Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

400 results about "Exhaust gas sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

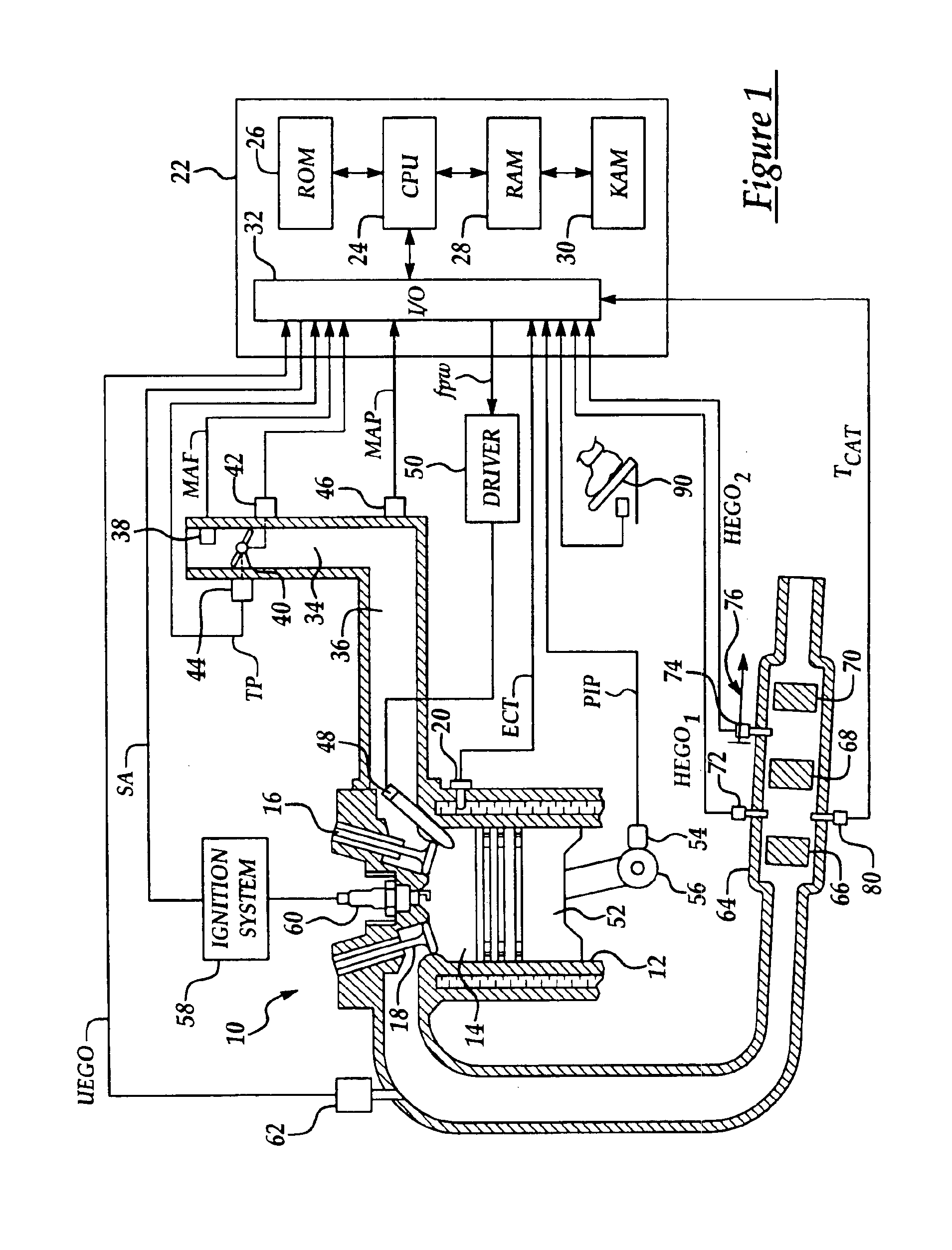

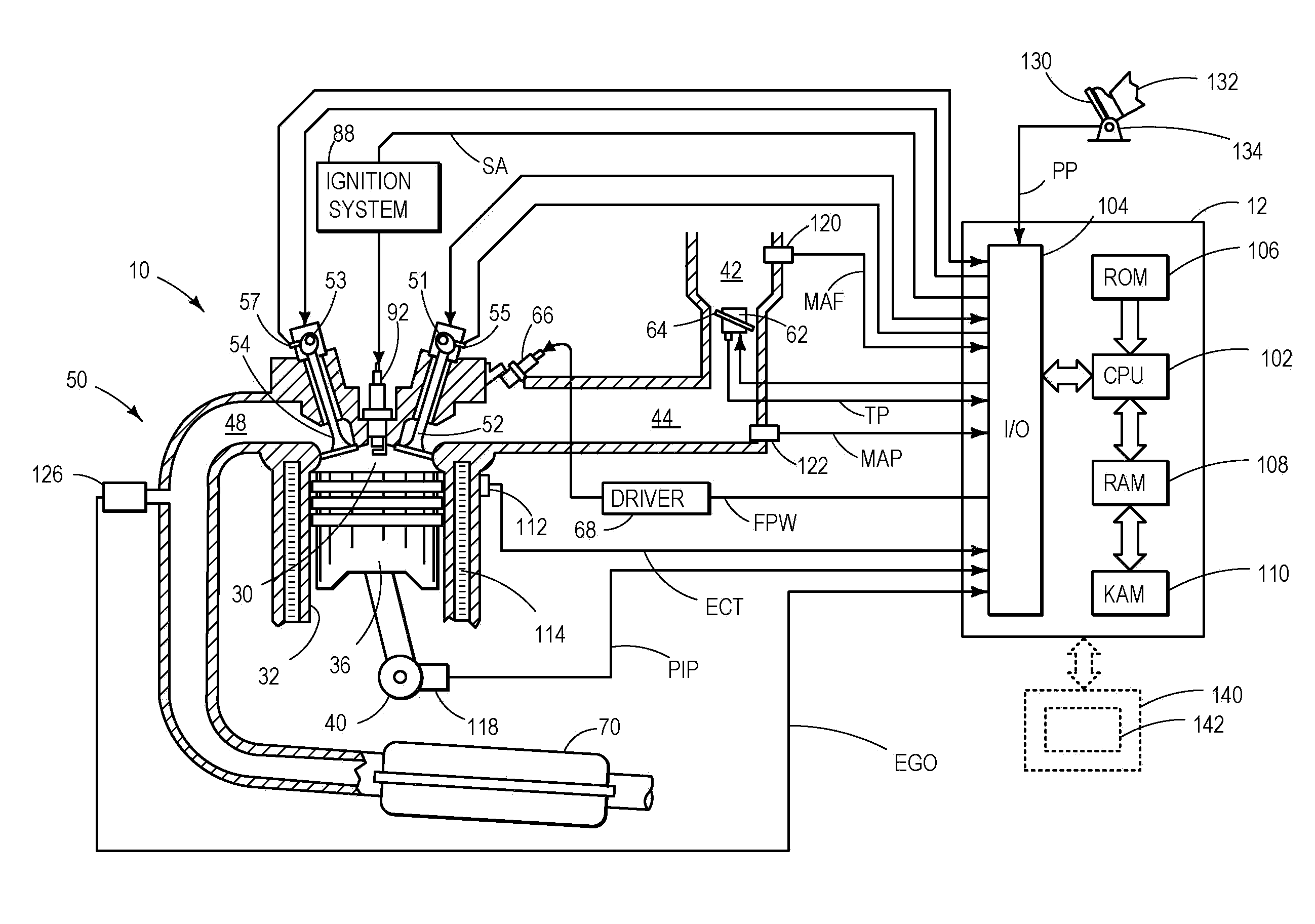

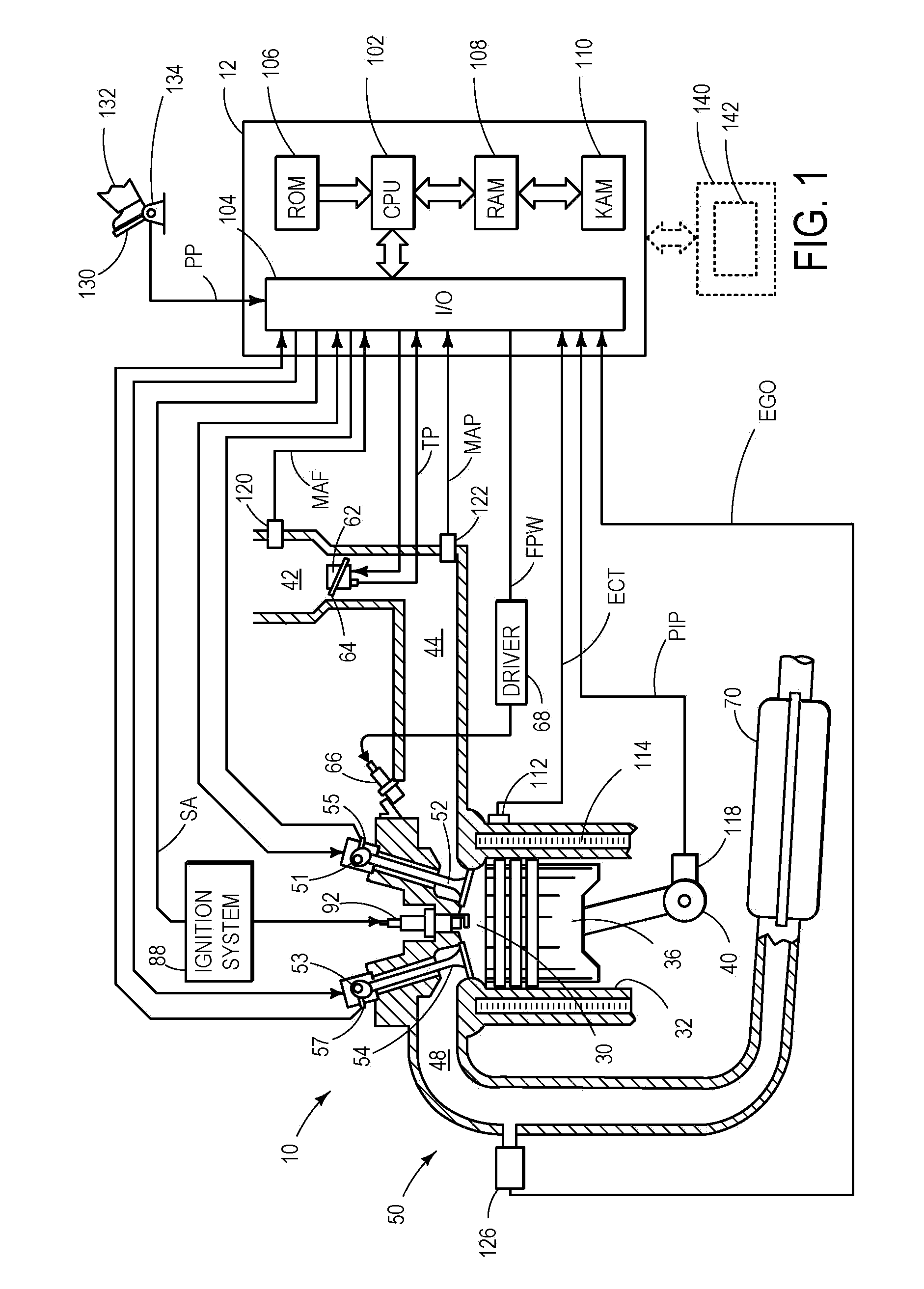

Engine control and catalyst monitoring with downstream exhaust gas sensors

InactiveUS6904751B2Low costSaving weightElectrical controlInternal combustion piston enginesIntegratorExhaust fumes

