Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Cut-resistant gloves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cut-resistant gloves are those designed to protect the wearer's hands from cuts while working with sharp tools. They can be divided into metal mesh gloves, cut-and-sewn, and seamless knitted gloves. Metal mesh gloves are a form of chainmail, and are made of rings of stainless steel. They are typically used in food applications.

Cut-resistant gloves containing fiberglass and para-aramid

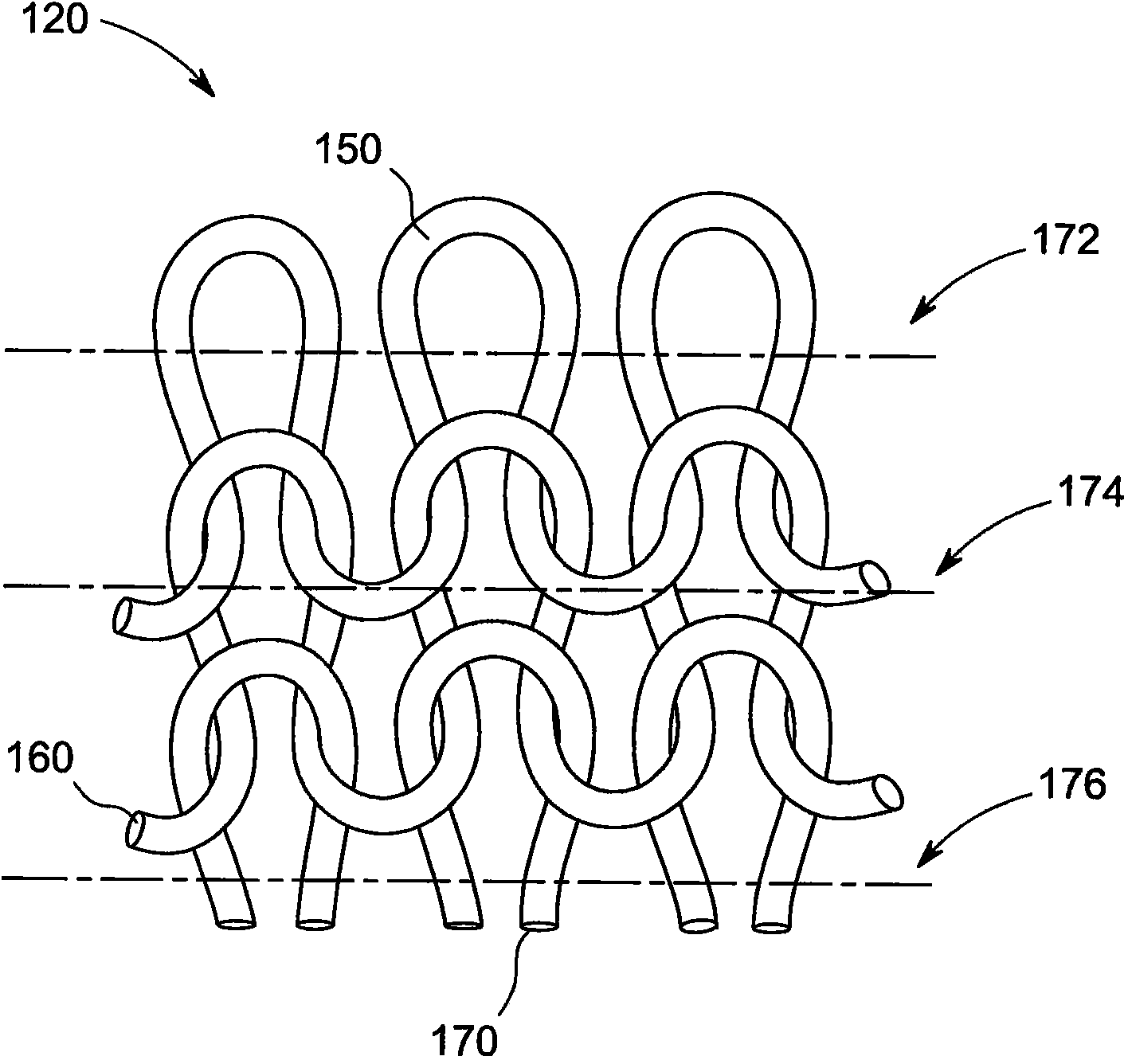

A cut-resistant knit glove comprising cut-resistant composite yarn, companion yarn and lining yarn. The cut-resistant composite yarn having a core comprising at least two core yarns and at least one first wrapping yarn helically wrapped around the core. The companion yarn comprising para-aramid. The lining yarn comprises either (i) composite yarn having an elastomeric yarn core and at least one second wrapping yarn helically wrapped around the yarn core or (ii) yarn comprising aliphatic polyamide fiber, polyester fiber, natural fiber, cellulosic fiber, and mixtures thereof. The cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

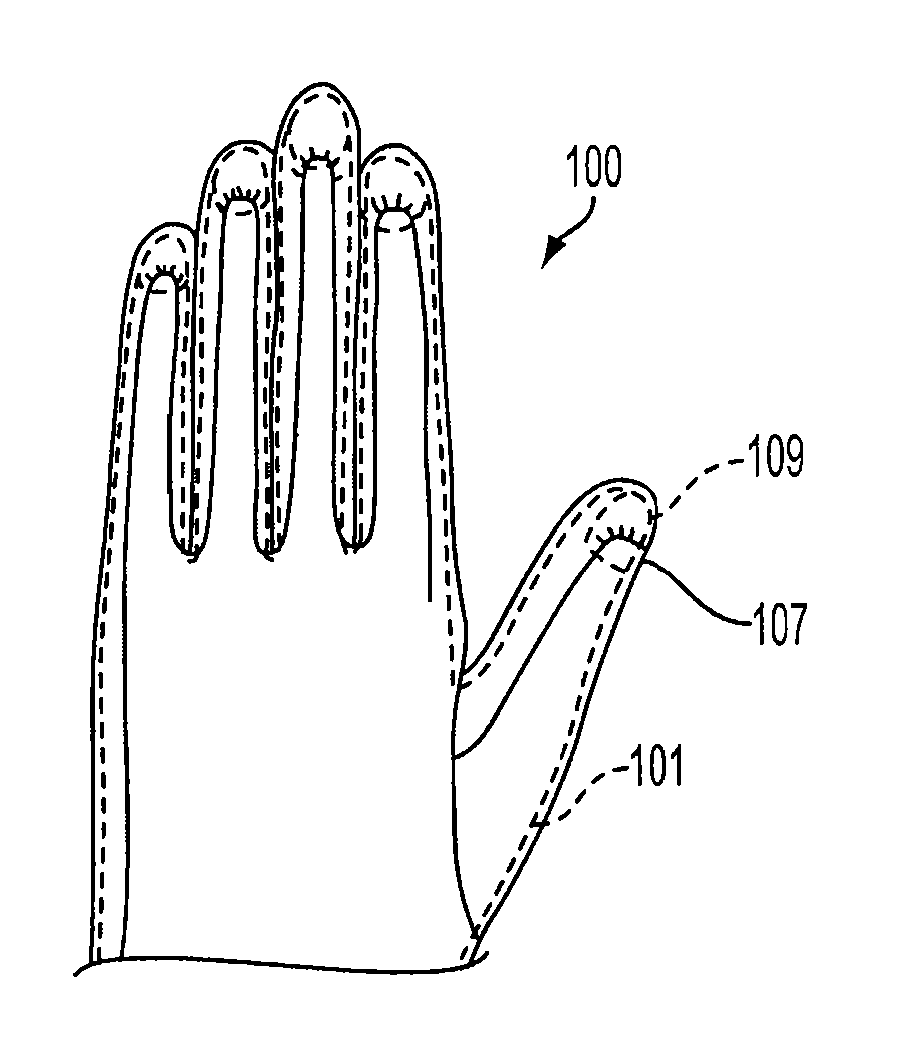

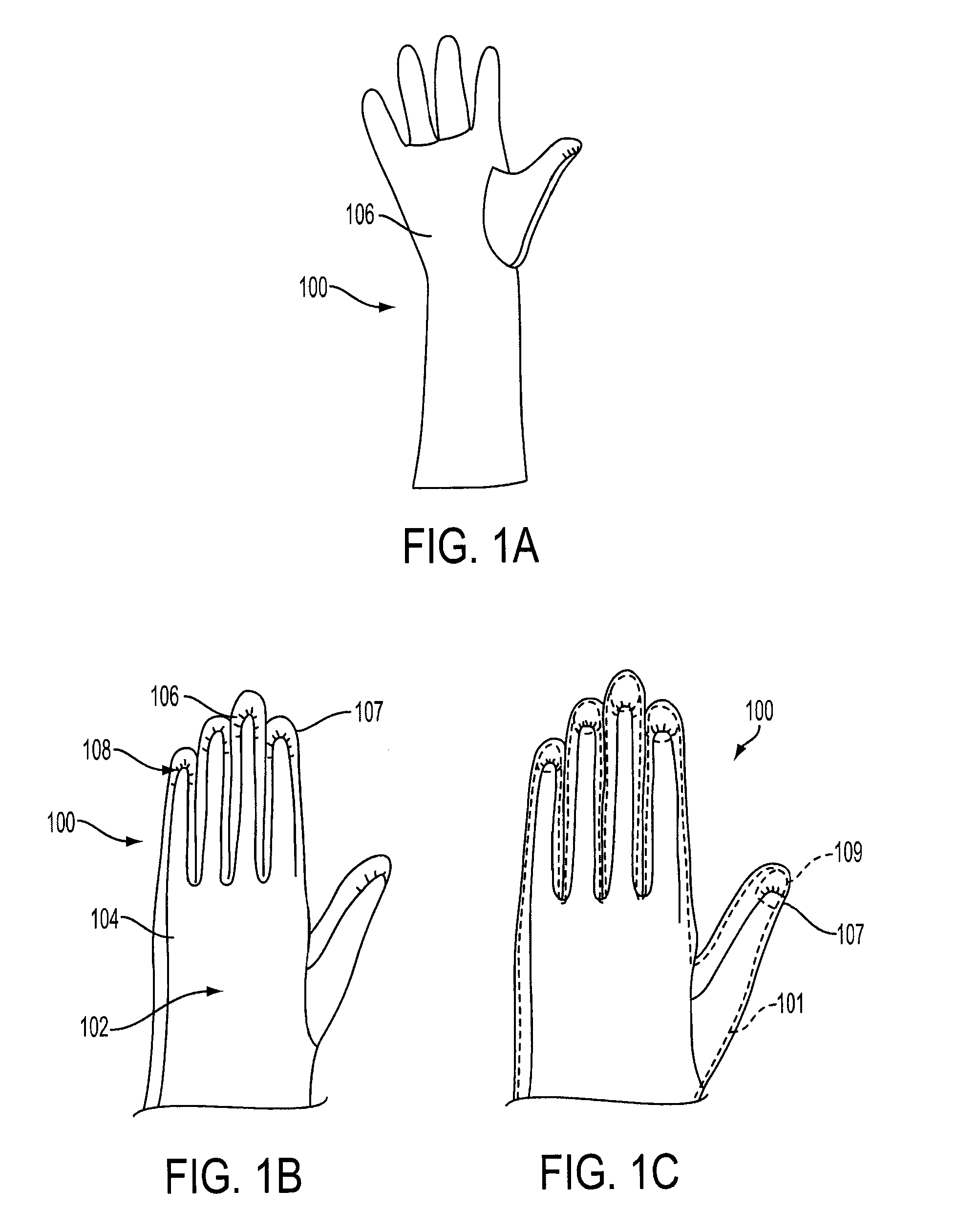

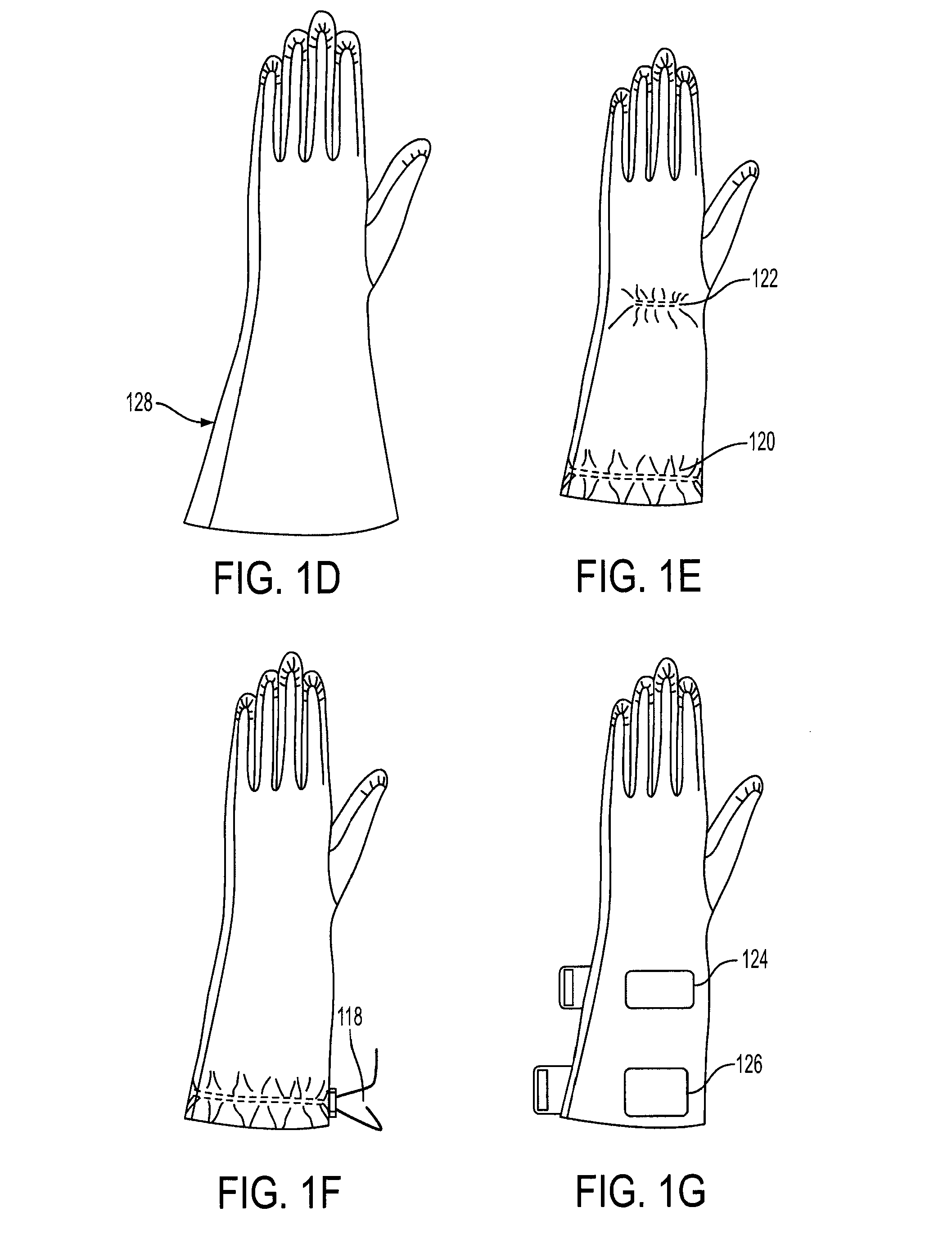

Puncture And/Or Cut Resistant Glove Having Maximized Dexterity, Tactility, And Comfort

A glove or partial glove comprising a palmar portion and a dorsal portion comprising one or more finger / thumb extensions, the portions joined together at a sealed seam, the seam positioned such that the seam on each of the finger / thumb extensions is positioned adjacent the dorsal aspect of the user's finger / thumb with the palmar aspect extending over the fingertip in a hood-like configuration. The glove portions may comprise a shear-thickening-fluid (STF) treated textile base, including a multi-ply construction in which each ply comprises an STF-treated textile base. The glove may comprise an integral pathogen barrier, such as a coating that is impervious to blood and bloodborne pathogens, and may have one or more features that aids donning and / or provides an adjustable fit. The glove or partial glove may be a first glove in a glove system including at least a second, latex glove to be worn over the first glove.

