Extrusion equipment and method for manufacturing shoe layer material

A layered material, extrusion equipment technology, applied in applications, household appliances, household components, etc., can solve the problems of reduced work efficiency, poor cooling effect, troublesome operation, etc., to improve cooling effect, improve fusion quality, and improve cooling. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

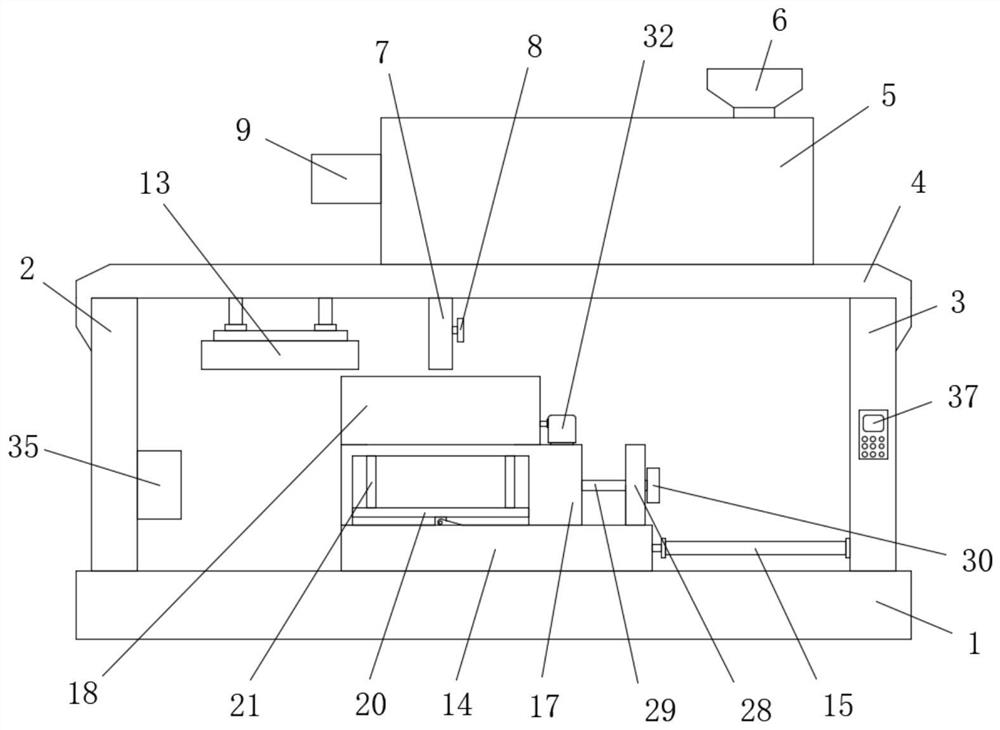

[0034] refer to Figure 1-8, an extrusion device for manufacturing shoe layer materials, comprising a base 1, the two sides of the top of the base 1 are symmetrically fixedly connected with a first riser 2 and a second riser 3 respectively, the first riser 2 and the second riser The top of the two vertical plates 3 is fixedly connected with the same top plate 4, and the top side of the top plate 4 is fixedly connected with a mixing box 5, and the top of the mixing box 5 is provided with a feed hopper 6 near the side of the second vertical plate 3, and the mixing box The bottom of 5 is provided with a discharge pipe 7 away from the side of the feed hopper 6, and one side of the discharge pipe 7 extends to the bottom of the top plate 4 and an electromagnetic valve 8 is installed. One side of the bottom is fixedly connected with an upper fixed mold 13, the top of the base 1 is slidably connected with a sliding seat 14, one side of the sliding seat 14 is fixedly connected with a t...

Embodiment 2

[0036] Further improved on the basis of embodiment one:

