Inert atmosphere protecting housing for laser producing, processing and molding metallic material

A metal material and inert atmosphere technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of unsatisfactory protection effect, high manufacturing requirements, high operating cost, etc., and achieve good protection effect and flexible design , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention provides an inert atmosphere protective box for laser preparation, processing and forming of metal materials. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

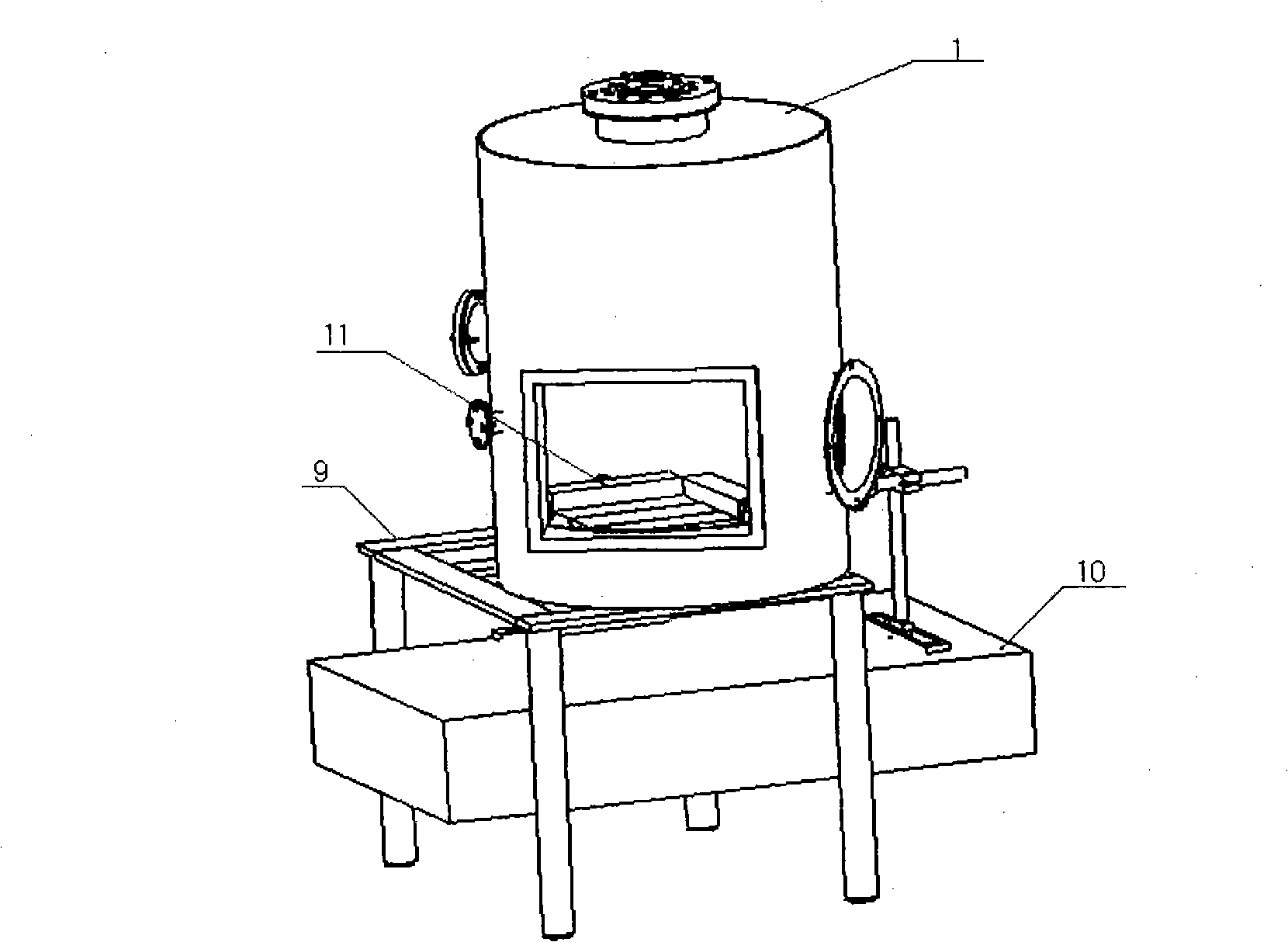

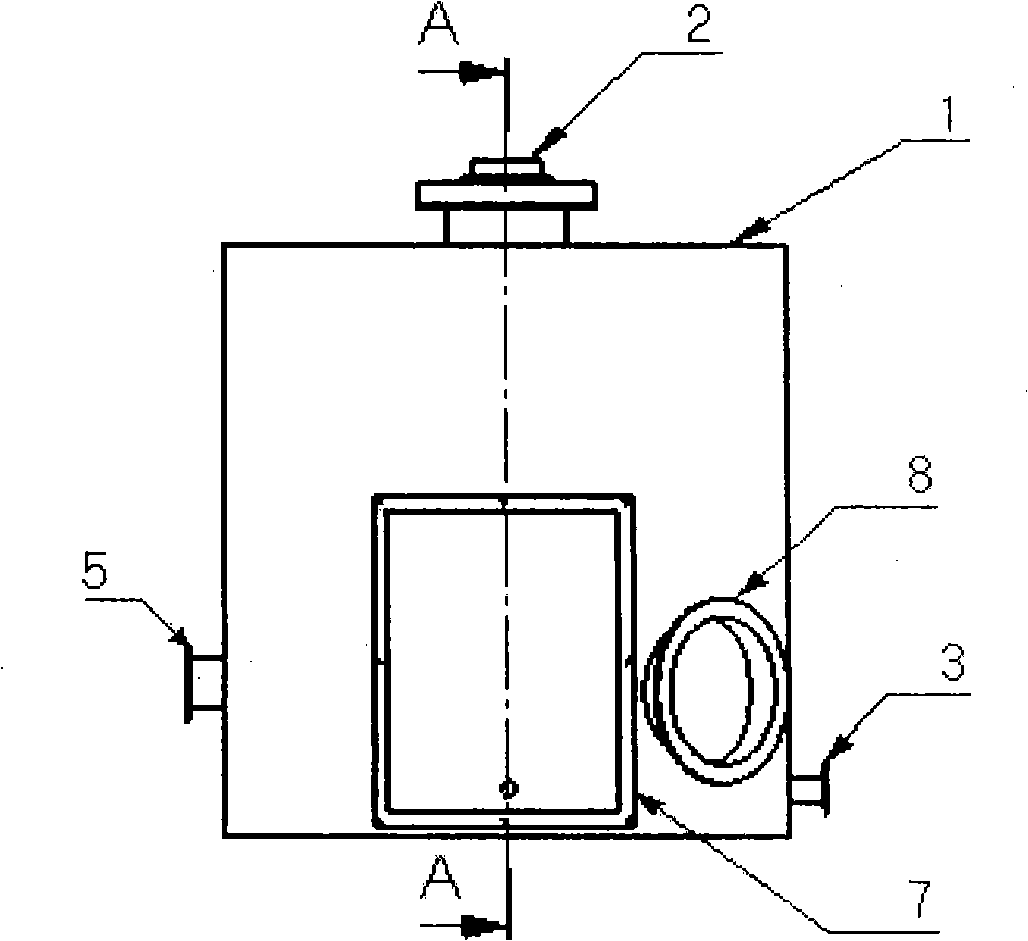

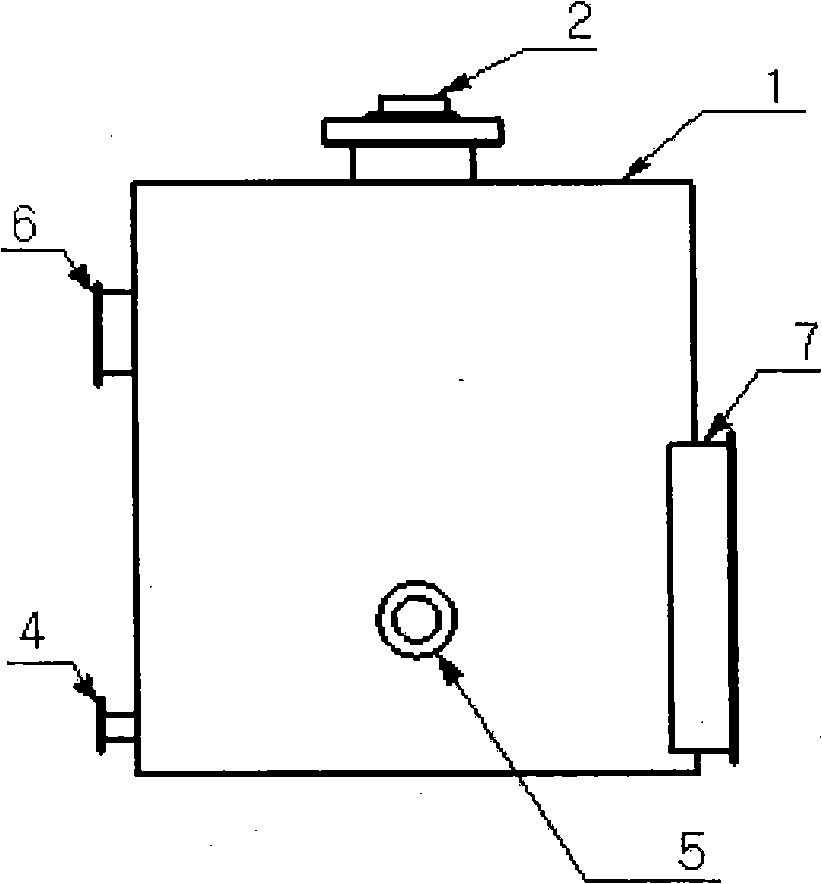

[0025] attached figure 1 It is a schematic diagram of the CNC machine tool system using the present invention. The cylindrical box 1 is fixed on a bracket 9 with adjustable level and height, and straddles the bed surface of the CNC machine tool; a laser vertical laser that can reciprocate along the Z-axis direction is inserted in the first flange hole 2. Straight light guide tube, the lower end of the laser vertical light guide tube is equipped with a laser focusing lens holder and a powder feeding head, and 12 quick-connect jacks on the first flange hole 2 are inserted with cooling water pipes, air pipes and powder pipes. To cool the laser focusing mirror and deliver protective gas and powder to the powder feeding head; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com