Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about "Holographic writing means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Holographic projection real-time 3D display system and method

ActiveUS20110254916A1Achieve normal displayRestore complex wavefrontsStereoscopic photographyHolographic writing meansWavefrontSpatial spectrum

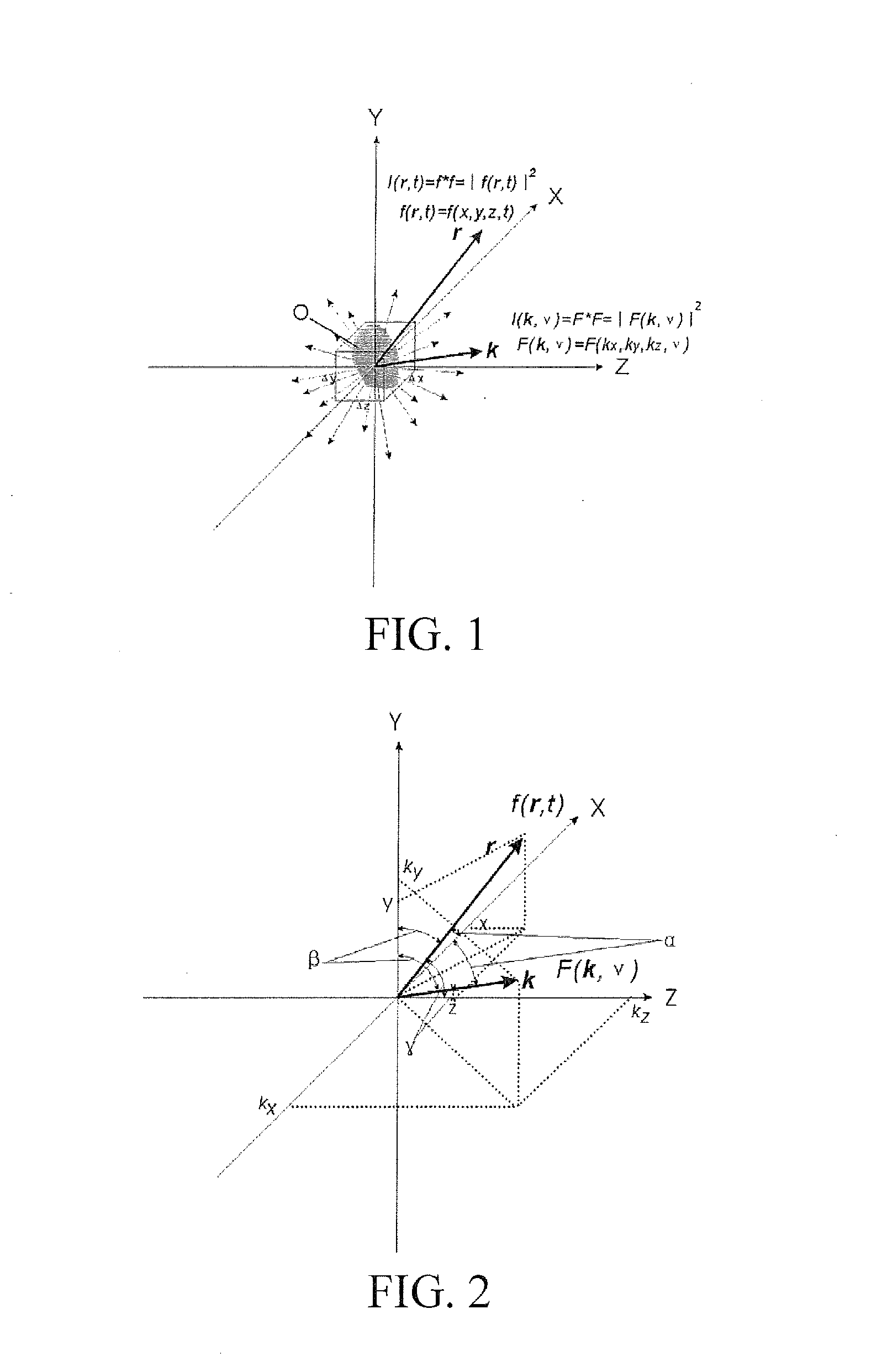

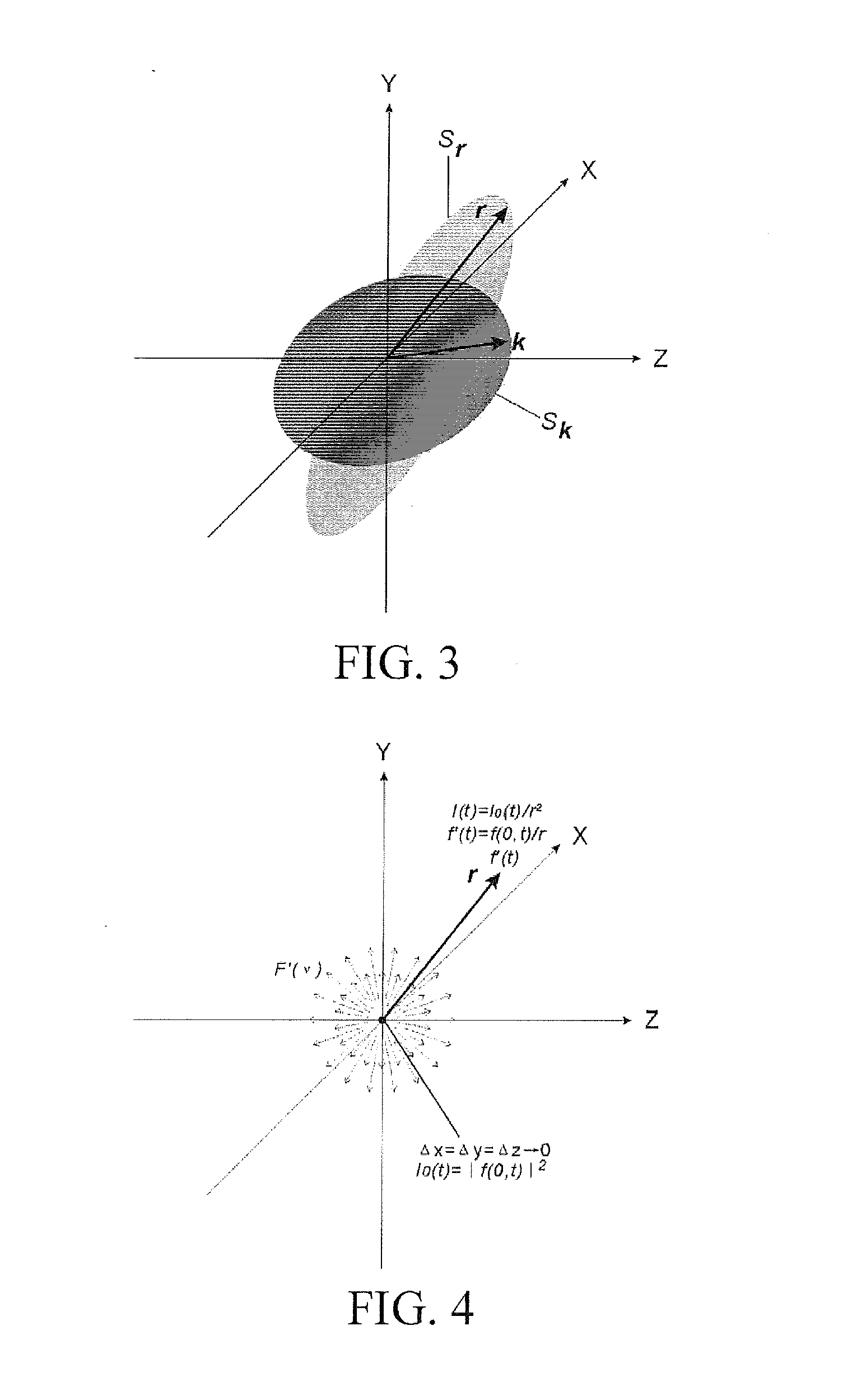

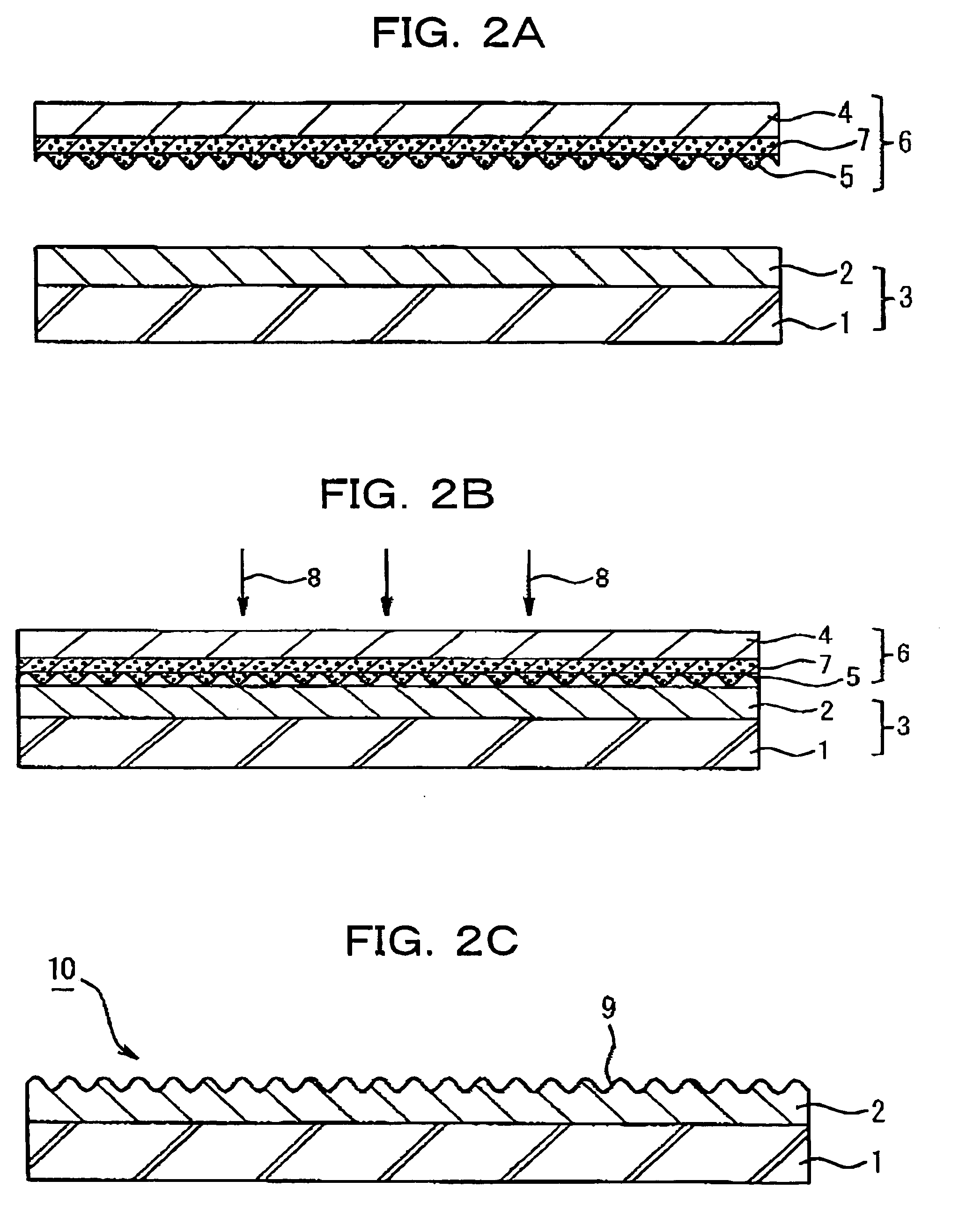

A real-time color holographic three-dimensional (3D) display system and method realized by using principles of digital holographic display and a common photographing / projection device array system are provided. For an object O to be displayed, an array of M×N cameras which are anchored to a certain reference point R in a space corresponding to the object O is used to perform spatial spectrum sampling and capturing on any spatial spectrum surface S of the object O with a sampling density being a spatial sampling angle ωmn. Each acquired spatial spectrum view image Imn is projected by a corresponding array of M×N projectors in each spatial spectrum capturing direction to a reference surface PR necessary for restoring 3D information of the original object O. Output of full spatial spectrums of the object O is realized through a spatial spectrum limited stretching function of a holographic functional screen placed on the reference surface PR which is used on discrete spatial spectrum input image information, thereby achieving digital holographic display intended to restore complex wavefronts.

