Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

509 results about "Eigenvalue computation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Document data creating apparatus, document data creating method and control program of the same

InactiveUS20080256105A1Improve convenienceEffectively utilizing the digital signatureDigital data processing detailsDigital data protectionDigital signatureDocument preparation

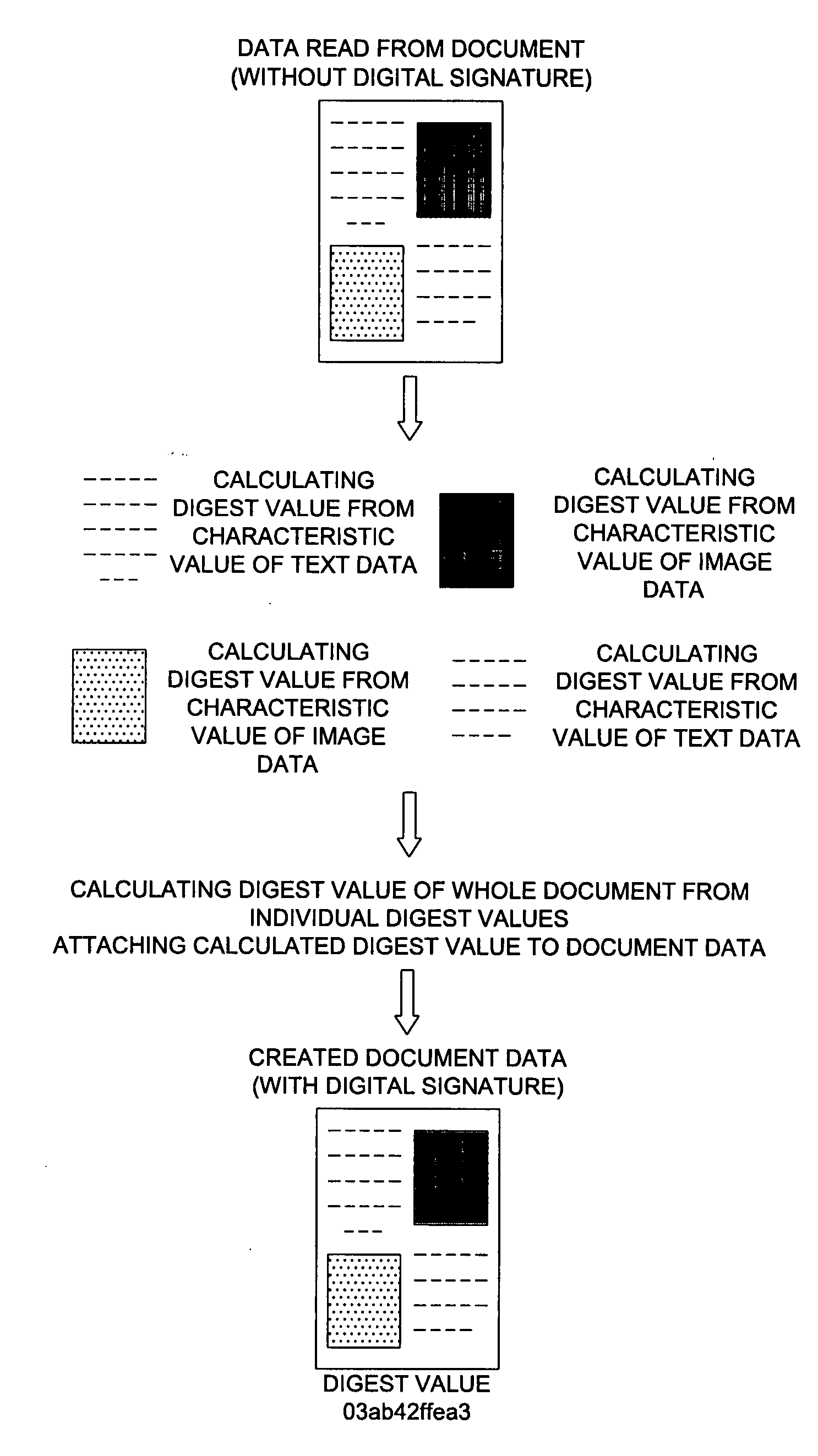

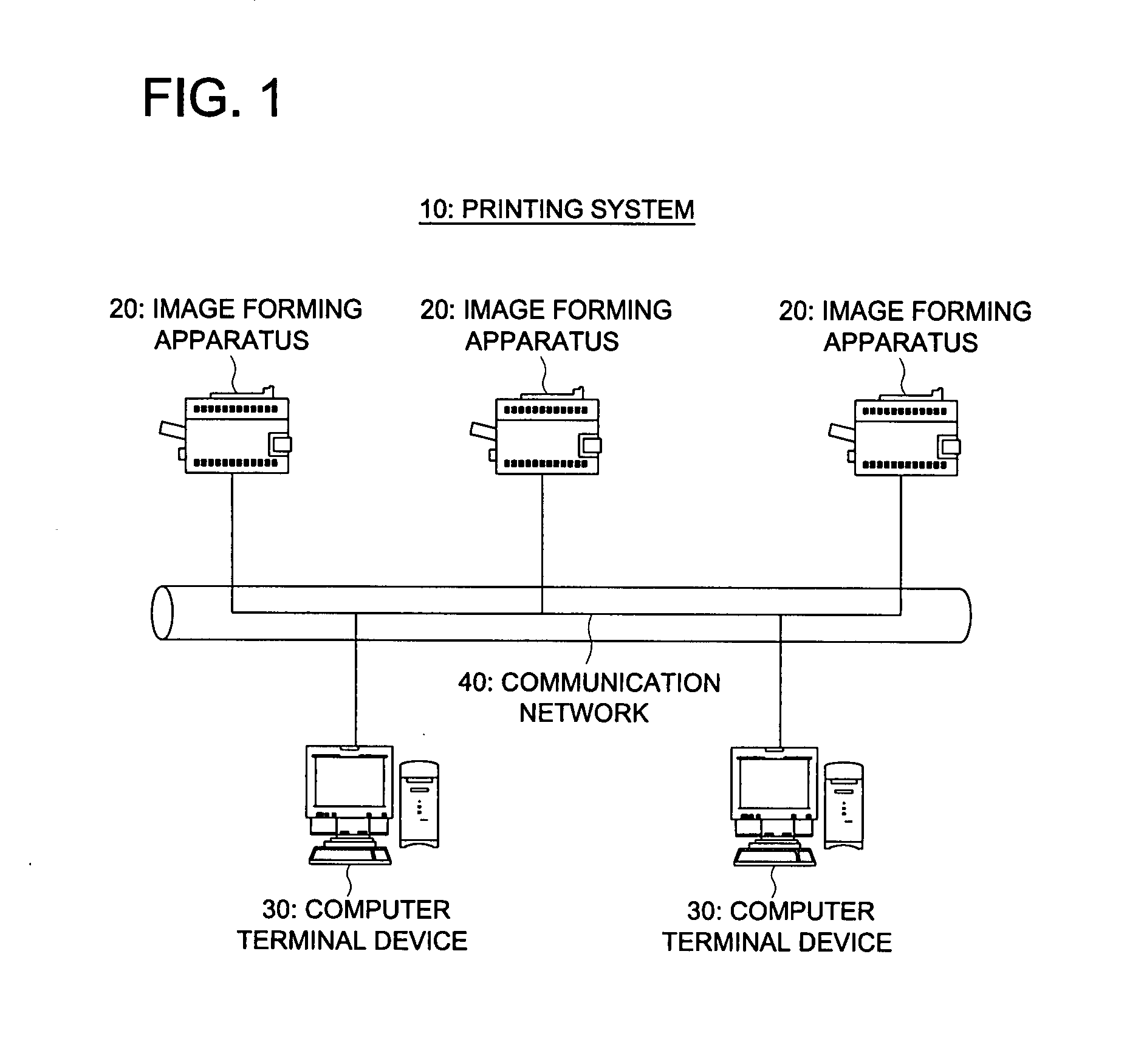

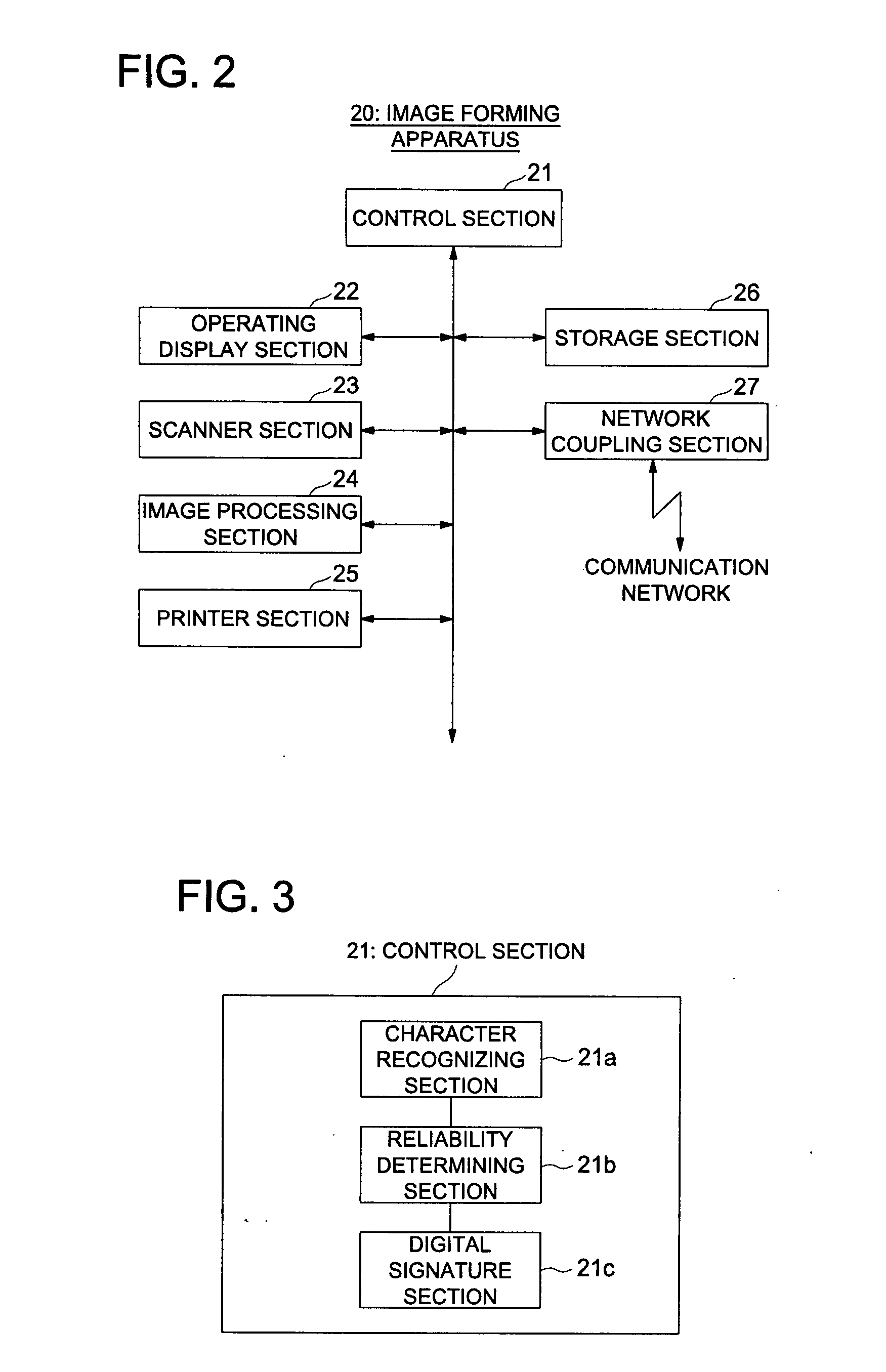

There is described a document data creating apparatus, a document data creating method and a program thereof, which make it possible to improve convenience of both the user and the creator of the document data by effectively utilizing the digital signature. The apparatus for creating document data that include a digital signature, includes: a character recognizing section to recognize a character based on image data inputted; a reliability determining section to determine a reliability degree of the character; a characteristic value calculating section to calculate a characteristic value of the document data; and a digital signature section to attach the characteristic value to the document data. When the reliability determining section determines that the reliability degree of the character is low, the digital signature section attaches a value, which is different from the characteristic value calculated by the characteristic value calculating section, to the document data as the digital signature.

Owner:KONICA MINOLTA BUSINESS TECH INC

Object detection apparatus, learning apparatus, object detection system, object detection method and object detection program

InactiveUS20060204103A1Minimize the numberWeight increaseCharacter and pattern recognitionImage extractionSample image

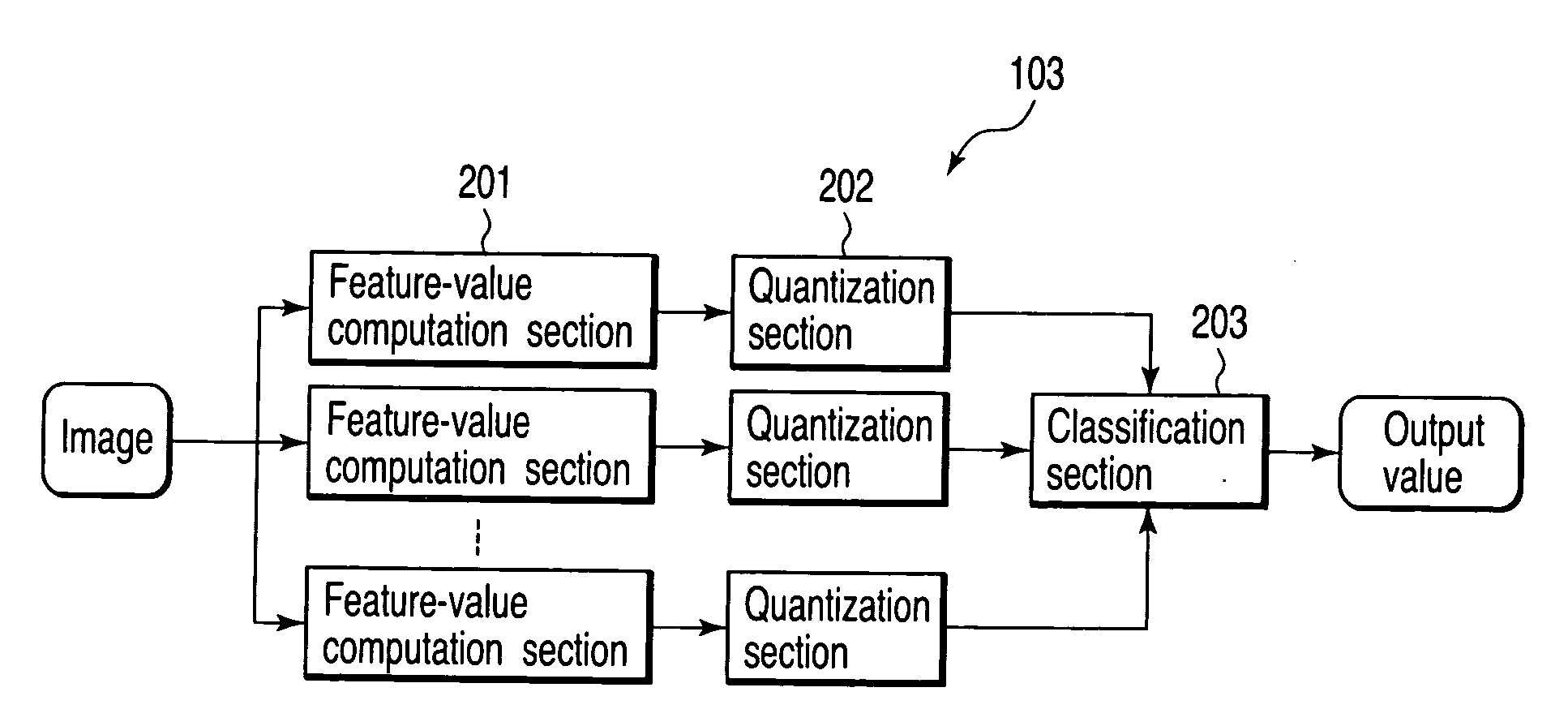

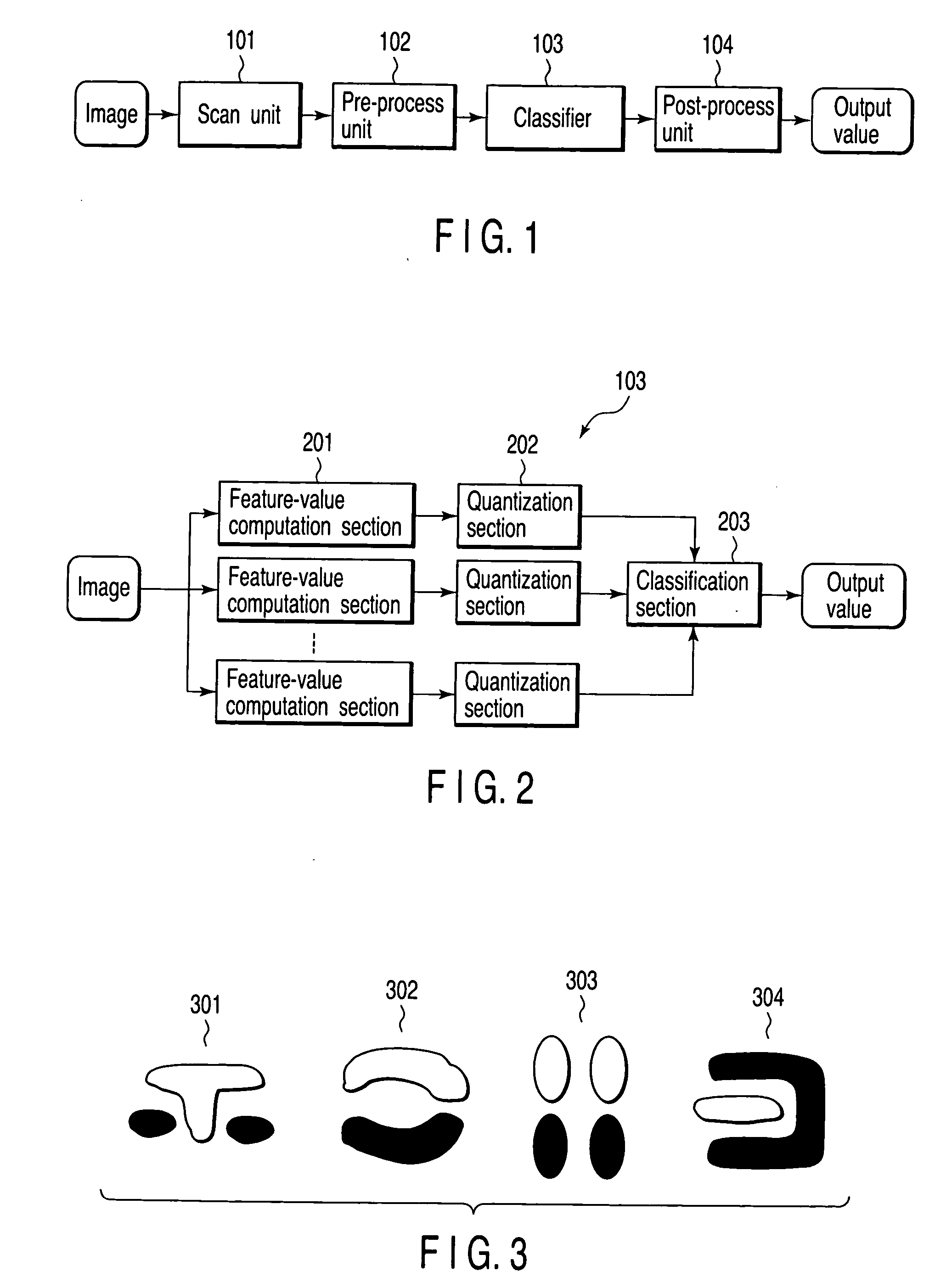

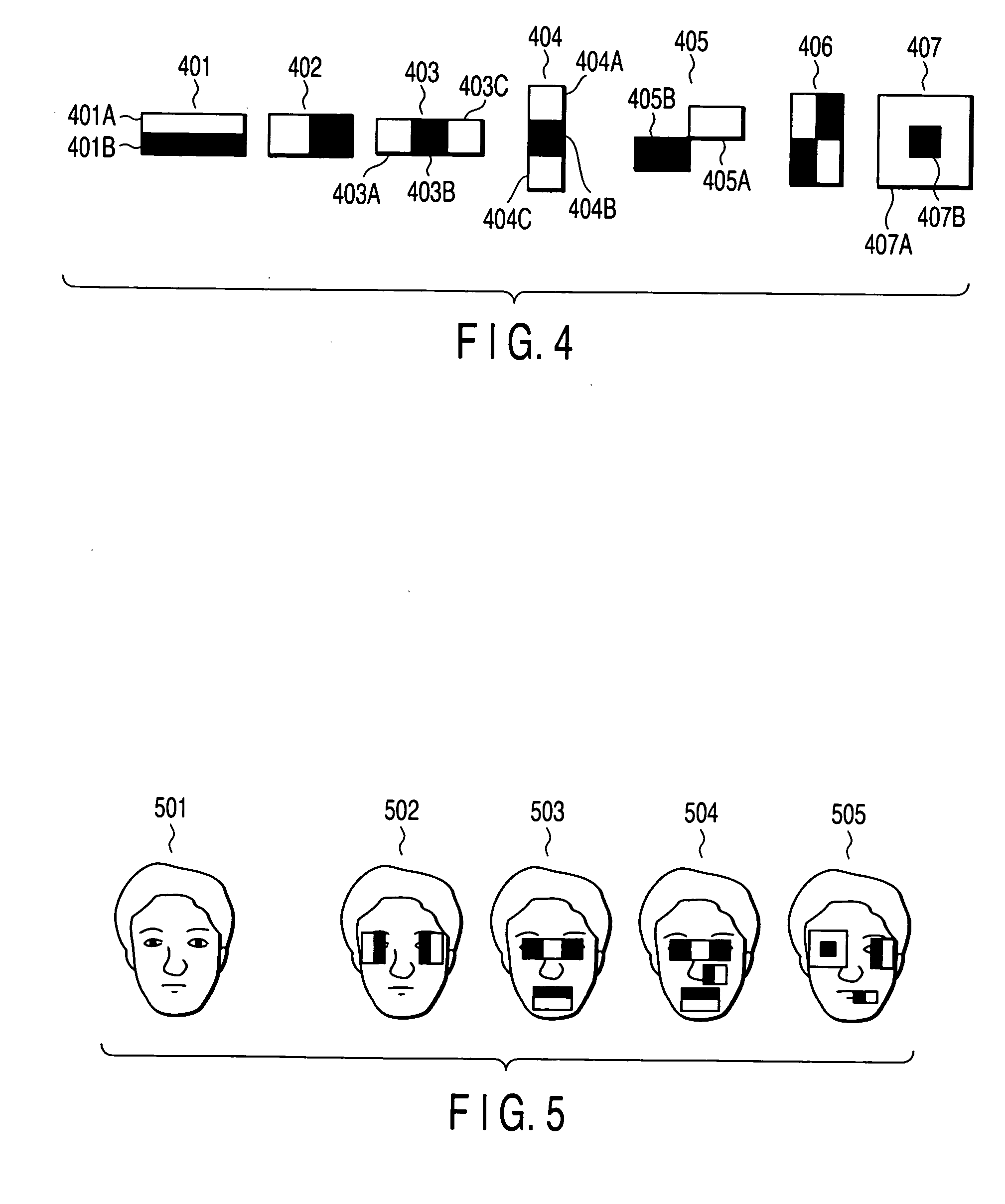

Object detection apparatus includes storage unit storing learned information learned previously with respect to sample image extracted from an input image and including first information and second information, first information indicating at least one combination of given number of feature-area / feature-value groups selected from plurality of feature-area / feature-value groups each including one of feature areas and one of quantized learned-feature quantities, feature areas each having plurality of pixel areas, and quantized learned-feature quantities obtained by quantizing learned-feature quantities corresponding to feature quantities of feature areas in sample image, and second information indicating whether sample image is an object or non-object, feature-value computation unit computing an input feature value of each of feature areas belonging to combination in input image, quantization unit quantizing computed input feature value to obtain quantized input feature value, and determination unit determining whether input image includes object, using quantized input feature value and learned information.

Owner:KK TOSHIBA

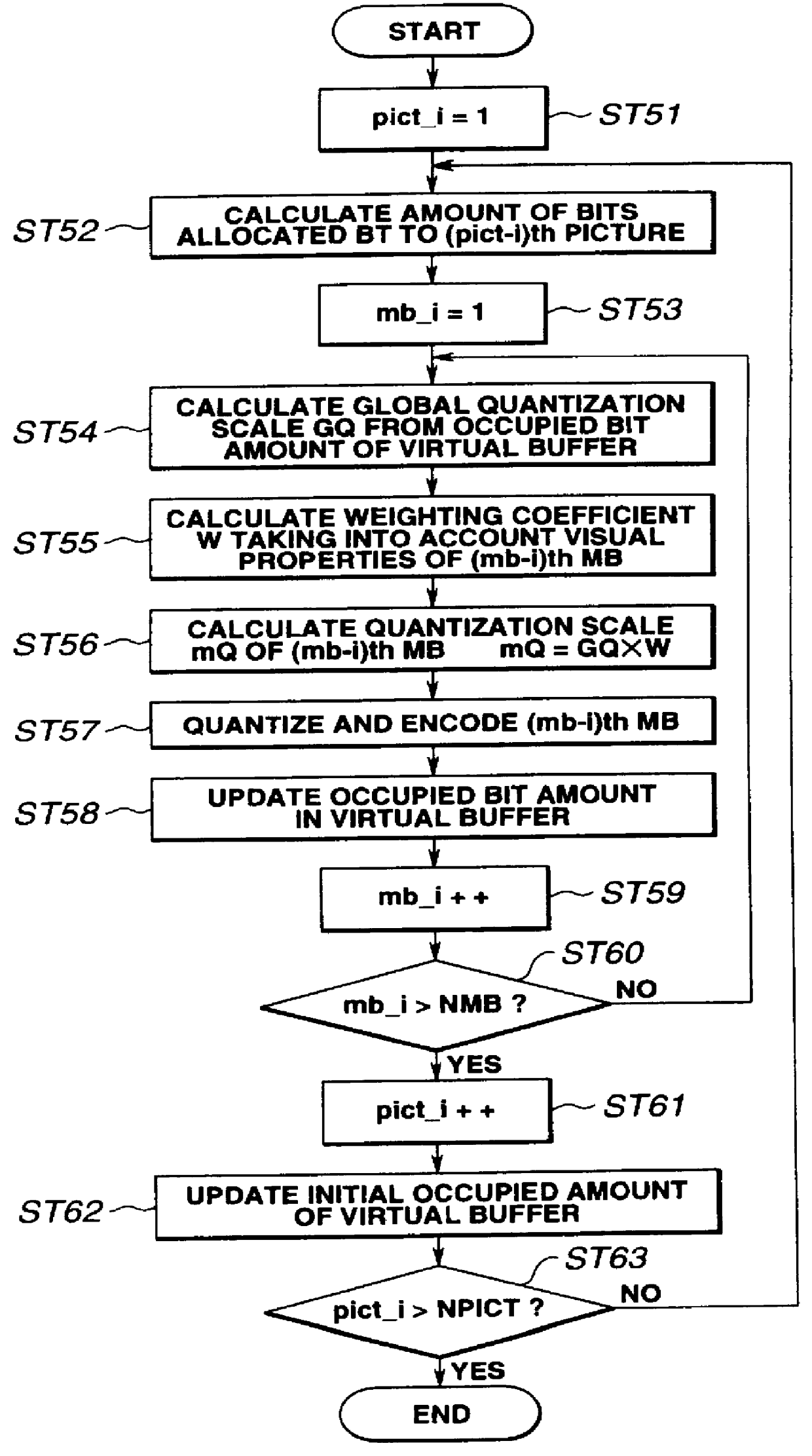

Picture signal encoding method and apparatus and signal recording medium

InactiveUS6167087ATelevision system detailsColor television with pulse code modulationVisibilityWeight coefficient

