Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about How to "Stitched tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

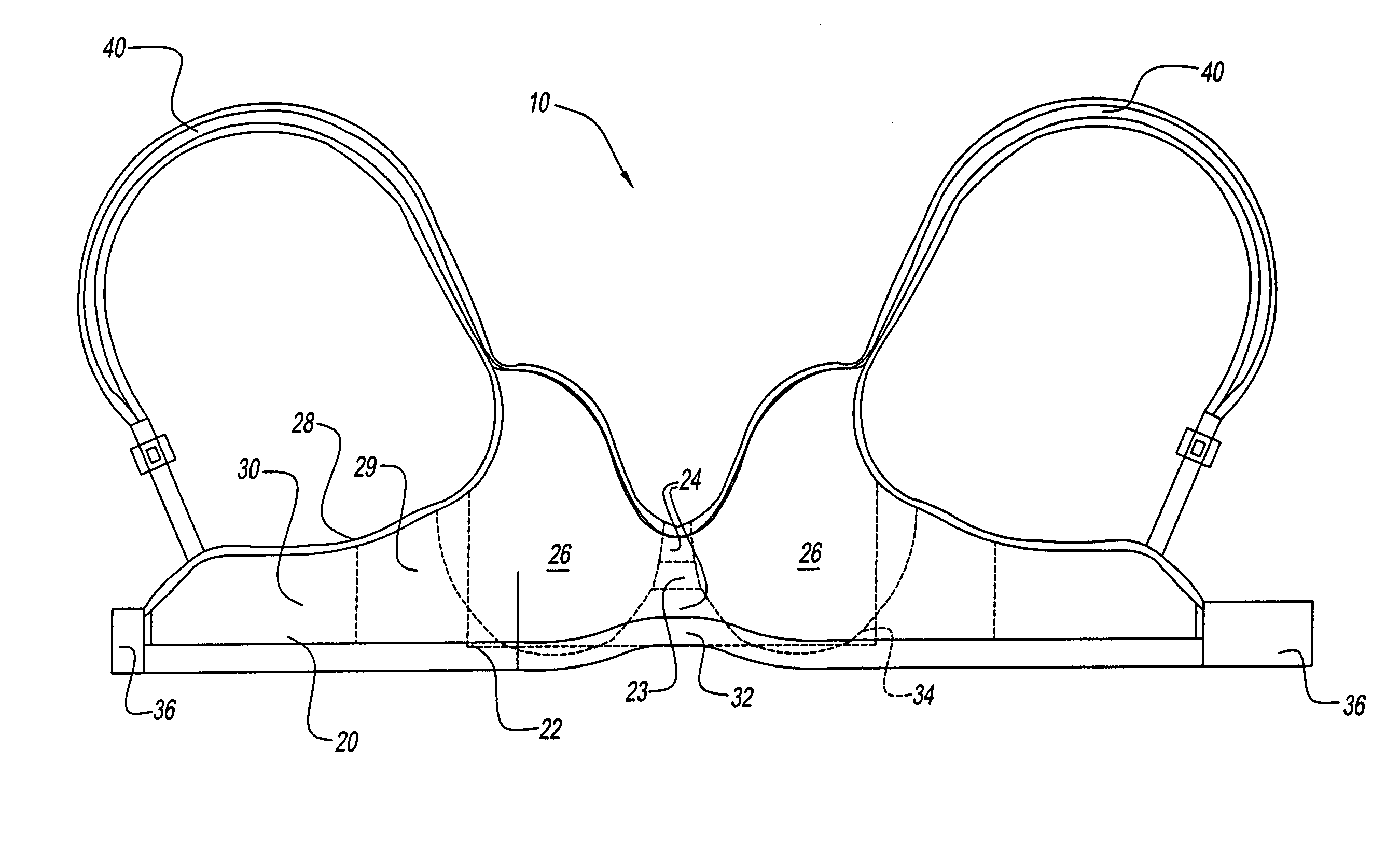

Circular knit bra having different areas of stretchability and method of making the same

InactiveUS7169011B2Progressive area of differential stretchabilityStitched tightlyWeft knittingBrassieresEngineering

Owner:HANESBRANDS

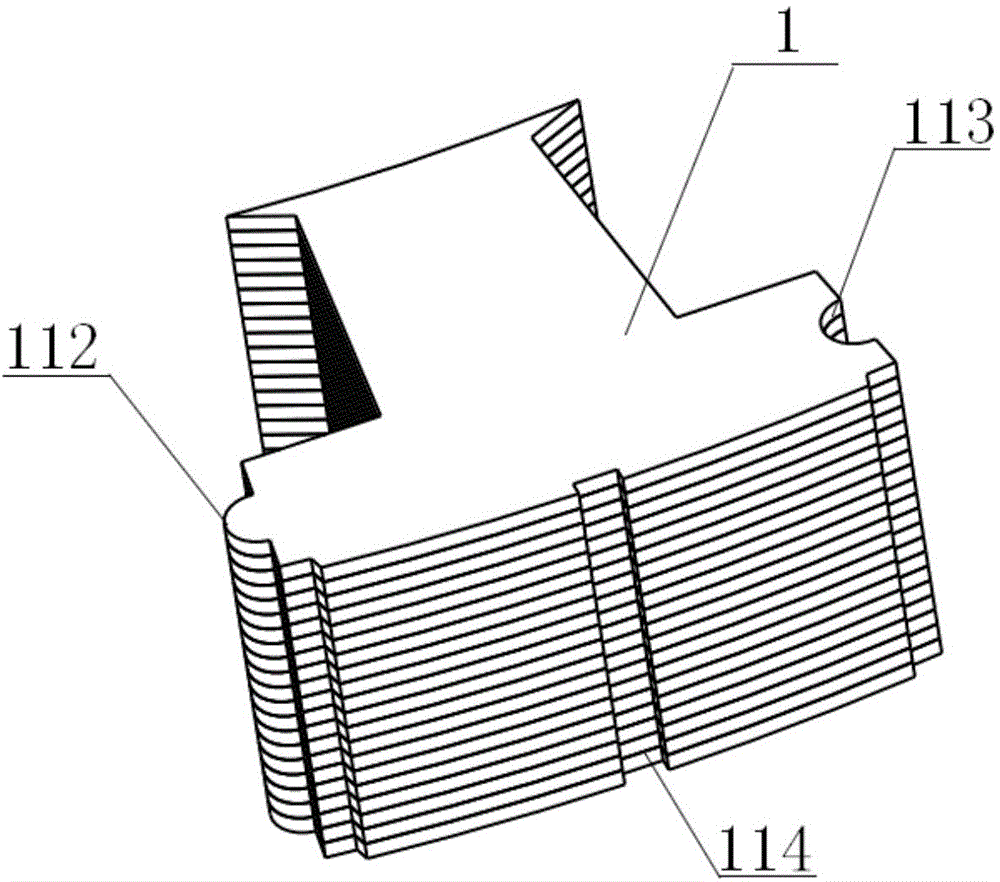

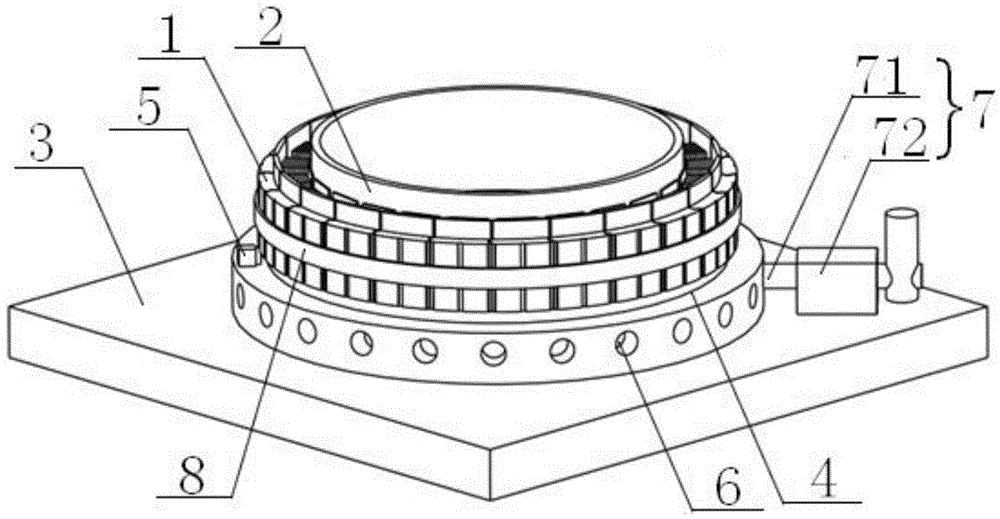

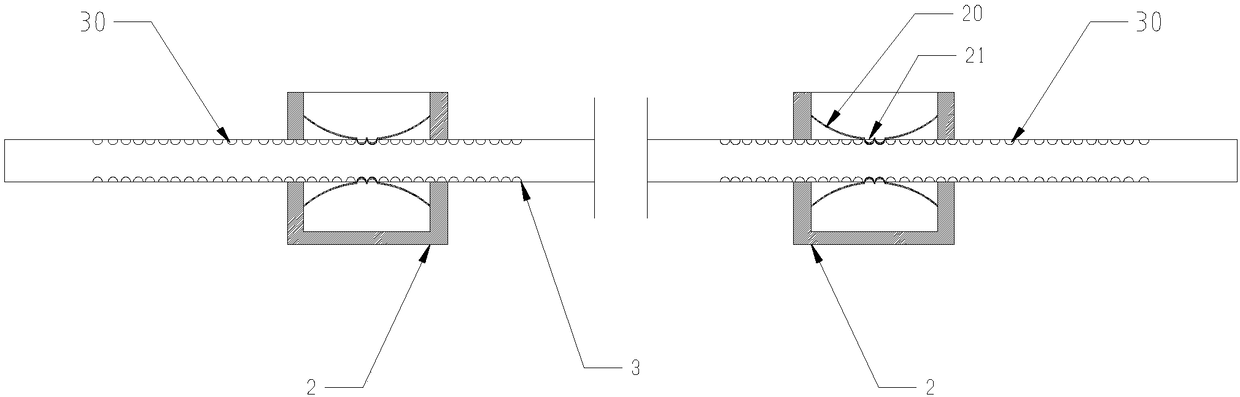

Method for assembling split stator core and assembly tool used thereby

ActiveCN104617716AFull transfer diffusionImprove connection strengthManufacturing stator/rotor bodiesHeat-affected zoneSpot welding

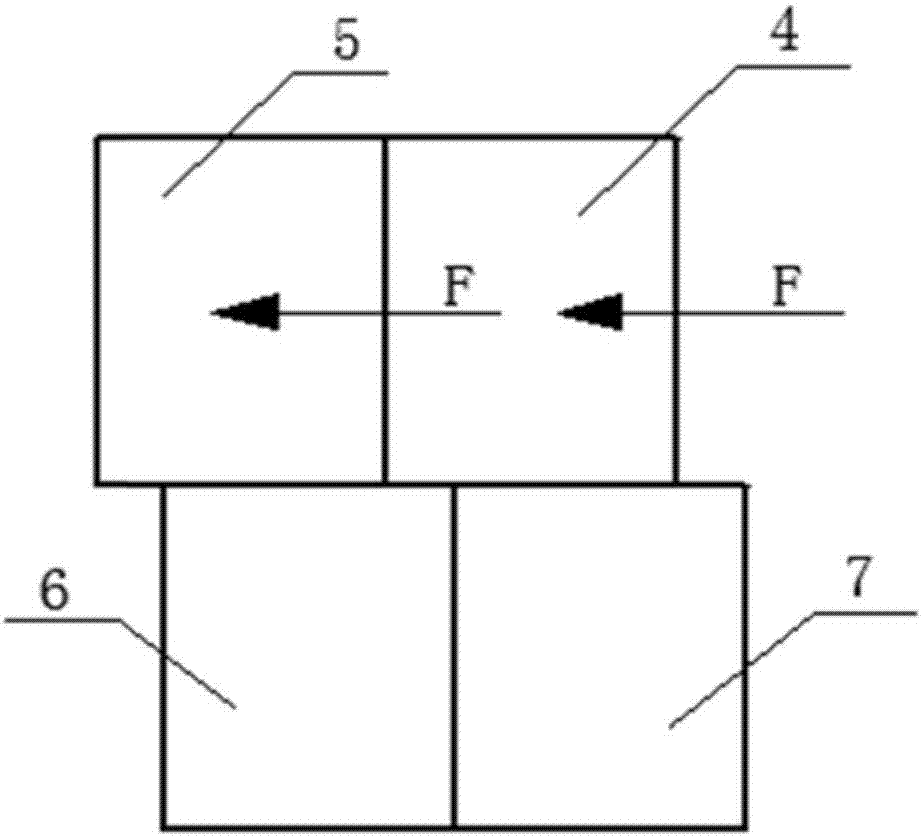

The invention discloses a method for assembling a split stator core and an assembly tool used thereby. The method comprises the following steps: a first core unit is placed on a splicing table with the outer cylindrical surface of an inner tube as a datum plane, and a positioning groove in the outer side face of the core unit and a positioning element on the top of the splicing table are positioned through embedding fit; other core units are sequentially spliced into a circular stator core through a connecting bulge and a connecting recess of the core unit; the stator core is tightly hooped by a hoop; the two ends of each weld are spot-welded and pre-fixed by laser; and the hoop divides each weld into an upper section and a lower section, and the upper section and the lower section of each weld are spot-welded by laser. According to the method of the invention, the core units are spliced by the inner tube and the hoop, which can improve the welding deformation resistance. The welds are pre-fixed by spot welding and spot-welded based on the principle of symmetry, which ensures the rounding precision of the stator core and improves the connecting strength. Moreover, the energy output of a single point of spot welding is low, the core has a small heat-affected zone and less deformation, and an inner water jacket and the stator core can be smoothly connected in a sleeving mode and fit tightly.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

