Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Contour following" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

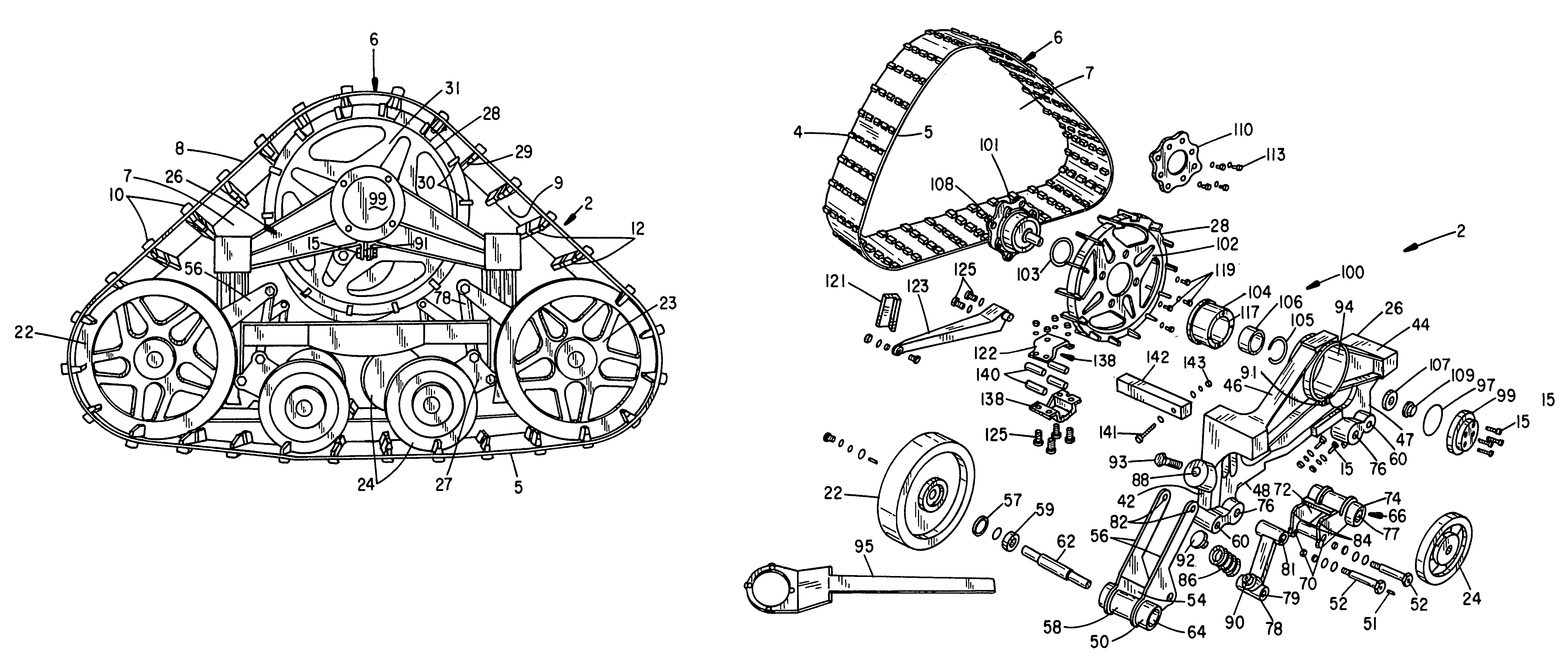

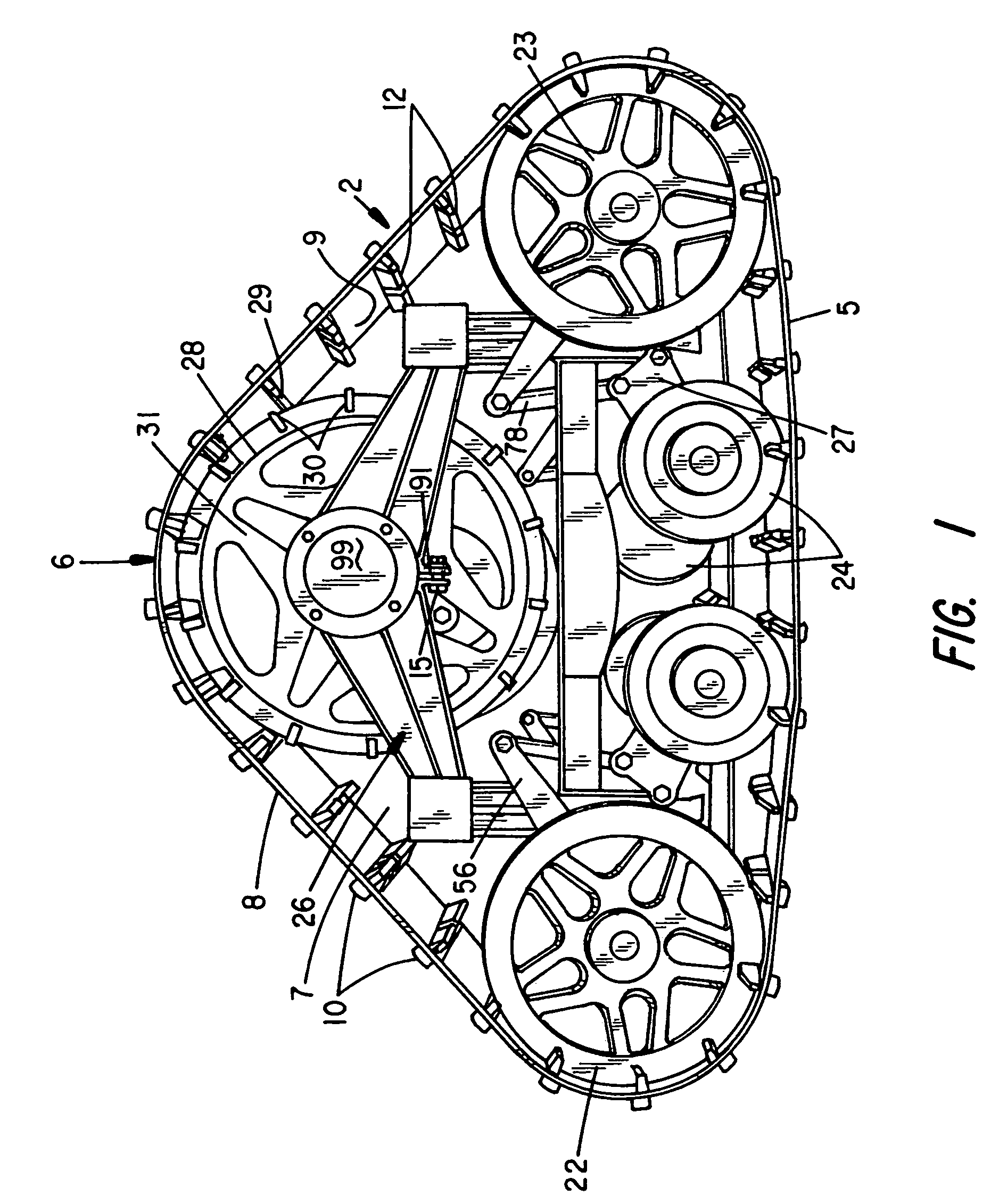

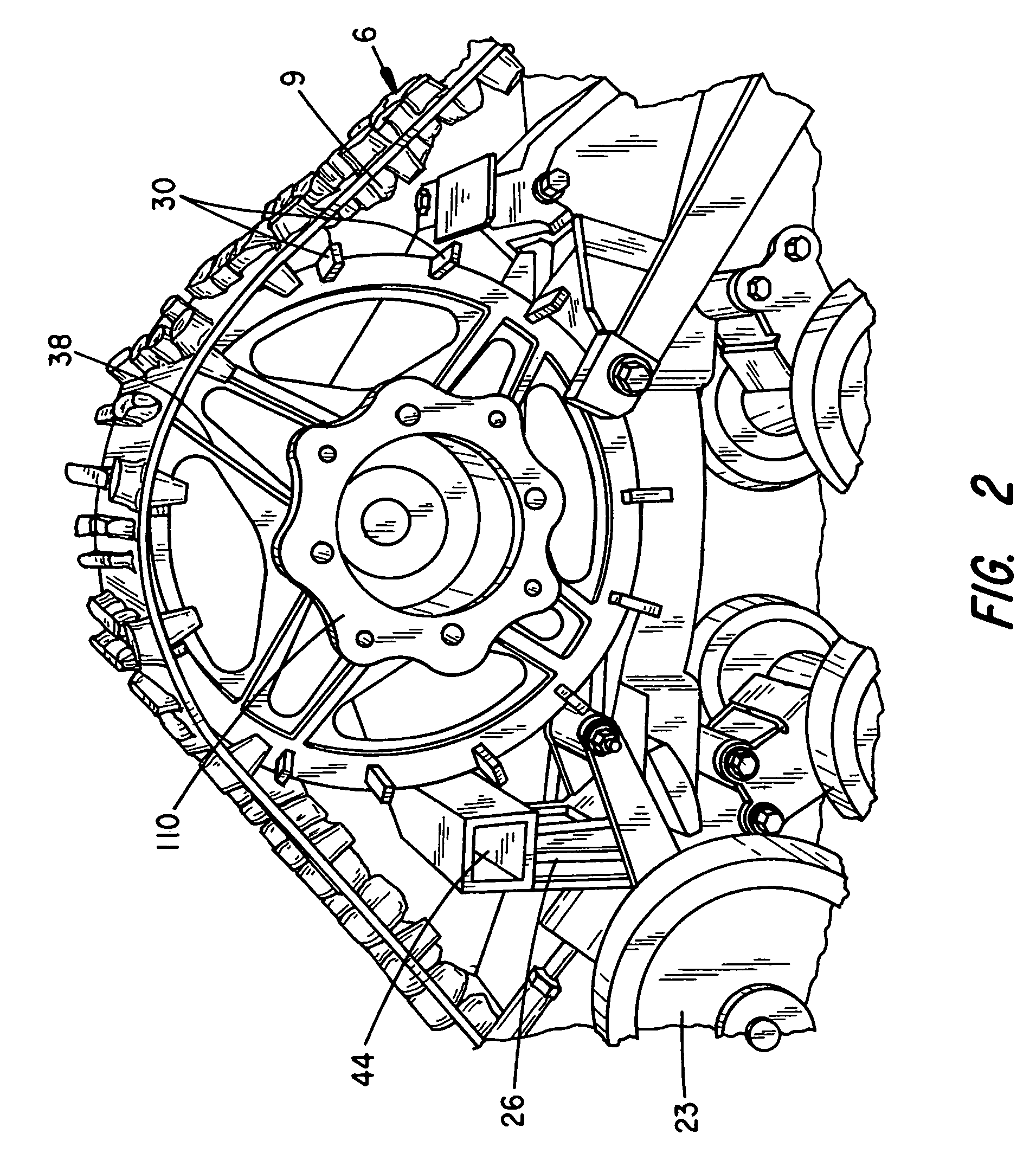

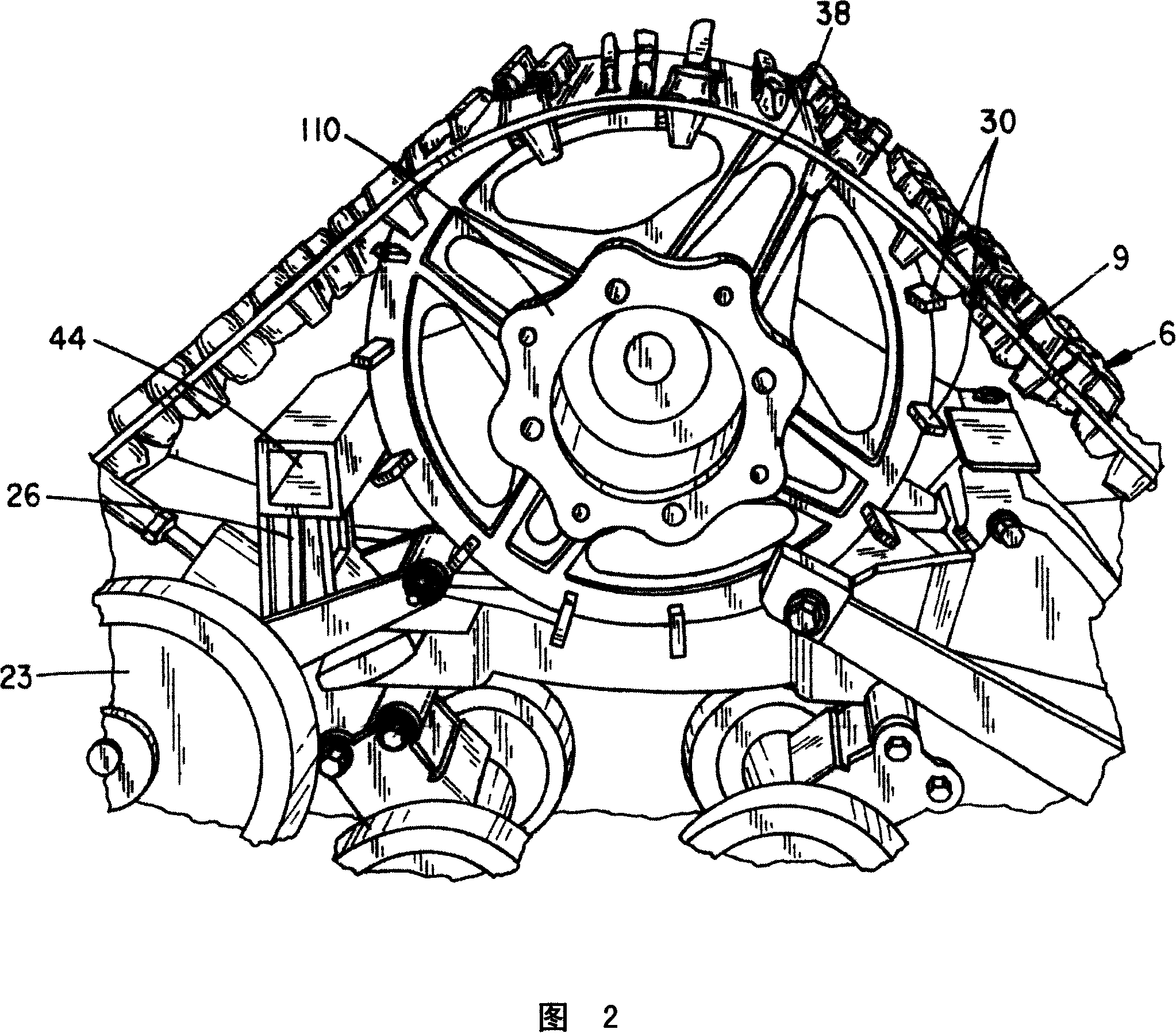

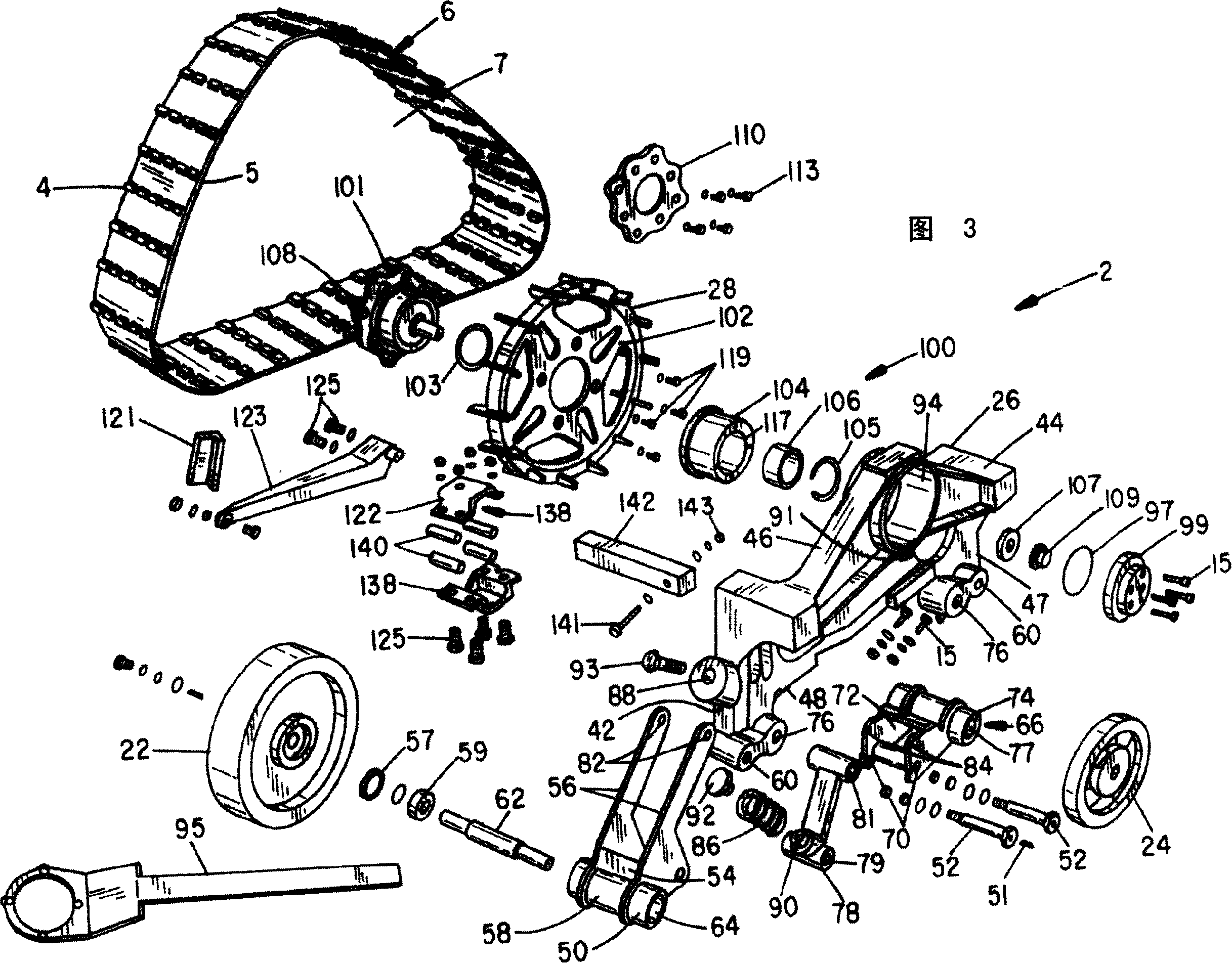

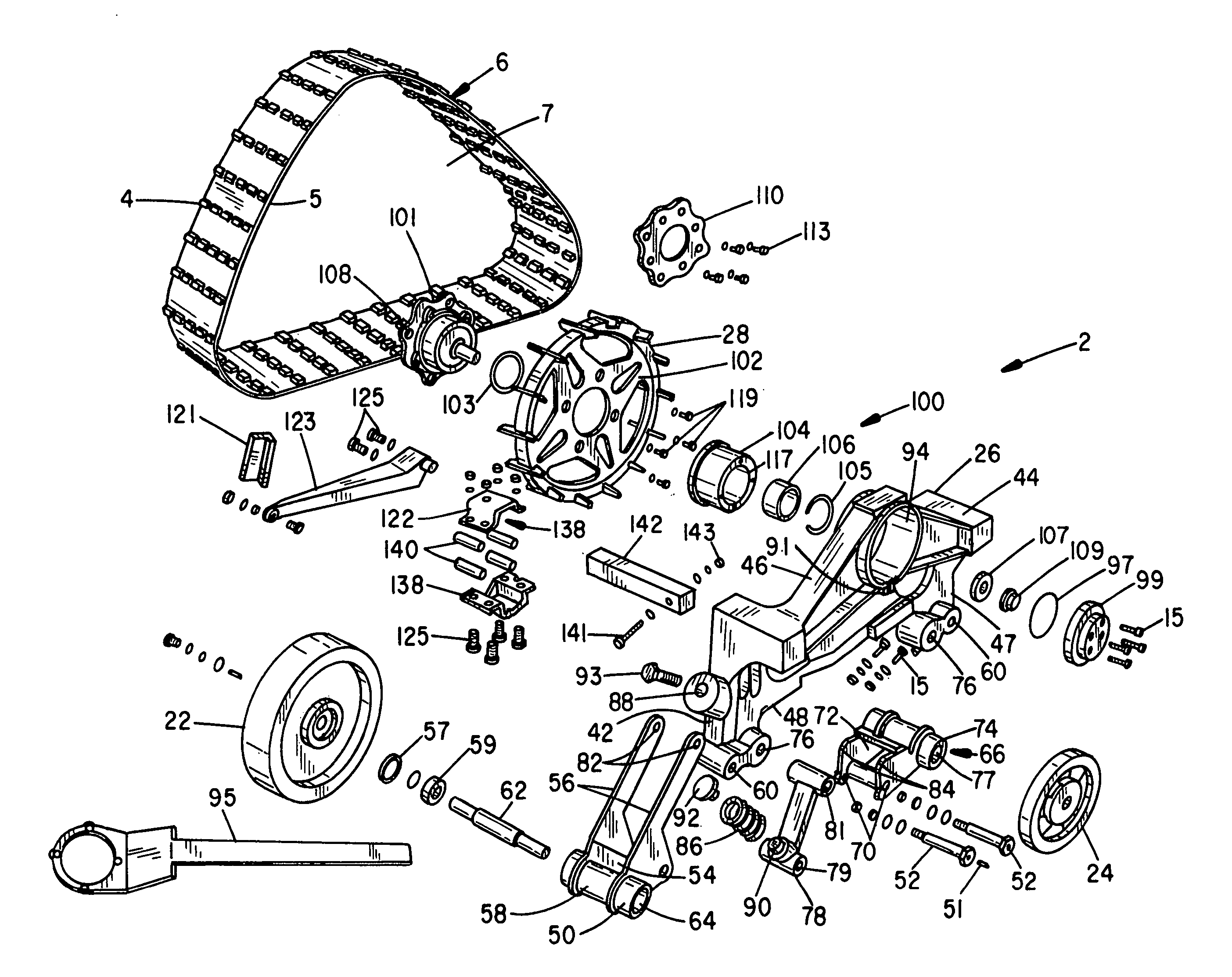

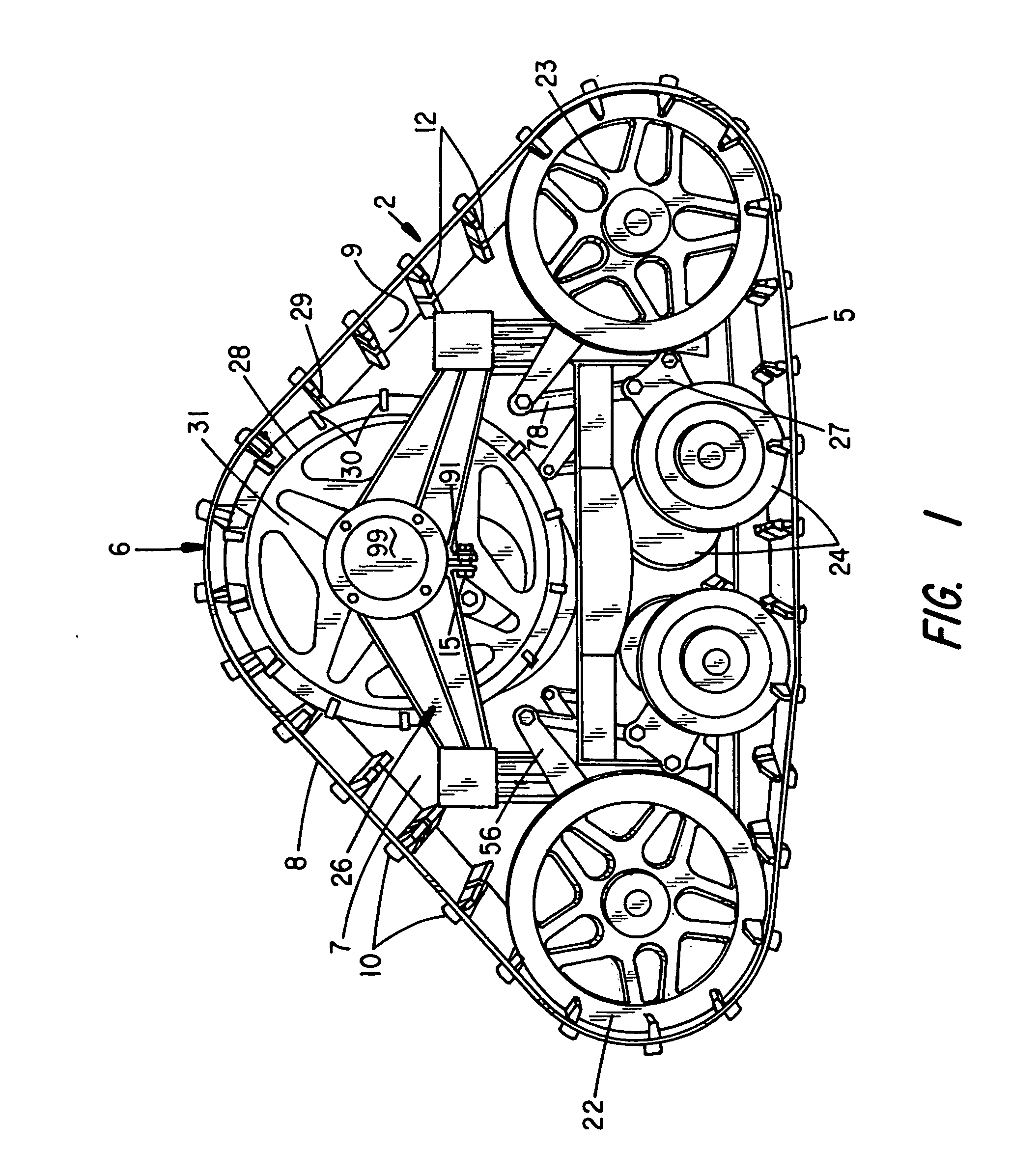

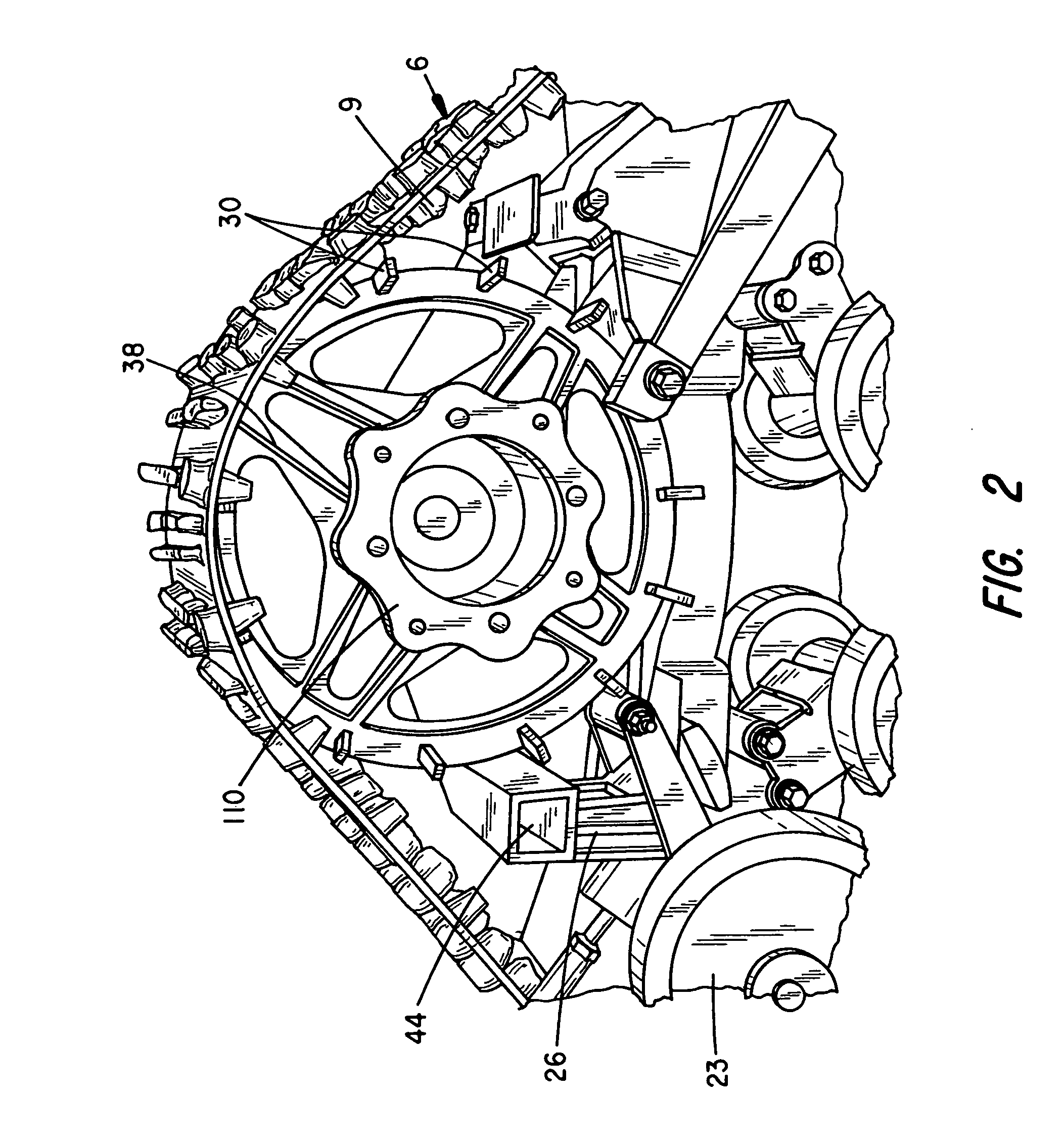

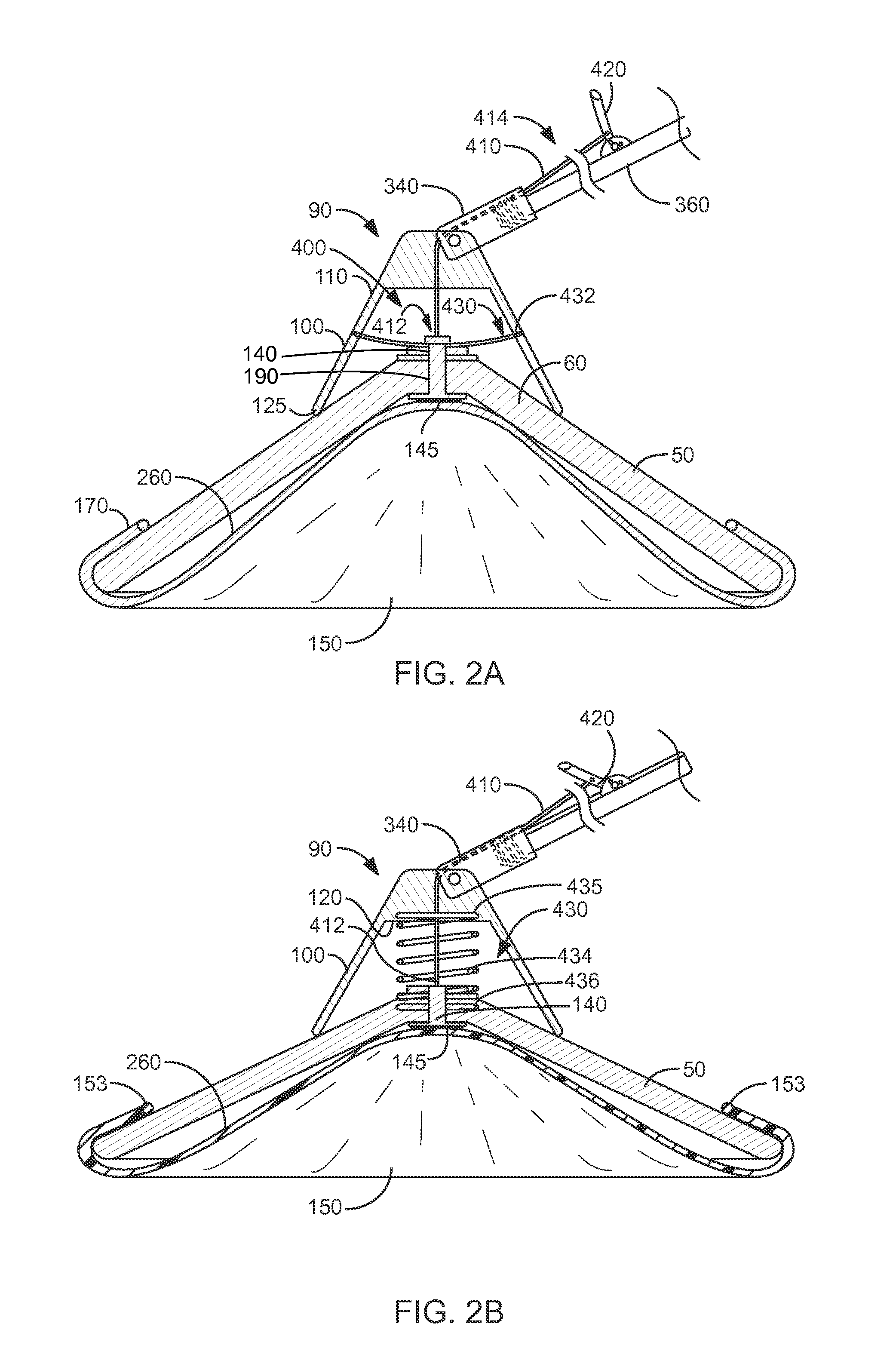

Terrain conforming track assembly

Owner:BRAZIER GLEN

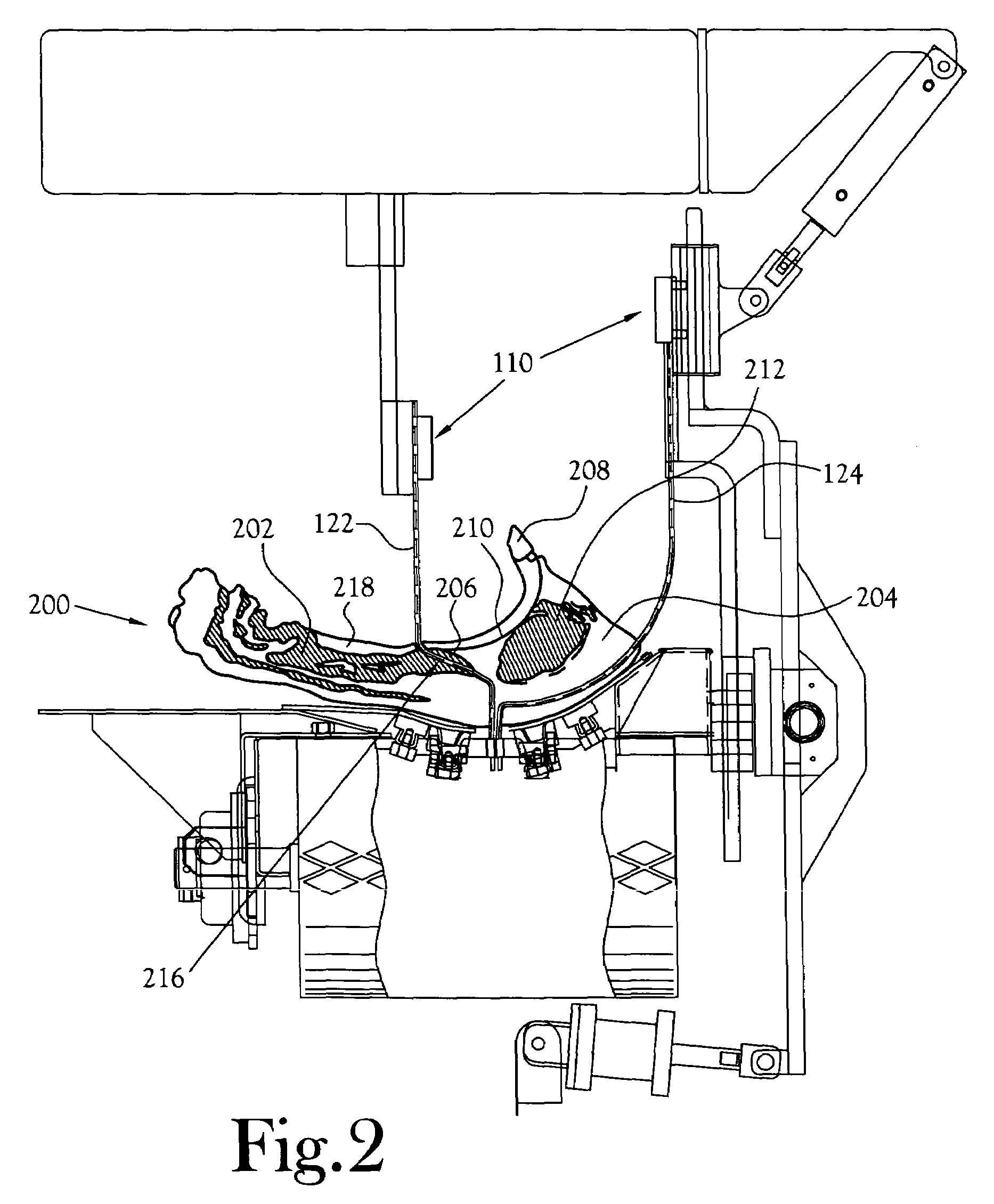

Device for weeding between seedlings and method for weeding

InactiveCN102282922AEffective protectionLow injury rateSoil-working equipmentsWeed killersHydraulic cylinderAgricultural engineering

The invention discloses an inter-seedling weeding device and method, and relates to the technical field of agricultural machinery. The inter-seedling weeding device comprises a ground contour following device, a hoe blade lifting device, a tool setting device and a hoe blade device; and the ground contour following device comprises a contour wheel, a sliding plate, two sliding blocks, a spring and a cylindrical slide rail. The contour wheel and the hoe blade device are fixedly arranged on the sliding plate; and the sliding blocks are fixedly arranged on the sliding plate, and the sliding blocks and the spring are sleeved outside the cylindrical slide rail. The hoe blade lifting device comprises a second parallelogram mechanism and a second hydraulic cylinder, and the second hydraulic cylinder is arranged at the opposite sides or the adjacent sides of the second parallelogram mechanism. The tool setting device comprises a first parallelogram mechanism and a first hydraulic cylinder; and the first hydraulic cylinder is arranged on the opposite sides or the adjacent sides of the first parallelogram mechanism. According to the inter-seedling weeding device and method, disclosed by theinvention, the hoe blade can be protected and the seedling injuring rate during weeding can be reduced.

Owner:CHINA AGRI UNIV

Dual-mode contour-following mop

InactiveUS20080040876A1Easy to disassembleReduce manufacturing costLiquid surface applicatorsLiquid processingDual modeContour following