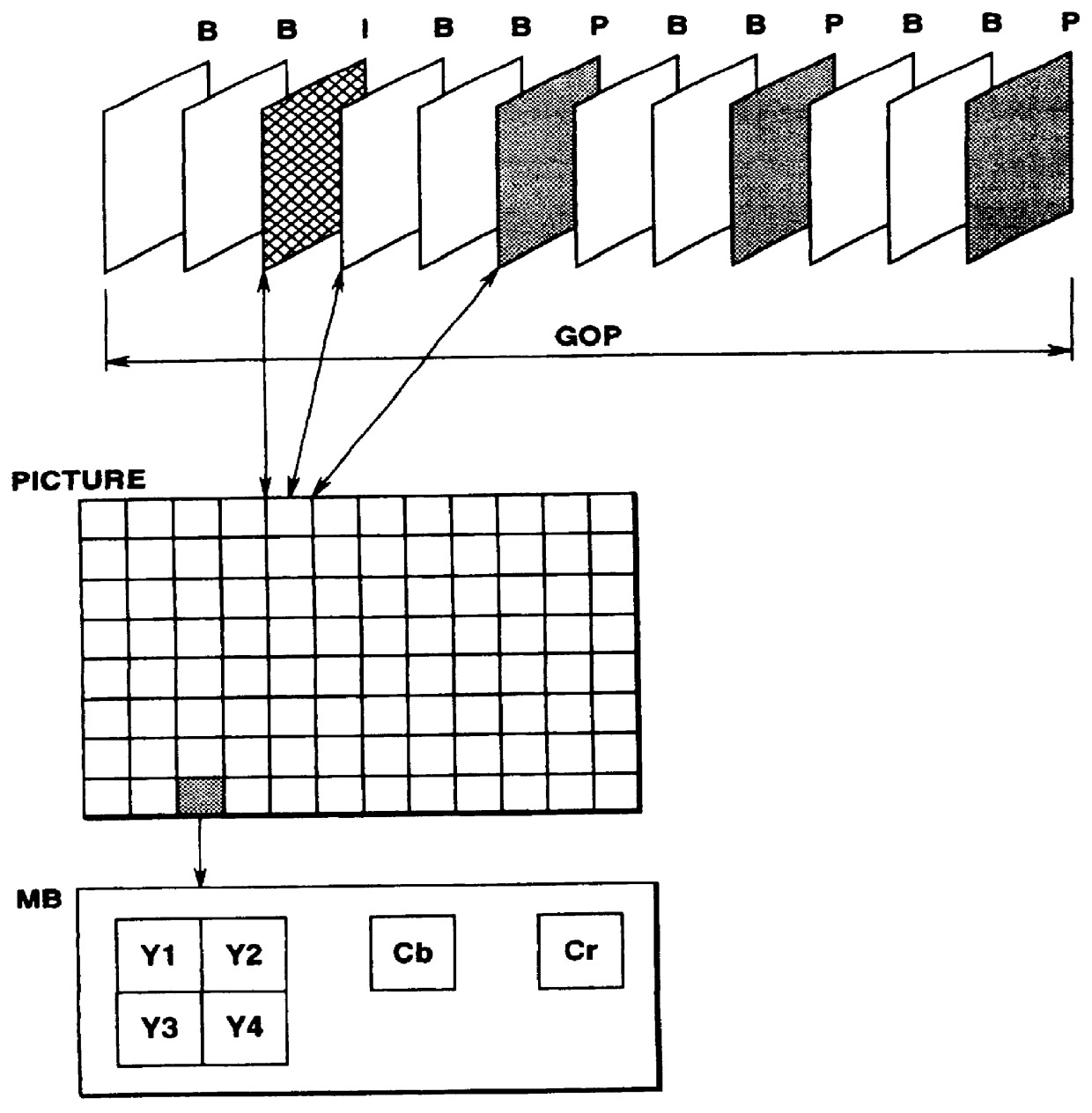

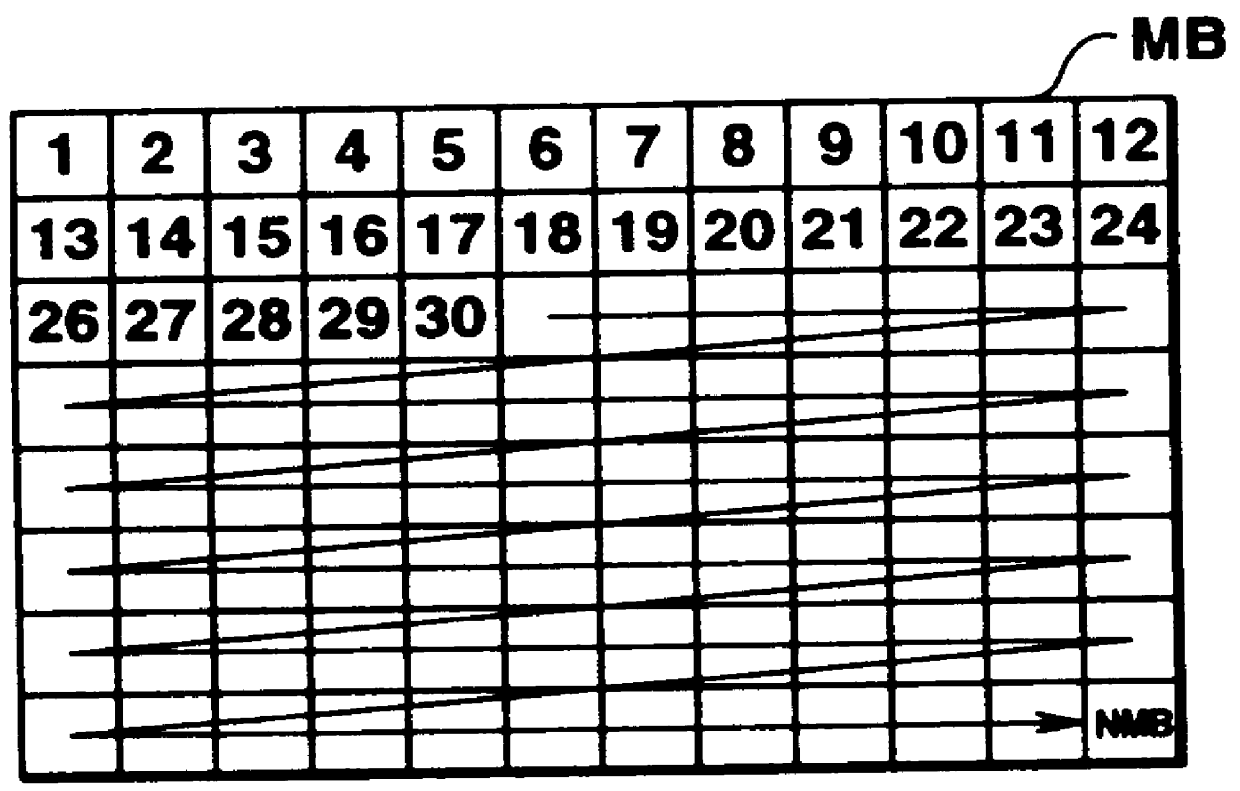

A picture signal encoding apparatus on which, even if a picture is not uniform in picture pattern, the picture can be rendered substantially uniform in picture quality, the volume of bits occupying a virtual buffer is stabilized, deterioration in picture quality is rendered less visible and in which stable rate control is assured. The picture signal encoding apparatus, dividing a picture making up moving picture signals into plural macro-blocks MB and encoding the signals from one macro-block to another, includes a relative coding difficulty calculating circuit for calculating the relative coding difficulty from one macro-block to another MB, and a characteristic value calculating circuit for calculating the weighting coefficients (characteristic values) specifying visibility degree of picture quality deterioration from one macro-block MB to another. The picture signal encoding apparatus also includes a bit rate controller for calculating the quantization scale for encoding each macro-block MB using the complexity degree and the volume of allocated bits for macro-block-based encoding.

Owner:SONY CORP

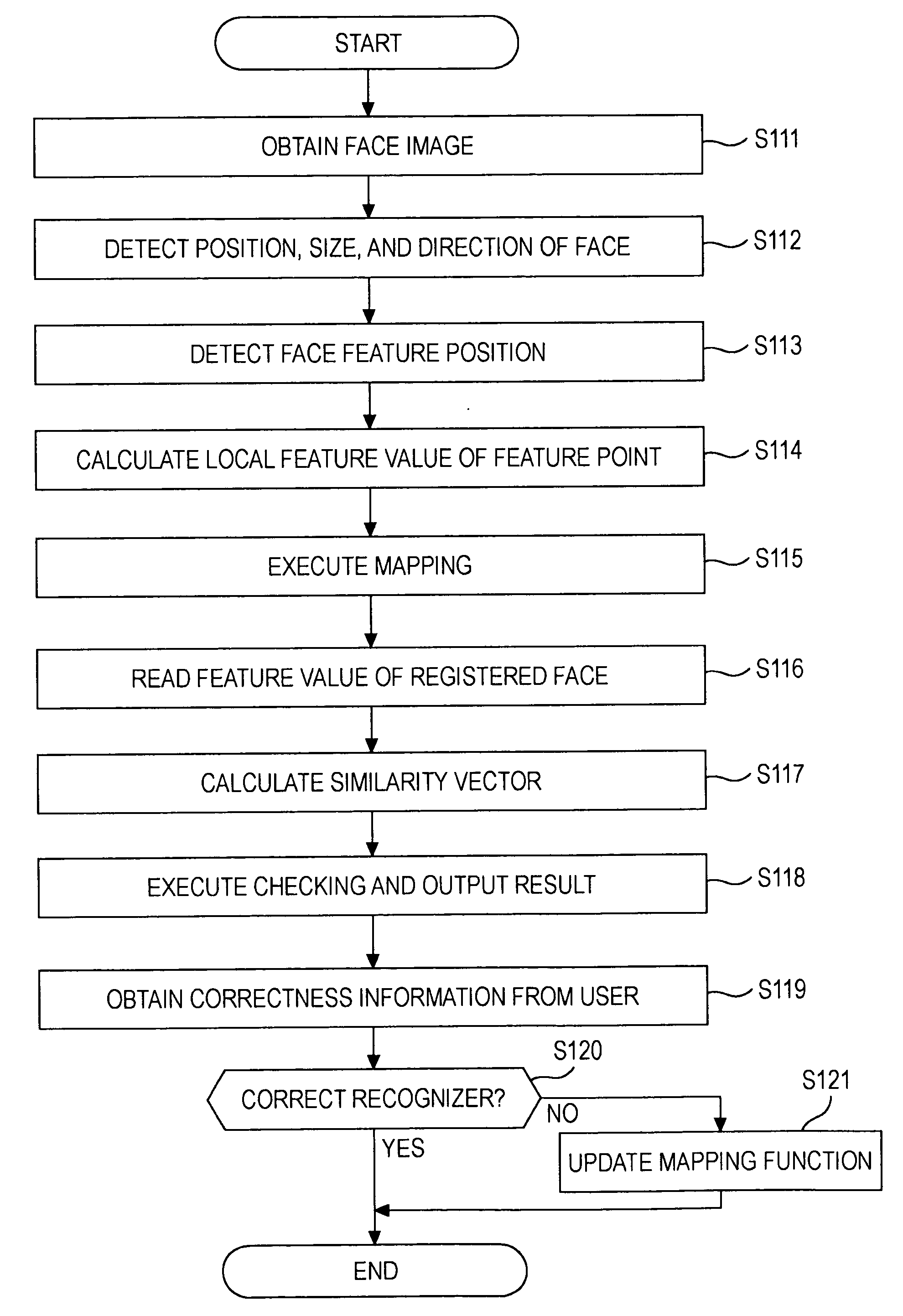

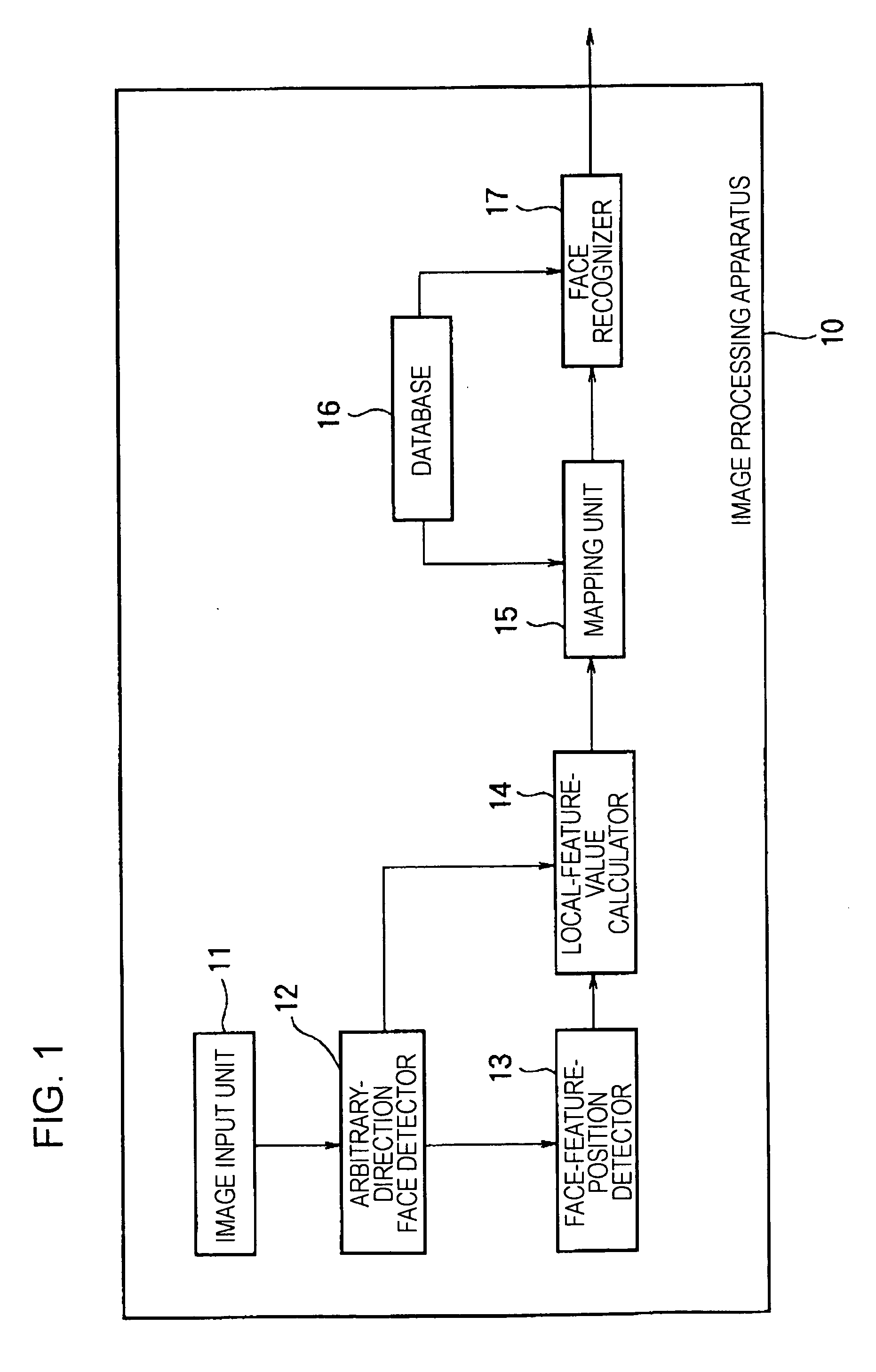

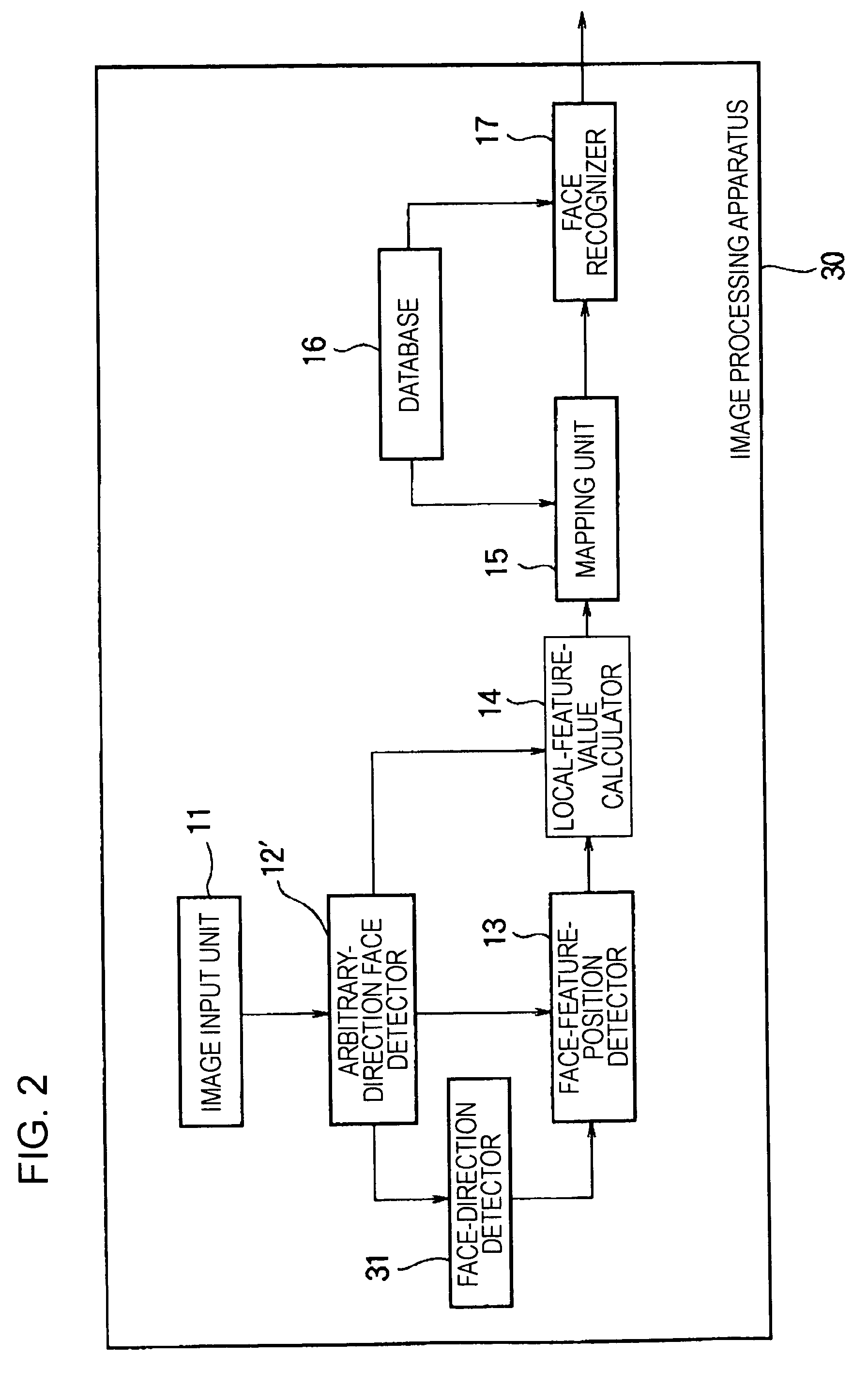

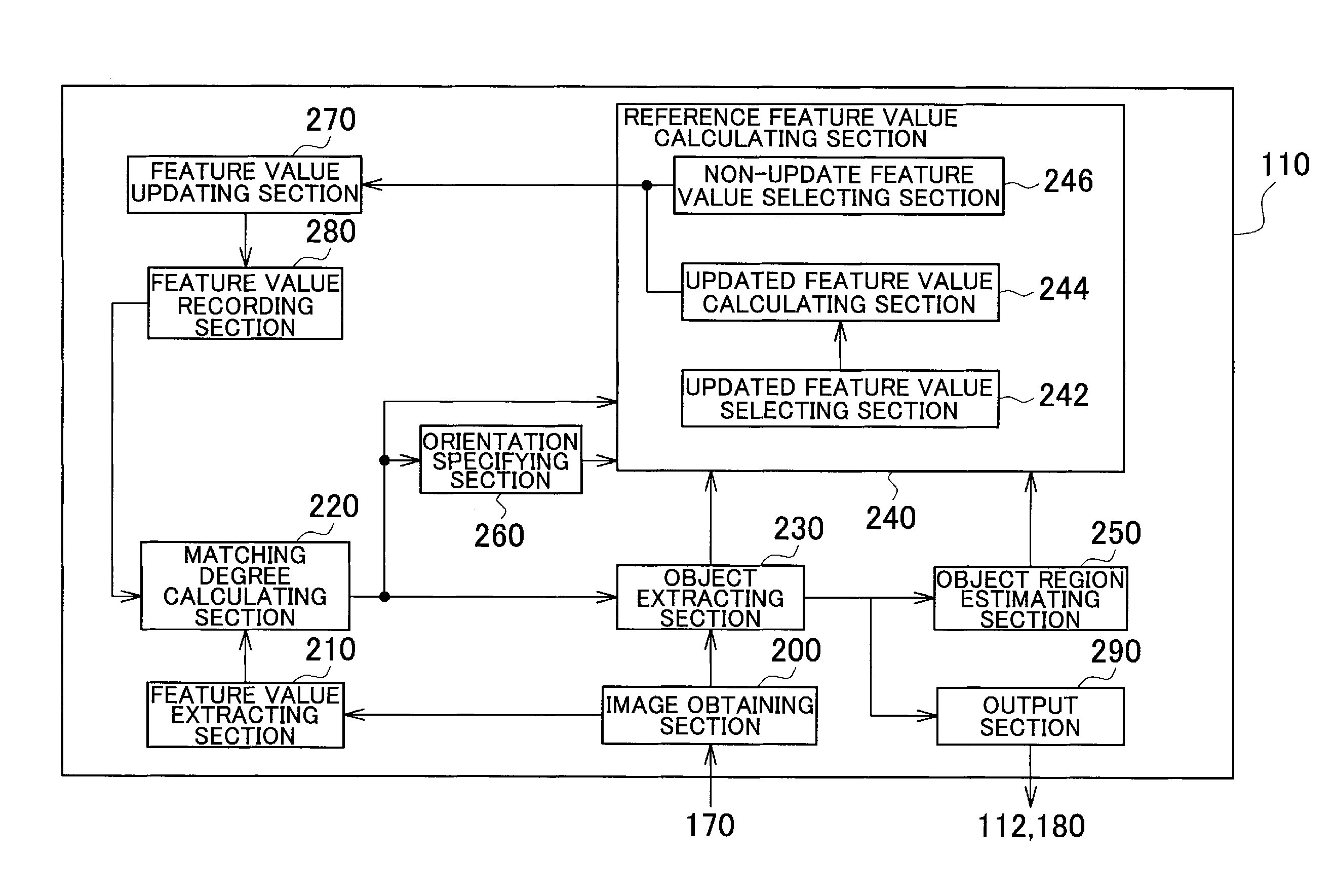

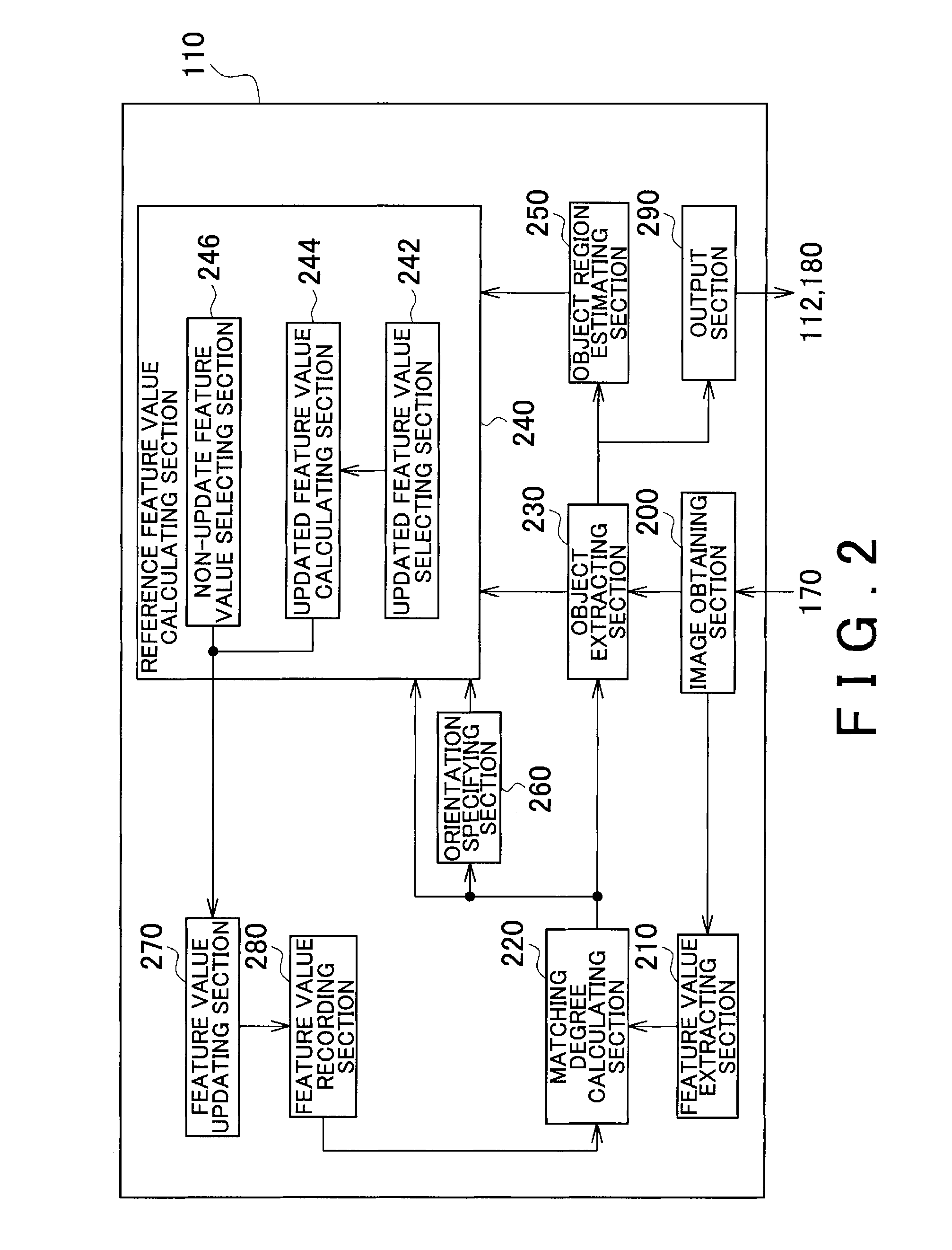

Image processing apparatus and method and program

InactiveUS20070047775A1Improve recognition accuracyReduce loadImage analysisCharacter and pattern recognitionPattern recognitionImaging processing

An image processing apparatus includes a face-image detector configured to detect a region of a face image from an image supplied thereto; a face-direction detector configured to detect a direction that a face in the detected face image is facing; a feature-position detector configured to detect feature positions corresponding to features of the face from the detected face image and the detected face direction; a feature-value calculator configured to calculate feature values at the detected feature positions; a mapper configured to map the calculated feature values using predetermined mapping functions; and a recognizer configured to recognize whether the detected face is a registered face, using the mapped feature values and feature values registered in advance.

