Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Uneven force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

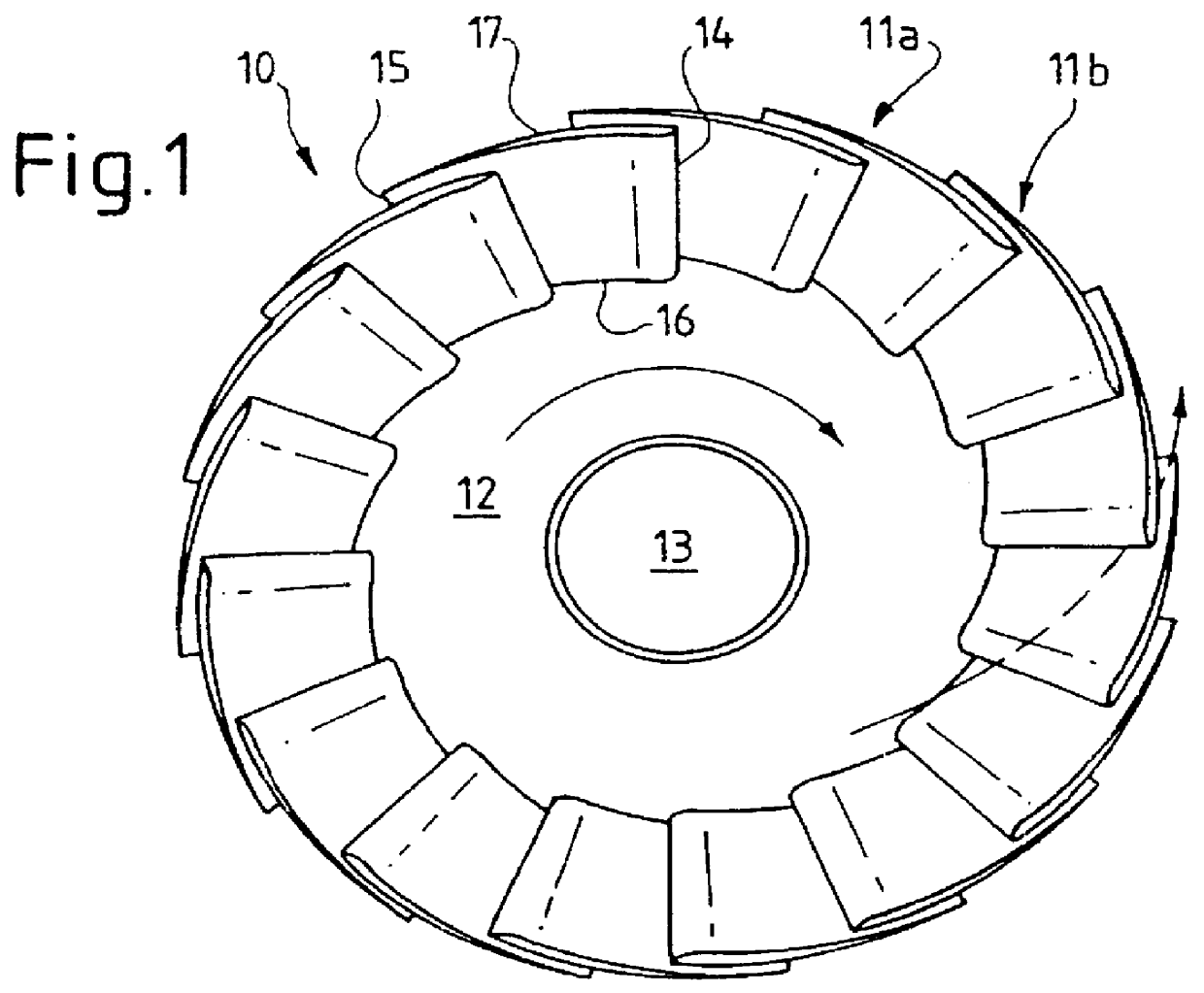

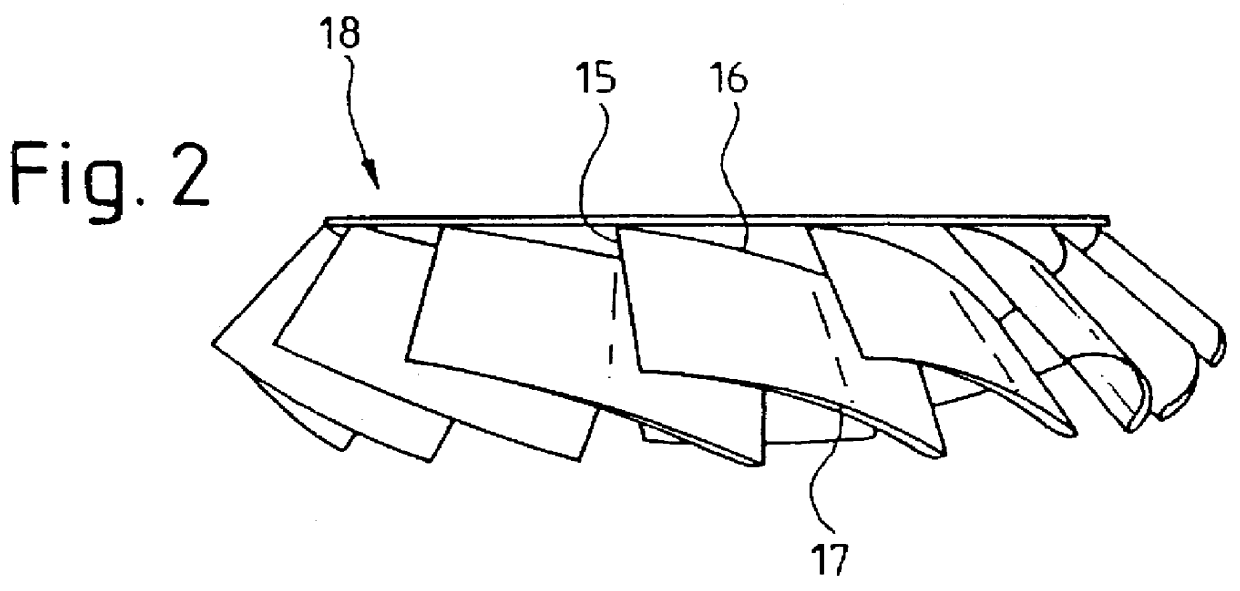

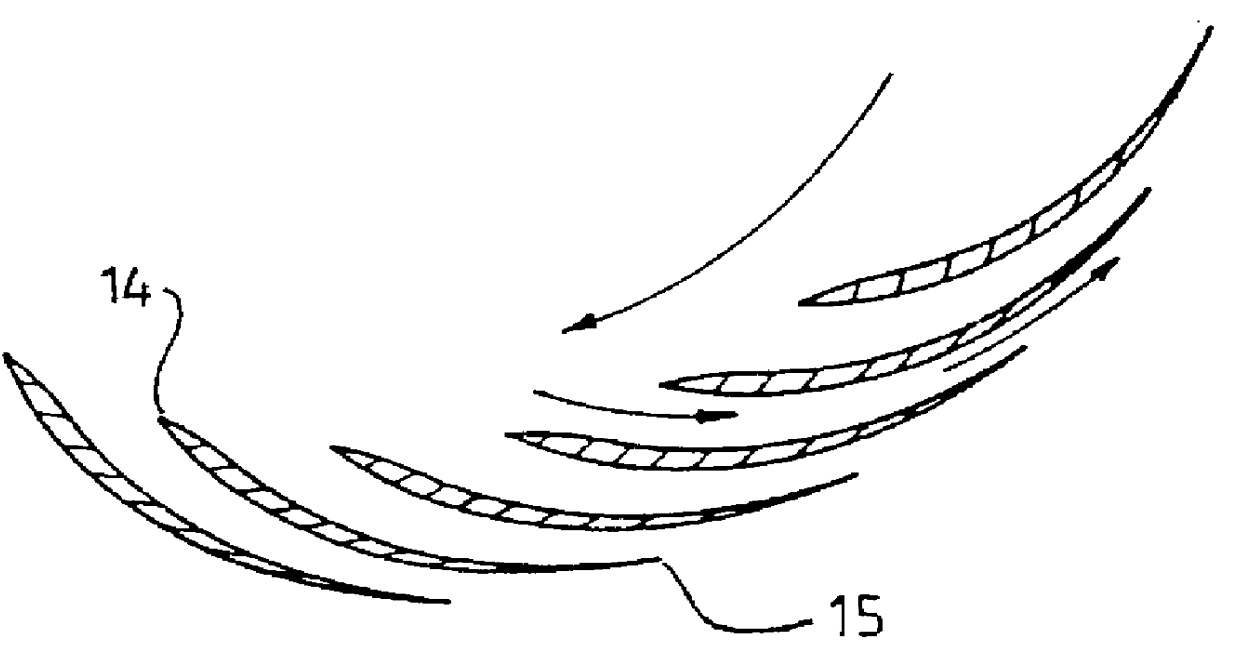

Adjustable pitch impeller

An impeller has a plurality of rotating passageways which can be defined between adjacent blades, the blades having a curved root portion and able to pivot across a part spherical hub to maintain a fine line contact. The passageways have a convergence to improve the efficiency of the impeller. The hub can be split into two relatively rotating portions, with the blades attached to each portion to provide an efficient means to vary the pitch of the blades.

