Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "To achieve the extrusion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

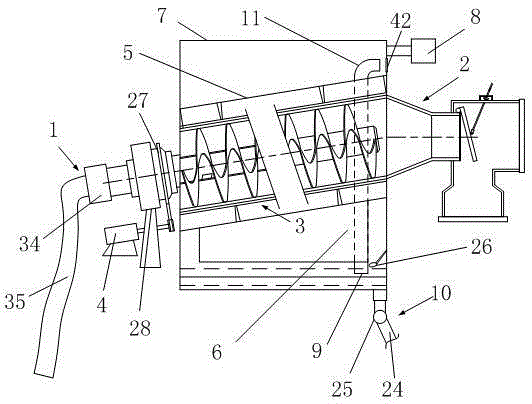

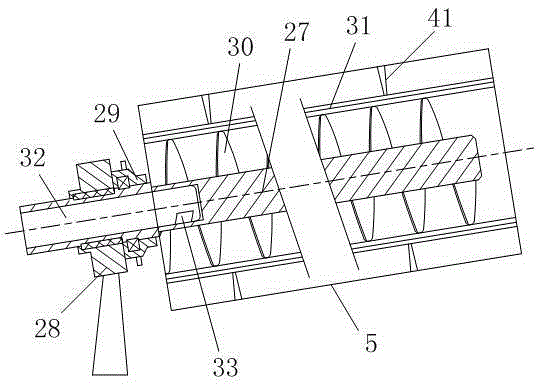

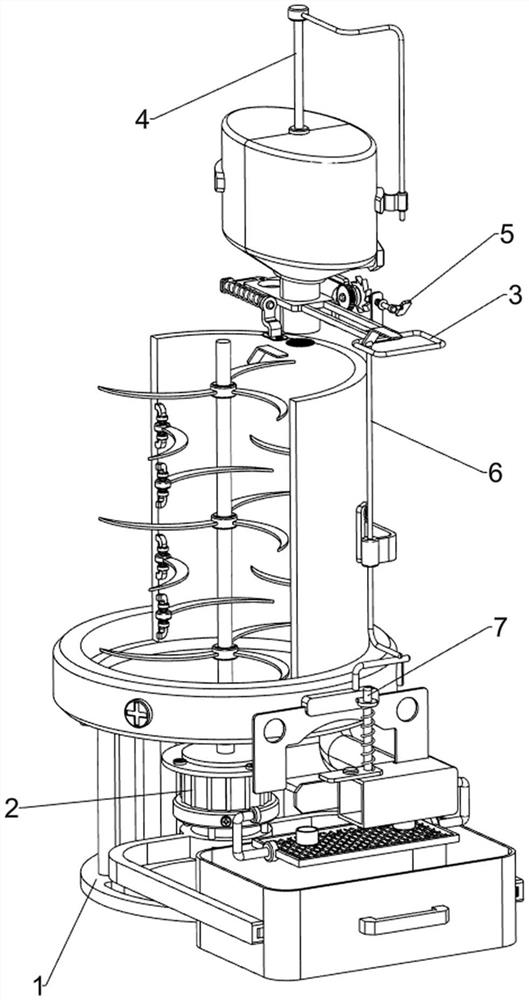

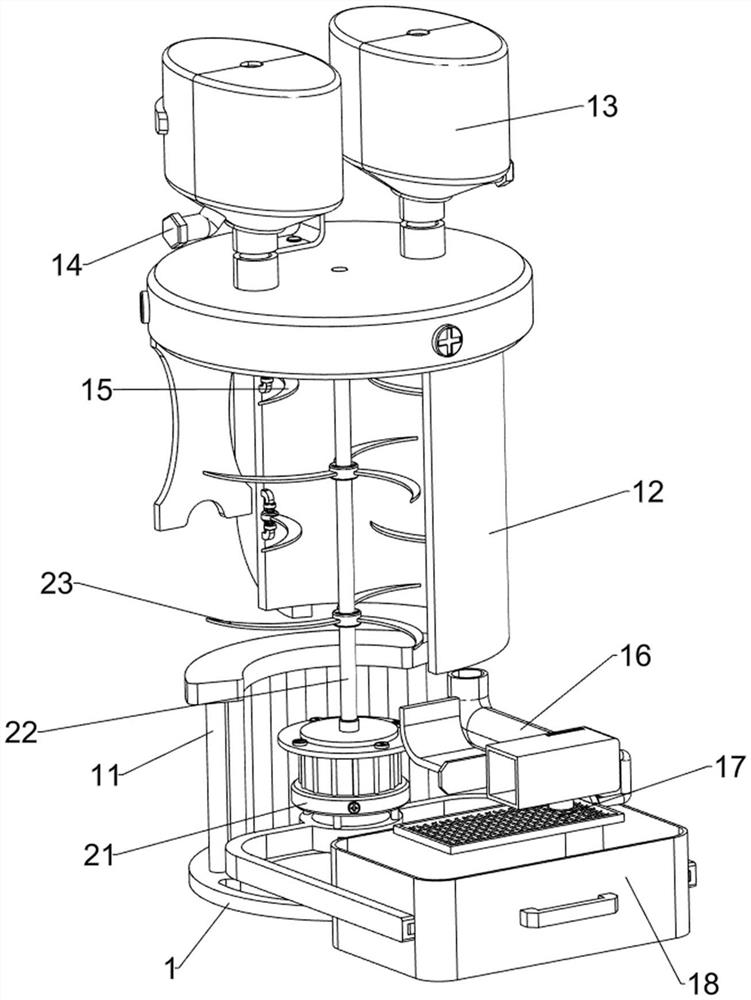

Automatic mixing device for colored glaze production

ActiveCN112844193AWell mixedAchieve broken effectTransportation and packagingRotary stirring mixersGlazeEngineering

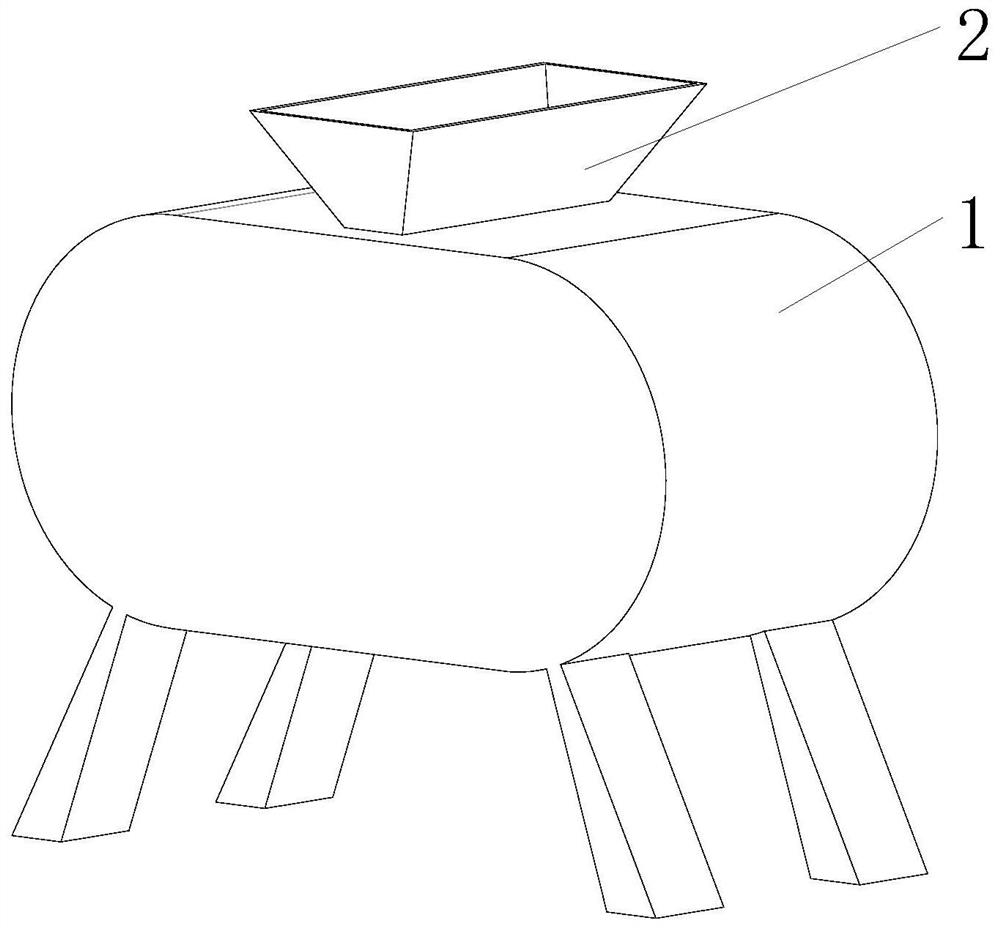

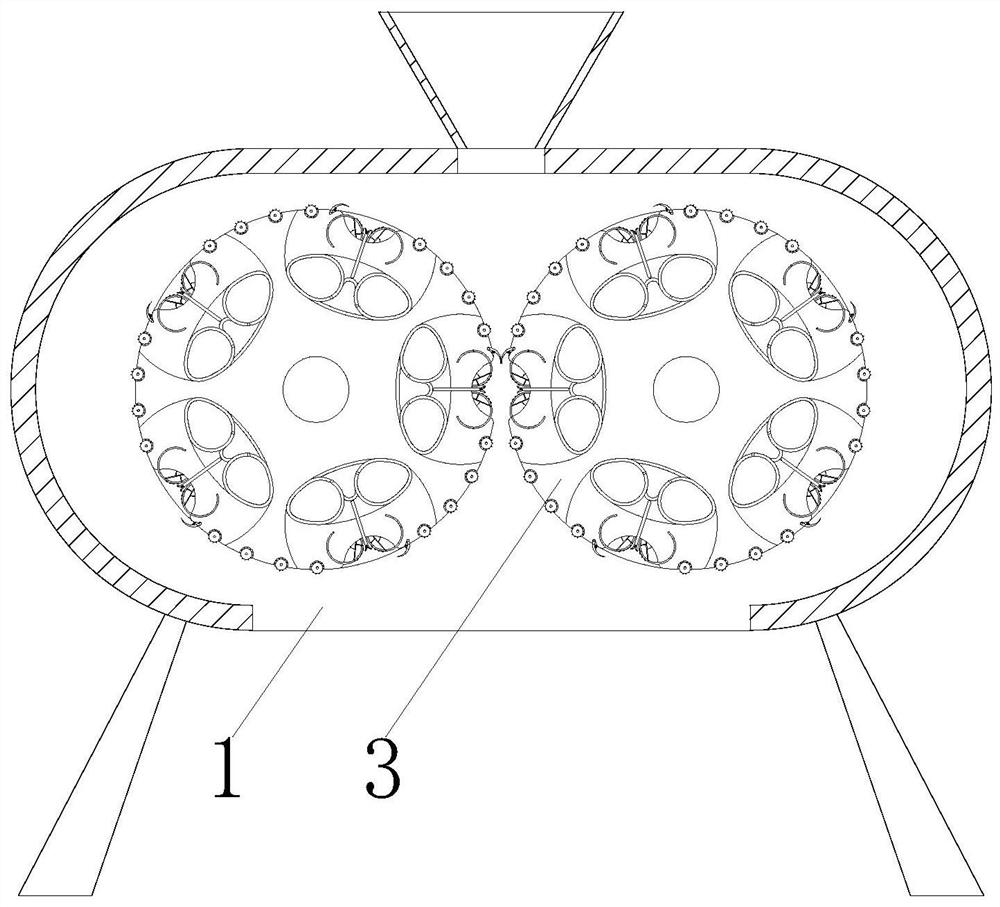

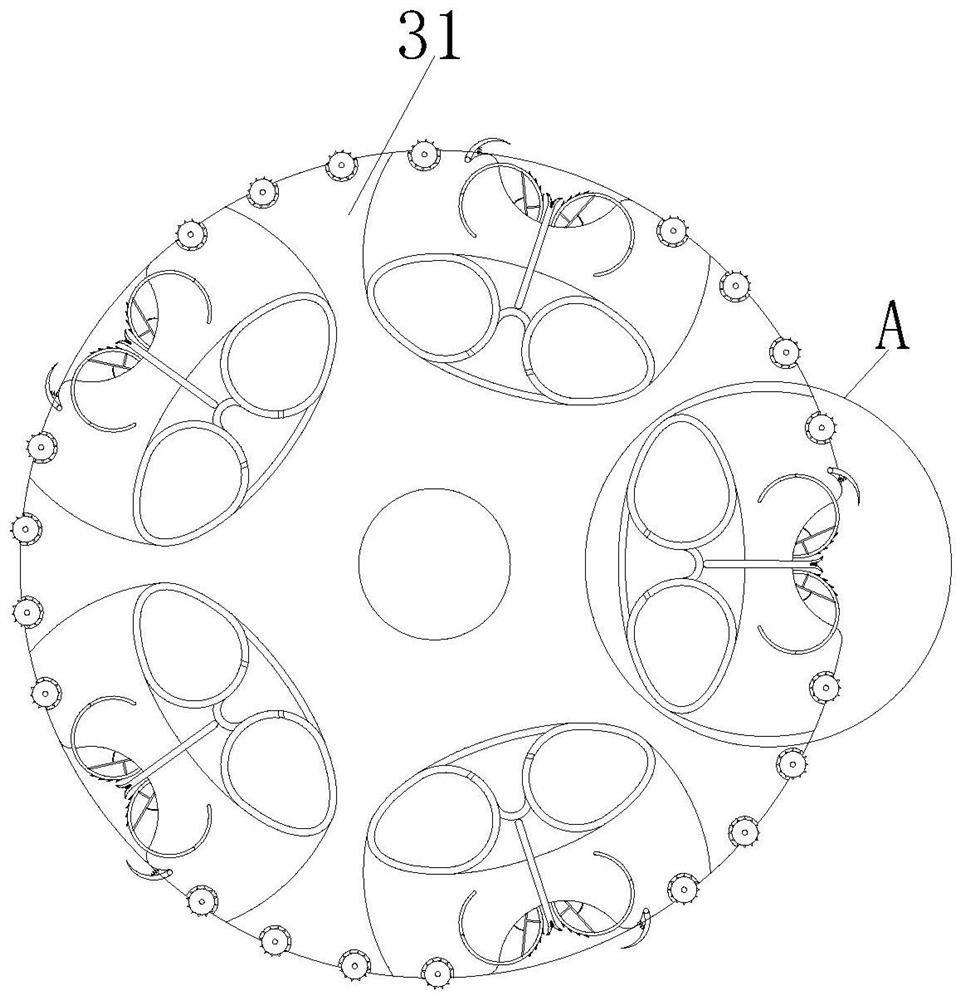

The invention relates to a mixing device, and particularly relates to an automatic mixing device for colored glaze production. The automatic mixing device for colored glaze production is good in mixing effect, capable of reducing the labor intensity of workers and easy and understandable to operate. The automatic mixing device for colored glaze production comprises a base, a fixed supporting column, a mixing box body, a discharging box, feeding openings, static crushing cutters, a discharging channel and a filter screen, wherein the fixed supporting column is arranged on the base; the mixing box body is arranged at the top of the fixed supporting column; the discharging box is arranged at the top of the mixing box body; the feeding openings are formed in the two sides of the lower part of the discharging box; three static crushing cutters are rotationally arranged on each of the upper side and the lower side in the mixing box body; the discharging channel is arranged at the bottom of the mixing box body; and the filter screen is arranged between the two sides of the discharging channel. By arranging the crushing mechanism, the colored glaze in the mixing box body is more uniformly mixed through the operation of the crushing mechanism, and the crushing effect is achieved.

Owner:高安常莹新型材料有限公司

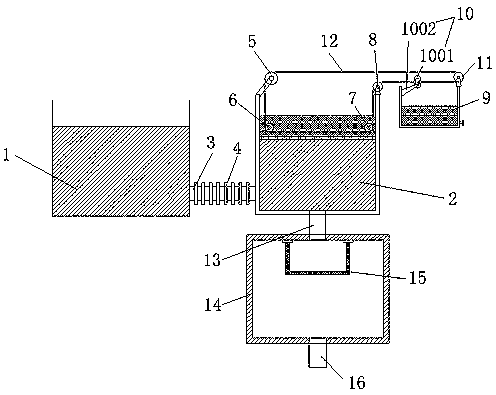

Coal chemical wastewater pretreatment device

PendingCN109205908ASimple structureRun smoothlyFatty/oily/floating substances removal devicesTreatment involving filtrationPre treatmentCoal chemical industry

The invention discloses a coal chemical wastewater pretreatment device, which comprises a wastewater pool and an oil removal pool, wherein the wastewater pool and the oil removal pool are communicatedthrough a water inlet pipe at the bottom; a plurality of heating rings are arranged on the water inlet pipe; the heating rings are tightly attached to the outer surface of the water inlet pipe; a first guide wheel, a second guide wheel, a third guide wheel and a fourth guide wheel are respectively arranged in the upper end wall and the inner wall of the oil removal pool; a filtering screen is ofa cuboid structure; the end part of a water outlet is contained in the filtering screen; the lower end of a water filtering box is provided with a connecting water pipe. In the wastewater flowing process, heating treatment is performed; the density of oil type substances is greatly reduced, so that the oil type substances float; the oil type substances are sucked by oil sucking cotton and are thenextruded into an oil collecting barrel; next, through the filtering screen in the water filtering box, it is further ensured that the oil type substances are totally cleared away. The coal chemicalwastewater pretreatment device has the advantages that the structure is simple; the operation is stable; the oil removal effect is good; the smooth proceeding of the subsequent wastewater treatment isensured.

