Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Suppresses speed fluctuations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

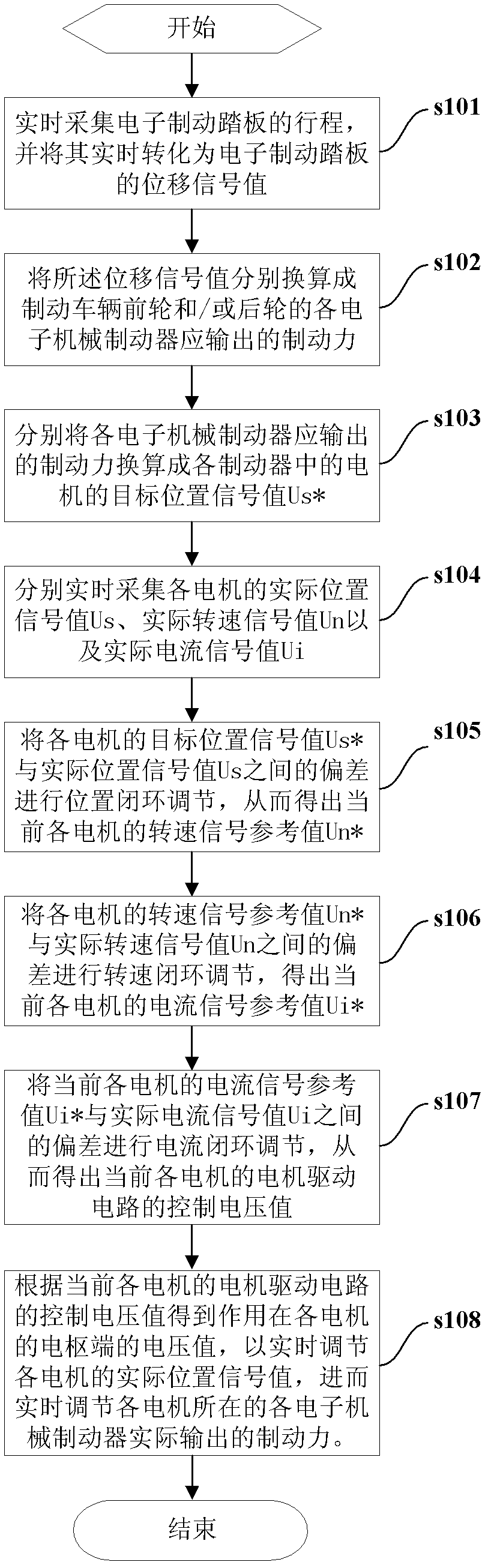

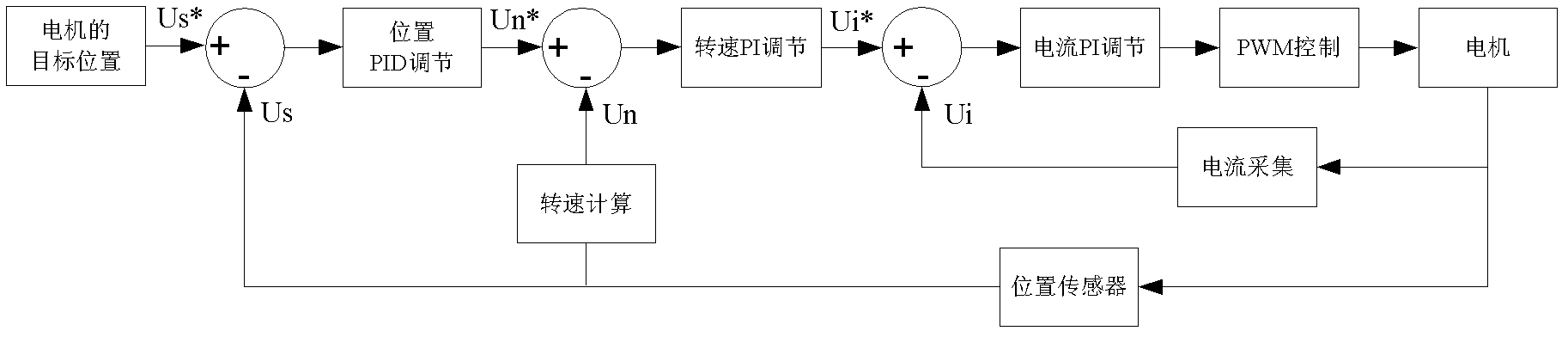

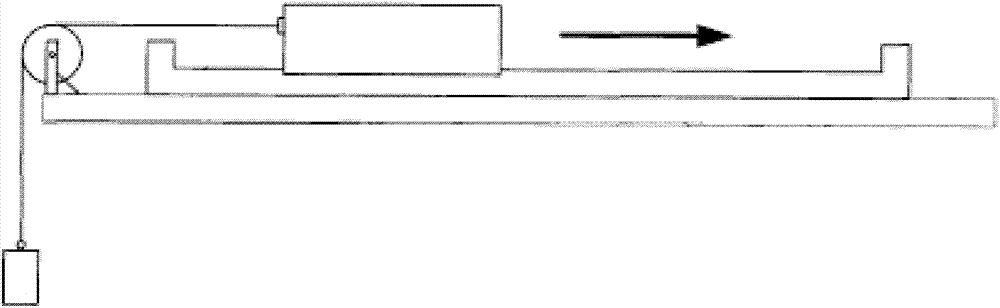

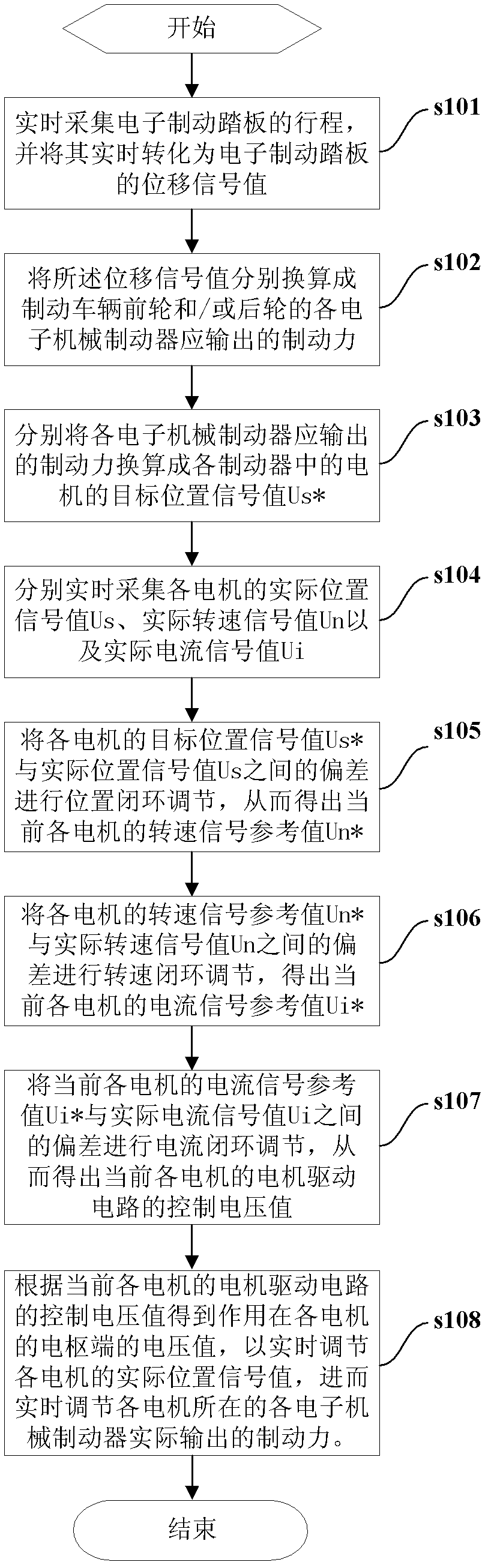

Brake force real-time adjusting method based on brake-by-wire system and adjusting device

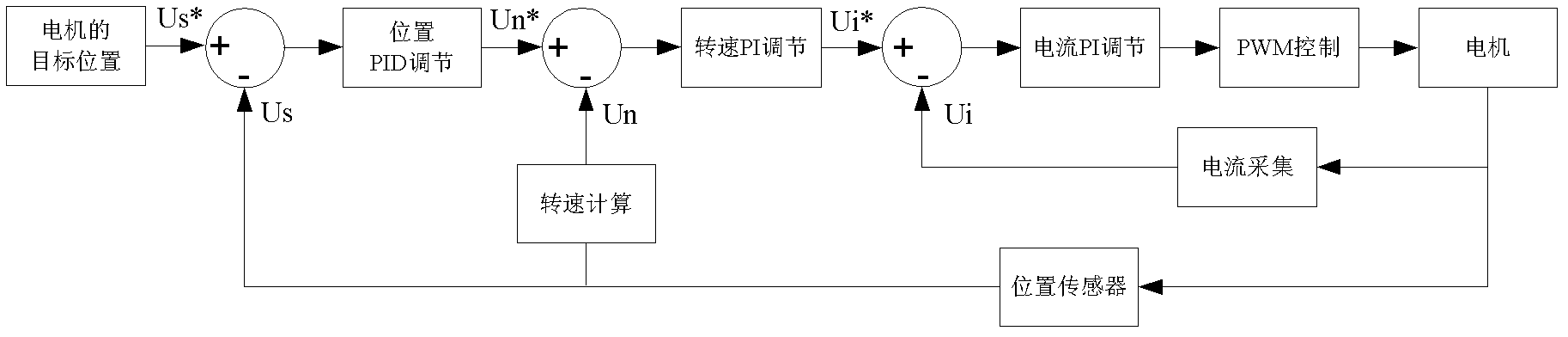

ActiveCN102582600AHigh braking precisionBrake force adjustmentElectrodynamic brake systemsBraking systemsAutomotive engineeringBrake force

The invention provides a brake force real-time adjusting method based on a brake-by-wire system. The brake force real-time adjusting method comprises following steps: respectively obtaining objective position signal values of motors in various electronic and mechanical brakes of front wheels and / or rear wheels of a brake vehicle according to strokes of electronic brake pedals; respectively acquiring actual position signal values, actual rotation speed signal values and actual current signal values of the motors in real time; and respectively realizing real-time closed-loop control for positions, rotation speeds and current of the motors according to deviation between the objective position signal values and the actual position signal values of the motors, the actual rotation speed signal values and the actual current signal values, and accordingly adjusting actually outputted brake force of the electronic and mechanical brakes with the motors in real time. Correspondingly, the invention provides a brake force real-time adjusting device. The brake force real-time adjusting method and the adjusting device can suppress fluctuation generated when brake force is adjusted in real time in the prior art, stability of the brake-by-wire system is improved, and a braking effect is good.

Owner:CHERY AUTOMOBILE CO LTD

Method for inhibiting speed fluctuation, control device and compressor control system

ActiveCN104113253AGuaranteed uptimeSuppresses speed fluctuationsElectronic commutation motor controlVector control systemsControl systemReference current

The invention discloses a method for inhibiting speed fluctuation of a permanent magnet synchronous motor. The method includes the steps of: obtaining a target rotating speed omega_ref, a feedback rotating speed, and a fluctuation rotating speed delta(omega), a q axis inductor Lq and a permanent magnet flux linkage (phi)f of the permanent magnet synchronous motor; performing PI adjustment on delta(omega) to obtain a q axis reference current Iq_ref, and obtaining a q axis target voltage Ud* according to Iq_ref, omega_ref, delta(omega) and (phi)f; performing PI control on a q axis actual voltage according to Ud* so as to obtain a q axis compensating current Iq_add; obtaiing a d axis target voltage Ud* according to Iq_ref, Iq_add, omega_ref, delta(omega) and Lq, and performing PI control on a d axis actual voltage according to Ud* to obtain a d axis compensating current Id_add; superposing Iq_add and Iq_ref to perform feedforward compensation on a q axis current, and superposing Id_add and a d axis reference current to perform feedforward compensation on a d axis current. The inhibition method can realize effective inhibition of speed fluctuation in operation of the permanent magnet synchronous motor by performing feedforward compensation on the d axis current and the q axis current. The invention also discloses a control device of the permanent magnet synchronous motor and a compressor control system.

Owner:GUANGDONG MEIZHI COMPRESSOR

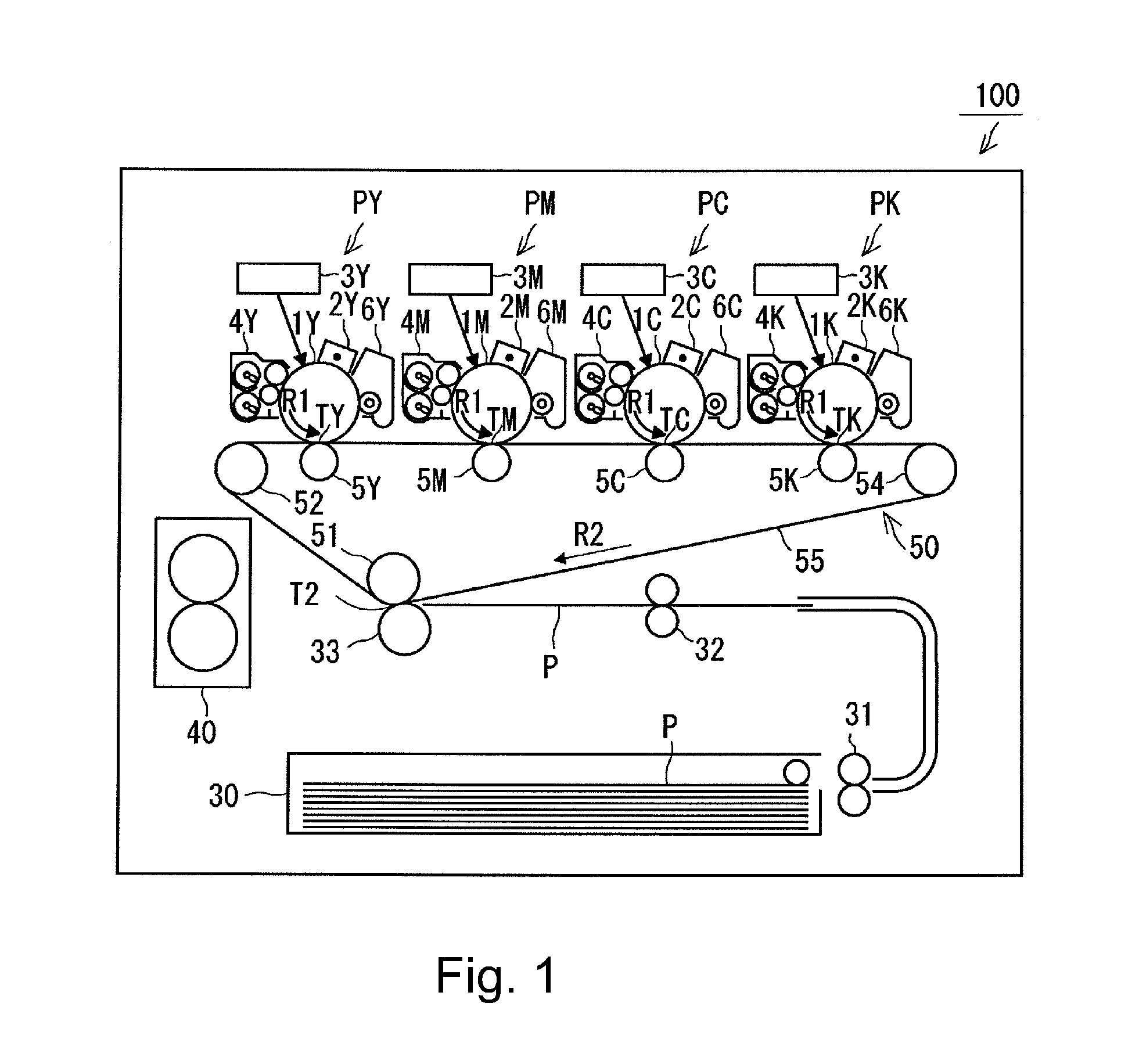

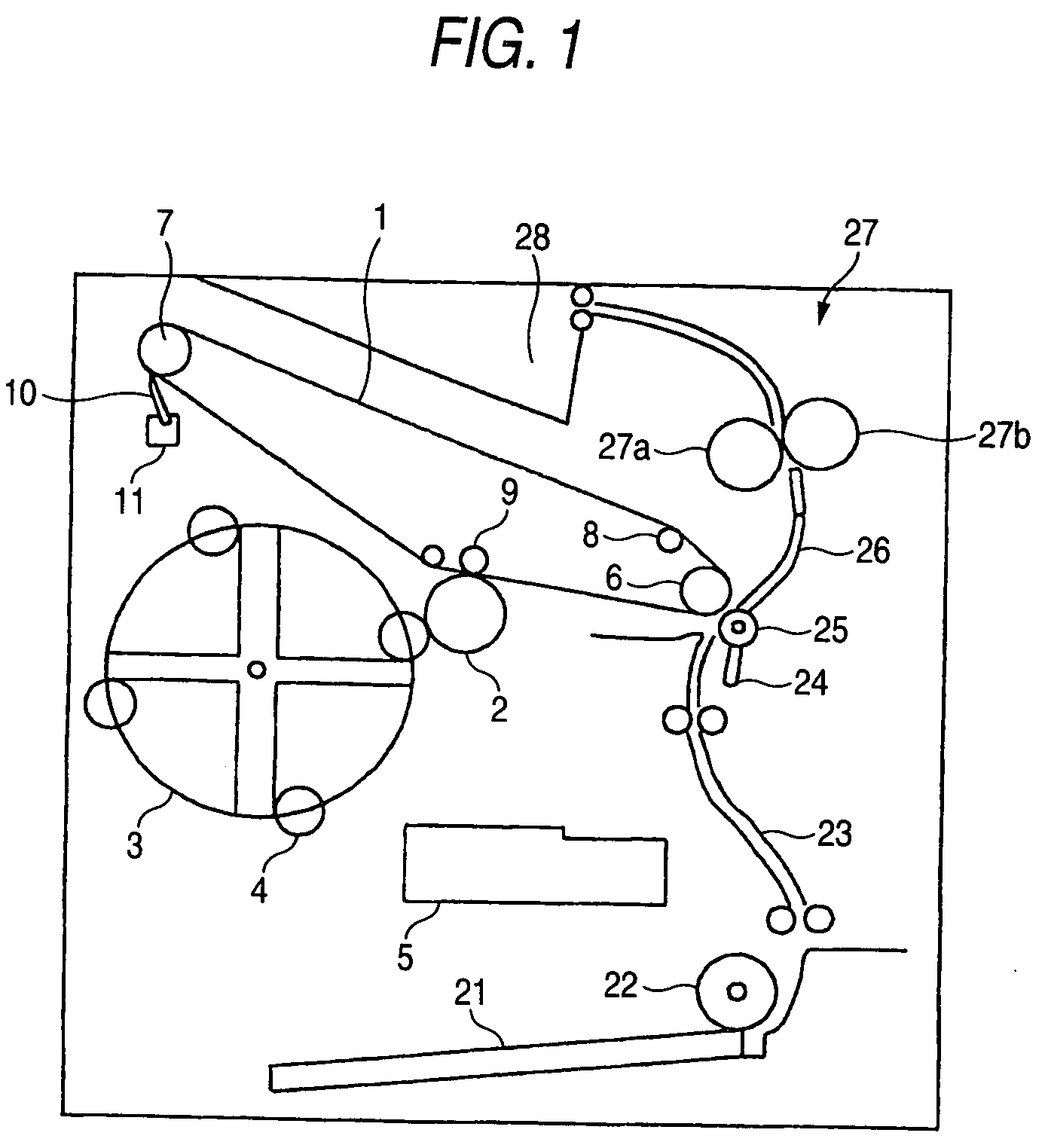

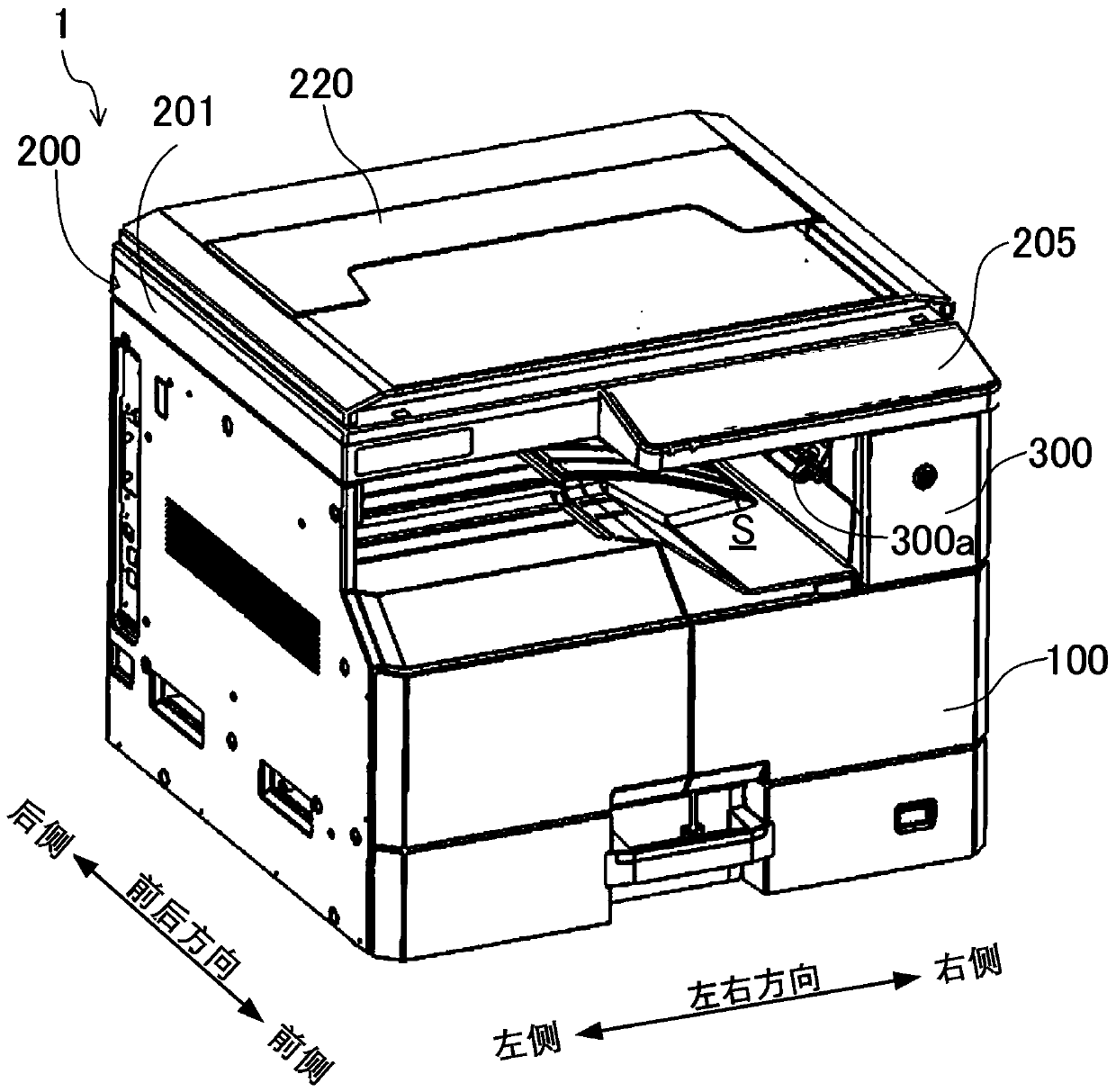

Image forming apparatus

ActiveUS20110249988A1Improve image qualitySuppresses speed fluctuationsGearboxesToothed gearingsEngineeringElectric motor

