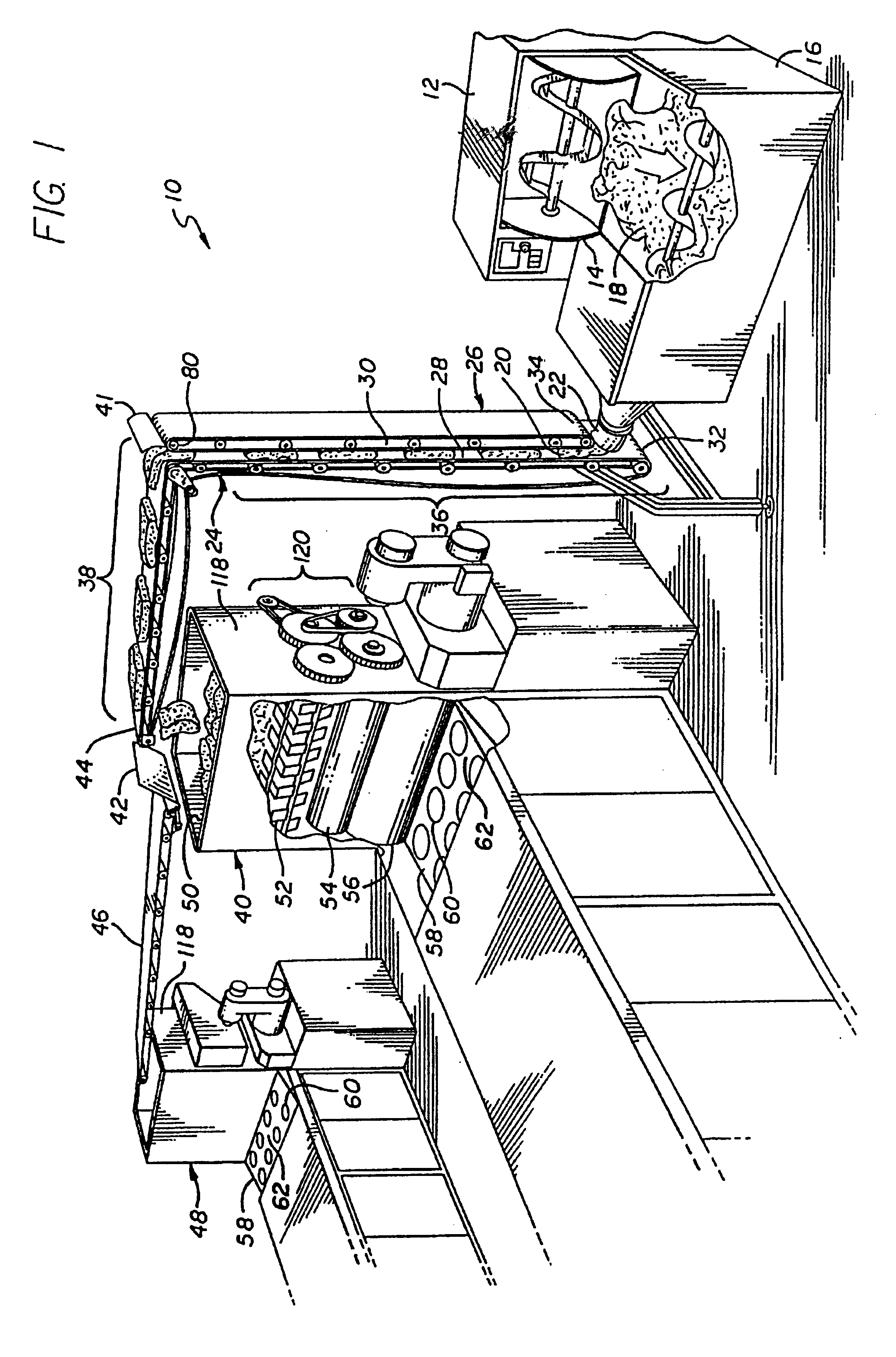

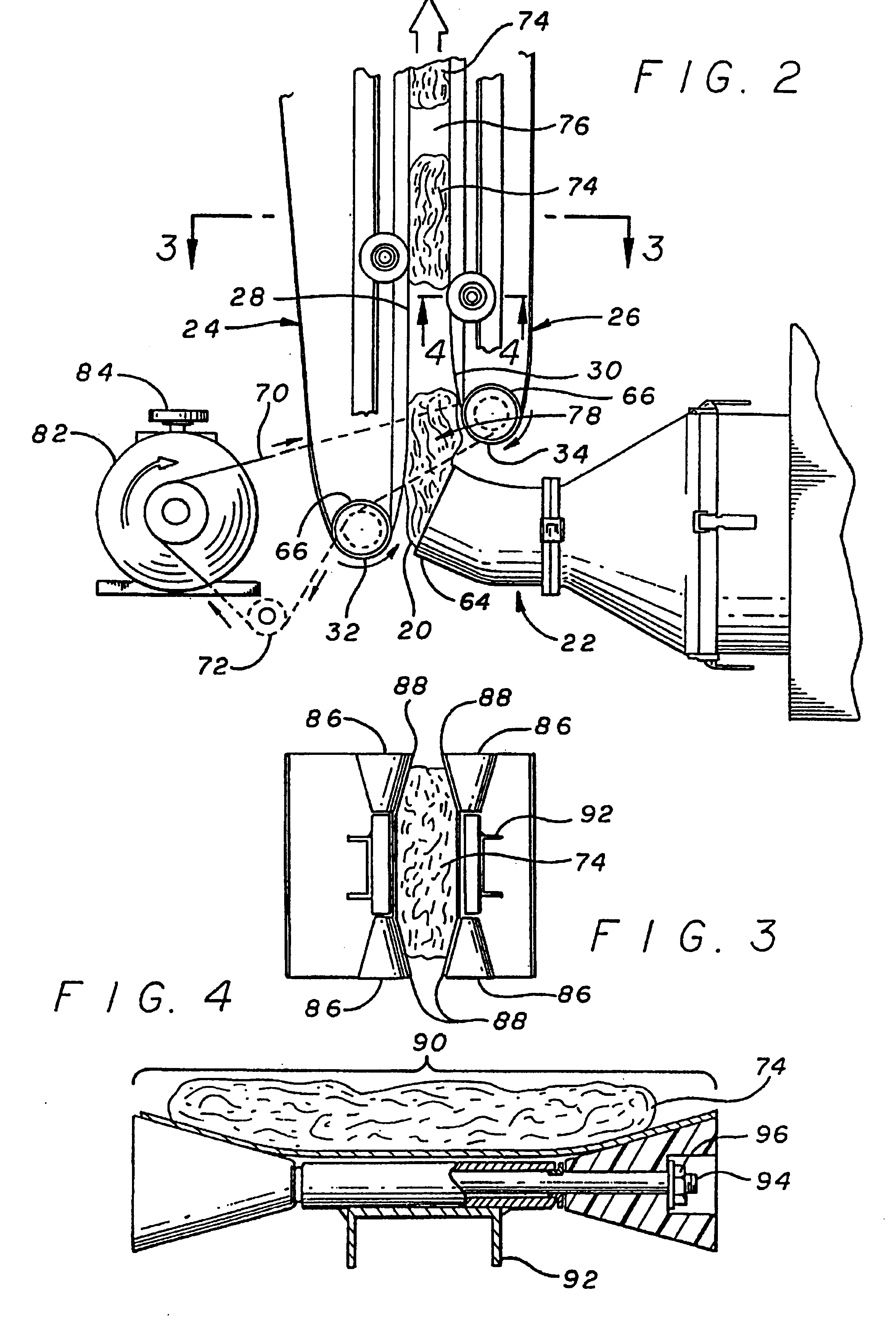

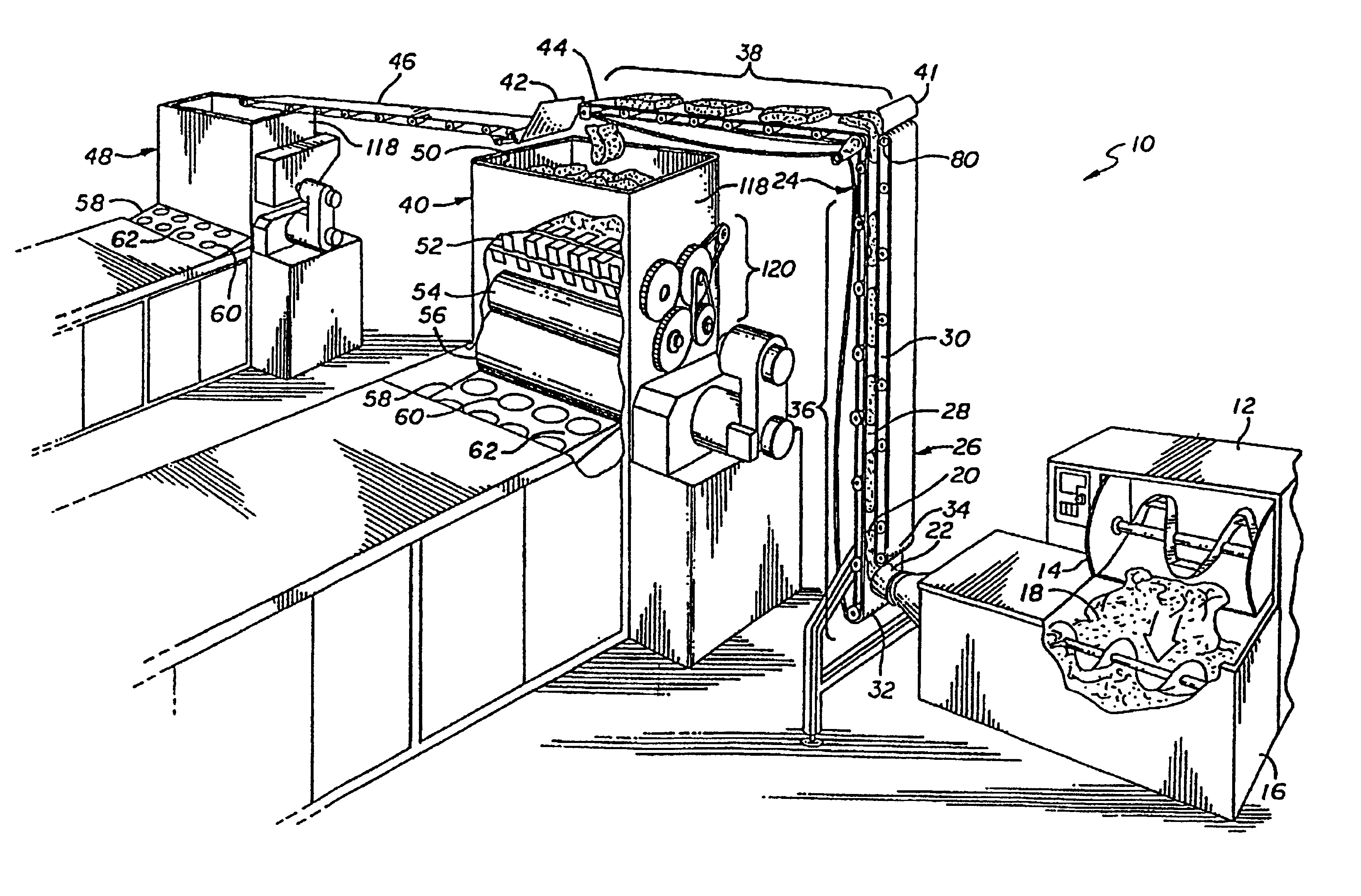

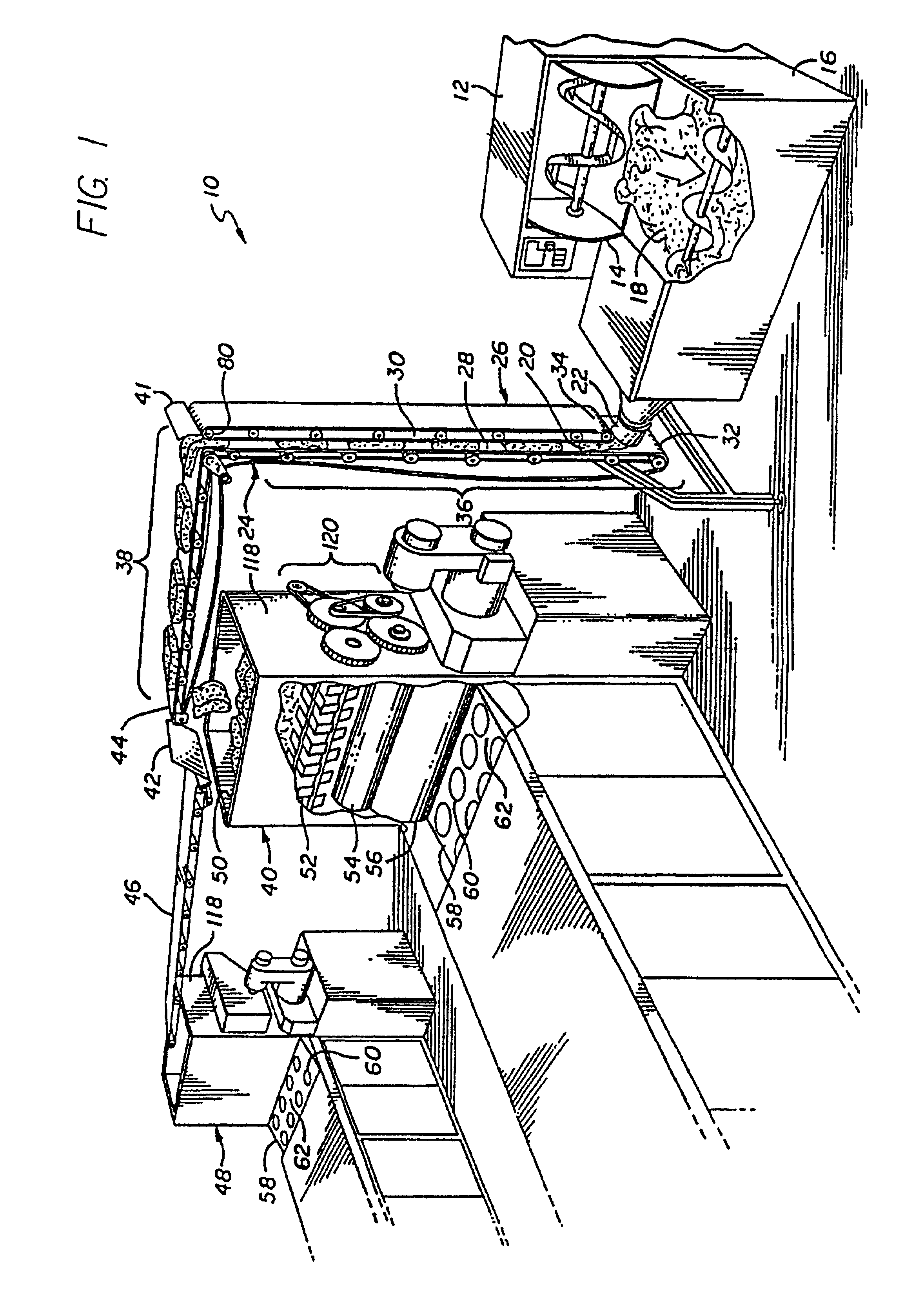

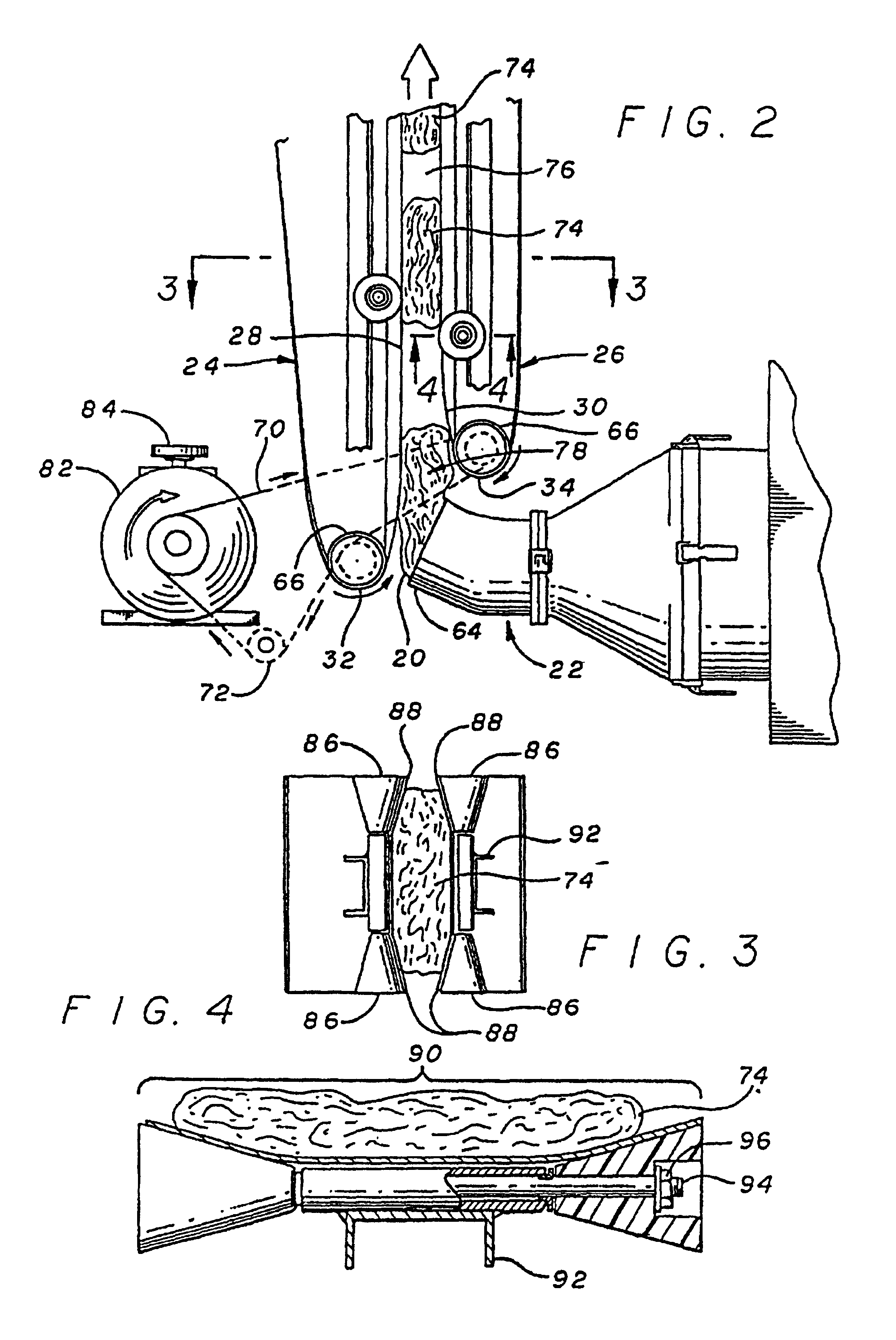

Methods for handling masa

Masa handling methods for the continuous processing of masa type dough in conjunction with commonly available feed processing equipment, such as a masa extruder, an oven, or cooling apparatus. One masa handling method includes a masa separator having a pair of opposed, endless belt conveyors having facing surfaces spaced apart to receive a generally continuous masa stream output from a nozzle on the masa extruder. When the masa stream moves between the conveyors, it is gripped by their facing surfaces and moved away from the nozzle, causing the masa to be separated into individual pieces, or logs. The masa handling method can also include feeding the masa to masa hoppers fed by at least two endless belt conveyors arranged in upstream and downstream positions relative to each other. The masa is transported along the conveyors and is automatically diverted into one masa hopper by a diverter gate operated by a controller that receives a signal from a sensor sensing a masa level within an associated one of the hoppers. The hopper has one or more rotating shafts having projections to remove gas bubbles from the masa and force it toward the sheeter rollers. A pair of primary rollers with scrapers can be provided within the hopper to roll the masa to an intermediate thickness before it passes between the sheeter rollers.

