Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Laser bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

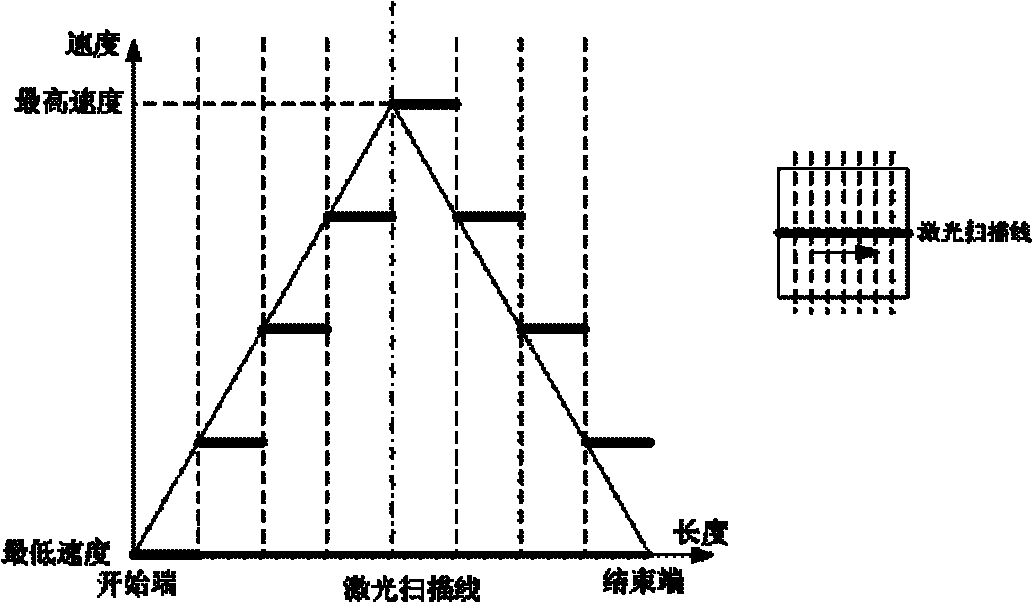

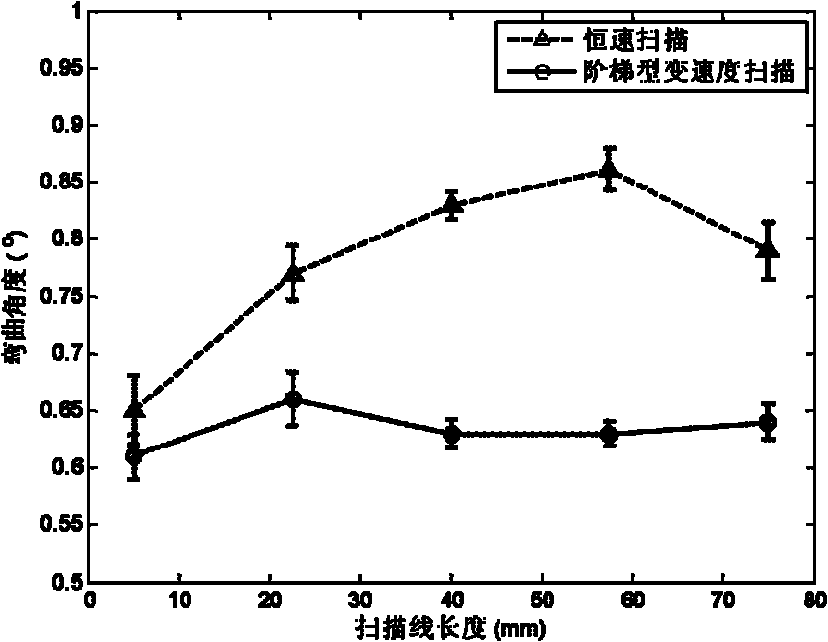

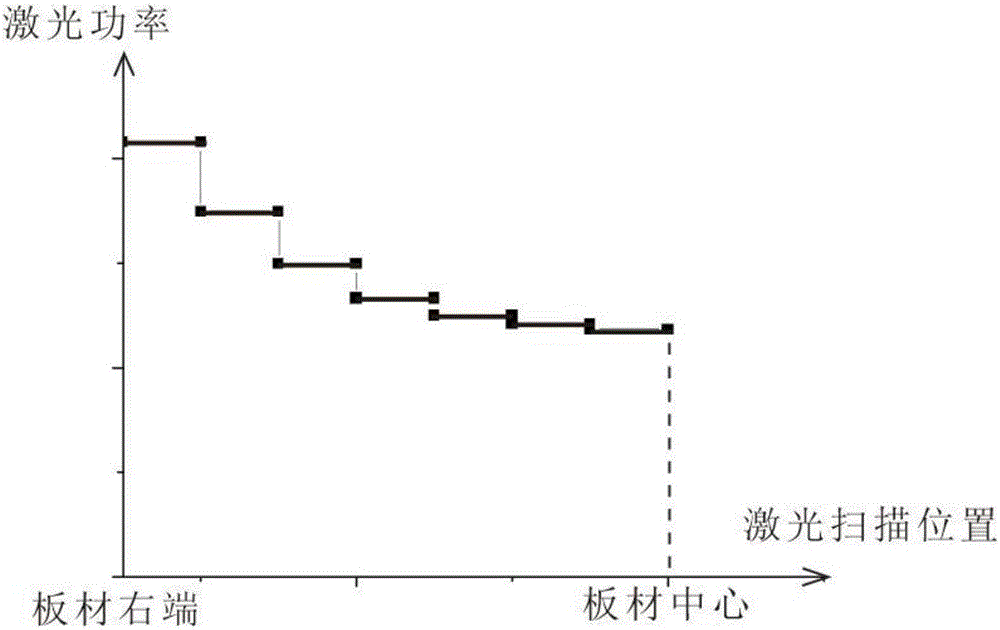

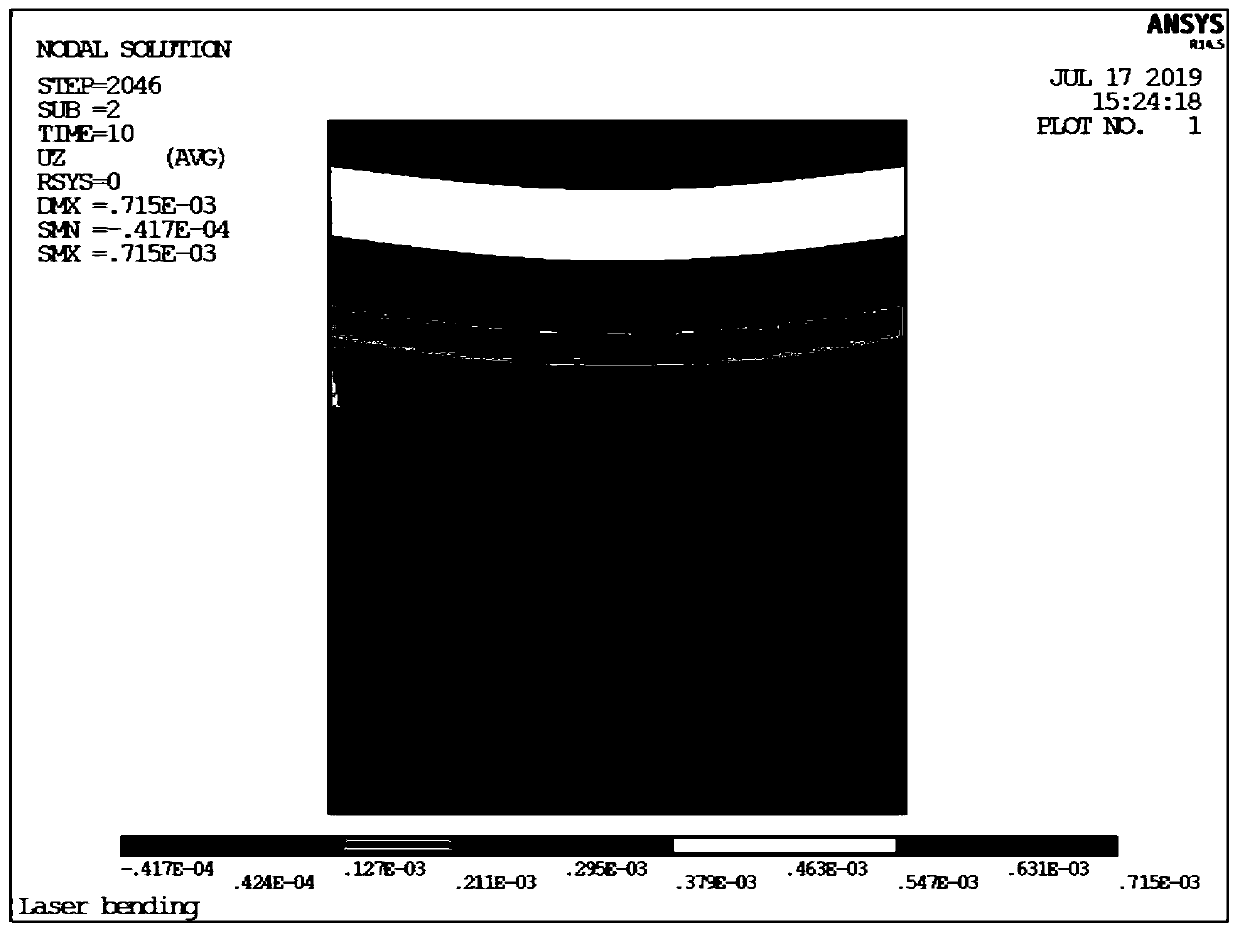

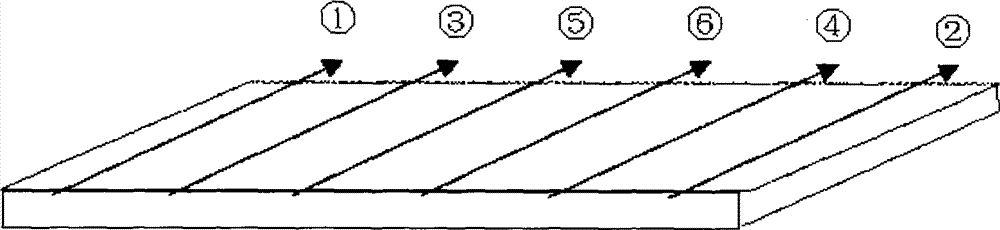

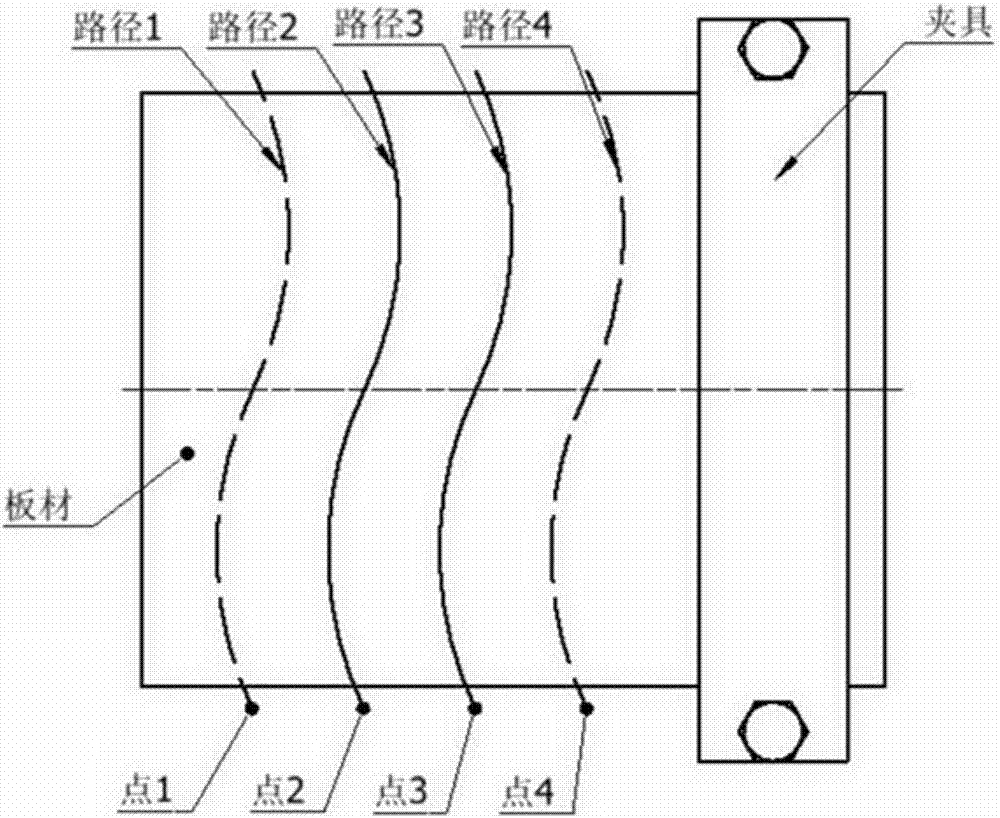

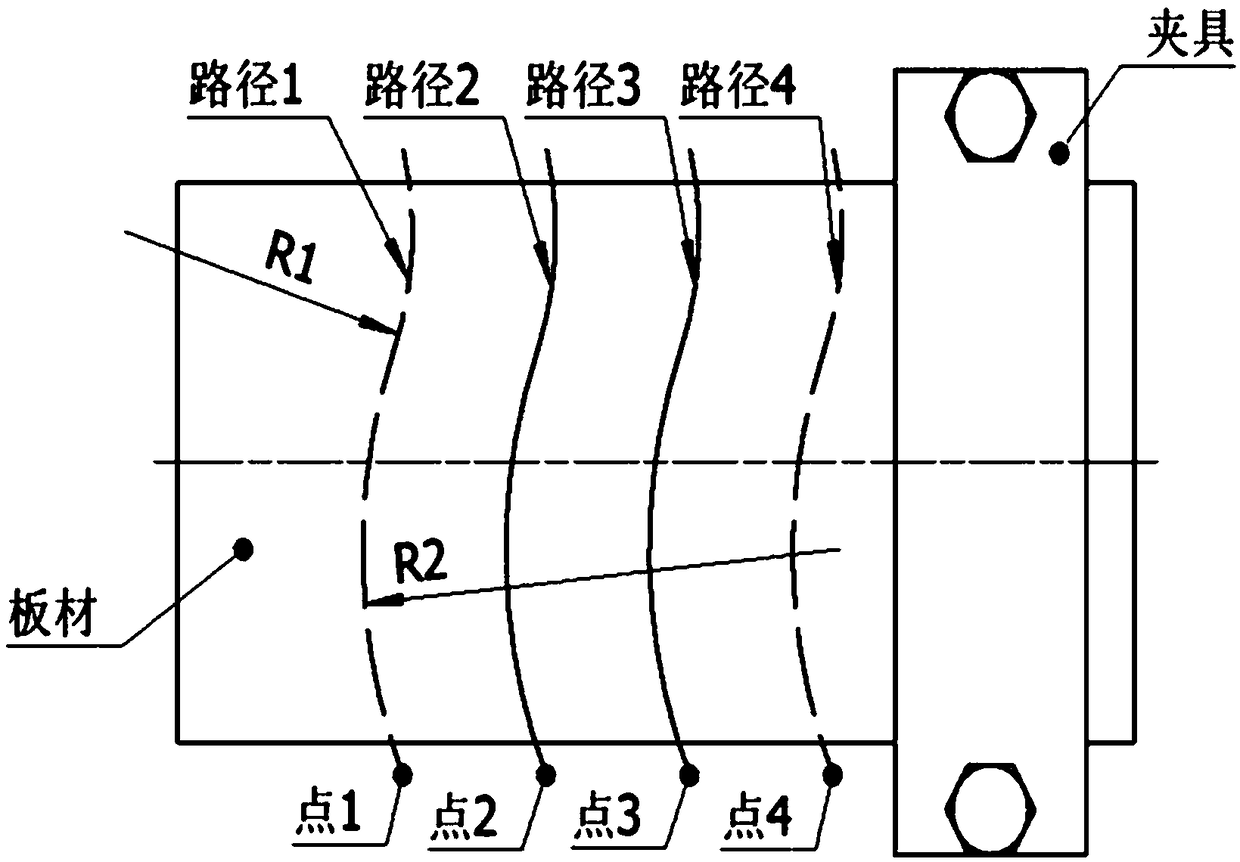

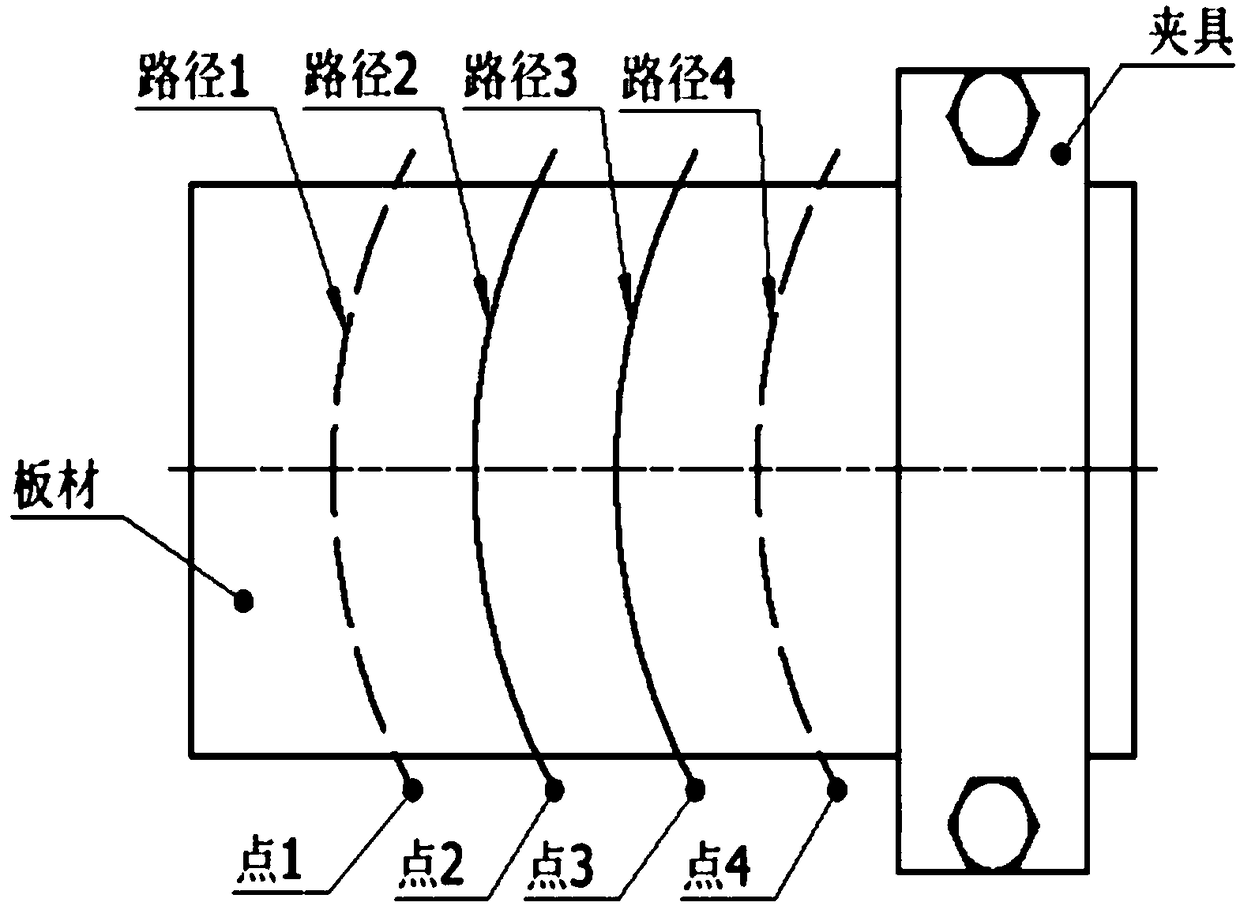

Step type variable speed scanning method for accuracy control of laser bend forming

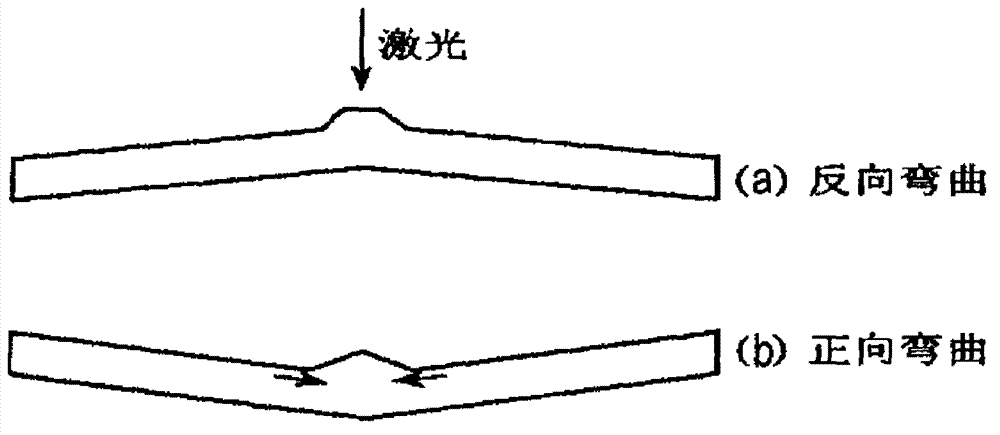

InactiveCN101804508AAchieve bendingReduce boundary effectsLaser beam welding apparatusNumerical controlLaser coating

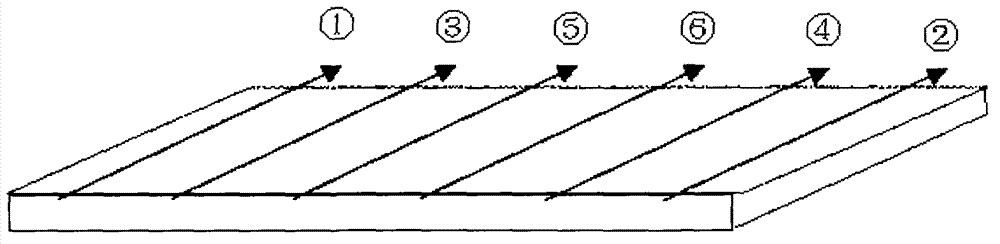

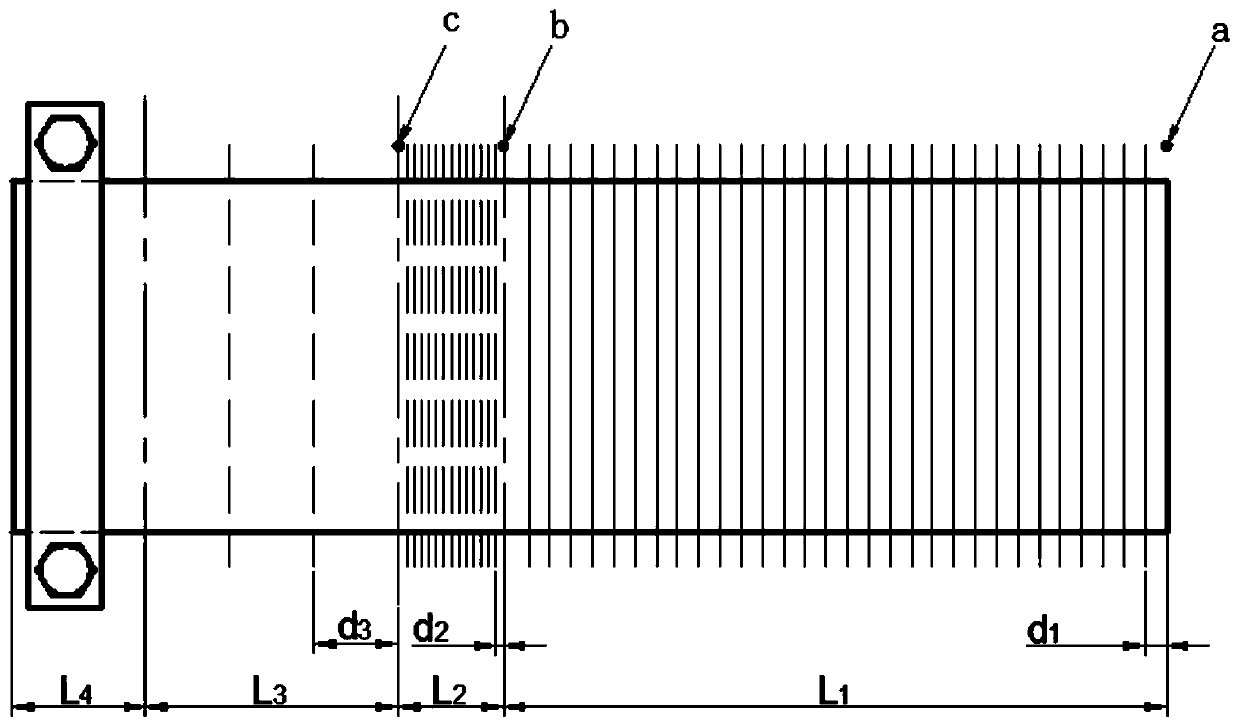

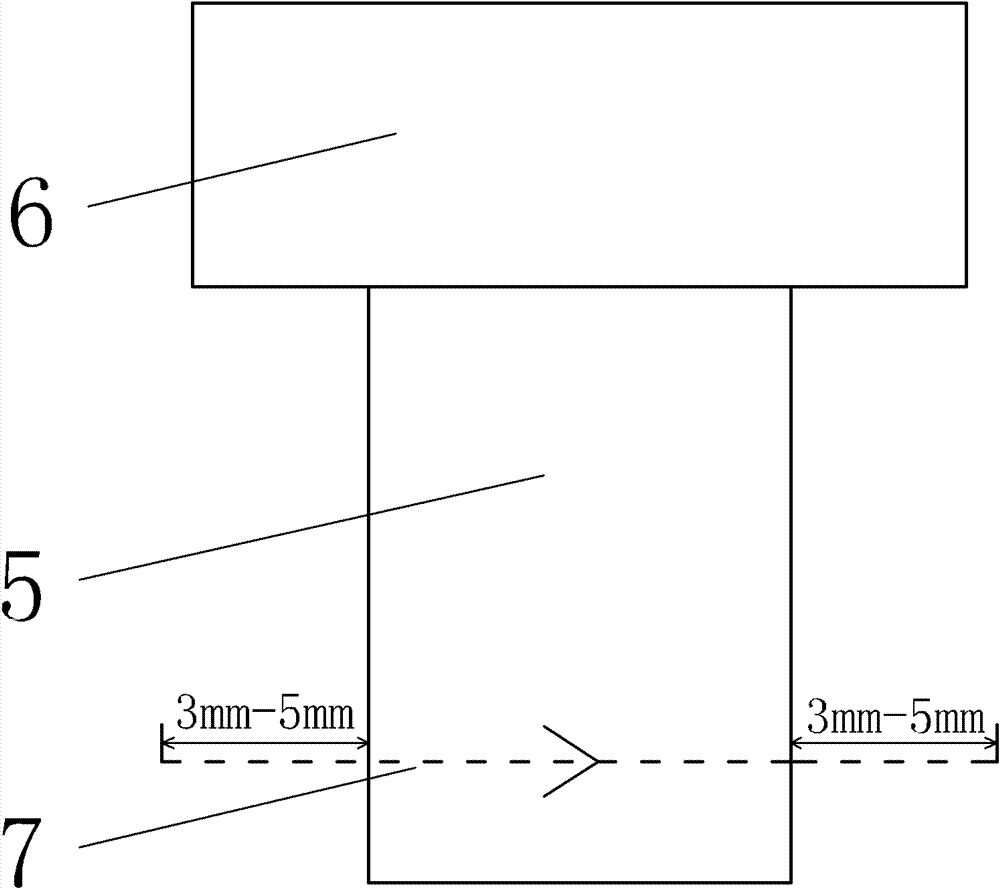

A step type variable speed scanning method for accuracy control of laser bend forming belongs to the technical field of plastic forming. A laser coating material is coated on the scanning area of a surface to be scanned, a sheet material to be detected is clamped on one side, the scanning speed of the scanning area is determined by the diagram method to generate the step type variable speed scanning scheme corresponding to the scanning area, and finally the sheet material to be detected is scanned and processed according to the step type variable speed scanning scheme in a laser numerical control manner. The measure and check after processing are performed after the sheet material is cooled naturally. The method of the invention can effectively reduce the phenomenon of border effect, enhance the forming accuracy of the sheet material, thereby realizing the different energy output of the different heating area to balance the geometric constraint of the sheet material and improve the border effect.