Owner:AFC TECH

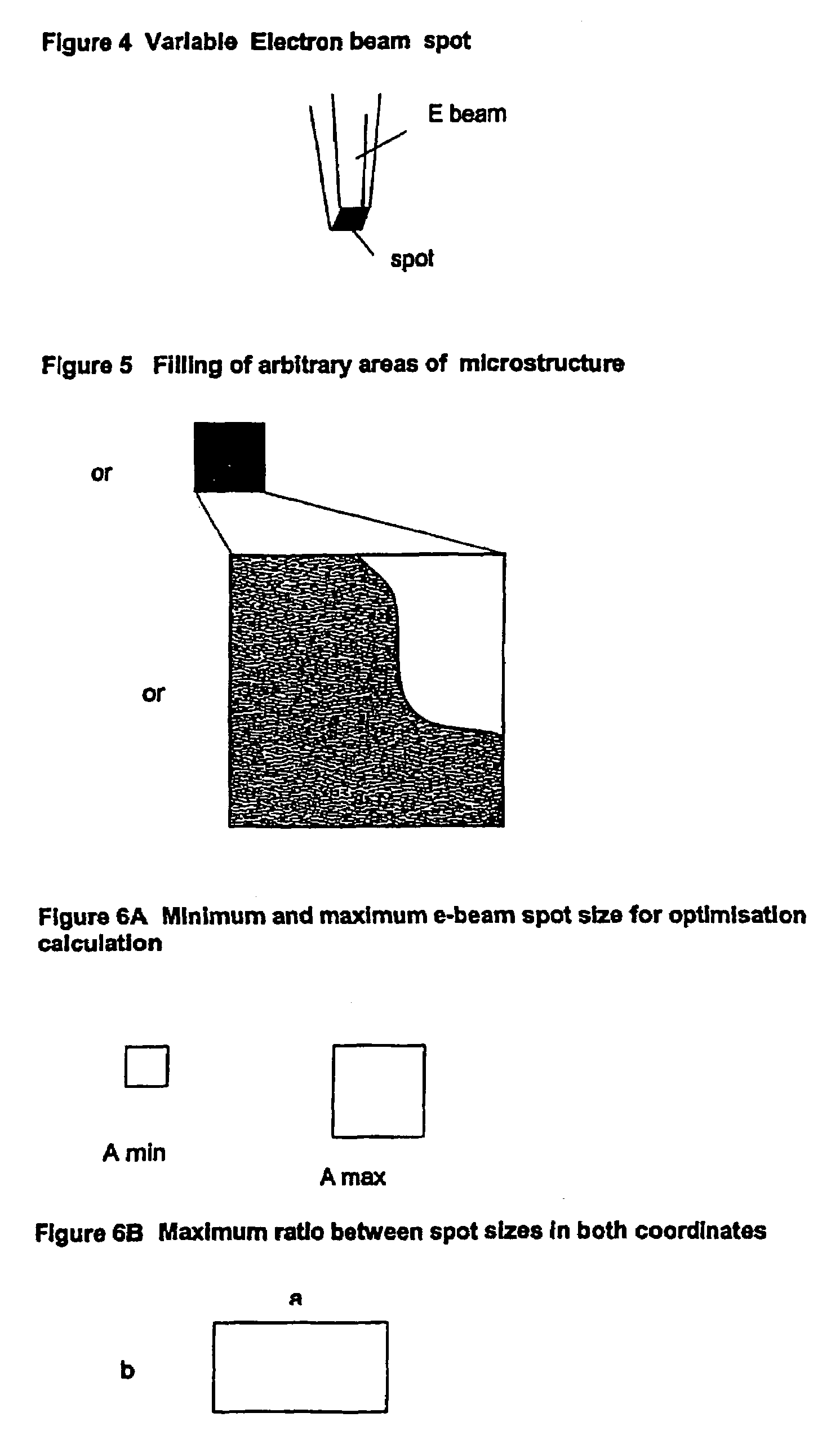

Optical device and method of manufacture

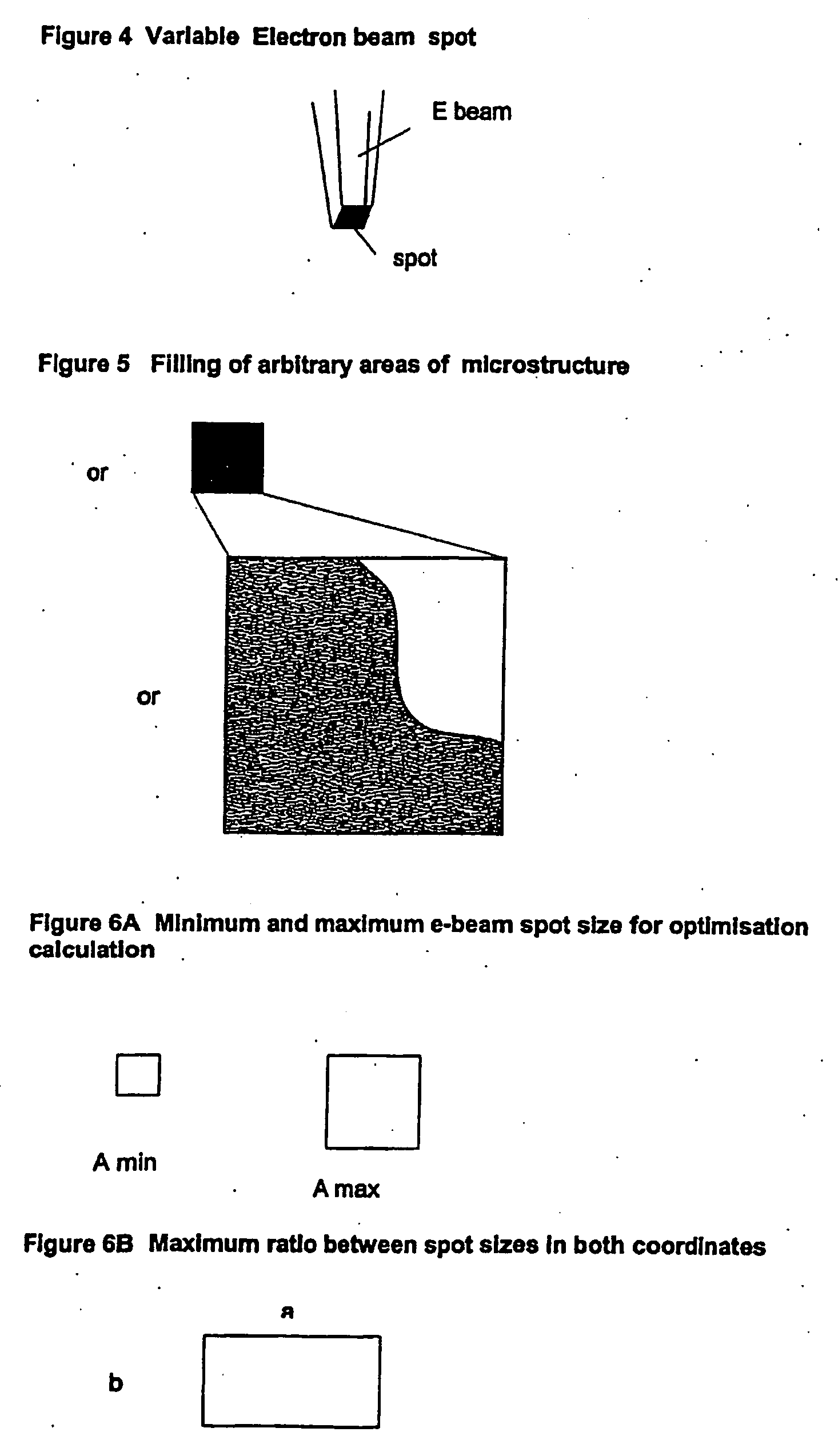

InactiveUS20070284546A1Unlimited flexibilityImprove the immunityDigitally marking record carriersMirrorsElectron-beam lithographyElectron bunches

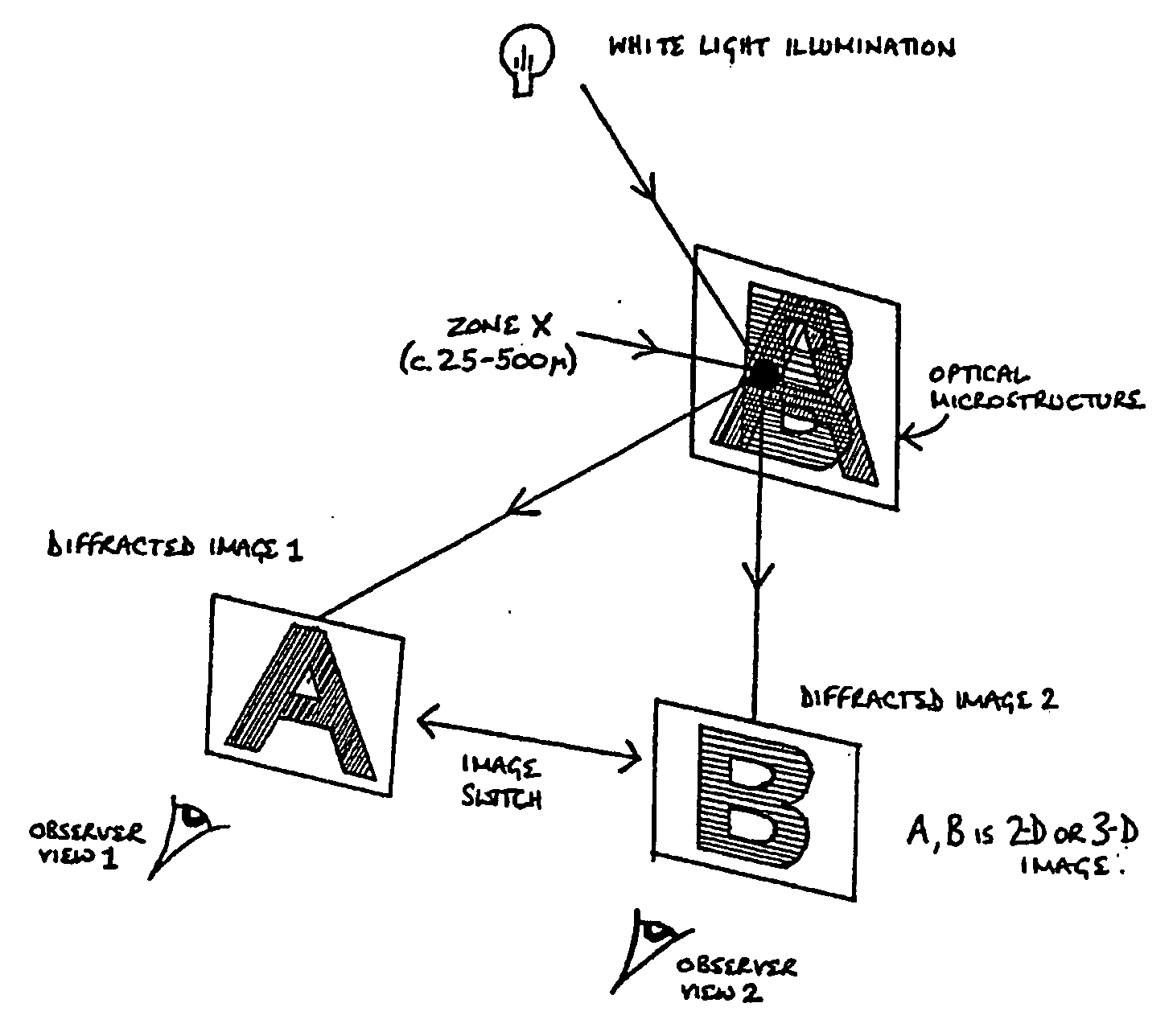

The present invention provides for a method of producing an optical device by means of electron beam lithography and including the step of varying the characteristics of the electron beam spot during formation of the device and also an apparatus for producing diffractive optical devices and / or holographic devices by means of electron beam lithography and including an electron beam lithograph, controlling and processing means, means for varying the characteristics of the electron beam spot during formation of the device, and wherein the processing means is arranged for compiling and pre-processing data and for providing optimisation and allocation control and to optical devices such as those produced thereby.