Owner:NEW FLUID TECH

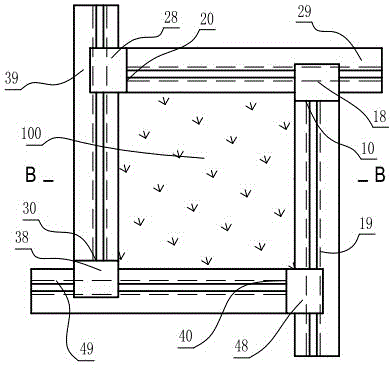

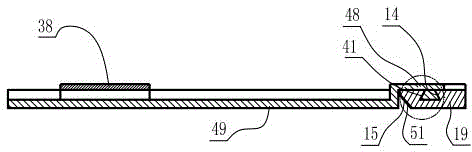

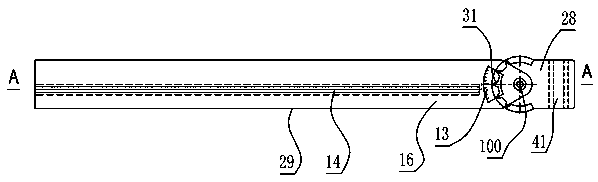

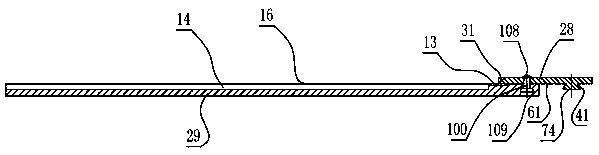

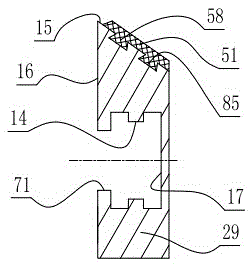

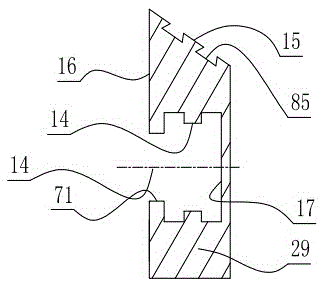

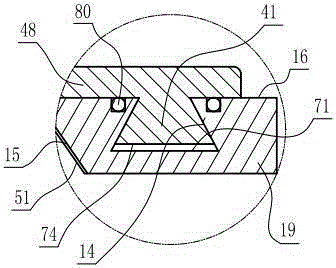

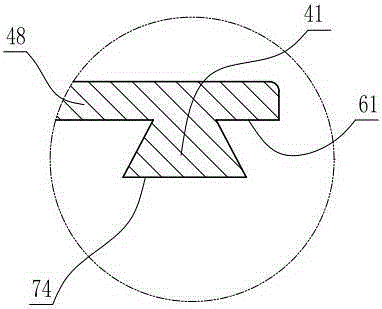

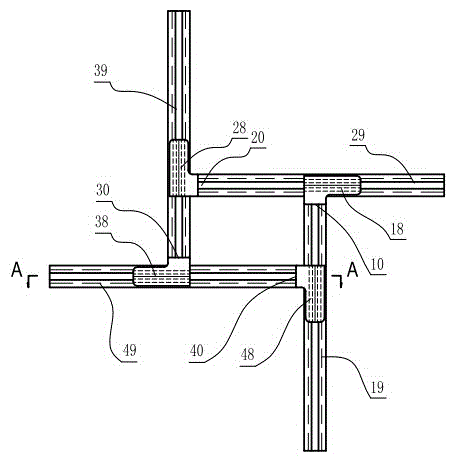

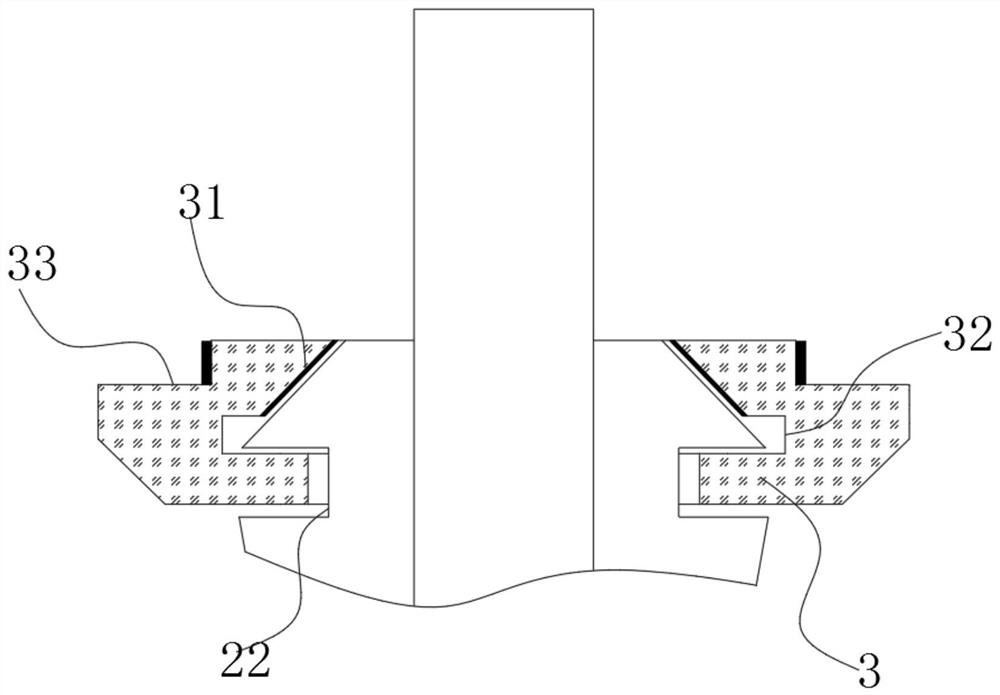

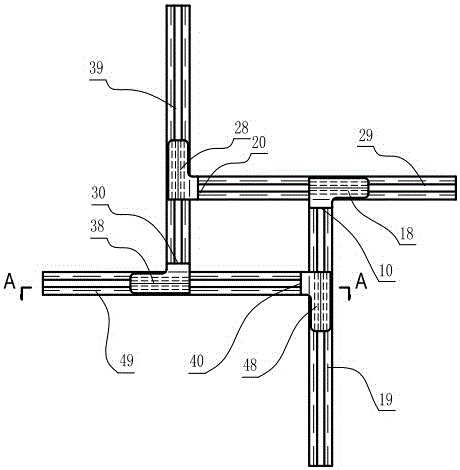

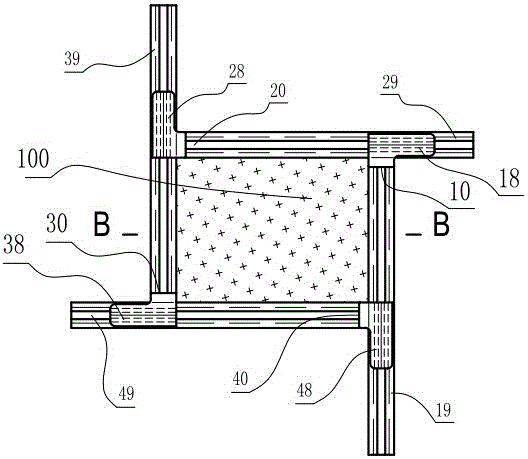

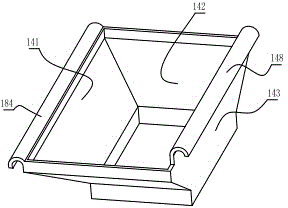

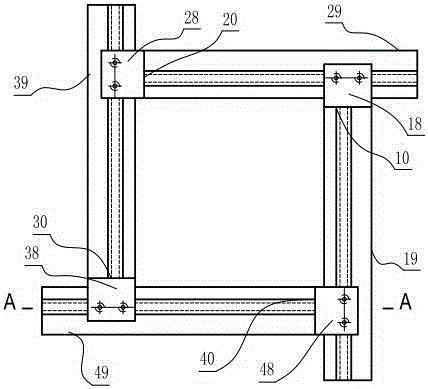

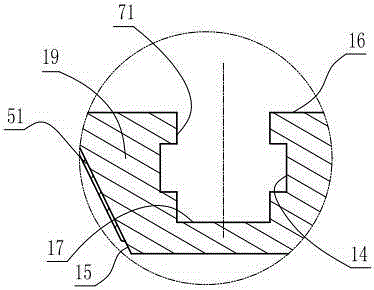

Natural rubber press plate with four edges capable of being adjusted to one plane through skewed slots

The invention relates to a press plate for glass testing, and especially relates to a natural rubber press plate with four edges capable of being adjusted to one plane through skewed slots. The press plate is composed of a clamping part and a sliding part. The improvements of the press plate are as follows: the sliding part is arranged on one end of the clamping part and is overlapped on the upper surface of the clamping part; the lower surface of the sliding part is taken as the sliding lower plane, the sliding lower plane is provided with a trapezoidal emboss, the upper surface of the clamping part is the clamping upper plane, and the clamping upper plane is provided with a trapezoidal groove. The sliding lower plane and the clamping upper plane are in the same height. The inner side of the clamping part is provided with a clamping slope, and a rubber press sheet is adhered on the clamping slope. The angle between clamping slope (15) and the clamping upper plane (16) is 51 to 53 degrees. A layer of rubber press sheet (51) is adhered on the clamping slope (15), and the thickness of the rubber press sheet (51) is 2.1 to 2.3 millimeters. When the width is adjusted to limit a tempered glass sheet (100) in the horizontal direction, and a downward force can be generated at the same time, so the tempered glass sheet (100) can be pressed against the flat plate (50) of a test platform so as to avoid the explosion of the tempered glass sheet (100) due to the uneven stress on the tempered glass sheet (100).

