Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Abstract concept" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

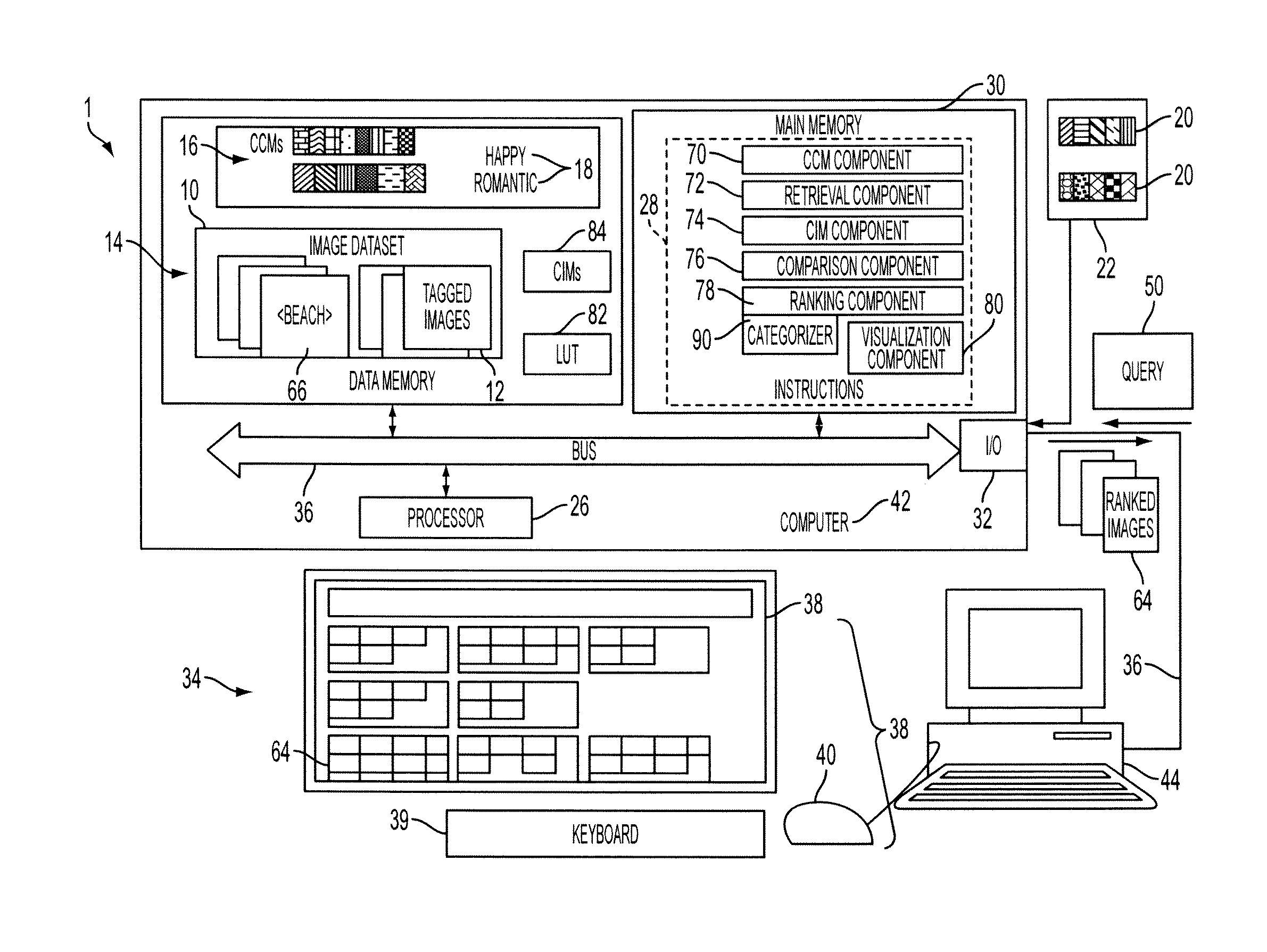

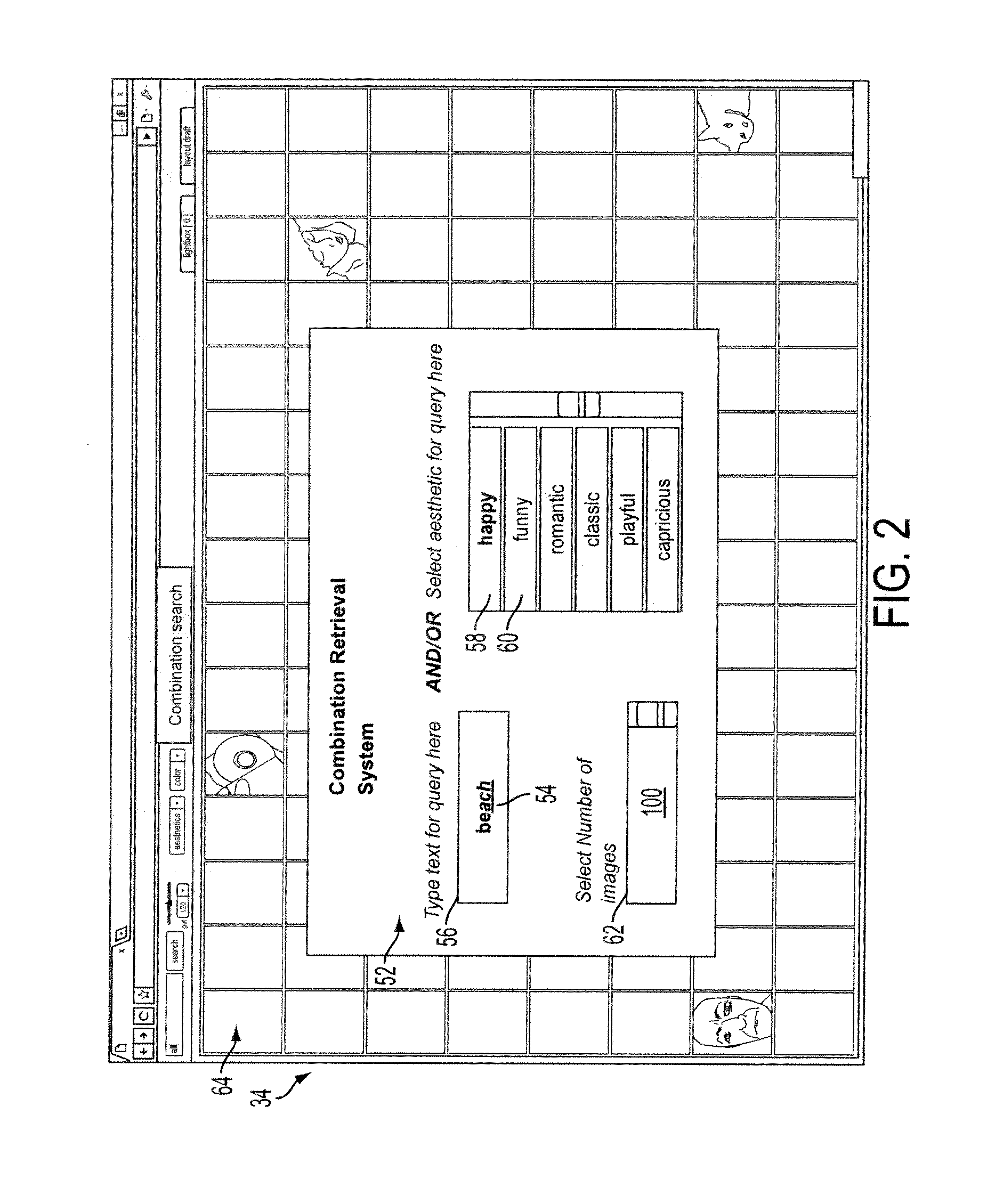

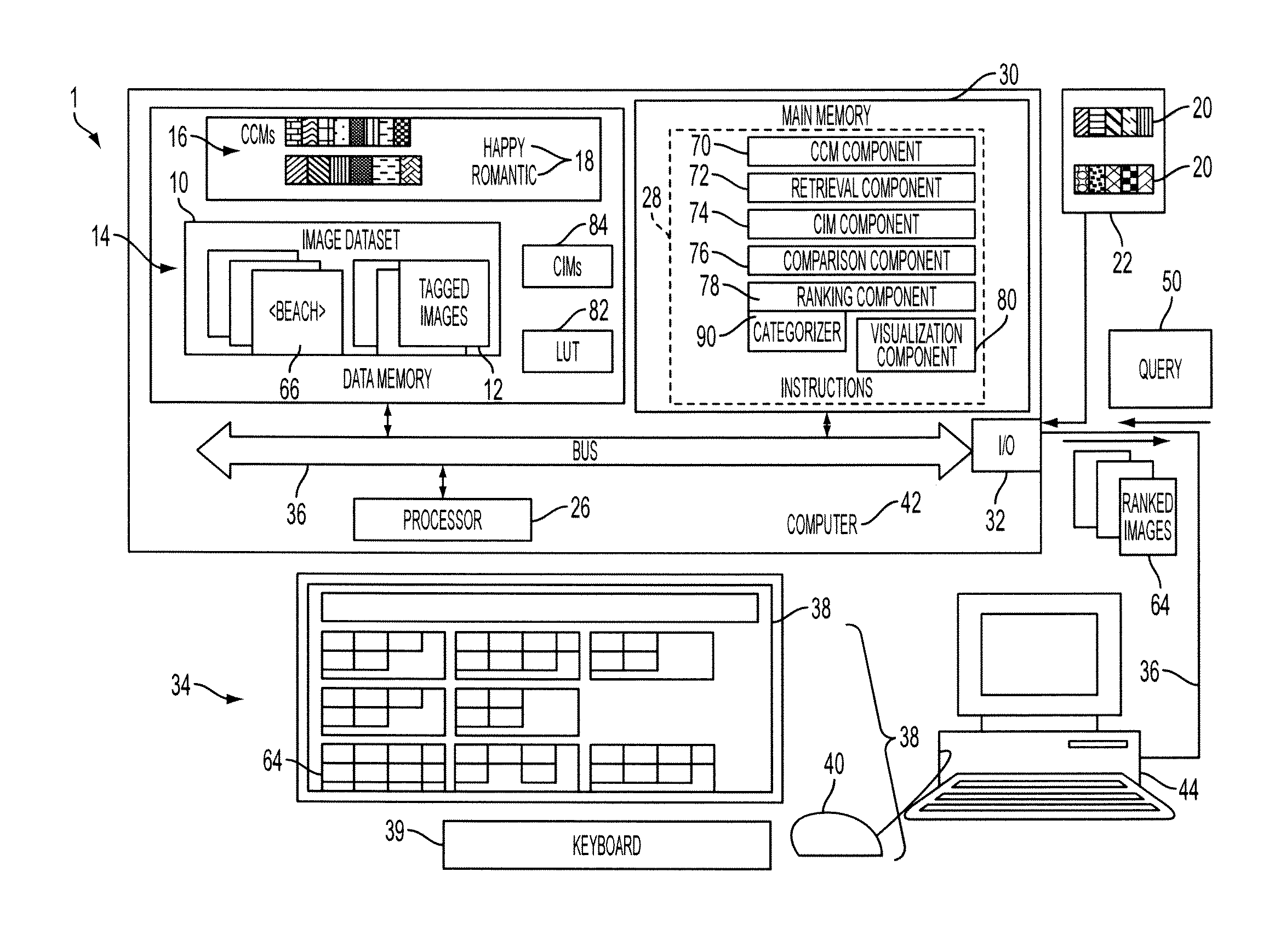

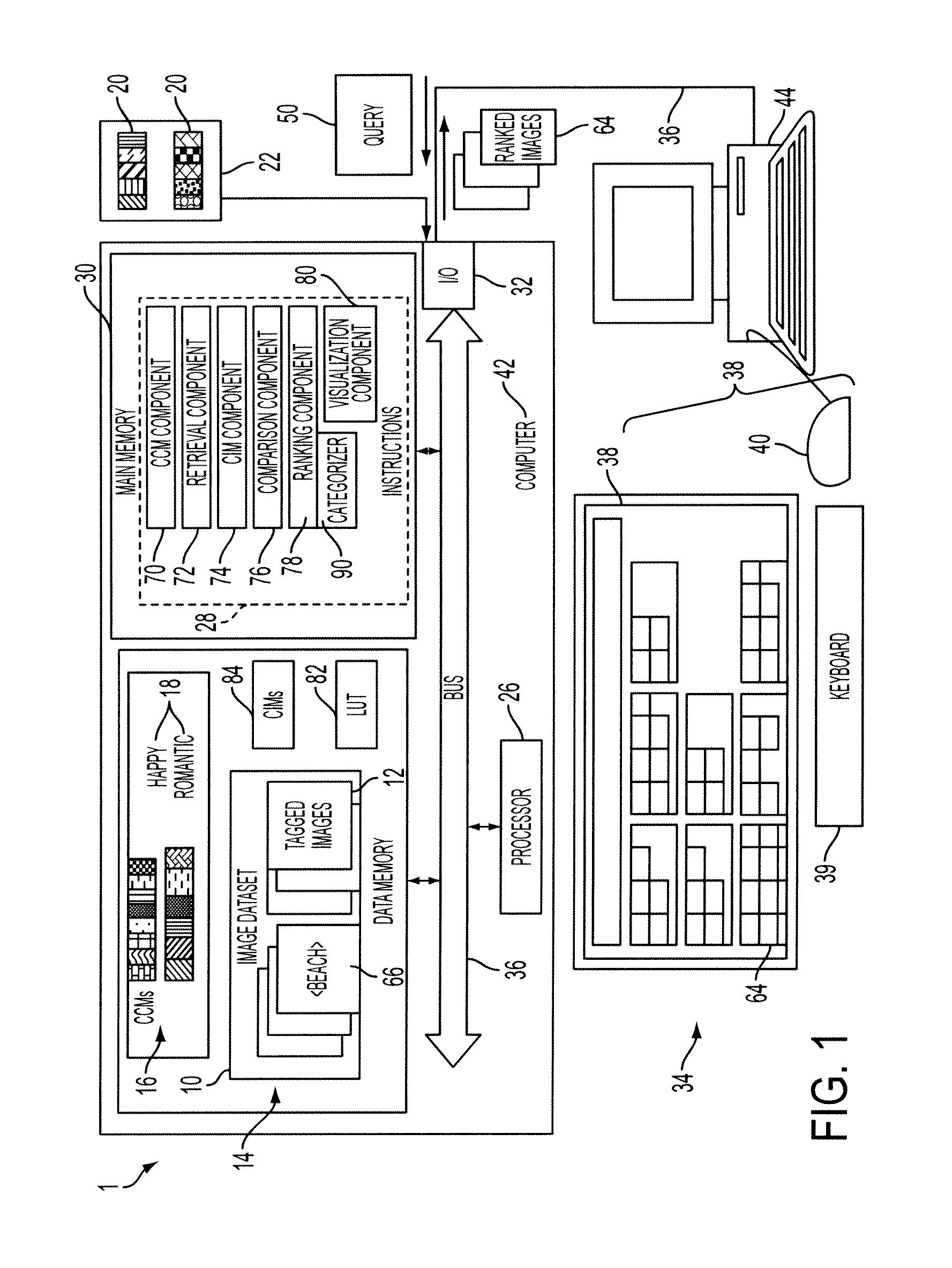

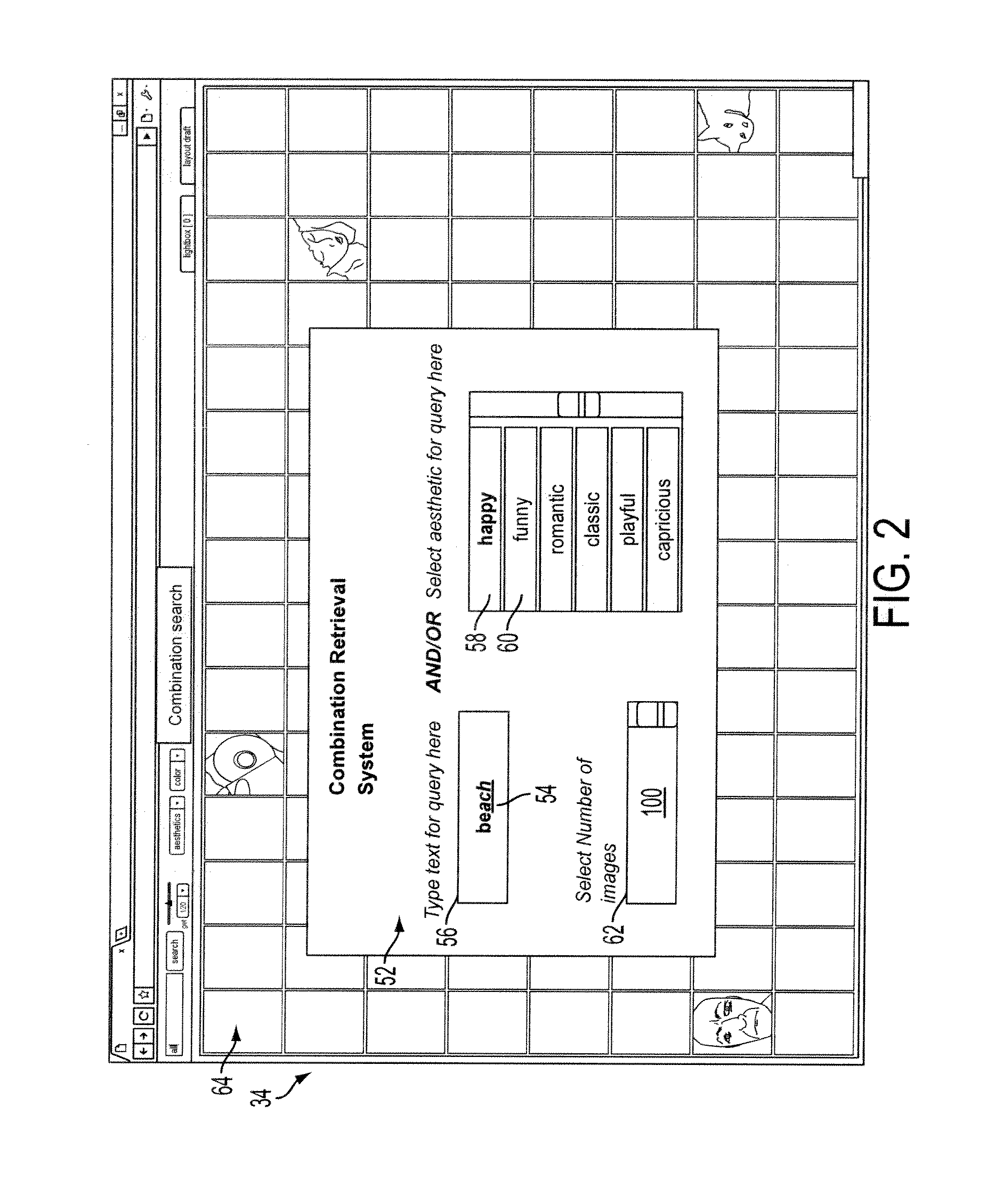

Image ranking based on abstract concepts

InactiveUS20120163710A1Mathematical modelsDigital data information retrievalPattern recognitionAbstract concept

A system and method for ranking images are provided. The method includes receiving a query comprising a semantic part and an abstract part, retrieving a set of images responsive to the semantic part of the query, and computing first scores for the retrieved images in the set of retrieved images. The first score of an image can be based on a relevance of that image to the semantic part of the query (and not to the abstract part of the query). The method further includes identifying a chromatic concept model from a set of chromatic concept models. This identification can be based on the abstract part of the query (and not on the semantic part of the query). The chromatic concept model includes an optionally-weighted set of colors expressed in a perceptually uniform color space. For retrieved images in the set of retrieved images, the method includes computing a chromatic image model based on colors of the image, the chromatic image model comprising a weighted set of colors expressed in the perceptually uniform color space and computing a comparison measure between the chromatic image model and the chromatic concept model. The retrieved images are scored with respective second scores that are based on the computed comparison measures. The retrieved images are ranked based on a combined score for a respective retrieved image which is a function of the first and second scores.

Owner:XEROX CORP

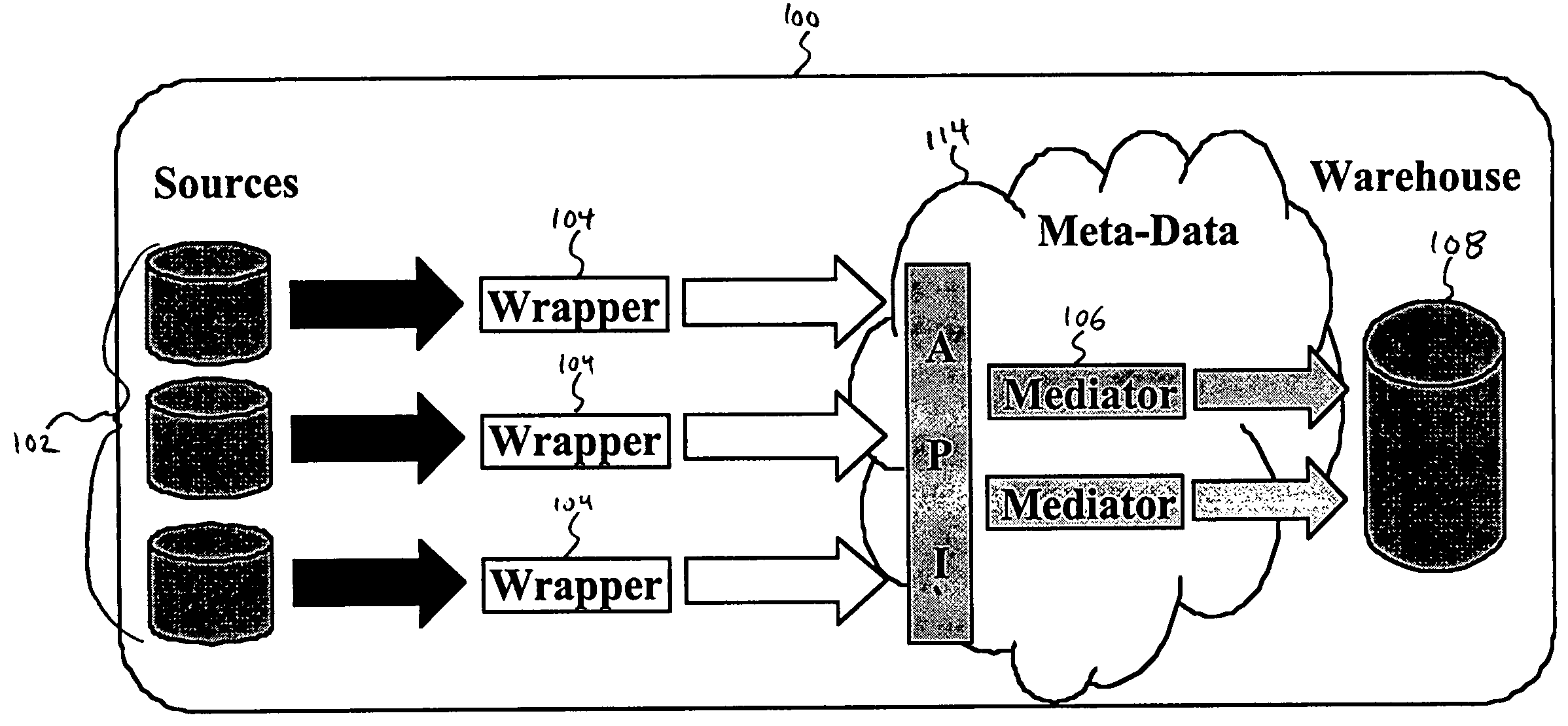

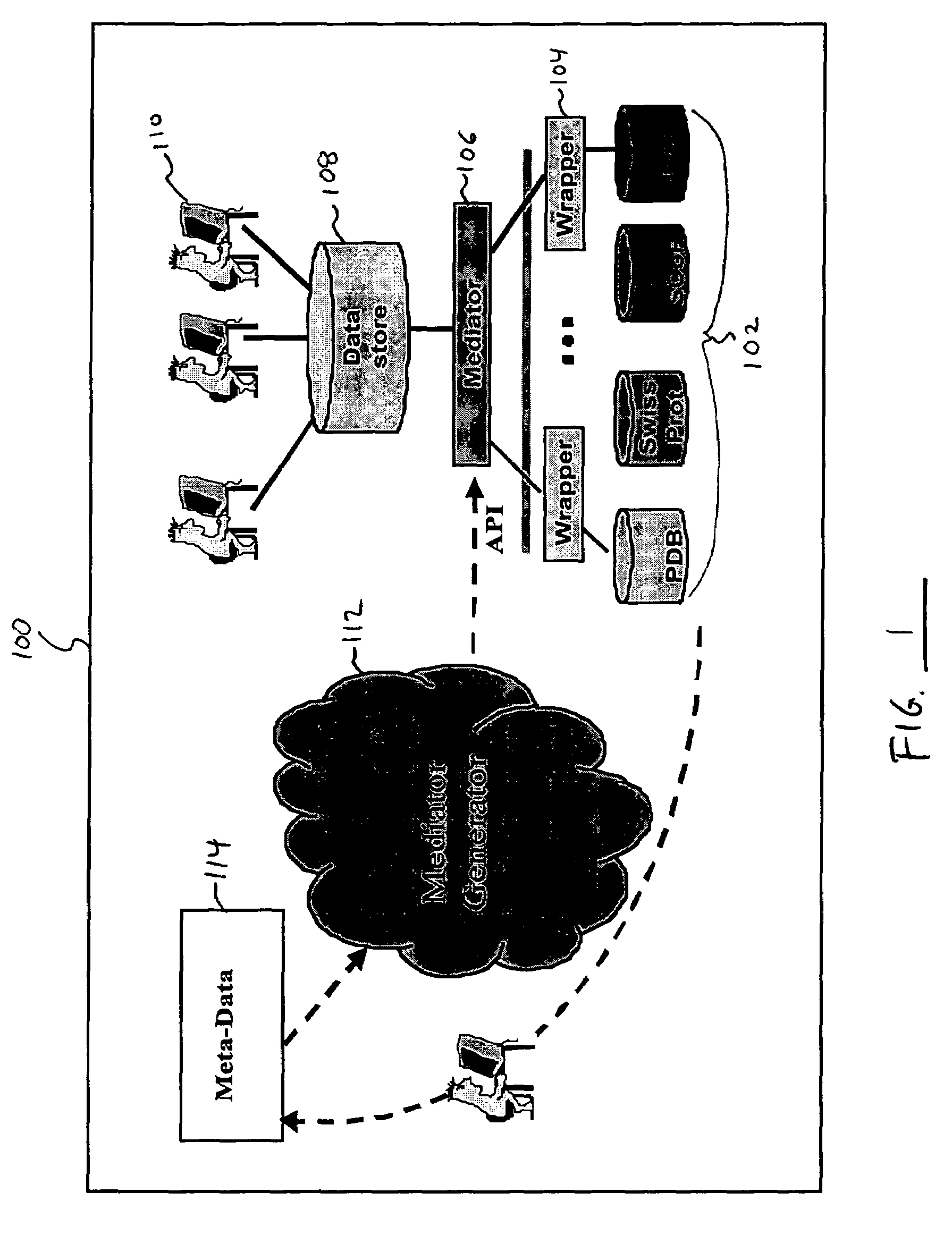

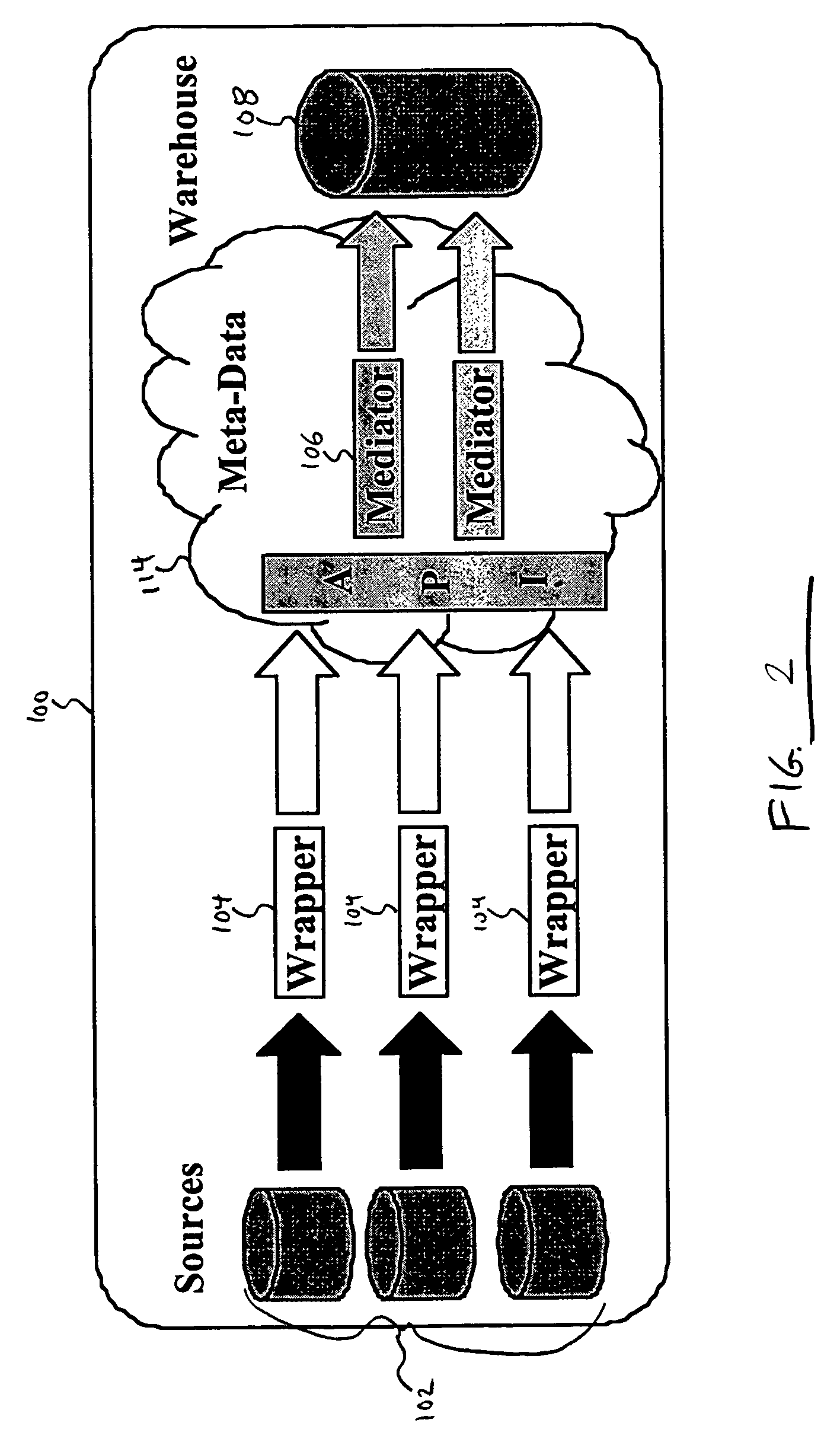

System and method for integrating and accessing multiple data sources within a data warehouse architecture