Owner:CASA HERRARA

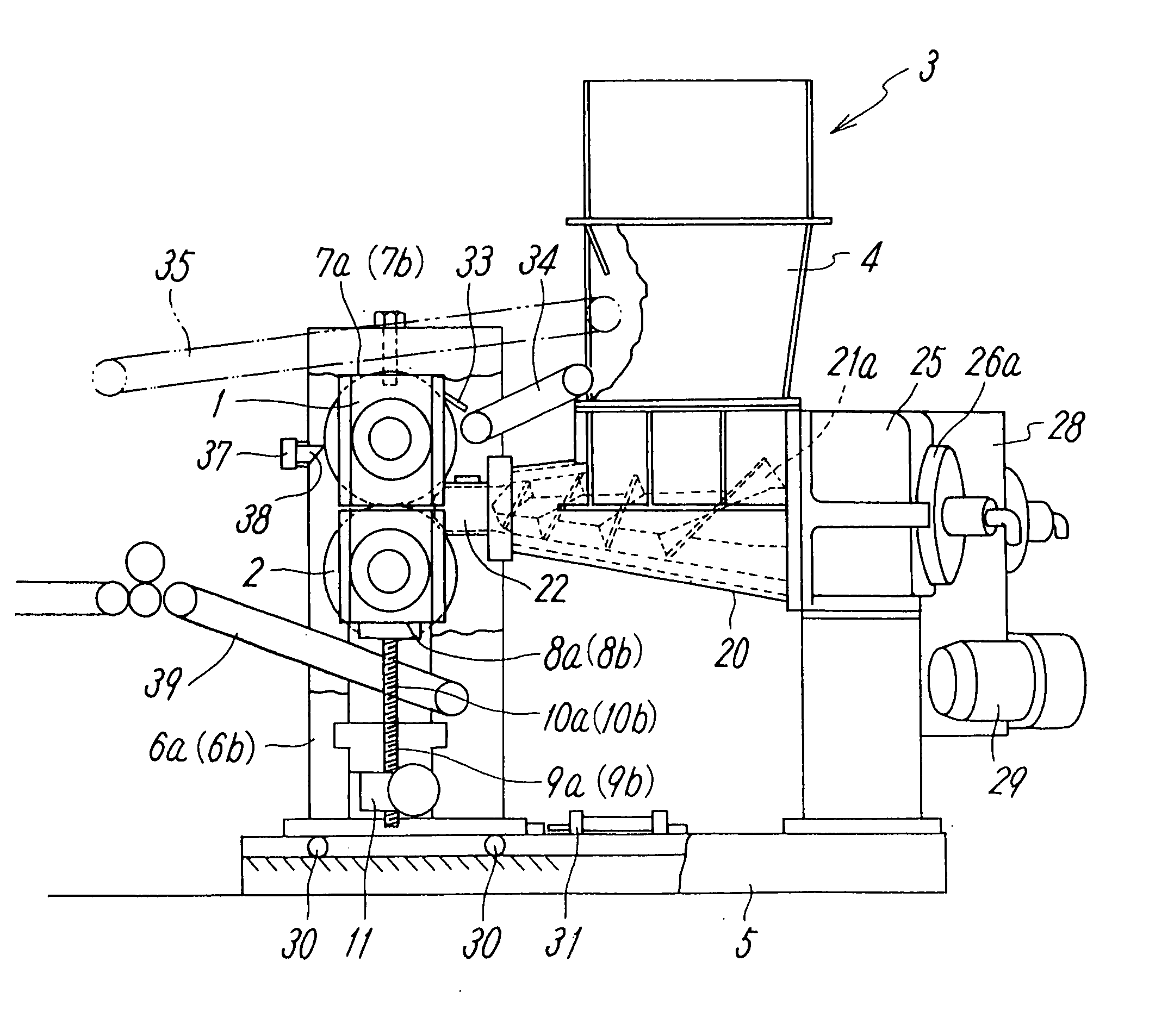

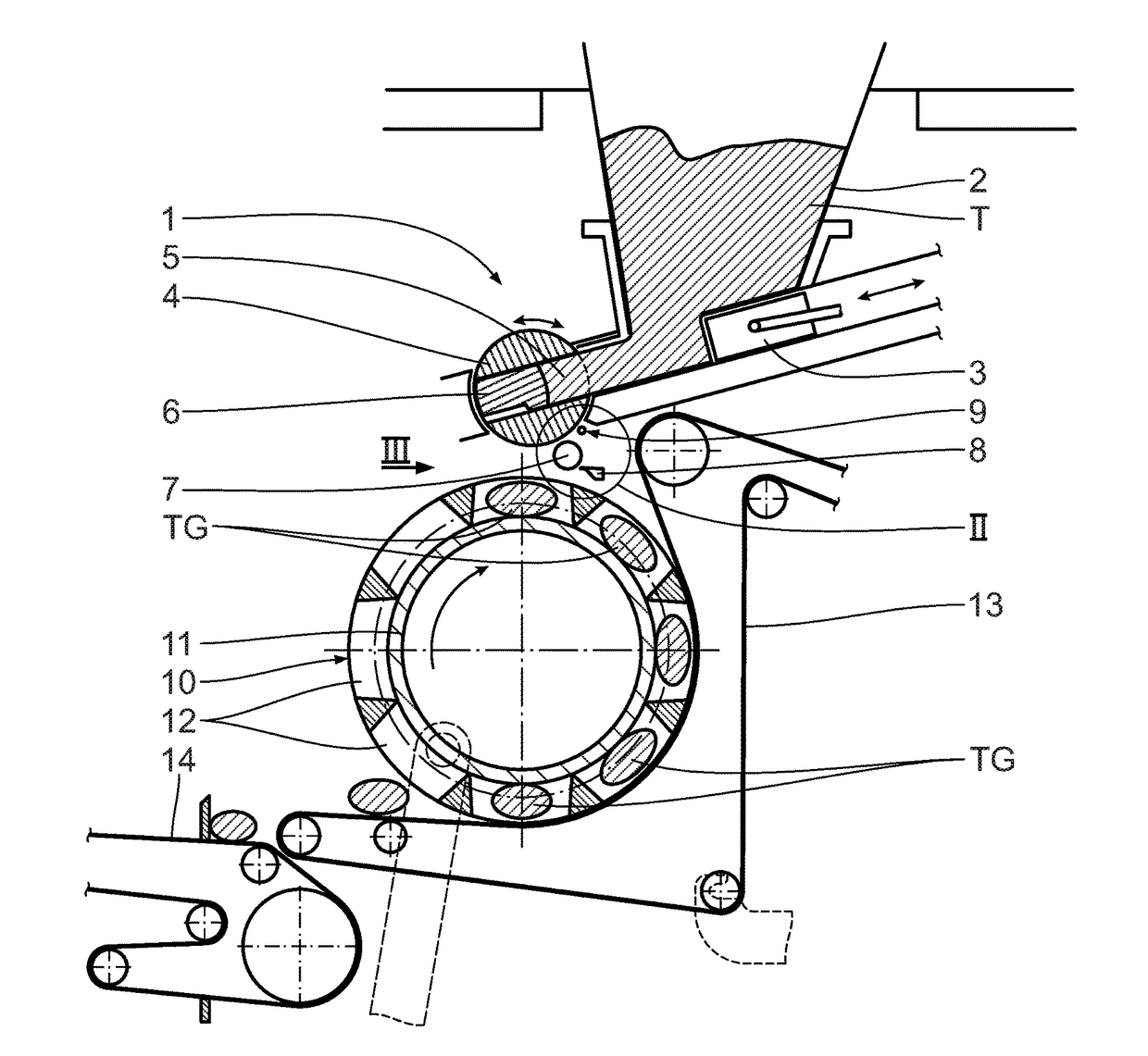

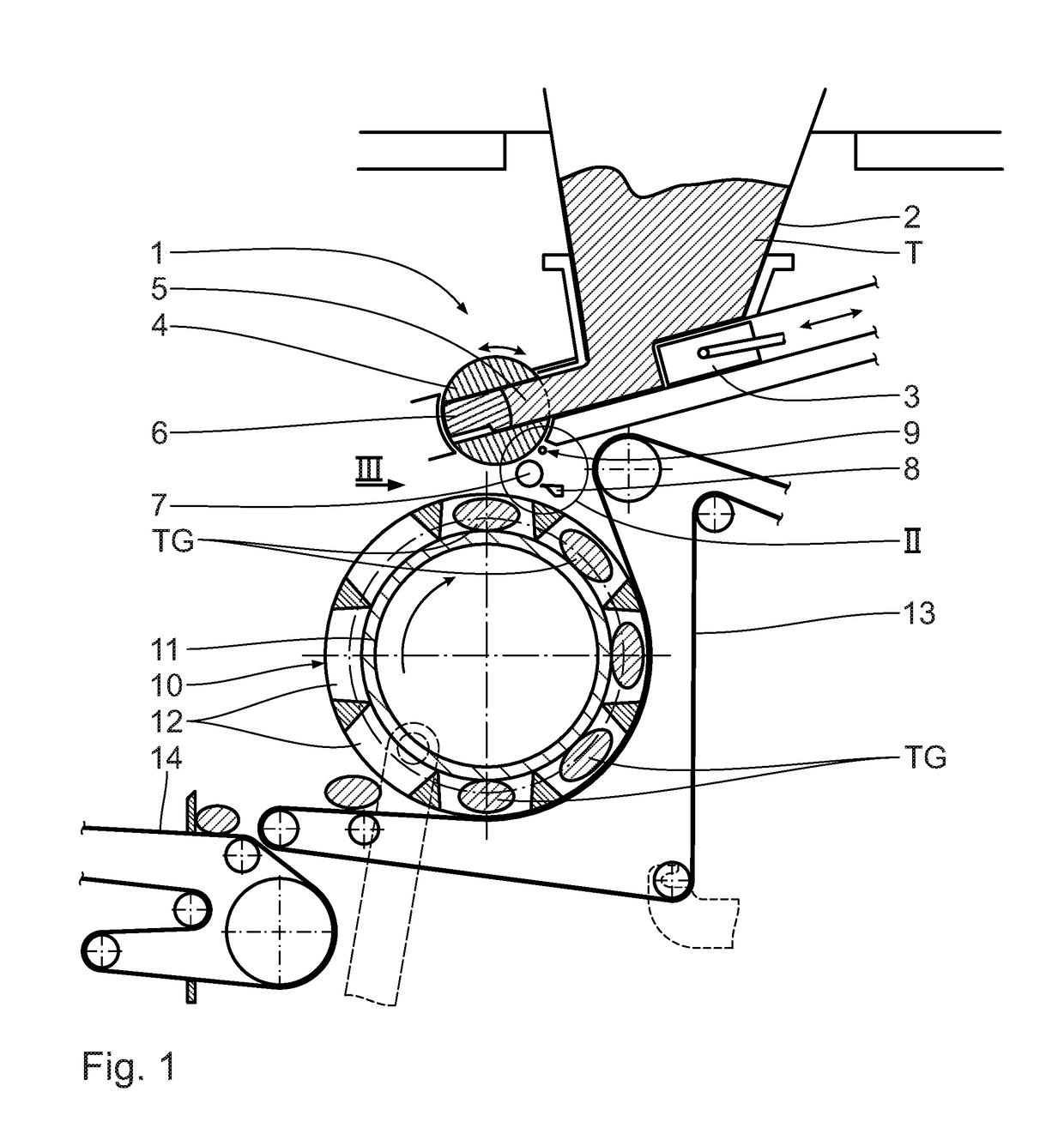

Rubber kneading machine

InactiveUS20050226093A1Maintain securityCleaned easily and securelyRotary stirring mixersTransportation and packagingProduction rateReduction drive

A rubber kneading machine obviates an operator having to touch rubber on a rotating roll surface to perform a rubber kneading operation, permits unattended operation, is intrinsically safe, improves a rubber kneading process productivity, secures stable quality of kneaded rubber, and allows a closed rubber supplying mechanism to be easily opened and exposed for easy cleaning. The rubber kneading machine includes two horizontal rolls closely disposed vertically, decelerators and variable speed motors rotating the rolls at different speeds, and a screw extruder supplying a rubber lump fed into a hopper at a proximal end to the rolls. A rubber circulating mechanism constructed mainly of a scraper and a belt conveyor, or a belt conveyor above the upper roll, feeds a rubber sheet, which has left the rolls, to the hopper. A mechanism releasing the screw extruder makes it possible to open and expose closed portions to facilitate cleaning.

Owner:SUZUKA ENG

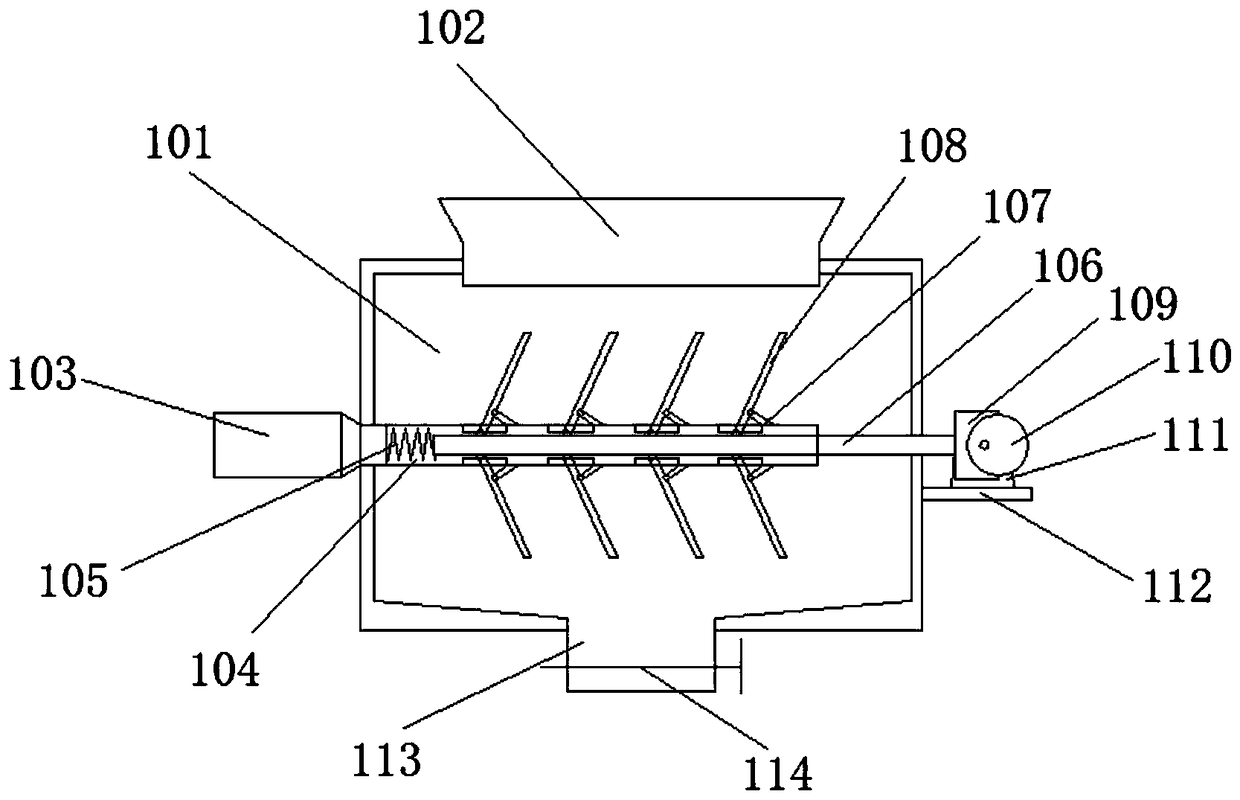

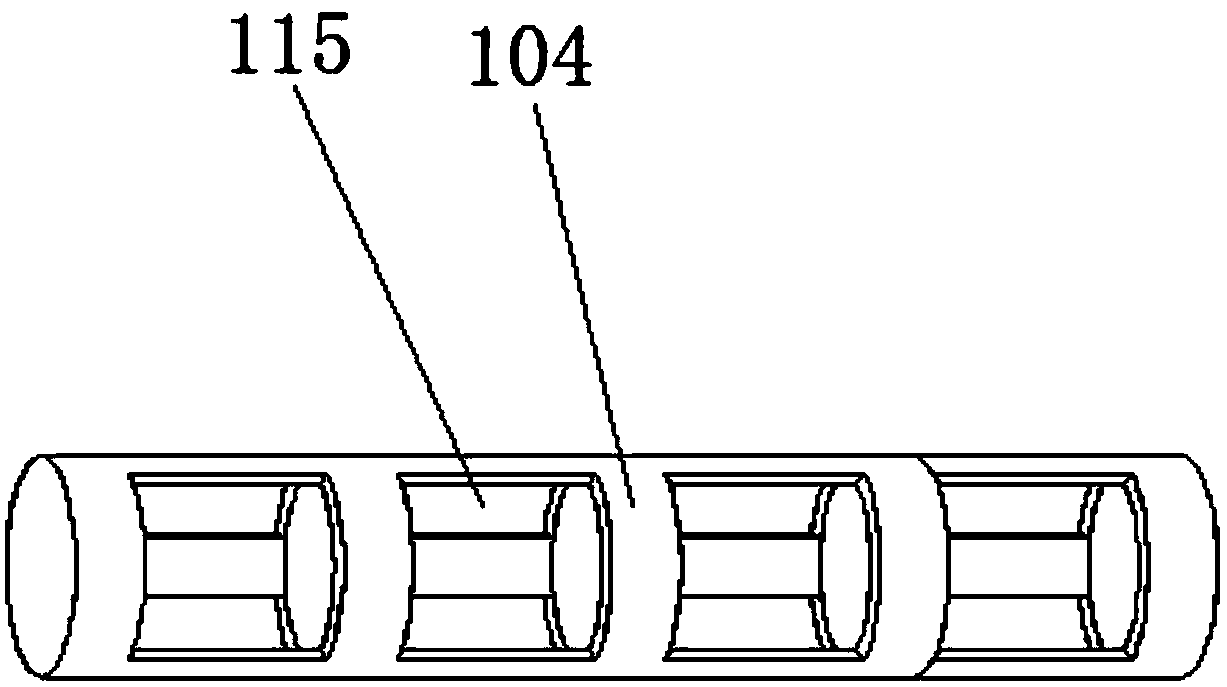

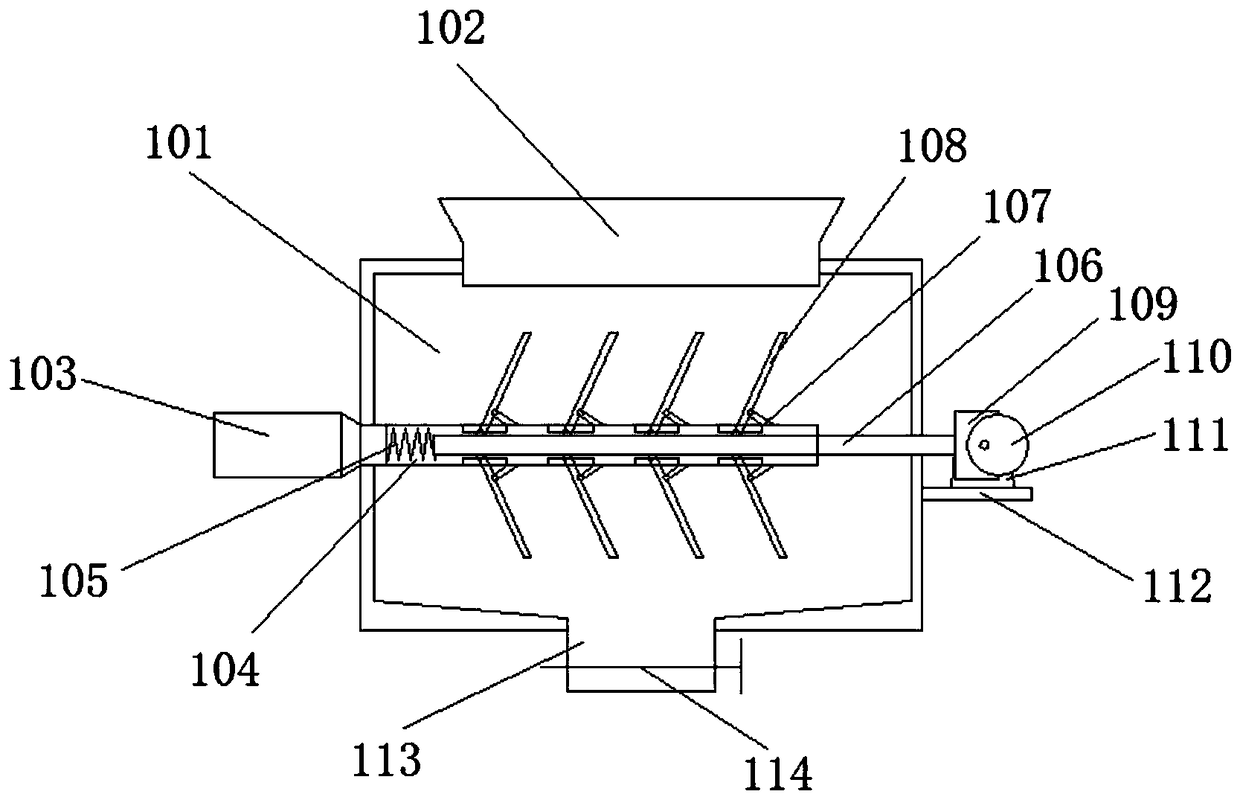

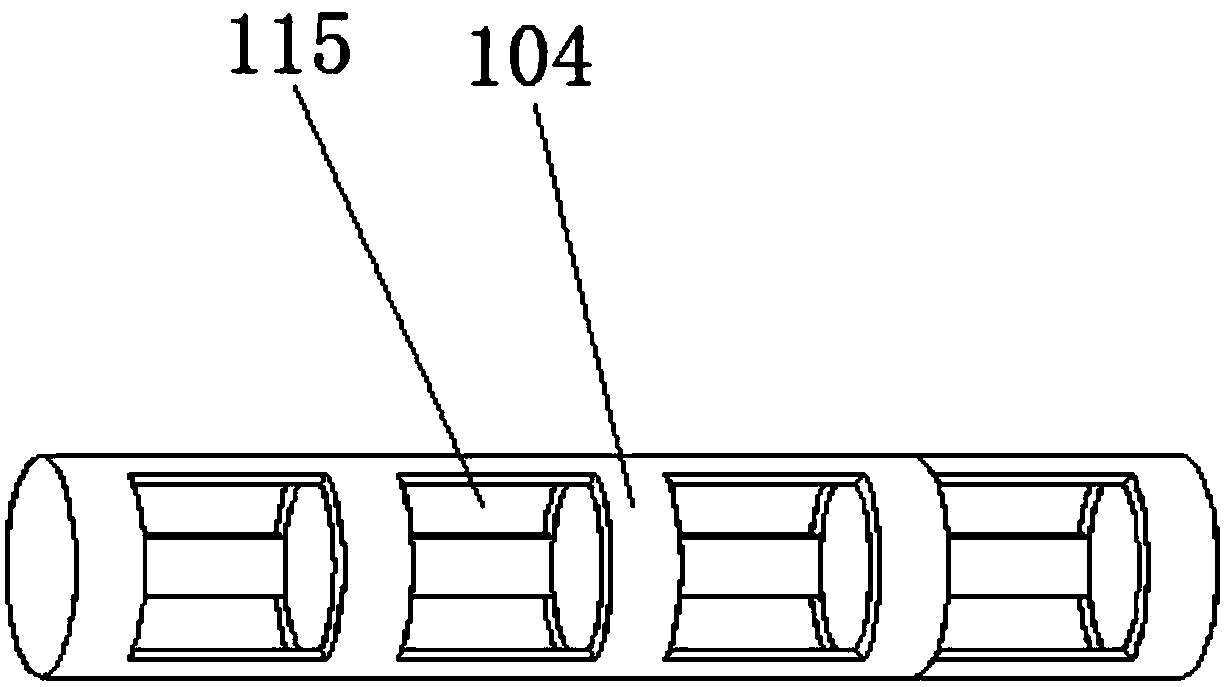

Flour mixing device of deep-fried dough stick machine

ActiveCN109006896AWell mixedImprove the mixing effectMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsDeep fryingAgricultural engineering

The invention discloses a flour mixing device of a deep-fried dough stick machine, and relates to the field of food processing. The flour mixing device includes a mixing mechanism, a dough kneading mechanism is arranged at the bottom of the mixing mechanism, a leavening cabin is connected to the right side of the dough kneading mechanism through a lifting machine, an extrusion machine is fixed tothe bottom of the leavening cabin, a discharging mechanism is arranged at the right end of the extrusion machine, a conveying machine is arranged below the discharging mechanism, a composite shaping mechanism is arranged at the middle of the conveying machine, a stretching detachment mechanism is arranged on the right portion of the conveying machine, and a deep-frying device is arranged at the bottom of the right end of the conveying machine. By adopting the flour mixing device of the deep-fried dough stick machine, a manual deep-fried dough stick making process can be stimulated, after wateris automatically added into flour and is mixed with the flour to make dough, the dough is kneaded, leavened, pressed, shaped and then stretched, finally, the dough is deeply fried, manual labor is greatly reduced, the mouthfeel of deep-fried dough sticks is ensured, the deep-fried dough sticks are efficiently and rapidly made, and the flour mixing device is suitable for being used in breakfast stores.

Owner:张乐

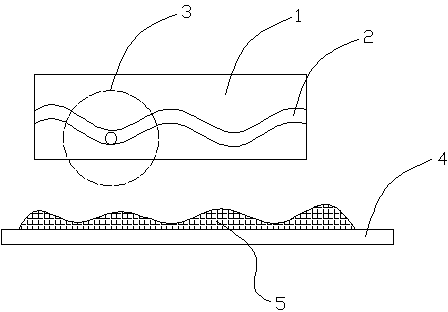

Flour rolling tool

InactiveCN103734213AIncrease softnessImprove uniformityMixing/kneading with rollersEngineeringMechanical engineering

The invention relates to a processing tool, and particularly relates to a flour rolling tool. The flour rolling tool comprises a slide block and a walking board, wherein the walking board is arranged below the slide block; a wave slide rail is arranged at the inner lateral wall of the slide block; a flour roller is arranged inside the slide block, and can slide along the slide rail. By adopting the flour rolling tool provided by the invention, the softness of the flour is improved, the uniformity of paste is increased, and a guarantee is provided for later production of high-quality noodles.