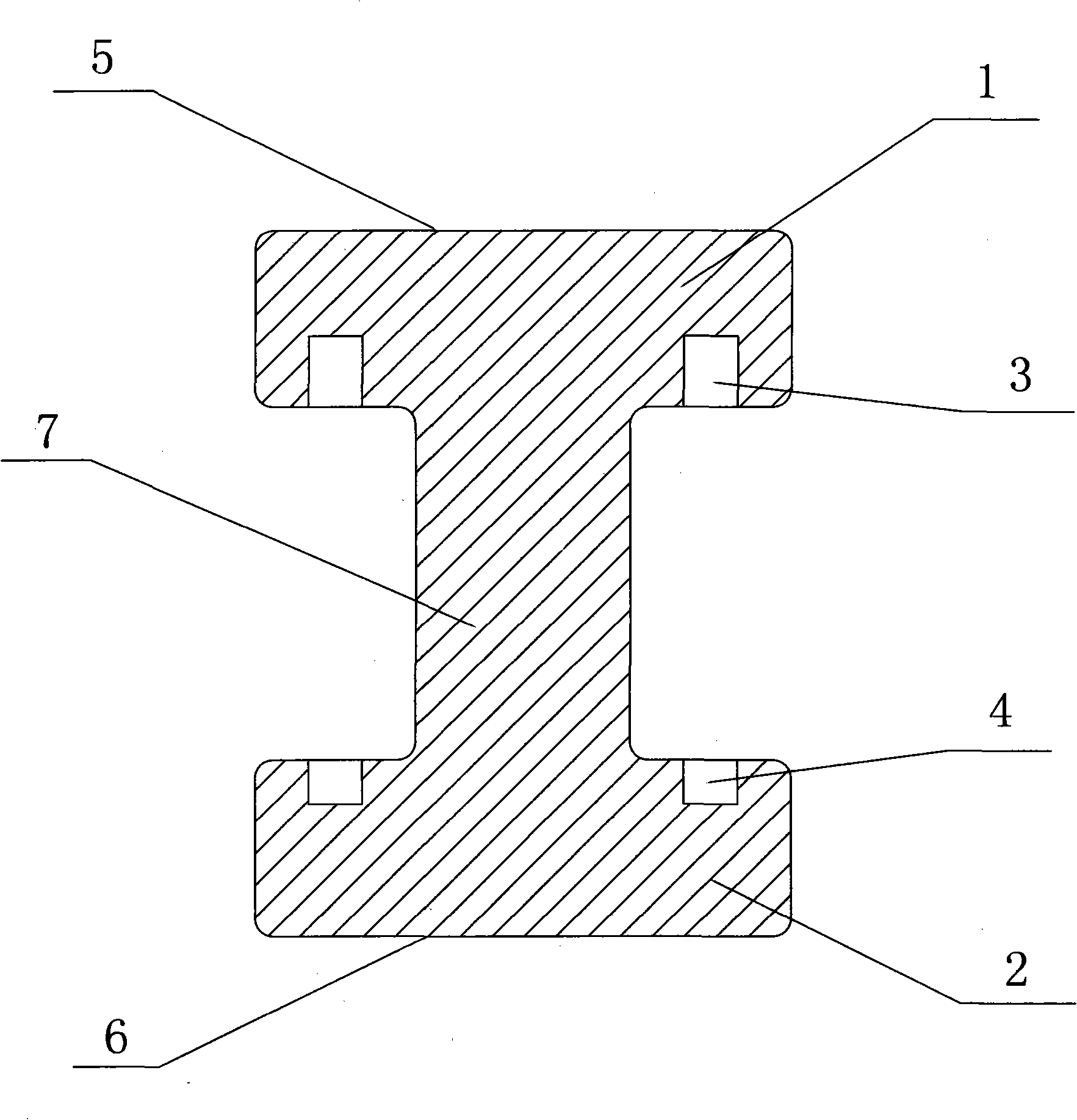

Ceramic suspending board for internal barrel of preheater cyclone barrel and connection method thereof

Provided is a ceramics hanging plate used in the inner tube of the preheater whirling barrel and connecting method, composed of a ceramics hanging plate and a fixing bar. The two sides of the ceramics hanging plate are symmetrically arranged with an upper fixing bar jack and a lower fixing bar jack corresponding on the upper hinging arm and the lower hanging arm; the length of the fixing bar does not exceed the depth of the fixing bar jack; the depth of the lower fixing bar jack is smaller than the length of the fixing bar. The connecting mode is as follows: after the top side of the upper hanging arm of the ceramics hanging plate C is butt-joint with the bottom of the lower hanging arm of the ceramics hanging plate A, then is embedded between the upper hanging arm and the lower hanging arm of the ceramics hanging plate B. A fixing bar in the fixing bar jack is used for fixing between the ceramics hanging plate and the hanging plate, connected in turn to the whole inner tube of the whirling barrel. The ceramics hanging plate is in the close joint, wherein the connection is reliable and not easy to fall off, which overcomes the defect of the unstable connection of the ceramics hanging plate, to make the ceramics hanging plate replace the alloy steel to obtain the wide addplcation, and greatly reduces the production cost of the corporation.

