Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "To achieve the winding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

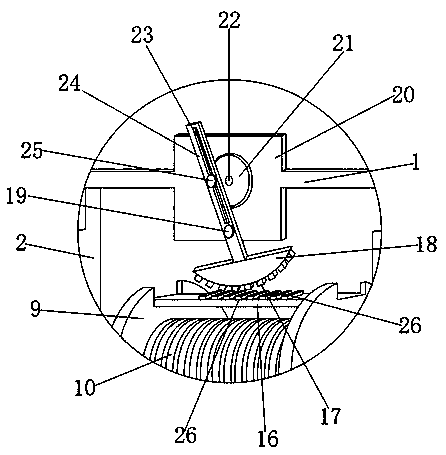

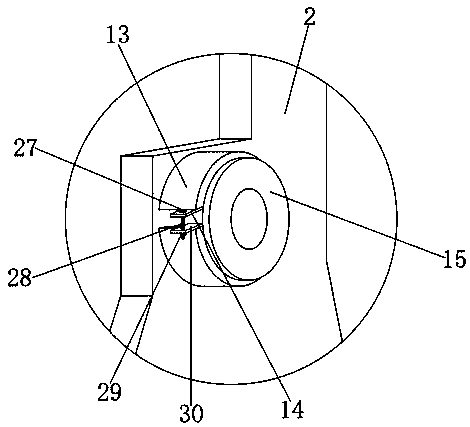

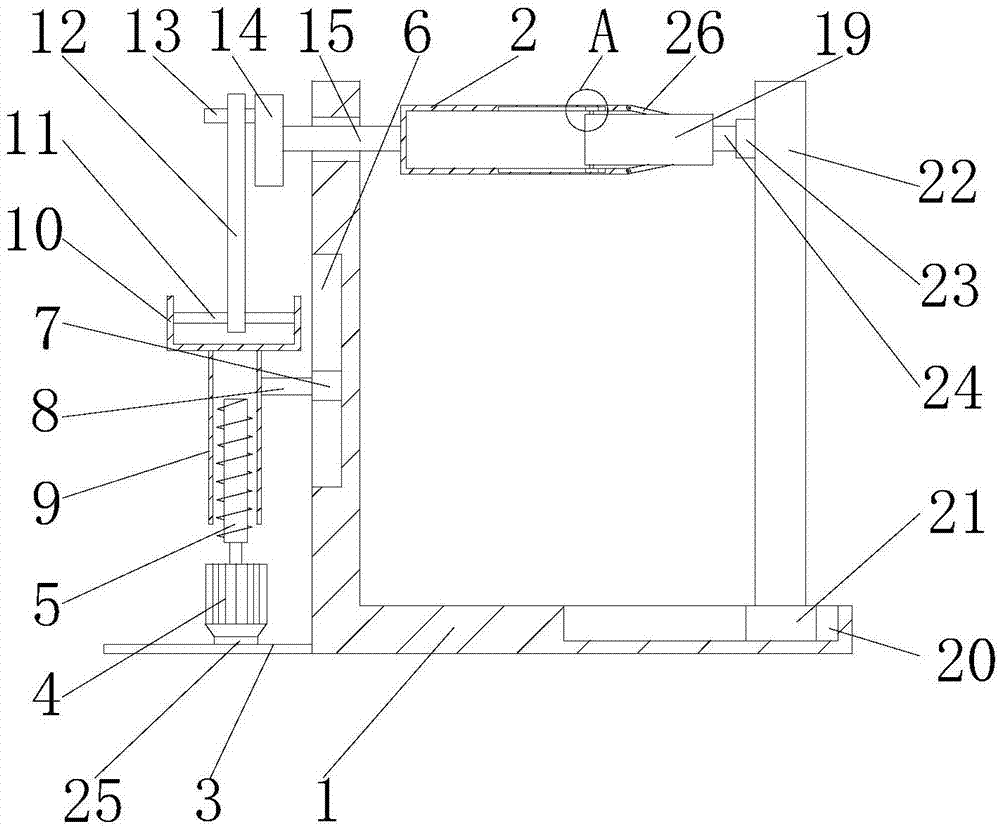

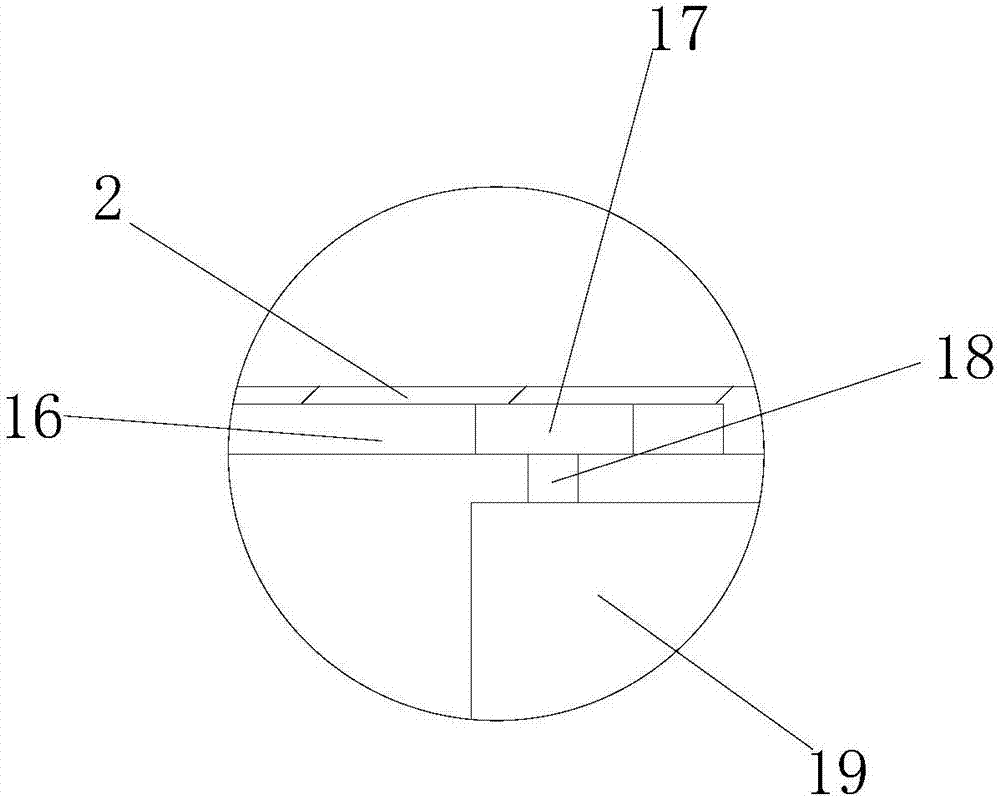

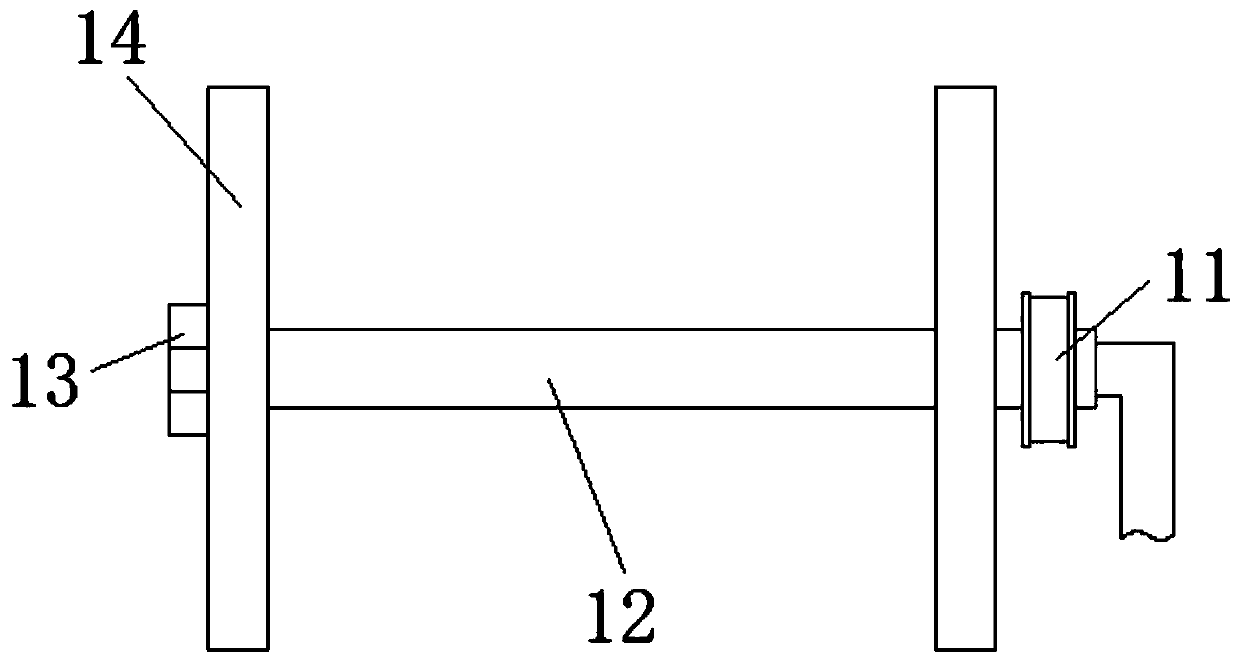

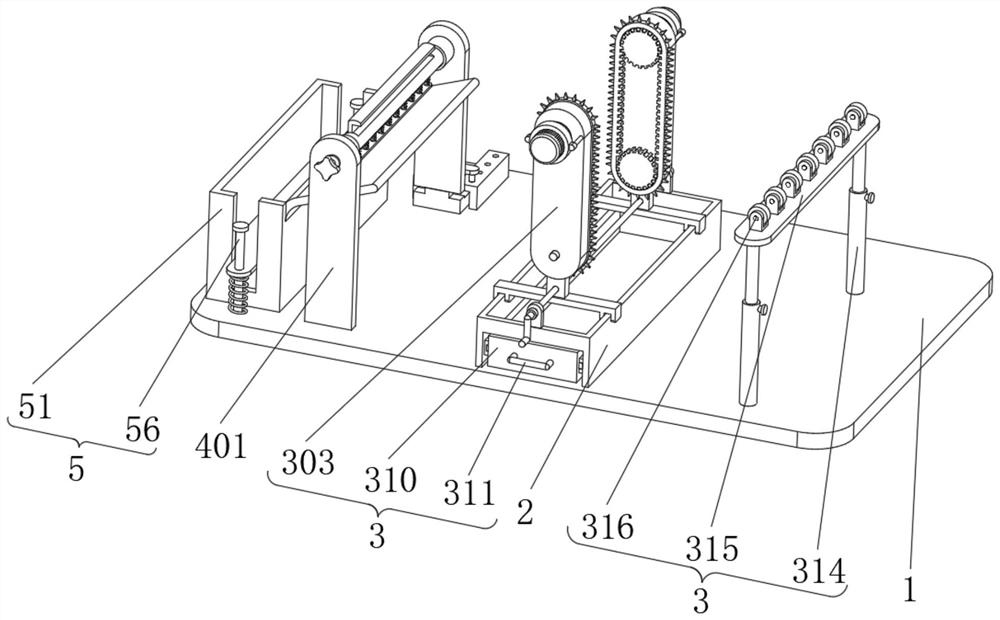

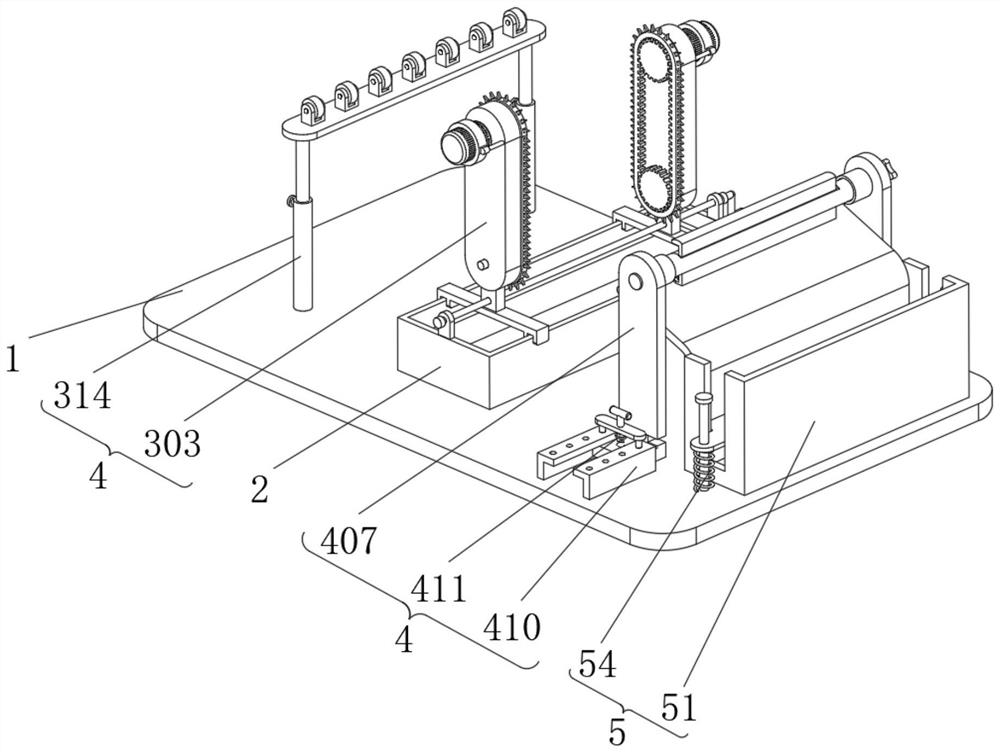

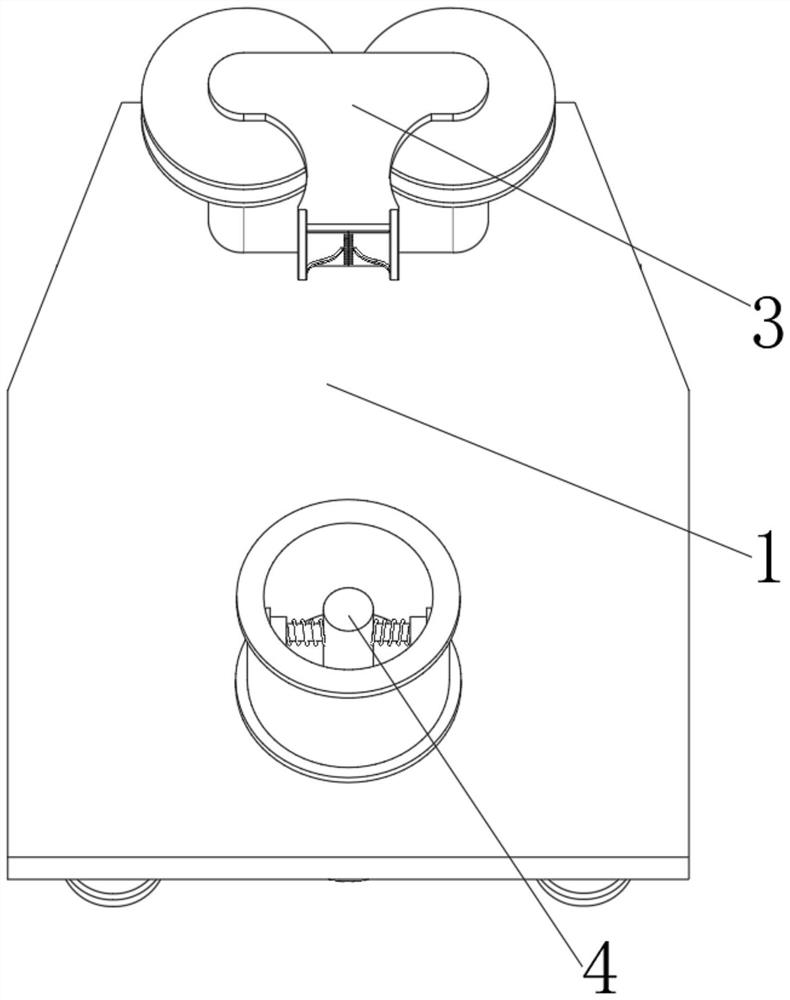

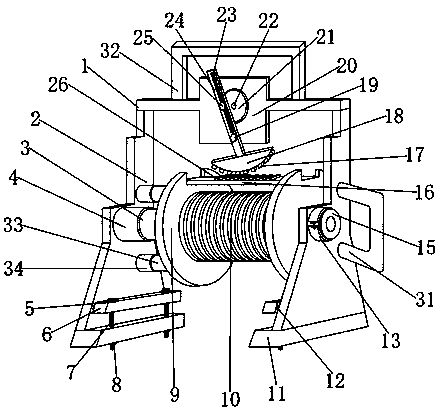

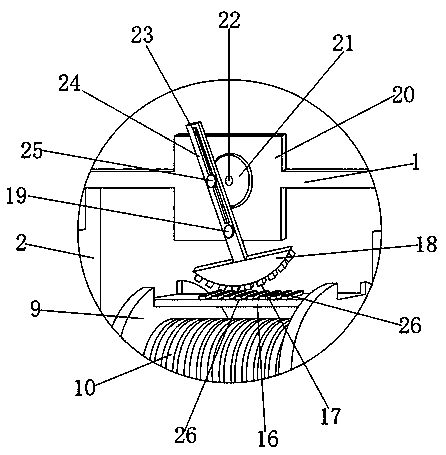

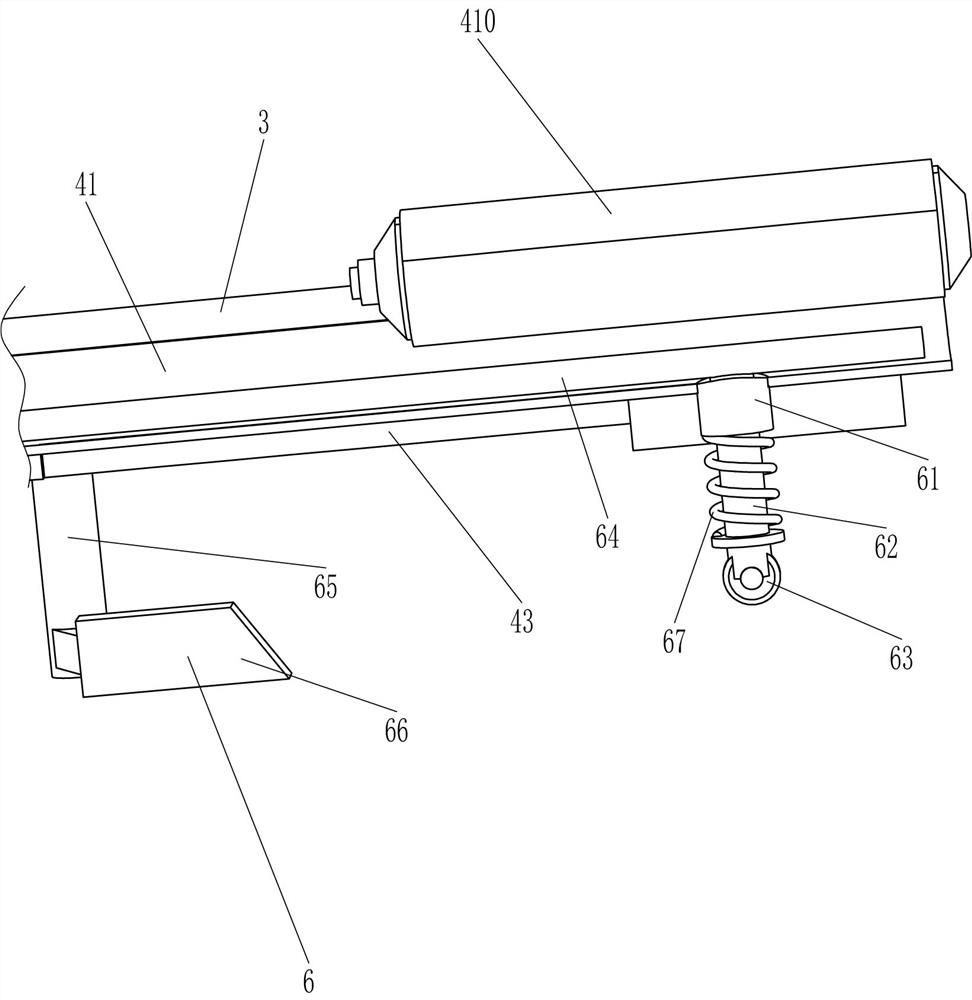

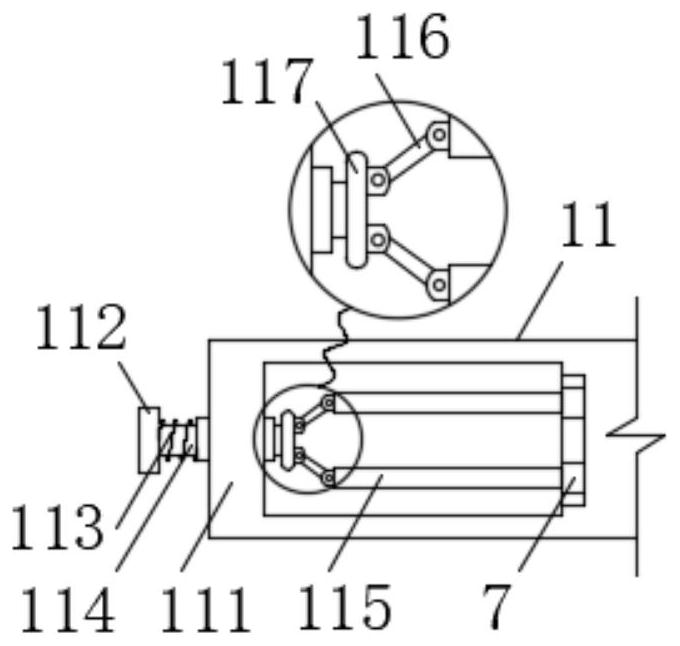

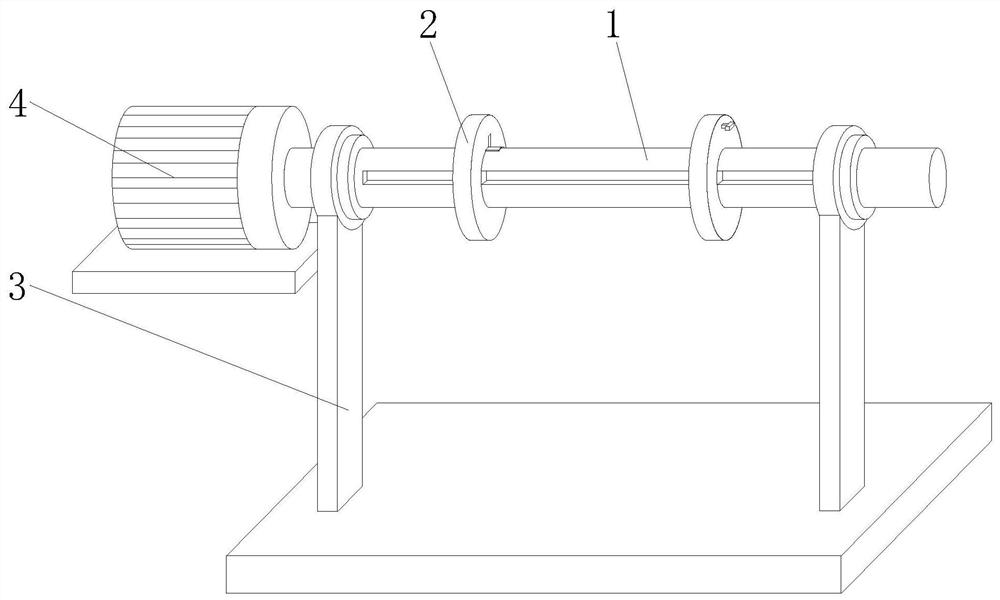

Equipment with quick take-up function for cable

InactiveCN112320473ATo achieve the winding effectEasy to cutFilament handlingElectric machineryElectric cables