Owner:OPTAGLIO

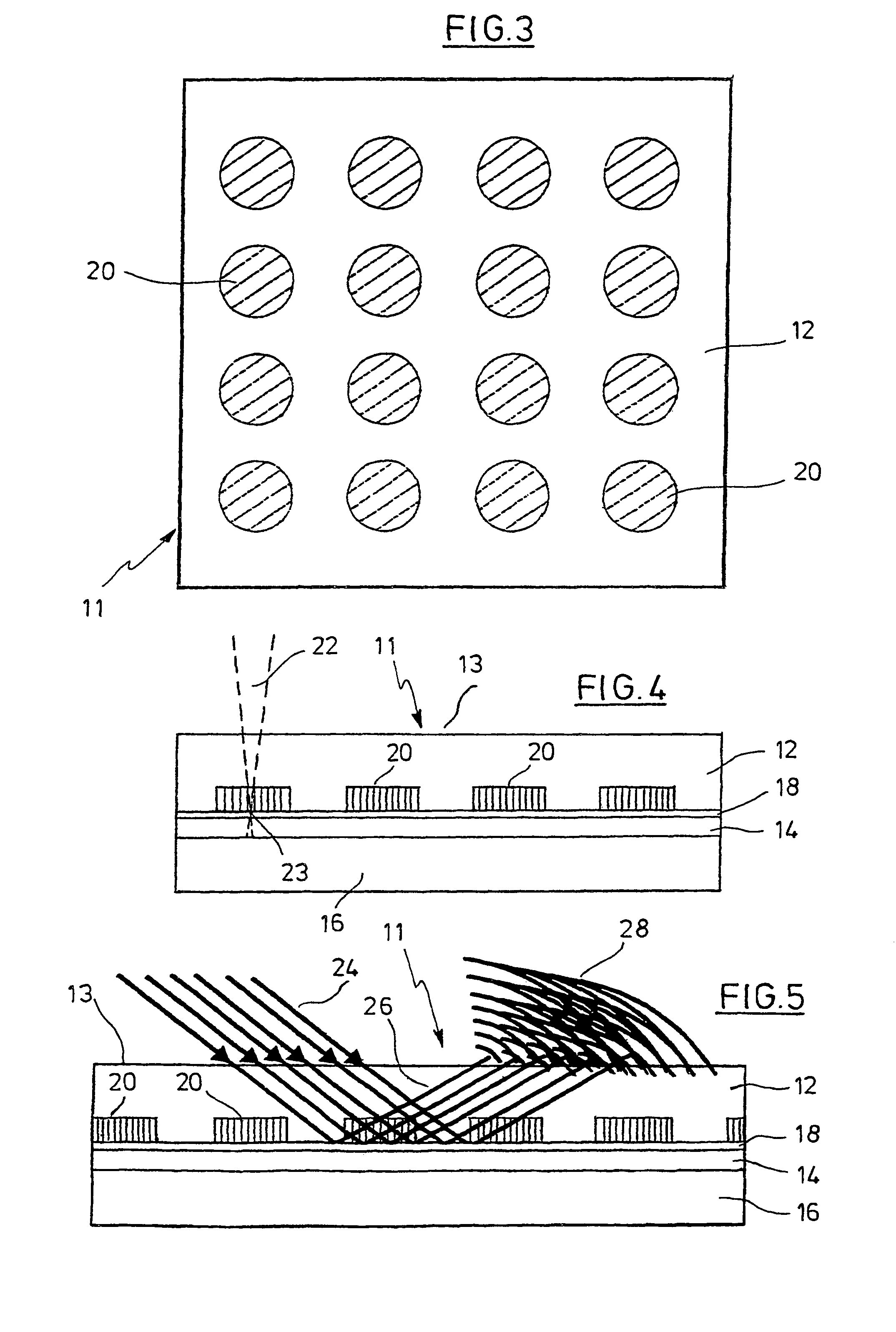

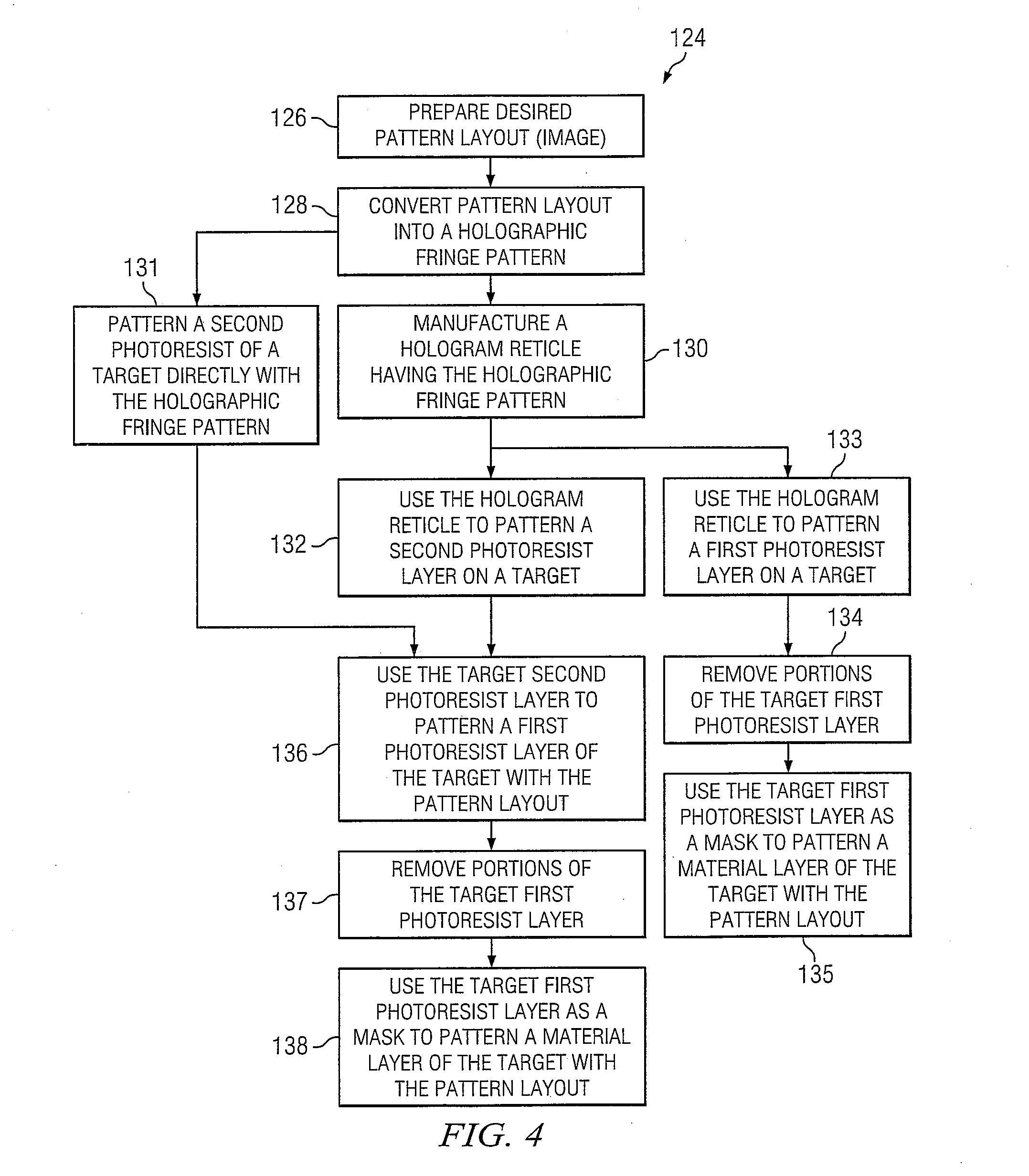

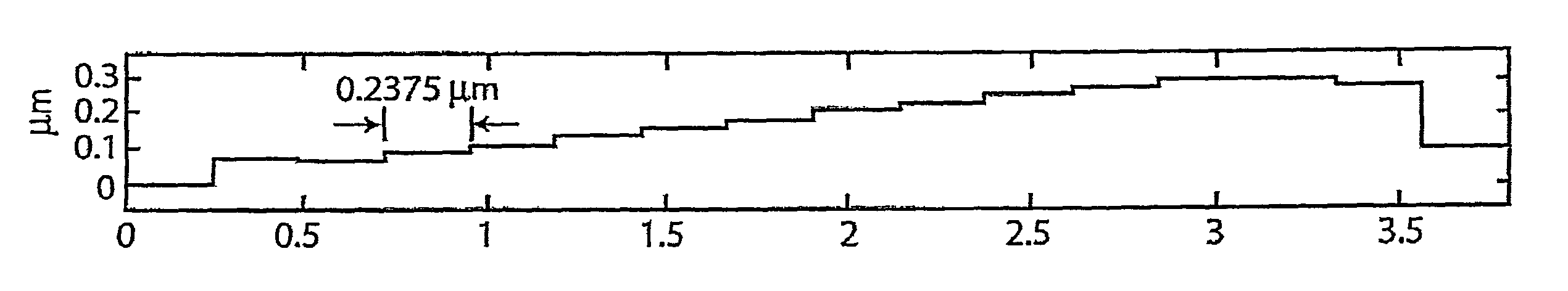

Holographic reticle and patterning method

InactiveUS20050147895A1Reduce needExpanding the photolithography process windowPhotomechanical apparatusHolographic object characteristicsDevice materialPhotoresist

A hologram reticle and method of patterning a target. A layout pattern for an image to be transferred to a target is converted into a holographic representation of the image. A hologram reticle is manufactured that includes the holographic representation. The hologram reticle is then used to pattern the target. Three-dimensional patterns may be formed in a photoresist layer of the target in a single patterning step. These three-dimensional patterns may be filled to form three-dimensional structures. The holographic representation of the image may also be transferred to a top photoresist layer of a top surface imaging (TSI) semiconductor device, either directly or using the hologram reticle. The top photoresist layer may then be used to pattern an underlying photoresist layer with the image. The lower photoresist layer is used to pattern a material layer of the device.