Owner:SONY CORP

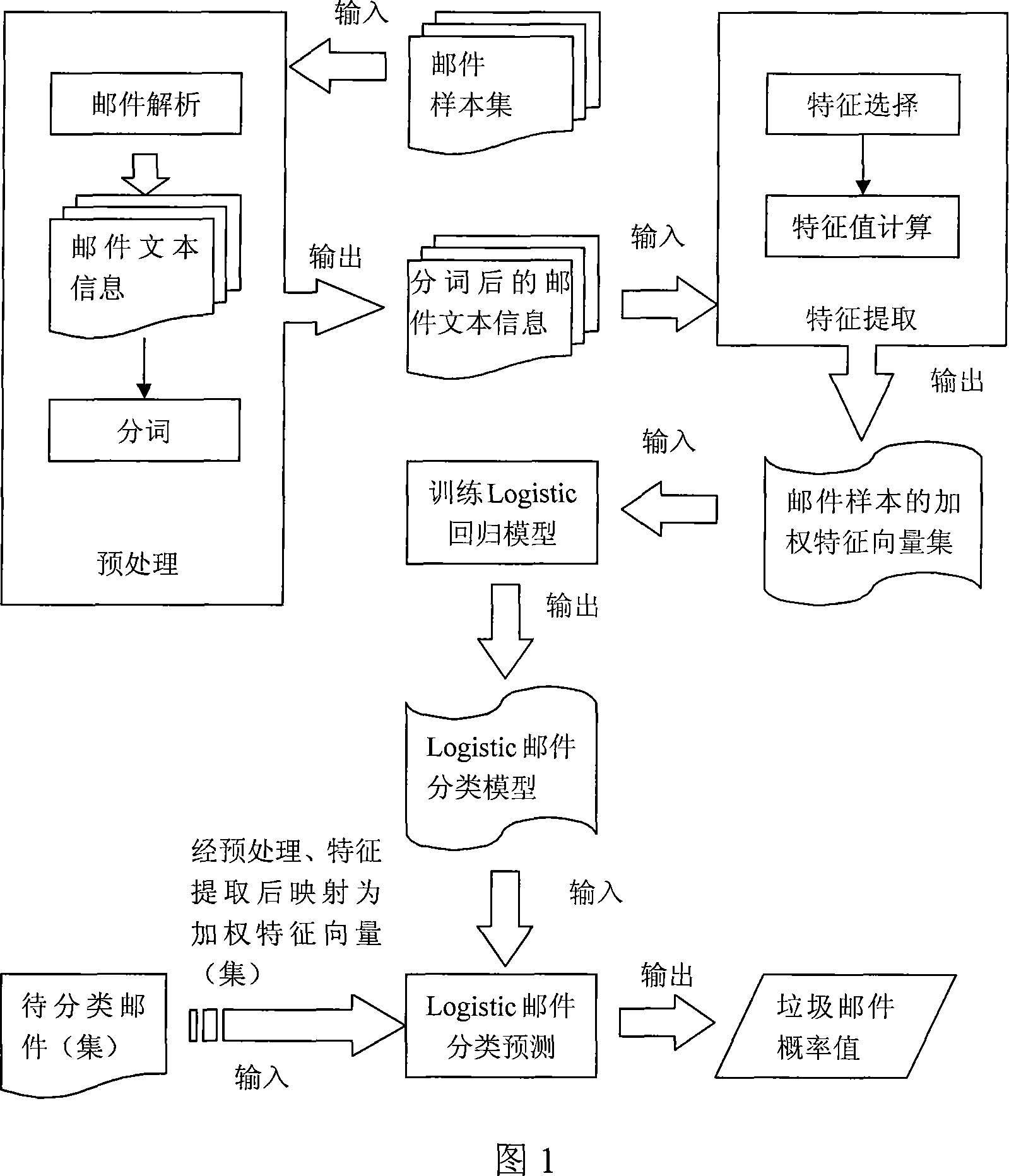

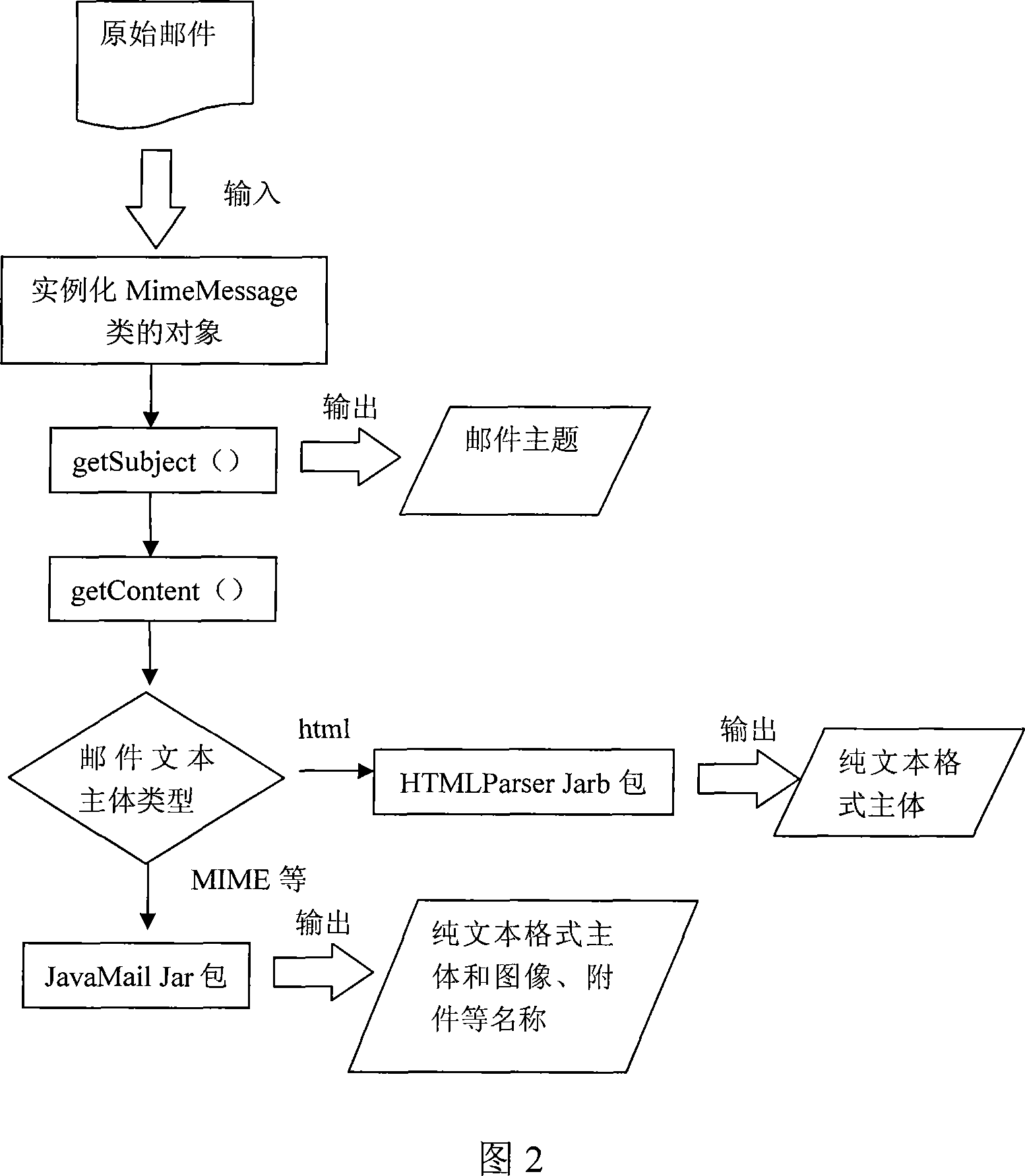

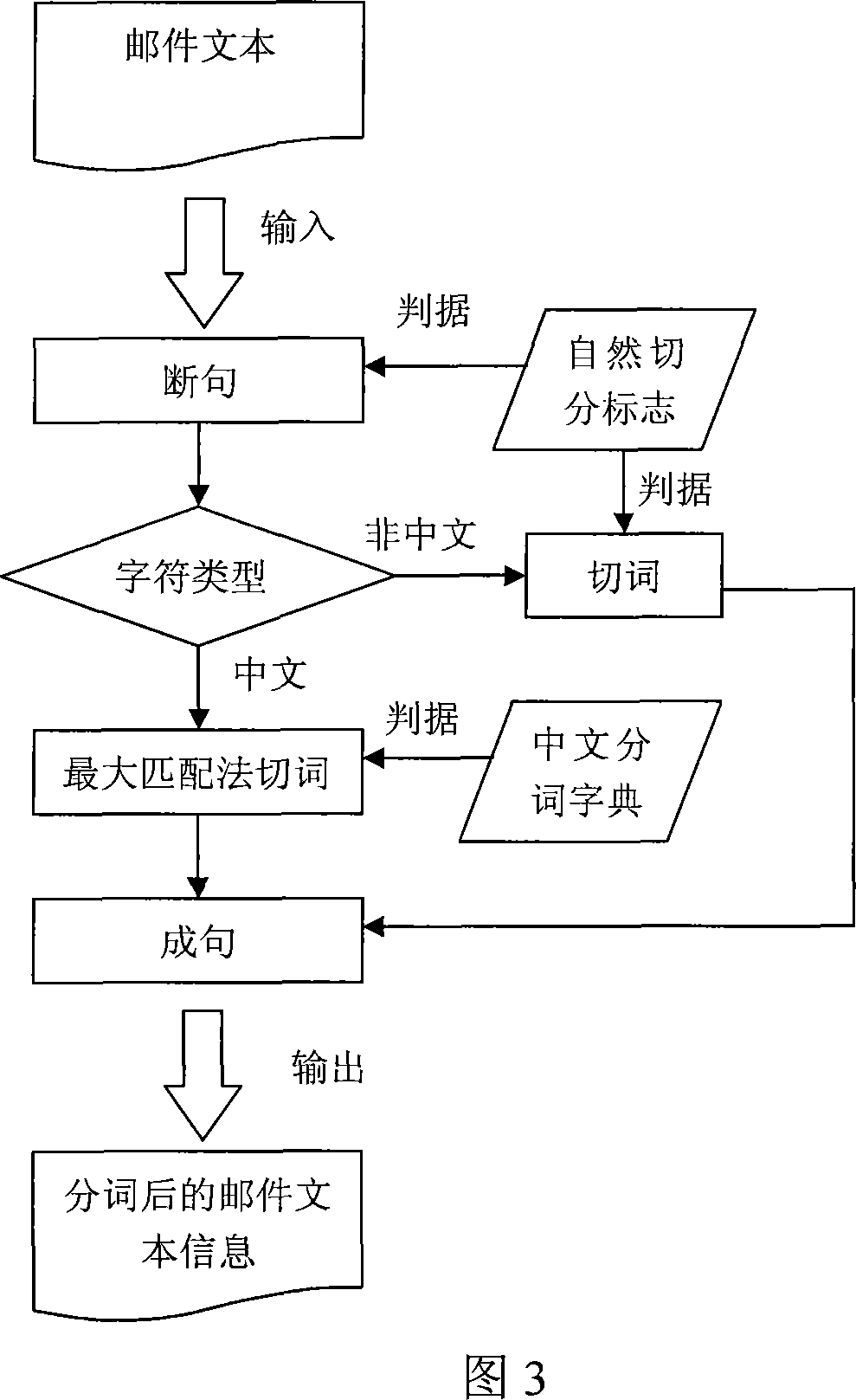

Method for filtering Chinese junk mail based on Logistic regression

InactiveCN101227435AFew adjustment parametersImprove classification effectOffice automationData switching networksFeature vectorRelevant information

The invention discloses a filtering method of recursive Chinese junk E-mail, which is based on Logistic. The method comprises the following steps: first, analyzing E-mails, extracting E-mail titles, E-mail main bodies and accessory relative information, second, segmenting words for version information which is extracted, third, accounting word frequencies of entries in E-mails, calculating weights of words through utilizing TF-IDF pattern, presenting the E-mail to be characteristic vector which is weighted, fourth, utilizing an LIBLINEAR tool kit to exercise the sample of the E-mail to get an Logistic recursive module, fifth, utilizing the Logistic recursive module to classify for new E-mails, getting the probability value whether the E-mails which are got are junk E-mails. The utility which utilizes the Logistic recursive module has the advantages of simple module, little amount of parameter, and high classifying accuracy in a data set whose text number and characteristic number are both bigger, the accuracy and efficiency of filtering junk E-mails are improved through dimension reduction and improved characteristic value calculating method, and meanwhile, the problem of choosing module exercise parameter which is faced in filtering junk E-mails is effectively solved.

Owner:ZHEJIANG UNIV

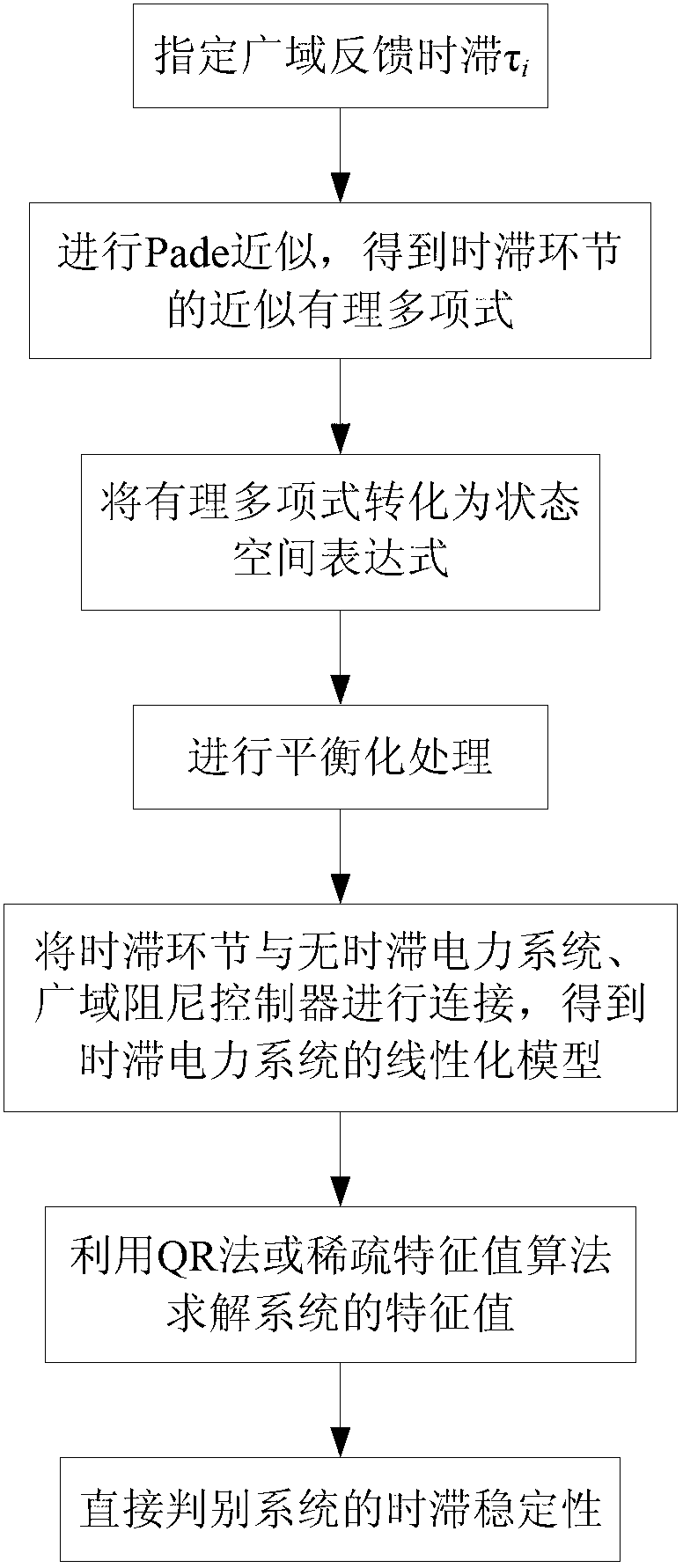

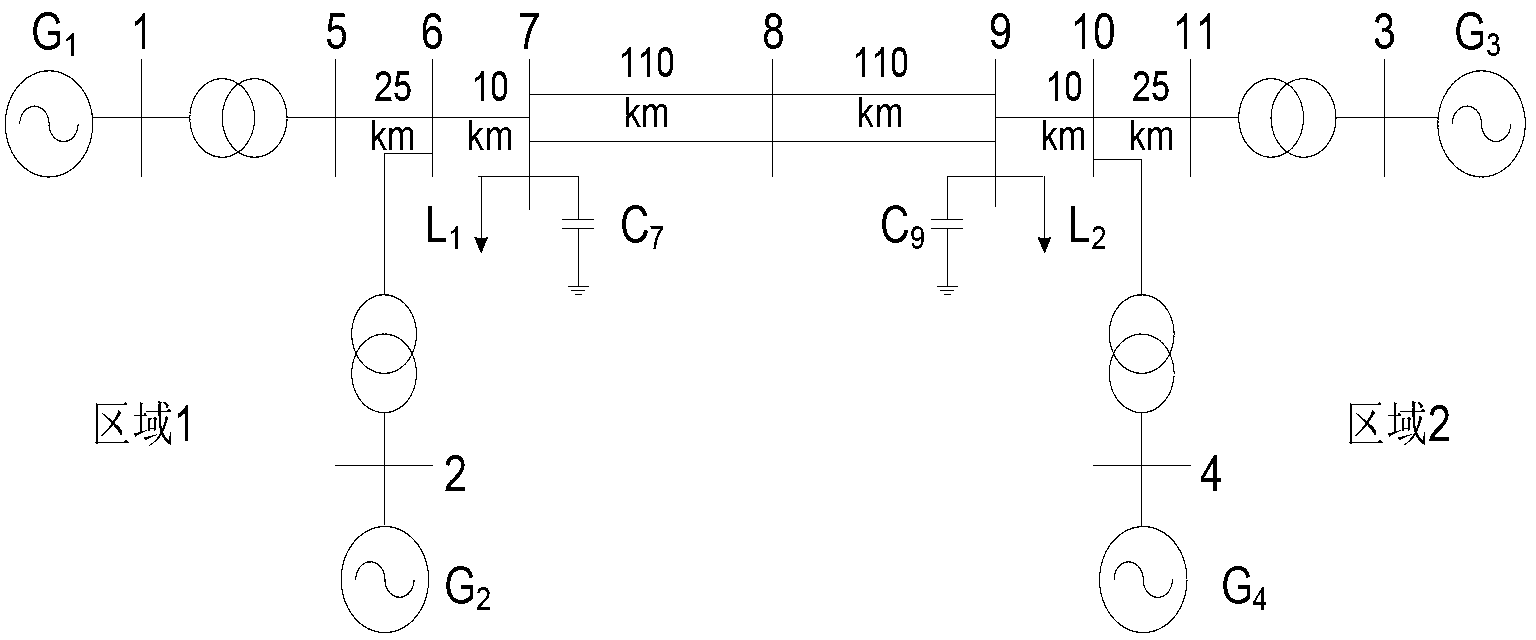

Method for calculating time-lag electric power system eigenvalue and discriminating stability based on Pade approximation

The invention discloses a method for calculating time-lag electric power system eigenvalues and discriminating stability based on Pade approximation. The method uses Pade approximation to make wide area feedback time-lag approximate to a rational polynomial. Though connecting with an electric power system without time-lag and a wide area damping controller, a linearized model of the time-lag electric power system is established. Finally, part of characteristic roots of the time-lag system is directly obtained according to a system state matrix, and then time-lag stability of the system is determined. According to an eigenvalue calculating result of a four-machine two-region example system, the method can relatively accurately solve part of the eigenvalues and eigenvectors which are corresponding to dynamic elements in the time-lag system. The method can conveniently and accurately determine time-lag stability of the system, correctly solve the number of the eigenvalues which are corresponding to a time-lag link and calculate precision which is related to order of the rational polynomial. In addition, the method is advantaged by small calculated amount, and short calculating time.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER

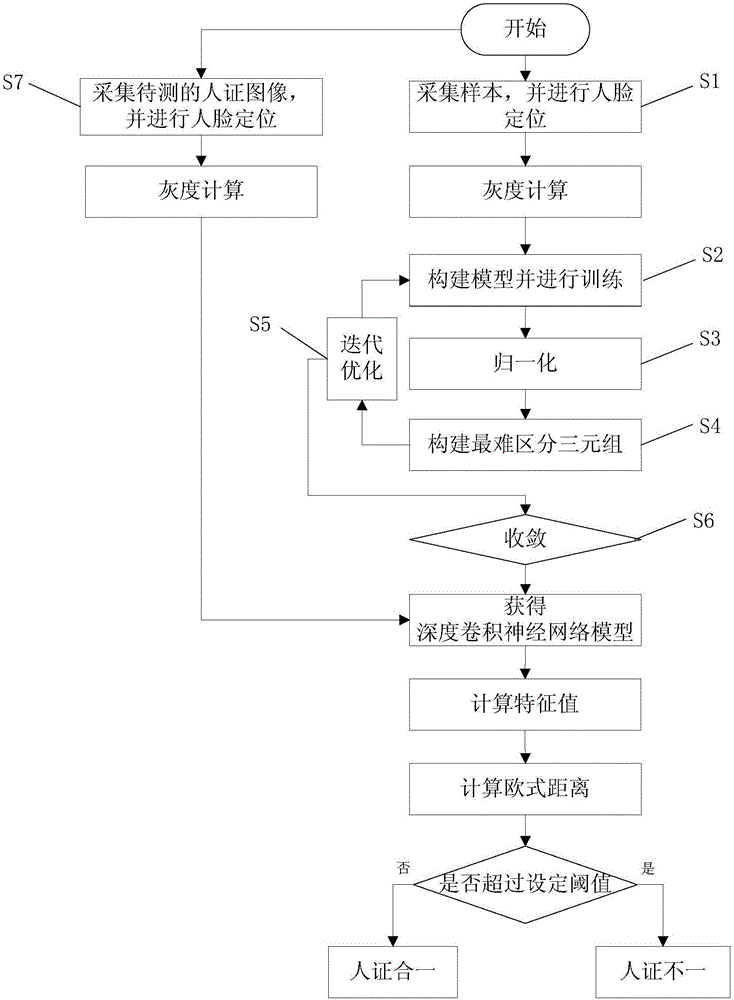

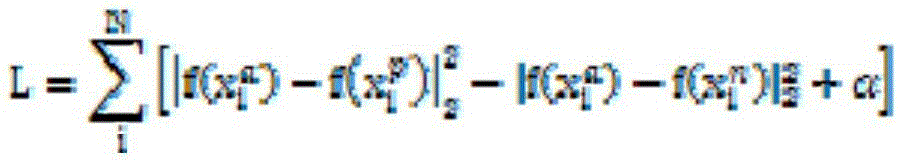

Witness and evidence integration recognition method and system based on deep convolutional neural network

ActiveCN106780906AImprove robustnessImprove performanceIndividual entry/exit registersNeural architecturesImaging FeatureEuclidean distance

The invention discloses a witness and evidence integration recognition method and system based on a deep convolutional neural network. By constructing the human face convolution neutral network model, a most difficult distinguishing triple and iterative optimization method is used for training the human face convolutional neural network model, and the deep convolutional neural network model is obtained, the model is used for calculating certificate image and human face image feature values, an Euclidean distance is calculated according to the feature values, and then whether the certificate image is consistent with the human image or not is judged. Compared with the prior art, the method and system has the good robustness for background, illumination, gesture and other changes, constant iteration training can be performed by means of depth learning, the human face recognition performance and the characteristic extraction accuracy are improved, and the system performance is effectively enhanced.

Owner:北京品恩科技股份有限公司

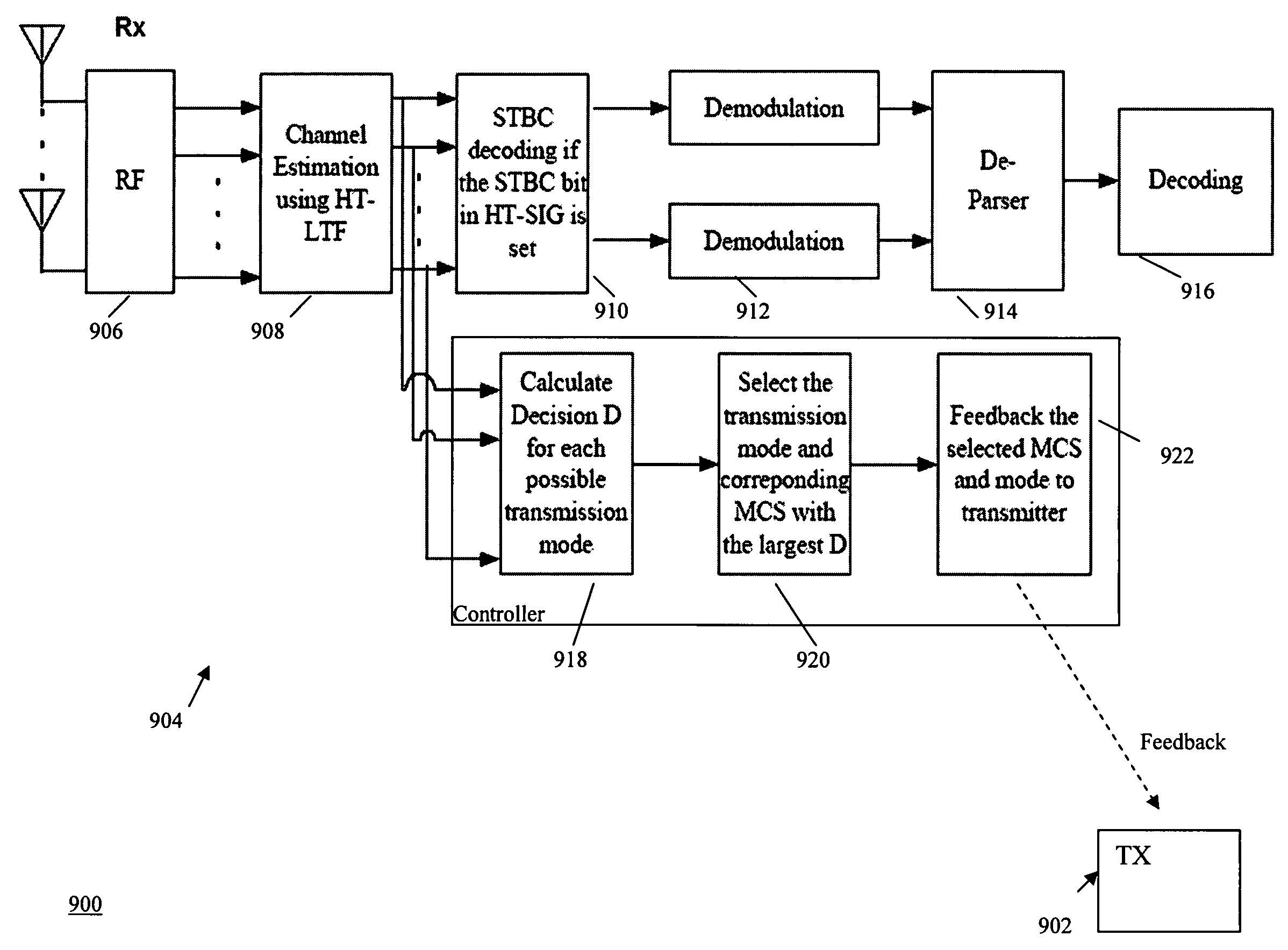

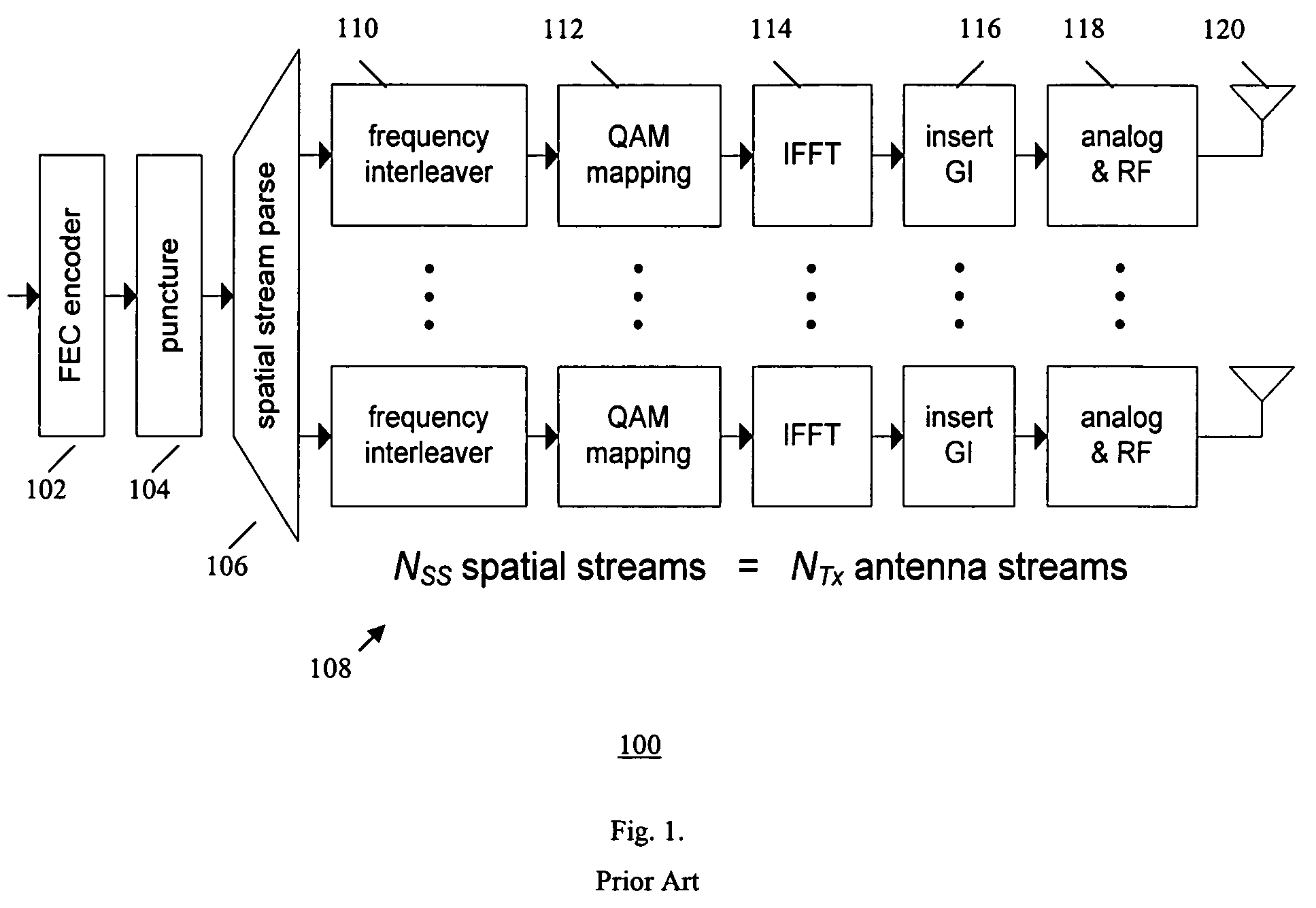

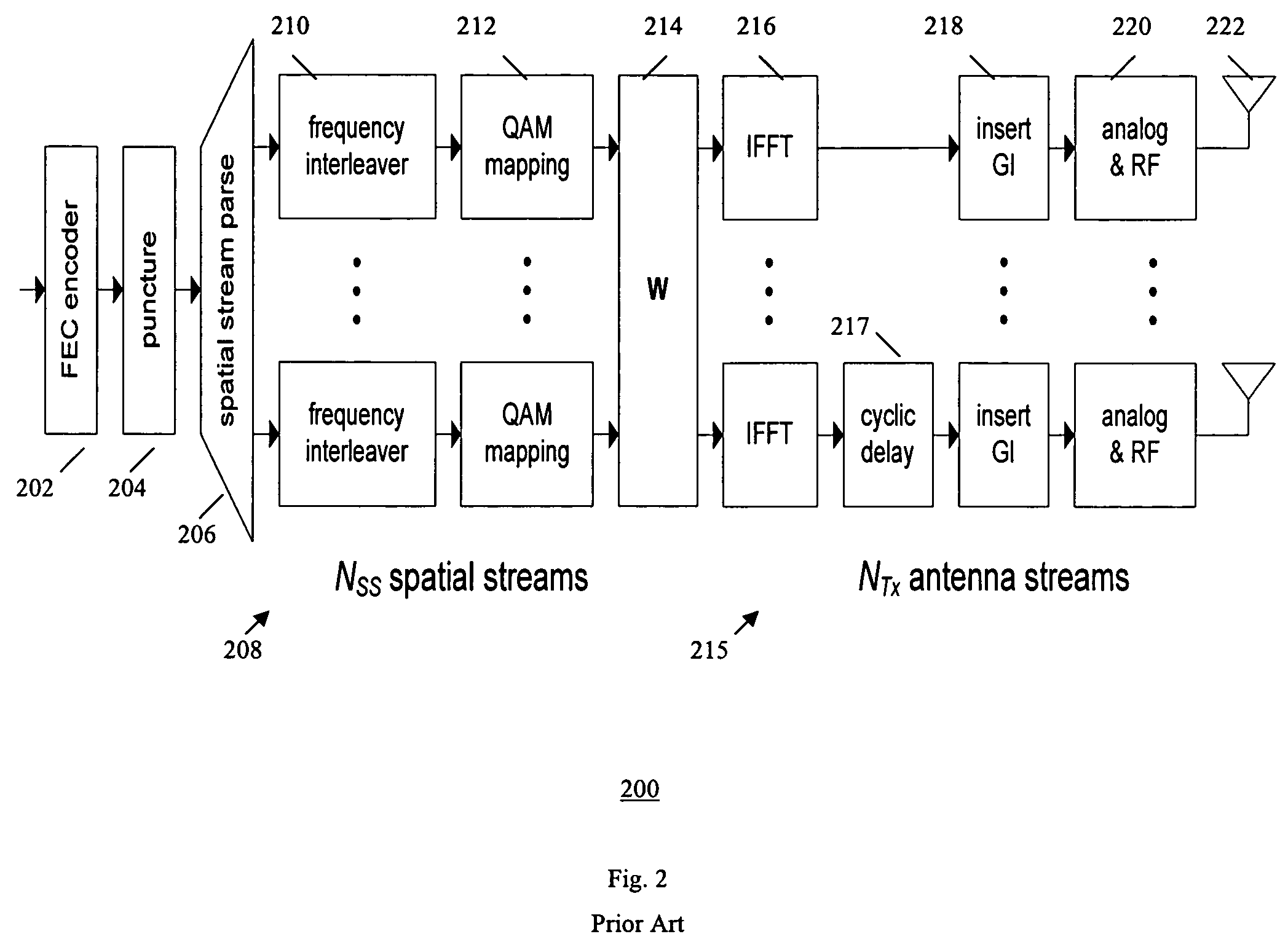

Method of switching transmission modes in IEEE 802.11n MIMO communication systems

InactiveUS7620067B2Improve performanceImprove system performanceFrequency-division multiplex detailsTransmission systemsSelf adaptiveDiversity scheme

A method and system is provided that selects transmission modes between spatial multiplexing, delay diversity and space-time coding in 802.11n systems. As such, eigen-value computation for mode selection is not required. This provides efficiency, in particular for basic receiver structure where a linear MMSE or ZF MIMO detector is applied. Further, mode selection using a simple metric provides accurate mode selection. In addition by switching between different transmission modes, a link adaptation algorithm according to the present invention provides improved system performance.

