Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Support balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

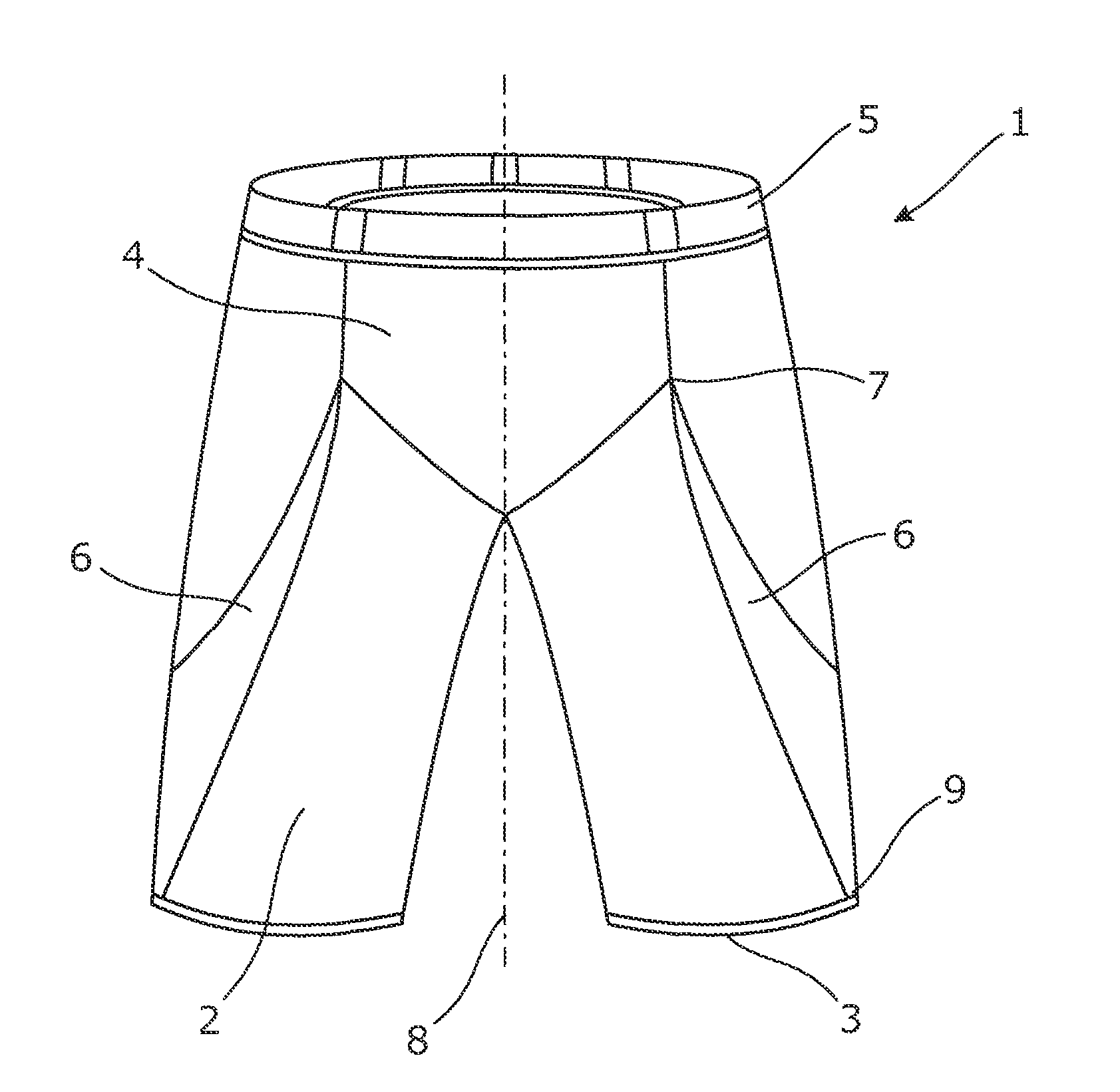

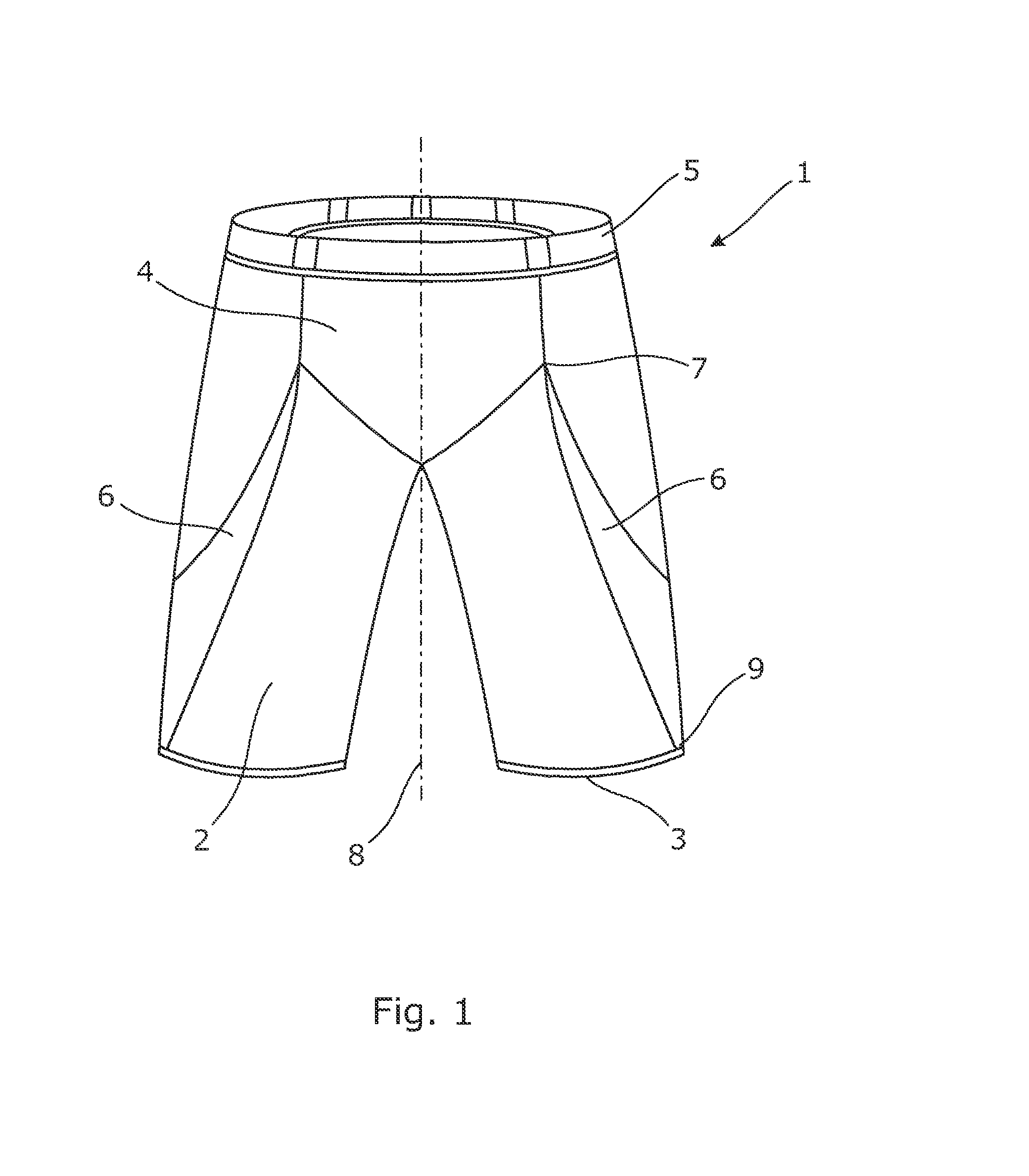

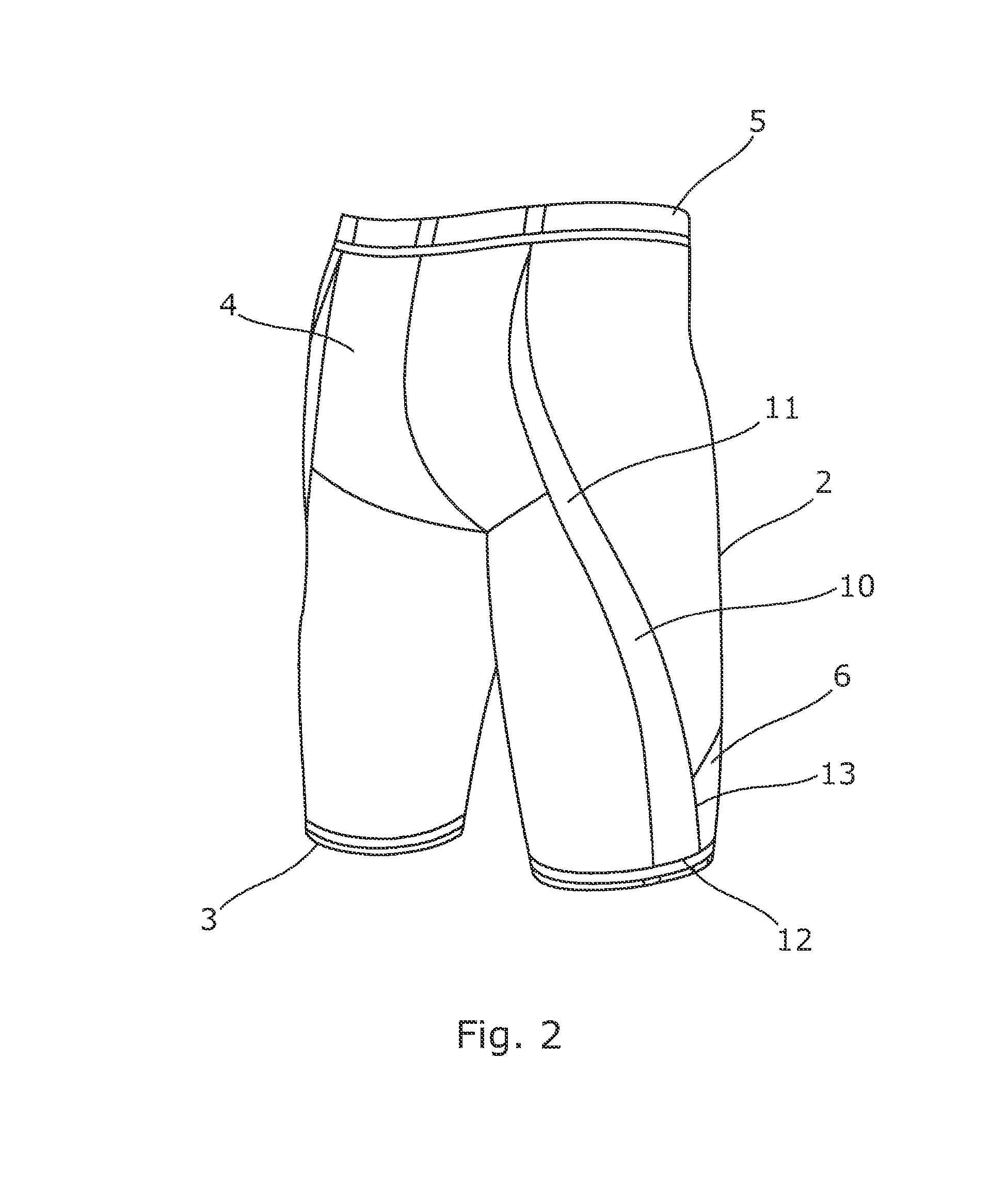

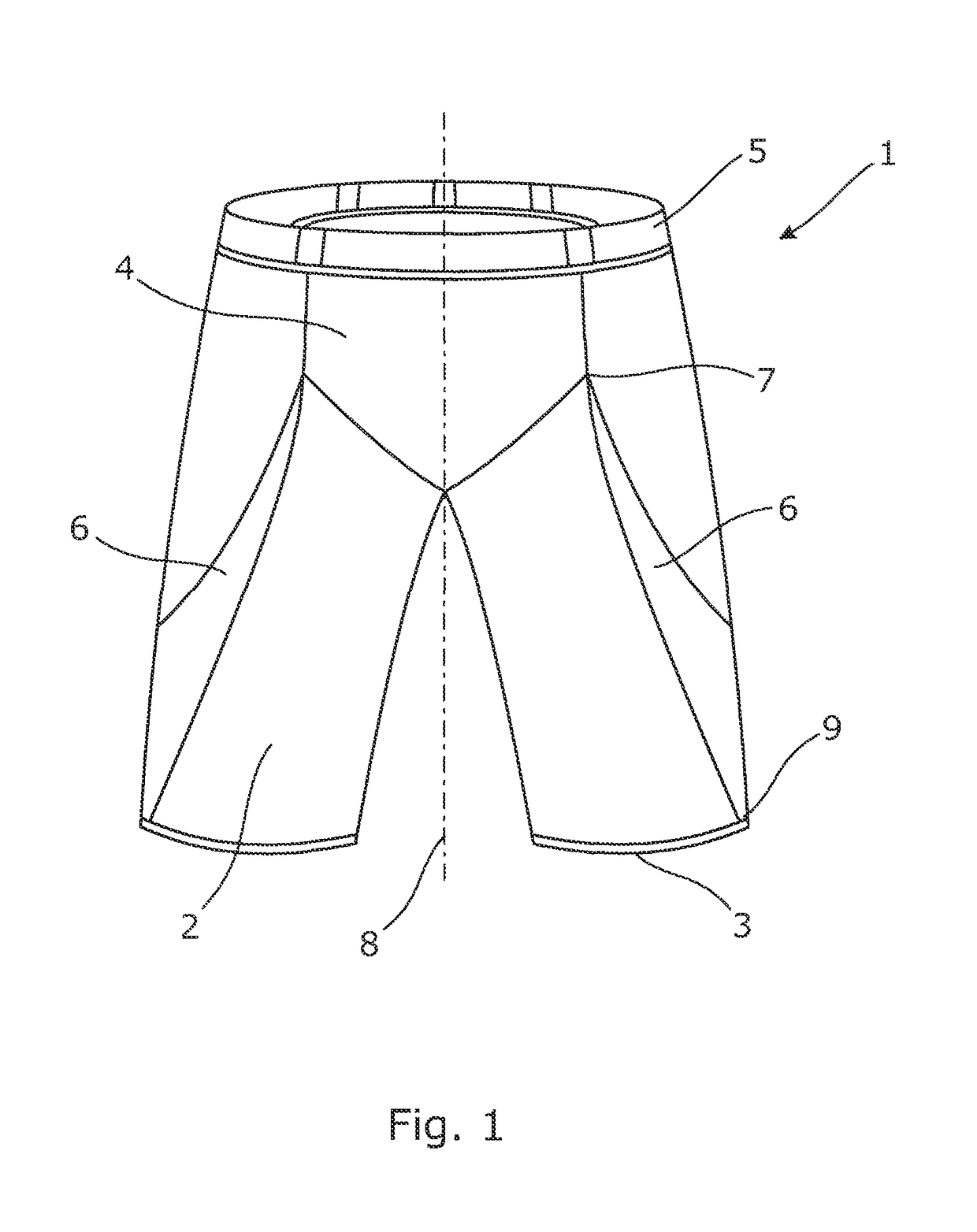

Sports Garment

ActiveUS20140096301A1Improve postureStraight spineGarment special featuresSwimming detailsThighEngineering

Owner:SPEEDO INTERNATIONAL LIMITED

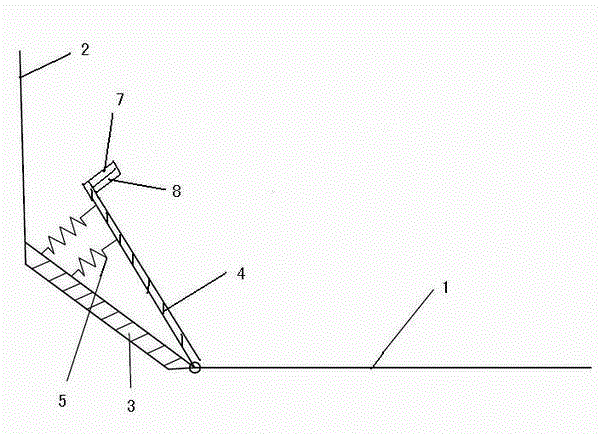

Footrest

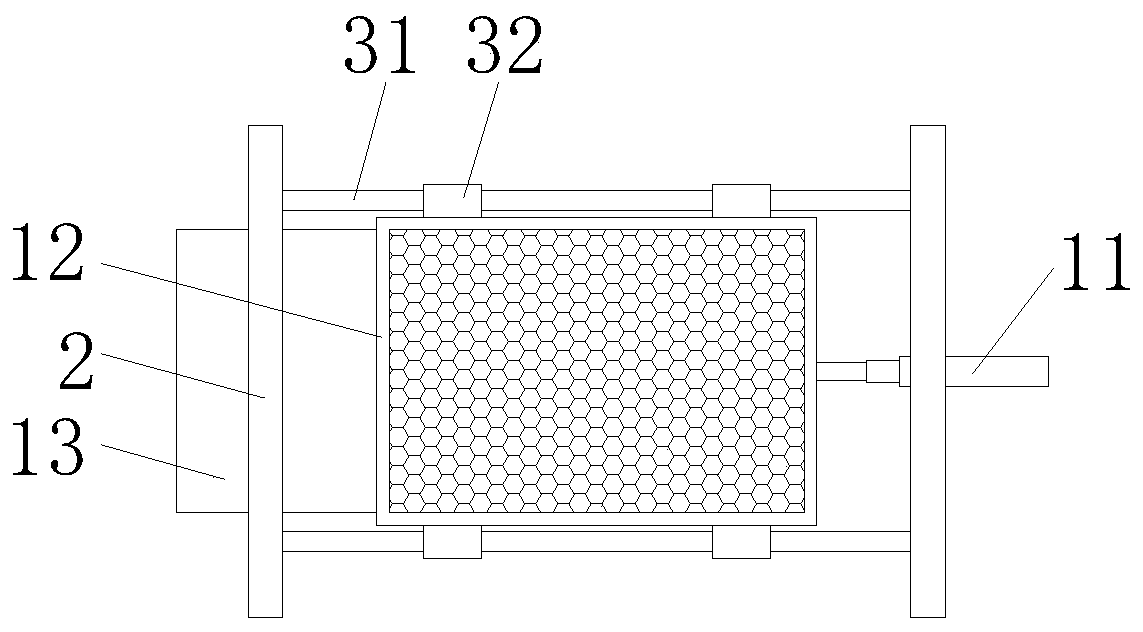

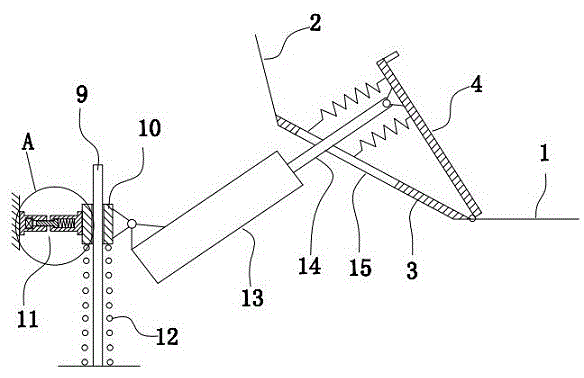

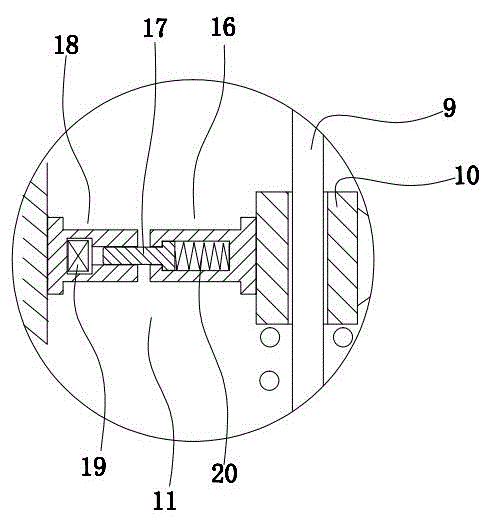

ActiveCN103909892AUniform support surfaceSupport balanceVehicle arrangementsPedestrian/occupant safety arrangementEngineering

The invention relates to a footrest and aims at providing a footrest capable of keeping the supporting effect for the left and right feet to be balanced when a vehicle is subjected to impact. The footrest comprises a lower footrest plate obliquely arranged between an automobile floor and a front surrounding plate, an upper footrest plate is arranged on the lower footrest plate, the bottom edges of the lower footrest plate and the upper footrest plate are hinged, and an elastic part is arranged between the lower footrest plate and the upper footrest plate. The footrest has the advantages of enabling the left and right feet to be subjected to the same supporting force, meanwhile playing a buffering role through the elastic part between the upper footrest plate and the lower footrest plate and suitable for popularization and usage.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Antifungal effects of Morinda citrifolia

InactiveUS20030225005A1Relieve inflammationCalming feelings of anxietyAntibacterial agentsBiocideBacteroidesAcetic acid

The present invention relates to antifungal and antibacterial activity of processed Morinda citrifolia products, as well as from various fractions of extracts from these processed products and the Morinda citrifolia L. plant, and related methods to determine mean inhibitory concentrations. In particular, the present invention relates to ethanol, methanol and ethyl acetate extracts from Morinda citrifolia L. and their inhibitory activities on common fungi and bacteria and the identification of mean inhibitory concentrations.

