Cable stripping device for constructional engineering

A technology for construction engineering and cables, which is applied in the field of cable stripping devices for construction engineering, and can solve the problems of unsatisfactory stripping efficiency and copper wire winding that cannot be recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

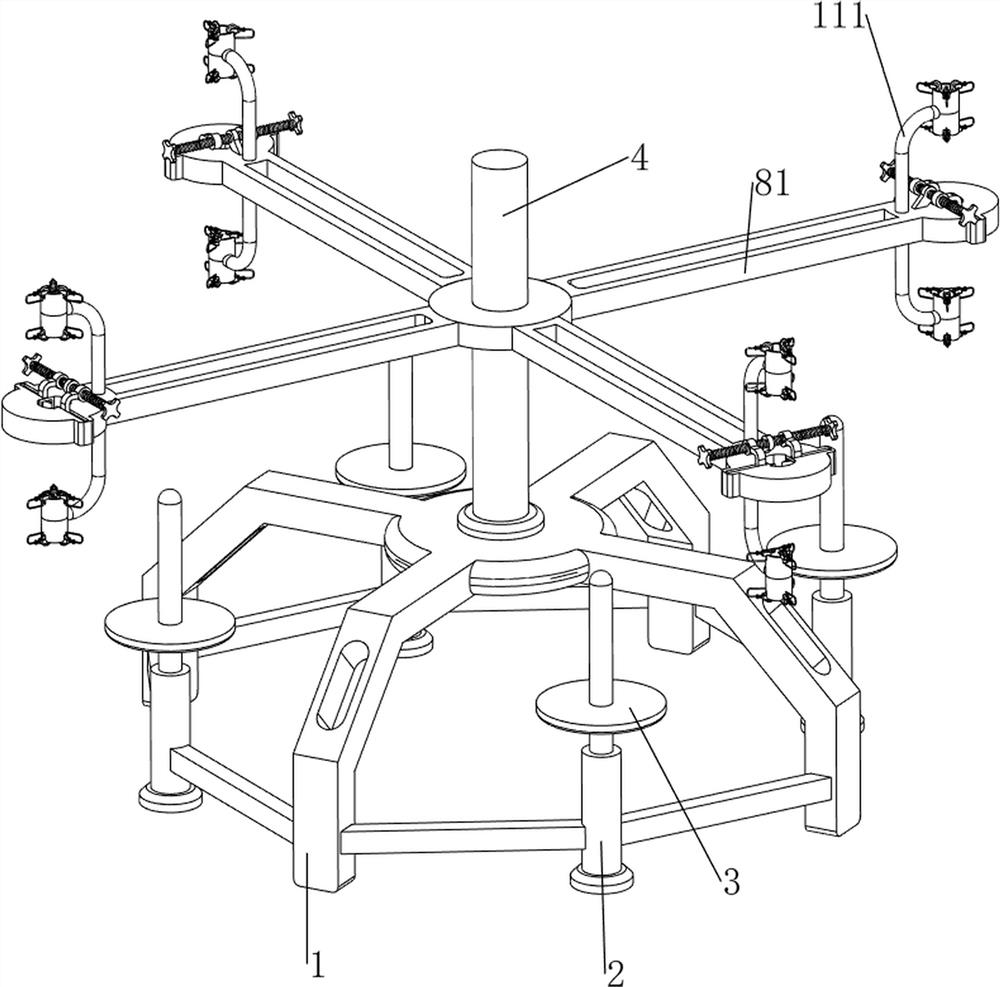

[0040] A kind of cable stripping device for construction engineering, such as Figure 1-5 As shown, it includes a support frame 1, a first installation rod 2, a turret 3, a second installation rod 4, a third installation rod 5, a guide rod 6, a power mechanism 7 and a peeling mechanism 8, and the lower part of the support frame 1 is along the circumferential direction Four first installation rods 2 are evenly spaced connected, and the upper parts of the four first installation rods 2 are connected with a turret 3 in a rotatable manner. There are four third installation rods 5 evenly spaced along the circumferential direction, and a guide rod 6 is connected to the four third installation rods 5. A power mechanism 7 is arranged between the support frame 1 and the turret 3. The second installation rod 5 Bar 4 middle part is provided with peeling mechanism 8.