Owner:SHANGHAI JIAO TONG UNIV

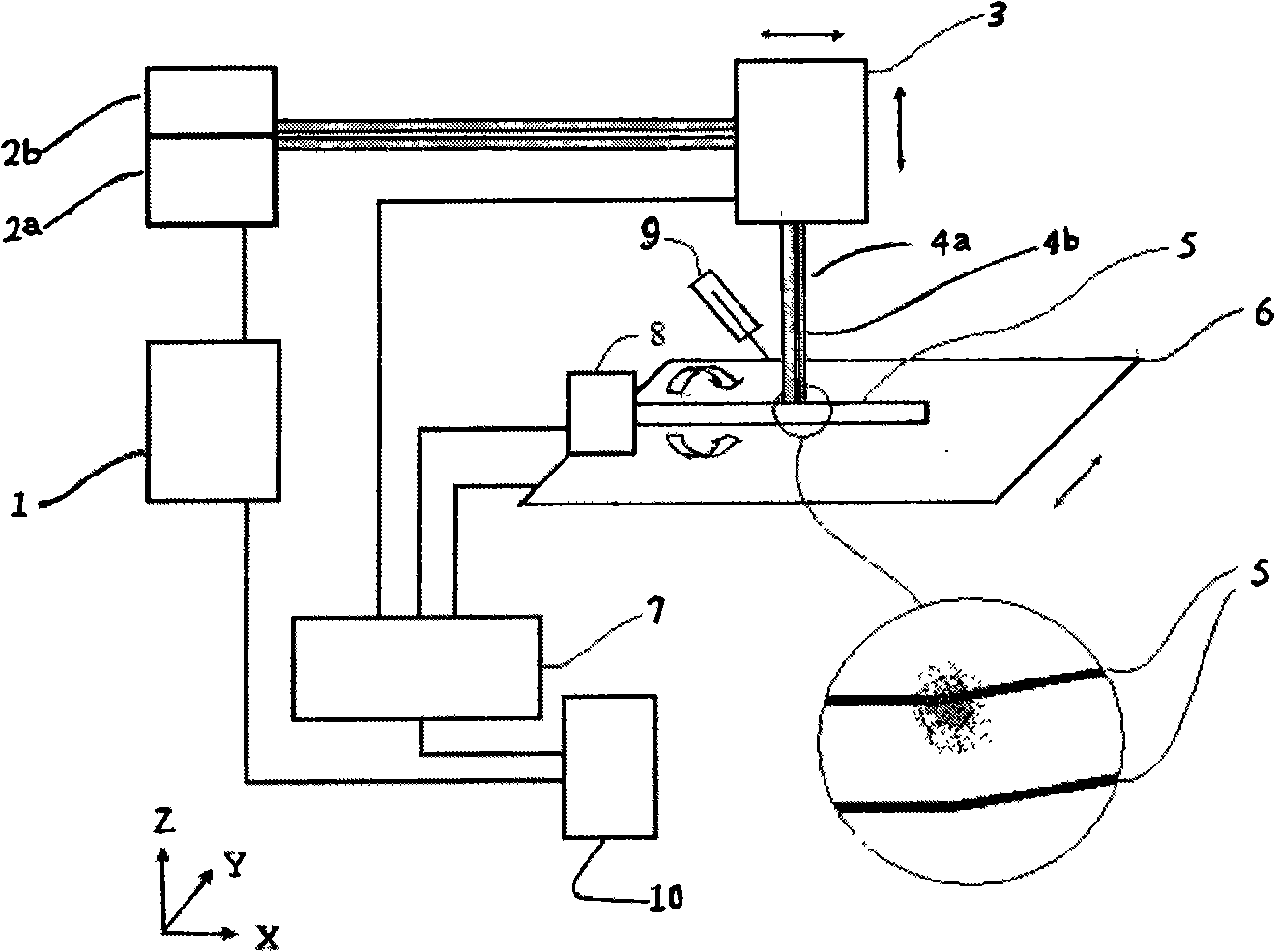

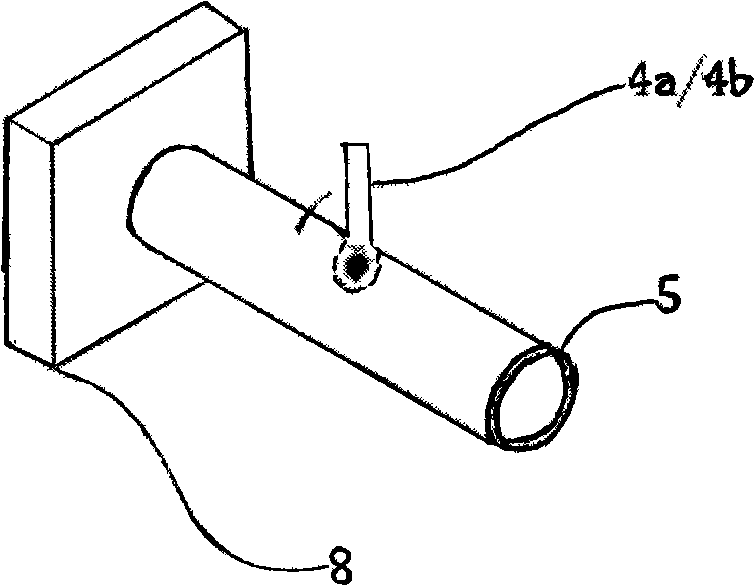

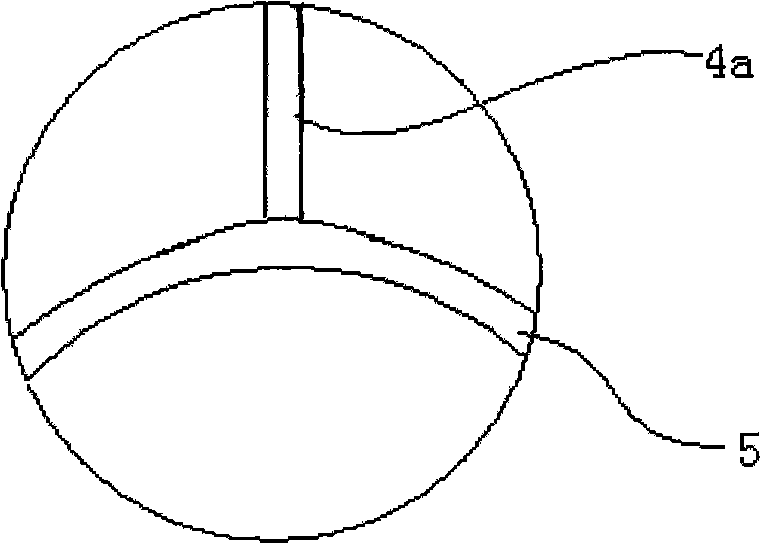

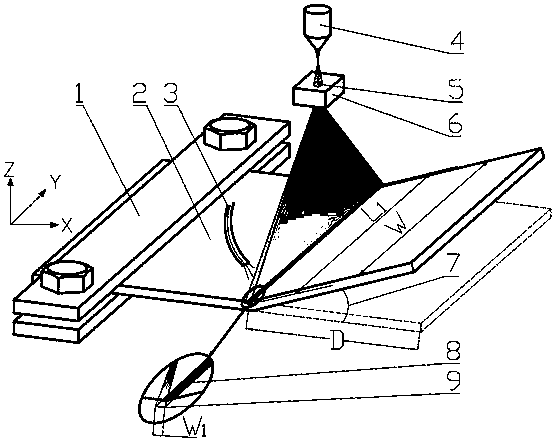

Laser bending shaping method and device of light-wall conduit

InactiveCN101332536AImprove fatigue lifeSmall bending radiusLaser beam welding apparatusControl systemTitanium

The invention discloses a laser bending forming method of a thin-walled tube and a special device used for realizing the method. The method adopts two laser beams to act on the thin-walled tube, wherein one laser beam is used for heating the thin-walled tube to soften the thin-walled tube and producing thermal stress along the thickness direction of the tube wall so as to cause the tube to bend and deform; the other laser beam forms a plasma on the surface of the tube, and further bends the thin-walled tube by the shock action produced by the plasma to obtain a fine grain structure. The special device for realizing the laser bending forming method of the thin-walled tube is composed of a laser generator system, a laser head system, a workbench system and a motion control system. By adopting the method, metal and alloy tubes made from steel, aluminum, copper, titanium and the like can be machined, which is a high-flexibility dieless forming technology.

Owner:SHANDONG UNIV

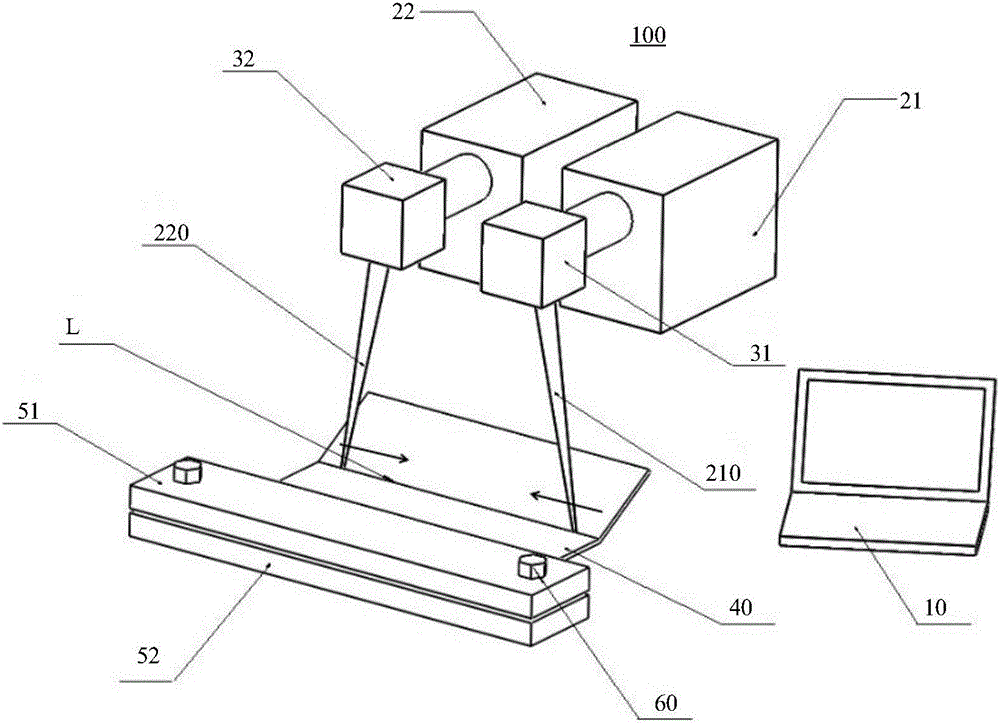

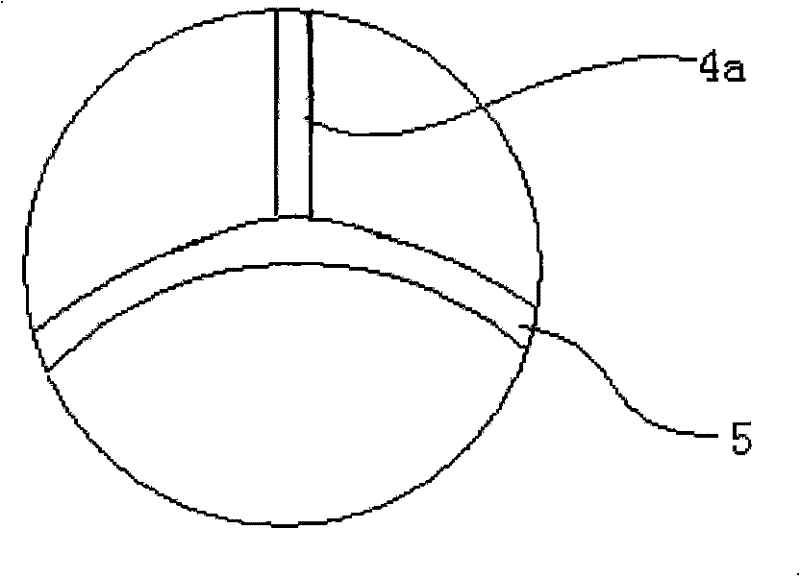

Laser segment-scanning plate bending forming device and method

InactiveCN106424324AImprove forming qualityReduces the difference in the angle of the bendShaping toolsBoundary effectsOptoelectronics

The invention relates to a laser segment-scanning plate bending forming device and method. The method comprises the steps that a metal plate to be machined is placed below a first scanning head and a second scanning head; scanning paths and scanning powers of a first laser device and a second laser device are set through a computer; the scanning paths of the first laser device and the second laser device are connected in the middle of the metal plate, and the scanning powers gradually decrease from the edges of the metal plate to the middle of the metal plate; the first scanning head and the second scanning head moves face to face and starts to scan along the respective scanning paths. Through the laser segment-scanning plate bending forming device and method, difference of laser bending angles in all positions of the metal plate can be reduced, the boundary effect is avoided, and the forming quality of plates improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Linear light spot laser bend forming method of metal sheet

InactiveCN110314980ALow costReduce warpageHeat treatment process controlLaser beam welding apparatusPoint lightLight spot

The invention belongs to the technical field of efficient, high-precision and high-performance laser bend forming of metal sheets and relates to a linear light spot laser bend forming method of a metal sheet. A multi-mode laser scanning rotating mirror or a single piezoelectric deformable mirror is used for converting Gaussian distribution type point light spots of a laser into evenly distributedlinear light spots, and meanwhile the laser is loaded on a bend line area to conduct bend formation on the metal sheet; and in this way, a temperature field on the bend line of the metal sheet is evenly distributed, and the purposes of reducing warping deformation, improving bend angle consistency and improving bend efficiency are achieved.

Owner:DALIAN UNIV OF TECH

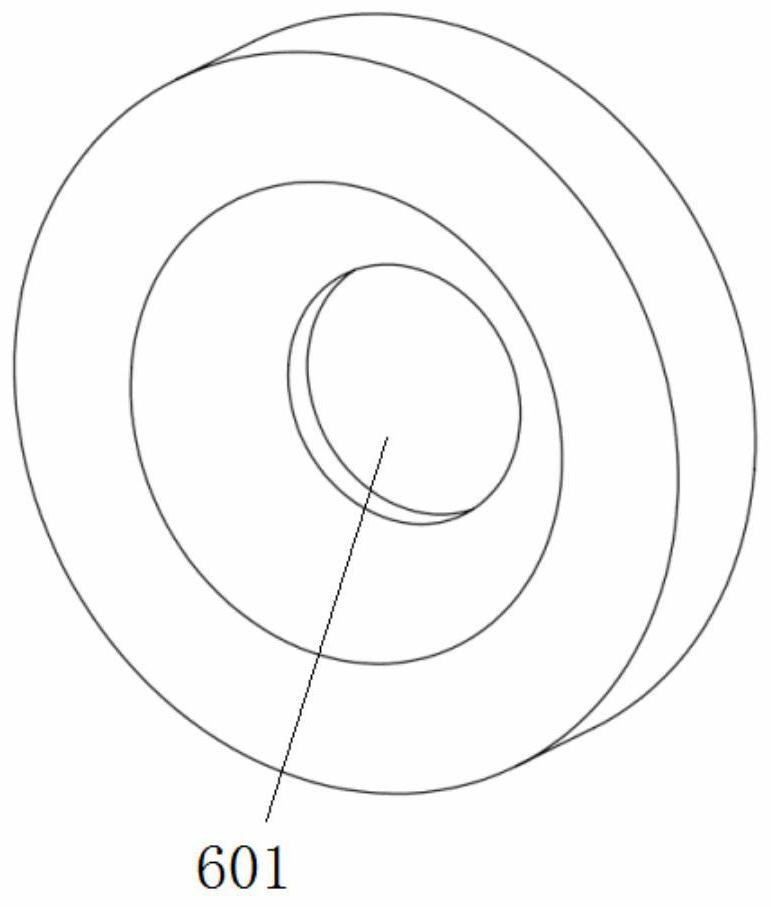

Progressive bending sheet metal

The invention provides a progressive bending sheet metal which is manufactured with the method of laser bending forming. According to the laser bending forming method, proper and unique technological parameters are chosen, deformation of the sheet metal is controlled accurately, and the progressive bending sheet metal is obtained at last. Interval between passes of the sheet metal is preferred to be 1.5-2mm, and reciprocating scanning time of each pass is preferred to be 10 times, diameter of a laser beam spot is 0.1mm, power is 20-25W, scanning speed is 15-20mm, and curvature of the sheet metal obtained at last is about 0.05-1mm.