Owner:CANON KK

Sheet post-processing apparatus and sheet post-processing method

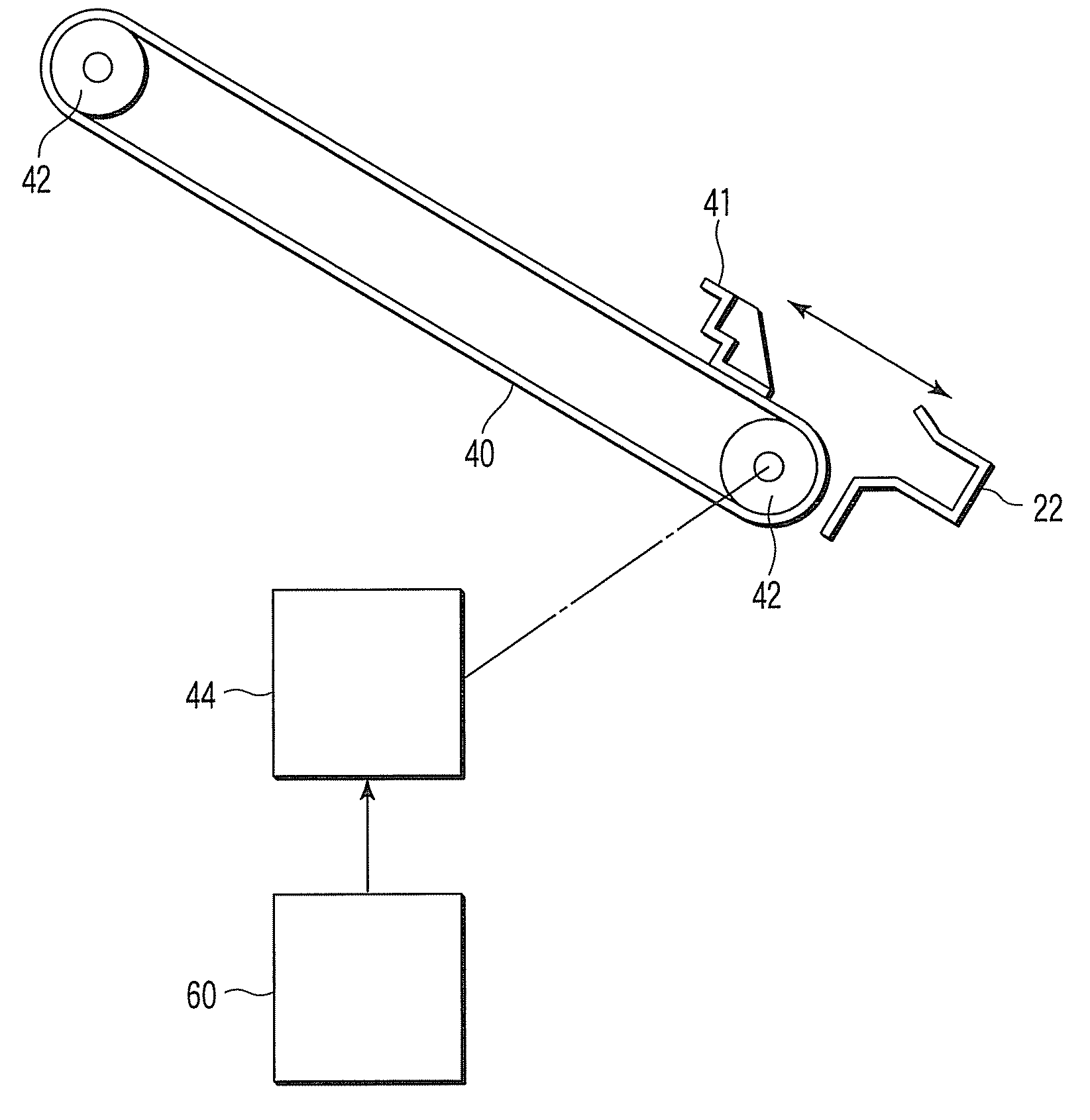

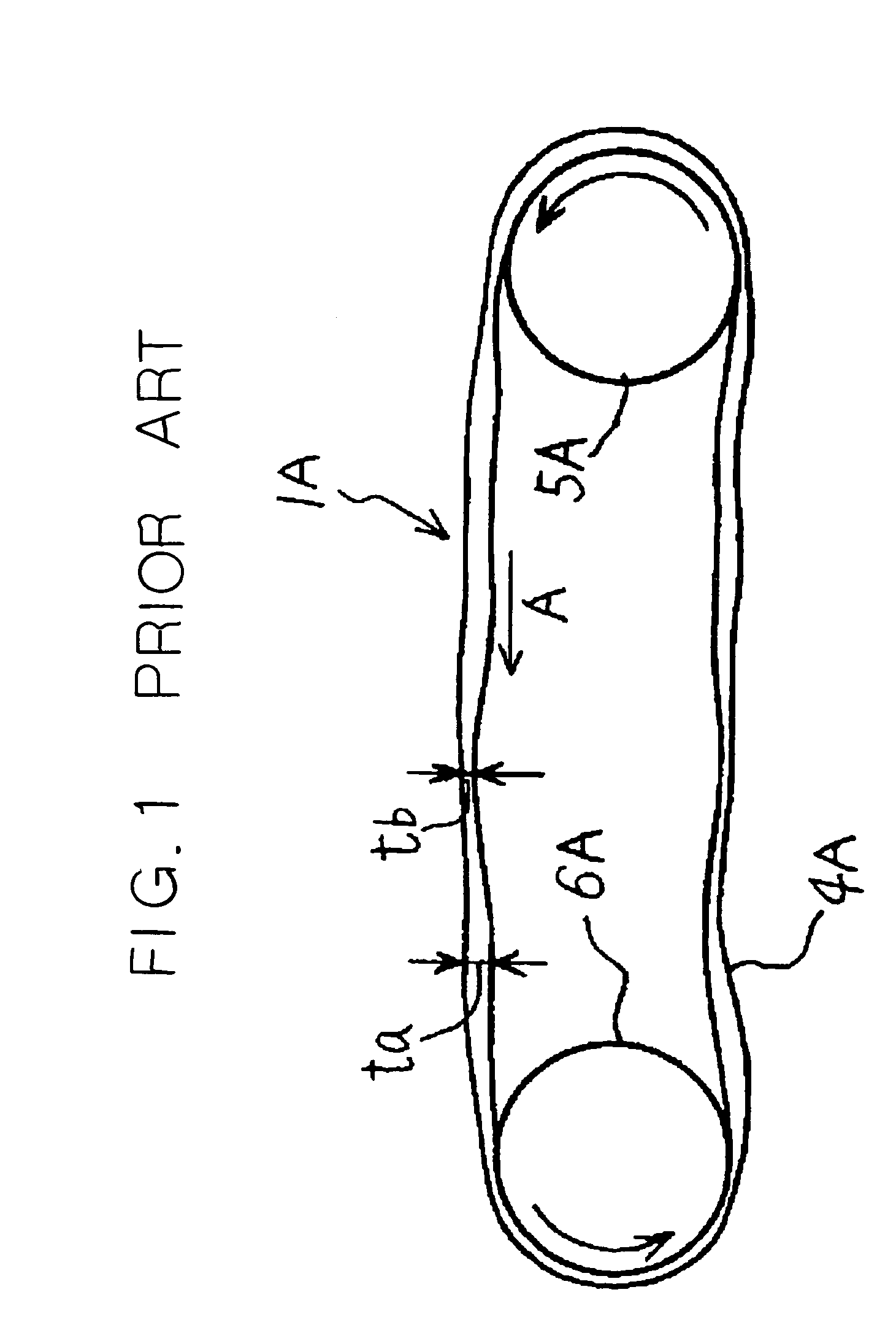

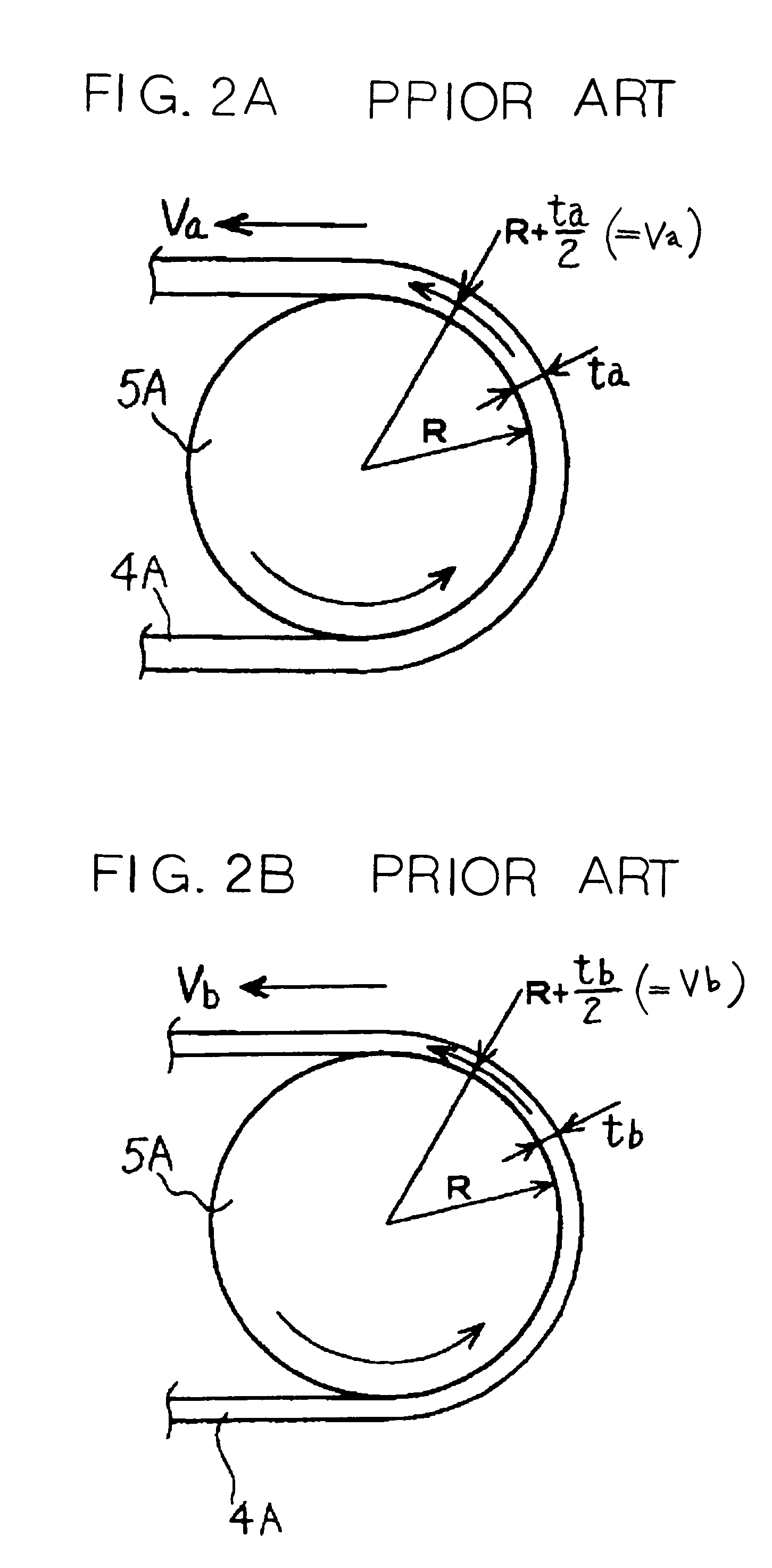

ActiveUS7862026B2Suppresses speed fluctuationsReduce discharge rateFunction indicatorsPile receiversEngineeringConveyor belt

A bundle claw attached to a sheet conveyor belt includes a concave portion having a bottom surface for regulating a position of a trailing end of the sheets, and, in the bottom surface, a surface on a lower side that comes into contact with the sheet conveyor belt is formed deeper than a surface on an upper side to form the step portion between the surface on the lower side and the surface on the upper side. Therefore, when a small number of sheets are discharged from a processing tray to a stacking tray, a trailing end of the sheets is located on the lower surface side of the concave surface of the bundle claw, where the trailing end of the sheets should be originally located, and does not move to the upper surface side of the concave surface of the bundle claw.

