Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Wash clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

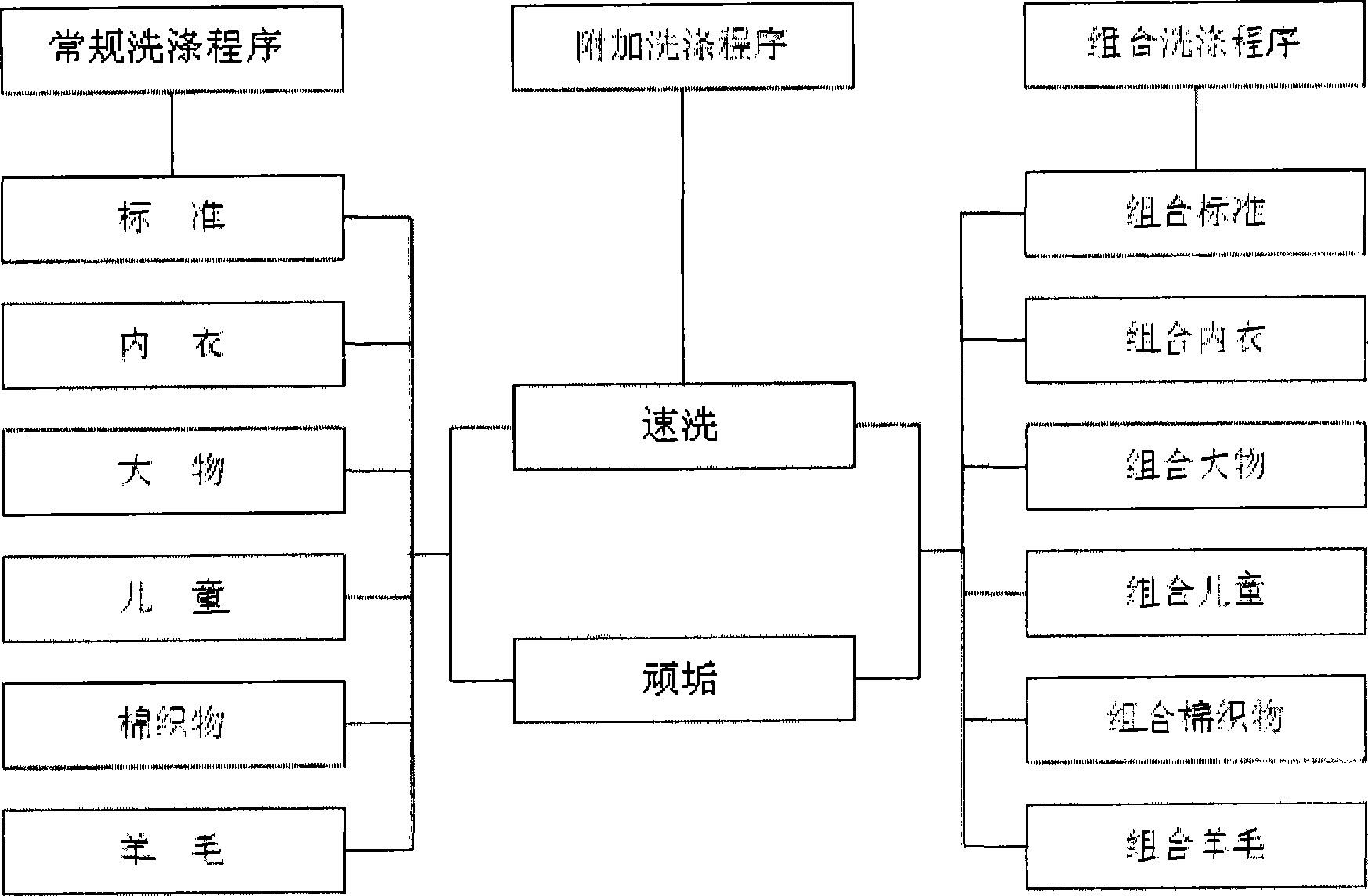

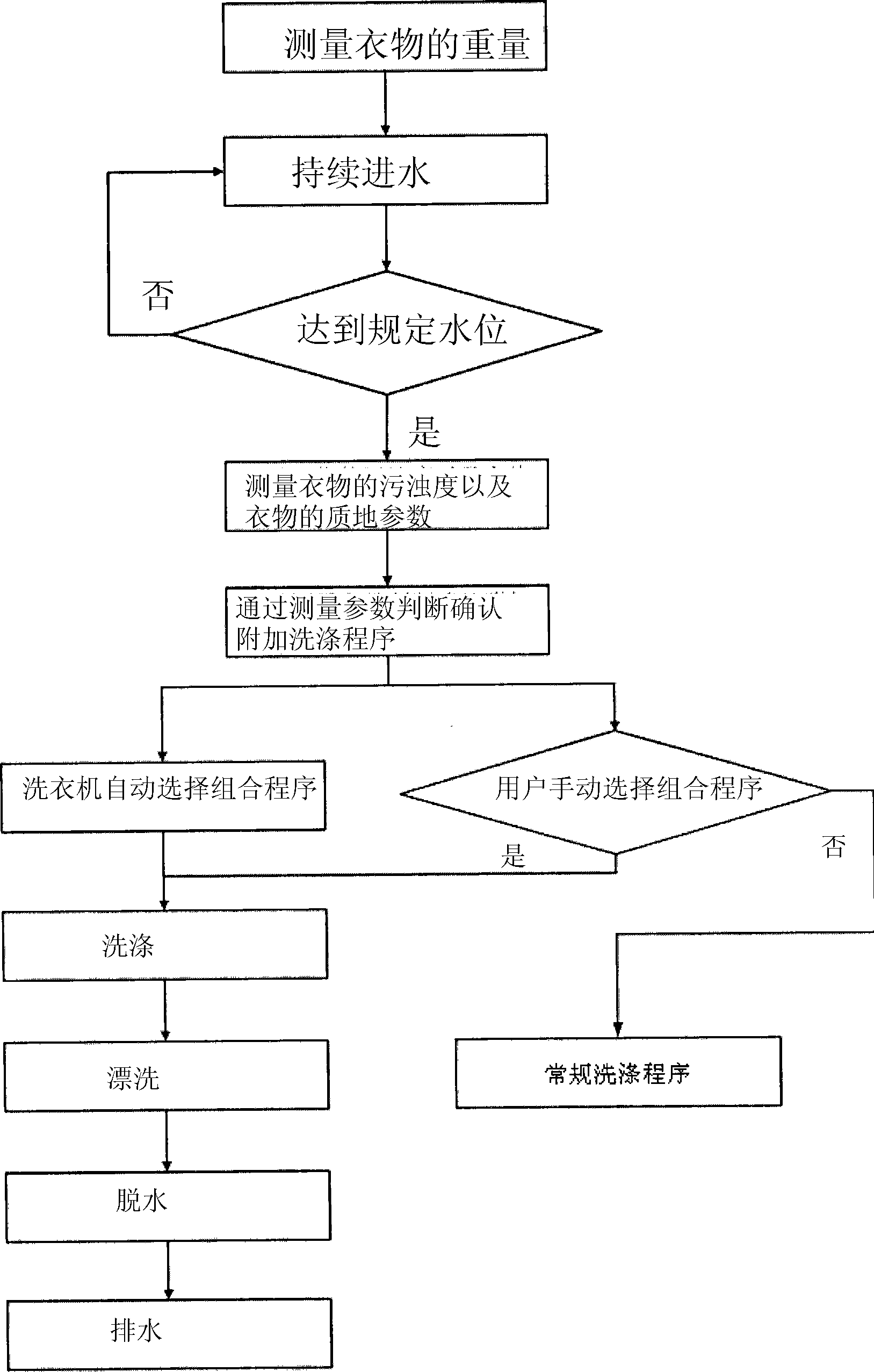

Combined washer washing program and washing machine using the same

ActiveCN101457456AImprove washing effectScience of washingControl devices for washing apparatusTextiles and paperProcess engineering

The invention relates to a series of methods for operating a washing machine and the washing machine applying the methods, in particular to combined washing procedures of conventional washing procedures and additional washing procedures as well as the washing machine applying the procedures. The combined washing procedures comprises not only the conventional washing procedures defined by the variety of clothes, but also the additional washing procedures which are the washing intensions of customers or defined by the texture, weight and smudginess of the clothes. The invention also provides the washing machine applying the combined washing procedures. By applying the technical proposal, the invention provides the combined washing procedures that multiple the variety and quantity of the washing procedures on the basis of the conventional washing procedures of an ordinary washing machine and the washing machine applying the combined washing procedures. The customers can freely combine the washing procedures in accordance with washings with various types and qualities, thus improving the washing effect and saving the water and power.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

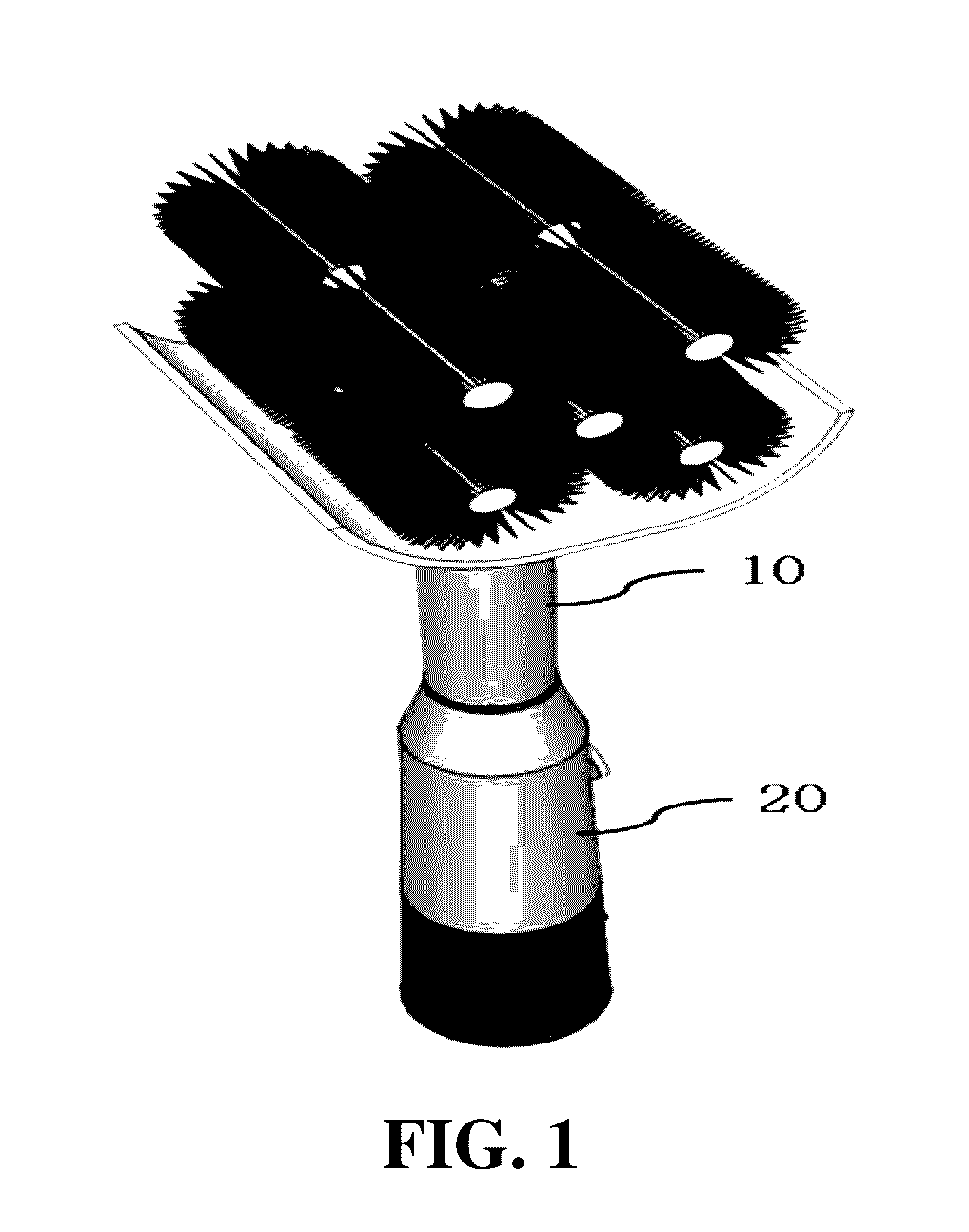

Rotary spraying head type painting device

Owner:ABB IND

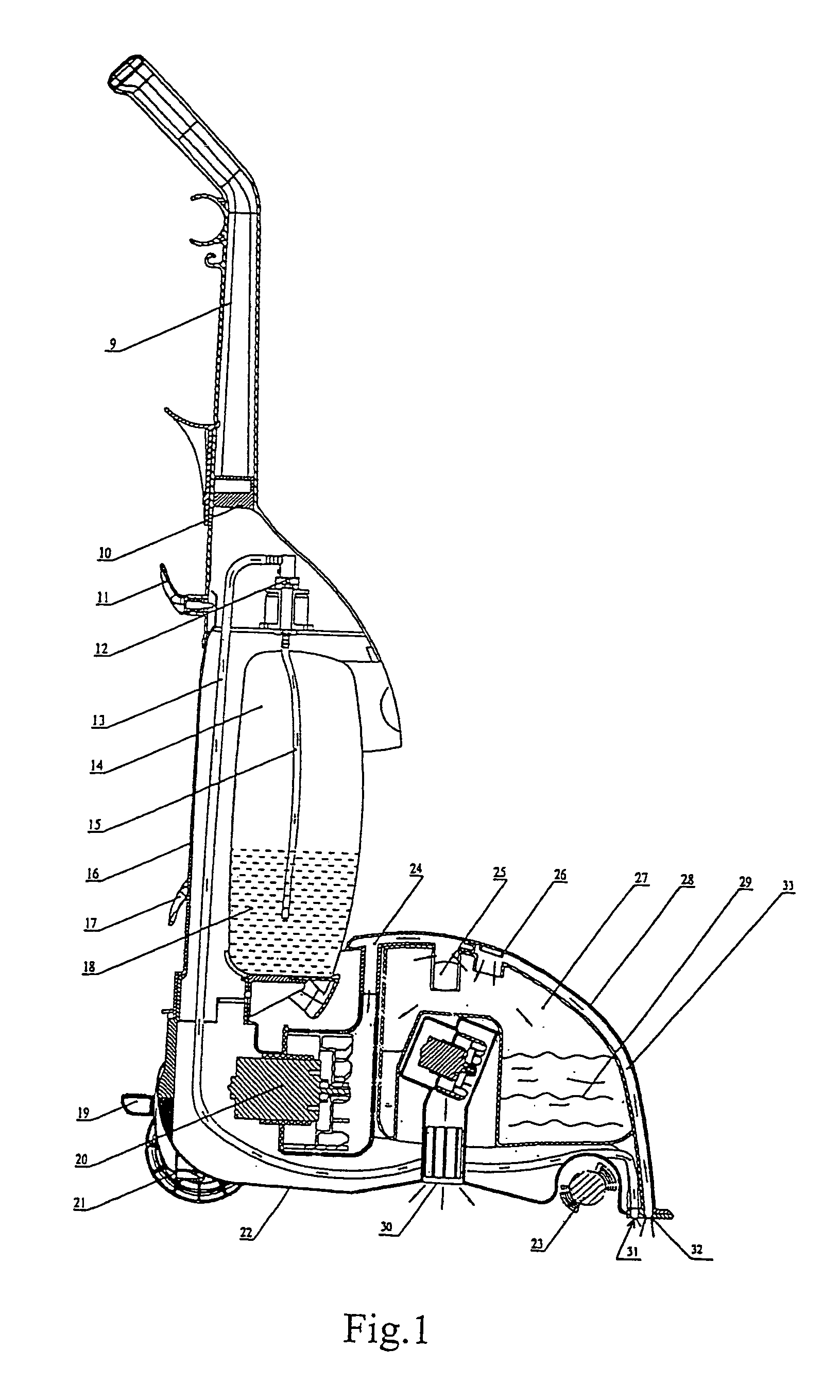

Water absorbing and drying cleaner

InactiveUS7000286B2Protect environmentProtect human healthCarpet cleanersFloor cleanersPulp and paper industryCleaning agent

A water absorbing and drying cleaner comprises a washing apparatus and a drying apparatus, wherein the washing apparatus and the drying apparatus are mounted in the casing of the water absorbing and drying cleaner, a drying inlet in the drying apparatus and a washing inlet in the washing apparatus are provided at the bottom of the water absorbing and drying cleaner along the progressive direction in washing, and the drying inlet is located behind the washing inlet. The invention has the features of novel in structure, clean in washing and fast in drying, can kill the acarids and other bacteria on the carpet or wooden floor to perform sterilization.

Owner:WANG DONGLEI

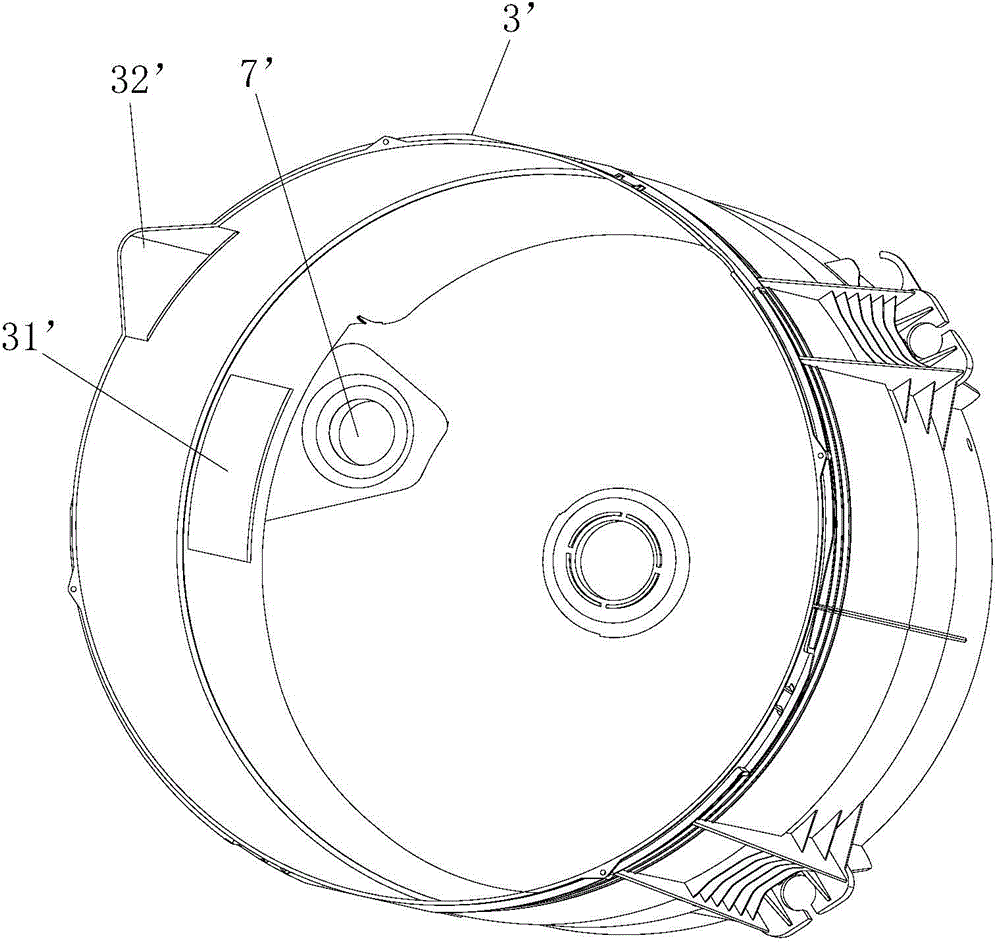

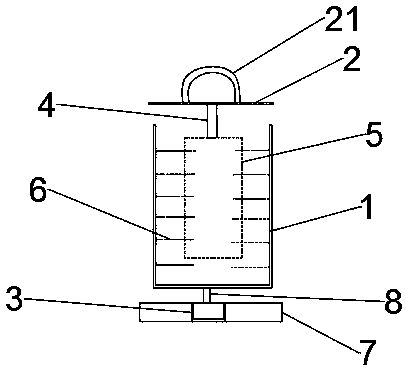

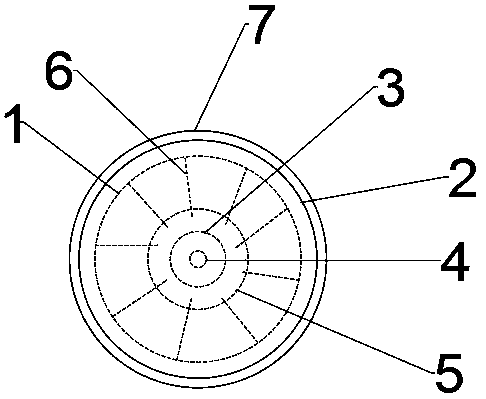

Impeller full-automatic washing machine

PendingCN105463790AReduce deliveryAvoid cross infectionOther washing machinesTextiles and paperImpellerWater discharge

The invention discloses an impeller full-automatic washing machine comprising an external barrel, an internal barrel disposed in the external barrel and an impeller disposed in the internal barrel. A drainage port is arranged on the bottom of the external barrel; the washing machine does not have a draining valve; the drainage port of the external barrel is directly communicated with a drain pipe; during washing and rinsing, washing water is only accommodated in the internal barrel and the external barrel contains no washing water; during dehydration, the washing water passes through the external barrel, the external barrel drainage port and the drain pipe from the upper part of the internal barrel and then is directly discharged; during water inlet, water is only charged into the internal barrel; after washing is finished, the internal barrel is driven to rotate at high speed to produce centrifugal force; water in the internal barrel and water in the clothes spirally rise and are discharged out of the external barrel via water discharging holes of the internal barrel; and the water can be directly discharged via the drain pipe. Without the draining valve, assembling technology of the external barrel components can be reduced, installation space of a barrel bottom driving device can be increased and cost can be reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