Owner:洛阳鹏飞耐磨材料股份有限公司

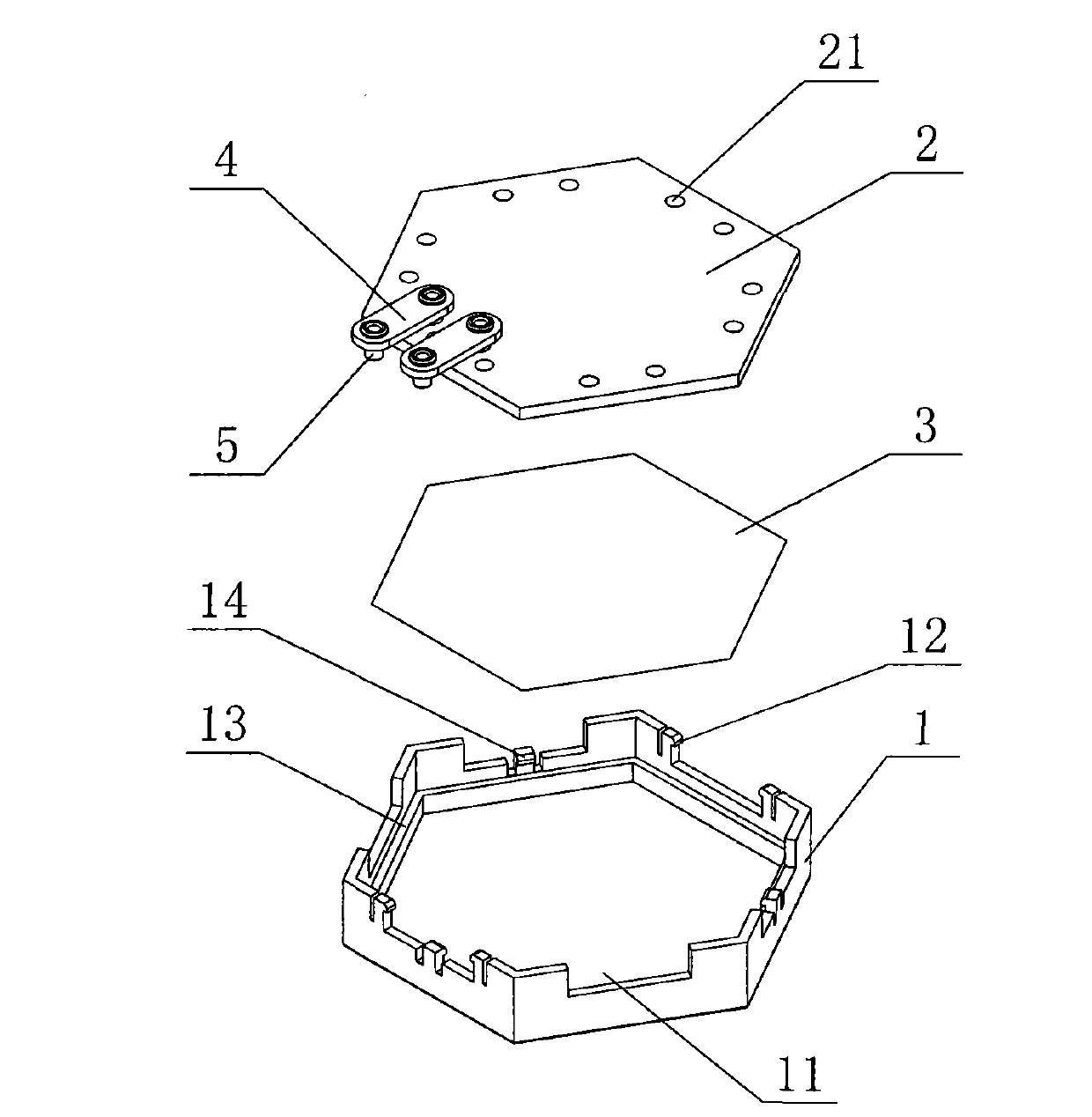

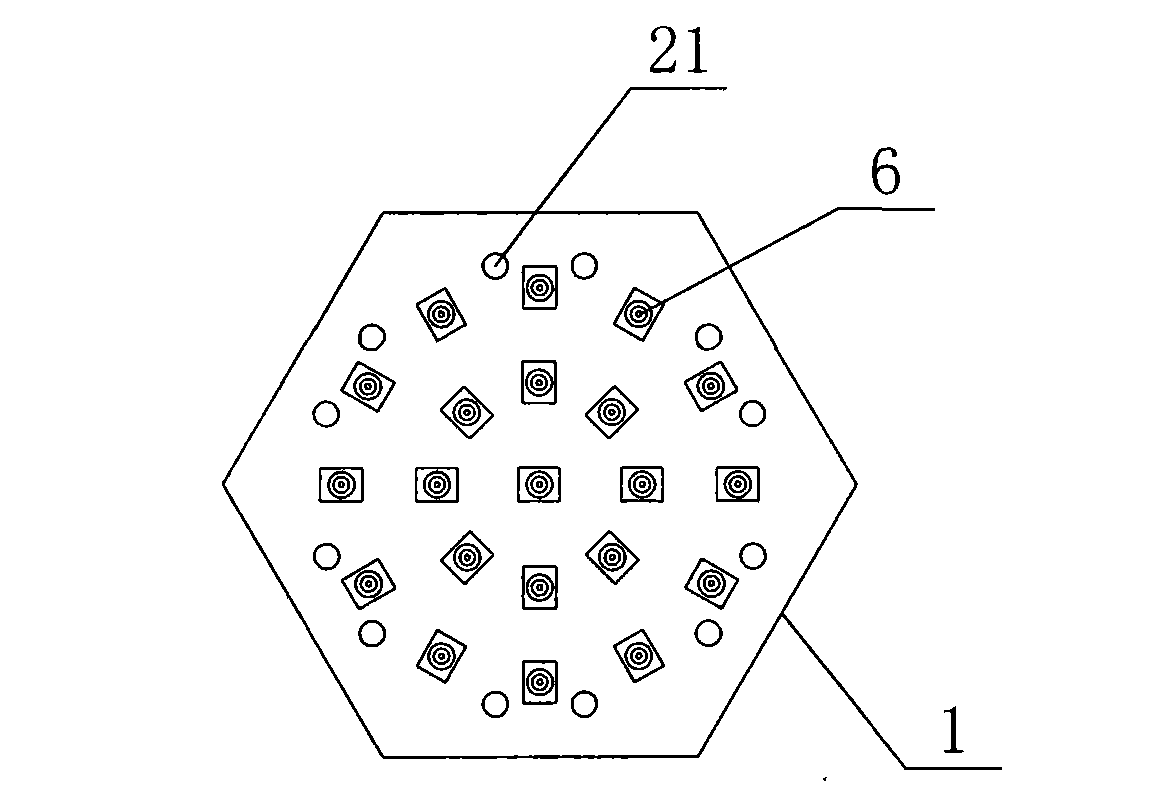

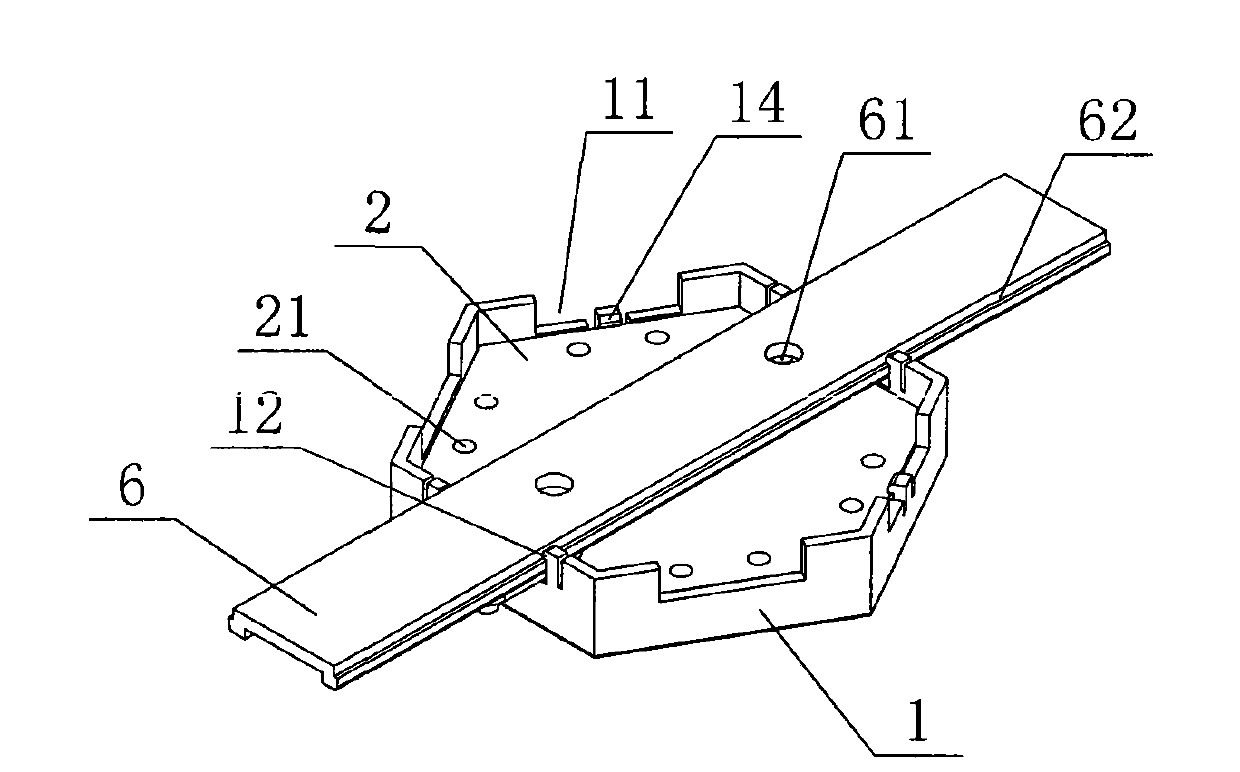

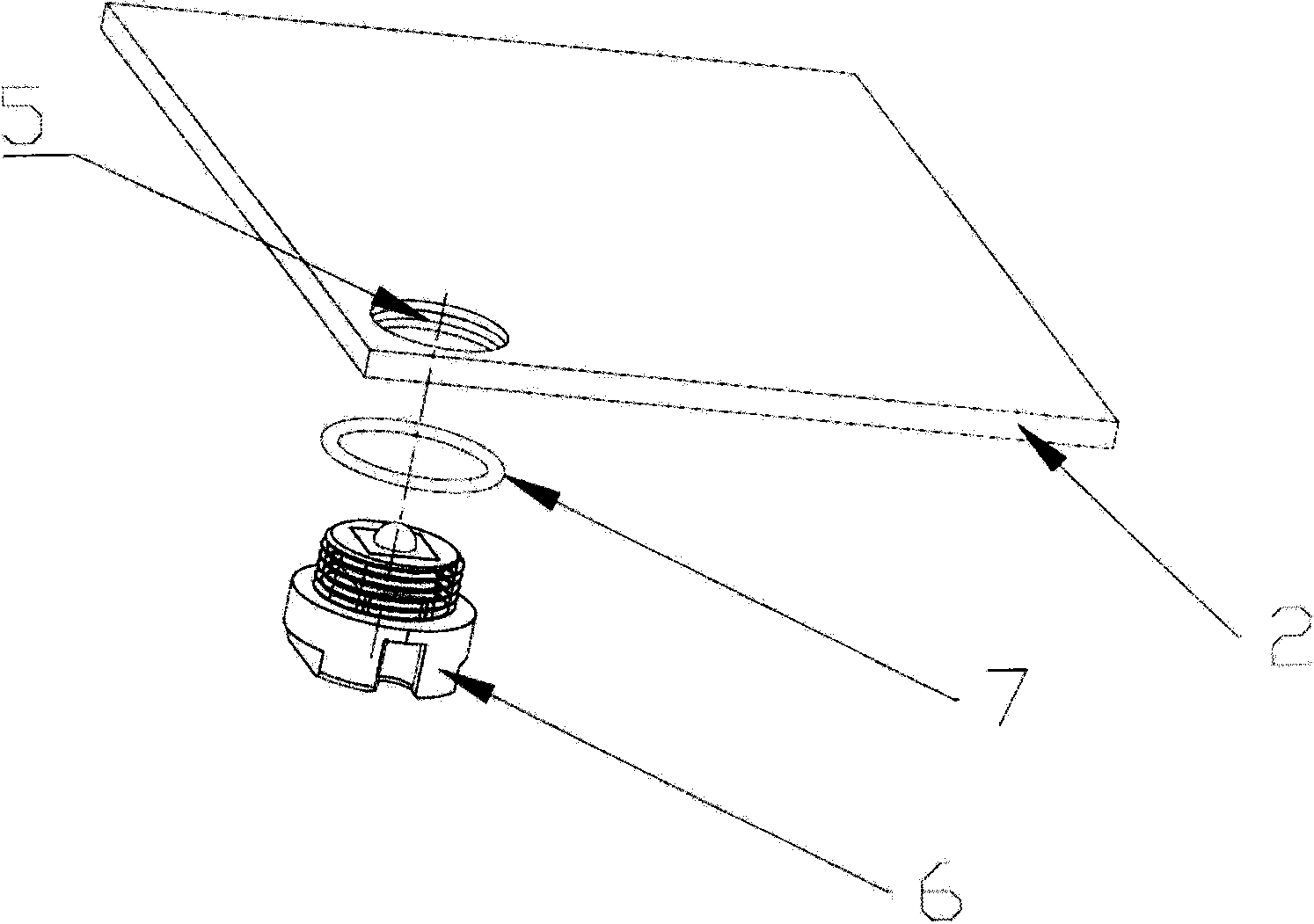

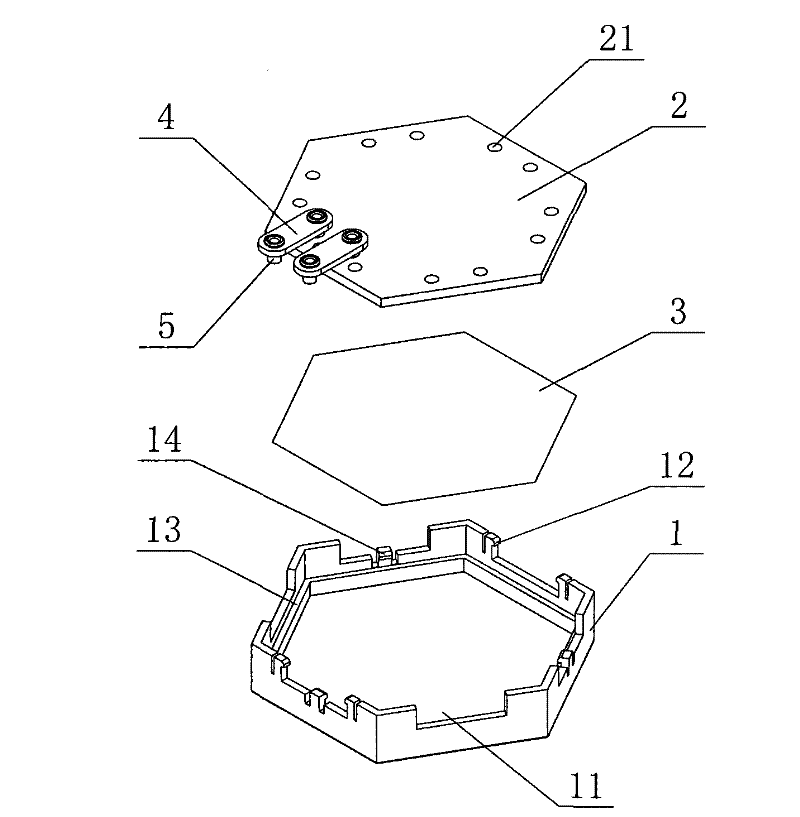

LED (light emitting diode) lamp unit and LED combined lamp

InactiveCN101769465AMany changes in shapeEasy to combinePoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

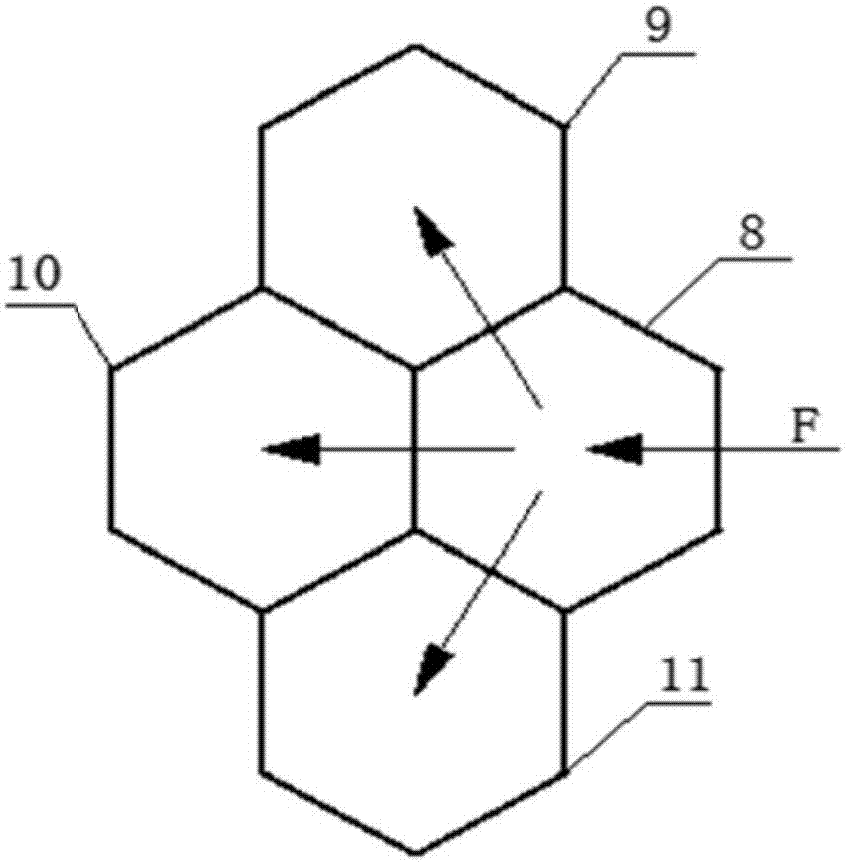

The invention discloses an LED (light emitting diode) lamp unit having simple and light structure, abundant combination change, flexible application, convenient connection and mounting and various illumination and decoration effects and a combined lamp. The LED combined lamp comprises a mounting plate (6) and the LED lamp units, wherein each LED lamp unit comprises a polygonal shell (1), a circuit board (2) and a conductive connecting piece (4); LEDs (6) are arranged on each circuit board (2), and the circuit board (2) is embedded in a shell (1); all the edges of each circuit board (2) are respectively provided with two conductive jacks (21) used as anode and cathode terminals of each LED lamp unit; both ends of each conductive connecting piece (4) are fixed with a conductive rivet (5), and the conductive rivets (5) are embedded in the anode and cathode conductive jacks (21) and tightly matched with the conductive jacks (21); adjacent LED lamp units are conductively connected through two conductive connecting pieces (4) and the conductive rivets (5) at both ends of the conductive connecting pieces (4); and the LED lamp units are fixedly connected with the mounting plate (6).

Owner:CE LIGHTING

Cylindrical-surface spliced spherical dot-matrix display screen

The invention provides a cylindrical-surface spliced spherical dot-matrix display screen. The display screen comprises display panels which are divided according to longitude lines and latitude lines and adjacently spliced on a spherical surface, the display panels are each shaped like a cylindrical surface which is bent along the spherical surface in the longitudinal direction, and spliced latitudinal edge lines of the display panels on the spherical surface in the bending direction are intersecting lines. Fine-tuning studs are arranged between the display panels and installation beams, and splicing gaps of the display panels can be reduced by properly selecting the length of the fine-tuning studs. The cylindrical-surface spliced spherical dot-matrix display screen has the advantages that the bent planar display panels are mutually spliced on the spherical surface in the shapes of cylindrical surfaces in an intersecting line mode, and splicing of the display panels can be more compact; by means of the fine-tuning studs, the display panel splicing gaps caused by manufacturing errors are reduced; in this way, the precisely manufactured watermelon-peel type spherical dot-matrix display screen is compact in appearance splicing, good in appearance effect, simple in structure and easy to manufacture and maintain.

Owner:潘尚法

Multifunctional silk quilt preparation method

ActiveCN110680144APrevent compactionSoda ash removalUpholstery manufactureBlanketPolymer scienceOrganic chemistry

The invention discloses a multifunctional silk quilt preparation method. Twin cocoons of spring silkworms are selected and used as raw materials for preparing the silk quilt, degumming treatment is carried out by steam cocoon cooking, silk quilt batt with the required size is prepared by a series of processes of cocoon stripping, cotton slitting, cotton sunning, stretching and the like, and the silk quilt batt is sleeved with a silk quilt batt cover and is sewn to prepare the silk quilt. The cooking and the degumming treatment are carried out and combing is carried out by adopting a fine cotton fluffer, so that the prepared silk quilt is uniform in thickness, fluffy, soft, breathable and warm; washing is carried out with mountain spring water after cooking, so that removal of soda in silkcotton and removal of odor in the silk cotton are facilitated and hardening of silk is effectively avoided; and flow drying is carried out through hot air flow in the sunning process of a silk cottonpocket, so that the silk cotton pocket is more uniform in heating, the drying efficiency of the silk cotton pocket is improved, the processing quality of the silk cotton pocket is improved, and the enterprise production benefit is improved.

Owner:桐乡瑞梦蚕桑科技有限公司

Rain-proof curved-surface display screen and rain-proof spherical display screen

InactiveCN104021737ASimple waySuitable for mass productionHermetically-sealed casingsIdentification meansSurface displayDot-matrix display

The invention provides a rain-proof curved-surface display screen and a rain-proof spherical display screen. The rain-proof curved-surface display screen is composed of a framework, panels, a dot matrix display assembly and screws. The framework is constructed in a curved surface shape, the portions, making contact with the edges of the panels, of the framework are coated with water-proof glue or provided with water-proof gaskets, the dot matrix display assembly is installed on the panels in a water-proof mode, and the panels are spliced and tightly attached and fixed to the framework through the screws. The rain-proof spherical display screen is formed by splicing rain-proof curved-surface display screens in a surrounded mode. Compared with the prior art, outdoor curved-surface and spherical display screens can be manufactured and obtained more easily, the structure is simple, splicing is compact, the similarity between the display screens and the curved surface or sphere is high, and the cost is lower; the way in which the dot matrix display assembly is directly installed on the panels in the water-proof mode is simple, and the rain-proof curved-surface display screen and the rain-proof spherical display screen are suitable for batch manufacturing, maintenance and replacement.

Owner:上海大晨显示技术有限公司

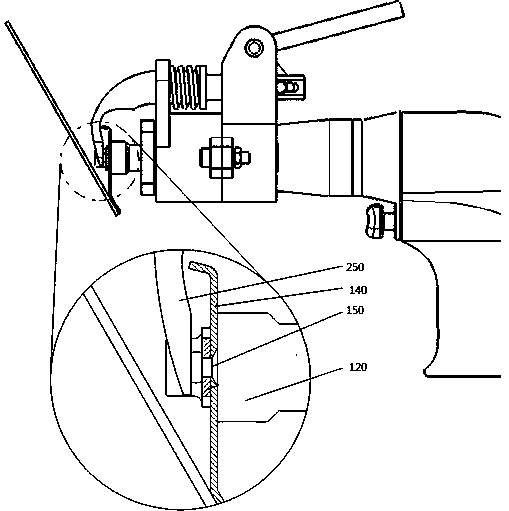

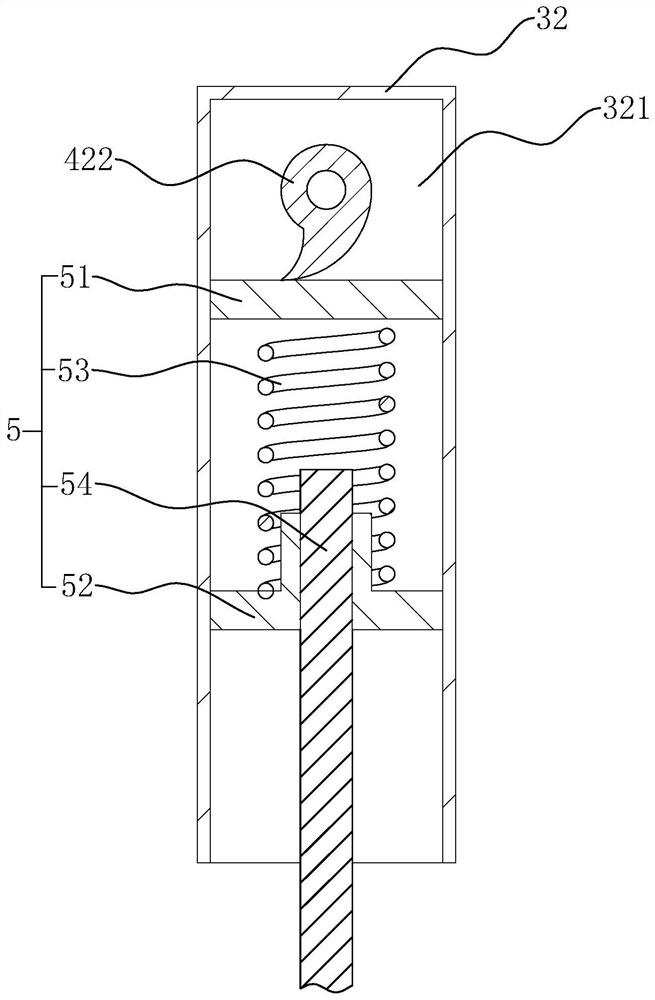

Supporting plate nut riveting assisting device

The invention discloses a supporting plate nut riveting assisting device. The supporting plate nut riveting assisting device comprises a front machine frame, a rear machine frame, a tight-and-loose handle, elbow ejector iron and a locking nut. The front machine frame comprises a main body and a large lug, the rear machine frame comprises a cylinder body and a mounting seat; the working end of a riveter sequentially penetrates through the cylinder body and the main body and is connected to the locking nut; a mounting plate is disposed in parallel with the large lug, and the large lug and the mounting plate are separately provided with a cavity and a mounting plate correspondingly; and one end of the tight-and-loose handle is installed at the top of the mounting plate in a hinged mode; the elbow ejector iron includes an assisting end and a driving end, wherein the assisting end is connected with the driving end through a bend cylinder body; and the driving end of the elbow ejector iron sequentially penetrates through a mounting hole, the mounting plate and is connected with a convex lug in a sliding mode. The supporting plate nut riveting assisting device reduces the complexity and difficulty of the riveting of a workpiece to be machined, improves the stability of the rapid forming and riveting quality of rivets, greatly reduces the difficulty and complexity of the riveting, andmeets the riveting demands of high quality and high efficiency in a space limited area.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

