Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Sulbenicillin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

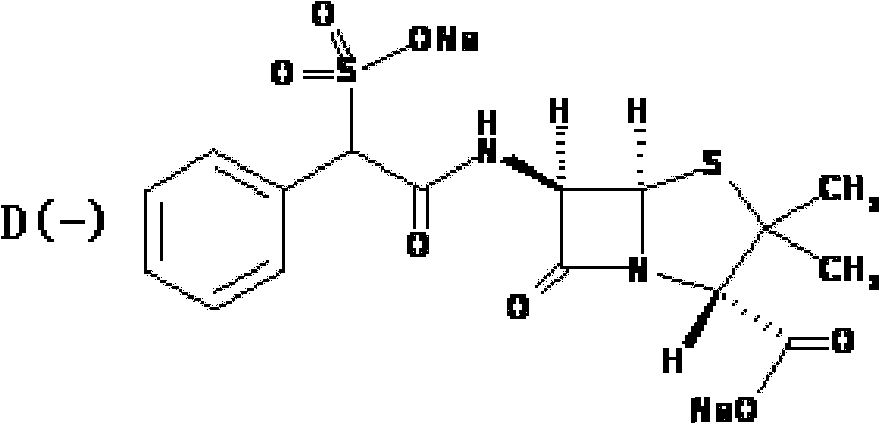

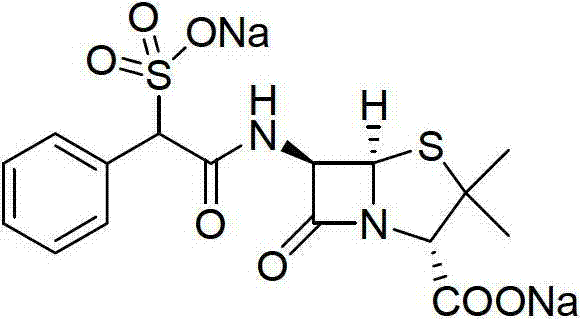

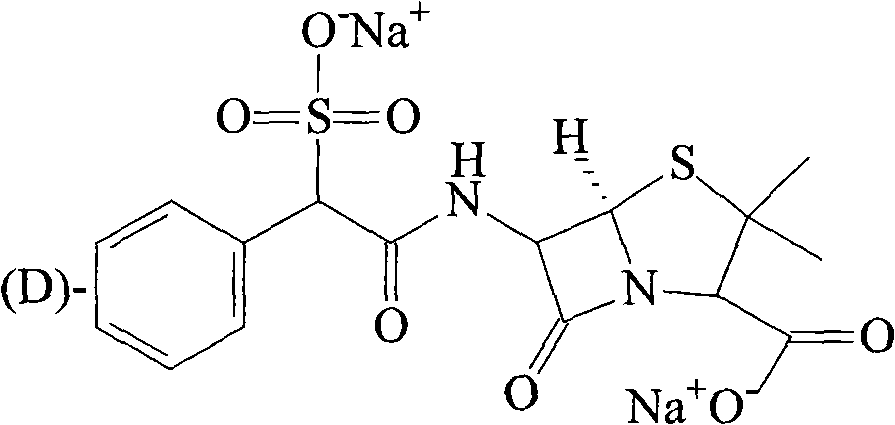

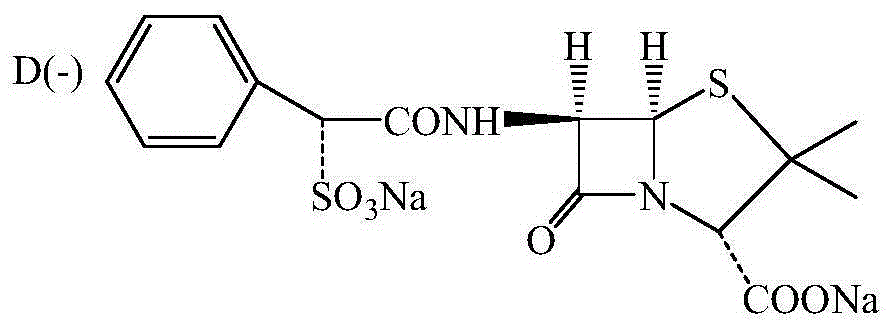

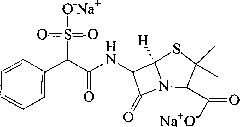

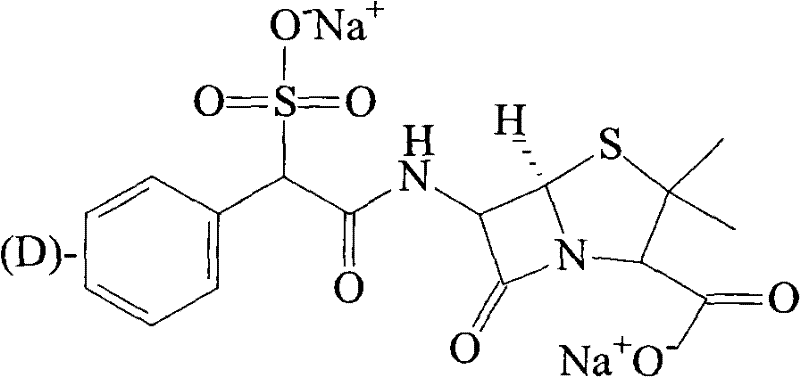

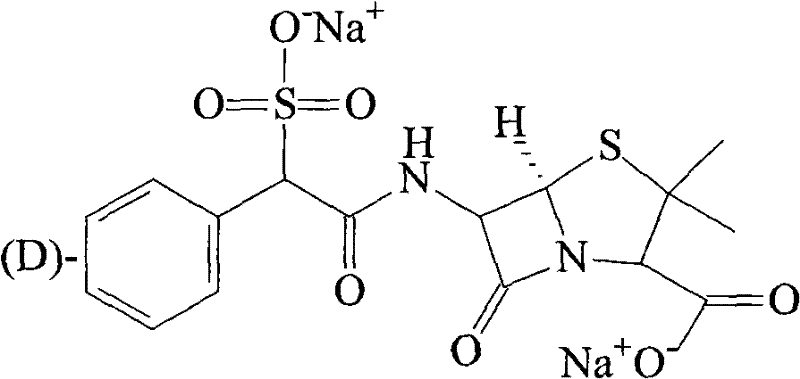

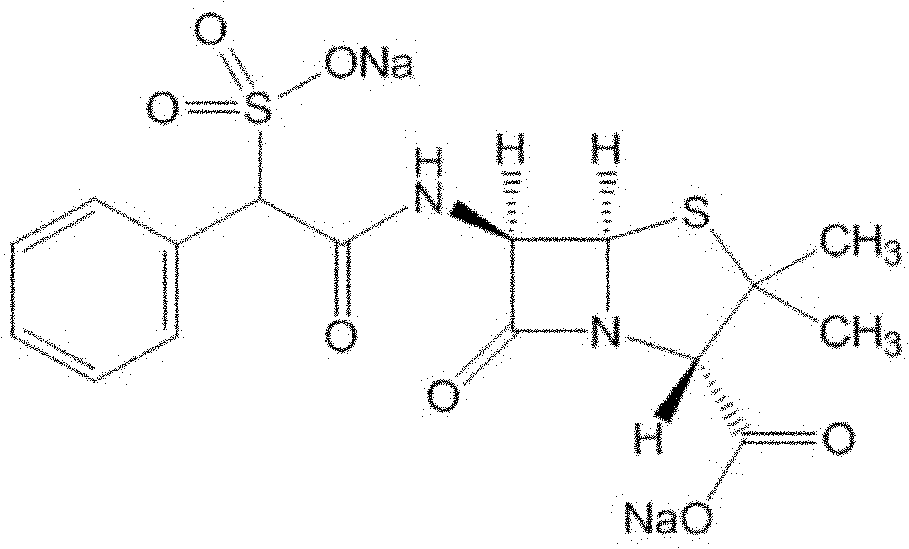

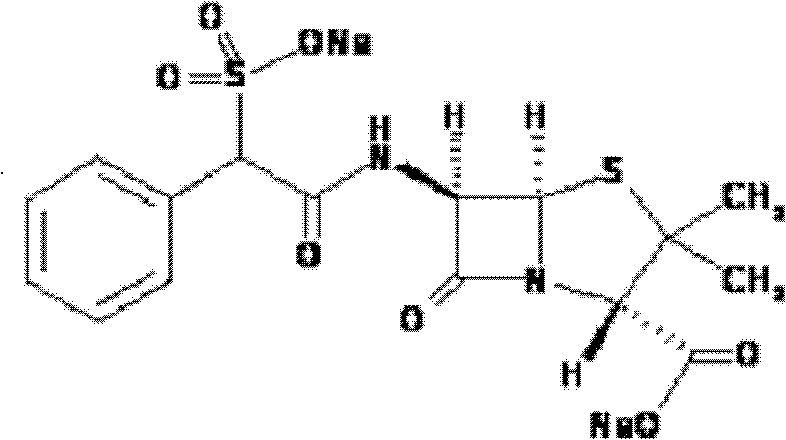

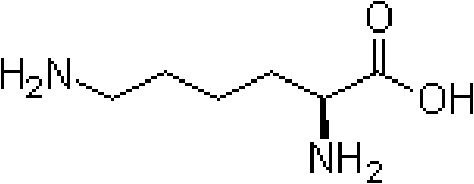

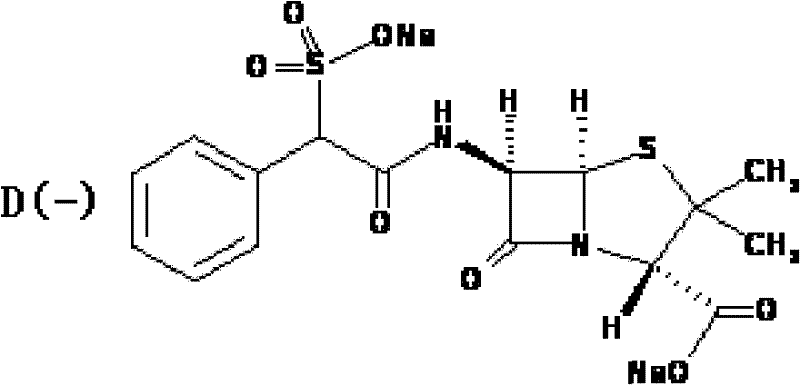

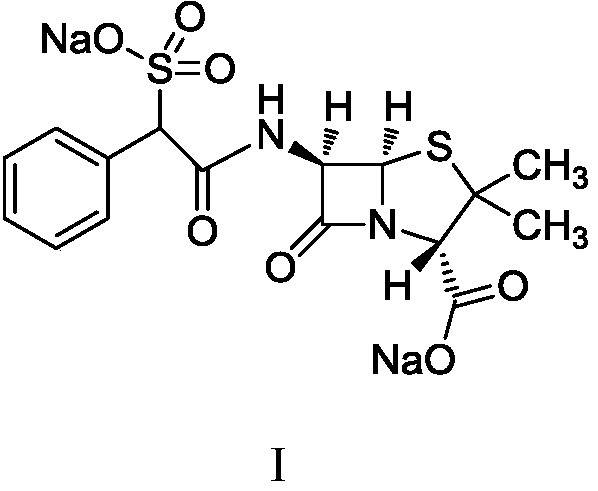

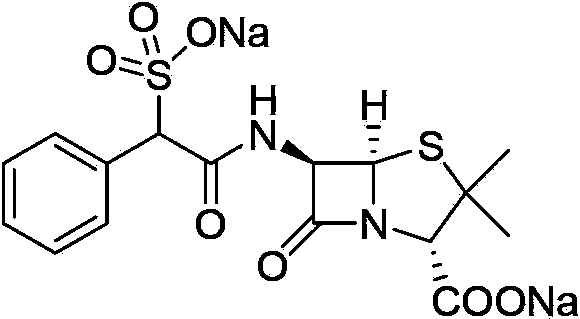

Sulbenicillin (INN) is a penicillin antibiotic. It has been used in combination with dibekacin.