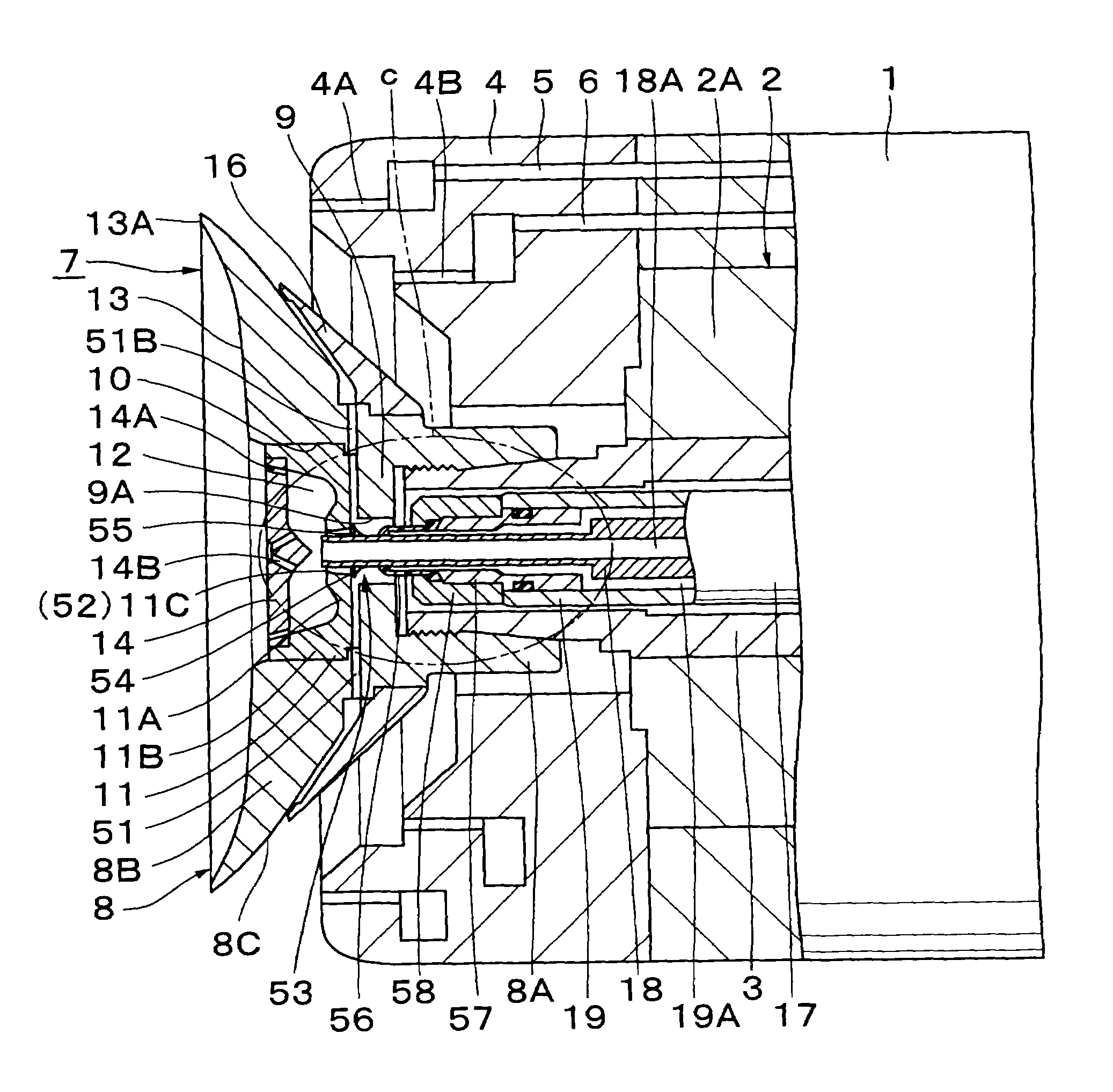

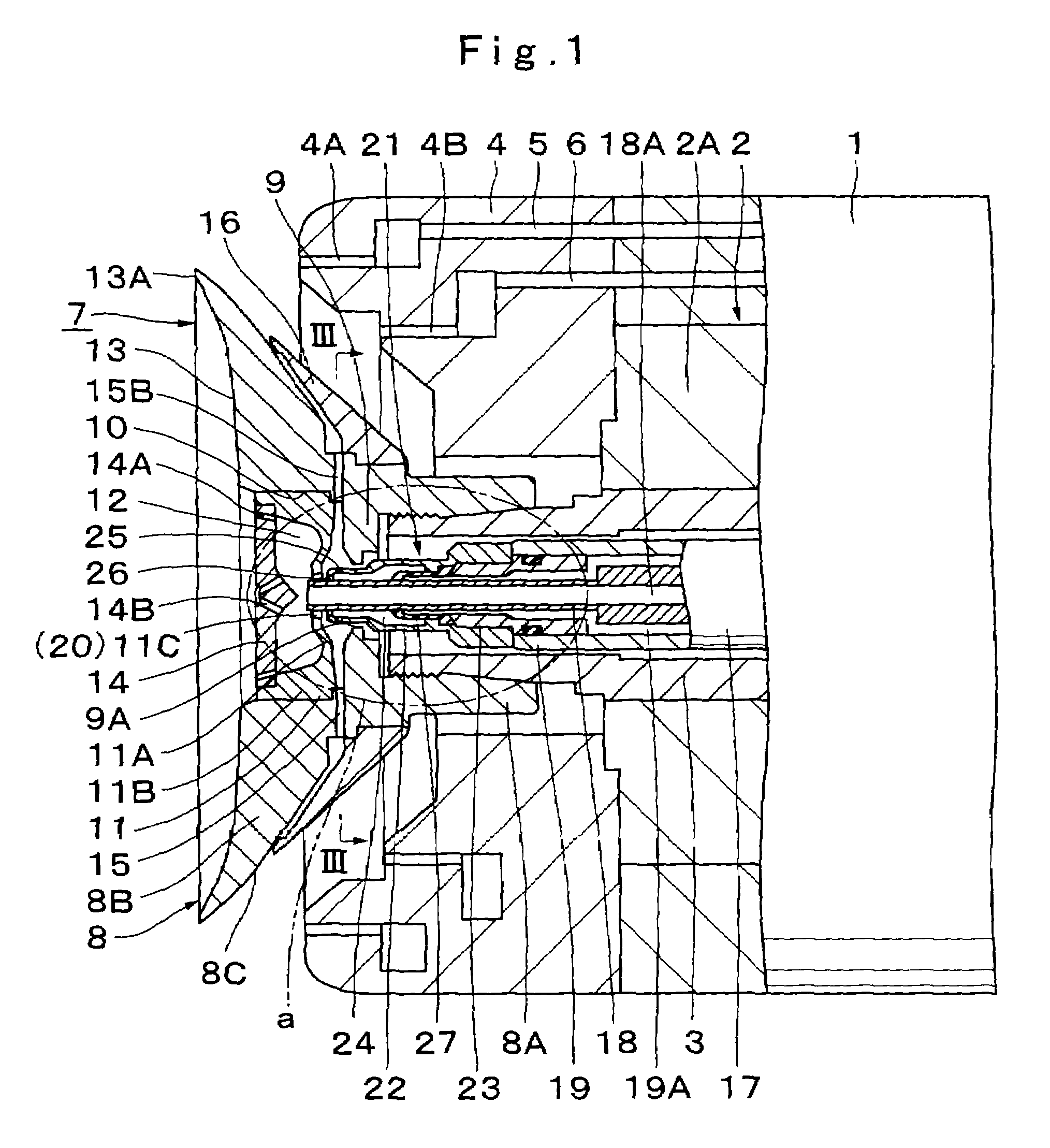

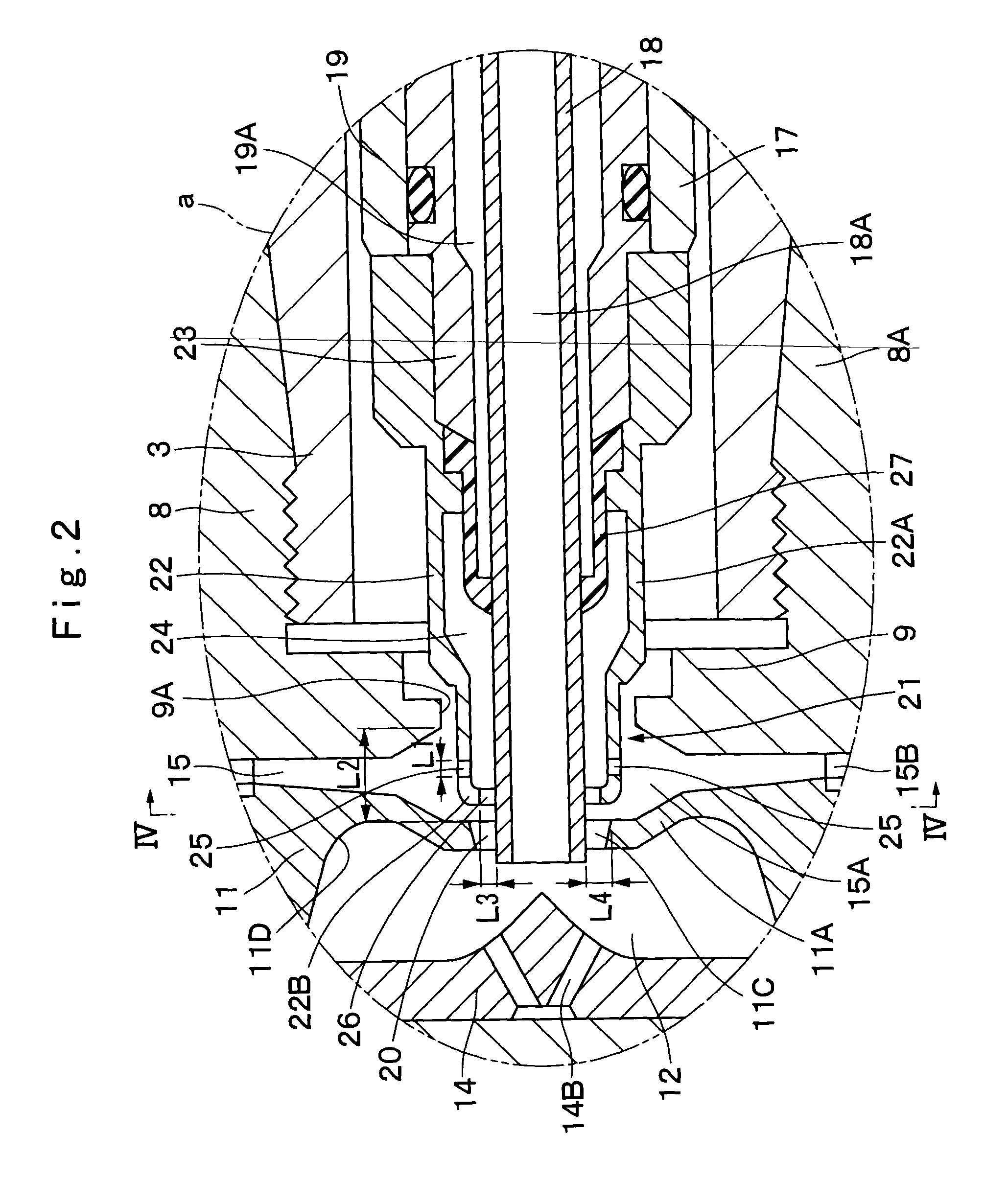

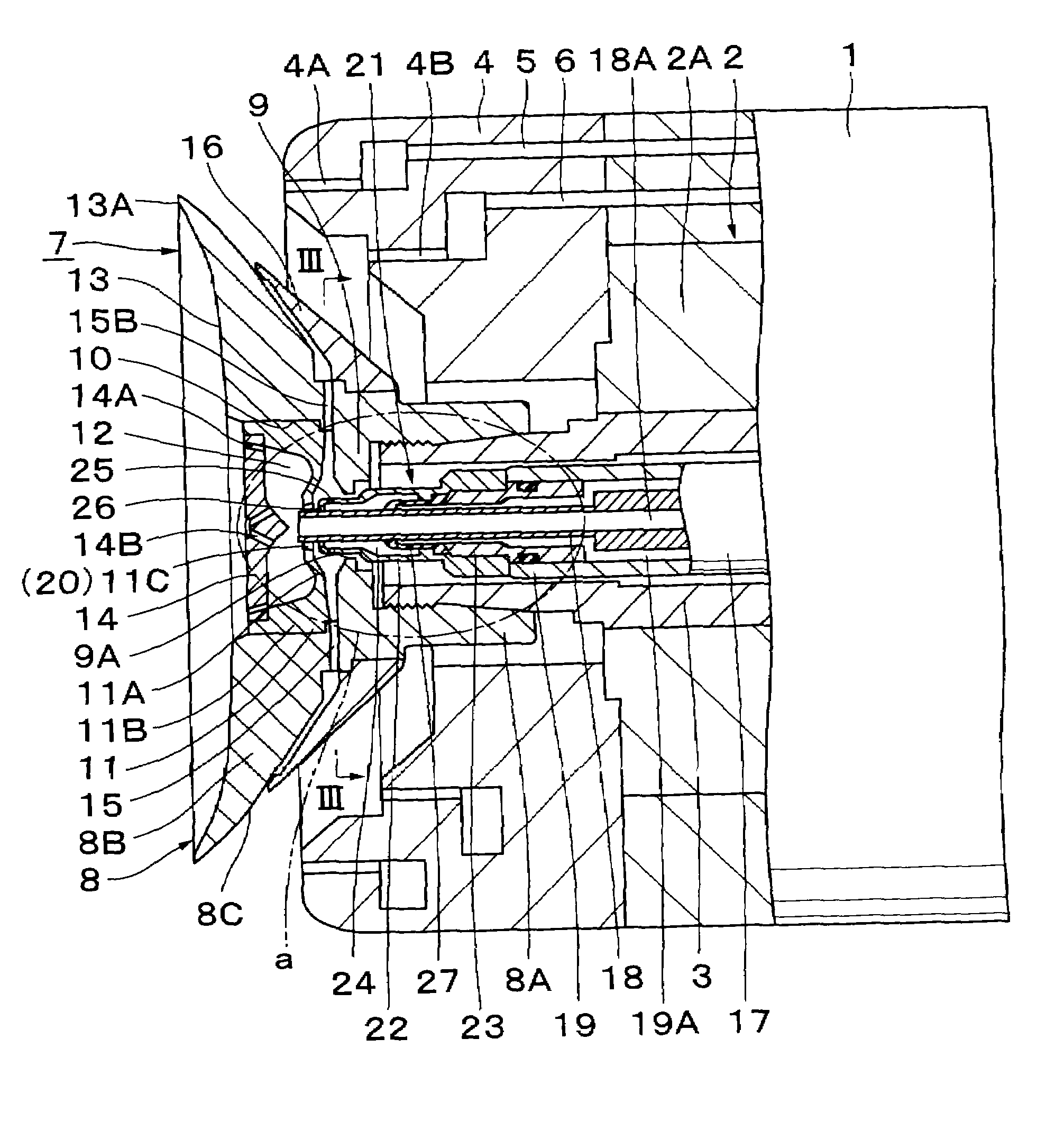

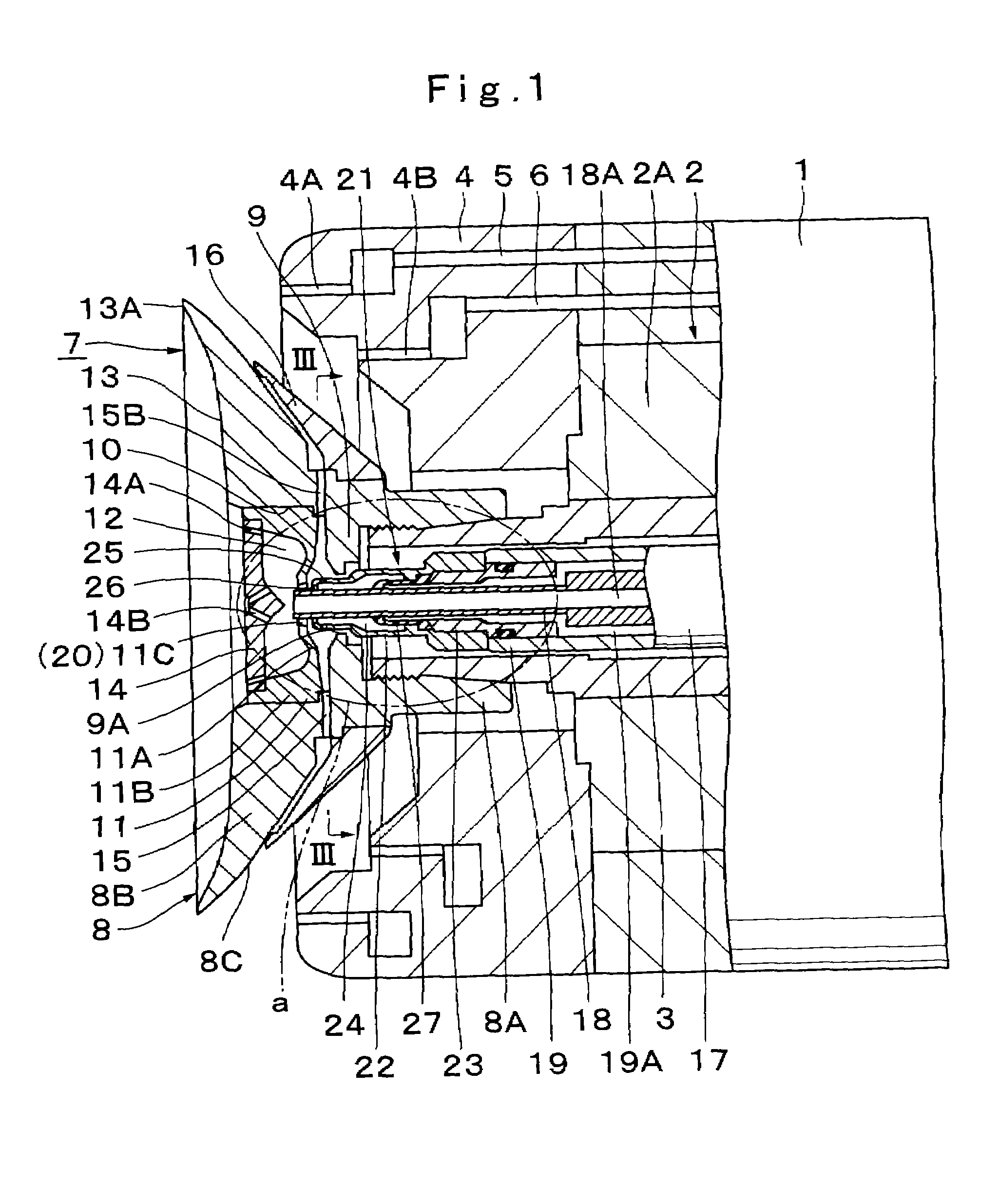

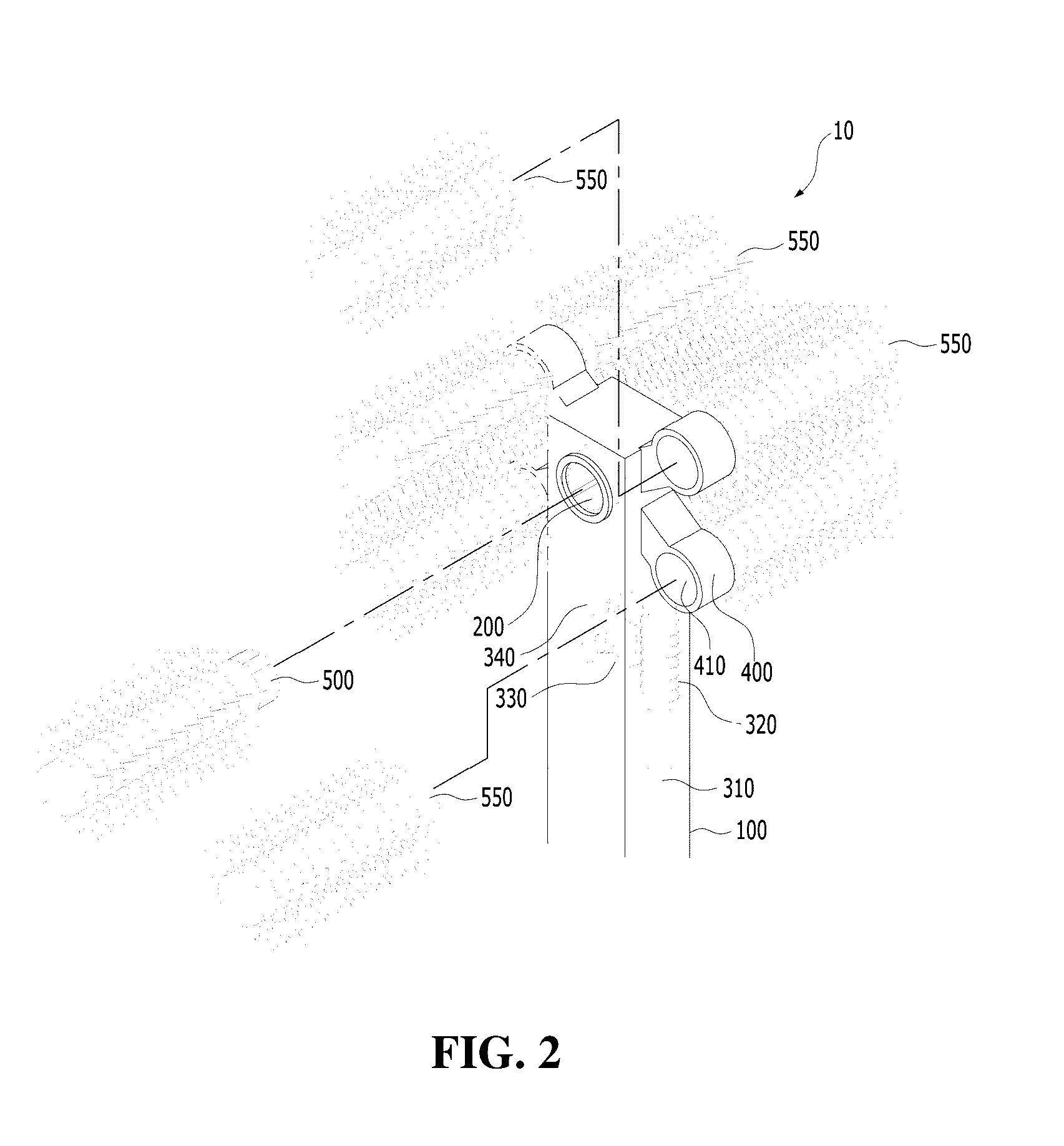

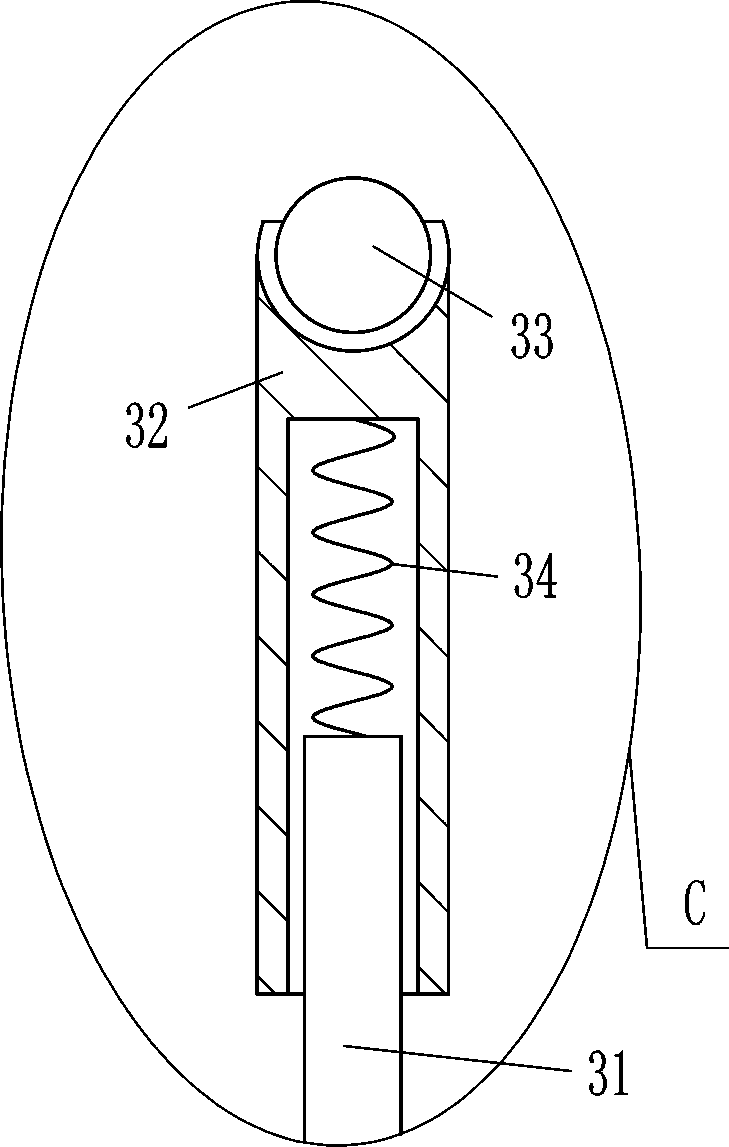

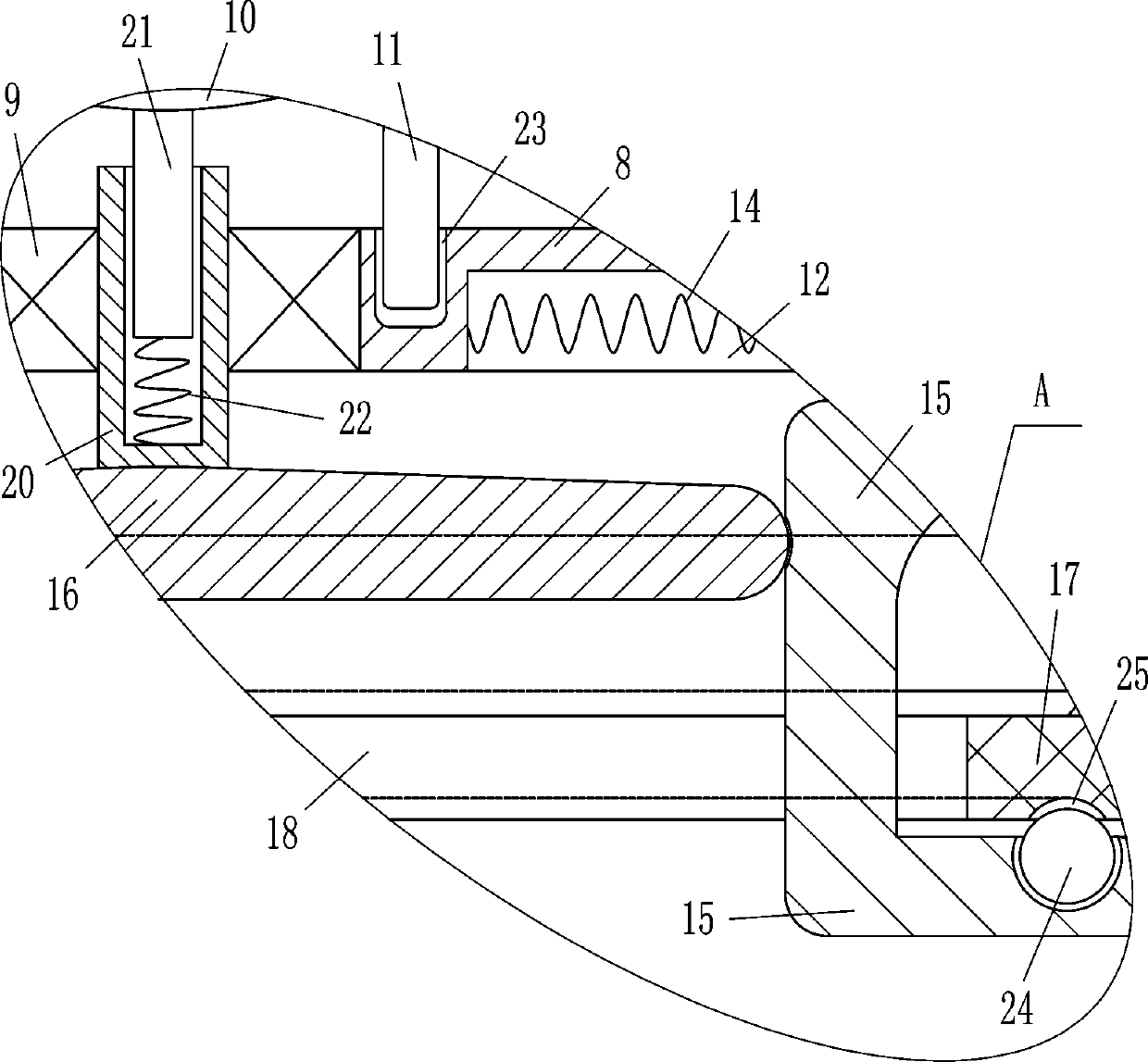

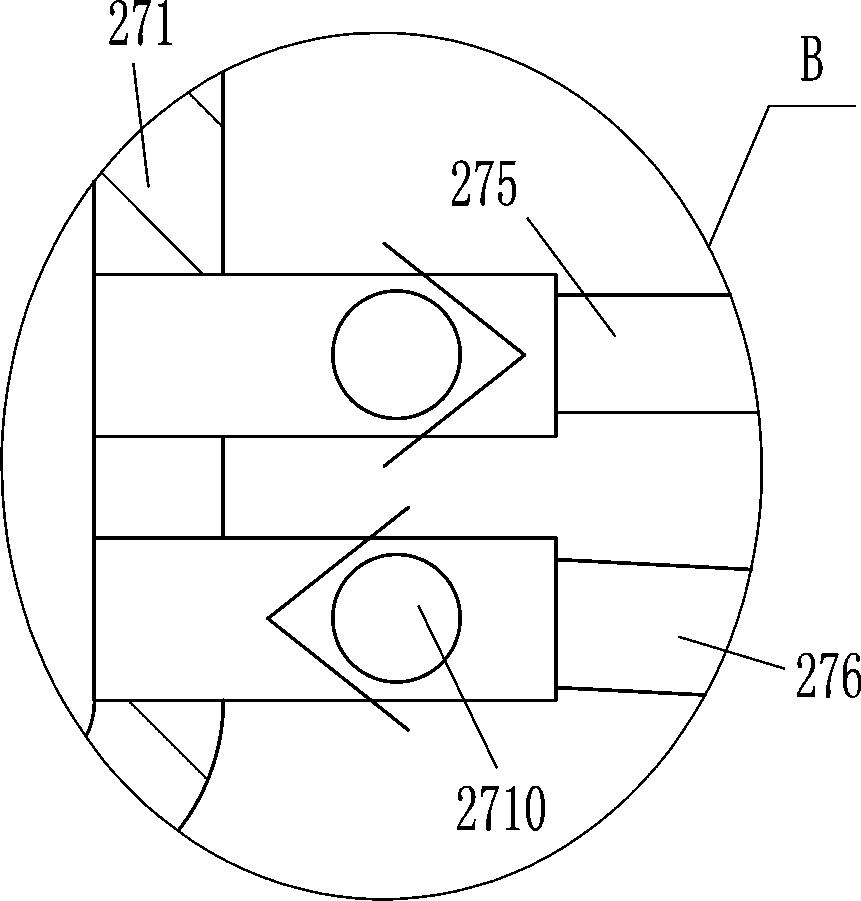

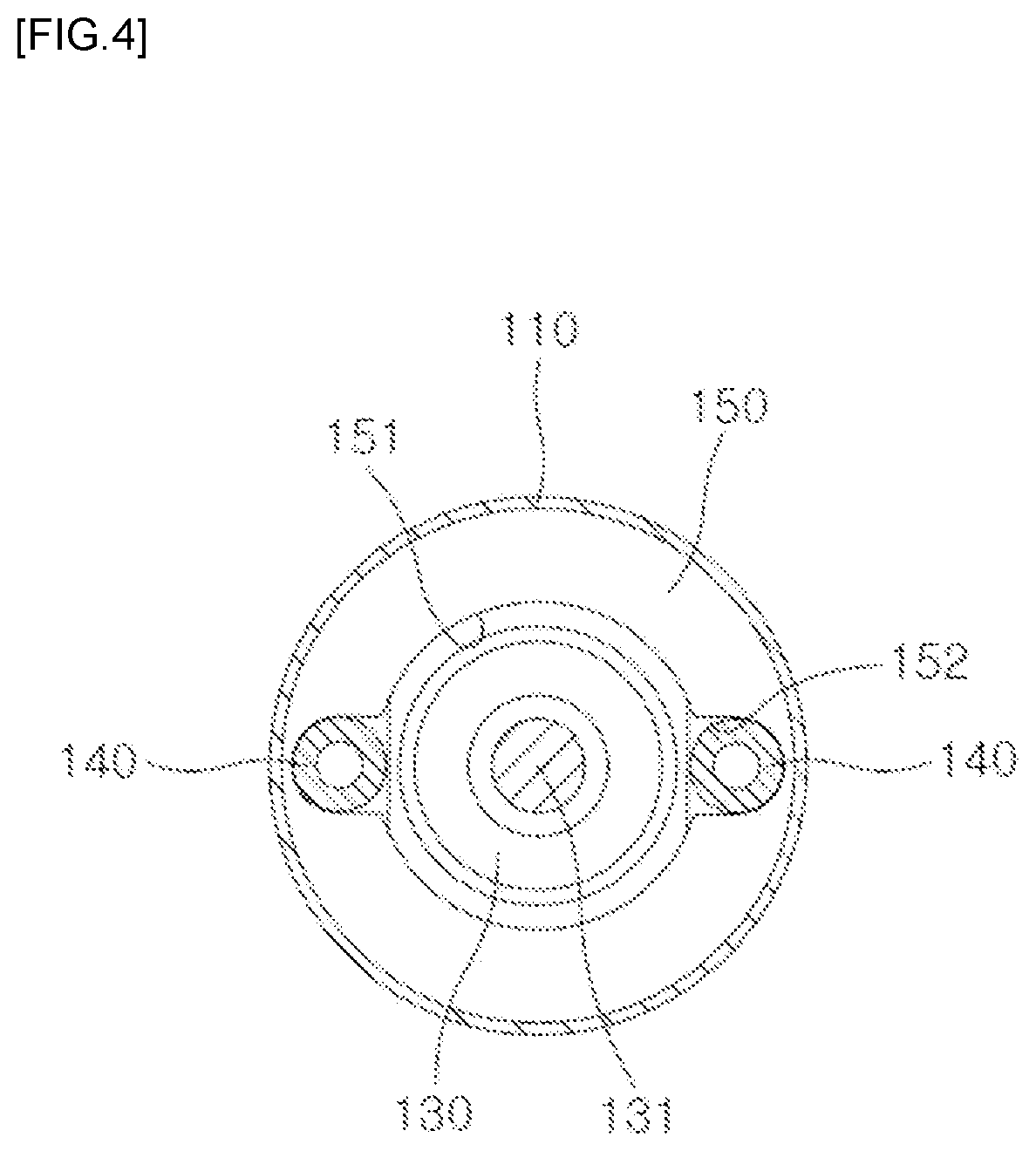

Rotary Spraying Head Type Painting Device

A first wash fluid discharging passage (15) having an outlet end thereof opened to an outer peripheral surface (8C) is provided on a rotary atomizing head (7) and positioned behind a paint reservoir (12). On the other hand, a second wash fluid discharging passage (20) having an outlet end thereof opened to the paint reservoir (12) is also provided on the rotary atomizing head (7) positioned around a fore end of a paint tube (18). In addition, a nozzle (22) is provided at a fore outlet end of a wash fluid tube (19). The nozzle (22) internally defines an annular chamber (24) for pooling a wash fluid. The nozzle (22) is provided with first and second outlet openings (25, 26) to spurt a wash fluid toward the first and second wash fluid discharging passages (15, 20). Further, a check valve (27) is provided in the annular chamber (24) of the nozzle (22) to prevent a reverse flow of a wash fluid.

Owner:ABB IND

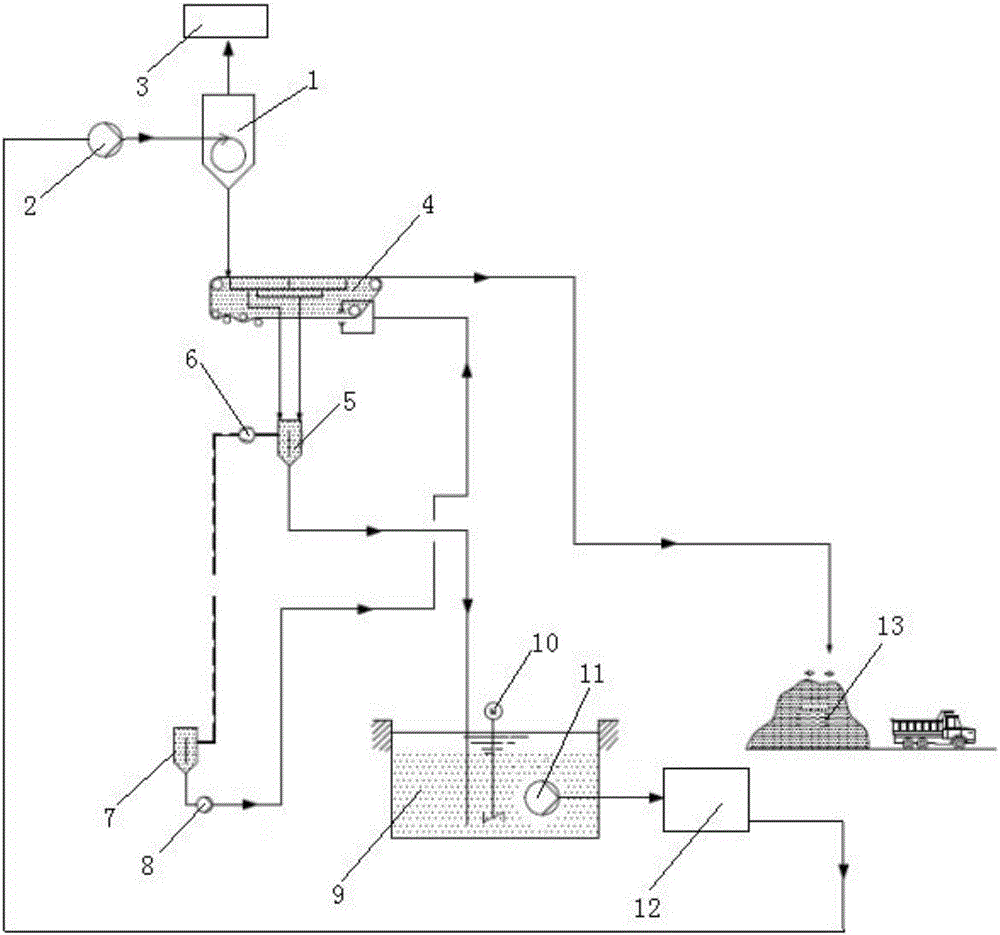

Multistage dehydration and separation system

InactiveCN106039997ASimple structureEasy maintenanceGas treatmentDispersed particle separationCycloneEngineering

The invention discloses a multistage dehydration and separation system which comprises an absorption tower, a gypsum slurry discharge pump, a gypsum cyclone, a gas-water separator, a filter cloth washing water tank, a filter liquor pond and a gypsum bin. A slurry pond is arranged at the bottom of the absorption tower; the gypsum slurry discharge pump is arranged outside the slurry pond, and one end of the gypsum slurry discharge pump is connected with the slurry pond; a feed inlet of the gypsum cyclone is connected with the other end of the gypsum slurry discharge pump, an overflow opening of the gypsum cyclone is connected with a wastewater treatment system, and a base flow opening of the gypsum cyclone is connected with a feed inlet of a vacuum belt dehydrator; a top inlet of the gas-water separator is connected with the vacuum belt dehydrator, a top outlet of the gas-water separator is connected with one end of a vacuum pump, and the other end of the vacuum pump is connected with an exhaust pipe; a top inlet of the filter cloth washing water tank is connected with the exhaust pipe, a bottom outlet of the filter cloth washing water tank is connected with one end of a filter cloth washing water pump, and the other end of the filter cloth washing water pump is connected with a filter cloth washing water port; the filter liquor pond is connected with a bottom outlet of the gas-water separator, a stirrer and a flow filter pump are arranged in the filter liquor pond, and the flow filter pump is connected with the absorption tower; the gypsum bin is connected with the vacuum belt dehydrator. The multistage dehydration and separation system has the advantage of simple structure, convenience in repair and maintenance, low cost, washing cleanliness, good dehydration effect and high dehydration efficiency.