Owner:UNIVERSITY OF DELAWARE

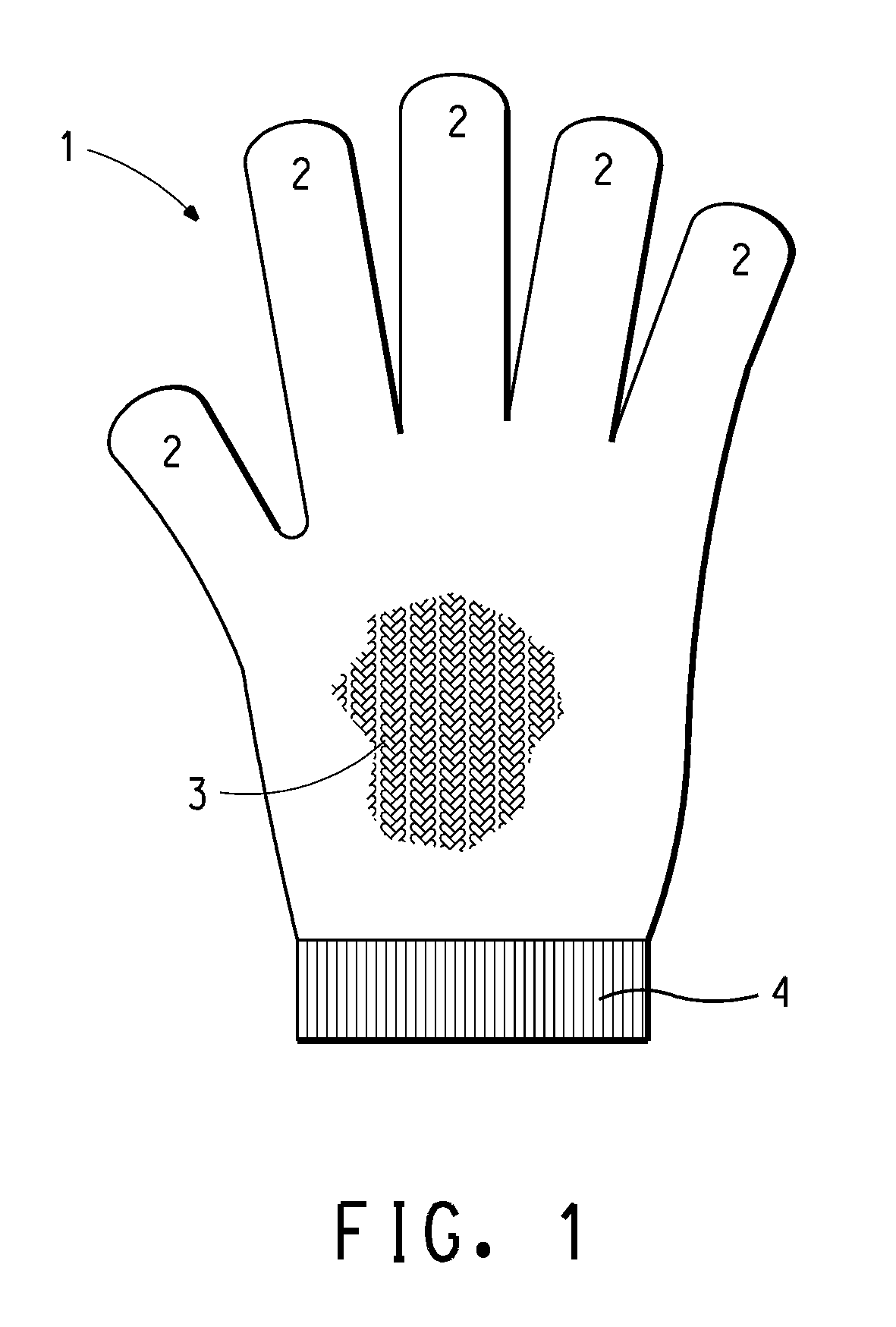

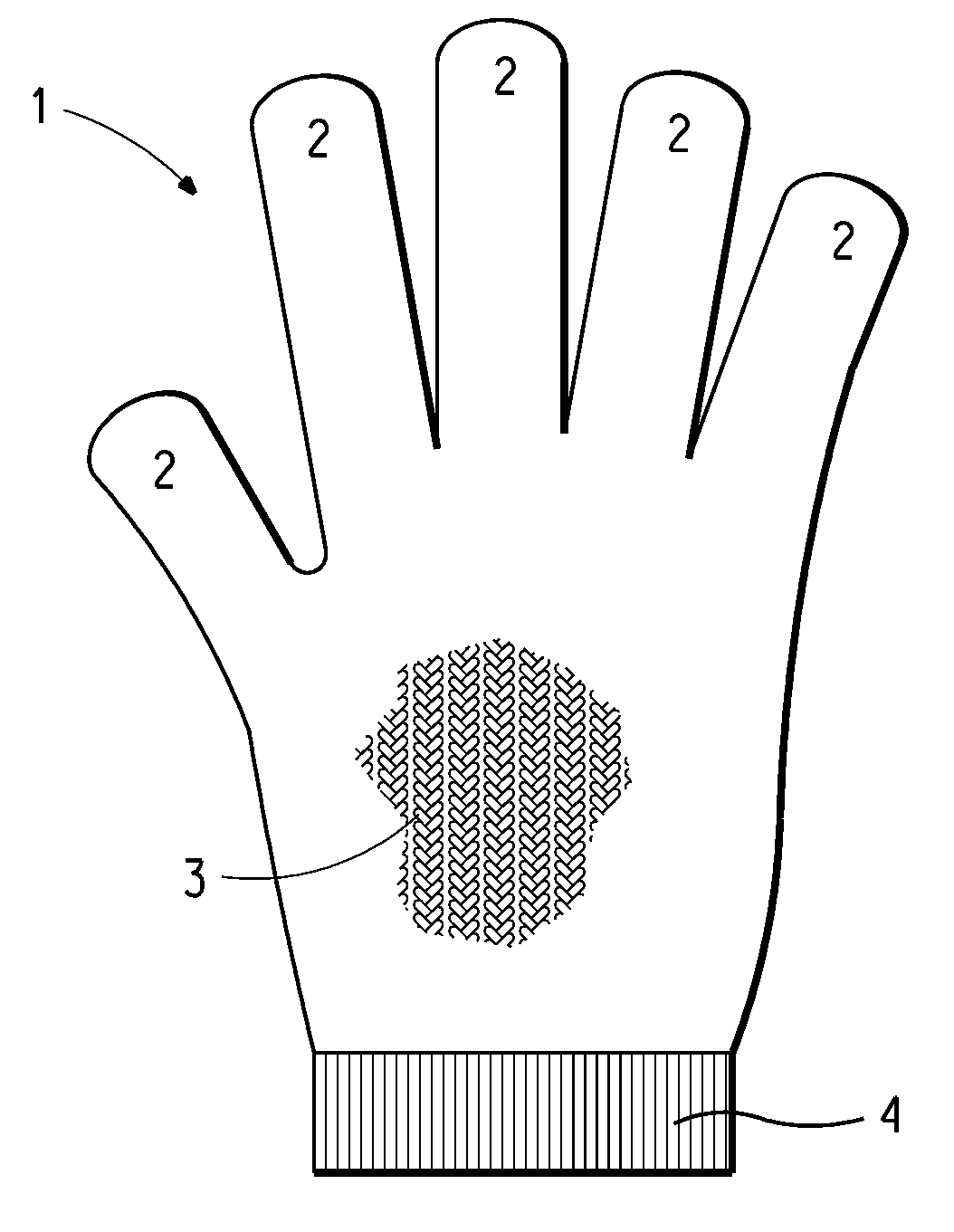

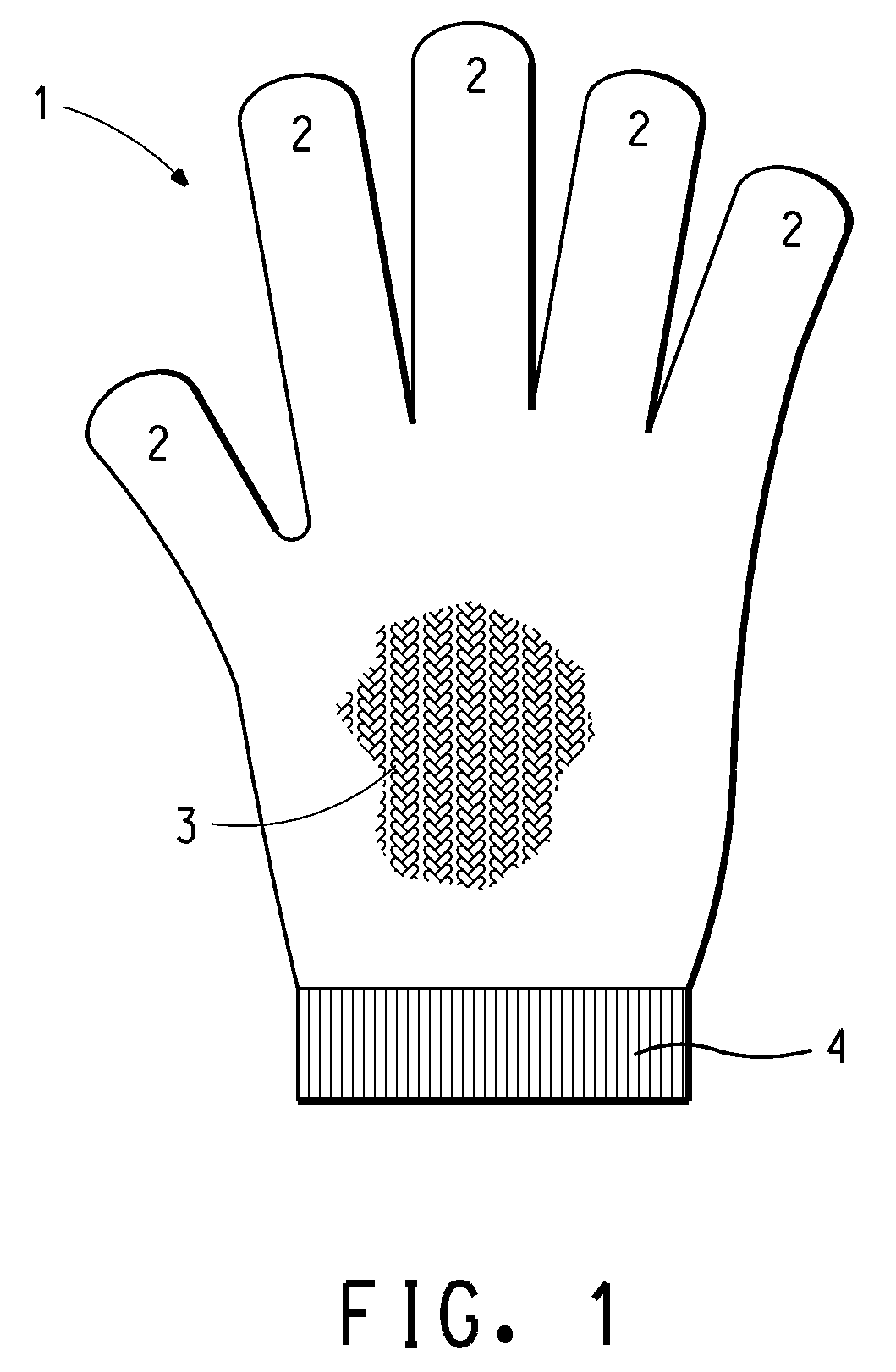

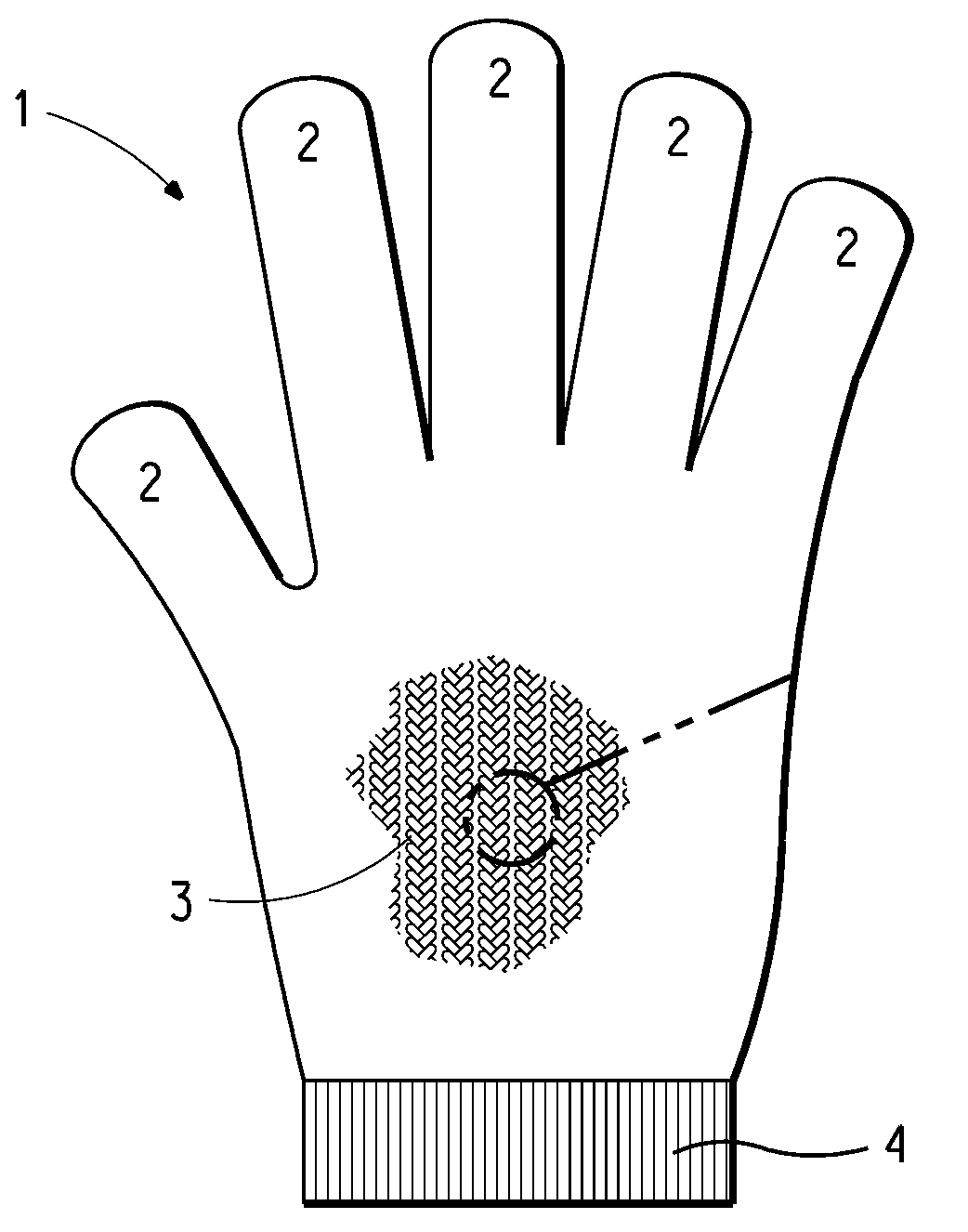

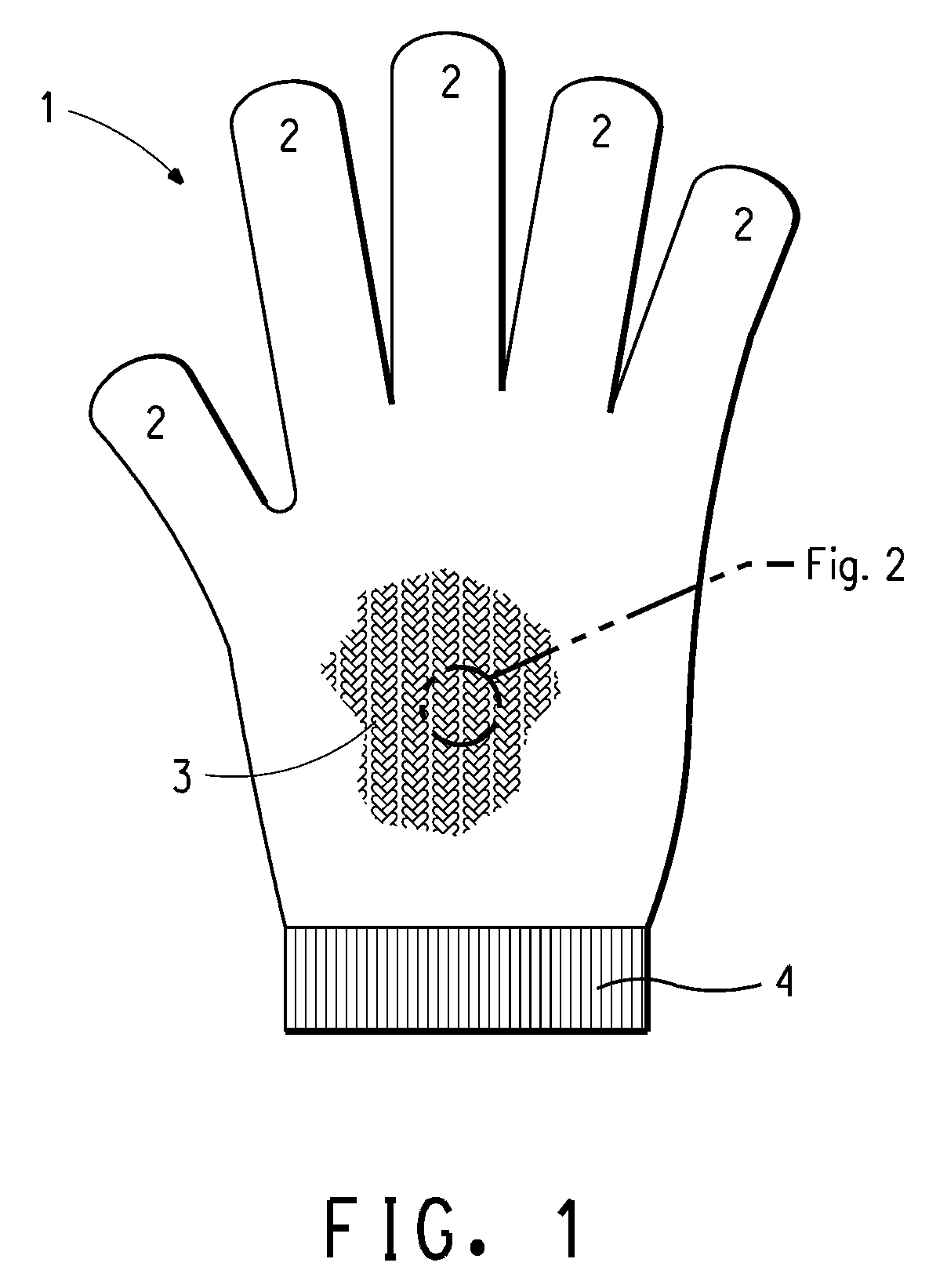

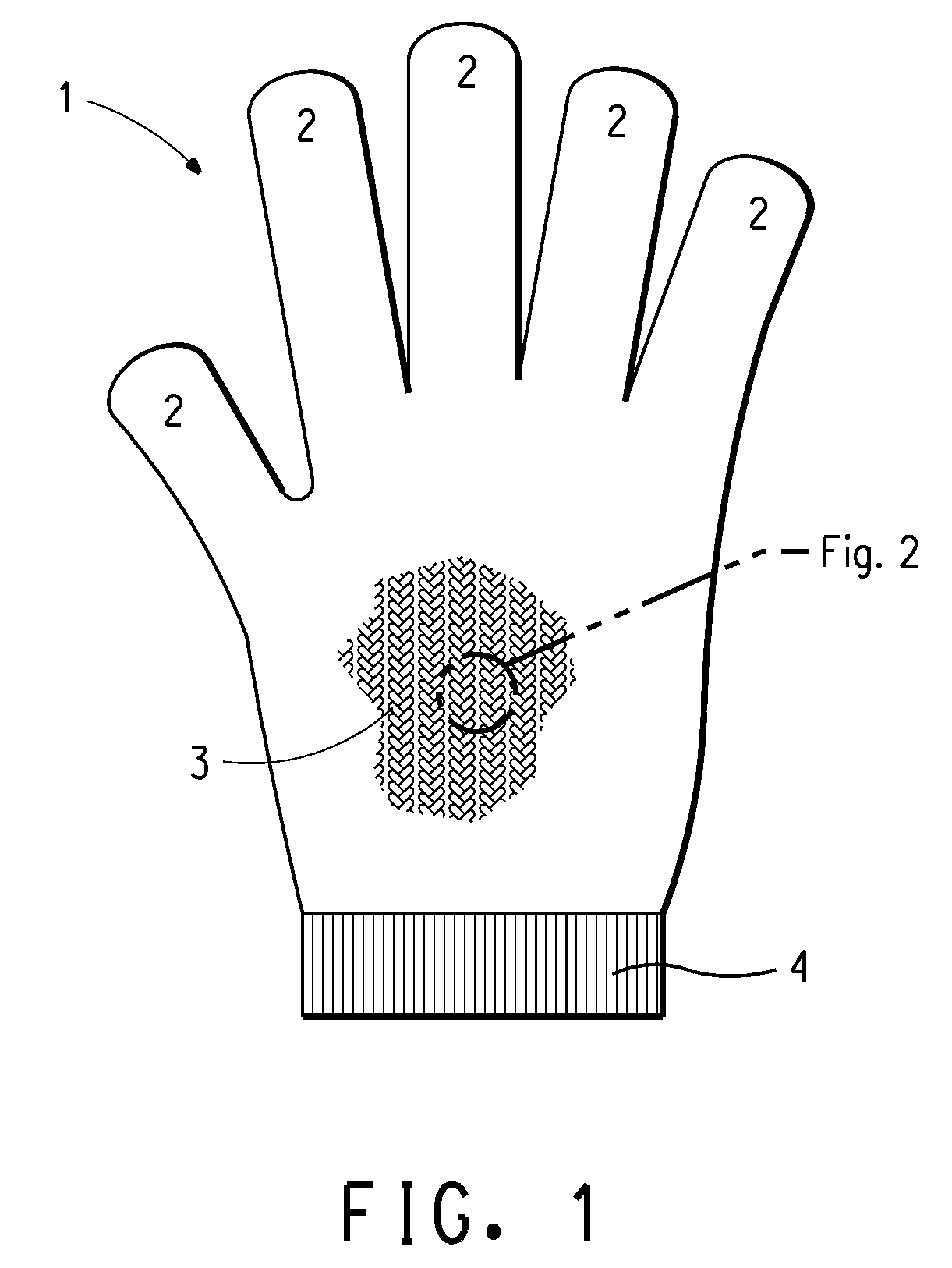

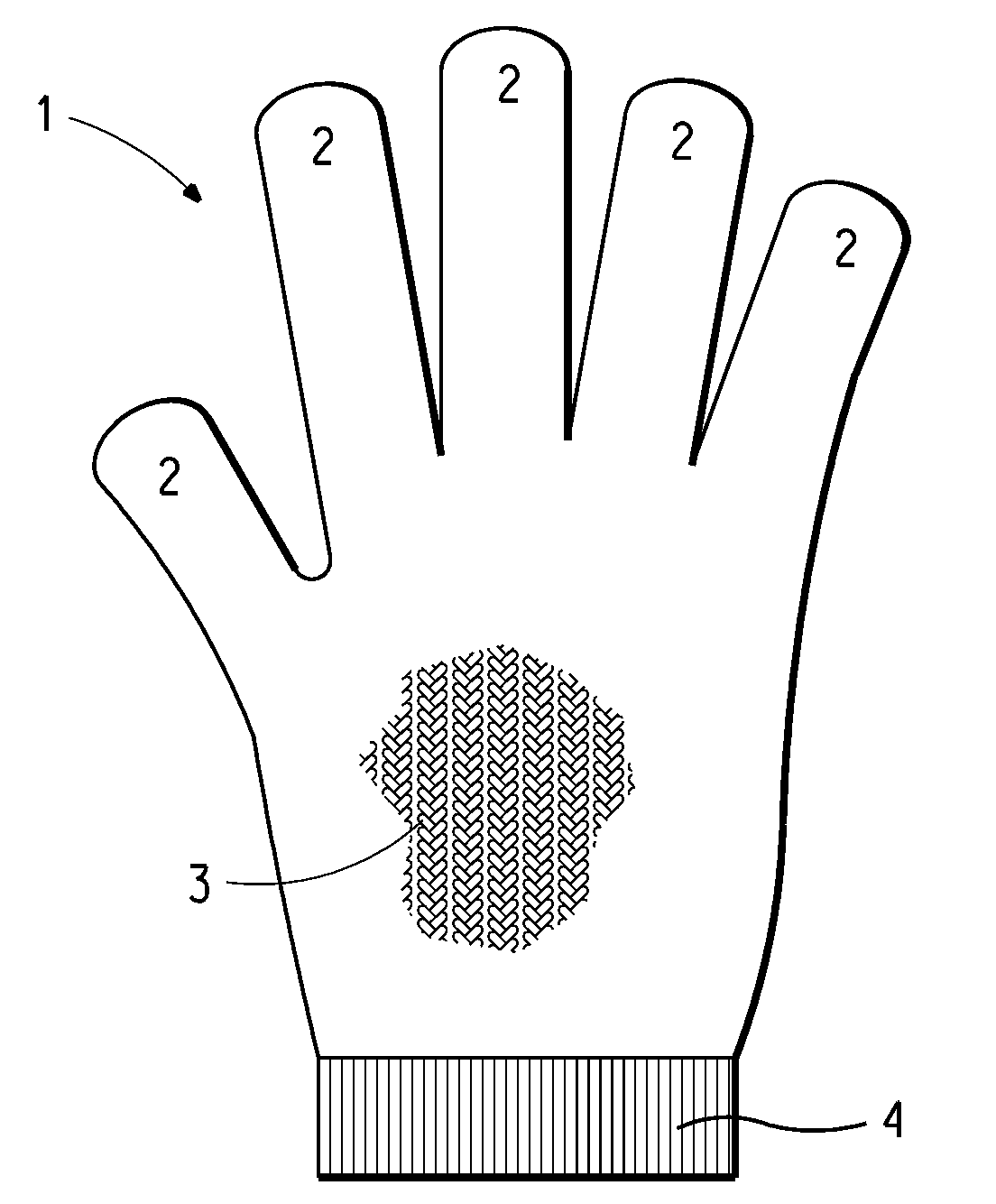

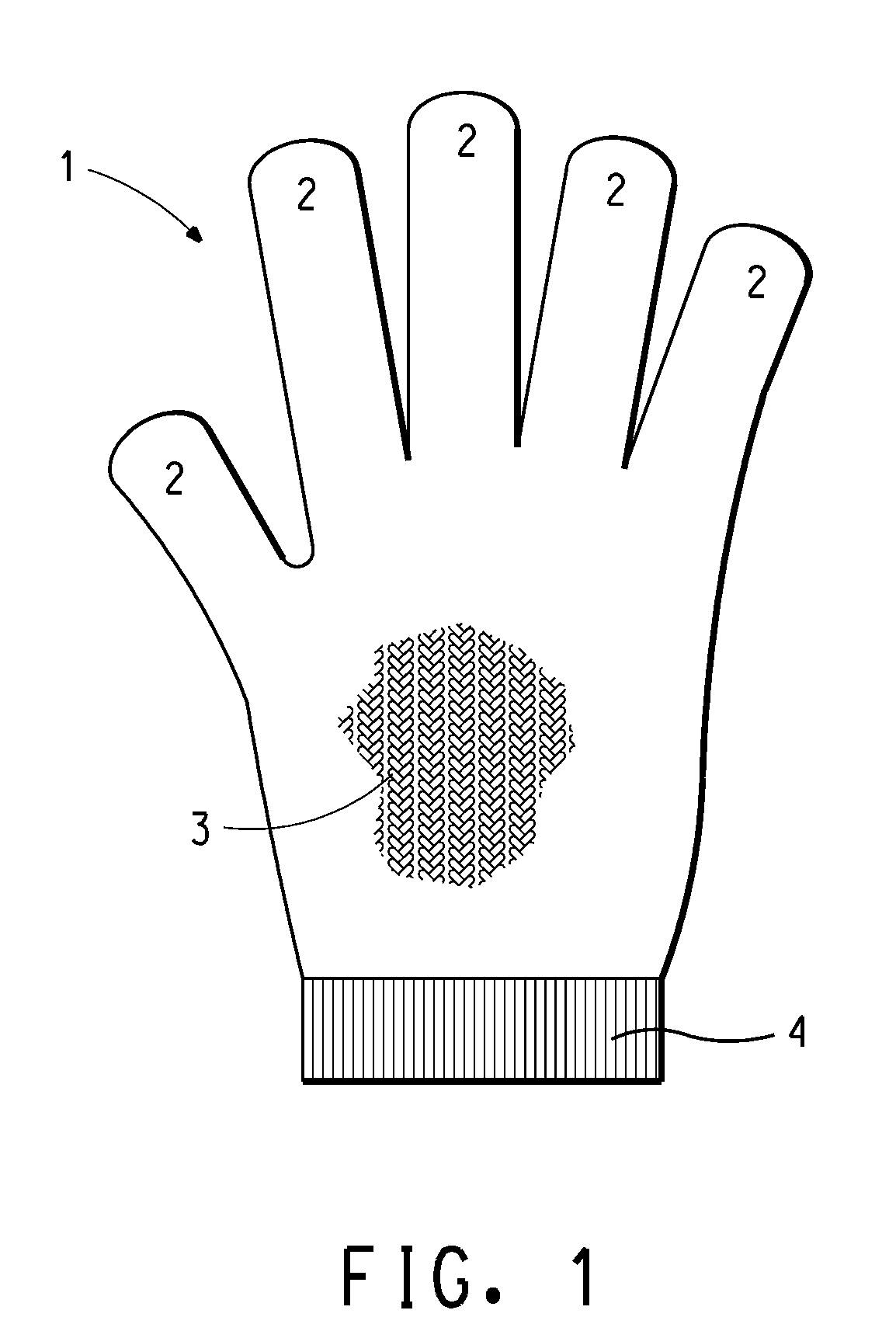

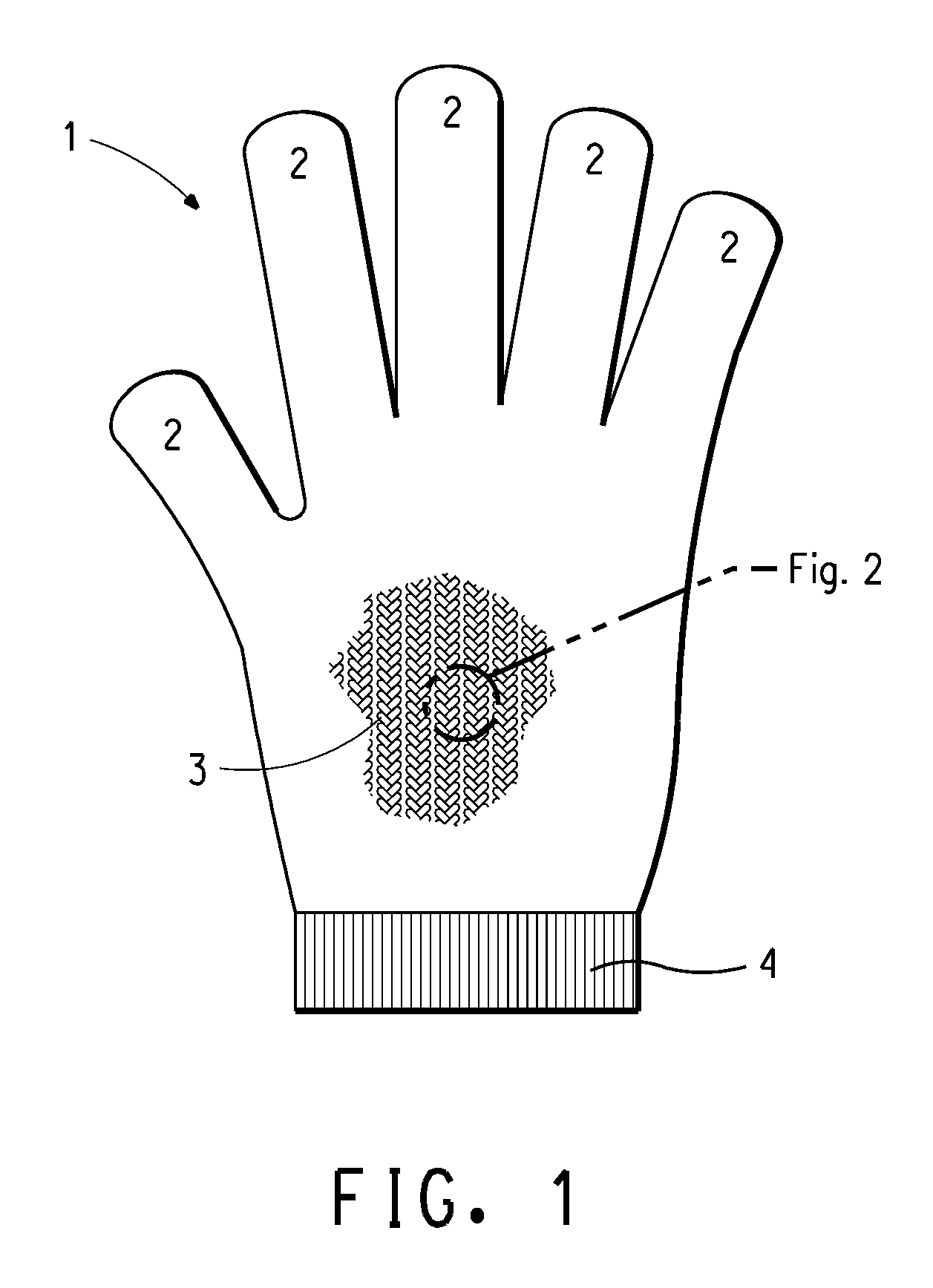

Cut resistant glove and apparel

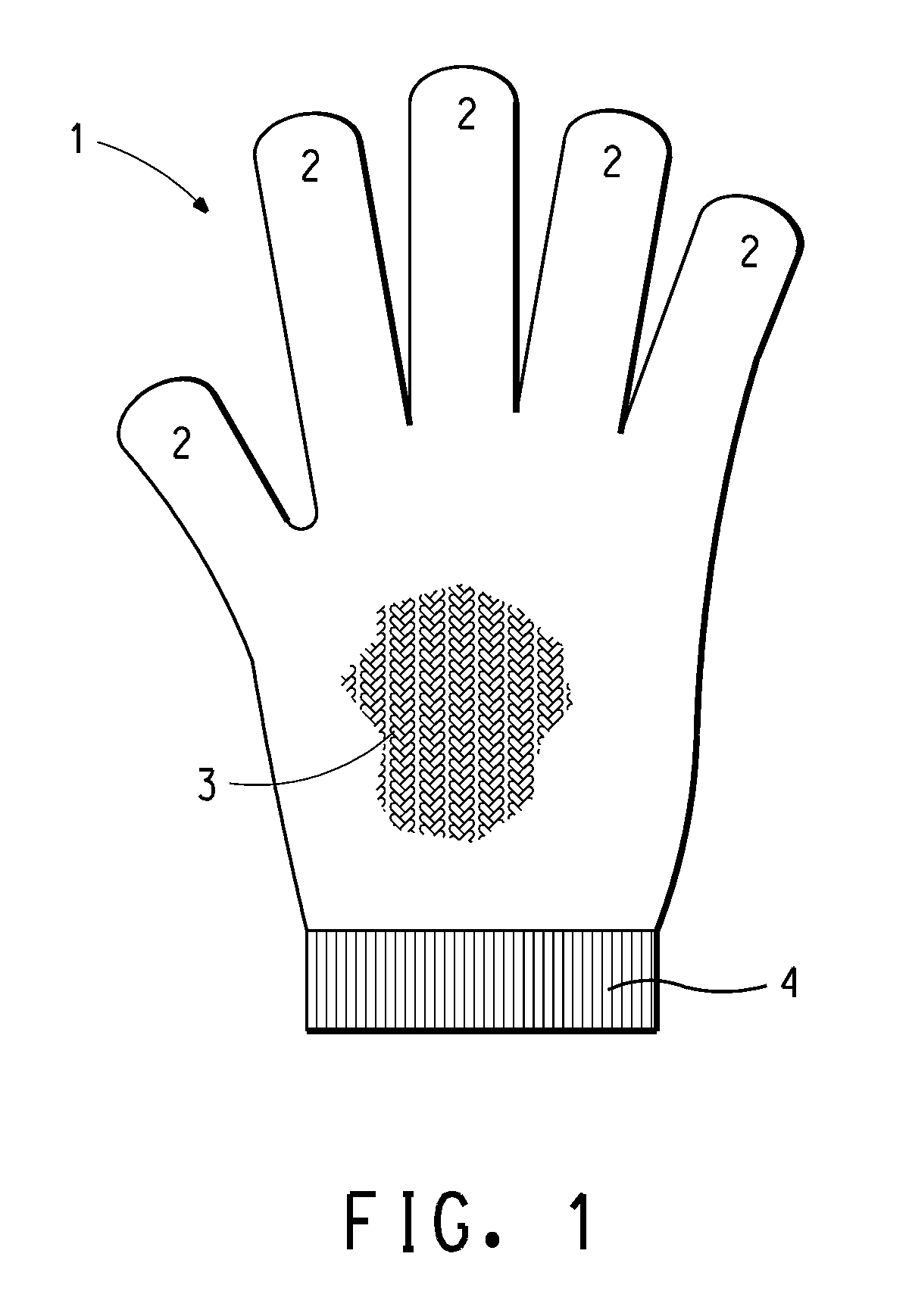

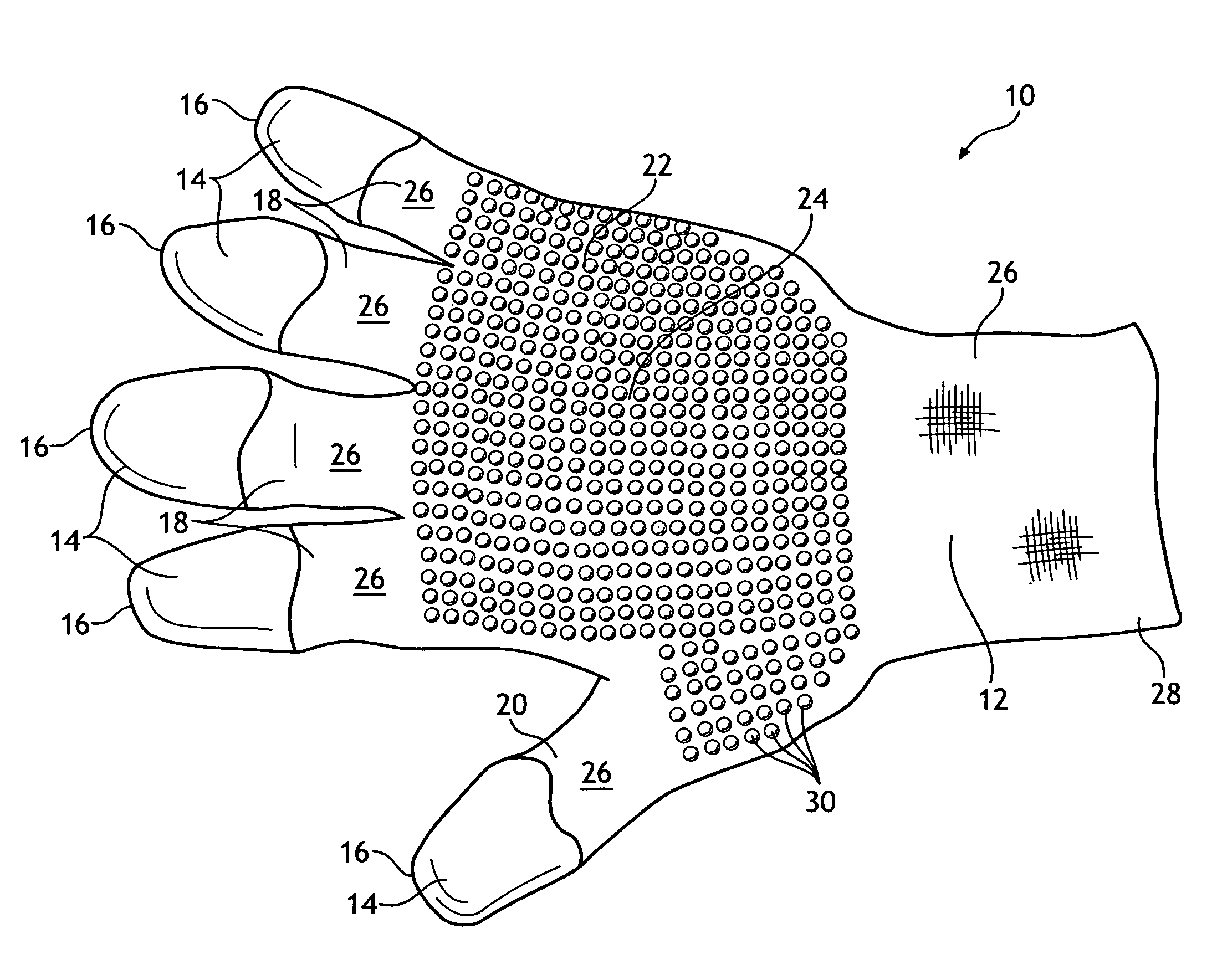

