Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Gas thermometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas thermometer is a thermometer that measures temperature by the variation in volume or pressure of a gas.

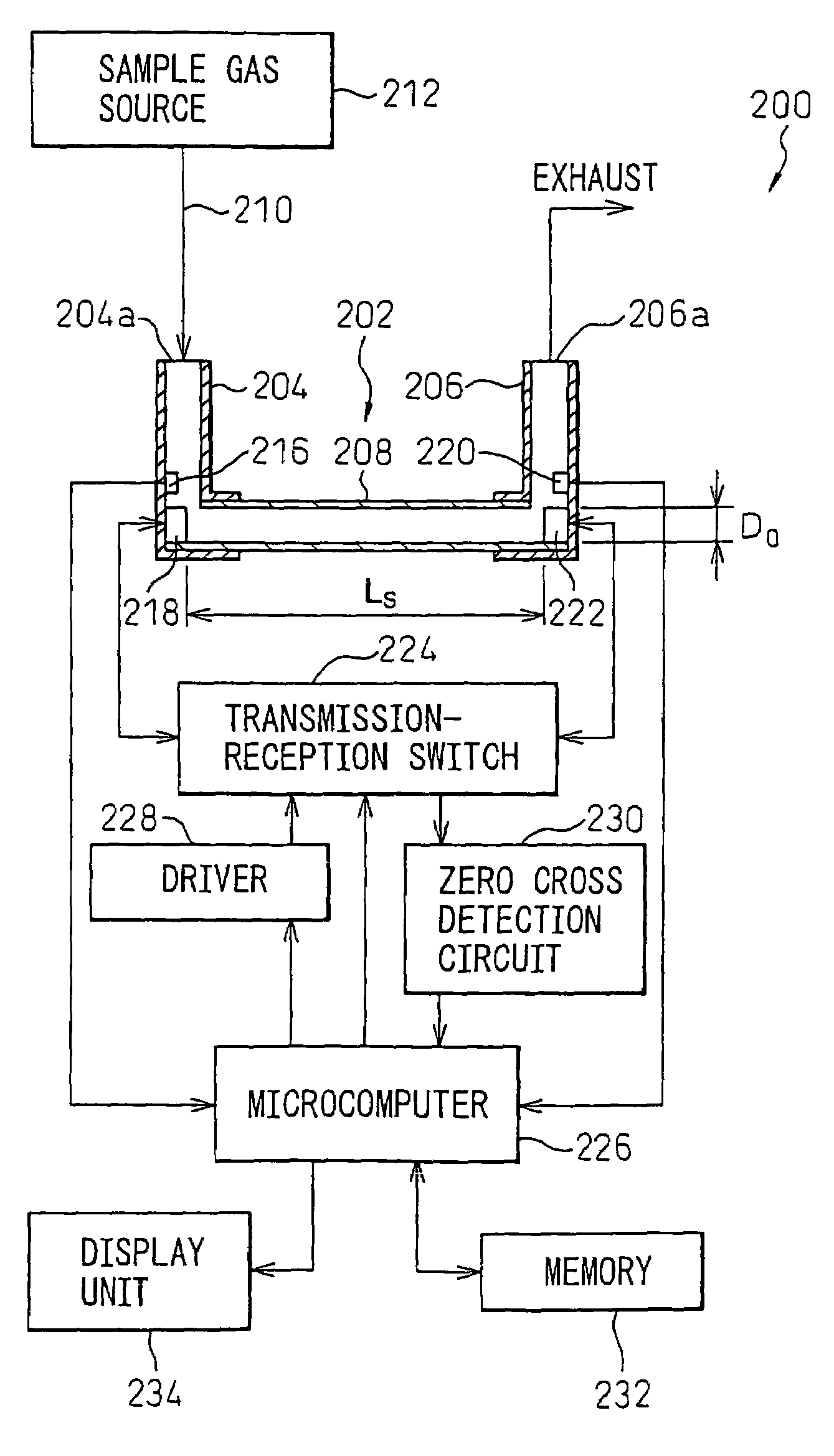

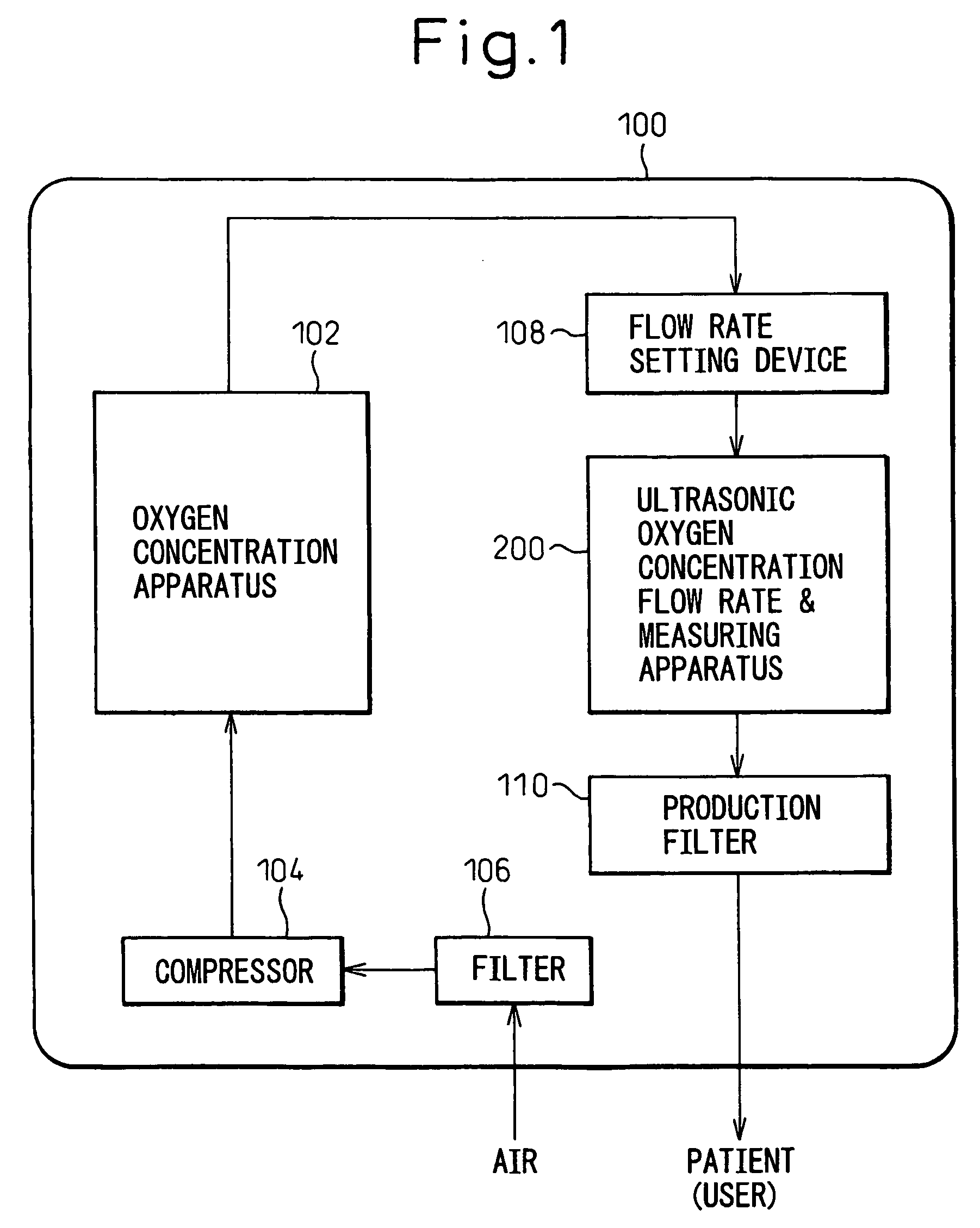

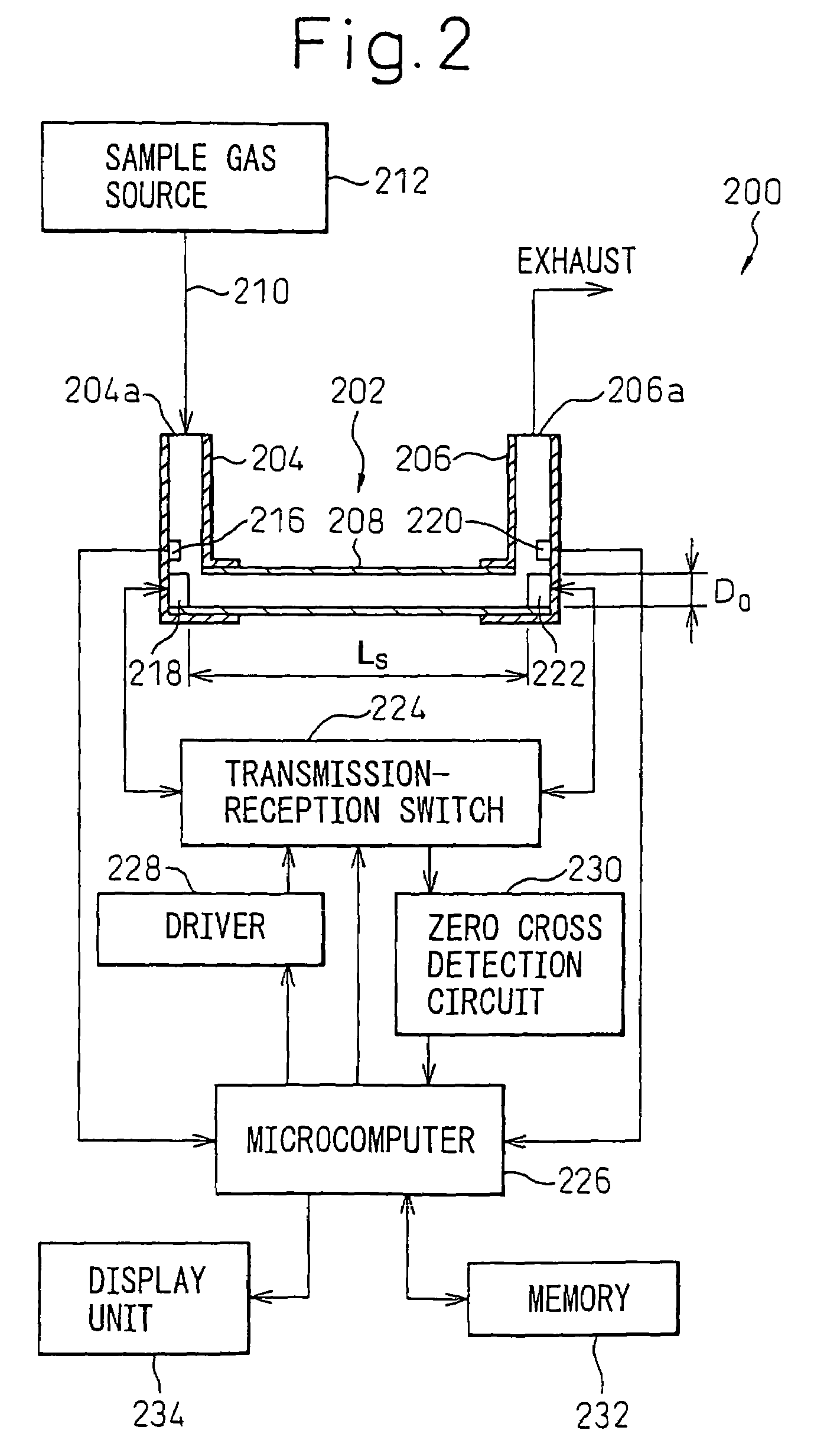

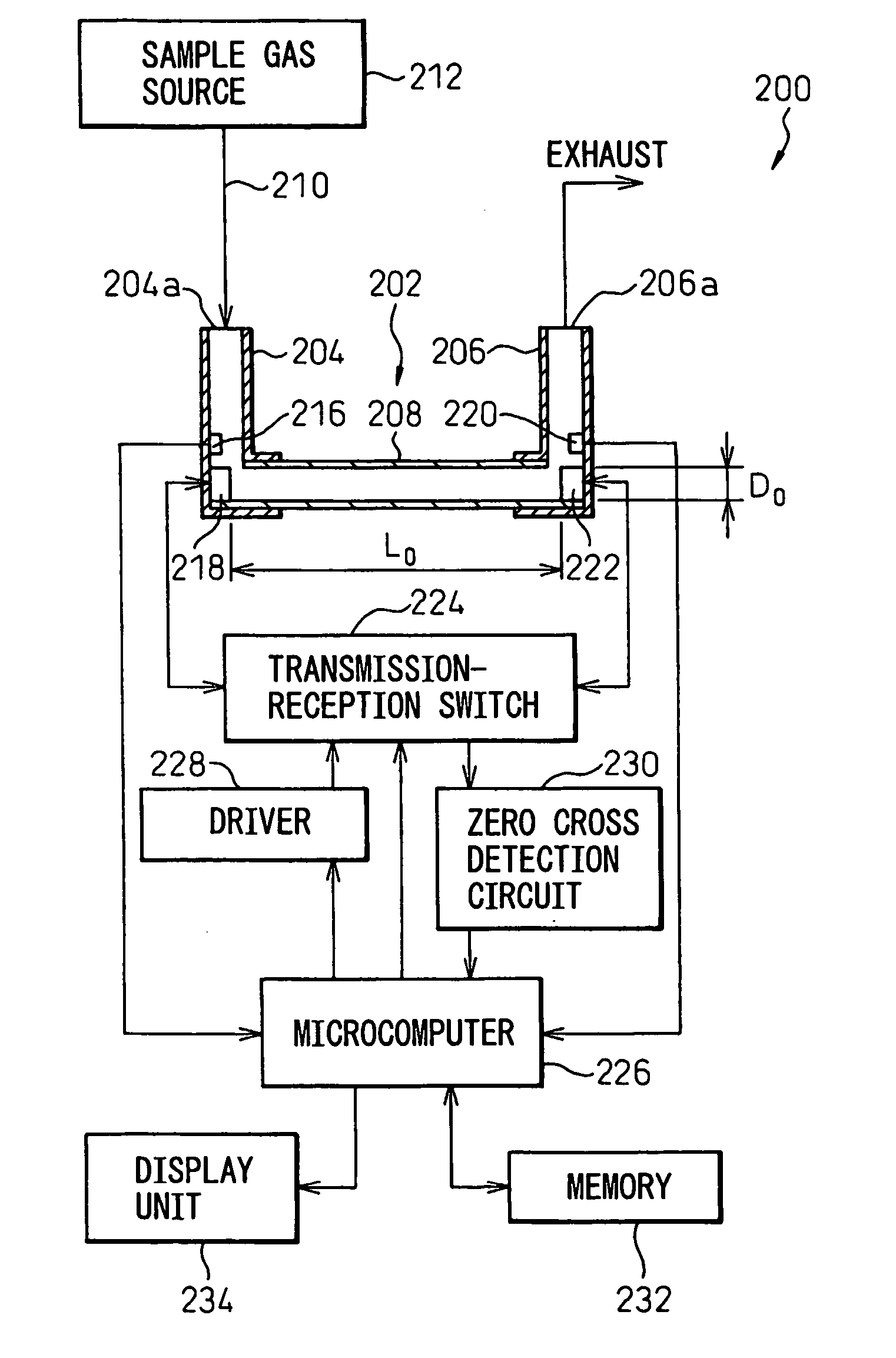

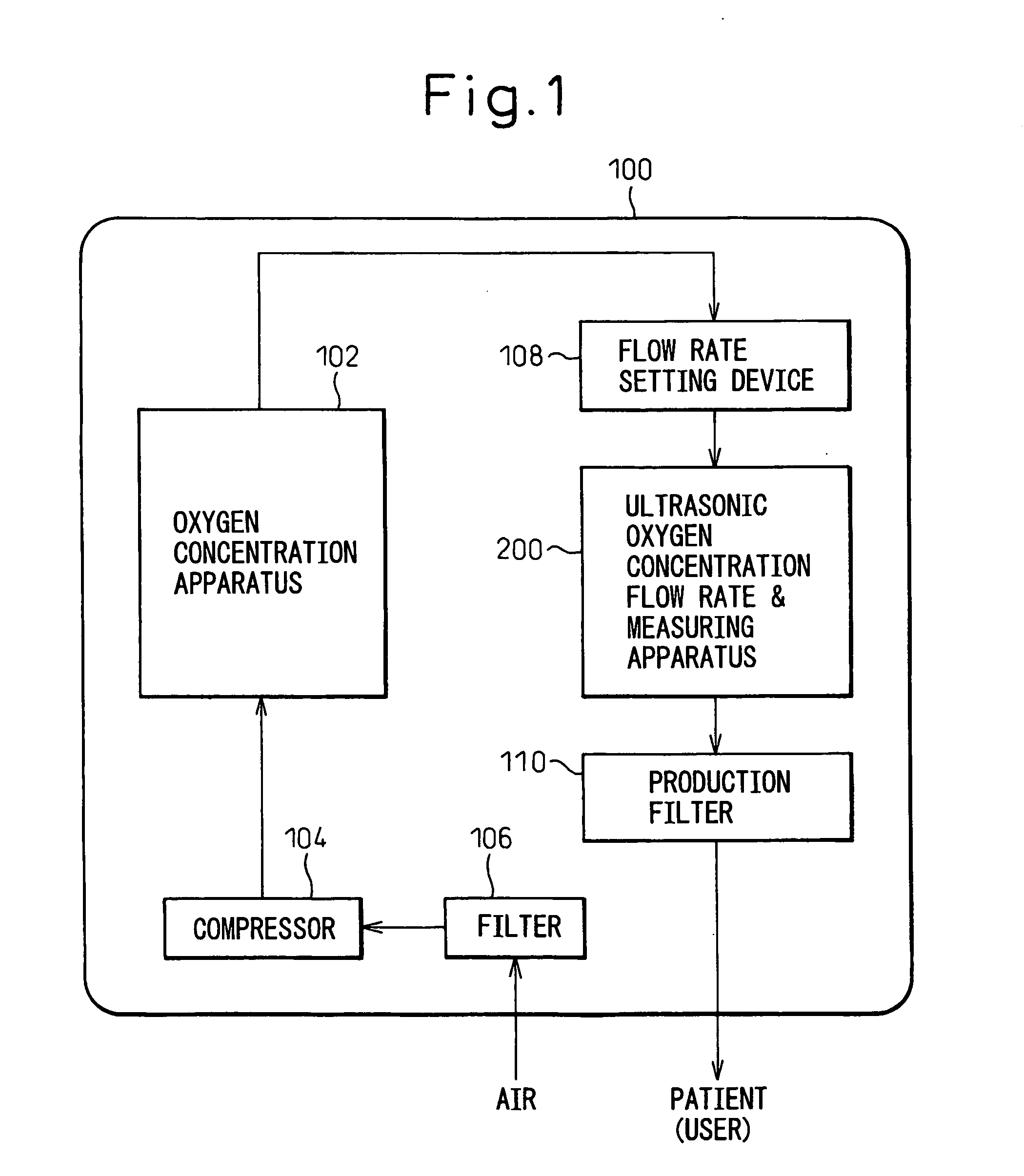

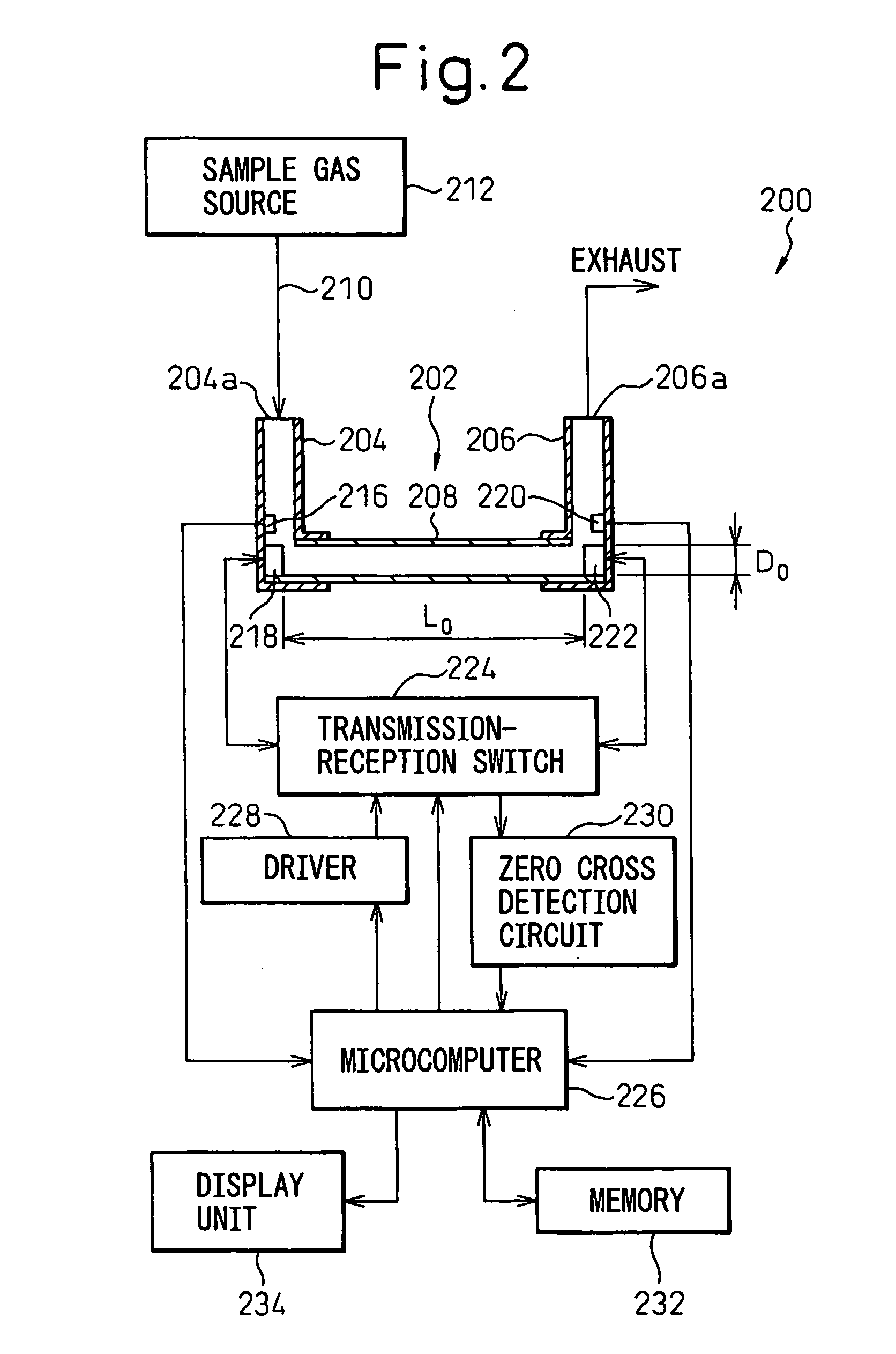

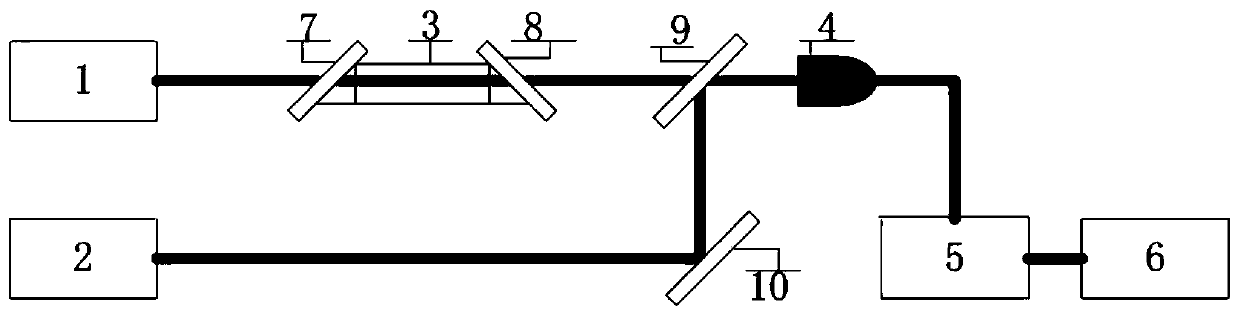

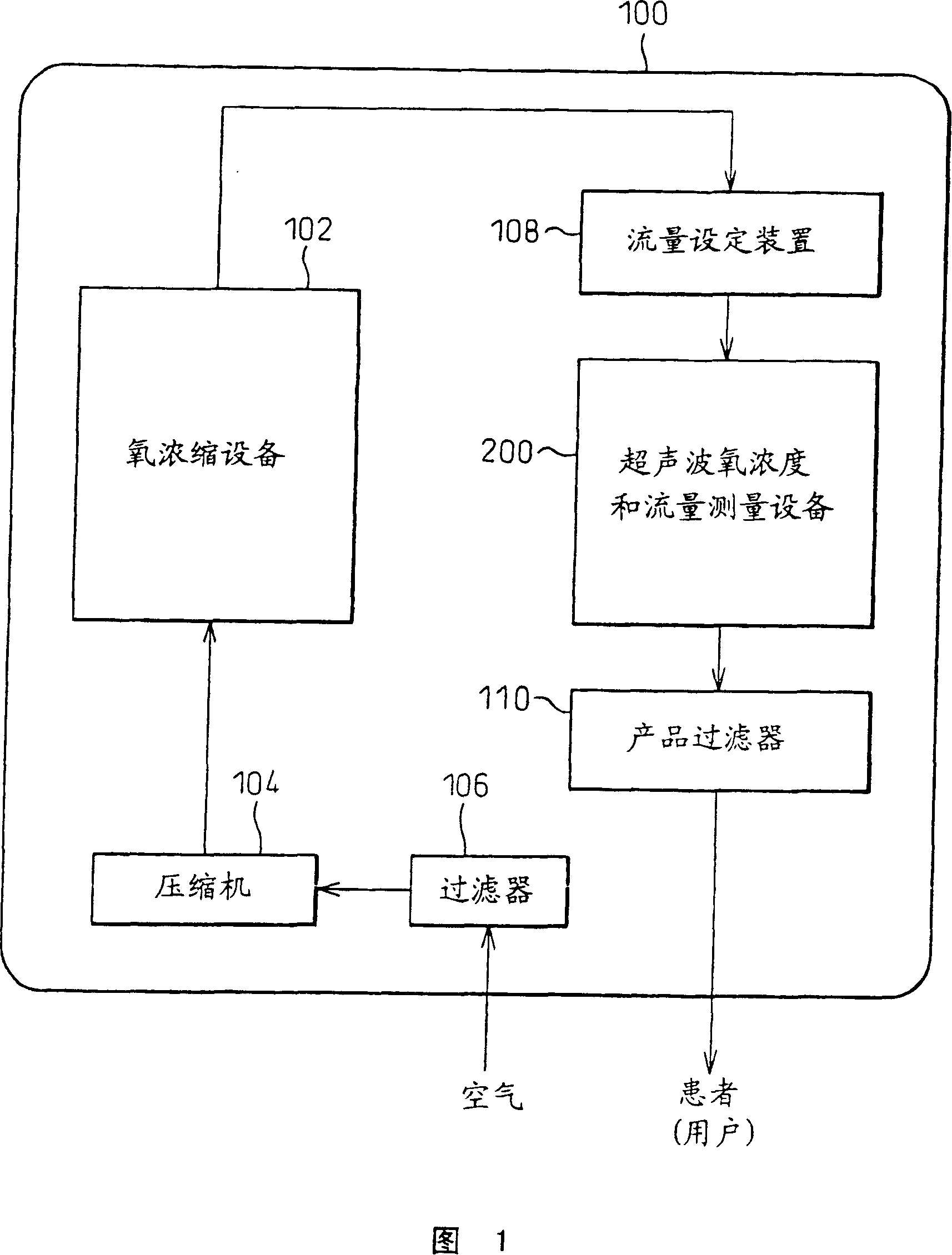

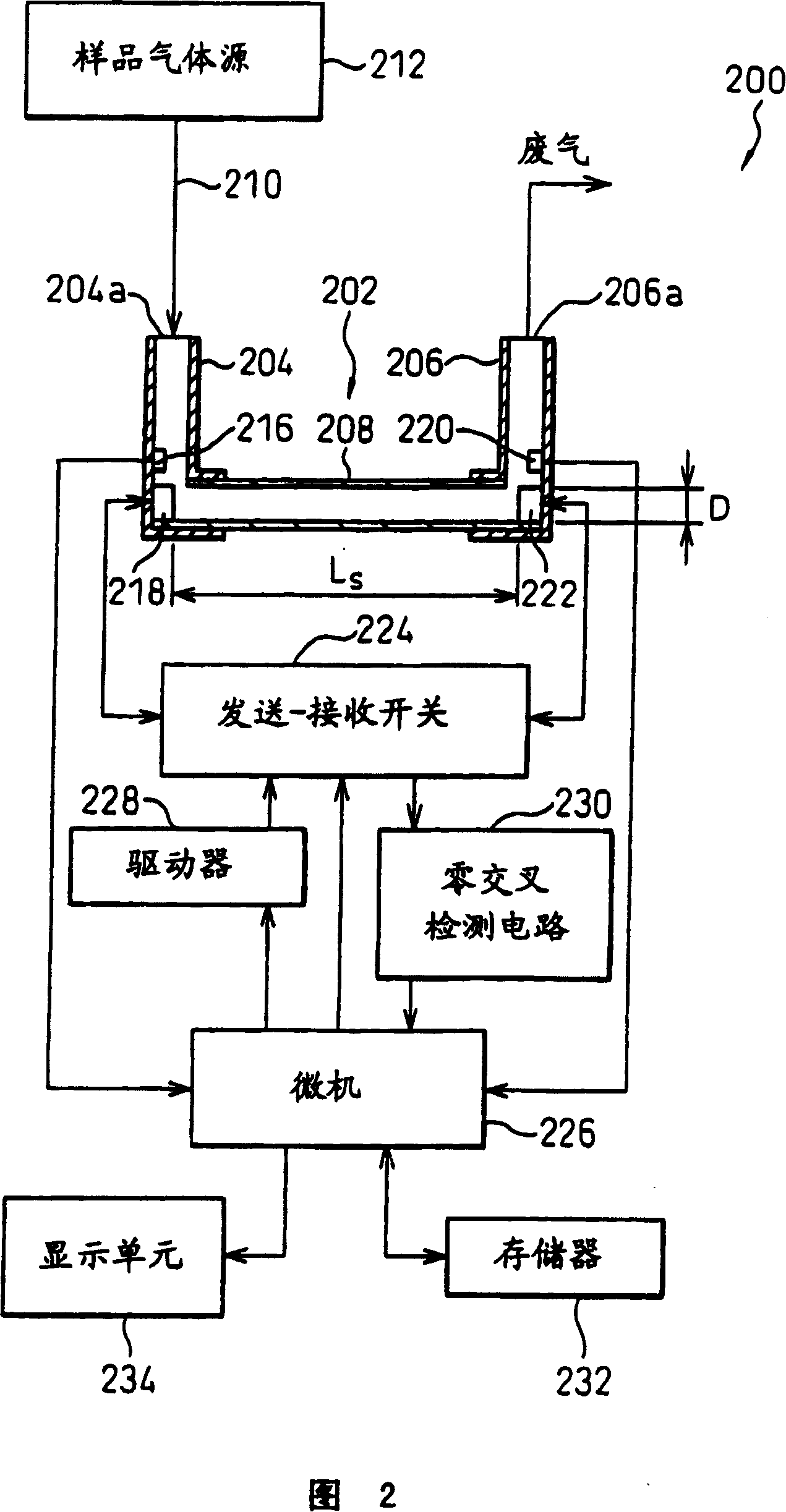

Ultrasonic apparatus and method for measuring the concentration and flow rate of gas