Owner:中科协创环境科技江苏有限公司

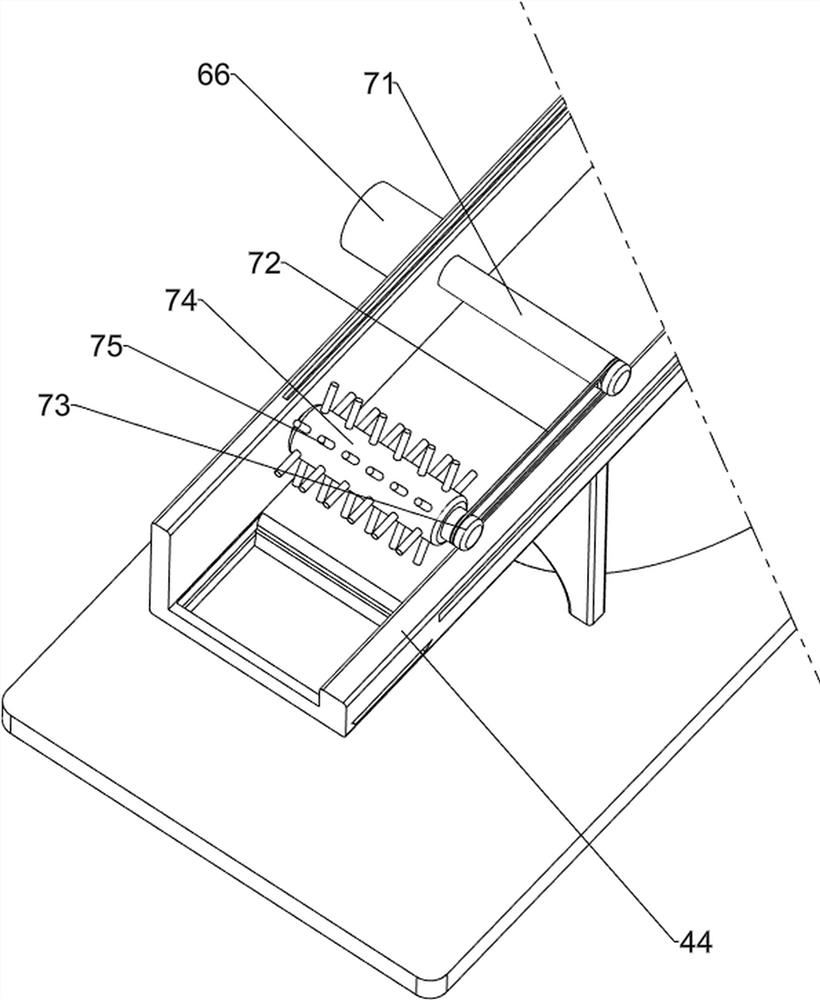

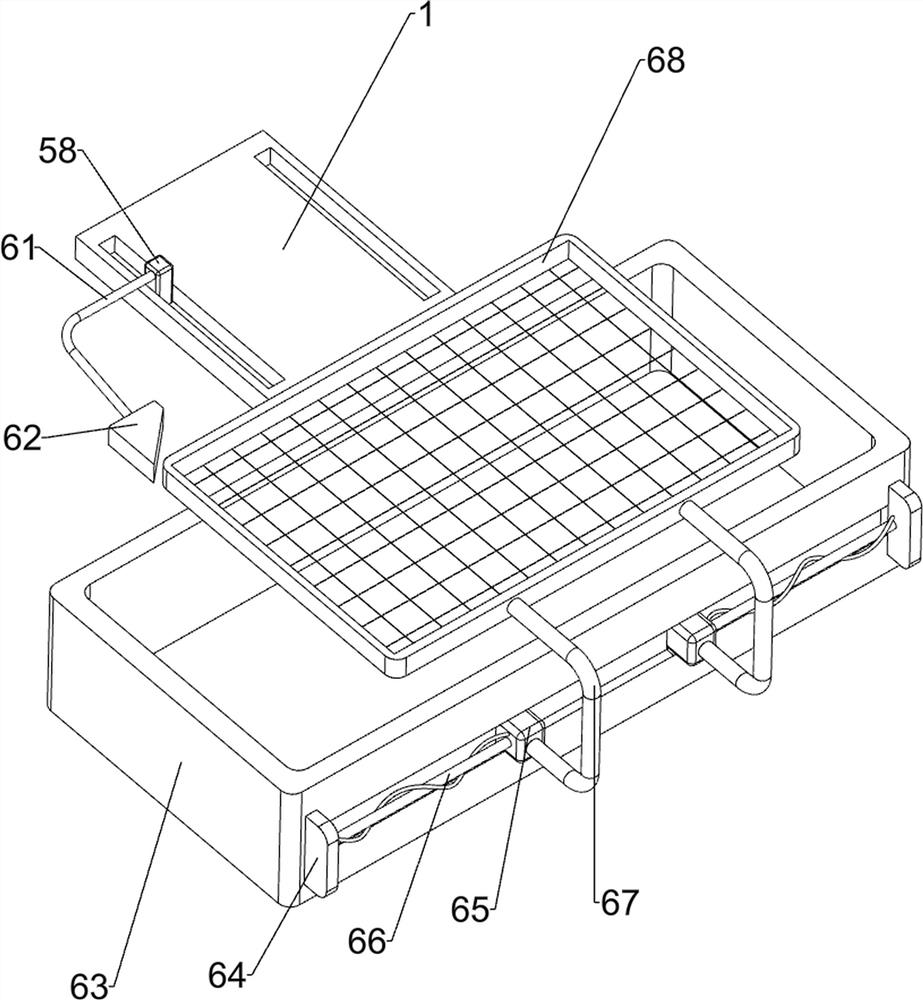

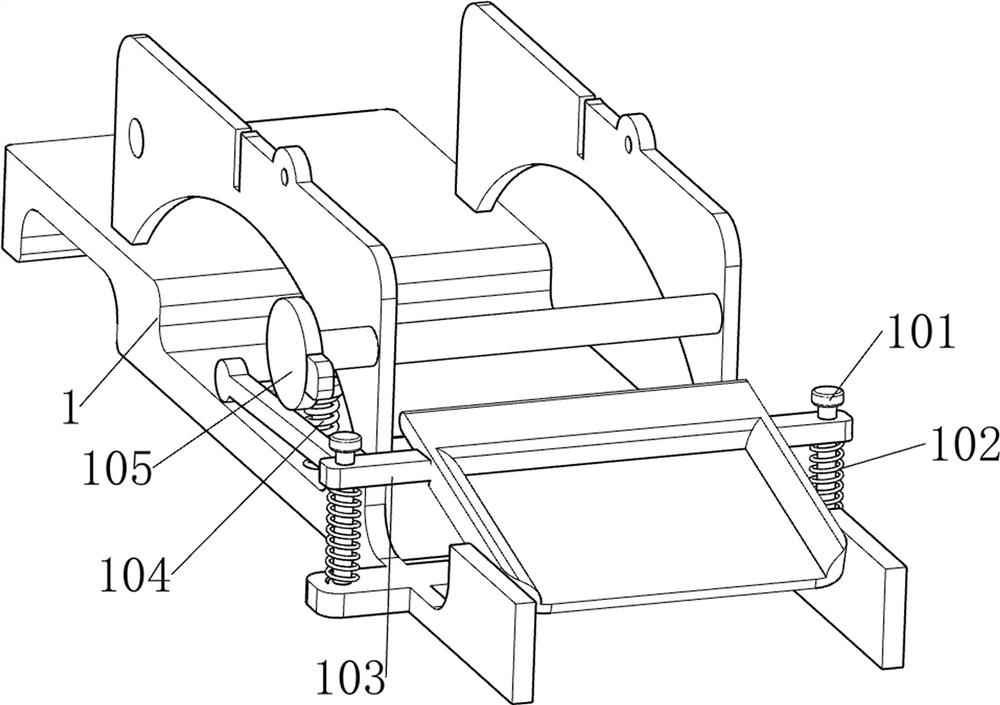

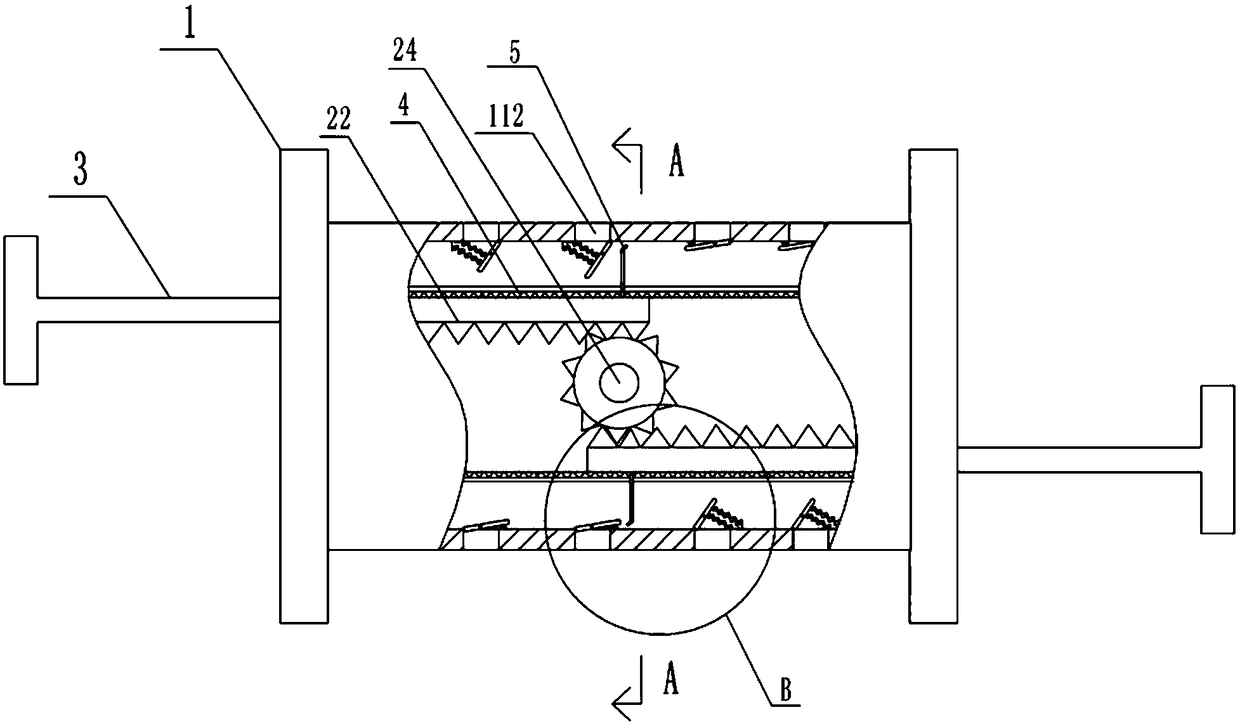

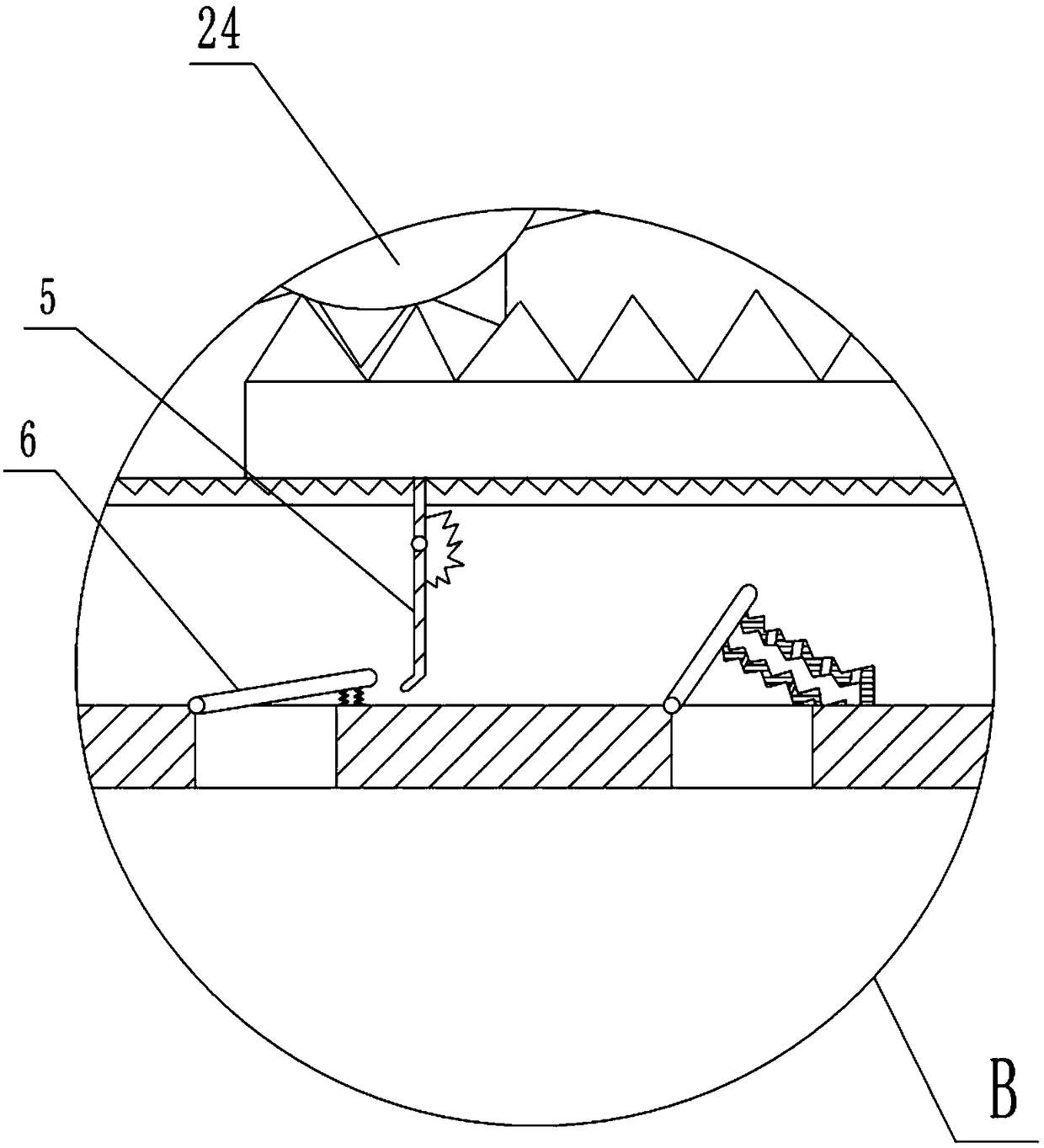

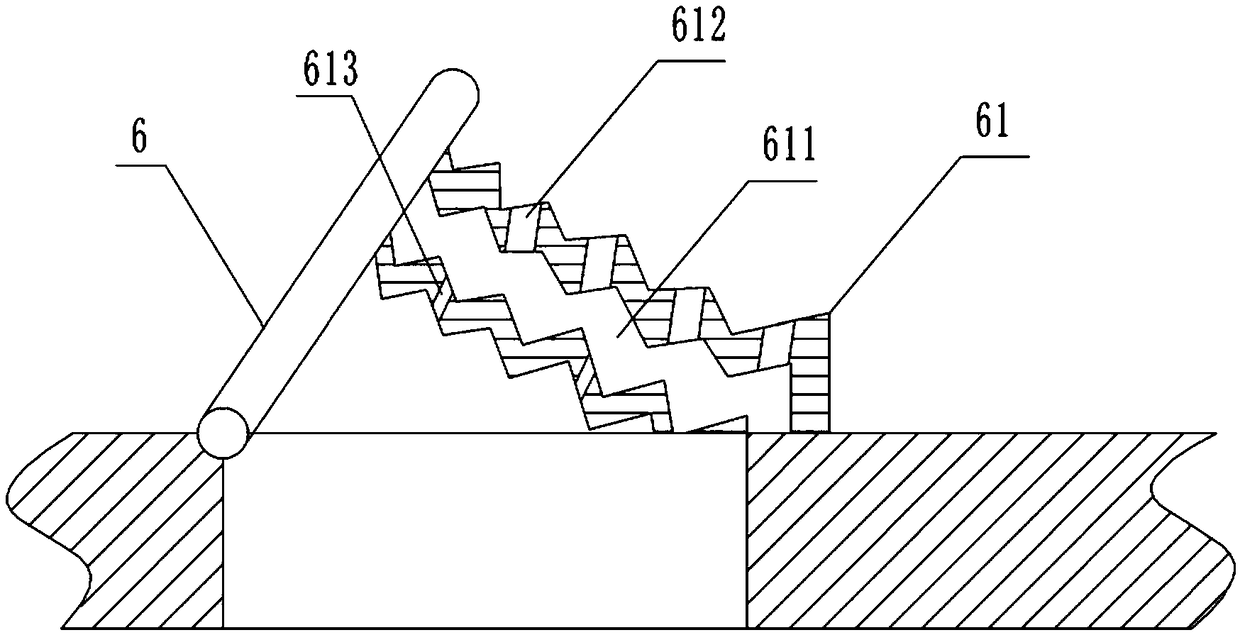

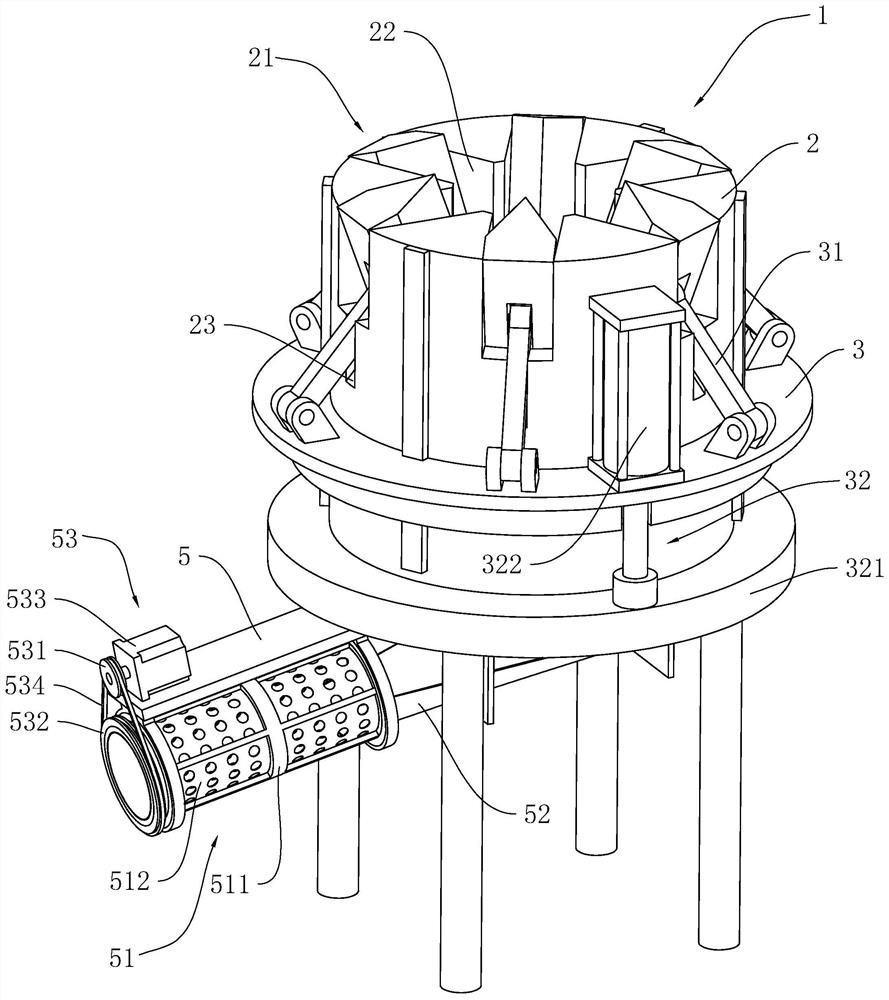

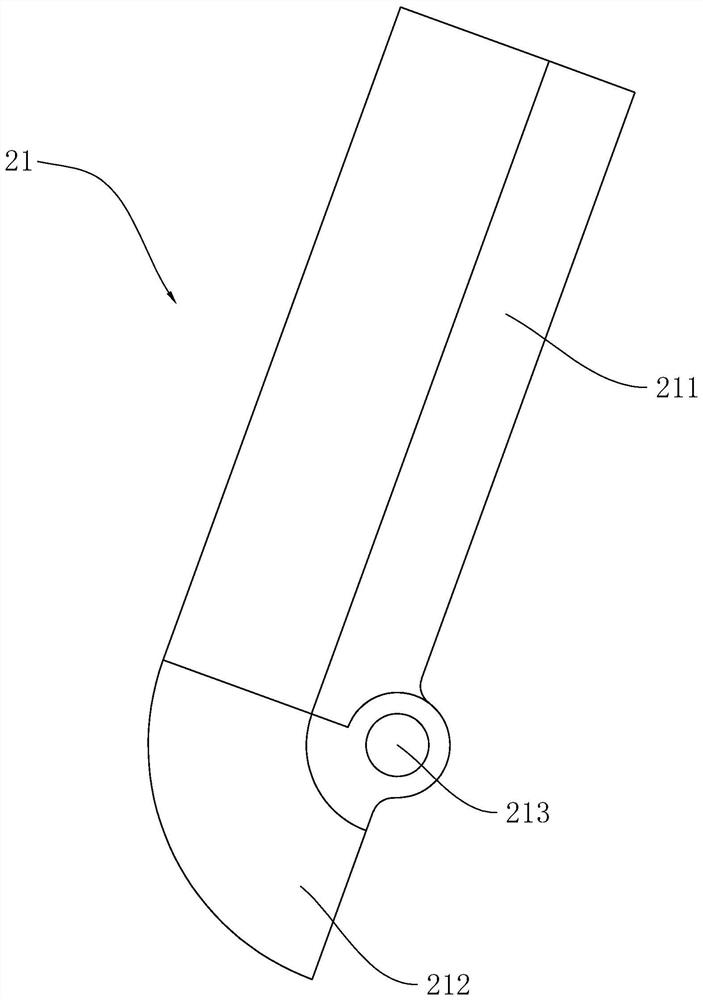

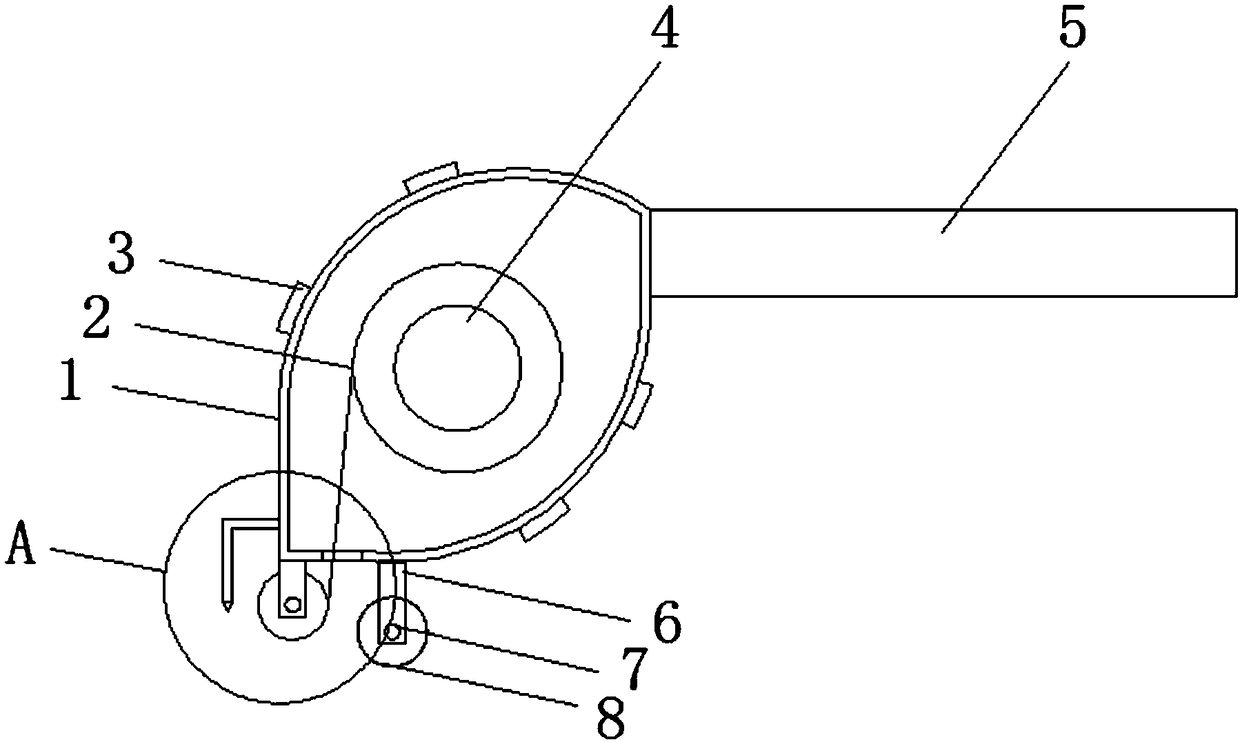

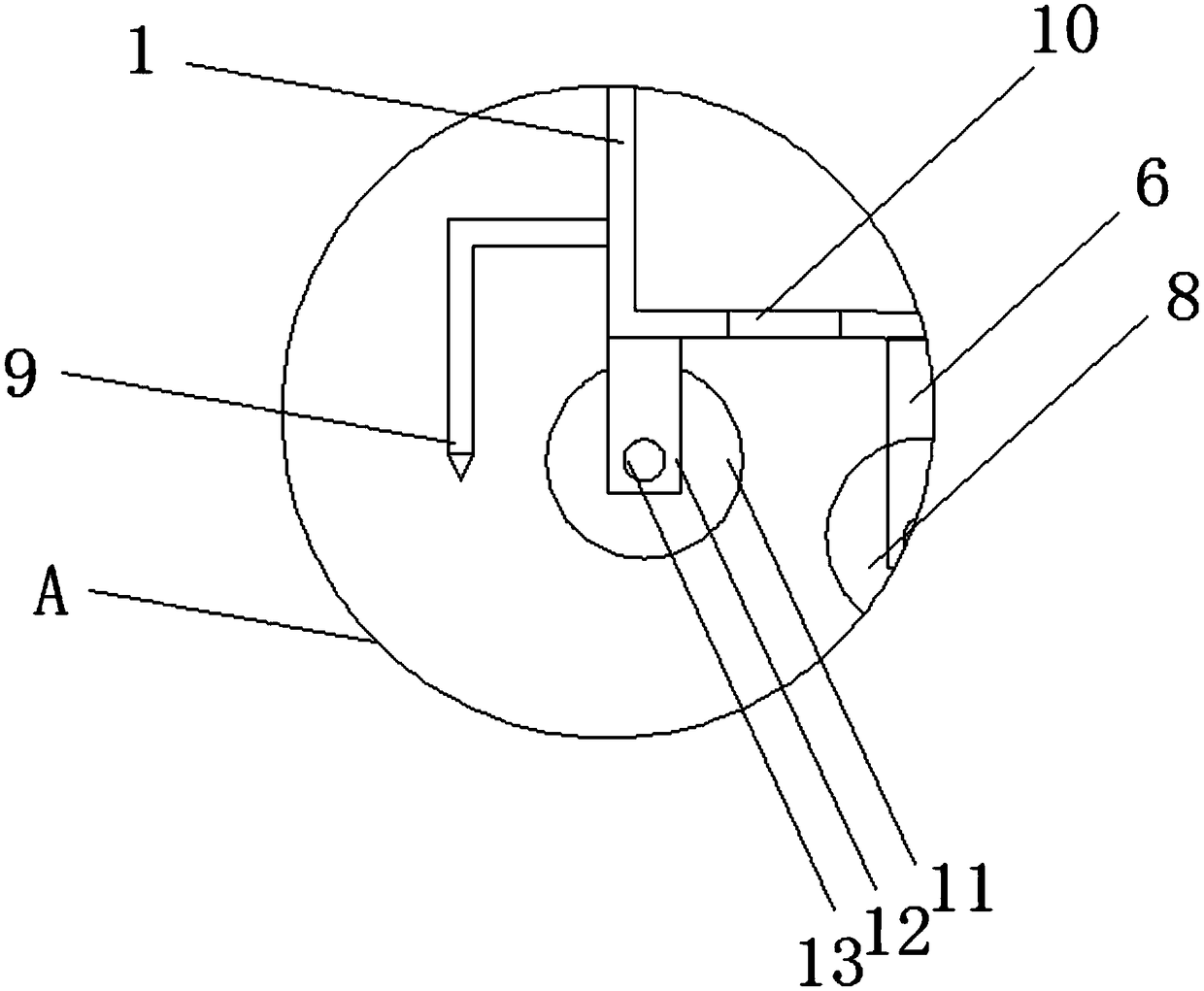

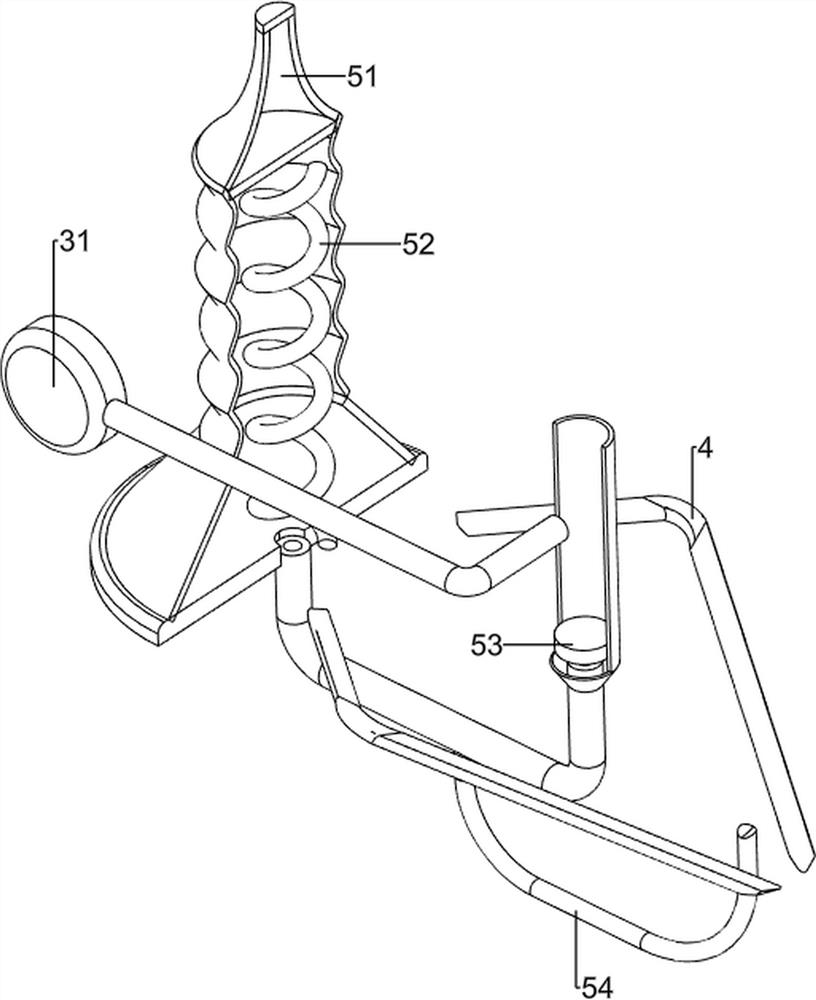

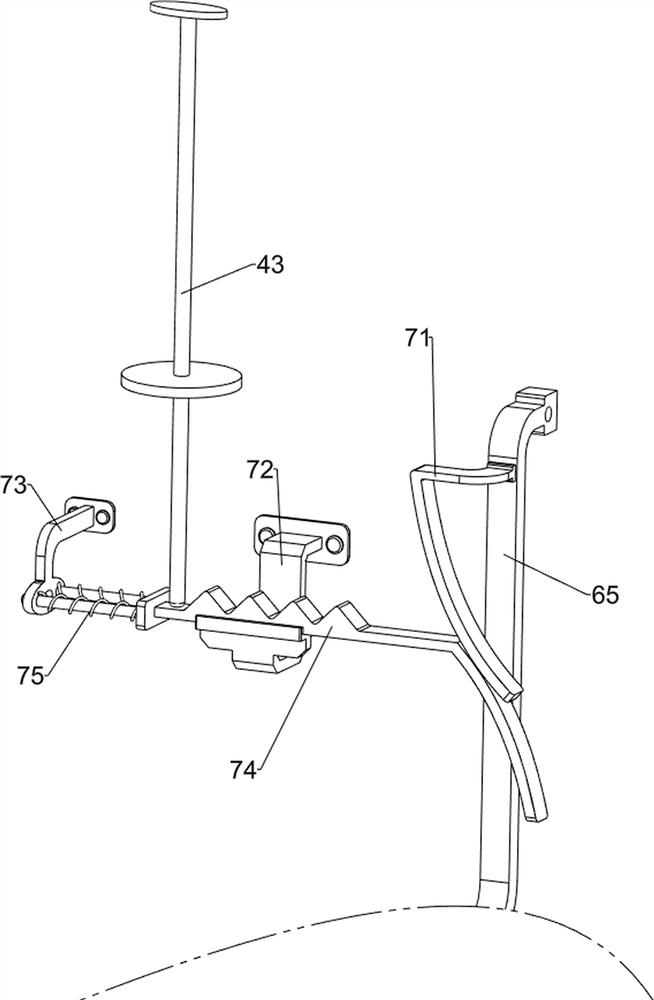

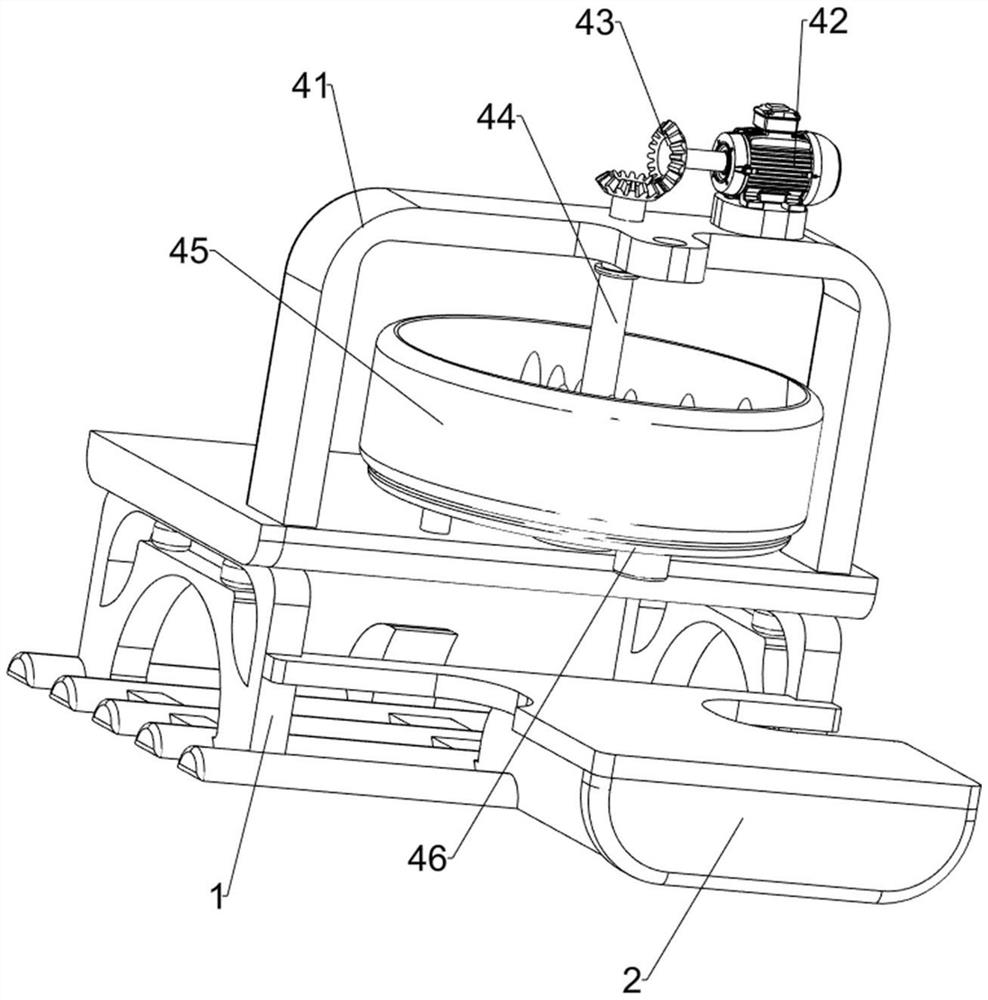

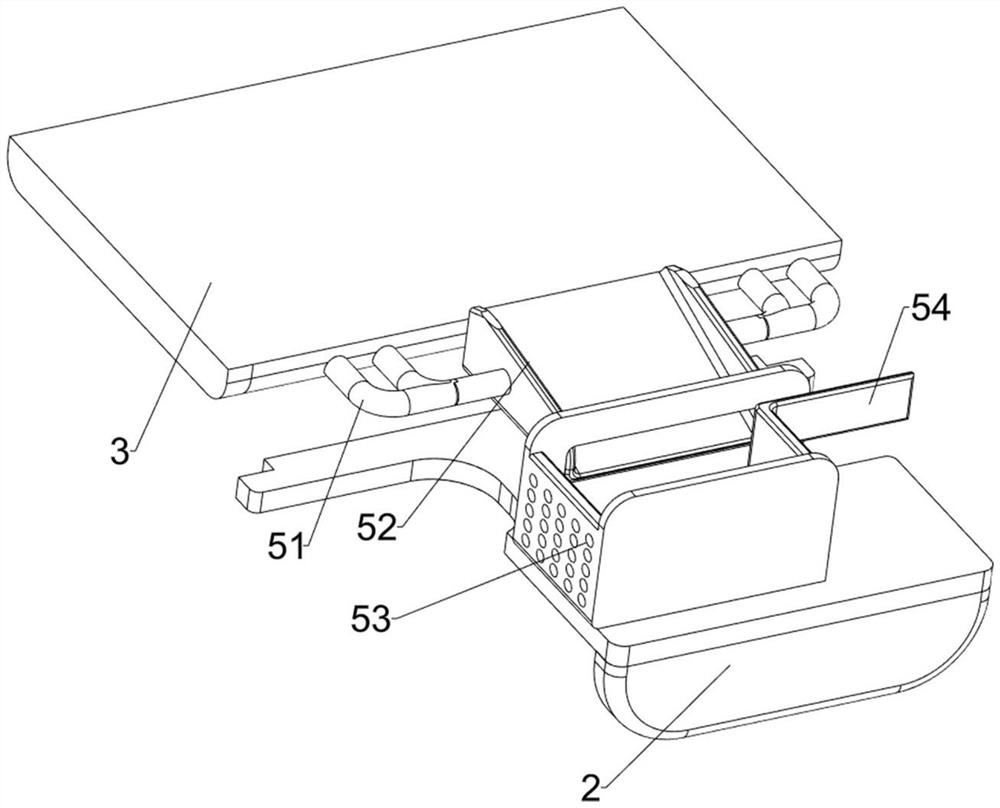

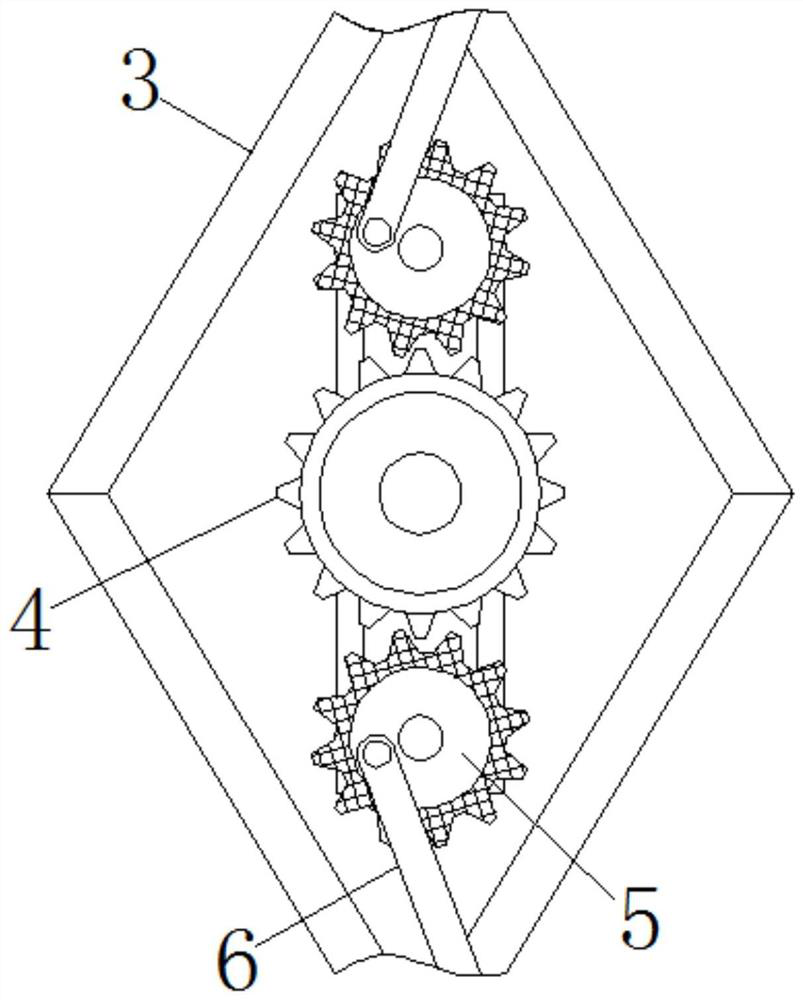

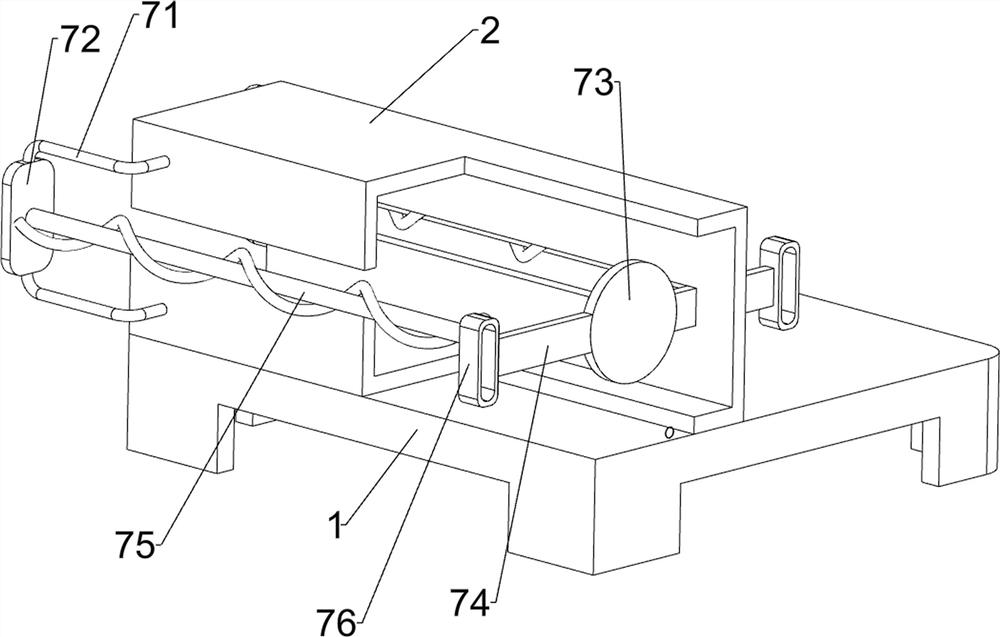

Agricultural automatic peanut shell breaking device

PendingCN112369618ARealize the driving effectTo achieve the extrusion effectHuskingHullingAgricultural scienceAgricultural engineering

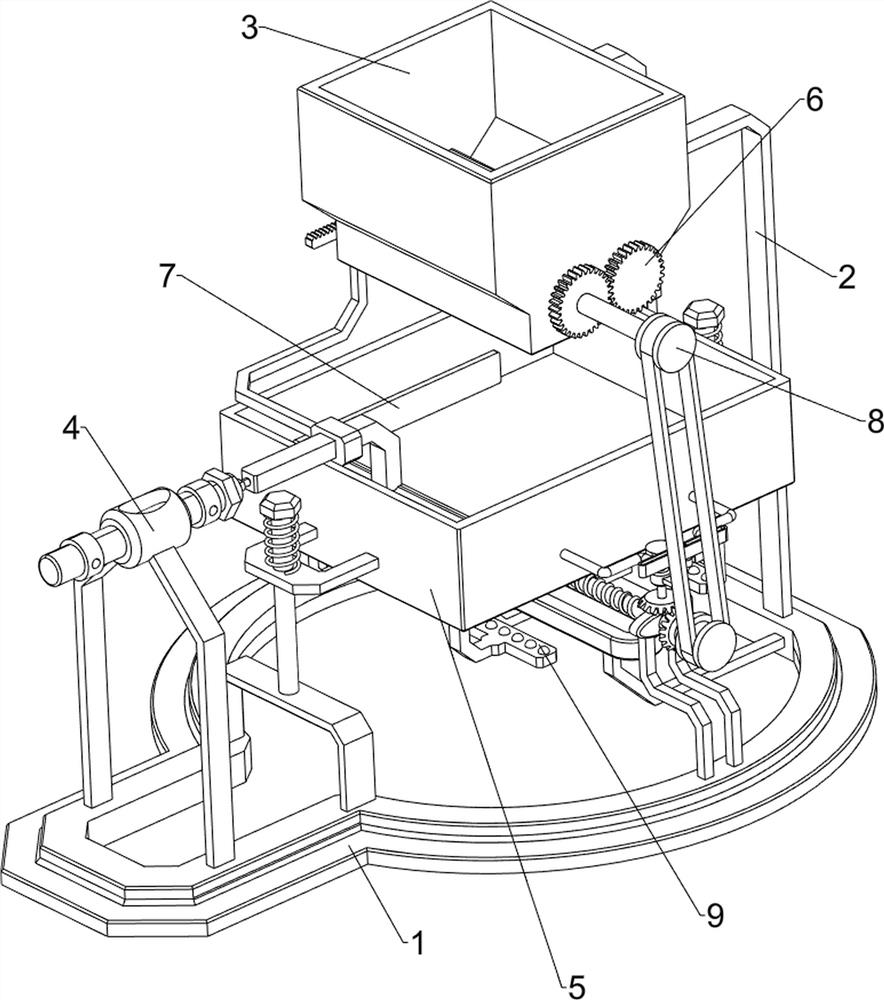

The invention relates to a shell breaking device, in particular to an agricultural automatic peanut shell breaking device. The agricultural automatic peanut shell breaking device is low in labor intensity, high in working efficiency and free of damage to peanuts. The agricultural automatic peanut shell breaking device comprises a base, brackets, a pushing mechanism and an extrusion mechanism, wherein three first supporting columns are arranged on the base; the two brackets are arranged on the front side of the base; the pushing mechanism is arranged among the tops of the three first supportingcolumns; and the extrusion mechanism is arranged on the left side of the upper front part of the base. According to the agricultural automatic peanut shell breaking device, an air cylinder telescopicrod extends forwards to drive a discharging plate to move forwards, then a first sliding block is driven to move forwards, a user manually pulls a material blocking plate rightwards, and peanuts falloff from a discharging port; and a first connecting rod drives a first rack to move downwards, so that a second sliding block is driven to move downwards, a first spring is compressed to extrude thepeanuts on the material blocking plate, shells of the peanuts are broken, and the extrusion effect is achieved.