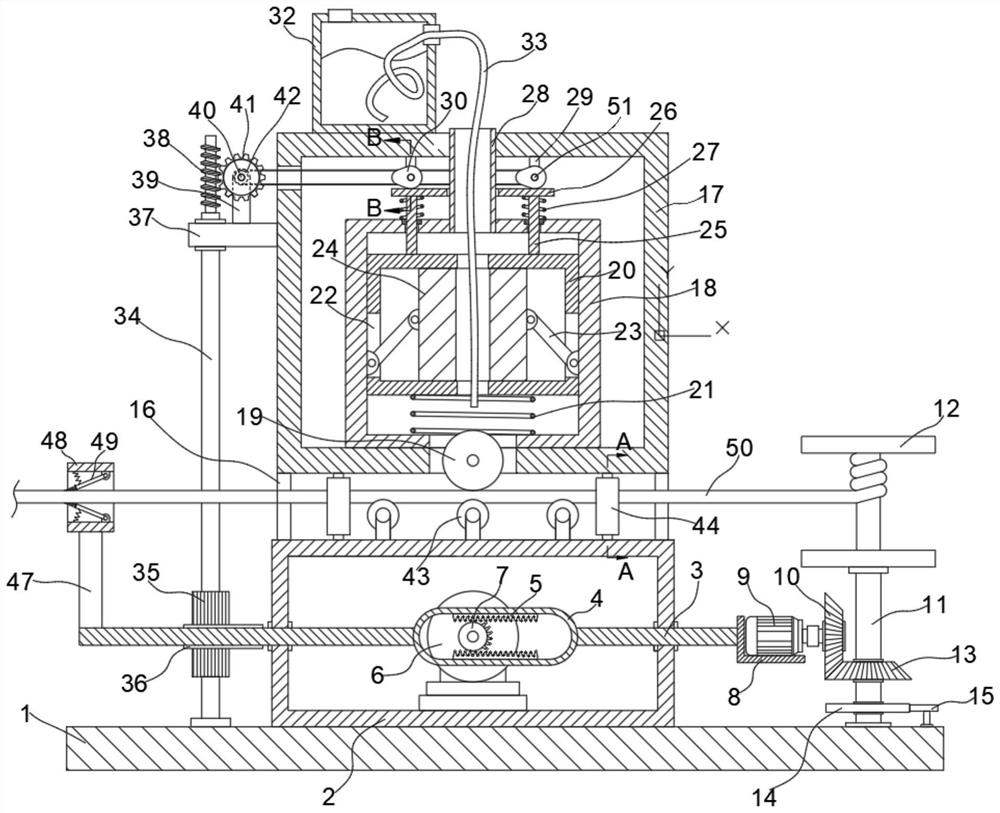

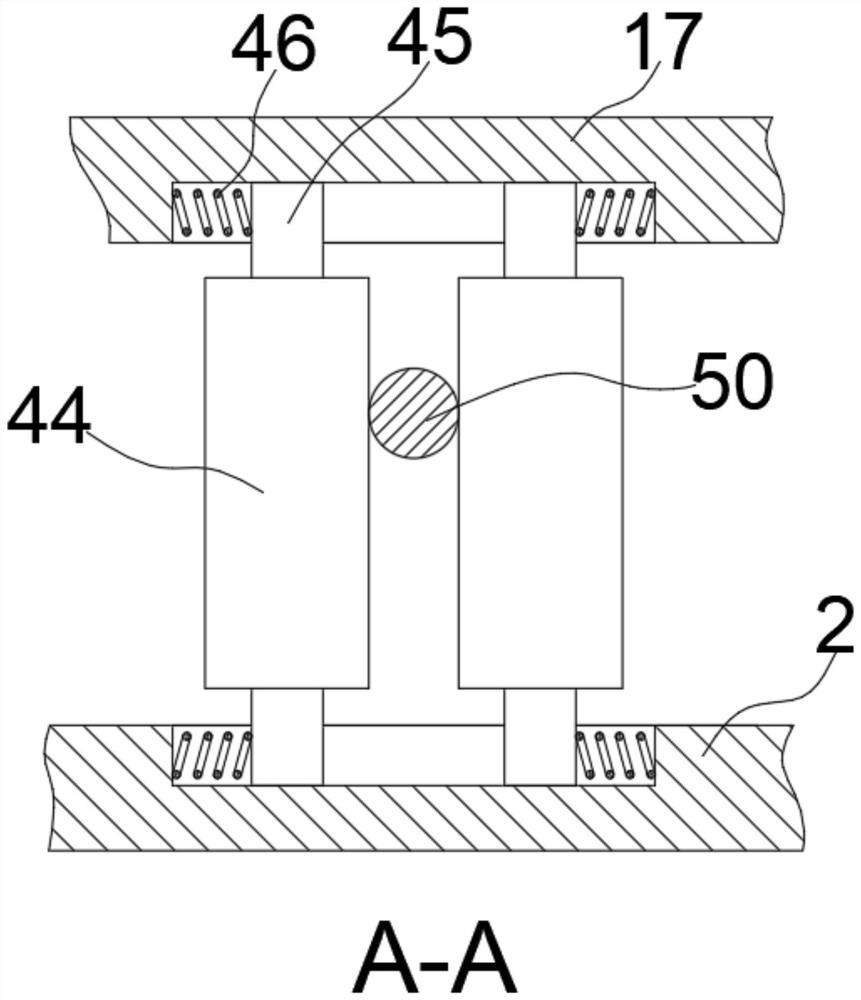

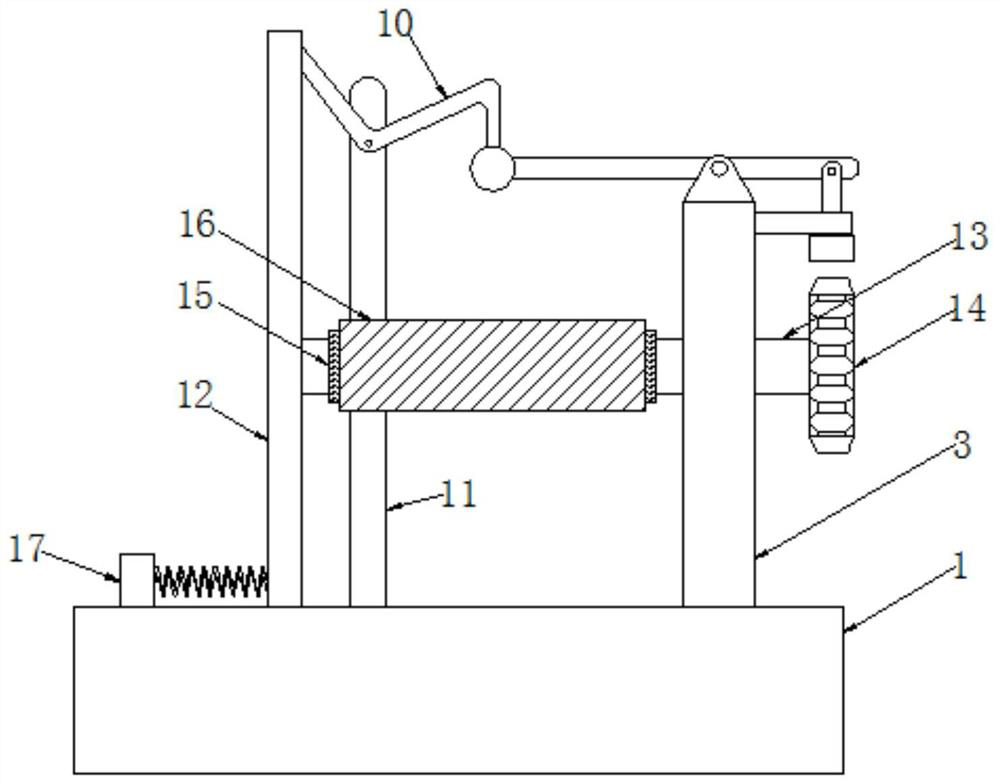

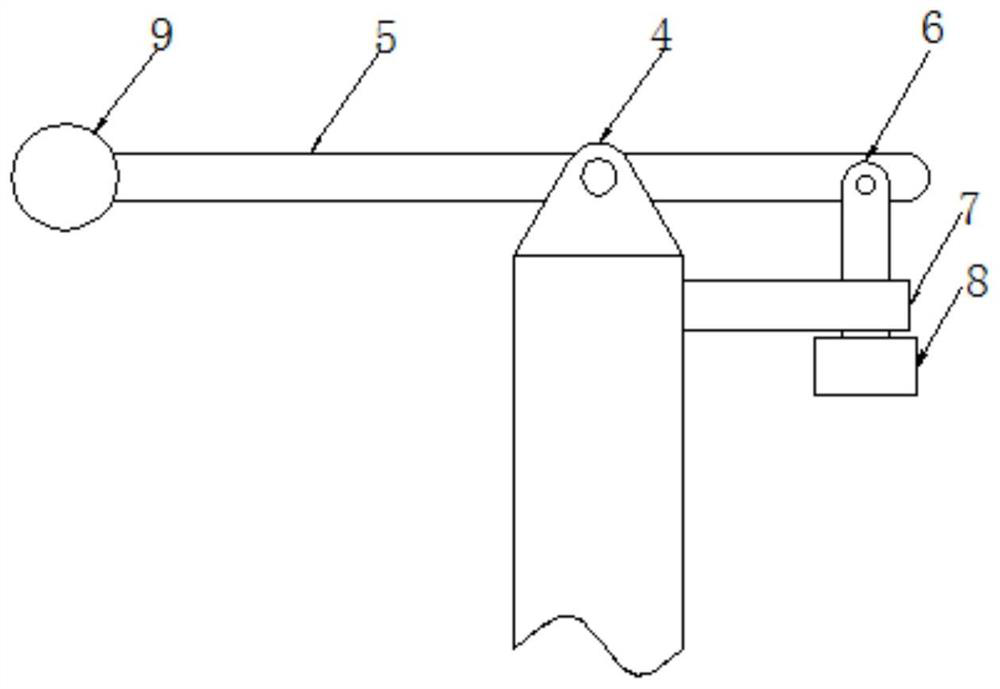

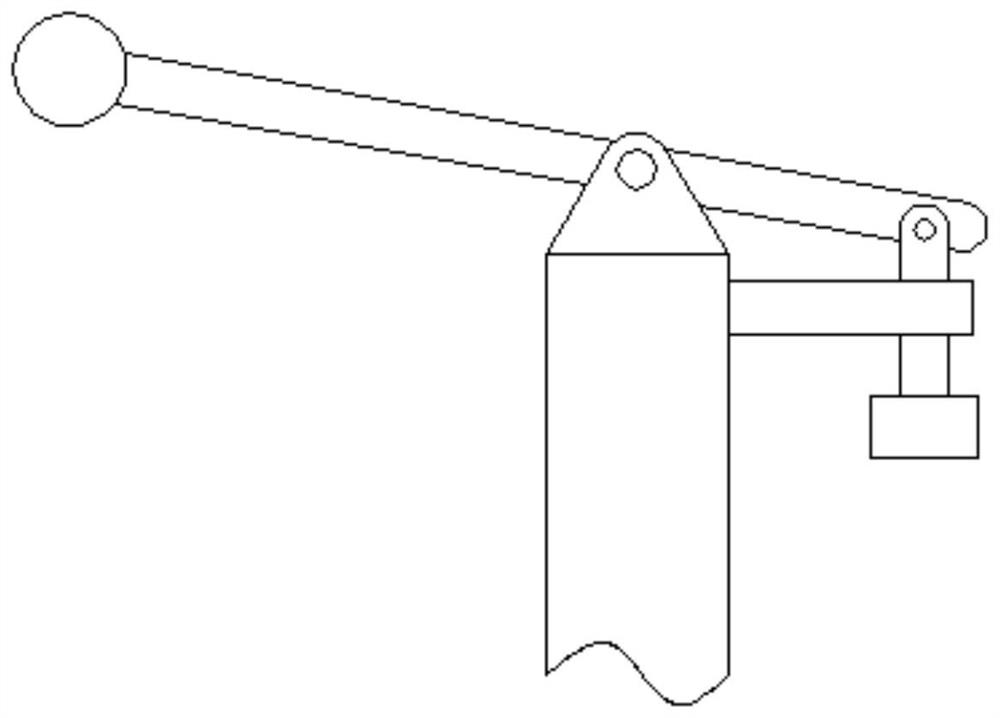

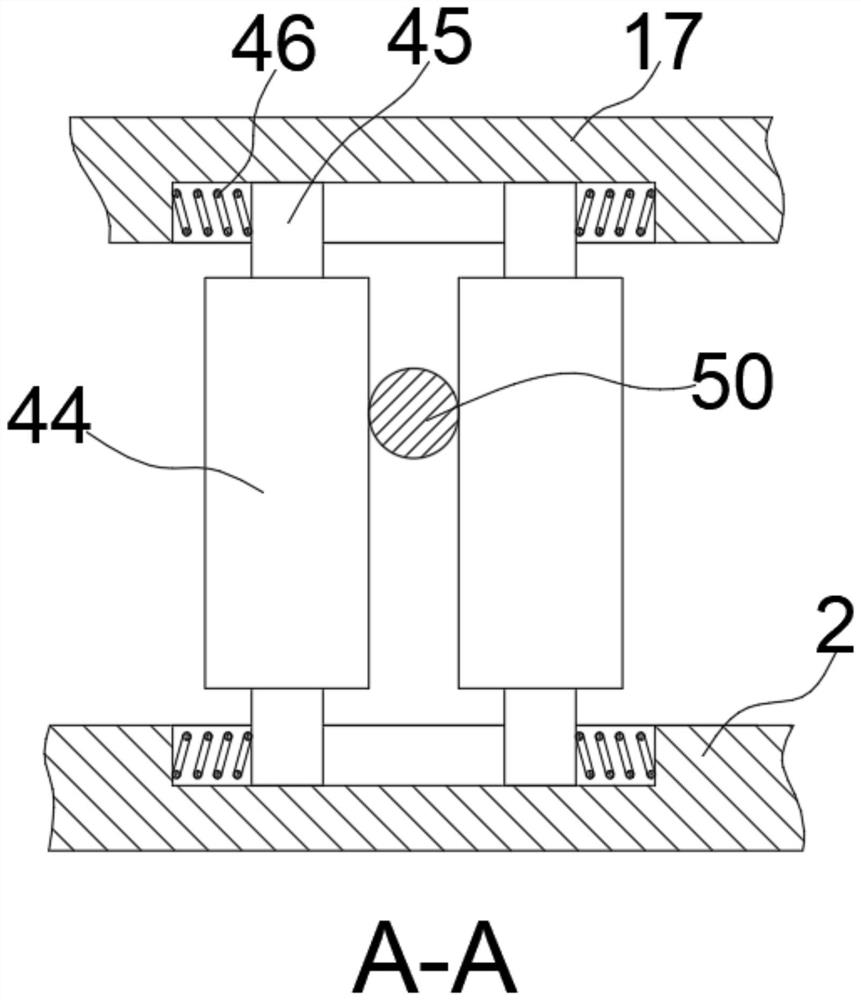

The invention relates to equipment with a take-up function, in particular to equipment with a quick take-up function for a cable. According to the equipment with the quick take-up function for the cable, the cable can be rapidly taken up, and the cable can be automatically cut off. The equipment with the rapid take-up function for the cable comprises a first supporting frame, a second supporting frame, a bottom plate, a coiling mechanism and an automatic rotating mechanism. The first supporting frame is provided with the second supporting frame. The bottom plate is arranged on the second supporting frame. The coiling mechanism is arranged on the bottom plate. The automatic rotating mechanism is arranged between the bottom plate and the coiling mechanism. According to the equipment with thequick take-up function for the cable, through mutual cooperation of the coiling mechanism and the automatic rotating mechanism, a motor is started, a rotating connecting rod automatically rotates, acable reel automatically rotates, accordingly, the cable is automatically wound, the effect of rapidly and automatically winding the cable is achieved, and through arrangement of a clamping mechanism,the cable is guided through a clamping rod.

Owner:江西万上实业有限公司

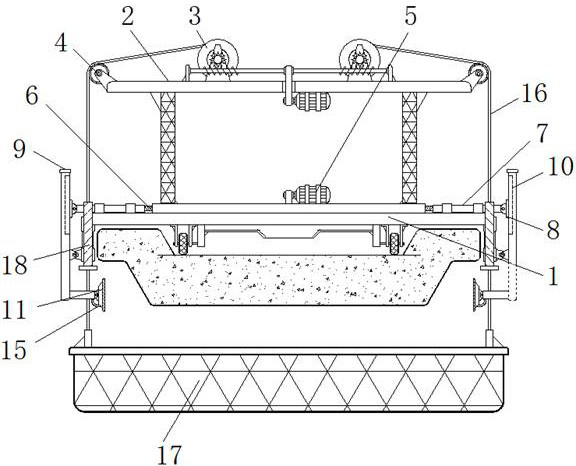

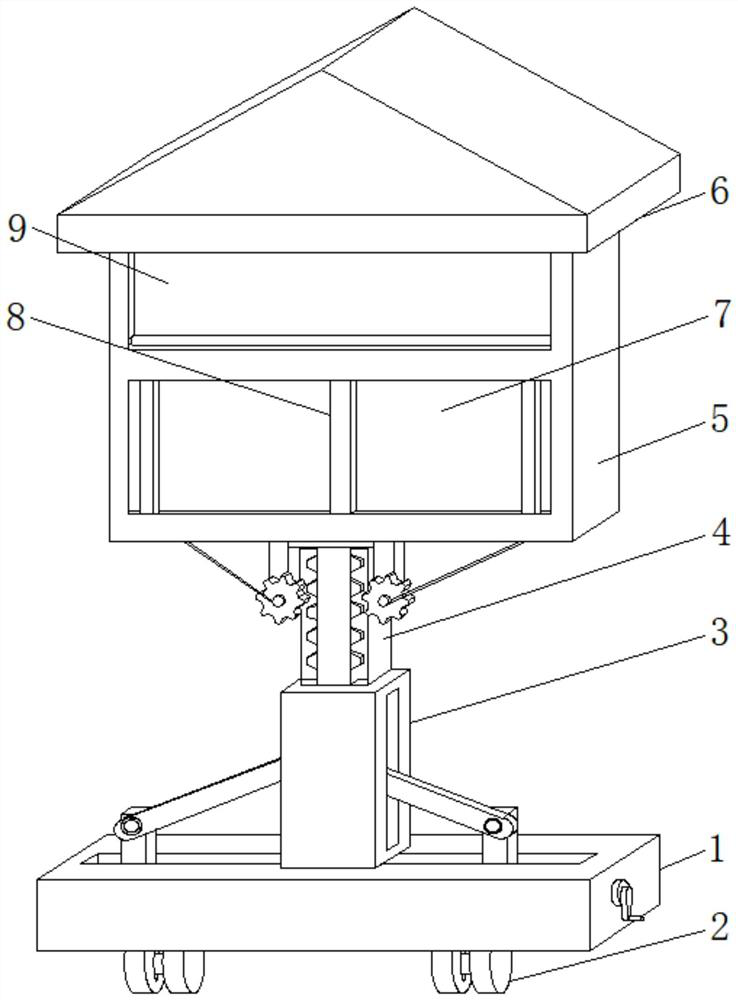

Quick lifting mechanism applied to bridge construction

InactiveCN111646362AImprove efficiency and stabilityReduce construction safety hazardsBase supporting structuresBraking devices for hoisting equipmentsElectric machineryWire rope

The invention discloses a quick lifting mechanism applied to bridge construction. The quick lifting mechanism comprises a movable rack, a motor crawler belt assembly and a hanging basket. The A trussis fixedly mounted on the top of the movable rack. The motor crawler belt assembly is fixedly mounted on the outer wall of the top of the movable rack. The outer wall of the end of the movable rack ishinged to the outer wall of the middle portion of a supporting frame. The upper half portion of the supporting frame is internally provided with sliding grooves. Wire ropes are wound on the outer walls of winding wheels and are attached to the outer walls of guide wheels. The hanging basket is fixed to the lower ends of the wire ropes. The edges of the ends of the movable rack are fixedly connected with locating tubes. The quick lifting mechanism applied to bridge construction facilitates position movement and change and positioning operation. The positioning and installation stability and efficiency of the mechanism are improved. Meanwhile, the quick lifting mechanism can be protected against falling in the using process. Potential construction safety hazards of the quick lifting mechanism during lifting motion are effectively reduced.

Owner:吕友飞

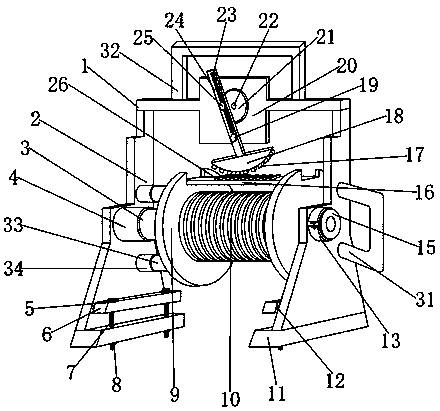

Automatic take-up and pay-off device for big data communication cable

The invention discloses an automatic take-up and pay-off device for a big data communication cable. The automatic take-up and pay-off device for the big data communication cable comprises a rack. Theupper end of the rack is fixedly connected with a cross beam. The center of the cross beam is fixedly connected with a motor box. An eccentric wheel is arranged at the center in the motor box. The outer side of the surface of the eccentric wheel is fixedly connected with an eccentric column. The outer wall of the eccentric column is sleeved with an oscillating bar. A groove is machined in the center of the oscillating bar. The eccentric column is connected with the oscillating rod through the groove in a sliding and clamping manner. The lower end of the oscillating bar is fixedly connected with a pendulum bob. First sawteeth are machined on the lower surface of the pendulum box. The lower end of the pendulum bob is provided with a transverse plate. Second sawteeth are machined on the uppersurface of the transverse plate. The second sawteeth are engaged with the first sawteeth. When the automatic take-up and pay-off device for the big data communication cable is used for taking up thecable, a servo motor is used for adjusting a coil to forwards rotate, a motor case is electrified and drives the eccentric shaft to rotate, the eccentric shaft drives the pendulum bob to swing, the sawteeth on the pendulum bob are engaged with the sawteeth on the transverse plate, and the transverse plate drives the coil to do reciprocating motion leftwards and rightwards so that the cable can beevenly wound on a winder.

