Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "The performance indicators meet the requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

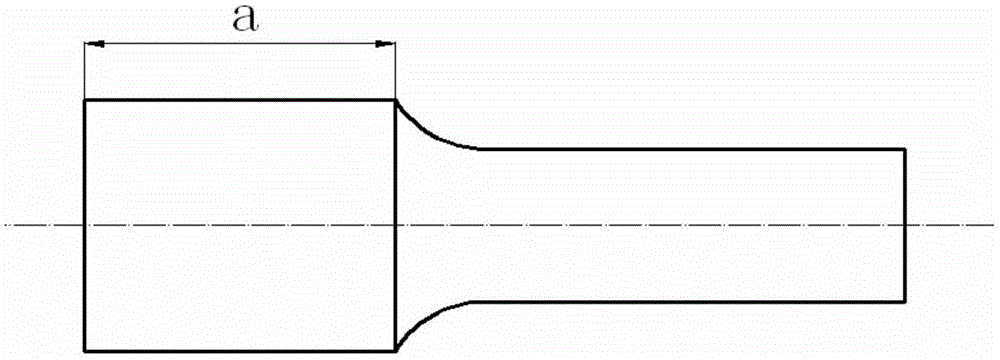

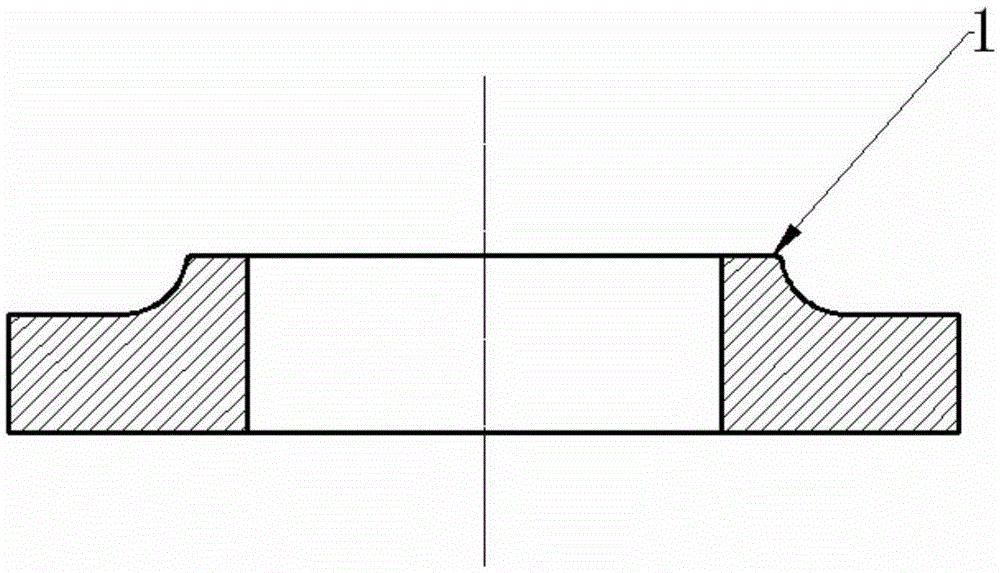

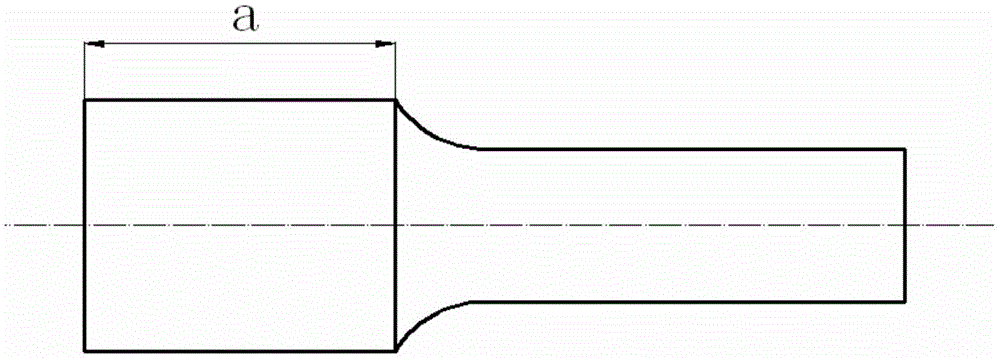

Isothermal forging forming method of titanium alloy complex sheet forged piece

InactiveCN105397001AImprove forming qualityDimensions are completeMetal-working apparatusMetallurgyTitanium alloy

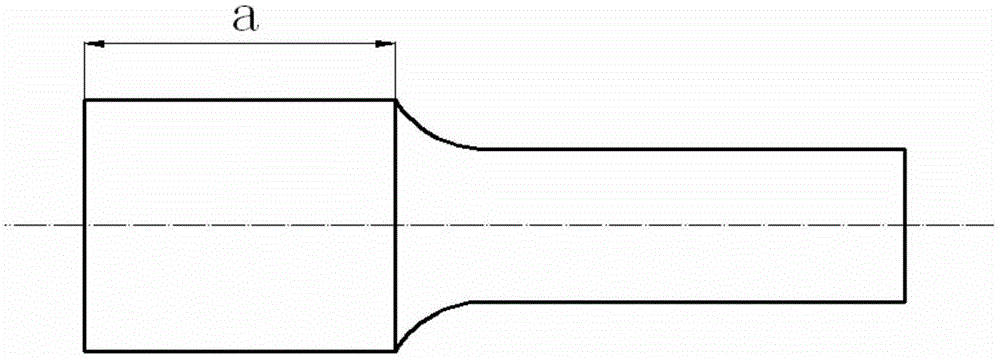

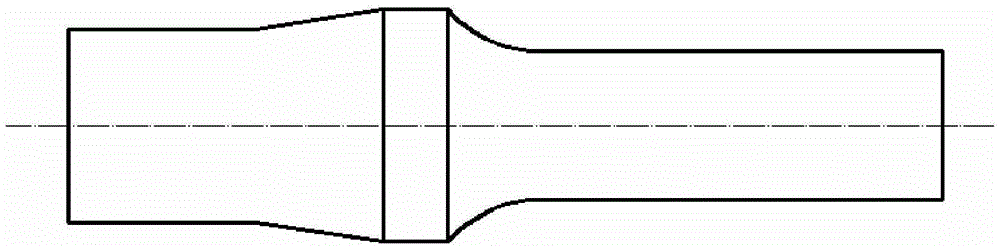

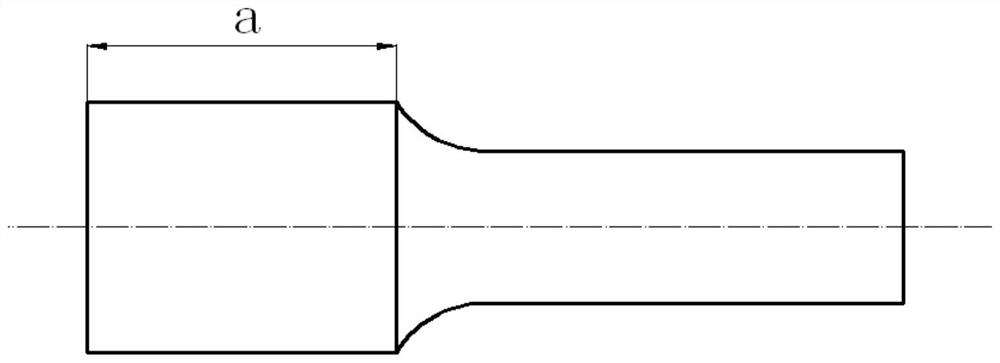

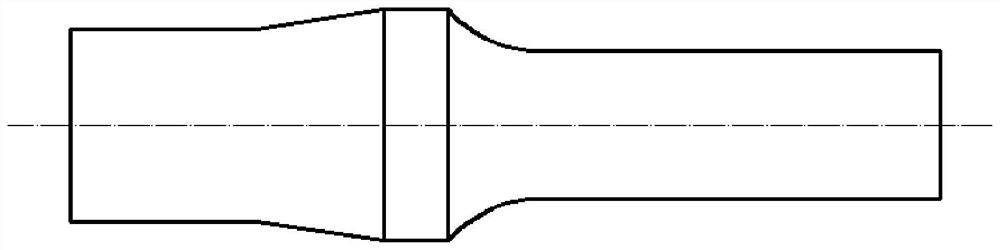

The invention discloses an isothermal forging forming method of a titanium alloy complex sheet forged piece. The isothermal forging forming method comprises the following steps: first, upsetting a blank on a free forging hammer, and then drawing the upset blank out; controlling the left end of the drawn-out blank to be unchanged, and splitting and drawing out an a position, which is a from the left end of the drawn-out blank, and then wholly upsetting the split and drawn-out blank flat; drawing out and shaping the left end of the wholly upset-flat blank to manufacture an intermediate blank; and finally, conducting isothermal forging forming on the intermediate blank. Through the adoption of the isothermal forging forming method, the forging forming of the titanium alloy complex sheet forged piece is realized effectively, and the forming quality of the titanium alloy complex sheet forged piece is improved. The isothermal forging forming method is used for isothermal forging forming of the titanium alloy complex sheet forged piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Rolling method of titanium alloy plate-shaped forgings

The invention discloses a rolling method of titanium alloy plate-shaped forgings. The rolling method comprises the following steps of: substituting forging a titanium alloy billet by adopting three upsetting and three drawing firstly; then carrying out upsetting, punching, frame reaming and rolling on the titanium alloy billet after substituting forging to prepare a high-cylinder and thin-walled ring, wherein the inner diameter of the ring is 85-90 percent of the outer diameter; cutting the high-cylinder and thin-walled ring into two hemi-toroidal parts by using wire cutting; and then straightening by a forging hammer to acquire two plate-shaped forgings. The rolling method effectively avoids the defects about uneven thickness, poor organization homogeneity, multiple forging times and the like of the forgings, improves the quality and the production efficiency of the forging and is used for producing the titanium alloy plate-shaped forgings.