Owner:AIYAR SANJAY

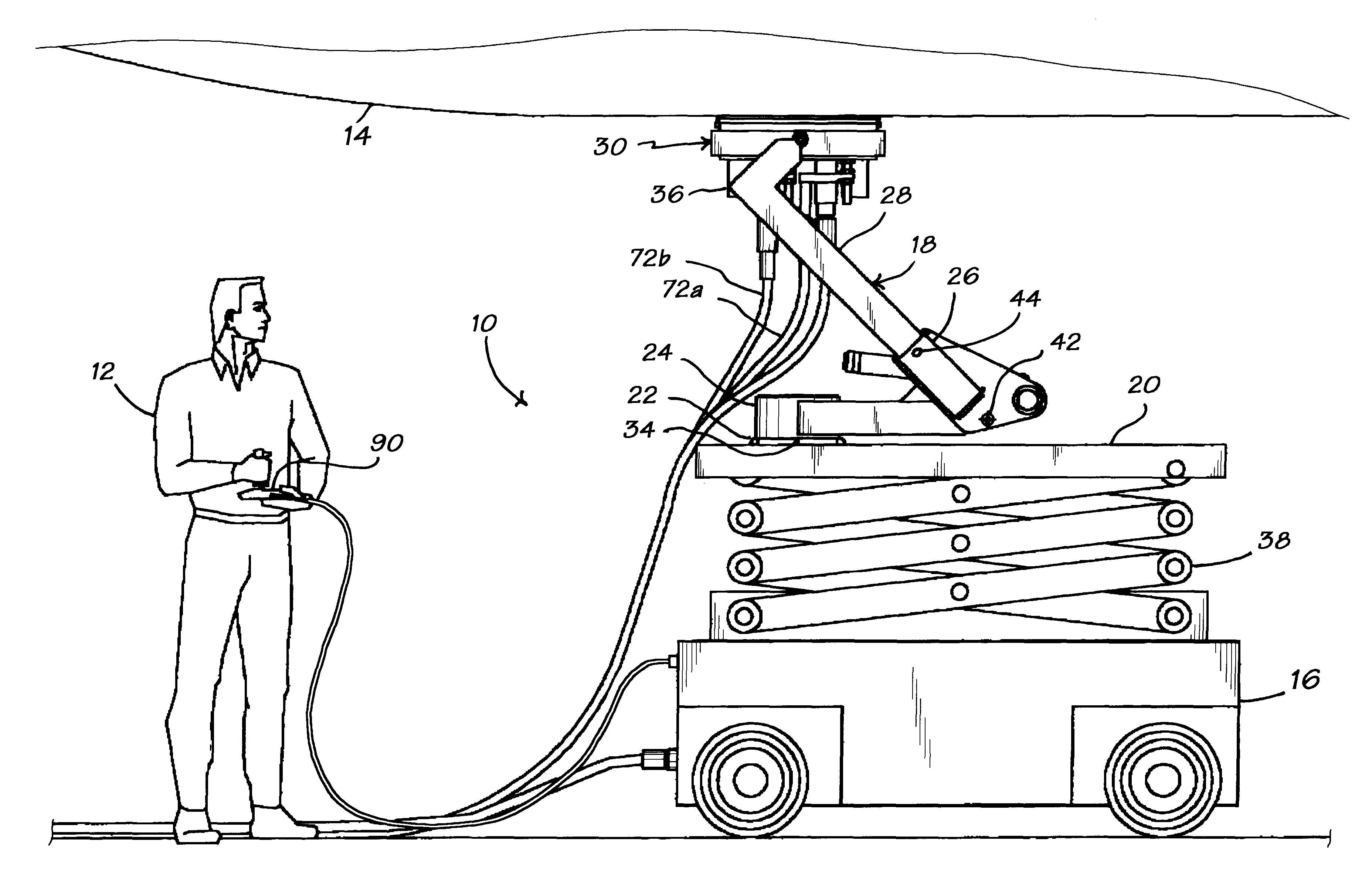

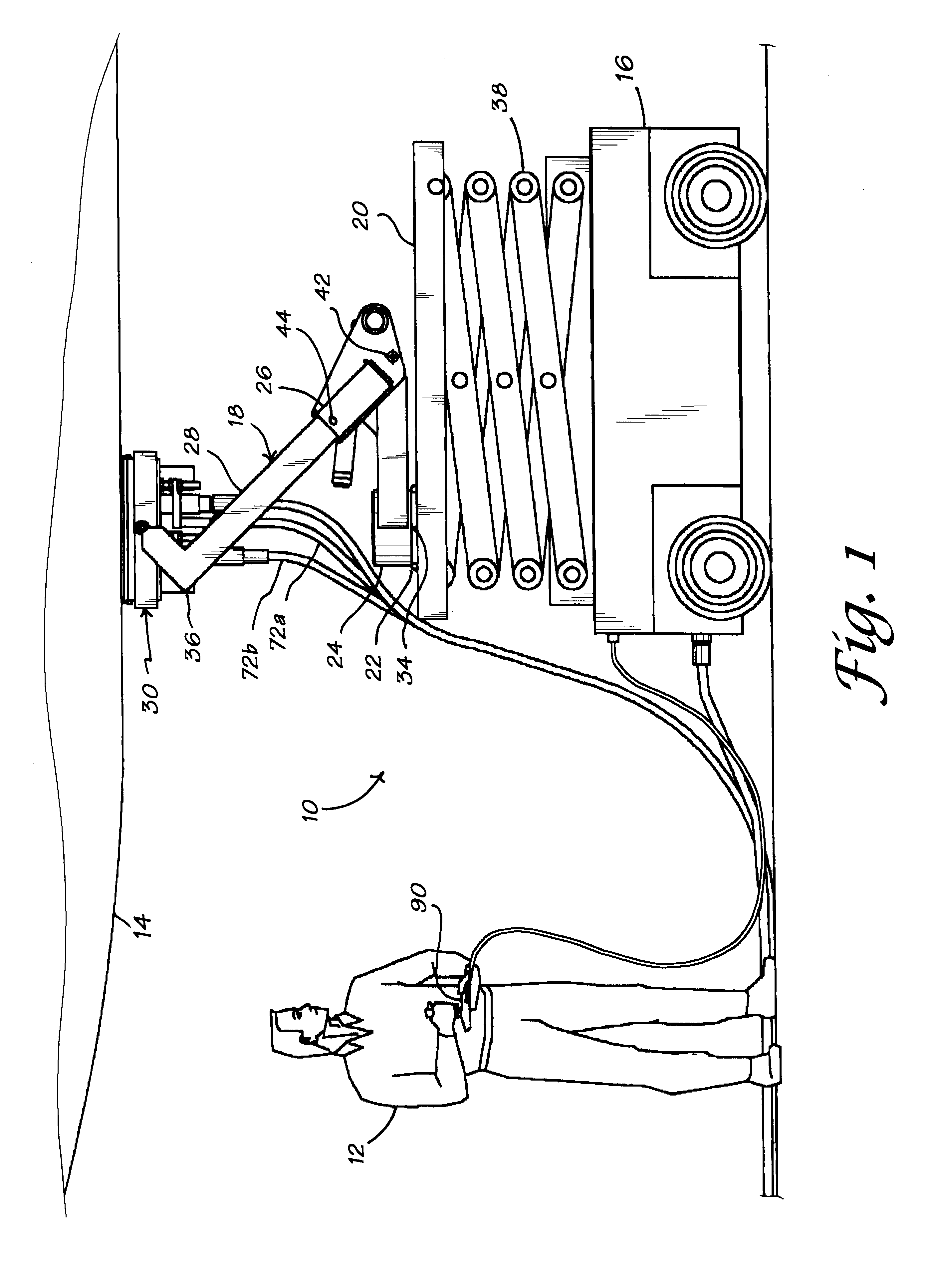

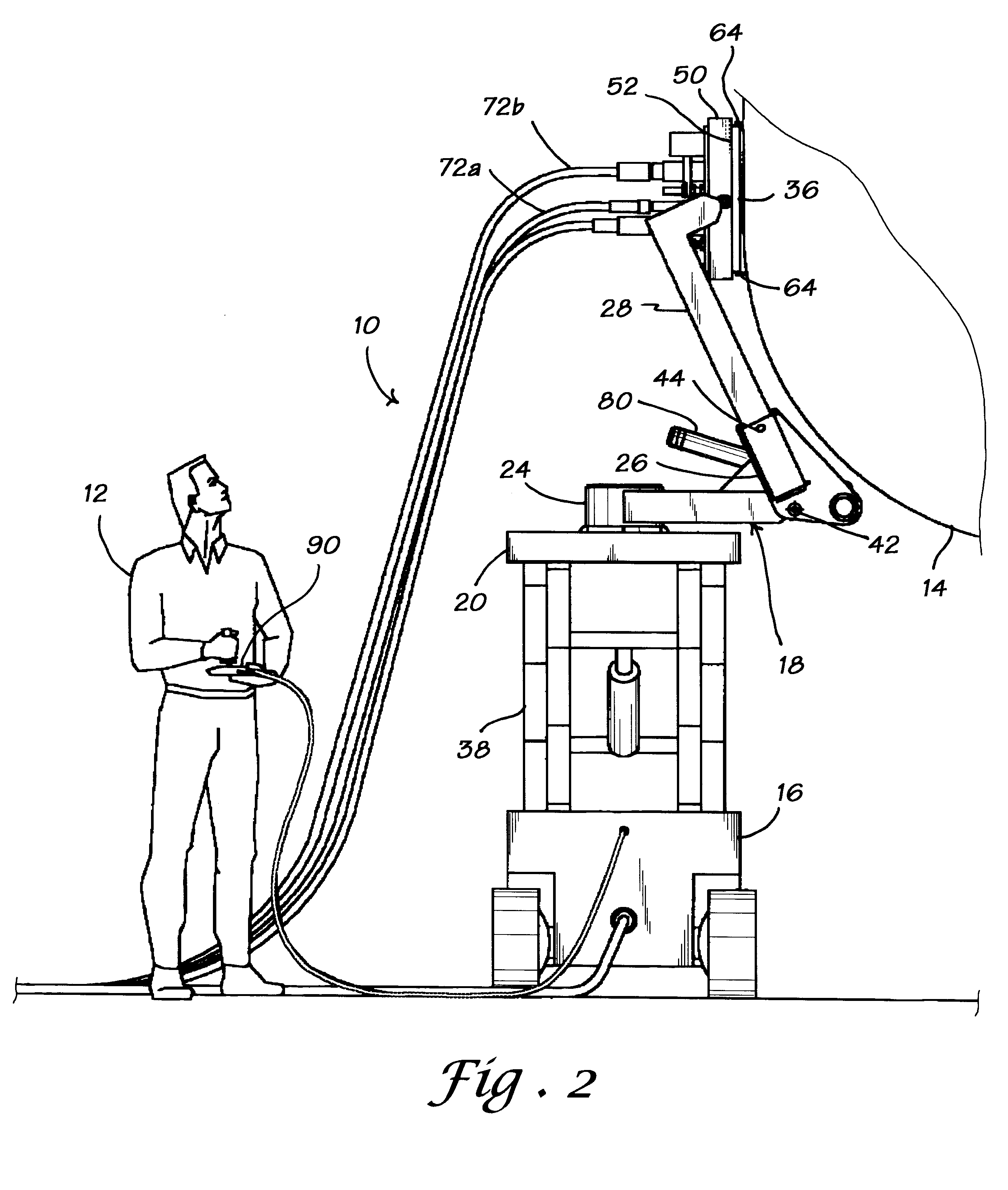

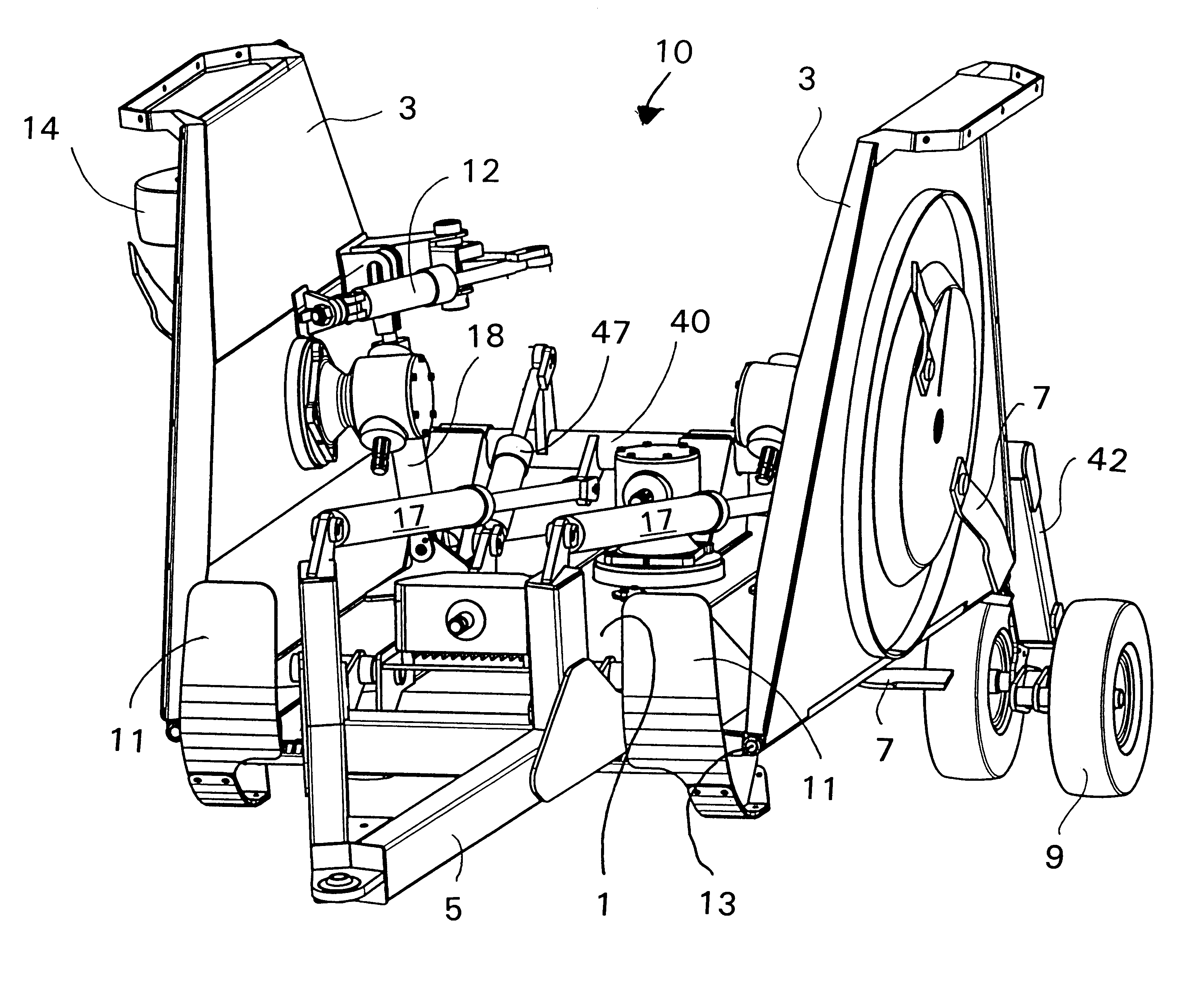

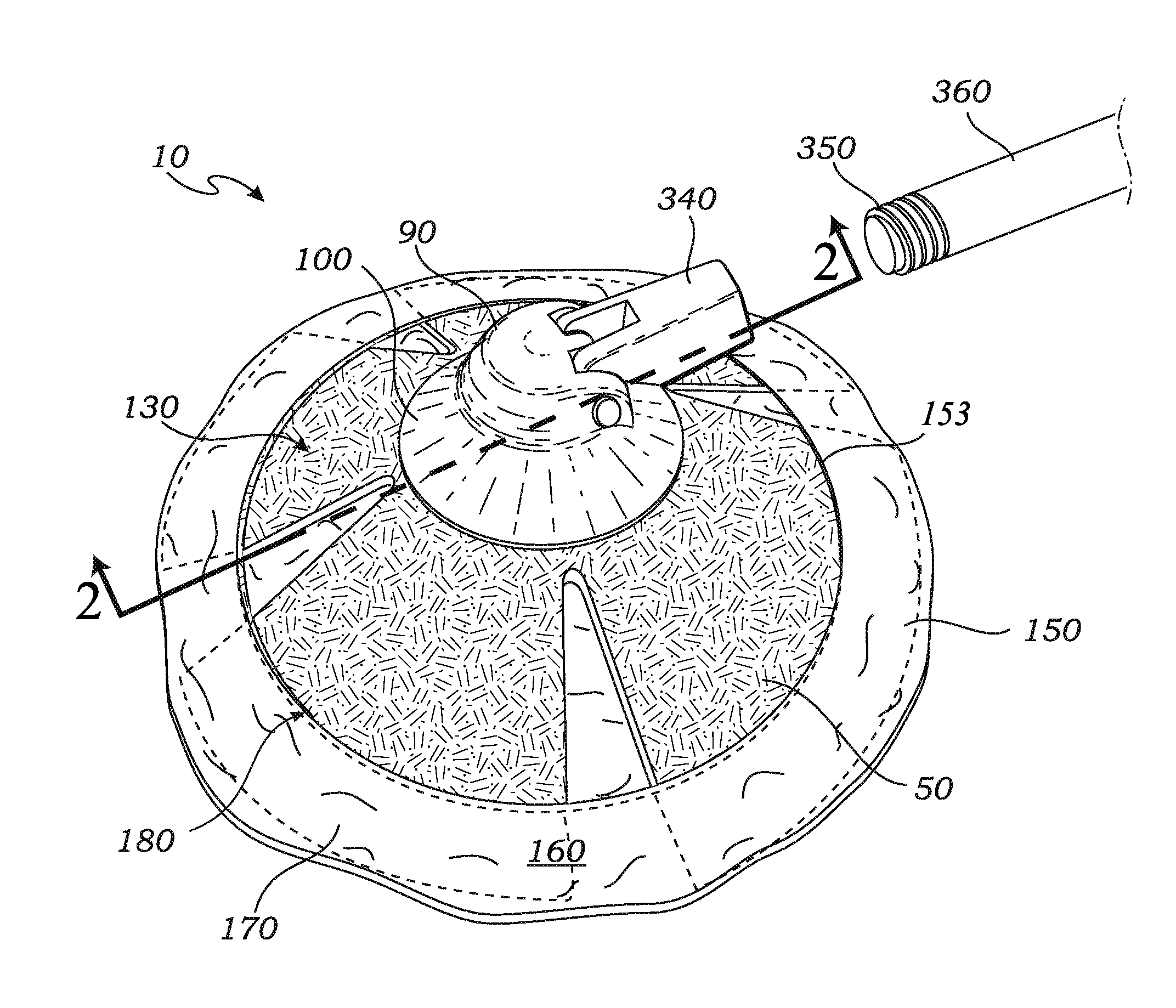

Contour-following apparatus for cleaning surfaces

InactiveUS6189473B1Furthering alignment with work surfaceEasy to cleanVessel cleaningHullsUltra high pressureContour following

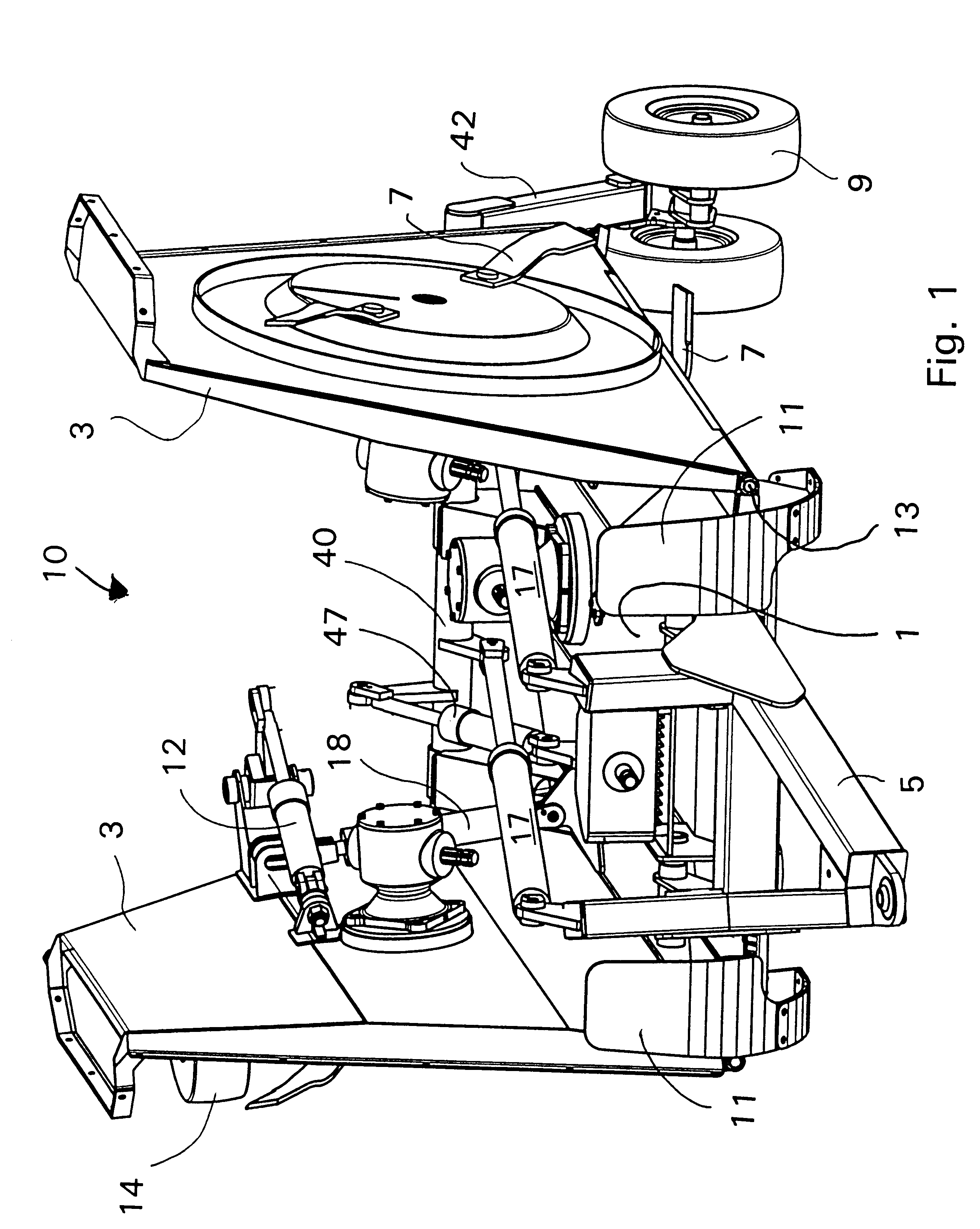

A modular apparatus for supporting and guiding a tool such as an ultra-high pressure water jet along a work surface, including a contour following assembly attached to a motorized lift vehicle. The contour following assembly includes a gimbals assembly with an instrument or tool carriage assembly, a positioning assembly that urges the gimbals assembly and the instrument carriage against the surface, and, optionally, a hydraulic, mechanical, or pneumatic pressure system that applies pressure to the positioning assembly. A scissors lift, hydraulic lift, telescoping arm, or other suitable device raises and lowers the apparatus. In operation, the gimbals assembly and the positioning assembly cooperate to maintain the instrument carriage in a user-selected position with respect to a work surface such as a ship hull, aircraft fuselage, storage tank, or the like. Depending on the type of tool selected, the apparatus may be used for cleaning or stripping surface coatings, buffing, painting, washing, and so forth. The apparatus is mobile, compact, cost-effective, and can be operated by a single operator.

Owner:REMOTE TOOLS

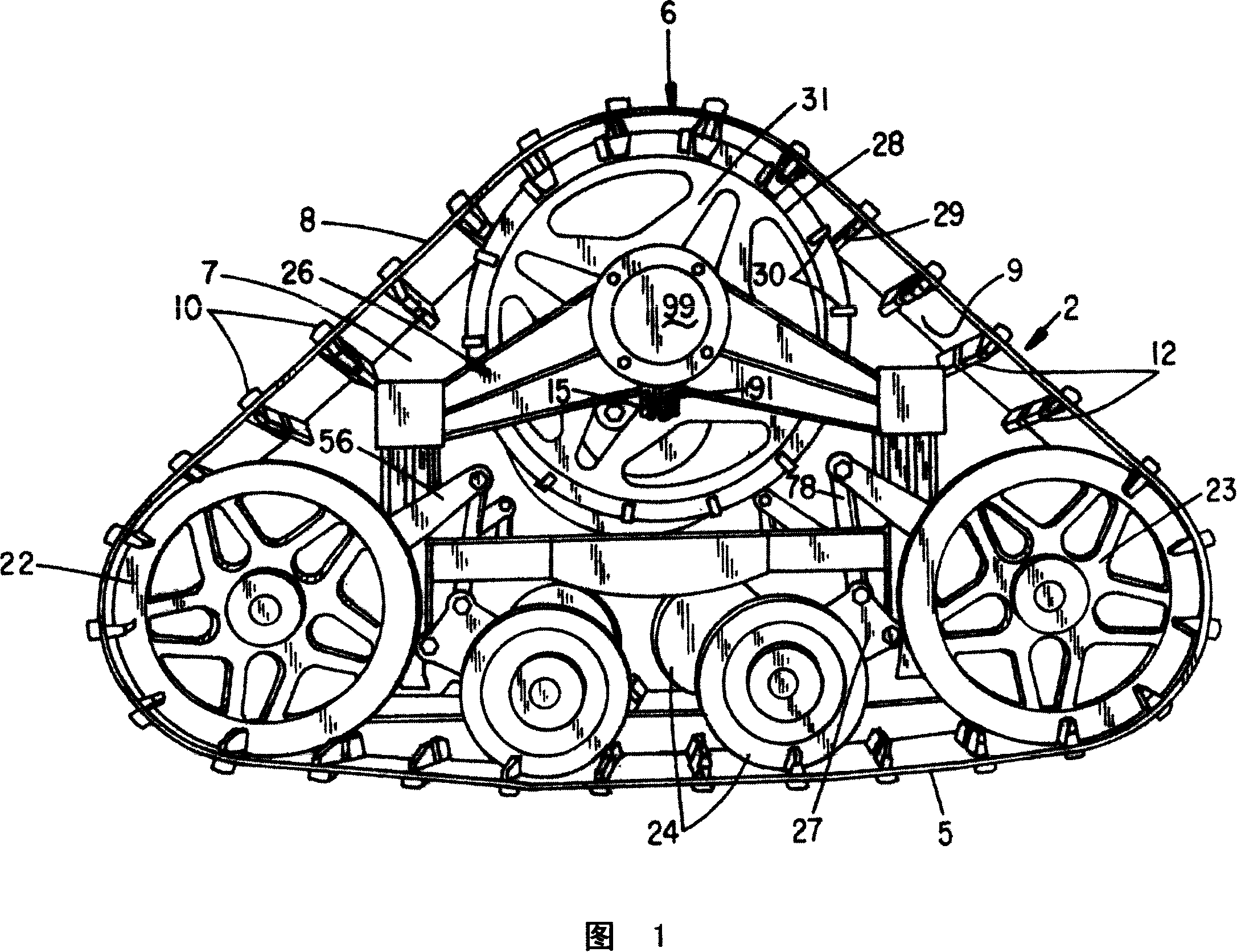

Terrain conforming track assembly

ActiveCN101138992AAdapt to terrain contour changesConducive to manipulationEndless track vehiclesTerrainShape change

An endless track assembly that mounts to a wheeled vehicle. The assembly provides 1) a track suspension having fixed or adjustable, independently biased sets of idler wheels to vary the track contour without affecting track tension, 2) an eccentric bearing housing at a drive sprocket controls track tension, 3) a contoured peripheral edge at the drive sprocket prevents ice and mud buildup, 4) rubber-coated, plastic idler wheels facilitate track movement, 5) a multi-vehicle compatible adapter mounting plate accommodates a variety of vehicles, 6) a rotation limited torsion coupler and / or rotation limiting coupler arms prevent track contact with the vehicle, 7) a locking steering arm coupler prevents loss of steering control, 8) shaped track lugs and channels clear and direct debris away fromthe track suspension and drive assembly, and 9) a center, spring biased coupling suspension stabilizes and enhances the contour following and load handling capabilities in the center region of the track. The improved suspension particularly supports sets of idler wheels in pivotal relation to the track support frame and resiliently biases a pre-tensioned rocker arm that links adjacent suspension arms mounted to the adjoining idler wheels. Suspension arm movement induces expansion and contraction of tension springs coupled to the rocker arms to augments shape changes at the track contact surface to optimize traction and steering control.