Owner:TAHITIAN NONI INT INC

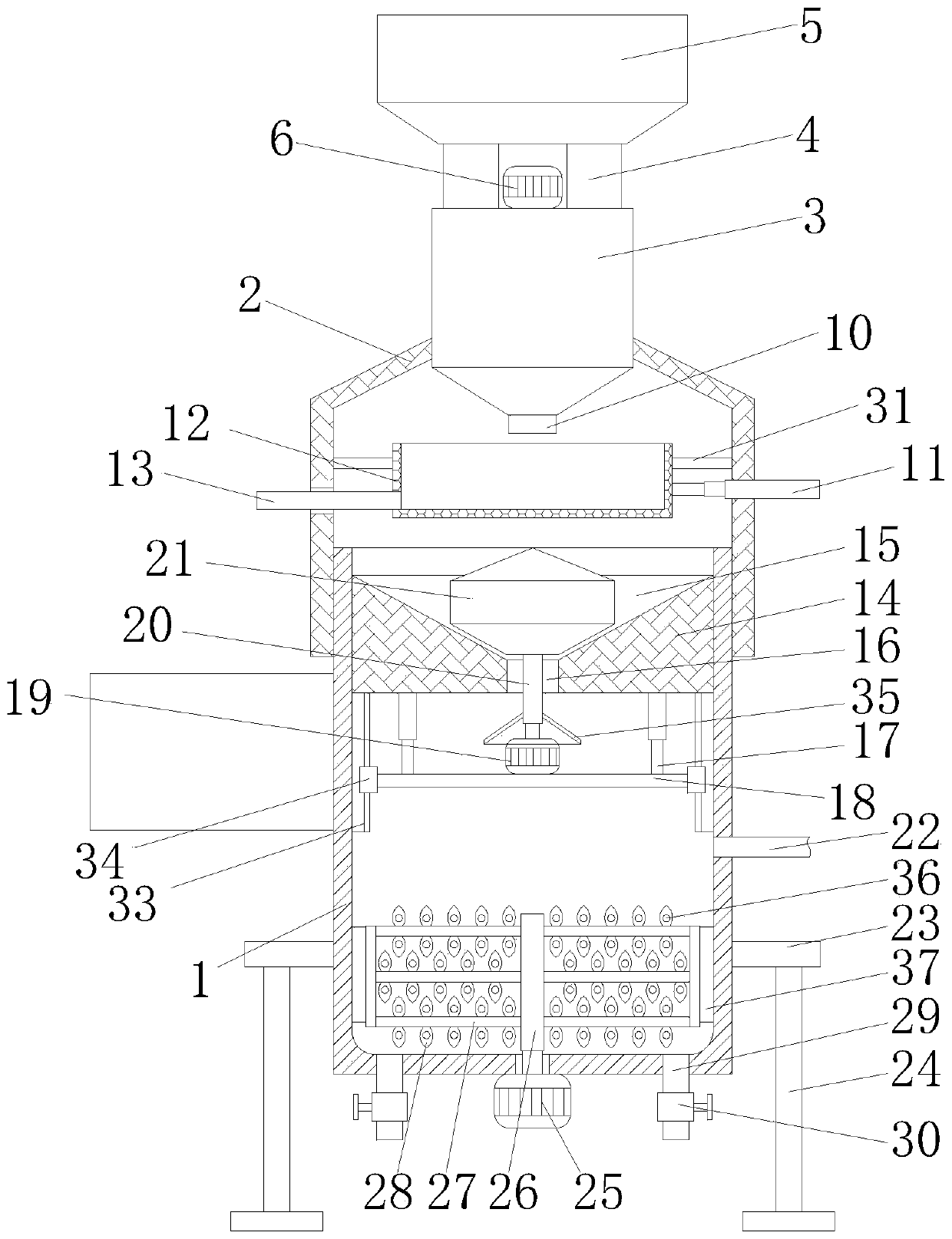

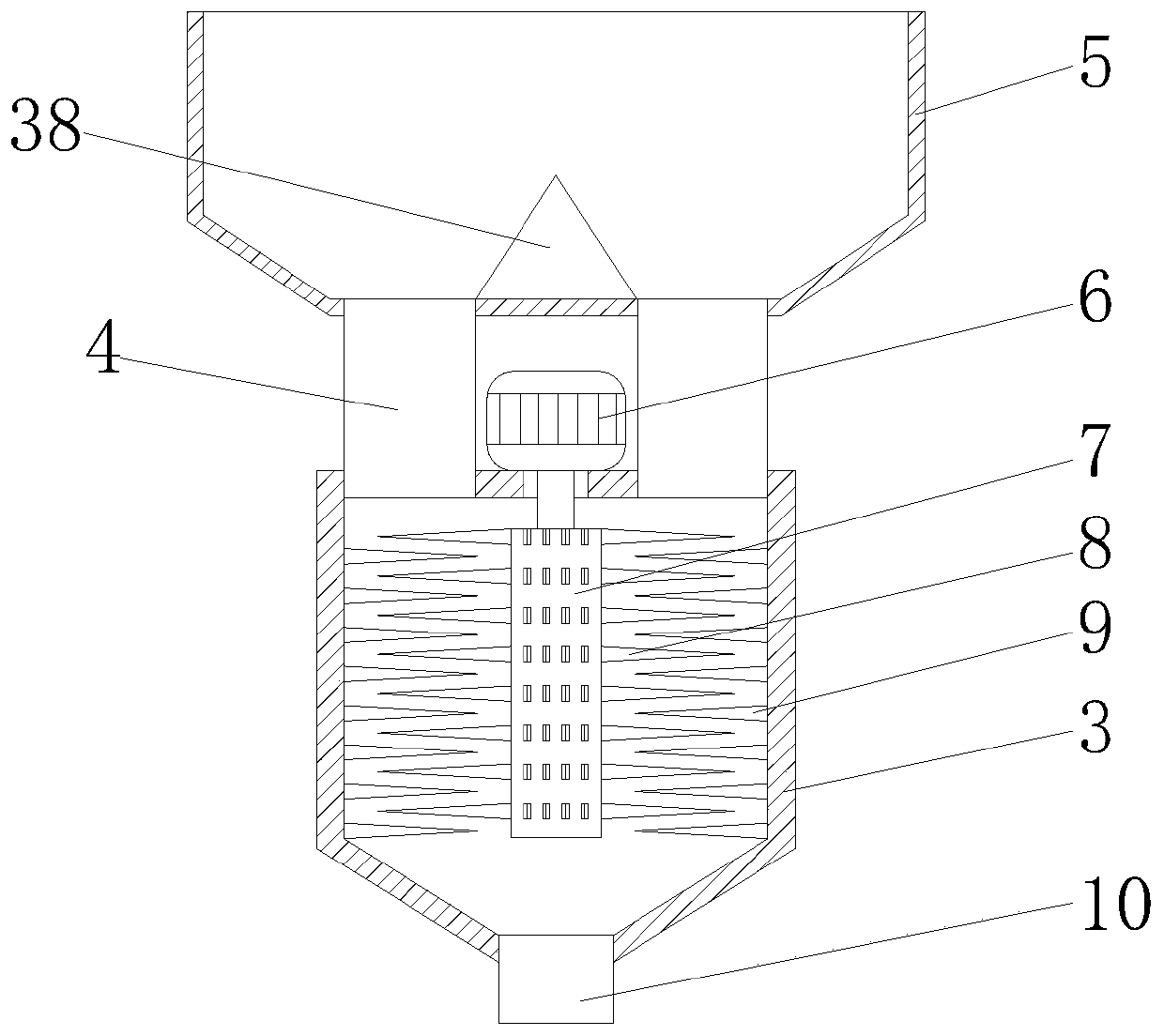

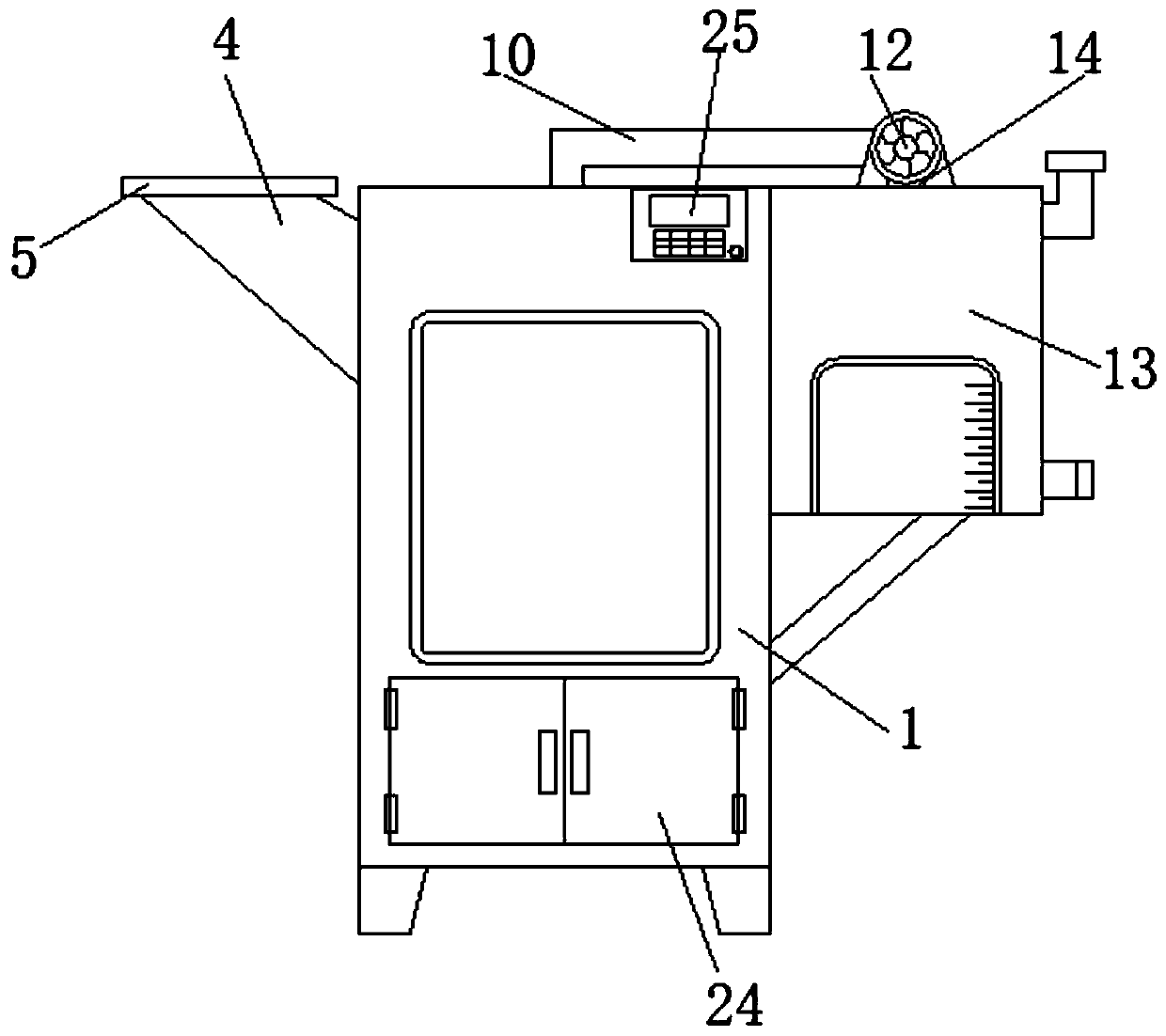

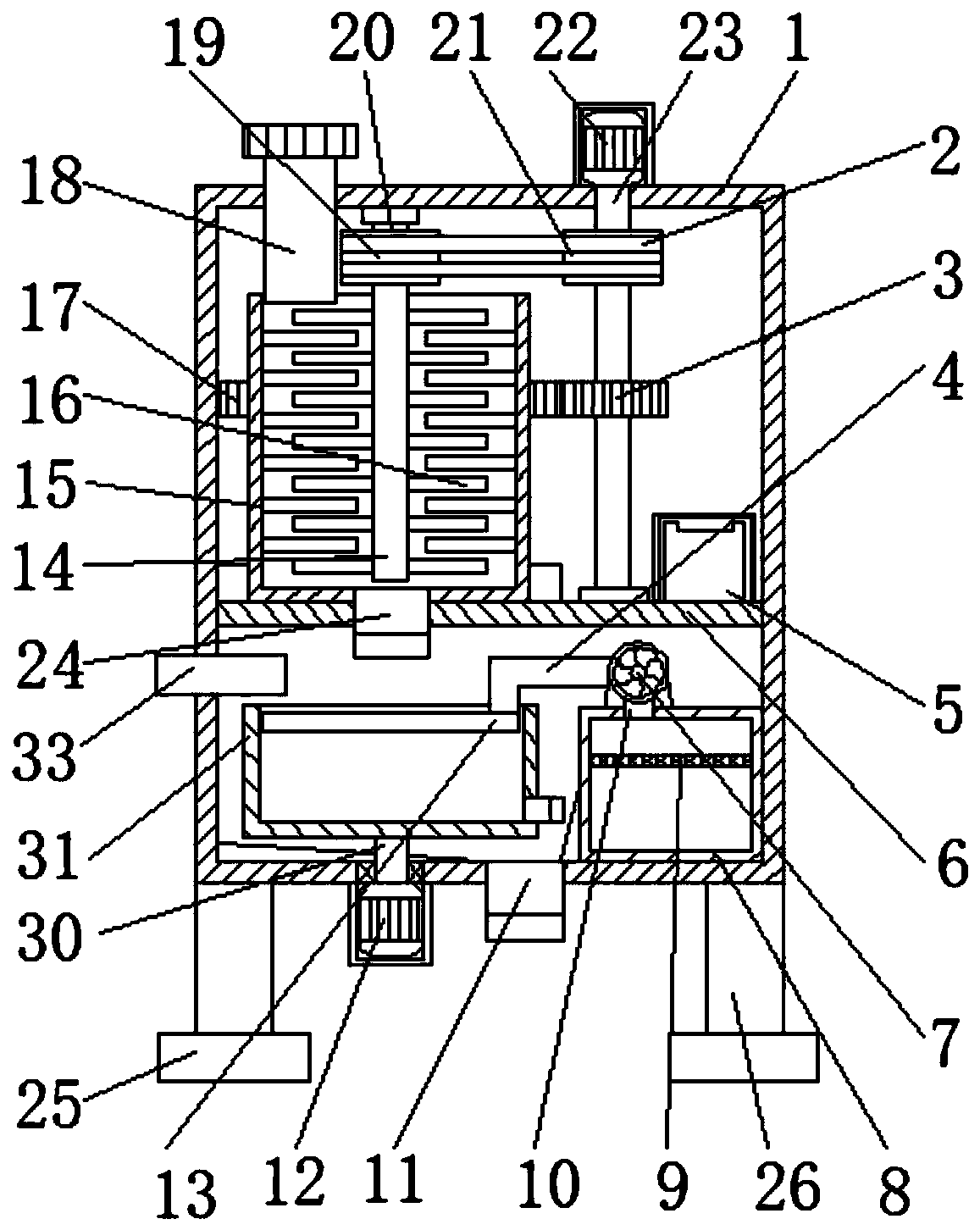

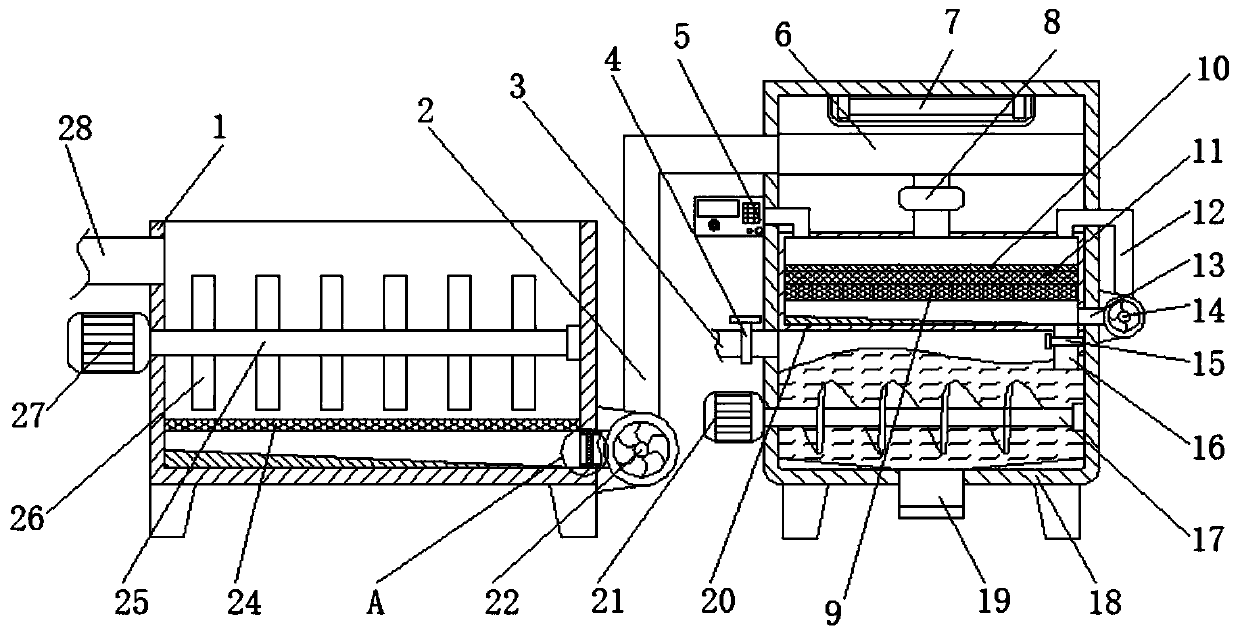

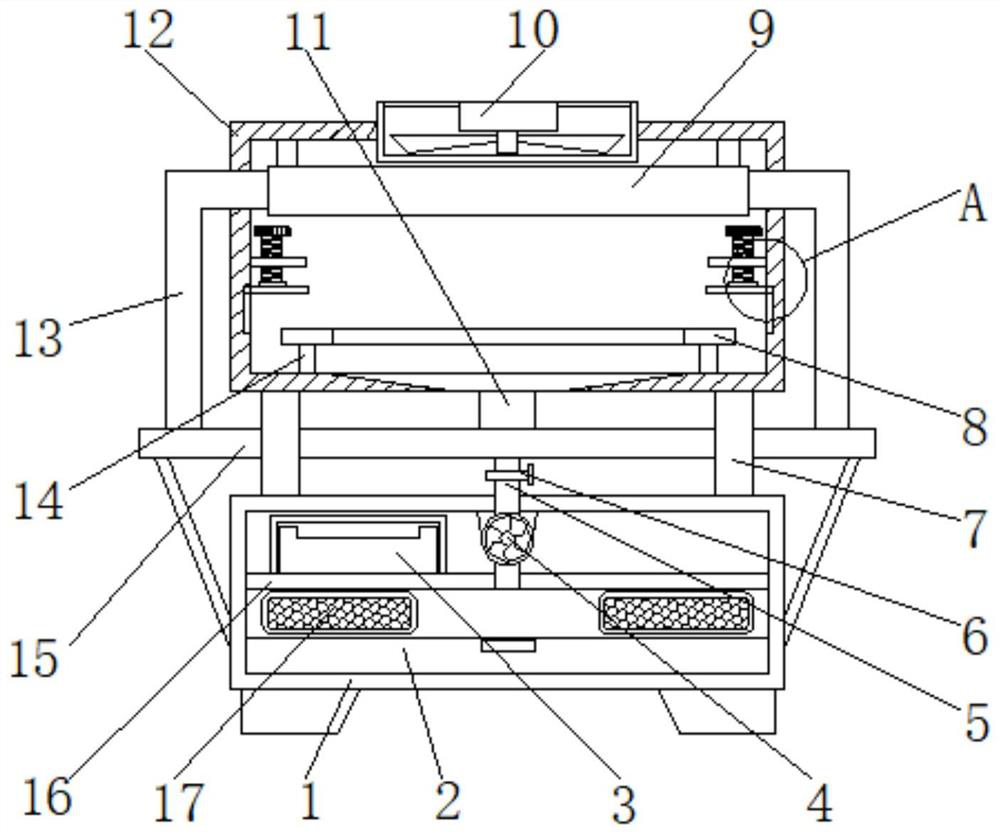

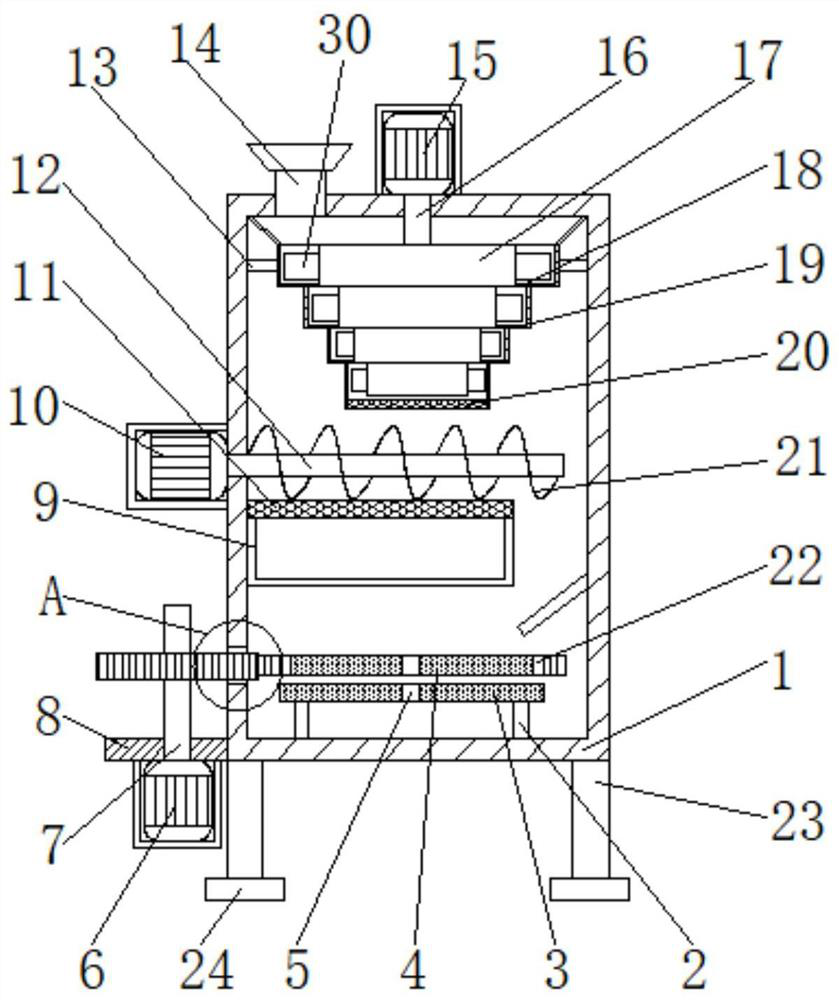

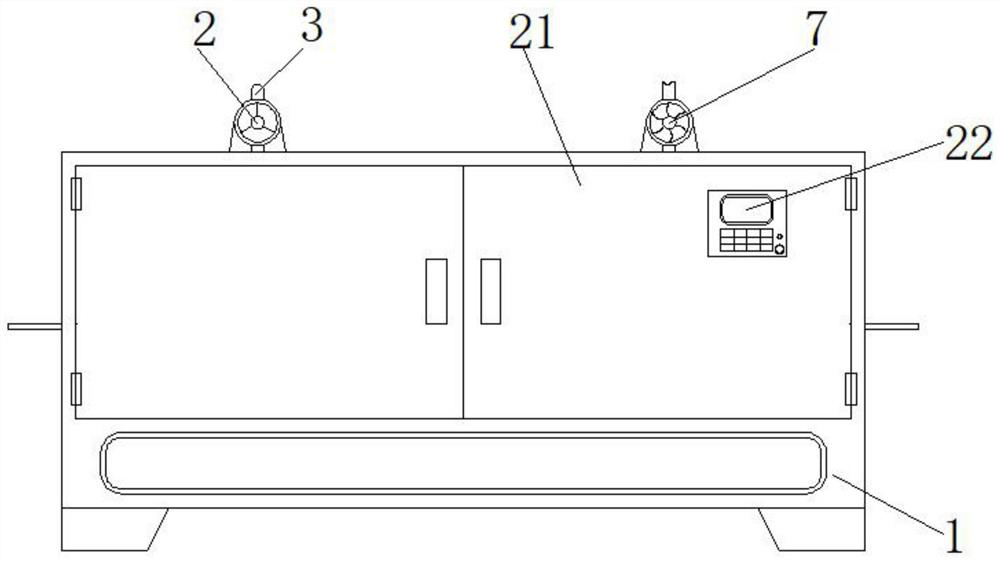

Efficient processing device for environment-protecting paint and using method of efficient processing device

InactiveCN111359756AWell mixedQuality improvementRotary stirring mixersTransportation and packagingElectric machineryProcess engineering

The invention discloses an efficient processing device for environment-protecting paint and a using method of the efficient processing device. The efficient processing device comprises a mixing box, wherein the tops of two sides of the mixing box are fixedly connected with supporting plates, and the tops of one opposite sides of the supporting plates are fixedly connected with a crushing box; thetwo sides of the top of the crushing box communicate with feeding pipes, and the tops of the feeding pipes communicates with a feeding hopper; and the top of the crushing box is fixedly connected witha first motor, the bottom of a rotating shaft of the first motor penetrates into an inner cavity of the crushing box, the bottom of the rotating shaft of the first motor is fixedly connected with a crushing shaft, and the surface of the crushing shaft is fixedly connected with first blades. The efficient processing device for the environment-protecting paint has the advantages of integrated design of crushing, grinding and mixing, uniform mixing of materials, high quality of finished products and high processing efficiency, and solves the problems that the quality of the finished products isreduced and the processing efficiency is reduced at the same time due to uneven mixing of the materials and slow mixing speed caused by the fact that a paint processing device cannot crush and grind large-particle materials in advance.