ActiveUS7213468B2Accurate measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesVolume/mass flow measurementUltrasound devicePropagation time

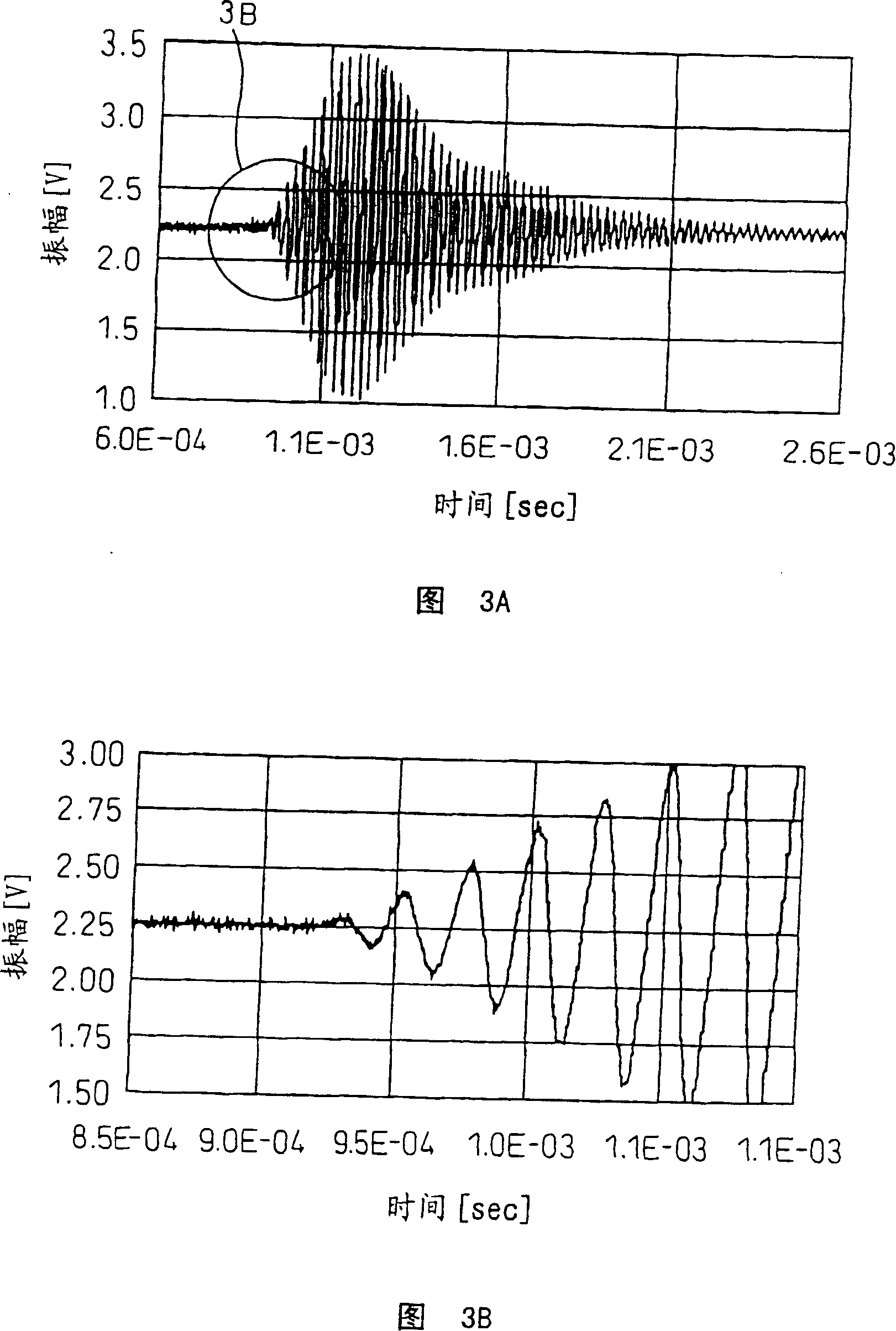

An ultrasonic apparatus measures the concentration and flow rate of a sample gas by calculating a possible propagation time range on the basis of the gas temperature, determining whether or not the phases at which two first trigger signals, respectively generated on the basis of forward and backward waveforms of the ultrasonic waves, coincide with each other, processing the zero-cross signals so that the phases coincide with each other, obtaining reference zero-cross time instant by calculating mean value of the forward and backward zero-cross time instants, obtaining an ultrasonic reception point by subtracting an integral multiple of the cycle of the ultrasonic waves so that the results of the subtraction falls into a possible propagation time range and estimating the ultrasonic propagation time on the basis of the ultrasonic reception point.

Owner:TEIJIN LTD

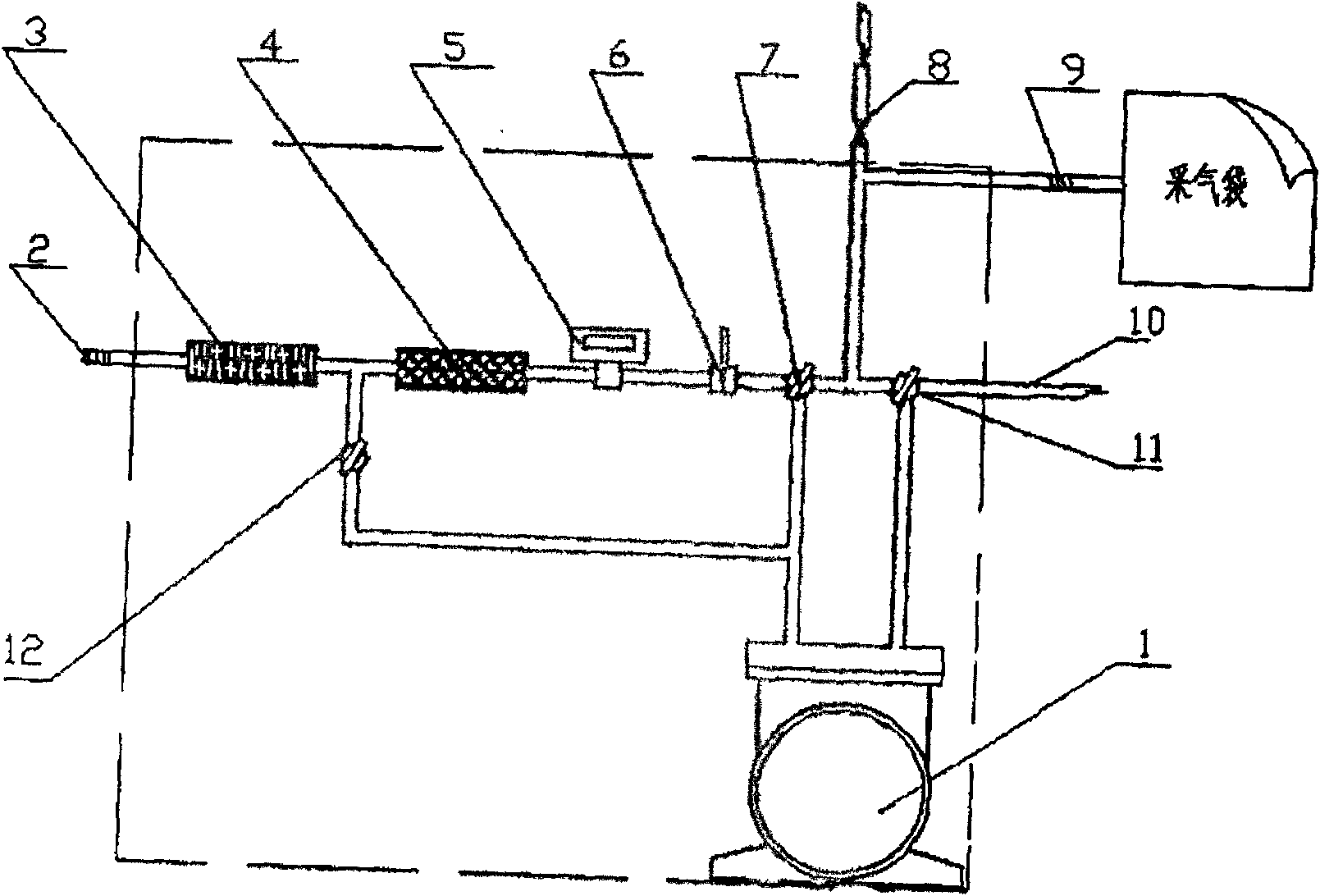

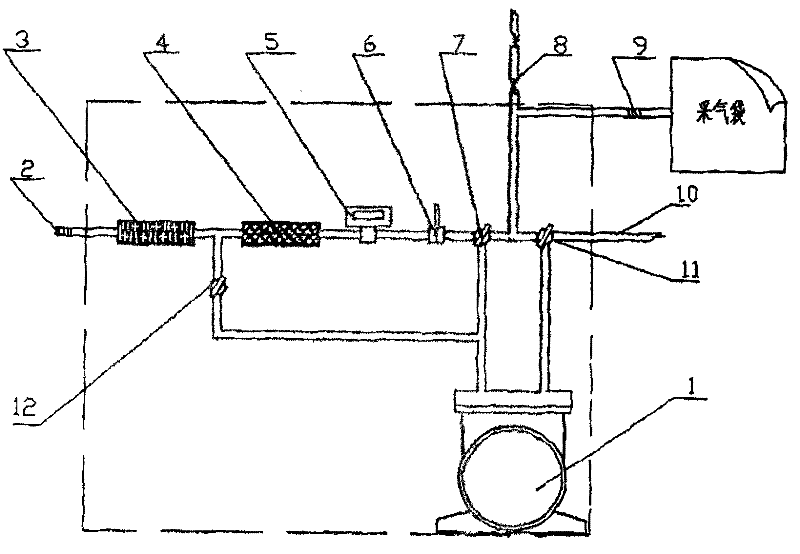

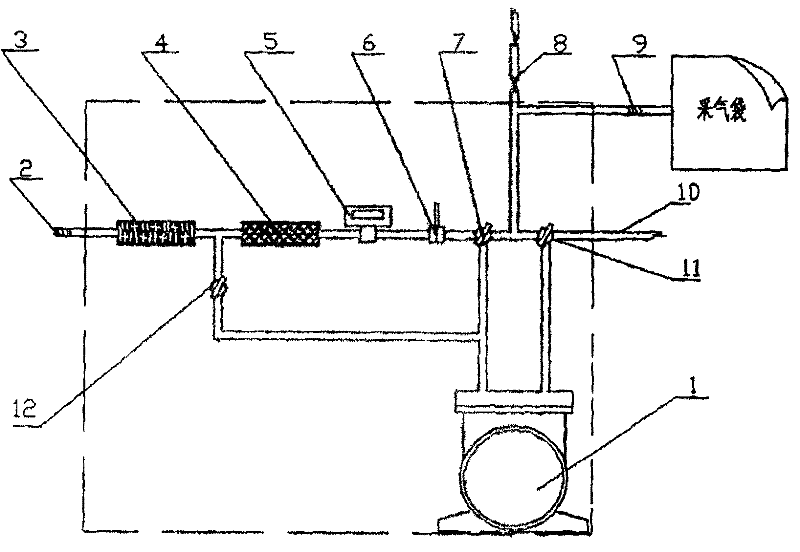

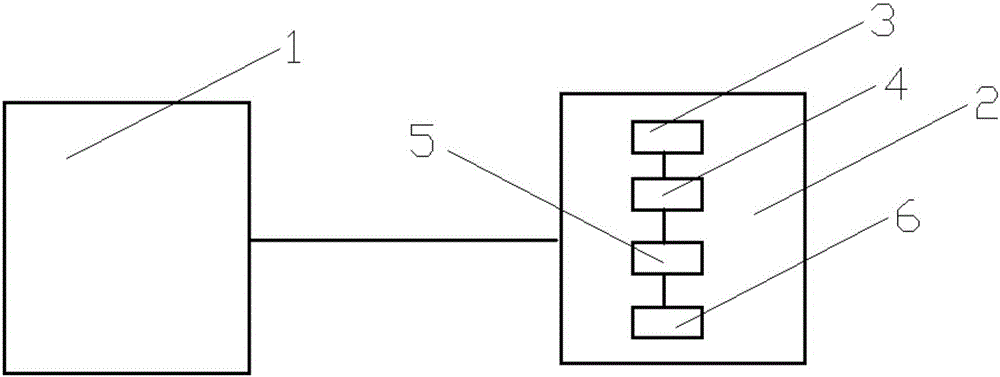

Multi-functional gas sampling system and gas sampling method

The invention discloses a multi-functional gas sampling system and a gas sampling method in the field of gas sampling devices. The system adopts the structure that a gas inlet opening and a gas outlet opening of an off-gas pump are respectively connected with a first switching valve and a second switching valve, an overvoltage protection valve and a gas collecting opening are arranged between the first switching valve and the second switching valve, and a gas thermometer, an integrating flowmeter, a water drain pipe, a dust collecting pipe and a gas inlet opening which are connected in series in sequence are connected on a connector opposite to a connector of the first switching valve and the overvoltage protection valve. The gas sampling method comprises the following steps: 1. processing gas to be sampled for a gas sampling pipeline by a prepumping gas passage; 2. cleaning a gas sampling bag; and 3. collecting the gas. The filtrating and the dehydrating are performed to the gas required for analysis, and then the gas is transformed into dried gas to be filled in a special gas container so as to ensure that the gas is in a stable state; the volume and the total mass of the dried gas are accurately measured, and the analyzed gas is accurately measured and analyzed; and the invention is suitable for sampling combustible gas, atmosphere, biological metabolites and tail gas in chemical plants, and the like.

Owner:TSINGHUA UNIV

Ultrasonic apparatus and method for measuring the concentration and flow rate of gas

ActiveUS20060185443A1Accurate measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesVolume/mass flow measurementUltrasound devicePropagation time

An ultrasonic apparatus measures the concentration and flow rate of a sample gas by calculating a possible propagation time range on the basis of the gas temperature, determining whether or not the phases at which two first trigger signals, respectively generated on the basis of forward and backward waveforms of the ultrasonic waves, coincide with each other, processing the zero-cross signals so that the phases coincide with each other, obtaining reference zero-cross time instant by calculating mean value of the forward and backward zero-cross time instants, obtaining an ultrasonic reception point by subtracting an integral multiple of the cycle of the ultrasonic waves so that the results of the subtraction falls into a possible propagation time range and estimating the ultrasonic propagation time on the basis of the ultrasonic reception point.

Owner:TEIJIN LTD

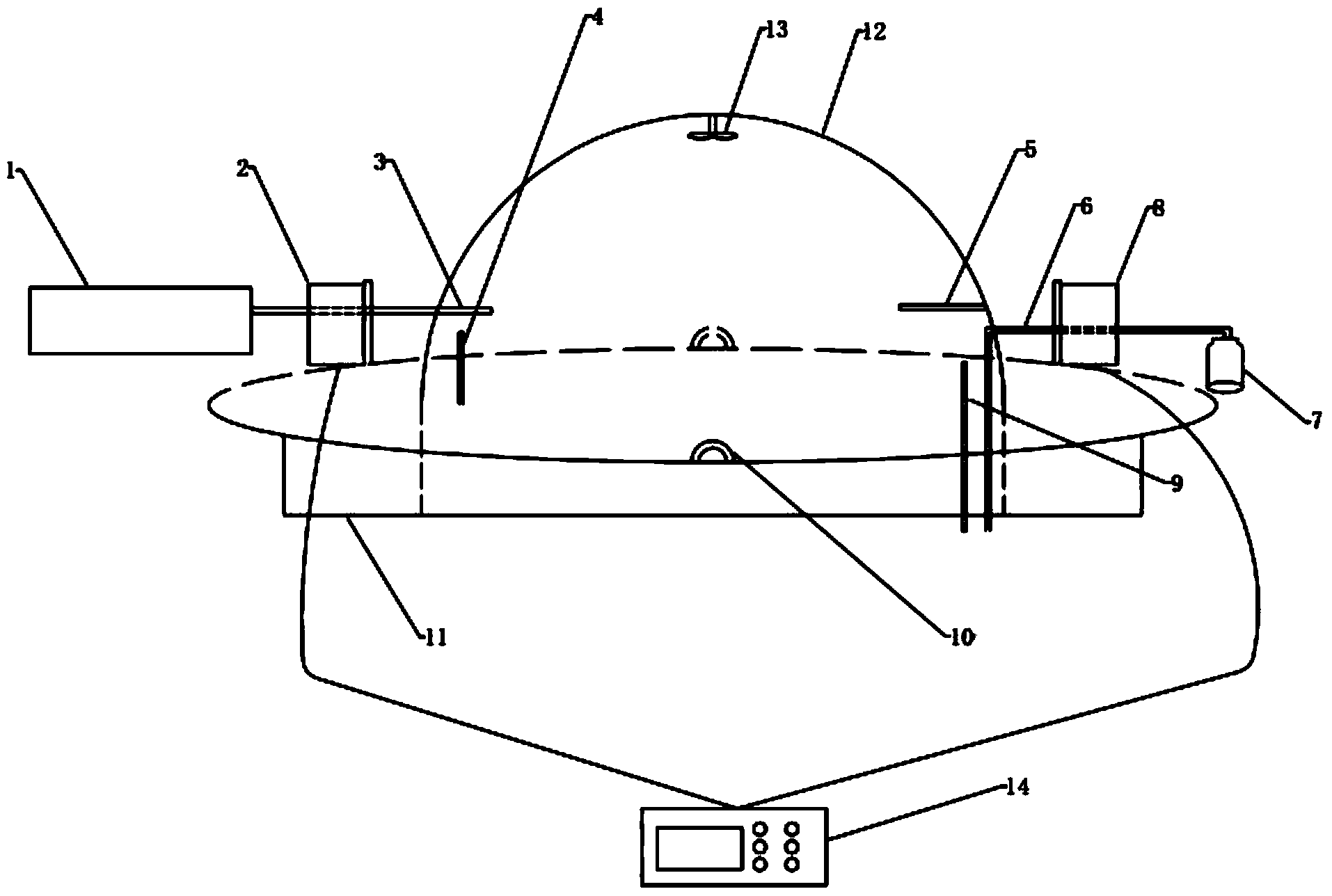

Collection device for treating N2O on water level of treatment unit in sewage treatment plant and sampling method

ActiveCN104236954AObvious advantageGood effectWithdrawing sample devicesLiquid temperatureText display

The invention discloses a collection device for treating N2O on a water level of a treatment unit in a sewage treatment plant and a sampling method, and belongs to the technical field of sewage sampling. The upper part of a collection flux box is of a hemispherical top type, and the lower part of the collection flux box is cylindrical; a baffle is arranged at the connecting part of the upper part and the lower part; the lower part of the baffle can be arranged in a floating plate in a sleeving manner; a small-size fan is arranged at the top of the baffle. According to the device, relevant sensors and pumps of a gas sampling system and a liquid sampling system are respectively integrated in two small-size equipment boxes, and the sealing property is high. The device is also provided with an in-box gas pressure meter, a gas thermometer and a liquid thermometer, so that relevant parameters can be measured in real time and are displayed in a text display of an on-line monitoring and control system; meanwhile, a control panel of the on-line monitoring and control system can be switched on to set the flow of a gas sampling pump and a liquid sampling pump. The device provided by the invention is simple in structure, high in integrality, convenient to carry and easy to operate, and can realize collection and measurement on release and dissolving N2O of the sewage treatment unit.