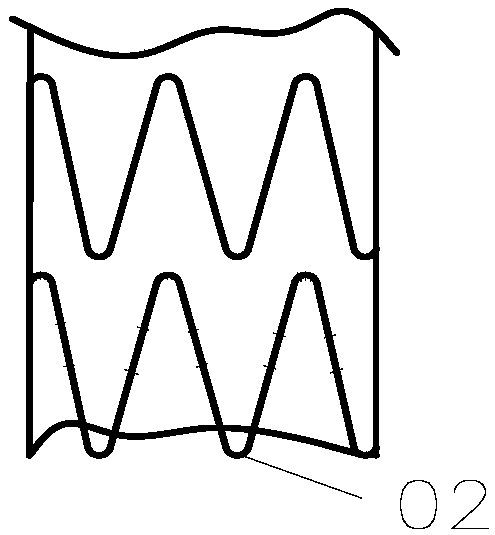

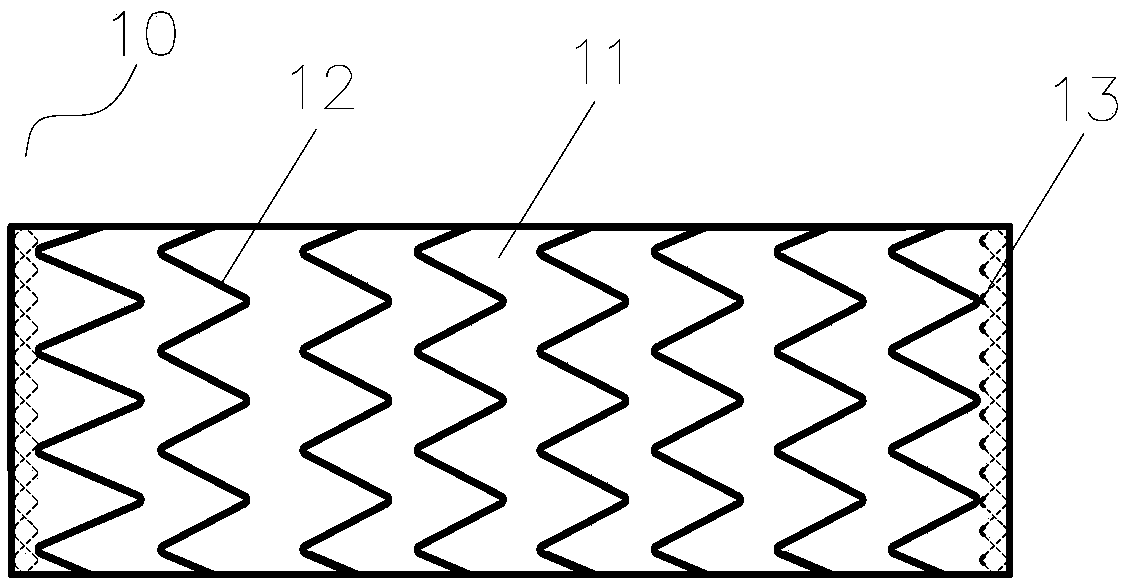

Covered stent

ActiveCN110833469AExcellent adhesionGuarantee the safety of useStentsBlood vesselsStent implantationEngineering

The invention provides a covered stent, which comprises a tubular covered membrane and at least one first stent unit connected with the end of the covered membrane, each first stent unit comprises first wave rings and second wave rings, and the first wave rings and the second wave rings are overlapped to form a plurality of intersection points; wherein each of the first wave ring and the second wave ring comprises a plurality of wave crests and a plurality of wave troughs, at least one sewing knot is arranged at at least one of the adjacent wave crests and wave troughs, and at least one sewingknot is arranged at the intersection point. According to the covered stent, the first stent unit is tightly sewn with the covered membrane, so that the adherence of the stent and the sealing performance of the covered stent are greatly enhanced, the problem of covered membrane flanging of the covered stent is solved, the use safety of the implanted stent is guaranteed, and I-type inner leakage isavoided.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

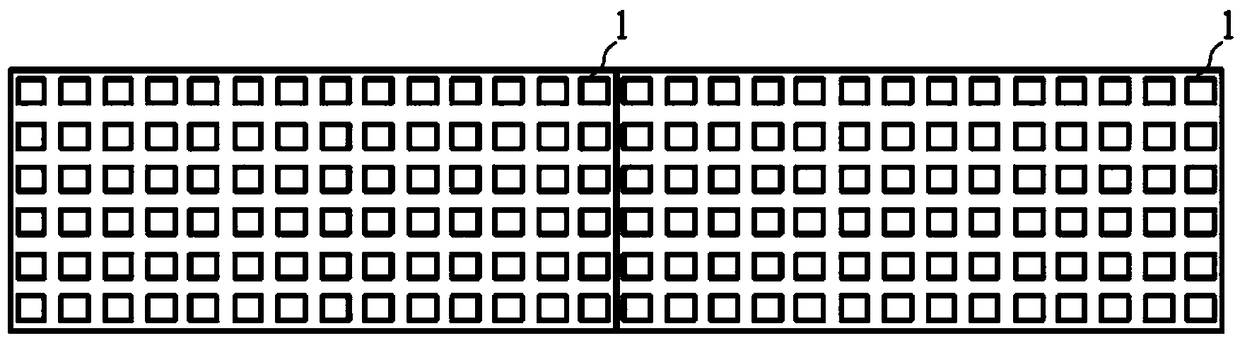

LED display screen module

ActiveCN109064914AImprove the fixing strengthClosely connectedIdentification meansLED displayEngineering

The invention discloses an LED display screen module. The LED display screen module includes multiple module bodies which are arranged in sequence. Every two adjacent modules are spliced together through a clamping assembly, wherein each clamping assembly includes a pushing assistance assembly and an elastic clamping component, and each pushing assistance assembly is slidingly arranged at one endof the corresponding module body; each elastic clamping component is arranged on the corresponding pushing assistance assembly and penetrates through a corresponding first square hole in the end faceof the corresponding module body and extends outward, and the elastic clamping components can be clamped to the adjacent module bodies to achieve splicing of every two adjacent module bodies. By adopting the structure above, the module bodies are spliced conveniently, and the fixation strength of the LED display screen module is enhanced conveniently.