InactiveUS7152070B1Data processing applicationsDigital data information retrievalPresent methodAnalysis data

A system and method is disclosed for integrating and accessing multiple data sources within a data warehouse architecture. The metadata formed by the present method provide a way to declaratively present domain specific knowledge, obtained by analyzing data sources, in a consistent and useable way. Four types of information are represented by the metadata: abstract concepts, databases, transformations and mappings. A mediator generator automatically generates data management computer code based on the metadata. The resulting code defines a translation library and a mediator class. The translation library provides a data representation for domain specific knowledge represented in a data warehouse, including “get” and “set” methods for attributes that call transformation methods and derive a value of an attribute if it is missing. The mediator class defines methods that take “distinguished” high-level objects as input and traverse their data structures and enter information into the data warehouse.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

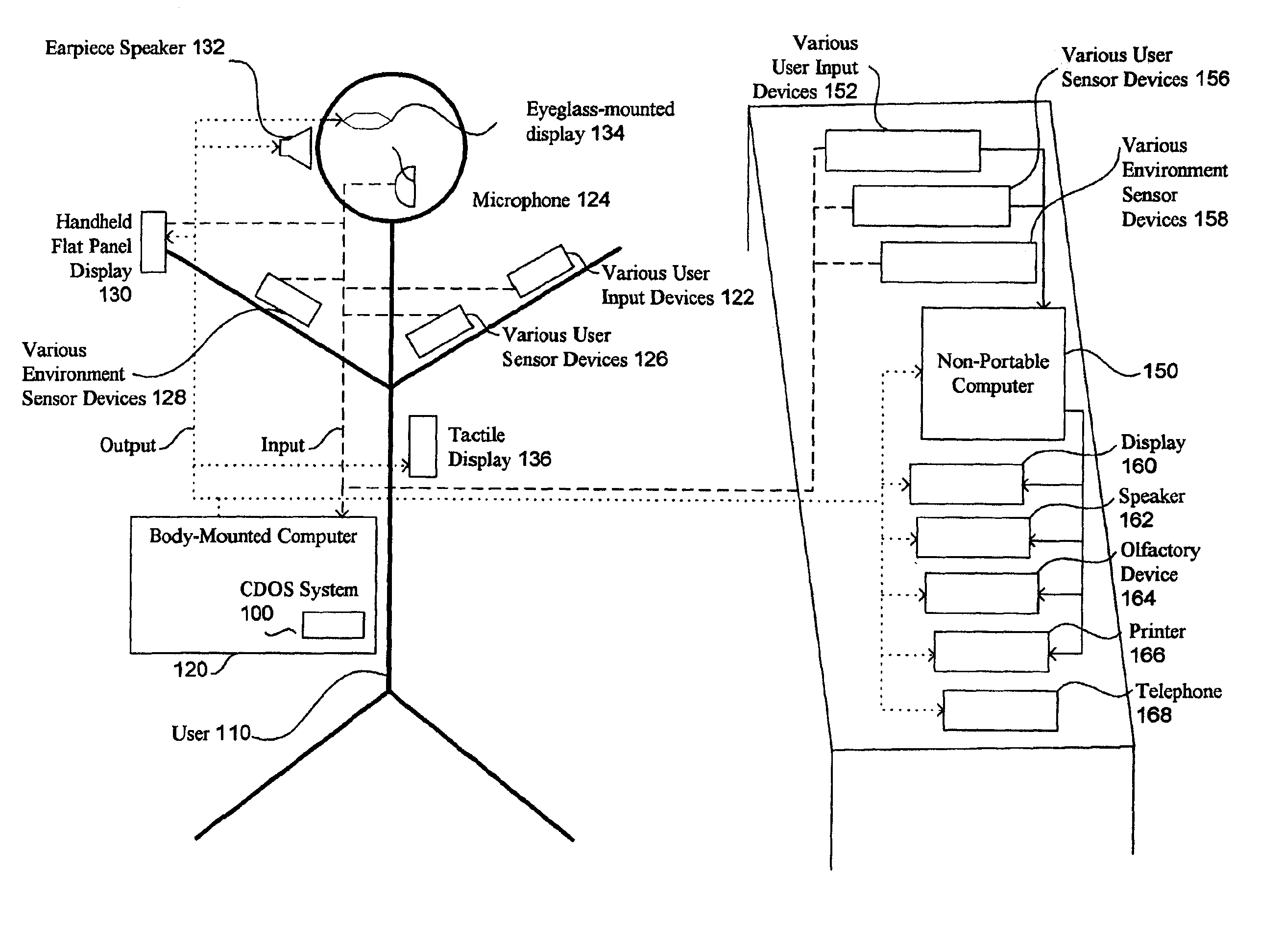

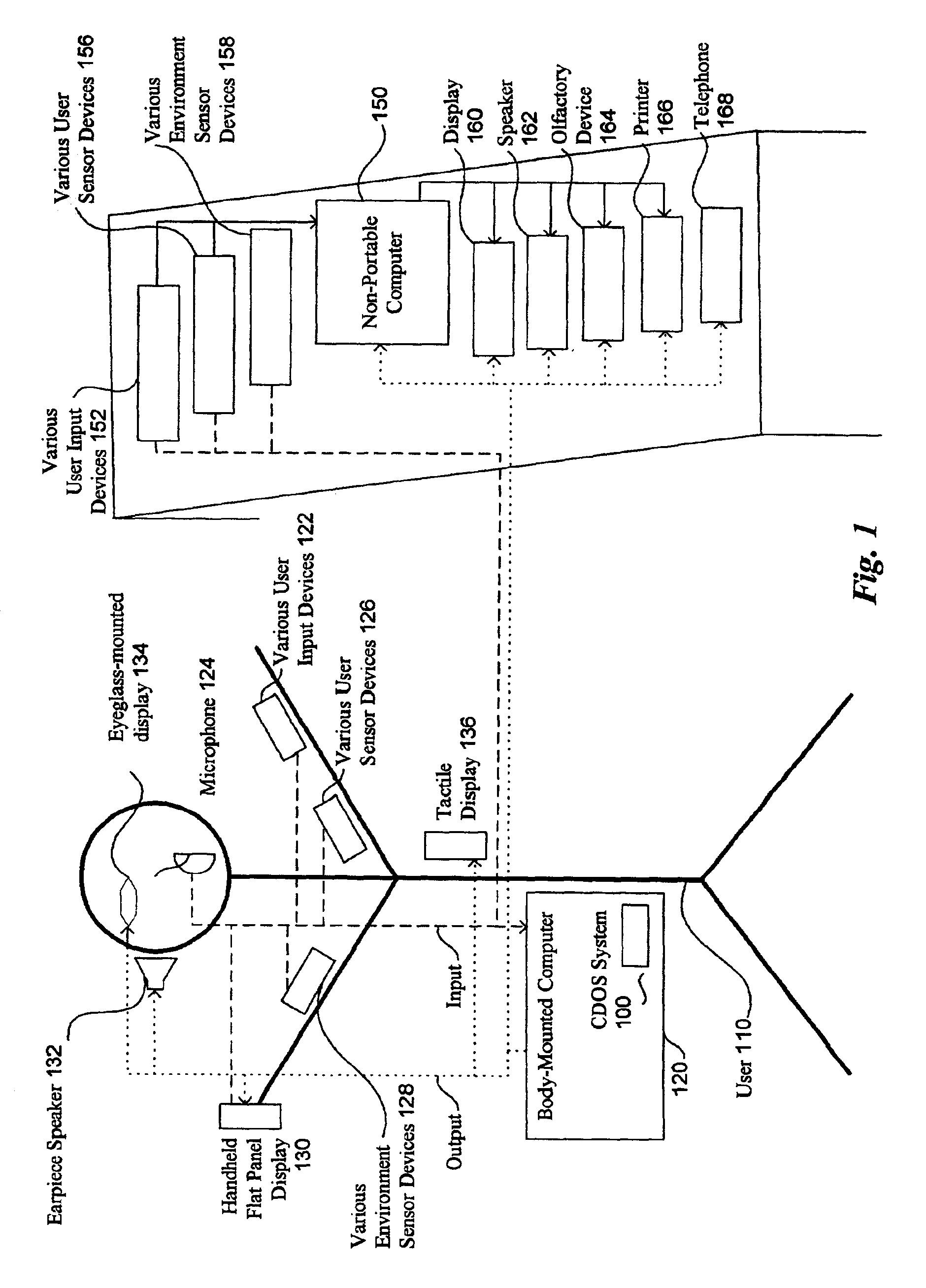

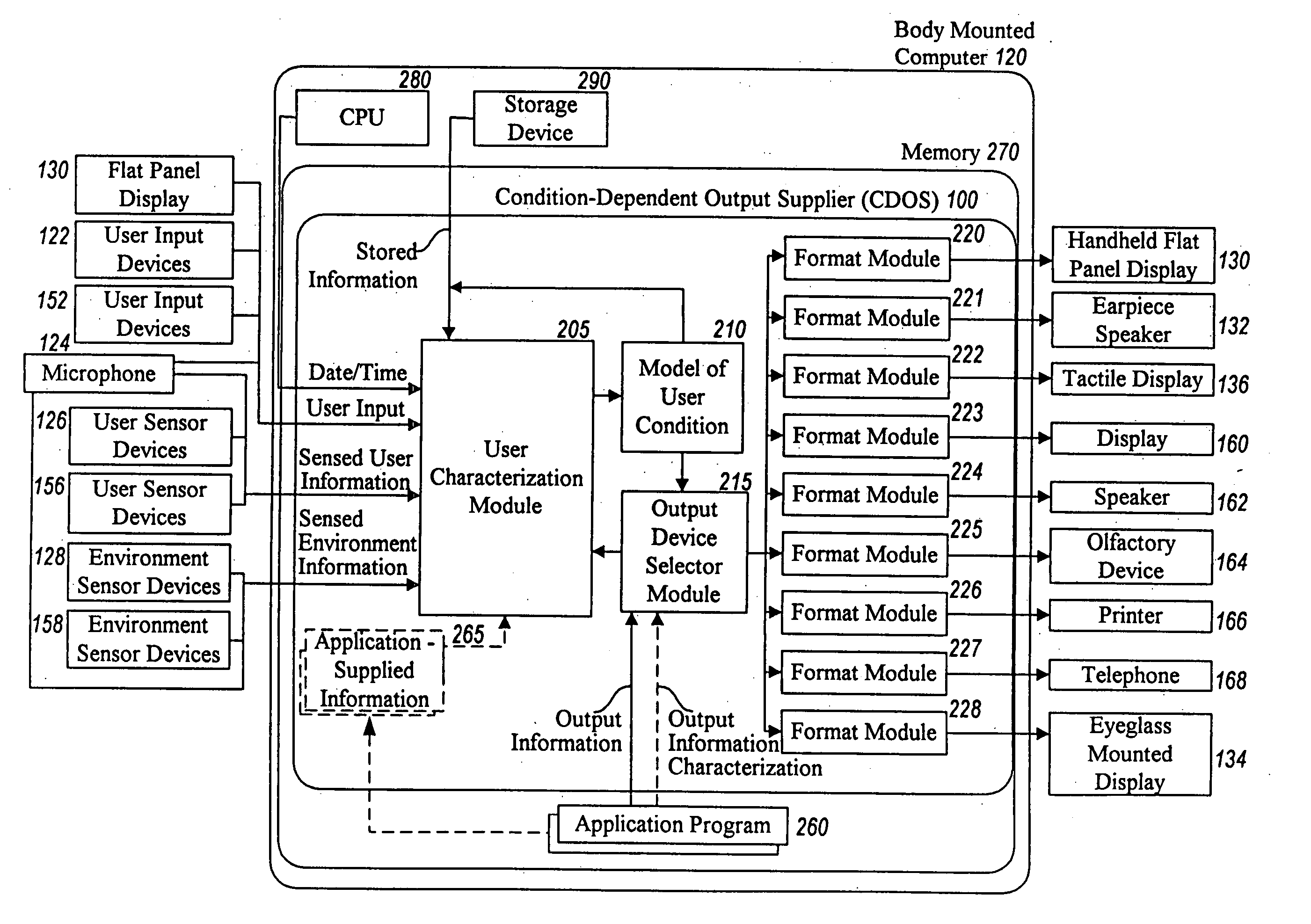

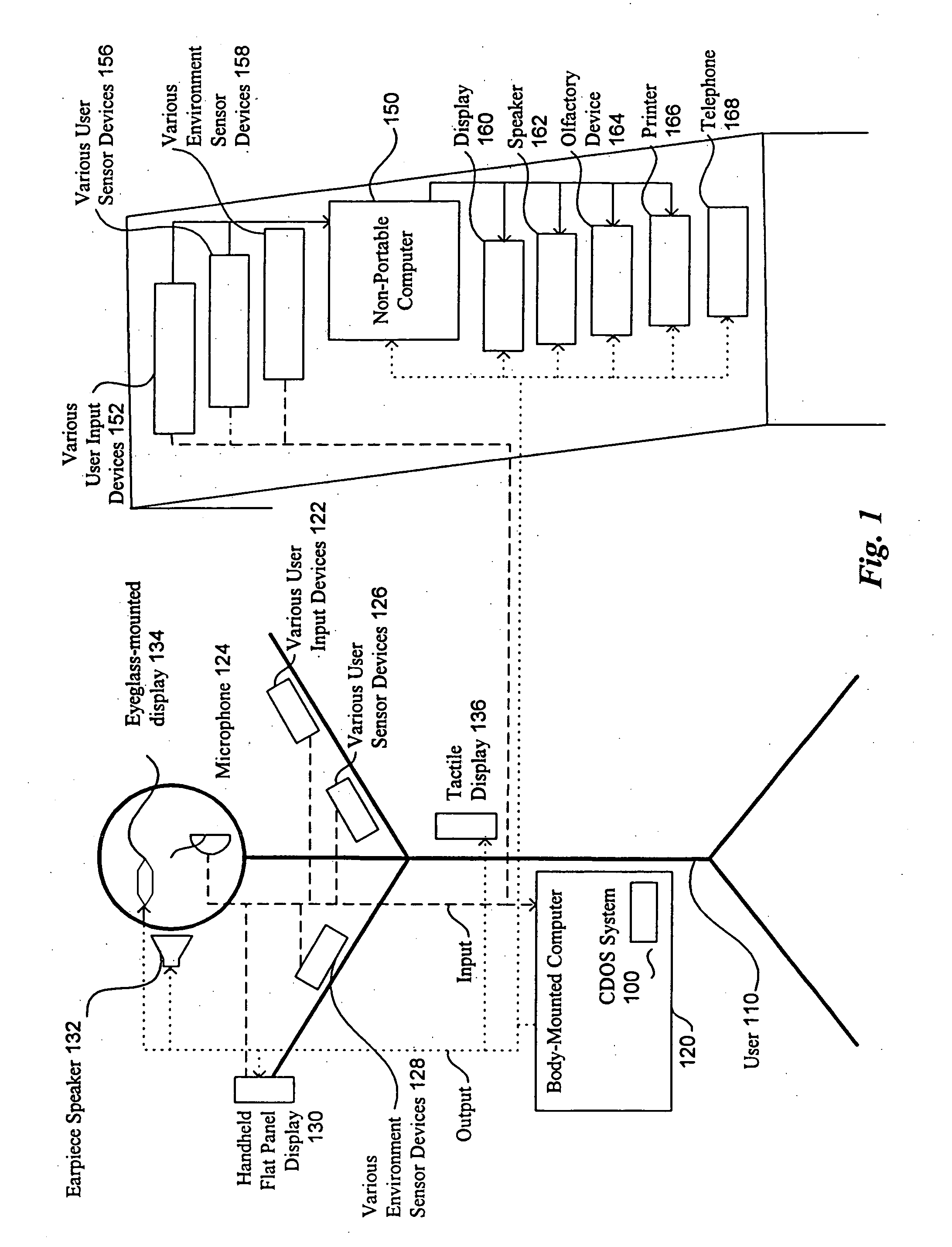

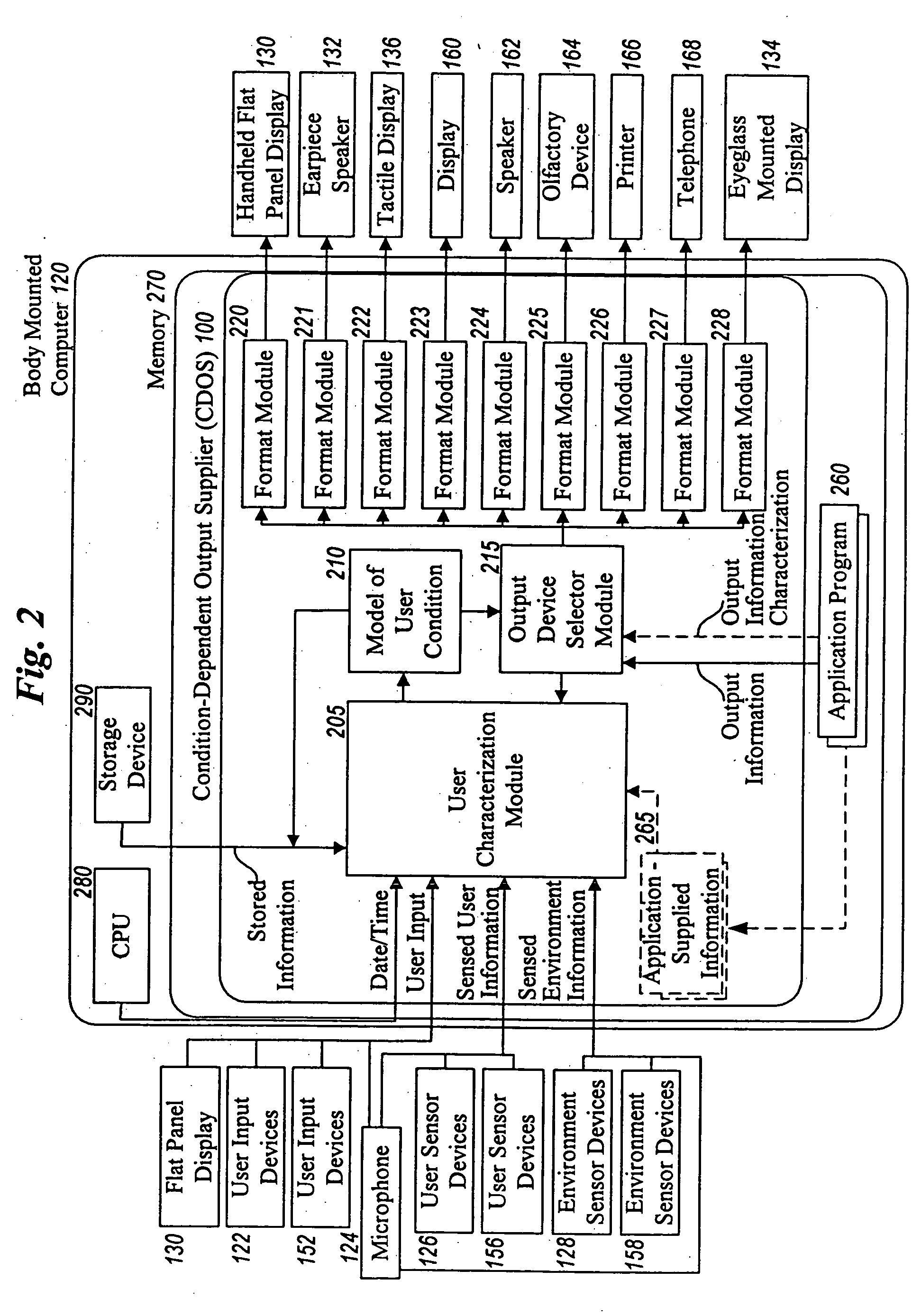

Method and system for controlling presentation of information to a user based on the user's condition

InactiveUS6874127B2Input/output for user-computer interactionDigital computer detailsAbstract conceptDisplay device

A system for controlling presentation of information to a user based on the user's current condition. In particular, the system monitors the user and the user's environment, and creates and maintains an updated model of the current condition of the user. The user condition can include a variety of condition variables, including abstract concepts such as the user's current cognitive load, desired level of privacy for output information, and desired scope of audience for output information. Upon receiving output information to be presented to the user (e.g., from an application program), the system determines an appropriate output device and an appropriate format with which to present the information to the user, and then presents the output information. The system can also receive description information about the output information that describes relevant factors for determining when and how to present the output information (e.g., the importance and urgency of the output information, the consequences of the user not receiving or ignoring the output information, etc.). Some versions of the system execute on a wearable computer having a variety of available output display devices.

Owner:MICROSOFT TECH LICENSING LLC

Method and system for controlling presentation of information to a user based on the user's condition

InactiveUS20060053377A1Input/output for user-computer interactionDigital computer detailsAbstract conceptDisplay device

A system for controlling presentation of information to a user based on the user's current condition. In particular, the system monitors the user and the user's environment, and creates and maintains an updated model of the current condition of the user. The user condition can include a variety of condition variables, including abstract concepts such as the user's current cognitive load, desired level of privacy for output information, and desired scope of audience for output information. Upon receiving output information to be presented to the user (e.g., from an application program), the system determines an appropriate output device and an appropriate format with which to present the information to the user, and then presents the output information. The system can also receive description information about the output information that describes relevant factors for determining when and how to present the output information (e.g., the importance and urgency of the output information, the consequences of the user not receiving or ignoring the output information, etc.). Some versions of the system execute on a wearable computer having a variety of available output display devices.

