Device for restraining vibration of high-speed rolling mill by reducing speed fluctuation of rolling inlet of aluminum foil

A technology of entrance speed and fluctuation suppression, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of rack tension fluctuation, affecting the quality of rolled steel products, fluctuations, etc., to improve surface quality and production efficiency , easy maintenance and repair, simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

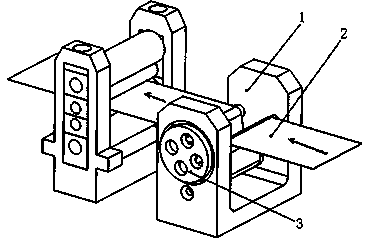

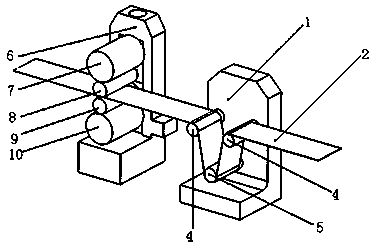

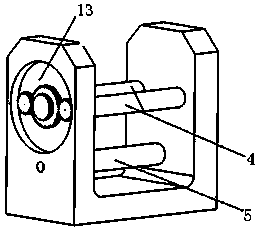

[0022] Such as figure 1 As shown, the device for reducing the fluctuation of the entrance speed of aluminum foil rolling and suppressing the flutter of the high-speed rolling mill, its structure includes: stand 1, guide roll 4, tension roll 5, flywheel 3, large gear 11, pinion 12 and rolling mill equipment . Such as figure 2 As shown, at the front end of the rolling mill equipment, a frame 1 of the device is set at the rolling entrance of the aluminum foil 2, wherein the guide roller 4 is installed on the upper part of the frame 1, and the tension roller 5 is installed on the lower part of the frame 1. The tight roller 5 is installed in the middle of the two guide rollers 4; the small gear 12 is installed at the left end roll neck of the guide roller 4, and the large gear 11 is installed on the journal of the flywheel 3; the flywheel 3 is installed in the flywheel instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com