Owner:北京淇方天环保科技有限公司

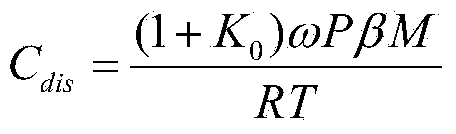

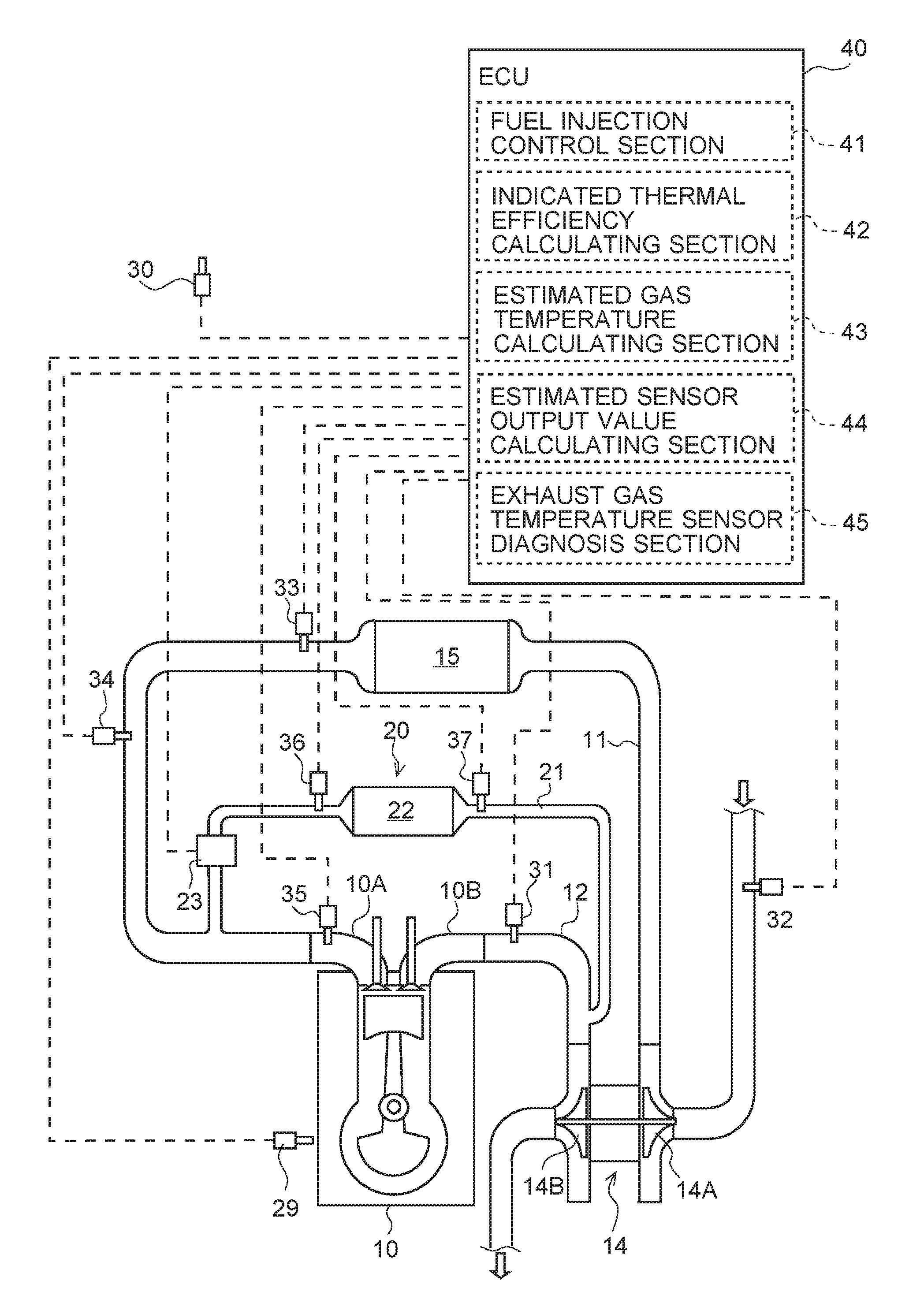

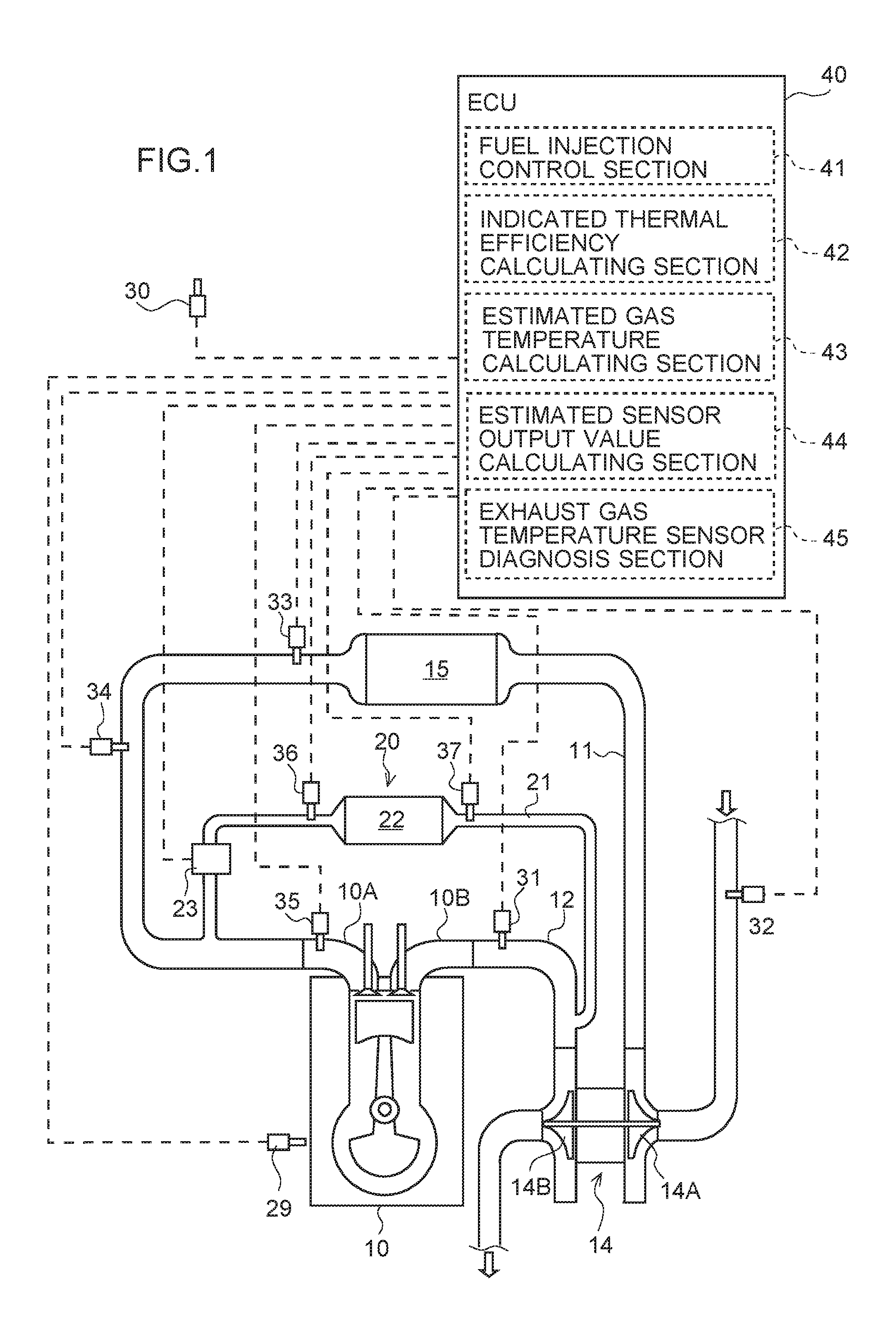

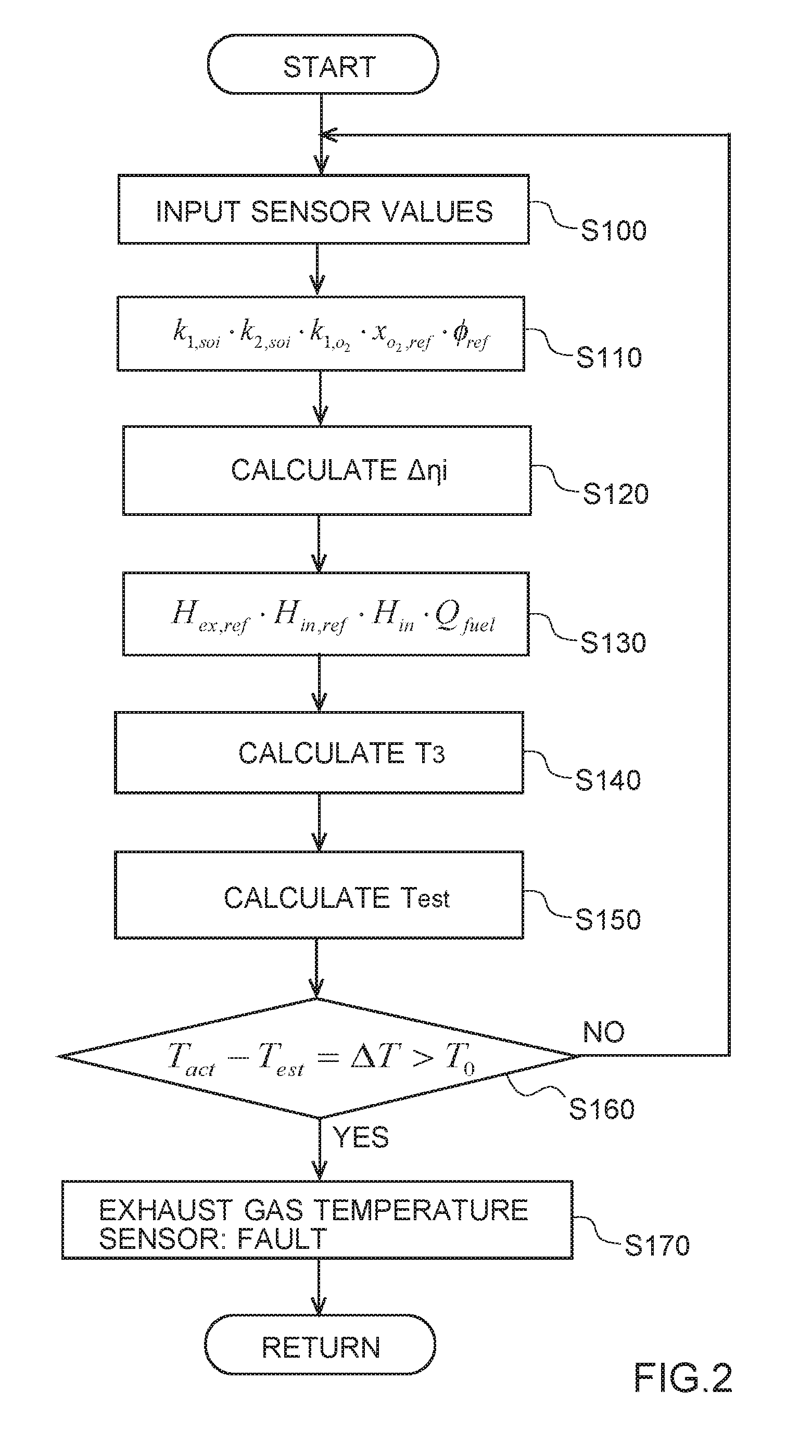

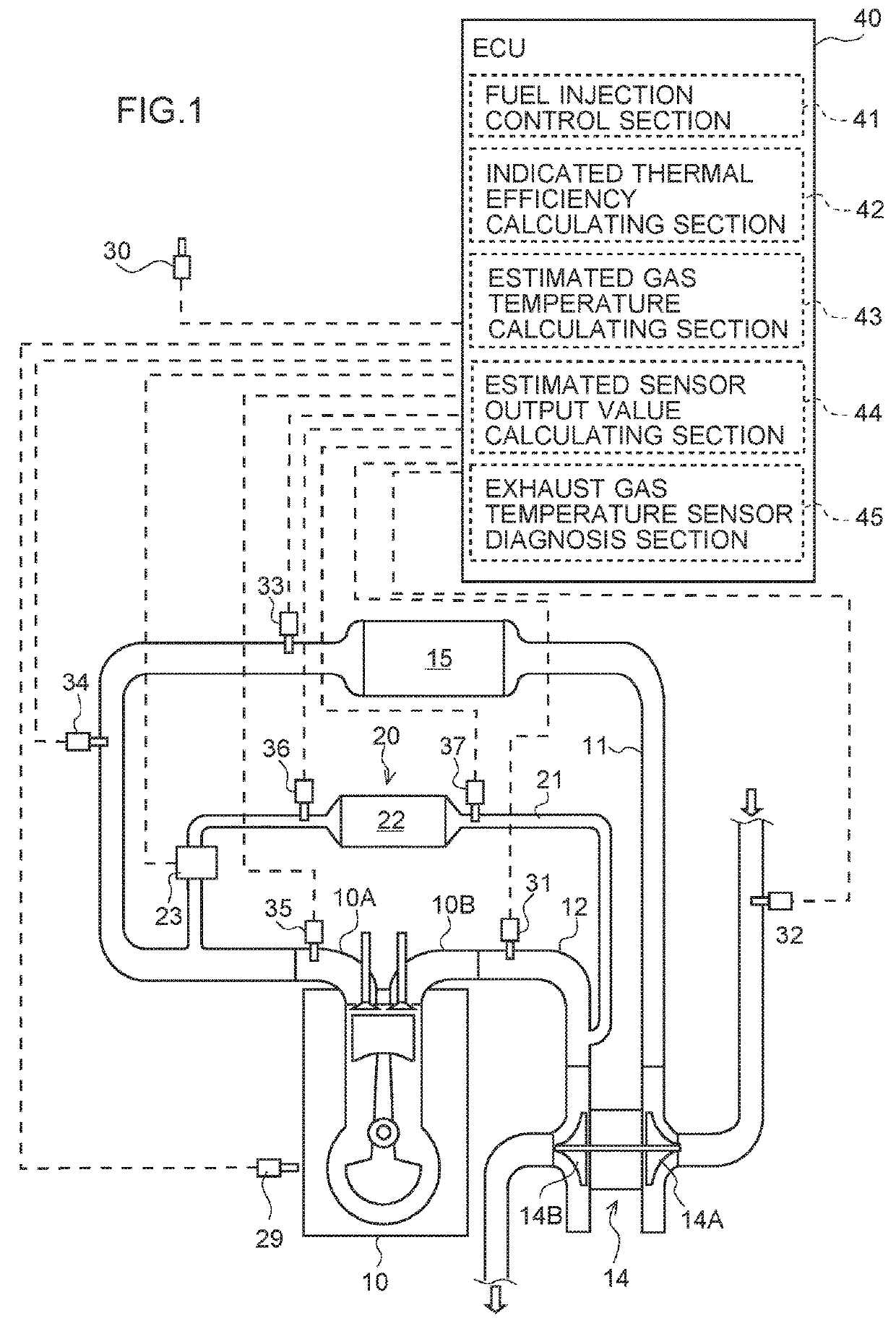

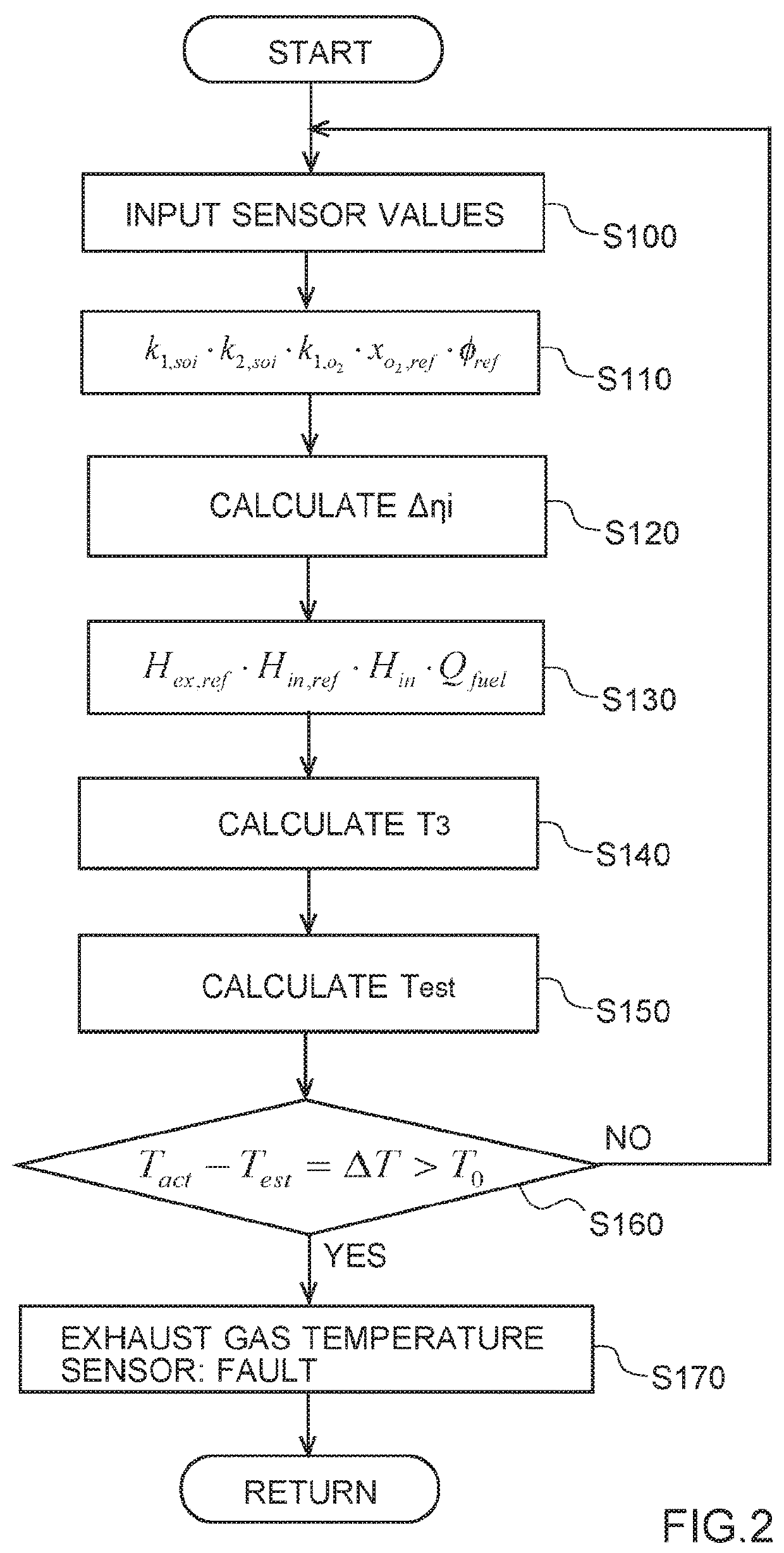

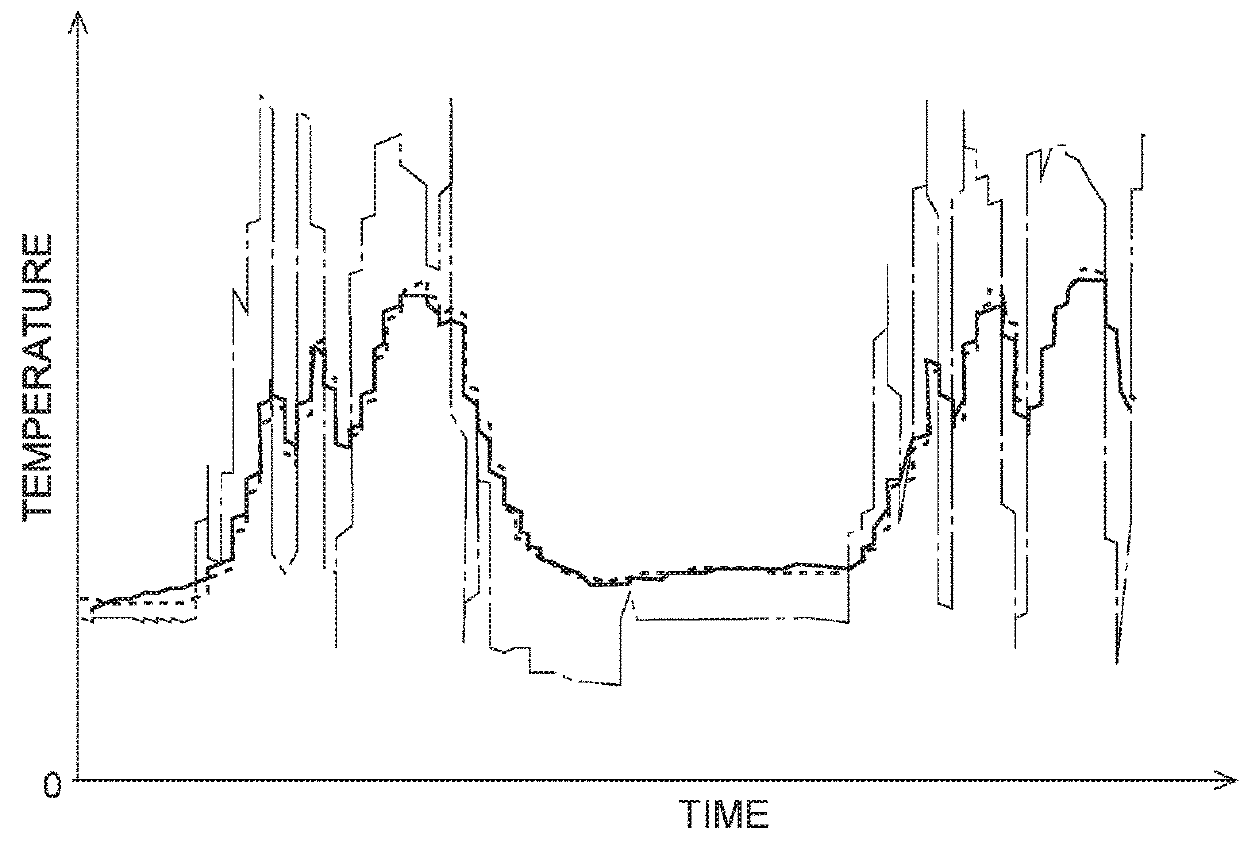

Sensor output value estimation device

InactiveUS20160160777A1Effective estimateThermometer detailsTemperature measurement in motorsResponse delayProcess engineering

A sensor output value estimation device that effectively estimates sensor output values reflecting a response delay of a temperature sensor. The device includes an estimated gas temperature calculation unit for calculating an estimated gas temperature of an engine on a basis of at least a running condition of the engine and a state quantity of the gas in the engine. The device also includes an estimated sensor output value calculation unit for calculating an estimated sensor output value reflecting the response delay of the temperature sensor on a basis of the calculated estimated gas temperature and a pre-stored first model formula specifying a relation among the temperature change time constant of the temperature sensor, the gas flow rate, and the gas temperature.

Owner:ISUZU MOTORS LTD +1

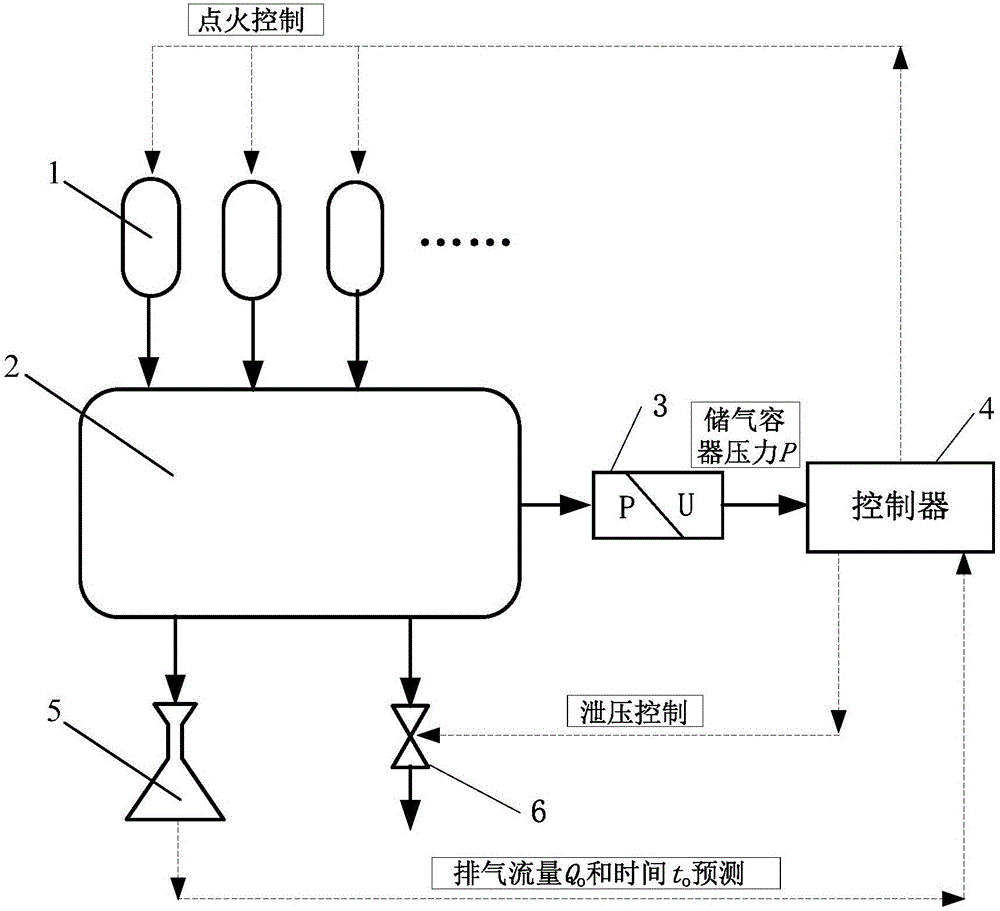

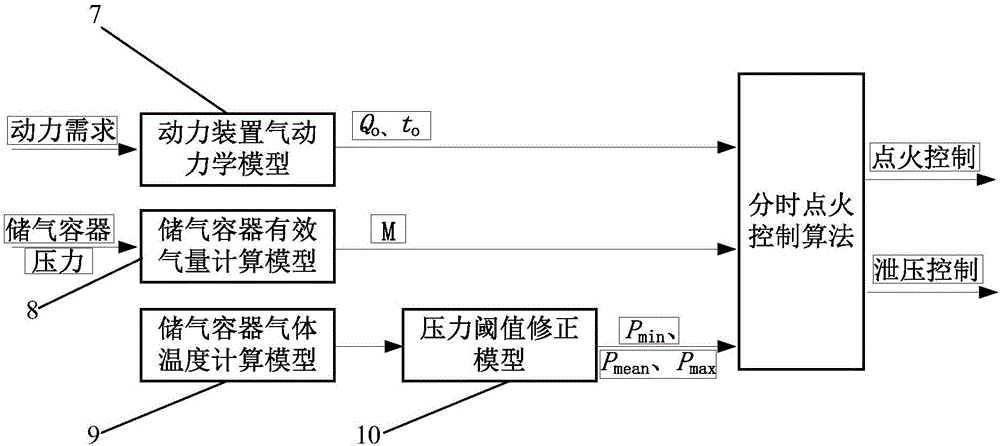

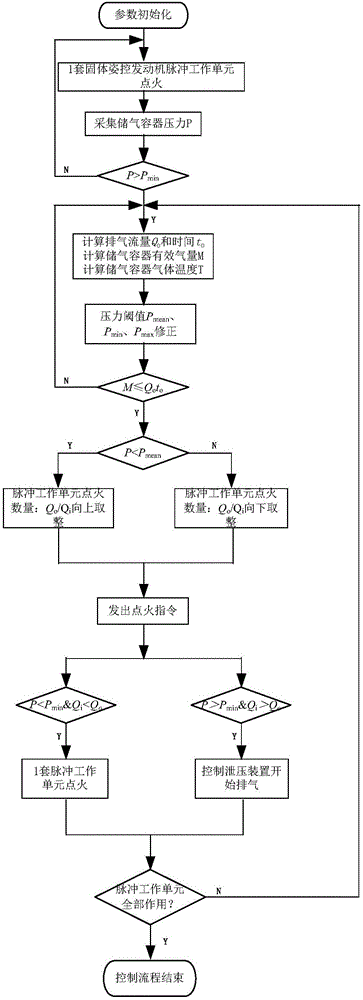

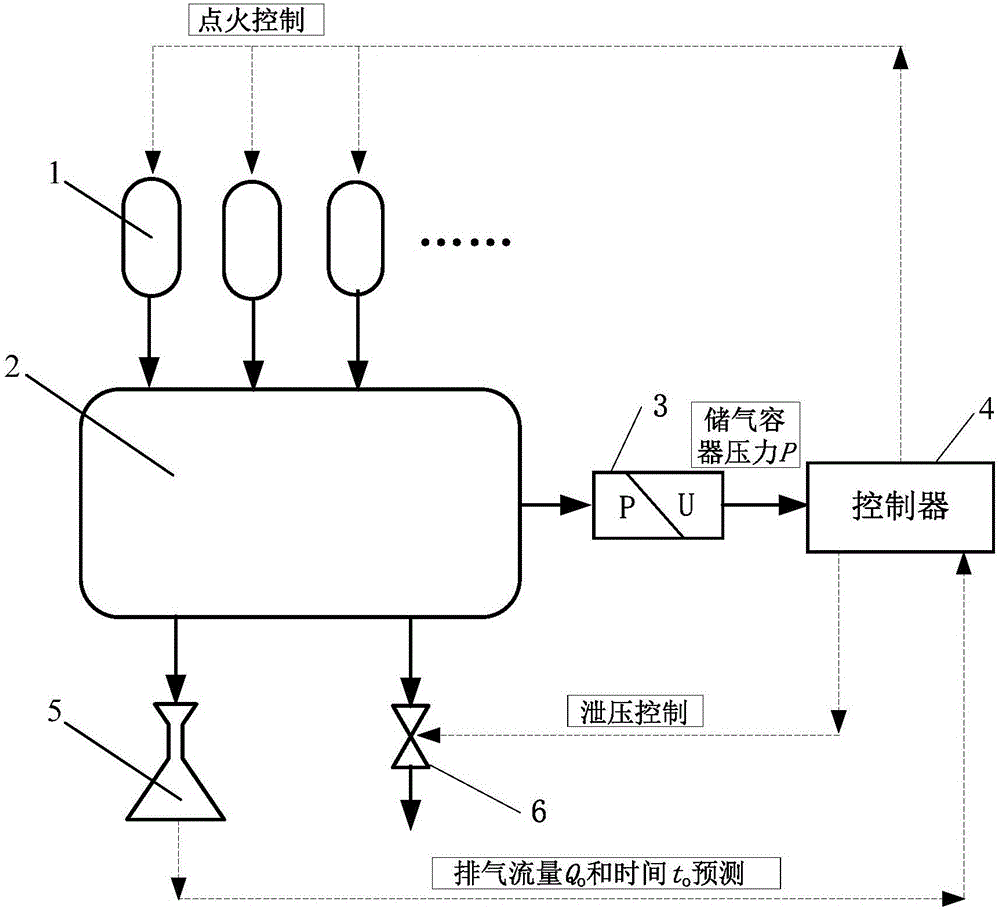

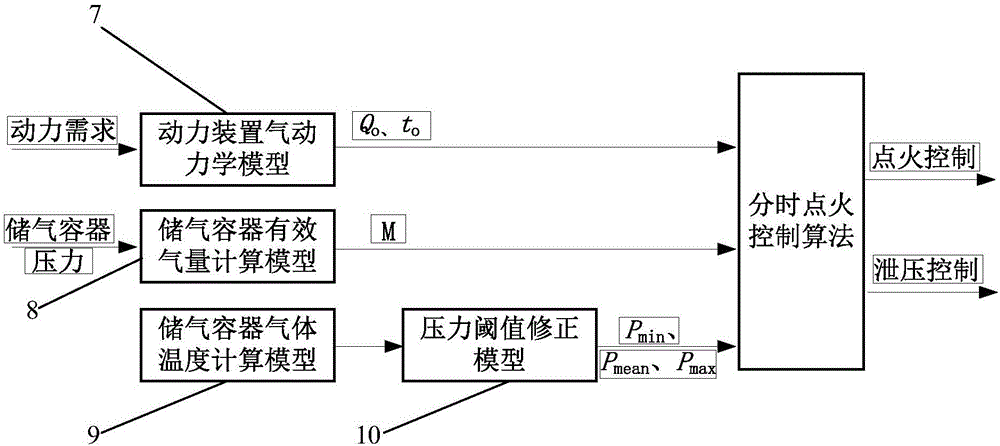

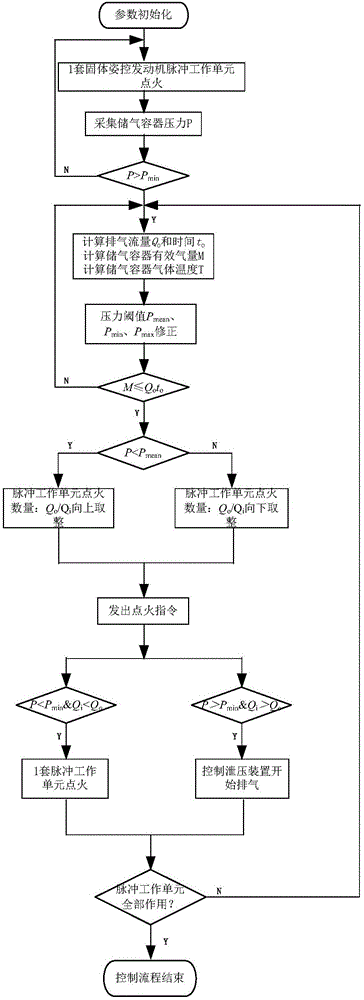

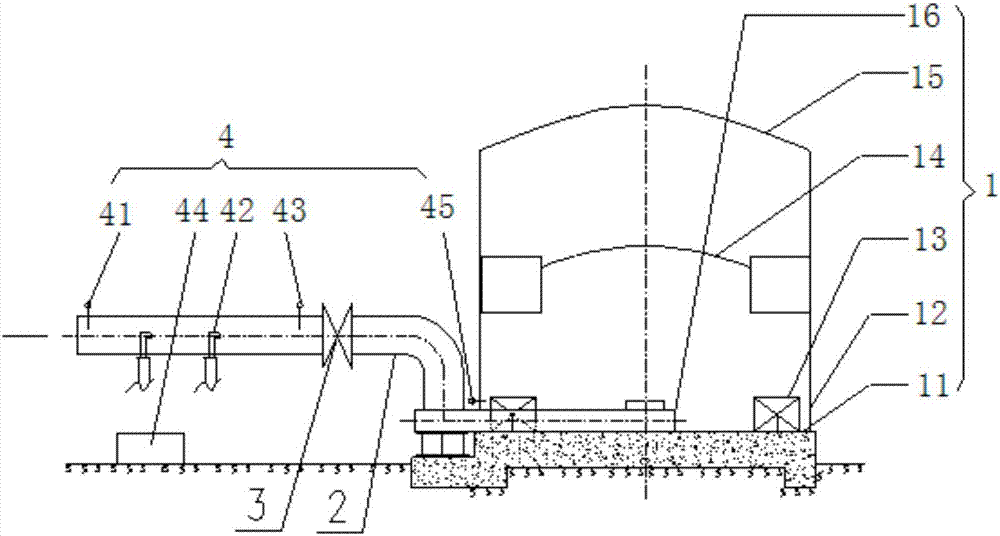

Time-sharing ignition control algorithm and system based on pressure self-stabilization design

ActiveCN106121866ASmall pressure fluctuation rangeImprove utilization efficiencyRocket engine plantsAttitude controlTime-sharing

The invention discloses a time-sharing ignition control algorithm and system based on the pressure self-stabilization design. The algorithm comprises the steps that exhaust gas flow Qo and time to are predicted through a power device gas kinetic model according to the working condition and operating characteristics of a solid attitude control engine; pressure P of a gas storage container is collected in real time, and the effective gas production amount M in the gas storage container is calculated through an effective gas amount calculation model of the gas storage container; a gas temperature T in the gas storage container is calculated through a gas storage container gas temperature calculation model, and a pressure threshold value is corrected according to the gas temperature T; and based on the principle of using gas input and output to achieve optimum matching, the ignition number and time of a pulse working unit of the solid attitude control engine can be determined by using a control algorithm to compare M with Qo, to and compare P with the pressure threshold value. By the adoption of the algorithm and system, optimum matching between gas production amount pulse input and exhaust gas amount intermittent output is realized, and therefore the pressure fluctuation range of the gas storage container can be made smaller, and gas utilization efficiency is higher.