Owner:新昌县杨辉网络科技有限公司

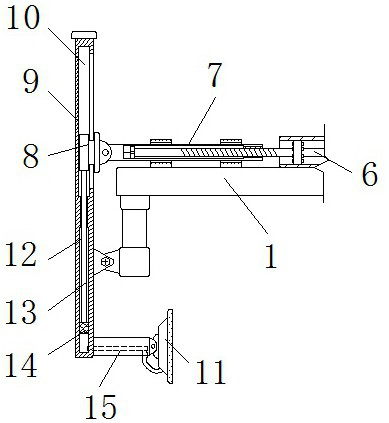

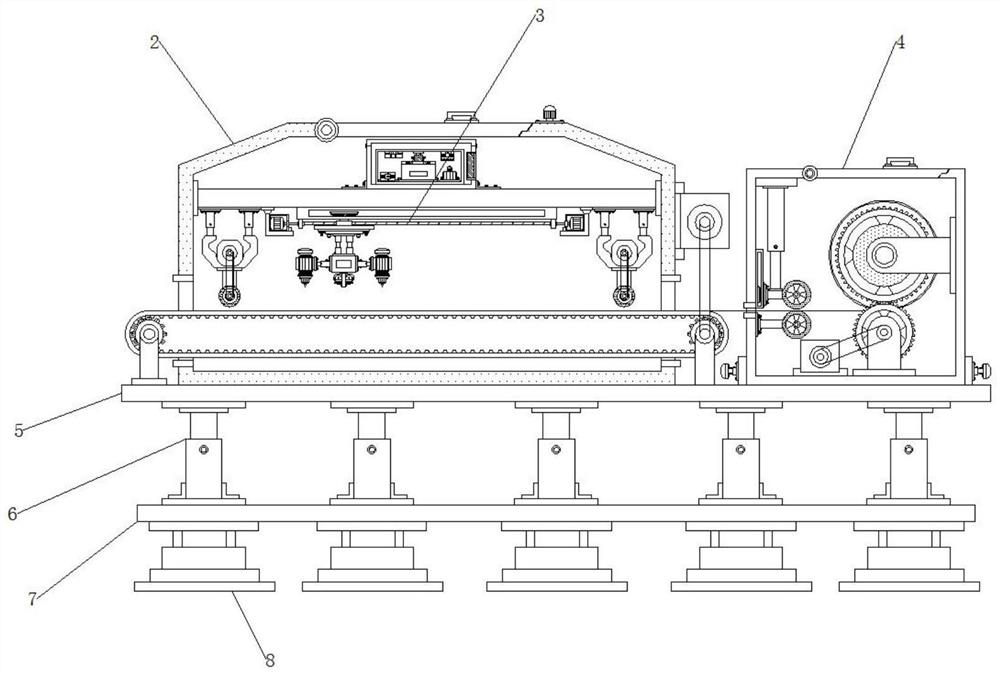

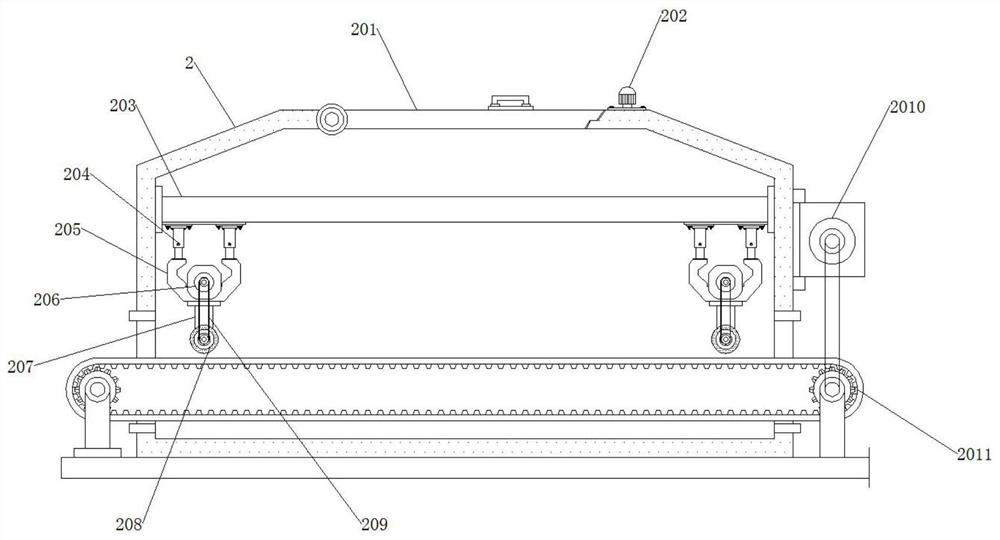

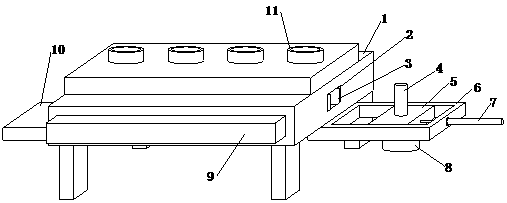

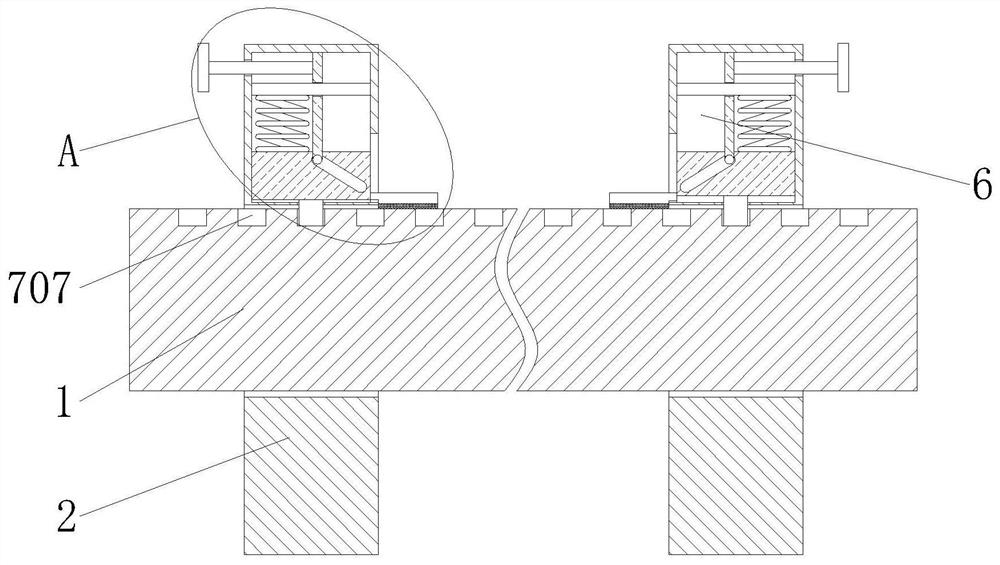

Roller device for spinning

InactiveCN107472952ATo achieve the winding effectImprove work efficiencyWebs handlingSlide plateEngineering

The invention discloses a roller device for spinning. The roller device comprises a base, wherein a roller body is arranged at the top of the base; a supporting plate is fixedly connected to the bottom of the left side of the base; a motor is arranged at the top of the supporting plate; the output shaft of the motor is fixedly connected with a threaded rod; and a first sliding groove is formed in the center of the left side of the base. According to the roller device for spinning, the threaded rod, the first sliding groove, a first sliding block, a first sliding plate, a threaded sleeve, a concave frame, a cross rod, a pull rod, a fixed shaft, a rotary plate and a movable rod are arranged and matched, so that the effect of cloth winding is achieved; second sliding grooves, second sliding blocks, second sliding plates, a rotating cylinder, a third sliding groove, a third sliding block, a vertical rod, a bearing and a rotating rod are arranged and matched, so that the effect of easily adjusting the length of a roller is achieved, thus the textile personnel can wind the cloth according to the size of the cloth, the working efficiency of the textile personnel is improved, and the practicability of the roller device for spinning is improved.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

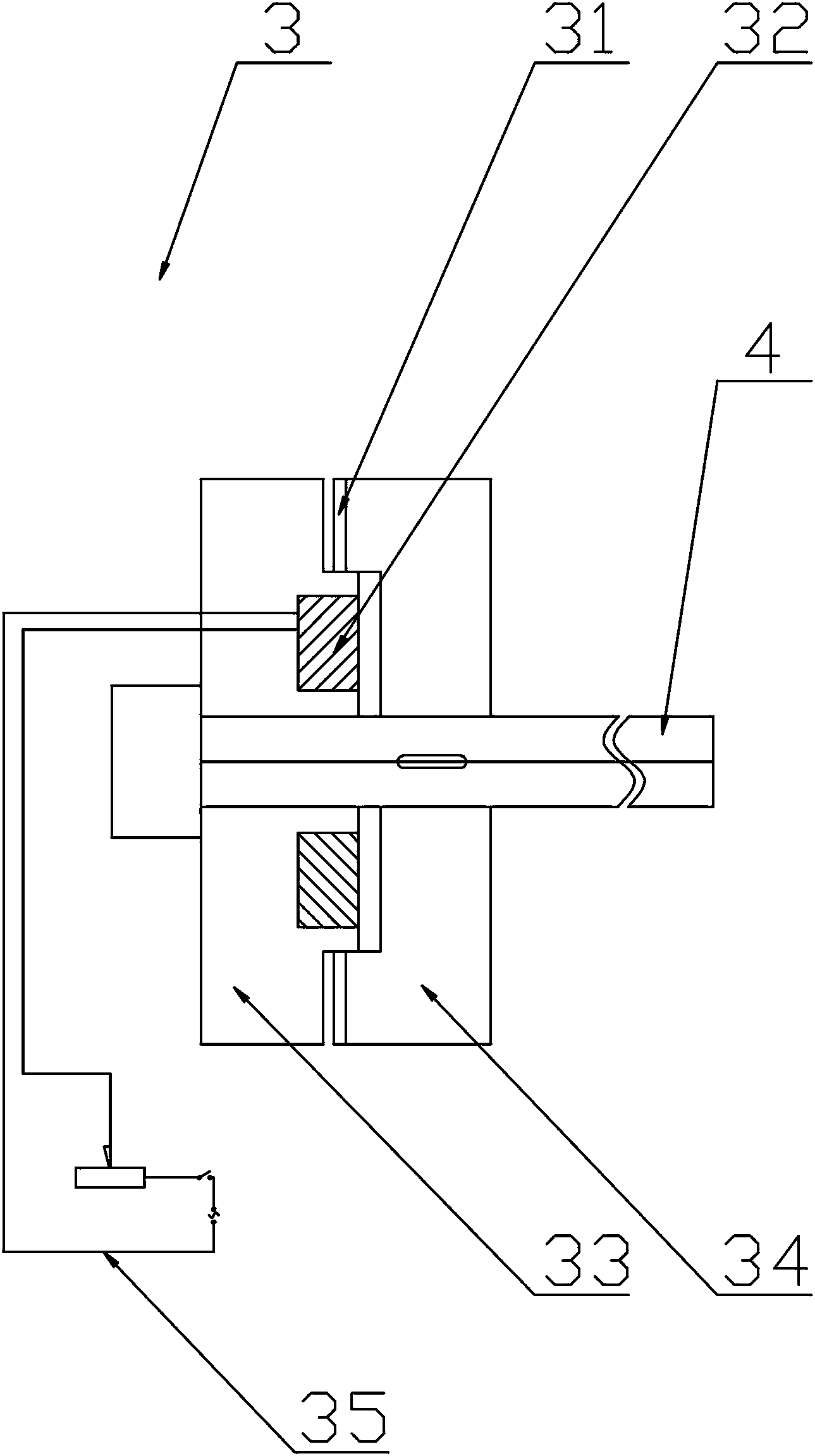

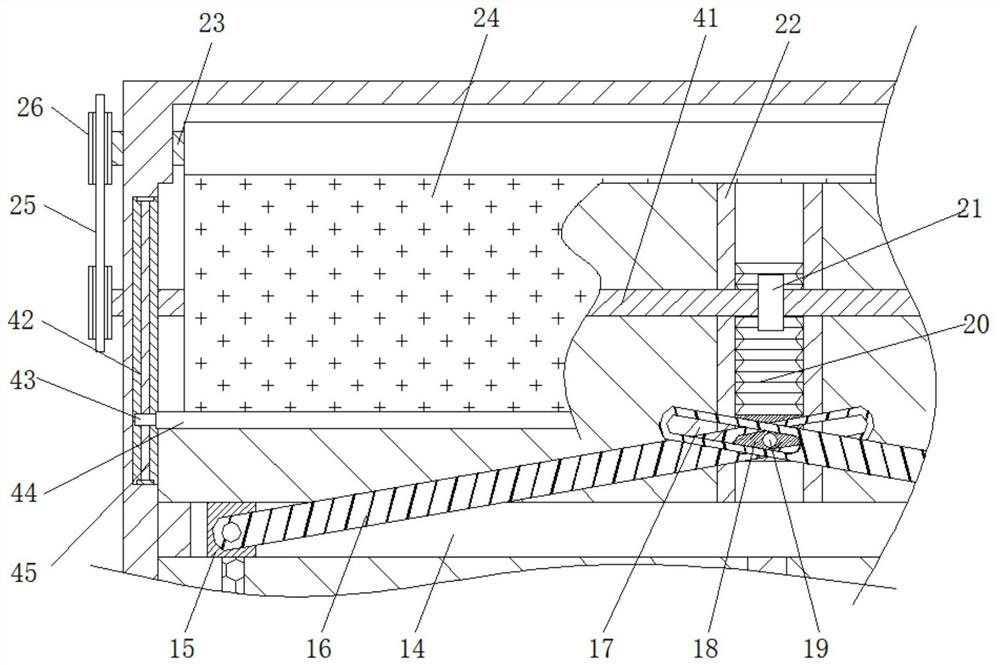

Pipe flaring equipment

PendingCN114013017ATo achieve the effect of temporary limitImprove cleanlinessFouling preventionHollow article cleaningClassical mechanicsEngineering

The invention provides pipe flaring equipment, and relates to the technical field of flaring machines. The pipe flaring equipment comprises a flaring machine and a cleaning structure, the surface of the flaring machine is provided with a driver, the surface of the flaring machine is provided with a clamp holder, the surface of the flaring machine is provided with two heating furnaces, the surface of the flaring machine is uniformly and fixedly connected with three pipe frames, a cleaning structure is arranged on the surface of the flaring machine and comprises a fixing frame, the fixing frame is fixedly connected to the surface of the flaring machine, an air cylinder is fixedly connected to one end of the fixing frame, a sliding frame is fixedly connected to the output end of the air cylinder, and a gear ring is slidably connected to the surface of the sliding frame. The invention solves the problems that: before a traditional pipe flaring machine flares a pipe, the surface of the pipe is inconvenient to clean, after the pipe is heated and during flaring, the flaring position of the pipe is prone to being uneven due to impurities on the surface of the pipe when the pipe is flared by equipment, and then the production quality of the pipe flaring machine is affected to a certain degree.

Owner:常州市德胜塑料机械有限公司

Slitting and tape breaking device for die cutting of self-adhesive labels

InactiveCN112456214AAchieve the effect of cutting and slittingImprove work efficiencyArticle deliveryWebs handlingAdhesiveEngineering

The invention discloses a slitting and tape breaking device for die cutting of self-adhesive labels. The slitting and tape breaking device comprises a slitting and tape breaking device main body, a slitting mechanism, a tape breaking mechanism and a collecting mechanism, the slitting mechanism is connected to one side of the slitting and tape breaking device main body in an embedded mode, the collecting mechanism is connected to the other side of the slitting and tape breaking device main body in an embedded mode, a mounting plate is connected to the bottom end of the slitting and tape breaking device main body in an embedded mode, a hydraulic telescopic plate is connected to the bottom end of the mounting plate in an embedded mode, a fixed base is connected to the bottom end of the hydraulic telescopic plate in an embedded mode, the slitting mechanism facilitates cutting and slitting of machined products, the working efficiency of the device is improved, The belt breaking mechanism facilitates transverse belt breaking treatment on a machined product, the multifunctionality of the device is improved, the belt breaking mechanism is composed of a second motor, a threaded lead screw,a movable block, a transverse mover, a telescopic rod and a laser cutter, the belt breaking mechanism facilitates transverse belt breaking treatment on the machined product, the multifunctionality ofthe device is improved, and the practicability of the device is improved. and wide development prospects are realized in the future.

Owner:芜湖韩大防伪科技有限公司

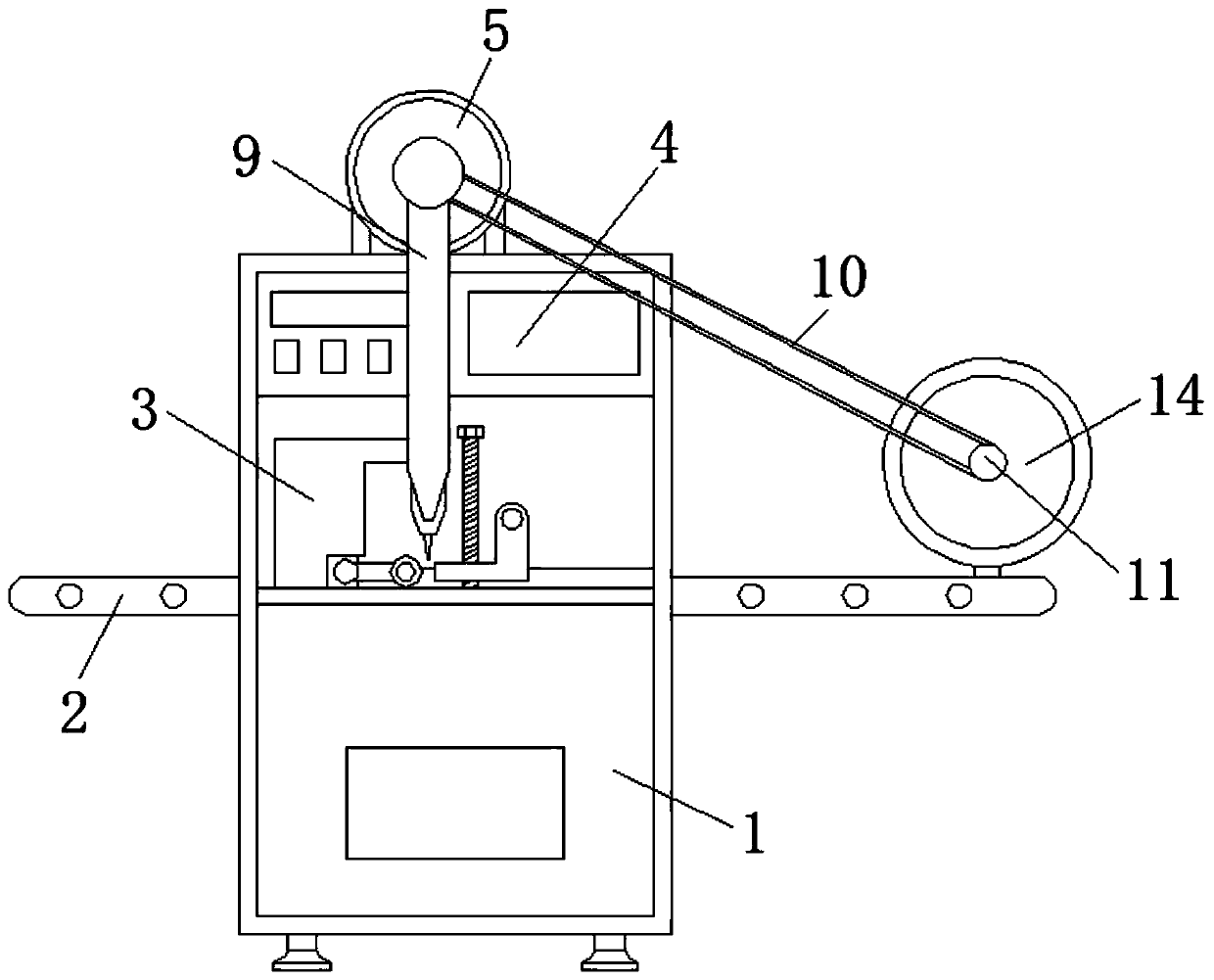

Wire and cable surface lettering equipment

ActiveCN112265365APrevent printing from being clear enoughAchieve the effect of replenishing inkFilament handlingCleaning using toolsEngineeringStructural engineering

The invention discloses electric wire and cable surface lettering equipment, the electric wire and cable surface lettering equipment comprises a base, a driving mechanism is arranged at the top of thebase, an ink adding mechanism is arranged at the top of the driving mechanism, a cleaning mechanism is arranged on one side of the driving mechanism, a winding mechanism is arranged at the top, awayfrom the cleaning mechanism, of the base, and a transmission mechanism is arranged between the ink adding mechanism and the driving mechanism. According to the electric wire and cable surface lettering equipment, by arranging the driving mechanism, the ink adding mechanism, the cleaning mechanism and the winding mechanism, the surface of a cable can be cleaned, lettering can be conducted on the cable while winding is conducted, meanwhile, ink can be continuously supplemented to a lettering wheel, and the situation that lettering is not clear due to the fact that the ink of the lettering wheelis too little is prevented.

Owner:安徽扬子线缆有限公司

Alumite waste collection machine

InactiveCN103723545ACompact structureTo achieve the winding effectWebs handlingElectromagnetic clutchSingle plate

An alumite waste collection machine comprises a motor and a speed reducer connected with the motor, wherein the speed reducer is connected with a rolling shaft through an electromagnetic clutch, and the electromagnetic clutch is a single-plate friction clutch. The alumite waste collection machine is simple and compact in structure and is integrally modularized. According to the principle of the alumite waste collection machine, the motor and the speed reducer drive the electromagnetic clutch, the electromagnetic clutch controls the rolling tension of the rolling shaft, meanwhile, alumite is conveyed to the rolling shaft through a guide shaft wheel and a compression shaft wheel, the rolling speed of the rolling shaft and the unrolling speed of the alumite of printing equipment are made to be balanced, and the rolling effect is achieved.

Owner:HUBEI GOLDEN THREE GORPRINTING IND

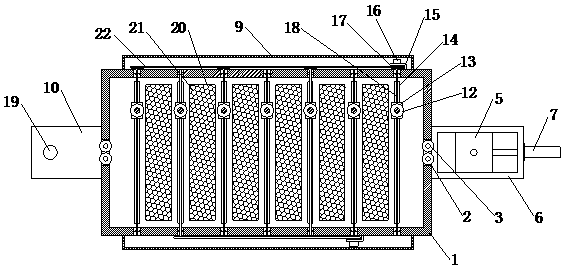

Yarn drying device for spinning and drying operation method thereof

ActiveCN110906721AIncrease or decrease lengthReasonable structural designFilament handlingDrying gas arrangementsYarnSpinning

The invention discloses a yarn drying device for spinning and a drying operation method thereof. The drying device comprises a long flat box, a square opening, a fixed pulley, a first inflatable shaft, a traction plate, a rectangular frame, an air cylinder, a first motor, a protective cover, a side supporting plate, an exhaust fan, wire guide wheels, a T-shaped block, a strip-shaped sliding groove, an L-shaped plate, a second motor, a belt wheel, a long screw, a second inflatable shaft, a square strip hole, electric heating wires and triangular belts. The drying device is advantaged in that the drying device is reasonable in structural design, seven wire guide wheels are distributed in a staggered traction manner, to-be-dried yarns can be distributed in the drying structure in a broken line shape, flexible adjustment is achieved, the length of the yarn in the drying structure is increased or decreased, hot air in the drying structure can flow upwards from the bottom, the drying effectis achieved, the dried yarn is wound together through the rotating first air expansion shaft, the connected traction plates are driven by the started air cylinder to move outwards, the effect of drying and winding at the same time is achieved, and that the yarn can still be normally wound when the diameter of a yarn roll is gradually increased can be guaranteed.