Owner:GUIZHOU ANDA AVIATION FORGING

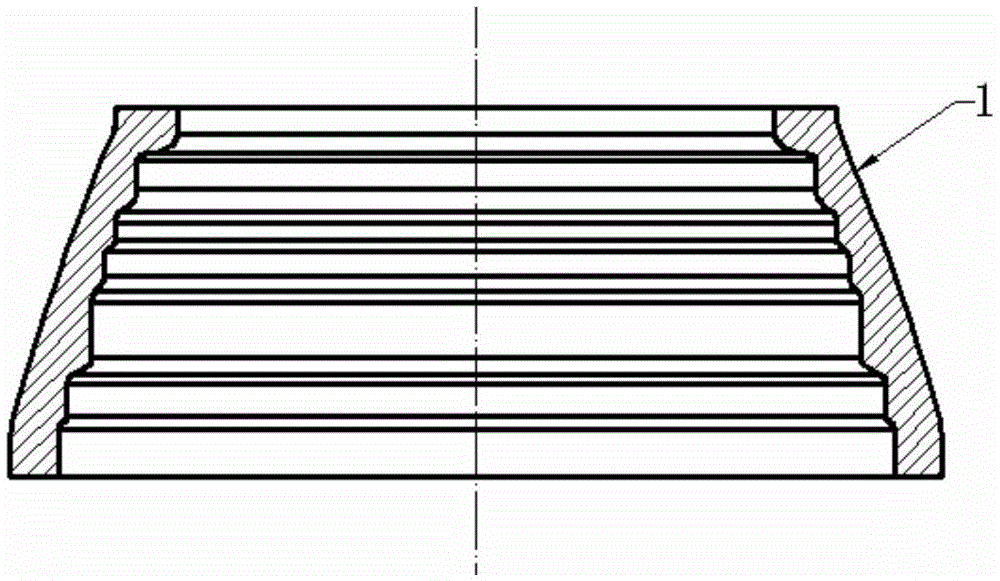

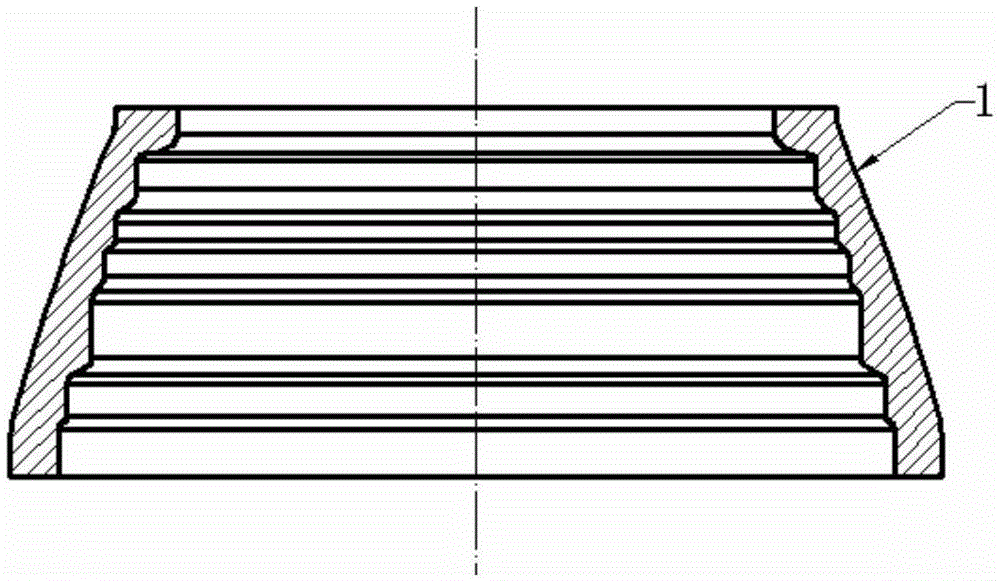

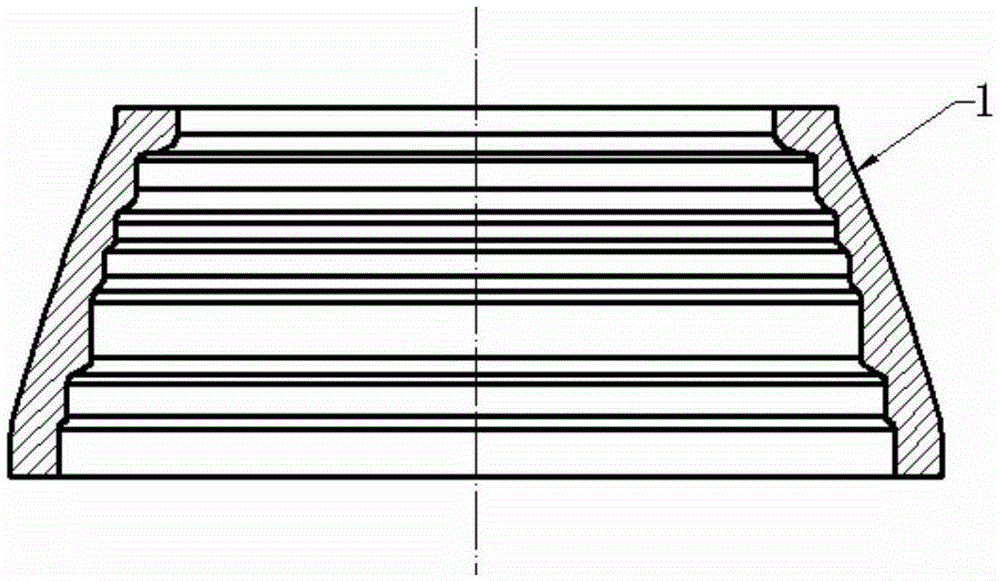

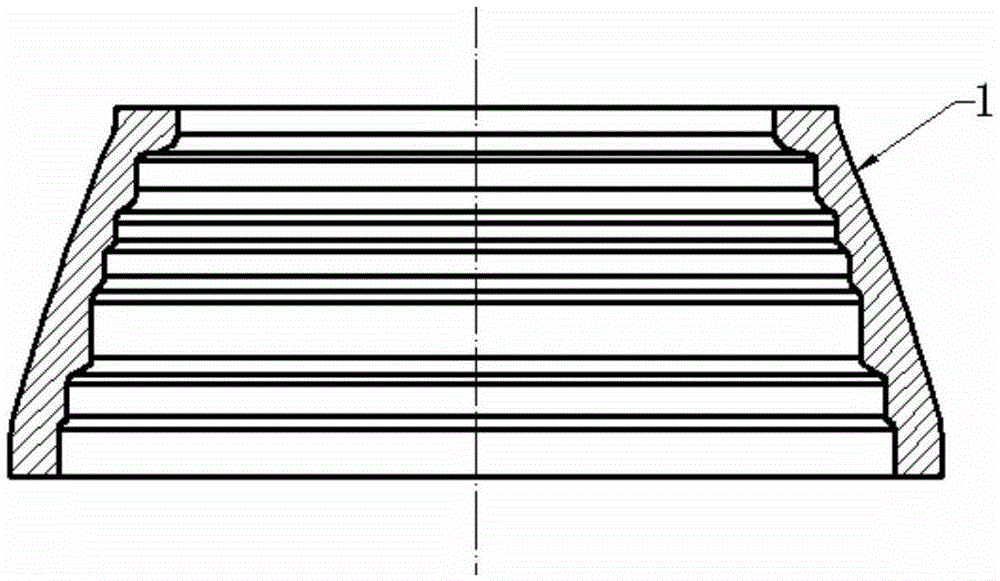

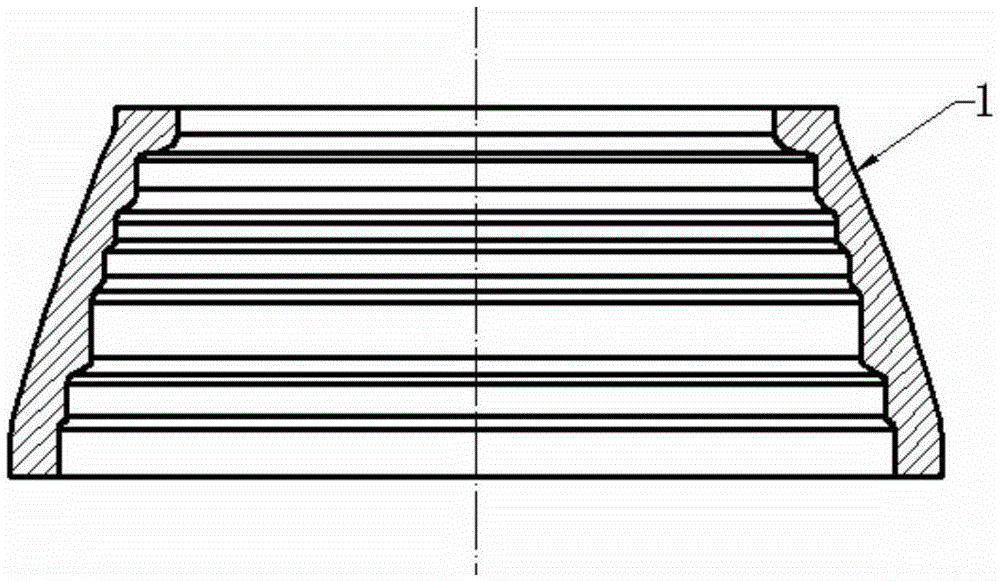

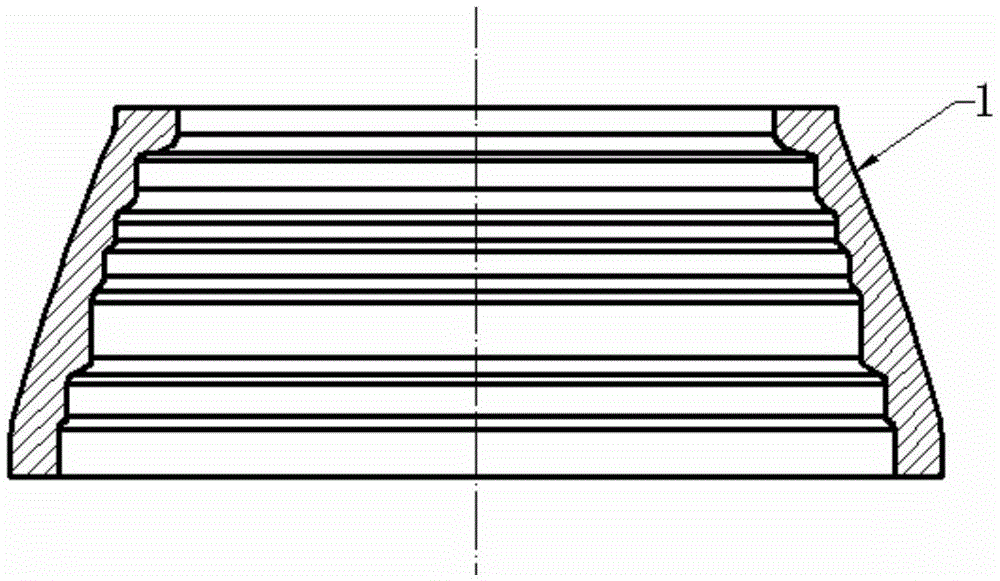

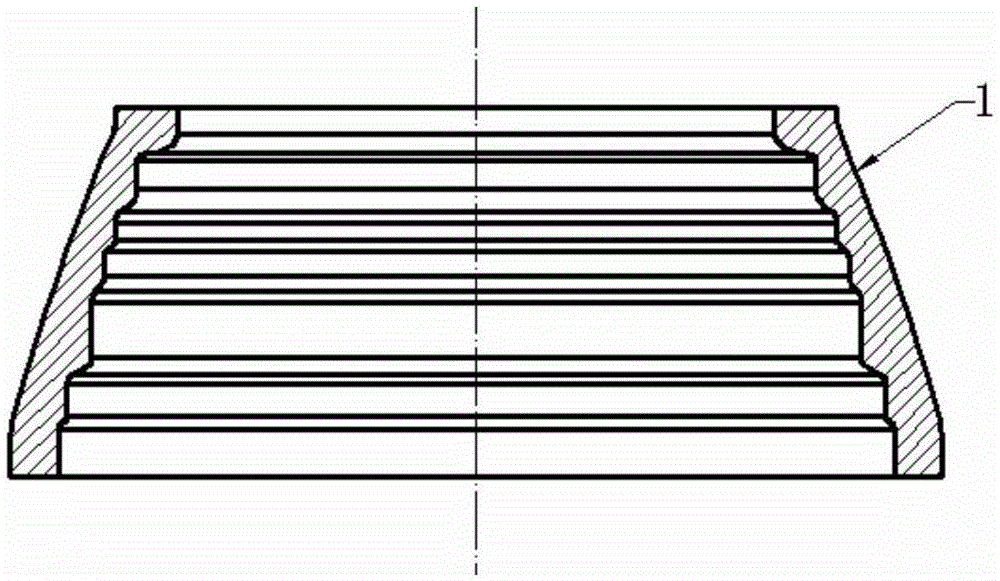

Forming method of nickel-based high-temperature alloy multi-step large special-shaped ring part

InactiveCN105537473AOvercoming the difficulty of forming with many sudden changes in the cross-sectionConsistent cross-sectional areaMetal rollingForgingMetal

The invention discloses a forming method of a nickel-based high-temperature alloy multi-step large special-shaped ring part. The forming method comprises the following steps of preparing an intermediate ring blank under the assistance of mappingsoftware at first and then putting the intermediate ring blank into a ring rolling mill for rolling; during rolling, elevating by 5mm-10mm a worktable top where the intermediate ring blank is located, enabling a main roller to contact with a lower end of the intermediate ring blank first, and enabling a metal material to fill a die cavity starting from bottom to top, thereby gradually completing the formation of various steps, and finally, bulging the rolled multi-step large special-shaped ring part. Such a method is capable of realizing multi-step large special-shaped ring parts, and capable of effectively avoiding the phenomenon of rib deflection or drifting during the formation of the multi-step large special-shaped ring parts, thereby improving the properties of forgings. The method is applicable to the formation of the nickel-based high-temperature alloy multi-step large special-shaped ring parts.

Owner:GUIZHOU ANDA AVIATION FORGING

Forming method for large special-shaped structural steel multi-step ring piece

InactiveCN105382157AConsistent cross-sectional areaPrevent roll climbMetal rollingMetalGraphics software

The invention discloses a forming method for a large special-shaped structural steel multi-step ring piece. The forming method includes the steps that an intermediate ring billet is manufactured through the assistance of graphics software, and the intermediate ring billet is placed in a looping mill to be rolled; in the rolling process, a working table top where the intermediate ring billet is located is lifted by 5-10 mm to enable a main roller to make contact with the lower end of the intermediate ring billet firstly, and it is guaranteed that a mold cavity starts to be filled with metal materials from bottom to top to complete forming of all steps gradually; and then the rolled large special-shaped structural steel multi-step ring piece is subjected to bulging. By means of the method, the large special-shaped structural steel multi-step ring piece can be formed, the rib deviating or rib crossing phenomenon in forming of the large special-shaped structural steel multi-step ring piece can be effectively avoided, and therefore the performance of the forged piece is improved. The method is suitable for forming of the large special-shaped structural steel multi-step ring piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Rolling method of high-temperature alloy plate shaped forging

InactiveCN105397417AAvoid uniformityAvoid defects such as too many forging firesSuperalloyHot Temperature

The invention discloses a rolling method of a high-temperature alloy plate shaped forging. The method comprises the following steps: performing substituting forging for a high-temperature alloy blank in a manner of upsetting at three times and drawing out at three times; then processing the high-temperature alloy blank subjected to the substituting forging by upsetting, punching a hole, expanding the hole through a mandrel supporter and rolling, so as to obtain a high-barrel thin-wall ring part, wherein the inside diameter of the ring part is 85 to 90% of the outside diameter; then performing linear cutting, namely, cutting the high-barrel thin-wall ring part into two semicircular ring parts; straightening through a forging hammer to obtain two plate shaped forgings. With the adoption of the method, the defects of the forging, such as non-uniform thickness, poor structure uniformity and a plurality of forging times, can be effectively avoided, thus the quality of the forging can be improved, and the production efficiency can be improved. The method is applied to the production of the high-temperature alloy plate shaped forging.

Owner:GUIZHOU ANDA AVIATION FORGING

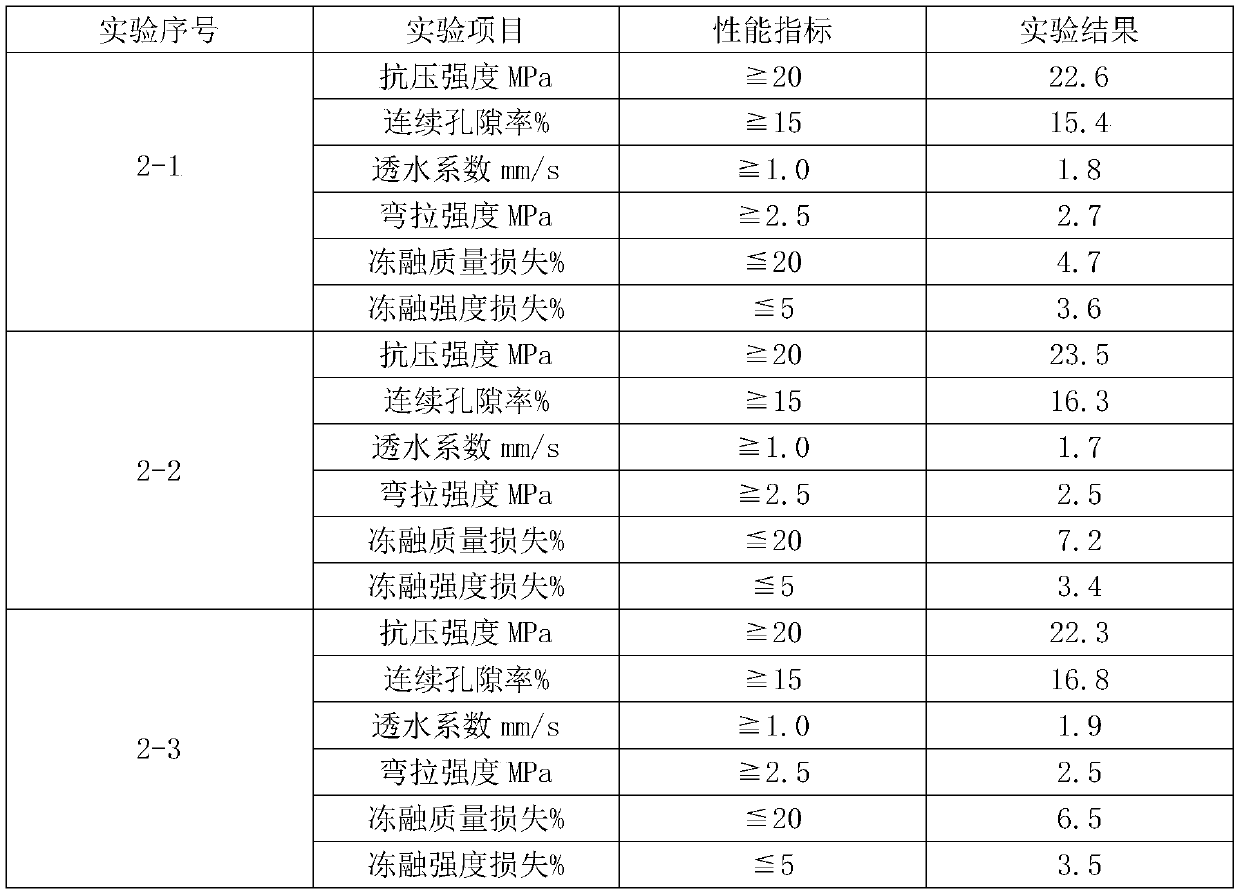

Formula and production technology of red brick-containing recycled aggregate permeable concrete

The invention discloses a formula and a production technology of red brick-containing recycled aggregate permeable concrete. The permeable concrete prepared from red brick-containing recycled aggregates promotes the recycling of building wastes, is a novel environmentally-friendly material, promotes the sustainable development of the building industry, has great social, economic and environmentalcomprehensive benefits, saves a large amount of natural resources, and has significant economic and environmental benefits.

Owner:XUCHANG JINKE RESOURCE RECYCLING CO LTD

Forming method of cobalt-based high-temperature alloy multi-step large special-shaped ring

InactiveCN105396995AOvercoming the difficulty of forming with many sudden changes in the cross-sectionConsistent cross-sectional areaMetal rollingSuperalloyAbnormal shaped

The invention discloses a forming method of a cobalt-based high-temperature alloy multi-step large special-shaped ring. The forming method comprises the following steps: firstly, adopting drawing software to assist the preparation of an intermediate ring blank, and putting the intermediate ring blank in a ring rolling mill for rolling; during rolling, elevating a worktable top where the intermediate ring blank is located by 5mm-10mm to enable a main roller to contact with a lower end of the intermediate ring blank firstly and guarantee the filling of a die cavity with a metal material starting from bottom to top, thereby gradually completing the formation of all the steps, and then bulging the rolled multi-step large special-shaped ring. Such a method is capable of forming the multi-step large special-shaped ring, and also capable of effectively avoiding a phenomena of rib deviation or rib crossing during the formation of the multi-step large special-shaped ring, thereby improving the properties of the forging. The method is suitable for the formation of the cobalt-based high-temperature alloy multi-step large special-shaped rings.