Owner:牟立勇

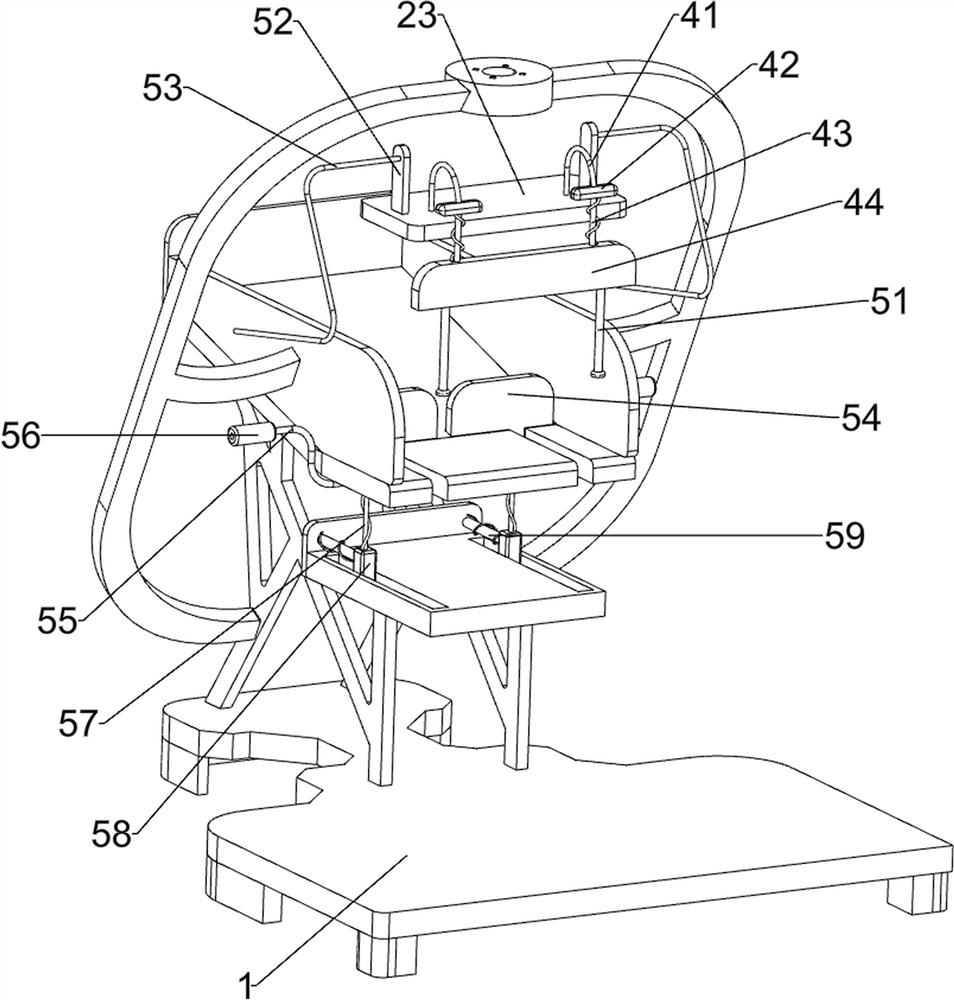

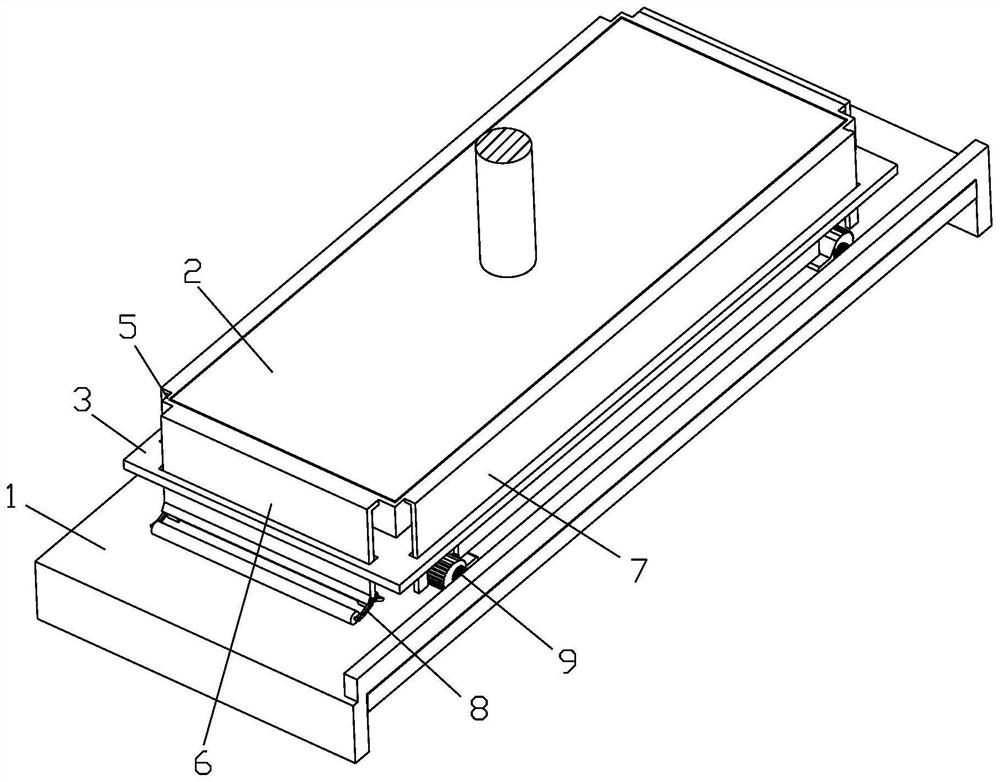

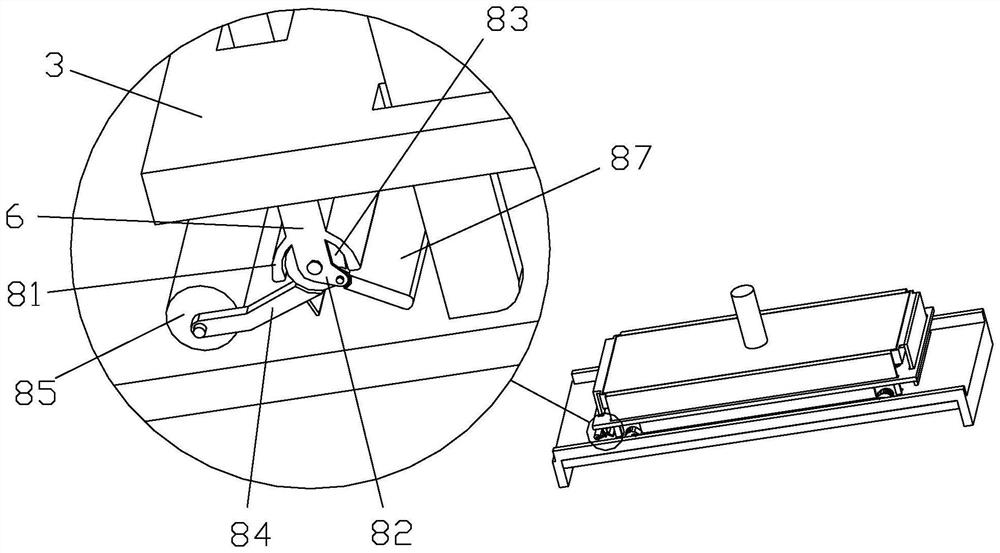

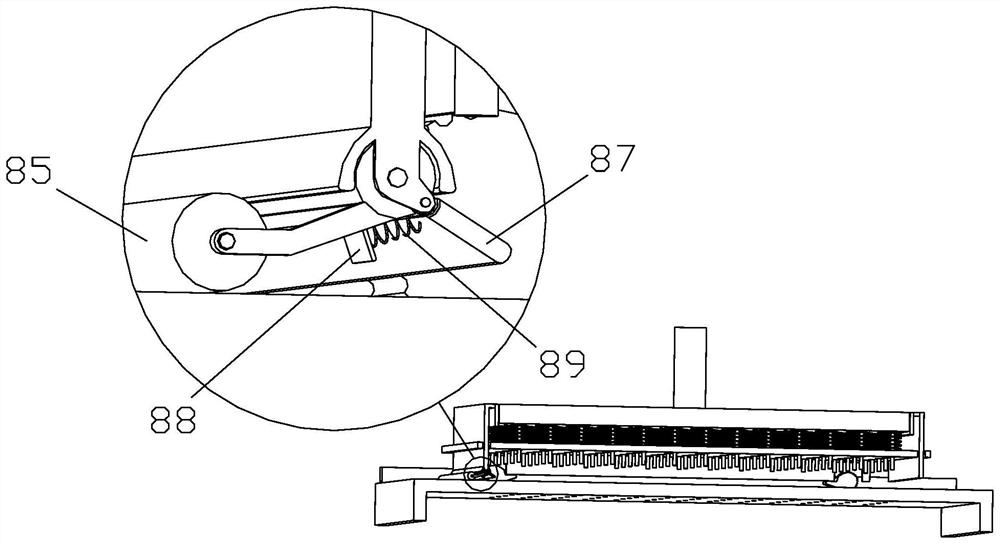

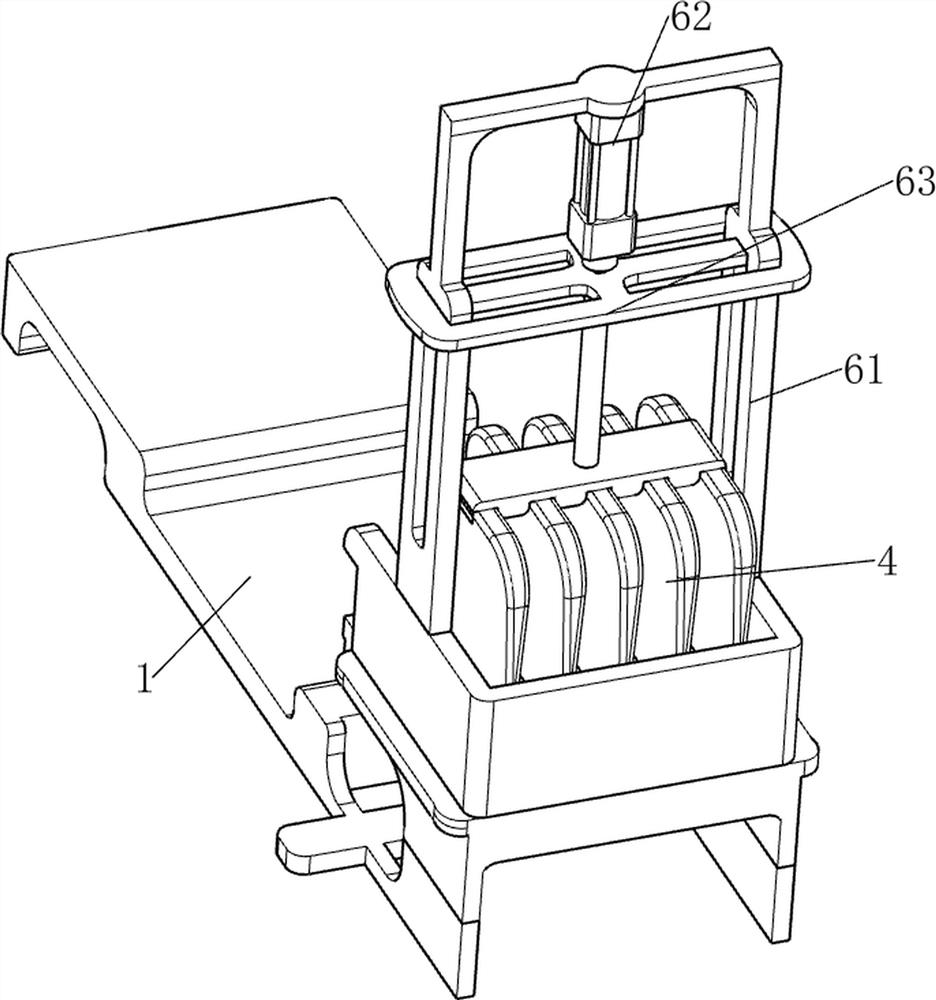

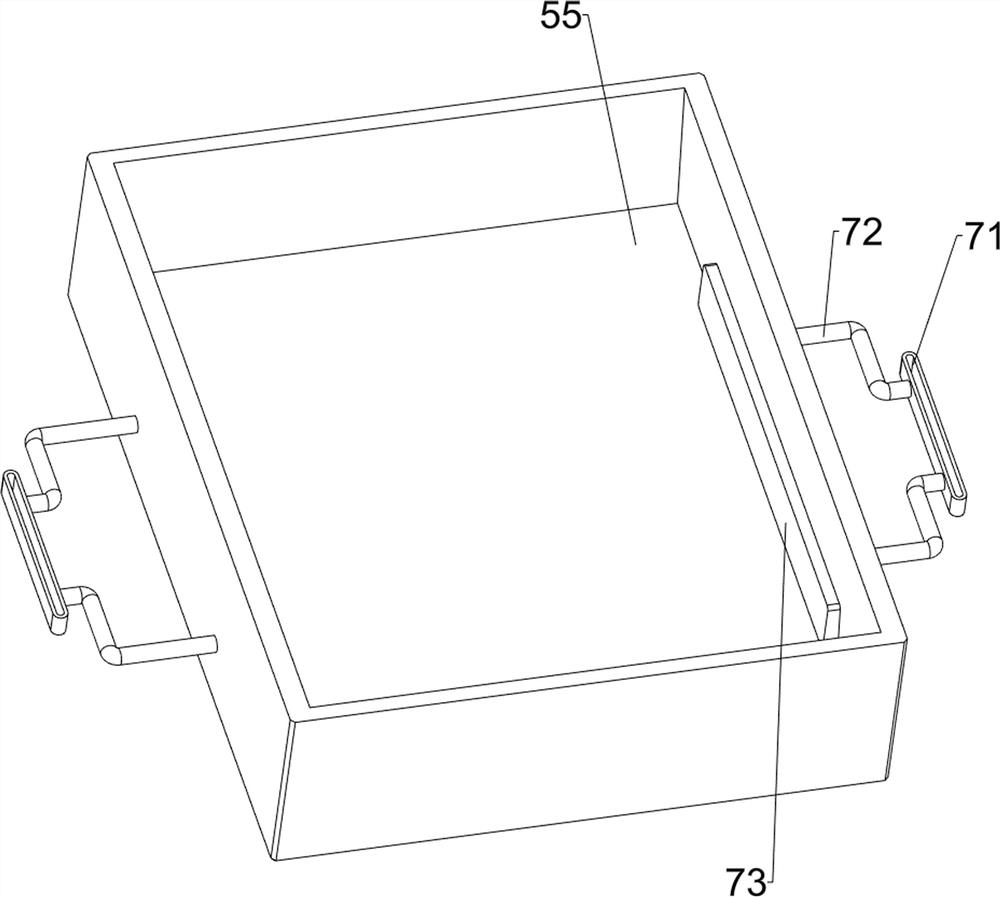

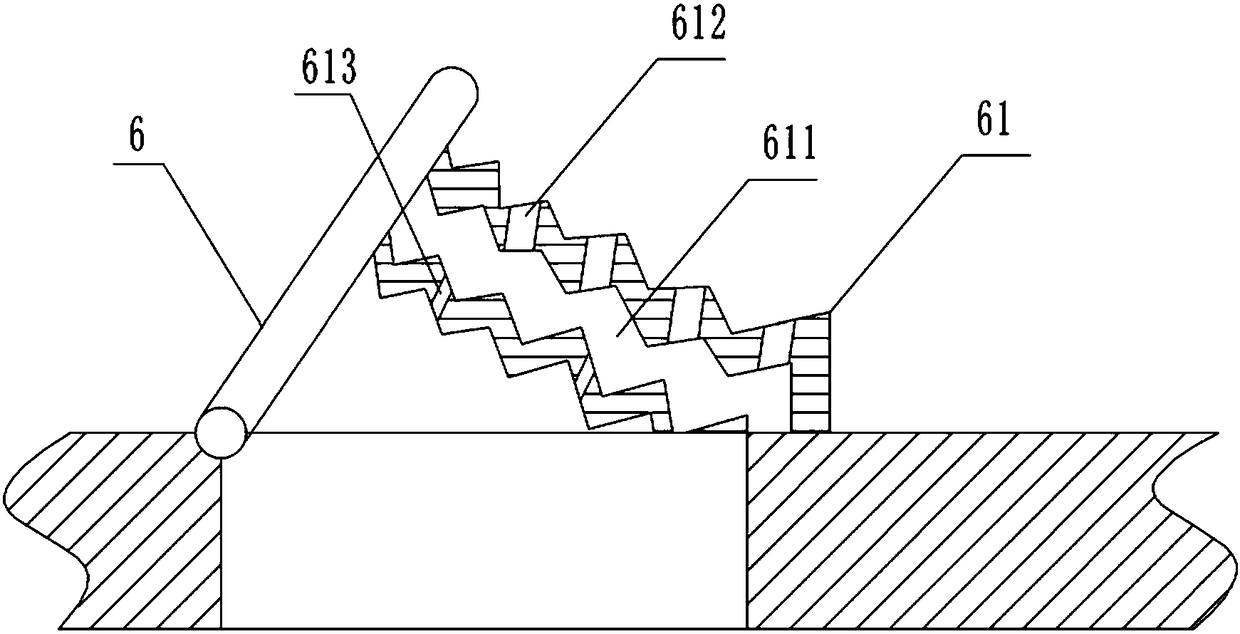

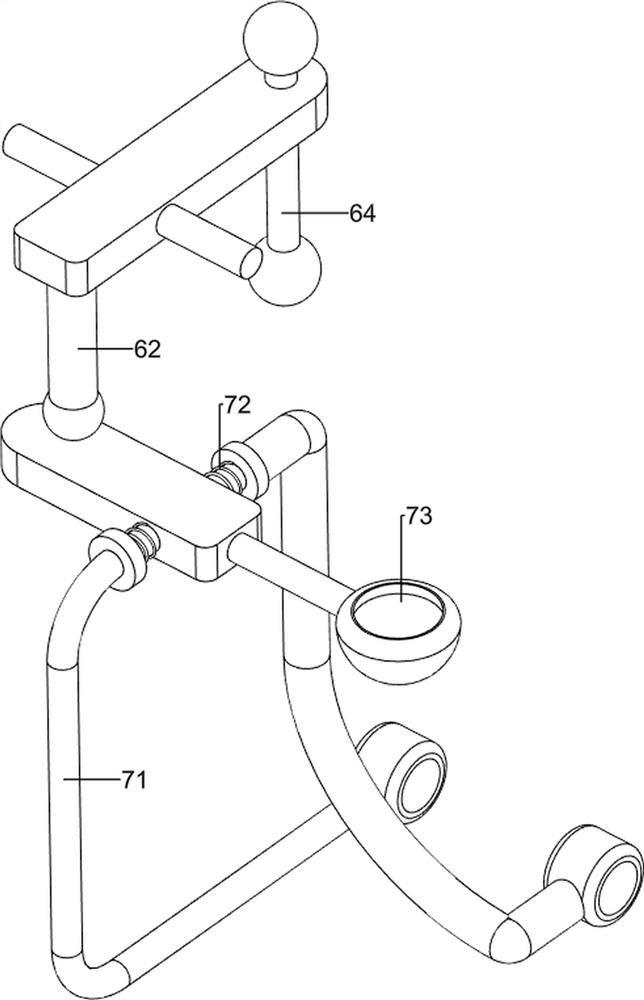

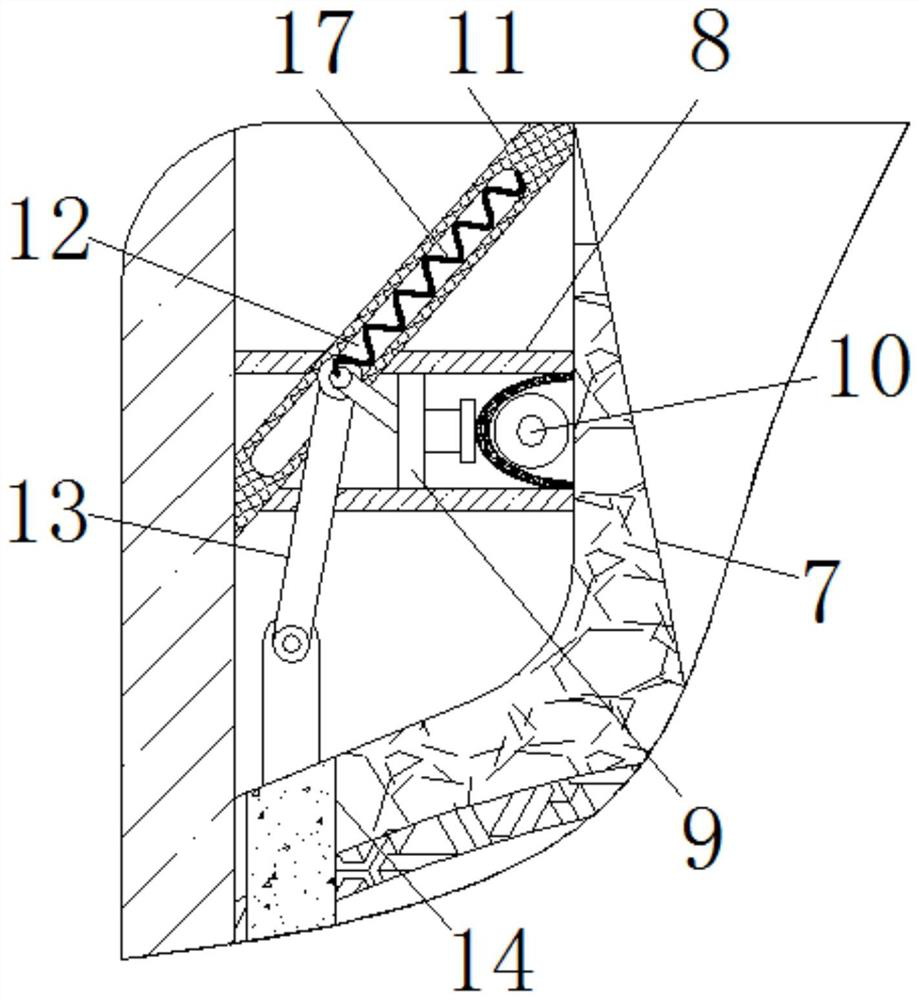

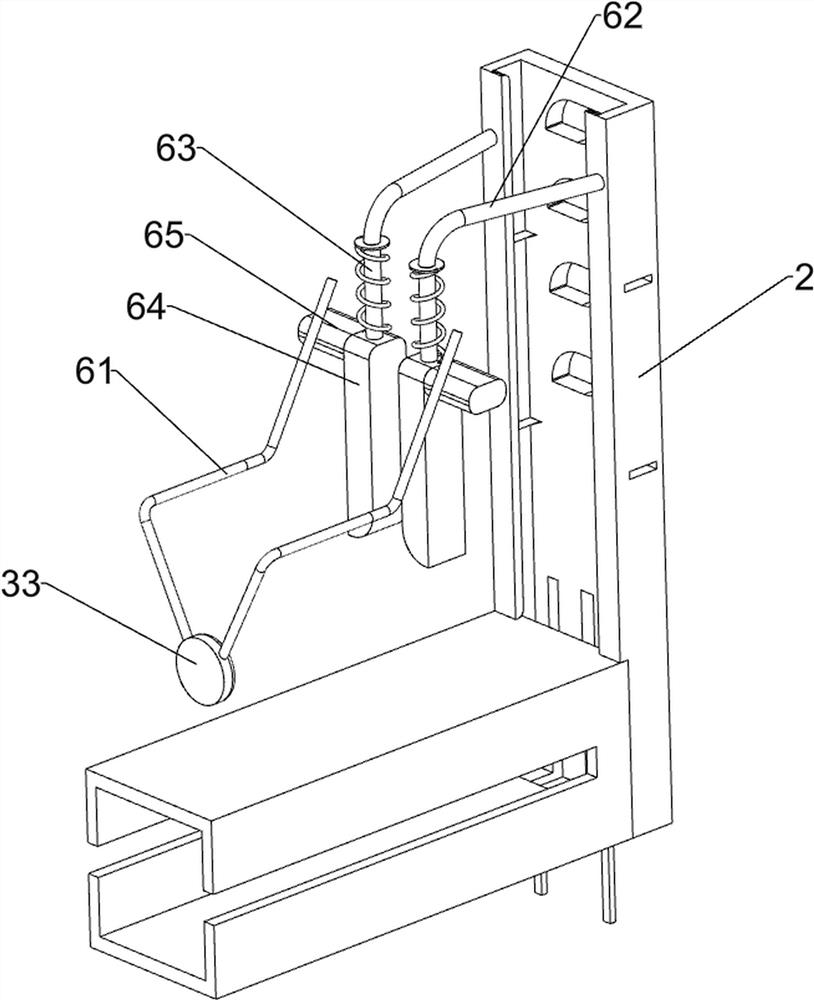

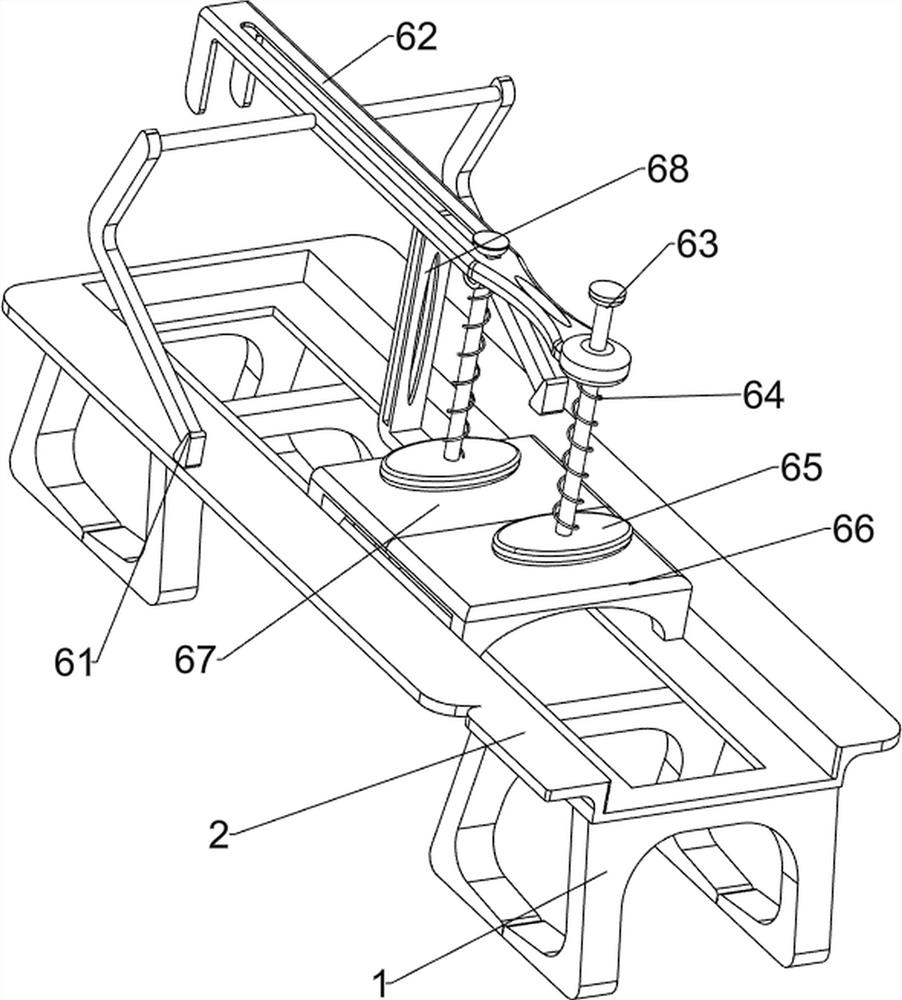

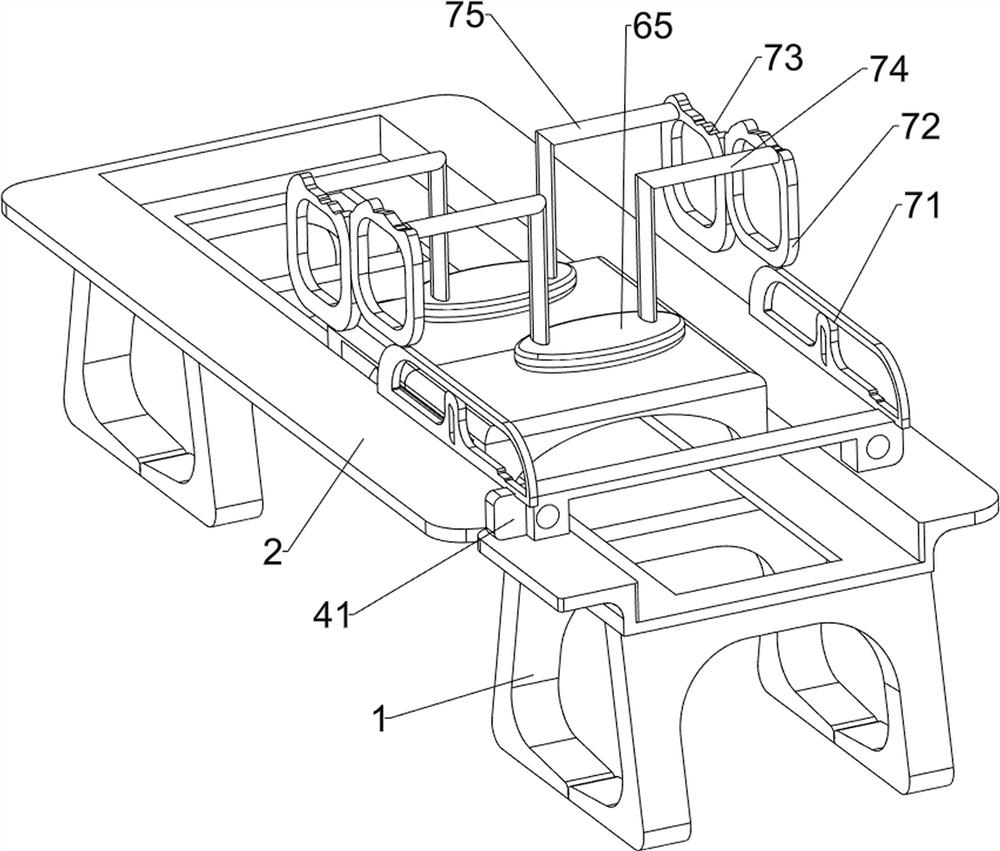

Agricultural extrusion type garlic granule stripping device

ActiveCN112869210ATo achieve the extrusion effectRealize the blocking effectSievingGas current separationAgricultural engineeringProcess engineering

The invention relates to a stripping device, in particular to an agricultural extrusion type garlic granule stripping device. The agricultural extrusion type garlic granule stripping device provided by the invention has the advantages that garlic cloves are thoroughly extruded, and automatic material control and automatic material discharging are realized. An agricultural extrusion type garlic granule stripping device comprises a base, wherein an extrusion mechanism is arranged on the front side of the base; and a material control mechanism arranged on the rear side of the base. A cylinder telescopic rod drives a push block to move downwards, so that a pressing plate is driven to move downwards, the pressing plate makes contact with garlic cloves, the pressing plate extrudes the garlic cloves, the garlic cloves are extruded into garlic granules, and the extrusion effect is achieved; the second telescopic assembly drives the material blocking plate to move downwards, the material blocking plate makes contact with the base, the second telescopic assembly is compressed, the material blocking plate blocks the discharging opening of the base, garlic granules on the base are blocked, and the material blocking effect is achieved.

Owner:陆丰市放心农业发展有限公司

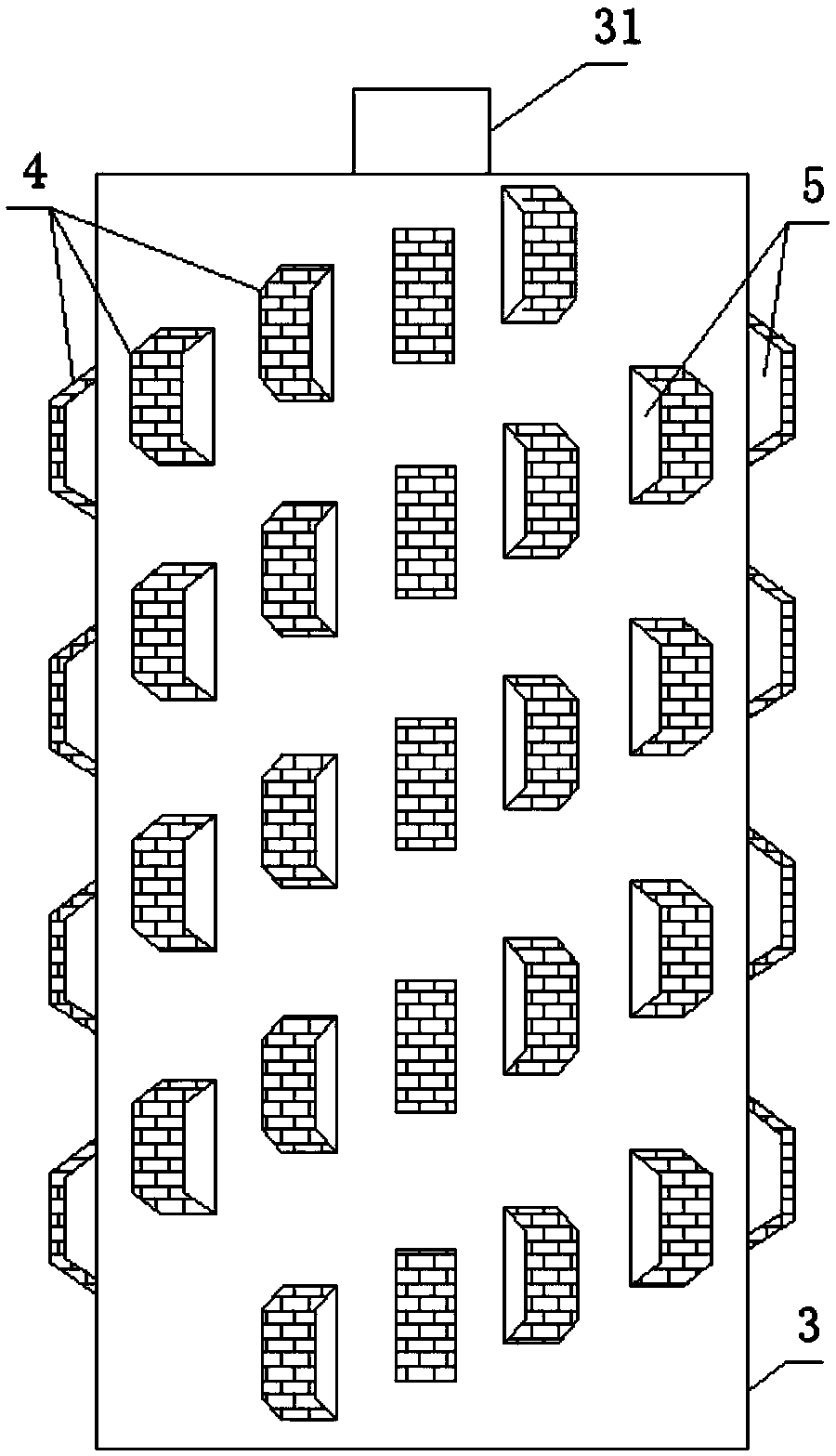

Forming process and forming device of carbon fiber preform

ActiveCN114474958AAchieve compositeImprove fitLamination ancillary operationsLaminationFiberCarbon fibers

The invention relates to a forming process and a forming device of a carbon fiber preform, the forming device comprises a needling plate, the upper end face of the needling plate is vertically and downwards provided with a needling hole in a penetrating manner, a supporting plate is arranged above the needling plate, the upper end face of the supporting plate is provided with a driving mechanism, and the lower end face of the supporting plate is provided with a needling body corresponding to