Automatic potato peeling machine

A peeling machine, automatic technology, applied in the peeling of vegetables or fruits, food processing, food science and other directions, can solve the problems of low degree of automation, difficult cleaning, low serving efficiency, etc., to achieve high degree of automation, prevent rolling over Fast, easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

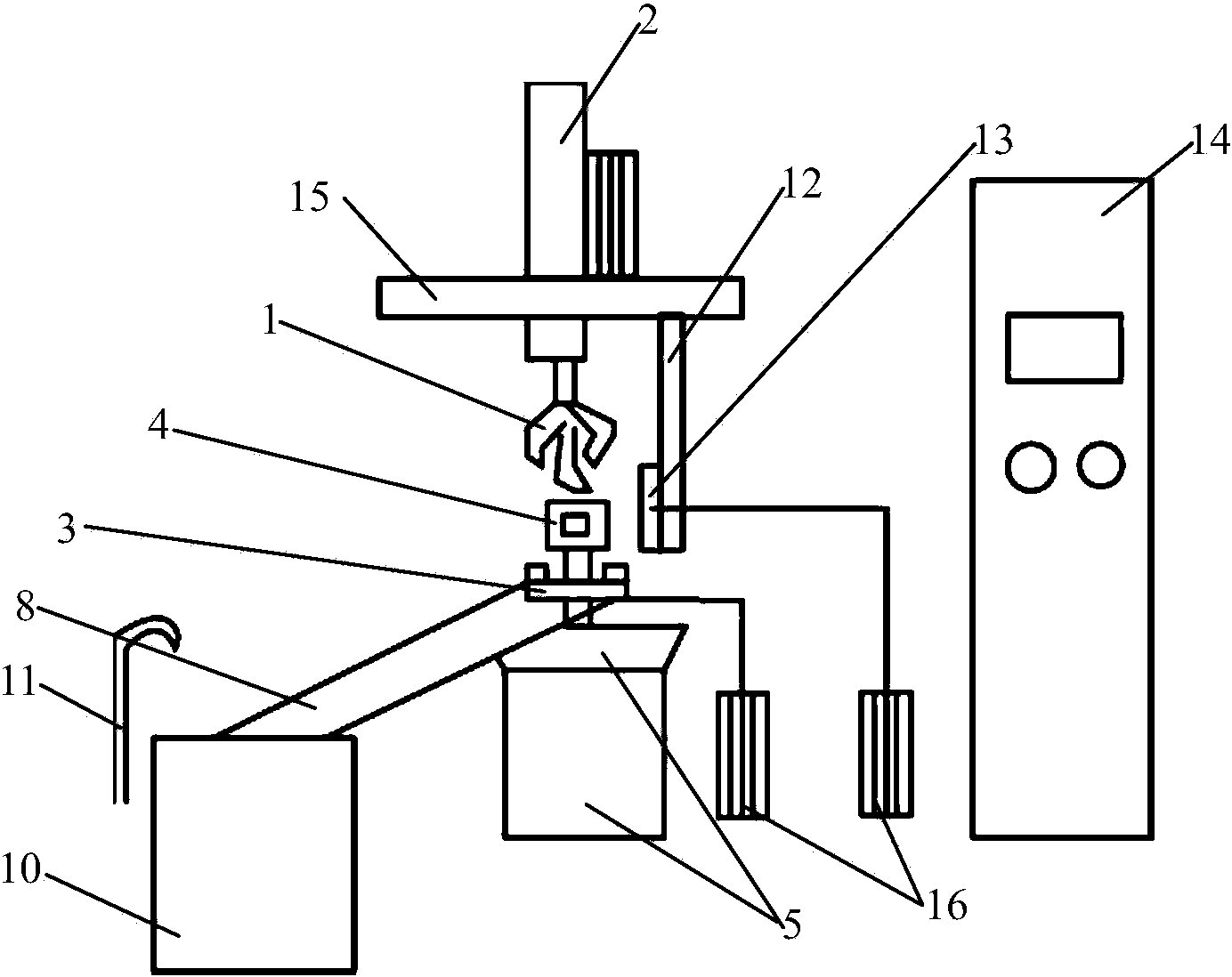

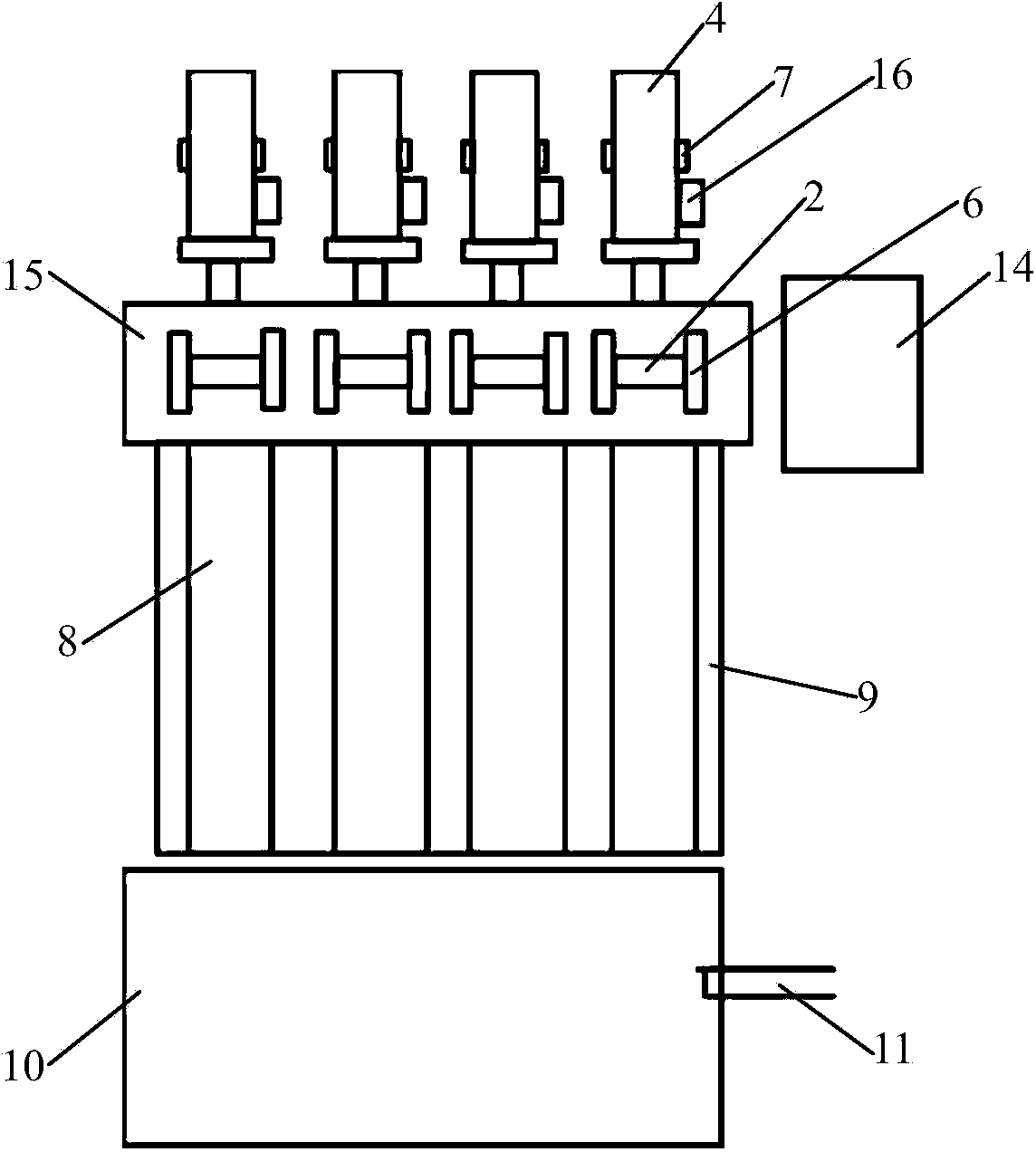

[0015] Example: such as Figure 1-2 As shown, the present invention provides a kind of automatic peeling machine for potatoes, comprising air claw 1, lifting cylinder 2, rotating tray 3, push-pull cylinder 4, collection box 5, lifting cylinder 2 is fixed on the support one 6 by fixing plate 15, described The lower part of the lifting cylinder 2 is connected with the air claw 1, the lower end of the air claw 1 is provided with the rotary tray 3, and the collection box 5 is provided below the rotary tray 3, and the upper opening of the collection box 5 is an inverted trapezoid. The top opening area of the collection box 5 is larger than the bottom area, and the length and width are larger than the length and width of the entire peeling system, so as to prevent the potato peels from falling on the ground. The push-pull cylinder 4 is provided at the rear of the rotary tray 3 , the height of the push-pull cylinder 4 is higher than the height of the rotary tray 3 by 3-6cm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com