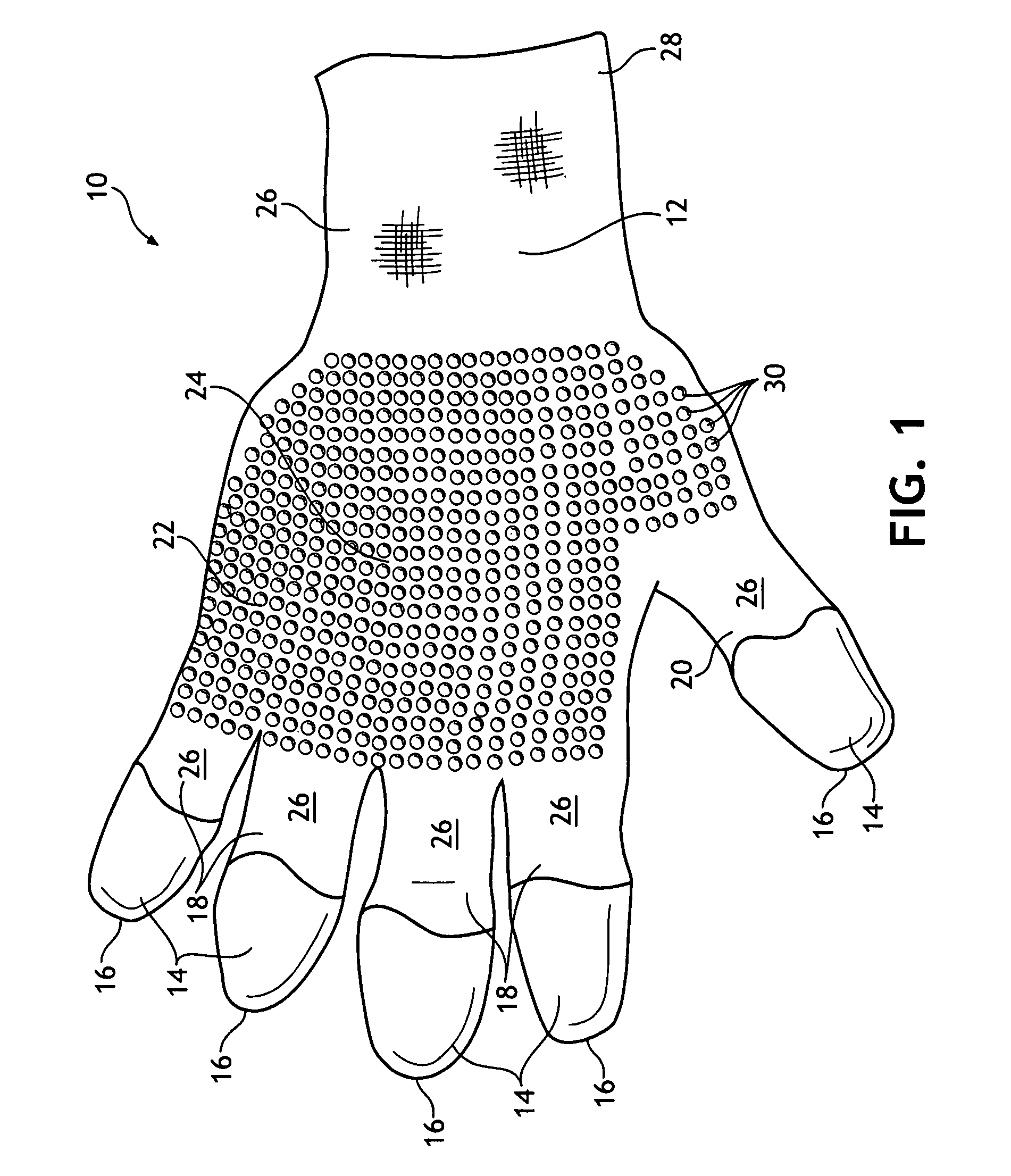

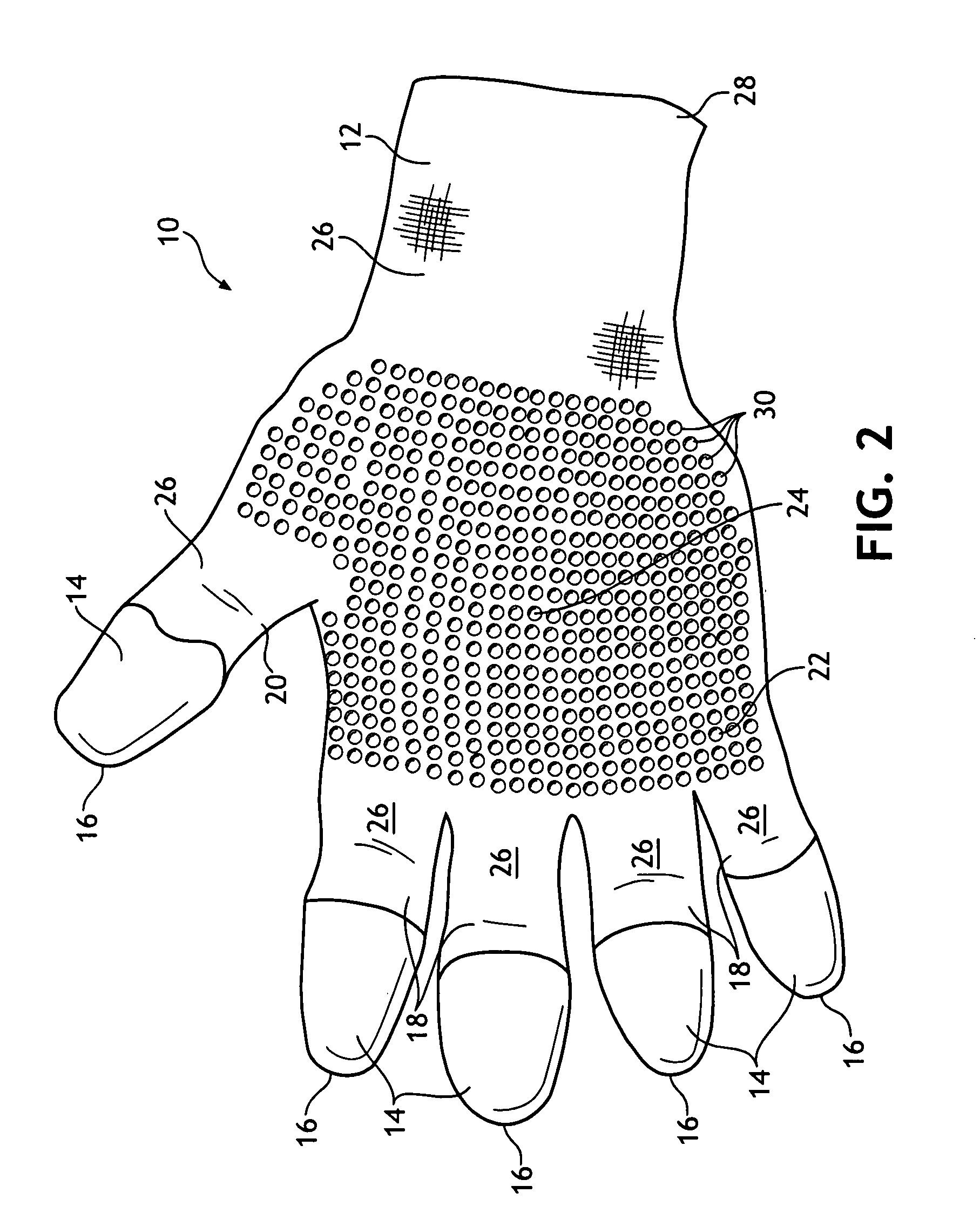

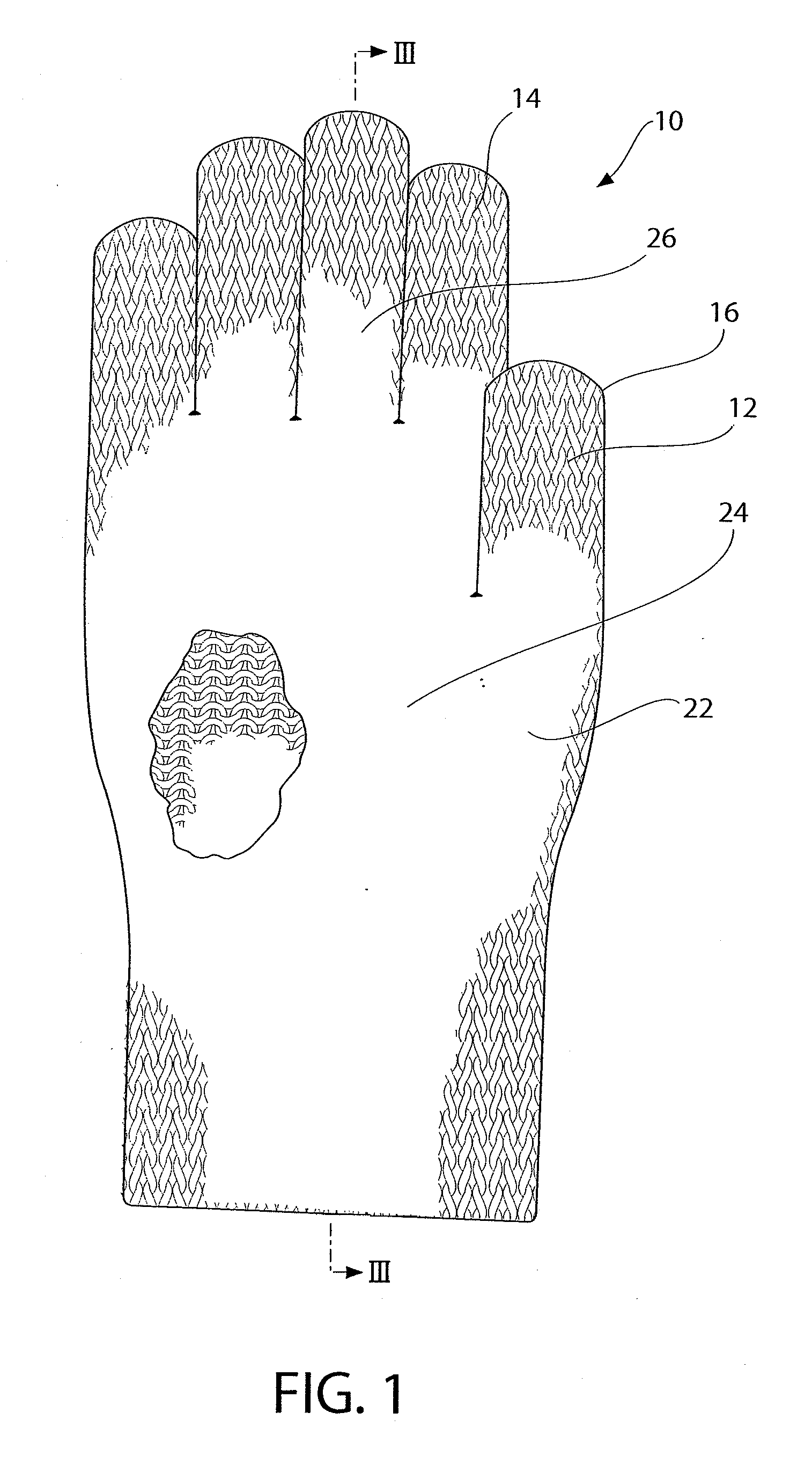

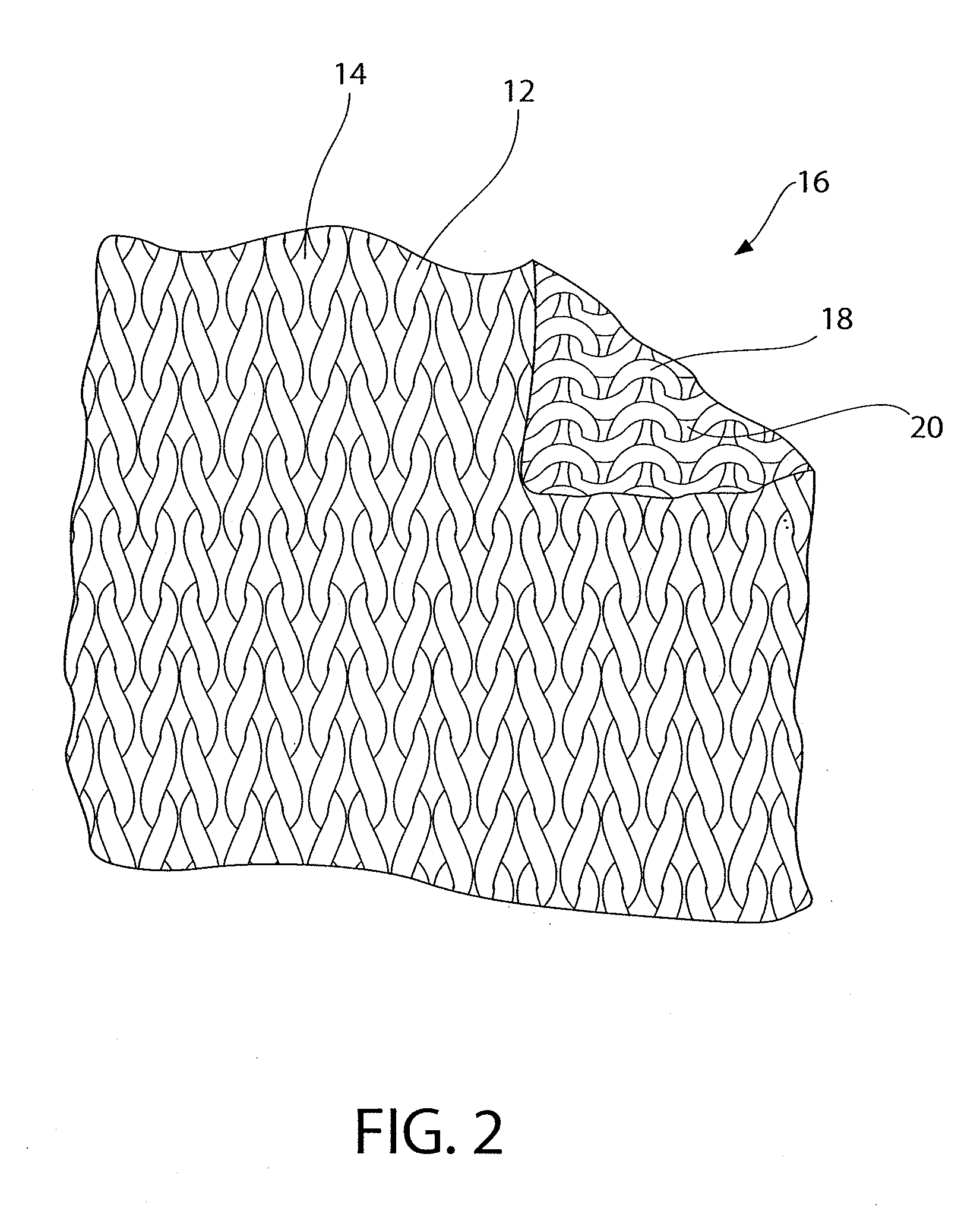

A glove or apparel formed at least partially from a knitted thread substrate and including areas on an outer surface which has a substantially continuous surface surrounding ends of the finger portions and thumb portion of the glove and areas which have a substantially non-continuous surface positioned over the palm portion and the back of the hand portion of the glove.