Owner:TAIWAN SEMICON MFG CO LTD

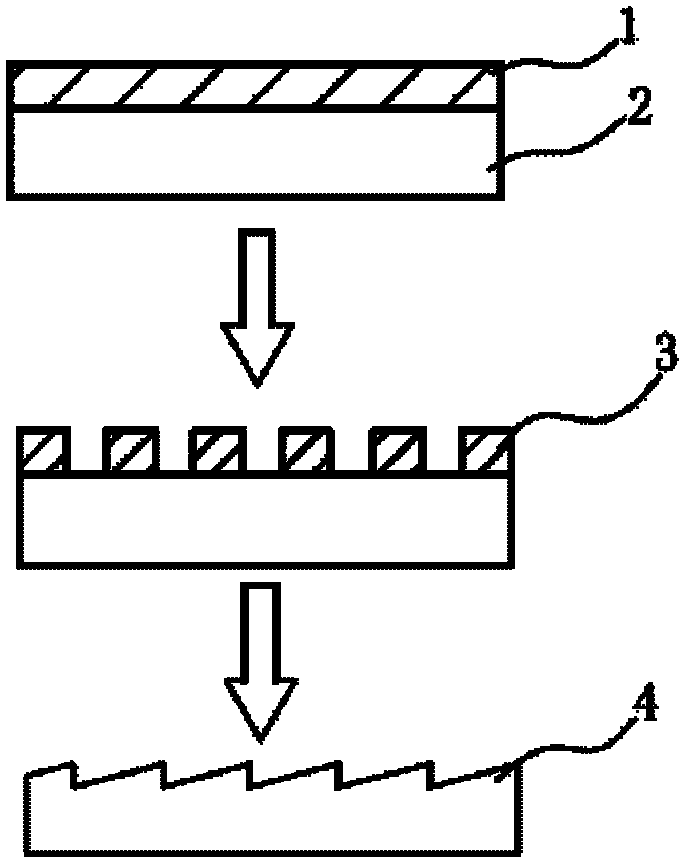

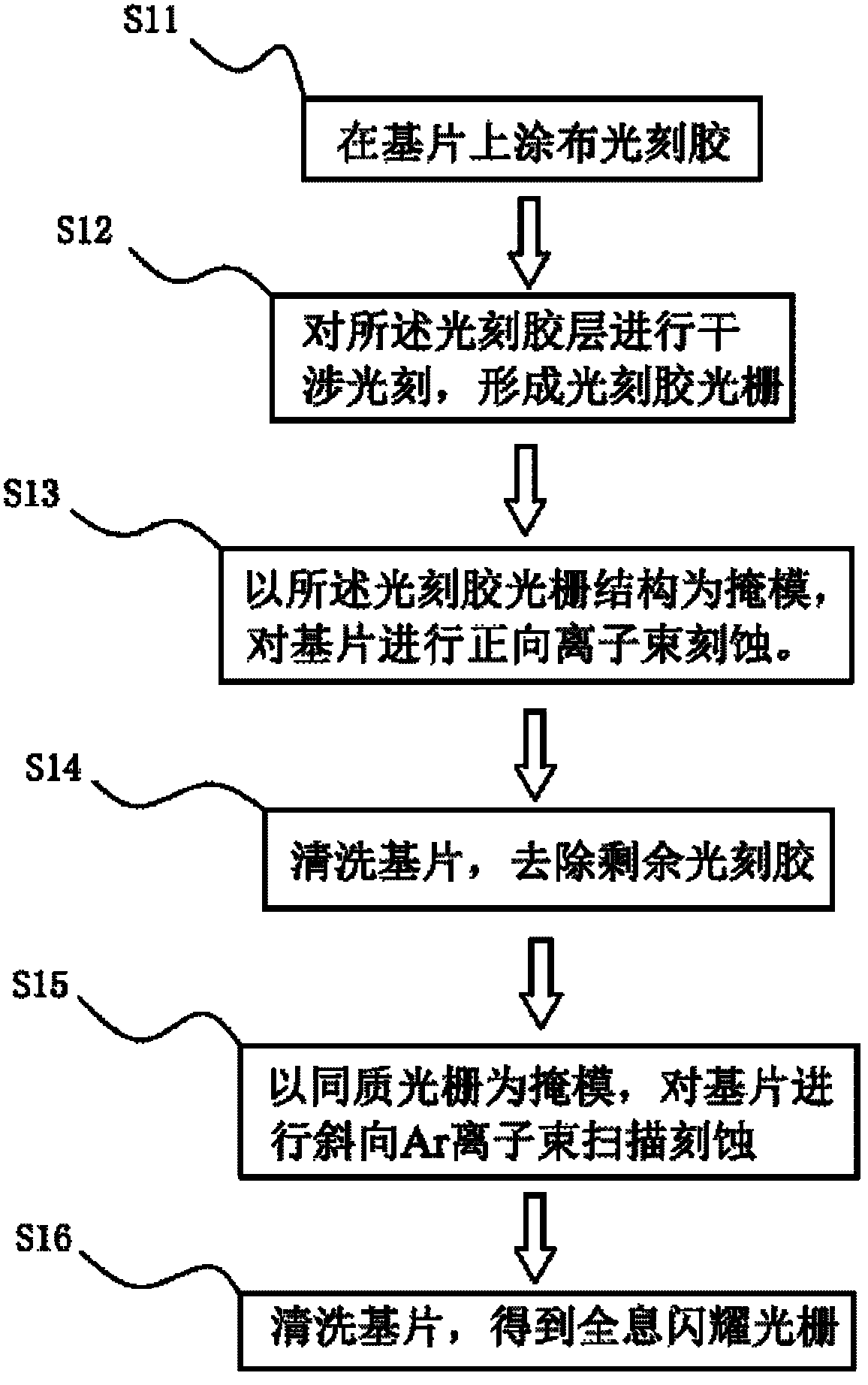

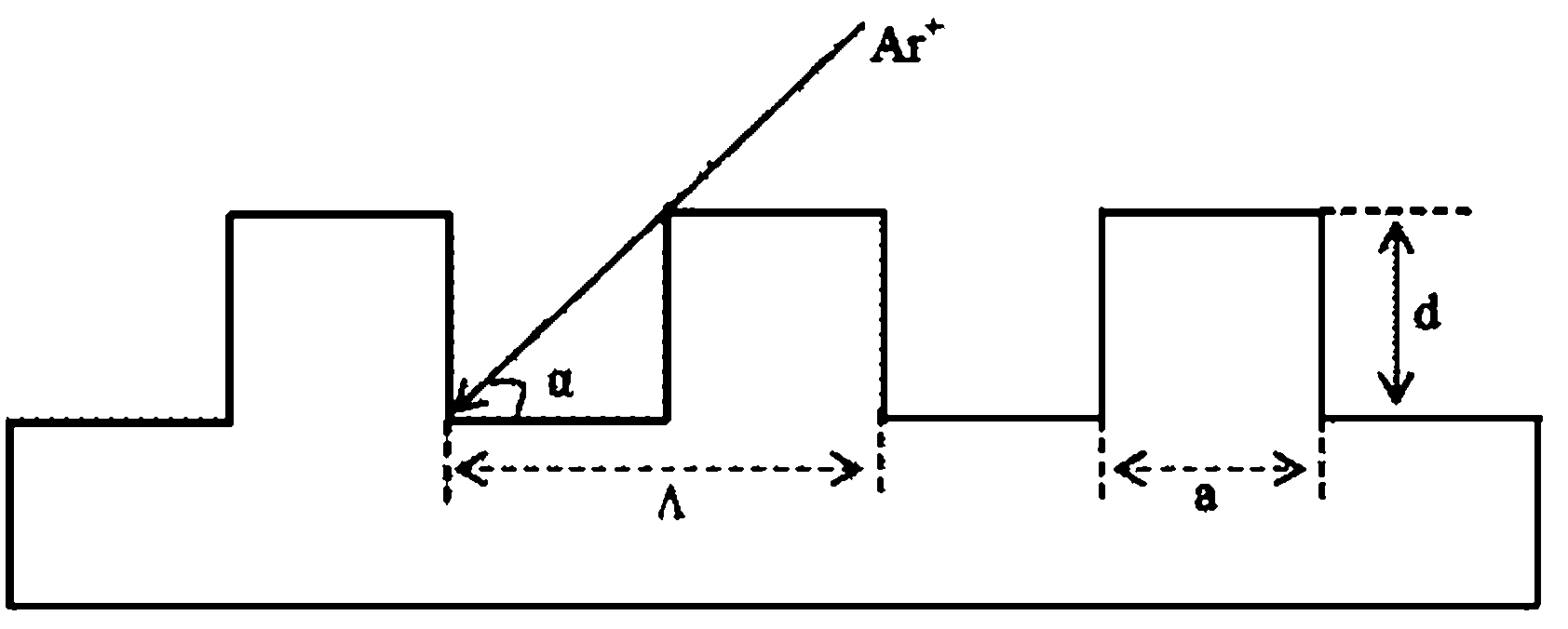

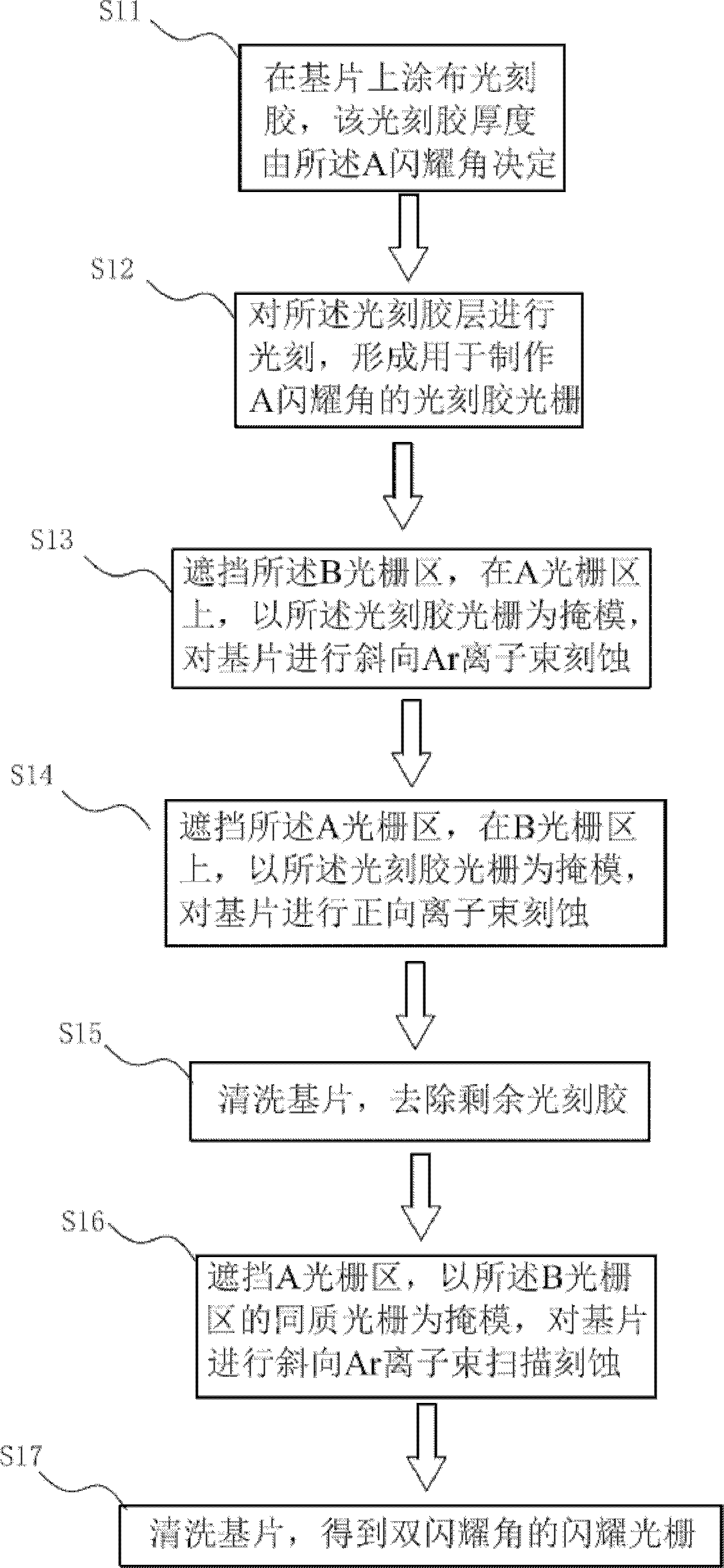

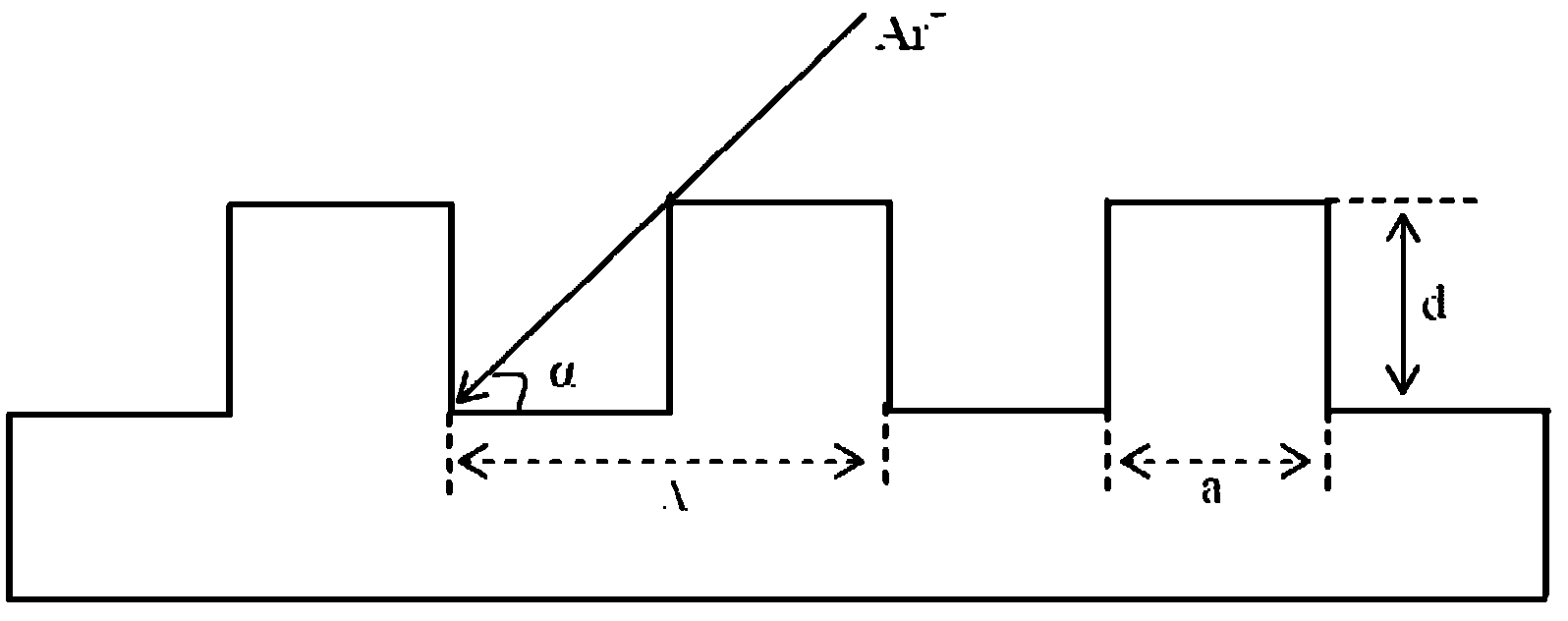

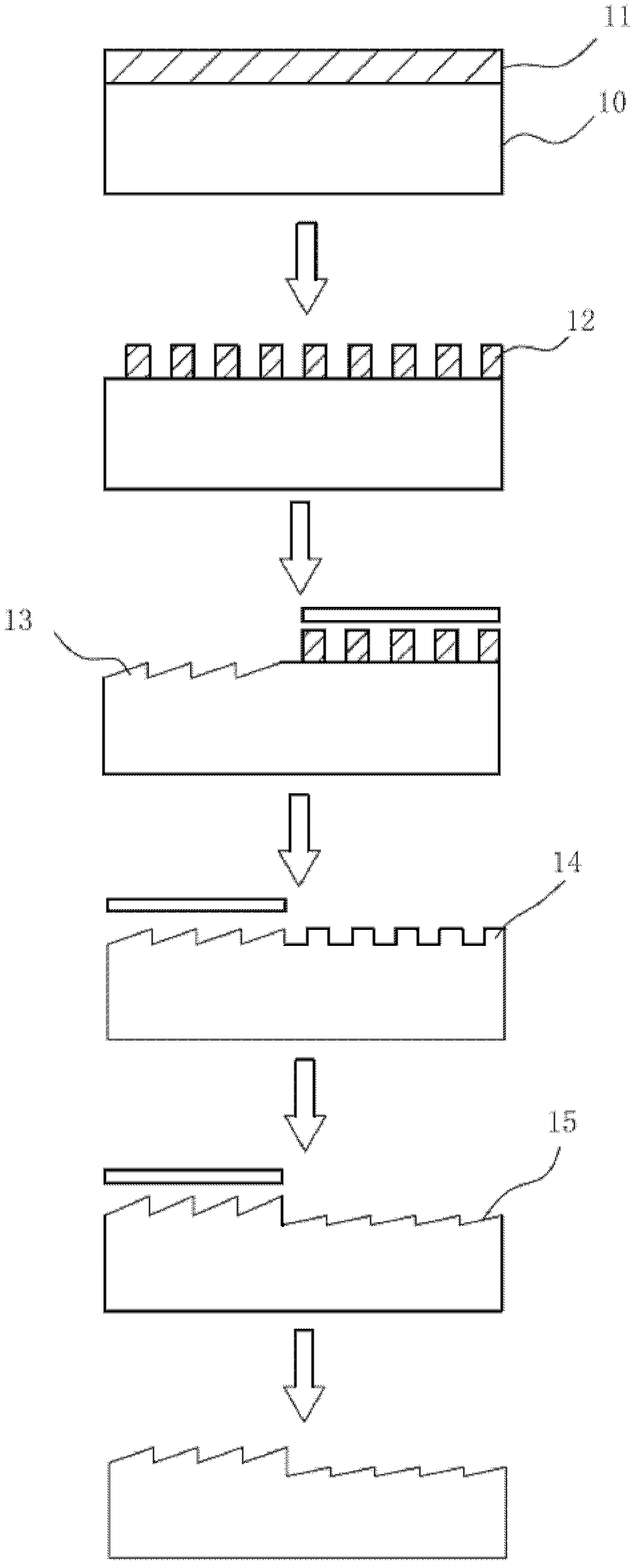

Holographic blazed grating manufacturing method

InactiveCN102360093AEasy to controlVacuum evaporation coatingPhotomechanical apparatusBlazed gratingGrating