Owner:G·布拉齐尔

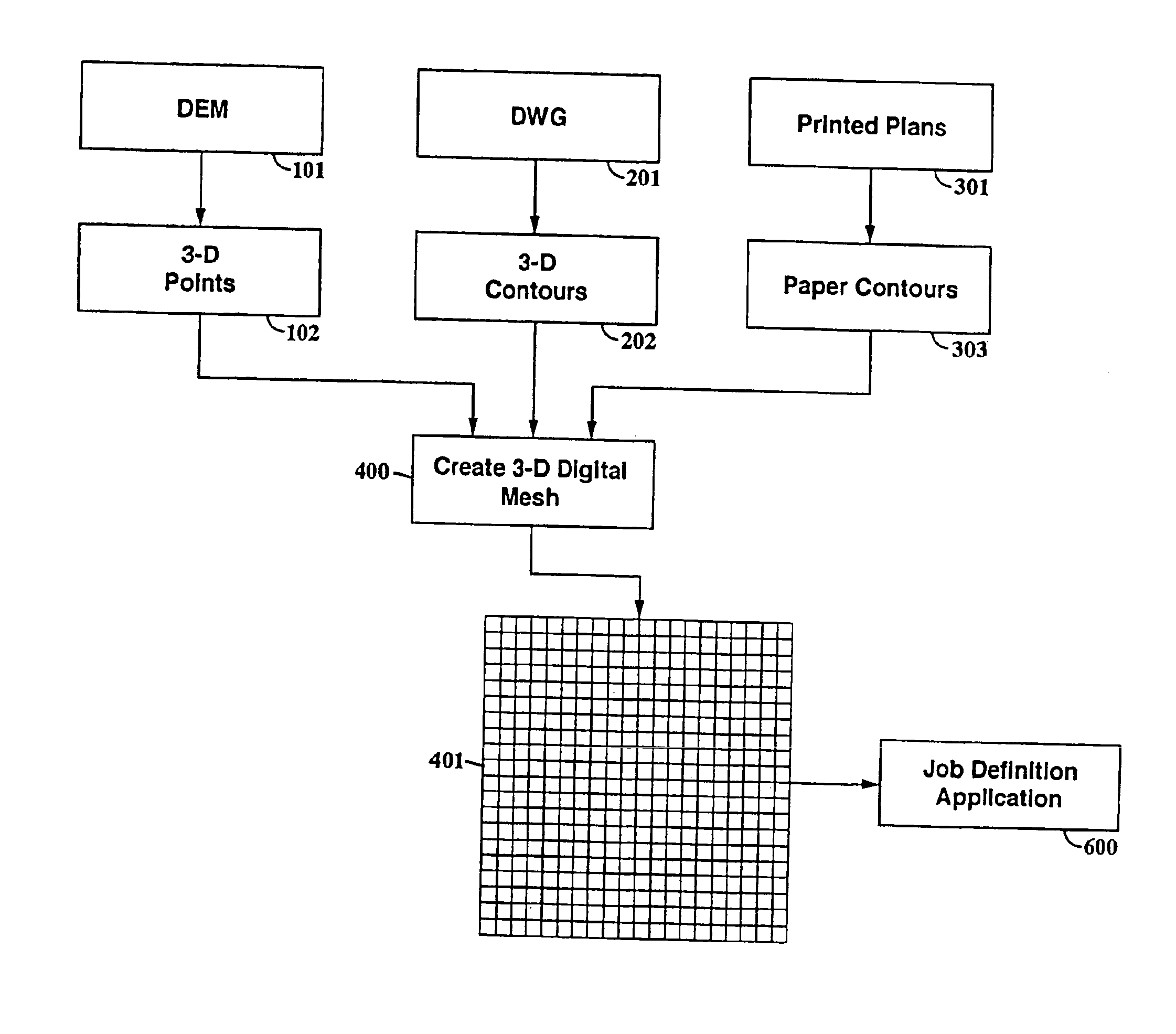

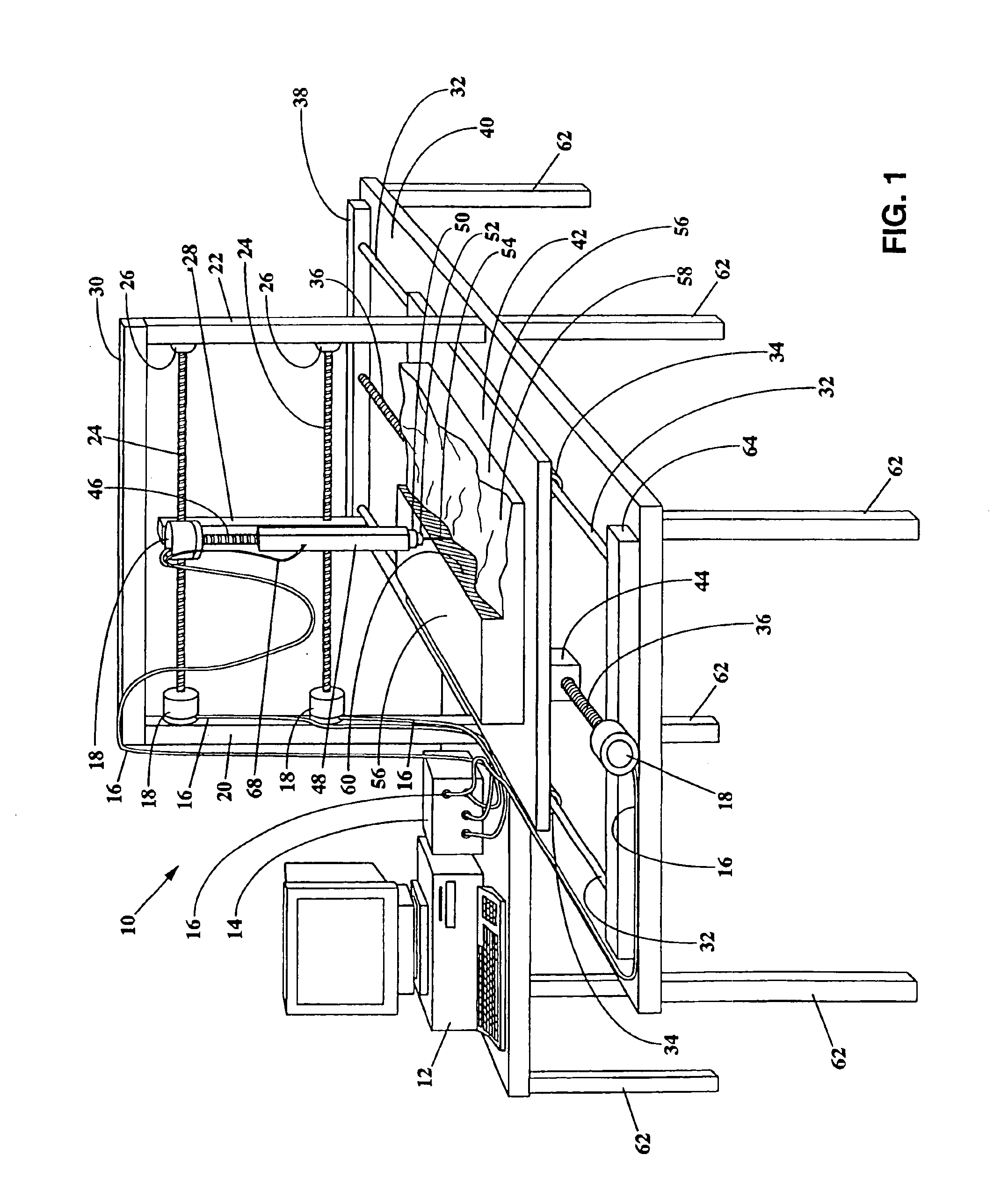

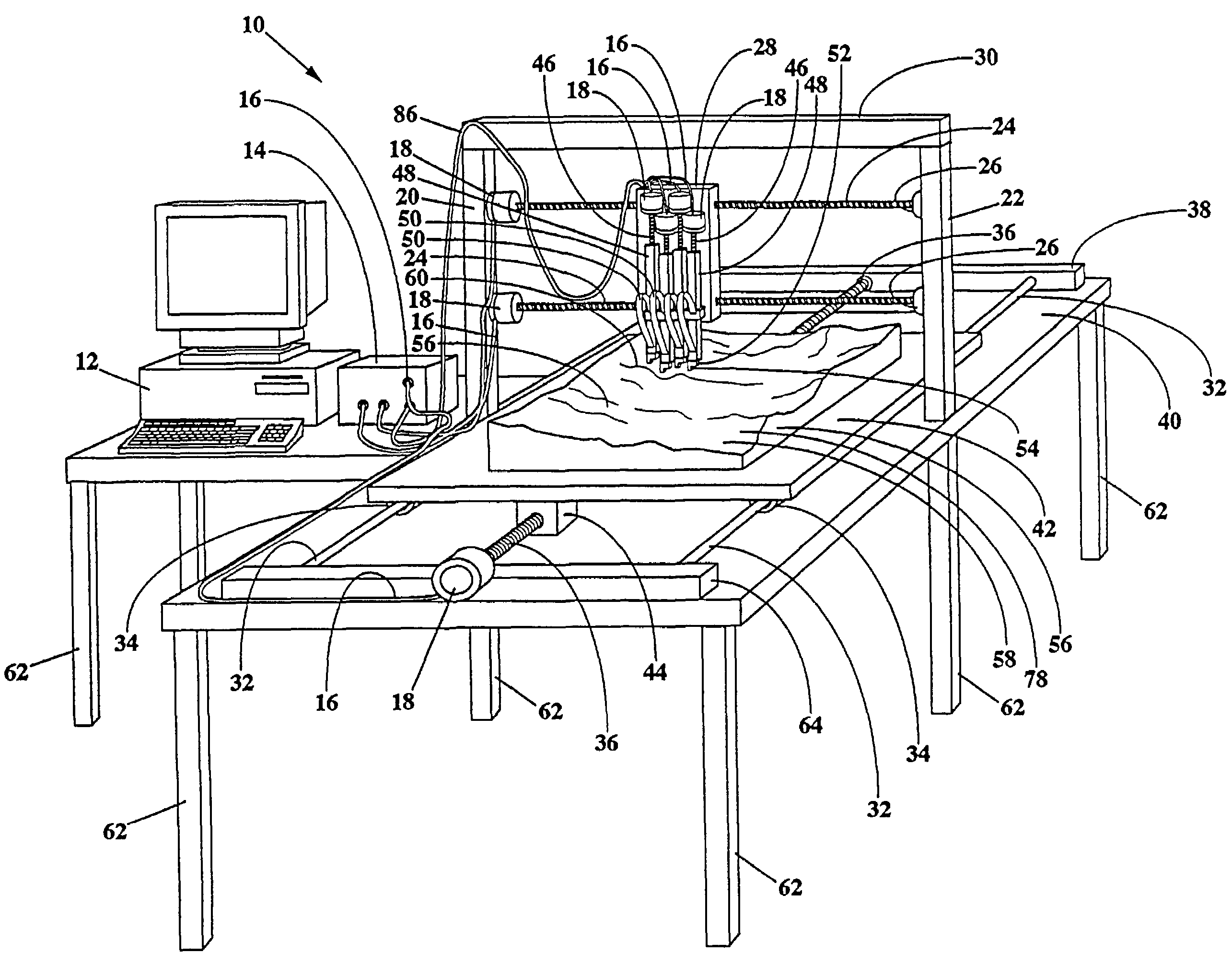

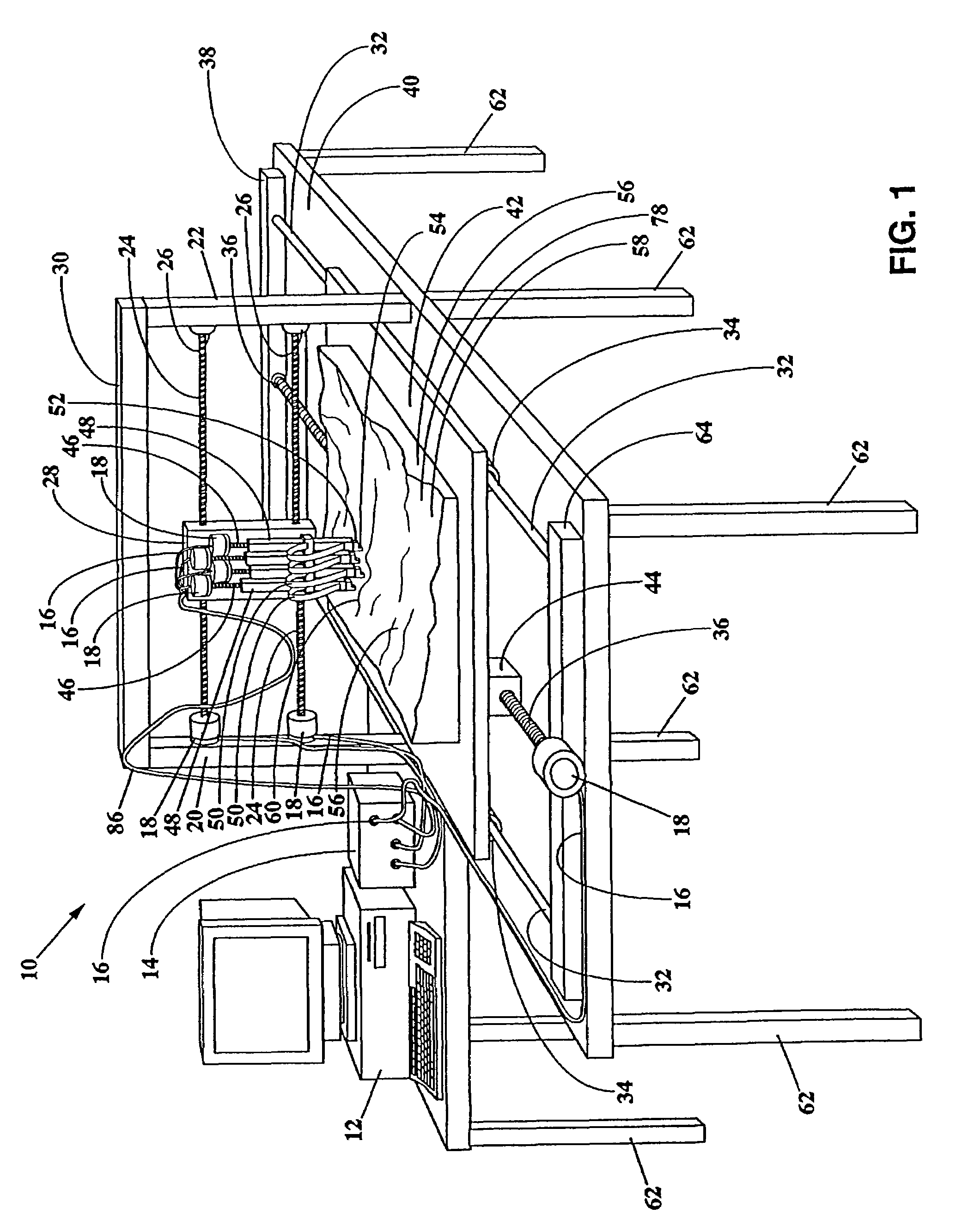

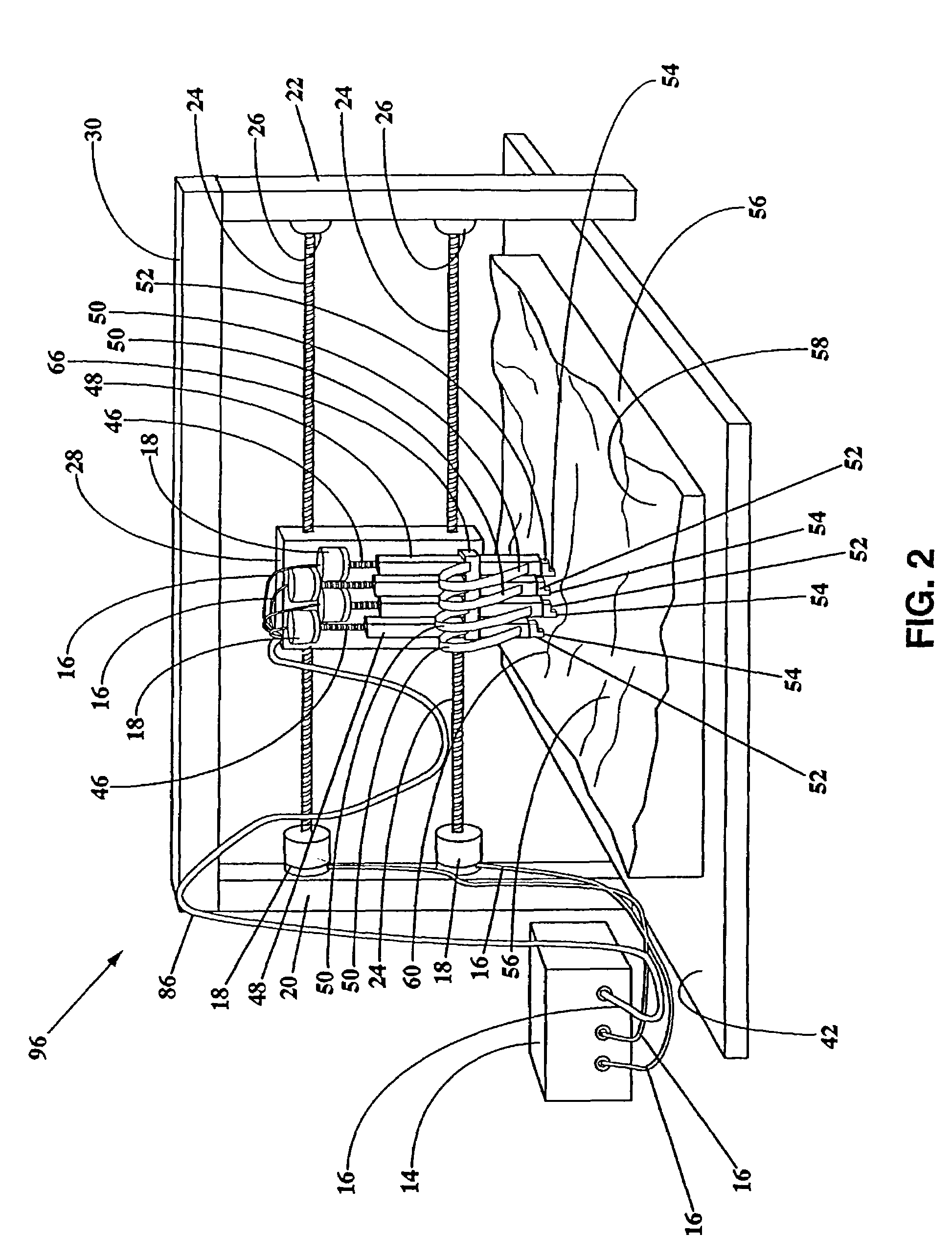

Hi-accuracy three-dimensional topographic modeling apparatus

InactiveUS7216003B2Accurate scaleSimple surfaceOrnamental structuresMilling machinesTerrainMaterial removal

A cutting apparatus includes a hi-accuracy three-dimensional cutting apparatus for topographic modeling that is electronically coupled with a computer. The computer has a central processor that executes instructions, a memory for storing instructions to be executed, and non-volatile storage for storing the messages. The executable computer instructions of the system include one or more algorithms for converting the complex and randomly-occurring contours found in natural terrain into an efficient series of modeling material removal swaths defined in simplified 2-axis cross-sections that are cut adjacent and parallel to one another. The swaths are defined in a simplified 2-axis surface contour-following rotation cutting device moved by the system's CPU, driver software, driver circuitry and / or logic circuitry. This multi-axis control of the system assures that each of the swaths are seamlessly rendered next to one another while also maintaining an optimal proximity between the upper surface of the 3D model and the rotation cutting device.

