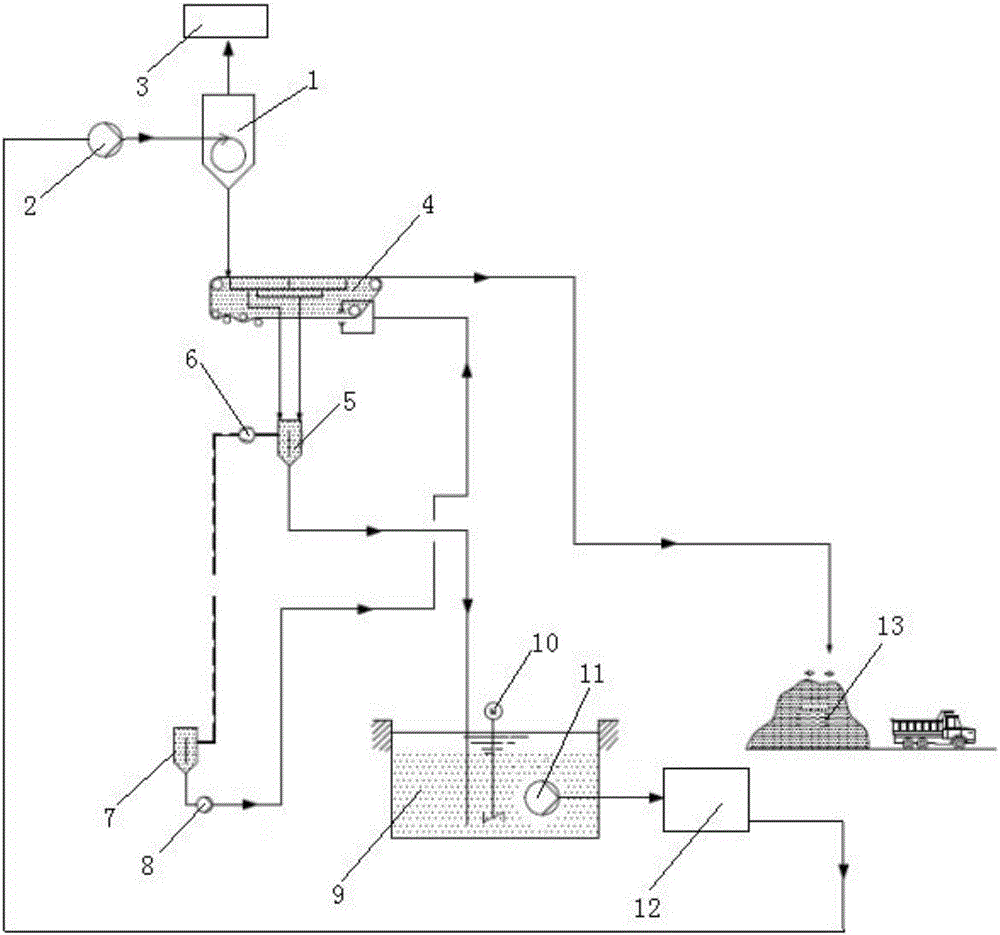

Multistage dehydration and separation system

A separation system and gas-water separator technology, applied in the field of desulfurization, can solve the problems of insufficient cleanliness, unsatisfactory dehydration effect, etc., and achieve the effects of high dehydration efficiency, good dehydration effect, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1, such as figure 1 Shown, a kind of multistage dehydration separation system of the embodiment of the present invention. A slurry pool is provided at the bottom of the absorption tower 12 . The gypsum slurry discharge pump 2 is arranged outside the slurry tank, and one end of the gypsum slurry discharge pump 2 is connected with the slurry tank. The feed port of the gypsum cyclone 1 is connected to the other end of the gypsum slurry discharge pump 2, the overflow port of the gypsum cyclone 1 is connected to the wastewater treatment system 3, and the bottom flow port of the gypsum cyclone 1 is connected to the vacuum belt dehydrator 4 feed port connection. The top inlet of the gas-water separator 5 is connected to the vacuum belt dehydrator 4 through a vacuum tube, the top outlet of the gas-water separator 5 is connected to one end of the vacuum pump 6, and the other end of the vacuum pump 6 is connected to the exhaust pipe. The top inlet of the filter cloth r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com