Multi-condition fault detection method for chemical system based on local adaptive standardization

A local self-adaptive and fault detection technology, applied in the fields of chemical process monitoring, industrial data processing and process system engineering, it can solve problems such as failure to complete the fault detection task and no general fault detection method yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

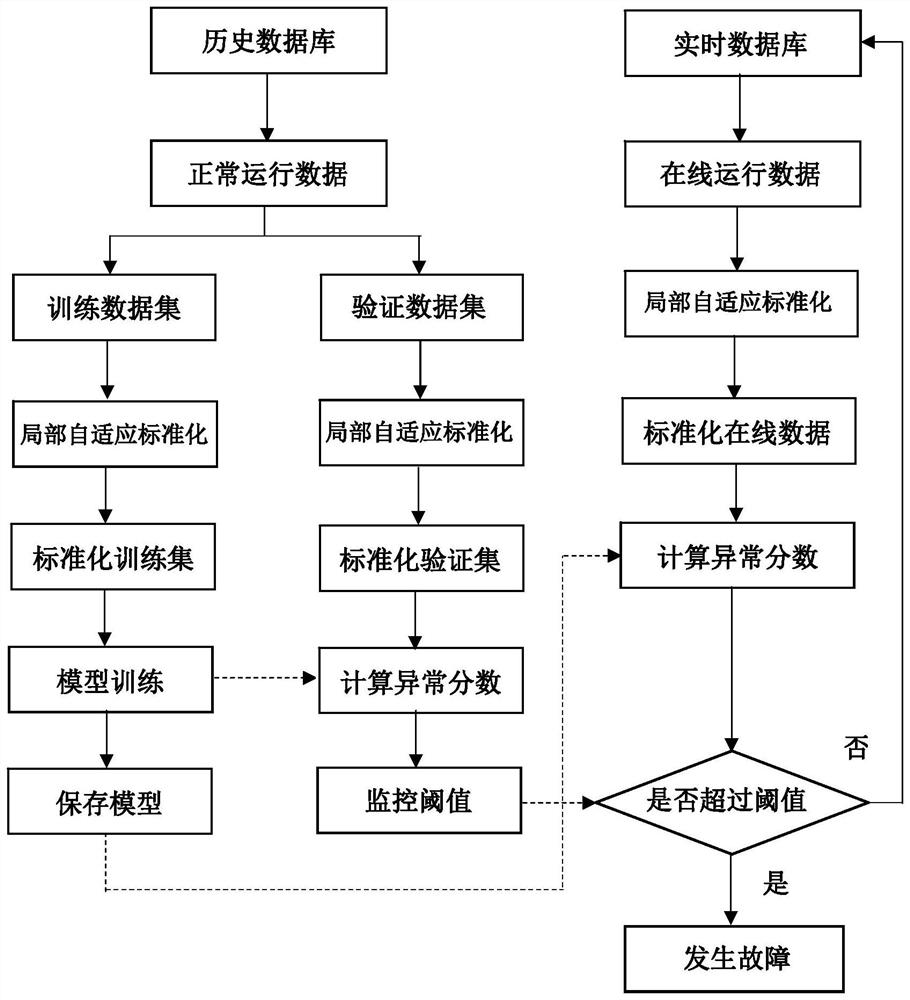

[0081] The local self-adaptive standardization-based fault detection method for multi-working conditions in chemical industry systems proposed by the present invention has a block diagram of the overall process as shown in figure 1 shown, including the following steps:

[0082] (1) Obtain the normal operation data set D under N working conditions from the historical database of the chemical industry system history , data set D history There are m rows and n columns of data, where m represents the process variables of the chemical system, such as temperature, time, pressure, etc., and n represents the total running time;

[0083] (2) The normal operation data set D in step (1) history Divide into training set D train and validation set D valid , the training set D train include m lines n train Column data, validation set D valid include m lines n valid column data, where the training set D train D of the historical uptime data set history The ratio is 60%≤a≤90%;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com