Owner:SUZHOU HUANYAN ELECTRIC

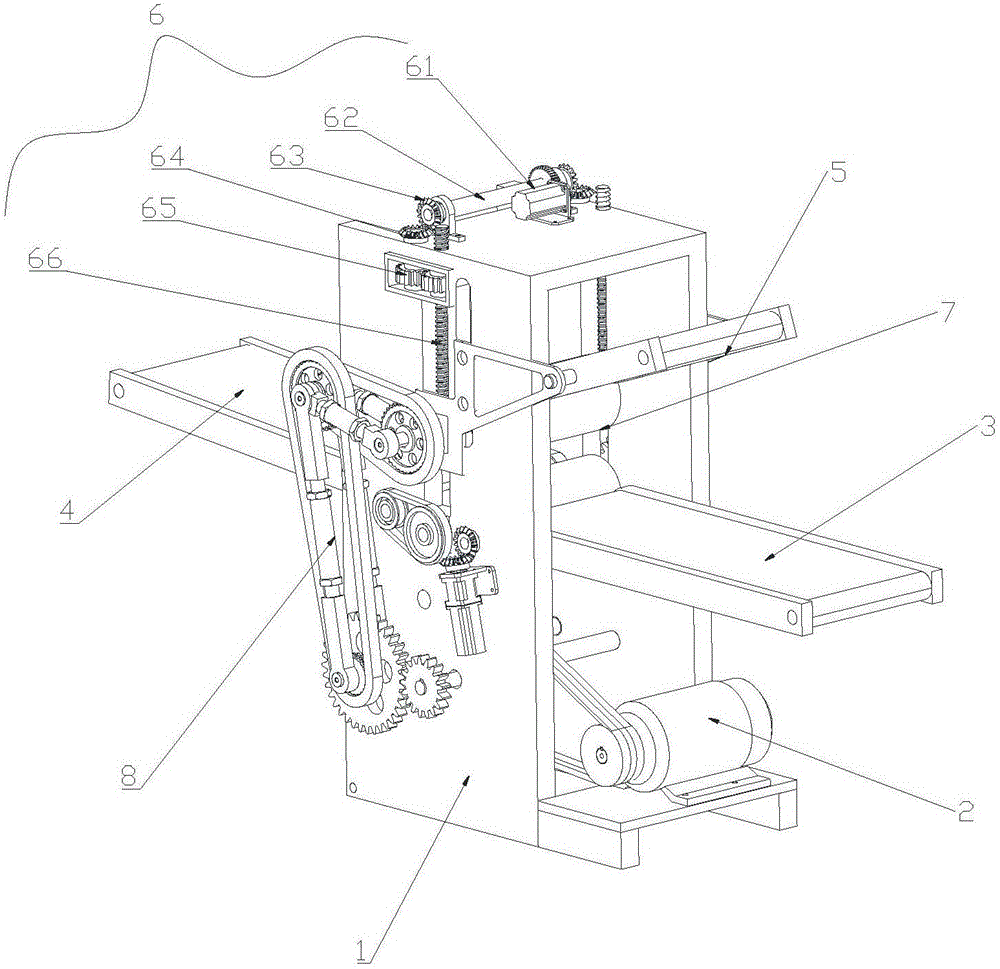

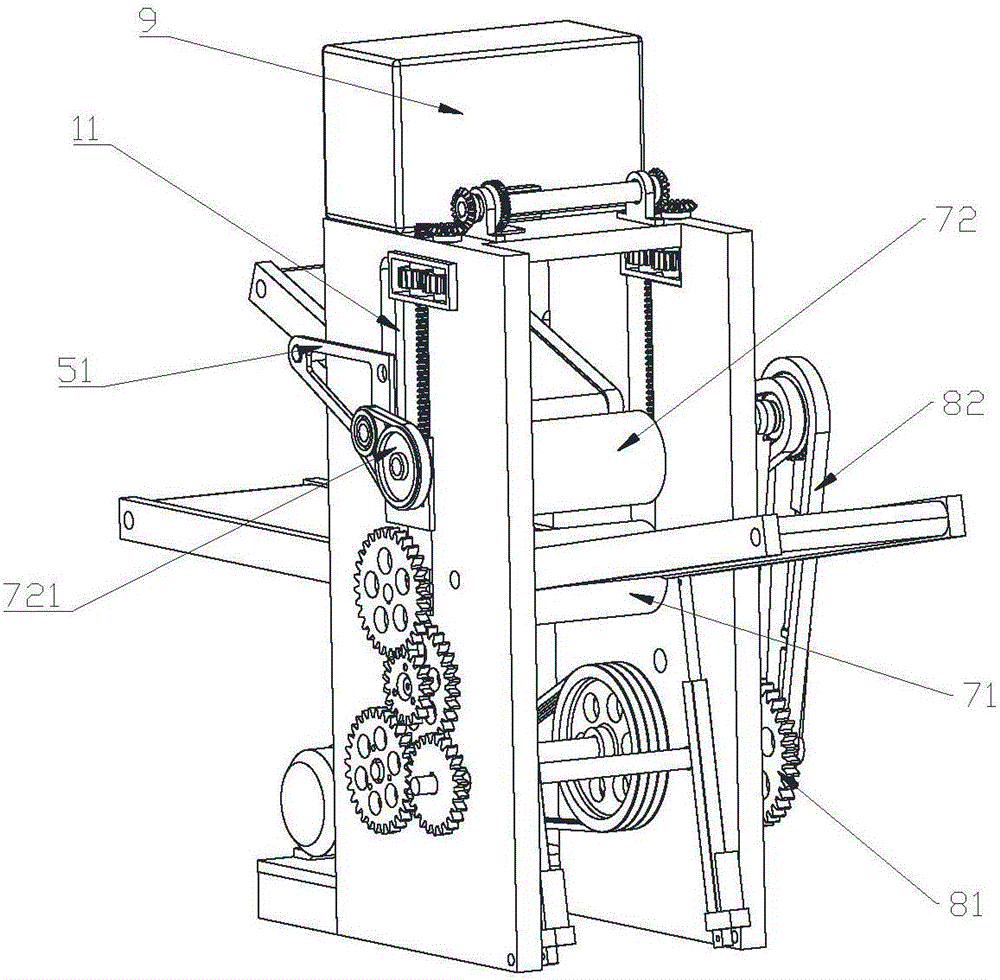

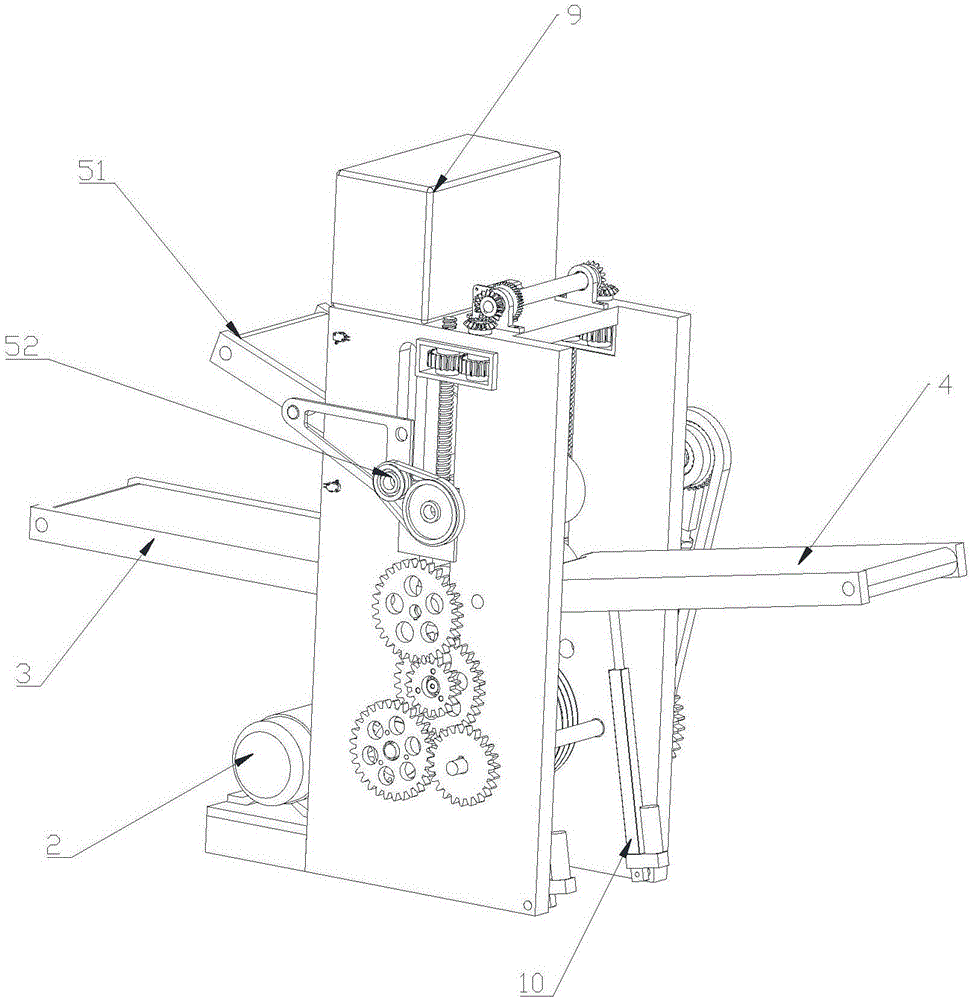

One-step noodle forming mechanism with rolling and cutting and a noodle machine integred with producing and cooking

ActiveUS20150320055A1Great tasteQuality improvementMouldsDrying solid materials without heatGear wheelEngineering

A one-step noodle forming mechanism with rolling and cutting is provided, including multi-layer noodle roller sets in s disposed on a machine frame and noodle forming blades disposed below the multi-layer noodle roller sets, in which the multi-layer noodle roller sets and the noodle forming blades are driven to rotate by the same motor through a gear transmission mechanism. The dough entering the noodle forming mechanism is directly made into noodles through rolling and cutting of multiple layers. A noodle machine integrated with producing and cooking including the noodle forming mechanism is also provided.

Owner:RADIAND BEIJING ELECTRIC TECH DEV +1

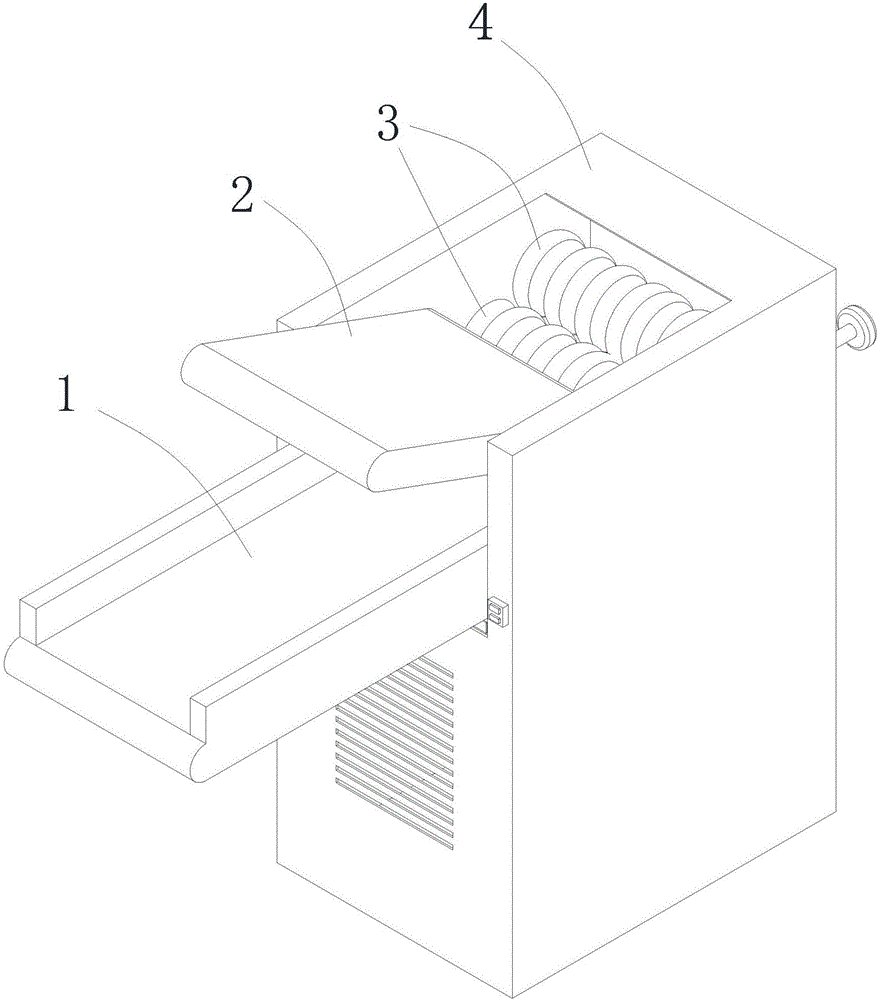

Dough kneading device for flour-made food processing

ActiveCN108617724AAccurate quality controlEasy to cleanMixing/kneading structural elementsMixing/kneading with rollersEngineeringSingle chip

The invention discloses a dough kneading device for flour-made food processing. The dough kneading device comprises a base and is characterized in that a transverse slide guide rail is arranged in themiddle of the upper surface of the base, a third fixing plate is arranged on the left side of the slide guide rail, a screw is rotatably connected to the right side of the third fixing plate througha bearing, square support columns are arranged at the front end and the rear end of the right side of the upper surface of the base, a second connecting rod is arranged on the inner side of the upperend of each square support column, a liquid feeding hopper is arranged on the front second connecting rod, a flour feeding hopper is arranged on the rear second connecting rod, and a single-chip microcomputer is arranged on the right side of the upper surface of the base. The dough kneading device has the advantages that the device is provided with an electronic weighing device and an electronic counter, the weight of needed flour and water can precisely controlled, the flour and the water can be automatically mixed according to a certain proportion, production efficiency is increased, dough does not need secondary processing during use, a dough kneading bin can move by the slide guide rail below the dough kneading bin, the kneaded dough can be conveniently taken out, and the dough kneading bin can be conveniently cleaned.

Owner:安徽品滋味食品股份有限公司

Methods for handling masa

InactiveUSRE41573E1Safe separationOperational securityDough treatmentRotary stirring mixersEngineeringGas bubble

Mass handling methods for the continuous processing of masa type dough in conjunction with commonly available feed processing equipment, such as a masa extruder, an oven, or cooling apparatus. One masa handling method includes a masa separator having a pair of opposed, endless belt conveyors having facing surfaces spaced apart to receive a generally continuous masa stream output from a nozzle on the masa extruder. When the masa stream moves between the conveyors, it is gripped by their facing surfaces and moved away from the nozzle, causing the masa to be separated into individual pieces, or logs. The masa handling method can also include feeding the masa to masa hoppers fed by at least two endless belt conveyors arranged in upstream and downstream positions relative to each other. The masa is transported along the conveyors and is automatically diverted into one masa hopper by a diverter gate operated by a controller that receives a signal from a sensor sensing a masa level within an associated one of the hoppers. The hopper has one or more rotating shafts having projections to remove gas bubbles from the masa and force it toward the sheeter rollers. A pair of primary rollers with scrapers can be provided within the hopper to roll the masa to an intermediate thickness before it passes between the sheeter rollers.

Owner:CASA HERRARA

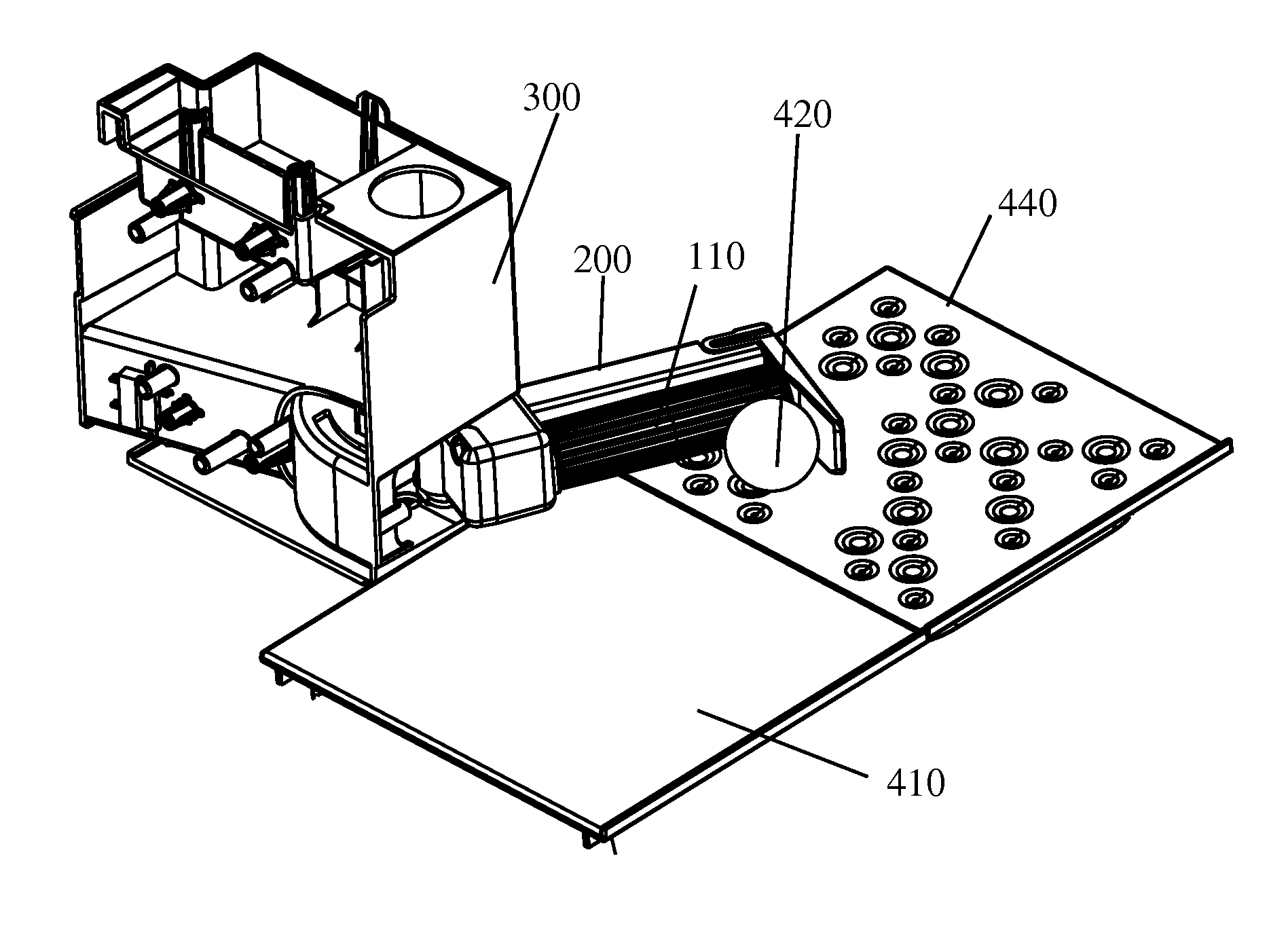

Transfer apparatus and the method of using the same in a food preparation appliance

ActiveUS9277752B2Reduce viscosityReduce adhesionMixing/kneading with rollersDisc dough shapingEngineeringBack support

A novel transfer apparatus having several movable parts is used for moving the dough product from a first position to a final position. The transfer apparatus uses the arm to move the dough product and a motor and software that controls the movement of the arm. A roller residing in the arm also has its own motor and software to control its rotational movement. The components of the arm such as a roller, back support and the flap each have their own unique shape and structure to maximize efficiency. The transfer apparatus may be used as an insertable apparatus in any food processing machine and also used as an integral part of the flat bread making machine.

Owner:ZIMPLISTIC

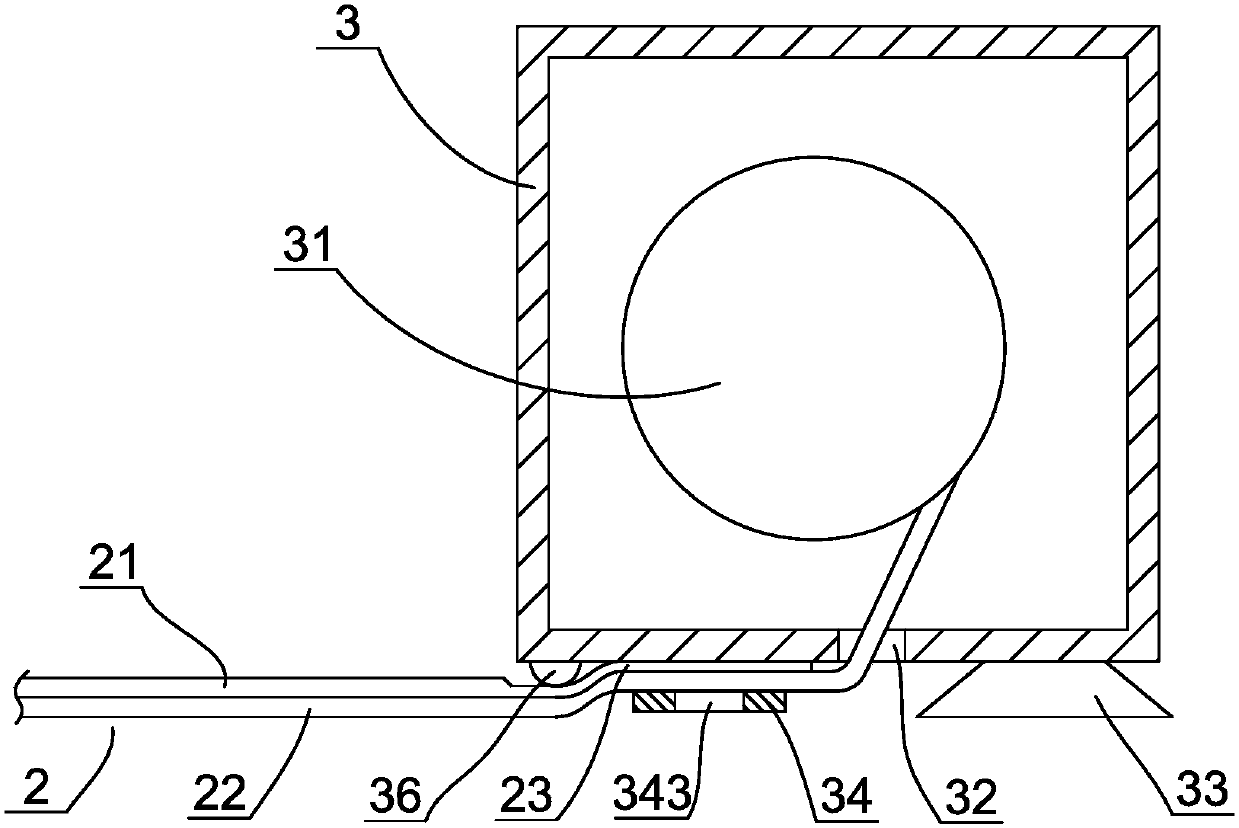

Dough kneading device and dough kneading method

ActiveCN107691546AAvoid bloatingPrevent leakageMixing/kneading structural elementsMixing/kneading with rollersFermentationMechanical engineering

The invention discloses a dough kneading device and a dough kneading method. The dough kneading device comprises a dough pressing roll, a sheet-shaped bag body composed of an upper gasket and a lowergasket, and a U-shaped frame composed of a receiving box body and pressure strips; sealing clamps are arranged on two sides of the sheet-shaped bag body; a winding roll is arranged in the receiving box body; the bottom surface of the receiving box body is provided with a strip opening, an elastic sealing strip and a vacuum sucker; the front side edge of the lower gasket is connected with the winding roll; the dough pressing roll comprises a rolling shaft, a dough kneading roller which can sleeve the rolling shaft and a dough rolling roller; a plurality of hemispherical bulges are arranged on the circumferential surface of the dough kneading roller; and two ends of the rolling shaft are connected with the pressure strips on the left side and the right side respectively in a sliding manner.By adopting the dough kneading device, during dough kneading, the dough kneading roller rolls dry and wet raw materials in the sheet-shaped bag body and enables the rolled dry and wet raw materials toform a dough blank, then the sheet-shaped bag body is flattened, dough kneading is finished on the upper gasket and the lower gasket, and then fermentation and exhaust of a dough are finished in thesealed sheet-shaped bag body to start preparation of wheaten foods. The dough kneading device provided by the invention can effectively improve the preparation efficiency of the wheaten foods and is convenient in storage at the same time.