Owner:FUJIAN HIGREEN CAILIANG OPTOELECTRONICS TECHCO LTD

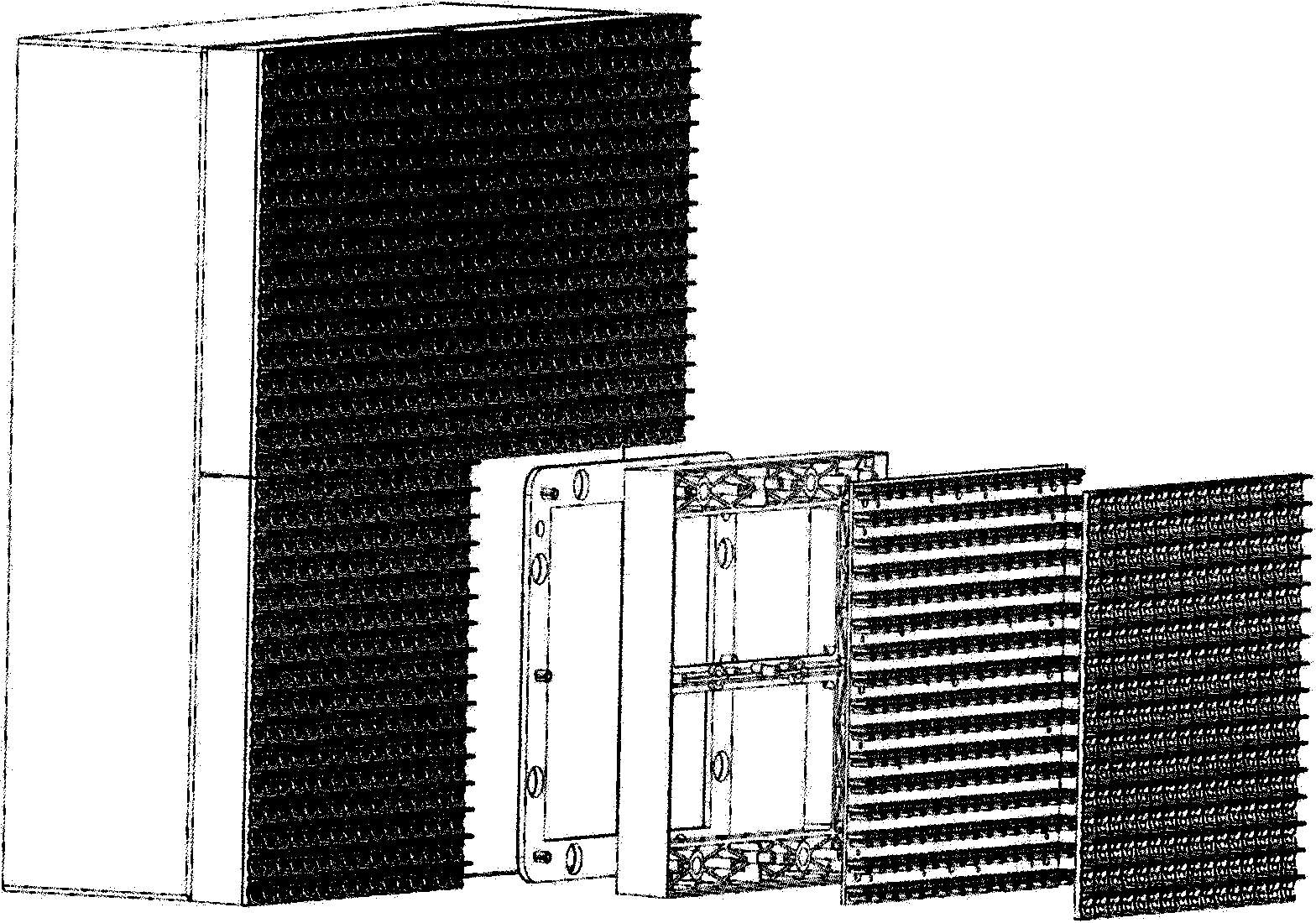

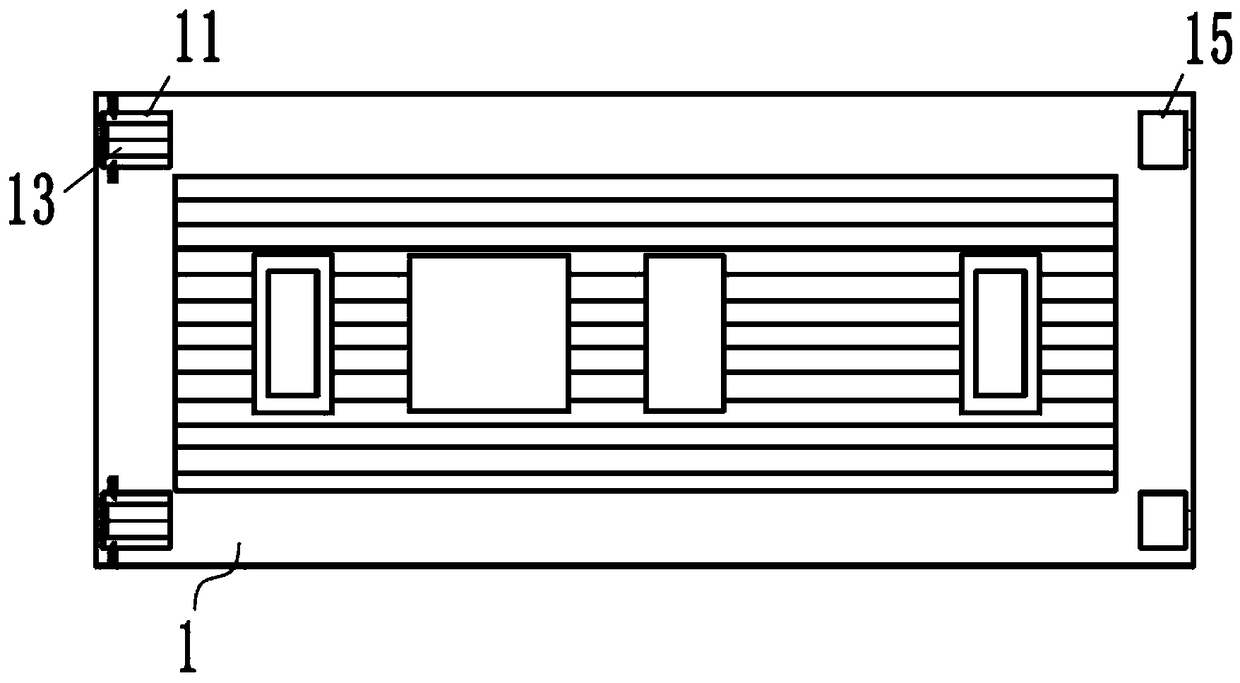

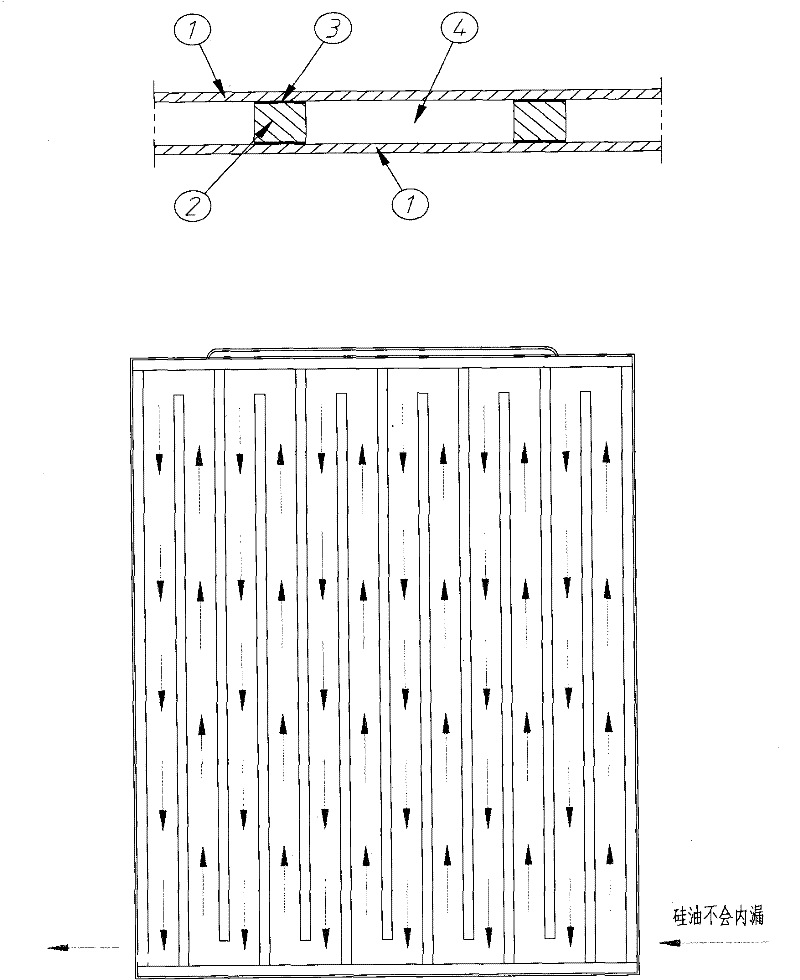

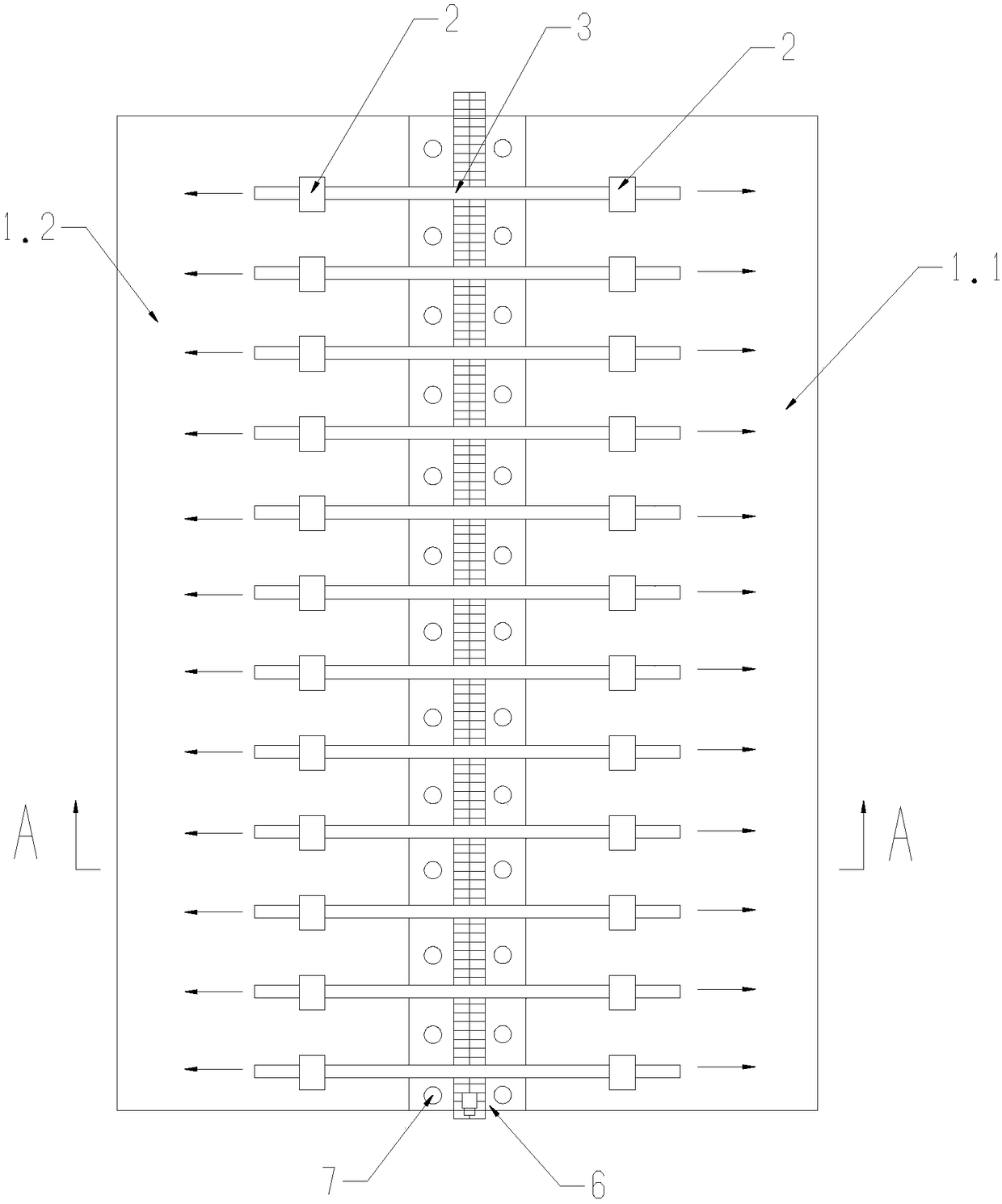

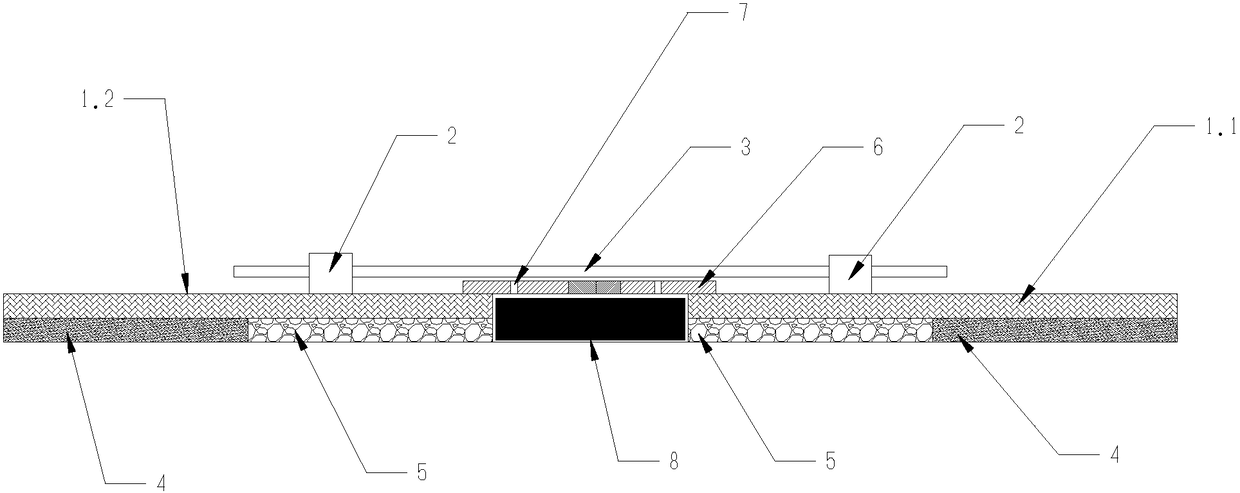

Heat exchange plate layer structure and manufacturing method of freeze drier

InactiveCN102636005AReduce distortionLow flatnessDrying solid materials without heatPlatinumEngineering

The invention relates to a heat exchange plate layer structure and a manufacturing method of a freeze drier. The heat exchange plate layer structure is characterized in that an integral seal structure formed by the welding of copper-platinum brazing is arranged among upper and lower bottom plates and division bars which are arranged at intervals. The manufacturing method comprises the steps of: placing copper platinum among the upper and lower bottom plates and the division bars which are arranged at intervals, clamping the copper platinum by using a clamp, putting the copper platinum into a vacuum brazing furnace and melting the copper platinum at high temperature, implementing vacuum on the vacuum brazing furnace in a process, melting the copper platinum when the brazing temperature is achieved, cooling, and then pouring silicone oil so as to form the heat exchange plate layer structure of the freeze drier. The heating of local parts caused by welding does not exist, the plate layer transformation is small, the smoothness is good, the heat exchange plate layer structure is beneficial to polishing and reshaping, the division bars and the upper and lower bottom plates are closely spliced, the welding is good, and silicone oil can not be in short circuit so as to avoid fleeing to the other side of the plate layer directly from the upper parts or the lower parts of the division bars; the temperature of the plate layer is very uniform, the welding is conducted in the plate layer, so that the influence on the exterior of the plate layer is low, and the smoothness of the plate layer is guaranteed; and the welding seams are arranged in the plate layer, and the whole plate does not have holes and gaps and the possibility of the plate layer leakage does not exist.

Owner:SHANGHAI SUPARMIN ELECTROMECHANICAL SCI & TECH CO LTD

Wound closure device with bandage

The invention discloses a wound closure device with a bandage. A row of lock catches used for locking the bandage are arranged on skin adhesive tape; one end of the bandage passes through the lock catch of the left-side skin adhesive tape, and the other end of the bandage passes through the lock catch of the right-side skin adhesive tape; the bandage is cylindrical, a row of circular-arc-shaped locating grooves are arranged on the bandage, spring plates are respectively arranged above and below the bandage, the spring plates are arranged in the lock catches, circular-arc-shaped bosses are arranged on the spring plates, and the bosses are matched with the locating grooves. The wound closure device with the bandage can easily realize irregular skin wound suture and skin wound suture with different depth and width, in the process of wound healing, the medicine applying and nursing of the wound can be convenient, the wound can be easily and quickly removed after healing, and the pain of taking out stitches is avoided.

Owner:WUHAN HAOHONG TECH

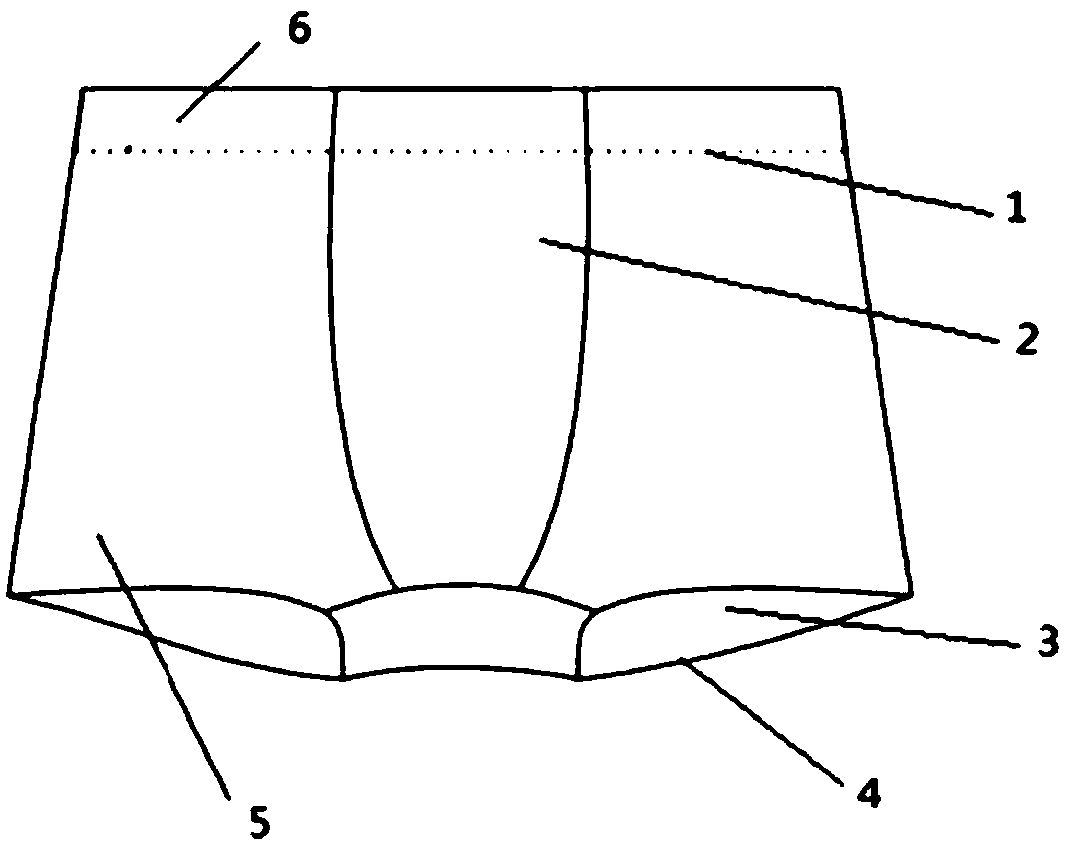

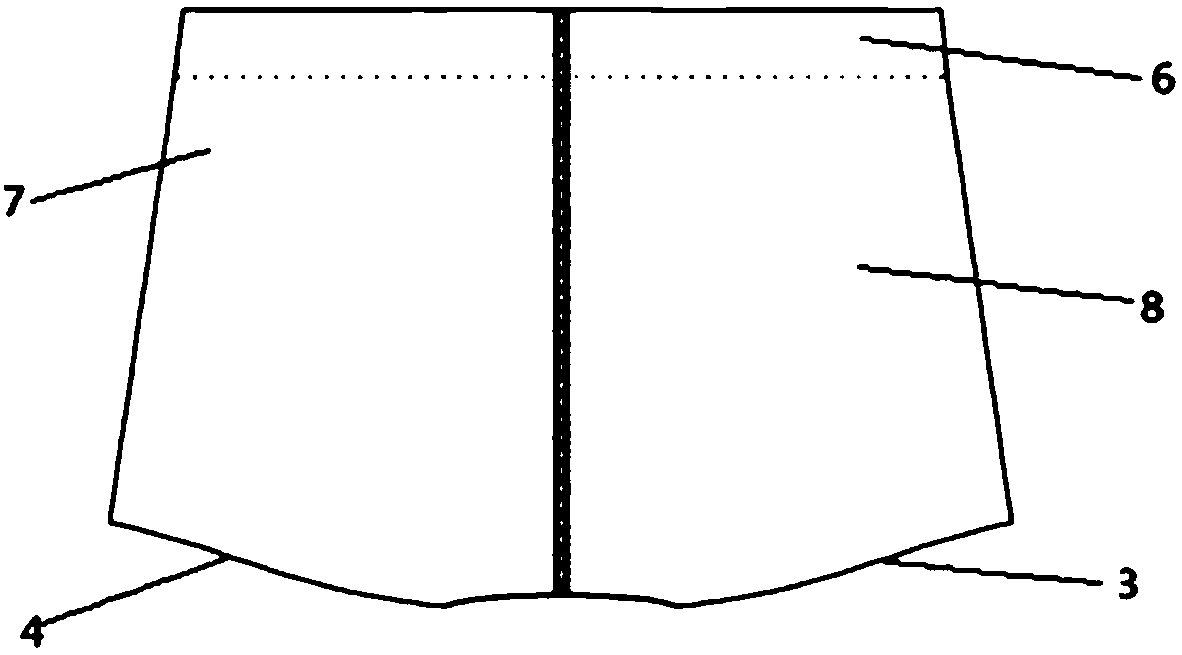

Three-dimensional stereoscopic seamless underpants

The invention discloses three-dimensional stereoscopic seamless underpants which comprise seamless underpants, three bottom front rise threads and two bottom back rise threads. An ultrathin seamless tightening piece is arranged on the top of the seamless underpants, underpants tightening piece polyester face bottom is arranged at the bottom of the ultrathin seamless tightening piece, an underpantsfront convex face is arranged at the bottom of the underpants tightening piece polyester face bottom, underpants front face pants are arranged on two sides of the underpants front convex face, adhesive dispensing layers are arranged on the surfaces of leg opening hems, overlock stitch layers are arranged inside the three bottom front rise threads, a drawing stitch layer is arranged inside the twobottom back rise threads, and the underpants tightening piece polyester face bottom is made of ultrafine polyester fabrics. The three-dimensional stereoscopic seamless underpants have the advantagesthat front underpants of the three-dimensional stereoscopic seamless underpants with the ultrathin seamless tightening piece can be spliced with front convex positions without traces, back underpantsof the three-dimensional stereoscopic seamless underpants can be spliced with back convex positions without traces, accordingly, three-dimensional stereoscopic effects can be realized by the three-dimensional stereoscopic seamless underpants, and the three-dimensional stereoscopic seamless underpants can closely fit with wearers without compressive feeling; the three bottom front rise threads andthe two bottom back rise threads of the three-dimensional stereoscopic seamless underpants are closely and naturally stitched with one another, and accordingly the three-dimensional stereoscopic seamless underpants integrally appear attractive.

