Method for preparing isononyl alcohol from mixed octylene

A technology of isononanol and octene, applied in the field of heterogeneous catalysis, can solve the problems of limited industrial application of catalysts, loss of catalytic active components, limited loading of phosphorus ligands, etc., achieves excellent alcohol product selectivity, reduces Separation cost, the effect of reducing the cost of subsequent purification and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

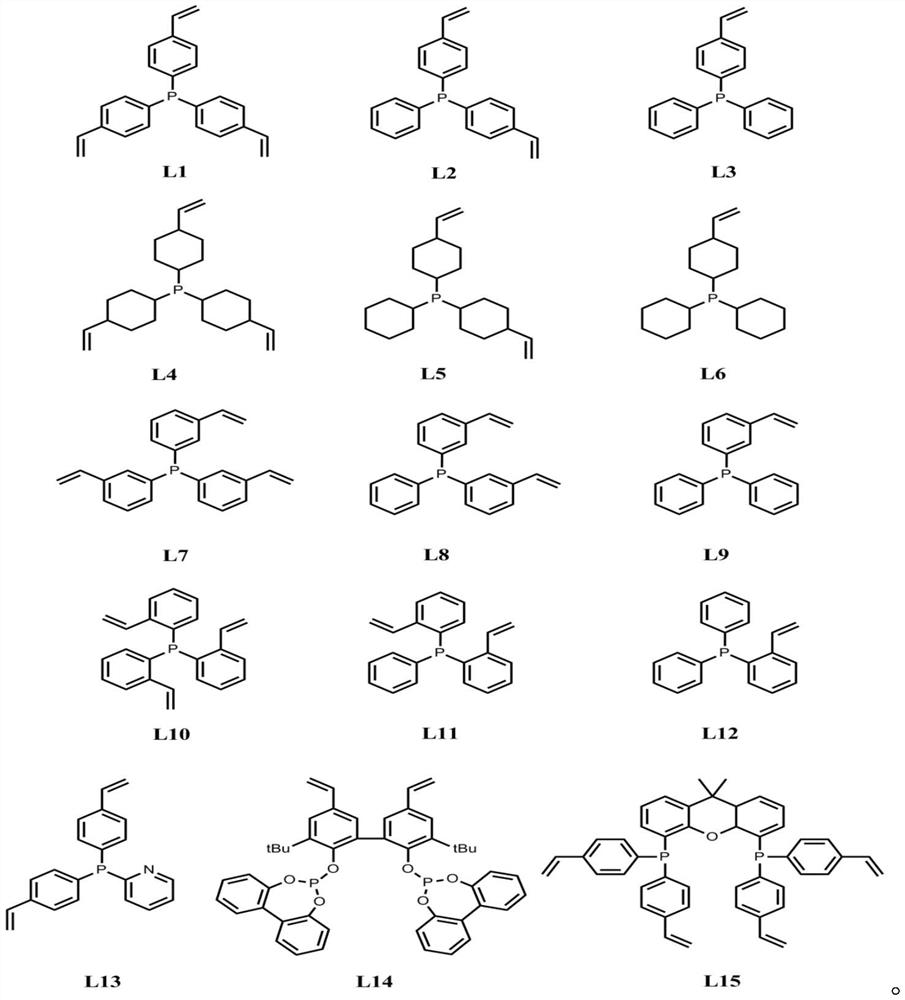

[0029] 1) Preparation of heterogeneous catalyst for hydroformylation

[0030] Under 298K and an inert gas Ar protective atmosphere, 10.0 grams of tris (4-vinylphenyl) phosphine ligands were dissolved in 100 ml of tetrahydrofuran solvent, and 0.25 grams of free radical initiator azobisisobutyronitrile was added to the above solution, Stir for 0.5 hours. The stirred solution was transferred to a hydrothermal autoclave, and polymerized by solvothermal method at 373K and an inert gas Ar atmosphere for 24h. After the above polymerization, cool to room temperature, and vacuum remove the solvent under the temperature condition of 333K to obtain a porous organic polymer containing a phosphine ligand (its specific surface area is 1025m 2 / g, the pore volume is 1.48m 3 / g, the pore size distribution is 0.2-100.0nm). Under the protective atmosphere of 298K and inert gas Ar, 0.1253 g of rhodium acetylacetonate dicarbonyl was weighed and dissolved in 200 ml of tetrahydrofuran solvent, a...

Embodiment 2

[0038] 1) Preparation of heterogeneous catalyst for hydroformylation

[0039] The preparation of the hydroformylation heterogeneous catalyst is the same as in Example 1.