Owner:宁波市博祥新材料科技有限公司

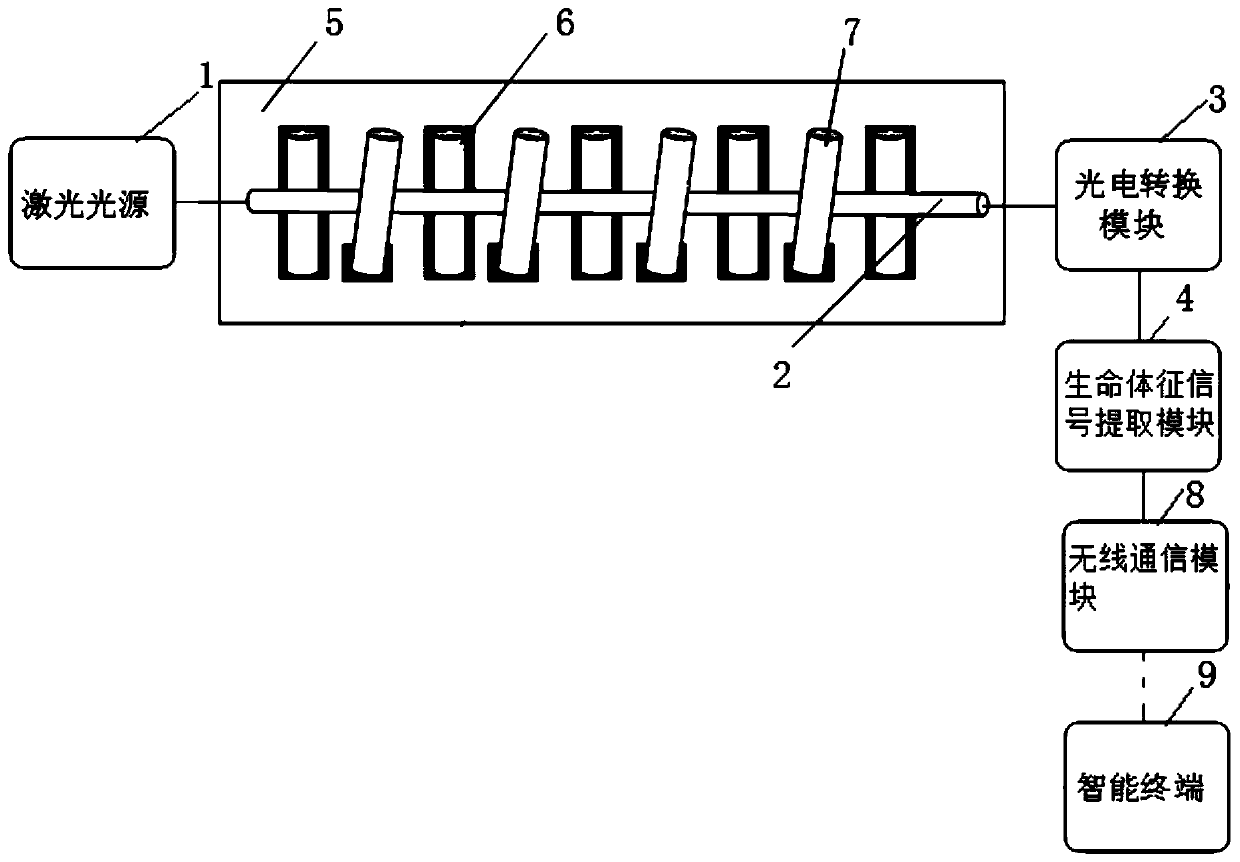

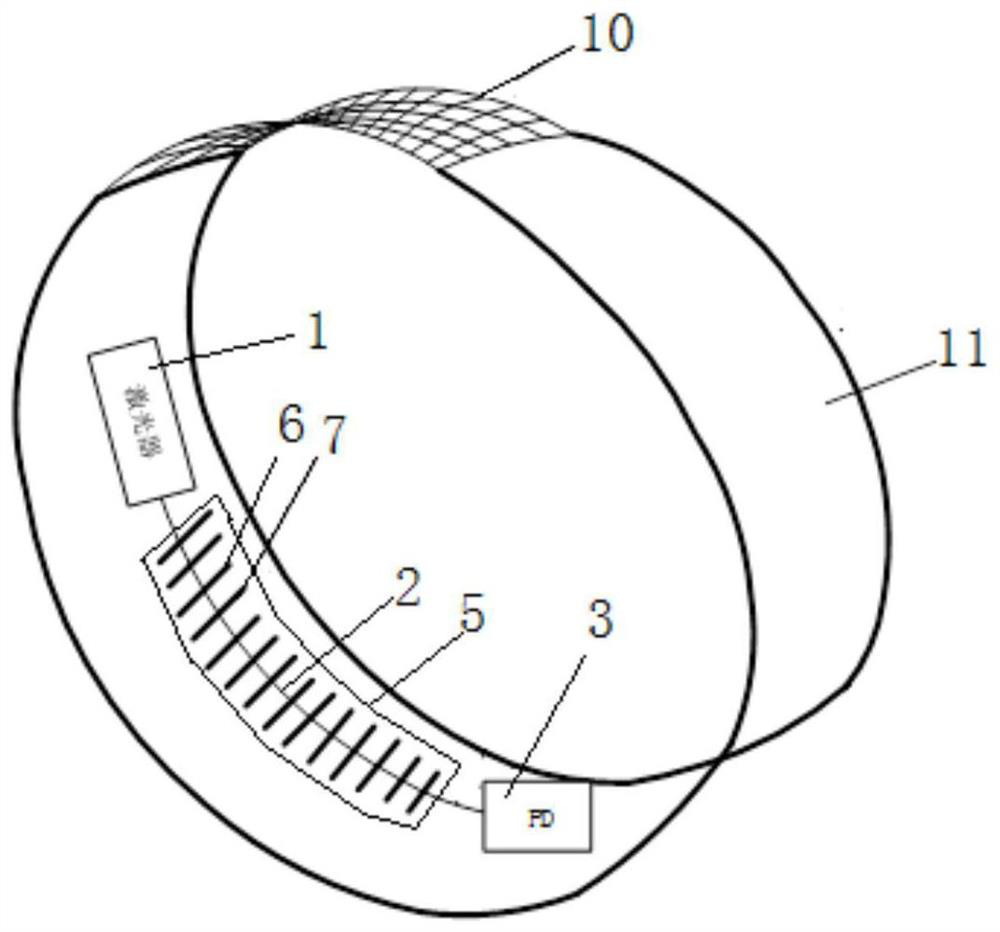

Wearable vital sign monitoring device and method

ActiveCN110974198APromote reductionImprove accuracyDiagnostic recording/measuringSensorsHuman bodyMedicine

The invention relates to a wearable vital sign monitoring device. A laser light source of the wearable vital sign monitoring device is used for emitting laser to a sensing optical fiber; two ends of the sensing optical fiber are respectively connected with a laser light source and a photoelectric conversion module; the sensing optical fiber is bent after bearing the pressure of pulse or breathingor heartbeat movement of a human body, and a laser signal transmitted in the sensing optical fiber is lost at a bent part and is modulated based on a bending loss principle; the photoelectric conversion module is used for converting the modulation signal of the laser bending loss output by the sensing optical fiber into an electric signal representing the pulse or breathing or heartbeat movement of the human body; and a vital sign signal extraction module is used for extracting the corresponding human body pulse or breath or heartbeat frequency from the electric signal representing the human body pulse or breath or heartbeat movement. According to the invention, the vital sign information of the human body can be accurately monitored in real time.

Owner:WUHAN UNIV OF TECH

Laser forming method for metal sheet

The invention discloses a laser forming method for a metal sheet. According to the laser forming method for the metal sheet, appropriate and unique technological parameters in a laser bending forming method are selected to accurately control the deformation amount of the metal sheet and obtain the metal sheet with continuous bending deformation. The interval between every two adjacent paths is preferably 1.5-2 millimeters, the reciprocating scanning times of each path is preferably 10 times, the diameter of each laser beam spot is 0.1 millimeter, the power is 20-25 watts, the scanning speed is 15-20 millimeters, and the curvature of a finally obtained thin sheet is about 0.05-1 millimeter.

Owner:青岛述诚智能装备股份公司

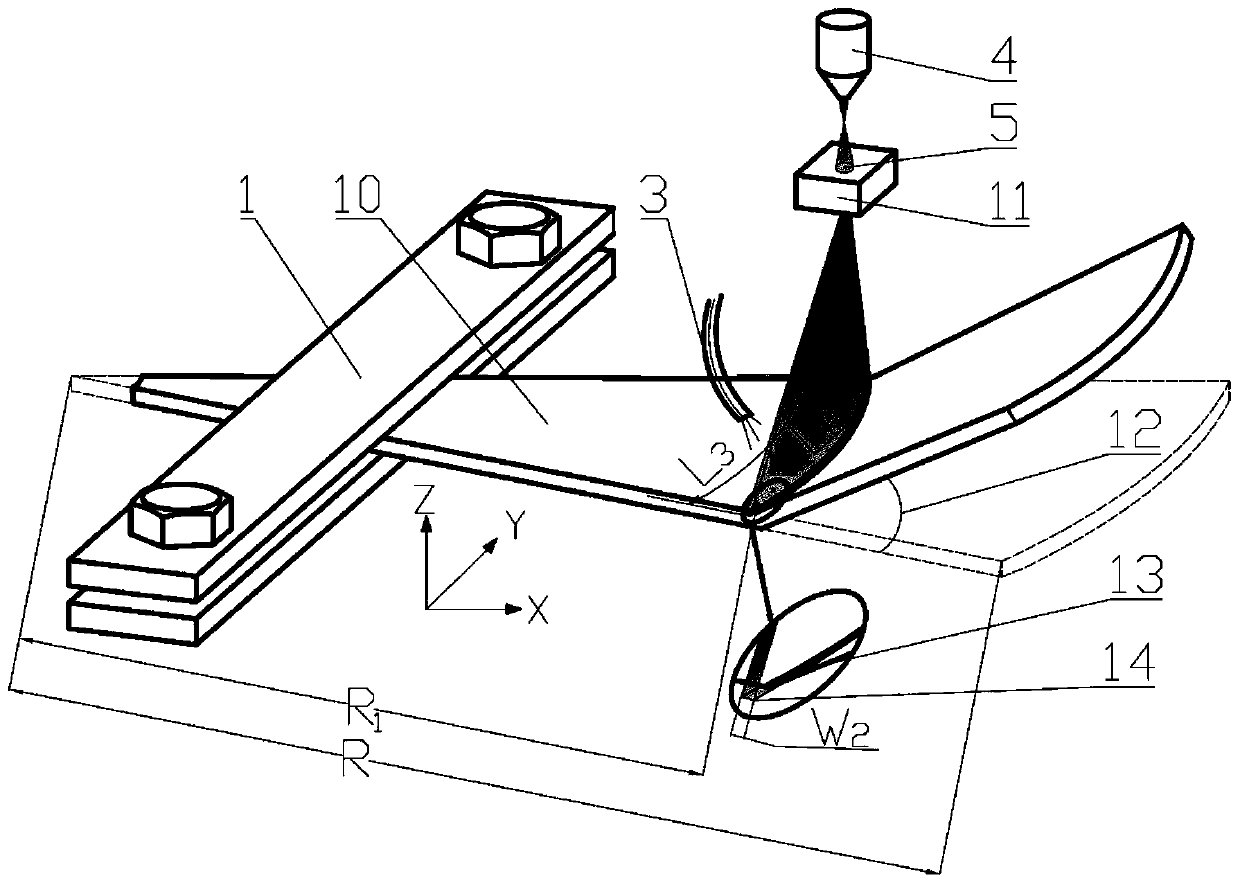

Reverse laser forming method for single-segment arc surface of metal sheet

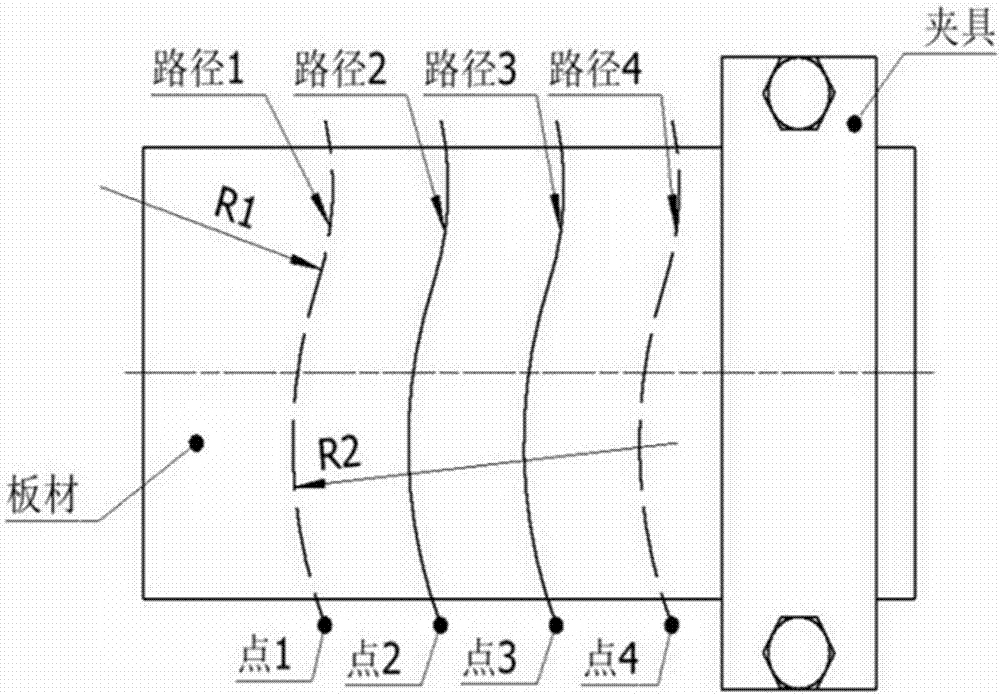

InactiveCN111496062AGuaranteed smoothnessEffective guidance for accurate and rapid flexible bending formingMetal-working feeding devicesPositioning devicesScan lineLaser scanning

The invention belongs to the field of metal sheet laser bending forming, and particularly relates to a reverse laser forming method for a single-segment arc surface of a metal sheet. The reverse laserforming method can be used for rapid bending and forming of a single-segment arc surface or a multi-segment arc surface structure of the metal sheet. Considering the influence of the spacing of a scanning line on the smoothness of the formed arc surface, the reverse laser forming method can finish the route planning for the arc surface expected to be formed by reversing the spacing of the scanning line and the bending angle of each scanning line, the laser power, laser defocusing amount, laser scanning speed and scanning times on each scanning line are changed to ensure that the bending angleof each scanning line is the same, and the high-precision laser rapid bending and forming of different types of arc surfaces is achieved. The reverse method of the arc surface can guide the precise,rapid and flexible bending and forming of the specific arc surface effectively, and ensure the smoothness of the arc surface as much as possible under the appropriate small spacing of the scanning line; at the same time, through similar means, multi-segment arc surface processing can be completed.

Owner:DALIAN UNIV OF TECH

Method for forming arc groove in metal plate by adopting laser flexible bending forming technology

The invention provides a method for forming an arc groove in a metal plate by adopting a laser flexible bending forming technology. The method can be used for rapid bending forming of groove structures of single arc lines, different arc combined lines and the like of metal plates. According to the method, on the basis of a temperature gradient mechanism, when a laser scans the metal plate, a laser scanning line region can generate an obvious temperature gradient along the laser scanning paths and then can generate the non-uniform thermal stress distributed along a scanning line so that three-dimensional curved surface deformation of the plate can be generated; and the arc groove is formed according to the expected shape, the shape of the laser scanning line, all the laser parameters of each scanning path and the laser scanning frequency of each path are changed, proper path planning is combined, and therefore rapid high-precision laser bending forming of arc grooves of different types can be realized.

Owner:DALIAN UNIV OF TECH

Novel optical information transmission system based on plasma spectrum

The invention relates to a novel optical information transmission system based on a plasma spectrum. The novel optical information transmission system comprises an optical transmission system laser signal transmitting base station, a laser bending adjusting module, a laser signal oscillation amplifying module and a plasma spectrum signal optical receiving base station. According to the novel optical information transmission system based on the plasma spectrum, base stations only need to be established at the two ends of signal transmission, line laying does not need to be conducted in the transmission process, and a catadioptric lens is adopted to adjust an optical path except for partial object shielding; the cost of line laying and maintenance in current optical fiber transmission is completely saved, an optical signal enters a receiver and then enters a plasma detection pool firstly, a plasma spectrum is excited to be received by a spectrograph, the special property of the plasma spectrum enables the wavelength of each independent signal to be accurately controlled at a nanometer level or even an angstrom level, and the detection accuracy is greatly improved. And the use efficiency of the signal wave band is greatly improved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