Owner:湖北三江航天红林探控有限公司

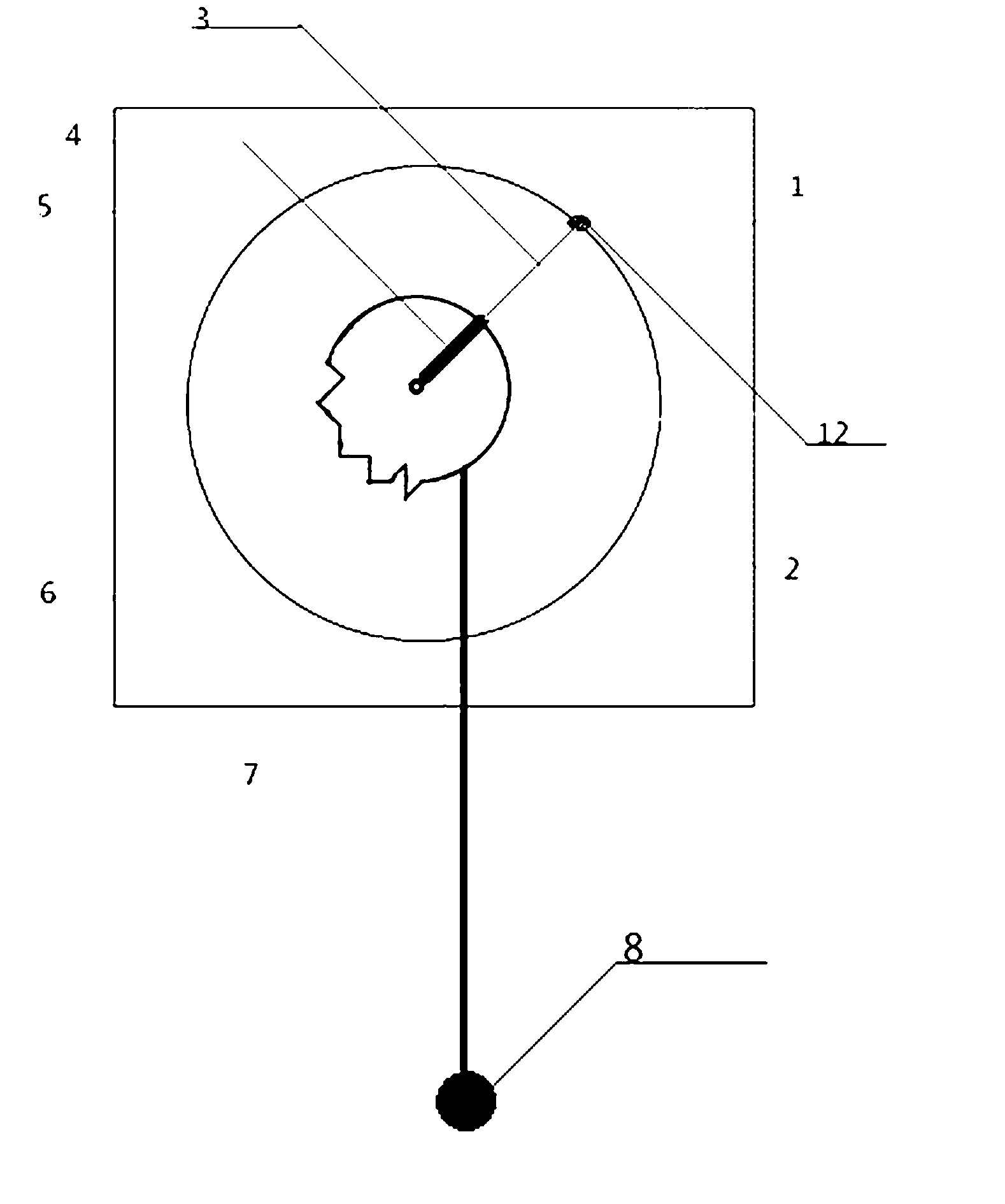

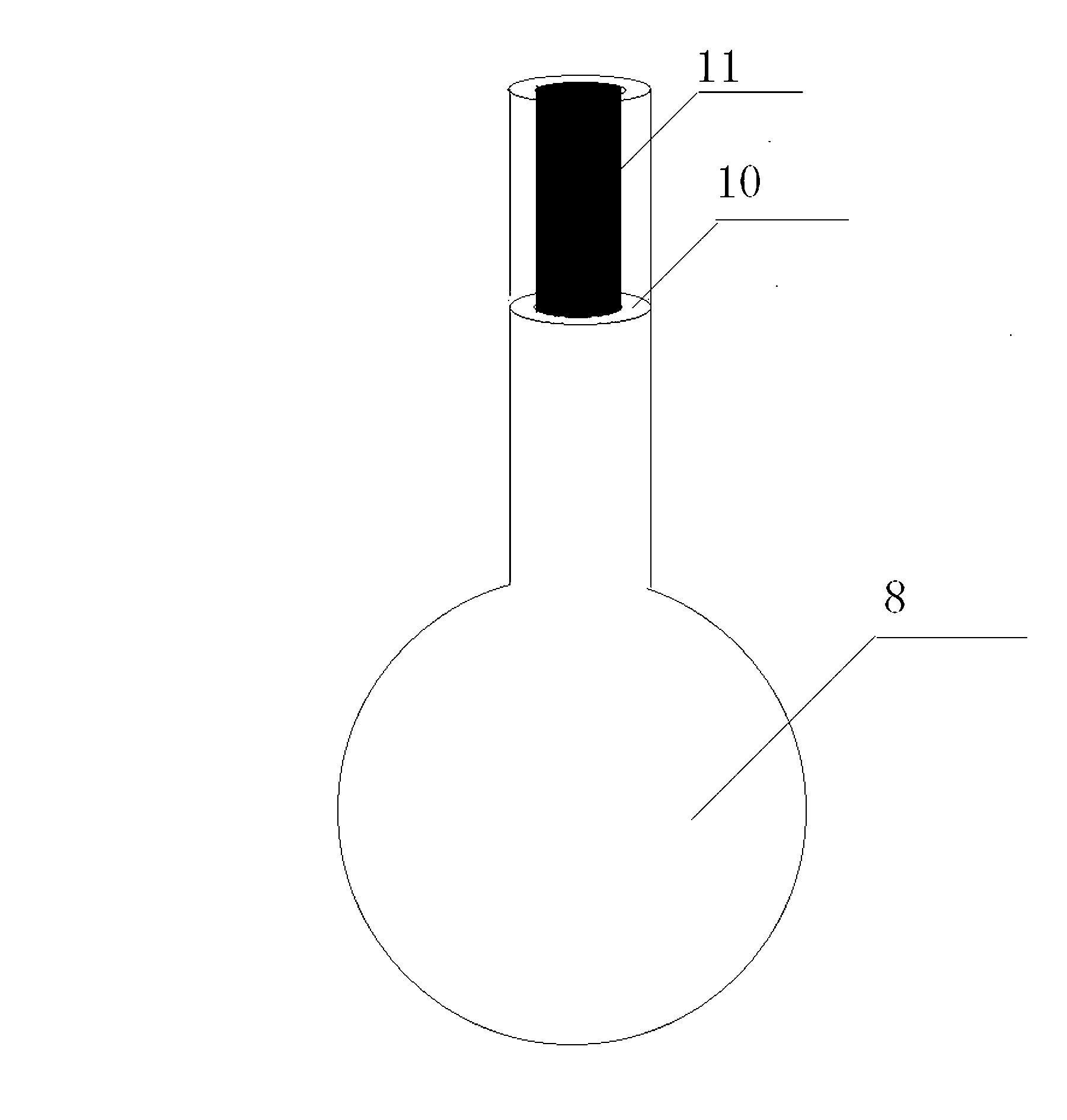

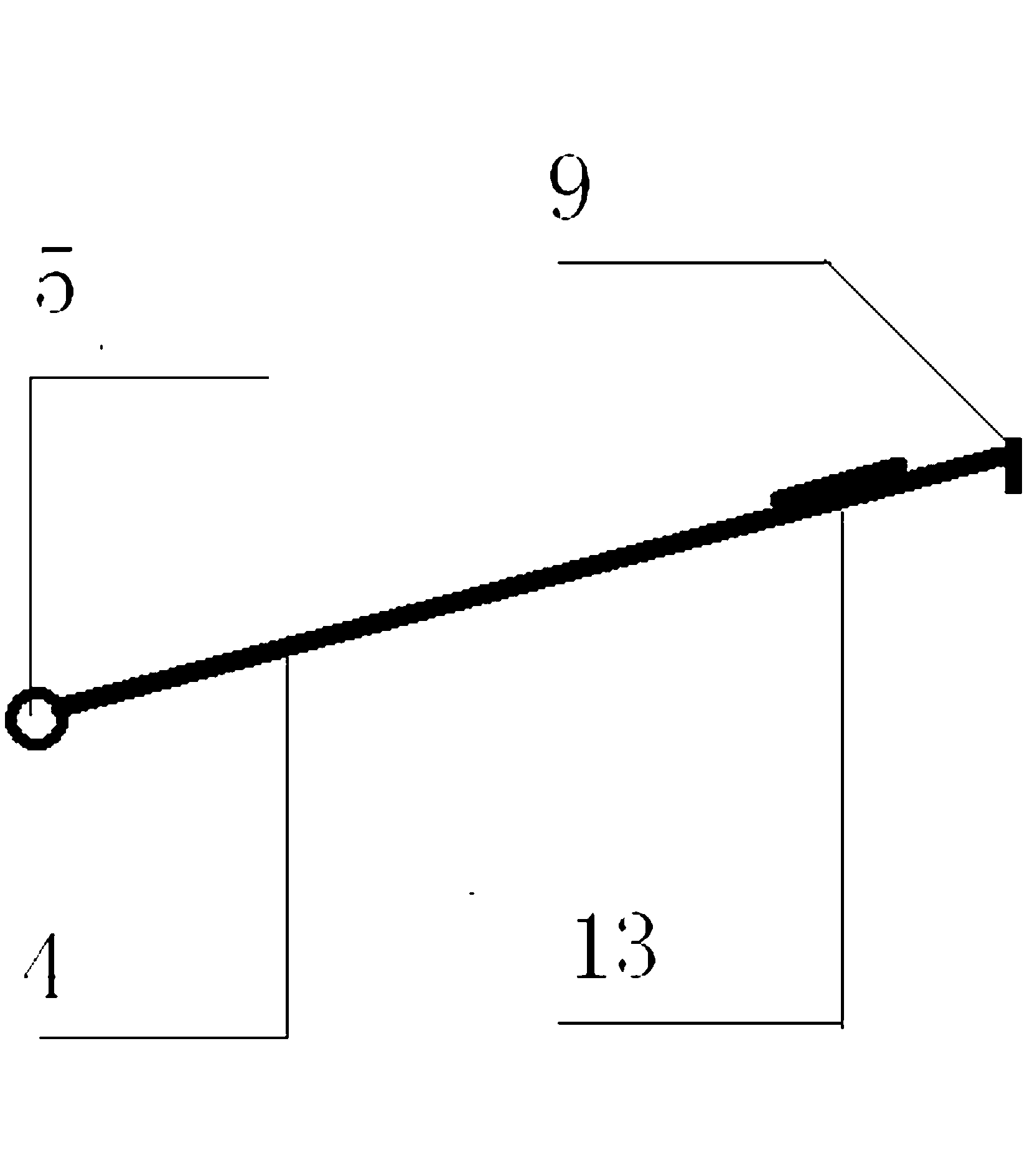

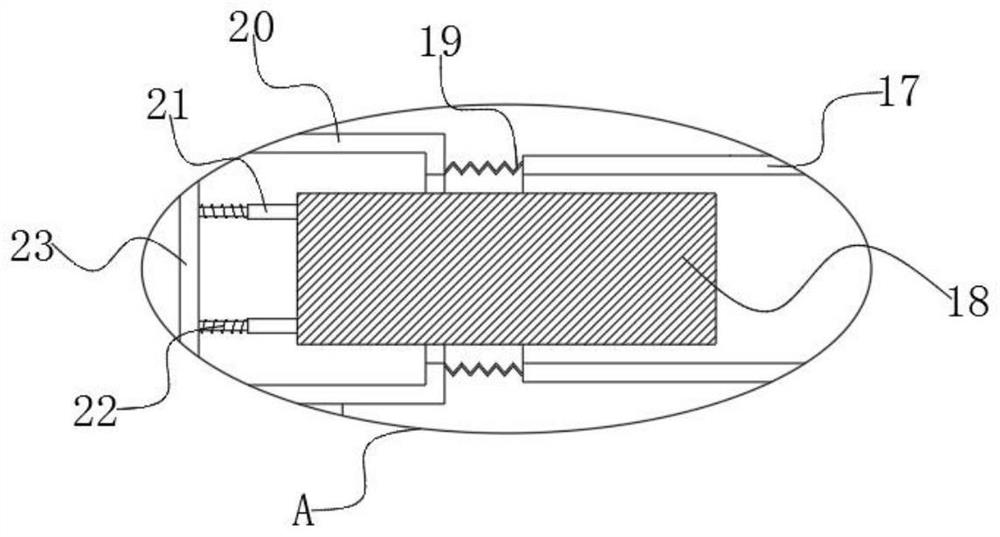

Gas thermometer

InactiveCN102798478ASmaller specific heatHigh precisionThermometers using material expansion/contactionGas thermometerTemperature testing

The invention relates to a temperature testing device, in particular to a gas thermometer, which has a wide measuring range and can measure the temperature of an object in a high-precision and high-speed manner. The gas thermometer comprises a temperature measuring part and a temperature indicating part, wherein a gas storage ball is arranged on the temperature measuring part; the gas storage ball is connected with a gas-guide tube; an elastic force application device is arranged on the gas-guide tube; the top end of the elastic force application device is wrapped with an interlayer thin skin; an elastic force application object is arranged inside the interlayer thin skin; the temperature indicating part comprises a dial scale, a fixed tray and a rotating bar; the rotating bar is connected with the gas storage ball; a laser is installed on the rotating bar; the rotating bar is connected with the interlayer thin skin through a magnetic sheet; and a fixed rotation point is arranged at the tail end of the rotating bar. The temperature testing device can measure the temperature of the object in a high-speed and high-precision manner.

Owner:毛陈

Sensor output value estimation device

InactiveUS10041427B2Effective estimateTemperature measurement in motorsElectrical controlResponse delayProcess engineering

Owner:ISUZU MOTORS LTD +1

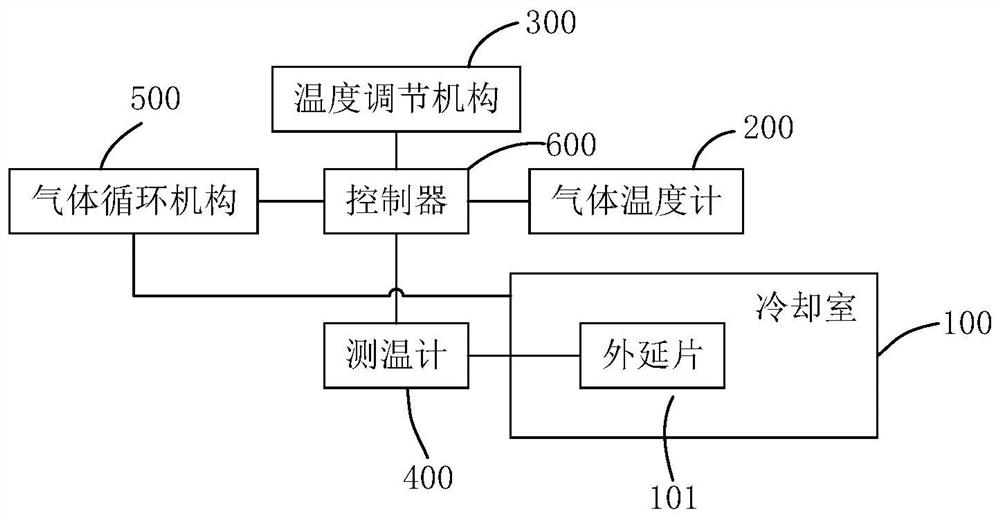

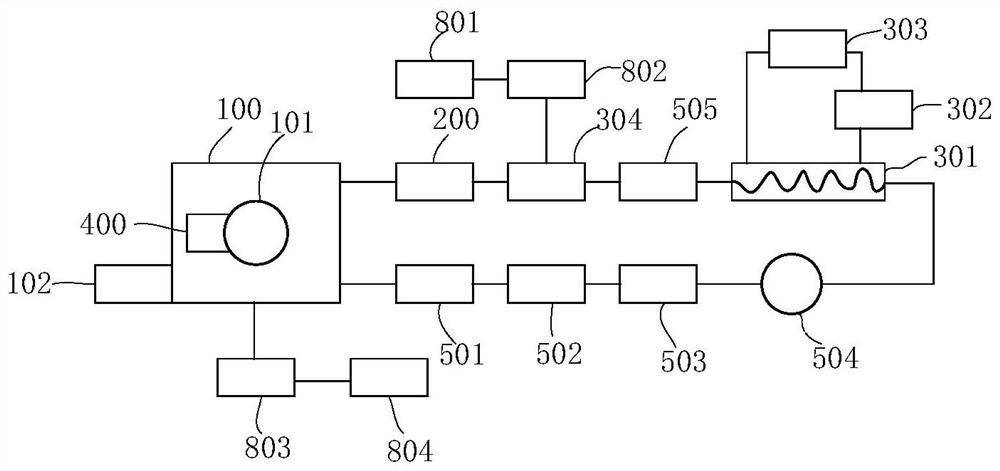

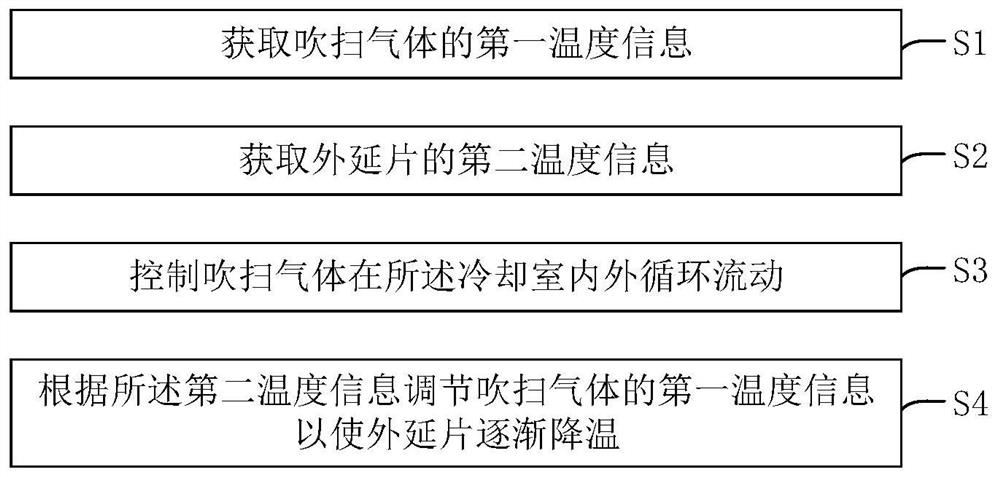

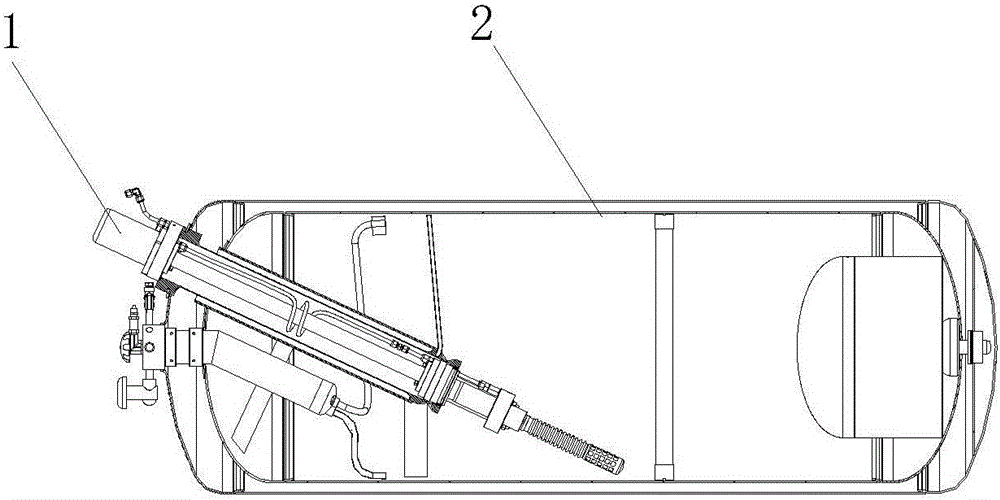

Epitaxial furnace purging and cooling system, method and device, electronic equipment and storage medium

ActiveCN113638043APrevent normative deformationPrevent dislocationFinal product manufactureFrom chemically reactive gasesInformation controlPhysical chemistry

The invention relates to the technical field of epitaxial growth, and particularly discloses an epitaxial furnace purging and cooling system, method and device, electronic equipment and a storage medium. The system comprises a cooling chamber which is used for placing an epitaxial wafer and is filled with purging gas for purging and cooling the epitaxial wafer, a gas thermometer used for acquiring first temperature information of the purging gas, a temperature adjusting mechanism, a thermodetector used for acquiring second temperature information of the epitaxial wafer, a gas circulation mechanism, and a controller used for controlling the purging gas to circularly flow so as to circularly purge and cool the epitaxial wafer, and controlling the temperature adjusting mechanism to adjust the first temperature information of the purging gas according to the second temperature information so as to gradually cool the epitaxial wafer. The system controls the temperature adjusting mechanism to adjust the first temperature information of the purge gas according to the second temperature information, and prevents the epitaxial wafer from generating normative deformation and dislocation when the epitaxial wafer is cooled due to overlarge temperature difference between the purge gas and the epitaxial wafer.

Owner:JIHUA LAB

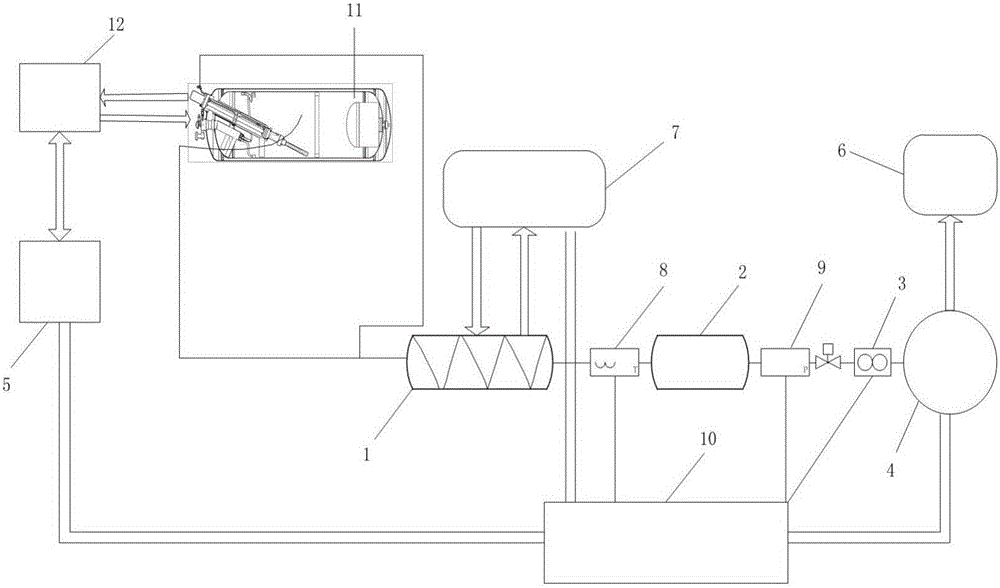

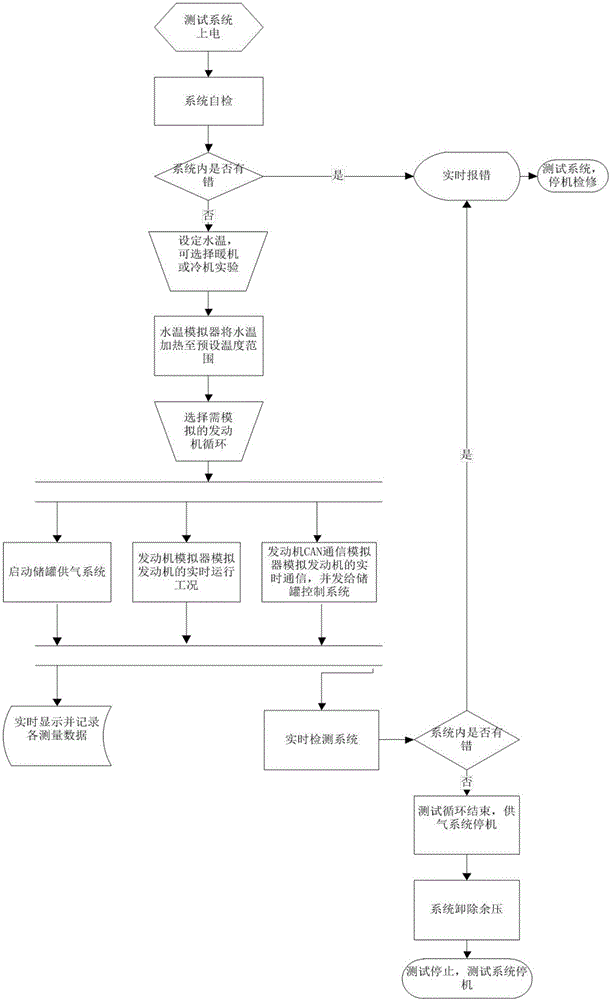

Liquified natural gas (LNG) storage tank gas supply performance experiment device and method

InactiveCN105784402ARealize real-time calibrationRealize real-time simulationStructural/machines measurementLiquid storage tankStreamflow

The present invention relates to an LNG storage tank gas supply performance experiment device. The LNG storage tank gas supply performance experiment device comprises a gas supply device, a simulation control device and a data detection device, the gas supply device comprises a liquid-storage tank, a gasifier and a buffer tank, and the simulation control device comprises an engine simulator, a gas tank controller, an engine communication simulator, a water temperature simulator and an experiment table. The engine simulator is connected with the output port of the buffer tank via a gas pipeline, the data detection device comprises a gas thermometer, a gas pressure gauge and a gas flow meter, and the gas thermometer, the gas pressure gauge and the gas flow meter are all arranged on the gas pipeline of a gas supply loop. The experiment device of the present invention can detect the performance of the liquid-storage tank accurately, at the same time, enables the experiment cost to be reduced, the experiment safety to be improved and the experiment cycle to be shortened by adopting an inert gas to substitute for a liquified natural gas. The present invention also provides an experiment method the gas supply performance test.

Owner:HANGZHOU WEST PORT LOW TEMPERATURE TECH CO LTD

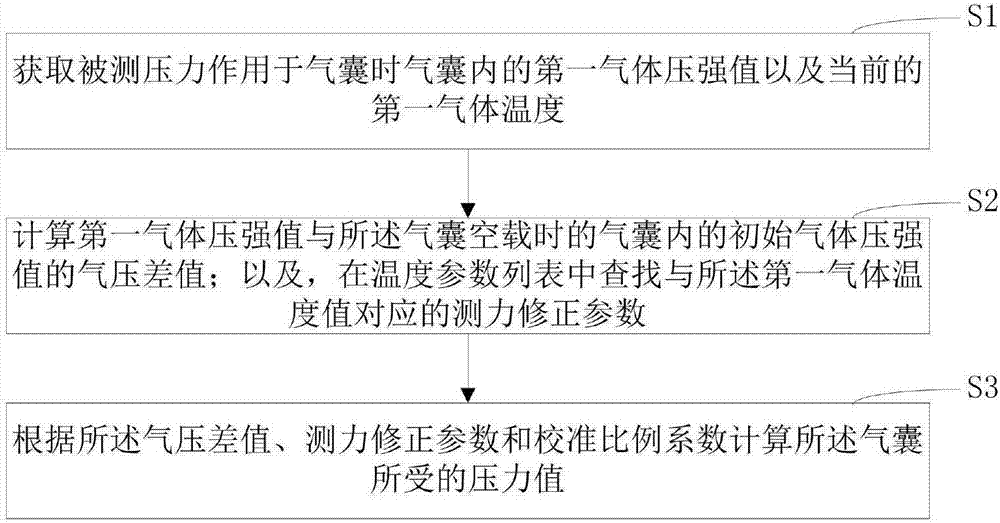

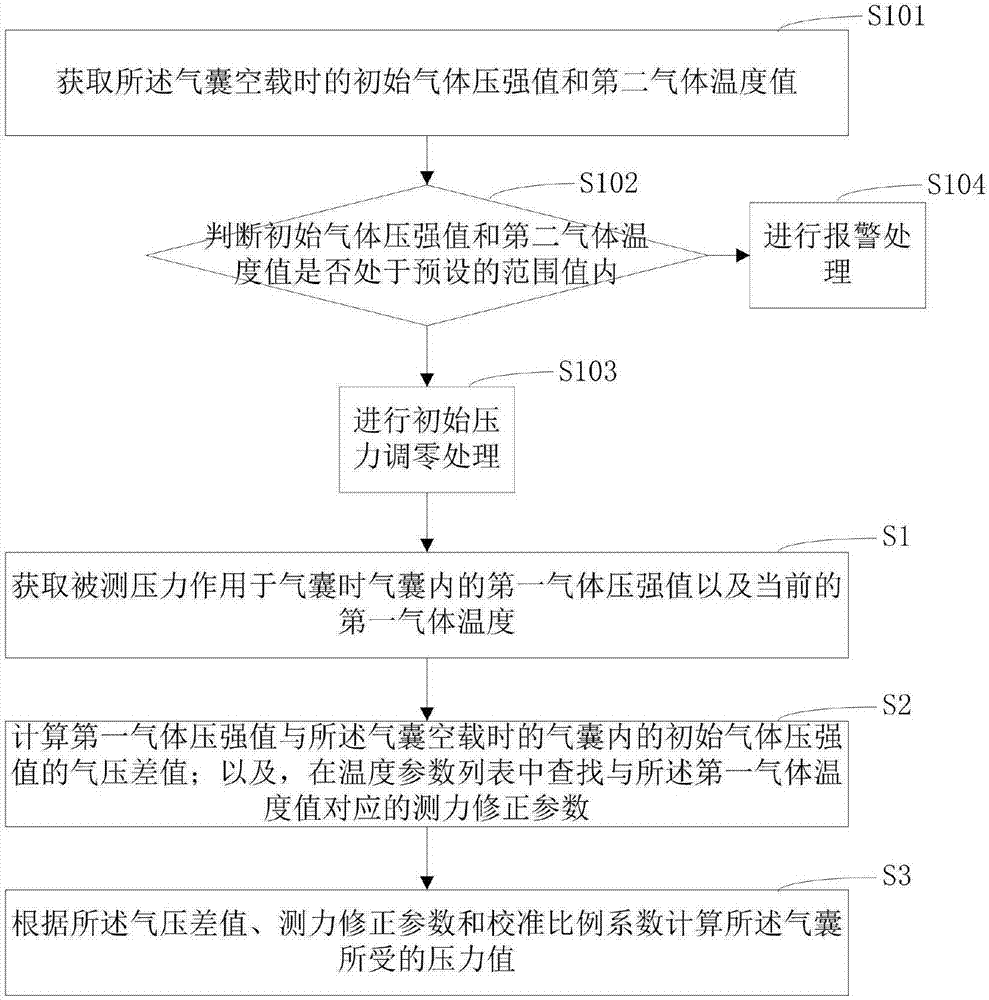

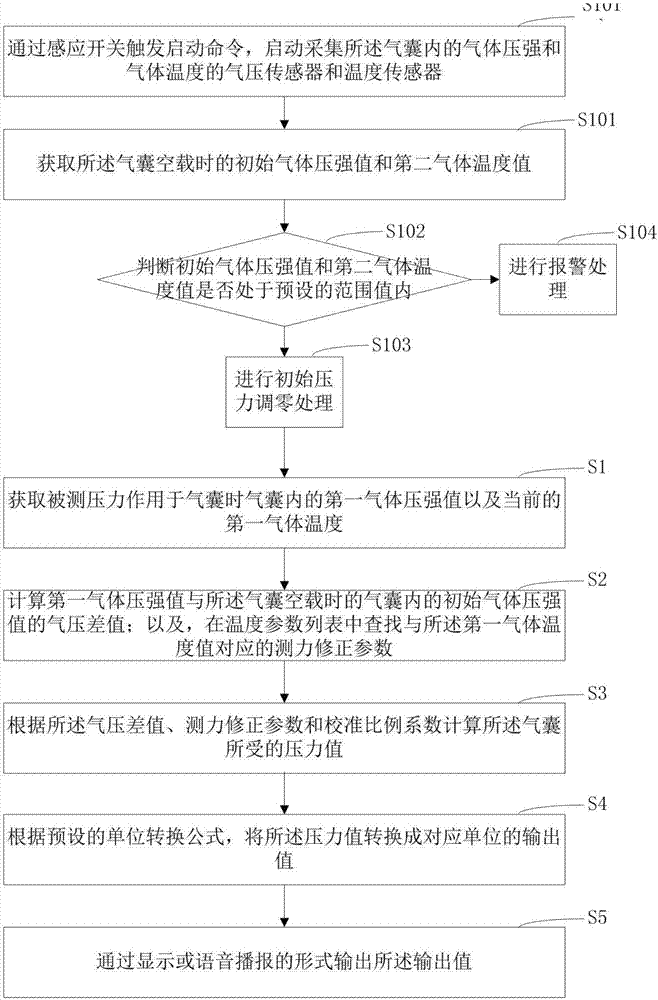

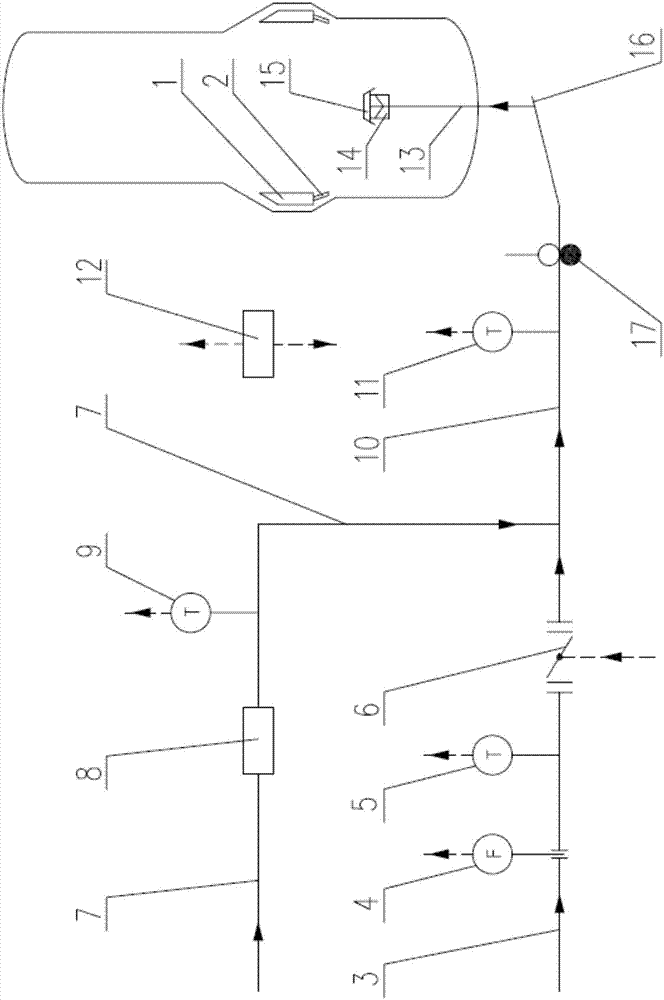

Force measurement method and device, and force measurement device

ActiveCN107101776ASimple conditions of useEasy to useFluid pressure measurementFootwearMeasurement deviceEngineering

The present invention discloses a force measurement method and device, and a force measurement device. The method comprises: obtaining first gas pressure value in an air bag when measured pressure is acted at the air bag and the current first gas temperature; calculating the gas pressure difference between the first gas pressure value and the initial gas pressure value in the air bag when the air bag is zero load; searching a force measurement correction parameter corresponding to the first gas temperature value in a temperature parameter list; and according to the gas pressure difference value, the force measurement correction parameter and the calibration proportion coefficient, calculating the pressure value of the air bag, wherein the calibration proportion coefficient is a coefficient through preset weight calibration after the pressure at the outer surface of the air bag is converted to internal gas pressure difference. The force measurement method and device, and the force measurement device employ gas pressure change of the air bag and the correction of the pressure value through adoption of the temperature to perform force measurement, the air bag is employed to make a force measurement device, the force measurement device is simple in usage condition and can be conveniently used on an intelligent wearable device, such as intelligent shoes and the like.