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

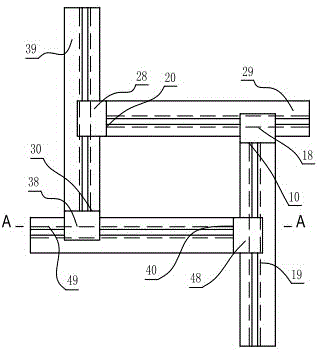

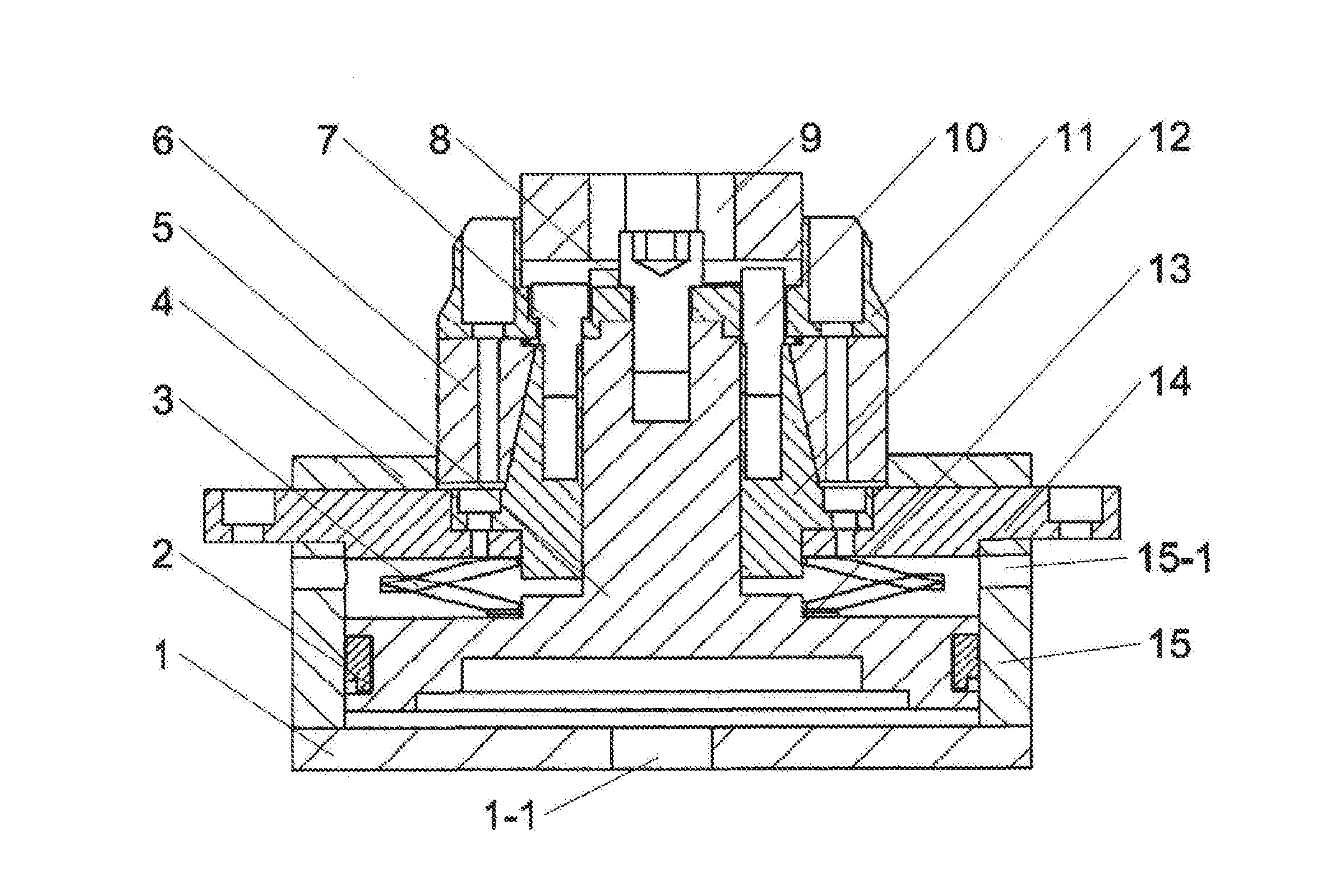

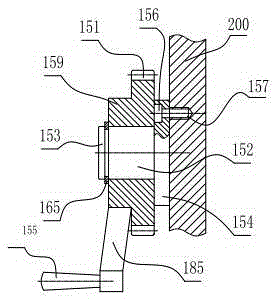

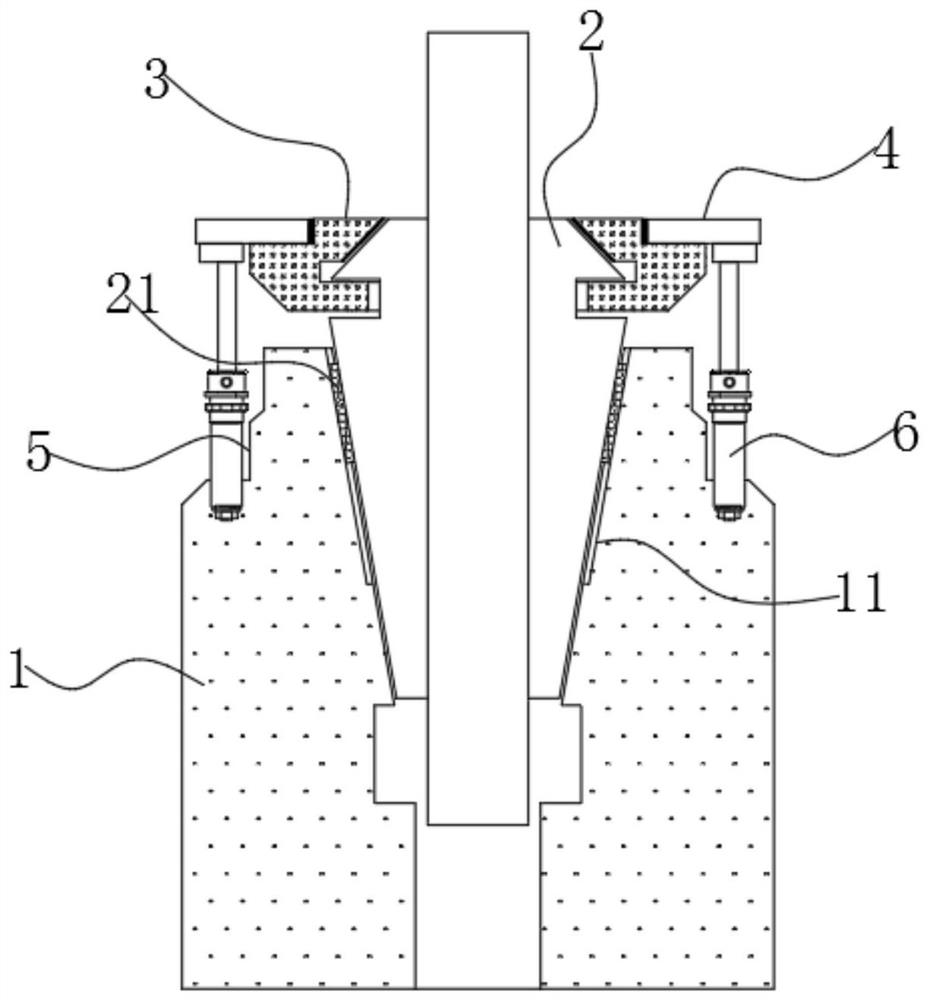

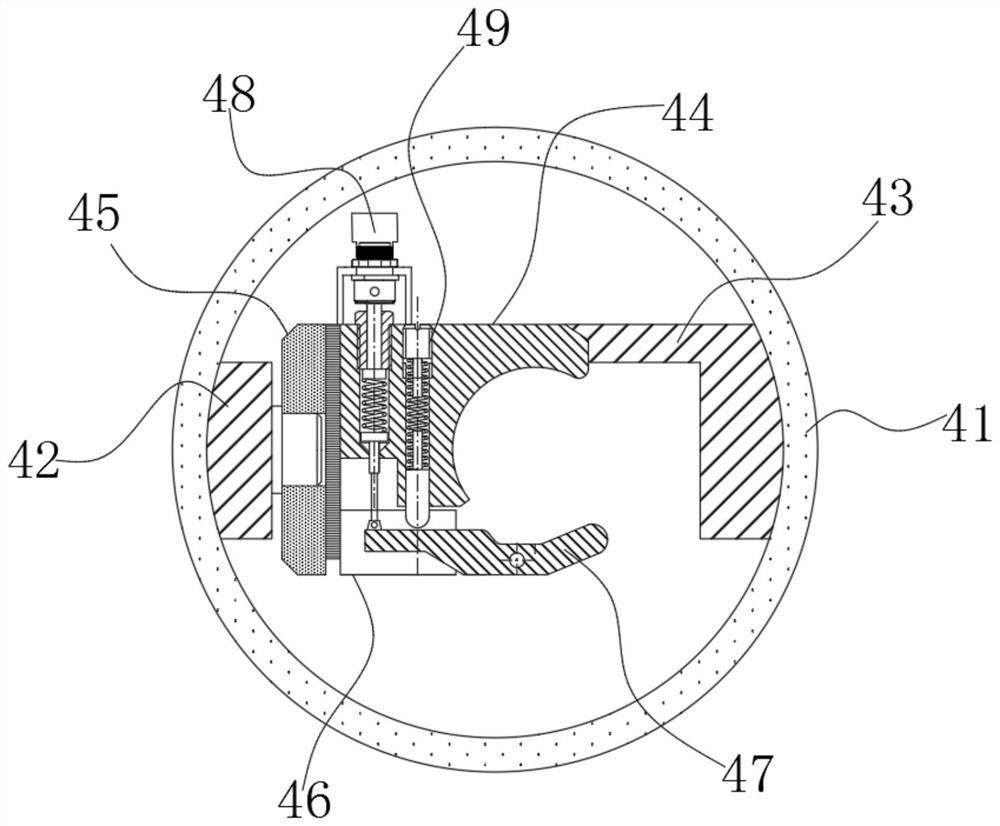

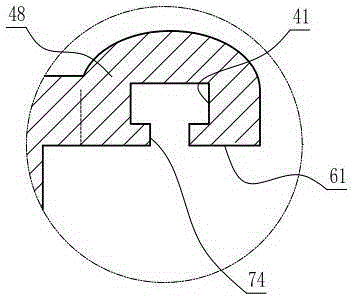

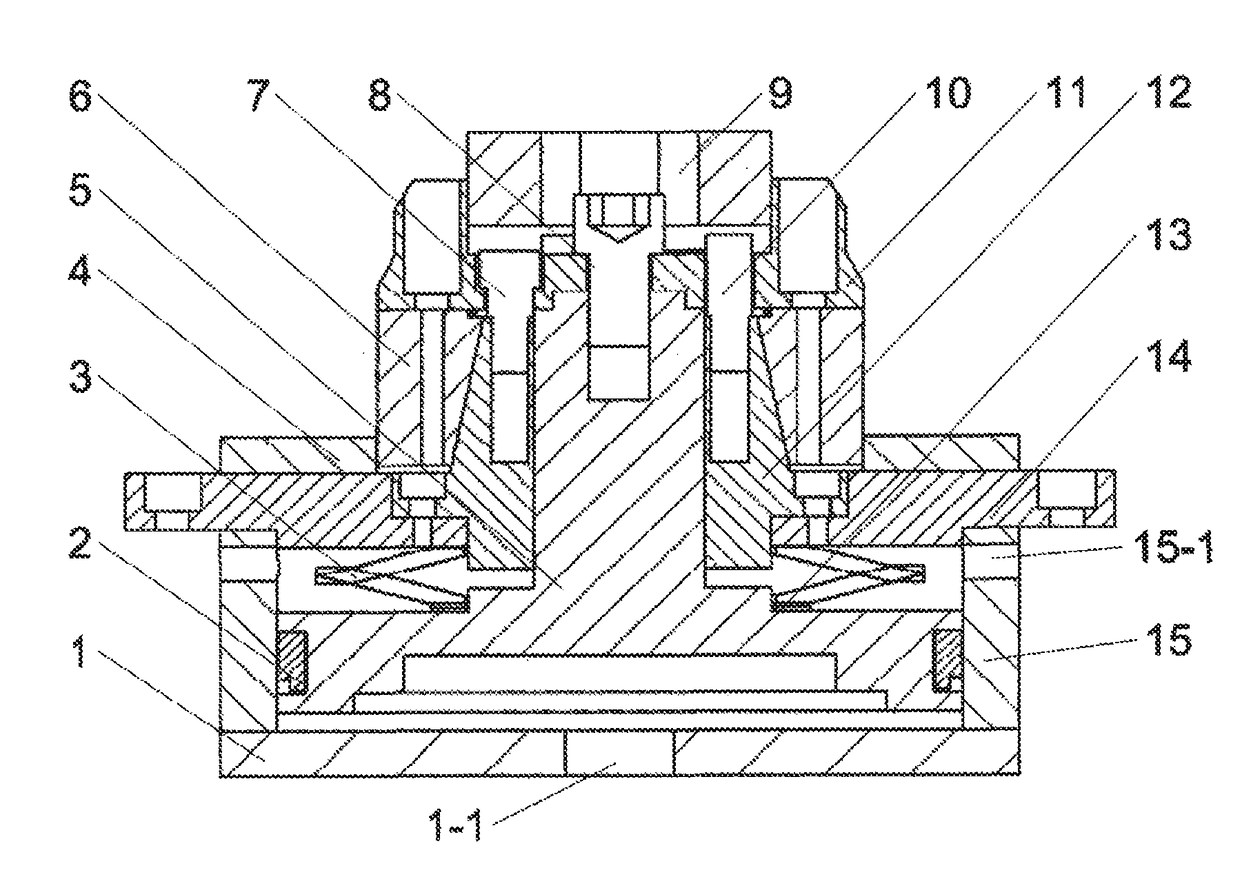

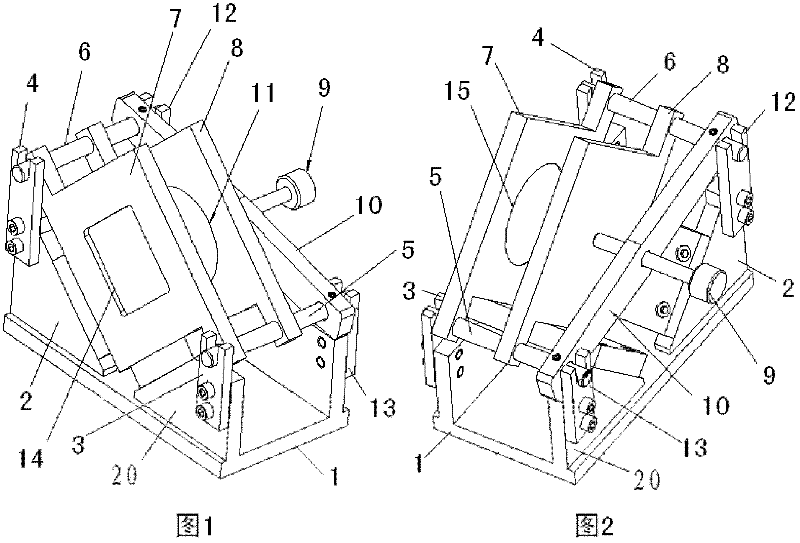

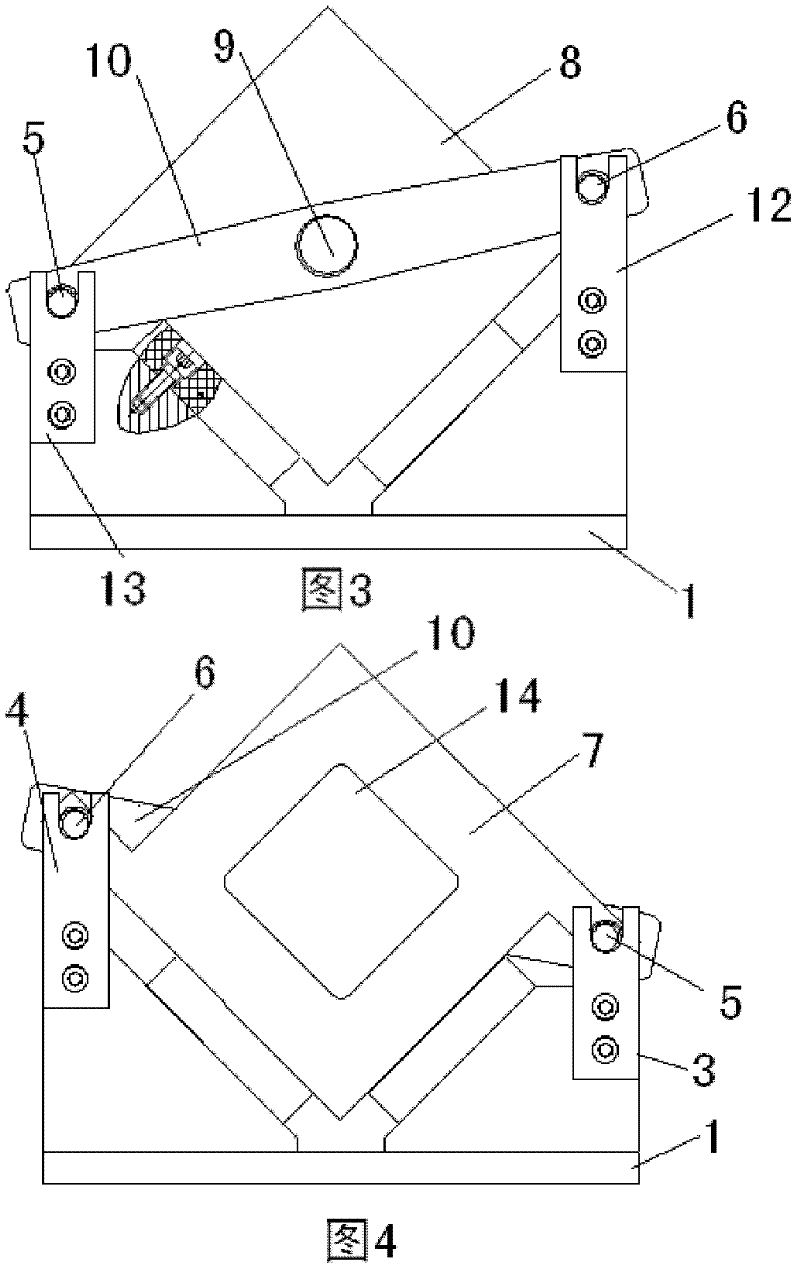

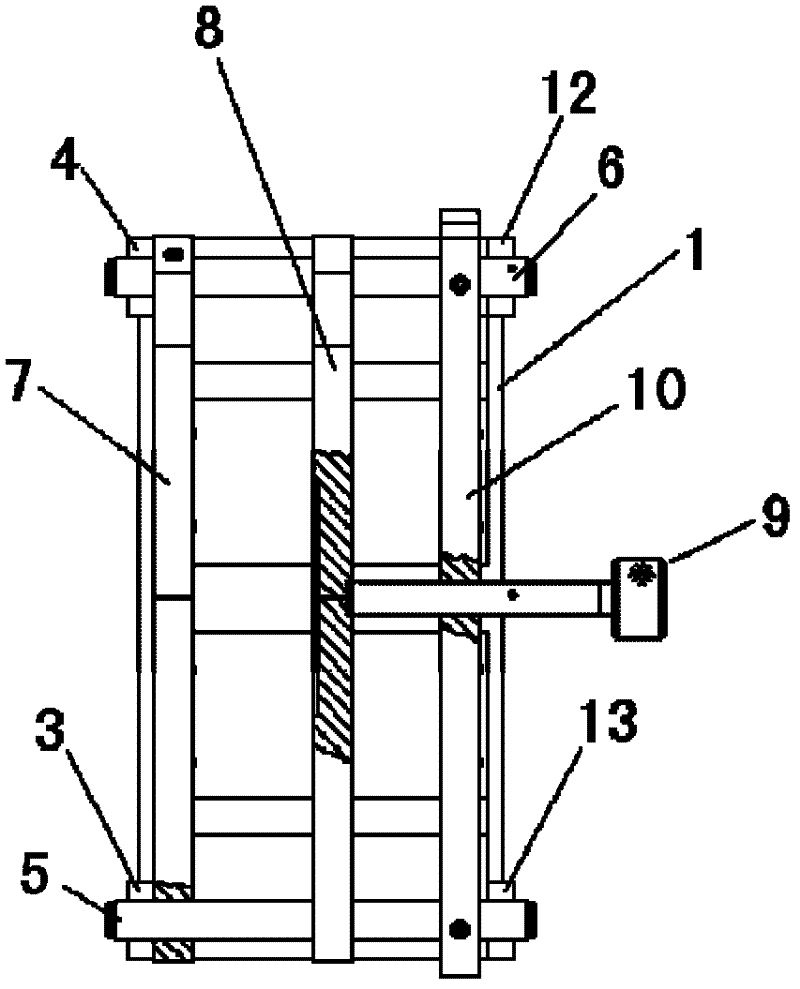

Pneumatic-Type Precision Annular Workpiece Inner Positioning Surface Clamping Device

ActiveUS20160339528A1Reduce manufacturing costSimple designSleeve/socket jointsWork clamping meansClosed chamberEngineering

A pneumatic-type precision annular workpiece inner positioning surface clamping device, wherein a rod portion of a piston assembly (5) is inserted into a central hole of the wedge-shaped block (12), and the piston portion of the piston assembly (5) is located in a closed chamber of a cylinder body (15); a disc spring (3) is sleeved on the piston assembly (5); an air intake hole (1-1) is provided in the lower plate (1), an air vent hole (15-1) is provided at the upper portion of the cylinder body (15); and an elastic hinge block (6) is sleeved outside the wedge-shaped block (12). The pneumatic-type precision annular workpiece inner positioning surface clamping device has a simple structure, high reliability and strong adaptability.

Owner:HARBIN INST OF TECH

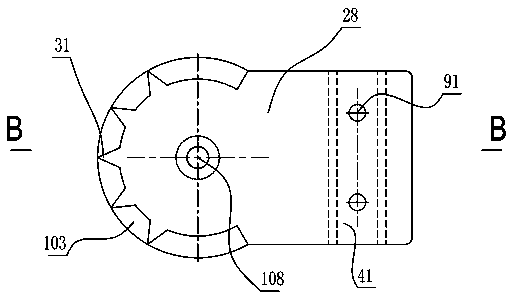

Inclined-plane turn angle arbitrary four-side engineering rubber fixing rest pliers

InactiveCN105547820AAchieve fixationAvoid stickingStrength propertiesIsosceles trapezoidInterference fit

The invention relates to fixing rest pliers for glass detection, and in particular relates to a pair of inclined-plane turn angle arbitrary four-side engineering rubber fixing rest pliers. The pair of inclined-plane turn angle arbitrary four-side engineering rubber fixing rest pliers has following improvement: one end of an upper clamping plane is provided with an inclined-plane groove the bottom surface of which is provided with a bottom plane of the groove; the cross section of the inclined-plane groove is isosceles trapezoid; a lower slipping plane is provided with a rotary through hole; a rotary plate chamber arc surface is arranged at one side of the rotary through hole; the turn angle chamber arc surface is provided with a turn angle arc surface protruding pointer; an inclined-plane convex rail is positioned on the lower slipping plane; the cross section of the inclined-plane convex rail is also isosceles trapezoid; the lower slipping plane is provided with two plane screw holes; the inclined-angle convex rail is also provided with two convex rail stepped holes; convex rail screws pass through the convex rail stepped holes and are fit with the plane screw holes in a spirally fastening mode so as to fix the convex rail contact surface on the lower slipping plane; inclined planes at two sides of anti-falling raised lines and inclined planes at two sides of anti-falling grooves are in interference fit so as to generate extrusion and expansion force and prevent falling accidents caused by glue aging; heights of the anti-falling raised lines and depths of the anti-falling grooves are in clearance fit for the convenience of installation and binding.