Owner:KK TOSHIBA +1

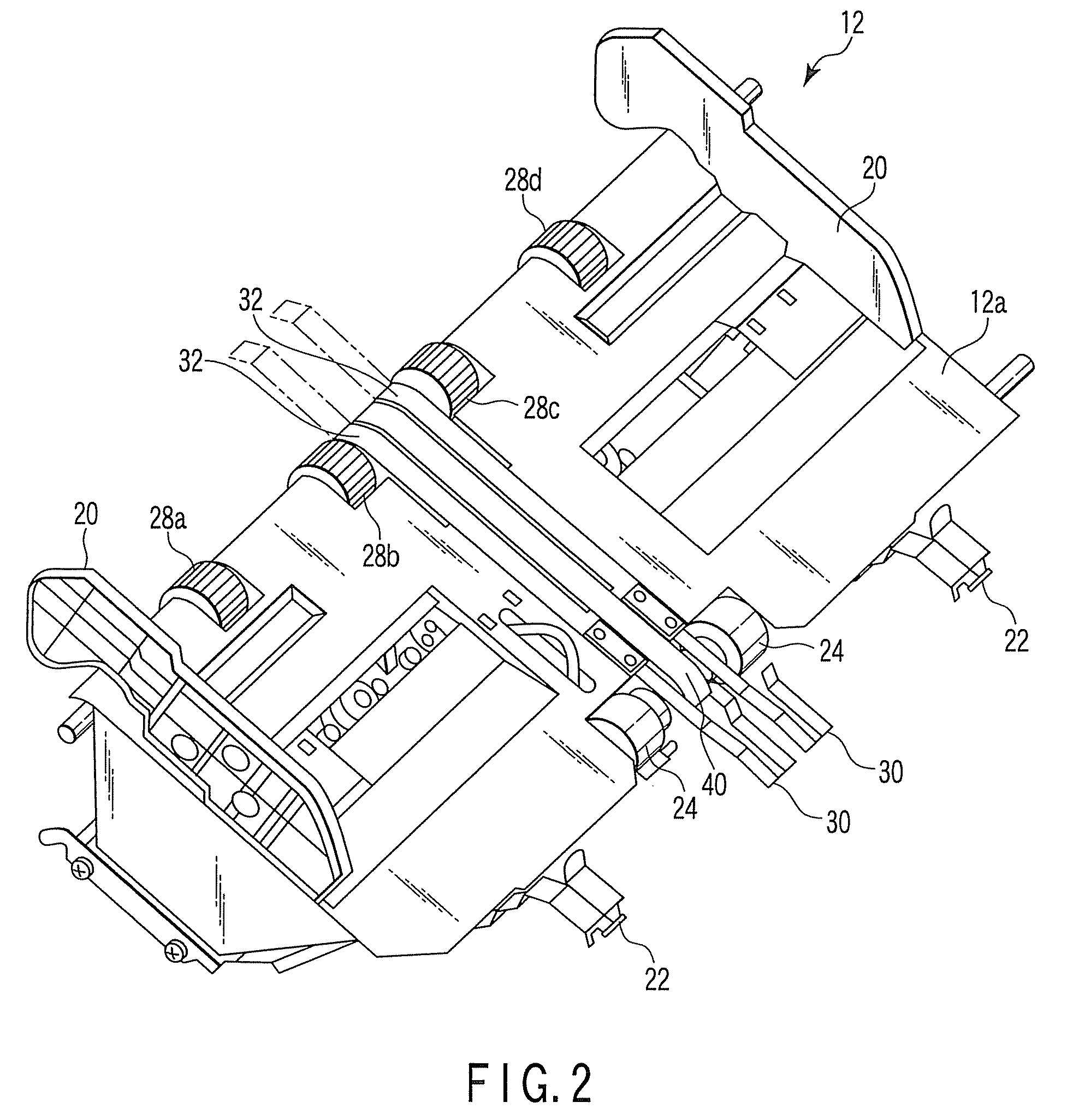

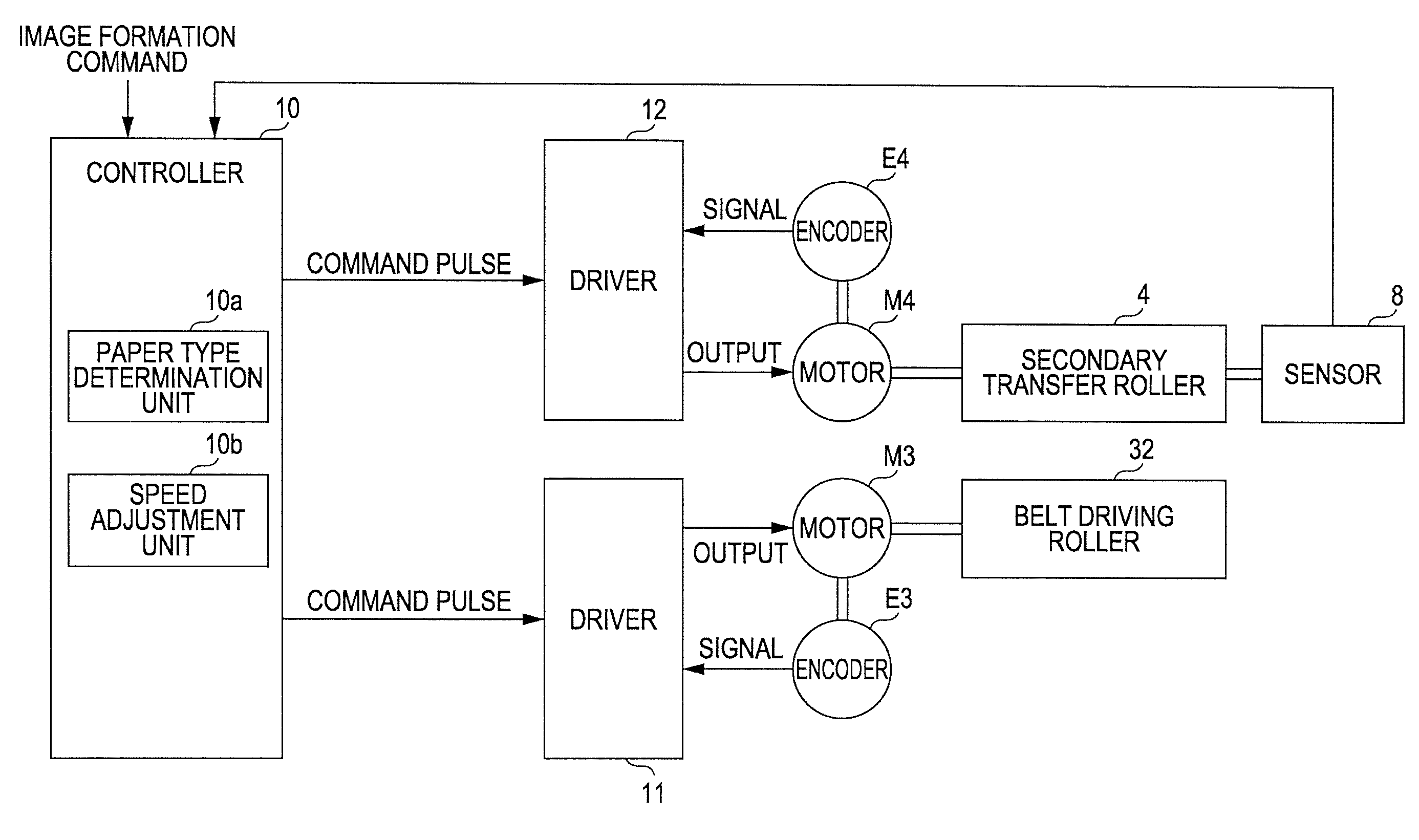

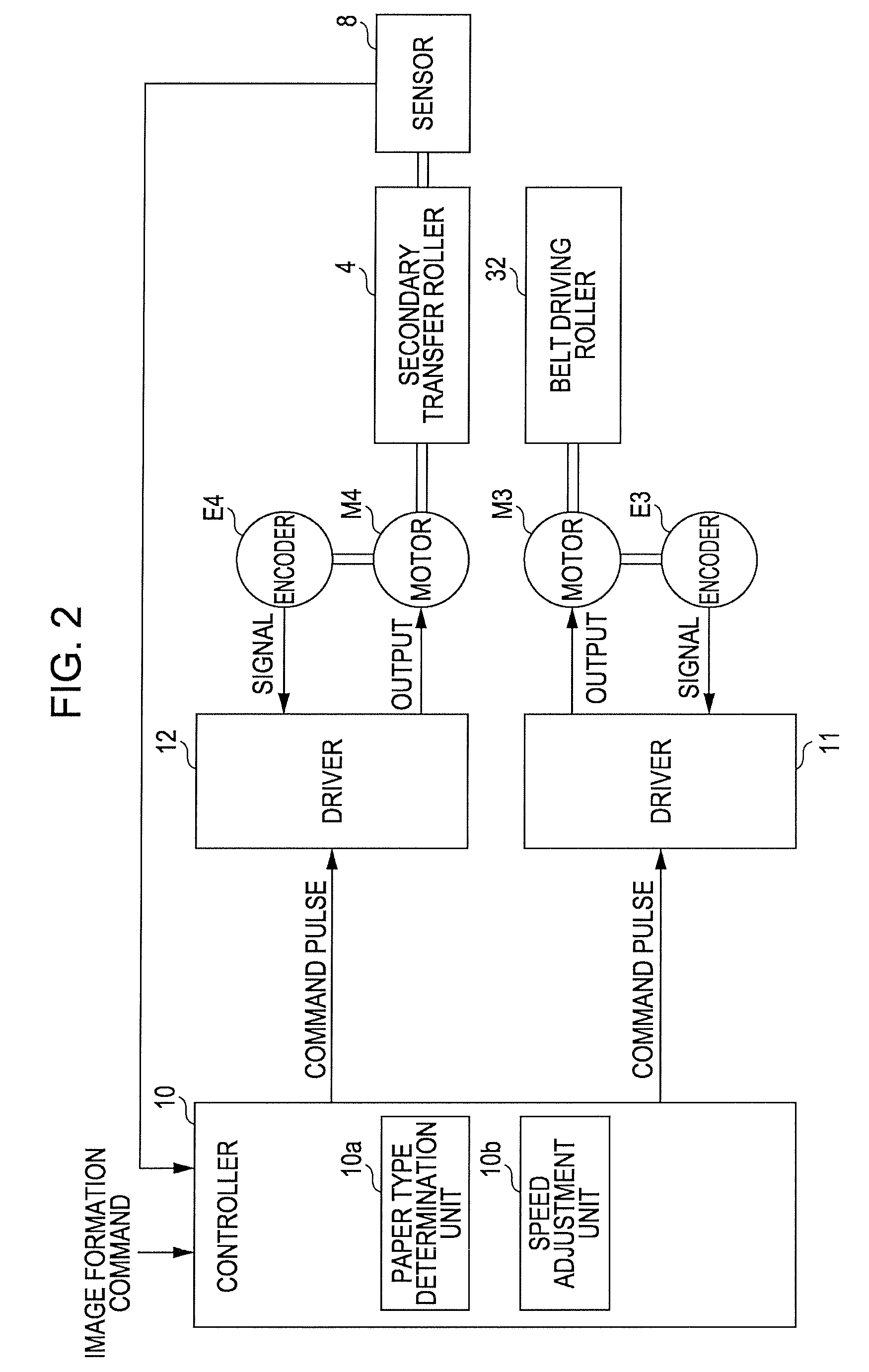

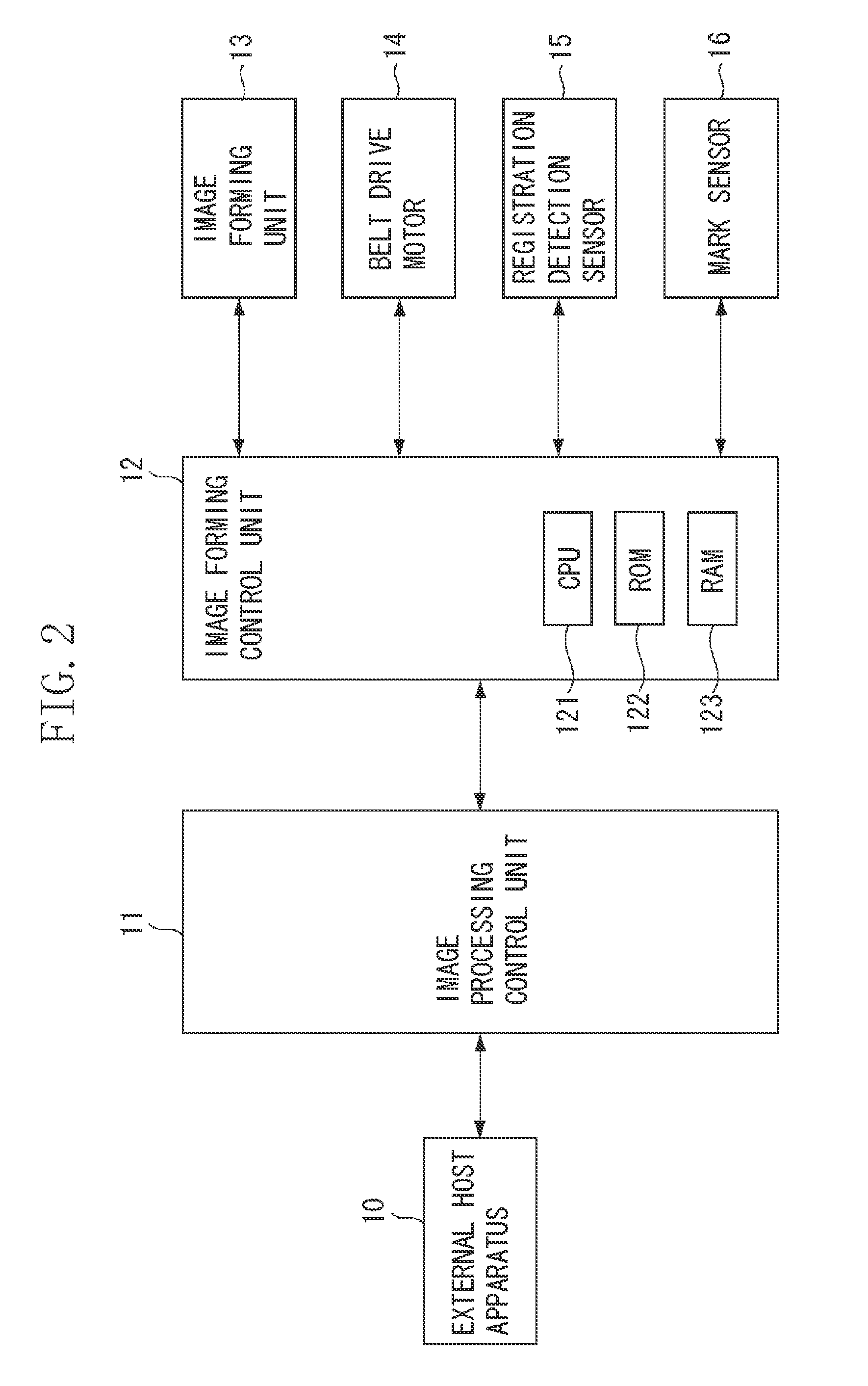

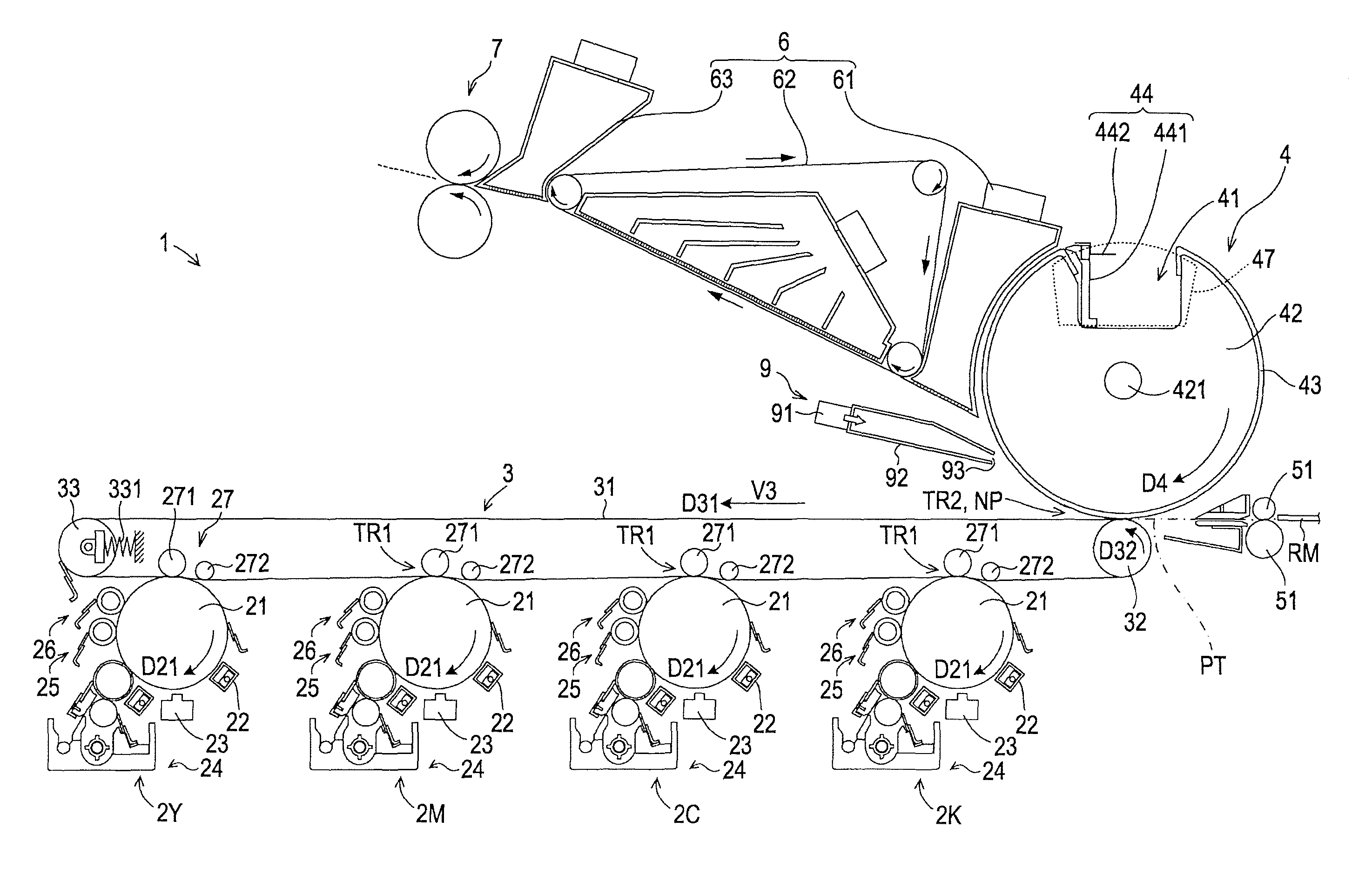

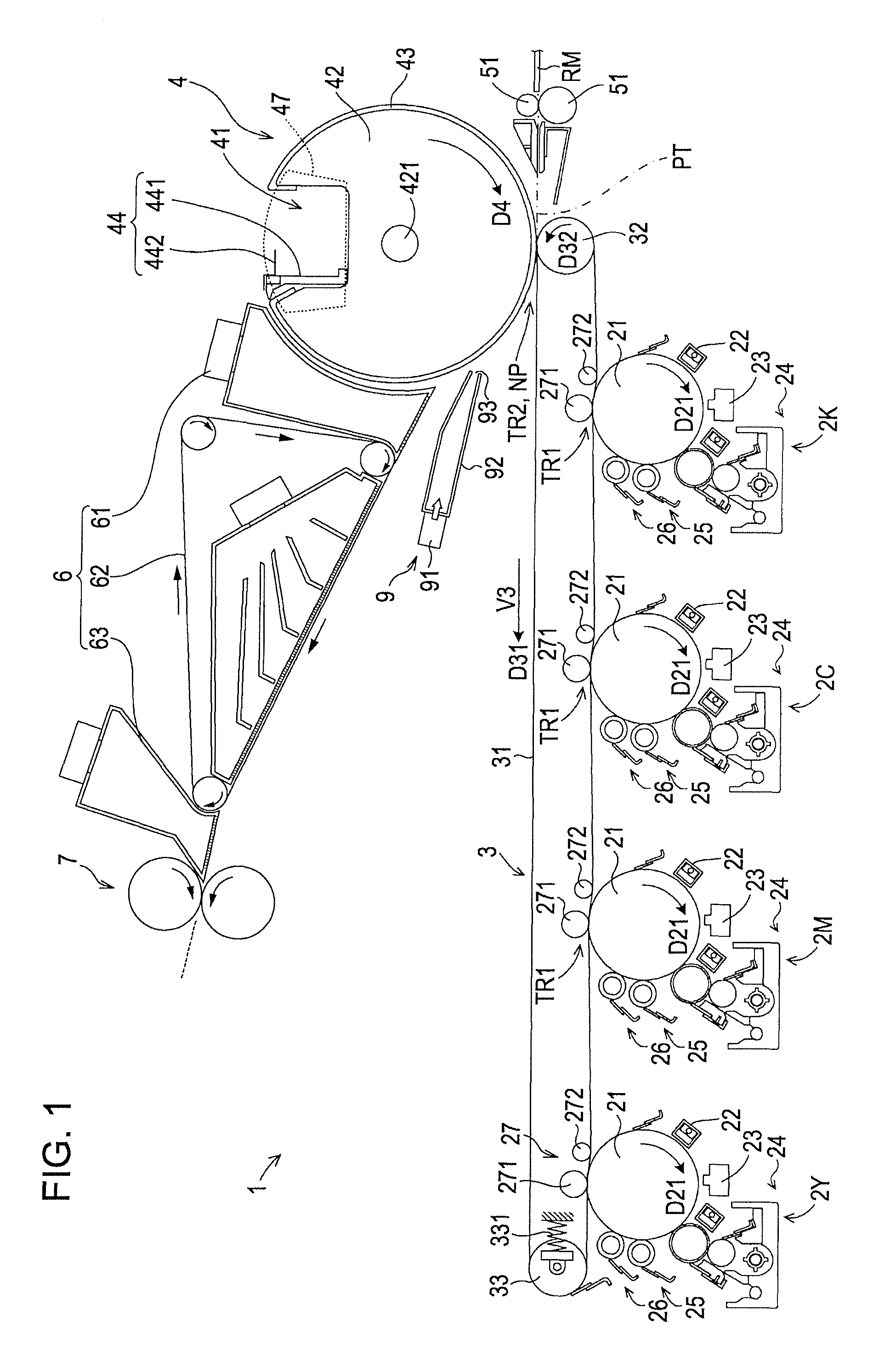

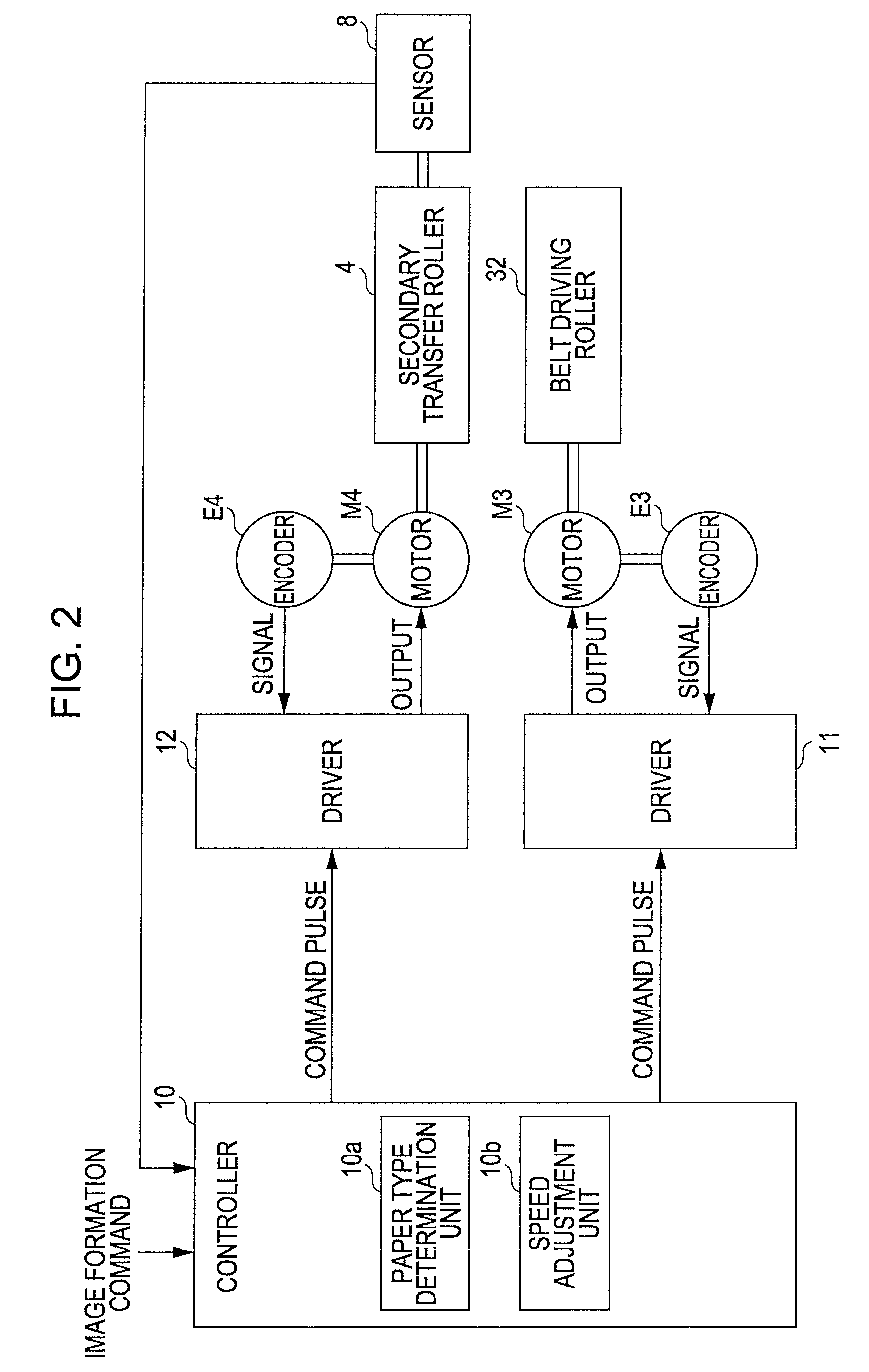

Image forming apparatus and image forming method

InactiveUS20110058830A1Favorable mannerSimple structureElectrographic process apparatusMaterial typeEngineering

An image forming apparatus including: an image bearing belt that bears an image; an image creation unit that transfers the image on the image bearing belt; a first driving source; a driving roller that is rotationally driven by the first driving source and causes the image bearing belt to move; a transfer roller that has a concaved portion in a circumferential surface, forms a transfer nip by the transfer roller making contact with the image bearing belt, and transfers the image on the image bearing belt to a recording material; a second driving source that rotationally drives the transfer roller; a material type determination unit that determines a type of the recording material; and a control unit that controls a number of rotation of the transfer roller when the recording material is nipped by the transfer nip based on information of the type determined by the material type determination unit.