Owner:淮北森诺环保科技有限公司

Sports garment

ActiveUS9763483B2Improve stabilityStabilising effect on the wearer's hip jointGarment special featuresSwimming detailsThighMuscles of the hip

Owner:SPEEDO INTERNATIONAL LIMITED

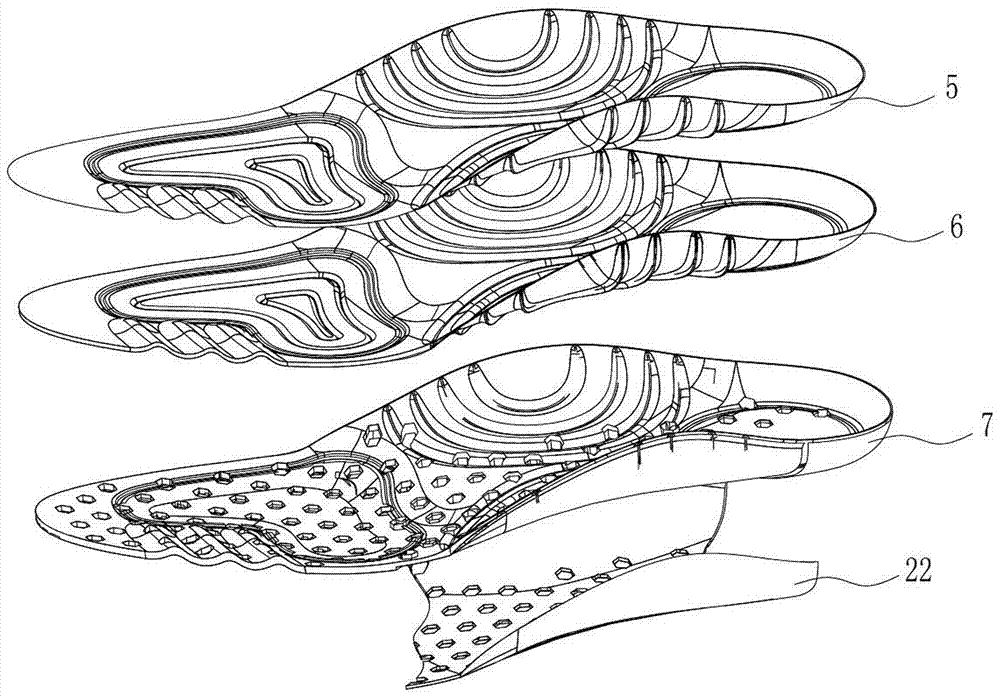

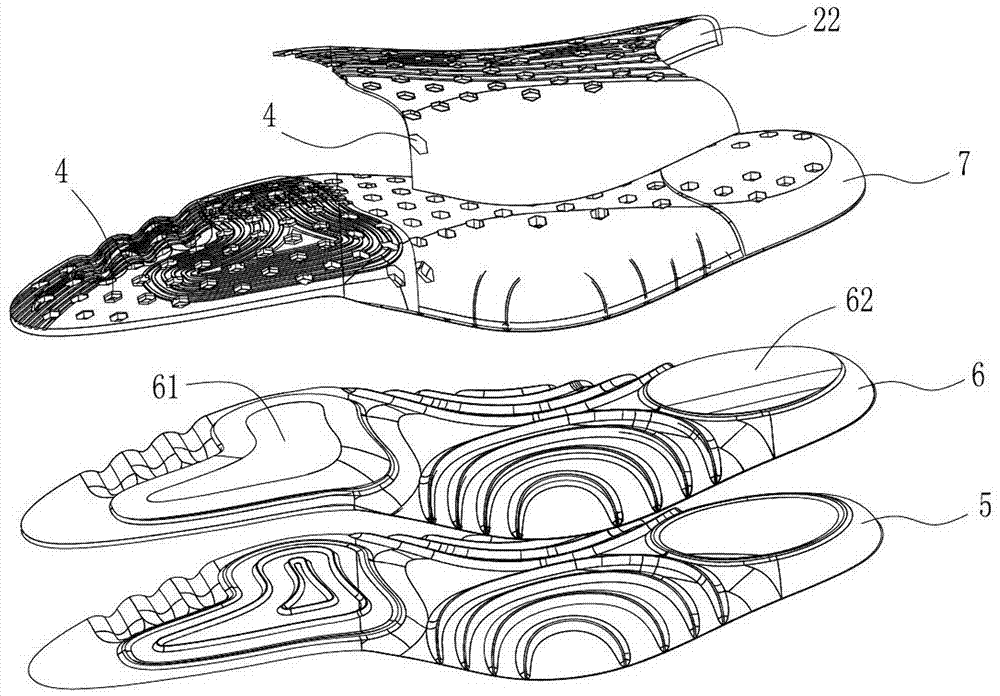

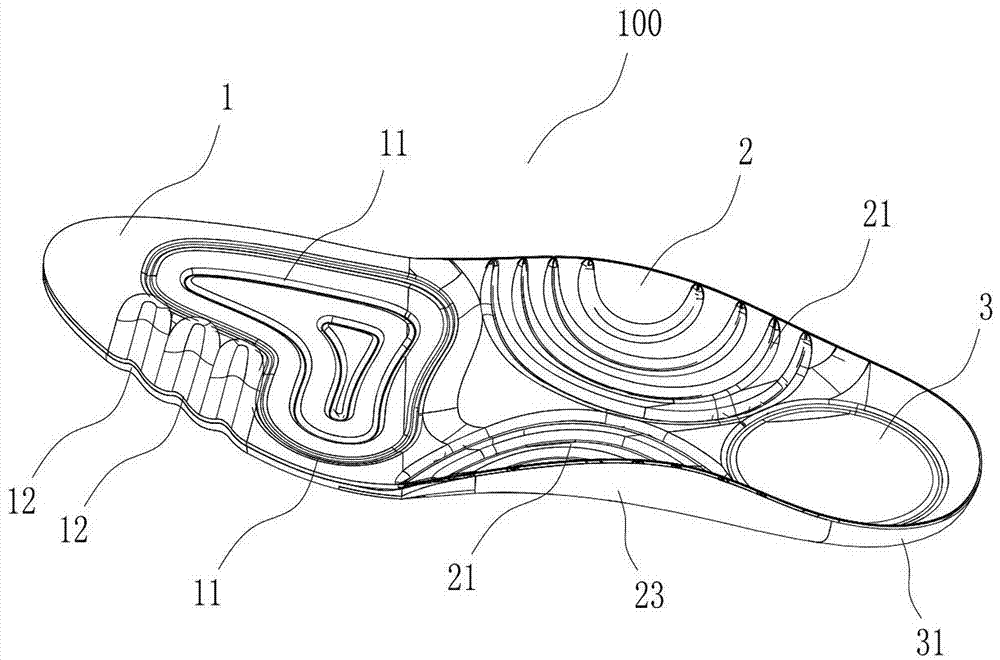

Shoe pads having protection effect during strenuous exercise

PendingCN107440231AReduce the risk of accidental injuryImprove breathabilityInsolesReticular formationEngineering

The invention discloses shoe pads having a protection effect during strenuous exercise. Each shoe pad comprises a shoe pad body, wherein the shoe pad body sequentially comprises a shoe pad half sole, a shoe pad middle-rise part and a shoe pad heel from the front end to the rear end, 2-5 rings of annular grooves are arranged at the upper side of the shoe pad half sole, and 2-5 horizontal wavy grooves are formed at the positions, corresponding to the toes of the human body, of the shoe pad half sole; 3-5 C-shaped grooves are formed in each of two sides of the shoe pad middle-rise part; a plant fiber arch supporting cushion plate is arranged at the lower side of the shoe pad middle-rise part; 80-150 small holes are distributed at the lower side of the shoe pad body, so that an elastic net-shaped structure is formed; the shoe pad body comprises a bamboo carbon fiber layer, a first PU polyurethane foam layer and a second PU polyurethane foam layer in the sequence from top to bottom, and a half sole cushioning pad and a heel cushioning pad are arranged at the lower side of the first PU polyurethane foam layer. The shoe pads having a protection effect during strenuous exercise provided by the invention have good damping and foot protecting effects and good slip resistance, can prevent the ankles from being injured, and are good in breathability.