Owner:GUIZHOU ANDA AVIATION FORGING

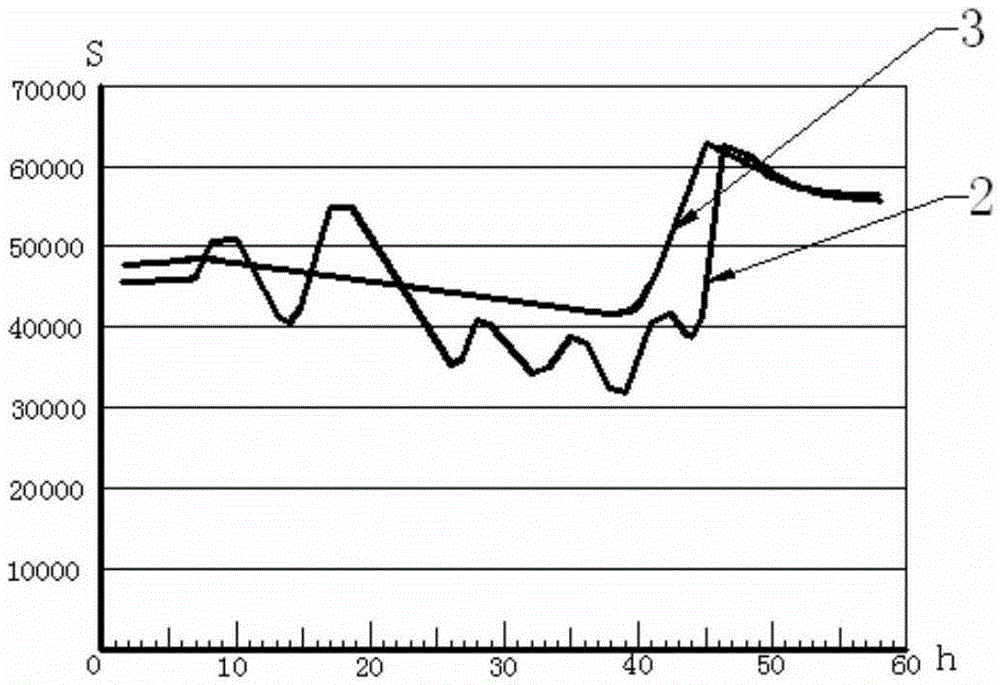

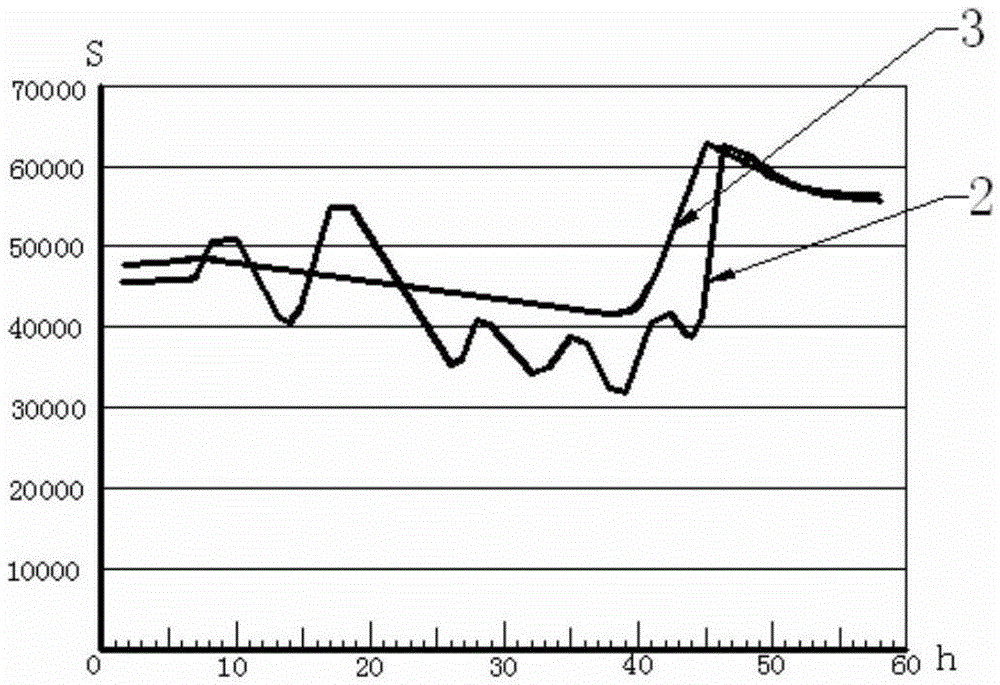

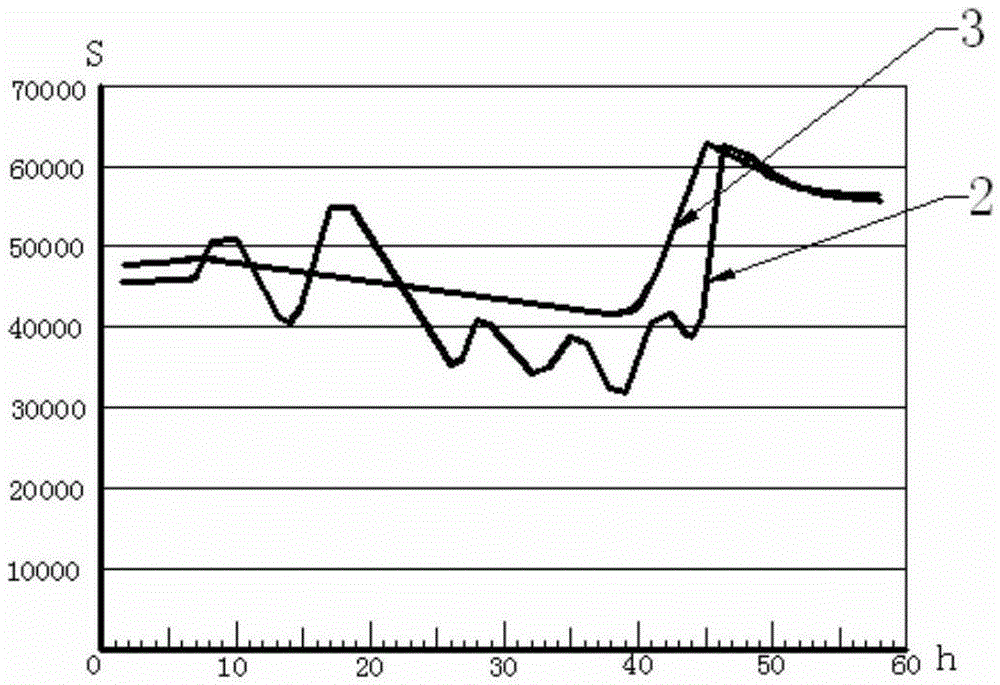

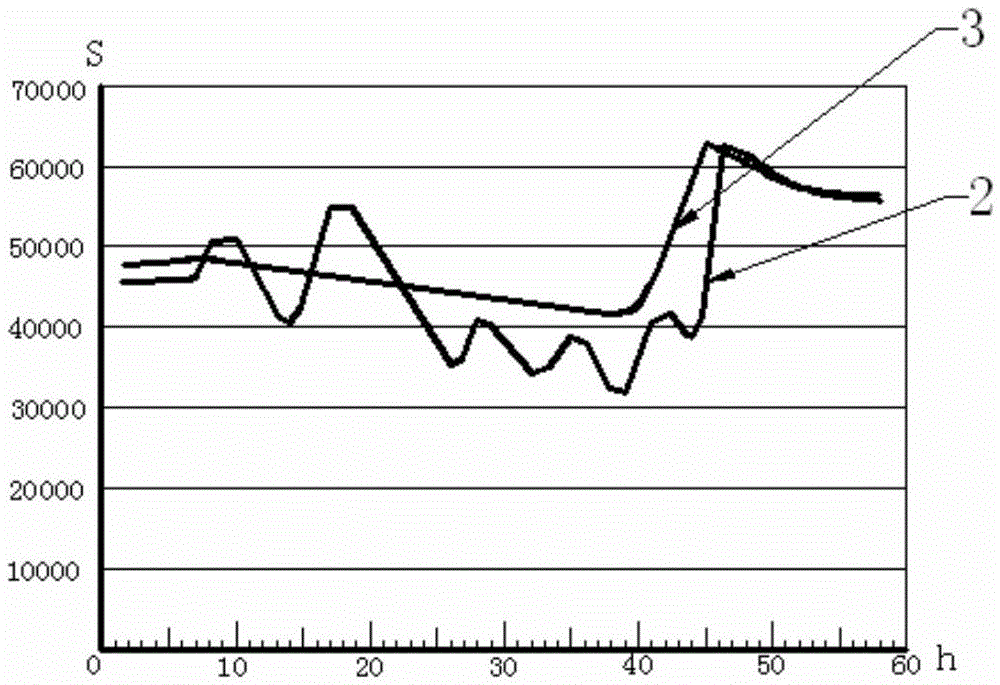

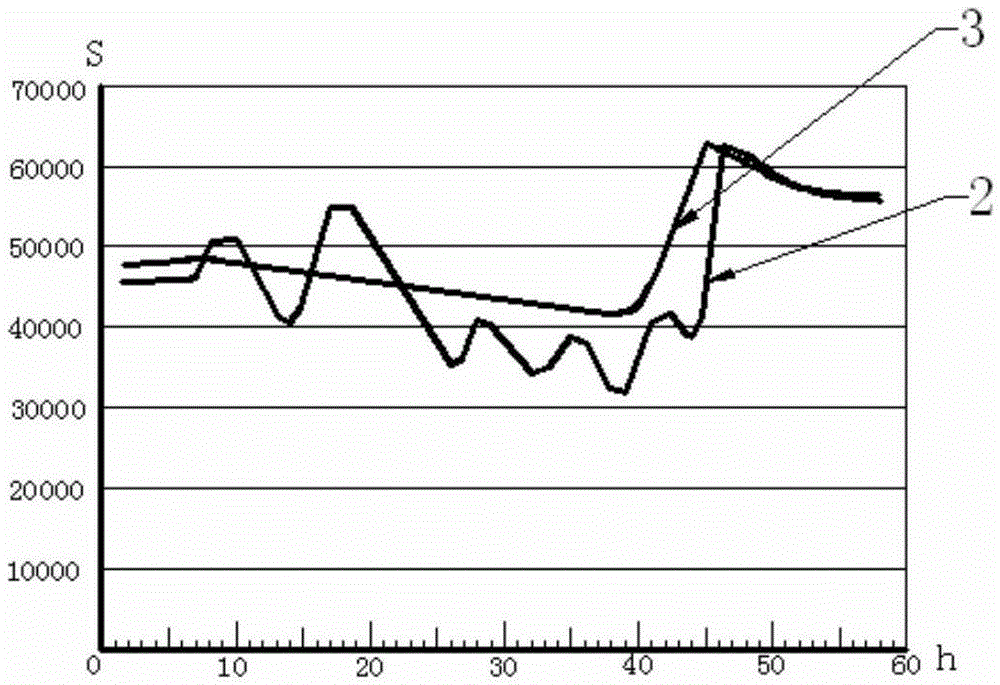

High-efficiency and low-cost 610 MPa hydropower steel and production method thereof

InactiveCN106222557AGrain refinementThe performance indicators meet the requirementsSlow coolingPre treatment

The invention discloses high-efficiency and low-cost 610 MPa hydropower steel and a production method thereof. The hydropower steel comprises the following chemical components in percentage by mass: 0.07-0.09% of C, 0.15-0.35% of Si, 1.40-1.60% of Mn, not greater than 0.15% of P, not greater than 0.08% of S, 0.015-0.035% of Nb, 0.030-0.050% of V, 0.008-0.030% of Ti, 0.10-0.30% of Ni, 0.10-0.30% of Mo, and the balance Fe and inevitable impurities. A process route comprises KR hot metal pre-treatment, converter smelting, LF and RH refining, continuous casting, slow cooling, continuous casting blank heating, rolling, cooling, straightening, finishing and tempering. According to the high-efficiency and low-cost 610 MPa hydropower steel and the production method thereof, which are disclosed by the invention, a production flow is shortened, energy consumption is reduced, a high-cost limit of a traditional production process is overcome, and the product quality is ensured.