the needling hole; a cleaning plate is arranged between the needling plate and the supporting plate, a through hole is vertically and upwards formed in the upper end face of the cleaning plate, and the needling body penetrates through the through hole in a sliding mode. When the needling body penetrates into the needling hole, the cleaning plate is pressed on the upper end face of the composite layer to achieve a certain extrusion effect on the composite layer, so that the carbon fiber woven fabric and the carbon fiber net felt are better attached together, and when the supporting plate drives the needling body to rise quickly, and the rising speed of the cleaning plate is lower than that of the supporting plate, the cleaning plate can be used for cleaning the carbon fiber woven fabric and the carbon fiber net felt. The needling bodies are drawn out from the through holes in the cleaning plate, and then the fibers adsorbed on the surfaces of the needling bodies are removed.

Owner:宜兴市飞舟高新科技材料有限公司 +1

Energy-saving and environment-friendly plastic bottle recycling device

PendingCN114043642ARealize the effect of crushing plastic bottlesRealize the effect of cutting plastic bottlesPlastic recyclingMechanical material recoveryMechanical engineeringIndustrial engineering

The invention relates to a recycling device, in particular to an energy-saving and environment-friendly plastic bottle recycling device. According to the energy-saving and environment-friendly plastic bottle recycling device, automatic plastic bottle cutting, automatic plastic bottle conveying and automatic plastic bottle compressing are achieved. An energy-saving and environment-friendly plastic bottle recycling device comprises a bottom frame, and a cutting table is arranged on the bottom frame; the top of the cutting table is provided with the material blocking frame; the transmission mechanism is arranged on the bottom frame; the chopping mechanism is arranged at the top of the material blocking frame; and the cutter is arranged on the chopping mechanism. An extruding block is pushed towards the inner side, after the extruding block makes contact with a plastic bottle, the extruding block extrudes the plastic bottle, and the effect that the extruding block flattens the plastic bottle is achieved.

Owner:陈根祥

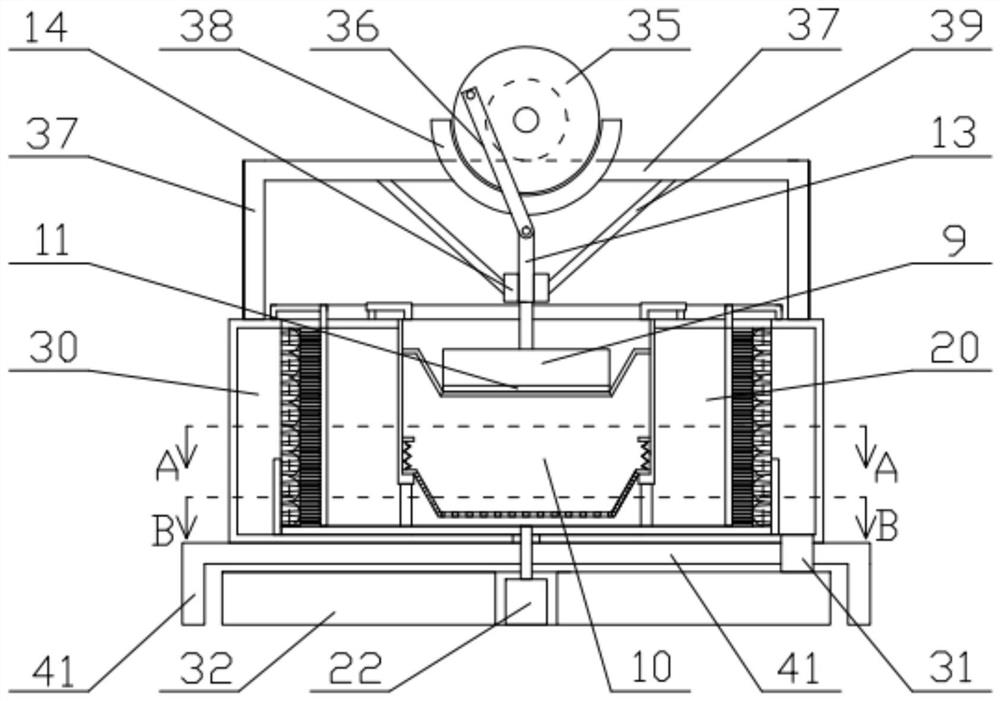

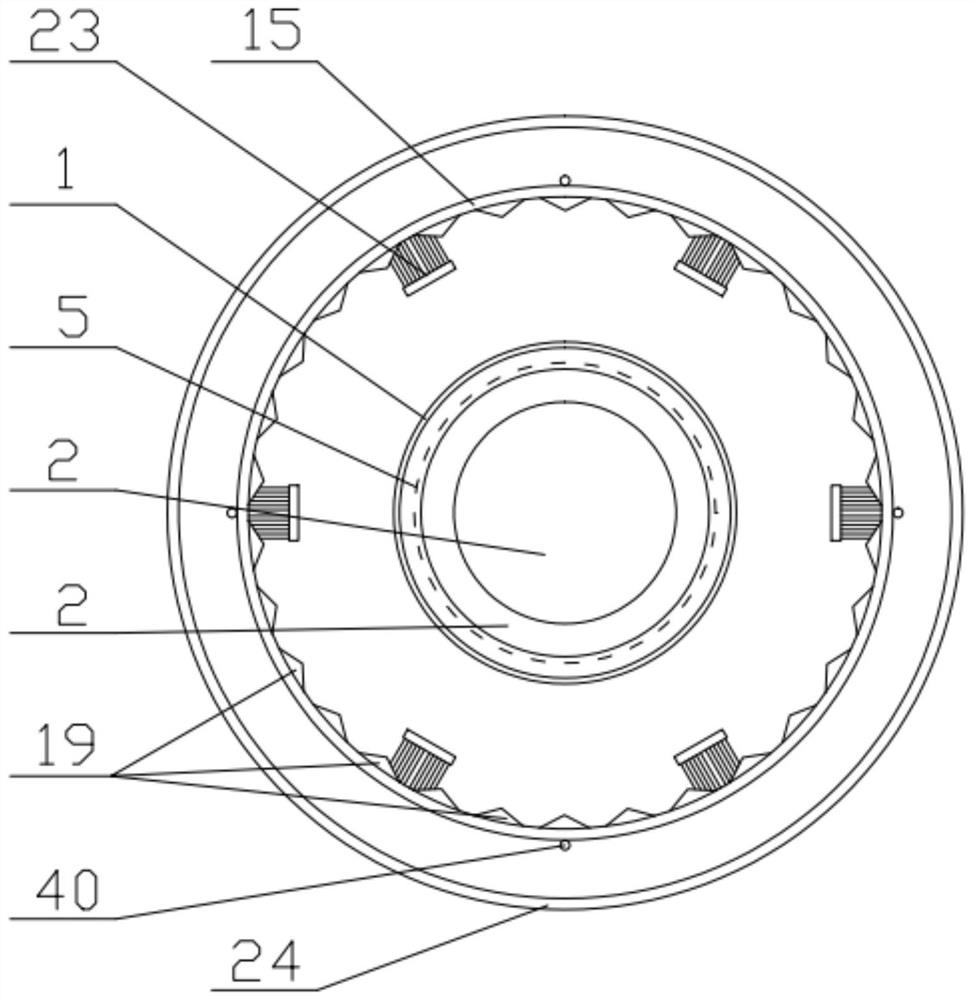

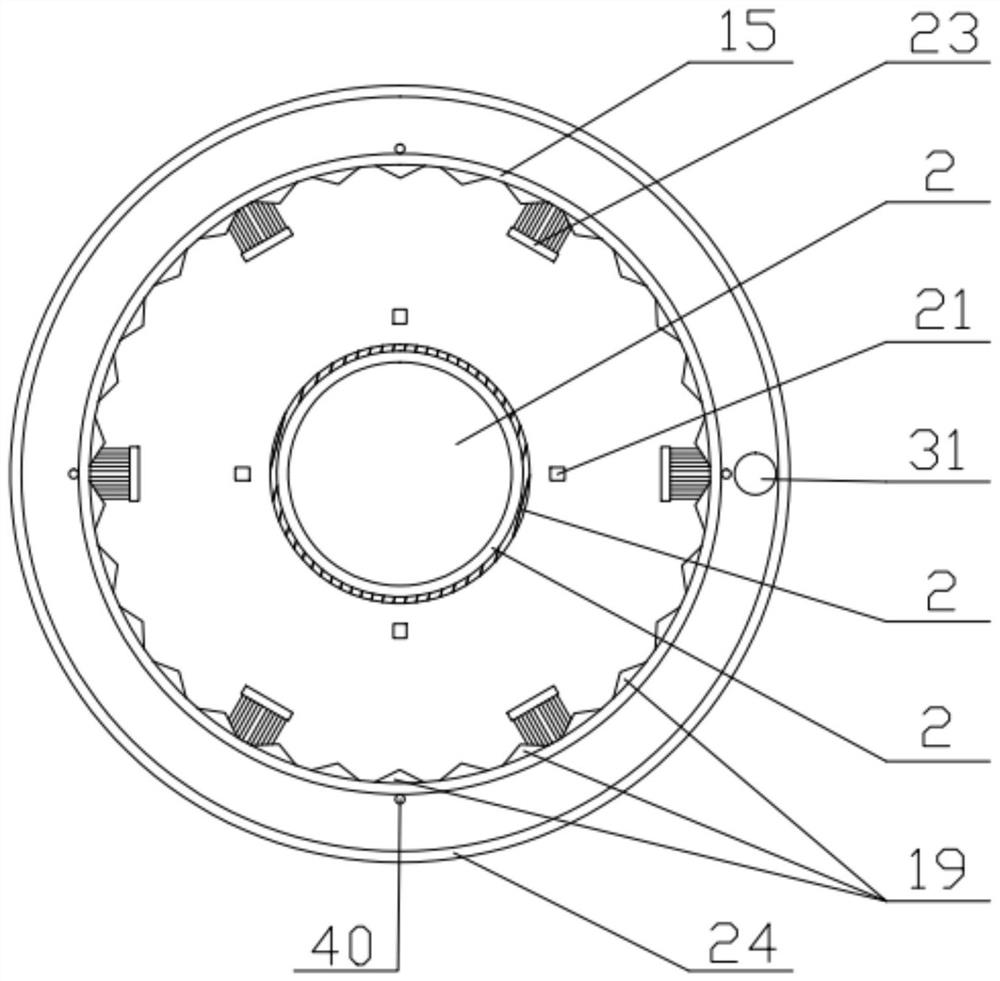

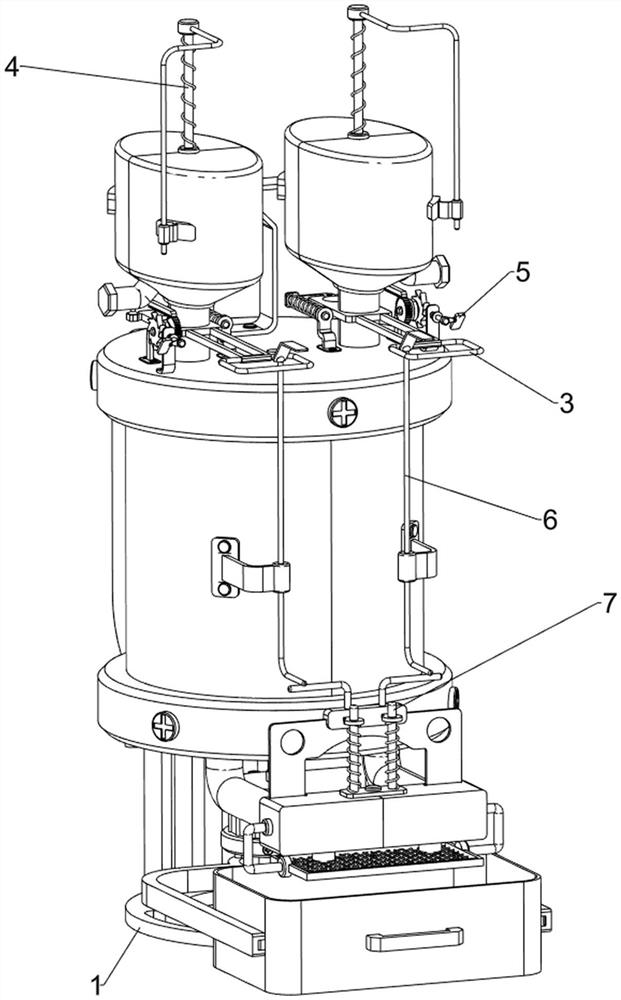

A kind of traditional Chinese medicine dregs medicine liquid separator

ActiveCN109200668BTo achieve the extrusion effectFully extractedPharmaceutical product form changeCentrifugesLiquid storage tankEngineering

