Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Indirect test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indirect test is administered to determine if there was a potential bad reaction to a blood transfusion. Blood banks use the indirect Coombs test to determine whether there is likely to be an adverse reaction to blood to be transfused.

Method for simulating load test with transformer substation bus differential protection current

ActiveCN101694505AChanging the indirect test methodEliminates defects that may only be found during load testingElectrical testingElectricityIndirect test

The invention discloses a method for simulating a load test with transformer substation bus differential protection current. A heavy-current device is utilized to replace a power transmission power supply to be accessed between a main transformer earthing isolating switch and a main transformer current mutual inductor; an outgoing earthing isolating switch is utilized to simulate load; a heavy-current device three-phase wiring zero line is grounded to simulate different faults of one phase and faults between phases. The invention can replace a load test of a bus differential current loop and can simulate fault states and change the traditional transformer substation bus differential protection current loop indirect test methods. The transformer substation double-bus differential protection current loop, a relative breaker, the isolating switch and a current mutual inductor control operation loop are precisely simulated before power is transmitted, and a bus differential protection normal running state and fault state are simulated well so as to ensure that the protection current loop is in a correct state before the power is transmitted. Defects which can be possibly found in transformer substation load test are eliminated. The invention is more accurate, safer and more reliable.

Owner:STATE GRID CORP OF CHINA +1

Device and method for testing torsional rigidity and mode of shafting

PendingCN108072488AEasy to implementEasy to operateMachine part testingStatic/dynamic balance measurementModal testingAccelerometer

The invention relates to a device and method for testing the torsional rigidity and mode of shafting, and belongs to the field of rigidity and mode test. In the device, a mass disc is bonded to the free end of a shaft to be tested, additional square blocks are bonded to the two sides, opposite to each other, in the side arm of the shaft to be tested respectively, and accelerometers are mounted onthe additional square blocks respectively. The device is easy to realize, convenient to operate and high in test precision, and fills the blanks in the field of torsional rigidity and mode test of theshafting. According to the method, the characteristic that the additional square blocks can act torsional moment excitation and test response of the tested shaft in the torsional direction is used, the mass disc is used to change the mass characteristic of the shaft, the torsional rigidity and moment of inertia of the tested shaft are calculated, the torsional rigidity and mode measured by the method can reflect the torsional oscillation characteristic of the shafting visually, and the method further has the advantage of high precision.

Owner:BRILLIANCE AUTO

Polymer pressure-specific volume-temperature relation indirect test method and its device

ActiveCN101149369AEven by forceEliminates the need for a vacuum to remove airMaterial testing goodsIndirect testEngineering

A kind of method and equipment test the relation of polymer pressure, specific volume, temperature indirectly, uses the test equipment which is compose of the pressure medium mercury, seal liquid, sample room, pressure vessel, compression system, heat and cold system, pressure sensor, displacement sensor, thermoelectric couple and data processing system. This method using the character that the mercury and the seal liquid do not dissolve in each other, it can avoid the disadvantage that the mercury is toxic and is easy to volatilize in the indirect method of the polymer P-V-T test simply, at the same time, it has a series other merits such as can make the inner to reach high vacuum degree, to make the sample stress uniformly, the compress coefficient is small, impress pressure is direct, the measure precision is high and so on, it also resolves the problem that it vent the air in the presence of vacuum. It can use the relation of the polymer pressure-specific volume-temperature sets the mold technology parameter of the polymer product or design the module and do CAE analysis.

Owner:BEIJING UNIV OF CHEM TECH

Method for automatically testing C compiler

ActiveCN107329889AFast automated testingReduce work intensitySoftware testing/debuggingIndirect testHardware simulator

The invention discloses a method for automatically testing a C compiler. According to the method, an assembly is embedded into a C source file, and an HEX file obtained through the C compiler, an assembler and a linker in a compiling mode is combined with a lower computer hardware simulator to verify an expected result, so that the aim of verifying a CSCC compiler is achieved. Automatic testing is quickly achieved through the method, the correctness of a tool chain of the whole C compiler is indirectly tested by utilizing the whole IDE development environment, and the problems that the C compiler is used for compiling manually, simulation setting is tedious and the operation speed is low are solved.

Owner:CHIPSEA TECH SHENZHEN CO LTD

Microbubble performance test and assessment experimental platform and test and assessment method thereof

The invention belongs to the technical field of microbubble performance test and relates to a microbubble performance test and assessment experimental platform and a test and assessment method thereof. The microbubble performance test and assessment experimental platform is characterized in that a scum collection tank is arranged at the top of a flotation column, a bottom backflow gate valve is connected with a microbubble generation device which generates an air-liquid mixture of microbubbles and water, and the air-liquid mixture is injected to the lower portion of the flotation column through a backflow water distribution unit; a microbubble particle size test sampling port is connected with a laser particle analyzer through a sampling tube and a sample adding controller, and the laser particle analyzer is connected with a computer. The test and assessment method includes: according to a direct test and assessment method, completing online test of microbubble particle size distribution conditions by the aid of the laser particle analyzer and the computer; according to an indirect test and assessment method, injecting waste water into the flotation column, allowing part of bottom waste water to flow back into the flotation column through the microbubble generation device, and testing pollutants in different axial heights of the flotation column to complete indirect test and assessment. By the microbubble performance test and assessment experimental platform and the test and assessment method thereof, test and assessment of various microbubble generation techniques and product performances can be realized.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Processing method and processing system of DDR (Double Data Rate) test waveform data file

The invention discloses a processing method and processing system of a DDR (Double Data Rate) test waveform data file. The processing method of the DDR test waveform data file comprises the following steps: S1, carrying out traversing on an original data file of all DDR test waveforms and forming a tree-like list; S2, carrying out format conversion on the original data file and screening by adopting a first parameter; taking screened data as direct test data; S3, converting the direct test data into indirect test data by adopting a second parameter; S4, comparing the direct test data and the indirect test data with corresponding standard evaluation data respectively. The processing method and processing system of the DDR test waveform data file, disclosed by the invention, can be used for automatically extracting data from the DDR test waveform data file; a testing result is automatically judged and a testing report is automatically output, and the reliability is high.