Owner:SAMSUNG ELECTRONICS CO LTD

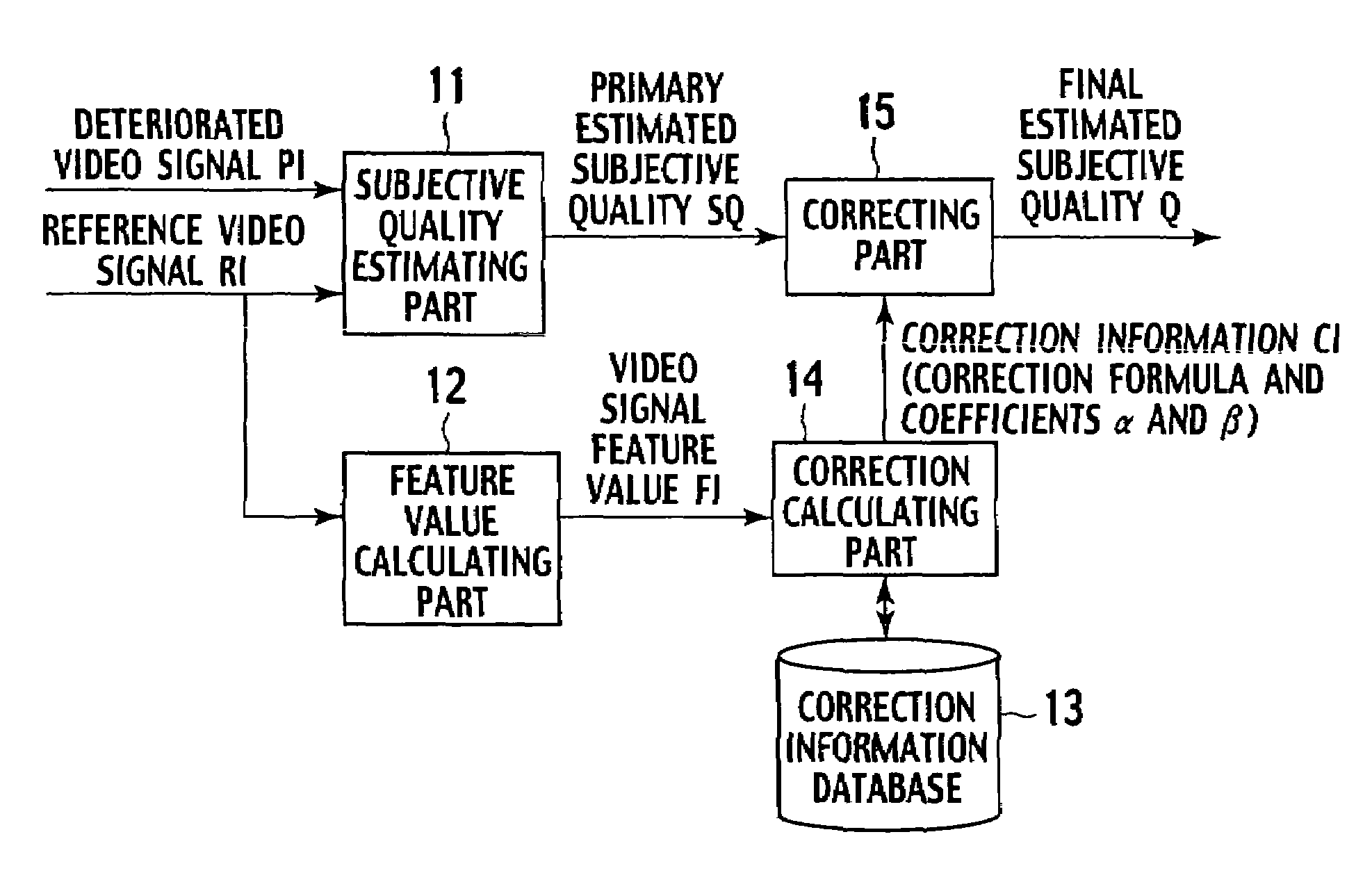

Video quality assessing apparatus, video quality assessing method, and video quality assessing program

ActiveUS7705881B2Accurately and invariably estimating a subjective quality of optional video imagesTelevision systemsVideo qualityComputer science

A subjective quality estimating part (11) receives an undeteriorated reference video signal (RI) and a deteriorated video signal (PI) produced from the reference video signal, calculates video signal feature values for both the signals, and according to a difference between the calculated video signal feature values of the signals, estimates a subjective quality of the deteriorated video signal. A feature value calculating part (12) calculates the video signal feature values of the reference video signal. A correction information storing part (13) stores correction information that corresponds to video signal feature values and is used to correct the subjective quality. A correction calculating part (14) receives the video signal feature values of the reference video signal from the feature value calculating part (12), retrieves correction information corresponding to the received video signal feature values from the correction information storing part (13), and transfers the retrieved correction information to a correcting part (15). According to the transferred correction information, the correcting part (15) corrects the subjective quality estimated by the subjective quality estimating part (11).

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

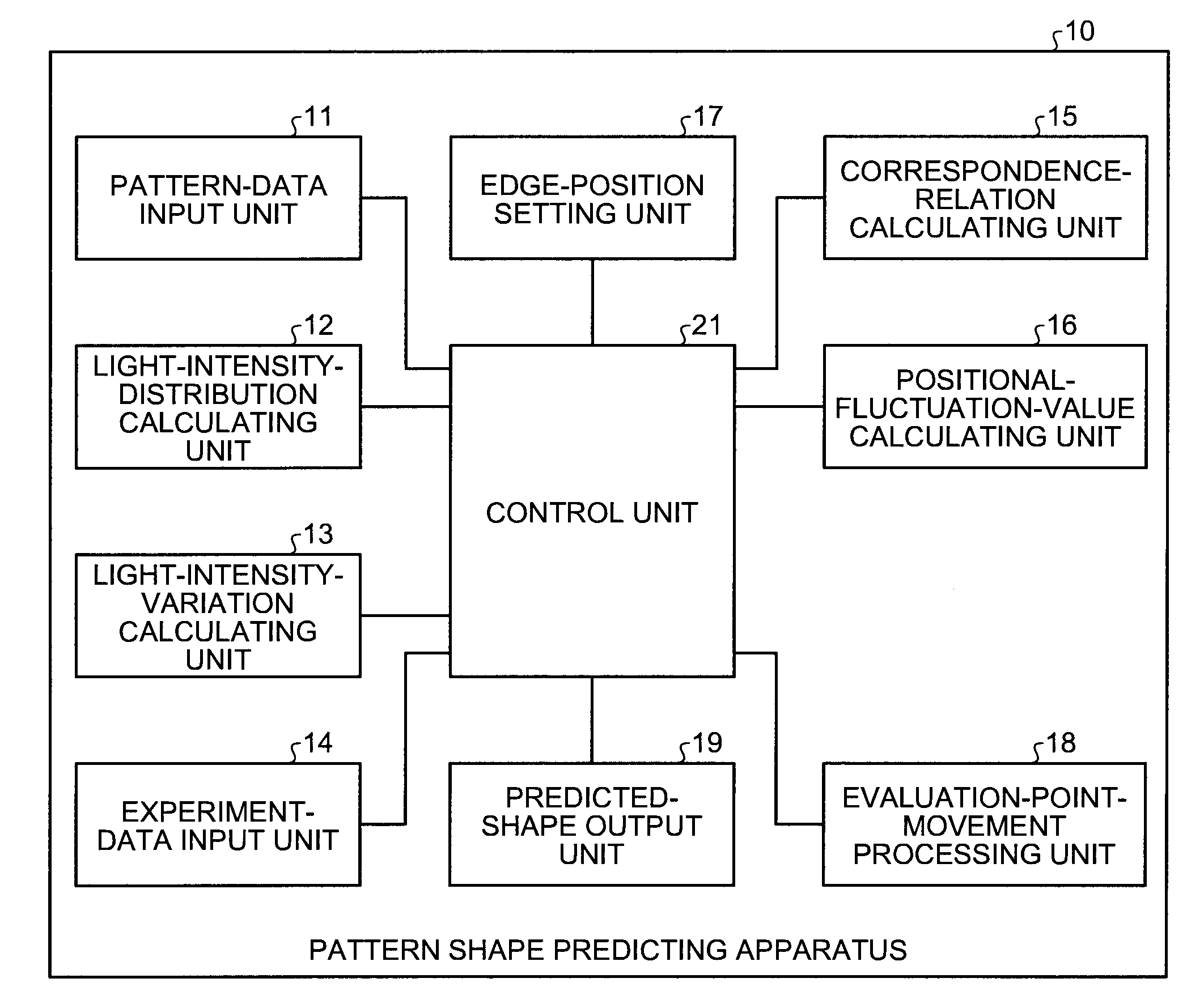

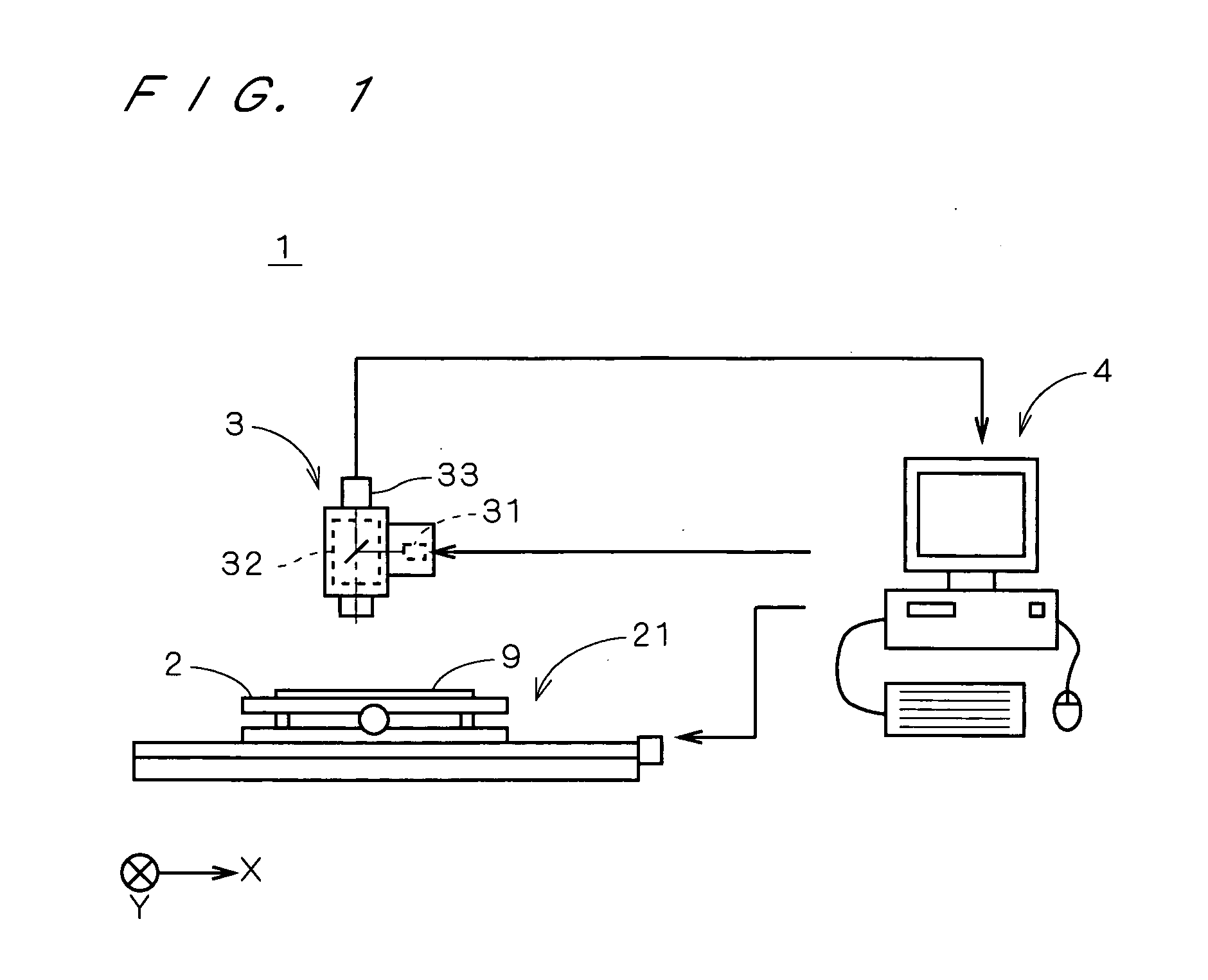

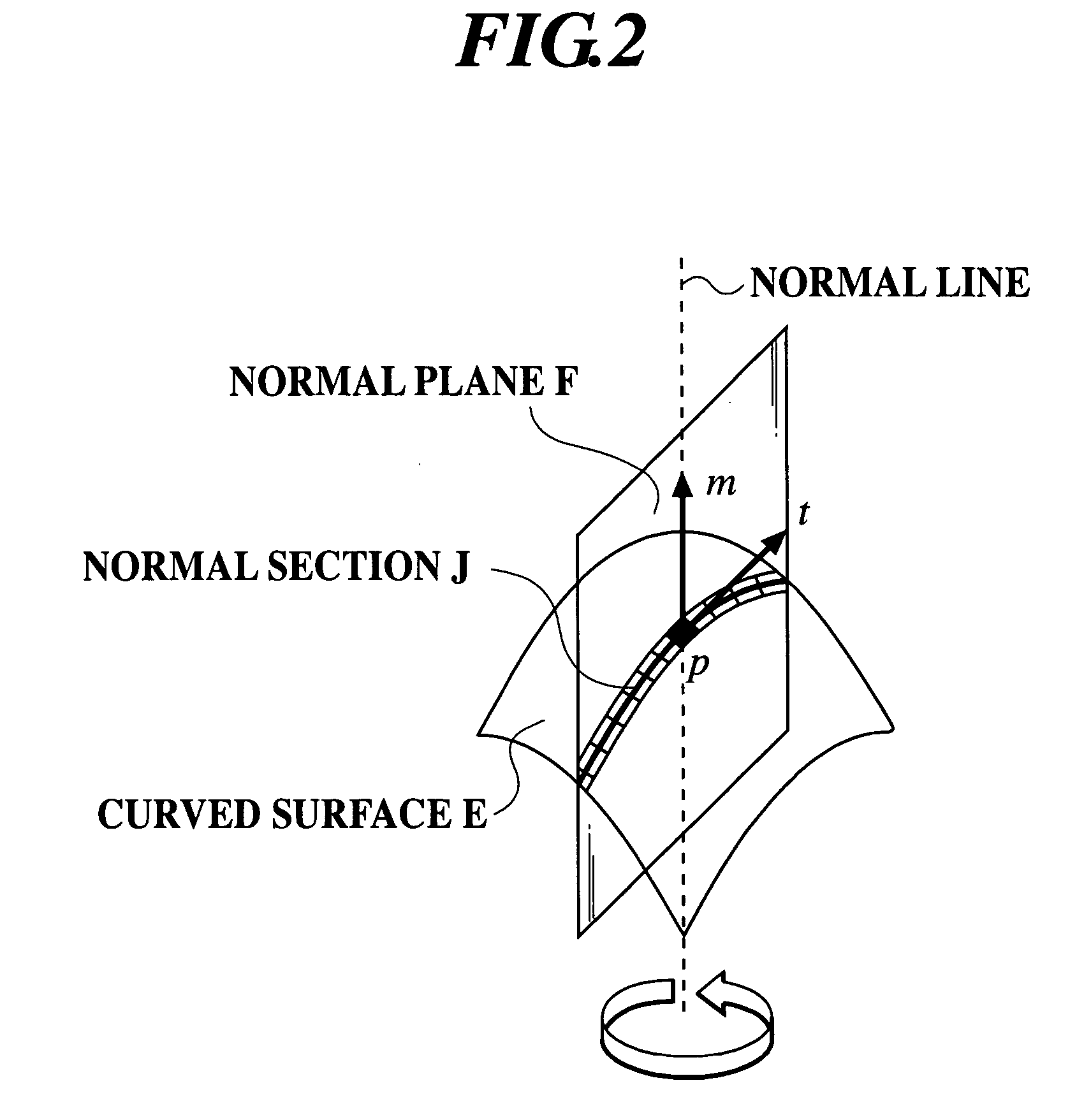

Pattern shape predicting method and pattern shape predicting apparatus

InactiveUS20100030545A1Analogue computers for electric apparatusSemiconductor/solid-state device manufacturingPattern recognitionEigenvalue computation

A pattern shape predicting method comprising: predicting, with simulation, an intensity distribution of a pattern image concerning a pattern shape of a pattern on substrate formed on a substrate based on pattern data; calculating a first pattern edge position from the intensity distribution of the pattern image; calculating a feature value of the intensity distribution of the pattern image in a predetermined range including the first pattern edge position; calculating a fluctuation amount of the first pattern edge position from the feature value using a correlation; and predicting a second pattern edge position taking into account the fluctuation amount with respect to the first pattern edge position.

Owner:KK TOSHIBA

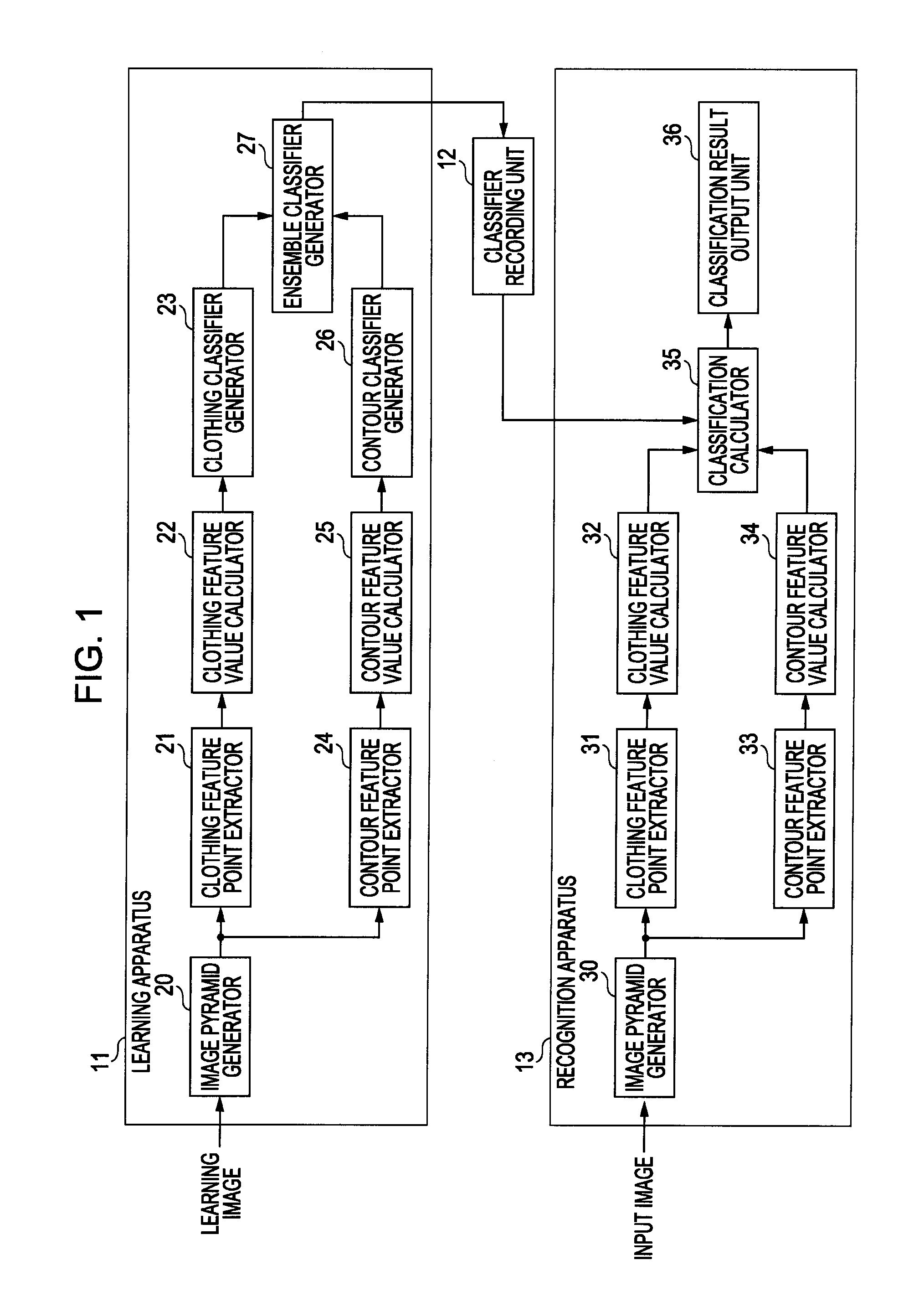

Learning Apparatus and Method, Recognition Apparatus and Method, Program, and Recording Medium

ActiveUS20100086176A1Calculation efficiency is improvedEasy to calculateCharacter and pattern recognitionPattern recognitionStatistical learning

A learning apparatus includes an image generator, a feature point extractor, a feature value calculator, and a classifier generator. The image generator generates, from an input image, images having differing scale coefficients. The feature point extractor extracts feature points from each image generated by the image generator. The feature value calculator calculates feature values for the feature points by filtering the feature points using a predetermined filter. The classifier generator generates one or more classifiers for detecting a predetermined target object from an image by means of statistical learning using the feature values.

Owner:SONY CORP

Apparatus and method for inspecting pattern

InactiveUS20060067570A1Improve accuracyEasy to classifyImage enhancementImage analysisReference imageVolumetric Mass Density

An operation part (50) in a pattern inspection apparatus (1) comprises a defect candidate image generator (511) for generating a binary defect candidate image representing a defect candidate area in an inspection image by comparing the inspection image with a reference image, in an inspection image masking part (521) the inspection image is masked with the defect candidate image to obtain a masked inspection image. In a feature value calculation part (531), an autocorrelation feature value is obtained from the masked inspection image, and outputted to a classifying part (54). The classifying part (54) comprises a classifier (541) outputting a classification result on the basis of the autocorrelation feature value and a classifier construction part (542) for constructing the classifier (541) by learning. It is thereby possible to easily perform the high accurate classification of defect candidate using the autocorrelation feature value which is hard to characterize as compared with geometric feature value or feature value representing density.