The invention discloses a traditional Chinese medicinal residue-medicinal liquid separator, and belongs to the field of traditional Chinese medicine production equipment, wherein the separator includes a press filter cartridge, a centrifugal separation cartridge and a liquid collecting cartridge; a press hammer and a driving mechanism are arranged directly above the pressure filter cartridge; a rotating motor is connected at the bottom of the centrifugal separation cartridge; the bottom of the liquid collecting cartridge is connected with a liquid storage tank through an infusion tube, and a liquid taking port is arranged on the liquid storage tank. The press filter cartridge comprises a first circular side wall, and a support bottom plate and a covering top plate which are slidingly connected on the first circular side wall; a magnetic attraction effect exists between the press hammer and the covering top plate; the press hammer is connected with a movable rod of a telescopic sleeve rod structure; a buffer spring is fixed on a flange edge of the support bottom plate. The centrifugal separation cartridge includes a second circular side wall, a first top panel and a first bottom panel. The inner side wall of the second circular side wall is provided with a corrugated convex rib, and the centrifugal separation cartridge is internally provided with a cleaning brush fixed on the liquid collecting cartridge. A medicinal liquid can be completely and adequately extracted, the separation effect between the medicinal liquid and the medicinal residue is good, wasting of the medicinalliquid is avoided, the separation effect is good and the separation efficiency is high.

Owner:王华

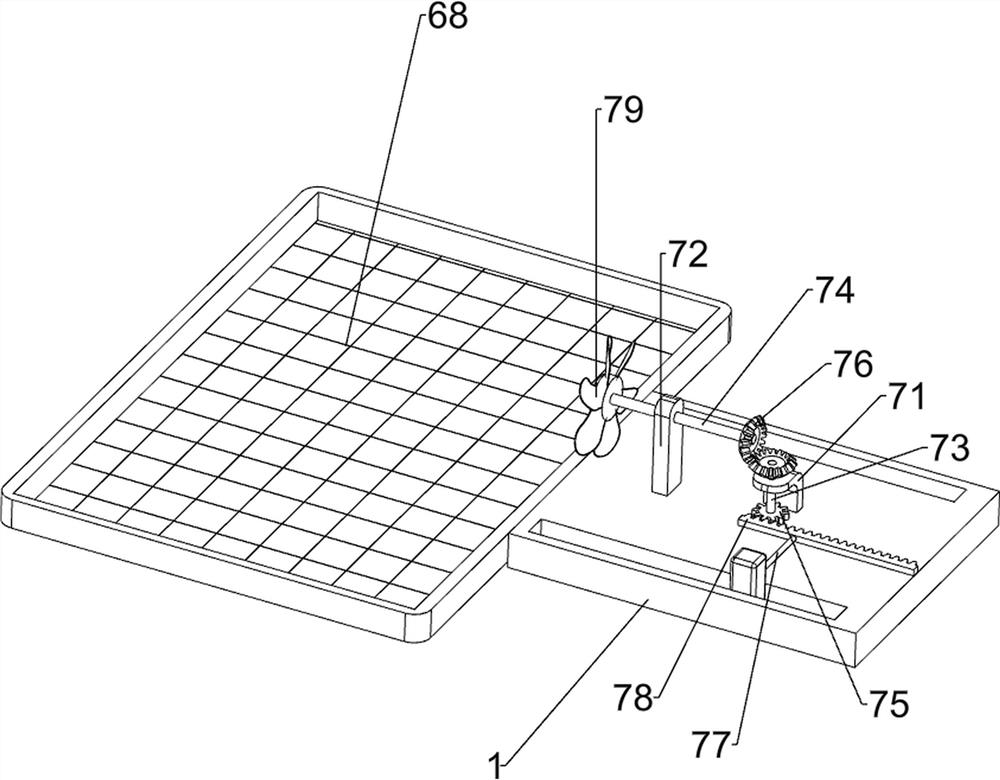

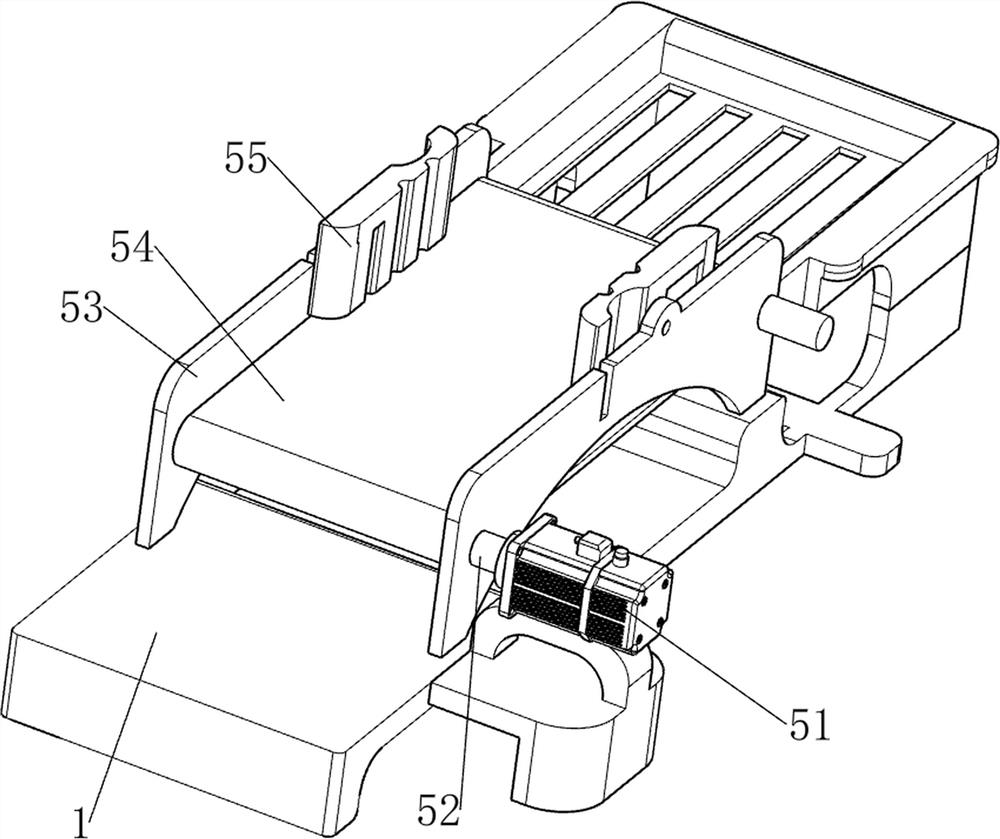

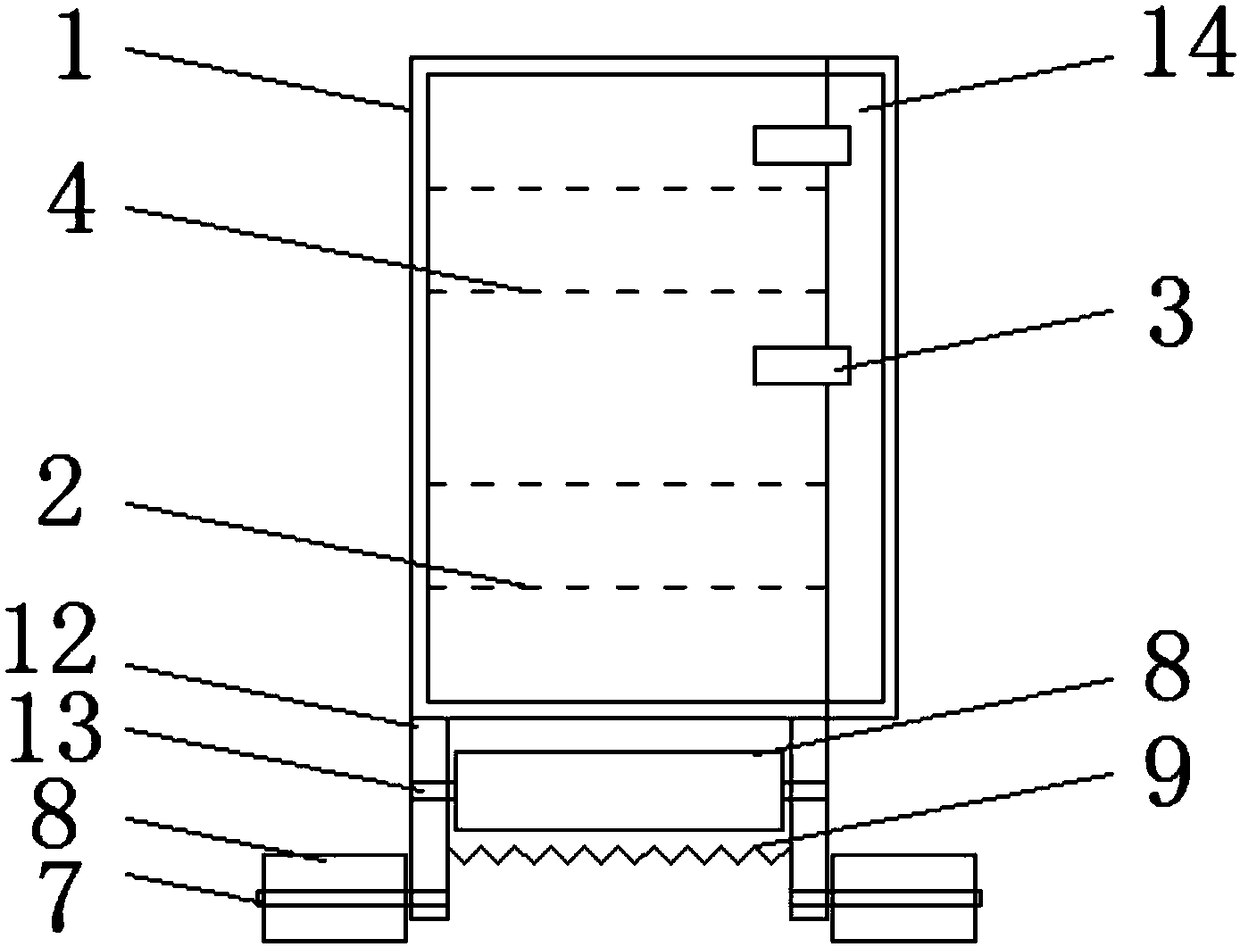

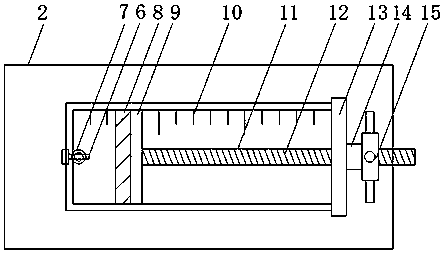

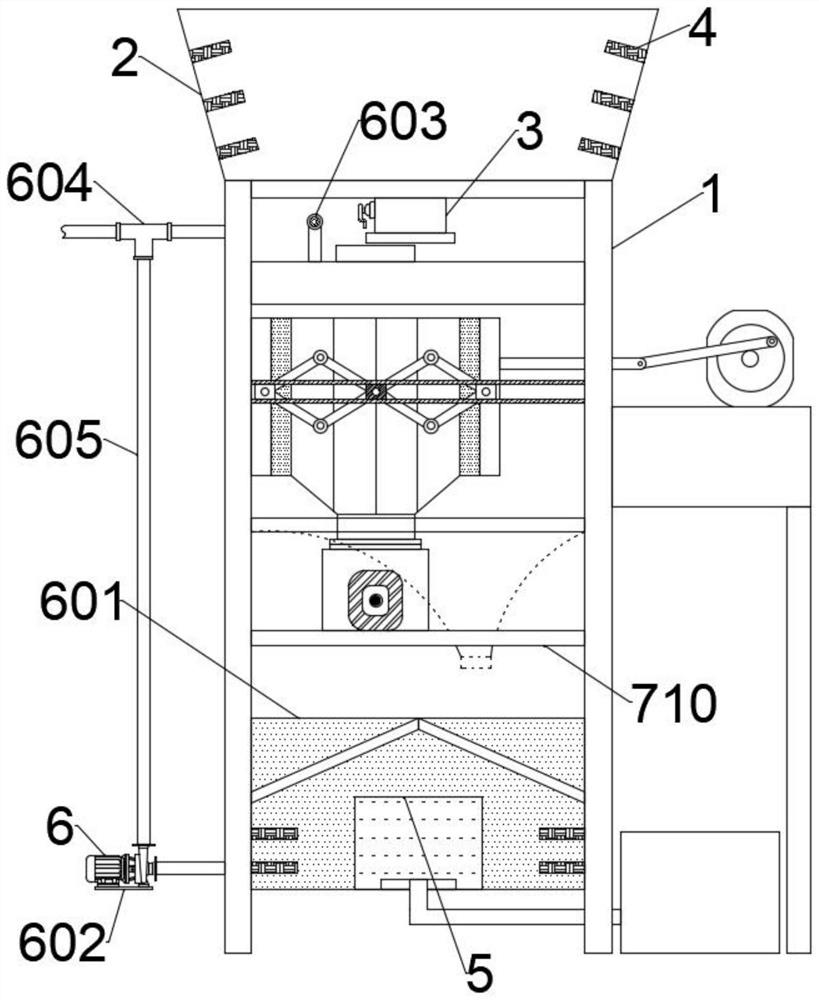

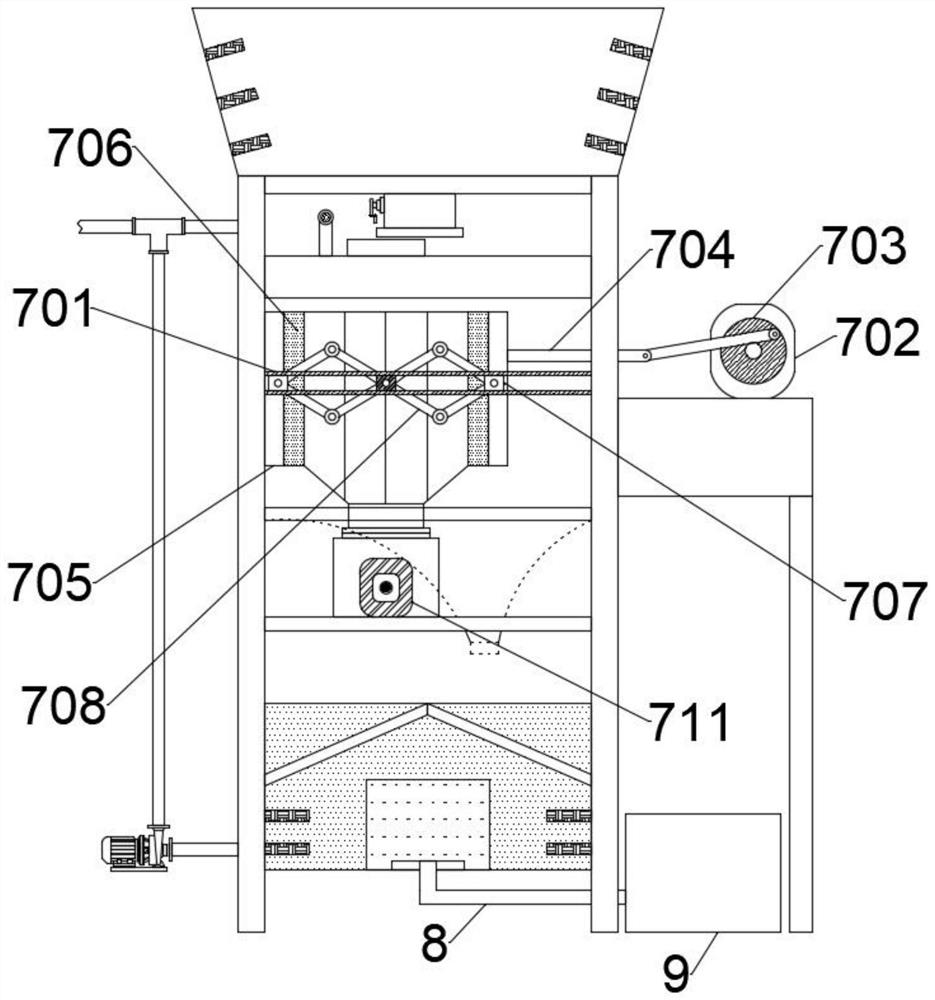

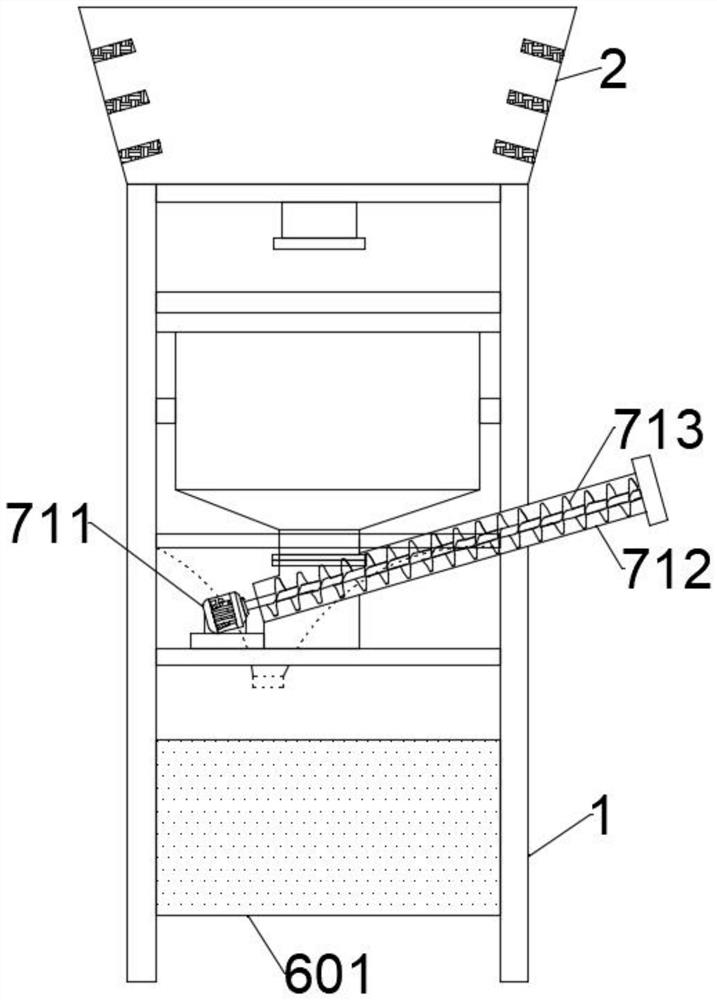

Automatic discharging and grinding device for refined wheat flour

PendingCN112973856ATo achieve the effect of advancingTo achieve the effect of shakingGrain treatmentsControl engineeringAgricultural engineering

The invention relates to a grinding device, in particular to an automatic discharging and grinding device for refined wheat flour. The invention provides the automatic discharging and grinding device for the refined wheat flour, so that automatic grinding is achieved, the grinding speed is relatively high, and the labor intensity of workers is reduced. The automatic discharging and grinding device for the refined wheat flour comprises a base, a first support, a discharging box, a propelling mechanism, a shaking mechanism and a grinding mechanism, wherein the first support is arranged on the base; the discharging box is arranged on the upper side of the first support; the propelling mechanism is arranged on the base; the shaking mechanism is arranged between the two sides of the base; and the grinding mechanism is arranged between the discharging box and the propelling mechanism. According to the automatic discharging and grinding device for the refined wheat flour provided by the invention, a first push rod drives the grinding mechanism to move rightwards and rotate, and wheat flour is ground, so that a propelling effect is achieved; and a shaking box moves up and down, so that the shaking box shakes, the flour is shaken, and a shaking effect is achieved.

Owner:王仕长

Peanut kernel shelling device

InactiveCN113854585AImprove peeling efficiencyEasy to peelHuskingHullingEngineeringStructural engineering

The invention relates to the technical field of food processing, and discloses a peanut kernel shelling device which comprises a device body, a placing opening is formed in the upper end of the device body, and a shelling mechanism and a film removing mechanism used for removing films on the surfaces of peanut kernels are arranged in the device body. The shelling mechanism comprises a rolling shaft, a rubber blocking block, an oval air bag, a special-shaped air bag, an elastic extrusion rod, a positioning rod, a reset memory plate, a rolling ball, a shelling rod and a reset spring, the rolling shaft is rotationally installed in the device body, an arc-shaped groove is formed in the surface of the rolling shaft, the rubber blocking block is fixedly installed in the arc-shaped groove, an extrusion opening is formed in one side of the rubber blocking block, the other side of the rubber blocking block is oval and hollow, the oval air bags are fixedly installed in the arc-shaped groove, and the number of the oval air bags is two. According to the invention, peanut kernels can be well separated from shells, meanwhile, damage to peanuts can be reduced, and the integrity of the peanuts is kept.

Owner:李浩伟

a crane

The invention relates to the technical field of the structure of loading suspension elements, in particular to a crane. The crane comprises a coiling block body. The coiling block body is internally provided with a cavity. An outer sleeve is arranged in the cavity. The two ends of the outer sleeve are fixedly connected with the cavity wall of the cavity. An oil cavity is formed between the outer sleeve and the cavity wall of the cavity. The coiling block body is provided with an oil inlet part. An inner sleeve and a push rod are arranged in the outer sleeve. One end of the push rod is fixed tothe inner sleeve. The other end of the push rod extends out of the coiling block body. The push rod is slidably connected with the coiling block body. The sleeve wall of the outer sleeve is providedwith strip-shaped slots. An elastic folding layer is arranged in the strip-shaped slots. Shifting bars penetrating through the elastic folding layer are fixed to the outer wall of the inner sleeve. The cavity wall of the cavity is provided with oil outlet holes. Cover plates are arranged at the oil outlet holes. A soft folding layer is fixed to the side, close to each oil outlet hole, of the corresponding cover plate. Through the crane, a steel wire rope can be lubricated conveniently, and solid impurities such as gravels can be cleaned.

Owner:徐州天骋智能科技有限公司

High-carbon ferro-chrome powder processing technology and production line for processing high-carbon ferro-chrome powder

ActiveCN113878122AWell mixedTo achieve the extrusion effectProcess efficiency improvementGrain treatmentsProduction lineMetallurgy

The invention relates to a high-carbon ferro-chrome powder processing technology and a production line for high-carbon ferro-chrome powder processing, and relates to the field of metal powder processing technology. The high-carbon ferro-chrome powder processing technology comprises the following steps: preliminary crushing treatment on metal raw materials: crushing the high-carbon ferro-chrome raw materials into particles through a crusher; crushing treatment of the metal raw materials: crushing the granular high-carbon ferrochrome raw materials into powder through a pulverizer; screening of the metal raw materials: screening the powdery high-carbon ferrochrome raw materials through a screening machine, and thus obtaining high-carbon ferrochrome powder of which the fineness meets the requirement; mixing of the metal raw materials: fulling mixing the high-carbon ferrochrome powder through a mixing machine, and thus obtaining finished high-carbon ferrochrome powder that is uniform in thickness, the high-carbon ferrochrome powder comprising 55%-65% of Cr, 1%-3% of Si, 7%-9% of C, 0.01%-0.04% of P, 0.01%-0.05% of S and the balance of Fe. The high-carbon ferrochrome powder has the effect of improving the using effect of the metal powder in a welding process.

Owner:南京永保新材料有限公司

Crane

The invention relates to the technical field of the structure of loading suspension elements, in particular to a crane. The crane comprises a coiling block body. The coiling block body is internally provided with a cavity. An outer sleeve is arranged in the cavity. The two ends of the outer sleeve are fixedly connected with the cavity wall of the cavity. An oil cavity is formed between the outer sleeve and the cavity wall of the cavity. The coiling block body is provided with an oil inlet part. An inner sleeve and a push rod are arranged in the outer sleeve. One end of the push rod is fixed tothe inner sleeve. The other end of the push rod extends out of the coiling block body. The push rod is slidably connected with the coiling block body. The sleeve wall of the outer sleeve is providedwith strip-shaped slots. An elastic folding layer is arranged in the strip-shaped slots. Shifting bars penetrating through the elastic folding layer are fixed to the outer wall of the inner sleeve. The cavity wall of the cavity is provided with oil outlet holes. Cover plates are arranged at the oil outlet holes. A soft folding layer is fixed to the side, close to each oil outlet hole, of the corresponding cover plate. Through the crane, a steel wire rope can be lubricated conveniently, and solid impurities such as gravels can be cleaned.