Owner:CIG SHANGHAI

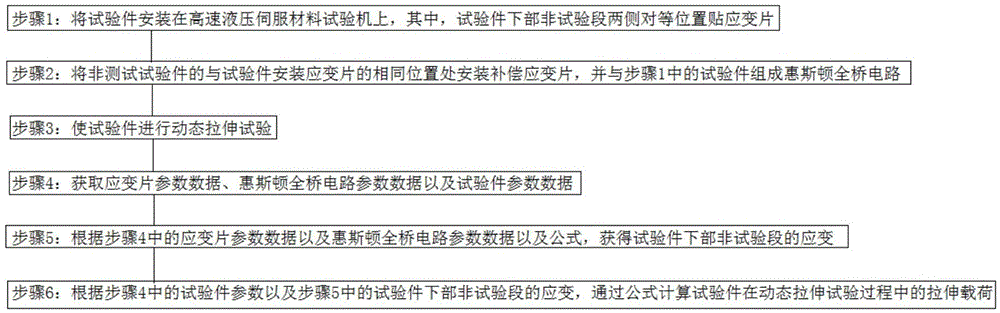

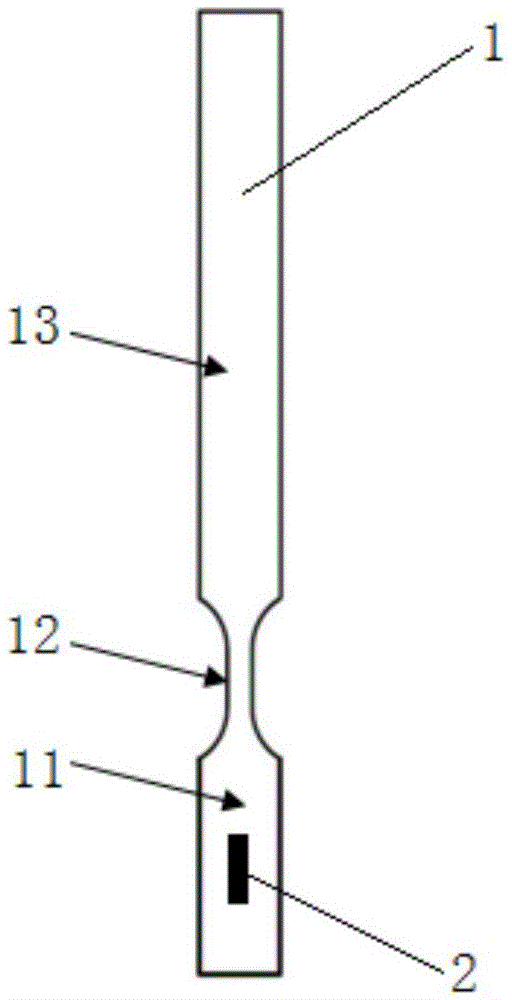

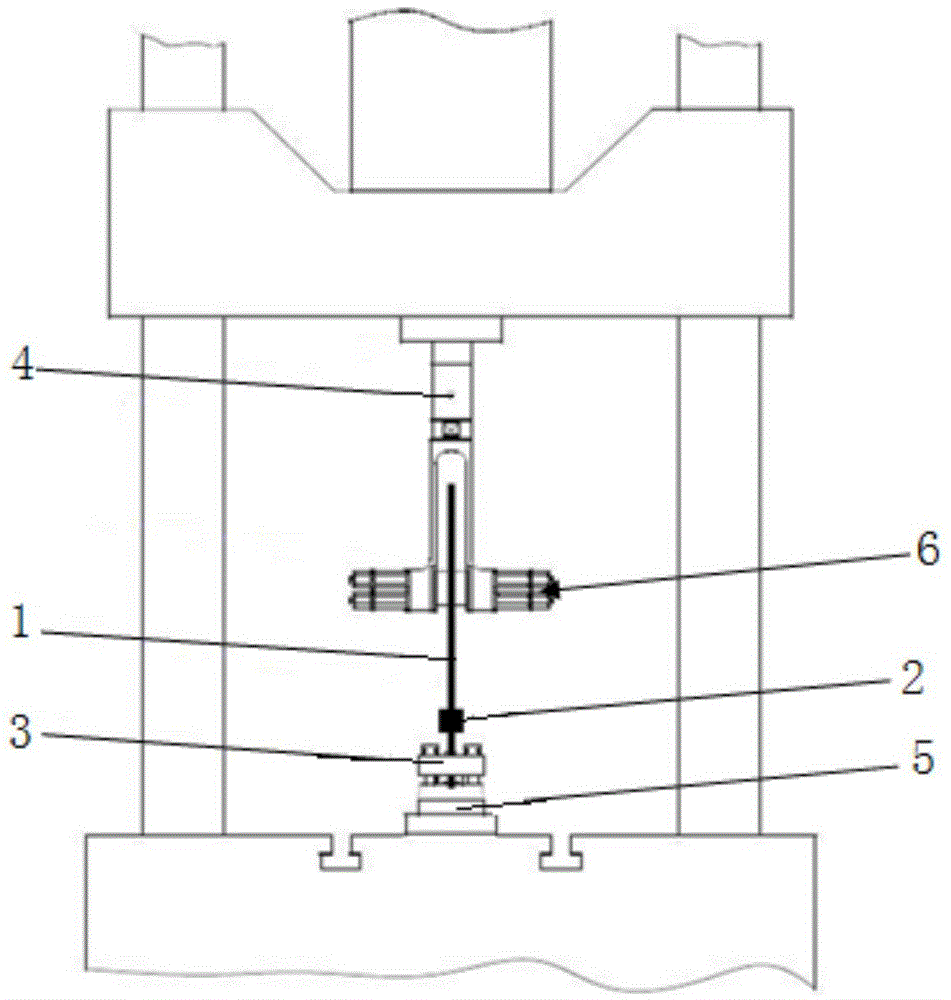

Indirect strain rate dynamic tensile load testing method applicable to metal materials

InactiveCN105651608AInertia Effect EliminationCoupling will notMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementIndirect testFull bridge

The invention discloses an indirect strain rate dynamic tensile load testing method applicable to metal materials. The method comprises steps as follows: Step 1, a test piece is mounted on a high-speed hydraulic servo material tester, wherein strain gauges are pasted in corresponding positions of two sides of a non-test section at the lower part of the test piece; Step 2, a dummy gauge is mounted in the same position, where the strain gauges of the test piece are mounted, of a non-test piece, and the non-test piece and the test piece form a Wheatstone full-bridge circuit; Step 3, a dynamic tensile test is conducted on the test piece; Step 4, parameters of the strain gauges, the Wheatstone full-bridge circuit and the test piece are acquired; Step 5, strain of the non-text section at the lower part of the test piece is acquired; Step 6, the tensile load of the test piece in the dynamic tensile test process is acquired through formula calculation. The method has the advantages that the inertia effect of a static clamping fixture is eliminated and the resonant frequency of a testing system is not coupled into test data.

