Dough kneading device and method

A technology of noodle roll and dough, which is applied in the field of noodle making and forming equipment, which can solve the problems of single dough kneading method, low efficiency of kneading device, high labor intensity, etc., and achieve good taste, good toughness, simple and efficient process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

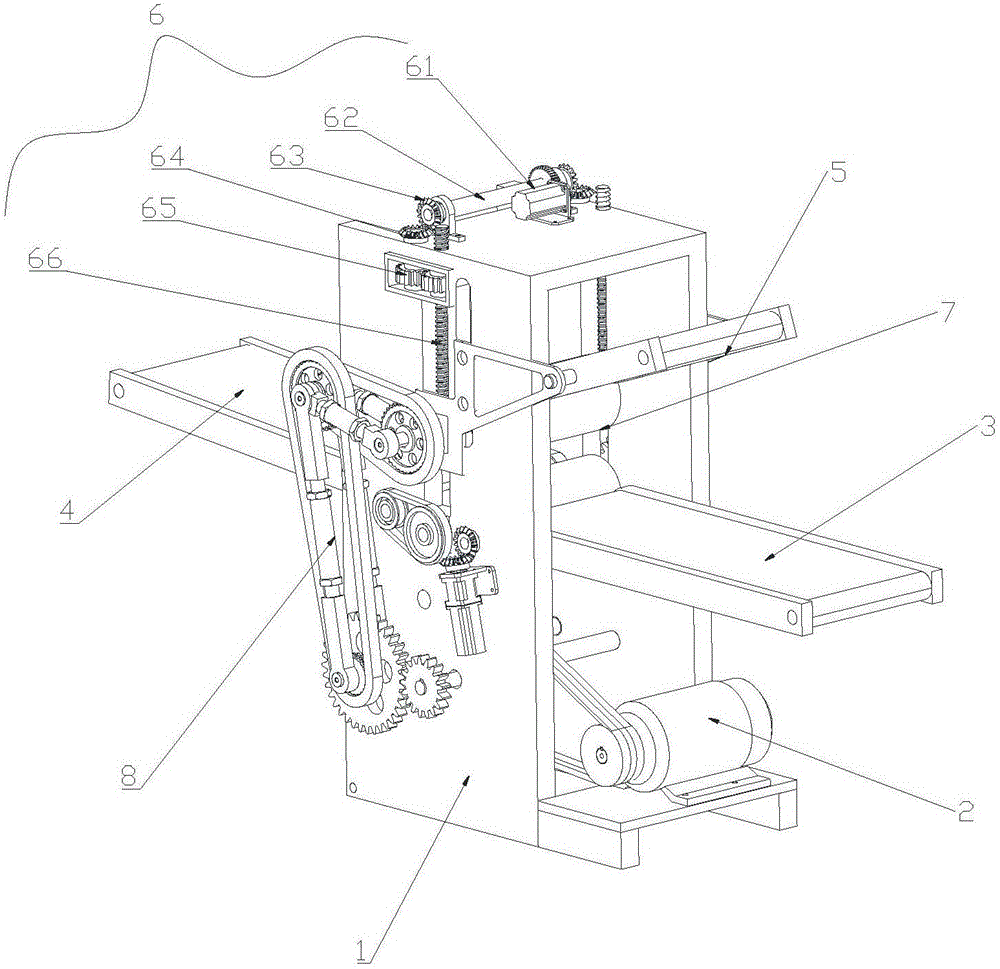

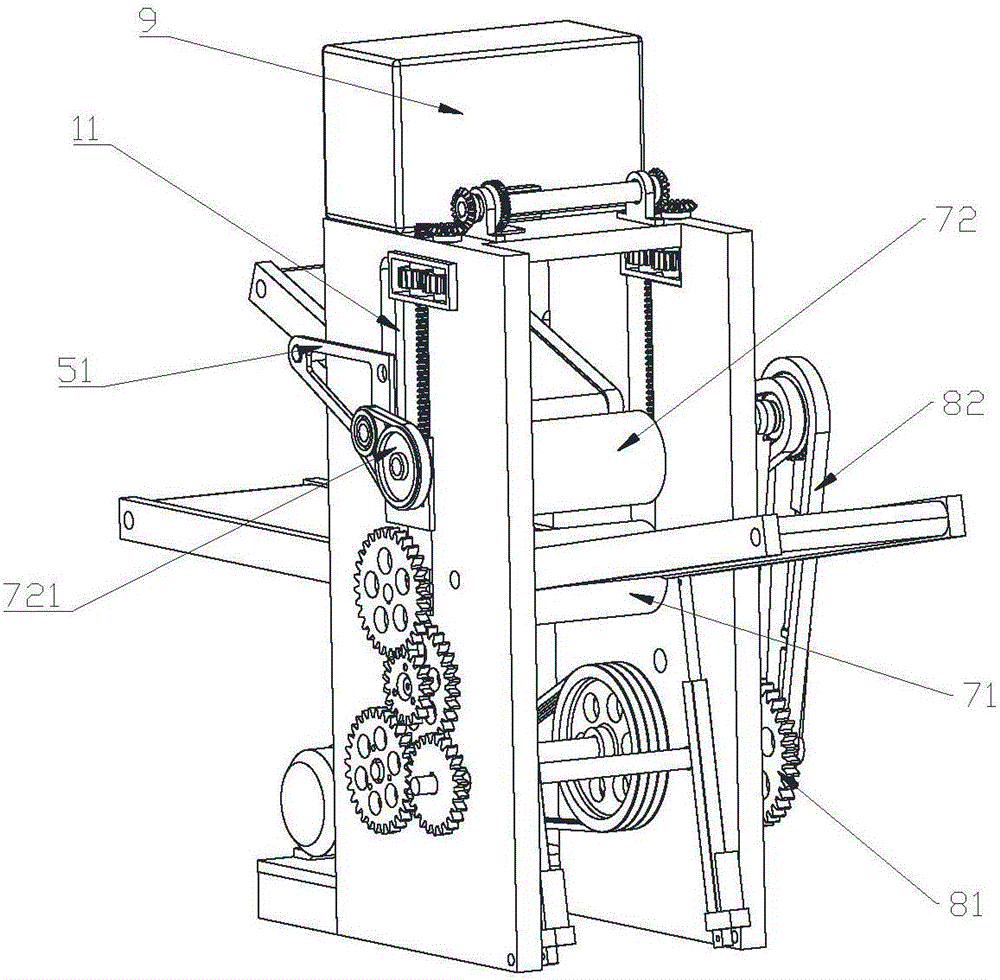

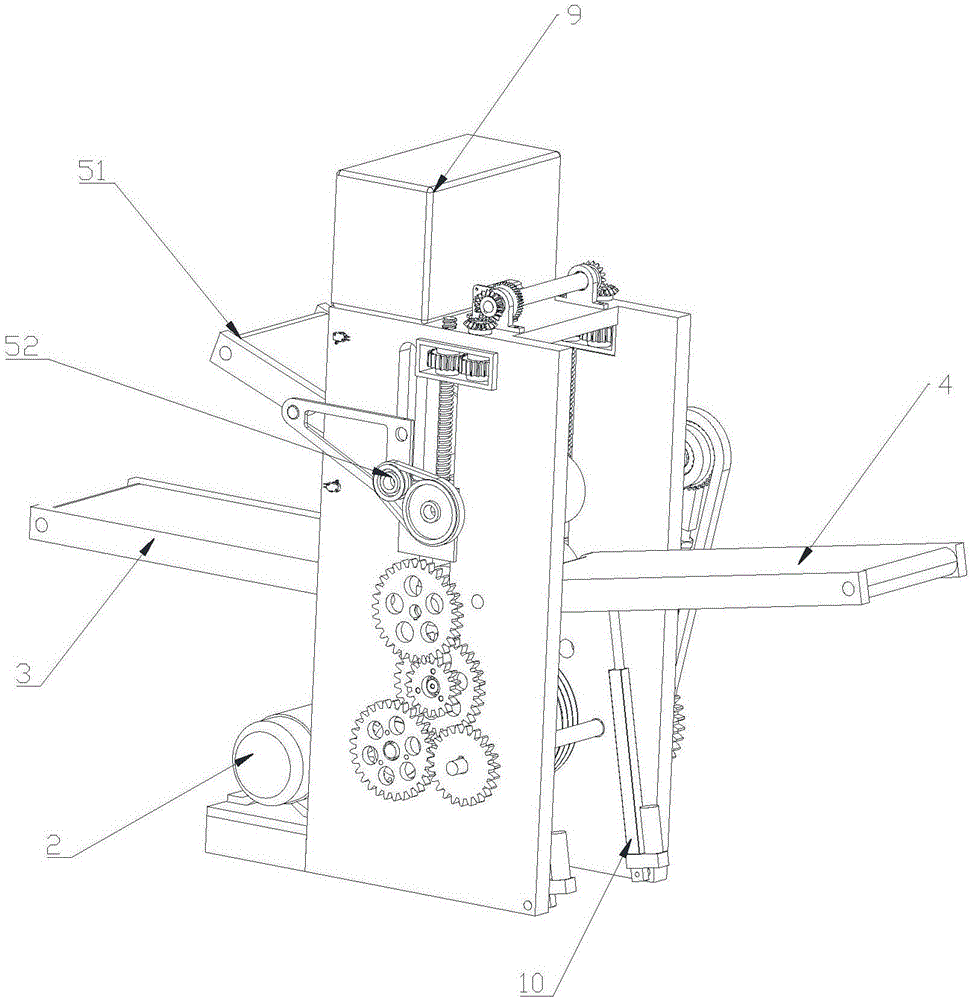

[0032] Embodiment 1, please refer to the attached figure 1 And attached figure 2 : According to the simplest kneading mode of repeatedly extruding dough, the kneading device at least includes: a frame 1, which is used for fixedly installing other kneading mechanisms or components as an installation and fixing base. The frame 1 is provided with a main motor 2 and a press roller assembly 7, and the front and rear sides of the kneading roller 72 of the press roller assembly 7 are respectively provided with a front conveyor belt assembly 3 and a rear conveyor belt assembly 4 for conveying the dough. During the reciprocating movement of 100 from the front conveyor belt