Owner:SHANDONG IRON & STEEL CO LTD

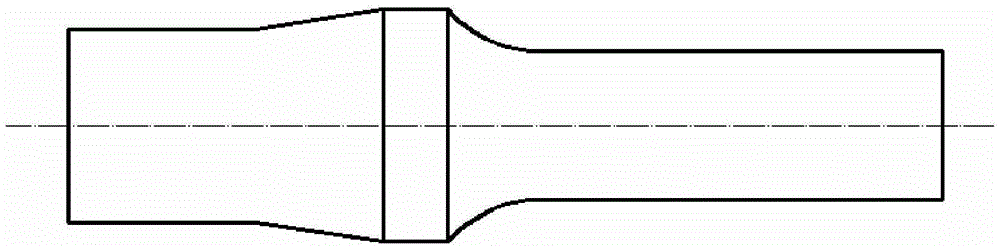

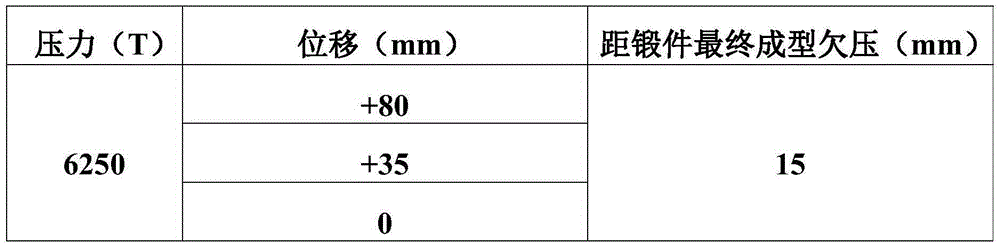

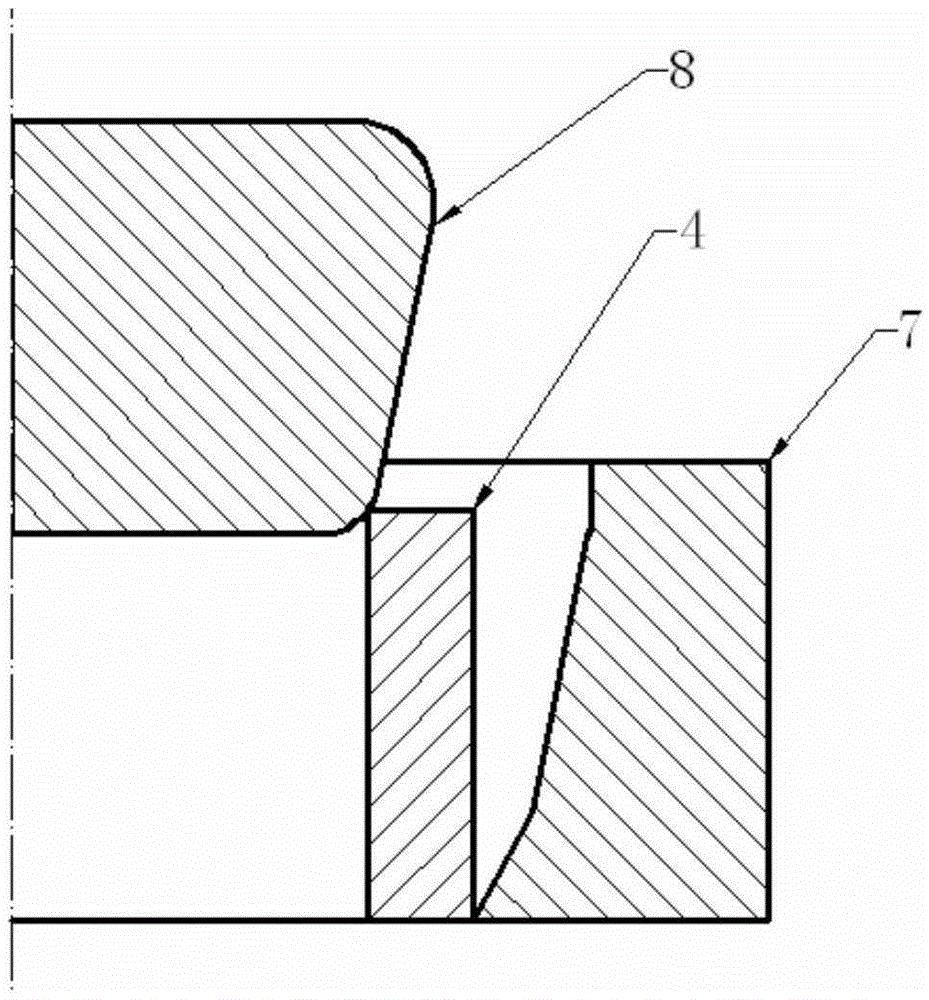

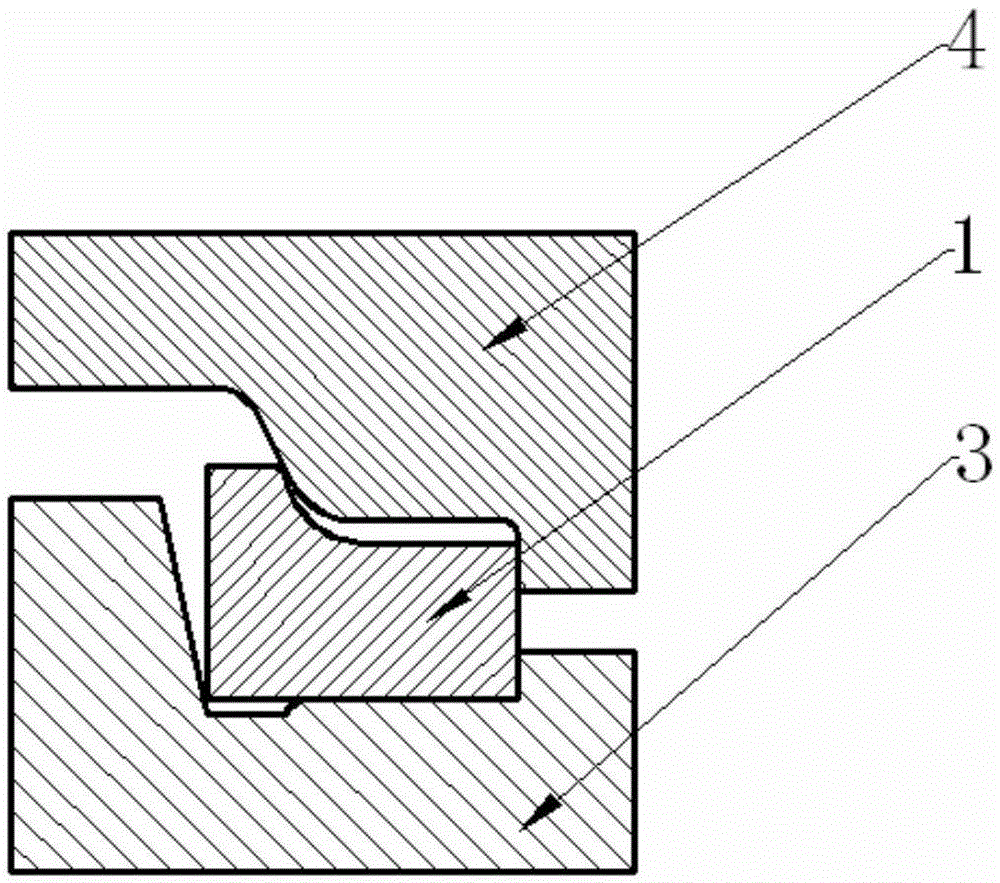

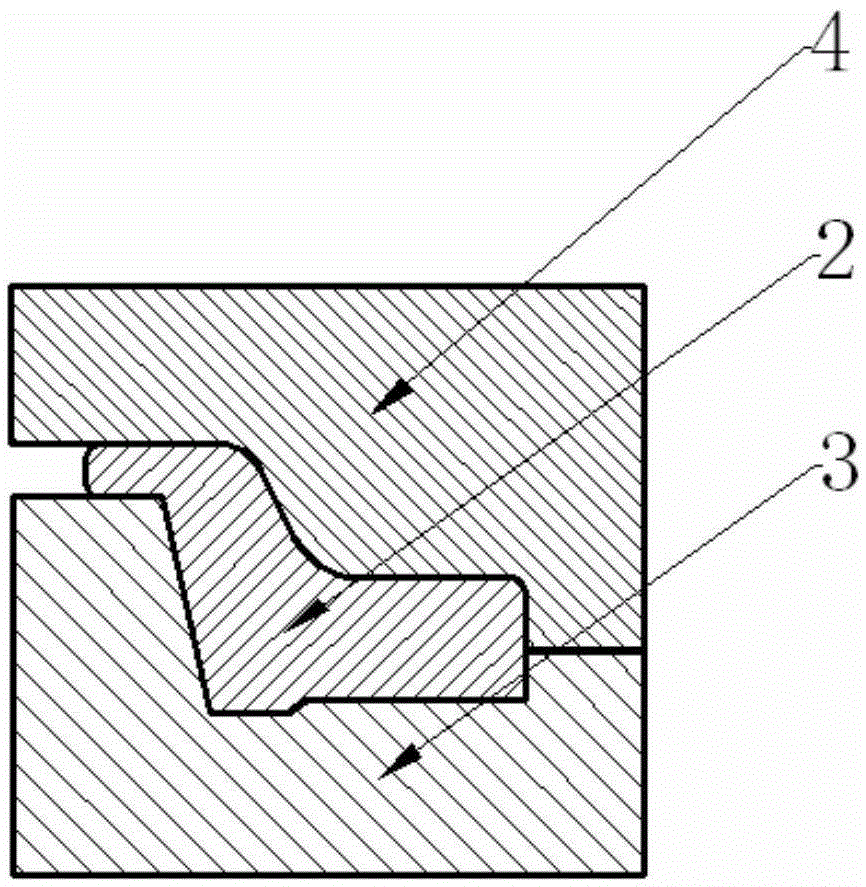

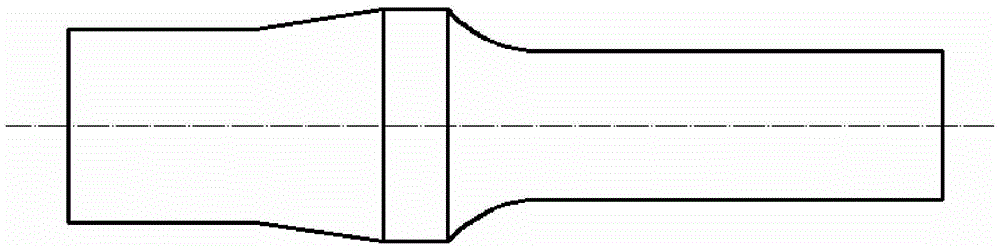

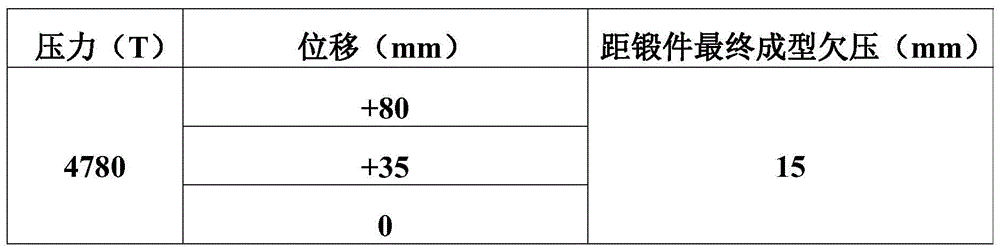

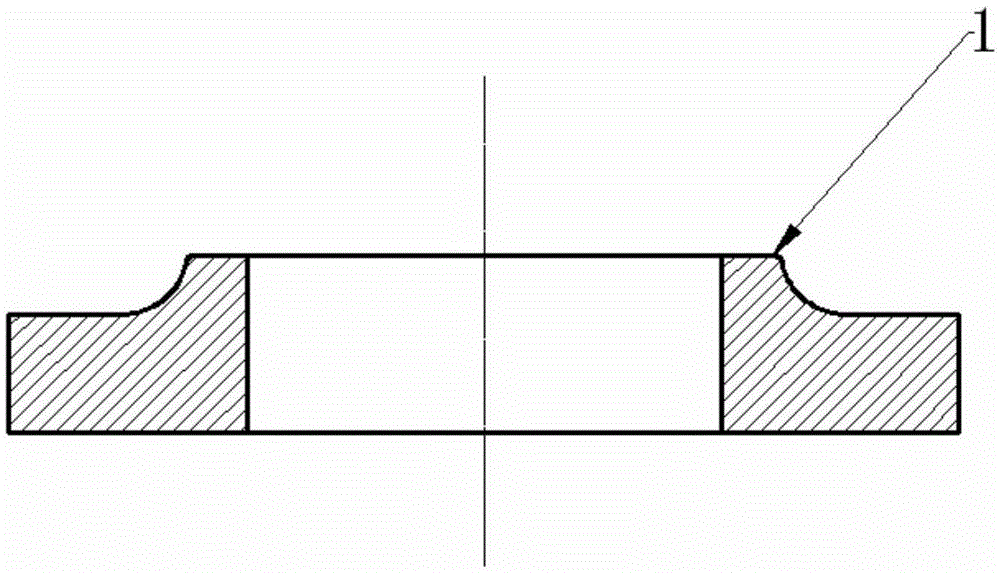

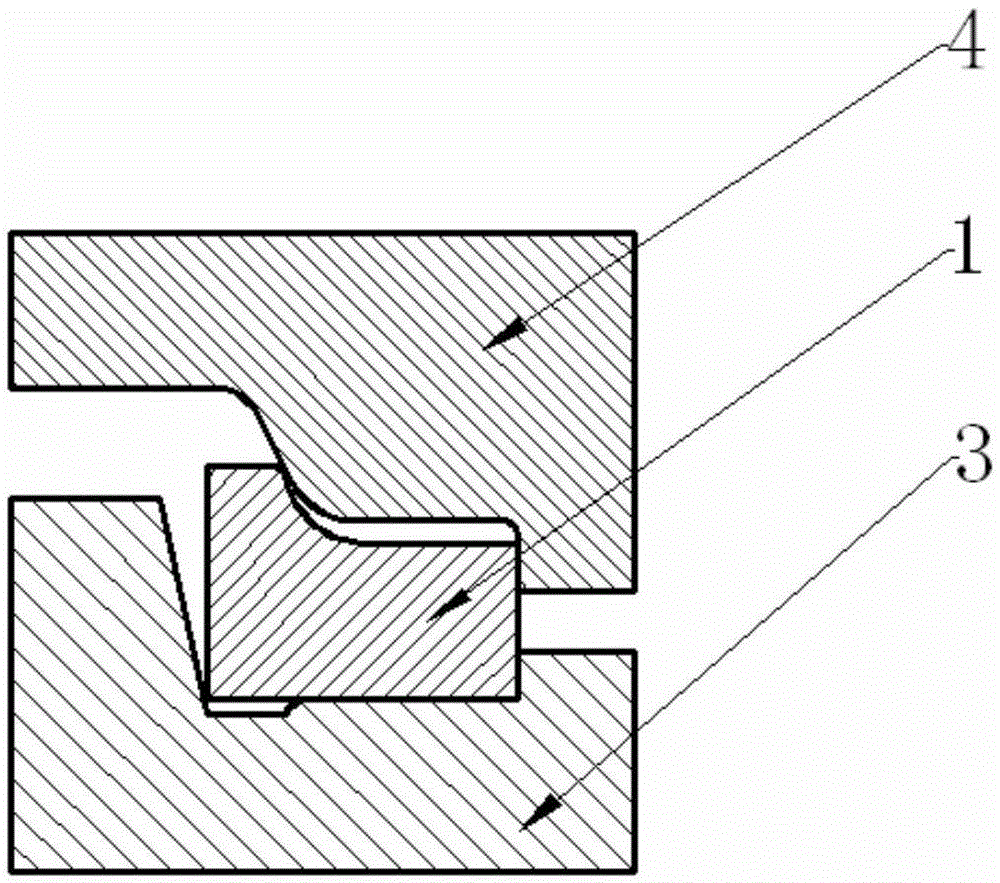

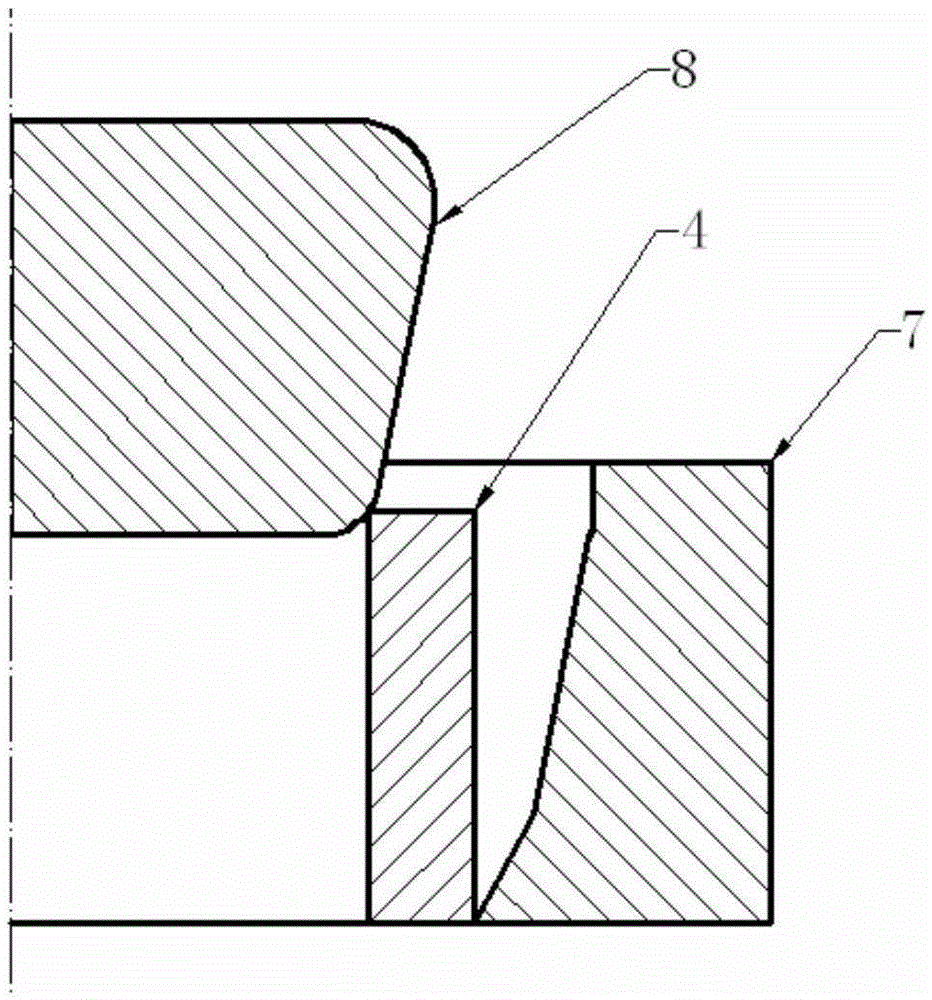

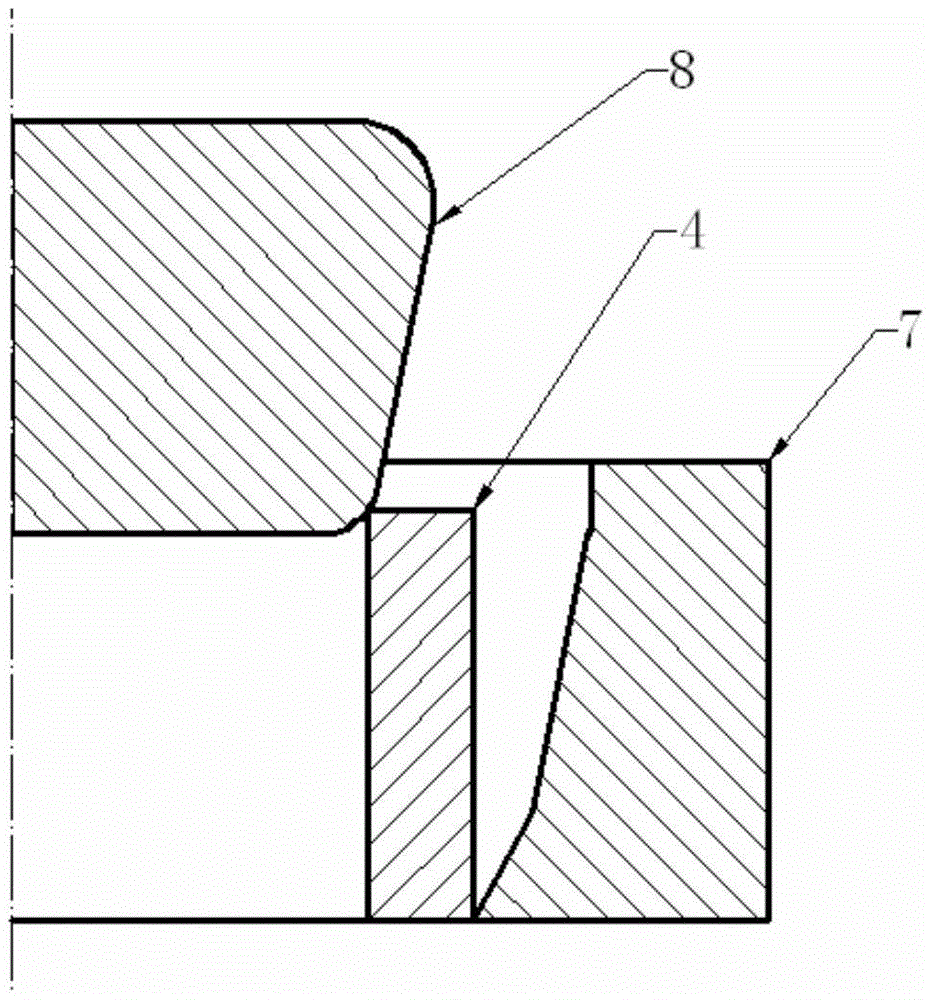

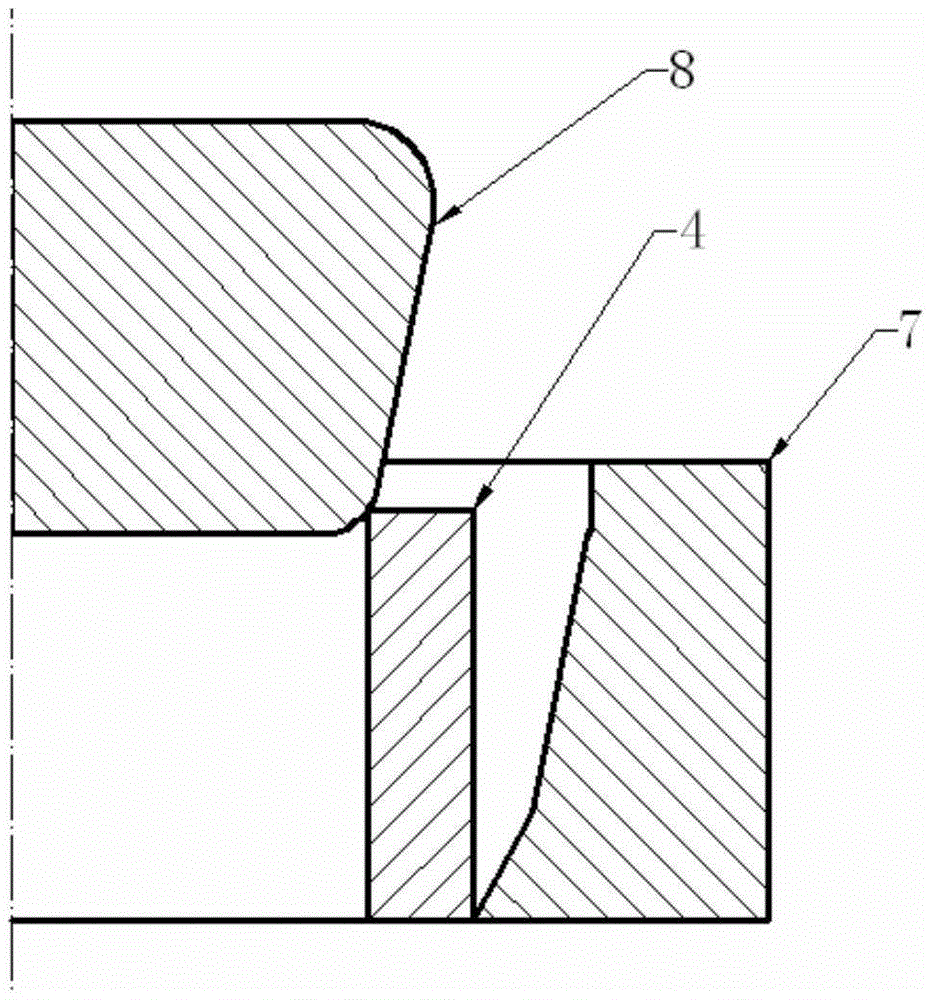

Forming method of large GH4169 alloy die forging

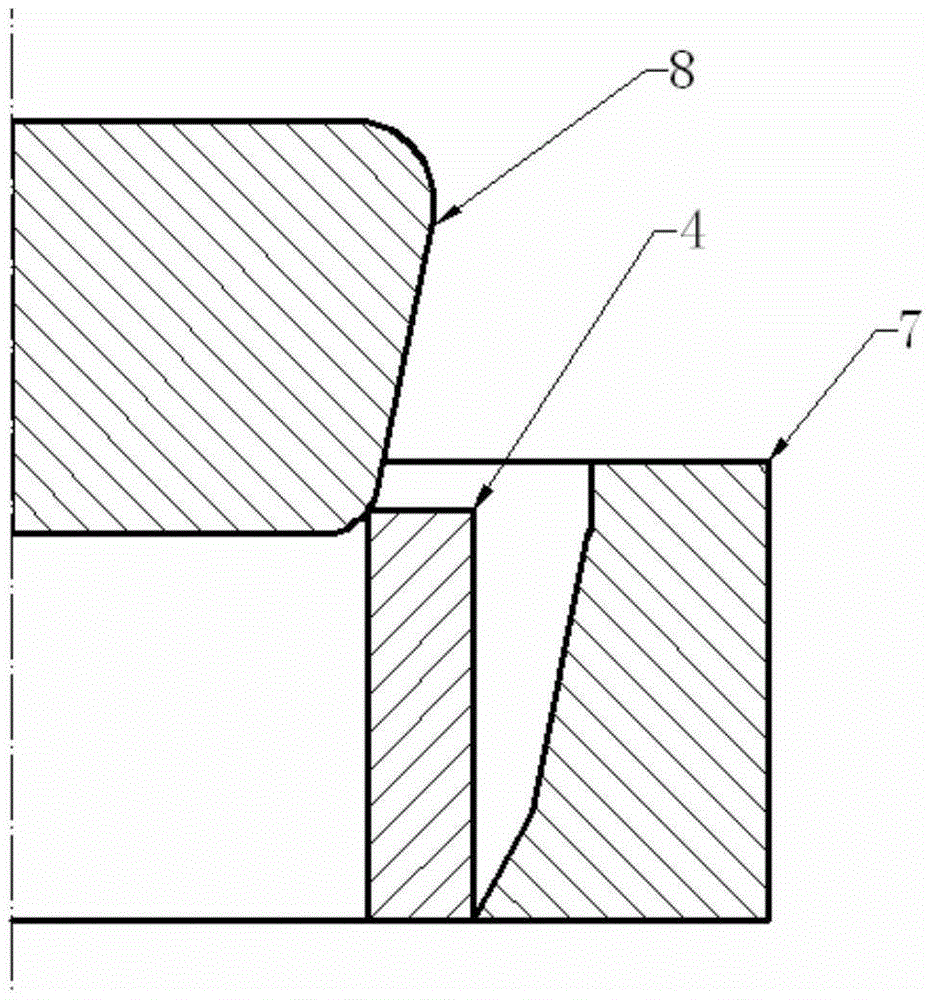

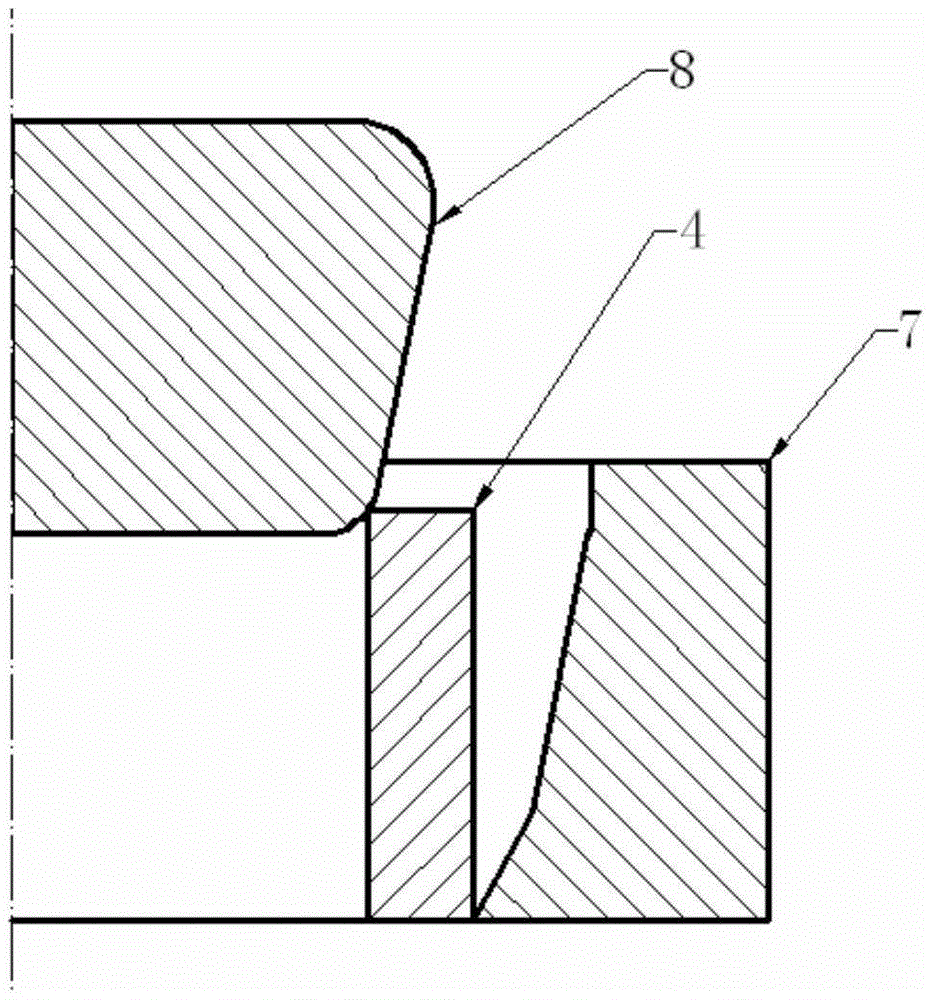

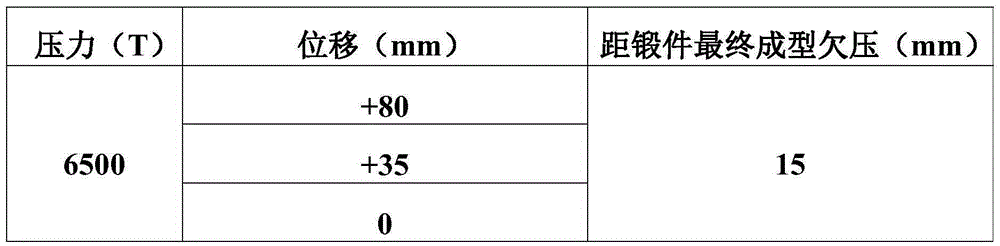

InactiveCN105397004ARealize formingImprove forming qualityMetal-working apparatusWheelsAlloyLubricant

The invention discloses a forming method of a large GH4169 alloy die forging. The method comprises the following steps: heating a GH4169 alloy bar material; upsetting and punching; then rolling to obtain a rectangular ring billet; transferring the rectangular ring billet into a forming die to forge into an irregular ring billet; placing the irregular ring billet into a forming die cavity which is coated with a lubricant; driving an upper die to downwards press at the speed of being not less than 1.5mm / s, so as to form the forging. With the adoption of the method, the large GH4169 alloy die forging can be effectively formed; a shoulder part of a small head of the forging can be completely filled, and thus the forming quality of the large GH4169 alloy die forging can be improved. The method is applied to the formation of the large GH4169 alloy die forging.

Owner:GUIZHOU ANDA AVIATION FORGING

Forming method for aluminum alloy multi-step large special-shaped ring

The invention discloses a forming method for an aluminum alloy multi-step large special-shaped ring. The forming method comprises the following steps: firstly, adopting drawing software to assist the preparation of an intermediate ring blank, and putting the intermediate ring blank in a ring rolling mill for rolling; during rolling, elevating a worktable top where the intermediate ring blank is