Owner:SEIKO EPSON CORP

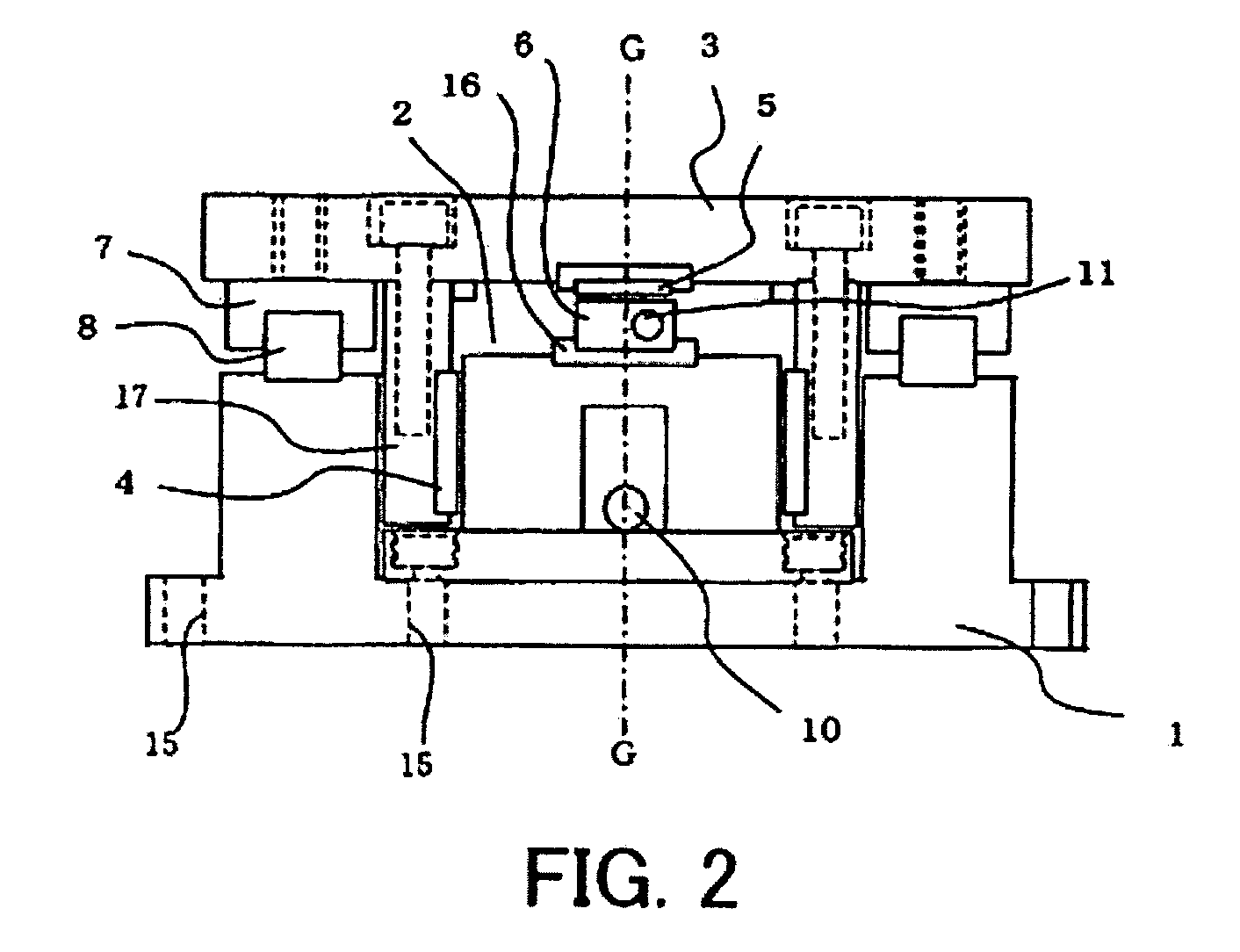

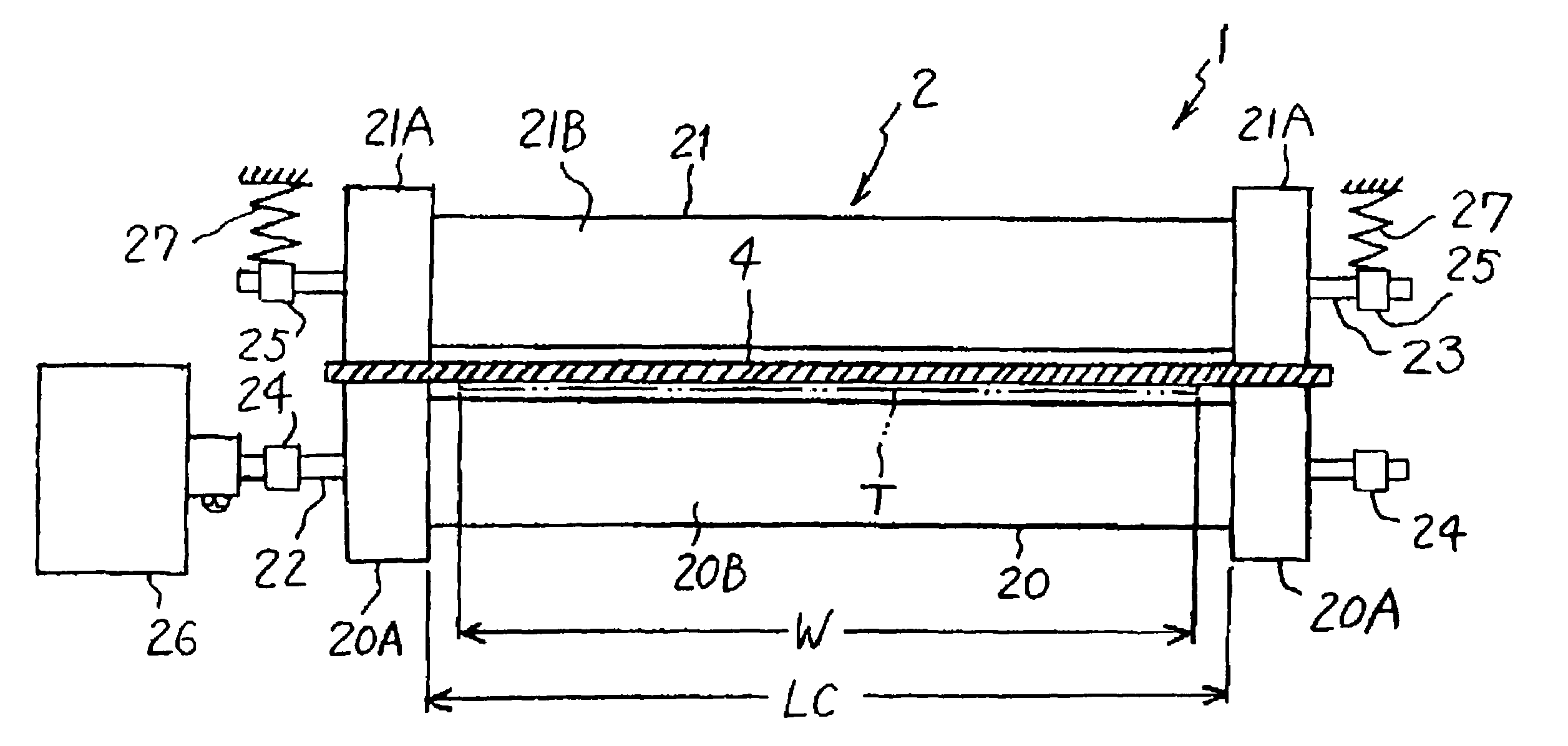

Moving magnet type linear slider

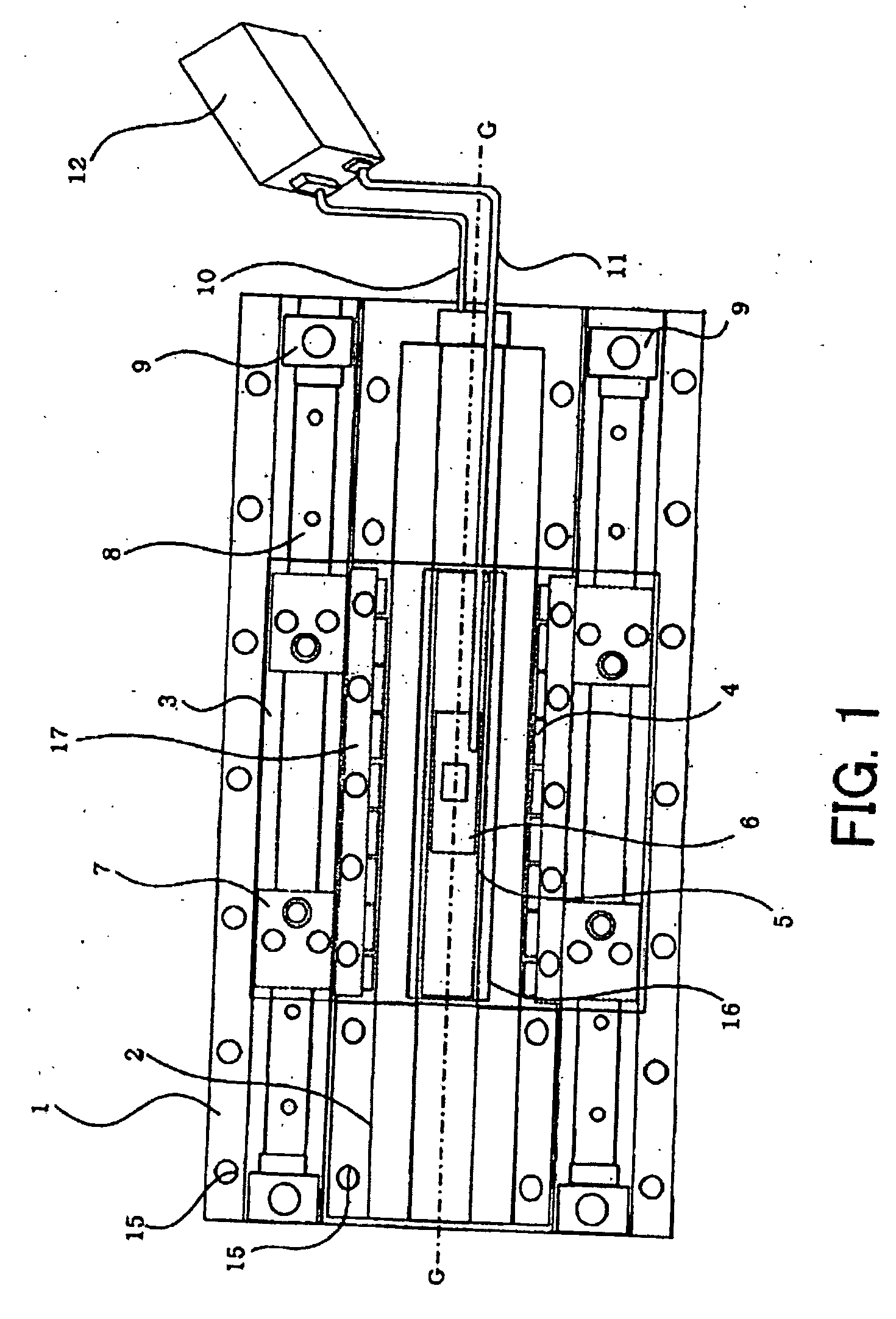

InactiveUS7276821B2Easily increasing the servo gainSuppresses speed fluctuationsAC motor controlDC motor speed/torque controlLinear motorConductor Coil

In some embodiments, a moving magnet type linear slider capable of minimizing the effect of microvibration at the time of driving a linear motor, easily increasing the servo gain and suppressing the speed ripple is provided. The moving magnet type linear slider includes a linear motor for reciprocating a table, and a detector for detecting the relative position of the table and a fixed base. The linear motor includes an armature in which polyphase armature winding is wound around the armature core secured to a fixed base and a field permanent magnet secured to the lower surface of the table in the vertical direction and arranged between the inner side surface of the linear guide and the outside surface of the armature via gaps therebetween. The detector includes a linear scale secured to the lower surface side of the table and a sensor head secured to the upper surface side of the armature, and the central axis of the detector is substantially aligned with the thrust central axis G-G of the armature.

Owner:YASKAWA DENKI KK

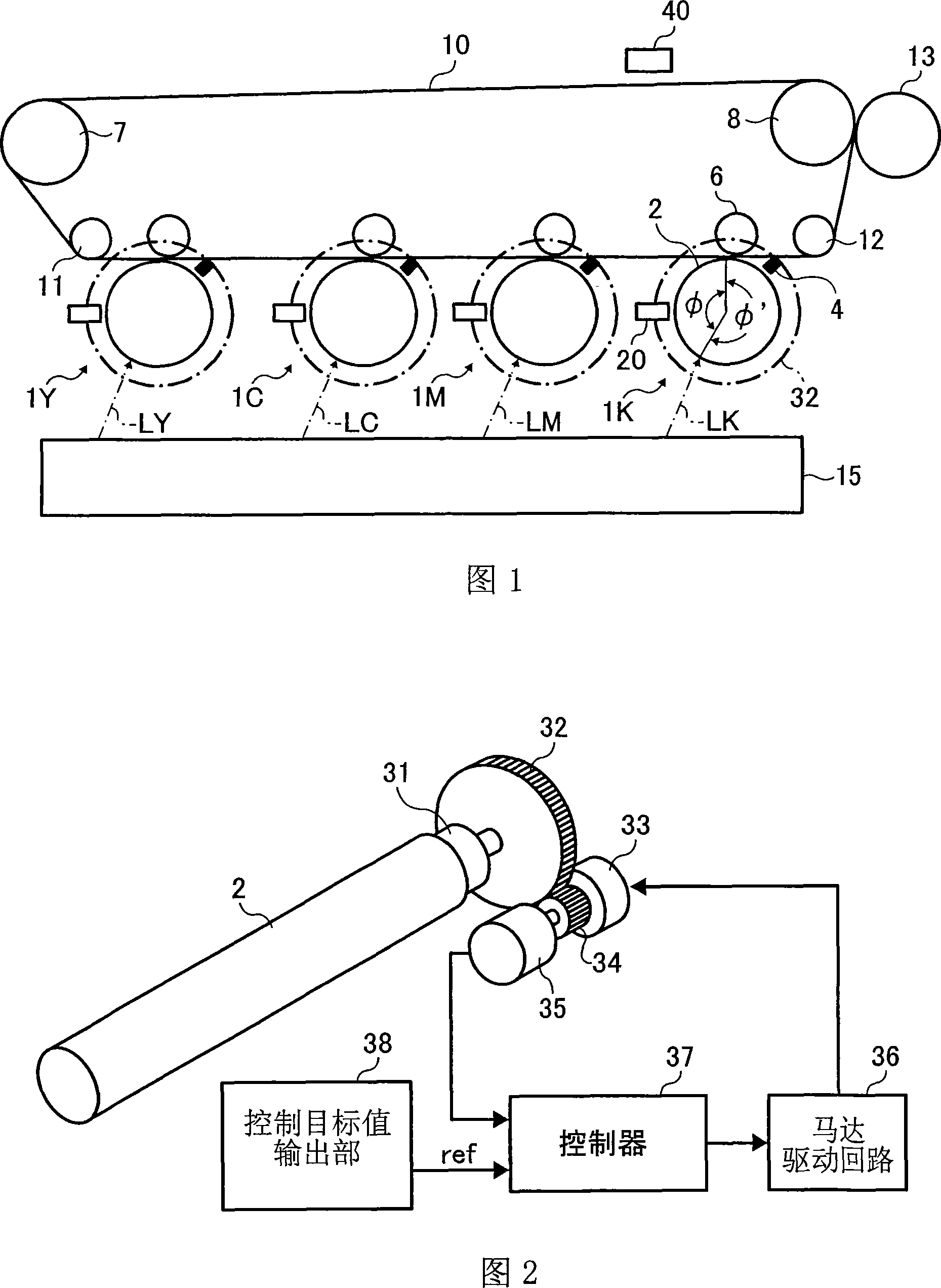

Image forming apparatus for setting a velocity difference between a photosensitive drum and an intermediate transfer belt

ActiveUS8417162B2Solution to short lifeSuppresses speed fluctuationsElectrographic process apparatusEngineeringMechanical engineering