Owner:CHINA AIRPLANT STRENGTH RES INST

Device and method for indirectly testing performance of fire detection tube

The invention discloses a device and a method for indirectly testing the performance of a fire detection tube. A medium capable of generating high pressure gas is filled in a gas bottle of the device; one end of the tested fire detection tube is connected with the outlet of a pressure regulating valve, and the other end of the tested fire detection tube is sealed by an end connector; a test section at the center of the fire detection tube is fixed on a fixed plate; a cover plate is arranged on a test box; the fixed plate is positioned on the test box; a part of the fire detection tube on the fixed plate is soaked into the liquid medium; a timer is arranged on the lateral surface of the test box below the fixed plate; a heat source is arranged at one side of the test box and is completely soaked into the liquid medium; and a temperature testing element is arranged on the test box and is arranged in the liquid medium. The invention realizes the purpose of conveniently and accurately regulating the test pressure; when the fire detection tube is broken, gas can overflow out of the liquid medium and can not pollute the liquid medium; the indirect method which uses the liquid medium for simulating the heating environment in the working process of the fire detection tube has the advantages of high control accuracy of test temperature, simple structure, safe operation and low cost; and the device can be used as standard equipment to be popularized and used.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for inversely calculating parameters of super-large-diameter shield tunnel segment joint

ActiveCN104615870AAvoid experimental errorSpecial data processing applicationsScale modelIndirect test

The invention discloses a method for inversely calculating parameters of a super-large-diameter shield tunnel segment joint. By comparing a test result of an existing reduced-scale model and a test result of a full-scale model, tunnel segment joint mechanical parameter correction coefficients of the two different scale models of the diameter are obtained, and according to the linear relation, the coefficients are applied to reduced-scale test results of other super-large-diameter shield tunnels for inversely calculating design parameters of the corresponding super-large-diameter shield tunnel lining joint. The method has the advantages that the existing test results are fully utilized, by means of an indirect test mode, the segment joint mechanical parameters of full-size tests of shield tunnels with the different diameters can be derived, the situation that large-diameter full-size tests are directly carried out is avoided, and the method brings remarkable economic benefits; for the obtained mechanical parameter correction coefficients, test errors caused by the different diameters and different reduced-scales can be avoided relatively.

Owner:SHANGHAI TUNNEL ENGINEERING RAILWAY TRANSPORTATION DESIGN INSTITUTE

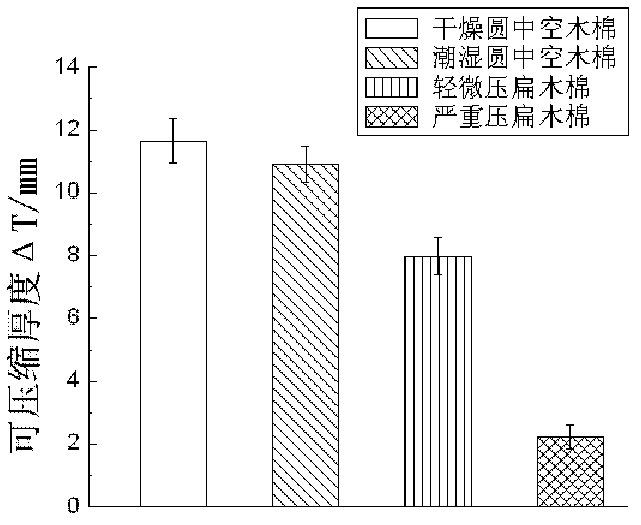

Indirect test evaluating method for hollowness of bombax cotton fiber

InactiveCN102507321AAvoid secondary deformationPreparing sample for investigationMaterial strength using tensile/compressive forcesFiberIndirect test

The invention relates to an indirect test evaluating method for the hollowness of a bombax cotton fiber. The indirect test evaluating method comprises the following steps of: manufacturing corresponding samples according to the shapes and types of products; testing by use of a compression tester of a fibrous material, measuring a relation curve of pressure and the thickness of the samples in a compression process and a relation curve of pressure and the thickness of the samples in a reset process to obtain a characteristic index so as to evaluate the hollowness state of the fiber; and carrying out calculation and result analysis according to the characteristic index. According to the indirect test evaluating method disclosed by the invention, on the premise of not breaking the original structure of product, compressible thickness and filling power are converted by directly testing the compression performance index of the bombax cotton fiber so that the hollowness state of the bombax cotton fiber in the product is indirectly and effectively evaluated. The indirect test evaluating method disclosed by the invention not only is simple, easy and feasible, but also can be used for avoiding the secondary deformation of the hollow structure of the bombax cotton fiber caused by a section observation method.

Owner:DONGHUA UNIV

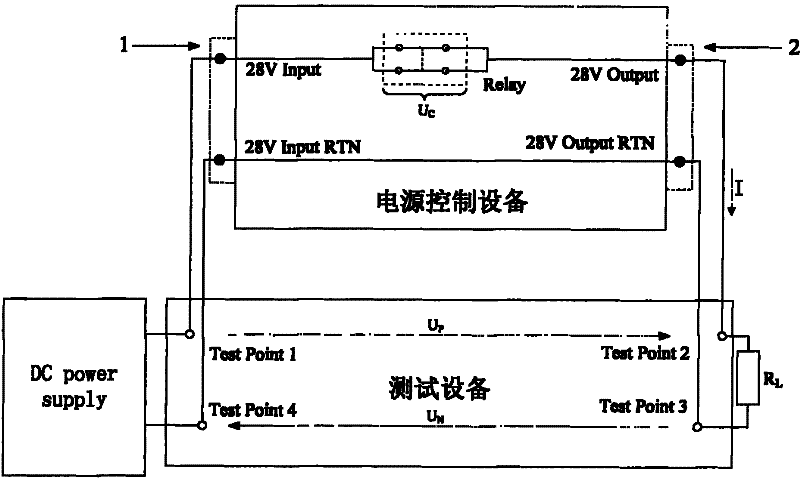

Indirect test method for voltage drops on relay contacts

InactiveCN102193017ANo security risksCurrent/voltage measurementCircuit interrupters testingIndirect testVoltage drop

The invention discloses an indirect test method for voltage drops on relay contacts in power control, relating to a relay test technique. In the method, the test can be performed from the outside of a device without opening a case, contacting internal circuits and producing potential safety hazards, and the test can be implemented just by arranging a simple test circuit at the outside of the device and then connecting the simple test circuit with the device by virtue of a connector. The indirect test method for the voltage drops on relay contacts in power control disclosed by the invention is accurate and credible in test results, and safe and convenient in test process.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