Owner:DAINIPPON SCREEN MTG CO LTD

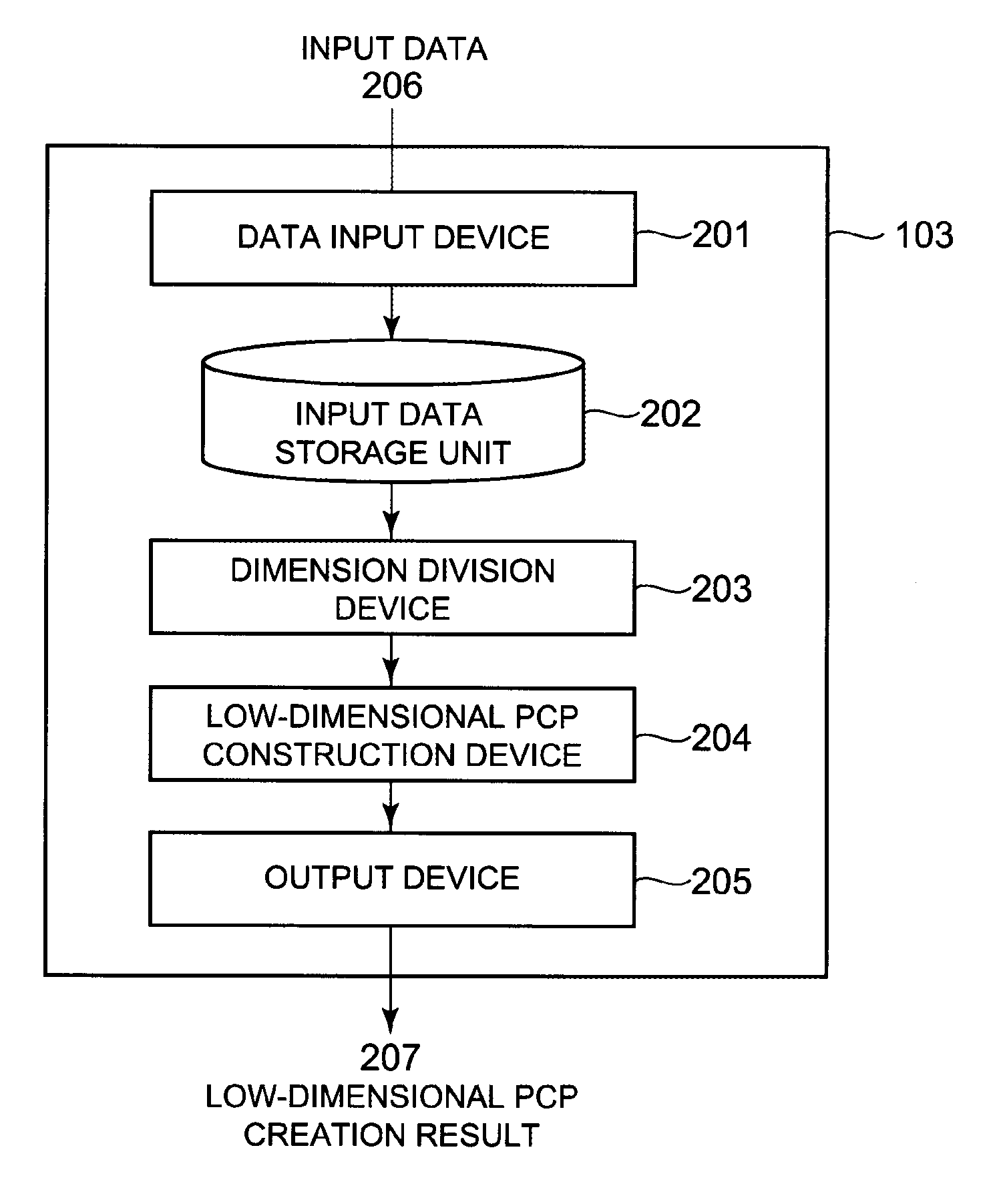

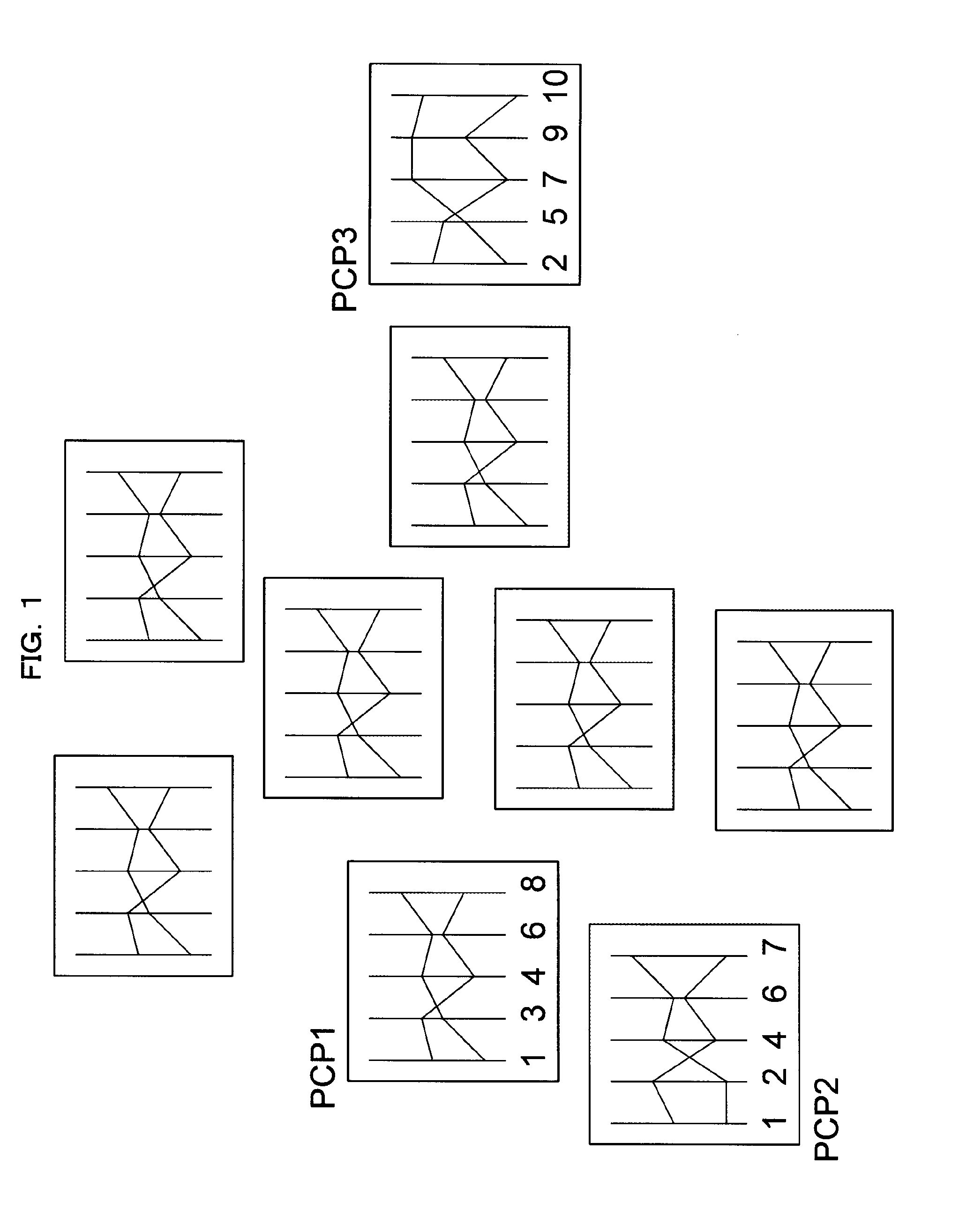

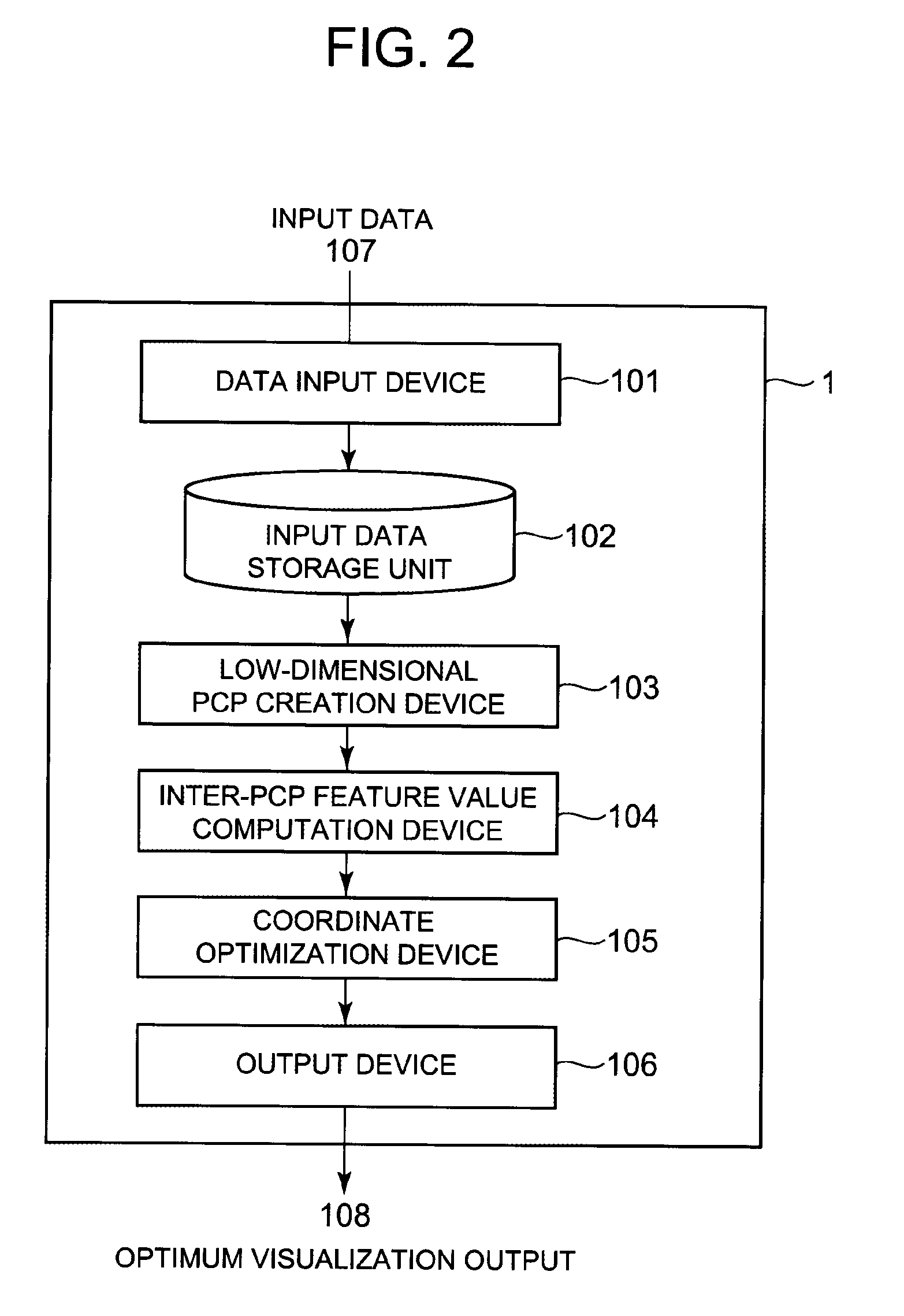

Multidimensional data visualization apparatus, method, and program

A multidimensional data visualization apparatus capable of visualizing a data distribution in an input space of high-dimensional data so as to enable understanding of relationships between input dimensions is provided. Low-dimensional parallel coordinates plot creation element 71 creates, from input multidimensional data, a plurality of low-dimensional parallel coordinates plots that are each a graph in which data relating to part of dimensions in the multidimensional data is represented by a parallel coordinates plot. Feature value computation element 72 computes, for each pair of low-dimensional parallel coordinates plots, a feature value indicating a relationship between the low-dimensional parallel coordinates plots forming the pair. Coordinate computation element 73 computes coordinates at which each low-dimensional parallel coordinates plot is arranged, based on the feature value computed by the feature value computation element 72.

Owner:NEC CORP

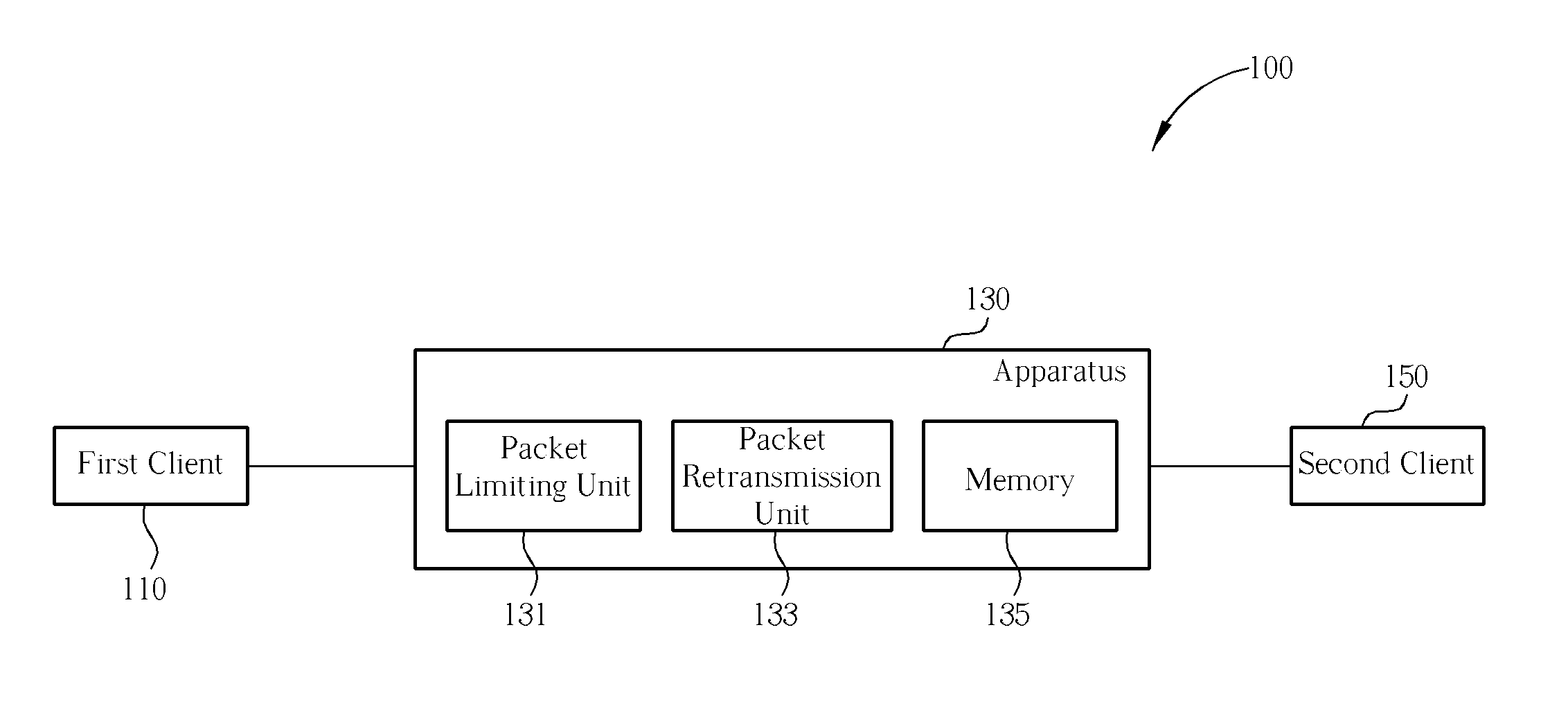

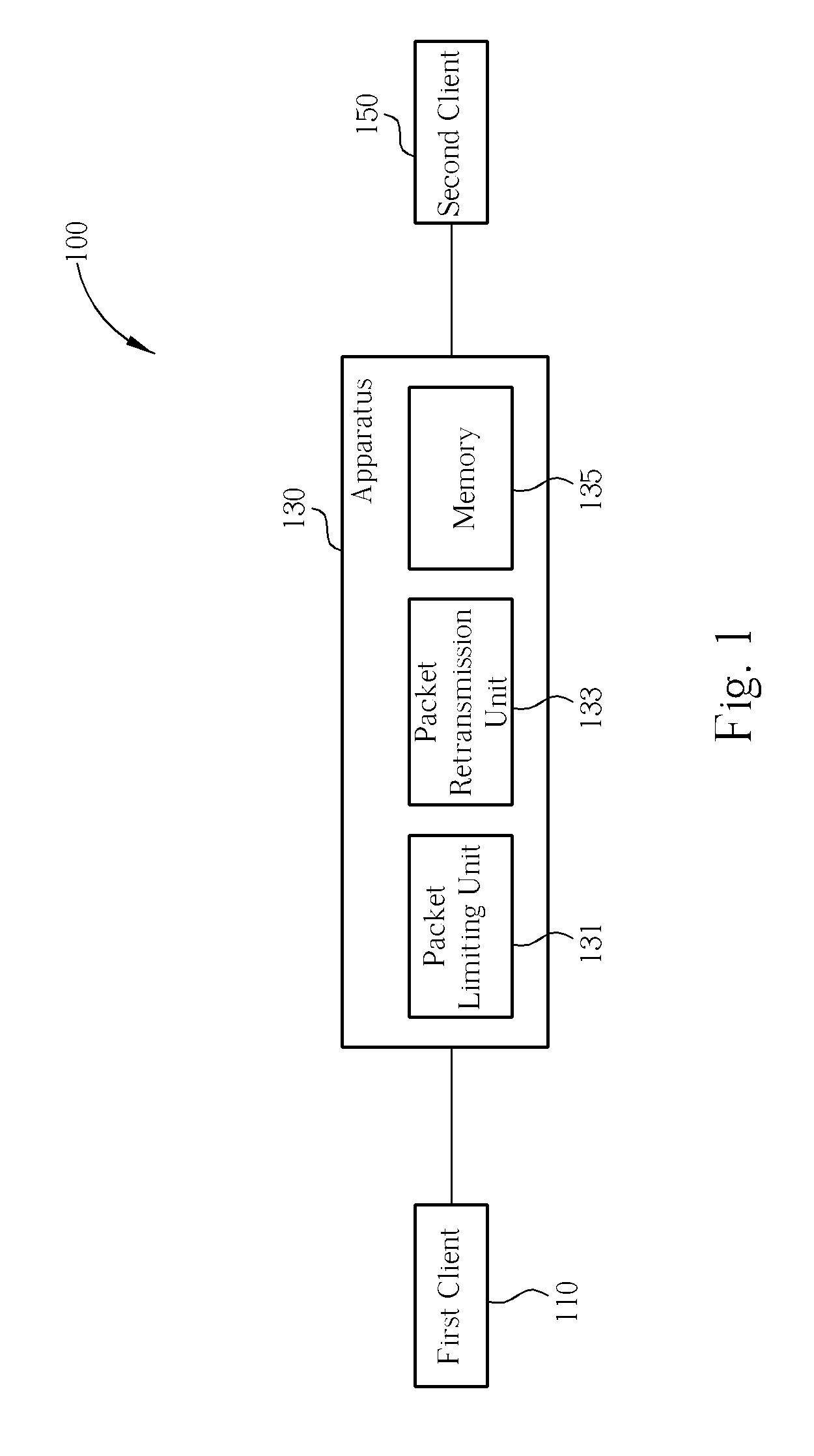

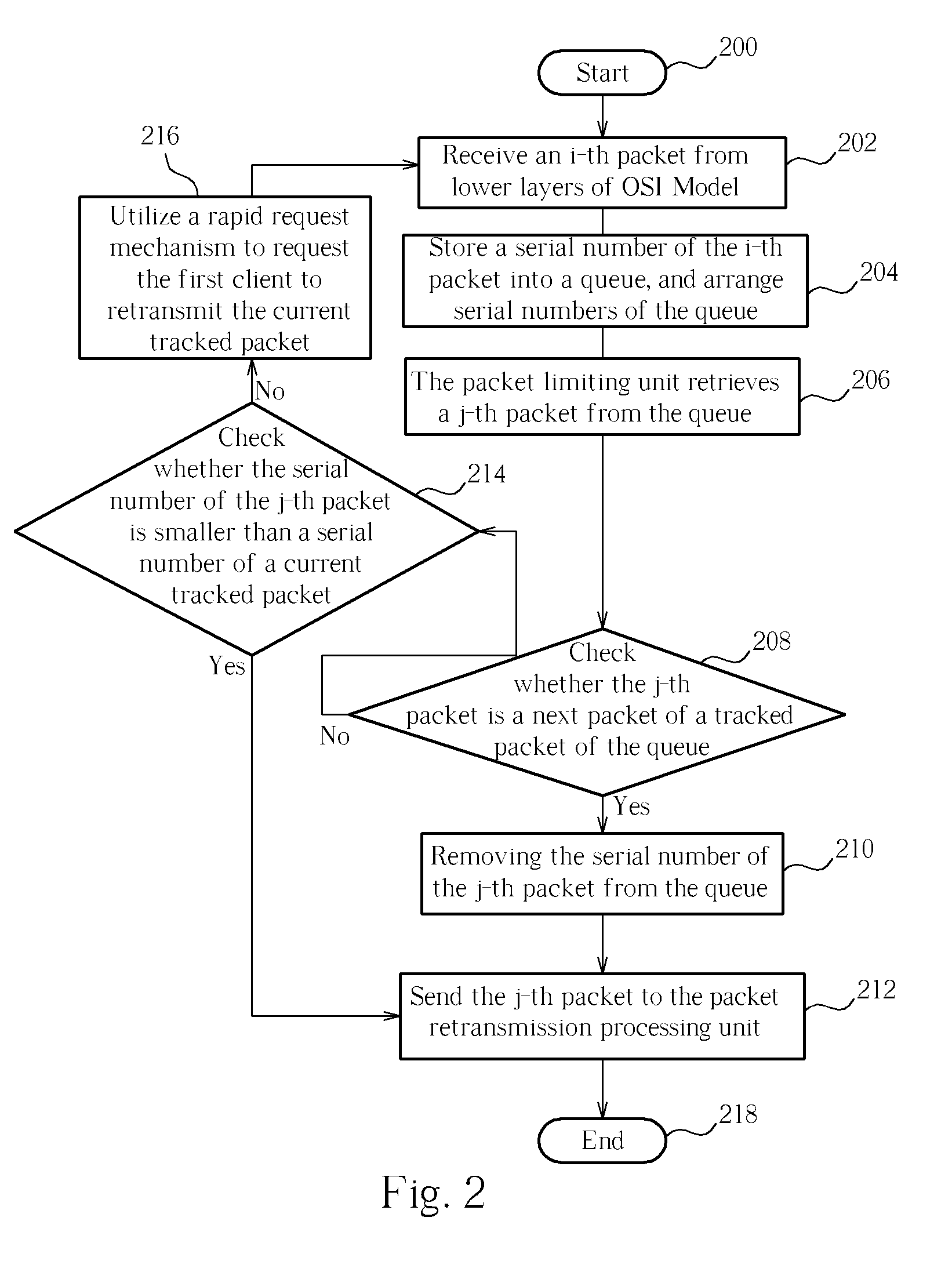

Network Flow/Stream Simulation Method

InactiveUS20070097982A1Reduce window sizeError preventionData switching by path configurationLinked listReal-time computing

Before packets enter a router, a packing limiting unit abandons out-of-order packets, decreases a window size, and stores temperately part of said out-of-order packets for having packets pass the packet limiting unit with a better efficiency and a precise order. After packets enter said router, a packet retransmission processing unit acquires a characteristic values and messages calculated from each characteristic value of a packet for obtaining the order, size, header, and check bits for assisting in identifying packets, and stores the characteristic values with a link list for saving memory utility. With both the abovementioned methods, problems of out-or-order and retransmission during packets are transmitted, and of an over-used amount of memory, are solved.

Owner:DRAYTEK

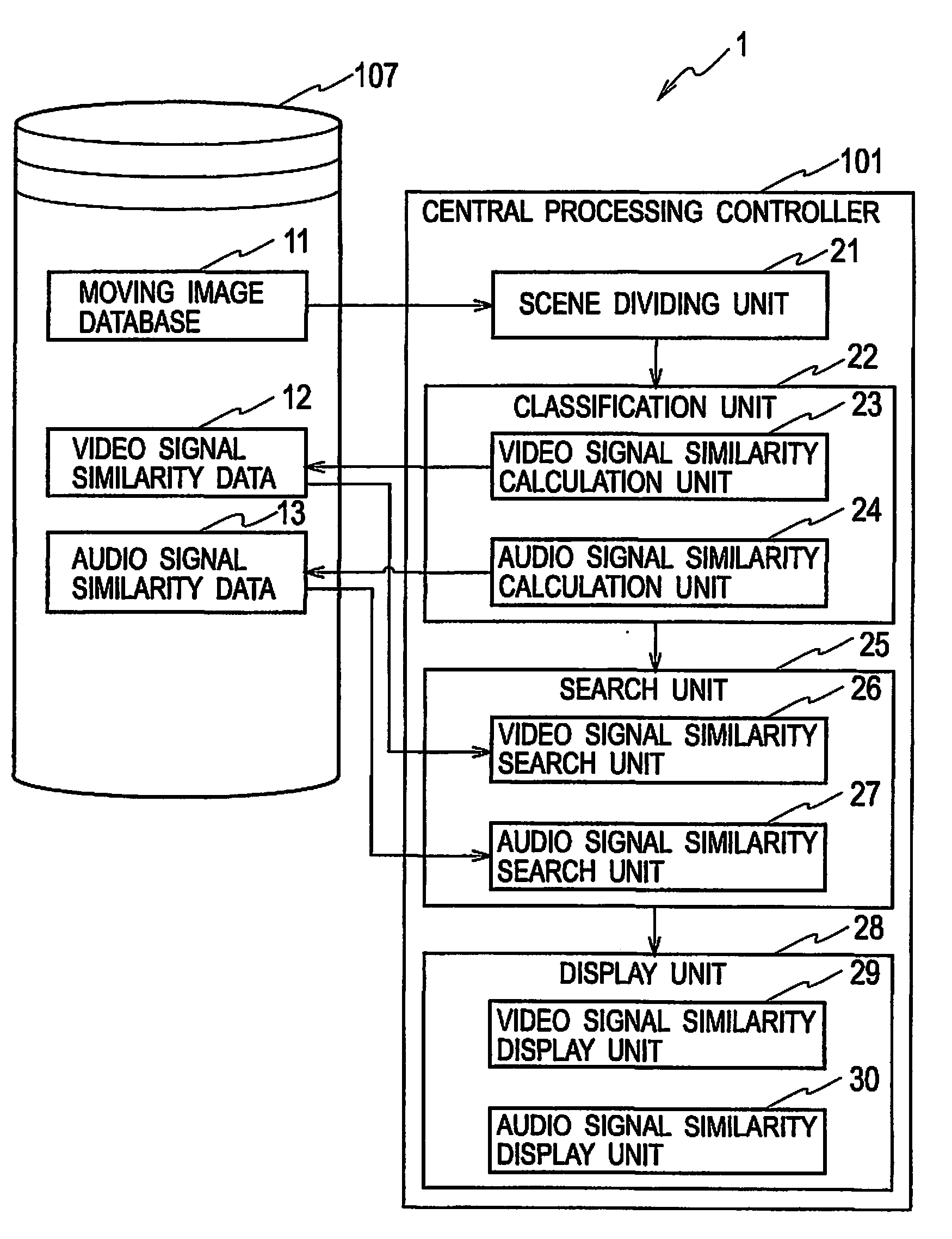

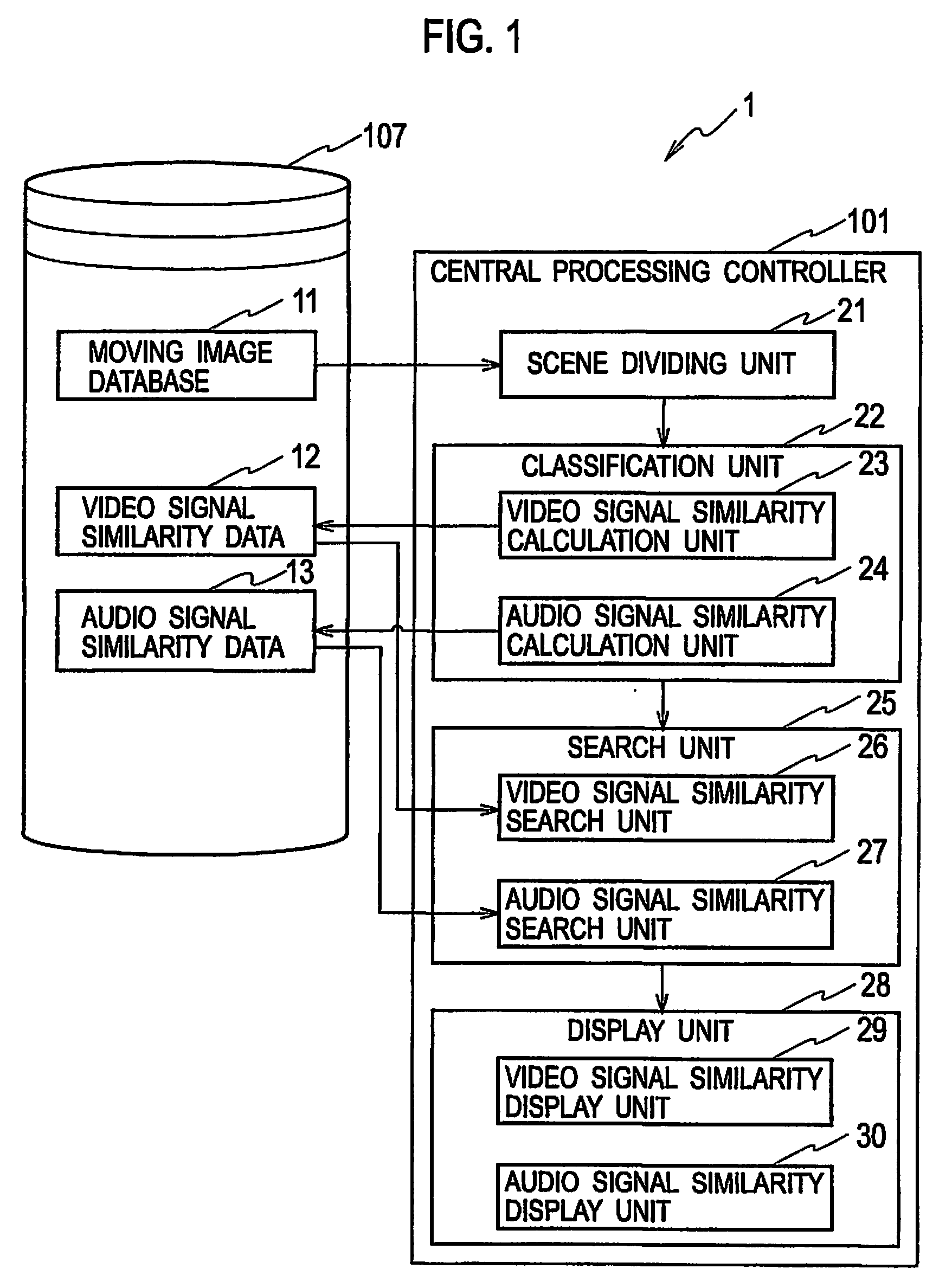

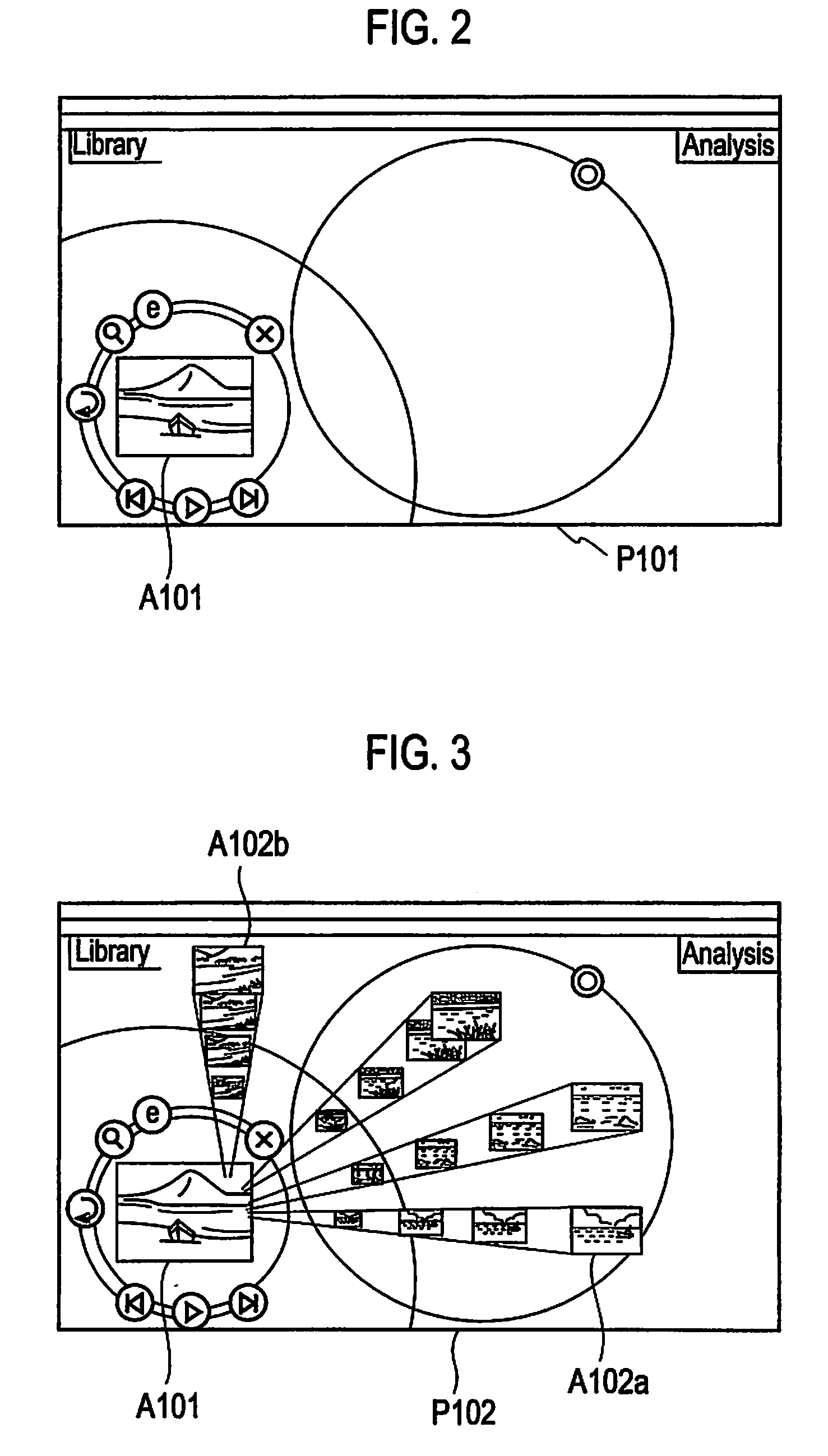

Moving image search device and moving image search program

InactiveUS20110225196A1Television system detailsDigital data processing detailsValue setAudio signal flow

A moving image search device includes: a moving image database (11) for storage of sets of moving image data; a scene dividing unit (21) which divides a visual signal of the sets of moving image data into shots and outputs, as a scene, continuous shots having a small characteristic value set difference of an audio signal to the shots; a video signal similarity calculation unit (23) which calculates, for each of scenes obtained by the division by the scene dividing unit (11), video signal similarities to the other scenes according to a characteristic value set of the visual signal and a characteristic value set of the audio signal, and thus generates video signal similarity data (12); a video signal similarity search unit (26) which searches the scenes according to the video signal similarity data (12) to find a scene having a smaller similarity to the each scene than a certain threshold (12); and a video signal similarity display unit (29) which acquires and displays coordinates corresponding to the similarity for each of the scenes searched out by the video signal similarity search unit (26).