Owner:CANON KK

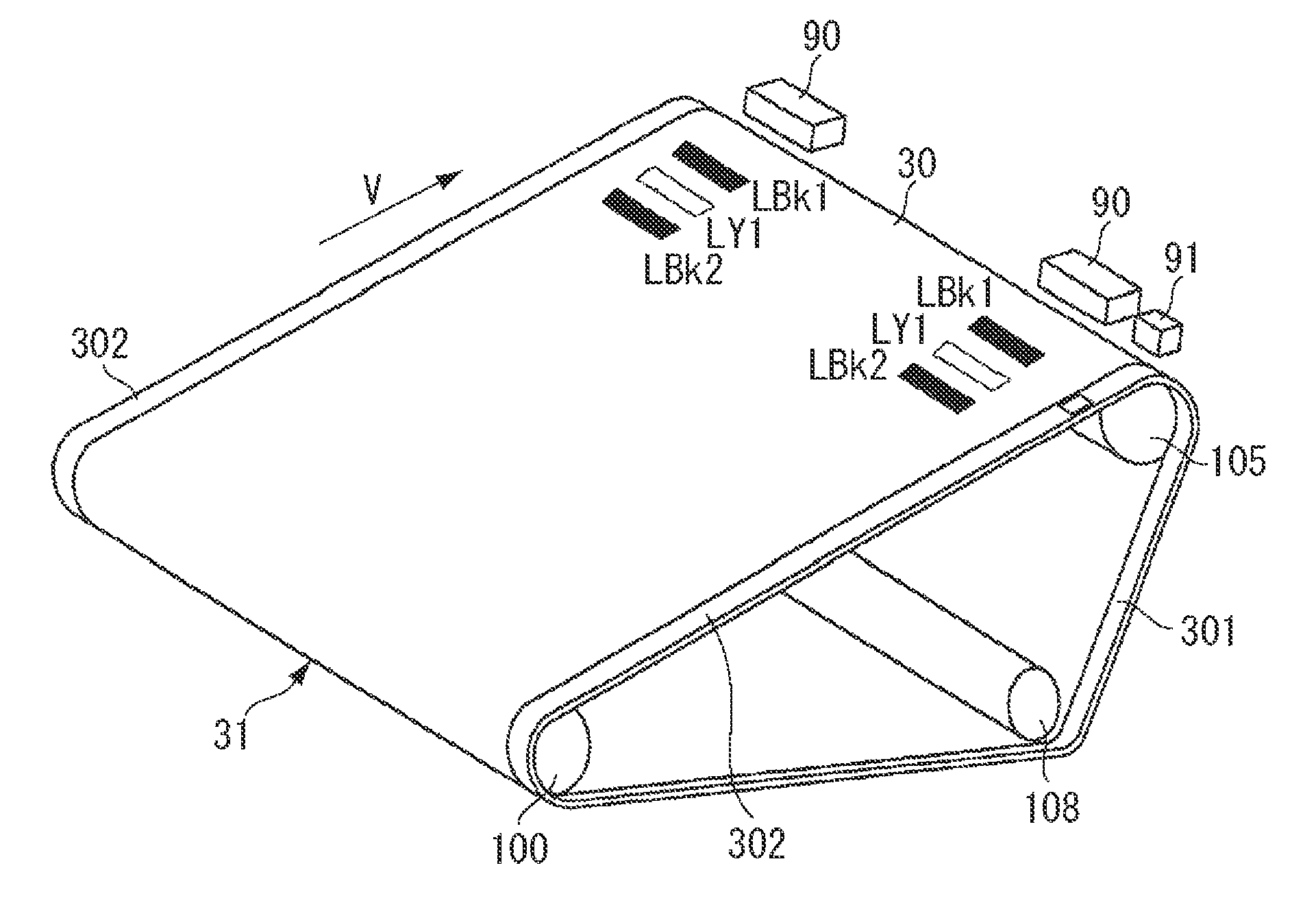

Image forming apparatus

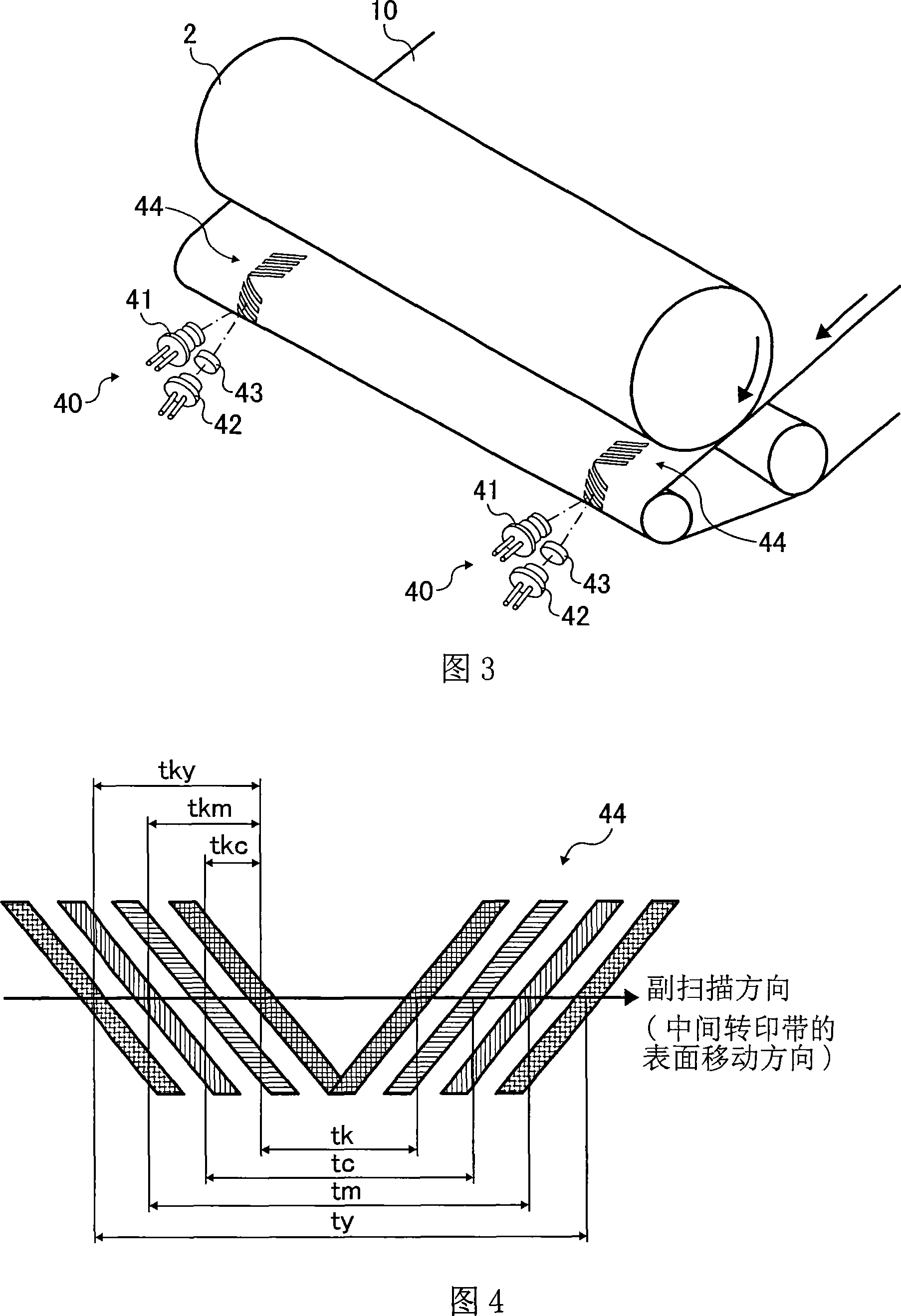

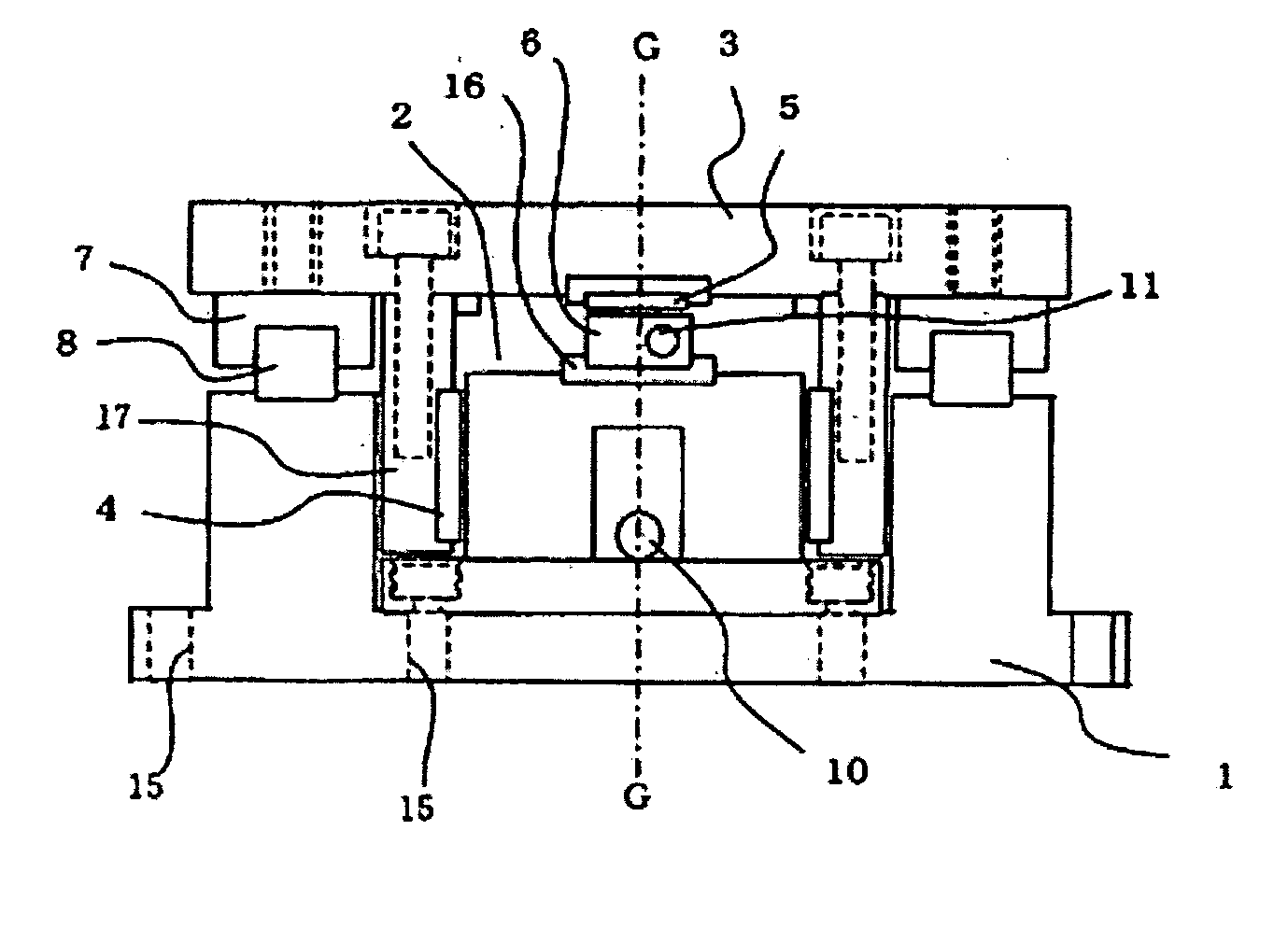

InactiveCN101105662APrevent image position deviation and color deviationImprove qualityElectrographic process apparatusDevice formPattern detection

An image forming apparatus including an image bearing member, an image forming device forming a latent image on the image bearing member and visualizing the latent image; a transfer device transferring the visual image onto a receiving material, using a moving member; a drive controller controlling driving of the image bearing member so that the rotation angular speed of the image bearing member is identical to the targeted rotation angular speed; a pattern detection device detecting pattern images formed on the moving member; and a correction device determining the variation in rotation angle or angular speed per one revolution of the image bearing member on the basis of the detection data and correcting the targeted rotation angular speed by superimposing a correction value to negate the variation in rotation angle or angular speed per one revolution of the image bearing member on the target.

Owner:RICOH KK

Moving magnet type linear slider

InactiveUS20070103008A1Easily increasing the servo gainSuppresses speed fluctuationsMotor/generator/converter stoppersAC motor controlLinear motorConductor Coil

In some embodiments, a moving magnet type linear slider capable of minimizing the effect of microvibration at the time of driving a linear motor, easily increasing the servo gain and suppressing the speed ripple is provided. The moving magnet type linear slider includes a linear motor for reciprocating a table, and a detector for detecting the relative position of the table and a fixed base. The linear motor includes an armature in which polyphase armature winding is wound around the armature core secured to a fixed base and a field permanent magnet secured to the lower surface of the table in the vertical direction and arranged between the inner side surface of the linear guide and the outside surface of the armature via gaps therebetween. The detector includes a linear scale secured to the lower surface side of the table and a sensor head secured to the upper surface side of the armature, and the central axis of the detector is substantially aligned with the thrust central axis G-G of the armature.

Owner:YASKAWA DENKI KK

Underwater drag reduction bionic micro-nano structure

The invention discloses an underwater drag reduction bionic micro-nano structure which comprises U-shaped structures of bionic dolphin spine skin and sawtooth structures of bionic mosquito stylets. Aswimming bladder comprises a conical body structure at the front end and a cylindrical body structure at the rear end, the sawtooth structures are distributed on the surface of the conical body structure, and the U-shaped structures are distributed on the surface of the cylindrical body structure. According to the invention, the micro structures of bionic dolphin spine skin and the micro structures of bionic mosquito stylets are adopted, and the novel micro-nano combined structure is formed by combining the two micro-structures and is applied to the swimming bladder, and a good drag reductioneffect is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