located by 5mm-10mm to enable a main roller to contact with a lower end of the intermediate ring blank firstly and guarantee the filling of a die cavity with a metal material starting from bottom to top, thereby gradually completing the formation of all the steps, and then bulging the rolled multi-step large special-shaped ring. Such a method is capable of forming the multi-step large special-shaped ring, and also capable of effectively avoiding a phenomena of rib deviation or rib crossing during the formation of the multi-step large special-shaped ring, thereby improving the properties of the forging. The method is suitable for the formation of the aluminum alloy multi-step large special-shaped rings.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for formation of beta-phase titanium alloy multi-step large profiled ring

InactiveCN105363973AOvercoming the difficulty of forming with many sudden changes in the cross-sectionConsistent cross-sectional areaMetal rollingBeta phaseTitanium alloy

The invention discloses a method for the formation of a beta-phase titanium alloy multi-step large profiled ring. The method comprises the following steps: firstly, adopting cartographic software for assisted preparation of an intermediate ring blank, placing the intermediate ring blank into a ring rolling mill for rolling, during rolling, lifting up a working table on which the intermediate ring blank is positioned for 5 mm to 10 mm, so as to enable a main roller to be in contact with the lower end of the intermediate ring blank firstly, ensuring that a metal material starts to fill a die cavity from the bottom to the top, gradually accomplishing the formation of all steps, and then carrying out bulging to the rolled multi-step large profiled ring. Due to the adoption of the method, the multi-step large profiled ring is achieved, and the phenomenon of rib deviation or rib stringing occurred during the formation of the multi-step large profiled ring can be effectively avoided, therefore, the performance of a forge piece is improved. The method provided by the invention is applicable to the formation of the beta-phase titanium alloy multi-step large profiled ring.

