Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Industrial data processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial data processing is a branch of applied computer science that covers the area of design and programming of computerized systems which are not computers as such — often referred to as embedded systems (PLCs, automated systems, intelligent instruments, etc.). The products concerned contain at least one microprocessor or microcontroller, as well as couplers (for I/O).

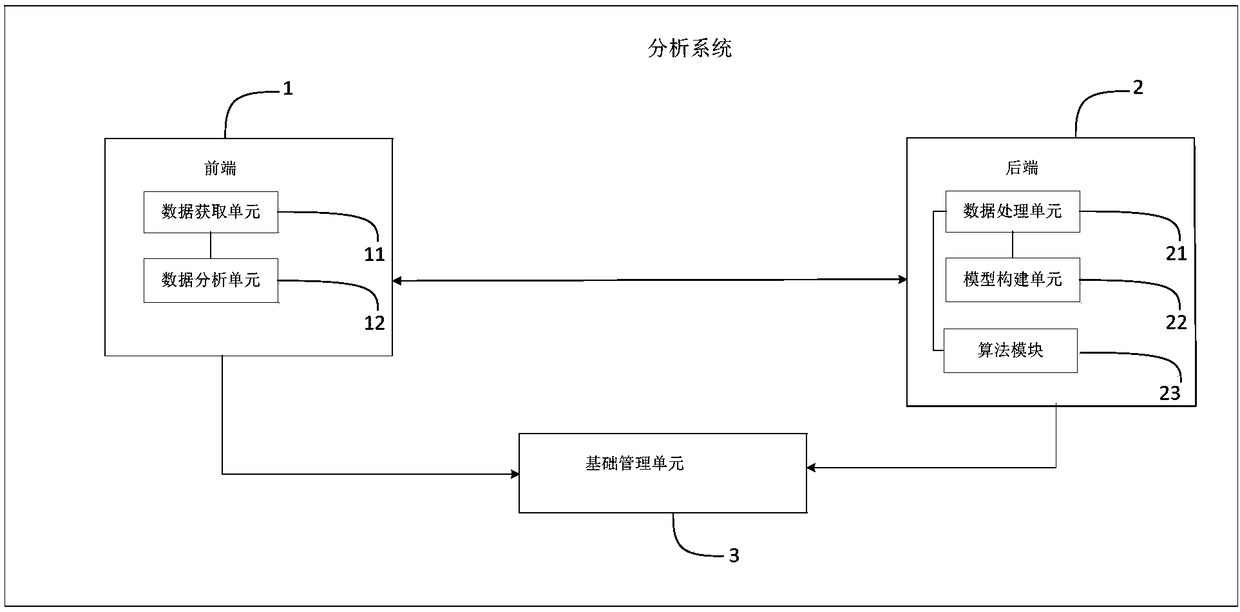

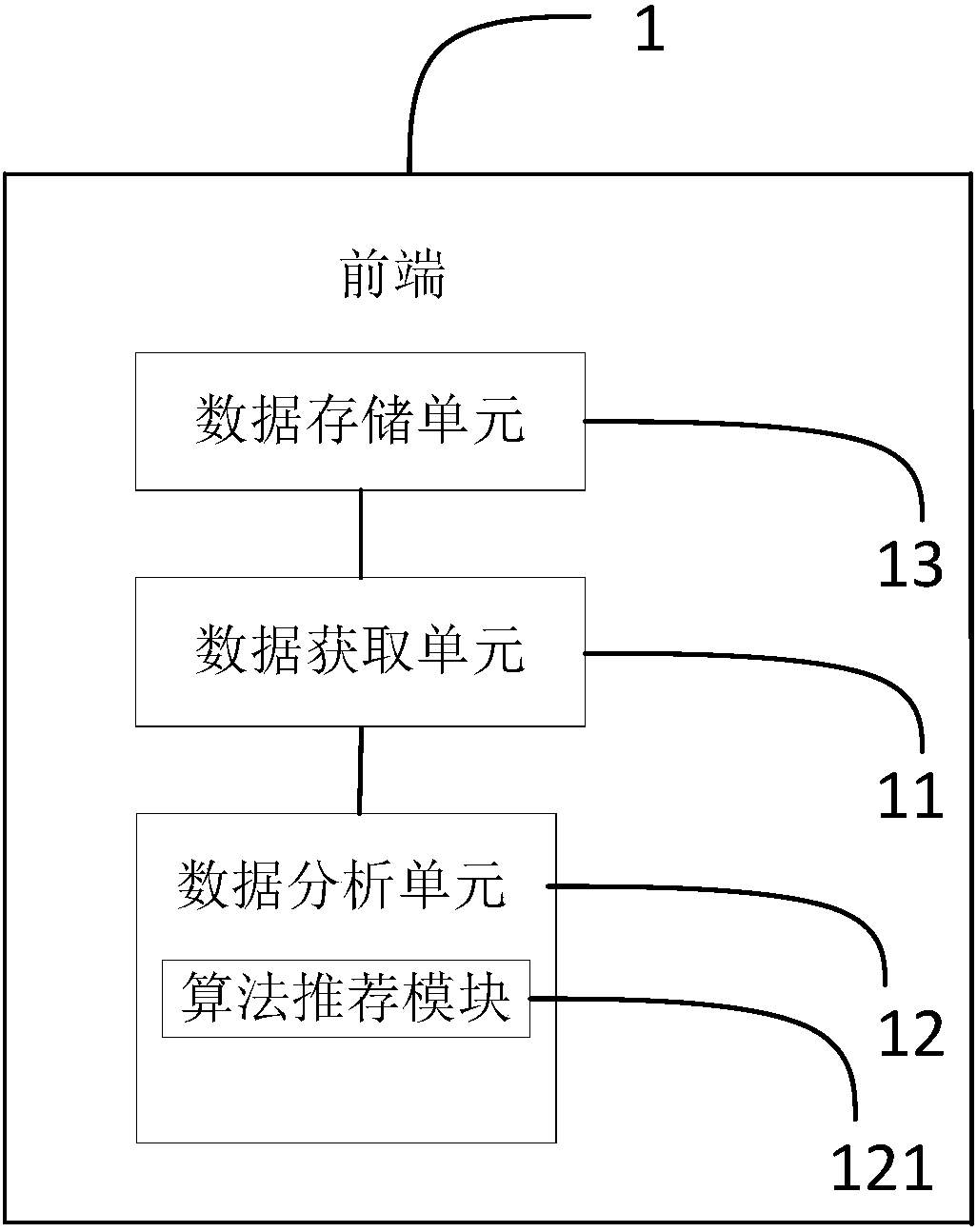

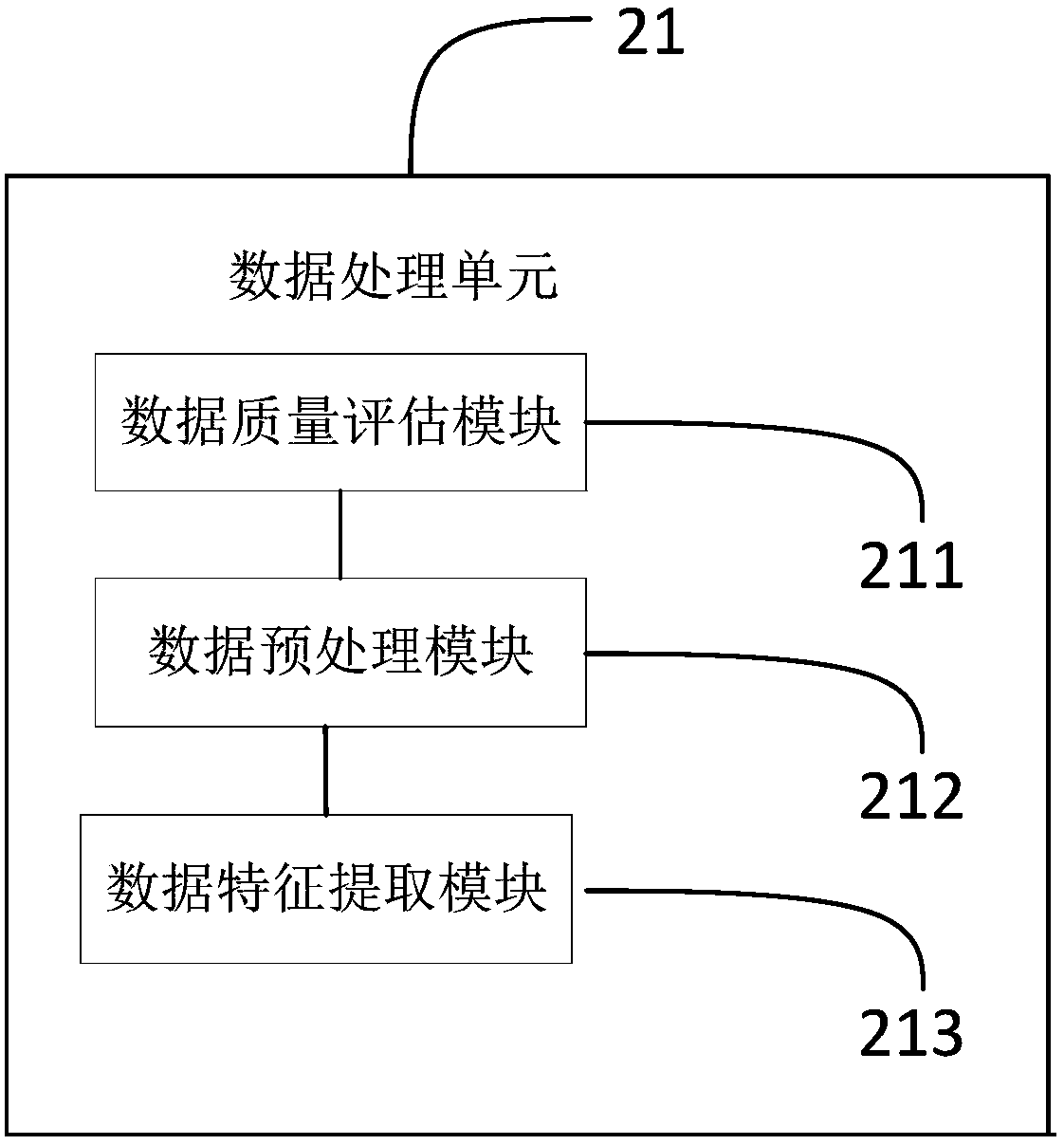

Analysis system based on industrial data

InactiveCN108229828AIncrease the degree of reuseImprove development efficiencyResourcesSpecial data processing applicationsData selectionComputer module

The present invention provides an analysis system based on industrial data. The analysis system based on industrial data is applied to industrial devices. The analysis system comprises a plurality ofalgorithm modules, and concretely comprises: a data obtaining unit configured to obtain industrial data of an industrial device; a data analysis unit configured to select algorithm modules requiring being called and configuration parameters corresponding to the algorithm modules according to the industrial data to form call information of the algorithm modules; a data processing unit configured tocall corresponding algorithm modules according to the call information, wherein the algorithm modules perform processing of the industrial data according to the configuration parameters and return aprocessing result to the data analysis unit; and a model construction unit configured to process the industrial data according to the algorithm modules called by the data processing unit to form an industrial data processing model. The problems are solved that a customized analysis method brings large code compiling work for developers to influence the project enforcement efficiency and cause lowdevelopment efficiency in the prior art.

Owner:SHANGHAI ELECTRICGROUP CORP

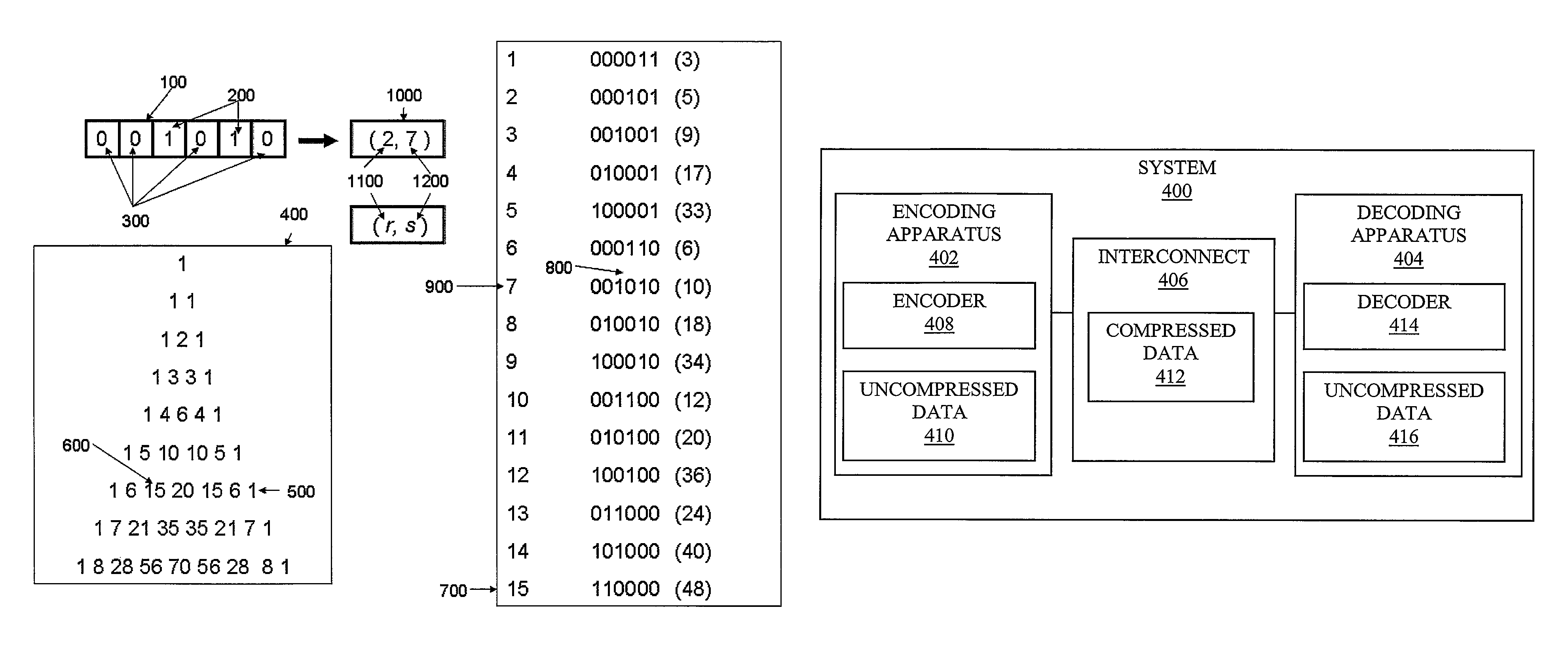

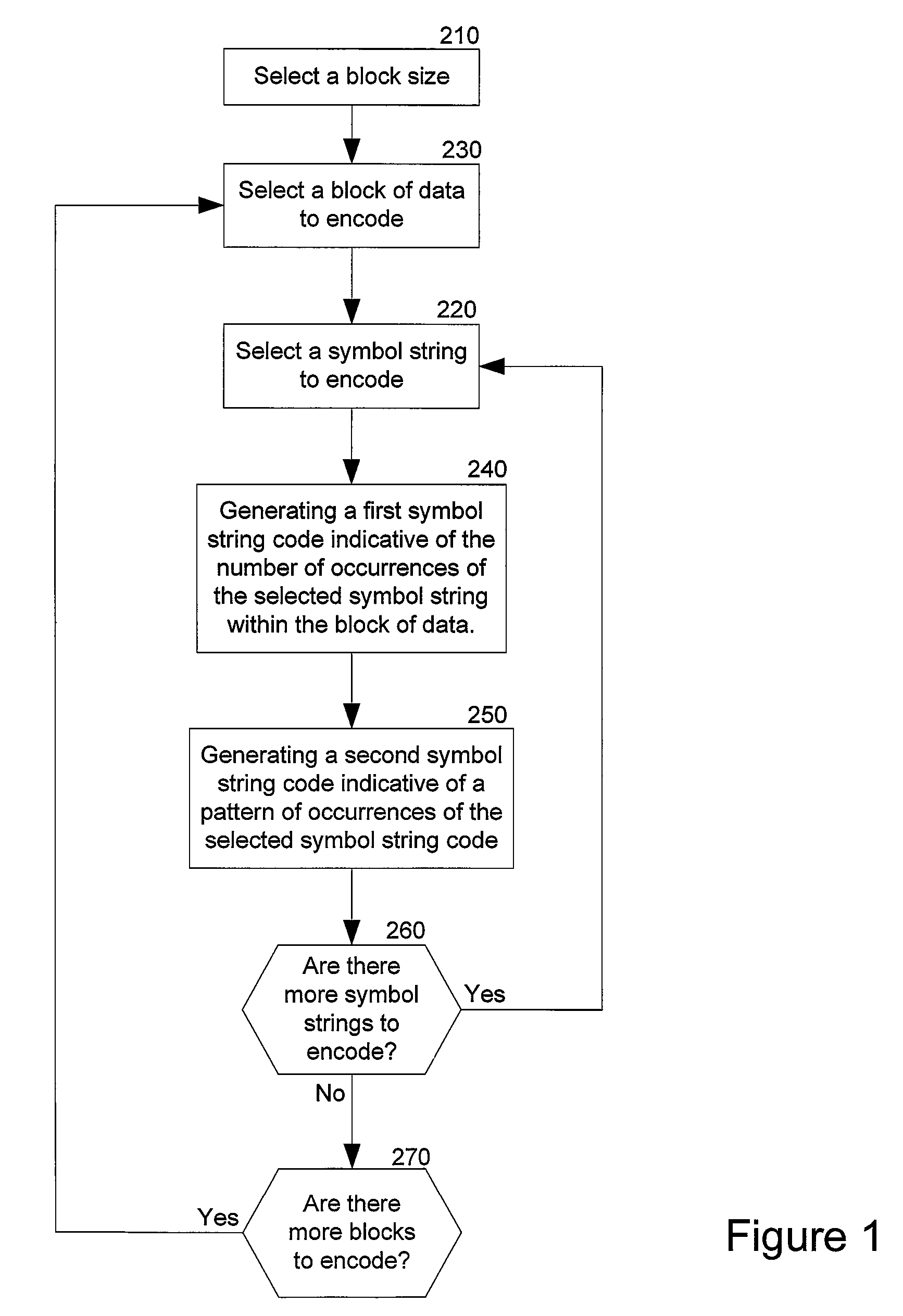

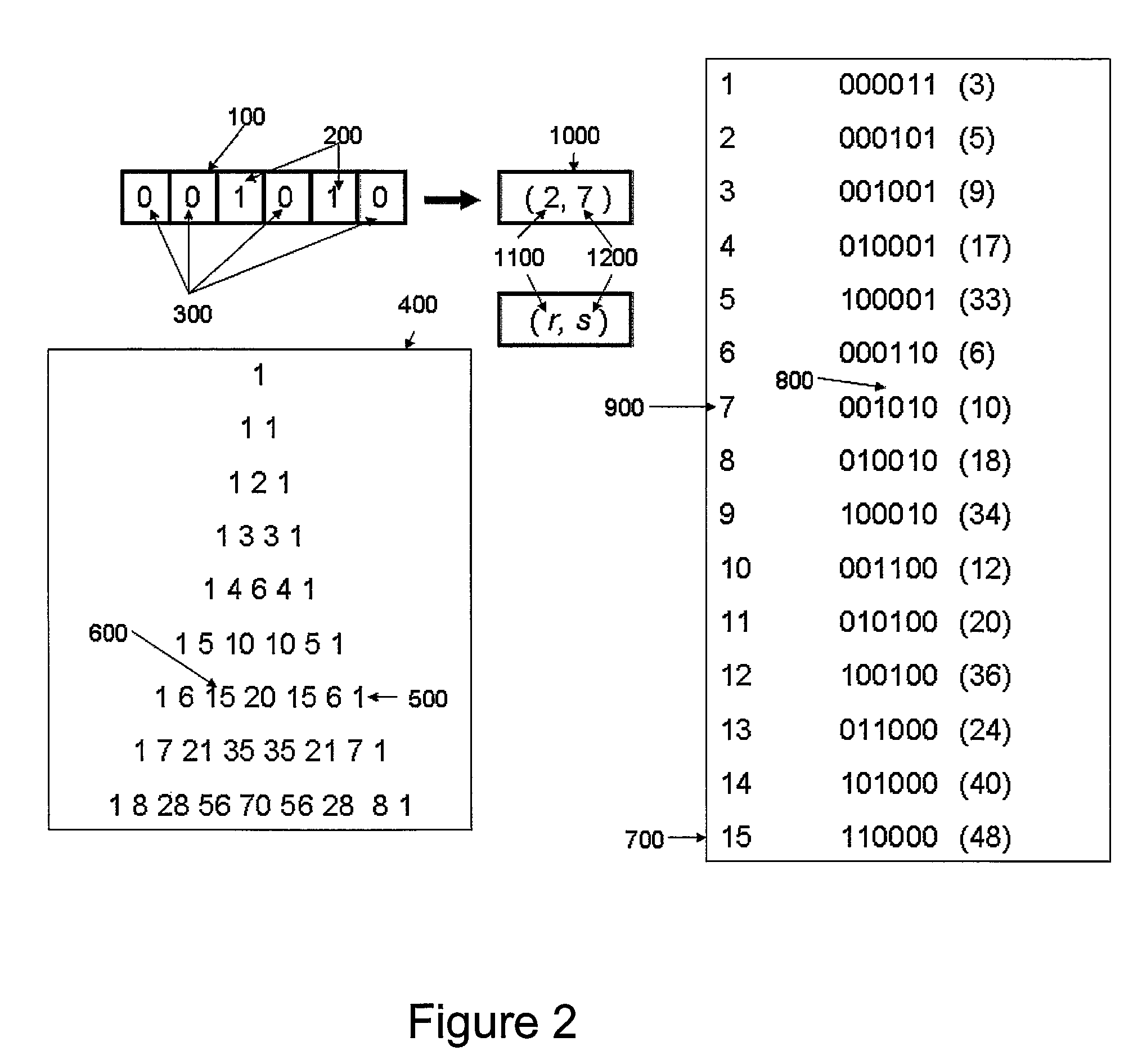

Combinatorial coding/decoding for electrical computers and digital data processing systems