Owner:DATANG ENVIRONMENT IND GRP

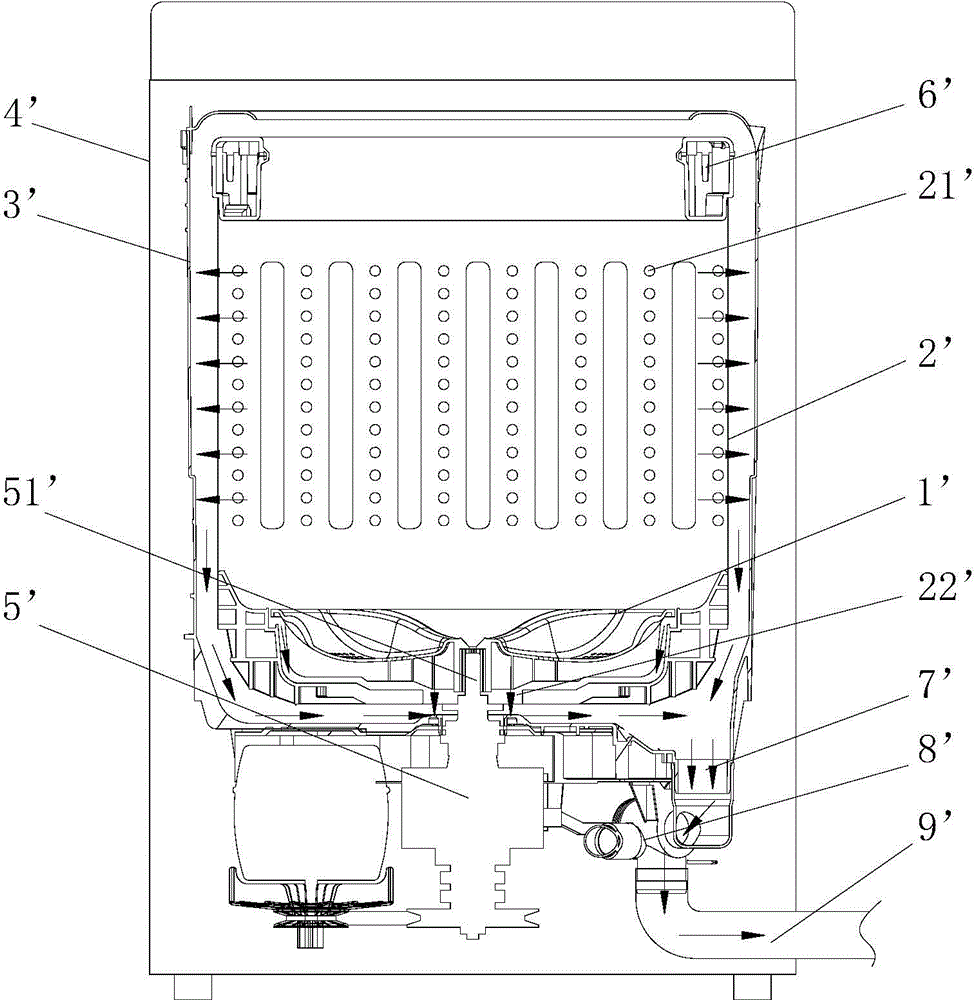

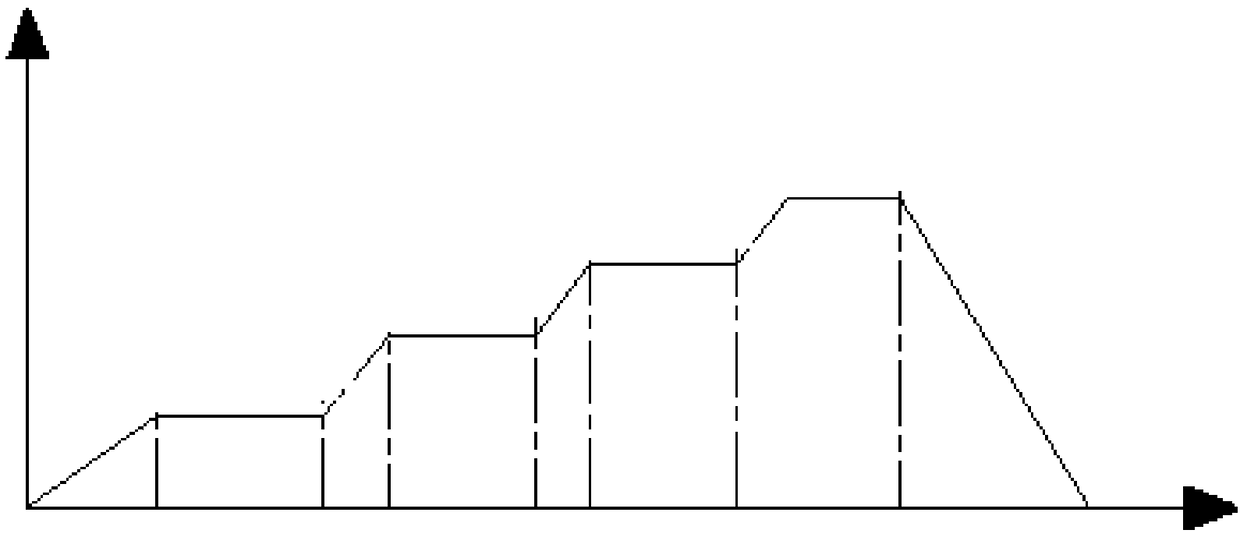

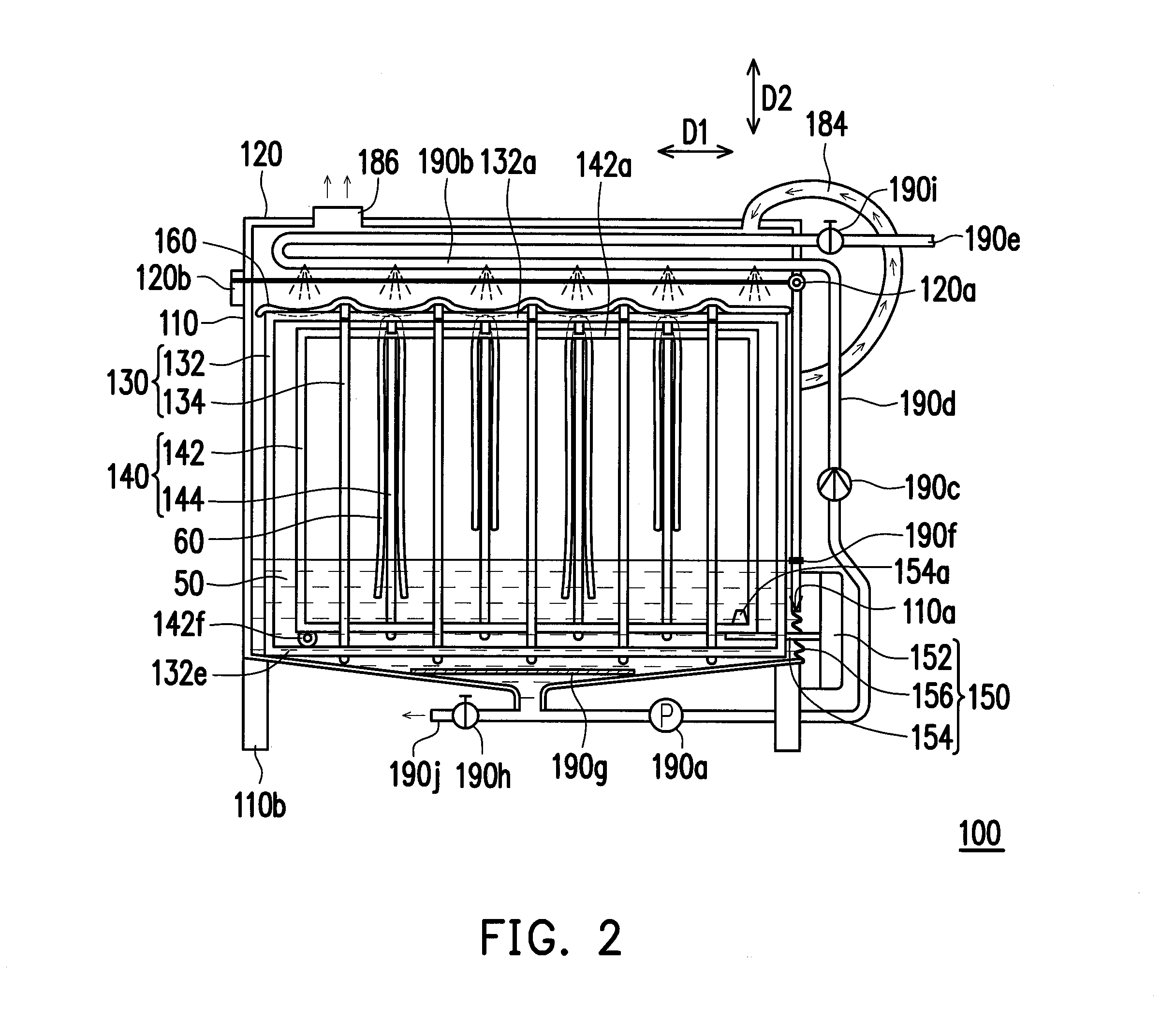

Centrifugal washing method and washing machine

ActiveCN103266445AReduce wearSave waterOther washing machinesTextiles and paperEngineeringPower consumption

The invention discloses a centrifugal washing method and a washing machine. The method includes: enabling clothes in a rotatable inner drum to rotate along with the inner drum and closely attach to the inner wall of the inner drum under the action of centrifugal force, and enabling washing liquid to be sprayed to the clothes continuously from an axial pipeline at the inner center of the inner drum and to penetrate the clothes under the action of the centrifugal force to take away stain, so that the clothes are washed and wear of the clothes is reduced, wherein the liquid level of the washing liquid is constantly lower than the lowest position of the inner drum during washing. The washing machine using the method avoids splashing and huge increase of washing foam caused by the fact that the inner drum in high-speed rotation hits the washing liquid. Meanwhile, water resource is saved, resistance of the washing liquid to the inner drum in high-speed rotation is weakened, power consumption is reduced, and washing is cleaner and more even.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

A method for cleaning dishes and chopsticks and dishwasher thereof

InactiveCN1883360AAvoid collisionWash cleanTableware washing/rinsing machine detailsWater flowProcess engineering

A method and dish-washing machine for cleaning bowl and chopsticks. The bowl and chopsticks are located between positioning columns at the bottom of washing basket, and the washing basket is rotating inside the washing barrel driven by a electric motor. Water is thrown out through holes on washing basket wall, rising along inner wall of the washing barrel. Guided by water guide board, water flows downwards and slantways sprinkles to bowl and chopsticks in the washing basket, carries out cleaning, and ozone is connected into washing barrel to do disinfection simultaneously. Up-cover of this dish-washing machine is installed on top of washing barrel, washing basket is nested on transmission shaft, upward positioning column is located on the bottom of washing barrel, and lower part of the up-cover provides a water guide board. Advantages are: avoiding collision of bowl and chopsticks, strong washing surging force, even sprinkling, good washing effect; the spraying water can be circularly used with small consumption of water and power.