Owner:MICROSOFT TECH LICENSING LLC

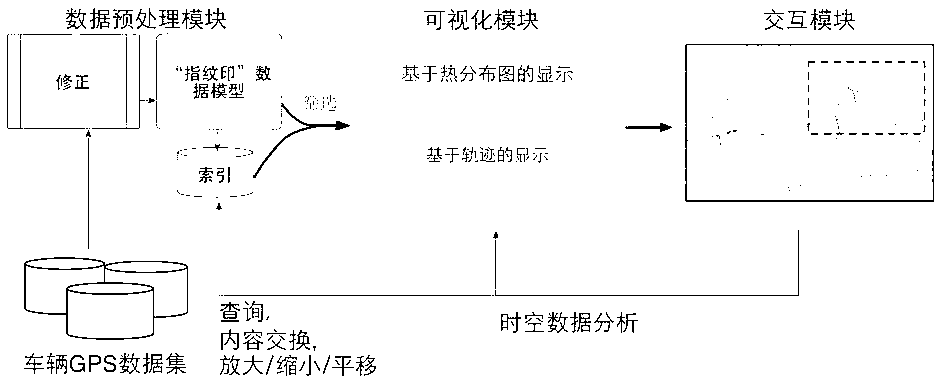

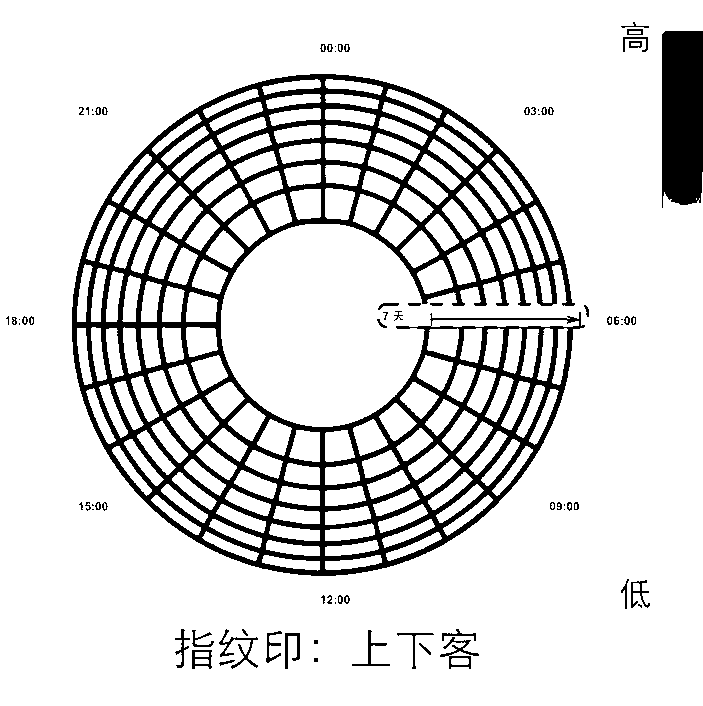

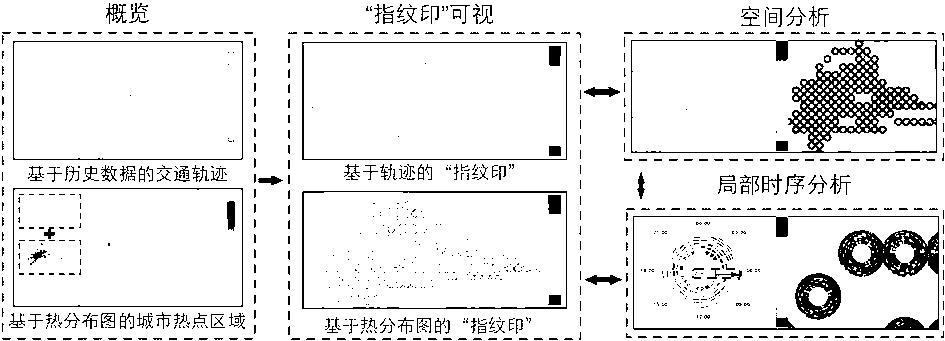

Visual mining method for vehicle GPS (global positioning system) data analysis and abnormality monitoring

ActiveCN103020222AQuick understandingQuick discoverySpecial data processing applicationsTime responseAbstract concept

The invention relates to a visual mining method based on a visualization technology for vehicle GPS (global positioning system) data analysis and abnormality monitoring. Original vehicle GPS data are converted by a data conversion module into a unique visual ''fingerprint stamp'' data model, a data index for real-time response to user interaction is provided to help a user to analyze data; and a visual vehicle data model is combined with a display based on a heat distribution map and a trajectory through a visualization module, detection of urban hot spot areas and traffic trajectory abnormality monitoring based on historical data are performed, and certain abstract concepts in the data, such as frequent rules and periodic rules, are displayed in an easy-to-understand way for an analyzer. The analysis threshold can be lowered, the scope of application can be expanded, and the analysis efficiency can be improved. Rich interaction operations can be realized through a user interaction module, monitoring and analysis can be performed by the user, and analysis and support can be provided for decisions of the user.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

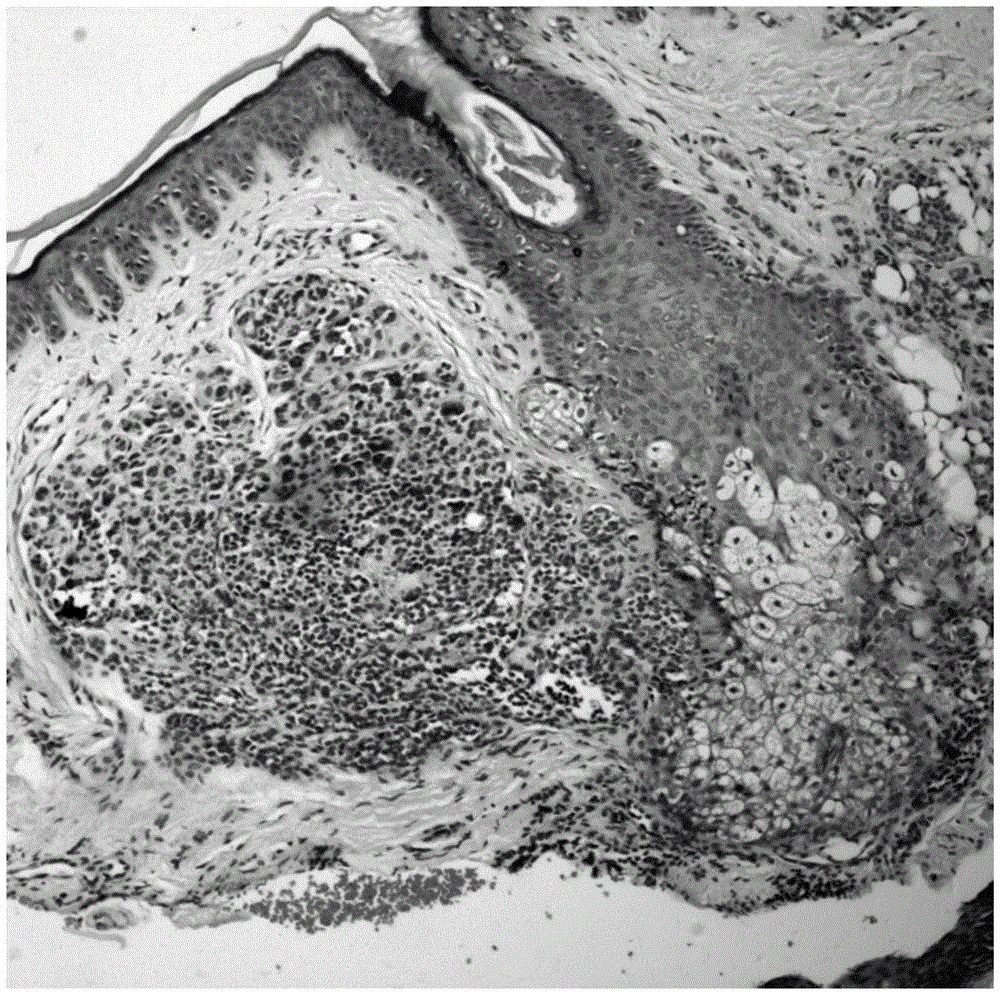

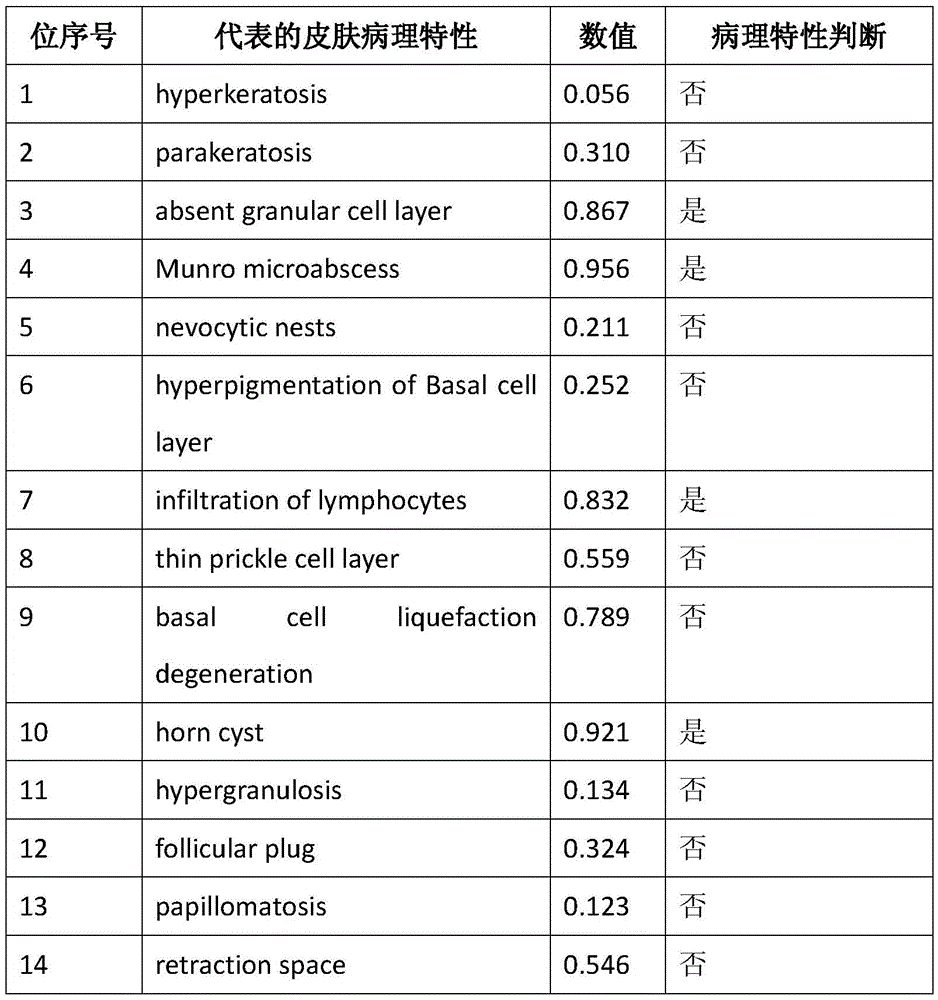

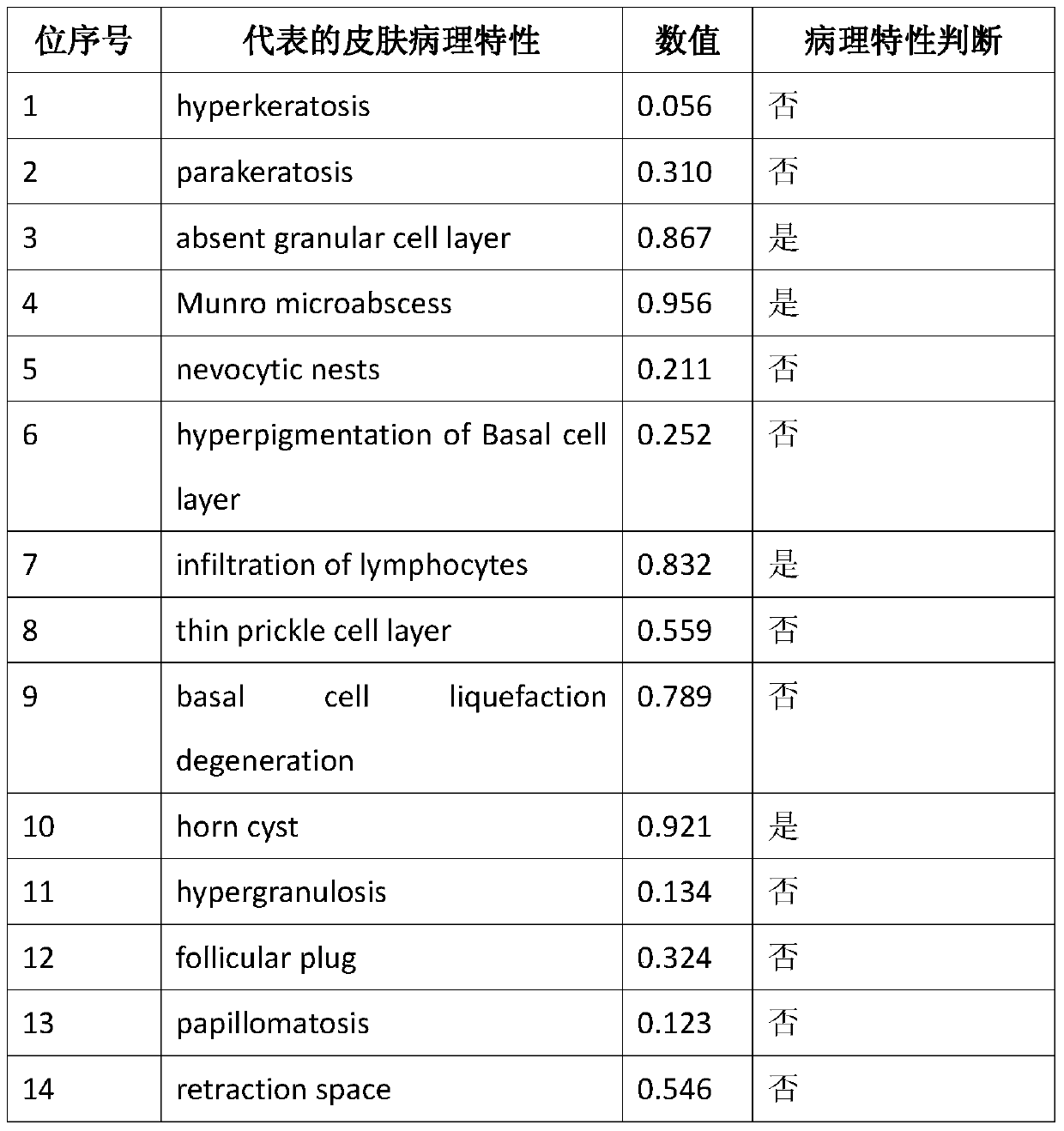

Deep learning-based skin biopsy image pathological characteristic recognition method

InactiveCN105469100AReduce error rateImprove practicalityImage enhancementImage analysisAbstract conceptBiopsy lesion

The invention relates to a deep learning-based skin biopsy image pathological characteristic recognition method. The method includes the following steps that: a plurality of layers of stacked automatic encoders are utilized to re-express the characteristics of a biopsy image; a series of convolutional neural networks are utilized to perform convolution and sampling on the characteristics of the image layer by layer, so that an abstract characteristic expression of the original skin biopsy image can be obtained; the characteristics obtained by the plurality of layers of stacked automatic encoders and the characteristics obtained by the convolutional neural networks are spliced together; and the recognition of pathological characteristics is completed by a multi-channel neural network. According to the deep learning-based skin biopsy image pathological characteristic recognition method of the invention, abstract concept expression is extracted through a deep learning model, and therefore, the method has high adaptability to factors such as color difference, illumination and magnification factors, and therefore, the accuracy of a computer in the recognition of pathological characteristics of skin biopsy images can be greatly improved.

Owner:GUANGDONG UNIV OF TECH

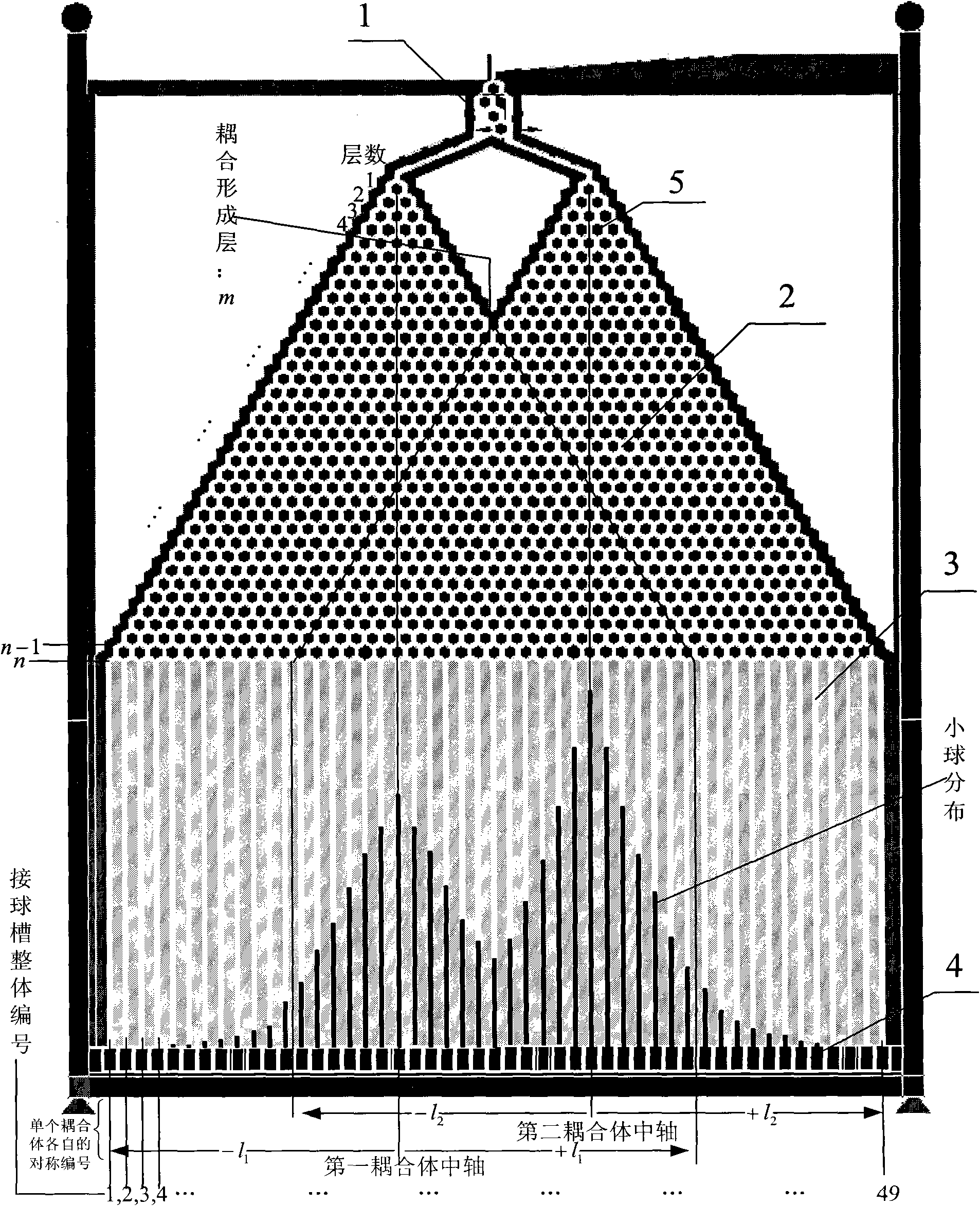

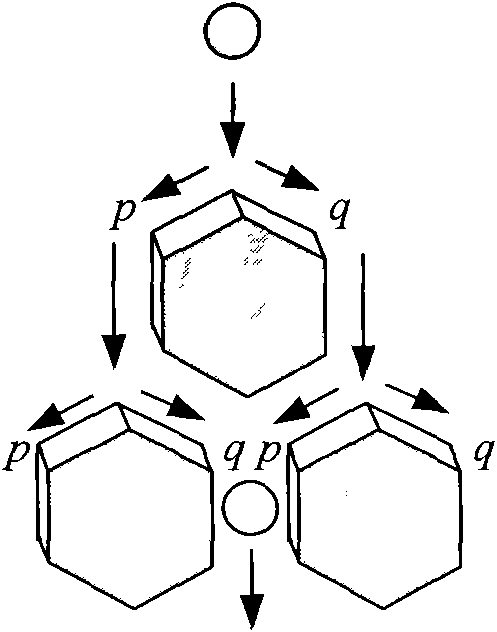

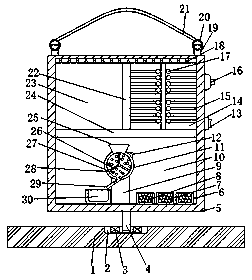

Coupled normal distribution probability demonstration instrument

InactiveCN101630459AIntuitive and visual teachingReduce manufacturing difficultyEducational modelsGraphicsAbstract concept

The invention discloses a coupled normal distribution probability demonstration instrument, improves the normal distribution demonstration instrument Galton pinboard, and is used for visually demonstrating normal distribution coupling relation. The construction scheme is as follows: regular hexagonal prisms form nails which are vertically adhered on front and back substrates, the adjacent surface of two adjacent regular hexagonal prisms and front and back substrates form clearance which constitutes a globule running channel, thus ensuring that the probability of globules falling into a left pipeline or a right pipeline after touching a nail is equal and the globules fall off along the channel and vertically touch the nail edge of the next layer. The substrate is provided with a globule feeding device, a regular hexagonal prism honeycomb array, globule catching tubes and a globule storage box; the globule feeding device is constructed into different globule feeding proportions of two paths of the globules according to binomial distribution principle, the regular hexagonal prism honeycomb array is formed by coupling two independent normal distribution models, and channel of the last layer are the globule catching tubes, all globule catching tubes form an array face which visually demonstrate coupled normal distribution probability graphics of the globules entering the regular hexagonal prism honeycomb array. The invention materializes abstracts concept to material objects, which plays an active role for the instruction of probability theory.

Owner:XIDIAN UNIV

Image ranking based on abstract concepts

InactiveUS8532377B2Digital data information retrievalDigital data processing detailsPattern recognitionAbstract concept

Owner:XEROX CORP

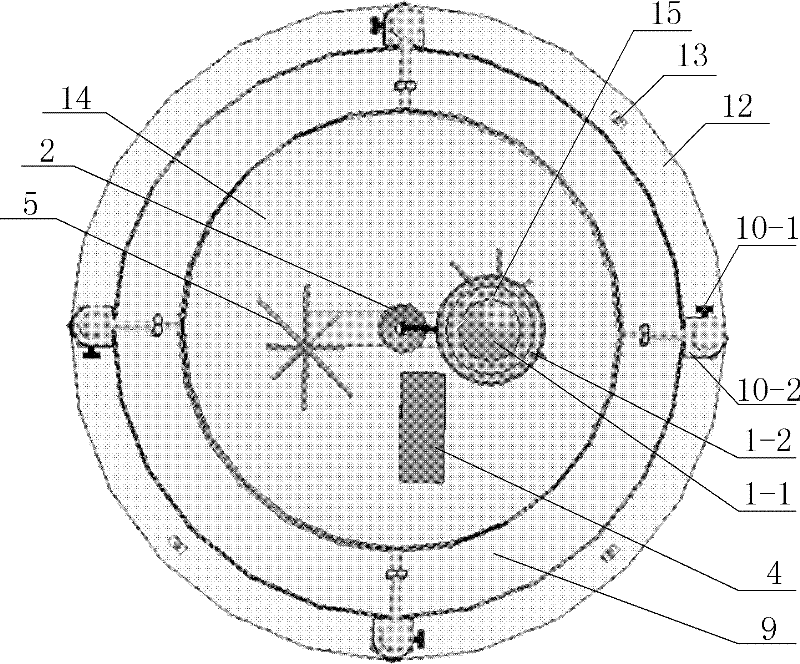

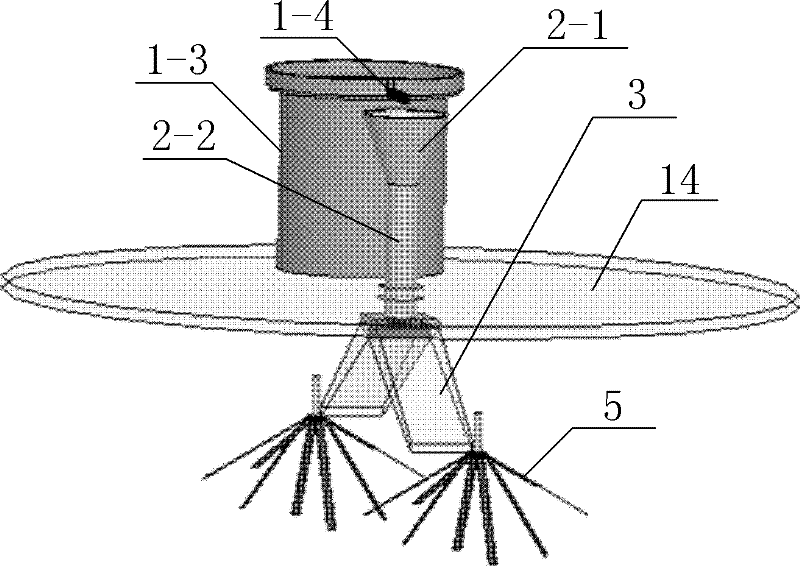

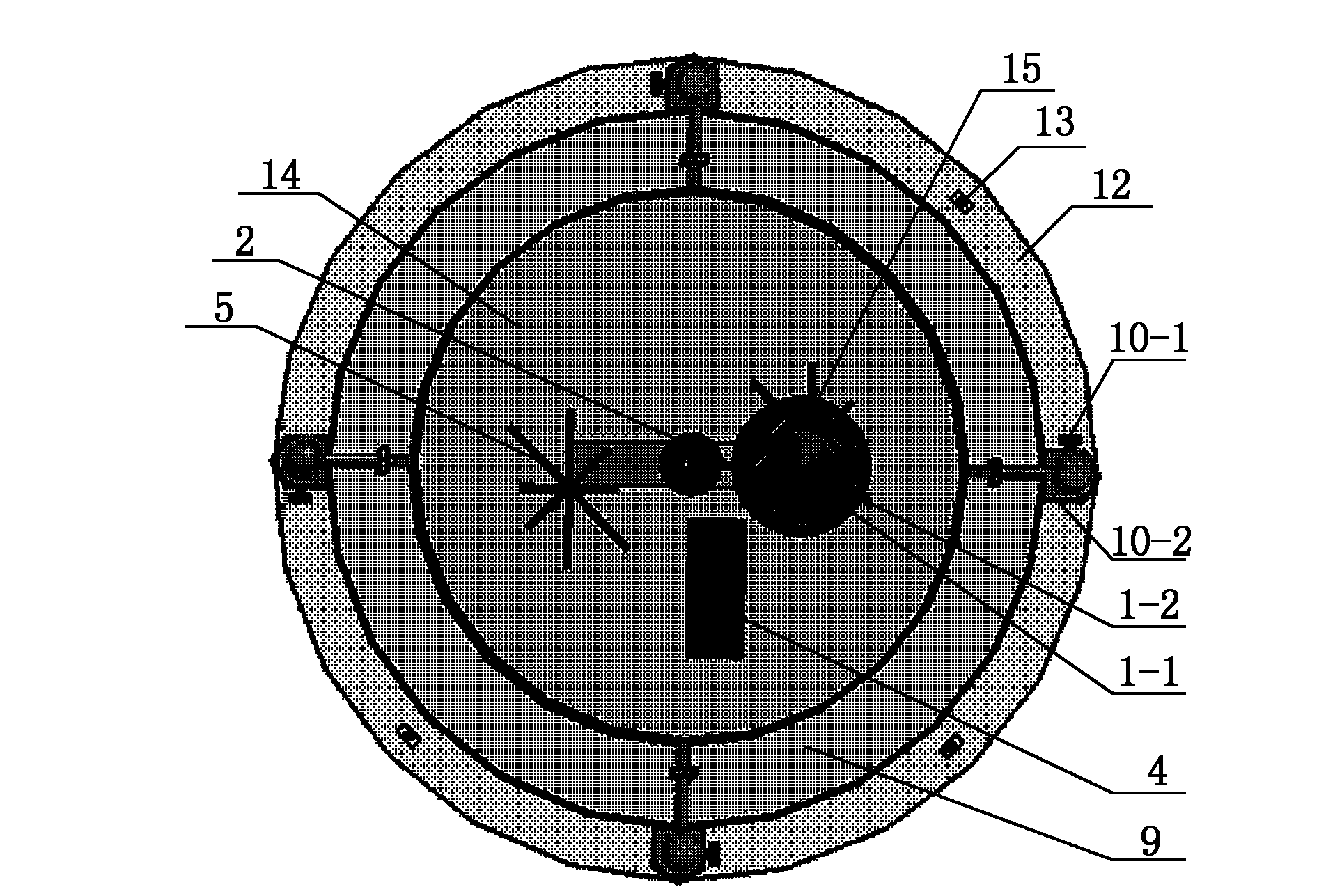

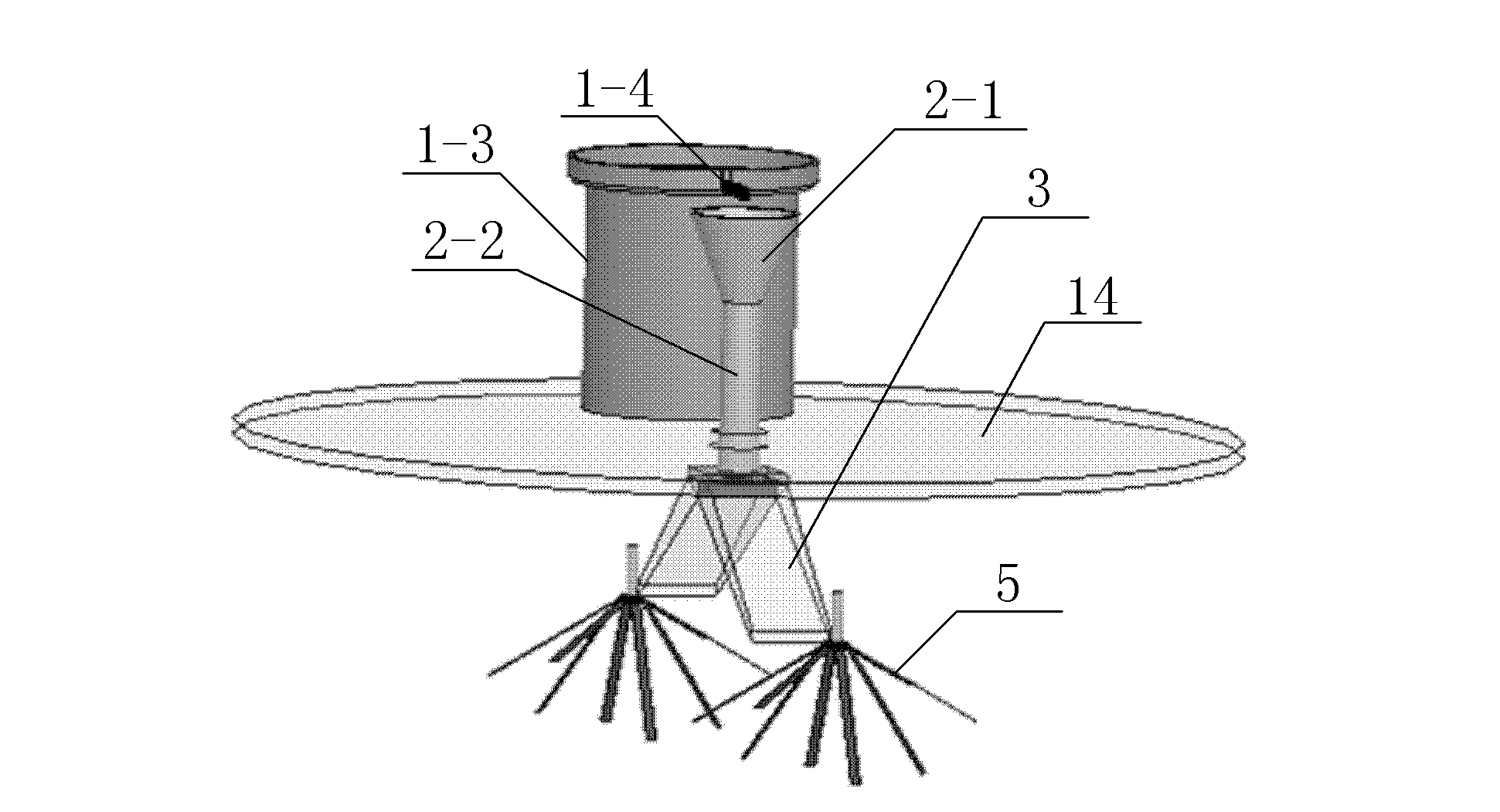

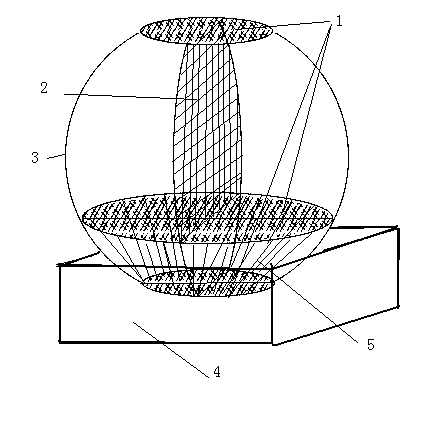

Demonstration instrument for Buffon probability experiment

InactiveCN102522031AIntuitive and visual teachingEasy to understandEducational modelsAbstract conceptDiameter ratio

The invention discloses a demonstration instrument for a Buffon probability experiment, and mainly aims to solve the problem of influence of personal habits on an experimental result and effectively simulate Buffon probability experiment conditions by a machine instead of manual labor. The demonstration instrument comprises a bracket structure (6), a circular bottom plate (12) and a vertical cylinder (7). An electromagnetic vibration disk (1) is positioned on a hollow top plate (14) above the vertical cylinder (7). A needle scattering shaft (2) penetrates through the center of the top plate. Rotating arms (3) are arranged at the lower end of the needle scattering shaft. A rotating claw (5) is connected to the lower end of each rotating arm. The needle scattering shaft, the rotating arms, the rotating claws and the vertical cylinder form an experimental small needle running channel. A horizontal needle receiving disk (9) is arranged on the circular bottom plate (12). Small needles are scattered from the electromagnetic vibration disk, pass through the small needle running channel and fall on the horizontal needle receiving disk. The number of the small needles and the number of intersection points of the small needles with three groups of parallel lines are counted to obtain a circumference-to-diameter ratio. By the demonstration instrument, an abstract concept is embodied, andthe teaching of a probability theory is vivid and convenient to comprehend.