Owner:张志雄

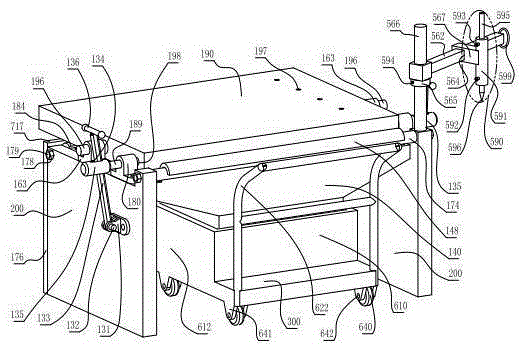

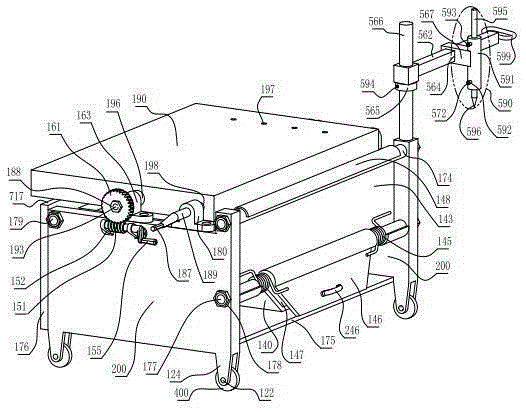

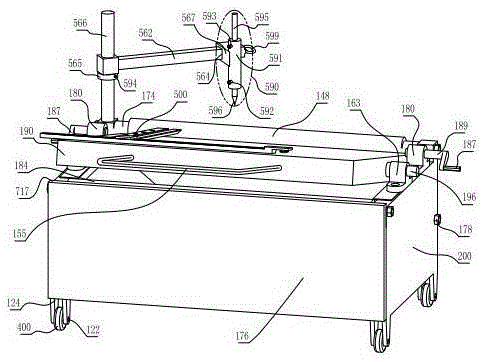

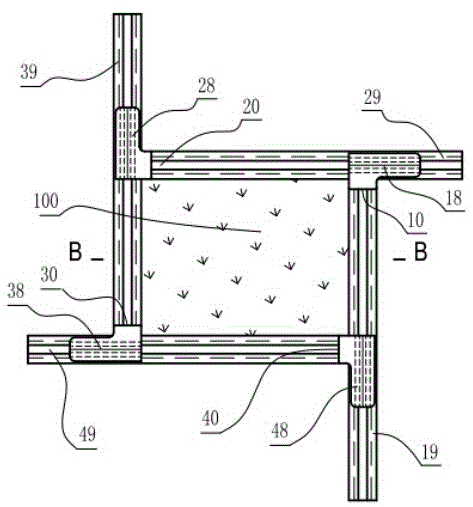

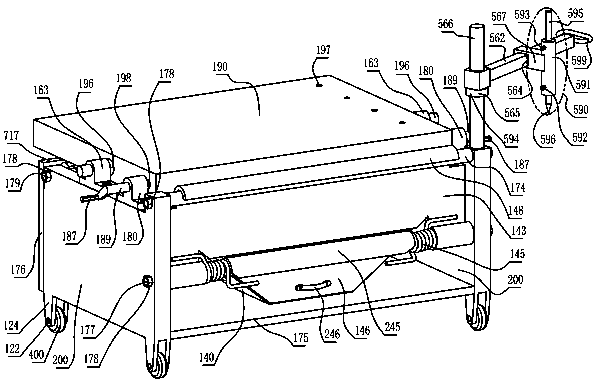

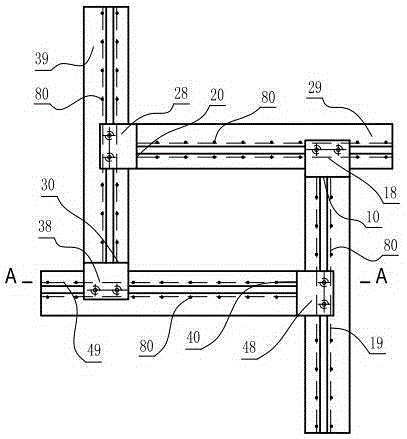

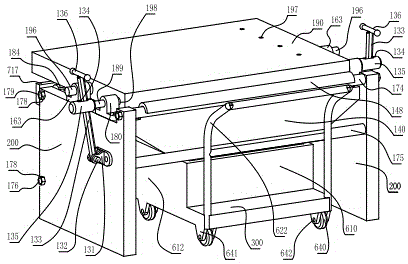

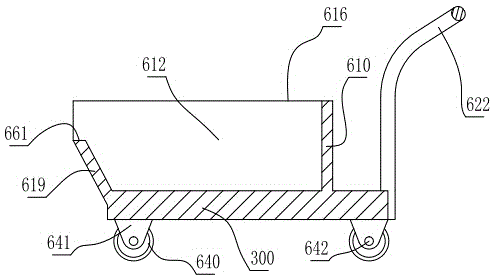

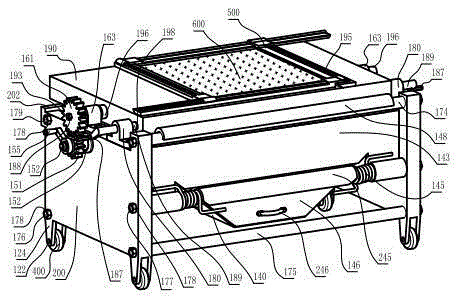

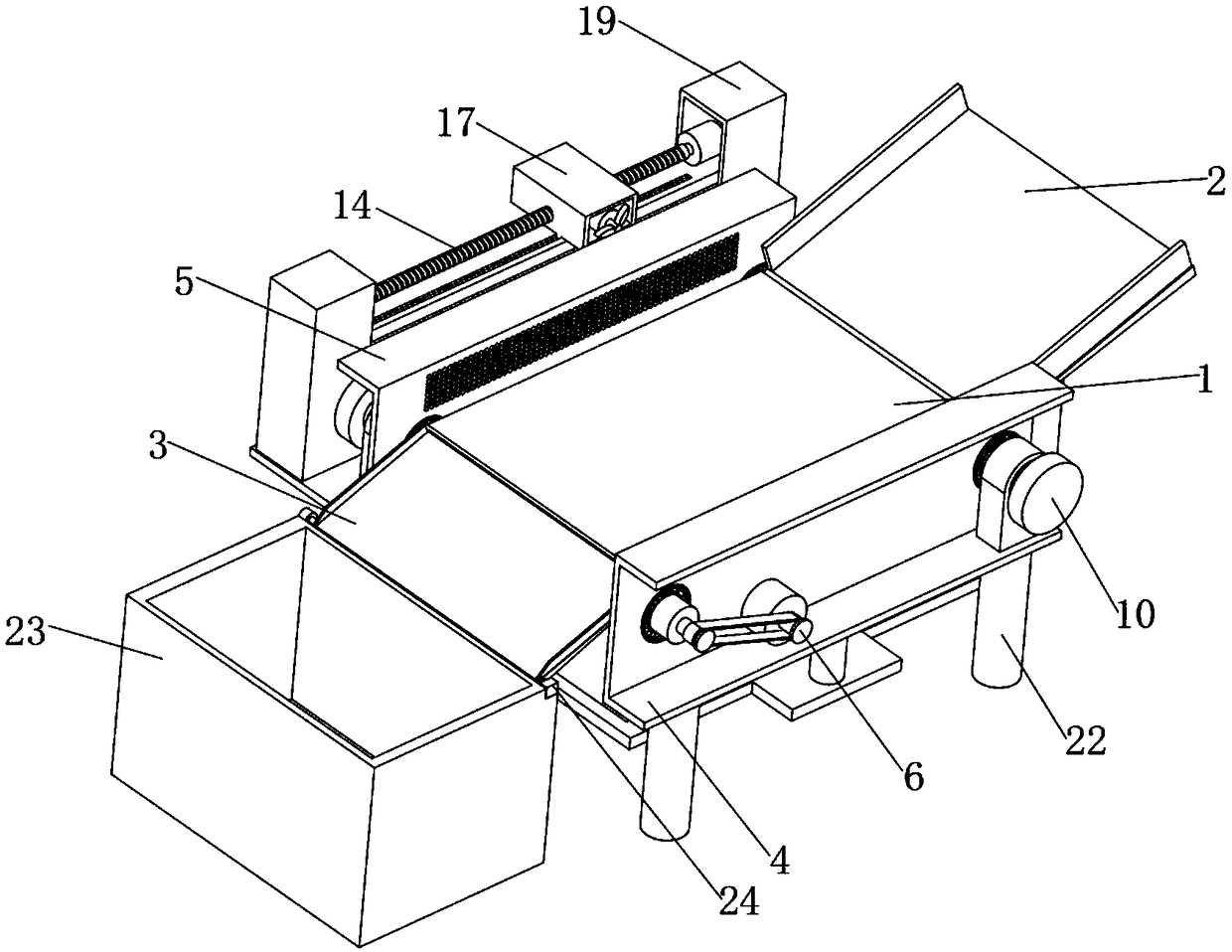

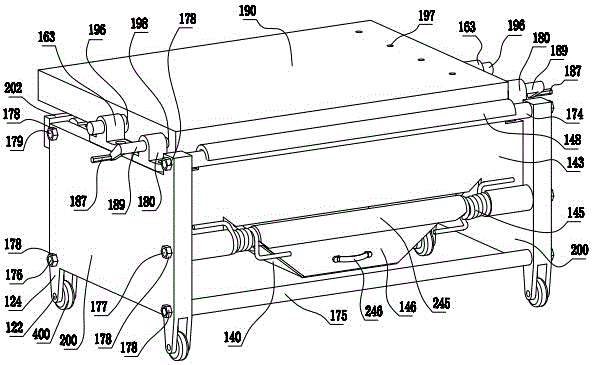

Pluggable lockpin hydraulic rotary table bearing clamping plate copper alloy glass testing system

InactiveCN105334120AEasy to removeMake sure not to spillStrength propertiesGlass chipRolling-element bearing

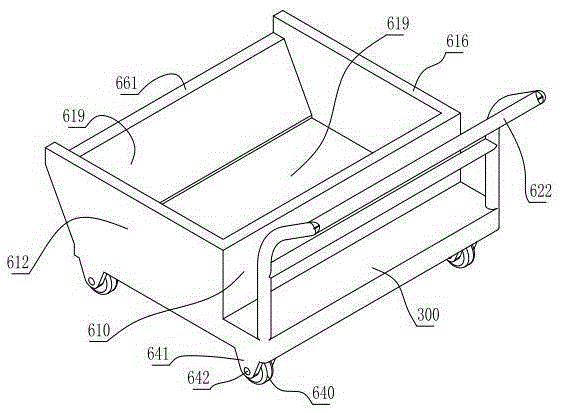

The invention relates to a tempered glass testing system and provides a pluggable lockpin hydraulic rotary table bearing clamping plate copper alloy glass testing system. A lower port of a cullet guide device falls in an upper port of a cullet collecting vehicle. As an improvement, a supporting bottom plate is fixed to the lower end of a broken notch, a T-shaped guide rail is arranged in the center of the lower plane of the rear end of a testing table board, and a hydraulic lifting mechanism is arranged between the T-shaped guide rail and the supporting bottom plate; an impact upright column is arranged on the upper plane of a supporting side plate on one side, and a cylinder impactor is fixed to the impact upright column in a sliding mode; a hydraulic stretching cylinder is combined with the T-shaped guide rail to drive the testing table board to swing and rotate, and cullet removal is facilitated; through cooperation of the cullet guide device and the cullet collecting vehicle, it is guaranteed that cullet does not scatter; by means of the cylinder impactor, the strength of hammering at each time is consistent, and it is guaranteed that breaking test standards are uniform; a bearing on each edge is in sliding fit with a rolling bearing on a clamping plate on the same plane and an adjacent bearing sliding groove, and tempered glass with different widths can be continuously and randomly adjusted.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Arbitrary quadrilateral butadiene styrene rubber wheel corner fixed clamp

InactiveCN105547821AAchieve fixationInhibit sheddingStrength propertiesInterference fitButadiene-styrene rubber

The invention relates to a glass detection fixed clamp, and particularly relates to an arbitrary quadrilateral butadiene styrene rubber wheel corner fixed clamp. As the improvement, a rotary through hole is formed in a lower slippage plane; the other side of the rotary through hole is provided with a rotary table chamfering arc surface; the rotary table chamfering arc surface is located on a back plane of the lower slippage plane; a corner arc surface convex pointer is arranged on the rotary table chamfering arc surface; a step shaft pin is arranged on the other side of the rotary through hole; a wheel hole matching section is arranged on the step shaft pin; the outer end of the wheel hole matching section is a shaft pin outer end; a shaft pin screw hole is formed in the center of the shaft pin outer end; the outer circle of the wheel hole matching section is matched with a wheel inner hole in a rotatable manner; the shaft pin screw hole is matched with a wheel screw; a screw head of the wheel screw simultaneously shields a wheel step surface; a wheel slide groove is formed in one end of an upper clamping plane; a transition notch is formed between the wheel slide groove and the upper clamping plane; an anti-releasing groove is formed in a clamping inclined slope; an anti-releasing convex strip is arranged on a rubber pressing sheet; and the anti-releasing convex strip and the anti-releasing groove are in embedded type interference fit, so that quadrilateral glass with arbitrary included angles is fixed.

Owner:张志雄

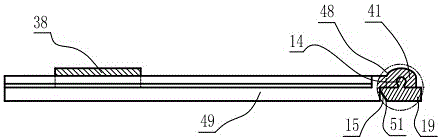

Adjustable tungsten alloy pressing plate with slide balls on four edges of chute slide ways on same plane

The invention relates to a glass test pressing plate, in particular to an adjustable tungsten alloy pressing plate with slide balls on four edges of chute slide ways on the same plane. As an improvement, the lower surface of a slide plate is a slide plate lower plane. Inclined-face protruding rails are arranged on the slide plate lower plane. The upper surface of a clamping part is a pressing plate upper plane. Inclined-face grooves are formed in the pressing plate upper plane. The slide plate lower plane and the pressing plate upper plane are located at the same height. Fixed slopes are arranged on the inner side of the pressing plate upper plane. Rubber pressing pieces are attached to the fixed slopes. The bottom faces of the inclined-face grooves are groove bottom planes. The lower faces of the inclined-face protruding rails are protruding rail top planes and groove bottom planes. The depth between the pressing plate upper plane and the groove bottom planes is larger than the height between the slide plate lower plane and the protruding rail top planes. Particularly, sliding balls are fixed in ball base step holes in the pressing plate upper plane. The outwards-protruding ball faces of the sliding balls make contact with the sliding plate lower plane so that slippage of the sliding plate lower plane on each fixing device relative to the pressing plate upper plane in another fixing device can be smoother and easier.