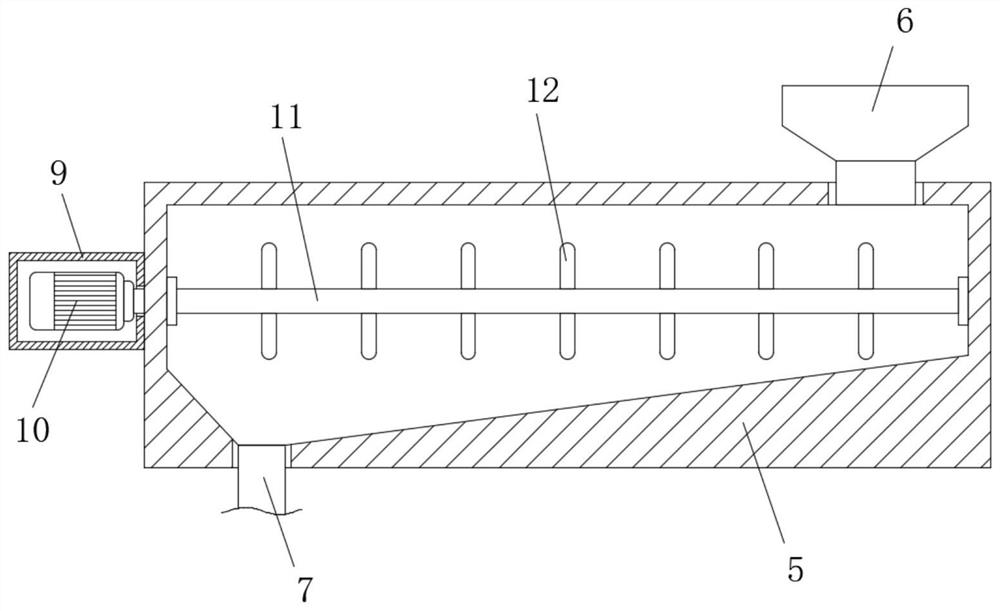

[0037] In this embodiment, the stirring assembly includes a protective box 9 fixedly connected to the outer wall of the mixing box 5 near the first riser 2, a rotating motor 10 is fixedly installed in the protective box 9, and a stirring motor 10 is fixedly connected to the output shaft of the rotating motor 10. Shaft 11, one end of the stirring shaft 11 extends to the inside of the mixing box 5 and is rotatably connected with the inner wall of the side of the mixing box 5 away from the protective box 9, and the stirring shaft 11 is provided with a plurality of stirring blades 12 on the side inside the mixing box 5, Start the rotating motor 10 to drive the stirring shaft 11 to rotate, which can drive the stirring blade 12 to rotate, and then the raw materials in the mixing box 6 can be fully mixed.

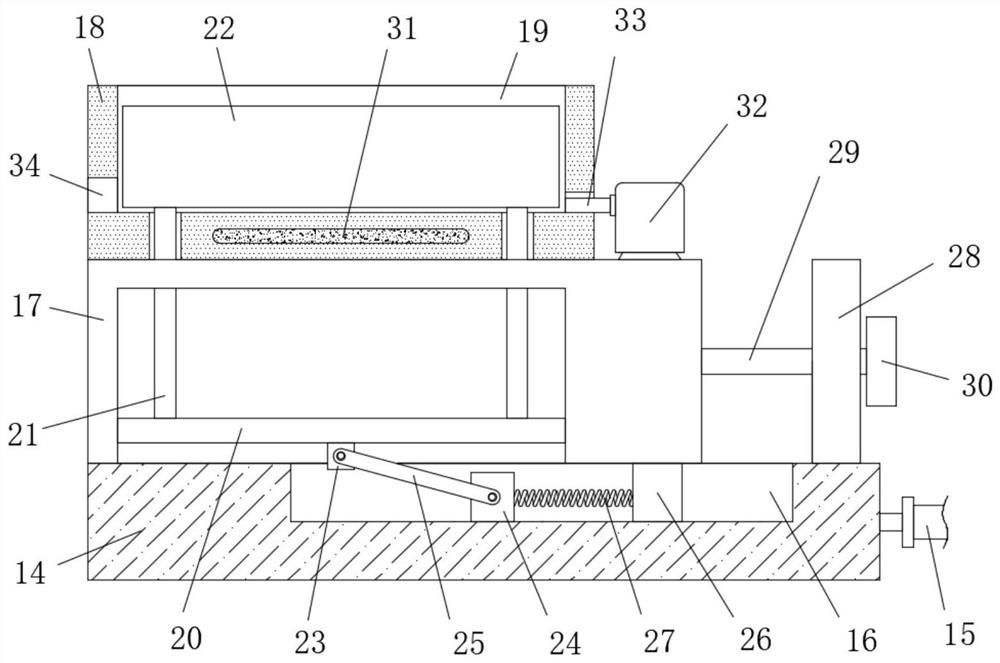

[0038] In this embodiment, the same slide plate 20 is slidably connected to the inner walls of both sides of the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com