Owner:SOLID TERRAIN MODELING

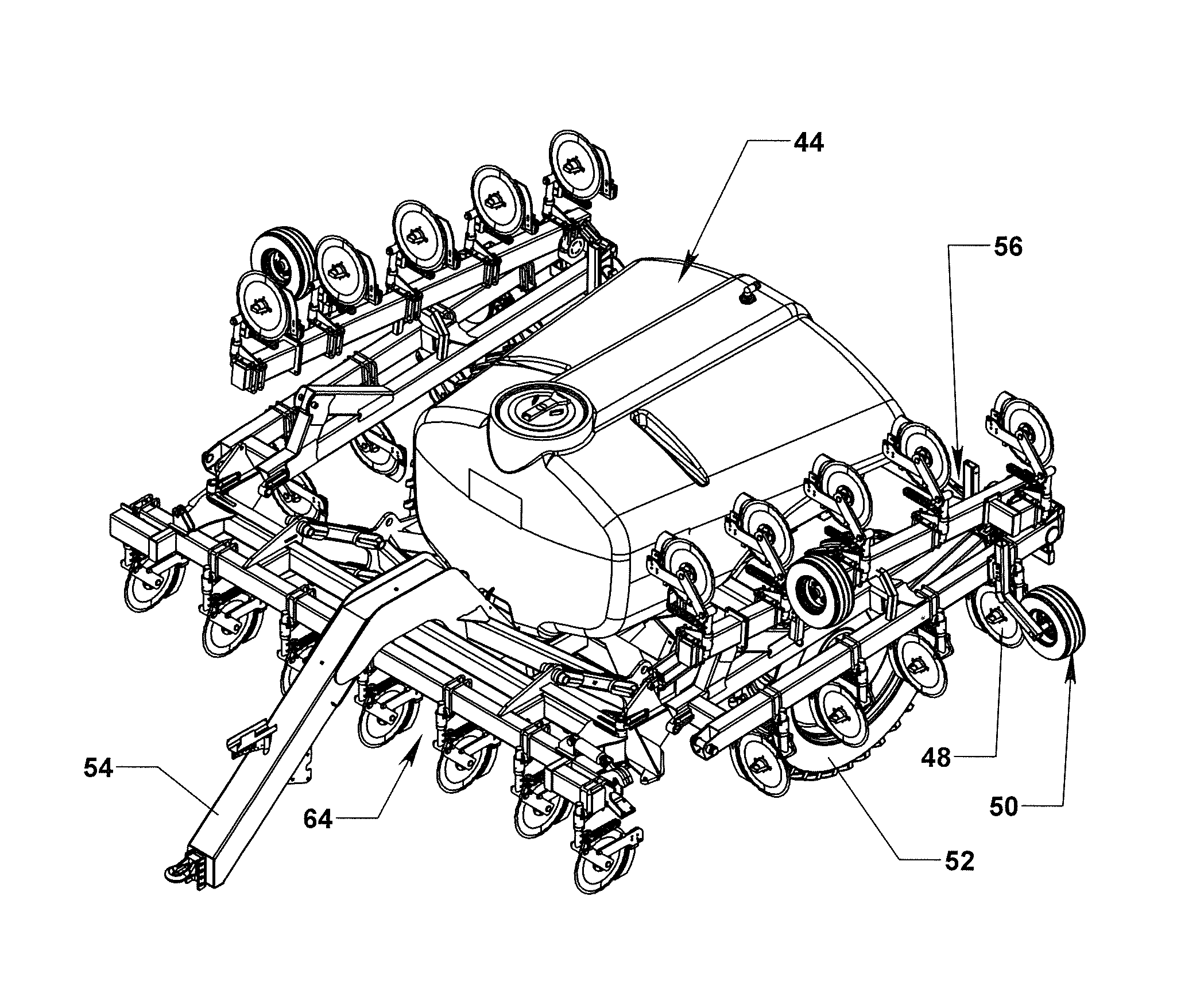

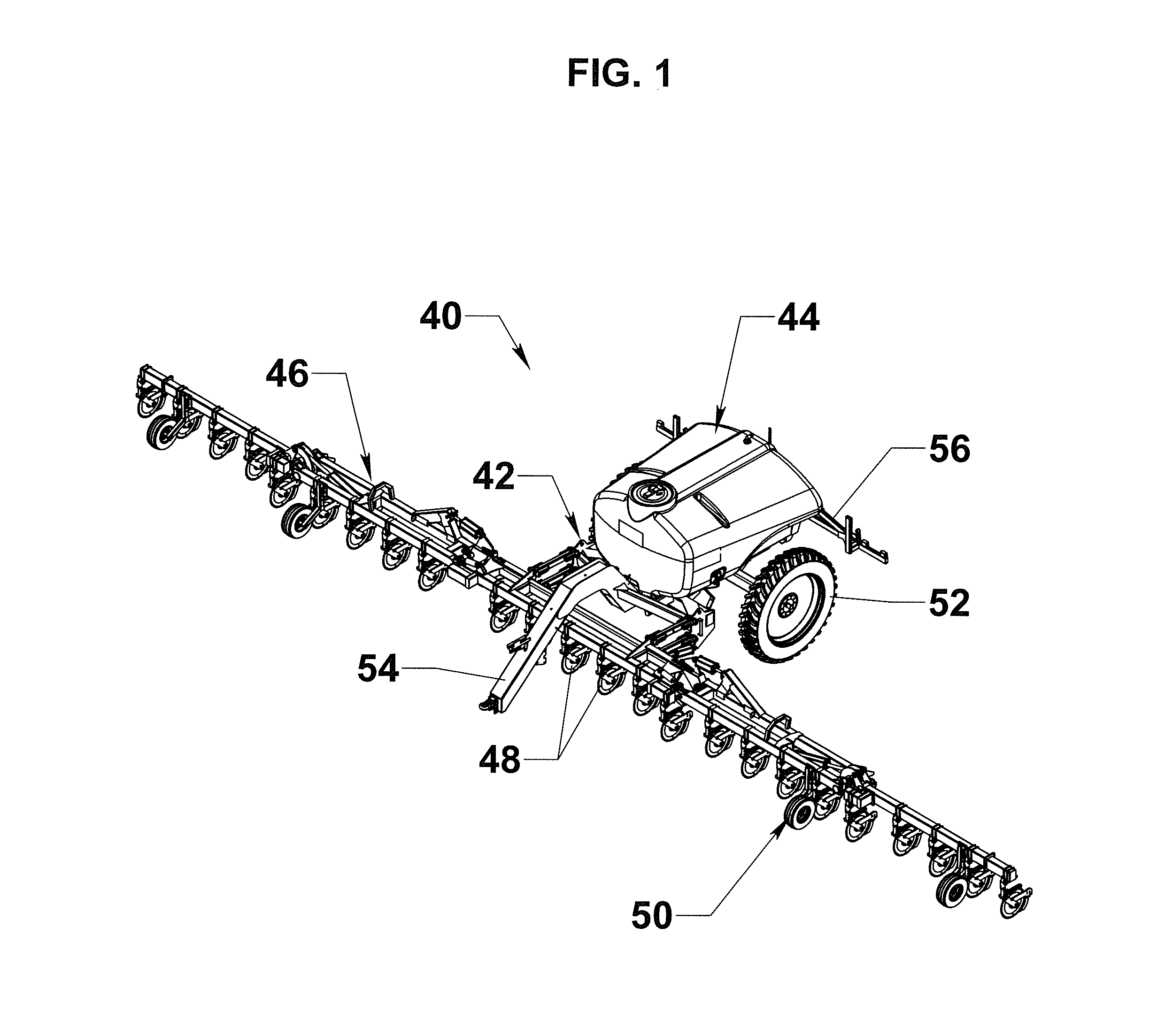

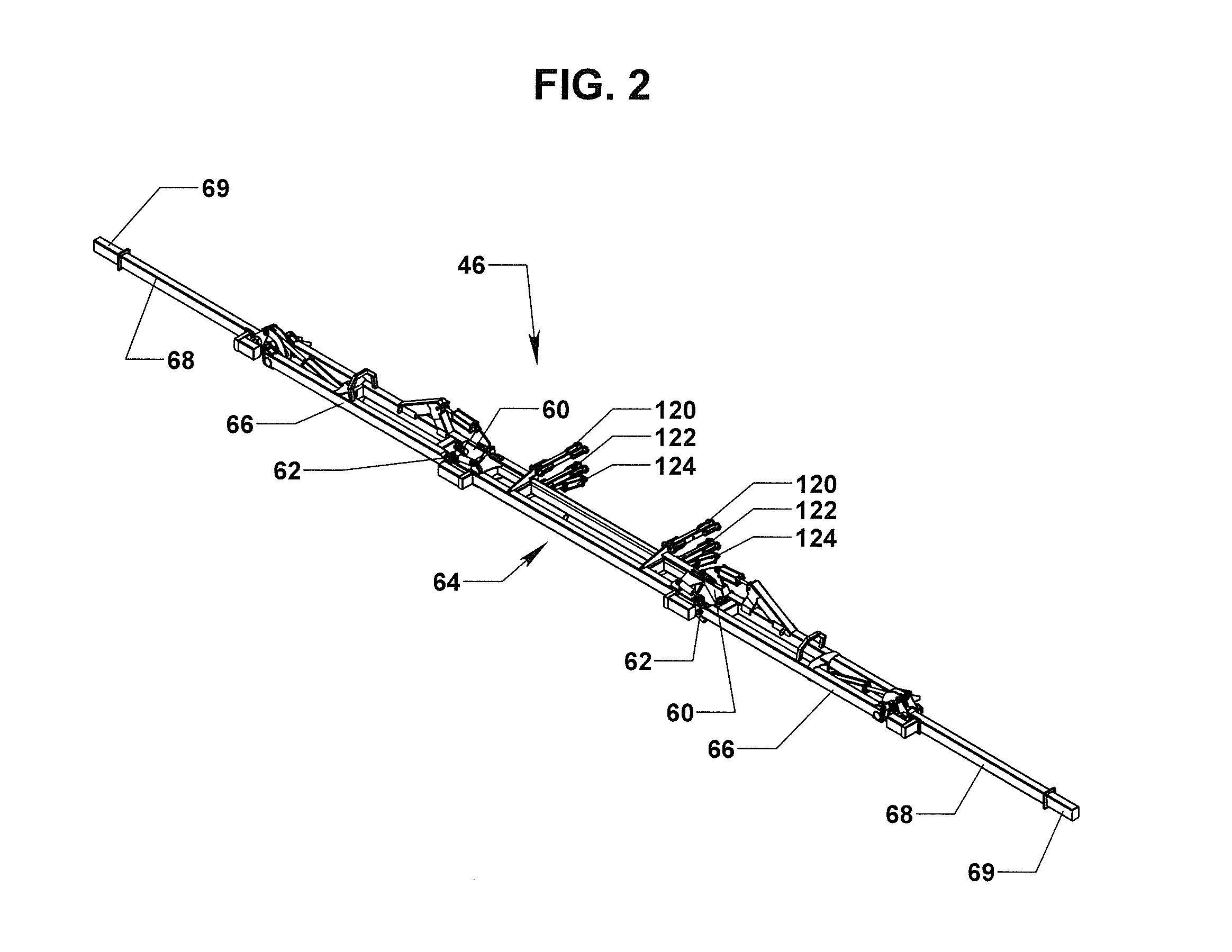

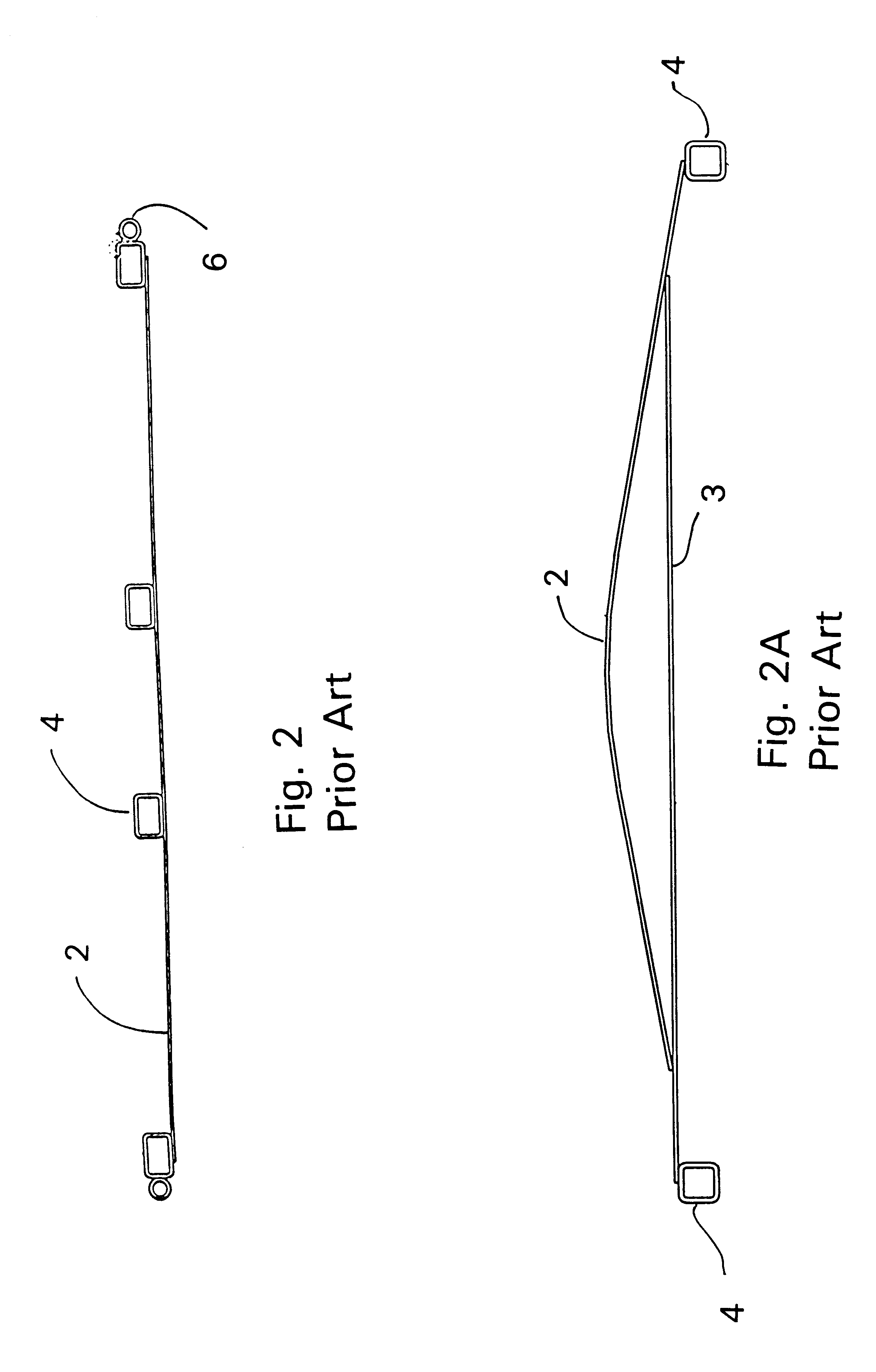

Side folding toolbar for chemical applicator

A multi-row agricultural soil treatment implement includes a semi-trailed carriage and a rearward folding toolbar. The toolbar is suspended from the semi-trailed carriage through parallel links and includes a center section, flex hinges, main wings, main wing latches, and outer flip wings operatively connected to hydraulic cylinders to move them between transport and field position. The main wings fold rearward relative to the center section and are supported by a transport rack but they retain the ability to pivot up or down as needed for ground contour following capability or row end turning.

Owner:FAST DISTRIBUTING +1

Terrain conforming track assembly

An endless track assembly that mounts to a wheeled vehicle. The assembly provides 1) a track suspension having fixed or adjustable, independently biased sets of idler wheels to vary the track contour without affecting track tension, 2) an eccentric bearing housing at a drive sprocket controls track tension, 3) a contoured peripheral edge at the drive sprocket prevents ice and mud buildup, 4) rubber-coated, plastic idler wheels facilitate track movement, 5) a multi-vehicle compatible adapter mounting plate accommodates a variety of vehicles, 6) a rotation limited torsion coupler and / or rotation limiting coupler arms prevent track contact with the vehicle, 7) a locking steering arm coupler prevents loss of steering control, 8) shaped track lugs and channels clear and direct debris away from the track suspension and drive assembly, and 9) a center, spring biased coupling suspension stabilizes and enhances the contour following and load handling capabilities in the center region of the track. The improved suspension particularly supports sets of idler wheels in pivotal relation to the track support frame and resiliently biases a pre-tensioned rocker arm that links adjacent suspension arms mounted to the adjoining idler wheels. Suspension arm movement induces expansion and contraction of tension springs coupled to the rocker arms to augments shape changes at the track contact surface to optimize traction and steering control.

Owner:BRAZIER GLEN

Contour follower

ActiveUS20060040590A1Solid-state devicesMagnetic field measurement using galvano-magnetic devicesCollision detectionEngineering

A contour follower includes a plurality of sensors spaced around a waterjet nozzle, each of the sensors being configured to measure a distance between a working surface and a first plane, perpendicular to a longitudinal axis of the nozzle. The sensors may include hall-effect sensors lying in the first plane and magnets lying in a second plane, parallel to the working surface. A detecting circuit processes signals from the sensors to determine an angle of the working surface, relative to the first plane, and a distance between an aperture of the nozzle and the working surface. A collision detection sensor provides a signal in the event the device approaches to within a selected distance of an obstruction in the plane of the working surface. A shield plate blocks and dampens secondary spray-back of cutting fluid occurring at low angles above the working surface.

Owner:FLOW INT

Double deck rotary mower body

A rotary mower for cutting vegetation including grass, brush and the like, and more particularly to a rotary ditch mower having a main body and extension wings or side sections supporting a number of cutting blades. The main body and extension wings are supported by contour following ground wheels and the main body also foldably supports the extension wings which may be inclined relative to the main body. The mower is also provided with a hitch pole for pull behind connection with a tractor and an articulation mechanism of the main body and extension wings for adjustment of cutting height over varying terrain during cutting operations as well as for raising the extension wings to a transport position and for raising the mower to a substantially vertical position, i.e., the main body and extension wings raised perpendicular with respect to the ground to facilitate servicing and maintenance of the mower.