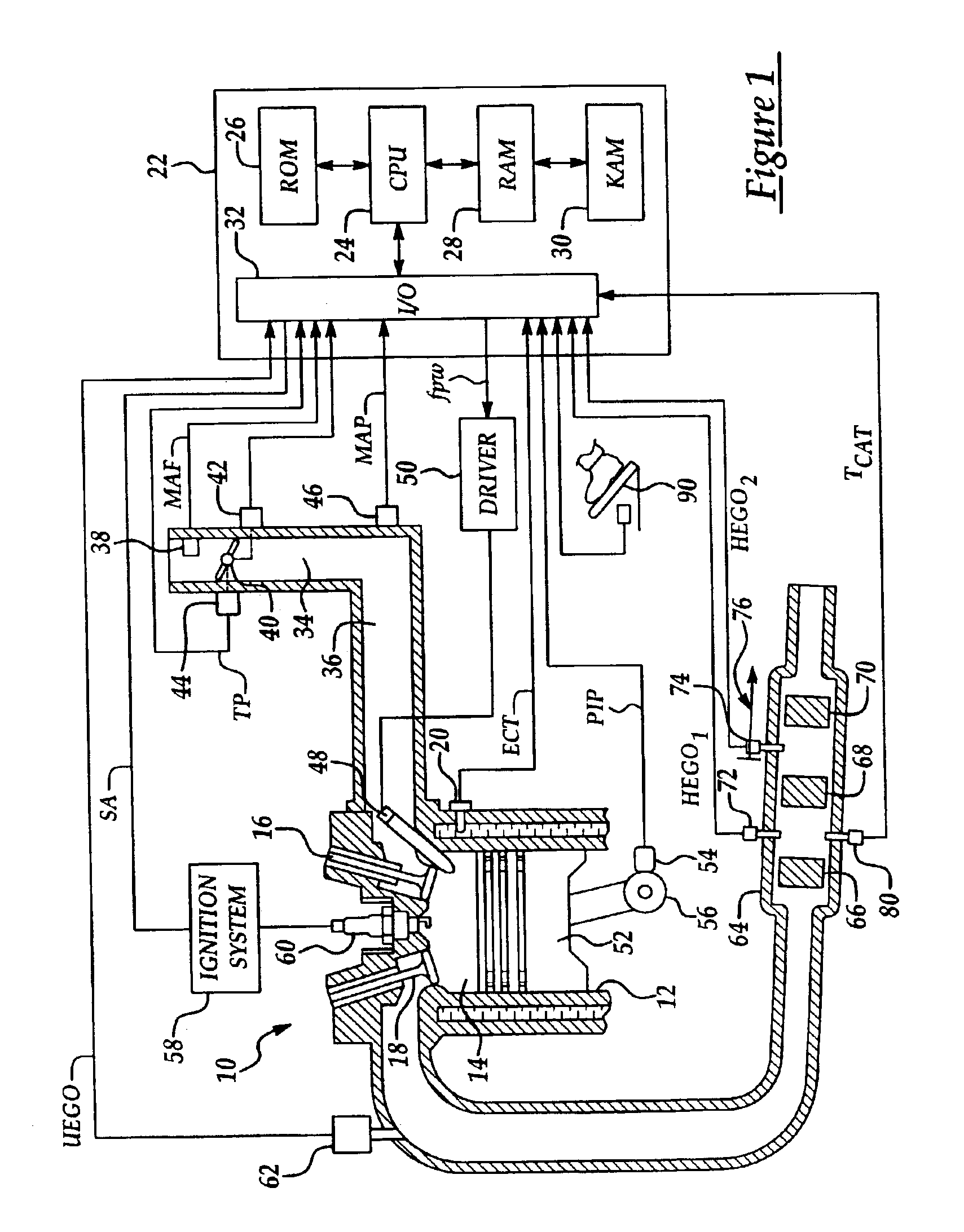

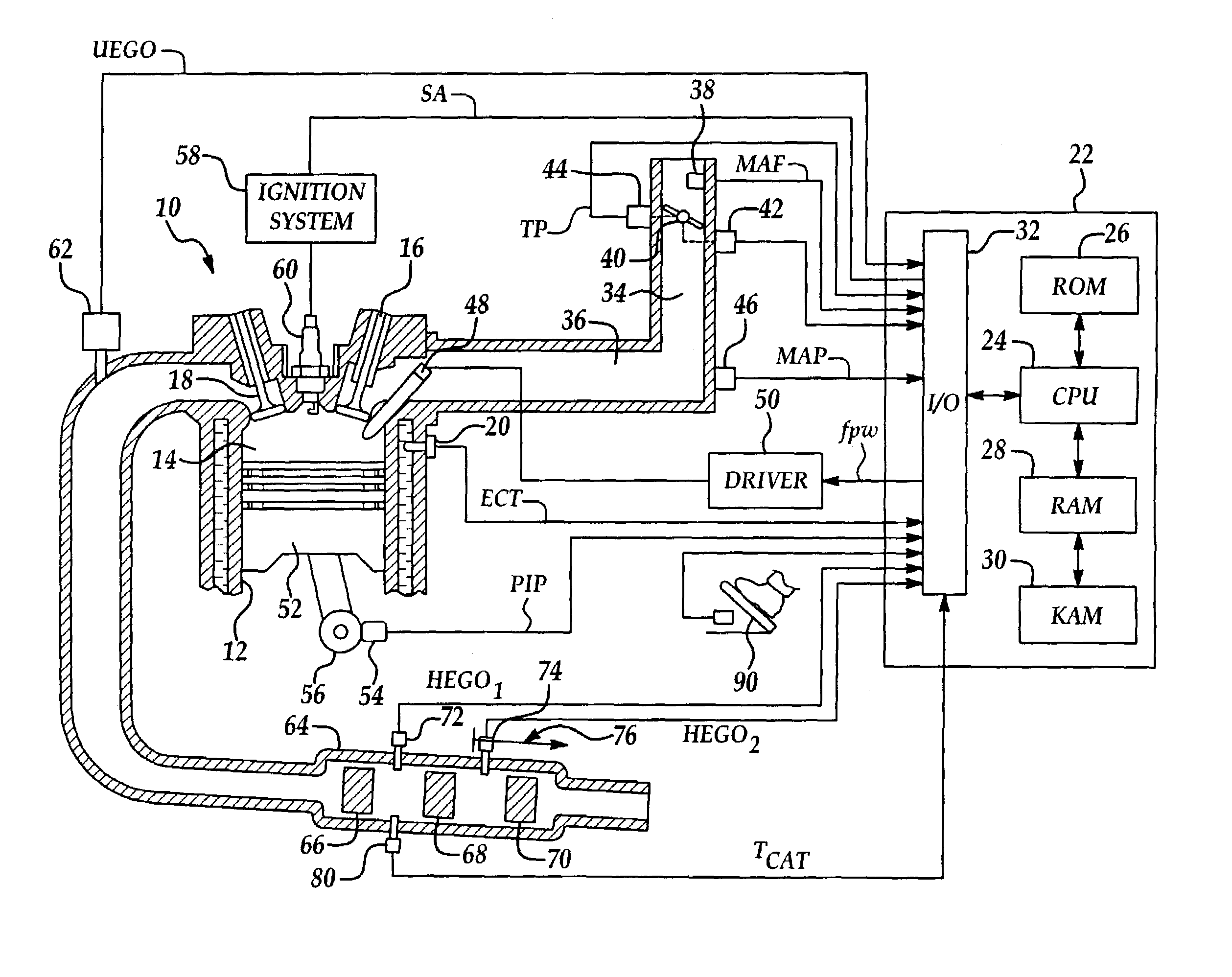

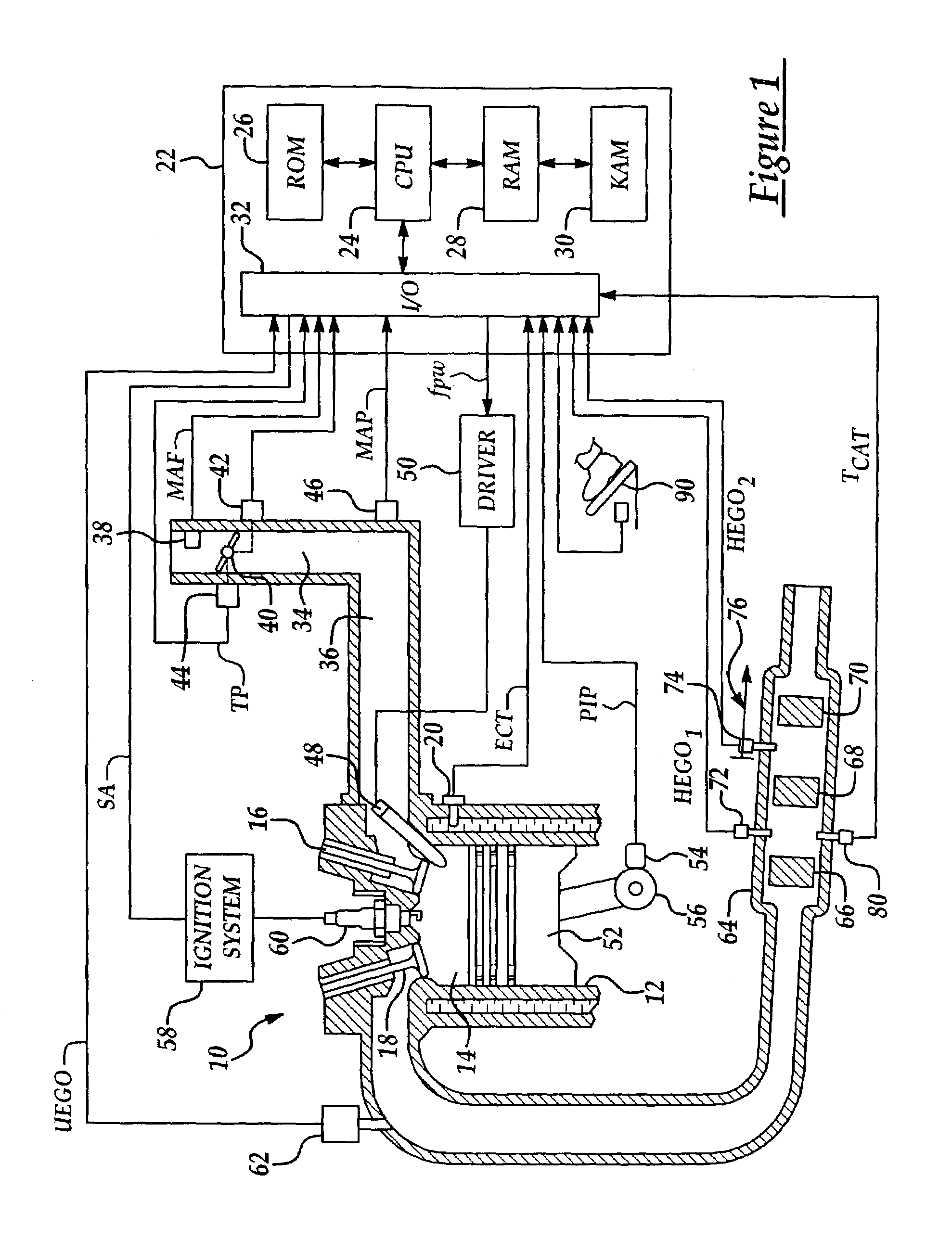

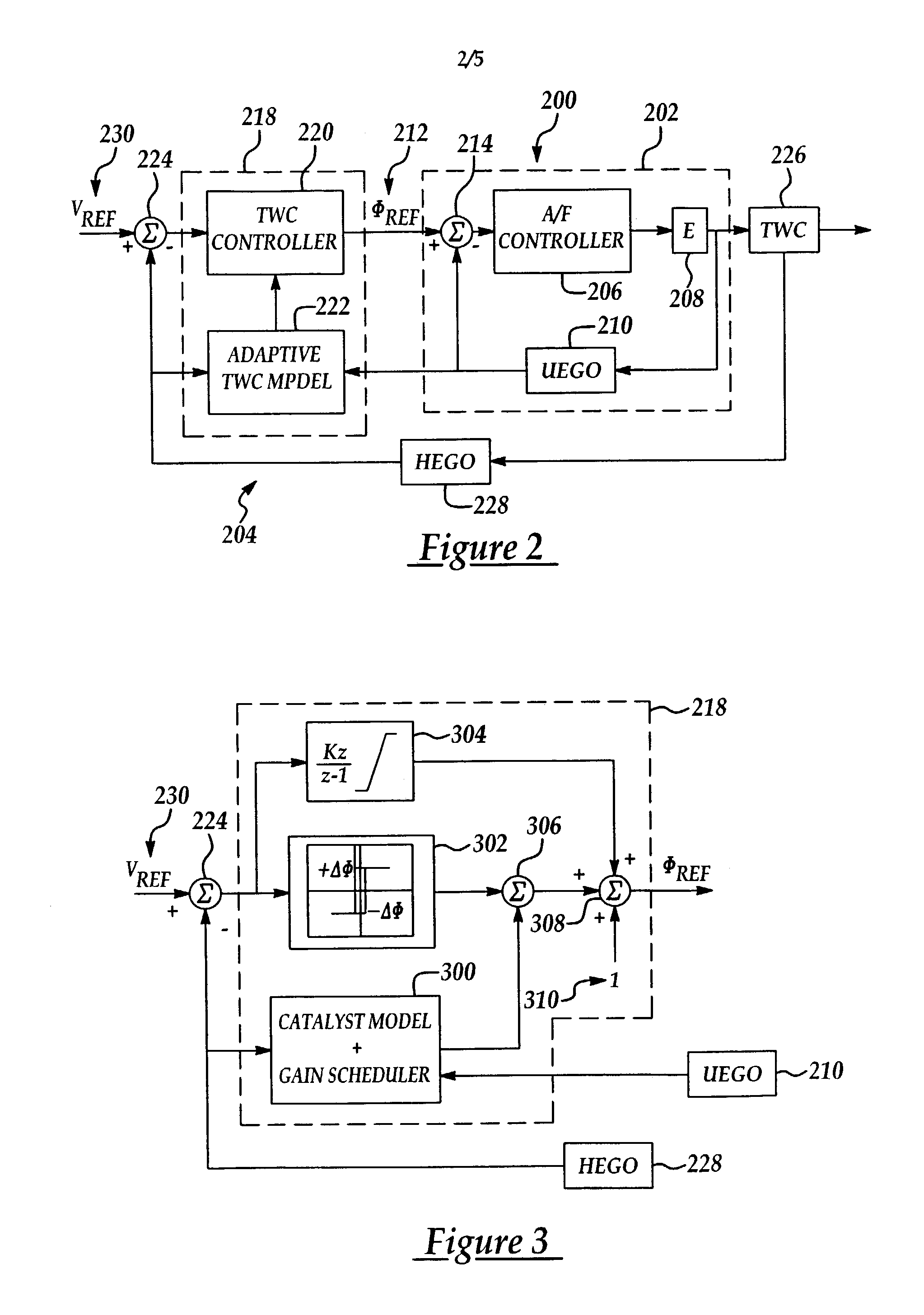

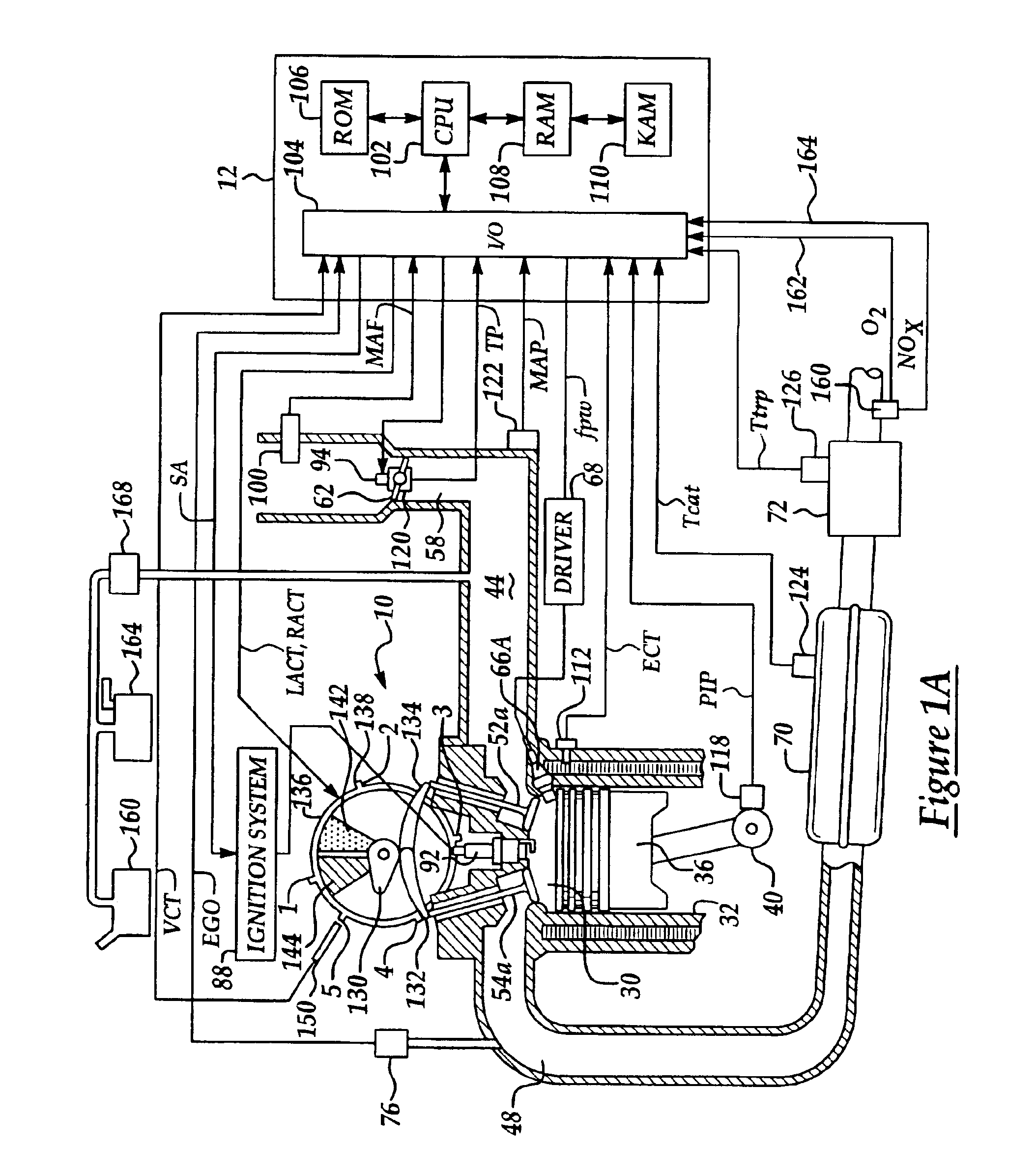

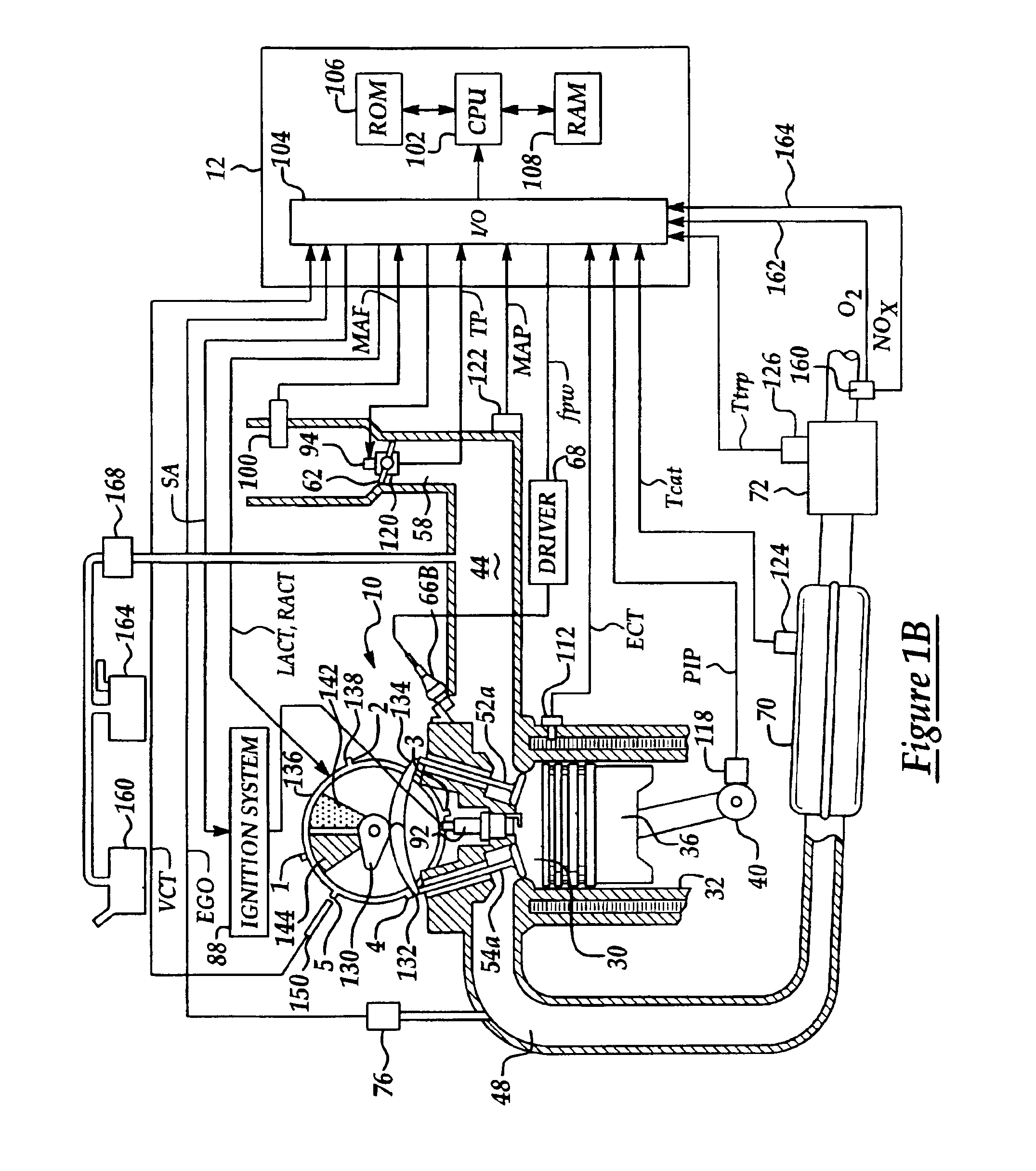

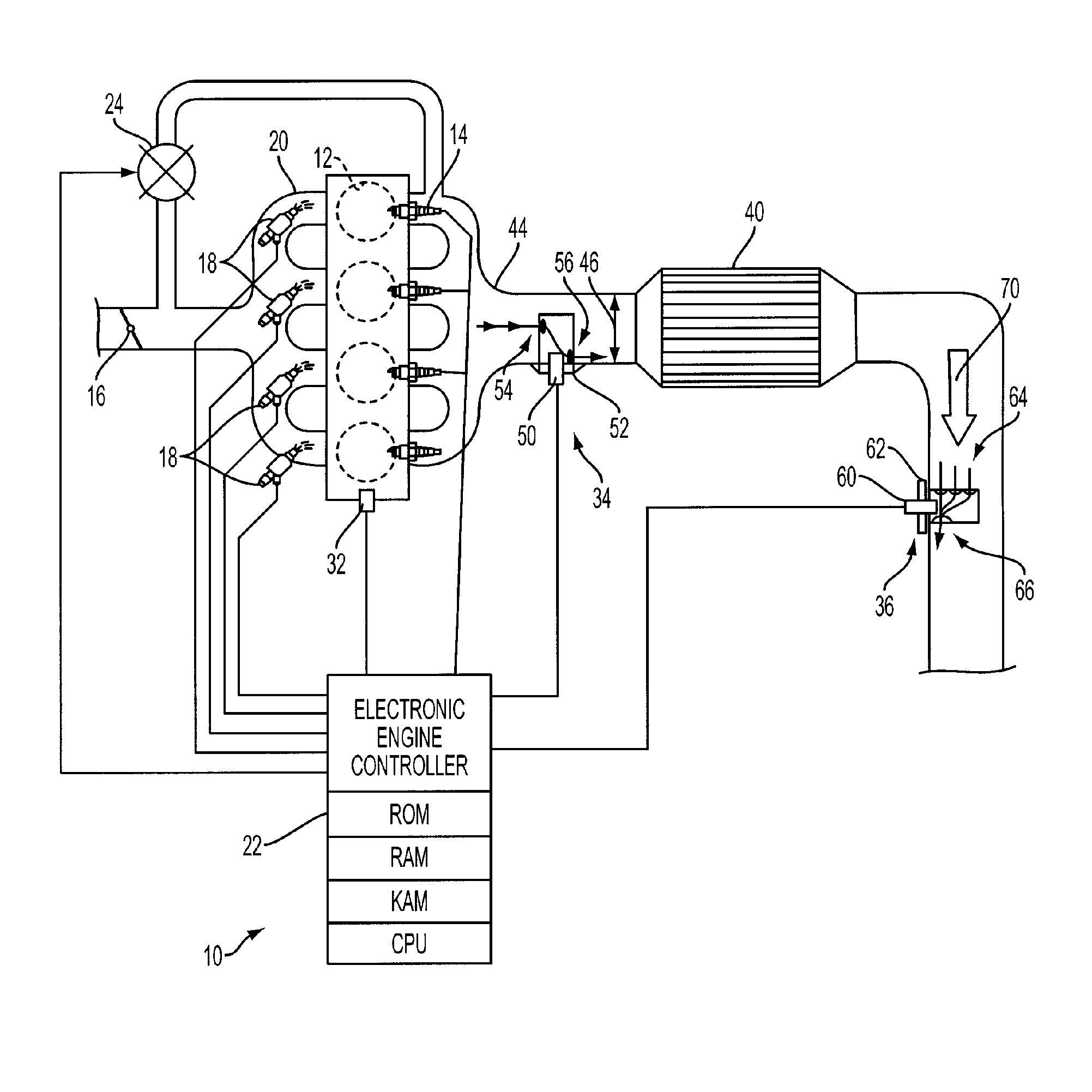

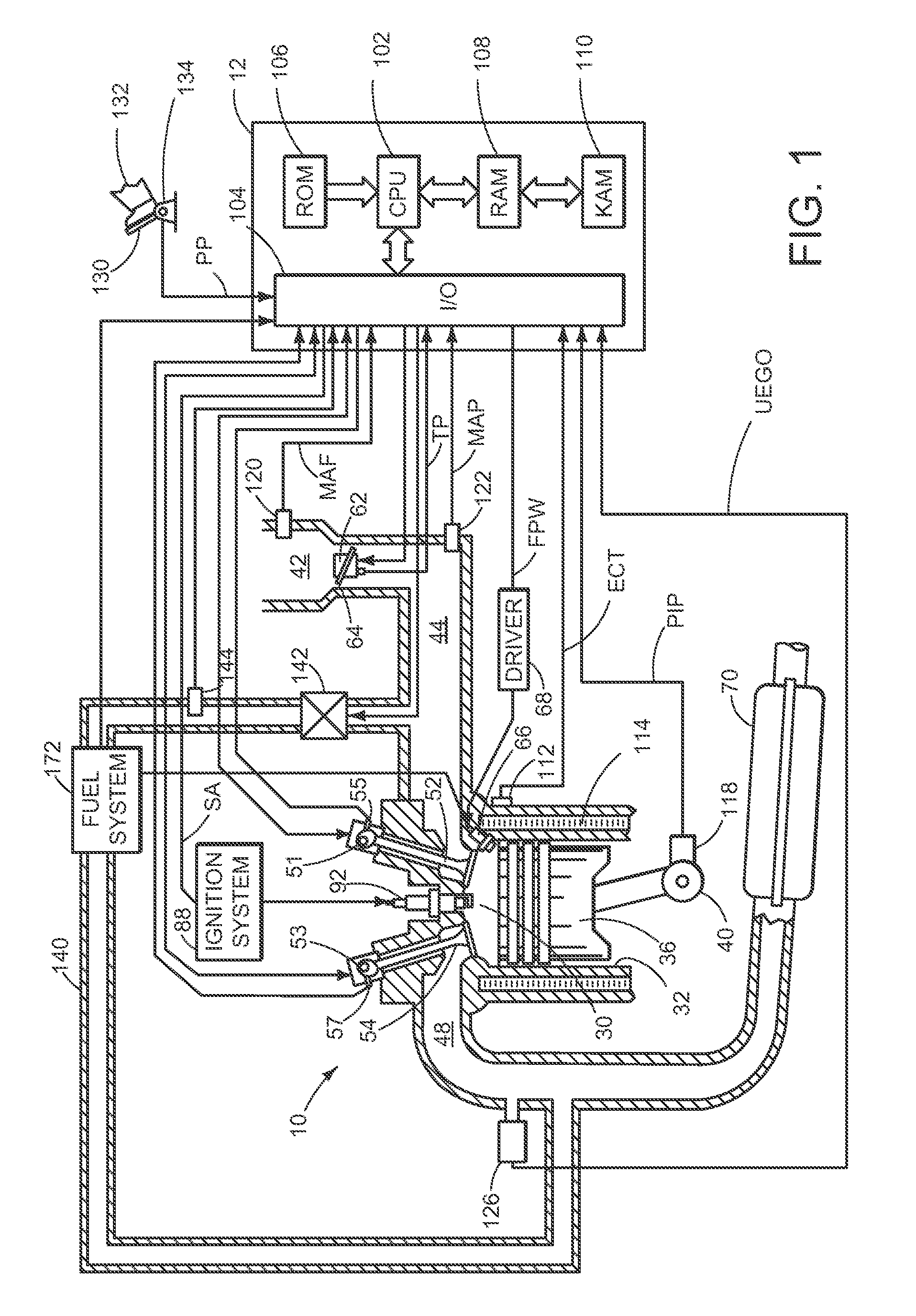

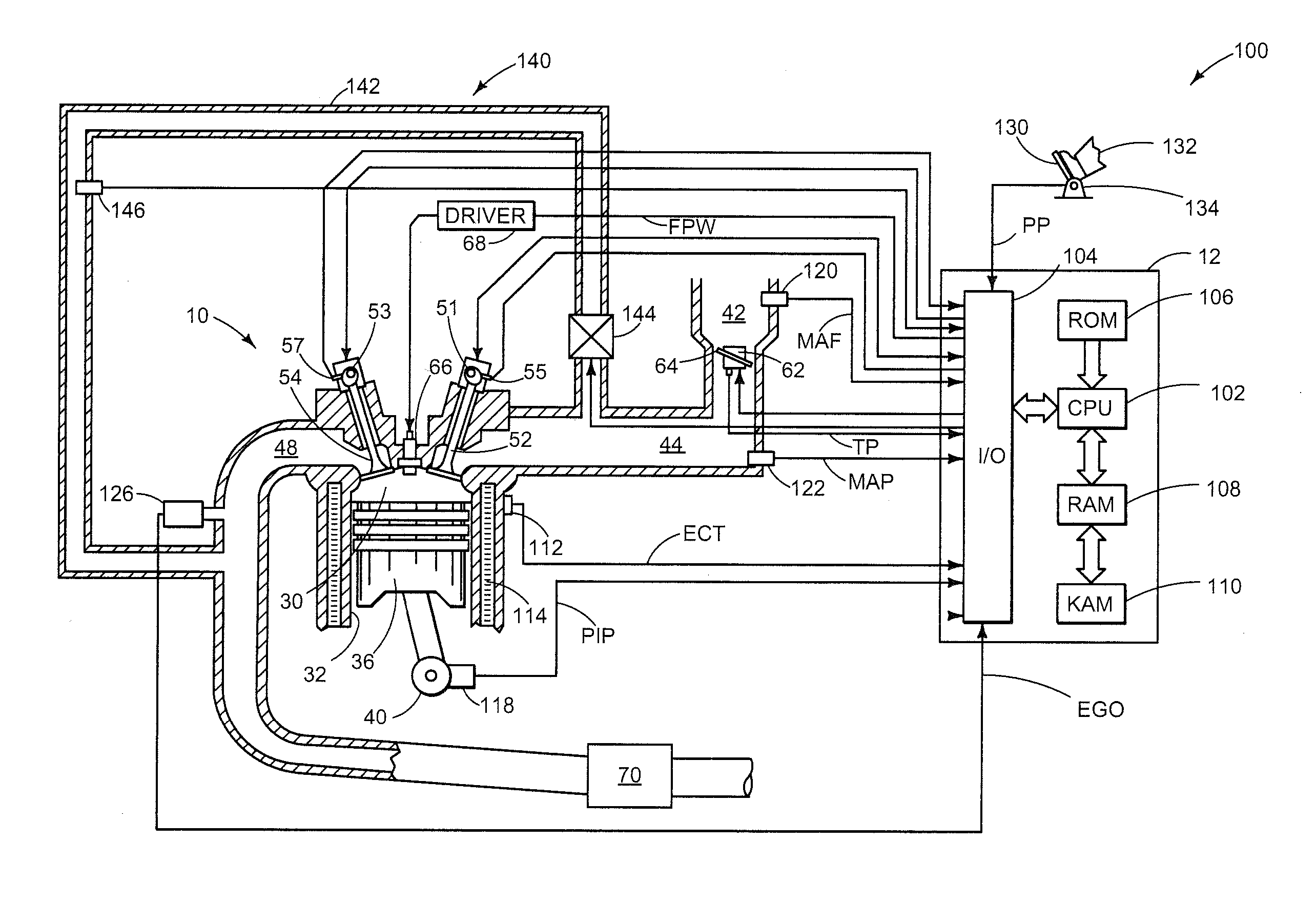

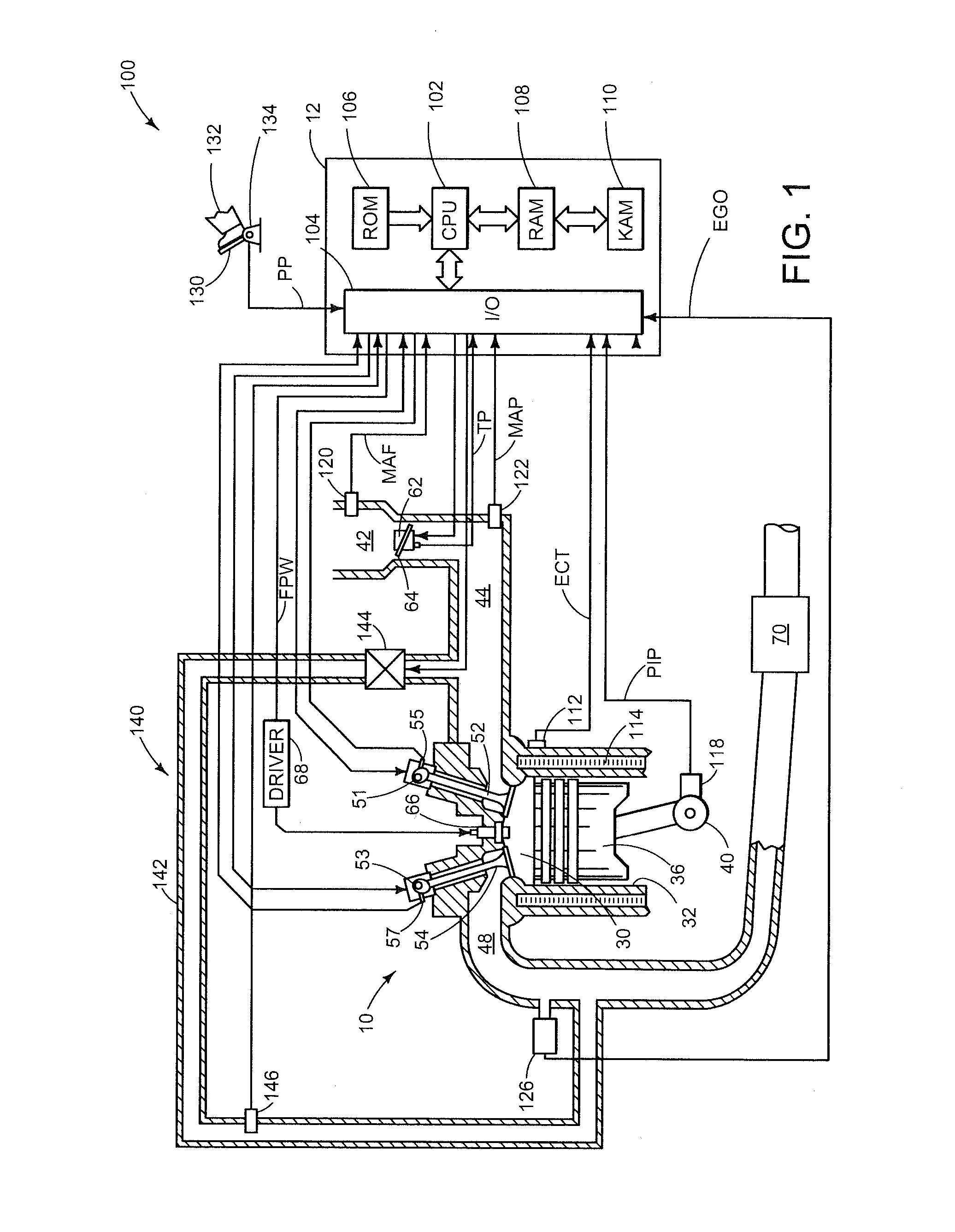

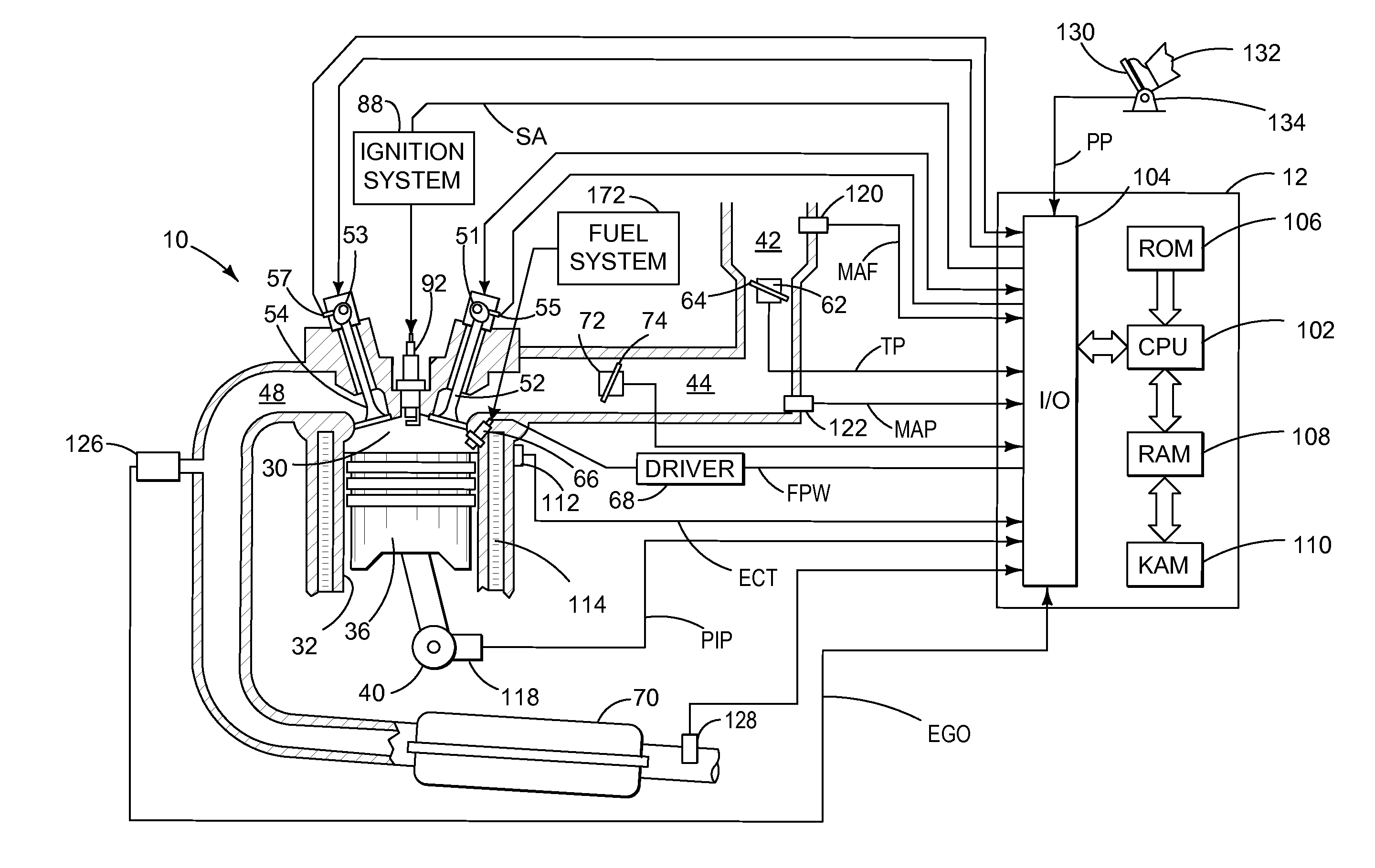

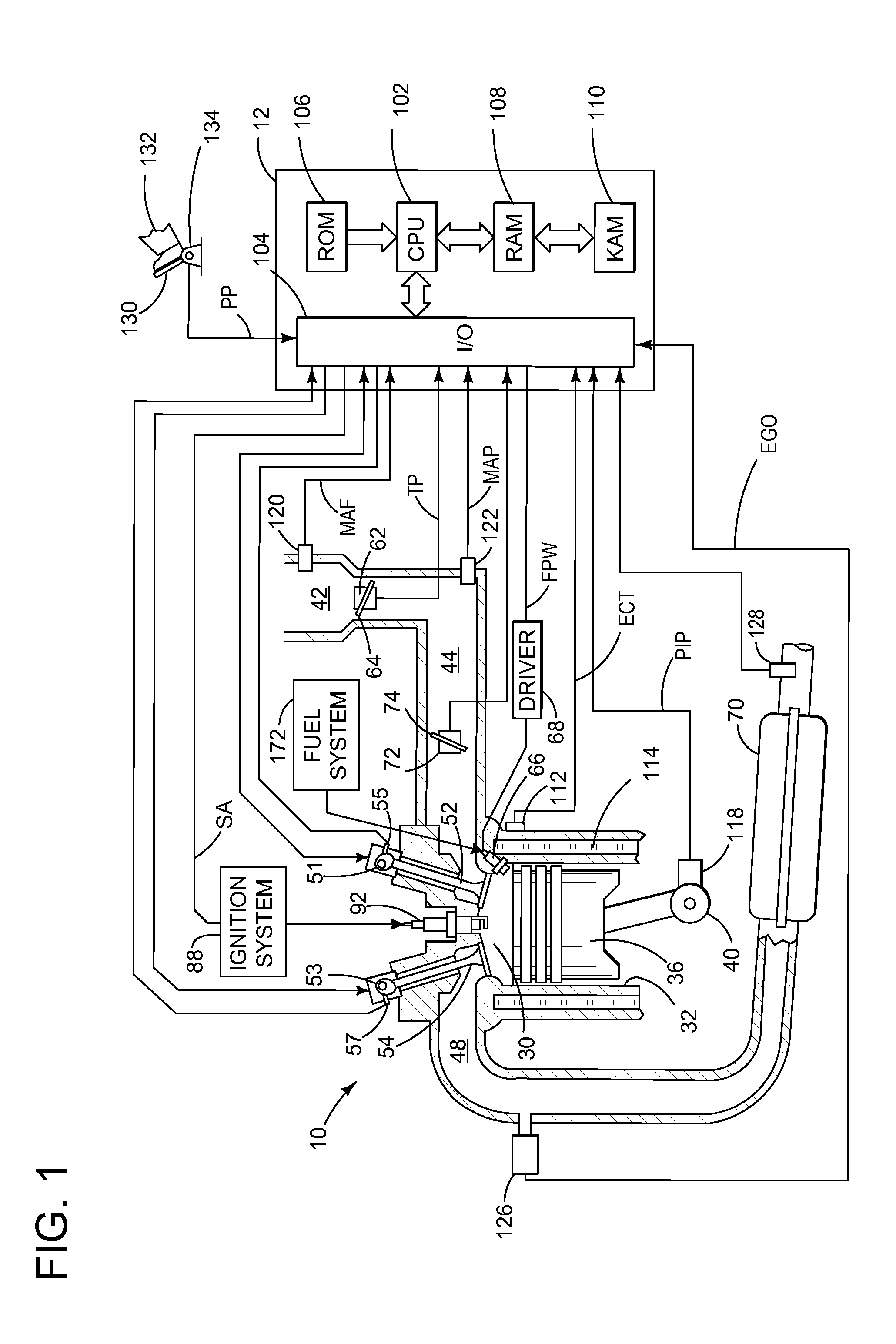

A system and method for controlling an internal combustion engine for low emissions include an inner feedback control loop to control the engine fuel / air ratio with feedback provided by a first exhaust gas sensor and an outer feedback control loop that modifies a reference fuel / air ratio provided to the inner feedback control loop based on feedback signals provided by a second exhaust gas sensor positioned downstream relative to a portion of the catalyst and a third exhaust gas sensor positioned downstream relative to the second exhaust gas sensor. Catalyst gains are determined by modeling the catalyst as an integrator with an unknown gain and estimating the catalyst gain based on the exhaust gas sensors with the gain used to monitor catalyst performance and / or modify the engine fuel / air ratio.

Owner:FORD GLOBAL TECH LLC

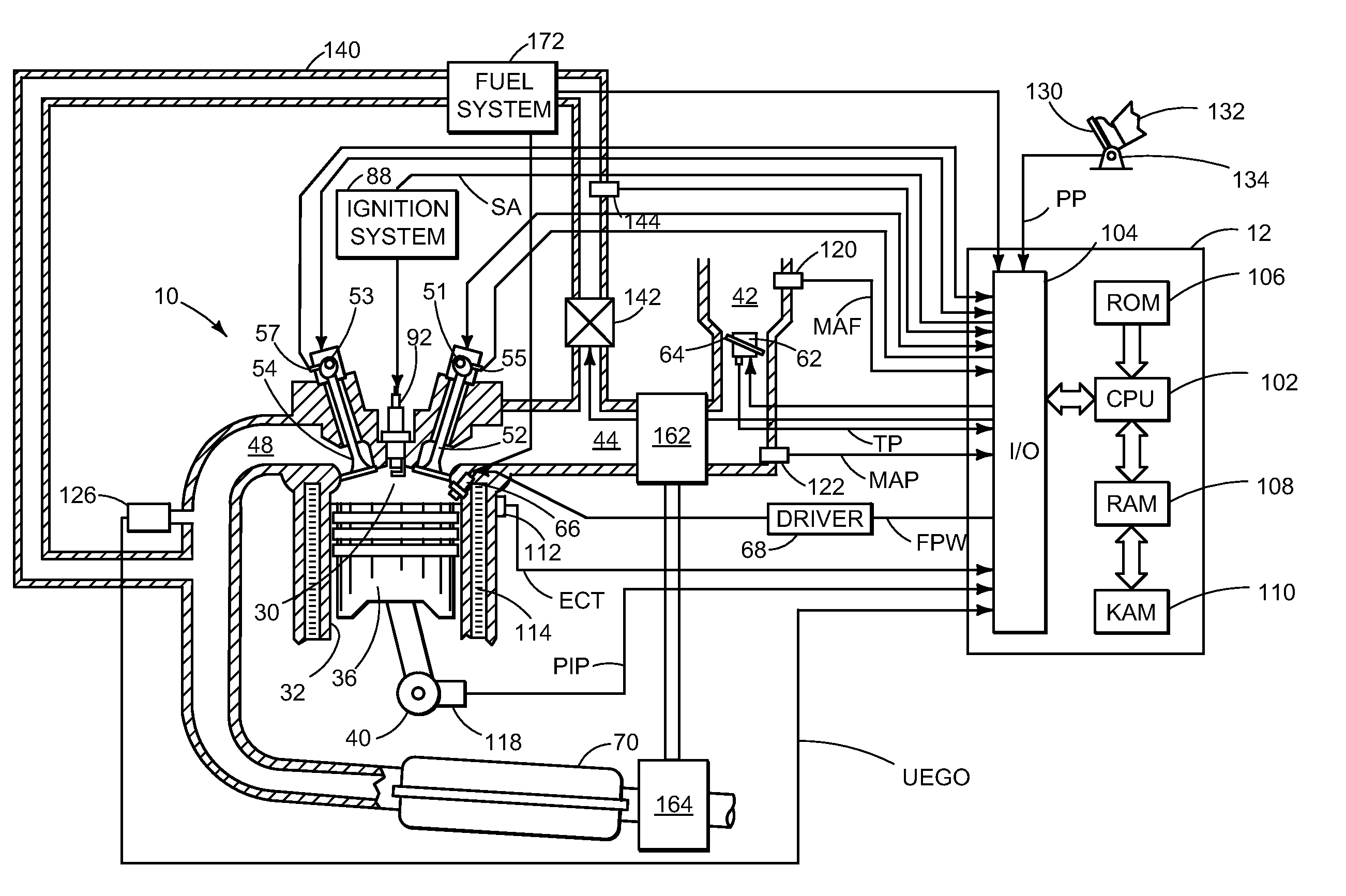

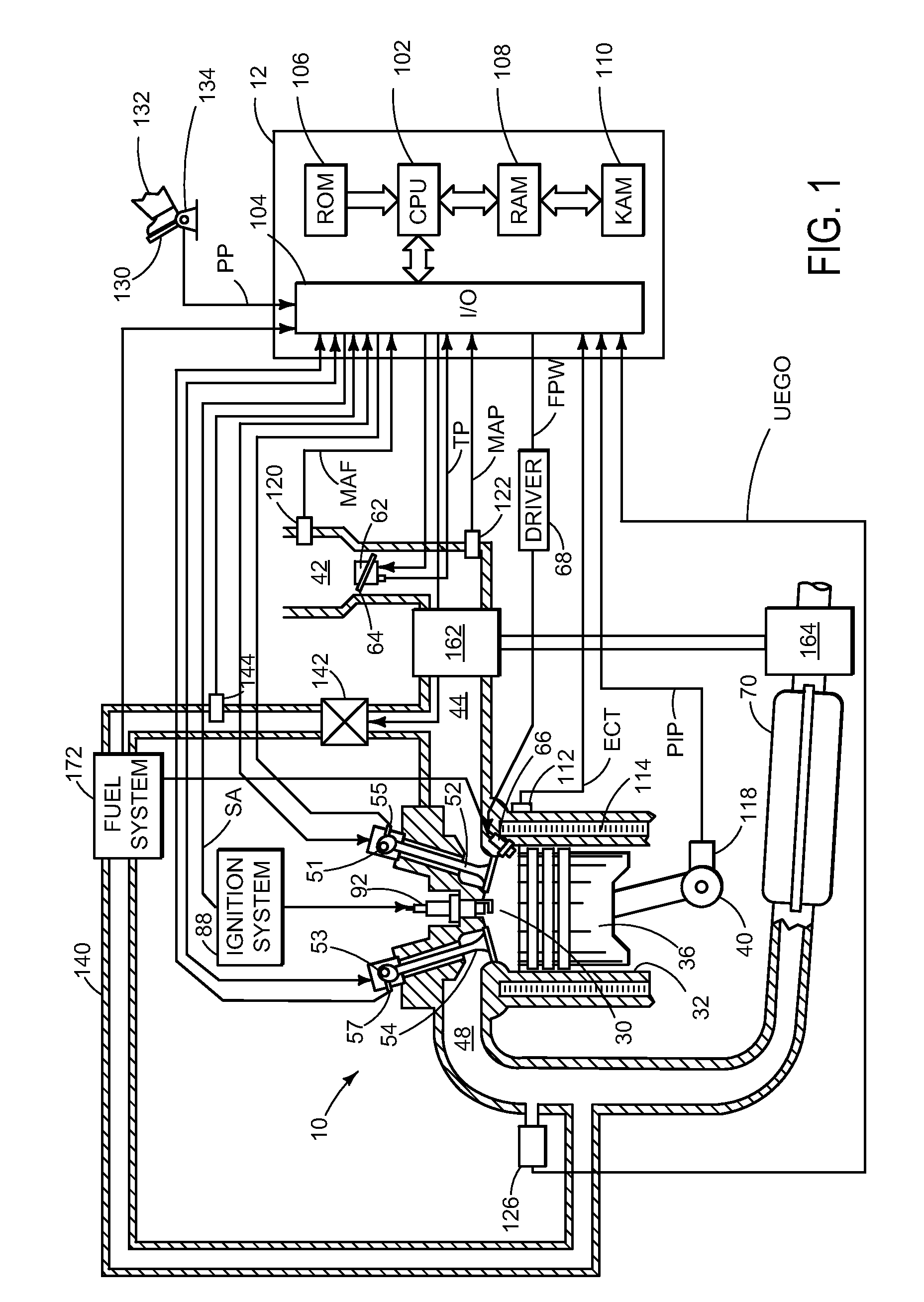

Robust maximum engine torque estimation

ActiveUS20070051351A1Improve economyImprove efficiencyElectrical controlCombustion enginesControl theoryLinearity

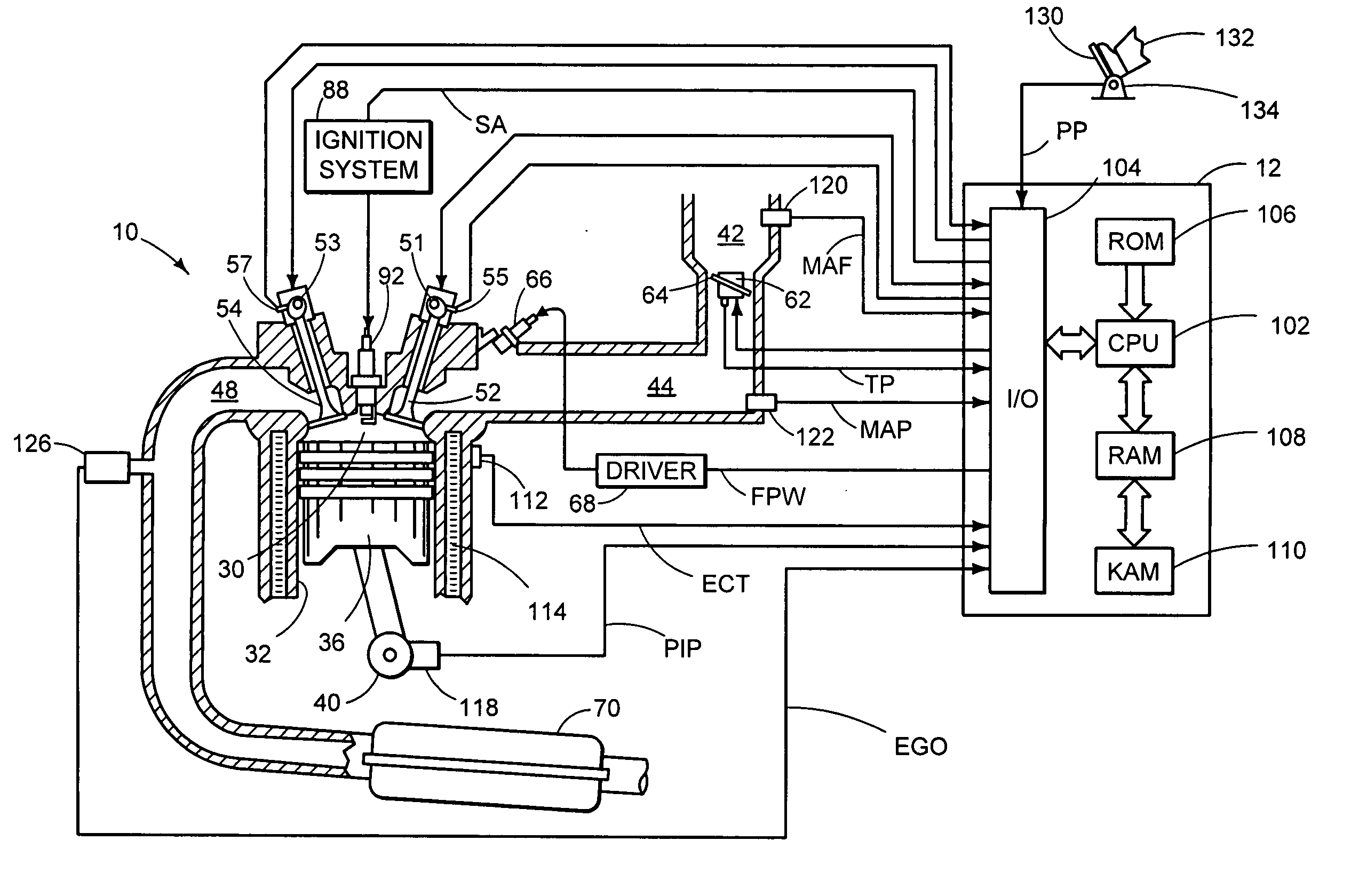

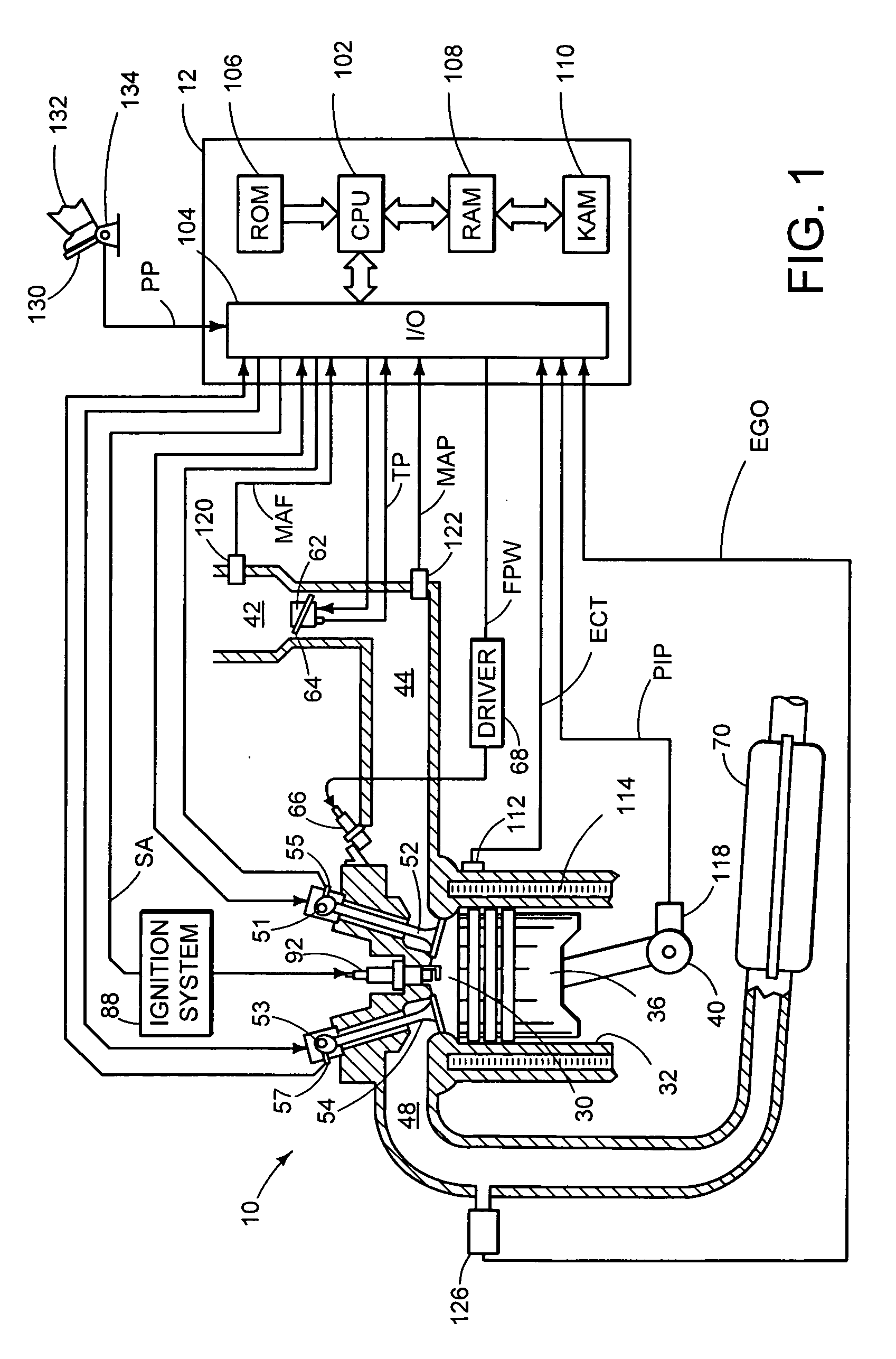

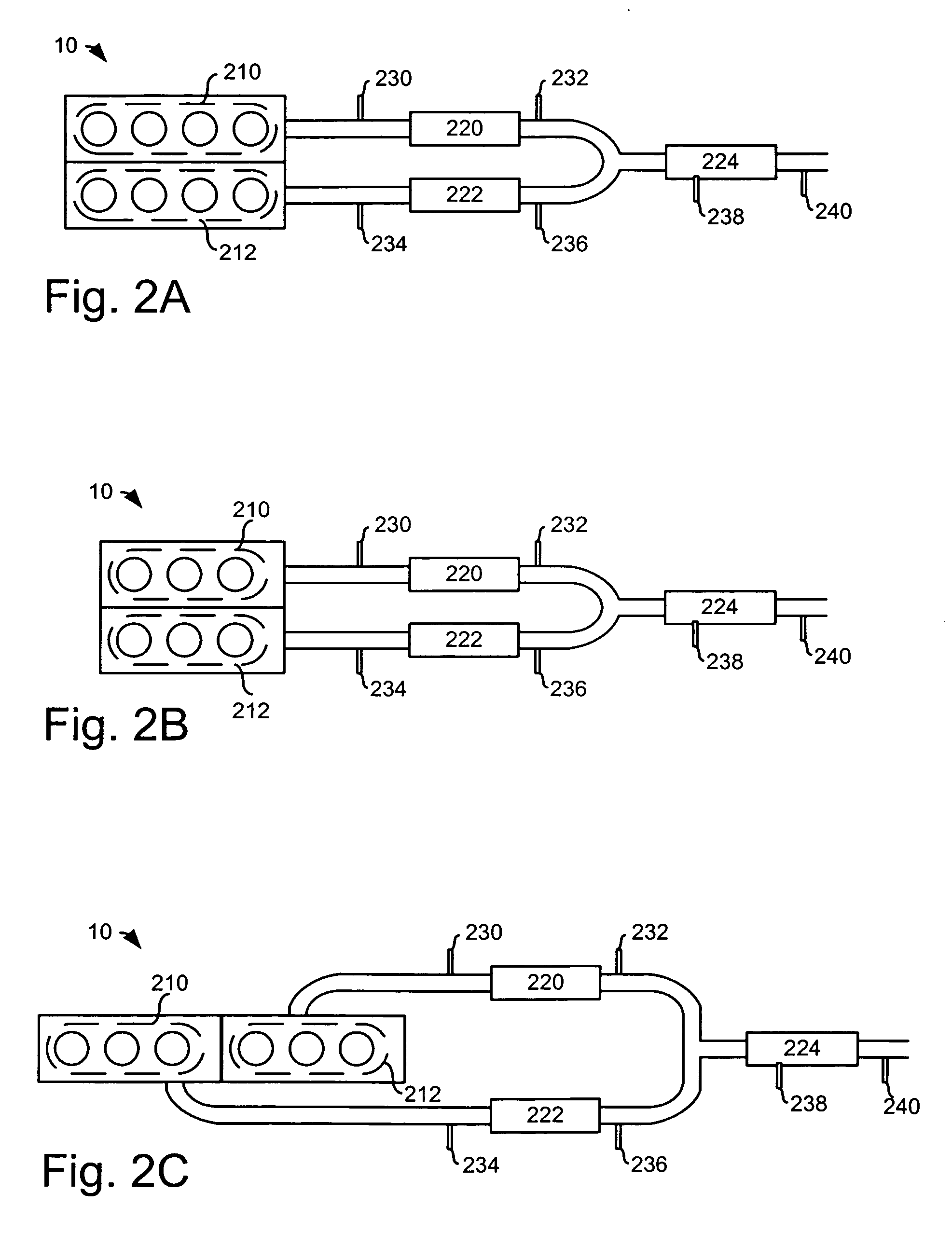

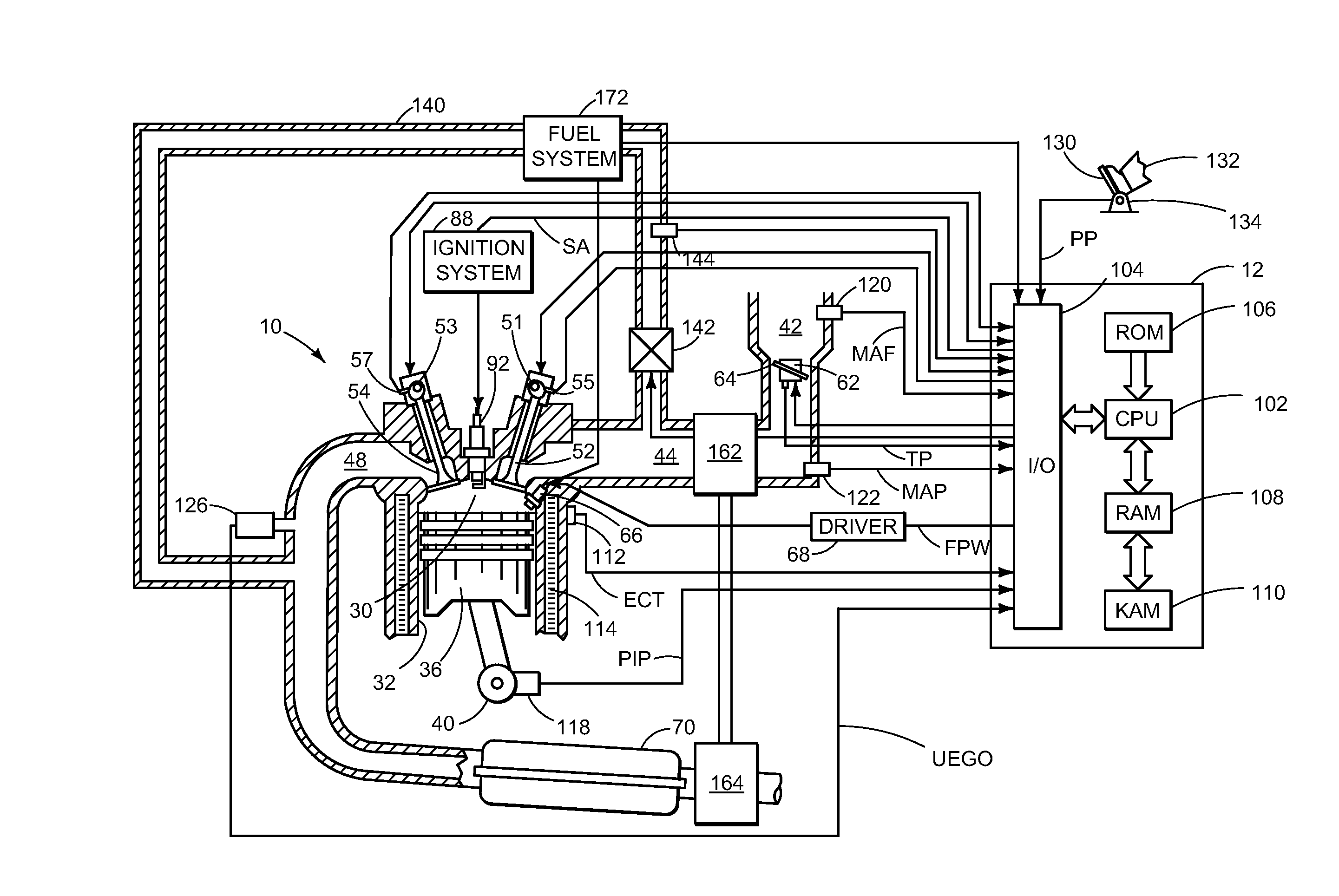

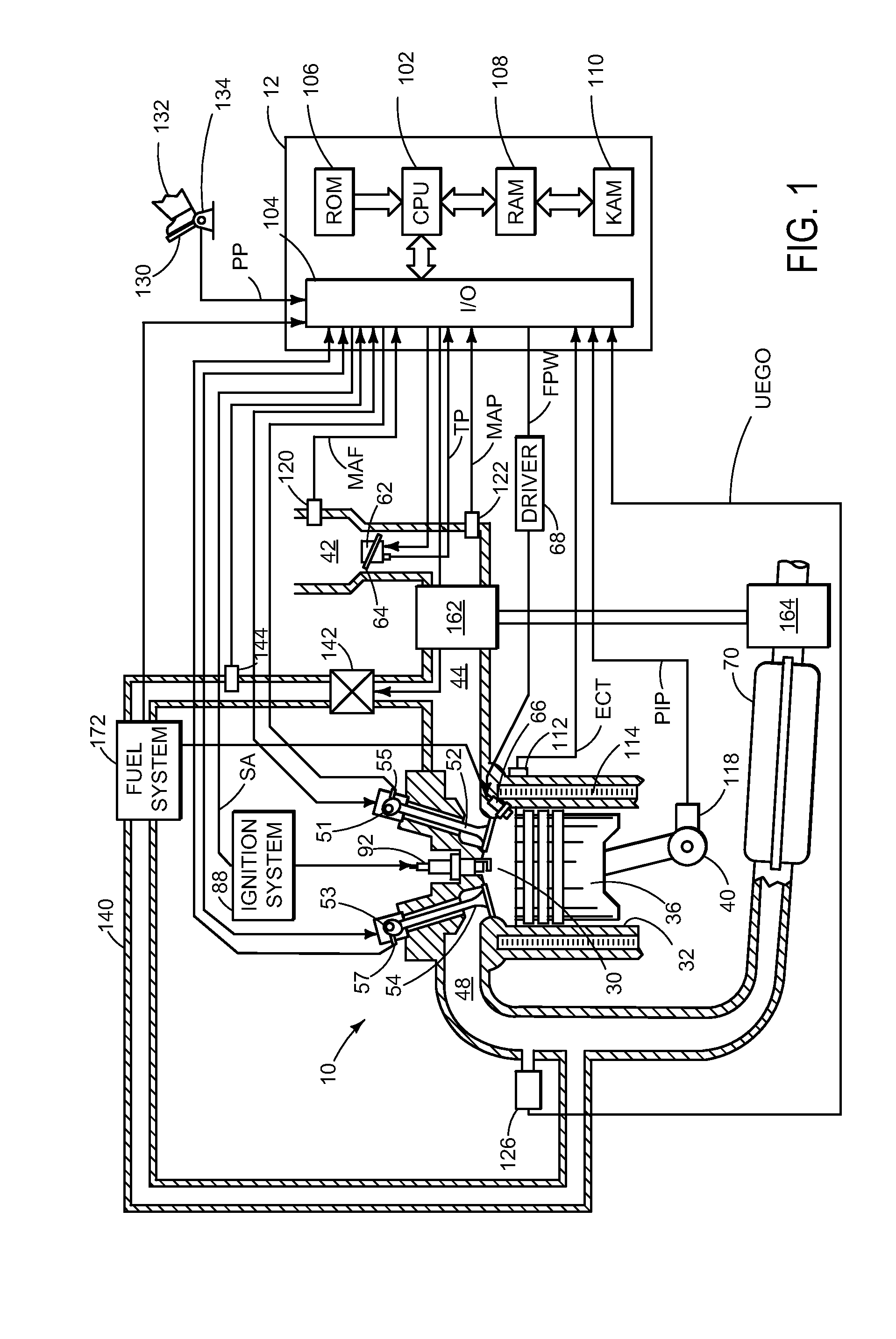

A system for a vehicle comprising of an engine including a first cylinder group and a second cylinder group; a linear exhaust gas sensor coupled exclusively to the first cylinder group; a switching exhaust gas sensor coupled exclusively to the second cylinder group; and a controller configured to operate the engine in at least a first mode and a second mode, where in the first mode the first and second cylinder groups combust air and fuel, where in the second mode at least one of the first and second cylinder groups combusts air and injected fuel and the other one of the first and second cylinder groups pumps air without injecting fuel, and where the controller is further configured to estimate torque of the engine in each of the first and second modes of operation based on the air-fuel ratio of the first cylinder group and the air-fuel ratio of the second cylinder group independent of the switching sensor and dependent on the linear sensor.

