a crane

A technology of cranes and reels, applied in the direction of clockwork mechanism, hoisting device, etc., can solve the problems of wire rope wear, trouble, not easy to clean, etc., and achieve the effect of saving lubricating oil and facilitating lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

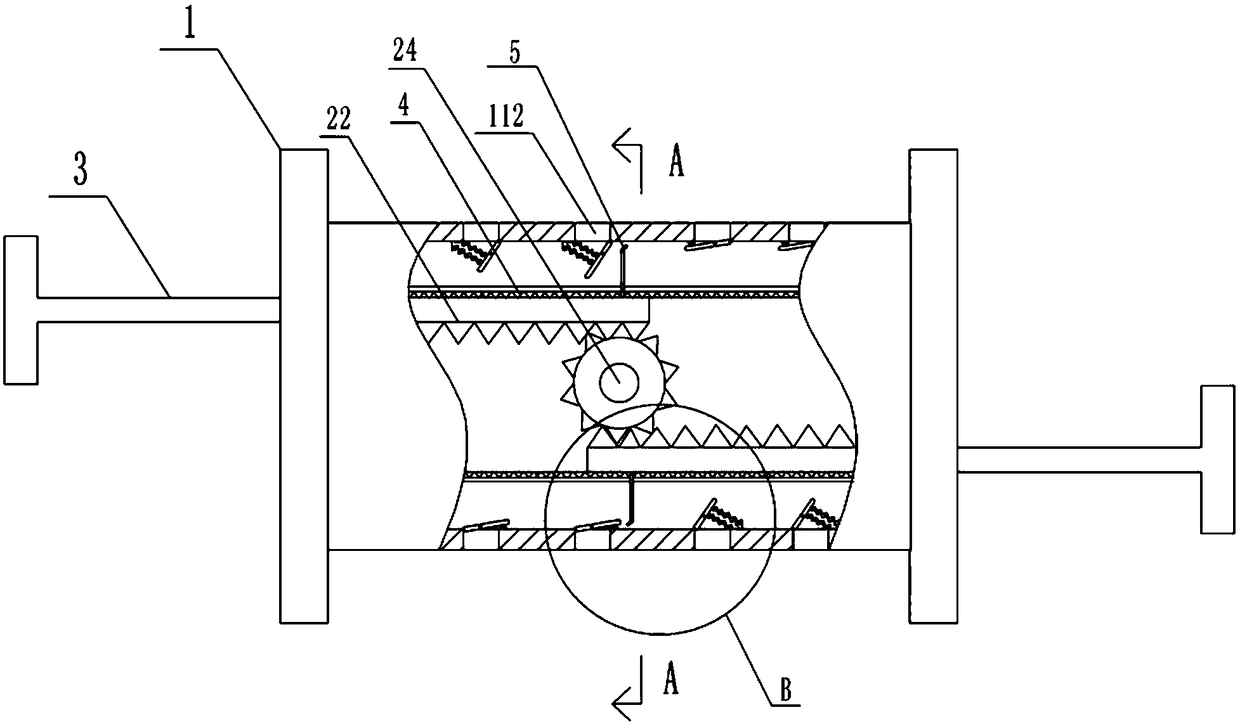

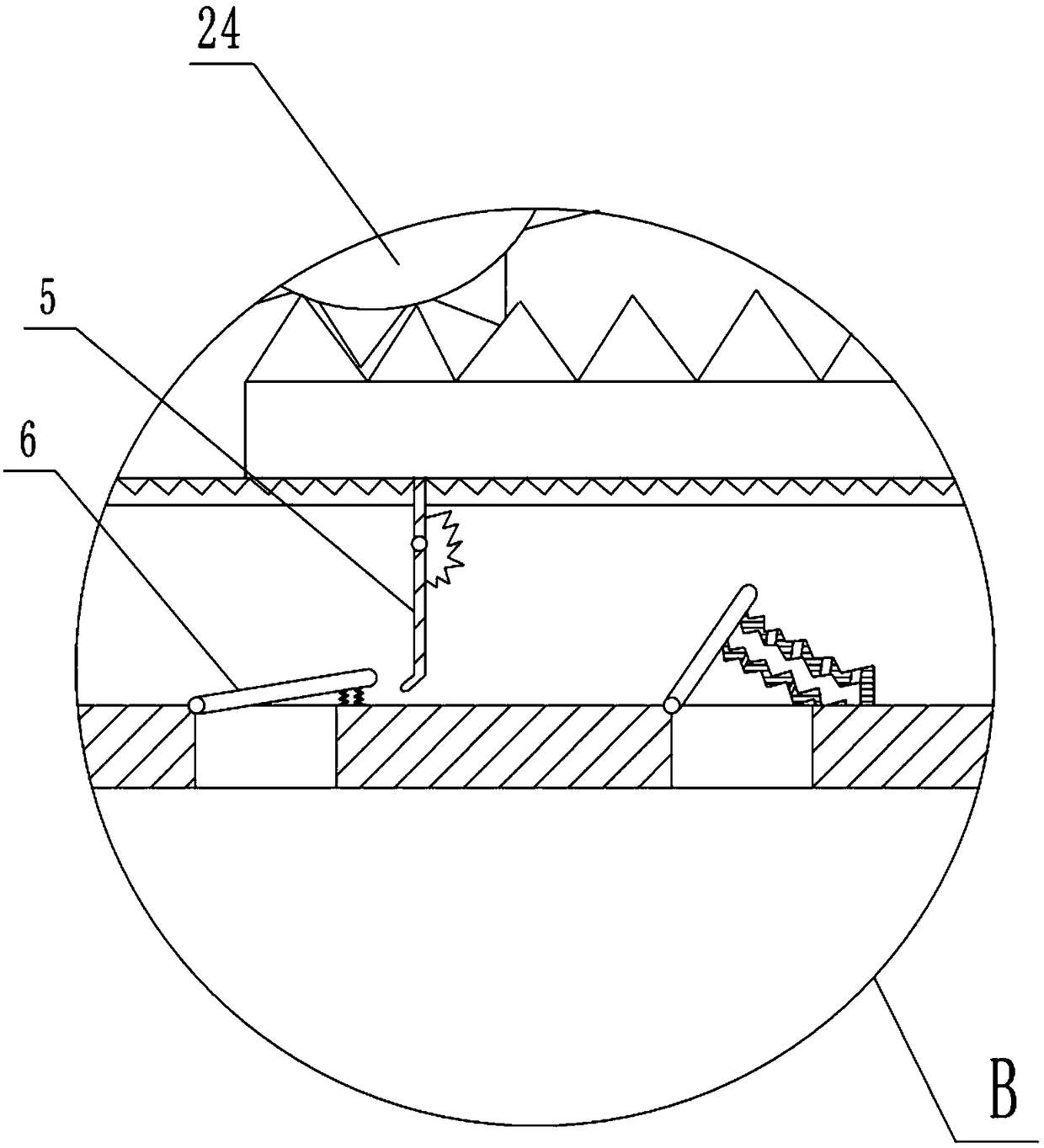

[0030] Such as figure 1 , figure 2 , image 3 and Figure 5 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0031]A kind of crane, comprises reel body 1, and reel body 1 is provided with cavity inside, and outer sleeve 111 is arranged in the cavity, and the two ends of outer sleeve 111 are fixedly connected with the chamber wall of cavity; An oil chamber 12 for containing lubricating oil is formed between 111 and the wall of the cavity. The reel body 1 is provided with an oil inlet portion for feeding the oil chamber 12, and the oil inlet portion is an oil inlet hole with a cover. The outer sleeve 111 is provided with an inner sleeve 2 and a push rod 3, and the inner sleeve 2 is slidingly connected with the inner wall of the outer sleeve 111; one end of the push rod 3 is fixed to the inner sleeve 2, and the other end of the push rod 3 protrudes to the outside of the reel body 1, and the push rod 3 is slidably connected w...