Owner:GUIZHOU ANDA AVIATION FORGING

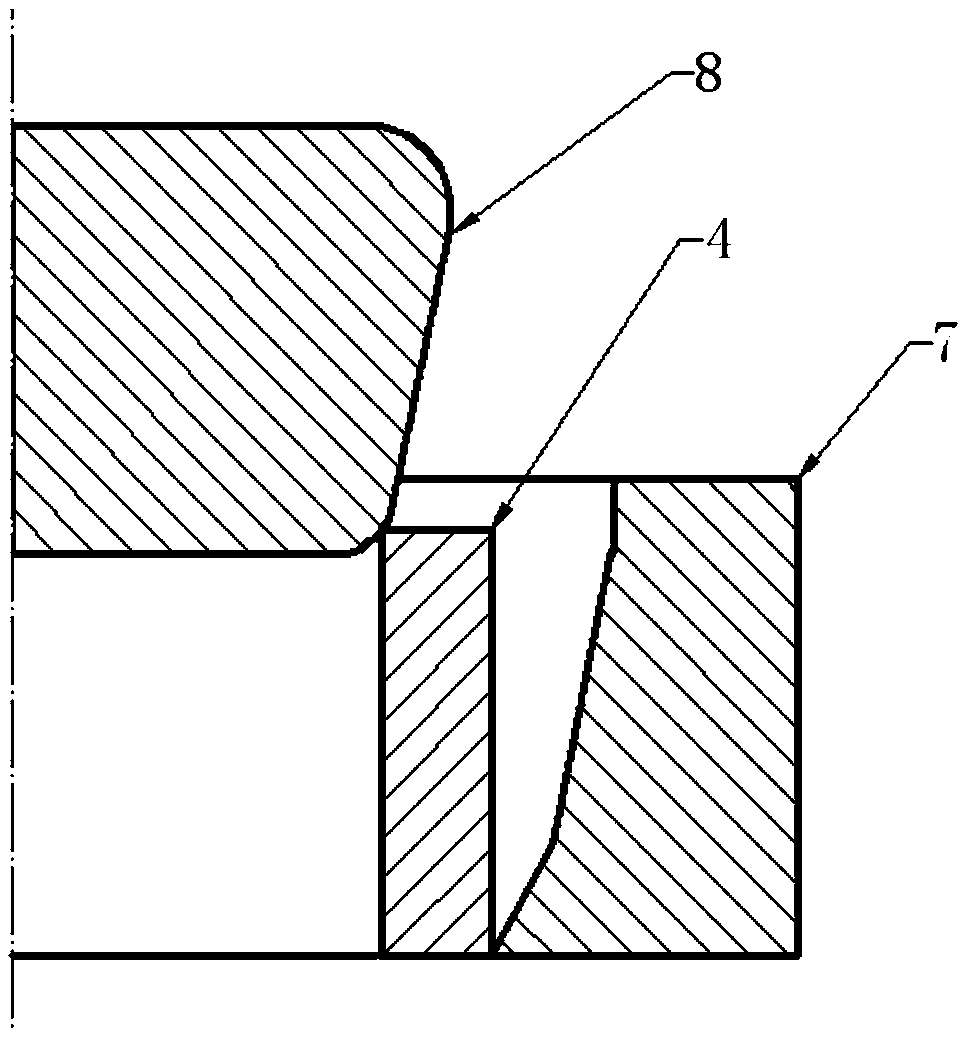

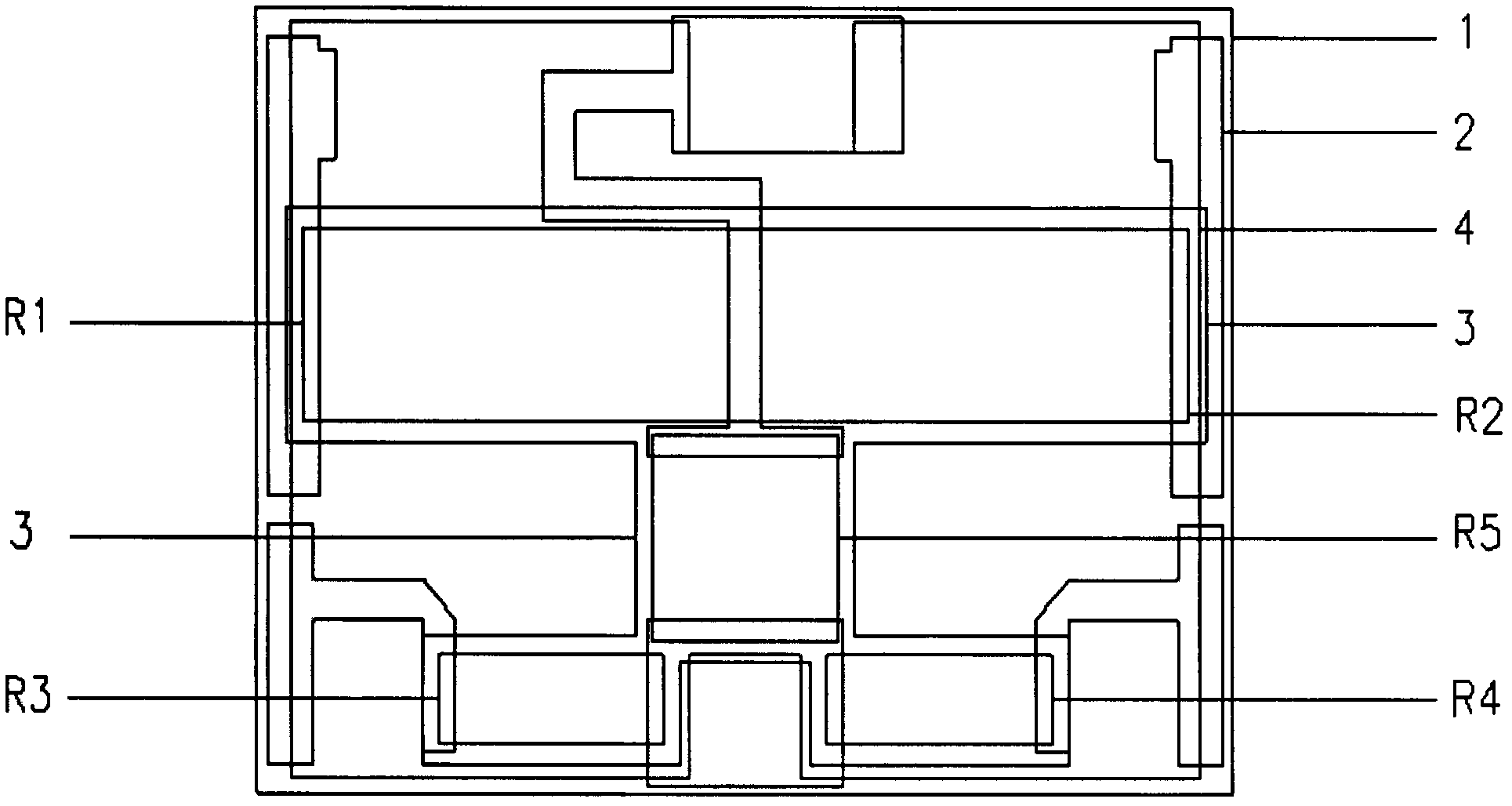

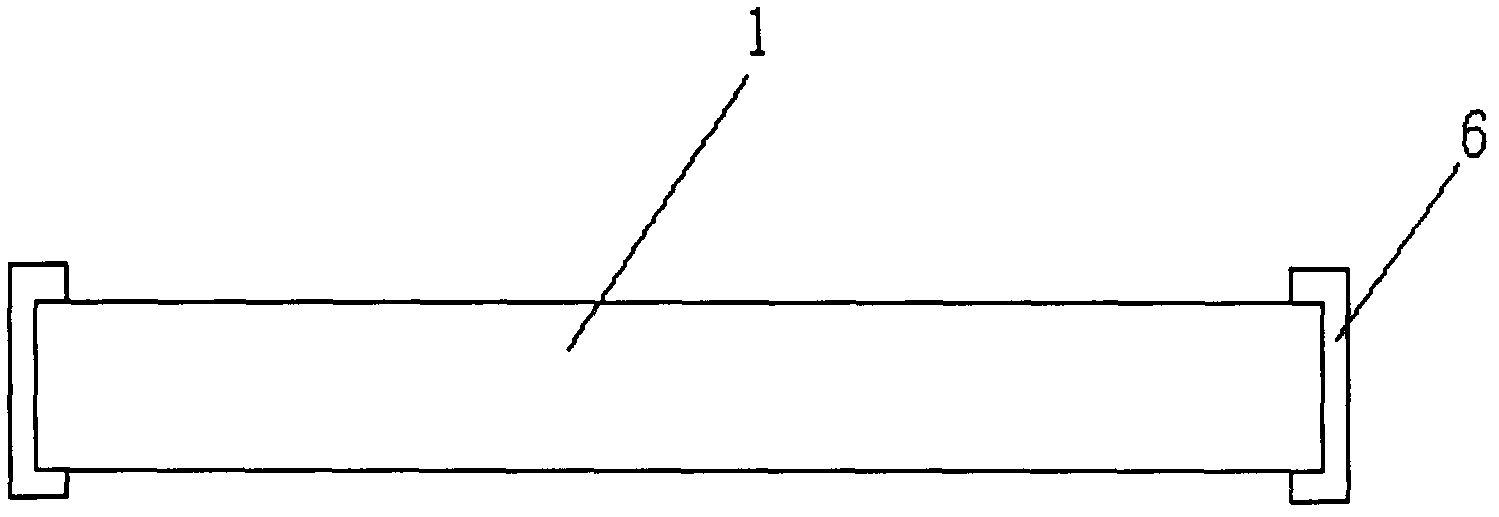

Large-power 100 W-9 dB attenuation sheet with aluminum nitride ceramic substrate

InactiveCN102361132AIncreased high and low temperature impact resistanceSimple designWaveguide type devicesPerformance indexCeramic substrate

The invention discloses a large-power 100 W-9 dB attenuation sheet with an aluminum nitride ceramic substrate. The sheet comprises an aluminum nitride substrate, wherein a conductor layer is printed at the back side of the aluminum nitride substrate; a plurality of resistors and silver paste lead wires are printed at the front side of the aluminum nitride substrate; the silver paste lead wires are connected with the resistors to form an attenuation circuit; and glass protective films are printed on the resistors. The needed attenuation value is obtained by changing the size of resistance value and surface resistivity in the attenuation circuit and good stationary wave properties can be obtained through the design of the lead wires. According to the large-power 100 W-9 dB attenuation sheet with the aluminum nitride ceramic substrate provided by the invention, the area of the resistors is enlarged, the high and low temperature impact resistance of the attenuation sheet is increased and the performance indexes of products meet the requirements. Meanwhile, the quenching damages to the resistors at a high temperature when an output end is welded with the lead wires are avoided, the risk of damaging the resistors in the actual use process due to quenching the resistors is avoided, the design of the circuit is improved, the attenuation precision reaches 9+ / -0.8 dB within 3 G (Gigabyte) and the standing wave satisfies the market demand, so that the products can be applied to 3G (The 3rd Generation Telecommunication) networks.

Owner:苏州市新诚氏通讯电子股份有限公司

Molding method for multistep large profiled ring made of iron-based high-temperature alloy

InactiveCN105499448AOvercoming more cross-sectional mutation areasConsistent cross-sectional areaMetal rollingForgingSoftware

The invention discloses a molding method for a multistep large profiled ring made of an iron-based high-temperature alloy. The molding method comprises the steps of preparing an intermediate ring blank under the assist of drawing software; rolling the intermediate ring blank in a ring rolling mill; during rolling, raising the working face where the intermediate ring blank is located by 5-10mm to ensure that a master roller firstly contacts with the lower end of the intermediate ring blank and a die cavity is started to be filled with a metal material from bottom to top to finish the molding of all steps step by step; and then, bulging the rolled multistep large profiled ring. By using the method, the multistep large profiled ring can be achieved, the rib deviation or jumping phenomenon generated when the multistep large profiled ring is molded can be effectively avoided, and furthermore the performances of forgings are improved. The method is suitable for molding the multistep large profiled ring made of the iron-based high-temperature alloy.

Owner:GUIZHOU ANDA AVIATION FORGING

Forming method for bearing steel multi-step large special-shaped ring

The invention discloses a forming method for a bearing steel multi-step large special-shaped ring. The forming method comprises the following steps: firstly, adopting drawing software to assist the preparation of an intermediate ring blank, and putting the intermediate ring blank in a ring rolling mill for rolling; during rolling, elevating a worktable top where the intermediate ring blank is located by 5mm-10mm to enable a main roller to contact with a lower end of the intermediate ring blank firstly and guarantee the filling of a die cavity with a metal material starting from bottom to top, thereby gradually completing the formation of all the steps, and then bulging the rolled multi-step large special-shaped ring. Such a method is capable of forming the multi-step large special-shaped ring, and also capable of effectively avoiding a phenomena of rib deviation or rib crossing during the formation of the multi-step large special-shaped ring, thereby improving the properties of the forging. The method is suitable for the formation of the bearing steel multi-step large special-shaped rings.

Owner:GUIZHOU ANDA AVIATION FORGING

Isothermal forging forming method of high-temperature alloy complex sheet forging

InactiveCN105397002AImprove forming qualityDimensions are completeMetal-working apparatusMaterial distributionSuperalloy

The invention discloses an isothermal forging forming method of a high-temperature alloy complex sheet forging. The isothermal forging forming method comprises the following steps: firstly, upsetting a blank on a free forging hammer, and then drawing out; controlling the left end of the blank to be unchanged, carrying out material distribution at the position a away from the left end of the blank, drawing out, and then wholly upset-extruding the blank; then drawing out the left end of the blank, and shaping to prepare an intermediate billet; and finally, carrying out isothermal forging forming on the intermediate billet. The isothermal forging forming method can effectively realize forging forming of the high-temperature alloy complex sheet forging, improves the forming quality of the high-temperature alloy complex sheet forging and is used for isothermal forging forming of the high-temperature alloy complex sheet forging.

Owner:GUIZHOU ANDA AVIATION FORGING

Isothermal forging forming method for clamping plate forge piece made of 2024 aluminum matrix composite

InactiveCN105478642AImprove forming qualityDimensions are completeMetal-working apparatusMaterial distributionIsothermal forging

The invention discloses an isothermal forging forming method for a clamping plate forge piece made of a 2024 aluminum matrix composite. The method includes the steps that firstly, a blank on a free forging hammer is upset and then drawn out; secondly, the left end of the blank is controlled to be unchanged, material distribution and drawing out are conducted on the position a away from the left end of the blank, and then the blank is upset-extruded overall; thirdly, the left end of the blank is draw out and shaped, and an intermediate blank is obtained; and finally, isothermal forging forming is conducted on the intermediate blank. By the adoption of the method, the clamping plate forge piece made of the 2024 aluminum matrix composite can be forged and formed effectively, and the forming quality of the clamping plate forge piece made of the 2024 aluminum matrix composite is improved; and the method is used for isothermal forging forming of the clamping plate forge piece of the 2024 aluminum matrix composite.

Owner:GUIZHOU ANDA AVIATION FORGING

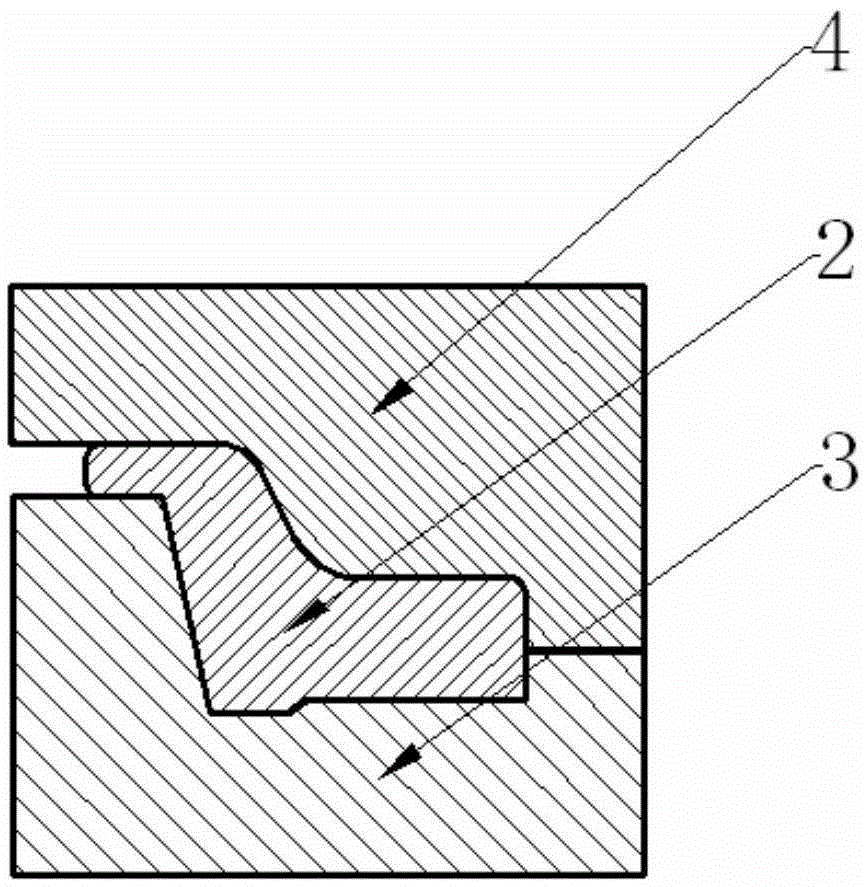

Forming method of large TC4 alloy die forging

The invention discloses a forming method of a large TC4 alloy die forging. The method comprises the following steps: heating a TC4 alloy bar material; upsetting and punching; then rolling to obtain a rectangular ring billet; transferring the rectangular ring billet into a forming die to forge into an irregular ring billet; placing the irregular ring billet into a forming die cavity which iscoated with a lubricant; driving an upper die to downwards press at the speed of being not less than 2mm / s, so as to form the forging. With the adoption of the method, the large TC4 alloy die forging can be effectively formed; a shoulder part of a small head of the forging can be completely filled, and thus the forming quality of the large TC4 alloy die forging can be improved. The method is applied to the formation of the large TC4 alloy die forging.

Owner:GUIZHOU ANDA AVIATION FORGING

Forming method for large special-shaped alpha-phase titanium alloy multi-step ring piece

InactiveCN105382158AConsistent cross-sectional areaPrevent roll climbMetal rollingTitanium alloyMetal

The invention discloses a forming method for a large special-shaped alpha-phase titanium alloy multi-step ring piece. The forming method includes the steps that an intermediate ring billet is manufactured through the assistance of graphics software, and the intermediate ring billet is placed in a looping mill to be rolled; in the rolling process, a working table top where the intermediate ring billet is located is lifted by 5-10 mm to enable a main roller to make contact with the lower end of the intermediate ring billet firstly, and it is guaranteed that a mold cavity starts to be filled with metal materials from bottom to top to complete forming of all steps gradually; and then the rolled large special-shaped multi-step ring piece is subjected to bulging. By means of the method, the large special-shaped multi-step ring piece can be formed, the rib deviating or rib crossing phenomenon in forming of the large special-shaped multi-step ring piece can be effectively avoided, and therefore the performance of the forged piece is improved. The method is suitable for forming of the large special-shaped alpha-phase titanium alloy multi-step ring piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Forming method for large special-shaped multi-step stainless steel ring piece

InactiveCN105414418AOvercoming the difficulty of forming with many sudden changes in the cross-sectionConsistent cross-sectional areaMetal rollingAbnormal shapedForge

The invention discloses a forming method for a large special-shaped multi-step stainless steel ring piece. The method includes the steps that drawing software is adopted to assist in manufacturing a middle ring blank, the middle ring blank is put into a ring rolling mill to be rolled, in the rolling process, the workbench face where the middle ring blank is located is lifted up by 5 mm to 10 mm so that a main roller can firstly make contact with the lower end of the middle ring blank, it is guaranteed that a die cavity is filled with a metal material from bottom to top, and forming of all steps is gradually finished; and bulging is conducted on the rolled large special-shaped multi-step ring piece. The large special-shaped multi-step ring piece can be manufactured through the method, and the rib deviation or rib mess phenomenon can be effectively avoided when the large special-shaped multi-step ring piece is formed, so that the performance of forge pieces is improved. The method is suitable for forming of the large special-shaped multi-step stainless steel ring piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Rolling and heat treatment method for 6061 aluminum alloy ring part

The invention discloses a rolling and heat treatment method for a 6061 aluminum alloy ring part. The rolling and heat treatment method comprises the following steps: firstly, taking a 6061 aluminum alloy bar of a certain specification, heating the 6061 aluminum alloy bar until a deformation temperature, and then carrying out upsetting, punching, pre-rolling and finish rolling, thereby obtaining the 6061 aluminum alloy ring part, wherein the deflection of pre-rolling is 25%-30% and the deflection of finish rolling is 30%-40%; and further, carrying out heat treatment by using a heat treatment system that has a solution temperature at 535 DEG C and an aging temperature at 162 DEG C by preserving heat for more than 5 hours, and preserves heat for 8-10 hours. The method is capable of improving the forming quality of the ring part and avoiding a mixed crystal phenomenon. The method is used for the rolling and het treatment of the 6061 aluminum alloy ring parts.