Owner:DEGELMAN IND LP

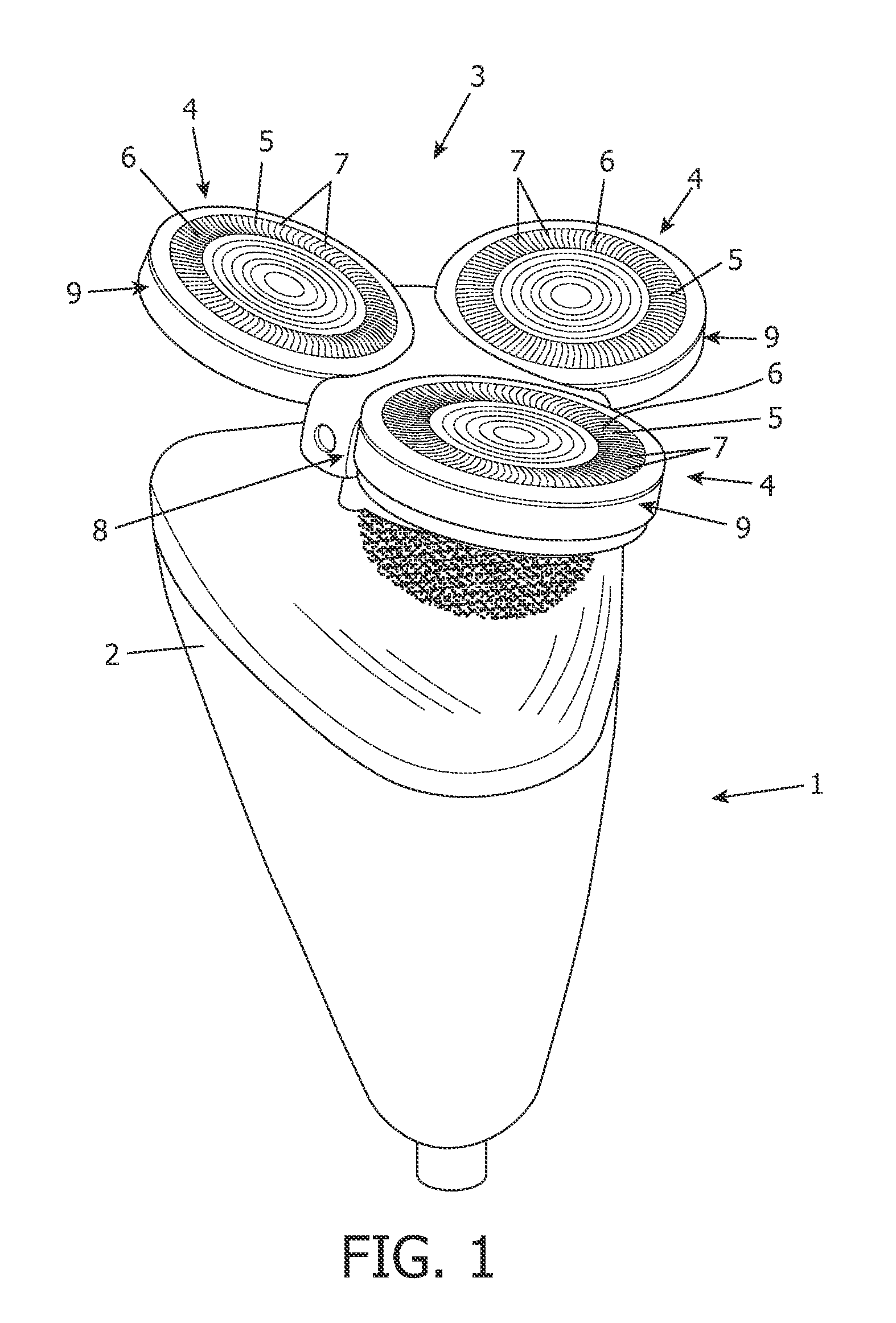

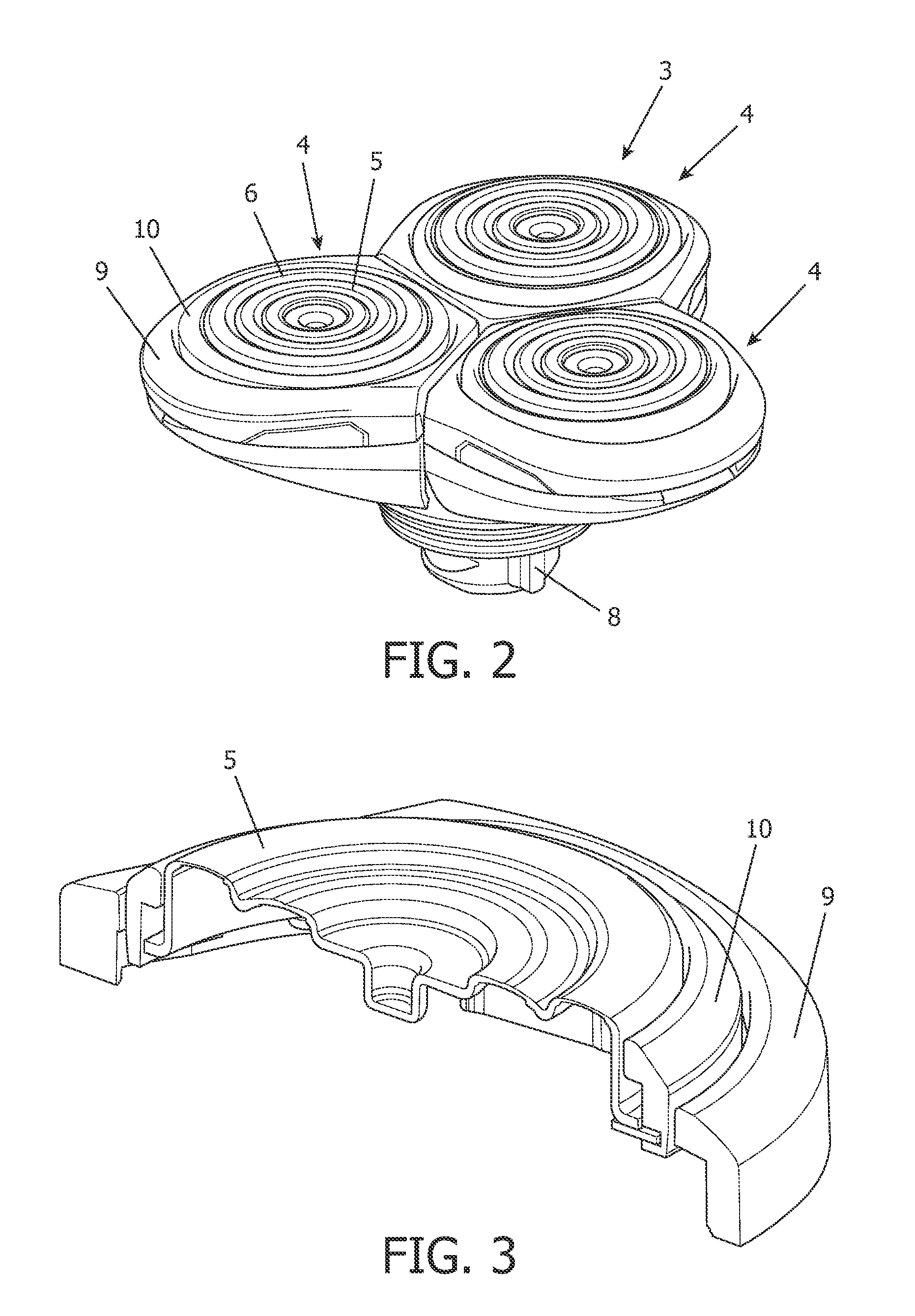

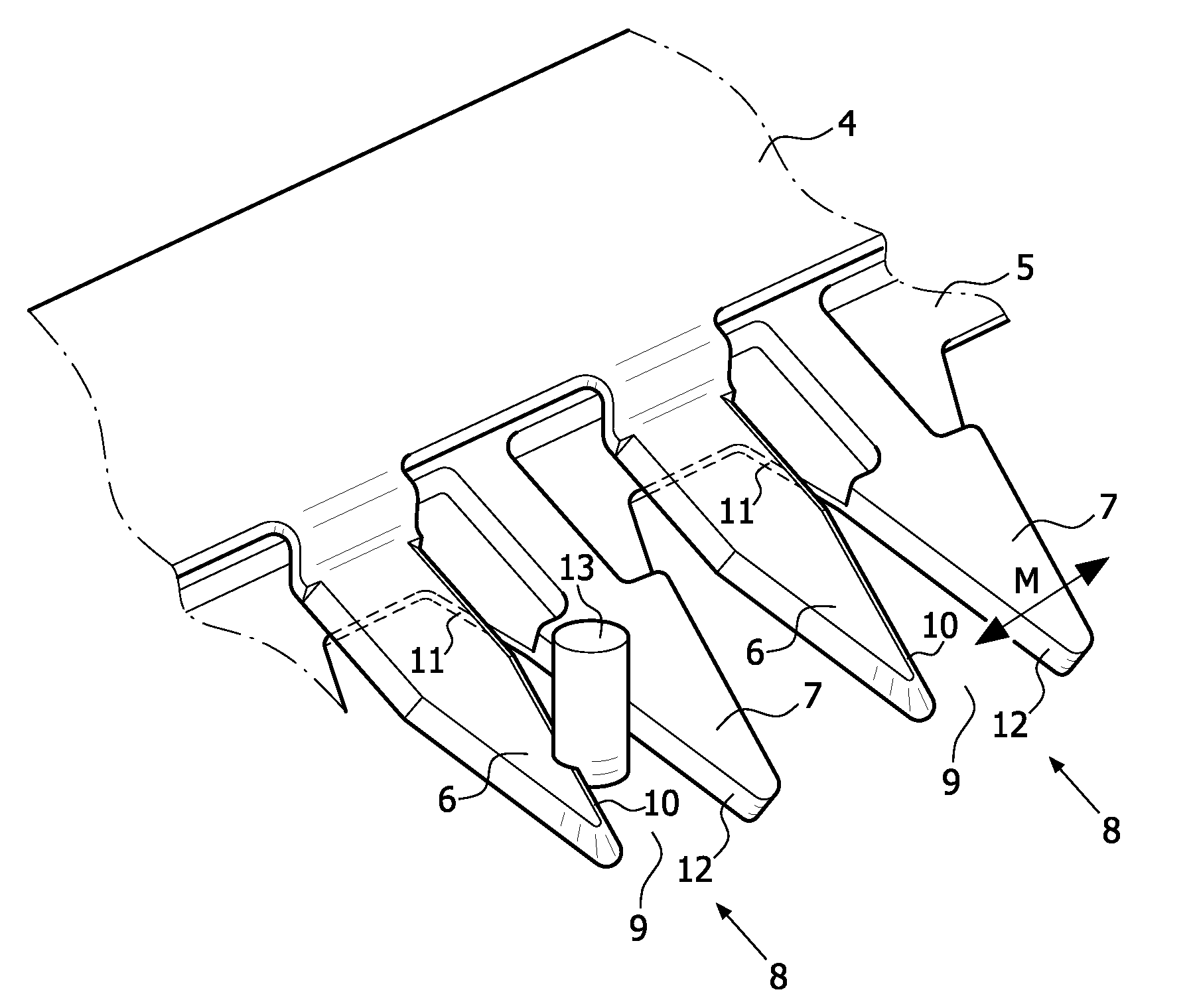

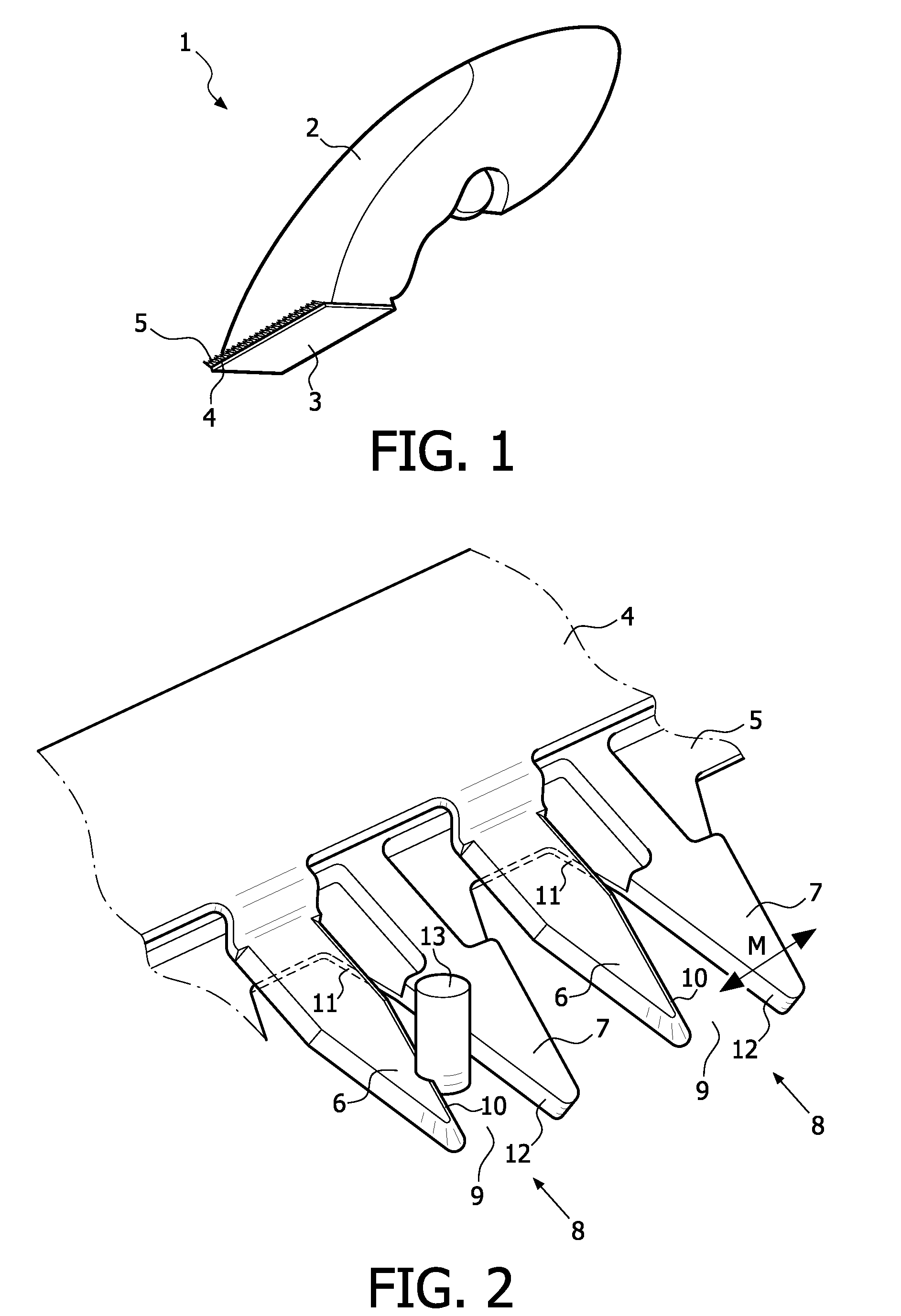

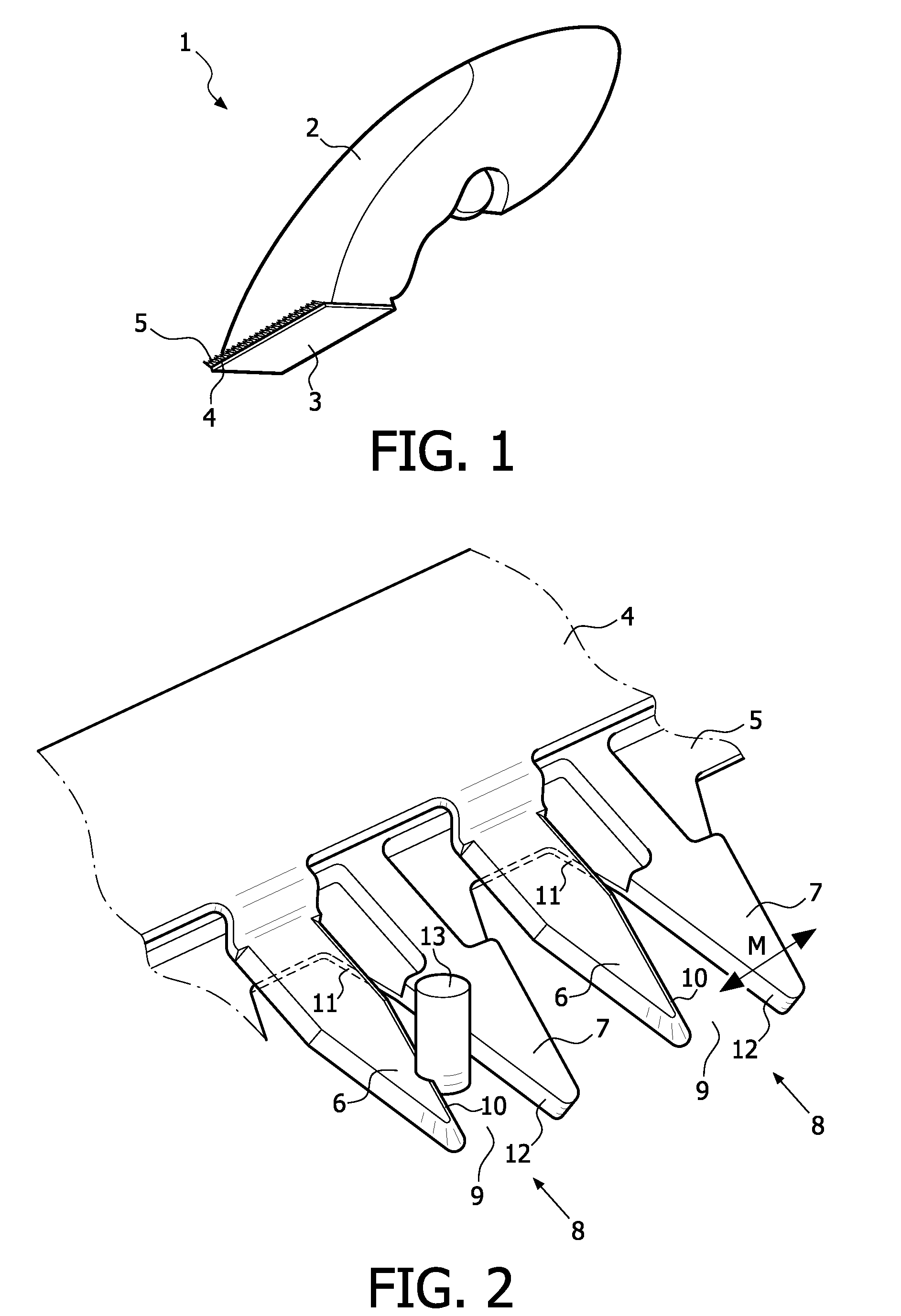

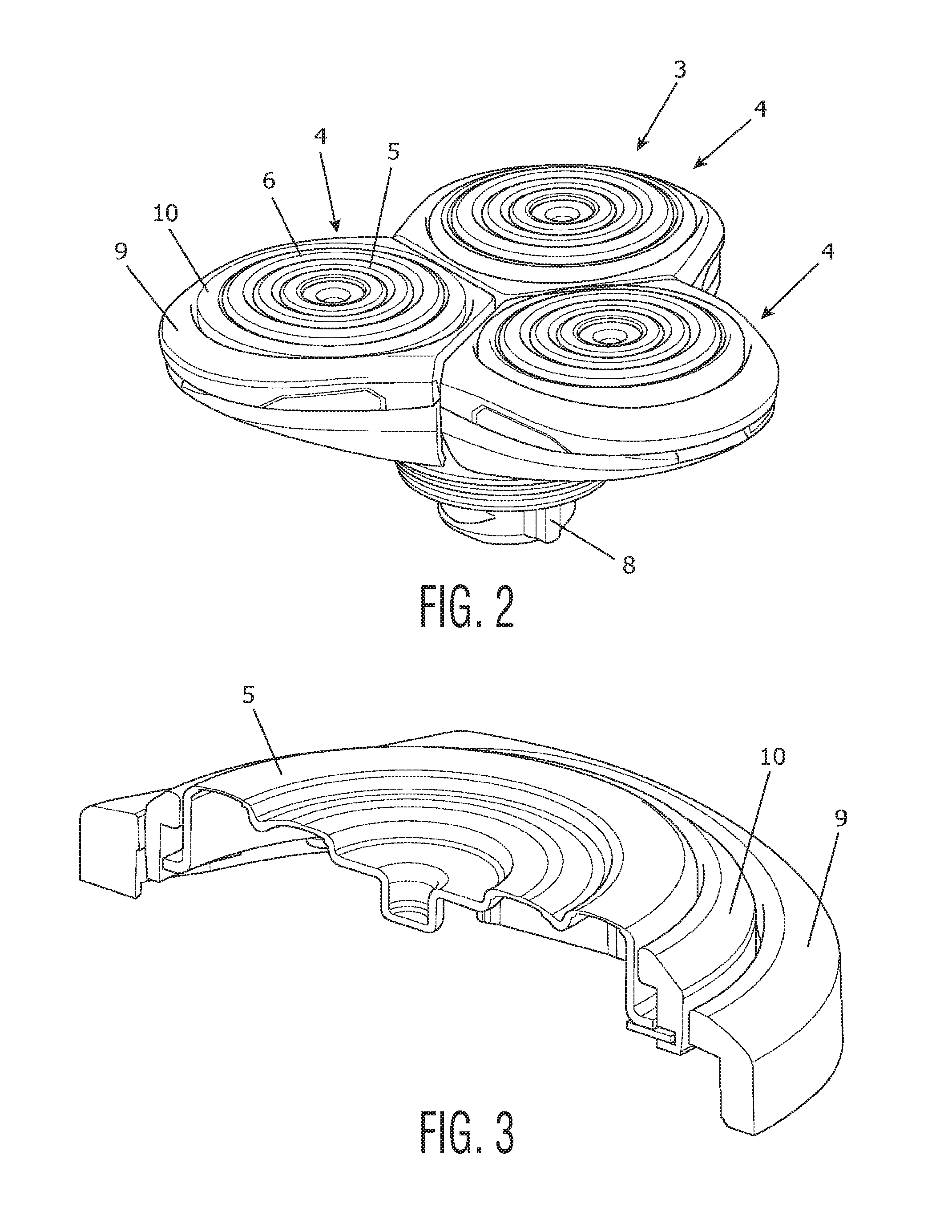

Shaving device with improved contour following

ActiveUS20110308088A1Promote resultsLow stiffnessMetal working apparatusEngineeringMechanical engineering

A shaving head (3) comprises at least one cutting unit (4) in which an external cutting member (5) which has a function in contacting skin to be subjected to a shaving action is arranged, and which is suspended relative to a holder (8) of the shaving head (3) through suspension means. In particular, the suspension means comprise at least two pivot constructions, wherein one pivot construction enables a member (9) of the suspension means to be pivotable relative to the holder (8), and wherein another pivot construction enables the external cutting member (5) to be pivotable relative to the suspension member (9) as mentioned. Furthermore, a pivoting stiffness of a connection of the latter pivot construction is lower than a pivoting stiffness of the first pivot construction. In this way, good contour following performance is obtained at two levels, in both relatively small and relatively large curvature changing areas.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Hi-resolution three-dimensional imaging apparatus for topographic and 3d models

The present invention is directed to an automated system that includes a hi-resolution three-dimensional imaging apparatus for topographic modeling that is electronically coupled with a computer. The system incorporates one or more algorithms for converting the complex and randomly-occurring contours found in natural terrain into an efficient series of adjacent and parallel coloring-agent imaging paths or swaths (comprised of inks, dyes, paints, and / or pigments). The swaths are defined in simplified 2-axis surface contour-following printer-head movements by the system's CPU, printer driver software, driver circuitry and / or logic circuitry. This multi-axis control of the system assures that each of the swaths are seamlessly rendered next to one another while also maintaining an optimal proximity between the upper surface of the 3D model and the nozzle end of one or more hi-resolution printer. A single coloring-agent such as black ink, may be used solely, or in combination with a plurality of colors such as a Cyan, Magenta, Yellow and Black or “CMYK” combination. The system also incorporates algorithms for applying accurately registered indicia of a prescribed color, or colors, onto the surface of models including man-made boundaries such as property lines, easements, right-of-ways, land-development features; naturally occurring boundaries such as ridges and flow-lines, bodies of water, lakes, lake-beds, rivers, river-beds and forested areas including tree varieties; lettering including the accommodation of a variety of fonts; graphical embellishments; and cartographic elements.

