Noodle machine

A noodle machine and noodle cutting technology, applied in the direction of dough mixer, dough forming machinery or equipment, dough sheeting machine/rolling machine/rolling pin, etc., can solve the problem of elongation, destruction of gluten network structure, and no elongation Function and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

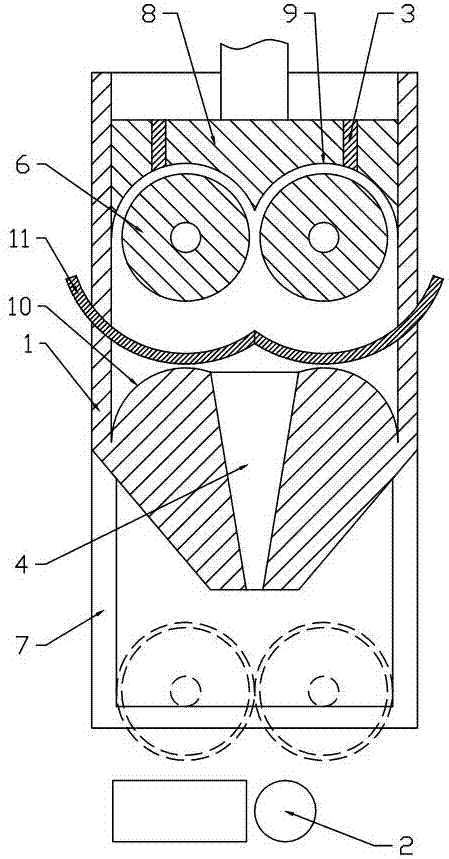

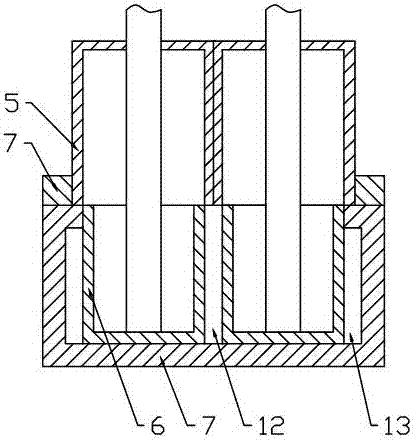

[0017] The reference signs in the accompanying drawings of the description include: material barrel 1, surface cutting mechanism 2, nozzle 3, discharge port 4, roll holder 5, surface roller 6, chute 7, piston 8, wedge-shaped surface 9, convex surface 10, Arc plate 11, scoop surface gap 12, extrusion gap 13.

[0018] The embodiment noodle machine is basically as attached figure 1 Shown: It includes a material barrel 1 for kneading, a rolling mechanism and a noodle cutting mechanism 2. There is a nozzle 3 inside the material barrel 1, and a discharge port 4 is provided at the bottom of the material barrel 1. The calendering mechanism is installed under the material barrel 1, and the surface is cut. The mechanism 2 is installed below the calendering mechanism. The cross section of the material barrel 1 is rectangular. Two roller holders 5 are installed on the side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com