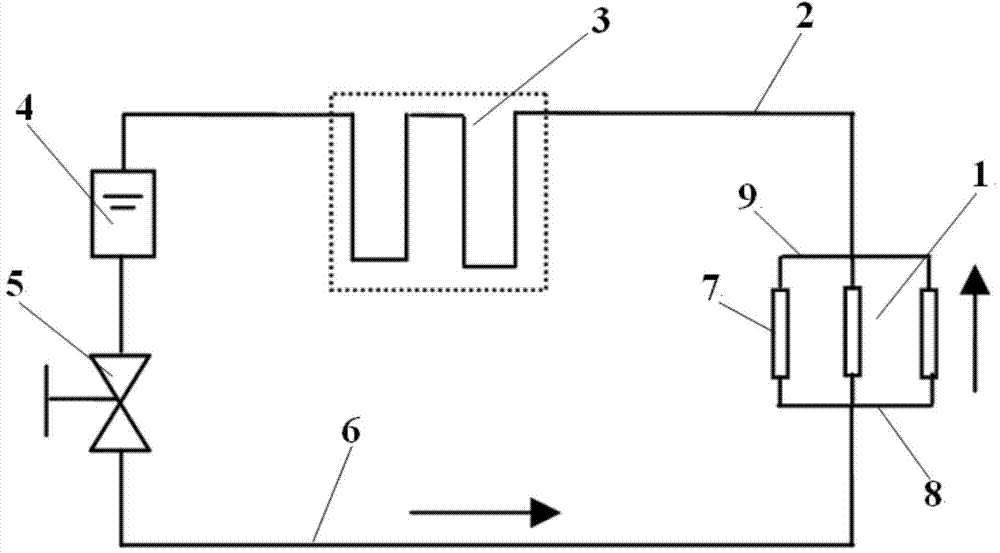

Indirect testing method for non-condensable gas amount of gravity driven two-phase fluid loop

ActiveCN104501900ASimple methodEasy to implementVolume measurement apparatus/methodsIndirect testTemperature difference

The invention discloses an indirect testing method for the non-condensable gas amount of a gravity driven two-phase fluid loop. By the adoption of the indirect testing method, the non-condensable gas amount of the gravity driven two-phase fluid loop in the moon-day period can be obtained. The indirect testing method comprises the following steps: firstly, analyzing to confirm that the non-condensable gas amount of the gravity driven two-phase fluid loop corresponds to the temperature difference of an evaporator and a liquid reservoir one to one, calibrating the relationship of the temperature difference of the non-condensable gas amount and the evaporator and the liquid reservoir, so as to obtain a relationship curve, and acquiring the non-condensable gas amount of the gravity driven two-phase fluid loop according to the temperature difference of the evaporator and the liquid reservoir and the calibrated relationship curve in the operation process of the practical gravity driven two-phase fluid loop. The method is simple to realize, the non-condensable gas amounts of the gravity driven two-phase fluid loop in a plurality of moon-day periods can be effectively acquired.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

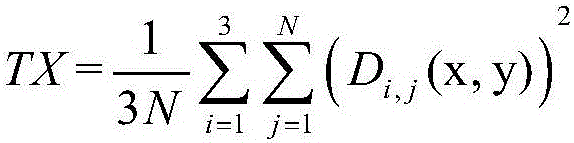

Method for testing apparent characteristics of road aggregate

InactiveCN106780457AAvoid errorsShorten the timeImage enhancementImage analysisTest efficiencyIndirect test

The invention discloses a method for testing apparent characteristics of a road aggregate. The method comprises the steps of cleaning a to-be-tested aggregate, drying the cleaned to-be-tested aggregate, and putting the dried to-be-tested aggregate in a sealed drying box for cooling; imaging the aggregate under a high-magnification camera through an aggregate image measurement system (AIMS); calculating a sphericity index SP for representing a three-dimensional shape of the aggregate; calculating an angularity index GA of the aggregate to represent an aggregate size and a contour change feature; and calculating a texture index TX of the aggregate to represent a surface texture of the aggregate. According to the new method provided by the invention, the apparent characteristics of the tested aggregate are all obtained by an instrument, so that errors generated due to subjective factors of test personnel in an indirect test method and a direct test method are effectively avoided, the time of the test personnel is saved, and the test efficiency is greatly improved.

Owner:WUHAN UNIV OF TECH +1

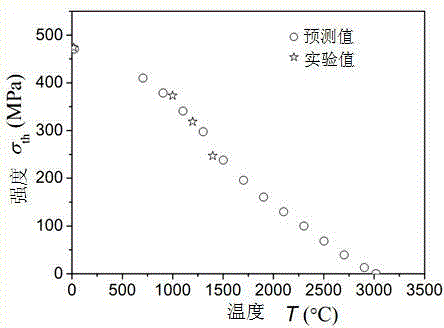

Method for indirectly testing high-temperature strength of ultra-high temperature ceramic material

InactiveCN104390997AAvoid difficultiesReliable prediction of high temperature strengthMaterial thermal analysisIndirect testMathematical model

The invention discloses a method for indirectly testing high-temperature strength of an ultra-high temperature ceramic material. The method comprises the following steps: establishing a mathematical model between the material strength and elasticity modulus under different temperatures according to the experimental data of the measured elasticity modulus of the ultra-high temperature ceramic material along with temperature change and the material strength and elasticity modulus under a reference temperature, and calculating the high-temperature strength of the material at the temperature which corresponds to the elasticity modulus of the ultra-high temperature ceramic material. The method disclosed by the invention has the technical effects that reliable prediction of the high-temperature strength of the material at each temperature is realized.

Owner:CHONGQING UNIV

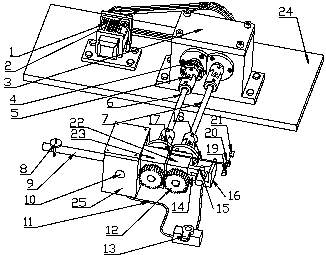

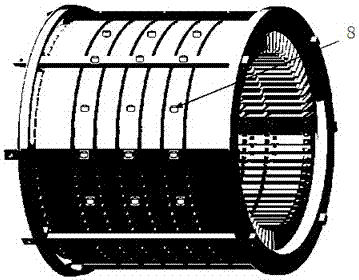

Plastic gear wear life testing machine for single support self-compensation loading system

InactiveCN109084979AAchieve variable speedAct as overload protectionMachine gearing/transmission testingInvestigating abrasion/wear resistanceSingle supportIndirect test

The invention discloses a plastic gear wear life testing machine for a single support self-compensation loading system. The machine is on the basis of an indirect test principle of a ''discontinuous phase method'', and uses an adjustable composite load loading system. A test gear pivot box is supported by a simple hinge, so as to realize the combination loading of a torque and a bending moment ina dynamic meshing simulation process of a test gear. According to the plastic gear wear life testing machine for the single support self-compensation loading system, the dynamic measurement of gear tooth wear can be completed, and the self-compensation loading function of the testing machine in a gear transmission process can be achieved.