Owner:宁波北仑思行硅胶制品有限公司

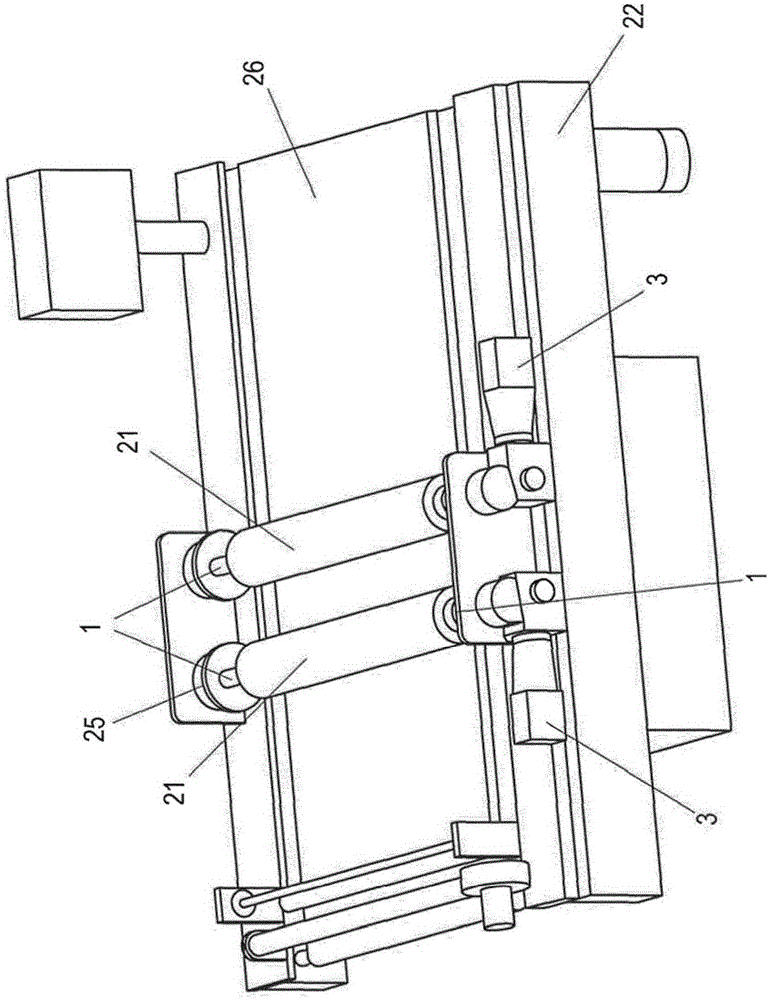

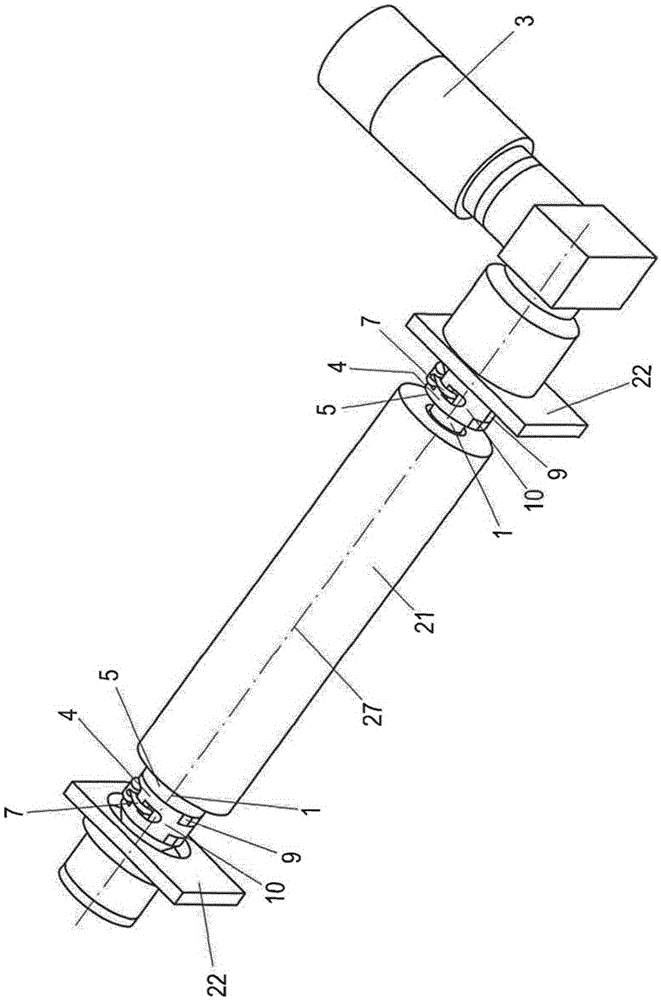

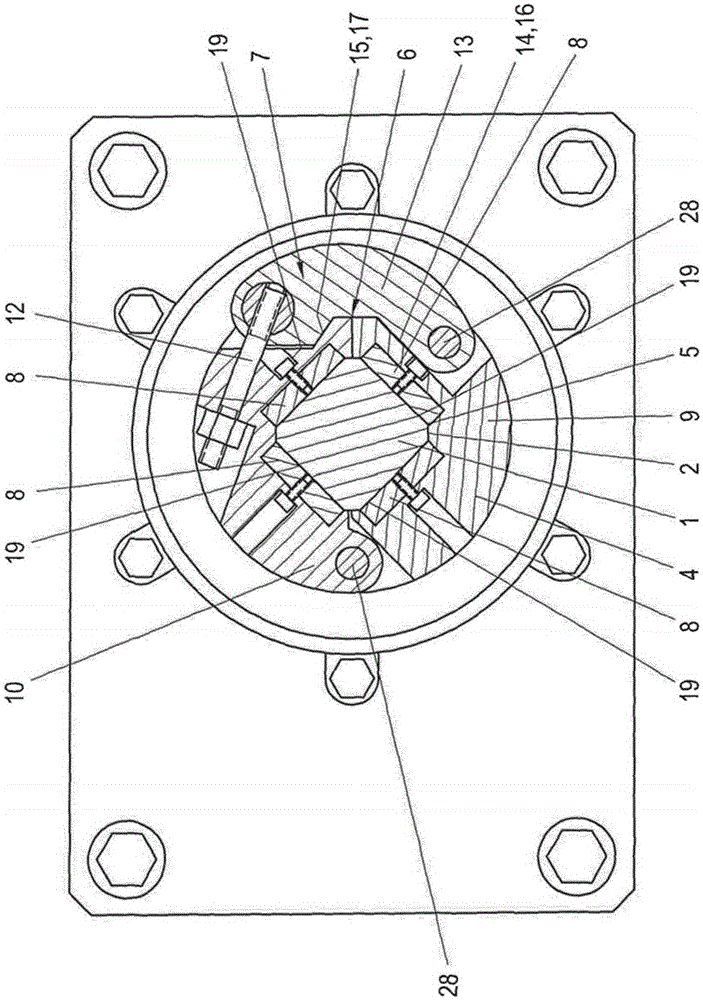

Rolling bearing retainer, rolling bearing, and production method for rolling bearing retainer

InactiveCN105247232AEasy to replaceExtended service lifeCouplings for rigid shaftsFood shapingCouplingEngineering

The invention relates to a shaft coupling and to a roller arrangement comprising a shaft coupling for coupling a shaft journal (1), having a polygonal cross section (2), to a drive (3) or a bearing axis (25), comprising a coupling body (4) which can be rotationally driven and which comprises a coupling opening (5) for receiving the shaft journal (1). Said coupling body (4) has several parts and is designed so that it can be open along a separation line (6), said separation line (6) dividing the coupling opening (5). A clamping device (7) for maintaining the shaft journal (1) in a positive fit in the coupling opening (5) is provided, said coupling opening (5) is formed, at least partially, by clamping jaws (8) which are pressed, preferably flushly, against the shaft journal (1) by means of the clamping device (7) when in the closed position.

Owner:HAAS FOOD EQUIP

Bionic dough kneading device of deep-fried dough stick machine

ActiveCN109006895AWell mixedImprove the mixing effectMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsDeep fryingEngineering

The invention discloses a bionic dough kneading device of a deep-fried dough stick machine, and relates to the field of food processing. The bionic dough kneading device includes a mixing mechanism, adough kneading mechanism is arranged at the bottom of the mixing mechanism, a leavening cabin is connected to the right side of the dough kneading mechanism through a lifting machine, an extrusion machine is fixed to the bottom of the leavening cabin, a discharging mechanism is arranged at the right end of the extrusion machine, a conveying machine is arranged below the discharging mechanism, a composite shaping mechanism is arranged at the middle of the conveying machine, a stretching detachment mechanism is arranged on the right portion of the conveying machine, and a deep-frying device isarranged at the bottom of the right end of the conveying machine. By adopting the bionic dough kneading device of the deep-fried dough stick machine, a manual deep-fried dough stick making process canbe stimulated, after water is automatically added into flour and is mixed with the flour to make dough, the dough is kneaded, leavened, pressed, shaped and then stretched, finally, the dough is deeply fried, manual labor is greatly reduced, the mouthfeel of deep-fried dough sticks is ensured, the deep-fried dough sticks are efficiently and rapidly made, and the bionic dough kneading device is suitable for being used in breakfast stores.

Owner:蚌埠知博自动化技术开发有限公司

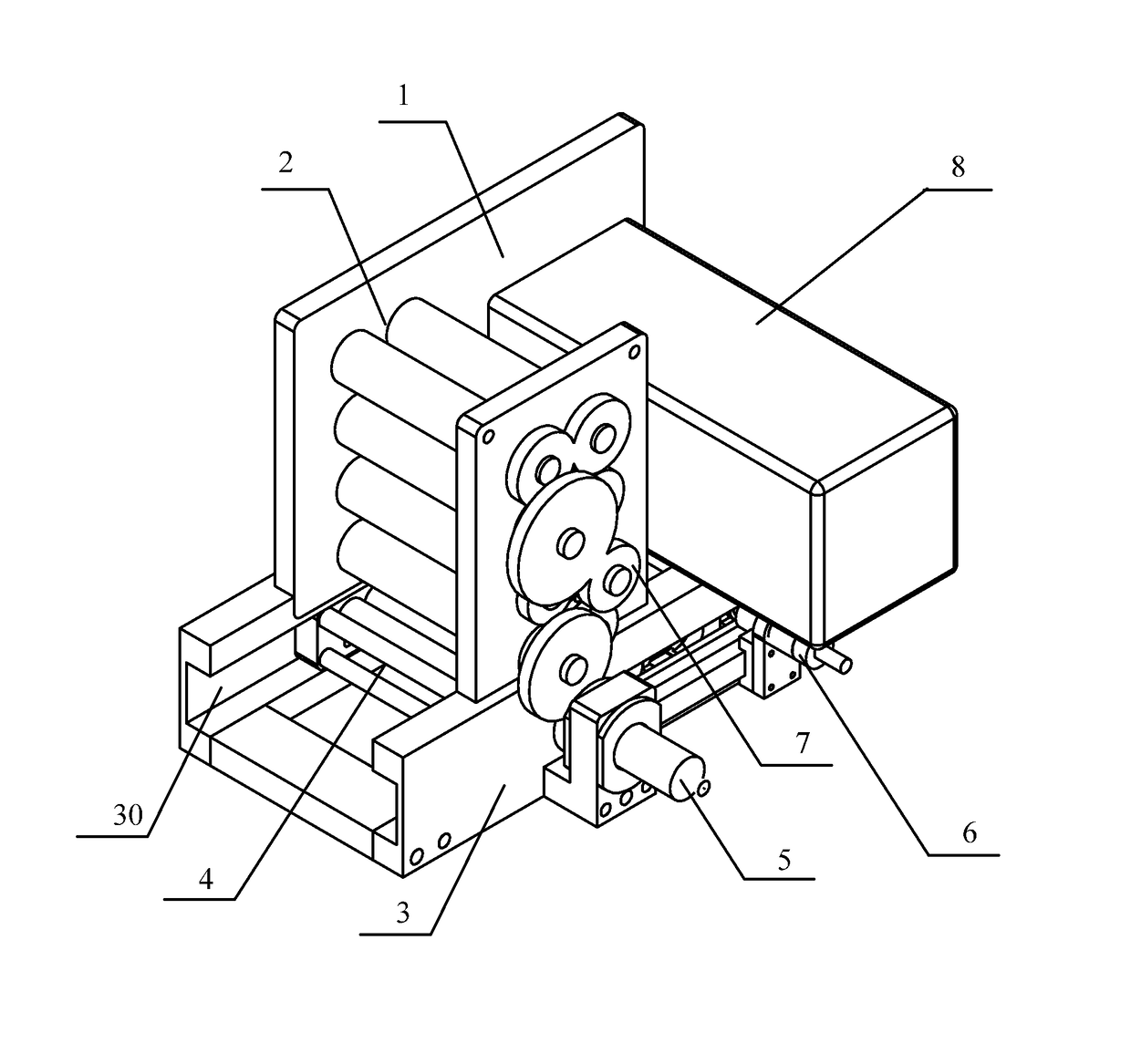

Hand-imitated flour kneading and pressing equipment

ActiveCN108174882AGuaranteed damageNot destroyedMixing/kneading structural elementsMixing/kneading with rollersEngineeringMechanical engineering

The invention discloses hand-imitated flour kneading and pressing equipment, which comprises a rack, wherein the rack comprises supporting frames on two sides and a reinforcement rod arranged betweenthe supporting frames; the rack is fixedly provided with a kneading and pressing mechanism used for kneading and pressing a dough by simulating a hand, and a folding and pressing mechanism used for folding and pressing the dough kneaded and pressed by the kneading and pressing mechanism; and a material conveying mechanism is arranged between the kneading and pressing mechanism and the folding andpressing mechanism. A flour kneading and pressing process is decomposed into a kneading and pressing process and a folding process by referring to a manual flour kneading process, the kneading and pressing mechanism is used for simulating hand kneading and pressing to press flour, flour is folded through the folding and pressing mechanism, the kneading and pressing mechanism and the folding and pressing mechanism are cooperated to knead and press flour, a flour kneading and pressing process can be automatically carried out, in addition, hand flour kneading is simulated, gluten networks are ensured not be damaged in a flour kneading process, the formation of gluten networks is increased, wheat protein is accelerated to fully adsorb water, and the taste and the flavor of the dough are improved.

Owner:帕玛特自动化科技(山东)有限公司

Dough kneading device and method

InactiveCN106106599AImprove toughnessGreat tasteMixing/kneading structural elementsMixing/kneading with rollersEngineeringConveyor belt

The invention discloses a noodle kneading device and a method thereof. The noodle kneading device comprises: a frame, on which a main motor is arranged, a pressing roller assembly, the front and rear sides of the lower kneading roller of the pressing roller assembly are respectively provided with There are a front conveyor belt assembly and a rear conveyor belt assembly for conveying the dough blanks, when the dough blanks are reciprocating from the front conveyor belt assembly and the rear conveyor belt assembly, or the dough blanks are circulated from the front conveyor belt assembly and the upper conveyor belt assembly to the rear conveyor belt assembly During the process, the main motor drives the pressing roller assembly to knead and press the dough. The noodle kneading device and method thereof of the present invention can realize automatic noodle kneading and molding process without manual intervention, simple and efficient process, and kneaded noodle dough with better strength and good taste.

Owner:深圳厨奇自胜智能装备技术有限公司

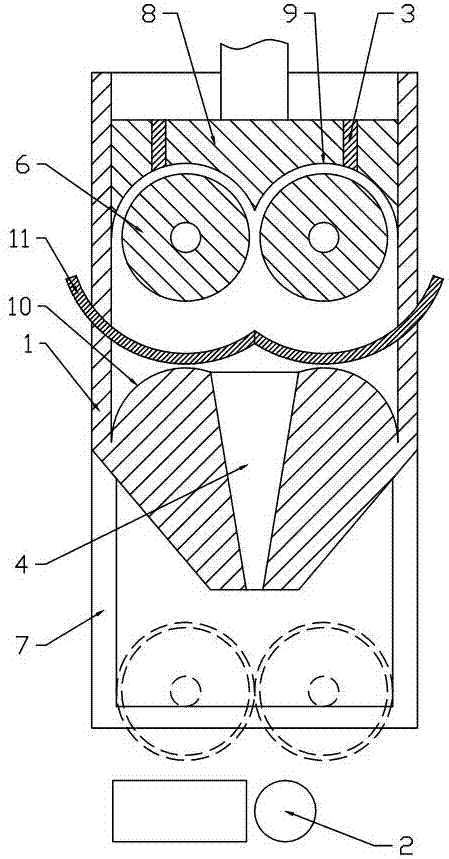

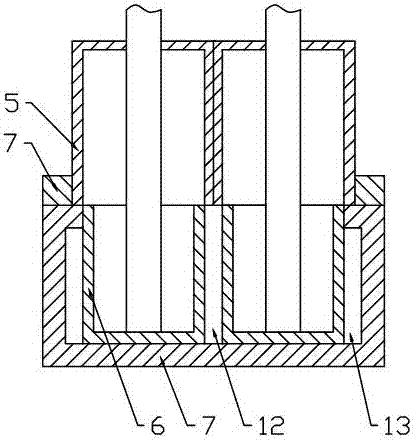

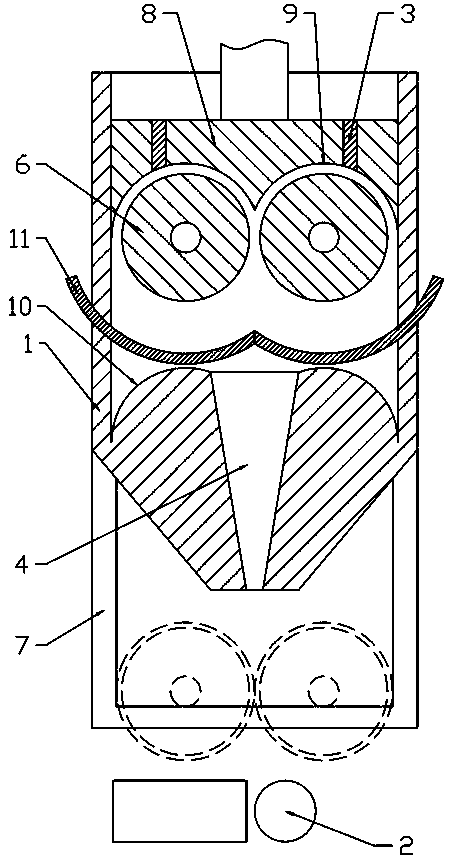

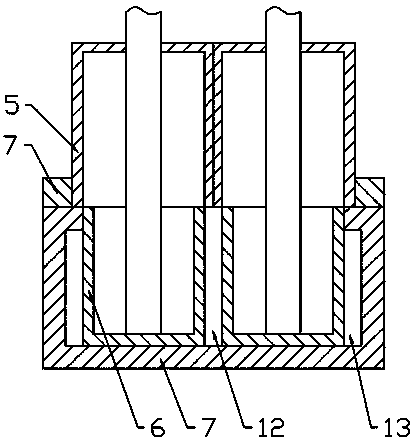

Noodle machine

ActiveCN106857738AMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsEngineeringPiston

The present invention relates to the fields of mechanical devices for processing dough and discloses a noodle machine. The noodle machine comprises a material bucket used for dough kneading, a rolling mechanism and a dough piece cutting mechanism. A material outlet is arranged at the bottom of the material bucket, the rolling mechanism is arranged at the lower part of the material bucket, the dough piece cutting mechanism is arranged under the rolling mechanism, the cross section of the material bucket is rectangular, two roller containing devices are arranged at the side wall of the material bucket, the inside of the roller containing devices is hollow, the roller containing devices communicates with the material bucket, a dough kneading roller is in slide connection within each of the roller containing devices, a driving device for driving the dough kneading rollers to rotate is connected to the end faces of the dough kneading rollers, a material scooping gap of 5-10 mm is formed between the two dough kneading rollers, and a squeezing gap of 3-8 mm is formed between each dough kneading roller and the side wall of the material bucket; and a piston is slidably connected within the material bucket, one side, facing towards the material outlet, of the piston is wedge-shaped, and a tip end of the wedge-shape faces toward the material scooping gap. The present invention aims to provide the noodle machine. The noodle machine mechanically produces the noodles, forms regular gluten structures in the interior of the dough in the dough kneading processes, and ensures the mouthfeel of the finished products of the noodles.