Owner:FORD GLOBAL TECH LLC

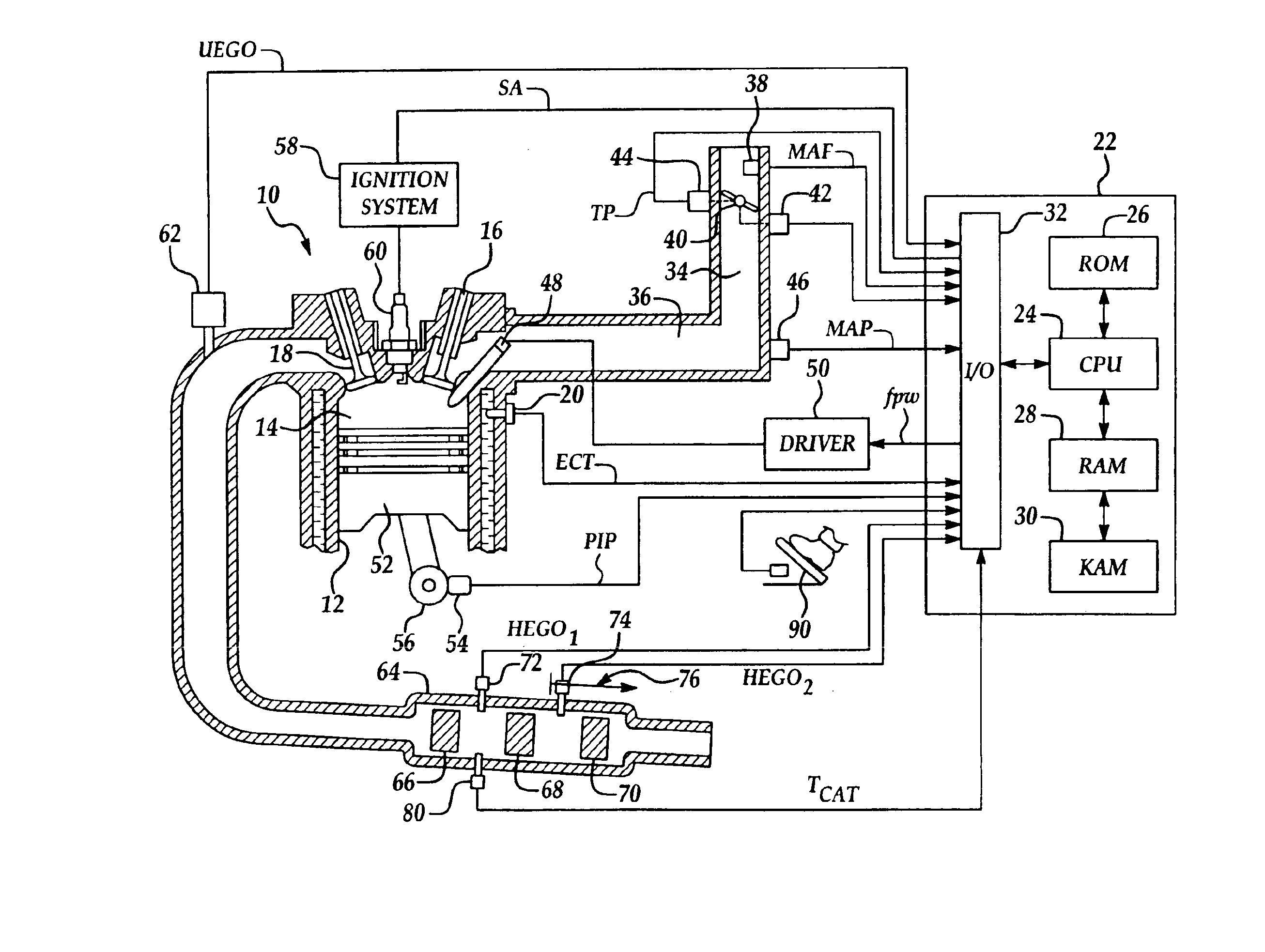

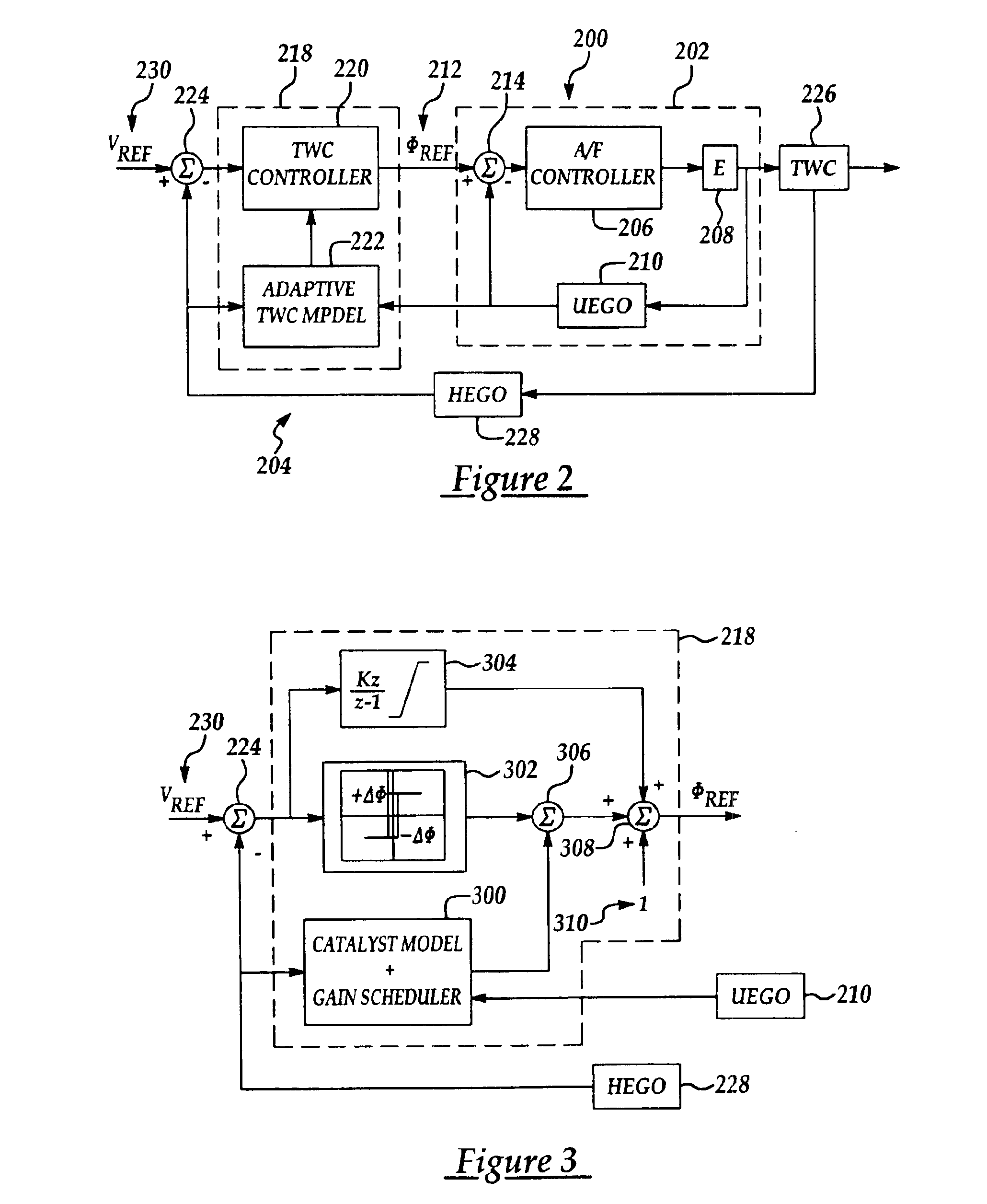

Fuel/air ratio feedback control with catalyst gain estimation for an internal combustion engine

ActiveUS7000379B2Low costSaving weightElectrical controlInternal combustion piston enginesIntegratorFeedback control

A system and method for controlling an internal combustion engine for low emissions include an inner feedback control loop to control the engine fuel / air ratio with feedback provided by a first exhaust gas sensor and an outer feedback control loop that modifies the fuel / air ratio reference provided to the inner feedback control loop based on feedback signals provided by the first exhaust gas sensor and a second exhaust gas sensor. The fuel / air ratio reference signal controller adapts to the oxygen storage capacity of the catalyst by modeling the catalyst as an integrator with an unknown gain and estimating the catalyst gain based on the first and second exhaust gas sensor signals. Using the estimated catalyst gain, an adaptive controller gain factor is determined and subsequently used to determine the fuel / air ratio reference signal provided to the fuel / air ratio controller of the inner feedback control loop.

Owner:FORD GLOBAL TECH LLC

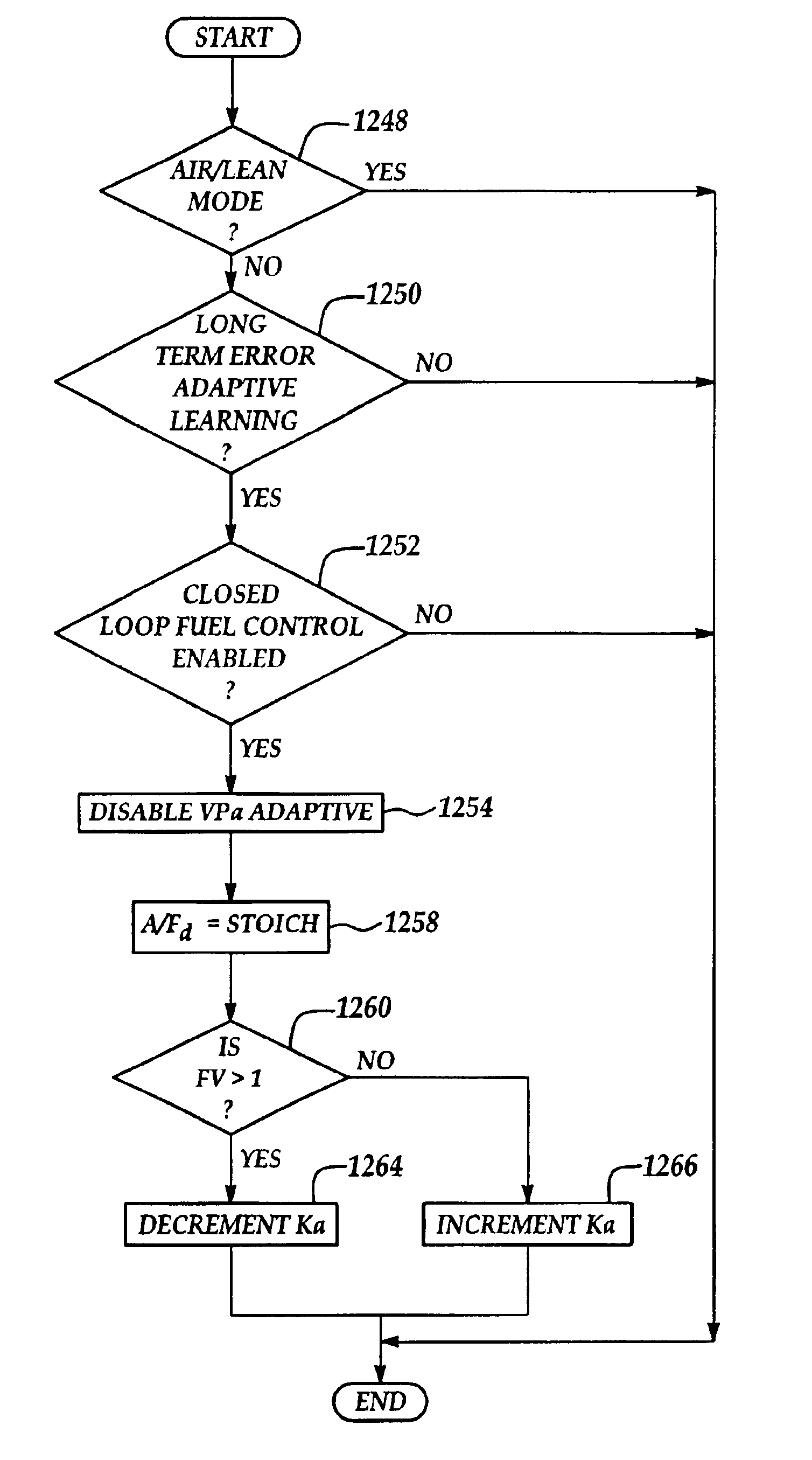

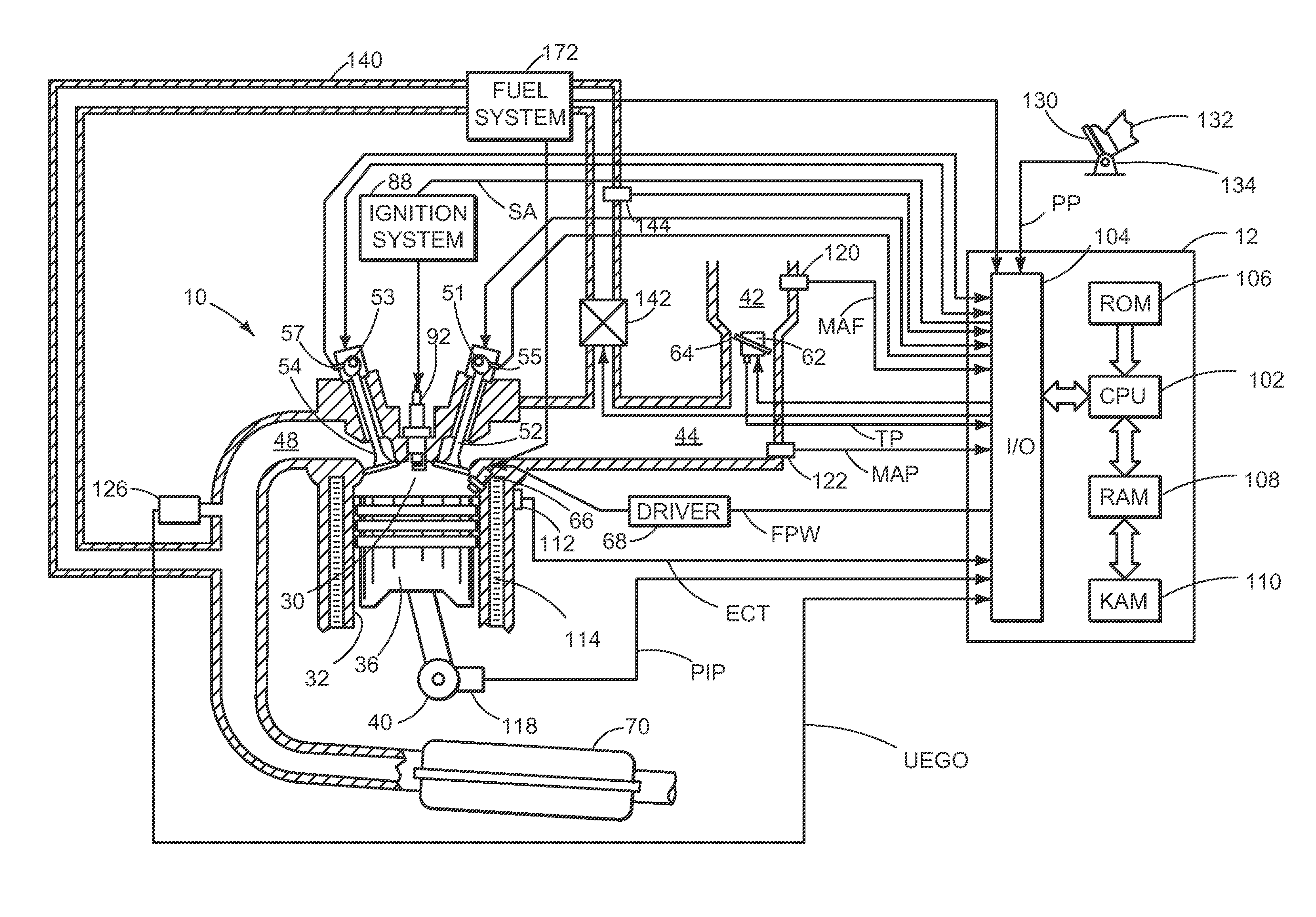

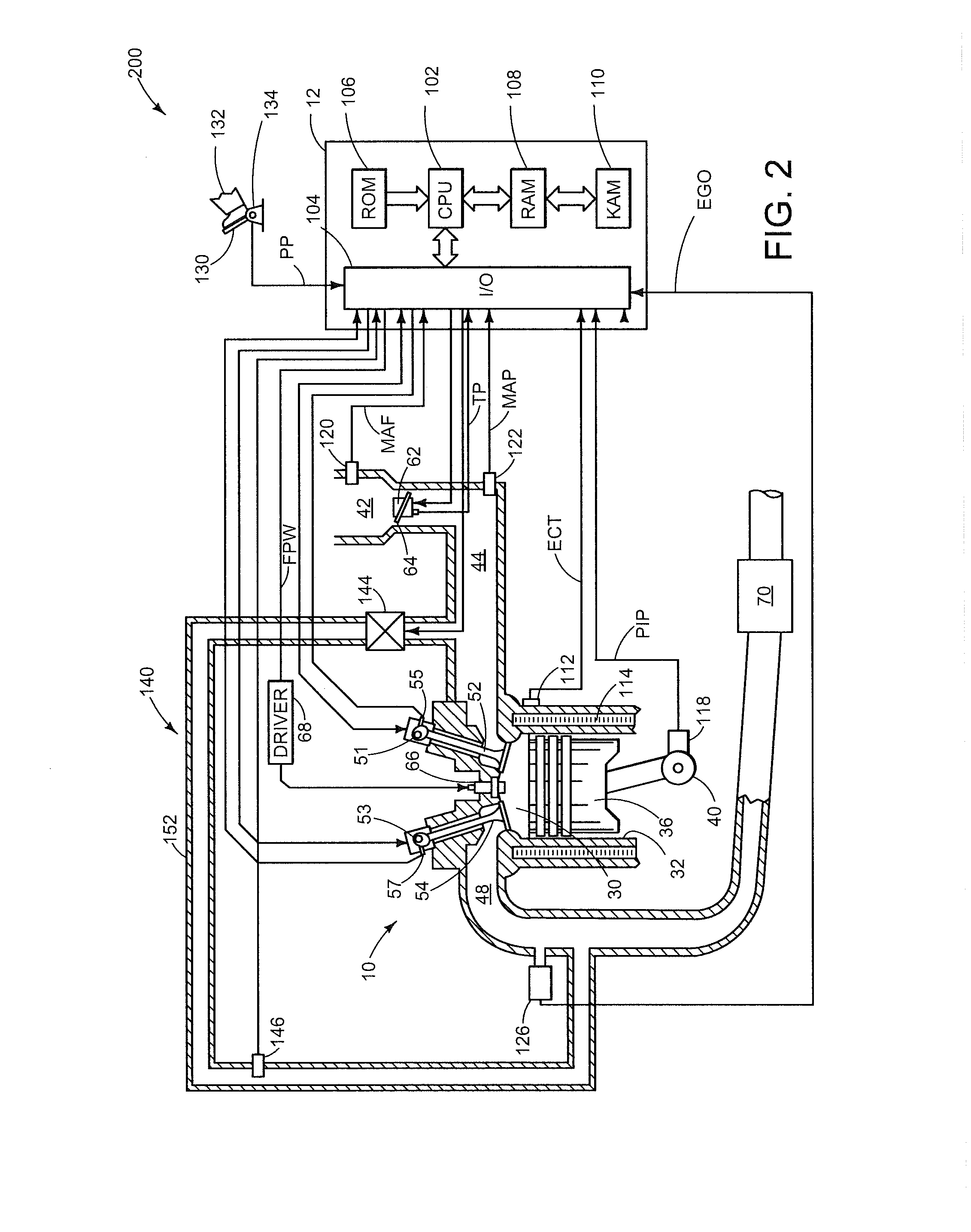

Method and system of adaptive learning for engine exhaust gas sensors

InactiveUS6736120B2Accurate operationLow heat generationElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

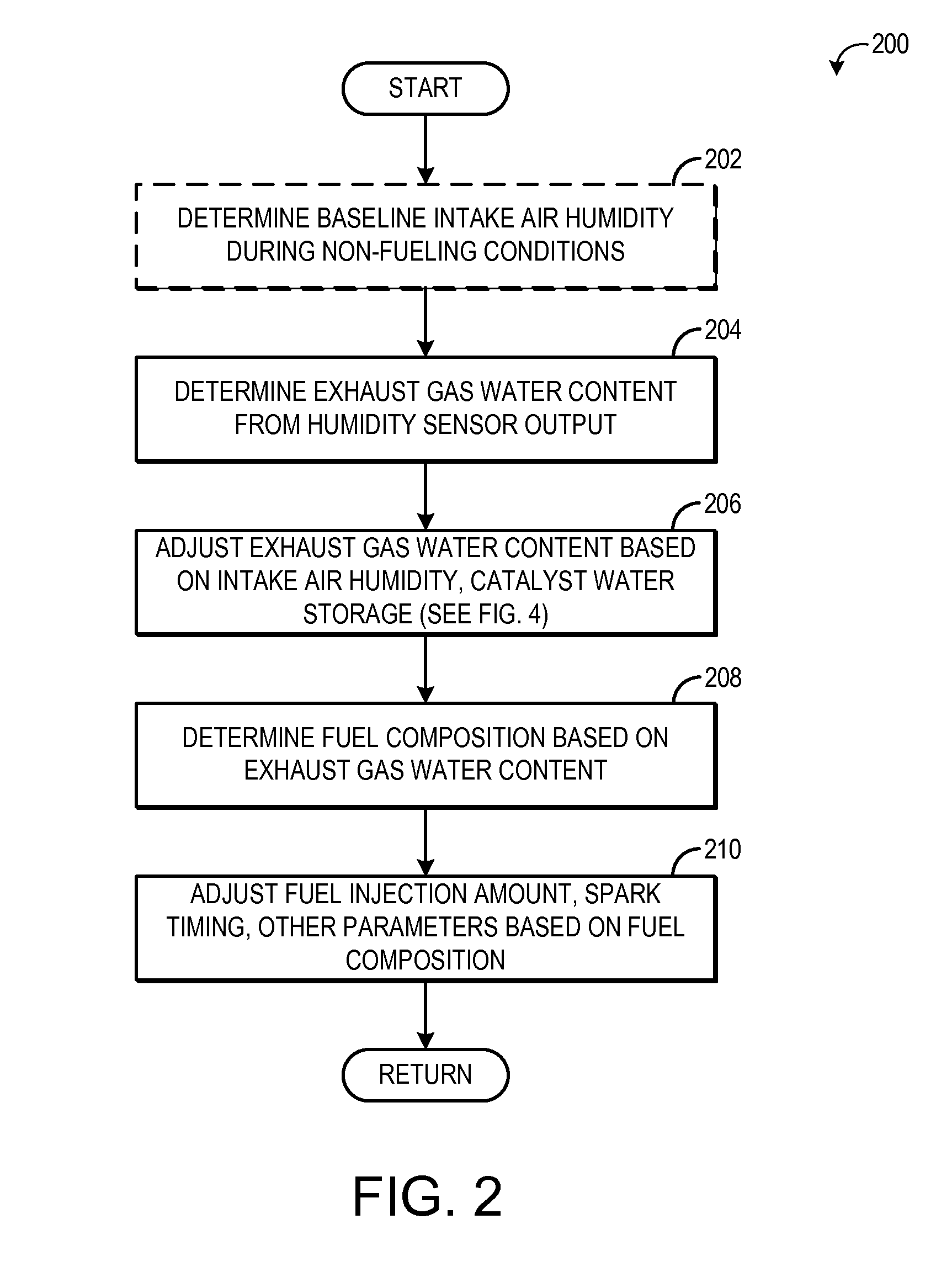

Fuel alcohol content detection via an exhaust gas sensor

InactiveUS20110132342A1Degrade fuel alcohol content identificationReduce distractionsInternal-combustion engine testingElectrical controlAlcohol contentMotor fuel

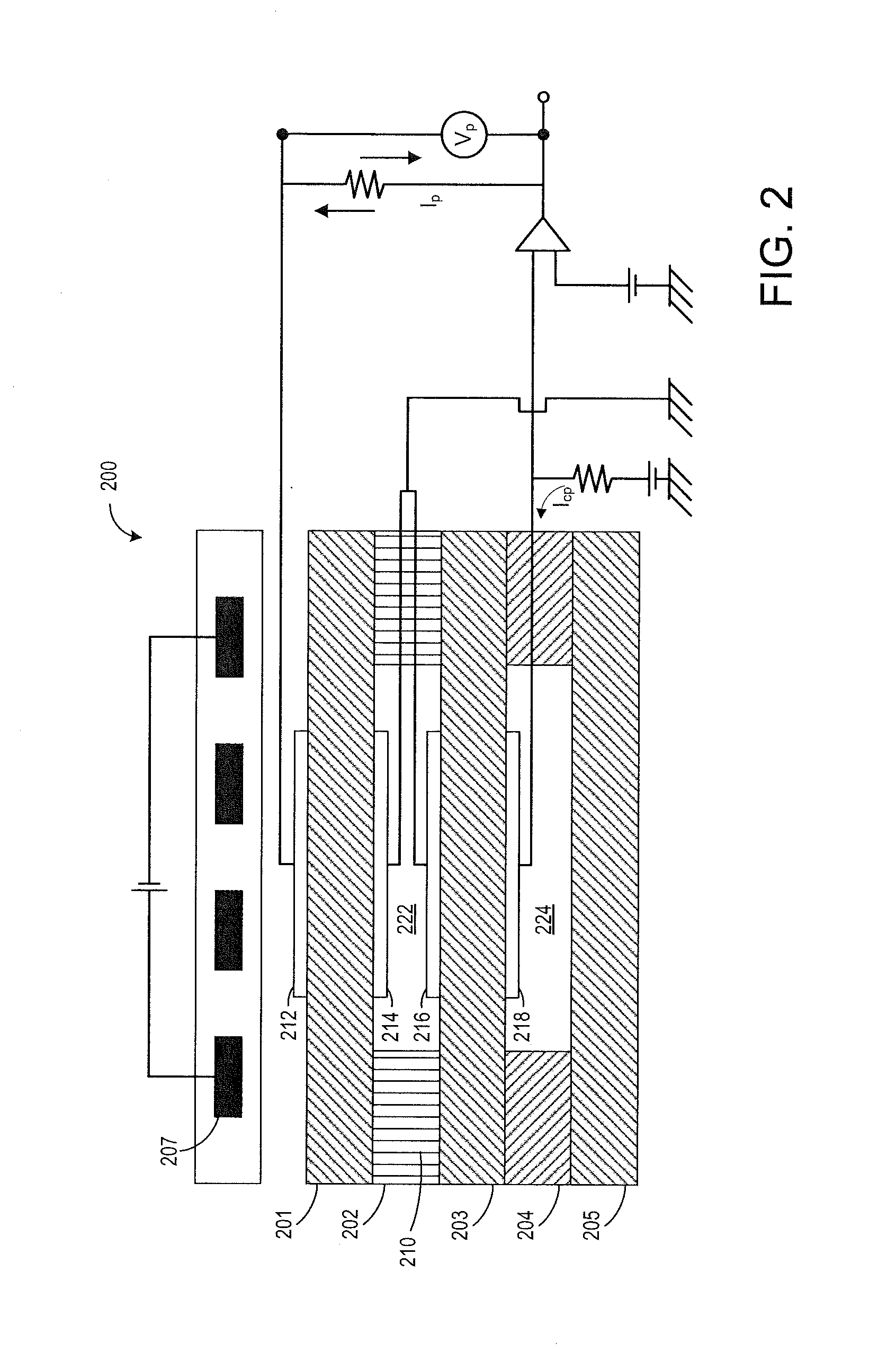

Various systems and methods are described for an exhaust gas sensor coupled to an exhaust system of an engine. One example method comprises, during selected engine fueling conditions, alternating between applying different voltages to the sensor; and identifying an amount of alcohol in fuel injected to the engine based on sensor outputs at the different voltages.

Owner:FORD GLOBAL TECH LLC

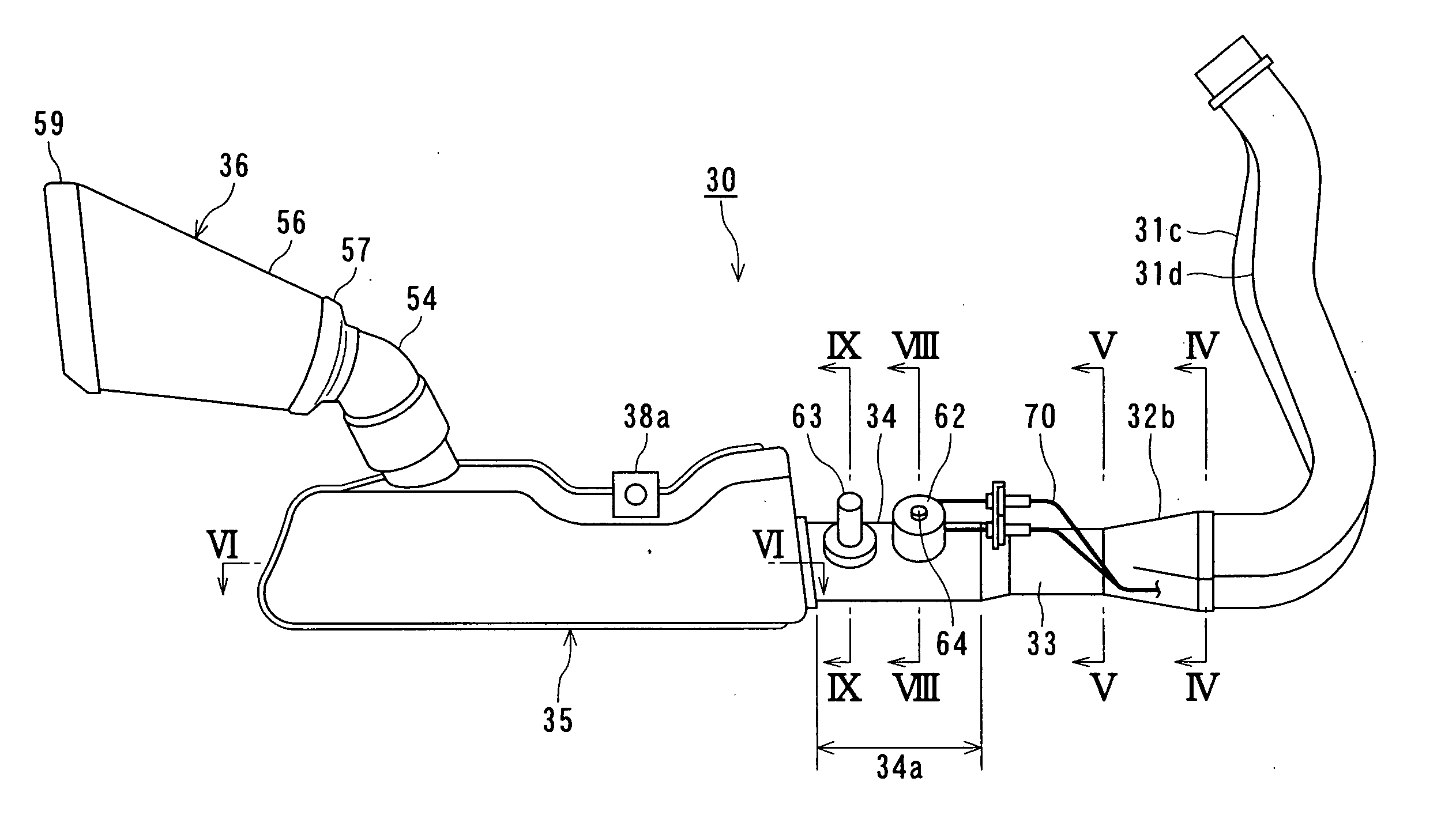

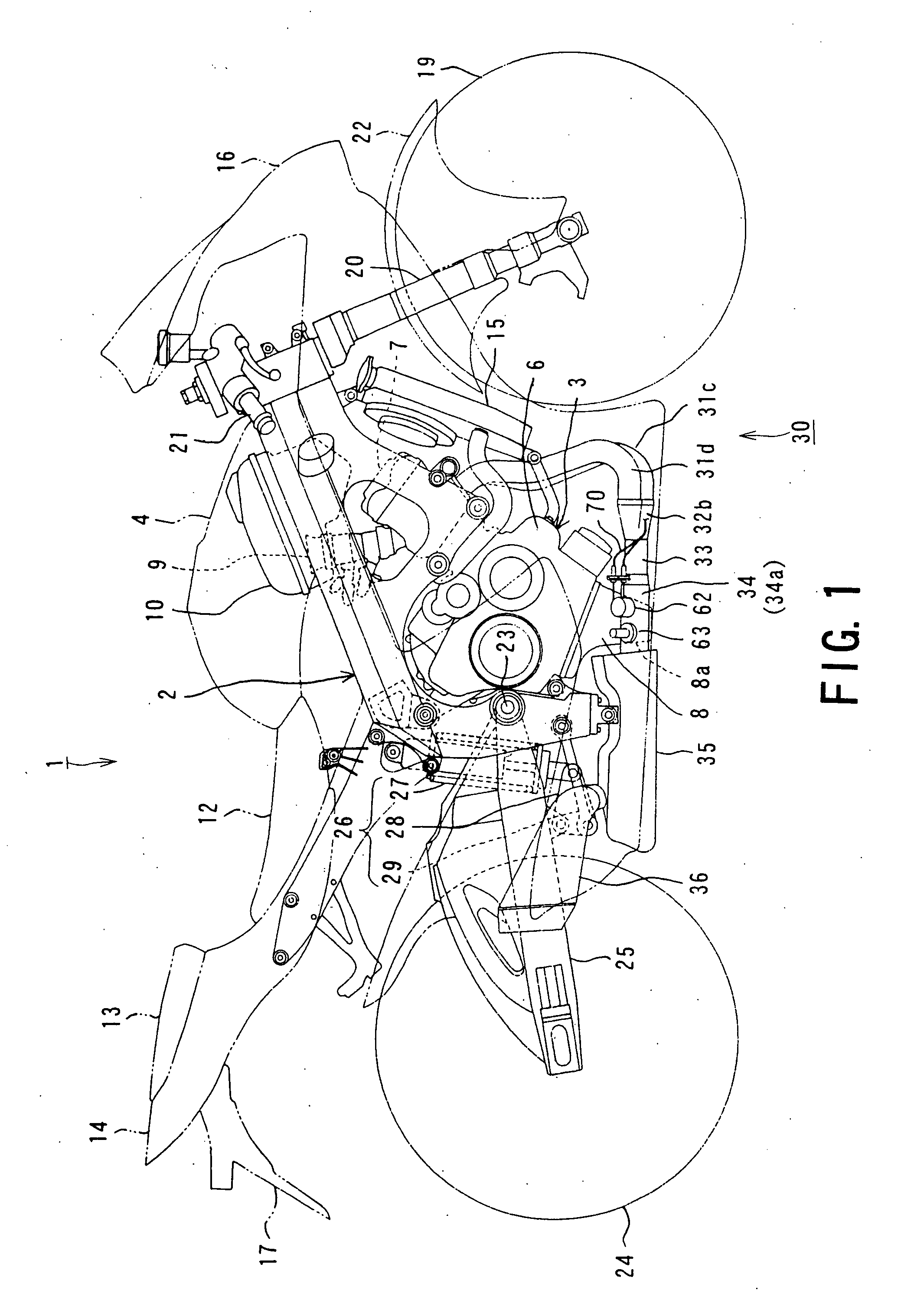

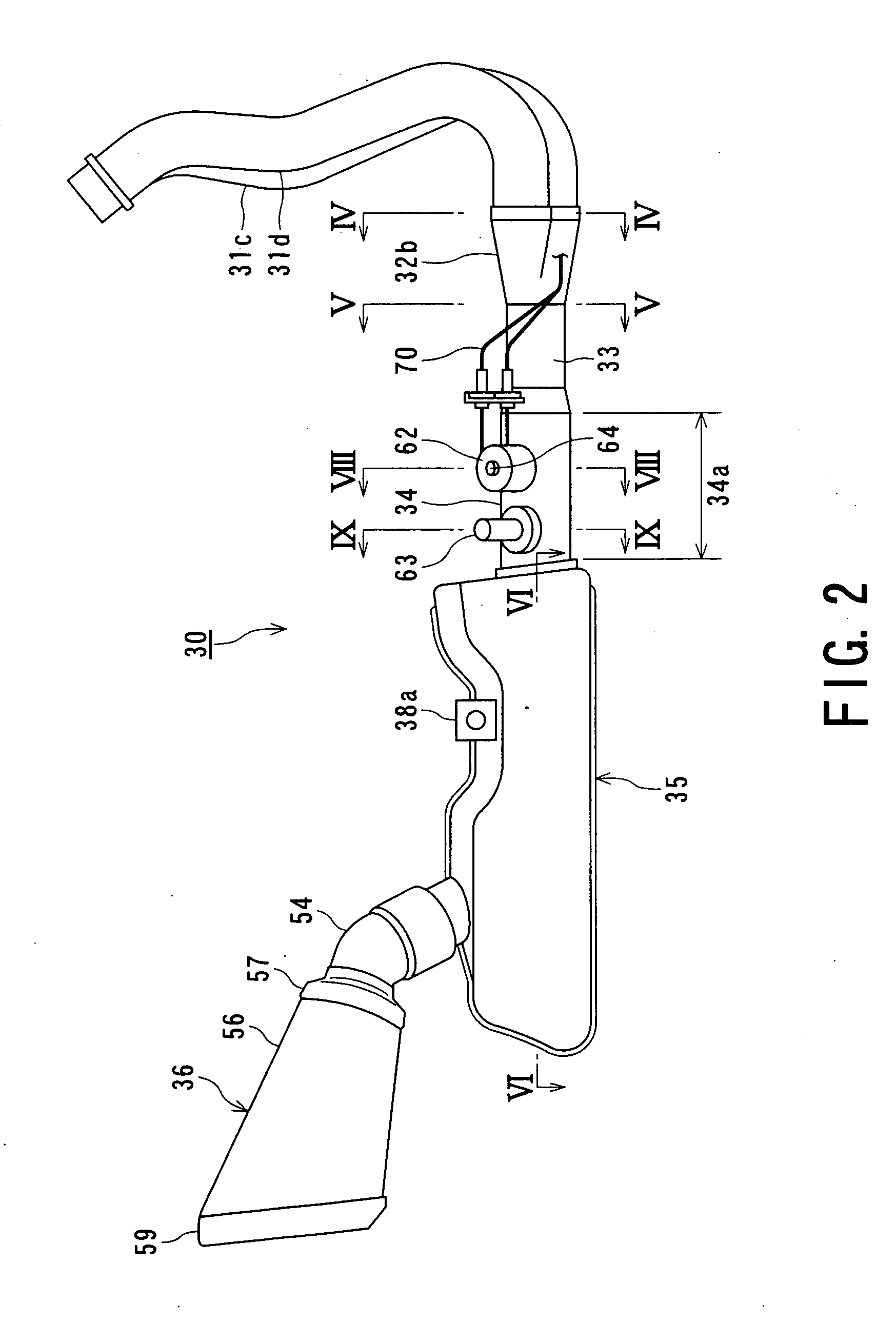

Exhaust system for motorcycle

ActiveUS20060242952A1Operation efficiency can be improvedImpairing running stabilityExhaust apparatusSilencing apparatusCrankcaseExpansion chamber

An exhaust system for a motorcycle having an engine mounted on a front half of a body frame of the motorcycle includes a plurality of first exhaust pipes extending from exhaust ports of the engine, a collecting section at which the first exhaust pipes are collected, a second exhaust pipe including a substantially straight portion connected to a downstream side of the collecting section and disposed under a crankcase of the engine, an expansion chamber connected to a downstream side of the second exhaust pipe and located under a rear wheel suspension arranged behind the engine, an exhaust outlet disposed on a most downstream portion of the expansion chamber, and an exhaust throttle valve and an exhaust gas sensor disposed on the straight portion of the second exhaust pipe.