Owner:UNIV OF JINAN

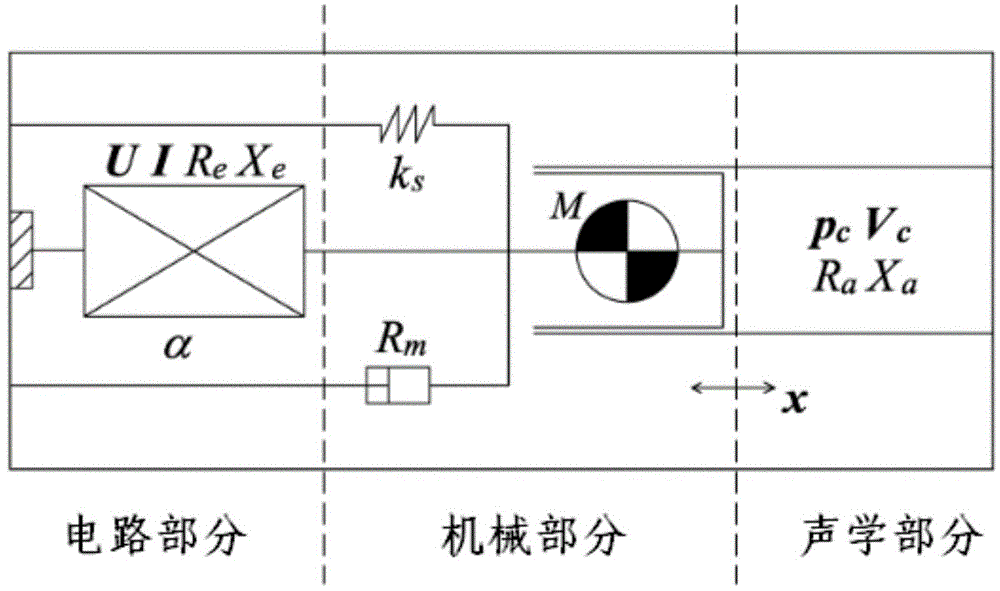

A Method for Indirect Measurement of Spring Stiffness and Mover Mass of Linear Compressor

ActiveCN104895776BAvoid damageSimple test methodMachine part testingPump testingIndirect testResonance

The invention discloses a method for indirectly measuring spring rigidity of a linear compressor and mover mass. The method comprises the following steps: connecting acoustic load in an outlet of the compressor to pressurize the whole system; determining at least two groups of incompletely-equivalent acoustic impedance imaginary parts and angular frequency data under the condition that the acoustic impedance real parts of the acoustic load are ensured to be unchanged; combining resonance conditions of the compressor; and calculating to obtain the spring rigidity and the mover mass, wherein the angular frequency data is angular frequency corresponding to highest electro-acoustic conversion efficiency of the compressor. Compared with the prior art, the method has the beneficial effects that: on the premise of not disassembling the linear compressor, an indirect test is performed on the compressor, the test method is simple and easy to operate, and damages, caused by disassembling the compressor, to internal structural parts of the compressor are avoided.

Owner:ZHEJIANG UNIV

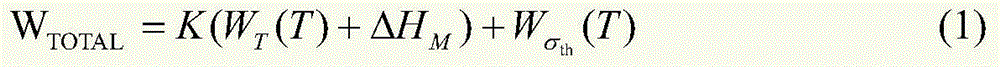

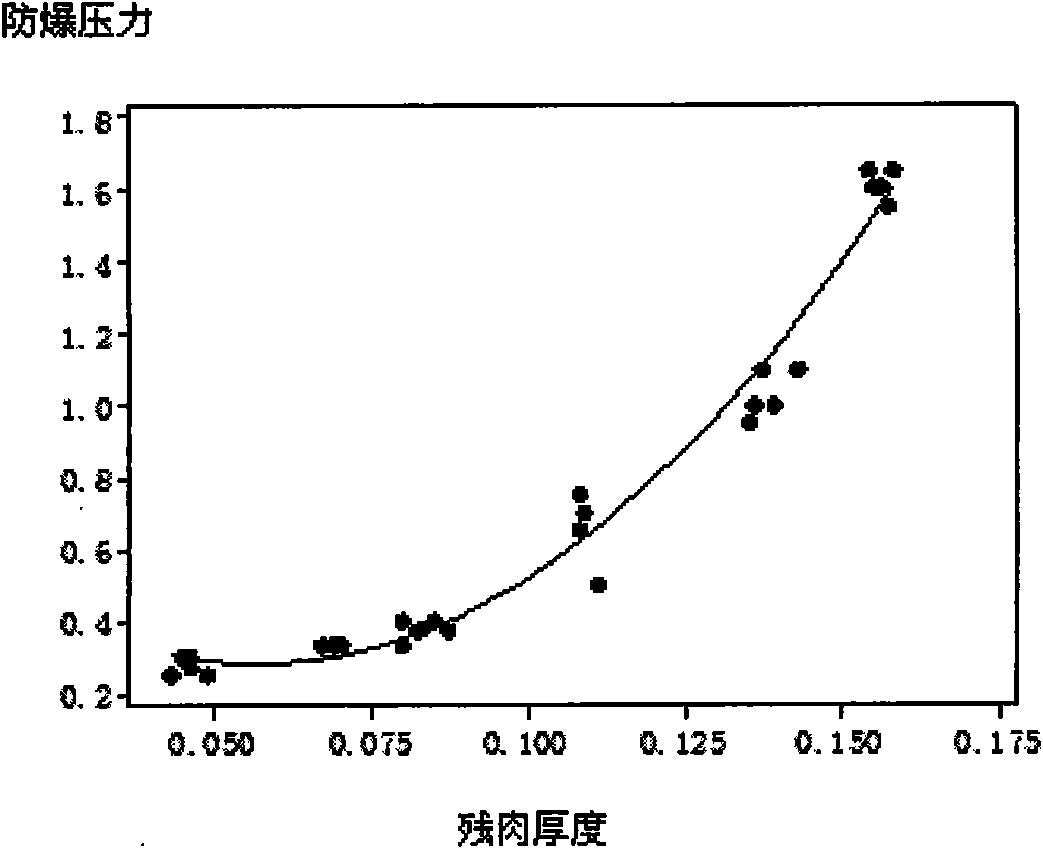

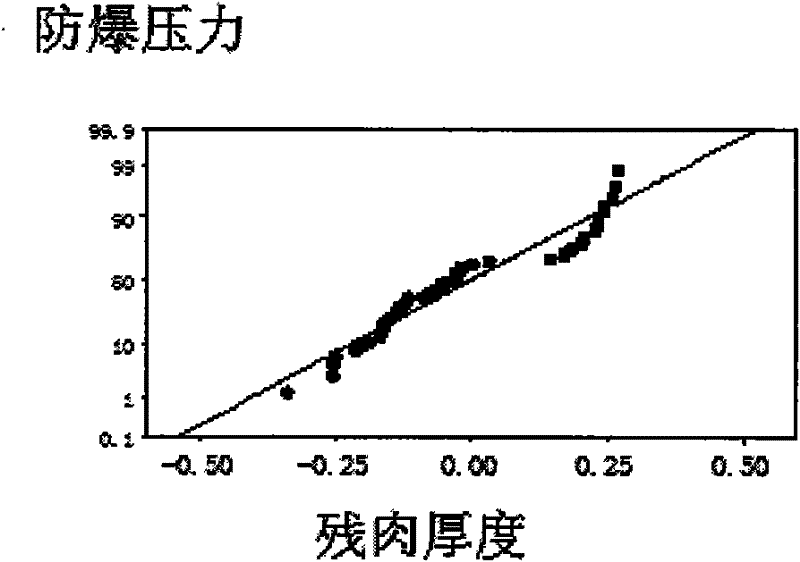

Indirect test method for explosion-proof pressure of metal battery shell

InactiveCN101603872AFast measurementImprove accuracyFluid pressure measurementNon destructiveIndirect test