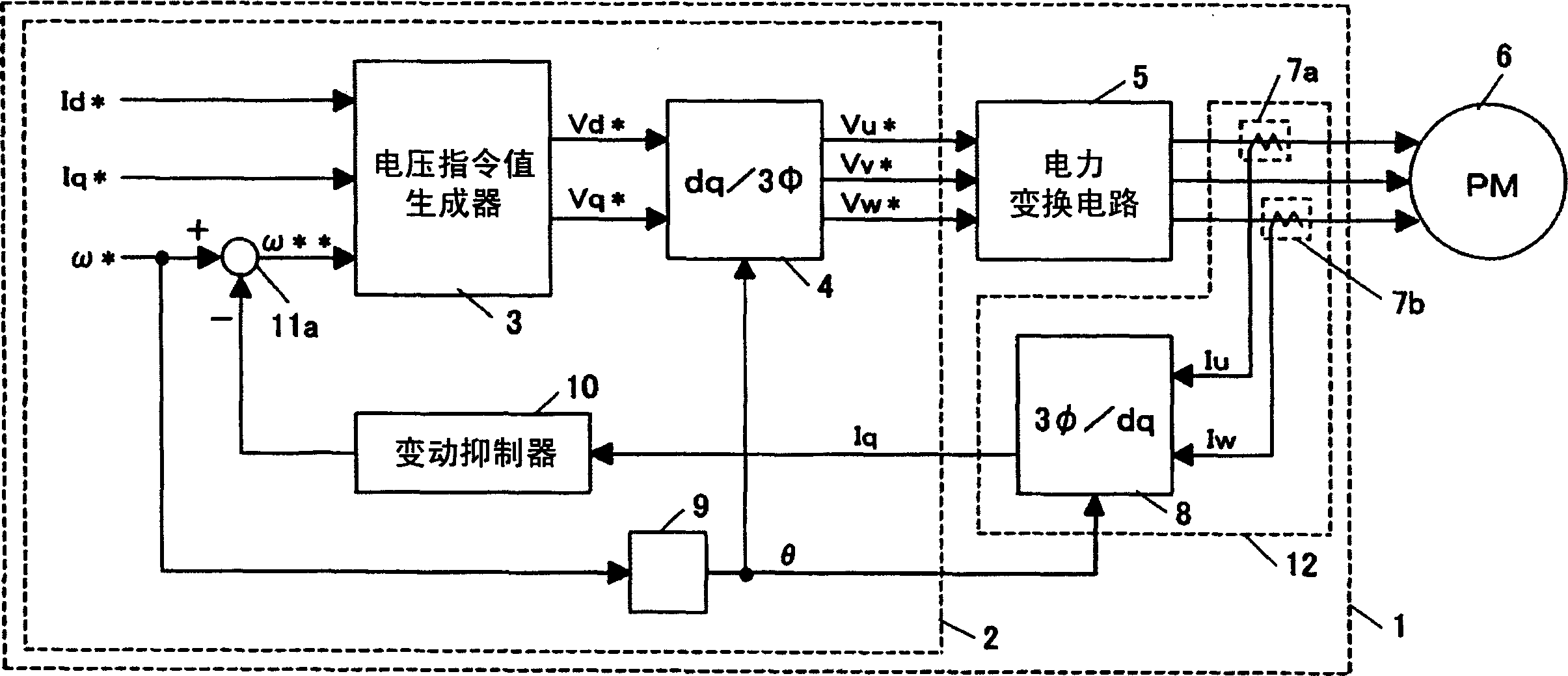

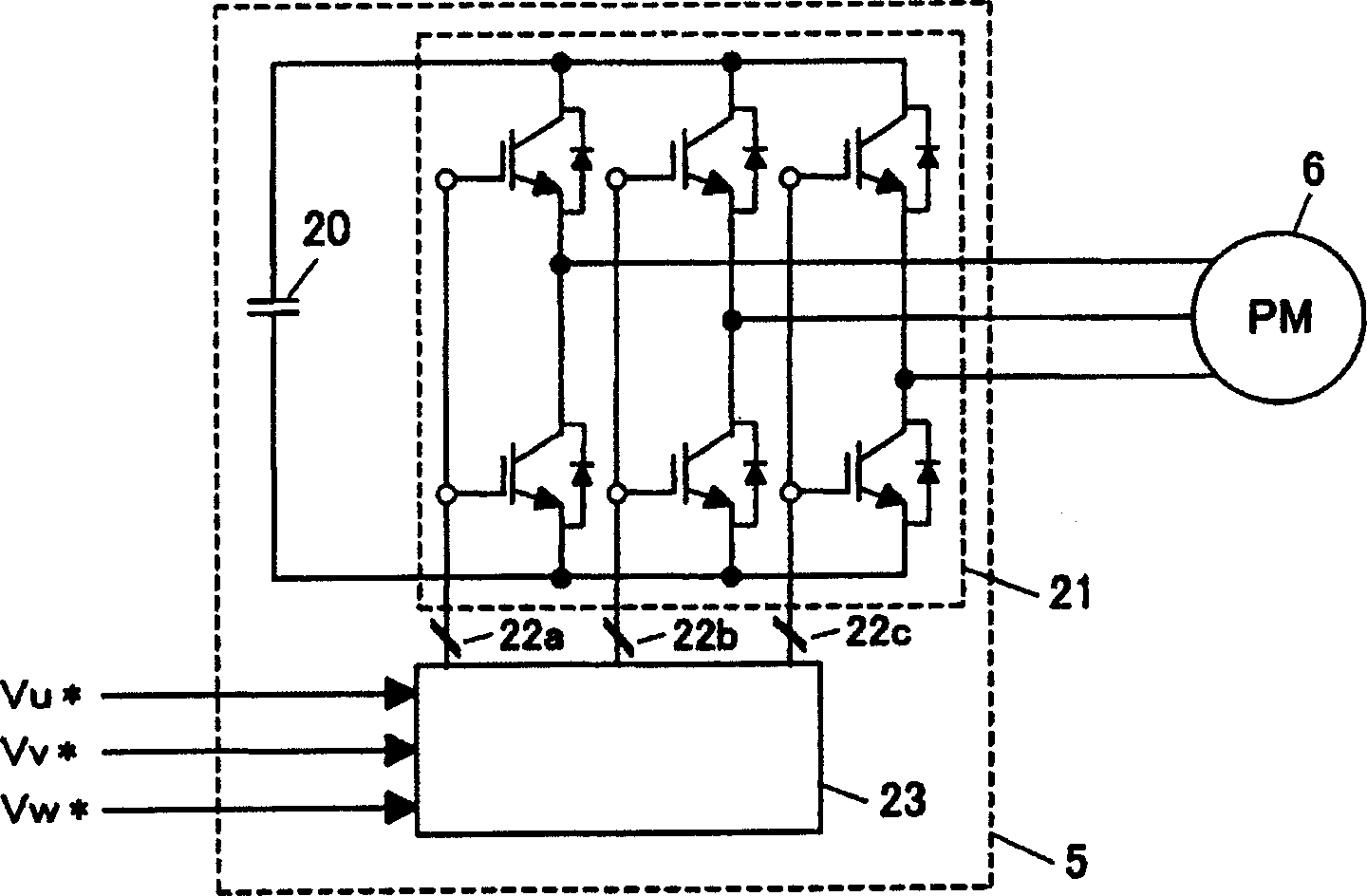

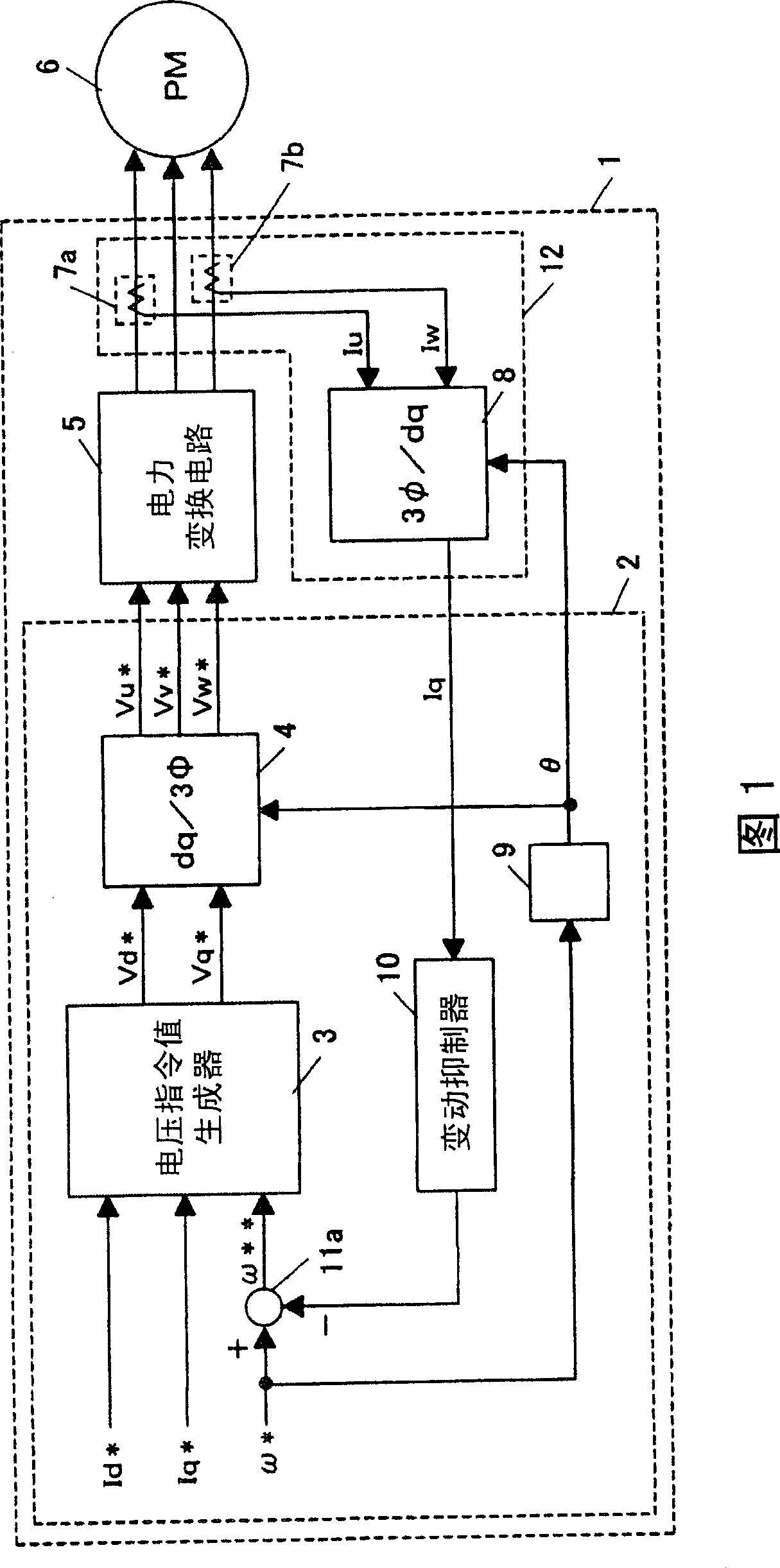

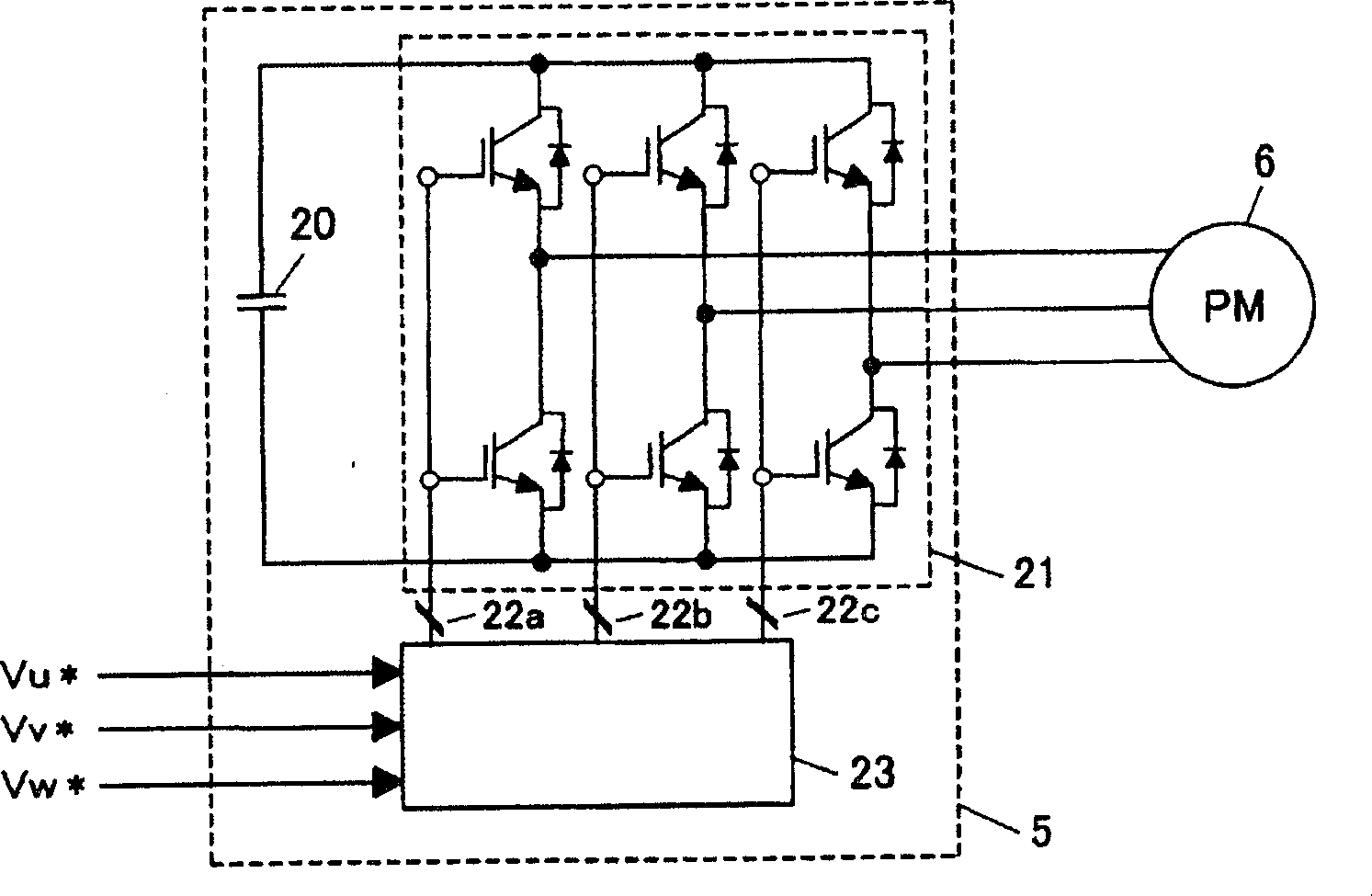

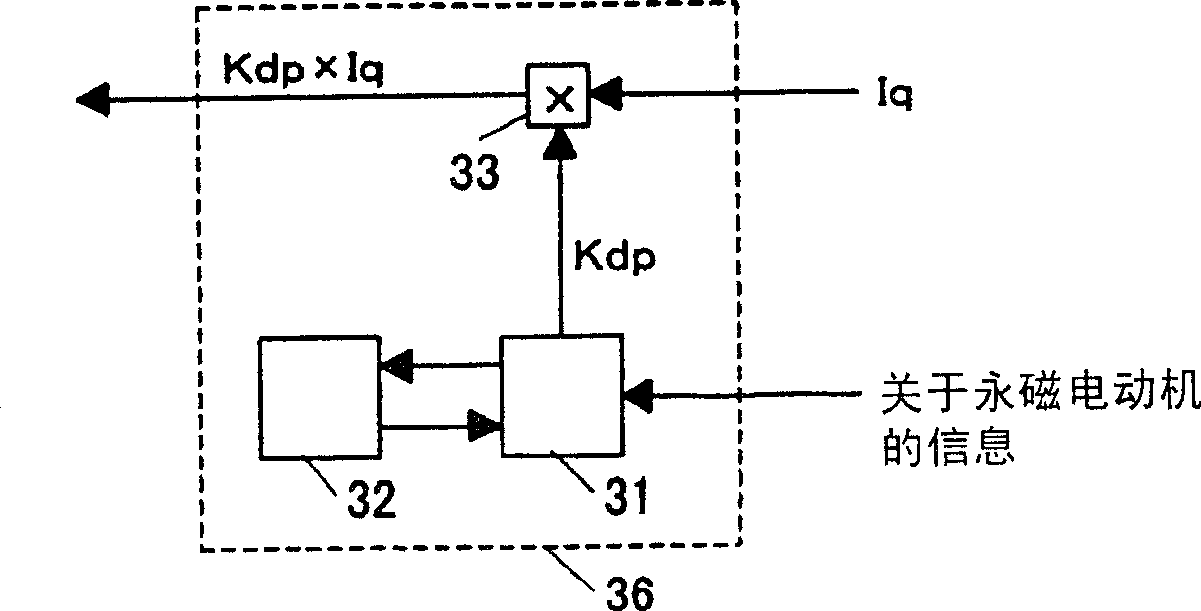

Permanent magnetism synchrounous electromotor control device

InactiveCN1897456ASuppresses speed fluctuationsAC motor controlVector control systemsPermanent magnet synchronous motorPermanent magnet motor

The present invention provided a controller which effectively controls the velocity when starting a permanent magnet synchronous motor in synchronous operation mode. The controller for a permanent magnet synchronous motor, which is equipped with a permanent magnet synchronous motor that has a permanent magnet as a field, a voltage command maker which gets a voltage command to be applied to the above permanent magnet motor, according to a d-axis current command, a q-axis current command, and a frequency command, and a power converting circuit which applies voltage to the above permanent magnet synchronous motor, according to the above voltage command, detects the q-axis current of the permanent magnet synchronous motor when starting the above permanent magnet synchronous motor in synchronous operation mode, and applies gain to the detected q-axis current value, and subtracts the operation results from the above frequency command thereby modifying the frequency command.

Owner:HITACHI APPLIANCES INC

Image forming apparatus having a medium transporting belt formed in an endless shape and having a first and second region

InactiveUS7209694B2Easy to cleanSuppresses speed fluctuationsElectrographic process apparatusMechanical engineeringElectrode

A belt member is seamed to form an endless belt which is stretched by a plurality of roller members and circulated in a first direction. The belt member is provided with an electrode portion at a first end portion thereof in a second direction perpendicular to the first direction. A cleaning member is abutted against the belt member. A seam of the belt member extends obliquely relative to the first direction such that an end of the seam confronting the electrode portion is situated in an upstream side of the first direction.

Owner:SEIKO EPSON CORP

Permanent magnetism synchrounous electromotor control device

InactiveCN100463357CSuppresses speed fluctuationsAC motor controlVector control systemsPermanent magnet synchronous motorPermanent magnet motor

The present invention provided a controller which effectively controls the velocity when starting a permanent magnet synchronous motor in synchronous operation mode. The controller for a permanent magnet synchronous motor, which is equipped with a permanent magnet synchronous motor that has a permanent magnet as a field, a voltage command maker which gets a voltage command to be applied to the above permanent magnet motor, according to a d-axis current command, a q-axis current command, and a frequency command, and a power converting circuit which applies voltage to the above permanent magnet synchronous motor, according to the above voltage command, detects the q-axis current of the permanent magnet synchronous motor when starting the above permanent magnet synchronous motor in synchronous operation mode, and applies gain to the detected q-axis current value, and subtracts the operation results from the above frequency command thereby modifying the frequency command.

Owner:HITACHI APPLIANCES INC

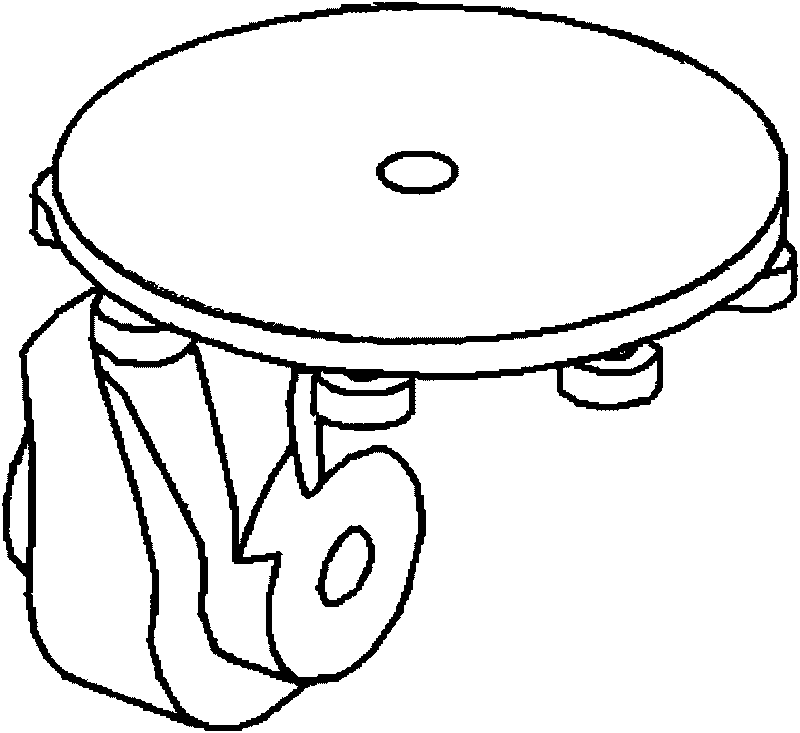

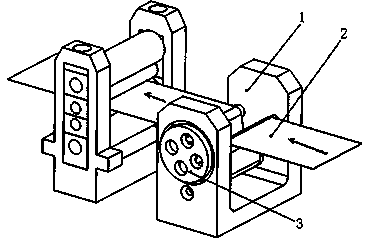

Coaxial radial push rod high-speed dividing mechanism

ActiveCN101245841AWide range of graduationsAchieve high-speed indexingGearingIntermittent motionEngineering

The invention discloses a co-axial type radial thrust rod high speed indexing mechanism, comprising a box body, an input shaft and an output shaft. The axial lines of the input shaft and the output shaft are on a same line; the end part of the input shaft is fixed with a driving cirque which is provided with at least a pair of symmetrical radial through holes; the output shaft is fixedly connected with at least a pair of symmetrical cranks; the end part of the crank is respectively provided with at least one first roller; the box body is fixed with an internal profile conjugate cam; each pair of symmetrical through holes on the driving cirque are internally provided with a thrust rod respectively; one end of the thrust rod is provided with a second roller which is contacted with the internal profile conjugate cam; the other end of the thrust rod is in flat bottom structure which is contacted with the first roller at the end part of the crank. The indexing mechanism of the invention can be widely applied to automatic machines with large indexing number range, compact structure, large rigidity, high bearing force, coaxial input and output and high speed indexing intermittent motion, such as various machines of printing, packaging, foods, ceramics, pharmacy, military industries, etc.

Owner:连云港市邦本科技有限公司

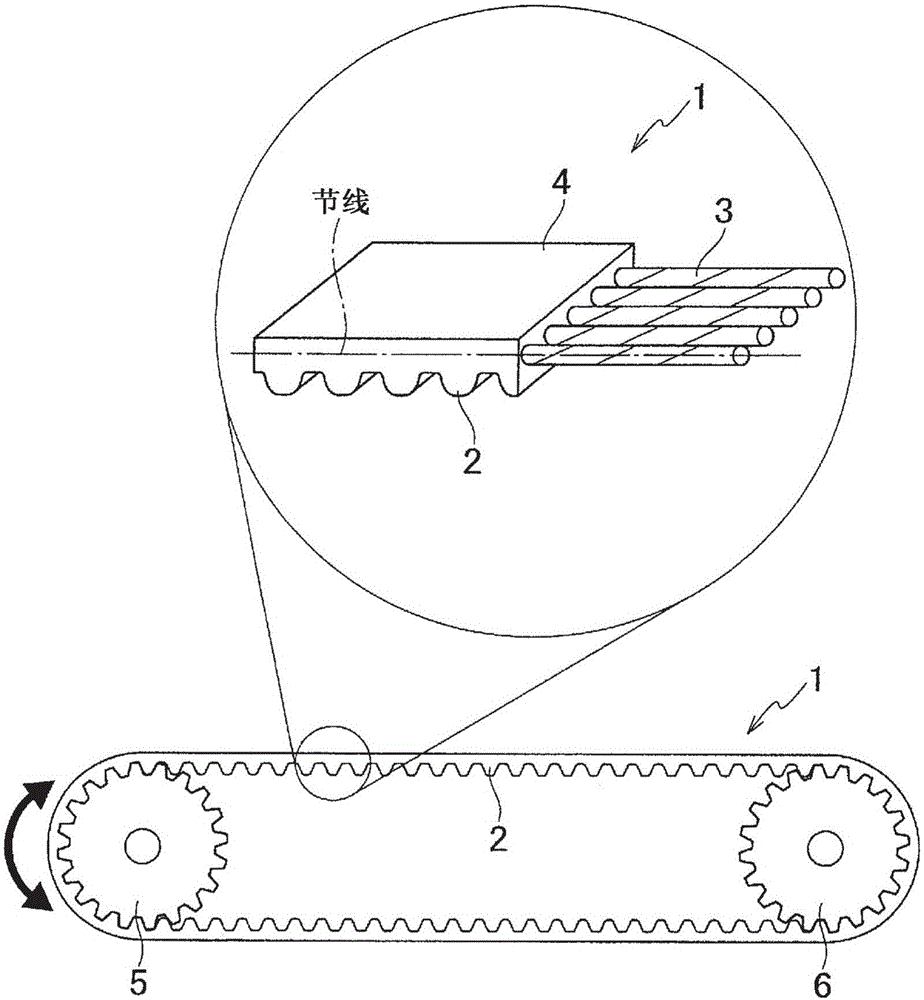

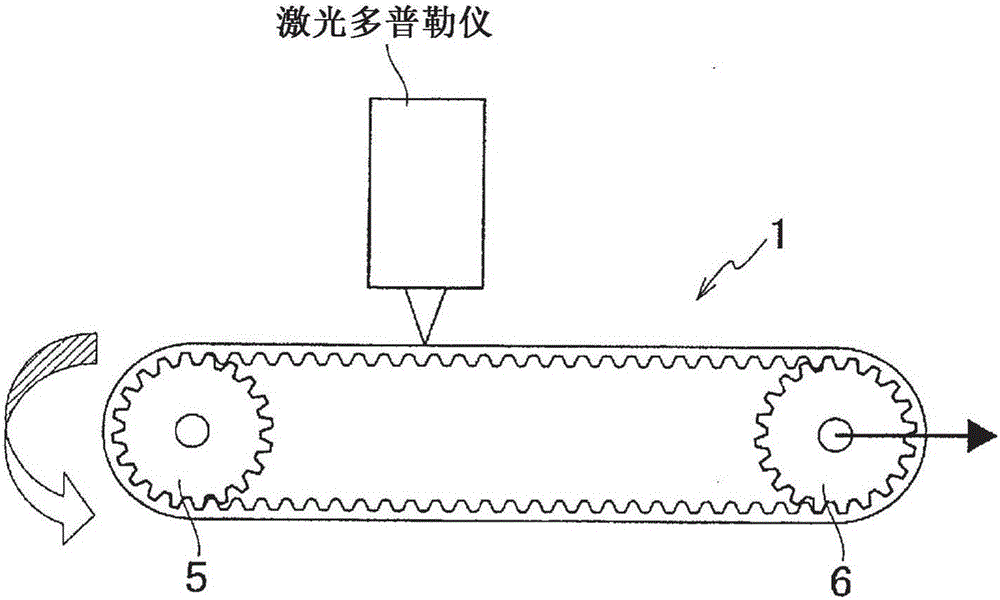

Toothed belt

The present invention pertains to a toothed belt equipped with a back section, a tooth section, and core wires embedded in the back section. The back section and the tooth section include a urethane resin composition, and the core wires are twisted cords comprising a group of glass fiber filaments, or are twisted cords comprising a group of polyarylate fiber filaments. When the core wires are twisted cords comprising a group of glass fiber filaments, the pitch of the tooth section is 0.45-0.60 mm, the diameter of the glass fiber filaments is 6-9 microns, and the wire diameter of the core wires is 0.14-0.20 mm. When the core wires are twisted cords comprising a group of polyarylate fiber filaments, the pitch of the tooth section is 0.45-0.71 mm, and the wire diameter of the core wires is 0.14-0.28 mm.

Owner:MITSUBOSHI BELTING LTD

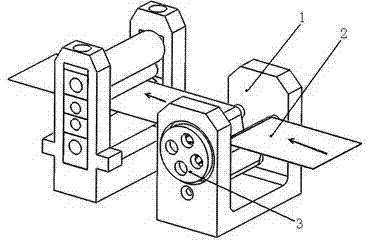

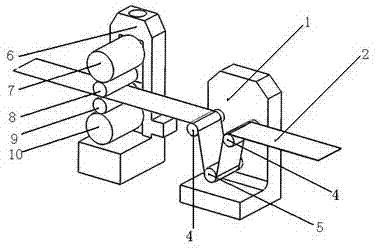

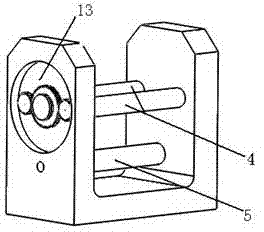

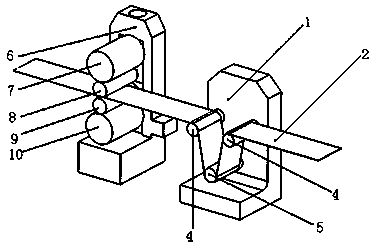

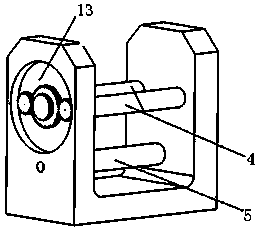

Device for restraining vibration of high-speed rolling mill by reducing speed fluctuation of rolling inlet of aluminum foil

InactiveCN102921735AReduce speed fluctuationsSuppresses speed fluctuationsRolling equipment maintainenceMetal rolling arrangementsEngineeringFlywheel

The invention discloses a device for restraining the vibration of a high-speed rolling mill by reducing the speed fluctuation of a rolling inlet of an aluminum foil. A frame is arranged at the front end of the mill equipment and at the rolling inlet of the aluminum foil. Two guide rollers and a tensioning roller are arranged in the frame, wherein the two guide rollers are mounted at the upper part of the frame; the tensioning roller is mounted at the lower part of the frame and between the two guide rollers; a small gear is mounted on a roll neck at one end of each guide roller; a big gear is mounted on the shaft neck of a flywheel; the flywheel is mounted in a flywheel mounting groove in the outer side of the frame; and the small gear on each guide roller and the big gear on the flywheel are matched in a gear engaging manner. The device provided by the invention has the advantages of simple mechanism structure and easiness in maintenance and repair, and has a good effect of restraining the speed fluctuation of the rolling inlet of the aluminum foil.