Owner:林修鹏

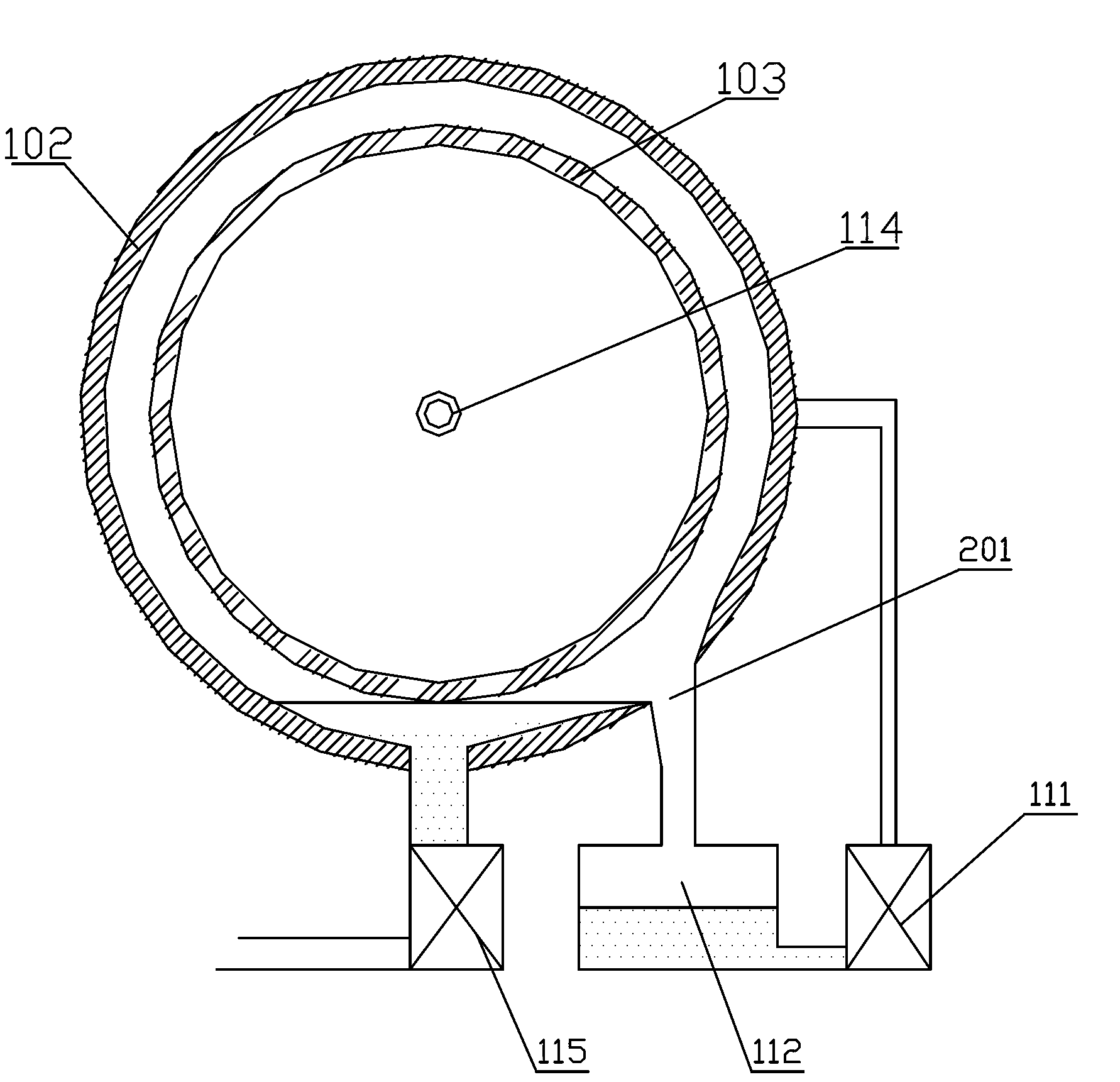

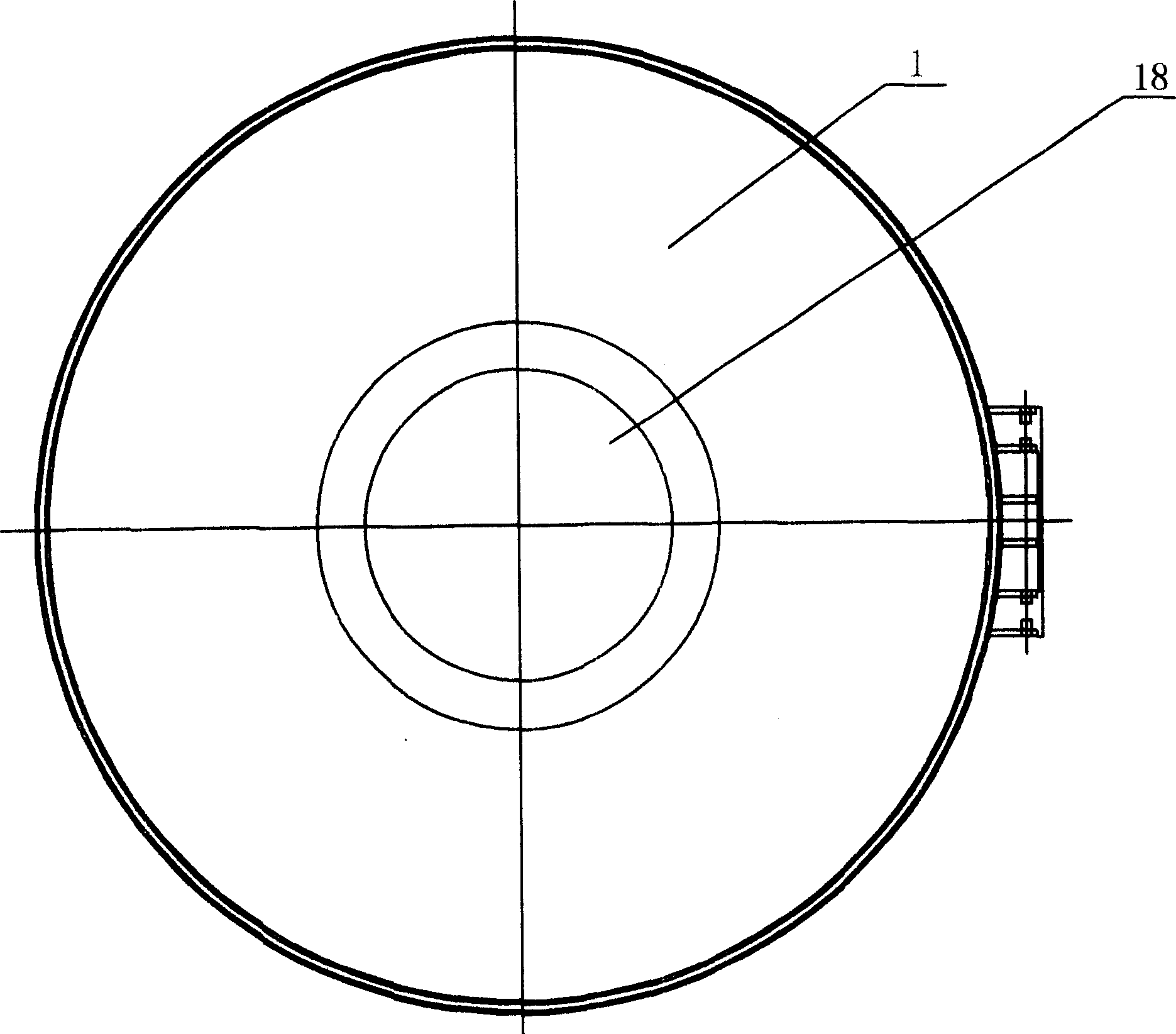

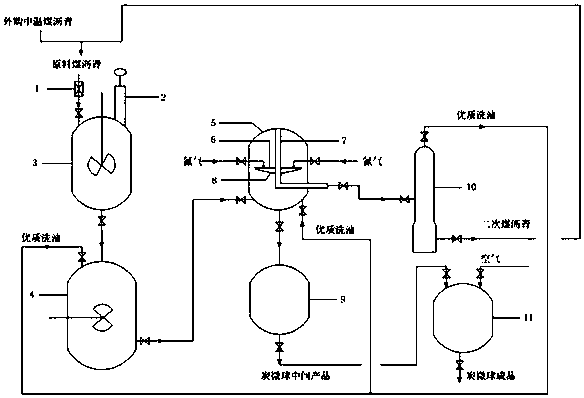

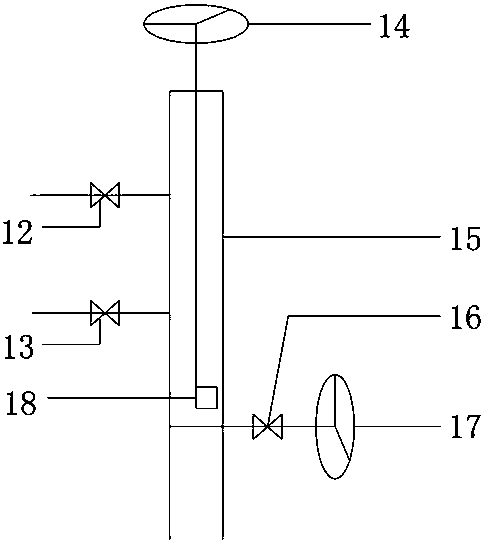

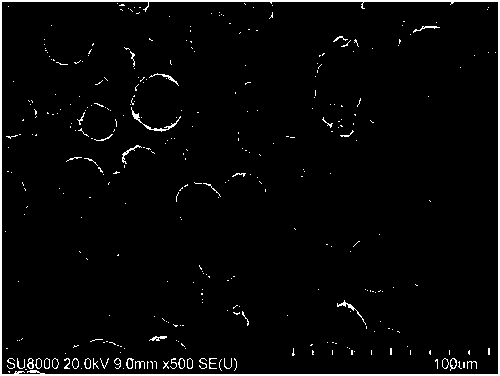

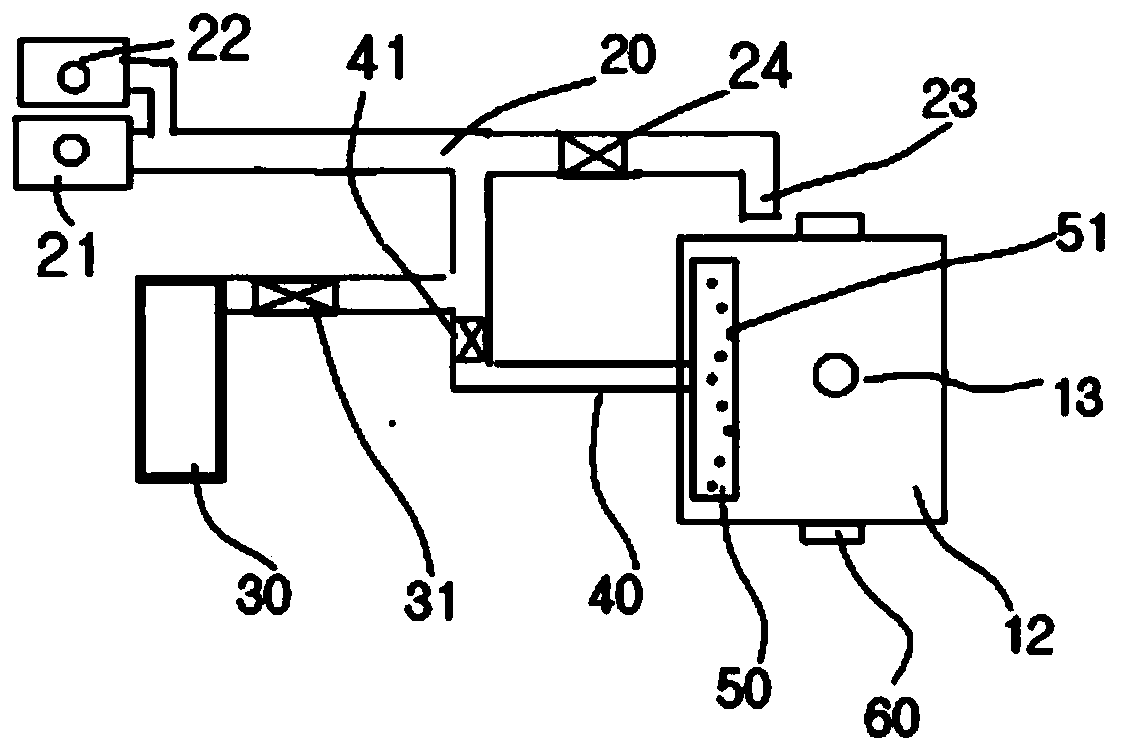

Device and method for preparing mesocarbon microbeads from medium-temperature coal pitch

The invention provides a device and method for preparing mesocarbon microbeads from medium-temperature coal pitch, and belongs to the field of high-performance coal pitch-based carbon materials. The device for preparing the mesocarbon microbeads from the medium-temperature coal pitch comprises a reaction kettle, a washing kettle, a filter kettle and a drying kettle, and further comprises an oxidation kettle and a distillation tower, and the upper part of the reaction kettle is provided with a mass flow meter and a sampler; and the method for preparing the mesocarbon microbeads from the medium-temperature coal pitch includes the processes of raw material coal pitch preparation, a thermal polycondensation reaction, washing of a reaction product, separation, drying, oxidation, and recovery ofa washing solvent and secondary coal pitch. The method provided by the invention has the advantages that the process is simple and easy to operate and the efficiency is high, the product yield is high, the particle sizes are uniform, the surface is smooth and the performance is excellent.

Owner:王强 +1

Water trough with ultrasonic washing device

The invention provides a water trough with an ultrasonic washing device. The water trough comprises a water trough table, wherein a water trough body for containing tableware or vegetables or fruits is formed in one side of an upper plate; a water drainage opening is formed in one side of the water trough body; a direct drinking water pipe is arranged on the upper part of the water trough body and is connected with a washing water supply pipe which extends out of the direct drinking water pipe and is used for supplying washing water; a washing water open and close valve is additionally arranged on the washing water supply pipe; the washing water supply pipe is connected with a nozzle pipe; a washing liquid storage barrel is arranged on the washing water supply pipe; ultrasonic vibrators are additionally arranged on two sides of the external surface of the water trough body; a water level adjustment sensor is arranged on one side of the nozzle pipe; when washing water rises to a set water level, the ultrasonic vibrators are started.

Owner:CHEONIL

Washing machine and washing method thereof

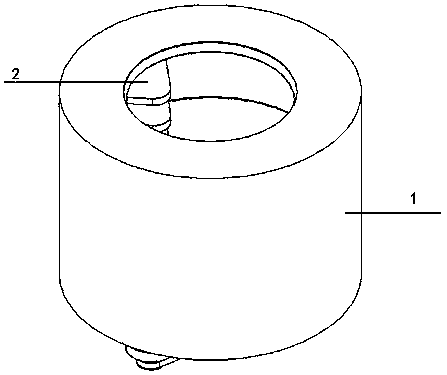

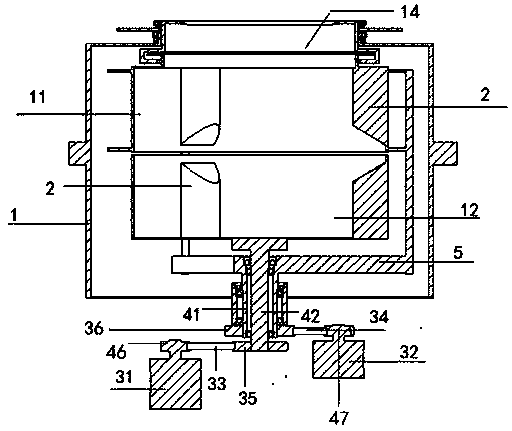

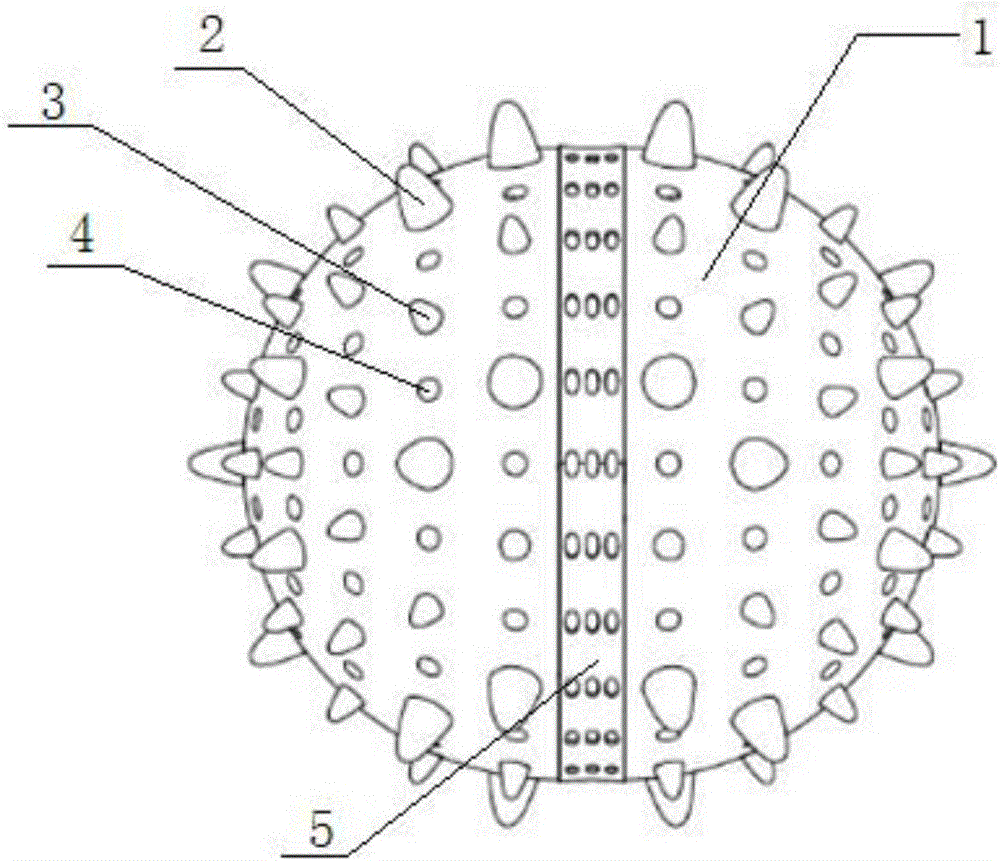

ActiveCN109680450AWash cleanImprove washing effectOther washing machinesWashing machine with receptaclesEngineeringCircular motion

The invention relates to a washing machine which comprises an inner bucket and an outer bucket, and is characterized in that multiple circular motion tracks are formed along the circumferential direction of inner walls of the inner bucket; each circular motion track is provided with a washing block (2); the washing blocks (2) move along each circular motion track; and the displacement between thewashing blocks (2) on two adjacent circular tracks is changed, and the clothes between the two washing blocks are rubbed back and forth. The effect of washing the clothes by human hands is simulated in a manner of enabling the washing blocks to move back and forth, so that the clothes is washed and cleaned, and water can be saved.

Owner:曹建胜

Water processor for clothes washing

ActiveCN106676838AImprove antioxidant capacityStrong reductionOther washing machinesWater/sewage treatmentImpellerLaundry washing machine

The invention relates to a water processor for clothes washing. The water processor is shaped like a hollow ball; multiple water processing stripes on which raised parts and hollow holes are arranged are disposed on the surface; a water inlet stripe is disposed at the center of the spherical surface of the water processor; and a filter ball is disposed inside. The filter ball is made of an anti-microbial ceramic material and a reduction anti-microbial material. Working principles of the water processor provided by the invention are different from working principles of an impeller washing machine and a roller washing machine; based on the high oxidation ability of ionized water, alkaline ionized water and dirt conduct a saponification reaction, so the dirt can be decomposed and stripped thoroughly; the cleaning rate is high; the dirt removal ability is high; and wear to clothes is slight. Alkaline ionized water generated during clothes washing can clean the clothes; all contact parts between a washing machine and the water can be cleaned; and sterilization effects are achieved during the cleaning, so bacteria breeding can be avoided. The water processor for the clothes washing provided by the invention has the same principles of an ozone washing machine; ozone is not generated; and ozone damage is avoided.

Owner:ZHEJIANG WATERHOR ENVIRONMENTAL PROTECTION TECH CO LTD

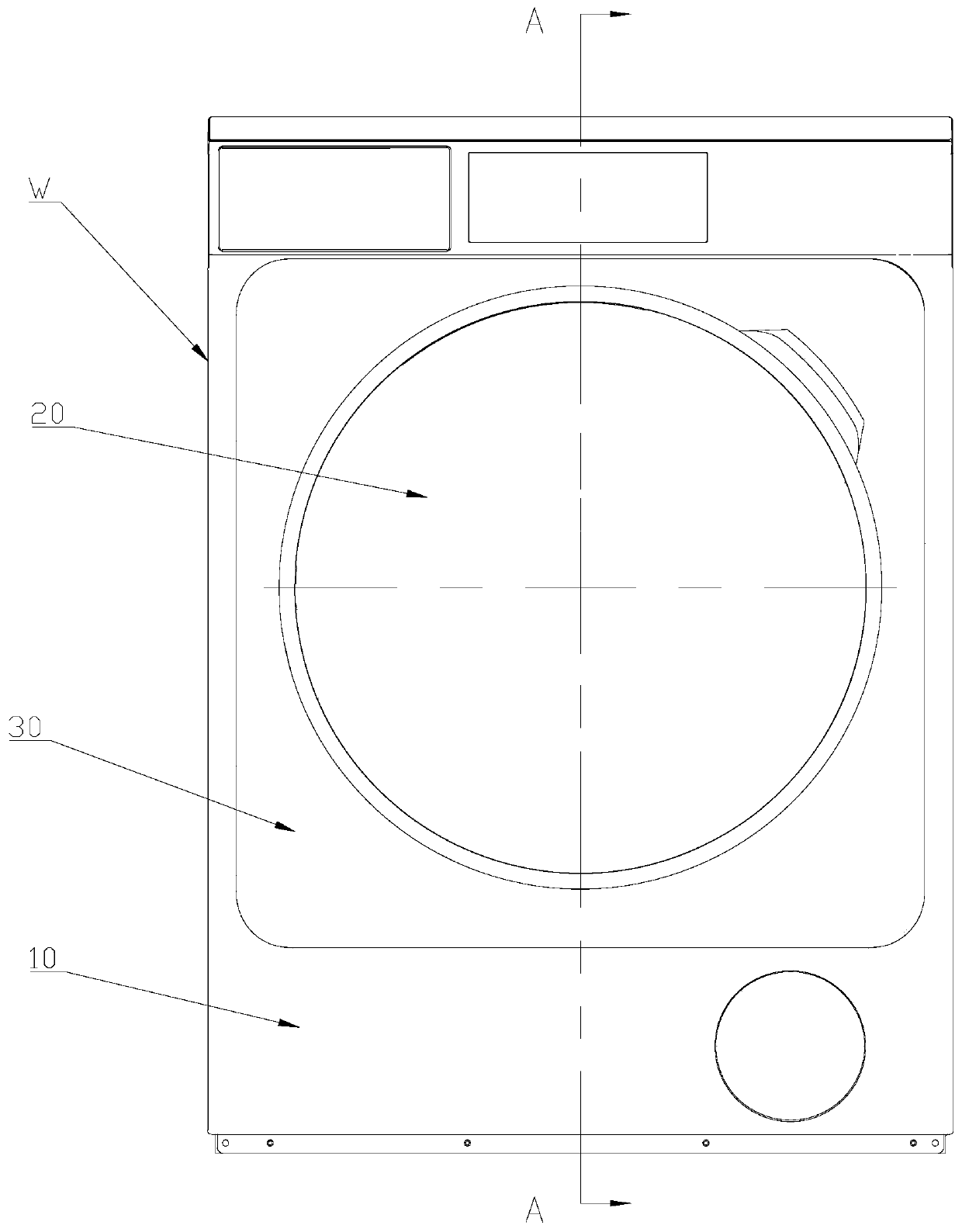

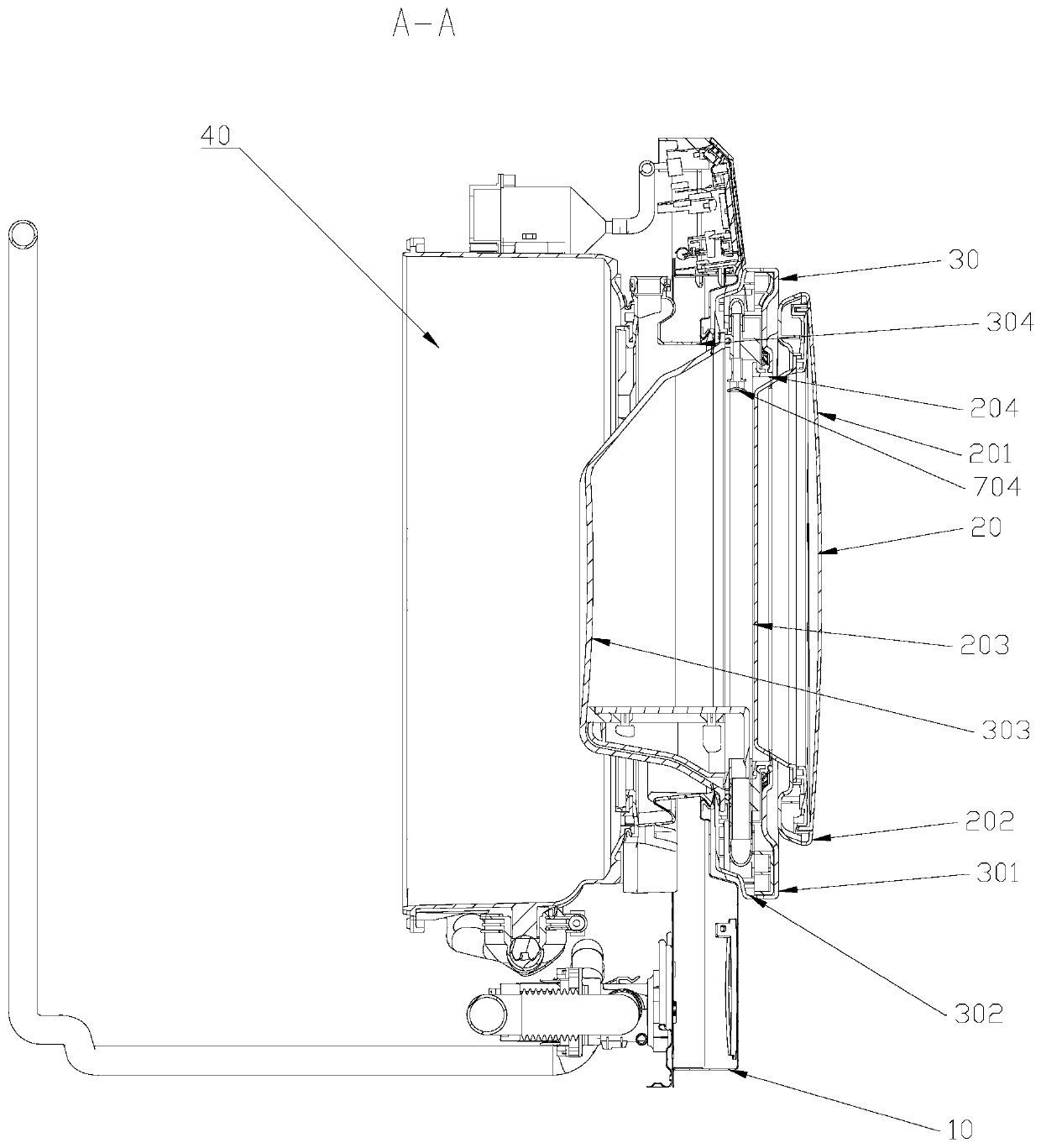

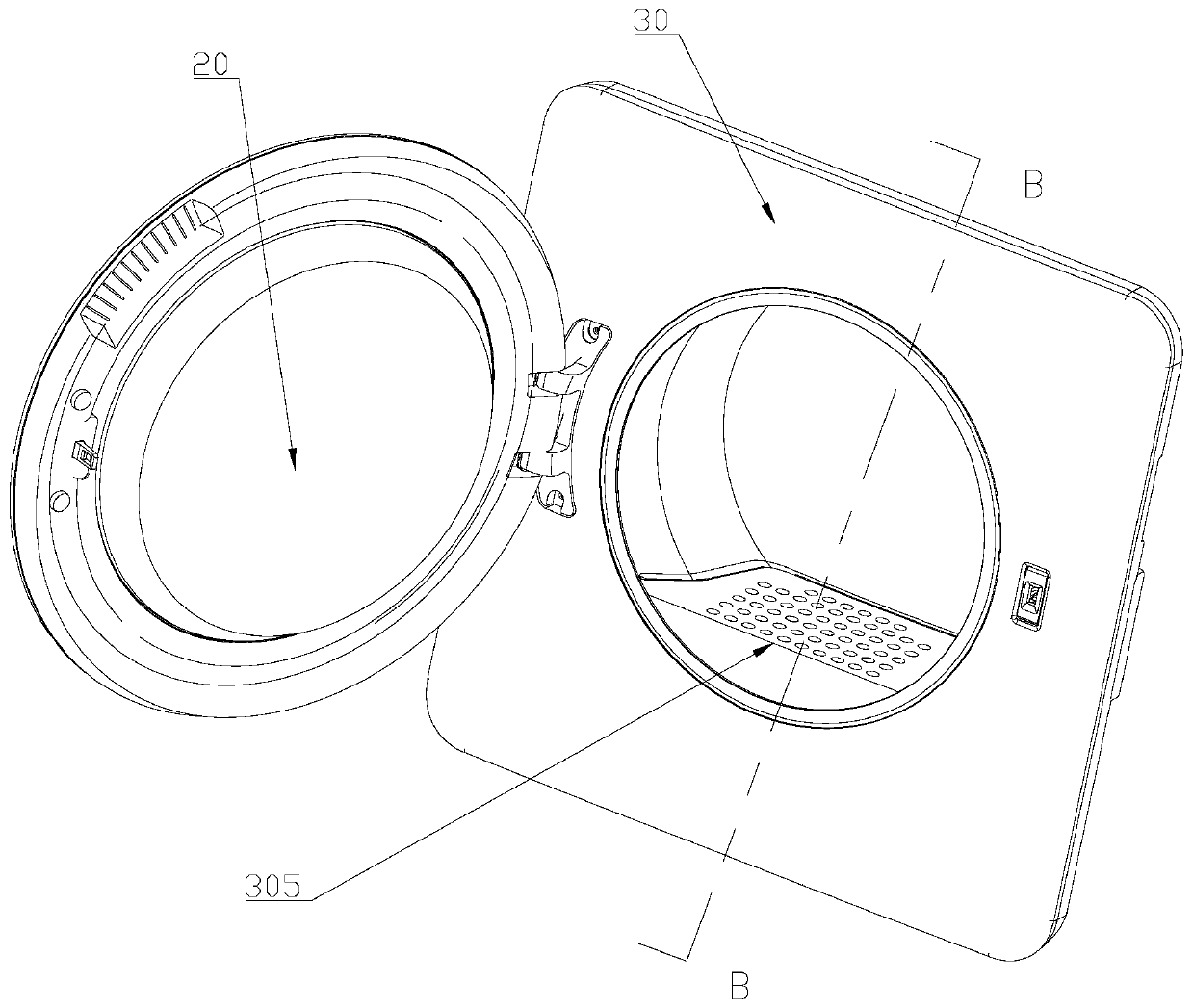

Washing machine

PendingCN110872756AWash cleanEnhanced agitationOther washing machinesWashing machine with receptaclesLaundry washing machineProcess engineering

The invention relates to the field of washing machines and discloses a washing machine, comprising a first washing unit with a first washing chamber, a door cover assembly, and a second washing unit with a second washing chamber. The door cover assembly comprises a second door (20) and a first door (30); an inner chamber of the first door serves as the second washing chamber; the first door is pivoted to the end face of a front seal door (10) of the washing machine through a first door pivot member so as to open and close the first washing chamber, and the second door is pivoted to the front end face of the first door to open and close the second washing chamber; the second washing unit comprises a second washing unit water inlet pipe (805) and a second washing unit water outlet pipe (806); a water outlet (704) is formed at the top of the second washing chamber; the second washing unit water inlet pipe is connected with the water outlet, and the second washing unit water outlet pipe isconnected to the bottom of the second washing chamber. The washing machine having two washing chambers independent relatively is suitable for sort washing and meets users' requirements well; the washing machine adopts a static-state washing mode, and accordingly has high safety and reliability and good washing effect.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