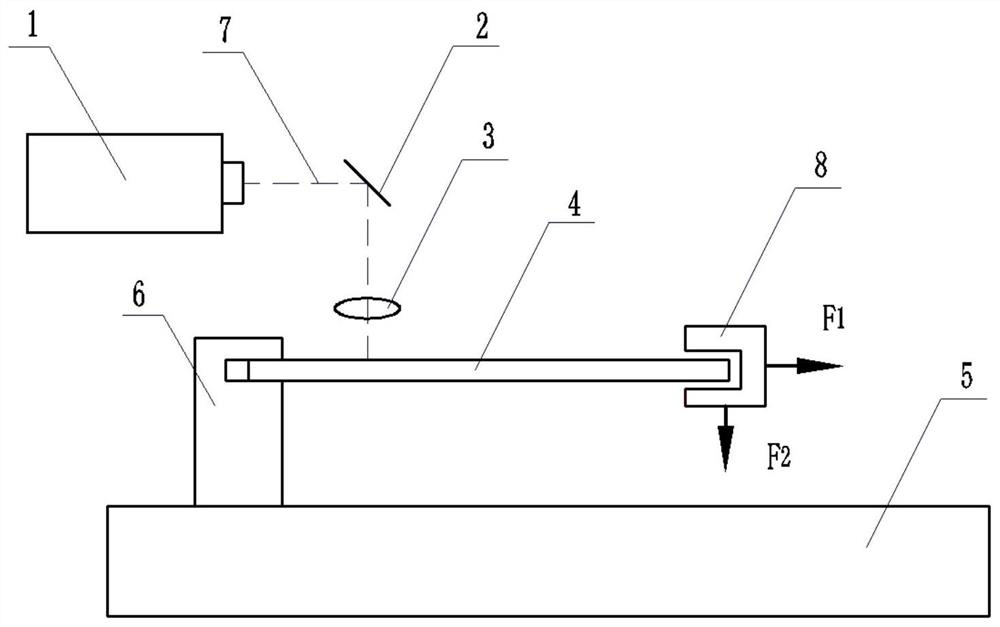

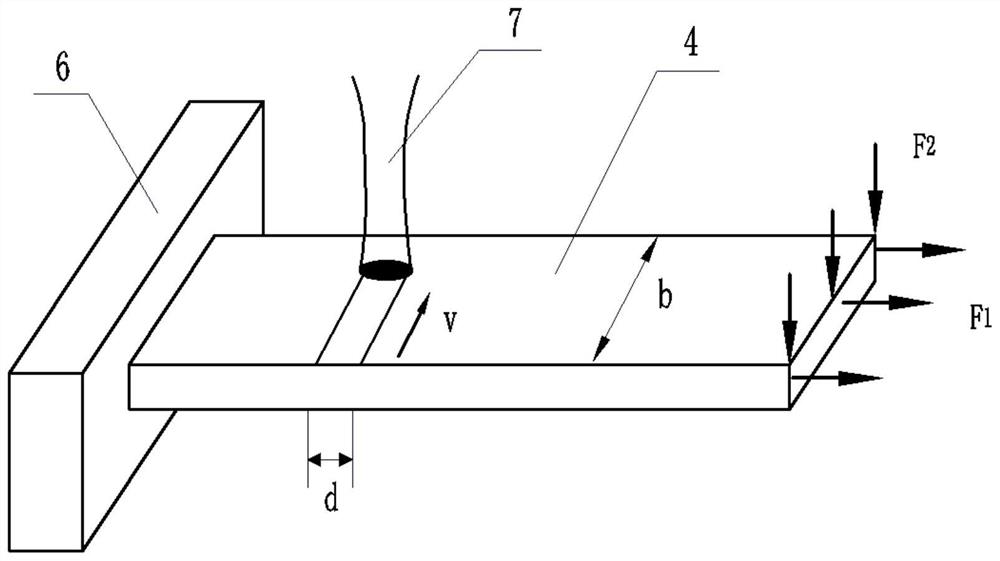

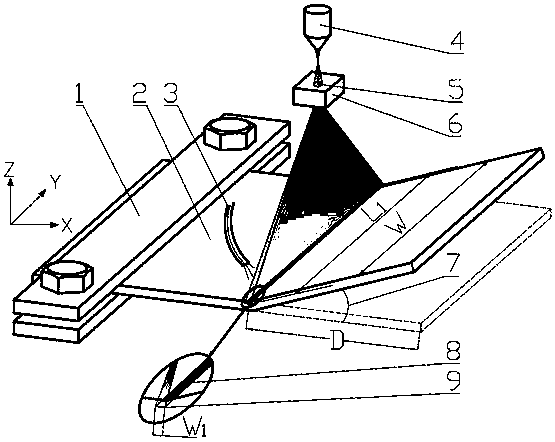

Novel stretch-bending process for metal plate laser thermoforming

The invention provides a method for achieving laser bending metal plate forming through a pre-stretch-bending method. Resilience can be reduced to a large extent, and then the bending angle of a plateis increased. The method comprises the steps that firstly, a formed workpiece is fixed to a three-dimensional numerical control platform, one end of the workpiece is fixed through a clamp, and a stretch bending device firstly applies longitudinal tension and then applies transverse pressure to the other free end of the workpiece; and then the upper surface of the plate is heated in a scanned modeby using laser, finally, after the hating area of the plate is completely cooled, the stretch bending device is removed, and the transverse pressure and the longitudinal tension are relieved. A largenumber of literatures prove that the stress state inside the plate can be changed under bending force, more tangential pressure stress generated on the inner side of a neutral layer of the laser heated area is converted into tensile stress, the whole cross section of the plate is under the action of the tensile stress in the tangential direction, and after relieving, resilience of inner-layer fibers and outer-layer fibers counteract each other so that the resilience can be greatly reduced, and then the bending angle of the plate is increased; and the method is suitable for forming of high-hardness, high-brittleness and difficult-to-deform and medium-thickness plate materials, and has a great application prospect in the fields of aerospace, medical treatment and automobile manufacturing.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

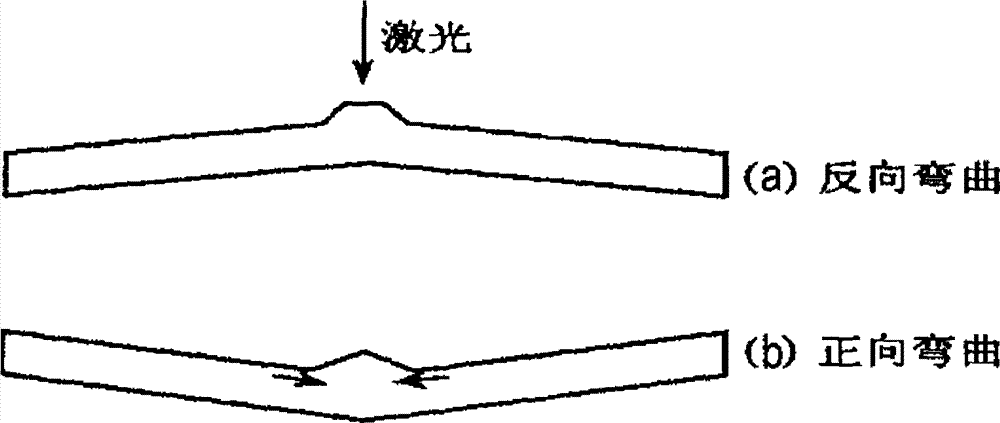

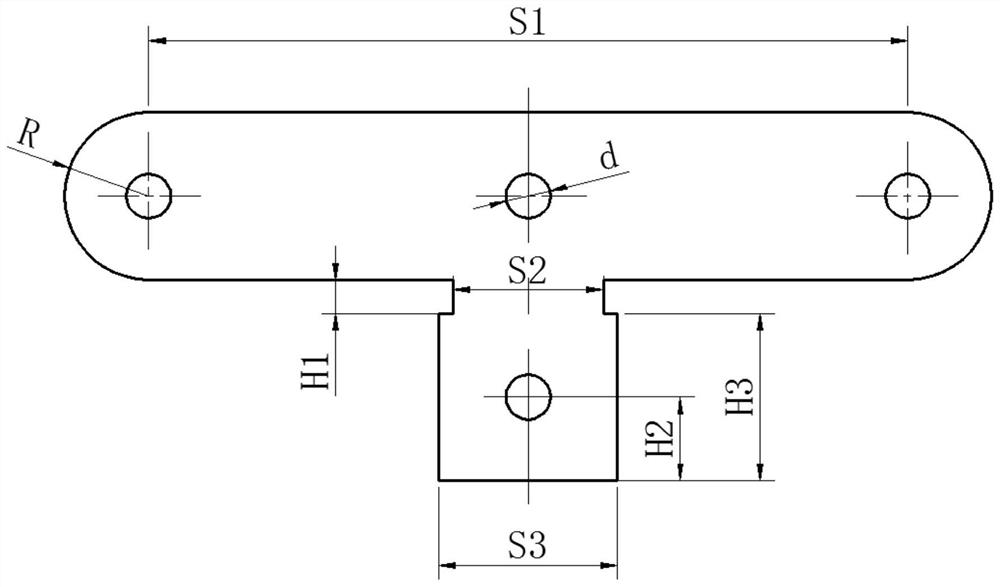

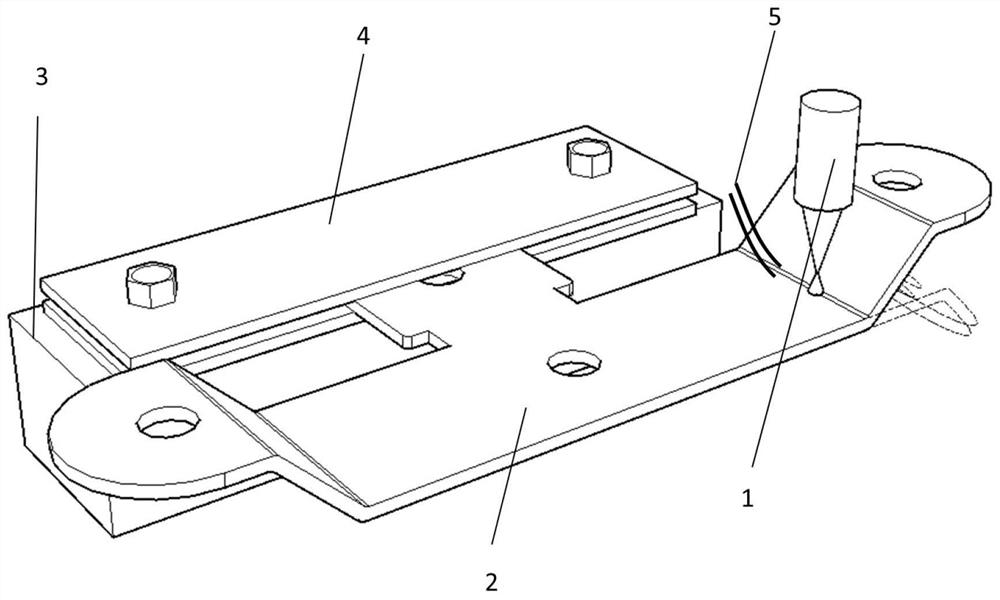

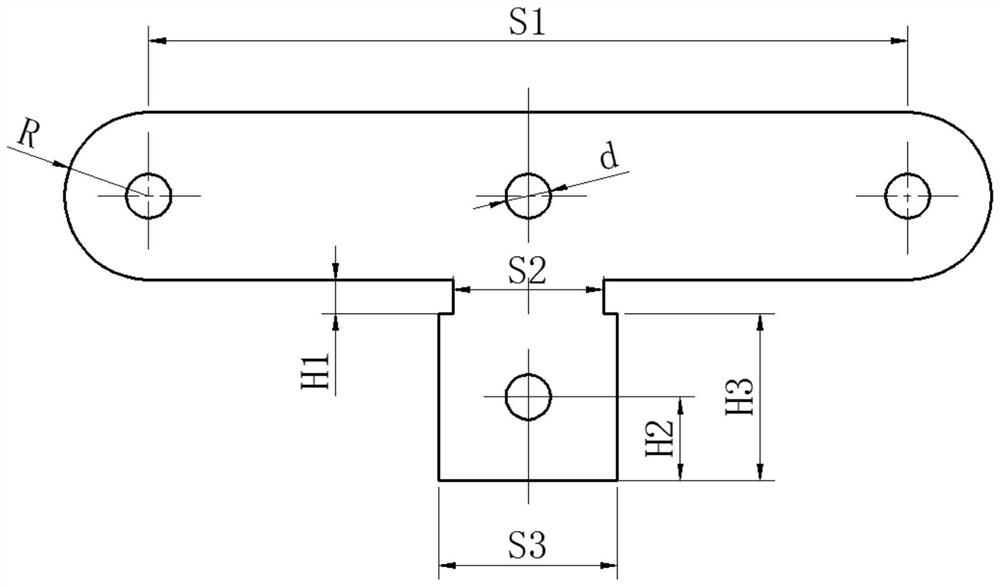

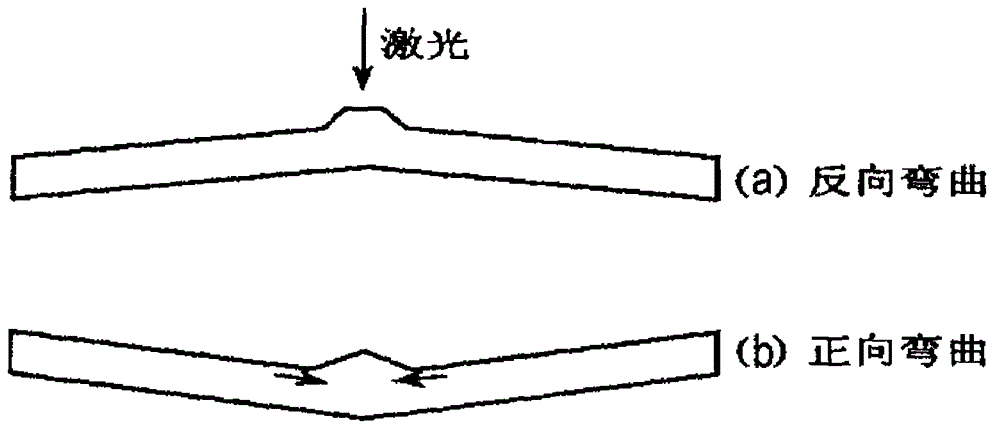

Laser bending forming method for knife switch knife holder

ActiveCN112427543AImprove plasticityImprove forming qualityShaping toolsLaser scanningLight scanning

The invention provides a laser bending forming method for a knife switch knife holder. The laser bending forming method can be used for die-free rapid bending forming of the knife switch knife holder.Firstly, based on a temperature gradient mechanism, when laser scans a metal plate, a laser scanning line area can generate uneven thermal stress due to the temperature gradient, so that the plate isbent towards a laser beam, and meanwhile, a scanning area generates new residual stress and strain distribution; and secondly, based on the buckling mechanism, laser scanning is conducted on the pre-bent back face position, and under the influence of residual stress and strain generated by pre-bending, the plate is bent in the direction opposite to the laser beam. When a knife holder sample pieceis formed through laser, high-precision laser rapid bending forming of knife holders of different sizes and shapes can be achieved by changing laser parameters and the number of laser scanning timesof all paths in combination with proper path planning.

Owner:DALIAN UNIV OF TECH

Solid rocket ramjet air inlet way machining method

InactiveCN108161349AShorten the timeEasy to processTurbine/propulsion air intakesRam jet enginesRamjetEngineering

The invention discloses a solid rocket ramjet air inlet way machining method. The solid rocket ramjet air inlet way machining method comprises following steps that a, an air inlet way is divided intothree independent portions including a front segment, a middle segment and a tail segment; b, the front segment and the tail segment are machined; c, a whole titanium alloy steel plate is machined into an air way middle shell with the door-shaped cross section through a laser bending pre-forming method, the top face and the side face of a middle segment shell inner runner are subject to finish machining, a bottom plate of the middle segment is machined into the designed size and precision, and the shell and the bottom plate are spliced and welded and formed; d, the front segment, the middle segment and the tail segment of the air inlet way are sequentially in abut joint and welded into the complete air inlet way. The air inlet way is subject to segmented machining, the segments with the fixing requirement are machined, machining of all segments is more easier, a large device is not needed, machining precision is easily ensured, the yield is improved, production cost is reduced to the maximum degree, and the machining time of the middle segment of the air inlet way is greatly shortened.