Owner:XYLON LLC +1

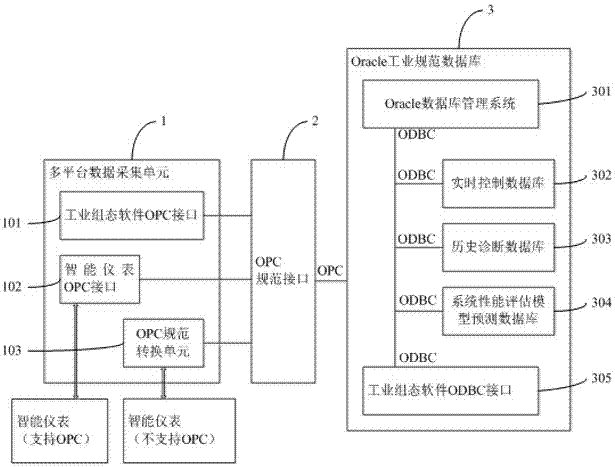

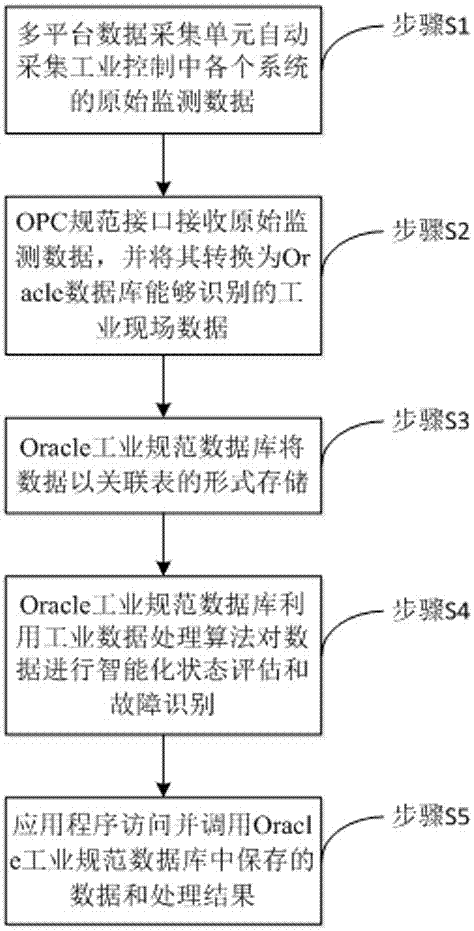

Large-scale industrial information control system based on Oracle database and control method thereof

InactiveCN107291060AEasy to integrate and analyzeEliminate transport barriersProgramme controlElectric testing/monitoringProcess equipmentIndustrial systems

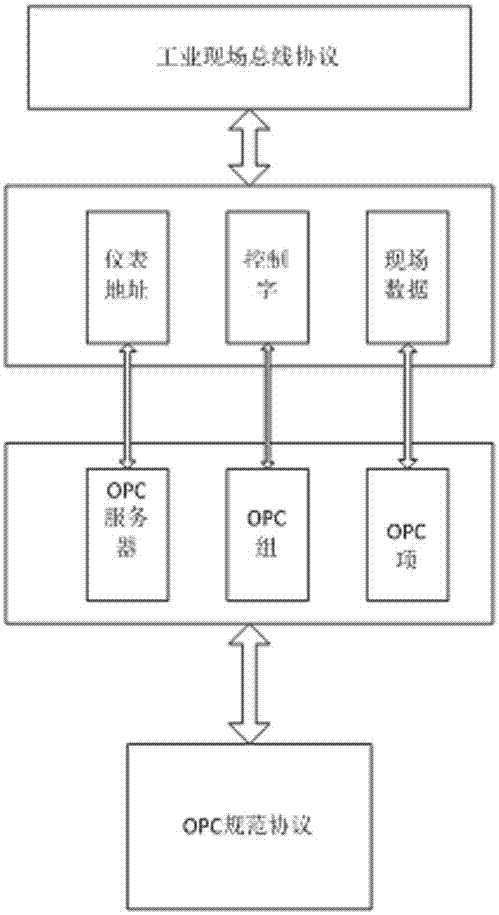

The invention relates to a large-scale industrial information control system based on an Oracle database and a control method thereof. A multi-platform data acquisition unit is used for collecting original monitoring data of all systems under industrial control. An OPC standard interface is used for receiving the original monitoring data and convert the received data into industrial field data that can be identified by a database. An Oracle industrial standard database is used for storing the data in an associated table manner and processing the data based on an industrial data processing algorithm. The industrial field data and equipment state information are collected to reduced the dispersion degree of the data and eliminate an information transmission barrier; an information operation platform is provided for industrial manufacturing; because the Oracle database has the large data storage capacity, the concurrent operation is carried out frequently and the real-time performance is good; and on the basis of the high data storage and processing capabilities, unified integration of the data, the deep analysis and performance evaluation and prediction of the industrial system become feasible and practical, so that the process equipment efficiency is improved, the maintenance cost is lowered, and the high security requirement is met.

Owner:SHANGHAI MARITIME UNIVERSITY

Industrial big data processing system based on artificial intelligence algorithm

InactiveCN111556032AReasonable production and processingScientific production and processingMachine learningTransmissionAlgorithmIndustrial equipment

The invention discloses an industrial big data processing system based on an artificial intelligence algorithm. The invention belongs to the technical field of industrial data processing. The supportbased on an artificial intelligence algorithm can be realized; industrial equipment information is acquired offline; useless information is removed after preprocessing; useful data information and simple integration processing are realized; a proper artificial intelligence algorithm is selected for processing according to the data type; then, the information is uploaded to a cloud server after security encryption; data processing and analysis are carried out by utilizing the strong computing power and computing speed of the cloud server; decision support is provided for industrial production;reasonable, scientific and efficient production and processing by utilizing industrial equipment are facilitated; the industrial data processing and analyzing speed and precision can be rapidly improved, a large amount of industrial data query and analysis can be achieved, an existing industrial production mode is effectively improved through rear remote centralized processing and front visual query, and industrial intellectualization and Internet of Things development are protected.

Owner:JIANGSU TIANREN IND INTERNET RES INST CO LTD

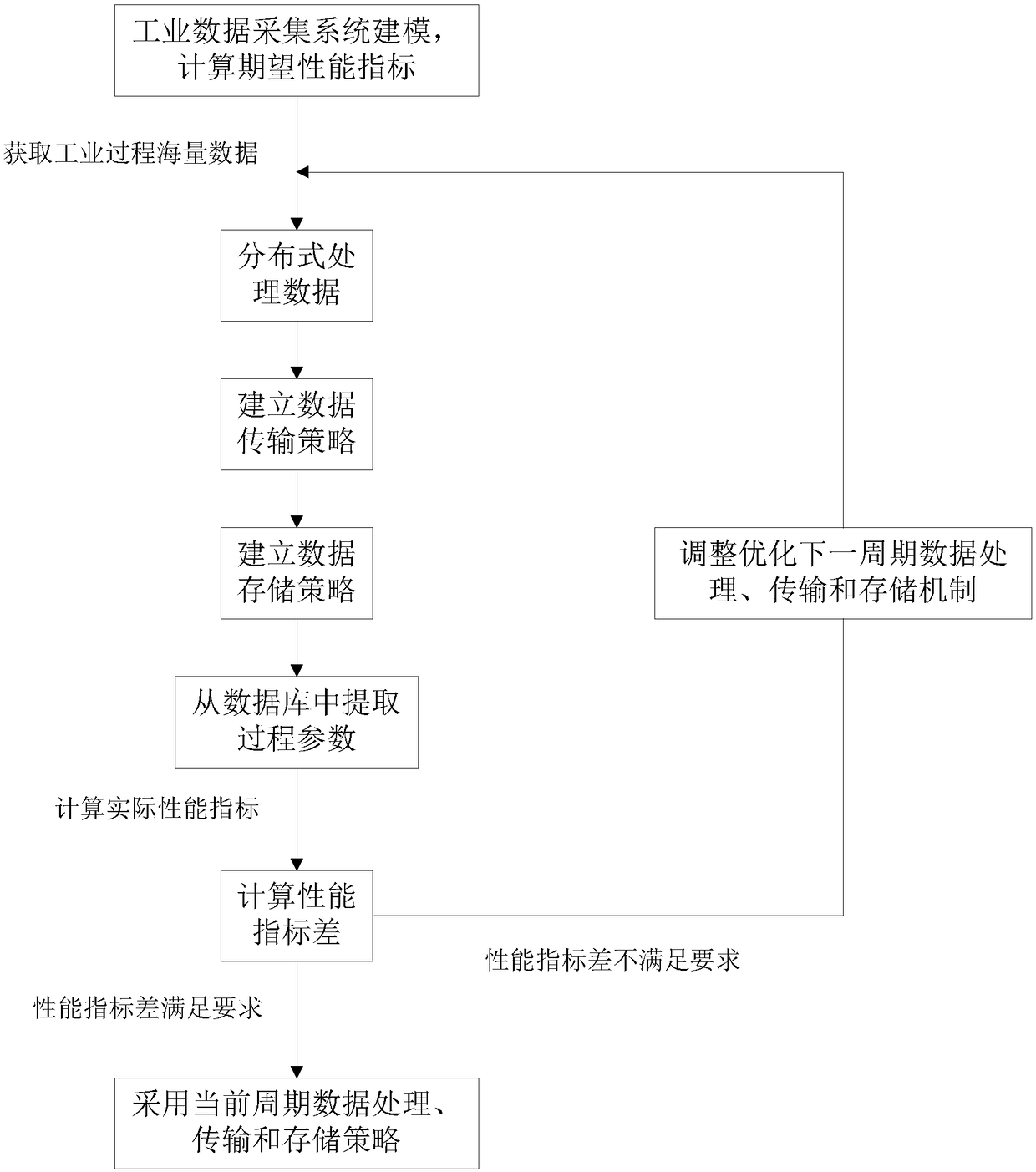

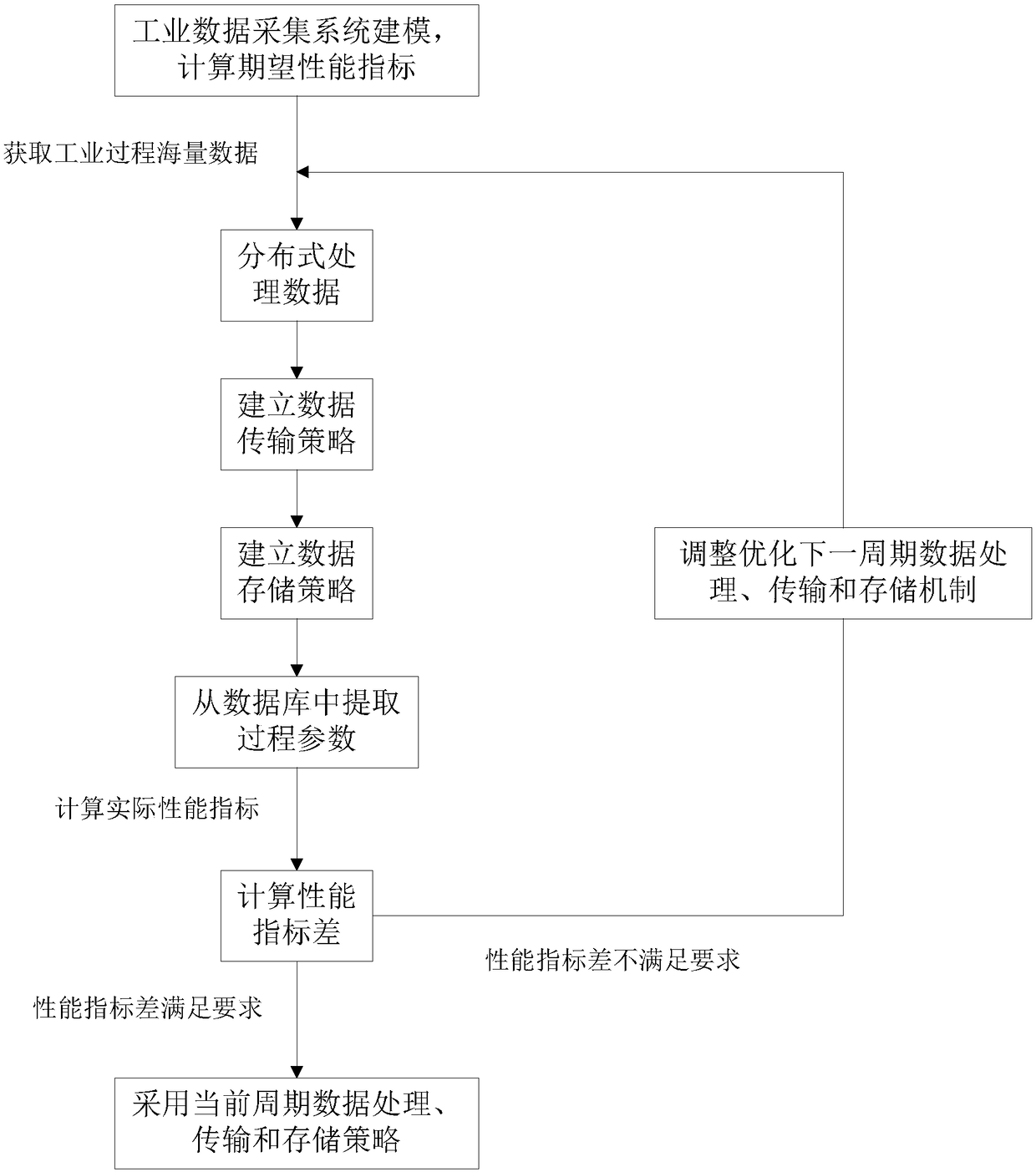

Optimized execution estimation method for massive data processing and storage processes in industrial processes

InactiveCN108416067AImprove the efficiency of collection and storage processSorted orderlyRelational databasesDatabase distribution/replicationTransport layerEstimation methods

The invention discloses an optimized execution estimation method for massive data processing and storage process in an industrial process. The method includes S1: structural modeling of industrial data acquisition systems; S2: calculating desired performance indicators of industrial data processing and storage processes according to the model; S3: a strategy for establishing a massive data processing layer, a transport layer, and a storage layer; S4: extracting process parameters related to performance indicators from the database; S5: calculating actual performance indicators; S6: comparing the expected performance index and the actual performance index, and adjusting the data processing and storage mechanism of the next cycle until the performance of the industrial data acquisition system meets the requirements. The beneficial effects obtained by the method are: the efficiency of the whole data collection and storage process can be improved, the data can be sorted and excavated in anorderly manner, and the storage space is saved, optimizing the collection and storage process of massive data in industrial processes, and preparing for subsequent data analysis.

Owner:CHONGQING UNIV

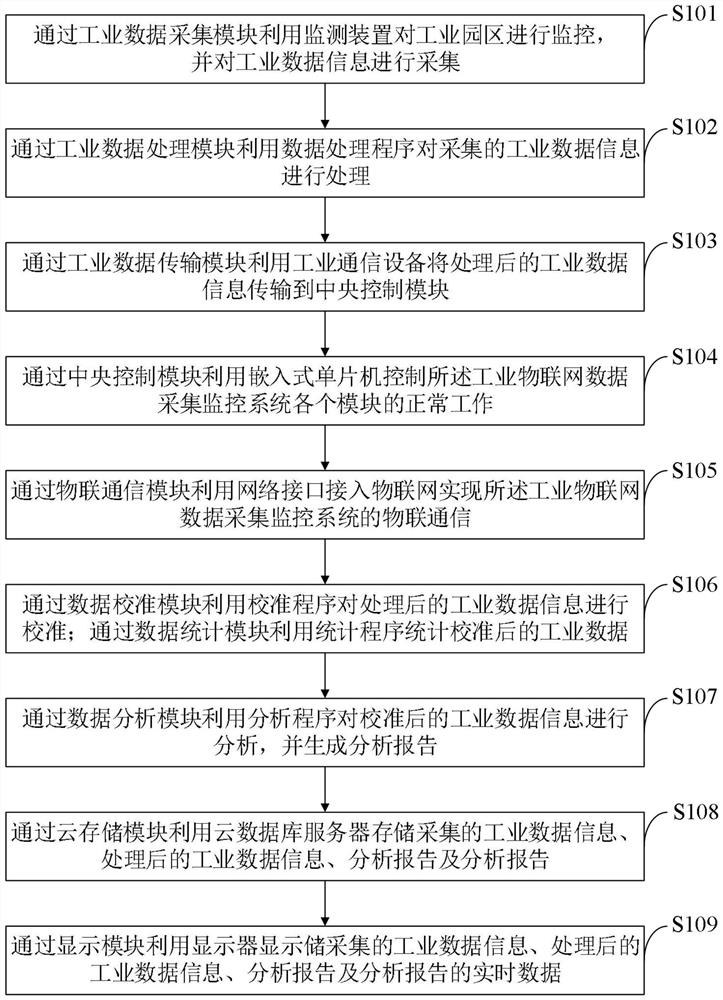

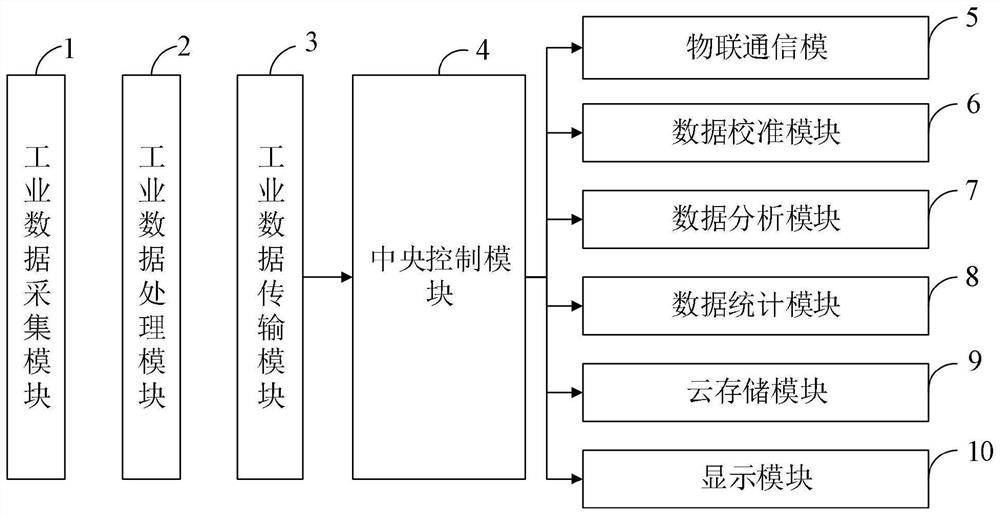

Embedded industrial Internet of Things data acquisition monitoring system and method

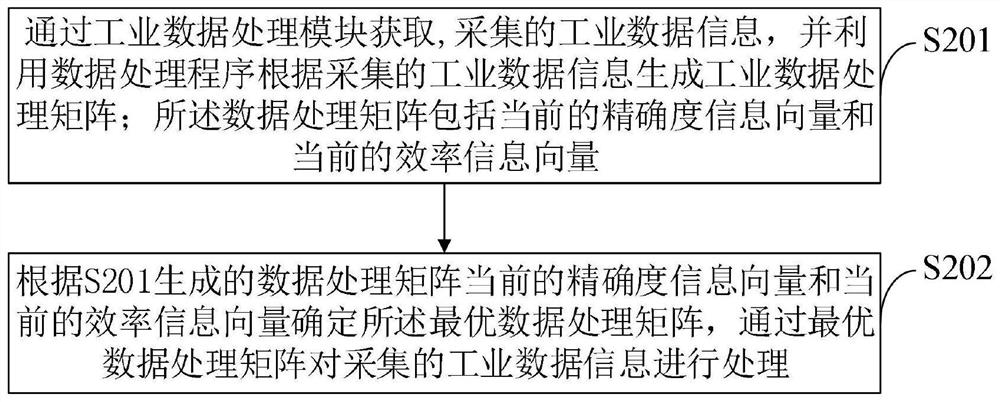

PendingCN111752195AHigh precisionImprove efficiencyProgramme controlComputer controlData acquisitionIndustrial Internet

The invention belongs to the technical field of Internet of Things data acquisition and monitoring. The invention discloses an embedded industrial Internet of Things data acquisition monitoring systemand method. The embedded industrial Internet of Things data acquisition monitoring system comprises an industrial data acquisition module, an industrial data processing module, an industrial data transmission module, a central control module, an Internet of Things communication module, a data calibration module, a data analysis module, a data statistics module, a cloud storage module and a display module. Through the industrial data processing module, the accuracy, efficiency and quality of data processing are improved, data visualization is achieved through the analysis module, trend comparative analysis can be conducted on various kinds of data, the incidence relation between the data is found, the requirement for data analysis in industrial production is met, engineers are assisted inaccurately mastering the current production state and the historical production state, and more scientific and reasonable decisions are made; the cloud storage module is simple in storage, can be compatible with various databases, is large in page view, and meets the demands of third-party access.