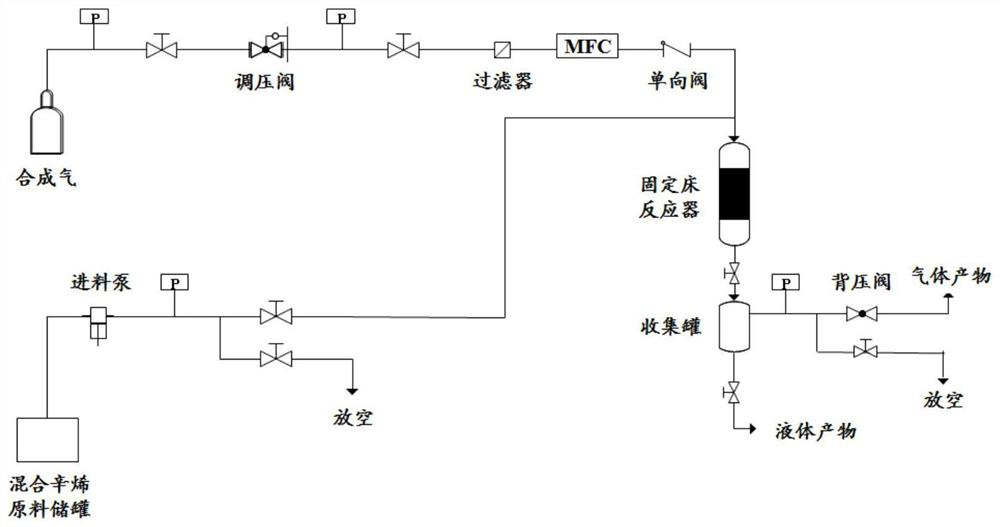

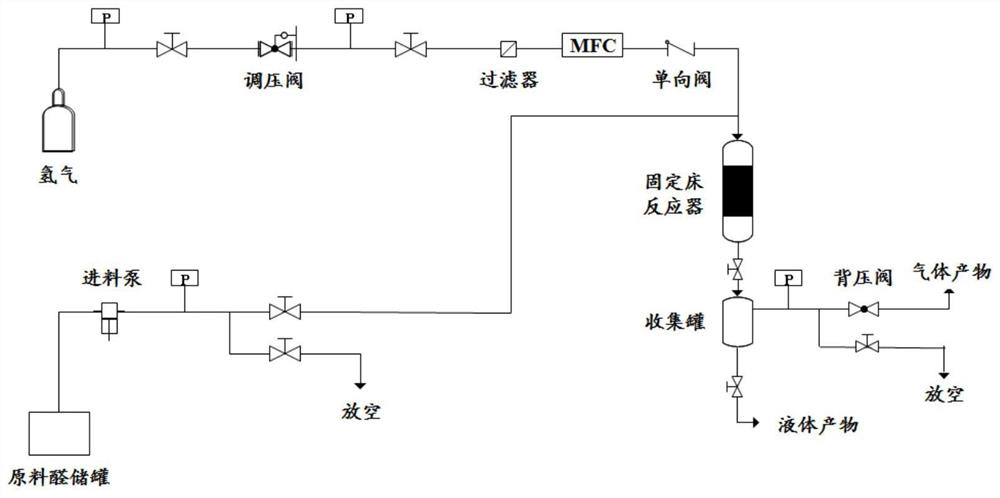

[0040] 2) Mixed octene hydroformylation reaction process

[0041] The hydroformylation heterogeneous catalyst prepared above is loaded into a fixed-bed reactor, and quartz sand is loaded at both ends. into the synthesis gas (H 2 :CO=1:1) and raw material mixed octene (2,4,4-trimethyl-1-pentene content 90.6%, 2,4,4-trimethyl-2-pentene content 9.2%), The mixed octene is transported into the reaction system by a high-pressure pump, and the synthesis gas is directly fed in the form of gas. At 373K, 3MPa, mixed octene liquid hourly space velocity 2.13h -1 , Syngas gas space velocity 1125h -1 conditions for the hydroformylation reaction. The reaction product was collected at 2.5°C via a collection tank equipped with circulating cooling. The obtained liquid phase product was analyzed by HP-7890N gas chromato...

Embodiment 3

[0047] 1) Preparation of heterogeneous catalyst for hydroformylation

[0048] The preparation of the hydroformylation heterogeneous catalyst is the same as in Example 1.

[0049] 2) Mixed octene hydroformylation reaction process

[0050] The hydroformylation heterogeneous catalyst prepared above is loaded into a fixed-bed reactor, and quartz sand is loaded at both ends. into the synthesis gas (H 2 :CO=1:1) and raw material mixed octene (2,4,4-trimethyl-1-pentene content 90.6%, 2,4,4-trimethyl-2-pentene content 9.2%), The mixed octene is transported into the reaction system by a high-pressure pump, and the synthesis gas is directly fed in the form of gas. At 413K, 5MPa, mixed octene liquid hourly space velocity 0.2h -1 , Syngas gas space velocity 1125h -1 conditions for the hydroformylation reaction. The reaction product was collected at 2.5°C via a collection tank equipped with circulating cooling. The obtained liquid phase product was analyzed by HP-7890N gas chromatog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com