Owner:GUIZHOU ANDA AVIATION FORGING

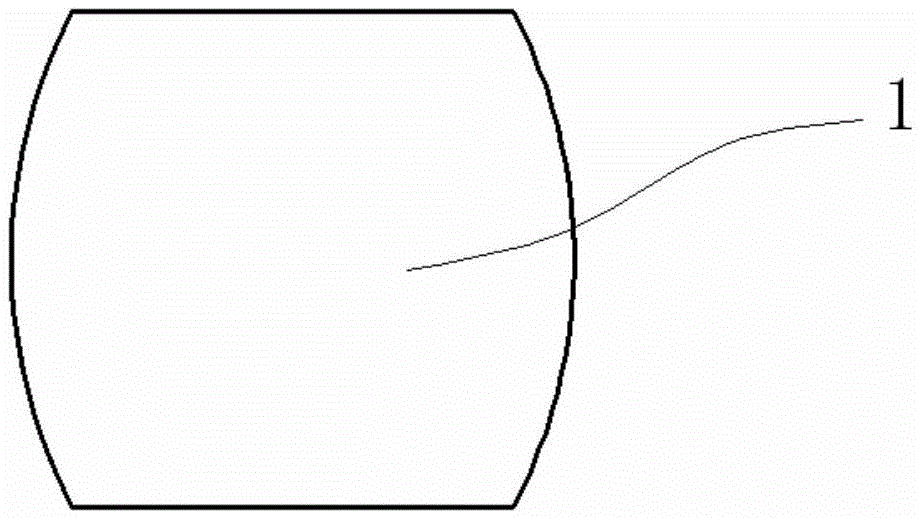

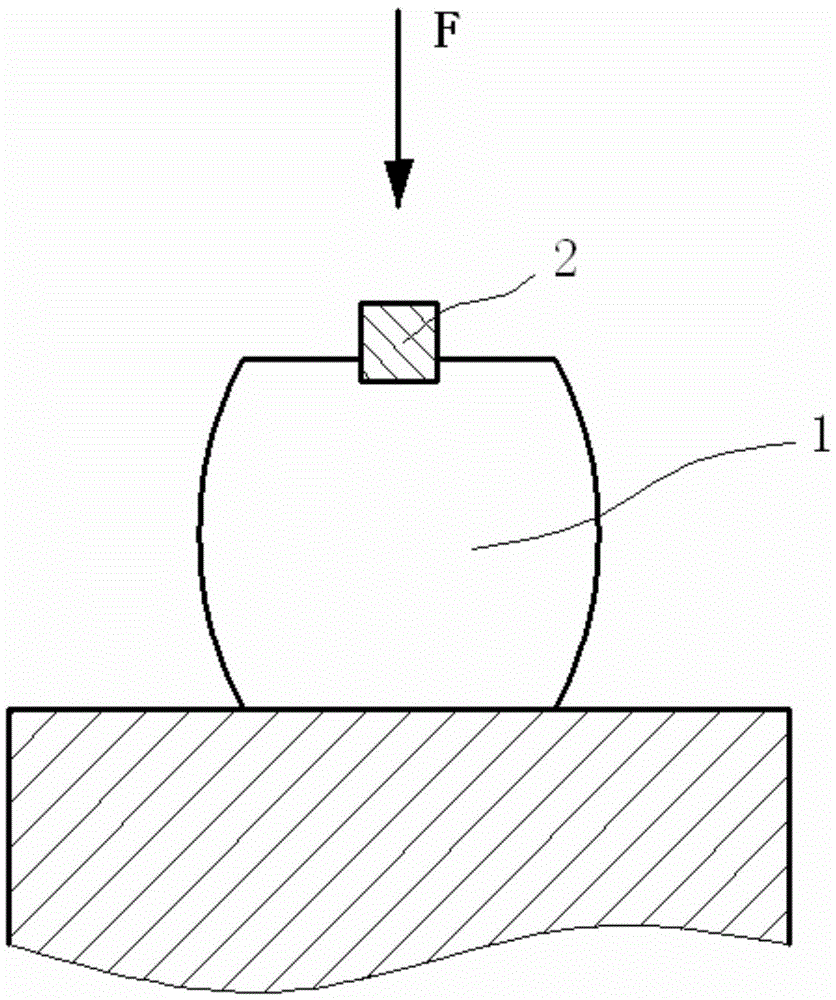

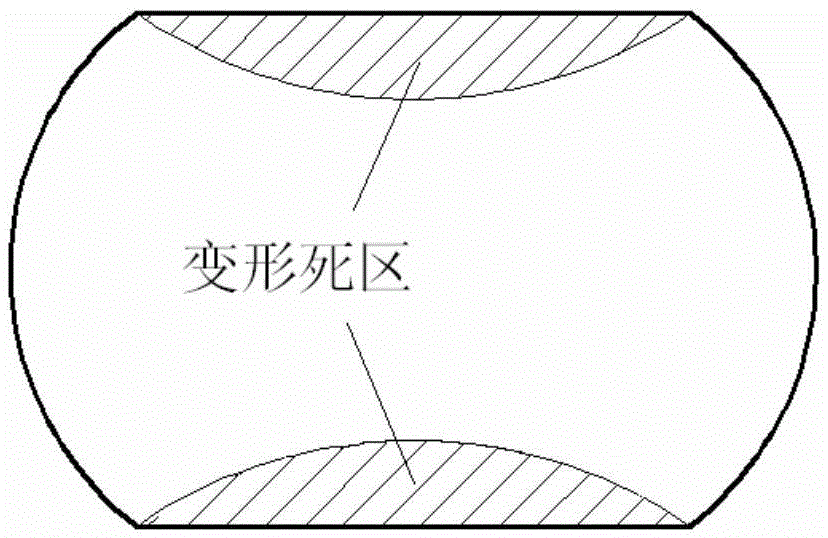

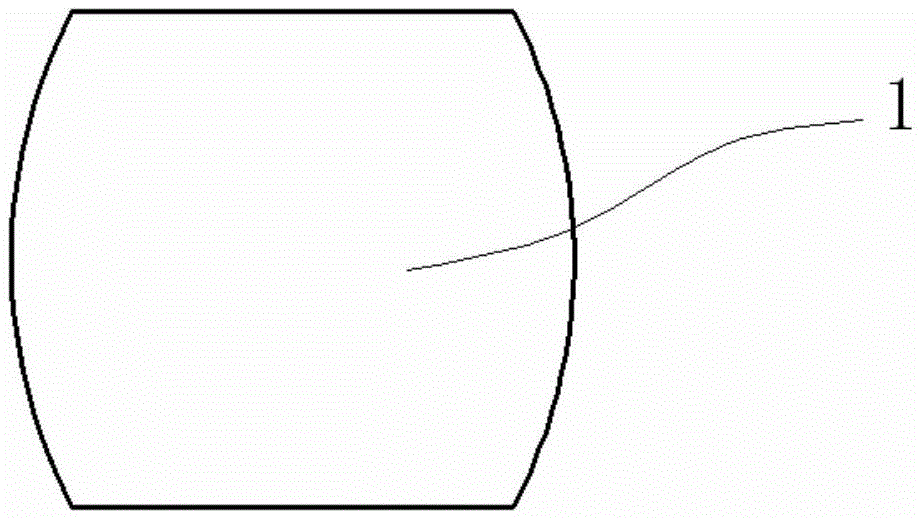

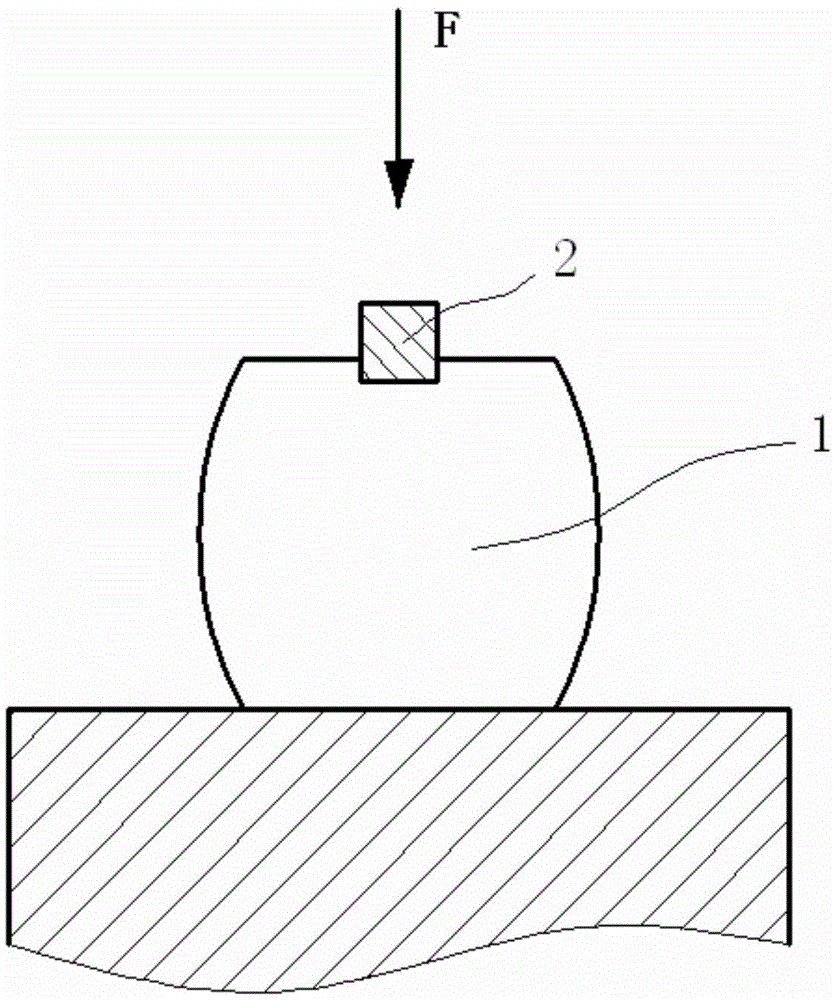

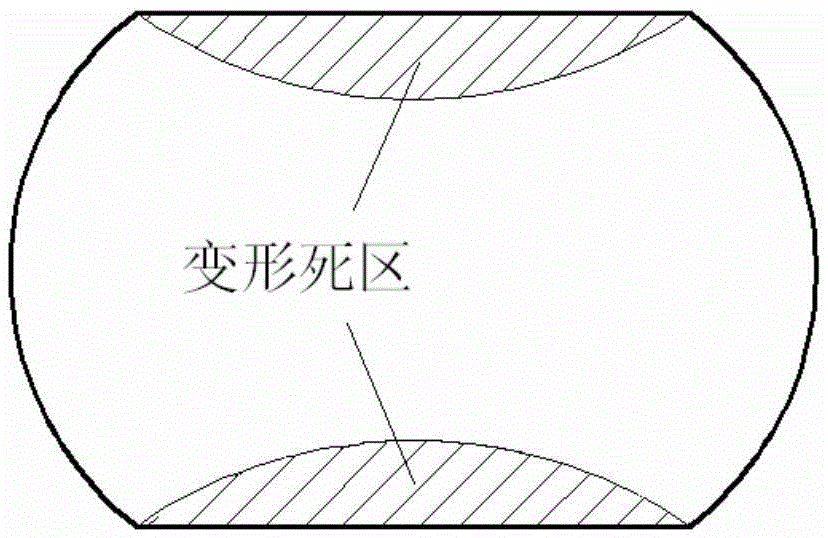

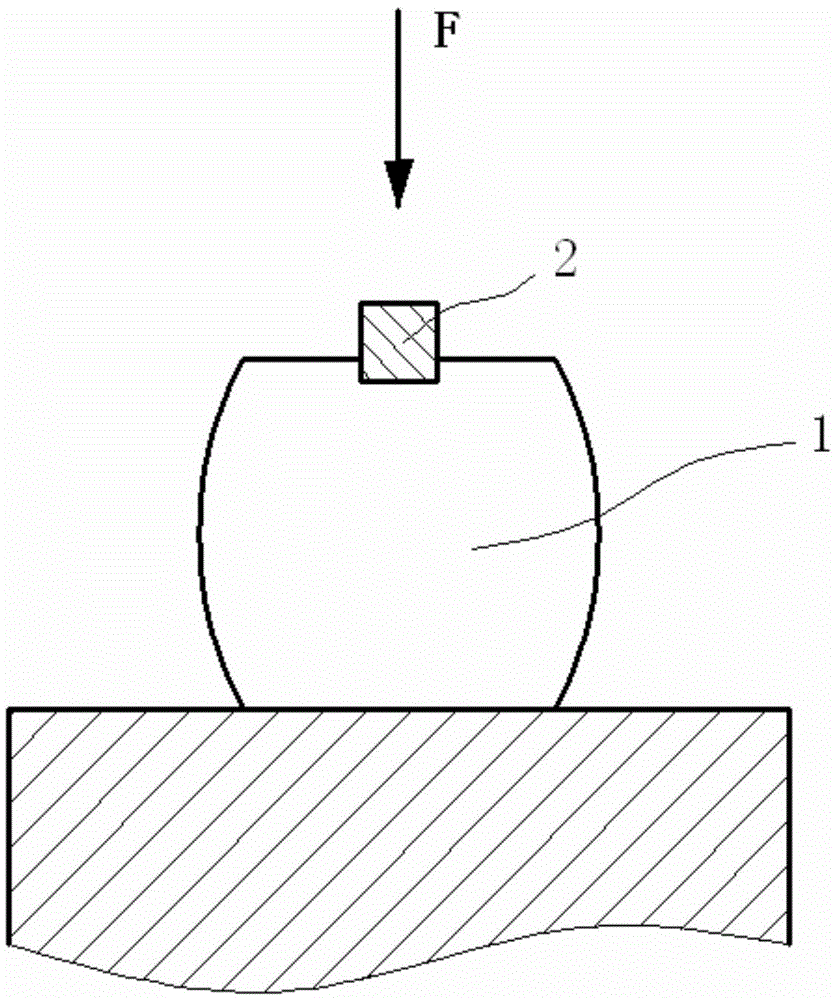

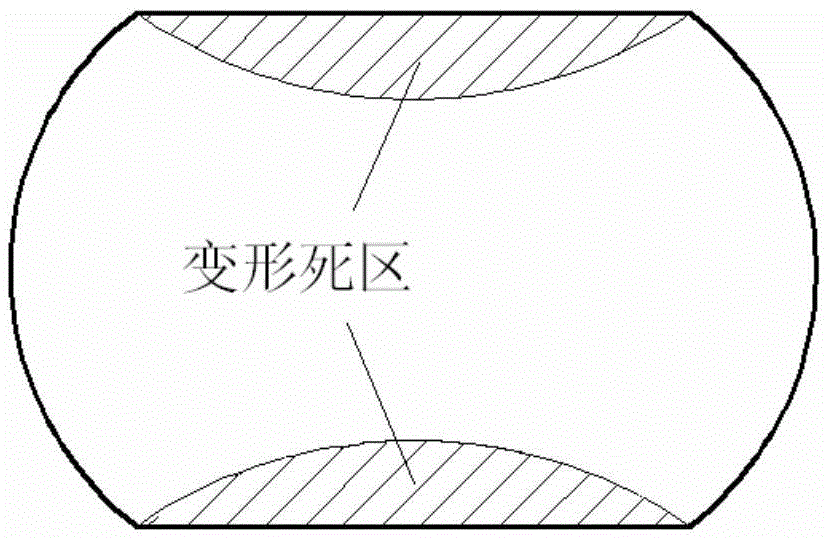

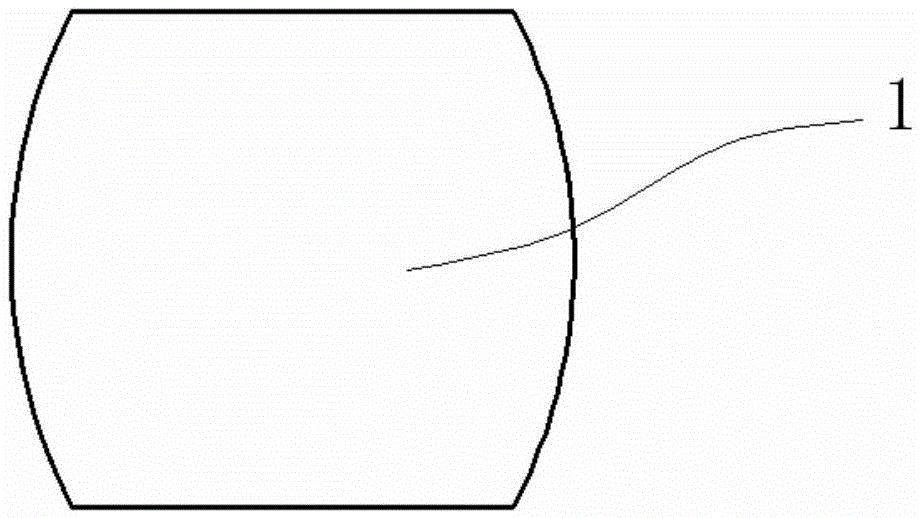

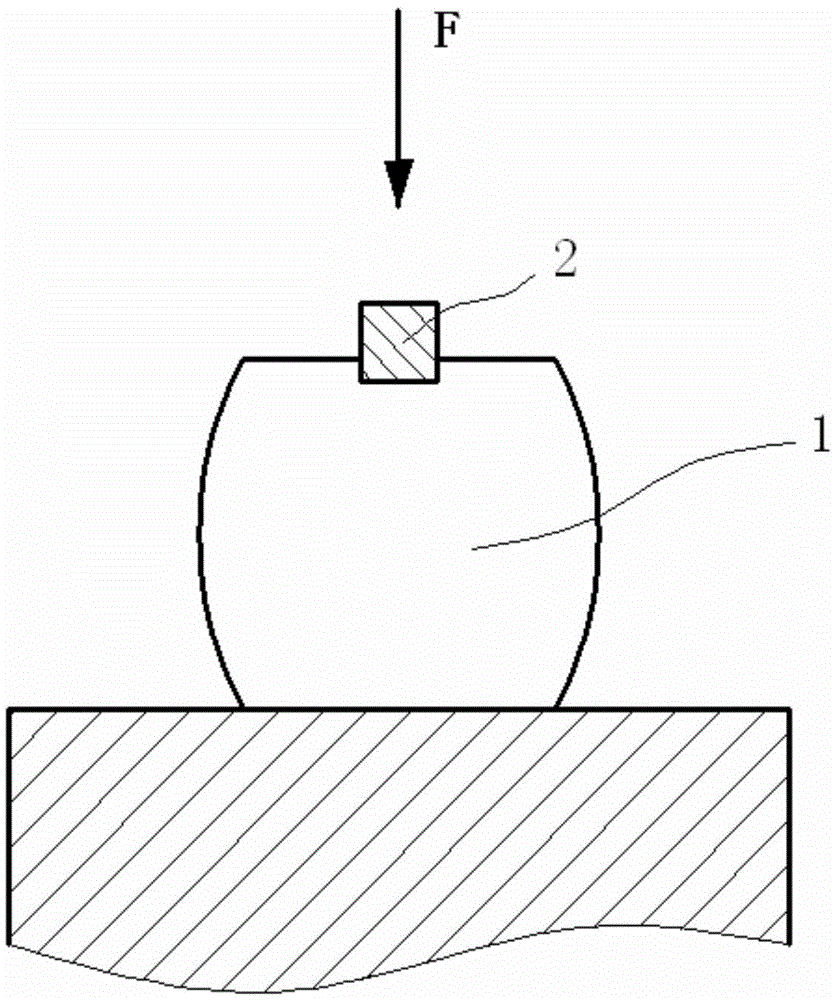

Upsetting method of alpha-beta-phase titanium alloy cake blank

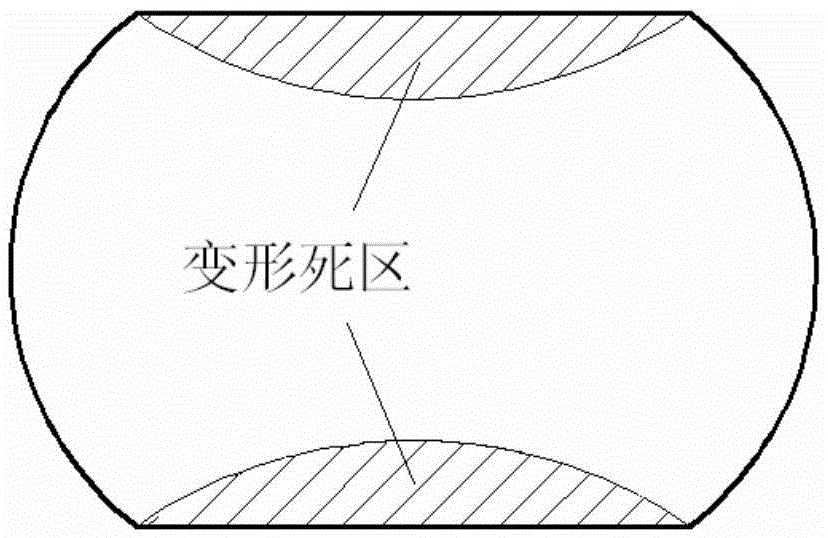

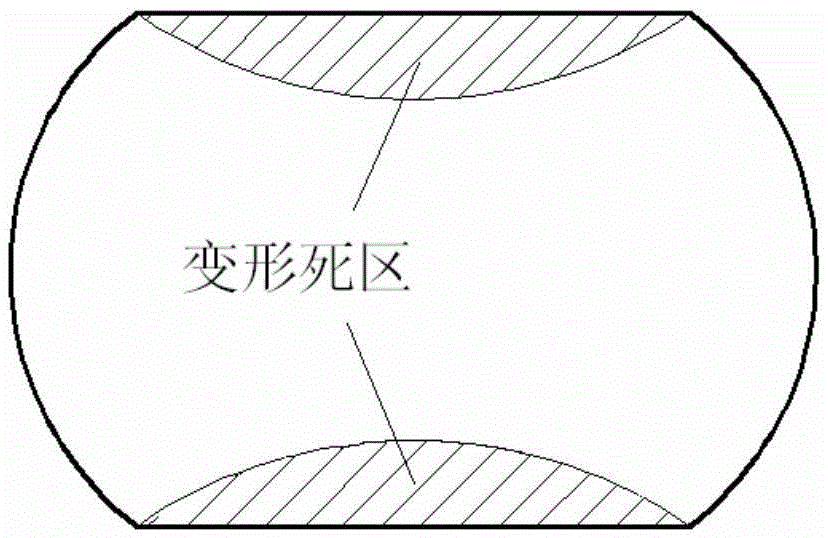

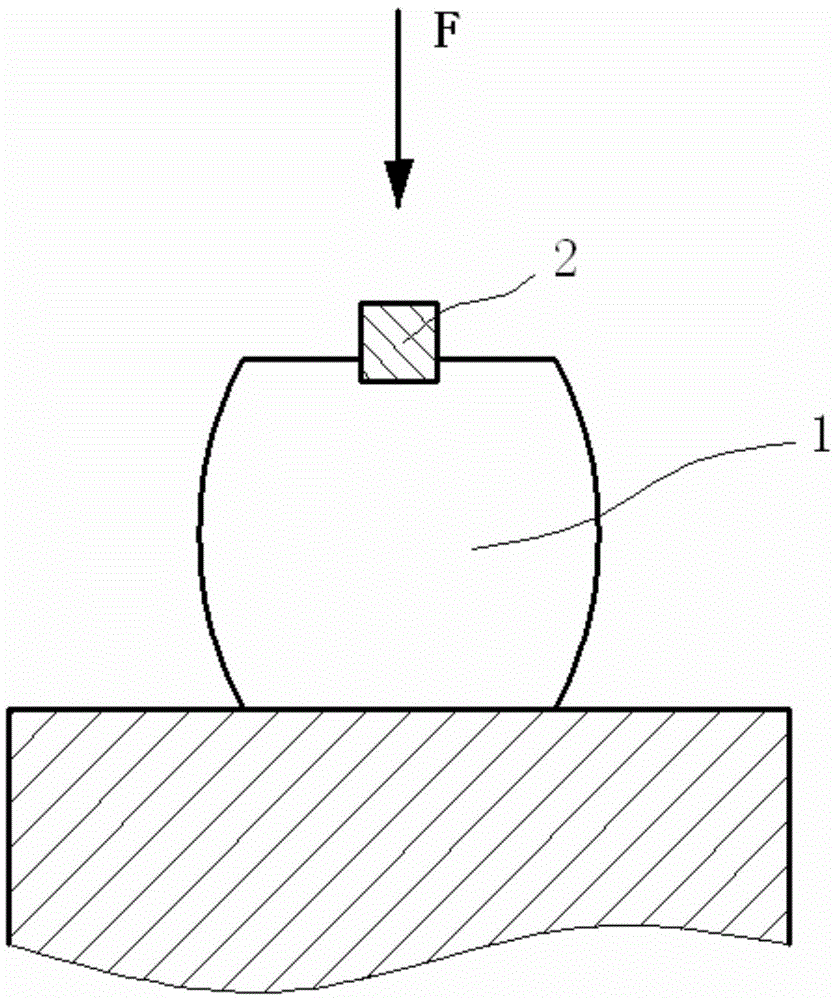

InactiveCN105522090AUniform deformationThere is no deformation dead zoneMetal-working apparatusBeta phaseTitanium alloy

The invention discloses an upsetting method of an alpha-beta-phase titanium alloy cake blank. The upsetting method comprises the following steps: at first, an alpha-beta-phase titanium alloy bar is upset in a conventional method, so as to enable the deformation of the alpha-beta-phase titanium alloy bar to be up to 25% to 35%; and the end surface of a middle cake blank is locally deformed by a dedicated tool. The upsetting method has the advantages that defects such as deformation dead zones generated in a conventional upsetting method can be eliminated effectively, and the structure homogeneity of the alpha-beta-phase titanium alloy cake blank can be improved effectively, so that the performance of a forging is improved. The upsetting method is used for upsetting the alpha-beta-phase titanium alloy cake blank.

Owner:GUIZHOU ANDA AVIATION FORGING

Forming method for large special-shaped alpha-beta two-phase titanium alloy multi-step ring piece

InactiveCN105382159AOvercoming the difficulty of forming with many sudden changes in the cross-sectionPrevent roll climbMetal rollingTitanium alloyMetal

The invention discloses a forming method for a large special-shaped alpha-beta two-phase titanium alloy multi-step ring piece. The forming method includes the steps that an intermediate ring billet is manufactured through the assistance of graphics software, and the intermediate ring billet is placed in a looping mill to be rolled; in the rolling process, a working table top where the intermediate ring billet is located is lifted by 5-10 mm to enable a main roller to make contact with the lower end of the intermediate ring billet firstly, and it is guaranteed that a mold cavity starts to be filled with metal materials from bottom to top to complete forming of all steps gradually; and then the rolled large special-shaped multi-step ring piece is subjected to bulging. By means of the method, the large special-shaped multi-step ring piece can be formed, the rib deviating or rib crossing phenomenon in forming of the large special-shaped multi-step ring piece can be effectively avoided, and therefore the performance of the forged piece is improved. The method is suitable for forming of the large special-shaped alpha-beta two-phase titanium alloy multi-step ring piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for forging formation of 16Cr3NiWMoVNbE forge piece

The invention discloses a method for forging formation of a 16Cr3NiWMoVNbE forge piece. The method comprises the following steps: firstly, taking a 16Cr3NiWMoVNbE steel ingot in certain specification, and heating the steel ingot to reach a required temperature according to a certain heating curve; upsetting the steel ingot, wherein during upsetting, the press amount is 40 to 45 mm each time, after each time of pressing, pausing for 3s to 5s is performed; when the press amount reaches 200 to 250 mm, carrying out rolling drawing; upsetting to reach a required size; and then heating the steel ingot for 10 to 15 min to reach a temperature of 1070 DEG C to 1120 DEG C, and rolling for formation after upsetting and punching. Due to the adoption of the method, low magnitude clear crystal on the 16Cr3NiWMoVNbE steel ingot can be avoided, and meanwhile trace elements in alloy can also be homogenized. The method is used for forging formation of the 16Cr3NiWMoVNbE forge piece.

Owner:GUIZHOU ANDA AVIATION FORGING

A high-efficiency and low-cost 610mpa hydropower steel and its production method

InactiveCN106222557BGrain refinementThe performance indicators meet the requirementsSlow coolingPre treatment

The invention discloses high-efficiency and low-cost 610 MPa hydropower steel and a production method thereof. The hydropower steel comprises the following chemical components in percentage by mass: 0.07-0.09% of C, 0.15-0.35% of Si, 1.40-1.60% of Mn, not greater than 0.15% of P, not greater than 0.08% of S, 0.015-0.035% of Nb, 0.030-0.050% of V, 0.008-0.030% of Ti, 0.10-0.30% of Ni, 0.10-0.30% of Mo, and the balance Fe and inevitable impurities. A process route comprises KR hot metal pre-treatment, converter smelting, LF and RH refining, continuous casting, slow cooling, continuous casting blank heating, rolling, cooling, straightening, finishing and tempering. According to the high-efficiency and low-cost 610 MPa hydropower steel and the production method thereof, which are disclosed by the invention, a production flow is shortened, energy consumption is reduced, a high-cost limit of a traditional production process is overcome, and the product quality is ensured.

Owner:SHANDONG IRON & STEEL CO LTD

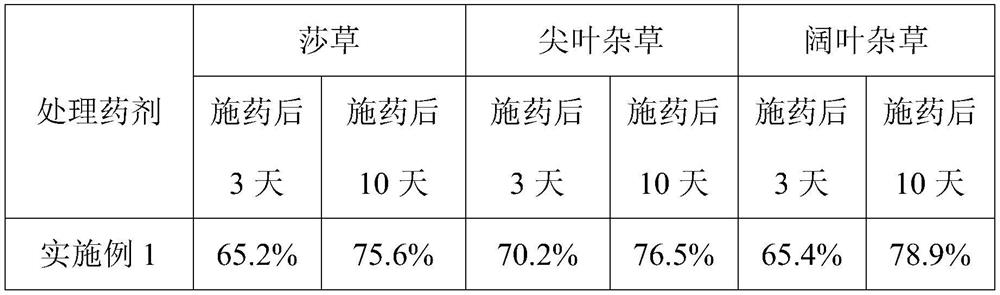

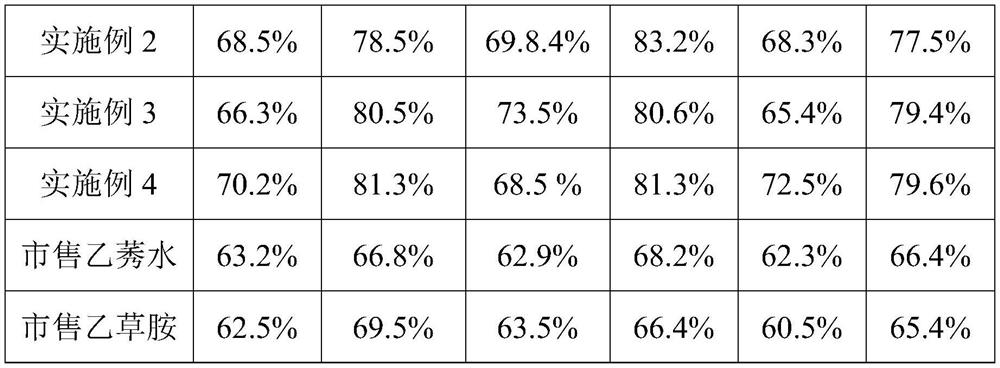

High-stability herbicide for paddy field and preparation method thereof

PendingCN114467951AStore for a long timeReduce usageBiocideAnimal repellantsInorganic saltsBensulfuron methyl