Embodiment 2

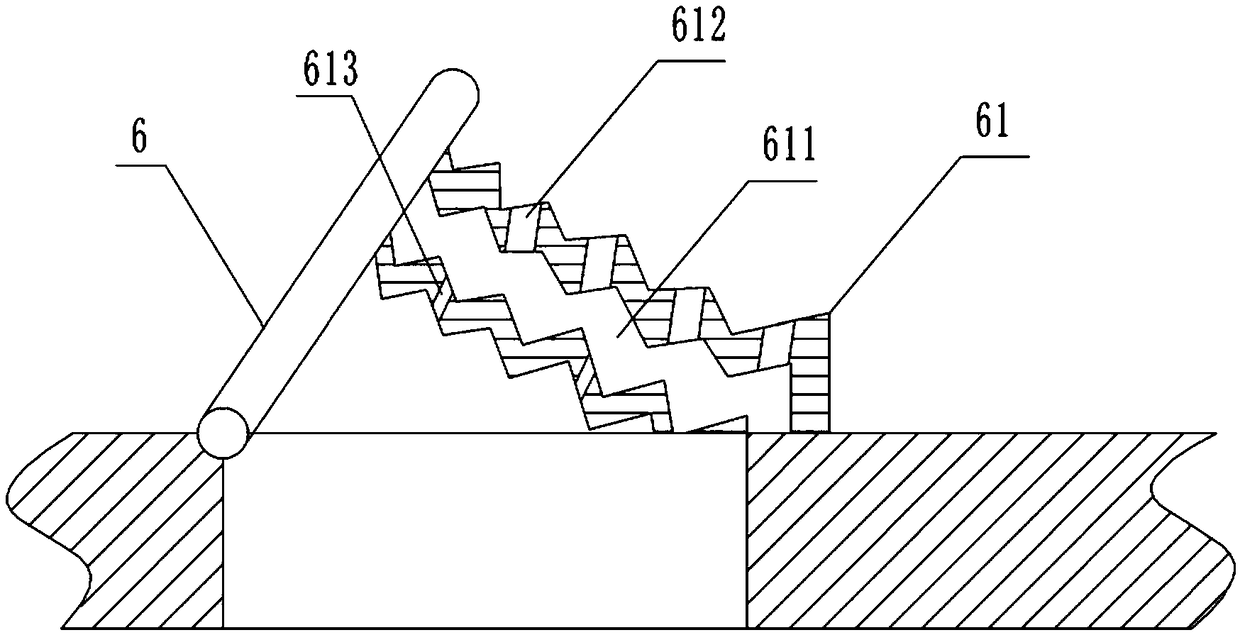

[0040] The difference between this embodiment and Embodiment 1 is that, in order to further enable the swing bar 52 to return to its original position, the cover plate 6 can better squeeze the soft folding layer 61, such as Figure 6 As shown, the cover plate 6 is provided with an opening, and a shaft 62 is rotatably connected to the opening, and a pressing plate 63 is fixed on the shaft 62 . A block 64 for preventing the pressing plate 63 from turning upward is also fixed on the upper surface of the cover plate 6 . Such as Figure 6 The left side of the blocking block 64 shown is bent downward and fixedly connected with the cover plate 6 ; the right side of the blocking block 64 is bent downward and contacts the upper surface of the pressing plate 63 .

[0041] After the cover plate 6 is fully opened, pull the push rod 3 on the left side, and the left side push rod 3 drives the left side for the shape sleeve to move to the left, and the swing rod at the lower end of the togg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com