The invention discloses an indirect test method for explosion-proof pressure of a metal battery shell, and aims to provide an indirect test method for explosion-proof pressure for realizing the measurement of the explosion-proof pressure by quantitatively detecting the residue thickness of an explosion-proof valve with high test speed, high accuracy and no damage to the metal shell. The method comprises the following steps: carrying out regression analysis for the explosion-proof pressure of the metal battery shell and the residue thickness of the explosion-proof valve to obtain a fitted equation of the residue thickness of the explosion-proof valve and the explosion-proof pressure of the battery shell; measuring the residue thickness of the explosion-proof valve of the metal battery shell to be tested; and inserting the residue thickness of the explosion-proof valve of the metal battery shell to be tested into the fitted equation of the residue thickness of the explosion-proof valve and the explosion-proof pressure of the metal battery shell to obtain the explosion-proof pressure of the metal battery shell to be tested. The method of the invention belongs to indirect and non-destructive test, and has no damage to the metal shell. And the method has the advantages of high measurement speed for the residue thickness, high accuracy, good test repeatability for the explosion-proof pressure, neat test environment and convenient measurement.

Owner:TIANJIN LISHEN BATTERY

Unsaturated soil variable structure suction testing device

The invention relates to an unsaturated soil variable structure suction testing device, in particular to an unsaturated soil variable structure suction direct testing device, and belongs to an innovative technology in the field of unsaturated soil variable structure suction testing devices. The unsaturated soil variable structure suction testing device comprises two parts, namely a sample preparation device and a testing device, wherein the sample preparation device is composed of two semi-cylindrical molds, the degree of tightness of the molds is controlled through three outer clamps outside, and a micro soil sample can be manufactured. After the soil sample is manufactured, short plastic pipes with slightly larger diameters sleeve two ends of the soil sample, are adhered to a force transferring plate together with the soil sample, and then are placed in the testing device as shown in accompanying diagrams. Load application is carried out by slowly adding water, the total weight of the upper half part of a broken soil body, the force transferring plate on the top and water in a water container is tested after the soil sample is broken. According to the unsaturated soil variable structure suction testing device disclosed by the invention, the variable structure suction under different degrees of saturation can be directly tested, and the difficulty that the variable structure suction is tested by an indirect testing manner only at present is avoided.

Owner:SUN YAT SEN UNIV

Test method for loss of double-branch alternating-current permanent-magnet motor

ActiveCN110346721AMeet the needs of iron loss testingAvoid calculationDielectric property measurementsDynamo-electric machine testingIndirect testDirect test

The invention discloses a test method for loss of a double-branch alternating-current permanent-magnet motor, comprising steps of connecting an electricity generating branch to an adjustable resistor-inductance load, and connecting an electric branch to a motor control driver, running the control driver, wherein the load is pure resistant, testing a rotation speed of the motor, a current waveformand a phase voltage value of the electric branch, and a current waveform and a phase voltage value and a power factor angle of the electricity generating branch; stopping running of the motor, disconnecting a generator unit load, calculating a winding resistance; testing a quadrature-direct axis inductance of the motor, testing a back electromotive force of the motor under no load and solving a total magnetic flux Phi 0 of each pole of a permanent magnet; running the motor again to obtain iron loss of the motor. Compared to a direct test method for loss, the method of the invention does not require an external mechanical load device, so as to save test cost. Compared with an indirect test method for loss, the method of the invention does not need to use an iron loss tester, so as to avoidcomplicated calculation and adjustment of instrument parameters, and considers the influence of rolling process on the loss test.

Owner:HARBIN ENG UNIV

Device for indirectly testing one-time purification efficiency of air purifying component and method thereof

ActiveCN101839813BGuaranteed one-time efficiencyAvoid errorsStructural/machines measurementIndirect testEngineering

The invention relates to a device for indirectly testing the one-time purification efficiency of an air purifying component and a method thereof. On the basis of the prior art, the method comprises the following steps of: firstly closing a test passageway before testing by setting an adjusting passageway; adjusting the concentration and the humiture of a pollutant in a test cabin through the adjusting passageway to be a set value; and testing. The invention has the advantages that the invention controls the concentration of the pollutant which enters into the front end of a purifying component to be a constant value by adjusting a pollutant-generating device, thereby guaranteeing that the one-time purification efficiency is tested under the constant concentration of the blowing-in pollutant, preventing the computation of the one-time efficiency from having an error, leading a testing result to be more exact, and guaranteeing the purification efficiency and the accuracy of the test computation of the purification life.

Owner:上海建科集团股份有限公司 +1

Polymer pressure-specific volume-temperature relation indirect test method and its device

ActiveCN101149369BEven by forceEliminates the need for a vacuum to remove airMaterial testing goodsIndirect testEngineering

A kind of method and equipment test the relation of polymer pressure, specific volume, temperature indirectly, uses the test equipment which is compose of the pressure medium mercury, seal liquid, sample room, pressure vessel, compression system, heat and cold system, pressure sensor, displacement sensor, thermoelectric couple and data processing system. This method using the character that the mercury and the seal liquid do not dissolve in each other, it can avoid the disadvantage that the mercury is toxic and is easy to volatilize in the indirect method of the polymer P-V-T test simply, at the same time, it has a series other merits such as can make the inner to reach high vacuum degree, to make the sample stress uniformly, the compress coefficient is small, impress pressure is direct, the measure precision is high and so on, it also resolves the problem that it vent the air in the presence of vacuum. It can use the relation of the polymer pressure-specific volume-temperature sets the mold technology parameter of the polymer product or design the module and do CAE analysis.

Owner:BEIJING UNIV OF CHEM TECH

Indirect testing method for equipment to excitation load of hull structure under vertical unbalance excitation force

ActiveCN102692331BGood precisionEasy to operateStructural/machines measurementApparatus for force/torque/work measurementHull structureIndirect test

The invention aims at providing an indirect testing method for equipment to excitation load of a hull structure under vertical unbalance excitation force. The indirect testing method comprises the following steps of: installing a first group of vibration isolators on feet of tested equipment, and installing both the tested equipment and the vibration isolators on a rigid mass block; distributing an accelerator sensor at the feet of the tested equipment and at the top of the vibration isolators, and sequentially connecting a signal amplifier and a signal collection instrument; starting the test equipment and calculating the speed response value under the first group of vibration isolators; replacing the vibration isolators, and calculating the speed response value under a second group of vibration isolators, thus obtaining the turbulence force equivalent mass of the tested equipment. The tested equipment is arranged on the vibration isolators and then installed on a hull base which is equivalent to a spring and the rigidity mass block, thus finally obtaining the excitation force load of the tested equipment to the hull base. The indirect testing method is good in accuracy, simple and convenient as well as easy to operate, and high in controllability.