Owner:SUZUKI MOTOR CORP

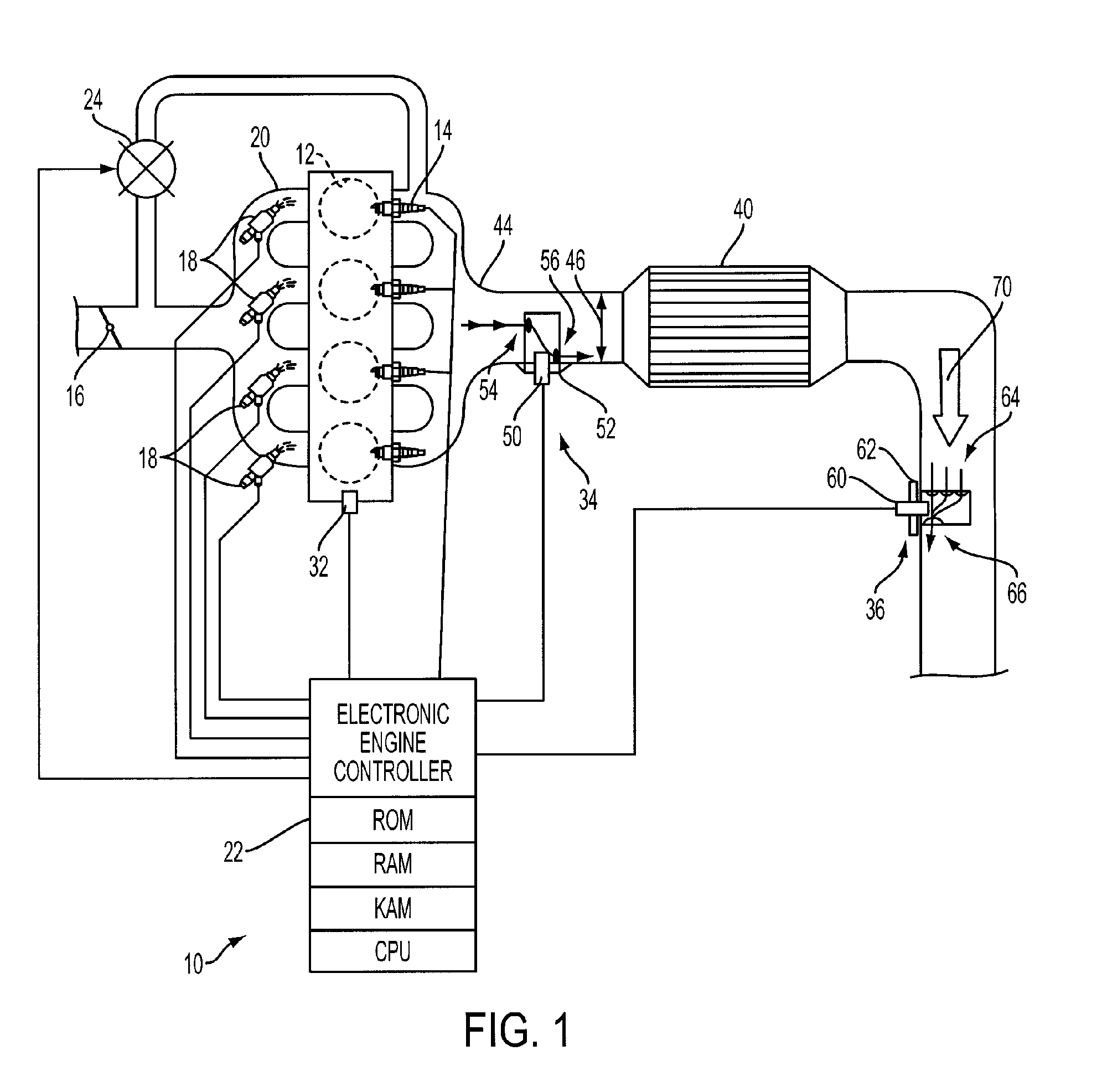

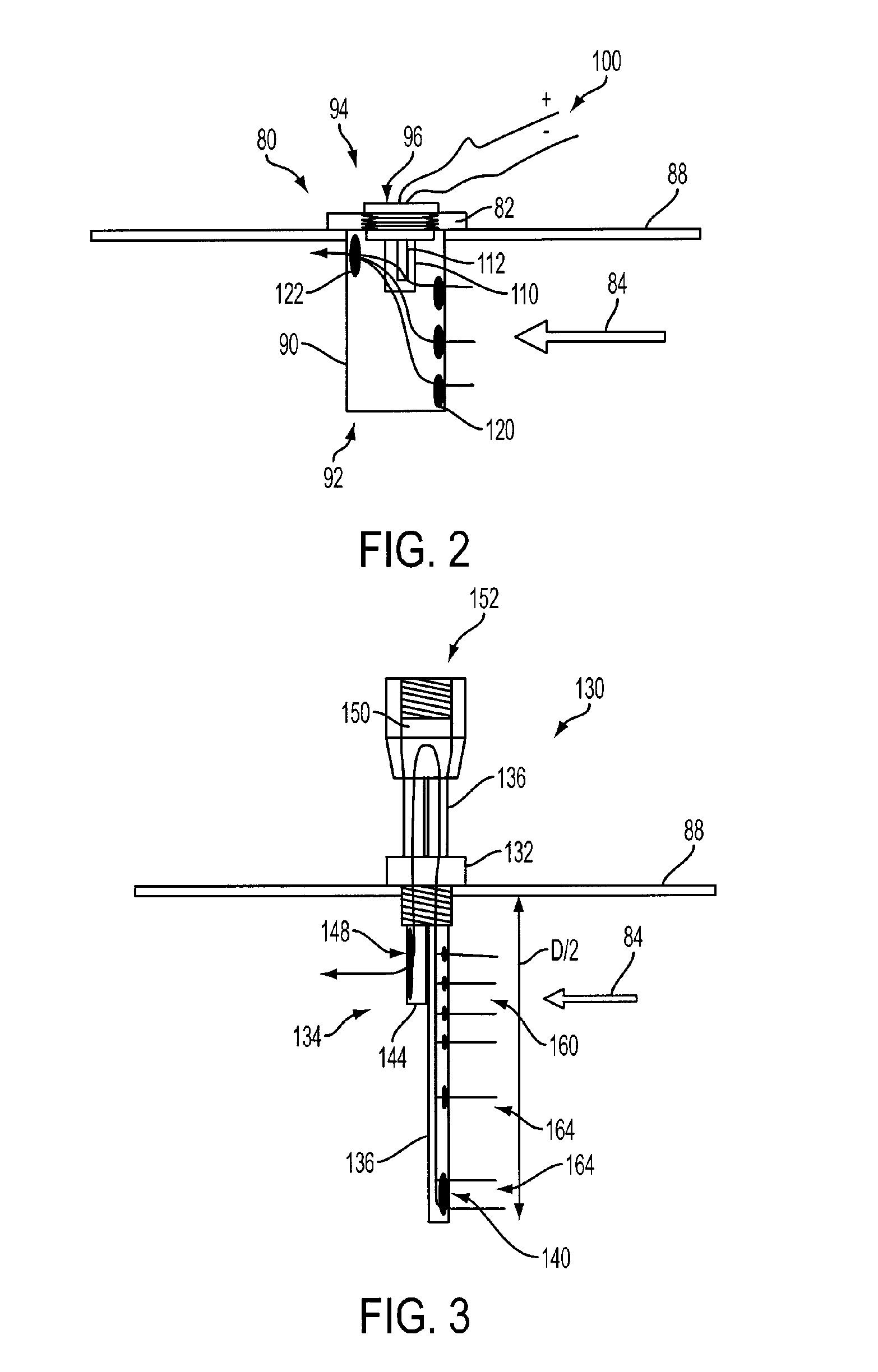

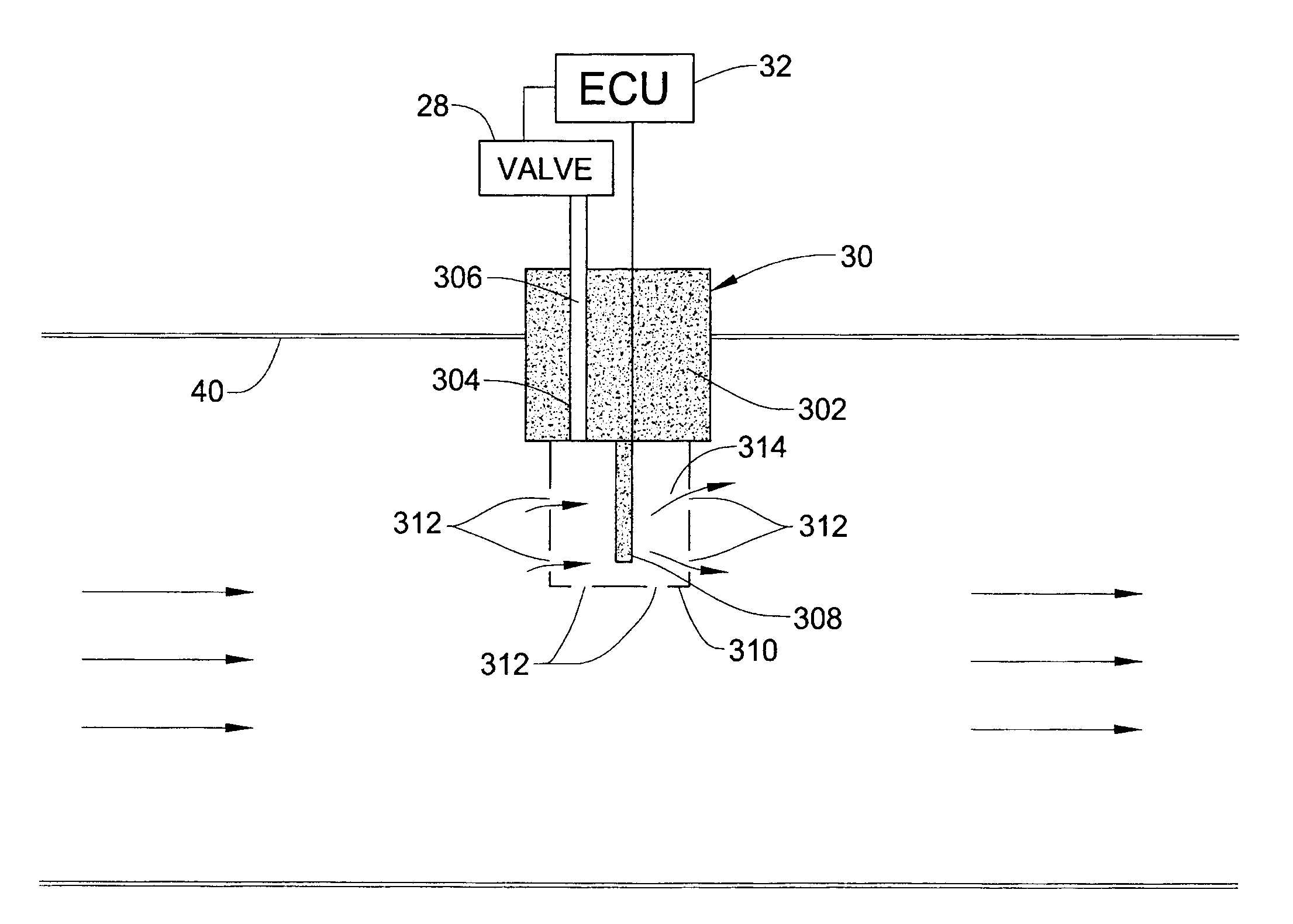

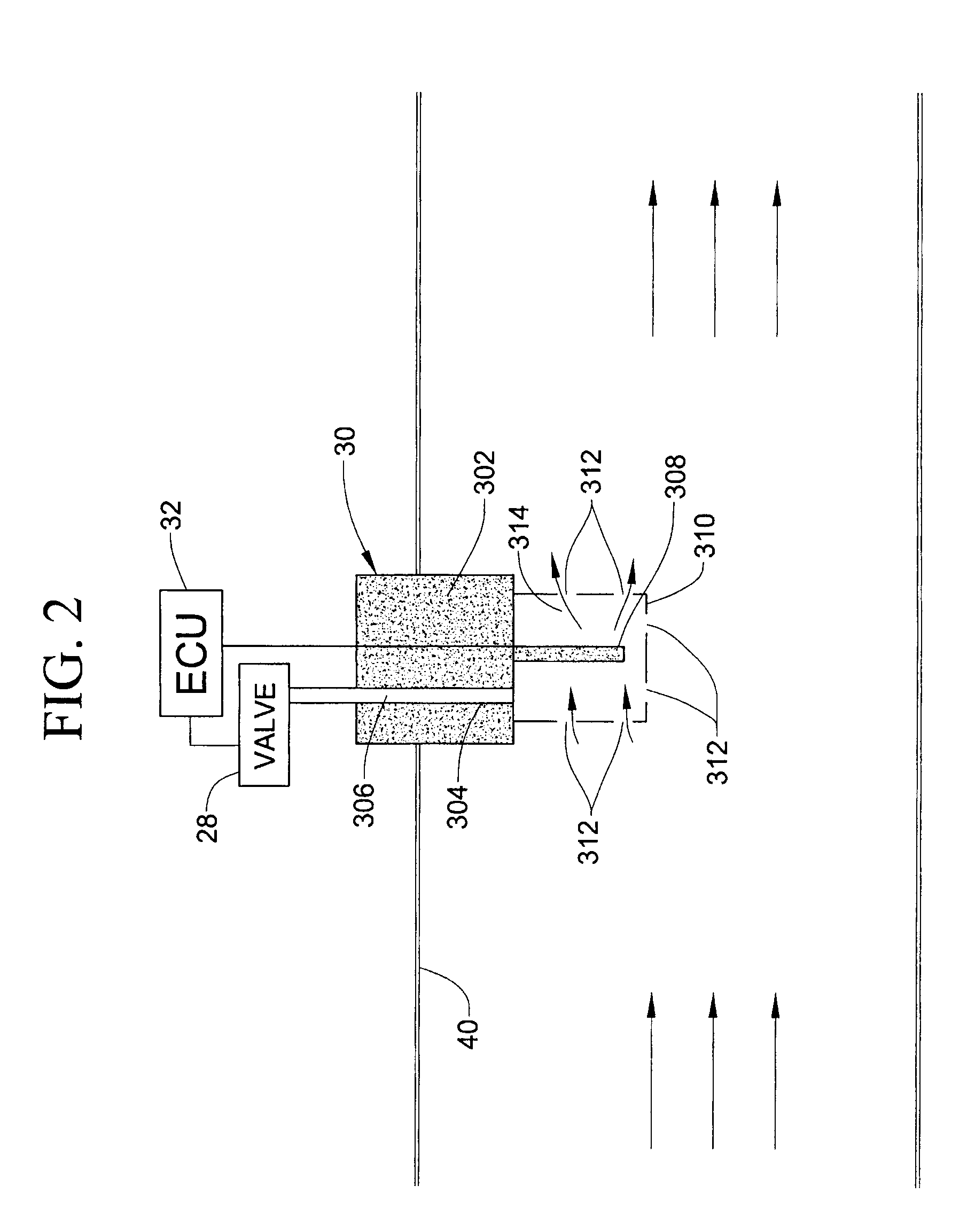

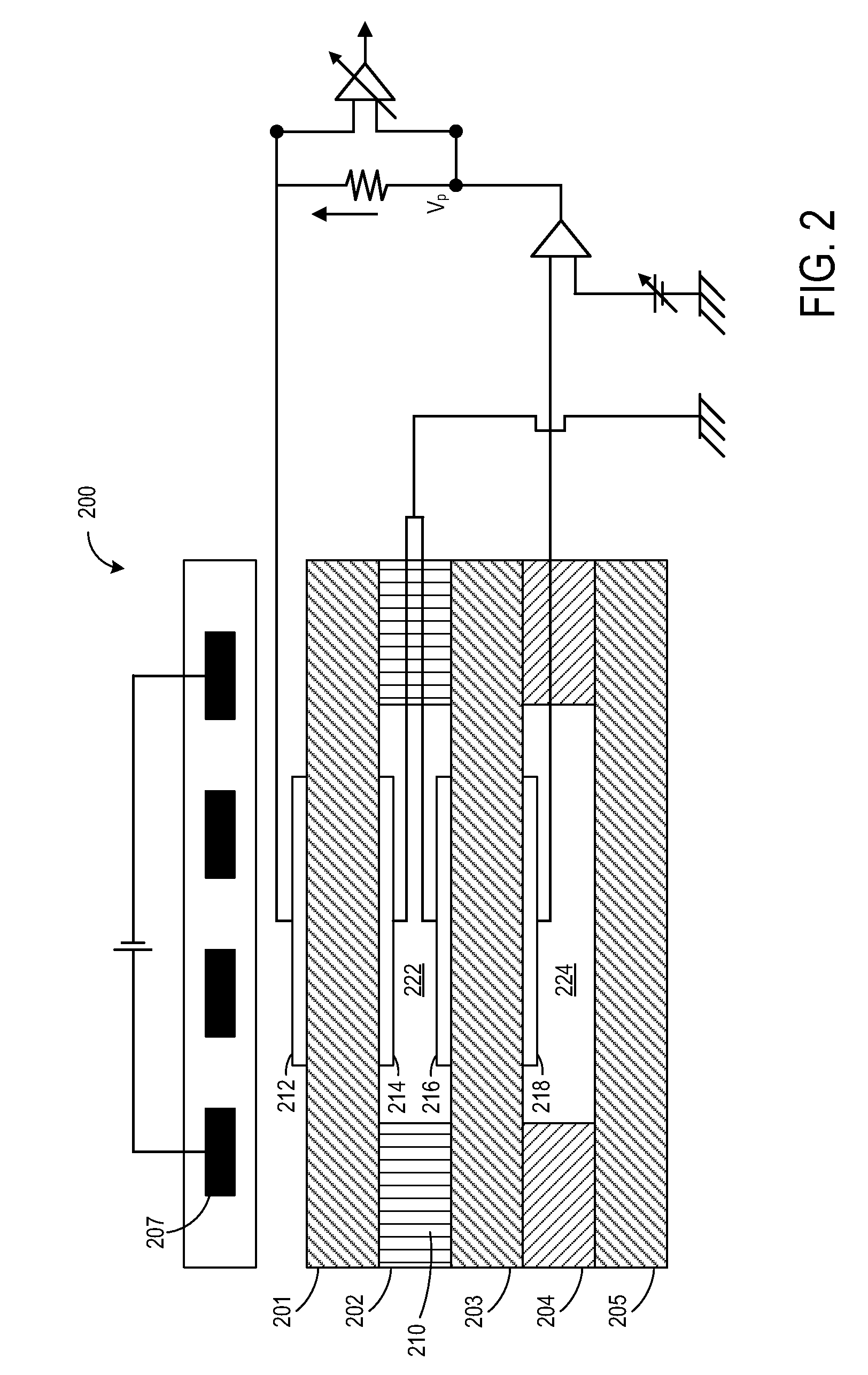

System and method for improving performance of a fluid sensor for an internal combustion engine

ActiveUS20070214862A1Improve performanceEasy to controlExhaust apparatusEngine testingOn boardExhaust gas sensor

A system and method for improving sensor performance of an on-board vehicle sensor, such as an exhaust gas sensor, while sensing a predetermined substance in a fluid flowing through a pipe include a structure for extending into the pipe and having at least one inlet for receiving fluid flowing through the pipe and at least one outlet generally opposite the at least one inlet, wherein the structure redirects substantially all fluid flowing from the at least one inlet to the sensor to provide a representative sample of the fluid to the sensor before returning the fluid through the at least one outlet.

Owner:FORD GLOBAL TECH LLC

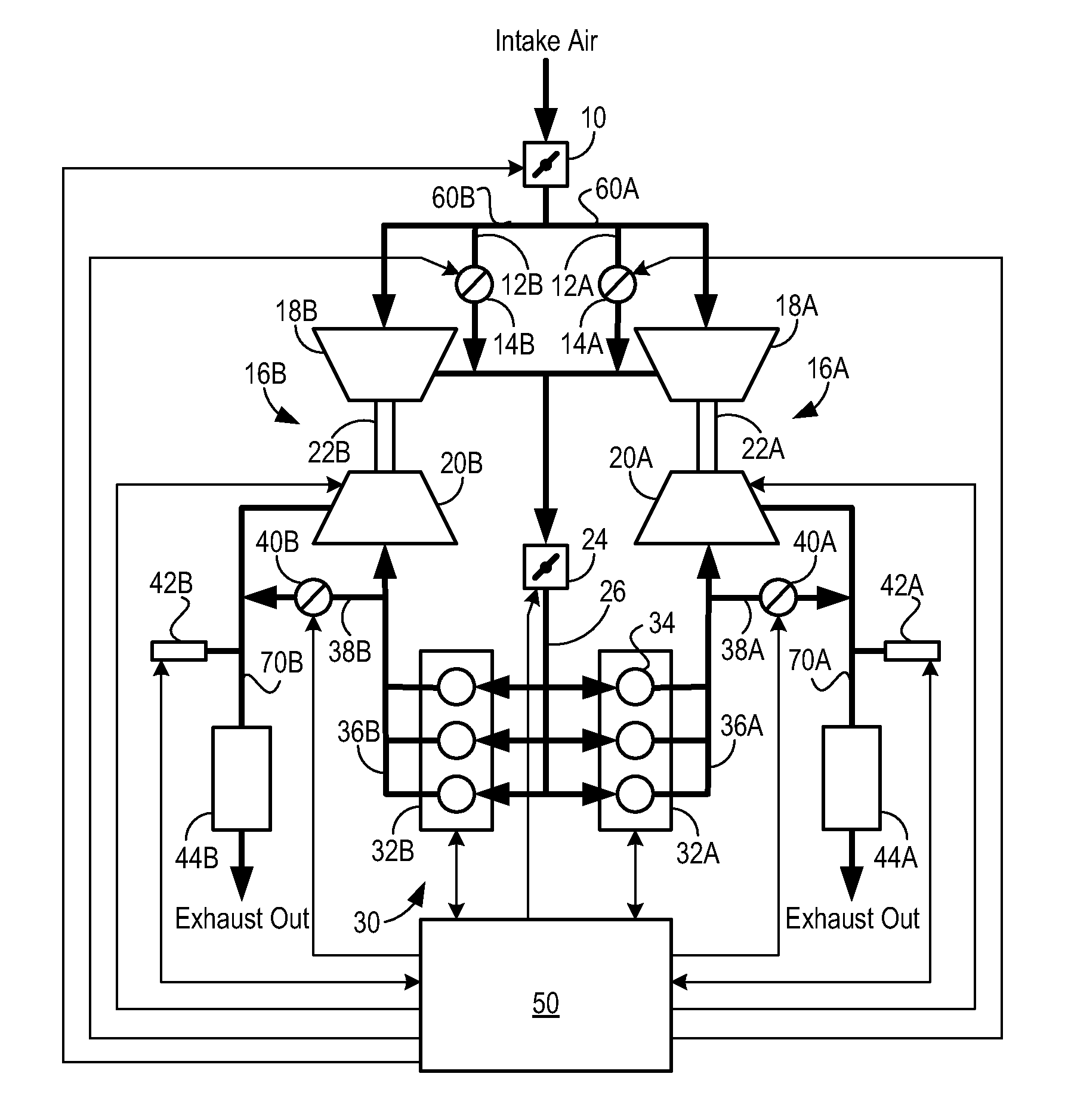

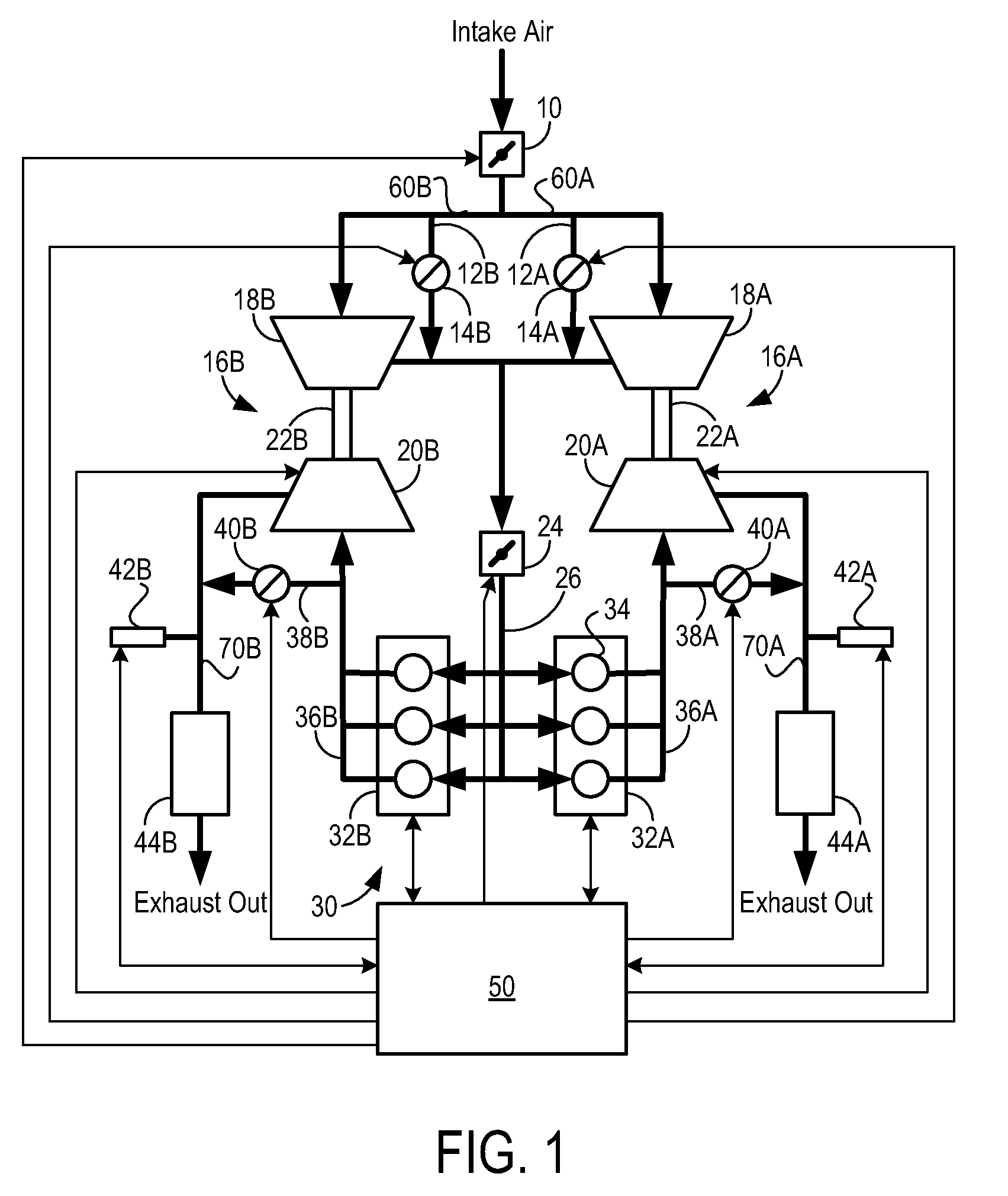

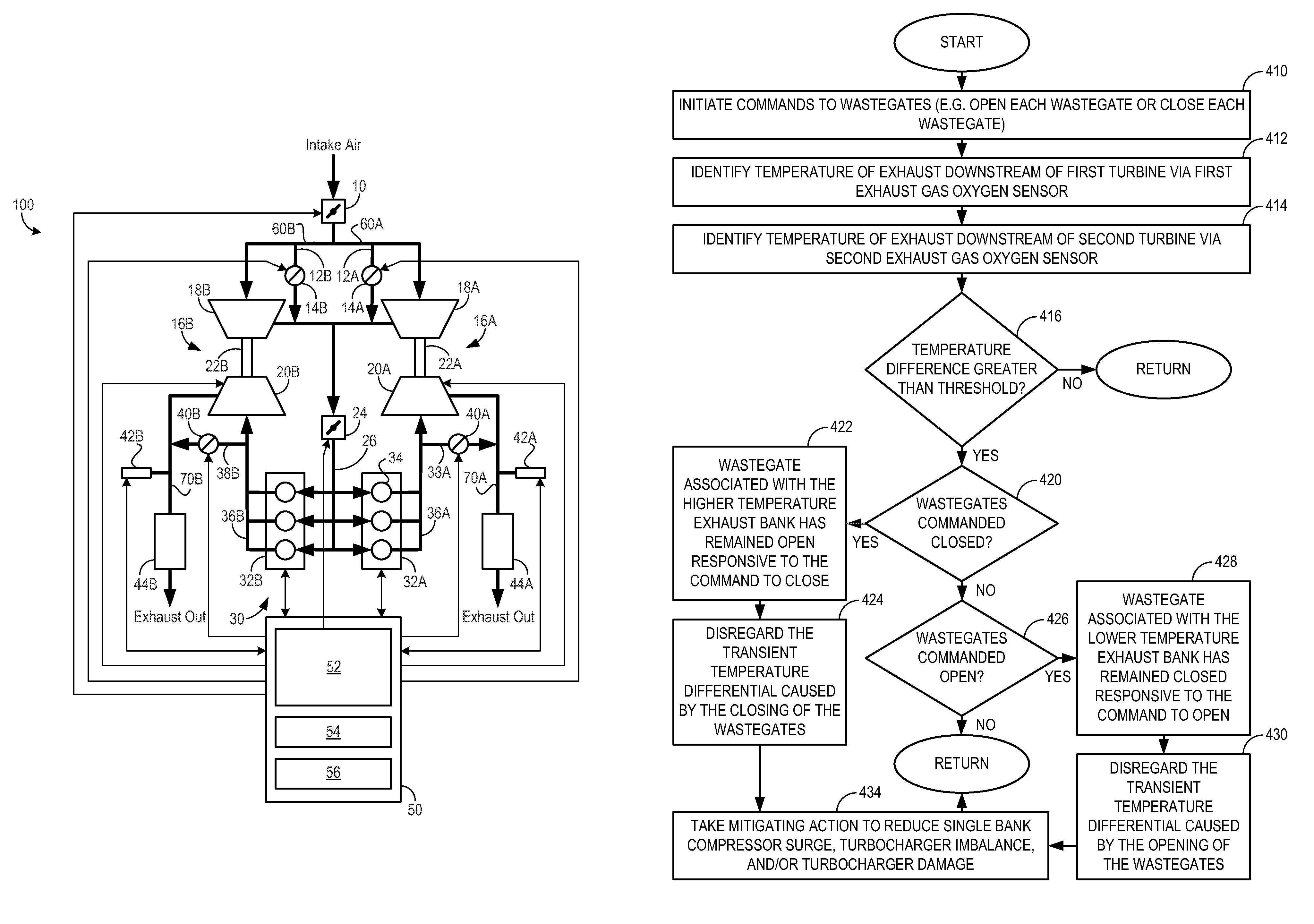

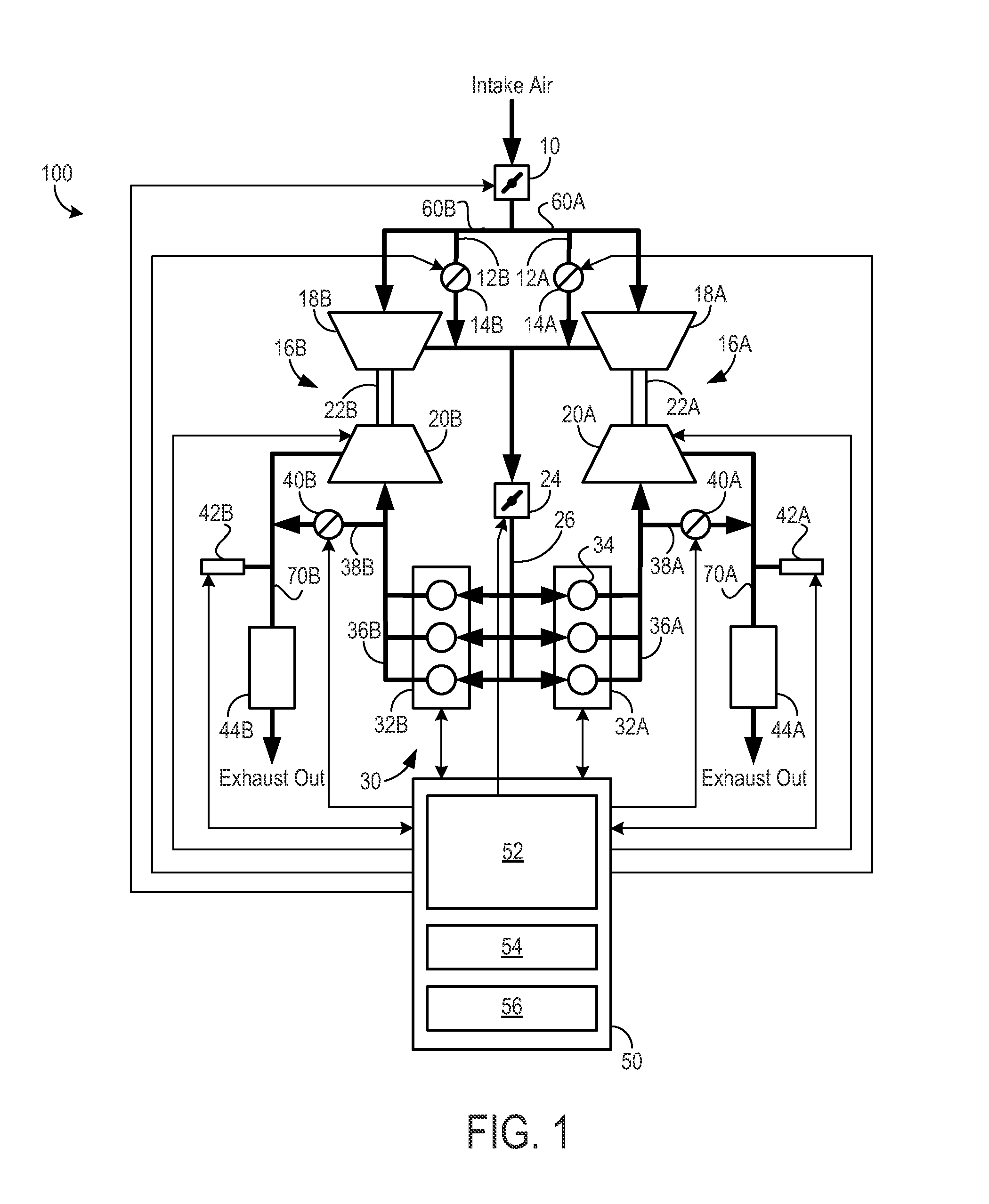

Approach for Identifying and Responding to an Unresponsive Wastegate in a Twin Turbocharged Engine

ActiveUS20090077965A1Reduce turbocharger imbalanceReduce compressor surgeElectrical controlInternal combustion piston enginesWastegateControl system

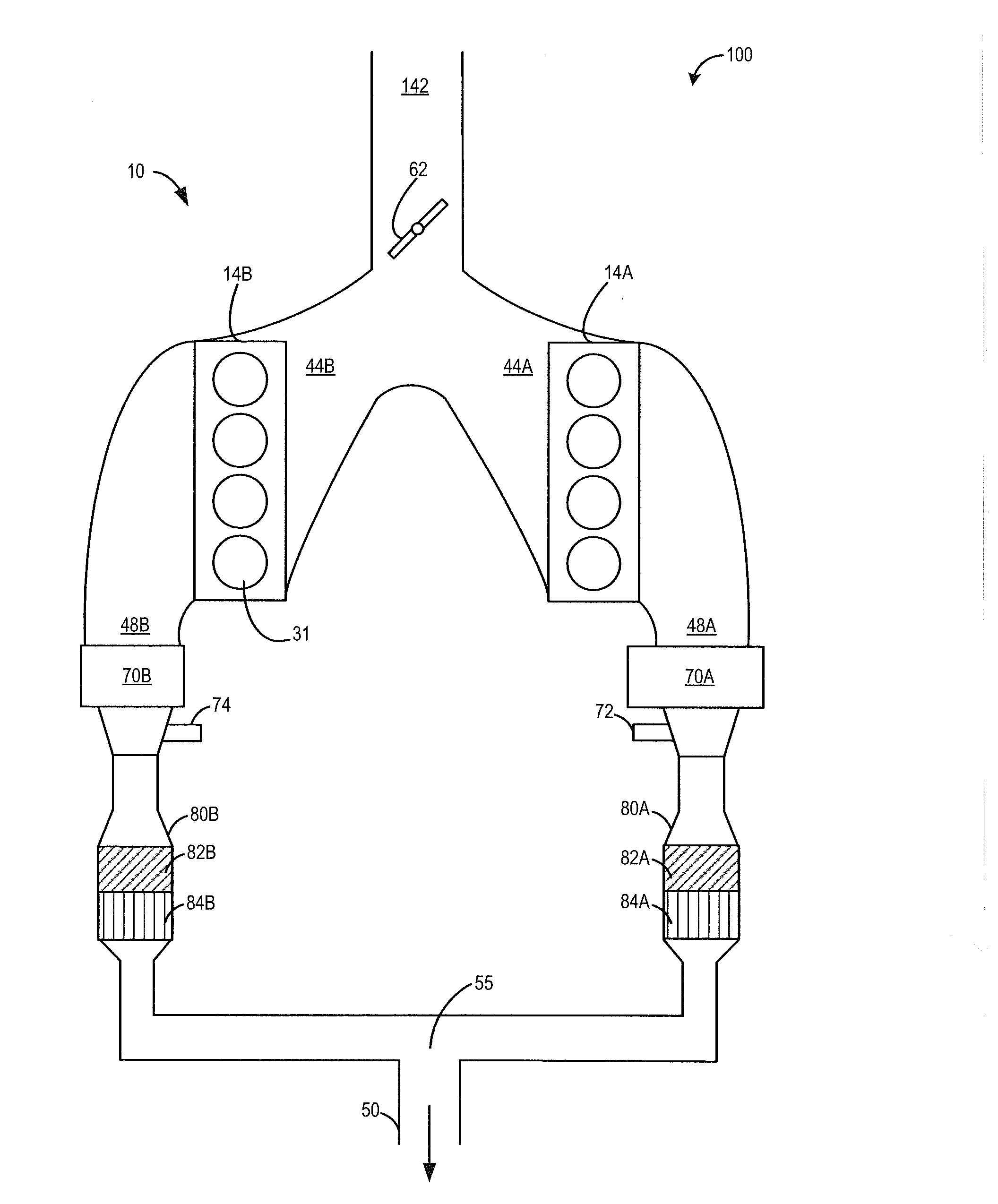

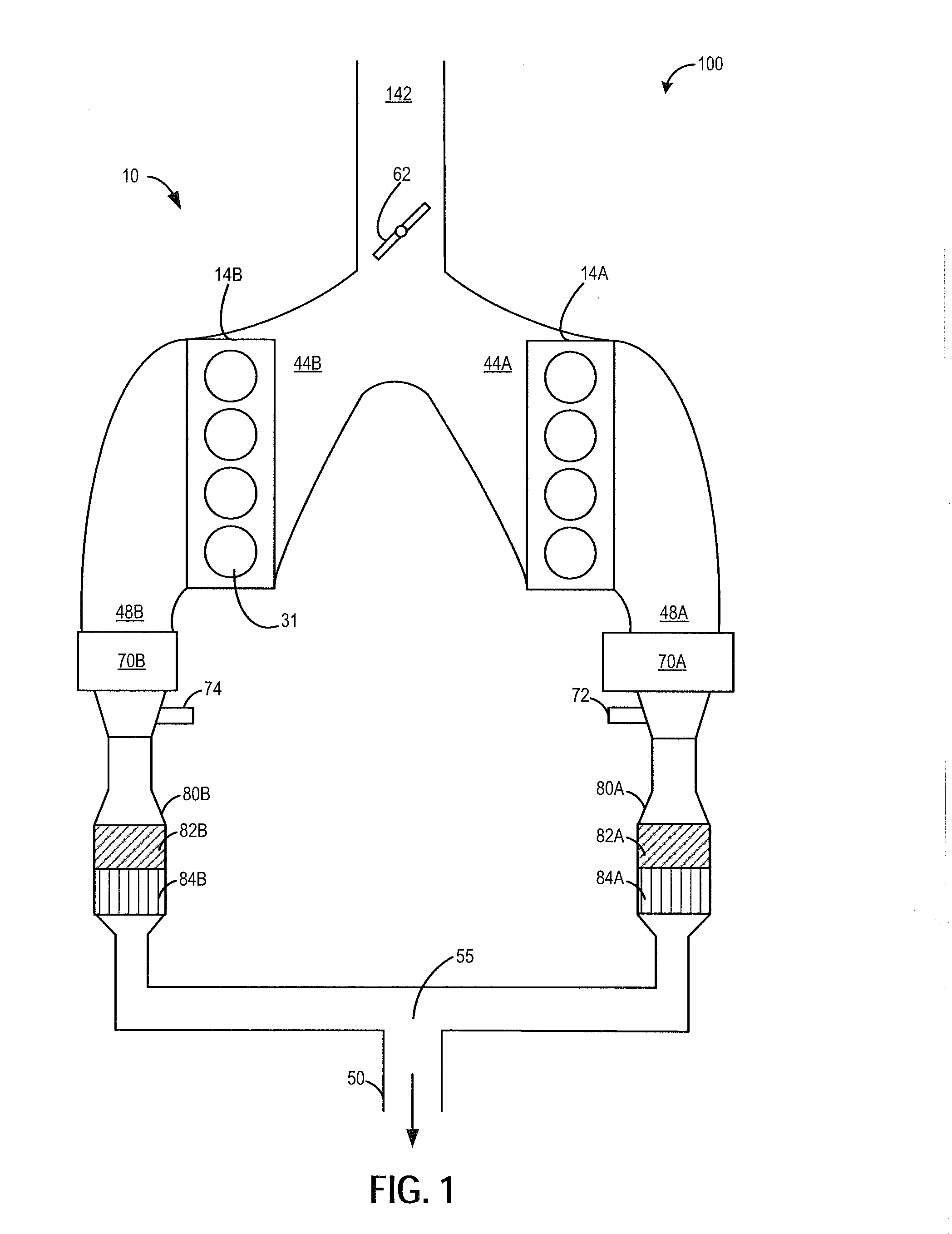

As one example, an engine system for a vehicle is provided, comprising an internal combustion engine including an air intake system and an exhaust system; a first turbocharger including a first compressor arranged along a first branch of the air intake system, a first turbine arranged along a first branch of the exhaust system, and a first turbine bypass passage include a first wastegate; a second turbocharger including a second compressor arranged along a second branch of the air intake system, a second turbine arranged along a second branch of the exhaust system, and a second turbine bypass passage including a second wastegate; a first exhaust gas sensor arranged along the first branch of the exhaust system downstream of the first turbine and first wastegate; a second exhaust gas sensor arranged along the second branch of the exhaust system downstream of the second turbine and the second wastegate; and a control system configured to command both the first wastegate and the second wastegate to a closed position or an opened position and to indicate one of said wastegates as unresponsive to said command in response to a temperature difference between the first and second branches indicated by the first and second exhaust gas sensors.