Owner:颜定伟

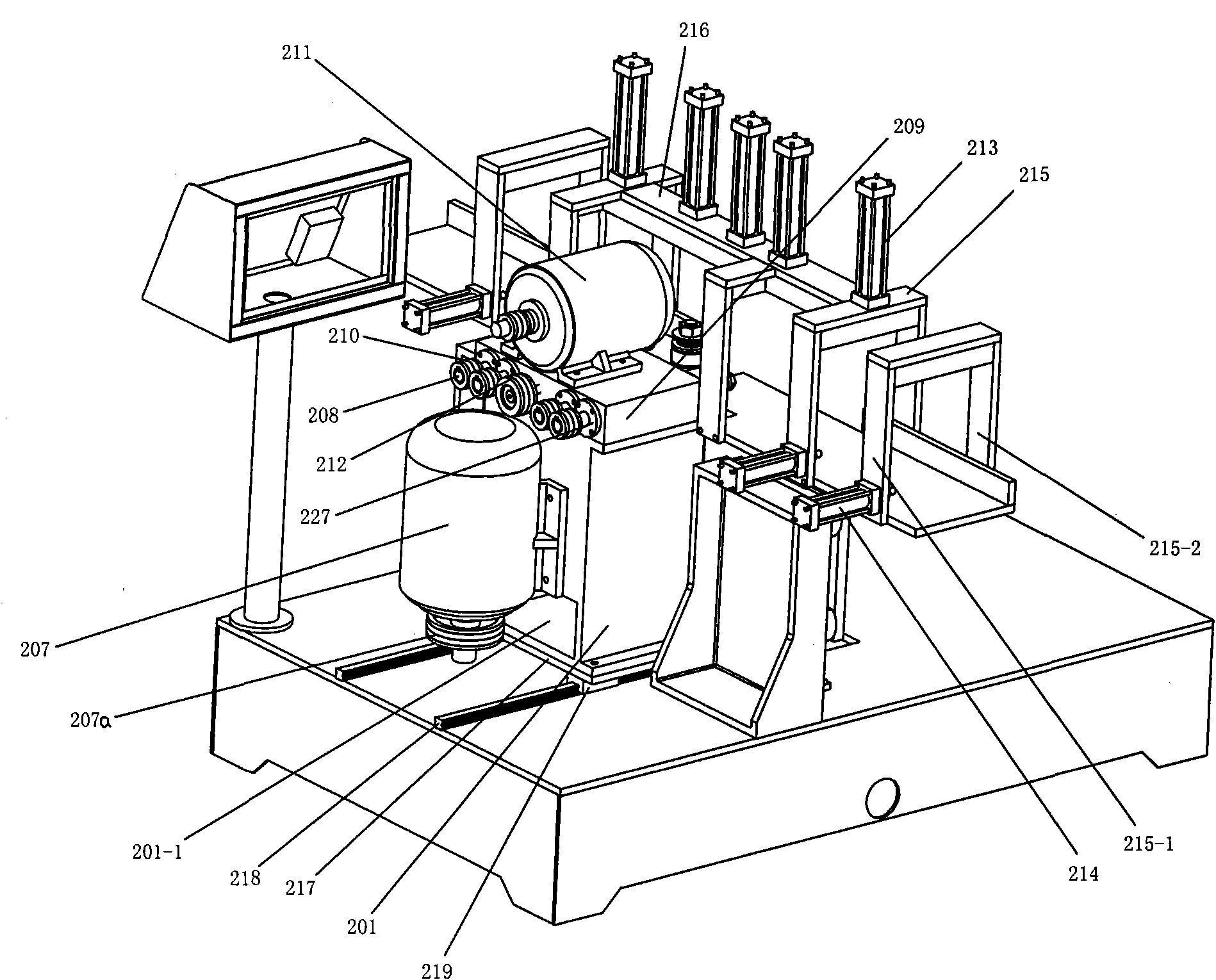

Numerical control wood house tenon machine

The invention relates to a numerical control wood house tenon machine. A machine body is provided with a drilling and milling device, a horizontal milling device with an air cylinder stabilizing mechanism, and a numerical control device. The wood house tenon machine with the structure has high automation degree, is precisely and compactly structured, effectively improves the processing precision of a tenon and makes the connection of the wood house tenons more compact and solid.