Owner:浙江伟伦新材料股份有限公司

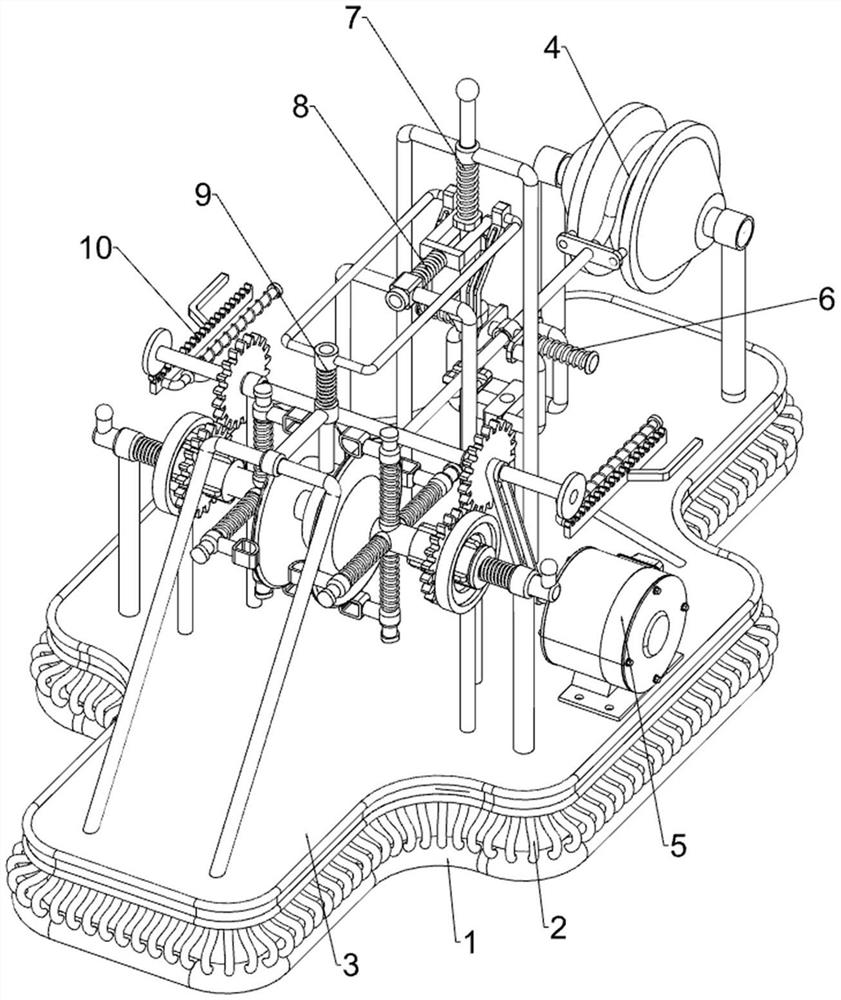

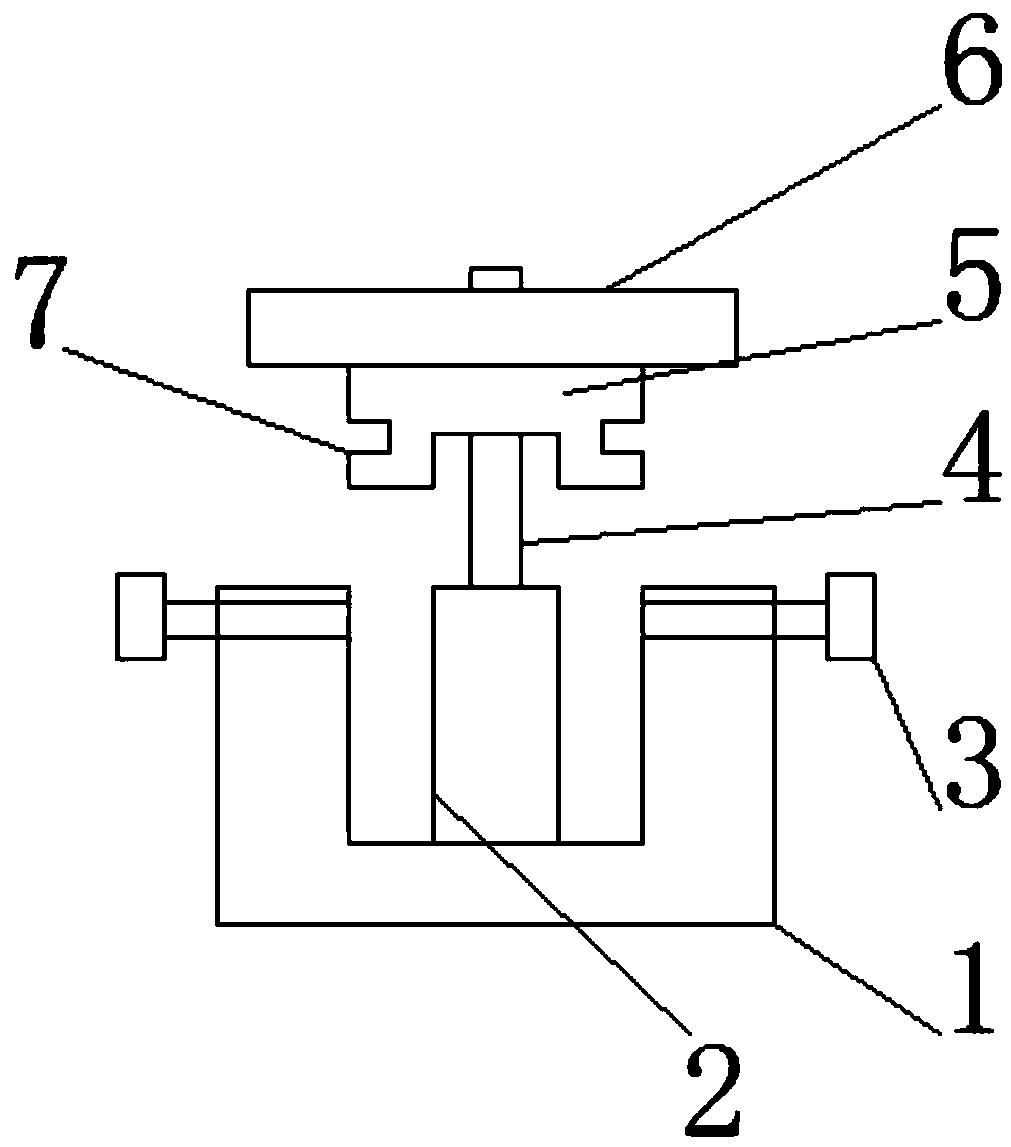

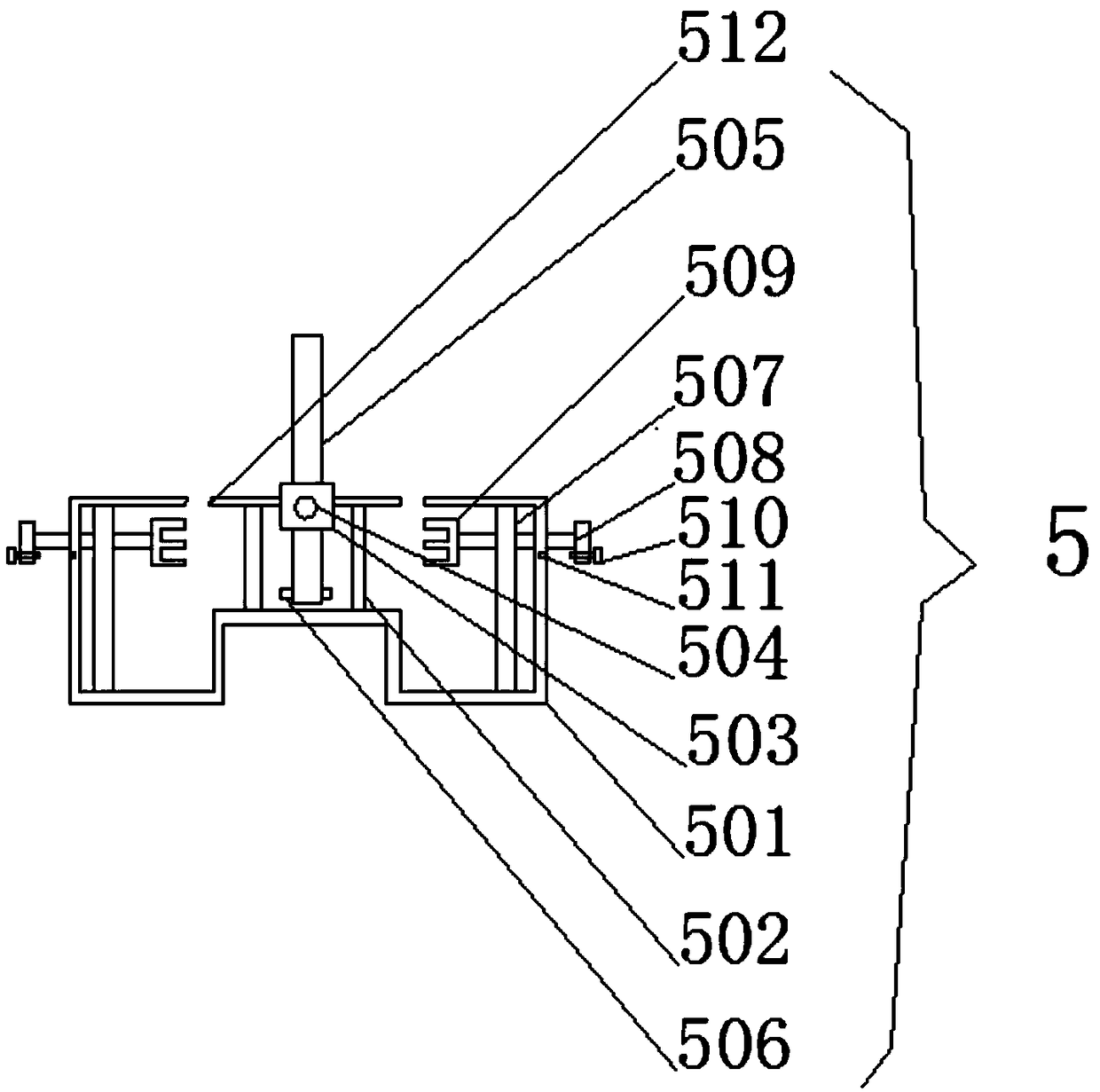

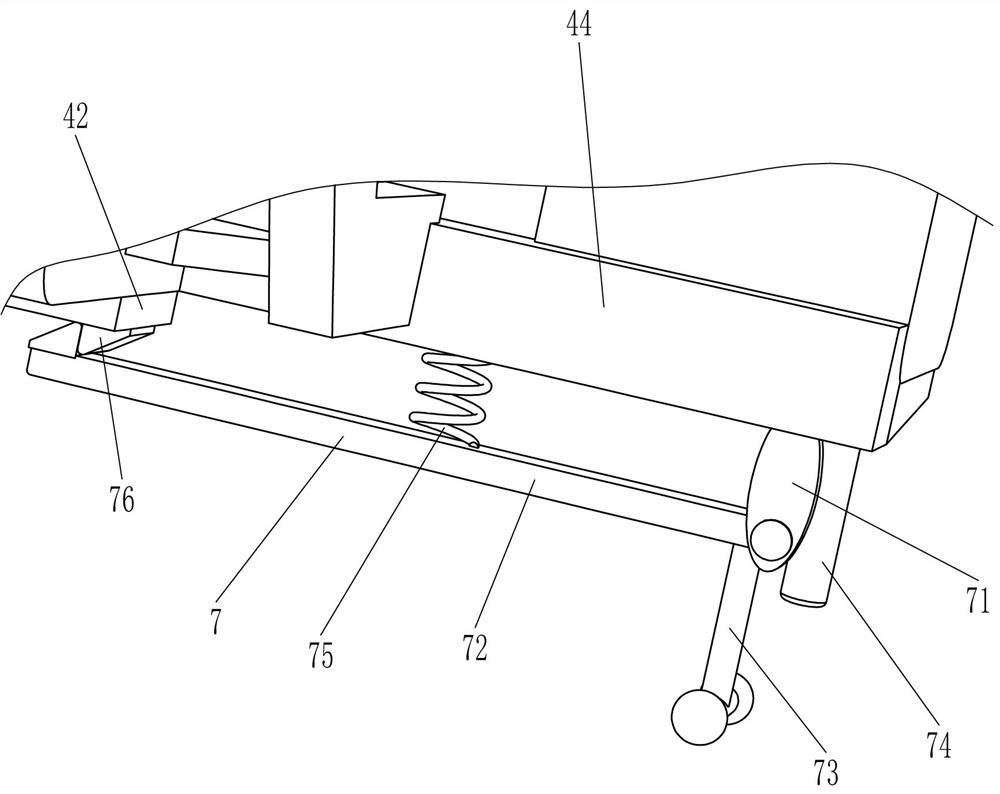

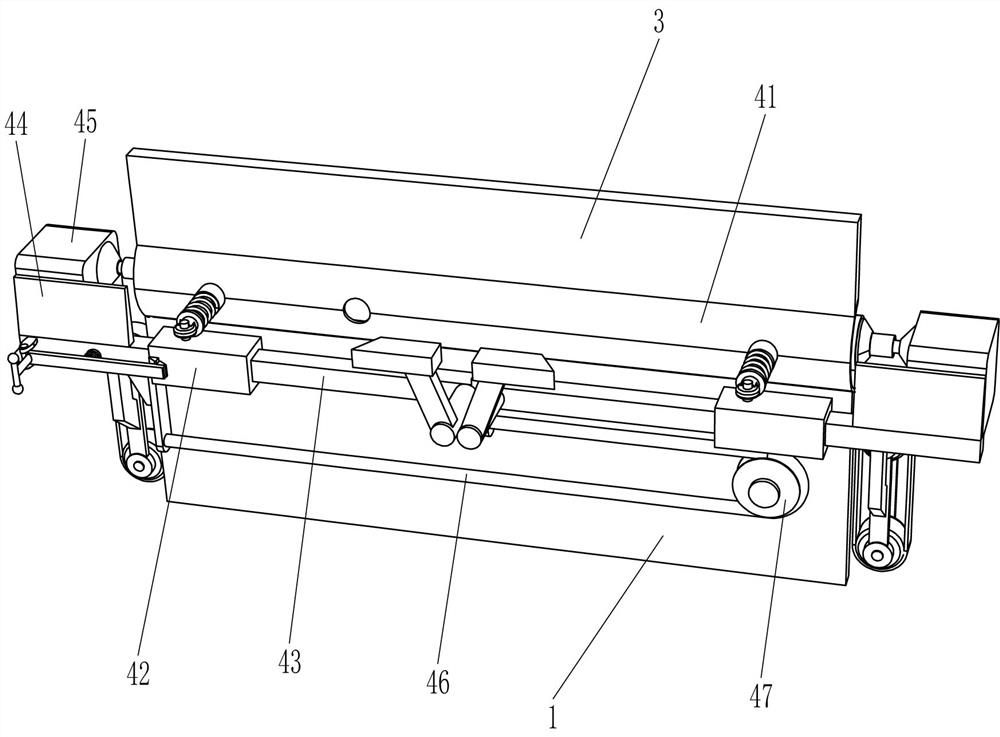

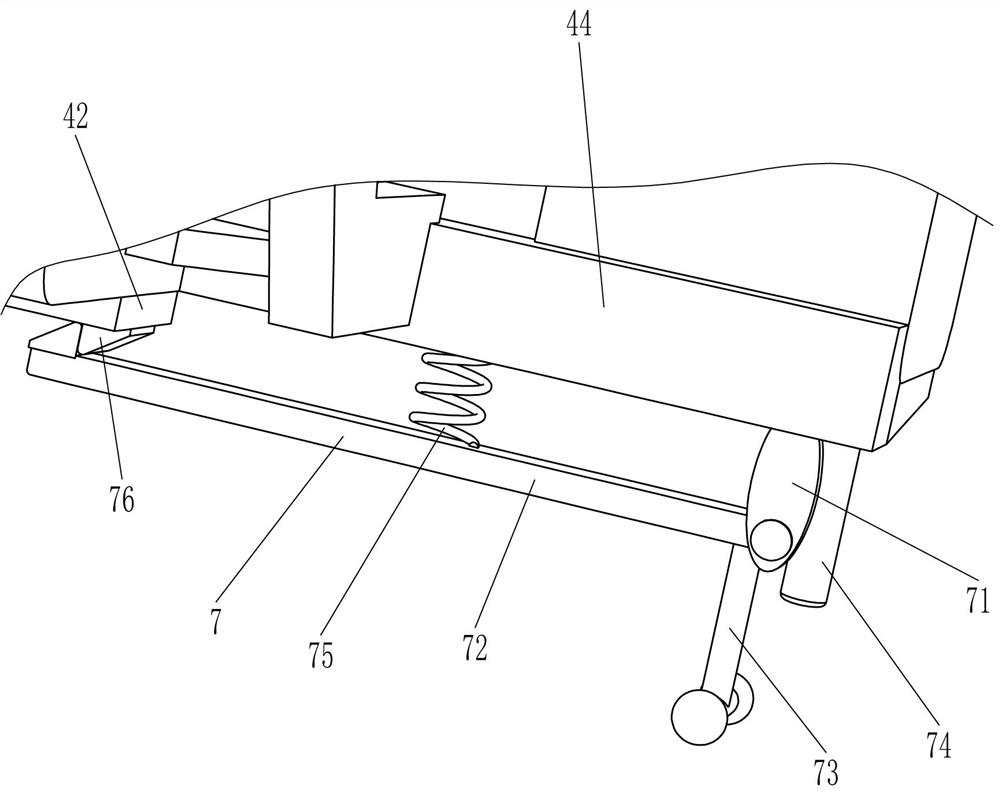

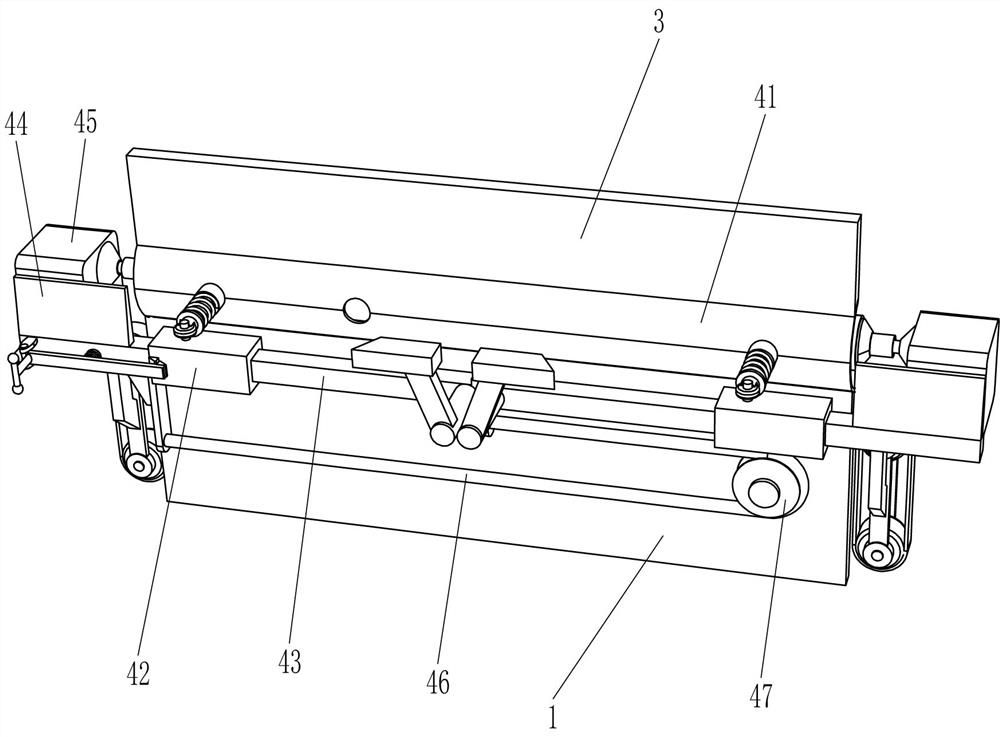

Floor sweeping wire harness rolling device

InactiveCN108750832APlay a protective effectTo achieve the winding effectCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention provides a floor sweeping machine wire harness rolling device, and relates to the technical field of rolling devices. The floor sweeping machine wire harness rolling device comprises a base. A support rod is fixedly arranged at the bottom of the base. A sliding rod is fixedly arranged at the top end of the support rod. The sliding rod is sleeved with a device table. The upper portionof the device table is fixedly provided with a transverse plate. According to the floor sweeping machine wire harness rolling device, through the arrangement of the device table, fulcrum bars fixedlyarranged at the bottom of an outer box and a fixing plate fixedly arranged on the tops of the fulcrum bars and mutual cooperation of an installing block, a bearing and a rotation rod, first screws arranged at the right ends of rotation shafts can be matched with first screw grooves, when rolling work is finished, the rotation shafts are fixed, and therefore a rolled wire harness can be fixed; through the arrangement of supporting rods, the rolled wire harness can be fixed; through the arrangement of the support rod, the sliding rod is fixed to the upper end of the support rod, the transverseplate penetrating the upper end of the sliding rod and the device table are mutually matched, and accordingly the rolling effect is achieved; and the supporting rods are arranged, and the rotation shafts penetrate the right side of the outer box and the supporting rods.