Owner:KIMBERLY-CLARK WORLDWIDE INC

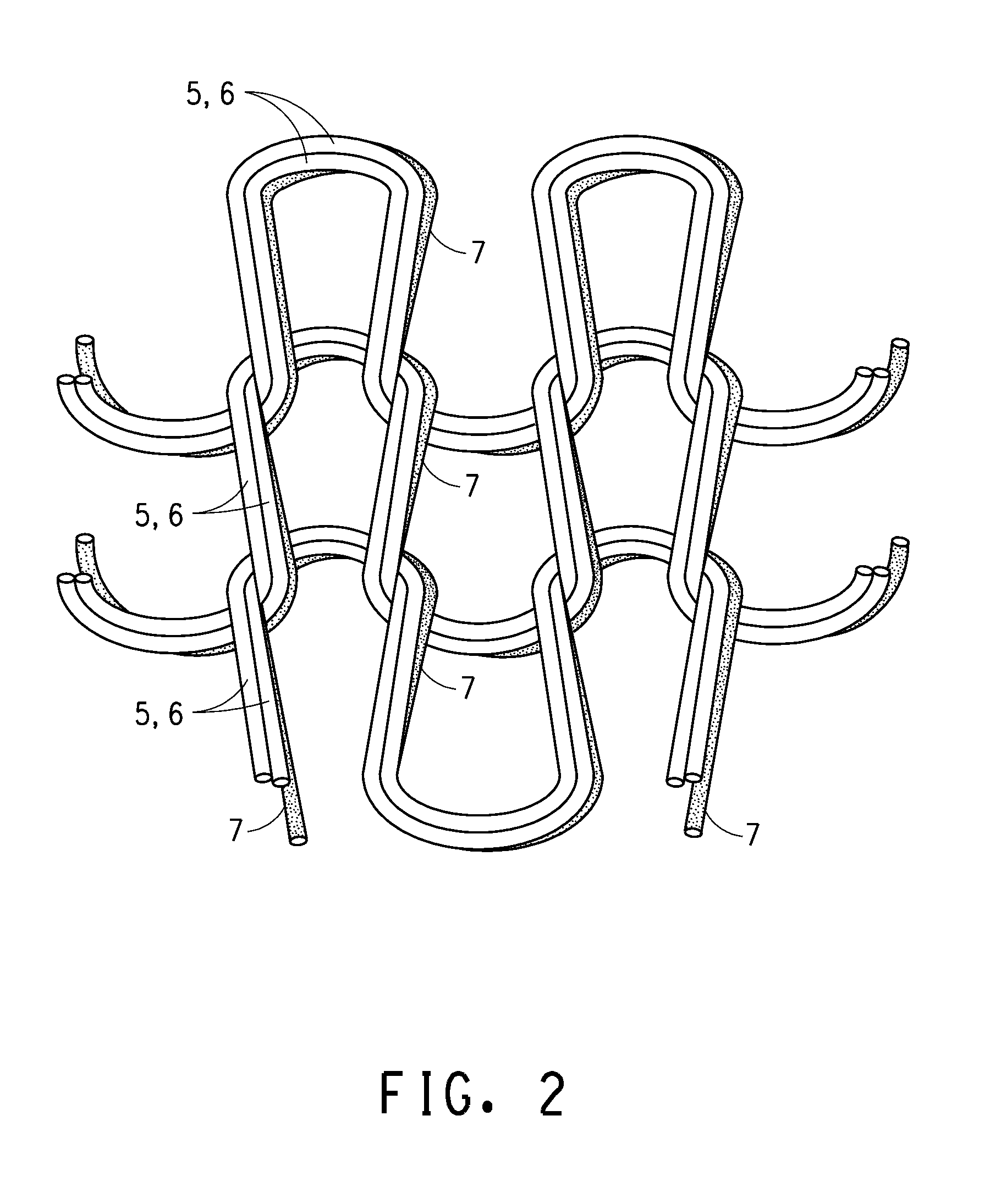

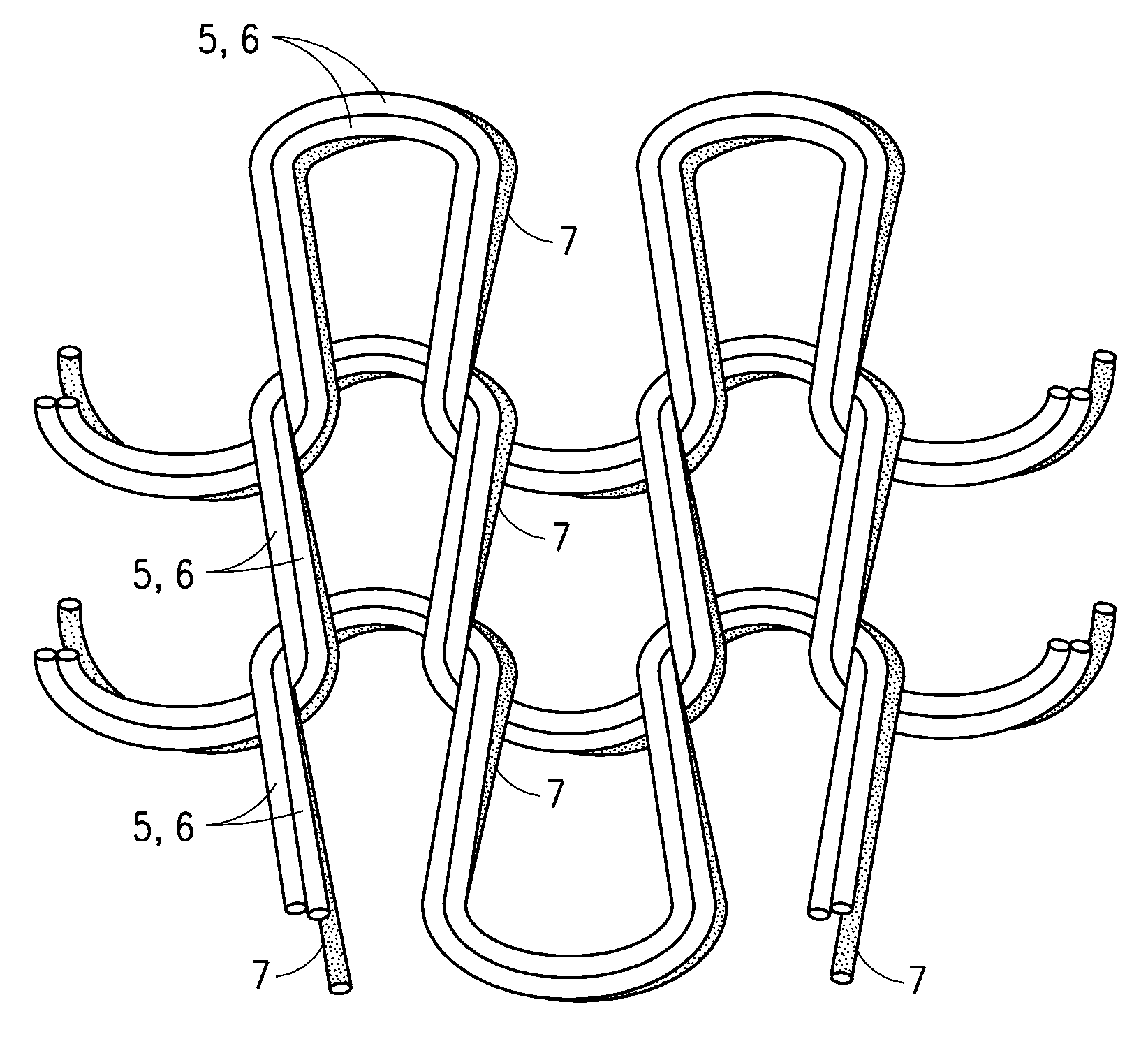

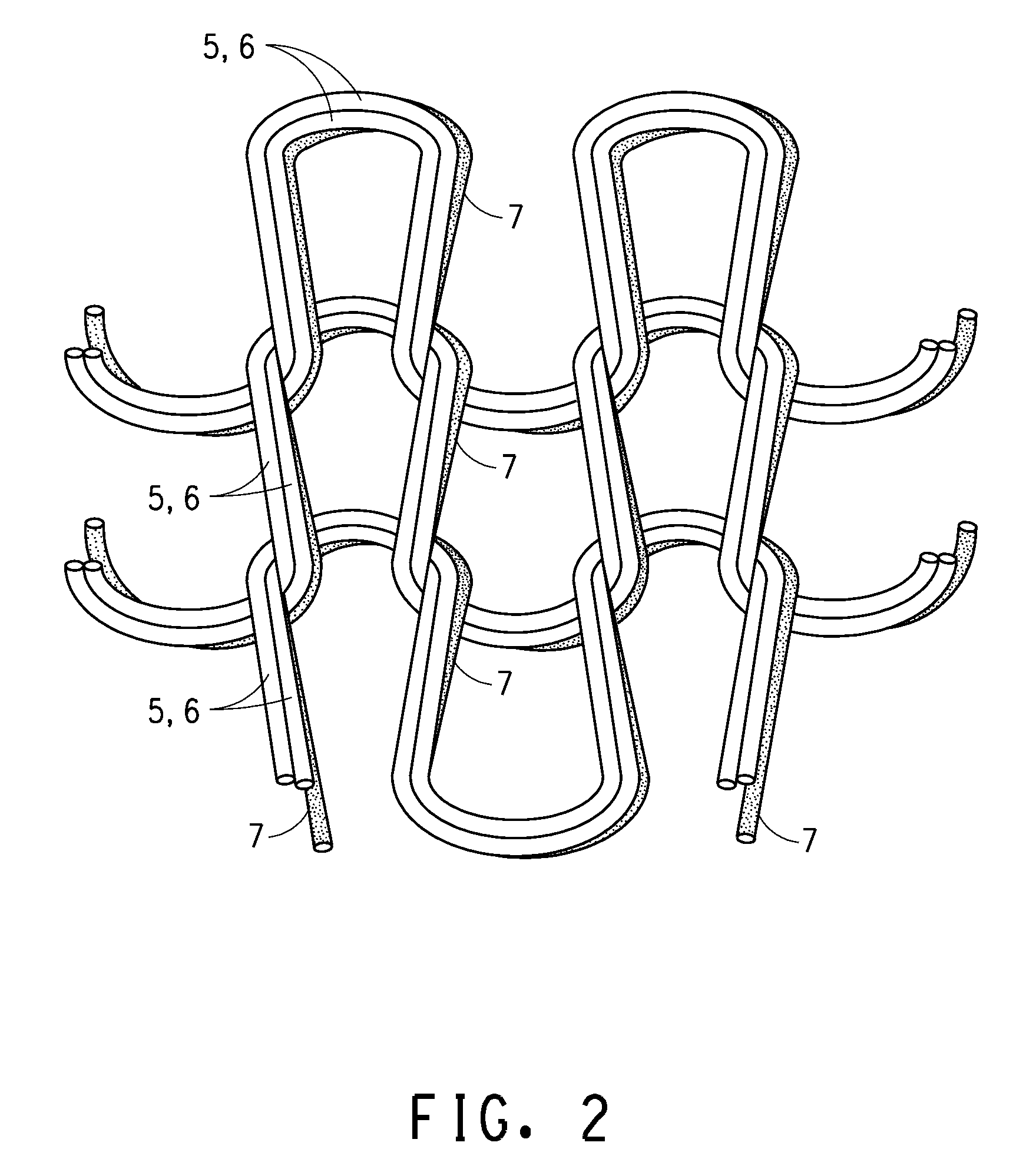

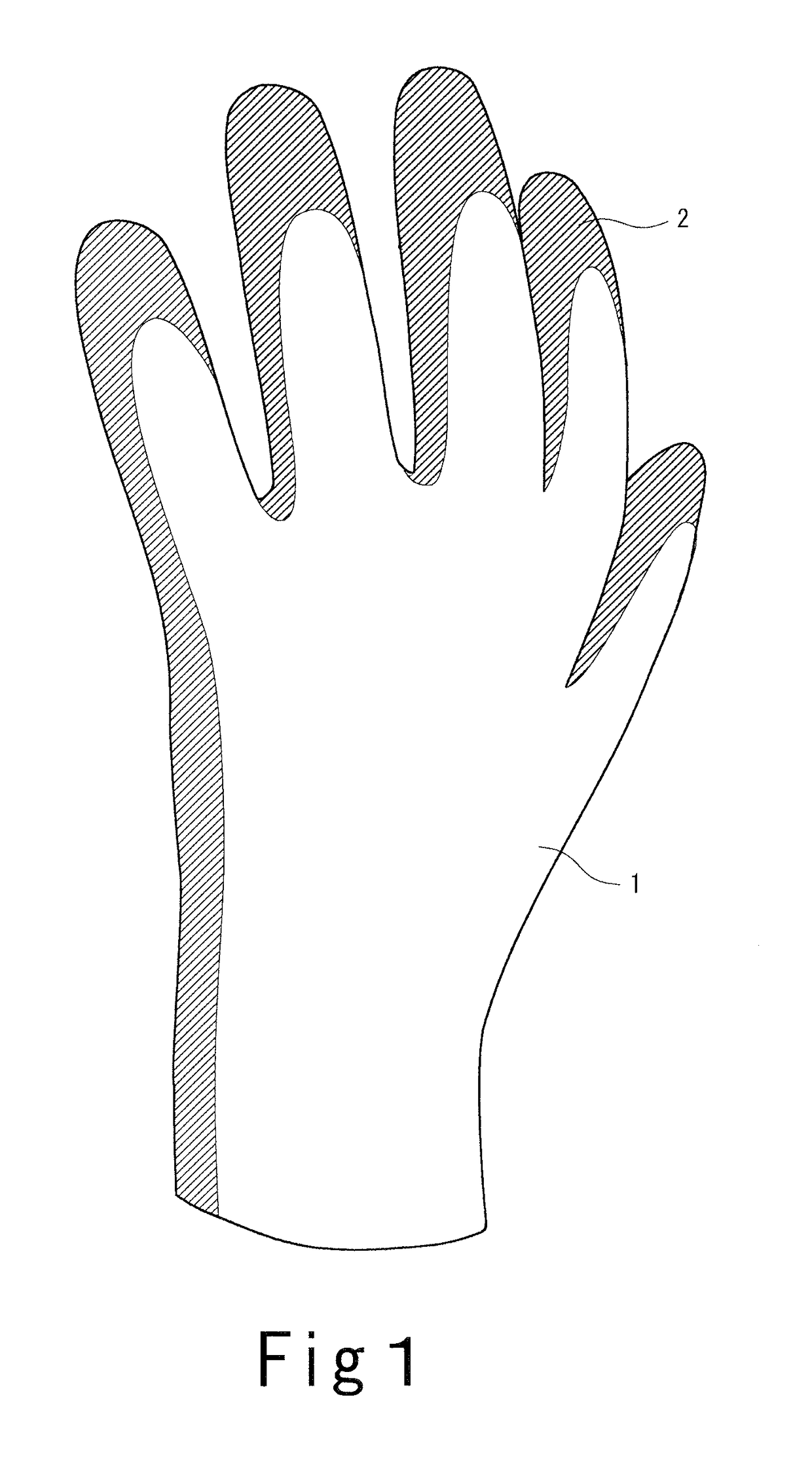

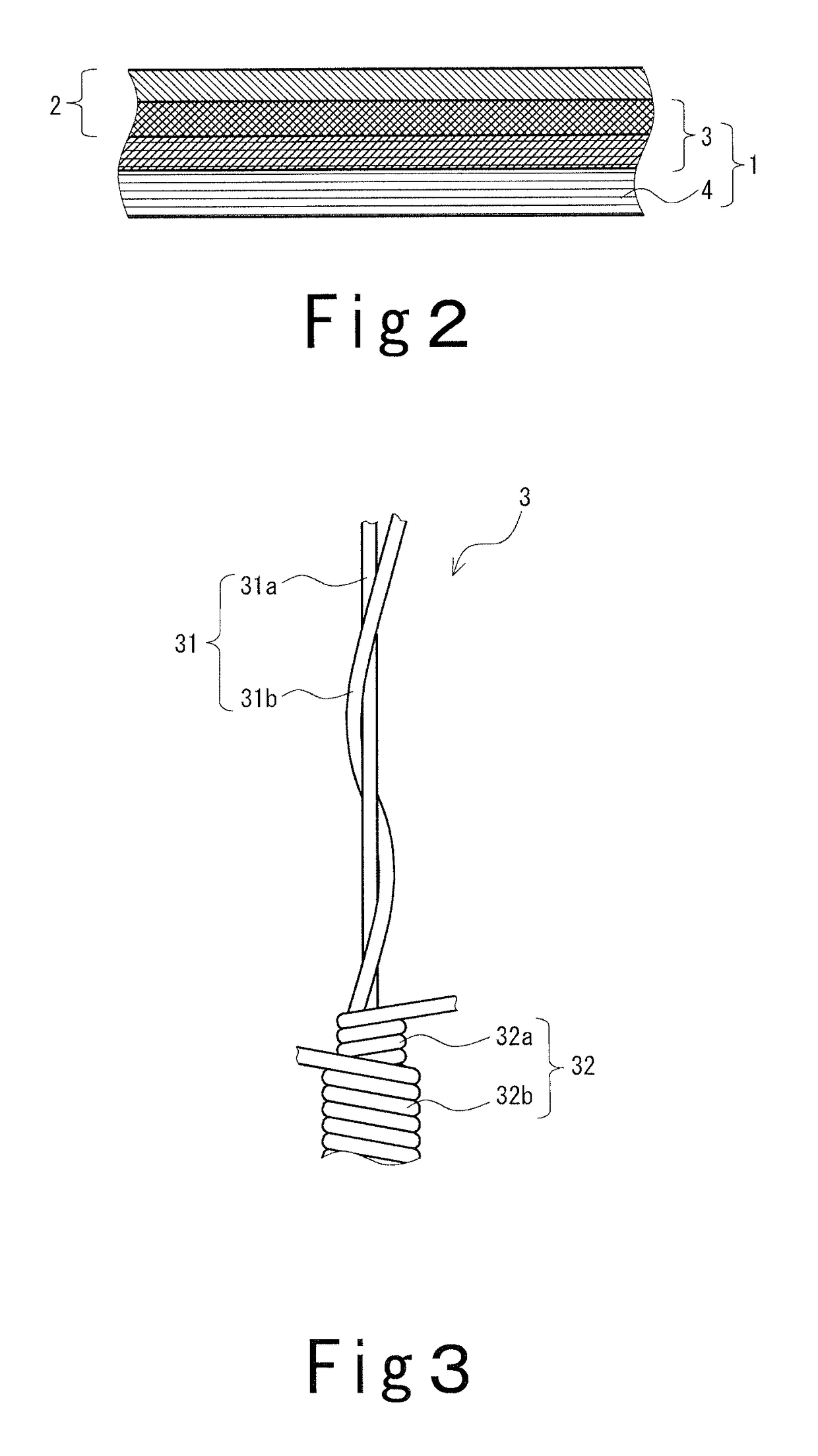

Cut-Resistant Glove

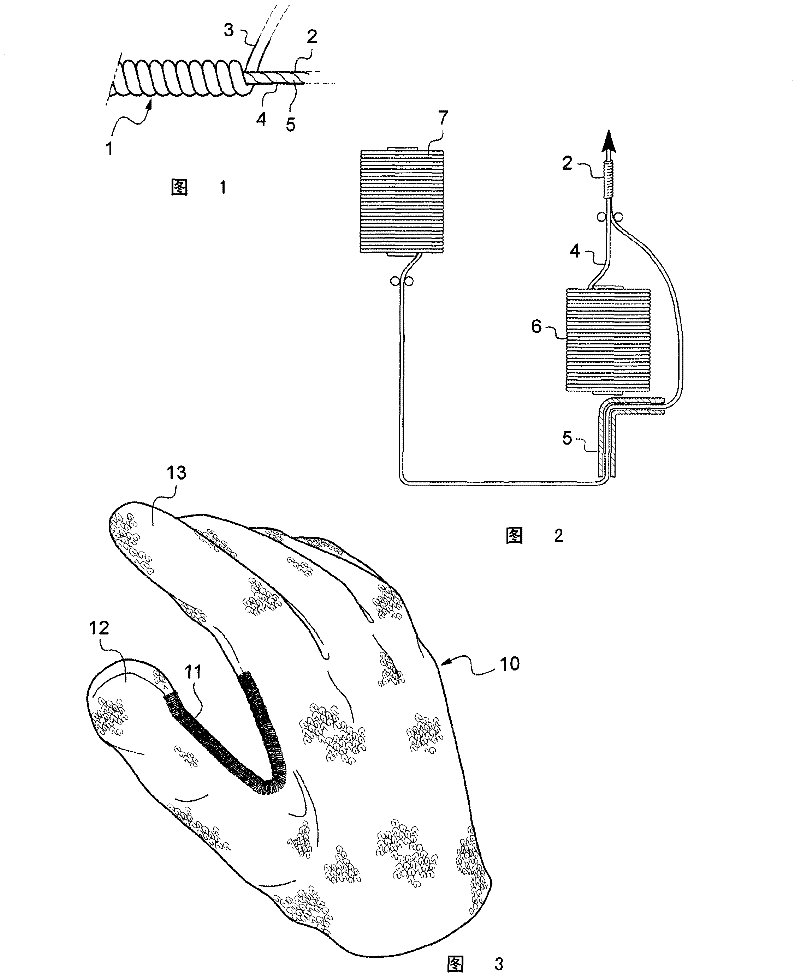

InactiveUS20080098501A1Increase elasticityFeel goodWeft knittingGlovesMoisture absorptionUltimate tensile strength

A cut-resistant glove is provided which is formed of a composite yarn comprising a core and a covering layer formed by wrapping a covering fiber around the core, the core being composed of a metal thin wire and an attending yarn comprising a filament yarn, the surface of which is coated with a rubber or a resin. The cut-resistant glove is excellent not only in moisture absorption property, putting-on-feeling, use feeling and workability in the state of being put on, but also in non-slip property, water proofness, strength and cut-resistant property.

Owner:SHOWA GLOVE

Cut-resistant gloves containing fiberglass and para-aramid

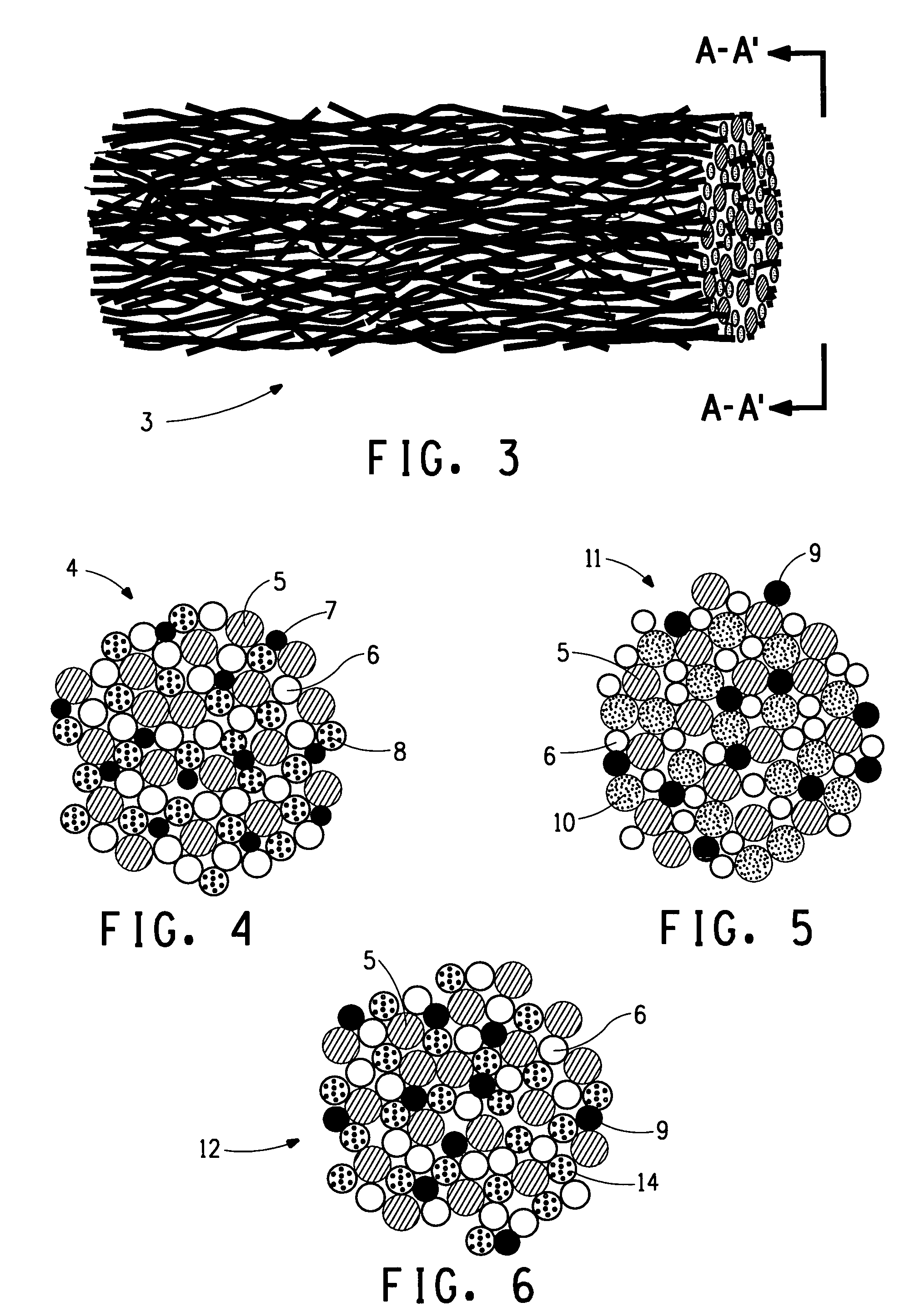

This invention relates to a cut-resistant knit glove comprising:a) cut-resistant composite yarn having a core yarn and at least one first wrapping yarn helically wrapped around the core yarn, the core yarn including at least one 50 to 200 denier (56 to 220 dtex) glass fiber filament yarn and the first wrapping yarn being one 100 to 600 denier (110 to 680 dtex) para-aramid yarn;b) companion yarn selected from the group consisting of aliphatic polyamide, polyester, and mixtures thereof; andc) lining yarn comprising a composite yarn of from 100 to 500 denier (110 to 560 dtex), the composite yarn having an elastomeric yarn core comprising at least one elastomeric yarn and at least one second wrapping yarn helically wrapped around the yarn core, the second wrapping yarn including at least one 20 to 300 denier (22 to 340 dtex) yarn selected from the group consisting of aliphatic polyamide, polyester, natural fibers, cellulosic fibers, and mixtures thereof;wherein the cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

Cut-resistant gloves containing fiberglass and para-aramid

This invention relates to a cut-resistant knit glove comprising:a) cut-resistant composite yarn having a core comprising at least two core yarns and at least one first wrapping yarn helically wrapped around the core, the core yarns including at least one 50 to 200 denier (56 to 220 dtex) glass fiber filament yarn and at least one 100 to 600 denier (110 to 680 dtex) para-aramid yarn, the first wrapping yarn including at least one 20 to 300 denier (22 to 340 dtex) yarn selected from the group consisting of aliphatic polyamide, polyester, and mixtures thereof;b) companion yarn selected from the group consisting of aliphatic polyamide, polyester, and mixtures thereof; andc) lining yarn comprising a composite yarn of from 100 to 500 denier (110 to 560 dtex), the composite yarn having an elastomeric yarn core comprising at least one elastomeric yarn and at least one second wrapping yarn helically wrapped around the yarn core, the second wrapping yarn including at least one 20 to 300 denier (22 to 340 dtex) yarn selected from the group consisting of aliphatic polyamide, polyester, natural fibers, cellulosic fibers, and mixtures thereof;wherein the cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