Owner:HANGZHOU DIANZI UNIV

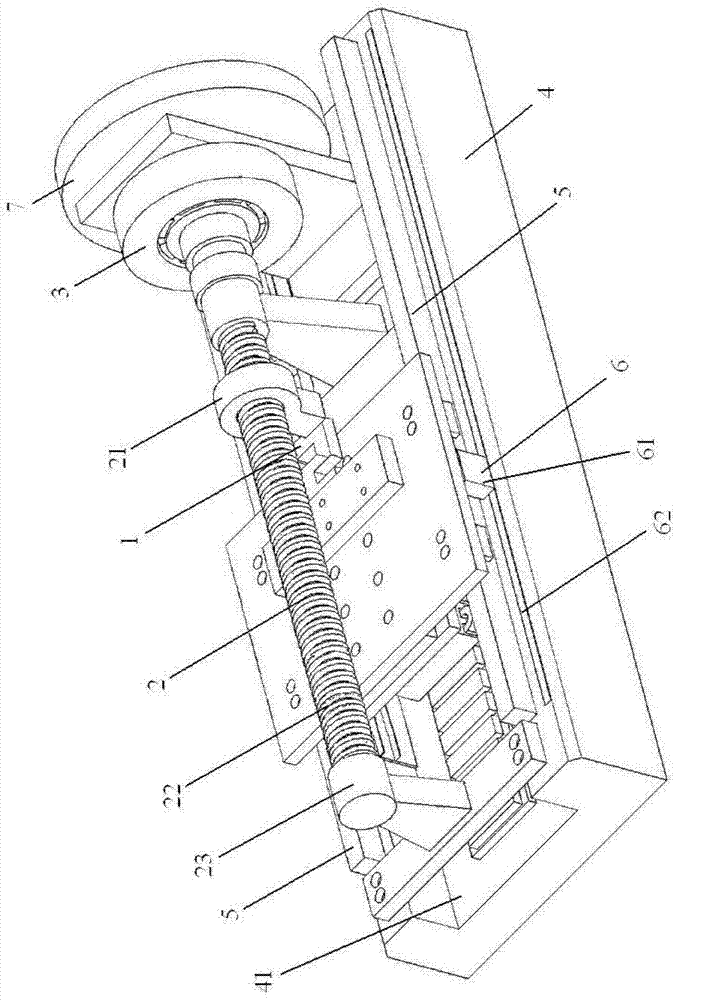

Method for testing force characteristic of linear electric motor

ActiveCN102435944BImplement bidirectional testingSuppresses speed fluctuationsApparatus for force/torque/work measurementDynamo-electric machine testingLinear motionElectricity

The invention relates to a device and a method for testing a force characteristic of a linear electric motor, which relate to the technical field of motor test, and aims at the main problems existing in various linear electric motor test devices at present. A pull pressure sensor is used for testing the output force of a linear electric motor to be tested, and is also used for testing the force applied to a rotor of the linear electric motor to be tested; a ball screw is used for converting gyroscopic motion of a loading servo motor into linear motion of the rotor of the linear electric motor to be tested, and comprises a nut, a screw rod and a fixed support; the loading servo motor is used for driving the screw rod of the ball screw to rotate and dragging the nut of the balls screw to do linear motion; a base is used for fixing a stator of the linear electric motor to be tested and the fixed support of the ball screw, so that the rotor of the linear electric motor to be tested driven by the nut of the ball screw and the stator of the linear electric motor to be tested fixed on the base are located at a normal working position of the linear electric motor; a guide rail is used for guiding and supporting the rotor of the linear electric motor to be tested to move on the base along the motion direction of the rotor of the electric motor; and a displacement sensor is used for measuring the displacement of the rotor of the linear electric motor to be tested.

Owner:HARBIN INST OF TECH

Image forming apparatus

ActiveUS8744313B2Improve image qualitySuppresses speed fluctuationsGearboxesPortable liftingRotational axisDrive shaft

An image forming apparatus driving unit includes a rotatable member which is rotatably supported, a pair of bearing portions for rotatably supporting the rotatable member, and a motor for driving the rotatable member. In addition, a driving gear is provided on a driving shaft of the motor, and a driven gear, provided outside the pair of bearing portions with respect to a rotational axis direction of the rotatable member, engages with the driving gear to be rotated integrally with the rotatable member. At least one of the driven gear and the driving gear has, with respect to the rotational axis direction of the rotatable member, a crown shape so that a central tooth surface of a tooth projects more than end tooth surfaces of the tooth at a side where the driven gear and the driving gear engage each other. During driving of the driving gear, a first position where a pressure received by the tooth surface is at a maximum and a second position where an amount of crowning formed on the driven gear or the driving gear is at a maximum are offset in a same direction.

Owner:CANON KK

Speed fluctuation suppression method, control device and compressor control system

ActiveCN105450098BSuppresses speed fluctuationsReduce dependenceTorque ripple controlVector control systemsControl systemPermanent magnet synchronous motor

The invention discloses a speed fluctuation suppressing method of a permanent magnet synchronous motor, which comprises the following steps: obtaining the target rotational speed and the feedback rotational speed of the permanent magnet synchronous motor, and calculating the fluctuation rotational speed of the permanent magnet synchronous motor according to the target rotational speed and the feedback rotational speed; The speed is iteratively learned and controlled to obtain the compensation speed, and the compensation speed is superimposed on the given speed of the previous control cycle of the permanent magnet synchronous motor to obtain the given speed of the current control cycle; according to the given speed of the current control cycle The magnetic synchronous motor is controlled to suppress the speed fluctuation of the permanent magnet synchronous motor. The suppression method obtains the compensation speed by performing iterative learning control on the fluctuation speed to correct the given speed of the speed loop, so as to effectively suppress the speed fluctuation of the permanent magnet synchronous motor during operation. The invention also discloses a control device of the permanent magnet synchronous motor and a compressor control system with the same.

Owner:ANHUI MEIZHI PRECISION MFG

High-speed indexing mechanism of front connection type cam connecting rod

InactiveCN101701620AHigh division timesSuitable for high-speed indexing transmissionGearingConnection typeEngineering

The invention discloses a high-speed indexing mechanism of a front connection type cam connecting rod, comprising a box body, an input shaft and an output shaft. A conjugate cam is fixedly connected to the box body; the axes of the input shaft and the output shaft are on a same straight line; the transmission between the input shaft and the output shaft is realized by a parallel-connection combined cam connecting rod mechanism which consists of the conjugate cam and one or two sets of connecting rod mechanisms; each set of connecting rod mechanisms comprises an input rod fixedly connected to the input shaft and an output rod fixedly connected to the output shaft; a first connecting rod and a second connecting rod are sequentially hinged between the input rod and the output rod; a hinge point between the input rod and the first connecting rod is positioned in the middle area of the first connecting rod; and two ends of the first connecting rod respectively contact with inner outline lines of two cams in the conjugate cam. The invention can meet the working condition requirement of a high-speed automatic machine on realizing higher indexing frequency.

Owner:启东晟涵医疗科技有限公司

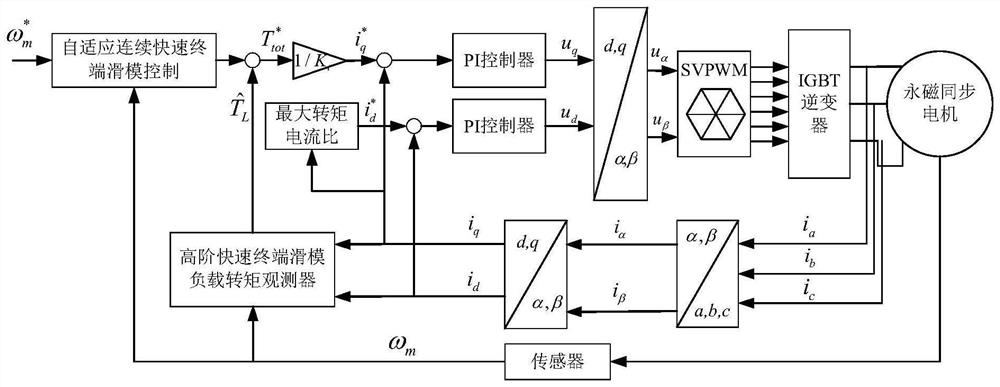

Adaptive Continuous Sliding Mode Control Method for Permanent Magnet Synchronous Motor Based on Torque Observation

ActiveCN111342720BEliminate chatterSuppresses speed fluctuationsElectronic commutation motor controlVector control systemsMaximum torqueLoad torque

The invention discloses a permanent magnet synchronous motor self-adaptive continuous sliding mode control method based on load torque observation, comprising: establishing a permanent magnet synchronous motor mathematical model; using a high-order fast terminal sliding mode load torque observer to estimate permanent magnet synchronous The load torque of the motor system is used for feed-forward compensation of the speed controller of the permanent magnet synchronous motor; the design of the adaptive continuous fast terminal sliding mode permanent magnet synchronous motor drive controller obtains the q-axis reference current under the system disturbance; the maximum torque ratio is used The strategy calculates the q-axis reference current; obtains the dq-axis control voltage through the current controller, and finally drives the permanent magnet synchronous motor to rotate through the drive module. The control method of the present invention combines a high-order fast terminal sliding mode load torque observer and an adaptive continuous fast terminal sliding mode controller, which can not only effectively control the speed of the permanent magnet synchronous motor, but also effectively weaken the chattering caused by the sliding mode and improve the Speed control accuracy and dynamic performance.

Owner:NANJING UNIV OF SCI & TECH

Brake force real-time adjusting method based on brake-by-wire system and adjusting device

ActiveCN102582600BHigh braking precisionBrake force adjustmentElectrodynamic brake systemsBraking systemsLoop controlElectric machinery

The invention provides a brake force real-time adjusting method based on a brake-by-wire system. The brake force real-time adjusting method comprises following steps: respectively obtaining objective position signal values of motors in various electronic and mechanical brakes of front wheels and / or rear wheels of a brake vehicle according to strokes of electronic brake pedals; respectively acquiring actual position signal values, actual rotation speed signal values and actual current signal values of the motors in real time; and respectively realizing real-time closed-loop control for positions, rotation speeds and current of the motors according to deviation between the objective position signal values and the actual position signal values of the motors, the actual rotation speed signal values and the actual current signal values, and accordingly adjusting actually outputted brake force of the electronic and mechanical brakes with the motors in real time. Correspondingly, the invention provides a brake force real-time adjusting device. The brake force real-time adjusting method and the adjusting device can suppress fluctuation generated when brake force is adjusted in real time in the prior art, stability of the brake-by-wire system is improved, and a braking effect is good.

Owner:CHERY AUTOMOBILE CO LTD

High-speed dividing mechanism of back connection type cam connecting rod

InactiveCN101705983AHigh division timesSuitable for high-speed indexing transmissionGearingConnection typeEngineering

The invention discloses a high-speed dividing mechanism of a back connection type cam connecting rod, which comprises a box body, an input shaft and an output shaft, wherein a conjugate cam is fixedly connected to the box body, axial lines of the input shaft and the output shaft are in one straight line, the transmission between the input shaft and the output shaft is realized by a parallel connection combined cam connecting rod mechanism which comprises the conjugate cam and one or two sets of connecting rod mechanisms, each set of connecting rod mechanism comprises an input rod fixedly connected to the input shaft and an output rod fixedly connected to the output shaft, a first connecting rod and a second connecting rod are sequentially hinged between the input rod and the output rod, the hinge point between the output rod and the second connecting rod is positioned in the middle region of the second connecting rod, and two ends of the second connecting rod are respectively in contact with inner outlines of two cams in the conjugate cam. Two end parts of the second connecting rod in contact with the inner outlines of the conjugate cam are provided with rollers. The two sets of connecting rod mechanisms are symmetrically arranged. The invention can meet the working condition requirement for higher dividing times of a high-speed automatic machine.

Owner:启东晟涵医疗科技有限公司

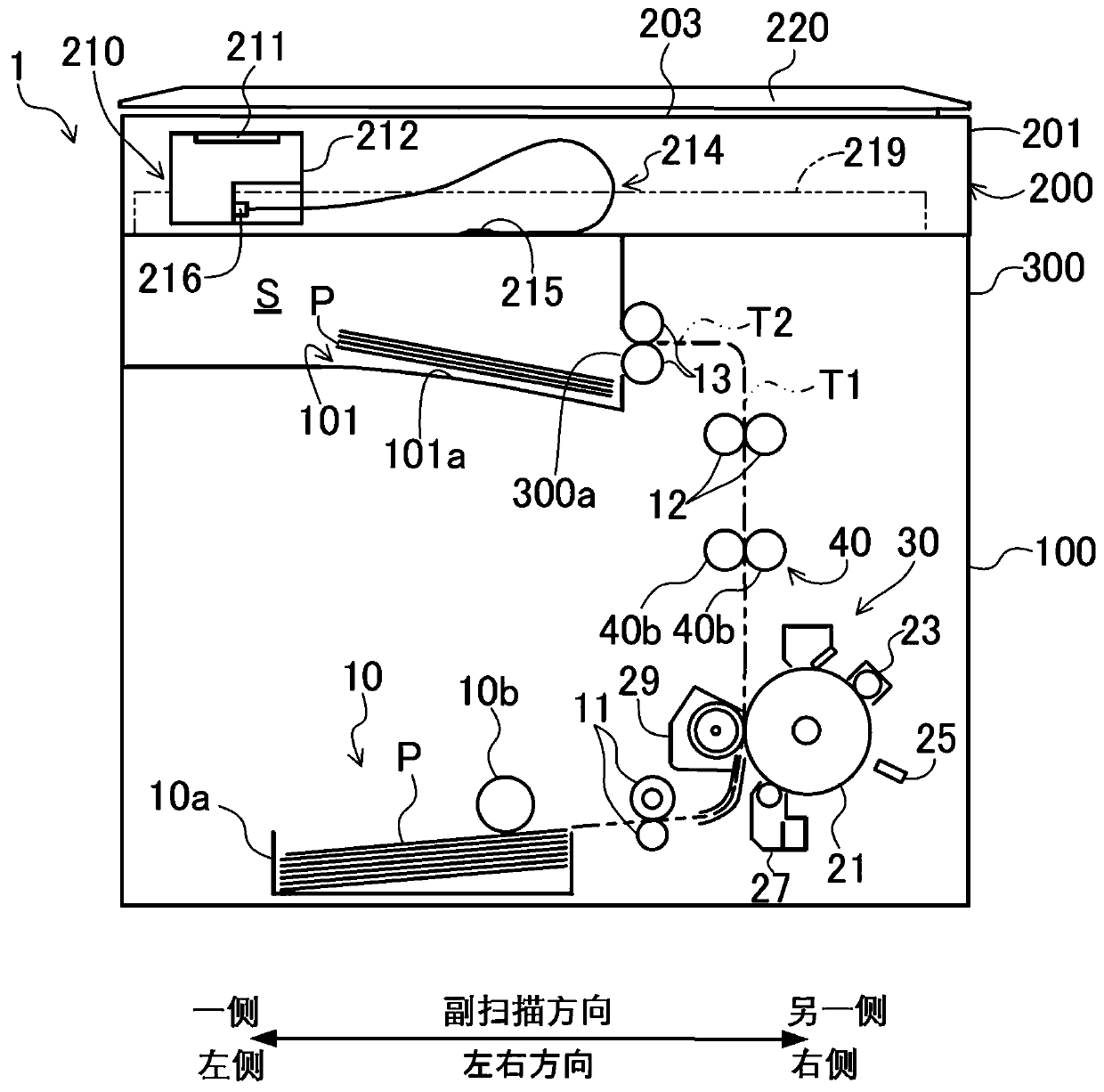

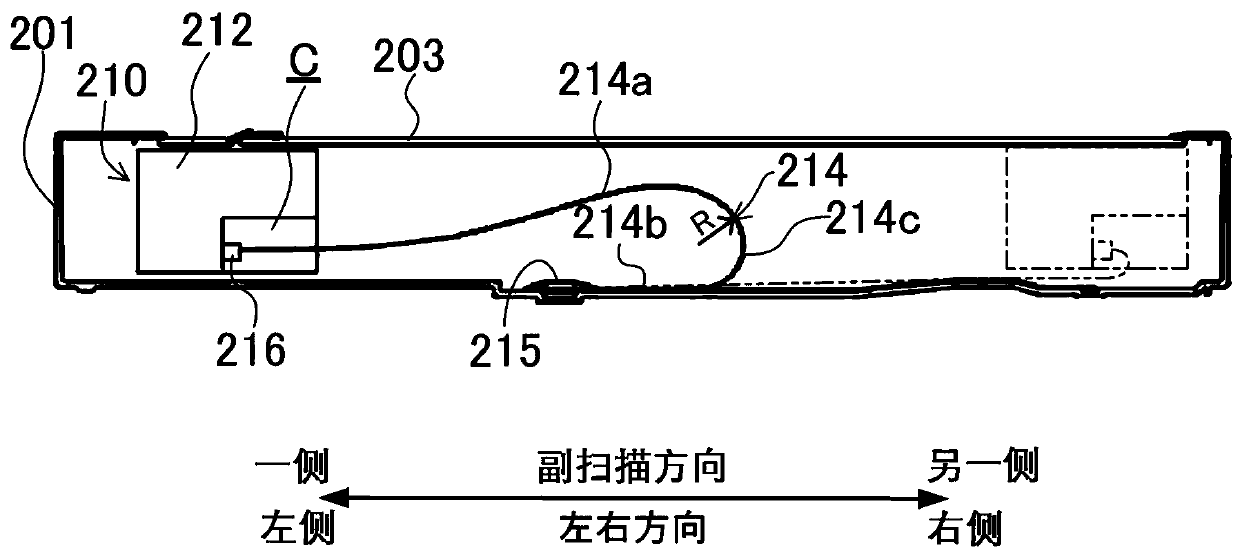

Image-reading device

ActiveCN107852442ASuppresses speed fluctuationsElectrographic process apparatusPhotographic printingElectric cablesAngle of inclination

An image-reading device provided with an angle regulation unit (212a) for regulating the angle of inclination of a flat cable (214) to a document placement glass (203) as seen from a sub-scanning direction so that when the top surface part of the flat cable (214) contacts the document placement glass (203) due to the movement of an image-reading unit (210), the contact part leans to one side in the main scanning direction of the flat cable (214).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