Owner:湖南楚冠农业科技股份有限公司

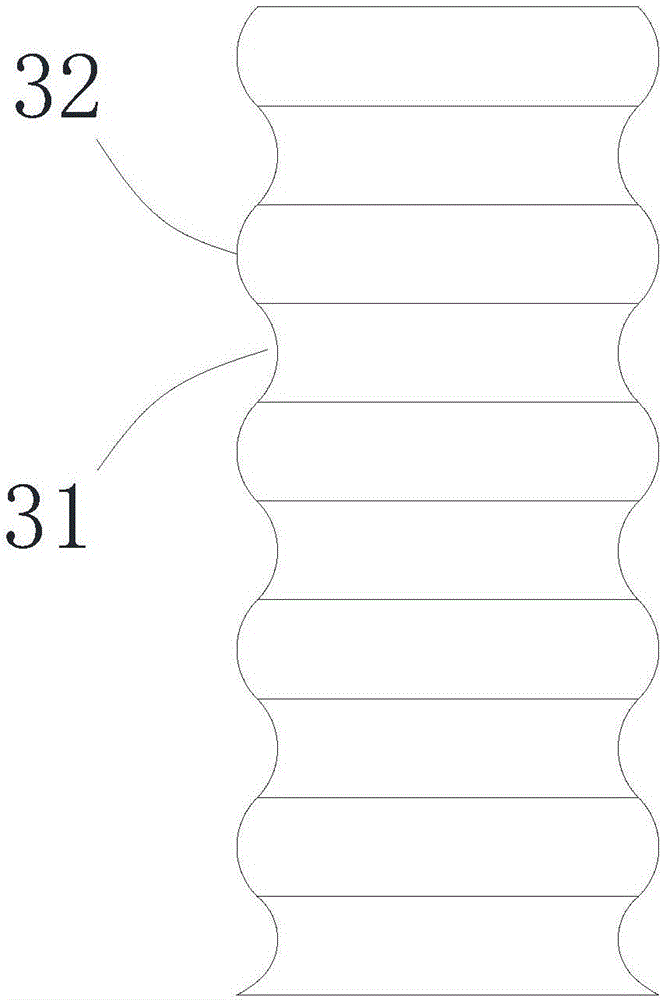

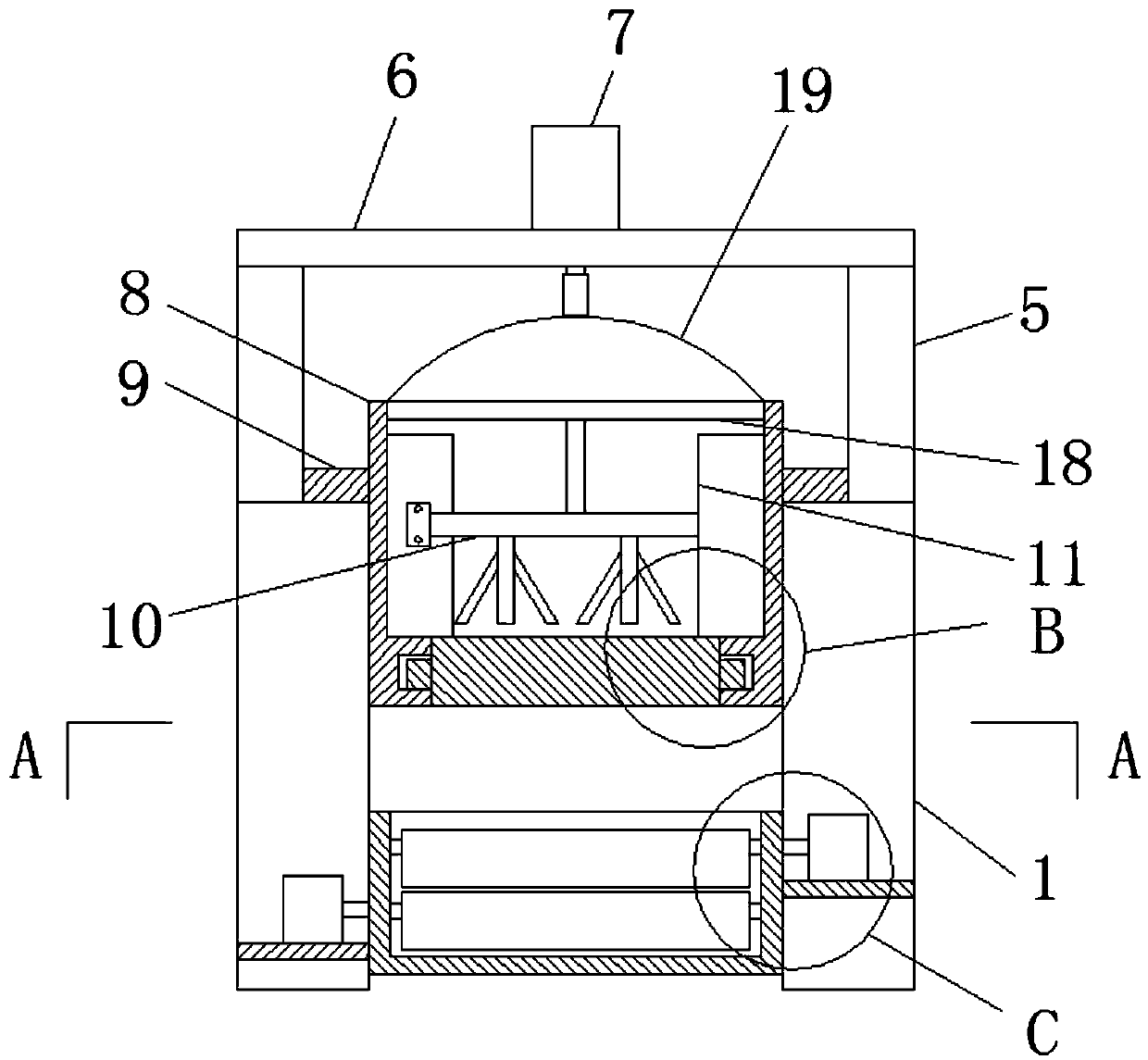

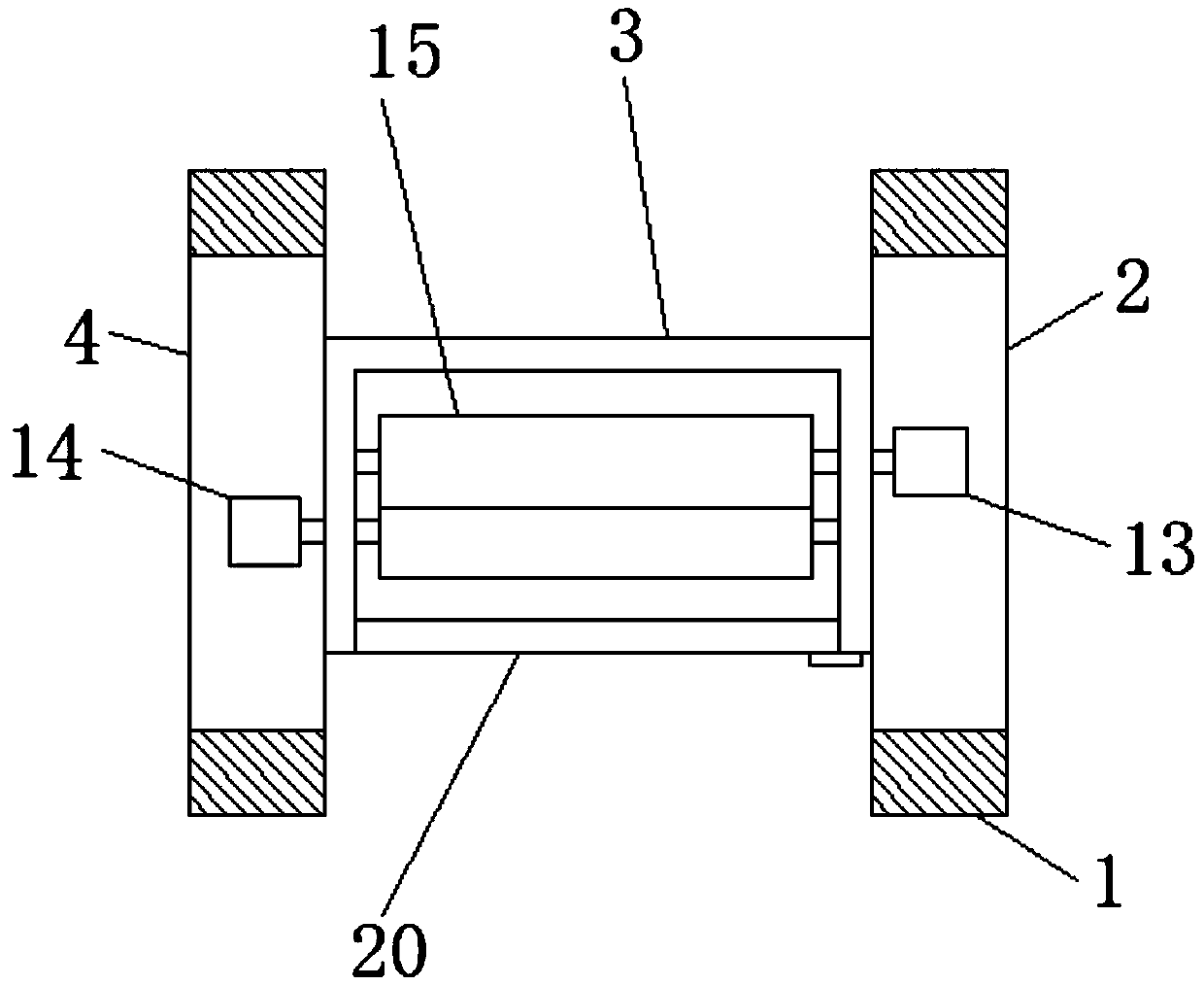

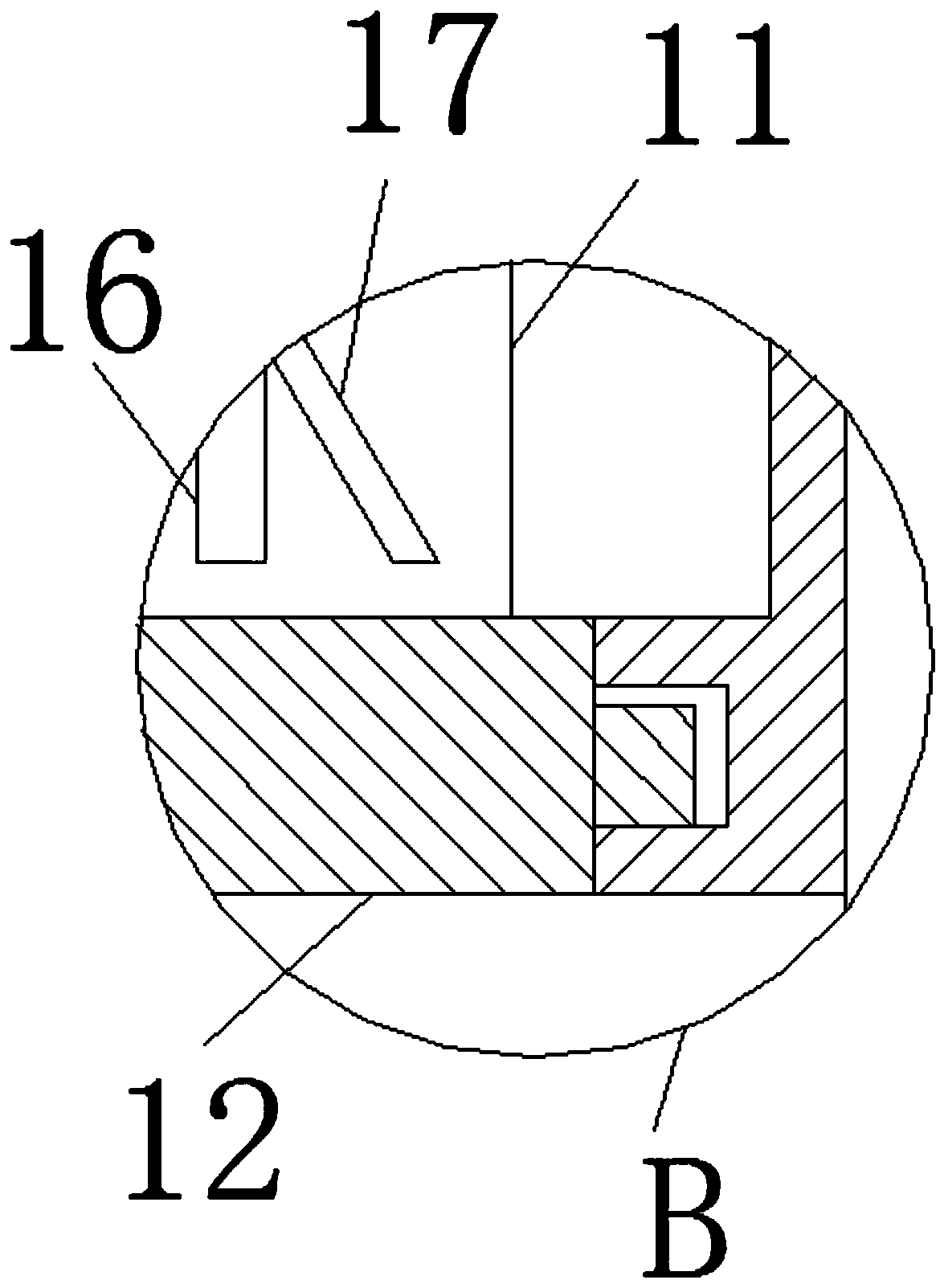

Full-automatic vertical type dough pressing kneading machine

InactiveCN106614864AImprove kneading effectReduce moisture contentMixing/kneading structural elementsMixing/kneading with rollersEngineeringMechanical engineering

The invention provides a full-automatic vertical type dough pressing kneading machine, and relates to a food machine field. The full-automatic vertical type dough pressing kneading machine comprises a vertical case; the upper end face and the front face of the vertical case are respectively provided with openings; two kneading rollers are installed at the inner part of the vertical case, and two kneading rollers are matched to each other so as to realize the rolling; a rolling convex part and a rolling concave part encircled along the peripheral direction are arranged on the roller surfaces of two kneading rollers; the rolling convex part and the rolling concave part are arranged alternatively, wherein the rolling convex part of one kneading roller is fitted with the rolling concave part of the other kneading roller, the rolling concave part of one kneading roller is fitted with the rolling convex part of the other kneading roller. According to the kneading machine, two kneading faces can roll the paste through mutual cooperation of the rolling concave part and the rolling convex part; the paste can extend along the rolling direction while also crossly expand in the gap where the rolling concave part is fitted with the rolling convex part, thus the paste can be better kneaded; the kneading efficiency and quality are improved.