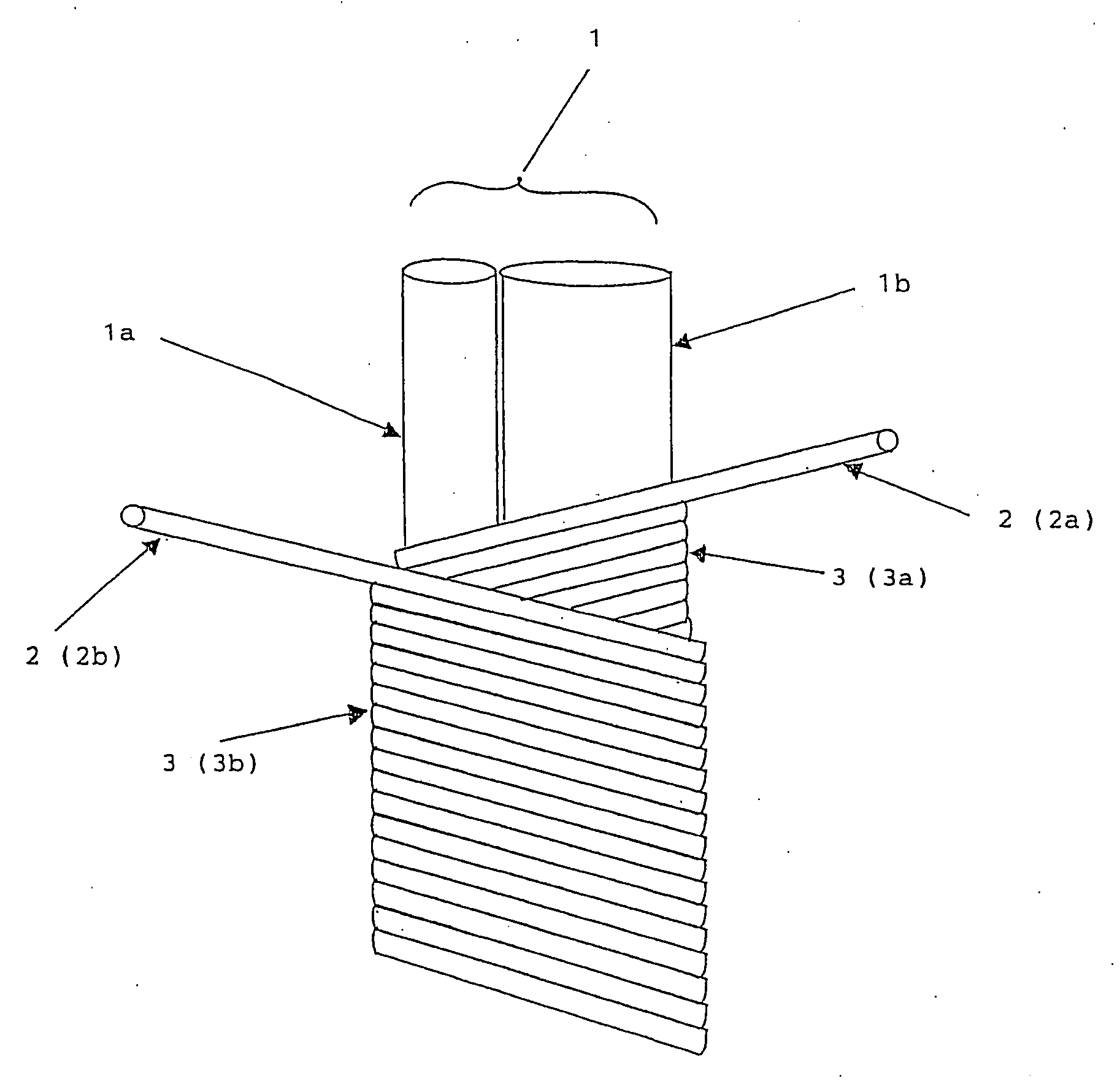

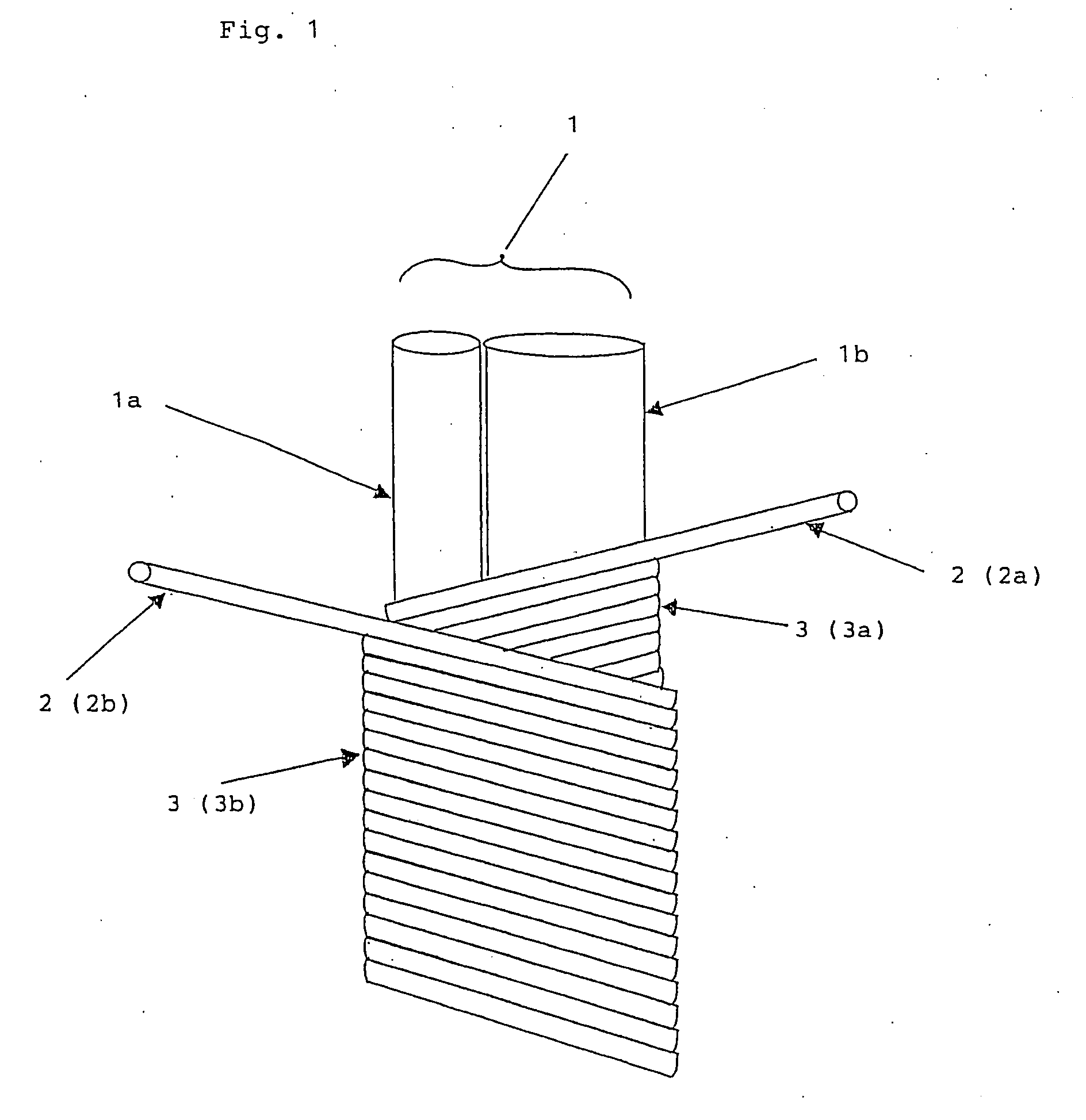

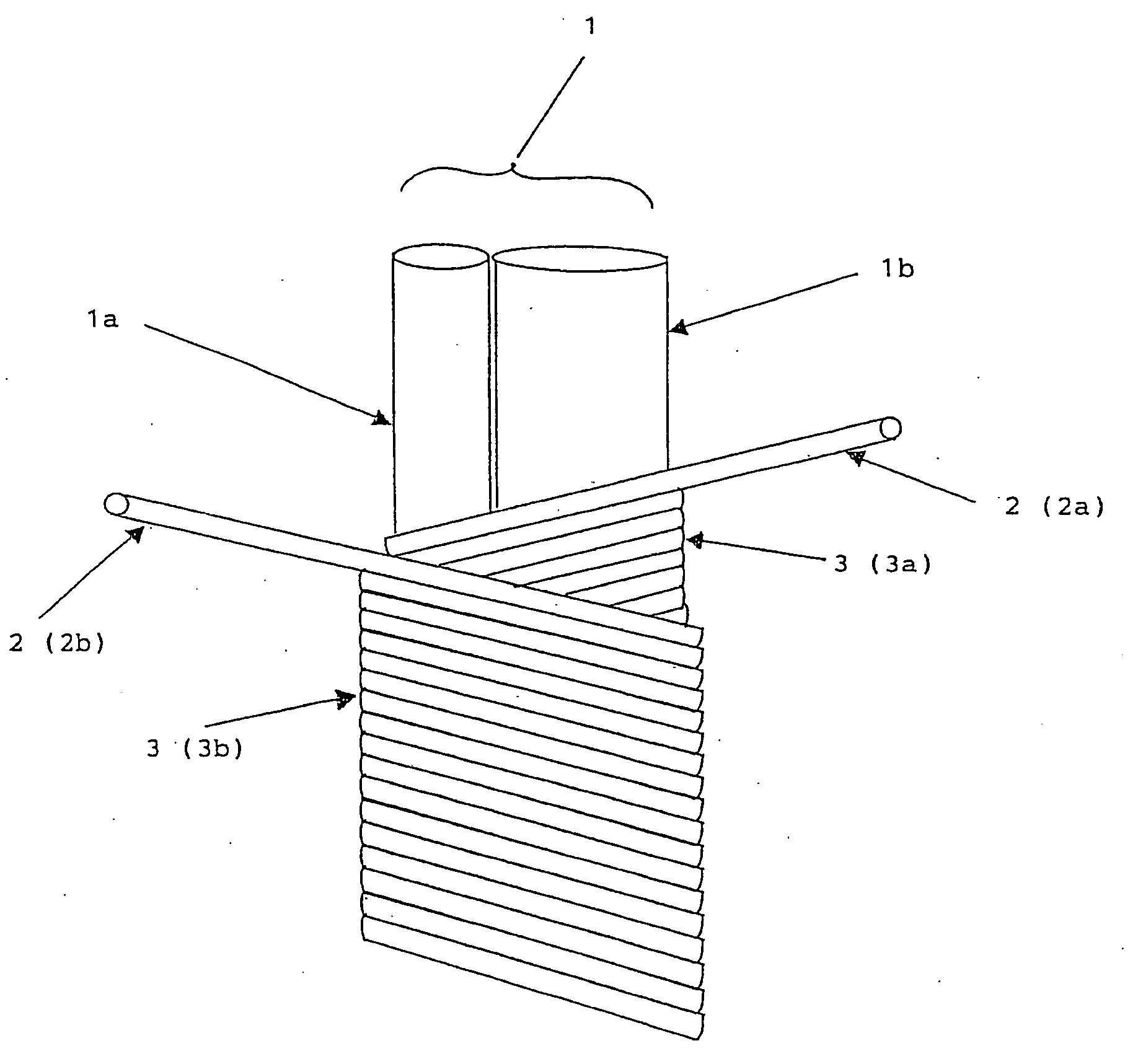

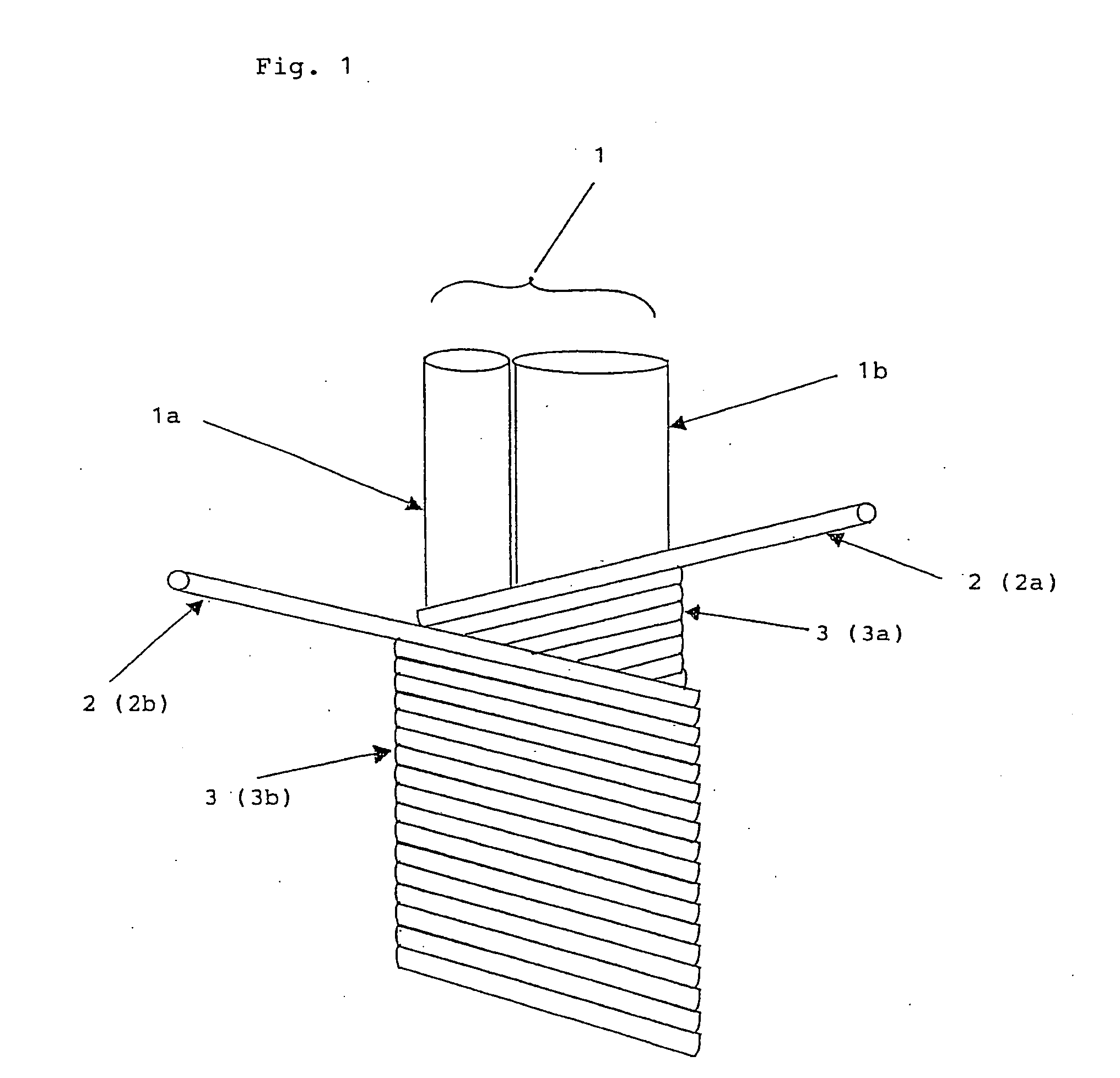

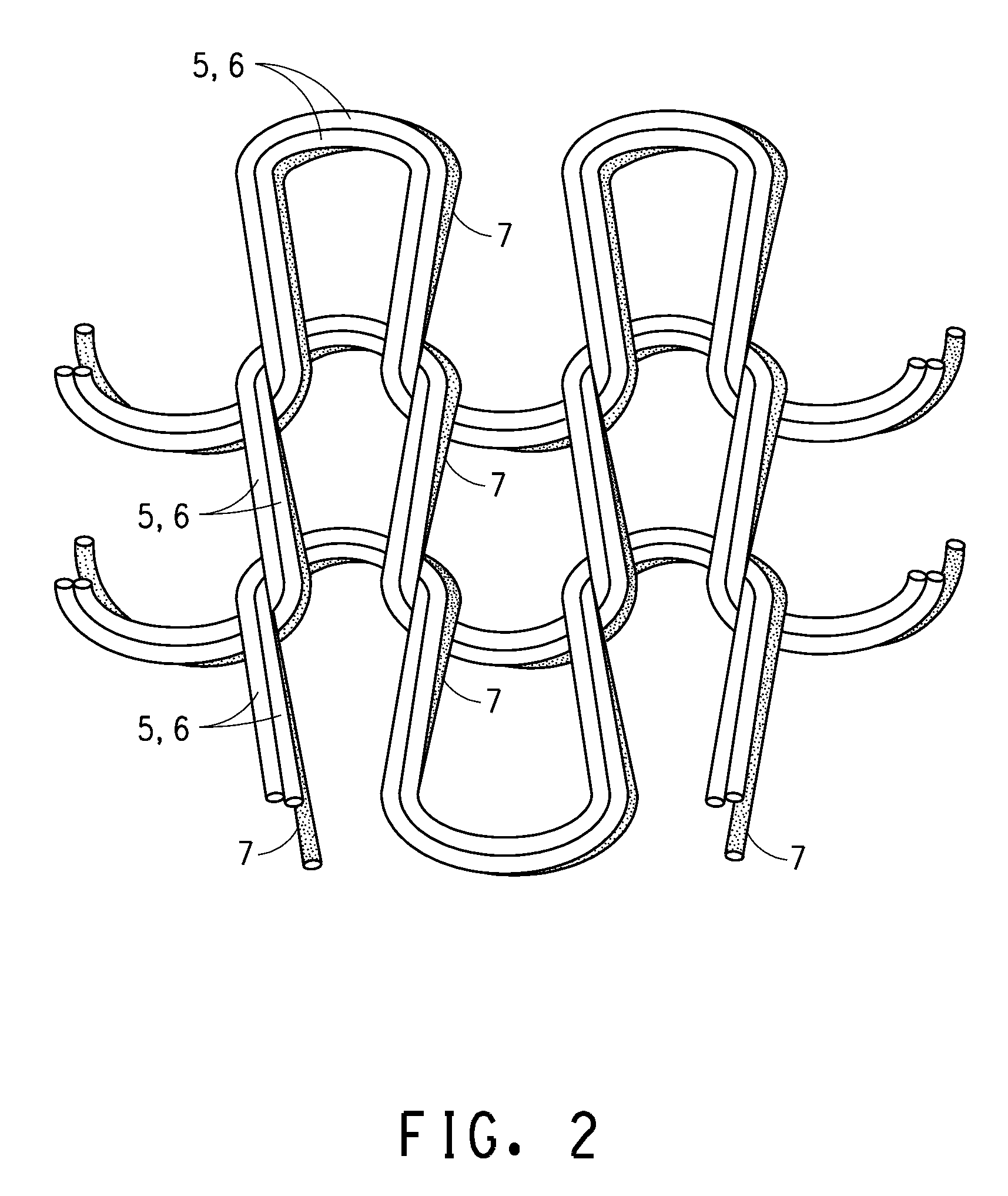

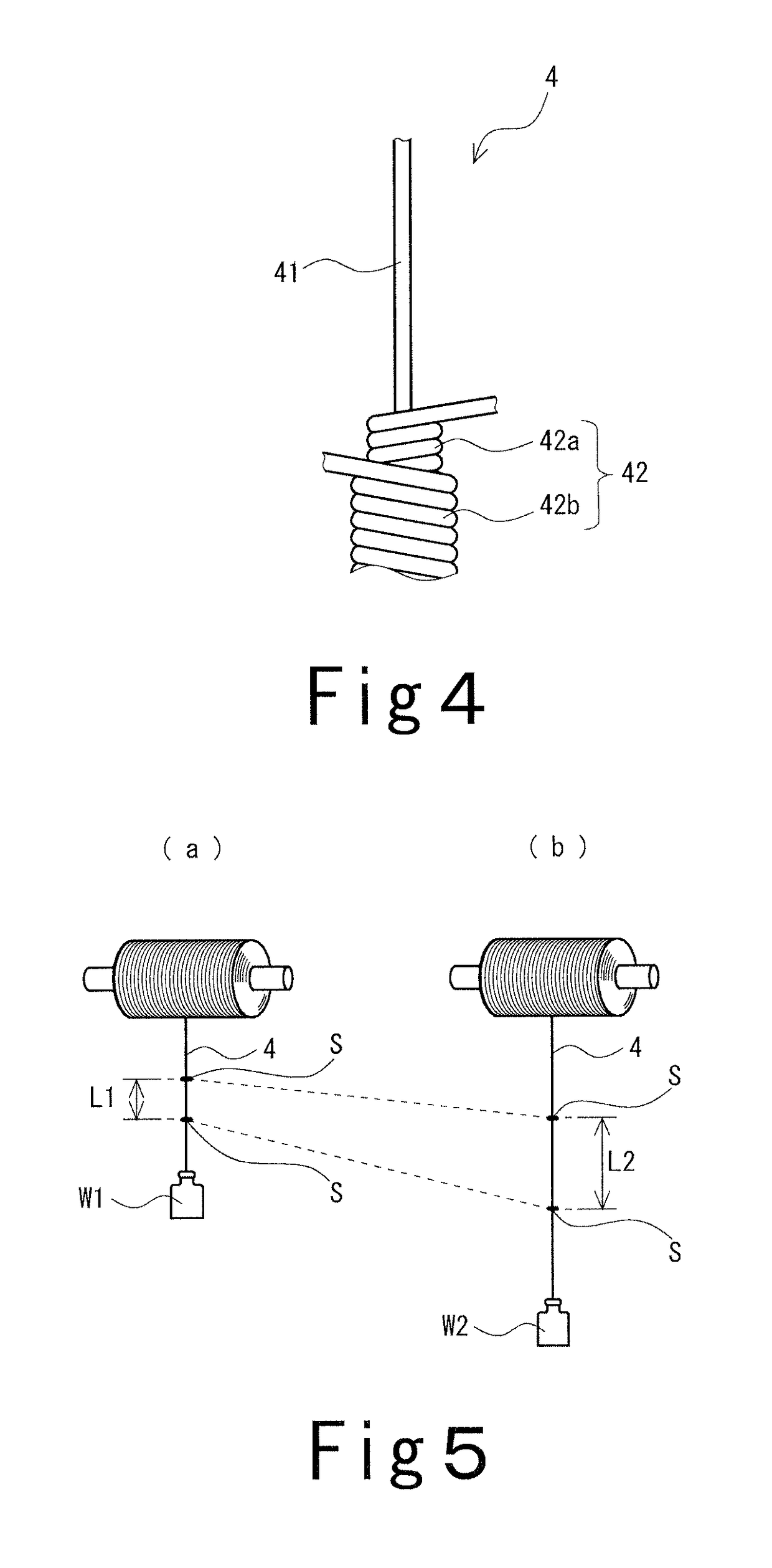

Composite Yarn and Cut-Resistant Glove Using the Yarn

A composite yarn is provided which comprises a core and a covering layer formed by wrapping a covering fiber around the core, the core being composed of a metal thin wire and an attending yarn comprising a filament yarn, wherein the attending yarn is wound around the metal thin wire at 5 to 60 turns per meter of the metal thin wire. A cut-resistant glove formed of the composite yarn is also provided. The composite yarn of the present invention is preferably usable for protective products such as protective fabrics, protective clothes, protective aprons and protective gloves used for protecting workers and a cut-resistant glove formed of the composite fiber is excellent not only in moisture absorption property, but also in putting-on-feeling, use feeling and workability in the state of being put on.

Owner:SHOWA GLOVE

Cut-resistant gloves containing fiberglass and para-aramid

This invention relates to a cut-resistant knit glove comprisinga) cut-resistant composite yarn having a core comprising at least two core yarns and at least one first wrapping yarn helically wrapped around the core, the core yarns including at least one 50 to 400 denier (56 to 440 dtex)glass fiber filament yarn and at least one 200 to 800 denier (220 to 890 dtex) para-aramid yarn, the first wrapping yarn including at least one 100 to 800 denier (110 to 890 dtex) yarn selected from the group consisting of aliphatic polyamide, polyester, and mixtures thereof;b) companion yarn of 200 to 1600 denier (220 to 1800 dtex) selected from the group consisting of aliphatic polyamide, polyester, natural fiber, cellulosic fiber, and mixtures thereof; andc) lining yarn comprising a composite yarn of from 500 to 1200 denier (560 to 1300 dtex) comprising aliphatic polyamide fiber, polyester fiber, natural fiber, cellulosic fiber, and mixtures thereof; and wherein the cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

Cut-resistant gloves containing fiberglass and para-aramid

A cut-resistant knit glove comprising cut-resistant composite yarn, companion yarn and lining yarn. The cut-resistant composite yarn having a core comprising at least two core yarns and at least one first wrapping yarn helically wrapped around the core. The companion yarn comprising para-aramid. The lining yarn comprises either (i) composite yarn having an elastomeric yarn core and at least one second wrapping yarn helically wrapped around the yarn core or (ii) yarn comprising aliphatic polyamide fiber, polyester fiber, natural fiber, cellulosic fiber, and mixtures thereof. The cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

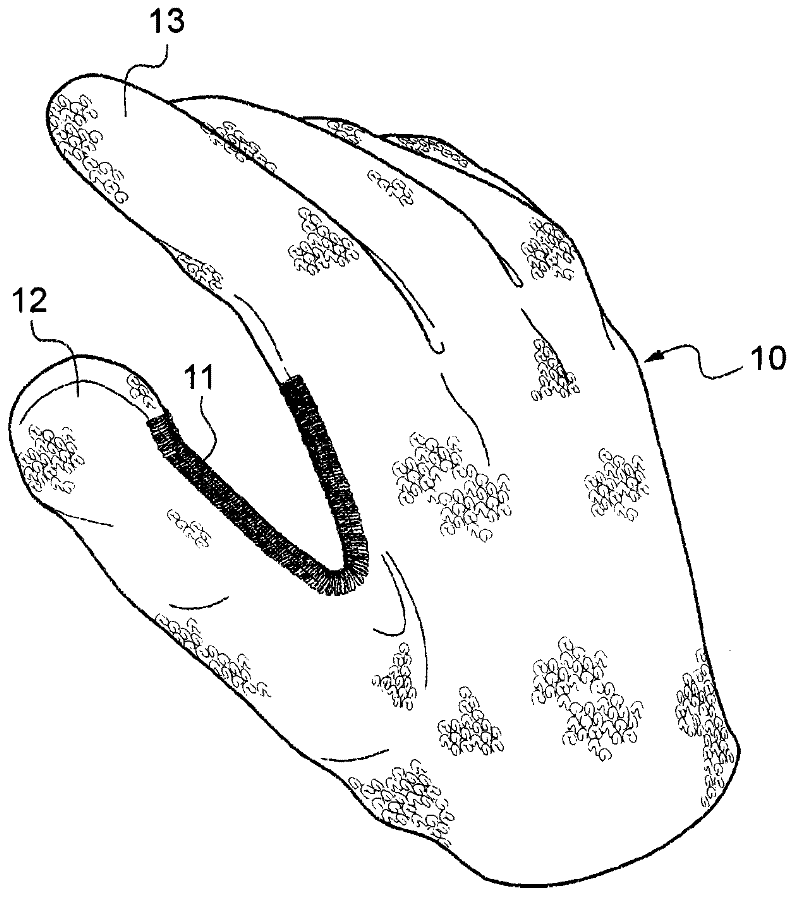

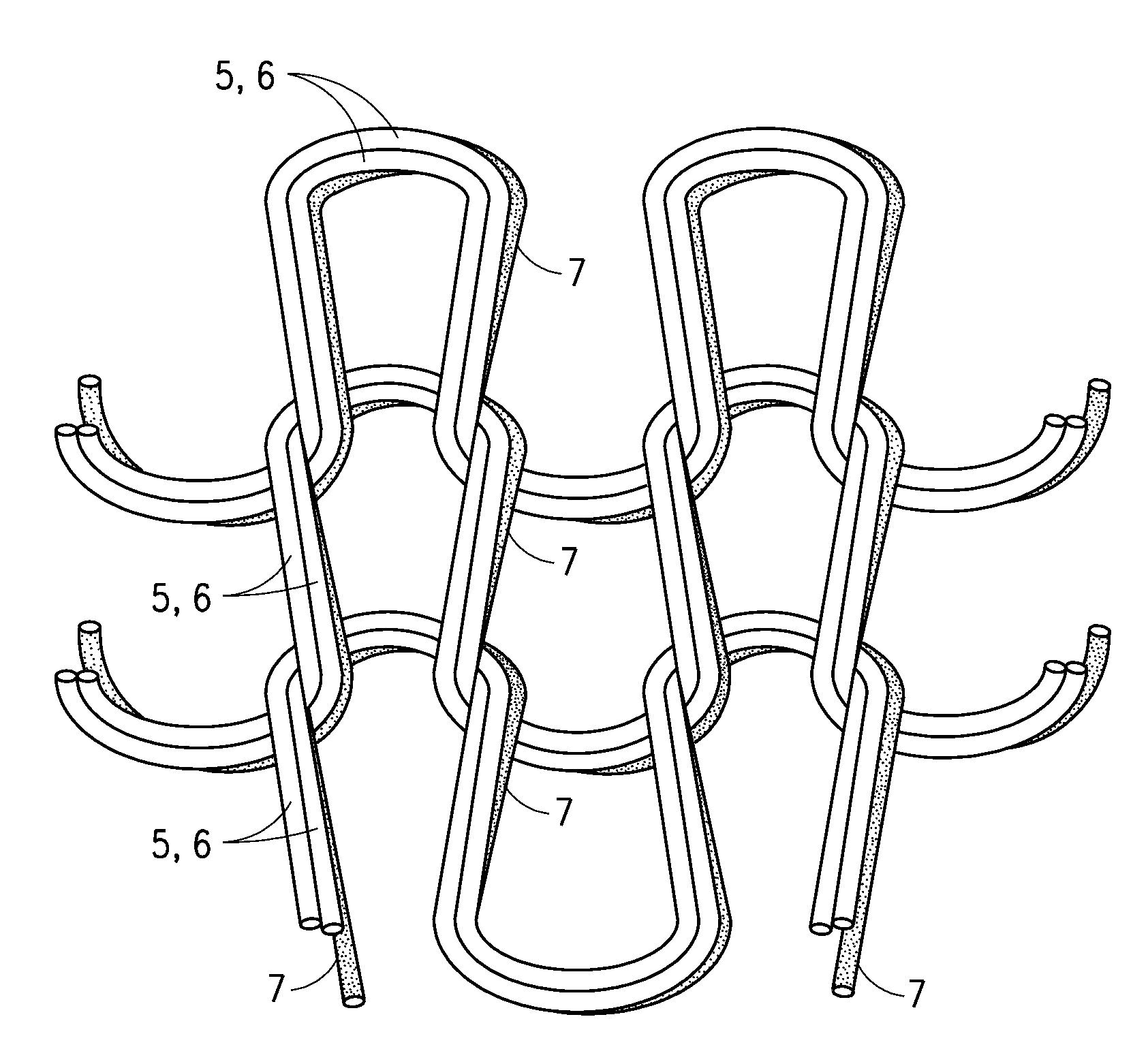

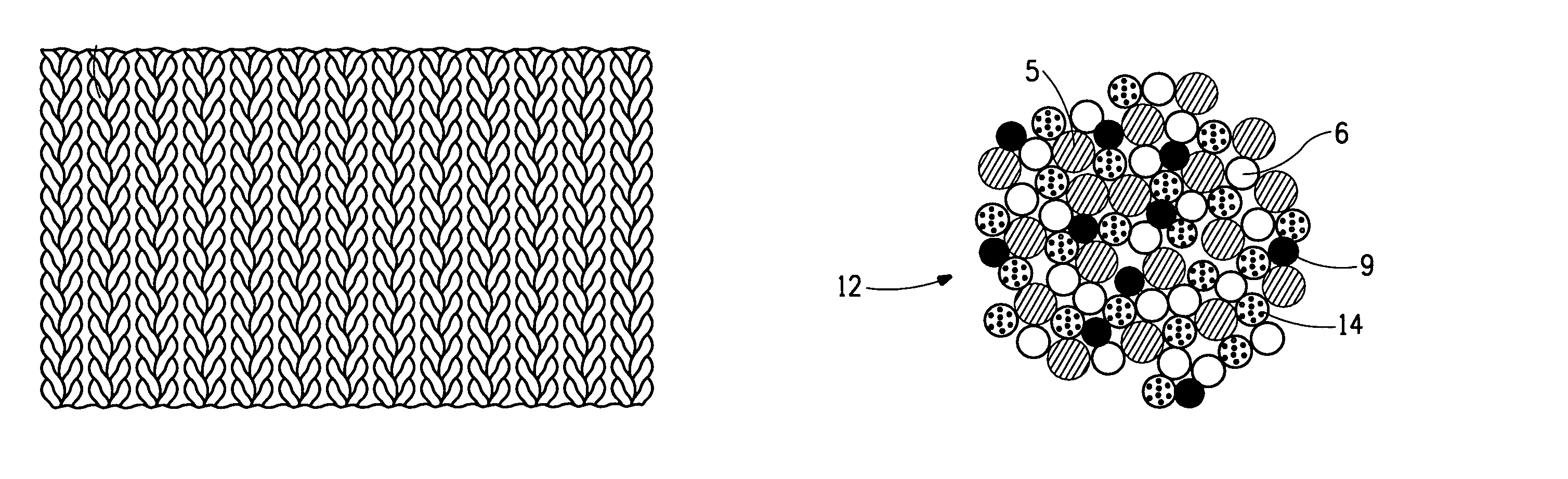

Knitted cut-resistant glove, without fiberglass

The invention relates to a knitted cut-resistant glove, without fiberglass. This glove (10) is knitted using three yarns, that is, a first composite yarn prepared by wrapping one or more highly abrasion-resistant polyamide yarns on a composite core made by direct cabling of a stainless steel yarn and one or more highly abrasion-resistant polyamide yarns, a second polyamide elastane yarn, and a third para-aramid yarn, the double-sided knitting being carried out by plating so that the first and second yarns are located on a first side of the knit while the para-aramid yarn is located on the second side of the knit.