Owner:胡建新

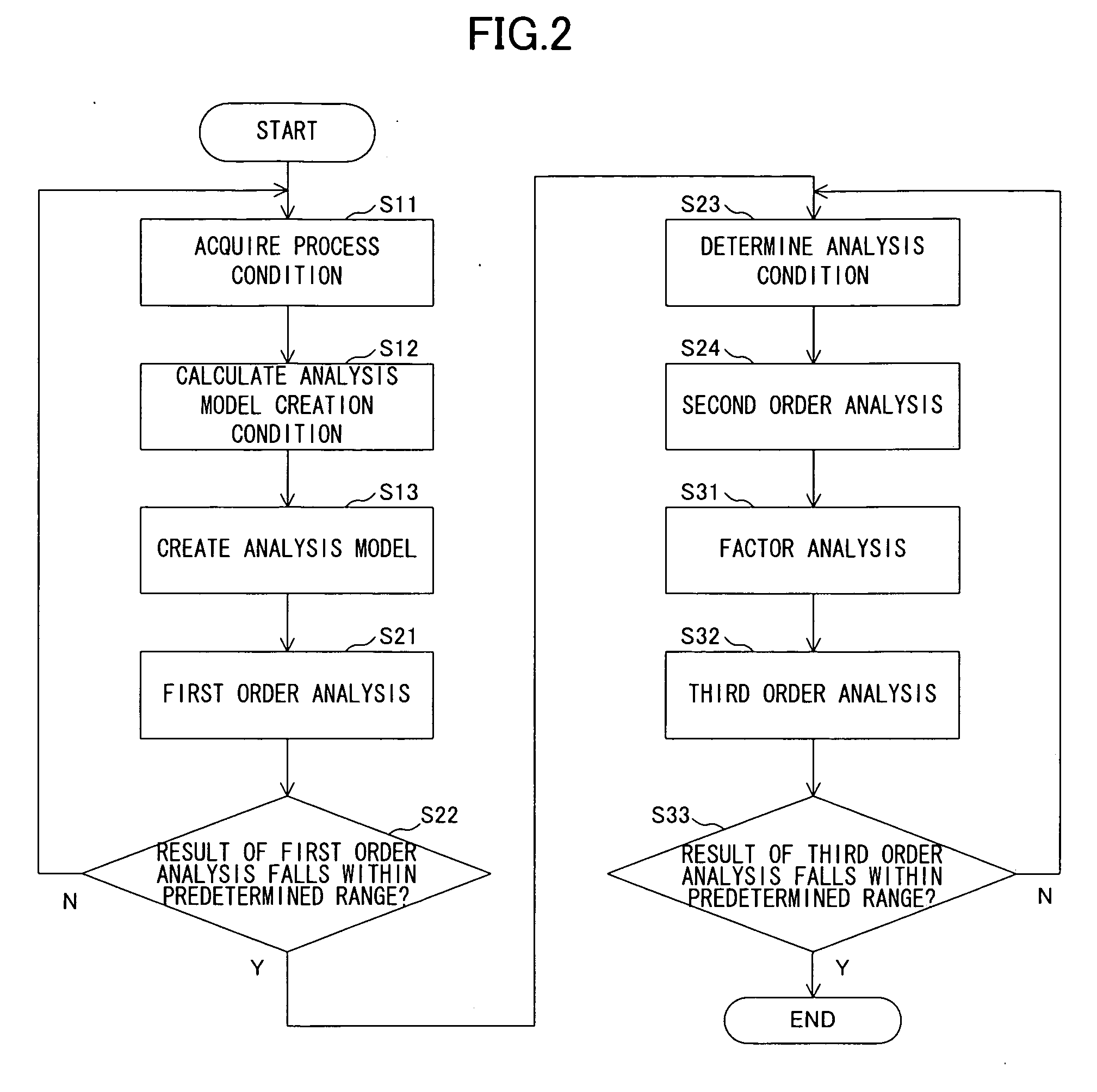

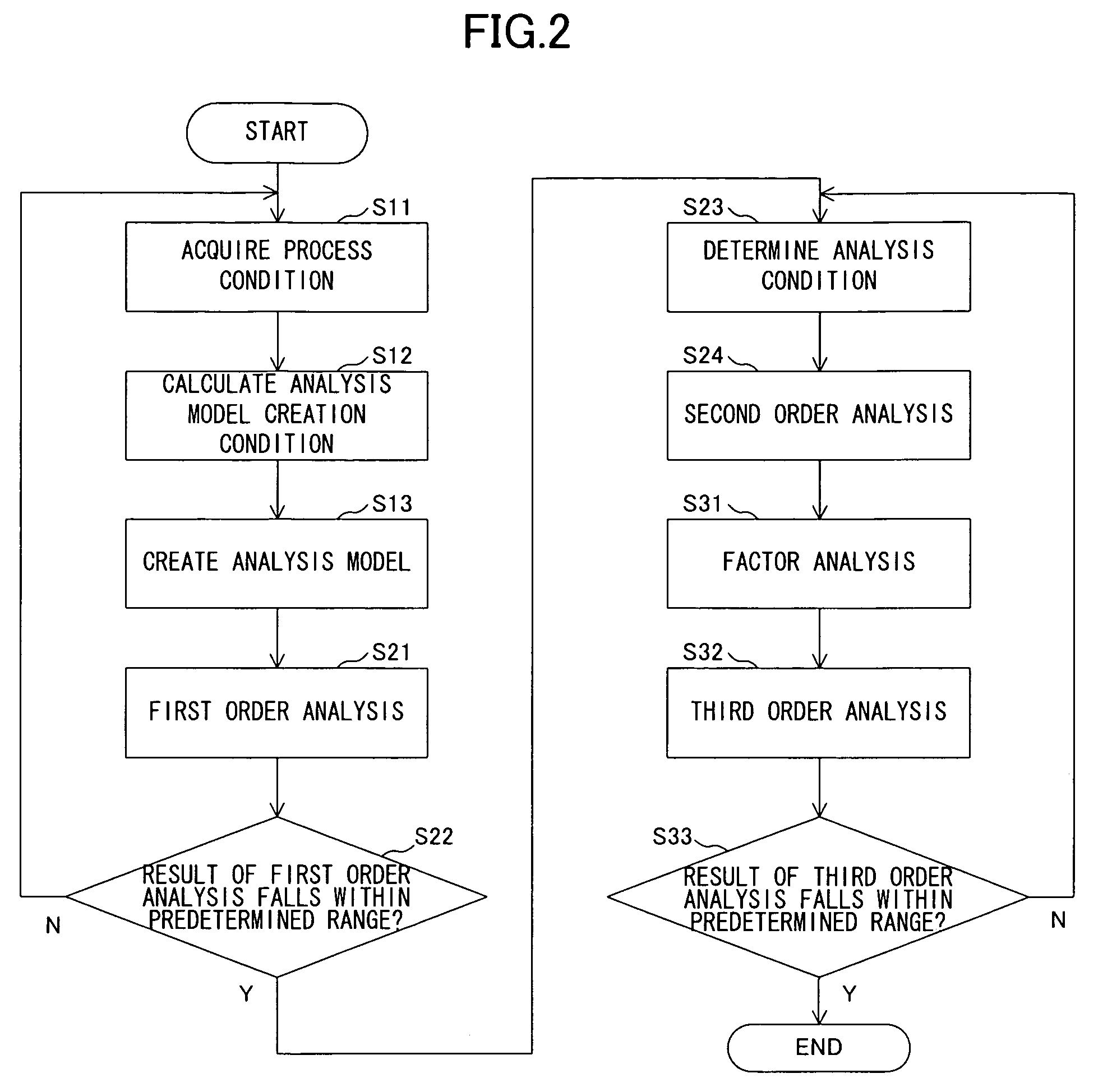

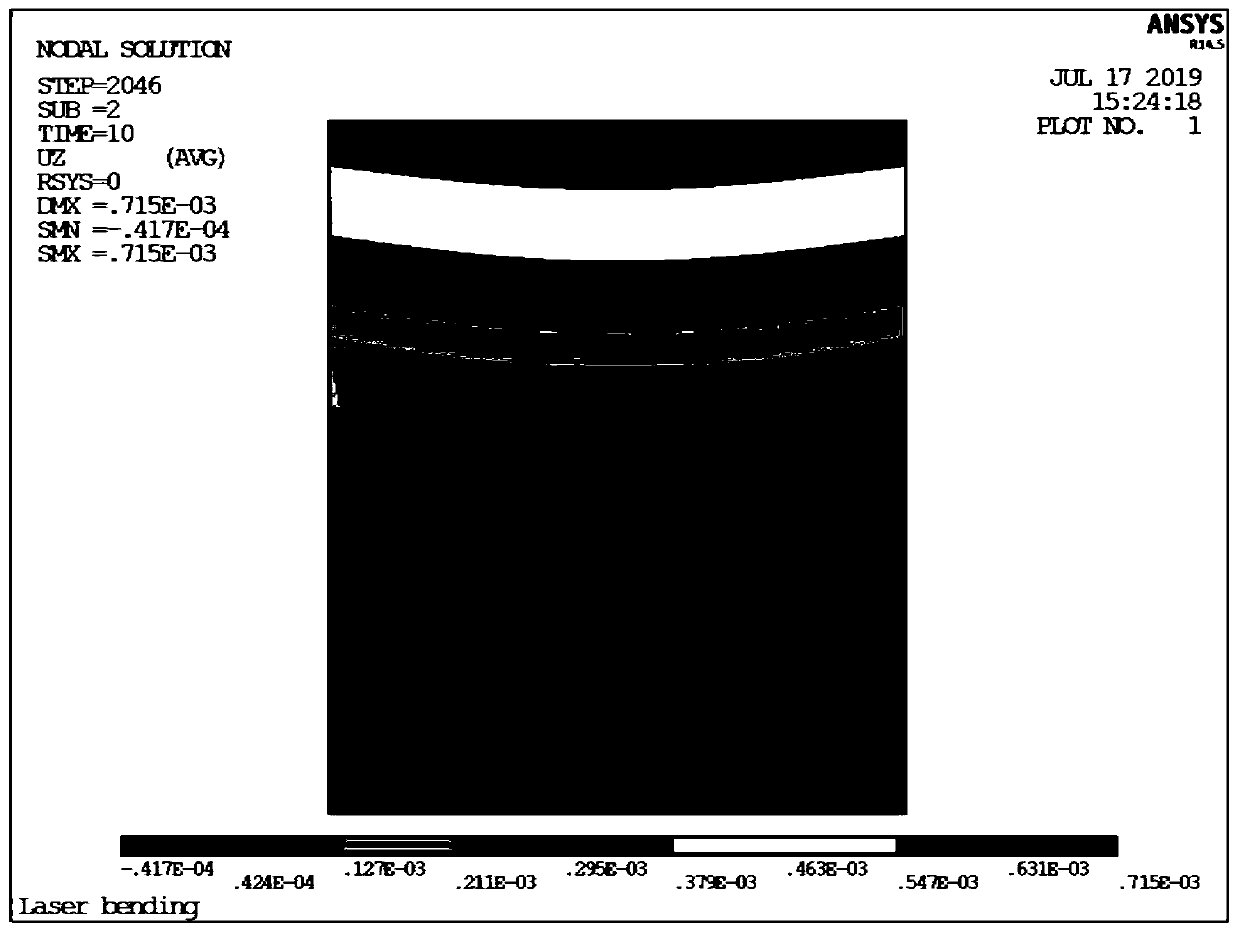

Bending process estimation apparatus, bending process estimation program, and bending process estimation method

InactiveUS20070067060A1Small sample sizeShorten analysis timeDesign optimisation/simulationSpecial data processing applicationsEstimation methodsEngineering

The present invention has been made to provide a laser bending process estimation apparatus, a laser bending process estimation program, and a laser bending process estimation method capable of estimating a result of a laser bending process without an actual workpiece. A laser bending process estimation apparatus that estimates a result of a bending process performed using a laser beam comprises: a process condition acquisition section 1 that acquires a process condition of the bending process; an analysis model creation section 3 that creates an analysis model based on the process condition acquired by the process condition acquisition section 1; and an analysis section 5 that performs heat transfer analysis and heat stress analysis based on the analysis model created by the analysis model creation section 3 to calculate an analysis result of the bending process.

Owner:FUJITSU LTD

Laser forming method for metal sheet

The invention discloses a laser forming method for a metal sheet. According to the laser forming method for the metal sheet, appropriate and unique technological parameters in a laser bending forming method are selected to accurately control the deformation amount of the metal sheet and obtain the metal sheet with continuous bending deformation. The interval between every two adjacent paths is preferably 1.5-2 millimeters, the reciprocating scanning times of each path is preferably 10 times, the diameter of each laser beam spot is 0.1 millimeter, the power is 20-25 watts, the scanning speed is 15-20 millimeters, and the curvature of a finally obtained thin sheet is about 0.05-1 millimeter.

Owner:青岛述诚智能装备股份公司

Bending process estimation apparatus, bending process estimation program, and bending process estimation method

InactiveUS7254459B2Effective estimateReduce in quantityDesign optimisation/simulationSpecial data processing applicationsEstimation methodsEngineering

Owner:FUJITSU LTD

Bending and forming method of thin silicon wafer

InactiveCN102070119AAchieving plastic featuresImprove flexibilityDecorative surface effectsChemical vapor deposition coatingLaser scanningLaser bending

The invention discloses a bending and forming method of a thin silicon wafer, which scans the thin silicon wafer by utilizing Nd:YAG pulse laser and provides power and temperature conditions for bending the thin silicon wafer by thermal action of laser and a thin silicon wafer material. In the bending and forming method, extra temperature environment does not need to be provided in the stage of laser scanning, the bending and forming mainly utilize the thermal action of the laser and the thin silicon wafer material to realize the plastic characteristic of the silicon wafer, and further are realized by stress difference generated by different temperatures on the upper surface and the lower surface. In the bending and forming method, 1064nm pulse laser is utilized to realize bending and forming of the silicon material with the thickness being 0.1mm-0.3mm, a 30-degree bending angle can be obtained, the bending quality is good, simultaneously, the operation is convenient, and the technology is simple, so that the bending and forming method is beneficial to realizing automatization. The laser bending technology adopted by the invention belongs to a non-contact processing form, has no contact damage to the surface of the material, and can effectively avoid damage caused by being contacted with external force in the bending process of the silicon wafer.

Owner:DALIAN UNIV OF TECH

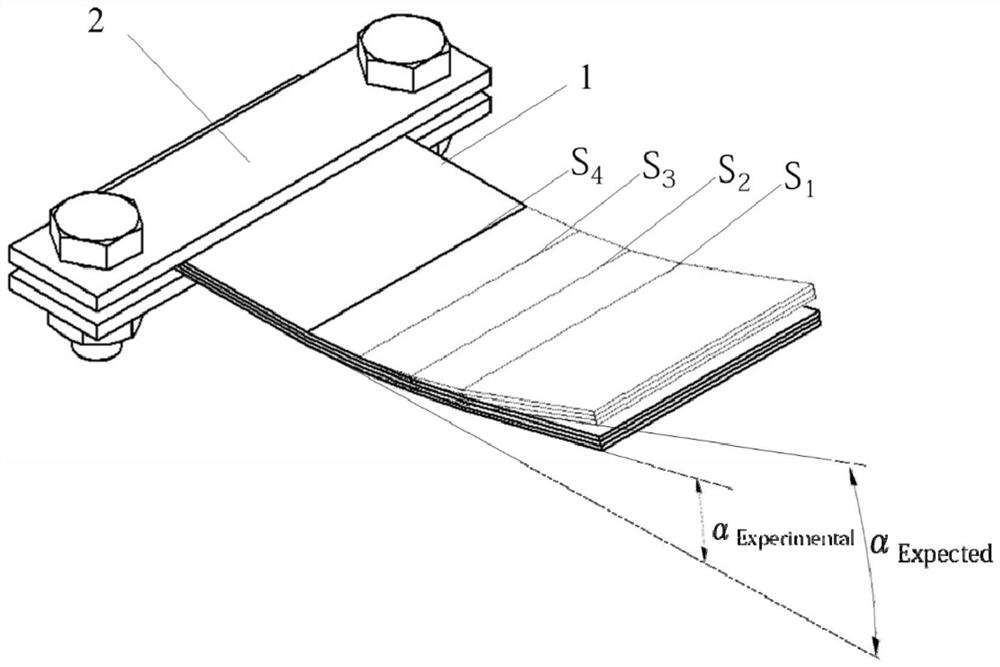

Method for improving laser bending forming precision of single curved surface of fiber metal laminate

ActiveCN114309260AReach the target bending angleReduce residual stressMetal working apparatusFiber metal laminateLaser bending

The invention belongs to the technical field of laser bending forming of fiber metal laminates, and relates to a method for improving laser bending forming precision of a single curved surface of a fiber metal laminate. According to the invention, an upper and lower layer alternate scanning laser bending forming method is adopted, and the elastic recovery deformation of a bending area in laser multi-channel scanning bending forming is corrected. And the upper-layer metal laser bending forming and the lower-layer metal pre-bending laser bending forming based on the temperature gradient mechanism are alternately carried out until the target bending angle is reached. And the lower metal layer and the upper metal layer are plastically deformed, so that the elastic recovery of the formed bending area caused by the interference of subsequent scanning is inhibited. And the single-curved-surface laser bending forming precision of the fiber metal laminate is improved, the internal residual stress of the plate is reduced, and the single-curved-surface technical requirements of the metal laminate are met.

Owner:DALIAN UNIV OF TECH

A laser processing device for a parabolic streamline hole

ActiveCN111822888BAchieve laser processingMeet the process requirementsLaser beam welding apparatusLaser processingEngineering

The invention relates to the field of laser processing, in particular to a laser processing device for a parabolic streamline hole, comprising a casing, a laser focusing lens, a laser window and a nozzle. A laser window is arranged on one side of the cavity, and a nozzle is arranged on the other side. An interface is arranged on the casing to communicate with the hydraulic equalization cavity. A laser focusing lens is arranged in the casing and outside the laser window. The laser is injected from the back end opening of the casing and irradiated in the nozzle after passing through the laser focusing lens, the laser window and the liquid in the hydraulic equalization chamber in sequence, and the casing outside the nozzle is provided with a jet port, After the liquid passes through the nozzle, a jet is formed and ejected from the jet port. The jet is bent by gravity to form a parabolic shape and is injected into the workpiece to be processed. The laser enters the jet and propagates along the direction of the jet. The invention bends the laser with the jet, and can efficiently realize the laser processing of the parabolic streamline hole.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

A method of laser bending and forming of knife switch knife holder seat

ActiveCN112427543BAchieve laser flexible formingImprove plasticityShaping toolsLaser scanningMetal sheet

The invention provides a method for laser bending forming of a blade switch blade holder, which can be used for rapid bending forming of the blade switch blade holder without a mold. First, based on the temperature gradient mechanism, when the laser scans the metal sheet, the laser scanning line area will generate uneven thermal stress due to the temperature gradient, causing the sheet to bend toward the laser beam, and at the same time, the scanning area will generate new residual stress and strain distribution. Secondly, based on the buckling mechanism, the laser scanning is performed on the pre-bending back position, and the plate is bent away from the laser beam due to the influence of the residual stress and strain generated by the pre-bending. When laser forming the sample of the tool holder, by changing the laser parameters and the number of laser scans of each path, combined with appropriate path planning, high-precision laser rapid bending of tool holders of different sizes and shapes can be realized.