Owner:DONGGUAN SHUNFENG SPORTS EQUIP CO LTD

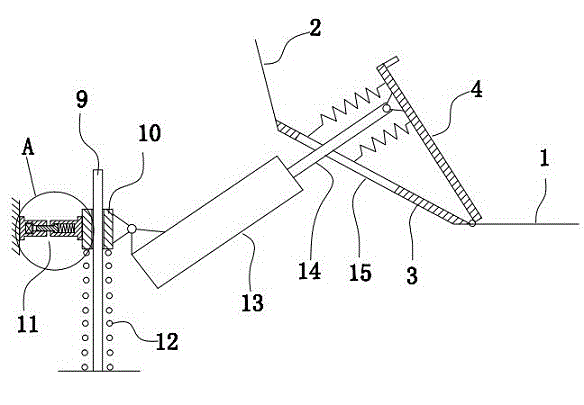

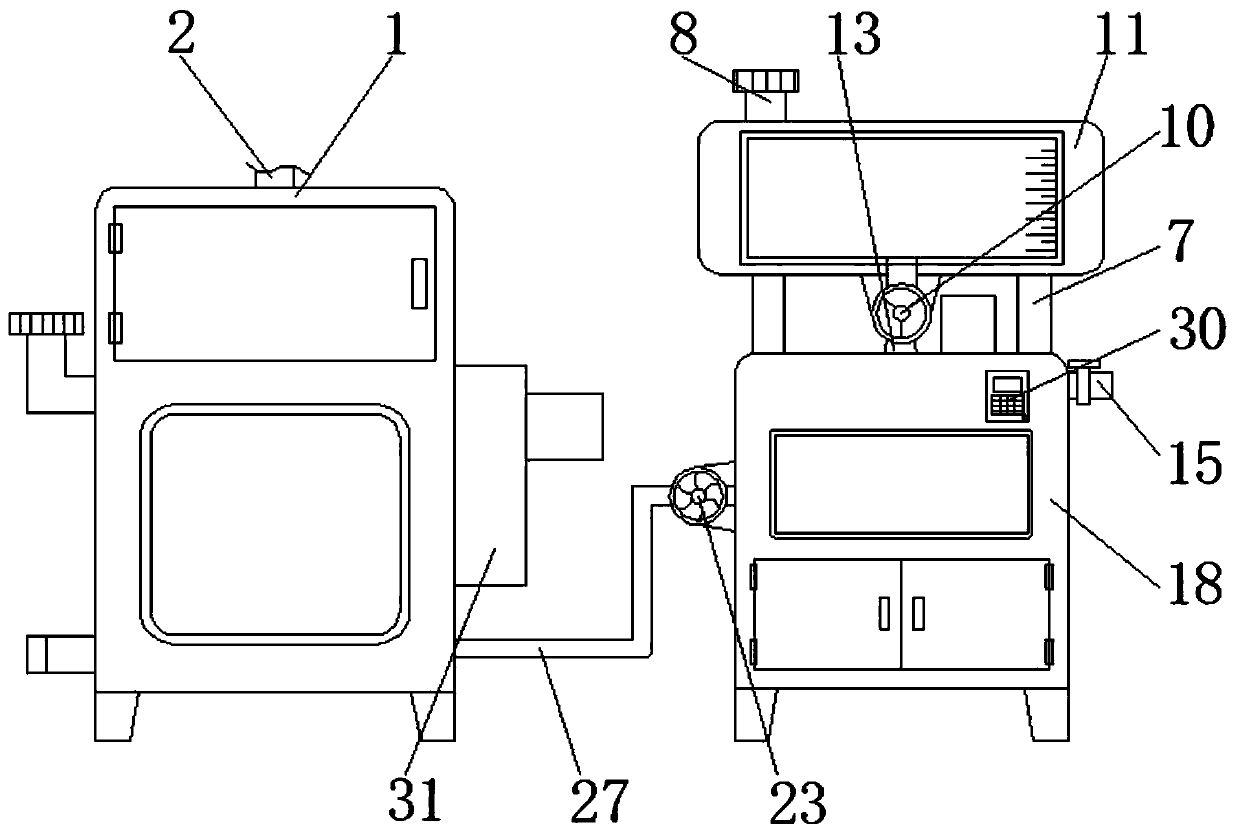

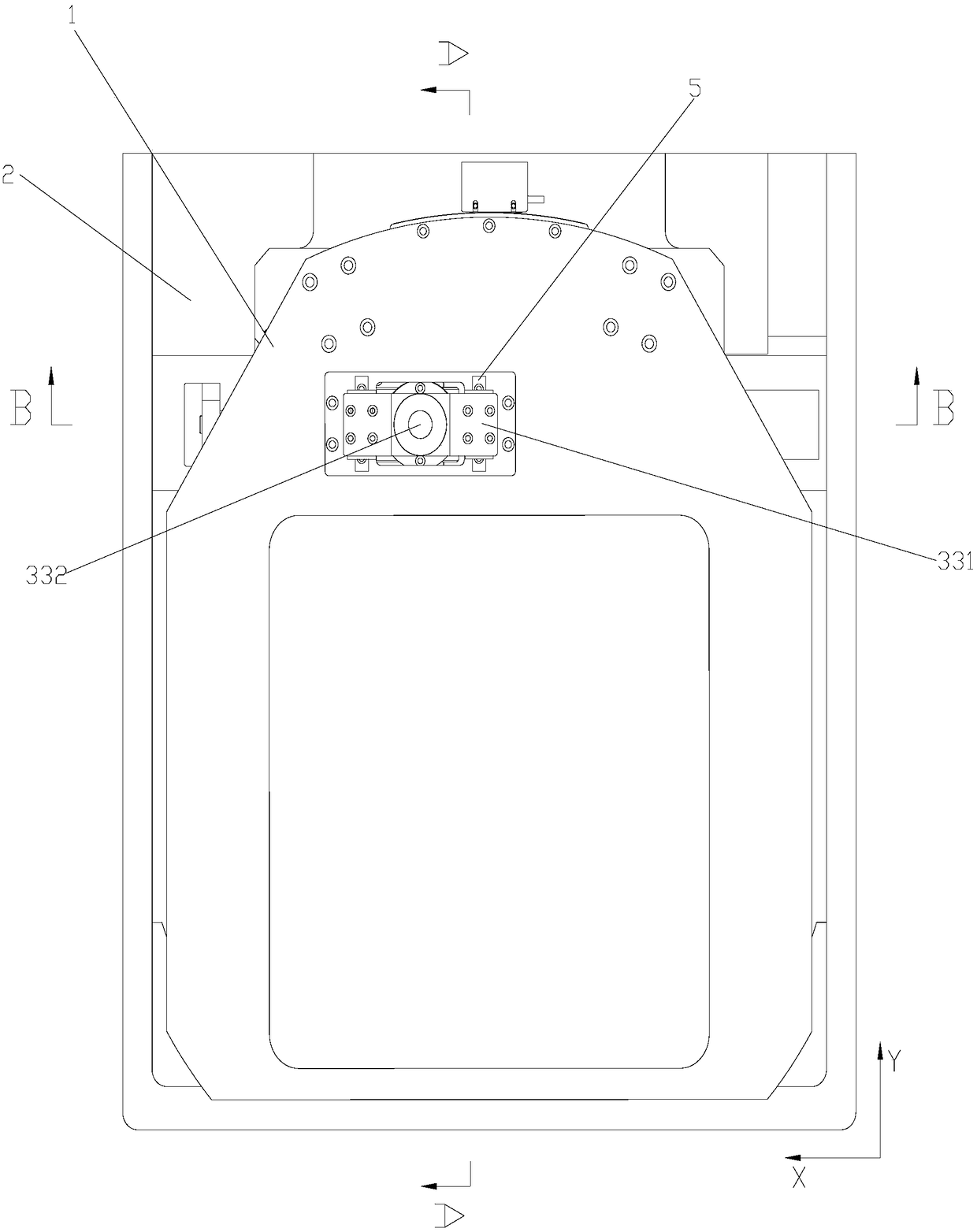

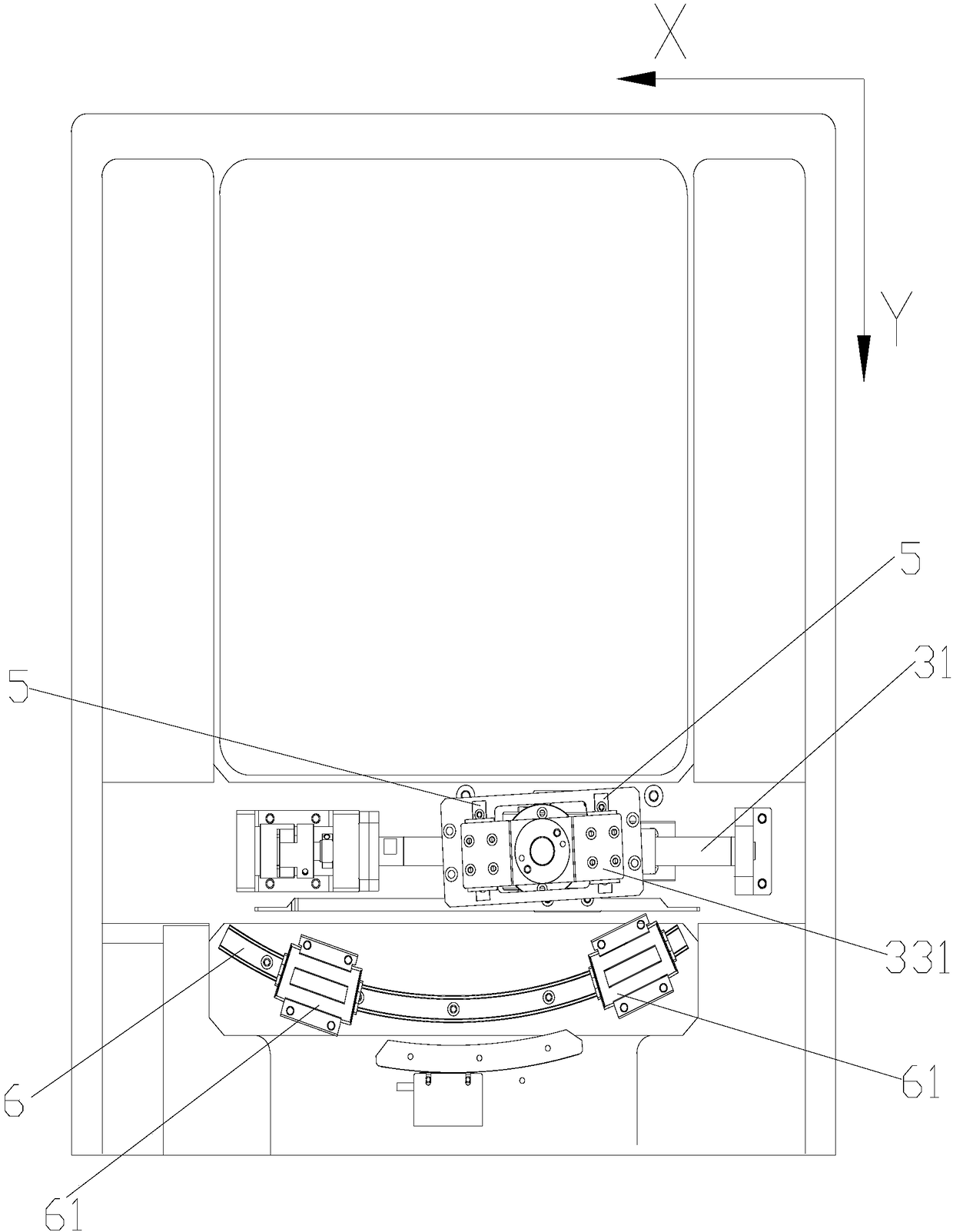

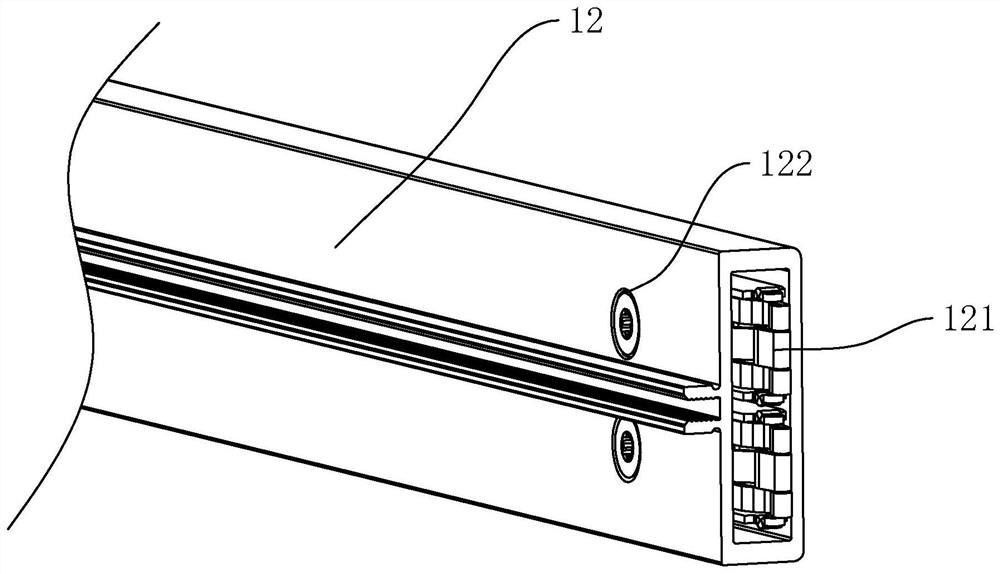

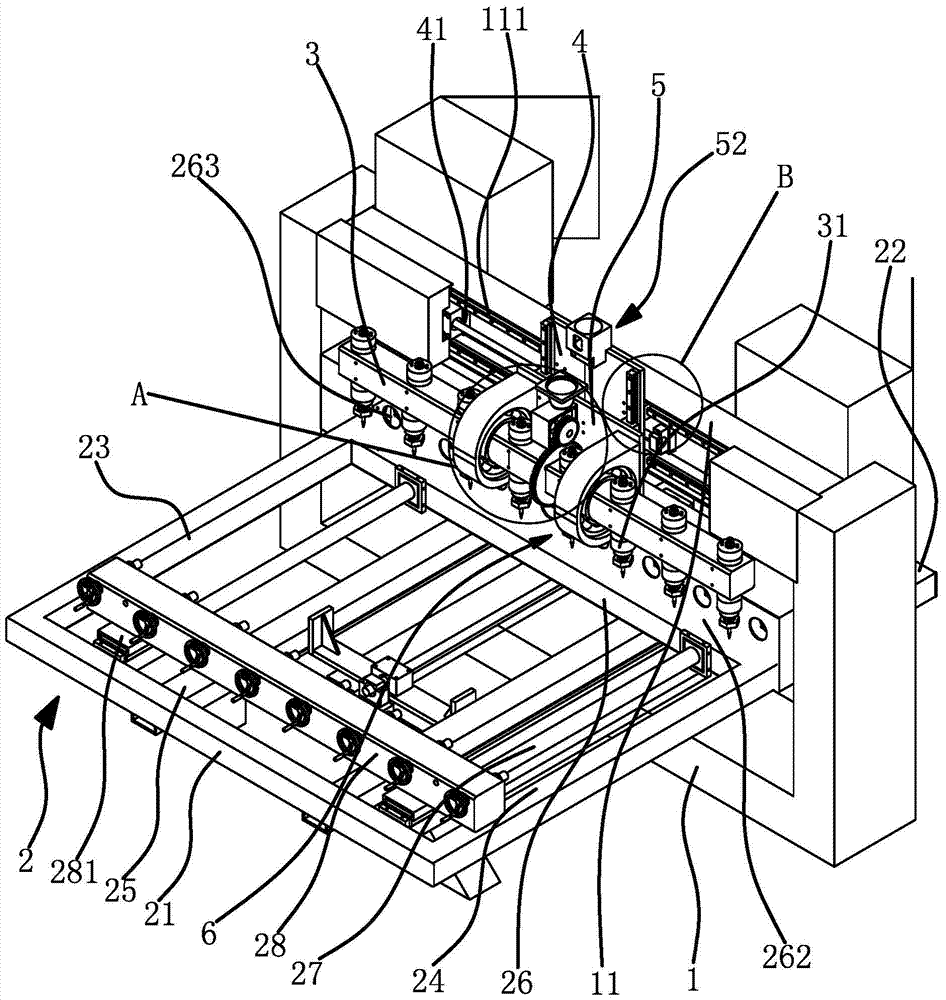

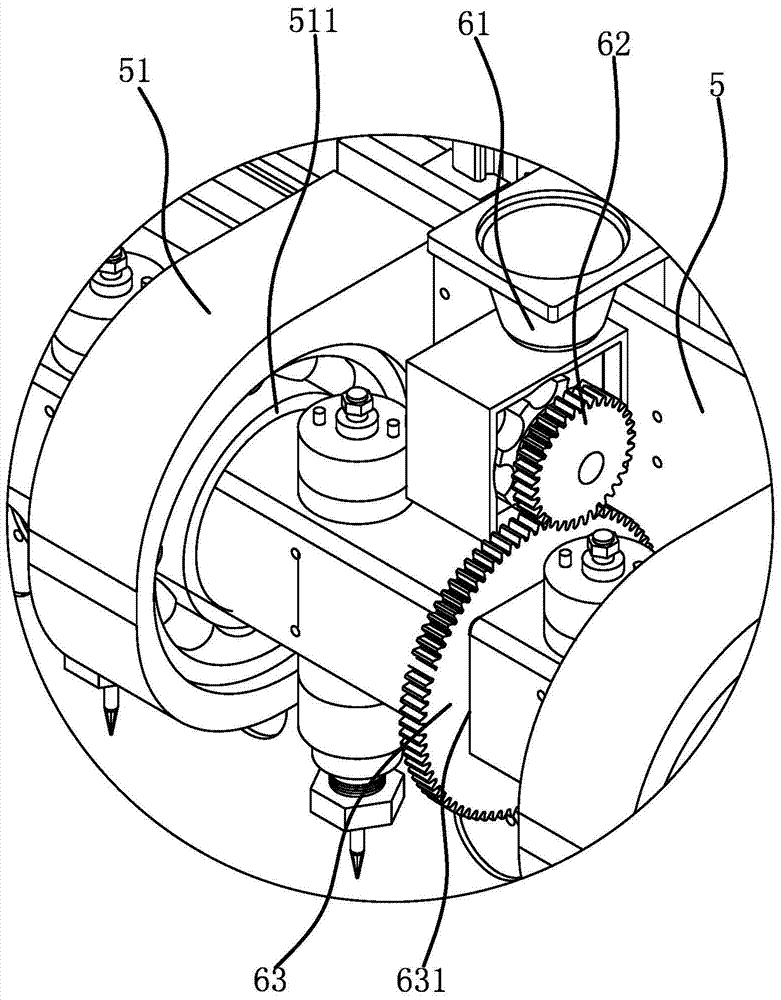

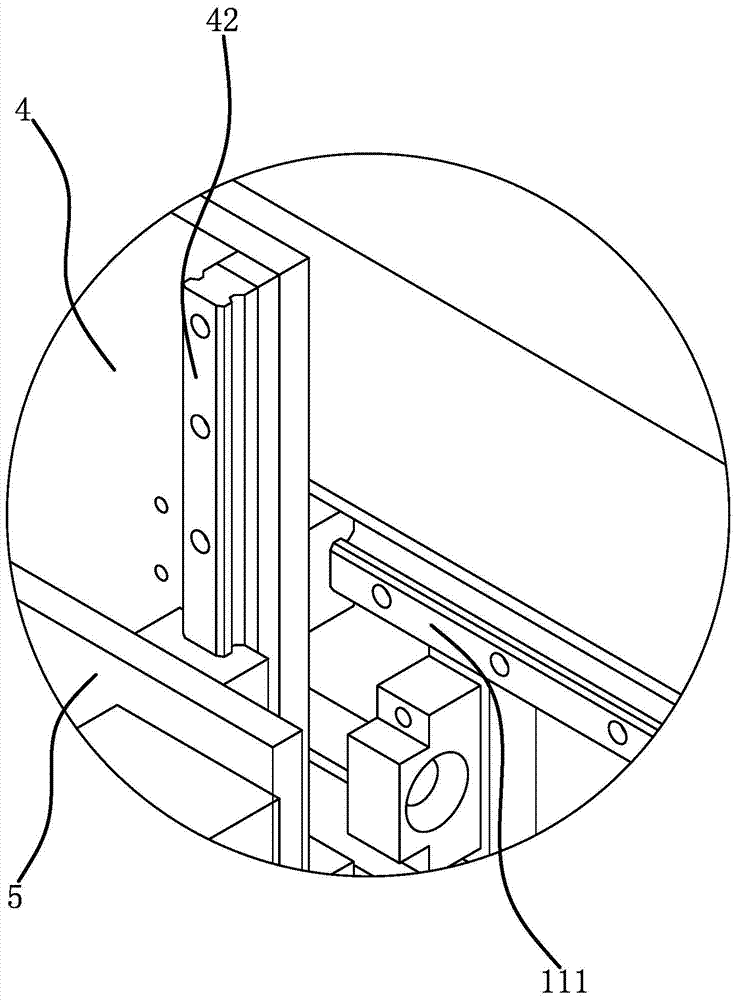

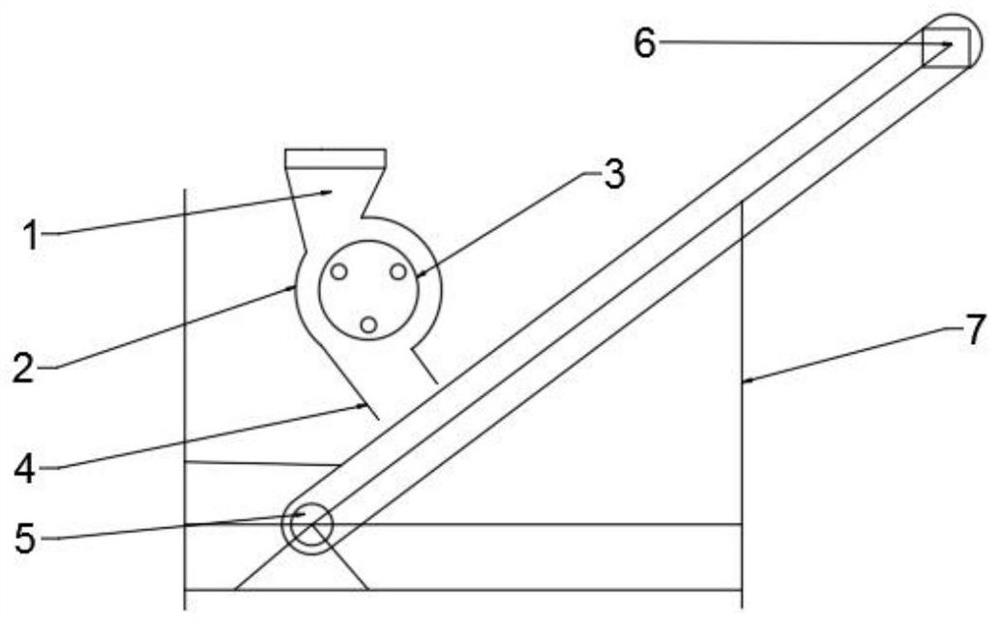

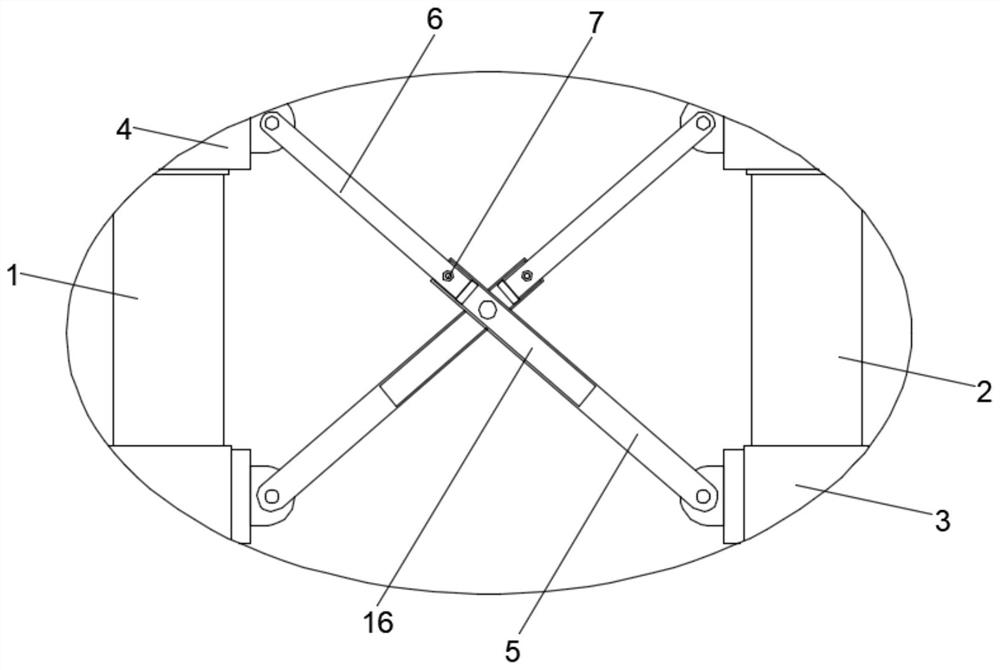

Three-dimensional engraving machine

The invention provides a three-dimensional engraving machine, and belongs to the technical field of mechanical equipment. The three-dimensional engraving machine solves the problem that the angle regulation of a machine head is difficult to realize in the moving engraving process of the existing three-dimensional engraving machine. The three-dimensional engraving machine comprises a machine frame and a work table, wherein a cross beam is arranged above the work table, a cutter frame is arranged at the side part of the cross beam, a transverse dragging plate is arranged on the side surface of the cross beam, a vertical dragging plate capable of doing reciprocating movement in the vertical direction is arranged on the transverse dragging plate, a bearing seat is fixedly arranged on the vertical dragging plate, the cutter frame is connected with the bearing seat through a bearing, and a driving mechanism capable of driving the cutter frame to do reciprocating swinging by using the axial line of the cutter frame in the long strip direction as the axis center is arranged on the vertical dragging plate. The three-dimensional engraving machine has the advantages that the angle regulation of the machine head can be realized in the moving engraving process, so that the machine head can be used for engraving a product in different angles.

Owner:吴善旺

Mine crusher with good dust removal effect and use method

InactiveCN111545285AReduce thermal frictionExtended service lifeUsing liquid separation agentDirt cleaningElectric machineryMining engineering

The invention discloses a mine crusher with a good dust removal effect and a use method. The mine crusher comprises a box, the rear side of the box is fixedly connected with a shell, the left side ofthe rear side of the shell is fixedly connected with a first motor, the output end of the first motor is fixedly connected with a driving shaft, the front side of the driving shaft penetrates into aninner cavity of the shell and is fixedly sleeved with an arc-shaped baffle, the right side of the back of the inner cavity of the shell is movably connected with a driven shaft, and the front sides ofthe driving shaft and the driven shaft penetrate into an inner cavity of the box and are movably connected with the front side of the inner cavity of the box. The mine crusher has the advantages of being good in dust removal effect and convenient to clean, and solves the problems that an existing mine crusher usually has a poor dust removal effect, as spray cooling cannot be performed on internaldevices of the existing mine crusher during dust removal, thermal friction needs to be reduced to prolong the service life of the existing mine crusher, and as the existing mine crusher is usually inconvenient to clean after being used, certain use inconvenience is likely to be caused to a user.