Owner:XIDIAN UNIV

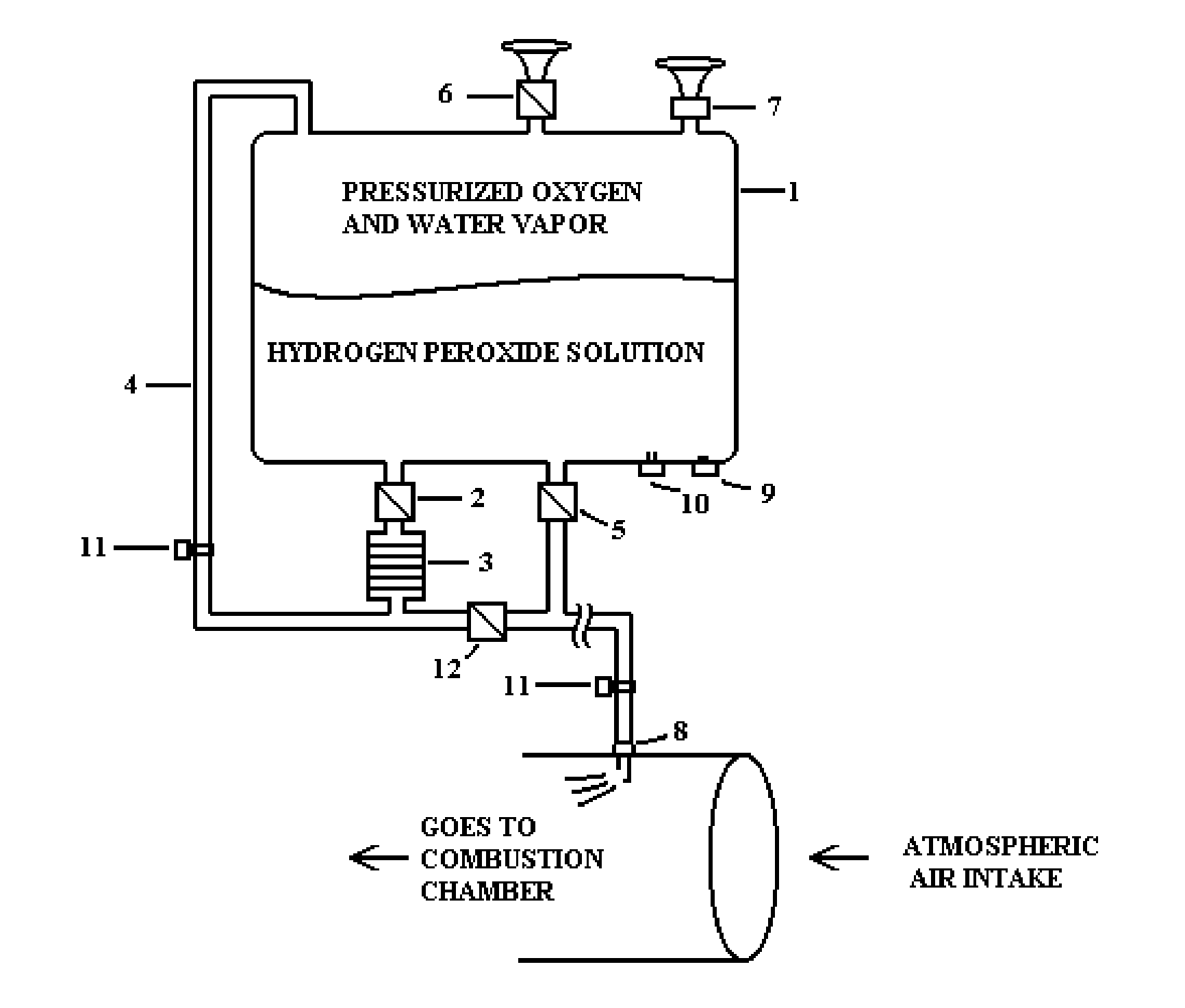

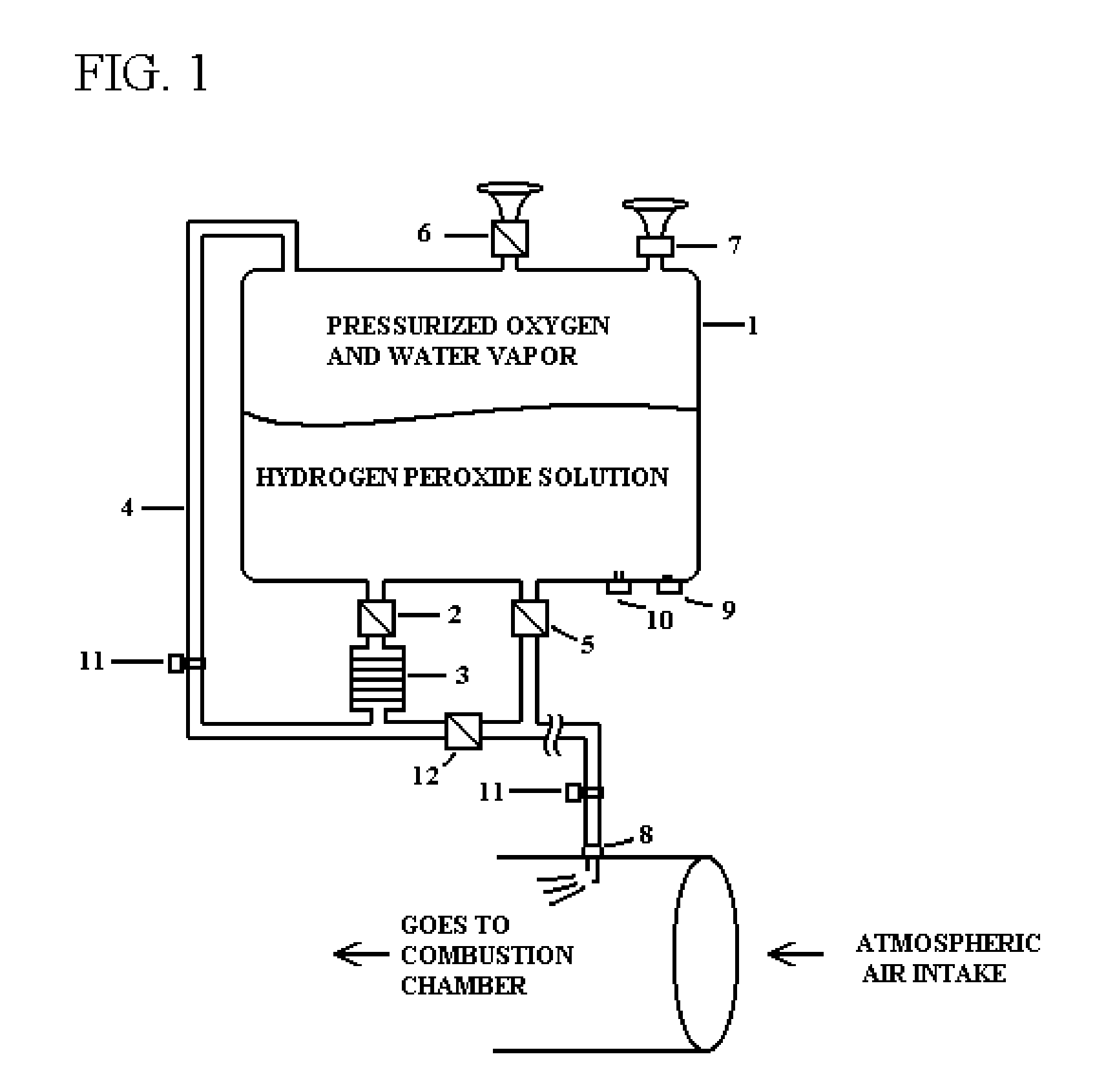

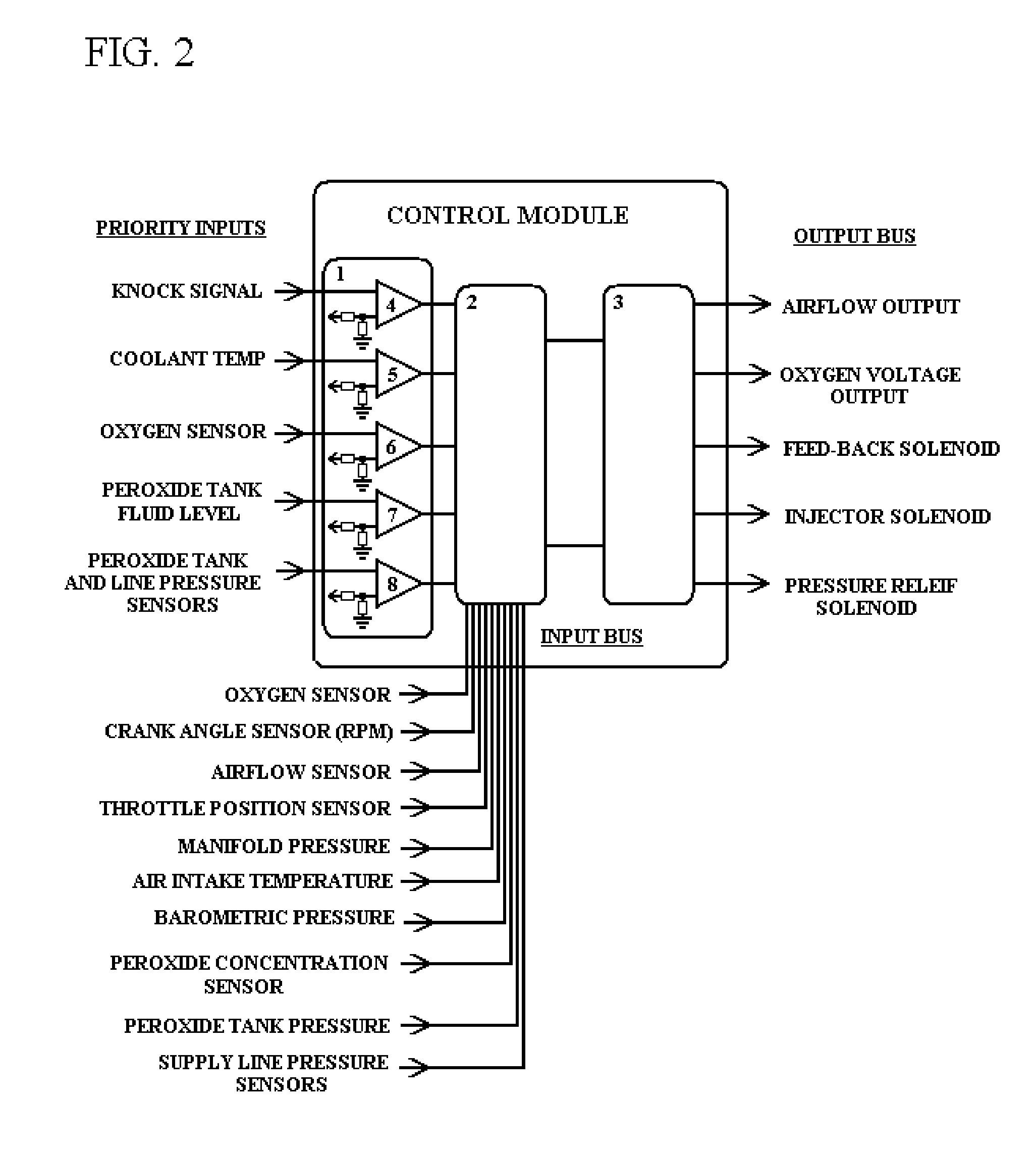

Hydrogen peroxide injection engine and combustion fuel supplamentation

InactiveUS20070084423A1Easy maintenancePromote repairNon-fuel substance addition to fuelInternal combustion piston enginesSystems designCatalytic decomposition

This invention is a electronic and mechanical system that comprises of several sub-systems which carries out a new method of using different concentrations of self-propelled hydrogen peroxide-based solutions for direct propulsion in engines designed to use only gas pressure as energy or the system may act as a fuel supplement in existing combustion engines, by manipulating existing oil-based fuel engine's sensor signals to give the system the ability to make the engine run much leaner conditions, or inject less fuel while simultaneously injecting varying concentrations of hydrogen peroxide / water / alcohol solution, consequently saving gas by lowering intake temperatures to reduce the occurrence of knock and exploiting this reduction in temperature by reducing the amount of fuel needed by the engine at all engine running ranges. Standard mechanical pump fluid injection is not new and neither is pressurized propellant system designs, but this system becomes vary abstract when analyzing its method of using an essential, non-cryogenic, safe, self-propelled liquid monopropellant, in hydrogen peroxide; one of the best natural heat absorbers, in water, and releasing the potential of the hydrogen peroxide catalytic decomposition affect in a method of controlled decomposition pressurization within a feed-back loop while adding oxygen to combustion, and the water as a supplement to reduce excess heat in an engine. The system uses a self-pressurizing, concentration-monitoring, high purity stainless steel or aluminum peroxide storage tank which when used in conjunction with a metallic screen catalytic feed-back loop provides pressurized hydrogen peroxide-based solution to the injection solenoid, and when the solenoid is open allows pressurized water and oxygen to the injectors and into an engine. This system allows for a non-cryogenic, safe, non-polluting fuel source for many applications which will only produce water and oxygen, when used as hydrogen peroxide / water for a purely pressure engine, or significantly reduces fuel consumption in piggy-backed hybrid configurations using varying concentrations of hydrogen peroxide, water, alcohol and other fuels for use in the supplementation of combustion in existing fossil fuels engines. Retrofitting this system into existing gasoline, diesel and other fossil fuel engines will be very low cost, since it can intercept most of the factory sensor signals and send manipulated signals to the existing factory ECM inputs to allow the system to change the amount of injected standard fuel and adjust for the much lower intake air temperatures and extra oxygen provided by the decomposed hydrogen peroxide solution injection, while significantly reducing factory fuel system consumption the entire time that the system is actually injecting solution. No system developed has brought the benefits of all of these elements together in this manner. The level of sophistication and methods at which this system regulates itself, manipulates external fuel systems, decomposes hydrogen peroxide solutions into water and oxygen for self-pressurizing the system, and brings these elements together in a synergistic alliance with each other, all while injecting a precise amount of pressurized water and oxygen supplement to combustion events in an engine, are the truly abstract concepts behind this system. Combined with the system's easy adaptability and upgradeability should give a complete insight into the truly abstract design and methodology of this system.