Owner:HOKKAIDO UNIVERSITY

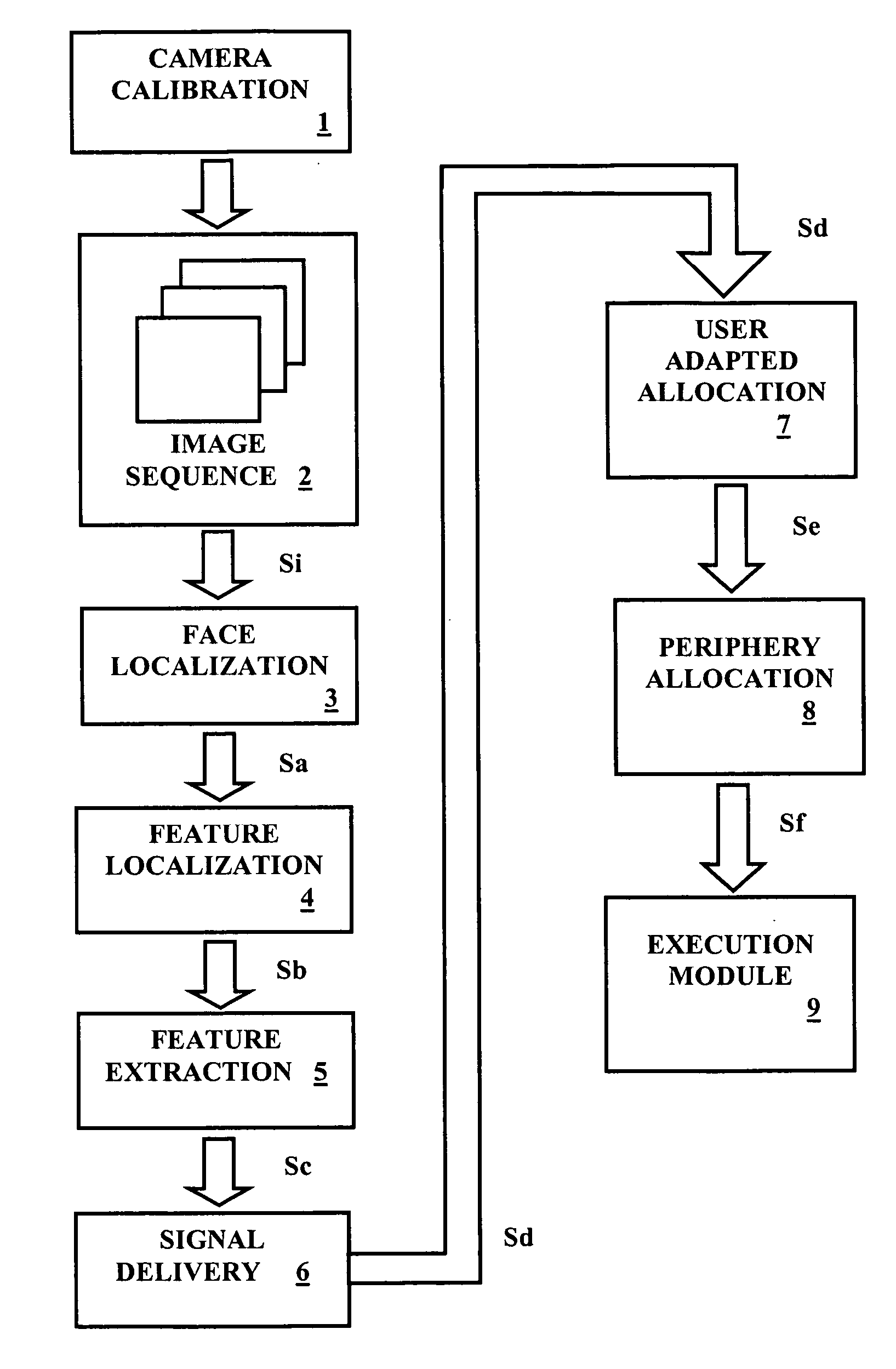

Facial feature analysis system for users with physical disabilities

InactiveUS20060153430A1Safe and reliableHigh degreeCharacter and pattern recognitionInput/output processes for data processingDiscriminatorFeature extraction

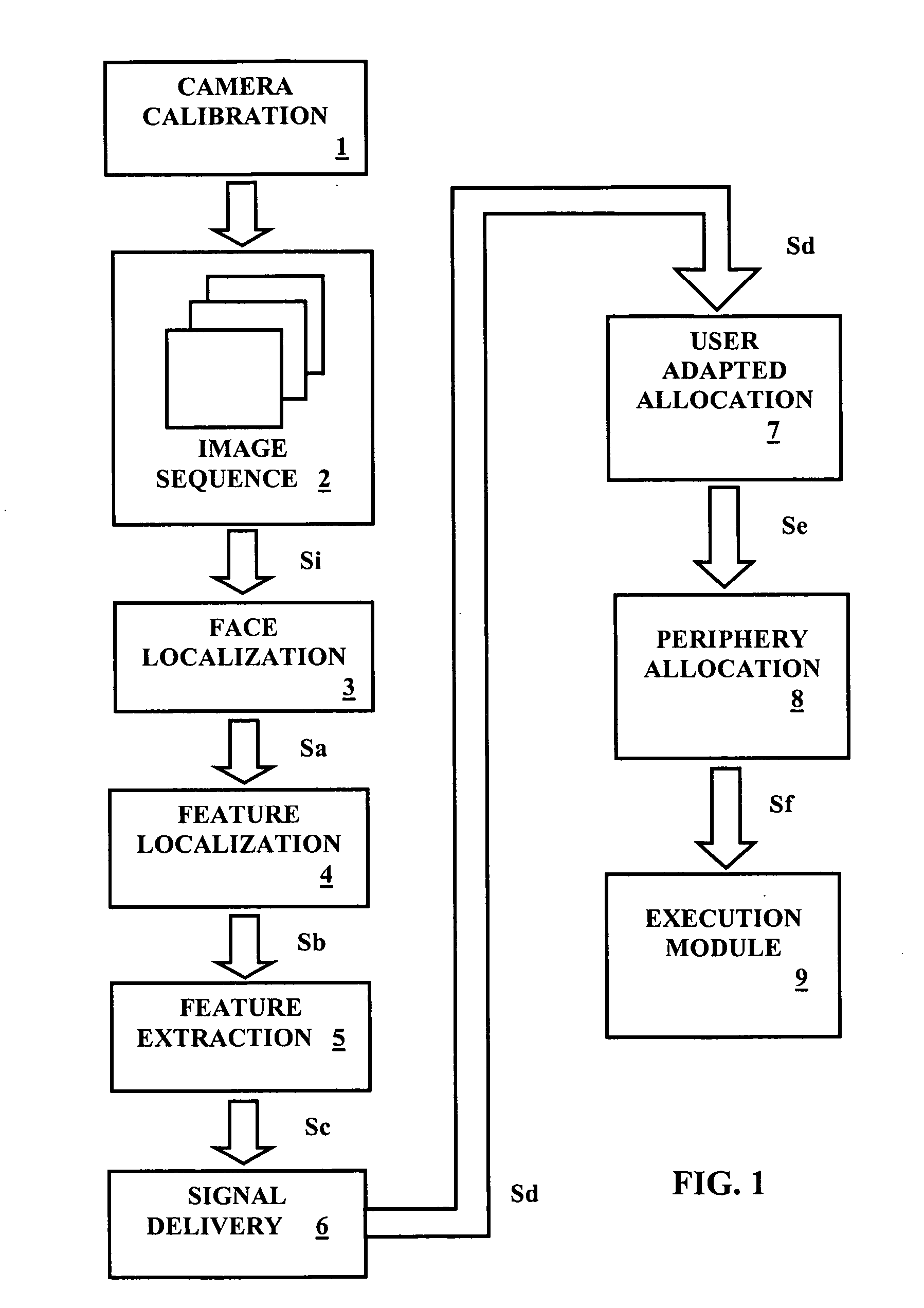

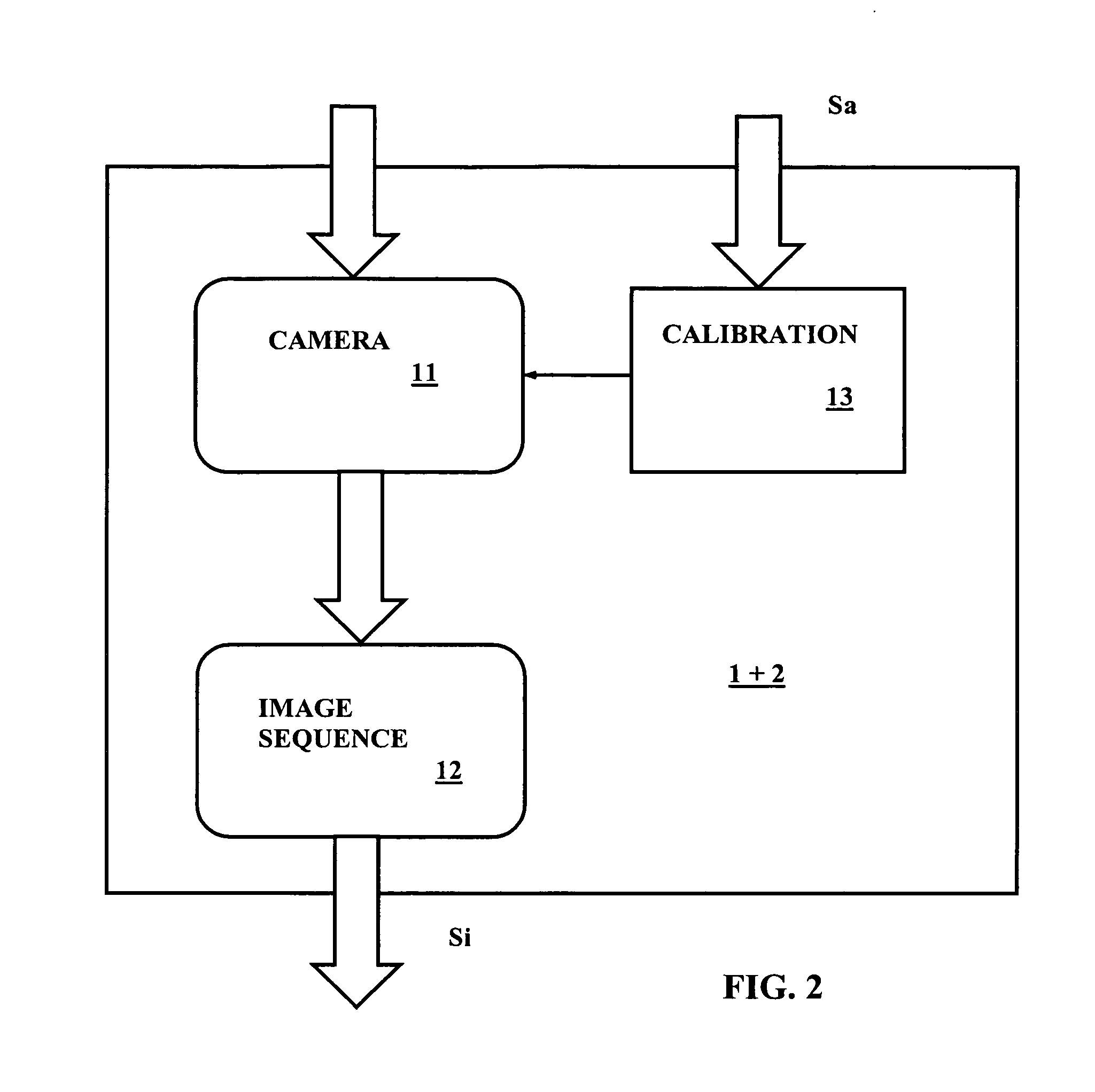

A facial feature analysis system for command applications for users with physical disabilities, like impaired users of wheelchairs, patient beds or other appliances is provided. The disclosed system includes a virtual filter bank and a virtual discriminator. The virtual filter bank comprises a feature localization main module having an ancillary data bank which supplies a special signal Sg for control functions. The system calculates face localization based on parameters of a holistic face-model, calculates feature localization based on parameters of an adaptive face graph, calculates feature extraction using stored feature values corresponding to selected validation and provides output signals using a signal delivery main module controlled by static and dynamic classification. The virtual discriminator bank calculates a user adapted allocation based on a face feature of the user and provides a periphery allocation for at least one command modus. and for calculating execution signals for said manipulators.

Owner:INVACARE INT

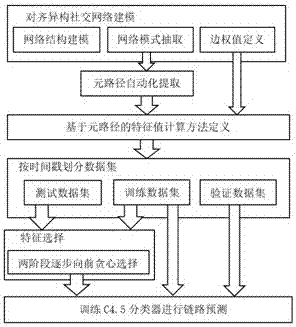

Meta-path-based link prediction method for aligned heterogeneous social networks

InactiveCN107145527AEfficient miningReduce sparsityData processing applicationsWebsite content managementData setTimestamp

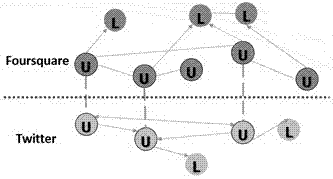

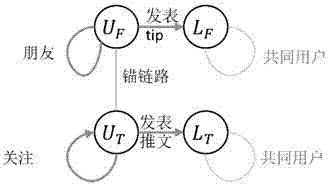

The invention discloses a meta-path-based link prediction method for aligned heterogeneous social networks, mainly solves the problem of link prediction (mainly including friend relationship prediction and position prediction) in the aligned heterogeneous social networks, and relates to related technologies of the aligned heterogeneous social networks, feature selection, link prediction and the like. The method mainly comprises six steps of (a) modeling the aligned heterogeneous social networks; (b) automatically extracting a meta-path; (c) defining a meta-path-based eigenvalue calculation method; (d) dividing data sets according to timestamps; (e) proposing a two-stage gradual forward greedy feature selection algorithm for performing feature selection; and (f) training a decision tree classifier based on a feature selection result to perform the link prediction. Based on the method, the aligned heterogeneous social networks consisting of Foursquare and Twitter are subjected to the link prediction; and the method has practical application values for entity recommendation, accurate marketing, criminal gang discovery and the like in the social networks.

Owner:SOUTHEAST UNIV

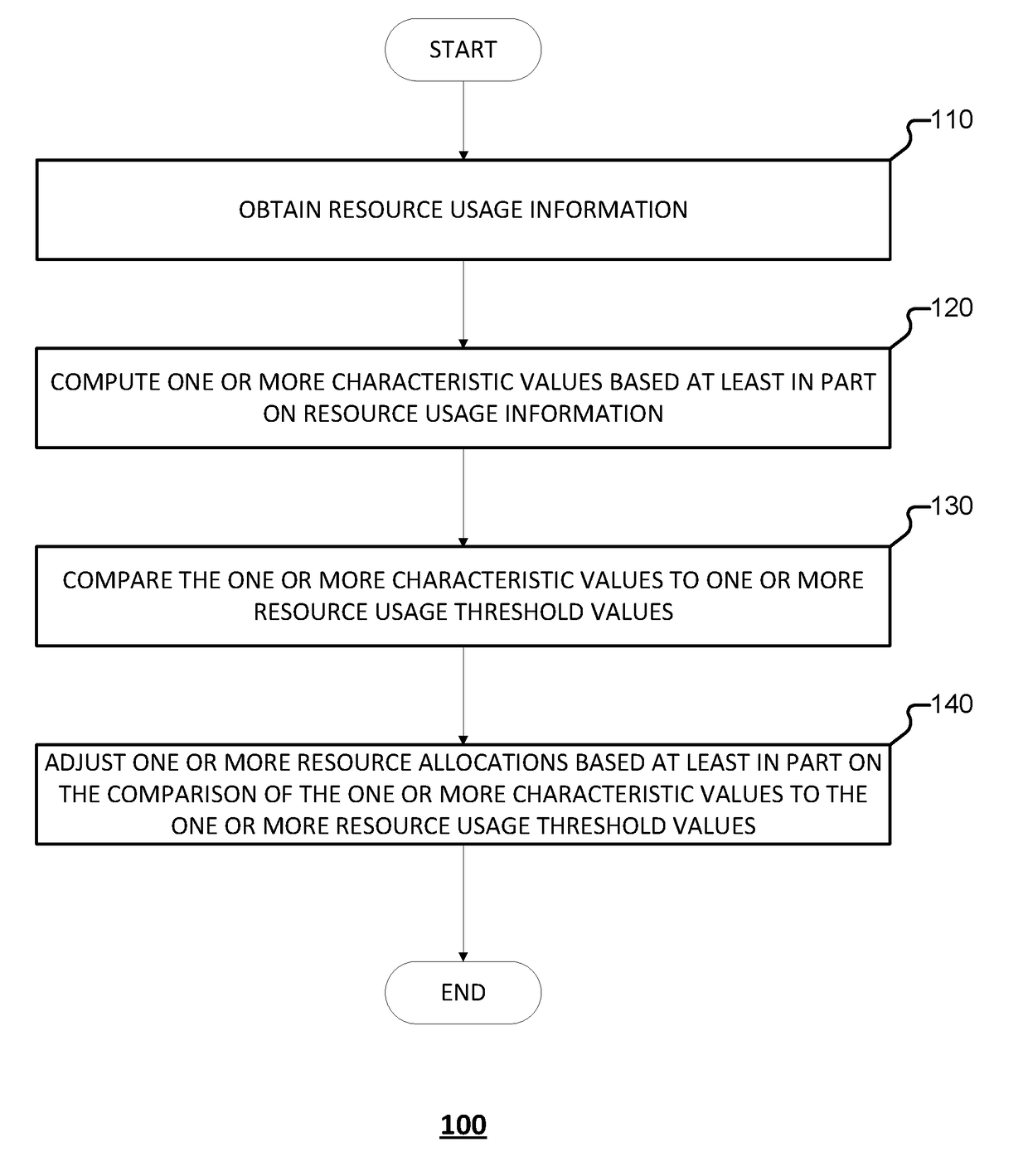

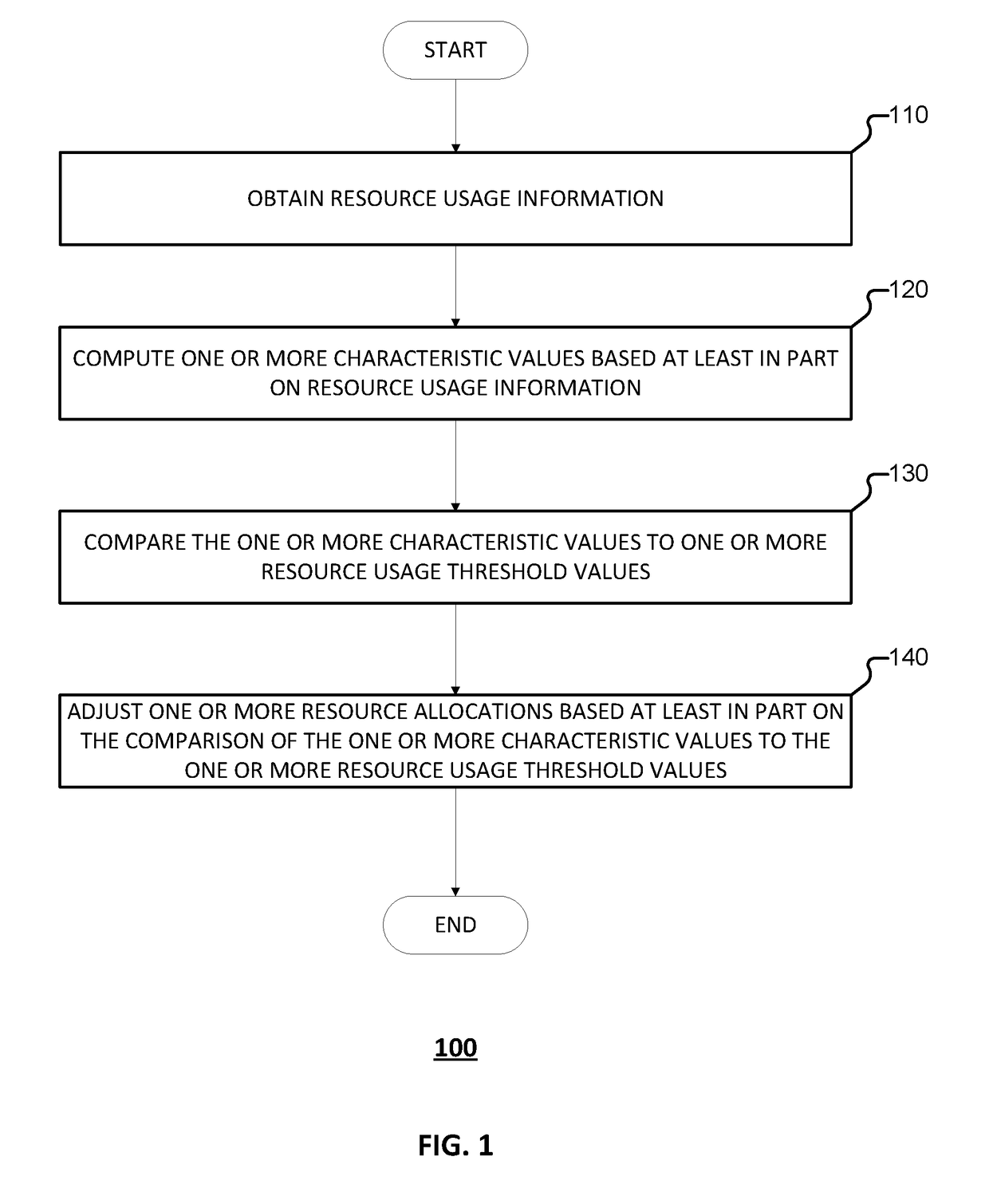

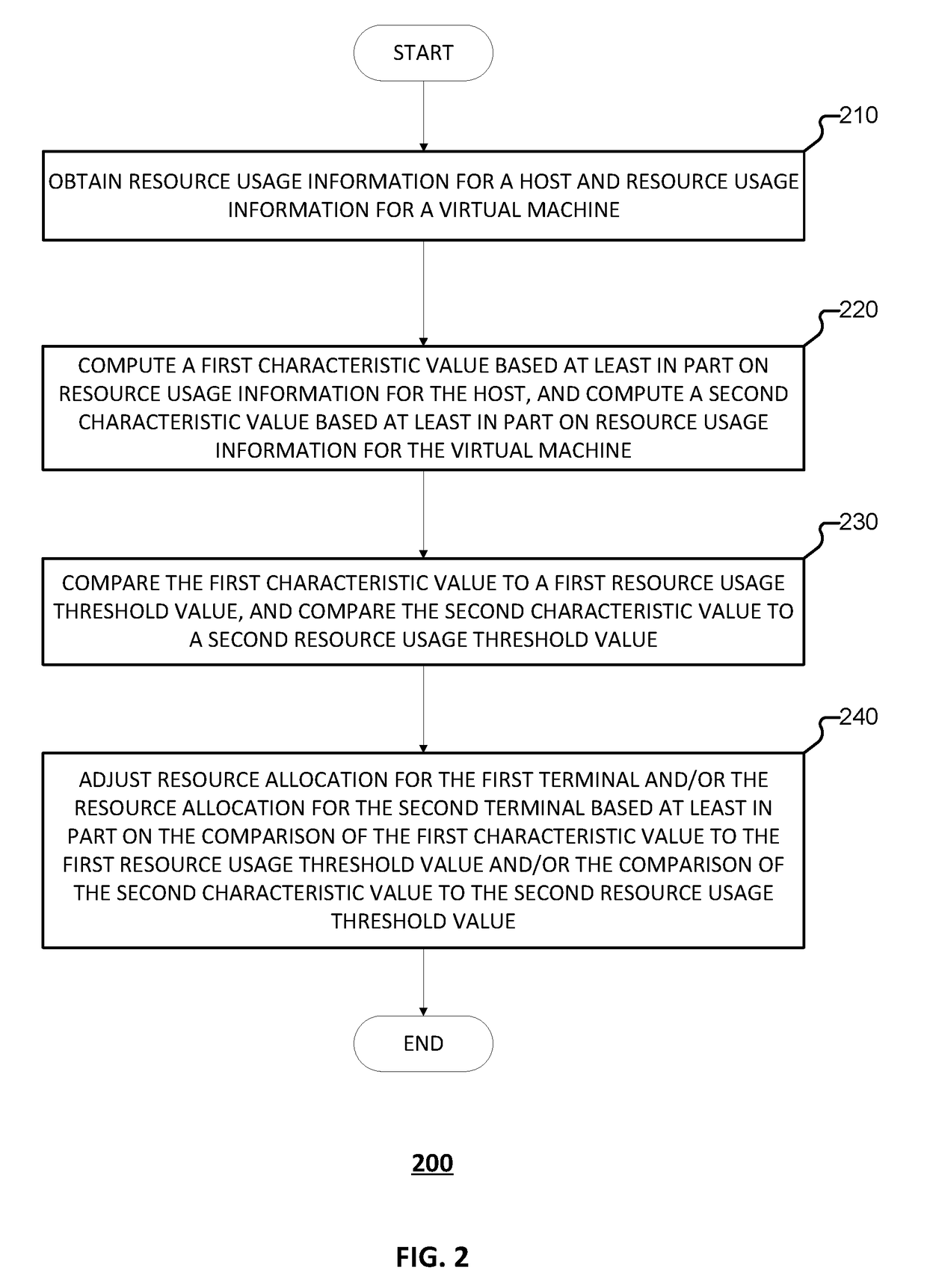

Method, system, and device for allocating resources in a server

InactiveUS20170201574A1Efficient resource allocationEasy to configureProgram controlNetworks interconnectionComputing systemsResource allocation

Embodiments of the present application relate to a method, device, and system for allocating resources in a server. The method includes obtaining first resource usage information associated with the first host computing system and second resource usage information associated with the second host computing system, computing a first characteristic value and a second characteristic value, wherein the first characteristic value is computed based at least in part on the first resource usage information, the second characteristic value is computed based at least in part on the second resource usage information, obtaining a first comparison result based on comparing the first characteristic value to a resource usage threshold value of the first host, and a second comparison result based on comparing the second characteristic value to a resource usage threshold value of the second host computing system, and adjusting resource allocations for the first host computing system or the second host computing system.