Owner:芜湖勇沃汽车部件有限公司

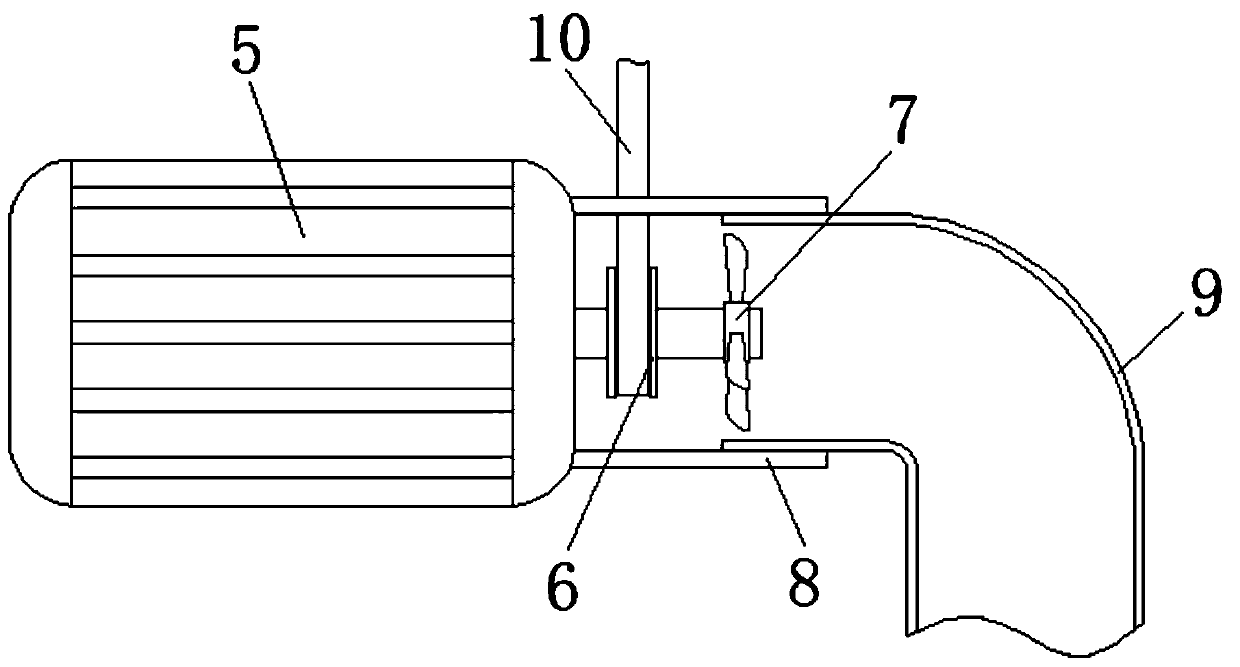

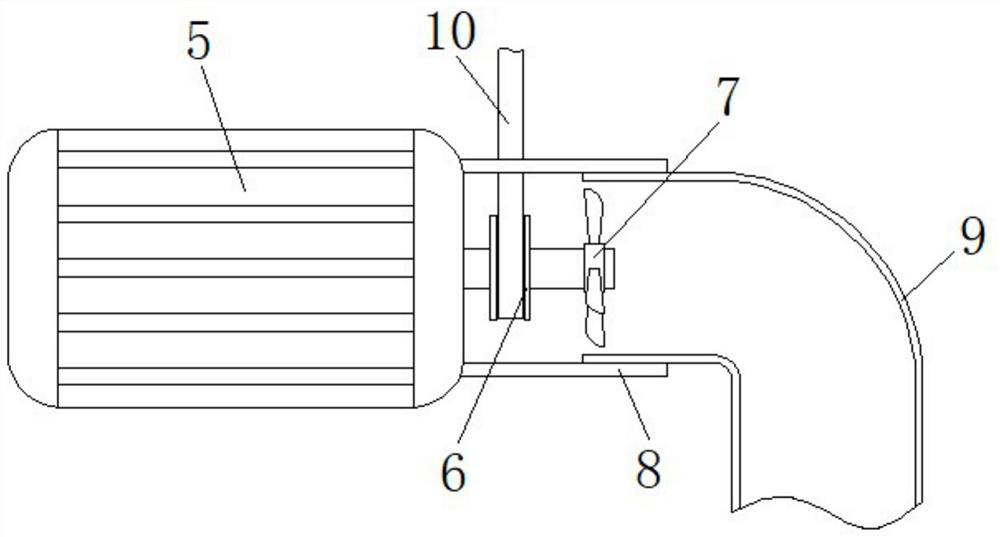

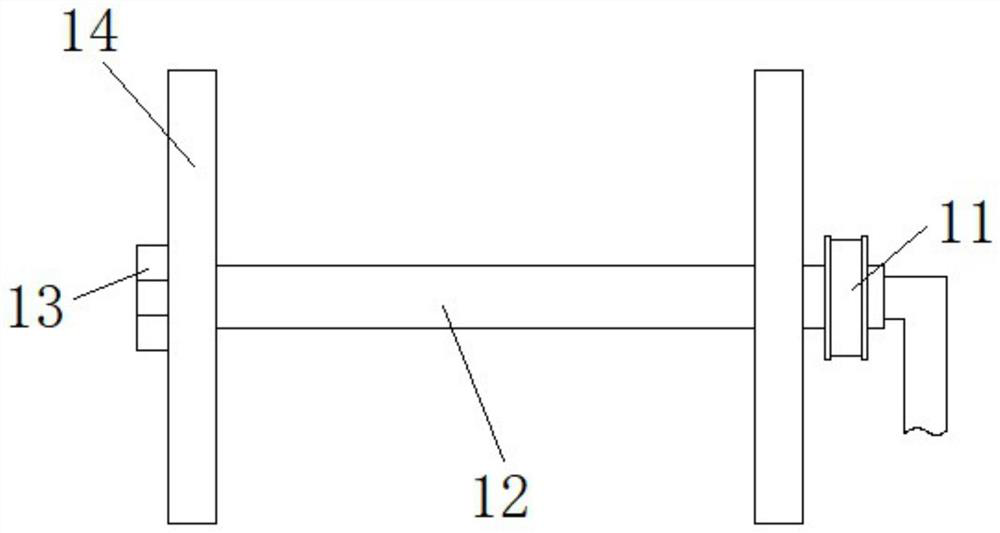

Intelligent control thermal cutting machine for chemical fiber production and method for automatic thermal cutting in chemical fiber production

ActiveCN111304786AAvoid clutterTo achieve the winding effectMetal working apparatusSevering fibresFiberElectric machinery

An embodiment of the invention discloses an intelligent control thermal cutting machine for chemical fiber production. The machine comprises a machine body; the middles of the left and right sides ofthe machine body are fixedly connected with placing platforms which extend to outside; the machine body is divided into an upper layer and a lower layer; the upper part of the machine body is providedwith a thermal cutting device and a main control device located above the thermal cutting device; a motor is mounted in the middle of the top surface of the machine body; one end of an output shaft of the motor is fixedly sleeved with a rotating ring I and fan blades; the fan blades are located on the left side of the rotating ring I; and the upper and lower sides of the right side of the motor are fixedly connected with connection rods which extend to outside. According to the intelligent control thermal cutting machine for chemical fiber production, the motor is designed and used together with a rotatable main shaft, so that after the thermal cutting machine cuts off chemical fibers, the main shaft can be driven by the motor to rotate for winding chemical fiber materials, the problem that the chemical fibers are disordered as the chemical fibers are not sorted after being cut off by the thermal cutting machine and the chemical fibers are relatively low in flexibility is avoided, andthe practicality of the thermal cutting machine is greatly improved. Correspondingly, the invention further discloses a method for automatic thermal cutting in chemical fiber production.

Owner:青岛奥利普奇智智能工业技术有限公司

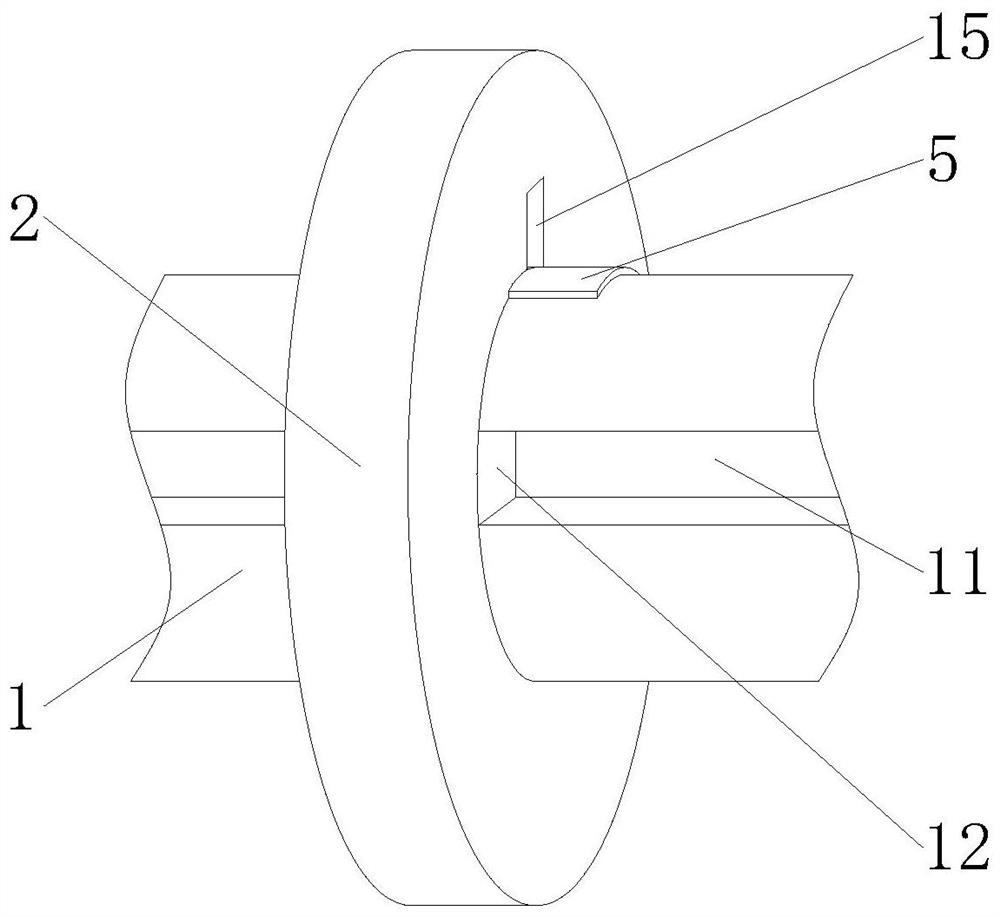

Textile silk yarn auxiliary equipment for preventing breakage and improving winding quality in winding process

InactiveCN112723001ATo achieve the winding effectImprove winding qualityFilament handlingYarnEngineering

The invention relates to the technical field of textile fabrics, and discloses textile silk yarn auxiliary equipment for preventing breakage and improving winding quality in the winding process. The textile silk yarn auxiliary equipment comprises a driving shaft, a clamping plate is movably connected to the exterior of the driving shaft, a speed limiting plate is movably connected to the exterior of the clamping plate, and a speed limiting magnet is movably connected to the interior of the speed limiting plate. The top of the speed limiting plate is movably connected with an adjusting spring, the top of the adjusting spring is movably connected with a speed reducing rod, and the top of the speed reducing rod is movably connected with an electrified magnet. When a silk yarn is clamped at a certain position, a winding roller can apply tension to the silk yarn, the tension finally compresses a buffer spring to drive a piezoelectric switch to generate current, the electrified magnet is powered on to generate magnetism, at the moment, the electrified magnet can apply repulsive force to the speed limiting magnet, the speed limiting magnet makes contact with the clamping plate to prevent the speed limiting magnet from continuing to rotate till the speed limiting magnet stops rotating, and therefore the effect that winding is stopped immediately when silk yarn breakage is about to happen in the winding process is achieved.

Owner:陈宗汉

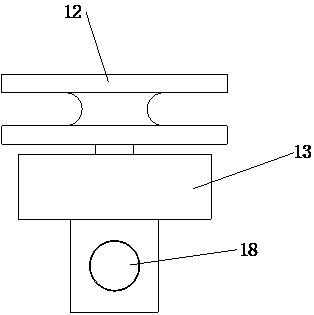

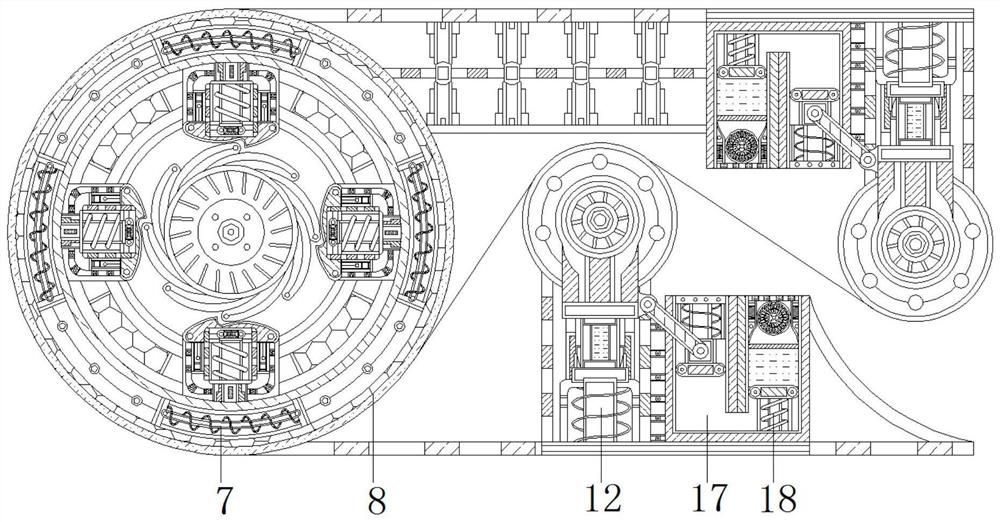

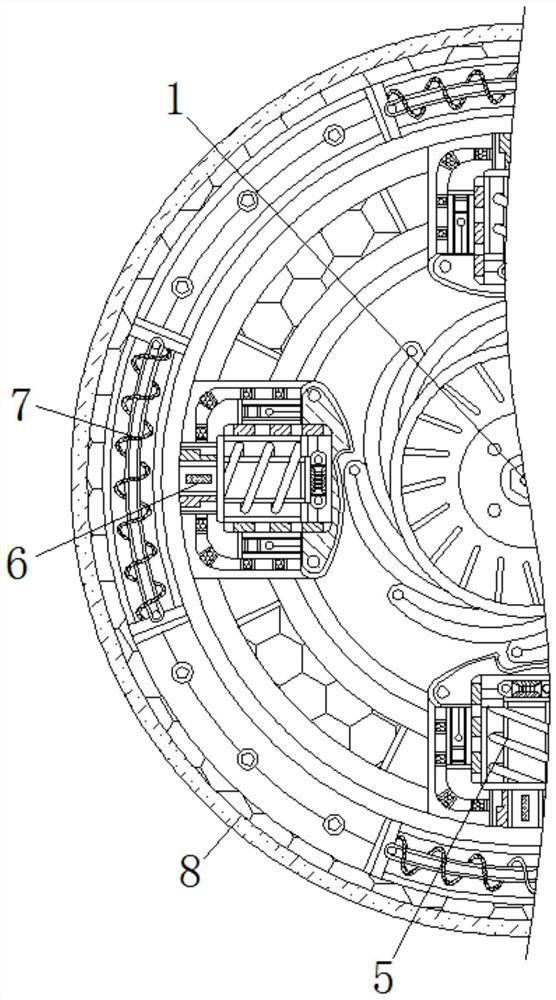

A straw mat winder for mass production of straw mats

ActiveCN111807116BTo achieve the winding effectAvoid wrinklesWebs handlingAgricultural engineeringPulp and paper industry

The invention relates to a winding machine, in particular to a straw mat winding machine for batch production of straw mats. The technical problem to be solved by the present invention is how to design a straw mat winder for mass production of straw mats that can save manpower during operation and can level and roll up the straw mats. The invention provides such a straw mat winder for mass production of straw mats, which includes: a bracket, the top of which is connected with a slant plate; a baffle, which is connected to one side of the slant plate; plate; clamping mechanism, which is set on the winding mechanism. In the present invention, the straw mat is rolled up through the cooperating operation of the winding mechanism and the clamping mechanism, so as to achieve the effect of rolling the straw mat.