Owner:HARBIN ENG UNIV

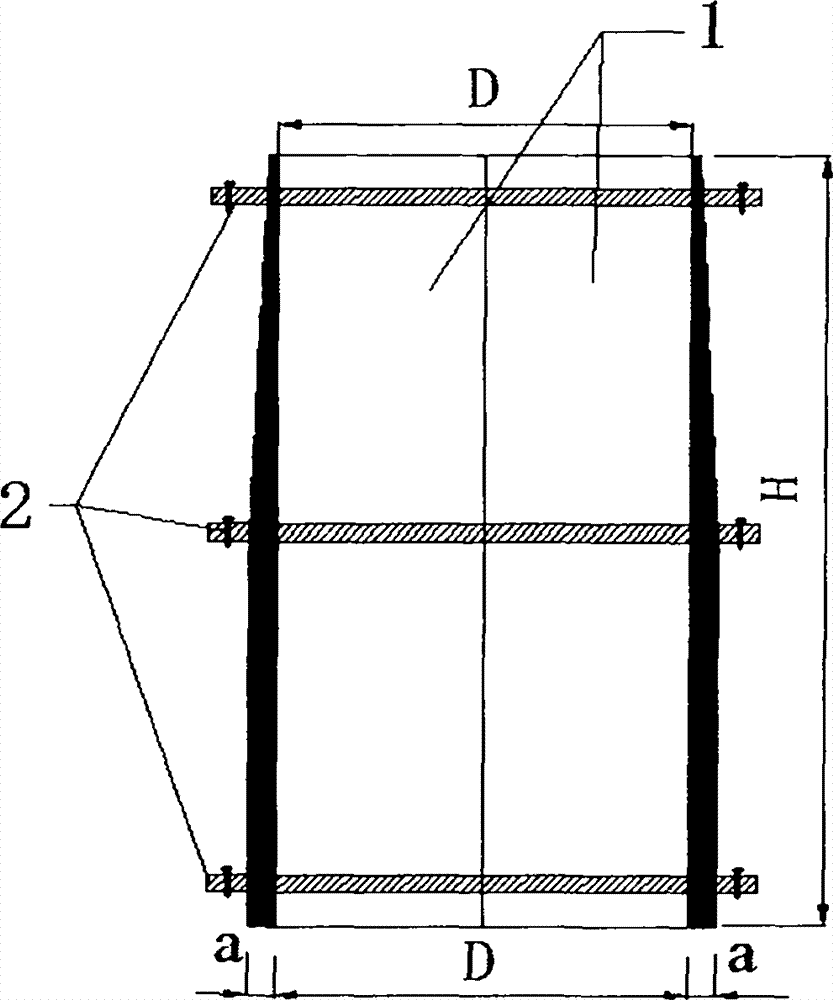

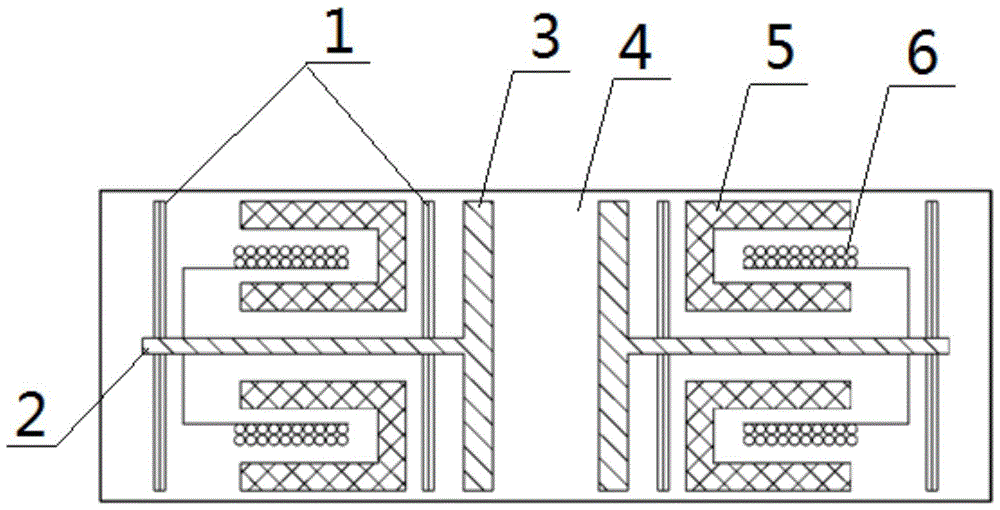

An indirect test and alarm device for oxidation temperature of residual coal in goaf

The invention discloses a worked-out-section residual coal oxidizing temperature indirect test and alarm device which is applicable to detection and alarm for the oxidizing temperature of residual coal in places where people are hard to enter therein, such as a worked out section under an underground coal mine. The device is composed of small gas-releasing holes (1), an upper high-strength steel ball half (2), a glass ball (3), temperature-sensing special smell liquid (4), a steel wire gauze (5), a breathable cushioning light interlayer (6) and a lower high-strength steel ball half (8). When the temperature of the worked out section rises, the temperature-sensing special smell liquid (4) is heated to be expanded, the glass ball (3) is squeezed and crushed, then special smell is released, the special smell is emitted to the worked out section through the cushioning light interlayer (6) and the small gas-releasing holes (1) in the surface of a high-strength steel ball, gas is diffused to corners on the work surface under the action of air leakage of the worked out section, the category of the smell of the gas flowing out of the positions, located at the corners, of the worked out section is tested, and whether the oxidizing temperature of the residual coal at a certain point of the worked out section reaches a set alarm value or not is judged.

Owner:ANHUI UNIV OF SCI & TECH

Indirect test method for Miglitol purity

InactiveCN101487827BIncrease relative volatilitySolve the problem that cannot be detected by GC methodOrganic chemistryComponent separationMiglitolAcetic anhydride

The invention discloses an indirect testing method of the purity quotient of miglitol, comprising the following steps: 1) the miglitol to be tested is taken as substrate, and acetic anhydride is taken as acetylation reagent to have acetylation reaction, so that esterification reaction liquid containing acetic acid-beta-(3, 4, 5-triacetyl oxygroup-2-acetoxyl methyl-1-piperidine)-ethyl ester is obtained; or the miglitol to be tested is taken as substrate, propionic andydride is taken as acetylation reagent, and acetylation reaction is carried out under the catalysis of anhydrous pyridine, so that the esterification reaction liquid containing the acetic acid-beta-(3, 4, 5-triacetyl oxygroup-2-acetoxyl methyl-1-piperidine)-ethyl ester is obtained; 2) gas chromatography is carried out on the esterification reaction liquid, and the retaining time and the peak area of all the components in gas chromatograph can be obtained; after the peak area of the light components is eliminated, the purity quotient of the obtained miglitol is calculated according to normalization method. The indirect testing method has the characteristics of simple testing method and accurate testing result.

