Bending and forming method of thin silicon wafer

A technology of bending and forming silicon wafers, which is applied in the fields of technology for producing decorative surface effects, decorative art, gaseous chemical plating, etc., can solve the problems of uncontrollable external force forming, easy breakage of silicon wafers, and damage of silicon wafers, etc., to achieve Good bending effect, beneficial to automation, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

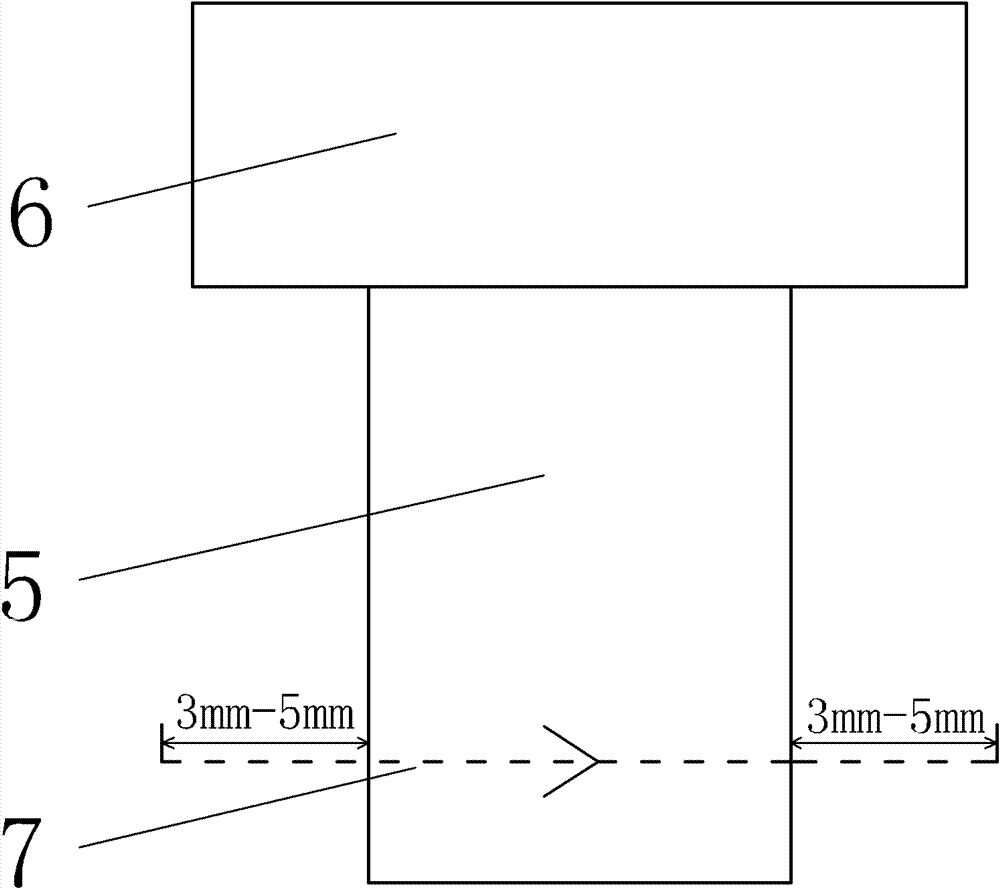

[0024] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, a method for bending and forming a thin silicon wafer uses a laser beam 3 with a wavelength of 1064 nm output by a Nd:YAG pulsed laser to scan the silicon wafer, and the thin silicon wafer is formed by the thermal action of the laser beam 3 and the material of the thin silicon wafer 5. Sheet 5 is bent to provide power and temperature conditions, specifically including the following steps:

[0025] A. Select a thin silicon wafer 5 with a length of 2 to 10 mm and a thickness of 0.1 to 0.3 mm to be scanned, and clean it with deionized water;

[0026] B. Install the thin silicon wafer 5 on the pre-adjusted workbench, and fix one end of it with the fixture 6; select the pulse width of the Nd:YAG pulsed laser between 1 and 10ms, and adjust it through the online video system 1 The focus lens 2, after determining the laser beam focal position 4, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com