Owner:籍芳

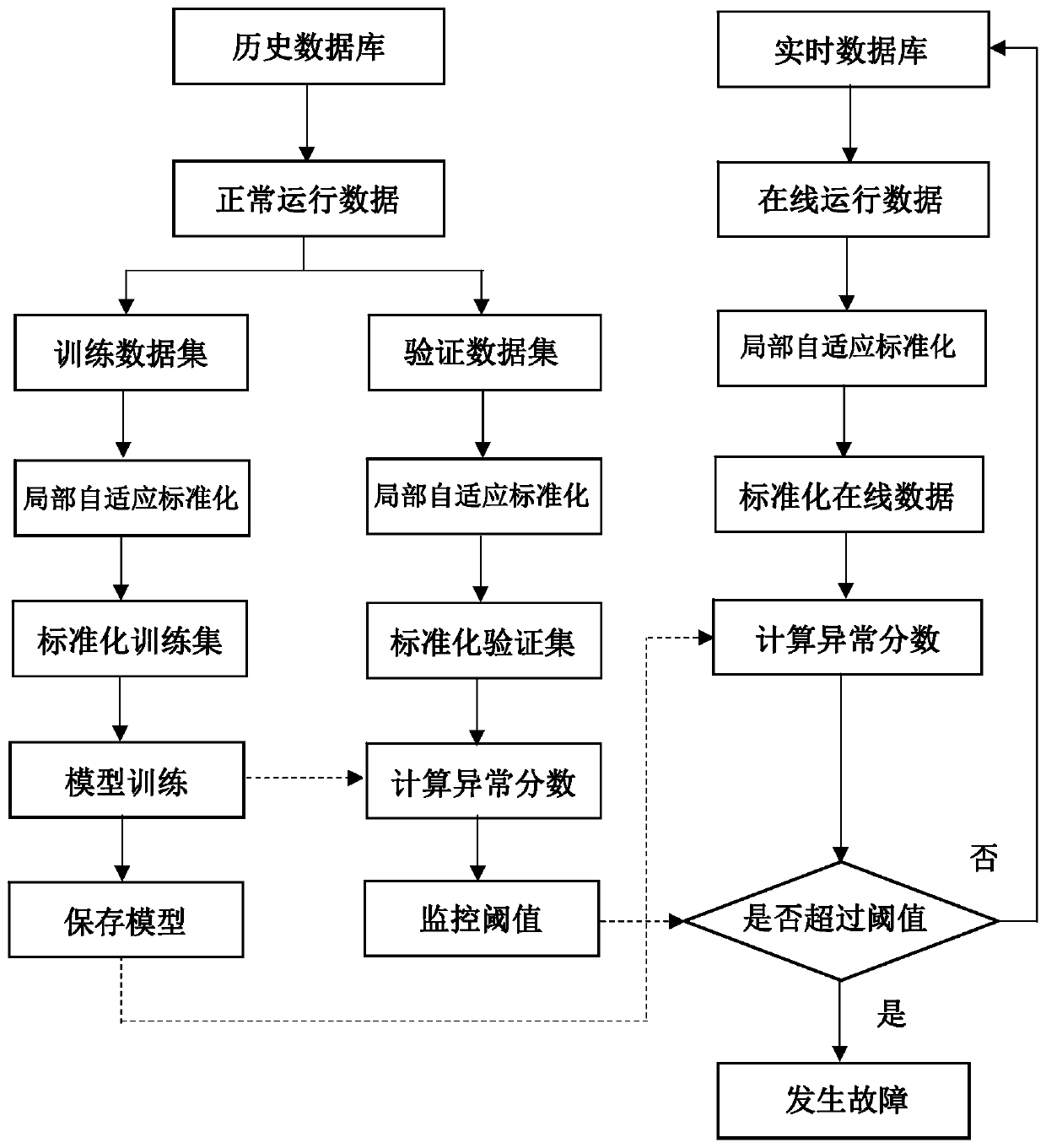

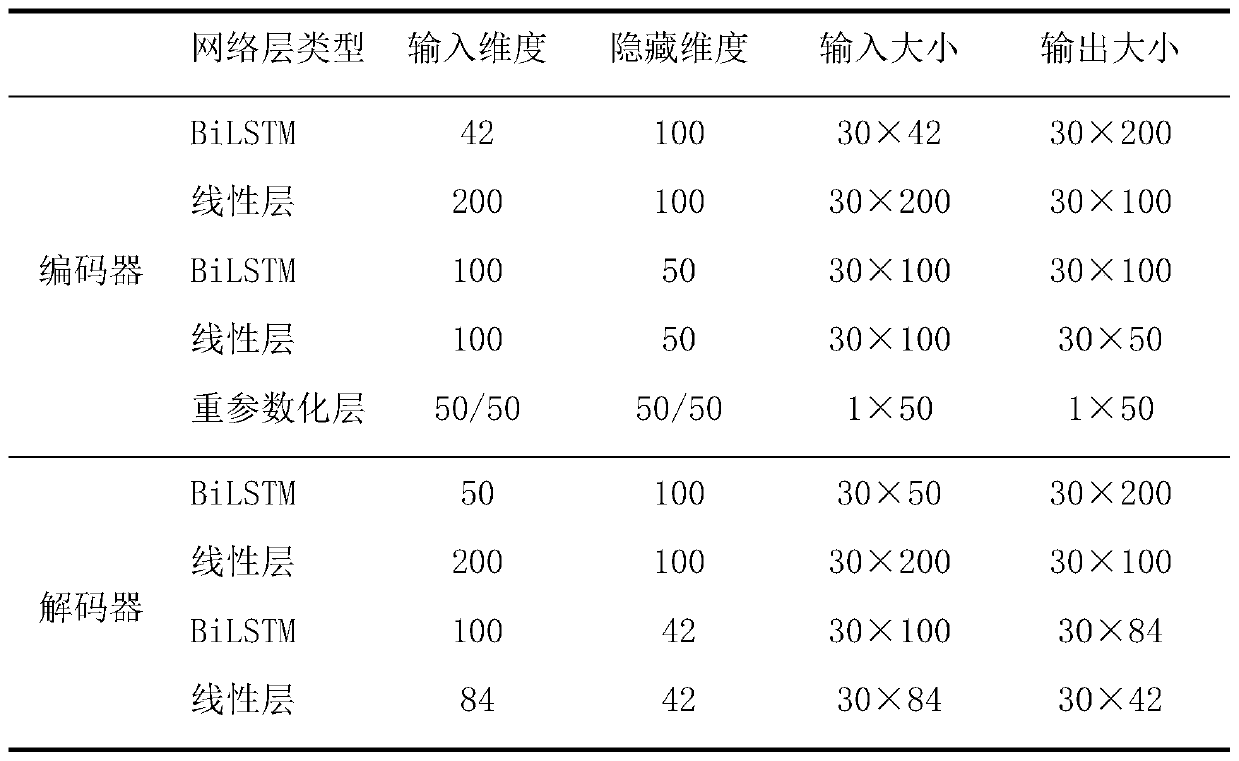

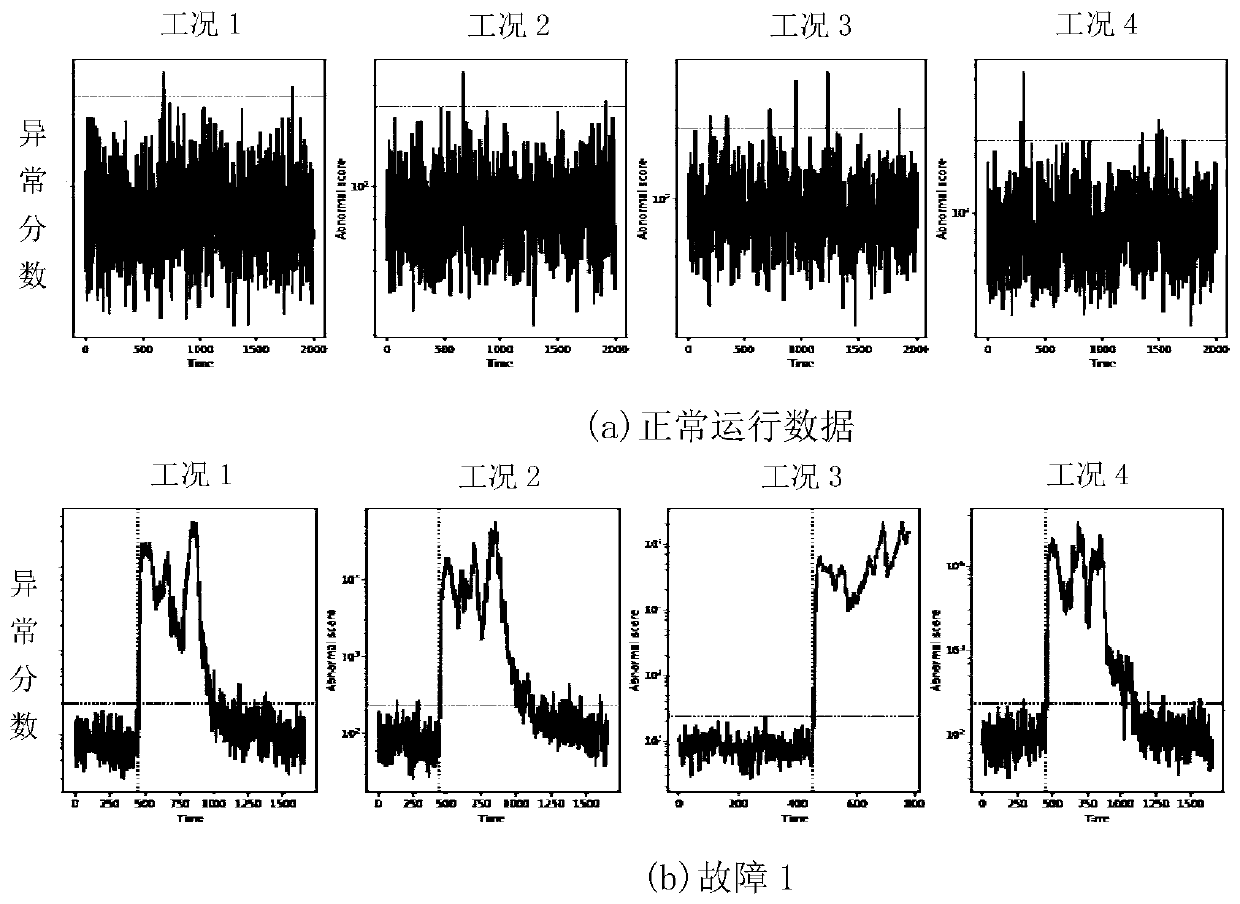

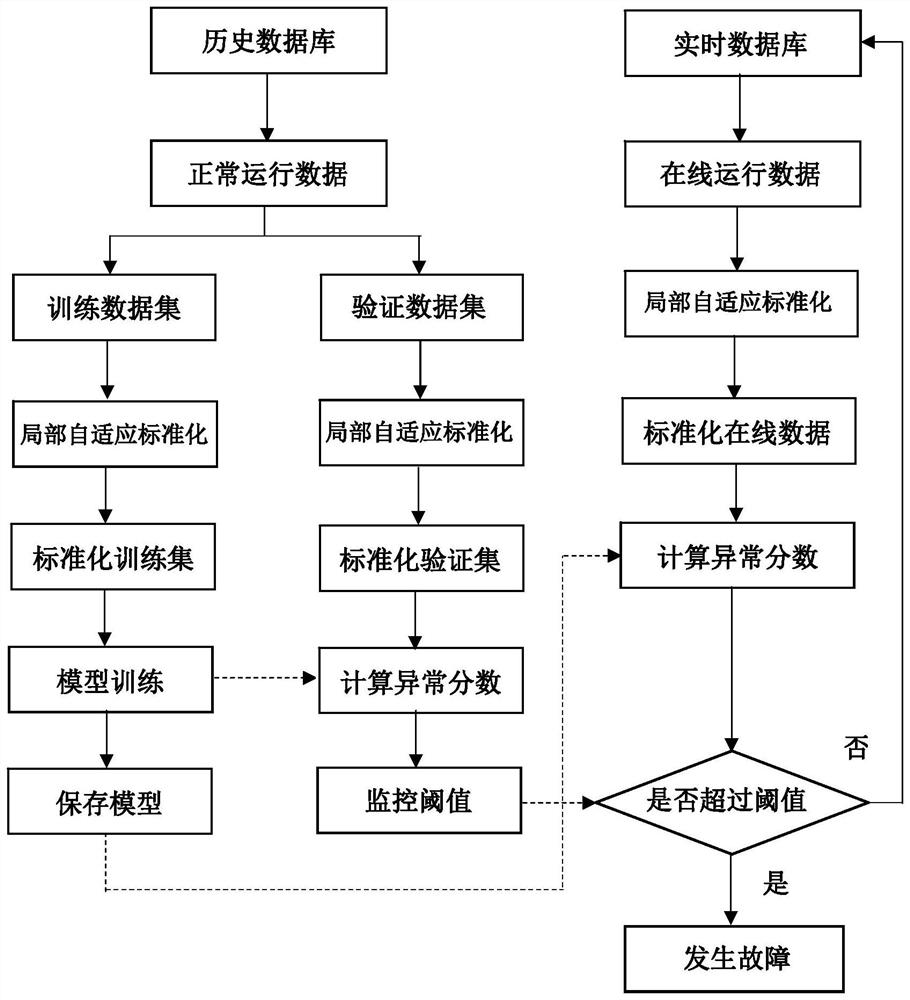

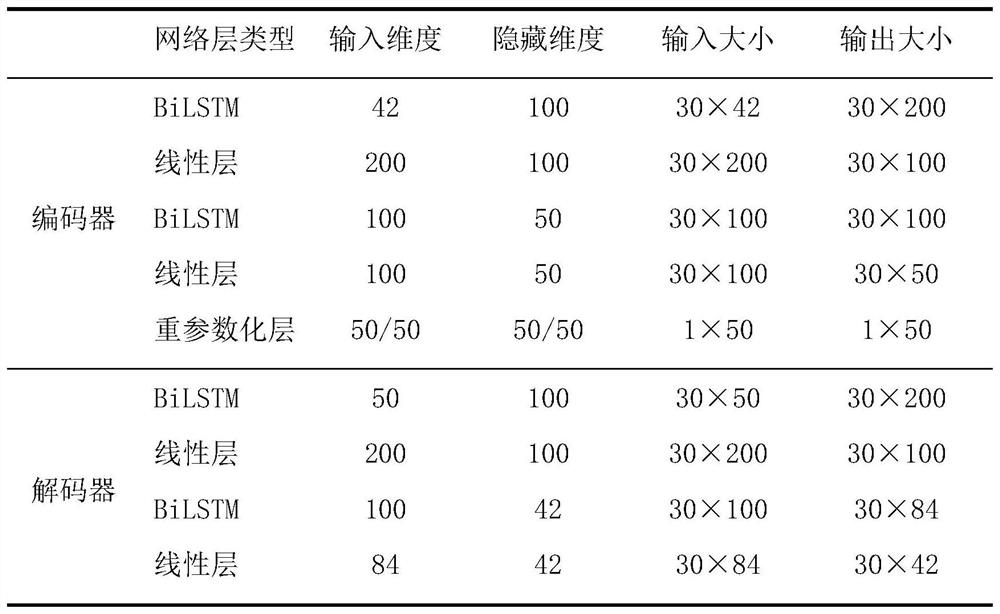

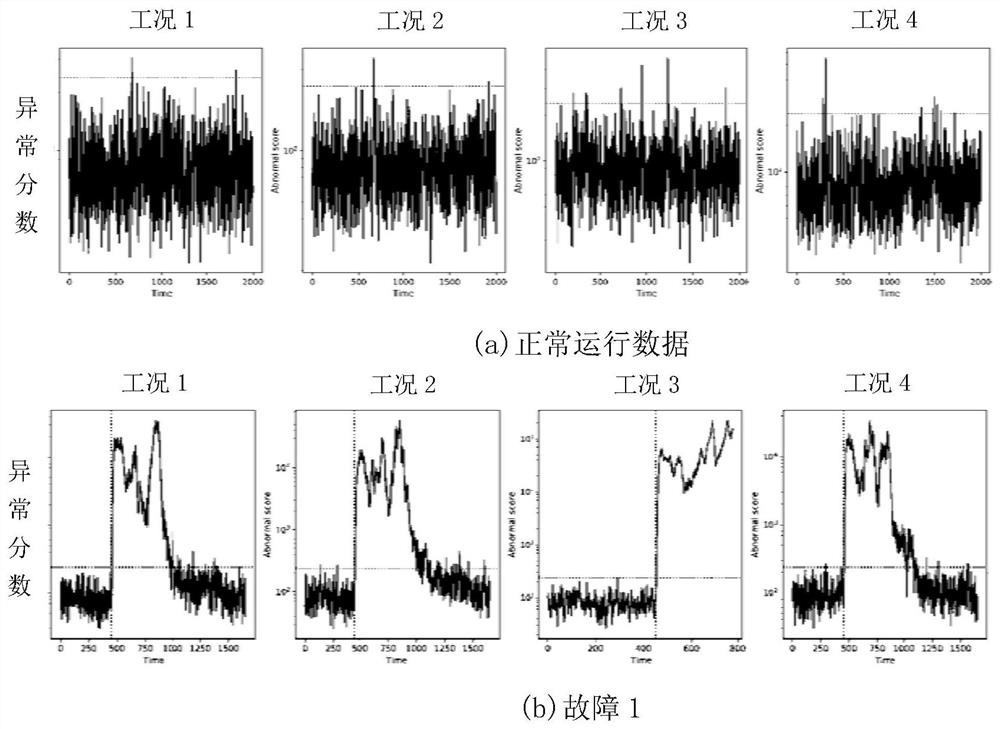

Chemical engineering system multi-working-condition fault detection method based on local adaptive standardization

ActiveCN111367253AImprove accuracyImprove generalization abilityProgramme controlElectric testing/monitoringNeural network nnAdaptive capacity

The invention relates to a chemical system multi-working-condition fault detection method based on local adaptive standardization and belongs to the technical field of chemical process monitoring, industrial data processing and process system engineering. According to the method, a local adaptive standardization method is provided, the variational automatic encoder technology of the deep neural network is applied, an average value of the data in the local moving window is calculated to serve as an average value parameter of local adaptive standardization, different average values are used fordifferent data, and the adaptive capacity is achieved. The method is advantaged in that local adaptive standardization processing is utilized, and fault detection is carried out by detecting whether the data in a local moving window deviates or not, and the method can be suitable for any working condition, has higher accuracy and stronger generalization ability, can meet the requirement of real-time detection, and avoids chemical accidents or reduces the harm caused by accidents through early warning of faults.