The invention provides a holographic blazed grating manufacturing method. Through making a homogeneous grating on a substrate, taking the homogeneous grating as mask, and carrying out oblique ion beam etching, a needed blazed grating is obtained. Since time of positive ion beam etching can be controlled when making the homogeneous grating, a groove depth of the homogeneous grating is accurately controlled. In addition, after obtaining a photoresist raster through interferometric lithography, ashing technology can be increased further, a duty cycle of the photoresist raster is controlled, and a duty cycle of a needed homogeneous grating is controlled. According to the manufacturing method of the present invention, multi-parameter control of blazed grating manufacture is realized, and manufacture precision is raised.

Owner:SUZHOU UNIV

Manufacturing method for holographic dual-blazed grating

ActiveCN102323634AAvoid secondary photoresist lithography processEasy to controlPhotomechanical apparatusDiffraction gratingsBlazed gratingGrating

The invention discloses a manufacturing method for a holographic dual-blazed grating. The two blaze angles of the holographic dual-blazed grating are respectively a blaze angle A and a blaze angle B. Different control of the two blaze angles is realized by performing oblique ion beam etching by using a photoresist grating and a homogenous grating as masks on two grating areas A and B, so that a secondary photoresist photoetching process is avoided. When the homogenous grating is manufactured, the positive ion beam etching time can be controlled so that the groove depth of the homogenous grating is controlled precisely. In addition, the homogenous grating mask and the substrate are made of the same material, and the etching rate of the homogenous grating mask and the etching rate of the substrate are kept consistent all the time, so that precise control of the blaze angles can be realized.