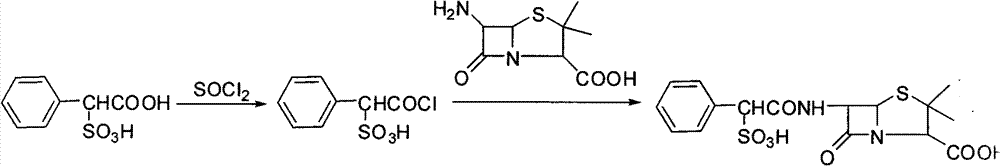

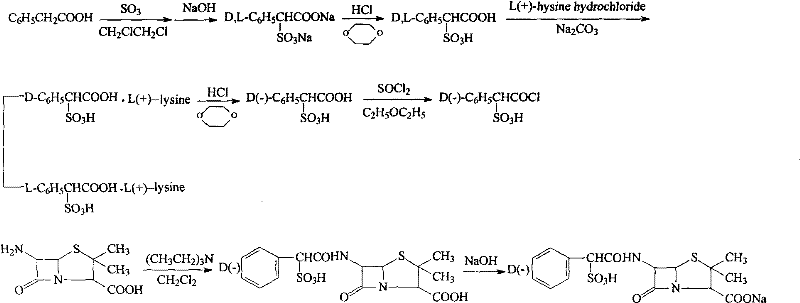

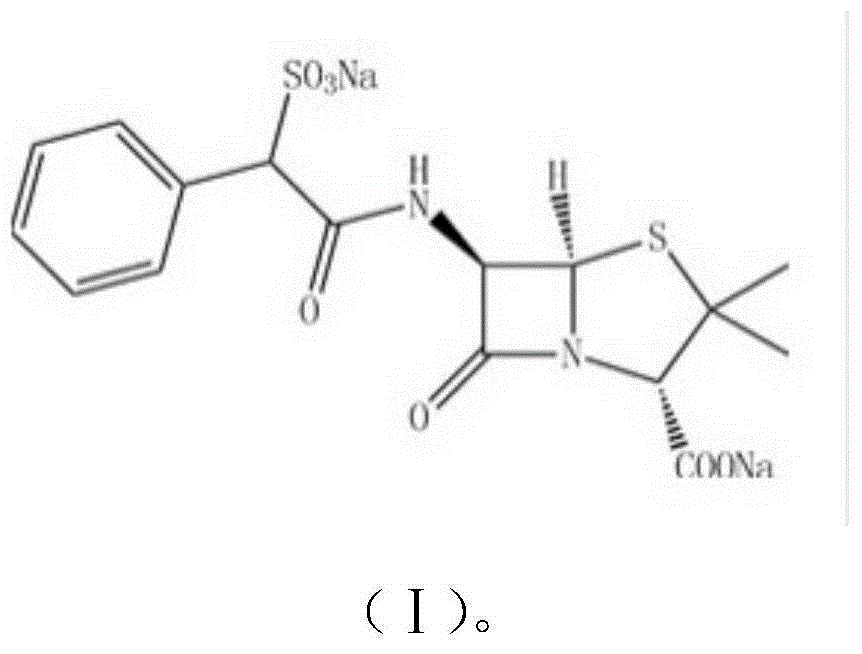

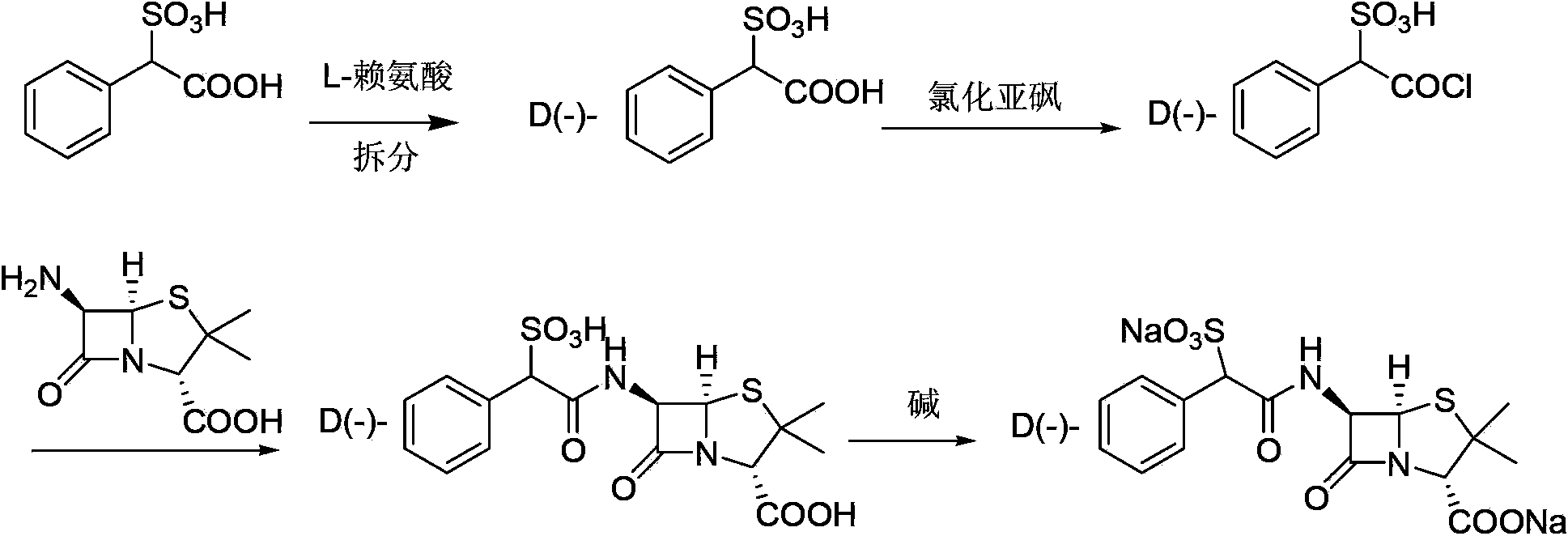

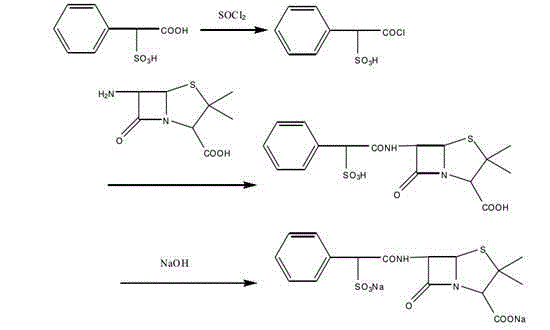

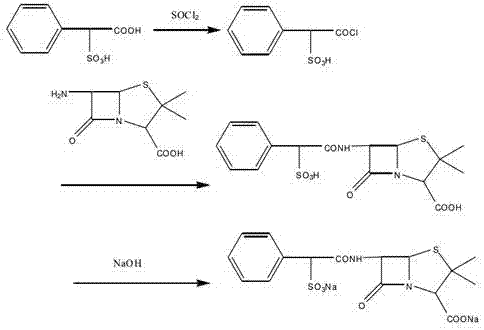

Preparation method of D(-)-sulbenicillin sodium

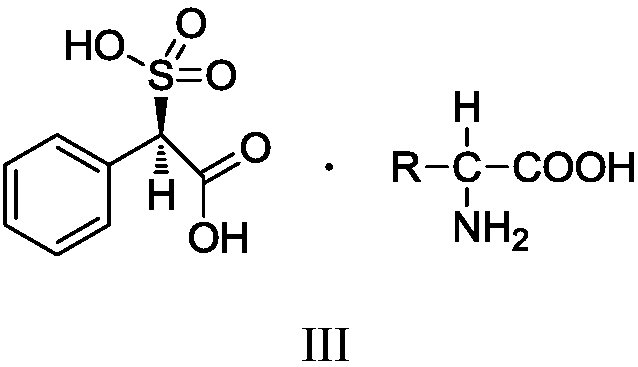

The invention provides a preparation method of D(-)-sulbenicillin sodium, which comprises the following steps: preparing D(-)-sulfophenylacetyl chloride from D(-)-sulfophenylacetic acid; preparing a D(-)-sulbenicillin sodium crude product from the D(-)-sulfophenylacetyl chloride and 6-APA; and purifying to obtain the final product D(-)-sulbenicillin sodium, wherein the 6-APA and the D(-)-sulfophenylacetyl chloride are added to a mixed solvent of water, ethanol and 2-methyltetrahydrofuran and react at the pH of 5.6-7.0 and the room temperature of 15-25 DEG C for 20-40 minutes. The preparation method has mild reaction condition, high yield and high purity of the obtained product.

Owner:HUNAN SANQING PHARMA +1

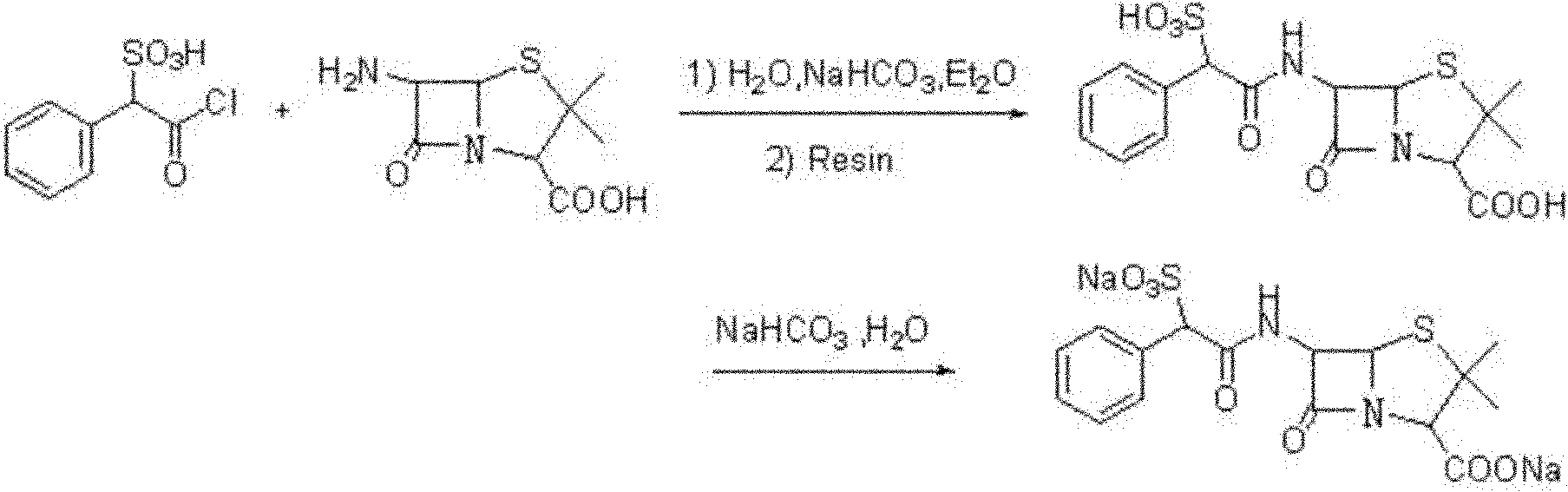

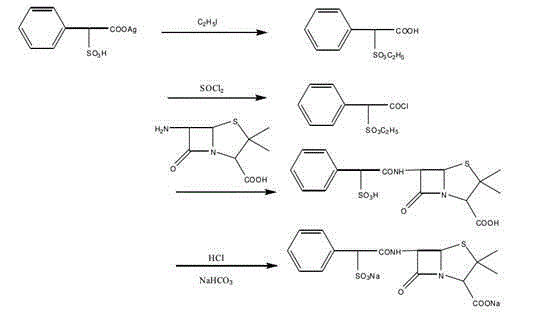

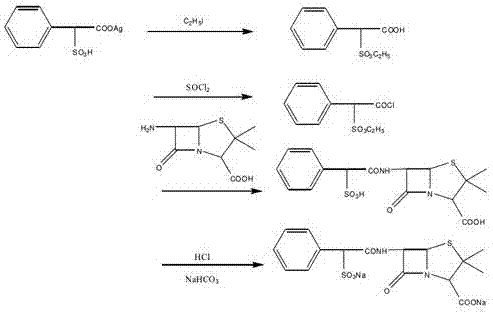

Method for preparing sulbenicillin disodium

The invention provides a method for preparing sulbenicillin disodium. The method comprises the following steps of: preparing alpha-sulfophenylacetyl chloride from alpha-sulfophenylacetic acid; reacting the alpha-sulfophenylacetyl chloride with 6-aminopenicillanic acid (APA) in the mixed solvents of water, ethanol and tetrahydro-2-methylfuran under the condition of the pH value of 5.6 to 7.0 and the temperature of 15 to 25 DEG C for 20 to 40 minutes to obtain crude sulbenicillin disodium; and obtaining the aqueous solution of the sulbenicillin disodium by post treatment and then cooling and drying the aqueous solution of the sulbenicillin disodium to obtain the final product, namely the sulbenicillin disodium. The method has the advantages of reducing energy consumption and saving production cost along with simple process, mild reaction condition and high yield.