Owner:HONEYWELL SAFETY PROD EURO

Cut-resistant gloves containing fiberglass and para-aramid

This invention relates to a cut-resistant knit glove comprising:a) cut-resistant composite yarn having a core yarn and at least one first wrapping yarn helically wrapped around the core yarn, the core yarn including at least one 50 to 200 denier (56 to 220 dtex) glass fiber filament yarn and the first wrapping yarn being one 100 to 600 denier (110 to 680 dtex) para-aramid yarn;b) companion yarn selected from the group consisting of aliphatic polyamide, polyester, and mixtures thereof; andc) lining yarn comprising a composite yarn of from 100 to 500 denier (110 to 560 dtex), the composite yarn having an elastomeric yarn core comprising at least one elastomeric yarn and at least one second wrapping yarn helically wrapped around the yarn core, the second wrapping yarn including at least one 20 to 300 denier (22 to 340 dtex) yarn selected from the group consisting of aliphatic polyamide, polyester, natural fibers, cellulosic fibers, and mixtures thereof;wherein the cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

Cut-resistant gloves containing fiberglass and para-aramid

This invention relates to a cut-resistant knit glove comprisinga) cut-resistant composite yarn having a core yarn and at least one first wrapping yarn helically wrapped around the core yarn, the core yarn including at least one 50 to 400 denier (56 to 440 dtex) glass fiber filament yarn and the first wrapping yarn being one 100 to 600 denier (110 to 680 dtex) para-aramid yarn;b) companion yarn of 200 to 1600 denier (220 to 1800 dtex) selected from the group consisting of aliphatic polyamide, polyester, natural fiber, cellulosic fiber, and mixtures thereof; andc) lining yarn comprising a composite yarn of from 250 to 1200 denier (280 to 1300 dtex) comprising aliphatic polyamide fiber, polyester fiber, natural fiber, cellulosic fiber, and mixtures thereof; and wherein the cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

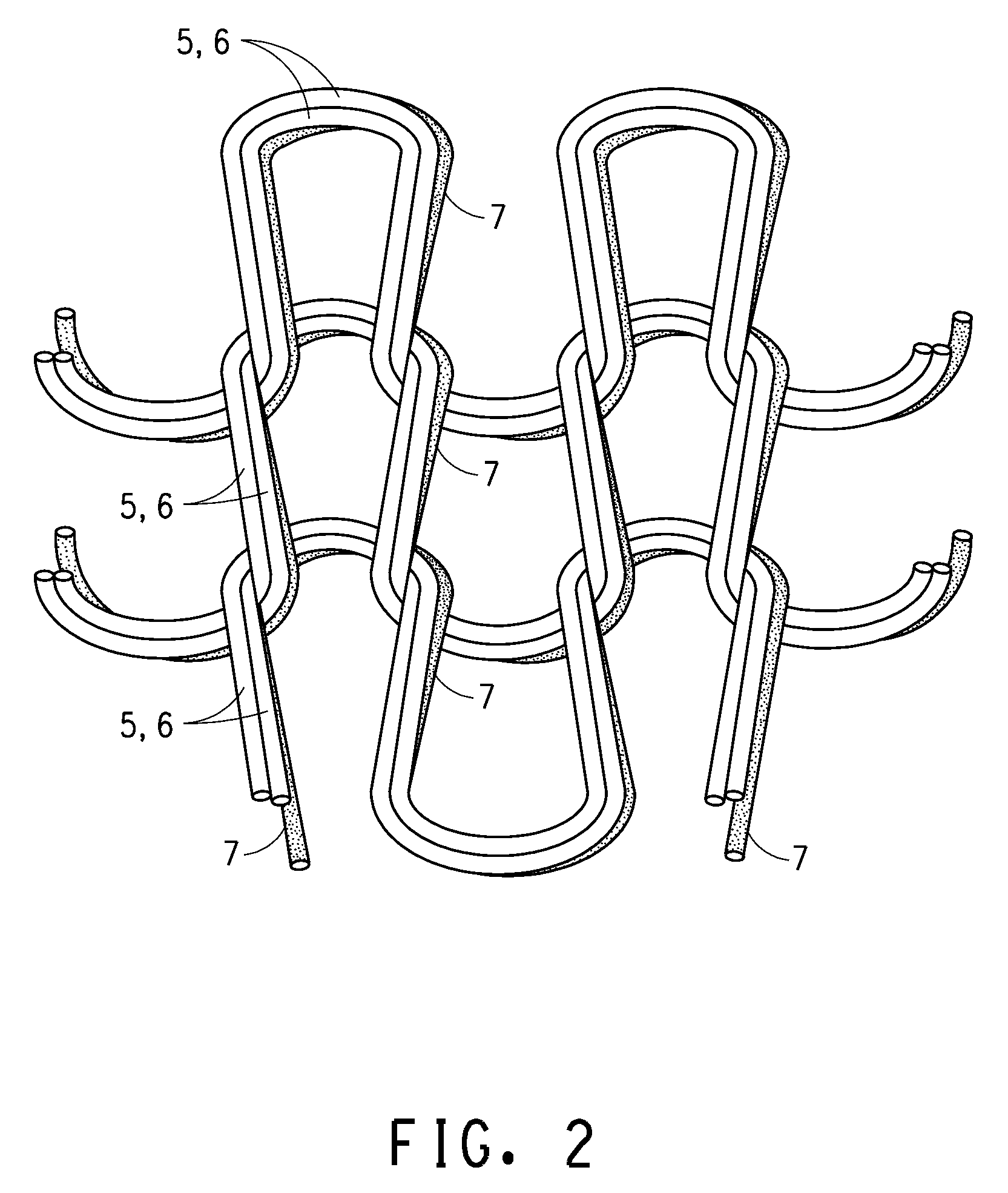

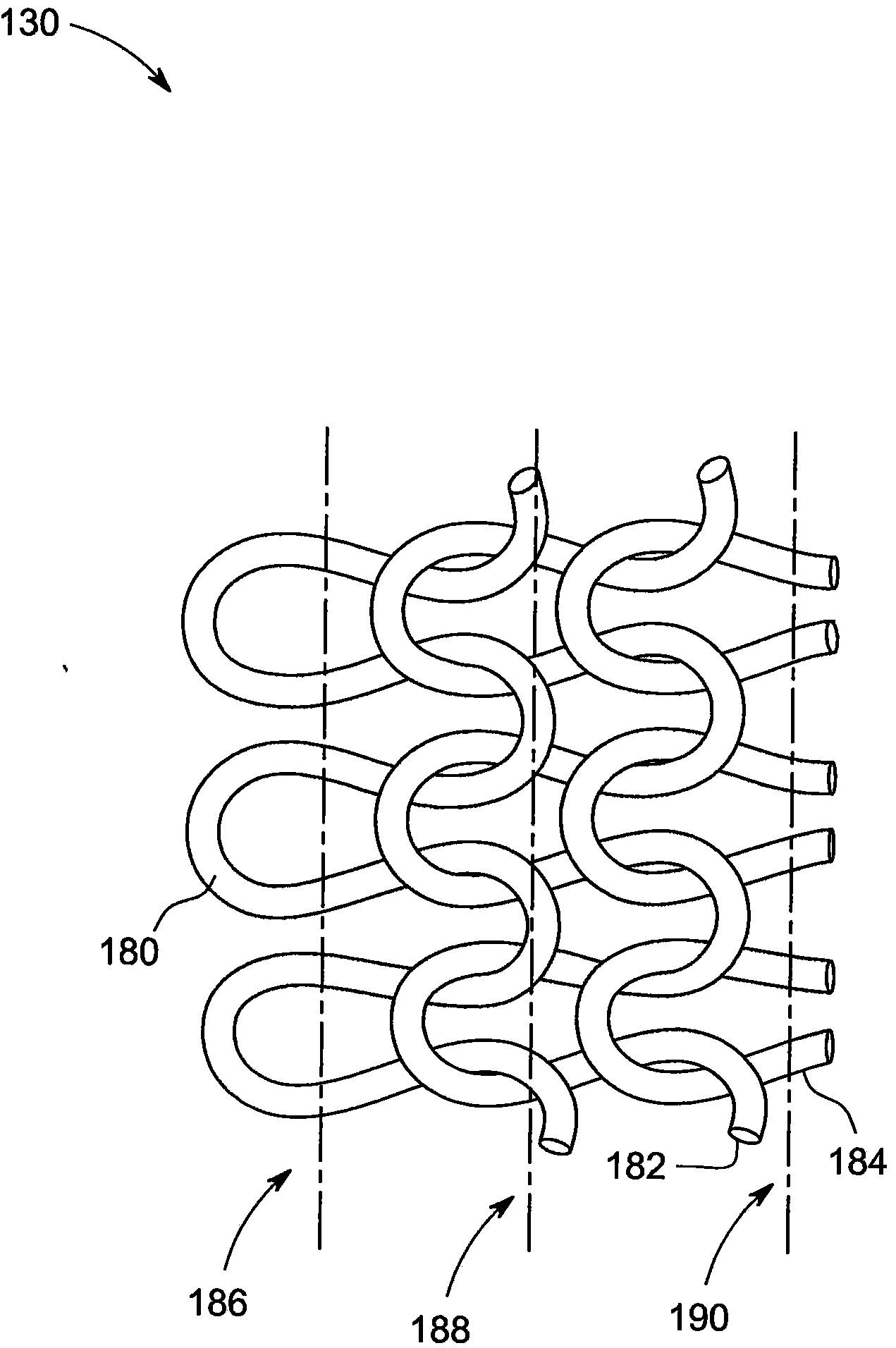

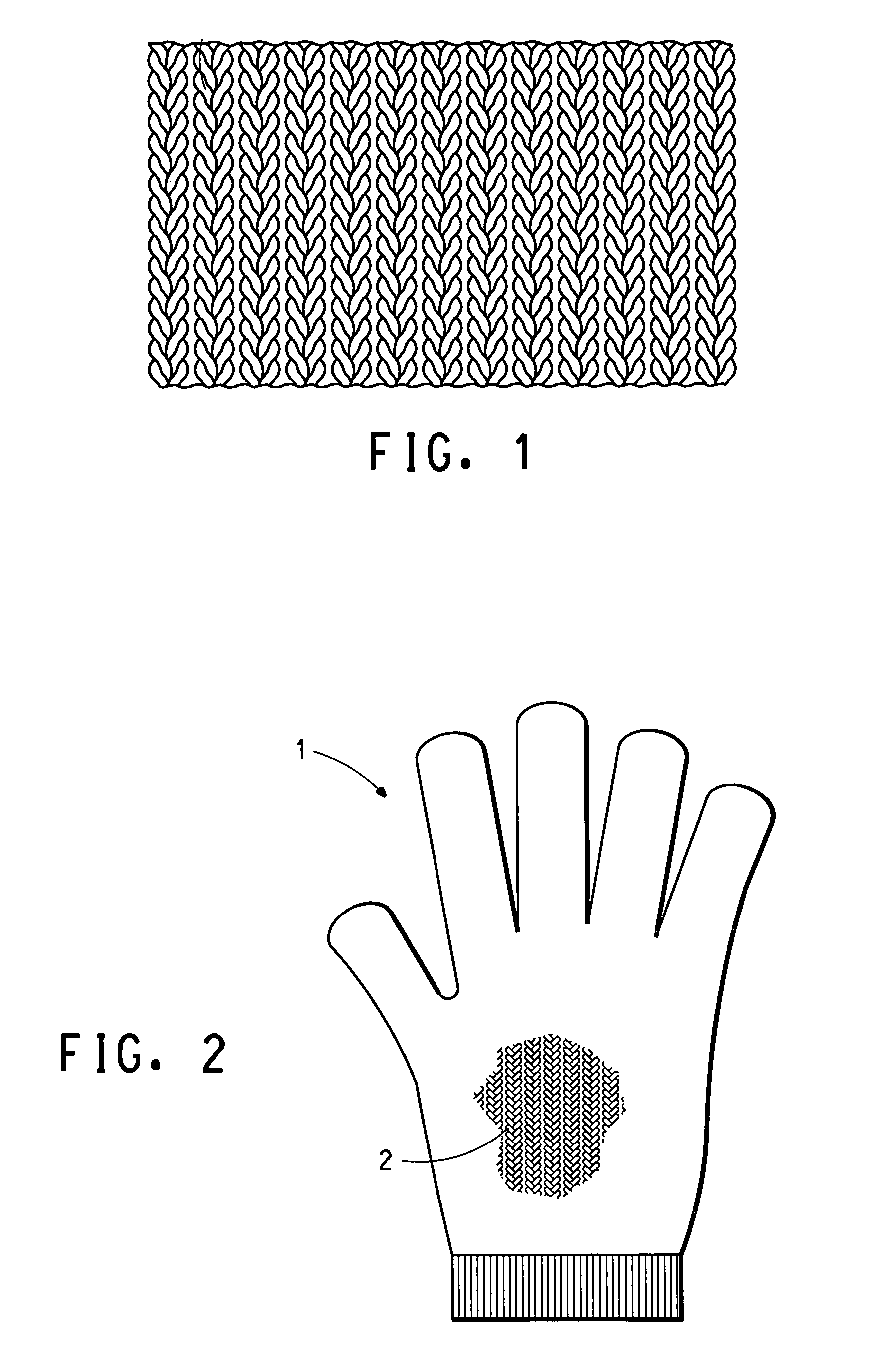

Plaited glove

A cut resistant glove is provided having an inner surface and an outer surface wherein the inner surface is adapted for contacting a hand of a user, and the outer surface is visible while the user is wearing the glove. The glove includes a two layer knit fabric of a plaited construction including a first layer on the inner surface and a second layer on the outer surface. The outer surface is constructed from non-stretchable, cut resistant yarn, wherein the yarn has filaments that are generally parallel to one another and the inner surface is constructed from a stretchable, elastic yarn.

Owner:BANOM

Cut-resistant gloves containing fiberglass and para-aramid

This invention relates to a cut-resistant knit glove comprisinga) cut-resistant composite yarn having a core yarn and at least one first wrapping yarn helically wrapped around the core yarn, the core yarn including at least one 50 to 400 denier (56 to 440 dtex) glass fiber filament yarn and the first wrapping yarn being one 100 to 600 denier (110 to 680 dtex) para-aramid yarn;b) companion yarn of 200 to 1600 denier (220 to 1800 dtex) selected from the group consisting of aliphatic polyamide, polyester, natural fiber, cellulosic fiber, and mixtures thereof; andc) lining yarn comprising a composite yarn of from 250 to 1200 denier (280 to 1300 dtex) comprising aliphatic polyamide fiber, polyester fiber, natural fiber, cellulosic fiber, and mixtures thereof; and wherein the cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

Cut-resistant gloves containing fiberglass and para-aramid

This invention relates to a cut-resistant knit glove comprisinga) cut-resistant composite yarn having a core comprising at least two core yarns and at least one first wrapping yarn helically wrapped around the core, the core yarns including at least one 50 to 400 denier (56 to 440 dtex)glass fiber filament yarn and at least one 200 to 800 denier (220 to 890 dtex) para-aramid yarn, the first wrapping yarn including at least one 100 to 800 denier (110 to 890 dtex) yarn selected from the group consisting of aliphatic polyamide, polyester, and mixtures thereof;b) companion yarn of 200 to 1600 denier (220 to 1800 dtex) selected from the group consisting of aliphatic polyamide, polyester, natural fiber, cellulosic fiber, and mixtures thereof; andc) lining yarn comprising a composite yarn of from 500 to 1200 denier (560 to 1300 dtex) comprising aliphatic polyamide fiber, polyester fiber, natural fiber, cellulosic fiber, and mixtures thereof; and wherein the cut-resistant composite yarn, the companion yarn, and the lining yarn are co-knit in the glove with the lining yarn plated on the interior of the glove and the cut-resistant composite yarn and companion yarn forming the exterior of the glove.

Owner:DUPONT SAFETY & CONSTR INC

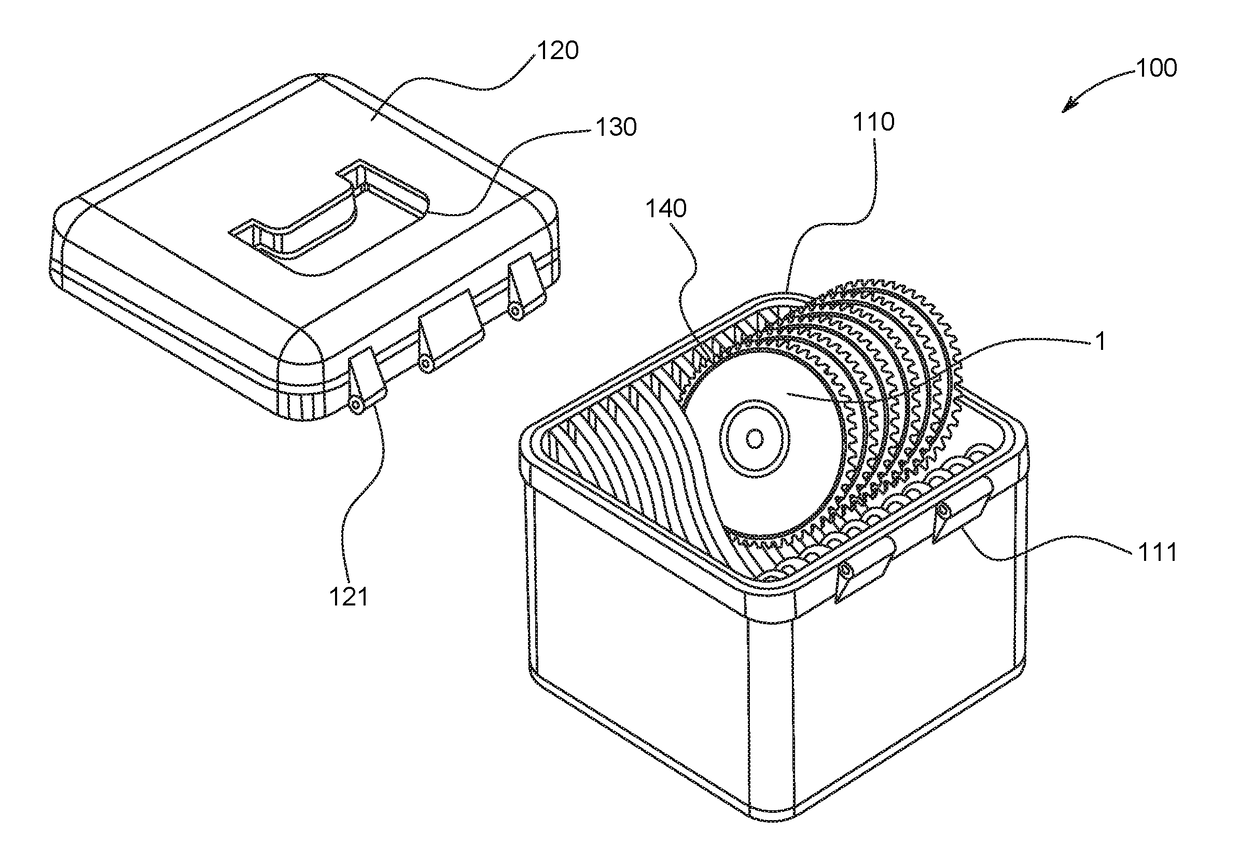

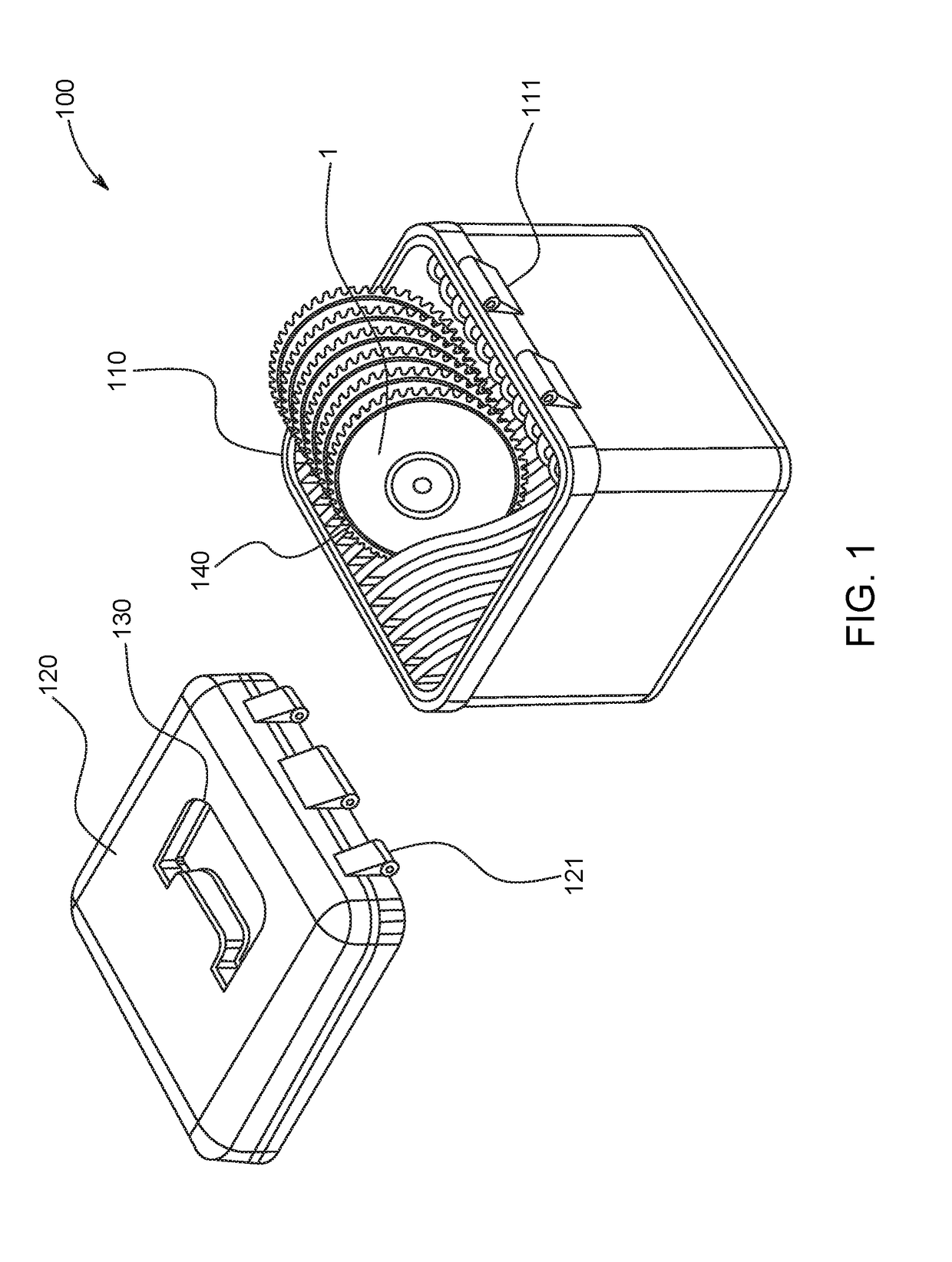

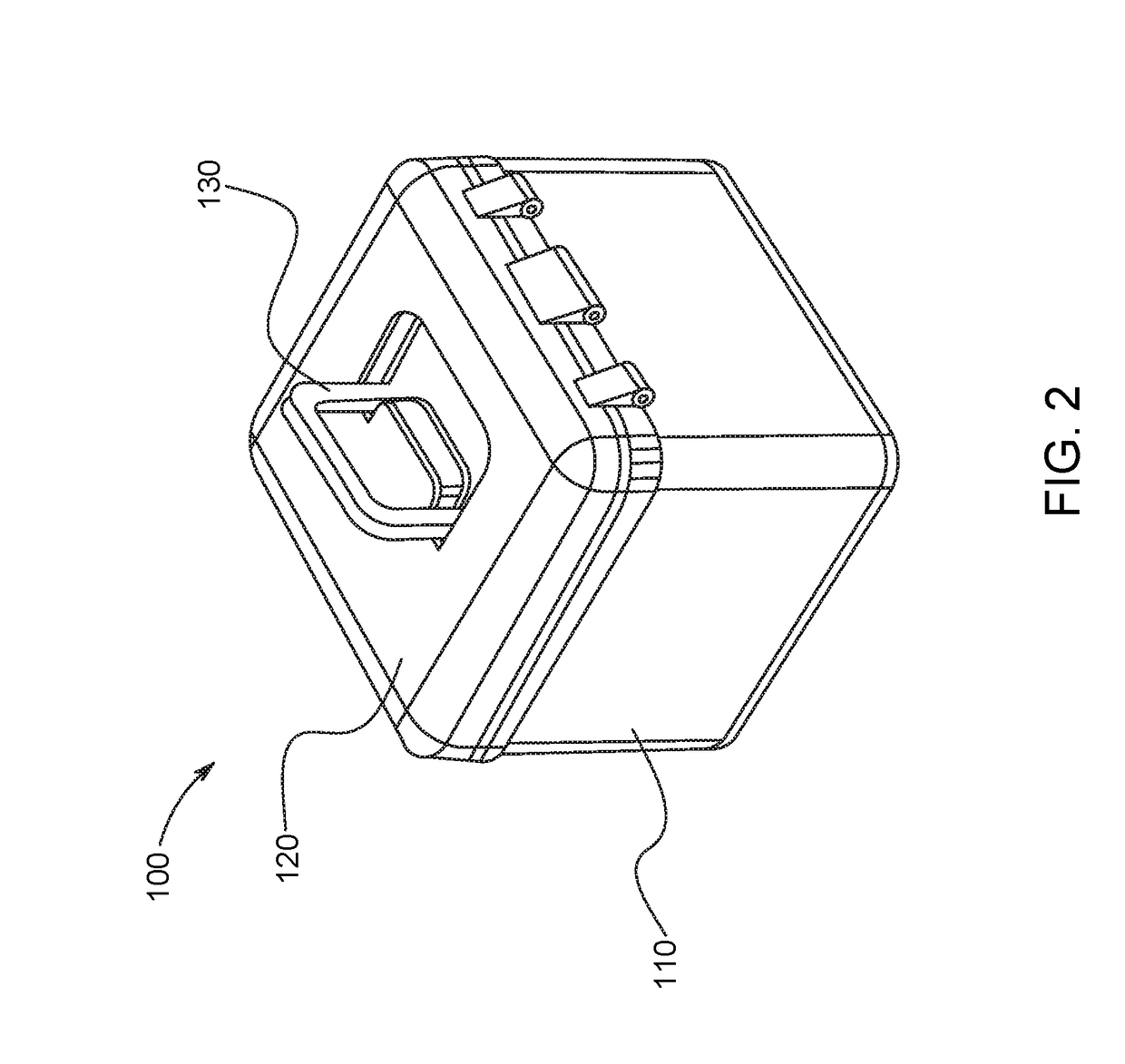

Saw blade caddy

InactiveUS20180222033A1Facilitates storage of and accessRemovable lids/coversLidsAramidBiomedical engineering