Owner:FORD GLOBAL TECH LLC

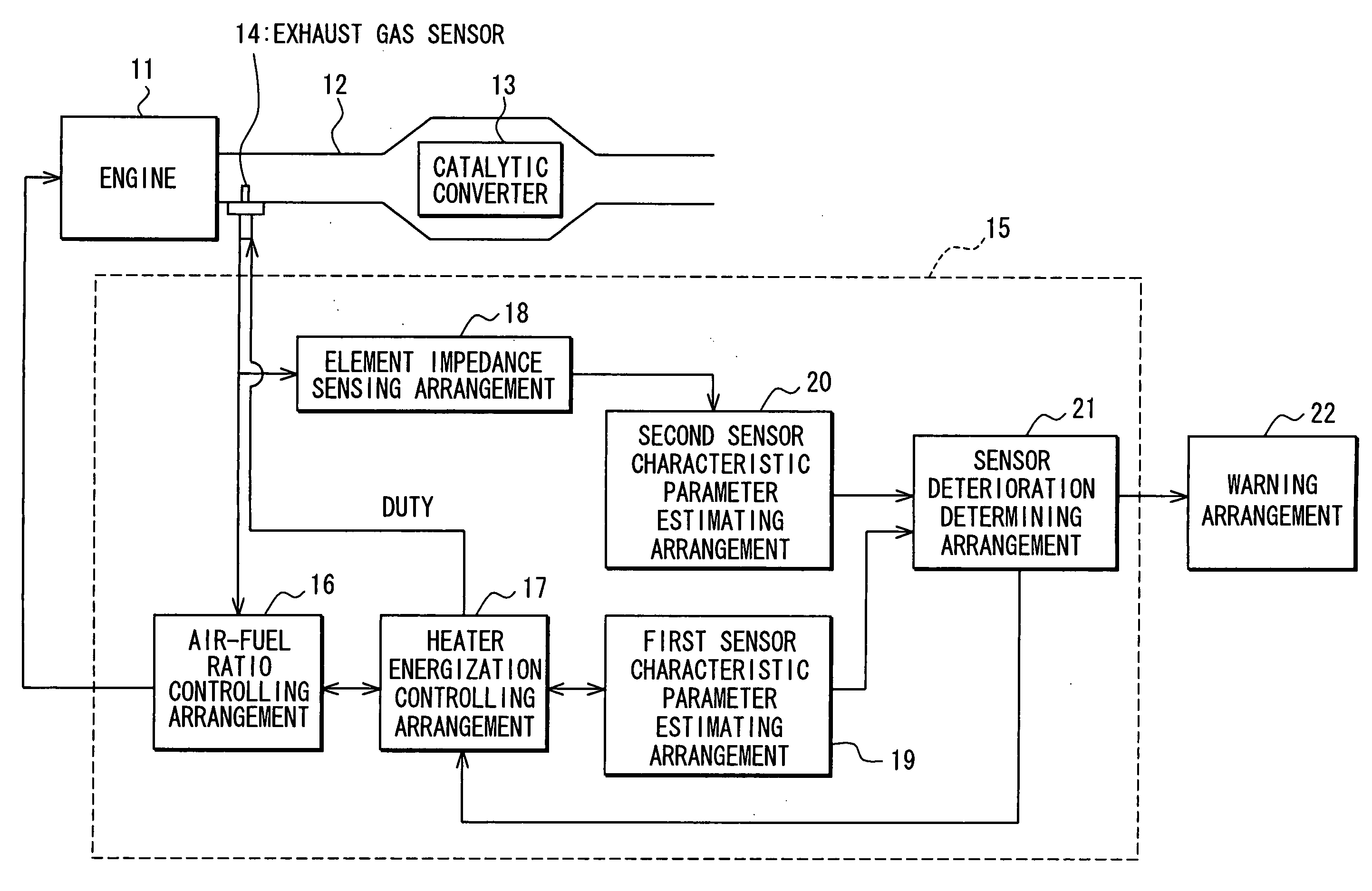

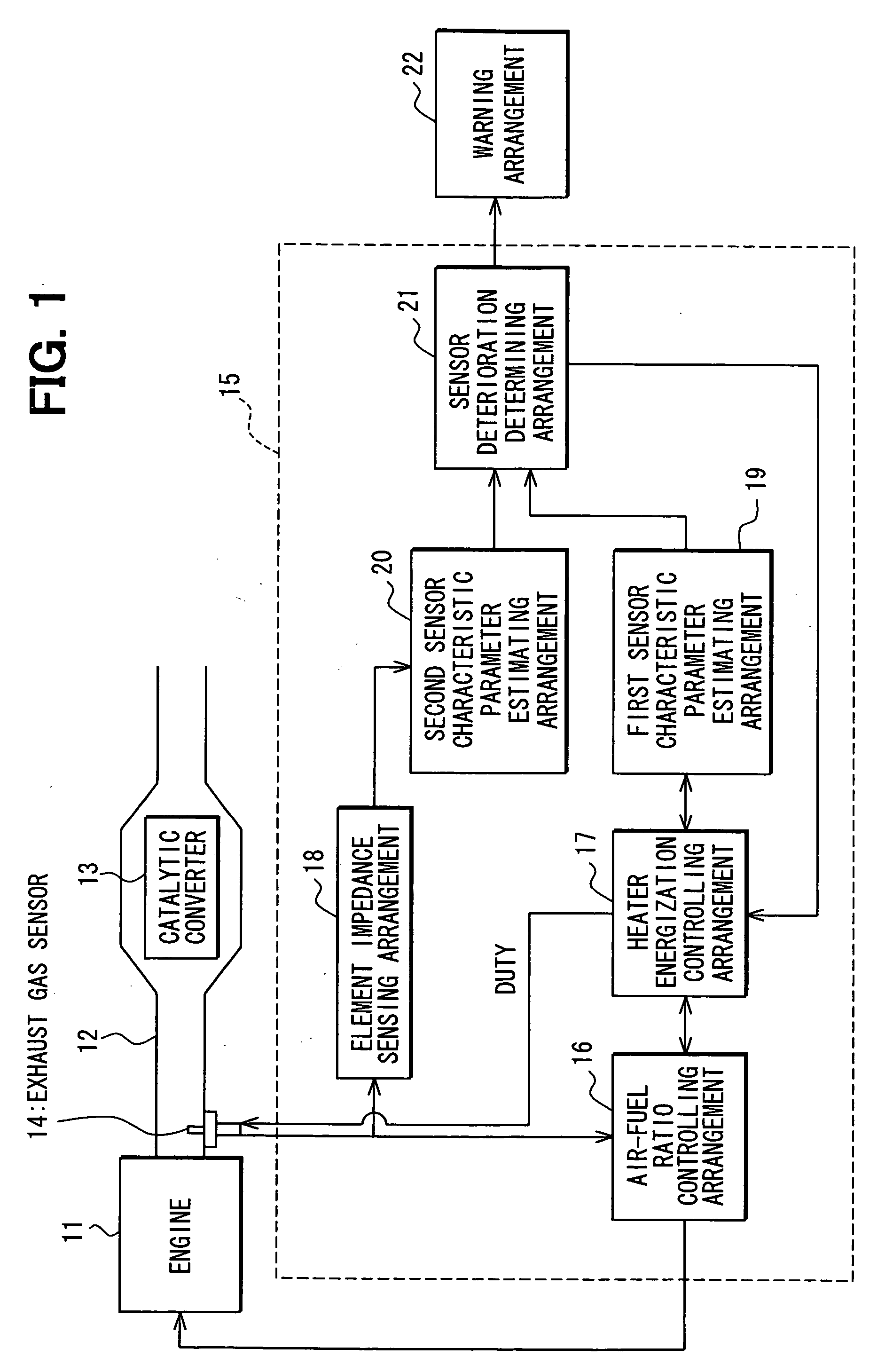

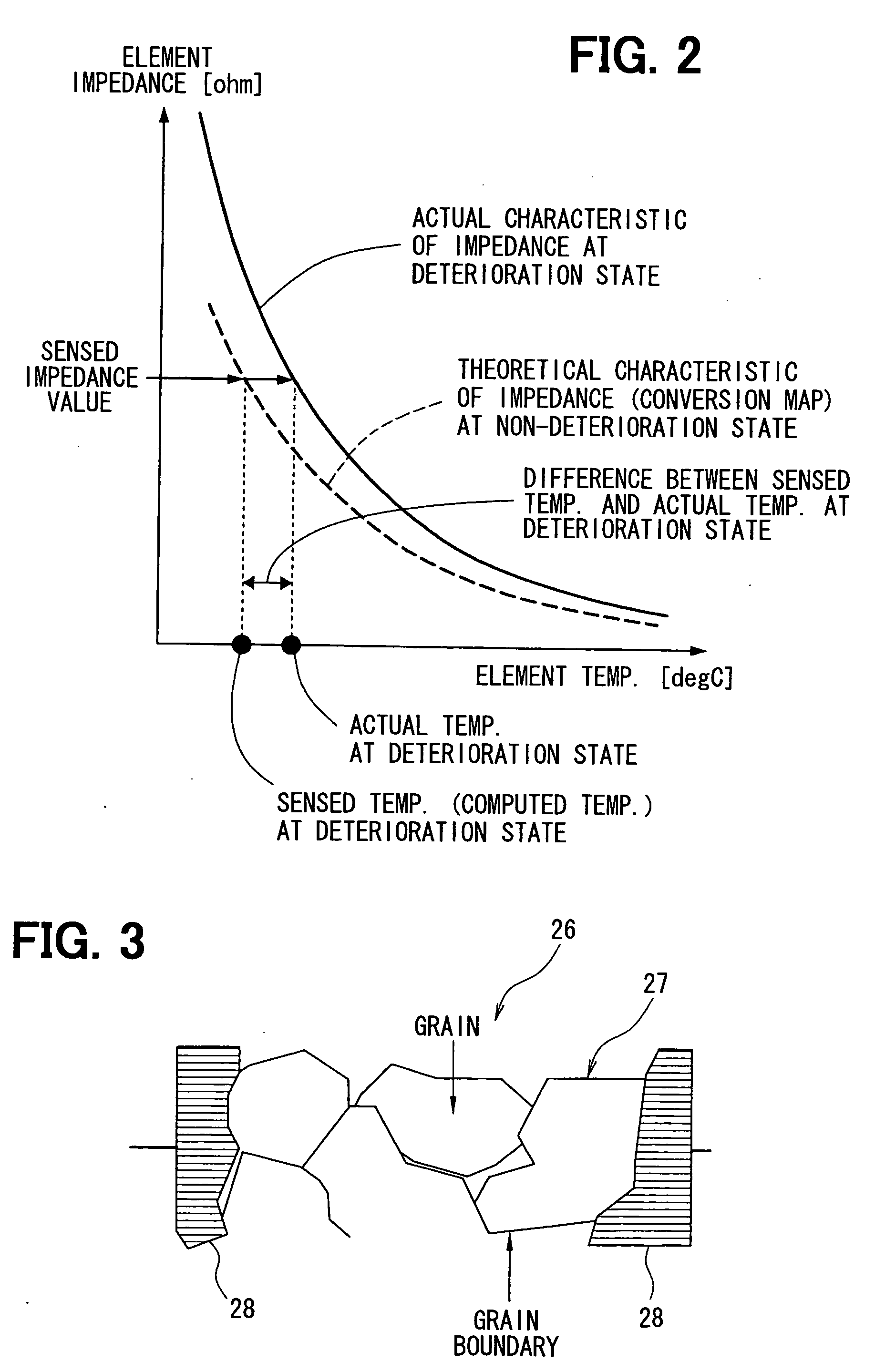

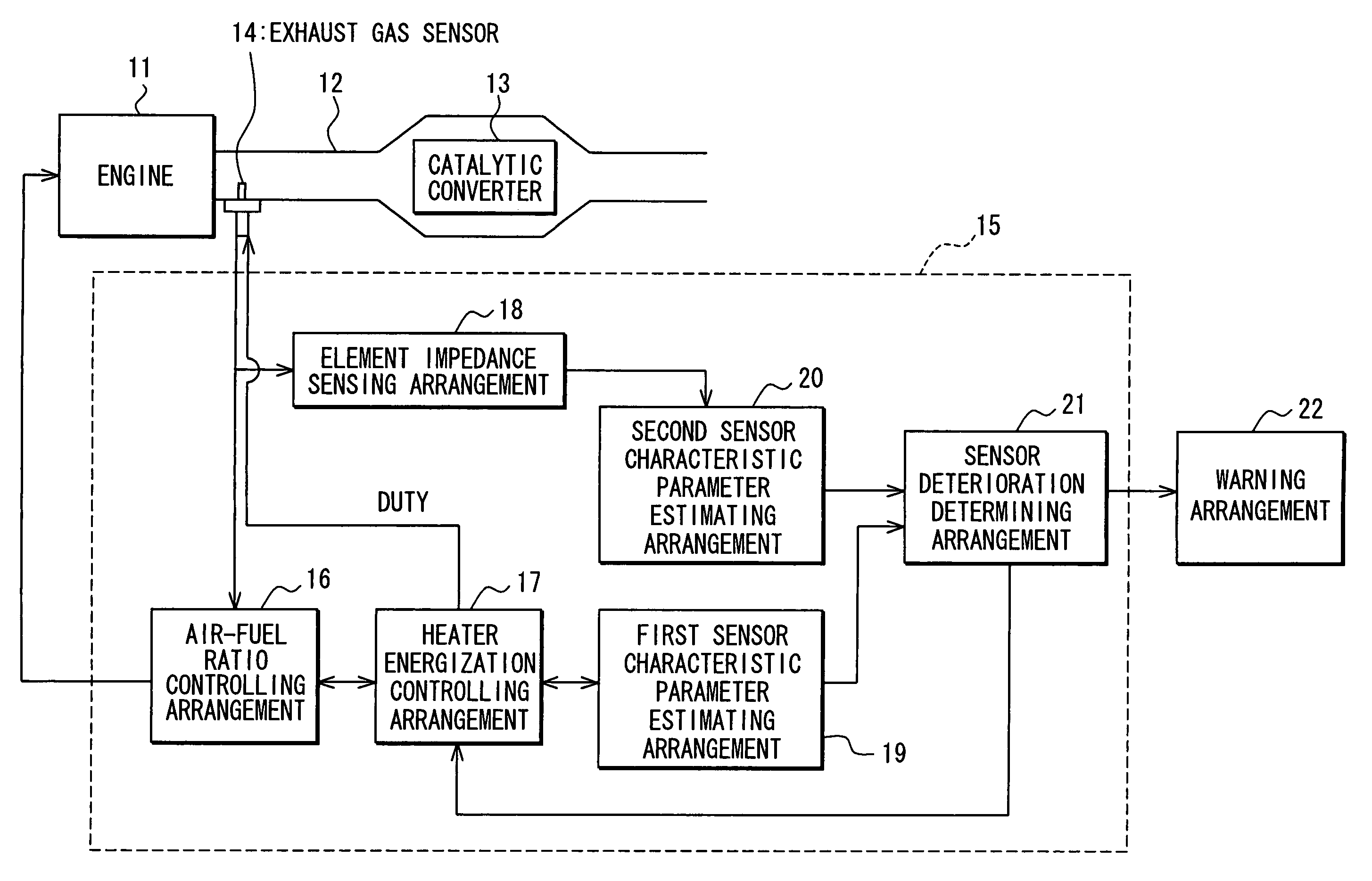

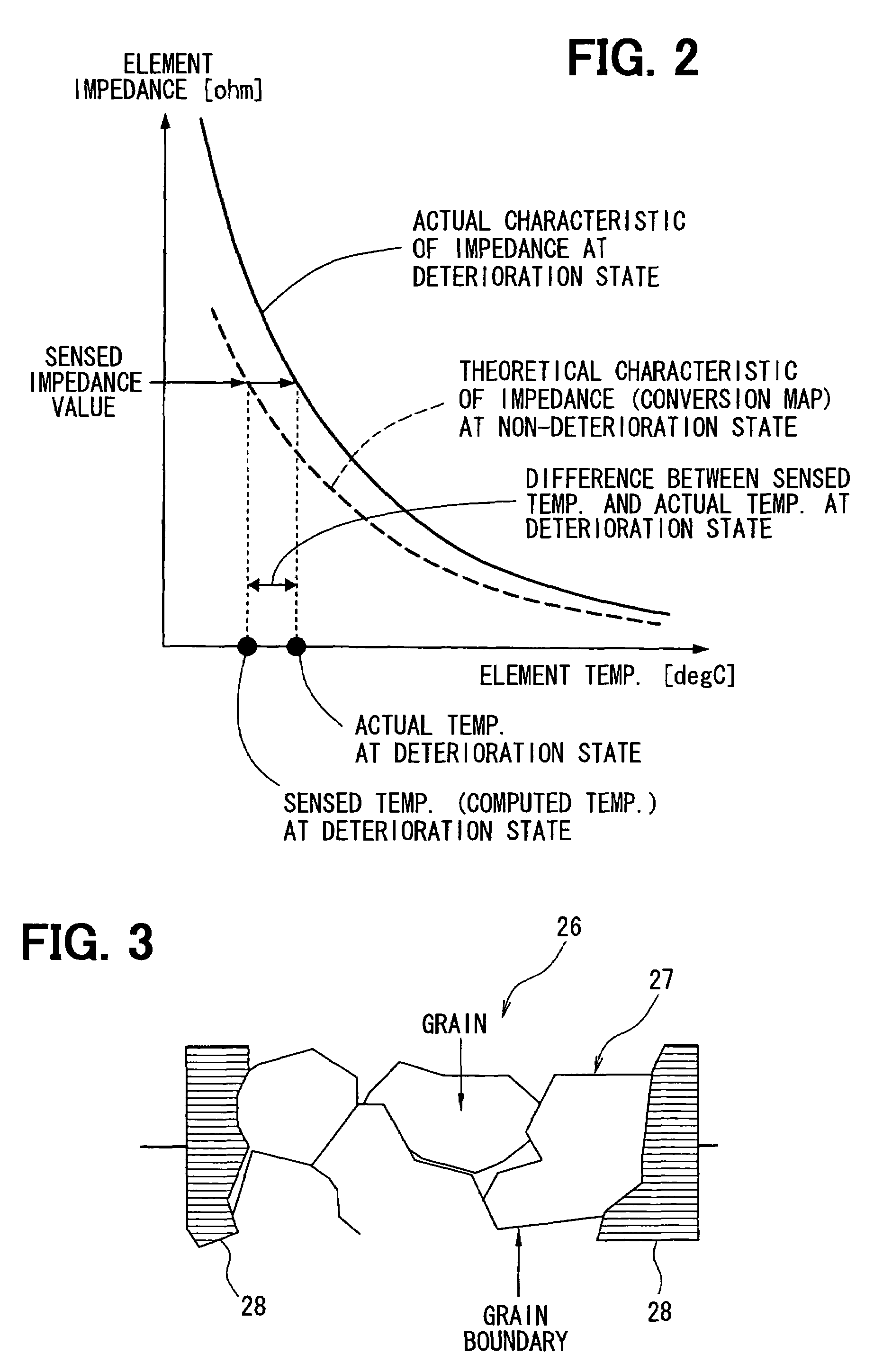

Apparatus and method for detecting deterioration of exhaust gas sensor

InactiveUS20070010932A1Analogue computers for vehiclesInternal-combustion engine testingThermal energyExhaust fumes

A deterioration detecting apparatus for an exhaust gas sensor of an internal combustion engine, the exhaust gas sensor including a sensor element and a heater that heats the sensor element, computes a first sensor characteristic parameter, which is related to a characteristic of the sensor element, by estimating an interchange state of thermal energy between the sensor element and a periphery of the sensor element. The deterioration detecting apparatus senses impedance of the sensor element. The deterioration detecting apparatus computes a second sensor characteristic parameter, which is related to the characteristic of the sensor element, based on the sensed impedance. The deterioration detecting apparatus determines a degree of deterioration of the exhaust gas sensor by comparing the first sensor characteristic parameter and the second sensor characteristic parameter.

Owner:DENSO CORP

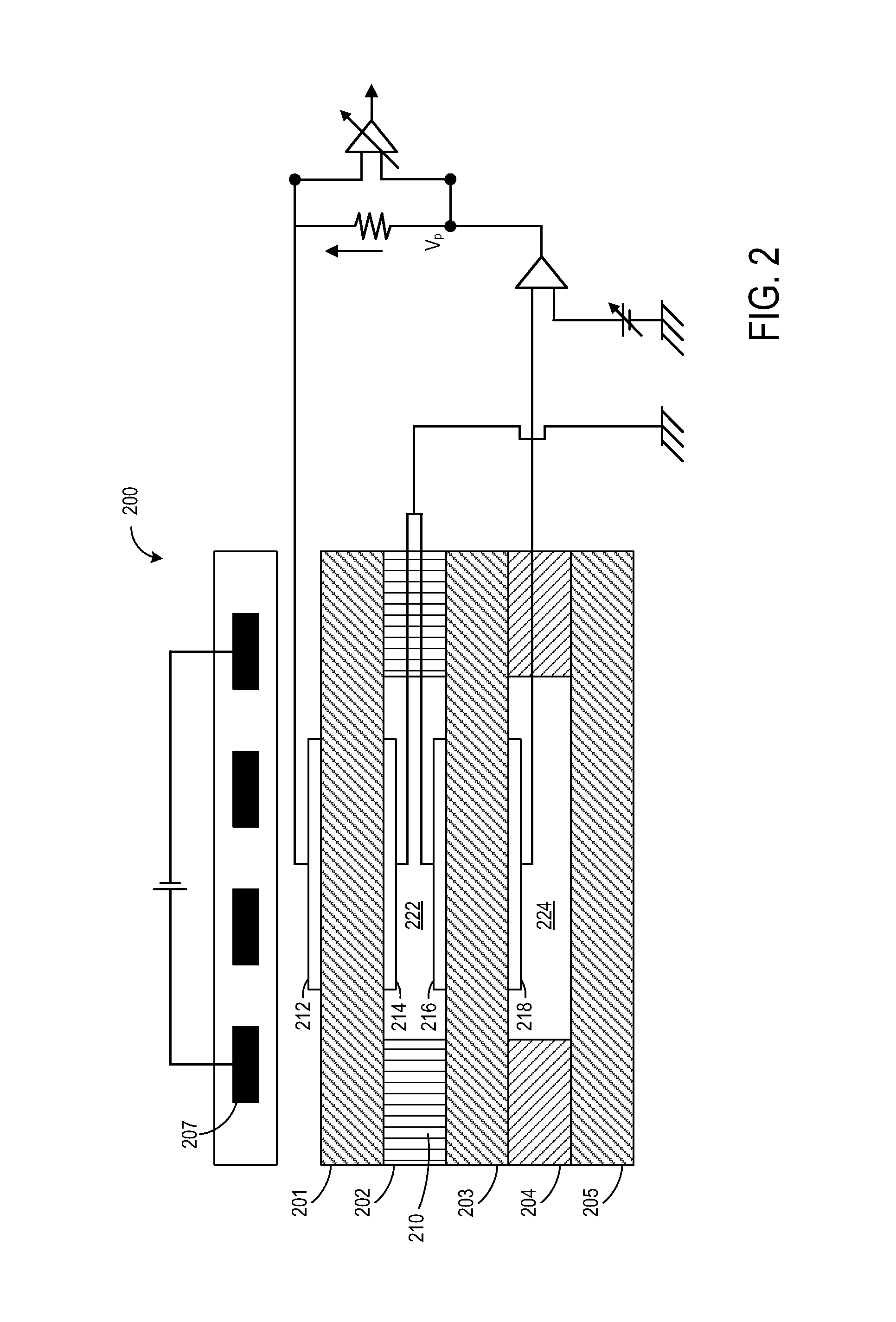

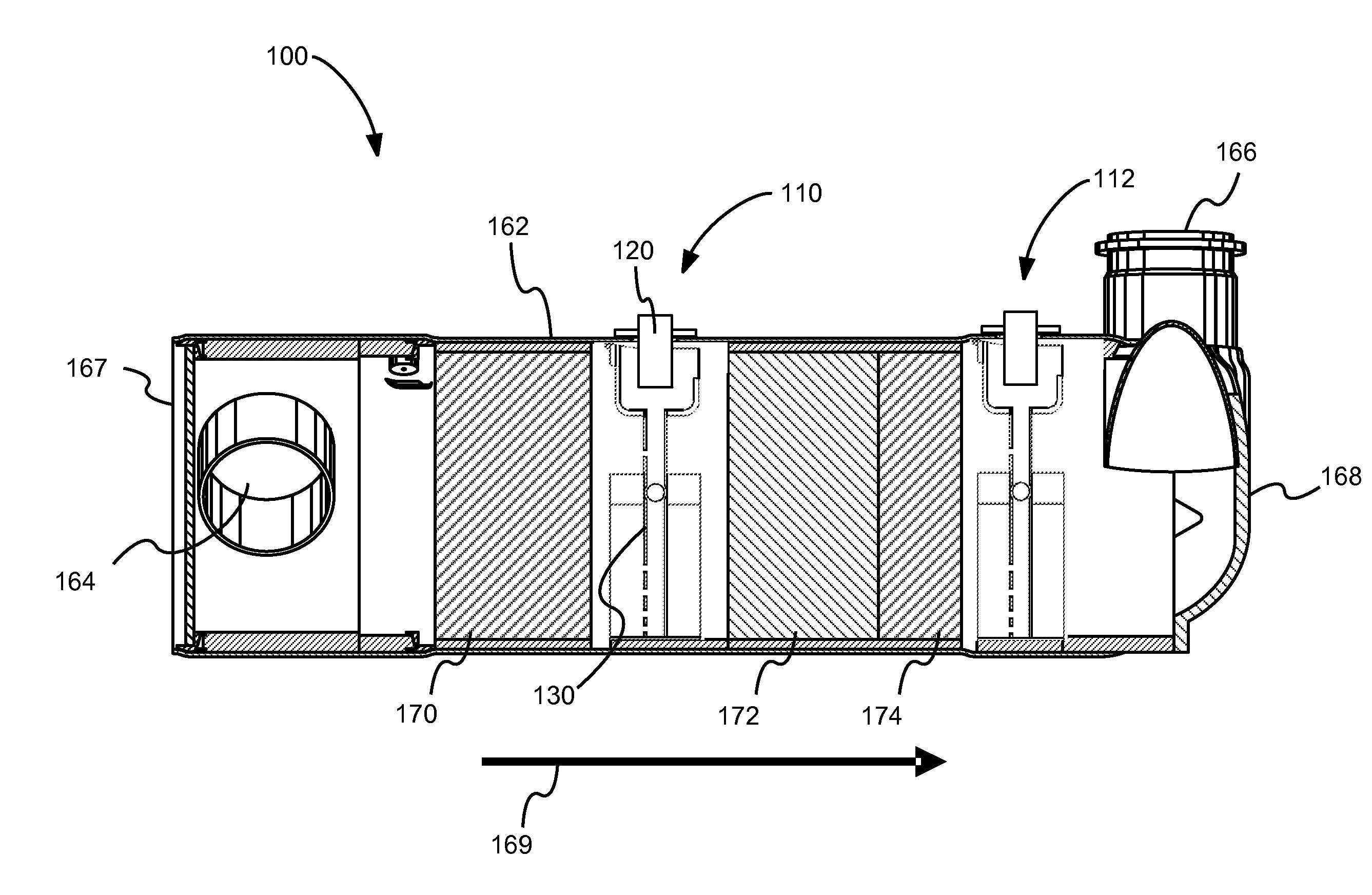

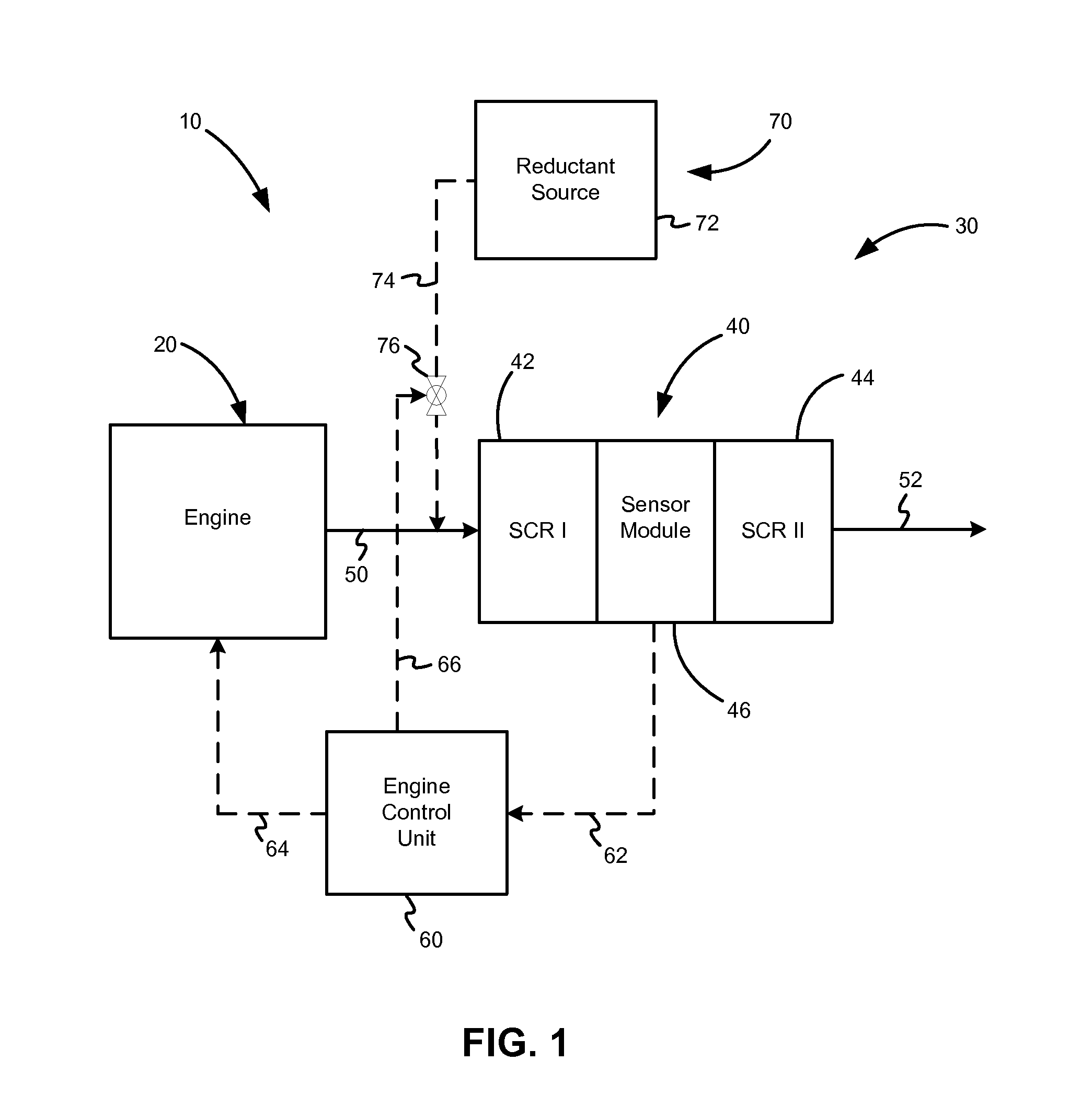

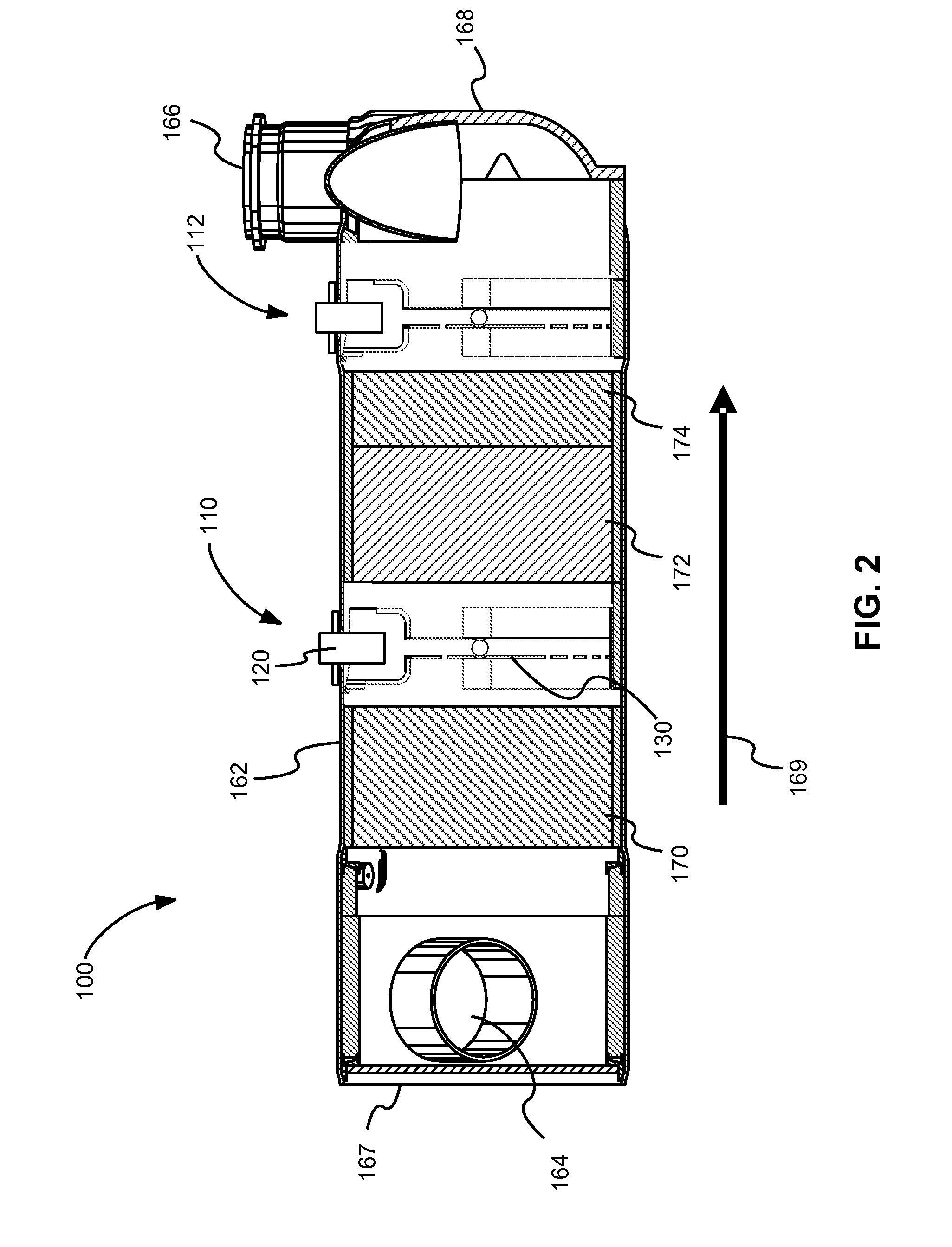

Exhaust gas sensor module

InactiveUS20130213013A1Overcomes shortcomingInternal-combustion engine testingSamplingEngineeringCatheter

Described herein is a sensor module for sensing characteristics of a fluid flowing through a fluid conduit. The sensor module includes a sample probe with at least one sample arm that extends radially inwardly from a sidewall portion of the fluid conduit to a center portion of the fluid conduit, defines a fluid flow channel, and includes a plurality of inlet apertures. The sample probe also includes a sensor well that is located at a radially outer end of the at least one sample arm. The sensor well defines an interior volume that is in fluid communication with the fluid flow channel, an upstream portion closed to an first portion of the fluid conduit upstream of sensor well, and a discharge aperture open to a second portion of the fluid conduit downstream of the sensor well. The sensor module also includes a sensor positioned in the interior volume.

Owner:CUMMINS INTPROP INC

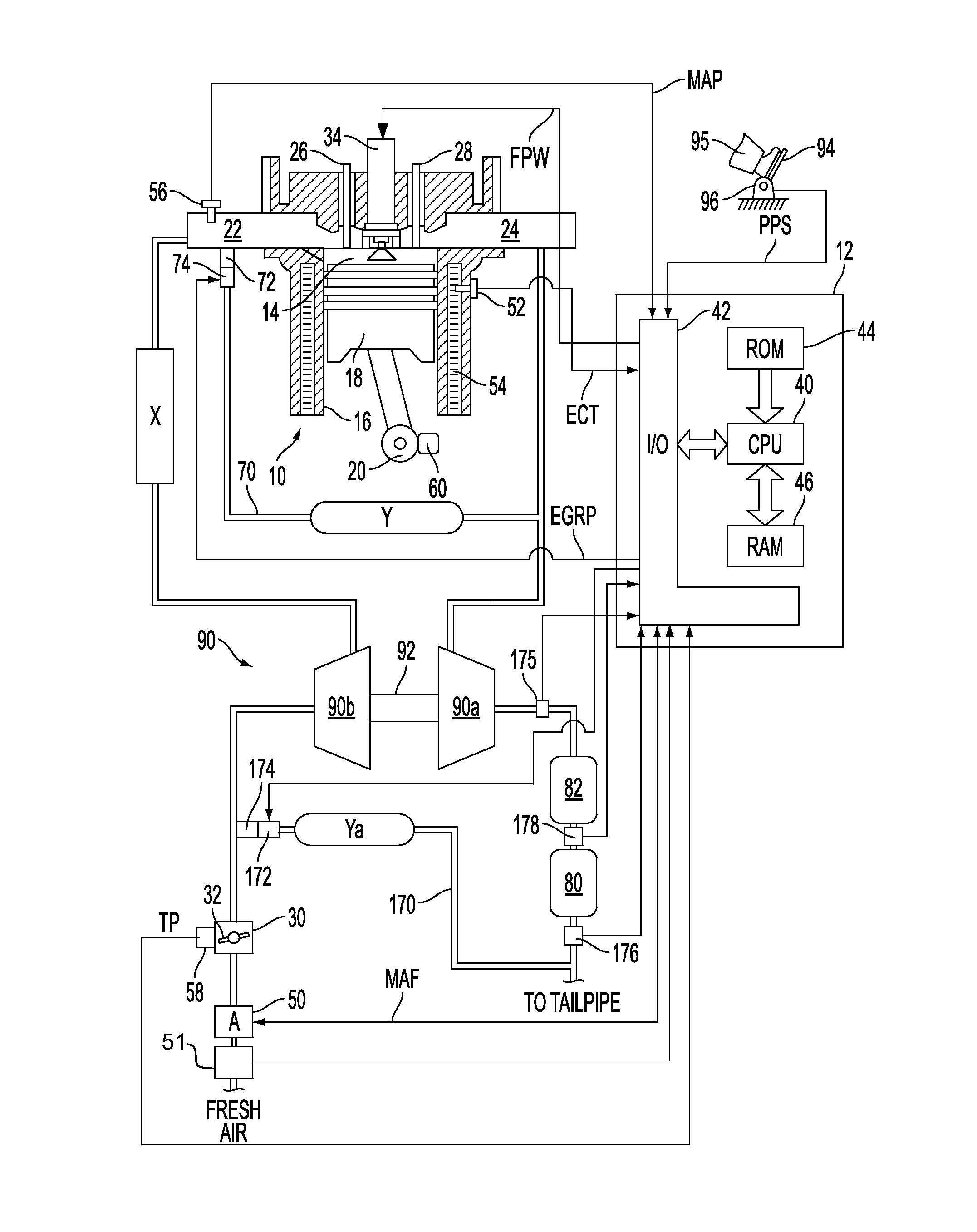

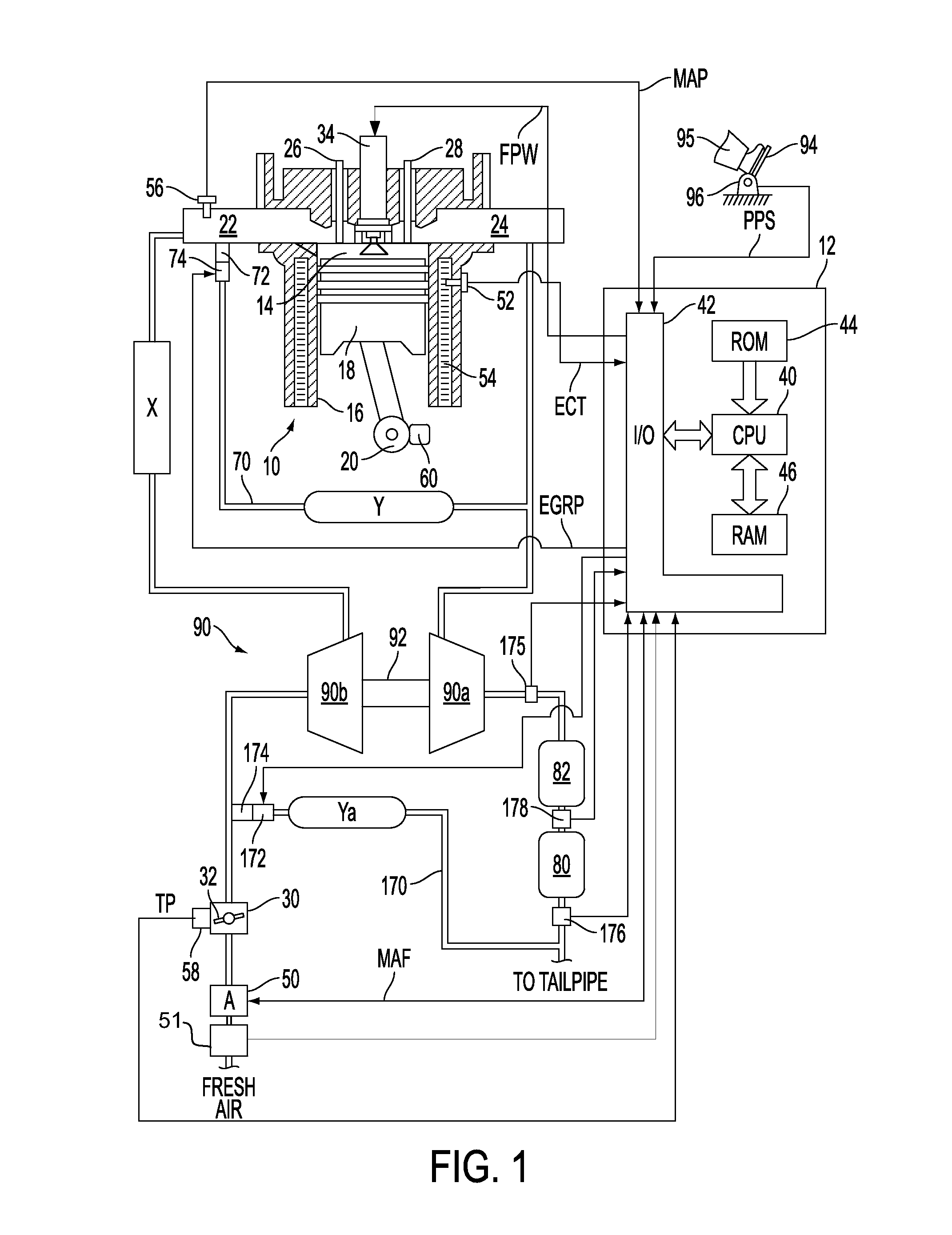

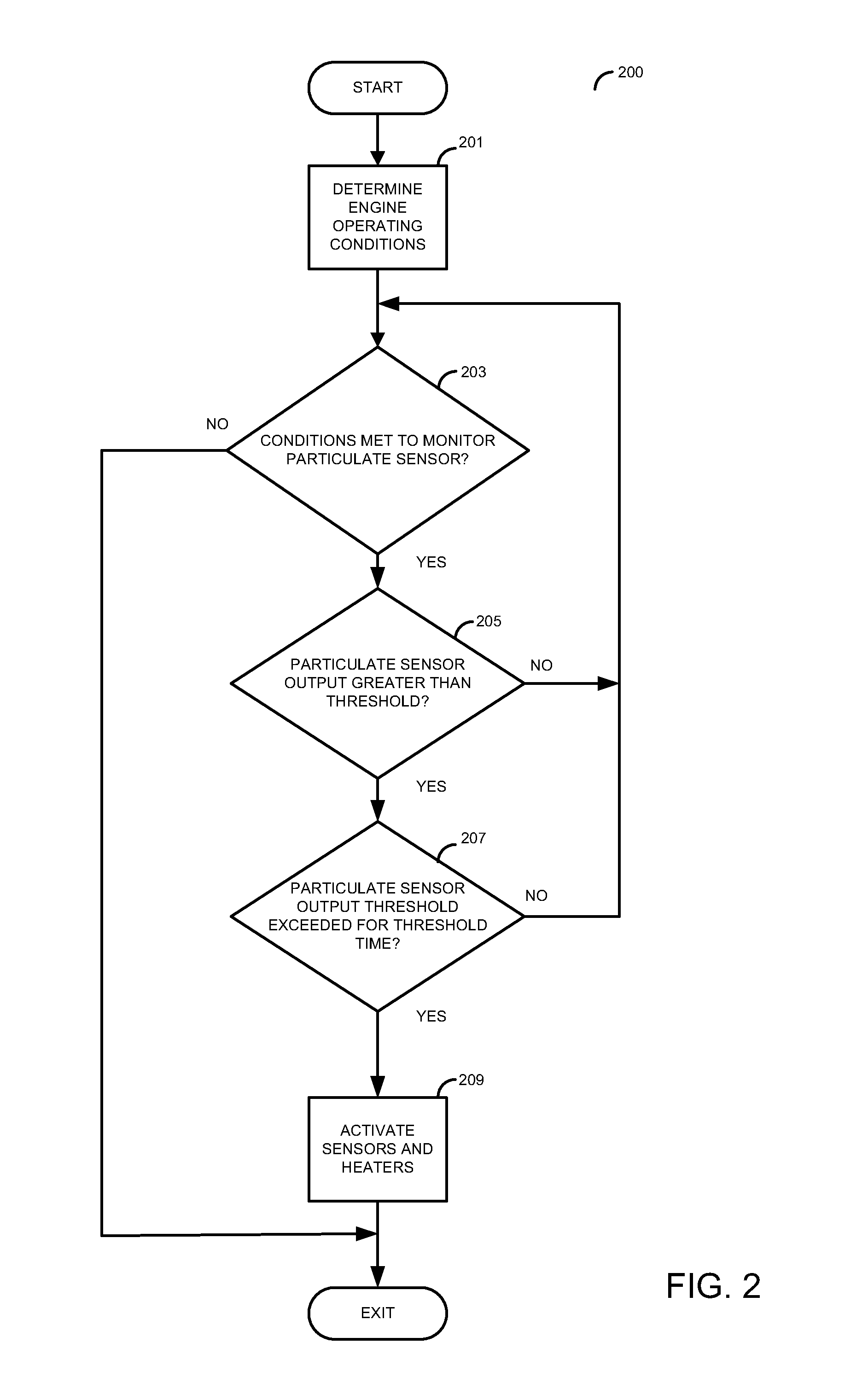

System for an engine having a particulate matter sensor

ActiveUS20110047985A1Easy to controlPerformance of oxygen degradeElectrical controlInternal combustion piston enginesParticulatesWater vapor

A system for improving operation of an engine having a particulate matter sensor is presented. The system may be used to improve engine operation during cold starts especially under conditions where water vapor or entrained water droplets are present in vehicle exhaust gases. In one embodiment, an engine controller that activates a heater of an exhaust gas sensor after an output of a particulate matter sensor exceeds a threshold value after an engine is started.

