Washing equipment capable of rapidly dehydrating optical lens

A technology for optical lenses and washing equipment, applied in lighting and heating equipment, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of low efficiency, slow drying speed, energy and efficiency, etc., to improve washing efficiency. , the effect of reducing cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

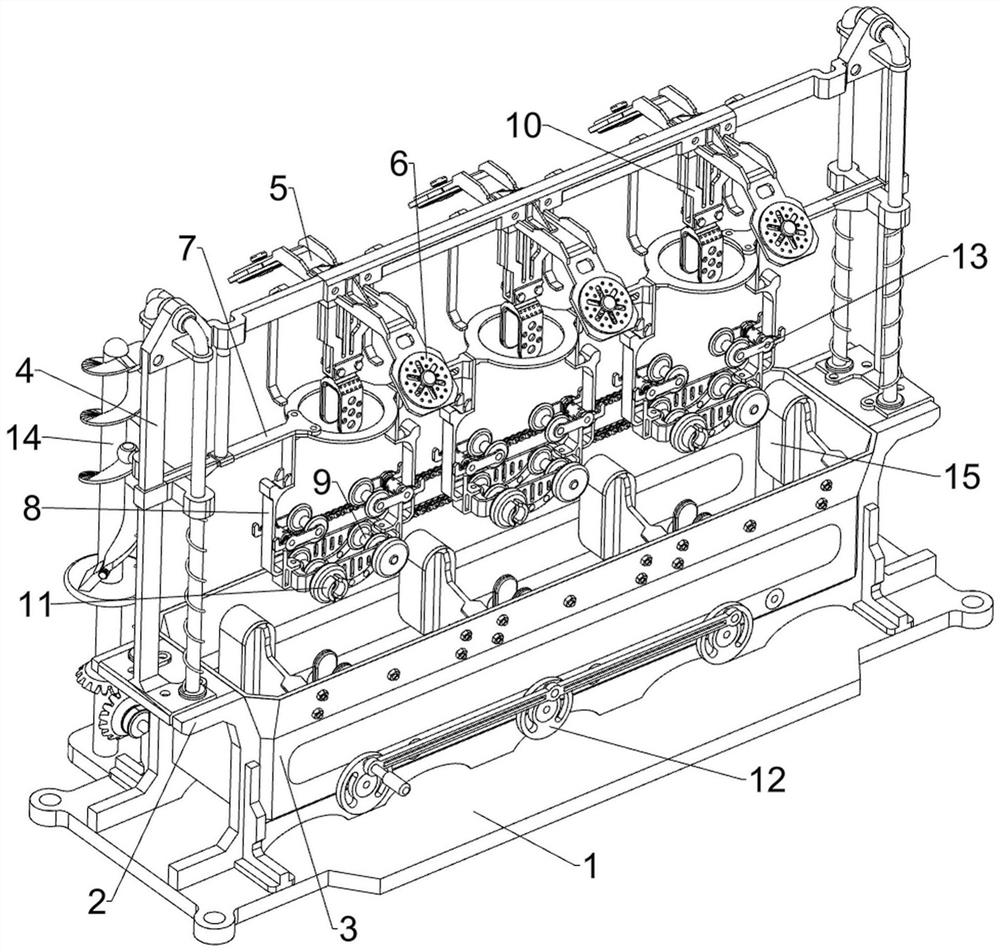

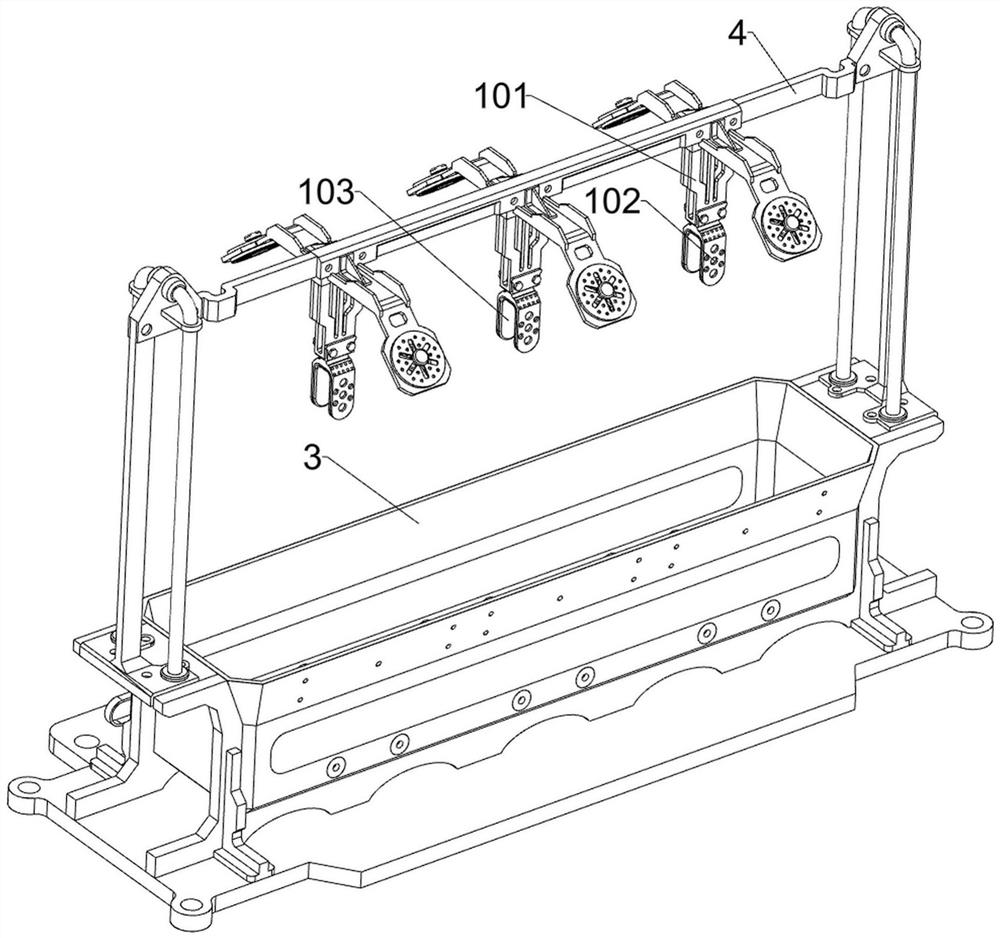

[0038] combine Figure 1-15 As shown, the present application provides a washing device capable of rapidly dehydrating optical lenses, including a base 1, a mounting base 2, a box body 3, a first fixing frame 4, a first mounting frame 5, a fan 6, a sliding frame 7, a second A connecting frame 8, a first limiting wheel 9, a second limiting wheel 91 and a drying assembly 10, the top of the base 1 is connected with a mounting seat 2, and the mounting seat 2 is connected with a box body 3, and the box body 3 is used to hold clean water and cleaning agent, the top of the mounting seat 2 is connected with the first mounting frame 4 by means of bolt connection, and the front and rear sides of the first mounting frame 4 are evenly spaced and connected with three first mounting frames 5 and six first mounting frames. 5 are equipped with fan 6, the fan 6 is used to dry the optical lens after washing, the middle part of the first fixed frame 4 is slidably connected with a sliding frame 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com