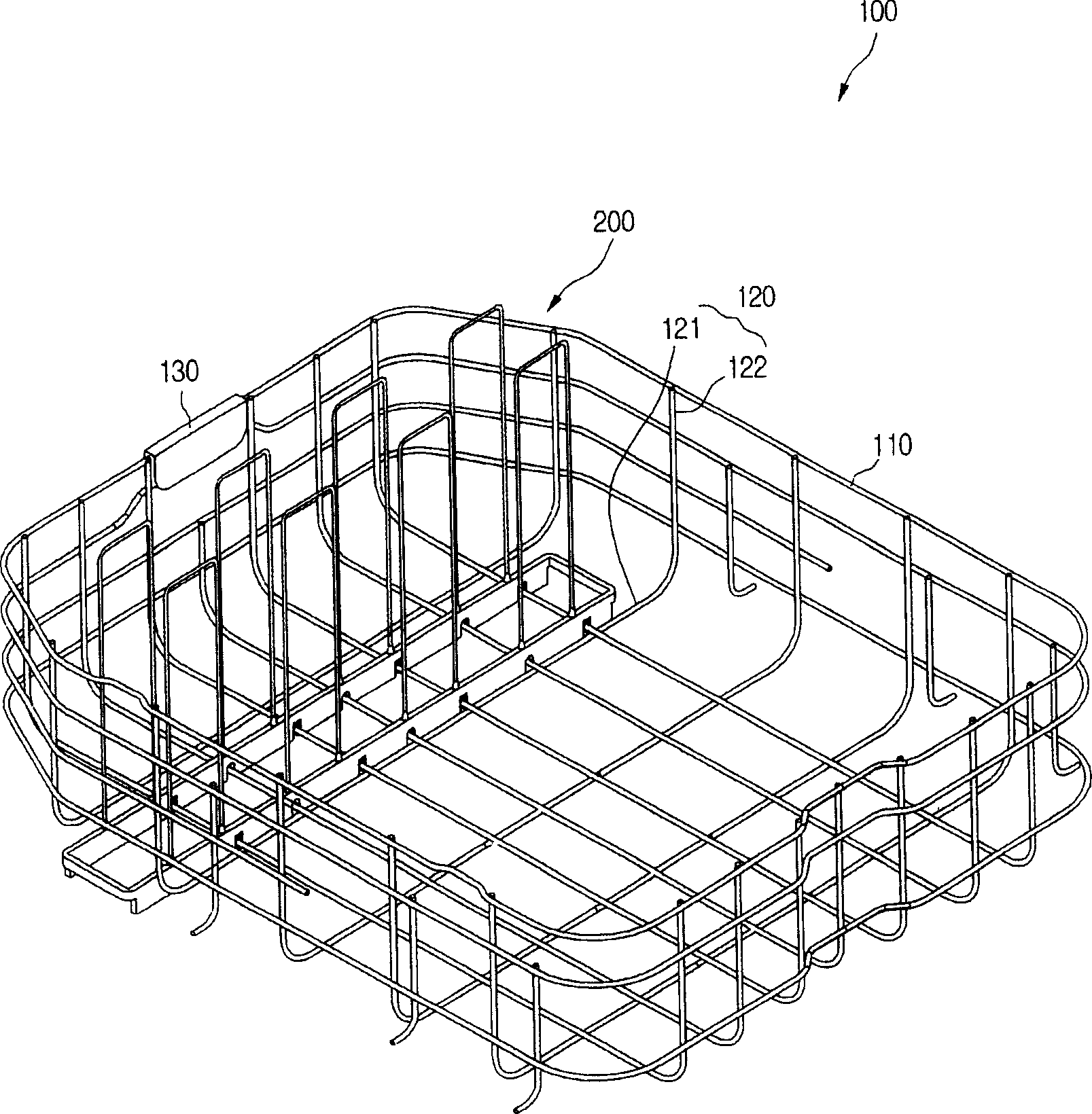

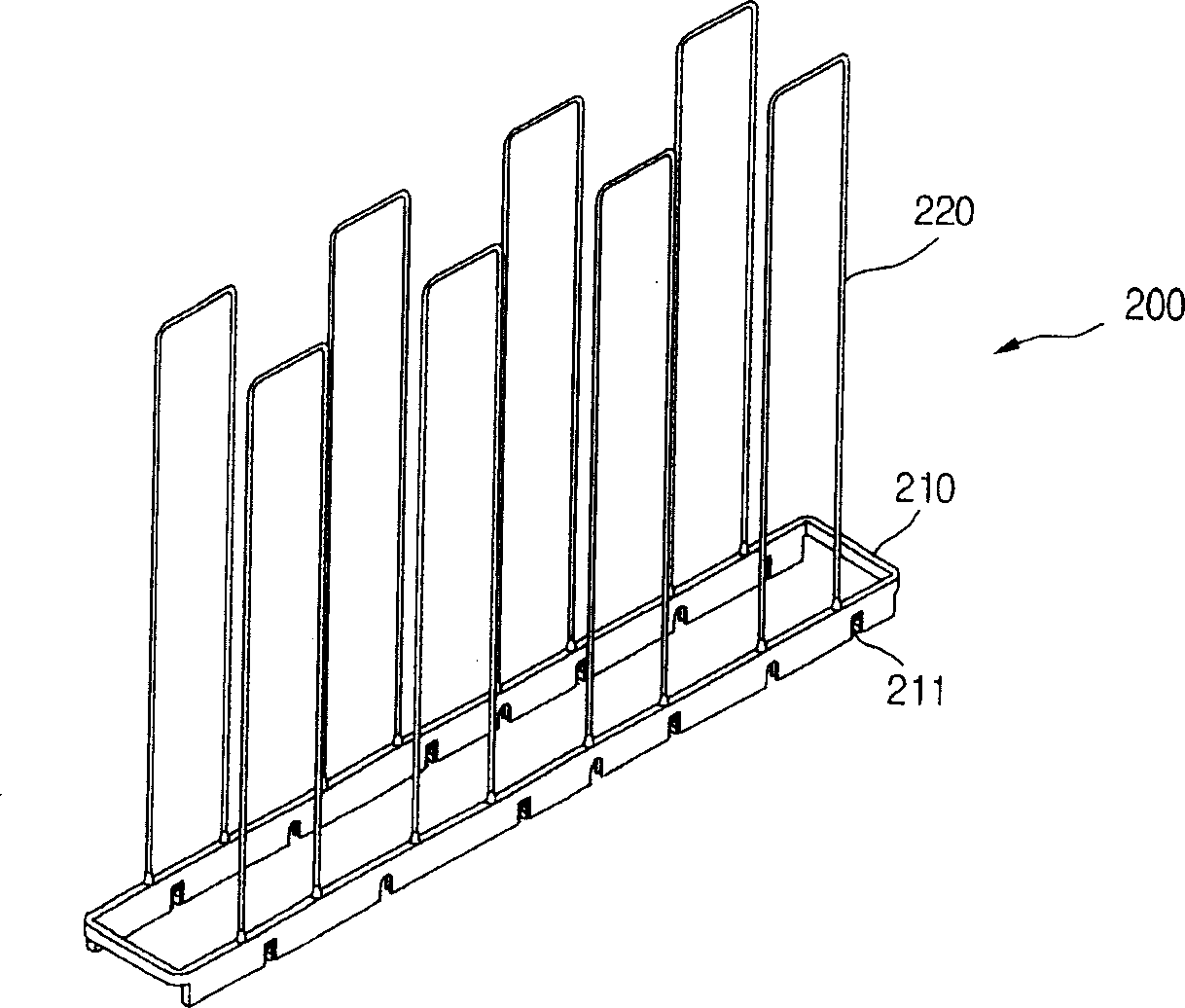

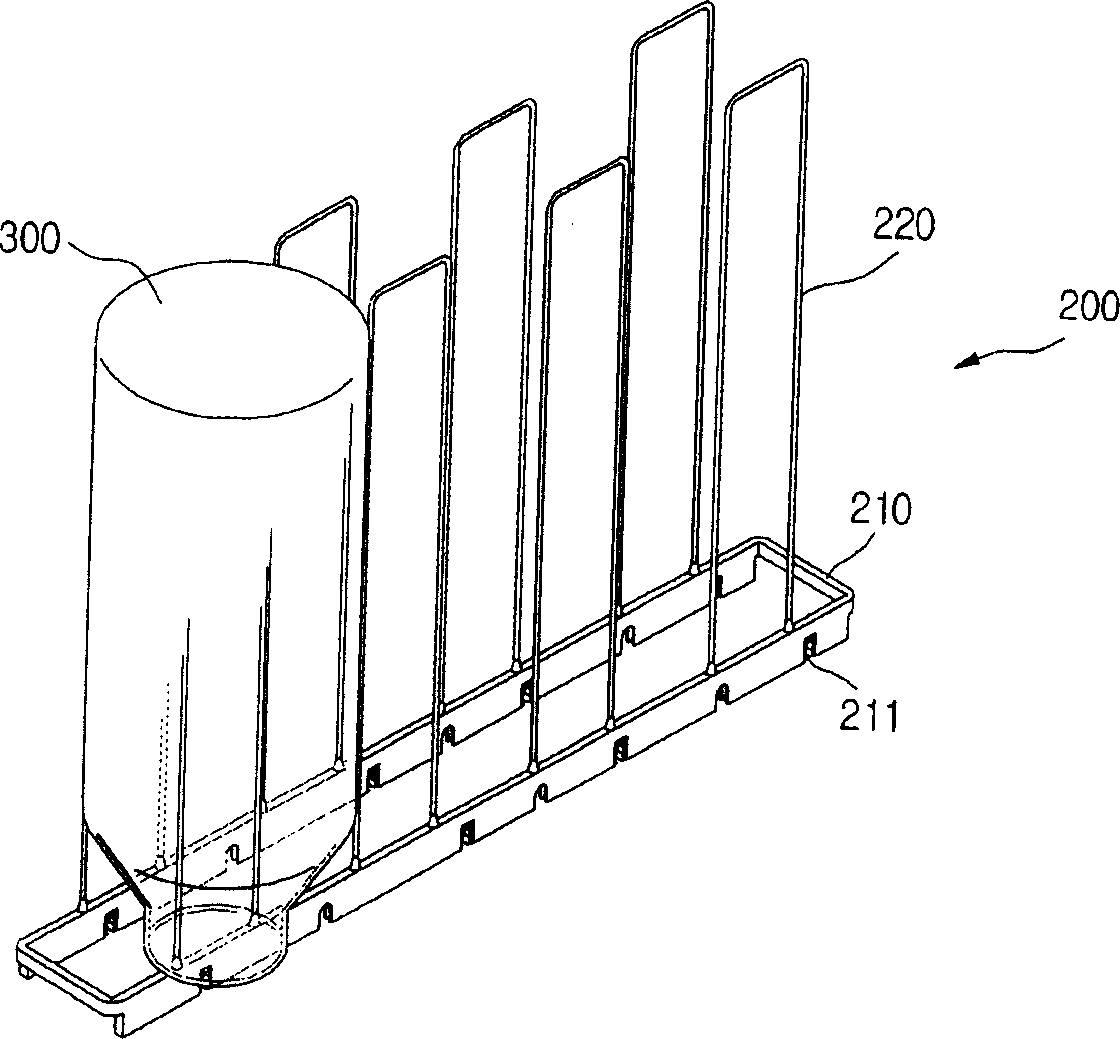

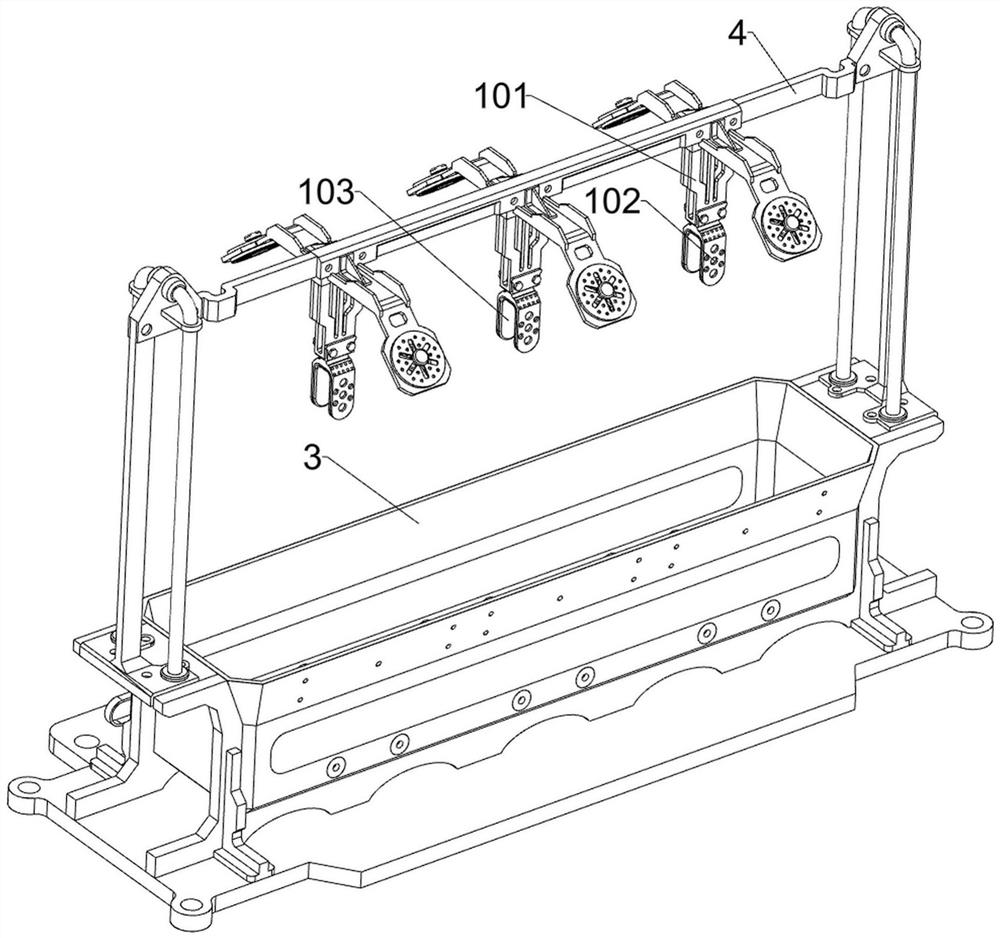

Tableware tray of dish washing machine

InactiveCN1899208AImprove space utilizationWash cleanTableware washing/rinsing machine detailsEngineeringBottle

The present invention discloses a kind of tableware tray of dish washer with fixed tableware basket and sprayer inside the cleaning room. The present invention includes outer frame, and tableware tray with ends connected to the outer frame and with formed bottom holding frame, and features the tray body detachably installed inside the tableware tray and bottle rack comprising bottle supporting forks combined to the upper part of the tray body. The tableware tray in the said structure can hold turned milk bottle and other long tableware.

Owner:NANJING LG PANDA APPLIANCES

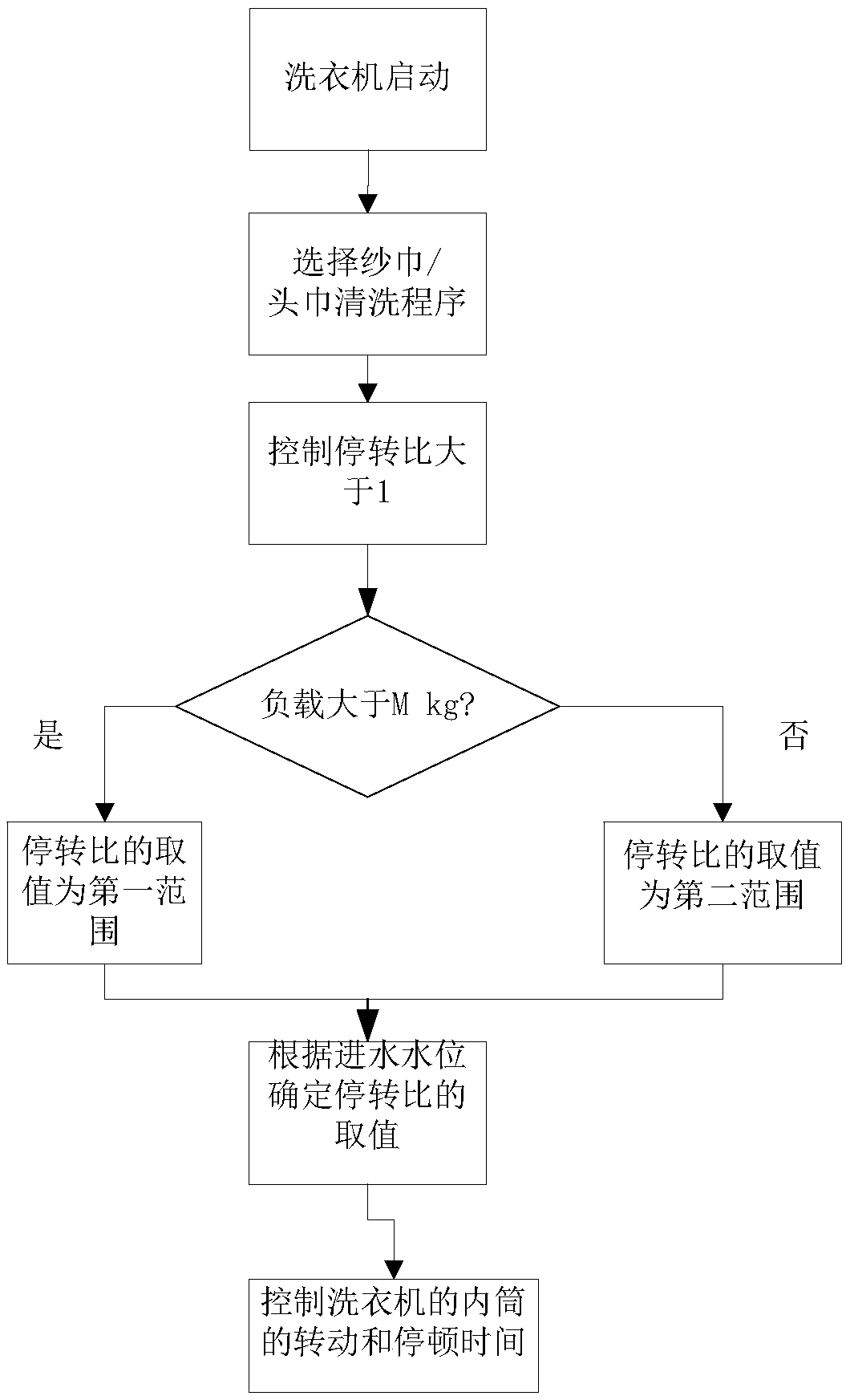

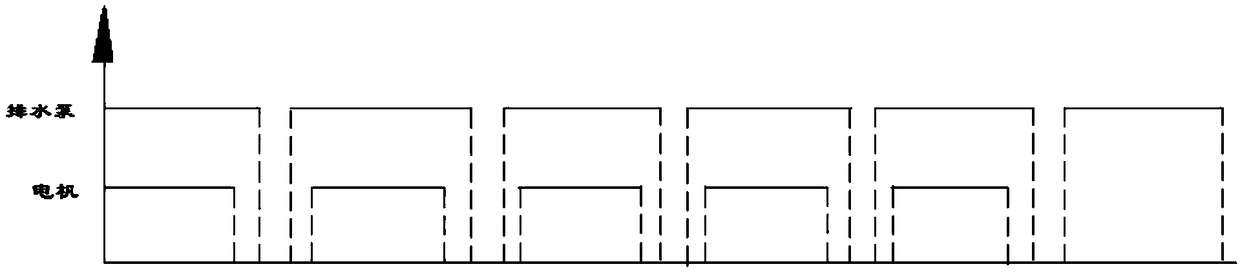

Washing machine control method and washing machine

PendingCN109338659ANo wear and tearWash cleanControl devices for washing apparatusTextiles and paperMachine controlWater flow

The invention belongs to the technical field of washing machines, and particularly relates to a washing machine control method. The washing machine control method comprises the steps that an inner cylinder rotates for T time and stops for t time when a washing machine works, the washing machine is provided with a gauze kerchief washing program and / or a kerchief washing program, and when the gauzekerchief washing program and / or the kerchief washing program are / is selected to be executed, the rotation stopping ratio (t / T) of the inner cylinder is controlled to be greater than 1. The washing machine control method has the advantages that water flow is especially suitable for washing kerchiefs, veils and other washing made from special materials so that abrasion cannot be caused, the washingcan be washed cleanly in a shorter time, and water and energy are saved. The invention further relates to the washing machine adopting the washing machine control method.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

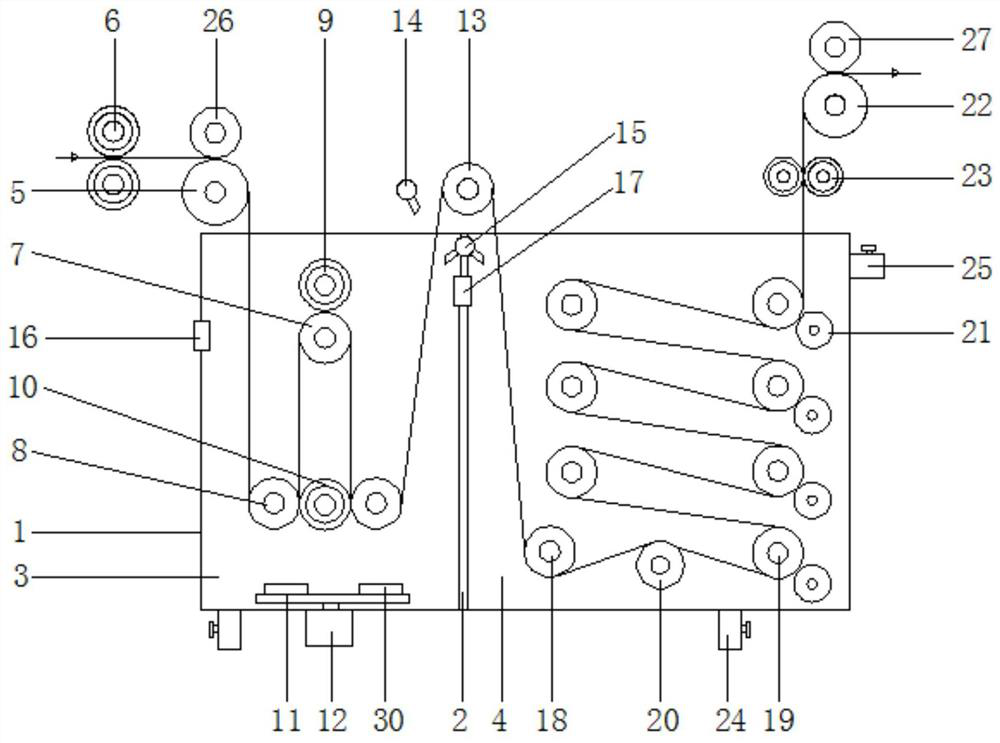

Efficient water washing tank

InactiveCN111926480AImprove cleaning efficiencySimple structureMechanical cleaningPressure cleaningDust controlWater resources

The invention relates to an efficient water washing tank. The tank includes a tank body, a vertical separating plate is connected with an inner chamber of the tank body, a pre-washing tank and a rinsing tank are formed on the left and right sides of the vertical separating plate respectively, a feeding guide roll is connected with the left side of the top of the pre-washing tank in a rotating mode, two dust removal rolls are arranged on the left side of the feeding guide roll, the dust removal rolls are connected in an attaching mode, an upper cloth guide roll and two lower cloth guide rolls are connected with the top and the bottom of an inner chamber of the pre-washing tank respectively in a rotating mode, the two lower cloth guide rolls are arranged in parallel, and an upper scrubbing roll is connected with the top of the upper cloth guide roll in an attaching mode. According to the efficient water washing tank, the structure is simple, the stability and reliability can be achieved,the cleaning capacity is strong, the cleaning efficiency is high, fabric can be pre-washed, washed, and rinsed fully, the effect of washing can be improved, through the arrangement of the pre-washingtank and the rinsing tank, the fabric can be pre-washed, dirt on the surface of the fabric can be removed, then washing can be carried out fully, so that the cleaning is cleaner, the utilization of water resources can be improved, and a wide application prospect can be achieved.