Owner:临沂临港国有资产运营集团有限公司

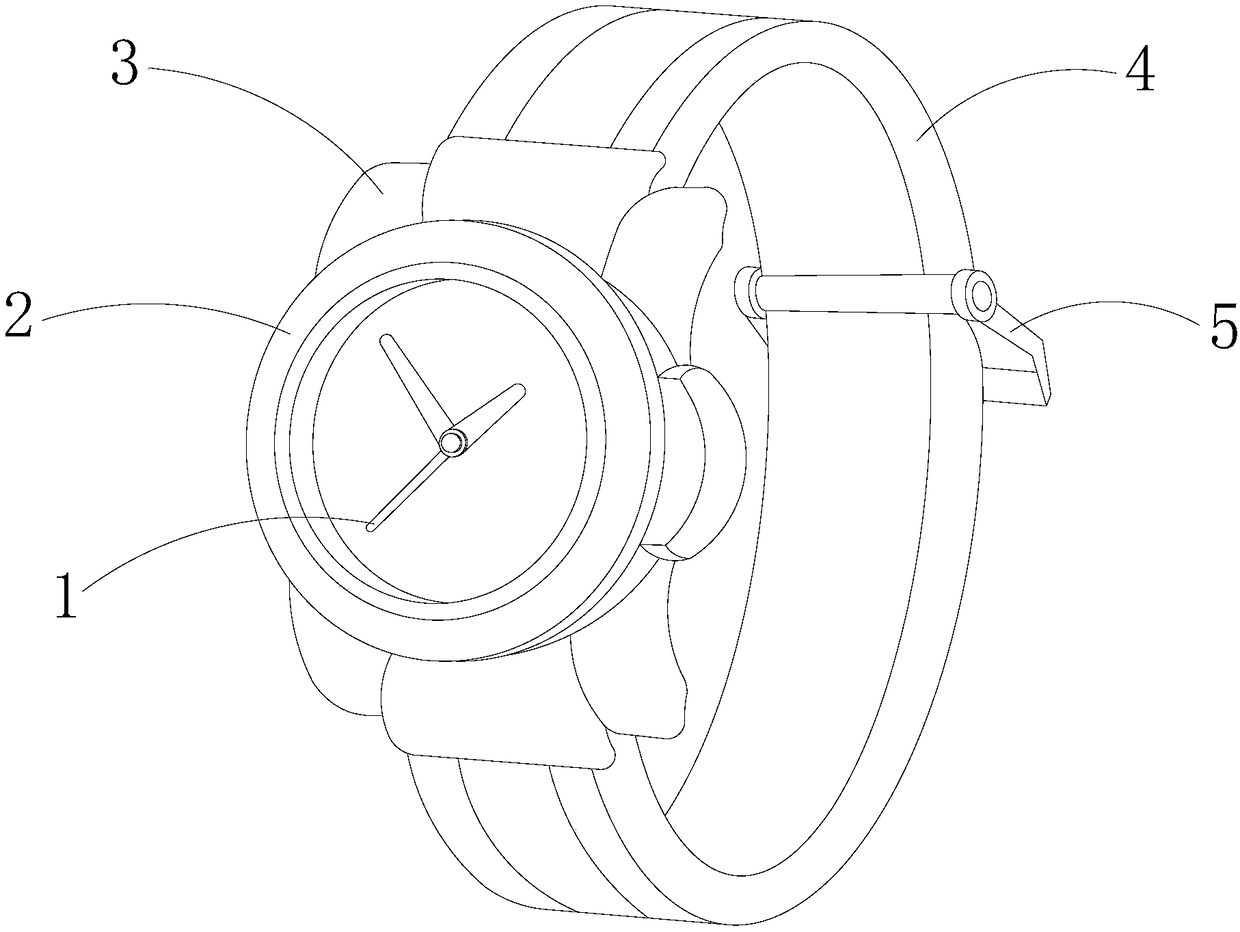

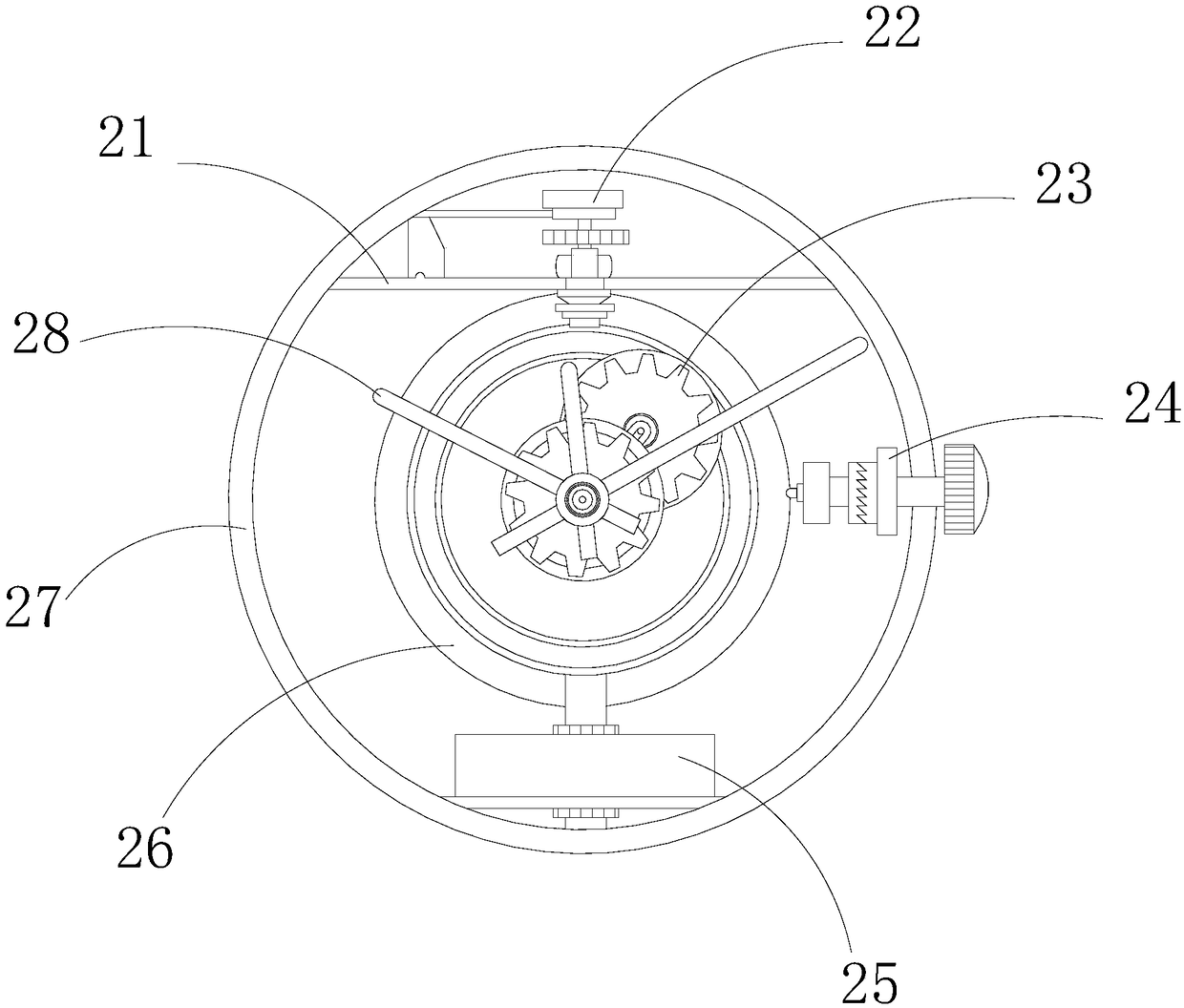

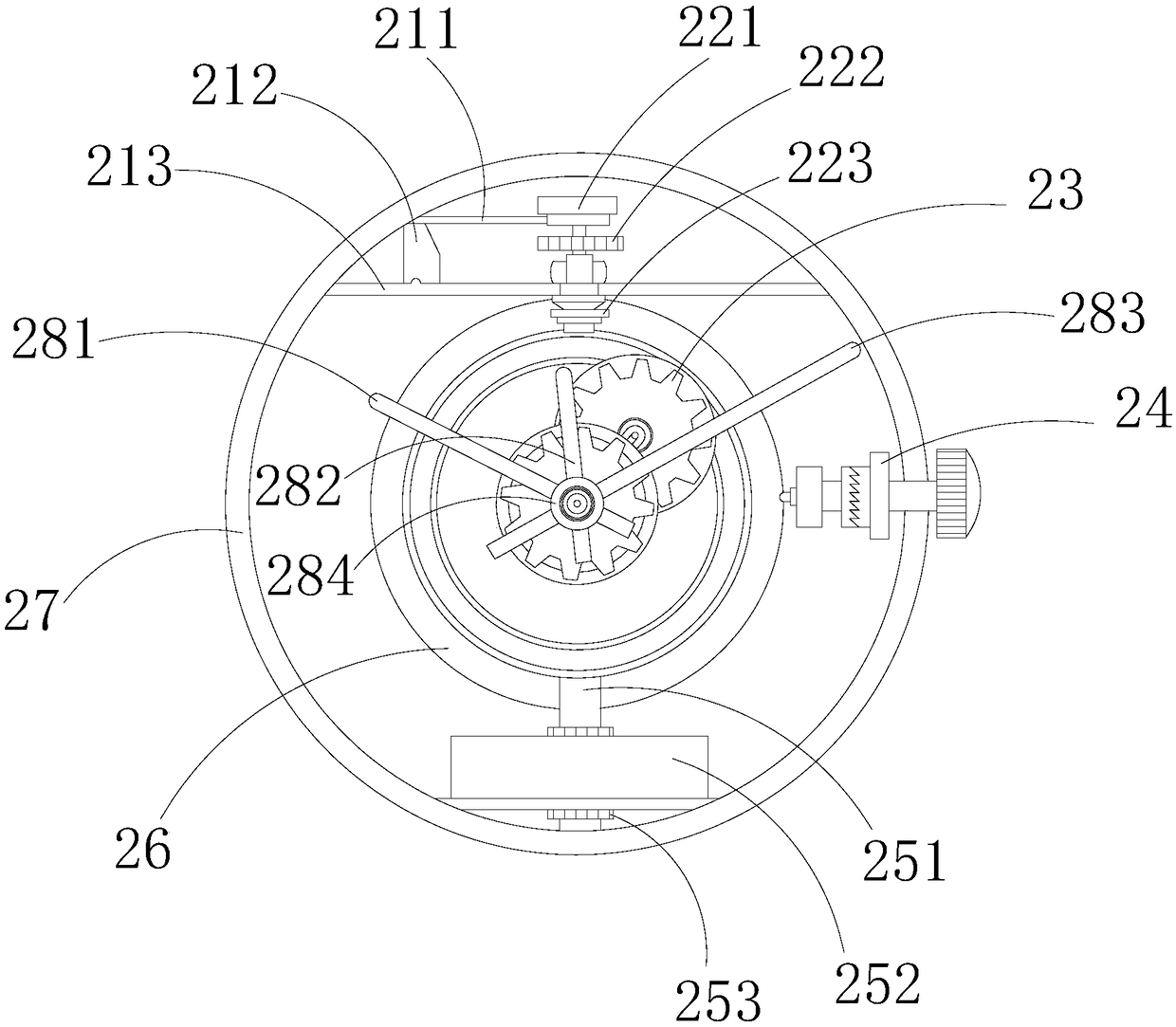

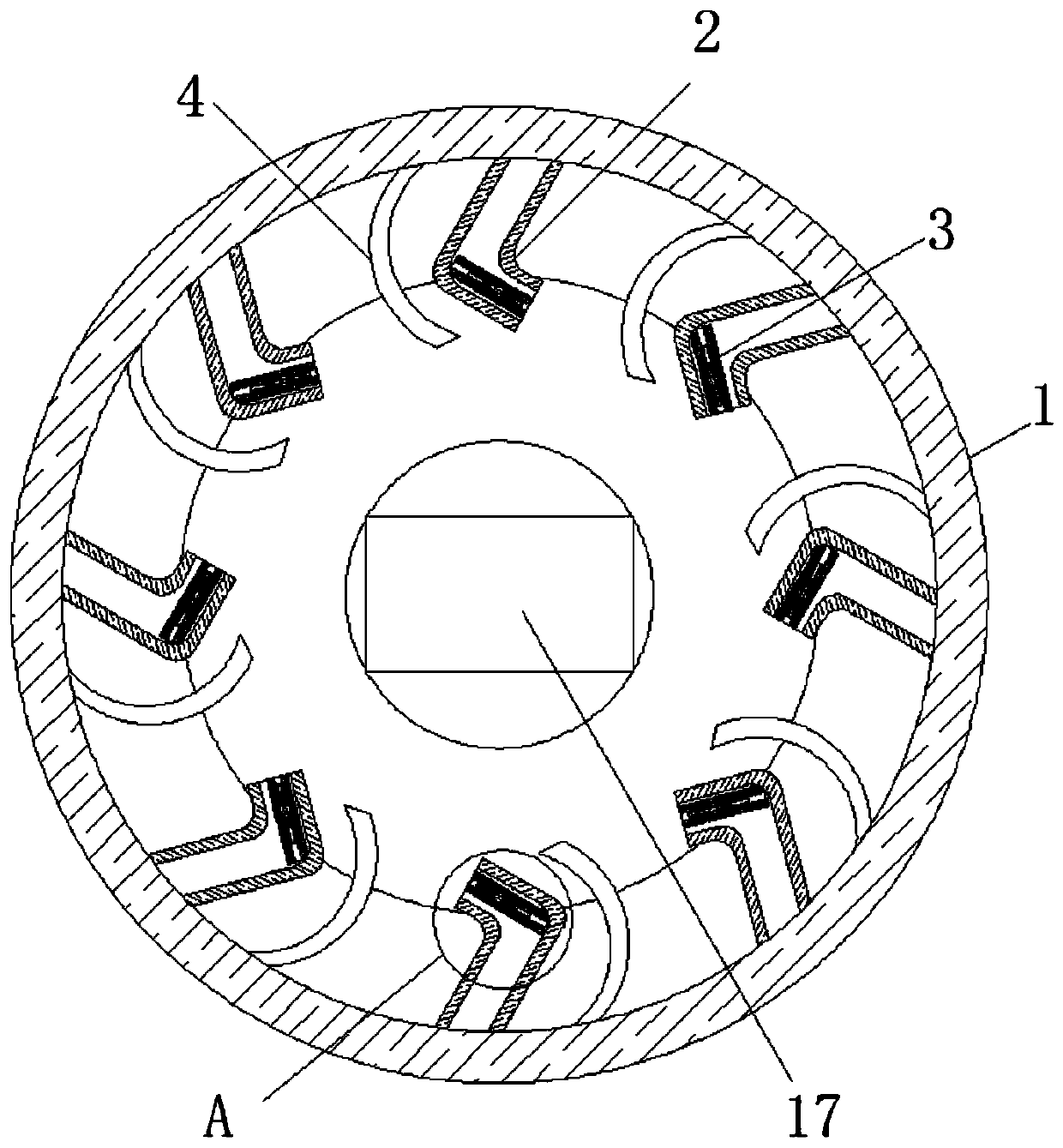

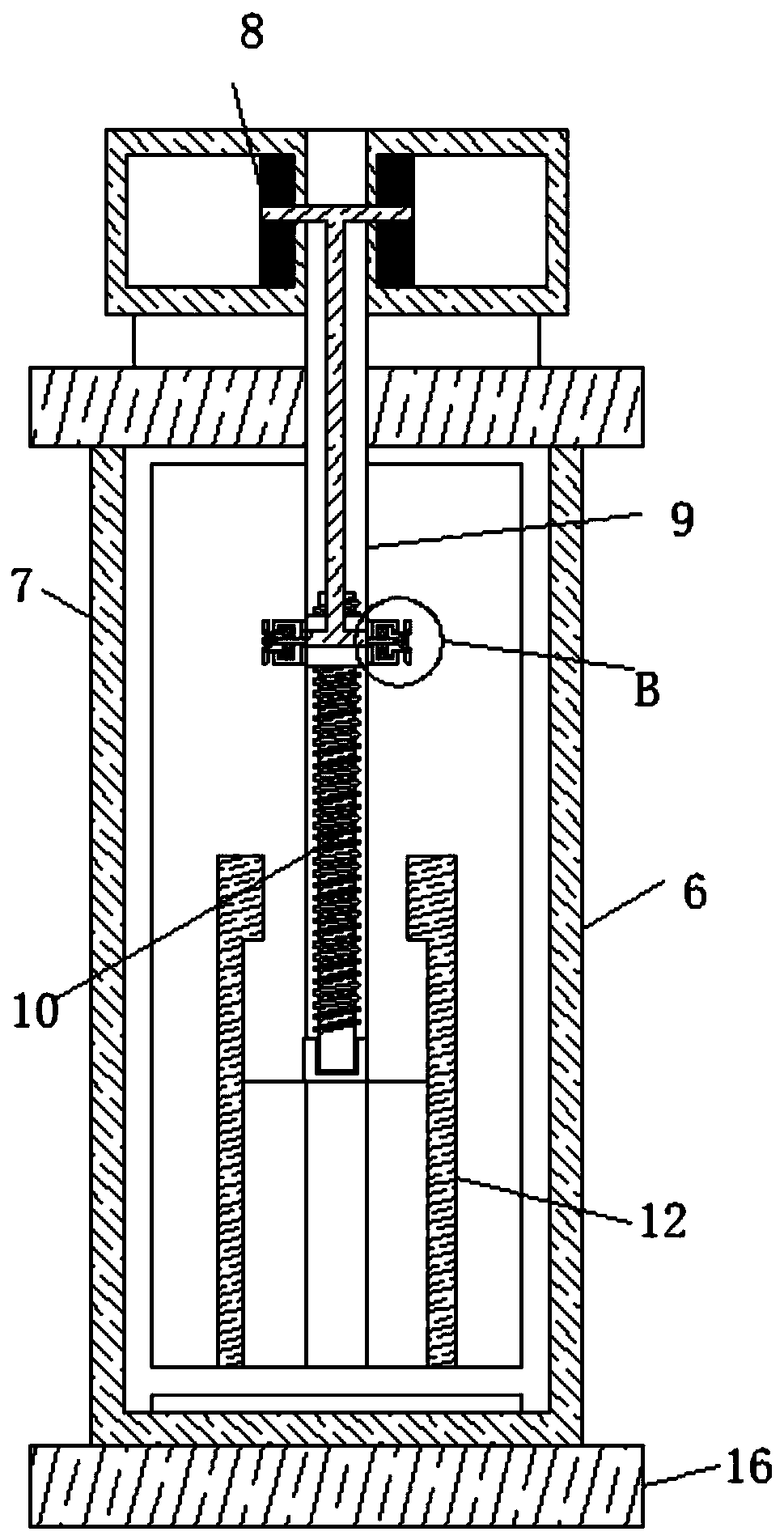

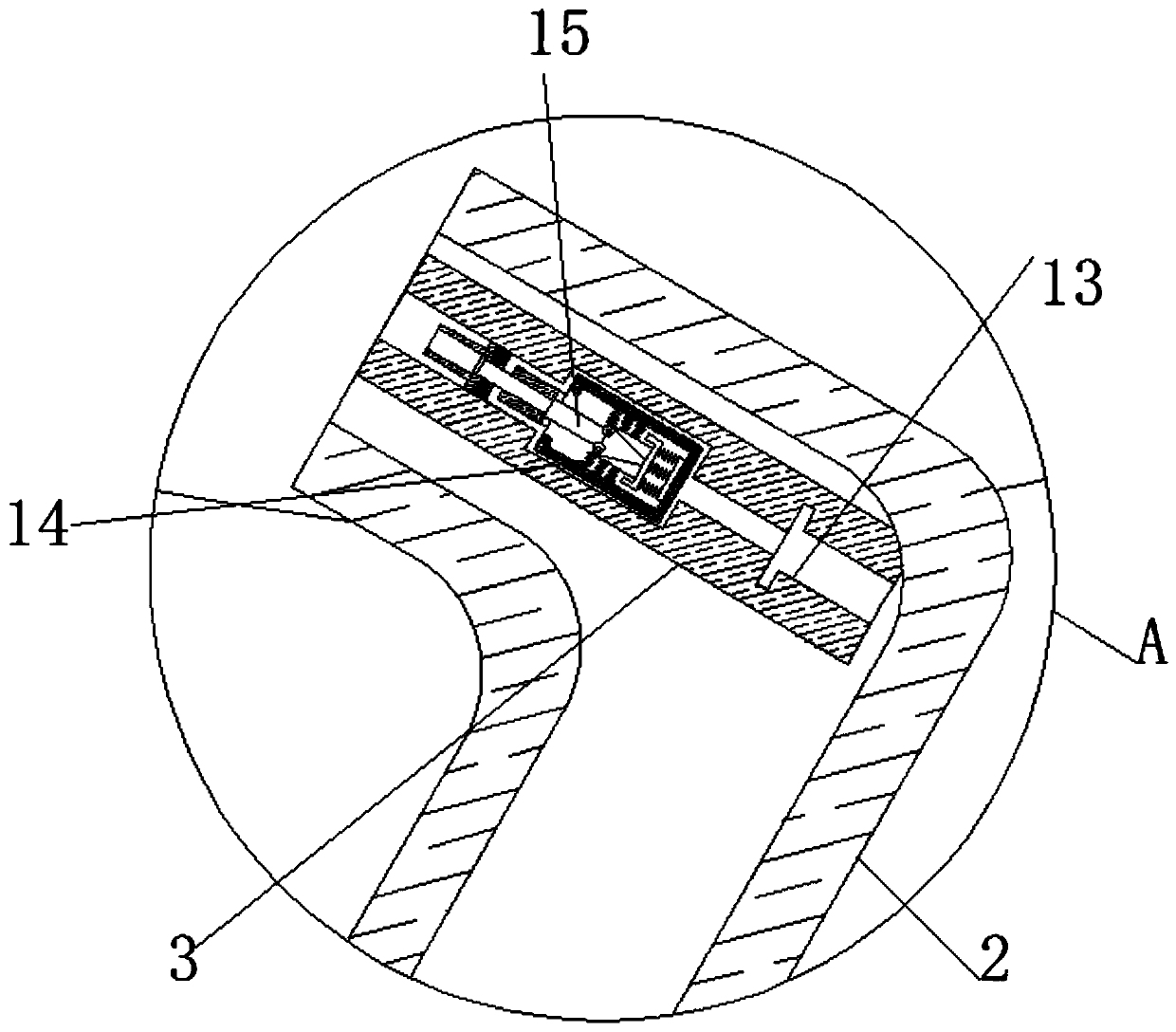

Watch winding device

The invention discloses a watch winding device. The structure of the watch winding device comprises watch hands, a winding device, a watch case, watch bands and a fixing device. The watch hands are horizontally mounted at the front end of the watch case and mechanically connected to the winding device; the winding device has a circular cross section and is fixed horizontally to the rear ends of the watch hands in a matched way; the axes of the watch case and the winding device are collinear; two watch bands are provided and evenly mounted on the left and right ends of the watch case in clearance fit; and the fixing device and the watch bands are of an integrated structure. According to the watch winding device, the improved winding device is an improvement of a manual mechanical watch withminute wheel pinion added, and the minute wheel can be rotated by movement of the wrist to achieve the effect of winding when the watch is worn.

Owner:刘钰婷

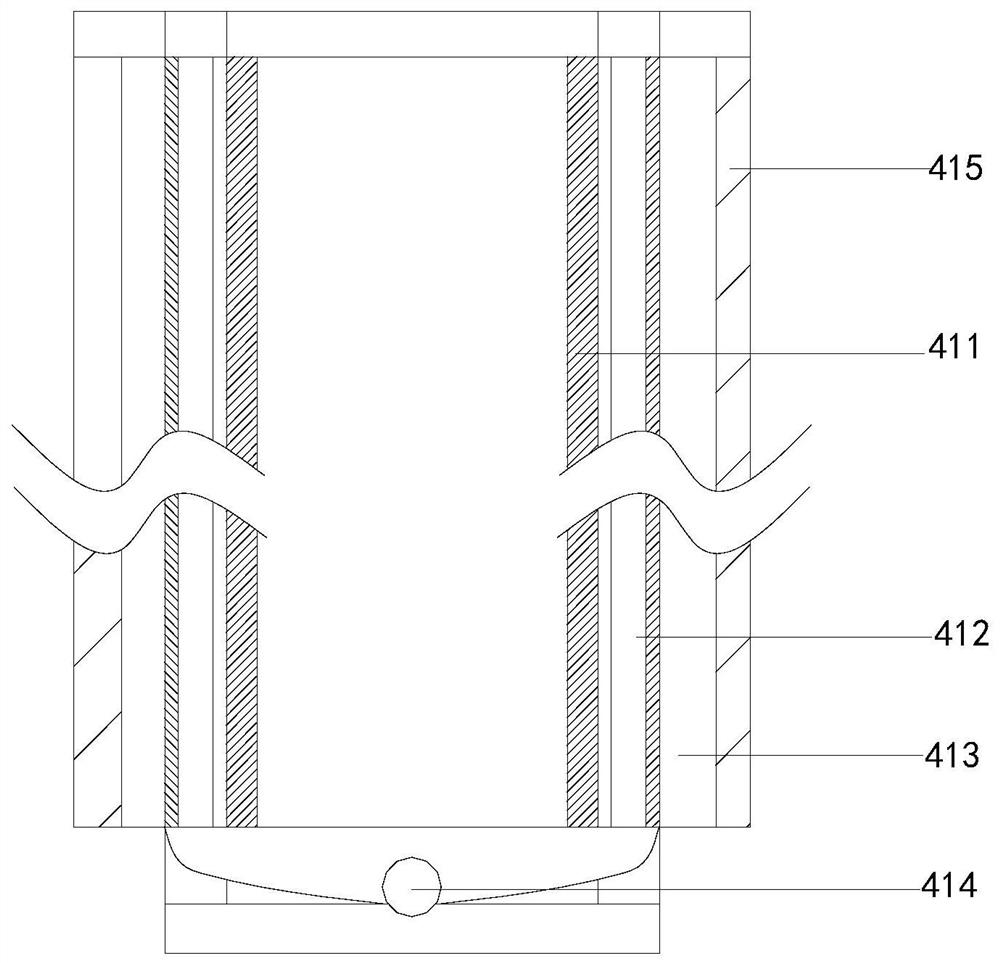

Battery cell winding device utilizing guiding property and pressurizing property of airflow

InactiveCN110808400AWon't fallTo achieve the winding effectAssembling battery machinesFinal product manufactureStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of battery cell winding, and discloses a battery cell winding device utilizing the guiding property and the pressurizing property of an airflow, which comprises a shell. A gas ejector pipe is fixedly connected to the interior of the shell; a gas ejector mechanism is fixedly connected in the gas ejector pipe; a film outlet pipeline is fixedly connected in the shell and located at two sides of the gas ejector pipe; a guide plate is movably connected in the film outlet pipeline; the end, away from the shell, of the film outlet pipeline is movably connected with a film rolling mechanism; the film rolling mechanism comprises a support frame; the upper portion of the support frame is fixedly connected with a sliding rail; a connecting rod is slidablyconnected to the surface of the sliding rail; the diaphragm between the surfaces of the battery cells is suspended in the film outlet pipeline. As the vent pipe in the gas ejector mechanism is designed to be stepped, the end close to the gas ejector pipe is a narrow end, and the generated airflow pressure is large, so that when a certain position of the diaphragm is continuously blown by the airflow, the diaphragm can be cut, and the effect of cutting off the diaphragm without generating burrs is achieved.

Owner:杨小妹

An intelligent control hot cutting machine for chemical fiber production and an automatic hot cutting method for chemical fiber production

ActiveCN111304786BAvoid clutterTo achieve the winding effectMetal working apparatusSevering fibresFiberElectric machinery

The embodiment of the present application discloses an intelligent control hot cutting machine for chemical fiber production, which includes an organic body. The middle parts of the left and right sides of the body are respectively fixedly connected with placing tables protruding outward. The body is divided into upper and lower layers, and a hot cutting device is installed above the body. And the main control device located above the eager cutting device, the motor is installed in the middle of the top surface of the body, and one end of the output shaft of the motor is fixedly sleeved with the swivel one and the fan blade, the fan blade is located on the left side of the swivel ring one, and the motor is on the right side The upper and lower sides are respectively fixedly connected with outwardly protruding connecting rods. The intelligent control hot cutting machine for chemical fiber production adopts the design of the motor and the joint use of the rotatable main shaft, so that after the device cuts the chemical fiber, it can use the motor to drive the main shaft to rotate, so as to achieve the effect of winding the chemical fiber material and avoid hot cutting. The lack of finishing and the low toughness of the chemical fiber after the machine cuts the chemical fiber leads to the messy problem of the chemical fiber, which greatly improves the practicability of the device. Correspondingly, this application also proposes a method for automatic hot cutting of chemical fiber production.

Owner:青岛奥利普奇智智能工业技术有限公司

A textile yarn drying device and its drying operation method

ActiveCN110906721BIncrease or decrease lengthReasonable structural designFilament handlingDrying gas arrangementsYarnSpinning

The invention discloses a yarn drying device for spinning and a drying operation method thereof. The drying device comprises a long flat box, a square opening, a fixed pulley, a first inflatable shaft, a traction plate, a rectangular frame, an air cylinder, a first motor, a protective cover, a side supporting plate, an exhaust fan, wire guide wheels, a T-shaped block, a strip-shaped sliding groove, an L-shaped plate, a second motor, a belt wheel, a long screw, a second inflatable shaft, a square strip hole, electric heating wires and triangular belts. The drying device is advantaged in that the drying device is reasonable in structural design, seven wire guide wheels are distributed in a staggered traction manner, to-be-dried yarns can be distributed in the drying structure in a broken line shape, flexible adjustment is achieved, the length of the yarn in the drying structure is increased or decreased, hot air in the drying structure can flow upwards from the bottom, the drying effectis achieved, the dried yarn is wound together through the rotating first air expansion shaft, the connected traction plates are driven by the started air cylinder to move outwards, the effect of drying and winding at the same time is achieved, and that the yarn can still be normally wound when the diameter of a yarn roll is gradually increased can be guaranteed.