Owner:TSINGHUA UNIV

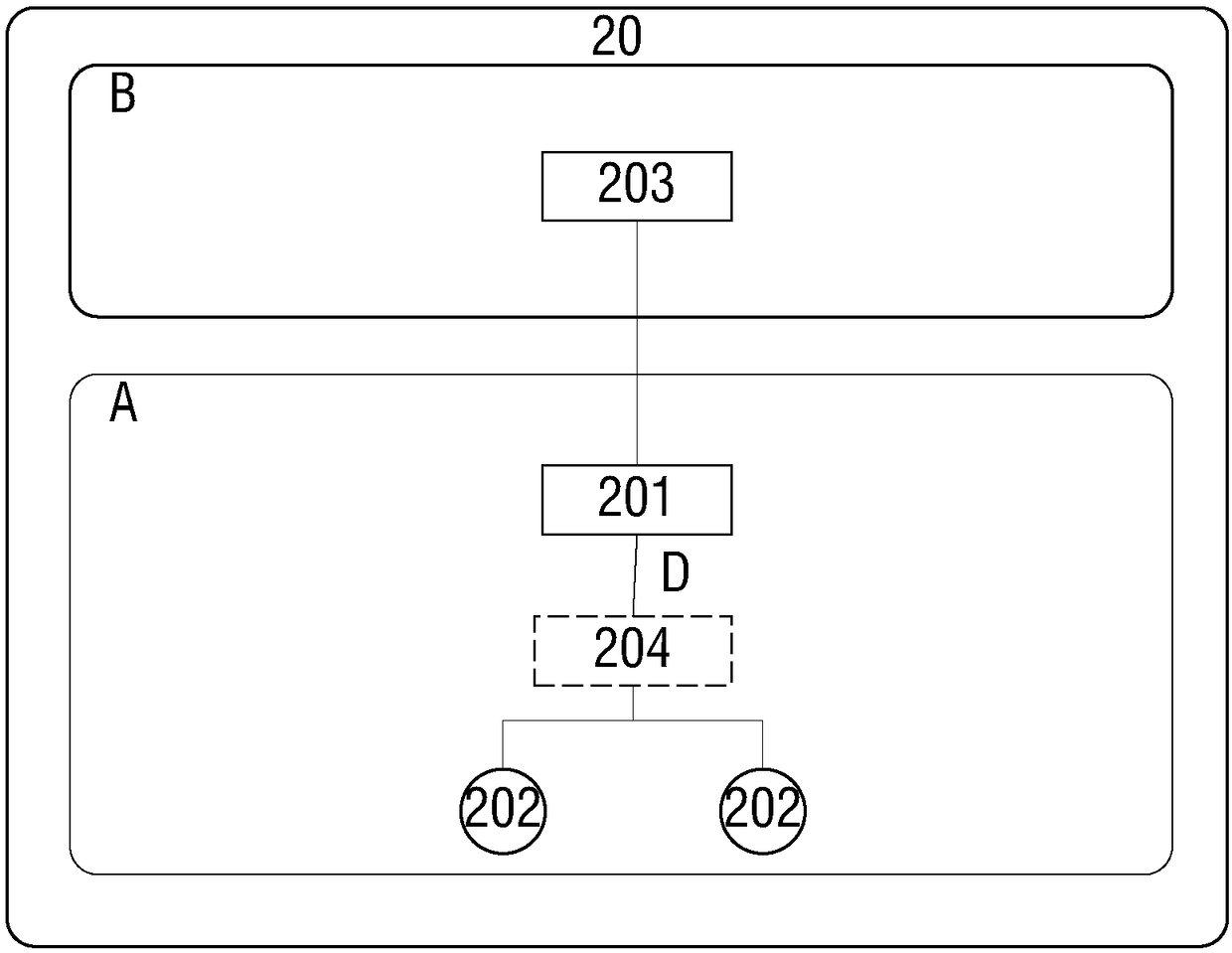

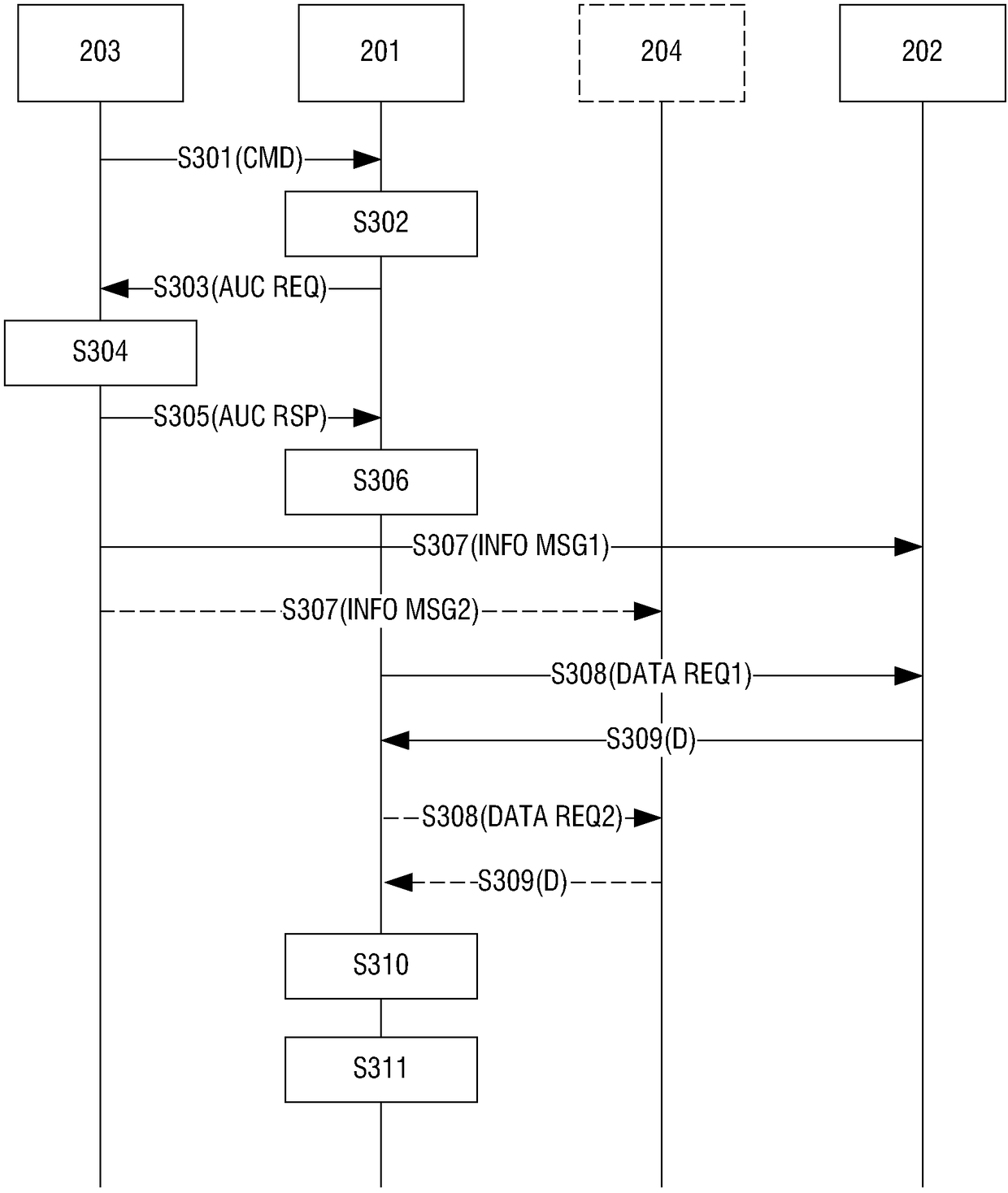

An industrial big data processing system and method

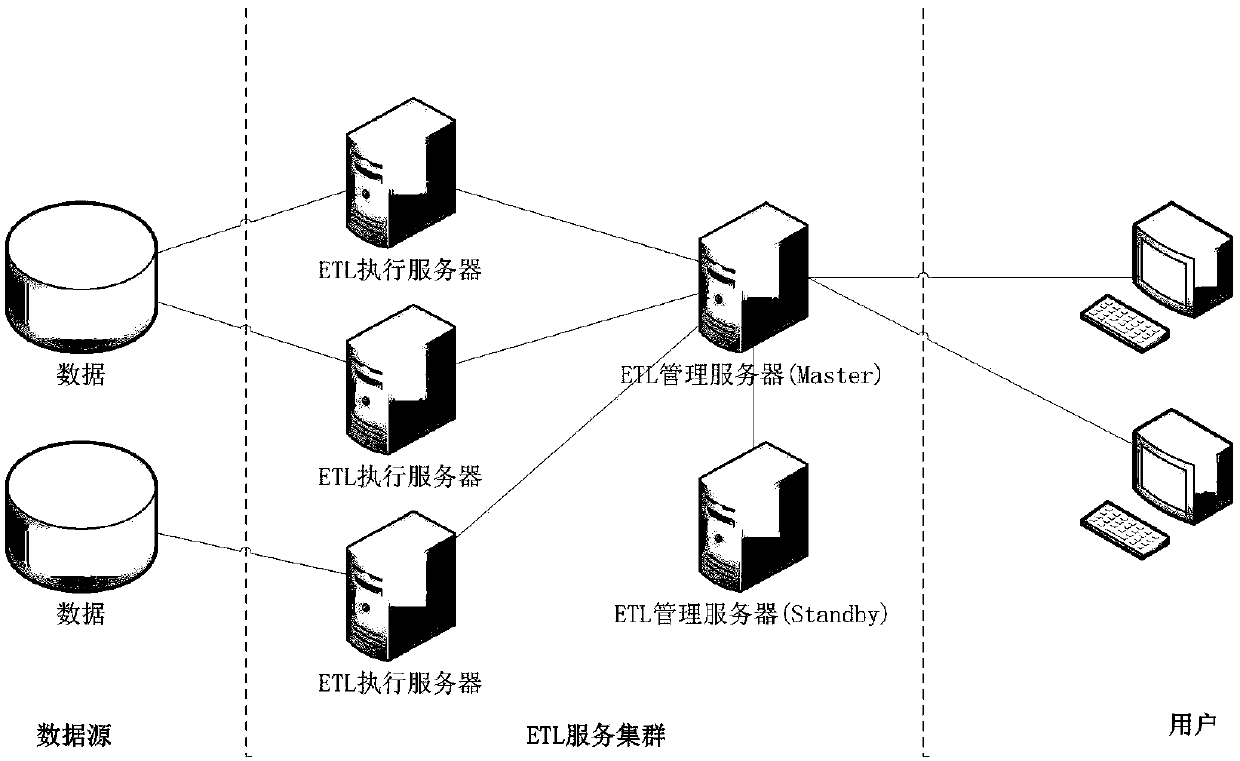

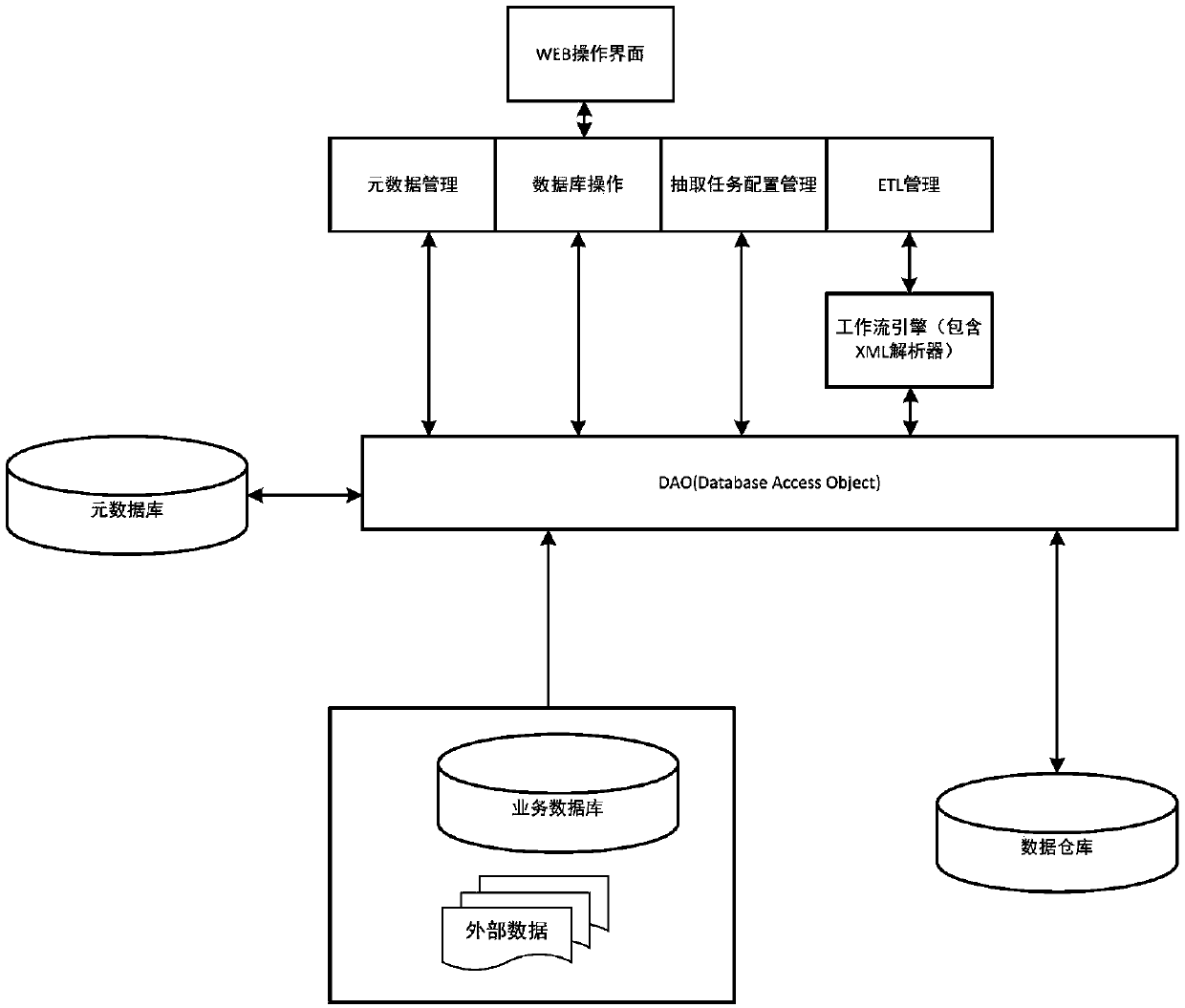

ActiveCN109669975AImprove analysis accuracyImplement query analysisDatabase management systemsData sourceHigh availability

The invention discloses an industrial big data processing system and method, and the system comprises an ETL service cluster, a data source, and a user terminal. The user terminal and the data sourceare connected to the ETL service cluster, the ETL service cluster comprises a management server and a plurality of distributed parallel execution servers, each execution server is connected to the same or different data sources, and all the execution servers are connected to the management server. The whole process of industrial data processing is deployed in a distributed and high-availability mode, so that the robustness of the system and the safety and the consistency of data are ensured; the industrial data processing and analyzing speed and precision can be rapidly improved, and a large amount of data can be inquired and analyzed.

Owner:CHENGDU UNION BIG DATA TECH CO LTD

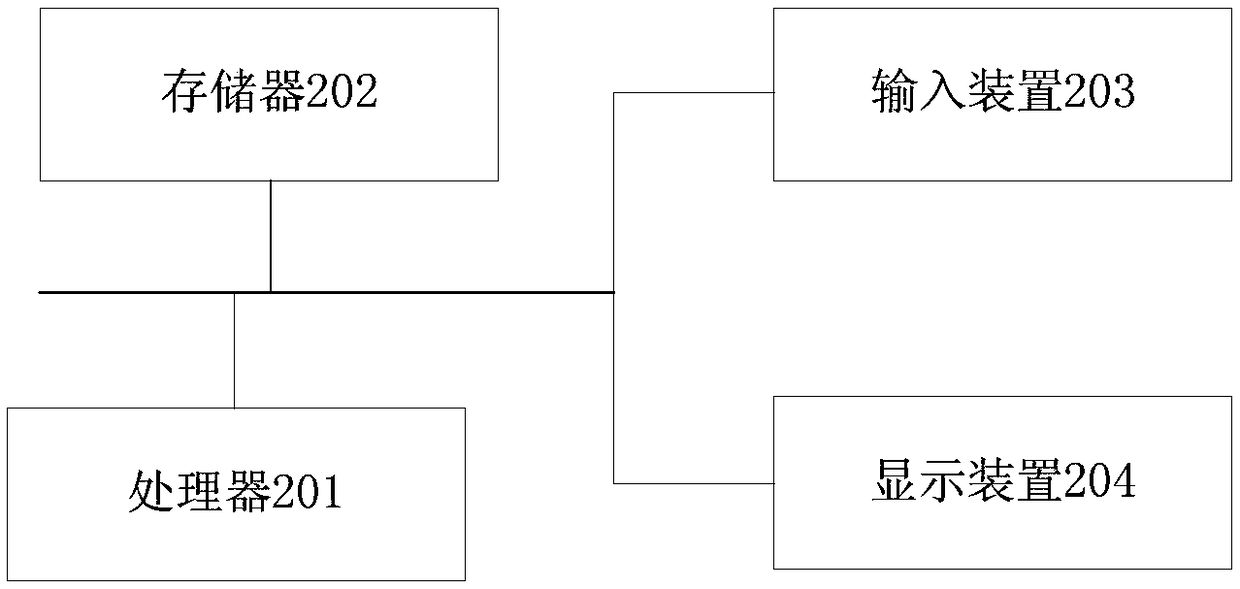

Building ground decoration industrial data processing method, electronic device and storage medium

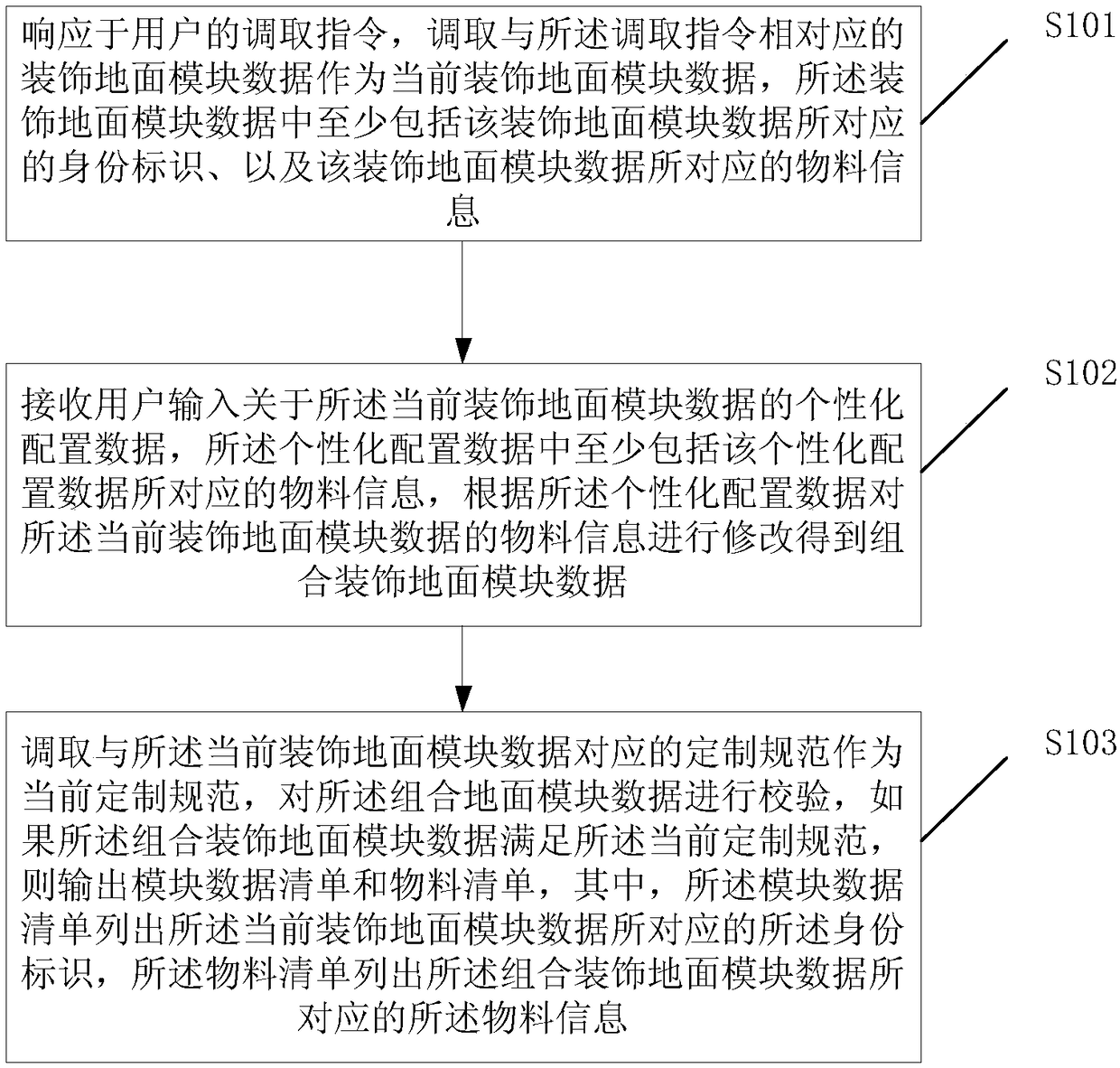

PendingCN108229014AIncrease profitMeet decoration needsGeometric CADSpecial data processing applicationsPersonalizationUser input

The invention discloses a building ground decoration industrial data processing method, an electronic device and a storage medium. The method includes the steps of responding to a calling instructionof a user, calling decoration group module data corresponding to the calling instruction as current decoration ground module data, receiving individualized configuration data related to the current decoration ground module data and input by the user, modifying material information of the current decoration ground module data according to the individualized configuration data to obtain combined decoration ground module data, calling a customizing standard corresponding to the current decoration ground module data as a current customizing standard, verifying the combined ground module data, andoutputting a module data list and a material list if the combined decoration ground module data meets the current customizing standard. With the building decoration part modularization as the core, the industrial production organization as the basis and the on-site decoration type construction as the means, a novel assembly type ground system suitable for industrialization on the Internet era is obtained.