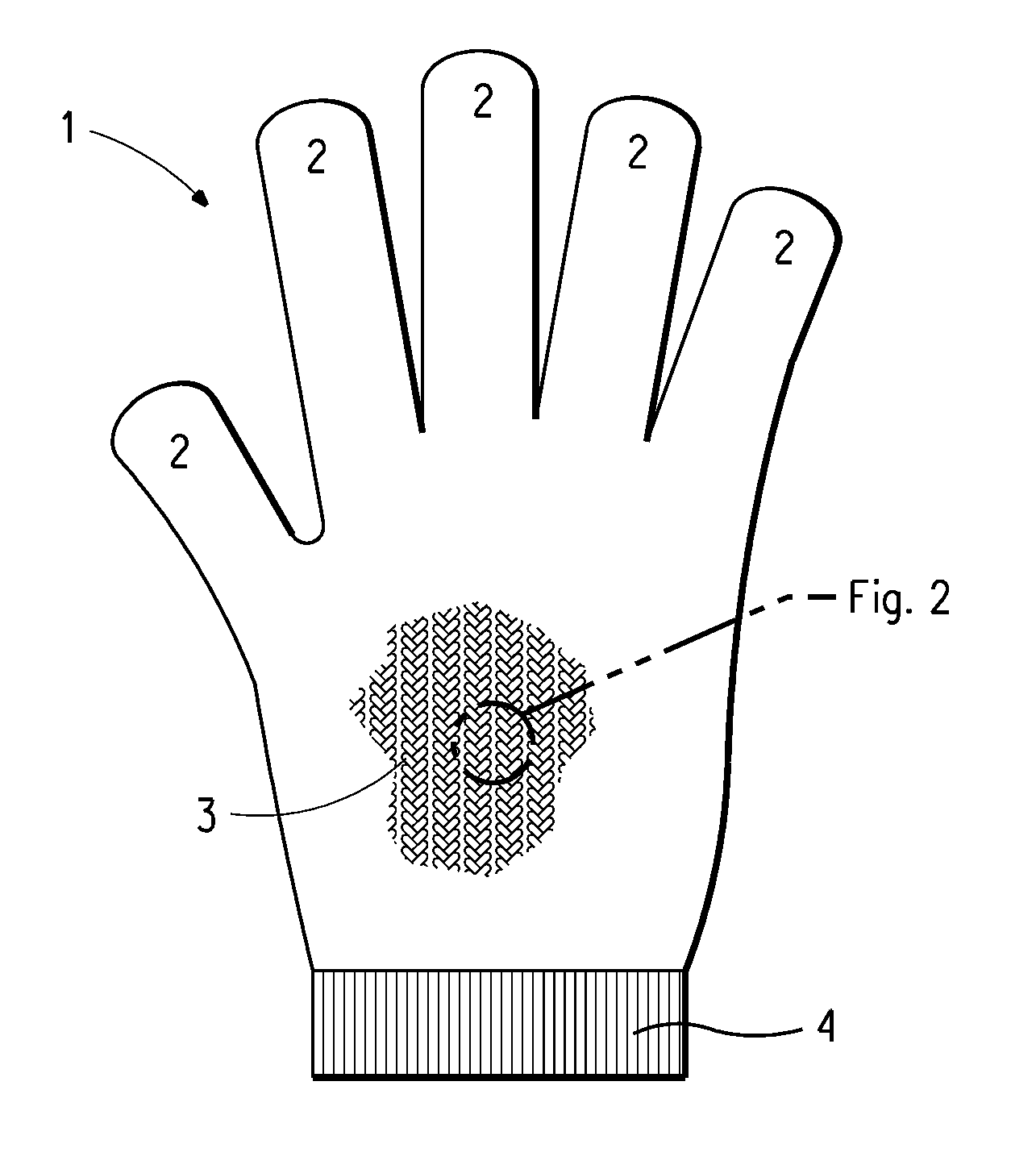

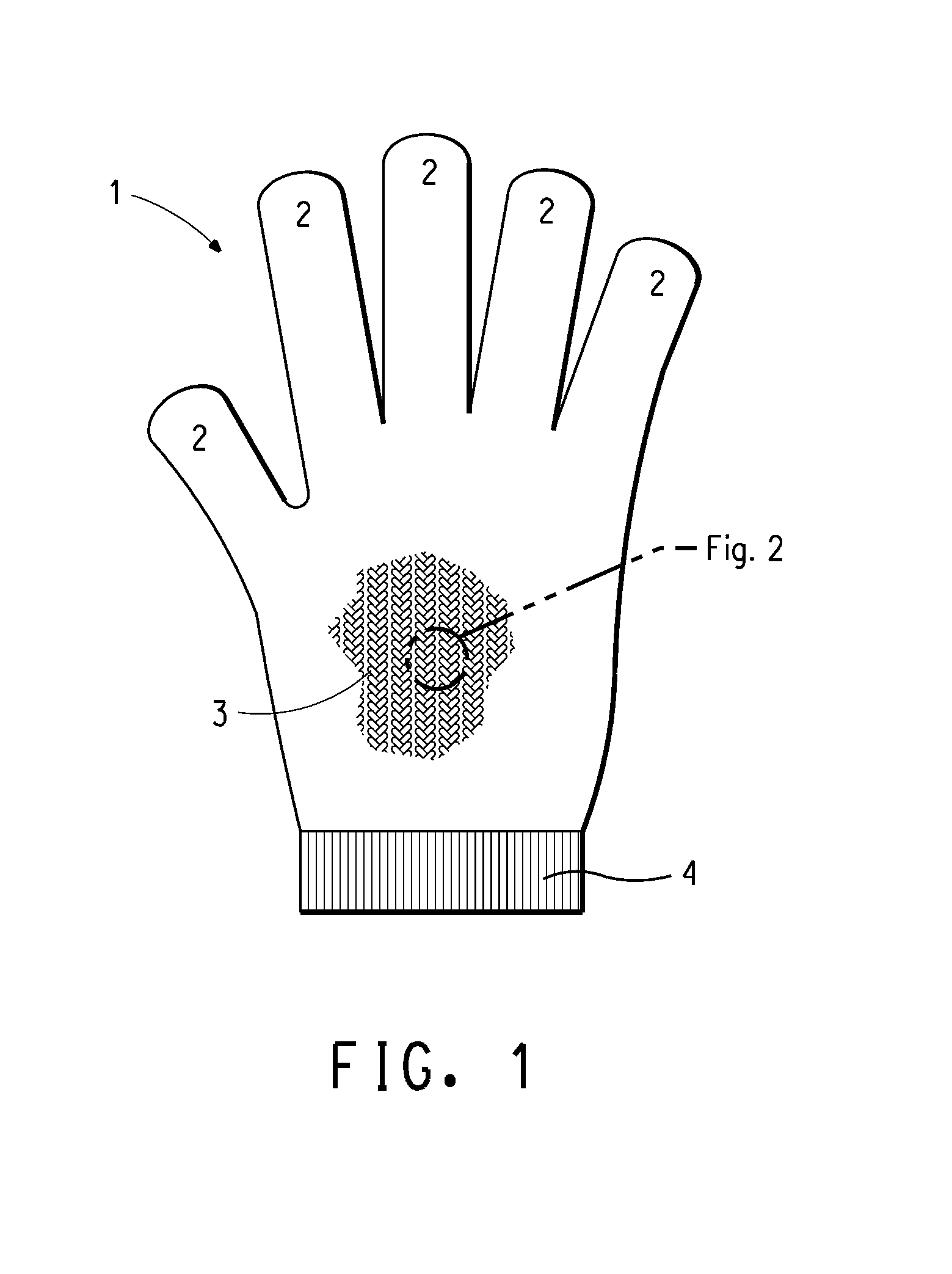

A disposable cut resistant glove, including a body, a plurality of fingers attached to the body, a thumb attached to the body, and a plurality of strips of para-aramid synthetic fiber disposed over and around the plurality of fingers and the thumb.

Owner:LIVELL TERRY

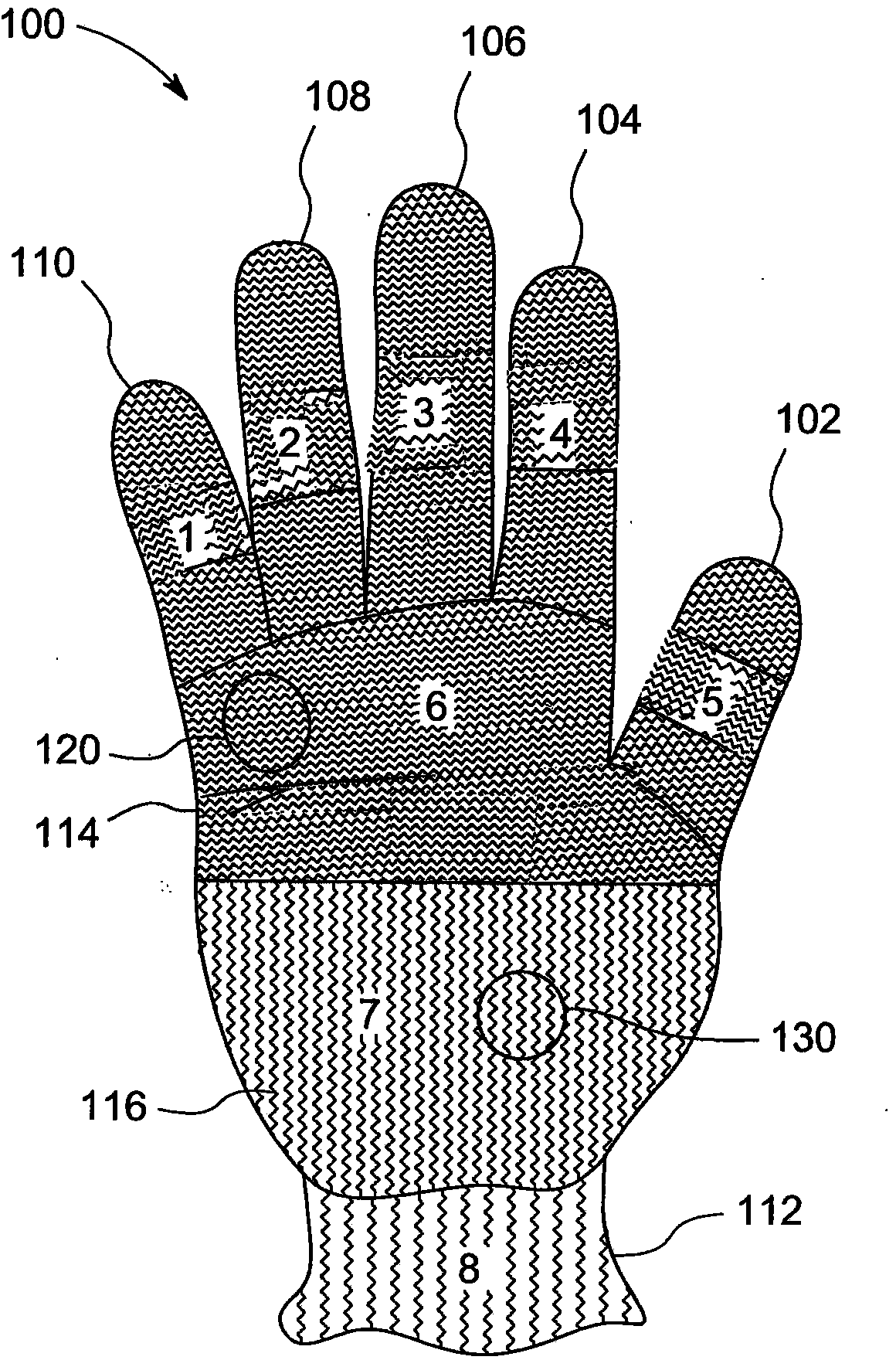

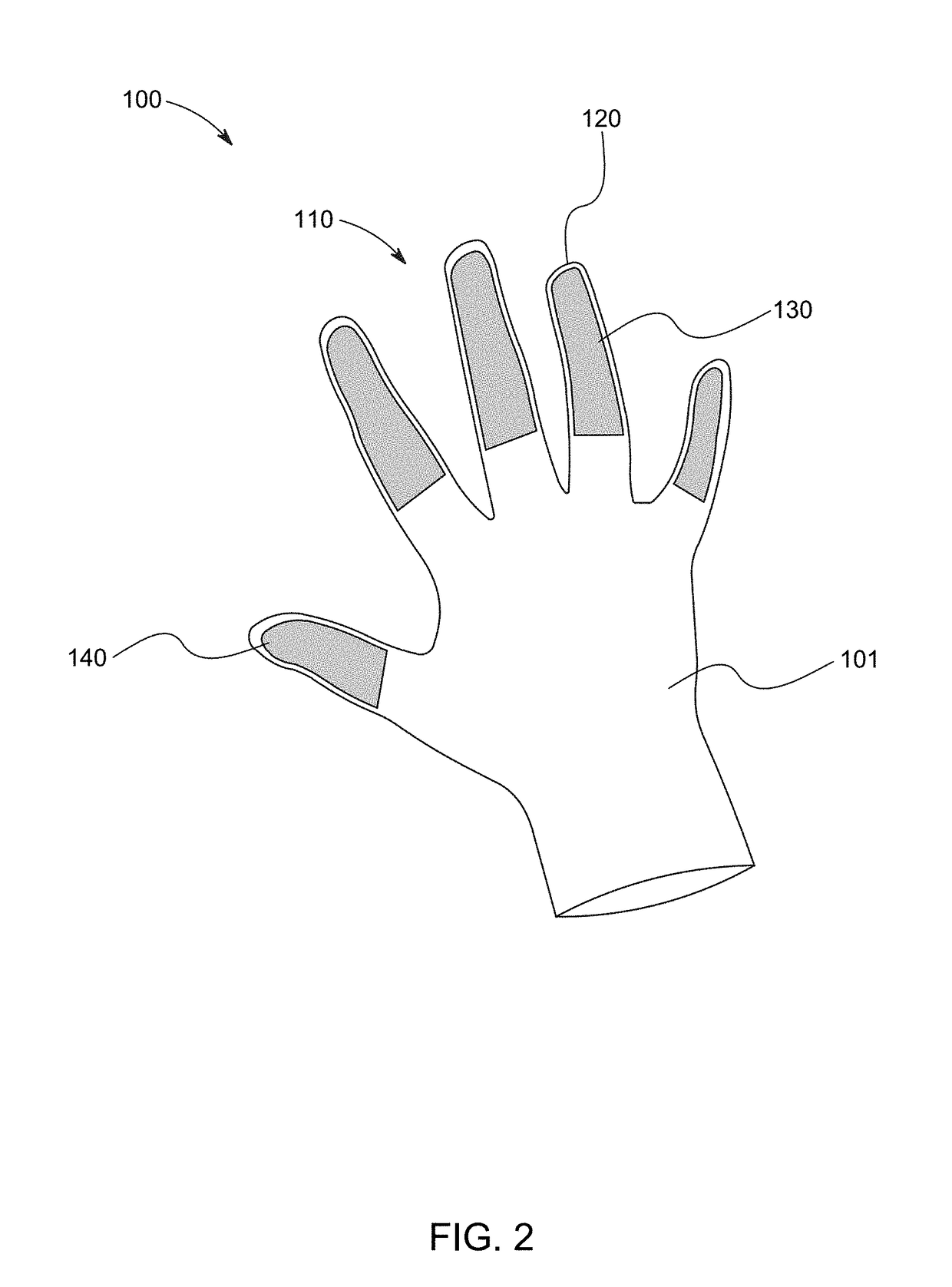

Zonal cut resistant glove

Owner:ANSELL

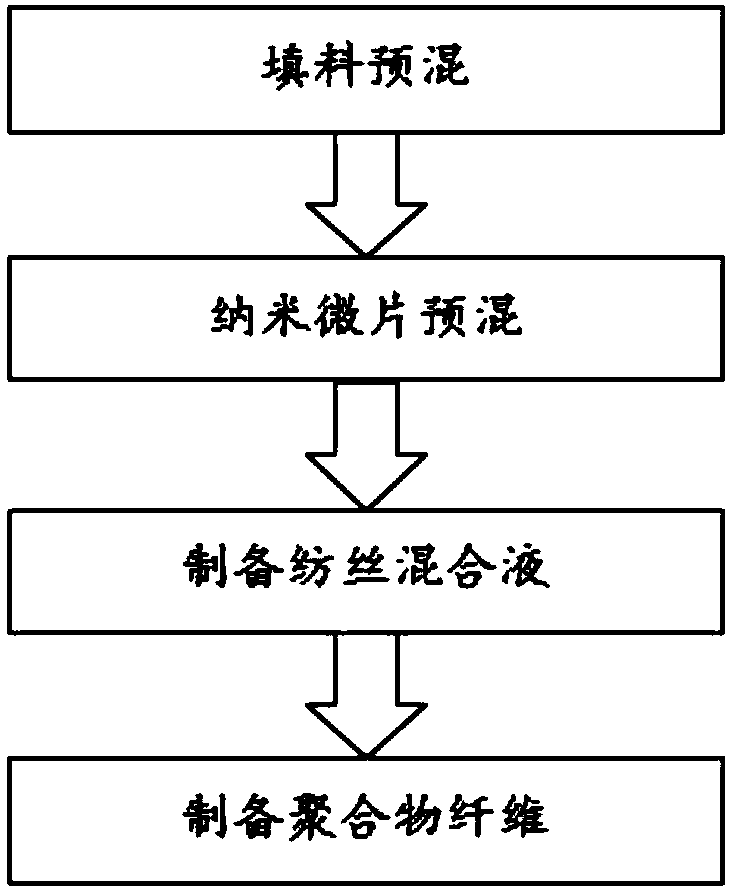

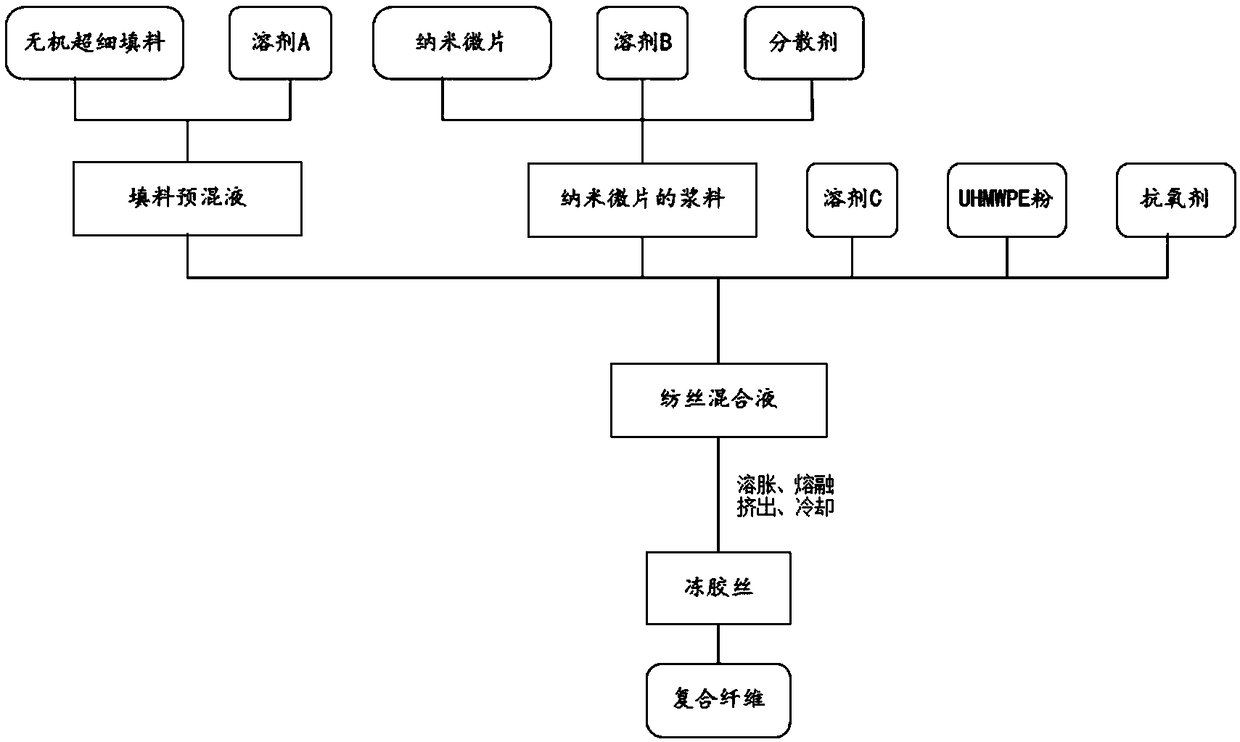

Polymeric fiber and preparation method thereof

InactiveCN109355726AEasy to prepareEasy to operateMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer scienceToughness

The invention provides a polymeric fiber and a preparation method thereof. The polymeric fiber comprises, by weight, 2-10% of an inorganic superfine filling material and 0.1-3% of nano microsheets; the inorganic superfine filling material comprises superfine micropowder and / or superfine fiber. The preparation method of the polymeric fiber, as a composite fiber, prepared herein is simple and highlyoperable; the prepared composite fiber has high strength, good toughness and good spinnability, can fully meet the demands of textile processes, and is applicable to the field of cutting-resistant gloves.