Owner:孙冬兰

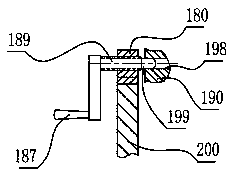

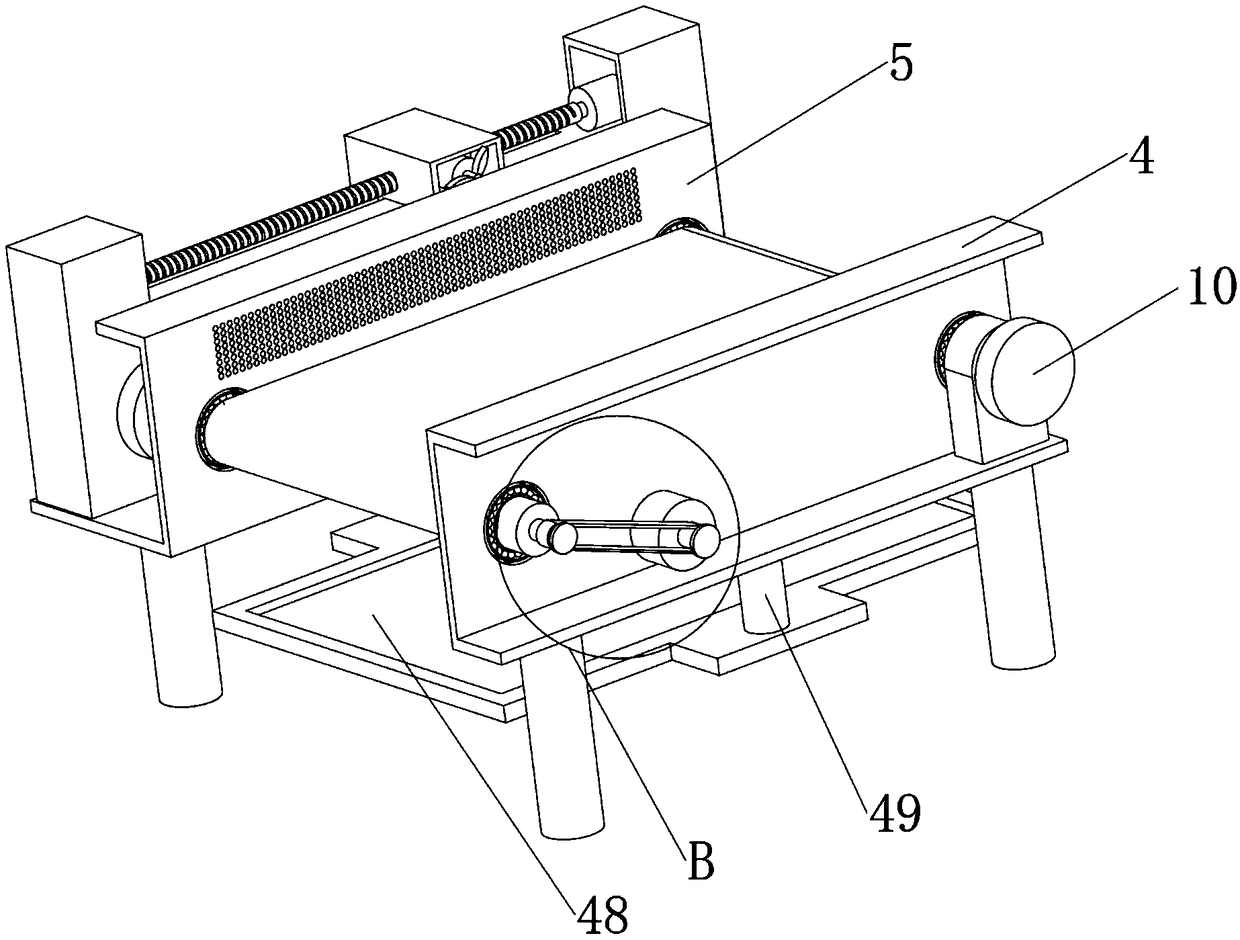

Assembling method for glass testing through air cylinder hammer with worm gear rotary table and threaded lock pins

InactiveCN105290783AAvoid the possibility of crackingLow costAssembly machinesStrength propertiesControl systemControl room

The invention relates to an assembling method for a glass testing hammer, in particular to an assembling method for glass testing through an air cylinder hammer with a worm gear rotary table and threaded lock pins. According to an improvement, the method for glass testing includes the following assembling and operation steps that firstly, sliding balls are mounted in ball seat stepped holes in a sliding plate lower plane; secondly, clamping plate portions and sliding plate portions on wheel coplanar clamping plates are assembled; and thirdly, entire assembling is carried out, the height of a height locating ring is adjusted so that when an air cylinder piston rod operates to the lowest position, an impact hammer conical tip can right make contact with a tempered glass plate fixed to a testing platen, an impact frame square hole in an impactor rack is in sliding fit with an impact cross bar, an air inlet and outlet pipe upper connector and an air inlet and outlet pipe lower connector are each connected with a high-pressure air pipe, and the high-pressure air pipes are connected to a high-pressure air source control system. An air cylinder impactor can be conveniently and remotely connected to an air pressure power source control room, and thus the dangerous step of breaking up the tempered glass plate is controlled remotely, and onsite operators are prevented from being injured by accidental splashing at the moment of glass breaking.

Owner:孙冬兰

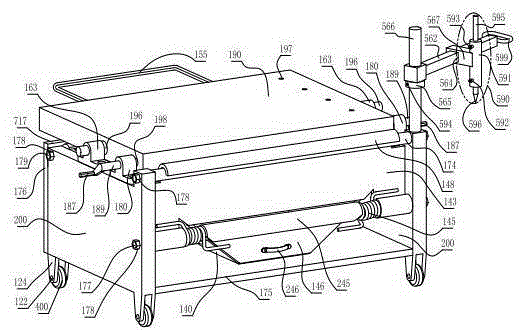

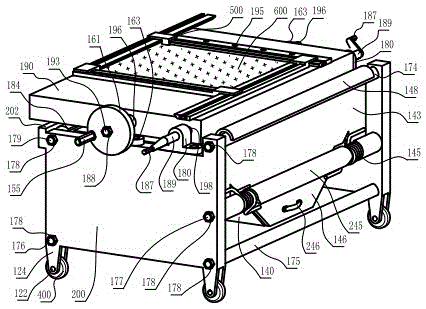

Handle overall-bedplate screw pin wheel pressing plate copper base glass detection equipment

PendingCN105319125AEasy to removeOvercome the defect of no self-lockingStrength propertiesTest specificationStructural engineering

The invention relates to tempering glass testing and detecting equipment and provides handle overall-bedplate screw pin wheel pressing plate copper base glass detection equipment. As improvement, a vertical face of the rear end of a testing bedplate is provided with a bedplate handle, the two curved ends of the bedplate handle are handle end heads, and the handle end heads of the two curved ends are fixed to the vertical face of the rear end of the testing bedplate; an upper plane of a supporting side plate on one side is provided with an impact stand column, an impact cross rod is rotatably fixed to the impact stand column, a height positioning ring is liftably fixed to the impact stand column, the height positioning ring is provided with a tightening screw, and the height positioning ring supports the impact cross rod; an air cylinder impactor is fixed to the impact cross rod in a slidable mode, the knocking strength is consistent each time through the air cylinder impactor, and it is guaranteed that crushing test specifications are unified; a coplanar wheel pressing plate assembly is fixed to the upper plane of the testing bedplate, and tempering glass plates of different specifications and sizes are adjusted continuously at will; a middle pull rod in front of a rack, an upper pull rod in front of the rack and an upper pull rod behind the rack jointly fix a broken glass recycling container.

Owner:孙冬兰

Handle table plate threaded lock pin nitrile rubber step press plate glass detection device

ActiveCN105300787ASave cost on test consumablesAvoid polluting the environmentStrength propertiesSelf lockingEngineering

The invention relates to a tempered glass test inspection device, in particular to a handle table plate threaded lock pin nitrile rubber step press plate glass detection device. As the improvement, a table plate handle is arranged on the vertical surface of the back end of a test table plate; a test table plate reversible structure can be driven to be set, so that broken glass pieces can be conveniently cleared away; a broken glass recovery container is adopted, so that the broken glass pieces cannot be scattered; a support cross beam supports the back lower plane of the test table plate; lock pin rocking handles arranged at the two sides are combined; screw stud locking pins are matched with inner holes of a lock pin support seat through screw threads, so that cylindrical ball heads at the end parts of the screw stud locking pins enter screw conical stud lock holes formed in the two sides of the test table plate for locking and positioning. The defect that a transmission gear and a manual gear are matched, and a self locking function is not realized is overcome, so that in the whole process for testing a tempered glass plate, the stability and the firmness are maintained; a container material door spring is arranged between a material door hook and a container front lower hook arranged at each of two sides; a container discharging door is enabled to be tightly attached to a discharging opening of the container; the broken glass pieces are prevented from being scattered.

Owner:东营玖润化工机械有限公司

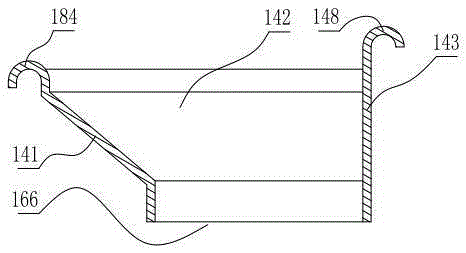

Bearing slideway periphery same-plane-adjustable butadiene styrene rubber fixing device

The invention relates to a glass testing device, and especially relates to a bearing slideway periphery same-plane-adjustable butadiene styrene rubber fixing device. The improvements of the fixing device are as follows: a sliding part is arranged on one end of a clamping part, the sliding part is overlapped on the upper surface of the clamping part; the lower surface of the sliding part is taken as the sliding lower plane, the sliding lower plane is provided with rolling bearing, a bearing pin shaft is arranged between the rolling bearing and the sliding lower plane; furthermore, a transition groove is arranged between a bearing slideway and a clamping upper plane; the bottom of the bearing slideway is provided with a blind groove space; moreover, one end of the bearing slideway is opened; the external end of the bearing pin shaft is provided with an opened pin for shaft to stop the rolling bearing, the opened pin for shaft is arranged in the blind groove space, a gap between the opened pin for shaft and the blind groove space; the sliding lower plane and the clamping upper plane are in the same height; the inner side of the clamping part is provided with a clamping slope, rubber press sheets are adhered on the clamping slope; sliding cooperation exists between the rolling bearing of each press plate and neighbored bearing slideway, and the random and continuous adjustment on tempered glass plate with different widths can be achieved.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

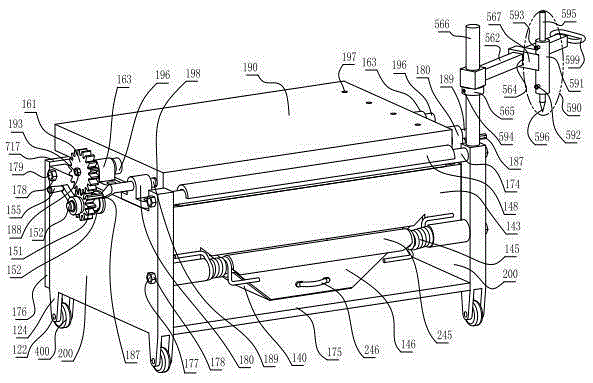

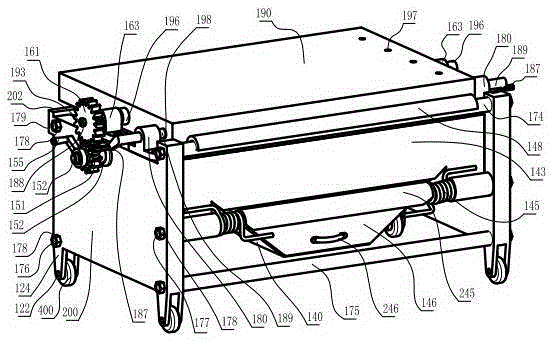

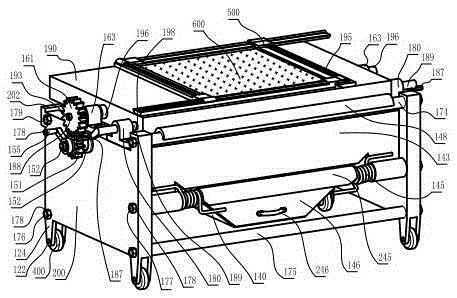

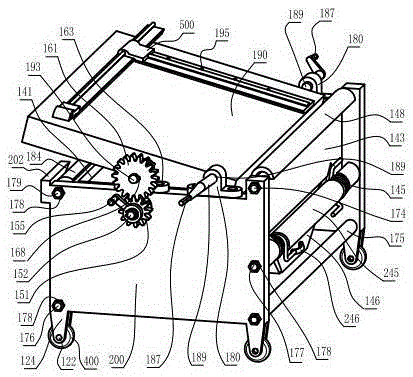

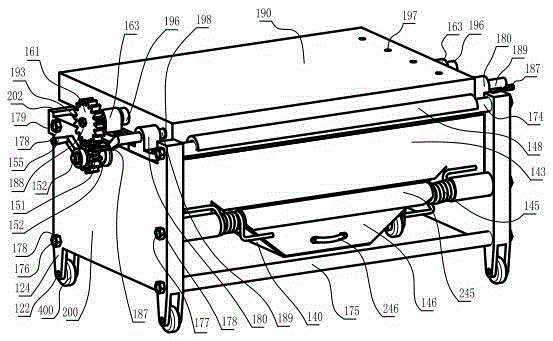

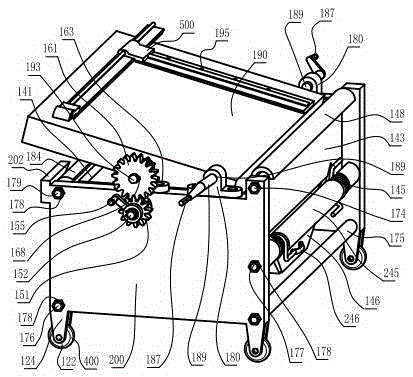

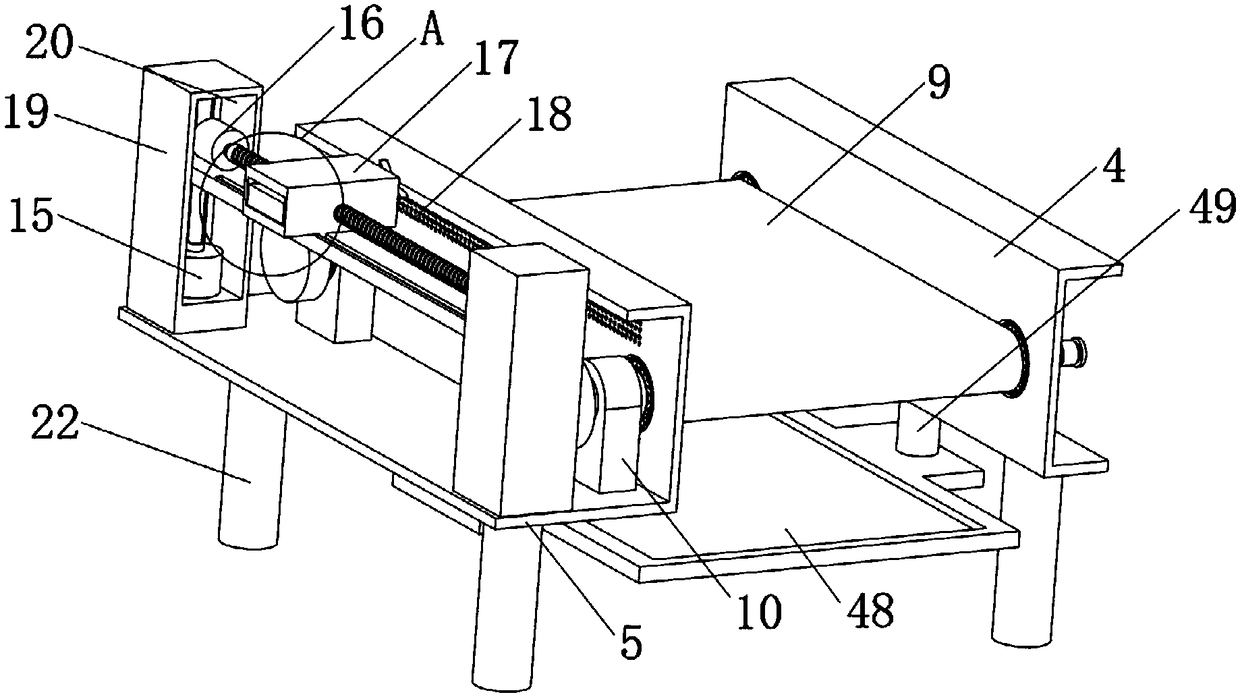

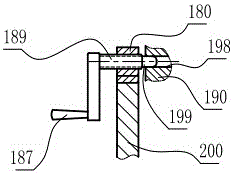

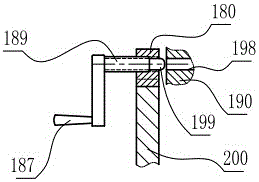

Titanium-based glass detection system with gears, bedplate, stud lockpins and circular track pressing plate

InactiveCN105300818AEasy to removeOvercome the defect that the fit does not have self-lockingStrength propertiesGear driveGear wheel

The invention relates to a tempered glass test detection system, in particular to a titanium-based glass detection system with gears, a bedplate, stud lockpins and a circular track pressing plate. A whole rack is composed of supporting side plates on the two sides, a rear shearing force plate and a bottom shearing force plate; as an improvement, a transmission gear is fixed on a bedplate rotating shaft on one side; the transmission gear is matched with a manual gear; the manual gear can be rotationally fixed in a manual axle; an axle flange is arranged on the inner end of the manual axle; the axle flange is fixed on the outer side surface of the corresponding supporting side plate; an axle snap spring is arranged at the outer end of the manual axle; the axle snap spring is blocked on the outer side surface of the manual axle; a handwheel step circle is arranged on the outer side surface of the manual gear; the handwheel step circle is fixedly connected with a handwheel cross rod; a handwheel shaking handle is arranged at the outer end of the handwheel cross rod; an impact vertical pillar is arranged on the upper plane of the supporting side plate on one side; an impact cross bar is rotationally fixed on the impact vertical pillar; a height positioning ring is fixed on the impact vertical pillar in a liftable manner; an air cylinder impacter is fixed on the impact cross bar in a sliding manner.