Owner:SUZHOU UNIV

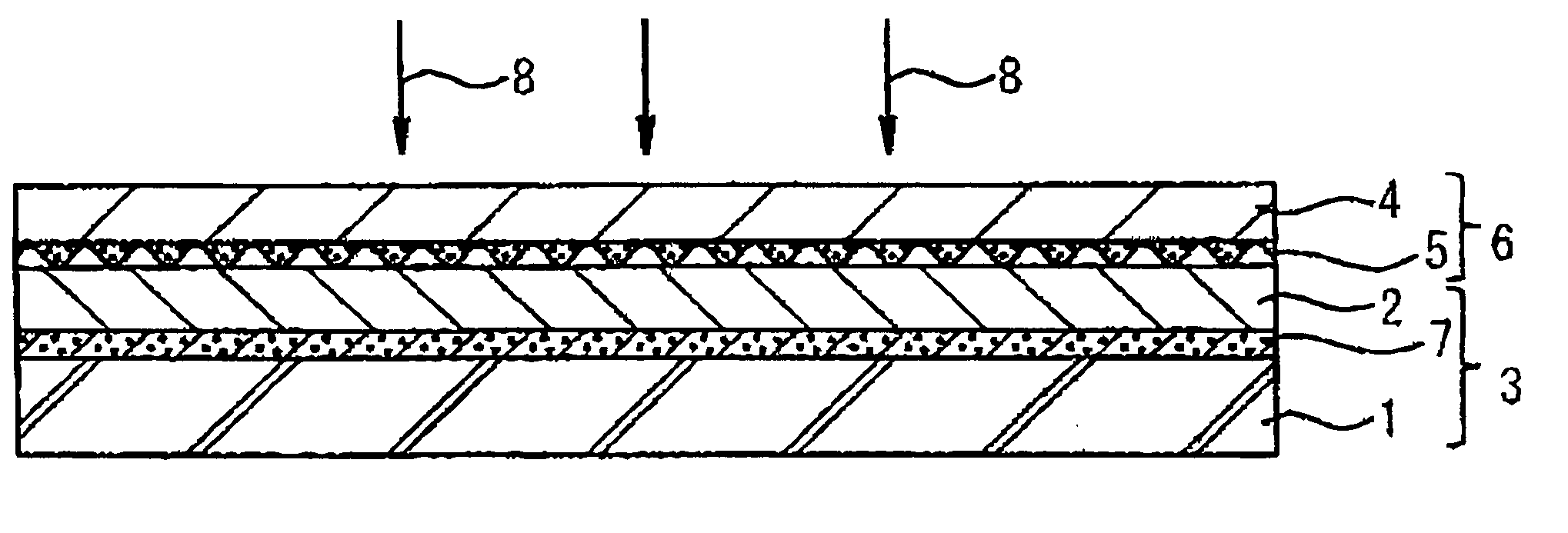

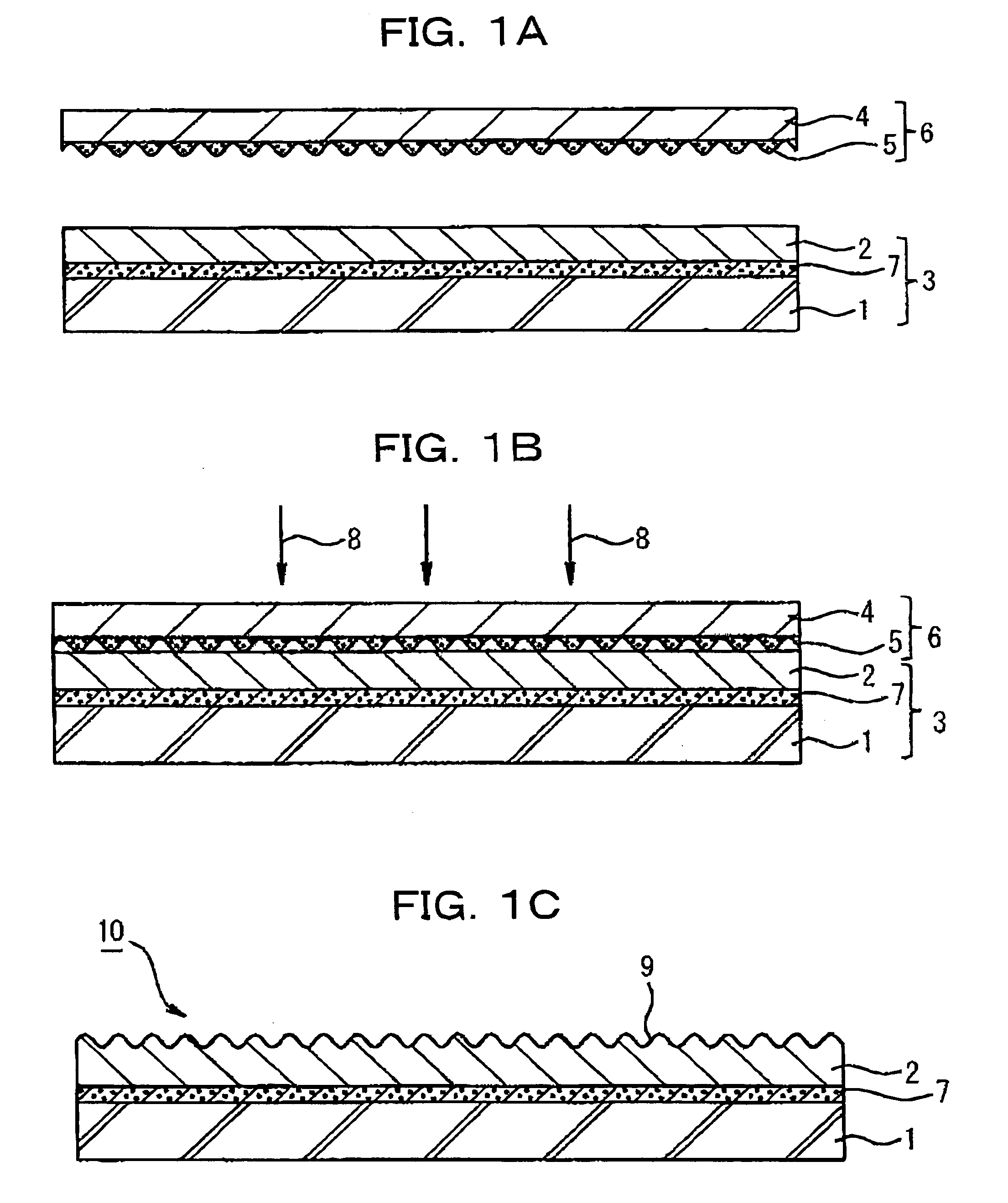

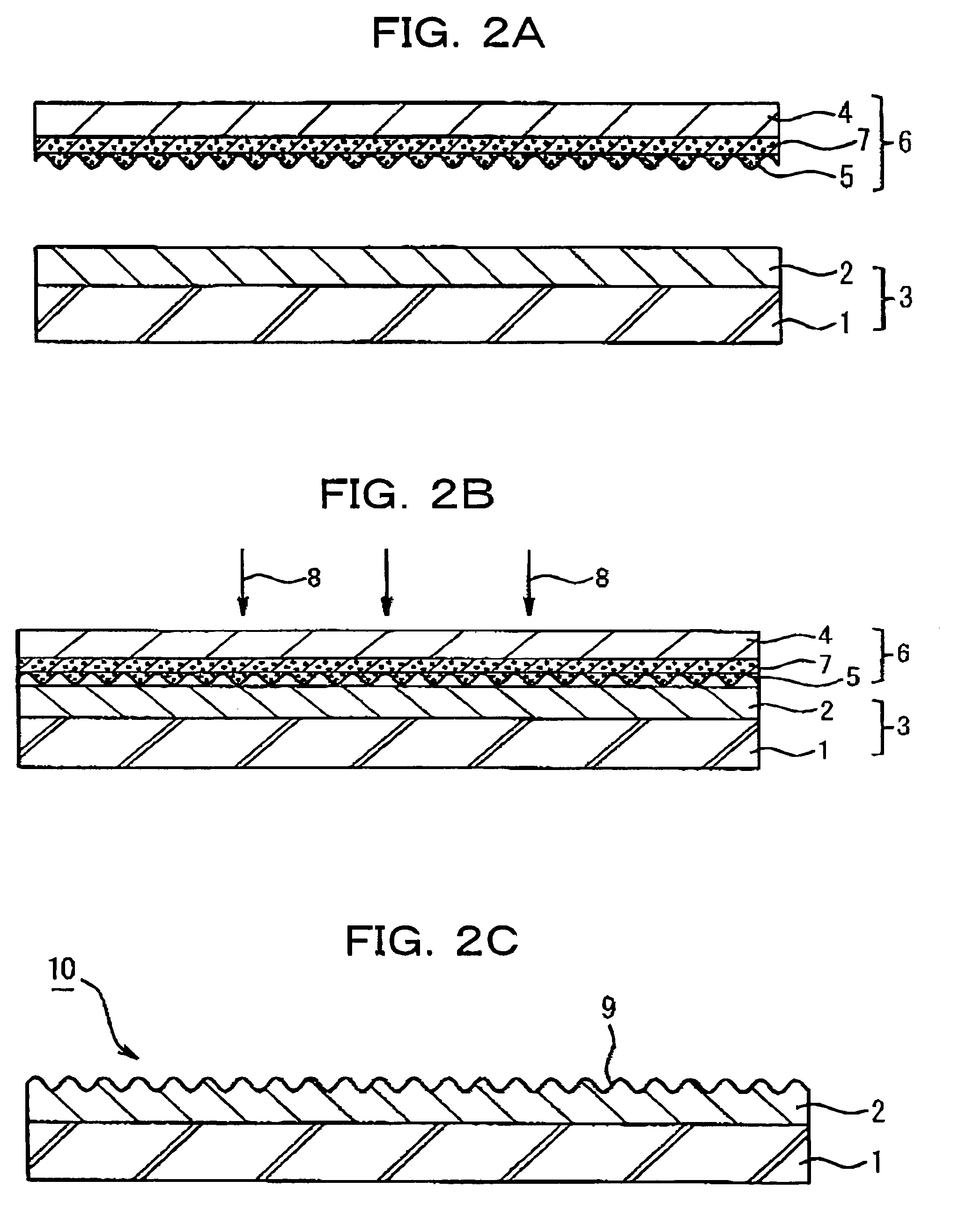

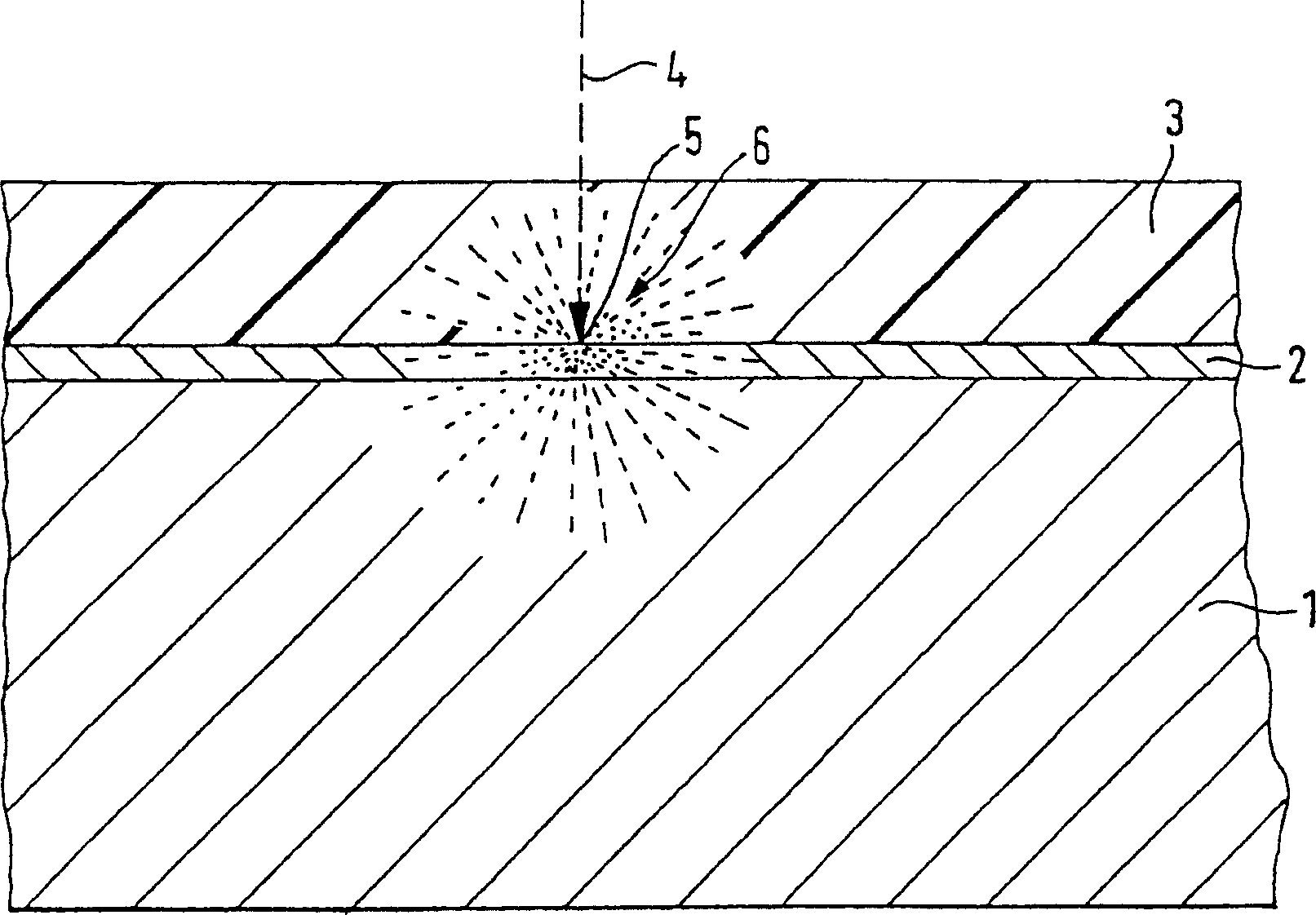

Method for forming fine concavo-convex patterns, method for producing optical diffraction structure, and method for copying optical diffraction structure

ActiveUS20050057789A1Promote formationIncrease speedPhotomechanical apparatusHolographic object characteristicsOptical diffractionPhotothermal conversion

A method for forming fine concavo-convex patterns by using a relief formation material 3 having a relief formation layer 2 composed of a resin having thermoplasticity and a relief pattern sheet 6 having on a surface thereof fine concavo-convex patterns 5, wherein a photothermal conversion layer 7 is formed in the relief formation material 3 or the relief pattern sheet 6; the photothermal conversion layer 7 is irradiated with light 8 to make the photothermal conversion layer 7 generate heat in the state that the relief formation layer 2 is brought into contact with the fine concavo-convex patterns 5; and the fine concavo-convex patterns 5 are formed on the relief formation layer 2.

Owner:DAI NIPPON PRINTING CO LTD

Optical device and methods of manufacture

InactiveUS20050052745A1Diffusion transfer processesOther printing matterSurface structureComputer science

An optical device which generates an optically variable image, the image being optically variable in that it varies according to the position of observation, is manufactured by dividing an optically invariable image into multiple pixels. Colour component values are determined for each pixel. For each of the pixels of the optically invariable image, there is determined an associated pixel surface structure which has a three-dimensional surface shape and curvature which is related via a mathematical of computer algorithm to the oclour component values of the associated pixel in the optically invariable image, each pixel surface structure being an individual reflective or diffractive surface structure which produces an observable optical effect. An assembly of the reflective or diffractive pixel surface structures is produced which when illuminated generates a plurality of observable optical effects wihch combine to form an optically variable reproduction of the optically invariable image.

Owner:CCL SECURE PTY LTD

Optical element and manufacturing method thereof

InactiveUS6934074B2High diffraction efficiencyIncrease production capacityHolographic object characteristicsHolographic writing meansOptical property

An optical element has of a set a plurality of three-dimensional cells. A specific amplitude and a specific phase are defined in each individual cell. Each cell has a concave part formed by hollowing a part having an area corresponding to the specific amplitude by a depth corresponding to the specific phase. The individual cell has a specific optical property so that, when incident light is provided to the cell, emission light is obtained by changing an amplitude and a phase of the incident light in accordance with the specific amplitude and specific phase defined in the cell.

