Automatic dough rolling rounding device

A technology of rounding and pastry, which is applied in the field of automatic pastry rounding equipment, can solve the problems of environmental impact, uneven rounding of pastry dough, waste of raw materials, etc., and achieve the goals of saving raw materials, uniform rounding effect, saving and purifying the workshop environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0014] The present invention will be described in detail below with reference to the accompanying drawings and examples.

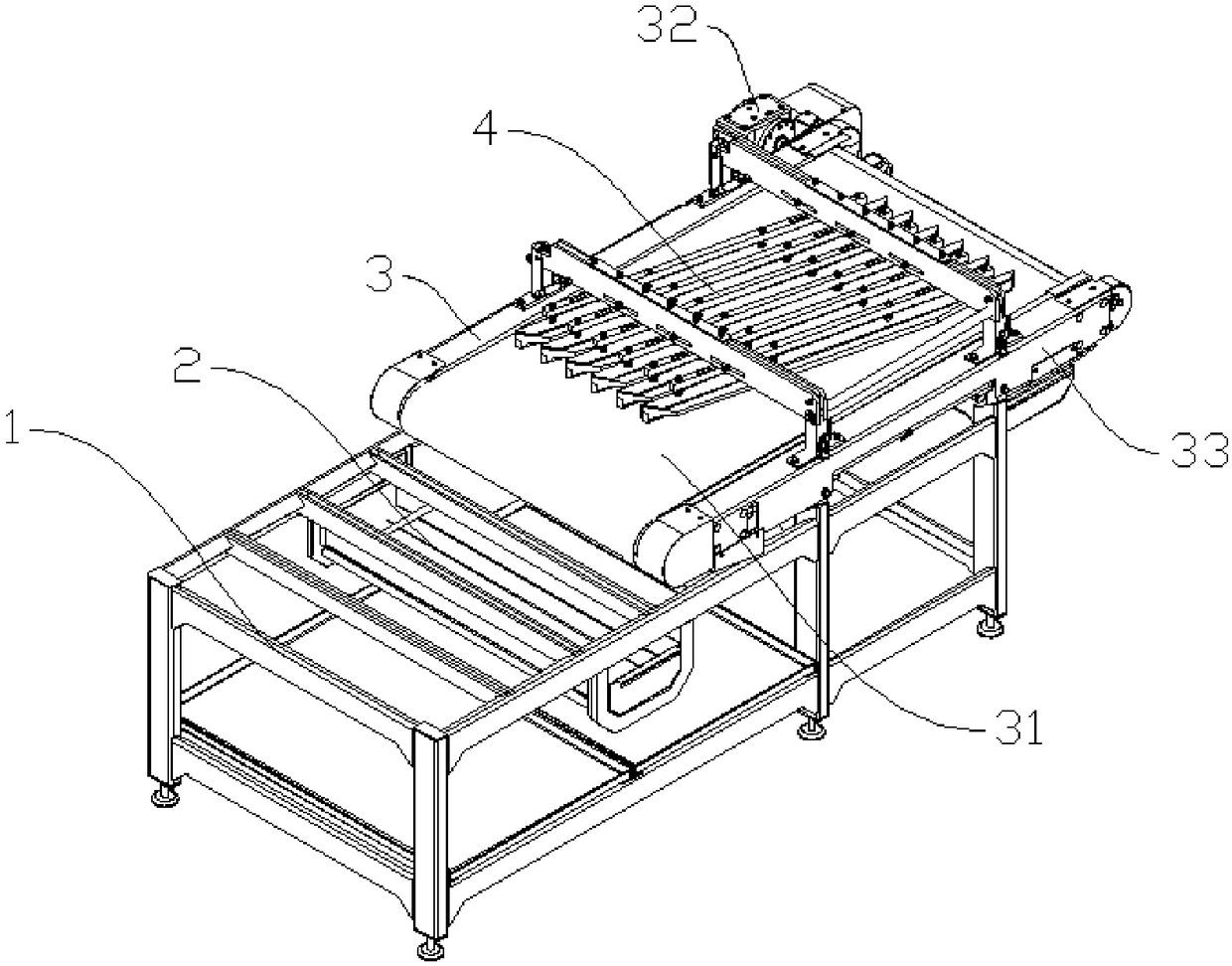

[0015] The automatic pastry rounding equipment is characterized in that it includes a frame 1, a noodle joint groove 2, a rounding transmission device 3 and a rounding rack 4, and also includes a conveyor belt 31, a motor 32 and a transmission device bracket 33. The rounding rack 4 is set On the rounding transfer device 3, the rounding transfer device 3 is arranged on the frame 1, and the joint groove 2 is arranged on the frame 1 near the tail end of the rounding transfer device 3, and the rounding transfer device 3 is composed of a conveyor belt 31 , Motor 32 and conveyor bracket 33 are made up.

[0016] The above descriptions are only preferred embodiments of the present invention, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com