Owner:HUNAN SANQING PHARMA +1

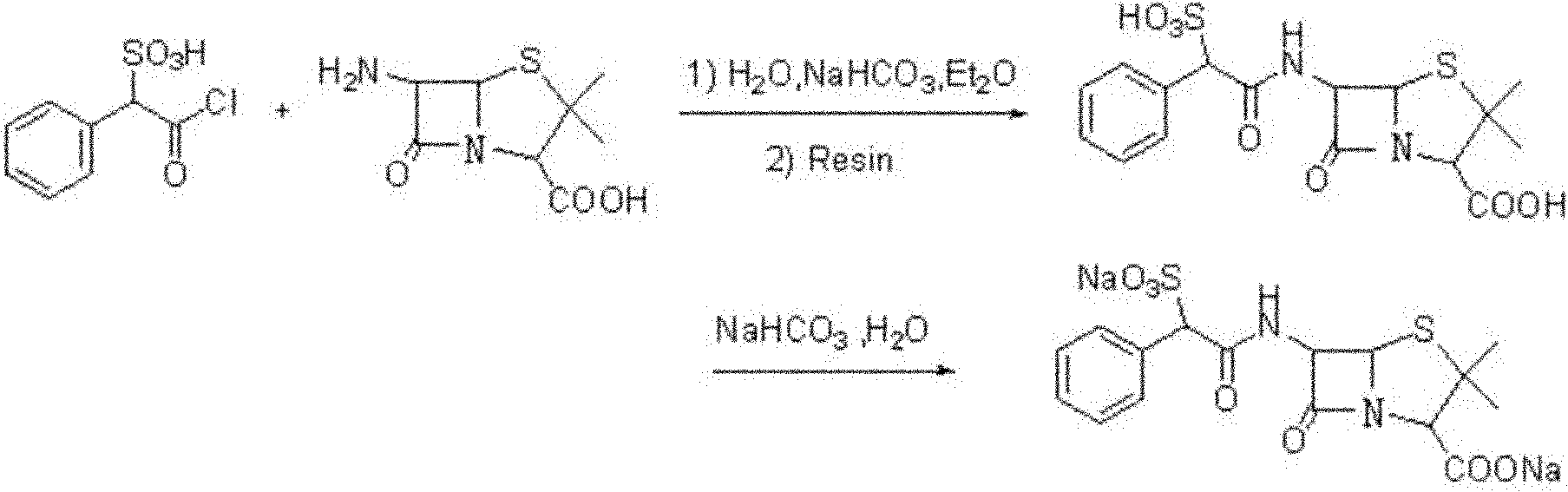

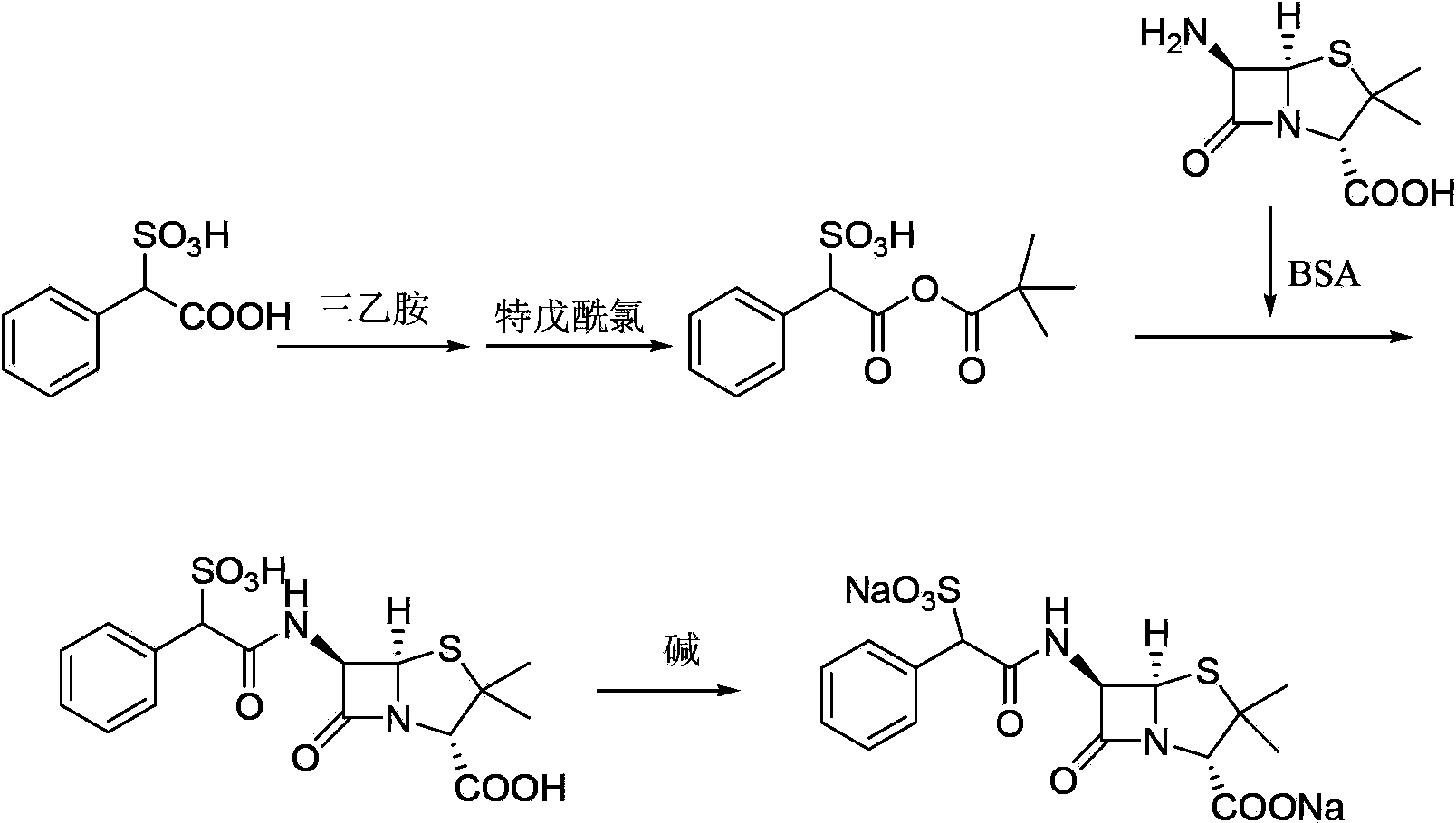

Sulbenicillin sodium preparation method

ActiveCN103319502ALow cost and readily availableEasy to removeOrganic chemistrySulbenicillinOrganic solvent

The invention discloses a sulbenicillin sodium preparation method, and belongs to the technical field of medicine. According to the preparation method, alpha-sulfophenylacetic acid reacts with chloroformate to produce a mixed anhydride, 6-APA and an organic alkali are subjected to salt formation, and then dissolved in an organic solvent, the obtained material is subjected to a condensation reaction in the mixed anhydride solution, acidification liquid separation is performed after completing the reaction, the organic phase is retained, and sodium2-ethylhexanoate is added to the organic phase to carry out salt formation to obtain the sulbenicillin sodium, wherein the sulbenicillin sodium is further subjected to sterile crystallization through a system comprising water, ethanol and acetone to obtain sulbenicillin sodium for injection. The preparation method has characteristics of low cost, good quality and easy operation, and is suitable for industrialization.

Owner:REYOUNG PHARMA

Method for preparing D (-)-sulbenicillin sodium

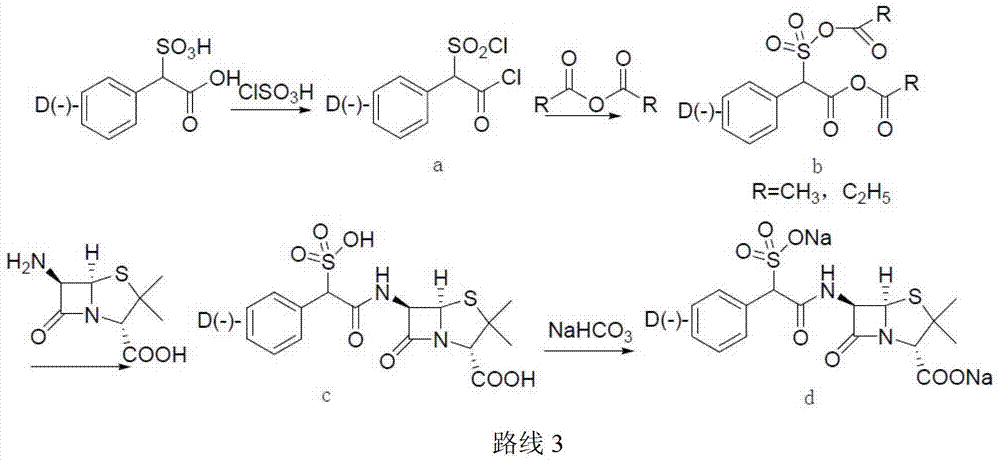

The invention discloses a method for preparing D (-)-sulbenicillin sodium, belongs to the technical field of medicine. The method comprises the following steps that D (-)-sulfophenylacetic acid and chlorosulfonic acid react to generate a compound a, and the compound a and anhydride react to generate a compound b; then the compound b and 6-APA react to obtain D (-)-sulbenicillin; and the D (-)-sulbenicillin and alkali react and then are subjected to freeze-drying to obtain the D (-)-sulbenicillin sodium. Sulfo group and carboxyl group are generated into a mixed anhydride mode at the same time through an intermediate b prepared by the preparation method, the polarity is small, and the solubility in an organic solvent is good. Meanwhile, as the highly-acidic sulfo group is protected, the problem that the pH value in the reaction process is difficultly controlled is solved. The efficiency is increased, and the impurity generation is reduced. The sulbenicillin sodium prepared by the method has high yield and good quality and is easier to industrialize.