Owner:DAI NIPPON PRINTING CO LTD

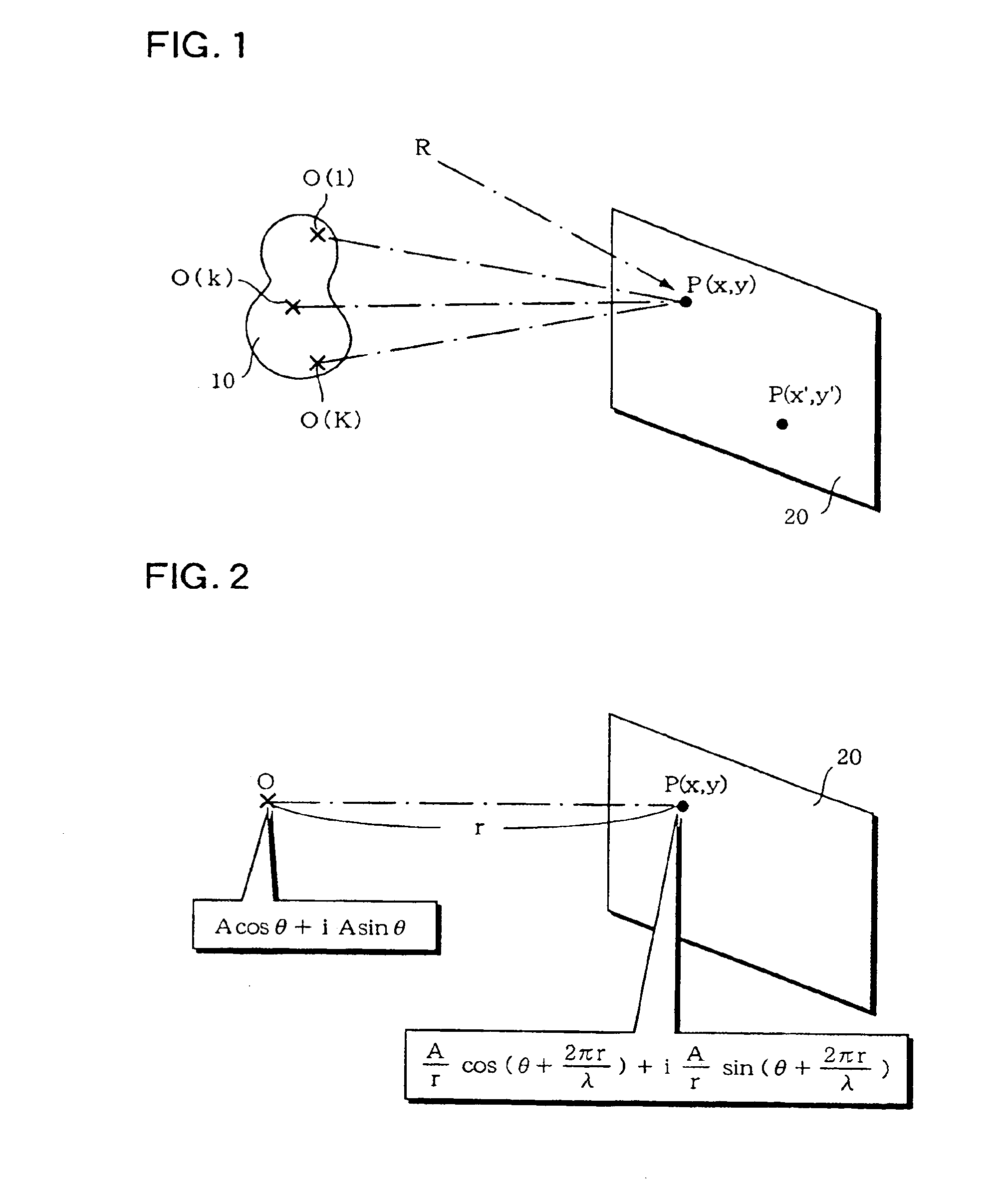

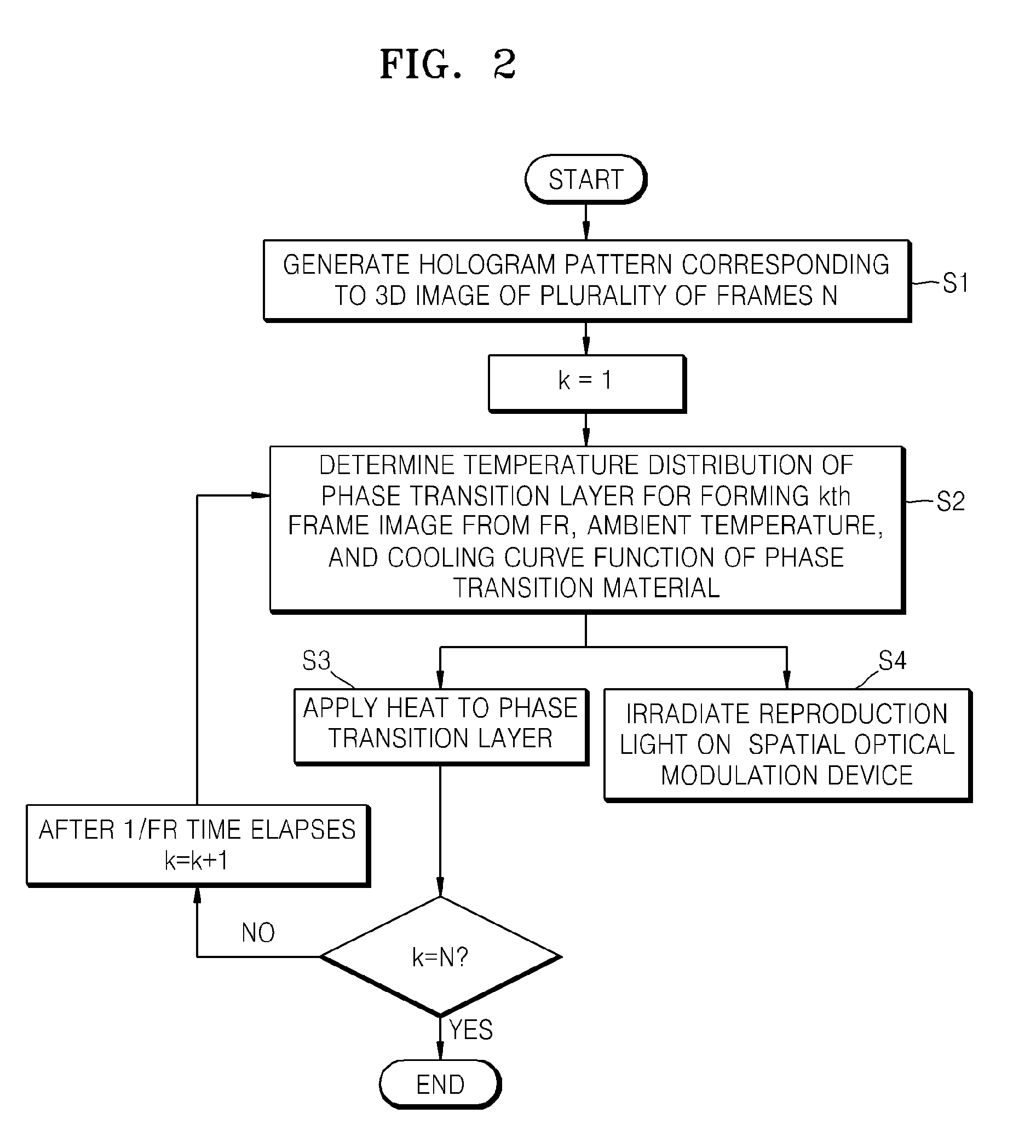

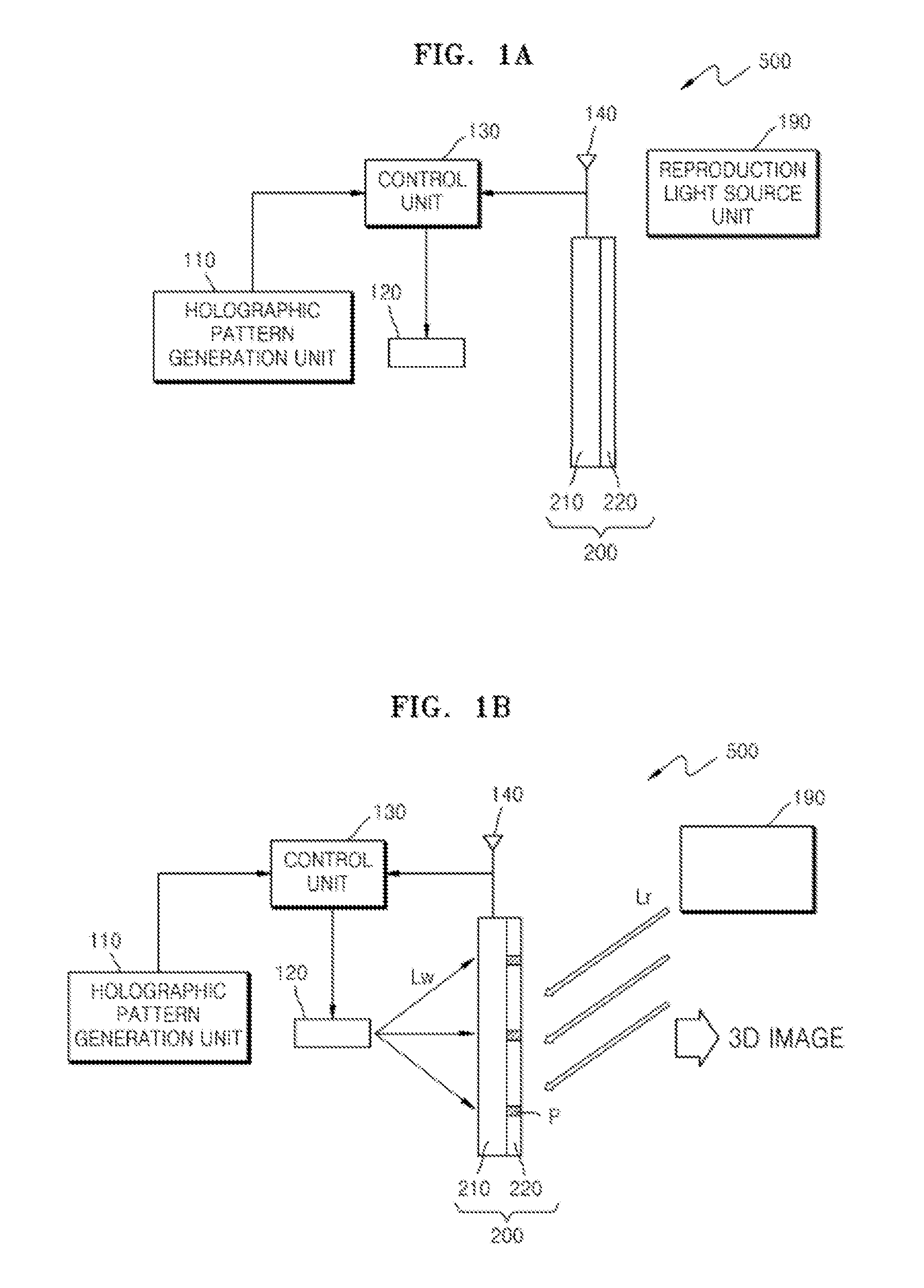

Apparatus and method for displaying holographic three-dimensional image

ActiveUS20150160612A1Active addressable light modulatorHolographic writing meansInformation control3d image

An apparatus for displaying a holographic three-dimensional (3D) image is provided. The apparatus includes: a holographic pattern generation unit; a spatial optical modulation device including a phase transition layer formed of a phase transition material, a phase of which is changed by a temperature. A holographic pattern generated by the holographic pattern generation unit is optically addressed on the spatial optical modulation device. The apparatus also includes a heat source for applying heat to the phase transition layer; a control unit for controlling the heat source according to holographic pattern information generated by the holographic pattern generation unit; and a reproduction light source for irradiating light for image reproduction onto the spatial optical modulation device.

Owner:SAMSUNG ELECTRONICS CO LTD

Optical device and method of manufacture

InactiveUS7435979B2Unlimited flexibilityDigitally marking record carriersMirrorsElectron-beam lithographyElectron

The present invention provides for a method of producing an optical device by means of electron beam lithography and including the step of varying the characteristics of the electron beam spot during formation of the device and also an apparatus for producing diffractive optical devices and / or holographic devices by means of electron beam lithography and including an electron beam lithograph, controlling and processing means, means for varying the characteristics of the electron beam spot during formation of the device, and wherein the processing means is arranged for compiling and pre-processing data and for providing optimization and allocation control and to optical devices such as those produced thereby.

Owner:OPTAGLIO

Method Of Producing Diffractive Structures In Security Documents

InactiveUS20070278785A1Quick buildStrong of laser radiationOther printing matterRadiation applicationsLaser beamsMicrostructure

A method of producing a security document or article including a substrate (100), which is transparent at least to visible light, and a diffractive optical microstructure (112). The method includes applying an opacifying layer (102) to at least one surface of the transparent substrate (100). An area of the opacifying layer (102) is exposed to laser radiation (108) to ablate apertures (110) in selected portions of the opacifying layer (102), thereby forming a diffractive optical microstructure (112) on the surface of the substrate (100). The laser radiation may be patterned prior to exposing the opacifying layer (102), for example by passing the radiation through a mask (104). Alternatively, a focussed or collimated laser beam (206) may be directed onto the selected portions of the opacifying layer (102). Laser radiation may be directed onto the opacifying layer (102) either directly, or through the transparent substrate (100). Security documents or articles made in accordance with the method are also provided.

Owner:CCL SECURE PTY LTD

Hologram Appearing Package Image

A package that has at least one hologram on its exterior surface is formed from a paper, paperboard or thermoplastic substrate material that has an inner surface and an outer surface. The outer surface has a radiation curable particulate metal containing coating. This coating is cured and zero to one or more ink containing coatings are applied to the radiation curable particulate metal containing coating in areas that are not to have a hologram. Each of these ink containing coatings are cured, and a substantially transparent radiation curable coating is applied to the areas deficient in the zero to one or more ink coatings. This substantially transparent radiation curable coating is contacted with a substantially transparent holographic shim in an area not having thereon ink containing coatings while curing radiation is applied to the substantially transparent radiation curable coating and the substantially transparent shim.

Owner:COLGATE PALMOLIVE CO

Method for forming fine concavo-convex patterns, method for producing optical diffraction structure, and method for copying optical diffraction structure

ActiveUS7245406B2Promote formationIncrease speedPhotomechanical apparatusDiffraction gratingsOptical diffractionEngineering

Owner:DAI NIPPON PRINTING CO LTD

Hologram appearing package image

A package that has at least one hologram on its exterior surface is formed from a paper, paperboard or thermoplastic substrate material that has an inner surface and an outer surface. The outer surface has a radiation curable particulate metal containing coating. This coating is cured and zero to one or more ink containing coatings are applied to the radiation curable particulate metal containing coating in areas that are not to have a hologram. Each of these ink containing coatings are cured, and a substantially transparent radiation curable coating is applied to the areas deficient in the zero to one or more ink coatings. This substantially transparent radiation curable coating is contacted with a substantially transparent holographic shim in an area not having thereon ink containing coatings while curing radiation is applied to the substantially transparent radiation curable coating and the substantially transparent shim.

Owner:COLGATE PALMOLIVE CO

Holographic data-storage medium

InactiveUS7151623B2Low production costSimple structureRecord information storageHolographic writing meansLight beamReflective layer

In an example holographic data storage medium, which has a polymer film which serves as a storage layer and can be changed locally by heating, the polymer film is set up as a top layer of the data storage medium. Arranged underneath the polymer film is an absorber layer which has an absorber dye. The absorber dye is set up to at least partly absorb a write beam serving to put information in and to discharge the heat produced in the process at least partly locally to the polymer film. In an advantageous refinement of the example data storage medium, there is an adhesive layer underneath the absorber layer and a partly transparent reflective layer between the polymer film and the absorber layer.

Owner:TESA SCRIBOS

Holographic reticle and patterning method

ActiveUS8227150B2Reduce needLow costPhotomechanical apparatusHolographic object characteristicsPhotoresistReticle

A hologram reticle and method of patterning a target. A layout pattern for an image to be transferred to a target is converted into a holographic representation of the image. A hologram reticle is manufactured that includes the holographic representation. The hologram reticle is then used to pattern the target. Three-dimensional patterns may be formed in a photoresist layer of the target in a single patterning step. These three-dimensional patterns may be filled to form three-dimensional structures or else used in a multi-surface imaging composition. The holographic representation of the image may also be transferred to a top photoresist layer of a top surface imaging (TSI) semiconductor device, either directly or using the hologram reticle. The top photoresist layer may then be used to pattern an underlying photoresist layer with the image. The lower photoresist layer is used to pattern a material layer of the device.

Owner:TAIWAN SEMICON MFG CO LTD

Holographic Reticle and Patterning Method

ActiveUS20100297538A1Reduce needExpanding the photolithography process windowHolographic object characteristicsPhotomechanical exposure apparatusPhotoresistReticle

A hologram reticle and method of patterning a target. A layout pattern for an image to be transferred to a target is converted into a holographic representation of the image. A hologram reticle is manufactured that includes the holographic representation. The hologram reticle is then used to pattern the target. Three-dimensional patterns may be formed in a photoresist layer of the target in a single patterning step. These three-dimensional patterns may be filled to form three-dimensional structures or else used in a multi-surface imaging composition. The holographic representation of the image may also be transferred to a top photoresist layer of a top surface imaging (TSI) semiconductor device, either directly or using the hologram reticle. The top photoresist layer may then be used to pattern an underlying photoresist layer with the image. The lower photoresist layer is used to pattern a material layer of the device.