Owner:徐州天骋智能科技有限公司

Handheld-type box sealing machine

InactiveCN108438359AAchieve levelingEasy to packWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses a handheld-type box sealing machine comprising a tape box and rolling wheels. A fixing shaft is fixed at the middle of the inner part of the tape box, A tape is connected to the position, located on the outer side of the fixing shaft, in the tape box. A movable cover is arranged on one side of the tape box and is fixed on the tape box by a fixed button. A handle is welded on the upper side of one end of the tape box and a shear knife is welded on the lower side of the end, different from the handle, of the tape box. A tape opening is formed in the middle of the lower end of the tape box. A second fixing bar is welded at the lower end of the tape box and located on one side of the tape opening. A second rotating shaft is fixed at the end, different from the tape box,of the second fixing bar. The rolling wheels are movably arranged at the middle of the outer side of the second rotating shaft. A first fixing bar is fixed at the position, at the other end of the tape opening, of the lower end of the tape box. A first rotating shaft is fixed at the lower end, on the outer side of the tape box, of the first fixing bar. The handheld-type box sealing machine is flexible to use.

Owner:FOSHAN HANGESI ENVIRONMENTAL PROTECTION TECH CO LTD

Precision mold with positioning function

PendingCN114669730AWith positioning functionTo achieve the extrusion effectOil canControl engineering

The invention discloses a precision mold with a positioning function, and relates to the technical field of precision molds. The precision mold with the positioning function comprises a fixed mold block, a movable mold block and a liquid storage bin, the fixed mold block is fixed to the left side of the liquid storage bin, the movable mold block makes contact with the left side of the fixed mold block, a forming cavity is formed between the movable mold block and the fixed mold block, and the interior of the liquid storage bin communicates with the forming cavity through a connecting channel and a flowing channel formed in the fixed mold block; a pressure pump is fixedly installed at the top of the liquid storage bin, and a movable sleeve is fixed to the top of the movable module. According to the precise mold with the positioning function, the extrusion effect on an elastic film can be achieved through left-right movement of a movable sleeve on a sliding rod by arranging an extrusion block, the internal pressure of an oil storage device is increased when the elastic film is extruded, and lubricating oil in the oil storage device can be discharged from a gap in the oil outlet position of the oil storage device; and lubricating oil can enter the joint of the movable sleeve and the sliding rod through the through groove, so that the automatic lubricating effect is achieved.

Owner:刘亚峰

Toy for leisure and entertainment of children

ActiveCN113262503ATo achieve the effect of inflatingRealize the effect of hittingToy vehiclesSimulationSupport plane

The invention relates to a toy, in particular to a toy for leisure and entertainment of children. The invention provides a toy for leisure and entertainment of children, and the toy is simple in structure, large in attraction to children and simple to operate. The toy for leisure and entertainment of children comprises: wheels and a supporting plate frame, wherein the supporting plate frame is arranged between the two wheels, and the supporting plate frame is rotationally connected with the wheels; frames which are arranged between the two sides of the two wheels, and are rotationally connected with the wheels; a first opening and closing frame which is arranged between the two frames in a sliding manner; a second opening and closing frame which is arranged between the two frames in a sliding manner; two first supporting frames which are arranged on the supporting plate frame; an inflation mechanism which is arranged between the two first supporting frames and the supporting plate frame; and a clock plate which is arranged on the inflation mechanism. By arranging the inflation mechanism, people push the inflation mechanism to operate, and the inflation effect can be achieved.

Owner:义乌市露丹文化用品有限公司

Device used in bioengineering and for facilitating gel quantitative containing

PendingCN108454910ATo achieve the extrusion effectEasy loadingLiquid materialEngineeringScrew thread

The invention discloses a device used in bioengineering and for facilitating gel quantitative containing. The device comprises a workbench, a charging pipe, an extrusion plate and a rotating ring. Supporting rods are welded to the two sides of the upper end of the workbench. The charging pipe is mounted on the supporting rods. A feeding pipe is mounted on the side, corresponding to a funnel, of the upper end of the charging pipe in a communicating manner. A second valve is movably mounted on the feeding pipe. The extrusion plate is mounted in the charging pipe in a sliding manner. A rubber plug is mounted on the side end face of the extrusion plate. An extrusion rod is welded to the middle of the side, different from the rubber plug, of the extrusion plate. An external thread is formed onthe outer side of the extrusion rod. A fixed cover is mounted at the end, different from the funnel, of the charging pipe. A fixed block is fixed to the middle of the outer side of the fixed cover. The rotating ring is mounted on the extrusion rod in a threaded manner. Handles are arranged in the middle of the outer side of the rotating ring in an annular array manner. The device can achieve the effect of quantitative subpackage on gel.

Owner:HUZHOU GUANGBO BIOTECH

Novel amorphous alloy material particle cleaning equipment

PendingCN113926771ARealize the effect of stirring and cleaningTo achieve the effect of waterCleaning using liquidsAlloy

The invention relates to particle cleaning equipment, and particularly relates to novel amorphous alloy material particle cleaning equipment. The novel amorphous alloy material particle cleaning equipment is high in cleaning efficiency, convenient to use and capable of improving the production progress. The novel amorphous alloy material particle cleaning equipment comprises a fixing piece, first baffles, a discharging box, a collecting box, a cleaning box, a conveying mechanism, a stirring cleaning mechanism and rotary cleaning blades. The first baffles are arranged on the two sides of the fixing piece. The discharging box is arranged between the two first baffles. The collecting box is arranged on the fixing piece in a sliding manner. The cleaning box is arranged between the fixing piece and the two first baffles. The conveying mechanism is arranged between the fixing piece and the first baffles. The stirring cleaning mechanism is arranged between the cleaning box and the conveying mechanism. The two rotary cleaning blades are arranged on the stirring cleaning mechanism. According to the novel amorphous alloy material particle cleaning equipment, the conveying mechanism is arranged, the conveying mechanism operates to convey novel material particles, and the conveying effect is achieved.

Owner:郭武平

Oil-water separator with automatic cleaning function

PendingCN114538541ATo achieve the extrusion effectImprove filtration efficiencyFatty/oily/floating substances removal devicesSpecific water treatment objectivesElectric machineryWater reservoir

The invention discloses an oil-water separator with an automatic cleaning function, relates to the technical field of oil-water separation, and is used for solving the problem that the purity of separated oil and water is low due to the fact that an existing oil-water separator does not filter an oil-water mixture. The bottom of the reservoir communicates with a sewage outlet pipe, a switch is arranged on the outer side of the sewage outlet pipe, a filtering assembly is arranged in the middle of the inner side of the rack, a cleaning assembly is arranged at the bottom of the rack, and the filtering assembly comprises a sliding rail, a first motor, a disc, a transverse rod, a mounting plate, an extrusion plate, a first sliding block, a framework, filtering cloth, a sliding plate, a second motor, a conveying cylinder and conveying rotary blades. The two ends of the sliding rail are fixedly connected to the inner side of the rack, and a first motor is arranged on the outer side of the rack. Compared with the prior art, an oil-water mixture can be filtered firstly and then separated, the function of self-cleaning the filter cloth is achieved, and the effect of prolonging the service life of equipment is achieved.

Owner:宿州市耶伊勒精密机械有限公司

A kind of plastic particle extrusion molding device for production

ActiveCN112757523BEvenly distributedAchieve the effect of mixing plastic raw materialsProcess engineeringMaterials science

The invention relates to a molding device, in particular to an extrusion molding device for plastic particles for production. The invention provides a plastic particle extrusion molding device for production, which is easy to operate, discharges a small amount of waste gas and realizes automatic stirring. A production plastic particle extrusion molding device, comprising: a base frame, a first support frame is arranged on the front side of the base frame; a second support frame, a second support frame is arranged on the base frame; a stirring mechanism, the second support frame A stirring mechanism is arranged on the front side of the top; an extrusion mechanism is arranged between the first support frame and the second support frame. In the invention, the plastic raw material is poured into the stirring frame, and the turret stirs the plastic raw material, so that the plastic raw material is evenly distributed, and the effect of stirring the plastic raw material by the turret is realized.

Owner:无棣县伟达网具制品有限公司

Automatic disinfection rotary display stand for surgical operating instruments

PendingCN112843274ARealize the rotation effectAchieve bactericidal effectLavatory sanitoryRadiationSurgical instrumentSurgical operation

The invention relates to a disinfection rotary display stand, in particular to an automatic disinfection rotary display stand for surgical operating instruments. The invention provides the automatic disinfection rotary display stand for the surgical operating instruments, which can realize automatic disinfection and automatic cleaning and is convenient for people to observe. The automatic disinfection rotary display stand for surgical operating instruments comprises a base and first supporting columns arranged on the two sides of the base, a rotating mechanism arranged between the tops of the first supporting columns on the two sides and the base, a box body arranged on the upper side of the rotating mechanism, and a sterilizing mechanism arranged on the rotating mechanism. Through rotation of a rotating frame, the sterilizing mechanism can disinfect and sterilize surgical operating instruments in all directions, people control a servo motor to rotate reversely, an output shaft of the servo motor rotates reversely to drive a rotating screw to rotate reversely to drive the sterilizing mechanism to move downwards, and the rotating effect is achieved.

Owner:杨明英

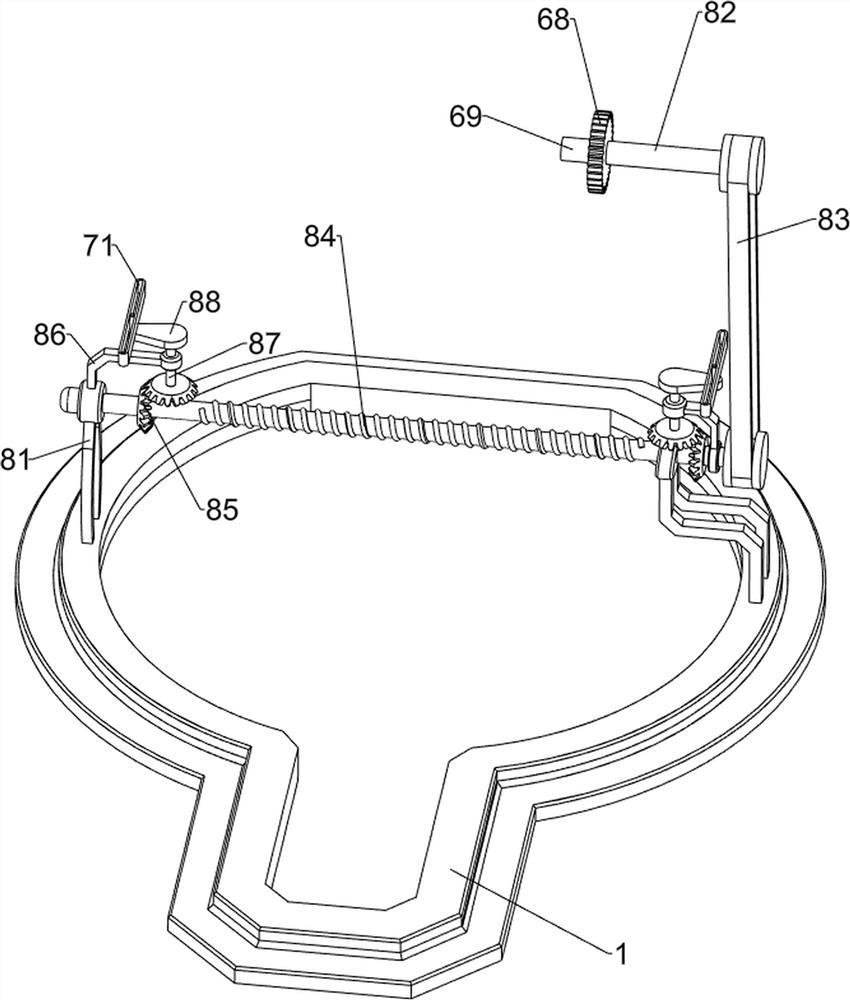

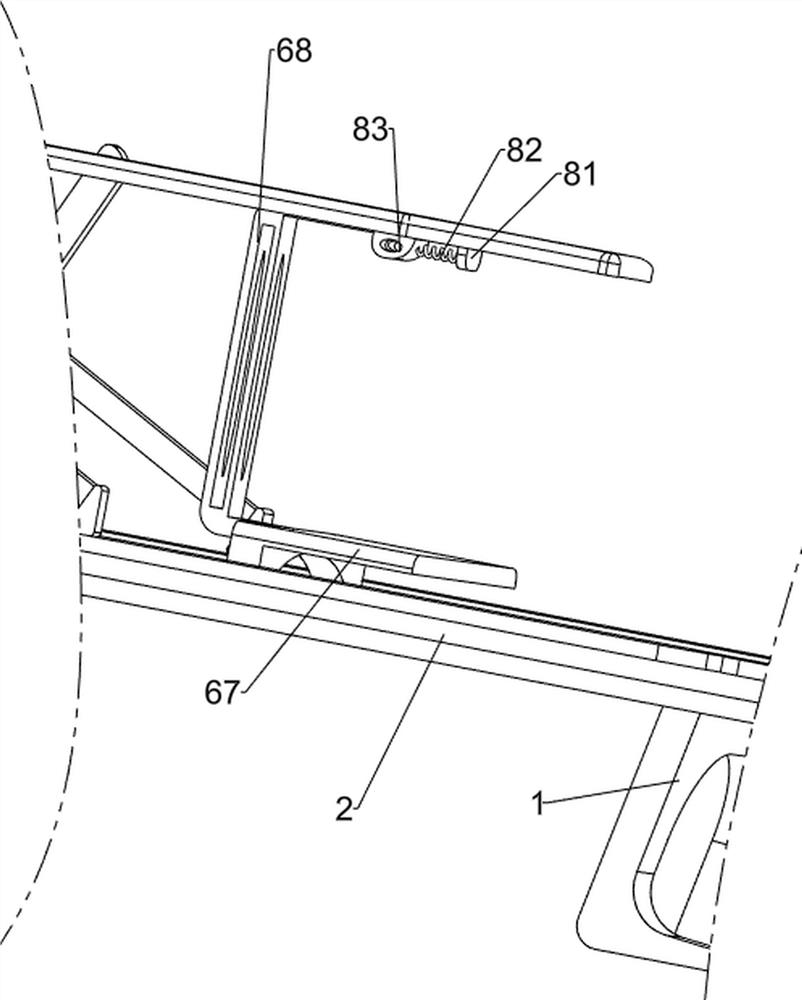

Insertion box pasting mold and using method thereof

PendingCN112172245AAvoid deformationReduce consumptionBox making operationsPaper-makingStructural engineeringMechanical engineering

The invention relates to the technical field of insertion box processing equipment, in particular to an insertion box pasting mold and a using method thereof. The insertion box pasting mold is used for improving the quality and production efficiency of insertion box pasting and reducing the production cost and comprises an operation platform connected to a base through a sliding structure, the operation platform is connected with a plate supporting mold through a supporting plate mold clamp capable of turning and combining, width limiting plates are connected to the two sides of a supporting plate mold through adjusting structures, locking buckles are connected to the width limiting plates, baffles are connected to the bottom of the supporting plate mold through detachable connecting pieces, the base is further connected with a bridge frame, and the bridge frame is connected with a pressing structure used for pressing the sticking face of the insertion box and a box disassembling structure used for disassembling the stuck insertion box from the supporting plate mold, and the using method of the insertion box pasting mold is that the insertion box is stuck on the basis of the structure. According to the insertion box pasting mold and the using method thereof, the production requirement can be met only through one supporting plate mold, consumption of materials and manpower is reduced, the flattening step is omitted as well, and automatic pulling-out of the insertion box is achieved.

Owner:河南省邮电科技有限公司

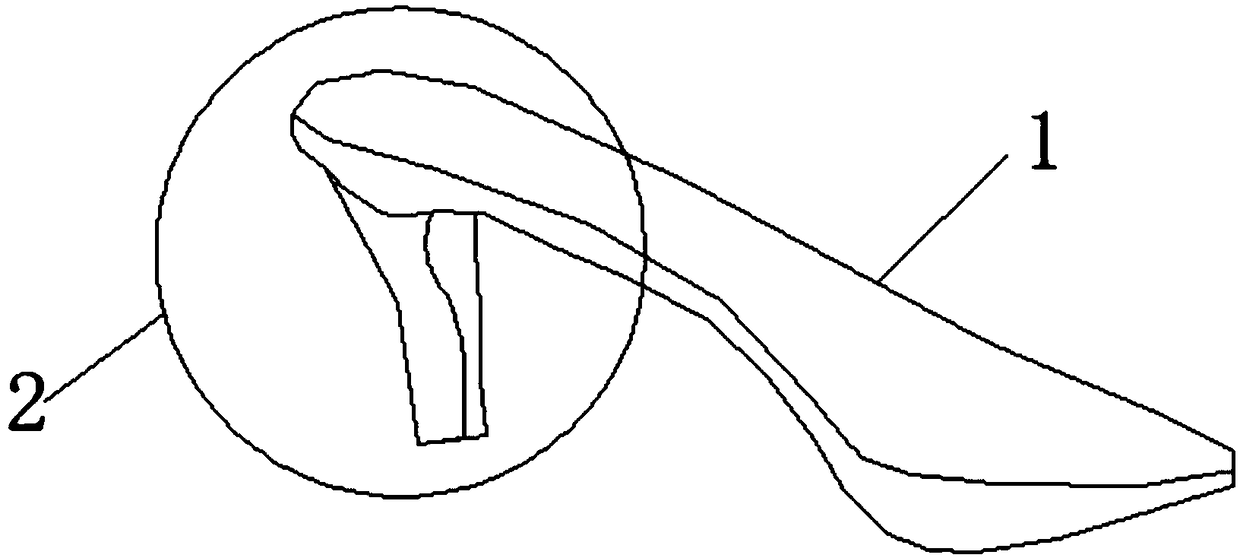

Sports type high-heeled shoe

InactiveCN109349741ATo achieve the extrusion effectReach manual controlHeelsTop-piecesEngineeringAnkle

The invention relates to the technical field of high-heeled shoes, and discloses a sports type high-heeled shoe. In use, a high-heeled shoe is processed according to some special circumstances, so that the comfort degree of the high-heeled shoe is improved, and emergencies are solved. According to the technical scheme, the bottoms of iron supporting columns are connected in slotted holes formed inthe front side of a thickened plate, through the cooperation of welded seal of upper stopping blocks, it can be achieved that round balls swing left and right in the slotted holes, the iron supporting columns penetrate through long-slot through strips to tilt and form a plurality of tilted bracings to the ground, and the comfort degree that the high-heeled shoes are put on the feet is improved. Arc-shaped blocks connected to the inner walls on the back sides of the tops of the iron supporting columns are adopted to cooperate with arc-shaped protruding plates, the arc-shaped protruding platesswing towards the left, so that it is achieved that welding blocks in spring expansion cylinders formed in the front sides of the arc-shaped blocks are squeezed, during squeezing, it can be achieved that squeezing supporting columns are titled, and the squeezing supporting columns are titled to form a disc shape, the area that the shoe makes contact with the ground is increased, and the ankles areprevented from being sprained by the high-heeled shoes.

Owner:庞成军

Fermentation tank temperature control device based on grape brewing

PendingCN113150900ATo achieve the extrusion effectEvenly heatedAuxillary controllers with auxillary heating devicesWine preparationPhysicsWheel drive

The invention relates to the technical field of temperature control devices, and discloses a fermentation tank temperature control device based on grape brewing. The device comprises a frame; the interior of the frame is rotatably connected with a stirring roller; the left and right ends of the stirring roller are fixedly provided with fixed plates; and the interior of each fixed plate is rotatably connected with a rotating wheel. According to the fermentation tank temperature control device based on grape brewing, the stirring roller drives the rotating wheels in the fixed plates to rotate, the rotating wheels drive a connecting wheel to rotate, then the connecting wheel can drive a guide rod to slide up and down in a sleeve through the action of the guide rod in the rotating process, then a supporting rod is driven to slide in an inclined rod, and then a sliding plate is driven to move left and right in a transverse plate, so that the extrusion effect on a flexible bag is achieved; and the flexible bag can take out hot air flow in the transverse plate, and the hot air flow and grapes which are being stirred in the frame are heated, so that the uniform heating effect is achieved.