Owner:山东安信制药有限公司

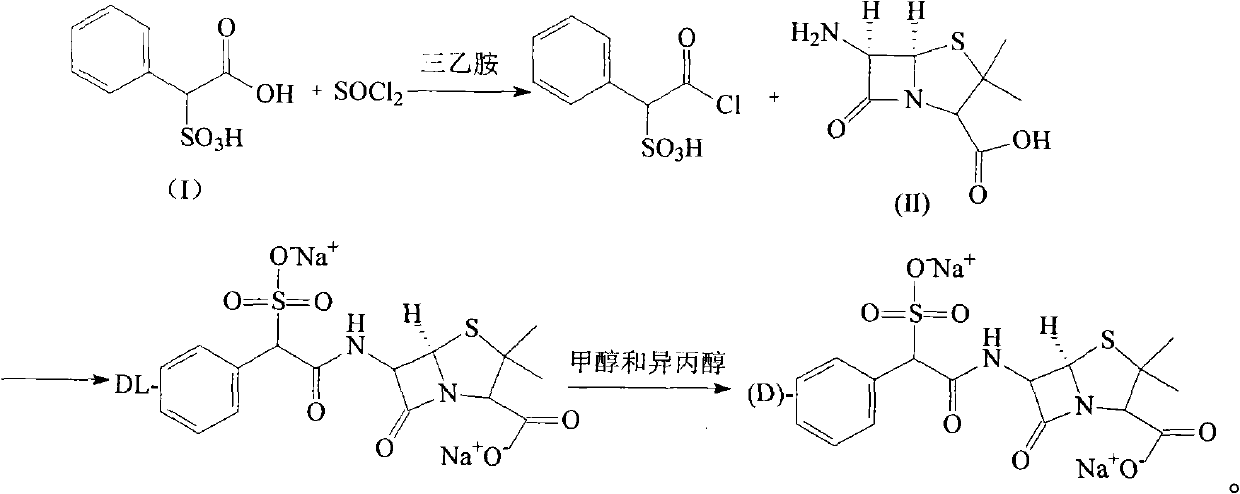

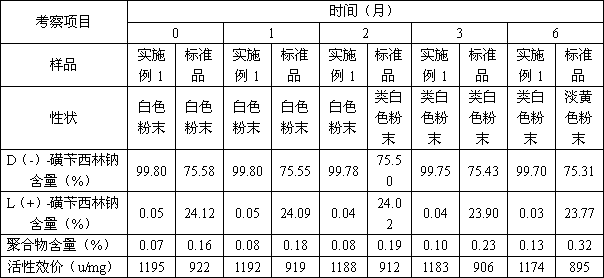

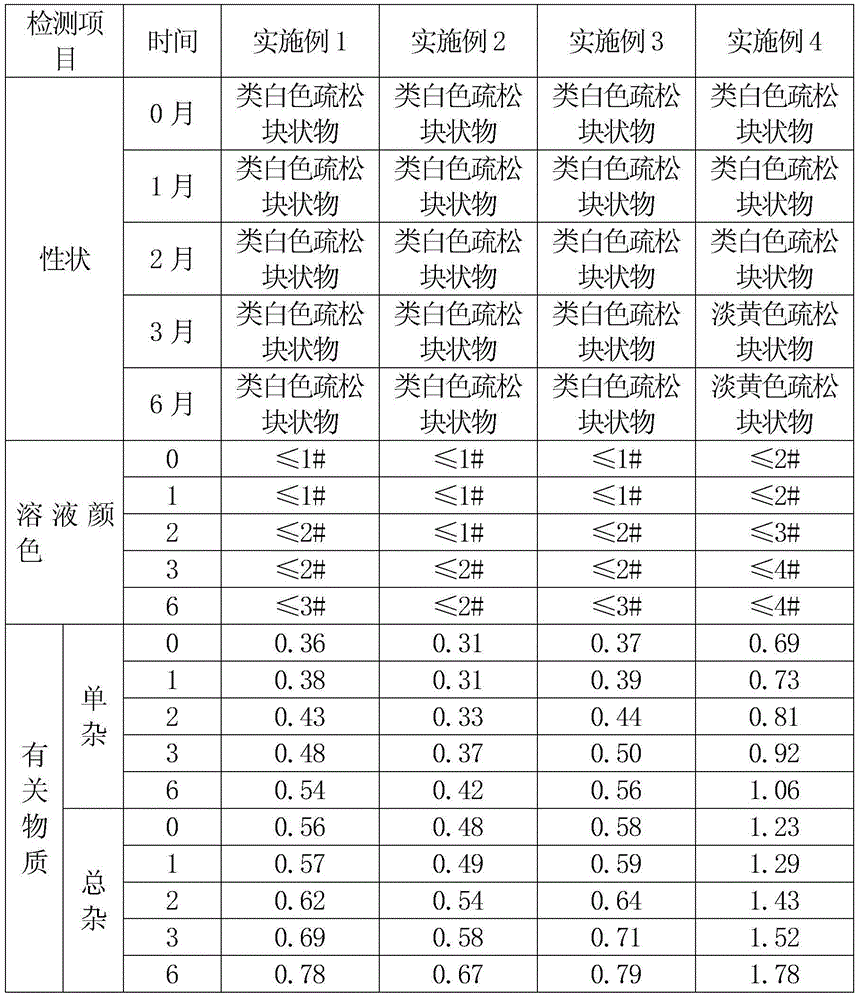

Sulbenicillin sodium compound and new preparation method thereof

The invention relates to a sulbenicillin sodium compound and a new preparation method thereof. A racemic body containing not less than 75% of D-sulbenicillin sodium and not more than 25% of L-sulbenicillin sodium is obtained by a recrystallization method through the differences of dissolubilities of the D-sulbenicillin sodium and the L-sulbenicillin sodium in a mixed solvent of methanol and isopropyl alcohol. The invention has the advantages of simple reaction process, easy operation, low cost, and high product purity.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

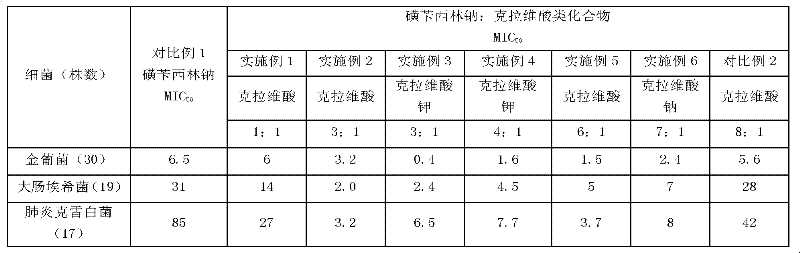

Antibacterial compound drug of sulbenicillin sodium for injection

InactiveCN1732931AInhibitory activityHigh antibacterial activityAntibacterial agentsHeterocyclic compound active ingredientsCompounding drugsSulbenicillin

The invention provides an antibacterial composition of sulbenicillin sodium for injection, which comprises sulbenicillin sodium and sulbactam sodium by the weight ratio of 1-32:1. The antibacterial compound preparation has substantial synergy actions, and can effectively inhibit the reactivity of beta-lactamase.

Owner:张舰

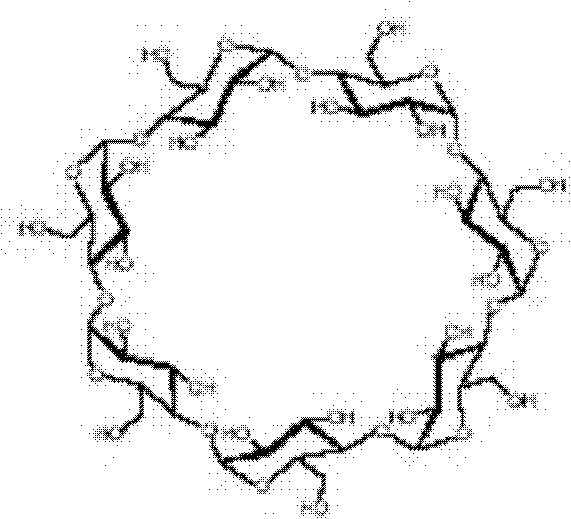

Method for purifying D (-)-sulbenicillin sodium

The invention provides a method for purifying D (-)-sulbenicillin sodium, which comprises the following steps of: mixing a sulbenicillin sodium crude product and water in a weight ratio of (1-10):1, and dissolving; allowing solution to pass through a beta-cyclodextrin membrane-loaded porous ceramic tube at the flow speed of between 1 and 10 dl / second; adding a solvent, stirring until crystals are not precipitated, and cooling at a low temperature; and centrifuging to obtain the D (-)-sulbenicillin sodium. The content of the D (-)-sulbenicillin sodium processed by the method is 99 percent, and the yield is 65 percent; and the method is simple and convenient and low in requirement on equipment, and the cost of generating the D (-)-sulbenicillin sodium is reduced effectively.