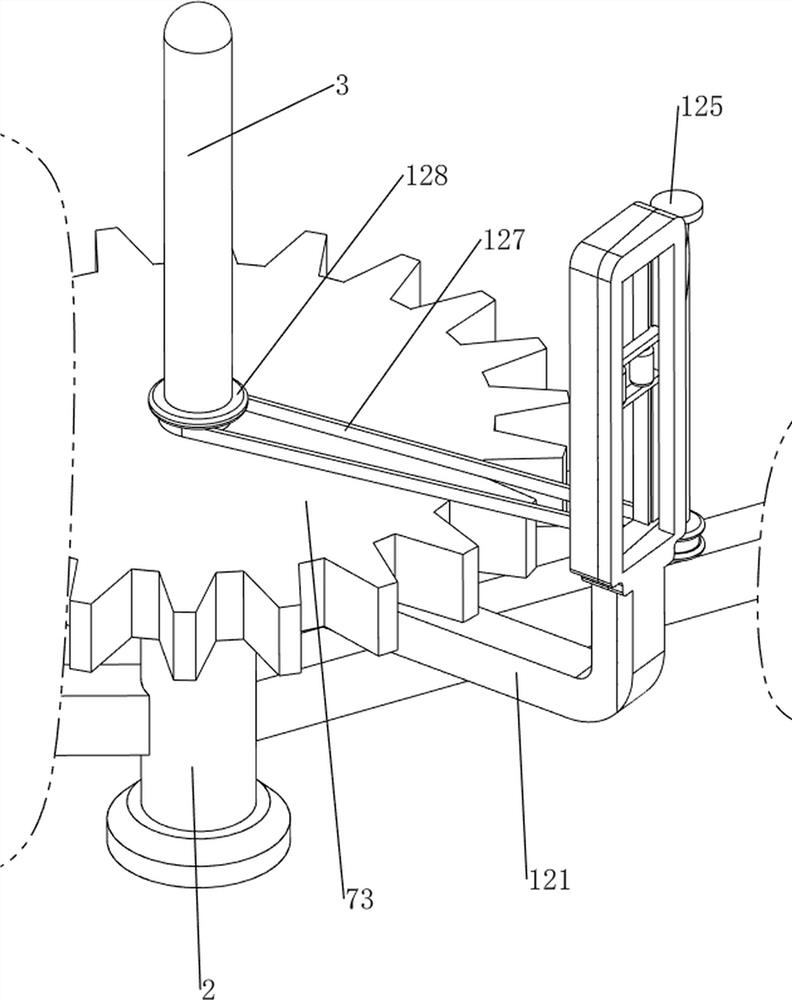

[0041] Such as figure 1 , image 3 and Figure 5 As shown, the power mechanism 7 includes a frame 70, a motor 71, a f...

Embodiment 2

[0045] On the basis of Example 1, such as figure 1 , Figure 6 , Figure 7 and Figure 8 As shown, it also includes a limit mechanism 9, the third mounting rod 5 is provided with a limit mechanism 9, the limit mechanism 9 includes a mounting block 91, a first return spring 92, a pressing plate 93, a guide rod 94, a second return spring 95 , wedge-shaped block 96 and pressure bar 97, four third mounting rods 5 are connected with a mounting block 91, the mounting block 91 is located above the guide rod 6, and the outer walls of the four mounting blocks 91 are connected with three groups of guide rods 94 along the circumference , two guide rods 94 are a group, each group of guide rods 94 is slidably connected with a wedge-shaped block 96, each guide rod 94 is covered with a second return spring 95, the two of the second return spring 95 The ends are respectively connected with the mounting block 91 and the wedge-shaped block 96, and each wedge-shaped block 96 is connected with...

Embodiment 3

[0049] On the basis of Example 2, such as figure 1 , Figure 9 , Figure 10 and Figure 11 As shown, a guide mechanism 11 is also included, and the mounting plate 81 is provided with a guide mechanism 11. The guide mechanism 11 includes a fixed rod 111, a guide cylinder 112, a first connecting rod 113, a first sliding frame 114, and a second fixed block 115. , the first common spring 116 and guide wheel 117, the outside of four mounting plates 81 is all connected with a fixed rod 111, and fixed rod 111 is positioned at the inboard of first fixed block 82, and the top and bottom of four fixed rods 111 are all connected with One guide cylinder 112, the upper and lower parts of the four guide cylinders 112 on the upper side and the lower parts of the four guide cylinders 112 on the lower side are connected with three first connecting rods 113 evenly spaced, and each first connecting rod 113 top is connected with A second fixed block 115, each first connecting rod 113 tops are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com