Owner:LEBEAUX KELVIN

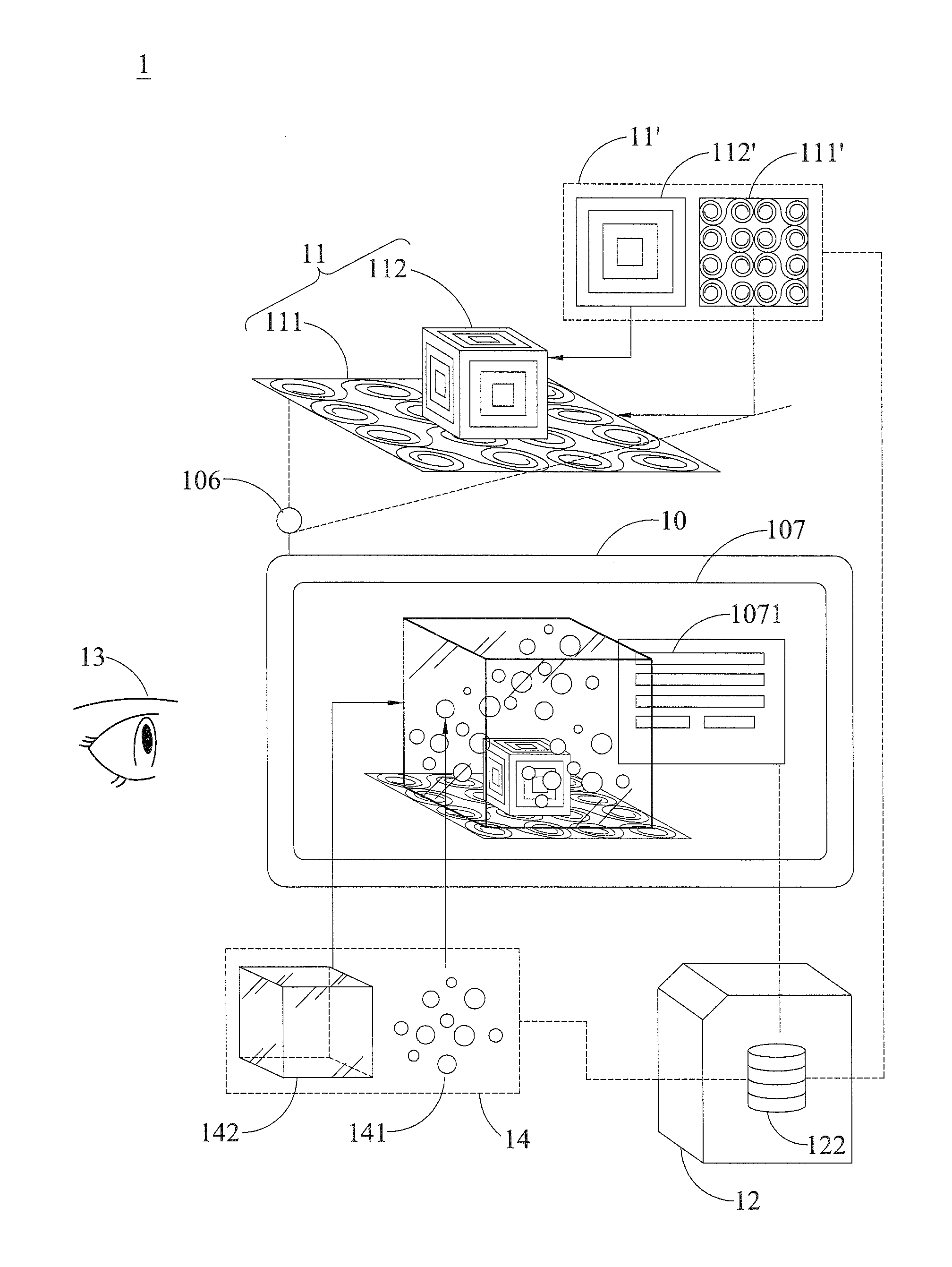

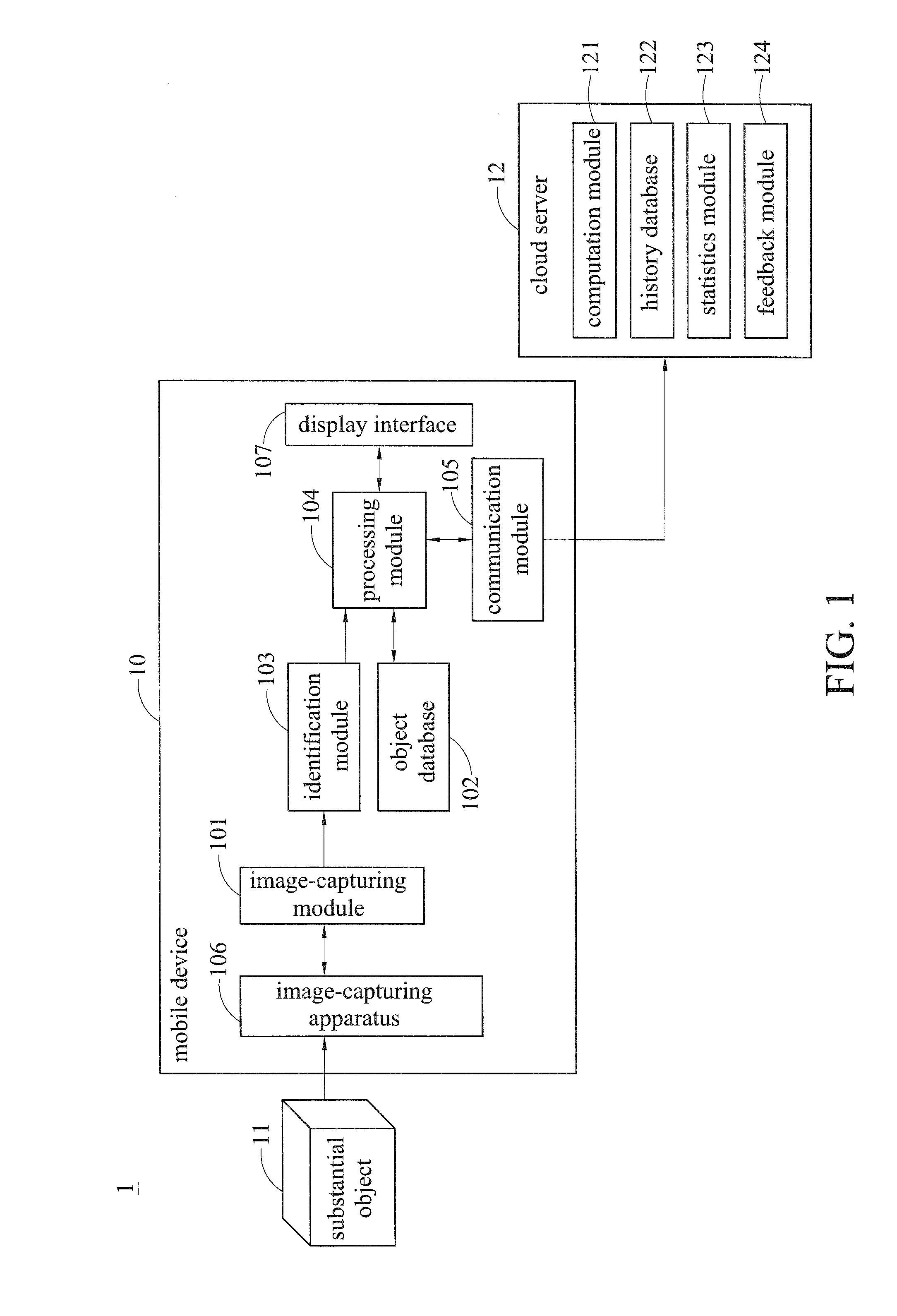

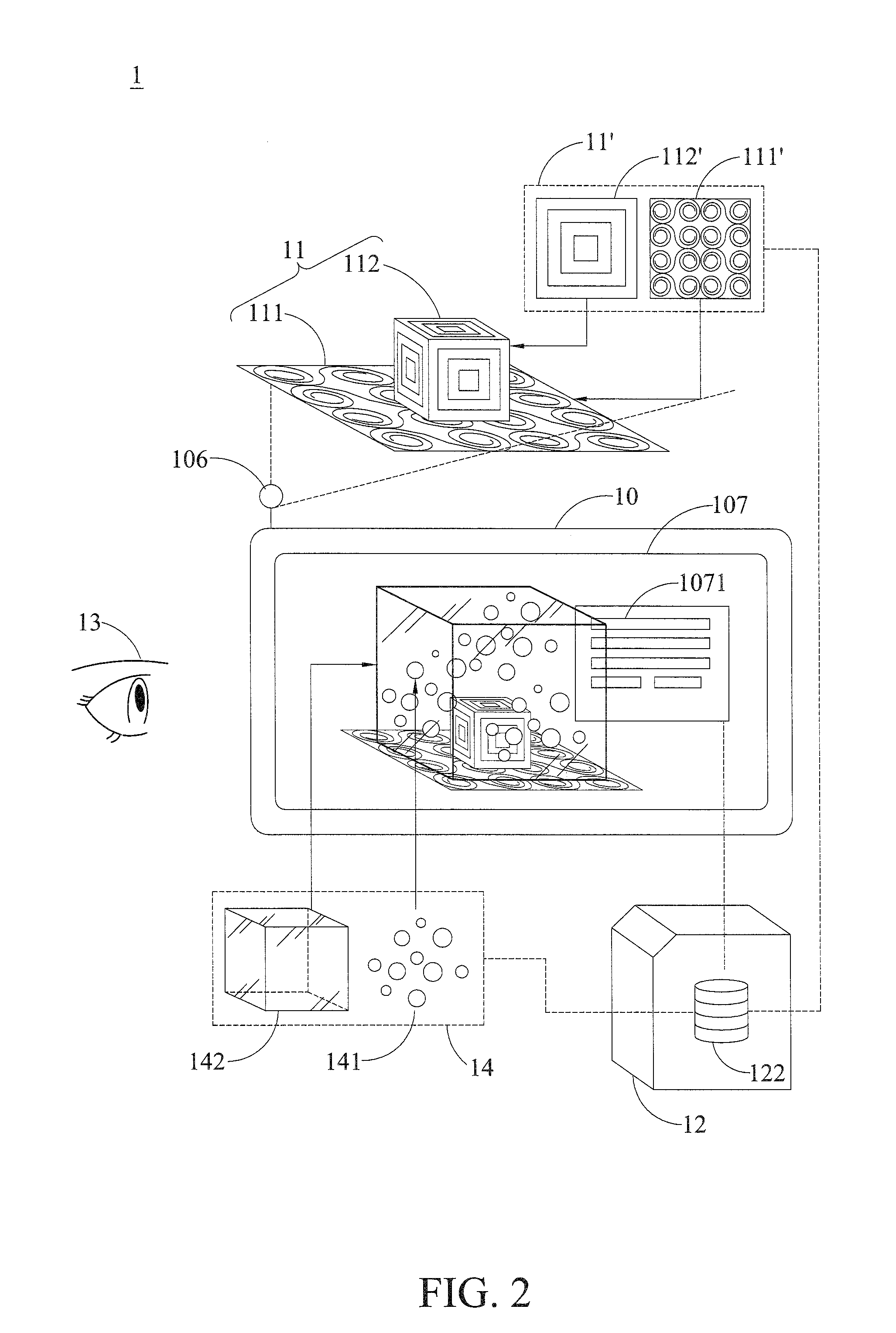

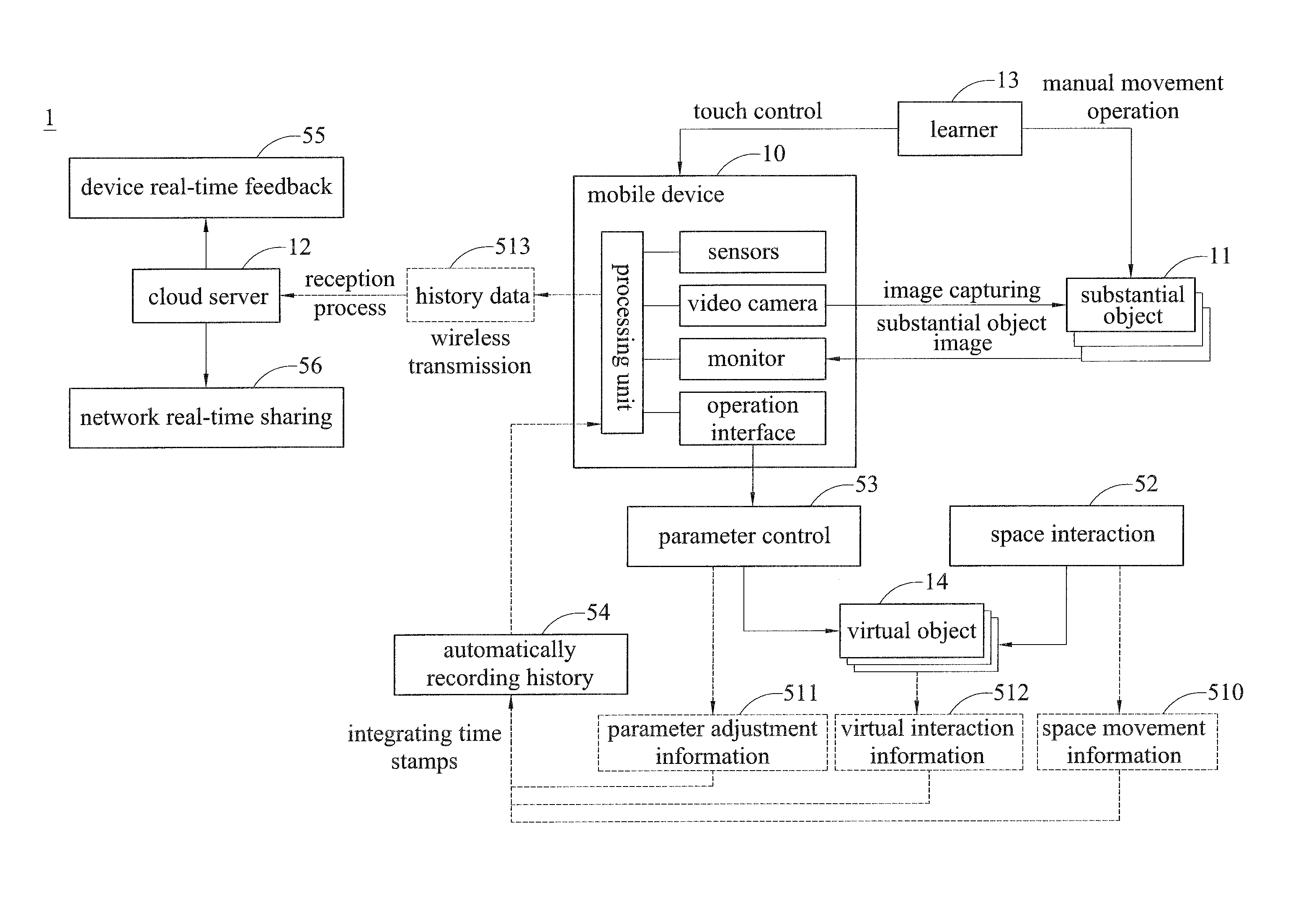

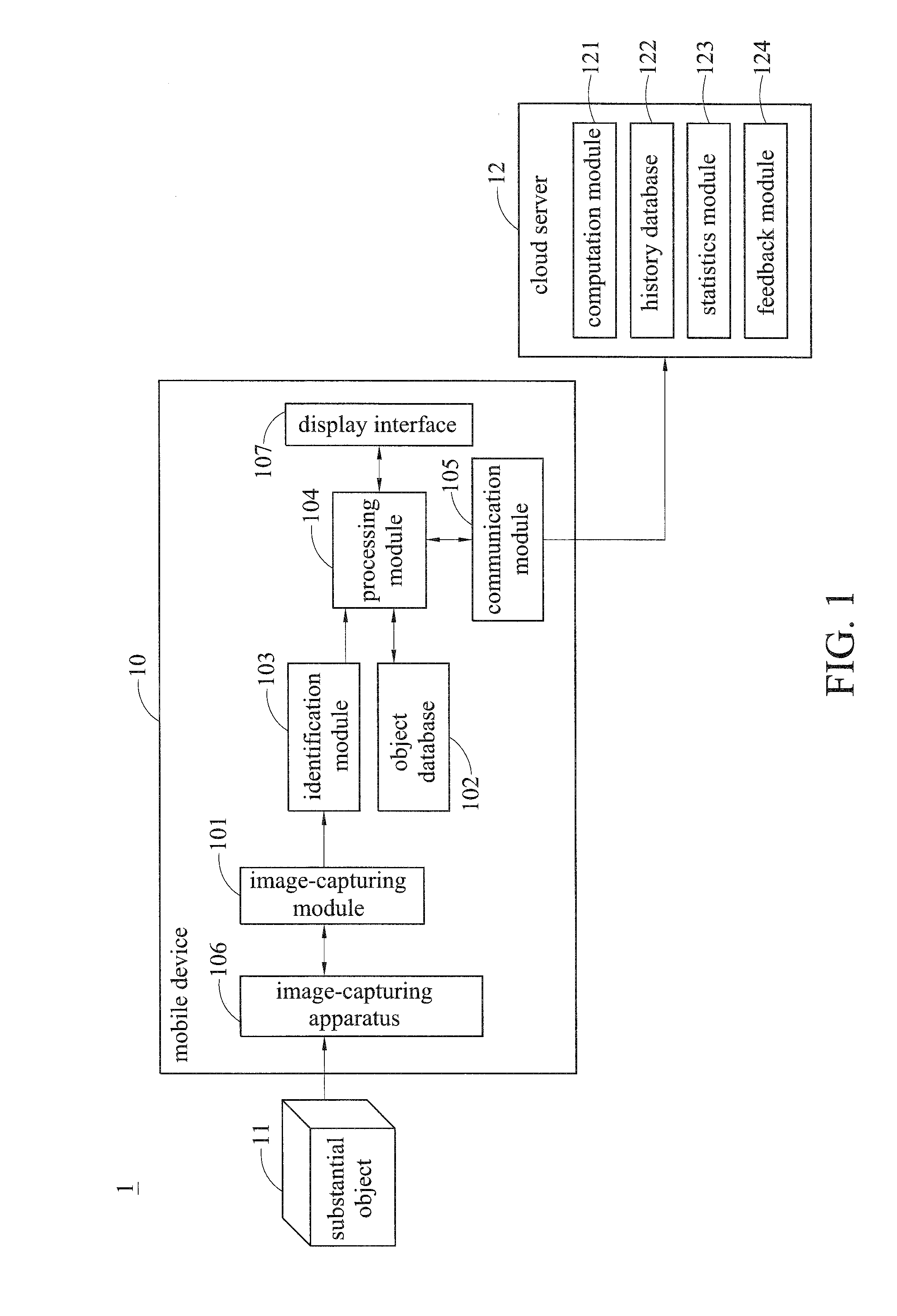

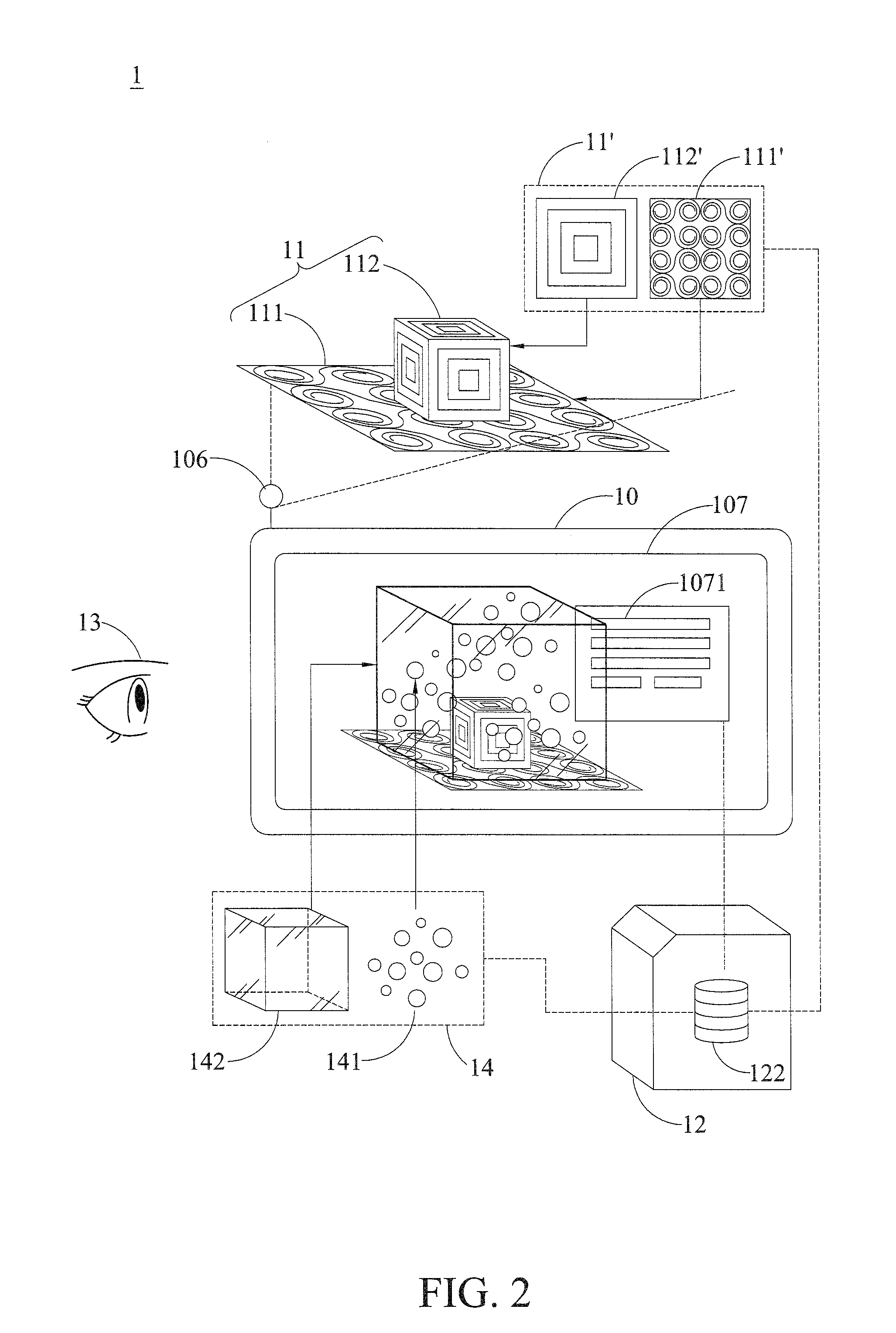

Learning system with augmented reality and related learning method

ActiveUS20150029183A1Convenient teachingEasy to testDigital data information retrievalCathode-ray tube indicatorsAbstract conceptStudy methods

A learning system with augmented reality is provided. The learning system includes a cloud server recording an operation history of a learner and providing feedback messages, and a mobile device having an image-capturing module capturing an image of a substantial object. Also, the learning system comprises an object database storing a simulated object corresponding to the substantial object, an identification module identifying the image and generating image information, and a processing module which receives and analyzes the image information, obtains the simulated object from the object database according to analyzing results, and displays the simulated object on a display interface of the mobile device. The learning system allows learner to operate simulated object operation instructions on the display interface or directly operate the substantial object to control a display status of the simulated object, and the operation history of learner is transmitted to the cloud server. Learner conducts simulation scientific experiments and substantial operational trainings by operating the simulated object or the substantial object, thereby facilitating learning abstract concepts without being limited by the time and space constraints in a conventional learning system.

Owner:NATIONAL TAIWAN NORMAL UNIVERSITY

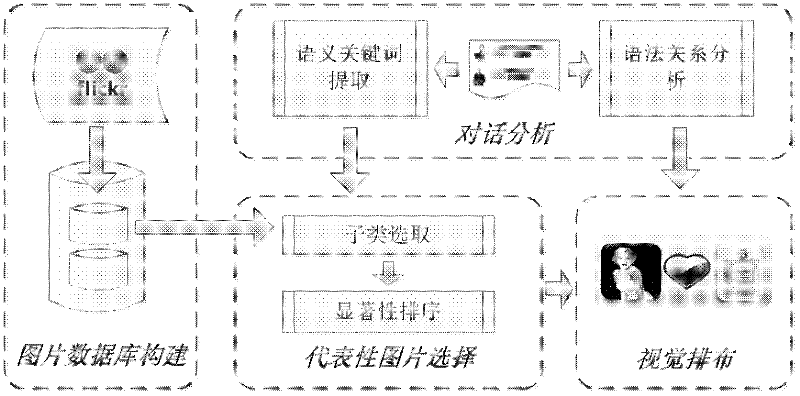

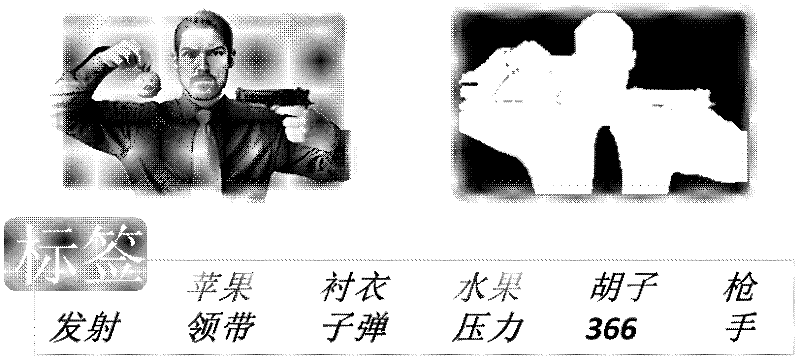

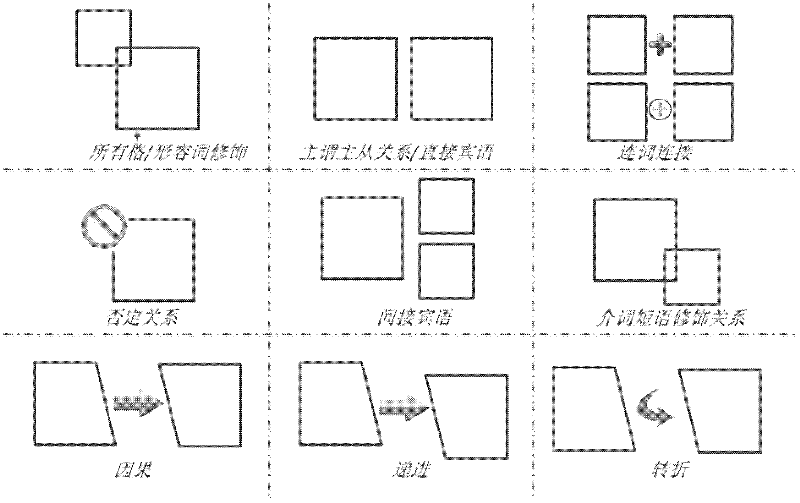

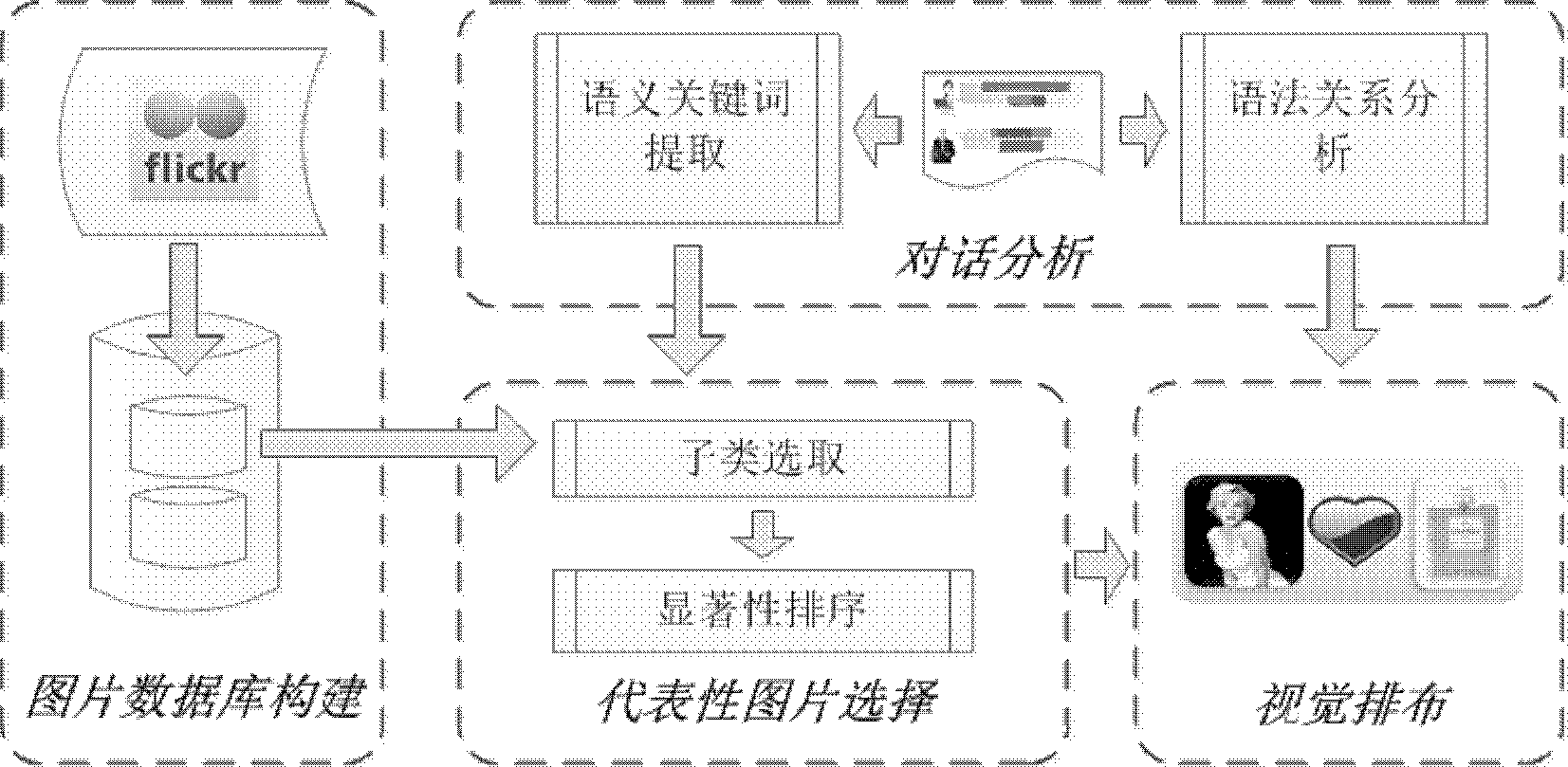

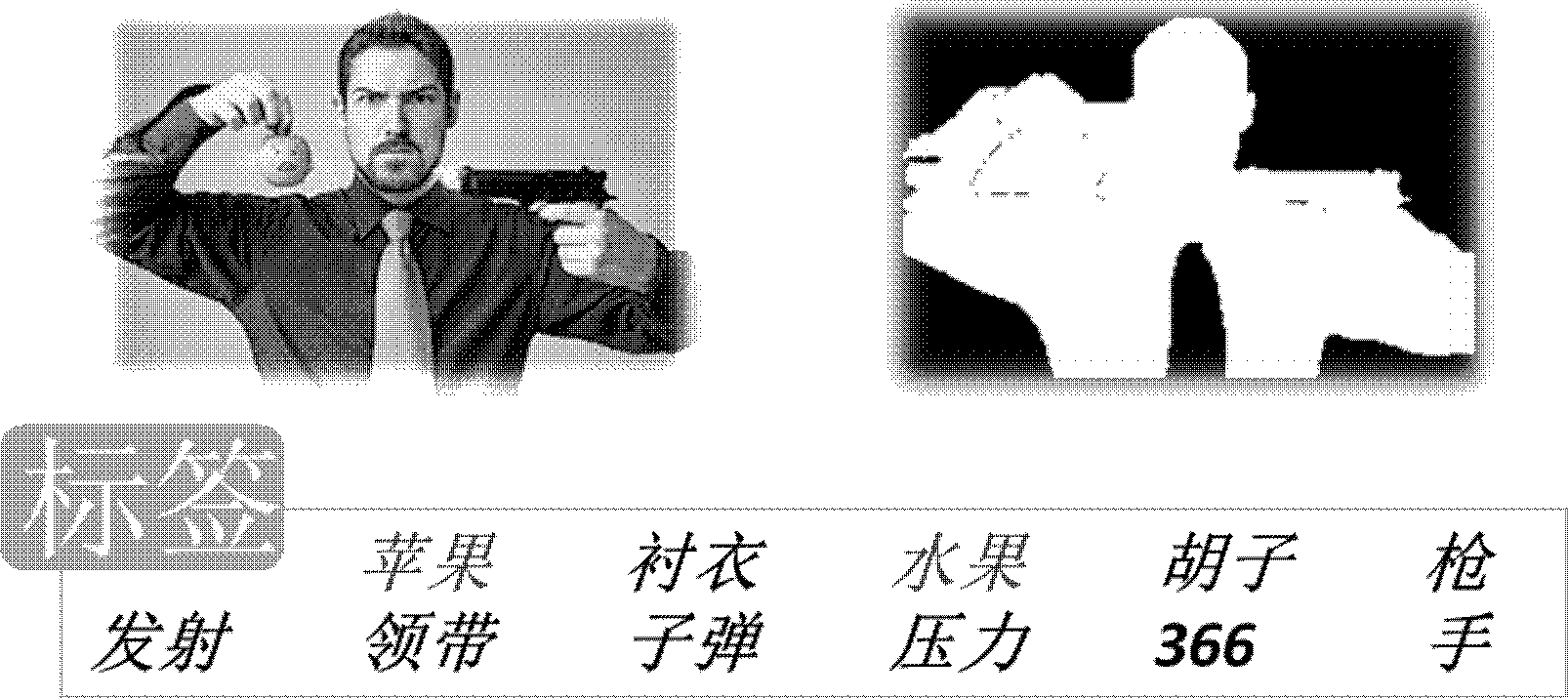

Method and system for instant messaging with visual messaging assistance

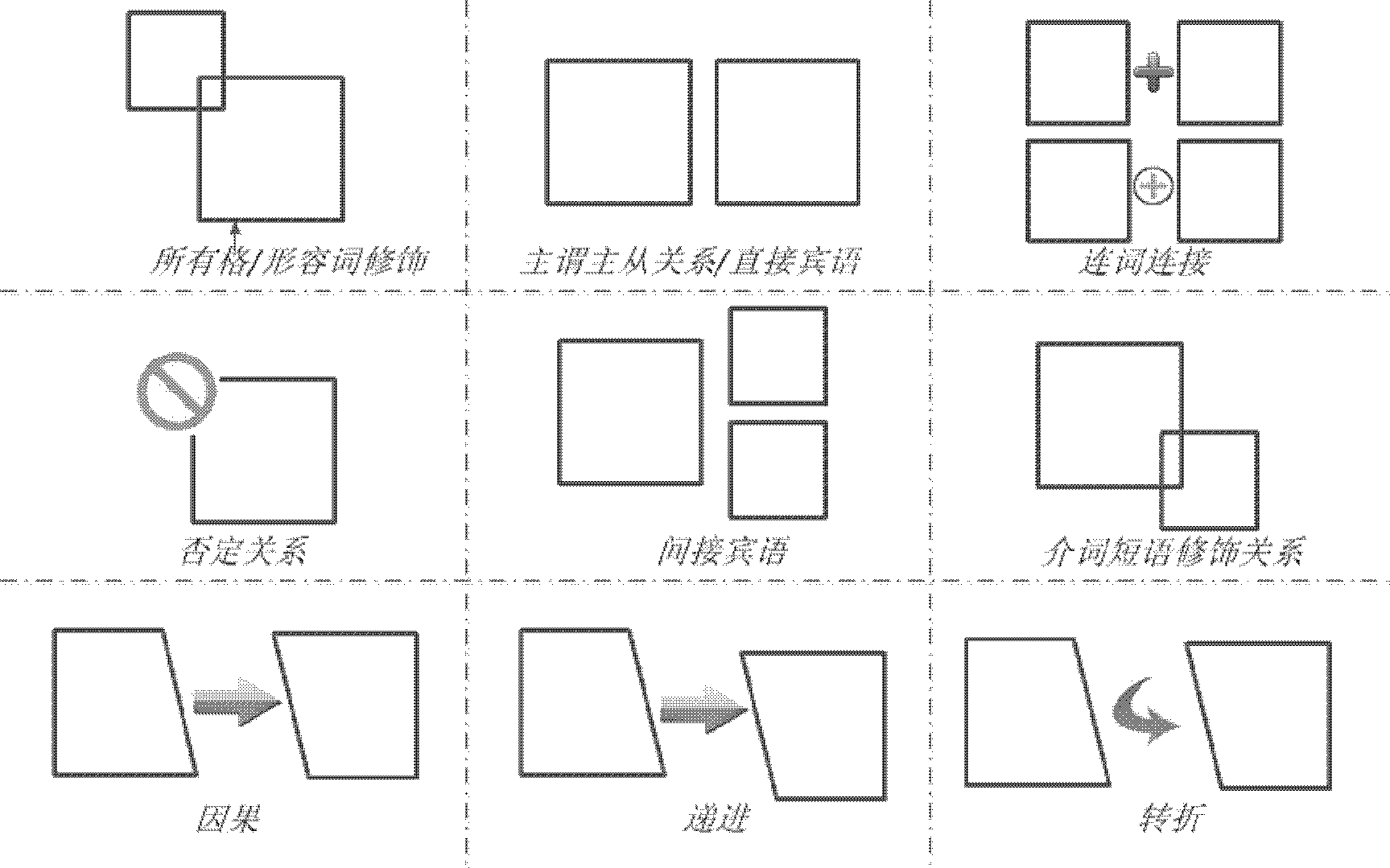

ActiveCN102567509AHigh expressionWake up memoriesData switching networksSpecial data processing applicationsGrammatical relationVisual perception