Owner:吴江新生喷织有限责任公司

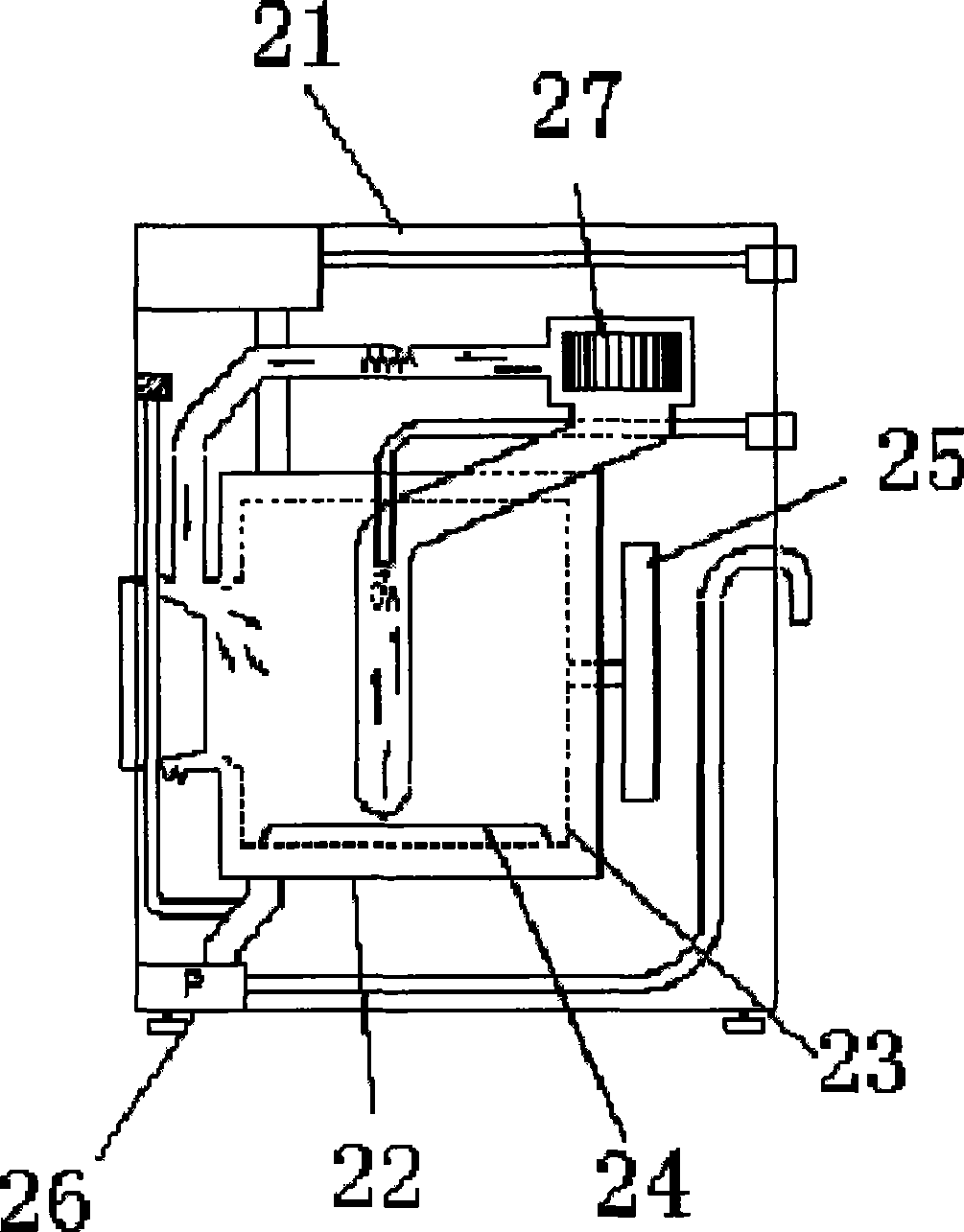

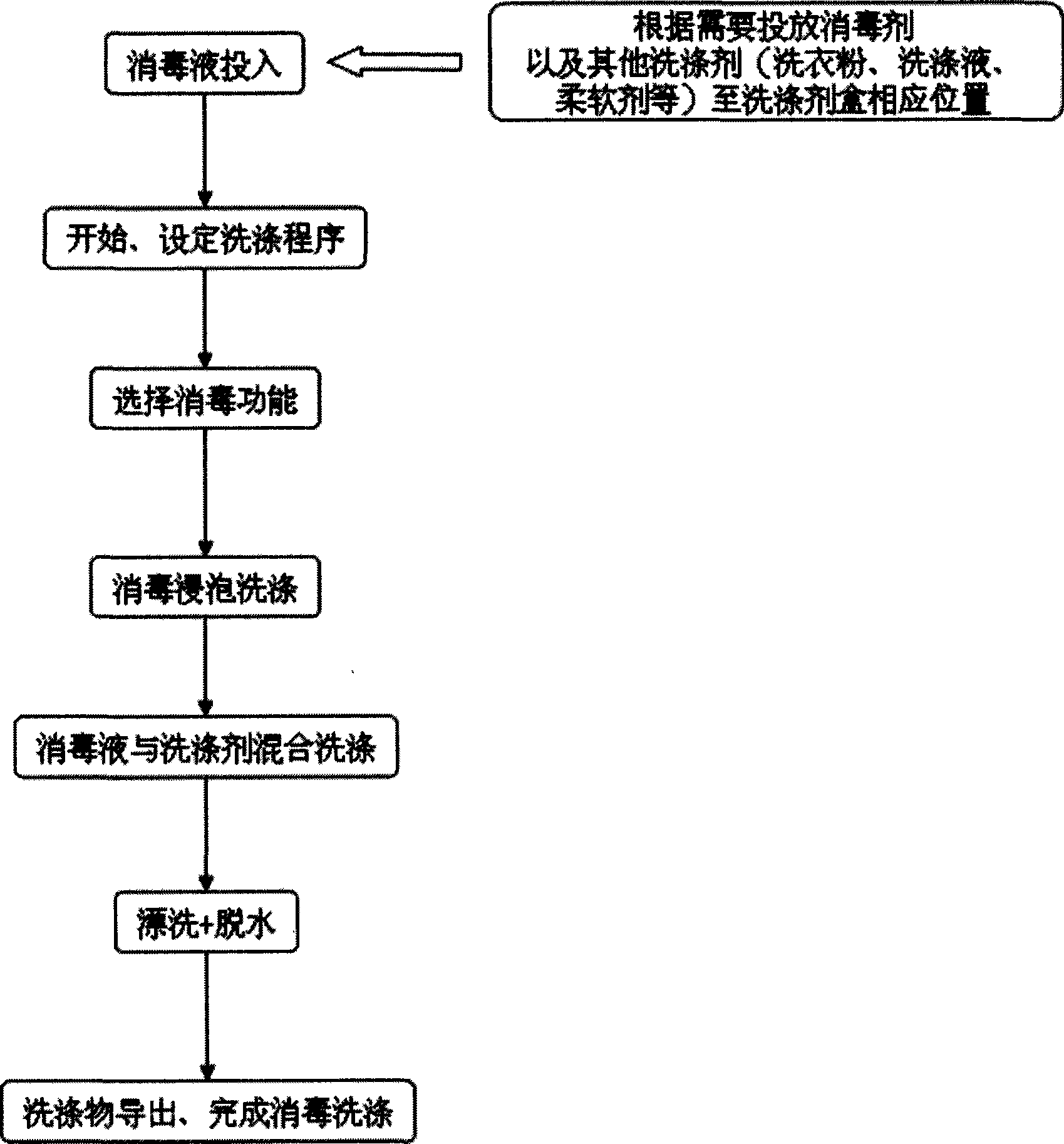

Disinfecting and washing method of washing machine

InactiveCN101381940AIncrease disinfection functionImprove performanceOther washing machinesTextiles and paperDisinfectantPulp and paper industry

The invention discloses a disinfecting washing method for washing machines. The method comprises the following steps of putting disinfectant into a disinfectant box, starting a washing machine, setting a washing program, selecting a washing mode with a disinfecting function, adding the disinfectant and water together into the washing machine, soaking, disinfecting, washing, rinsing, dewatering and leading out washing and finishing washing. The method can add the disinfectant, detergent and the water together into the washing machine, and mix the disinfectant with the detergent so as to soak, disinfect and wash washing. The method can use the disinfectant to disinfect the clothes in the washing machine so as to ensure more clean and sanitary washing, thereby meeting the requirement for disinfecting and washing the washing.

Owner:NANJING LG PANDA APPLIANCES

Toothbrush head for electric toothbrush

The present invention relates to a toothbrush head which is constituted by a body, a first rotation pipe, a drive unit, a support, a rotator, and an auxiliary rotator and can clearly wash every nook and corner of teeth and wash upper teeth and lower teeth at once only by a method that just slightly bits a part of a body unlike the existing tooth brushing method in which a user brushes his / her teeth by rapidly moving his / her hand left and right and up and down and right to reduce a tooth brushing time. As a correct washing method of the teeth, only when the teeth are brushed while rotating a toothbrush vertically from an upper side to a lower side of the teeth, food wastes can be easily removed and an injury of gum parts connected with the teeth due to wrong tooth brushing (tooth brushing performed in a horizontal direction of a set of teeth) can be prevented and the present invention is configured to be suitable for the tooth brushing.

Owner:SAKE

Canteen rice washing machine

The invention relates to a washing machine, in particular to a canteen rice washing machine. The technical purpose of the invention is to provide the canteen rice washing machine which can be used forwashing a large amount of rice more conveniently and washing the rice clean comprehensively. According to the technical implement scheme, the canteen rice washing machine comprises a base, a frame, awater draining pipe, a valve, a vertical rod, a slide sleeve, a fastening bolt, a transverse plate, a first bearing pedestal, a handle, clamping rods, first slide blocks, first springs and the like;and the right side of the top of the base is fixedly connected with the frame capable of holding water, the lower portion of the right side of the frame is connected with the water draining pipe, thewater draining pipe communicates with the interior of the frame, and the valve capable of being used for controlling the water to be drained is arranged on the water draining pipe. According to the canteen rice washing machine, rice can be poured into a net frame, the net frame is moved into the frame, the rice is made to make contact with the water, a rocking bar is rocked so that the net frame can be rotated, the rice can be washed through the water and does not need to be rubbed manually, operation is more convenient, the working efficiency is high, and washing is more comprehensive.

Owner:南京幸庄科技创新产业园管理有限公司

Cylinder moving sock washing device

The invention discloses a cylinder moving sock washing device and belongs to the technical field of washing utensils. The cylinder moving sock washing device comprises a cylinder body, a cylinder cover, a motor, a support, a driving shaft, a sock sheathing rod, brush hairs and a base, wherein the cylinder body is cylindrical; the inner wall of the cylinder body is provided with a plurality of brush hairs; in addition, the length of the brush hairs is slightly longer than the distance between the outer wall of the sock sheathing rod and the inner wall of the cylinder body; the cylinder cover comprises a handle which is circular; the handle is arranged at the upper part of the cylinder cover and is conveniently used for closing the cylinder cover with hand when the cylinder cover is not used; the motor is arranged in the base; the driving shaft is connected with the motor and the base; the base is arranged at the lower part of the cylinder body; the base is internally provided with the motor; and the sock sheathing rod is fixedly connected with the lower end of the support. The cylinder moving sock washing device solves the difficult problem that socks are inconveniently mixed with clothes for washing; and by separately washing, the socks are conveniently and cleanly washed without great effort.

Owner:汉中斯巴达科技有限公司

Handmade natural detergent

InactiveCN106753901ANo pollutionIngredient safetyDetergent compounding agentsInorganic non-surface-active detergent compositionsBottleTest strips

The invention discloses a handmade natural detergent. The handmade natural detergent is prepared by means of the following steps: (1) removing some of white parts in fresh shaddock peels, and cutting the fresh shaddock peels into strips which are 2-3cm wide; (2) putting the strip-shaped fresh shaddock peels into a glass container, and adding cold boiled water to make the cold boiled water at least immerse the shaddock peels; (3) adding an appropriate amount of dietary alkali, uniformly stirring, and covering the glass container with a lid to perform sealed storage for 3-7 days, wherein the content of the dietary alkali is 1 percent of the cold boiled water approximately; (4) when the shaddock peels are faded in color to be almost the same as extraction liquid after 3-7 days, uncovering the glass container, and detecting the PH value of the extraction liquid by using a PH test strip until the PH value is about 8; (5) filtering the extraction liquid by using a filter screen, and injecting the extraction liquid into a detergent bottle; (6) adding tea tree essential oil into the detergent bottle for use, wherein the content of the tea tree essential oil is 0.5 percent of the extraction liquid approximately. The handmade natural detergent has the advantages of safety, environmental friendliness and low cost, people enjoy DIY and the joy of success, and meanwhile, the detergent which makes people feel relieved to use is obtained.

Owner:申艾平

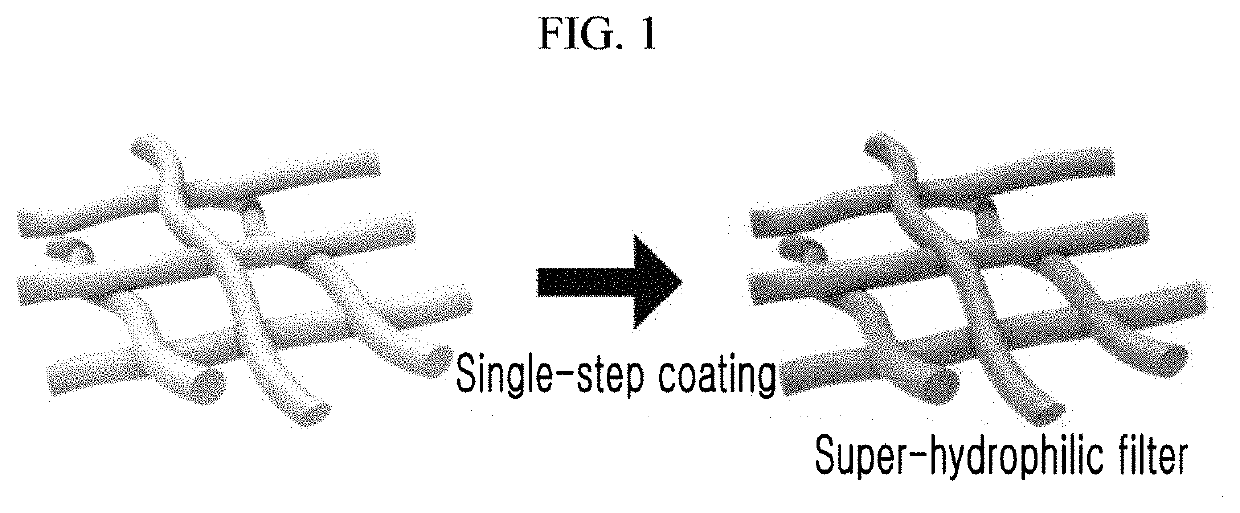

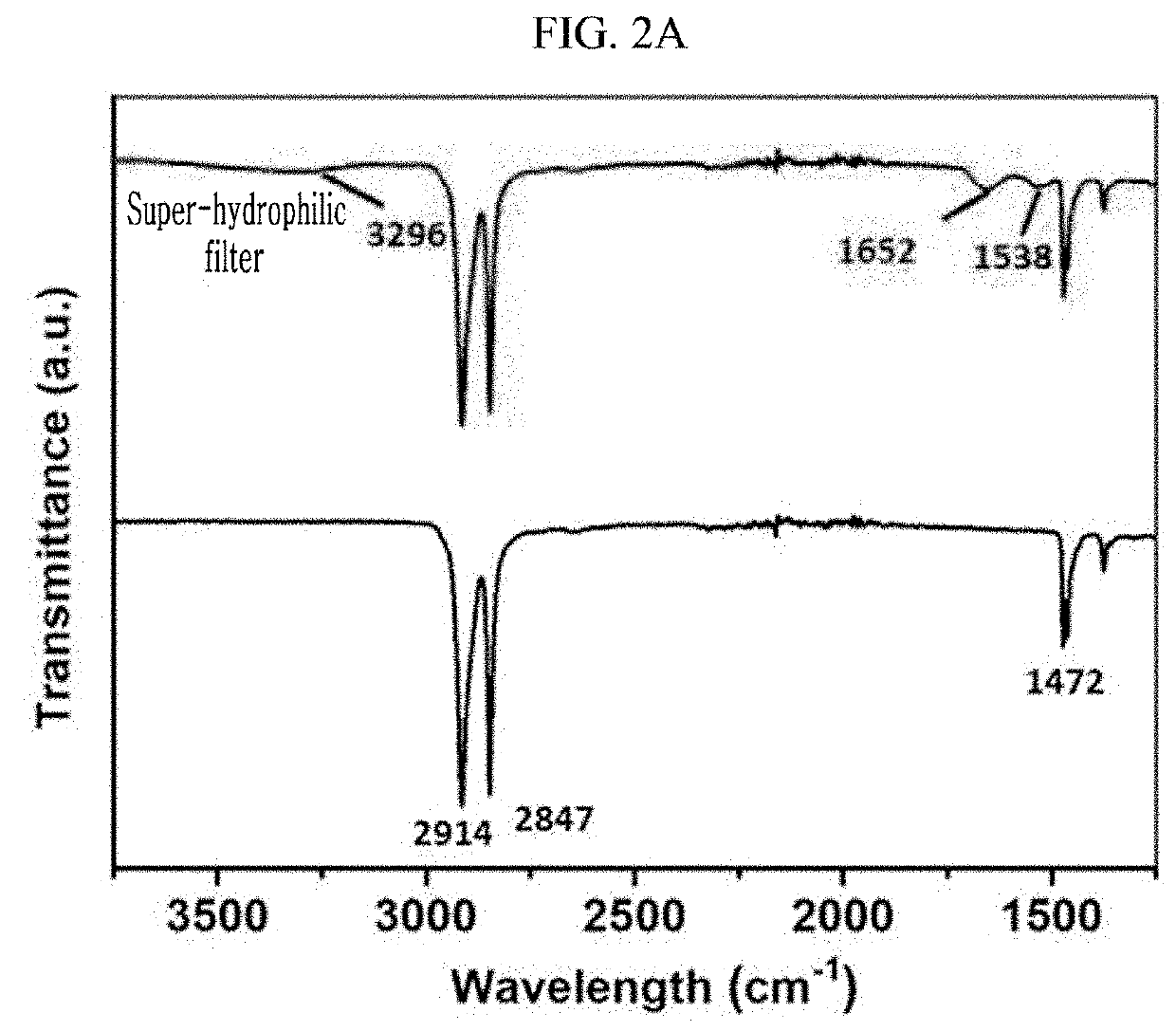

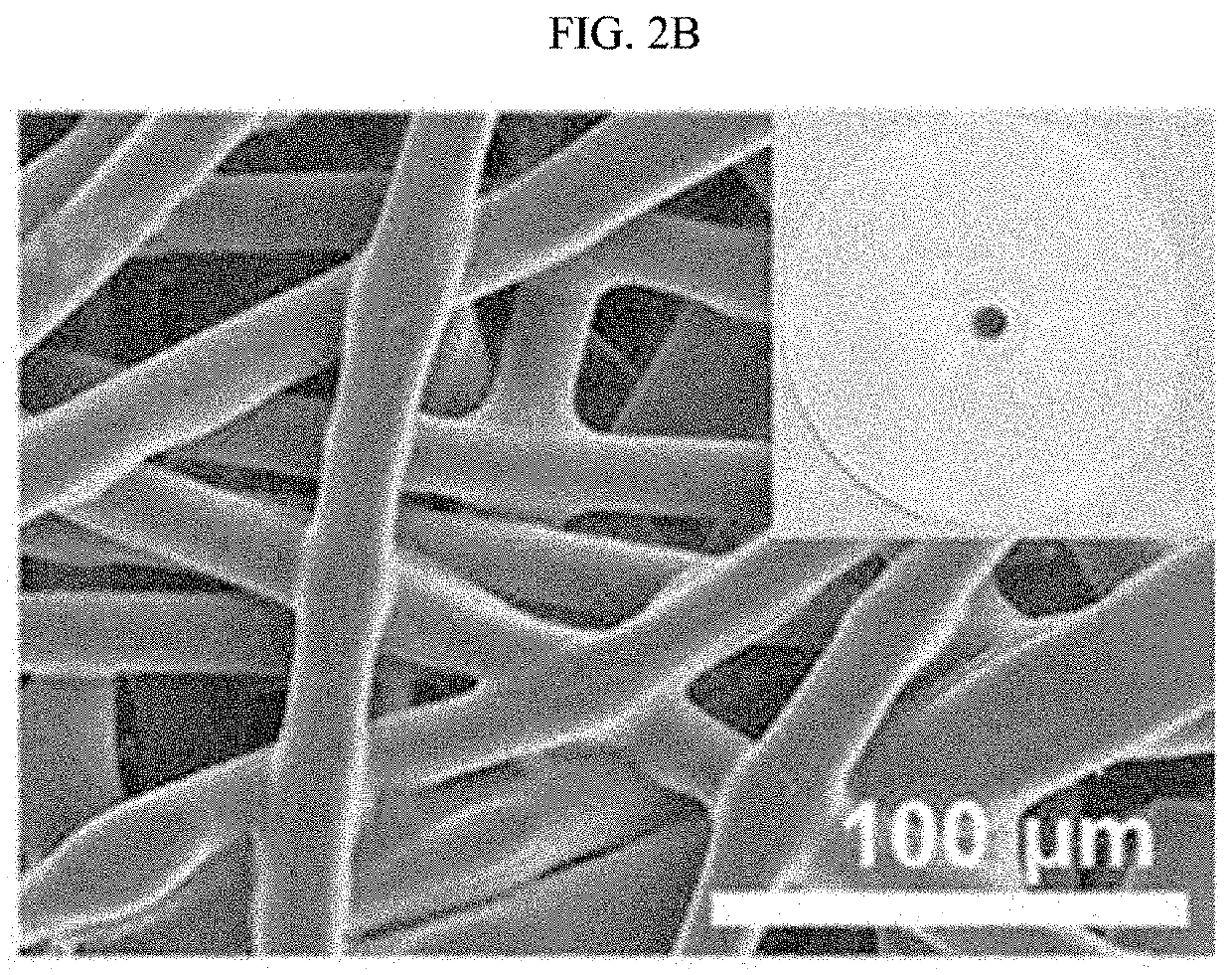

Super-hydrophilic surface treatment method of filtration medium, super-hydrophilic filter for oil-water separation and method of fabricating the same

InactiveUS20220118380A1Wash cleanSatisfies requirementSemi-permeable membranesMembranesHydrophilic coatingMeth-

A super-hydrophilic surface treatment method of a filter medium of a filter for oil-water separation according to the present invention includes preparing a filter medium or a filter including the filter medium using a polymer base or a metal base, and forming a hydrophilic coating layer to the filter medium or the filter including the filter medium by cross-linking bis-acrylamide (N,N-methylenebisacrylamide).

Owner:POSTECH ACAD IND FOUND

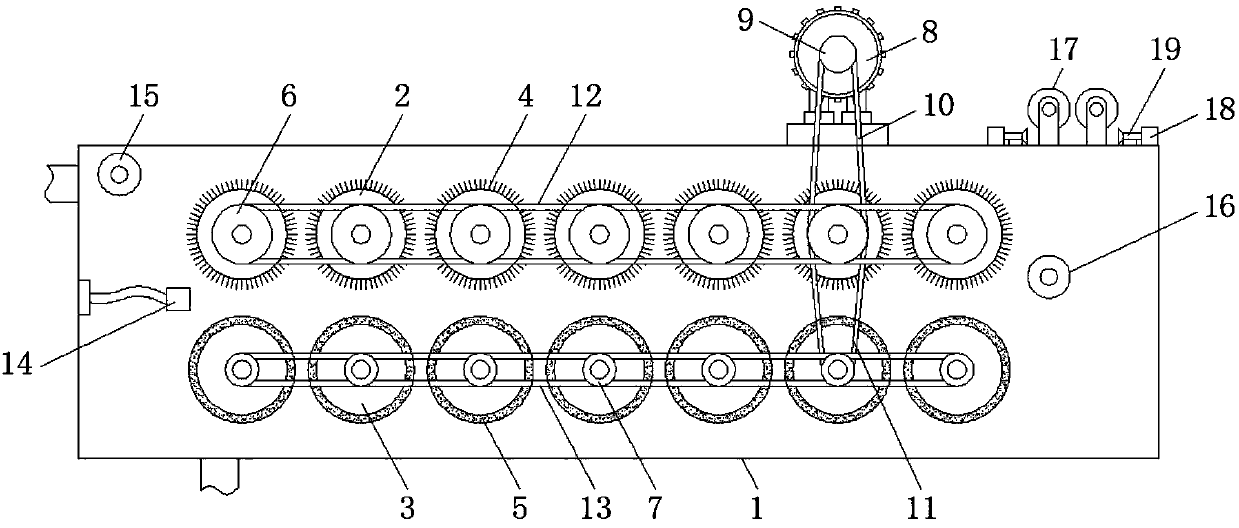

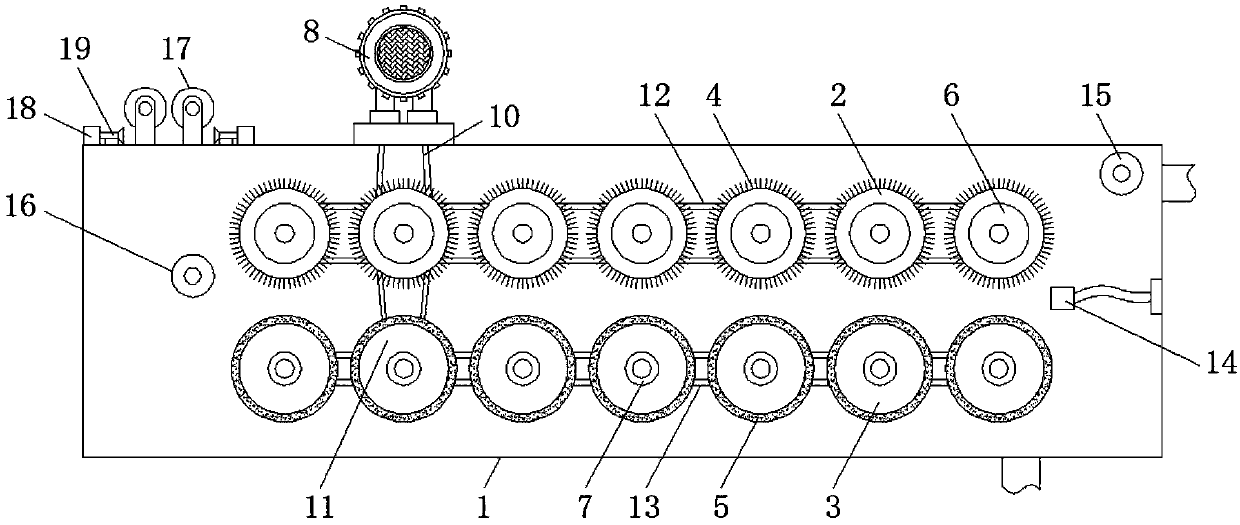

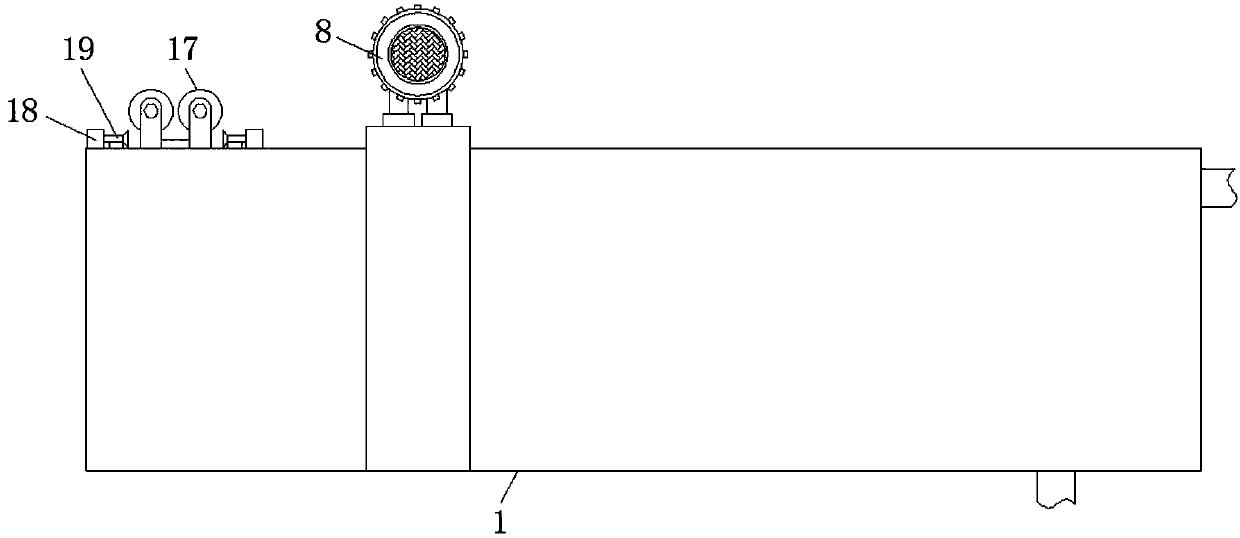

Rinse tank for washing woollen blanket

InactiveCN109957896AEfficient washingWash cleanMechanical cleaningPressure cleaningBristlePulp and paper industry

The invention discloses a rinse tank for washing a woollen blanket. The rinse tank comprises a washing sink; the washing sink is internally provided with upper roller wheels and lower roller wheels which are arranged at equal intervals; mandrels are respectively arranged at the axes of the upper roller wheel and the lower roller wheel; soft bristles are evenly distributed on the outer side faces of the upper roller wheels; soft hair layers are arranged on the outer side faces of the lower roller wheels; a first driving wheel is arranged at one ends of the mandrels of the upper roller wheels, and a second driving wheel is arranged at one ends of the mandrels of the lower roller wheels. The rinse tank can be used for effectively washing the woollen blanket, thus enabling the woollen blanketto be washed more cleanly; furthermore, the rinse tank also can effectively reduce the damage to the woollen blanket during washing, thus enabling the comfort level of the woollen blanket to be greatly improved; after the woollen blanket is washed, a squeeze roll wheel set is used for squeezing the woollen blanket so as to squeeze part of water from the woollen blanket, so that the time spent fordrying the woollen blanket in the air can be effectively shortened.