Owner:浙江伟伦新材料股份有限公司

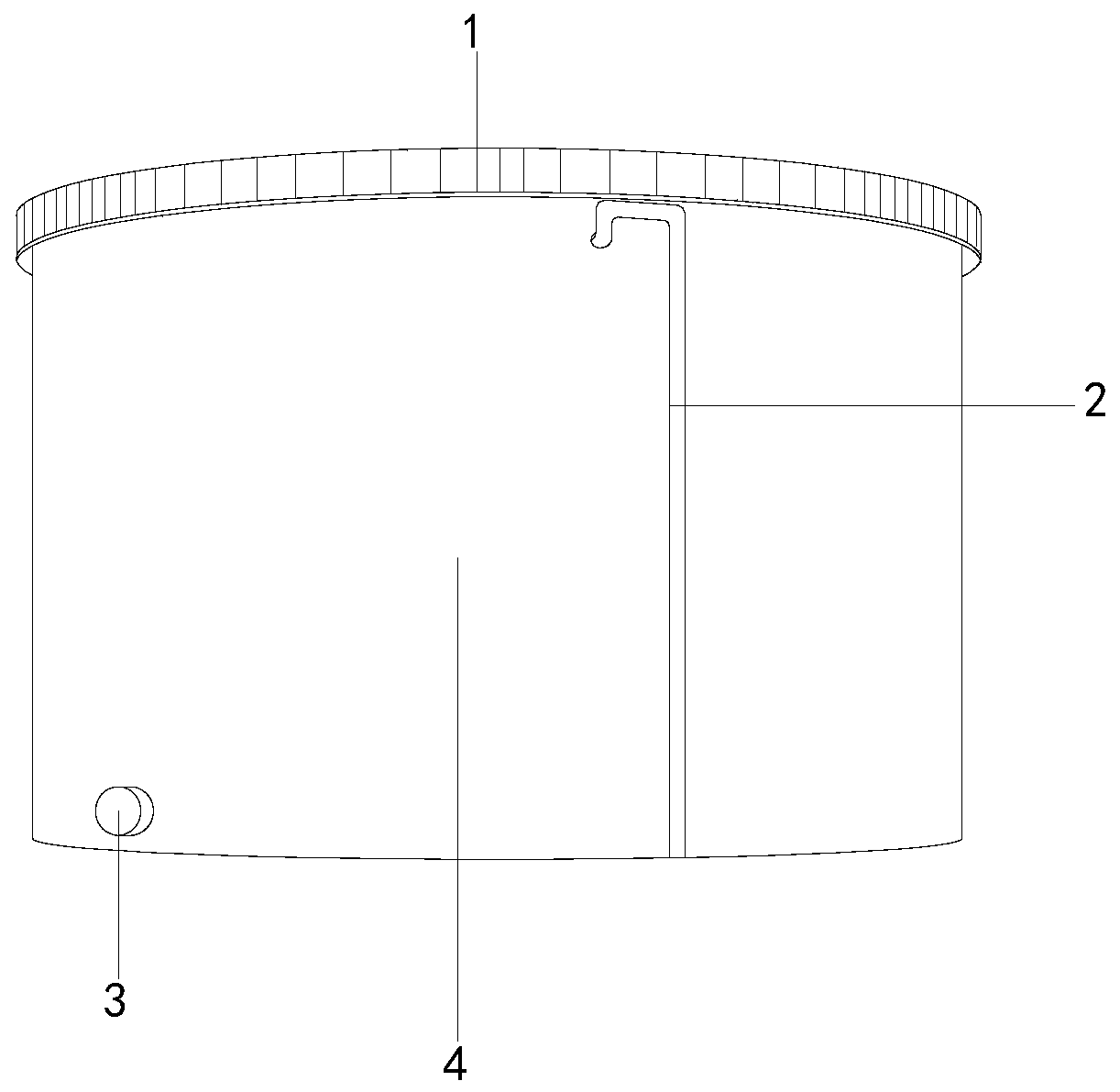

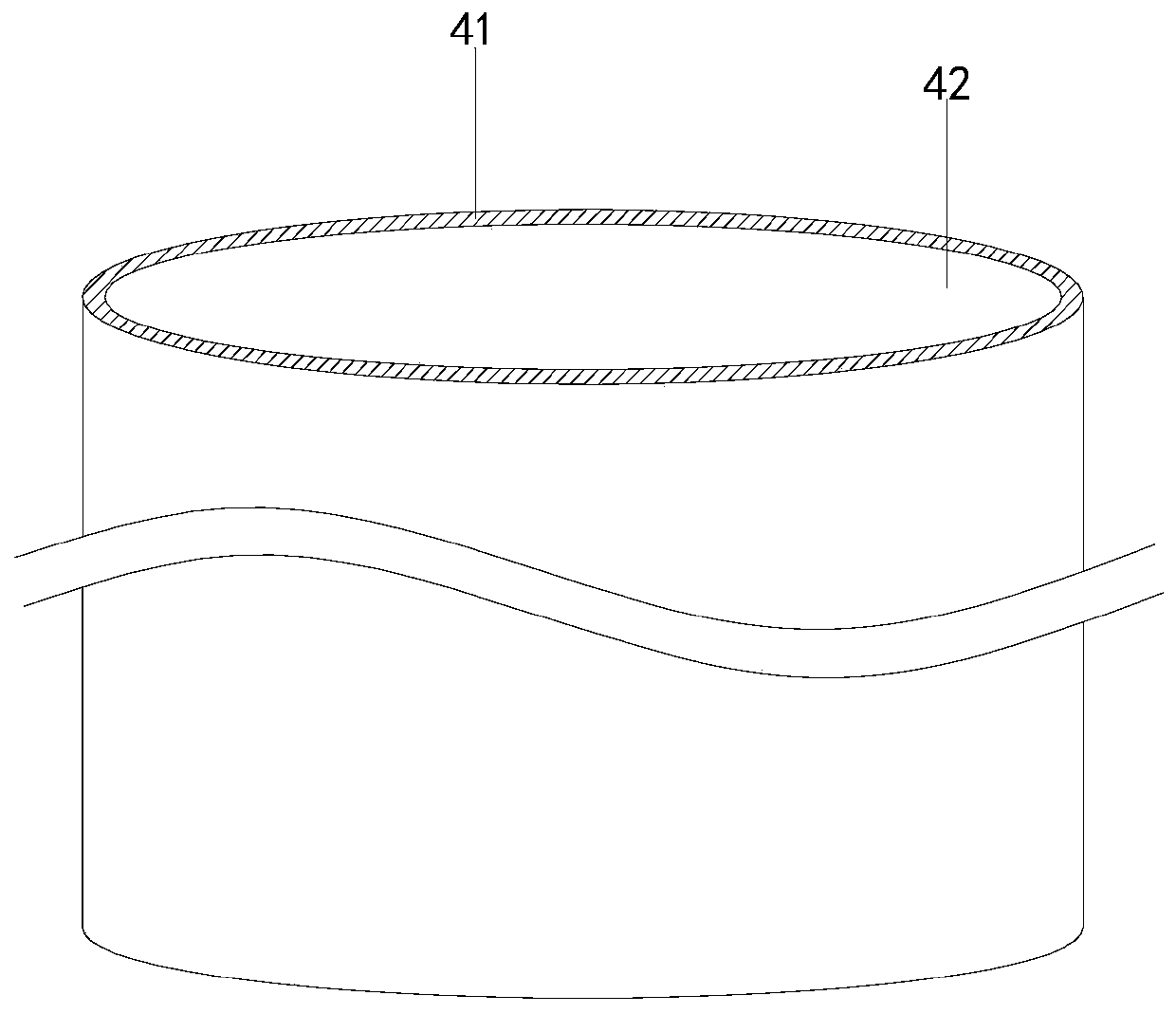

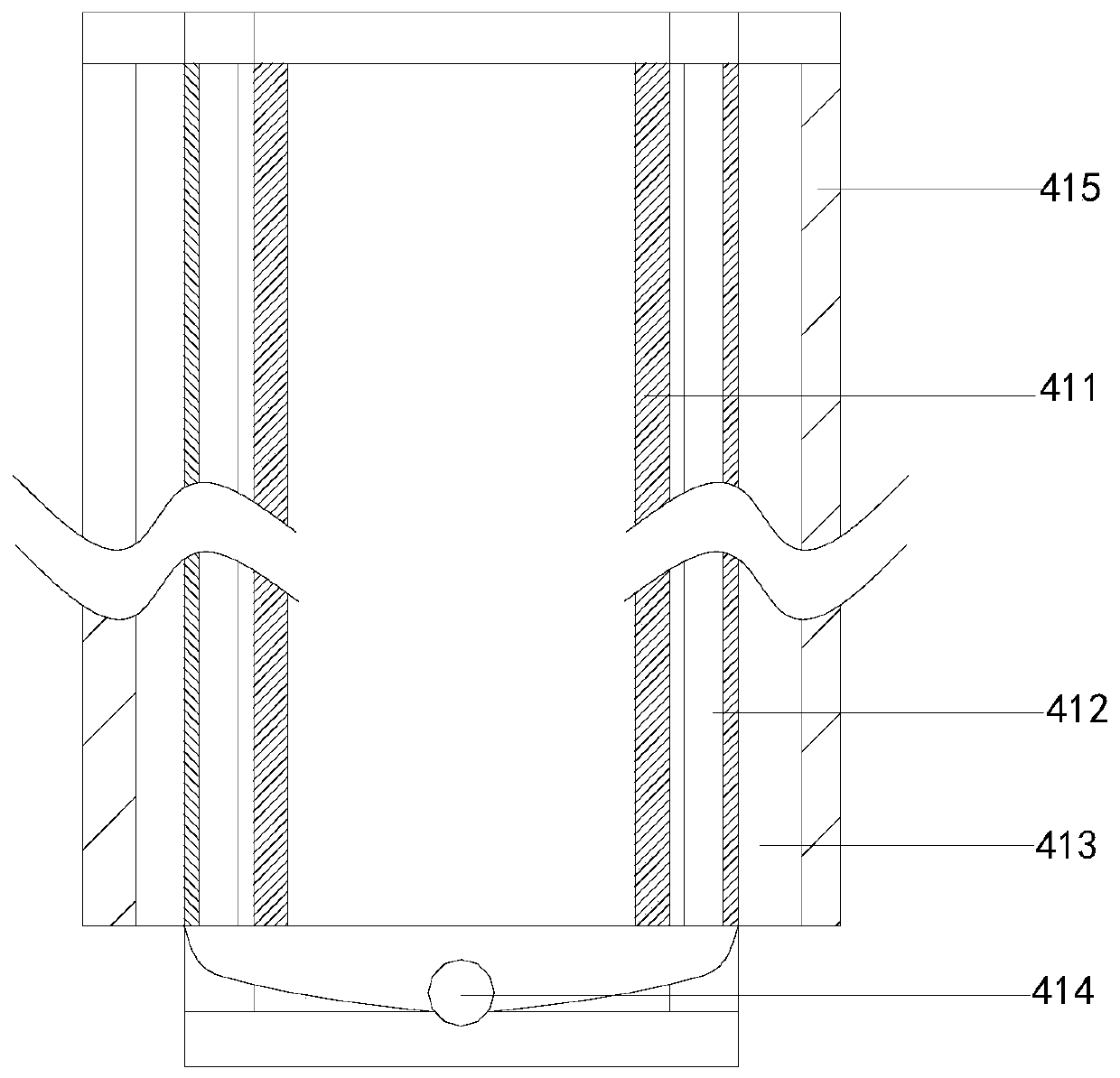

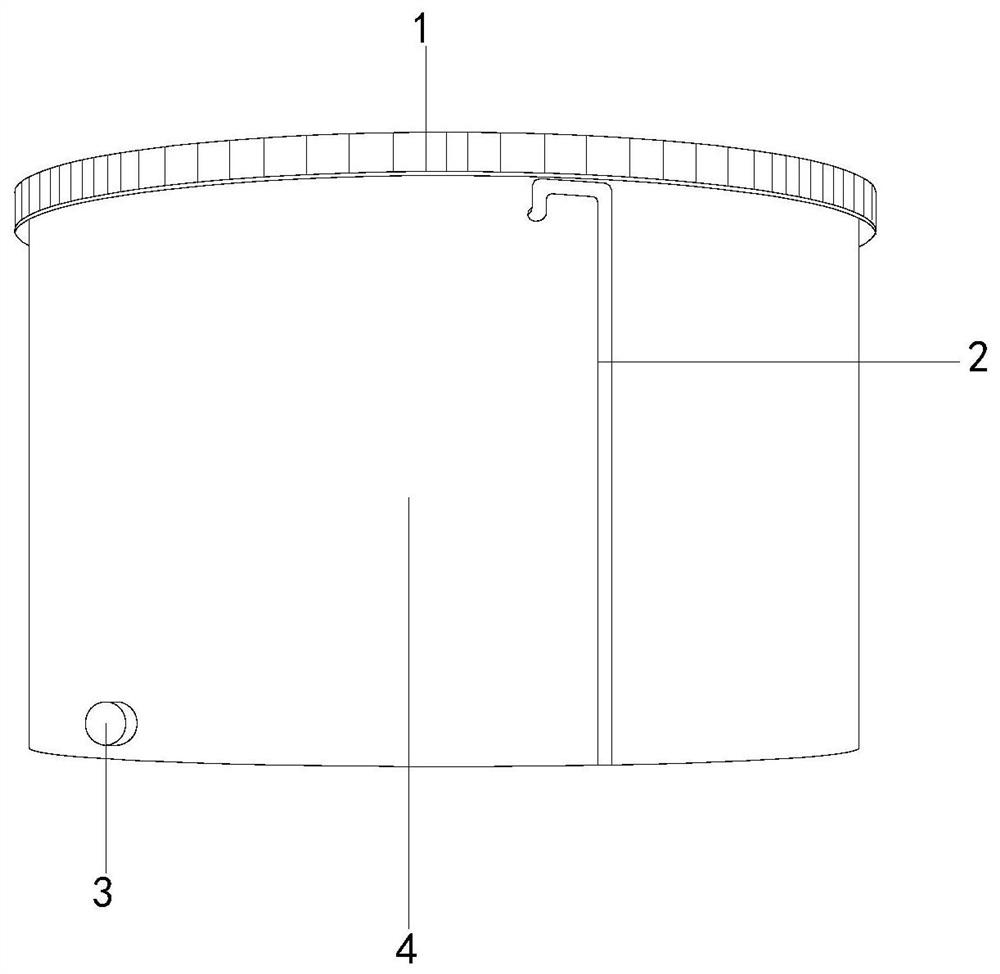

Offshore oil storage tank

ActiveCN111422517AAvoid stopAvoid Galvanic CorrosionHollow article cleaningLarge containersHolding tankElectrochemical corrosion

The invention discloses an offshore oil storage tank. The offshore oil storage tank structurally comprises a fence, an oil pumping pipeline, an oil outflow pipe and a storage tank. The storage tank isprovided with a protection mechanism and a containing tank. As water is coagulated to form water drops, the water drops stagnate in the falling and sliding process to form water films, after the water drops slide from a sliding mechanism, part of the water drops are collected on an absorption block, the water drops are prevented from stopping in the sliding process, the sliding area of the waterdrops is defined through grooves, the situation that the water films are formed as the sliding area of the water drops is too large is avoided, most of the water drops slide to a filter net through inclined linear structures on sliding strips to enter a collecting groove in the protection mechanism, the situation that the water films are formed by the water drops on the surface of the storage tankis avoided, and electrochemical corrosion of the surface of the storage tank is avoided. Shaft wheels are mounted at the two ends of a threaded rod, the threaded rod rotates, the situation that the threaded rod rotates too rapidly is avoided, salt crystals on the surface of the sliding mechanism are cleaned away through a cleaning groove in the moving process, the salt crystals are prevented fromstagnating on the surface of the storage tank, and the situation that the surface of the storage tank rusts due to salt is avoided.

Owner:江苏微纳光膜科技有限公司

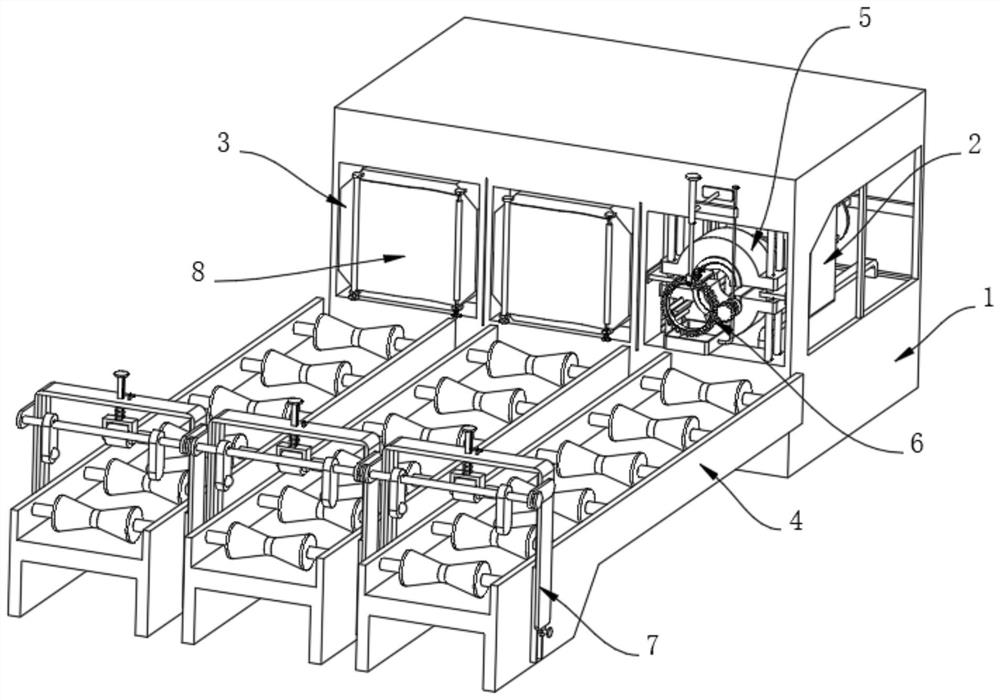

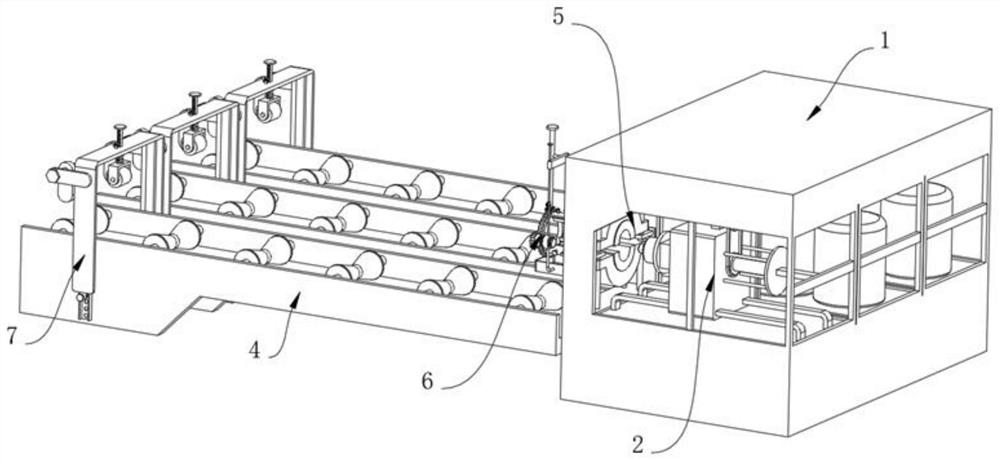

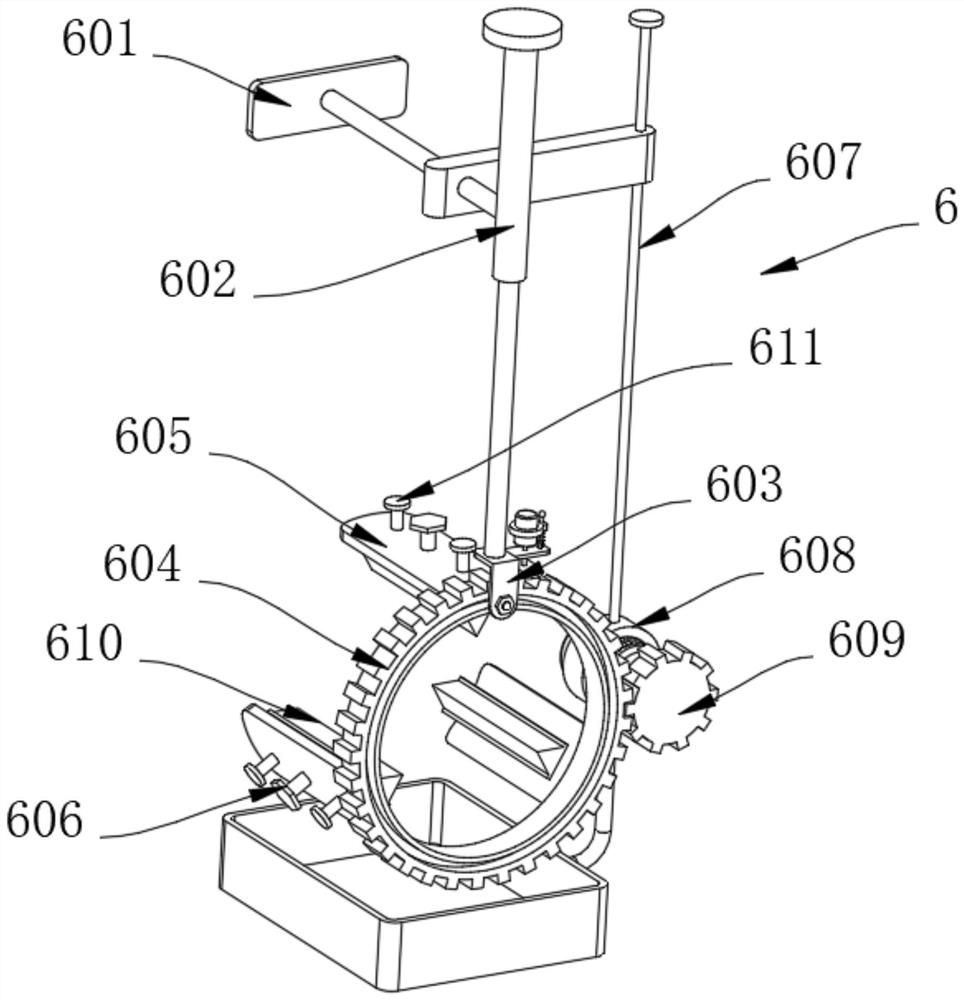

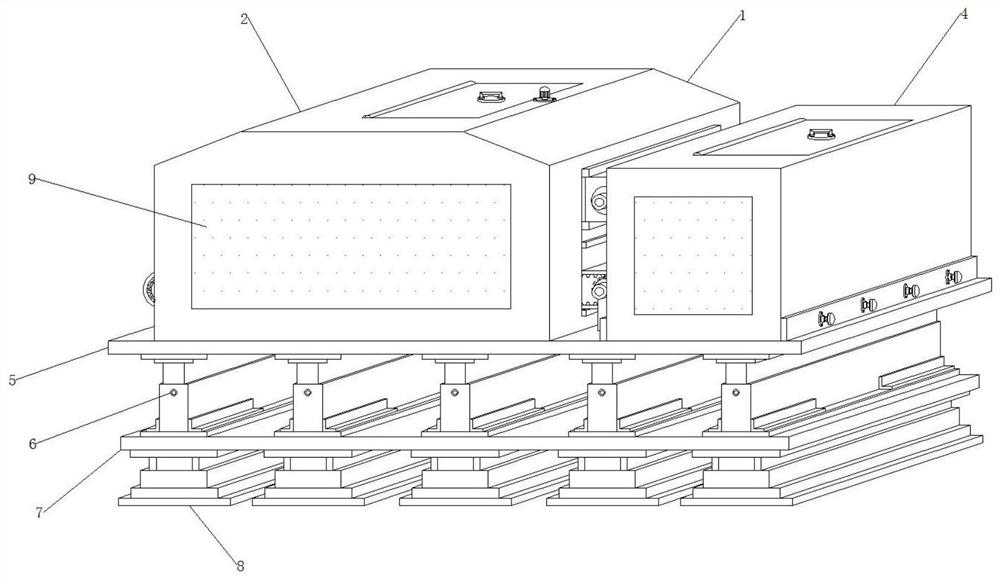

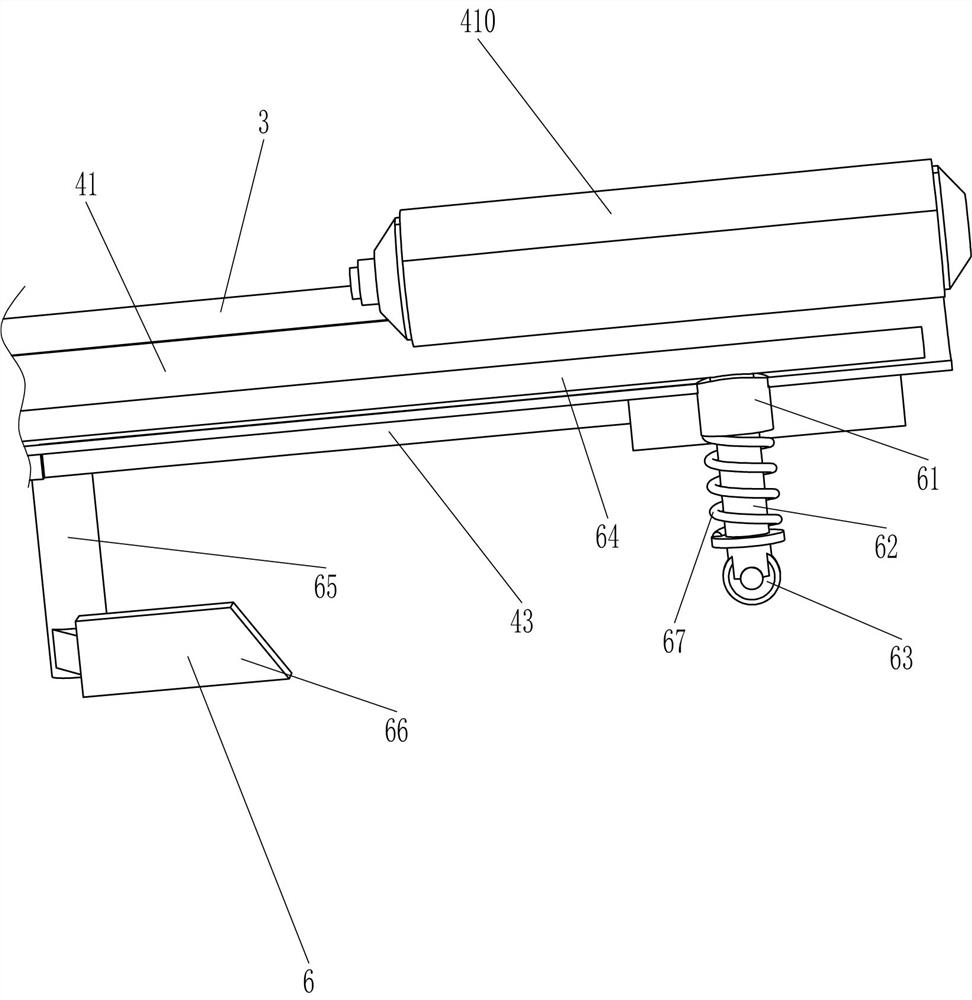

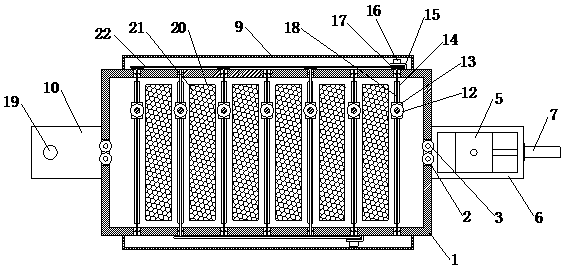

Composite air filter cotton processing equipment and processing technology thereof

ActiveCN113338025AOvercome limitationsTo achieve the effect of unified collection and processingSevering textilesTextile disintegration and recoveryAir filtrationAir filter

The invention provides composite air filter cotton processing equipment and a processing technology thereof, and relates to the technical field of air filter cotton processing equipment. The composite air filter cotton processing equipment comprises a base plate and a cutting device, a supporting frame is fixedly installed on the upper surface of the base plate, and the cutting device is arranged at the end, away from the base plate, of the supporting frame. The cutting device comprises two sliding plates, the two sliding plates are evenly and slidably connected to the upper end of the supporting frame, a driving rod is rotatably connected to the end, away from the base plate, of the supporting frame, opposite threads are formed in the arc surfaces of the two ends of the driving rod, the arc surfaces of the driving rod are both in threaded connection with the two sliding plates, a fixing plate is fixedly connected to the sides, away from the supporting frame, of the sliding plates, and a first gear is rotationally connected with the surface of the fixing plate. According to the air filter cotton processing equipment, the problems that traditional air cotton trimming and cutting equipment has certain limitation on air cotton with different widths, the cutting width is inconvenient to adjust, and the air cotton production efficiency is reduced are solved.