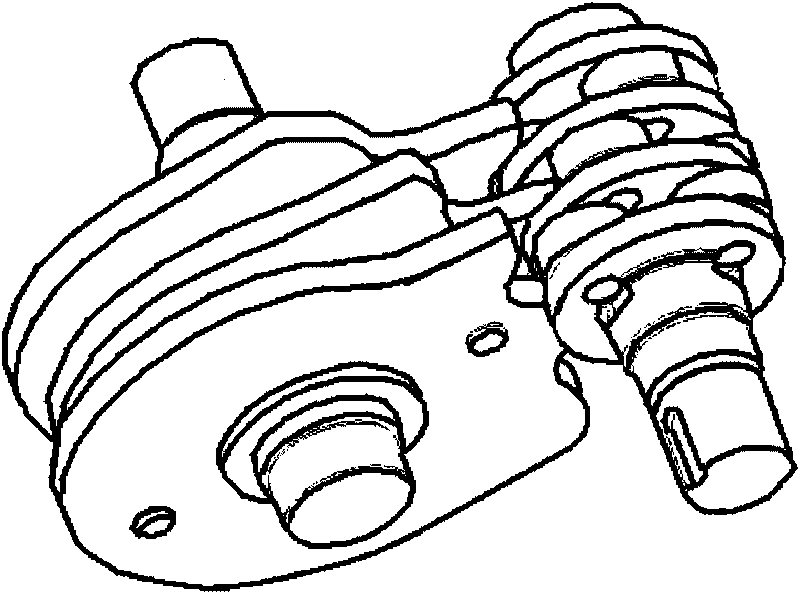

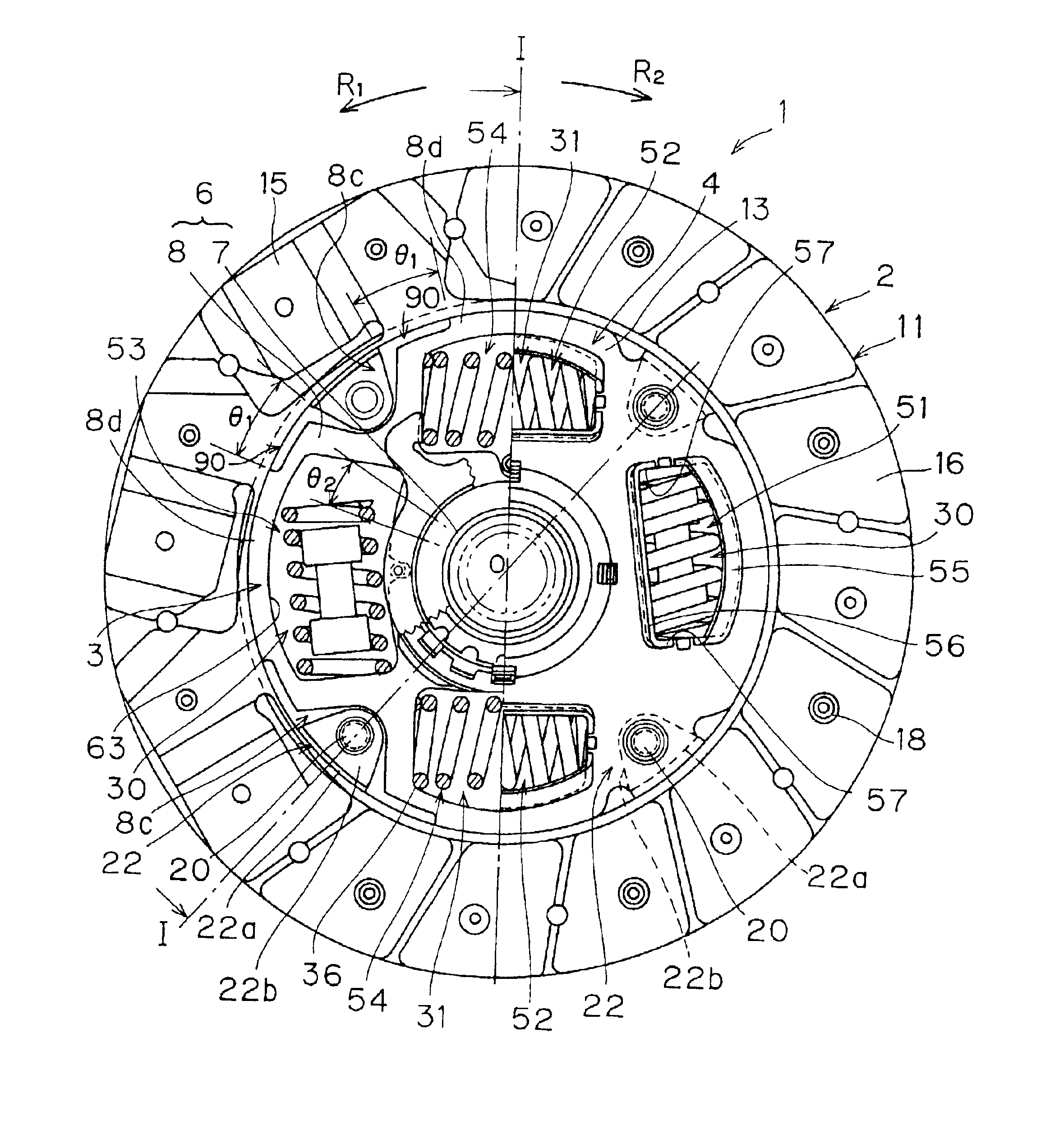

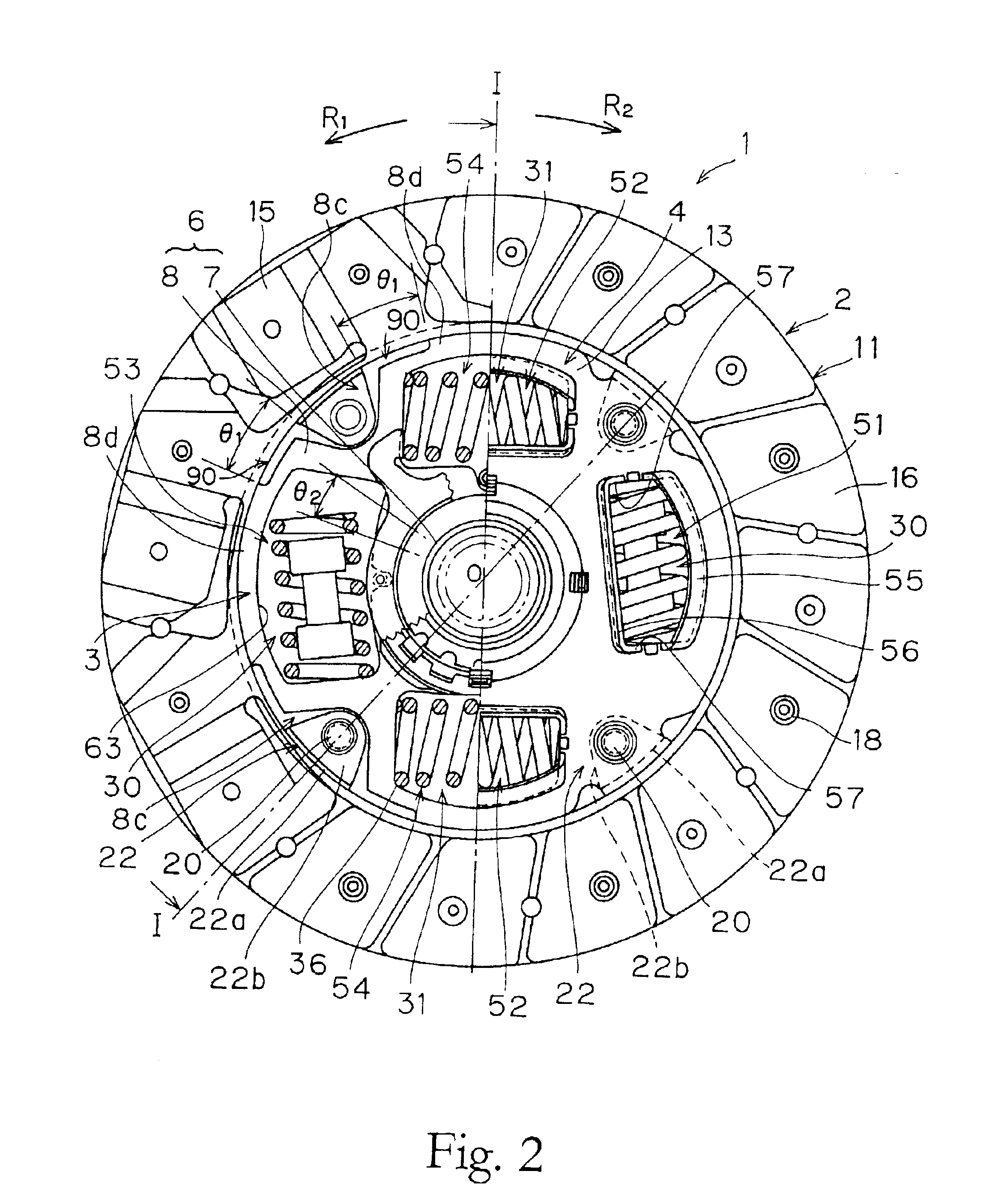

Damper mechanism

InactiveUS6872142B2Preferable performanceSimple structureClutchesRotating vibration suppressionEngineeringAngular range

Coil springs 33 and 36 couple input and output rotary members 2 and 3 together such that they can rotate relative to each other. The coil springs 33 and 36 have a torsion characteristic having a positive region and a negative region that has a lower rigidity than the positive region. A second friction generating section 71 is arranged such that friction is generated rotationally-between the input rotary member 2 and the output rotary member 3 due to the elastic force of the coil springs 33 and 36 when the two rotary members 2 and 3 rotate relative to each other. A friction suppressing mechanism secures rotational gaps 91 and 92 on only the negative side of the torsion characteristic. These rotational gaps serve to prevent the elastic force of the coil springs 33 and 36 from acting on the second friction generating section 71 within a prescribed angular range.

Owner:EXEDY CORP

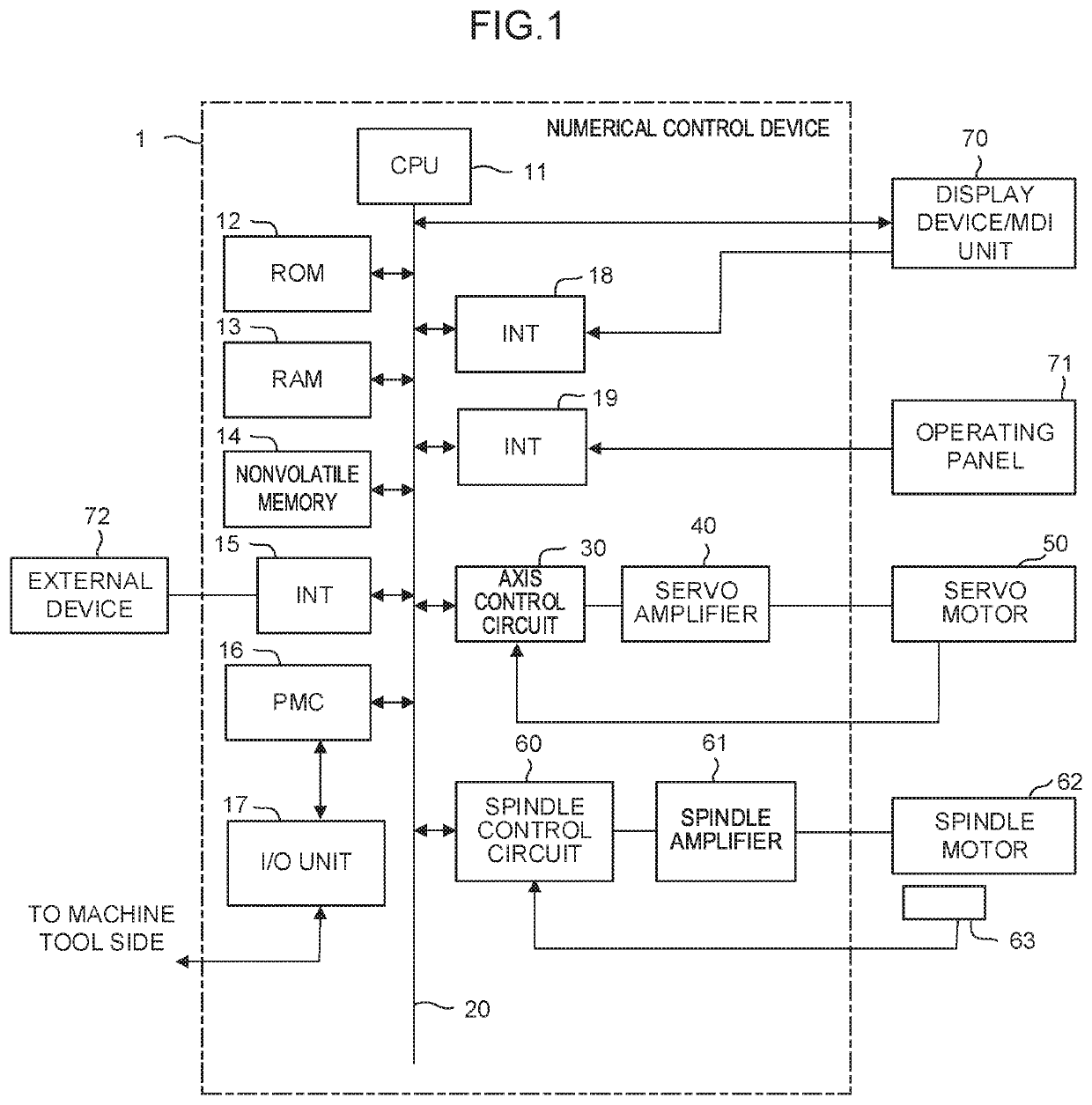

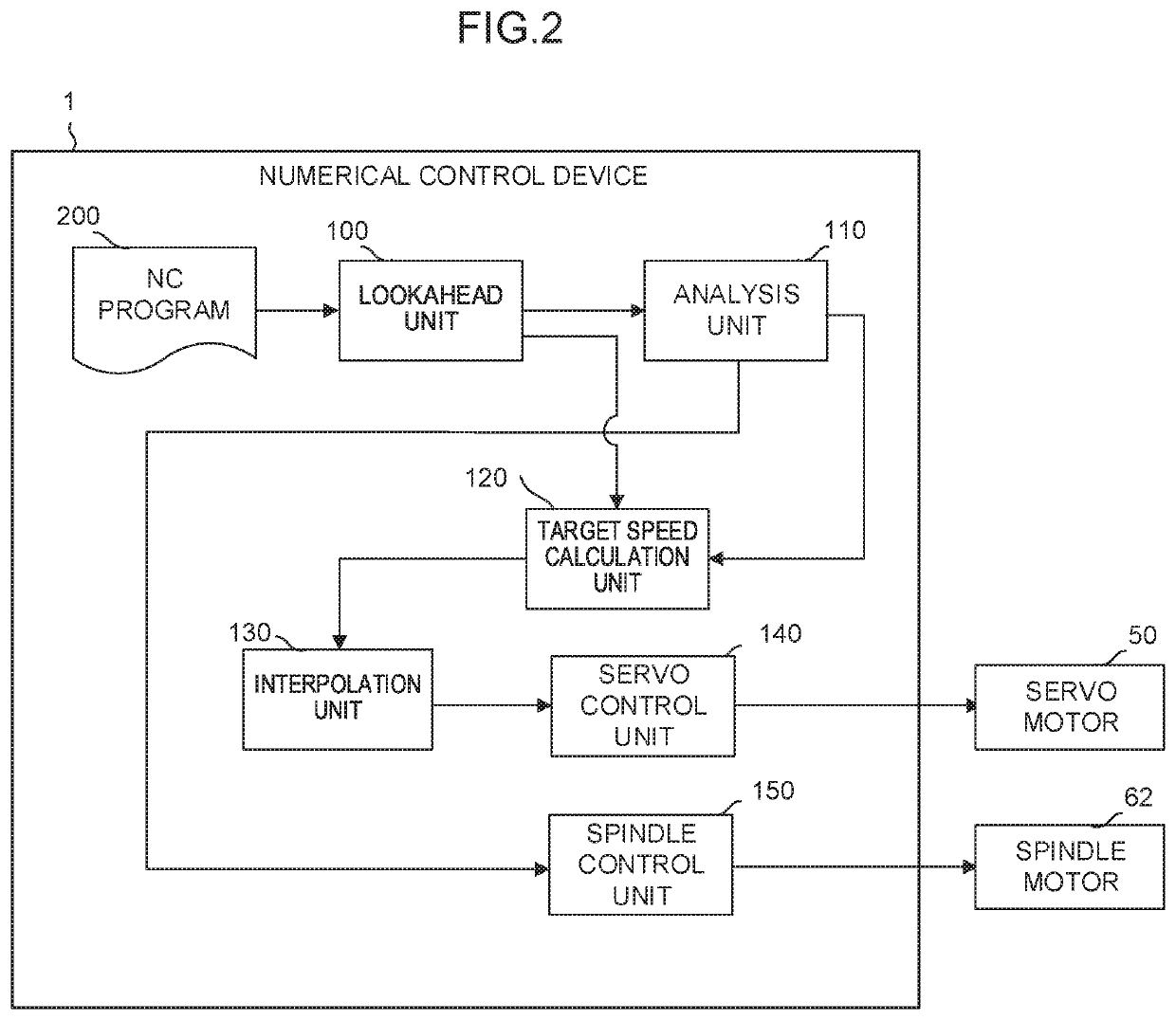

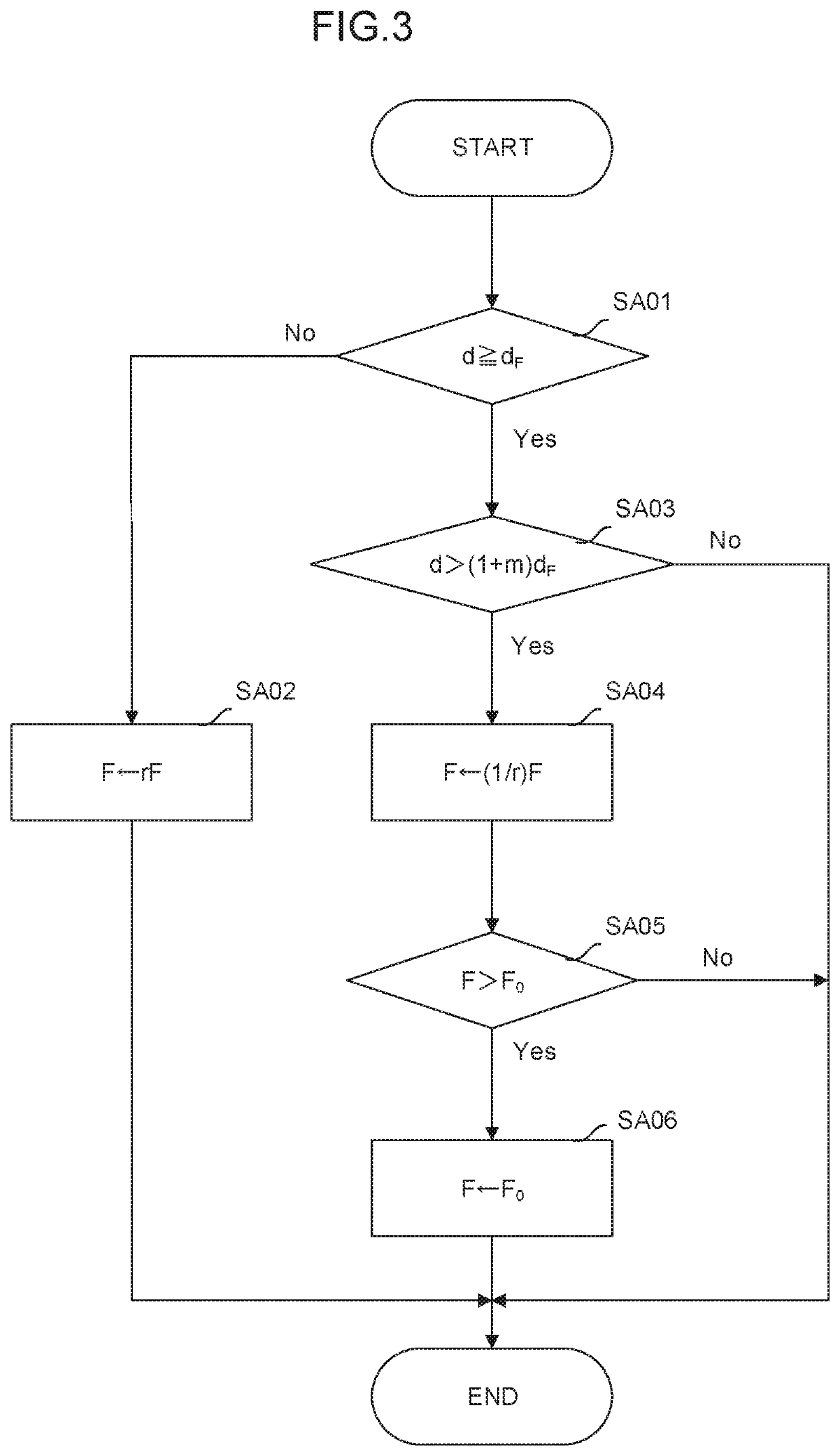

Numerical controller

ActiveUS11126163B2Suppresses speed fluctuationsSuppress fluctuationsComputer controlSimulator controlData controlSimulation

Owner:FANUC LTD

Coaxial eccentric wheel high-speed dividing mechanism

ActiveCN100545485CRealize high-speed indexing transmissionImprove dynamic propertiesGearingDrive shaftAgricultural engineering

The invention discloses a coaxial eccentric wheel high-speed indexing mechanism, which includes a box body, an input shaft and an output shaft. The drive ring is provided with at least one pair of symmetrical radial through holes; the output shaft is fixedly connected with an eccentric wheel; the box body is fixedly connected with an inner profile conjugate cam; each pair of The symmetrical radial through holes are respectively provided with push rods, and the two ends of the push rods are in contact with the eccentric wheel and the inner profile conjugate cam respectively; A roller is arranged on the end of the rod that is in contact with the conjugate cam of the inner profile.

Owner:连云港市邦本科技有限公司

Image forming apparatus and image forming method

InactiveUS8385759B2Simple structureAbrasion can be suppressedElectrographic process apparatusMaterial typeImage formation

Owner:SEIKO EPSON CORP

Device for restraining vibration of high-speed rolling mill by reducing speed fluctuation of rolling inlet of aluminum foil

InactiveCN102921735BReduce speed fluctuationsSuppresses speed fluctuationsRolling equipment maintainenceMetal rolling arrangementsGear wheelEngineering

The invention discloses a device for restraining the vibration of a high-speed rolling mill by reducing the speed fluctuation of a rolling inlet of an aluminum foil. A frame is arranged at the front end of the mill equipment and at the rolling inlet of the aluminum foil. Two guide rollers and a tensioning roller are arranged in the frame, wherein the two guide rollers are mounted at the upper part of the frame; the tensioning roller is mounted at the lower part of the frame and between the two guide rollers; a small gear is mounted on a roll neck at one end of each guide roller; a big gear is mounted on the shaft neck of a flywheel; the flywheel is mounted in a flywheel mounting groove in the outer side of the frame; and the small gear on each guide roller and the big gear on the flywheel are matched in a gear engaging manner. The device provided by the invention has the advantages of simple mechanism structure and easiness in maintenance and repair, and has a good effect of restraining the speed fluctuation of the rolling inlet of the aluminum foil.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com