Owner:孙冬兰

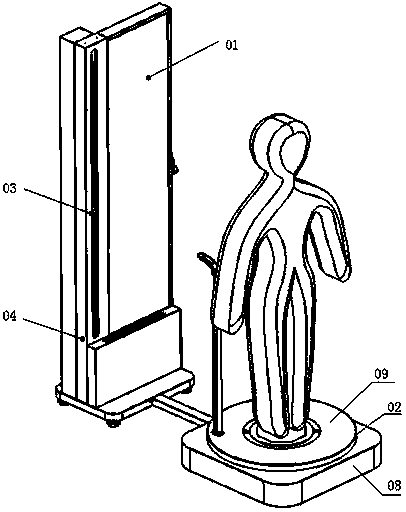

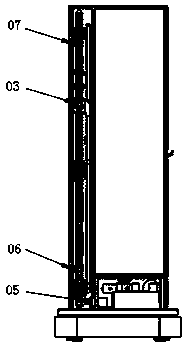

Human body composition detection device through human body three-dimensional scanning

PendingCN108143421ASimple structureReduce volumeDiagnostic recording/measuringSensorsHuman bodyEngineering

The invention relates to a human body composition detection device through human body three-dimensional scanning. The device comprises a screen and a human body rotary table which is connected with the screen, a guide rail assembly where a depth camera moves up and down is arranged on the screen, and a guide rail motor for driving the depth camera to move up and down is arranged below the guide rail assembly; a first photoelectric sensor is arranged at the upper end of the guide rail assembly, a second photoelectric sensor is arranged at the lower end of the guide rail assembly, the human bodyrotary table comprises a rotation platform and a weighing platform, and the weighing platform is located on the rotation platform. After the human body composition detection device through human bodythree-dimensional scanning is started, a lifting camera can ascend and descend back and forth according to the height of the human body to scan the shape of the human body continuously, the structureis simple, multiple cameras are saved, only one depth camera which can move up and down is used for scanning and shooting, and the device is small in size, convenient, flexible, easy to disassemble,assemble and transport and convenient to use.

Owner:XIAN SUANIER ELECTRONICS TECH

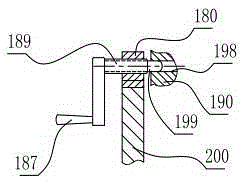

Clamping mechanism for collet chuck of CNC lathe

The invention discloses a clamping mechanism for a collet chuck of a CNC lathe. The clamping mechanism is characterized in that a through groove is arranged in the middle of a tool bar and used for allowing a tool to pass through, and a conical locking groove is further arranged in the through groove in one end of the tool bar and used for locking the collet chuck; the collet chuck is sleeved with a clamping sleeve, the clamping sleeve is connected to a plurality of sets of telescopic rods through clamping components, and the other ends of the telescopic rods are fixedly embedded into the tool bar; the clamping force applied to the clamping sleeve by the clamping components can be absorbed by the clamping sleeve; and the collet chuck can be driven to move towards the tool bar through contraction of the telescopic rods, so that the tool located in the collet chuck is locked step by step, the collet chuck and the tool in the collet chuck are stressed more uniformly, the situation that the tool shakes in the machining process is reduced, and the problems that an existing clamping mechanism is generally of a nut structure, the collet chuck is locked on the tool bar through a nut, the clamping and fixing effect is common, and the uniform locking force on the tool cannot be guaranteed are solved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

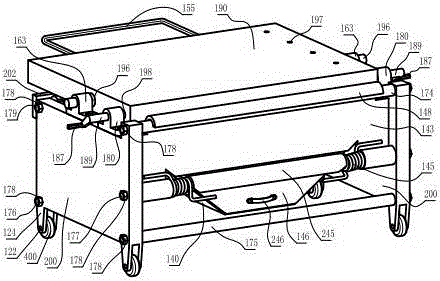

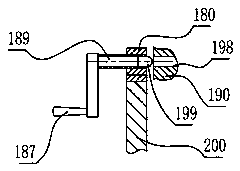

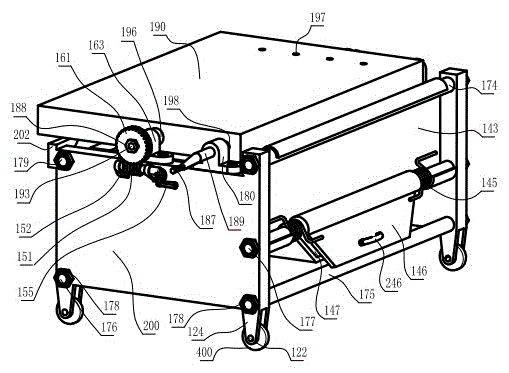

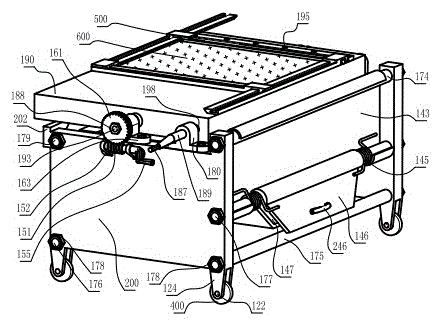

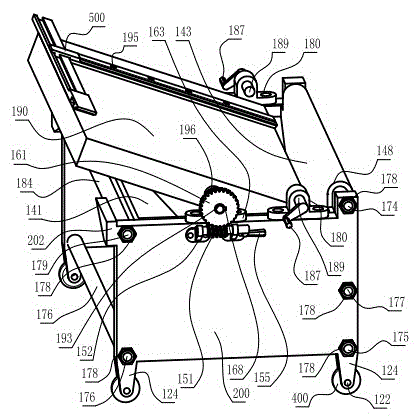

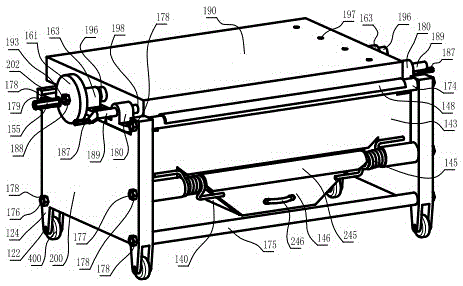

Hydraulic bedplate threaded locking pin step pressing plate zinc base glass test rack

InactiveCN105334100AEasy to removeMake sure not to spillStrength propertiesStructural engineeringTest Standardization

The invention relates to a tempered glass test checking rack, in particular to a hydraulic bedplate threaded locking pin step pressing plate zinc base glass test rack. The invention is characterized in that a broken gap is formed in the upper plane of a rear plate; a supporting baseplate is fixed at the lower end of the broken gap; the center of the lower plane of the rear end of a test bedplate is provided with a T-shaped guide rail; a hydraulic elevator mechanism is arranged between the T-shaped guide rail and the supporting baseplate; the upper plane of a supporting side plate on one side is provided with an impact stand column on which an impact cross rod is rotatably fixed; a height positioning ring is fixed on the impact stand column in a liftable way, and supports the impact cross rod; an air cylinder impactor is slidably fixed on the impact cross rod, and is applied to realize consistent severity during hammering each time and thus ensure the unification of breaking test standardization and unification; a rack front middle pull rod, a rack front upper pull rod and a rack rear upper pull rod together fix a broken glass recycling container; a step rail pressing plate assembly is fixed on the upper plane of the test bedplate, thus realizing continuous and random adjustment on tempered glass plates of different sizes.

Owner:孙冬兰

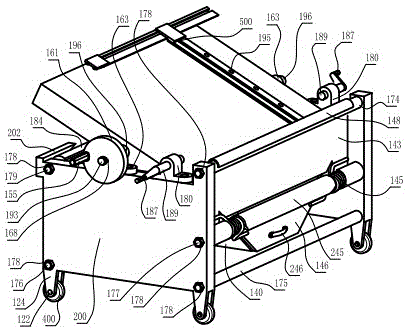

Glass detection device adopting worm gear table board, threaded lock pins and natural rubber V-type pressing plates

The invention relates to a tempered glass detection device, in particular to a glass detection device adopting a worm gear table board, threaded lock pins and natural rubber V-type pressing plates. The glass detection device comprises a testing table board and plate type racks, wherein a rack front upper pull rod, a rack front lower pull rod, a rack rear lower pull rod and a rack rear upper pull rod are arranged between the two plate type racks; table board rotating shafts are arranged on two sides of the testing table board and are rotationally fixed in a bearing support respectively; a support stop block is arranged at the rear upper part of each plate type rack and supports the rear lower plane of the testing table board; a drive worm gear is fixed on the table board rotating shaft on one side and is matched with a worm shaft, a worm support is fixed on the outer side surface of the corresponding plate type rack, and a worm cranking handle is further arranged at one end of the worm shaft; stud lock pins on two sides can enter conical stud locking holes in two sides of the testing table board to be locked and positioned; coplanar V-type slot pressing plate assemblies are fixed on the upper surface of the testing table board, and a broken glass recovery container is fixed on a rack front middle pull rod, the rack front upper pull rod and the rack rear upper pull rod.

Owner:威海烟华安全玻璃有限公司

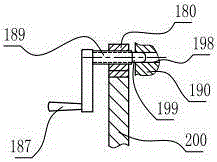

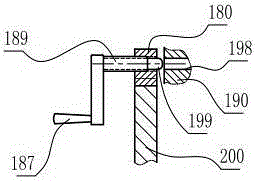

Rubber bearing clamping plate glass checking equipment for plate wheel bedplate thread lockpin engineering

The invention relates to a toughened glass testing and checking device, particularly to rubber bearing clamping plate glass checking equipment for the plate wheel bedplate thread lockpin engineering. As the improvement, bedplate rotating shafts are arranged on the two sides of a testing bedplate, the bedplate rotating shafts on the two sides are respectively rotatably fixed into bearing supports, and the bearing supports are fixed on the upper plane surfaces of plate-type racks; supporting stopping blocks are arranged at the upper back parts of the plate-type racks, and used for supporting the lower back plane surfaces of the testing bedplate; a manual plate wheel is also fixed on the bedplate rotating shaft on one side, a plate wheel flat key is arranged between the bedplate rotating shaft and the manual plate wheel, and a plate wheel crank handle is also arranged on the outer side surface of the manual plate wheel; external threads of screw stud lockpins are matched with internal threads of lockpin supports, the lockpin supports are fixed on the upper plane surface of the plate-type racks, and the cylindrical ball heads at the end heads of the screw stud lockpins on the two side can enter crew-cone-cylinder lock holes in the two sides of the testing bedplate to be locked and positioned; the manual plate wheel drives the testing bedplate to be arranged into a turnable structure, broken glass pieces can be conveniently cleaned, and a broken glass recycling container is configured to ensure that the broken glass pieces are not scattered.

Owner:东港智科产业园有限公司

Cis-polybutadiene rubber clamper with adjustable round sliding channel periphery

The present invention relates to a glass test clamper, particularly to a cis-polybutadiene rubber clamper with the adjustable round sliding channel periphery, wherein each clamping rule comprises a clamping portion and a sliding portion, and the following improvements are adopted: the sliding portion is positioned at one end of the clamping portion and is overlapped on the upper plane of the clamping portion, the lower surface of the sliding portion is a sliding lower plane, the sliding lower plane is provided with a circular concave groove, a transition concave groove with a symmetrical center is arranged between the circular concave groove and the sliding lower plane, the upper surface of the clamping portion is a clamping upper plane, the clamping upper plane is provided with a circular convex groove, a transition convex strip with a symmetrical center is arranged between the circular convex groove and the clamping upper plane, the sliding lower plane and the clamping upper plane are positioned at the same height, the inner side of the clamping portion is provided with a clamping slope, a rubber pressing sheet is attached on the clamping slope and adopts a synthetic cis-polybutadiene rubber, and the circular concave groove of each edge of the pressing plate and the adjacent circular convex groove form the sliding matching so as to continuously and randomly adjust the tempered glass plates with different widths.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