Owner:沈维民

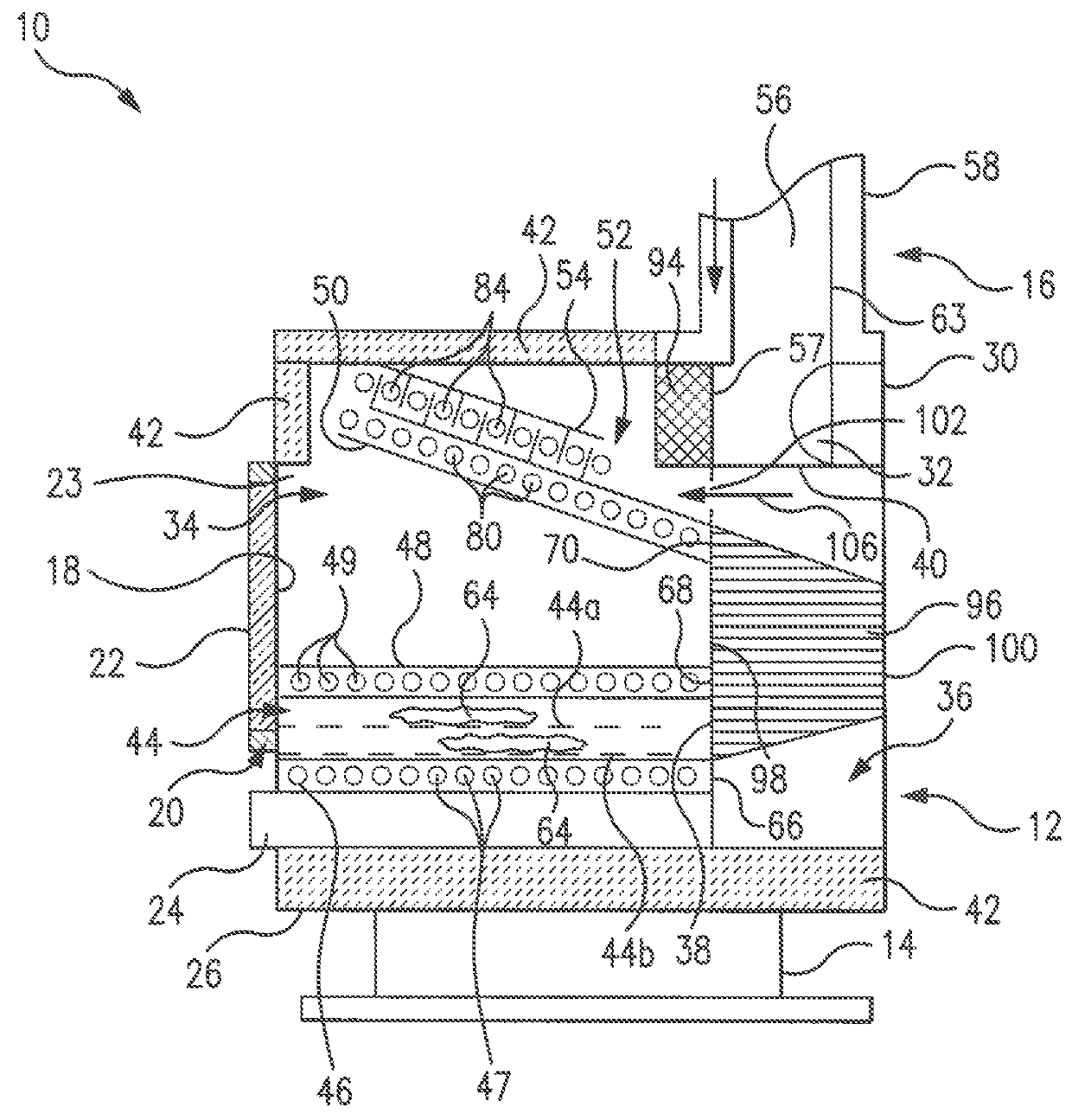

High efficiency solid fuel burning stove with optimized burning conditions and low level of emission

ActiveUS10041682B1Minimize emissionOptimize balanceFuel supply regulationCombustion-air/flue-gas circulation for stovesProcess engineeringForced-air

A solid fuel stove uses a dynamically controlled Combustion Fan and a Smart Controller system for automatic regulation of combustion conditions through the controlled forced air circulation based on sensors readings. The stove also uses emission reducing and efficiency boosting equipment such as a co-axial stack heat recovery sub-system and a self-cleaning particulate collector with enhanced particulates trapping capabilities.

Owner:UNIV OF MARYLAND

Soil conditioning agent and fertilizer

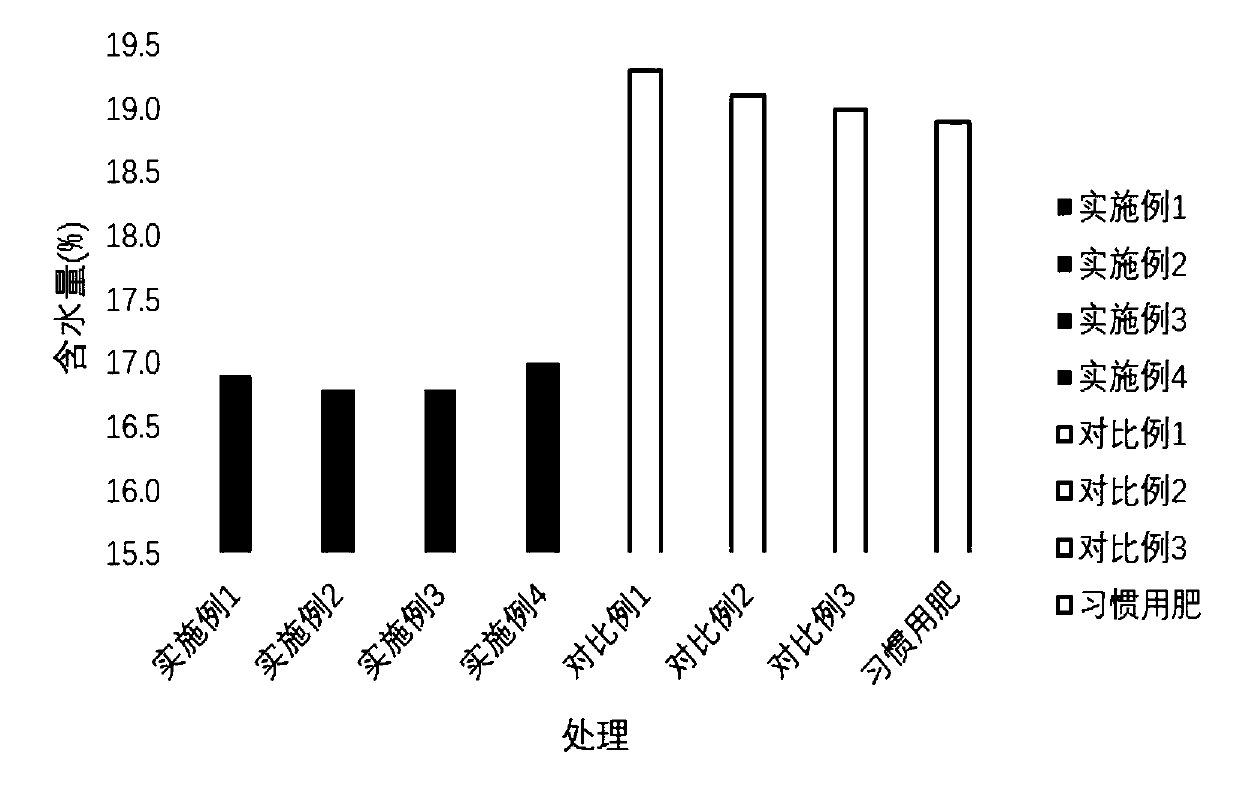

InactiveCN107673859AMaximize efficacyIncrease productionAgriculture tools and machinesAnimal corpse fertilisersFertilizerNutrient

The invention relates to the technical field of fertilizer and in particular relates to a soil conditioning agent and fertilizer. The soil conditioning agent is prepared from a degradation product ofa plant-derived raw material, a degradation product of an animal-derived raw material, a degradation product of a mineral-derived raw material and a biogenic raw material according to a certain ratio.The soil conditioning agent provided by the invention has remarkable yield increasing, quality improving and disease resisting effects on crops; all the raw materials have a synergistic effect, the soil also can be improved, the dosage of chemical fertilizer and pesticide is reduced and the culture pollution is reduced; the soil conditioning agent is a multi-factor biological activated conditioning agent meeting soil-crop nutrient cycling.

Owner:BEIJING GREEN LIFE AGRI TECH CO LTD

Storage device for microfiber fabrics

PendingCN111056150AAddresses issues that are susceptible to certain damageSupport balanceContainers preventing decayElectric machineryMicrofiber

The invention discloses a storage device for microfiber fabrics. The device comprises a box body, wherein the right side of the box body is fixedly connected with a shell, the top of the right side ofthe shell is fixedly connected with a motor, and the output end of the motor is fixedly connected with a first rotating shaft. According to the device, through the cooperative use of the box body, amesh box, a particle drying agent, a second rotating shaft, the first rotating shaft, a ultraviolet sterilization lamp, a winding roller, a humidity sensor, a driving wheel, a motor, the shell, a belt, a driven wheel, a small-sized dehumidifier, an electric telescopic rod, a transverse plate, a pressing plate, a second box door, a first box door and a controller, the problems that when existing storage device for the microfiber fabrics winds and stores the microfiber fabrics, flattening and tightening on the microfiber fabrics is usually inconvenient, so that wrinkles are prone to occur in thewinding process, the moisture-proof effect is usually poor, and the air humidity in the box body can not be automatically controlled, so that the microfiber fabrics are prone to be damaged to some extent in the storage process are solved.