Owner:HUNAN ER KANG PHARMA

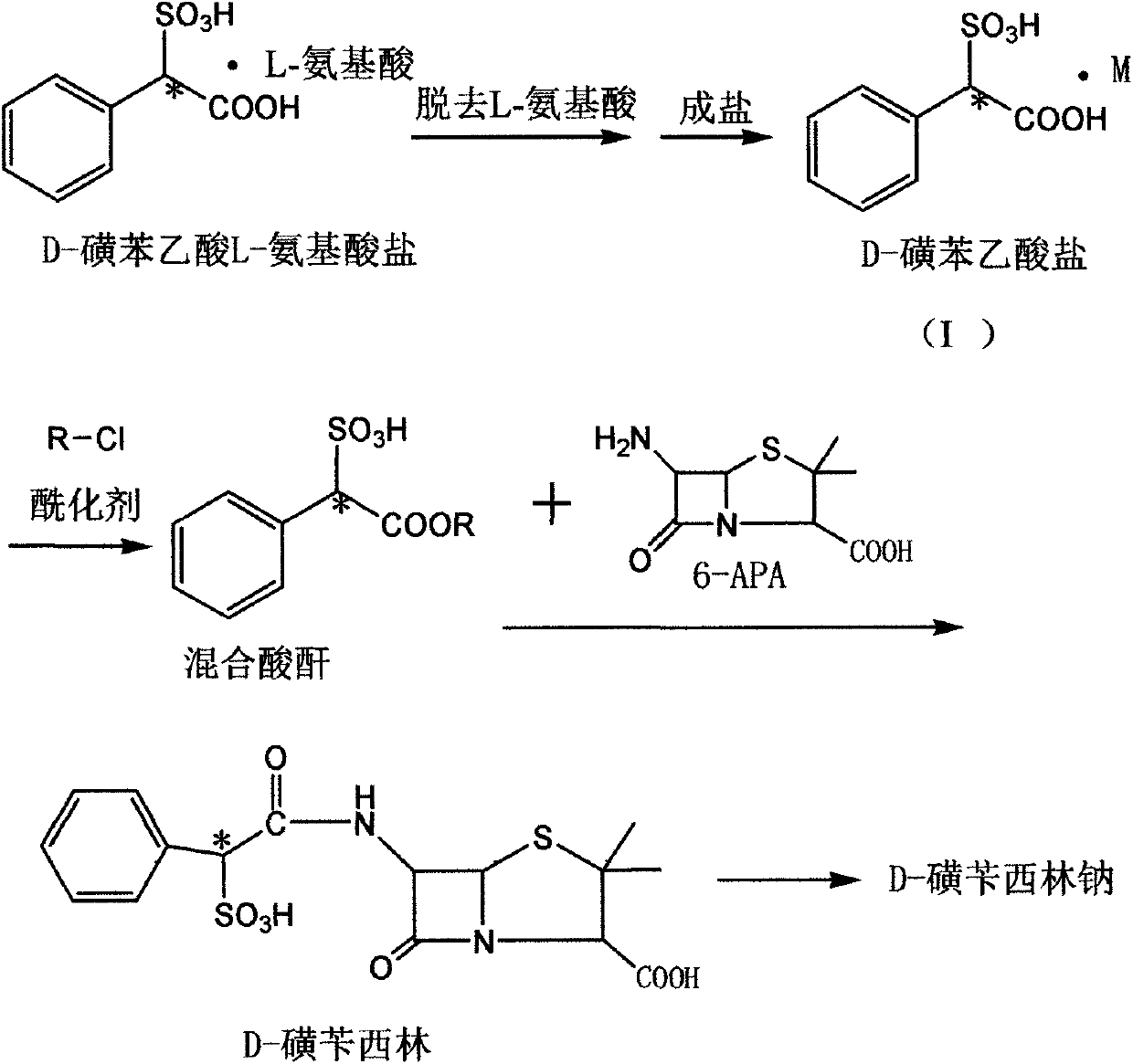

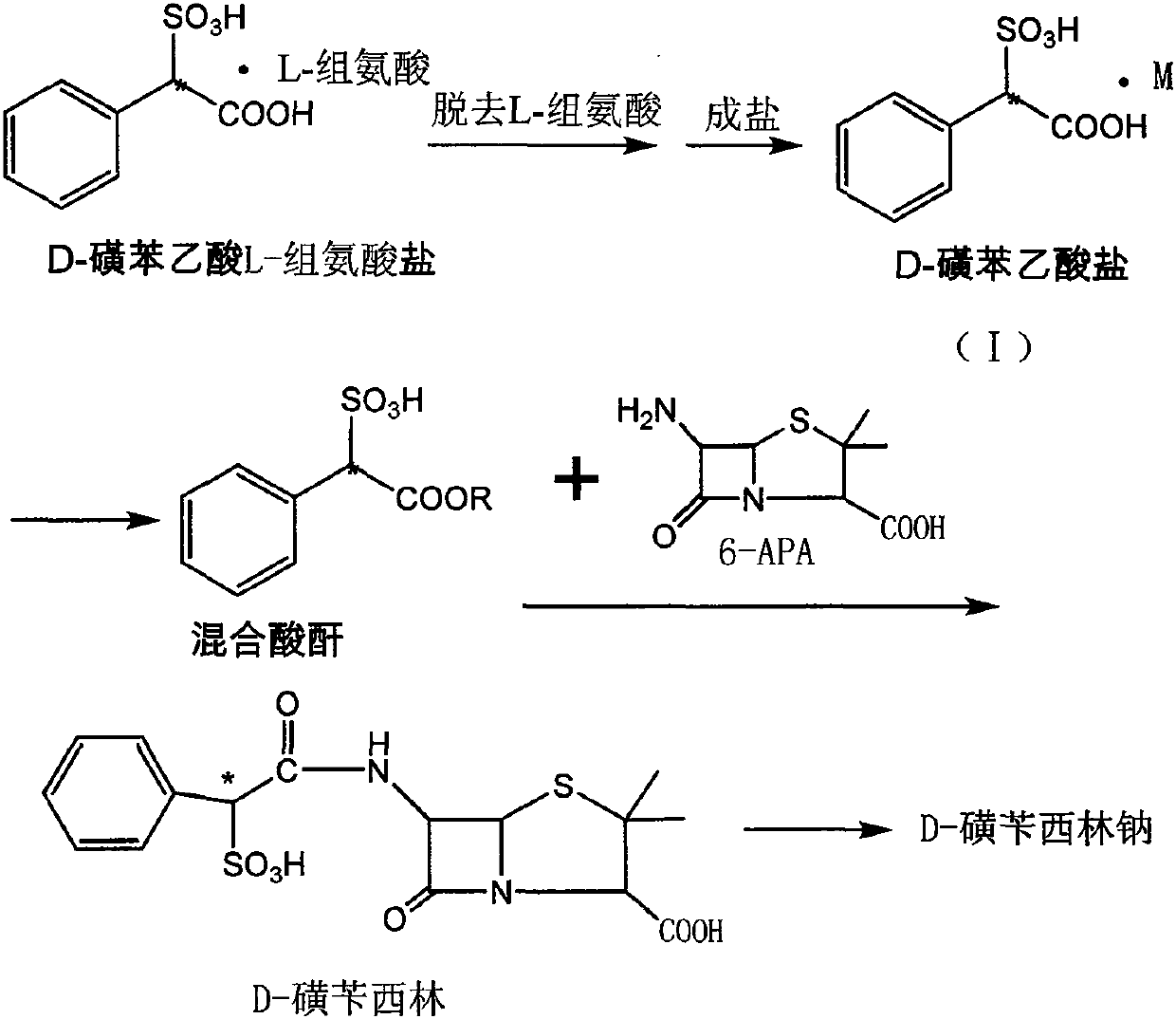

Method for preparing D-sulbenicillin sodium

ActiveCN107641130AAdequate responseIncrease consumptionOrganic chemistrySulbenicillinAfter treatment

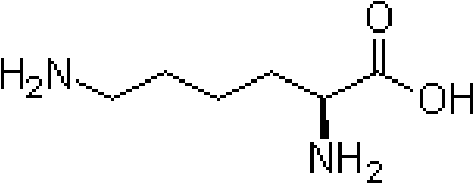

The invention discloses a method for preparing D-sulbenicillin sodium. The method includes steps of removing L-amino acid from L-amino acid salt of D-sulfophenylacetic acid in solvents and carrying out salt forming to obtain D-sulfophenylacetic acid salt; carrying out reaction on the D-sulfophenylacetic acid salt and acylating agents to obtain mixed acid anhydride; dissolving 6-APA in organic solvents under the effect of organic alkali; dropwise adding mixed acid anhydride solution into 6-APA solution, and carrying out sufficient reaction and after-treatment to obtain the D-sulbenicillin sodium. The D-sulfophenylacetic acid is an intermediate. The 6-APA is a matrix. The method has the advantages that the D-sulbenicillin sodium is prepared by the aid of novel synthetic routes, conditions are mild, the method includes stable process and is easy to implement, and the problems of instable processes of existing methods or insufficient optical purity of products and the like can be solved bythe aid of the method.

Owner:CHENGDU UNIV

Preparation method of sulbenicillin sodium

The invention provides a preparation method of sulbenicillin sodium. The preparation method comprises the following steps: condensing sulfophenylacetic acid and acyl chloride to generate mixed anhydride, condensing the mixed anhydride and protected 6-APA under an anhydrous condition, de-protecting to obtain sulbenicillin acid, reacting the obtained sulbenicillin acid with sodium isooctoate to obtain a salt, and crystallizing to obtain sulbenicillin sodium having a purity of above 99.2%. The preparation method has the advantages of simple operation, mild conditions, high yield, low cost and the like, and is suitable for the industrialized production; and the preparation method simultaneously allows the discharge amounts of three wastes to be substantially reduced and the environmental pollution to be small.

Owner:FUAN PHARM (GRP) CO LTD

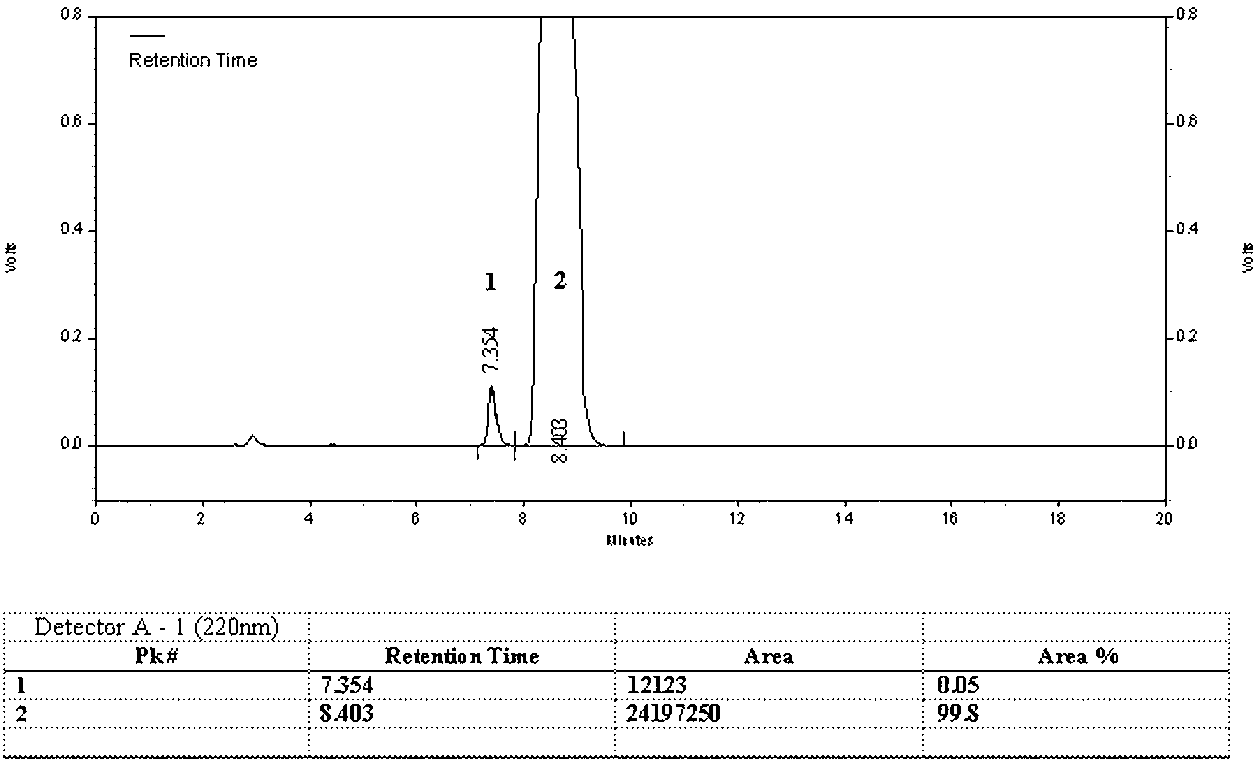

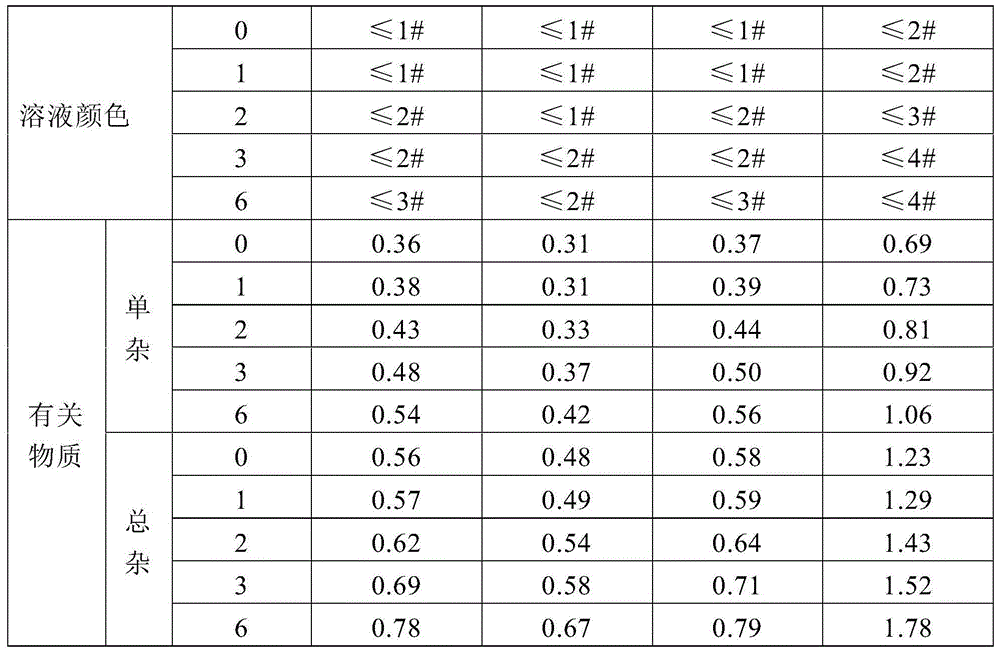

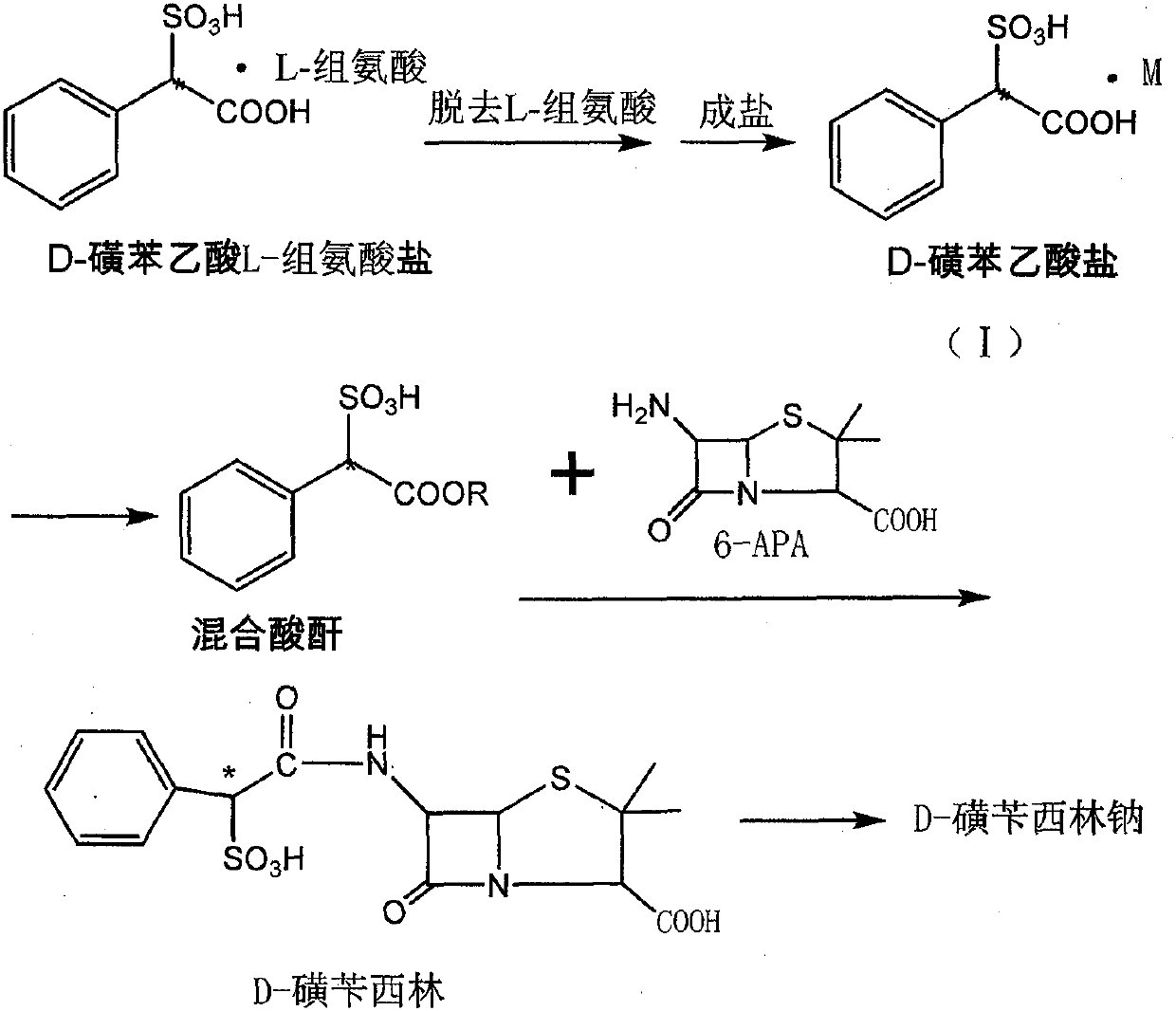

Sulbenicillin sodium injection

InactiveCN103191062AReduce moisture contentImprove stabilityAntibacterial agentsPowder deliveryBiotechnologySulbenicillin