Owner:毛周琪

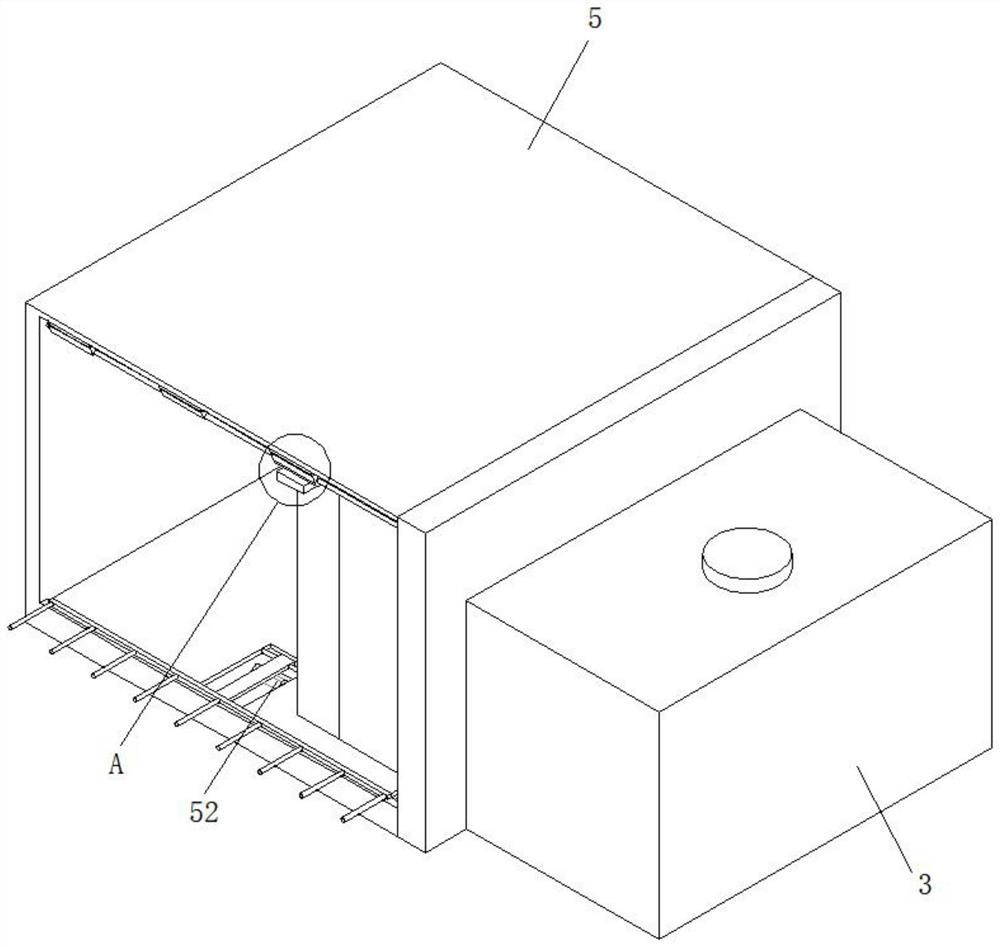

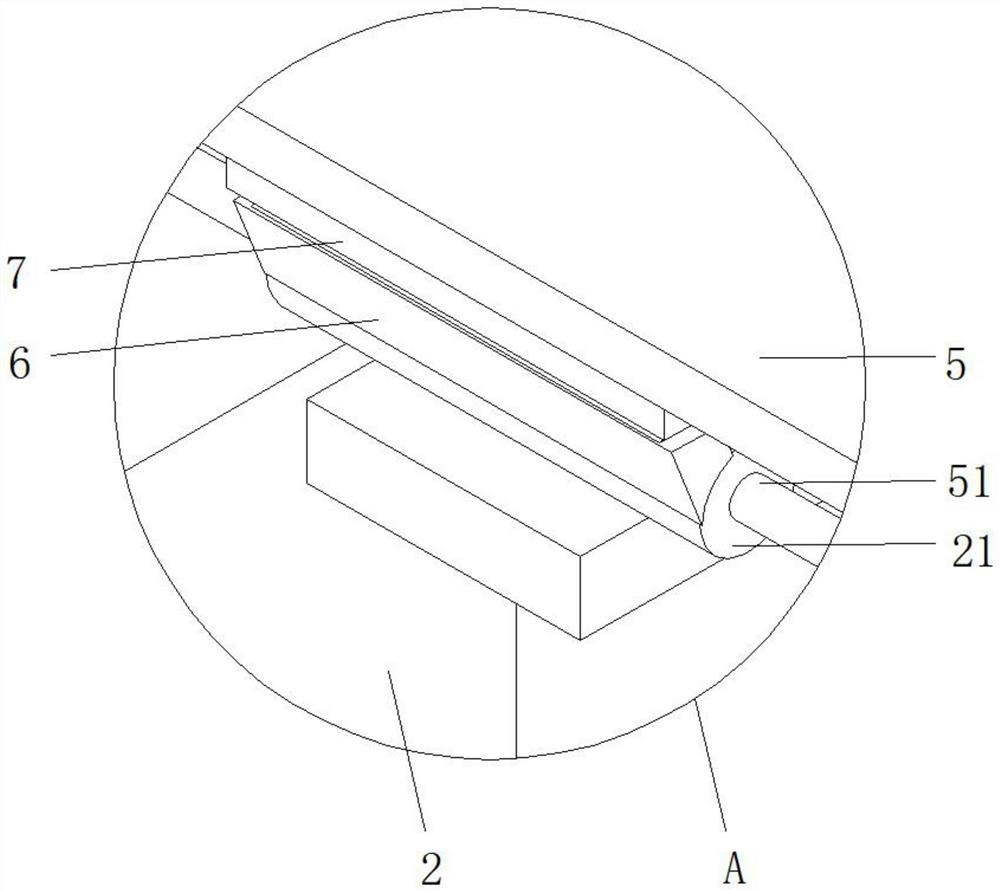

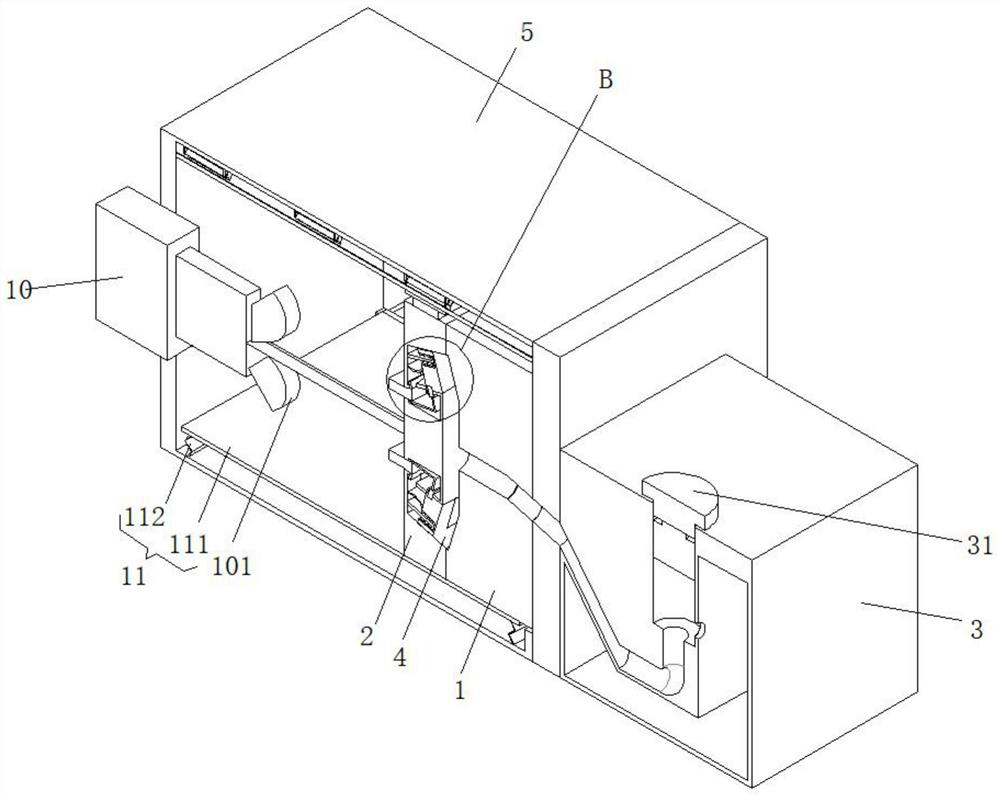

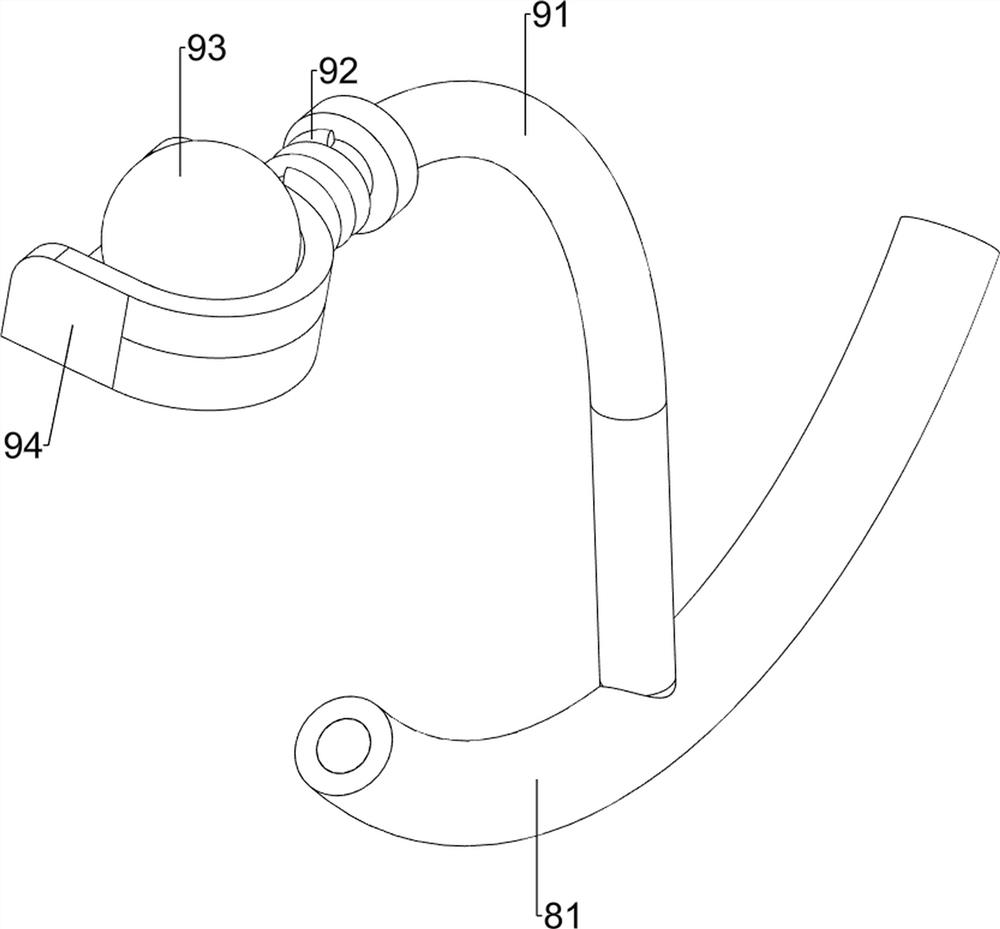

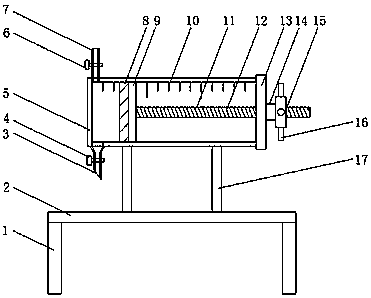

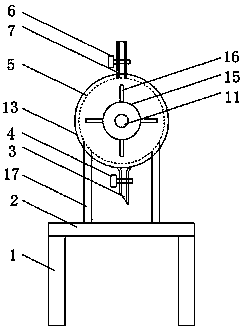

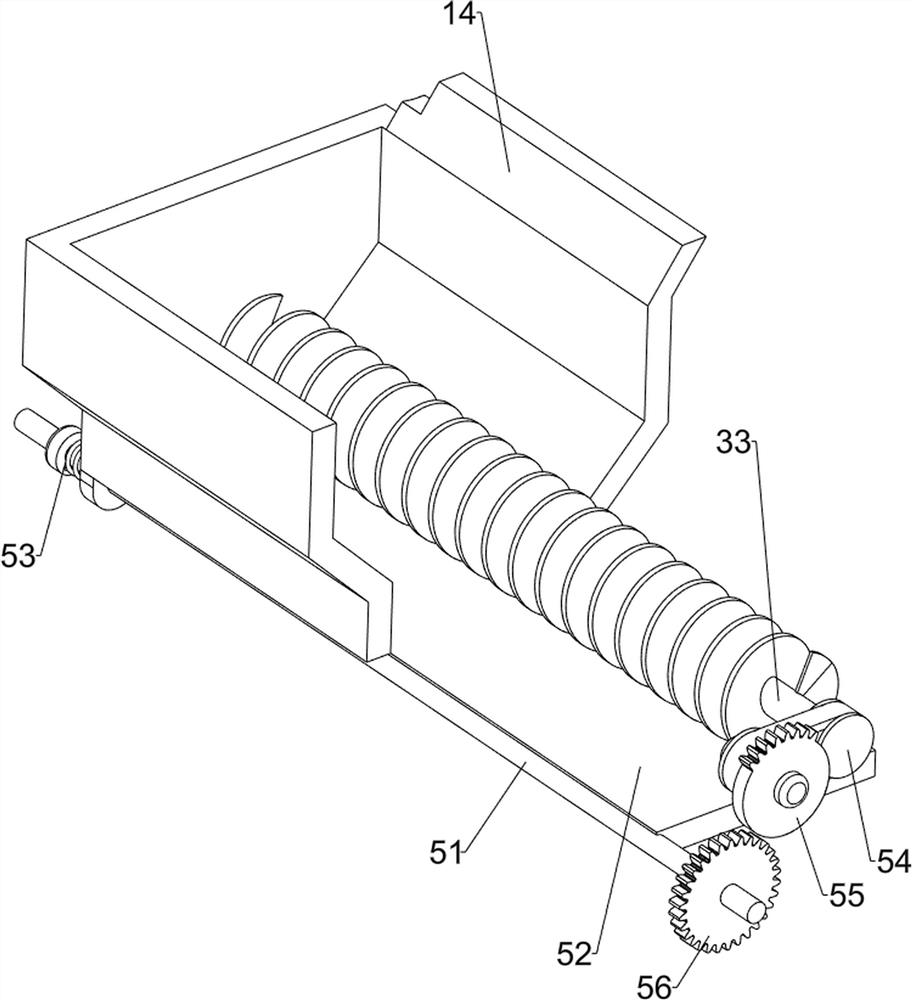

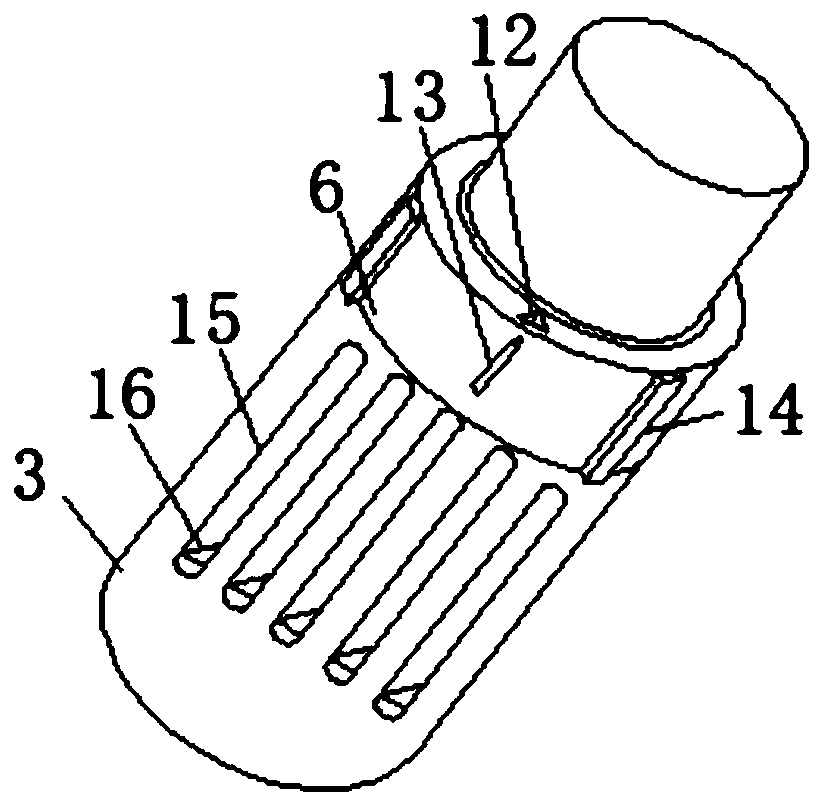

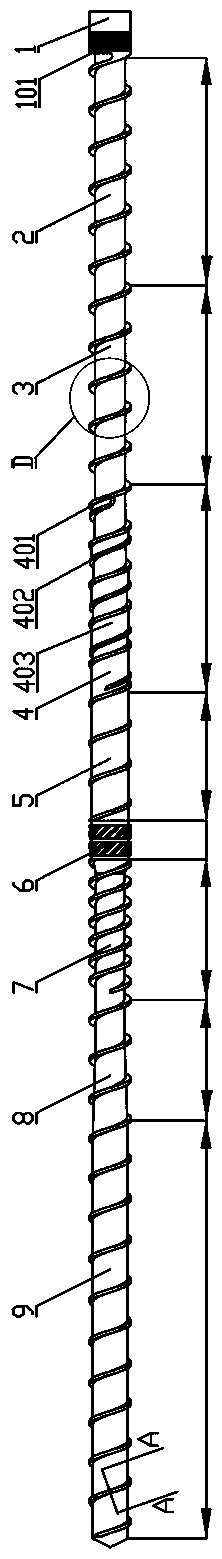

A vacuum suction type screw extrusion solid-liquid separation system

ActiveCN104147837BAvoid cloggingSmall footprintMoving filtering element filtersSuction forceEngineering

The invention discloses a vacuum-suction screw extrusion solid-liquid separation system including: a screw extrusion mechanism to which a continuously material-feeding mechanism and a continuously solid-discharging mechanism, a driving mechanism which provides rotation power to the screw extrusion mechanism, and a sealing box body which allows the screw extrusion mechanism to be sealed in and enables the continuously material-feeding mechanism and the continuously solid-discharging mechanism to be communicated with exterior. The system is characterized in that the screw extrusion mechanism is arranged obliquely with the height of an inlet height being lower than that of an outlet; a collecting tank is disposed on the bottom of the sealing box body, is communicated with the sealing box body and is used for collecting liquid, wherein the sealing box body is accommodated in a sealed water tank; the sealed water tank is also communicated with a vacuum machine which provides a vacuum suction force to the screw extrusion solid-liquid separation system; a water discharging outlet is disposed on the bottom of one end, which is closed to the continuously solid-discharging mechanism, of the collecting tank; and the water tank is provided with a continuously liquid-discharging mechanism. The system is high in reliability, is small in occupied area and can allow humidity of outlet materials to be controlled.

Owner:CHENGDU XINCHAOSHUN ENVIRONMENTAL TECH

Extrusion equipment and method for manufacturing shoe layer material

ActiveCN112223619BRealize the effect of tightening the limitPlay the effect of sliding limitDomestic articlesElectric machineCooling effect

Owner:WENZHOU POLYTECHNIC

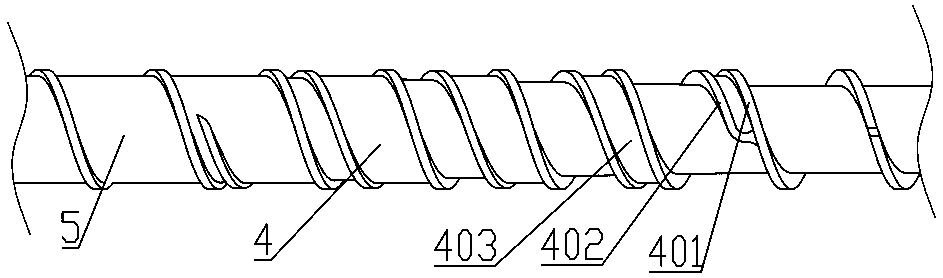

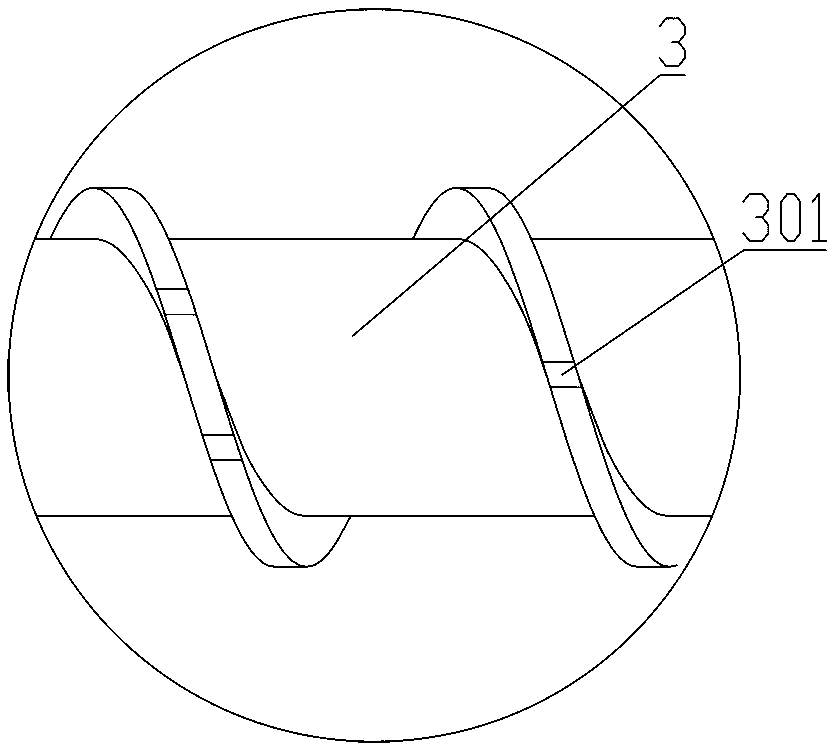

Environment-friendly stone paper extrusion forming screw, extruder and stone paper production process

The invention relates to an environment-friendly stone paper extrusion forming screw. The environment-friendly stone paper extrusion forming screw comprises a shaft portion, a connecting handle arranged at the end of the shaft portion and used for being connected to extrusion equipment and a thread arranged on the shaft portion. A pressure stabilization segment is arranged on the screw. A shaft portion of the pressure stabilization segment is equal in diameter, a thread of the pressure stabilization segment is equal in pitch, a chamfer R2 on the rear side of the thread of the pressure stabilization segment is 2-3 times the angle of a chamfer R1 on the front side, the radius range corresponding to the chamfer R1 on the front side of the thread of the pressure stabilization segment is 3-7 mm, and the radius range corresponding to the chamfer R2 on the rear side is 6-19 mm. The invention relates to an environment-friendly stone paper extruder which comprises a screw and a screw barrel. The invention further relates to a stone paper production process. The environment-friendly stone paper extrusion forming screw, the environment-friendly stone paper extruder and the stone paper production process have good dispersity to materials, the stable extrusion quantity and extrusion pressure and are especially suitable for extrusion production of stone paper formula materials.

Owner:贾中奇

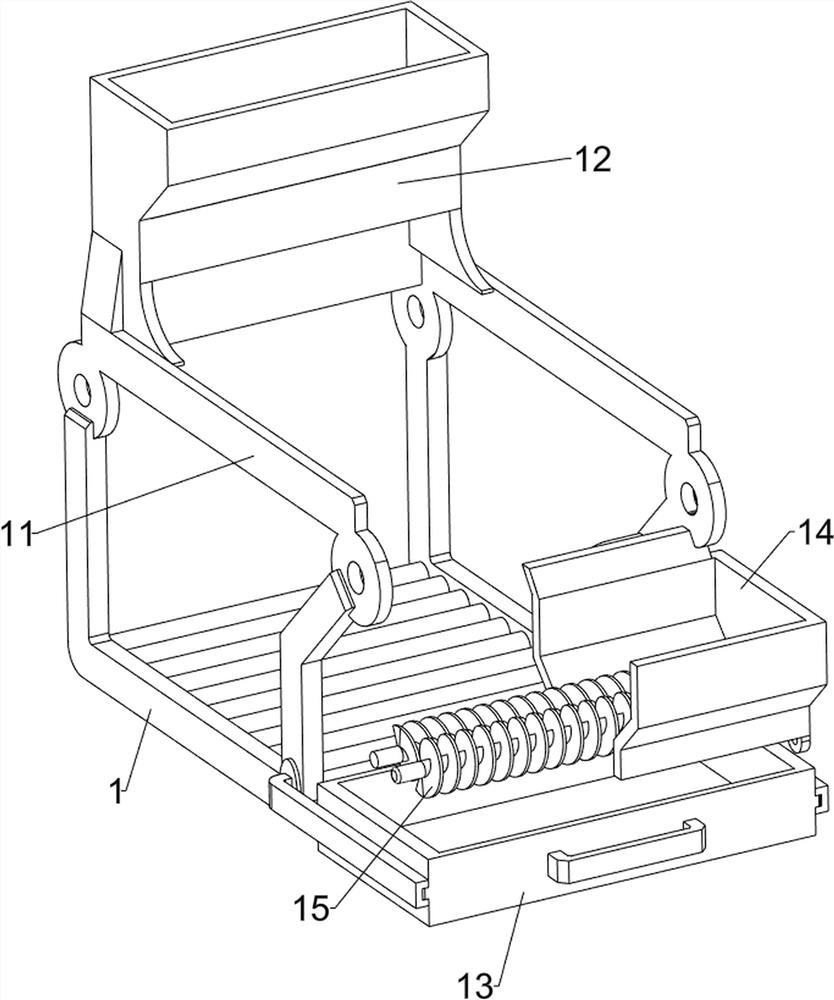

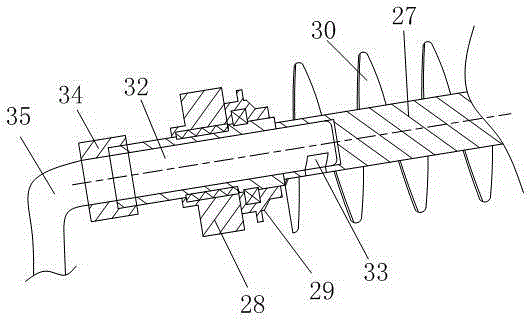

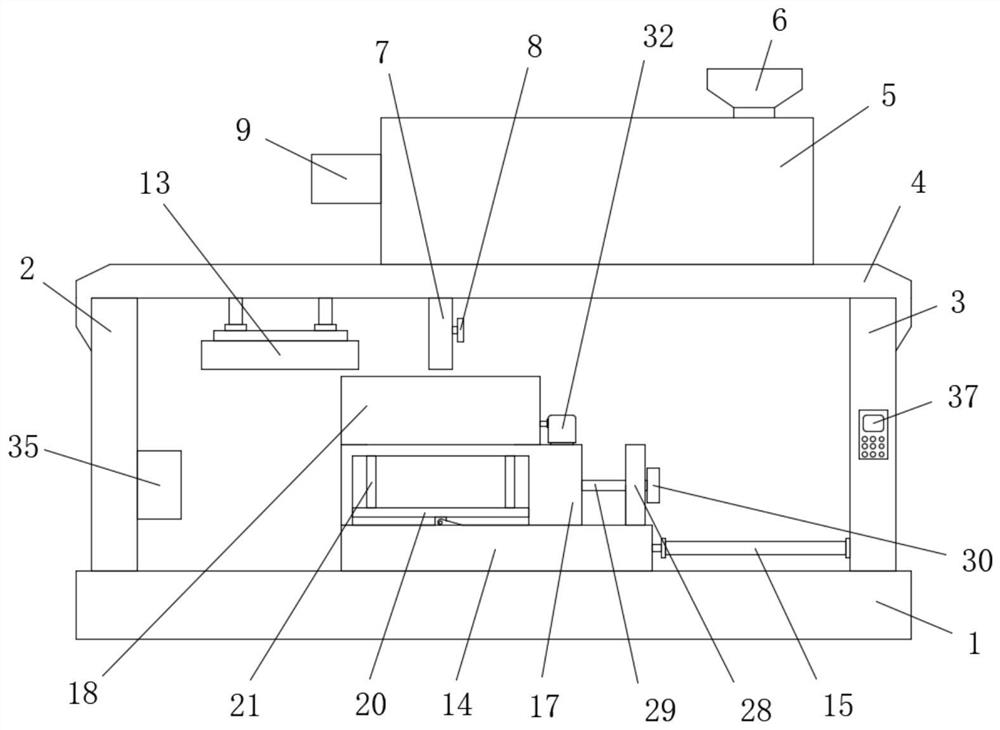

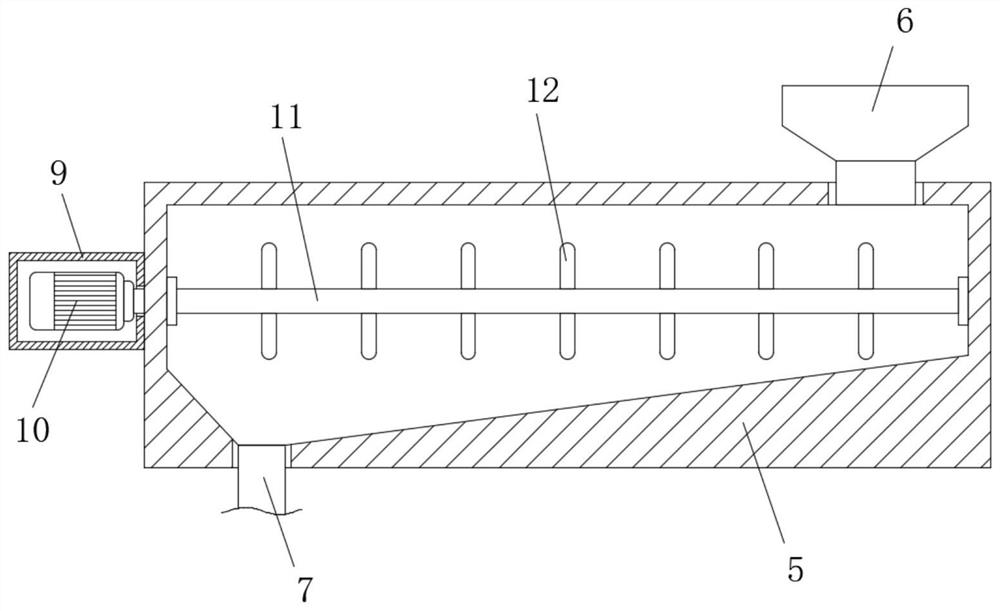

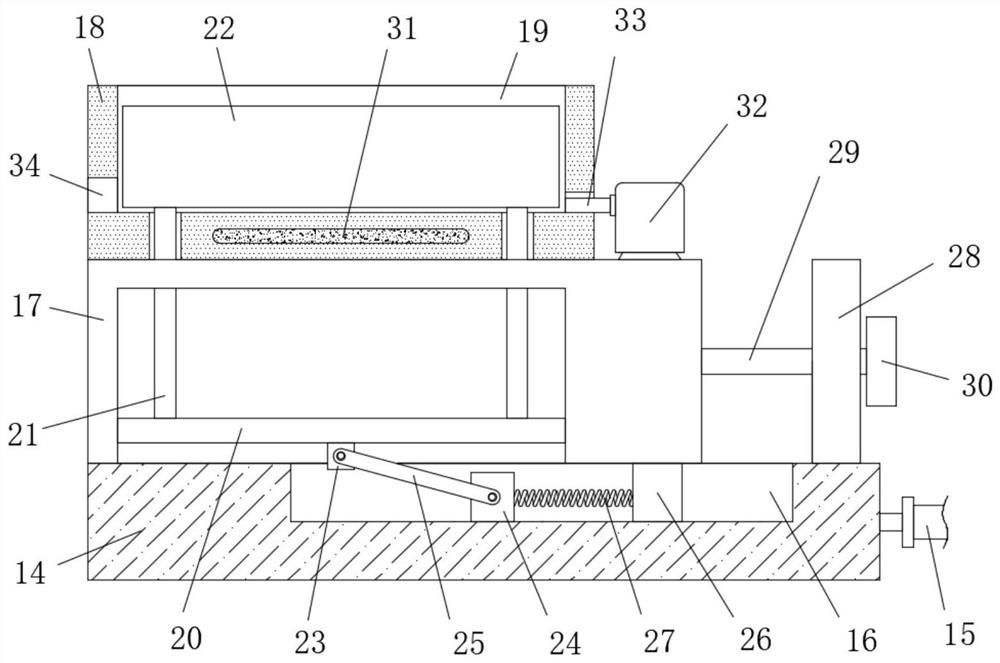

An automatic assembly equipment for industrial sauce rake

ActiveCN113172578BTo achieve the extrusion effectRealize the feeding effectMetal-working hand toolsEngineeringMechanical engineering

The invention relates to an assembly device, in particular to an automatic assembly device for an industrial sauce rake. The invention provides an automatic assembly equipment for an industrial sauce rake integrating extrusion, position control and material cutting. An automatic assembly equipment for industrial sauce rakes, comprising: a base and a first material box, the base is provided with the first material box; an extrusion mechanism is provided on the upper side of the first material box; a feeding mechanism, A feeding mechanism is provided on the first material box. In the present invention, by starting the first cylinder, the expansion rod of the first cylinder drives the extruding plate to move to the right, so that the right side of the wooden stick enters the hole, which realizes the effect of extruding the wooden stick; the first telescopic component drives the first The wedge is reset, so that the plank is directly above the first wedge, which realizes the feeding effect.

