Glass testing system adopting hydraulic platen, threaded lock pins and styrene butadiene rubber wheel pressure plates

A styrene-butadiene rubber and test system technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, instruments, measuring devices, etc., can solve the problems of uneven force around the surrounding area, long time spent, and glass shards splashing, etc. Achieve the effect of saving the cost of test consumables, ensuring personal safety, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

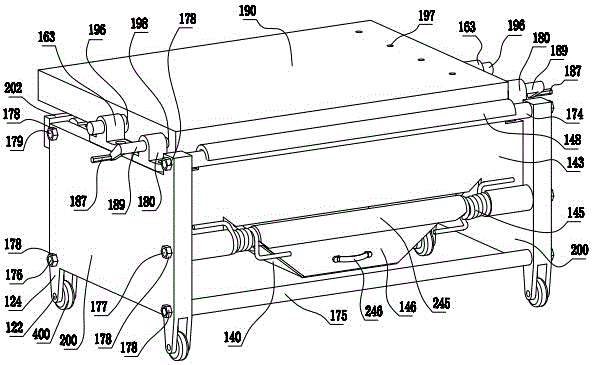

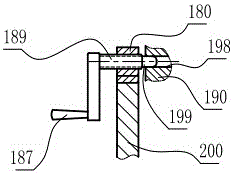

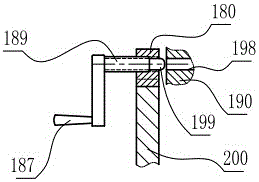

[0062] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 Middle: Hydraulic platform screw lock pin styrene-butadiene rubber wheel pressure plate glass test system, including test platform 190 and plate rack 200, between the two plate racks 200 there is a rack front pull-up rod 174 and a rack front pull-down rod 175 And pull-down rod 176 and frame rear pull-up rod 179 after the frame, frame front pull-up rod 174 and frame front pull-down rod 175 and frame rear pull-down rod 176 and frame rear pull-up rod 179 both ends all have tie rod nuts 178 fixes two plate racks 200, as an improvement:

[0063] There are platform rotating shafts 196 on both sides of the test platform 190, and the platform rotating shafts 196 on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com