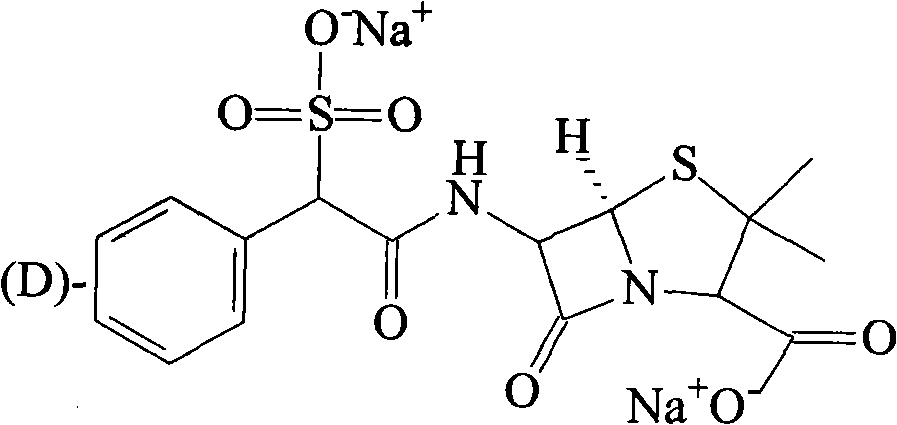

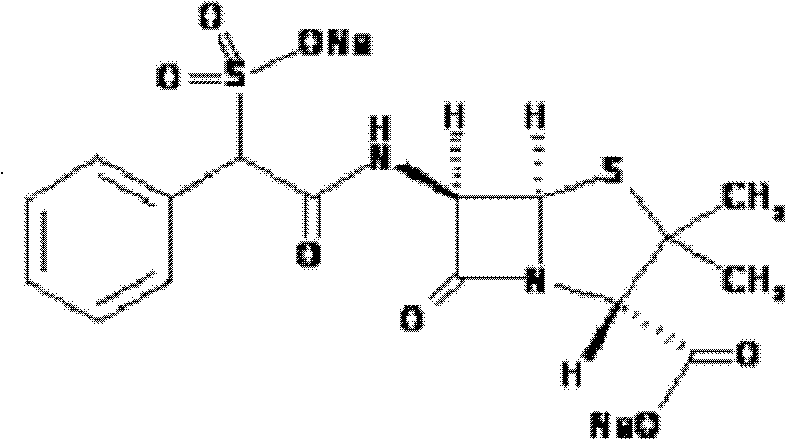

The invention provides sulbenicillin sodium injection. Freeze-dried sterile sulbenicillin sodium is used as a raw material and prepared into a product free of any solid auxiliary material or excipient by virtue of a sterile sub-packaging process; in terms of anhydrous substances, the content of the D(-)-sulbenicillin sodium is bigger than 99%, the content of the L(+)-sulbenicillin sodium is smaller than 0.5%, the content of the sulbenicillin sodium polymer is smaller than 0.3% and the content of moisture is smaller than 5%. Moreover, the sulbenicillin sodium injection has high product purity, strong anti-bacterial activity and good stability, so that medication safety of the human body can be ensured better.

Owner:辽宁科泰生物基因制药股份有限公司

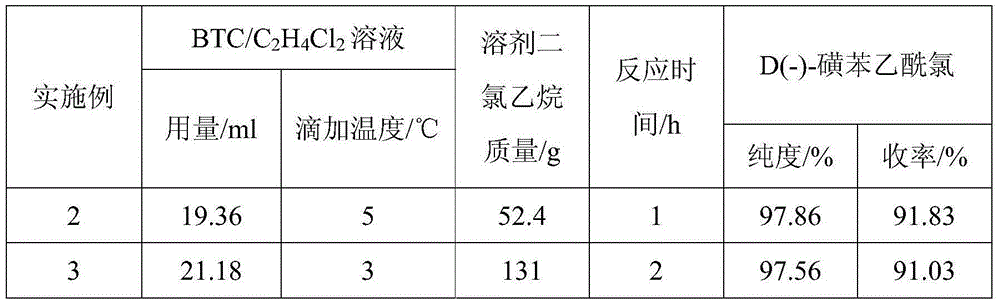

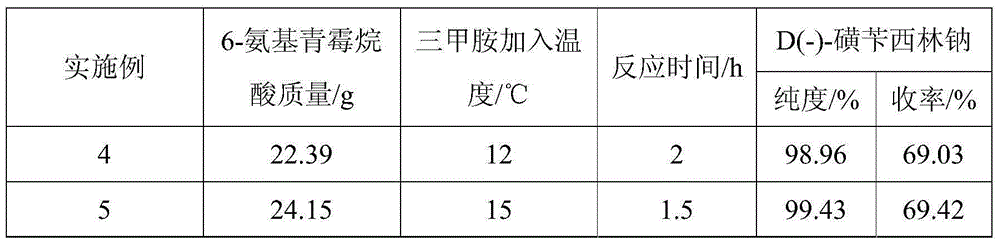

Preparing method for D(-)-sulbenicillin disodium

InactiveCN105218562AImprove reaction efficiencyLess side effectsOrganic chemistryEthane DichlorideSide reaction

The invention provides a preparing method for D(-)-sulbenicillin disodium. The preparing method includes the concrete operation steps that D(-)-sulfophenylacetic acid, dichloroethane and a catalyst dimethylformamide are added into a reaction container, a BTC / C2H4Cl2 solution serves as an acylating chlorination agent, and a dichloroethane solution of D(-)-sulfophenylacetyl chloride is obtained through preparation; D(-)-sulfophenylacetyl chloride and 6-aminopenicillanic acid are prepared into D(-)-sulbenicillin disodium through condensation and refining. The BTC / C2H4Cl2 solution is adopted as the acylating chlorination agent, reaction efficiency is high, the number of side reactions is small, sulfur dioxide pollution is avoided, and the preparing method is of significance in environment-friendly production; acetone and 75% ethyl alcohol are adopted as solvent in the condensation reaction, the pH value is controlled to be seven through trimethylamine, the condensation reaction is carried out at about 10 DEG C, reaction conditions are moderate, the process is simple and easy to operate, the purity and the yield of the obtained D(-)-sulbenicillin disodium are high, and the preparing method is suitable for industrial production.

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD

Sulbenicillin sodium liposome injection

InactiveCN101822640AImprove stabilityHigh encapsulation efficiencyAntibacterial agentsPharmaceutical non-active ingredientsSulbenicillinSide effect

The invention discloses a sulbenicillin sodium liposome injection, which is characterized by comprising the following components in part by weight preferably: 1 part of sulbenicillin sodium, 3 to 5 parts of soya bean lecithin, 0.8 to 2 parts of cholesterol, 0.2 to 1 part of dipalmitoyl phosphatidylethanolamine, 0.1 to 0.5 part of antioxygen and 5 to 10 parts of excipient. The liposome injection prepared by the invention has the advantages of obvious technical effect, high dissolvability and stability, high encapsulating rates, small side effect, high bioavailability and obvious curative effect.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

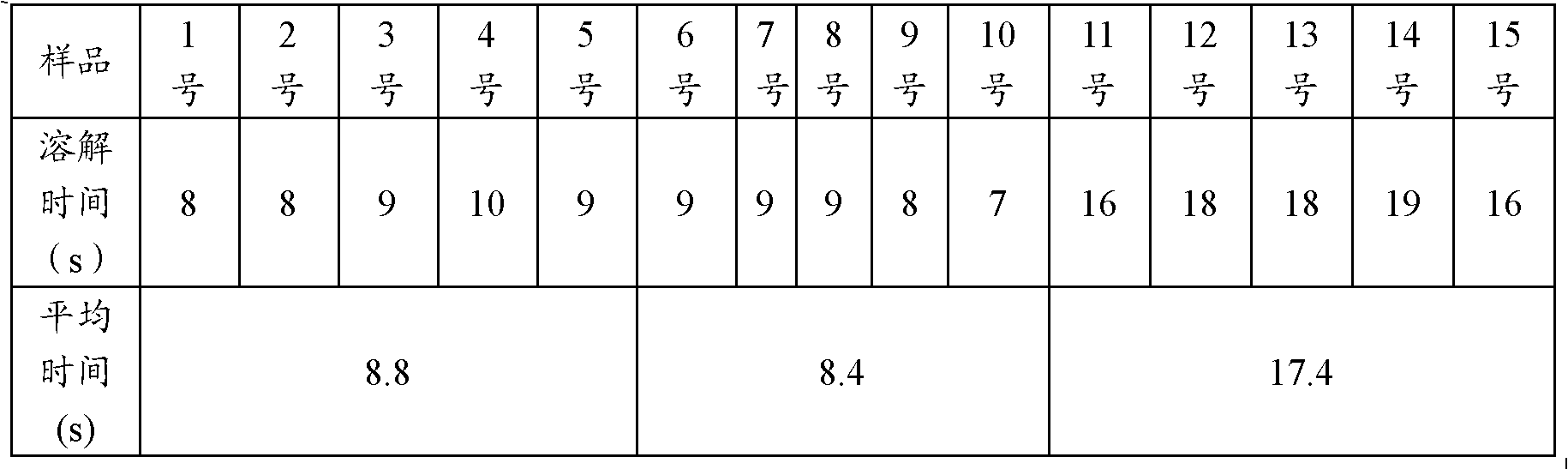

Highly-soluble sulbenicillin sodium colon-targeted starch capsule and preparation method thereof

InactiveCN108201531AMaintain colorMaintain transparencyAntibacterial agentsPharmaceutical non-active ingredientsPatient complianceHard Capsule

The invention provides a highly-soluble sulbenicillin sodium colon-targeted starch capsule and a preparation method thereof. According to the invention, a starch capsule is used and is filled with sulbenicillin sodium, the nested part of a capsule shell is sealed with a sealing material so as to prepare a hard capsule, and the prepared hard capsule is coated with a colon-soluble coating solution;and the colon-soluble coating solution is prepared by mixing a coating material, a coating solvent and a plasticizer. The invention has the following advantages: the prepared highly-soluble sulbenicillin sodium colon-targeted starch capsule has the triple effects of colon targeting performance, rapid disintegration and slow drug release, prolongs the circulation time of oral sulbenicillin sodium in the body and improves the absorption efficiency of sulbenicillin sodium; compared with the prior art where special colon-soluble capsule shells are selected, the highly-soluble sulbenicillin sodiumcolon-targeted starch capsule of the invention is high in filling percentage, and a coating process adopted in the invention is stable in process, easy to operate and suitable for large-scale industrial production; after coating, the starch hard capsule prepared by using the method can maintain the color and transparency of the original capsule and improve patient compliance; and the preparation method does not need special equipment, and is simple in process, easy to operate and low in cost.