Owner:SHENZHEN WATER WORLD INFORMATION CO LTD

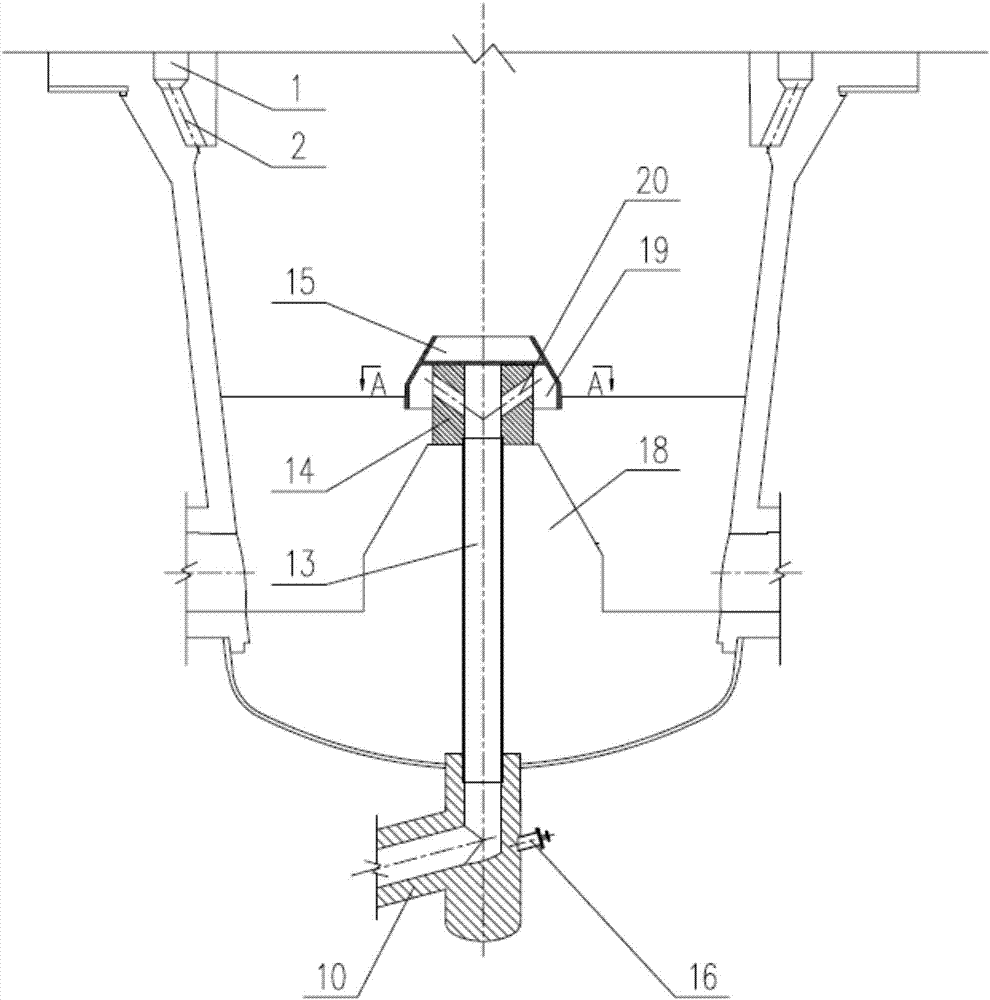

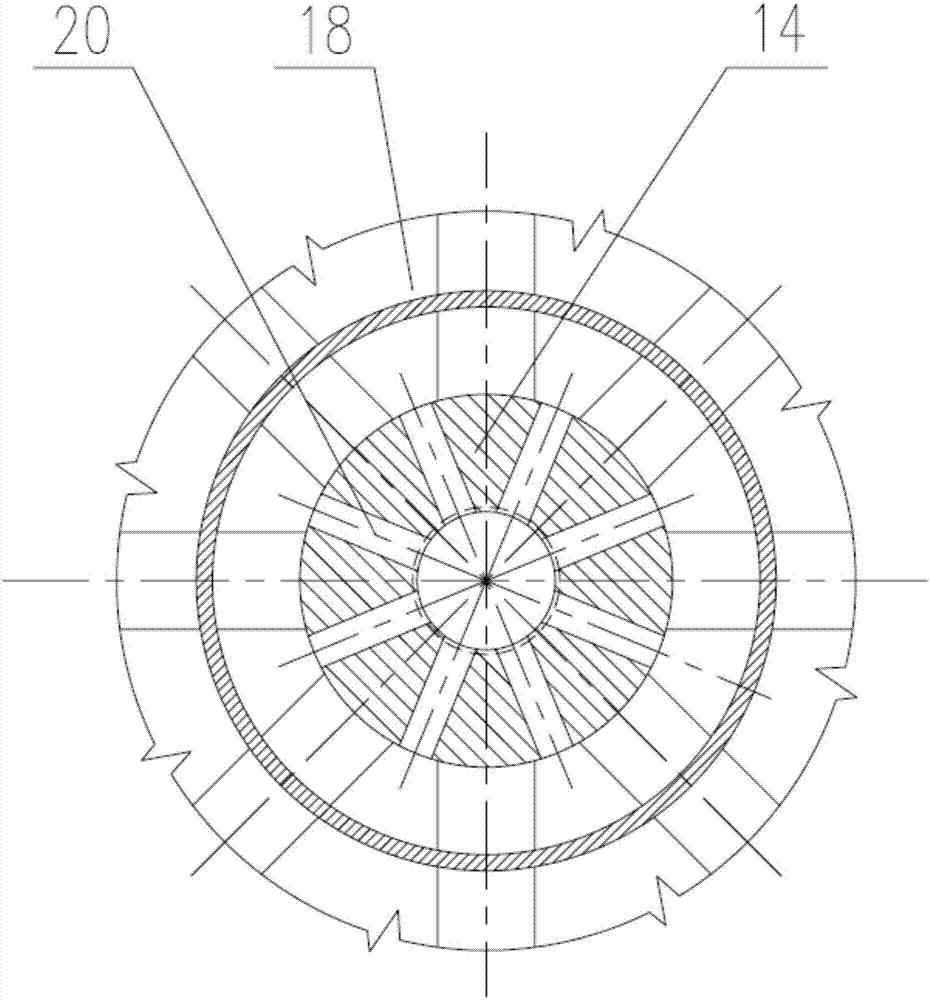

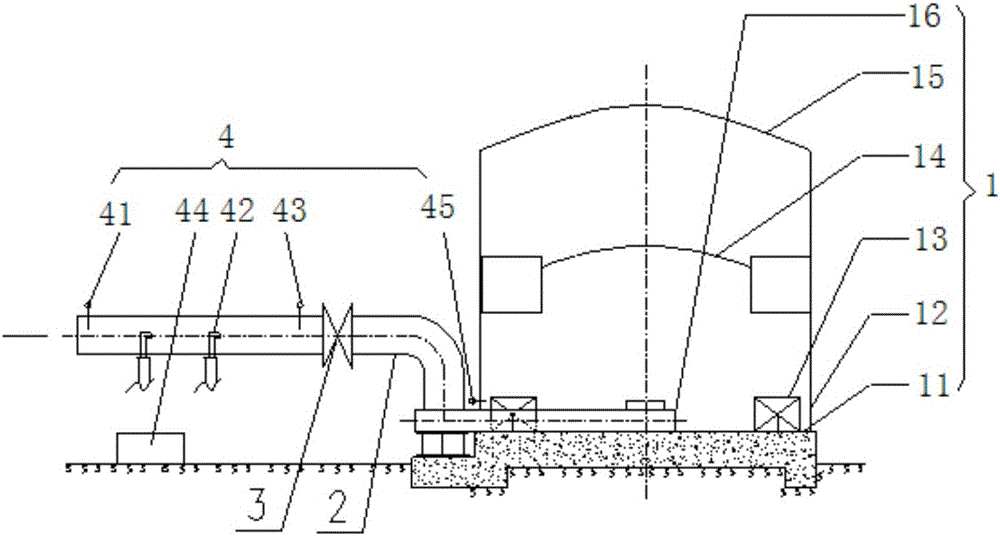

Shaft furnace air intake device and shaft furnace air intake method

The invention provides a shaft furnace air intake device and a shaft furnace air intake method. The device comprises a gas circular pipe, a gas hole, a reduced gas conveying and processing system, a detecting and control system, a bottom air intake pipeline, a gas distributor, a protective cover, a dust blowing facility and a gas separation facility, wherein the gas circular pipe and the gas hole allow air to enter from the middle of a shaft furnace. The reduced gas conveying and processing system comprises a cold gas pipeline, a hot gas pipeline, a hot gas dust collector and a mixed gas pipeline. The detecting and control system comprises a cold gas thermometer, a cold gas flowmeter, a cold gas flow adjusting valve, a hot gas thermometer, a mixed gas thermometer and relevant control systems. According to the shaft furnace air intake device and the shaft furnace air intake method, the reduced gas is conveyed into the central area of the shaft furnace reliably and efficiently, the flow and temperature of the reduced gas are controlled independently according to practical production demands, so that the gas flow in the shaft furnace is evenly distributed, the temperature fields are reasonably distributed, accordingly the metallization ratio of sponge iron is increased, the gas utilization rate of the shaft furnace and the production efficiency are improved, and the fuel ratio of the shaft furnace and the production cost are lowered.

Owner:BAOSTEEL ENG & TECH GRP +1

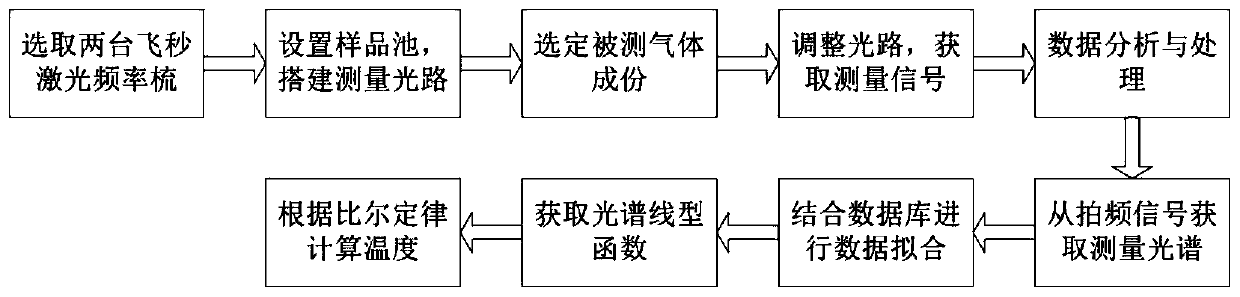

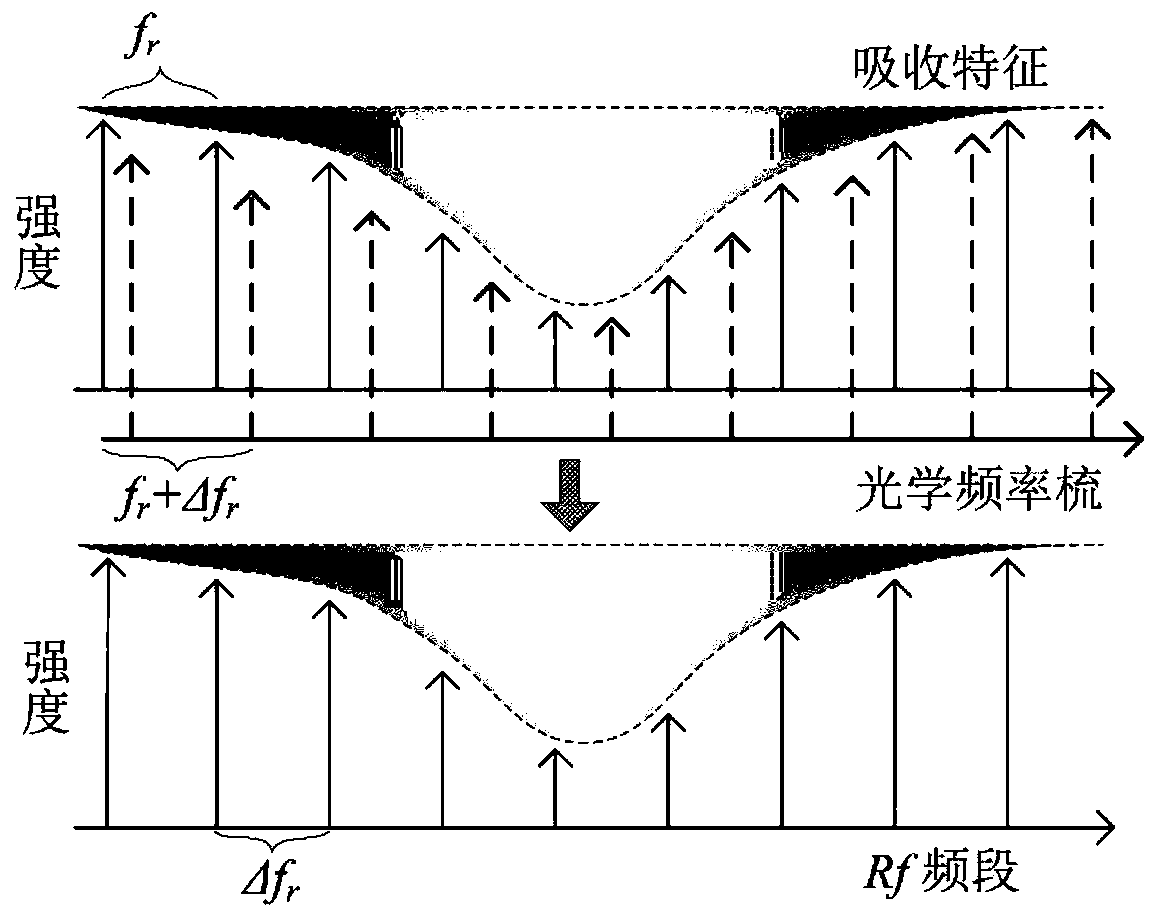

Method for accurately measuring temperature of combustion gas

ActiveCN111239072AIncrease sampling rateHigh measurement accuracyMaterial analysis by optical meansThermometers using physical/chemical changesFrequency spectrumGas composition

The invention discloses a method for accurately measuring the temperature of combustion gas, and belongs to the field of gas temperature measurement. The implementation method comprises: solving the repetition frequency difference of two frequency combs and the pulse time domain repetition period delay time; building measuring light path devices on two sides of the gas sample pool; selecting a gascomponent with absorption spectrum information in an infrared band; adjusting a light path, and determining a mapping relationship and a mapping coefficient between the beat frequency spectrum information and an original spectrum; collecting light intensity data detected by the photoelectric detector; analyzing to obtain frequency spectrum information, and converting to obtain an infrared absorption spectrum of the detected gas; according to an HITRAN database, converting to obtain all internal segmentation summation functions of molecules of the detected gas; substituting the function into an absorption spectrum linear function formula to obtain an absorption spectrum linear function; and substituting the absorption spectrum linear function into a measured gas temperature calculation formula to obtain the temperature of the measured gas, thereby realizing real-time non-contact accurate measurement of the temperature of the combustion gas. The method has the advantages of high real-time performance and high measurement precision.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

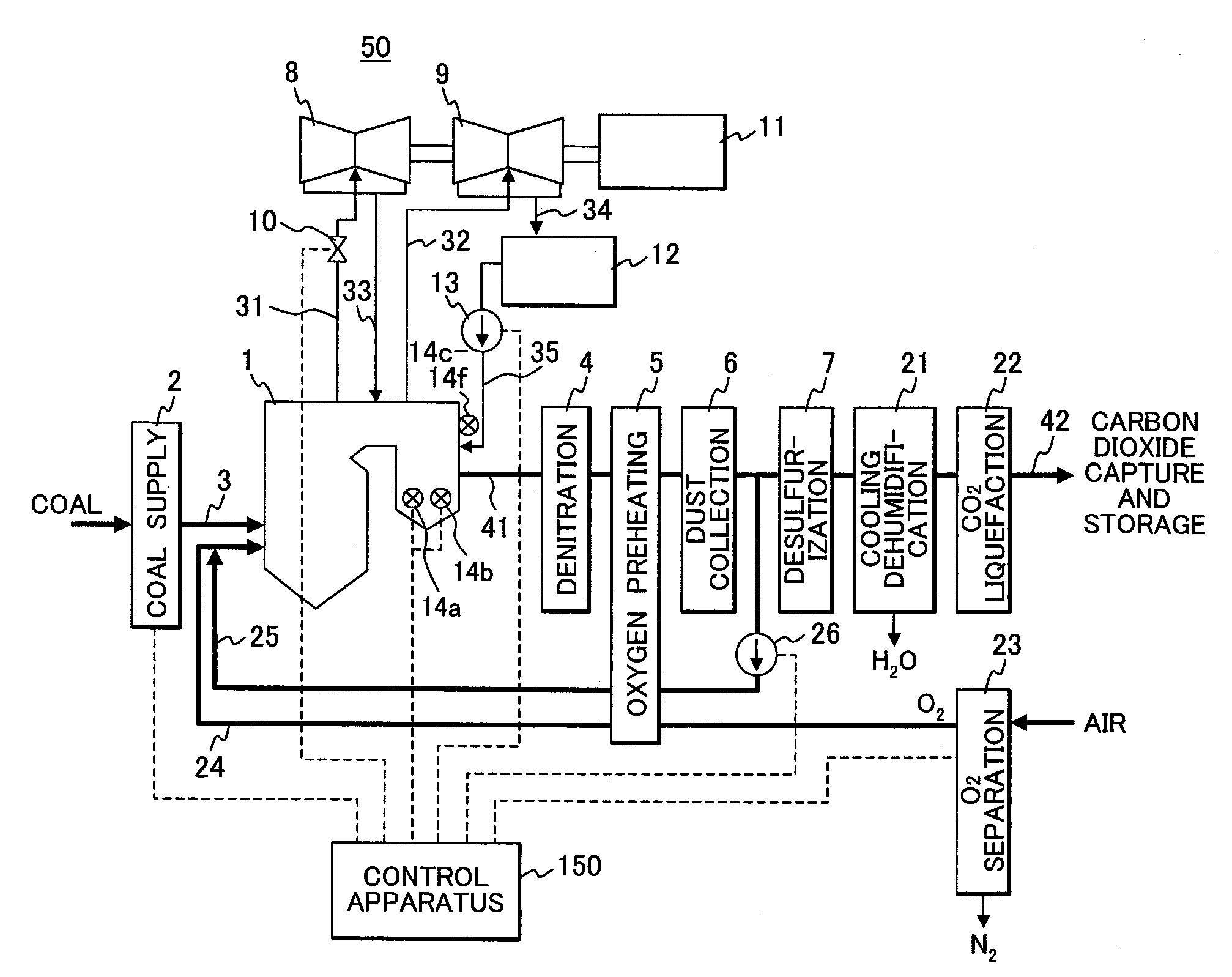

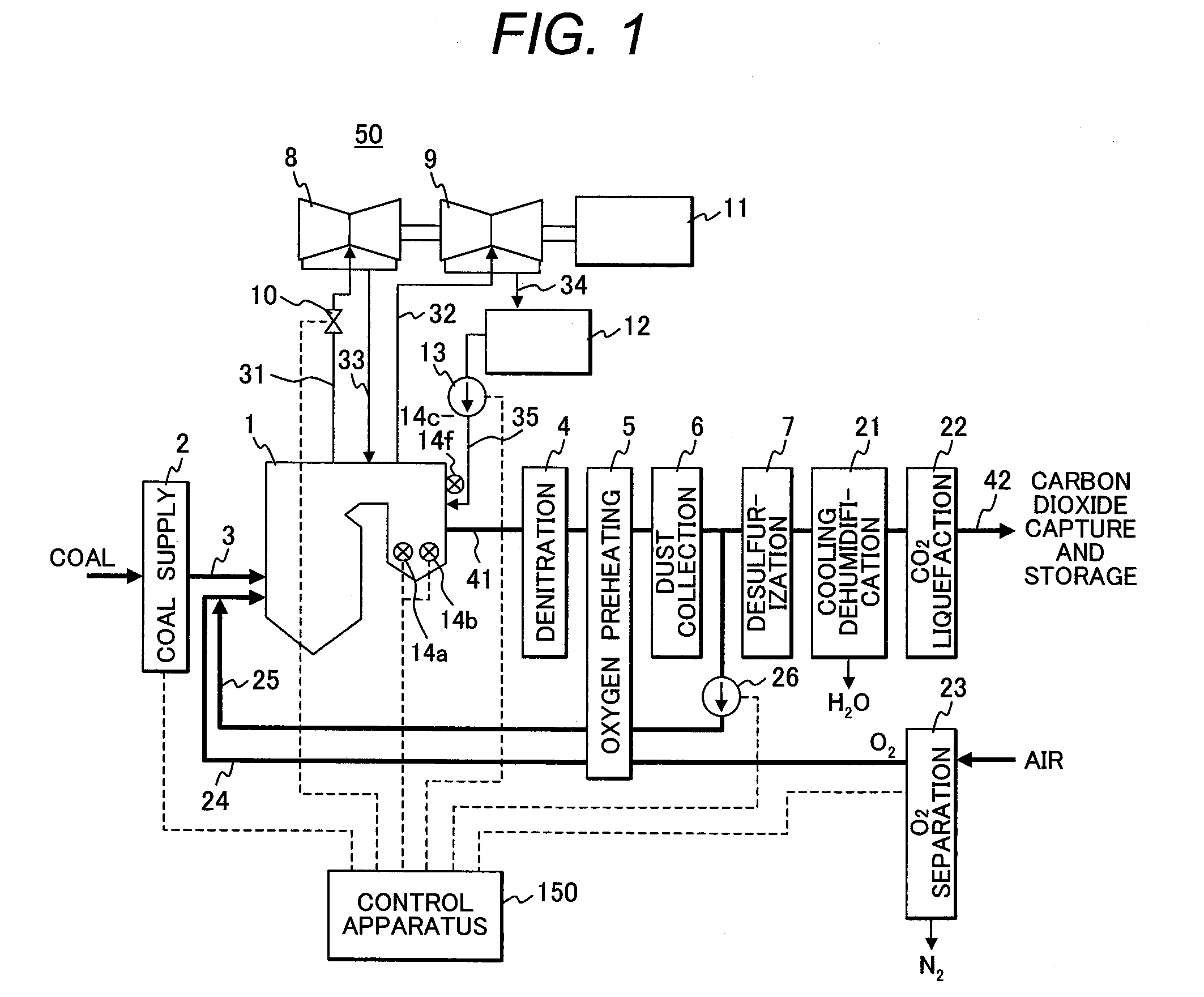

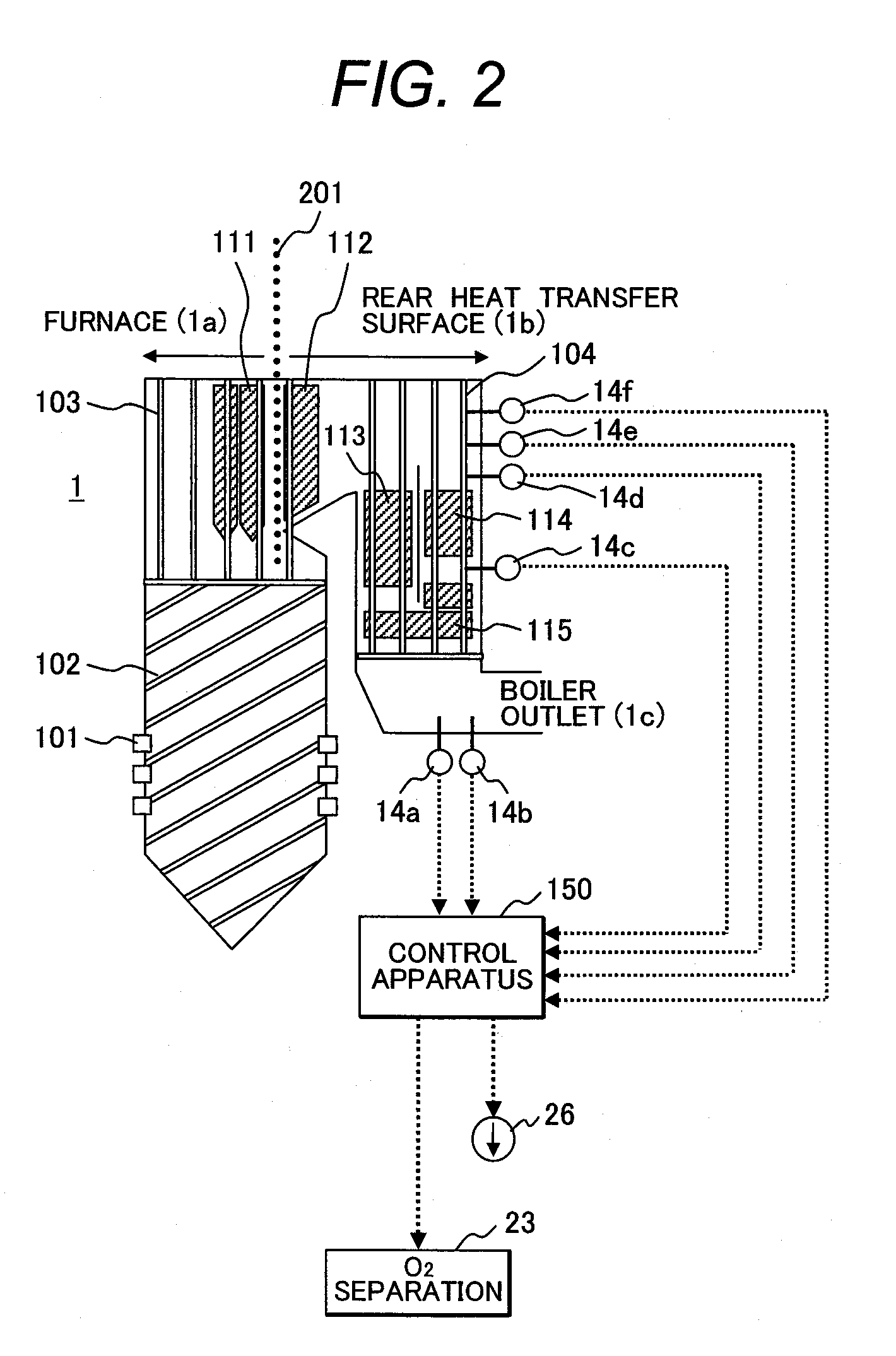

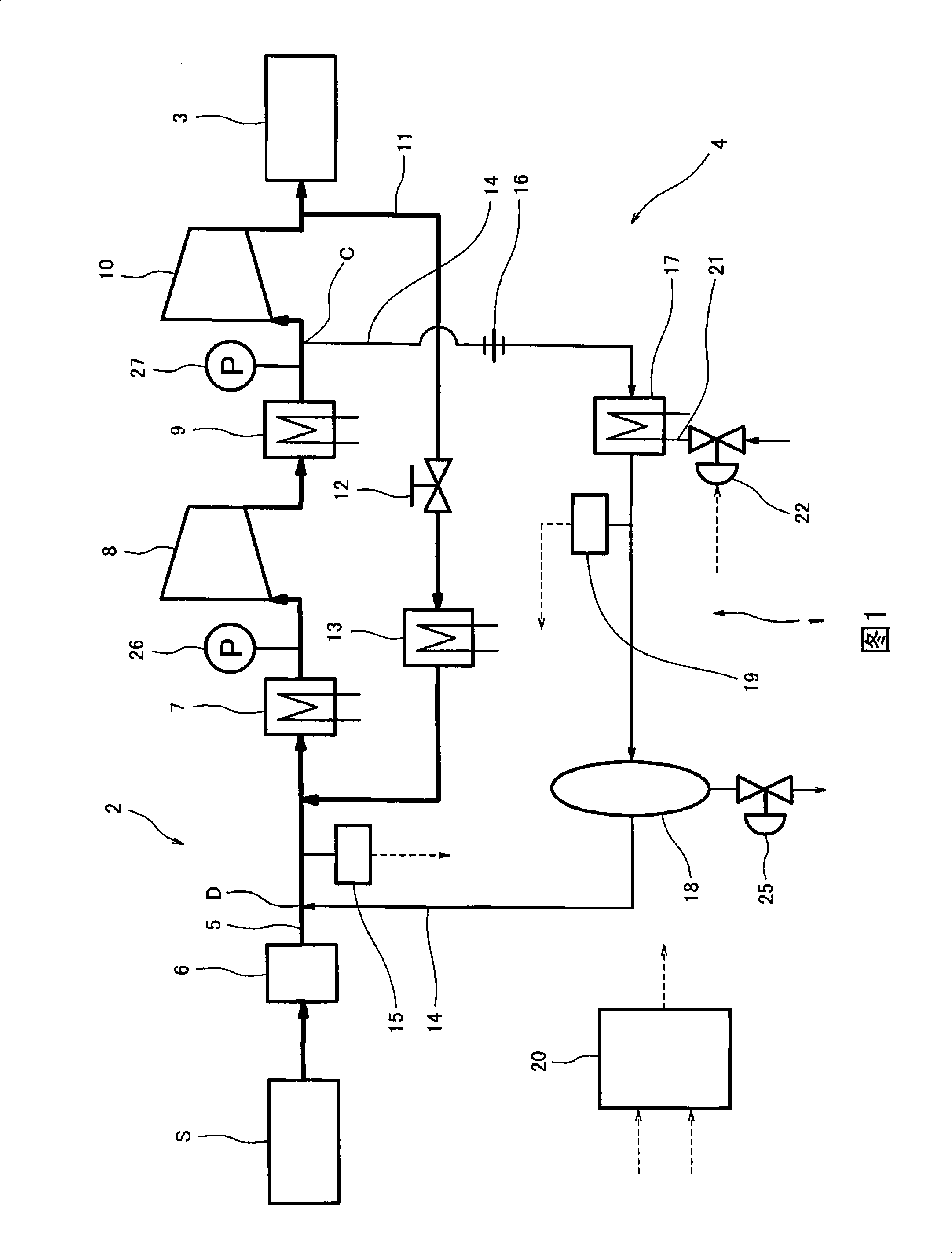

Oxyfuel boiler and a method of controlling the same

ActiveUS8413596B2Reduce restrictionsPrevent slaggingFluegas recirculationDirect carbon-dioxide mitigationCombustionFlue gas

An oxyfuel boiler 1 is equipped with an oxygen separation apparatus 23 to produce oxygen by separating oxygen from the air, a recirculation fan 26 to supply a portion of combustion flue gas branched from the combustion flue gas discharged from the boiler to the oxyfuel boiler 1, a temperature sensor 14a to detect gas temperature at a boiler outlet 1d in the oxyfuel boiler 1, and a control apparatus 150 to calculate gas temperature at a furnace outlet 1c in the boiler from the gas temperature at the boiler outlet 1d detected by the temperature sensor 14a and control the operating condition of the recirculation fan 26 so that the calculated gas temperature at the furnace outlet 1c becomes a desired preset gas temperature.

