Flour rolling tool

A tool and roll surface technology, which is applied in the field of roll surface tools, can solve the problems of difficulty in processing decent noodles, easy loosening, uneven dough, etc., and achieve the effect of improving softness and increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

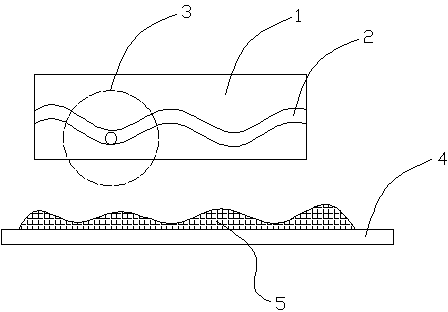

[0012] As shown in the figure: a roller surface tool, including a slider 1 and a running board 4; A surface roller 3 is provided, and the surface roller 3 slides along the slide rail 2 . The slider 1 moves up and down in the direction of the walking board 4 . Noodles 5 are placed on the pallet 4, and the pallet 4 is arranged on the assembly line.

[0013] After the flour on the walking board 4 contacts with water, the coagulation is sent to the slider 1 with the walking board 4, and the slider 1 goes down so that the noodle roller 3 contacts the dough, and walks through the wave-shaped slide rail 2, simulating manual kneading, so that the dough Evenly, it is then sent to a noodle machine for processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com