Owner:安徽省久阳农业机械有限公司

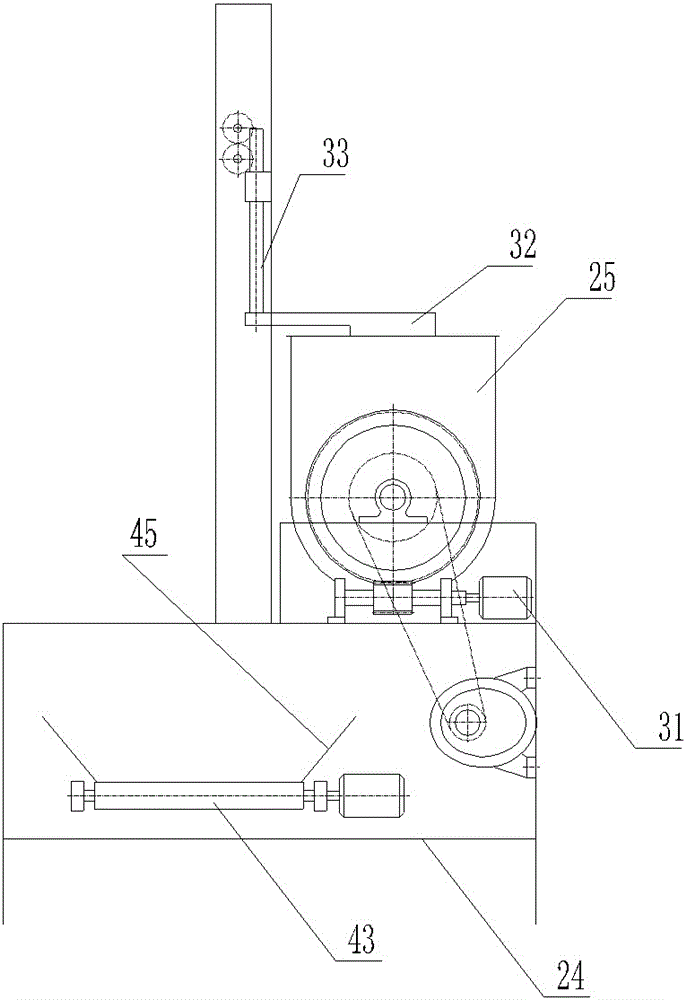

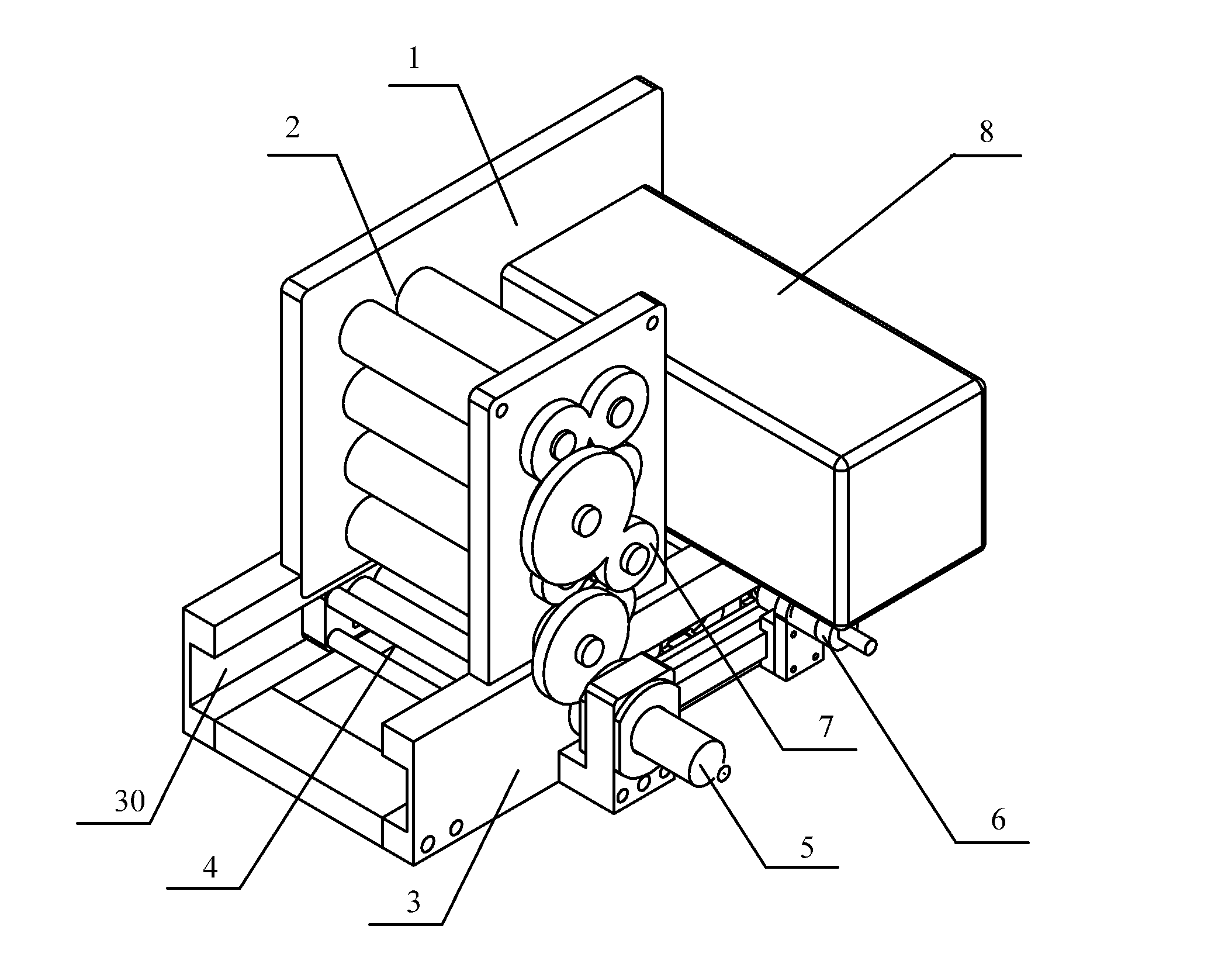

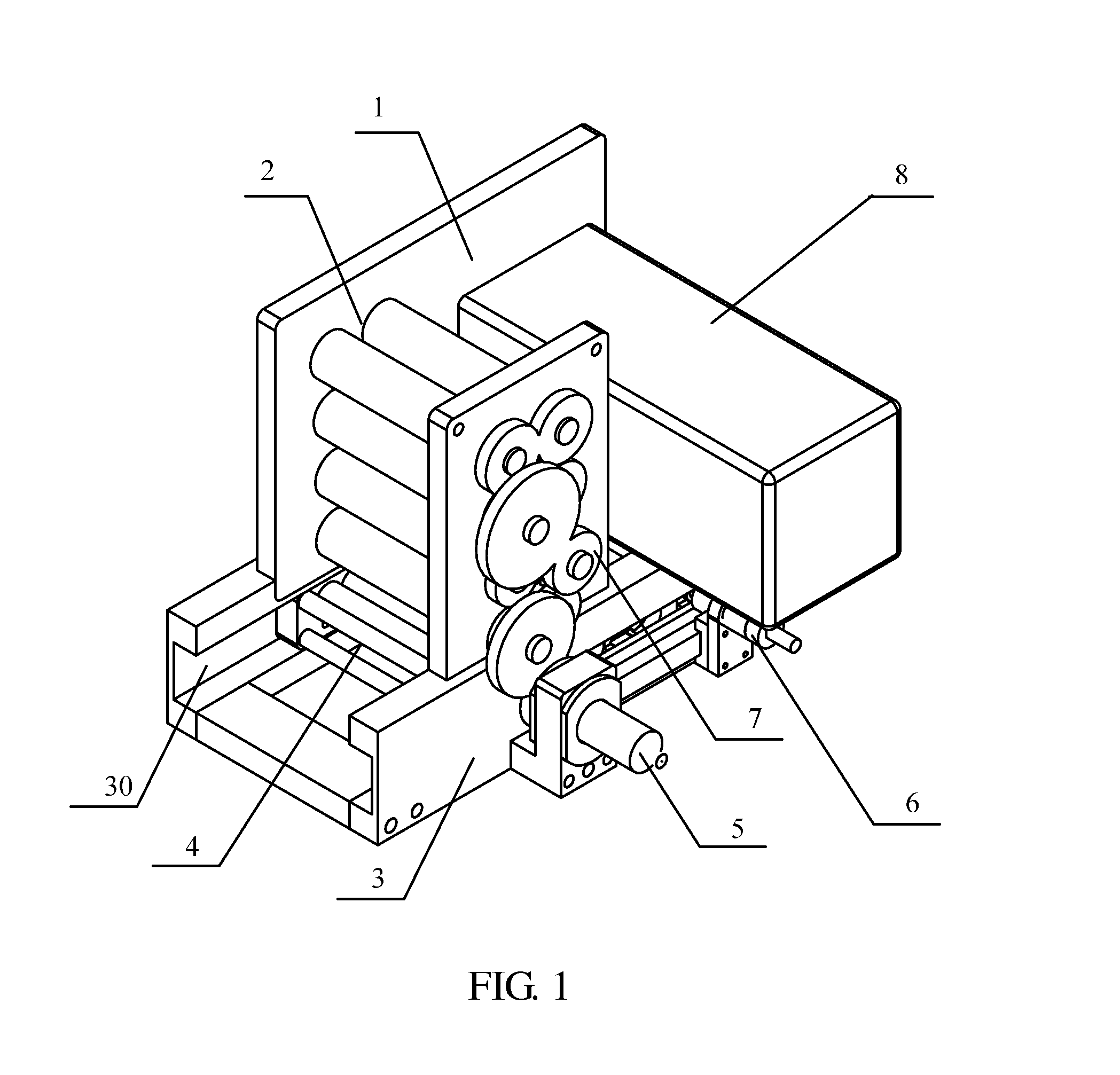

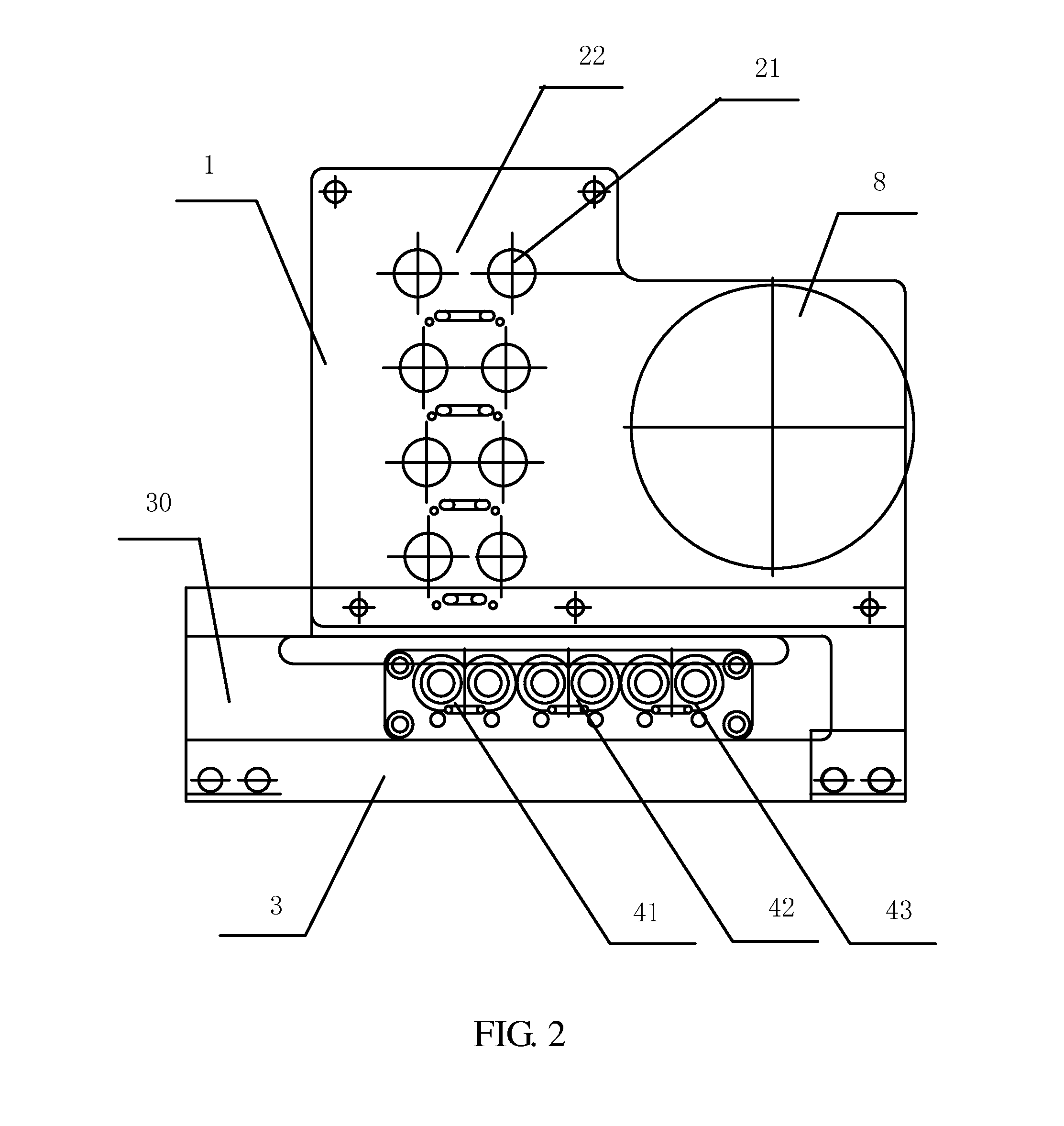

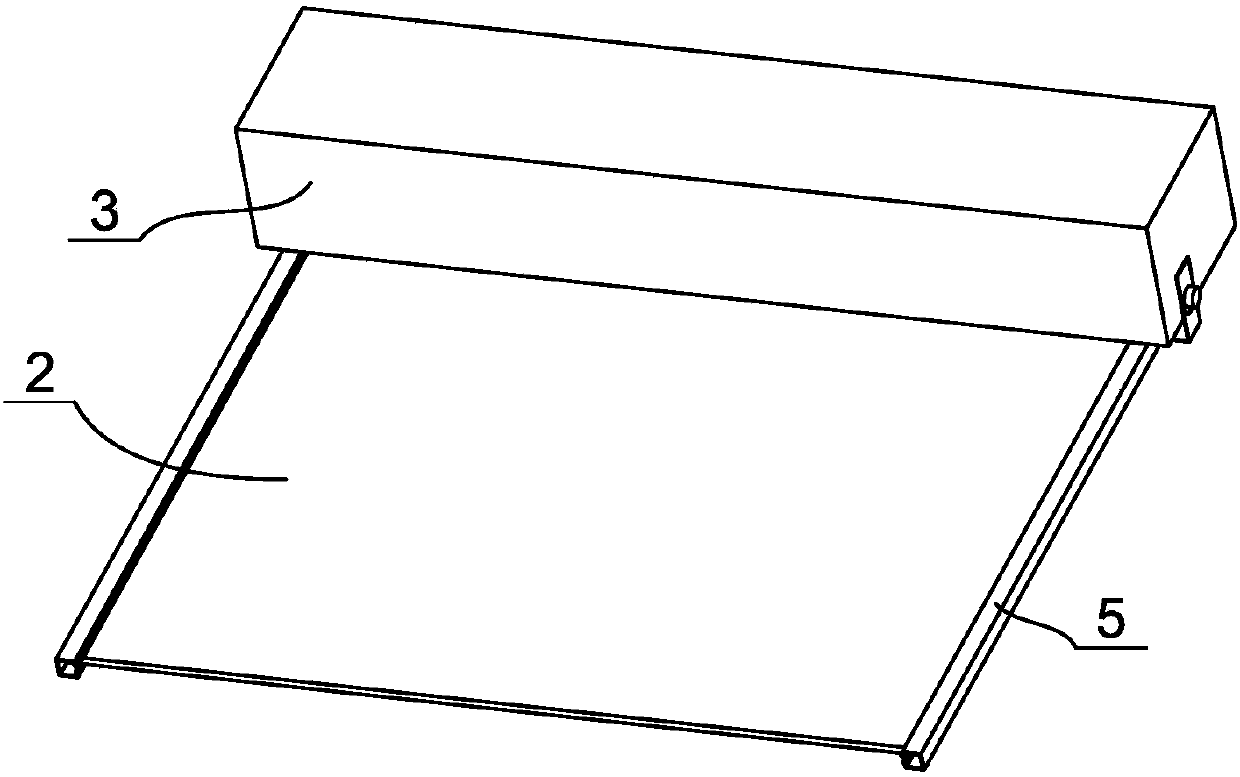

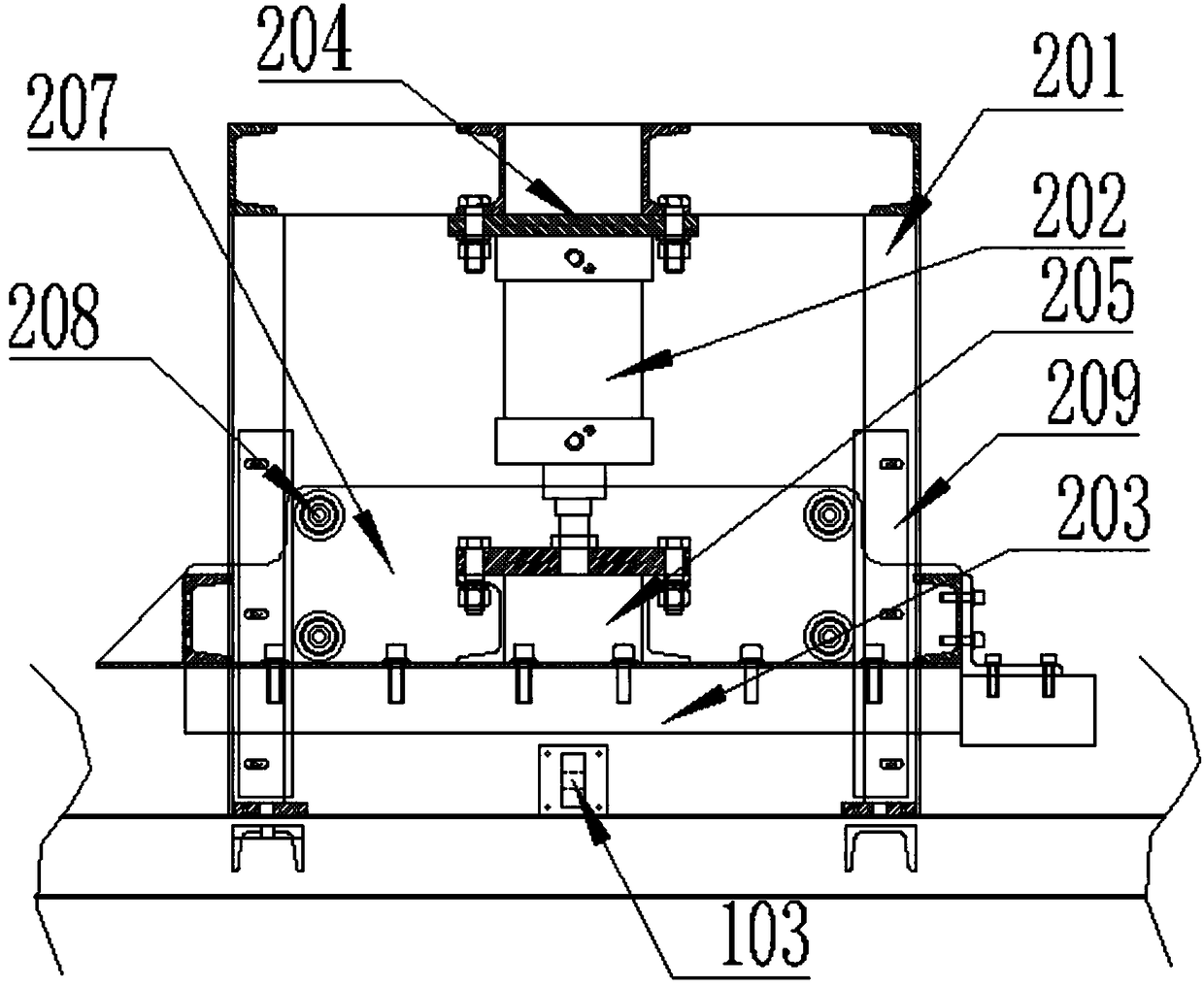

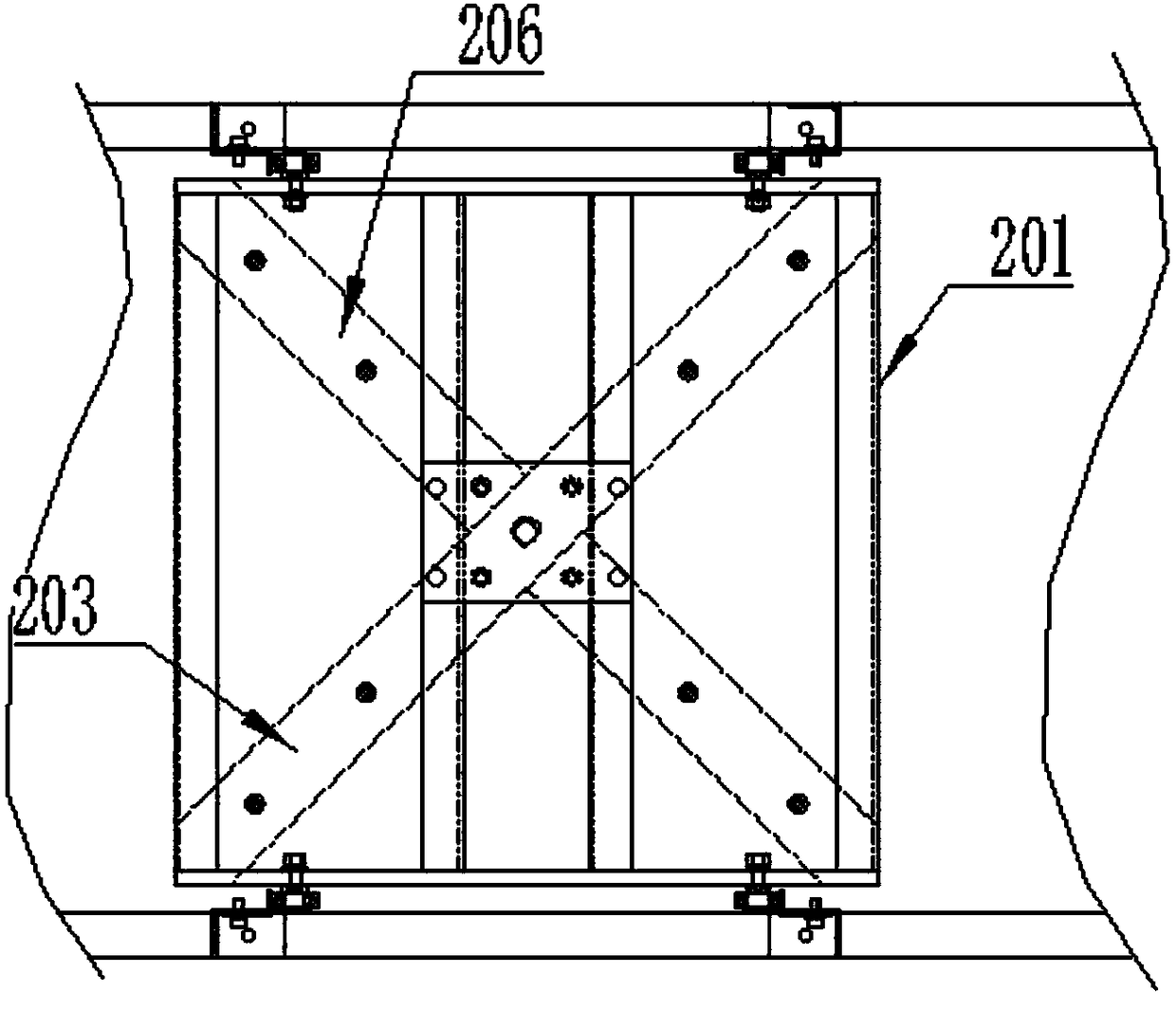

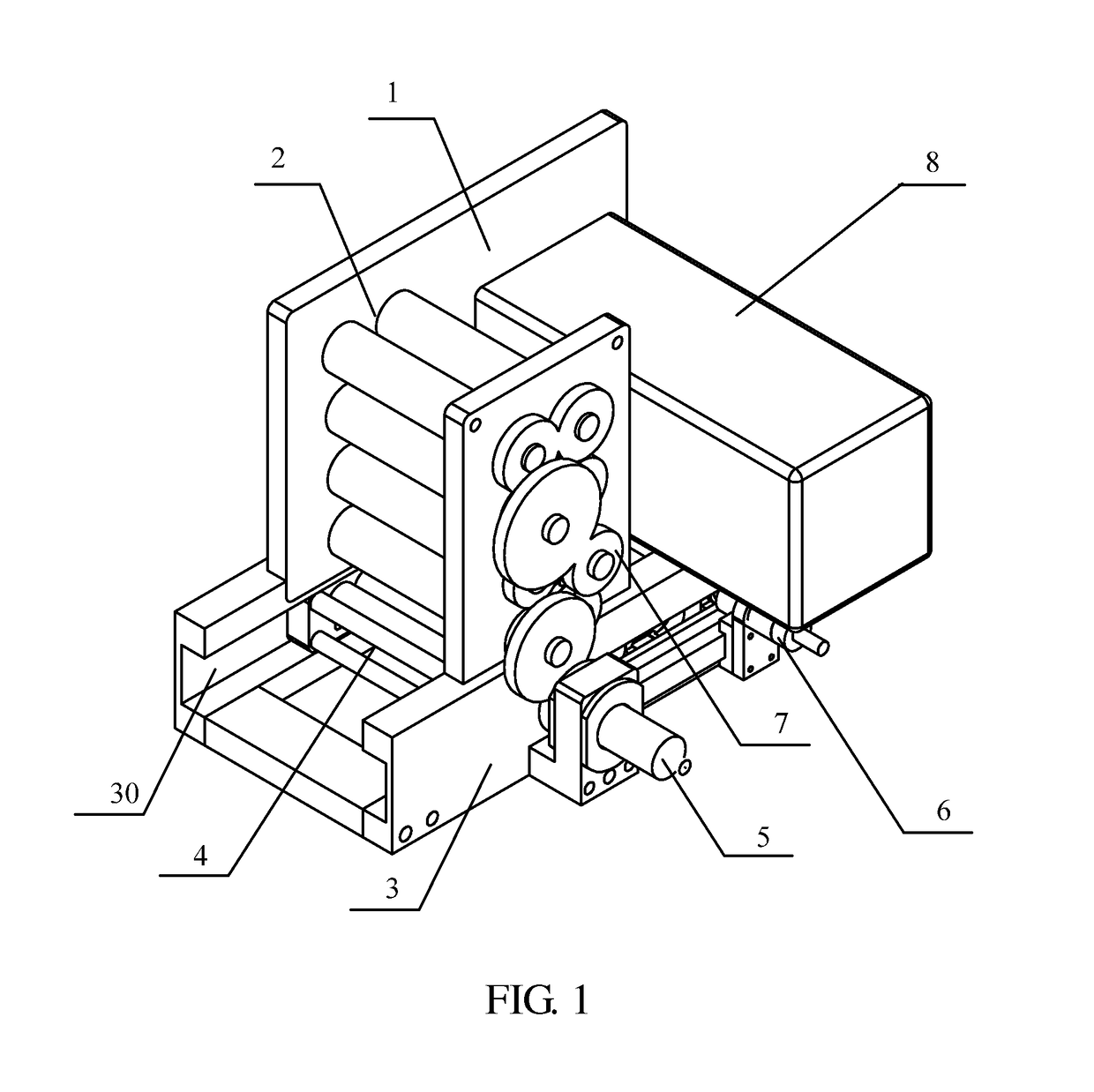

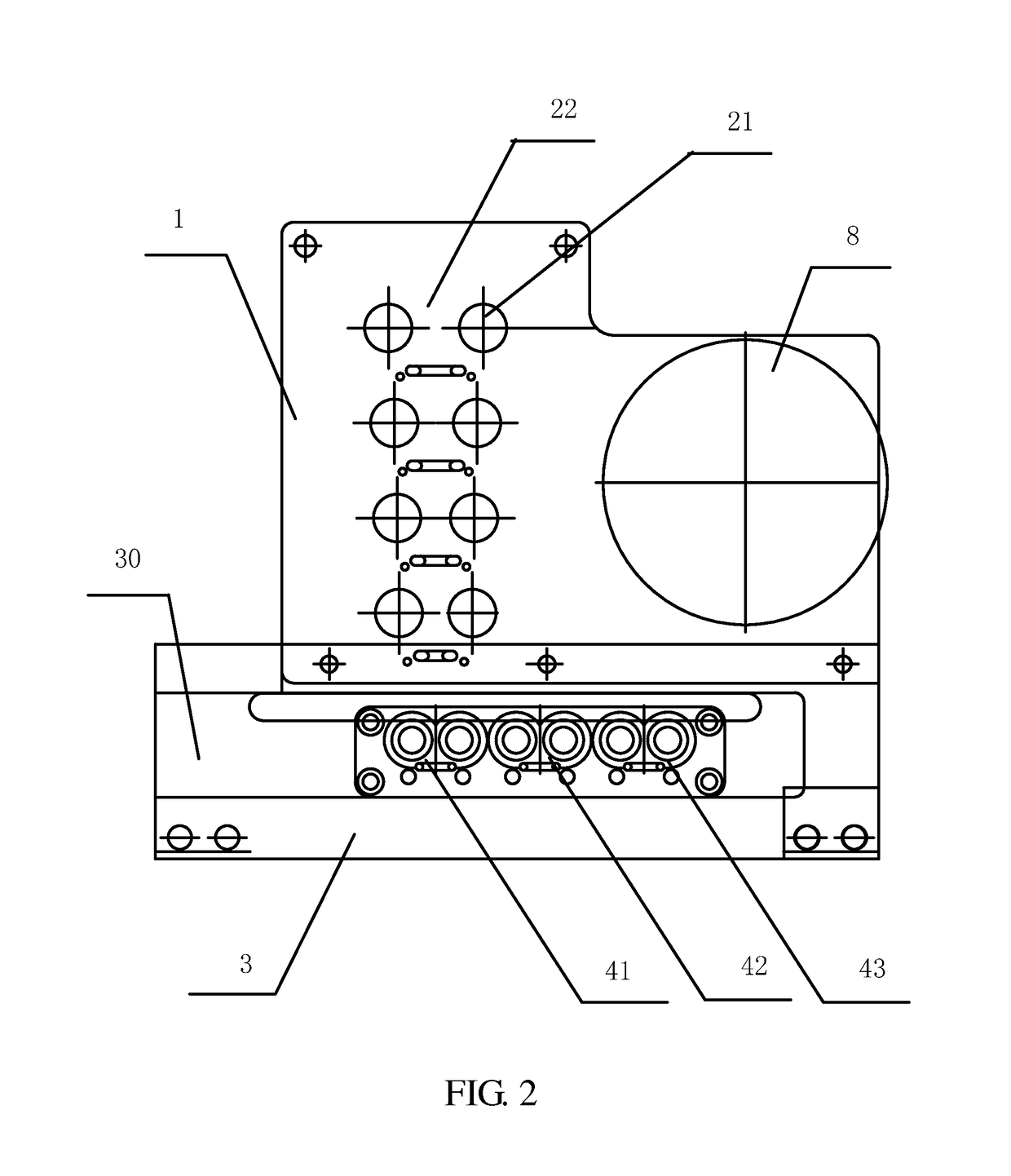

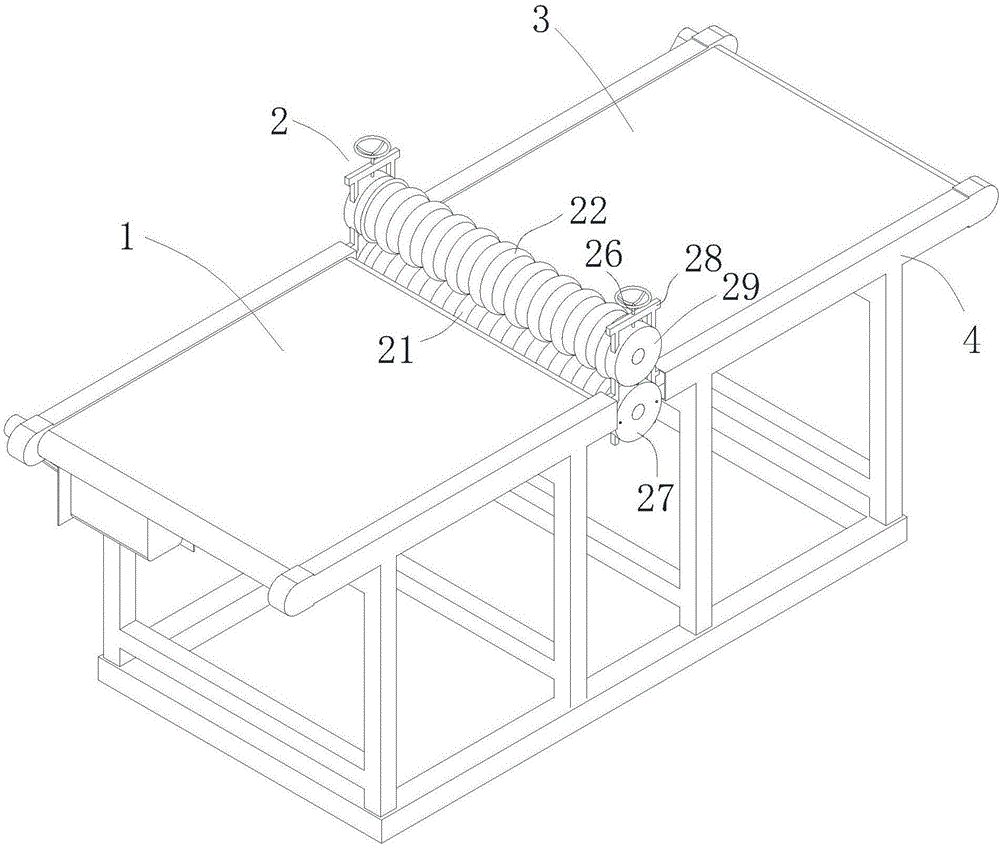

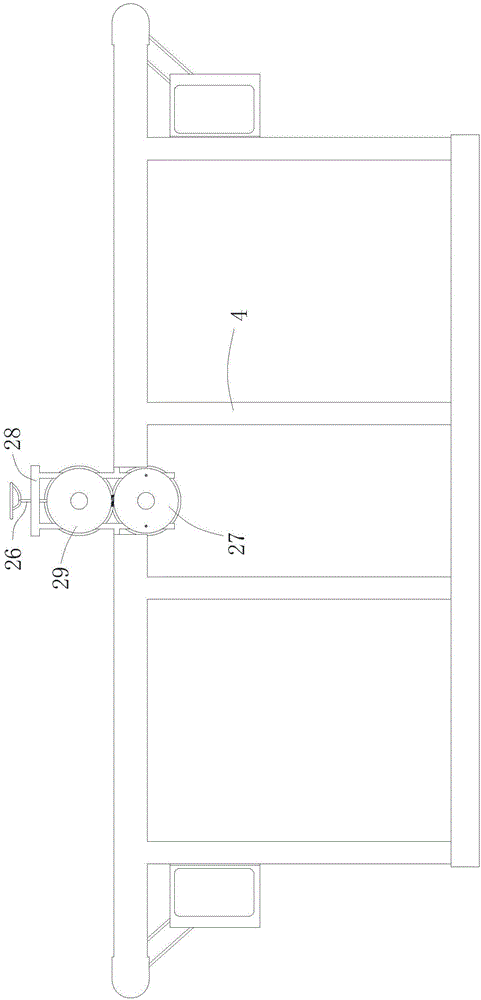

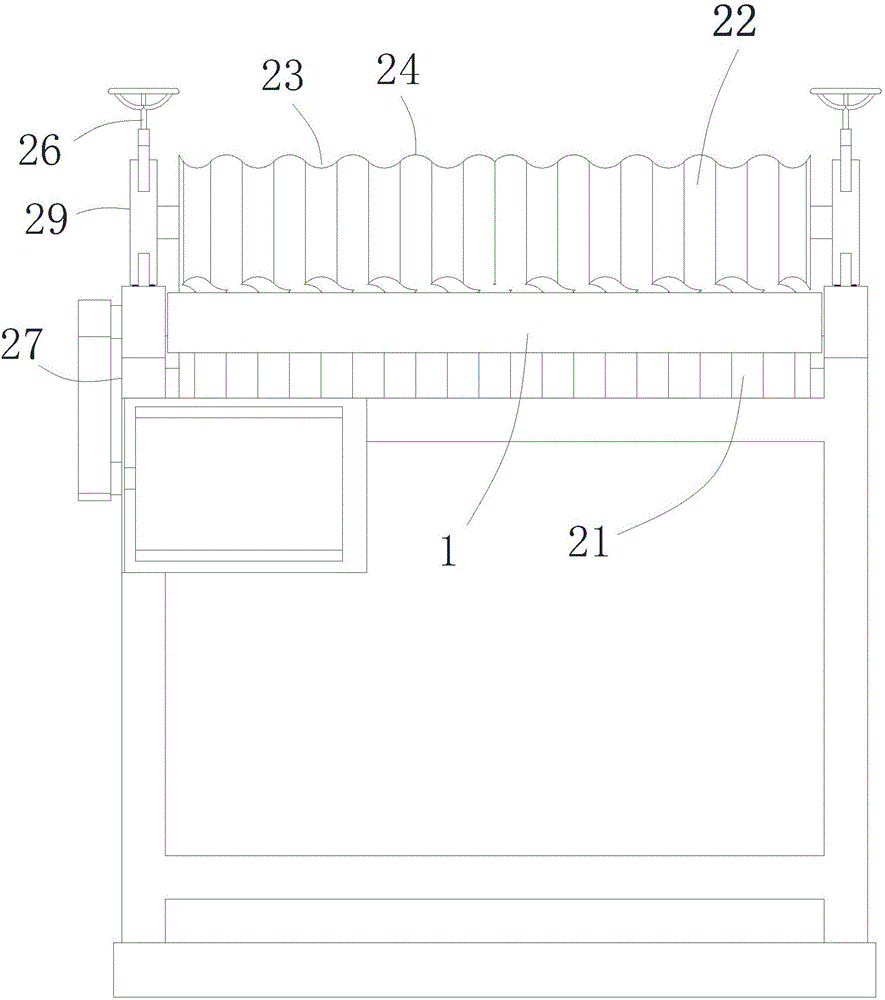

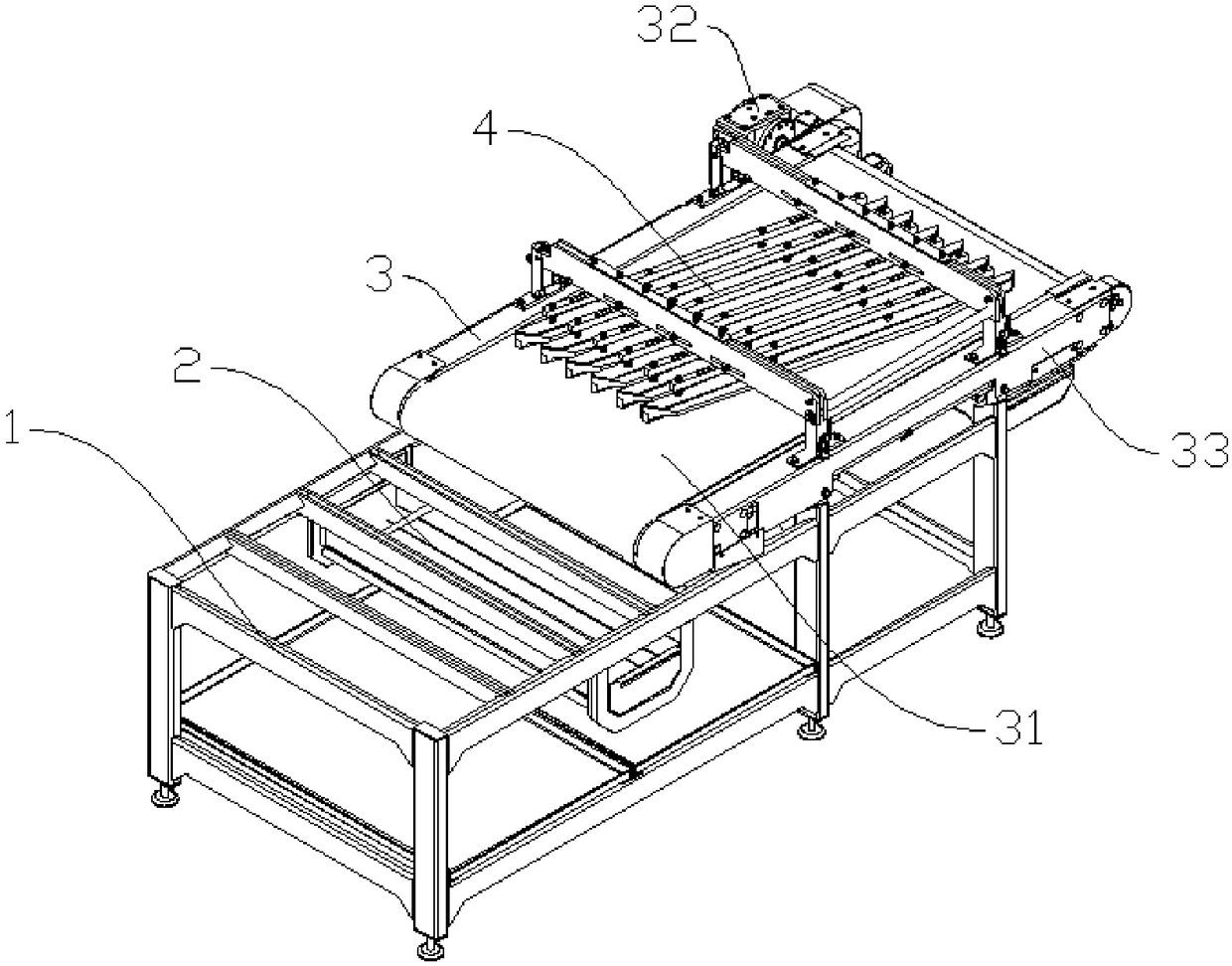

Novel double-handpiece full-automatic circulating dough kneading machine

ActiveCN104938550AImprove production efficiencyGood kneading qualityMixing/kneading with rollersReciprocating motionEngineering

The invention discloses a novel double-handpiece full-automatic circulating dough kneading machine. A first pair of dough kneading rollers are arranged at the front end of a longitudinal folding conveying device; a longitudinal folding synchronizing wheel is arranged above the longitudinal folding conveying device; longitudinal folding rotating plates continuously overturned toward the middle part of the longitudinal folding conveying device from the outside to the inside are arranged on the two sides of the longitudinal folding conveying device; a longitudinal folding covering roller is arranged above the longitudinal folding conveying device; a second pair of dough kneading rollers are arranged at the back end of the longitudinal folding conveying device; an inclined conveying device is arranged on the second pair of dough kneading rollers; a guide plate is arranged at the rear part of the second pair of dough kneading rollers; a first-layer horizontal folding conveying device capable of conducting reciprocating motion is arranged on a rack; a second-layer horizontal folding conveying device is arranged under the first-layer horizontal folding conveying device; the rear end of the second-layer horizontal folding conveying device is connected with the first pair of dough kneading rollers. According to the novel double-handpiece full-automatic circulating dough kneading machine, two pairs of dough kneading rollers are adopted, so that automatic circular kneading and rolling can be realized, horizontal folding and longitudinal folding of strip dough can be realized, the production efficiency is high, the kneading and rolling quality is good, the automation degree is high, manual production can be avoided, and unsafe hidden dangers can be eliminated.