Owner:ZHEJIANG YASHA DECORATION

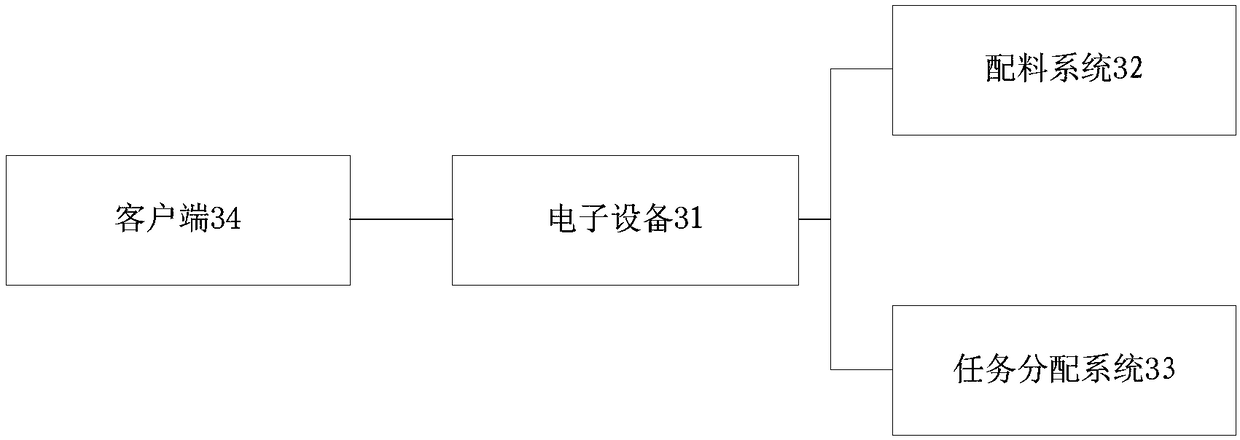

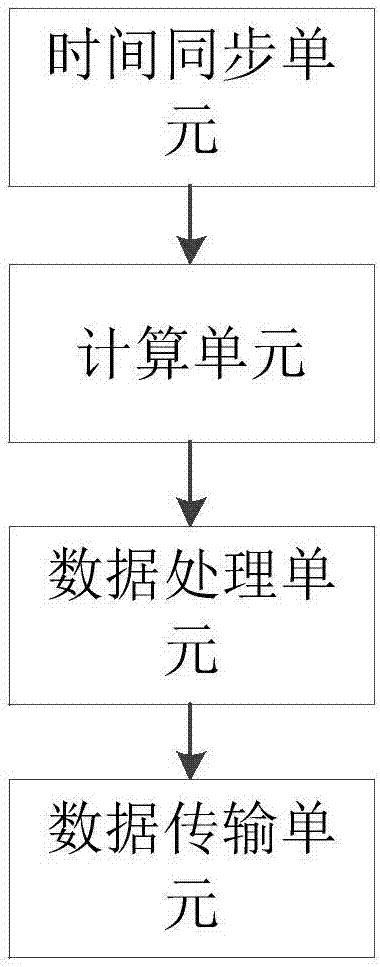

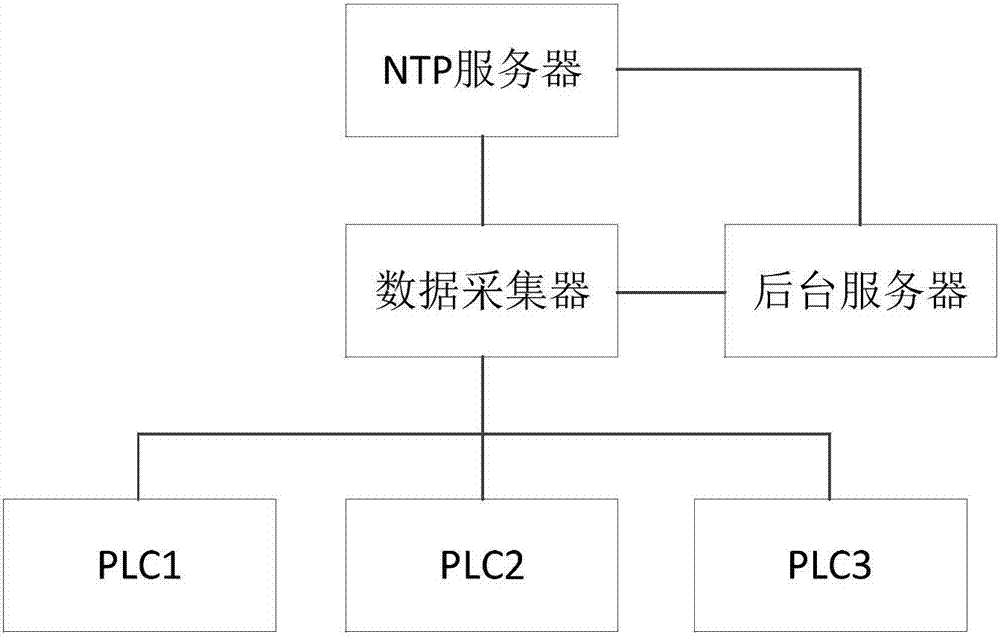

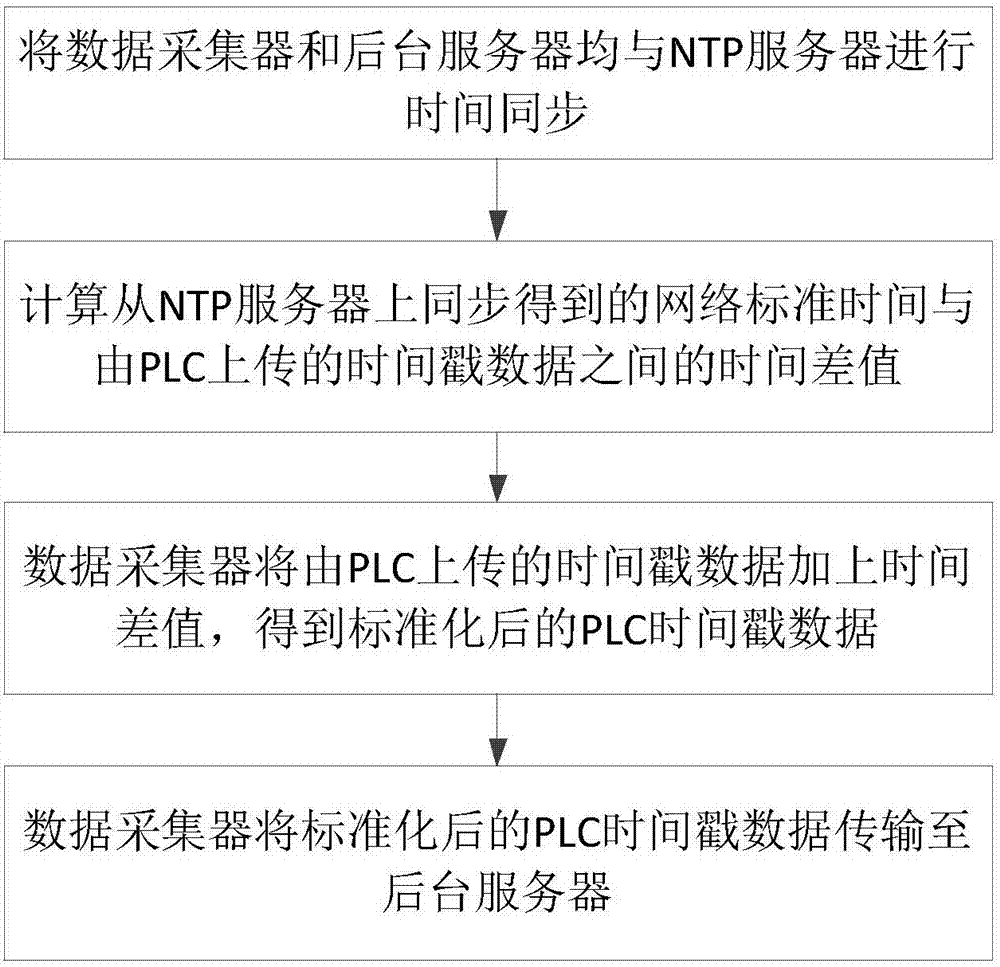

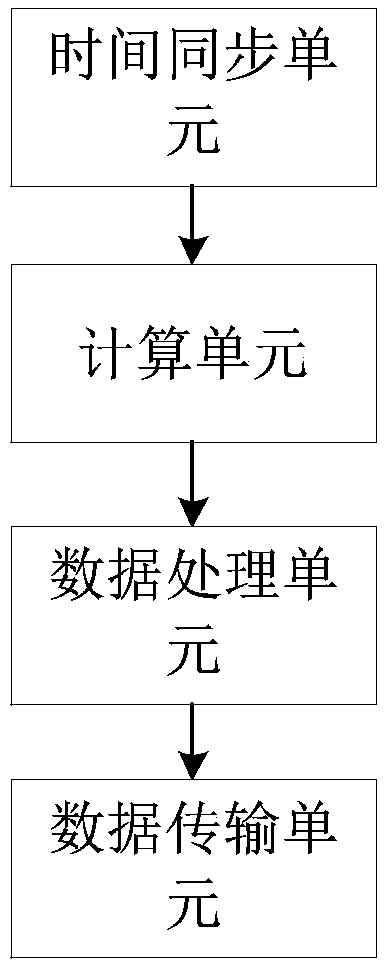

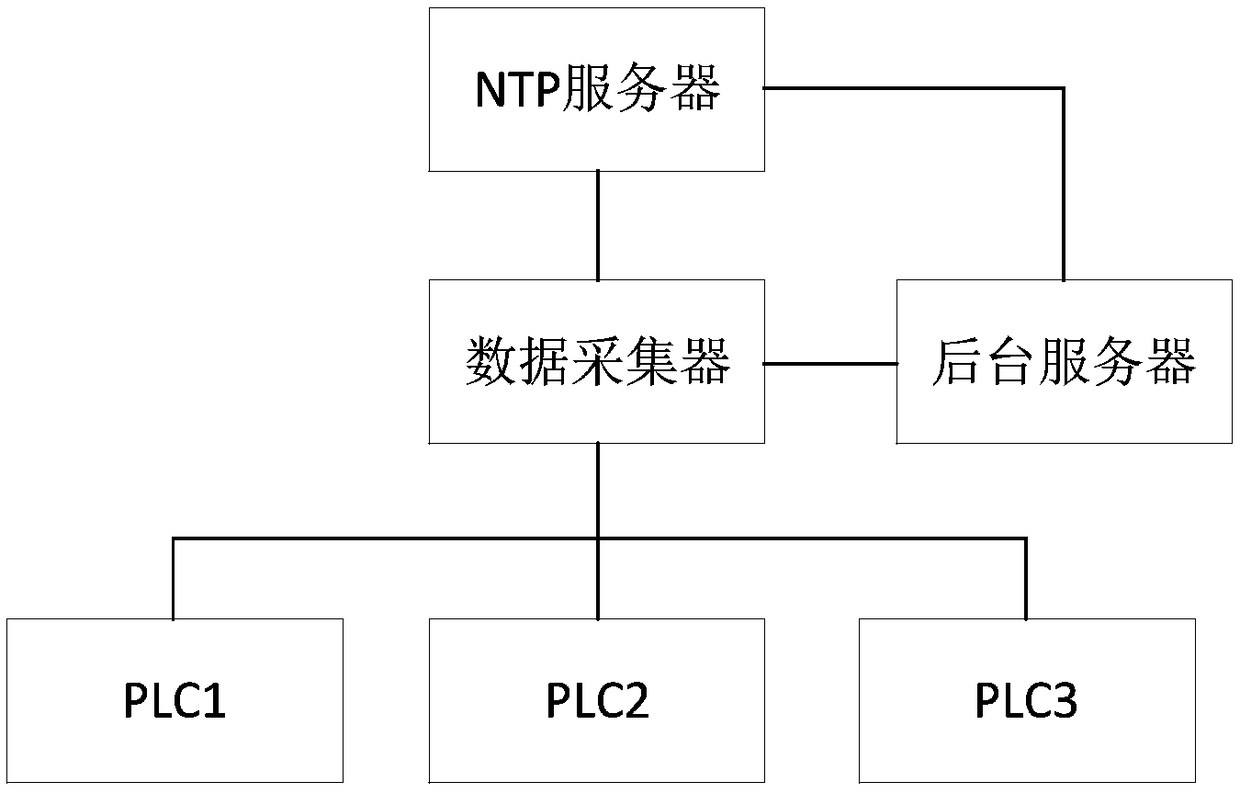

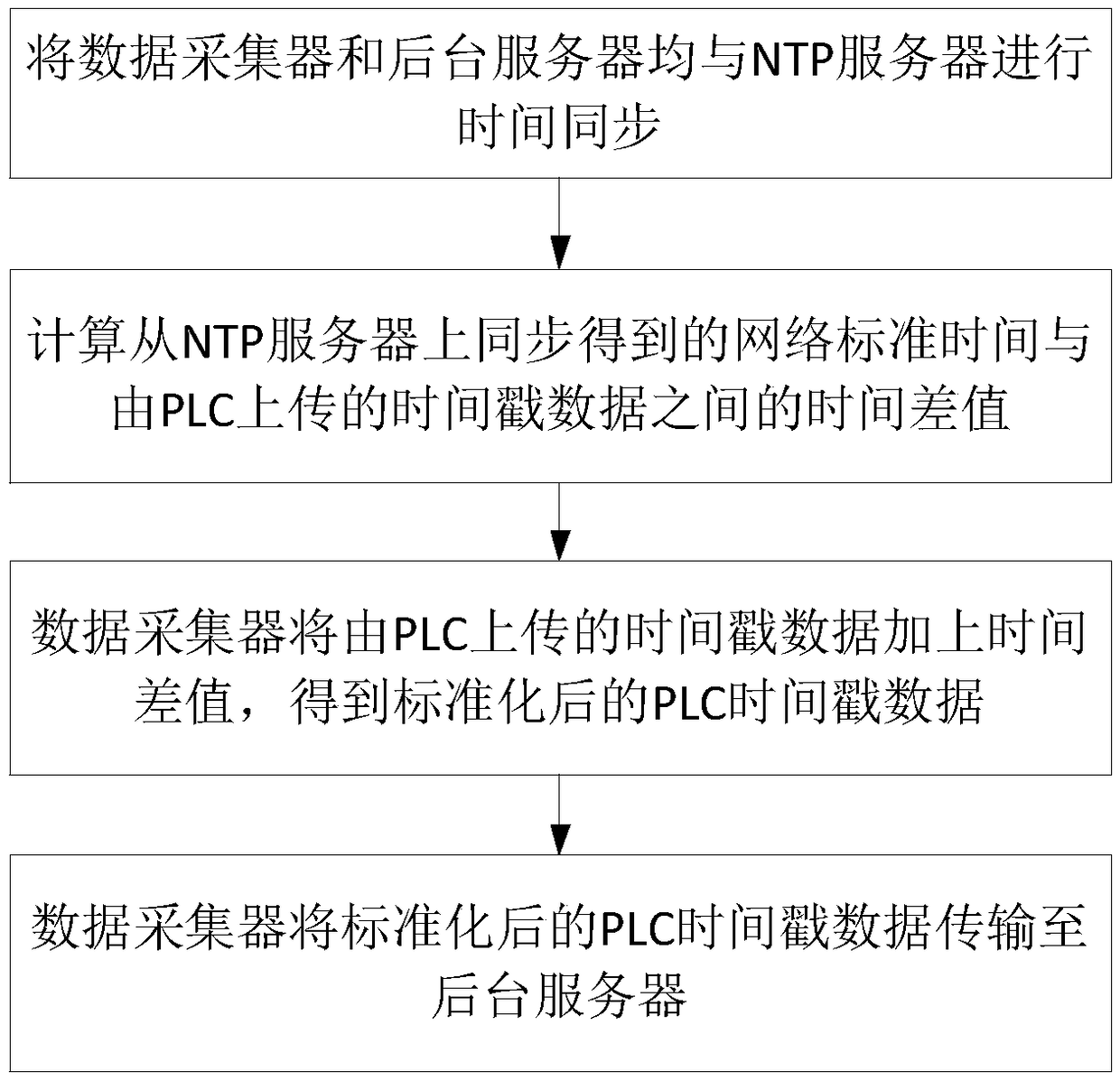

Time synchronization method and system

ActiveCN107276709AImprove accuracyIncrease authenticityTime-division multiplexProgramme control in sequence/logic controllersData synchronizationData acquisition

The present invention discloses a time synchronization method and system. The system includes a time synchronization unit, a calculation unit, a data processing unit and a data transmission unit. The method comprises the following steps: a data collector and a background server are time-synchronized with an NTP server; the time difference between the network standard time synchronized by the NTP server and the time-stamped data uploaded by a PLC is calculated; afterwards, the data collector adds the time difference to the time-stamped data uploaded by the PLC to obtain standardized PLC time stamp data, and uploads the standardized PLC time stamp data to the background server. By using the method and the system of the present invention, the time synchronization between the PLC, the data collector and the backstage server can be quickly and easily realized, real-time real data collection of the industrial data can be realized, the accuracy of subsequent industrial data processing results can be greatly improved, modification of the PLC is not required, and the high convenience is achieved. The time synchronization method and system can be widely applied in the field of industrial data acquisition.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

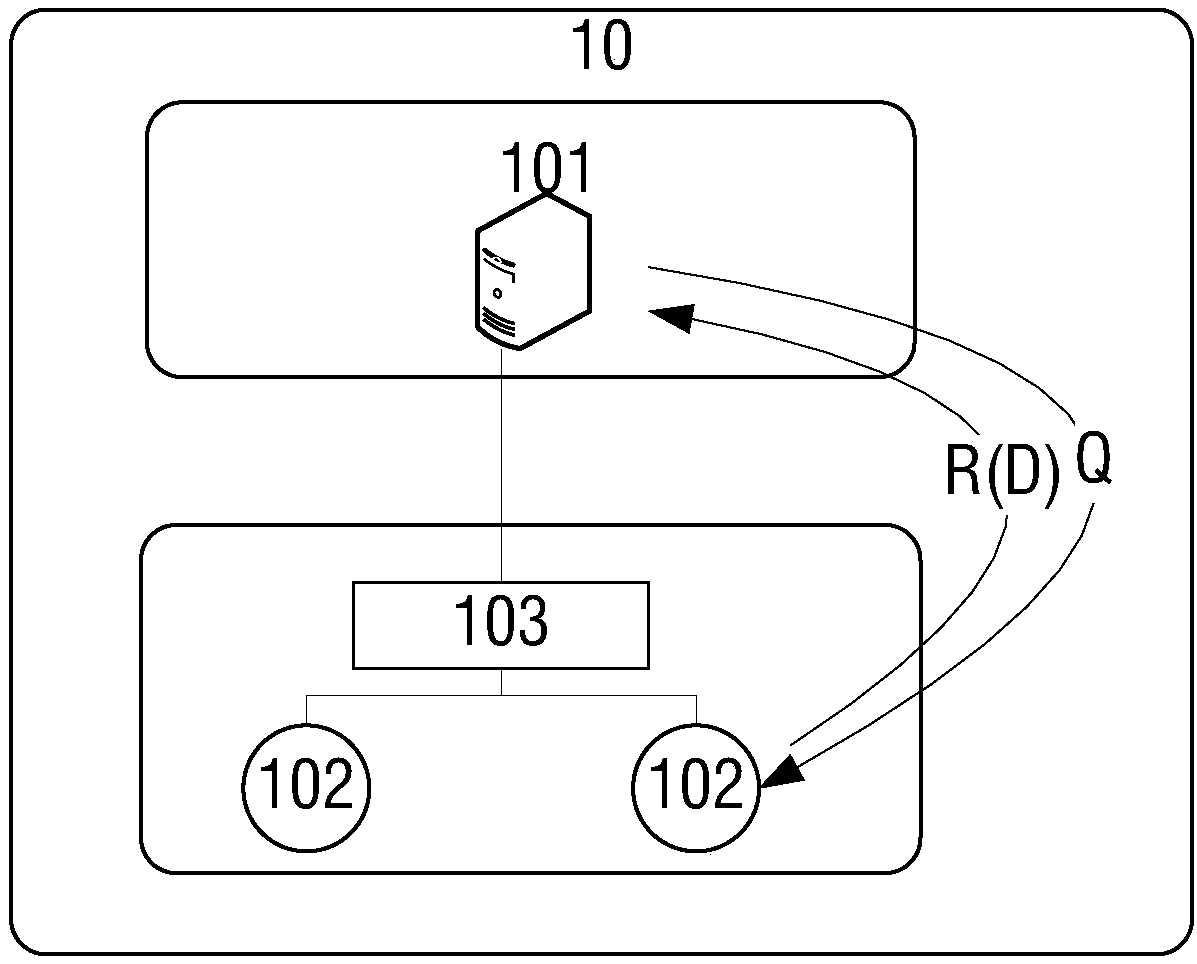

Field data processing method and device and system

ActiveCN108459563AAvoid processing powerGuaranteed safe transmissionDigital data protectionTransmissionIndustrial systemsSimulation

The invention relates to the technical field of industrial data processing, in particular relates to a field data processing method and device and a system for realizing the timely processing of the field data. In the embodiment of the invention, a field data processing device located at an industrial field in an industrial system receives field data from at least one field device in the industrial field. The received field data are processed, and the result of field data processing is provided so that the problem that the field data processing is not timely can be avoided.

Owner:SIEMENS AG

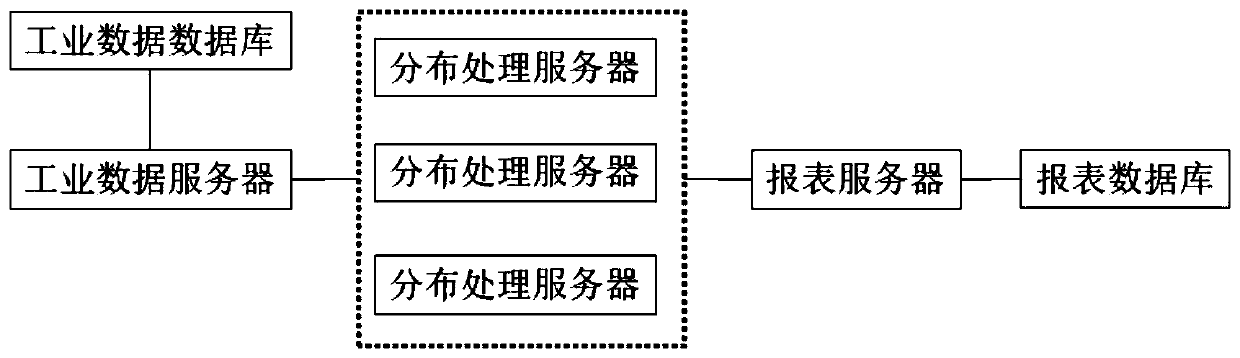

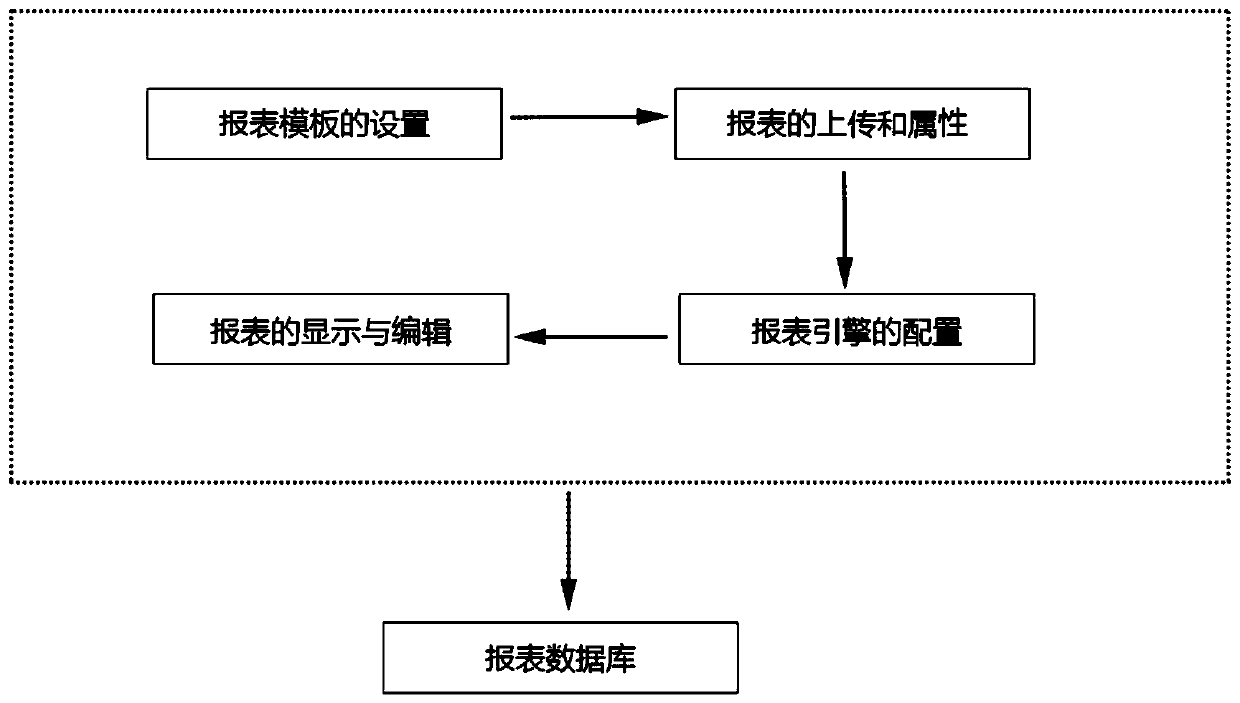

System for automatically generating report from industrial data

PendingCN111538731AAvoid heavy workAchieve separationNatural language data processingSpecial data processing applicationsData miningIndustrial engineering

The invention discloses a system for automatically generating a report from industrial data. The system comprises an industrial data server, a distributed processing server, a report server, an industrial data database and a report database, the industrial data server is used for collecting industrial data and driving the distributed processing server to process and package the distributed industrial data according to a pre-configured data processing rule and then input the packaged industrial data into the industrial data database; and the report server is used for selecting one of the automatically generated industrial report template files according to a preset timing task, calling the corresponding industrial data, and filling or replacing part or all of the activity cells in the industrial report template file after processing to generate a report file. According to the invention, the complex work of manual calculation and input can be overcome by automatically acquiring the industrial data and automatically generating the report, so that the report generation mode and the whole data and report processing process are more flexible, the adaptability is high, and the data processing pressure is relieved by adopting the distributed processing server.

Owner:山东慧泰智能科技有限公司

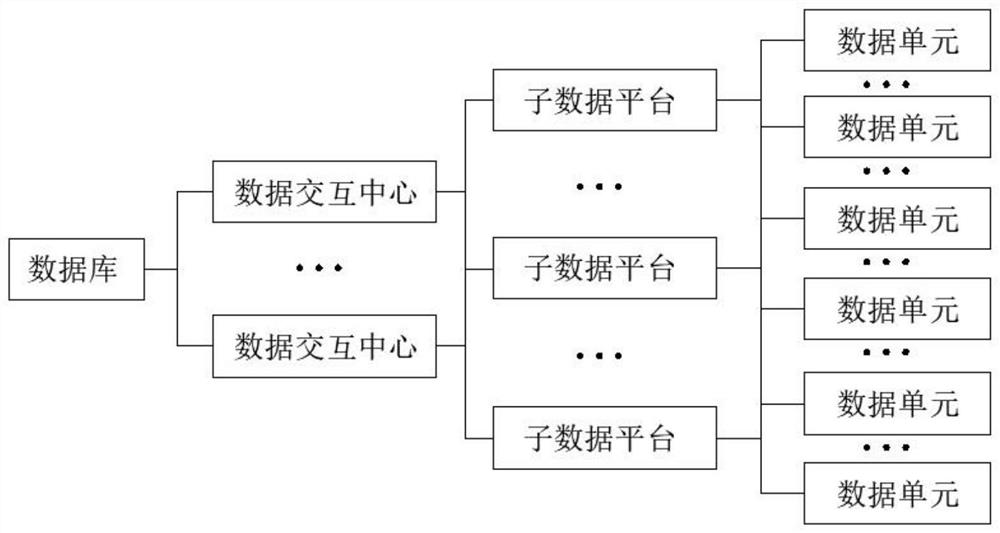

Big data interaction method for industrial production

PendingCN112085393ALow cost of safety production upgradeImprove compatibilityDatabase management systemsCo-operative working arrangementsData platformProcess engineering

The invention relates to industrial data processing, in particular to a big data interaction method for industrial production, and a main logic architecture of the method comprises a database, blockchain data, a data interaction center, a sub-data platform and a data unit. The method includes the step S1 that parameters such as a warehousing system, a security system, instruments and meters, equipment parameters, a power medium, a production process, a raw material ratio and the like in an industrial production link are independently parameterized and integrated by taking a time axis as a reference and are stored in a register, and the register is taken as a variable and the parameters are transparently transmitted into the sub-data platform through a DTU (Data Transfer Unit). Parameters such as an existing security system, instruments and meters, equipment parameters, a power medium, a production process and a raw material ratio are integrated to enter a data platform, unmanned automatic operation is achieved, an intensive means is adopted, safety production is achieved, and the upgrading cost is low.

