Forming method of large TC4 alloy die forging

A die forging and large-scale technology, which is applied in the field of TC4 alloy large-scale die forging forming, can solve the problems of destroying the forging flow line, difficult material filling, and reducing the mechanical properties of the forging, so as to achieve the effect of improving the forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] The main chemical element content (percentage by weight) of the alloy is: Al content 5.5%-6.8%, V content 3.5%-4.5%, Fe content ≤ 0.30%, C content ≤ 0.10%, N content ≤ 0.05% , H content ≤ 0.015%, O content ≤ 0.20%, other elements individually ≤ 0.10% and the sum ≤ 0.40%, the balance being Ti.

[0021] The steps of this method are as follows:

[0022] Step 1: Prepare rectangular ring blank

[0023] Take a TC4 alloy bar of a certain specification, put it into an electric furnace, heat it to 30°C below the phase transition point, and keep it warm;

[0024] The bar is taken out, and after upsetting and punching, it is rolled into a rectangular ring billet.

[0025] Step 2: Prepare shaped ring blank

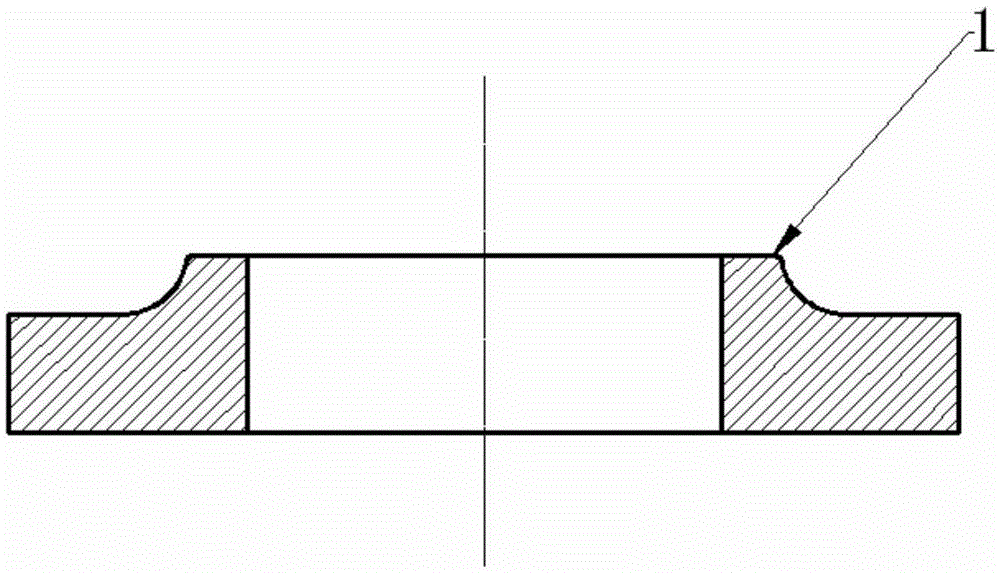

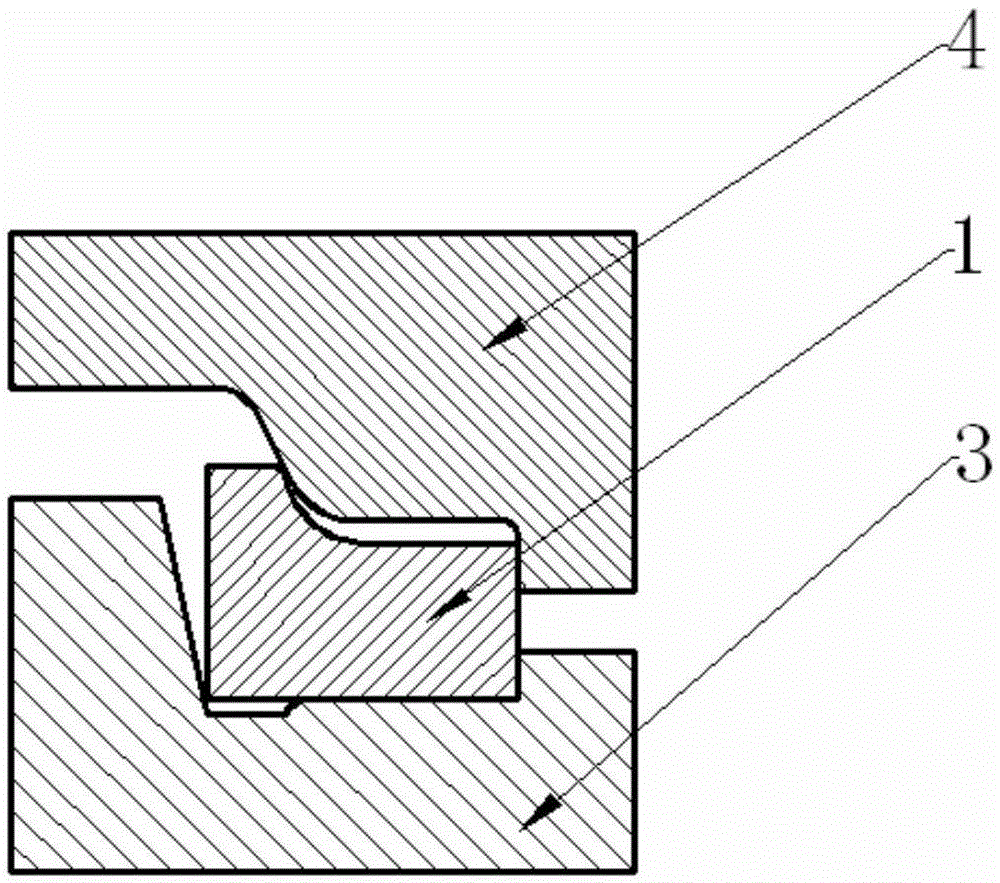

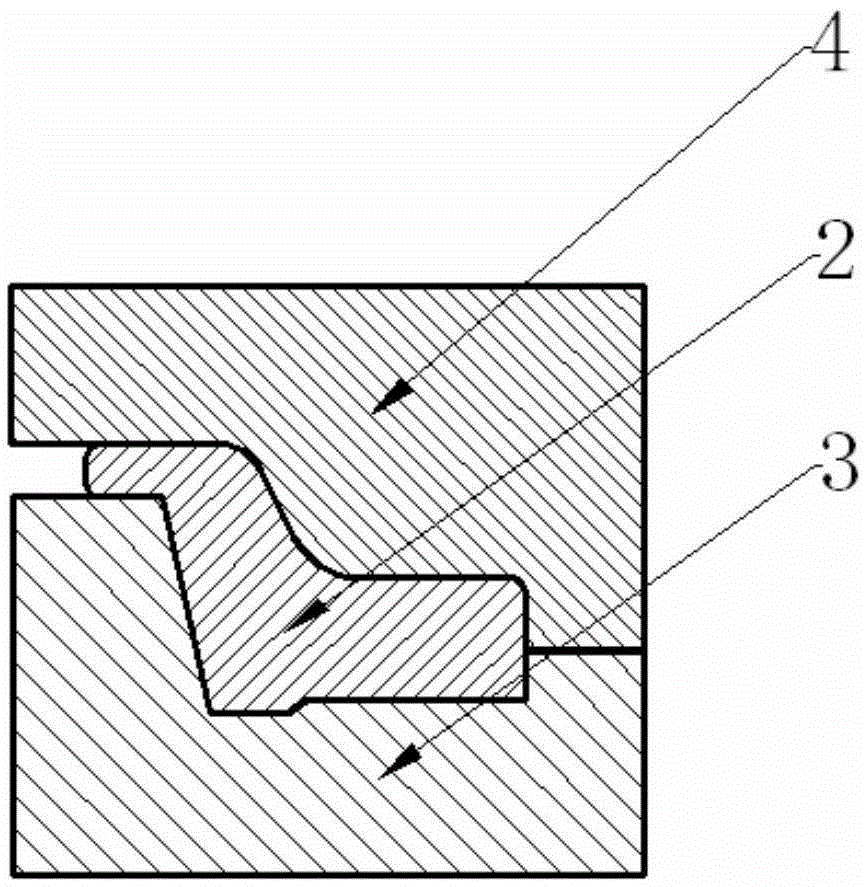

[0026] Return the rectangular ring billet to the furnace and heat it to 30°C below the phase transition point; preheat the tire film to 250°C; put the rectangular ring billet into the tire mold and forge it into a special-shaped ring billet 1, such as figure 1 shown.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com