Owner:TIANJIN LUNYITE CARPET CO LTD

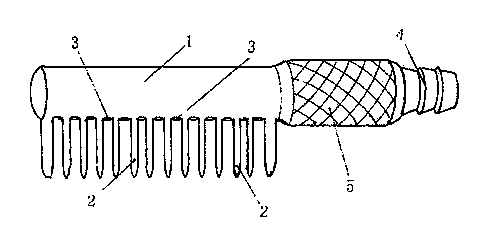

Comb with hair-flushing function

The invention provides a comb with a hair-flushing function, wherein one side of a tube body with an end socket is provided with a plurality of uniformly arranged comb teeth, spraying holes are formed between every two adjacent comb teeth in the tube body, the tail end of the tube body is provided with a connector connected with a water supply tube and a handle is arranged at the tail part of the tube body. When the comb is in use, the connector and the water supply tube are connected, so that the comb can be used for washing hair by holding the handle with a hand; and the hair can be conveniently washed and combed due to the comb teeth, so that hair roots can be washed clearer.

Owner:ZHUGELIANG MIDDLE SCHOOL

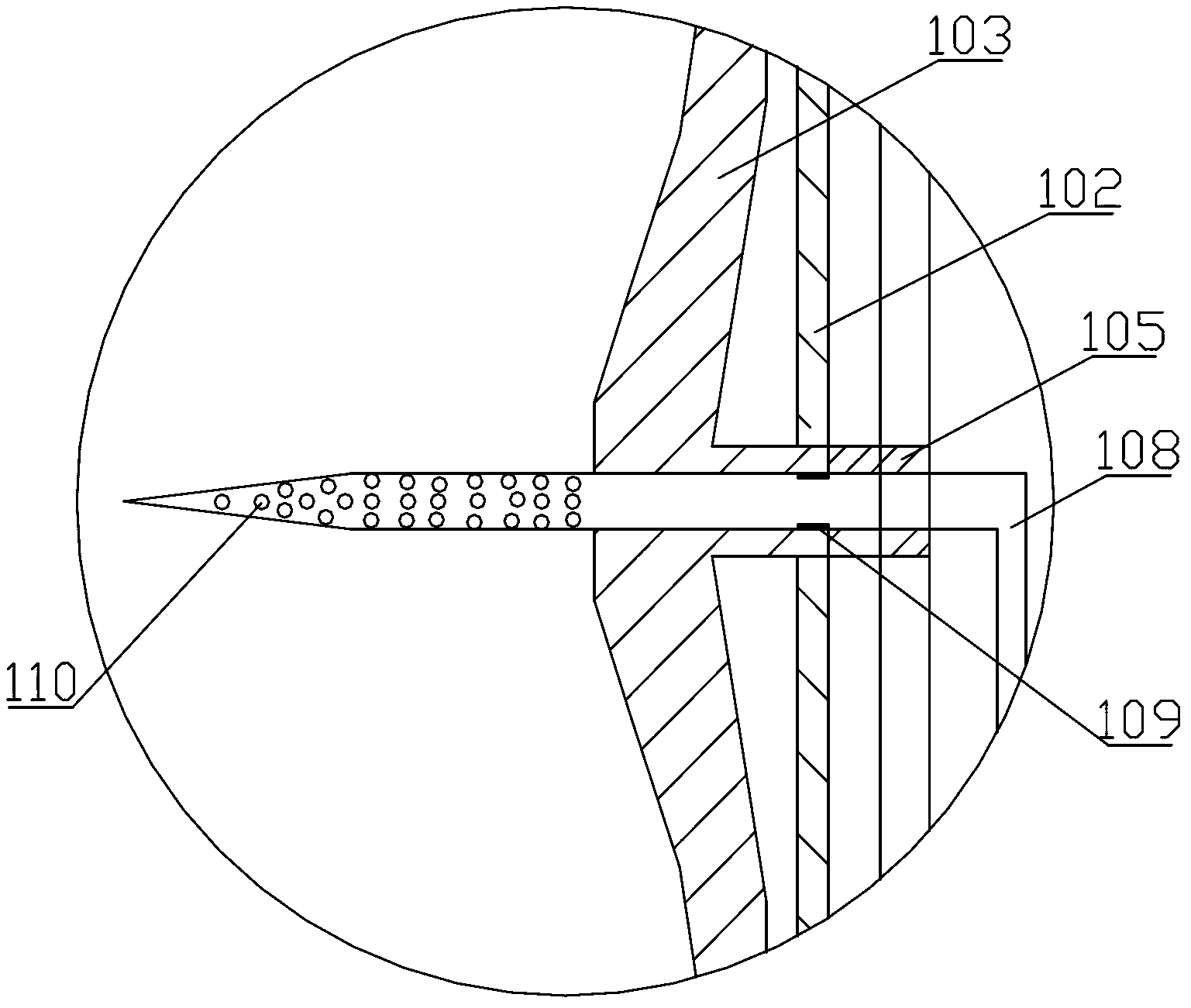

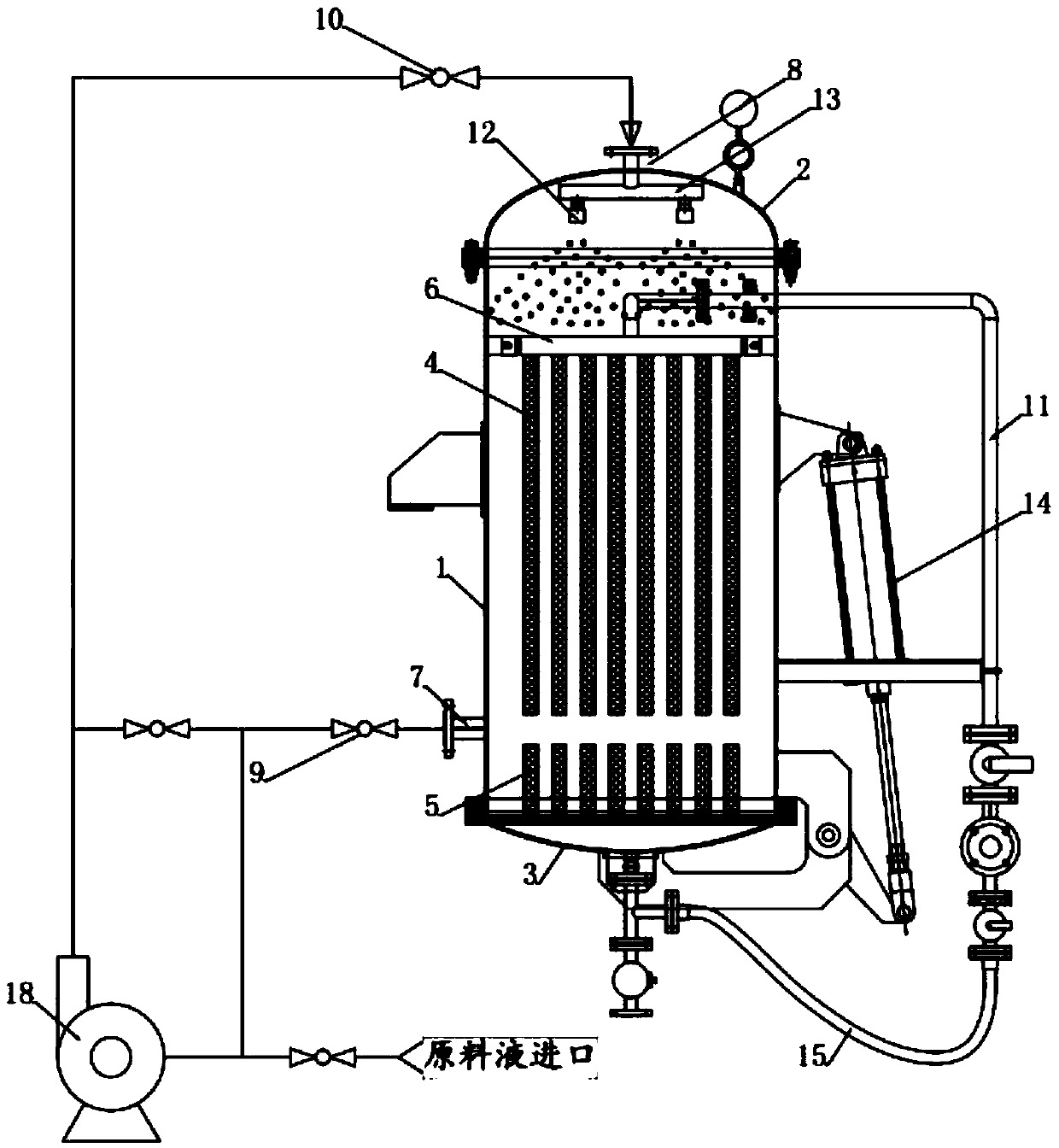

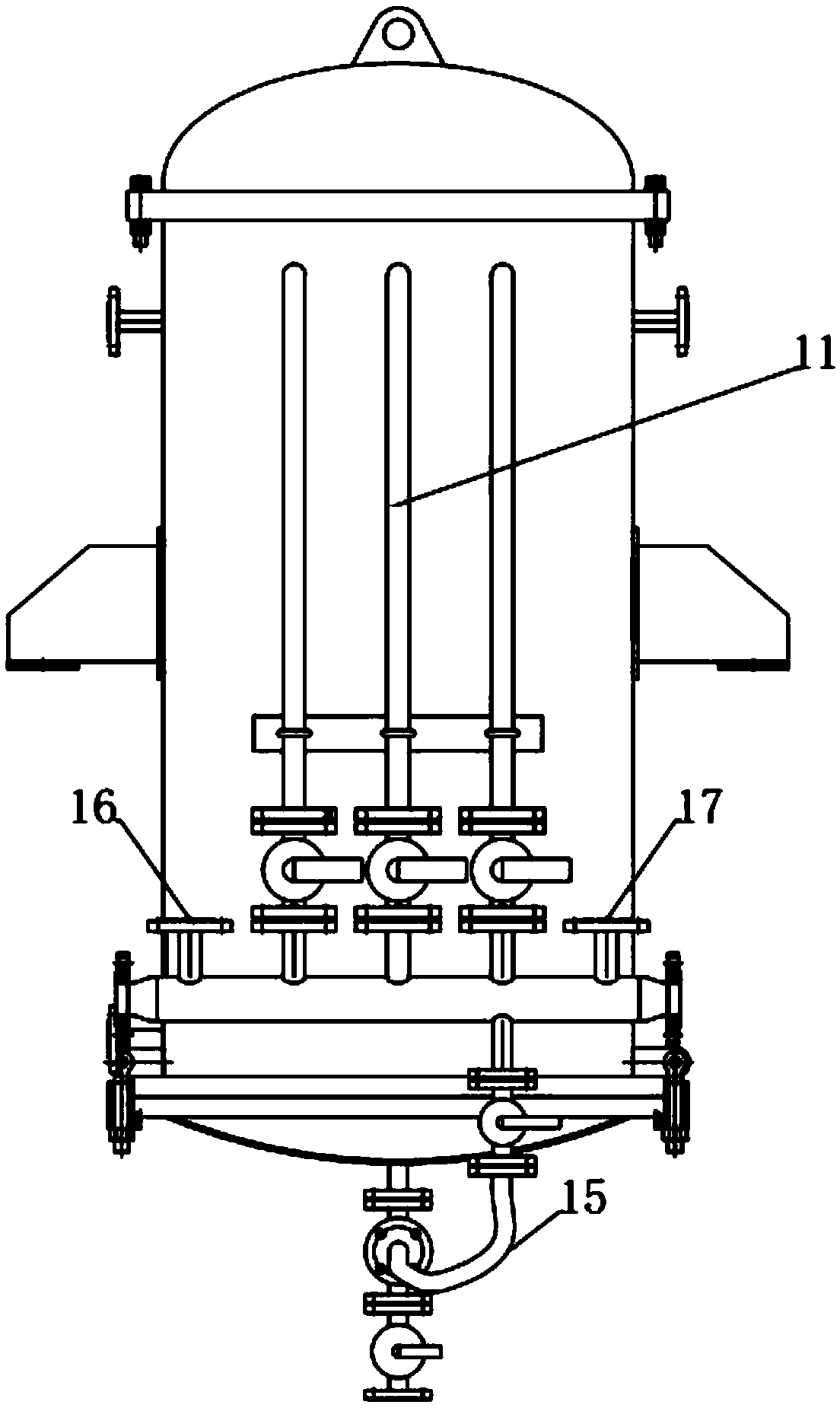

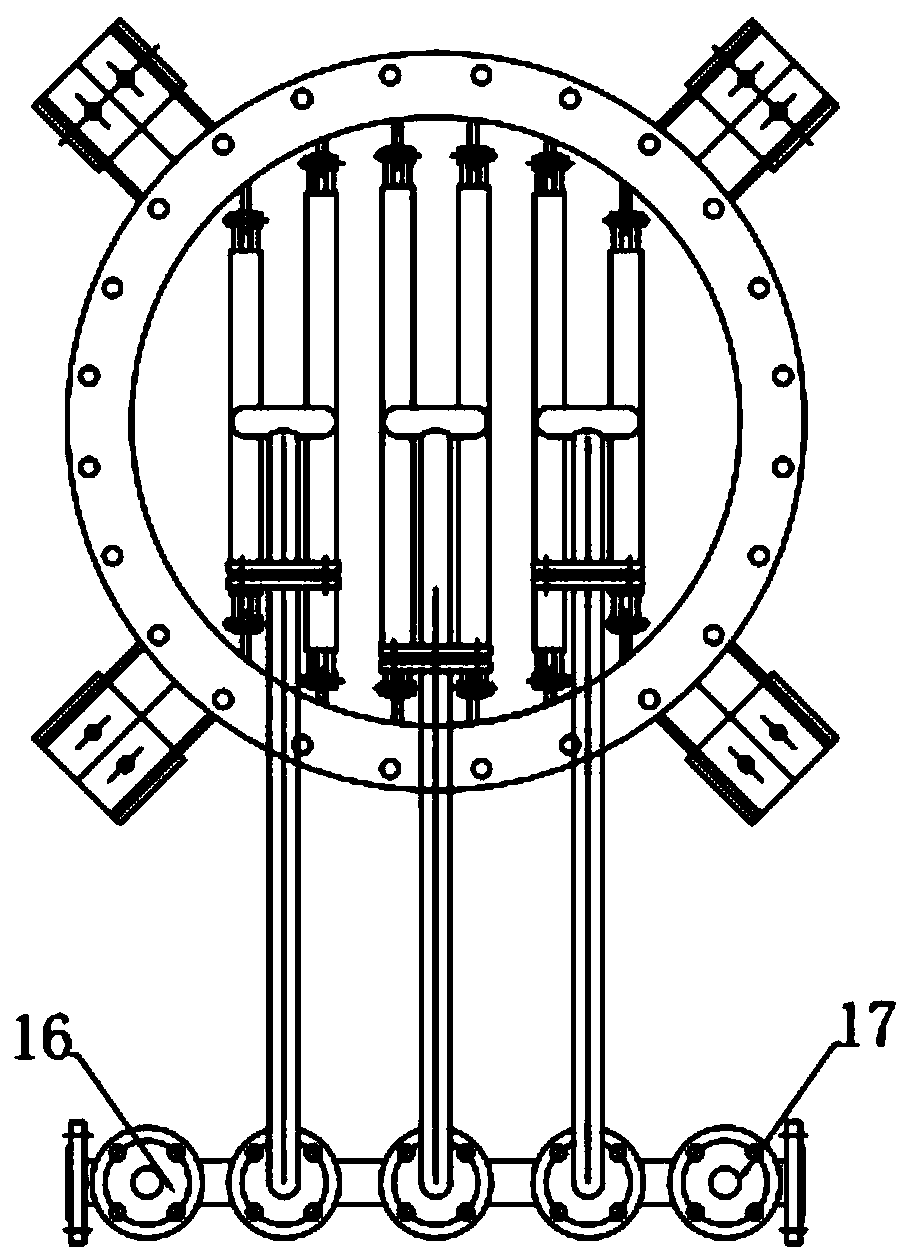

Microporous filter

PendingCN107837584ASpray evenlyImprove washing effectStationary filtering element filtersFiltrationSlurry

The invention provides a microporous filter. The microporous filter comprises a cylindrical shell, and the upper part and the lower part of the cylindrical shell are respectively provided with an upper head and a bottom head; the cylindrical shell is internally provided with a filter core, and the upper part of the upper head is communicated with a spraying mechanism; the lower part of the cylindrical shell is provided with a liquid inlet, and the liquid inlet and the spraying mechanism are separately communicated with a pump body; the upper part of the cylindrical shell is provided with a clear liquid outlet; the lower part of the bottom head is provided with a bubbling mechanism, and the bubbling mechanism is used for washing internal filter residues. The filter is provided with the spraying mechanism, air is introduced, and during washing, liquid can be atomized and sprayed out; and at the same time, the press filtration is continuously carried out for the lower part, atomized watercan be uniformly sprayed, and washing effects are increased; and at the same time, the bottom is provided with the bubbling mechanism, dense slurry deposed at the bottom can be bubbled, and washing is cleaner.

Owner:威孔过滤科技(苏州)有限公司

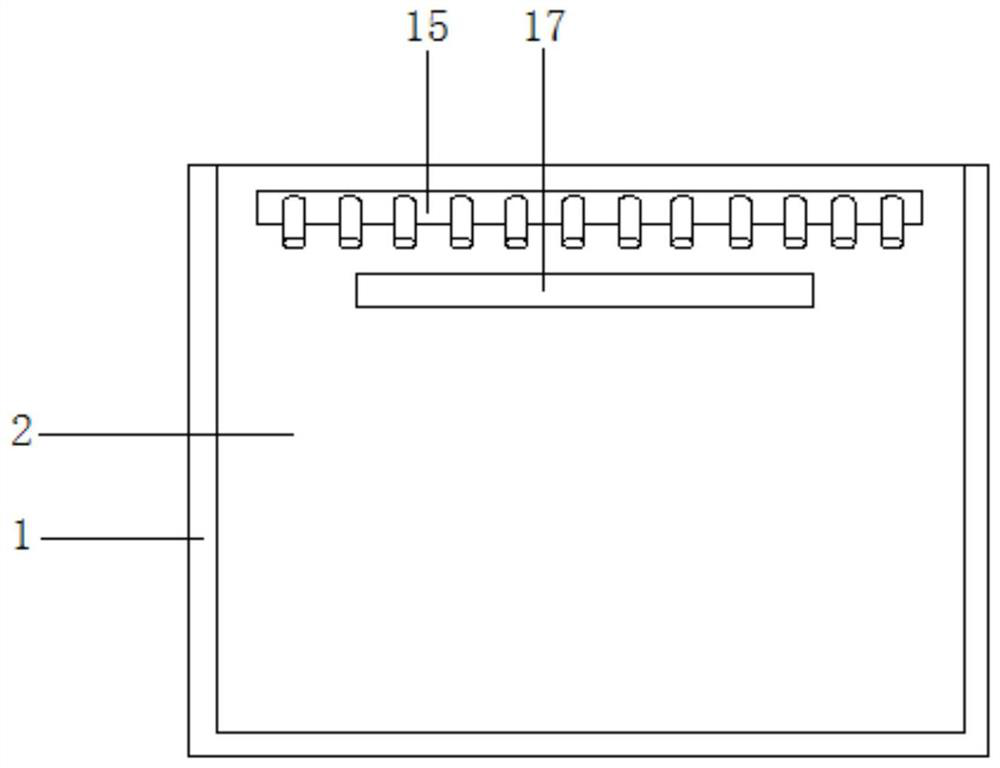

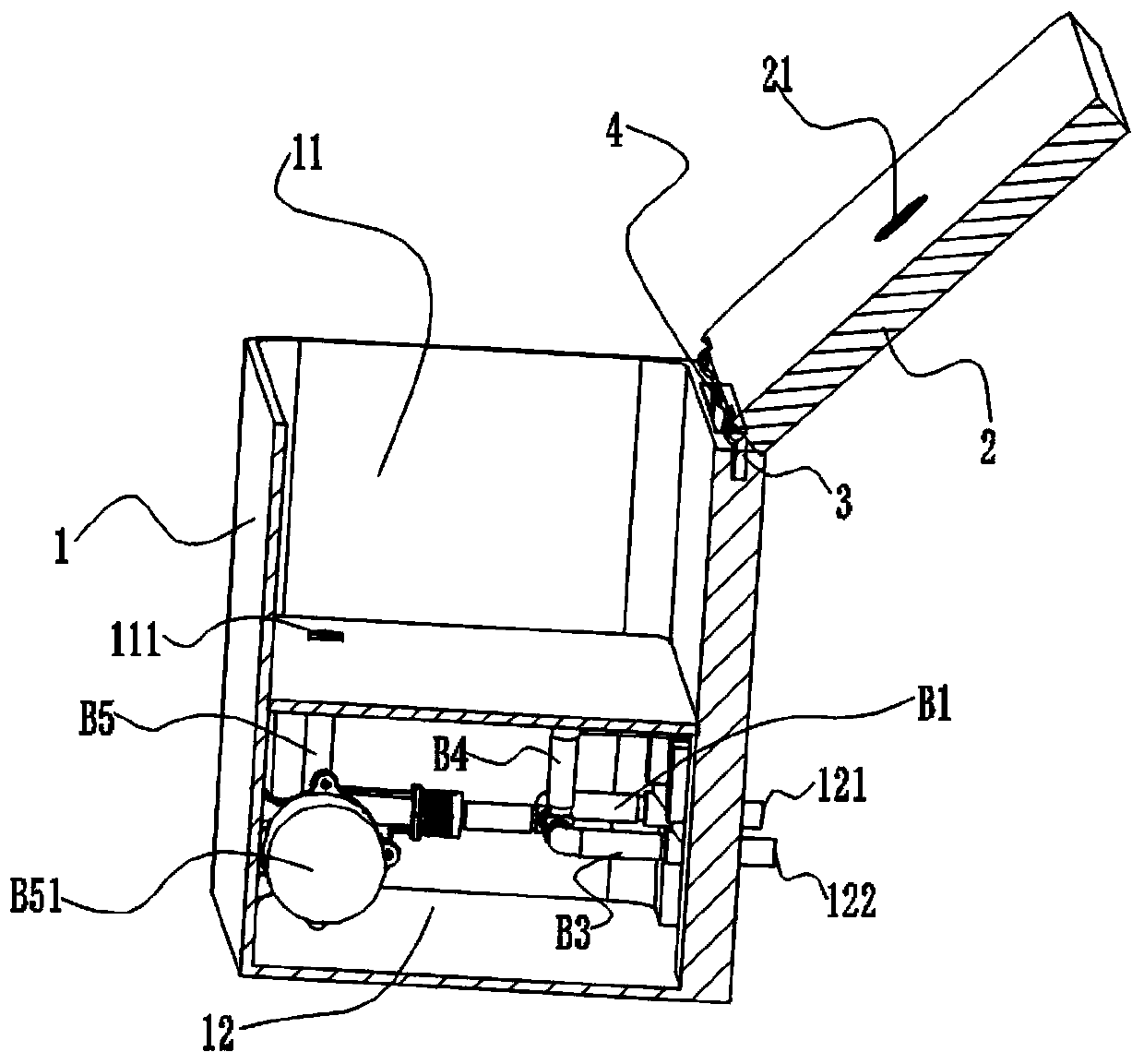

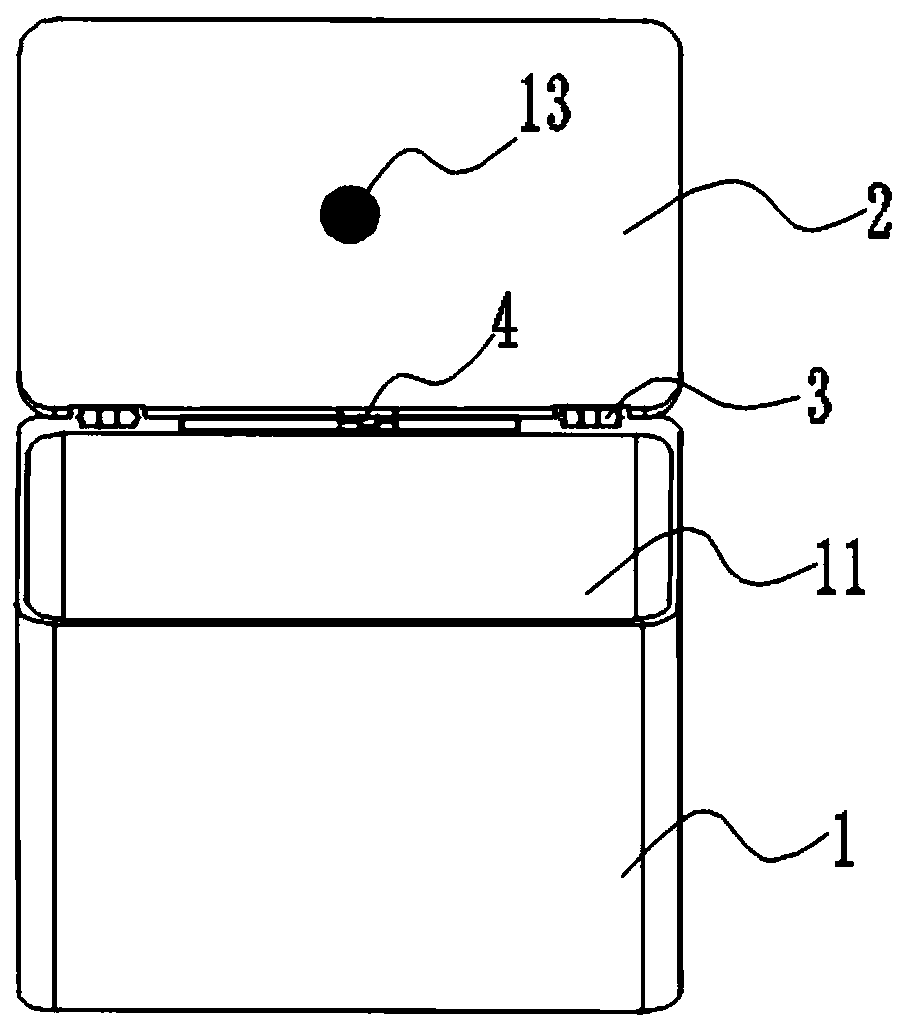

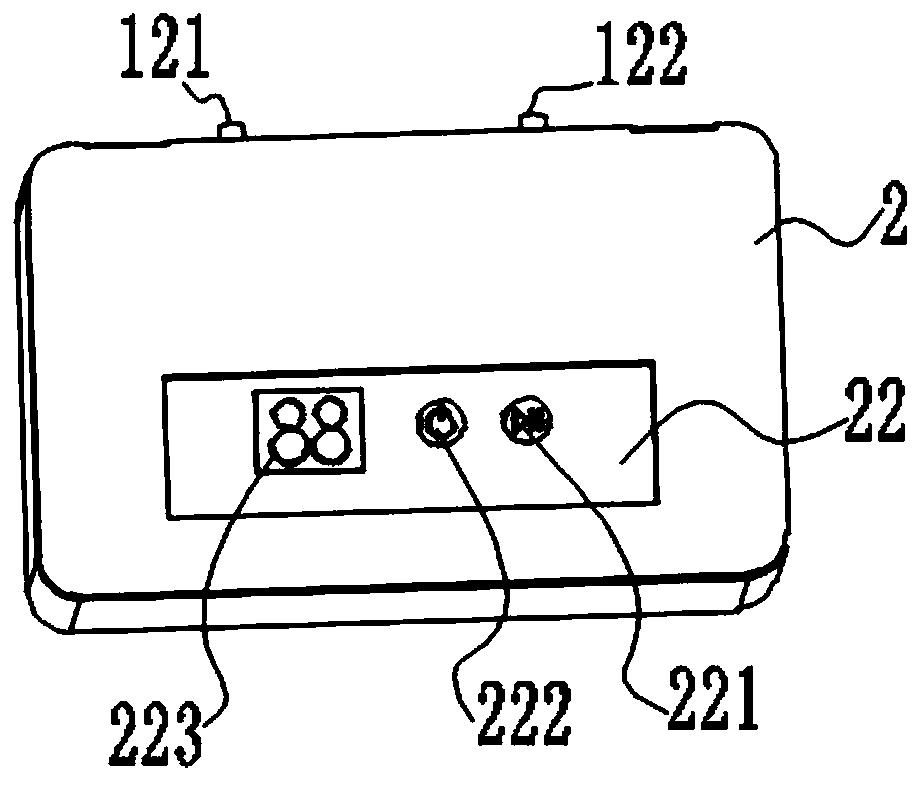

Top cover type cleaning device

PendingCN111118801AExpand the spraying areaWash cleanOther washing machinesWashing machine with receptaclesStructural engineeringTop cap

The invention relates to a top cover type cleaning device. The top cover type cleaning device comprises a barrel body, a top cover and a hinged part, wherein a washing cavity is formed in the barrel body; the top cover is hinged to the upper portion of the washing cavity and is used for sealing the washing cavity; a spraying structure is formed on the side, facing the washing cavity, of the top cover, so that the washing device can carry out spraying from the top cover to the washing cavity, and the spraying area and the washing effect formed by the top spraying mode are far superior to thoseof a side spraying mode; one end of the hinged part is fixed with the barrel body, and the other end of the hinged part is fixed with the top cover; and the hinged part comprises a memory alloy hinge,and opening or closing of the top cover can be controlled by controlling opening and closing movement of the memory alloy hinge, so that the loss rate of parts is greatly reduced, automatic opening and closing of the top cover are guaranteed, and experimental consumables are reduced.