Owner:QINGDAO HENGTUO ENVIRONMENTAL PROTECTION TECH

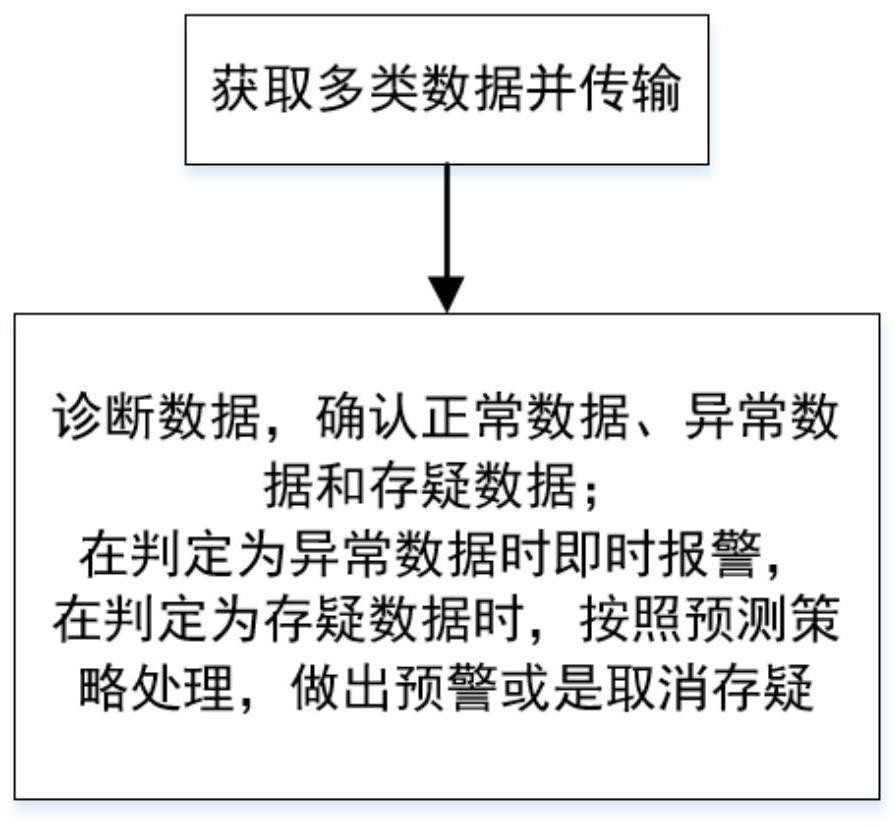

Industrial data processing method and storage medium thereof

PendingCN114116788ADigital data information retrievalError detection/correctionDiagnostic dataEngineering

The invention relates to the technical field of data processing, and discloses an industry data processing method and a storage medium thereof, and the method comprises the following steps: 1, obtaining and transmitting multiple types of data; 2, diagnosing data, and confirming normal data, abnormal data and suspected data; and when the data is judged to be abnormal data, an alarm is given immediately, and when the data is judged to be doubt data, early warning is made or doubt is cancelled according to prediction strategy processing. The method can achieve the effects of comprehensively processing data, improving the fault detection perfection and accuracy, and predicting faults.

Owner:慧物云通(深圳)科技有限公司

Assessment method for mass data processing and storage in industrial process

InactiveCN108564260AImprove the efficiency of collection and storage processSorted orderlyResourcesData acquisitionPerformance index

The invention discloses an assessment method for mass data processing and storage in industrial process. The method comprises the following steps of: S1, carrying out structured modeling on an industrial data acquisition system to obtain a model; S2, calculating expected performance indexes of an industrial data processing and storage process according to the model; S3, establishing a strategy with a mass data processing layer, a mass data transmission layer and a mass data storage layer; S4, extracting process parameters related to the performance indexes from a database; S5, calculating practical performance indexes; and S6, comparing the expected performance indexes with the practical performance indexes so as to assess performance of the industrial process. The method has the beneficial effects of improving the efficiency of the whole data acquisition and storage process and saving the storage space through assessing the performance.

Owner:重庆沐信润喆网络科技有限公司

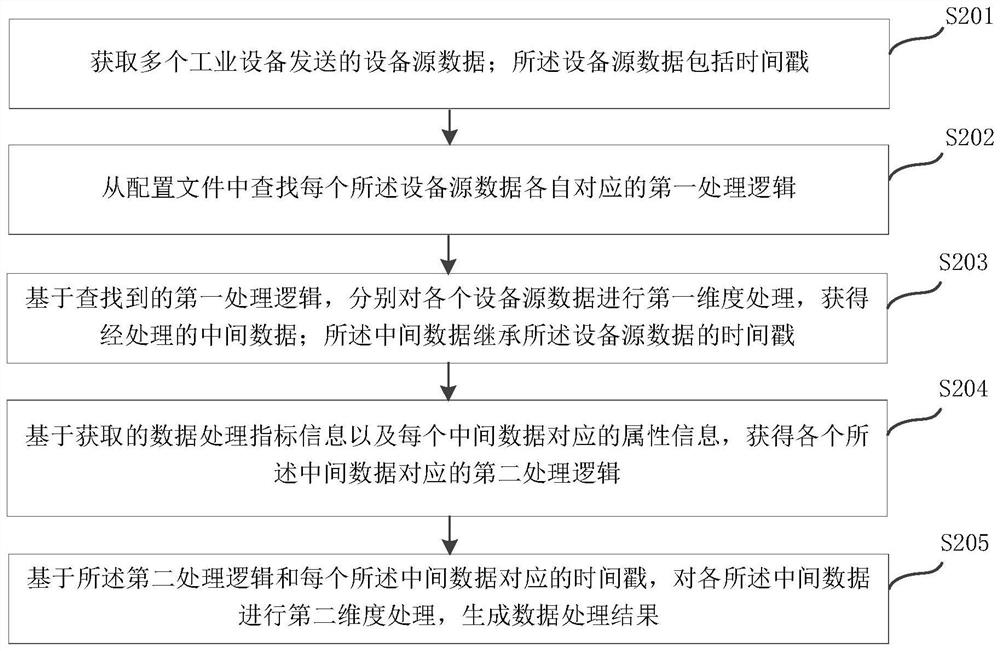

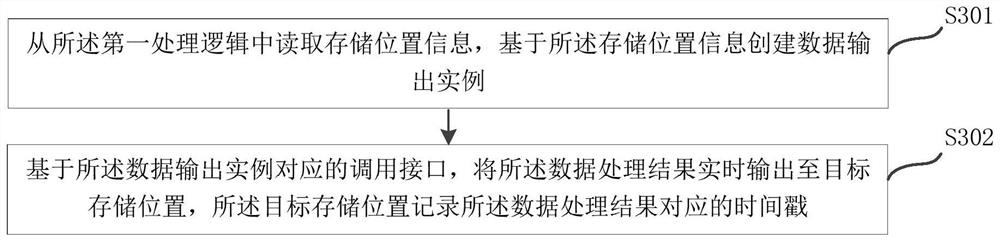

Industrial data processing method and device, equipment and medium

PendingCN114691723AImprove processing efficiencyReduce the amount of processing calculationsDatabase management systemsSpecial data processing applicationsIndustrial equipmentEngineering

The invention discloses an industrial data processing method and apparatus, a device and a medium. The method comprises the steps of obtaining device source data including timestamps sent by a plurality of industrial devices; searching a configuration file for a first processing logic corresponding to each piece of equipment source data; the first processing logics corresponding to the different device source data are used for pointing to a preset data format structure; based on the searched first processing logic, performing first dimension processing on the source data of each device to obtain processed intermediate data; and based on the obtained second processing logic and the timestamp corresponding to each piece of intermediate data, performing second dimension processing on each piece of intermediate data to generate a data processing result. Therefore, the data processing calculation amount is reduced, and the method is suitable for data processing in diversified industrial scenes.

Owner:浙江西图盟数字科技有限公司

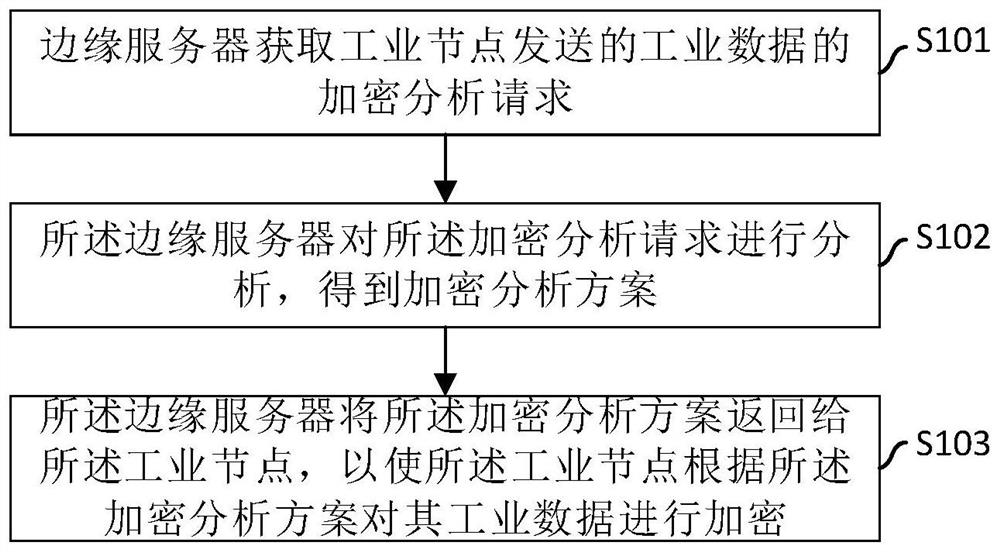

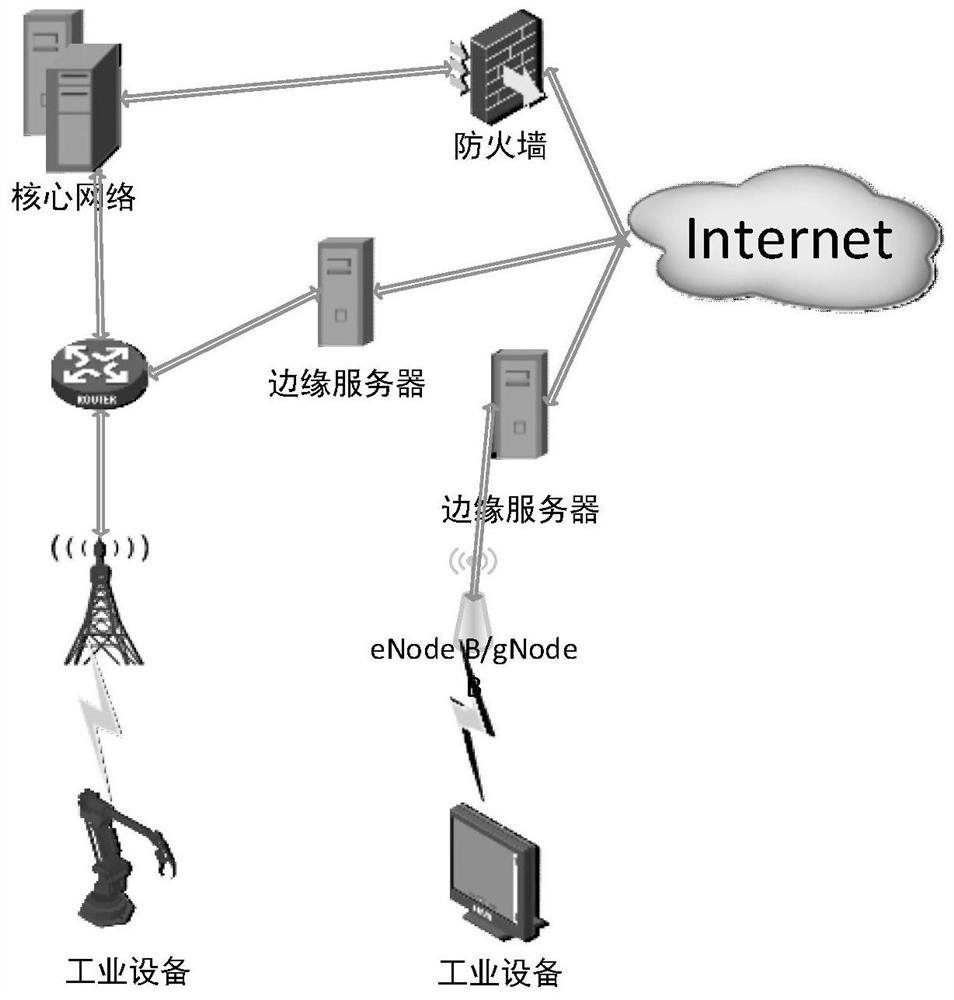

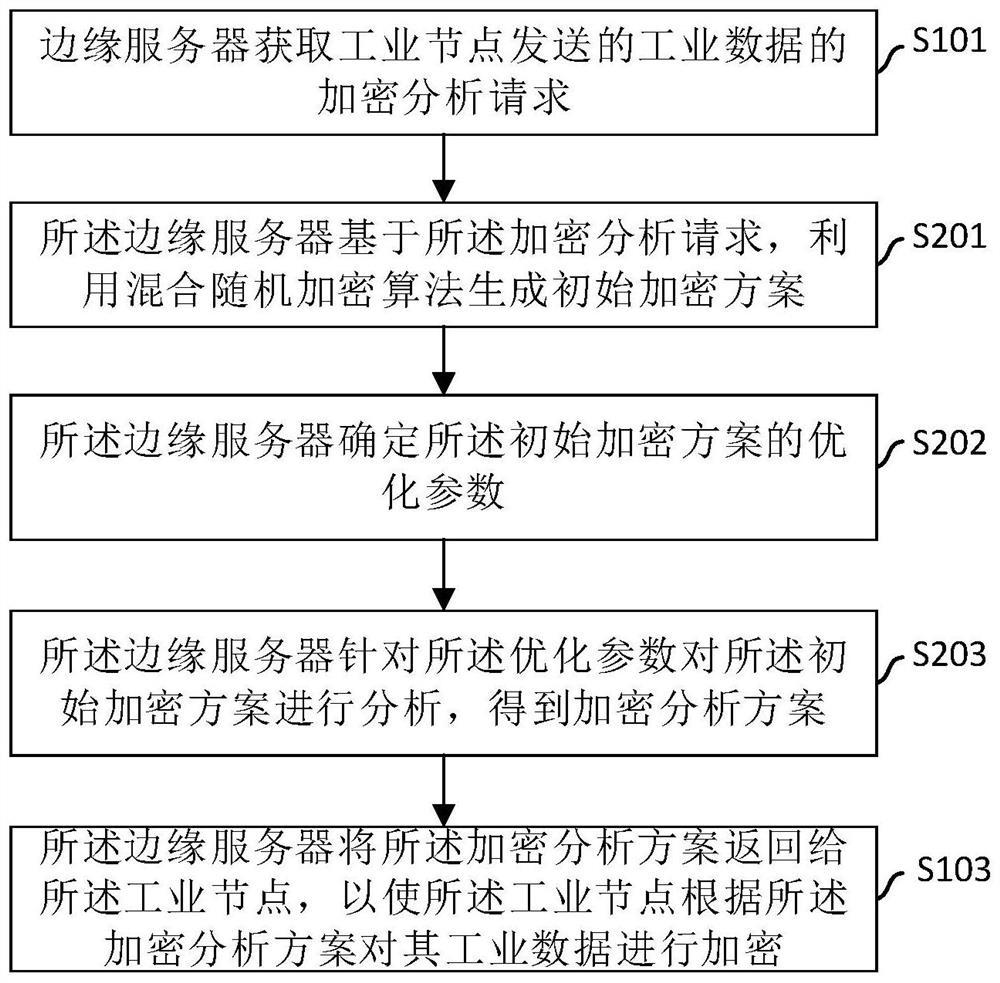

Industrial data encryption method, edge server and computer readable storage medium

ActiveCN112364365ASolve the high response delaySolve signaling congestionDigital data protectionNeural architecturesIndustrial data processingData processing

The invention provides an industrial data encryption analysis method, an edge server and a computer readable storage medium, and the method comprises the steps that the edge server obtains an encryption analysis request, sent by an industrial node, of industrial data; the edge server analyzes the encryption analysis request to obtain an encryption analysis scheme; and the edge server returns the encryption analysis scheme to the industrial node, so that the industrial node encrypts the industrial data according to the encryption analysis scheme. The embodiment of the invention can at least solve the problems of high response delay, signaling congestion, high industrial confidential data encryption cost and the like in the current industrial data processing process.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

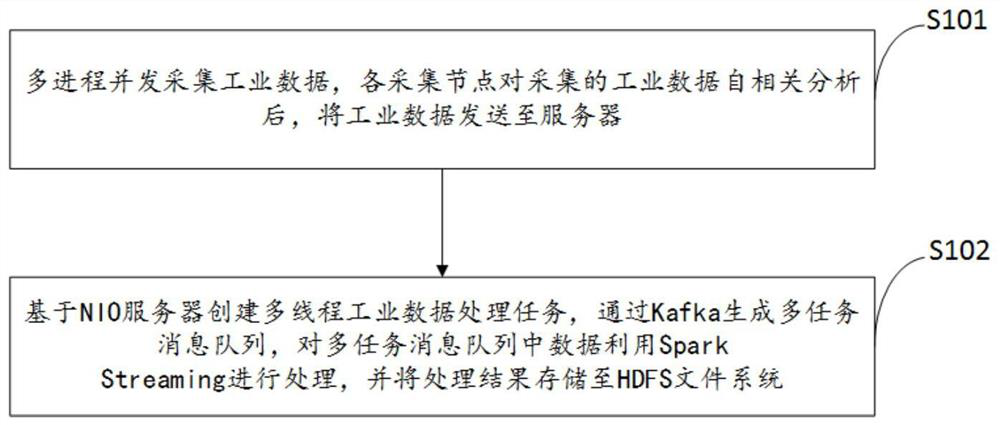

Industrial big data acquisition method and system

PendingCN113190524AImprove processing efficiencyGuarantee orderly managementDigital data information retrievalInterprogram communicationMessage queueFile system

The invention provides an industrial big data collection method and system. The method comprises the steps: carrying out the multi-process concurrent collection of industrial data, carrying out the self-correlation analysis of the collected industrial data through all collection nodes, and transmitting the industrial data to a server; and creating a multi-thread industrial data processing task based on an NIO server, generating a multi-task message queue through Kafka, processing data in the multi-task message queue by using Spark Streami ng, and storing a processing result to an HDFS file system. By means of the method, the processing efficiency of industrial data acquisition, storage and other processes can be improved, the server load is reduced, and orderly and reliable management of industrial big data is facilitated.

Owner:武汉卓尔信息科技有限公司

Multi-condition fault detection method for chemical system based on local adaptive standardization

ActiveCN111367253BImprove accuracyImprove generalization abilityProgramme controlElectric testing/monitoringNeural network nnAdaptive capacity

The invention relates to a chemical system multi-working-condition fault detection method based on local adaptive standardization and belongs to the technical field of chemical process monitoring, industrial data processing and process system engineering. According to the method, a local adaptive standardization method is provided, the variational automatic encoder technology of the deep neural network is applied, an average value of the data in the local moving window is calculated to serve as an average value parameter of local adaptive standardization, different average values are used fordifferent data, and the adaptive capacity is achieved. The method is advantaged in that local adaptive standardization processing is utilized, and fault detection is carried out by detecting whether the data in a local moving window deviates or not, and the method can be suitable for any working condition, has higher accuracy and stronger generalization ability, can meet the requirement of real-time detection, and avoids chemical accidents or reduces the harm caused by accidents through early warning of faults.

Owner:TSINGHUA UNIV

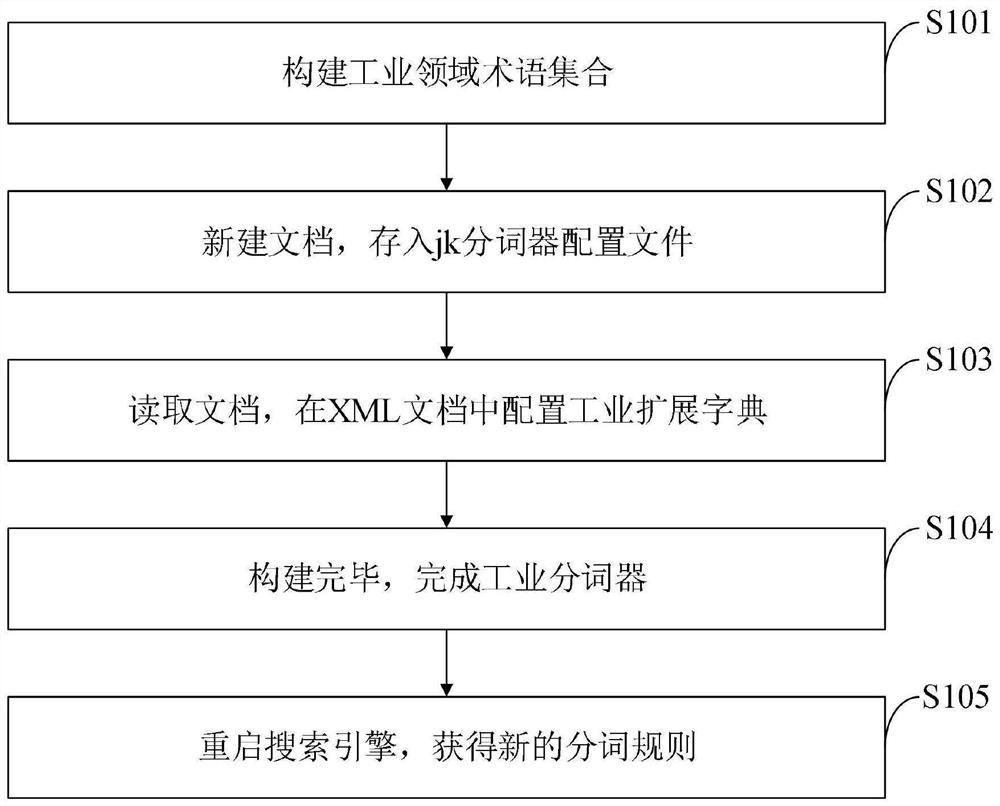

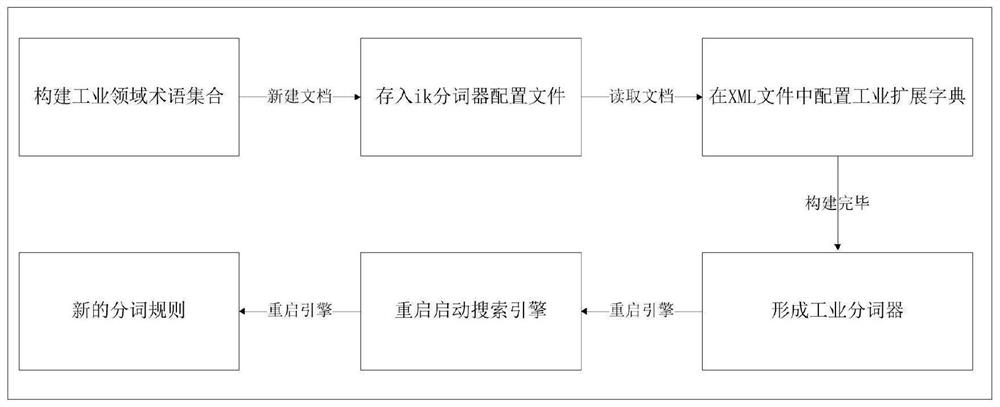

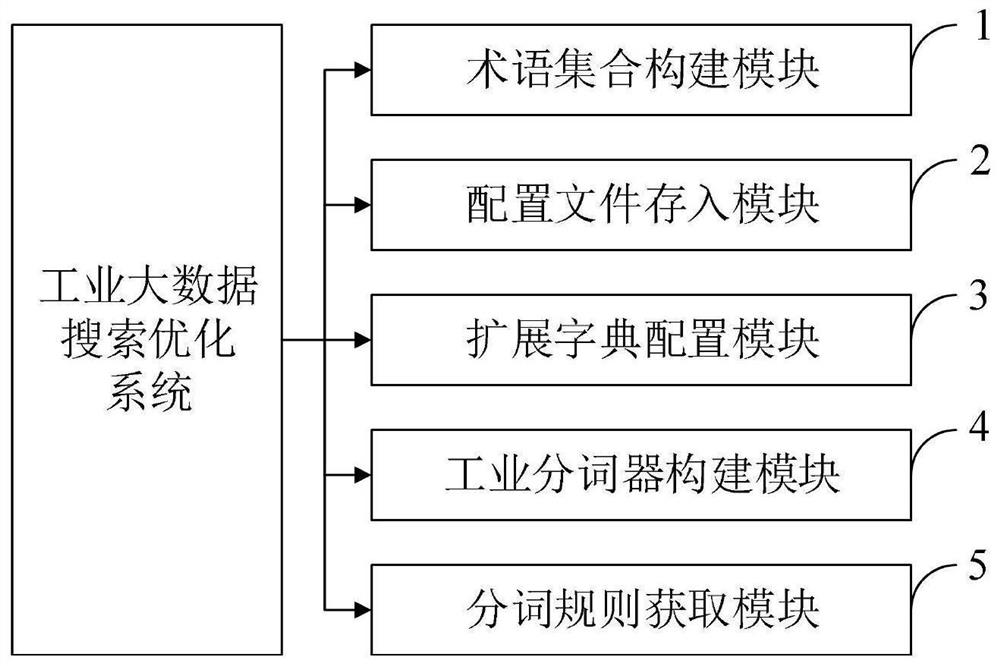

Industrial big data search optimization method, system, equipment, medium and terminal

PendingCN113553408AImprove classification effectImprove robustnessNatural language data processingText database queryingEngineeringChinese word

The invention belongs to the technical field of industrial data processing, and discloses an industrial big data search optimization method, system, device, medium and terminal. The industrial big data search optimization method comprises the steps of firstly collecting industrial field specialized vocabularies to form a related set, and storing the content into a new document and placing the document in an ik word segmentation device configuration folder; and then configuring an industrial extension dictionary in the XML document to form an industrial word segmentation device, restarting an Elasticsearch search engine, and at the moment, completing the construction of the industrial word segmentation device. The invention provides a word segmentation device specially applied to industry, an industrial word segmentation device is constructed by analyzing the technical principle of the word segmentation device, and the difference between the word segmentation results of the industrial word segmentation device and mainstream general Chinese word segmentation devices jieba and Ansj in the industrial field is compared, and the result shows that based on the industrial word segmentation device, more excellent classification performance and robustness are achieved according to the word segmentation, and the word segmentation effect and the search efficiency are effectively improved by expanding industrial specialized vocabularies.

