Oil-water separator with automatic cleaning function

An oil-water separator and automatic cleaning technology, applied in separation methods, liquid separation, water/sewage treatment, etc., can solve problems such as low purity, improve cleaning effect, quickly replace filter cloth, and reduce the time for replacing filter cloth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

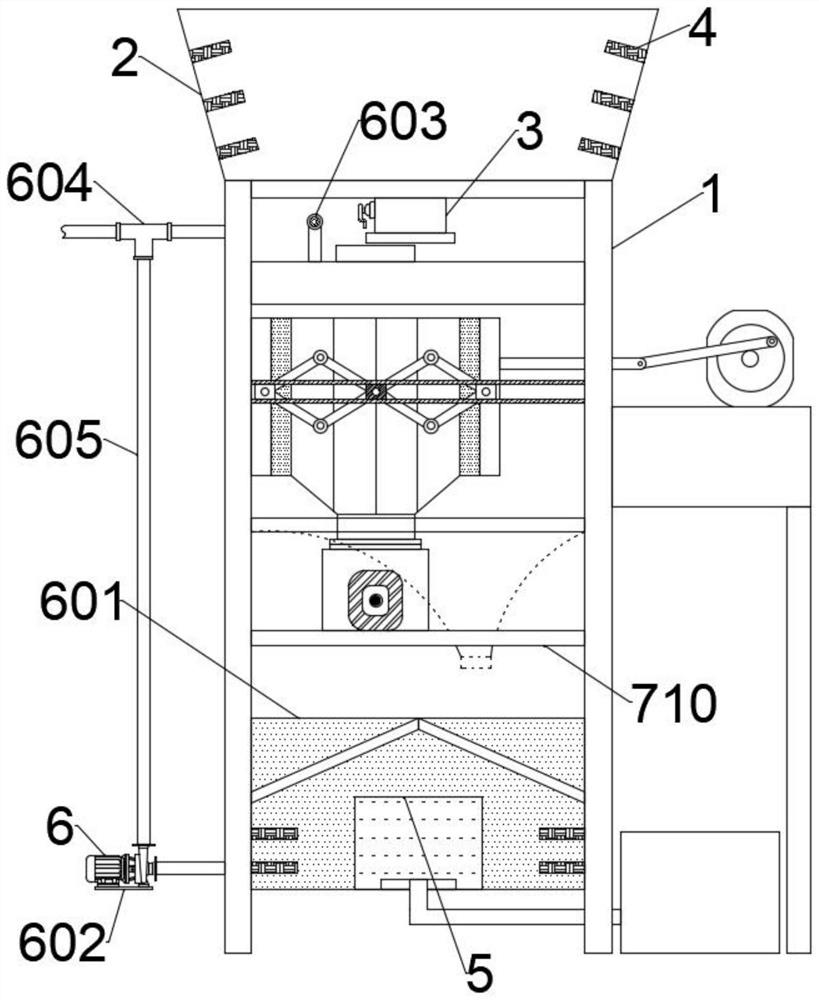

[0031] like Figure 1-3 As shown, the separation of the oil-water mixture in the present invention is to first remove impurities in the oil-water mixture, thereby improving the purity of the separated water and oil;