Owner:王朝民

One-step noodle forming mechanism with rolling and cutting and a noodle machine integred with producing and cooking

ActiveUS9763456B2Great tasteQuality improvementDrying solid materials without heatMixing/kneading with rollersEngineeringMechanical engineering

A one-step noodle forming mechanism with rolling and cutting is provided, including multi-layer noodle roller sets in s disposed on a machine frame and noodle forming blades disposed below the multi-layer noodle roller sets, in which the multi-layer noodle roller sets and the noodle forming blades are driven to rotate by the same motor through a gear transmission mechanism. The dough entering the noodle forming mechanism is directly made into noodles through rolling and cutting of multiple layers. A noodle machine integrated with producing and cooking including the noodle forming mechanism is also provided.

Owner:RADIAND BEIJING ELECTRIC TECH DEV +1

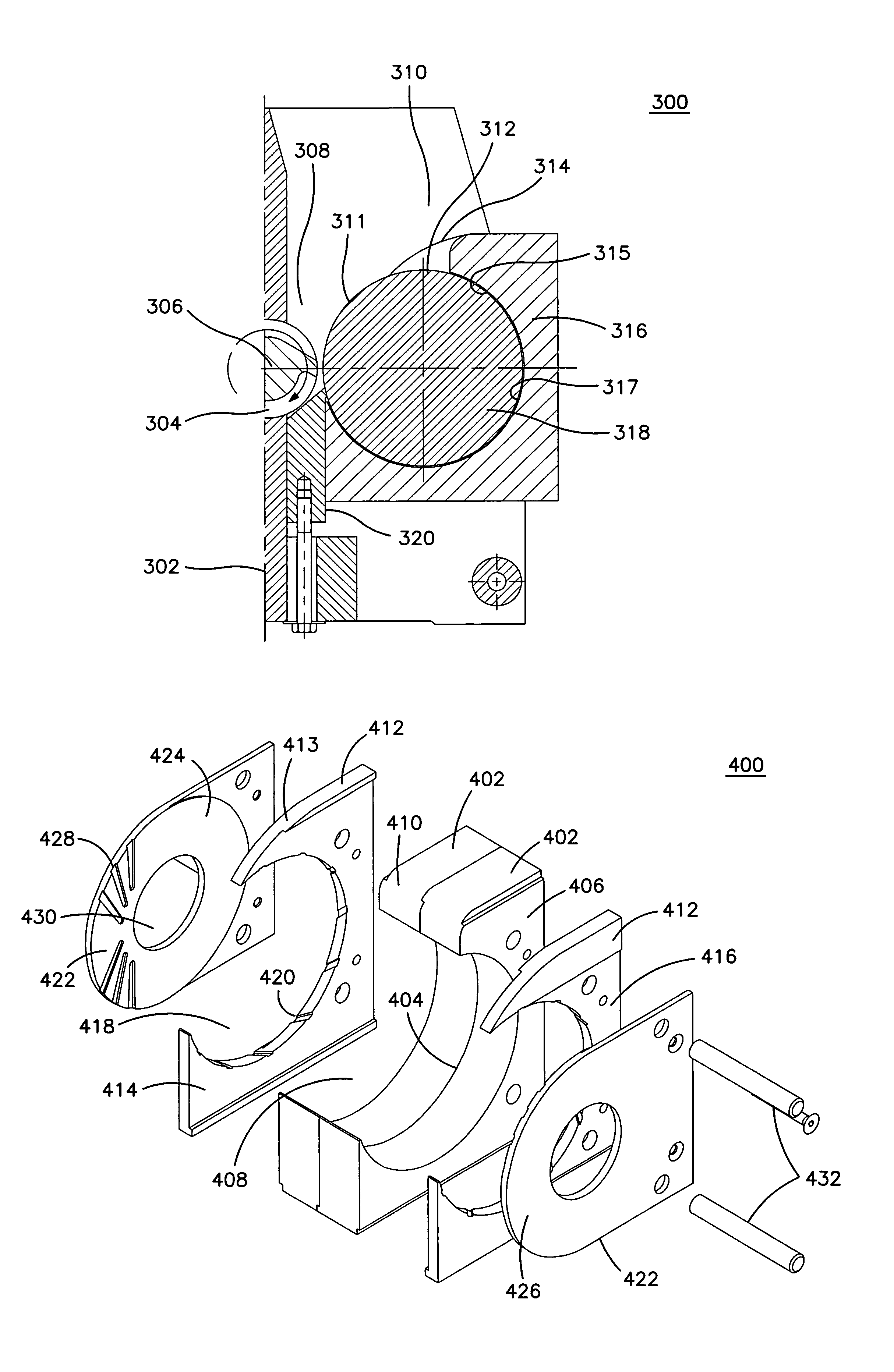

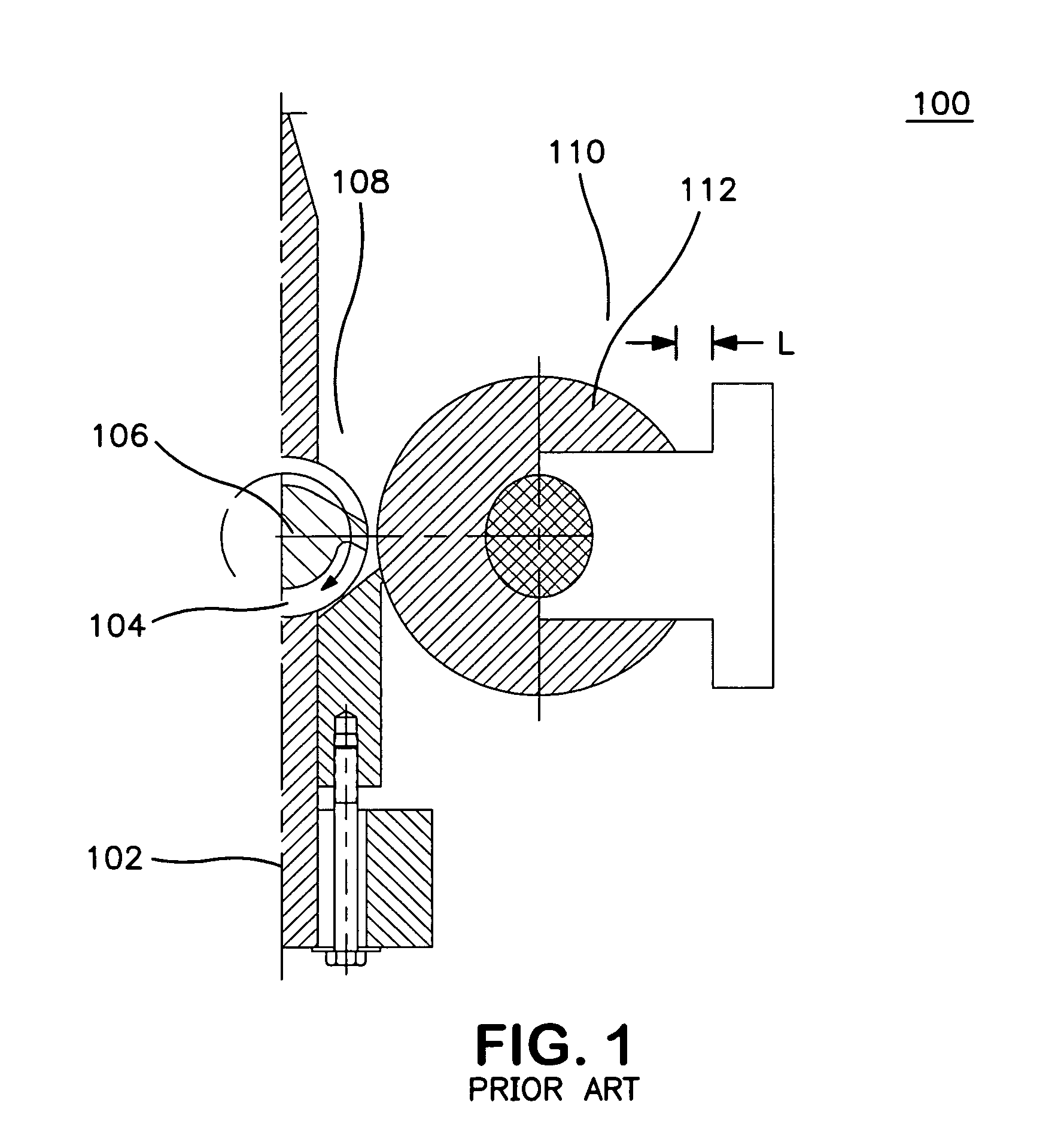

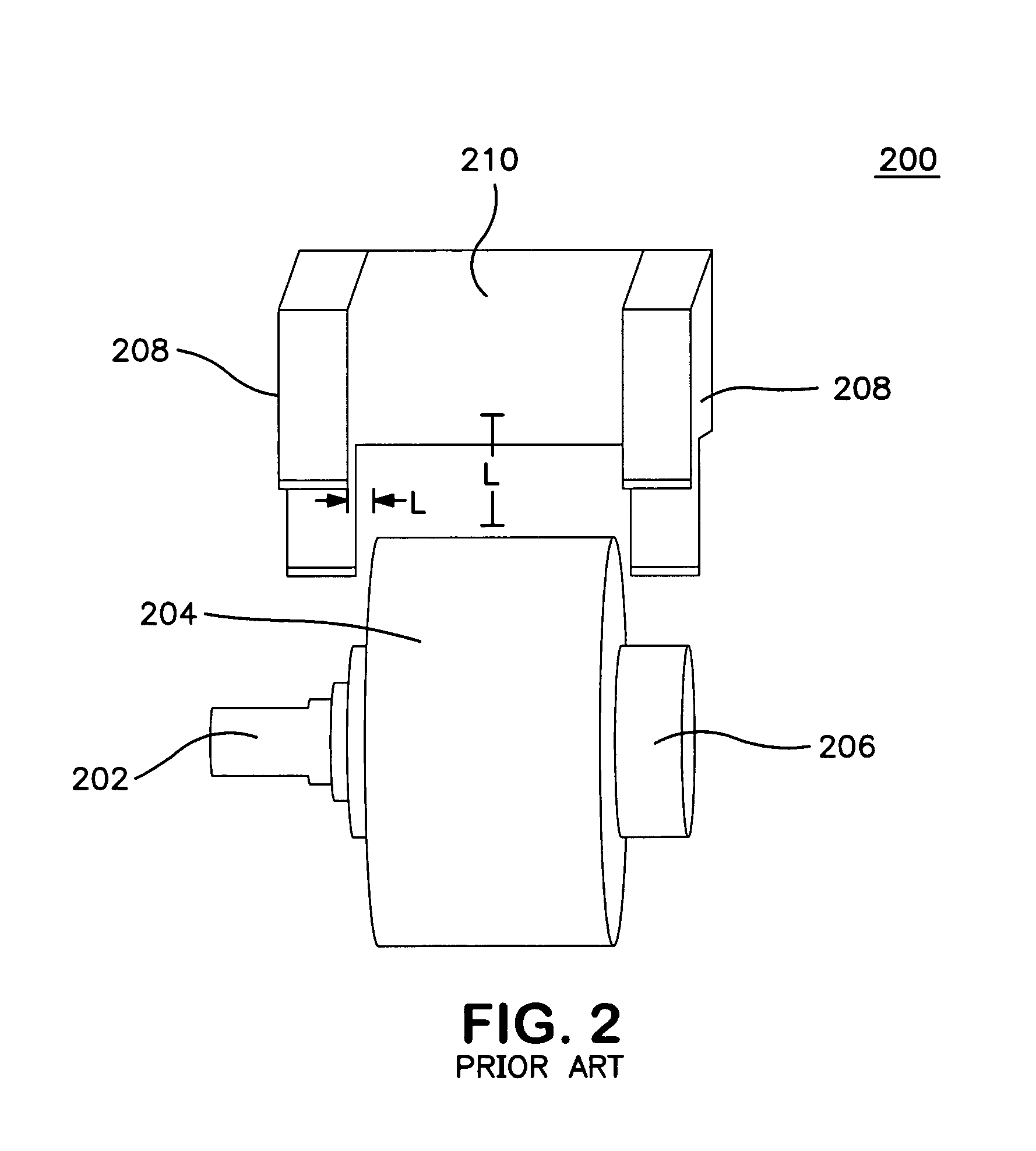

Leakage-free feed roll assembly for an extruder machine

ActiveUS7160099B2Reduce leakageReduce frictionRotary stirring mixersFrozen sweetsFriction reductionElastomer

The invention relates to a feed roll assembly for reducing leakage of an elastomeric material in a feed section of an extruder machine. A shell, feed roll seal plates, and feed roll end plates are used to reduce the leakage of elastomeric material. Elastomeric material is redirected back to the feed section through the use of a varying bore diameter of the shell and grooves contained in both the feed roll seal plates and the feed roll end plates. The shell, feed roll seal plates, feed roll end plates, and a feed roll scraper are each coated with a solid, dry lubricant coating to reduce friction. The invention provides desirable feedback of overflow elastomeric material and permits a retrofitting of the feed roll assembly to existing extruder machines.