The invention discloses a method and a system for instant messaging with visual messaging assistance. The method includes the following steps: constructing a picture database; extracting semantic key words based on text messages input by a user, and making an analysis to obtain grammatical relation between the key words; based on the extracted key words, selecting representative pictures in accordance with contexts of instant messaging from the picture database by utilizing context semantic clues and conspicuousness degree of pictures; reasonably arranging representative pictures to form visual information by utilizing grammatical relation between the key words, and transmitting the visual information together with the test messages to users of the other side. The invention further provides the system for instant messaging with visual messaging assistance, which combines the text messages for transmitting abstract concepts and the visual information for transmitting image concepts, helps users to better express themselves and understand the other side through complementation of the text messages and the visual information. Meanwhile, a machine translation module is also combined with the system for instant messaging with visual messaging assistance, and therefore, for users who speak different languages, the visual information and machine translation results can be jointly presented to users.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

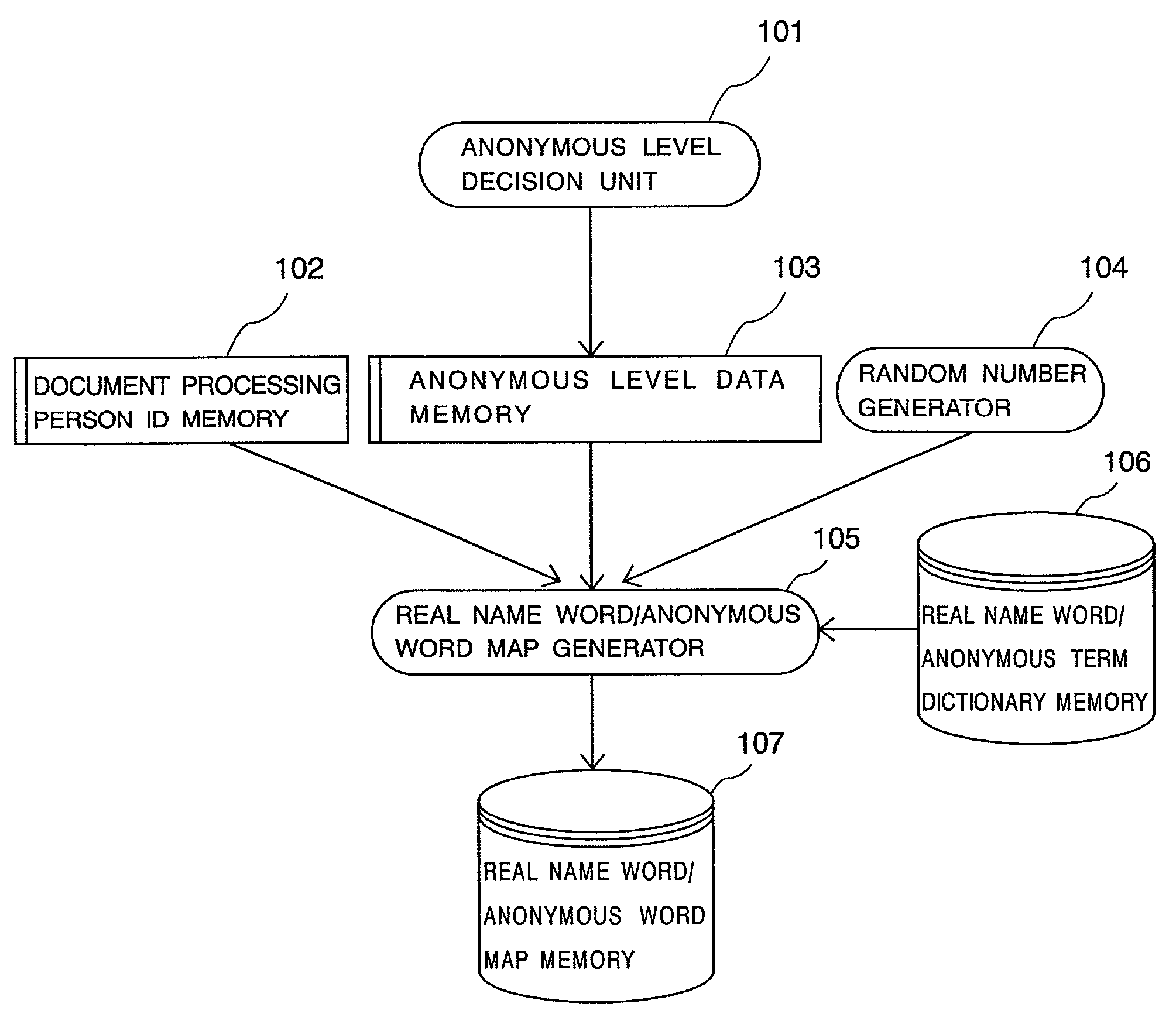

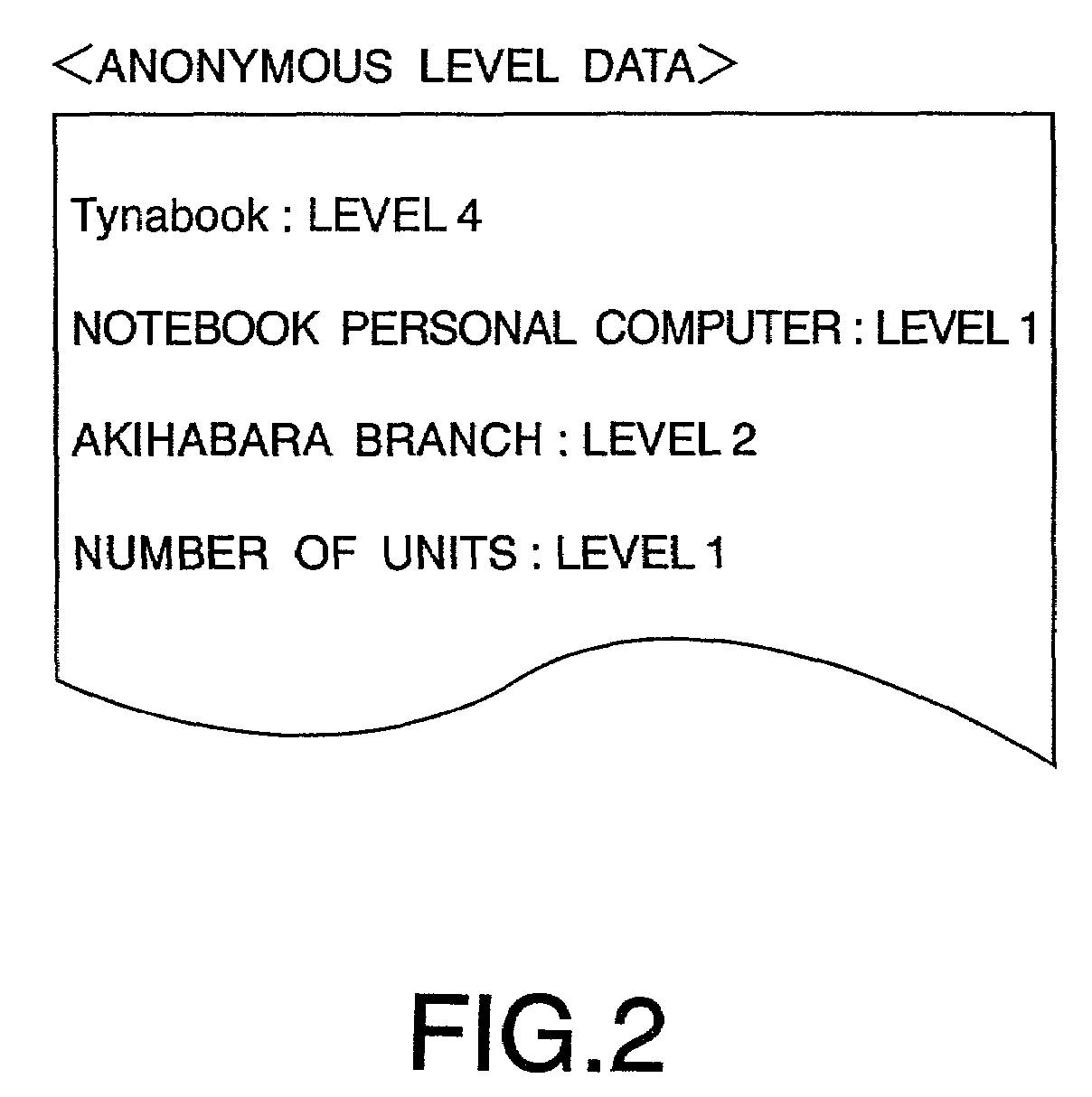

Apparatus and method for creating a map of a real name word to an anonymous word for an electronic document

InactiveUS7243304B2Protected contentUnauthorized memory use protectionHardware monitoringElectronic documentAbstract concept

An anonymous level decision unit decides an anonymous level to anonymize a real name word included in the electronic document. An additional label generation unit generates an additional label corresponding to the real name word based on an identifier. A dictionary stores a correspondence relationship between the real name word and an anonymous term as an abstract concept of the real name word. A map creation unit selects the anonymous term corresponding to the real name word based on the anonymous level from the dictionary, generates an anonymous word corresponding to the real name word by adding the additional label to the anonymous term, and correspondingly stores the real name word and the anonymous word. A map representing a correspondence relationship between the real name word and the anonymous word for the identifier is created.

Owner:KK TOSHIBA

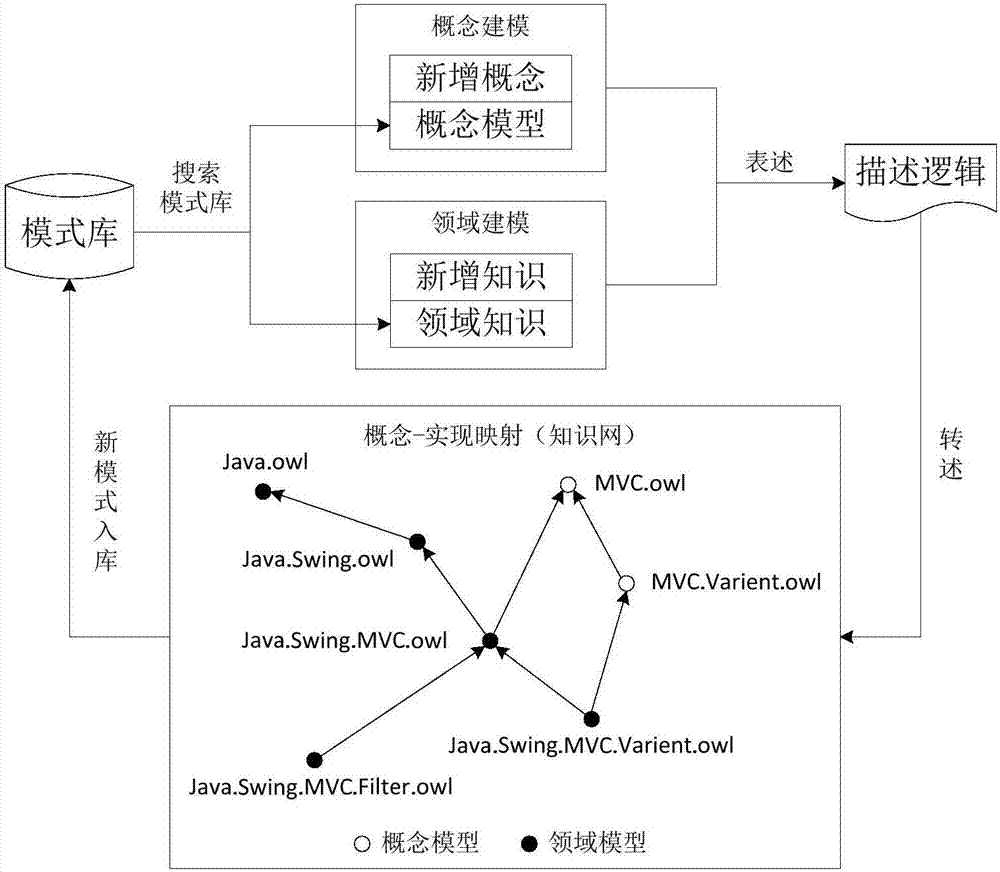

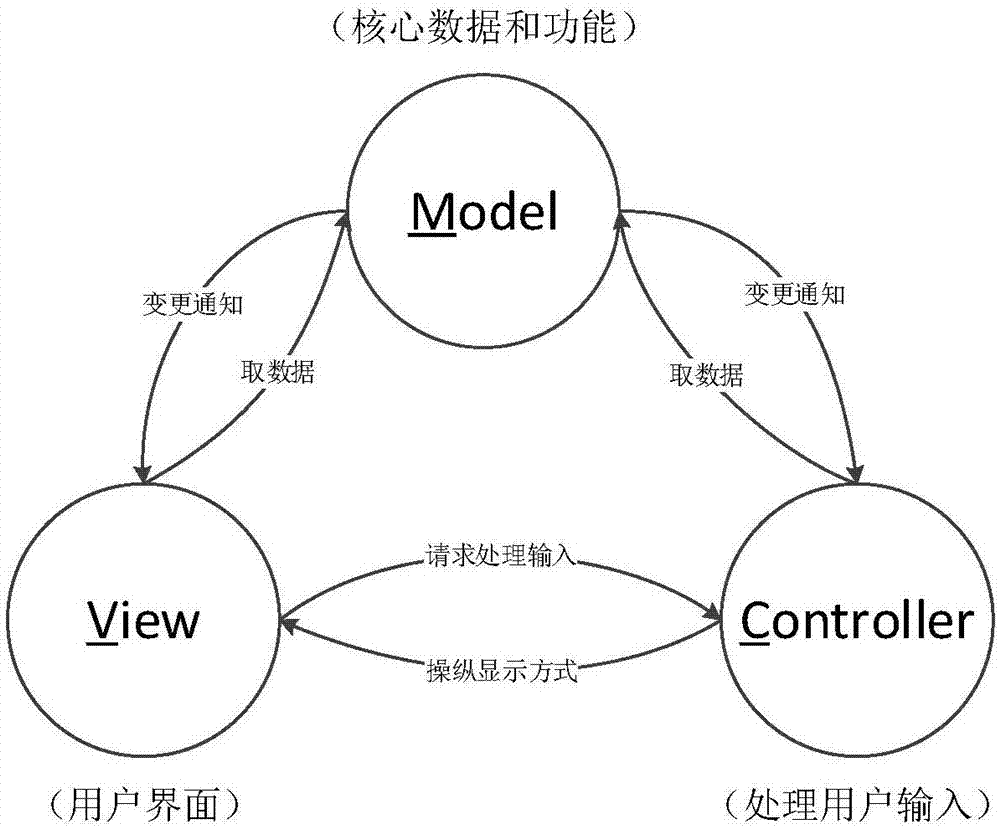

Ontology-based architectural pattern modeling method

The invention discloses an ontology-based architectural pattern modeling method. According to the method, description logic is used to perform concept modeling of an architectural pattern, a domain knowledge model is further introduced, finally a mapping relation between a high-level abstract concept and system realization is established, and therefore the model is applied to recognition of the architectural pattern. Considering extension and reuse problems of domain knowledge, the domain knowledge is organized into a netlike hierarchical structure during modeling. In the structure, a conceptmodel is at a high level, more domain knowledge is combined step by step at all lower levels to explain the high-level concept. New knowledge can be incrementally added into any node at any level andalso can be selectively reused to establish a new concept. The ontology-based architectural pattern modeling not only has the abstracting ability of concept modeling but also can utilize the domain knowledge to serve architectural pattern recognition, and therefore the automation degree and precision of architectural pattern recognition are improved.

Owner:SOUTHEAST UNIV

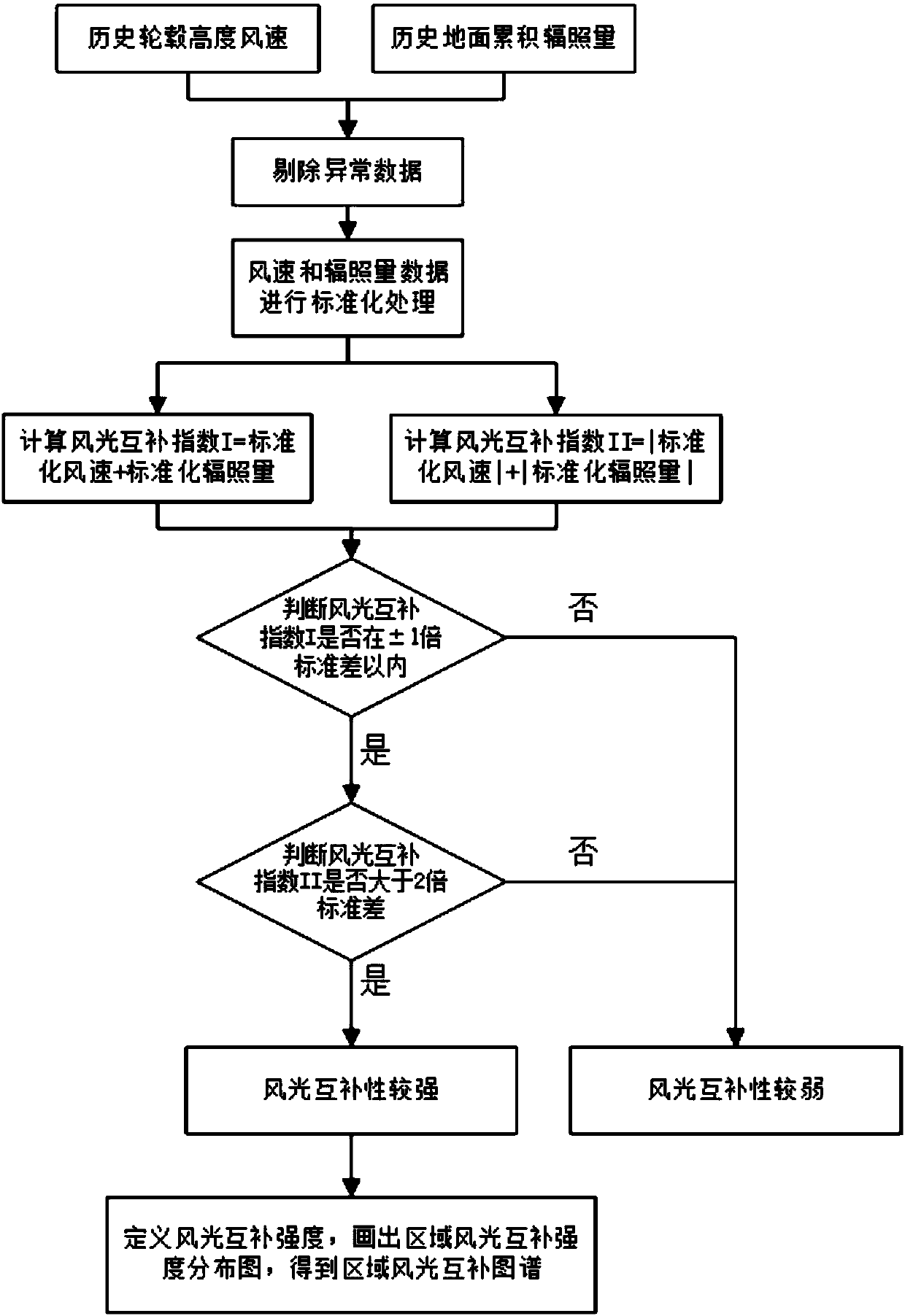

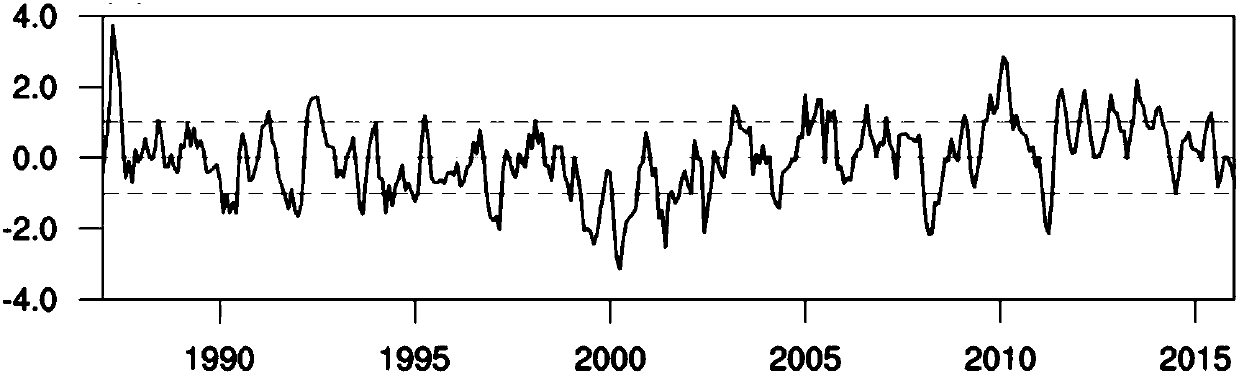

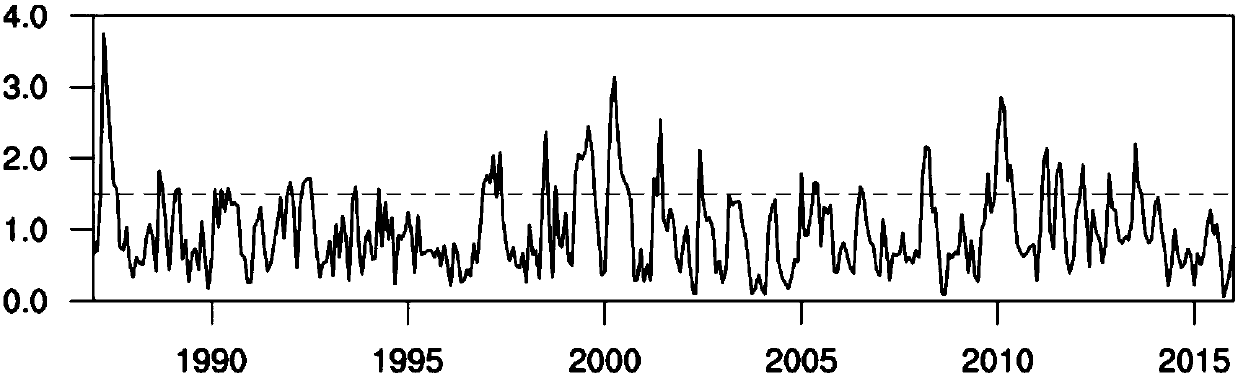

Method and system for evaluating complementarity of regional wind and light resources

ActiveCN108493999AFully consider the synergistic variabilityIntuitively see complementary propertiesSingle network parallel feeding arrangementsWind energy generationPower stationAbstract concept

The invention provides a method and system for evaluating the complementarity of regional wind and light resources. On the basis of a standardized wind speed sequence and a ground cumulative exposuredose standardized sequence, wind-light complementary intensities of all grid point in a region are obtained; and a regional wind-light complementary intensity two-dimensional map is drawn to evaluatea wind-light complementary intensity distribution situation of the region. According to the invention, wind and light variables are standardized to form new wind and light resource meteorological variables; and the wind and light resources are integrated and the synergistic changes of wind resources and light resources are considered fully. The abstract concept of wind and light complementation iscalculated and described quantitatively and the wind-light complementary resource distribution map is drawn by using the method, thereby providing a valuable reference base for wind-light resource evaluation, power station site selection, and new energy source matching and regulation in a certain region.

Owner:YUNNAN POWER GRID

Learning system with augmented reality and related learning method using mobile device to conduct simulations and operational training

ActiveUS9418484B2Facilitating knowledgeFacilitating of of strategyDigital data information retrievalImage data processingAbstract conceptStudy methods

A learning system with augmented reality is provided. The learning system includes a cloud server recording an operation history of a learner and providing feedback messages, and a mobile device having an image-capturing module capturing an image of a substantial object. Also, the learning system comprises an object database storing a simulated object corresponding to the substantial object, an identification module identifying the image and generating image information, and a processing module which receives and analyzes the image information, obtains the simulated object from the object database according to analyzing results, and displays the simulated object on a display interface of the mobile device. The learning system allows learner to operate simulated object operation instructions on the display interface or directly operate the substantial object to control a display status of the simulated object, and the operation history of learner is transmitted to the cloud server. Learner conducts simulation scientific experiments and substantial operational trainings by operating the simulated object or the substantial object, thereby facilitating learning abstract concepts without being limited by the time and space constraints in a conventional learning system.

Owner:NATIONAL TAIWAN NORMAL UNIVERSITY

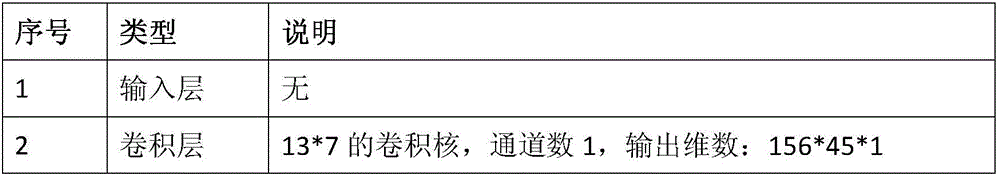

Multi-example learning method using deep learning technology

InactiveCN106682687ACharacter and pattern recognitionNeural learning methodsData setAbstract concept

The invention provides a multi-example learning method using a deep learning technology. A series of data filling and segmentation means are used to convert multiple-example samples into characteristic matrixes of the same size, and a convolutional neural network is used to carry out learning with monitoring and classification. According to the method of the invention, hidden abstract concepts in a multi-example data set can be discovered, errors of the data set can be tolerated effectively, and the generalization capability is high.