Owner:南通洁万家纺织有限公司

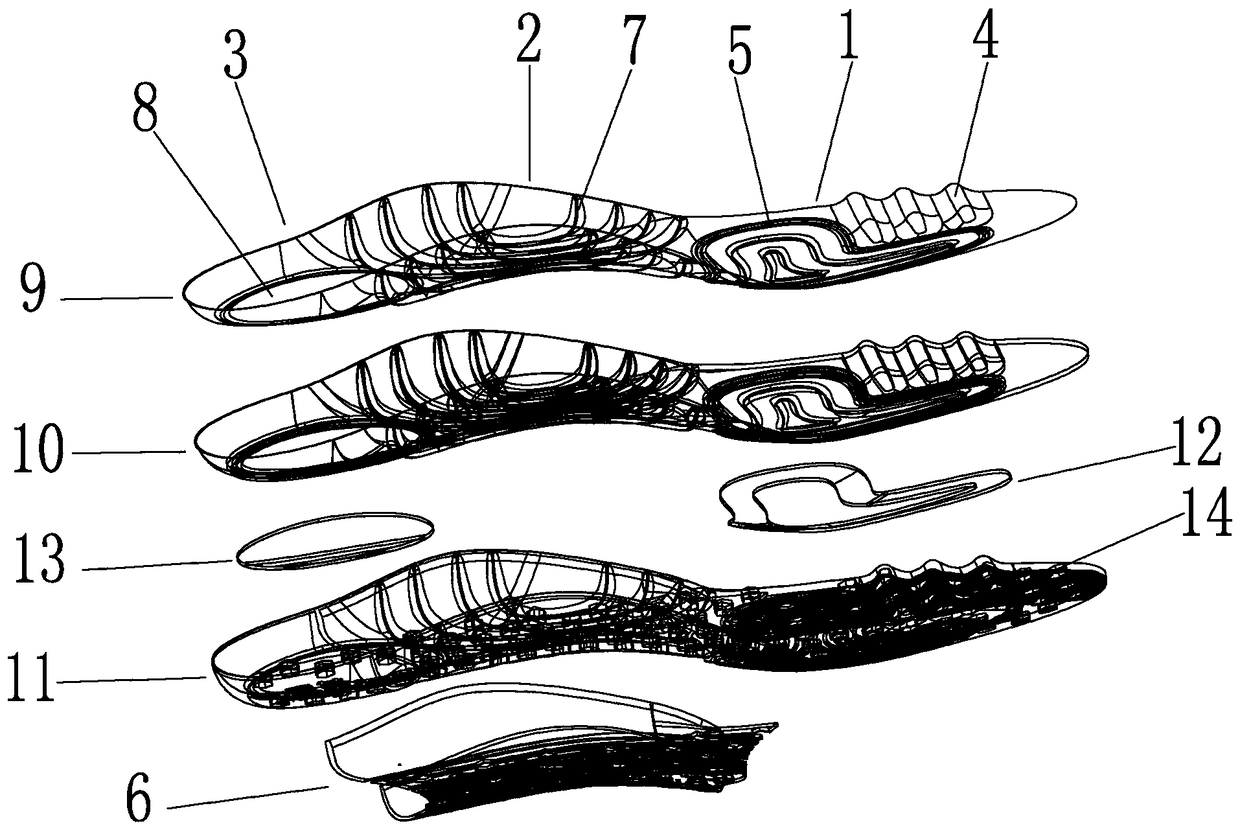

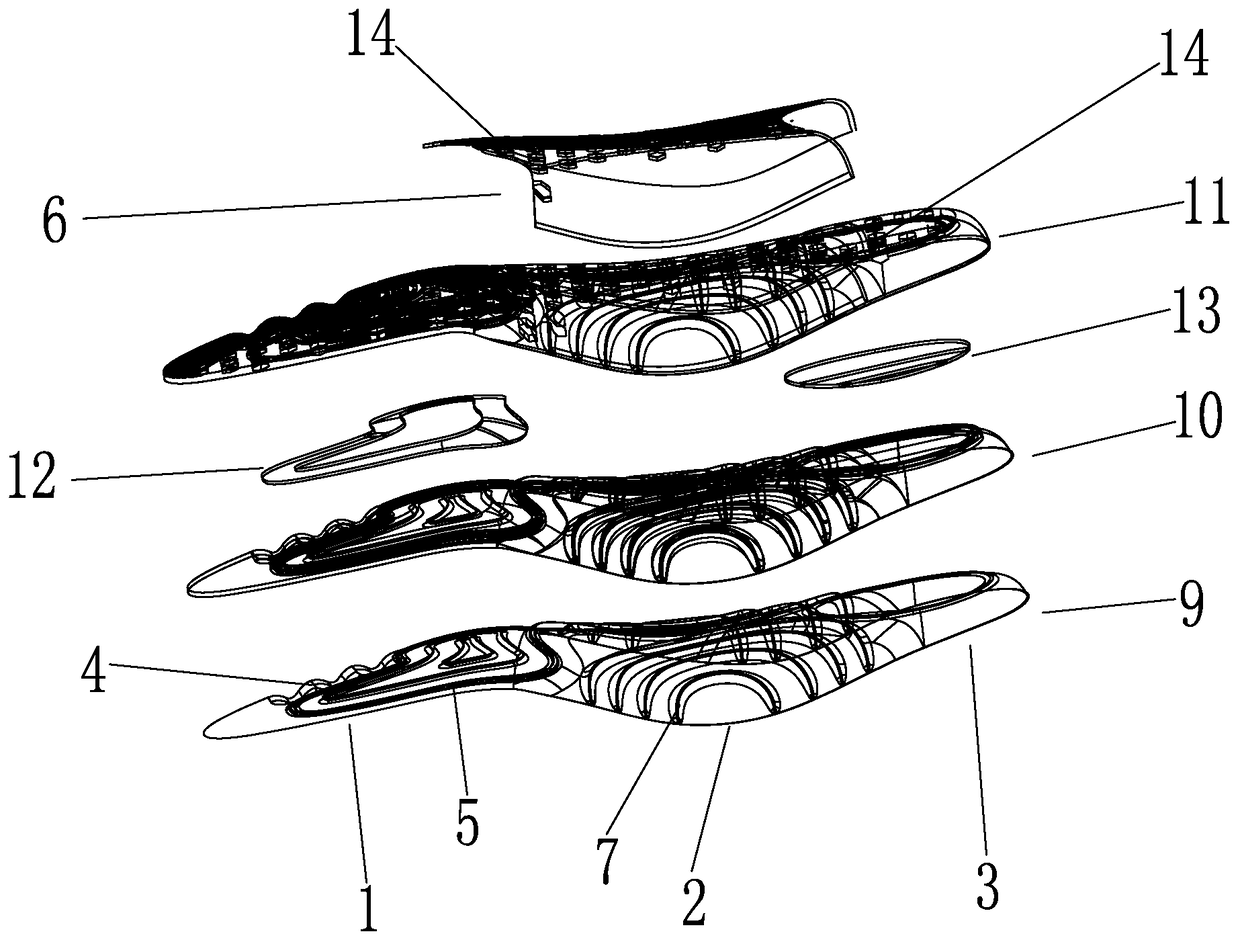

Basketball sports insole

The invention discloses a basketball sports insole. The basketball sports insole comprises an insole body, wherein the insole body comprises an insole half sole, an insole waistline and an insole heelpiece in sequence from front end to rear end, one side of the front end of the insole half sole is provided with an oval arch part, and the other side of the front end of the insole half sole is provided with a wavy gyrate groove; the outer edge of the insole waistline warp upward, both sides of the insole waistline are provided with C-shaped grooves respectively, and the lower side of the insolewaistline is provided with a plant fiber arch supporting gasket; the insole body comprises a nano-bamboo charcoal fiber layer, a first polyurethane foamed cotton layer and a second polyurethane foamedcotton layer in sequence from top to bottom, the lower side, corresponding to insole half sole, of the first polyurethane foamed cotton layer is provided with a half sole shock pad, the shape of thehalf sole shock pad corresponds to the shape of the wavy gyrate groove, and the lower side, corresponding to the insole heelpiece, of the first polyurethane foamed cotton layer is provided with a heelpiece shock pad. The basketball sports insole has the advantages that the shock absorption and foot protection effects are strong, the skid resistance is good, the ankle injury can be prevented, the breathability is good, and the durability is high.

Owner:DONGGUAN SHUNFENG SPORTS EQUIP CO LTD

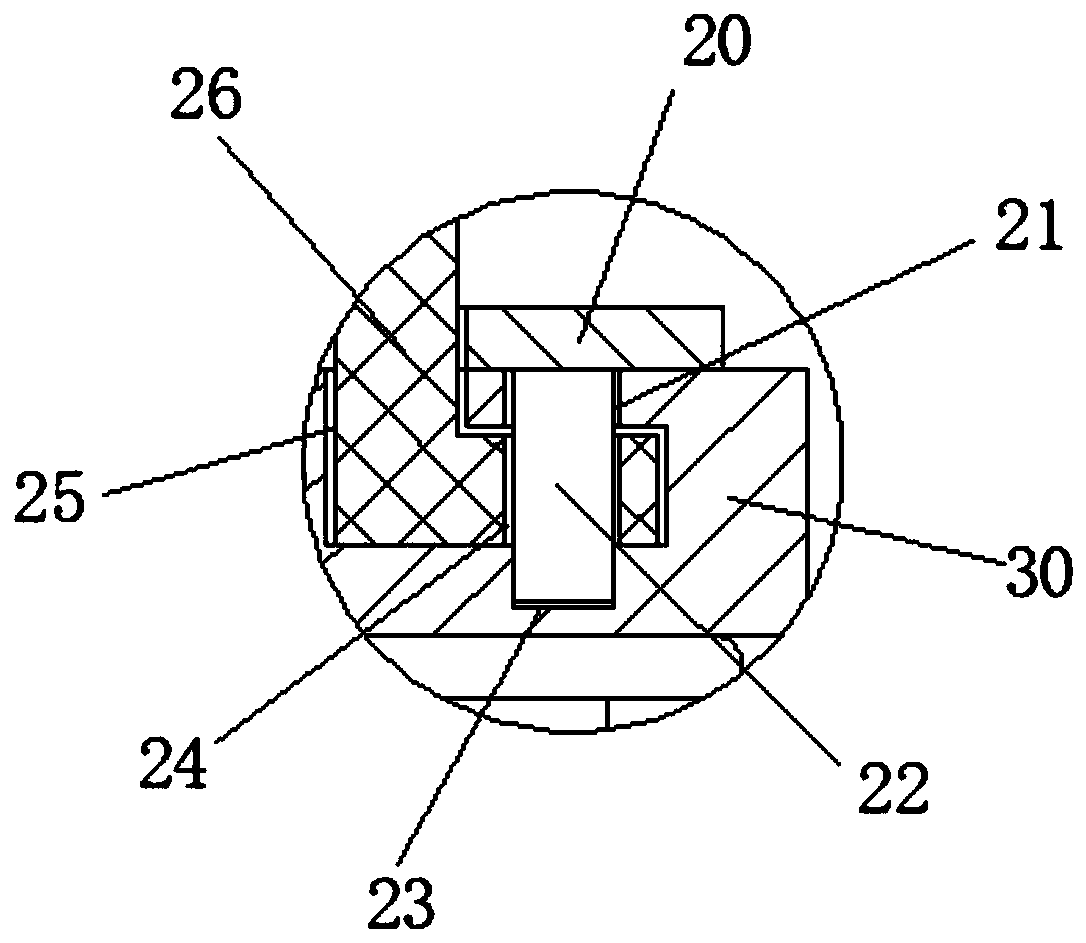

Food drying and screening device and use method thereof

InactiveCN111545450ASolve the problem that the service life may be affected to a certain extentSupport balanceSievingScreeningElectric machineDrying

The invention discloses a food drying and screening device and a use method thereof. The food drying and screening device comprises a box body, the left side of the top of the box body communicates with a feeding pipe, a motor is fixedly connected to the center of the top of the box body, a rotating shaft is fixedly connected to the output end of the motor, and the bottom of the rotating shaft penetrates into an inner cavity of the box body and is fixedly connected with a drying cylinder; and discharging grooves are formed in the two sides of the top of the drying cylinder, the bottom of the surface of the drying cylinder is fixedly sleeved with an electric heating wire, the bottom of the drying cylinder communicates with a first discharging valve, guide plates are fixedly connected to thecenters and the bottoms of the two sides of an inner cavity of the box body, and a second spring is fixedly connected to the rear side of the inner cavity of the box body and located between the upper and lower guide plates. The food drying and screening device has the advantage that the screening device is convenient to disassemble and clean, and the problem that the service life of an existingscreening device for food processing is likely to be influenced to a certain extent along with the increase of the service life of the screening device due to the fact that the screening device is usually inconvenient to disassemble and clean is solved.

Owner:董相美

Glass kiln denitration system

InactiveCN111359431ASupport balanceIncrease frictionGas treatmentDispersed particle filtrationExhaust valveInlet valve

The invention discloses a glass kiln denitration system. The glass kiln denitration system comprises a first box body and a second box body. The first box body, an air inlet pipe, a frame body, a belt, a first motor, an annular pipe, a support column, a second liquid inlet valve, an ammonia gas sensor, a water pump, a water tank, a second motor, a rubber hose, a rotating shaft, an exhaust valve, adriving gear, an atomizing nozzle, the second box body, a third filter screen, a drawer, a communicating pipe, a driven gear, a water pump, a belt pulley, a second spiral blade rod, a first spiral blade rod, a snake-shaped heat exchange pipe, a partition plate, a first filter screen, a controller, a shell, active carbon balls, and a second filter screen cooperate with each other to solve the problems that in the denitration process of an existing glass kiln denitration system, ammonia water and flue gas are generally not evenly combined, the denitration efficiency is low, in addition, the flue gas heat exchange structure is generally single, the flue gas heat exchange effect is poor, and the system is inconvenient to use.

Owner:淮北森诺环保科技有限公司

Angle adjusting device and silk-screen printing device

InactiveCN108357192AHigh precisionHigh control precisionScreen printersScreen printingScreen printingLinear motion

Owner:SUZHOU MAXWELL TECH CO LTD

Environment-friendly waste recycling device and using method thereof

The invention discloses an environment-friendly waste recycling device and a using method thereof. The environment-friendly waste recycling device comprises a box body, wherein a partition plate is transversely and fixedly connected to the centers of the two sides of an inner cavity of the box body; a first motor is fixedly connected to the right side of the top of the box body; the output end ofthe first motor is fixedly connected with a driving shaft; the bottom of the driving shaft penetrates through the inner cavity of the box body and is movably connected with the right side of the top of the partition plate; and a first belt wheel and a gear are fixedly arranged at the top and the center of the surface of the driving shaft in a sleeving mode correspondingly. The environment-friendlywaste recycling device has the advantages of being efficient in crushing and high in resource recycling rate, and the problems that an existing environment-friendly waste recycling device is single in crushing mode in the waste paper recycling process, so that the crushing effect is poor, the crushing efficiency is low, a small amount of paper pulp contained in extracted ink cannot be screened and separated, and resource waste can be caused to a certain extent are solved.

Owner:潘磊

Domestic sewage treatment and recycling equipment and using method thereof

InactiveCN111233268ASolve the problem that is easy to affect the user's useSolve the problem that the use has a certain impactWater/sewage treatment by irradiationSpecific water treatment objectivesElectric machinerySewage

The invention discloses domestic sewage treatment and recycling equipment and a using method thereof. The equipment comprises a sedimentation tank and a box body, the top of the left side of the sedimentation tank is communicated with a water inlet pipe, a first motor is fixedly connected to the center of the left side of the sedimentation tank, an output end of the first motor is fixedly connected with a rotating shaft, the right side of the rotating shaft penetrates into an inner cavity of the sedimentation tank and is movably connected with the right side of the inner cavity of the sedimentation tank, stirring rods are fixedly connected to the top and the bottom of the rotating shaft, first filter screens are transversely and fixedly connected to the bottoms of the two sides of the inner cavity of the sedimentation tank, a first water pump is fixedly connected to the bottom of the right side of the sedimentation tank, and the left side of the first water pump is communicated with afirst pipeline. The domestic sewage treatment and recycling equipment has the advantage of good treatment effect, and solves the problems that the existing domestic sewage treatment and recycling equipment generally cannot perform circulating treatment on sewage in the use process, so that the treatment effect is generally common, and a certain influence is easily caused to the use of a user.

Owner:重庆百重泉环保科技有限公司

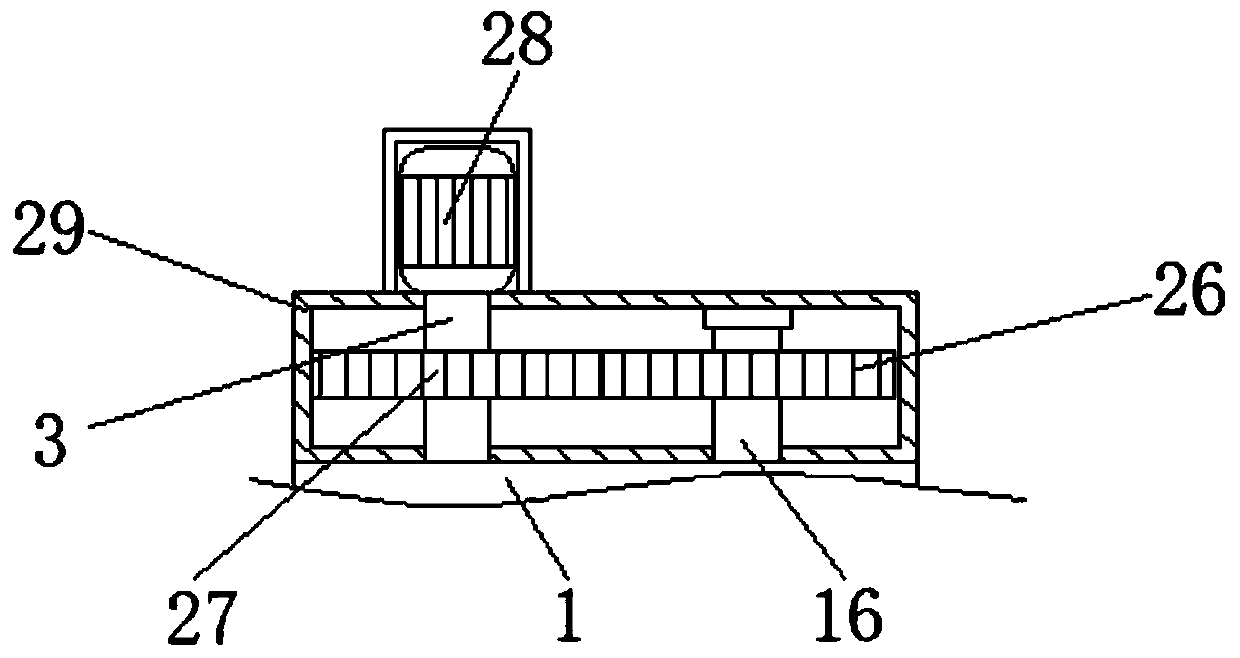

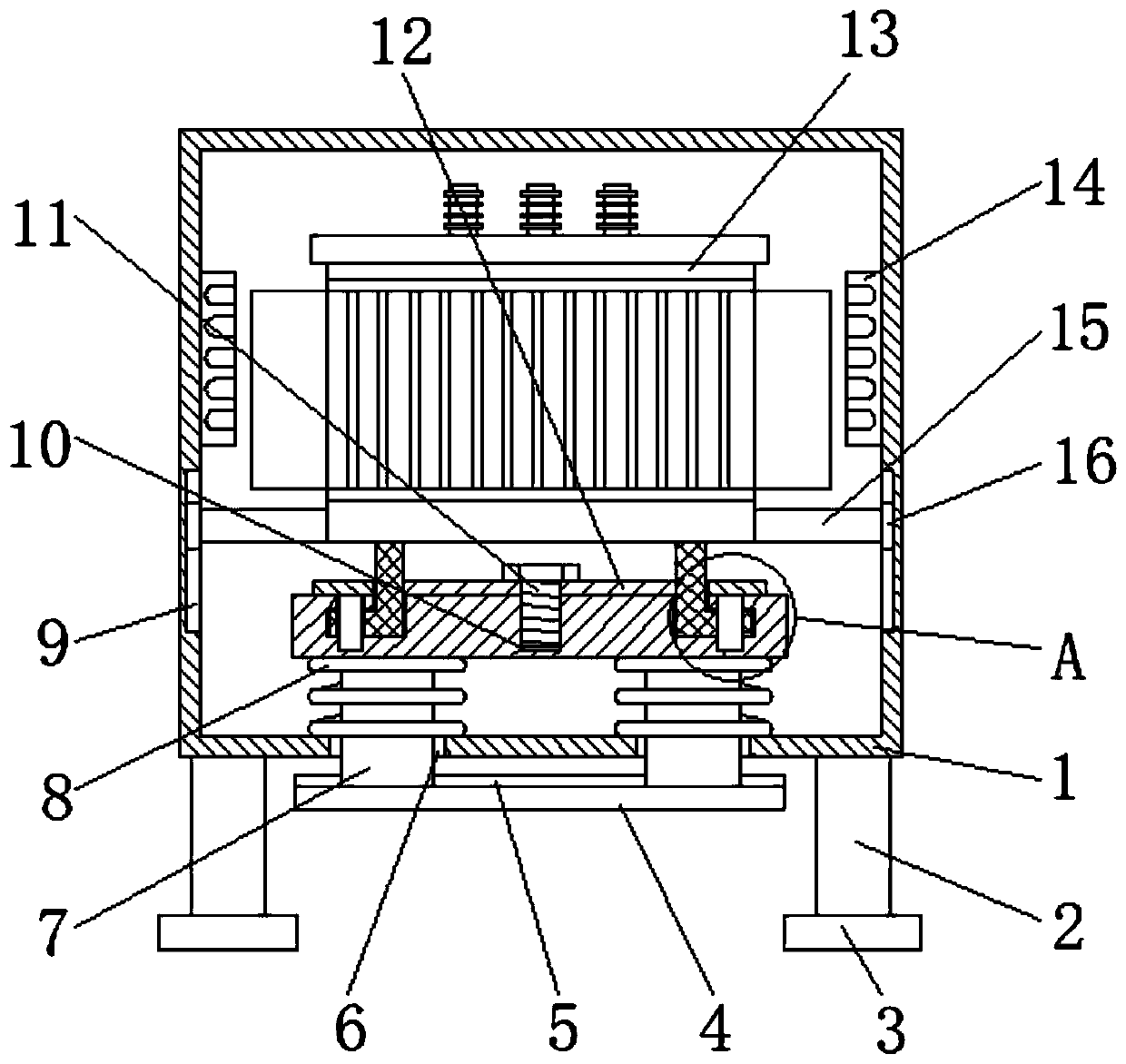

Noise reduction type transformer with long service life, and using method thereof

PendingCN111564279AReduce self-shockReduce noiseTransformers/reacts mounting/support/suspensionTransformers/inductances coolingTransformerEngineering

The invention discloses a noise reduction type transformer with long service life, and a using method thereof. The noise reduction type transformer comprises a shell, wherein a transformer main body is arranged in the inner cavity of the shell, connecting rods are fixedly connected to the four corners of the bottom of the transformer main body, a mounting seat is arranged at the bottom of the transformer main body, first mounting grooves used in cooperation with the connecting rods are formed in the four corners of the top of the mounting seat correspondingly, the sides, close to the inner cavities of the first mounting grooves, of the connecting rods extend to the inner cavities of the first mounting grooves and are movably connected with the inner cavities of the first mounting grooves,and a connecting plate is arranged at the top of the mounting seat. In the prior art, the existing noise reduction type transformer generally does not have a damping and buffering structure, so that the internal electrical elements of the transformer are prone to being damaged due to self-vibration in the operation process, the dustproof and heat dissipation effects are poor generally, and the service life of the transformer is possibly affected to a certain extent. According to the invention, the noise reduction type transformer is long in service life and can solve the problems in the priorart.