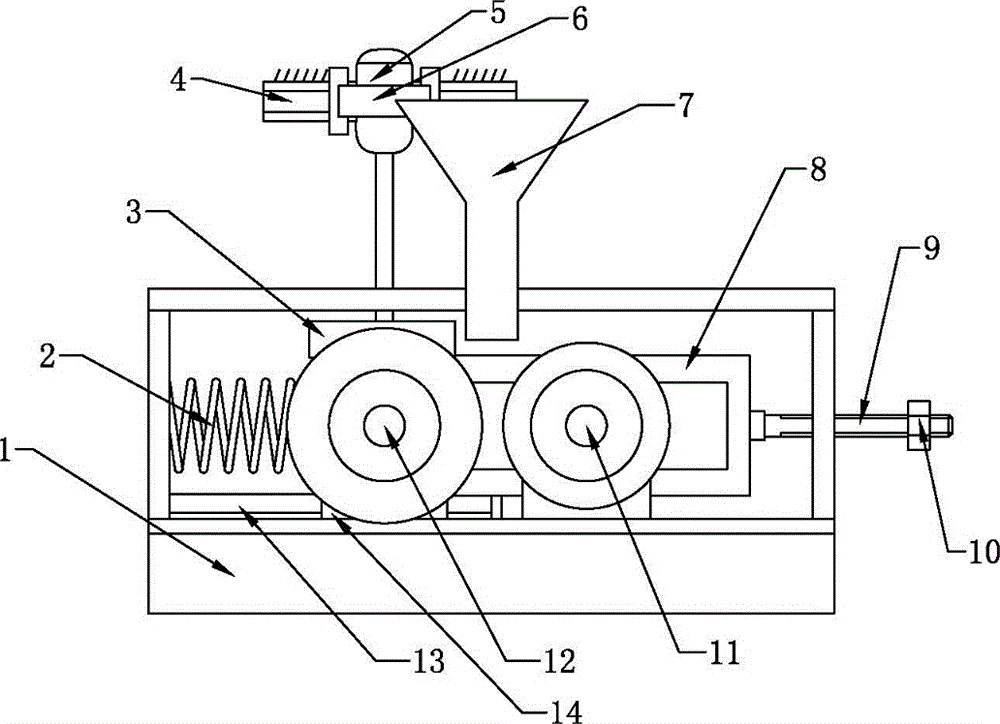

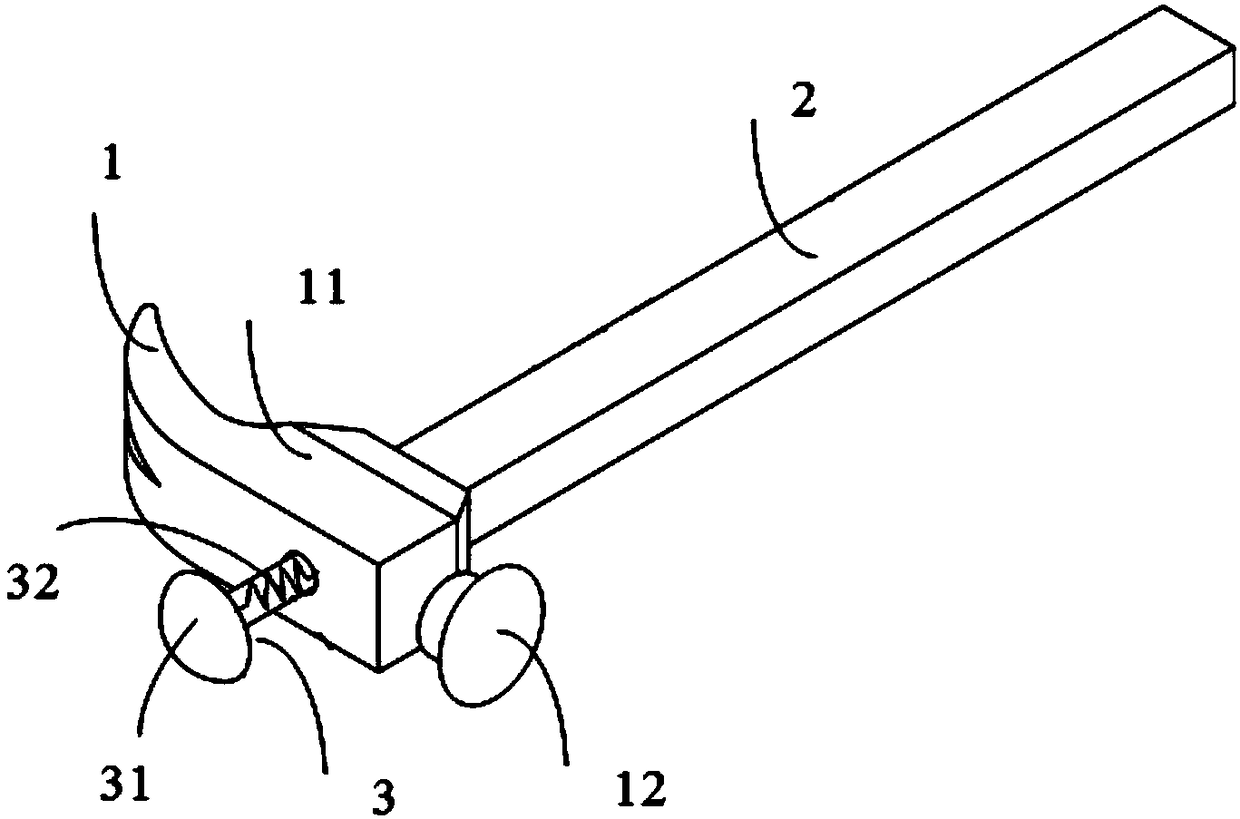

Roller type crusher for producing compound fertilizer

The invention relates to a crushing device, namely a roller type crusher for producing a compound fertilizer. The roller type crusher comprises a frame, a fixed roller and a flexible roller, wherein the fixed roller is connected with the frame, a flexible seat is arranged on the frame, the flexible roller is arranged on the flexible seat, a spring is arranged between the flexible seat and the frame, a position limiting rack is connected with one side of the flexible seat far away from the spring, a push rod is rotatably connected with one side of the position limiting rack far away from the flexible seat, an optical rod part is arranged on one side of the push rod near the position limiting rack, a screw part is arranged on one side of the push rod far away from the position limiting rack, a screw hole cooperated with the push rod is formed on the frame, the screw part of the push rod passes through the screw hole, a cylinder is arranged above the frame, a clamping block is arranged on the output end of the cylinder, and a clamping groove of the clamping block is arranged on the flexible seat. The problem of the prior art that the separation size of the existing roller type crusher cannot be adjusted is solved, and the roller type crusher can crush raw materials into different sizes.

Owner:CHONGQING YONGCHUAN DISTRICT TIANTANG CHEM PLANT

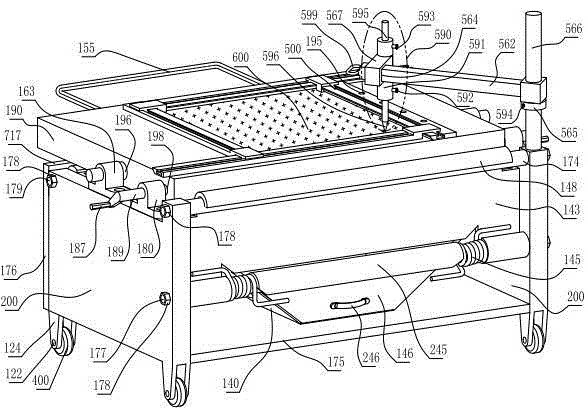

Tempered glass fragment number detecting and fixing device

The invention relates to a tempered glass testing and inspecting device, in particular to a tempered glass fragment number detecting and fixing device. As improved, a bearing slide press plate assembly is fixed on the upper plane of a testing platform, a rolling bearing of a press plate on each side is in sliding fit with a bearing slide on the adjacent side, so that tempered glass plates in different specifications and dimensions can be adjusted continuously and freely; a driving gear is also fixed on a platform rotary shaft on one side and cooperates with a manual gear, the manual gear is rotationally fixed on a manual axle, an axle flange is arranged at the inner end of the manual axle and fixed on the outer side surface of each corresponding plate rack, a shaft snap spring is arranged at the outer end of the manual axle and blocks on the outer side surface of the manual axle, a hand wheel cross bar is fixedly connected onto the hand wheel step circle of the manual gear, and a hand wheel crank handle is also arranged at the outer end of the hand wheel step circle. By the aid of cooperation of stud lock pins and inner hole threads of lock pin supports, tempered glass plates are kept firm in the whole test process.