Owner:XIDIAN UNIV

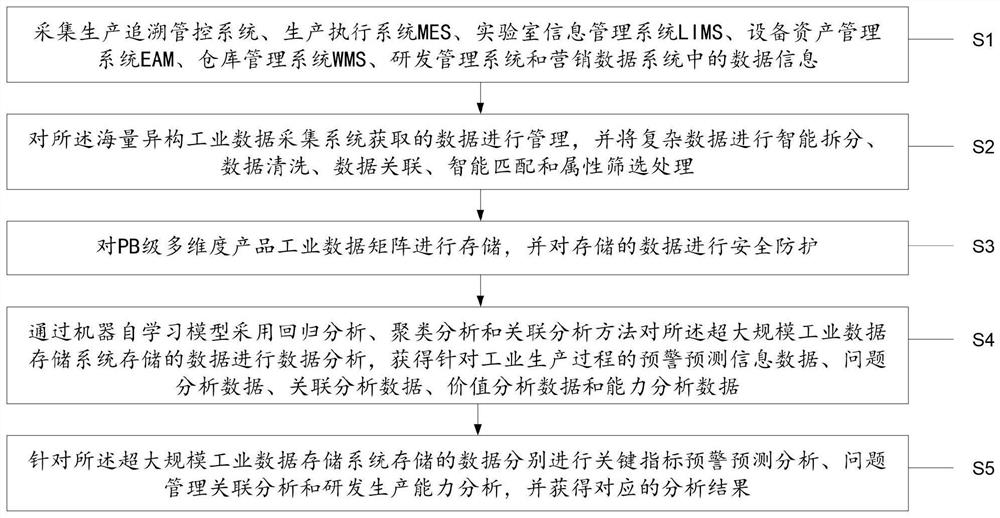

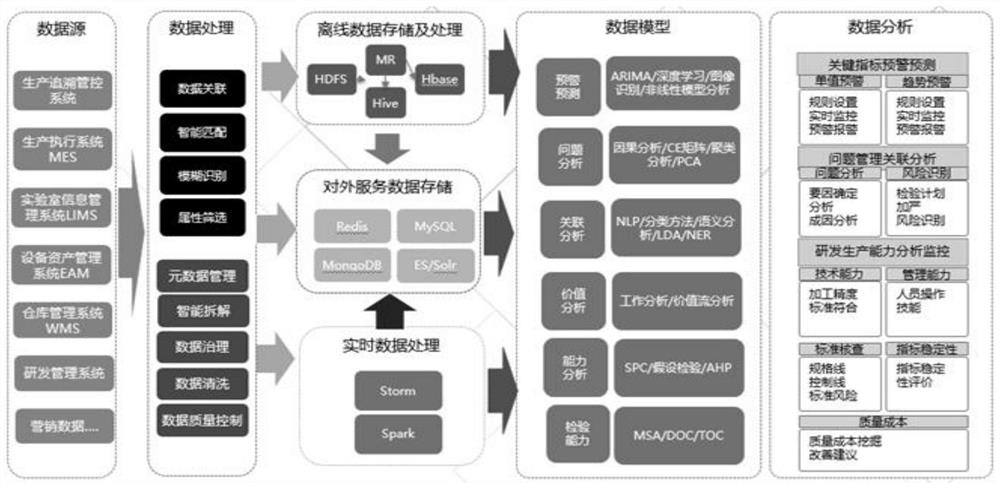

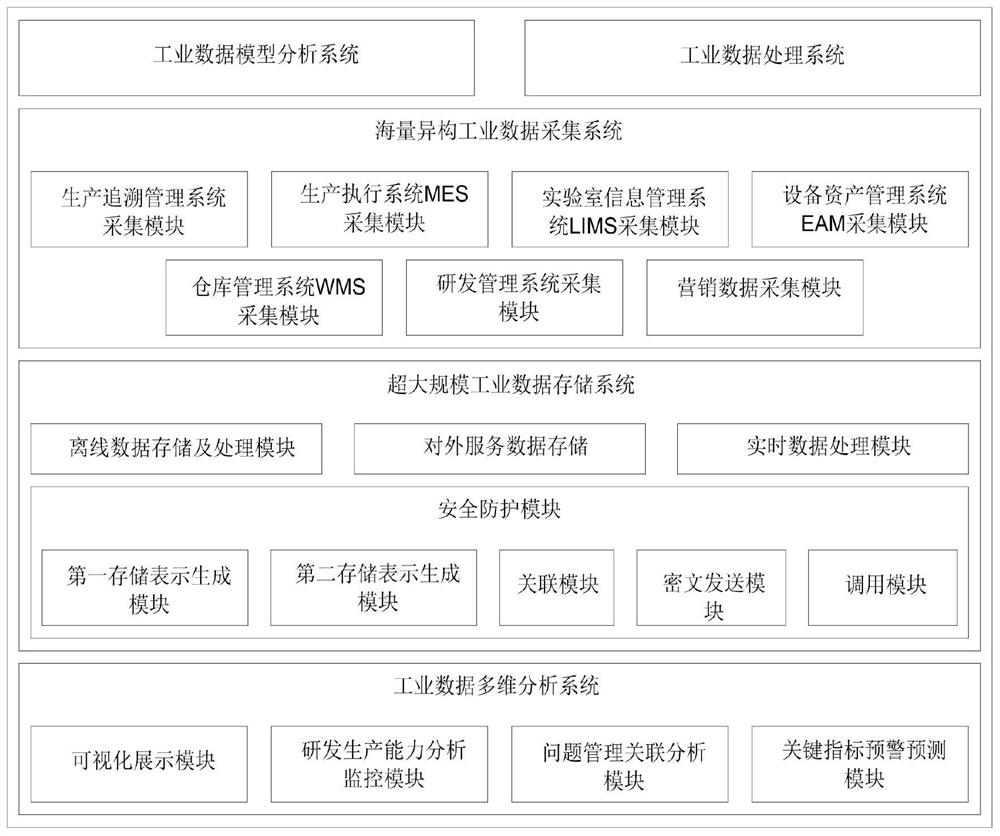

Industrial big data analysis platform and method based on multi-source heterogeneous data governance

ActiveCN112288317AStable supportAccurately grasp the relationshipDatabase management systemsResourcesAnalysis dataData information

The invention provides an industrial big data analysis platform and method based on multi-source heterogeneous data governance. The industrial big data analysis platform comprises a massive heterogeneous industrial data acquisition system, an industrial data processing system, a super-large-scale industrial data storage system, an industrial data model analysis system and an industrial data multi-dimensional analysis system. The method comprises the steps of collecting data information; managing the data acquired by the massive heterogeneous industrial data acquisition system, and performing intelligent splitting, data cleaning, data association, intelligent matching and attribute screening processing on the complex data; performing storage and security protection on the data matrix; obtaining each piece of analysis data through a machine self-learning model; and performing key index early warning prediction analysis, problem management association analysis and research and developmentproduction capacity analysis on the data stored in the super-large-scale industrial data storage system, and obtaining corresponding analysis results.

Owner:北京三维天地科技股份有限公司

A time synchronization method and system

ActiveCN107276709BImprove accuracyIncrease authenticityTime-division multiplexProgramme control in sequence/logic controllersData synchronizationData acquisition

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

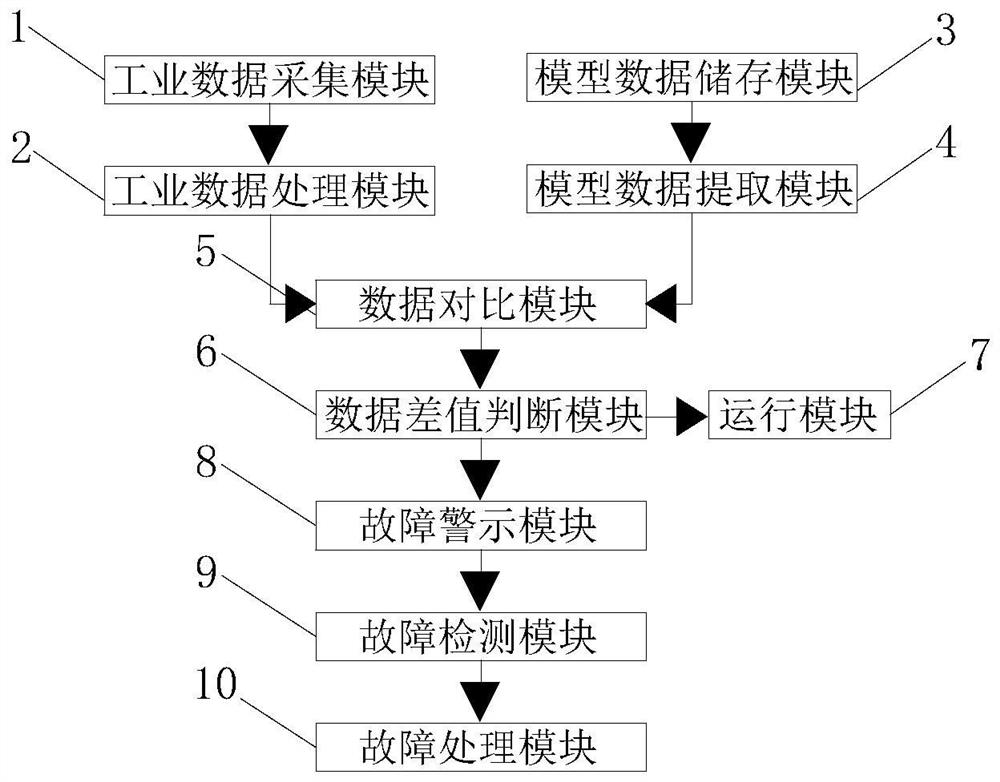

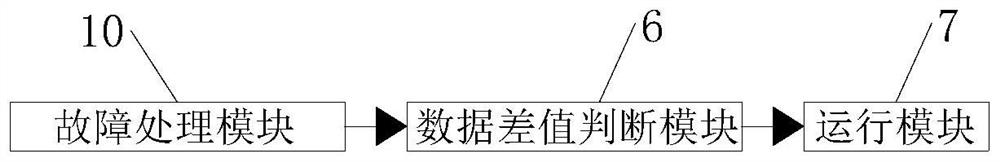

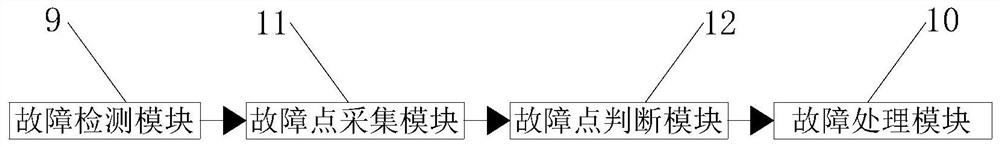

Industrial production process fault detection system with deep learning function

PendingCN114442599AWith deep learning capabilitiesProblems that affect the collection effectProgramme controlElectric testing/monitoringData acquisitionData acquisition module

The invention discloses a fault detection system with a deep learning function for an industrial production process, and relates to the technical field of fault detection, in particular to the fault detection system with the deep learning function for the industrial production process. The electrical output end of the industrial data acquisition module is connected with an industrial data processing module, and the electrical output end of the industrial data processing module is connected with a data comparison module; and the data difference judgment module is connected to the electrical output end of the data comparison module, and the electrical output end of the data difference judgment module is connected with an operation module and a fault warning module. According to the fault detection system with the deep learning function for the industrial production process, acquired data can be compared with an extracted data model through a data comparison module, and a data difference judgment module judges whether the data compared by the data comparison module is within a standard difference range or not.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

Industrial data processing method and device, storage medium and electronic device

PendingCN114780560AAchieve sharingSolution can not be reusedDatabase updatingSpecial data processing applicationsBusiness dataData mining

The invention discloses an industry data processing method and device, a storage medium and an electronic device. The method comprises the steps that industry field packets are generated by analyzing industry historical business data, the industry historical business data are covered with different business scene data, and each industry field packet is provided with corresponding industry data; storing the industry field package to a target server or a target client; the business scene data and the corresponding industry data are updated by updating the industry field packet, and the industry field packet is used for being reused in the business scene data. The technical problem that industry experience data cannot be reused or shared is solved.

Owner:普强时代(珠海横琴)信息技术有限公司

Injection molding industry data processing system and method based on big data

ActiveCN113246421AReal-time acquisition of detection dataGet jobs in real timeDesign optimisation/simulationNeural architecturesInjection molding machineIndustrial engineering

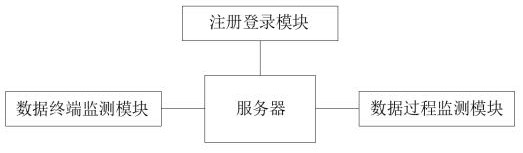

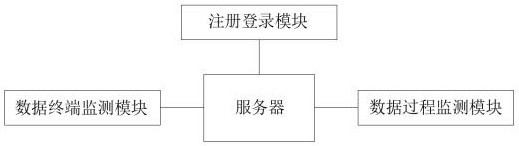

The invention discloses an injection molding industrial data processing system and method based on big data, and belongs to the technical field of industrial data processing. The system comprises a data process monitoring module, a data terminal monitoring module and a server, wherein the data process monitoring module is used for detecting and processing injection molding machine process data, the data terminal monitoring module is used for monitoring and processing the injection molding machine data according to injection molding machine production products, the process data of an injection molding machine is detected through the data process monitoring module, the detection data, the working duration and the working environment of the injection molding machine are obtained in real time, integrated and marked as input data, a prediction model is obtained, the input data is input into the prediction model to obtain an output result and mark an output result as a prediction label, the prediction label is the state label corresponding to the input data, the data problem in the operation process of the injection molding machine can be known in time, warning is provided for a user, the problem can be found in time, and loss is reduced.

Owner:广州中和互联网技术有限公司

A method, system and device for industrial data processing

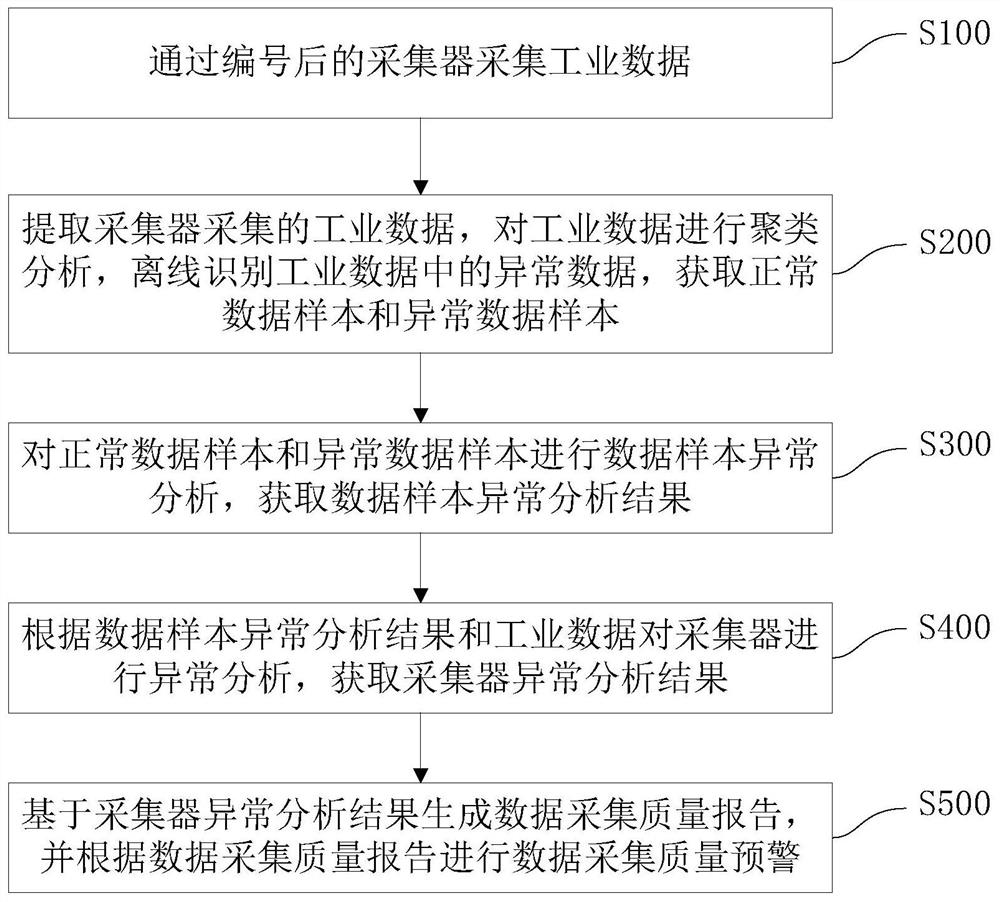

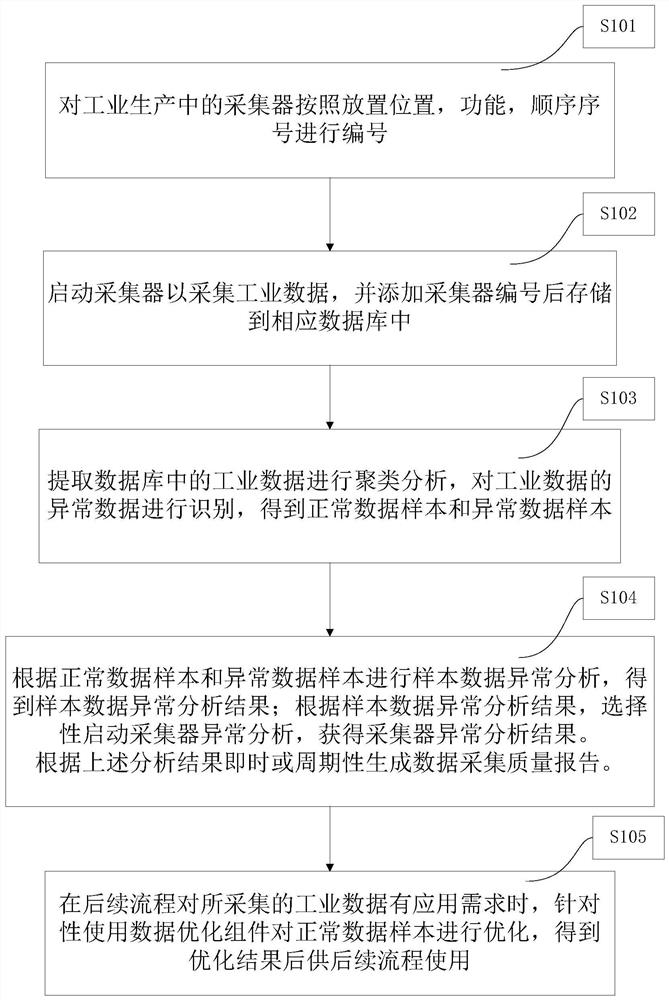

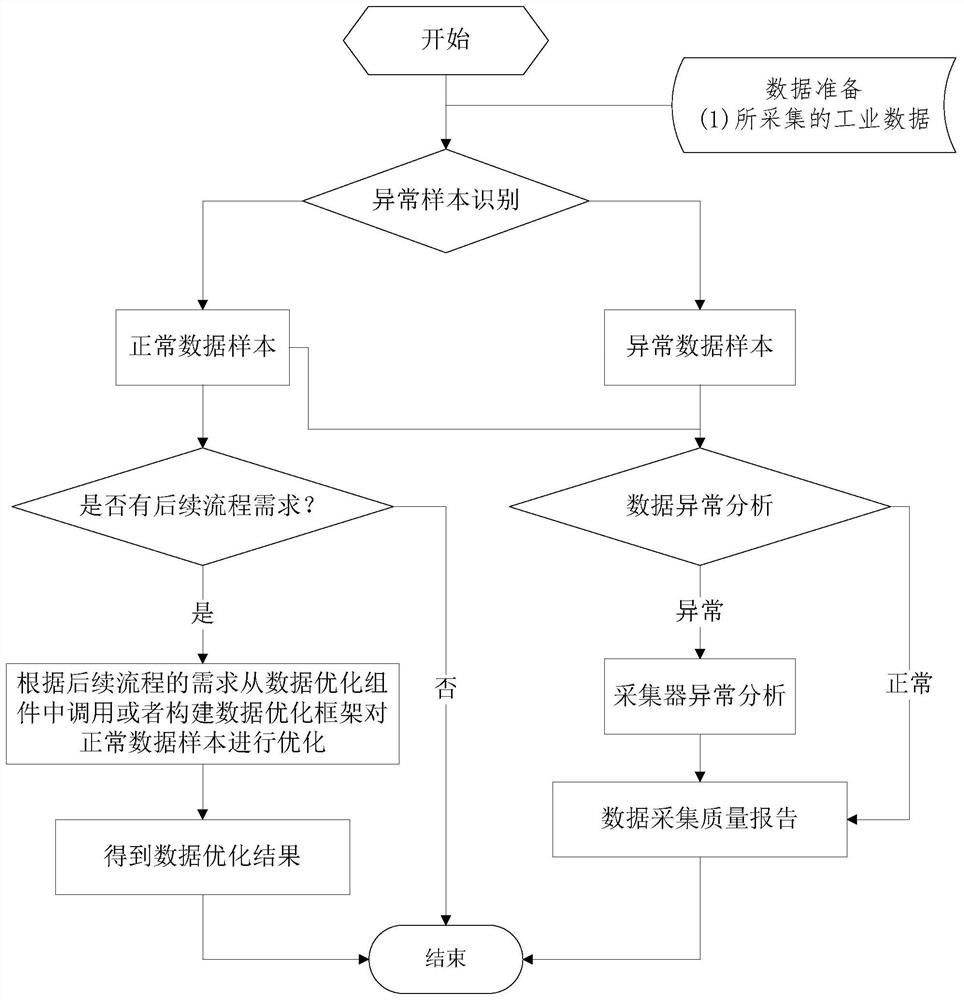

ActiveCN112114571BHigh development valueIncrease valueTotal factory controlProgramme total factory controlData miningData collecting

The present invention provides an industrial data processing method, system and equipment, which collect industrial data through numbered collectors; perform cluster analysis on industrial data, identify abnormal data in industrial data offline, and obtain normal data samples and abnormal data samples; Perform data sample abnormality analysis on normal data samples and abnormal data samples to obtain abnormal analysis results of data samples; perform abnormal analysis on collectors that collect industrial data according to abnormal analysis results of data samples, and obtain abnormal analysis results of collectors; based on abnormal analysis of collectors As a result, a data collection quality report was generated, and a data collection quality warning was carried out according to the data collection quality report. The invention solves the technical problems of narrow data optimization range and lack of collection quality analysis and early warning in the prior art. Moreover, the present invention also utilizes the abnormal analysis of data to realize the evaluation of collection quality, and then performs instant and periodic early warning for the debugging of the collector.