Owner:JIANGSU MINGAN ELECTRIC

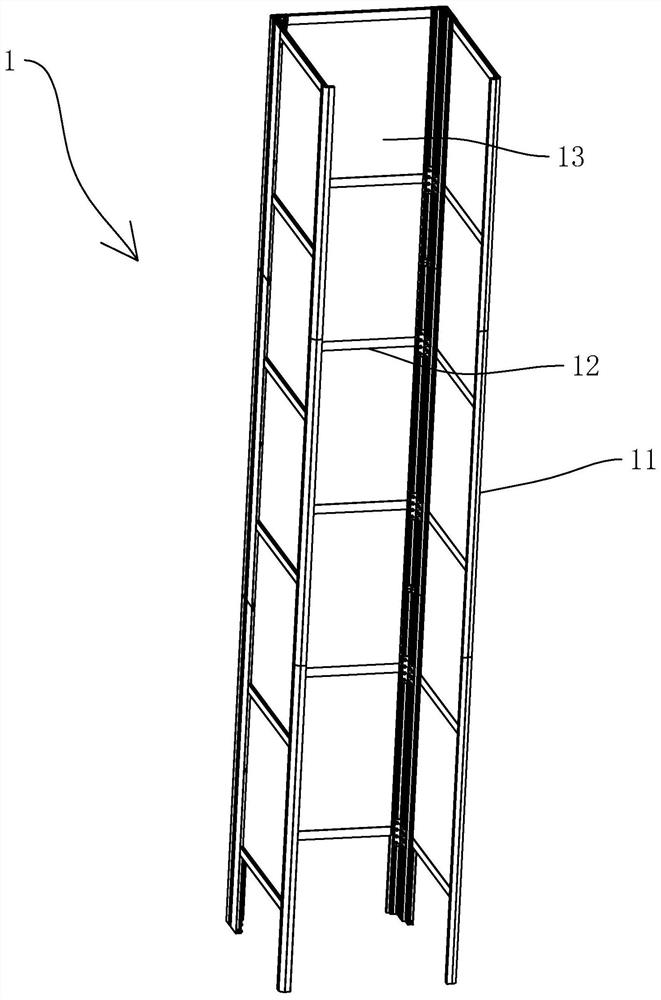

Easy-to-mount elevator and mounting method thereof

The invention relates to the technical field of elevators, in particular to an easy-to-mount elevator and a mounting method thereof. The easy-to-mount elevator comprises a mounting frame, a car frameand a lift car, wherein the mounting frame comprises frame stand columns, crosspieces and connecting plates; the car frame comprises a fixing plate, a locking plate and fork corners; and the lift carcomprises a car roof, a car bottom, side plates, a back plate and a car door, and moving wheels are detachably arranged on the car bottom. The easy-to-mount elevator and mounting method thereof comprises the following steps that S1, the mounting frame is assembled in a hoistway; S2, the car frame is assembled and the car frame is connected to the mounting frame; S3, the lift car is assembled in anexternal open space; S4, the lift car is pushed; and S5, the moving wheels on the lift car are dismounted. The elevator has the advantage of improving installation convenience of the elevator.

Owner:SUZHOU BOW INTELLIGENCE TECH CO LTD

Cleaning and drying device for power strip voltage withstanding instrument

PendingCN114554782AIncrease frictionSolve the problem of certain inconvenience caused by useHuman health protectionCleaning using gasesPhysicsEngineering

The cleaning and drying device comprises a first box body, supporting columns are fixedly connected to the four corners of the top of the first box body, a second box body is fixedly connected to the tops of the supporting columns, and a draught fan is installed at the top of the second box body in a penetrating mode. The first box body, the drawer, the storage battery, the air pump, the ash pumping pipe, the electromagnetic valve, a supporting column, a placing frame, an annular pipe, a fan, an air inlet end, a second box body, a circulating pipe, a supporting rod, a transverse pipe, a transverse plate, a ventilation filter screen, a box door, an air outlet hole, a threaded shaft, a guide block, a guide groove, a pressing plate, a fixing plate and a controller are arranged and used in cooperation; the problems that an existing power strip voltage withstanding instrument cleaning and drying device generally does not have a multi-air-duct circulating drying function in the using process, so that the drying efficiency is low possibly due to the single air duct in the using process, and certain inconvenience is possibly caused to a user in the using process of the power strip voltage withstanding instrument cleaning and drying device are solved.

Owner:昆山昊玺机电设备有限公司

A sanding machine for paint production

The invention discloses a dull polish machine for coating production. The dull polish machine comprises a box body, a first motor is fixedly connected to the center of the top of the box body, the output end of the first motor is fixedly connected with a first rotating shaft, the bottom of the first rotating shaft penetrates into an inner cavity of the box body, and a dull polish wheel is fixedlyconnected to the bottom of the first rotating shaft, a dull polish shell used in cooperation with the dull polish wheel is arranged in the inner cavity of the box body, dull polish blocks are fixedlyconnected to the two sides of the dull polish wheel correspondingly, an annular through groove is formed in the side, close to the grinding blocks, of the bottom of the dull polish shell, and a firstfilter screen is installed at the bottom of the dull polish shell in a penetrating mode. The dull polish machine has the advantage of high efficiency; and the problems that an existing dull polish machine for coating production is generally single in dull polish mode in the using process, so that the dull polish efficiency of the existing dull polish machine is low, the existing dull polish machine generally does not have a screening function, large particles obtained after primary dull polish cannot be subjected to secondary dull polish, and certain inconvenience is easily caused to a user inthe using process are solved.

Owner:CHONGQING HAODI PAINT

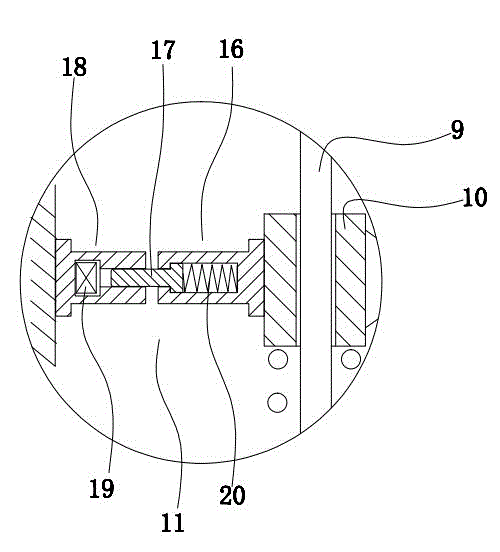

A three-dimensional engraving machine

ActiveCN104385817BImprove applicabilitySupport balanceModel makingFixed bearingIndustrial engineering

The invention provides a three-dimensional engraving machine, which belongs to the technical field of mechanical equipment. It solves the problem that it is difficult to adjust the angle of the machine head during the moving engraving process of the existing three-dimensional engraving machine. The three-dimensional engraving machine includes a frame and a workbench. There is a beam above the workbench. A tool rack is provided on the side of the beam. A horizontal carriage is provided on the side of the beam. The vertical carriage moves back and forth in the same direction. The bearing seat is fixed on the vertical carriage. The tool holder is connected to the bearing seat through the bearing. A drive mechanism that reciprocates for the axis. This three-dimensional engraving machine can realize the angle adjustment of the machine head during the mobile engraving process, so that the machine head can carve products at different angles.

Owner:吴善旺

Mixing device and mixing method for layered feeding in feed production

InactiveCN111672347ASupport balanceRotary stirring mixersTransportation and packagingFodderMaterial storage

The invention discloses a mixing device and a mixing method for layered feeding in feed production. The mixing device comprises a box body; the top and the bottom of the left side of the box body arefixedly connected with a material storage box and a liquid storage box correspondingly. A rotary drum is arranged in the inner cavity of the box body; the right side of the surface of the rotary drumis fixedly sleeved with a load-bearing bearing; supporting rods are fixedly connected to the front side and the rear side of the load-bearing bearing, the sides, close to the inner cavity of the box body, of the supporting rods are fixedly connected with the inner cavity of the box body, a baffle is arranged on the left side of the rotary drum, the bottom of the right side of the material storagebox communicates with a third pipeline, and the right side of the third pipeline penetrates into the inner cavity of the box body and communicates with the top of the baffle. The mixing device has theadvantages of layered feeding and efficient mixing, and solves the problems that an existing feed production mixing device generally does not have a layered feeding function in the use process, and the mixing mode is generally single, so that the mixing efficiency and effect of the existing feed production mixing device are easily influenced to a certain extent, and certain inconvenience is possibly caused to a user.

Owner:王其

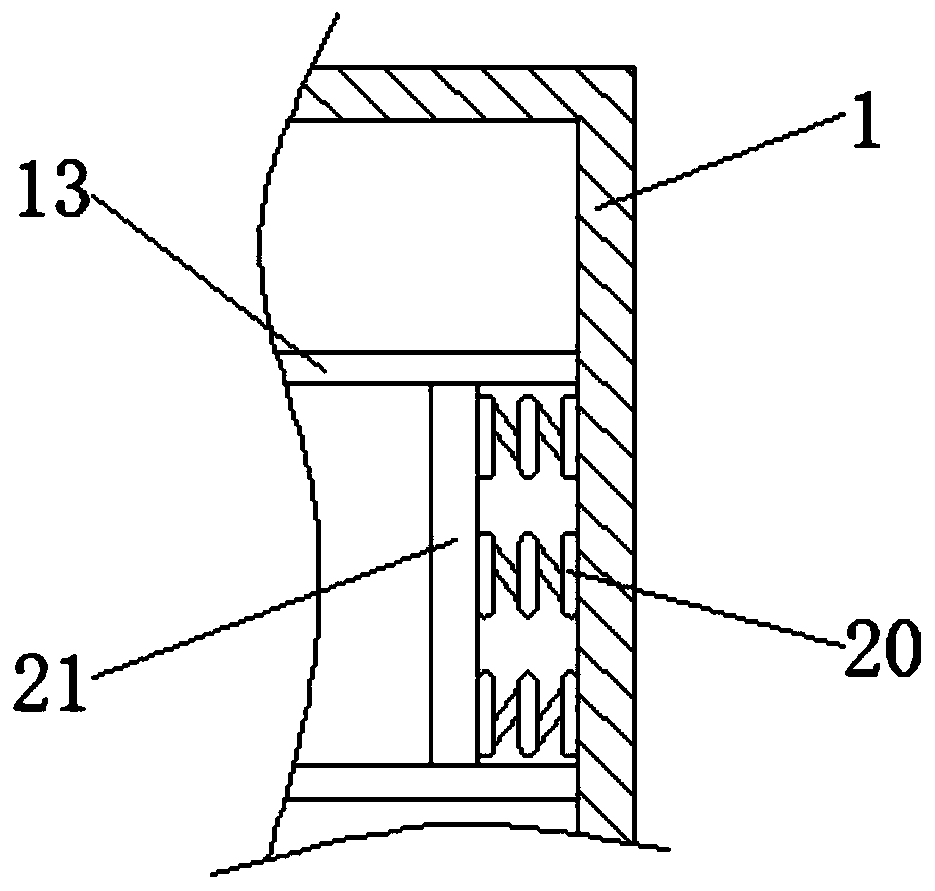

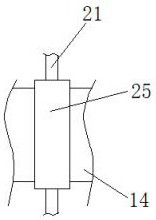

footrest

ActiveCN103909892BUniform support surfaceSupport balanceVehicle arrangementsPedestrian/occupant safety arrangementEngineering

The invention relates to a footrest and aims at providing a footrest capable of keeping the supporting effect for the left and right feet to be balanced when a vehicle is subjected to impact. The footrest comprises a lower footrest plate obliquely arranged between an automobile floor and a front surrounding plate, an upper footrest plate is arranged on the lower footrest plate, the bottom edges of the lower footrest plate and the upper footrest plate are hinged, and an elastic part is arranged between the lower footrest plate and the upper footrest plate. The footrest has the advantages of enabling the left and right feet to be subjected to the same supporting force, meanwhile playing a buffering role through the elastic part between the upper footrest plate and the lower footrest plate and suitable for popularization and usage.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Bamboo shoot shell crushing equipment and method for applying bamboo shoot shells to plant culture medium

ActiveCN112705323AImprove breathabilityIncrease surface areaGrowth substratesMicroorganism based treatmentFertilizerPesticide

The invention provides bamboo shoot shell crushing equipment and a method for applying bamboo shoot shells to a plant culture medium. The bamboo shoot shell crushing equipment comprises a feeding bin, a crushing chamber, a cutter disc, a motor, a discharging bin, a conveying belt, a transmission motor and a supporting frame. The crushing chamber is connected to the lower end of a collecting bin, the crushing chamber comprises a baffle and the cutter disc, the cutter disc is driven by a motor to rotate, the crushing chamber is connected with the discharging bin, the conveying belt is arranged below the discharging bin, the transmission motor is arranged at the top end of the conveying belt, and the whole bamboo shoot shell crushing equipment is fixed through the supporting frame. The bamboo shoot shells crushed by the bamboo shoot shell crushing equipment can form fiber bundles, the fiber bundles are connected through a latticed structure, the tail ends of the fiber bundles are wound into clusters, the latticed structure has good air permeability, the wound fiber clusters have good water retention and fertilizer retention properties, and after the plant culture medium is prepared, the wound fiber clusters have good water-retaining property, air permeability and good fertilizer efficiency, the sugar content of fruits can be improved, germs, worm eggs and grass seeds do not contained, the use of pesticides is reduced, and the growth of crops is promoted.

