Method for formation of beta-phase titanium alloy multi-step large profiled ring

A special-shaped ring and multi-step technology, applied in the direction of metal rolling, etc., can solve the problems of affecting the forming effect, unreasonable matching between blank and mold, unreasonable blank or mold design, etc., and achieve the effect of overcoming more cross-sectional mutation areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] The main chemical element content (percentage by weight) of the alloy is: 4.7%-5.7% Mo content, 4.7%-5.7% V content, 7.5%-8.5% Cr content, 2.5%-3.5% Al content, Fe content ≤ 0.30%, C content ≤ 0.05, N content ≤ 0.04%, H content 0.015%, O content 0.15%, the balance being Ti, and the sum of other elements ≤ 0.40.

[0033] The steps of this method are as follows:

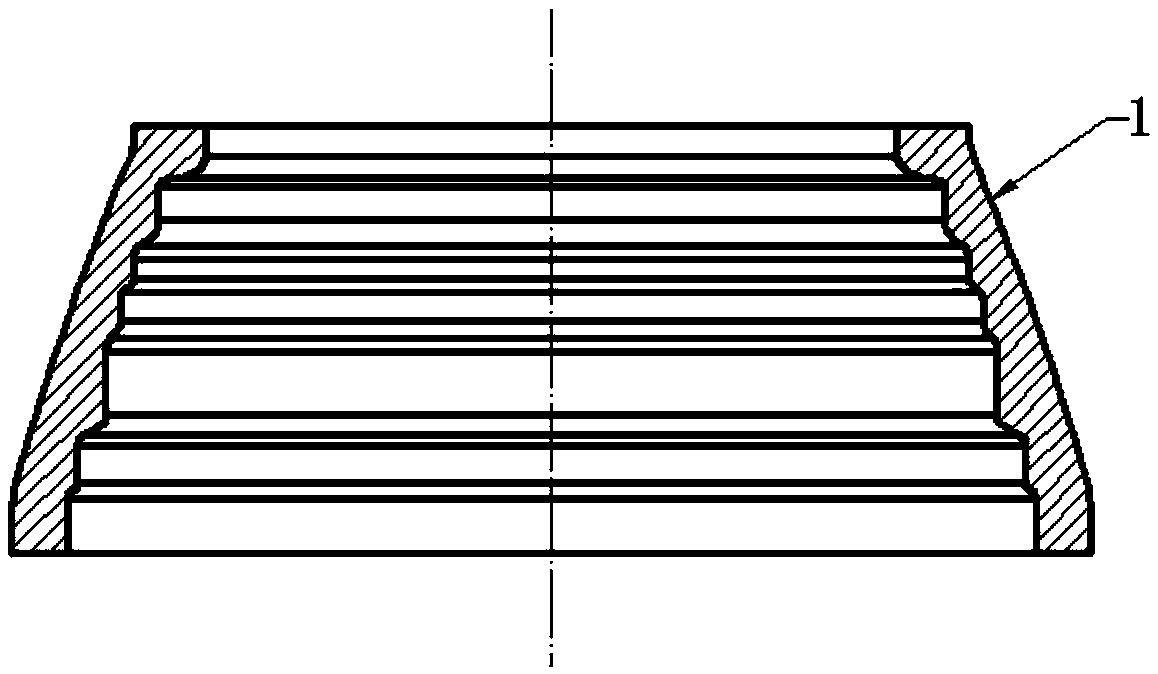

[0034] Step 1: Prepare intermediate ring blank

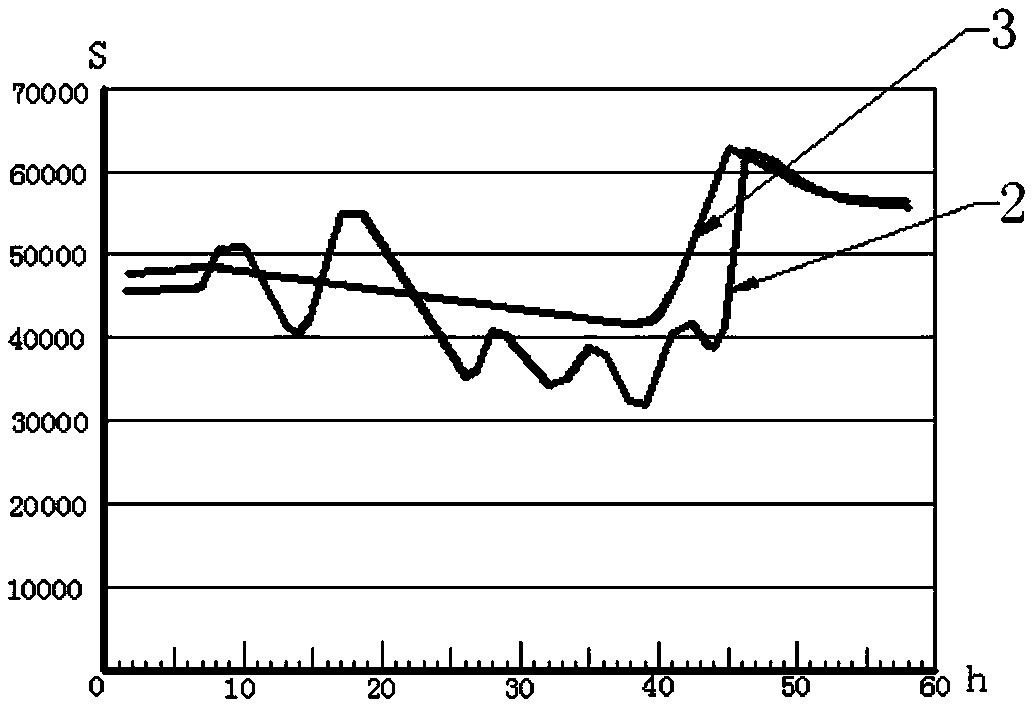

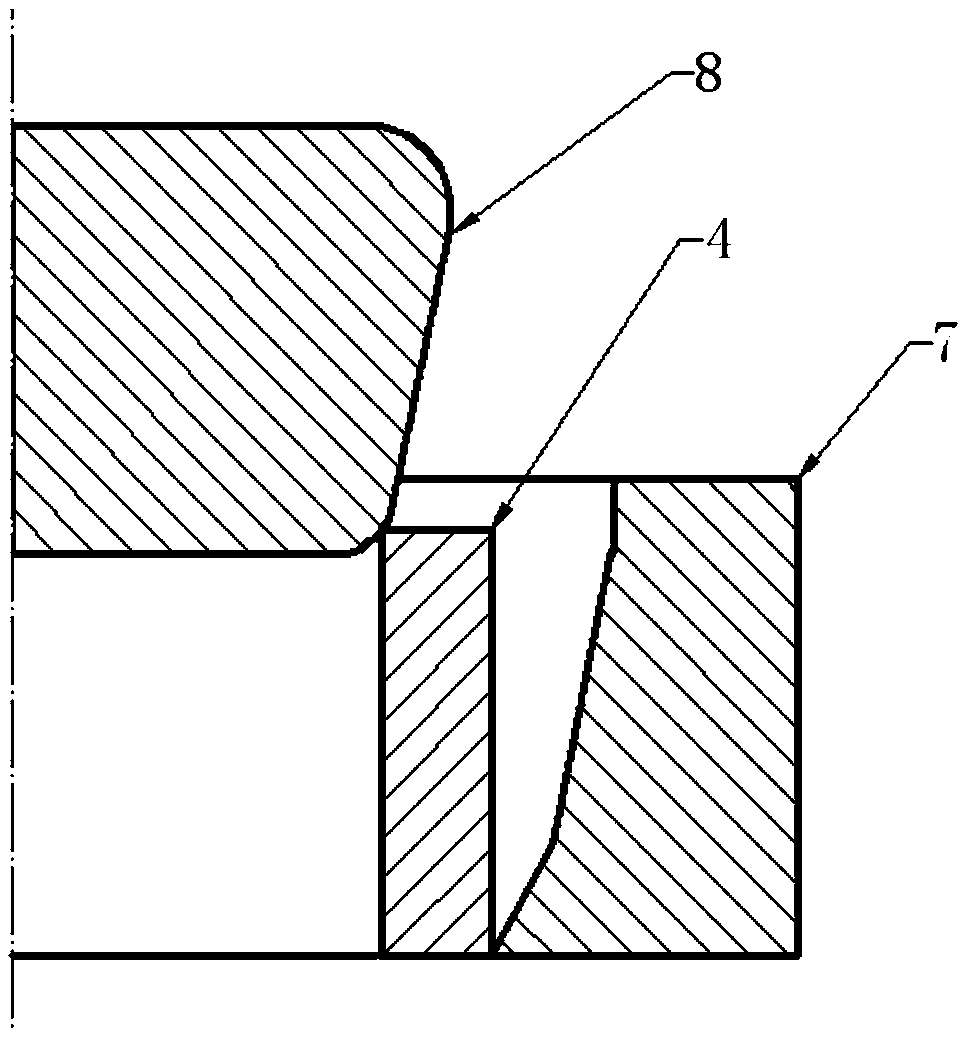

[0035] Such as figure 1 As shown, according to the structural characteristics of the β-phase titanium alloy multi-step large-scale special-shaped ring 1, the cross-section of the forging is cut equidistantly and layer by layer from the height direction with the help of drawing software, and the cross-sectional area data of the multi-step large-scale special-shaped ring 1 is obtained and made into a curve 2 ,Such as figure 2 As shown, the relationship between the cross-sectional area and height of the multi-step large-scale special-shaped ring 1 is obtained; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com