Owner:ZHEJIANG UNIV

Method for indirectly measuring spring rigidity of linear compressor and mover mass

ActiveCN104895776AAvoid damageSimple test methodMachine part testingPump testingIndirect testResonance

The invention discloses a method for indirectly measuring spring rigidity of a linear compressor and mover mass. The method comprises the following steps: connecting acoustic load in an outlet of the compressor to pressurize the whole system; determining at least two groups of incompletely-equivalent acoustic impedance imaginary parts and angular frequency data under the condition that the acoustic impedance real parts of the acoustic load are ensured to be unchanged; combining resonance conditions of the compressor; and calculating to obtain the spring rigidity and the mover mass, wherein the angular frequency data is angular frequency corresponding to highest electro-acoustic conversion efficiency of the compressor. Compared with the prior art, the method has the beneficial effects that: on the premise of not disassembling the linear compressor, an indirect test is performed on the compressor, the test method is simple and easy to operate, and damages, caused by disassembling the compressor, to internal structural parts of the compressor are avoided.

Owner:ZHEJIANG UNIV

Method of Indirect Measurement of Linear Compressor Motor Specific Thrust and Mechanical Damping Coefficient

ActiveCN104948442BAvoid damageSimple test methodPump testingPositive-displacement liquid enginesIndirect testLinear compressor

The invention discloses a method for indirectly measuring motor specific thrust and a mechanical damping coefficient of a linear compressor. The method comprises the following steps of connecting an acoustic load to an outlet of the compressor; pressurizing a whole system; finding out corresponding running frequency of the linear compressor when electric-acoustic conversion efficiency is maximum at the time by adjusting the running frequency of the linear compressor; adjusting an acoustic impedance real part under the running frequency condition; finding out the current compressor maximum electric-acoustic conversion efficiency and the corresponding acoustic impedance real part at the time by detection; and calculating to obtain the motor specific thrust and the mechanical damping coefficient. By the method, the motor specific thrust alpha and the mechanical damping coefficient Rm of the linear compressor can be detected simply. Compared with the existing testing method, the method has the advantages that the compressor can be indirectly tested on the premise that the linear compressor does not need to be disassembled, the testing method is simple and is easy to operate, and the circumstance that components of an inner structure are damaged due to disassembling of the compressor is avoided.

Owner:ZHEJIANG UNIV

Indirect test method for explosion-proof pressure of metal battery shell

InactiveCN101603872BFast measurementImprove accuracyFluid pressure measurementNon destructiveIndirect test

The invention discloses an indirect test method for explosion-proof pressure of a metal battery shell, and aims to provide an indirect test method for explosion-proof pressure for realizing the measurement of the explosion-proof pressure by quantitatively detecting the residue thickness of an explosion-proof valve with high test speed, high accuracy and no damage to the metal shell. The method comprises the following steps: carrying out regression analysis for the explosion-proof pressure of the metal battery shell and the residue thickness of the explosion-proof valve to obtain a fitted equation of the residue thickness of the explosion-proof valve and the explosion-proof pressure of the battery shell; measuring the residue thickness of the explosion-proof valve of the metal battery shell to be tested; and inserting the residue thickness of the explosion-proof valve of the metal battery shell to be tested into the fitted equation of the residue thickness of the explosion-proof valve and the explosion-proof pressure of the metal battery shell to obtain the explosion-proof pressure of the metal battery shell to be tested. The method of the invention belongs to indirect and non-destructive test, and has no damage to the metal shell. And the method has the advantages of high measurement speed for the residue thickness, high accuracy, good test repeatability for the explosion-proof pressure, neat test environment and convenient measurement.

Owner:TIANJIN LISHEN BATTERY

An identification method for electromagnetic excitation load of electric motor

ActiveCN104849004BOvercome the difficulty of test installationImprove accuracyVibration testingThermodynamicsIndirect test

The invention relates to an identification method of electromagnetic excitation load of a motor, which belongs to the field of structural acoustic design of electric motors, is suitable for identification of electromagnetic excitation load in structural acoustic design of electric motors and can be used for frequency characteristic analysis of electromagnetic excitation load of electric motors. The steps include: determining the equivalent method of the electromagnetic excitation load, measuring point arrangement, transfer function test, working condition response test and load identification. The invention has the advantages of improving the accuracy of identification of the electromagnetic excitation load of the motor, overcoming the difficulty of test installation in the traditional indirect test method, and considering the distribution characteristics of the electromagnetic excitation force with time and space, realizing the identification of the electromagnetic excitation load of the motor, etc. Efficiency calculation and frequency characteristic analysis, guiding the structural acoustic design of the motor, is a method for identifying the electromagnetic excitation load of the motor that is simple to test and install.

Owner:中国船舶重工集团公司第七一二研究所

Method for quickly analyzing punching crack defects of ultra-deep drawing steel plate

The invention relates to a method for quickly analyzing punching crack defects of an ultra-deep drawing steel plate. The method comprises the following steps: taking the center point of a steel platecut for forming as the center of a circle, dividing into N fan-shaped regions uniformly, equally dividing the center line of each fan-shaped region into M parts, measuring the hardness value of each equipartition point at each equipartition point, then calculating hardness extreme deviation and influence factors, finally judging the possibility of punching crack defects or ear-making defects in the steel plate; both N and M are integers. The method for quickly analyzing the punching crack defects of the ultra-deep drawing steel plate has the advantages that the strength of the steel plate canbe indirectly evaluated through detecting the hardness and the hardness detection is high in speed and less in time consumption, furthermore, the hardness detection of each point for the steel plate is performed and the 'microscopic' strength of each point is indirectly tested, so that the anisotropy trend of the formed steel plate is quickly tested, thereby saving time, being high in efficiency,and further saving resources.

Owner:ANGANG STEEL CO LTD

SRAM read and write indirect testing device and method based on LabVIEW

The invention discloses an SRAM read and write indirect testing device and an SRAM read and write indirect testing method based on LabVIEW, which are used for solving the technical problems that a testing interface for the existing direct reading and writing SRAM is not friendly and the control configuration for the direct reading and writing SRAM is not flexible. An FPGA circuit module is used for receiving SRAM signal parameter data sent from a serial port; a tested chip IS61LV10248 circuit module is used as a tested object; an SRAM read and write indirect testing control panel module basedon the LabVIEW is used for compiling a front panel human-computer interface; a write operation control command module is used for executing SRAM write operation; a data reading command module is usedfor executing SRAM read operation; an underlying serial port driving module is used for performing data interaction. The invention has the beneficial effects as follows: the testing interface is simple and intuitive, and a user interface can be created very conveniently; timing parameters are convenient to adjust; the integration is high, the reliability is good, and the external interference is less.

Owner:YULIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com