Owner:荣腾净化设备(广州)有限公司

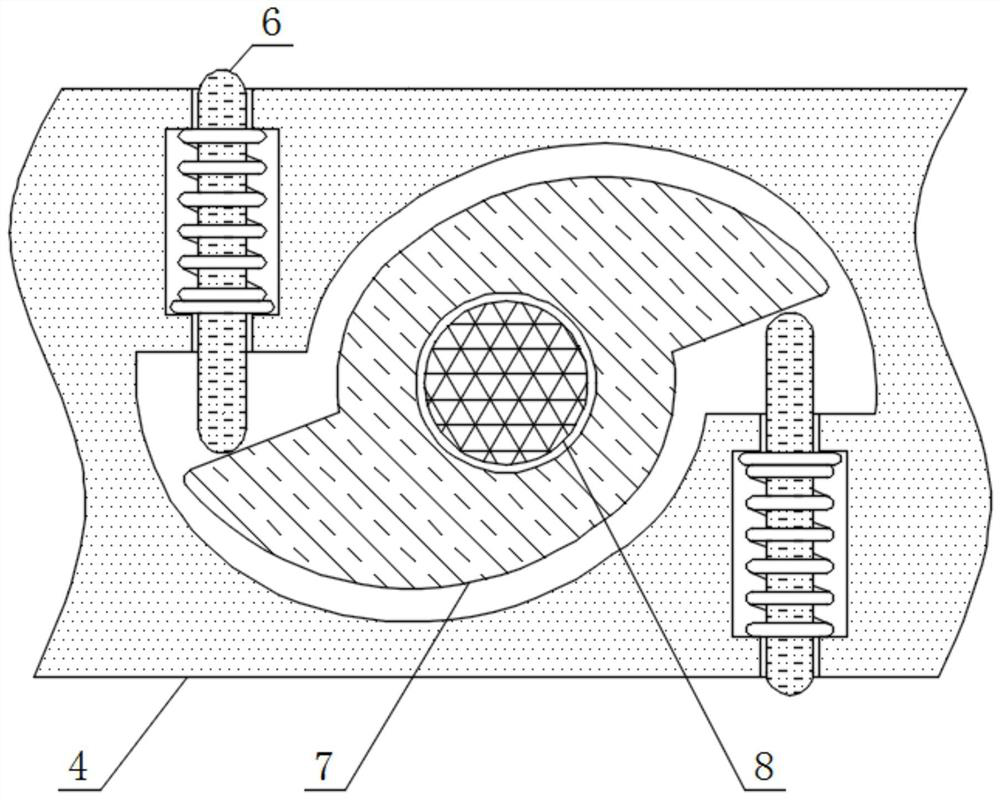

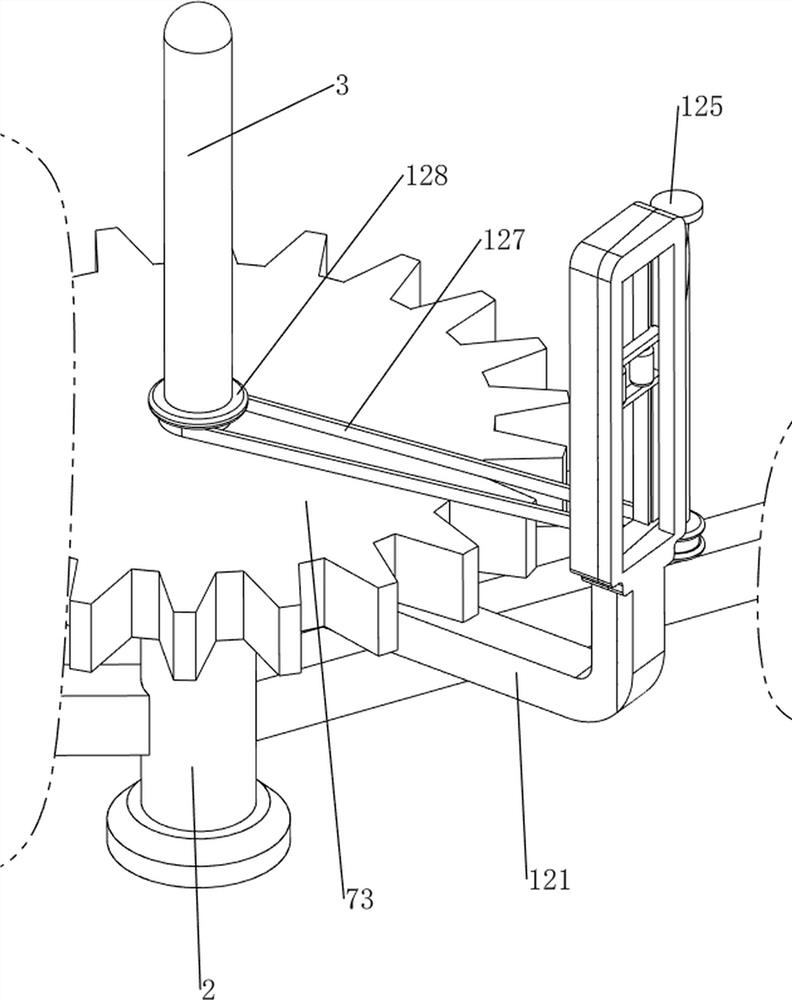

A self-braking winder for canvas processing based on the principle of quantitative winding

ActiveCN110510453BTo achieve the winding effectAvoid size inconsistenciesFilament handlingWinding machineRatchet

The invention relates to the technical field of canvas processing, and discloses a winding machine for canvas processing causing self-braking based on quantitative winding principle. The winding machine comprises a base, and a unidirectional rod is movably connected in the base; a ratchet wheel rotates and drives a drum to rotate and wind to achieve the winding effect, a doubling thread pushes a top block to move upwards, drives a clamping block to move downwards to engage with the ratchet wheel, the movement of the ratchet wheel is blocked, when the doubling thread on the drum reaches the required specifications, the ratchet wheel is stopped, so the produced drums with inconsistent sizes are avoided, the produced bobbins with inconsistent sizes are not conducive to subsequent storage anduse, the top block moves upwards and drives a stop rod to be away from a rotating rod, the bobbins are convenient to take out, and the unidirectional rod prevents the stop rod from closing the rotating rod under the condition of no drum, so the condition that the ratchet wheel rotates again when new drums are not sleeved outside the rotating rod is avoided, the ratchet wheel is always in a stationary state when the stop rod and the rotating rod are in a separating state, and when the stop rod is in contact with the rotating rod again, the ratchet wheel rotates again.

Owner:安徽徽一通讯科技有限公司

A wire and cable surface printing equipment

ActiveCN112265365BAchieve the effect of replenishing inkEasy to cleanFilament handlingCleaning using toolsStructural engineeringMechanical engineering

Owner:安徽扬子实业有限公司

Garment wire winding equipment based on garment production

PendingCN114590639ATo achieve the winding effectImprove compactnessFilament handlingWire rodElectric machinery

The invention discloses clothing wire winding equipment based on clothing production, and relates to the technical field of wire winding equipment. The garment wire winding equipment based on garment production comprises a workbench, a base is fixedly installed on the lower surface of the workbench, a winding mechanism is arranged on the upper surface of the workbench and comprises a motor, the motor is fixedly connected with the lower surface of the workbench, a movable column is fixedly installed on an output shaft of the motor, and the movable column is fixedly connected with the lower surface of the workbench. The two movable columns are symmetrically arranged, fixing pins are slidably installed on the surfaces of the movable columns, springs are fixedly installed at the ends, close to an output shaft of the motor, of the fixing pins, and the ends, away from the fixing pins, of the springs are fixedly connected with the output shaft of the motor. And the spring drives the fixing pin to reset, so that the winding drum can be detached, and the effect of fixing the winding drums of different specifications for winding can be achieved.

Owner:杭州佰朋服饰有限公司

An automatic retractable device for big data communication cables

ActiveCN109650185BUneven solutionSolve the disadvantages of handheldReciprocating motionElectric machine

The invention discloses an automatic take-up and pay-off device for a big data communication cable. The automatic take-up and pay-off device for the big data communication cable comprises a rack. Theupper end of the rack is fixedly connected with a cross beam. The center of the cross beam is fixedly connected with a motor box. An eccentric wheel is arranged at the center in the motor box. The outer side of the surface of the eccentric wheel is fixedly connected with an eccentric column. The outer wall of the eccentric column is sleeved with an oscillating bar. A groove is machined in the center of the oscillating bar. The eccentric column is connected with the oscillating rod through the groove in a sliding and clamping manner. The lower end of the oscillating bar is fixedly connected with a pendulum bob. First sawteeth are machined on the lower surface of the pendulum box. The lower end of the pendulum bob is provided with a transverse plate. Second sawteeth are machined on the uppersurface of the transverse plate. The second sawteeth are engaged with the first sawteeth. When the automatic take-up and pay-off device for the big data communication cable is used for taking up thecable, a servo motor is used for adjusting a coil to forwards rotate, a motor case is electrified and drives the eccentric shaft to rotate, the eccentric shaft drives the pendulum bob to swing, the sawteeth on the pendulum bob are engaged with the sawteeth on the transverse plate, and the transverse plate drives the coil to do reciprocating motion leftwards and rightwards so that the cable can beevenly wound on a winder.

Owner:新昌县杨辉网络科技有限公司

Straw mat winding machine for batch production of straw mats

ActiveCN111807116ATo achieve the winding effectAvoid wrinklesWebs handlingWinding machineProcess engineering

The invention relates to a winding machine, in particular to a straw mat winding machine for batch production of straw mats. The straw mat winding machine aims to solve technical problem of how to design a straw mat winding machine, which can save manpower during operation and can flatten and wind up straw mats, for batch production of the straw mats. The straw mat winding machine for batch production of the straw mats comprises a support, a baffle, a winding mechanism and a clamping mechanism, wherein the top of the support is connected with an inclined plate, the baffle is connected to one side of the inclined plate, the winding mechanism is arranged on the inclined plate, and the clamping mechanism is arranged on the winding mechanism. According to the straw mat winding machine, the straw mats are wound through cooperative operation of the winding mechanism and the clamping mechanism, and therefore the effect of winding the straw mats is achieved.

Owner:临沂临港国有资产运营集团有限公司

Intelligent cable corrector

PendingCN113608055AWill not cause alignment errorsReduced commissioning timeTesting dielectric strengthShort-circuit testingLoudspeakerMechanical engineering

The invention discloses an intelligent cable calibrator, and belongs to the technical field of cable calibrators. The intelligent cable calibrator comprises a calibrator, wherein the front surface of the calibrator is provided with a switch, an indicating lamp, a grounding detection hole and a loudspeaker, the upper surface of the calibrator is provided with a grounding detection mechanism, the calibrator is internally provided with a protection mechanism and a cable calibration mechanism, the cable calibration mechanism is located at the front side of the protection mechanism, and the back surface of the calibration mechanism is fixedly connected with a positioning mechanism. According to the invention, a calibration probe is arranged, and an on-off indicating lamp is arranged in the calibration probe, so that the green on-off indicating lamp on the cable calibration probe in hands of the cable calibration personnel at the two ends can be lightened only when the cable is connected. In the using process, cable calibration errors cannot be caused even under the conditions that the distance is long, the environment is noisy and information communication errors exist, and meanwhile, the cable calibrator can detect the cable grounding situation caused by cable damage, burrs and the like in advance in the cable calibration process. A lot of insulation problems are eliminated for cable voltage withstanding tests. The debugging time is saved.

Owner:刘清

Building engineering measurer capable of achieving quick collection

InactiveCN112611364AFast chargingAvoid sticking outSurveying instrumentsUsing mechanical meansDrive wheelArchitectural engineering

The invention relates to the technical field of building information collection, and discloses a building engineering measurer capable of achieving quick collection. The measurer comprises a cylinder, a winding roller is rotatingly connected to the interior of the cylinder, a rotating wheel is inserted into the winding roller, and two telescoping rods and two clamping rods are inserted into the rotating wheel. A driving wheel is inserted into the rotating wheel, a rotating shaft is fixedly connected to the front face of the driving wheel, a motor is rotatably connected to the front face of the rotating shaft, an opening is formed in the left side of the cylinder, a first extrusion wheel is rotatably connected to the inner top wall of the opening, and a second extrusion wheel is movably connected to the inner bottom wall of the opening; and the bottom of the second extrusion wheel is rotationally connected with an arc-shaped rod. By arranging the telescopic rod, when the winding roller stops rotating, the telescopic rod abuts against the position between arc-shaped teeth on the inner side wall of the winding roller under the action of a first spring, the winding roller is clamped, and therefore the effect of preventing the winding roller from rotating under the action of no external force is achieved, and the tape measure is prevented from stretching out by itself.

Owner:映堂文案策划(温州)有限公司

Rapid drawing paper winding device for culture media

InactiveCN113321032ATo achieve the winding effectPrevent side to side movementWebs handlingEngineeringMechanical engineering

The invention discloses a rapid drawing paper winding device for culture media. A rotating rod is included, and two limiting plates are movably connected to the surface of the rotating rod. By arranging a positioning mechanism, a user can place one side of a painting and calligraphy on the surface of the rotating rod, move the limiting plates to the two sides of the painting and calligraphy, press the positioning mechanism to drive a limiting soft plate to make contact with the surface of the painting and calligraphy and then clamp the painting and calligraphy, and rotate the rotating rod, so that the rolling effect is achieved, and the positioning mechanism achieves positioning of the limiting plates to prevent left-right movement; and the problems that an existing part of long painting and calligraphy is not convenient to operate during rolling, the user needs to support the painting and calligraphy with two hands during rolling, paper painting and calligraphy are fragile in material, corners of drawing paper are prone to being damaged, a certain clamping device is lacked at the rolling starting position, the effect that rotating and rolling are conducted after one side of the painting and calligraphy is clamped is not achieved,the operation difficulty and the use cost of the user are increased, and the use of the user is inconvenient are solved, and the rapid drawing paper winding device is worthy of popularization.

Owner:湖南青蓝文化传媒集团有限公司

offshore oil storage tank

ActiveCN111422517BAvoid stopAvoid Galvanic CorrosionHollow article cleaningLarge containersHolding tankElectrochemical corrosion

The invention discloses an offshore oil storage tank, the structure of which includes a guardrail, an oil suction pipeline, an oil outlet pipe, and a storage tank. The storage tank is provided with a protection mechanism and a storage tank. Water droplets are formed after condensation of water, and the water droplets fall during the falling process. A water film is formed after staying in the middle, and after the water drops slide from the sliding mechanism, part of it is collected on the absorbing block to prevent the water drops from stopping during the sliding process, and the groove limits the area of the water drops to prevent the water drops from being too large to form Most of the water film slides down to the filter net through the inclined linear structure on the sliding bar and enters the collecting tank in the protection mechanism, avoiding the formation of water film on the surface of the storage tank and preventing electrochemical corrosion on the surface of the storage tank. Both ends of the threaded rod A shaft wheel is installed to rotate the threaded rod to avoid the threaded rod from rotating too fast. During the movement, clean the salt crystals on the surface of the sliding mechanism in the cleaning tank to prevent the salt crystals from stagnating on the surface of the storage tank and prevent the salt from causing damage to the surface of the storage tank. Rust.

Owner:江苏微纳光膜科技有限公司

Green propaganda and display device for smart community and use method thereof

PendingCN113707010ARealize slidingAchieve cleaning effectBoard cleaning devicesWriting boardsDisplay deviceStructural engineering

The invention discloses a green propaganda and display device for a smart community and a using method thereof. The green propaganda and display device comprises a base, rolling wheels are fixedly connected to the two sides of the bottom end of the base, a handle is fixedly connected to one side of the base, a supporting column is fixedly connected to the top end of the base, and an extension column is movably sleeved with the supporting column; a display box is fixedly welded to the top ends of the extension columns through a bearing plate, top supporting columns are fixedly connected to the two sides of the top end of the display box, and a ceiling is fixedly connected to the top ends of the top supporting columns. Through mutual cooperation of a handle, a two-way screw rod and third sliding blocks, the purpose that the third sliding blocks at the two ends slide in the first sliding grooves in the horizontal direction in an opposite or back-to-back mode is achieved, so that a supporting rod is driven to rotate correspondingly, and an extension column pushes a second fixing rod through a second movable groove to achieve the purpose of limiting lifting motion in a supporting column; therefore, the effect of adjusting to a proper height for display is achieved.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

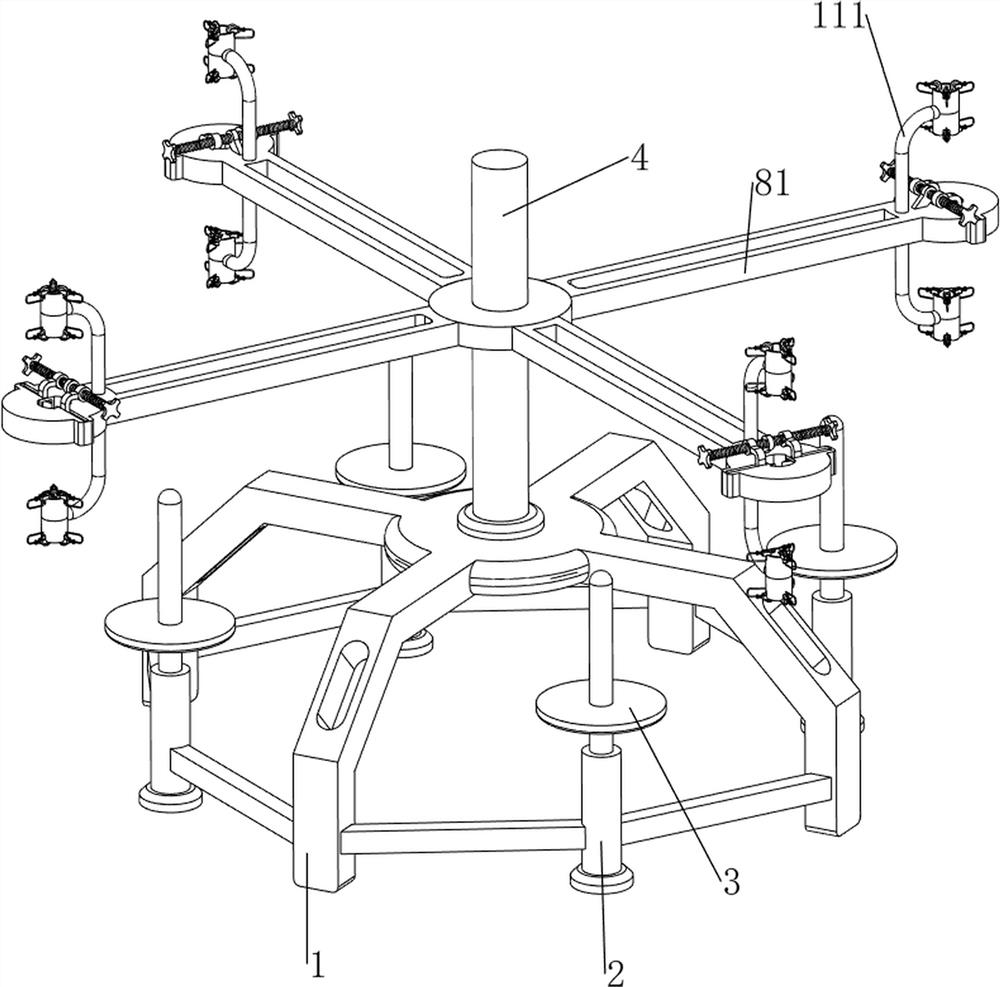

Cable stripping device for constructional engineering

PendingCN114301014ATo achieve the winding effectFacilitated releaseLine/current collector detailsApparatus for removing/armouring cablesCopper wireCopper-wiring

The invention relates to a cable stripping device for constructional engineering, which comprises a support frame, first mounting rods, rotating frames, a second mounting rod, a third mounting rod, a guide rod, a power mechanism and a stripping mechanism, and is characterized in that the lower part of the support frame is uniformly connected with the four first mounting rods at intervals in the circumferential direction, and the upper parts of the four first mounting rods are rotatably connected with the rotating frames; a second mounting rod is connected to the middle of the top of the supporting frame, four third mounting rods are uniformly connected to the upper portion of the second mounting rod at intervals in the circumferential direction, a guide rod is connected to each of the four third mounting rods, a power mechanism is arranged between the supporting frame and the rotating frame, and a peeling mechanism is arranged in the middle of the second mounting rod. According to the invention, four waste cables can be peeled at one time through the eight peeling knives, and the winding drum for winding copper wires can be driven to rotate through the rotation of the rotating frame, so that the copper wires can be wound.

Owner:苏金荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com