Owner:黄丽汶

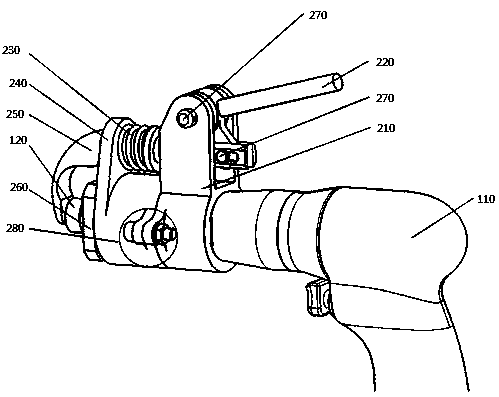

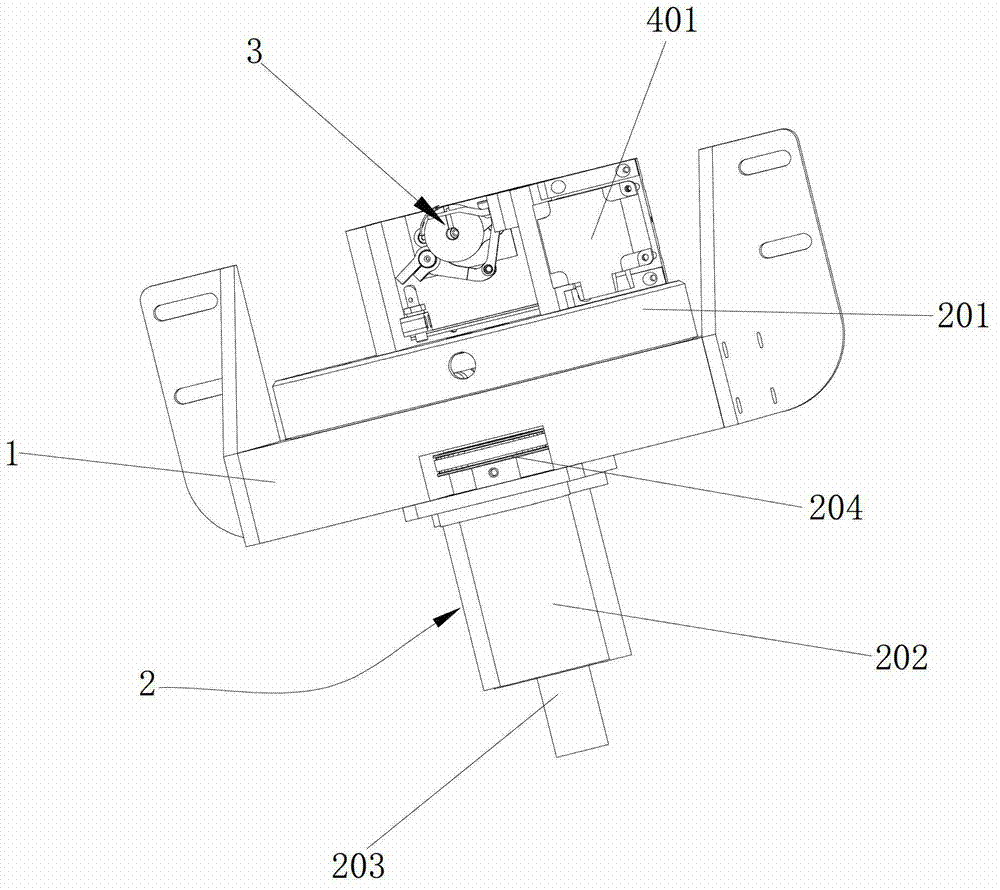

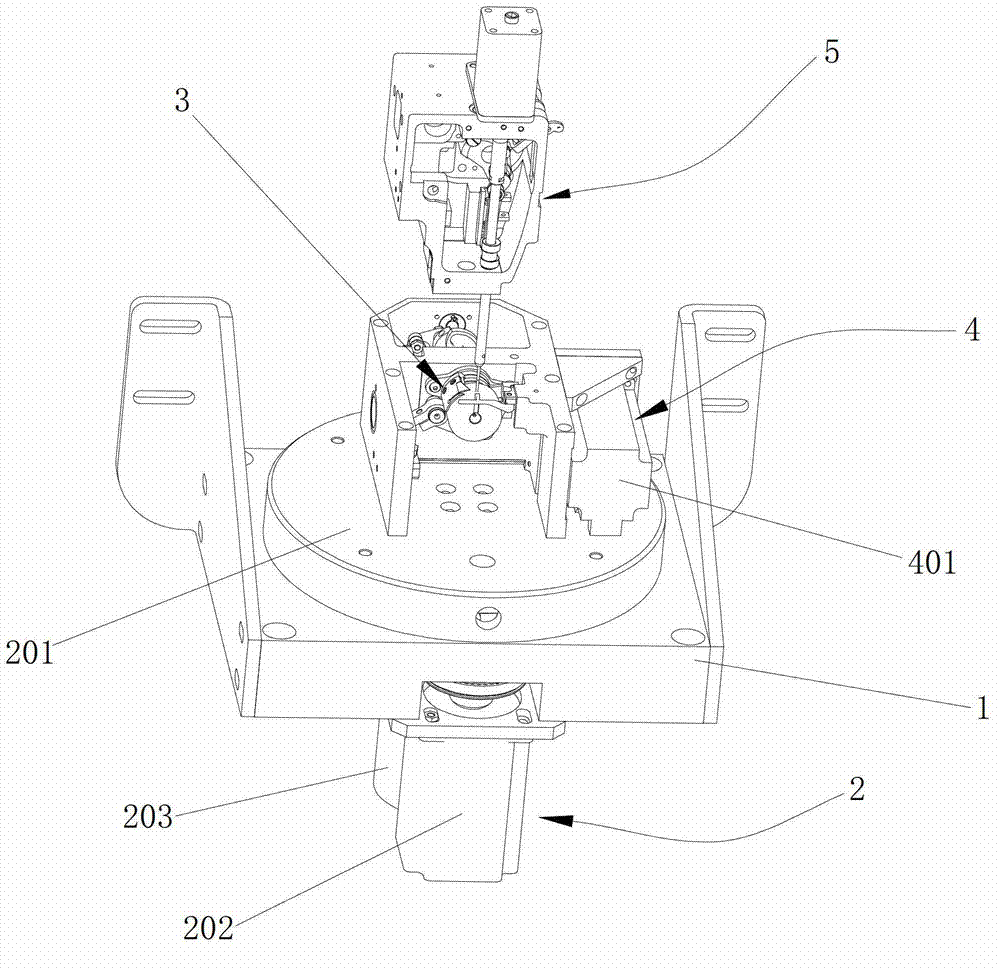

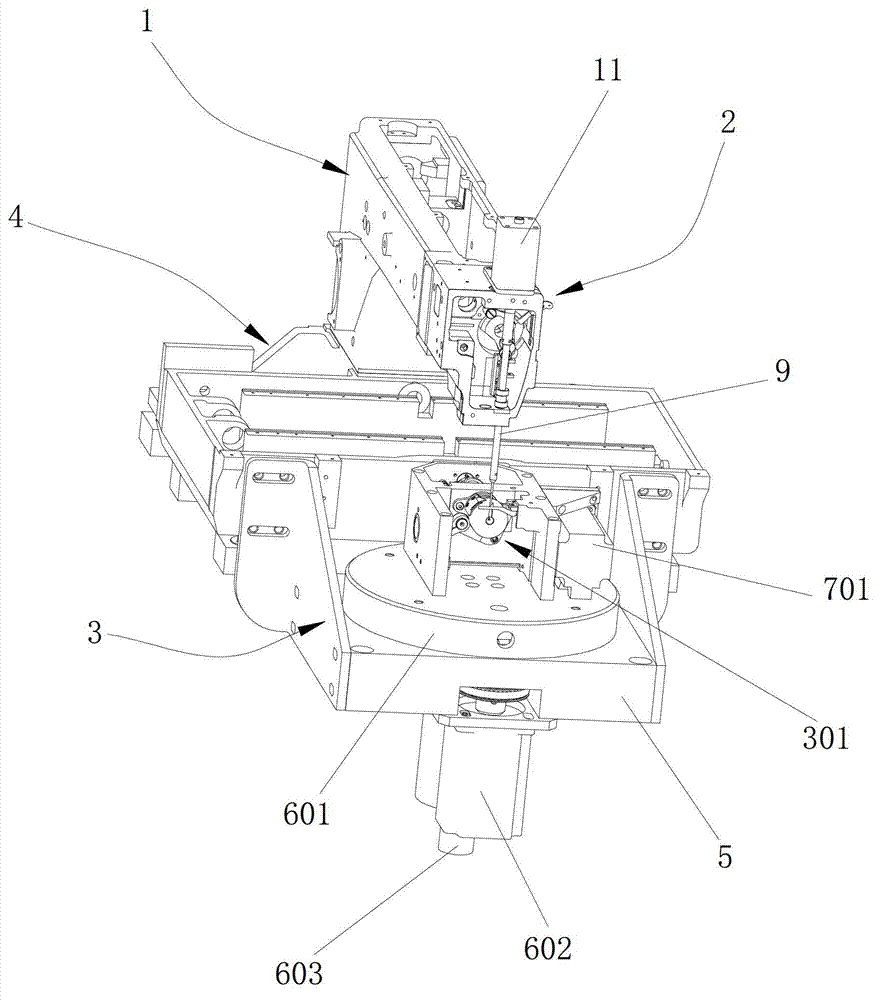

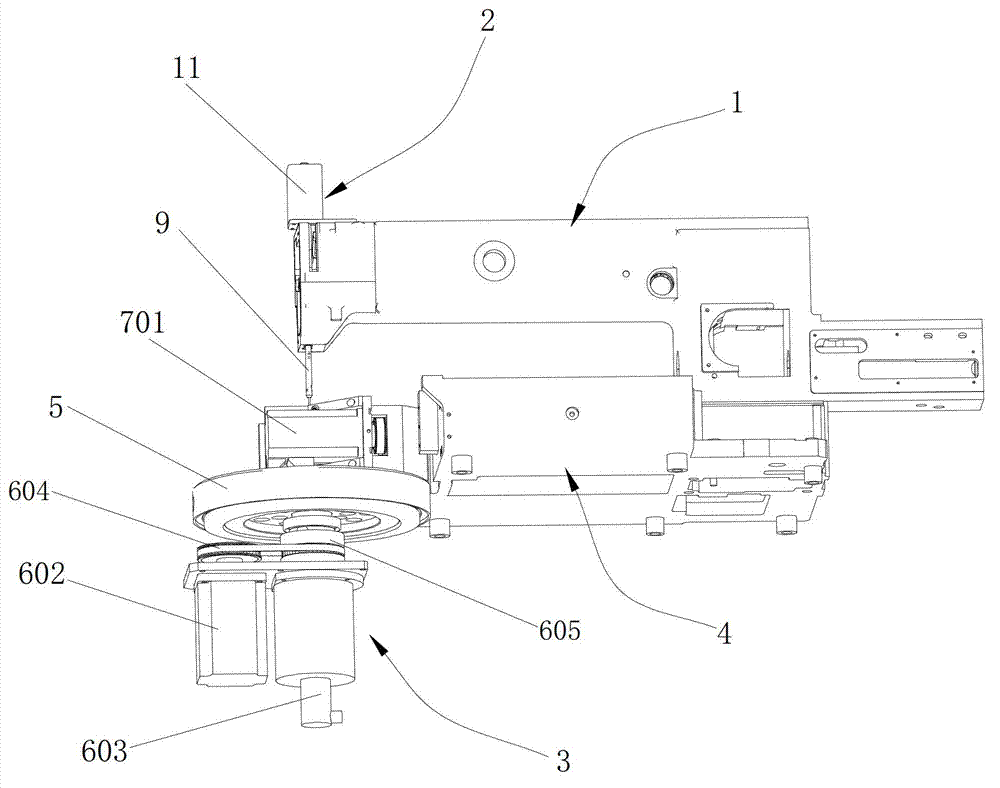

Synchronous rotating mechanism for shuttle race

ActiveCN103194866AAvoid influenceStitched tightlyNeedle barsLoop takersSewing needleMechanical engineering

The invention discloses a synchronous rotating mechanism for a shuttle race. The synchronous rotating mechanism comprises a base, a rotating device installed on the base, the shuttle race and a shuttle race drive mechanism, wherein the shuttle race and the shuttle race drive mechanism are arranged on the rotating device, capable of rotating along with the rotating device and in transmission connection, so that the shuttle race can rotate when a sewing mechanism sews materials. In the material sewing process of the sewing mechanism provided with the synchronous rotating mechanism, the rotating device can drive a rotary table to rotate correspondingly according to the stitch direction so as to drive the shuttle race to rotate correspondingly according to the stitch direction and be matched with a needle bar synchronous rotating mechanism for synchronous rotation, so that the stitching direction of a sewing needle is accordant with preset sewed stitches, high-quality and perfect sewing is achieved, stitches obtained through sewing have the advantages of being compact, neat, even and perfectly coincide with the set sewed stitches, the practicability is high, and wide industrial utilization values are provided.

Owner:ANHUI JIEYU SHOEMAKING MACHINERY TECH CO LTD +1

Light absorption heat preservation type building exterior wall gusset plate with buckles coupled

InactiveCN103206054AReduce light pollutionClosely connectedCovering/liningsBuilding materialEnvironmental resistance

The invention provides a light absorption heat preservation type building exterior wall gusset plate with buckles coupled, and belongs to the technical field of building materials. The light absorption heat preservation type building exterior wall gusset plate with the buckles coupled solves the problems that the external surface of an existing aluminous gusset plate is high in reflective rate, not firm in connection and easy to loosen, and produces light pollution easily. Lateral sides of metal plates on the front and the reverse sides of the light absorption heat preservation type building exterior wall gusset plate with the buckles coupled are connected to form a flat cylinder type gusset plate main body, wherein lightweight foam materials are shaped in the inner cavity of the gusset plate main body, concave and convex structures which enable light rays to have diffuse reflection effects are distributed on the outside surface of the metal plate on the front side of the light absorption heat preservation type building exterior wall gusset plate, more than one clamp groove or / and more than one bulge which limit transverse and longitudinal movement of a part which is clamped but not limit axial movement of the part which is clamped, and more than one bulge or / and more than one clamp groove which are clamped with the clamp grooves or / and the bulges in matched mode are arranged on the other side of the gusset plate main body. The light absorption heat preservation type building exterior wall gusset plate with the buckles coupled has the advantages of reducing the light pollution, and being green and environment-friendly, firm in connection, simple to disassemble, convenient to dismount for maintenance, long in life, beautiful in appearance and the like.

Owner:徐胜

Control method for independent intelligent pressure root drive mechanism of embroidery machine

ActiveCN102776730ASolve the problem of not being able to embroider thick materialsSolve the problem of genuine leather fabricsFeedersYarnMotor drive

The invention relates to a control method for an independent intelligent pressure root drive mechanism of an embroidery machine. The control method comprises the following steps: a step motor driving step, a pressure foot driving step and an eccentric wheel positioning step. The control method solves such technical problems of stitch skipping, yarn breaking, sewing material deviating and the like caused by the reason that the embroidery machine in the prior art can not embroider thick material and leather fabric, the position of the pressure foot is high and far from the needle plate, the tension of the yarns is small and the inclined angle is large; the yarns cannot be tightened in a process of embroidering thick yarns and thick materials; the frictional force of the needle and the sewing material is large, the pressure of the pressure root is insufficient in a recycling and raising process, and the fabric is raised by the needle; the control method is free of any influence of needle rod driving, stitch skipping and yarn breaking phenomenon, has the advantages of simple intelligent operation, uniform thick embroidered material and leather fabric stitch density, high embroidering speed, good quality, and the like.

Owner:FUJIAN YONGXIN NUMERICAL CONTROL TECH

Mounting method for partition board with good anti-seismic property

ActiveCN110761483AIncrease stiffnessRegular shapeWallsProtective buildings/sheltersEarthquake resistanceClassical mechanics

The invention relates to a mounting method for a partition board with good anti-seismic property. The mounting method comprises the following process steps: 1) mounting a full-length upper blocking slot under a building structure beam; 2) mounting a starting head section, a standard combined section and a lower guide slot which corresponds to a sealing head matching section; 3) mounting the starting head section, sequentially mounting each standard combined section, the sealing head matching section, embedding the bottom of each standard combined section and the bottom of the sealing head matching section into the lower guide slot, blocking the upper part of each standard combined section and the upper part of the sealing head matching section into the upper blocking slot, and blocking a suspending rope into an anti-seismic hanger; 4) mounting a sealing head section lower guide slot, and then mounting the sealing head section; and 5) mounting a buckle plate on the top of a wall body, and mounting a skirt board on the lower part of the wall body to accomplish mounting of the partition board. The mounting method for the partition board with good anti-seismic property has multiple advantages of being simple and convenient in construction, convenient in follow-up dismounting, excellent in performance, and the like.