Owner:CISDI INFORMATION TECH CO LTD

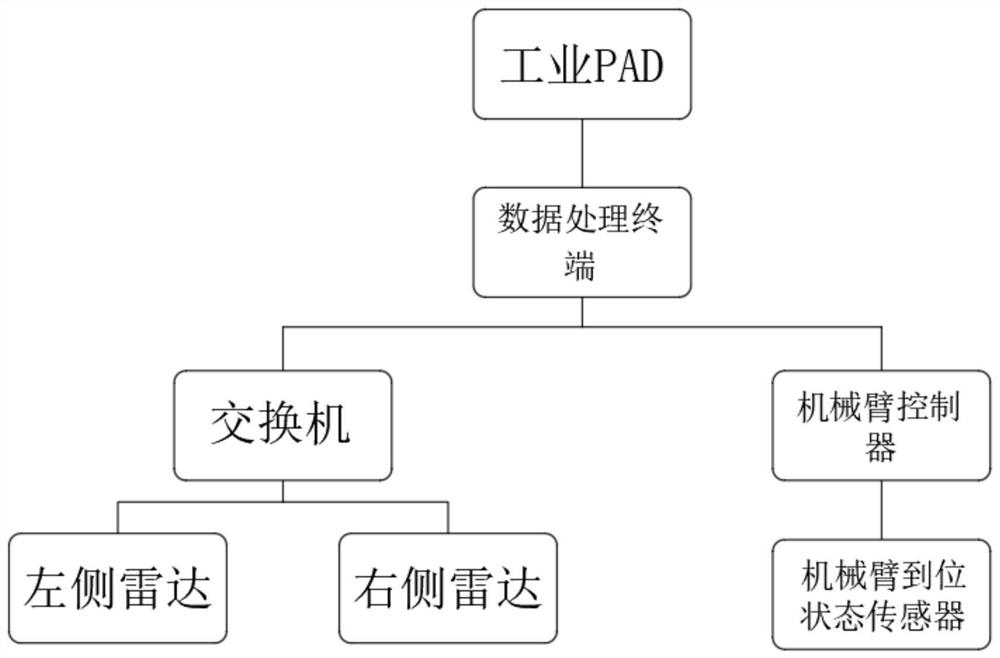

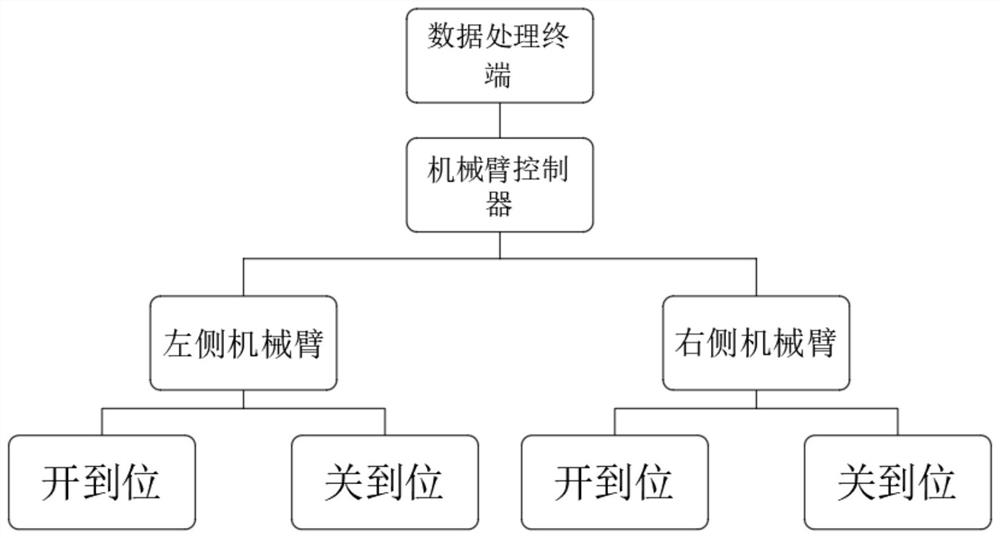

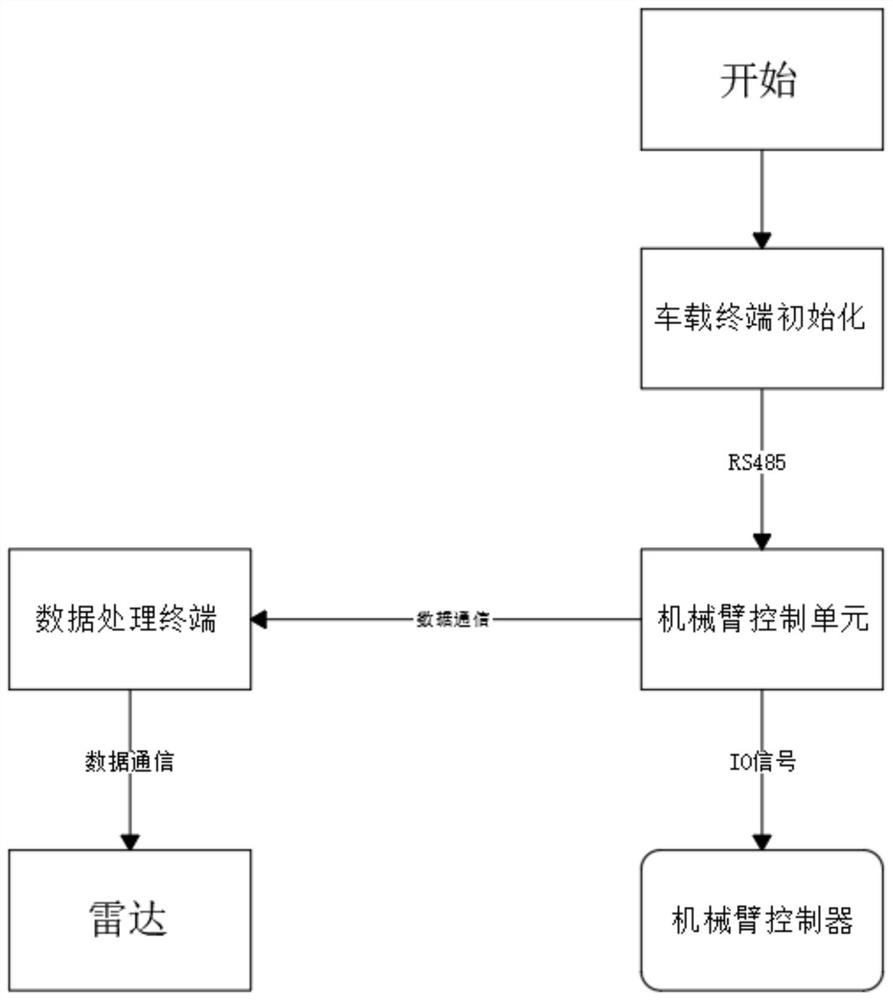

Intelligent obstacle avoidance control system for mechanical arm of spray boom type pesticide sprayer

The invention relates to the technical field of a spray boom type pesticide sprayer, and discloses an intelligent obstacle avoidance control system for a mechanical arm of a spray boom type pesticide sprayer. The intelligent obstacle avoidance control system comprises an industrial PAD, a data processing terminal, a switch, a radar and a mechanical arm controller; the industrial PAD is connected with the data processing terminal; the data processing terminal is respectively connected with the switch and the mechanical arm controller; the switch is connected with the radar; the mechanical arm controller is connected with a mechanical arm in-place state sensor; the mechanical arm in-place state sensor is respectively connected with a left mechanical arm and a right mechanical arm; and azimuth information of obstacle information is obtained by taking the radar data processing terminal as the center through data calculation, data required by obstacle avoidance of the mechanical arm is calculated, the state of the mechanical arm is controlled through a mechanical arm control unit so as to complete obstacle avoidance, and meanwhile, the data is uploaded to the data terminal through a data communication protocol.

Owner:JILIN ACAD OF AGRI MACHINERY

A data processing system and method for injection molding industry based on big data

ActiveCN113246421BReal-time acquisition of detection dataStay abreast of data issuesDesign optimisation/simulationNeural architecturesData terminalData processing system

The invention discloses an injection molding industrial data processing system and method based on big data, which belongs to the technical field of industrial data processing and includes a data process monitoring module, a data terminal monitoring module and a server; the data process monitoring module is used to monitor the injection molding machine process The data is detected and processed, and the data terminal monitoring module is used to monitor and process the data of the injection molding machine according to the products produced by the injection molding machine; the process data of the injection molding machine is detected through the data process monitoring module, and the detection data, working hours and Work environment, integrate and mark as input data; obtain predictive model; input the input data into the predictive model to obtain the output result and mark it as the predictive label, the predictive label is the state label corresponding to the input data, and can keep abreast of the injection molding machine during operation Data problems, provide warnings for users, so that problems can be found in time and losses can be reduced.

Owner:广州中和互联网技术有限公司

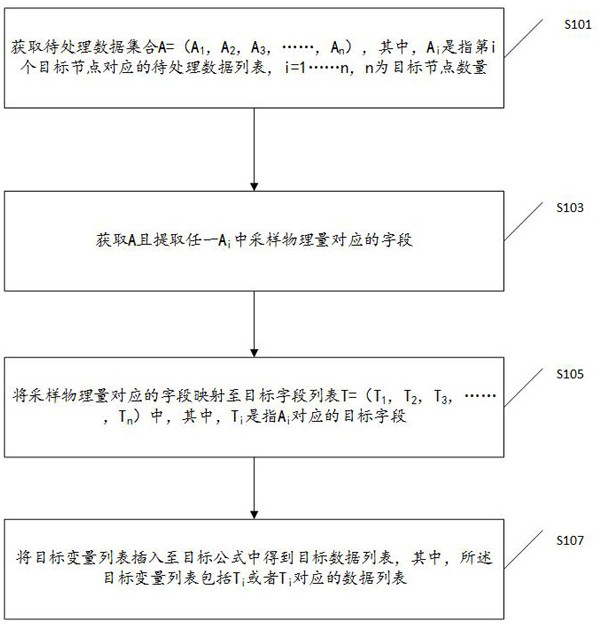

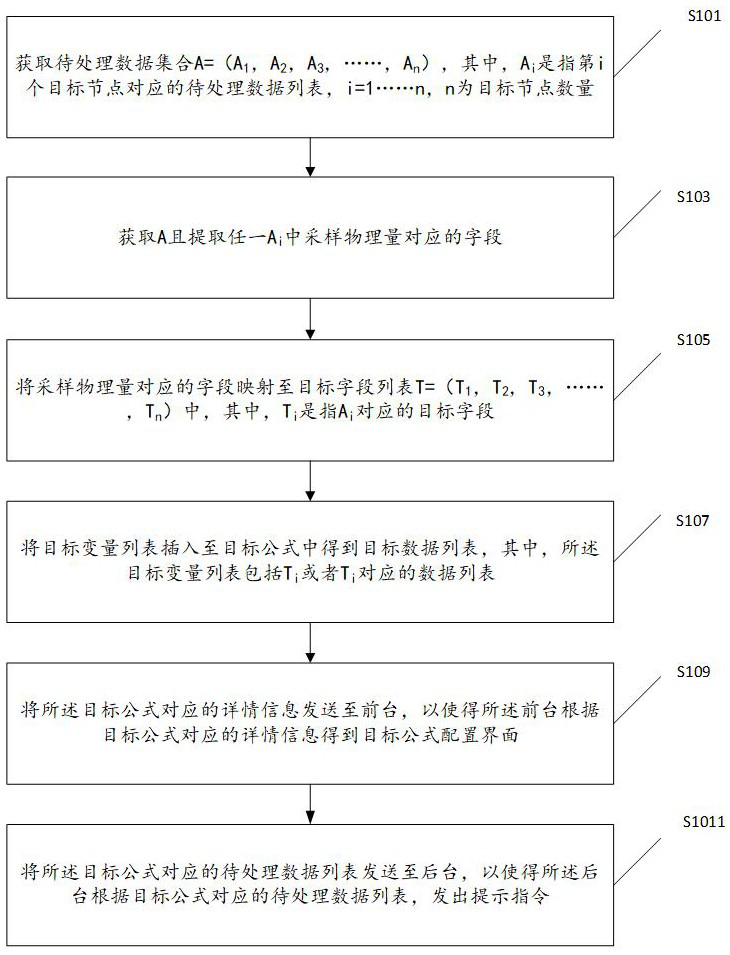

An industrial data processing system

ActiveCN113377785BAccurate calculationEasy to operateSpecial data processing applicationsDatabase indexingData setEngineering

The invention discloses an industrial data processing system, the system includes a database for storing plug-in ID lists, industrial data lists, target symbol lists and target function lists, a memory for storing industrial data processing programs, and a processor , the processor executes the industrial data processing program to realize the following processing steps: obtain the data set to be processed, extract the field corresponding to the sampled physical quantity in any list of the data to be processed, map the field corresponding to the sampled physical quantity to the target field list, insert the target variable list into Get the target data list in the target formula, wherein the target variable list includes the target field or the data list corresponding to the target field; There is also an association relationship between them to avoid affecting the calculation of other data when the plug-in corresponding to any data is abnormal.

Owner:天津宜科自动化股份有限公司

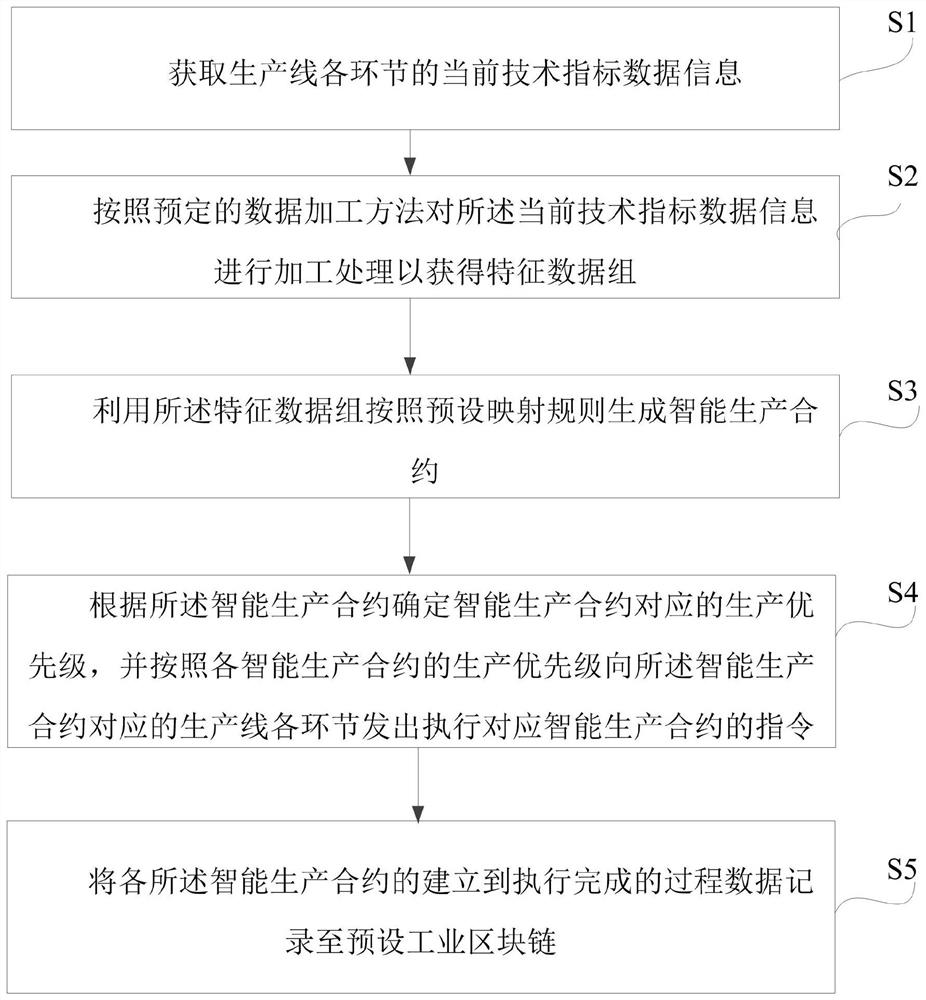

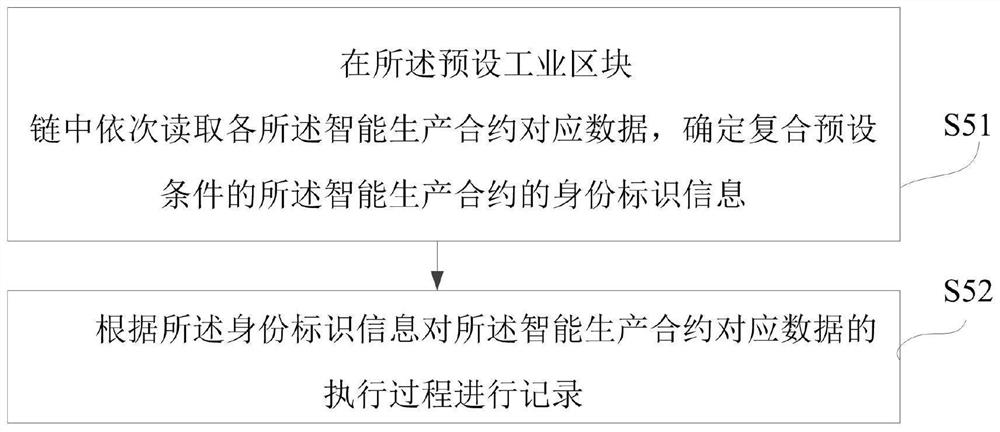

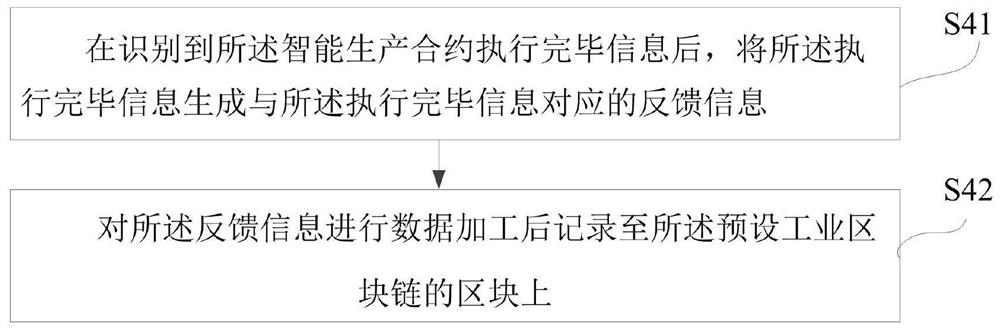

Industrial data processing method and system based on blockchain smart contract

PendingCN111881217AAutomated and fully monitoredDownsamplingDatabase distribution/replicationTotal factory controlData setData information

The invention relates to an industrial data processing method and system based on a blockchain smart contract. The method comprises the steps of obtaining current technical index data information of each link of a production line and performing processing according to a predetermined data processing method to obtain a feature data set; generating an intelligent production contract by utilizing thefeature data set according to a preset mapping rule; determining production priorities corresponding to the intelligent production contracts according to the intelligent production contracts, and sending instructions for executing the corresponding intelligent production contracts to all links of a production line corresponding to the intelligent production contracts according to the production priorities of all the intelligent production contracts; and recording process data from establishment to execution completion of each intelligent production contract to a preset industrial block chain.According to the technical scheme, the problems that in traditional industrial production, the quality and process information of the production process are generally monitored in a manual checking mode, the sampling rate is low, and the detection result has great one-sidedness are solved.

Owner:EPIC HUST TECH WUHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com