The invention discloses a high-stability herbicide for paddy fields, which is prepared from the following components in percentage by mass: 10 to 15 percent of pyriminobac-methyl, 10 to 12 percent of pretilachlor, 4 to 9 percent of bensulfuron methyl, 5 to 8 percent of inorganic salt, 0.2 to 0.5 percent of sodium dodecyl benzene sulfonate, 0.5 to 2.5 percent of fulvic acid, 0.5 to 1.5 percent of dispersing agent, 0.2 to 0.8 percent of antifreeze agent, 1 to 4 percent of hydrotalcite-like carrier, 0.4 to 1.2 percent of thickening agent, 0.5 to 1 percent of binding agent, 10 to 15 percent of water and the balance of oily solvent, the sum of the mass percentages of the components is 100%. The invention also discloses a preparation method of the herbicide. According to the weeding composition, pyriminobac-methyl, pretilachlor and bensulfuron methyl are used as active components, and after compounding, the pesticide resistance of weeds is slowed down through the synergistic effect of different effective components; in addition, by adding the anti-freezing agent, the thickening agent and the dispersing agent, the stability of the herbicide is improved, and it is guaranteed that all performance indexes meet the requirements within the period of validity.

Owner:华丰作物科技(黑龙江)有限公司

Upsetting method for alpha-phase titanium alloy biscuit

InactiveCN105583339AUniform deformationThere is no deformation dead zoneMetal-working apparatusMetallurgyTitanium alloy

The invention discloses an upsetting method for an alpha-phase titanium alloy biscuit. The upsetting method comprises the steps that an alpha-phase titanium alloy rod is firstly upset according to a conventional method, so that the deformation amount of the rod reaches 24%-32%; and then the end surfaces of a medium biscuit are subjected to partial deformation by using a special fixture. By adopting the upsetting method, the defects of a deformation dead zone and the like in a conventional upsetting method can be effectively eradicated; and the texture uniformity of the alpha-phase titanium alloy biscuit can be effectively improved, so that the performance of a forge piece is improved. The method is applicable to upsetting of the alpha-phase titanium alloy biscuit.

Owner:GUIZHOU ANDA AVIATION FORGING

Upsetting method of cake-shapedstainless steel billet

The invention discloses an upsetting method of a cake-shapedstainless steel billet. The upsetting method comprises the following steps of upsetting a stainless steel bar by a conventional method first such that the deformation of the stainless steel bar reaches 45%-50%; and then locally deforming an end face of an intermediate billet by using a special fixture. Such a method is capable of effectively eliminating defects such as a deformation dead zone occurring in a conventional upsetting method and also capable of effectively improving the structure uniformity of the cake-shapedstainless steel billet, and therefore, the properties of forgings can be improved. The method is applicable to the upsetting of the cake-shapedstainless steel billets.

Owner:GUIZHOU ANDA AVIATION FORGING

Upsetting method of bearing steel cake blank

InactiveCN105522093AUniform deformationImprove forging propertiesMetal-working apparatusForgeMaterials science

The invention discloses an upsetting method of a bearing steel cake blank. The method comprises the following steps: upsetting a bearing steel bar by a conventional method until the deformation of the bearing steel bar reaches 36 to 40%; partially deforming the end surface of a middle cake blank through a special tooling. With the adoption of the method, the defects such as a dead deformation area in the conventional upsetting method can be effectively removed, the structure uniformity of the bearing steel cake blank can be effectively improved, and thus the performance of a forge piece can be improved. The method is applied to the upsetting of the bearing steel cake blank.

Owner:GUIZHOU ANDA AVIATION FORGING

Upsetting method of cobalt-based high-temperature alloy cake blank

InactiveCN105522092AUniform deformationThere is no deformation dead zoneMetal-working apparatusSuperalloyCobalt

The invention discloses an upsetting method of a cobalt-based high-temperature alloy cake blank. The method comprises the following steps: upsetting a cobalt-based high-temperature alloy bar by a conventional method until the deformation of the cobalt-based high-temperature alloy bar reaches 18 to 25%; partially deforming the end surface of a middle cake blank through a special tooling. With the adoption of the method, the defects such as a dead deformation area in the conventional upsetting method can be effectively removed, the structure uniformity of the cobalt-based high-temperature cake blank can be effectively improved, and thus the performance of a forge piece can be improved. The method is applied to the upsetting of the cobalt-based high-temperature alloy cake blank.

Owner:GUIZHOU ANDA AVIATION FORGING

Isothermal forging forming method of 2024 aluminum matrix composite splint forge piece

InactiveCN114260399AImprove forming qualityDimensions are completeMetal-working apparatusIsothermal forgingForge

The invention discloses an isothermal forging forming method of a 2024 aluminum matrix composite splint forge piece, which comprises the following steps of: upsetting a blank on a free forging hammer, and drawing out; the left end of the blank is controlled to be unchanged, the position a away from the left end of the blank is divided and drawn out, and then the whole blank is upset to be flat; the left end of the blank is drawn out and shaped, and an intermediate blank is manufactured; and finally, the intermediate blank is subjected to isothermal forging forming. By means of the method, forging forming of the 2024 aluminum matrix composite clamping plate forge piece can be effectively achieved, and the forming quality of the 2024 aluminum matrix composite clamping plate forge piece is improved. The method is used for isothermal forging forming of the 2024 aluminum matrix composite splint forge piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com