Owner:GUANGDONG UNIV OF TECH

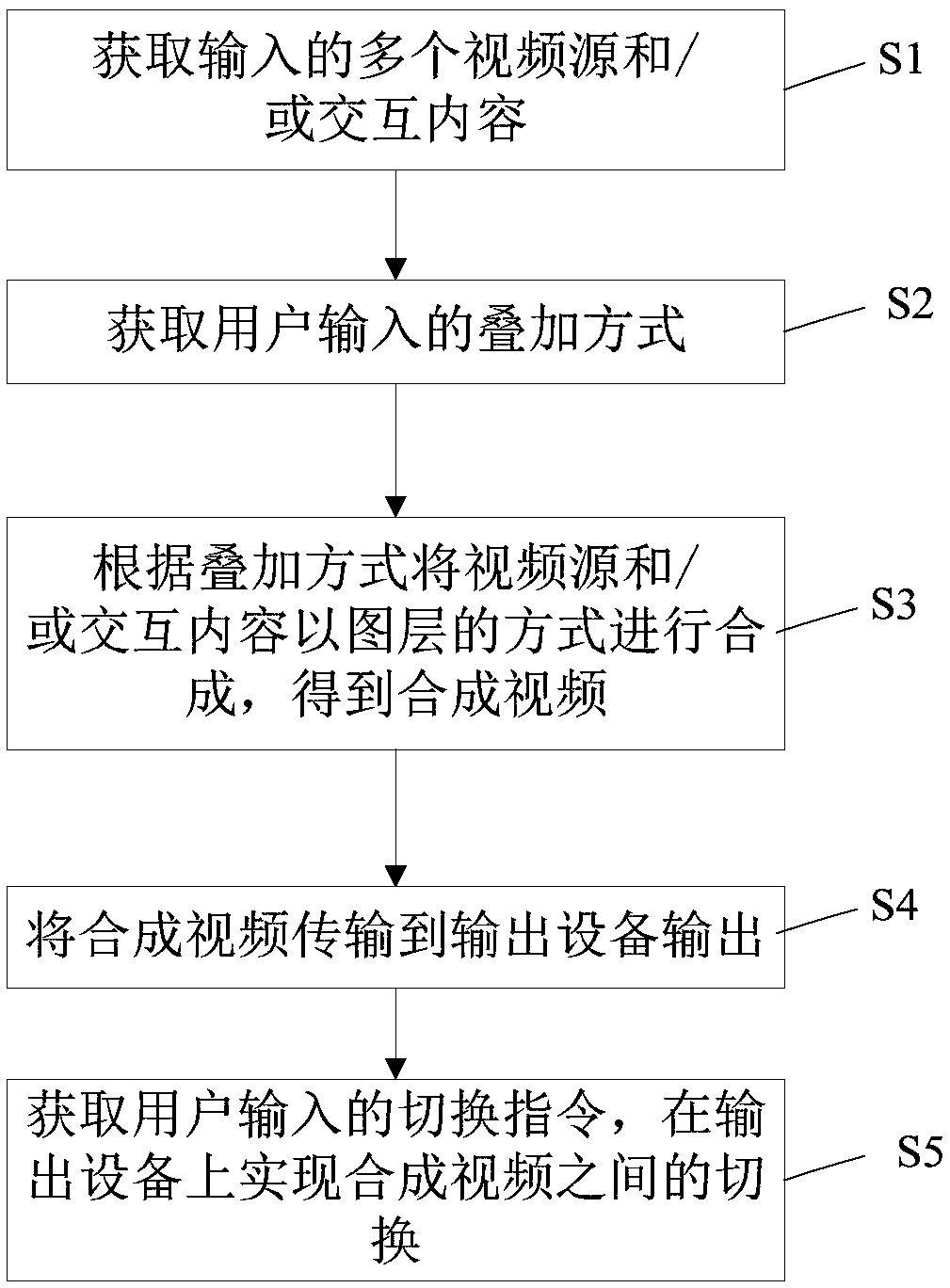

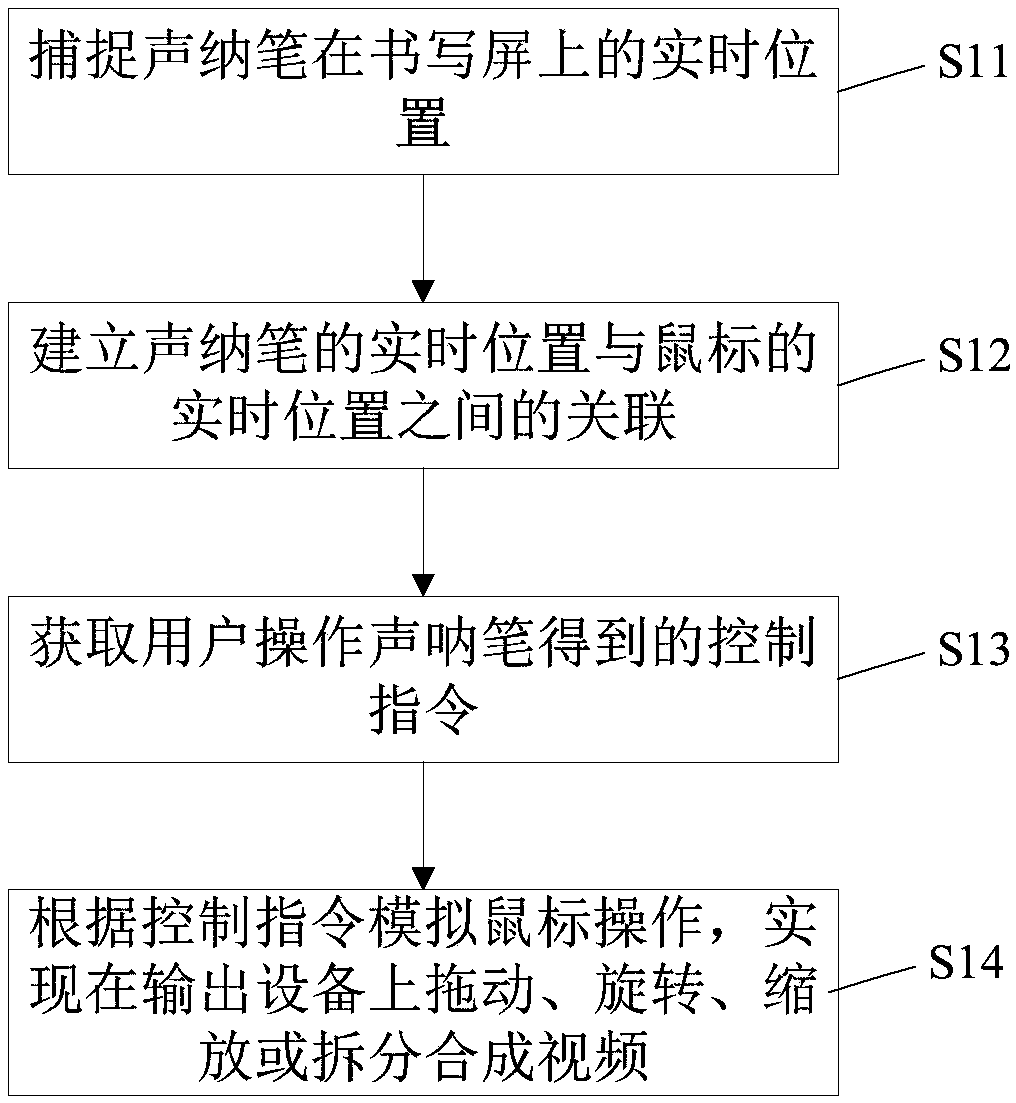

Real 3D virtual simulation interaction method and system

ActiveCN108831216AAccurate presentation of interactive contentEnable direct interactionAnimationElectrical appliancesAbstract conceptUser input

The invention provides a real 3D virtual simulation interaction method and system. The method comprises the following steps that multiple input video sources and / or interaction contents are obtained;a superposition mode input by a user is obtained; the video sources and / or interaction contents are synthesized according to the superposition mode to obtain a synthesis video; the synthesis video istransmitted to an output device and output; and a switching instruction input by the user is obtained, and switching among synthesis videos is realized in the output device. Via the method, a recording staff can make real-time interaction in the video sources or interaction contents cooperated with explained knowledge points, and the recording staff can explain an abstract concept and a practice process more concretely due to cooperation of the video sources or interaction contents. The output device is fused and analyzed and matched accurately via the multichannel 3D video, virtual and real interactive simulated multipath output is carried out, a practical video stream is collected and input to a real 3D virtual scene, and a teacher makes interaction with the real 3D virtual scene in realtime.

Owner:辽宁向日葵教育科技有限公司

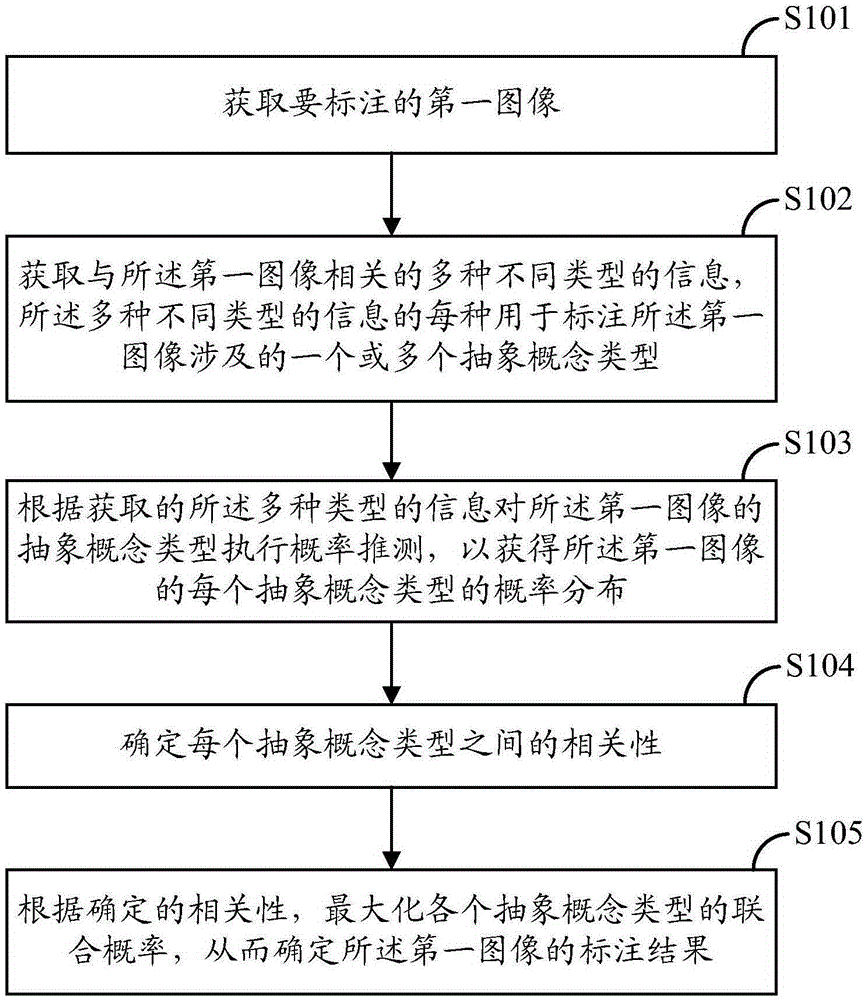

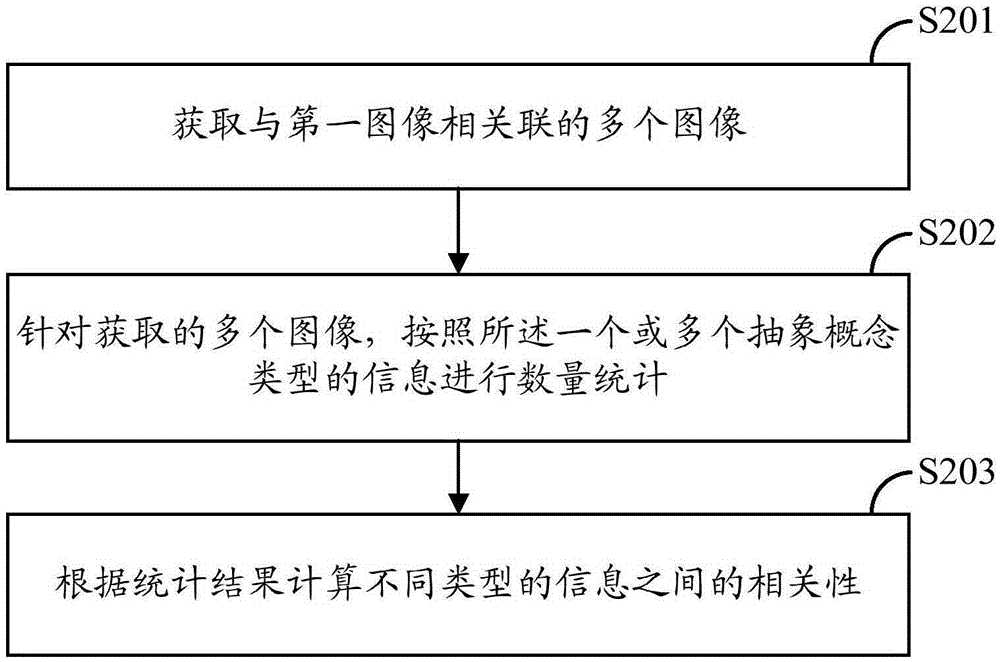

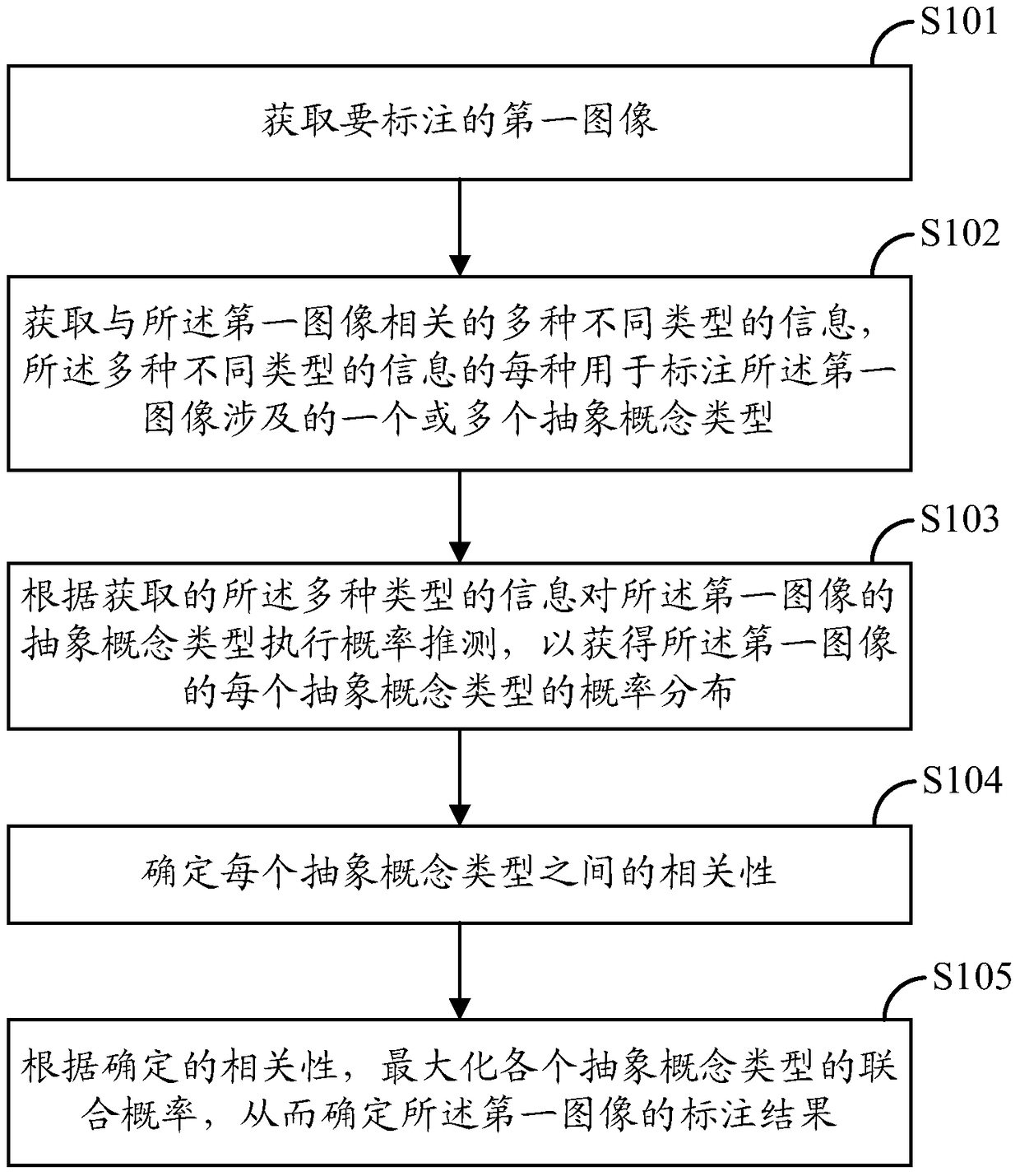

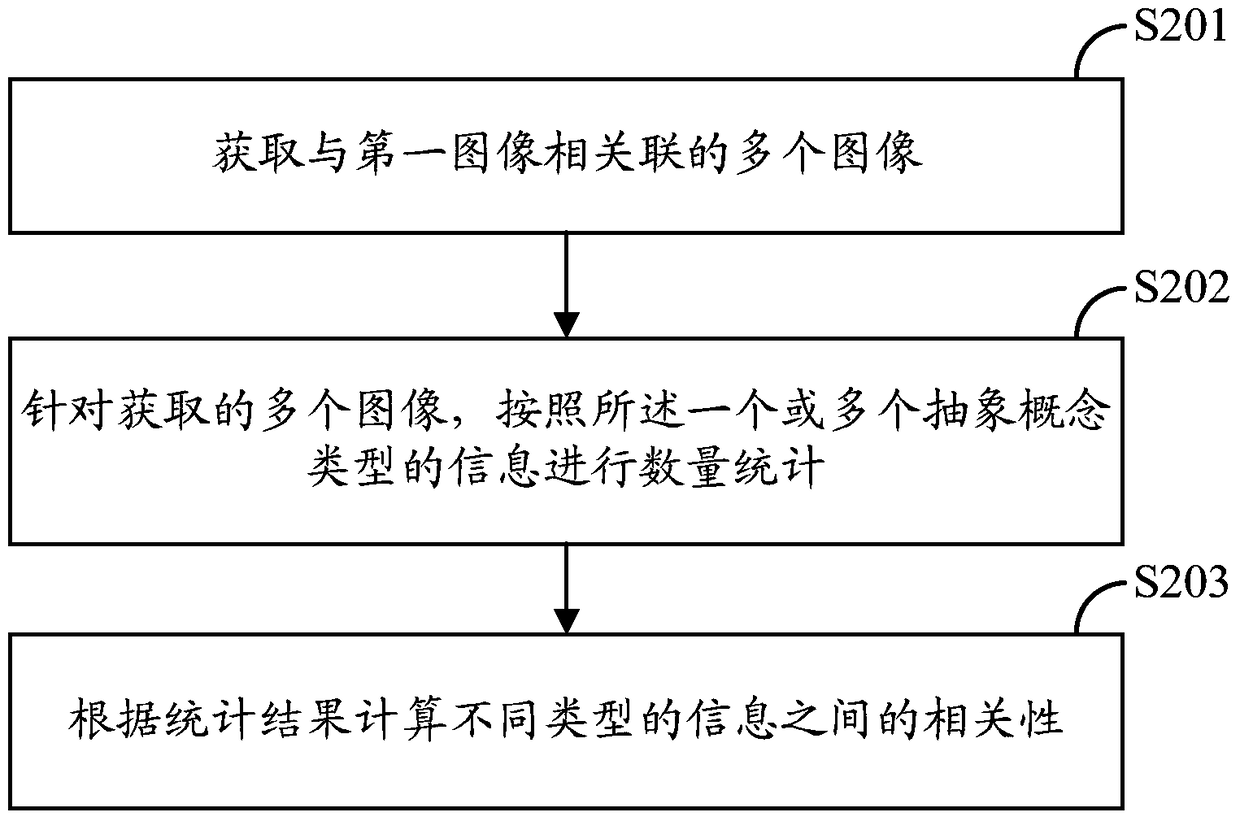

Image marking method and electronic equipment

ActiveCN105426925AAccurate labelingImprove user experienceCharacter and pattern recognitionPattern recognitionAbstract concept

The invention provides an image marking method and electronic equipment. The method comprises the steps that a first image to be marked is acquired; multiple different types of information related to the first image is acquired, and each of the multiple different types of information is used for marking one or multiple involved abstract concept types of the first image; probability speculation is performed on the abstract concept types of the first image according to the acquired multiple different types of information so that probability distribution of each abstract concept type of the first image is acquired; correlation between all the abstract concept types is determined; and joint probability of all the abstract concept types is maximized according to the determined correlation so that the marking result of the first image is determined.

Owner:LENOVO (BEIJING) CO LTD +1

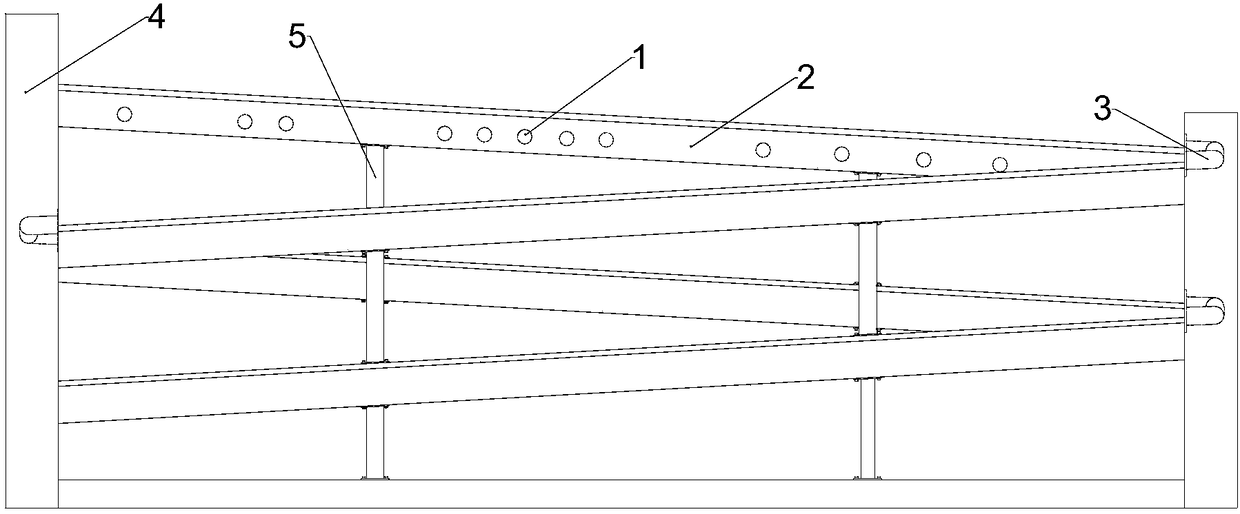

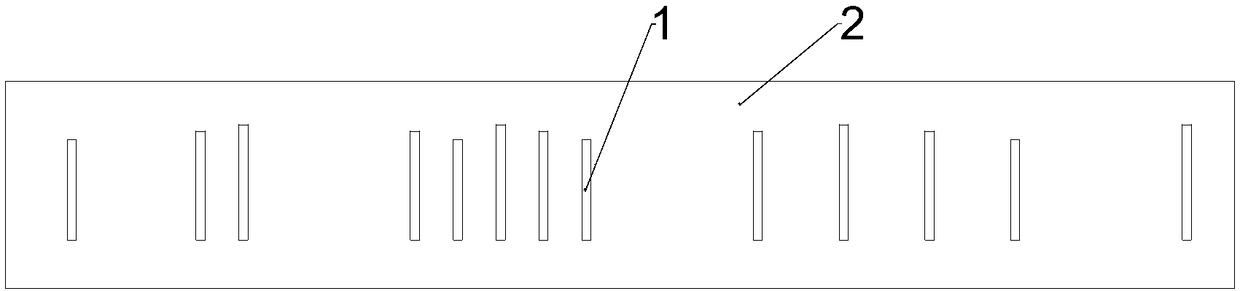

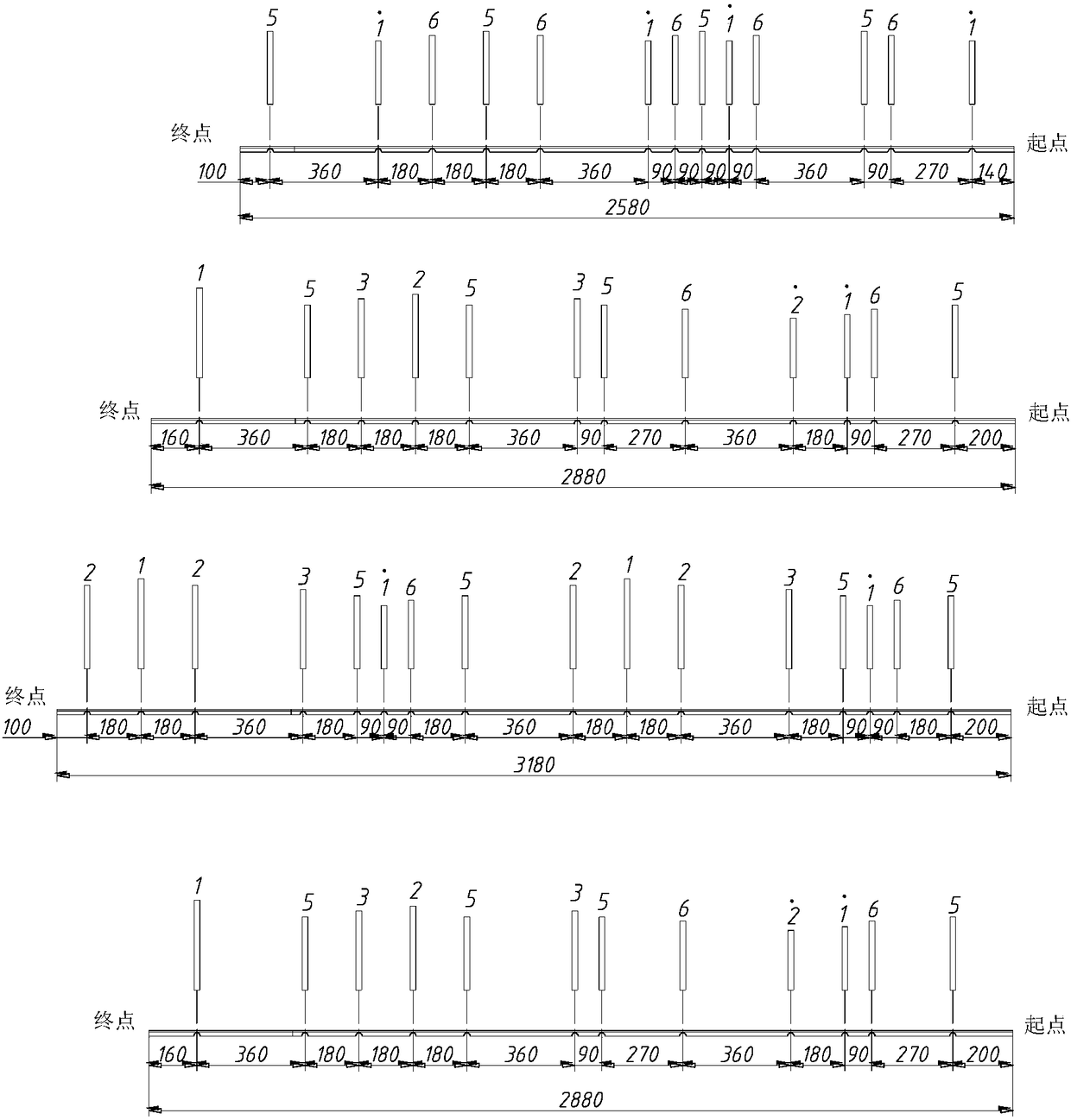

Demonstration equipment of producing music by rolling ball on ramp

PendingCN108335590AReduce difficulty understanding abstract conceptsIncrease viewing interestEducational modelsAbstract conceptEngineering

The invention provides demonstration equipment of producing music by rolling a ball on a ramp. The equipment comprises a rail, a plurality of metal pipes arranged on the rail in parallel, and a ball rolling along the rail, wherein an inclination angle exists between the rail and a horizontal plane; the metal pipes lie on the rail; axial directions of the metal pipes are perpendicular to an inclination direction of the rail; a tone of sound generated by collision of the ball to the metal pipes depends on the lengths of the metal pipes; and a rhythm of the sound generated by the collision of theball to the metal pipes depends on the distances between the metal pipes. The equipment is simple in structure, and employs an ingenious combination of a ball body and a shape of the rail; the ball body excites sounding devices arranged in specific positions in the rail to play the music in a natural rolling process; the knowledge of a sound characteristic is embodied and visualized; the difficulty of an audience to understand an abstract concept is reduced; the watching interest and positivity of the audience are raised; and the audience conveniently understands and masters the relevant knowledge.