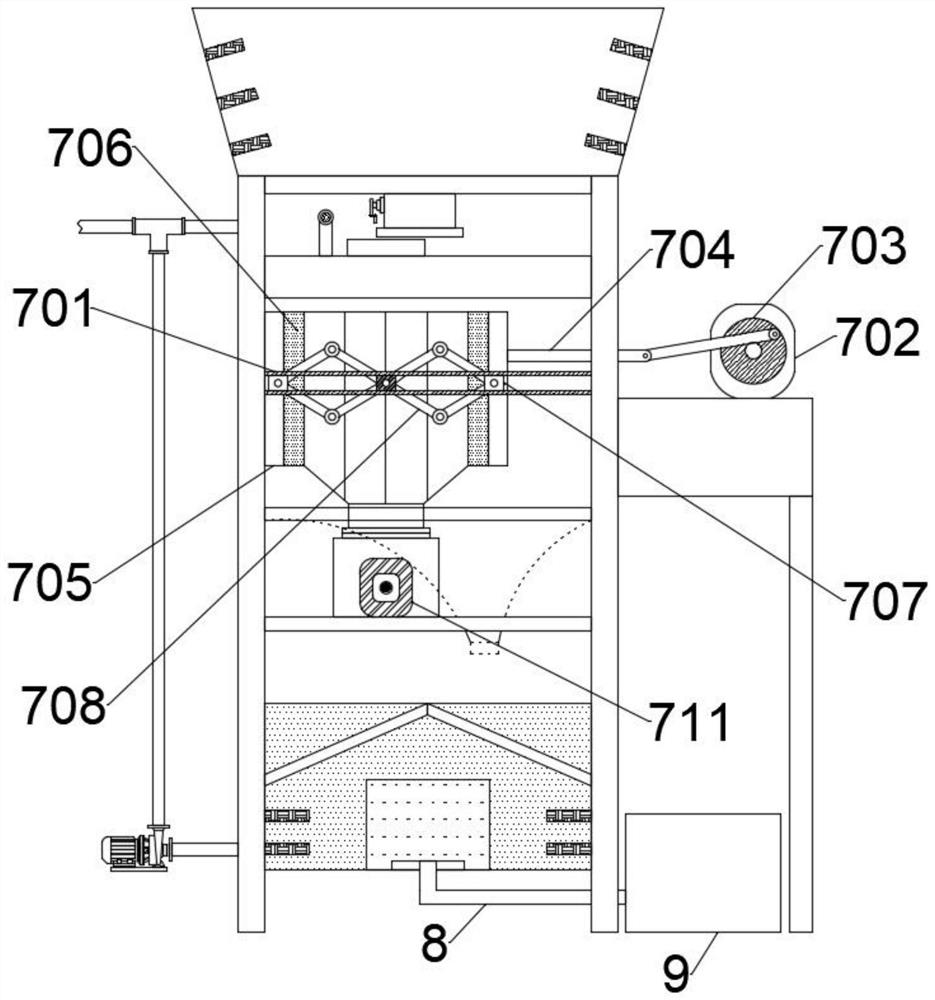

[0032] During the specific operation, start the motor 1 702 and the motor 2 711, pour the oil-water mixture into the reservoir 2 located at the top of the rack 1, and at the same time, the heating rod 4 inside the reservoir 2 heats the oil-water mixture to prevent the oil-water mixture from The problem of condensation of the oil-water mixture occurs due to the low outdoor temperature or the long standing time, and the separation of the oil-water mixture cannot be successfully completed. After the oil-water mixture is heated for a period of time, the switch is turned on, and the oil-water mixture enters the filter cloth 709 through the sewage outlet pipe 3, and the motor A 702 drives the disc 703 to rotate, the disc 703 drives the connecting rod to move, and then ...

Embodiment 2

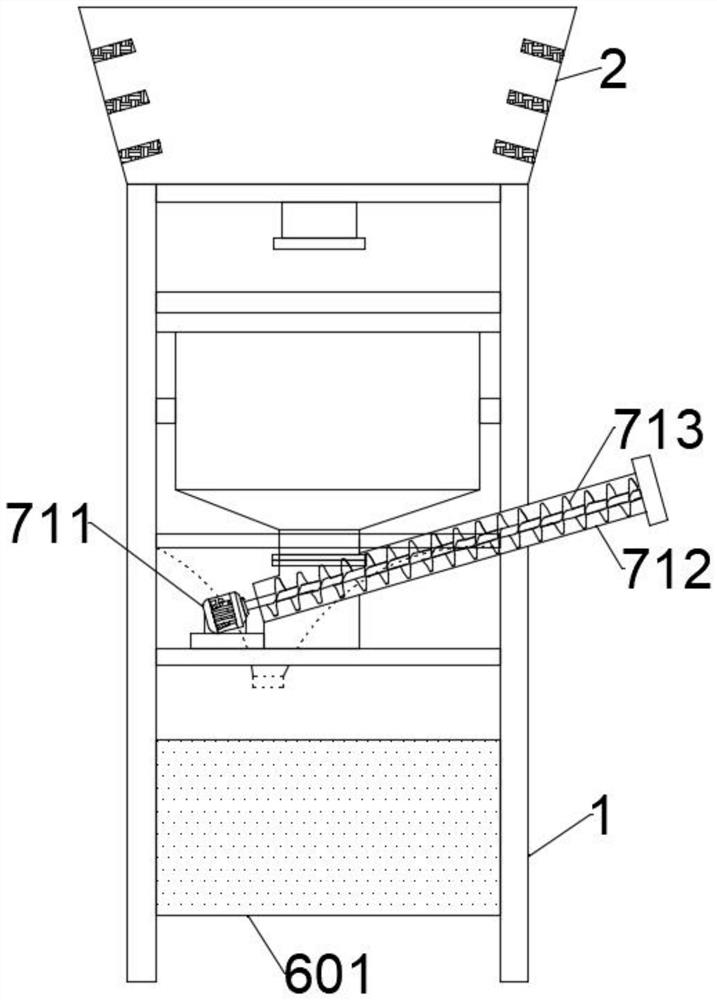

[0034] like Figure 1-6 As shown, the present invention is to solve the problem that impurities block the outer filter holes of the filter cloth 709 after being repeatedly squeezed, and the specific operations are as follows:

[0035]When the motor 1 702 drives the mounting plate 705 and the pressing plate 706 to reciprocate through a series of transmission structures, the intermittent pressing of the filter cloth 709 is realized. During this process, the two pressing plates 706 approach each other at the same time. The rotating arm 606 will be continuously squeezed, thereby driving the scraper 607 connected to one end of the rotating arm 606 to deflect. The impurities scraped from the inside of the filter cloth 709 fall into the conveying cylinder 712, and when the two pressing plates 706 move away from each other, the rotating arm 606 is gradually deflected under the action of the torsion spring 1 and returns to the initial state, while the scraper 607 The bottom-up scrapin...

Embodiment 3

[0037] like Figure 1-3 As shown, when the oil-water mixture enters the liquid collecting tank 601 included in the cleaning assembly 6, it will be filtered again by the filter plate disposed near the top of the liquid collecting tank 601. After the oil-water mixture enters the liquid collecting tank 601, the heating rod 4 will filter the oil-water mixture. Heating again to prevent the oil-water mixture from condensing. After heating for a period of time, the oil-water separation mechanism 5 separates the oil-water mixture, so that the oil flows into the oil storage tank 9 through the oil outlet pipe 8 for collection, and the water enters the water storage tank through the second outlet pipe. The water pump 602 diverts part of the water in the water storage tank to the water spray valve 603 through the first water outlet pipe 605 and the three-way valve 604 in turn, thereby achieving the purpose of water saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com