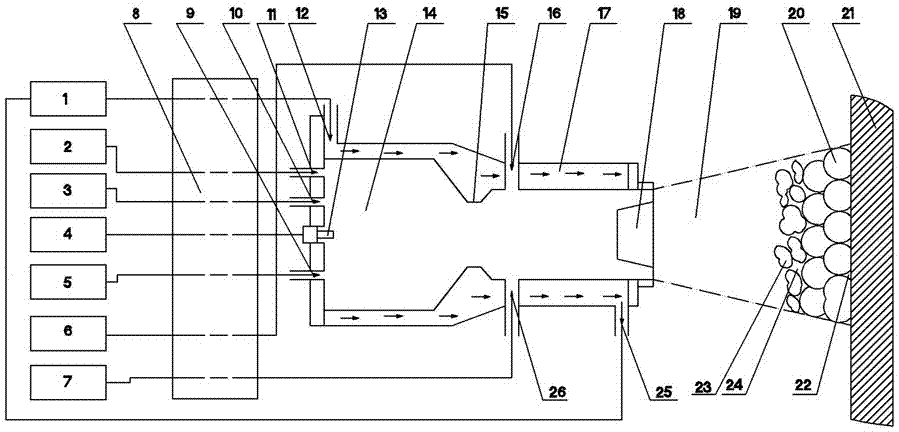

Easy-to-clean metal coating of electron-beam melting furnace wall, spraying method thereof and spraying device thereof

An electron beam smelting furnace and metal coating technology, which is applied in the direction of metal material coating process, coating, melt spraying, etc., can solve the problems of high economic cost impact of smelting and processing, difficulty in recycling cleaning objects, and difficulty in cleaning equipment to play a role and other problems, to achieve the effect of simple and effective spraying method, protection of health, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An electron beam smelting furnace wall easy-to-clean metal coating, the thickness of the metal coating is 0.1 mm, and the bonding strength with the furnace wall substrate is 4 N / mm 2 , its own porosity is 10%, the surface roughness is 15.0μm, the oxygen content is 1.10wt%, and the microhardness is 150 HV.

[0037] The metal coating is titanium coating.

[0038] The spraying method of the easy-to-clean metal coating on the wall of the electron beam smelting furnace comprises the following steps:

[0039] 1) Polishing treatment: The electron beam melting furnace wall is pre-ground and polished so that the surface roughness of the furnace wall substrate is 10 μm;

[0040] 2) Raw material preparation: choose hydrogenated dehydrogenation titanium powder with coarse particle size as the raw material, the particle size is 100 μm, and the purity is 99.46%~99.99%;

[0041] 3) Spraying treatment: Control the temperature in the combustion chamber of the spraying device to 1500°C...

Embodiment 2

[0044] An electron beam smelting furnace wall easy-to-clean metal coating, the thickness of the metal coating is 1mm, and the bonding strength with the furnace wall substrate is 18N / mm 2 , its own porosity is 30%, the surface roughness is 25.0μm, the oxygen content is 1.70wt%, and the microhardness is 250HV.

[0045] The metal coating is tantalum coating.

[0046] The spraying method of the easy-to-clean metal coating on the wall of the electron beam smelting furnace comprises the following steps:

[0047] 1) Polishing treatment: The electron beam melting furnace wall is pre-ground and polished so that the surface roughness of the furnace wall substrate is 18 μm;

[0048] 2) Raw material preparation: select coarse-grained metal powder (tantalum powder) as the raw material, and the particle size of the metal powder is 200 μm;

[0049] 3) Spraying treatment: Control the temperature in the combustion chamber of the spraying device to 1700°C and maintain the pressure at 12bar, t...

Embodiment 3

[0051] An electron beam melting furnace wall easy-to-clean metal coating, the thickness of the metal coating is 0.2mm, and the bonding strength between the furnace wall substrate is 6 N / mm 2 , its own porosity is 15%, the surface roughness is 18.0μmμm, the oxygen content is 1.25wt%, and the microhardness is 170 HV.

[0052] The metal coating is niobium coating.

[0053] The spraying method of the easy-to-clean metal coating on the wall of the electron beam smelting furnace comprises the following steps:

[0054] 1) Polishing treatment: Grinding and polishing the electron beam melting furnace wall first, so that the surface roughness of the furnace wall substrate is 12 μm;

[0055] 2) Raw material preparation: choose hydrogenated dehydrogenation titanium powder with coarse particle size as the raw material, the particle size of the metal powder is 120 μm, and the purity is 99.46%~99.99%;

[0056] 3) Spraying treatment: Control the temperature in the combustion chamber of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com