Owner:MITSUBISHI POWER LTD

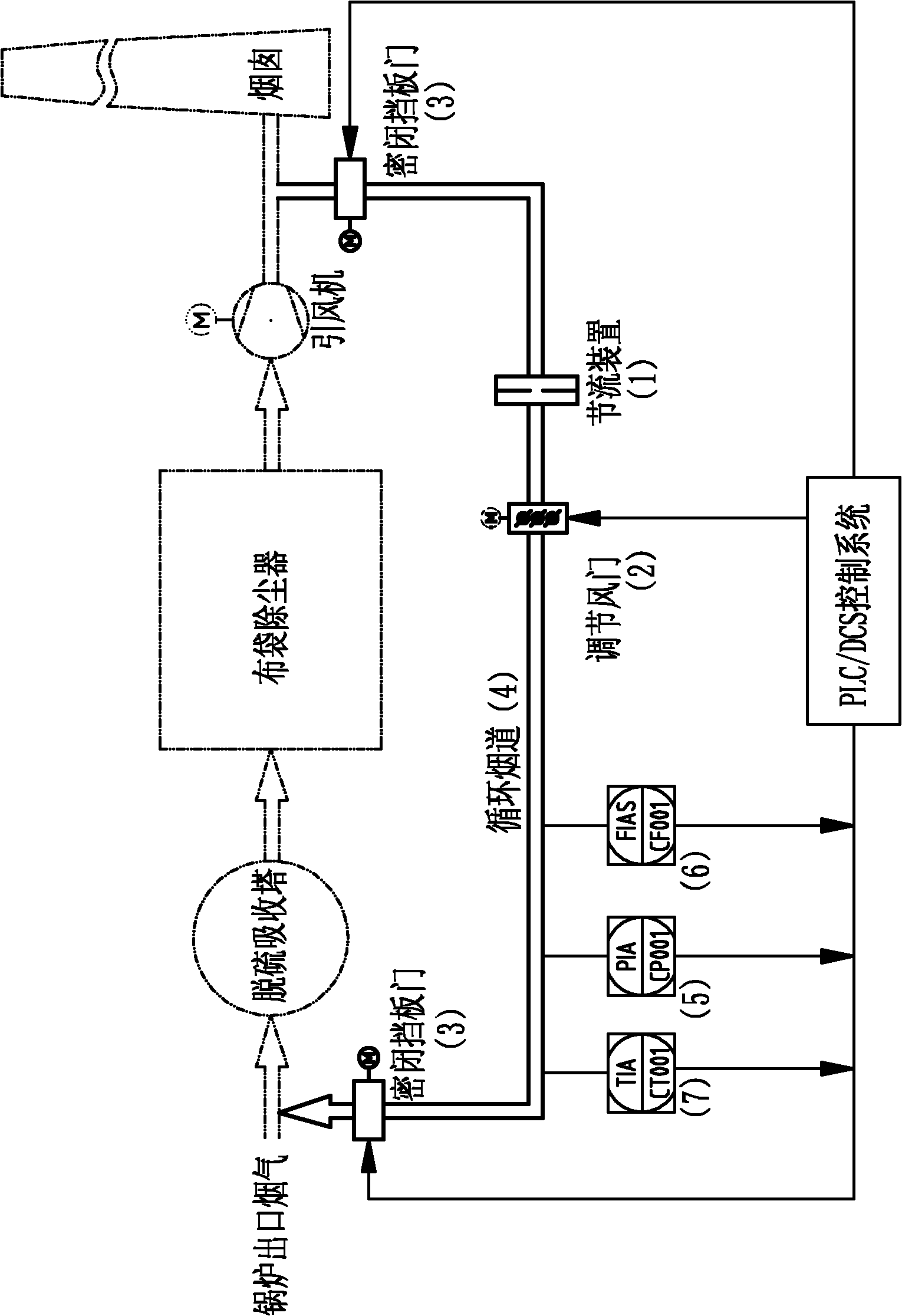

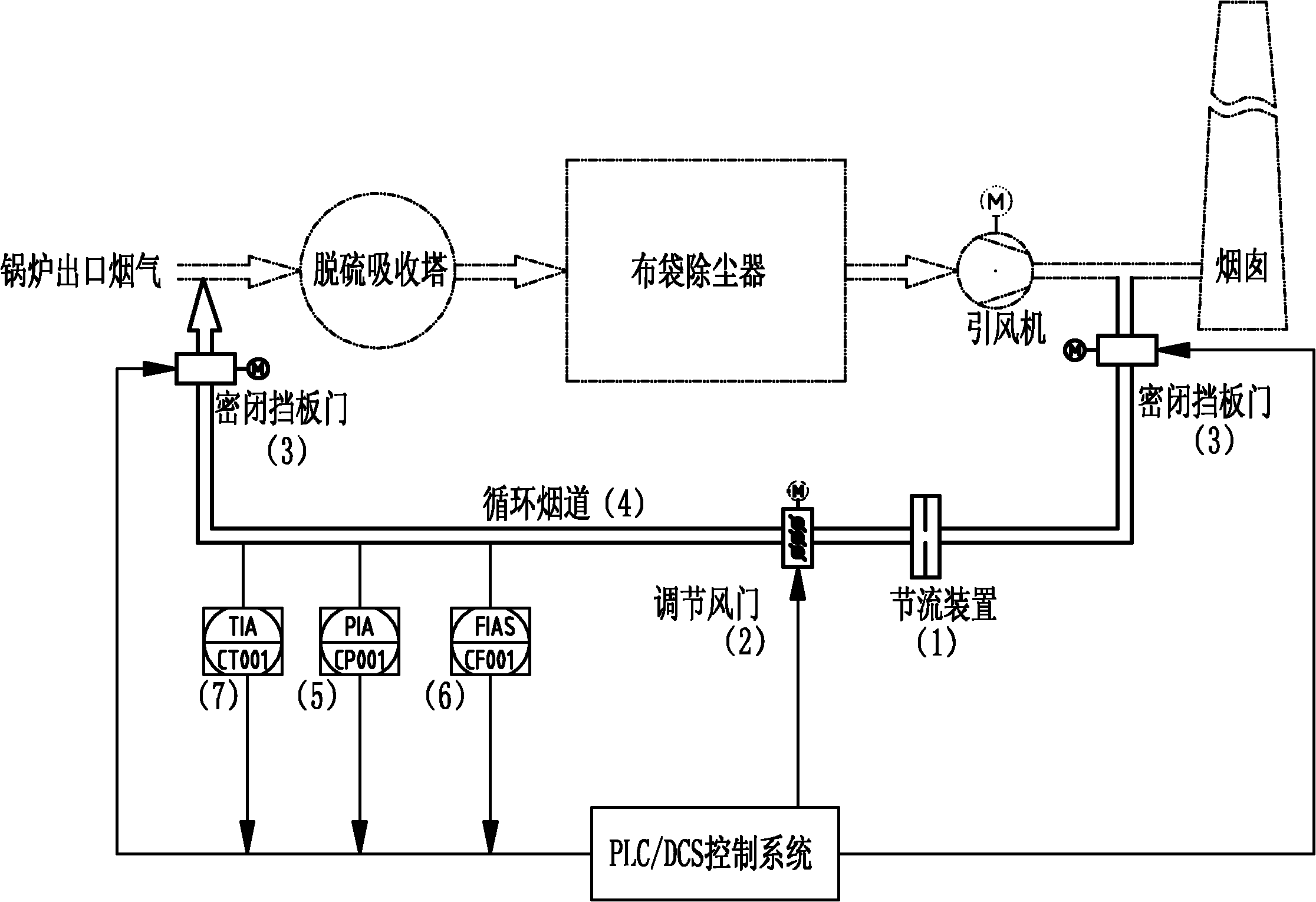

Clean flue gas circulation system

InactiveCN102008871AEasy to adjustConstant inlet pressureDispersed particle separationRefluxFlue gas

The invention discloses a clean flue gas circulation system consisting of a control system and a circulation flue, wherein the circulation flue is arranged between the outlet end of a draft fan and the inlet end of a desulfuration absorption tower. The clean flue gas circulation system is characterized in that a first airtight baffle door, a throttling device, an air damper and a second airtight baffle door are arranged on the circulation flue in sequence, a gas pressure gear, a gas flowmeter and a gas thermometer are arranged between the second airtight baffle door and the air damper, and the control system receives parameters output by the gas pressure meter, the gas flowmeter and the gas thermometer and outputs a result after comparison and calculation; when the calculation result is equal to or lower than a design threshold value, the two airtight baffle doors are opened manually or automatically or the air damper is adjusted at the same time; and when the calculation result is higher than the design threshold value, the two airtight baffle doors are closed manually or automatically. By using the clean flue gas circulation system provided in the invention, clean flue gas reflux quantity and required pressure drop can be adjusted conveniently, and the normal operation of a boil and a desulfuration system is not influenced during the starting or the stop of the system.

Owner:浙江博奇电力科技有限公司

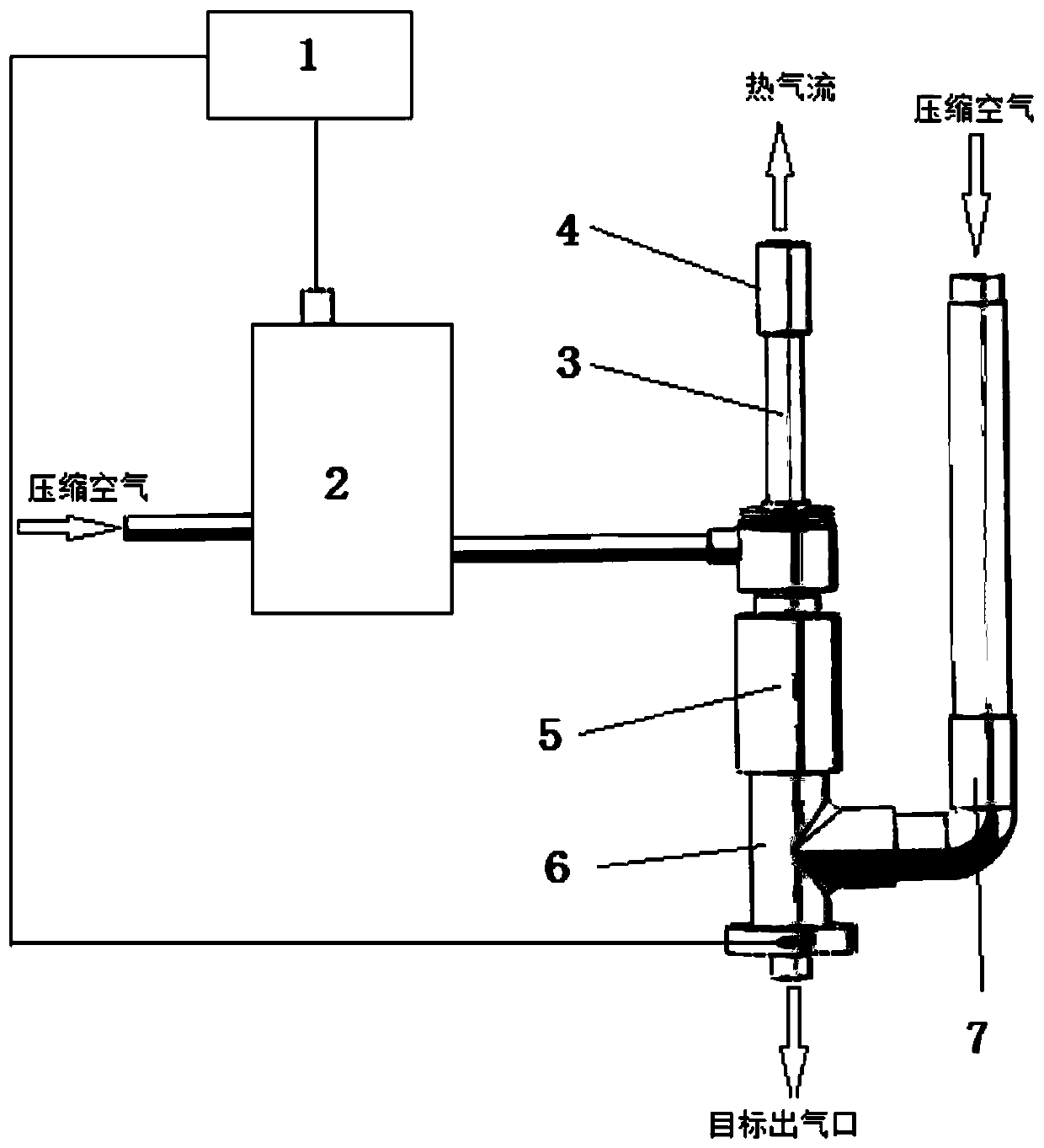

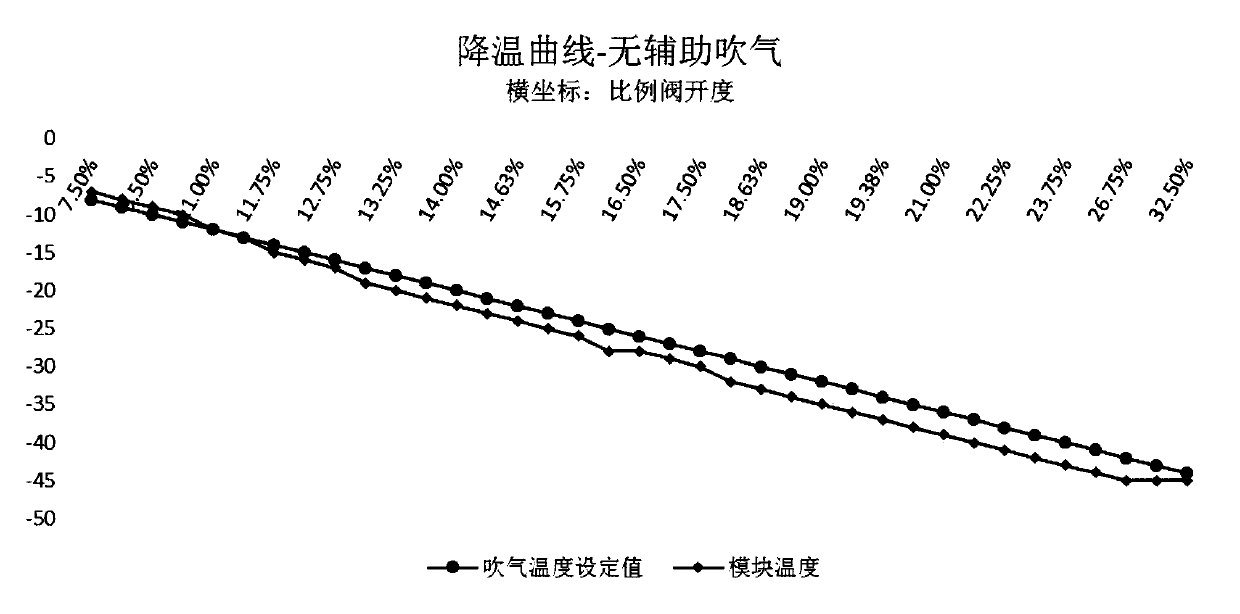

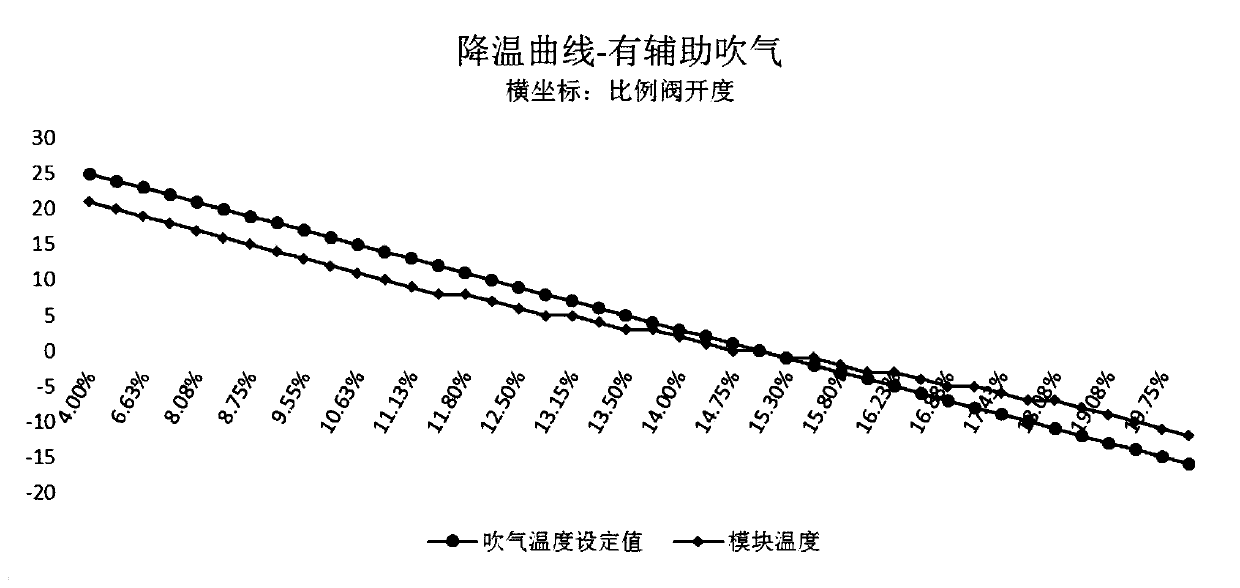

Device and method for low temperature production testing of optical communication module based on vortex tube

InactiveCN110108057APrecise automatic controlReduce use costCompression machinesRefrigeration safety arrangementComputer moduleEngineering

The invention belongs to the technical field of optical communication production testing, and specifically provides a device and method for low temperature production testing of an optical communication module based on a vortex tube. The device comprises a controller, a vortex tube, a gas thermometer, an auxiliary gas passage and a control valve; in a low-temperature mode, when the required gas outlet temperature is high, the auxiliary gas passage is opened, the controller controls the opening degree of the proportional flow control valve according to the gas temperature at a target gas outletto get the gas temperature of the target gas outlet and achieve a certain gas flow rate; and when the vortex tube needs defrosting, the auxiliary gas passage is opened, the proportional flow controlvalve is closed, and a heating tube is opened to defrost or deice. The device has the advantages of simple structure, no moving parts, low use cost and maintenance-free; accurate and automatic controlof the gas outlet temperature and the gas outlet volume at the cold end of the vortex tube is achieved, so that the control accuracy reaches + / - 1 DEG C; and the flow rate of the cold gas in a low-temperature range from 0 DEG C to 9 DEG C is increased, so that the cooling speed requirement of the production testing of the optical communication module is met.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

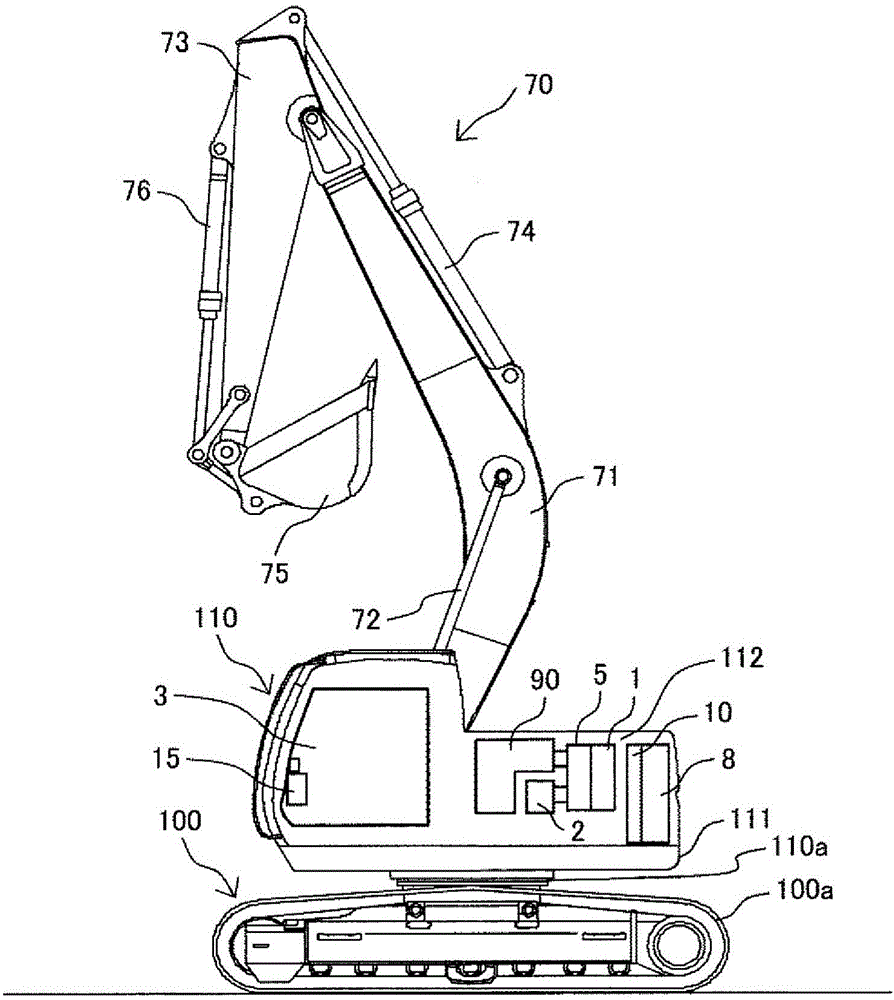

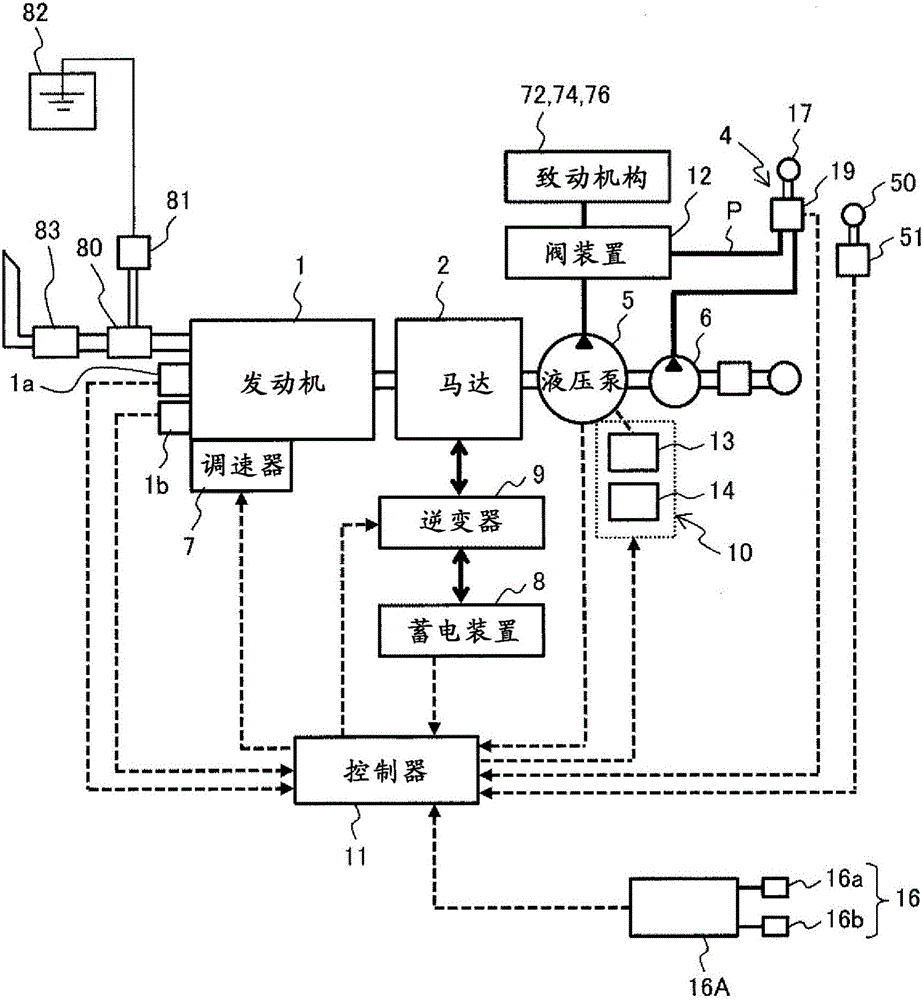

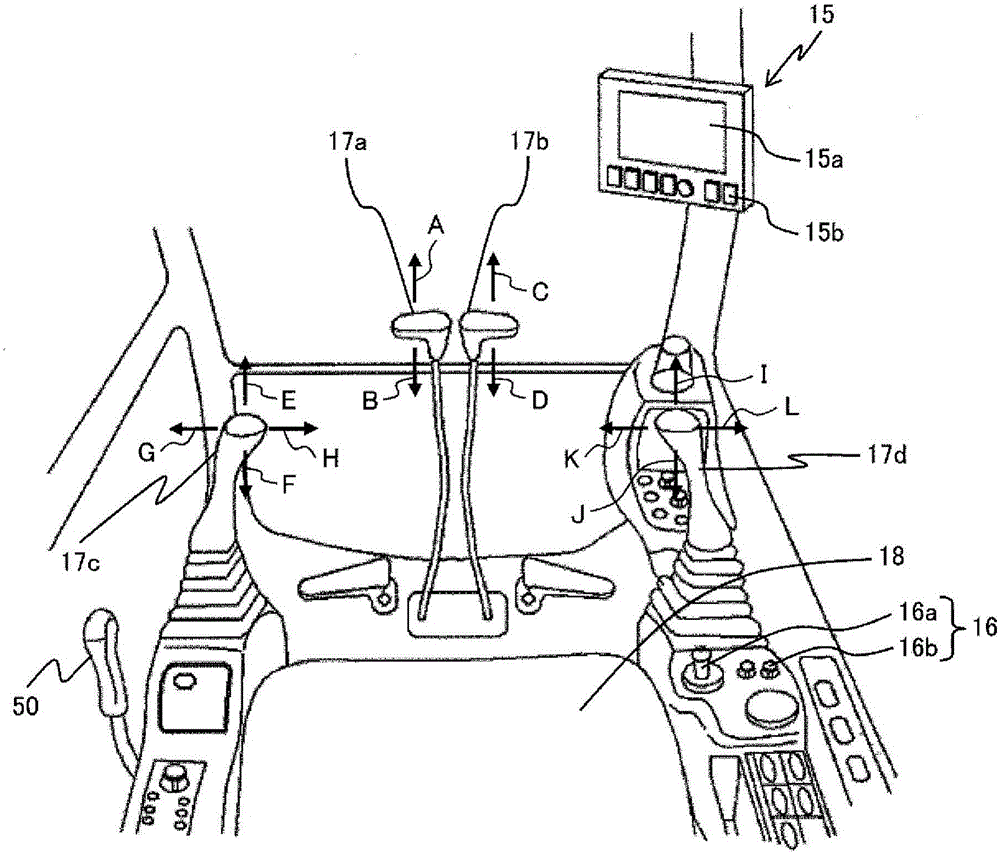

Hybrid construction machine

InactiveCN106795818AWarm up fastExtend your lifeHybrid vehiclesMechanical machines/dredgersMeasurement deviceTransmitted power

The objective of the present invention is to provide a hybrid construction machine wherein a power storage device can quickly be warmed up and the service life of the power storage device can be improved. This hybrid construction machine is equipped with: an engine (1); an electric motor that supplements the power of the engine (1) and generates power; a power storage device (8) that transmits power to and receives power from the electric motor; a warmup circuit (25) that circulates a heating medium heated by waste heat from the engine (1) or the electric motor, or by a heater (40), in the vicinity of the power storage device (8); a control device that controls the charging / discharging of the power storage device (8) and the circulation of the heating medium by the warmup circuit (25); and an outside air temperature measurement device that measures the outside air temperature. The control device performs a warmup operation by means of the heating medium, determines whether to perform charging / discharging of the power storage device (8) for the purpose of a warmup operation, in response to the outside air temperature as measured by the outside air temperature measurement device, and executes a warmup operation wherein the warmup operation based on charging / discharging of the power storage device (8) is performed at the same time.