Owner:临沂临港国有资产运营集团有限公司

Tearing force testing equipment for cloth production

InactiveCN112378739ARealize the clamping effectRealize the driving effectMaterial strength using tensile/compressive forcesEngineeringCotton material

The invention relates to testing equipment, particularly to tearing force testing equipment for cloth production. The tearing force testing equipment for cloth production is low in labor intensity, convenient to operate and capable of preventing arms from aching easily, and comprises: two brackets, wherein a panel is arranged at the tops of the two brackets; a first support frame arranged at the top of the front side of the panel; a clamping mechanism arranged on the front side of the panel; and pushing mechanisms arranged on the left side and the right side of the panel. According to the invention, by loosening a lower pressing plate, a first spring resets, so that the lower pressing plate is driven to move downwards to clamp cloth so as to achieve the clamping effect; and the telescopicrod of an air cylinder extends backwards to drive a pushing block to move backwards, and the pushing block moves backwards according to the track of a sliding rail, so that the pushing effect is achieved.

Owner:祝汪林

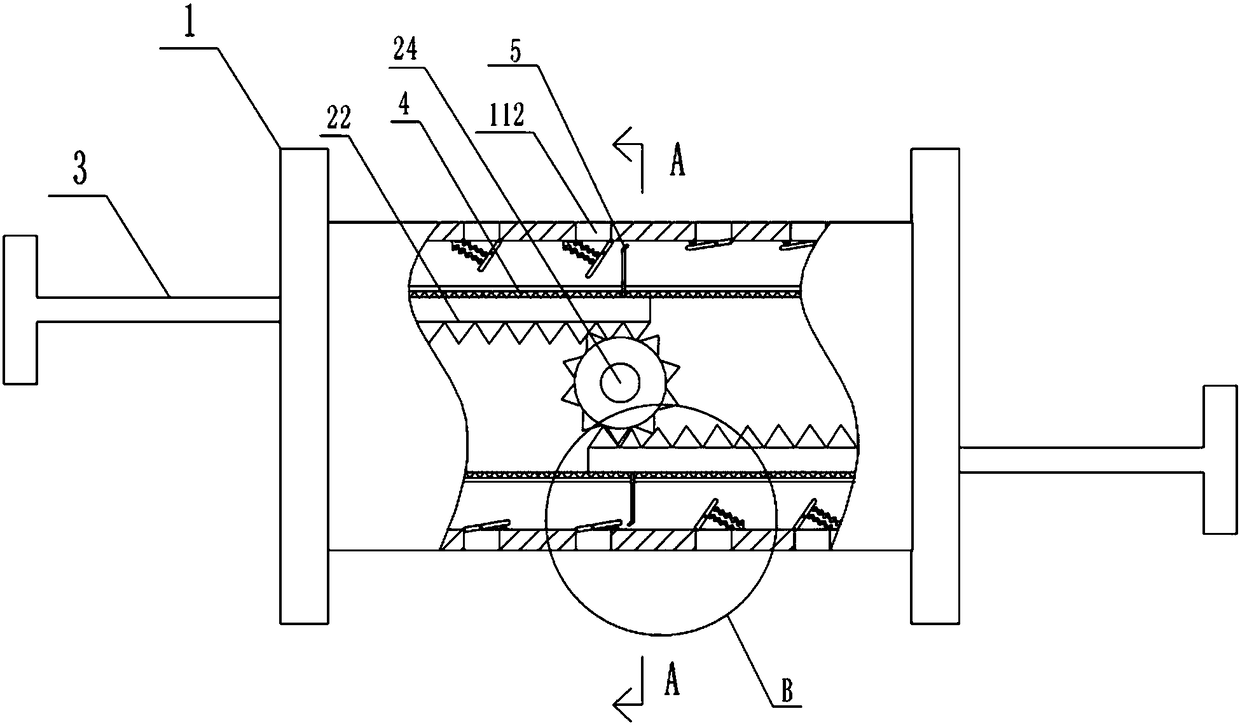

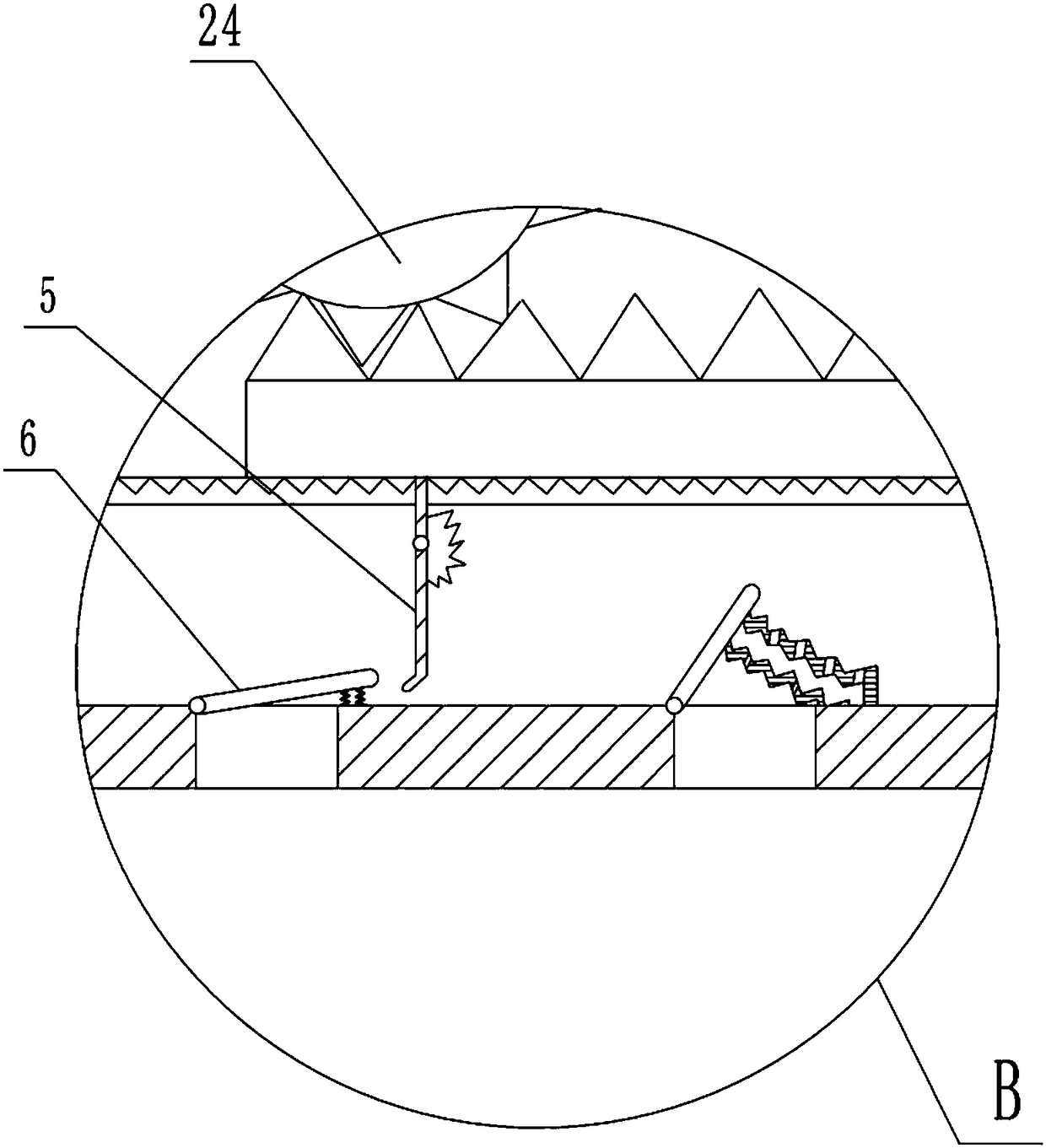

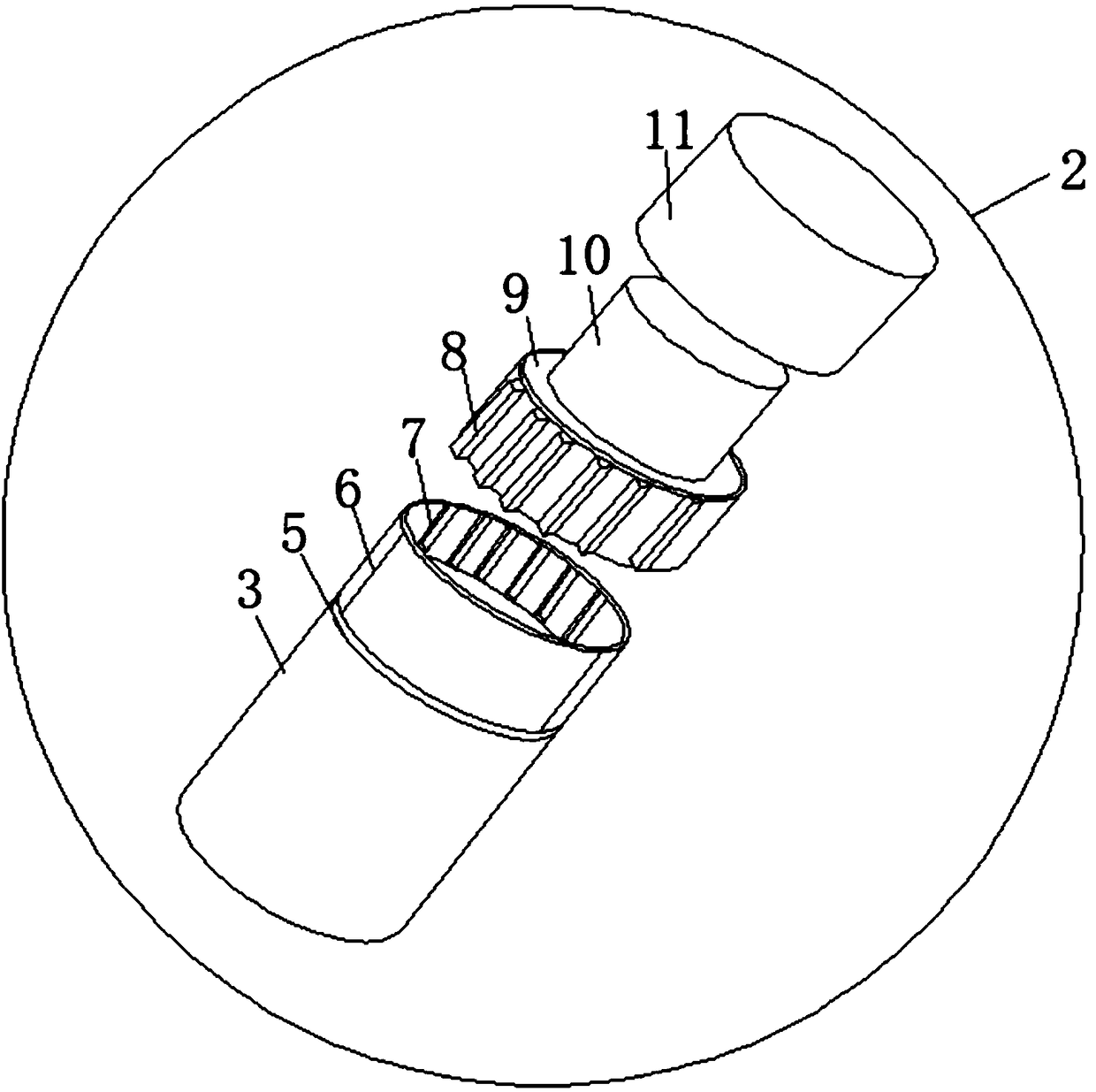

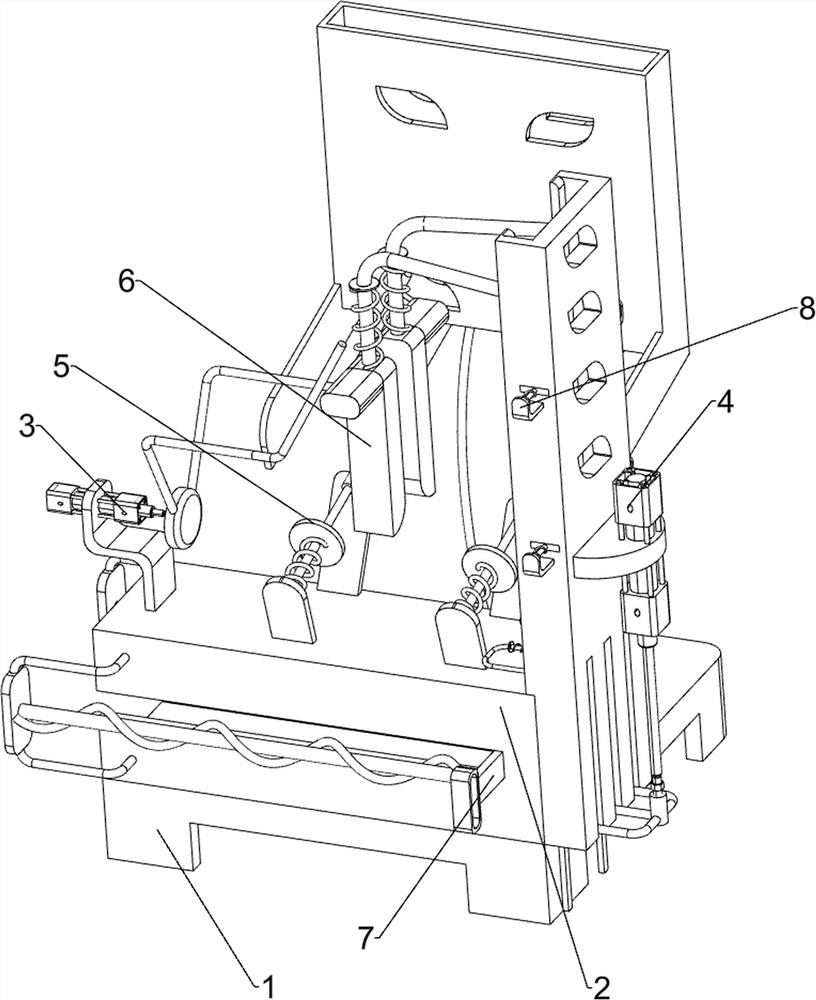

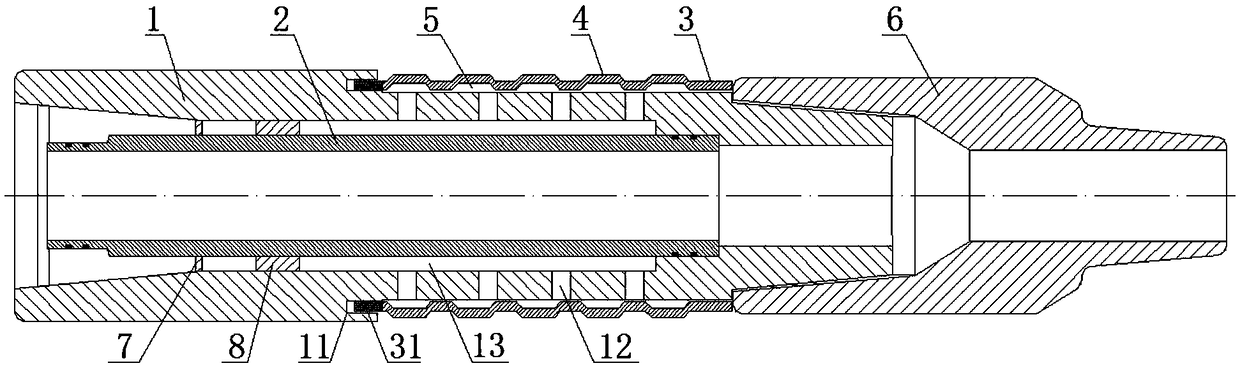

A gas lift positive circulation drilling mixer

The invention relates to the technical field of gas lift positive circulation drilling, in particular to a mixer for gas lift positive circulation drilling. The mixer comprises a joint body, an inner core, bridge-type outer floral pipes, convex blocks and a conversion joint. The inner core is arranged in an inner cavity of the joint body; annular gaps are formed between the inner core and the inner wall of the joint body; the outer side wall of the joint body is wrapped with the bridge-type outer floral pipes; and the convex blocks are fixed at one ends of the bridge-type outer floral pipes. Bridge holes with bulges in the middles are formed in the outer surfaces of the bridge-type outer floral pipes. Bridge hole cutting seams capable of jetting flow in two ways are formed between the bridge holes and the bridge-type outer floral pipes. Vent holes are formed in the side wall, wrapped with the bridge-type outer floral pipes, of the joint body in a penetrating mode. The end machined with an outer thread of the joint body is sleeved with the conversion joint in a threaded fit mode. According to the mixer, the direct impact of a high speed air flow to the hole wall of a well drilling can be effectively prevented, the bridge-type outer floral pipes can be easily disassembled and conveniently replaced, and the structure is simple and effective.

Owner:安徽省地勘局第一水文工程地质勘查院

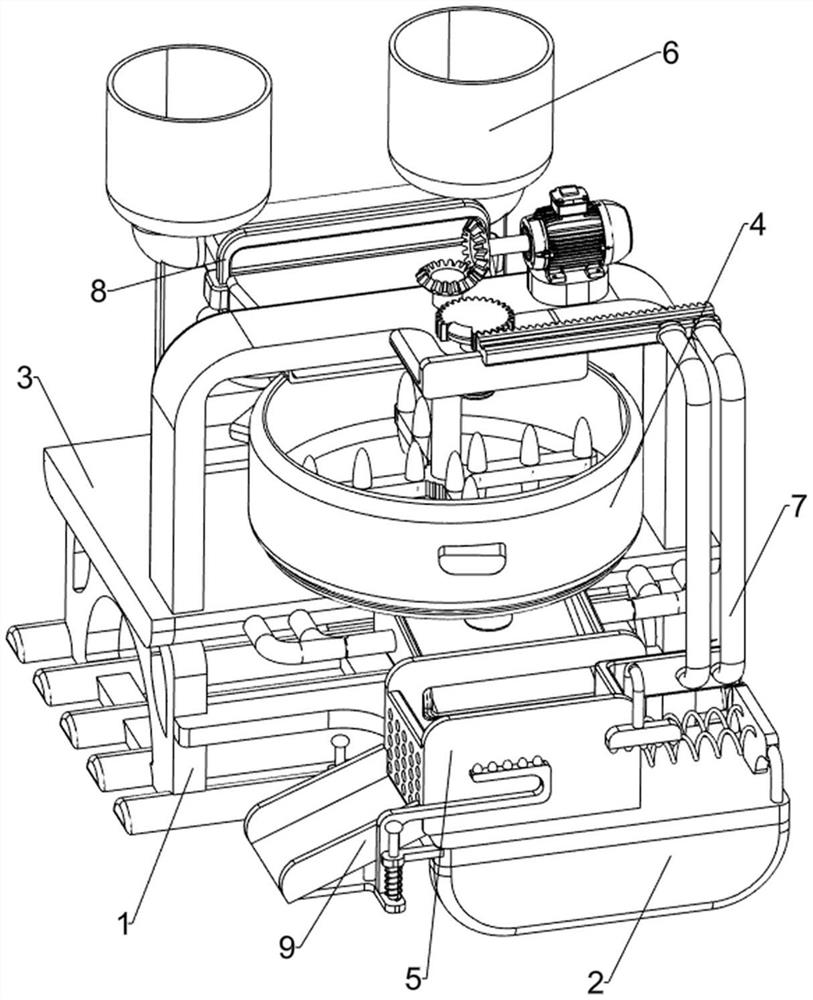

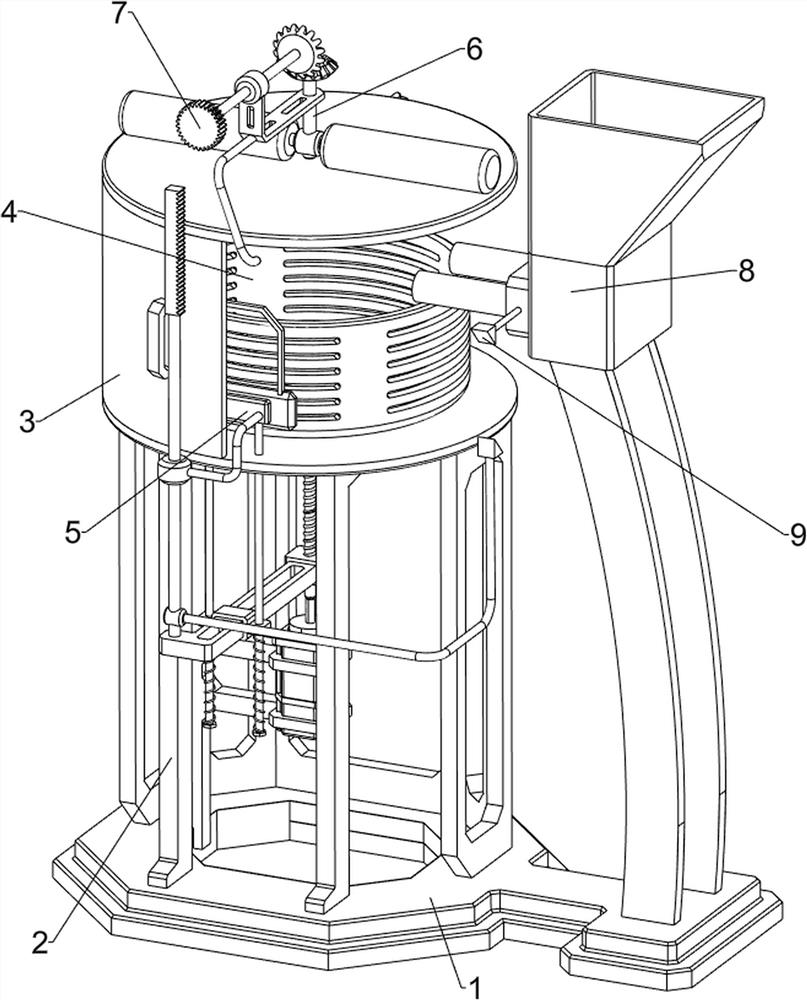

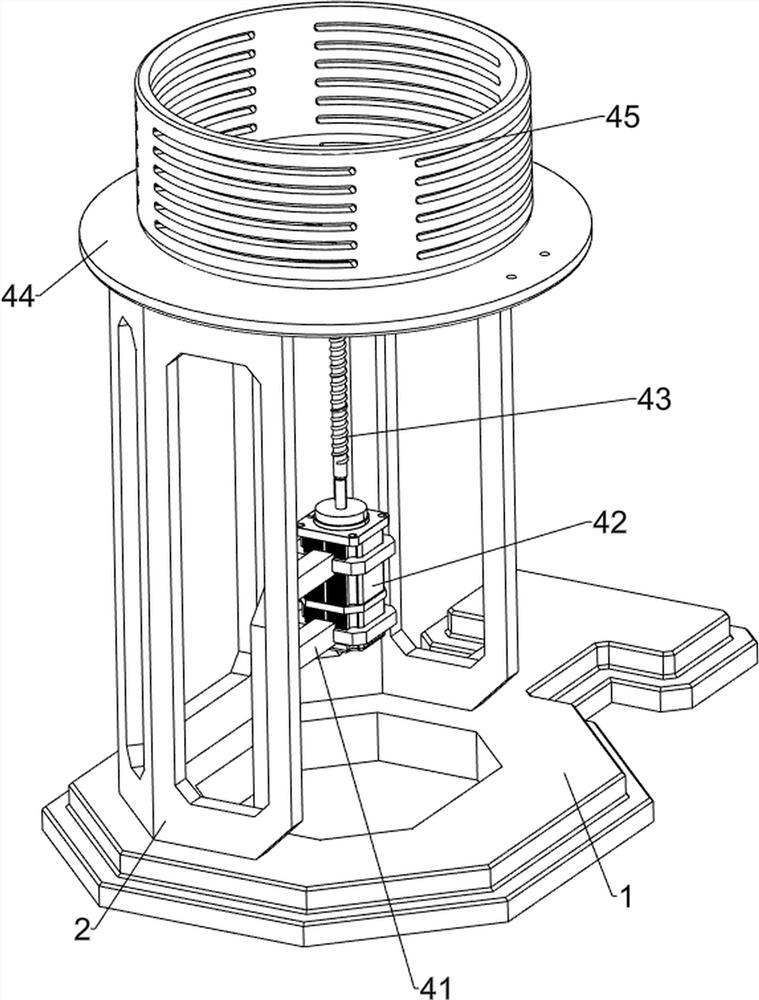

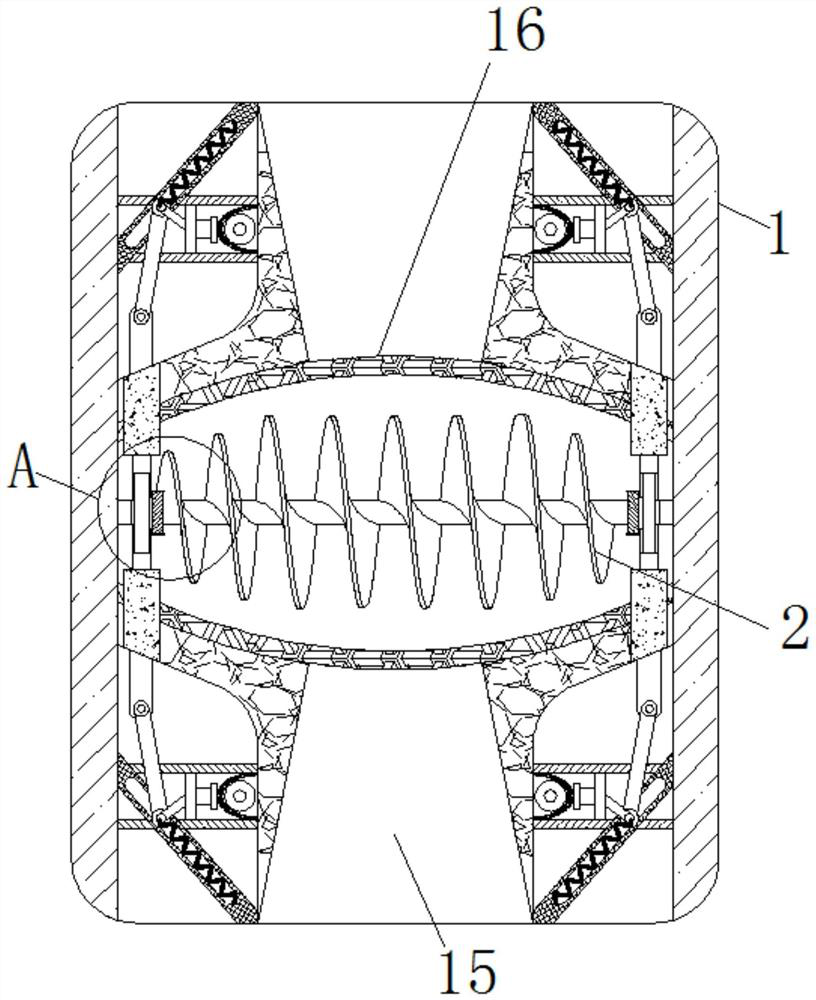

An automatic mixing device for color glaze production

ActiveCN112844193BWell mixedAchieve broken effectRotary stirring mixersTransportation and packagingThermodynamicsMixing effect

The invention relates to a mixing device, in particular to an automatic mixing device for the production of color glazes. The invention provides an automatic mixing device for color glaze production with better mixing effect, lower labor intensity of staff and simple and easy-to-understand operation. An automatic mixing device for the production of color glaze, comprising: a base and a fixed support, the base is provided with the fixed support; a mixing box is provided with a mixing box on the top of the fixed support; a discharge box is provided with a discharge material on the top of the mixing box box; feeding port, there are feeding ports on both sides of the lower part of the discharging box; static crushing knife, there are three static crushing knives rotating on the upper and lower sides inside the mixing box; channel; filter screen, there is a filter screen between the two sides of the discharge channel. The invention achieves the crushing effect by being provided with a crushing mechanism, and the operation of the crushing mechanism makes the color and glaze in the mixing box more uniformly mixed.

Owner:高安常莹新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com