Owner:FORD GLOBAL TECH LLC

Fuel alcohol content detection via an exhaust gas sensor

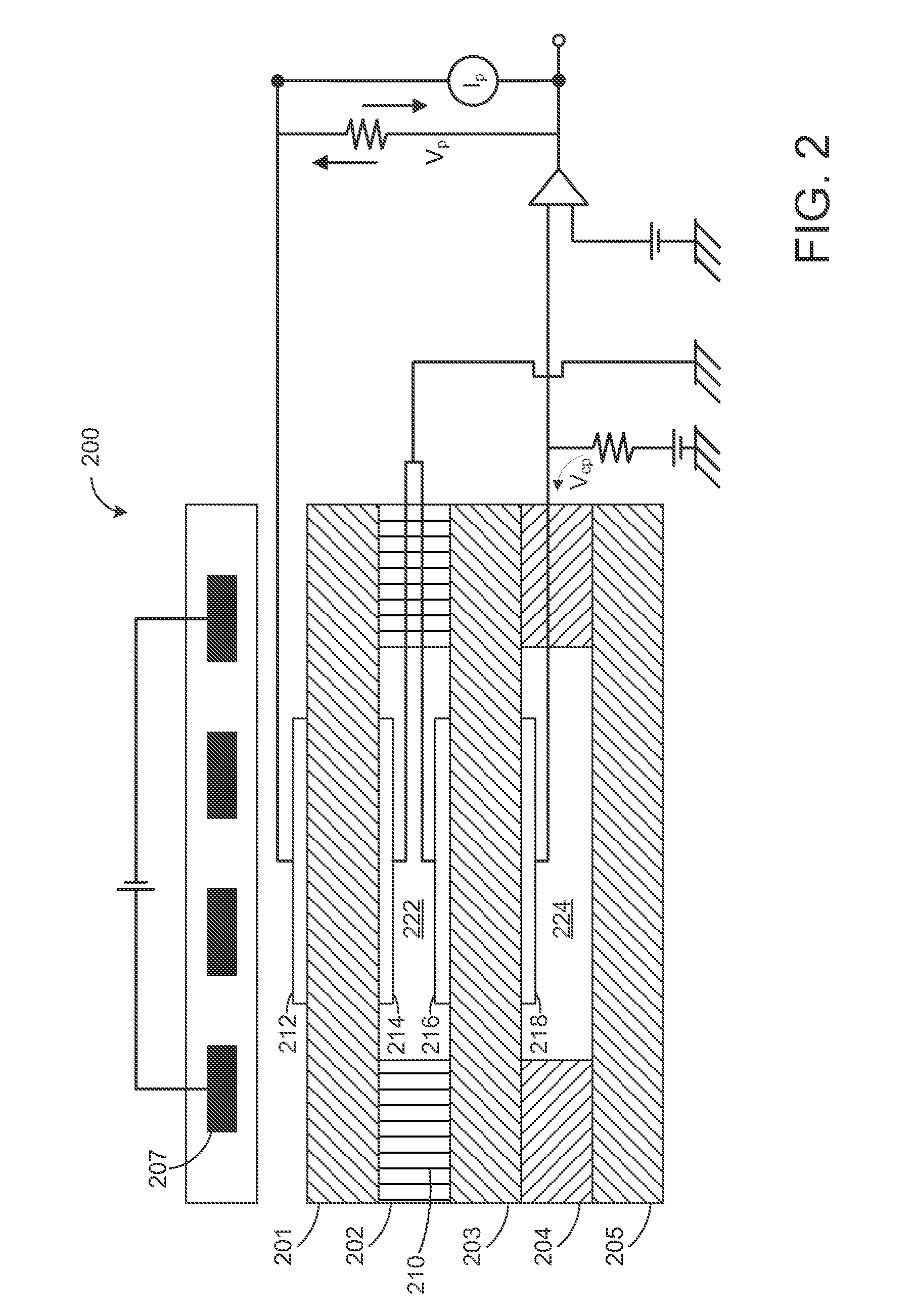

InactiveUS8522760B2Low alcohol contentReduce distractionsElectrical controlCombustion enginesAlcohol contentEngineering

Various systems and methods are described for an exhaust gas sensor coupled to an exhaust system of an engine. One example method comprises, during selected engine fueling conditions, alternating between applying first and second voltages to the sensor; and identifying an amount of alcohol in fuel injected to the engine based on sensor outputs at the first and second voltages.

Owner:FORD GLOBAL TECH LLC

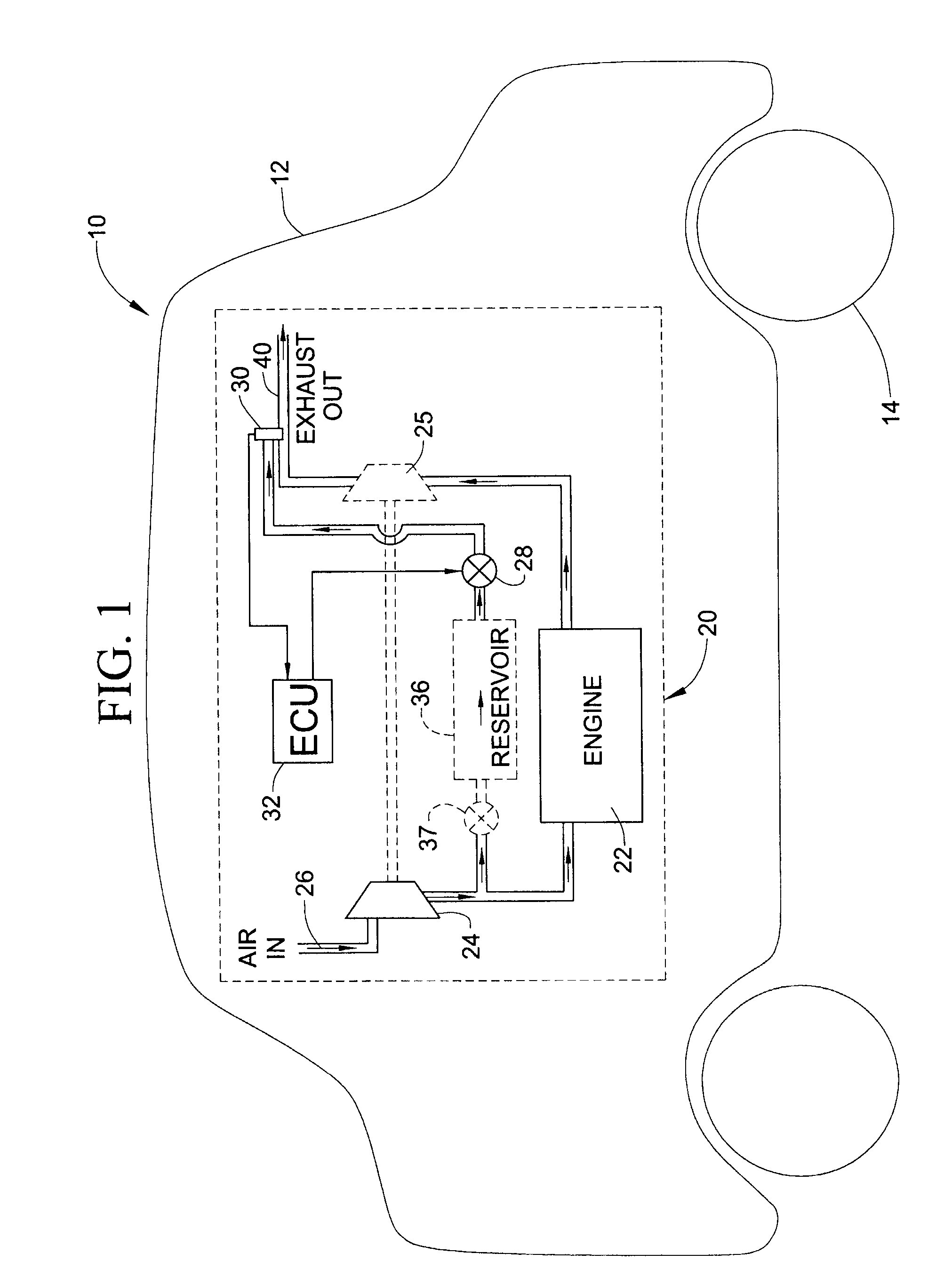

Sensor self-calibration system and method

A vehicle includes an engine, a booster, an exhaust gas sensor and a self-calibration arrangement for the exhaust gas sensor. When sensor calibration check is desired, a controlling unit opens a valve in order to subject a sensing element of the sensor to a supply of gas having a known gas concentration. Gas concentration signals from the sensor are compared with known concentration values, with the results being used to re-calibrate the sensor. The supply of gas can be received directly from the booster or from an optional reservoir. The invention is particularly applicable for use with a universal exhaust gas oxygen sensor in a vehicle powered by a diesel engine.

Owner:FORD GLOBAL TECH LLC

Engine control and catalyst monitoring based on estimated catalyst gain

InactiveUS6879906B2Low costSaving weightAnalogue computers for vehiclesElectrical controlIntegratorProcess engineering

A system and method for controlling an internal combustion engine determine a catalyst gain based on an exhaust gas sensor positioned upstream relative to a catalyst and at least one exhaust gas sensor positioned downstream relative to at least a portion of the catalyst and use the gain to determine the condition or performance of the catalyst. The gain may be determined by modeling the catalyst as an integrator with an unknown gain and estimating the gain using a polynomial approximation. The gain is compared to an expected value or threshold associated with current operating conditions, such as catalyst temperature and / or mass air flow.

Owner:FORD GLOBAL TECH LLC

Approach for identifying and responding to an unresponsive wastegate in a twin turbocharged engine

InactiveUS8001782B2Balance levelLoading can be alteredElectrical controlInternal combustion piston enginesWastegateControl system

An engine system for a vehicle is provided, comprising an internal combustion engine including an exhaust system; a first turbine including a first wastegate and arranged along a first branch of the exhaust system, a second turbine including a second wastegate and arranged along a second branch of the exhaust system; a first exhaust gas sensor arranged along the first branch of the exhaust system downstream of the first turbine and first wastegate; a second exhaust gas sensor arranged along the second branch of the exhaust system downstream of the second turbine and the second wastegate; and a control system configured to command the first and second wastegates to a closed or open position and to indicate one of said wastegates as unresponsive to said command in response to a temperature difference between the first and second branches indicated by the first and second exhaust gas sensors.

Owner:FORD GLOBAL TECH LLC

Methods and systems for humidity and pcv flow detection via an exhaust gas sensor

ActiveUS20140202437A1Accurate humidityIncrease pressureInternal-combustion engine testingElectrical controlAmbient humidityOxygen sensor

Methods and systems are provided for estimating a PCV flow to an engine based on the output of an exhaust gas oxygen sensor. During DFSO conditions, a reference voltage of the sensor is modulated initially with an intake throttle open and then with the intake throttle closed. PCV flow leaking past the piston valves in an aging engine, as well as an ambient humidity estimate, are inferred based on the outputs of the sensor during the modulating with the intake throttle open and closed.

Owner:FORD GLOBAL TECH LLC

Methods and systems for humidity detection via an exhaust gas sensor

ActiveUS20140202426A1Less waitingReduces pumping lossElectrical controlInternal combustion piston enginesAlcohol contentAmbient humidity

Various methods and system are described for determining ambient humidity via an exhaust gas sensor disposed in an exhaust system of a variable displacement engine. A reference voltage of a sensor coupled to an inactive engine bank is modulated between a first and second voltage to estimate ambient humidity. Concurrently, a reference voltage of a sensor coupled to an active engine bank is modulated between the first and second voltage, or at the first voltage, to estimate fuel alcohol content, or exhaust air-fuel ratio, respectively.

Owner:FORD GLOBAL TECH LLC

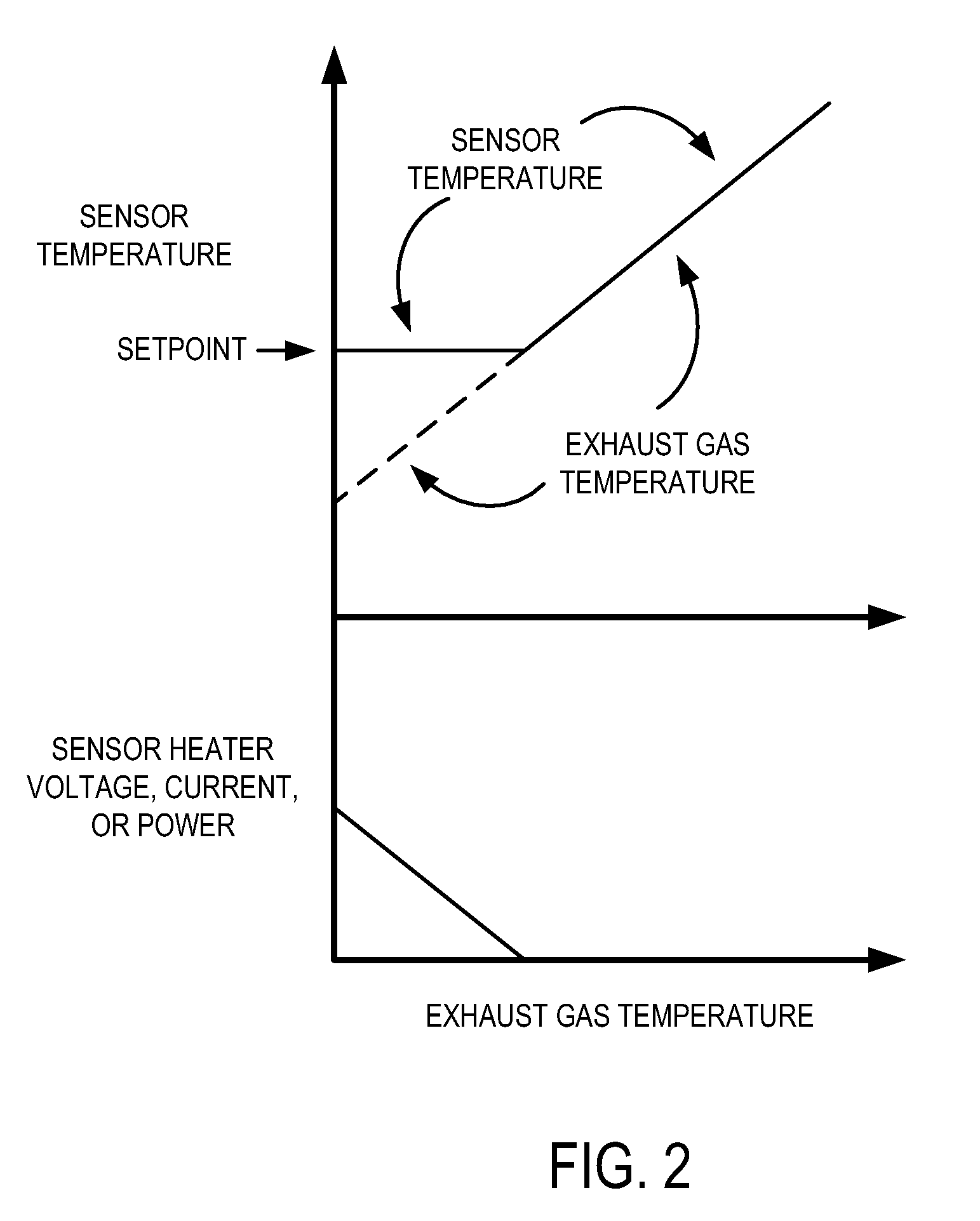

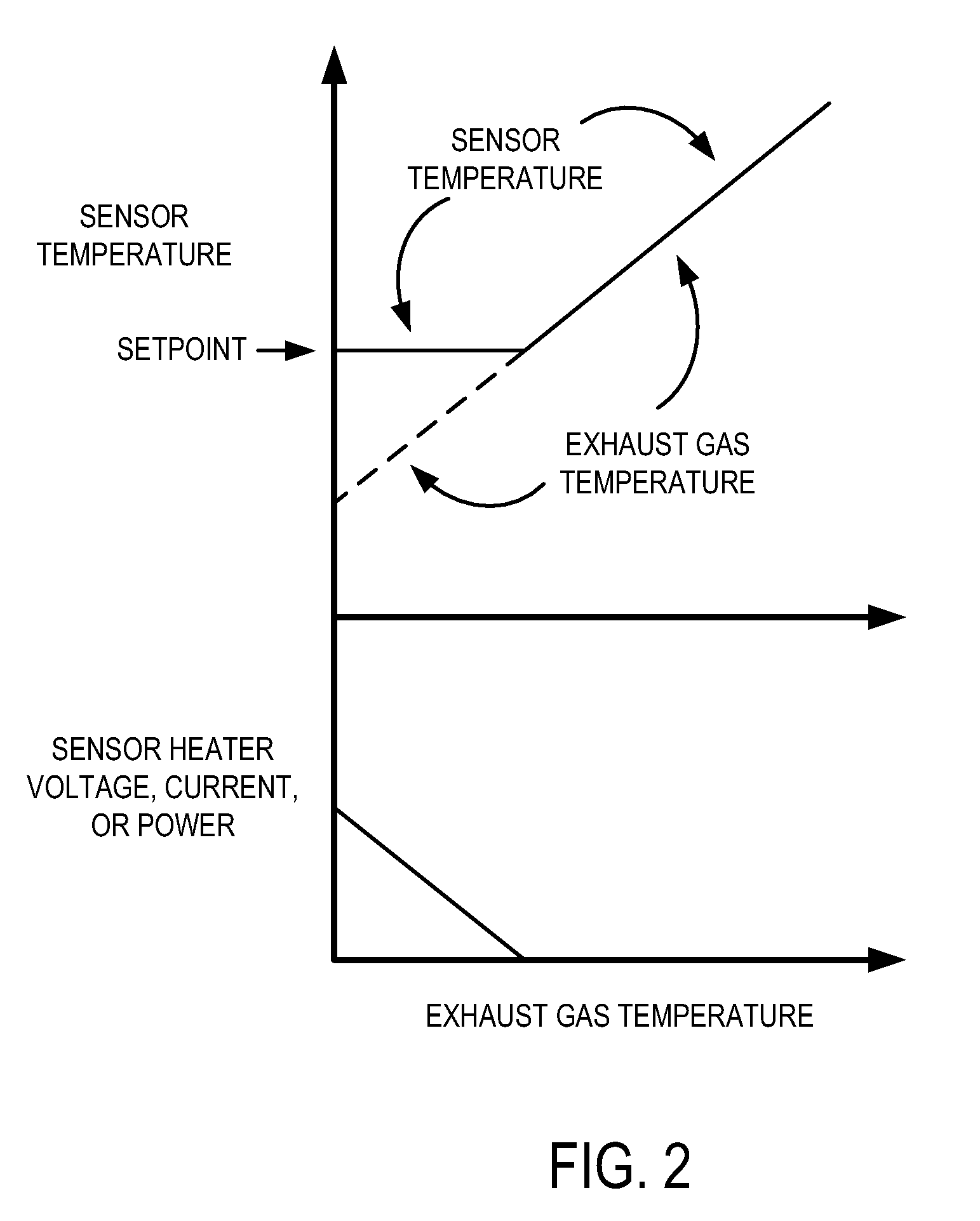

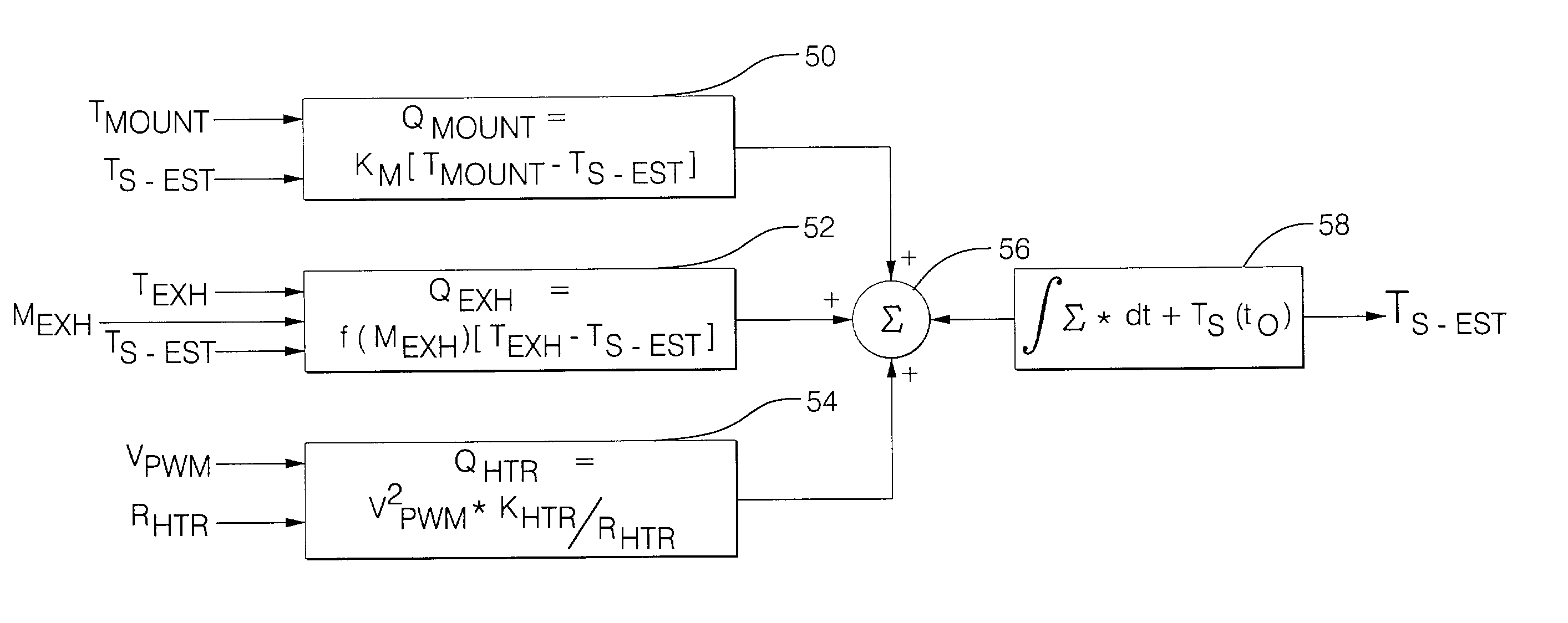

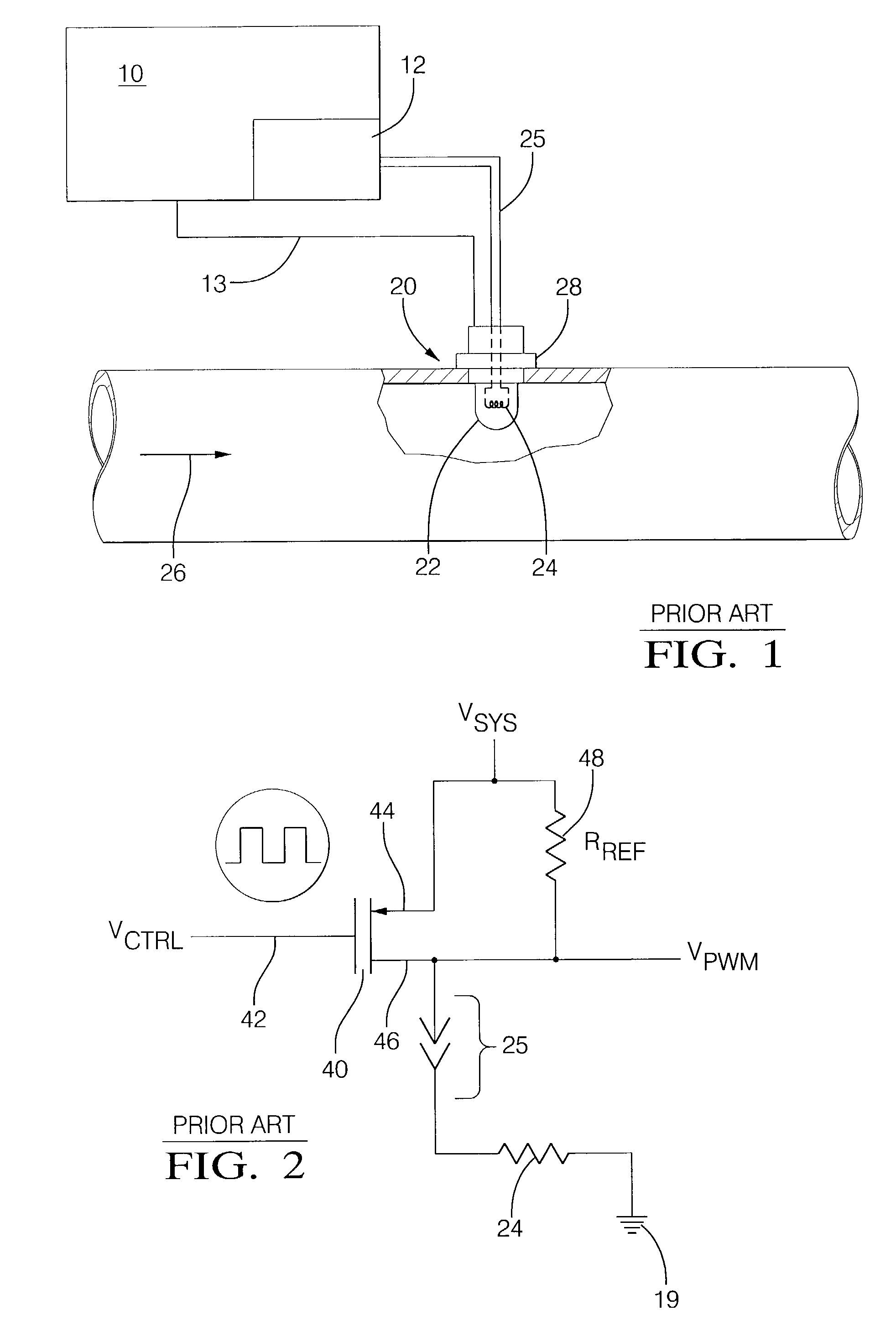

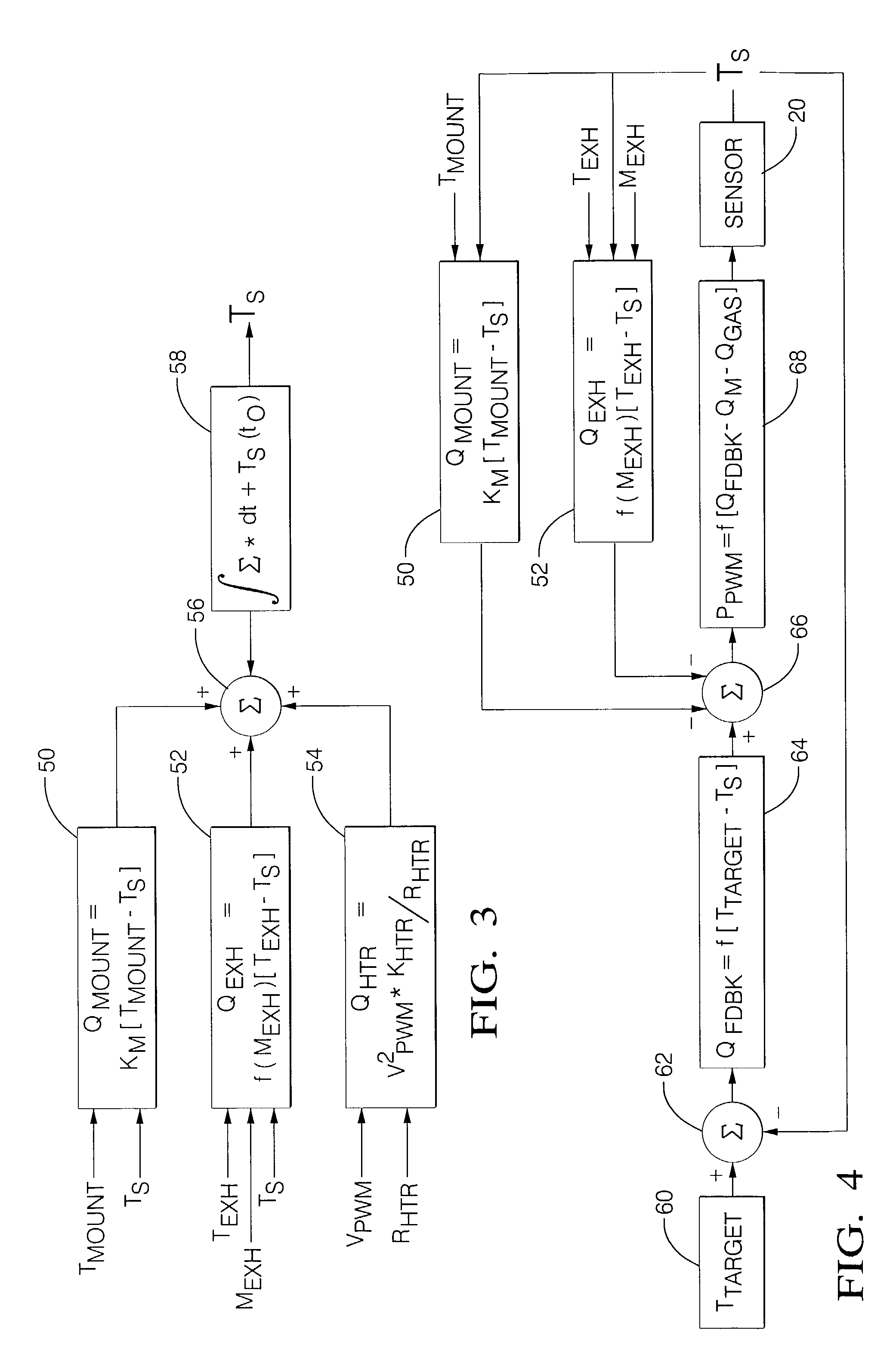

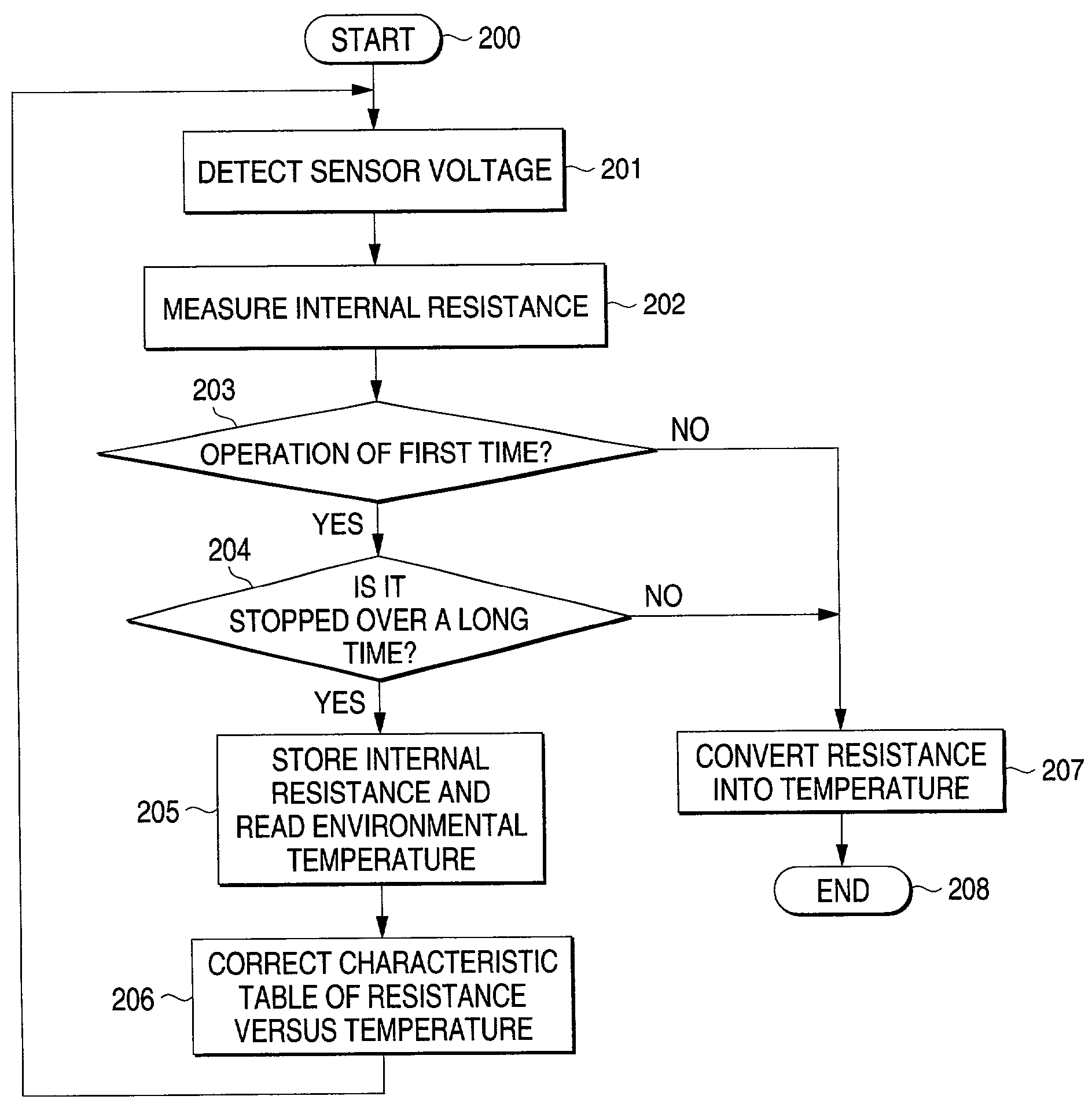

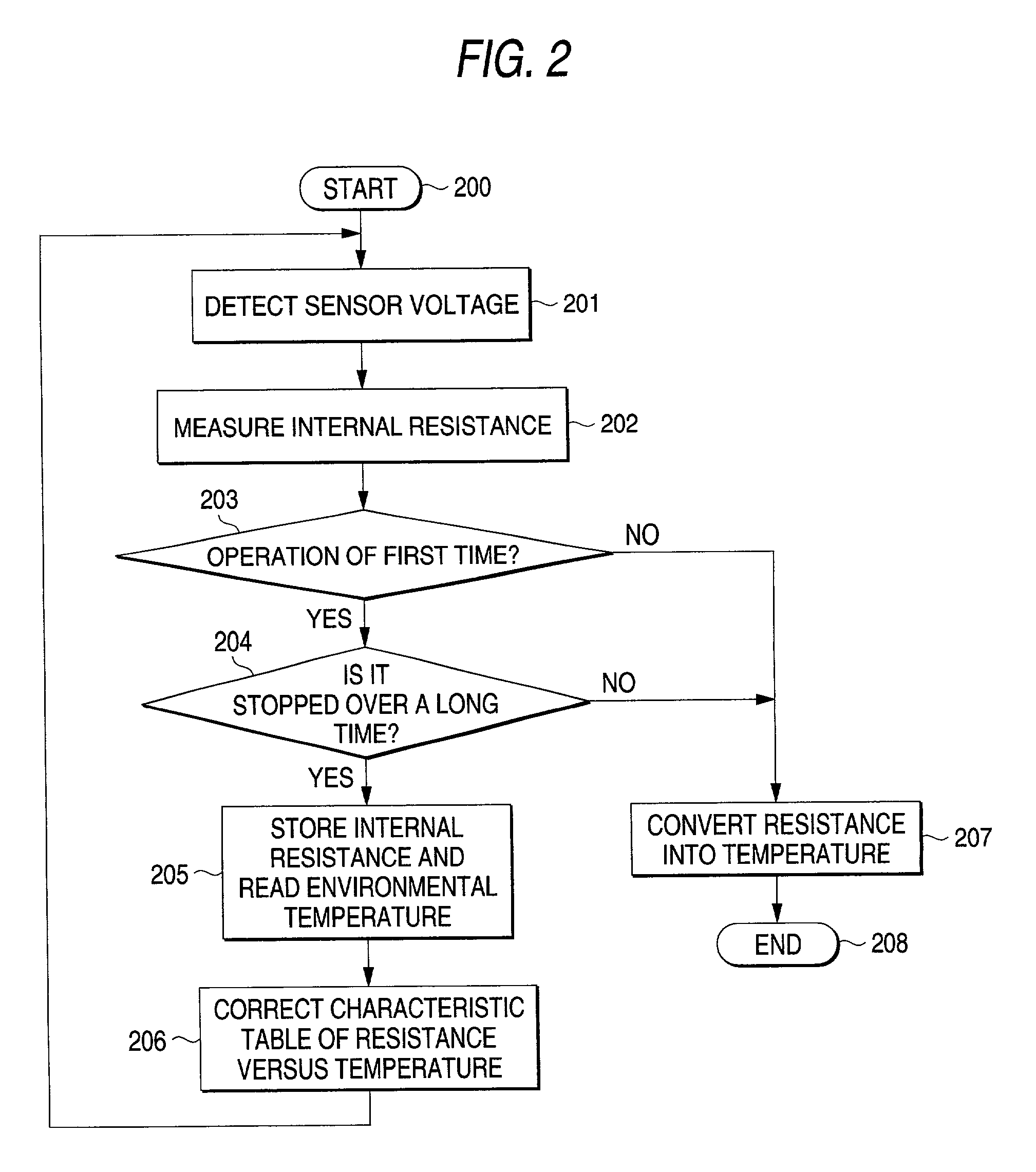

Method and apparatus to control an exhaust gas sensor to a predetermined termperature

InactiveUS7036982B2Accurate measurementImproved engine controlThermometer detailsTemperature measurement in motorsControl systemProcess engineering

The invention provides a control strategy and a control system to control a gas sensor to a target operating temperature. It relies upon both feedback and model-based feedforward control systems to achieve and then maintain the sensor at the target operating temperature. The mechanization includes a gas sensor with a heating element in a feedstream. The control strategy employs a control system for the heating element that is based upon the target operating temperature, the temperature of the heating element, and an effect of the feedstream and mounting structure on the temperature of the sensor. The control strategy enables the control system to optimize the heating of a sensor during warm-up and steady state operations.