Owner:NIHON KENKI CO LTD

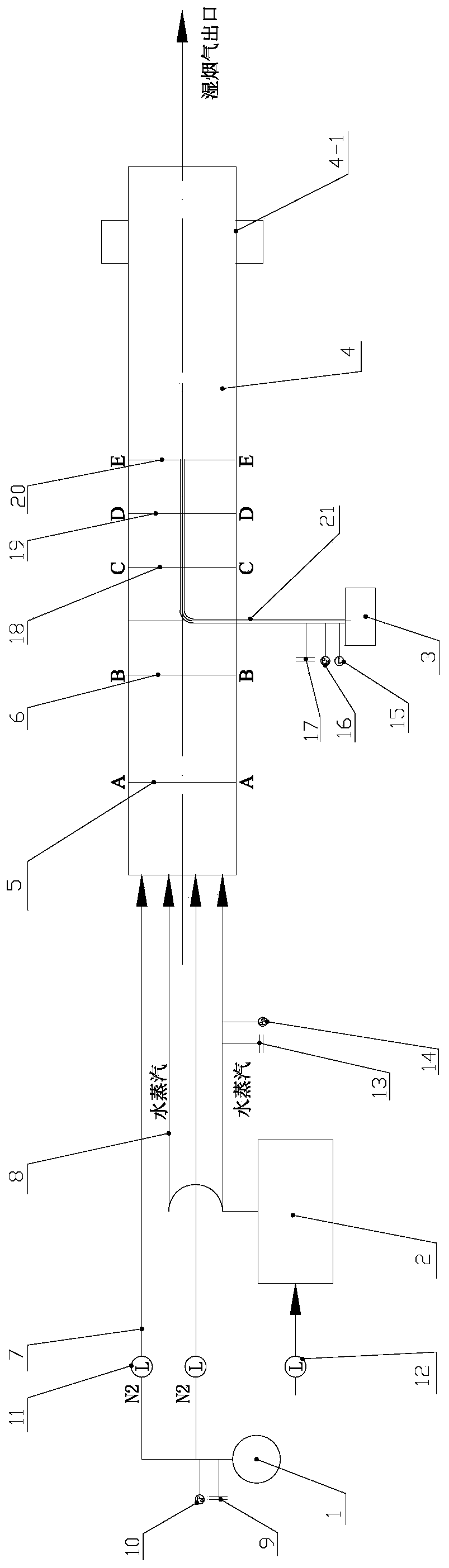

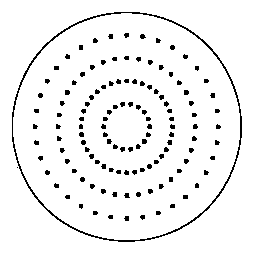

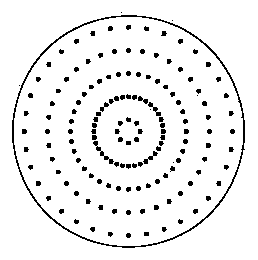

Saturated or supersaturated flue gas moisture content measuring and calibrating device

ActiveCN111220775ASolve the problem of not being able to calibrate accuratelyAccurate CalibrationAnalysing gaseous mixturesWater vaporFlue gas

The invention discloses a saturated or supersaturated flue gas moisture content measuring and calibrating device, and belongs to the technical field of flue gas humidity measuring and calibrating. According to the invention, the problem that the device or the method for calibrating the saturated or supersaturated flue gas moisture content measuring device in the prior art cannot accurately calibrate the saturated or supersaturated flue gas moisture content is solved. The single gas electric heating device conveys heated single gas to the inlet end of the heat insulation flue through at least two single gas pipelines. The electric heating water vapor generator conveys heated water vapor to the inlet end of the heat insulation flue through at least two water vapor pipelines. The at least twosingle gas pipelines and the at least two water vapor pipelines are arranged in an up-and-down staggered manner, a gas thermometer and a gas pressure meter are arranged on an outlet pipeline of the single gas electric heating device, and a gas mass flow meter is arranged on each single gas pipeline; and a first water flow meter is arranged on an inlet pipeline of the electric heating water vaporgenerator.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

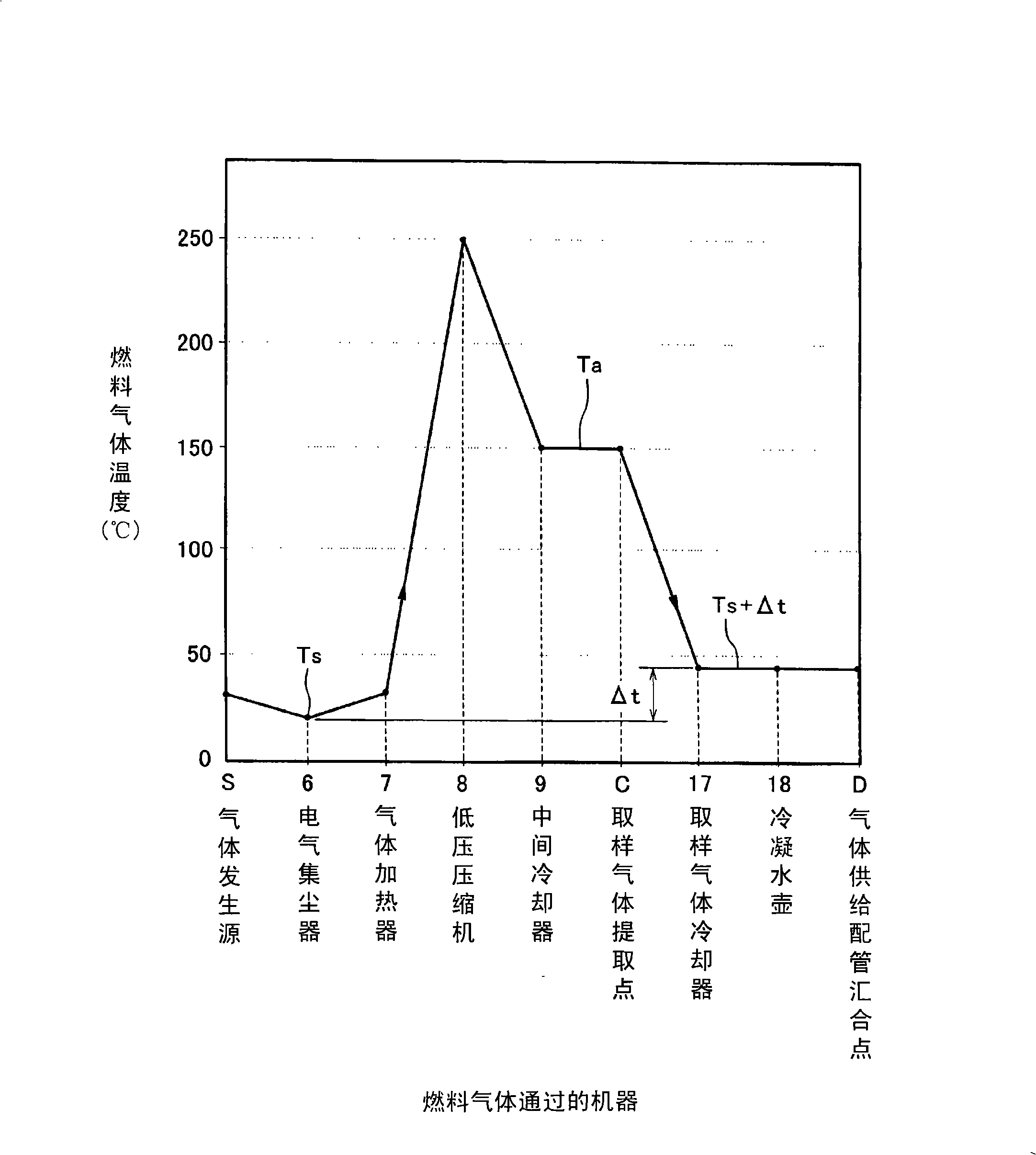

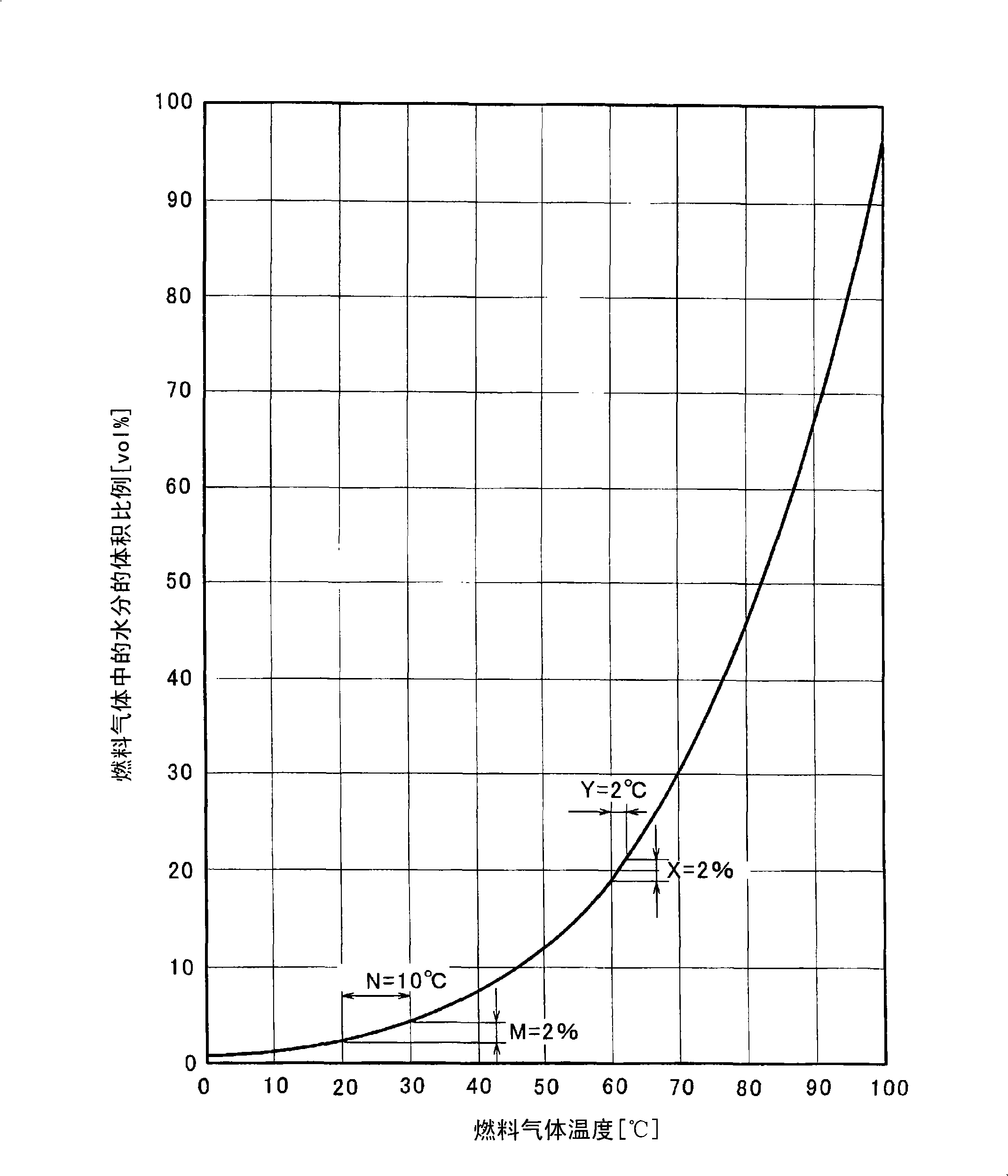

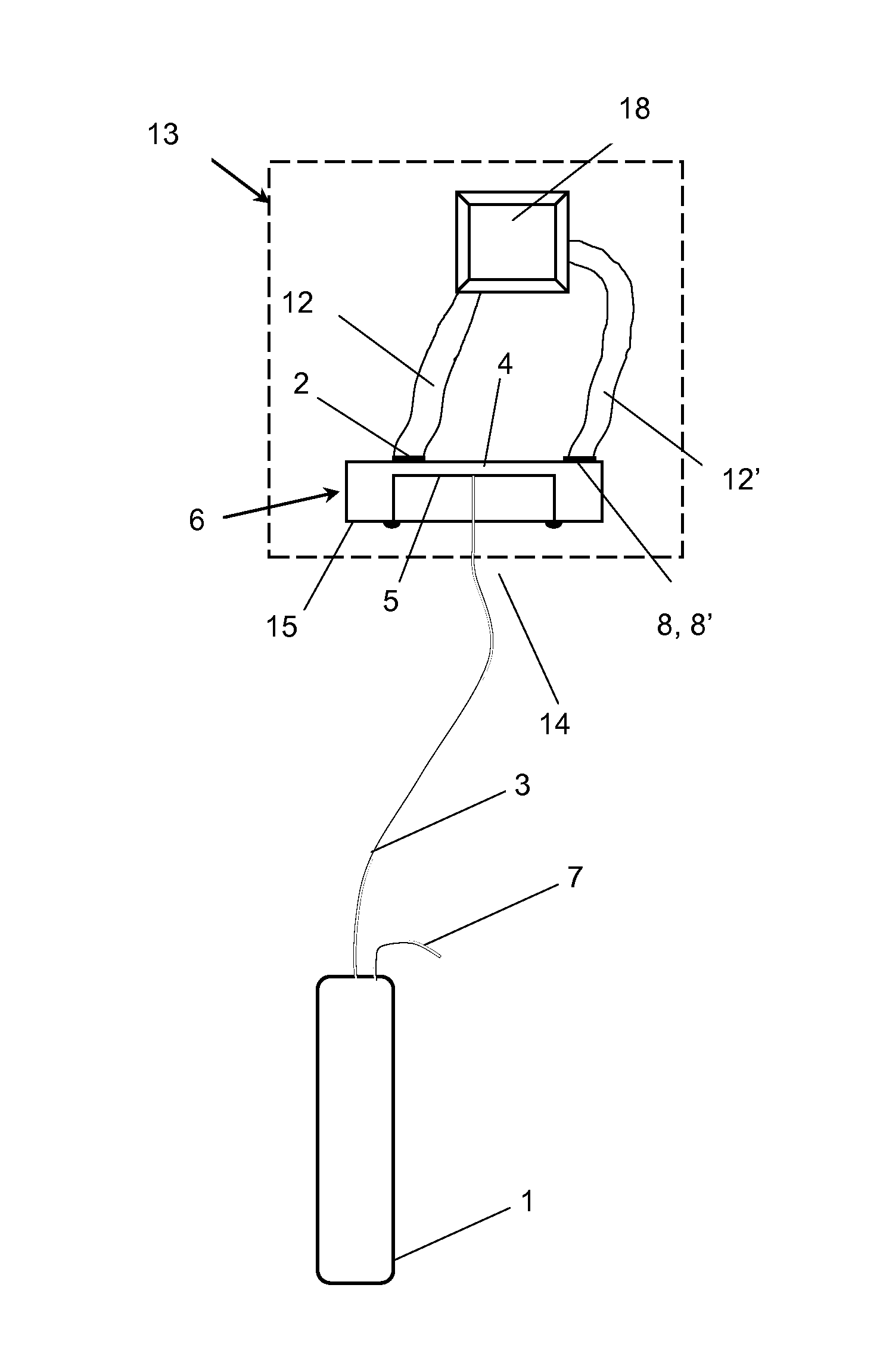

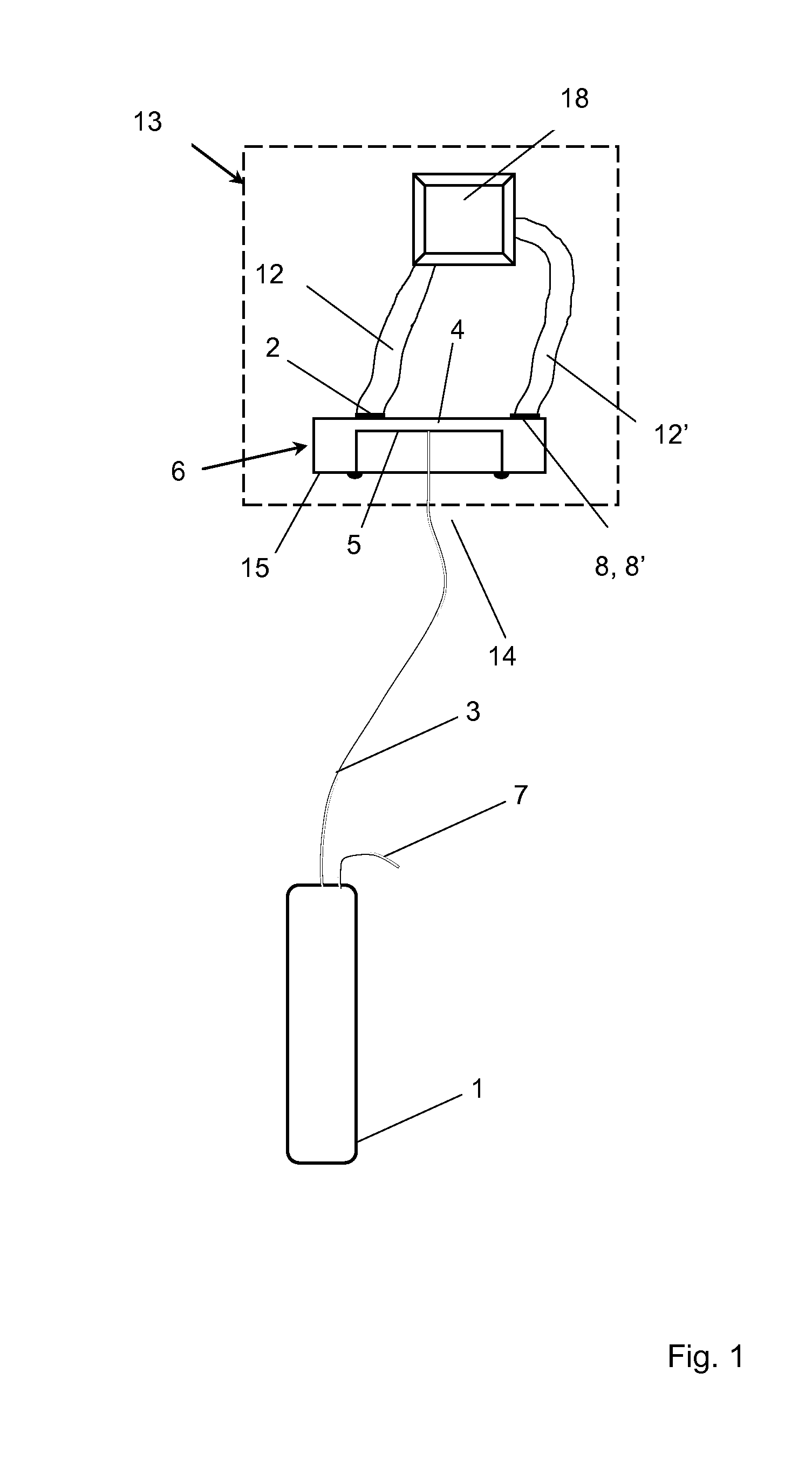

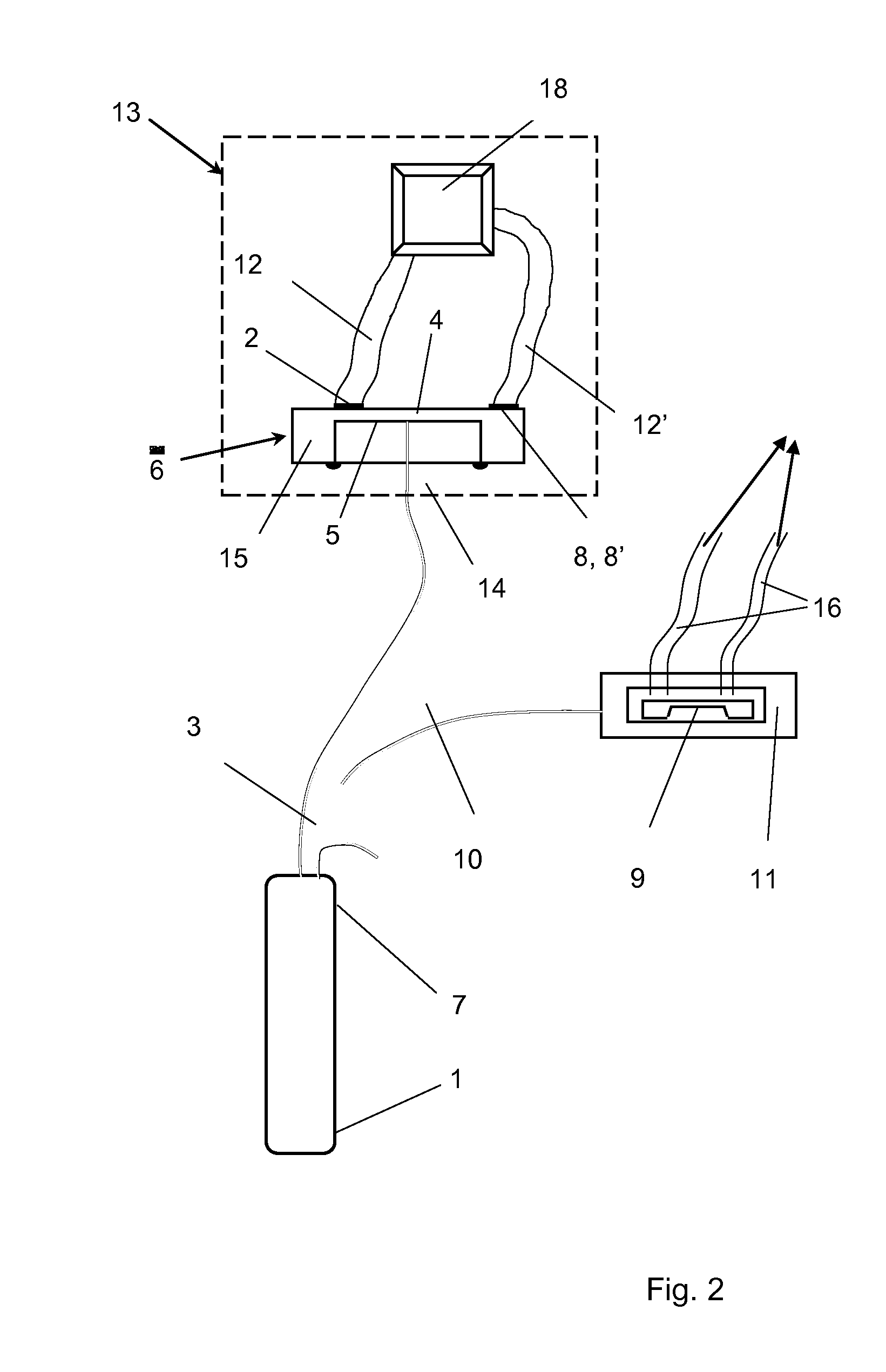

Fuel gas moisture monitoring device and moisture monitoring method

InactiveCN101268366AImprove reliabilitySolution to short lifeFuel testingUsing mechanical meansWater vaporNuclear engineering

Fuel gas moisture monitoring apparatus (1) that has a simple and robust construction and exhibits stable monitoring capability. The fuel gas moisture monitoring apparatus (1) includes gas extraction piping (14) for sampling of an aliquot of fuel gas having been fed to fuel gas supply facilities; fuel gas thermometer (15) disposed at a region of fuel gas supply piping (5) where the fuel gas is set for the state of steam saturation; squeezing member (16) for reducing of the pressure of gas having been sampled by the gas extraction piping (14) to substantially the same pressure as the steam saturation pressure at the temperature detected by the fuel gas thermometer (15); sample gas cooler (13) for adjusting of the temperature of the sample gas having been brought to substantially the same pressure as the steam saturation pressure to the temperature in the vicinity of the temperature detected by the fuel gas thermometer (15); and drain pot (18) fitted with a drain detector for detecting of any water condensed from the sample gas.