Owner:TAIWAN SEMICON MFG CO LTD

Computer-generated hologram fabrication process, and hologram-recorded medium

Owner:DAI NIPPON PRINTING CO LTD

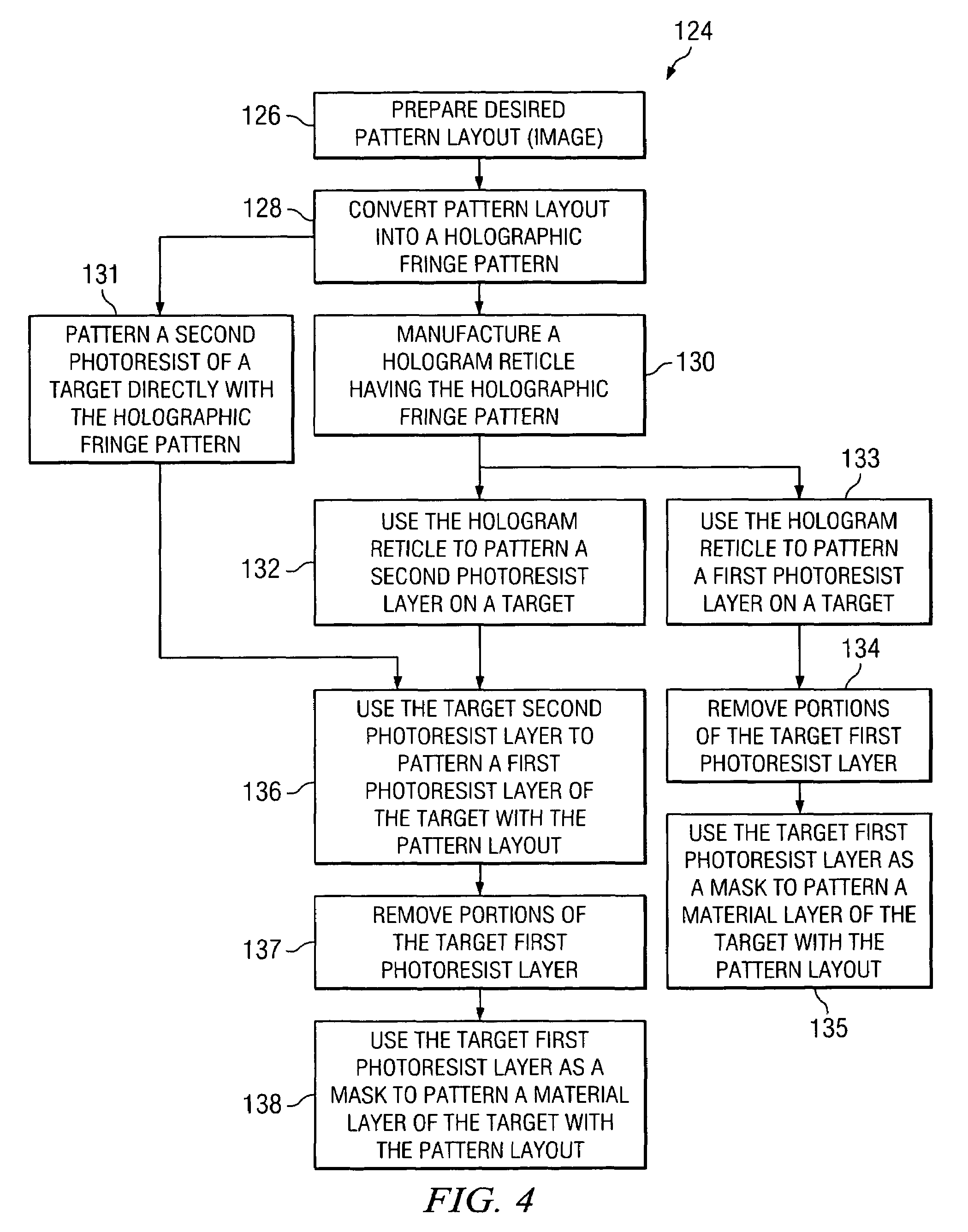

Structured Diamond Tool Made by Focused Ion Beam Nanomachining

ActiveUS20080149474A1Shorten the timeImprove accuracyVacuum evaporation coatingSputtering coatingGratingIon beam

A structured diamond tool having a predefined grayscale grating profile shape allows a corresponding grayscale grating profile to be machined into a work piece with a single pass with high accuracy. Manufacture of grayscale gratings using this technique saves time compared to the situation where the profile is machined by a single-point diamond tool with multiple passes. Also, more time-saving is realized if more than one period is machined in the diamond tool. Such a tool can be manufactured using a high precision focused ion beam (FIB), which is a true nanomachining tool that can machine features on the order of tens of nanometers. The diamond tool made by FIB therefore has extremely fine resolution and features required by the grayscale grating.

Owner:PANASONIC CORP

Method of producing diffractive structures in security documents

InactiveUS7871741B2Quick buildStrong of laser radiationRadiation applicationsPhotomechanical apparatusPaper documentDocument preparation

A method of producing a security document or article including a substrate (100), which is transparent at least to visible light, and a diffractive optical microstructure (112). The method includes applying an opacifying layer (102) to at least one surface of the transparent substrate (100). An area of the opacifying layer (102) is exposed to laser radiation (108) to ablate apertures (110) in selected portions of the opacifying layer (102), thereby forming a diffractive optical microstructure (112) on the surface of the substrate (100). The laser radiation may be patterned prior to exposing the opacifying layer (102), for example by passing the radiation through a mask (104). Alternatively, a focussed or collimated laser beam (206) may be directed onto the selected portions of the opacifying layer (102). Laser radiation may be directed onto the opacifying layer (102) either directly, or through the transparent substrate (100). Security documents or articles made in accordance with the method are also provided.

Owner:CCL SECURE PTY LTD

Holographic reticle and patterning method

InactiveUS7312021B2Reduce needLow costPhotomechanical apparatusHolographic object characteristicsPhotoresistSemiconductor

A hologram reticle and method of patterning a target. A layout pattern for an image to be transferred to a target is converted into a holographic representation of the image. A hologram reticle is manufactured that includes the holographic representation. The hologram reticle is then used to pattern the target. Three-dimensional patterns may be formed in a photoresist layer of the target in a single patterning step. These three-dimensional patterns may be filled to form three-dimensional structures. The holographic representation of the image may also be transferred to a top photoresist layer of a top surface imaging (TSI) semiconductor device, either directly or using the hologram reticle. The top photoresist layer may then be used to pattern an underlying photoresist layer with the image. The lower photoresist layer is used to pattern a material layer of the device.

Owner:TAIWAN SEMICON MFG CO LTD

Calculation method, recording method, optical film, and phase modulation structure

ActiveUS20190293492A1Reduce computing timeOptical measurementsHolographic object characteristicsPhase modulationCalculation methods

A phase modulation structure includes a recording surface including phase angle recording regions in a plurality of calculated element regions corresponding to reconstruction points of an image on a one-to-one basis, each phase angle recording region being formed of a plurality of unit blocks in each of which a phase angle is recorded, the phase angle being calculated based on a phase that is a sum of a plurality of phases of light from the corresponding reconstruction points; and a representative area that is one of divisions of the calculated element region, the representative area being obtained by radially dividing the calculated element region centered on a point on the calculated element region, the point being obtained by extending a normal line from the corresponding reconstruction point to the calculated element region on the recording surface.

Owner:TOPPAN PRINTING CO LTD

Holographic projection real-time 3D display system and method

ActiveUS8890932B2Restore complex wavefrontsStereoscopic photographyHolographic writing meansWavefrontSpatial spectrum

A real-time color holographic three-dimensional (3D) display system and method realized by using principles of digital holographic display and a common photographing / projection device array system are provided. For an object O to be displayed, an array of M×N cameras which are anchored to a certain reference point R in a space corresponding to the object O is used to perform spatial spectrum sampling and capturing on any spatial spectrum surface S of the object O with a sampling density being a spatial sampling angle ωmn. Each acquired spatial spectrum view image Imn is projected by a corresponding array of M×N projectors in each spatial spectrum capturing direction to a reference surface PR necessary for restoring 3D information of the original object O. Output of full spatial spectrums of the object O is realized through a spatial spectrum limited stretching function of a holographic functional screen placed on the reference surface PR which is used on discrete spatial spectrum input image information, thereby achieving digital holographic display intended to restore complex wavefronts.

Owner:AFC TECH

A method of manufacturing a holographic double blazed grating

ActiveCN102323634BAvoid secondary photoresist lithography processEasy to controlPhotomechanical apparatusDiffraction gratingsBlazed gratingGrating

The invention relates to a method for manufacturing a holographic double blazed grating. The two blaze angles of the holographic double blazed grating are A blaze angle and B blaze angle respectively. The homogeneous grating is used as a mask for oblique ion beam etching to achieve different control of the two blaze angles, avoiding the secondary photoresist lithography process. Since the time of forward ion beam etching can be controlled when making the homogeneous grating, the groove depth of the homogeneous grating can be precisely controlled. In addition, since the homogeneous grating mask and the substrate are formed of the same material, the etching time of the two The eclipse rate remains consistent throughout, allowing precise control of the blaze angle.

Owner:SUZHOU UNIV

Structured diamond tool made by focused ion beam nanomachining

ActiveUS8709219B2Improve featuresHigh resolutionVacuum evaporation coatingOptical articlesGratingImage resolution

A structured diamond tool having a predefined grayscale grating profile shape allows a corresponding grayscale grating profile to be machined into a work piece with a single pass with high accuracy. Manufacture of grayscale gratings using this technique saves time compared to the situation where the profile is machined by a single-point diamond tool with multiple passes. Also, more time-saving is realized if more than one period is machined in the diamond tool. Such a tool can be manufactured using a high precision focused ion beam (FIB), which is a true nanomachining tool that can machine features on the order of tens of nanometers. The diamond tool made by FIB therefore has extremely fine resolution and features required by the grayscale grating.

Owner:PANASONIC CORP

Method for producing resist substrates

InactiveCN1754128AHigh accelerating voltageLarge beam widthElectric discharge tubesRadiation applicationsResistSecondary electrons

The invention relates to a method for producing a substrate provided with a resist layer in the form of a relief structure comprising a diffraction structure. Said resist layer interacts with at least areas provided with a conductive layer which diffuses primary electrons and / or produces secondary electrons when the resist layer is exposed to an electron beam effect. For the inventive method, the material of the resist and conductive layers and exposition parameters are co-ordinated therebetween in such a way that the resist layer is also exposed outside the area exposed to the electron beam in such a way that the lateral parts of the relief structure hold an inclined shape.

Owner:GIESECKE & DEVRIENT GMBH

Hologram three-dimensional image information collecting device and method, reproduction device and method

ActiveCN101939703BRealize holographic three-dimensional displayStereoscopic photographyHolographic writing meansOptical axisSample image

A hologram three-dimensional image information collecting device and method, a reproducting device and method are disclosed. The collecting device comprises M*N two-dimensional image picking-up units Cmn to obtain M*N spatial spectrum sample images of an object O being three-dimensional displayed on an arbitrary spatial spectrum S (2); each sample point Smn corresponds to a body pixel Hmn of the object O; the information obtained by each two-dimensional image picking-up units Cmn corresponds to the spatial spectrum image Imn of the body pixel Hmn; thus, M*N sample spatial spectrum images information of the object O in an array is obtained; M*N two-dimensional image picking-up units Cmn are arranged on the spatial spectrum surface S (2) in a predetermined space sample angle Omegamn with their light axis focus on one reference point R in a corresponding space of the object O; each two-dimensional image picking-up unit Cmn focuses on a visual surface of the object O in the corresponding spatial spectrum direction to obtain a clear spatial spectrum image Imn in the direction; wherein, M, N, m and n are natural numbers and at least one of M and N is larger than 2.

Owner:AFC TECH

Electron diffraction holography

ActiveUS11460419B2Electric discharge tubesMaterial analysis by optical meansLight beamParticle physics

Methods for using electron diffraction holography to investigate a sample, according to the present disclosure include the initial steps of emitting a plurality of electrons toward the sample, forming the plurality of electrons into a first electron beam and a second electron beam, and modifying the focal properties of at least one of the two beams such that the two beams have different focal planes. Once the two beams have different focal planes, the methods include focusing the first electron beam such that it has a focal plane at or near the sample, and focusing the second electron beam so that it is incident on the sample, and has a focal plane in the diffraction plane. An interference pattern of the first electron beam and the diffracted second electron beam is then detected in the diffraction plane, and then used to generate a diffraction holograph.

Owner:FEI CO

Integrated three dimensional display and method of recording identification information

ActiveUS20210250569A1Information can be usedRecord information storageAdvertisingMechanical engineeringMonochrome

An integrated three-dimensional display includes a recording surface which includes a calculated element region in which phase components of light from light converging points of a holographic reconstructed image are calculated, and a phase angle recorded area for recording a phase angle calculated based on the phase components. The phase angle recorded area includes a plurality of monochromatic regions having a uneven structure surface. The phase angle is recorded in an overlap area in which the calculated element region and the phase angle recorded area overlap each other. Light converges on the light converging points at specific distances from the recording surface, the specific distances being determined for the respective light converging points even when light reflected from the plurality of monochromatic regions converges.

Owner:TOPPAN PRINTING CO LTD

Apparatus and method for displaying holographic three-dimensional image

ActiveUS9436159B2Active addressable light modulatorHolographic writing meansInformation control3d image

An apparatus for displaying a holographic three-dimensional (3D) image is provided. The apparatus includes: a holographic pattern generation unit; a spatial optical modulation device including a phase transition layer formed of a phase transition material, a phase of which is changed by a temperature. A holographic pattern generated by the holographic pattern generation unit is optically addressed on the spatial optical modulation device. The apparatus also includes a heat source for applying heat to the phase transition layer; a control unit for controlling the heat source according to holographic pattern information generated by the holographic pattern generation unit; and a reproduction light source for irradiating light for image reproduction onto the spatial optical modulation device.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com