Owner:DELPHI TECH IP LTD

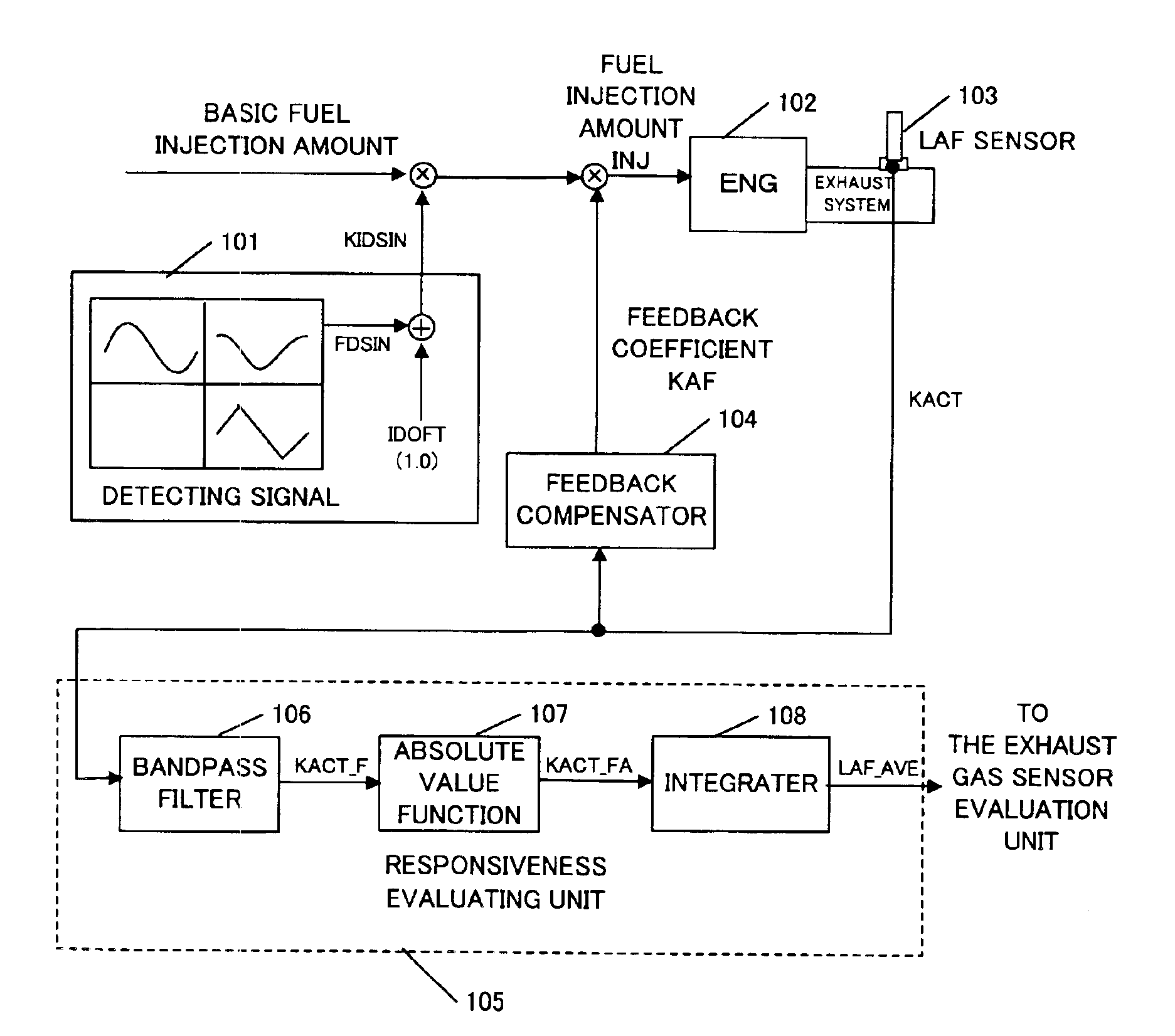

Diagnostic apparatus for an exhaust gas sensor

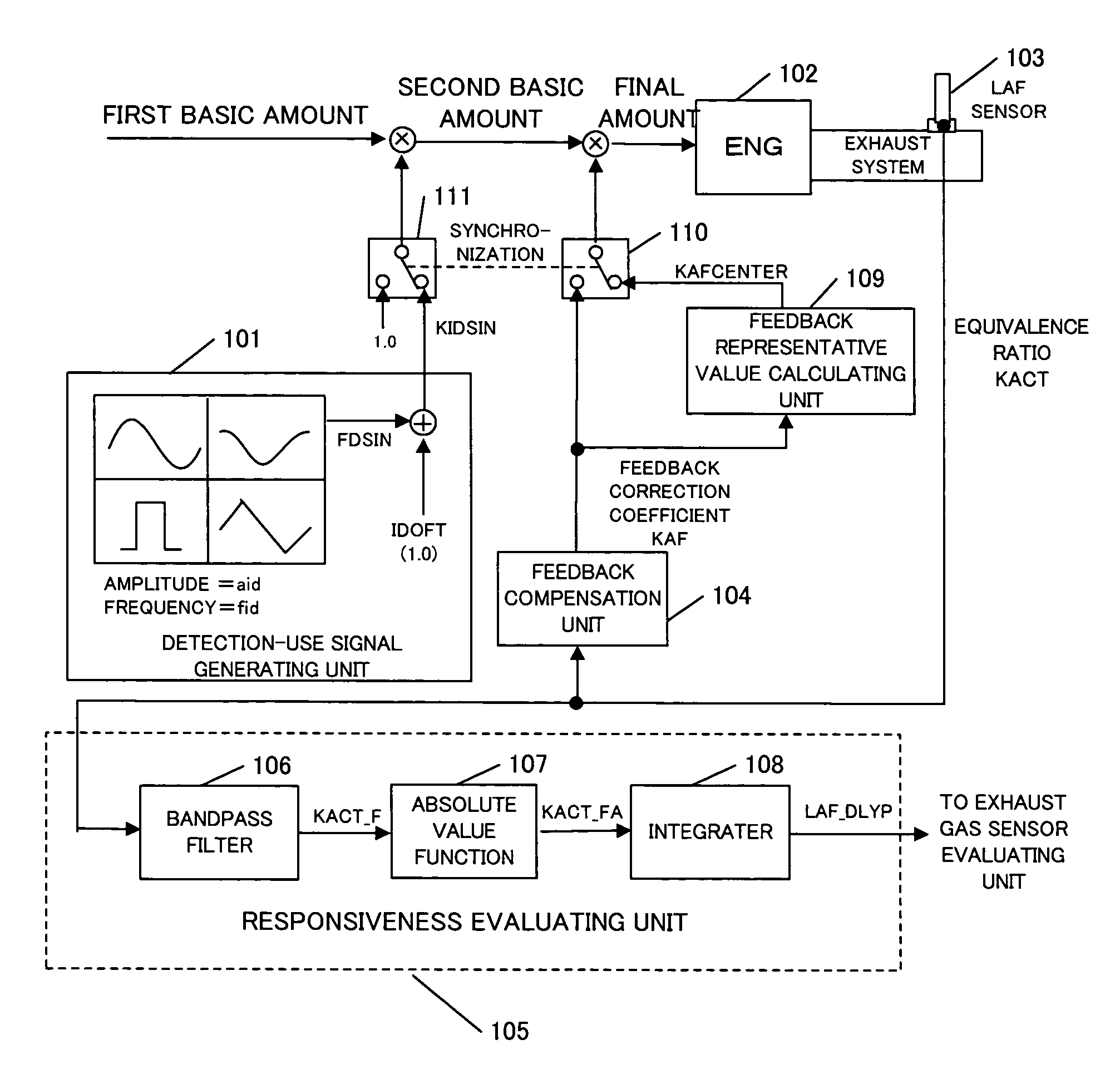

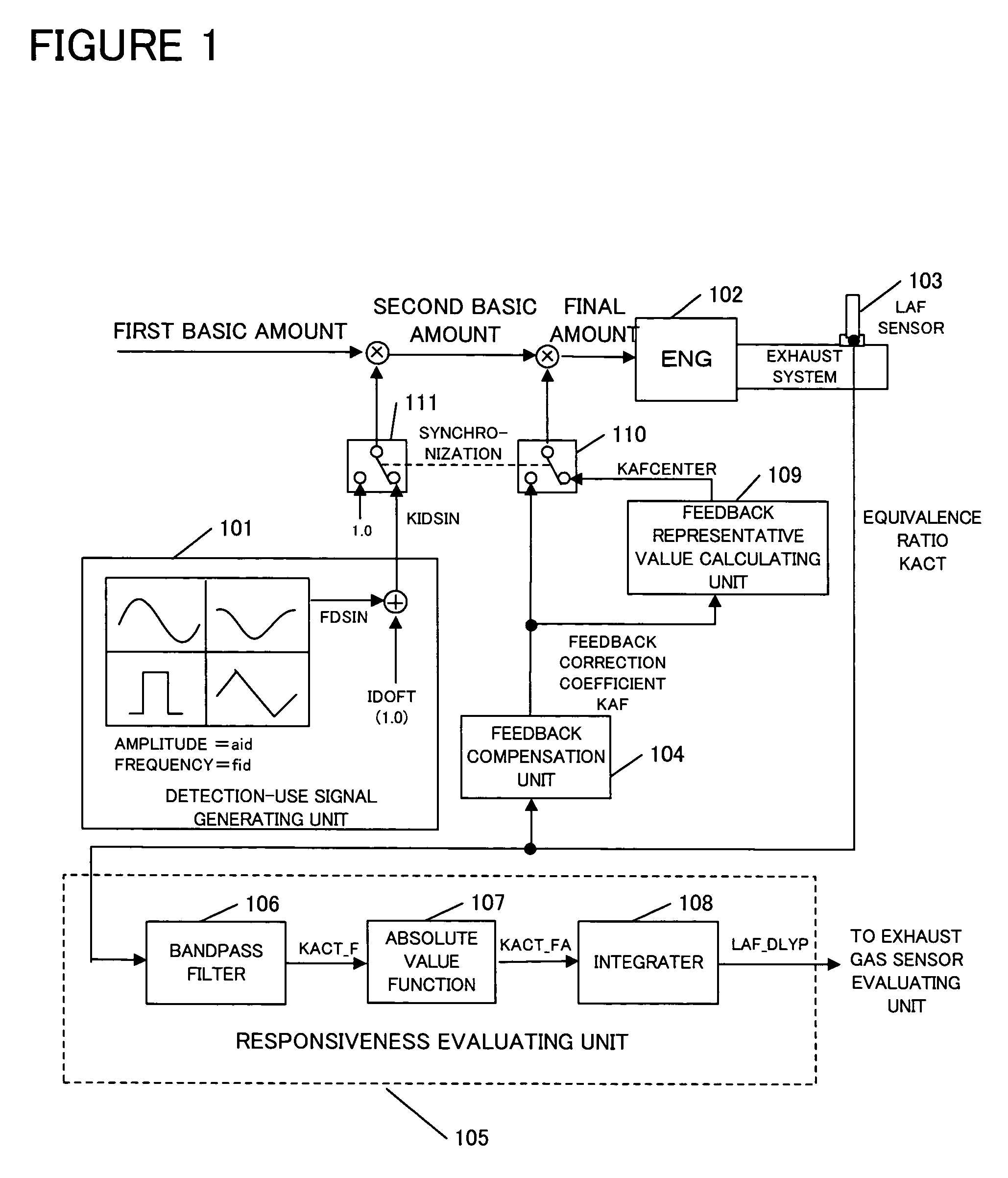

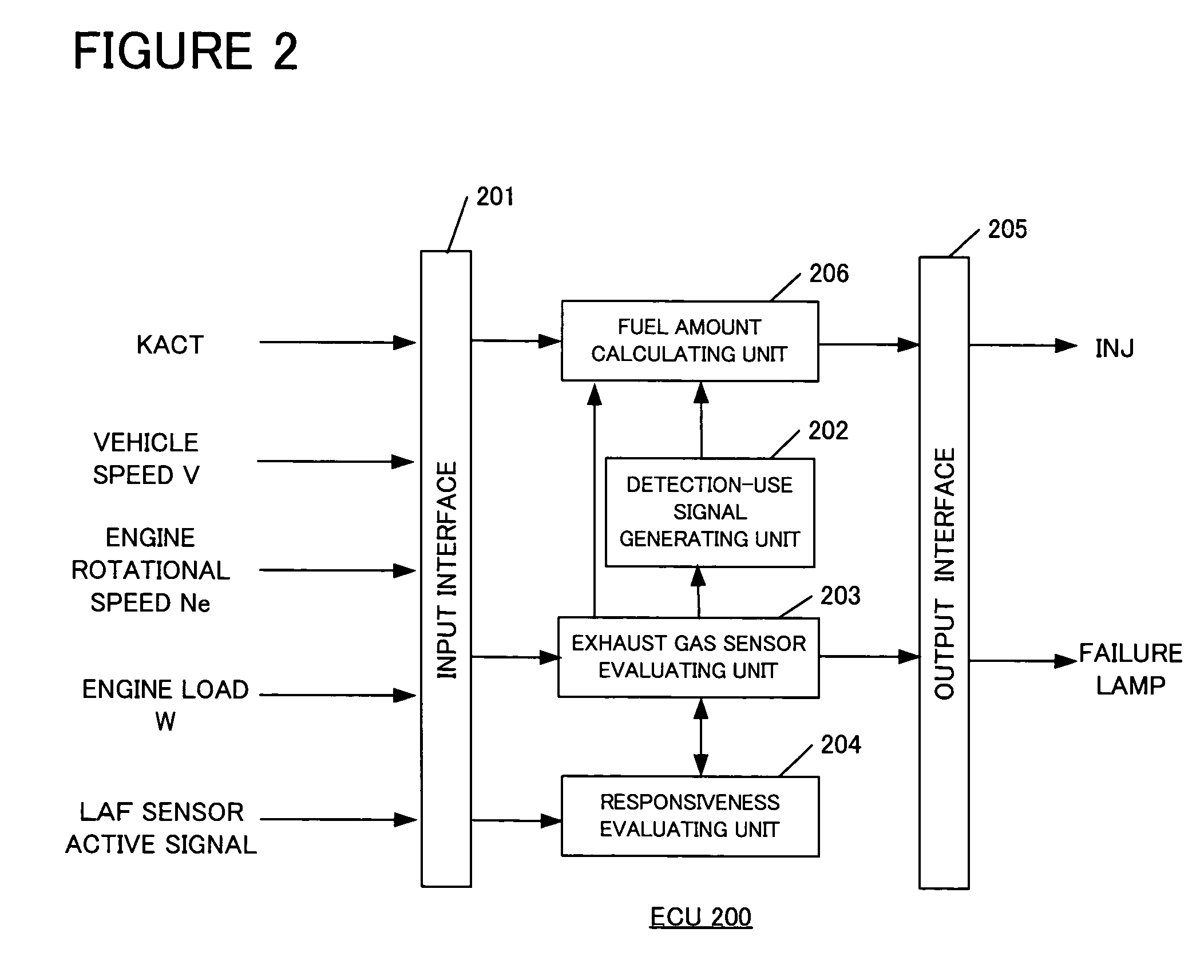

ActiveUS7021300B2Reduce the ratioDetection precision of the deterioration failure of the exhaust gas sensor may be improvedElectrical controlExhaust apparatusFrequency responseFuel injection

A deterioration failure diagnostic apparatus is provided for diagnosing an exhaust gas sensor disposed in an exhaust passage of an engine. The apparatus has a unit for generating a detecting signal and multiplying the generated signal to a first basic fuel injection amount to produce a second fuel injection amount. The apparatus includes a unit for calculating a feedback representative value based on feedback correction coefficients and multiplying the feedback representative value to the second fuel injection amount to produce a final fuel injection amount to be input to the engine. The apparatus includes a unit for extracting a frequency response corresponding to the detecting signal from an output of the exhaust gas sensor of the engine, the output being responsive to the calculated final fuel injection amount. A condition of the exhaust gas sensor is determined based on the extracted frequency response.

Owner:HONDA MOTOR CO LTD

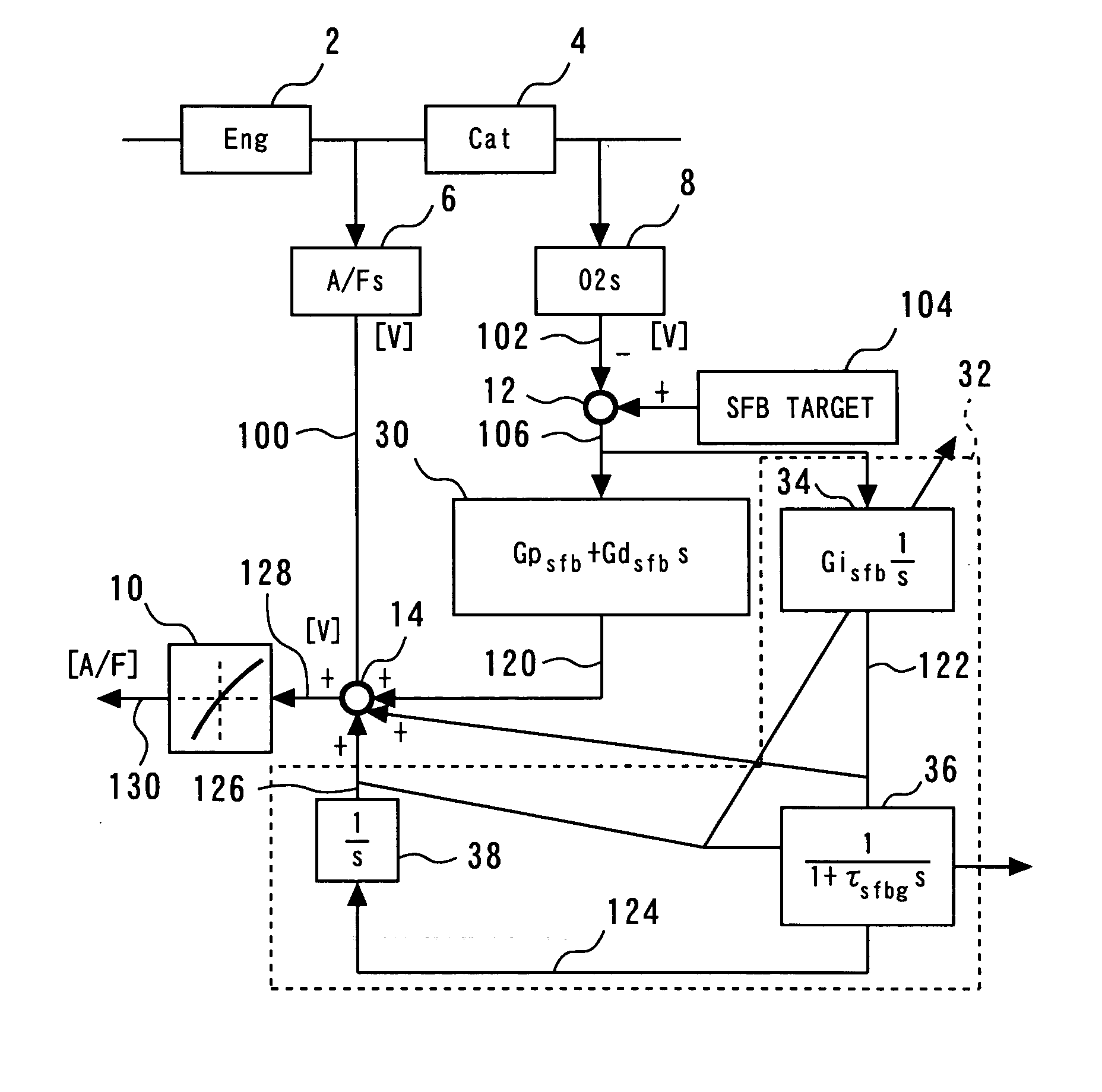

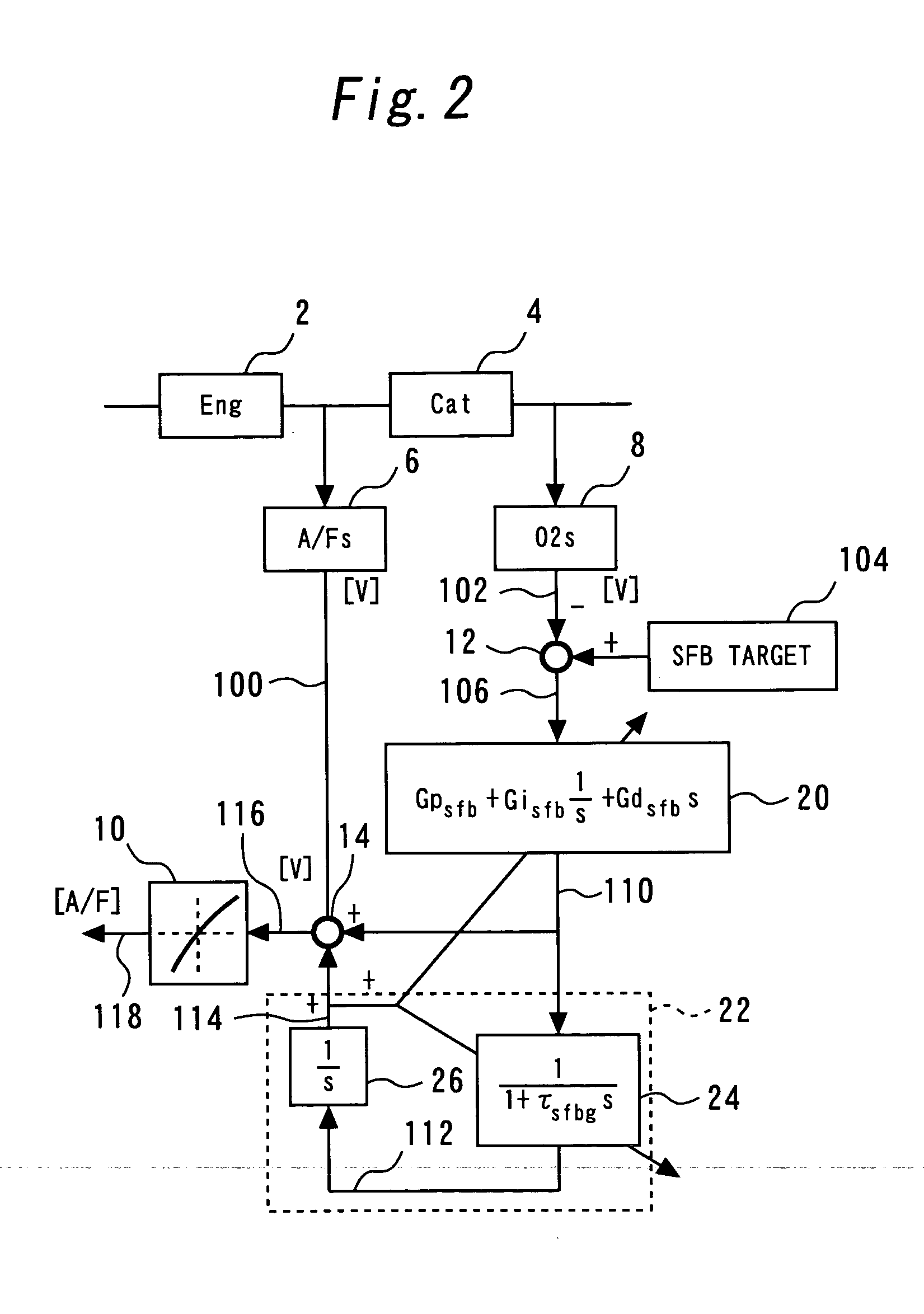

Air-fuel ratio controller for internal-combustion engine

ActiveUS20050072139A1Compensating for such errorElectrical controlExhaust apparatusData signalFeedback control

An output signal from a downstream-side exhaust gas sensor is fed back into a fuel injection rate so that the air-fuel ratio of the exhaust gases flowing out from a catalyst may match a reference value. In this sub-feedback control process, the integral value of the deviation between the output signal of the downstream-side exhaust gas sensor and a reference value is calculated, and the resulting integral-data signal is smoothed. A learning value for compensating for the permanent error included in an air-fuel ratio signal from an A / F sensor is learnt from the integral-data signal generated by the above smoothing operation.

Owner:TOYOTA JIDOSHA KK

Diagnostic apparatus for an exhaust gas sensor

ActiveUS6961653B2Easily decrease ratioDetection precision can be improvedAnalogue computers for vehiclesElectrical controlFrequency responseFuel injection

Owner:HONDA MOTOR CO LTD

Fuel alcohol content detection via an exhaust gas sensor

InactiveUS8495996B2Low alcohol contentReduce distractionsElectrical controlEngine testingAlcohol contentEngineering

Various systems and methods are described for an exhaust gas sensor coupled to an exhaust system of an engine. One example method comprises, during selected engine fueling conditions, alternating between applying different voltages to the sensor; and identifying an amount of alcohol in fuel injected to the engine based on sensor outputs at the different voltages.

Owner:FORD GLOBAL TECH LLC

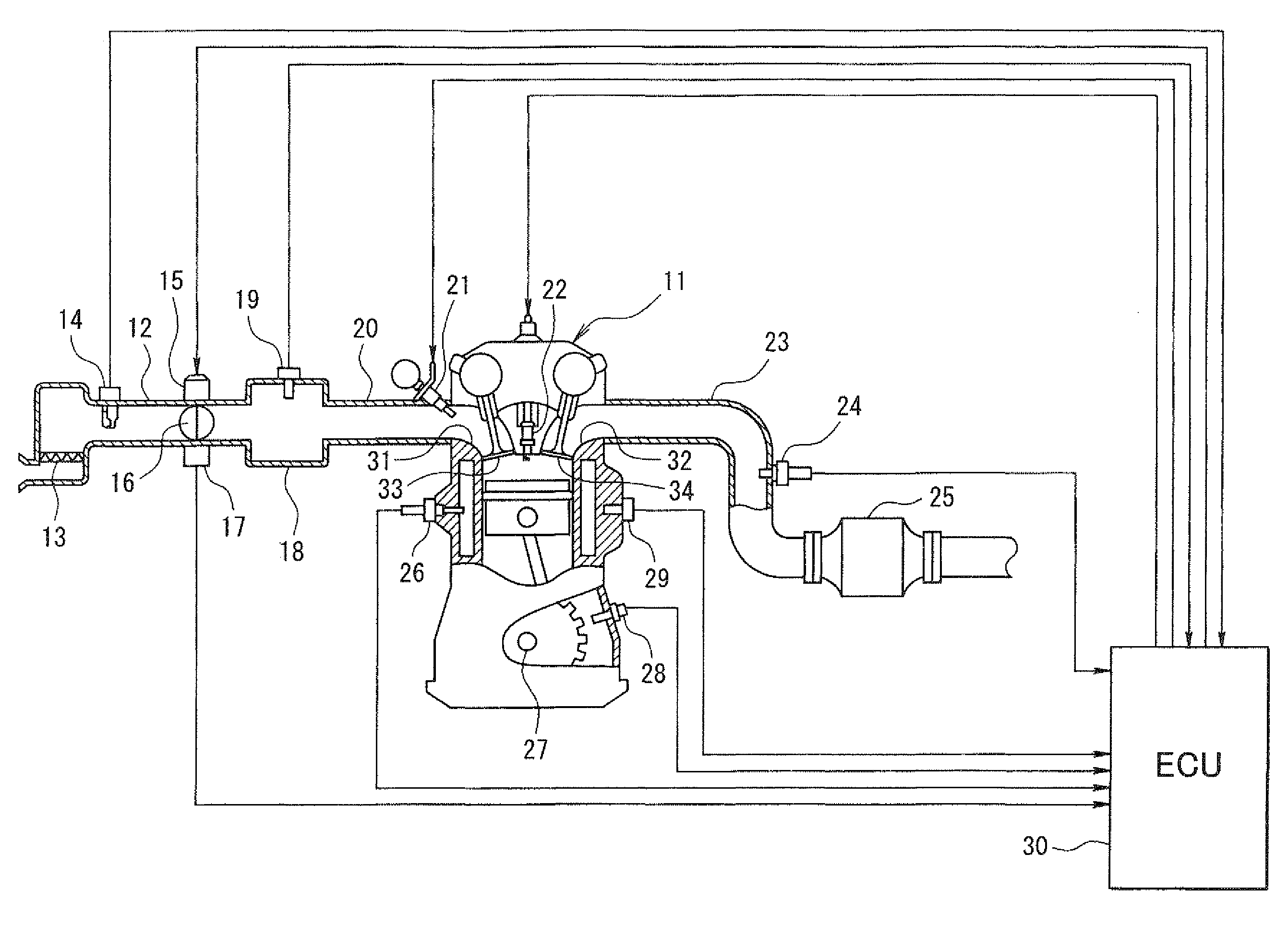

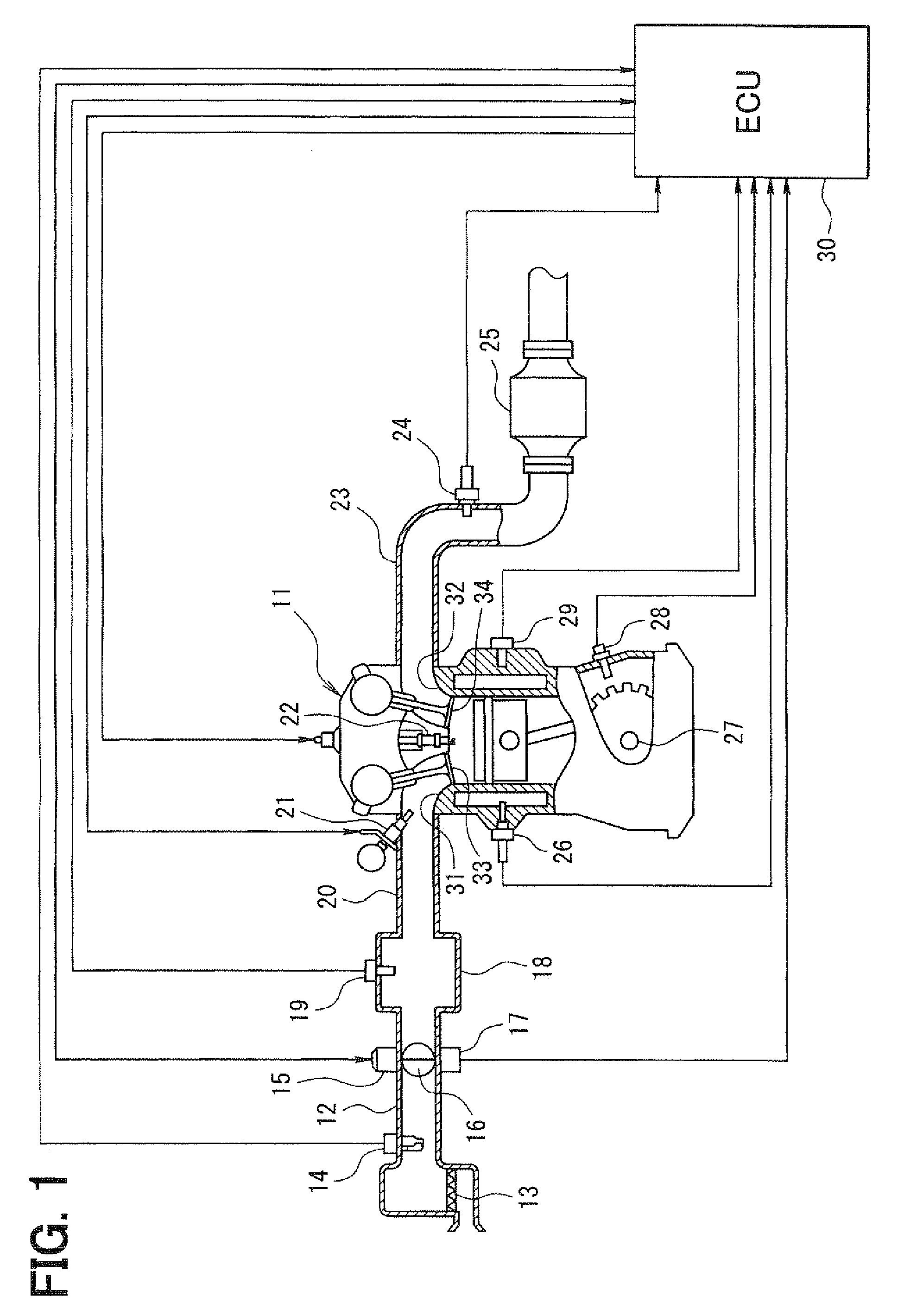

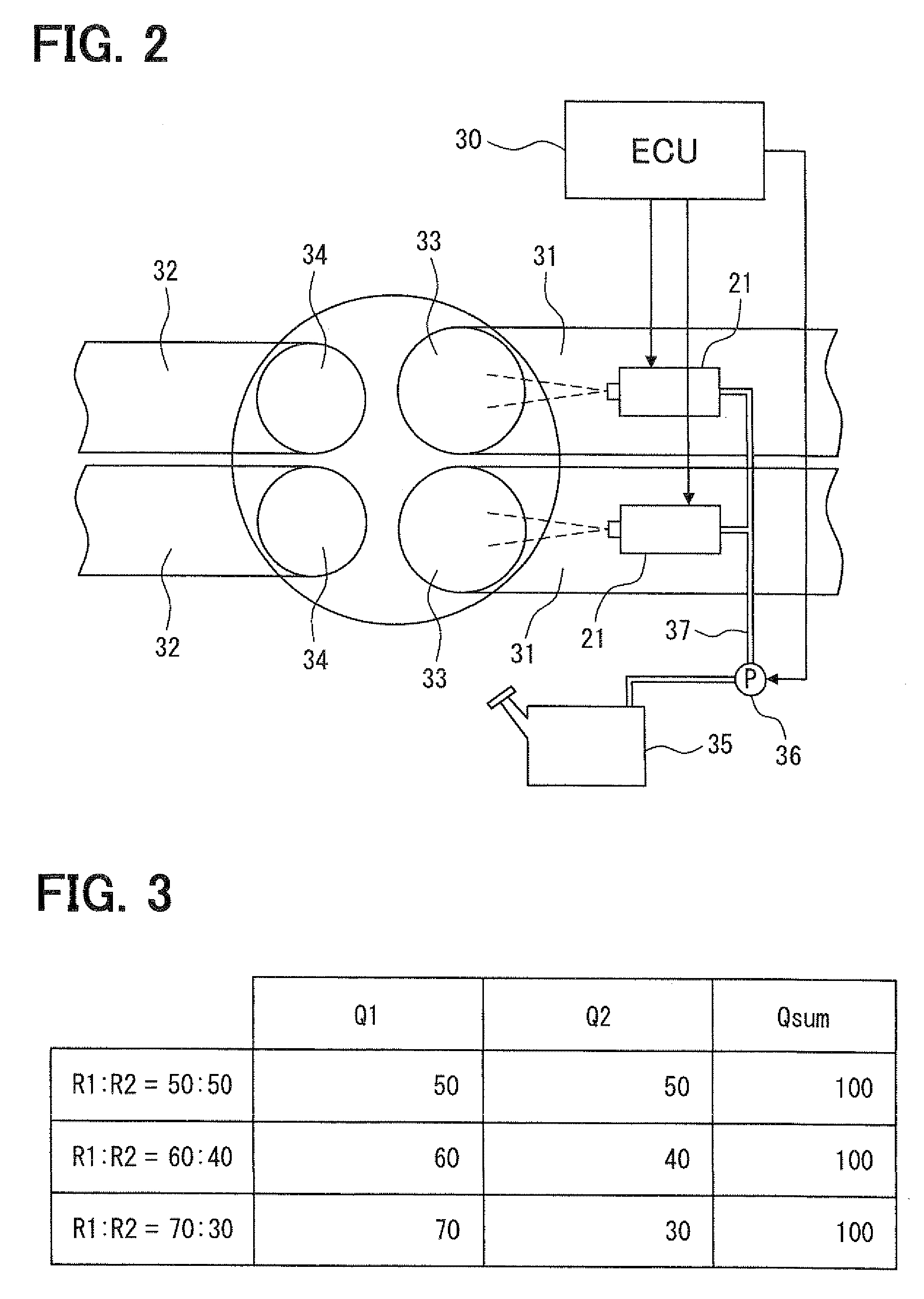

Abnormality diagnosis device of internal combustion engine

ActiveUS20090198434A1Torque shock can be suppressedDeterioration of drivability can be preventedElectrical controlDigital data processing detailsChange controlAir–fuel ratio

A cylinder causing an abnormal air-fuel ratio is specified. Injection ratio changing control for gradually changing a ratio between command injection quantities of two injectors of the abnormal cylinder while keeping the sum of the command injection quantities of the two injectors constant is performed on the abnormal cylinder. If the injection ratio changing control is performed under the same condition, a changing behavior of the actual sum injection quantity of the two injectors varies and a changing behavior of the air-fuel ratio varies depending on which one of the two injectors is abnormal. Therefore, the abnormal injector out of the two injectors is specified using a learning value of an air-fuel ratio feedback correction value based on an output of an exhaust gas sensor.

Owner:DENSO CORP

Exhaust humidity sensor

ActiveUS20140156172A1Reduce evaporationWithout compromising engine air-fuel ratio controlAnalogue computers for vehiclesElectrical controlEngineeringMoisture sensor

Embodiments for adjusting engine operating parameters based on output from an exhaust humidity sensor are provided. One example method for an engine comprises based on a dew point of exhaust gas, adjusting an exhaust gas sensor heater configured to heat an exhaust gas sensor disposed in an exhaust passage of the engine, the dew point based on output from a humidity sensor disposed in the exhaust passage.