Owner:DAVIS STANDARD

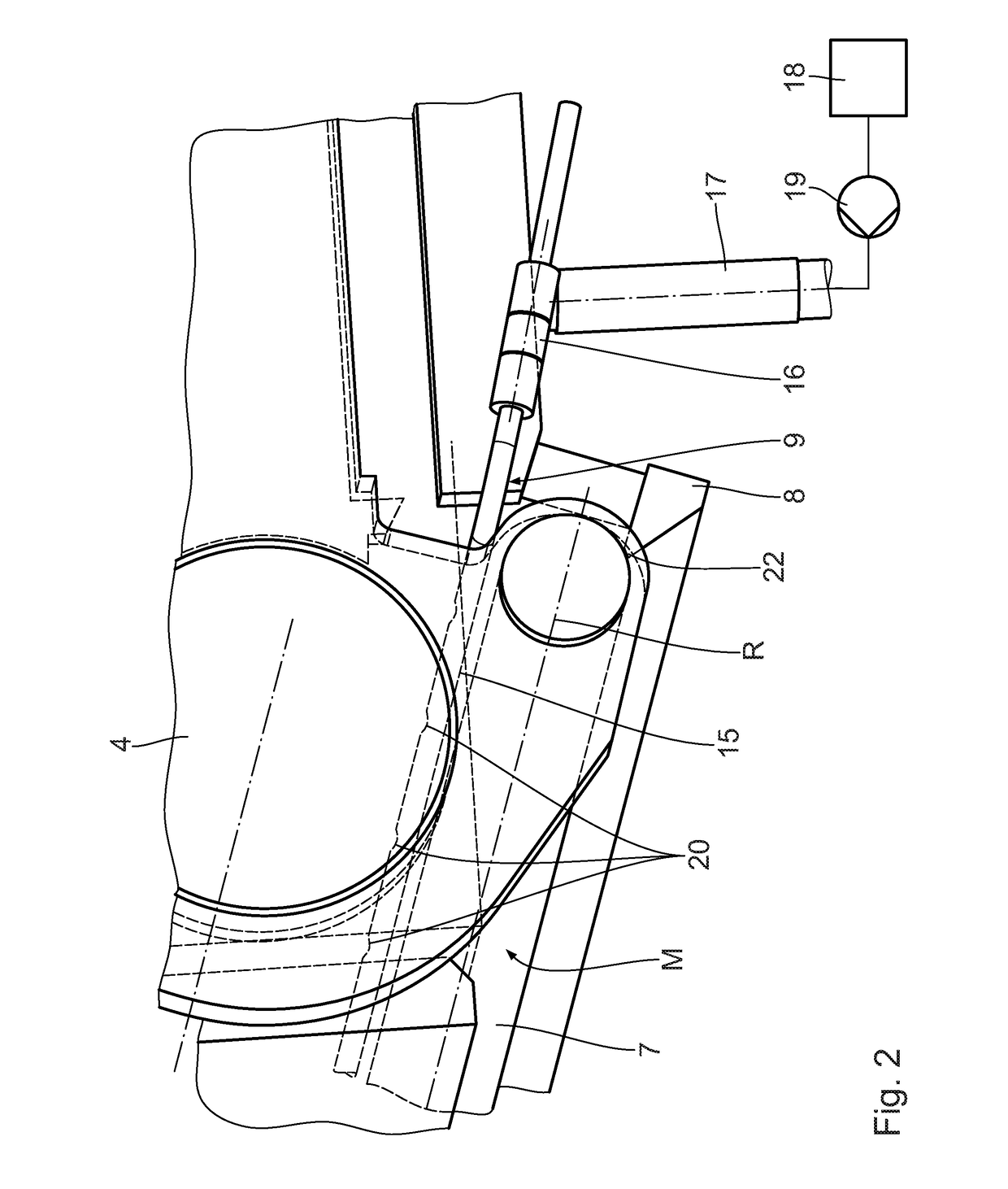

Transfer Apparatus for Dough Pieces

ActiveUS20180235242A1Effectively prevents the dropping roller from becoming stickyConveyorsDough homogenizationEngineeringMechanical engineering

A transfer apparatus for transferring a dough piece from a first processing station to the next, especially from a dough portioning device to a dough kneading device, includes a rotating dropping roller and a scraper. The rotating dropping roller is configured to release the dough piece from the first processing station. The scraper is associated with the dropping roller and is configured to support the dough piece released from the dropping roller. An oiling device is associated with the dropping roller and is configured to apply oil onto an outside surface of the dropping roller.

Owner:BACKNET GMBH

Compression roller for kneading dough

InactiveCN103734212AAvoid sticking rollersGreat tasteMixing/kneading with rollersPulp and paper industry

The invention relates to a compression roller for kneading dough and belongs to the field of production and processing. The compression roller for kneading the dough comprises a main roller and a secondary roller, wherein the secondary roller is arranged at the edge of the main roller; the secondary roller is movably connected with the main roller by a shaft. The compression roller for kneading the dough can be used for effectively avoiding a phenomenon that the dough is stuck to the roller. The dough is deeply extruded by the secondary roller so that the mouth feel of the dough is good.

Owner:SUZHOU HUANYAN ELECTRIC

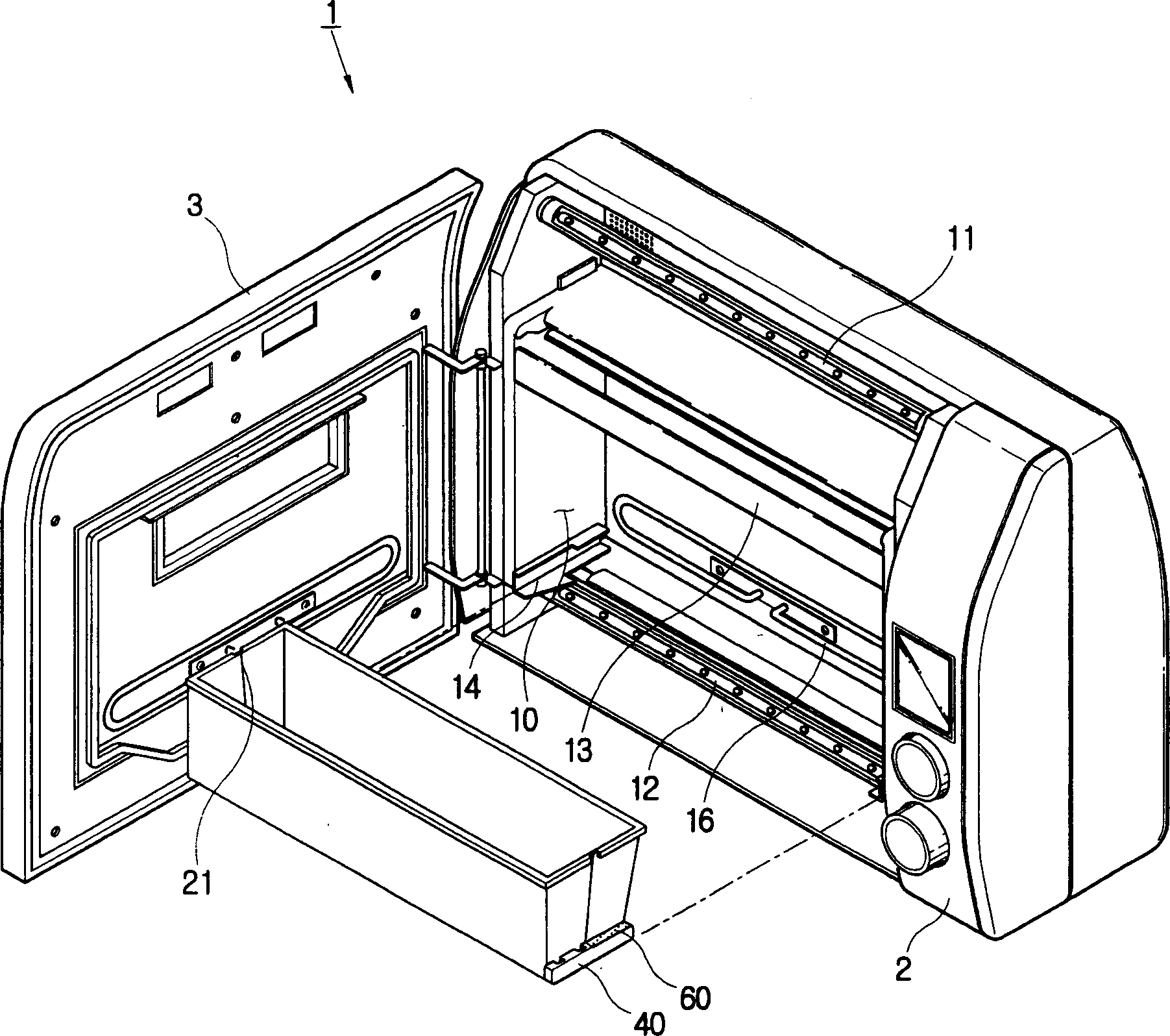

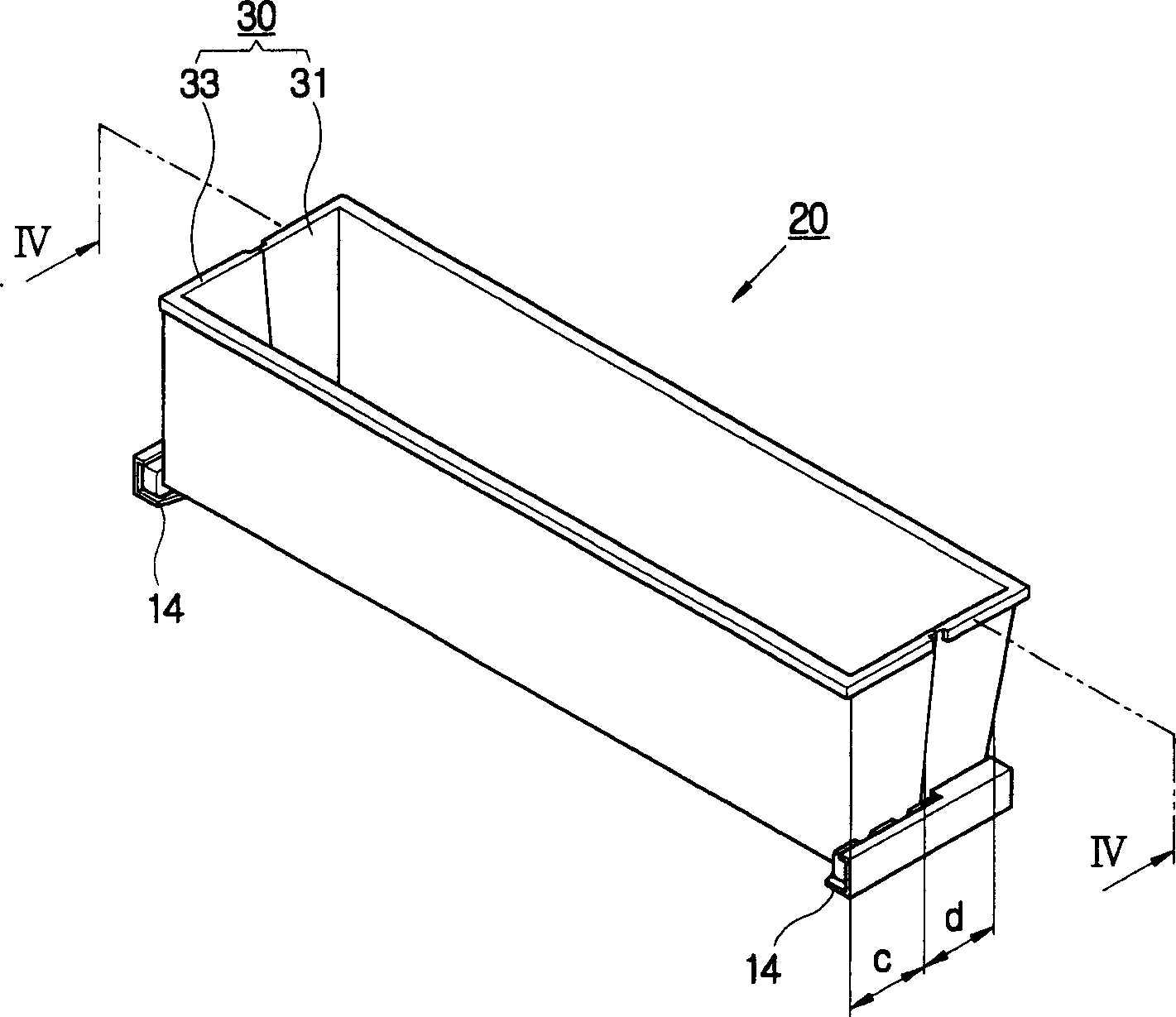

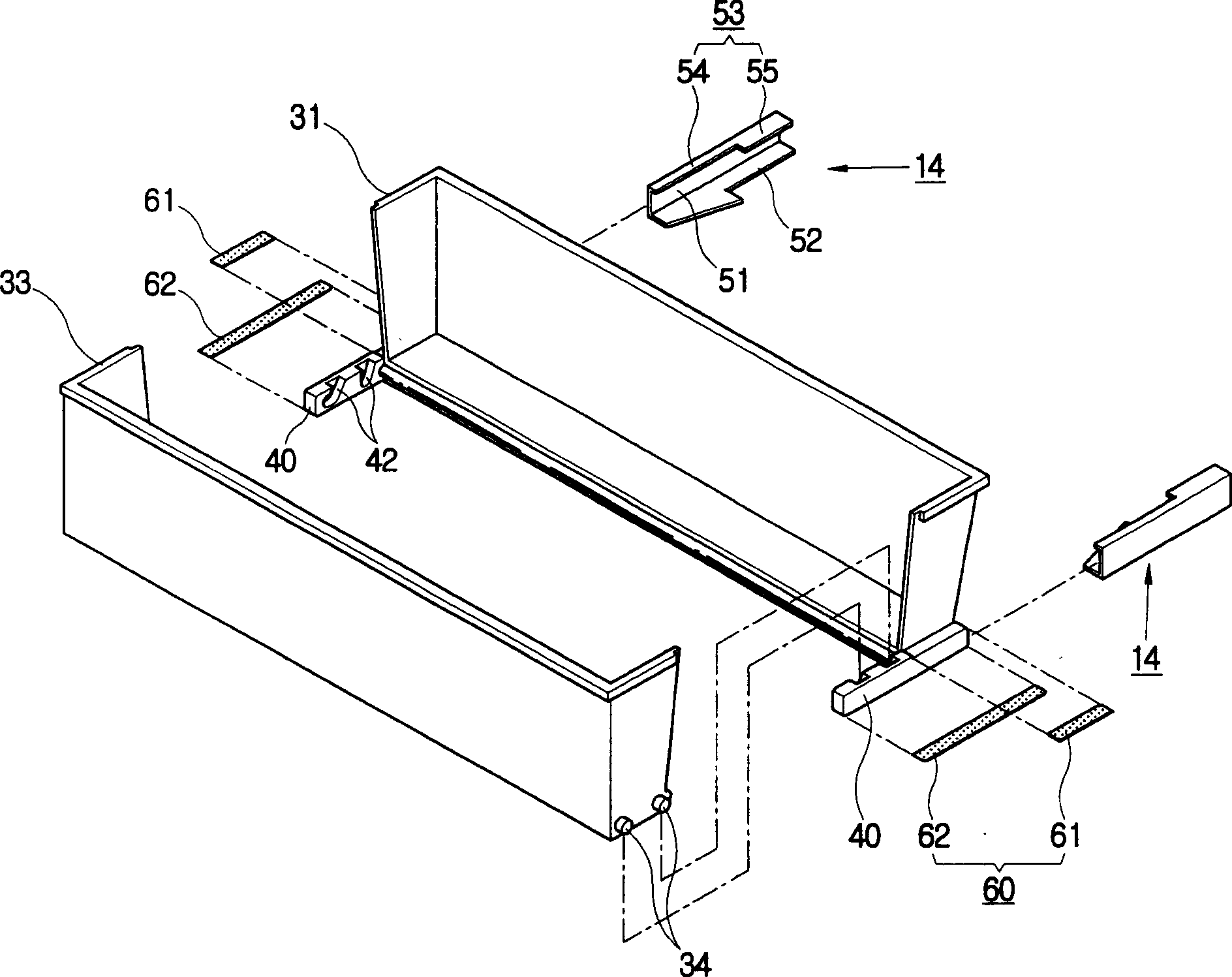

A bread maker

A bread maker including a main body forming an oven compartment; upper and lower kneading drums spaced from each other in upper and lower parts inside the oven compartment to hold opposite ends of a mixing bag, respectively, and to wind opposite ends of the mixing bag is provided. Further, a pair of tray members is disposed between the upper and lower kneading drums facing each other to form a slit to pass the mixing bag therethrough. The bread maker also includes tray holder members to be combined with opposite ends of a pair of tray members; a pair of guides mounted on inner sidewalls of the oven compartment facing each other to slidably guide the tray holder members by being slidingly combined with the tray holder members; and a shock absorber between the tray holder member and the guide. Accordingly, the shock absorber between the guide and the tray holder member prevents the tray holder member from minute movement while placed in the guide. Consequently, noise occurring due to direct contract of the guides with the tray holder members can be prevented, thereby providing the user with an improved and reliable bread maker.

Owner:SAMSUNG ELECTRONICS CO LTD

Compaction device for noodle production

InactiveCN110833081AWell mixedSimple structureMixing/kneading structural elementsMixing/kneading with rollersElectric machineryStructural engineering

Owner:庐江县海神面业有限公司

Rolling type dough kneading machine

InactiveCN106386926AImprove kneading effectReduce moisture contentMixing/kneading with rollersEngineeringConveyor belt

The invention provides a rolling type dough kneading machine, and relates to the field of food machinery. The rolling type dough kneading machine comprises a machine frame and a first conveyor belt and a second conveyor belt which are arranged on the machine frame, wherein a rolling type dough kneading mechanism is arranged between the first conveyor belt and the second conveyor belt; the rolling type dough kneading mechanism is composed of an upper roller and a lower roller; the upper roller and the lower roller are matched with each other for rolling dough; rolling convex parts and rolling concave parts surrounding in peripheral directions are arranged on the roller surface of the upper roller and the roller surface of the lower roller respectively; the rolling convex parts and the rolling concave parts are arranged at intervals; the rolling convex part of the upper roller is matched with the rolling concave part of the lower roller; and the rolling concave part of the upper roller is matched with the rolling convex part of the lower roller. According to the rolling type dough kneading machine provided by the invention, the upper roller and the lower roller are used for rolling the dough through interaction of the rolling concave parts and the rolling convex parts, and the dough can be extended in the rolling direction in the rolling process and simultaneously is transversely extended in gaps that the rolling concave parts are matched with the rolling convex parts, so that a better kneading effect is achieved for the dough, and the dough kneading efficiency and dough kneading quality are improved.

Owner:安徽省久阳农业机械有限公司

Automatic dough rolling rounding device

InactiveCN108260617AMeet product requirementsPurify the environmentMixing/kneading with rollersDough processingEngineeringManufacturing line

The invention provides an automatic dough rolling rounding device. The device comprises a frame, a flour receiving groove, a rolling rounding conveying device and a rolling rounding bent frame, and also comprises a conveyer belt, a motor and a conveying device support; the rolling rounding bent frame is arranged on the rolling rounding conveying device; the rolling rounding conveying device is arranged on the frame (1); and the flour receiving groove is arranged near the tail end of the rolling rounding conveying device on the frame. The circular degree of dough prepared by the automatic doughrolling rounding device of the invention reaches a circular state, the rounding effect is uniform, and the product requirements of production lines are met, and meanwhile, the arrangement of the flour receiving groove also achieves the beneficial effects of saving raw materials and purifying workshop environment.

Owner:天津优孚欧科技有限公司

noodle machine

ActiveCN106857738BMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsPistonWedge shape

The present invention relates to the fields of mechanical devices for processing dough and discloses a noodle machine. The noodle machine comprises a material bucket used for dough kneading, a rolling mechanism and a dough piece cutting mechanism. A material outlet is arranged at the bottom of the material bucket, the rolling mechanism is arranged at the lower part of the material bucket, the dough piece cutting mechanism is arranged under the rolling mechanism, the cross section of the material bucket is rectangular, two roller containing devices are arranged at the side wall of the material bucket, the inside of the roller containing devices is hollow, the roller containing devices communicates with the material bucket, a dough kneading roller is in slide connection within each of the roller containing devices, a driving device for driving the dough kneading rollers to rotate is connected to the end faces of the dough kneading rollers, a material scooping gap of 5-10 mm is formed between the two dough kneading rollers, and a squeezing gap of 3-8 mm is formed between each dough kneading roller and the side wall of the material bucket; and a piston is slidably connected within the material bucket, one side, facing towards the material outlet, of the piston is wedge-shaped, and a tip end of the wedge-shape faces toward the material scooping gap. The present invention aims to provide the noodle machine. The noodle machine mechanically produces the noodles, forms regular gluten structures in the interior of the dough in the dough kneading processes, and ensures the mouthfeel of the finished products of the noodles.

Owner:湖南楚冠农业科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com