Owner:ZHEJIANG INST OF QUALITY INSPECTION SCI

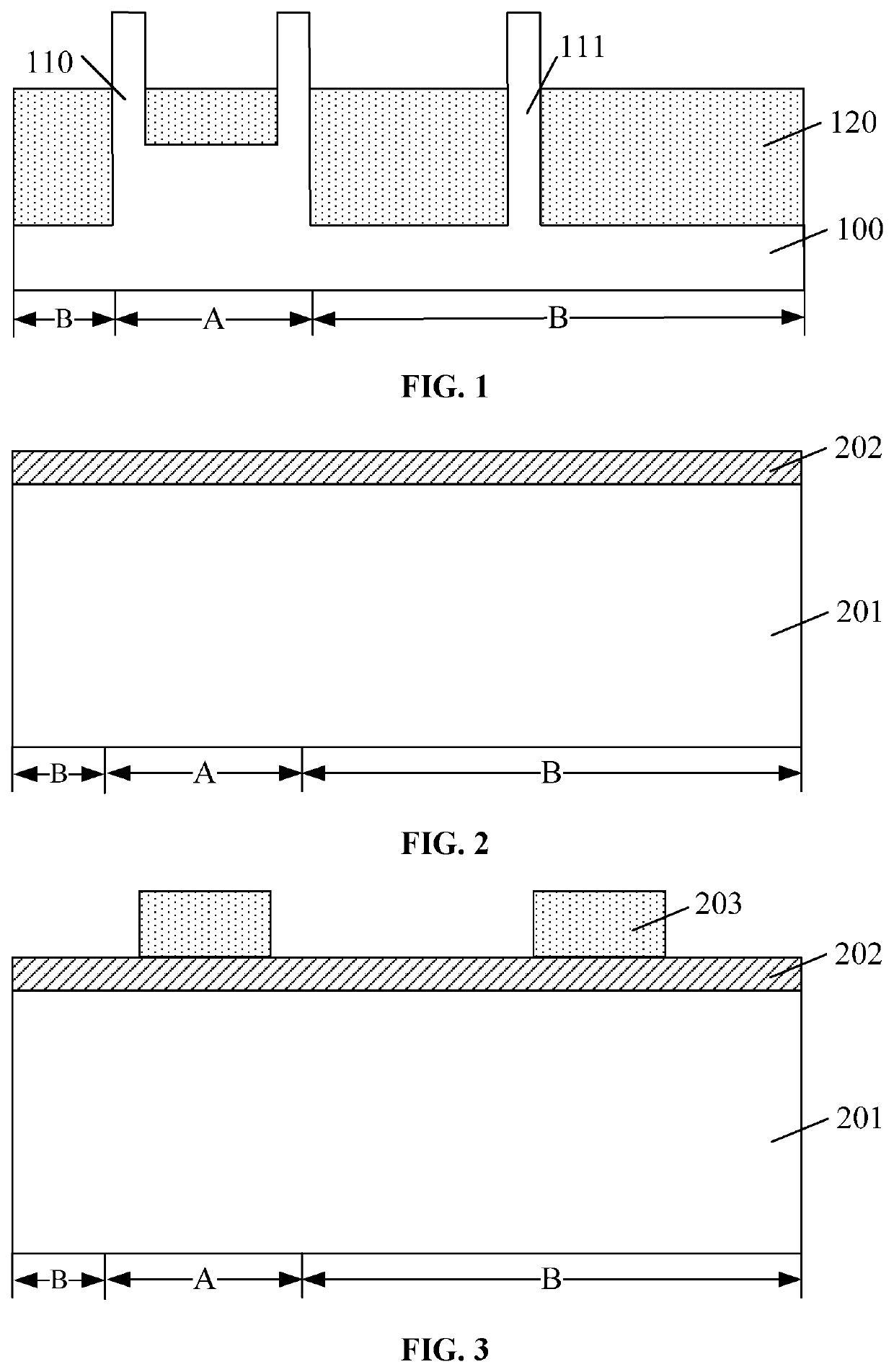

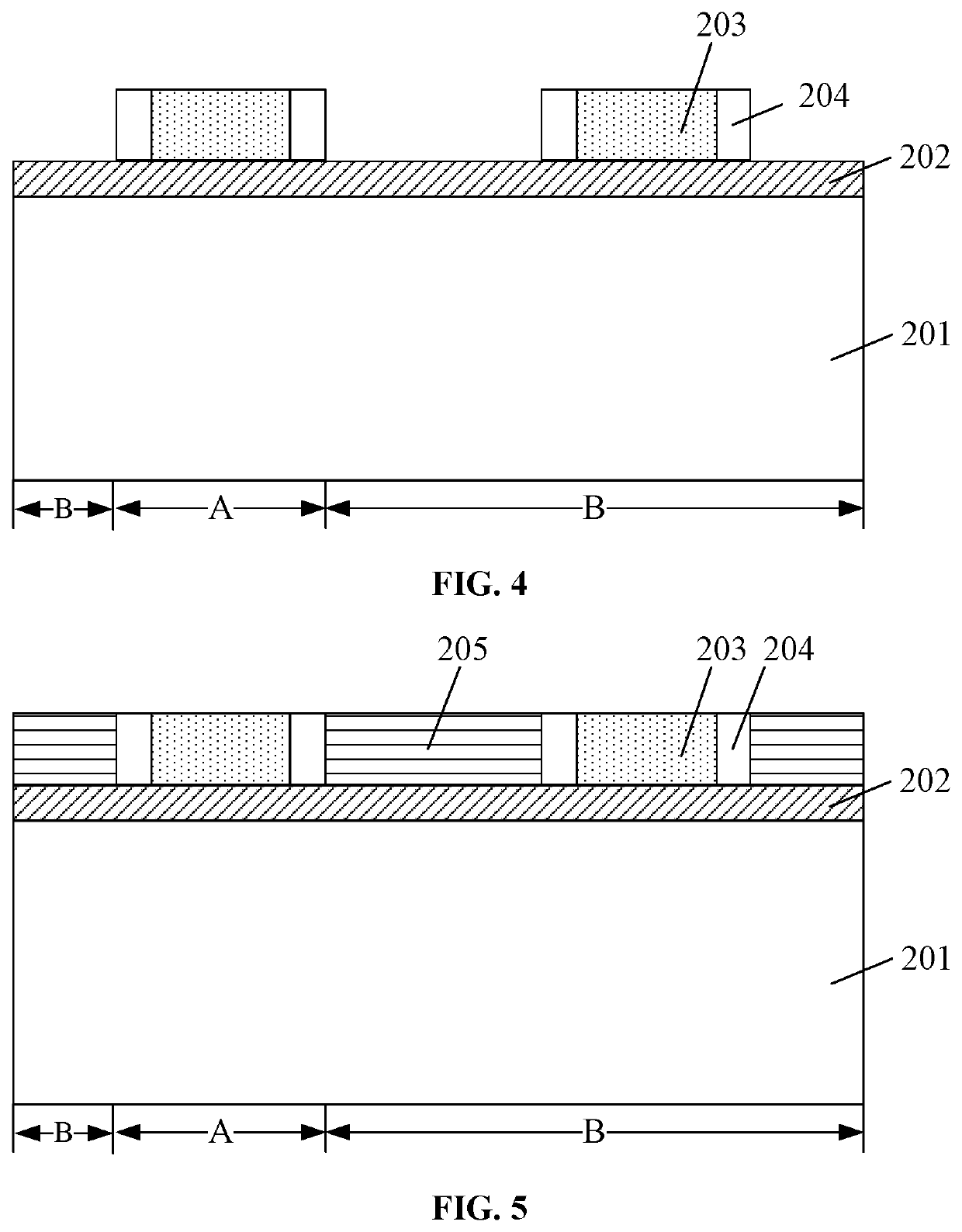

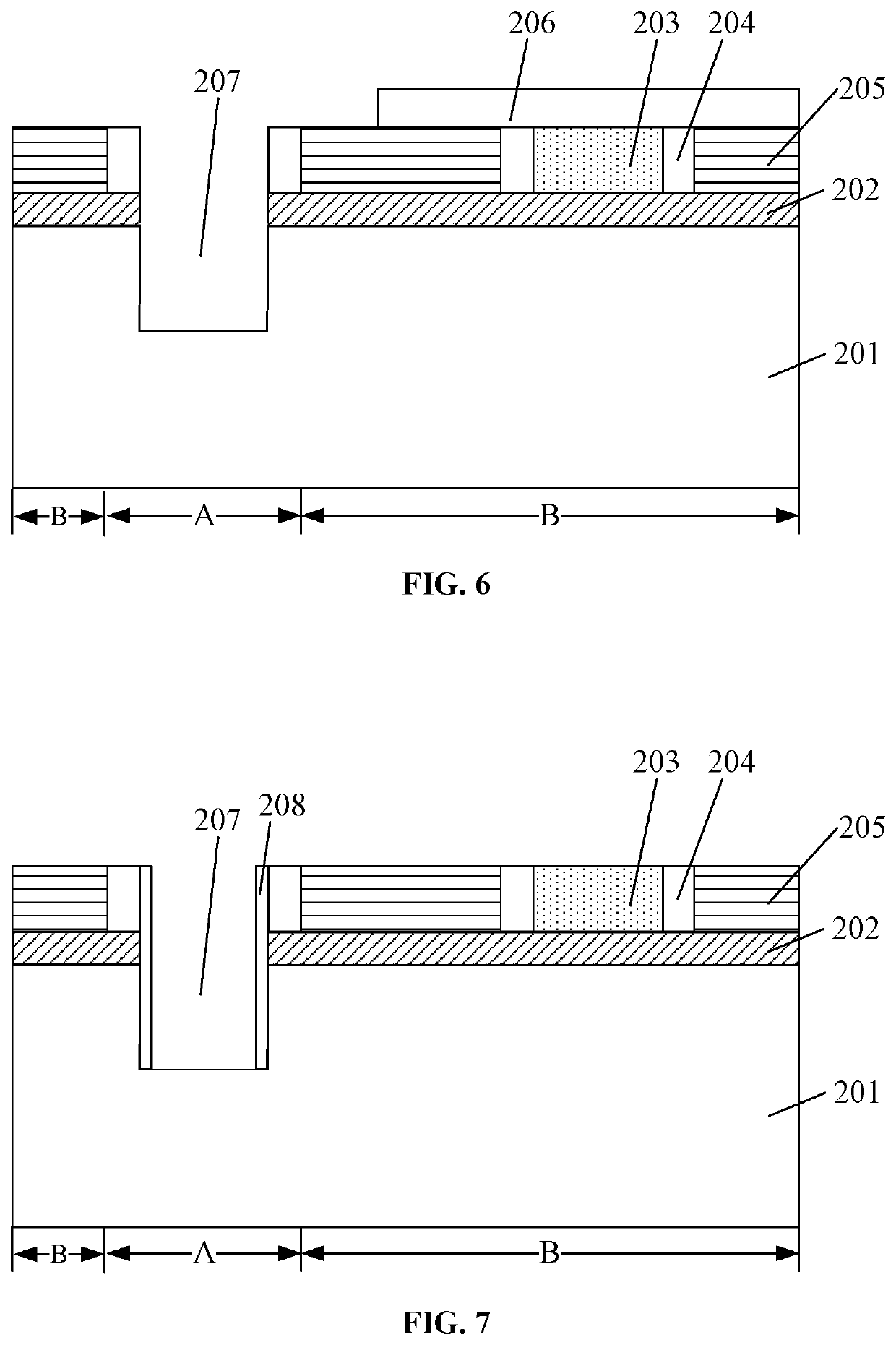

Semiconductor device and fabrication method thereof

ActiveUS20200144421A1High surfaceDesired performanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering physics

Semiconductor devices and fabrication methods are provided. An exemplary fabrication method includes providing an initial base substrate having a middle region and an adjacent edge region; forming a first opening in the middle region of the initial base substrate; forming a first adjustment layer on sidewall surfaces of the first opening; and forming a plurality of second openings with a depth greater than a depth of the first opening in the edge region of the initial base substrate. A portion of the initial base substrate between the first opening and the second opening forms a first fin, a portion of the initial base substrate between adjacent second openings form a second fin. The method also includes forming an isolation structure with a top surface lower than top surfaces of the first fin and the second fins on the surface of the initial base substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Ladder sliding channel four-side sliding bead coplanar aluminum alloy fixing device

The invention relates to a glass testing fixing device, in particular to a ladder sliding channel four-side sliding bead coplanar aluminum alloy fixing device. As an improvement, the lower surface of a step of a sliding plate part serves as a lower plane of the sliding plate, a step groove is formed in the lower plane of the sliding plate, and a centrosymmetric transitional groove is formed between the step groove and the lower plane of the sliding plate. The upper surface of a fixed part serves as a fixed upper plane, a step convex rail is arranged on the fixed upper plane, and a centrosymmetric transitional convex strip is arranged between the step convex rail and the fixed upper plane. The lower plane of the sliding plate and the fixed upper plane are located at the same height. A fixed slope is arranged on the inner side of the fixed upper plane, and a rubber pressing sheet is attached to the fixed slope. A sliding ball is fixed in a ball seat step hole in the upper plane of a pressing plate. The outward protruding spherical face of the sliding ball is in contact with the lower plane of the sliding plate, so that the lower plane of the sliding plate in one fixing device slides more smoothly and easily relative to the upper plane of the pressing plate in another fixing device, and it is ensured that the periphery of tested armor plate glass is stressed unevenly.

Owner:孙冬兰

Pneumatic-type precision annular workpiece inner positioning surface clamping device

ActiveUS9782833B2Reduce manufacturing costSimple designSleeve/socket jointsWork clamping meansClosed chamberPiston

Owner:HARBIN INST OF TECH

Insertion and pull locking pin, hydraulic Ti-based rotating table and natural rubber bearing clamping plate glass testing system

InactiveCN105181488ASave cost on test consumablesAvoid polluting the environmentMaterial strength using single impulsive forceNatural rubberStructural engineering

The invention relates to a tempered glass testing check system, in particular to an insertion and pull locking pin, hydraulic Ti-based rotating table and natural rubber bearing clamping plate glass testing system. As an improvement, table plate rotating shafts on the two sides are fixed in bearing supports in a rotating mode respectively, and the bearing supports are fixed to the upper planes of plate-type racks; segmented supporting beams support the two sides of the lower plane of the rear end of a testing table plate; a T-shaped guide rail is arranged in the center of the lower plane of the rear end of the testing table plate, and a hydraulic lifting mechanism is arranged between the T-shaped guide rail and a supporting bottom plate; a coplanar bearing clamping plate assembly is fixed to the upper plane of the testing table plate, a rack front upper pull rod and a rack rear upper pull rod fix a broken glass guider together, and a lower end opening of the broken glass guider is located in an upper end opening of a broken glass collecting cart; a hydraulic tension cylinder is combined with the segmented supporting beams to support the rear lower plane of the testing table plate, andplain pillar locking pins are arranged in insertion and pull locking holes in the two sides of the testing table plate in a combined mode to achieve locking and positioning. In this way, the whole hydraulic system does not need pressure maintaining in the whole tempered glass plate testing process, and the testing table plate is stable and solid.

Owner:张筱秋

Toughened glass fragment test immobilization method

PendingCN105334117AEasy to removeMake sure not to spillMaterial strength using single impulsive forceEngineeringTest platform

The invention relates to a toughened glass testing device, and discloses a toughened glass fragment test immobilization method. According to the improved toughened glass testing device, a bearing slide rail pressing plate subassembly is immobilized on the flat surface of a test platform; slide cooperation of a rolling bearing of a pressing plate on each side with a bearing slide rail of an adjacent edge is realized, so that continuous random adjustment of toughened glass of different size can be realized; a platform rotating shaft on one side is fixedly provided with a transmission gear, cooperation of the transmission gear with a corresponding manual gear is realized, the manual gear can be immobilized on a manual wheel shaft in a rotating manner, the inner end of the manual wheel shaft is provided with wheel shaft flanges, the wheel shaft flanges are immobilized on the outer side surface of a corresponding plate type rack, the outer end of the manual wheel shaft is provided with a shaft clamp spring, the shaft clamp spring is used for covering the outer side surface of the manual wheel shaft, a hand wheel step round part of the manual gear is fixedly connected with a hand wheel cross bar, and the outer end of the hand wheel step round part is provided with a hand wheel rocking handle; stabilization of toughened glass is achieved in the whole testing process via cooperation of screw bolt lockpins with lockpin support internal port threads.

Owner:ZHEJIANG INST OF QUALITY INSPECTION SCI

Crystal silicon solar battery dry etching clamp

InactiveCN102394254AUneven forceReduce stressFinal product manufactureSemiconductor/solid-state device manufacturingSilicon chipEngineering

A crystal silicon solar battery dry etching clamp belongs to the technical field of solar batteries and adopts the structure that a base plate is connected with a silicon chip stacked base; a first support seat and a fourth support seat are respectively fixed on the two side walls of the silicon chip stacked base through bolts; both a fixed clamp plate and a movable clamp plate are rectangular plates and connected with a first support shaft and a second support shaft respectively, and holes are formed on the opposite angles of the rectangular plates; a central round groove is formed on the inner side contact surface of the fixed clamp plate, and center square groove is formed on the outer side surface of the fixed clamp plate; a center groove is formed on the inner side contact surface of the movable clamp plate; and a bolt rod of an ejector rod is in threaded connection with a ejector rod support, and the top end of the ejector rod is in contact with the movable clamp plate. Due to the above structure, the clamp plate deformation and the uneven stress on the silicon chip caused by force applied to one point are avoided; and a contact surface center chamfer allows the force to bedispersed on the edges of the silicon chips and enables the silicon chip edges to be clamped tightly so as to reduce the stress on the middle areas of the silicon chips. Therefore, the possibility for the etching gas to permeate into the stacked silicon chips is reduced to the maximum degree, and the fragments are reduced; and the silicon chip stacked base allows the stack of the silicon chips tobe more concise, and the fraction between the silicon chips is reduced.

Owner:XINYU GIGA SOLAR NEW ENERGY

Rice wine brewing equipment

InactiveCN109055120AImprove cooling efficiencyExcellent cooling effectAlcoholic beverage preparationEngineeringMechanical engineering

The invention discloses rice wine brewing equipment which comprises a conveying device, a feeding plate and a discharge plate, wherein the feeding plate and the discharge plate are respectively arranged at both ends of the conveying device; a first support rack and a second support rack are respectively arranged on both sides of the conveying device; both ends of one side of the feeding plate arerespectively moveably clamped on the first support rack and the second support rack; both sides of the conveying device are rotationally connected with the first support rack and the second support rack through bearings respectively; a driving device is arranged on the first support rack; the output end of the driving device is fixedly connected with one end of the conveying device on the first support rack; the conveying device comprises a main rotating column, a secondary rotating column and a conveyer belt; both ends of the conveyer belt are respectively connected with the main rotating column and the secondary rotating column in a sleeving manner. By adopting the rice wine brewing equipment, manual operation in a sticky rice spreading cooling process can be reduced, and in addition, the heat radiation efficiency can be improved.

Owner:戴建设

Glass testing system adopting hydraulic platen, threaded lock pins and styrene butadiene rubber wheel pressure plates

ActiveCN105115811ASave cost on test consumablesAvoid polluting the environmentMaterial strength using repeated/pulsating forcesButadiene-styrene rubberSelf locking

The invention relates to a tempered glass testing and inspecting device, particularly to a glass testing system adopting a hydraulic platen, threaded lock pins and styrene butadiene rubber wheel pressure plates, and the improvement lies in that: a hydraulic stretching cylinder adopting the structure cooperates with a T-shaped guide rail to drive the testing platen to be overturned, so that chunk glass can be removed conveniently; through the threaded fit of stud lock pins and inner holes of lock pin supports, cylindrical bulbs at the end parts of the stud lock pins enter the spiral taper lock holes in the two sides of the testing platen, so as to be locked and located, and the defect that self-locking is unavailable for cooperation of a traditional transmission gear and a manual gear, as a result, the entire tempered glass plate is kept stable and solid during testing. According to the invention, two parts, namely an upper short pulley and a lower long pulley both arranged on the hydraulic stretching cylinder together control the T-shaped guide rail to swing by taking the platen rotating shaft as a center, and together control a T-shaped rail cross plate on the T-shaped guide rail to roll in a sliding manner; besides, the device adopting the structure avoids the error generated between rectilinear motion by a hydraulic piston rod and swing motion by the testing platen.

Owner:威海烟华安全玻璃有限公司

Hammer with position detecting function

The invention discloses a hammer with a position detecting function. The hammer comprises a hammer head and a hammer handle, and the hammer head and the hammer handle are fixedly connected. The hammerhead is provided with a hammer head body and a striking portion, and the striking portion is detachably mounted on the hammer head body. The hammer head body is further provided with a position detecting element, and the position detecting element is provided with an end portion and an elastic member. The end portion is connected with the hammer head body through the elastic member, and the elastic member detects the force applied to the striking portion and acts on the end portion. According to the hammer with the position detecting function, the position detecting element is arranged on thehammer head body, and the hammer head is unevenly stressed when a struck object is displaced; and the elastic member in the position detecting element acts on the end portion, thereby reminding a user to stop the striking behavior and correct the position.

Owner:江苏沙源检测校准技术有限公司

Wheel chute four-side slide ball coplanar nickel alloy adjusting fixture

The invention relates to a glass testing fixture, in particular to a wheel chute four-side slide ball coplanar nickel alloy adjusting fixture as an improvement. A step lower surface of a slide plate part is a slide plate lower plane; a step shaft pin is arranged on a slip lower plane; a shaft pin outer section is arranged on the step shaft pin; a shaft pin step is arranged between the shaft pin outer section and the step shaft pin; the outer end of the shaft pin outer section is a shaft pin outer end; a shaft pin screw hole is formed in the center of the shaft pin outer end; the outer circle of the shaft pin outer section is rotationally matched with a slip wheel inner hole; the inner side plane of a slip wheel is bonded with the shaft pin step; the shaft pin screw hole is matched with a wheel screw; the screw head of the wheel screw is bonded on the shaft pin outer end; the screw head of the wheel screw stops the inner side plane of the slip wheel; the exposed screw head of the wheel screw can be positioned in a blind groove space; a gap is formed between the exposed screw head of the wheel screw and the blind groove space; the slip wheel and a wheel chute are in slide fit; a slip ball is fixed in a ball base step hole on the slide plate lower plane; and the outer projection spherical surface of the slip ball is contacted with a fixed upper plane.

Owner:孙冬兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com