assembly 3 to the rear conveyor belt assembly 4 , the main motor 2 drives 7 pressing roller sets to knead and press the dough 100 . The main motor 2 drives the above-mentioned press roller assembly 7 to rotate along the rotating shaft to extrude the dough through the transmission belt, transmission gear and speed c...

Embodiment 2

[0033] Embodiment 2, in order to improve the process defect in embodiment 1, further, under the situation that can reduce artificial participation, complete the kneading and pressing manufacturing process of dough:

[0034] Please refer again to the attached figure 1 , the pressing roller assembly 7 in the first embodiment includes: an upper kneading roller 72 and a lower kneading roller 71, and the upper kneading roller 72 and the lower kneading roller 71 all rotate along the rotating shaft, thereby extruding the dough and kneading noodle.

[0035] On the basis of the dough kneading device in Embodiment 1, a lifting assembly 6 is also provided on the frame 1, and the lifting assembly 6 is connected to the upper kneading roller 72, and the upper kneading roller 72 is controlled by the lifting assembly 6 to lift, Thereby adjust the distance between the upper kneading dough roller 72 and the lower kneading dough roller 71. The upper kneading roller 72 drives the conveyor belt ...

Embodiment 3

[0038] Embodiment 3, due to the method of kneading dough in Embodiment 2, the dough can only be gradually thinned more than 100 times, and finally shaped. Not stable enough, it will affect the taste. In order to further improve the solution of Embodiment 2, an upper conveyor belt assembly 5 is also provided on the frame 1, the upper conveyor belt assembly 5 is located above the front conveyor belt assembly 3, and the height of the upper conveyor belt assembly 5 is synchronized with the upper kneading roller 72 lift. For more details, please refer to the attached figure 2 , the conveyor belt body of the upper conveyor belt assembly 5 is connected to the frame 1 through the connecting piece 51, and the frame 1 is provided with a longitudinal notch 11, so that the connecting piece 51 moves up and down along the notch 11 longitudinally. Further, in order to realize the automatic and rapid delivery of the dough 100 to the upper conveyor belt assembly 5, the rear conveyor belt asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com