Bamboo shoot shell crushing equipment and method for applying bamboo shoot shells to plant culture medium

A technology for crushing equipment and cultivation substrates, which can be applied to planting substrates, botanical equipment and methods, applications, etc., and can solve problems such as poor fertilizer efficiency, poor air permeability, and poor bamboo shoot shell crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

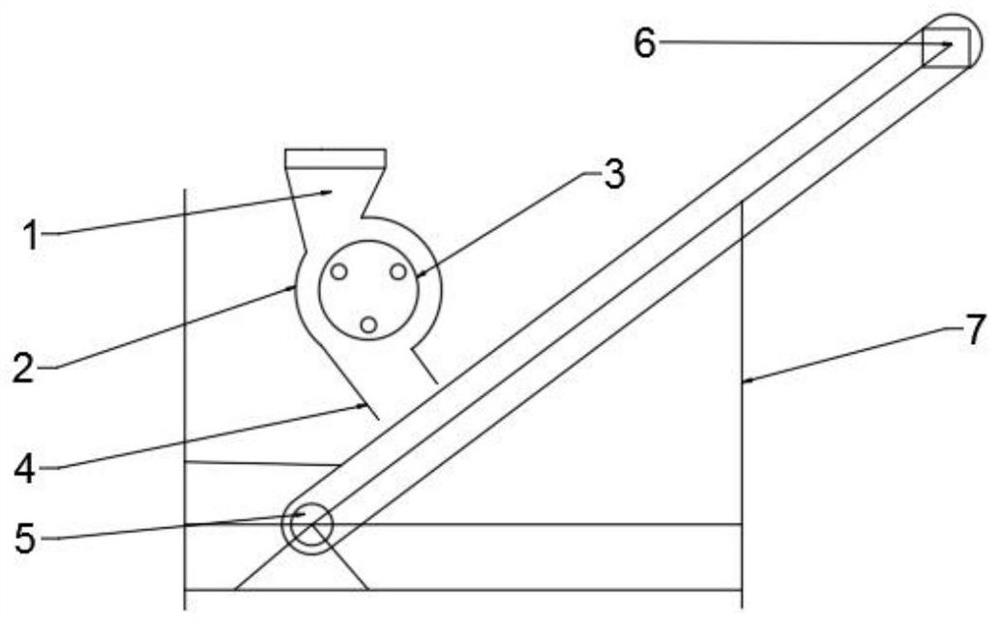

[0033] A bamboo shoot shell crushing equipment, characterized in that the crushing chamber (2) is fixedly connected to the bottom of the feeding bin (1), the inner wall of the crushing chamber (2) is provided with grid-like protrusions, and the crushing chamber (2) is provided with knives A spacer is set between the disc (3), the shell of the crushing chamber (2) and the central axis of the cutter disc (3), the cutter disc (3) is driven to rotate by the first motor, and the shaft of the cutter disc (3) passes through the shaft of the first motor The gears are connected, the cutter disc (3) is provided with three crushing rollers, and the crushing rollers are provided with 36 blades (302) separated by spacers (303), the blades are spaced 4cm apart, and the blades include a fixed ring (3021), a triangular pattern (3022), a thick The knife edge (3023), the sharp knife head (3034), the discharge bin (4) is set under the crushing chamber, the conveyor belt (5) is set under the disch...

Embodiment 2

[0045] The bottom of the feeding bin is fixedly connected to the crushing chamber, the inner wall of the crushing chamber is provided with grid-shaped protrusions, the cutter disc is arranged in the crushing chamber, and a gasket is arranged between the crushing chamber shell and the central axis of the cutter disc, and the cutter disc is driven by the first motor Rotate, the cutter disc shaft and the first motor shaft are connected by gears, the cutter disc is equipped with three crushing rollers, and the crushing rollers are provided with 42 blades spaced by spacers. The blades are spaced at 3.5cm. The blades include fixed rings, triangular patterns, thick blades, Sharp cutter head, the discharge bin is set under the crushing chamber, and the conveyor belt is set under the discharge bin. The conveyor belt and the frame are fixed by bolts, and the conveyor belt is driven by the transmission motor; the inclination angle between the conveyor belt and the ground is 30 degrees, and...

Embodiment 1

[0047] The bamboo shoot shell crushing equipment that embodiment one sets with embodiment two is different, and the bamboo shoot shell broken thing of both gained is carried out physical and chemical property test, and test result is as follows table 2:

[0048] Table 2 Effect of different parameters of bamboo crushing equipment on the physical and chemical properties of crushing

[0049]

[0050] It can be seen from Table 2 that reducing the distance between the blades can increase the release rate of organic matter, but the air permeability decreases, and there is no significant difference in water retention.

[0051] The crushing degree of the bamboo shoot shells obtained by the bamboo shoot shell crushing equipment designed by the present invention is moderate, and the unbroken bamboo shoot shells and ultrafinely pulverized bamboo shoot shells are selected to prepare plant cultivation substrates by the method provided in this embodiment, and planted in the same facility ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com