Owner:GREE ELECTRIC APPLIANCES INC

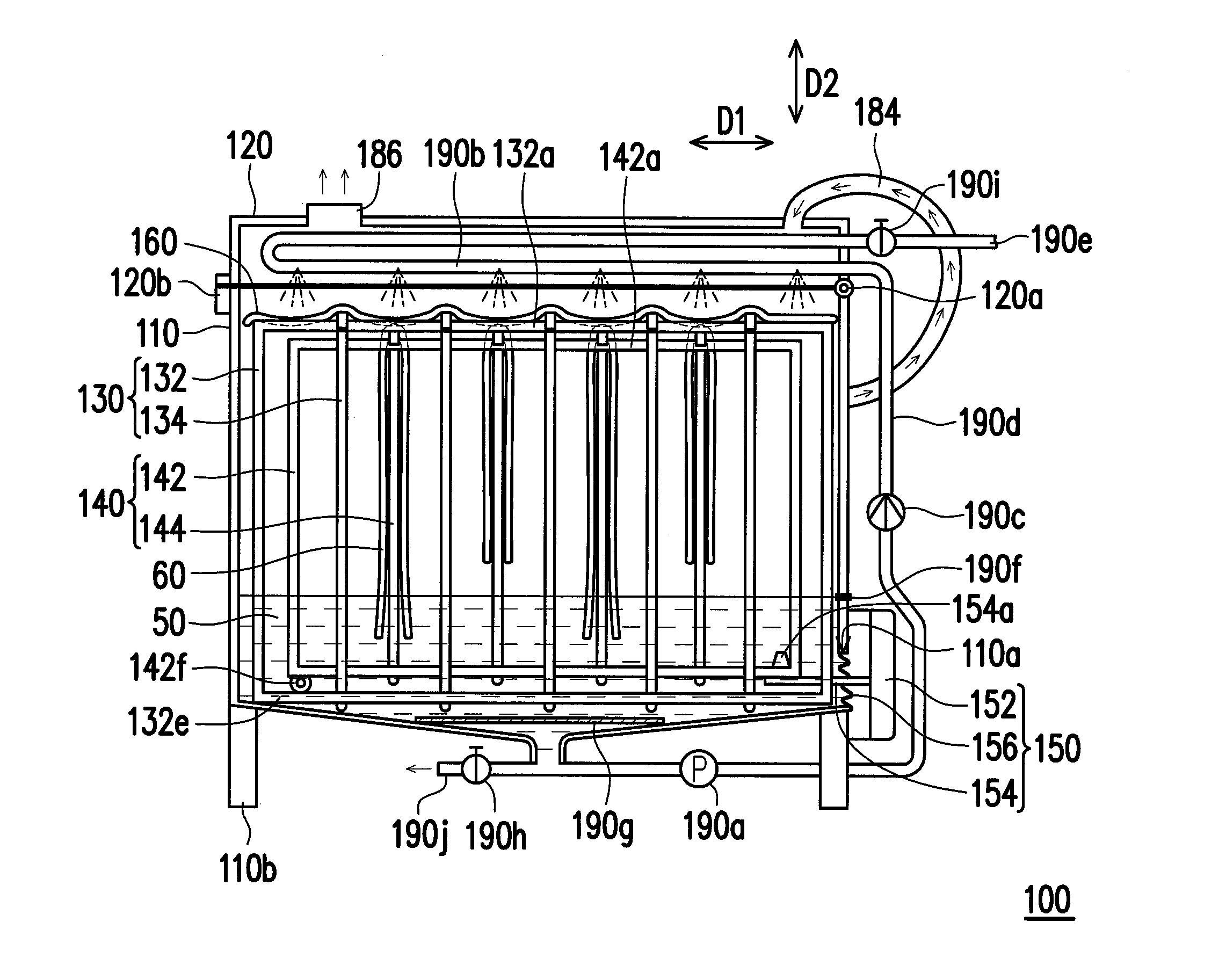

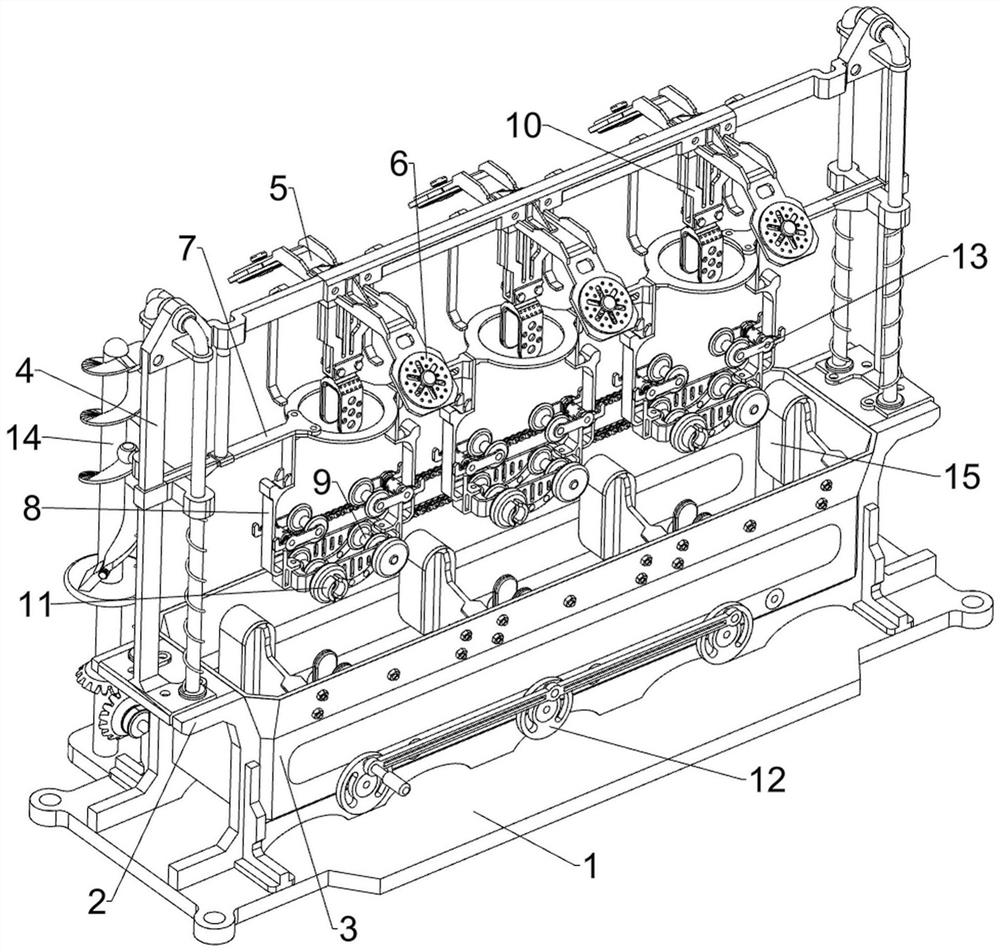

Cleaning apparatus

ActiveUS20150292133A1Easy to cleanSave consumptionOther washing machinesWashing machine with receptaclesReciprocating motionEngineering

A cleaning apparatus adapted to clean at least one object is provided. The cleaning apparatus includes a chamber, a fixed assembly, a movable assembly and a driving unit. The chamber is adapted to receive a cleaning liquid. The fixed assembly is disposed within the chamber. The movable assembly is movably disposed on the fixed assembly. The object is adapted to be hanged on the fixed assembly or the movable assembly. The driving unit is connected to the movable assembly and adapted to drive the movable assembly to perform a reciprocating motion along a first direction, so that the object is clapped by the fixed assembly and the movable assembly.

Owner:TATUNG COMPANY

Washing equipment capable of rapidly dehydrating optical lens

ActiveCN113976570ADry fastReduce cleaning costsDrying solid materials without heatDrying gas arrangementsEngineeringOptic lens

The invention relates to washing equipment capable of rapidly dewatering optical lenses, which comprises a base, a mounting seat, a box body, a first fixing frame, first mounting frames, a fan, a sliding frame, a first connecting frame and the like, the top of the base is connected with the mounting seat, the box body is connected in the mounting seat, and the top of the mounting seat is connected with the first fixing frame; the front side and the rear side of the upper portion of the first fixing frame are evenly connected with the three first mounting frames at intervals, the fans are installed on the six first mounting frames, the sliding frame is slidably connected to the middle of the first fixing frame, and the three first connecting frames are evenly connected to the bottom of the sliding frame at intervals. The sliding frame is moved downwards, so that the first connecting frame drives the optical lens to enter the box body, clear water and a cleaning agent in the box body wash the optical lens, water on the optical lens can be blow-dried through a draught fan, the optical lens is made to make contact with a water absorption cotton block upwards, and the optical lens is made to rotate; and therefore, the water absorption cotton block can completely wipe water on the optical lens.

Owner:上饶市桐宇光电科技有限公司

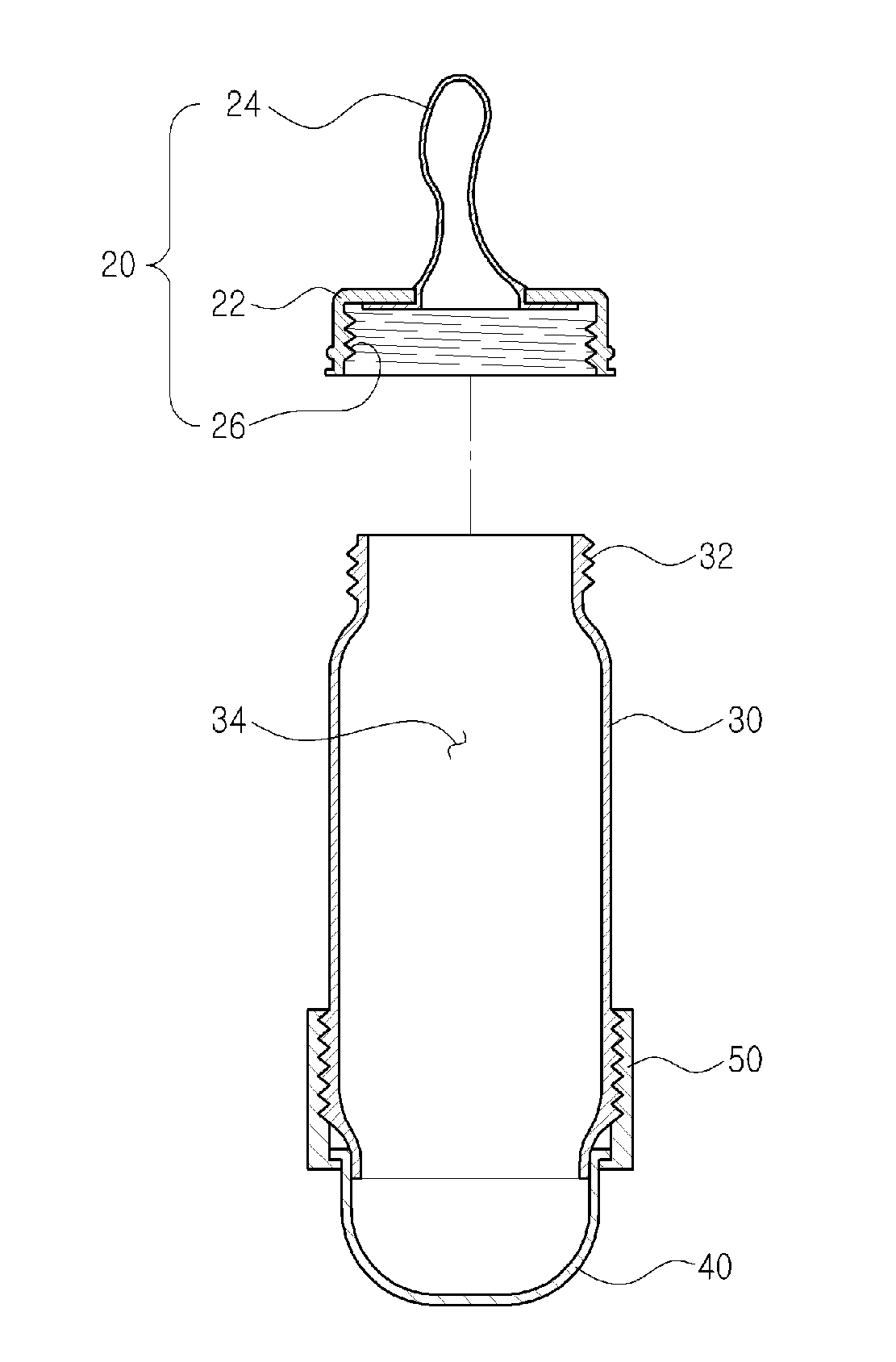

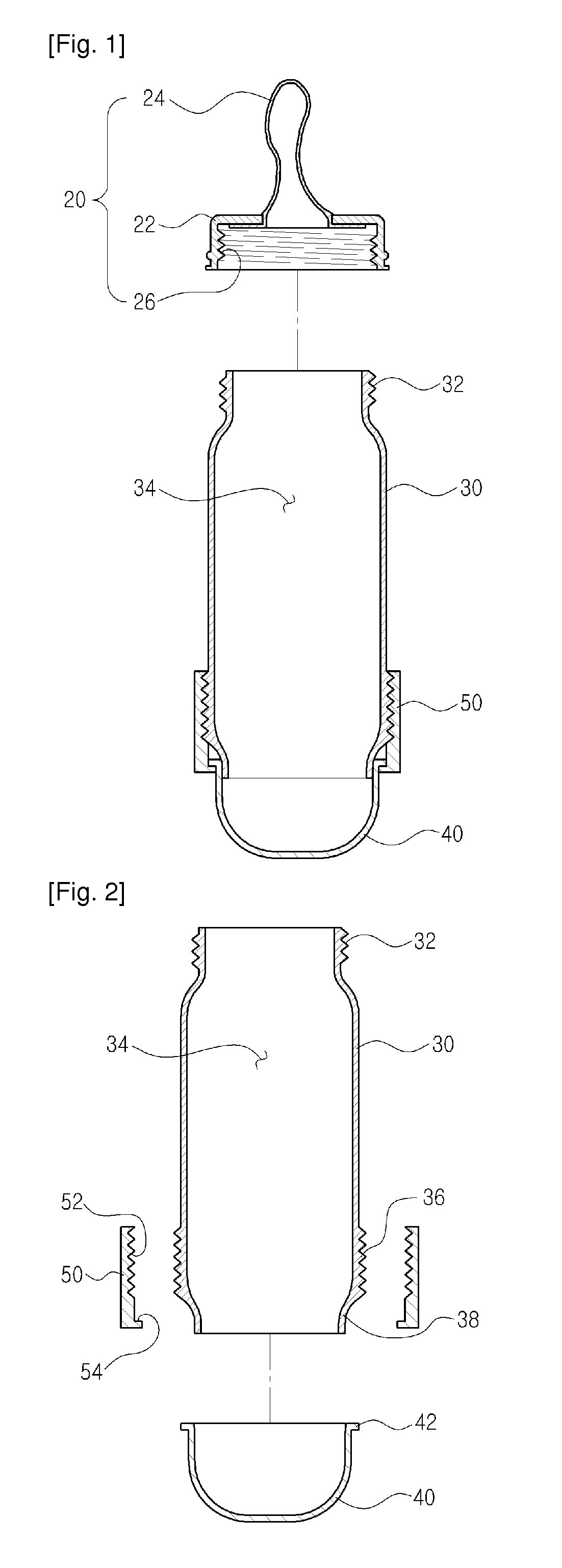

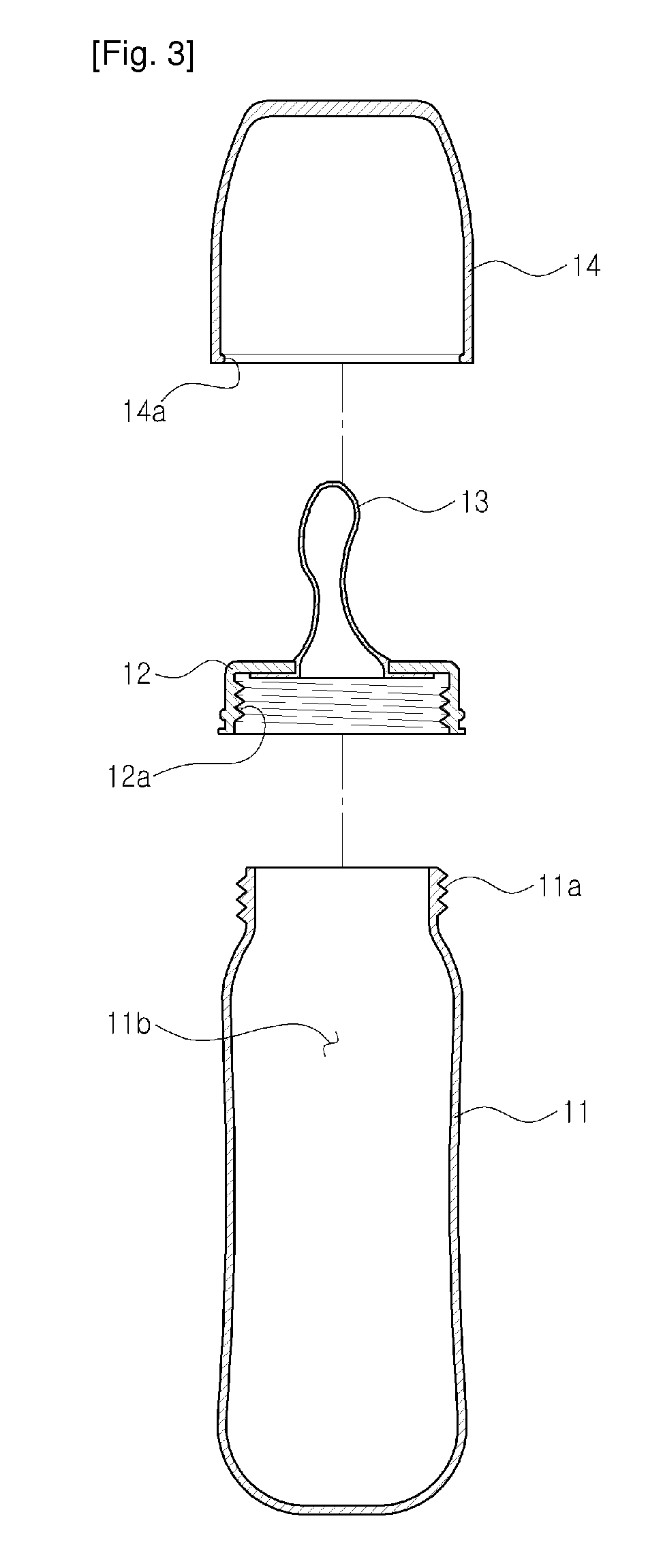

Separate type nursing bottle

Disclosed is a separate type nursing bottle, which includes two separate bodies so as to allow a user to cleanly wash the bodies in a convenient manner. The separate type nursing bottle includes an upper body, a lower body, and a connector. The upper body has a pipe-shape and includes screw parts formed at an outer circumferential surface of one end of the upper body and at an outer circumferential surface spaced a predetermined distance from another end of the upper body, respectively. The lower body has a bowl-shape, has an open side engaged with an outer circumferential periphery of the other end of the upper body, and includes a locking jaw formed along an outer circumferential periphery of one end of the open side. The connector has a pipe-shape, has a locking jaw so as to allow the connector to be assembled with an outer side of the upper body while one end of the connector is locked in the locking jaw of the lower body, and also has a screw part engaged with the screw part of the another end of the upper body. The upper body from the screw part to the other end is slanted toward a central axis of the upper body so that an inner diameter is smaller toward the other end. The lower body is made from material, which is more flexible than material of the upper body, so as to allow a shape of the lower body to be easily changed. As a result, there is a sanitary advantage in that the user can cleanly wash the interior of the nursing bottle, and convenience can be provided to the user while washing the bottle.

Owner:YU JE WOO

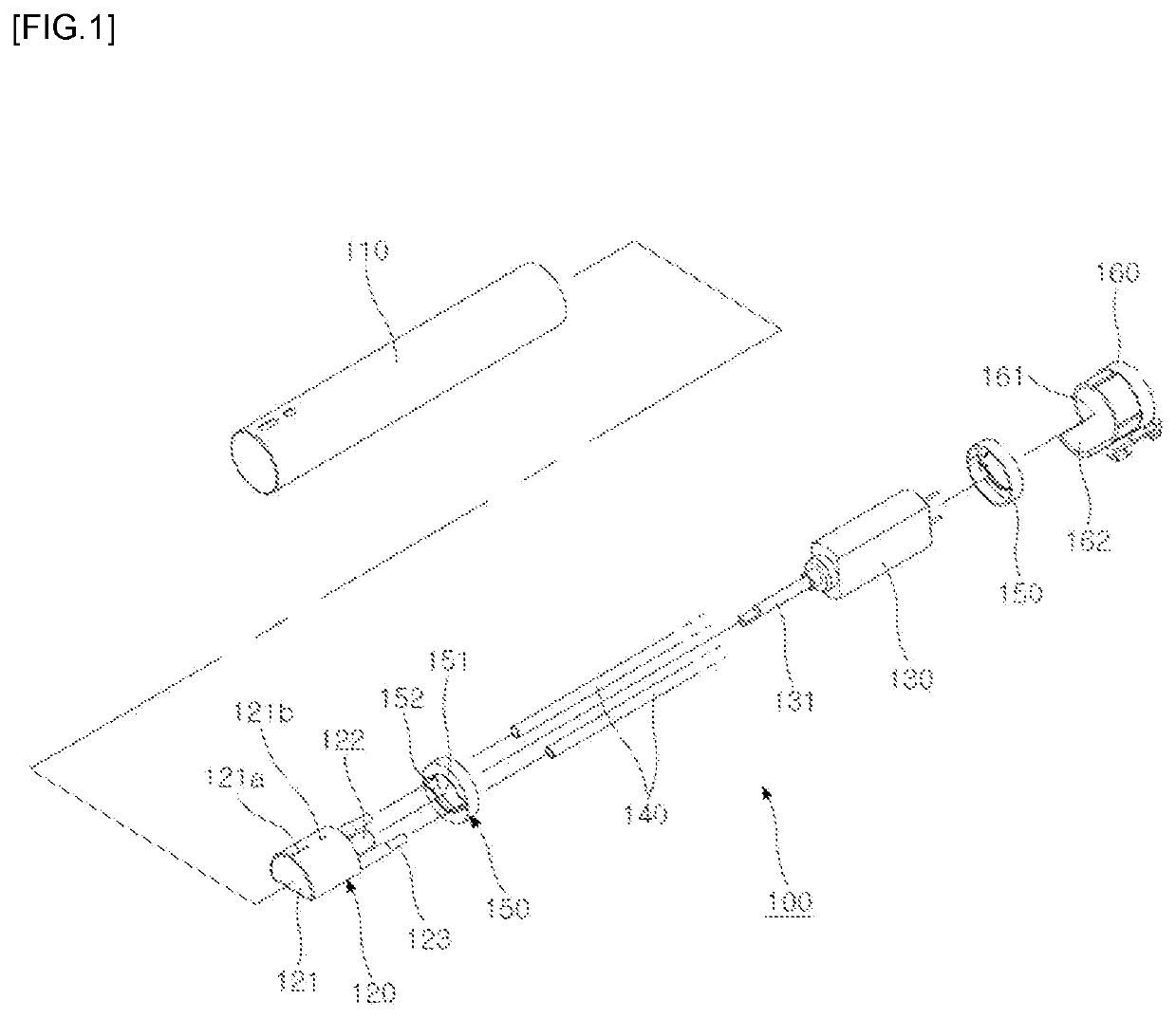

Vibration nozzle for bidet

PendingUS20210023580A1Maximized vibration efficiencyImprove product reliabilitySpray nozzlesLavatory sanitoryManufacturing cost reductionElectric machinery

Proposed is a vibration nozzle for a bidet, having a nozzle tip and a vibration motor that are formed to be separate such that the nozzle tip has maximized vibration efficiency so as to allow clean washing, the nozzle tip is coupled only to a part of the inside of the front end of a nozzle so as to be reduced in size, thereby having reduced manufacturing costs, and washing water supply pipes connected to the nozzle tip are arranged at both sides of the shaft of the vibration motor such that the diameter of the nozzle can be minimized and a structure for forming a separate water channel is unnecessary, and thus manufacturing costs can be reduced.

Owner:LIM YOUNG KYOUN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com