Owner:KAWASAKI HEAVY IND LTD

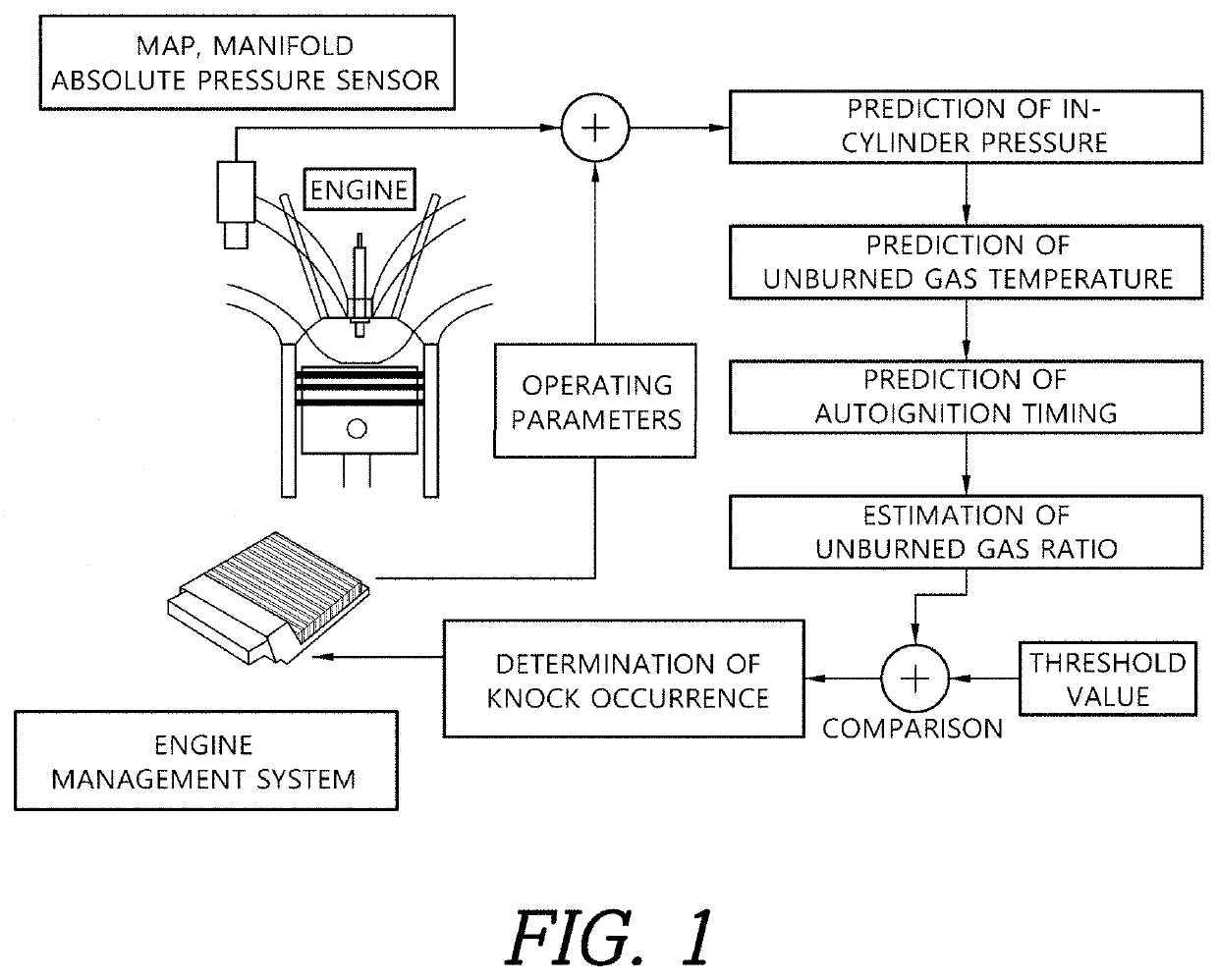

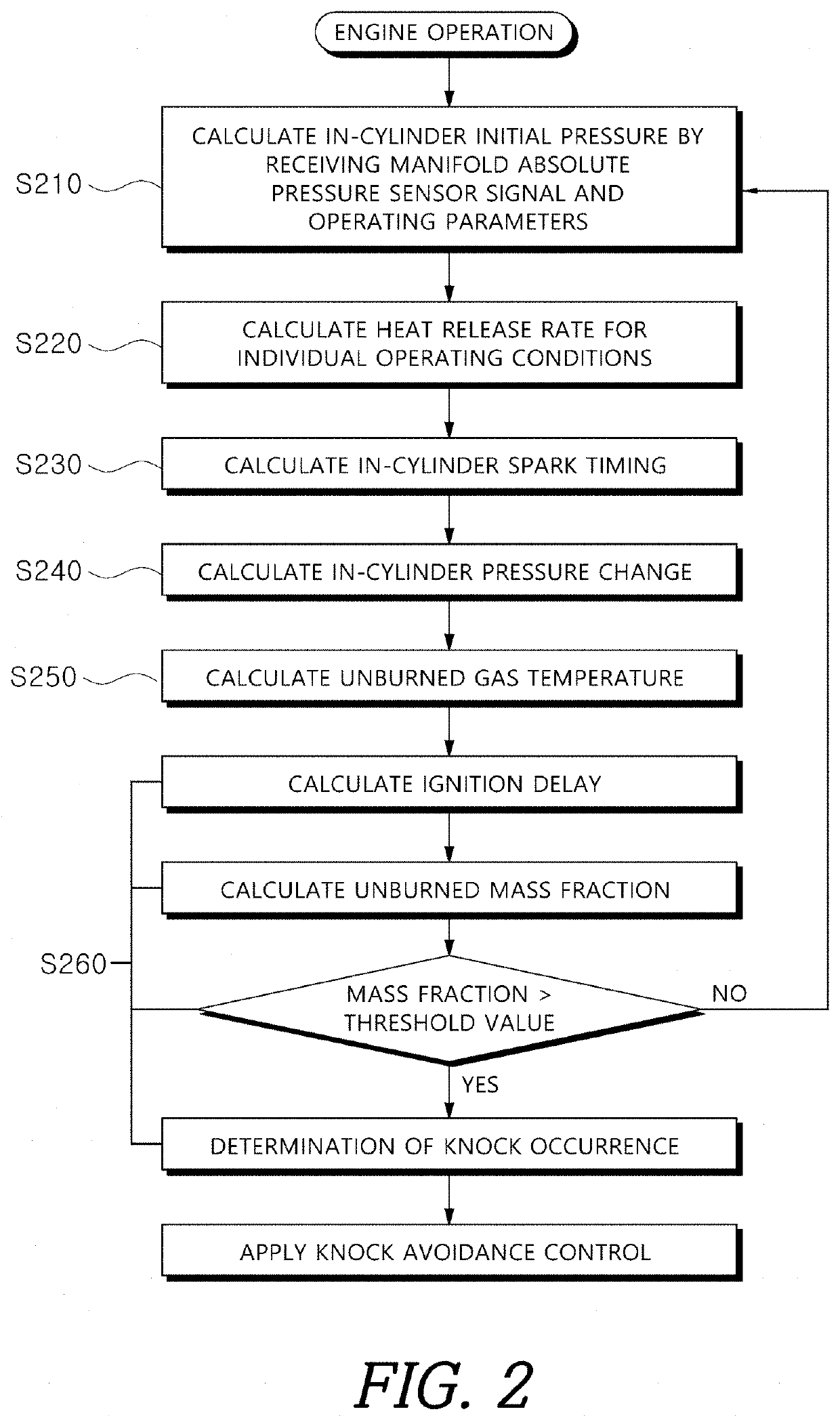

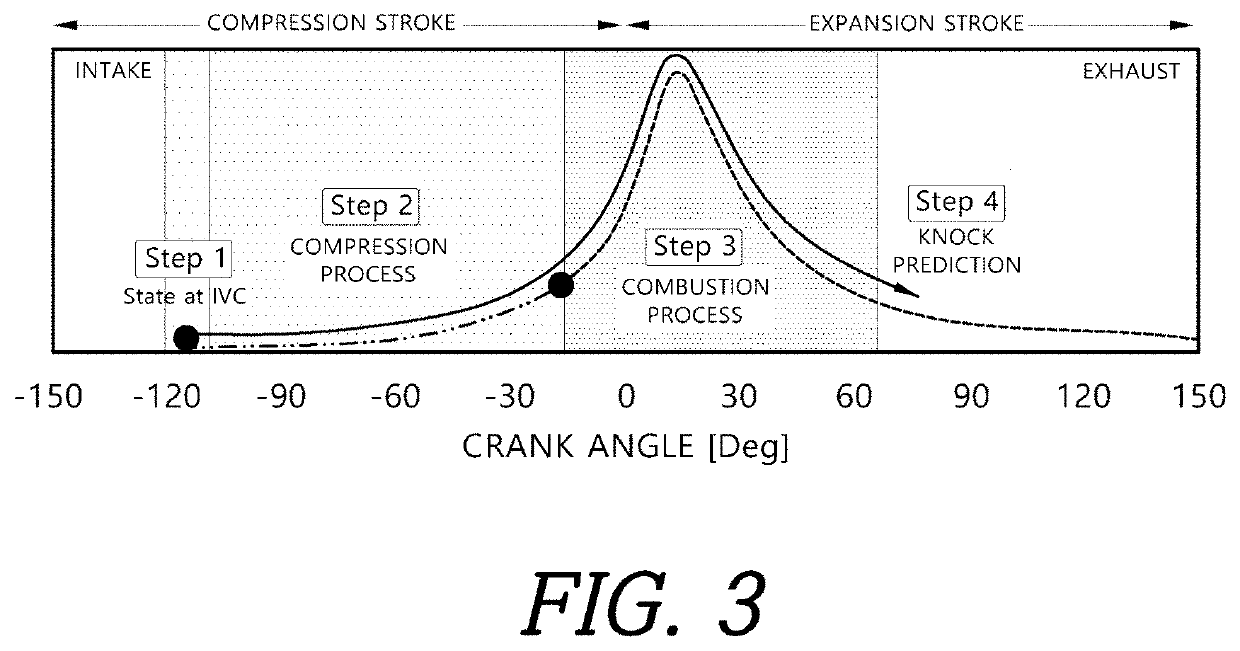

Method of predicting occurrence of engine knocking

Disclosed herein is a method of predicting engine knocking, which includes calculating initial pressure in cylinder based on operating data and pressure in intake manifold measured using manifold absolute pressure sensor, calculating pressure at spark timing in the cylinder by interpreting compression process as polytropic process based on the calculated initial pressure in the cylinder, calculating heat release rate for individual operating conditions based on the calculated pressure in the cylinder at spark timing, calculating pressure change in the cylinder based on the calculated heat release rate, calculating unburned gas temperature in adiabatic compression process based on the calculated pressure change in the cylinder, and determining whether knock occurs by calculating ignition delay based on the calculated unburned gas temperature and calculating unburned gas mass fraction at crank angle at the end of the ignition delay.

Owner:SEOUL NAT UNIV R&DB FOUND

Wide-range precision constant volume gas thermometer

InactiveUS20150030054A1Improve accuracyHigh precision measurementThermometers using material expansion/contactionThermometers using electric/magnetic elementsMeasurement deviceHeating power

A Constant Volume Gas Thermometer (CVTG) device for measuring the temperature with high precision over a wide temperature range comprises a pressure measurement device, which comprises a mechanical assembly forming a membrane. The capillary tube communicates with the bottom side of the membrane and a first pressure measurement element on the membrane generates a signal in dependence of a deformation of the membrane. Further, the CVTG comprises electronic means for reading and correlating the signal of said first pressure measurement element to the temperature of the gas cartridge. The gas volume inside the pressure measurement device is minimized by careful design and tight tolerances. To measure pressures below 0.1 MPa inside the CVGT with sufficient accuracy, the CVGT include a second pressure measurement device which is based on the Pirani measurement principle. A Pirani measurement device measures the thermal conductivity of the surrounding gas. To this end, a thermally insulated wire or surface is heated electrically to a defined temperature, while the surrounding gas is at ambient temperature. If the thermal conductivity of the surrounding gas changes, either the Pirani element's temperature changes, or the electrical heating power needs to be adapted in order to maintain the Pirani element's temperature.

Owner:RUEGER

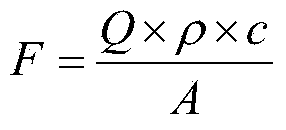

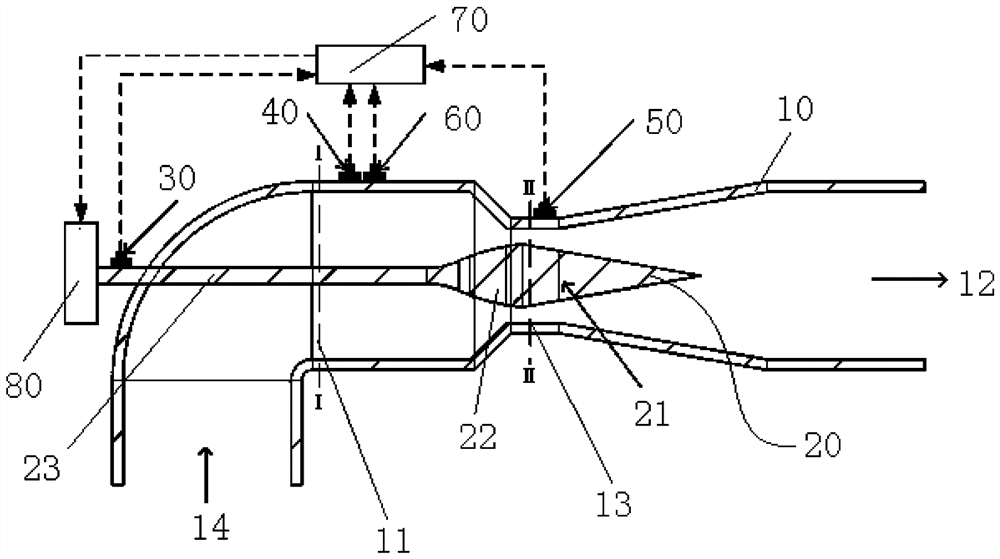

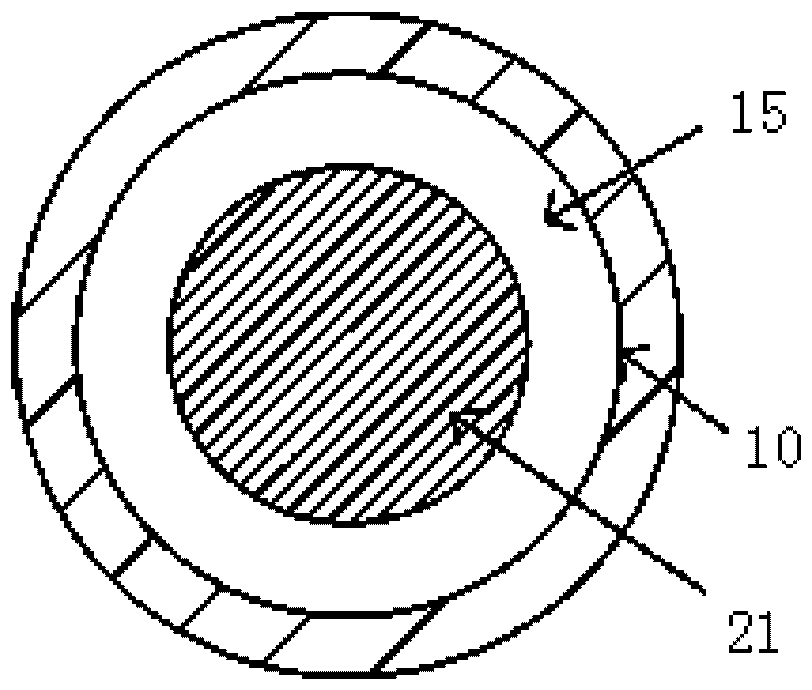

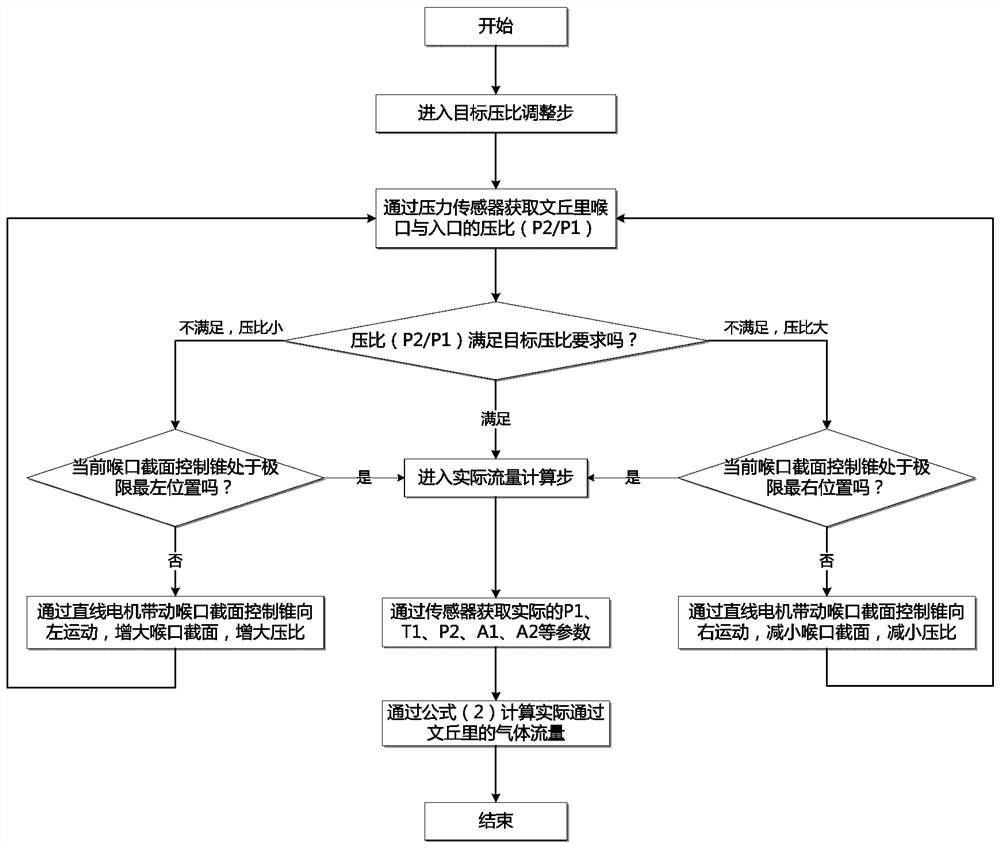

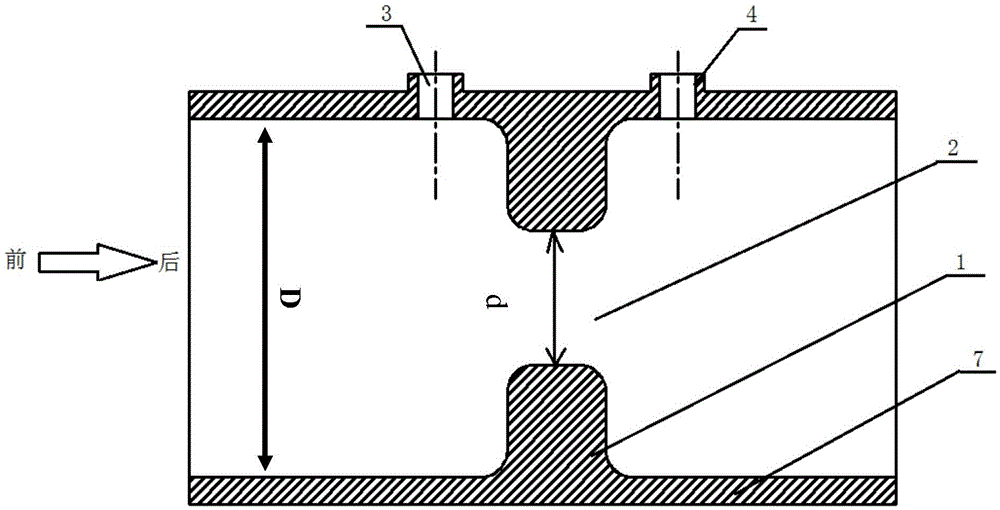

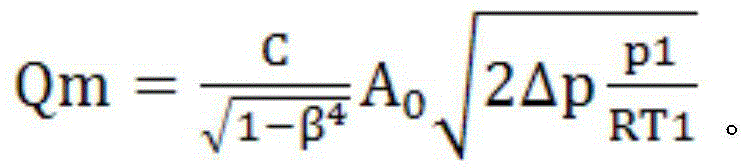

Flow measurement method of Venturi tube

InactiveCN114413979AMeeting Accurate Flow Measurement NeedsChange the flow cross sectionVolume/mass flow by differential pressureEngineeringMechanical engineering

The invention provides a venturi tube flow measurement method, which comprises the following steps: acquiring a pressure ratio between a throat of a venturi tube and an inlet of the venturi tube, and comparing the acquired pressure ratio with a preset pressure ratio range; according to the comparison result of the pressure ratio and the preset pressure ratio range, the position of an adjusting piece of the Venturi tube is adjusted, so that the adjusted pressure ratio is within the preset pressure ratio range; and calculating the gas flow of the venturi tube according to the detected cross-sectional area A1 of the inlet of the venturi tube, the detected cross-sectional area A2 of the throat of the venturi tube, the gas pressure P1 at the inlet of the venturi tube and the gas temperature T1 at the inlet of the venturi tube. Through the technical scheme provided by the invention, the technical problem of inaccurate flow measurement of the Venturi tube in the prior art can be solved.

Owner:WEICHAI POWER CO LTD

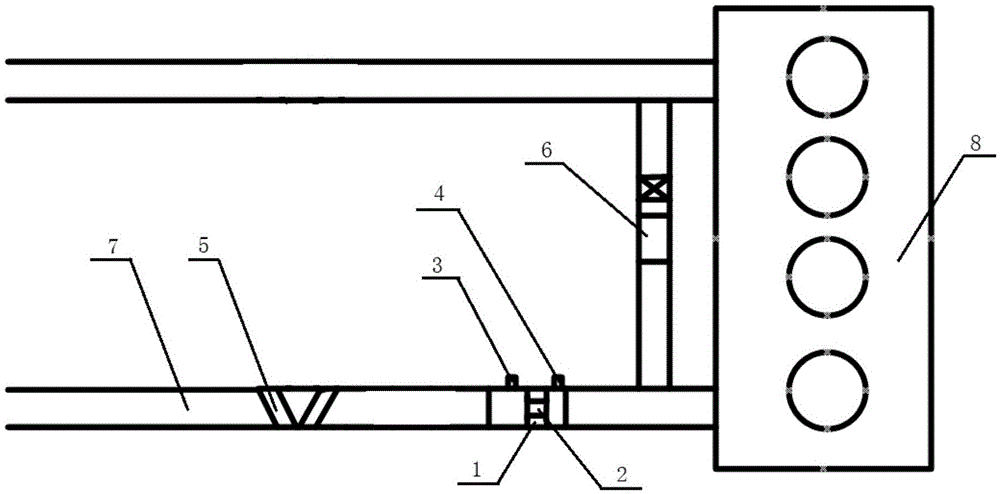

Device for measuring air intake flow of engine

InactiveCN105547381ASimple structureReduce axial sizeVolume meteringVolume/mass flow by differential pressureEngineeringInlet pressure

The invention provides a device for measuring the air intake flow of an engine. The device is basically not affected by a pipeline, and relative to a Venturi tube, the device has an extremely small axial dimension, and is simple in structure and more convenient and rapider to use. The measuring device comprises a pore plate, the pore plate is provided with an orifice communicated with an air intake tube of the engine, a first detection port and a second detection port are formed in the upstream portion and the downstream portion of the orifice respectively, the first detection port is used for detecting the inlet pressure of the orifice and the gas temperature of an inlet, the second detection port is used for detecting the outlet pressure of the orifice, and then the air intake flow is calculated according to the inlet pressure, the outlet pressure and the gas temperature of the inlet. The influences of pipeline arrangement of the upstream portion and the downstream portion of the pore plate on measurement are small, the structure of the pore plate is simple, especially the axial dimension is small, the requirements for installation space are low, needed installation space is small, and the device can be better suitable for measurement of the air intake flow of the engine.

Owner:WEICHAI POWER CO LTD

Ultrasonic apparatus and method for measuring the concentration and flow rate of gas

ActiveCN100374826CAnalysing fluids using sonic/ultrasonic/infrasonic wavesVolume/mass flow measurementUltrasound devicePropagation time

The present invention provides an ultrasonic apparatus measures the concentration and flow rate of a sample gas by calculating a possible propagation time range on the basis of the gas temperature, determining whether or not the phases at which two first trigger signals, respectively generated on the basis of forward and backward waveforms of the ultrasonic waves, coincide with each other, processing the zero-cross signals so that the phases coincide with each other, obtaining reference zero-cross time instant by calculating mean value of the forward and backward zero-cross time instants, obtaining an ultrasonic reception point by subtracting an integral multiple of the cycle of the ultrasonic waves so that the results of the subtraction falls into a possible propagation time range and estimating the ultrasonic propagation time on the basis of the ultrasonic reception point.

Owner:TEIJIN LTD

Gas spray cooling system arranged in front of gas holder

ActiveCN106399610AGive full play to the cooling effectGive full play to heat dissipationBlast furnace componentsBlast furnace detailsElectricityFrequency conversion

The invention provides a gas spray cooling system arranged in front of a gas holder, and belongs to the technical field of the gas holder and pipeline projects. The system comprises the gas holder, a gas pipeline outside the gas holder and a gas spray cooling device; the gas holder comprises a cylinder body and a gas pipeline inside the gas holder; and the gas spray cooling device comprises a plurality of sets of spray guns, a PLC frequency conversion control cabinet and a gas thermometer inside the gas holder, and the gas thermometer inside the gas holder is arranged at the lower part of the cylinder body of the gas holder, is electrically connected to the PLC frequency conversion control cabinet and is used for monitoring the temperature of gas in the gas holder and participating in start and stop control over the gas spray cooling device. According to the system, a monitoring point of the temperature of the gas in the gas holder is additionally arranged, the gas spray cooling device is started when the temperature in the gas holder exceeds a set value, and therefore the potential mixing and cooling function and the heat dissipation ability of the gas holder are given full play to. The system is of great significance for saving energy and lowering consumption of iron and steel enterprises and prolonging the service life of sealing oil of the gas holder.

Owner:CISDI ENG CO LTD

Multi-functional gas sampling system and gas sampling method

The invention discloses a multi-functional gas sampling system and a gas sampling method in the field of gas sampling devices. The system adopts the structure that a gas inlet opening and a gas outlet opening of an off-gas pump are respectively connected with a first switching valve and a second switching valve, an overvoltage protection valve and a gas collecting opening are arranged between thefirst switching valve and the second switching valve, and a gas thermometer, an integrating flowmeter, a water drain pipe, a dust collecting pipe and a gas inlet opening which are connected in seriesin sequence are connected on a connector opposite to a connector of the first switching valve and the overvoltage protection valve. The gas sampling method comprises the following steps: 1. processing gas to be sampled for a gas sampling pipeline by a prepumping gas passage; 2. cleaning a gas sampling bag; and 3. collecting the gas. The filtrating and the dehydrating are performed to the gas required for analysis, and then the gas is transformed into dried gas to be filled in a special gas container so as to ensure that the gas is in a stable state; the volume and the total mass of the dried gas are accurately measured, and the analyzed gas is accurately measured and analyzed; and the invention is suitable for sampling combustible gas, atmosphere, biological metabolites and tail gas in chemical plants, and the like.

Owner:TSINGHUA UNIV

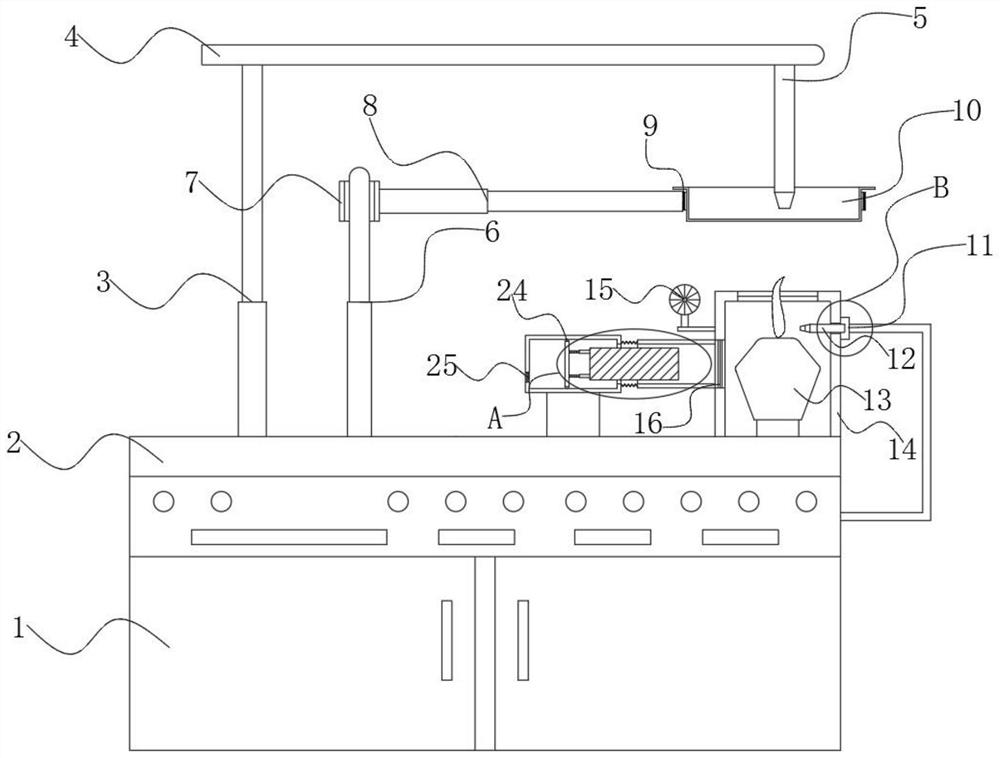

Device for monitoring and early warning papain

PendingCN114317260AImprove continuityImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature monitoringBiochemistry

The invention discloses a papain monitoring and early warning device which comprises an automatic biochemical analyzer, an experiment table is fixedly arranged at the top of the automatic biochemical analyzer, a first telescopic rod is fixedly arranged at the top of the experiment table, and a top plate is fixedly arranged at the top of the output end of the first telescopic rod. The papain milk vessel and the enzyme activity detector are arranged, the enzyme activity detector is used for detecting the enzyme activity of papain in papain milk in the papain milk vessel, and then the temperature in the lampshade is observed through the temperature monitor; the temperature monitor and the gas thermometer are matched for monitoring internal and external temperatures, so that the milk heating temperature in the papain milk vessel by the alcohol lamp is obtained, and the situation that the papain milk in the papain milk vessel is heated to disappear due to the fact that the temperature is too high when the enzyme activity degree is continuously detected is prevented; the continuity and the stability of the papain during continuous monitoring are improved.

Owner:GUANGXI SUBTROPICAL CROPS RES INST GUANGXI SUBTROPICAL AGRI PROD PROCESSING RES INST

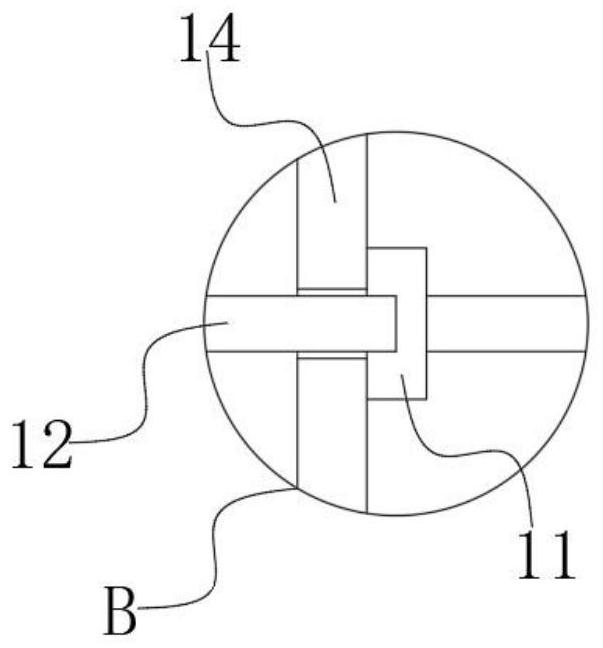

Anti-permeation equipment for gas thermometer

Anti-permeation equipment for a gas thermometer is disclosed, and comprises an anti-permeation module, a base frame, a rivet assembly, and a diffusion device. The equipment employs an adaptive electronic check sealing device and a reaction buffer part. The control element of the equipment tests the permeation density by passing the gas flow from the inner layer pipe by means of a test piston and a rod-shaped pin member. The test piston is a series multi-stage electromagnetic switch inspection piston. The equipment effectively irons out a defect that equipment just can test strip-like anti-seepage components in a staged manner, and cannot be carry out the testing of strip-like anti-seepage components at a time.

Owner:南京多旺温室工程有限公司

Time-sharing ignition control algorithm and system based on pressure self-stabilizing design

ActiveCN106121866BSmall pressure fluctuation rangeImprove utilization efficiencyRocket engine plantsAttitude controlTime-sharing

The invention discloses a time-sharing ignition control algorithm and system based on the pressure self-stabilization design. The algorithm comprises the steps that exhaust gas flow Qo and time to are predicted through a power device gas kinetic model according to the working condition and operating characteristics of a solid attitude control engine; pressure P of a gas storage container is collected in real time, and the effective gas production amount M in the gas storage container is calculated through an effective gas amount calculation model of the gas storage container; a gas temperature T in the gas storage container is calculated through a gas storage container gas temperature calculation model, and a pressure threshold value is corrected according to the gas temperature T; and based on the principle of using gas input and output to achieve optimum matching, the ignition number and time of a pulse working unit of the solid attitude control engine can be determined by using a control algorithm to compare M with Qo, to and compare P with the pressure threshold value. By the adoption of the algorithm and system, optimum matching between gas production amount pulse input and exhaust gas amount intermittent output is realized, and therefore the pressure fluctuation range of the gas storage container can be made smaller, and gas utilization efficiency is higher.

Owner:湖北三江航天红林探控有限公司

A gas spray cooling system in front of the gas cabinet

ActiveCN106399610BExtended service lifeBlast furnace componentsBlast furnace detailsElectricityFrequency conversion

The invention provides a gas spray cooling system arranged in front of a gas holder, and belongs to the technical field of the gas holder and pipeline projects. The system comprises the gas holder, a gas pipeline outside the gas holder and a gas spray cooling device; the gas holder comprises a cylinder body and a gas pipeline inside the gas holder; and the gas spray cooling device comprises a plurality of sets of spray guns, a PLC frequency conversion control cabinet and a gas thermometer inside the gas holder, and the gas thermometer inside the gas holder is arranged at the lower part of the cylinder body of the gas holder, is electrically connected to the PLC frequency conversion control cabinet and is used for monitoring the temperature of gas in the gas holder and participating in start and stop control over the gas spray cooling device. According to the system, a monitoring point of the temperature of the gas in the gas holder is additionally arranged, the gas spray cooling device is started when the temperature in the gas holder exceeds a set value, and therefore the potential mixing and cooling function and the heat dissipation ability of the gas holder are given full play to. The system is of great significance for saving energy and lowering consumption of iron and steel enterprises and prolonging the service life of sealing oil of the gas holder.

Owner:CISDI ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com