Rolling bearing retainer, rolling bearing, and production method for rolling bearing retainer

A technology of couplings and rollers, applied in the field of roller devices, can solve the problems of wear and tear of polygonal connection area, can not be used for processing noodles or formed bodies, etc., achieve quick opening and replacement, optimize maintenance cycle and maintenance time, increase The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

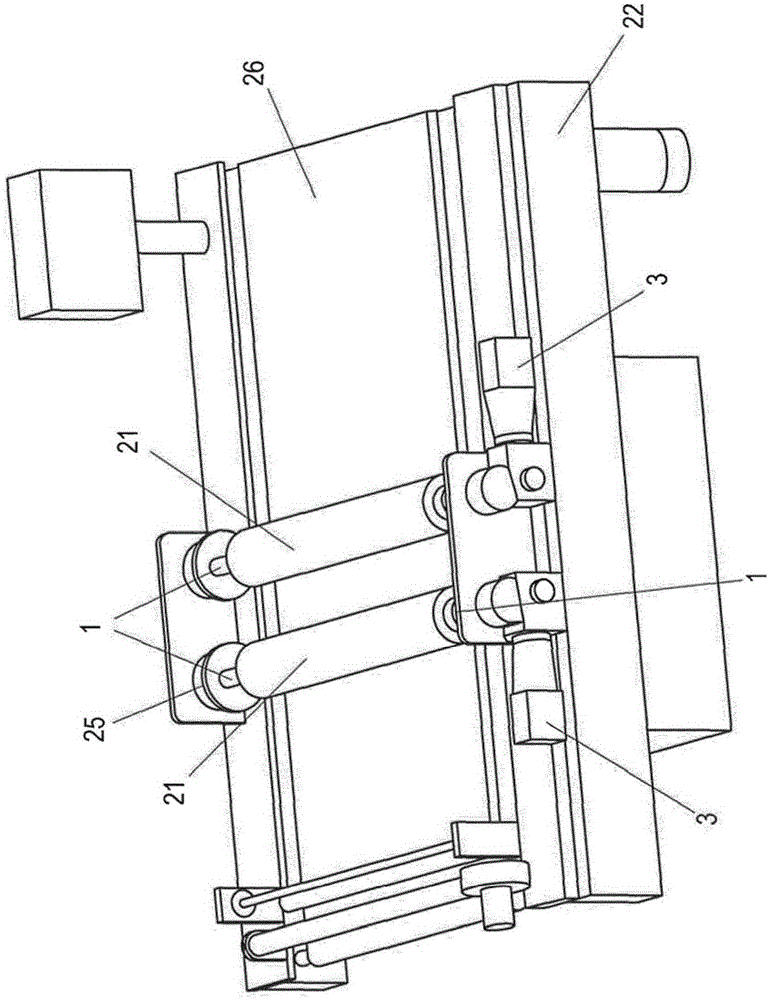

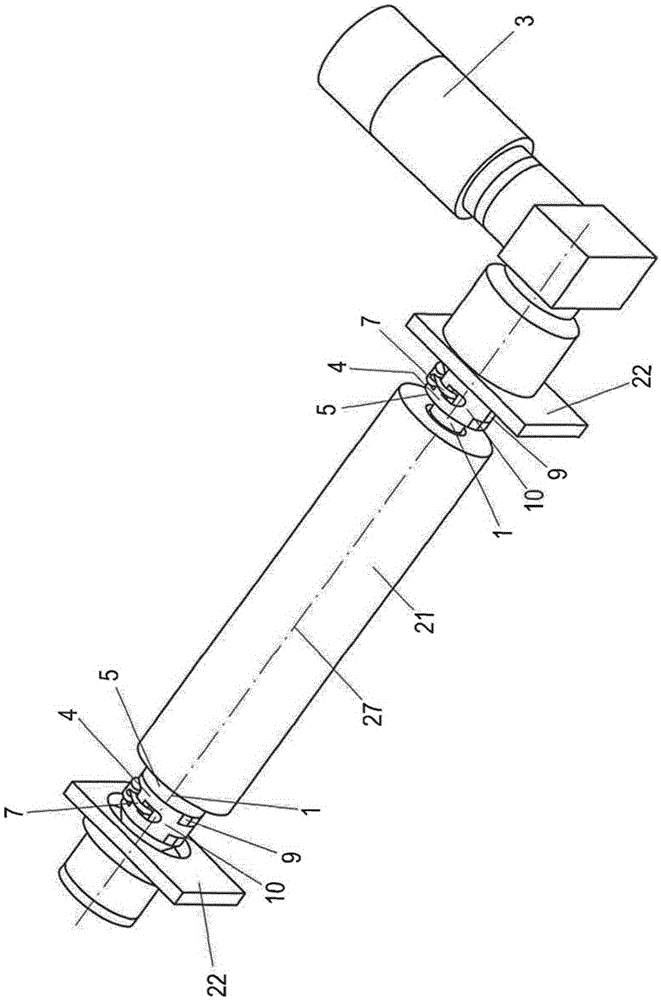

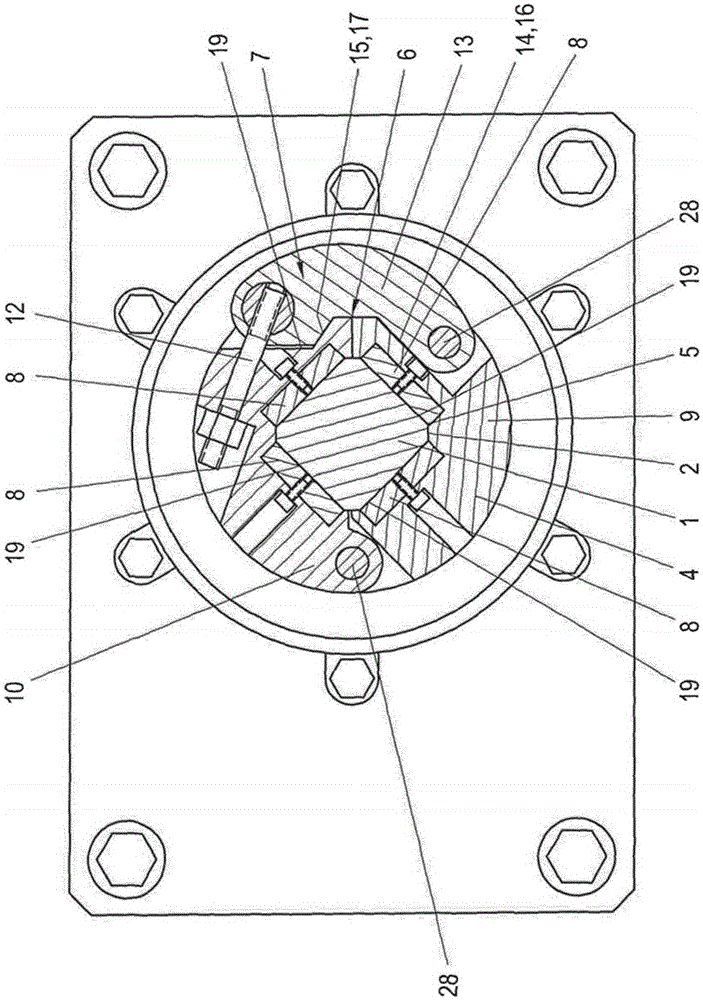

[0027] figure 1 A roller arrangement comprising two rollers 21 is shown. A conveyor belt 26 is arranged next to the rollers 21 . In this exemplary embodiment, the roller is designed as a cutting and / or profiling roller. In this case, the raw noodles are conveyed on the conveyor belt 26 in the direction of the rollers 21 . The rollers 21 have grooves and / or webs (Stegs) for cutting and shaping biscuit dough shapes.

[0028] Rollers 21 and conveyor belts 26 are connected to frame 22 . The roller 21 is rotationally driven by the drive 3 . Rollers 21 are provided for cutting and / or profiling (Nachform) biscuit dough forming bodies. The rollers are interchangeable to enable the production of various biscuit dough shapes. A coupling according to the invention is provided for this purpose.

[0029] Preferably located under the conveyor belt (in the figure 1 Not visible in ) is the glued reverse roller, which resists the pressure of roller 21 . The counter rollers are prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com