Owner:DALIAN UNIV OF TECH

Progressive bending sheet metal

The invention provides a progressive bending sheet metal which is manufactured with the method of laser bending forming. According to the laser bending forming method, proper and unique technological parameters are chosen, deformation of the sheet metal is controlled accurately, and the progressive bending sheet metal is obtained at last. Interval between passes of the sheet metal is preferred to be 1.5-2mm, and reciprocating scanning time of each pass is preferred to be 10 times, diameter of a laser beam spot is 0.1mm, power is 20-25W, scanning speed is 15-20mm, and curvature of the sheet metal obtained at last is about 0.05-1mm.

Owner:宁波市博祥新材料科技有限公司

Laser bending shaping method and of light-wall conduit

InactiveCN101332536BOptimizing Process ParametersReasonable deformationLaser beam welding apparatusControl systemTitanium

The invention discloses a laser bending forming method of a thin-walled tube and a special device used for realizing the method. The method adopts two laser beams to act on the thin-walled tube, wherein one laser beam is used for heating the thin-walled tube to soften the thin-walled tube and producing thermal stress along the thickness direction of the tube wall so as to cause the tube to bend and deform; the other laser beam forms a plasma on the surface of the tube, and further bends the thin-walled tube by the shock action produced by the plasma to obtain a fine grain structure. The special device for realizing the laser bending forming method of the thin-walled tube is composed of a laser generator system, a laser head system, a workbench system and a motion control system. By adopting the method, metal and alloy tubes made from steel, aluminum, copper, titanium and the like can be machined, which is a high-flexibility dieless forming technology.

Owner:SHANDONG UNIV

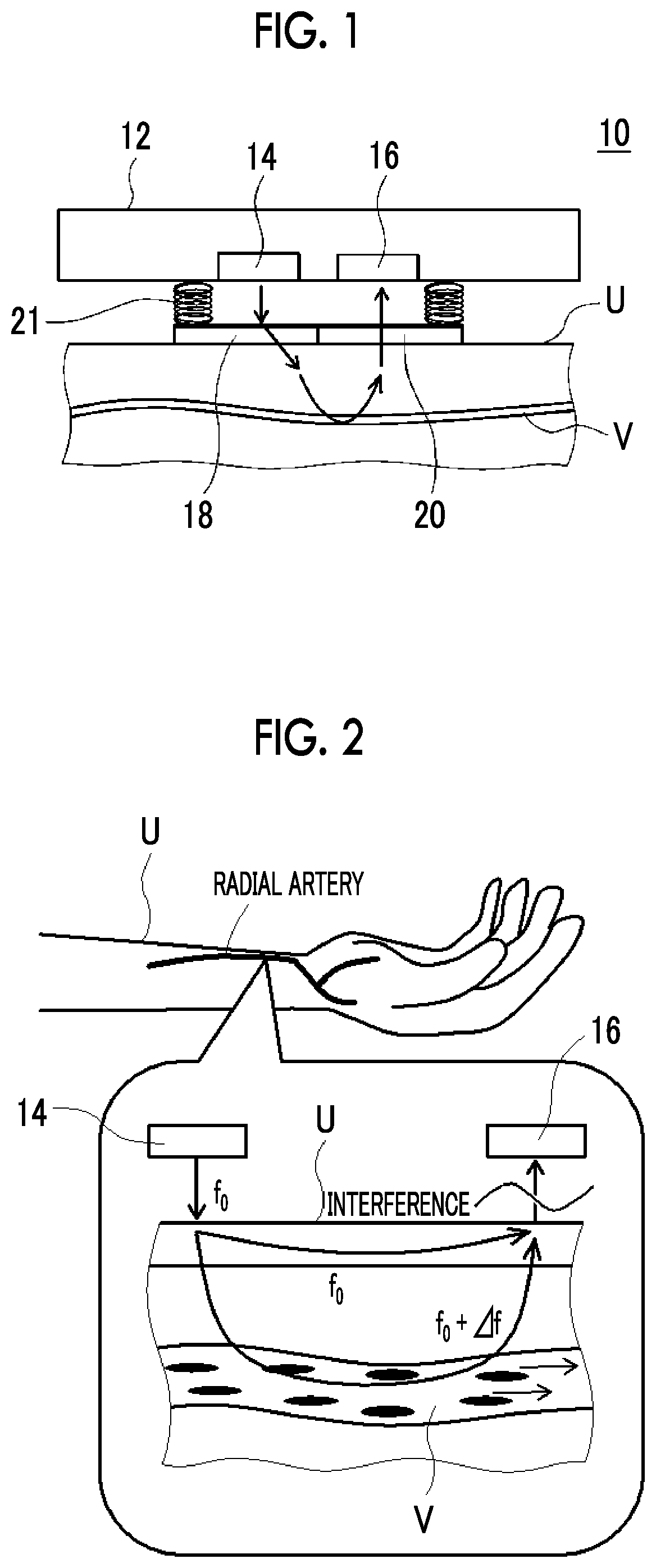

Flow rate measuring device

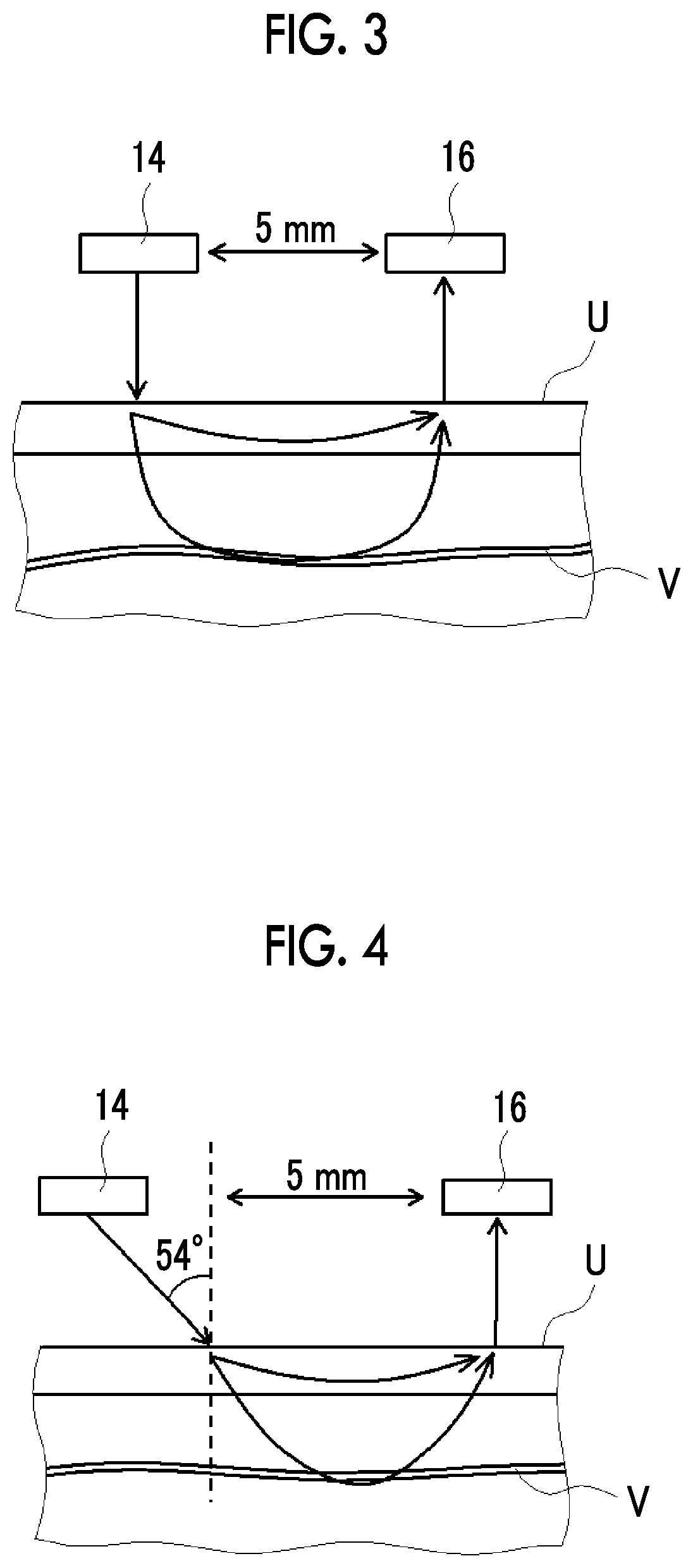

PendingUS20220214195A1Sufficient signal intensityVolume/mass flow measurementDiagnostic recording/measuringLaser lightMechanical engineering

Provided is a flow rate measuring device capable of ensuring sufficient signal intensity even with a low output light source. The flow rate measuring device that detects a flow velocity of a fluid flowing through an object by a Doppler effect of light, the flow rate measuring device includes a light source unit that emits laser light to the object, a light receiving unit that receives the laser light scattered by the object, and a light bending member that bends the laser light emitted from the light source unit and causes the laser light to be inclined with respect to a surface of the object and incident on the surface.

Owner:FUJIFILM CORP

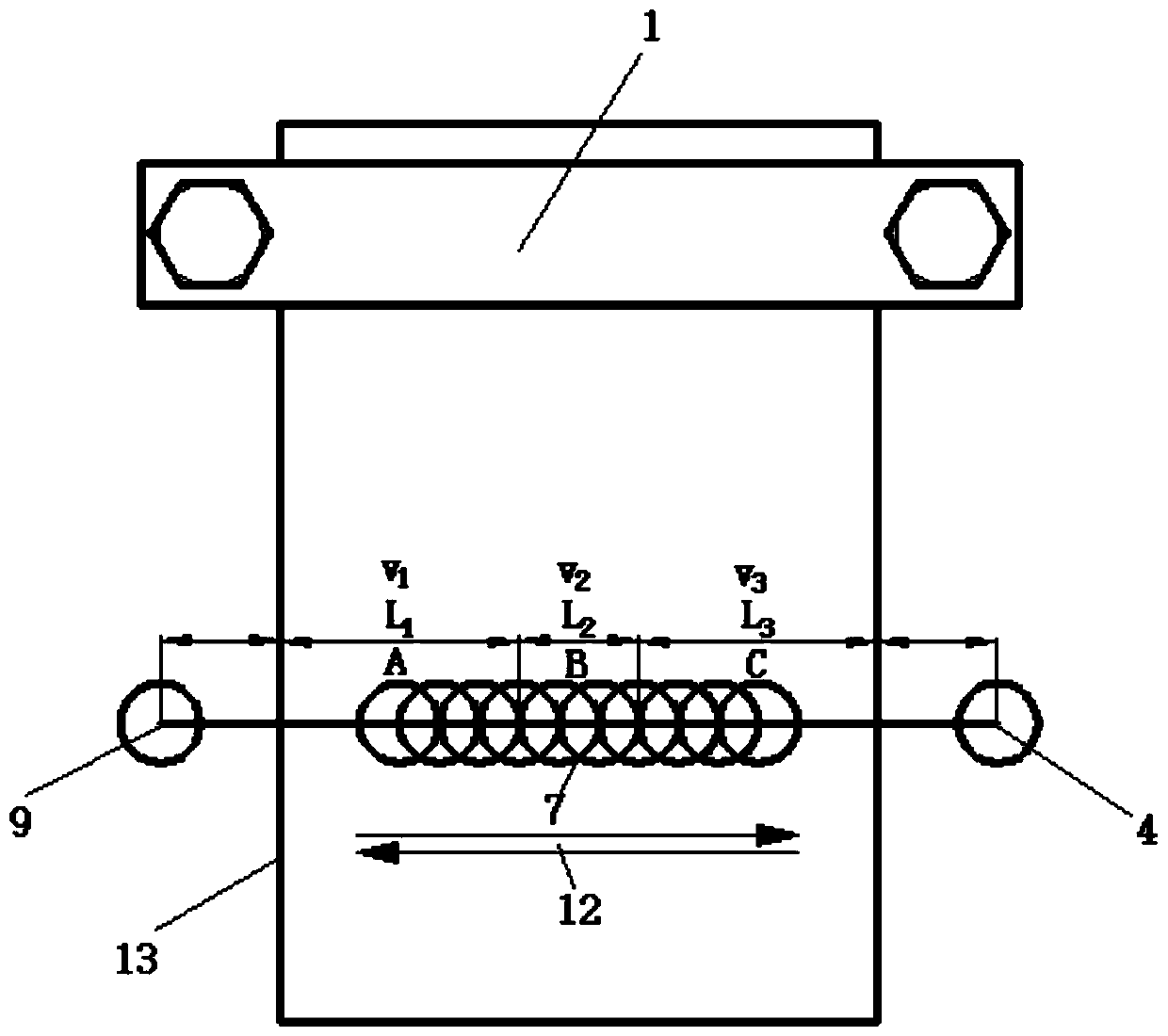

Prestress laser bending forming method for aluminum alloy high-ribbed wallboard

ActiveCN113894187AAchieve bendingReduce mechanical loadAircraft componentsShaping toolsLaser bendingPlastic property

The invention provides a prestress laser bending forming method for an aluminum alloy high-ribbed wallboard. The prestress laser bending forming method comprises the steps that S1, a plurality of to-be-formed areas are divided on the breadth of the aluminum alloy high-ribbed wallboard; S2, any to-be-formed area is selected to be subjected to pre-bending loading, so that the to-be-formed area enters slight plasticity; S3, a laser beam is used for scanning ribs with concentrated elastic stress in the to-be-formed area; S4, after the aluminum alloy high-ribbed wallboard is cooled to the room temperature, unloading is conducted, and forming of the to-be-formed area subjected to pre-bending loading is completed; and S5, the step S2, the step S3 and the step S4 are repeated in sequence for the rest to-be-formed areas, and an aluminum alloy high-ribbed wallboard bending forming piece is obtained. The pre-bending loading is carried out on the to-be-formed areas, so that the to-be-formed areas enter slight plasticity, and then the laser beam is used for scanning the rib parts with concentrated elastic stress, so that the bending forming of the aluminum alloy high-ribbed wallboard is realized, the overload damage and damage of the high-ribbed wallboard are avoided, and the forming precision of the high-ribbed wallboard is improved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