Owner:ALIBABA GRP HLDG LTD

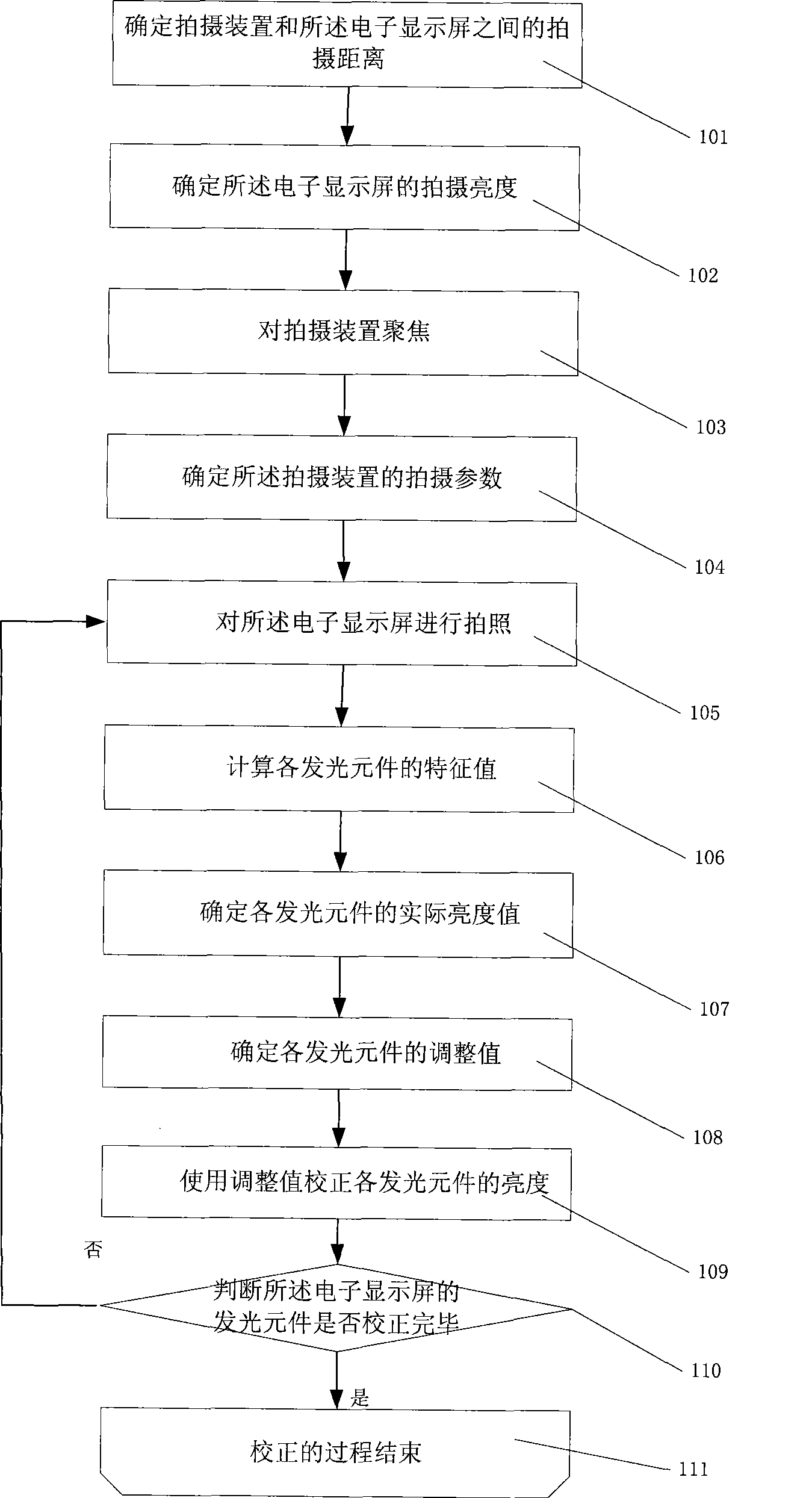

Electronic display screen system, method and system for correcting electronic display screen brightness

ActiveCN101377918AEfficiency for Improving Brightness UniformityShorten the timeTelevision system detailsCathode-ray tube indicatorsEffect lightComputer science

Owner:NANTONG GEMEI IND CNC EQUIP CO LTD

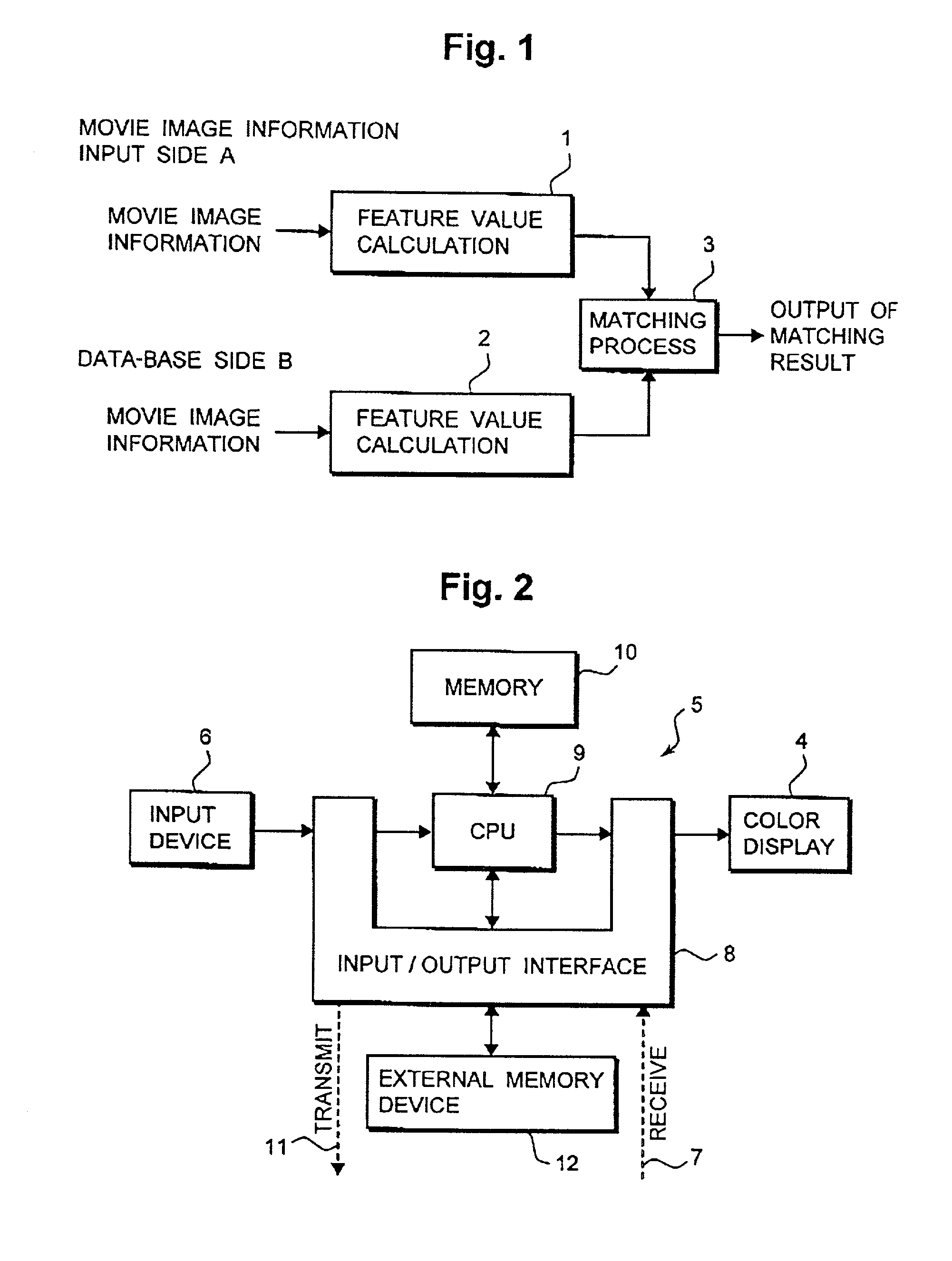

Method of and apparatus for retrieving movie image

InactiveUS20020106127A1Reduce processing timeDigital data information retrievalImage analysisPattern recognitionOutput device

The movie image retrieving apparatus includes an image input device 13 to which the movie images are inputted in a time-series manner, a feature value calculation device 14 which includes a feature value deriving section 16 for deriving the feature value and a quantization section 17 which quantizes the feature value with a predetermined quantization width to produce the feature value information, a comparative information selection device 15 for deriving the comparative feature value information from the data-base, and a matching device 18 for matching the feature value information and the comparative feature value information using a quantization error. The matching result is outputted from the output device 19. Load on the hardware is reduced and the time required for the search is shortened.

Owner:SATAKE CORP +1

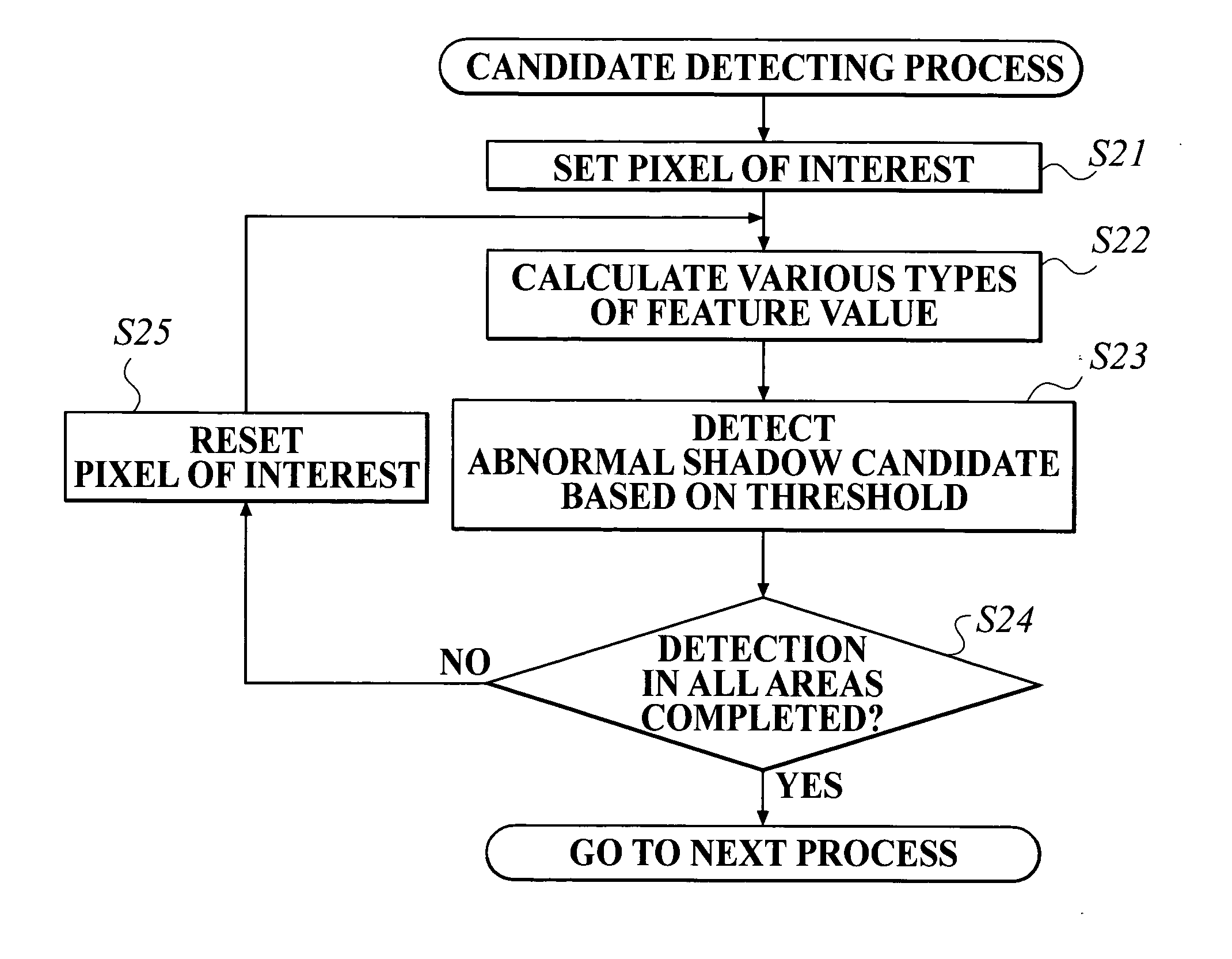

Image processing apparatus and signal processing apparatus

InactiveUS20050053270A1Possible to detectImprove detection accuracyImage enhancementImage analysisImaging processingDensity distribution

An image processing apparatus includes a feature value calculating section for setting a certain pixel in a processing target image as a pixel of interest, and for calculating a curvature of a curved surface which is obtained from density distribution of adjacent pixels which are located within a predetermined range from the pixel of interest, as a feature value of an image area within the predetermined range from the pixel of interest.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

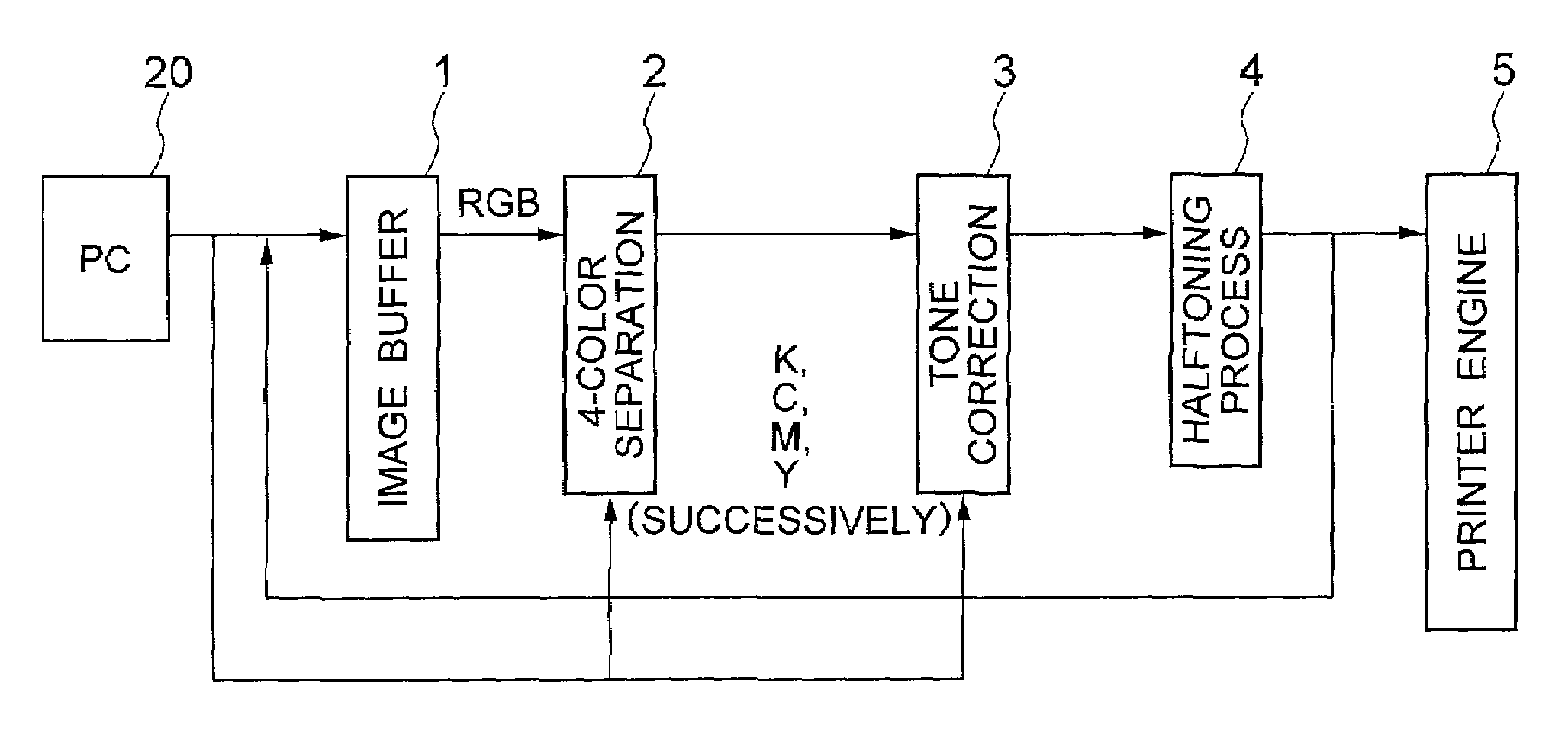

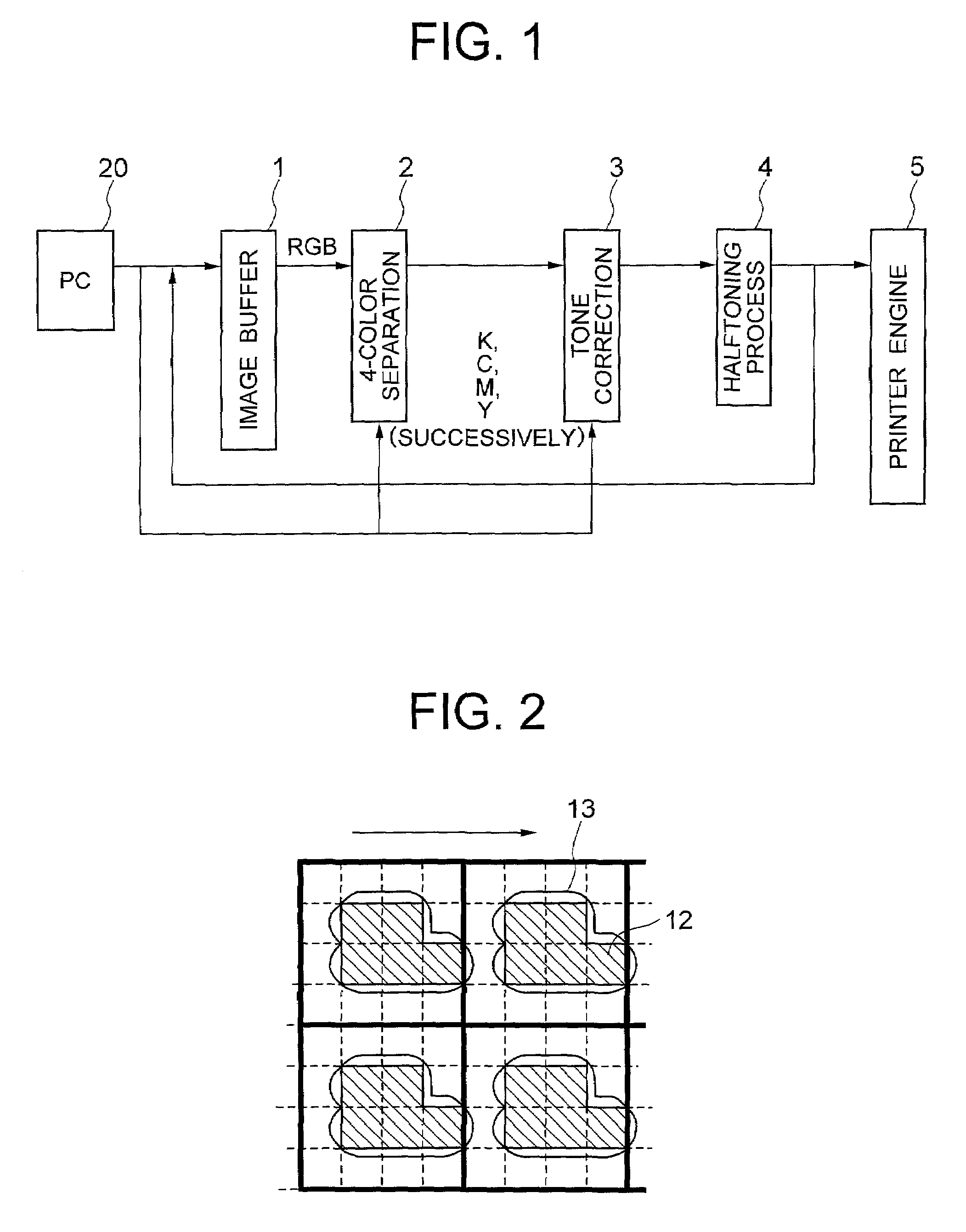

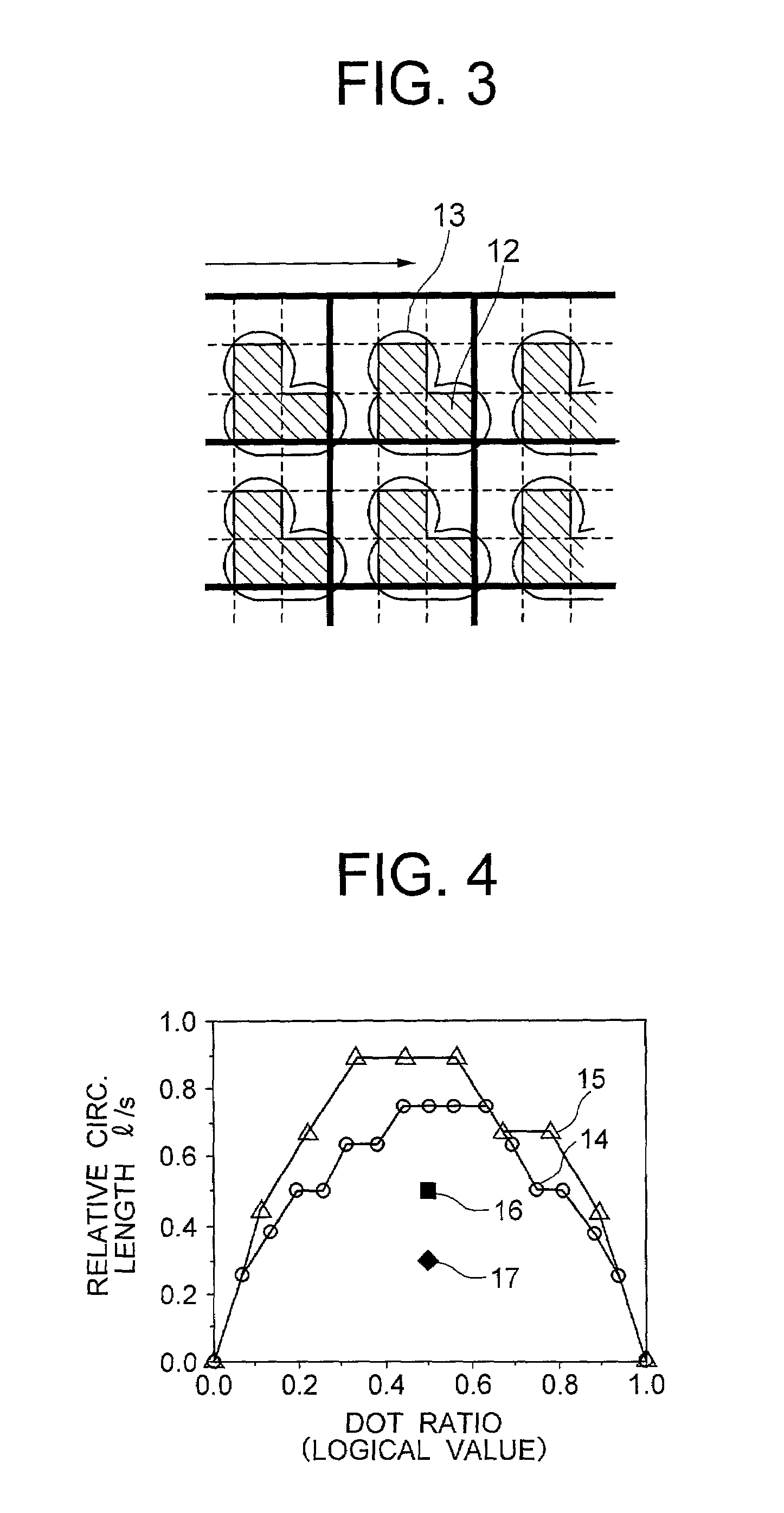

Image output device and test chart for the same

InactiveUS7130076B2High precision calibrationEasy to copyImage enhancementDigitally marking record carriersImage resolutionOutput device

In an image output device a test chart 18 including tests charts 6 of each color is used, and a tone correction table is calculated. The test charts 6 are patterned in a checkered pattern, each including continuous areas 10 in which the tones increase in steps and reference areas 11 for comparison with the continuous areas 10. The reference areas 11 are formed of white ground of paper in a highlight proof part 7, a solid pattern with a maximum density in a shadow proof part 8, and halftone dot-concentrated or line screens with a lower resolution than in the continuous areas in a middle proof part 9. Tone correction values are calculated from characteristic values of the highlight, shadow and middle parts, obtained from visual data of the test chart 18.

Owner:RICOH PRINTING SYST

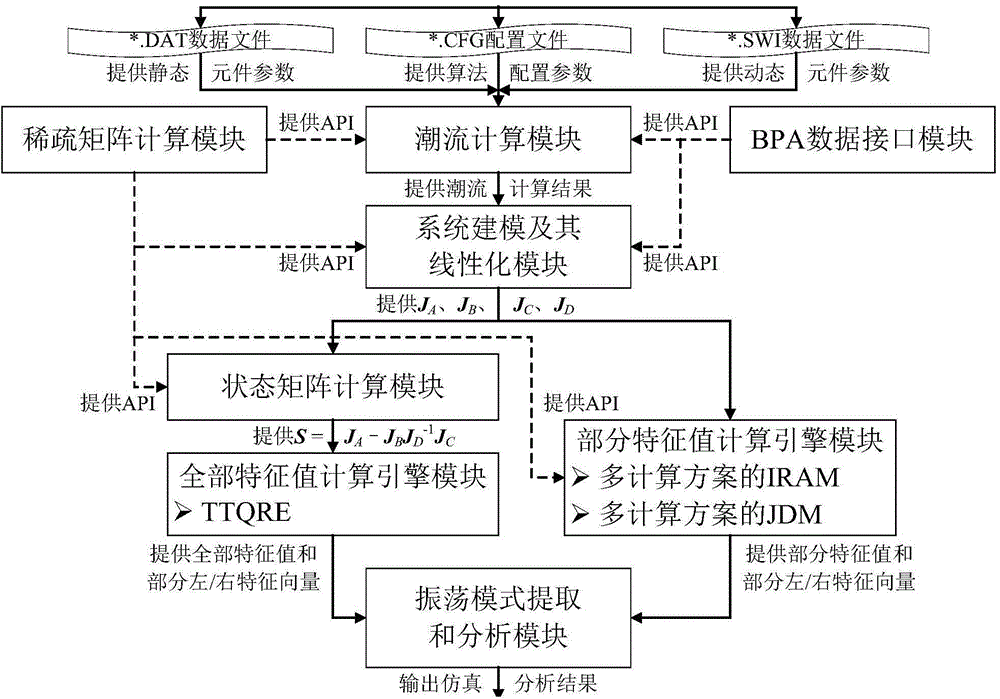

Feature value analysis system for small-interference stability of large-scale power system

InactiveCN104091092ASolve the problem of non-convergenceImprove calculation accuracySpecial data processing applicationsPower flowAlgorithm

The invention provides a feature value analysis system for small-interference stability of a large-scale power system, and belongs to the technical field of power system simulation and analysis. The feature value analysis system comprises a BPA data interface module for achieving seamless read-write operation of a BPA data file, a sparse matrix calculation module for achieving relevant sparse matrix processing in small-interference stability feature value analysis, a power flow calculation module, a system modeling and linearization module, a state matrix calculation module, an all feature value calculation engine module, a partial feature value calculation engine module and an oscillation mode extraction and analysis module. Omni-bearing and missing-free feature value simulation analysis for small-interference stability of an actual large-scale power grid is achieved by the adoption of TTQRE and IRAM and JDM with multiple calculation schemes.