Owner:FUJIAN AGRI & FORESTRY UNIV

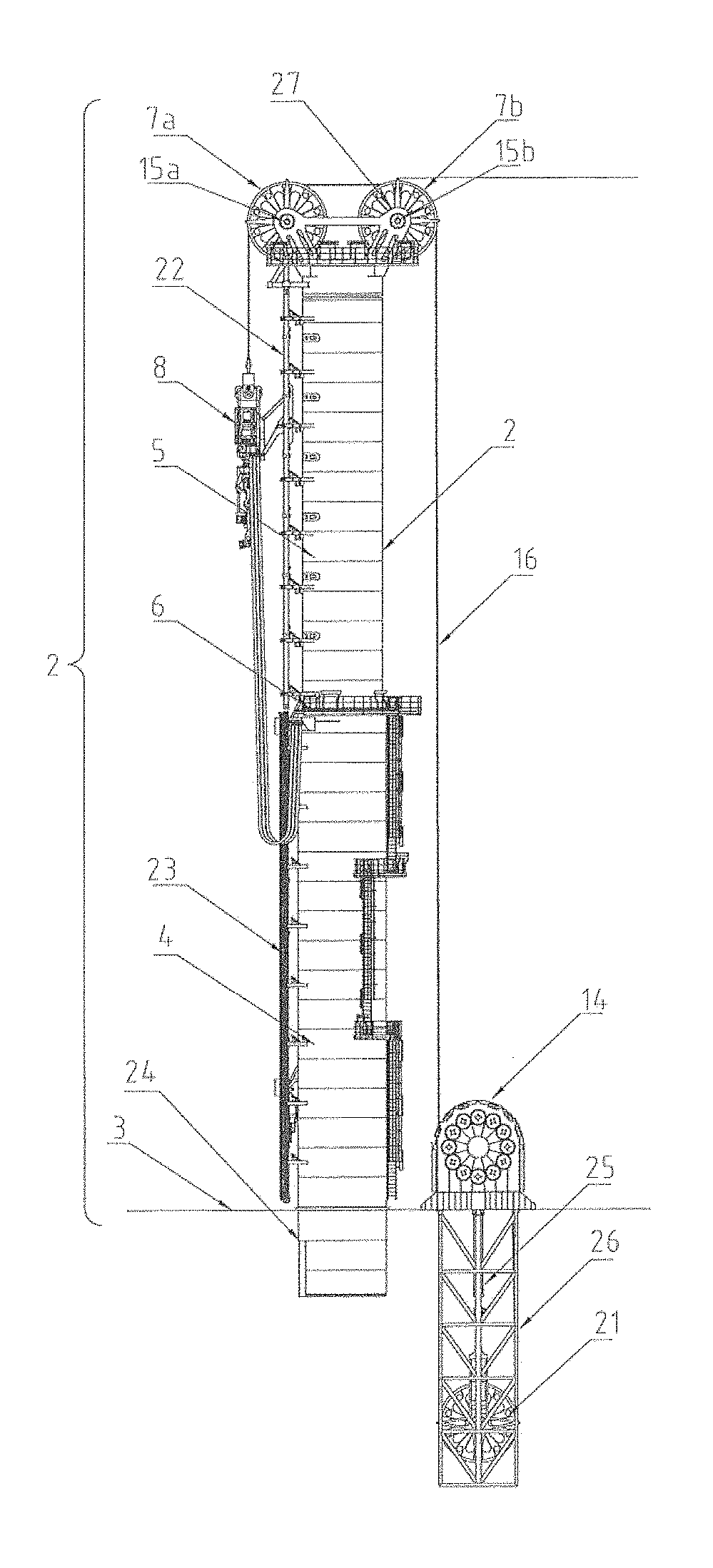

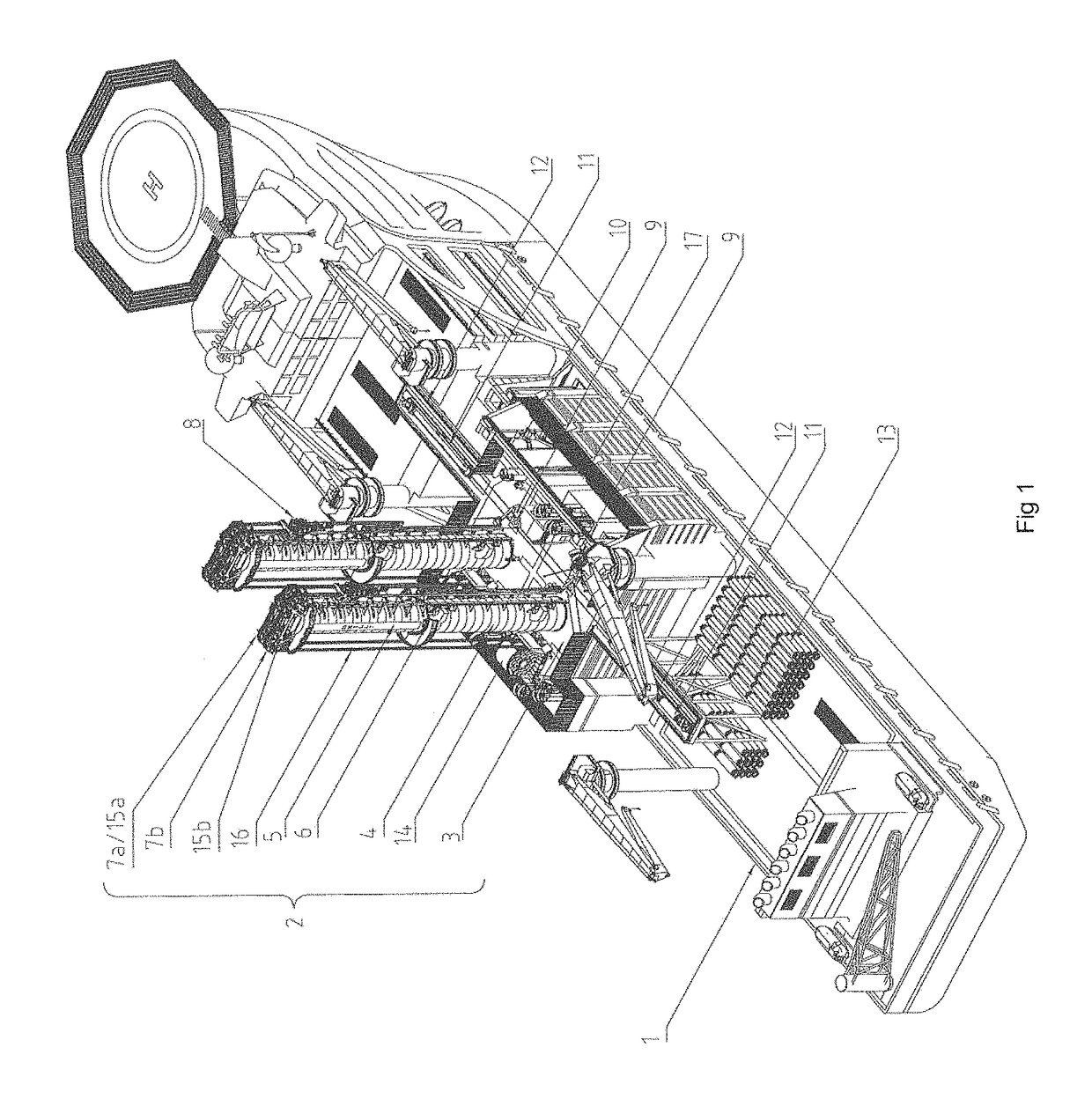

Drilling rig arrangement

The invention provides a system for operating a drilling rig on a drilling vessel, the system comprising a drilling tower (2) having at least two segments (4, 5), a first segment (4) is fixedly connected to the drilling vessel (1), a second segment (5) is connected to the first segment (4), said second segment (5) is adapted to move longitudinally relative the first segment (4) by raising and lowering means. A tool (8) is suspended from at least one wire (16), said at least one wire (16) is extending over at least one sheave (7a, 7b) on top of the second segment (5), said at least one wire (16) is coupled to with a passive compensator arrangement (20) and a winch (14), said passive compensator (20) is connected to the winch (14).

Owner:CASTOR DRILLING SOLUTION

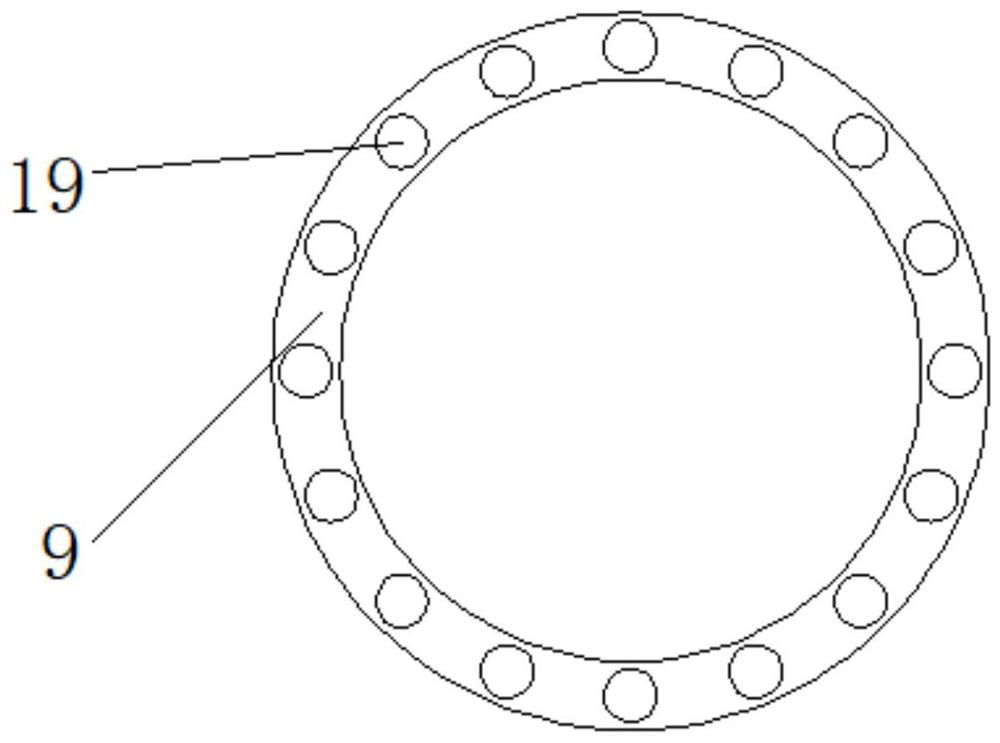

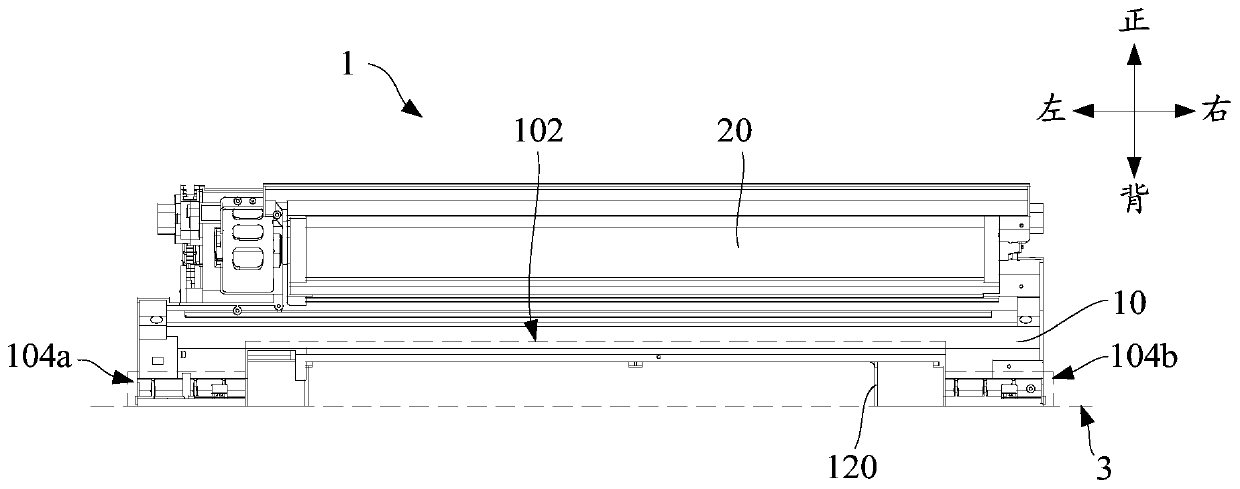

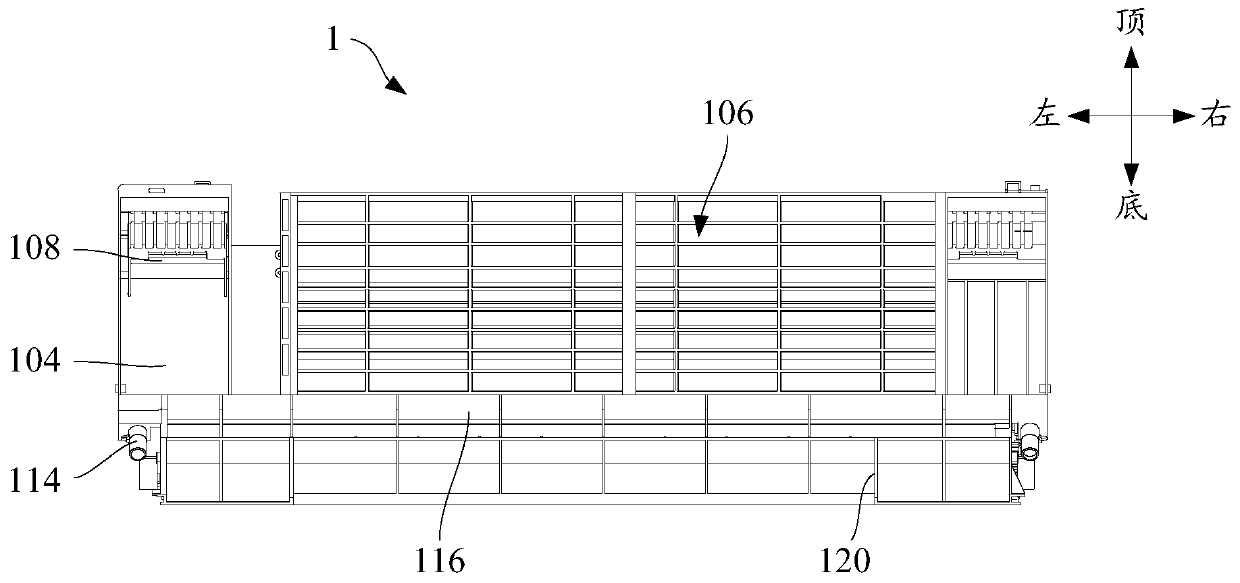

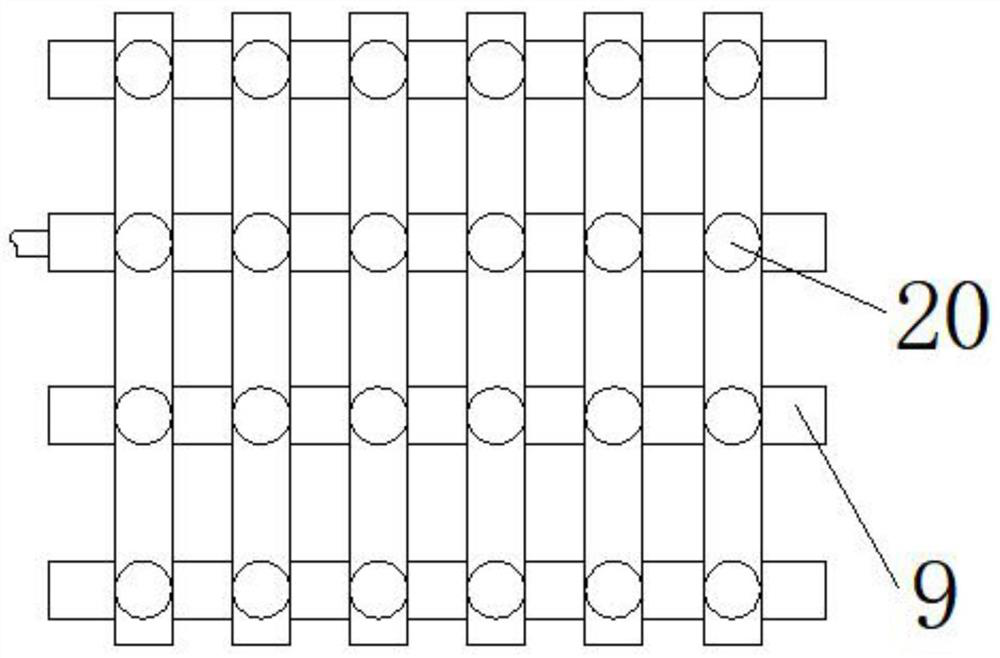

Chassis and wall mounting type air conditioner

PendingCN110057096AImprove energy efficiencyLower the altitudeLighting and heating apparatusSpace heating and ventilation detailsWall mountComputer engineering

The invention provides a chassis and a wall mounting type air conditioner, and the chassis is used for the wall mounting type air conditioner. The chassis is used for being assembled to an installation face and is provided with a back portion and the back portion is used for being opposite to the installation face, wherein the back portion is structured with a concave portion and convex portions,the two sides of the concave portion are formed with the convex portions correspondingly, the convex portions protrude outwards relative to the surface of the concave portion, and the wall of the concave portion is structured with air inlets. According to the chassis and the wall mounting type air conditioner, by means of improvement of an existing chassis, the back portion, opposite to the installation face, of the chassis is structured with the concave portion and the convex portions located on the two sides of the concave portion, the wall of the concave portion and the installation face can be segregated utilizing the convex portions, air flow can flow past the space between the concave portion and the installation face smoothly, guarantee of the air inlet quantity of the air inlets structured in the wall of the concave portion is facilitated, so that the wall mounting type air conditioner can be made to adopt an air inlet way of back portion air inlet, under the situation of not changing the original appearance of the wall mounting type air conditioner, the air inlet area is increased, the air inlet quantity is increased, the heat exchange efficiency is improved, and the energy efficiency is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Bamboo shoot shell crushing equipment and method for applying bamboo shoot shell to plant cultivation substrate

ActiveCN112705323BImprove breathabilityIncrease surface areaGrowth substratesMicroorganism based treatmentFiber bundleAgricultural engineering

The invention provides a bamboo shoot shell crushing equipment and a method for applying bamboo shoot shells to plant cultivation substrates, wherein the bamboo shoot shell crushing equipment includes a feeding bin, a crushing chamber, a cutter disc, a motor, a feeding bin, a conveyor belt, a transmission motor, Supporting frame; the lower end of the collection bin is connected to the crushing chamber, the crushing chamber includes a baffle and a cutter disc, the cutter disc is driven by a motor to rotate, the crushing chamber is connected to the discharge bin, a conveyor belt is set under the discharge bin, a transmission motor is set on the top of the conveyor belt, and the whole is supported by a support frame fixed. The bamboo shoot shells broken by the bamboo shoot shell crushing equipment provided by the application can form fiber bundles, the fiber bundles are connected by a grid structure and the ends are wound into agglomerates, the grid structure has good air permeability, and the entangled fiber clusters have good air permeability. Excellent water retention and fertilizer retention. After being prepared into a plant cultivation substrate, it not only has good water retention and air permeability, but also has good fertilizer efficiency, which can increase the sugar content of fruits, and does not contain germs, insect eggs, and grass seeds. The use of pesticides promotes the growth of crops.

Owner:FUJIAN AGRI & FORESTRY UNIV

Yarn cleaning device for spinning

PendingCN114657719ASupport balanceIncrease frictionTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsYarnSpinning

The spinning yarn cleaning device comprises a box body, a water tank is fixedly connected to the bottom of an inner cavity of the box body, and a dustproof filter screen is installed at the top of the water tank in a penetrating mode. The device is provided with a box body, a liquid pump, a liquid pumping pipe, a liquid outlet pipe, a driving shaft, a partition plate, an air pump, an air outlet pipe, a second pipe network, a ventilation filter screen, a first driven shaft, a second driven shaft, an annular pipe, a dustproof filter screen, a transmission roller, a water tank, a first through hole, a high-pressure nozzle, a first pipe network, a first air outlet hole, a box door, a controller, a second air outlet hole, a motor, a belt, a belt pulley and bristles. Through cooperative use of a second through hole and a shell, the problems that an existing yarn cleaning device for spinning is generally inconvenient to brush cloth in the cleaning process in the production process, the cleaning effect is generally poor, and generally, double-air-duct air drying after cleaning is not achieved, so that the cleaning effect is poor are solved. And certain inconvenience is possibly caused to further processing and utilization.

Owner:昆山旭杰复合材料有限公司

A combined box-type substation

ActiveCN110311319BSupport balanceEasy to pourSubstation/switching arrangement detailsDistribution substationsReinforced concreteTransformer

The invention discloses a combined box-type substation, comprising a primary load-bearing anchor rod and a secondary load-bearing anchor rod, the primary load-bearing anchor rod and the secondary load-bearing The sleeve and the load-bearing sleeve are respectively rotatably connected with a first-level sleeve rod and a first-level inner rod, and the free end of the first-level inner rod is slidably sleeved in the free end of the first-level sleeve rod. In the present invention, the setting sleeve and load-bearing sleeve are put on the first-level load-bearing anchor rod and the second-level load-bearing anchor rod, and the first-level load-bearing anchor rod and the second-level load-bearing anchor rod are used to adjust the distance between the first-level load-bearing anchor rod and the second-level load-bearing anchor rod. Limit and fix the load-bearing sleeve at different heights to fix the load-bearing trough and the pouring net, which is convenient for pouring the reinforced concrete layer structure; by fixing and welding the secondary sleeve rod on the reinforced concrete layer, the The rod is elastically connected to the secondary inner rod, and the secondary spring and the support rod are used to provide a load-bearing plate on the horizontal limit rod, providing a solid foundation for the installation of the electromechanical box with the transformer.

Owner:山东万盛电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com