Owner:HUNAN ERKANG XIANGYAO PHARMA

Sulbenicillin sodium, and preparation method of preparation thereof

The invention relates to a sulbenicillin sodium monohydrate. The sulbenicillin sodium monohydrate is prepared through a step of dissolving sulbenicillin sodium in water and a step of lyophilizing. A preparation method of the sulbenicillin sodium monohydrate has a high production efficiency, and the sulbenicillin sodium monohydrate has a high purity and a good stability, and is especially suitable for being exploited to form a powder injection.

Owner:SUZHOU ERYE PHARMA CO LTD

Sulbenicillin sodium compound and new preparation method thereof

The invention relates to a sulbenicillin sodium compound and a new preparation method thereof. A racemic body containing not less than 75% of D-sulbenicillin sodium and not more than 25% of L-sulbenicillin sodium is obtained by a recrystallization method through the differences of dissolubilities of the D-sulbenicillin sodium and the L-sulbenicillin sodium in a mixed solvent of methanol and isopropyl alcohol. The invention has the advantages of simple reaction process, easy operation, low cost, and high product purity.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

Antibacterial composite medicine containing sulbenicillin sodium and clavulanic acid compound

InactiveCN102210676AReduce dosageReduce financial burdenAntibacterial agentsPowder deliverySulbenicillinMedicine

The invention provides an antibacterial composite medicine containing sulbenicillin sodium and a clavulanic acid compound, a freeze-dried powder injection containing the antibacterial medicinal composition. The medicine consists of sulbenicillin sodium and a clavulanic acid compound, which are in a weight ratio of (2-7):1. Under the same antibacterial condition, the antibacterial composite medicine provided by the invention reduces medicine dose, economic load of patients and production cost.

Owner:HUNAN ERKANG XIANGYAO PHARMA

Medicinal composition of sulbenicillin sodium for injection and preparation method thereof

ActiveCN102119929AGood resolubilityImprove stabilityAntibacterial agentsPowder deliverySulbenicillinParticle injection

The invention discloses a medicinal composition of sulbenicillin sodium, in particular sulbenicillin sodium nano particle injection. The sulbenicillin sodium nano particle injection consists of sulbenicillin sodium, a carrier material, a stabilizer and an excipient, wherein the effective mean particle size of nano particles is 10 to 200nm. The invention also discloses the preparation method of the injection. The preparation method comprises the following steps of: mixing the sulbenicillin sodium and the stabilizer in water for injection, regulating a pH value, adding the carrier material and the excipient to obtain solution of sulbenicillin sodium nano particles, and freeze-drying to obtain the nano particle injection. The sulbenicillin sodium nano particle injection has the advantages of high resolubility, high stability, high loading rate, high clinical experiment safety and the like, and the process is suitable for industrialized mass production.

Owner:FUAN PHARM (GRP) CO LTD +1

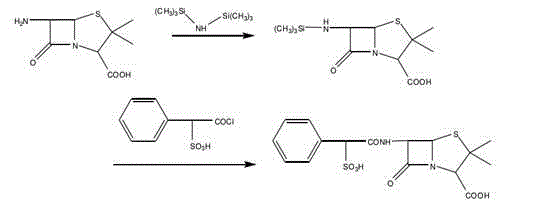

Sulbenicillin sodium and sulbenicillin sodium used for injection

InactiveCN102161667BReduce contentReduce pollutionAntibacterial agentsPowder deliverySulbenicillinPhenylacetic acid

The invention provides a synthesis method of sulbenicillin sodium and sulbenicillin sodium used for injection, which comprises the concrete steps of: using 6-APA and BSA to synthesize an organic salt, and dissolving the organic salt into dichloromethane; using a sulphur phenylacetic acid triethylamine salt and pivaloyl chloride to make mixed anhydride; carrying out anhydrous condensation on the sulphur phenylacetic acid triethylamine salt and the pivaloyl chloride in the dichloromethane; and then forming a sodium salt, free-drying and obtaining a finished product. The new technical process isstable and feasible, better and stable in product quality and strong in operability of production, and reduces the environmental pollution.

Owner:辽宁科泰生物基因制药股份有限公司

Method for purifying D (-)-sulbenicillin sodium

The invention provides a method for purifying D (-)-sulbenicillin sodium, which comprises the following steps of: mixing a sulbenicillin sodium crude product and water in a weight ratio of (1-10):1, and dissolving; allowing solution to pass through a beta-cyclodextrin membrane-loaded porous ceramic tube at the flow speed of between 1 and 10 dl / second; adding a solvent, stirring until crystals are not precipitated, and cooling at a low temperature; and centrifuging to obtain the D (-)-sulbenicillin sodium. The content of the D (-)-sulbenicillin sodium processed by the method is 99 percent, and the yield is 65 percent; and the method is simple and convenient and low in requirement on equipment, and the cost of generating the D (-)-sulbenicillin sodium is reduced effectively.

Owner:HUNAN ER KANG PHARMA

Preparation method of D(-)-sulbenicillin sodium

The invention provides a preparation method of D(-)-sulbenicillin sodium, which comprises the following steps: preparing D(-)-sulfophenylacetyl chloride from D(-)-sulfophenylacetic acid; preparing a D(-)-sulbenicillin sodium crude product from the D(-)-sulfophenylacetyl chloride and 6-APA; and purifying to obtain the final product D(-)-sulbenicillin sodium, wherein the 6-APA and the D(-)-sulfophenylacetyl chloride are added to a mixed solvent of water, ethanol and 2-methyltetrahydrofuran and react at the pH of 5.6-7.0 and the room temperature of 15-25 DEG C for 20-40 minutes. The preparation method has mild reaction condition, high yield and high purity of the obtained product.

Owner:HUNAN SANQING PHARMA +1

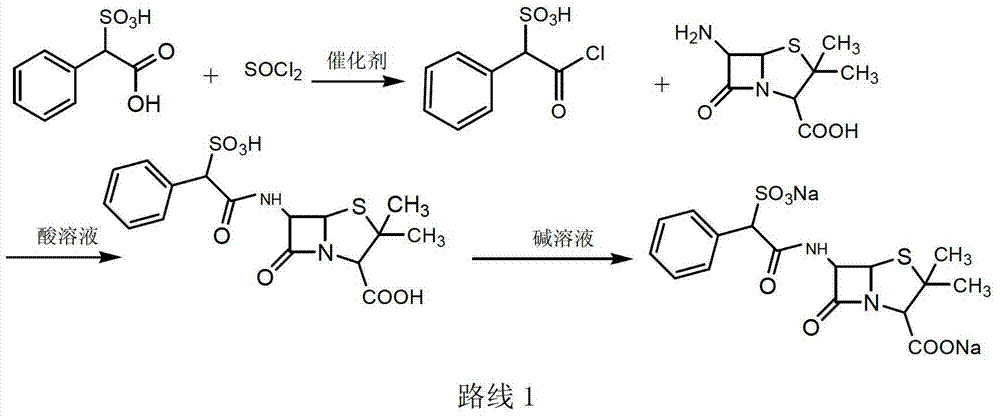

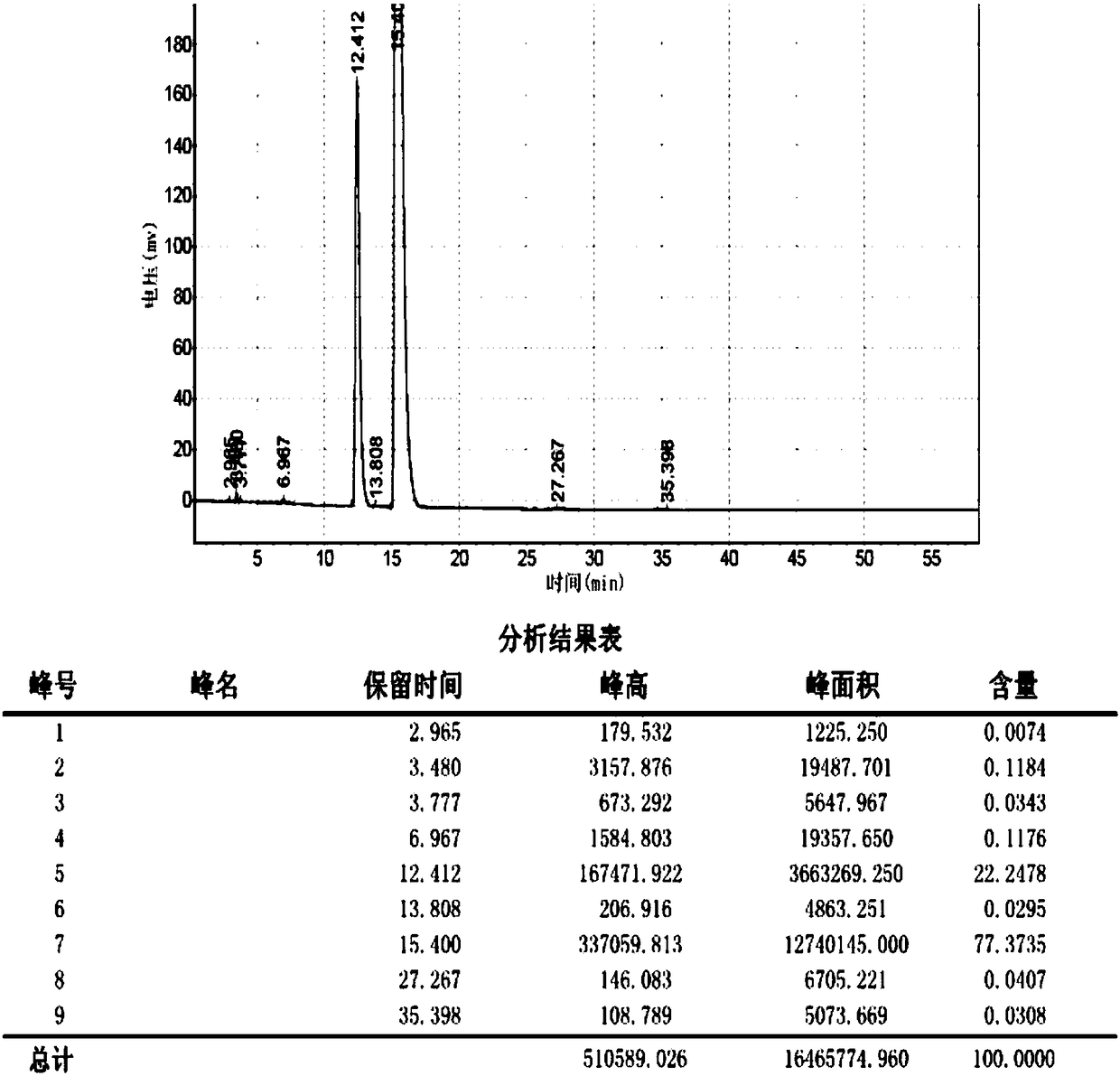

Synthesis process of D-sulbenicillin sodium

The invention relates to a D-sulbenicillin sodium synthesis process, which comprises: S1, weighing water, ethanol and 2-methyltetrahydrofuran, and mixing to obtain a mixed solvent; S2, adding 6-APA into a mixed solvent, keeping the temperature at 15-20 DEG C, adjusting the pH value, increasing the temperature to 23-25 DEG C, carrying out ultrasonic dispersion treatment, and adding an ethyl acetate solution of D-sulfophenylacetyl chloride in a dropwise manner; S3, putting into a pressurized reaction kettle, filling with inert gas, keeping the pressurized pressure at 1.5-2.5 MPa, controlling the temperature at 40-60 DEG C, and reacting for 50-80 minutes; S4, adjusting the pH value, adding n-butyl alcohol, and uniformly mixing; and S5, cooling, dropwise adding a sodium bicarbonate solution, stirring at a constant temperature, collecting a water-phase extracting solution, adding absolute ethyl alcohol and acetone, and carrying out a reaction to obtain a D-sulbenicillin sodium finished product. According to the synthesis process of the D-sulbenicillin sodium, the reaction is milder, the yield of the final product is obviously improved, the purity of the D-sulbenicillin sodium can be 96% or above, and the synthesis process is more suitable for industrial production.