Owner:FORD GLOBAL TECH LLC

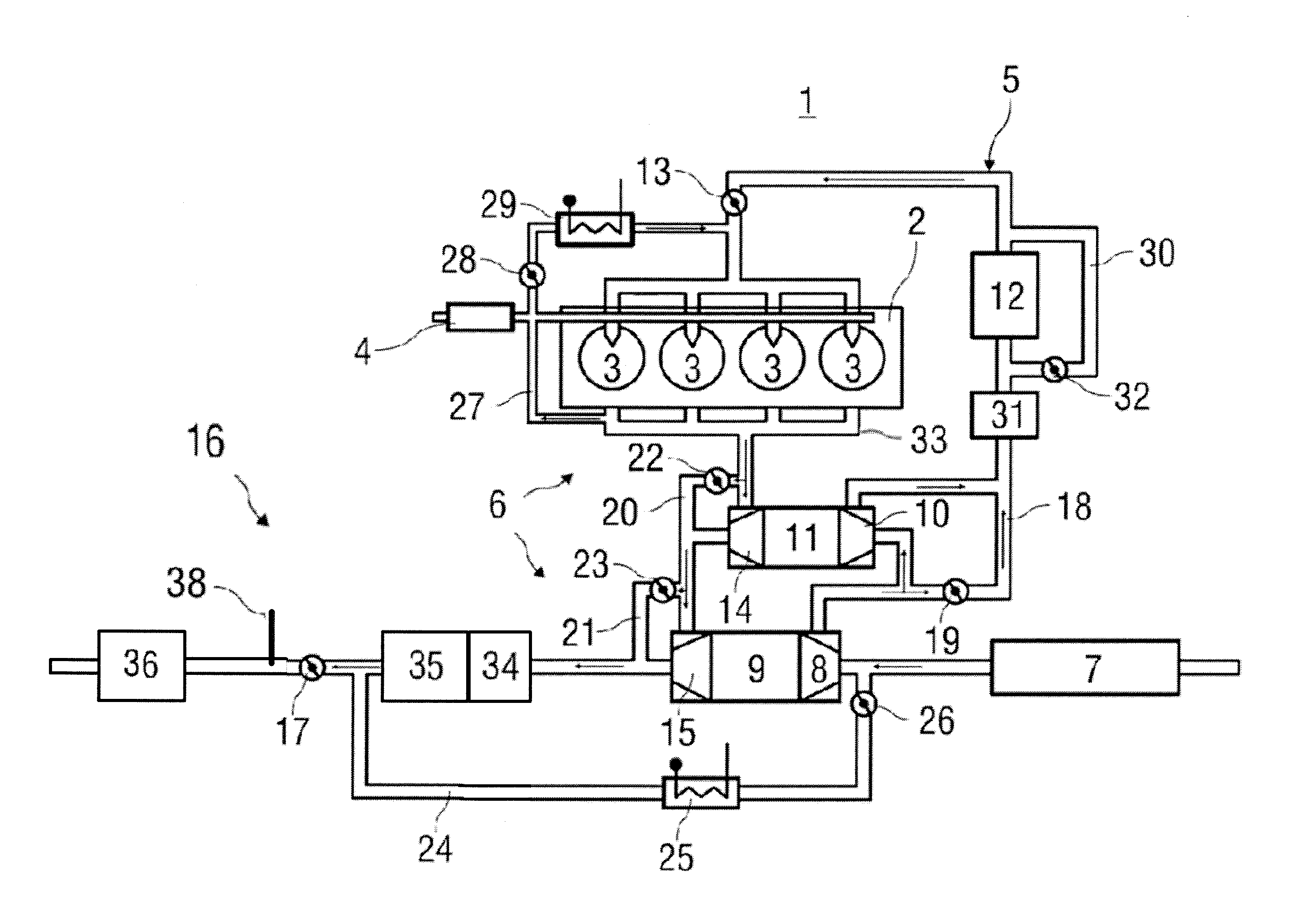

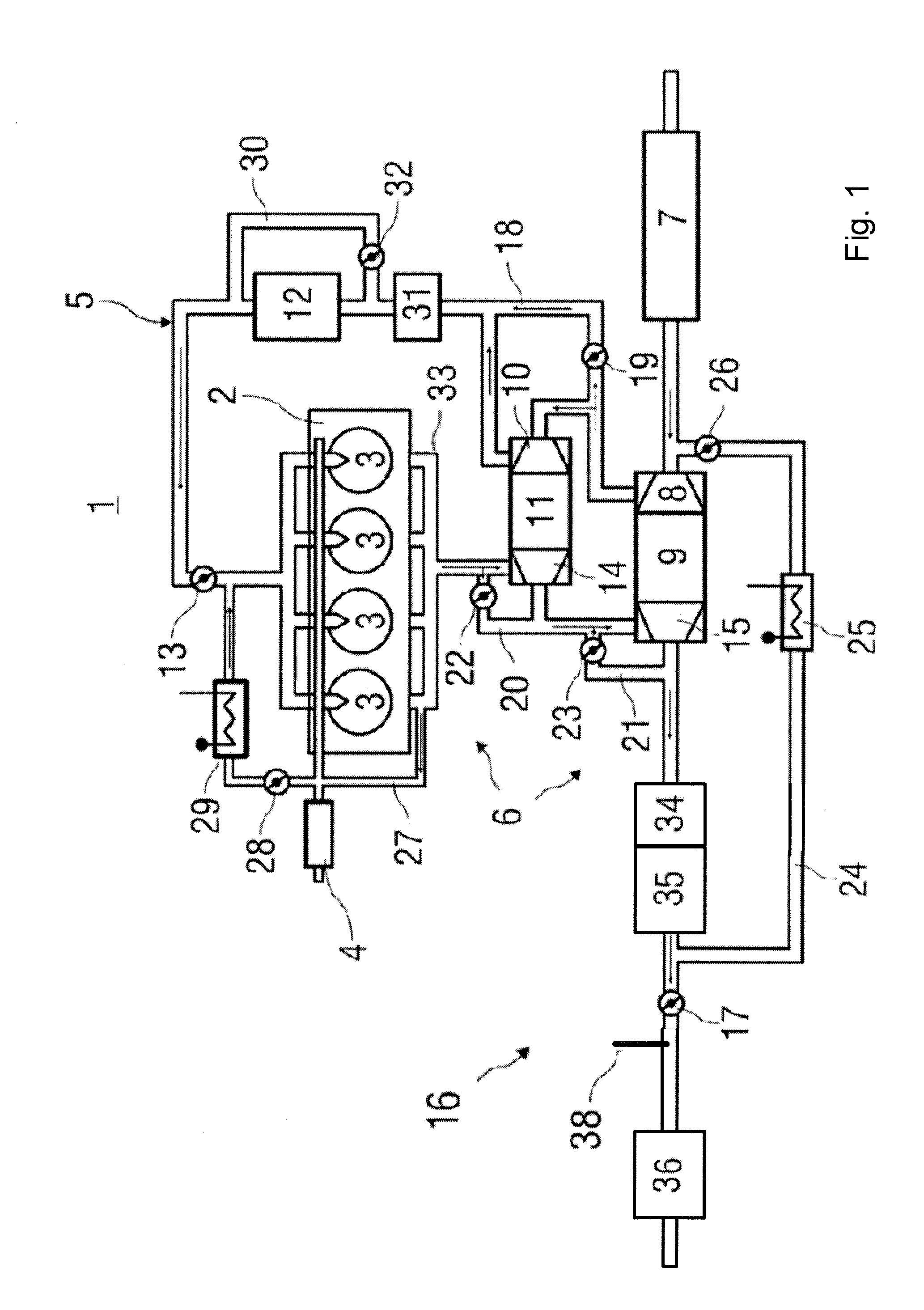

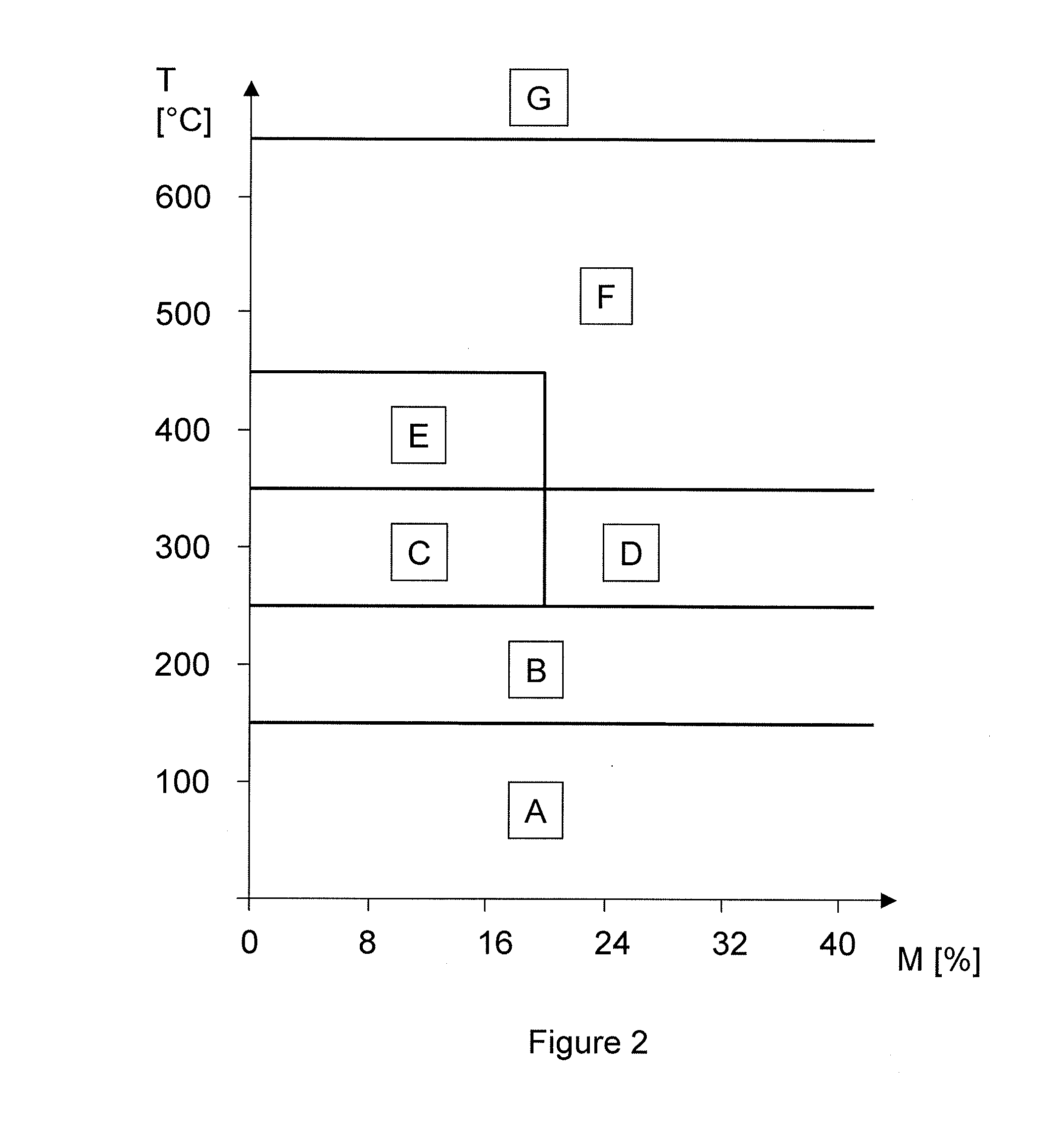

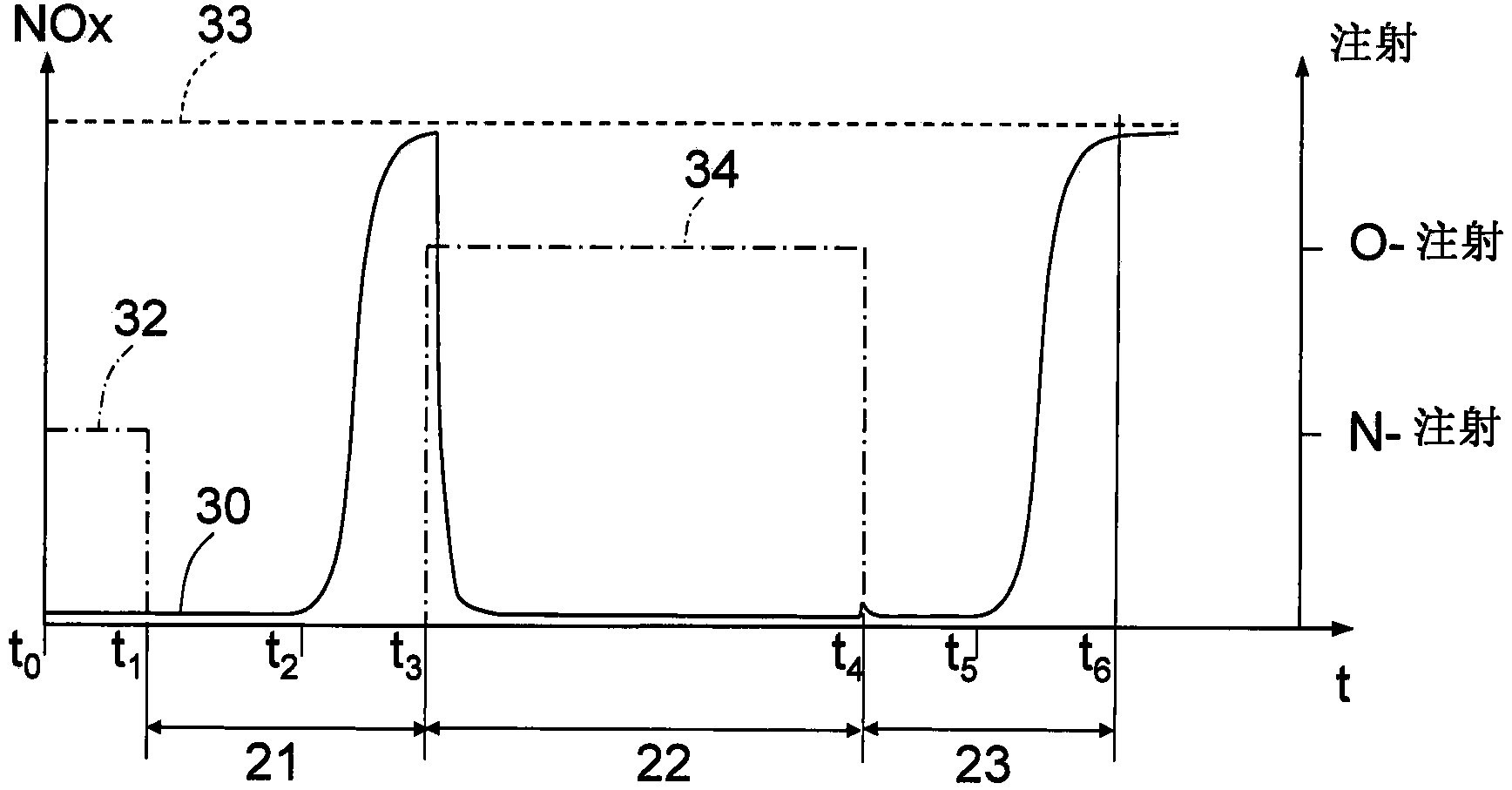

Operating Method for a Motor Vehicle Diesel Engine Having an Exhaust Emission Control System

InactiveUS20140041367A1Reduced operating requirementsLow pollutant emissionElectrical controlInternal combustion piston enginesControl systemDiesel engine

An operating method is provided for a motor vehicle diesel engine having an exhaust emission control system that includes a three-way catalytic converter and an SCR catalytic converter situated one behind the other in the flow direction of the exhaust gas. The diesel engine is operated, at least intermittently, with an air-fuel ratio of approximately λ=1.0 in a first operating range in which the SCR catalytic converter falls below a predefinable minimum temperature and with excess air that is typical for normal diesel engine operation in a second operating range in which the SCR catalytic converter exceeds the predefinable minimum temperature. An output signal of an exhaust gas sensor situated downstream from the three-way catalytic converter and which is correlated with a NOx concentration of the exhaust gas is used to set the air-fuel ratio in the first operating range.

Owner:DAIMLER AG

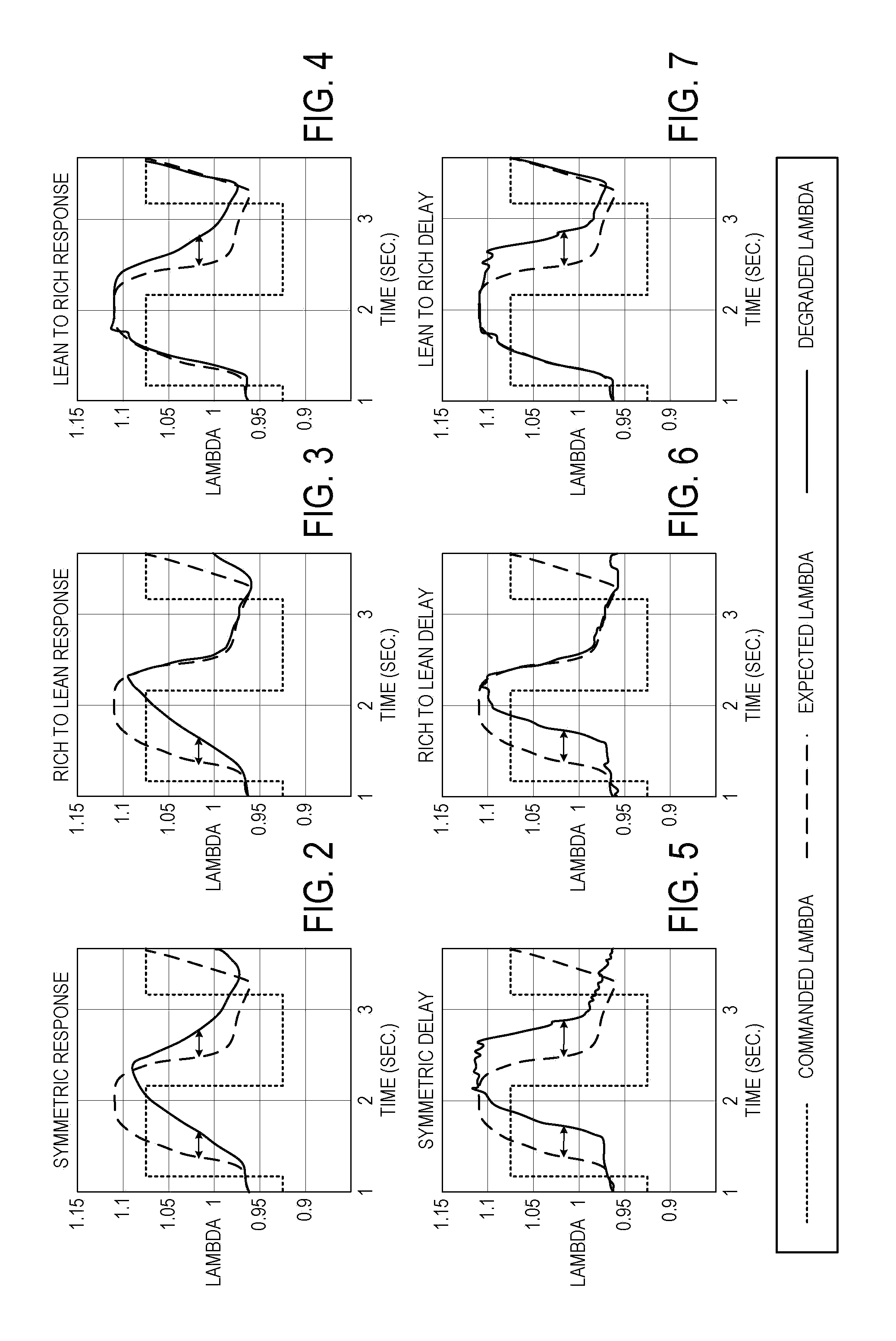

Approach for determining exhaust gas sensor degradation

ActiveUS20100242569A1Reduce the possibilityAccelerate emissionsAnalogue computers for vehiclesInternal-combustion engine testingAxis of symmetryAsymmetry

A method for determining degradation of an exhaust gas sensor positioned in an exhaust system for an internal combustion engine of a vehicle is provided. The method includes modulating an air / fuel ratio of gas exhausted by the internal combustion engine to the exhaust system through a cycle that includes at least one rich-to-lean transition and at least one lean-to-rich transition, indicating a degradation condition of the exhaust gas sensor in response to at least one of a rich-to-lean response duration of the exhaust gas sensor and a lean-to-rich response duration of the exhaust gas sensor being greater than a delay threshold, and indicating the degradation condition of the exhaust gas sensor in response to a ratio of the rich-to-lean response duration to the lean-to-rich response duration being greater than an asymmetry threshold that is relative to an axis of symmetry of the rich-to-lean response duration versus the lean-to-rich response duration.

Owner:FORD GLOBAL TECH LLC

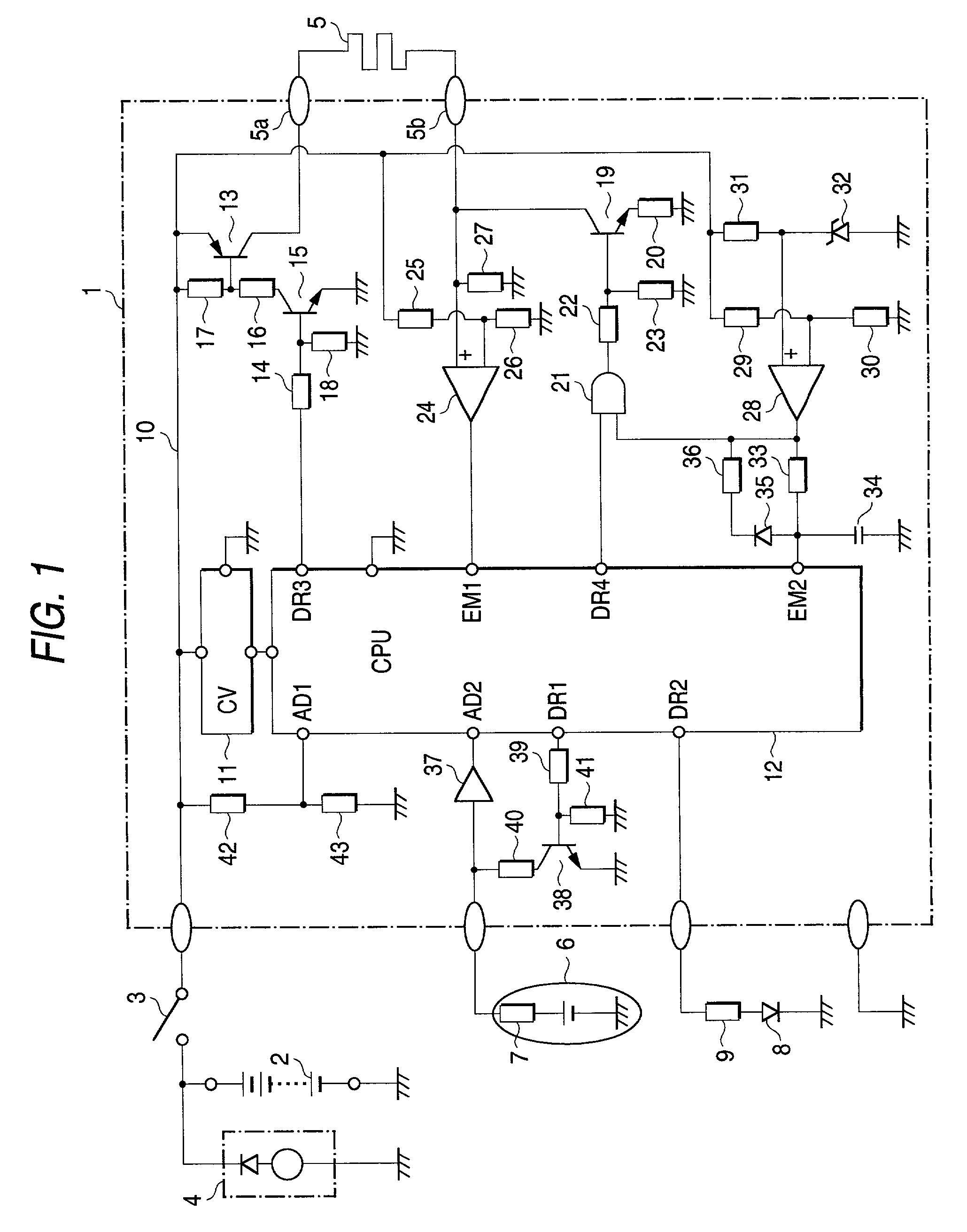

Heater control apparatus for exhaust gas sensor

InactiveUS20020000436A1Electrical controlOhmic-resistance heating detailsOvervoltageElectrical battery

The heater control apparatus comprises an exhaust gas sensor 6 for detecting an oxygen concentration in exhaust gases of an internal combustion engine, a heater 5 for heating this exhaust gas sensor 6 to a predetermined temperature, a power source including a battery 2 for supplying electric power to this heater 5 and a charging generator 4 for charging this battery 2, a switching element 19 inserted into a circuit for supplying electric power to the heater 5 from the power source, control means 12 for performing current-carrying control of the switching element 19 so as to maintain a temperature of the exhaust gas sensor 6 at a predetermined value, and an overvoltage detection element 28 for outputting an abnormal detection signal when a voltage of the power source exceeds a predetermined value, and it is constructed so that the switching element 19 is broken to stop the passage of current to the heater 5 by the abnormal detection signal of the overvoltage detection element 28 when a voltage of the charging generator 4 abnormally increases due to disconnection etc. of the battery 2 of the power source.

Owner:MITSUBISHI ELECTRIC CORP

Apparatus and method for detecting deterioration of exhaust gas sensor

A deterioration detecting apparatus for an exhaust gas sensor of an internal combustion engine, the exhaust gas sensor including a sensor element and a heater that heats the sensor element, computes a first sensor characteristic parameter, which is related to a characteristic of the sensor element, by estimating an interchange state of thermal energy between the sensor element and a periphery of the sensor element. The deterioration detecting apparatus senses impedance of the sensor element. The deterioration detecting apparatus computes a second sensor characteristic parameter, which is related to the characteristic of the sensor element, based on the sensed impedance. The deterioration detecting apparatus determines a degree of deterioration of the exhaust gas sensor by comparing the first sensor characteristic parameter and the second sensor characteristic parameter.

Owner:DENSO CORP

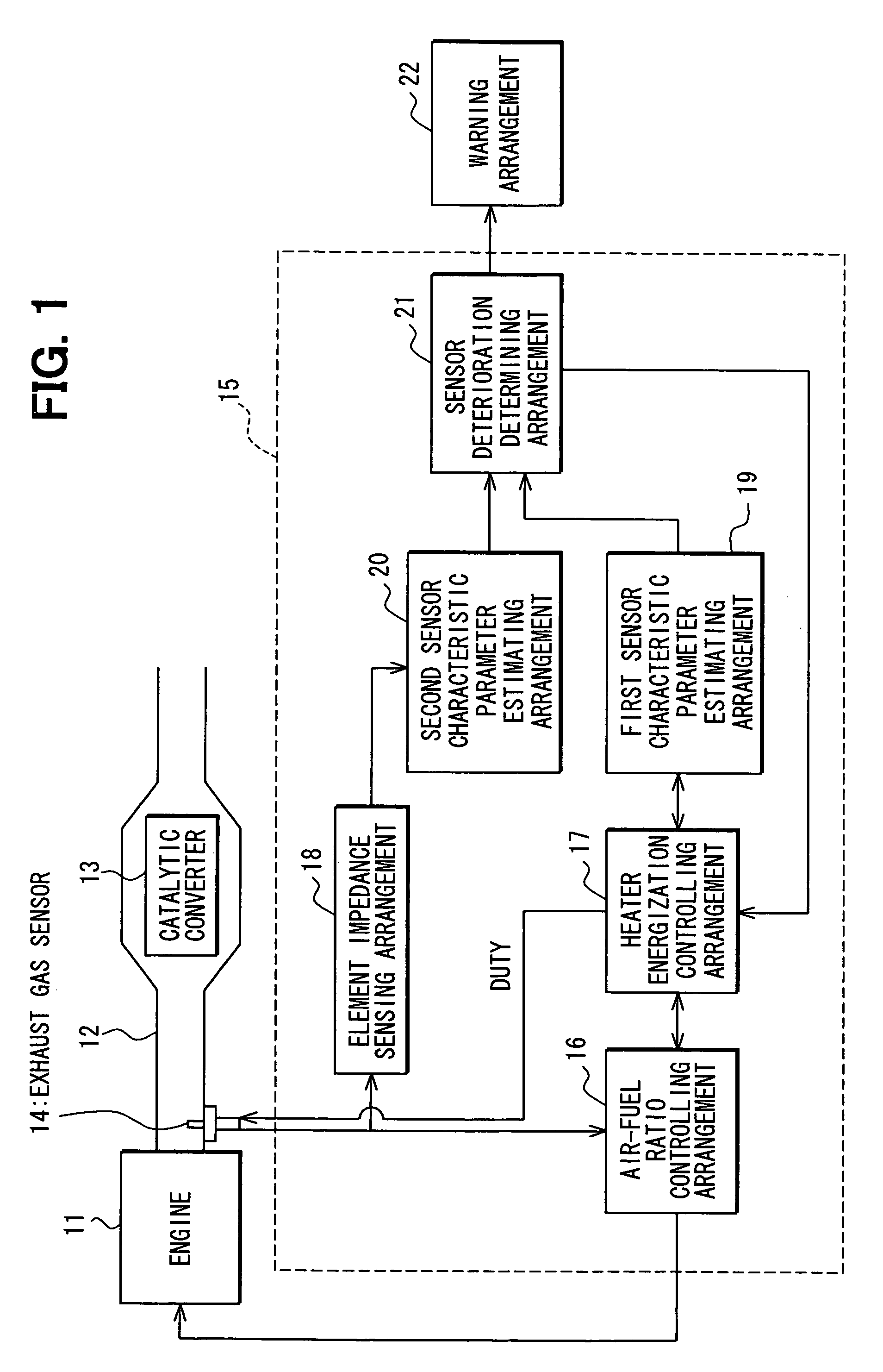

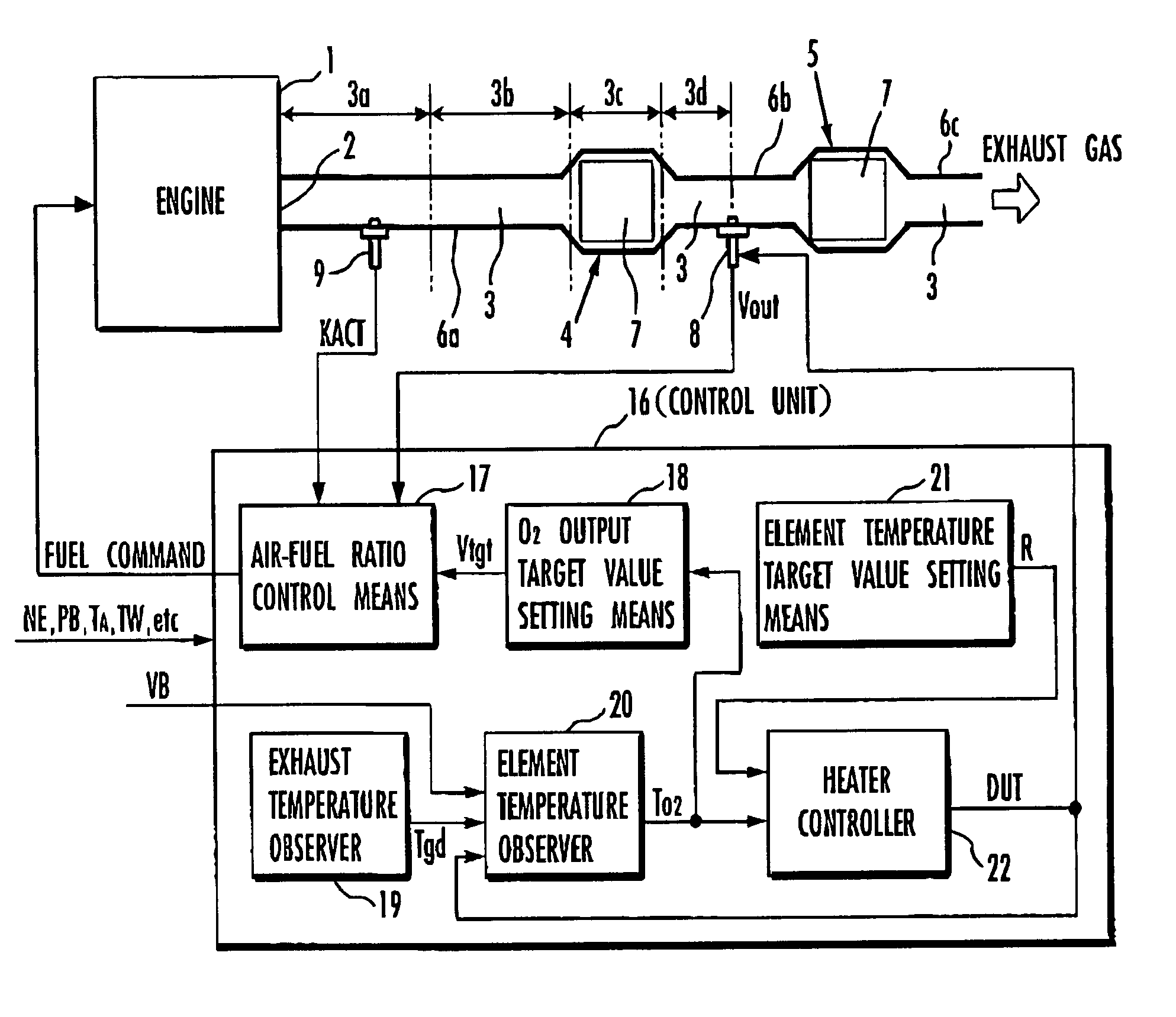

Apparatus for and method of controlling air-fuel ratio of internal combustion engine, and recording medium storing program for controlling air-fuel ratio of internal combustion engine

InactiveUS7047728B2Accurately determineImprove accuracyElectrical controlExhaust apparatusControl theoryAir–fuel ratio

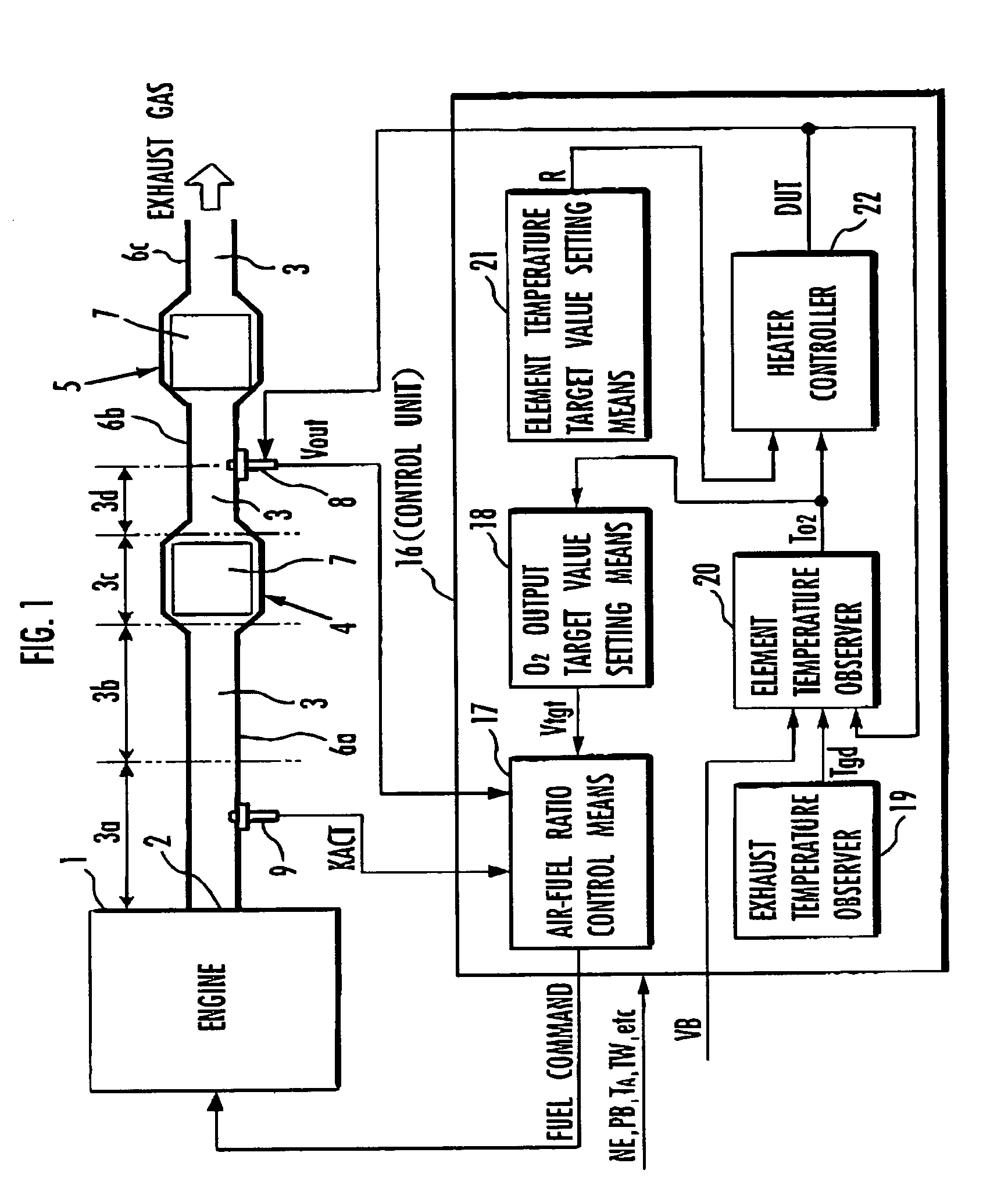

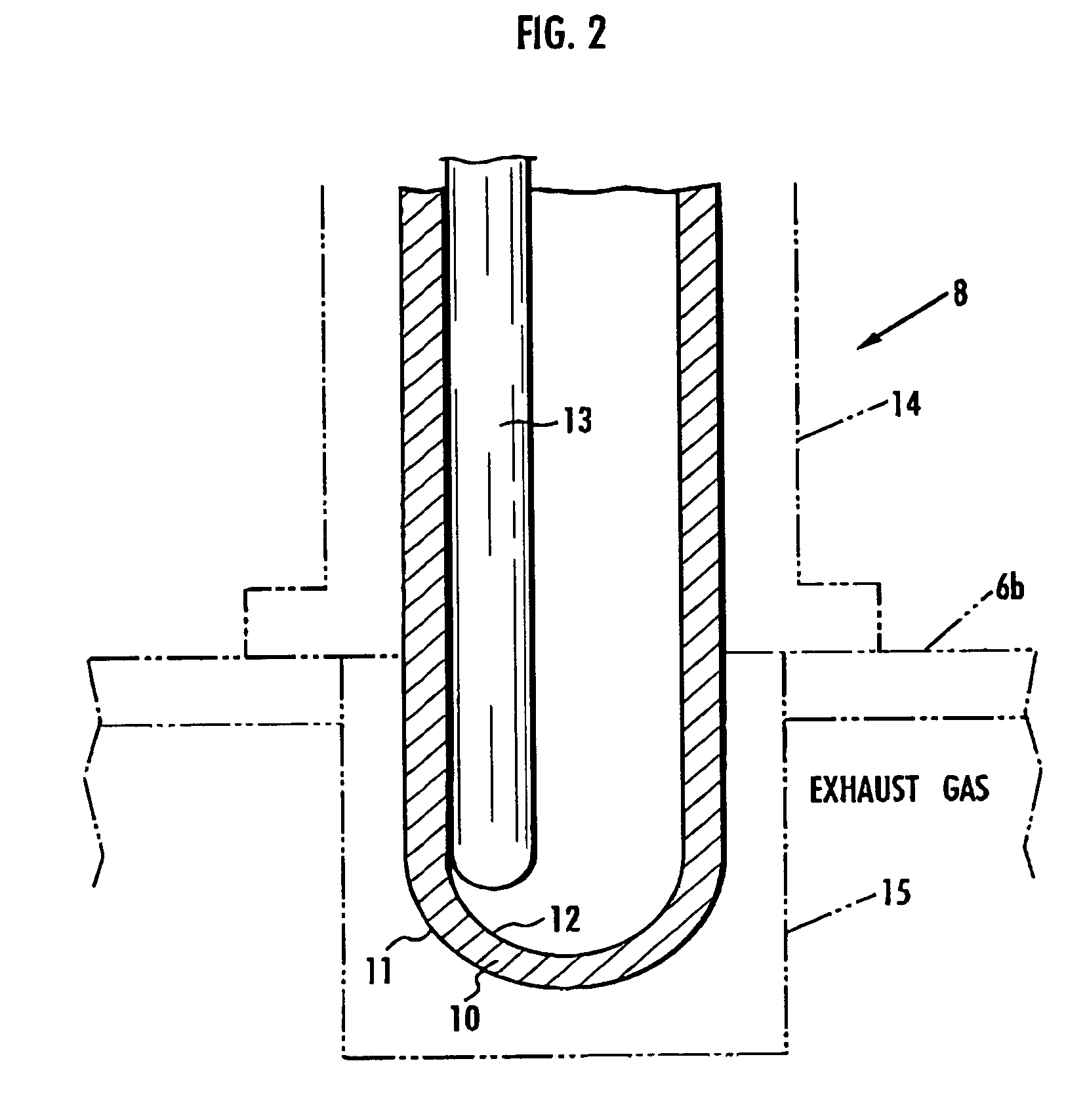

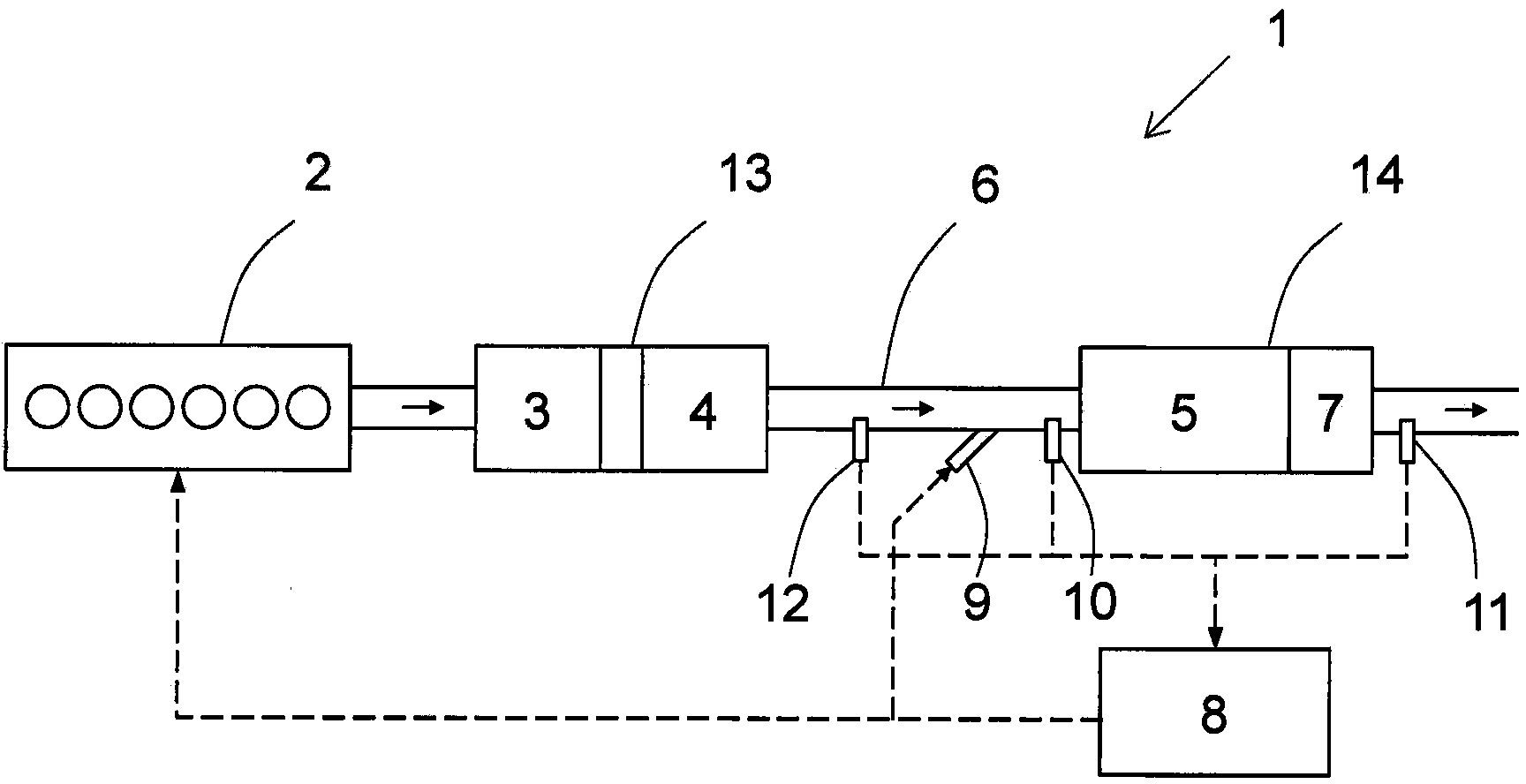

A target value Vtgt for an output Vout of an O2 sensor 8 (an exhaust gas sensor) disposed downstream of a catalytic converter 4 is set variably depending on a temperature TO2 of an active element 10 of the O2 sensor 8 by a target value setting unit 18, and the air-fuel ratio of an exhaust gas is controlled by an air-fuel ratio control unit 17 to converge the output Vout to the target value Vtgt. An exhaust gas temperature Tgd is estimated by an exhaust temperature observer 19, and the temperature TO2 of the active element 10 is sequentially estimated by an element temperature observer 20 using the estimated value of the exhaust gas temperature Tgd. A heater 13 of the O2 sensor 8 is controlled by a heater controller 22 to keep the temperature TO2 of the active element 10 at a predetermined target value R. The air-fuel ratio is thus controlled to maintain a desired exhaust gas purifying capability of the catalytic converter irrespective of the temperature of the active element of the exhaust gas sensor.

Owner:HONDA MOTOR CO LTD

Method for diagnosing selective catalytic reduction catalyst

Owner:VOLVO CONSTR EQUIP AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com