Owner:SOLID TERRAIN MODELING

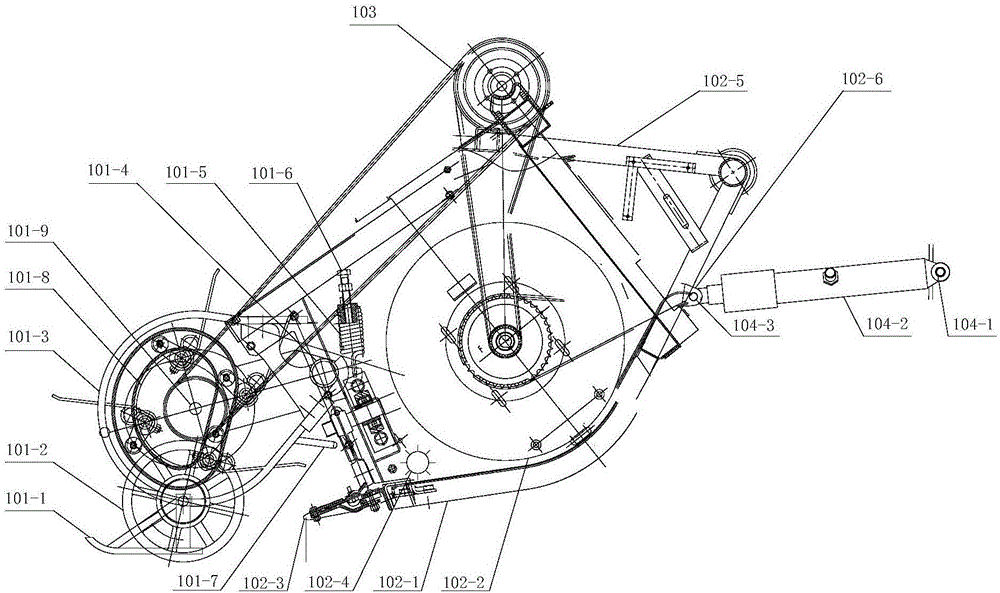

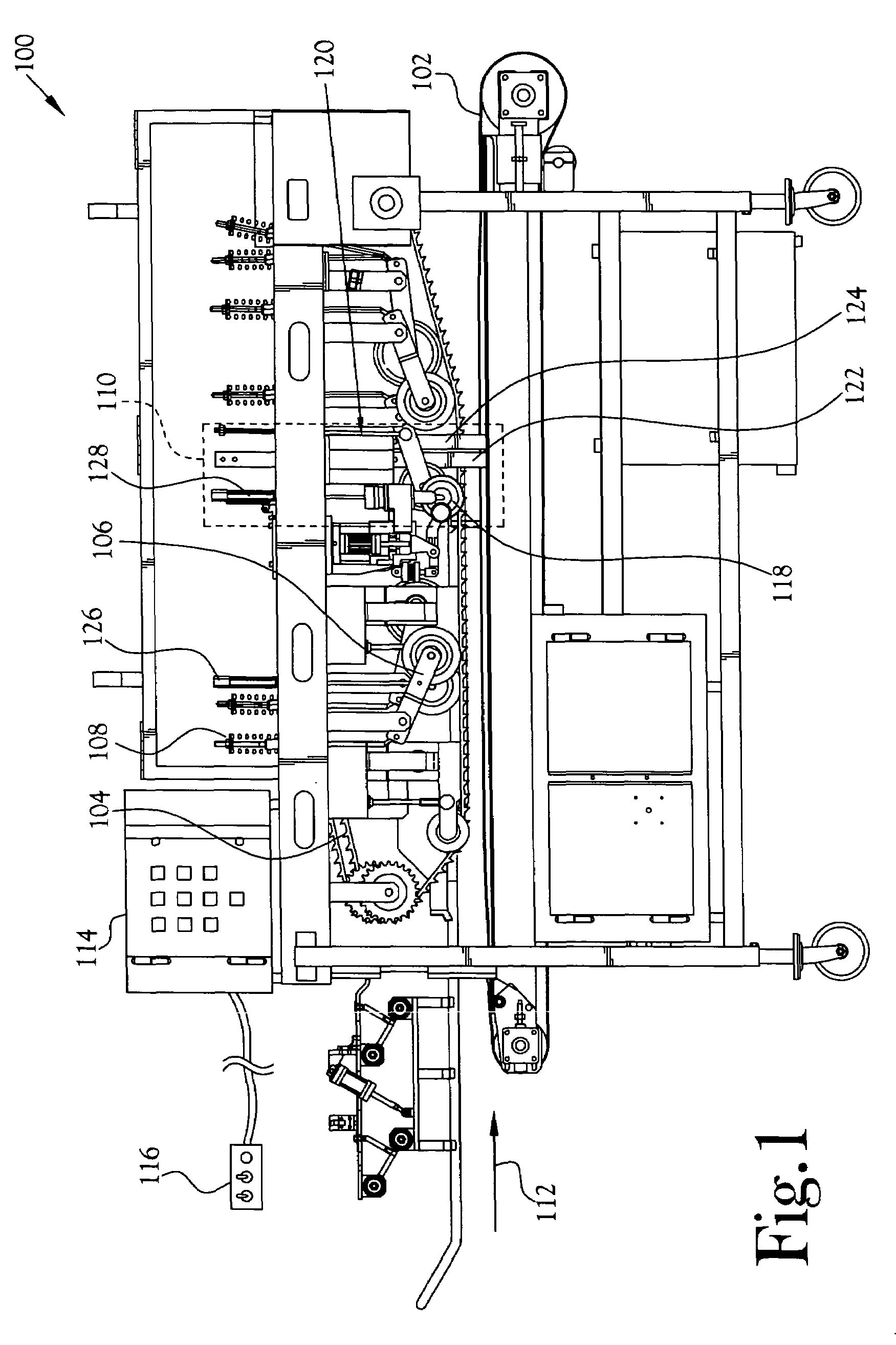

High-efficiency crawler-type pick-up baler and bale automatic stacking system thereof

ActiveCN106358605AImprove efficiencyImprove work efficiencyLoadersMowersDelivery PerformanceControl system

Owner:JIANGSU UNIV

Shaving device comprising a pivotably arranged assembly of cutting elements

ActiveUS20100299930A1Without loss of stiffnessIncrease stiffnessMetal working apparatusReciprocating motionContour following

A shaving device comprising cooperating hair cutting elements (4, 5) and means for driving the hair cutting elements (4, 5) is adapted to allow for automatic contour following during its application on the skin of a user. In particular, at least one cutting element (4, 5) is pivotably arranged in the shaving device, wherein a pivot axis (15) is intersecting at least one position where the cutting element (4, 5) is contacted by a driving member (14) for imposing the reciprocating movement on the cutting element (4, 5). In this way, a high drive stiffness is guaranteed, which is particularly important when a stroke of the movement of the cutting element (4, 5) is relatively small, for example, in an order of 100 μm.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Floor covering removal machine

A floor covering removal machine for removing a floor covering that is secured to a floor that includes a drive frame formed with an underside caster assembly, and feed, ejection, and oppositely arranged cutter sides. A variable speed, reversible, motorized drum is mounted about the frame and cooperates with a gripping idler roller that is releasably biased toward the drum to establish a grip interface which conveys the floor covering from the feed to the ejection sides. In operation, the floor covering is pulled through the grip interface and thereby removed from the floor. The machine also may include a collapsible guide handle extending from the drive frame and a motor speed control. Optional retractable floor covering cutters are included that are deployable in a floor contour-following configuration. An optional alignment laser pointer is mounted on the frame for alignment during operation.

Owner:MANNERS HERBERT C

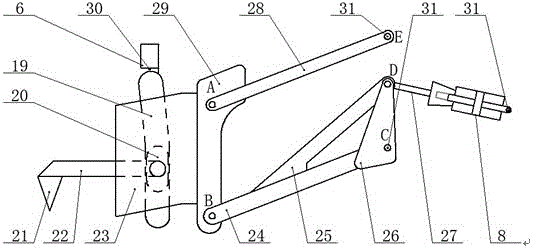

Hydraulic contour-following planting mechanism

The invention discloses a hydraulic contour-following planting mechanism which comprises a ground sensing mechanism, a hydraulic actuating mechanism and a planting device servo mechanism. The ground sensing mechanism is used for acquiring the undulation condition of ground and feeding the undulation condition of the ground back to the hydraulic actuating mechanism to control a hydraulic cylinder to stretch or draw back to drive the planting device servo mechanism to move up or down so as to ensure a consistent relative height between a duck bill planting component and the ground. The hydraulic contour-following planting mechanism is simple in structure and easy to popularize. The rear planting device servo mechanism adopts a parallelogram link structure, can bear a heavy load and amplify displacement, and ensures the balance and verticality of a planting device during a contour-following process, thus ensuring the uniformity of planting depth during a transplanting process, improving the planting quality and better meeting the requirement of field transplanting in dry land.

Owner:JIANGSU UNIV

Farmland plastic mulch lifter

InactiveCN105706550AMeet the requirements of recycling operationsLow impurity content in the received filmGatherer machinesPlastic mulchAgricultural engineering

The invention relates to a farmland mulch recycling machine, which includes a traction frame, a frame, a gearbox, a disc cutter, a transverse film cutting device, a film picking device, a film stripping device, a film collecting device, a transmission system of a transverse film cutting device, The transmission system of the film device, the transmission system of the film collecting device, the ground wheel and the film collection box are characterized in that the traction frame is set on the front side of the frame, the gearbox is set on the frame on the rear side of the traction frame, and the disc cutters are arranged in rows at intervals. The lower part of the beam of the frame, the rear side of the gearbox, the transverse film cutting device is set on the rear side of the disc cutter, the film picking device is set on the rear side of the transverse film cutting device, the film stripping device is set above the film picking device, and the film collecting device is set On the rear side of the stripping device, the film collecting box is set on the back side of the film collecting device, the ground wheels are set on both sides of the frame, and the transmission system of the transverse film cutting device, the film collecting device, and the stripping device are respectively installed on the frame. Above all, the present invention has the characteristics of low impurity rate of collected film, reliable operation, high clean rate and good ground profiling, etc., and can meet the requirements of residual film recovery operation.

Owner:SHIHEZI UNIVERSITY

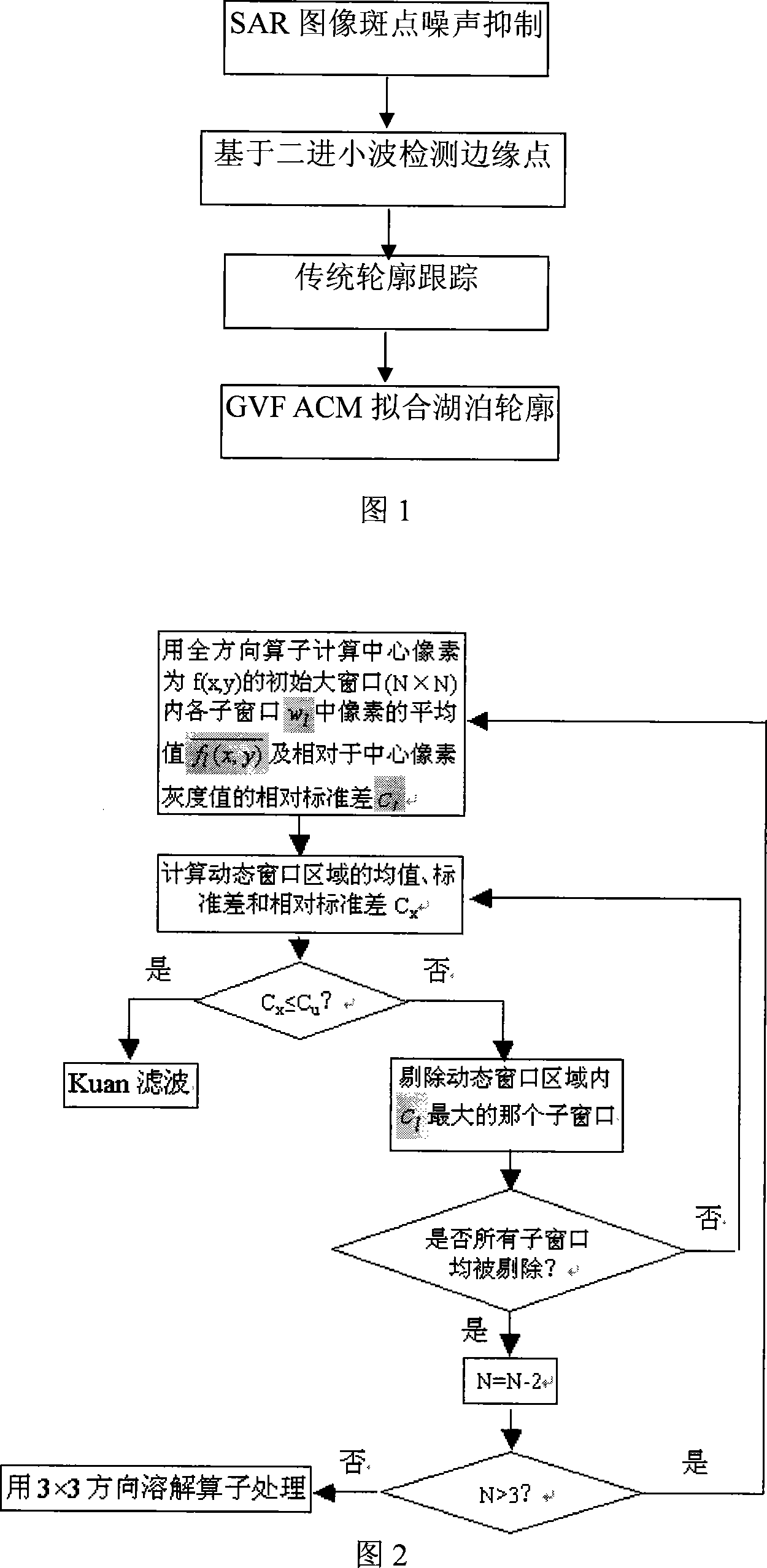

Method for detecting lakeshore and extracting lake profile from SAR image

InactiveCN101126811AEliminate the effects of extractionAccurate detectionCharacter and pattern recognitionRadio wave reradiation/reflectionRadarSynthetic aperture radar

The utility model discloses a method to detect the lake shore line and extract the lake contour from the synthetic aperture radar remote sensing image. The utility model adopts the technical proposal that: firstly, an all-direction self-adaptive dynamic window filter is utilized to do speckle noise suppression on the synthetic aperture radar remote sensing image; secondly, the fact that the singularity of the edge and the noise have different propagation laws according to scale variation in dyadic wavelets transformation is utilized to detect edge points; thirdly, the traditional contour following method is utilized to connect the edge points; finally, an active contour model based on gradient vector flow is utilized to fit the lake contour. The utility model effectively eliminates the influence of speckle noise in SAR image on flood boundary extraction, detects the lake shore line accurately and finally gets the lake contour.

Owner:BEIJING JIAOTONG UNIV

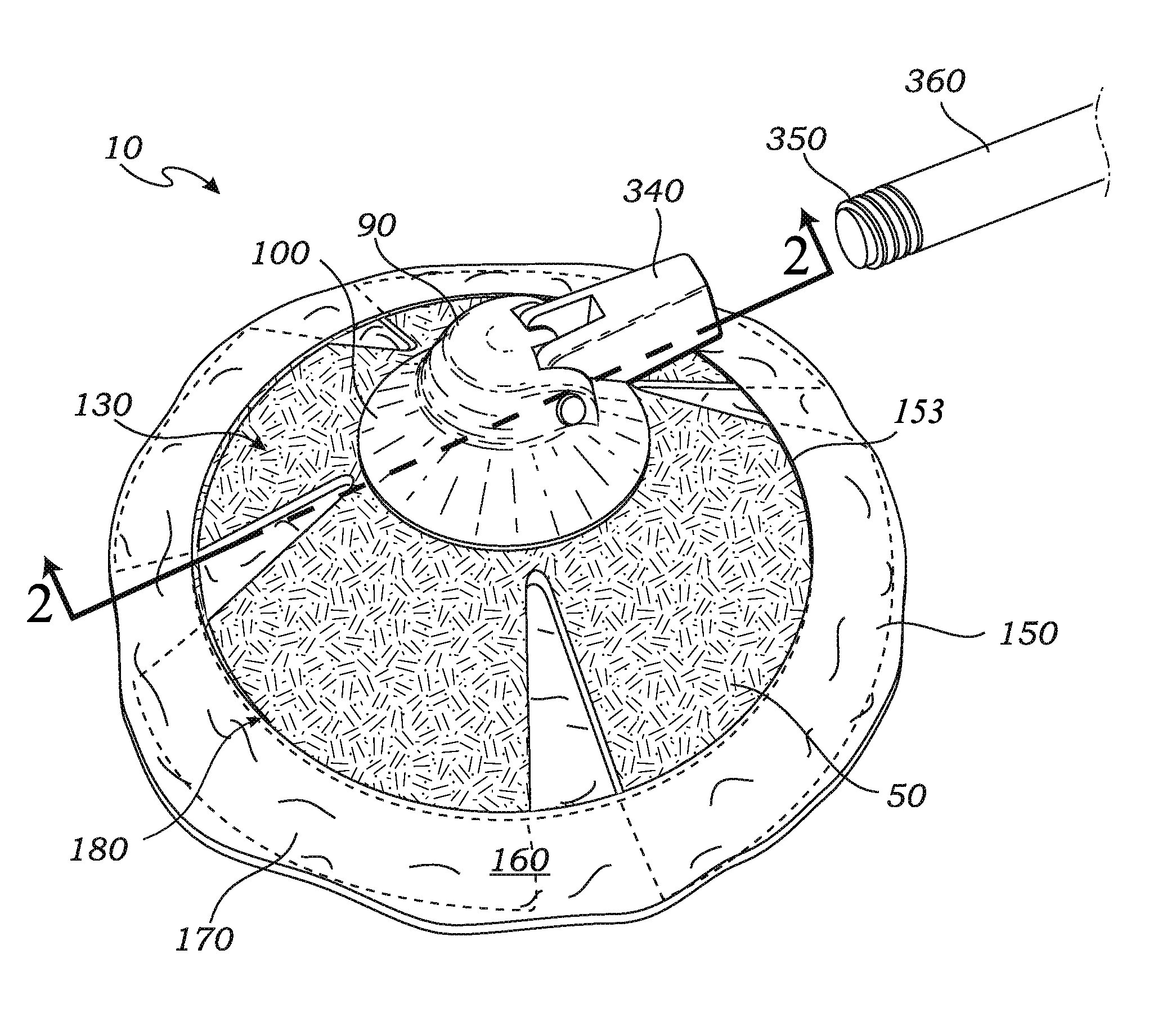

Adjustable contour-following mop

InactiveUS7908701B1Ensure close contactReduce manufacturing costBoard cleaning devicesLiquid processingContour followingMechanical engineering

An adjustable scrubbing implement for cleaning a surface is disclosed. A resilient base that comprises a center portion and a plurality of resilient fingers each is joined at a proximal end thereof to the center portion and extends radially away therefrom. The rigid cap comprises a side portion fixed at a top end thereof to an inside upper side of the cap, and terminates at a wider open lower end. The inside upper side includes a central aperture therethrough. The cap includes a handle receiving means pivotally fixed thereto for receiving a threaded end of an elongated handle. An adjustment means interposed between the cap and the resilient base moves the center portion of the base relative to the inside upper side of the cap. The downward angle of the fingers are defined by the relative distance between the center portion of the base and the inside upper side of the cap. Changing the downward angle of the fingers results in a change in the effective resiliency of the resilient base, which affects the amount of force required to cause the fingers to move into a compressed. As such, the scrubbing characteristics of the scrubbing implement may be selectively adjusted by adjusting the adjustment means.

Owner:AIYAR SANJAY

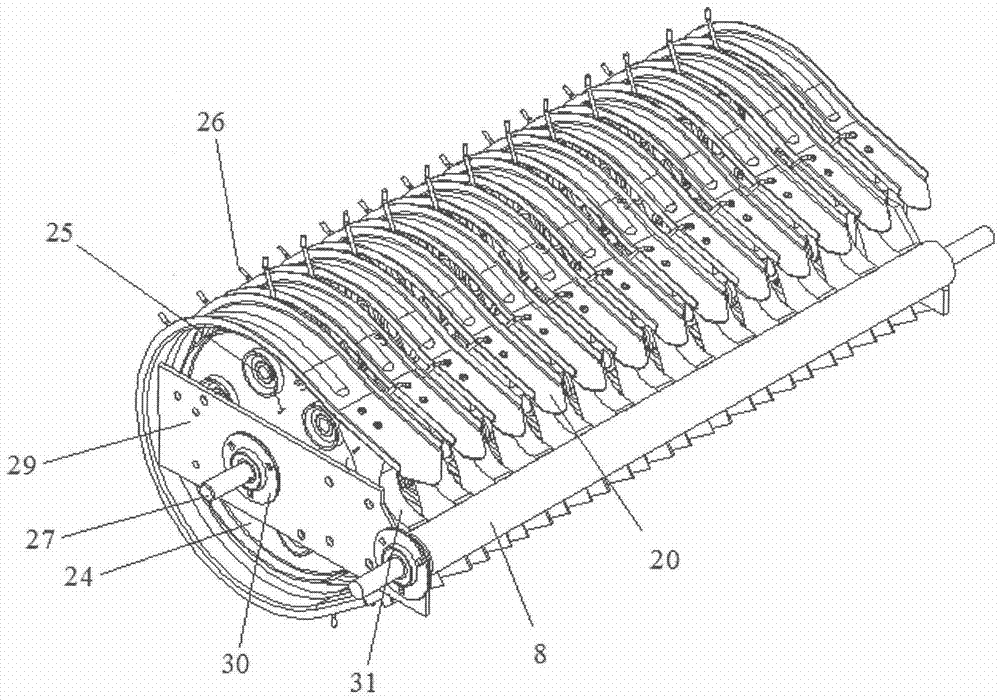

Ground-contour-following circular disc elastic claw pickup

The invention discloses a ground-contour-following circular disc elastic claw pickup for pickup operation of crop straws or pasture and relates to the technical field of straw harvesting and baling. The pickup mainly comprises a circular disc elastic claw roller, a suspended copying device and a floating grass pressing assembly. In the pickup operation of the pickup, the left and right copying wheels of the suspended copying device are in contact with the ground so that the integral pickup swings around a pipe shaft, and therefore, the pickup is suitable for ups and downs of the ground. Elastic claws in circling motion cooperate with the floating grass pressing assembly to form channels where picked materials flow so as to prevent the materials from being thrown out of the pickup and pick up the materials. According to the invention, a slideway of a conventional elastic claw pickup is cancelled; an elastic claw driving mechanism is simplified; and the main shaft of the pickup is allowed to have a relatively high rotating speed, so that the pickup operational efficiency of the crop straws or pasture is improved, and the pickup effect is good. Meanwhile, the ground copying circular disc elastic claw pickup disclosed by the invention is simple in structure, relatively convenient for batch production, low in manufacturing cost and convenient to use.