Owner:HAINAN HAILING CHEMIPHARMA CORP

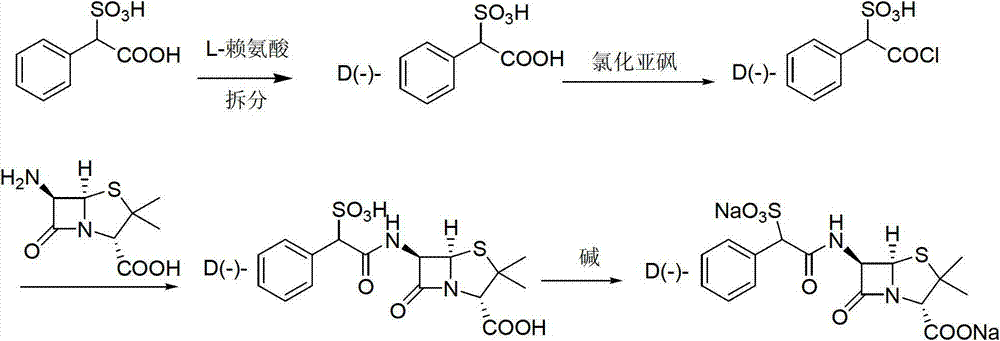

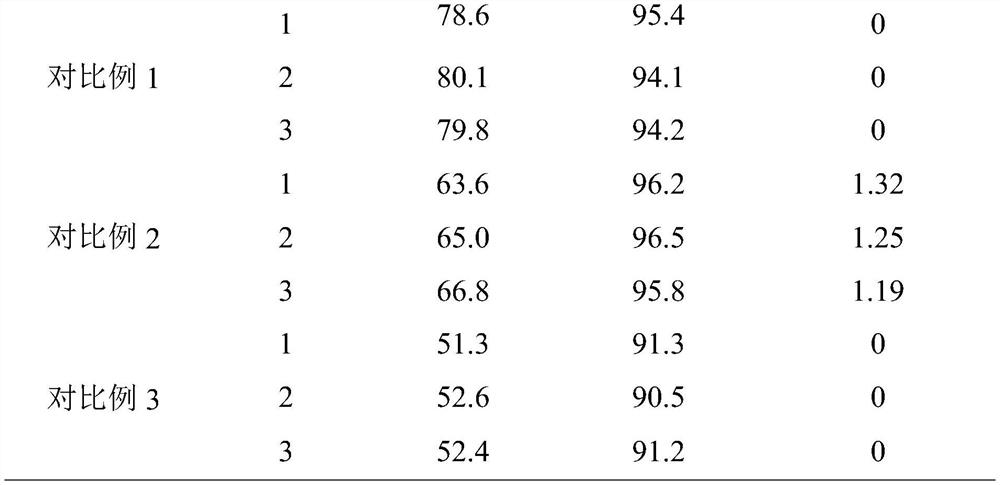

Preparation method of sulbenicillin sodium

ActiveCN108373475AEasy to splitTo achieve the purpose of removing the resolving agentOrganic chemistrySulbenicillinHydrolysis

The invention discloses a preparation method of sulbenicillin sodium. According to the invention, L-amino acid is firstly adopted to perform splitting on D, L-sulfonylphenylacetic acid to obtain D(-)-sulfonylphenylacetic acid, then D(-)-sulfonylphenylacetic acid is compounded with D, L-sulfonylphenylacetic acid to prepare a sulfonylphenylacetic acid mixture with D(-)-sulfonylphenylacetic acid to L(+)-sulfonylphenylacetic acid ratio being about 78%:22%, the sulfonylphenylacetic acid mixture is chlorinated and then reacts with 6-APA, and then reacts with sodium iso-octoate, to directly obtain asulbenicillin sodium mixture with the ratio of D(-)-sulbenicillin sodium to L(+)-sulbenicillin sodium being about 78%:22%. According to the invention, post-treatment process is simplified, no water isused in the step of producing sulbenicillin sodium, hydrolysis impurity level is reduced, product purity is more than 99.0%, and product mole rate is more than 90%.

Owner:山东四环药业股份有限公司

Preparation method of D-(-)-alpha-sulbenicillin sodium

InactiveCN108084207ASimple and fast operationLow toxicityOrganic chemistrySulbenicillinSevere toxicity

The invention provides a preparation method of D-(-)-alpha-sulbenicillin sodium. The method comprises the following steps: taking alpha-sulfonylphenylacetic acid as an initial raw material, performinga reaction with carbonyl diimidazole to generate an acyl imidazoles acylating agent, and performing condensation with 6-APA to obtain a diastereomer of sulbenicillin; separating D-(-)-alpha-sulbenicillin by a recrystallization method, and forming salt with sodium hydroxide to obtain the D-(-)-alpha-sulbenicillin sodium. During a acid anhydrides preparation process, usage of a severe-toxicity substance is avoided, during a preparation process, recrystallization is used, and the optically pure D-(-)-alpha-sulbenicillin is prepared, cost is saved, operation is simplified, yield is increased, andthe method is in favor of industrial production and environment protection.

Owner:HUNAN ER KANG PHARMA

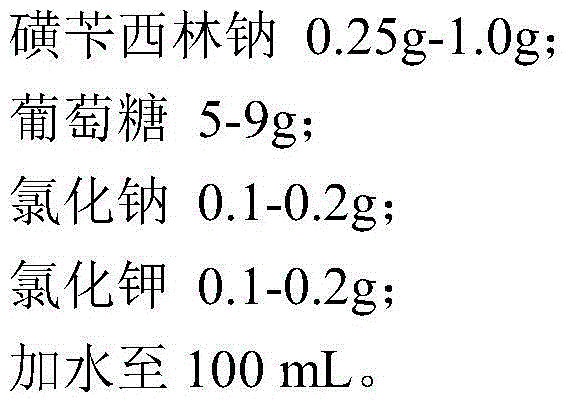

Children type sulbenicillin sodium and low-sodium carrier pharmaceutical composition

InactiveCN104940129AHigh purityIncrease internal pressureAntibacterial agentsOrganic chemistrySulbenicillinSodium Chloride Injection

The present invention relates to a children type sulbenicillin sodium pharmaceutical composition, especially to a combination application package, wherein the composition is a sulbenicillin sodium and low-sodium carrier infusion pharmaceutical combination preparation, which comprises sulbenicillin sodium for injection and a low-sodium carrier infusion, wherein the low-sodium carrier infusion contains a glucose and sodium chloride injection (15-200:1), a glucose, sodium chloride and potassium chloride injection (15-200:1:0-1) and the like. According to the present invention, the clinical application steps are simplified compared with the compatible mixing use of the sulbenicillin sodium and the low-sodium carrier infusion; and the clinical risk caused by the excessive sodium positioned in the blood and incapable of being metabolized due to the children kidney achieving the immature development state is reduced so as to improve the clinical application quality and the safety of the children medication are improved.

Owner:ZHEJIANG CHANGDIAN PHARMA

A kind of preparation method of d-sulbenicillin sodium

ActiveCN107641130BAdequate responseIncrease consumptionOrganic chemistrySulbenicillinOrganic solvent

The invention discloses a method for preparing D-sulbenicillin sodium. The method includes steps of removing L-amino acid from L-amino acid salt of D-sulfophenylacetic acid in solvents and carrying out salt forming to obtain D-sulfophenylacetic acid salt; carrying out reaction on the D-sulfophenylacetic acid salt and acylating agents to obtain mixed acid anhydride; dissolving 6-APA in organic solvents under the effect of organic alkali; dropwise adding mixed acid anhydride solution into 6-APA solution, and carrying out sufficient reaction and after-treatment to obtain the D-sulbenicillin sodium. The D-sulfophenylacetic acid is an intermediate. The 6-APA is a matrix. The method has the advantages that the D-sulbenicillin sodium is prepared by the aid of novel synthetic routes, conditions are mild, the method includes stable process and is easy to implement, and the problems of instable processes of existing methods or insufficient optical purity of products and the like can be solved bythe aid of the method.

Owner:CHENGDU UNIV

Children sulbenicillin sodium compound entity and pharmaceutical preparation thereof

InactiveCN104945417AHigh purityIncrease internal pressureAntibacterial agentsOrganic chemistrySolubilitySide effect

The present invention discloses a children sulbenicillin sodium compound entity, wherein the original research tradename is Lilacillin, and the chemical structural formula of the compound entity is defined in the specification. The preparation steps comprise: (1) dissolving a sulbenicillin sodium crude product in purified water, adding active carbon, carrying out stirring decolorizing, and filtering; (2) adding an extractant to the filtrate under the stirring, transferring and filling into a pressure resistance container, removing air bubbles, carrying out sealing oscillation, carrying out temperature control freezing, and taking out; and (3) carrying out liquid-solid separation, discarding the extractant, adding acetone in a dropwise manner at a temperature of 5 DEG C after the solid melts, stirring at a slow speed, growing the grain, filtering, washing, and carrying out vacuum drying to obtain the sulbenicillin sodium finished product. The children sulbenicillin sodium compound entity of the present invention has advantages of good solubility, good clarity, low related substance content, good stability, low toxic-side effect, and the like.

Owner:ZHEJIANG CHANGDIAN PHARMA

Process for preparing sulbenicillin sodium by enzymatic method

InactiveCN109694896ARelieve stressReduce energy consumptionFermentationChemical industryChemical synthesis

The invention discloses a process for preparing sulbenicillin sodium by an enzymatic method, and belongs to the technical field of pharmaceutical and chemical industry. In the method, a penicillin fermentation broth is used as a starting raw material, the steps of crystallization of 6-aminopenicillic acid, washing, drying and the like are omitted, and sulbenicillin sodium is obtained by direct reaction with sulfobenzylacetyl chloride under the action of penicillin acylase. Compared with a chemical synthesis method, the preparation process provided by the invention has the advantages of simpleoperation, low energy consumption, high safety and good stability. Therefore, the process is a low-cost and high-efficiency production process in promotion and application of industrial production.

Owner:慈溪市一众电器有限公司

Method for preparing D (-)-sulbenicillin sodium

The invention discloses a method for preparing D(-)-sulbenicillin sodium, belongs to the technical field of medicine. The method comprises the following steps that D(-)-sulfophenylacetic acid and chlorosulfonic acid react to generate a compound a, and the compound a and anhydride react to generate a compound b; then the compound b and 6-APA react to obtain D(-)-sulbenicillin; and the D(-)-sulbenicillin and alkali react and then are subjected to freeze-drying to obtain the D(-)-sulbenicillin sodium. Sulfo group and carboxyl group are generated into a mixed anhydride mode at the same time through an intermediate b prepared by the preparation method, the polarity is small, and the solubility in an organic solvent is good. Meanwhile, as the highly-acidic sulfo group is protected, the problem that the pH value in the reaction process is difficultly controlled is solved. The efficiency is increased, and the impurity generation is reduced. The sulbenicillin sodium prepared by the method has high yield and good quality and is easier to industrialize.

Owner:山东安信制药有限公司

Process for preparing sulbenicillin sodium by using enzymic method

ActiveCN104694611ARelieve stressReduce energy consumptionFermentationChemical synthesisSulbenicillin

The invention discloses a process for preparing sulbenicillin sodium by using an enzymic method, and belongs to the technical field of medicines and chemical engineering. The method comprises a step that by omitting the steps of crystallizing, washing and drying 6-aminopenicillanicacid, direct reaction on penicillin fermentation liquid used as an initial raw material and phenylacetyl chloride is carried out under a function of penicillin acylase to obtain sulbenicillin sodium. Compared with a chemical synthetic method, the preparation process provided by the invention is easy to operate, small in energy consumption, high in security and high in stability; therefore, the process is a production process with low cost and high efficiency in popularization and application of industrial production.

Owner:HUNAN ER KANG PHARMA

A kind of technology that enzymatic method prepares sulbenicillin sodium

ActiveCN104694611BRelieve stressReduce energy consumptionFermentationChemical synthesisSulbenicillin

The invention discloses a process for preparing sulfbenicillin sodium by enzymatic method, which belongs to the technical field of medicine and chemical industry. The method uses penicillin fermented liquid as a starting material, omits the steps of 6-aminopenicillanic acid crystallization, washing and drying, and directly reacts with sulfophenylacetyl chloride under the action of penicillin acylase to obtain sulfbenicillin sodium. Compared with the chemical synthesis method, the preparation process provided by the invention is simple in operation, low in energy consumption, high in safety and good in stability. Therefore, the present invention is a low-cost, high-efficiency production process in the popularization and application of industrial production.

Owner:HUNAN ER KANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com