Owner:SHANGHAI JIAO TONG UNIV +1

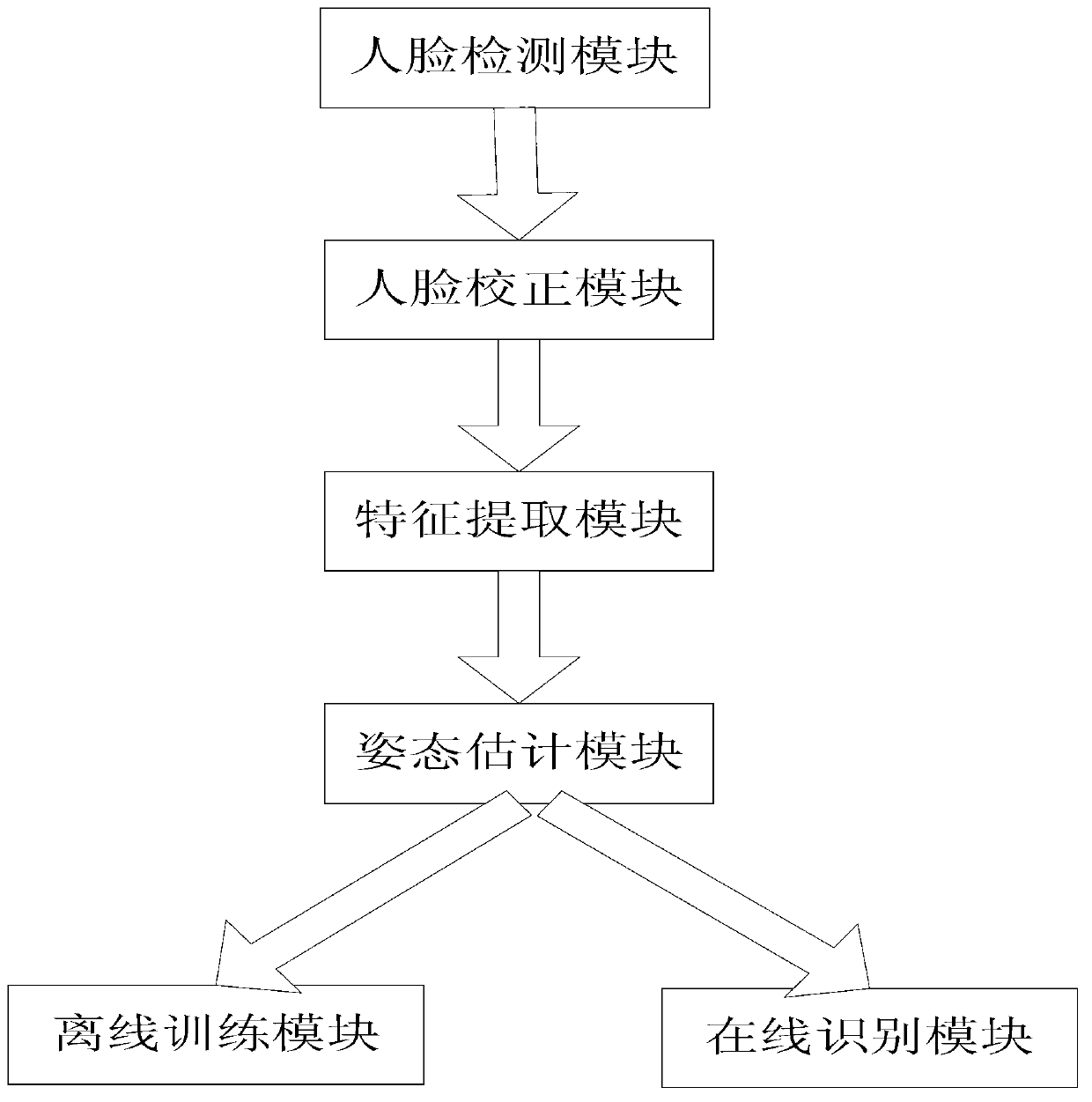

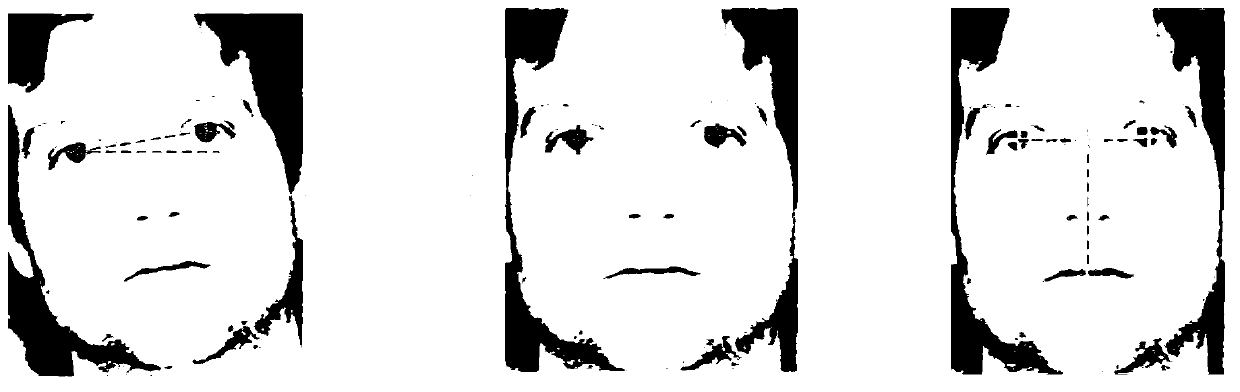

Multi-pose face recognition method based on hidden least square regression and device thereof

InactiveCN103218609ASimple calculationReduce time complexityCharacter and pattern recognitionPattern recognitionLeast squares

The invention discloses a self-adaption multi-pose face recognition method based on hidden least square regression. The self-adaption multi-pose face recognition method includes the multi-pose face recognition method based on the hidden least square regression. The method includes the steps of detecting a region size and a region position of an input facial image; correcting the detected facial image, obtaining a corrected facial image; extracting facial characteristic values from the corrected facial image; estimating a pose type of the corrected facial image according to the extracted facial characteristic values; selecting a corresponding transformational matrix of a pose type and a corresponding offset vector of the pose type according to the pose type, and calculating to obtain an identity characteristic vector of the facial image according to the transformational matrix, the offset vector and the extracted identity characteristic vector; and searching for a known facial image which has the highest similarity with the identity characteristic vector of the input facial image in a known facial image search library, and returning identity information of the known facial image to be used as a recognition result.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

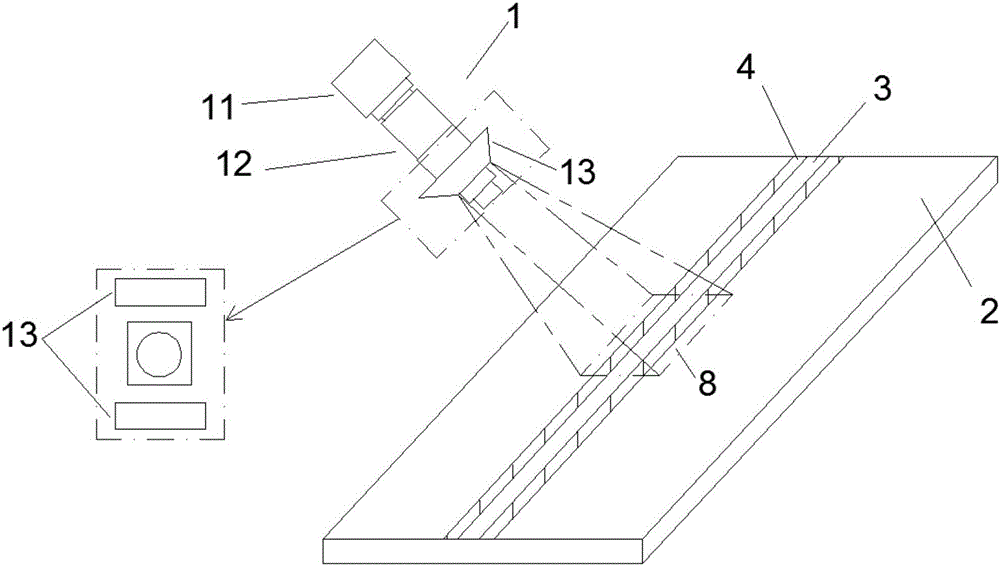

Detection method for identifying surface quality of continuous laser seam of metal workpiece online

ActiveCN106442543AOnline discrimination is accurateFast online discriminationOptically investigating flaws/contaminationAnti jammingMetallic materials

The invention provides a detection method for identifying the surface quality of a continuous laser seam of a metal workpiece online, wherein the method comprises the following steps: using a high resolution color area array camera, a high magnification micro lens and double LED illuminating systems to acquire an image of the surface of the seam; afterwards, when dividing a seam region and calculating the characteristic value, translating or rotating the workpiece to shoot an image for other positions of the seam, continuously shooting the image of the seam and completing real-time calculation until reaching a seam welding end or an overlapping point; finally integrating the calculation results of the images, and completing online judgement on the size, the position and the surface defect of the continuous seam. The method is used to complete online detection of the quality of a laser straight welded joint, a curve welding seam or a space welding seam of various ferrous metals and nonferrous metals, and belongs to the category of non-contact visual inspection; a device is simple and compact, high in response speed and strong in anti-jamming capability, has the characteristics of stability, reliability and convenience, and can be widely applied to the field of laser welding of metal materials.

Owner:龚新林 +5

Image analyzing apparatus, image analyzing method, and computer readable medium

ActiveUS20110026810A1Avoid trackingCharacter and pattern recognitionPattern recognitionEigenvalue computation

Owner:FUJIFILM CORP

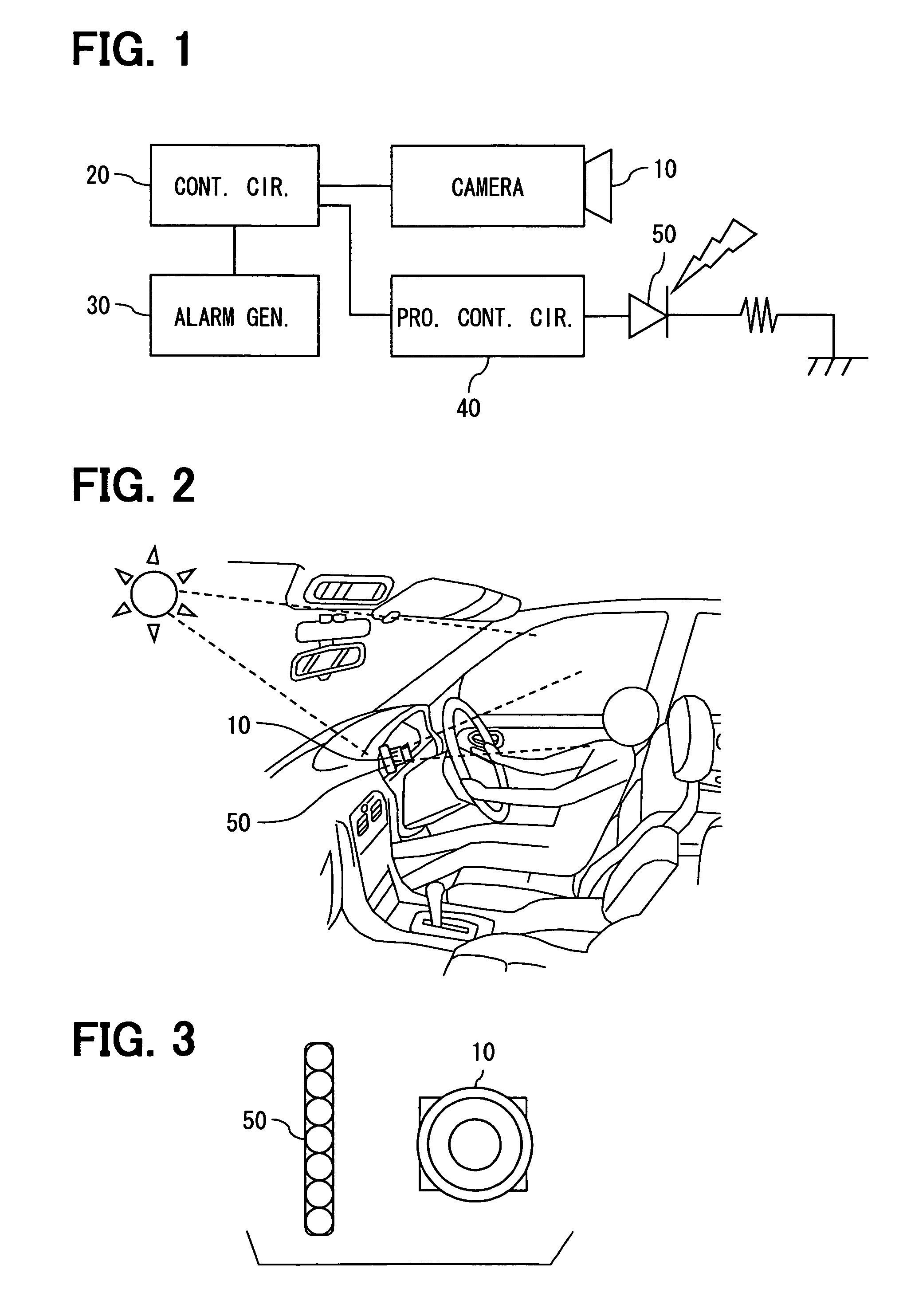

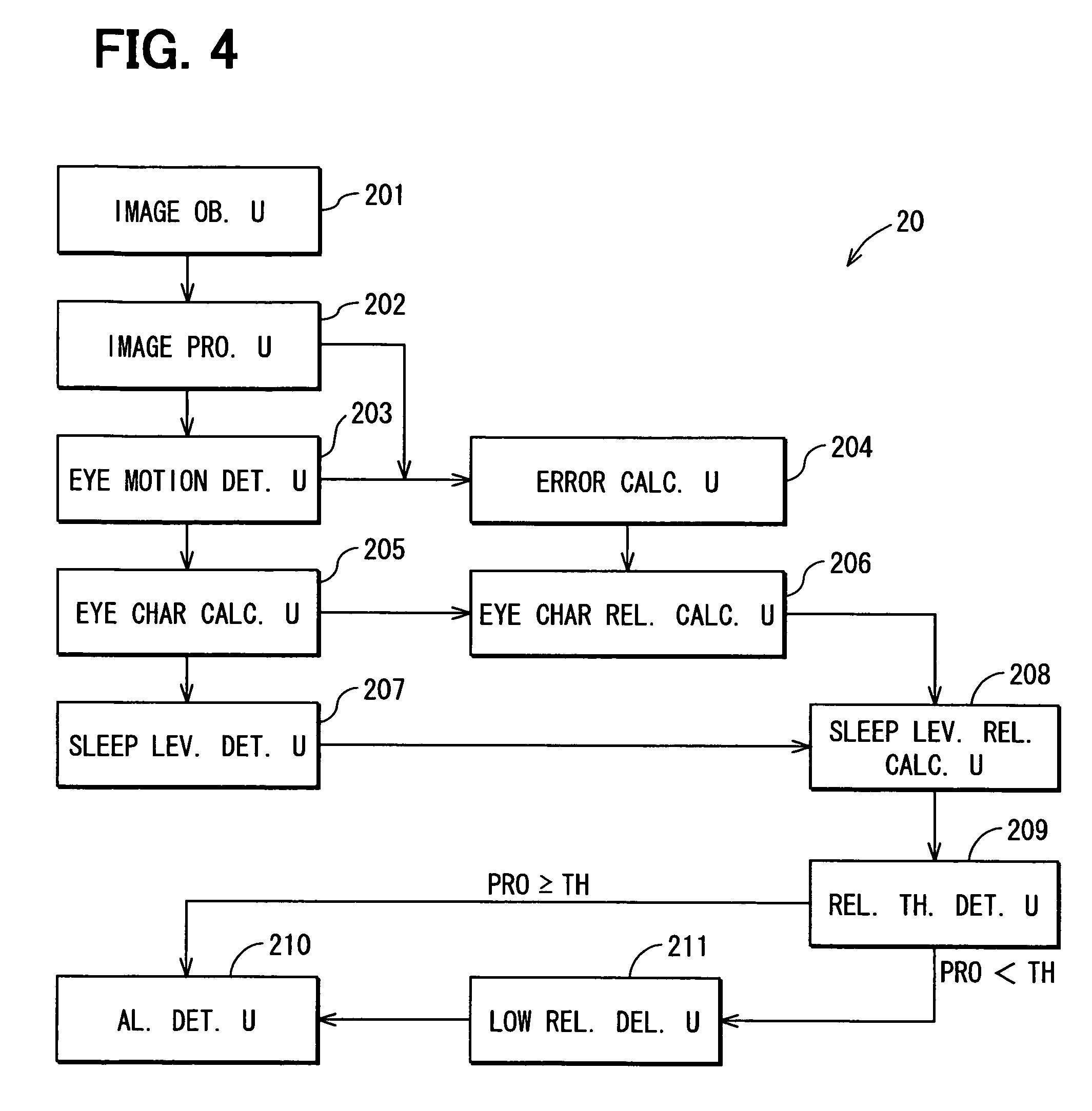

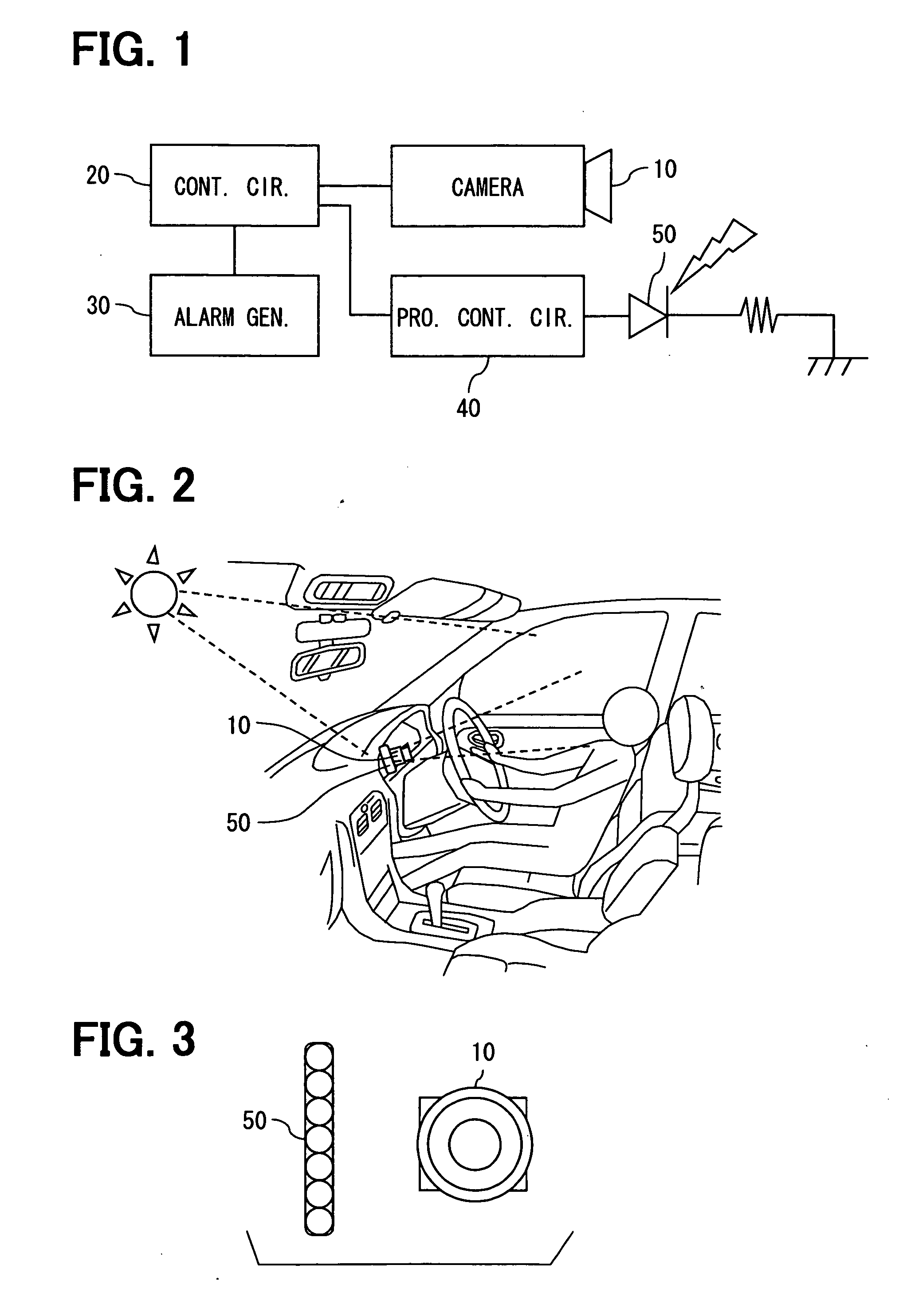

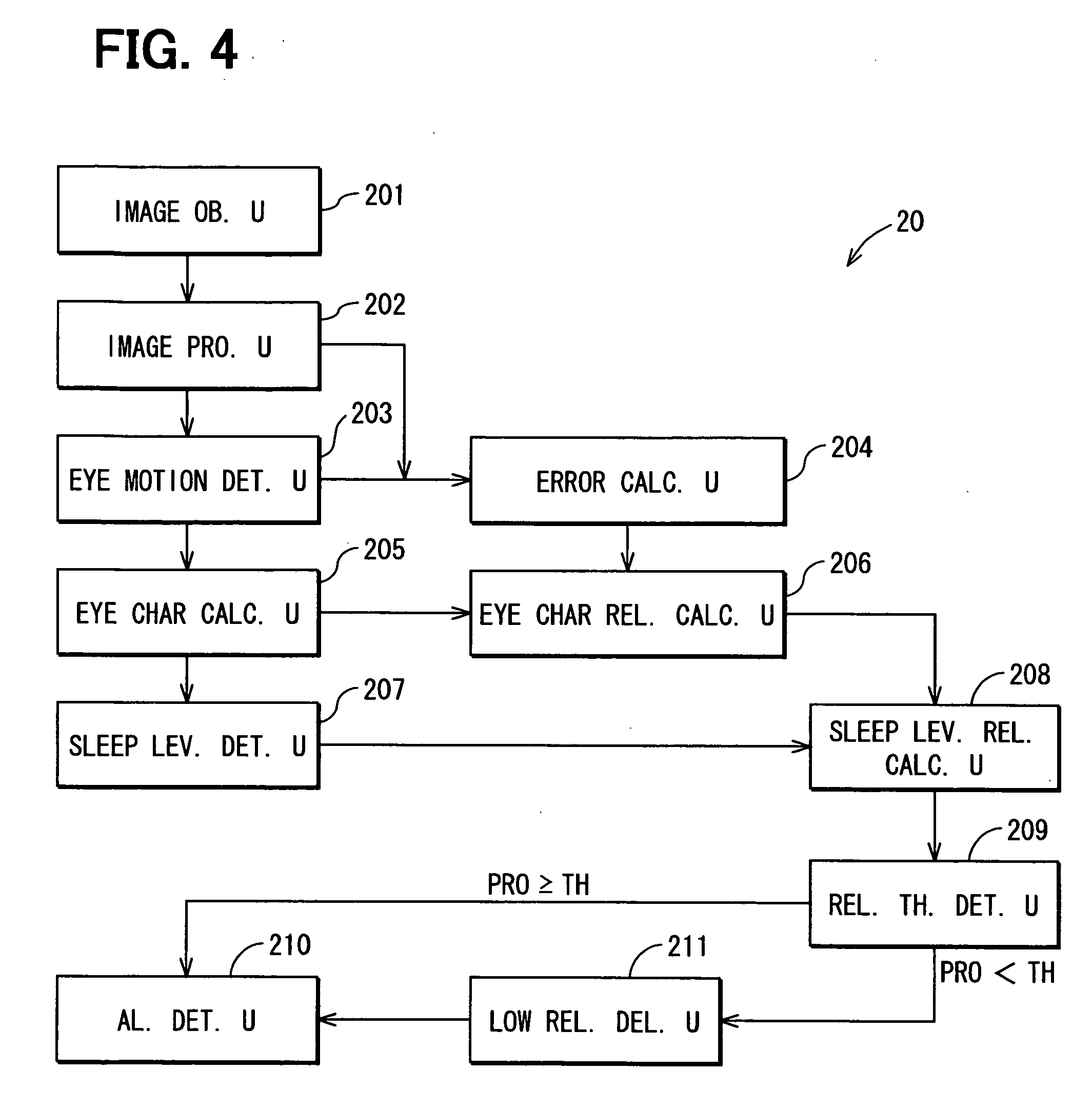

Sleepiness level determination device for driver

ActiveUS8094883B2Character and pattern recognitionDiagnostic recording/measuringMedicineComputer vision

A sleepiness level determination device includes: a detector processing a face image of an user and for detecting an eye image of the user based on the face image; a characteristic value calculating unit calculating a characteristic value regarding the eye based on the eye image; a sleepiness level determining unit determining a sleepiness level based on the characteristic value; and a reliability calculating unit calculating reliability of the sleepiness level based on the characteristic value.

Owner:DENSO CORP

Image evaluation device, image evaluation method, program, integrated circuit

ActiveUS20130028521A1Character and pattern recognitionPictoral communicationPattern recognitionTight frame

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

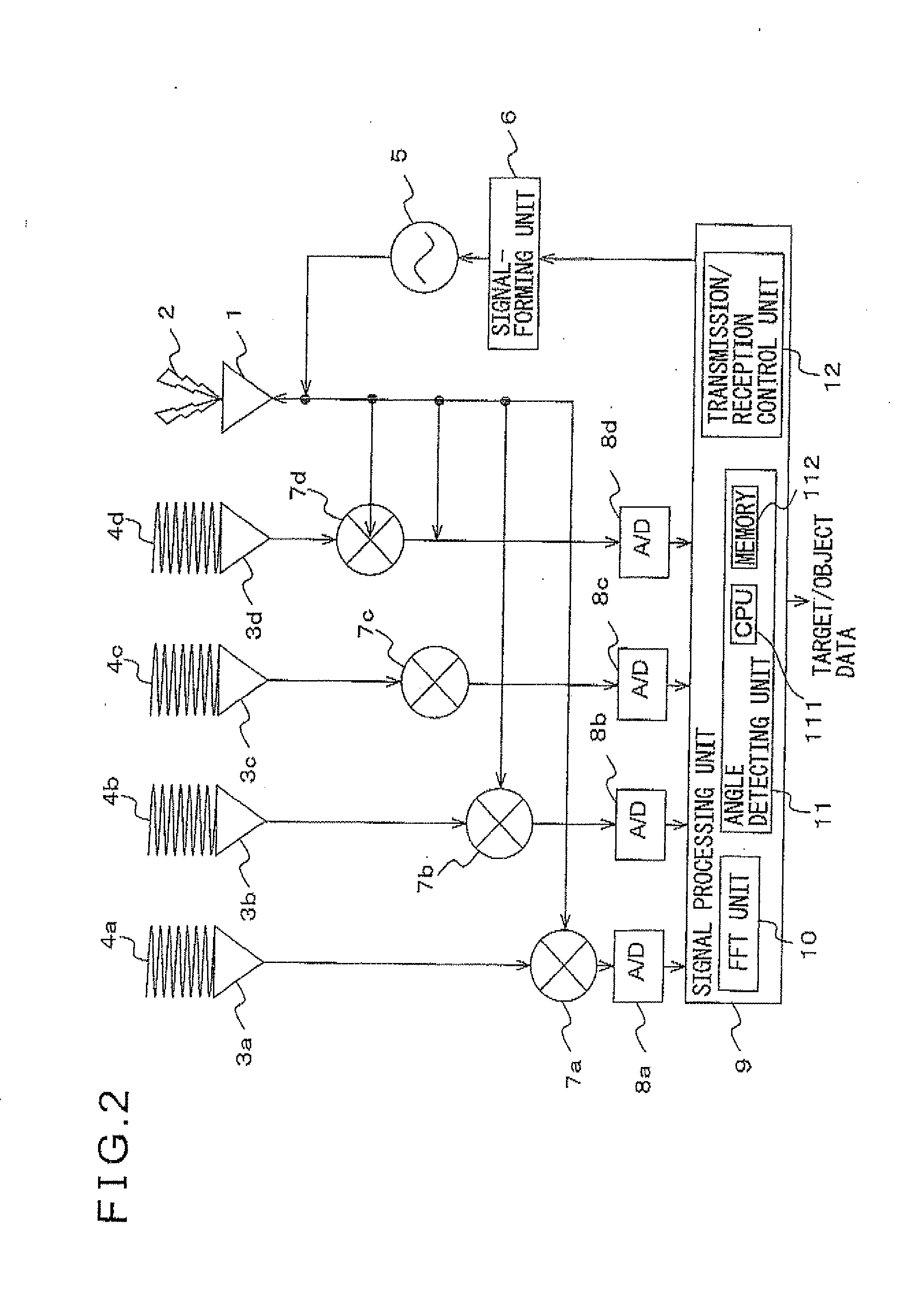

Radar device

ActiveUS20120112954A1Suppress processing timeMulti-channel direction-finding systems using radio wavesRadio wave reradiation/reflectionRadarEngineering

The conventional ESPRIT method is accompanied by the problem of very long signal processing time. The radar device of the invention includes a signal vector-forming unit for forming signal vectors based on waves reflected from an object and received by using a plurality of receiving antennas; a submatrix-forming unit for forming submatrices based on the signal vectors; a regular matrix operation unit for calculating a regular matrix from the submatrices; an eigenvalue decomposition unit for calculating an eigenvalue of the regular matrix; and an angle calculation unit for calculating an angle at where the object is present from the eigenvalue.

Owner:DENSO TEN LTD

Sleepiness level determination device for driver

ActiveUS20090097701A1Character and pattern recognitionDiagnostic recording/measuringDriver/operatorImage detection

A sleepiness level determination device includes: a detector processing a face image of an user and for detecting an eye image of the user based on the face image; a characteristic value calculating unit calculating a characteristic value regarding the eye based on the eye image; a sleepiness level determining unit determining a sleepiness level based on the characteristic value; and a reliability calculating unit calculating reliability of the sleepiness level based on the characteristic value.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com