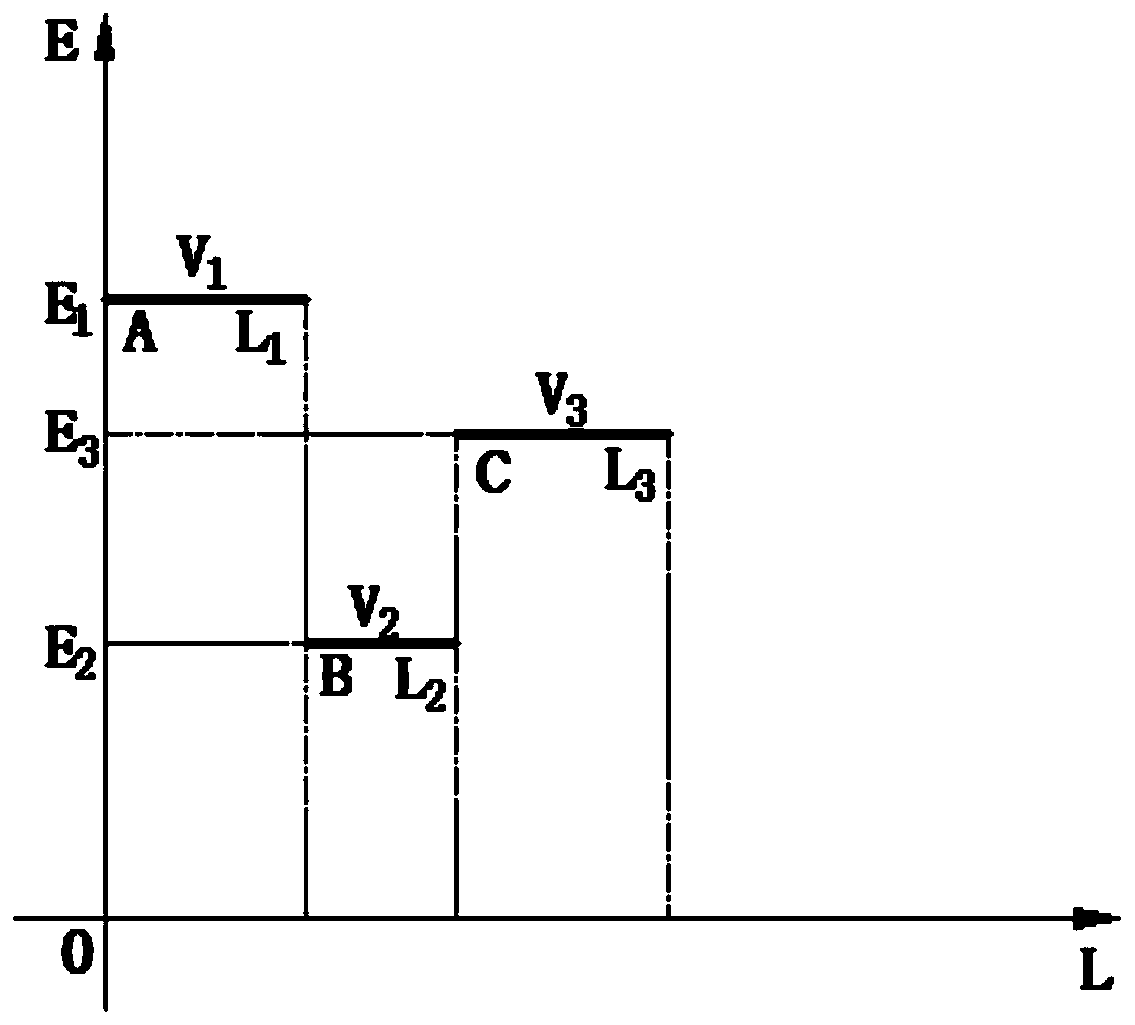

An energy control method for reducing warpage in laser bending of thin metal plates

The invention belongs to the technical field of metal sheet laser bending forming, and relates to an energy regulation and control method for reducing the bending amount of a metal sheet laser bendingforming. In the invention, a method combining three-stage variable speed with local energy compensation is adopted for correcting a warping deformation, and the energy coarse adjustment is carried out by adopting a three-section variable speed mode to adopt a low speed to ensure higher energy input at the section position with small bending angle and high bending angle adopting high speed to ensure lower energy input; the energy compensation method comprises the following steps of: carrying out energy compensation on a segment position with small bending angle by scanning a local area with small bending angle for lesser times after the local energy compensation mode is processed; and the combination of the two aspects can effectively reduce the bending amount in the laser bending processof the metal sheet and meet the technical requirements. The method can be applied to the field of metal sheet forming with high angle precision required by laser non-die bending processing.

Owner:DALIAN UNIV OF TECH

Bending and forming method of thin silicon wafer

InactiveCN102070119BAchieving plastic featuresImprove flexibilityDecorative surface effectsSemiconductor/solid-state device manufacturingLaser scanningSilicon

The invention discloses a bending and forming method of a thin silicon wafer, which scans the thin silicon wafer by utilizing Nd:YAG pulse laser and provides power and temperature conditions for bending the thin silicon wafer by thermal action of laser and a thin silicon wafer material. In the bending and forming method, extra temperature environment does not need to be provided in the stage of laser scanning, the bending and forming mainly utilize the thermal action of the laser and the thin silicon wafer material to realize the plastic characteristic of the silicon wafer, and further are realized by stress difference generated by different temperatures on the upper surface and the lower surface. In the bending and forming method, 1064nm pulse laser is utilized to realize bending and forming of the silicon material with the thickness being 0.1mm-0.3mm, a 30-degree bending angle can be obtained, the bending quality is good, simultaneously, the operation is convenient, and the technology is simple, so that the bending and forming method is beneficial to realizing automatization. The laser bending technology adopted by the invention belongs to a non-contact processing form, has no contact damage to the surface of the material, and can effectively avoid damage caused by being contacted with external force in the bending process of the silicon wafer.

Owner:DALIAN UNIV OF TECH

Laser Bending Forming Method of Linear Spot of Metal Sheet

InactiveCN110314980BLow costReduce warpageHeat treatment process controlLaser beam welding apparatusPoint lightLight spot

The invention belongs to the technical field of high-efficiency, high-precision and high-performance laser bending forming of metal plates, and relates to a linear spot laser bending forming method of metal thin plates. The present invention uses a multi-mode laser scanning rotating mirror or a single piezoelectric deformable mirror to convert the laser Gaussian-distributed point spot into a uniformly distributed line-shaped spot, and simultaneously loads it on the bending line area to bend and shape the metal sheet, so that the metal sheet bends The temperature field on the broken line is evenly distributed, so as to reduce warping deformation, improve the consistency of bending angle, and improve the bending efficiency.

Owner:DALIAN UNIV OF TECH

A method for forming arc grooves by laser flexible bending of metal sheets

The invention provides a method for forming an arc groove in a metal plate by adopting a laser flexible bending forming technology. The method can be used for rapid bending forming of groove structures of single arc lines, different arc combined lines and the like of metal plates. According to the method, on the basis of a temperature gradient mechanism, when a laser scans the metal plate, a laser scanning line region can generate an obvious temperature gradient along the laser scanning paths and then can generate the non-uniform thermal stress distributed along a scanning line so that three-dimensional curved surface deformation of the plate can be generated; and the arc groove is formed according to the expected shape, the shape of the laser scanning line, all the laser parameters of each scanning path and the laser scanning frequency of each path are changed, proper path planning is combined, and therefore rapid high-precision laser bending forming of arc grooves of different types can be realized.

Owner:DALIAN UNIV OF TECH

Wearable vital sign monitoring device and method

ActiveCN110974198BPromote reductionImprove accuracyDiagnostic recording/measuringSensorsHuman bodyEngineering

The invention relates to a wearable vital sign monitoring device. A laser light source of the wearable vital sign monitoring device is used for emitting laser to a sensing optical fiber; two ends of the sensing optical fiber are respectively connected with a laser light source and a photoelectric conversion module; the sensing optical fiber is bent after bearing the pressure of pulse or breathingor heartbeat movement of a human body, and a laser signal transmitted in the sensing optical fiber is lost at a bent part and is modulated based on a bending loss principle; the photoelectric conversion module is used for converting the modulation signal of the laser bending loss output by the sensing optical fiber into an electric signal representing the pulse or breathing or heartbeat movement of the human body; and a vital sign signal extraction module is used for extracting the corresponding human body pulse or breath or heartbeat frequency from the electric signal representing the human body pulse or breath or heartbeat movement. According to the invention, the vital sign information of the human body can be accurately monitored in real time.

Owner:WUHAN UNIV OF TECH

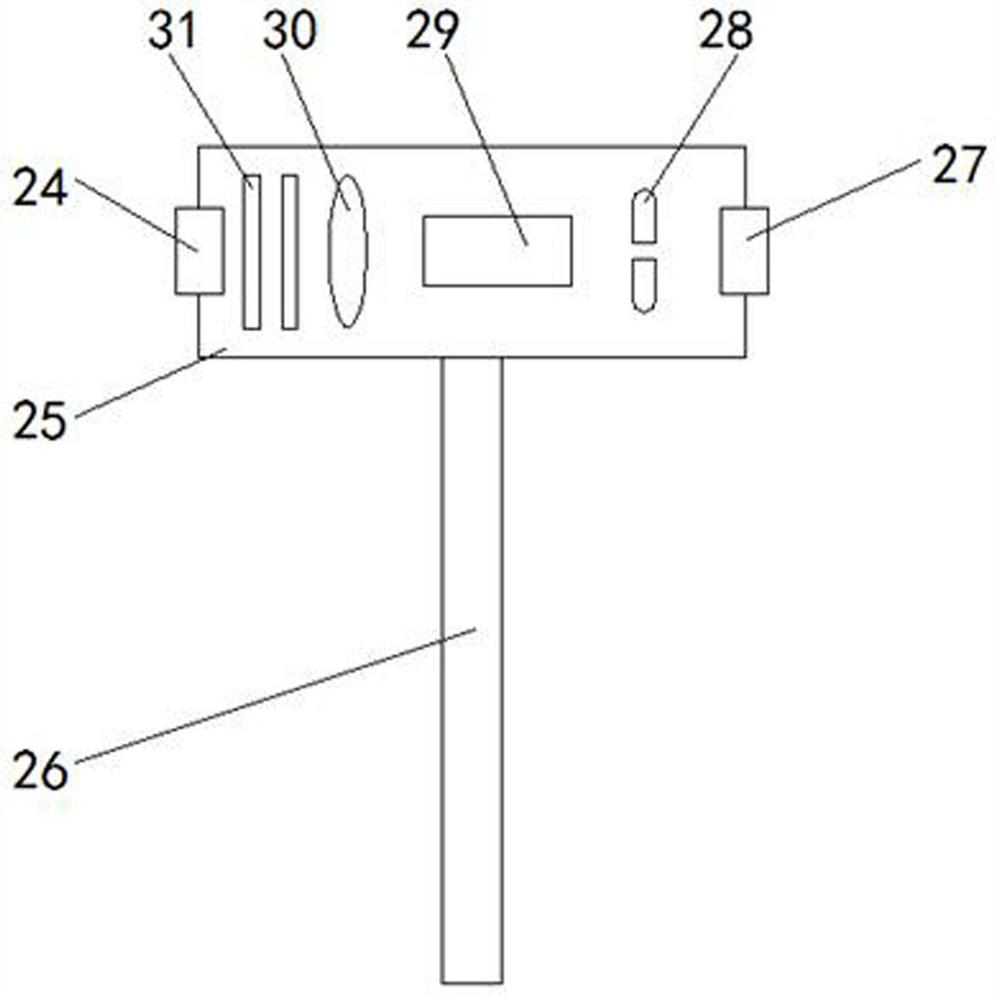

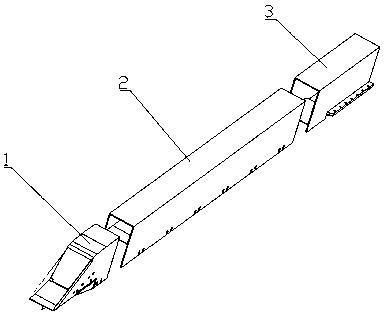

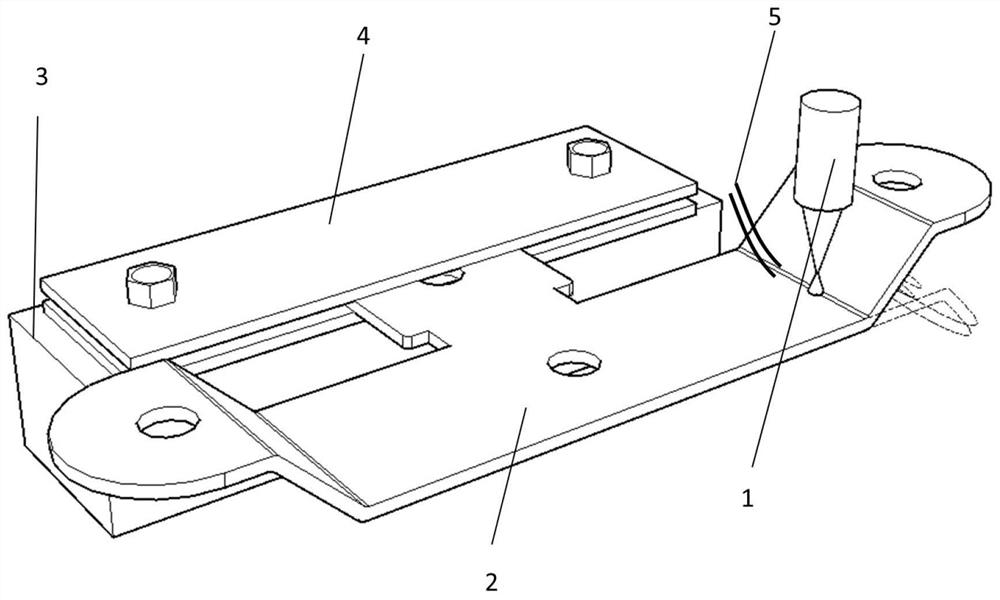

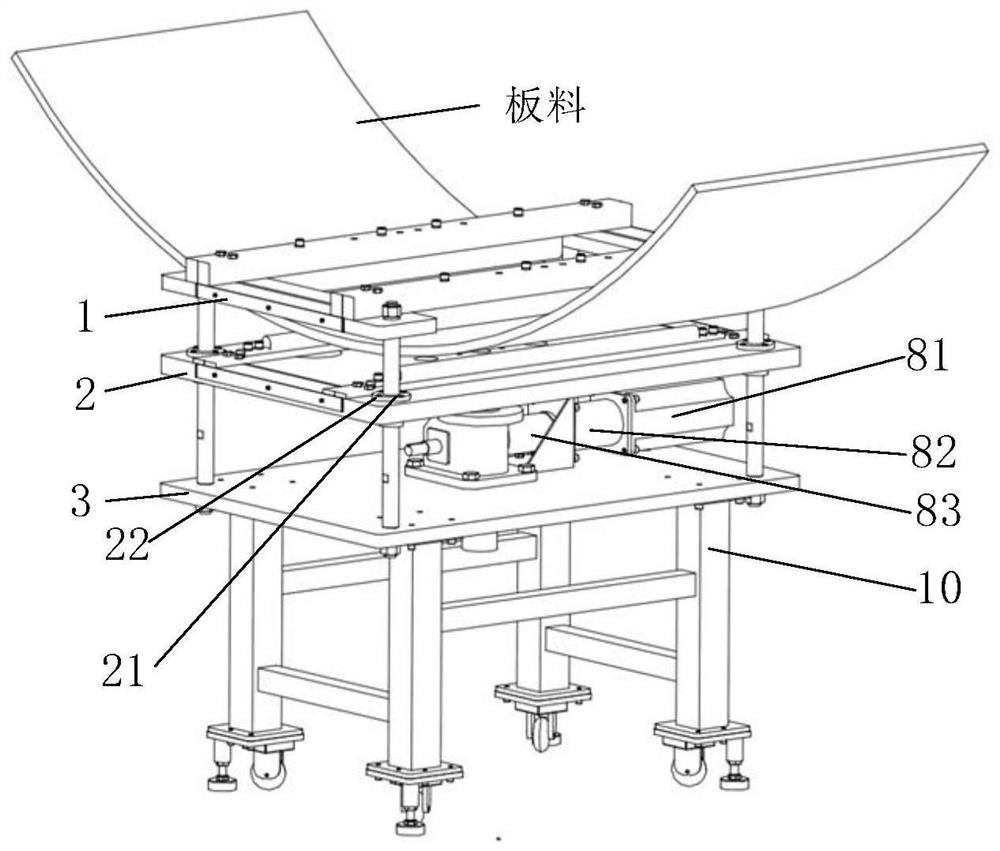

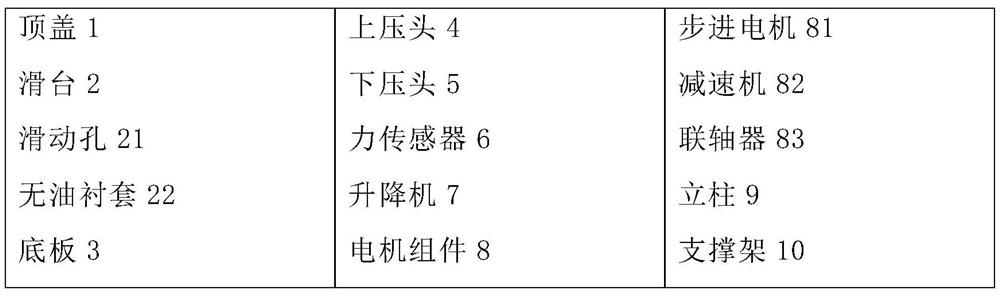

Flexible loading platform for sheet metal laser bending

ActiveCN111360106BImprove processing qualityMeet the process requirementsShaping toolsMetal working apparatusLaser processingElectric machinery

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com