Owner:JIANGSU UNIV

Shaving device comprising a pivotably arranged assembly of cutting elements

ActiveUS8458914B2Without loss of stiffnessIncrease stiffnessMetal working apparatusReciprocating motionContour following

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

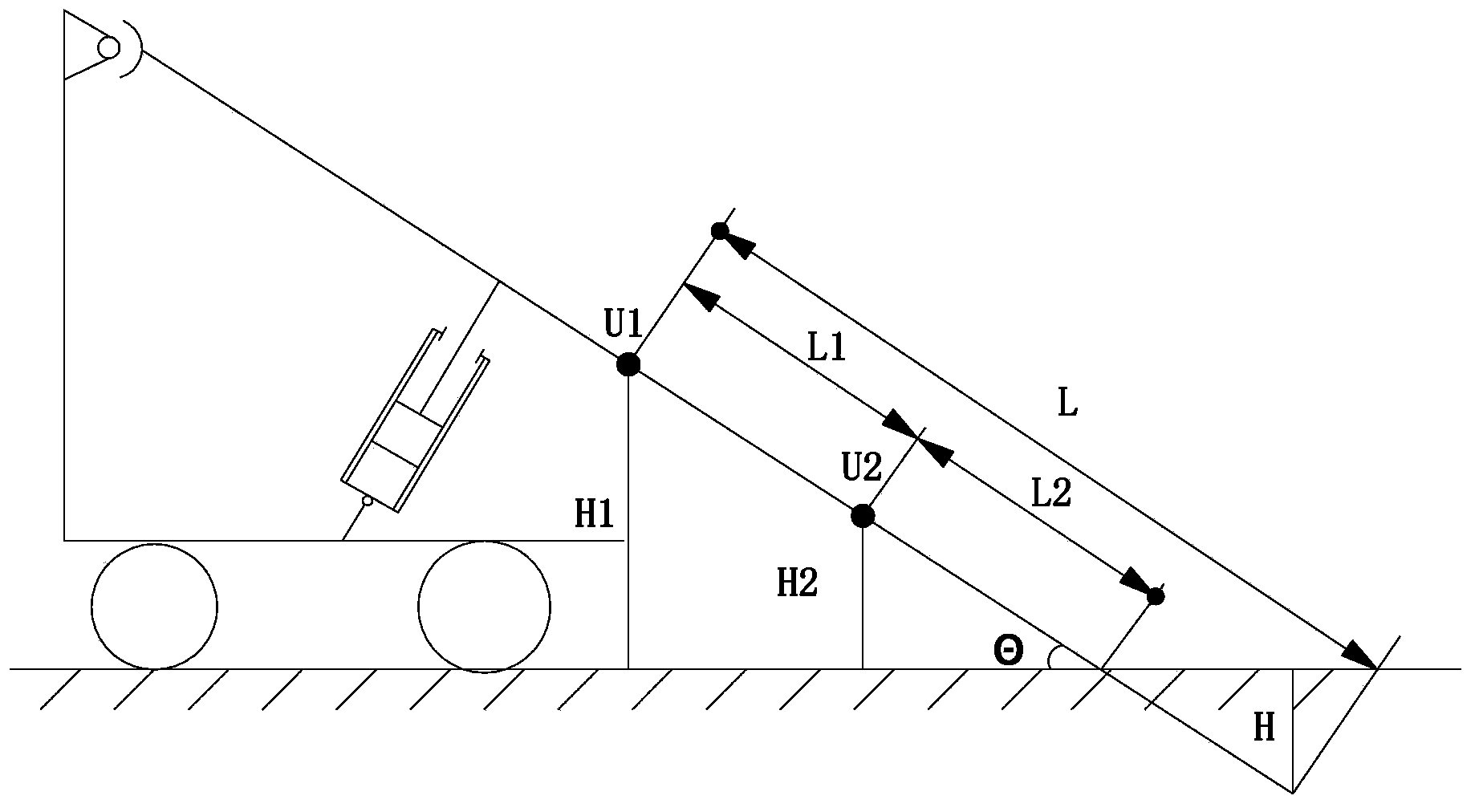

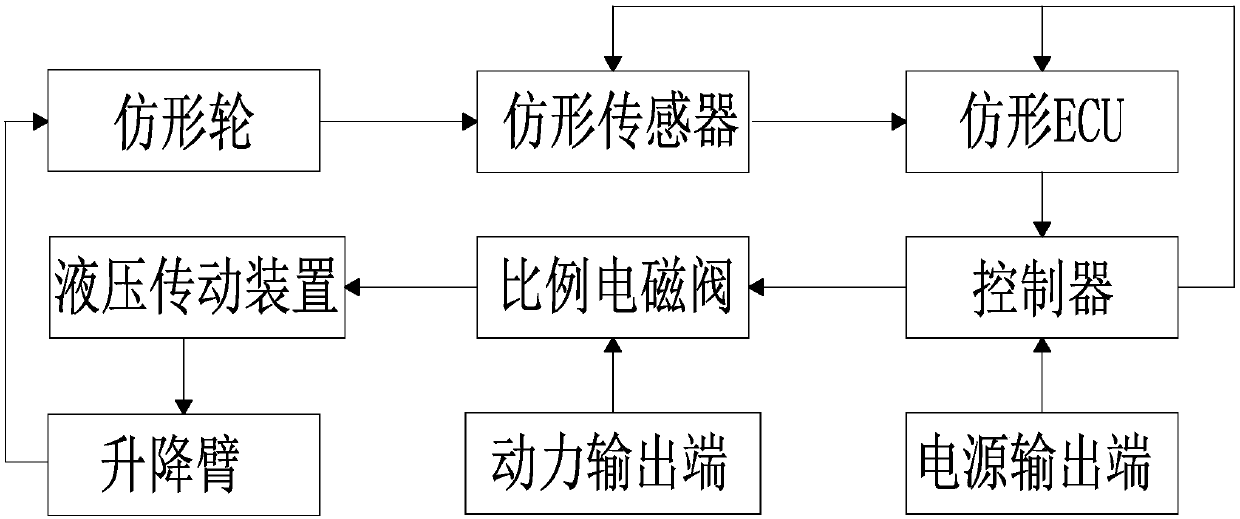

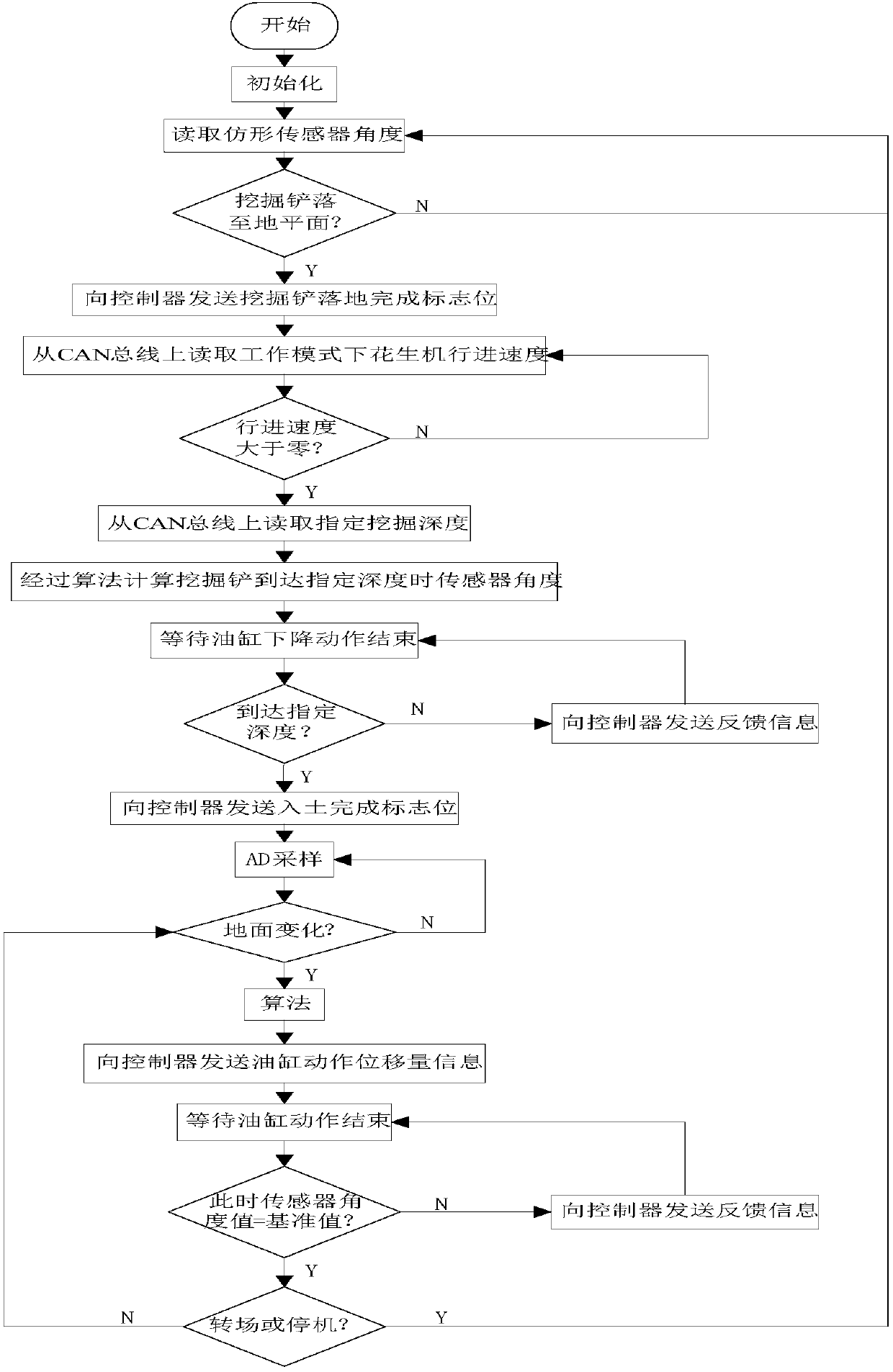

Automatic depth limiter of peanut combine harvester

ActiveCN103444347AAvoid launchImprove ranging accuracyDigger harvestersUltrasonic sensorControl signal

The invention relates to an auxiliary mechanism of a peanut combine harvester, in particular to an automatic depth limiter of the peanut combine harvester. The automatic depth limiter is characterized in that a ground-contour-following device (2) is arranged closely to the ground, an ultrasonic transducer (1) is disposed above the ground-contour-following device (2), an ultrasonic ranging module (3) of the ultrasonic transducer (1) is arranged aiming for a measurement datum plate (12), signals acquired by the ultrasonic ranging module (3) are transmitted and back fed to a controller (4), control signals of the controller are transmitted to a magnetic valve (5), and digging depth of a digging shovel is adjusted through a hydraulic tubing and a double-acting hydraulic cylinder (6); a guide tube component, formed by a lower guide tube (17) and an upper guide tube (15) with opposed openings, is vertically fixed onto an axle of a land wheel (9), a pressure spring (10) is arranged in the guide tubes, and a welded plate (14) and the horizontal measurement datum plate (12) are fixed onto the top of the upper guide tube (15). Through design of the ground-contour-following device, ultrasonic waves are prevented from being transmitted directly to the ground, ranging accuracy is improved, anti-interference performance is high, depth limiting accuracy is high, and breakage rate of peanut harvest is greatly reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Dual-mode contour-following mop

InactiveUS7328477B1Readily detachable fashionReduce manufacturing costLiquid surface applicatorsLiquid processingDual modeContour following

A scrubbing implement for cleaning a surface with contours is disclosed. The scrubbing implement includes a resilient base that includes a plurality of resilient fingers, each of which extend radially away from center of the base. A rigid cap comprises an inside upper end and a wider open lower end. The cap preferably includes a handle receiving means pivotally fixed to the cap for receiving a threaded end of an elongated handle. A flexible pad is included that comprises a cleaning surface on a lower side thereof. The pad has a peripheral lip forming an aperture in the pad for receiving the distal ends of each finger of the base. The flexible pad is fixed around the distal ends of the fingers such that the pad may be applied to the surface to scrub the surface. The fingers and flexible pad conform to the shape of the surface.

Owner:AIYAR SANJAY

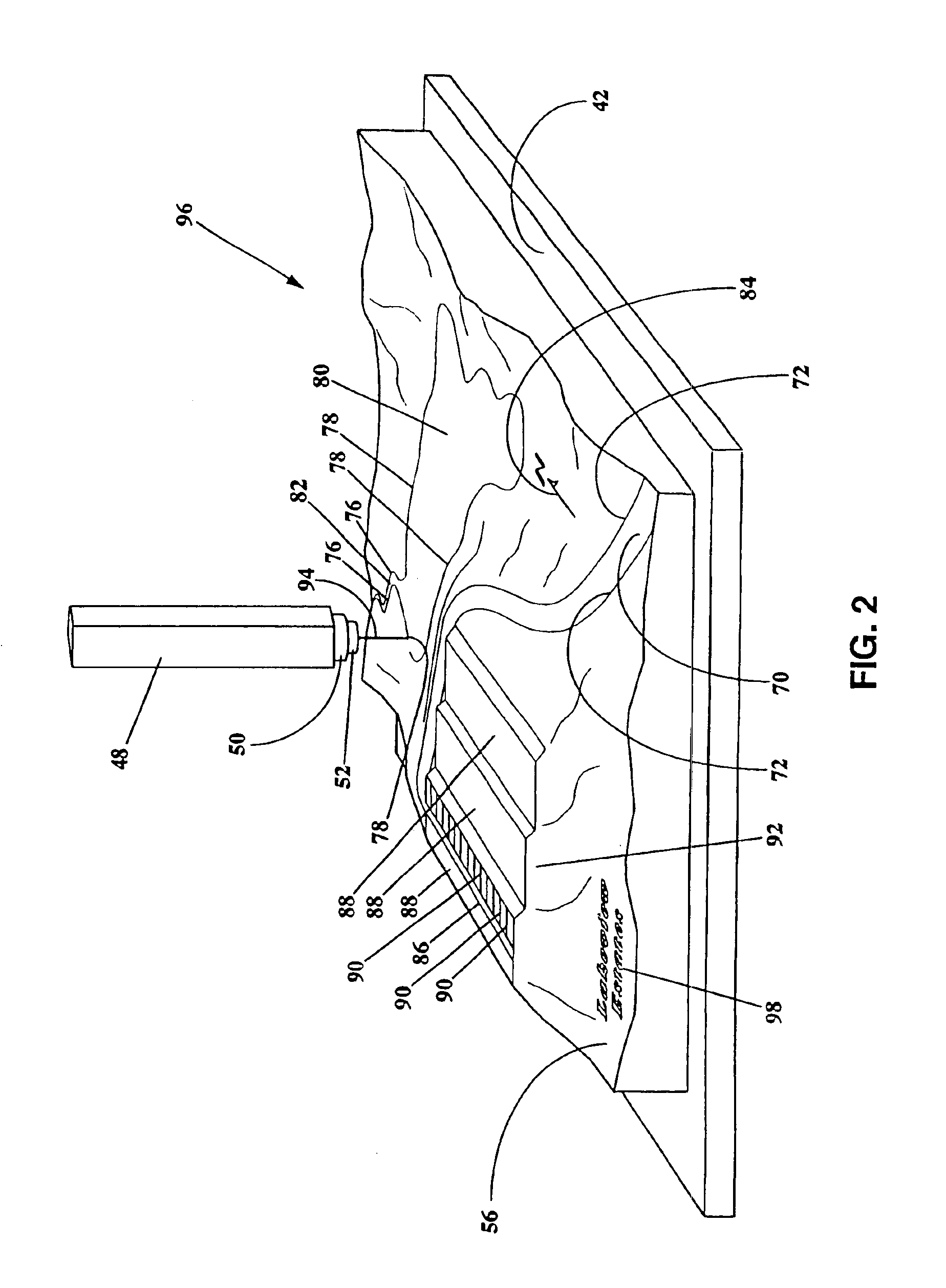

Articulated rotary mower

A rotary mower for cutting vegetation including grass, brush and the like, and more particularly to a rotary ditch mower having a main body and extension wings or side sections supporting a number of cutting blades. The main body and extension wings are supported by contour following ground wheels and the main body also foldably supports the extension wings which may be inclined relative to the main body. The mower is also provided with a hitch pole for pull behind connection with a tractor and an articulation mechanism of the main body and extension wings for adjustment of cutting height over varying terrain during cutting operations as well as for raising the extension wings to a transport position and for raising the mower to a substantially vertical position, i.e., the main body and extension wings raised perpendicular with respect to the ground to facilitate servicing and maintenance of the mower.

Owner:DEGELMAN IND LP

Ground-contour-following device for peanut harvester

PendingCN107787664AReal-time adjustment of digging depthDigger harvestersDesign optimisation/simulationEngineeringContour following

The invention discloses a ground-contour-following device for a peanut harvester. The device comprises a contour following sensing device, a lifting rack provided with a digging shovel and a control device, the contour following sensing device comprises rocker arm, the front end of the lifting rack is hinged to the rocker arm, and a contour wheel is rotationally arranged at the tail end of the rocker arm; the contour following sensor is arranged between the lifting rack and the rocker arm; a hydraulic drive device is connected to the lifting rack, the contour following sensor is in signal connection with the control device, and the control device is in control connection with the hydraulic drive device. According to the ground-contour-following device for the peanut harvester, by means ofthe contour wheel and the contour following sensor connected to the rocker arm, ground fluctuation can be sensed in advance, data measurement and data processing are conducted through the control device, and the hydraulic drive device is controlled to adjust the digging depth of the peanut harvester in real time.

Owner:WUZHENG

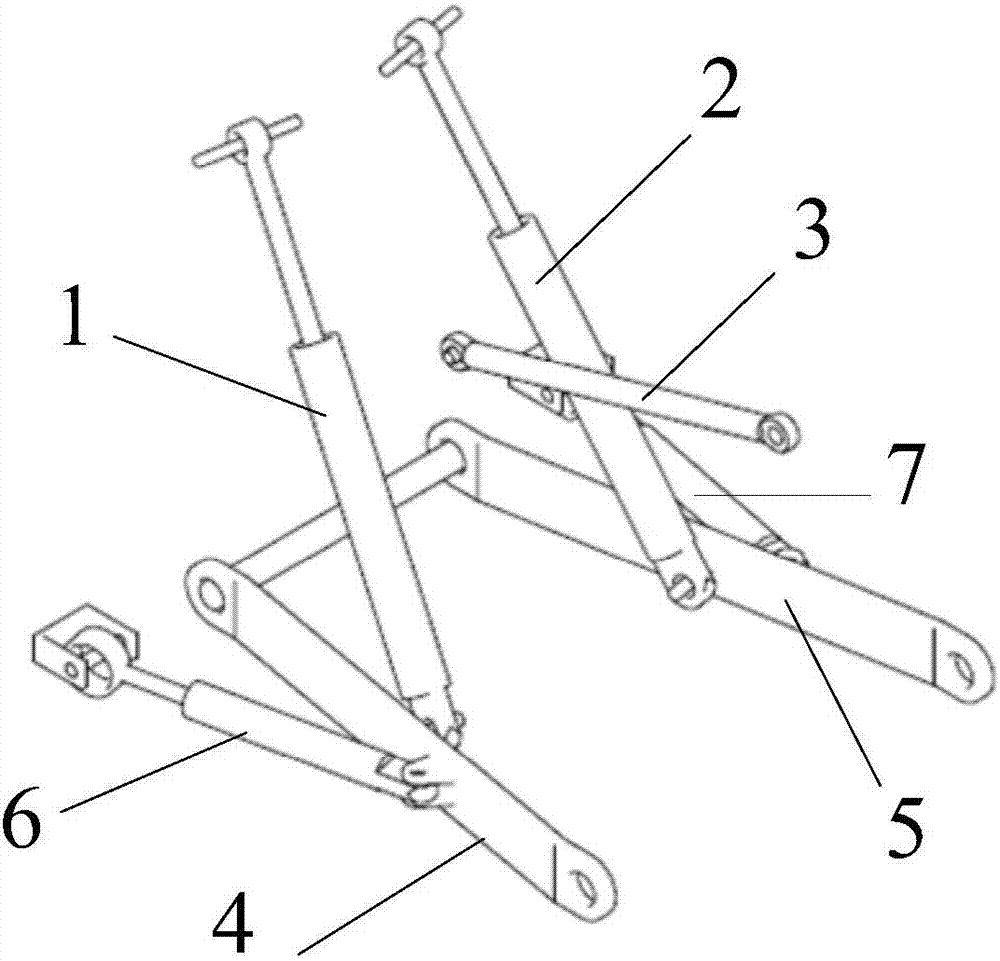

Ground contour following suspension mechanism for tractor used in hilly and mountainous areas

PendingCN107211610AWith lateral posture adjustable functionRealize the plowing operationAgricultural machinesAdjusting devicesHydraulic cylinderAutomatic control

The invention discloses a ground contour following suspension mechanism for a tractor used in hilly and mountainous areas. The ground contour following suspension mechanism comprises a left lifting hydraulic cylinder, a right lifting hydraulic cylinder, an upper pull rod, a left lower pull rod, a right lower pull rod, a limiting hydraulic cylinder and a self-regulating limiting rod. The suspension mechanism has a transverse posture adjustable function, the maximum transverse adjustable gradient of the suspension mechanism can reach 15 degrees, and the tractor can draw a farm instrument to implement ploughing operation in the hilly and mountainous areas. The suspension mechanism can adapt to large longitudinal gradient, the maximum adaptable longitudinal gradient can reach 23 degrees, and requirements of climbing and operation of the hilly and mountainous areas can be met. The suspension mechanism can be used as an executing mechanism of the ground contour following suspension mechanism, with the aid of a terrain following hydraulic control system, ground contour following can be controlled automatically, agricultural requirements of cultivated depth uniformity of operation and gradient adaptation of the hilly and mountainous areas are met further, the operation efficiency can be greatly improved, and the operation quality is improved.

Owner:CHINA AGRI UNIV

Shaving device with improved contour following

ActiveUS20160199987A1Promote resultsLow stiffnessMetal working apparatusEngineeringMechanical engineering

A shaving head includes at least one cutting unit in which an external cutting member is subjected to a shaving action. The external cutting member is suspended relative to a holder of the shaving head through suspension means. The suspension means includes at least two pivot constructions, wherein one pivot construction enables a member of the suspension means to be pivotable relative to the holder. The other pivot construction enables the external cutting member to be pivotable relative to the suspension member. Furthermore, a pivoting stiffness of a connection of the latter pivot construction is lower than a pivoting stiffness of the first pivot construction. In this manner, good contour following performance is obtained at two levels, in both relatively small and relatively large curvature changing areas.

Owner:KONINKLJIJKE PHILIPS NV

Shaving device with improved contour following

ActiveUS9216513B2Promote resultsLow stiffnessMetal working apparatusContour followingBuilding construction

A shaving head includes at least one cutting unit in which an external cutting member is subjected to a shaving action. The external cutting member is suspended relative to a holder of the shaving head through suspension means. The suspension means includes at least two pivot constructions, wherein one pivot construction enables a member of the suspension means to be pivotable relative to the holder. The other pivot construction enables the external cutting member to be pivotable relative to the suspension member. Furthermore, a pivoting stiffness of a connection of the latter pivot construction is lower than a pivoting stiffness of the first pivot construction. In this manner, good contour following performance is obtained at two levels, in both relatively small and relatively large curvature changing areas.

Owner:KONINK PHILIPS ELECTRONICS NV

Side folding toolbar for chemical applicator

A multi-row agricultural soil treatment implement includes a semi-trailed carriage and a rearward folding toolbar. The toolbar is suspended from the semi-trailed carriage through parallel links and includes a center section, flex hinges, main wings, main wing latches, and outer flip wings operatively connected to hydraulic cylinders to move them between transport and field position. The main wings fold rearward relative to the center section and are supported by a transport rack but they retain the ability to pivot up or down as needed for ground contour following capability or row end turning.

Owner:FAST DISTRIBUTING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com