Hydraulic contour-following planting mechanism

A hydraulic profiling and hydraulic technology, which is applied in the field of dry land transplanting machines, can solve the problems of affecting planting efficiency, hydraulic cylinder damage, poor operability, etc., and achieve the effects of good load bearing, enlarged displacement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

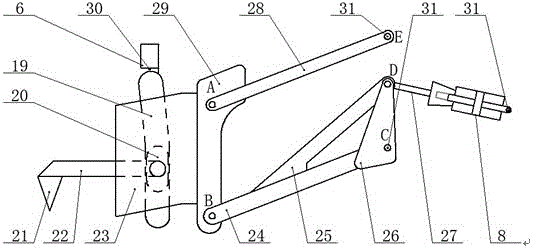

[0026] Such as figure 1 Shown: a hydraulic profiling planting mechanism, which is composed of a ground sensing mechanism 2, a hydraulic actuator, a planter follower mechanism 4, a front wheel 1, a rear wheel 3 and a frame 31. The front wheel 1 and the rear wheel 3 are rotatably installed on the frame 31 through the connecting rod, and the front wheel 1 is turned, and the rear wheel 3 is driven; the ground sensing mechanism 2 is fixedly installed on the frame 31 to sense changes in the ground; The follower mechanism 4 of the planter is rotatably installed on the frame 31 to adjust the relative height between the planter and the ground; the hydraulic actuator connects the ground sensing mechanism 2 and the follower mechanism 4 of the planter together to form a hydraulic pressure of the transplanter. Copy planting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com