Owner:HEFEI PANSHI AUTOMATION TECH

Method for improving expansibility of Hyperledger Composer block chain transaction system

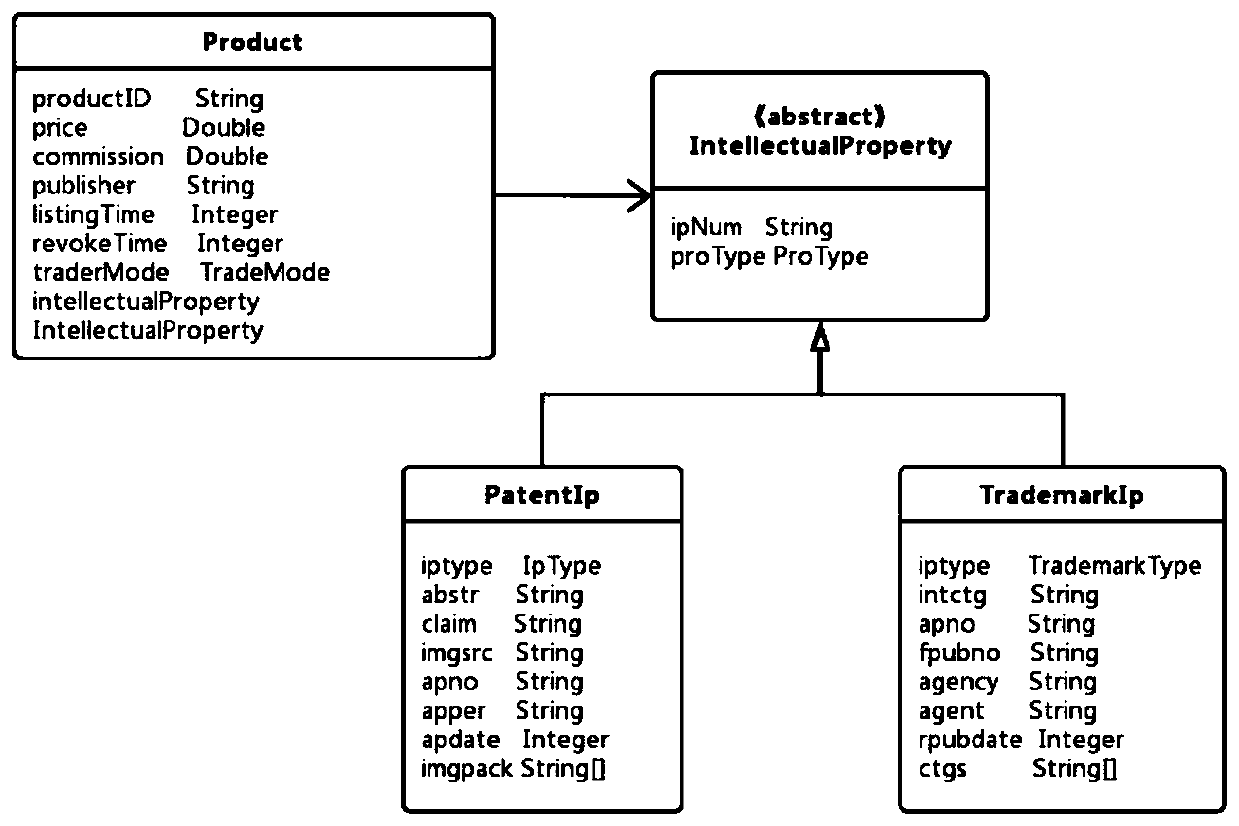

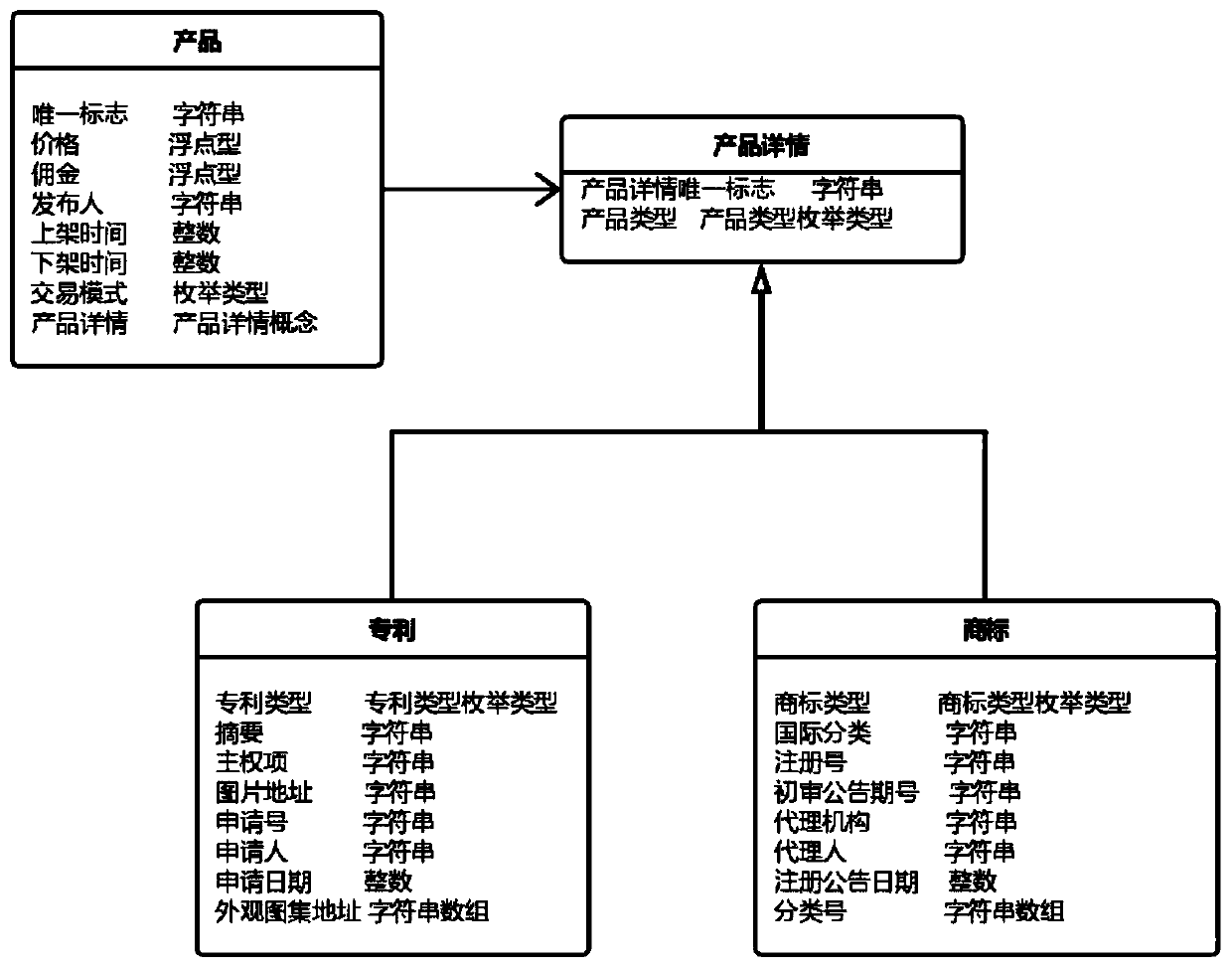

ActiveCN110187868AImprove scalabilityImprove interoperabilitySoftware designProduct typeAbstract concept

The invention discloses a method for improving the expansibility of a Hyperledger Composer block chain transaction system. The method comprises the following steps of defining a common attribute of atransaction system product asset Product in a service network model of an existing system; defining a product detail abstract concept: concept IntellectualProperty, the transaction system product asset Product being associated with the concept IntellectualProperty; and defining a product detail abstract concept: concept IntellectualProperty, and inheriting the concept IntellectualProperty when a concept is defined for a certain type of transaction products. According to the method provided by the invention, aiming at a new product type, the new transaction commodity type can be expanded only by expanding the concept in the business network model of the existing system, repeated development and deployment of a set of block chain transaction system are not needed, and the expandability of the system is improved.

Owner:广州科创空间信息科技有限公司

Method and system for instant messaging with visual messaging assistance

ActiveCN102567509BWake up memoriesData switching networksSpecial data processing applicationsGrammatical relationVisual perception

The invention discloses a method and a system for instant messaging with visual messaging assistance. The method includes the following steps: constructing a picture database; extracting semantic key words based on text messages input by a user, and making an analysis to obtain grammatical relation between the key words; based on the extracted key words, selecting representative pictures in accordance with contexts of instant messaging from the picture database by utilizing context semantic clues and conspicuousness degree of pictures; reasonably arranging representative pictures to form visual information by utilizing grammatical relation between the key words, and transmitting the visual information together with the test messages to users of the other side. The invention further provides the system for instant messaging with visual messaging assistance, which combines the text messages for transmitting abstract concepts and the visual information for transmitting image concepts, helps users to better express themselves and understand the other side through complementation of the text messages and the visual information. Meanwhile, a machine translation module is also combined with the system for instant messaging with visual messaging assistance, and therefore, for users who speak different languages, the visual information and machine translation results can be jointly presented to users.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Design method based on mind map logic expansion

PendingCN113935292AOpen up ideasAvoid thinkingNatural language data processingEditing/combining figures or textGeneration processAbstract concept

The invention discloses a design method based on mind map logic expansion, and belongs to the technical field of design. The method comprises: determining a first keyword, performing questionnaire analysis, and obtaining at least one keyword except the first keyword; and constructing a collinear network graph and a mind map, and determining an Nth keyword and the like. According to the method, a concept generation process for discussing design is taken as a core, a designer is regarded as a part which cannot be processed, an abstract concept generation process is subjected to clear steps, relative concrete language character keywords are taken as a carrier, association is established between abstract thinking and concrete two-dimensional or three-dimensional images, and a basic condition for combing related thinking factors and forming a design result is formed. According to the method, the thought of a designer can be effectively developed, the situation that the designer thoughts a design problem in a narrow and limited mode from the perspective of a design body is avoided, a large number of keyword elements can be efficiently and effectively gathered in a short time, design logic is formed, and logic thought support is provided for the production design process.

Owner:厦门合立道工程设计集团股份有限公司

Image annotation method and electronic device

ActiveCN105426925BAccurate labelingImprove user experienceCharacter and pattern recognitionAbstract conceptAnnotation

The invention provides an image labeling method and electronic equipment. The method includes: acquiring a first image to be labeled; acquiring multiple different types of information related to the first image, each of the multiple different types of information is used to label the first image related to one or more abstract concept types; perform probability inference on the abstract concept types of the first image according to the acquired information of the plurality of types, so as to obtain a probability distribution of each abstract concept type of the first image; determine The correlation between each abstract concept type; and according to the determined correlation, maximizing the joint probability of each abstract concept type, so as to determine the labeling result of the first image.

Owner:LENOVO (BEIJING) LTD +1

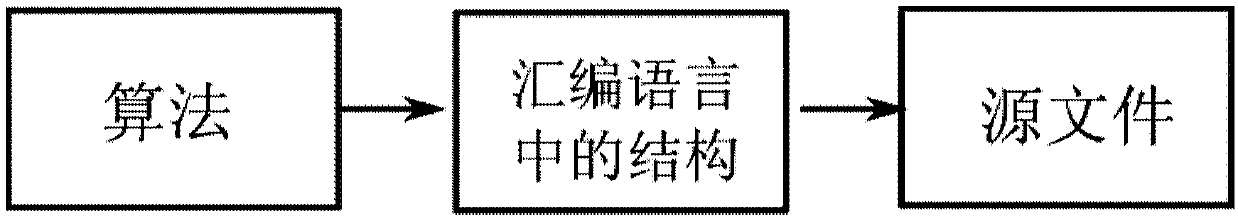

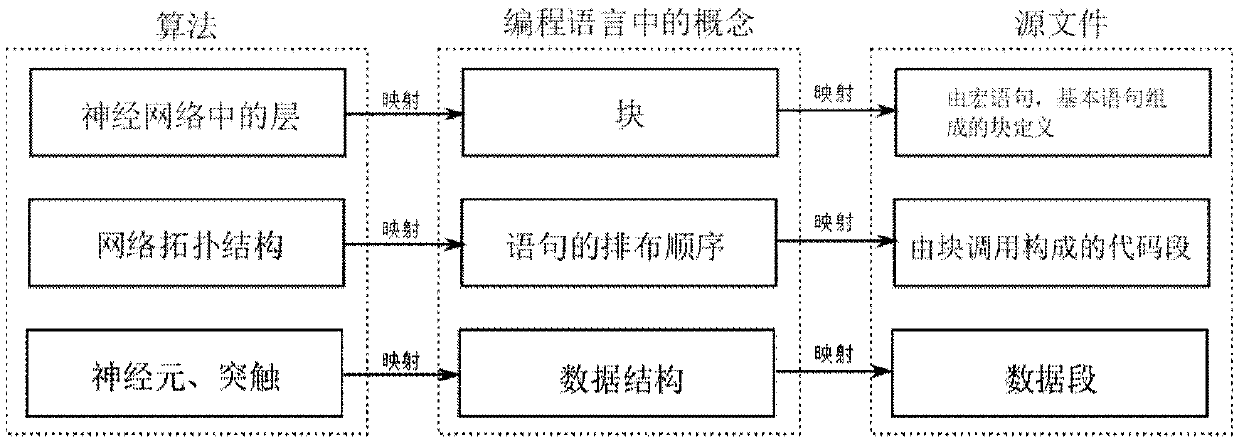

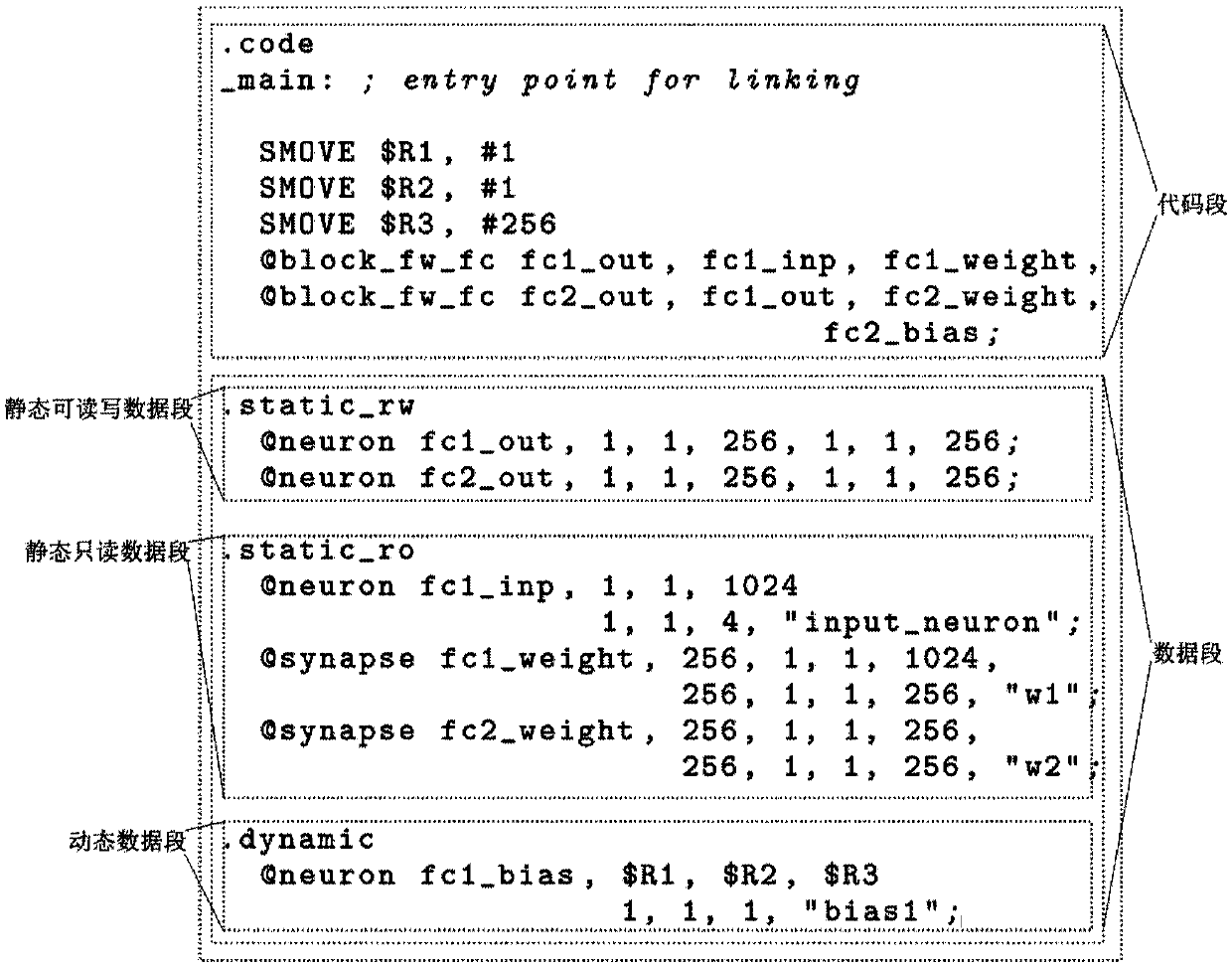

Language source program generation method and device for neural network processor

PendingCN110308899AParallel programming methods are efficientWrite easilyNeural architecturesCreation/generation of source codeNerve networkAbstract concept

The invention discloses a source program generation method and device for a neural network processor, and the method comprises the steps: enabling a neural network algorithm to be mapped into abstractconcepts in a programming language, wherein elements in the neural network algorithm is in one-to-one correspondence with elements in the abstract concepts; mapping an abstraction concept in a programming language into a source program. According to the method, the abstract neural network concept can be directly mapped into codes in a source program, a programmer does not need to face boring instructions, and the programmer can use the advanced abstract neural network concept for programming.

Owner:SHANGHAI CAMBRICON INFORMATION TECH CO LTD

Demonstration instrument for Buffon probability experiment

InactiveCN102522031BIntuitive and visual teachingEasy to understandEducational modelsAbstract conceptDiameter ratio

The invention discloses a demonstration instrument for a Buffon probability experiment, and mainly aims to solve the problem of influence of personal habits on an experimental result and effectively simulate Buffon probability experiment conditions by a machine instead of manual labor. The demonstration instrument comprises a bracket structure (6), a circular bottom plate (12) and a vertical cylinder (7). An electromagnetic vibration disk (1) is positioned on a hollow top plate (14) above the vertical cylinder (7). A needle scattering shaft (2) penetrates through the center of the top plate. Rotating arms (3) are arranged at the lower end of the needle scattering shaft. A rotating claw (5) is connected to the lower end of each rotating arm. The needle scattering shaft, the rotating arms, the rotating claws and the vertical cylinder form an experimental small needle running channel. A horizontal needle receiving disk (9) is arranged on the circular bottom plate (12). Small needles are scattered from the electromagnetic vibration disk, pass through the small needle running channel and fall on the horizontal needle receiving disk. The number of the small needles and the number of intersection points of the small needles with three groups of parallel lines are counted to obtain a circumference-to-diameter ratio. By the demonstration instrument, an abstract concept is embodied, and the teaching of a probability theory is vivid and convenient to comprehend.

Owner:XIDIAN UNIV

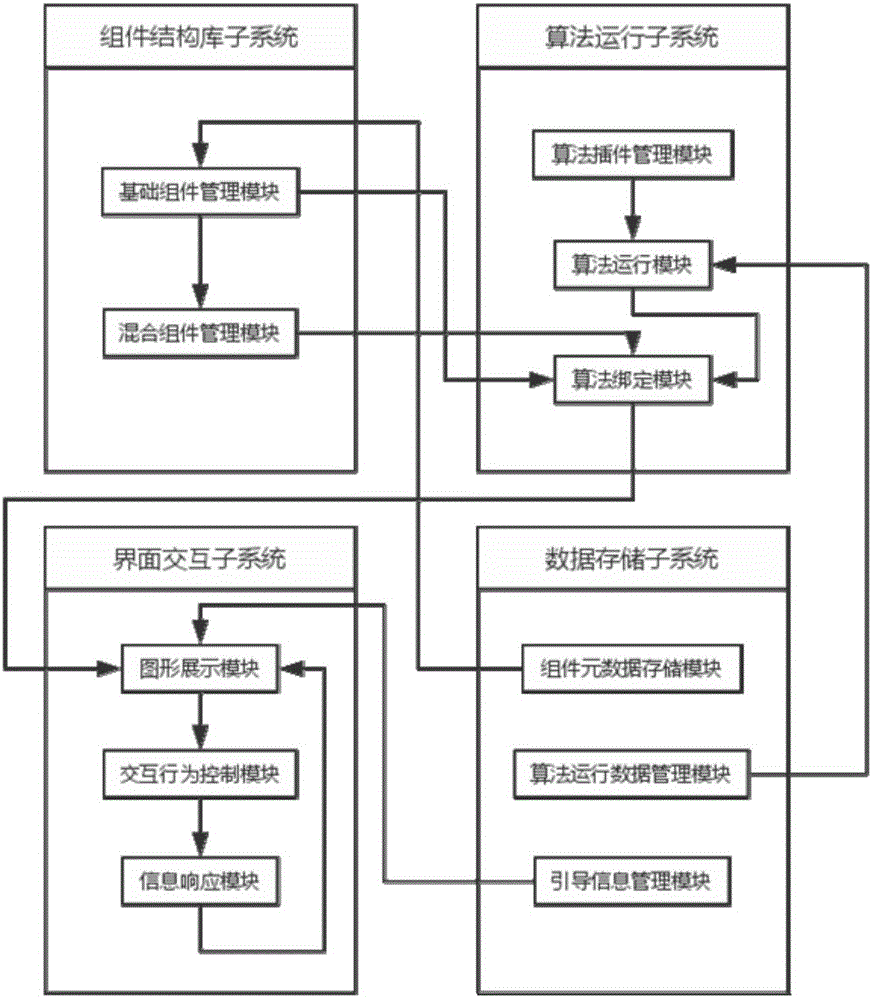

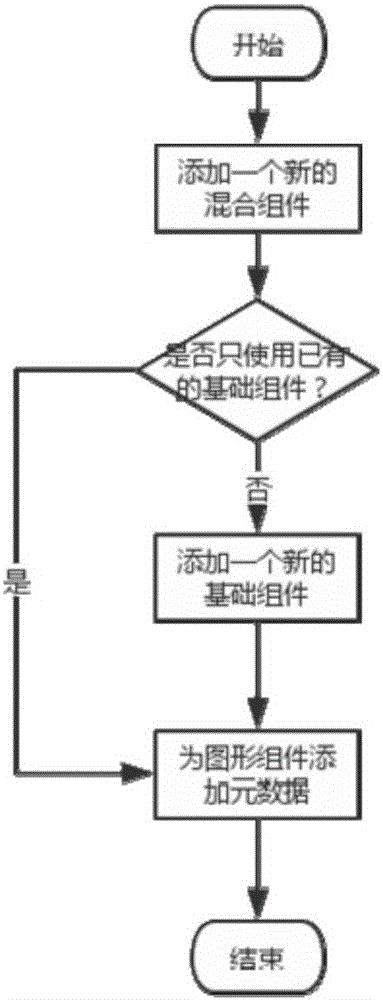

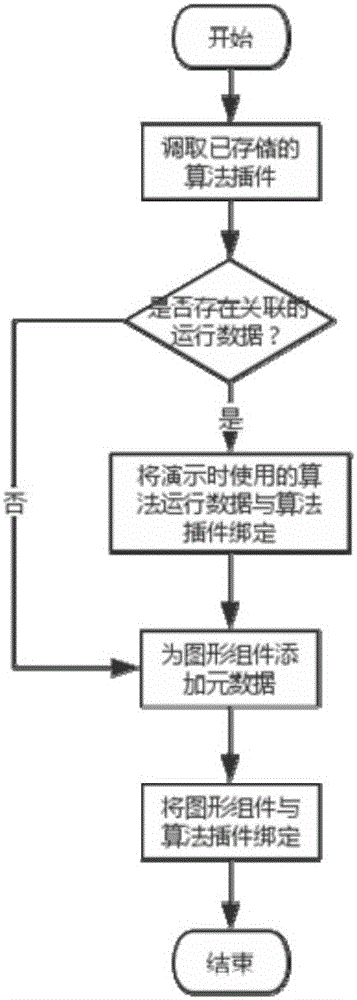

Abstract concept visual interaction method and system based on free component structure

ActiveCN106201263AImprove efficiencyInterestingElectrical appliancesInput/output processes for data processingGraphicsAbstract concept

The invention relates to an abstract concept visual interaction method and system based on a free component structure. The system comprises a component structure library sub-system, an algorithm operation sub-system, an interface interaction sub-system and a data storage sub-system. A user can study and observe a graphical demonstration process after complex concept abstraction by use of the system and interacts with a graphic component, thus the comprehension speed is increased, and the comprehension degree is deepened. The invention provides a high-efficiency visual teaching tool for the teaching staff and also provides an interesting information interaction and study platform with remarkably high interactivity for the learners while the user capability of solving complex problems is improved more effectively.

Owner:BEIJING JUDAOYOUDA NETWORK TECH

Pathological feature recognition method of skin biopsy images based on deep learning

InactiveCN105469100BReduce error rateImprove practicalityImage enhancementImage analysisAbstract conceptBiopsy lesion

The present invention relates to a method for identifying pathological characteristics of skin biopsy images based on deep learning, which uses a multi-layer stacked autoencoder to re-express the features of the biopsy images, and uses a series of convolutional neural networks to convolve the image features layer by layer and sampling to obtain an abstract feature expression of the original skin biopsy image; the features obtained by the multi-layer stacked autoencoder and the convolutional neural network are spliced, and finally a multi-channel neural network is used to complete the identification of pathological characteristics. The present invention extracts abstract concept expressions through a deep learning model, and has strong adaptability to factors such as image color difference, illumination, magnification, thereby greatly improving the accuracy of computer recognition of pathological characteristics of skin biopsy images.

Owner:GUANGDONG UNIV OF TECH

Demonstration device facilitating the teaching of high school mathematics

InactiveCN108682237AEasy to understand and masterImprove the ability to absorb knowledgeWriting boardsLighting elementsAbstract conceptEngineering

The invention particularly relates to a demonstration device facilitating the teaching of high school mathematics, which belongs to the technical field of teaching devices. The problems of the prior art that the specific demonstration direction is not explicitly indicated to the device, the demonstration device is single in structure and can only demonstrate one type of demonstration and the demonstration process is complex, and the effect is not obvious can be solved. The following scheme is provided and comprises a base. A counter bore is formed in the middle of the top of the base, and a bearing is welded to the inner wall of the counter bore. A connecting rod is welded to the inner wall of the bearing, and the top of the connecting rod is connected with a demonstration frame through abolt. A function demonstration groove is formed at the top of the outer wall of one side of the demonstration frame. According to the invention, the function part of high school mathematics can be demonstrated, and the teaching efficiency of teachers is improved; the abstract concept is changed into concrete object, so that the teaching of the teacher becomes easier; the brightness of the device can be increased, and the teacher can conveniently write the content of the demonstration during explanation; through demonstration and writing, the demonstration effect of the device is improved.

Owner:张浩博

Balance and osmosis demonstrator

InactiveCN103050039AEnhance memoryImprove learning efficiencyEducational modelsChemical reactionChemical physics

The invention relates to a teaching tool, and particularly relates to a teaching tool for simulating chemical balance and osmosis. A teacher difficultly explains a chemical balance principle. The chemical balance is a very abstract concept, and students receive the abstract concept difficultly because the concept, the characteristic and the formation process of the chemical balance state are unclear. The balance and osmosis demonstrator provided by the invention is capable of visualizing the micro and abstract chemical reaction principle, simulating the chemical balance state formation process and characteristics by using a visible macroscopic phenomenon, and simulating an osmosis process of a semipermeable membrane and a diffusion process of a cell membrane. The students can visually know the abstraction problem through observing the macroscopic phenomenon, and more durably memorizes the abstraction and learns the abstraction at higher efficiency.

Owner:王海龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com