Methods for handling masa

a masa processing and masa technology, applied in the field of apparatus and methods for the commercial manufacture of food or edible materials, can solve the problems of injuring the attending worker, affecting the safety of the attending worker, and affecting the safety of the pneumatic cutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

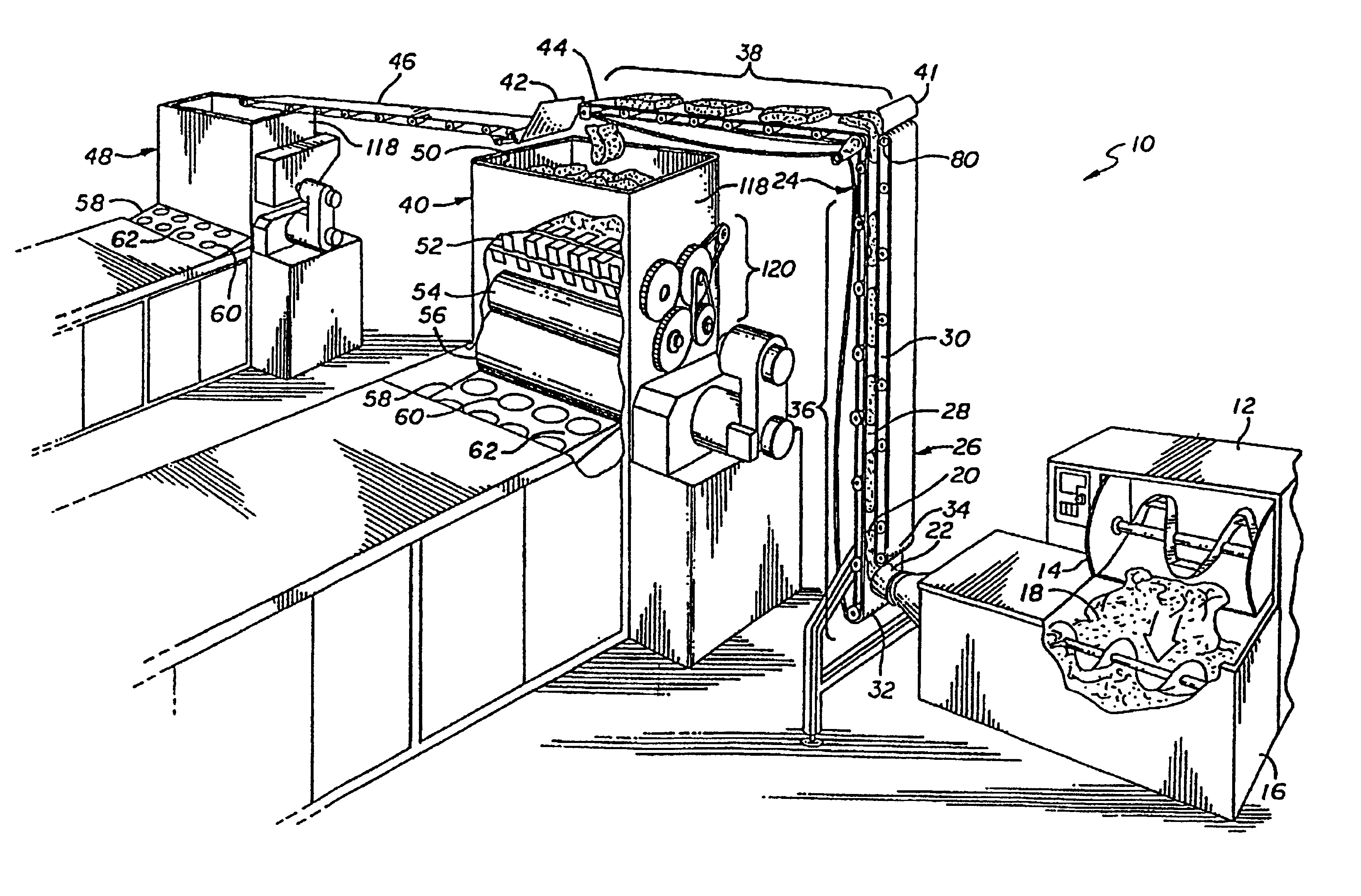

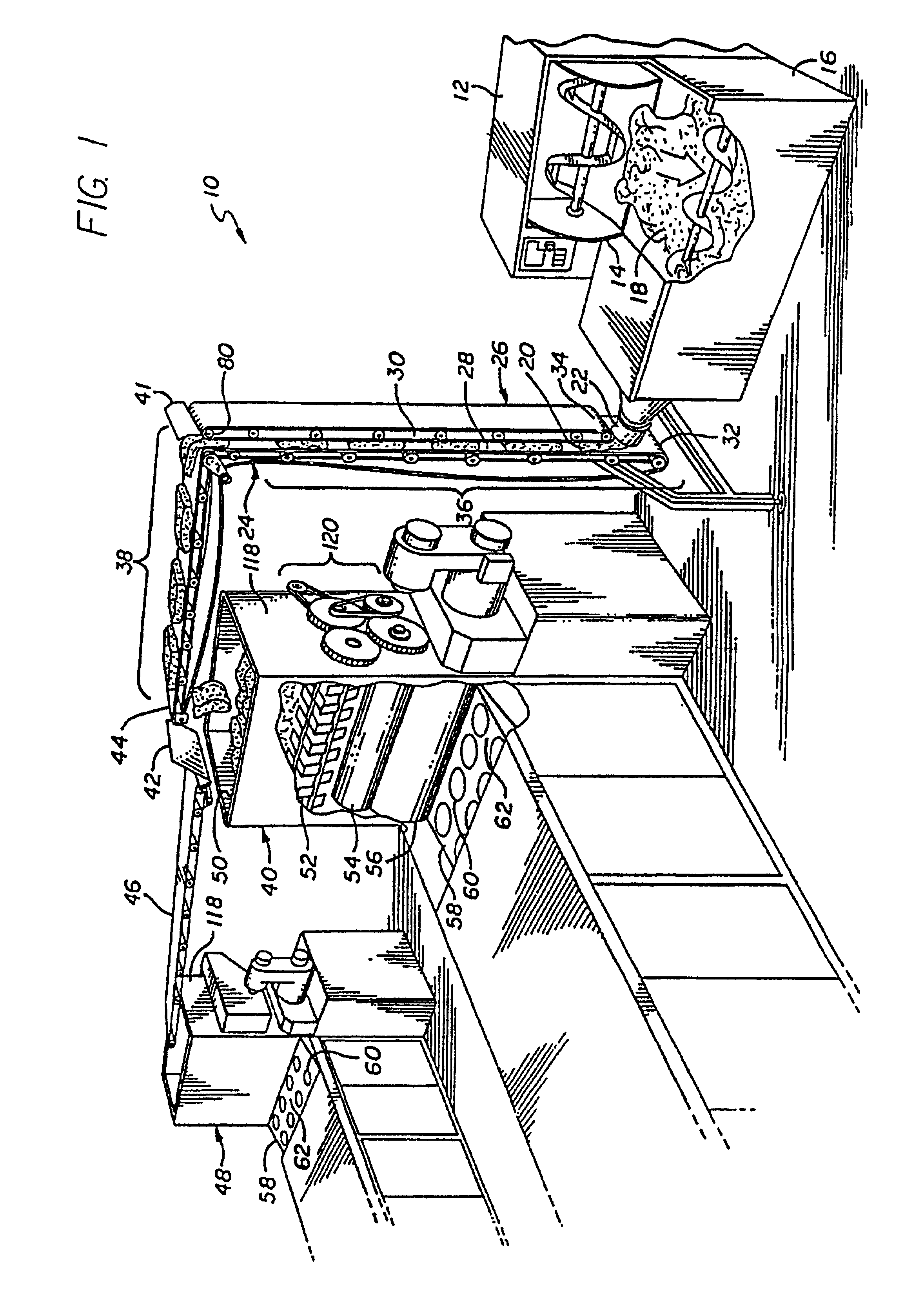

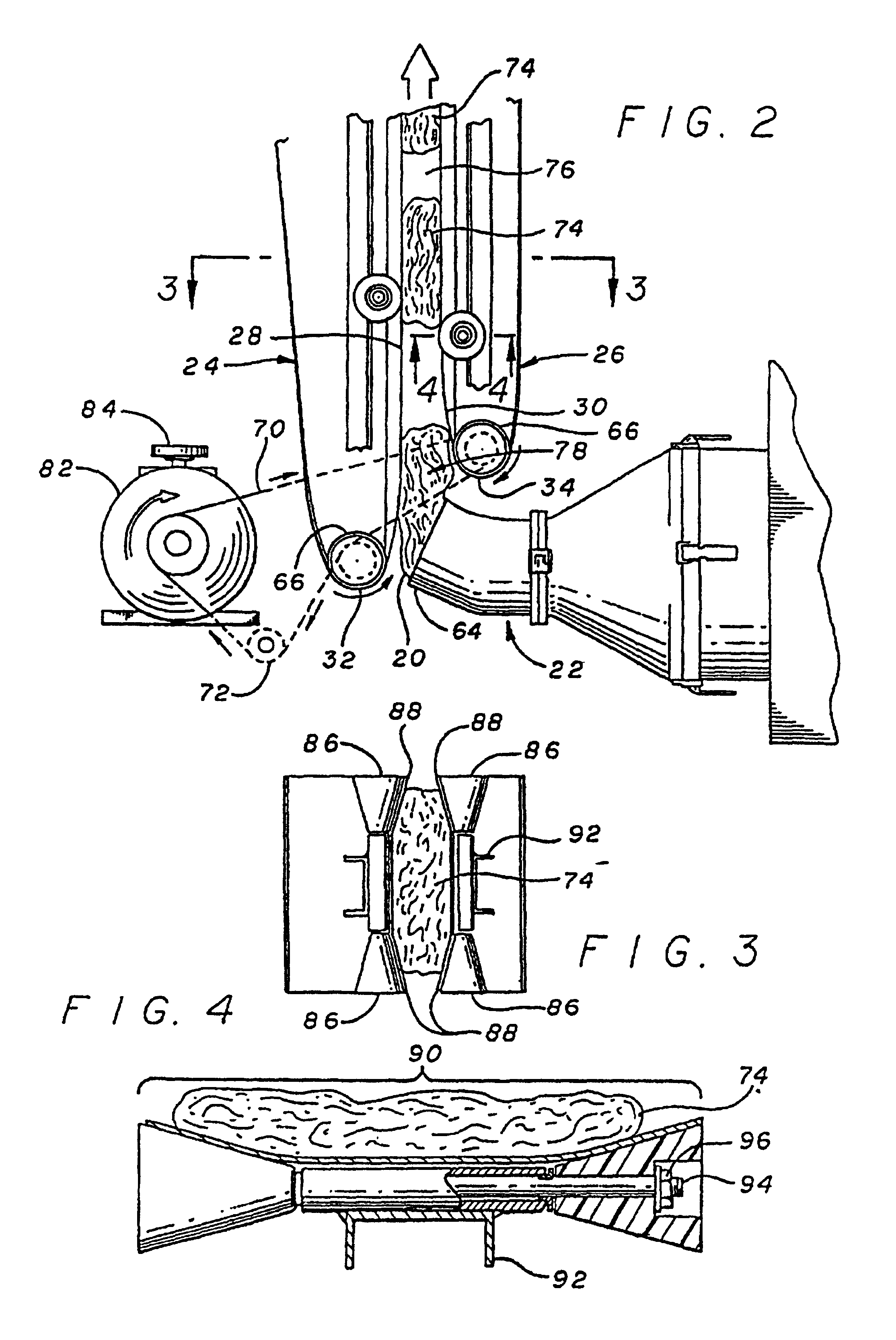

[0037]As shown in the exemplary drawings, the present invention is embodied in a masa handling system, generally referred to by the reference numeral 10, for use within a food processing system which produces a food product made from masa. Masa is a dough produced by cooking whole corn and grinding it wet or by combining instants corn masa hour with water in a commonly available mixer. This dough is generally referred to as “masa”. However, the term “masa” as used herein refers to this corn dough and other doughs having similar characteristics.

[0038]The preferred masa handling system 10 (FIG. 1) is a part of a larger arrangement of apparatus intended for the commercial production of tortillas or other food having a masa dough as an ingredient. The general arrangement of the preferred masa handling system 10 will now be described. A commonly available commercial mixer 122 is located at the beginning of the production line. The mixer 12 has a pivoting door 14 which can rotate downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com