Owner:JIANGSU HANVO SAFETY PROD CO LTD

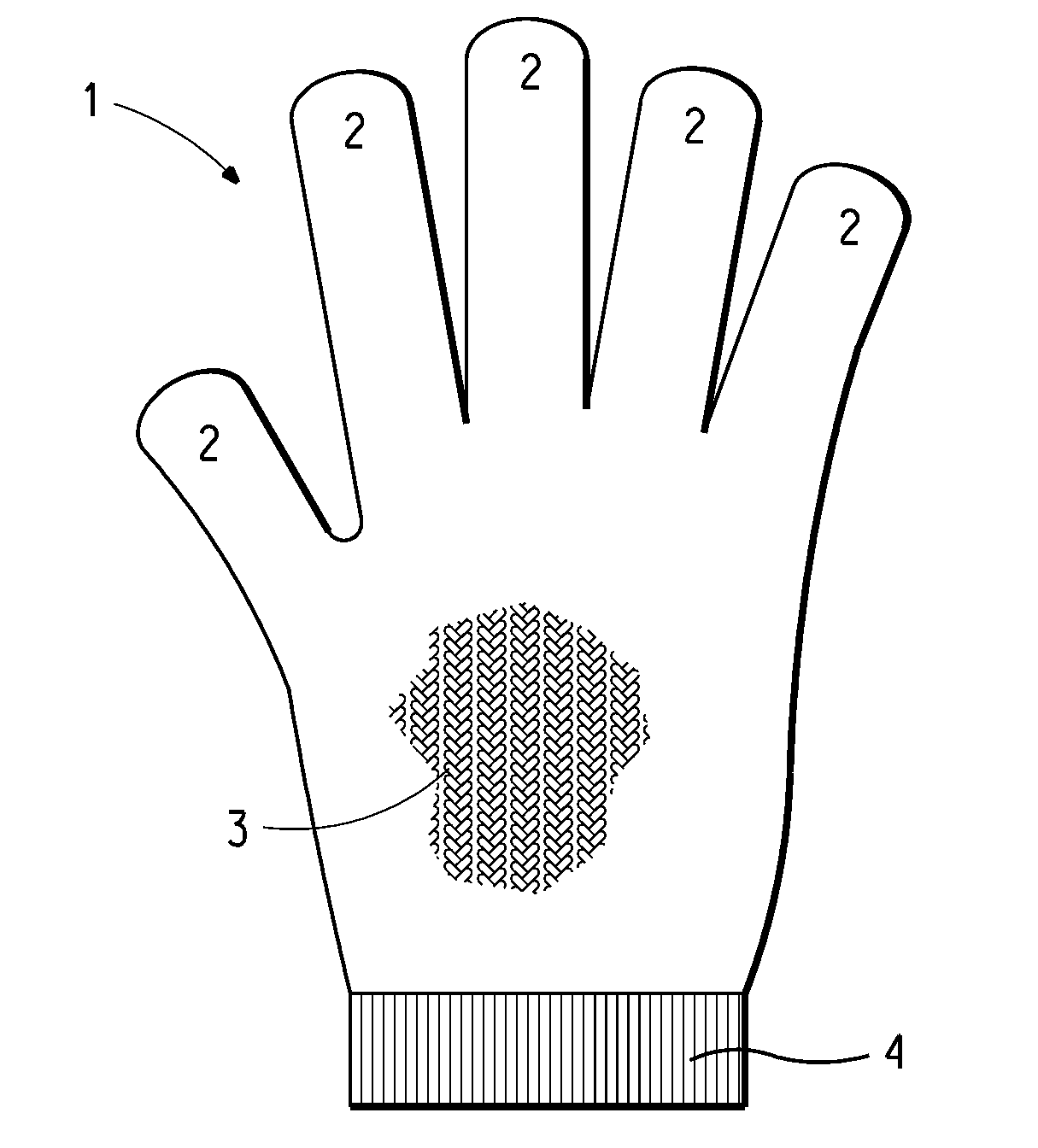

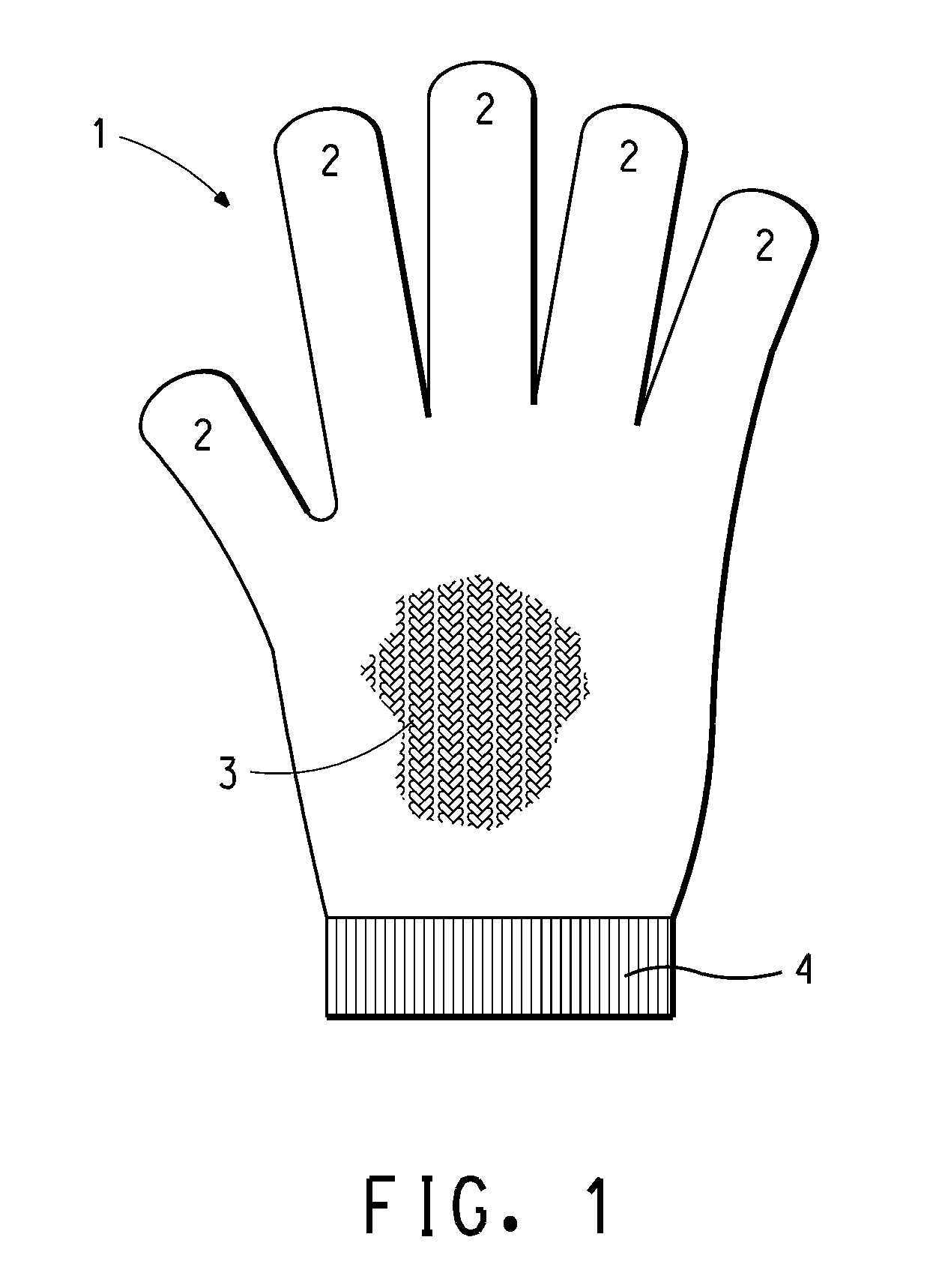

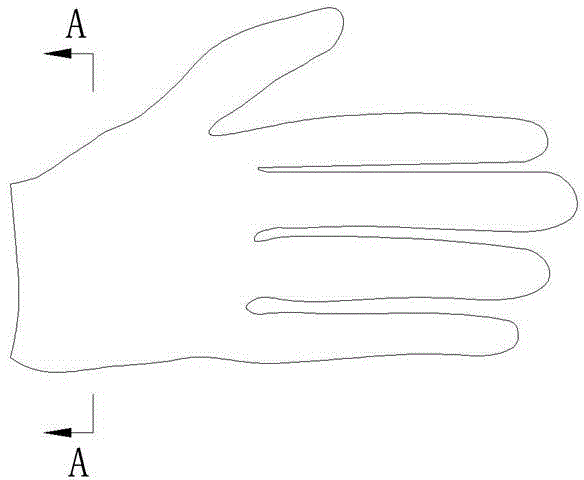

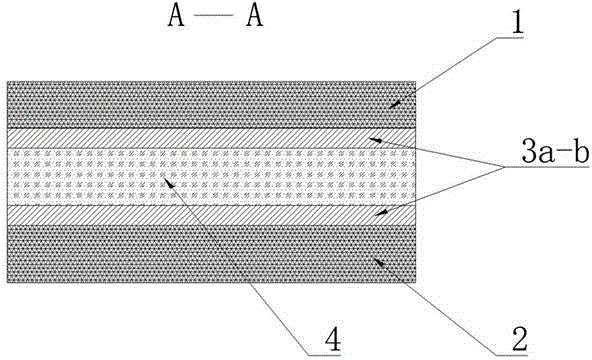

Cut resistant glove, and manufacturing method of cut resistant glove

ActiveUS10165810B2Superior in texture and fitWeft knittingOrnamental textile articlesGlass fiberEngineering

Provided is a cut resistant glove having stretchability and being superior in the texture and fit while a string made of a metal or glass fiber is prevented from sticking out, irrespective of the gauge number. A cut resistant glove having a glove main body manufactured by plating knitting using a ground yarn and an additional yarn, in which the ground yarn includes a core material, and a cover yarn wound around the core material, the core material having a string made of a metal or glass fiber, and the additional yarn being made of an organic fiber, and in which the ratio of the average thickness of the additional yarn to the average thickness of the ground yarn is no less than 0.9 and no greater than 2.5. The core material preferably further has a support yarn made of an organic fiber arranged along the string.

Owner:SHOWA GLOVE

Preparation method of ultra-high molecular weight polyethylene cotton type cut-resistant gloves

ActiveCN104814549BImprove cut resistanceIncrease elasticityProtective garmentSpecial outerwear garmentsGlass fiberPolymer science

The invention discloses a method for producing ultra-high molecular weight polyethylene cotton-type anti-cutting gloves. The gloves are formed by mixing and weaving of yarns such as ultra-high molecular weight polyethylene / polyester staple fiber blended yarns, polyester spandex wrap yarns, polyvinyl chloride (PVC) coated glass fiber spandex filament yarns and elastic yarns, cuffs of woven gloves are closed up by knitted rib cuffs, hot melting edge wrapping and one-time forming are achieved through a hot melting machine at the temperature from 120 DEG C to 180 DEG C, and surface chemical processing is performed through water-proof finishing agents so that finished products can be obtained. According to the method for producing the ultra-high molecular weight polyethylene cotton-type anti-cutting gloves, the process is simple, large-scale automatic production can be achieved, the anti-cutting performance of the gloves is high, the elasticity is good, a user can conveniently and comfortably wear the gloves, and the operation is flexible. Besides, the dust-proof effect is good, and harm to products due to falling of fibers of the gloves can be avoided. The gloves can be widely applied to people in special industries such as automobile assembly industry, glass industry, metal rolling sheet industry, cutting industry, recovery processing industry, police and the like.

Owner:JIANGSU HANVO SAFETY PROD CO LTD

Preparation method of surface-modified ultra-high molecular weight polyethylene (UHMWPE) fibers

InactiveCN113152079AImprove cut resistanceImproved interface adhesionAbrasion resistant fibresPolymer sciencePolymer chemistry

The invention relates to the technical field of fiber surface modification, in particular to a preparation method of a surface-modified ultra-high molecular weight polyethylene (UHMWPE) fiber. The UHMWPE fiber comprises an ultra-high molecular weight polyethylene fiber and an inorganic nanoparticle layer grafted on the surface of the ultra-high molecular weight polyethylene fiber. The preparation method comprises the following steps: grafting a silane coupling agent to the surface of the ultra-high molecular weight polyethylene fiber under the action of an initiator, and grafting nanoparticles to the surface layer of the ultra-high molecular weight polyethylene fiber through a hydrolysis reaction to construct a layer of inorganic nanoparticles. The layer of inorganic nanoparticles is grafted and fixed on the surface of the ultra-high molecular weight polyethylene fiber through chemical grafting, so that the wear resistance, the interface bonding performance and the cutting resistance of the fiber surface are remarkably improved on the premise of ensuring that the mechanical property of the ultra-high molecular weight polyethylene fiber is not reduced; and therefore, a solid foundation is provided for the application of the ultra-high molecular weight polyethylene in anti-cutting gloves, and puncture-proof and bulletproof places.

Owner:NANTONG UNIVERSITY

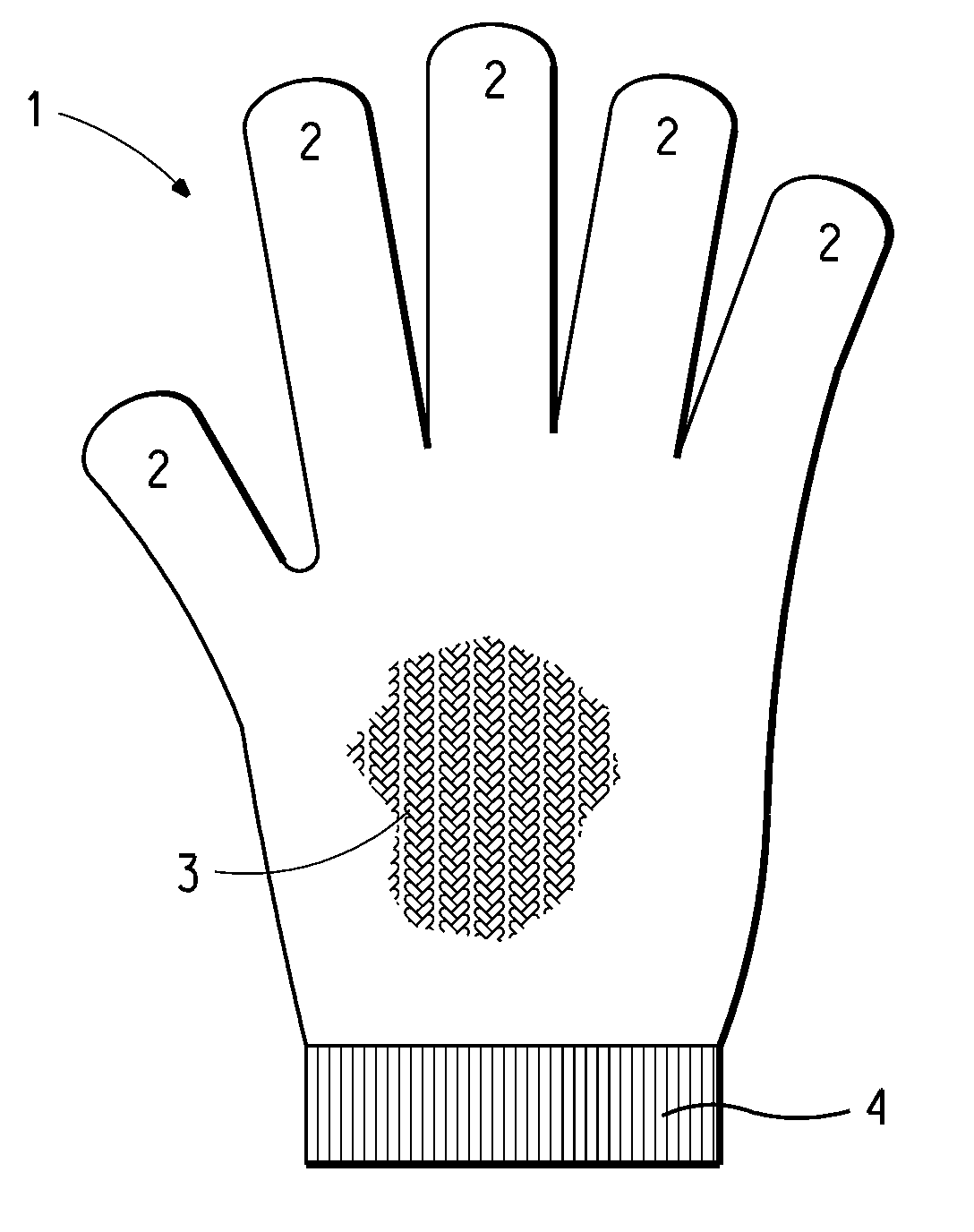

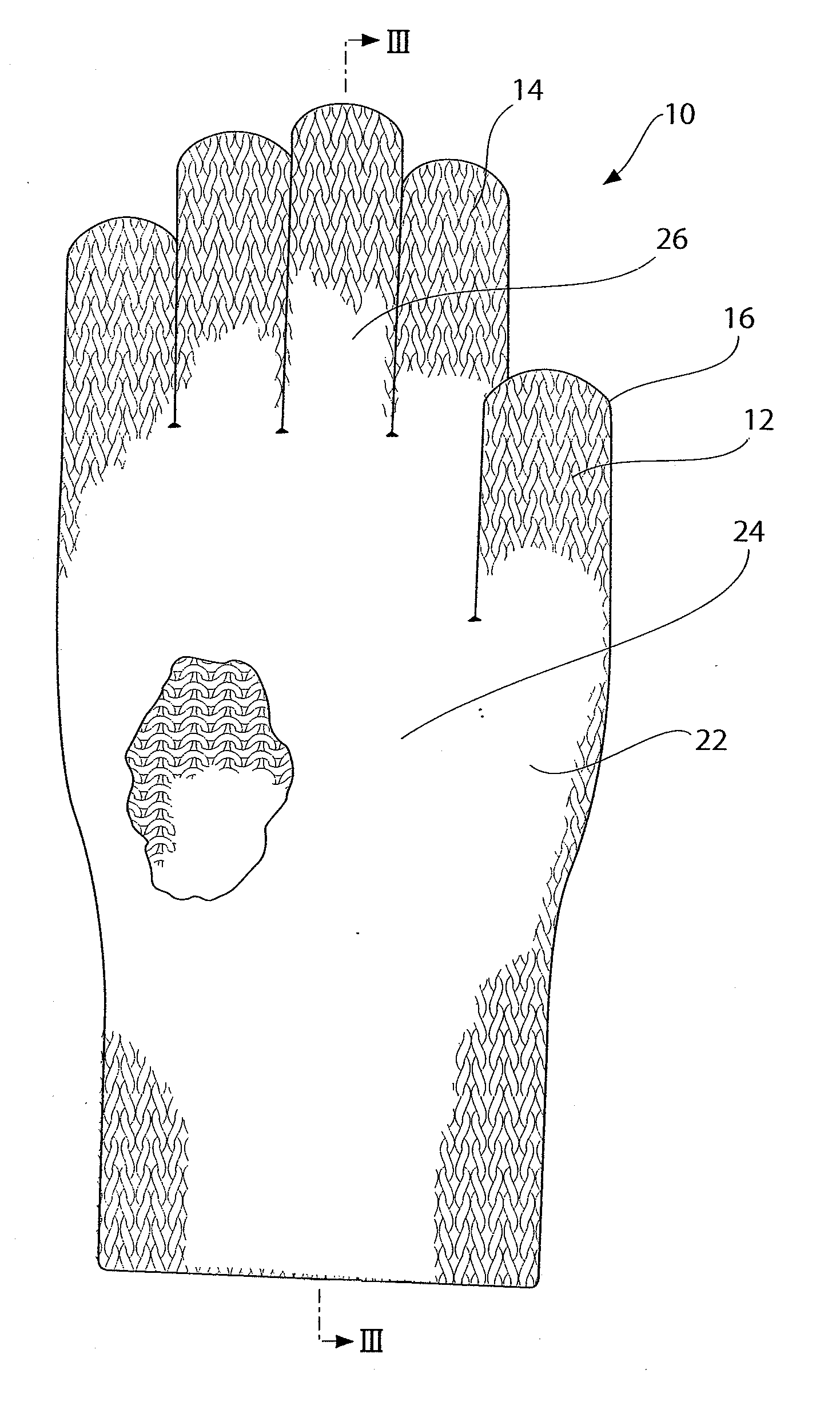

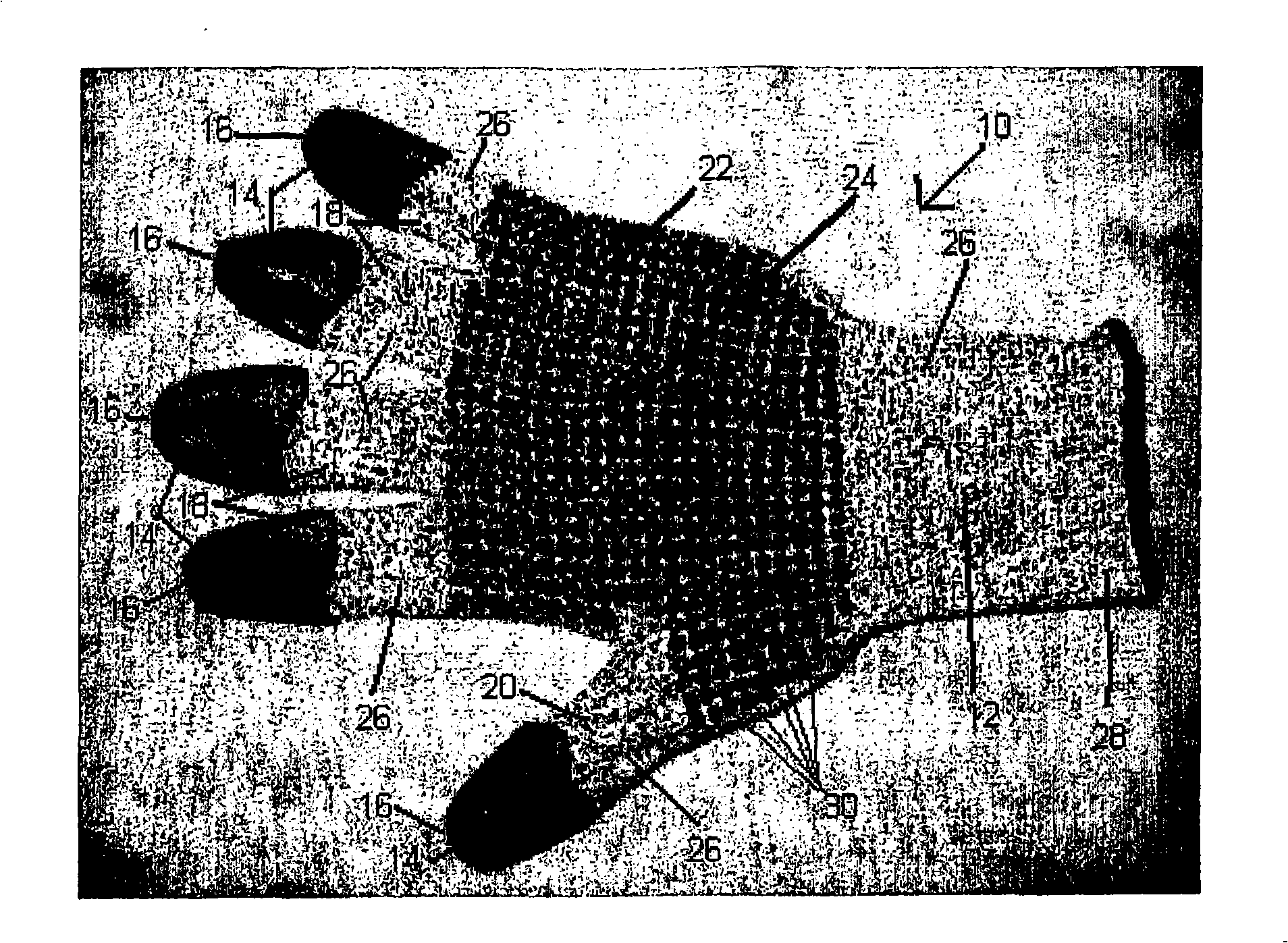

Cut resistant glove and apparel

A glove (10) or apparel formed at least partially from a knitted thread substrate and including areas (16) on an outer surface which has a substantially continuous surface (14) surrounding ends of the finger portions and thumb portion of the glove and areas which have a substantially non-continuous surface (22) positioned over the palm portion and the back of the hand portion of the glove.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Stain masking cut resistant gloves and processes for making same

This invention also relates to stain-masking cut resistant gloves and methods for making the same, the gloves comprising at least one aramid fiber and at least one lubricating fiber selected from the group consisting of aliphatic polyamide fiber, polyolefin fiber, polyethylene fiber, acrylic fiber, and mixtures thereof; wherein up to and including 15 parts by weight of the total amount of fibers in the glove are provided with a dye or pigment such that they have a color different from the remaining fibers; the dye or pigment selected such that the colored fibers have a measured “L” value that is lower than the measured “L” value for the remaining fibers.

Owner:DUPONT SAFETY & CONSTR INC

Preparation of gel-spun super-high molecular mass polytacryl and uses thereof

InactiveCN101255610AImprove creep resistanceGood dimensional stabilityFilament/thread formingMonocomponent polypropylene artificial filamentPolymer scienceTransmission belt

The invention relates to a method of preparing and applying a jelly glue spinning ultra-high molecular weight polypropylene fiber, comprising: (1) ultra-high molecular mass isotactic polypropylene and solvent are mixed, and swelled at 90 DEG C to 190 DEG C and dissolved to make up a solution of polypropylene; (2) the solution of polypropylene is quenched in a precipitating bath via measuring and spinning components to form a polypropylene jelly glue silk; (3) jelly glue fiber is balance deoiled, leached, hot air dried in the condition of 20 deg C to 80 deg C, multistage stretched, heat shaped in the condition of 160 deg C to 200 deg C to form polypropylene fiber final goods. The method not only has the advantages of that technics is simple, nucleator needn't to be crystallized, the prepared fiber is provided with a high mechanical character, a high calorifics character, and a low creep rate, but also has the advantages of that high-strength and high-modulus, resistance to chemical attack, higher use temperature and so on. The produces of the invention can be widely used for rope, cable, velas, fishing net, geotextile, filtercloth, cloth for PE and hygiene, bulletproof, cloth for preventing pricking, gloves for preventing cutting, transmission belt, thermoplasticity or thermosetting resin, and pressure container reinforcement.

Owner:DONGHUA UNIV

Pretreatment method for processing regenerated para aramid yarns

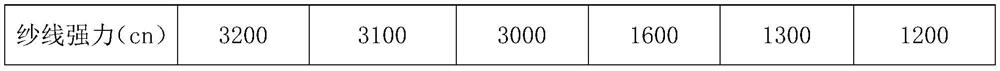

The invention relates to a pretreatment method for processing regenerated para aramid yarns. The pretreatment method comprises the steps of impregnating the regenerated para aramid yarns subjected to opening, fading or degumming treatment with a pretreatment solution by the weight ratio of 2-3 to 1 for 20-30 minutes, taking out the yarns and dehydrating and drying the yarns. The pretreatment method is simple in process and low in cost, the treated aramid yarns are high in strength, the yarn strength can reach 3000 CN, and the using requirements of common cut-resistant gloves are basically met.

Owner:SHANGHAI RISOO TECH TEXTILE

Flexible comfortable anti-cutting gloves

InactiveCN104397903ADoes not increase flexibilityDoes not interfere with free bendingProtective garmentTextile fiberSurface layer

The invention relates to a pair of flexible comfortable anti-cutting gloves, and aims to solve the problems of heaviness and poor comfort and finger flexibility of the existing anti-cutting gloves lined with steel wires. Each glove comprises a glove surface layer, a glove lining, two thin film layers and a protective inner lining, wherein each protective inner lining is positioned between the two thin film layers and is made of textile fibers which are soaked by shear thickening fluid. The pair of gloves has the same wear comfort and finger flexibility as those of the normal textile gloves and can become hard instantaneously during cutting, pricking and collision of hard objects to protect hands from being injured due to pricking, cutting and bruising; after the external injury disappears, the pair of gloves immediately restores to be in a soft state, and the wear comfort and the protection functions during cutting, pricking and collision are considered.

Owner:SICHUAN UNIV

Disposable cut resistant glove

A disposable cut resistant glove, including a body, a plurality of fingers attached to the body, a thumb attached to the body, and a plurality of strips of para-aramid synthetic fiber disposed over and around the plurality of fingers and the thumb.

Owner:SOARES JACOB

Preparation method of glass fiber coated yarns for gloves

InactiveCN109574508AImprove wear resistanceImprove the lubrication effectGlass making apparatusYarnGlass fiberRare earth

The invention discloses a preparation method of glass fiber coated yarns for gloves. By adoption of rare earth salt and a coupling agent for glass fiber modification, wear resistance and lubricating performance of glass fibers can be improved, and accordingly strength, wear resistance and lubricating performance of the glass fiber coated yarns can be improved. The glass fiber coated yarns has highstrength of the glass fibers, integrates elasticity and toughness of spandex and can be directly used for manufacturing of cut-resistant gloves with cut resistance.

Owner:GUANGZHOU ESEN PERSONAL PROTECTIVE EQUIP TECH CO LTD

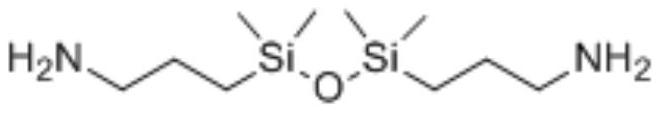

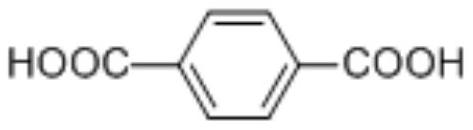

Method for preparing anti-cutting gloves from carbon fiber composite material

PendingCN113529242AImprove adhesionImprove interfacial adhesionGlovesWoven fabricsTerephthalic acidInterface bonding

The invention discloses a method for preparing anti-cutting gloves from a carbon fiber composite material, and relates to the technical field of carbon fiber composite materials. On one hand, oxidized carbon fibers are prepared through oxidation treatment of carbon fibers, and on the other hand, 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane and terephthalic acid are subjected to a condensation reaction to prepare resin; and by using the two modes, the cohesiveness of the carbon fibers and the resin is improved, and the interface bonding performance of the carbon fiber composite material is improved, so that the reprocessing performance of the carbon fiber composite material and the use quality of the anti-cutting gloves are improved.

Owner:吉祥三宝高科纺织有限公司

Cut resistant glove material and cut resistant gloves and manufacturing method thereof

InactiveCN111850786AImprove puncture resistanceHigh strengthWeft knittingFibre typesPolymer scienceAdhesive

The invention provides a cut resistant glove material and a pair of cut resistant gloves and a manufacturing method thereof. Firstly, aramid yarns are soaked in a pretreated solution according to theweight ratio of (2 to 3):1 and then are taken out to be dehydrated and spin-dried in 20 to 30 minutes, wherein the pretreated solution is prepared from 15 to 25 g of adhesives, 40 to 60 g of polymer synthetic lubricant and 20 to 80 g of penetrant in 1000 g of water; then a toughening plasticizer, a waterborne polyurethane solution and potassium dichromate are respectively weighed according to themass ratio of (6 to 8):(11 to 13):(79 to 81), and the solutions are mixed into a modified solution; and the pretreated aramid yarns are soaked in the prepared modified solution for modified treatment,wherein in a modified treatment process, the temperature is 55 DEG C to 65 DEG C, and the modified time is 15 min to 25 min. According to the manufacturing method, the used aramid yarns are pretreated, so that the strength of the aramid yarns is increased, and 20 S / 2 of yarns are taken as an example, the yarn strength can reach 3000 CN; and toughening modification is performed on the aramid yarns, so that the puncture resistant performance of the gloves is greatly improved. The produced cut resistant gloves meet the EN388 cut resistant standard.

Owner:安徽省吉祥纺织工程先进技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com