Owner:浙江华汇装饰工程股份有限公司 +1

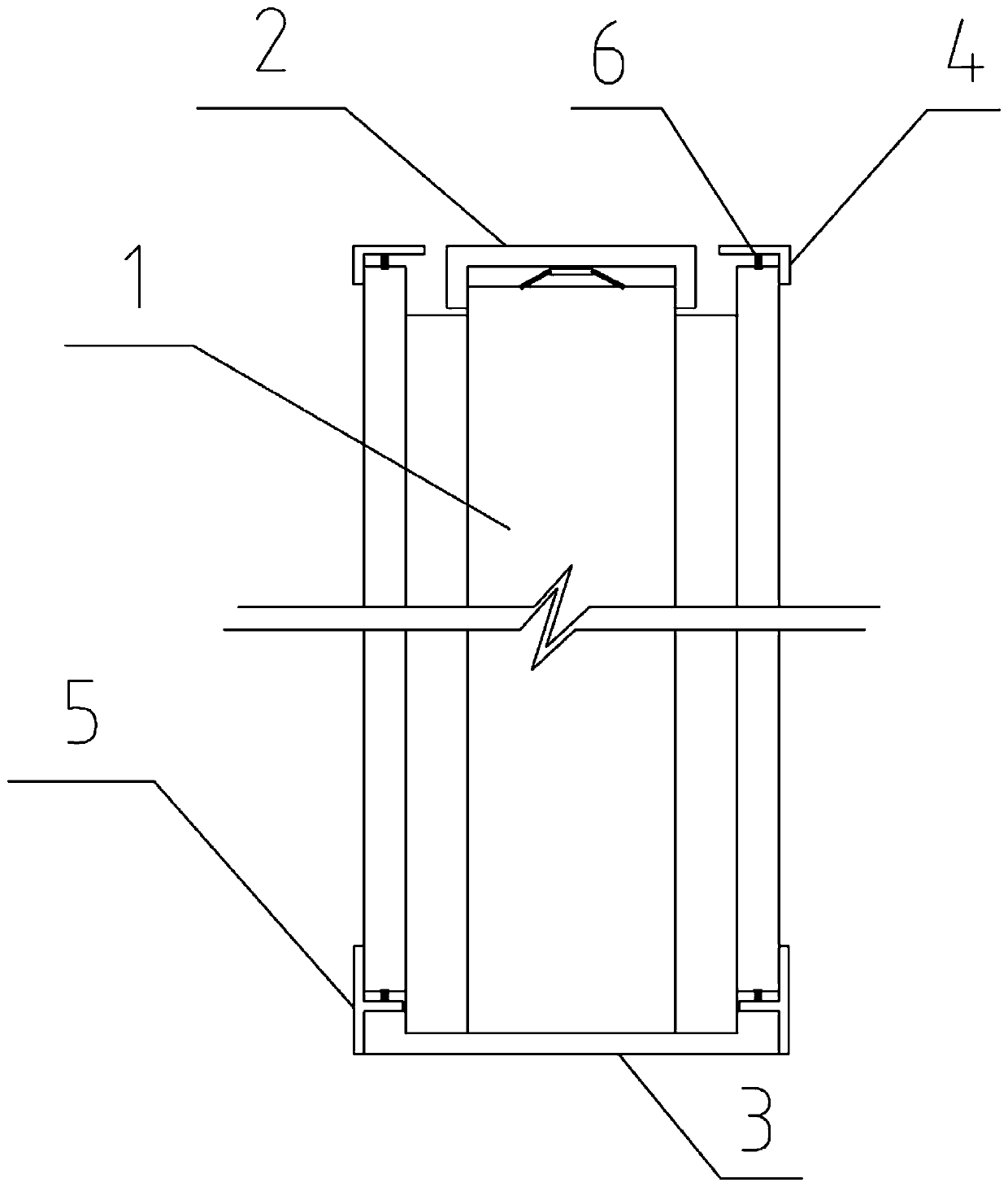

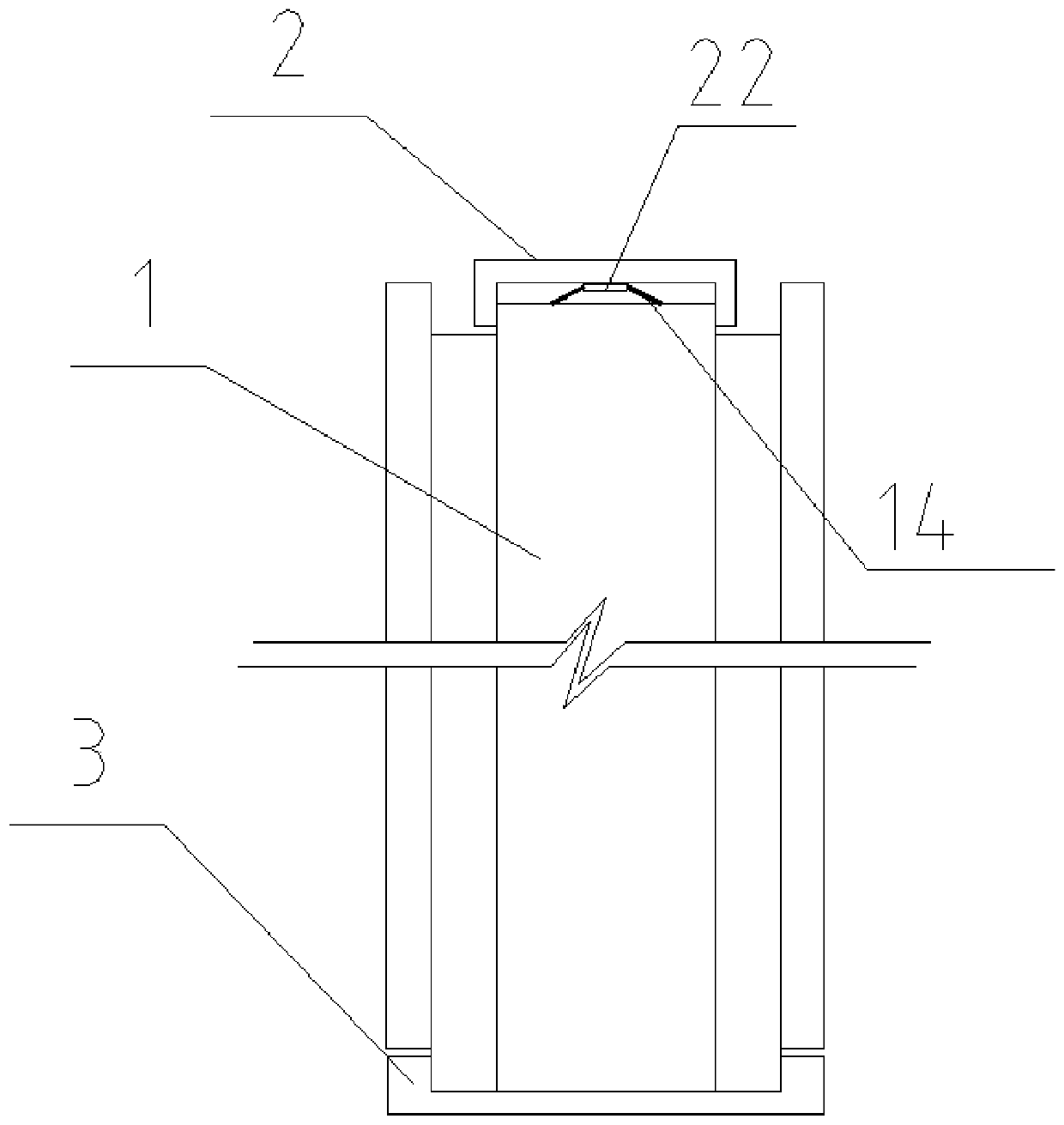

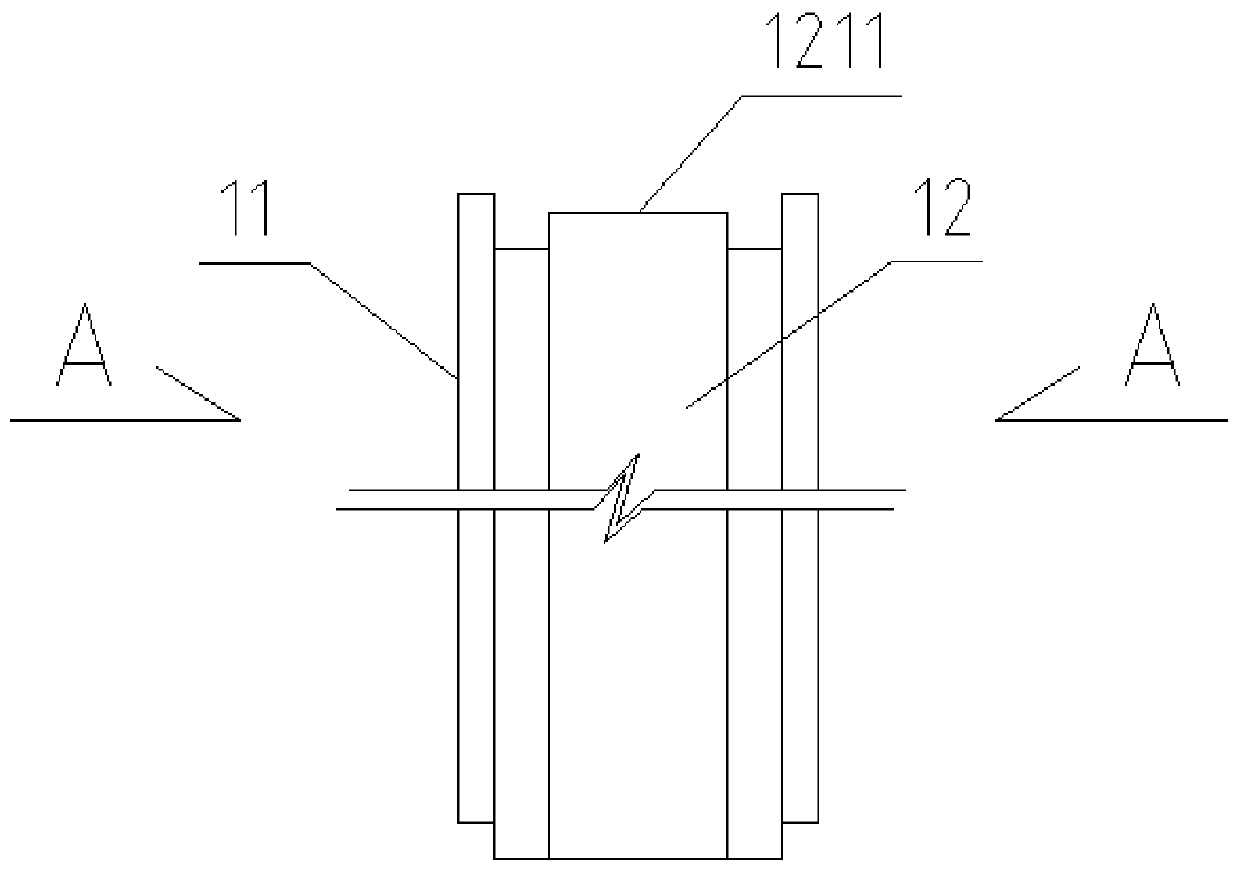

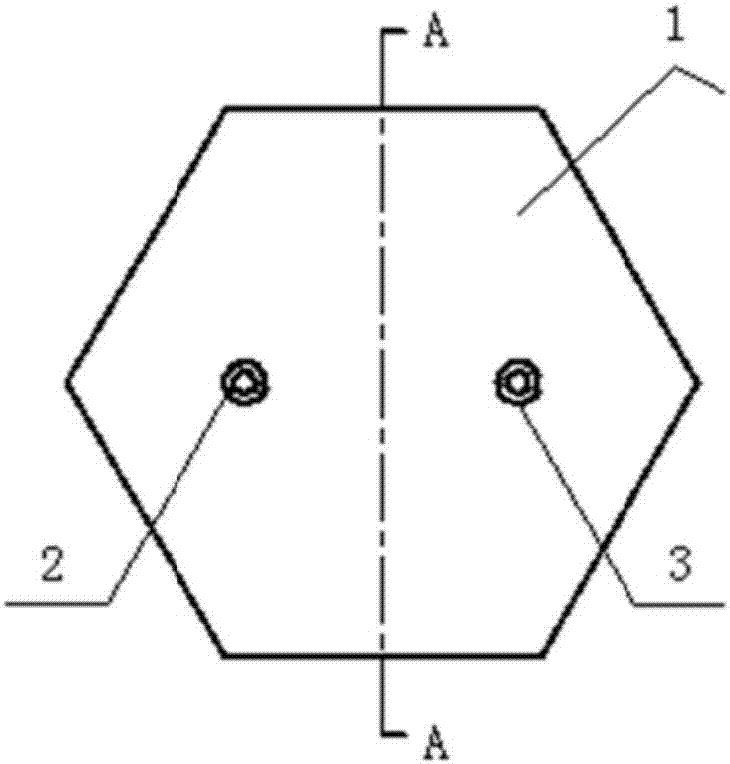

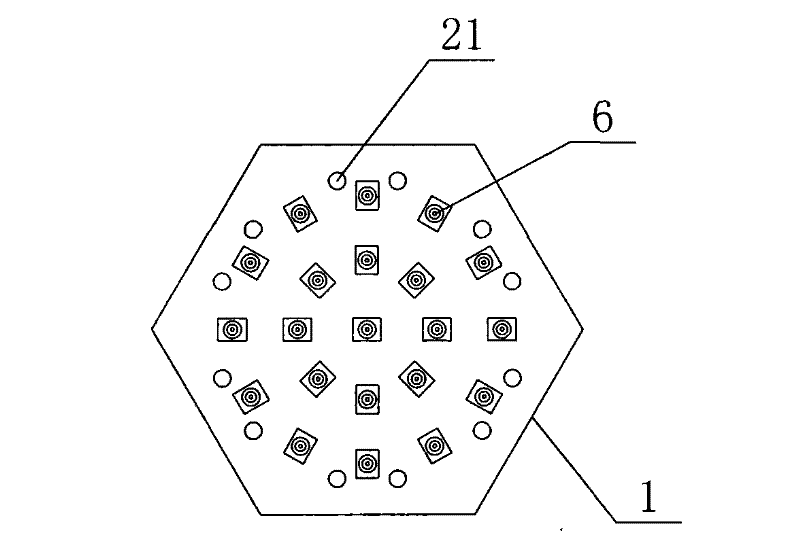

Lining plate structure of ore grinding machine and assembling method of lining plate structure

The invention discloses a lining plate structure of an ore grinding machine and an assembling method of the lining plate structure. The lining plate structure comprises a lining plate main body (1) which is shaped like a regular hexagon; a first screw hole (2) and a second screw hole (3) are formed in the lining plate main body (1); the size of the first screw hole (2) is same as that of the second screw hole (3); and the first screw hole (2) and the second screw hole (3) are formed in the diagonal line of the regular hexagon and are symmetrically formed along the center of the regular hexagon. The technical problems of increasing the ore grinding cost, influencing the ore grinding efficiency of a ball mill and delaying production due to the adoption of the lining plate structure of the ore grinding machine in the prior art are solved.

Owner:GUIZHOU UNIV

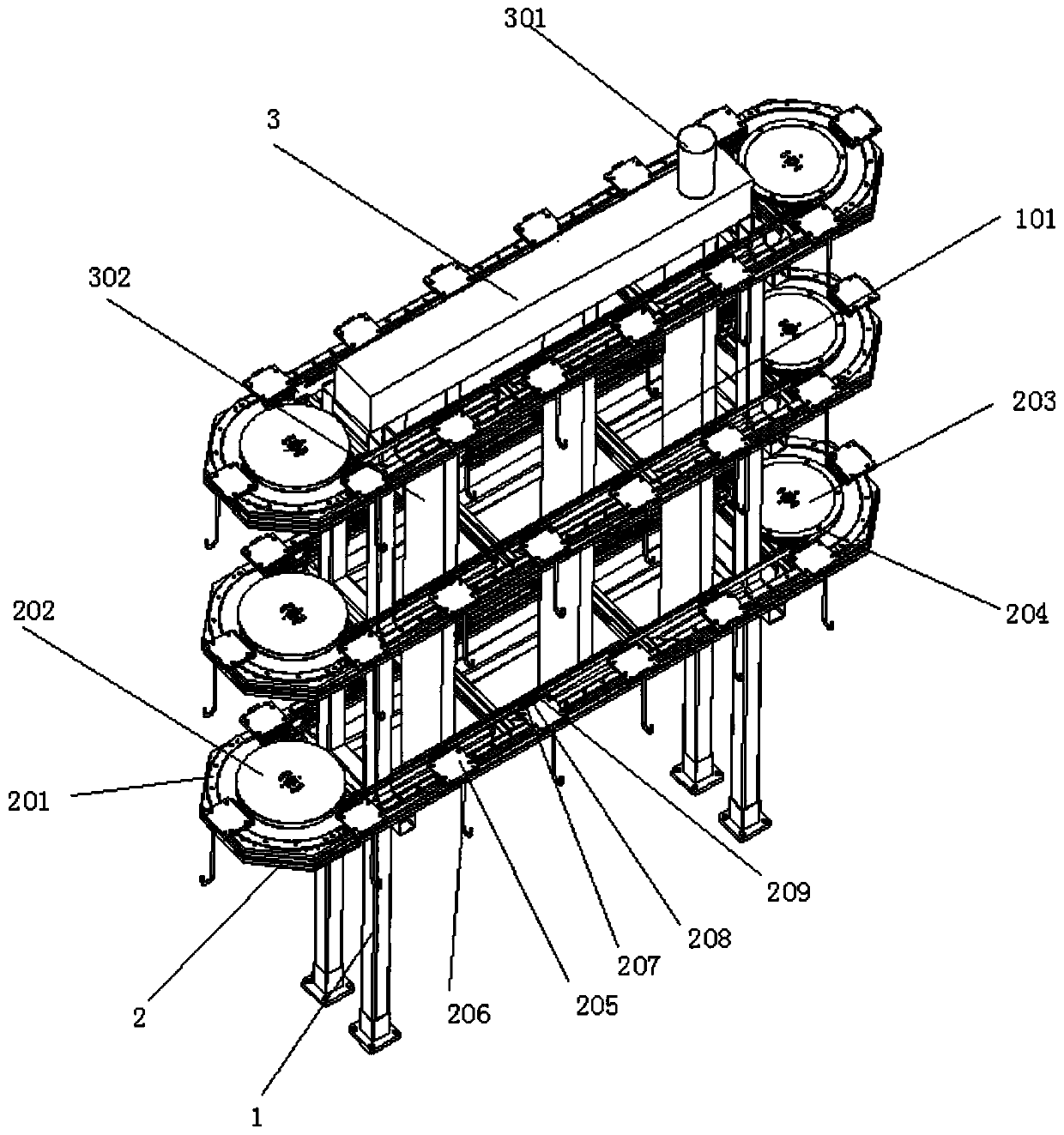

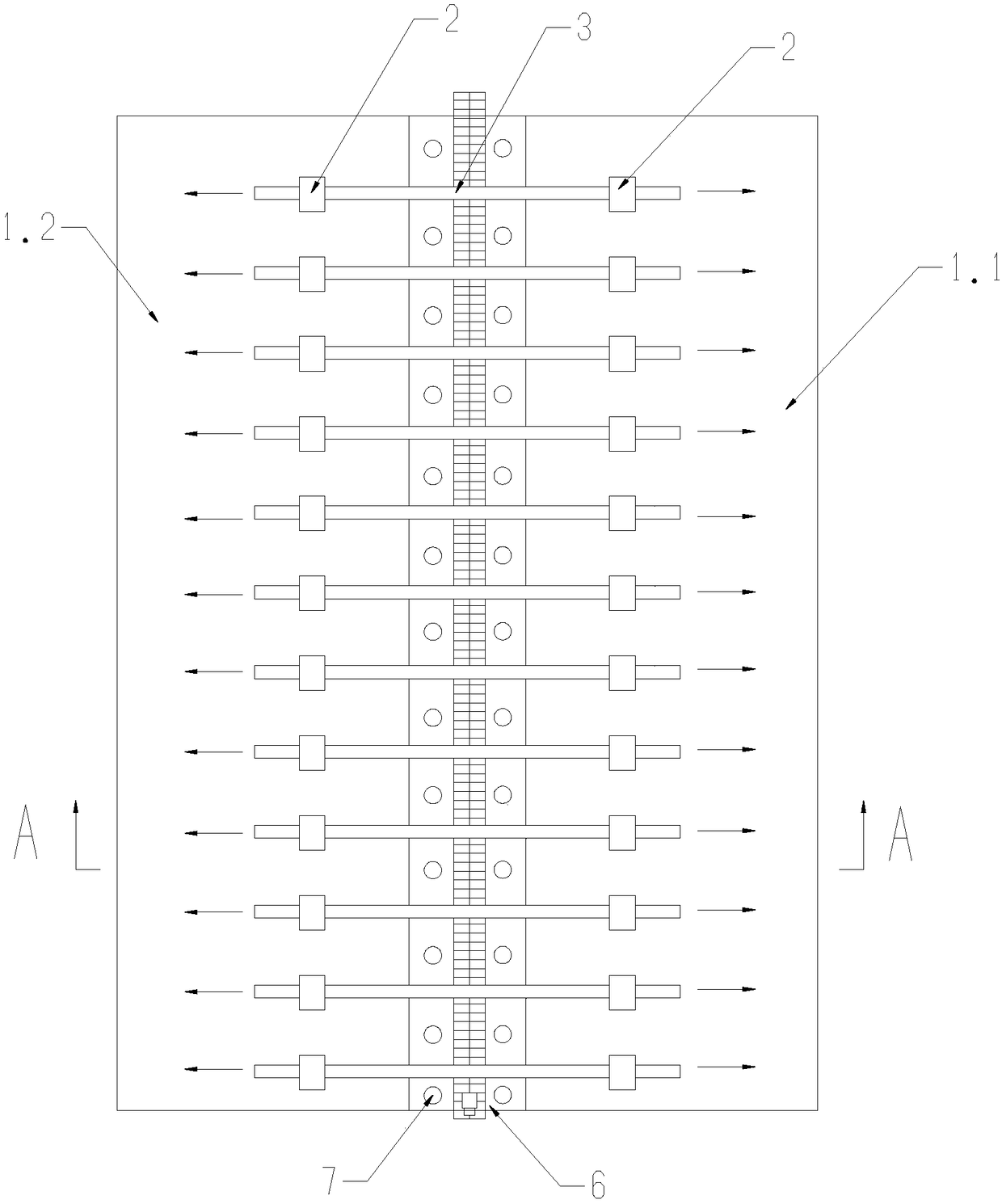

A multi-screen combined electronic display

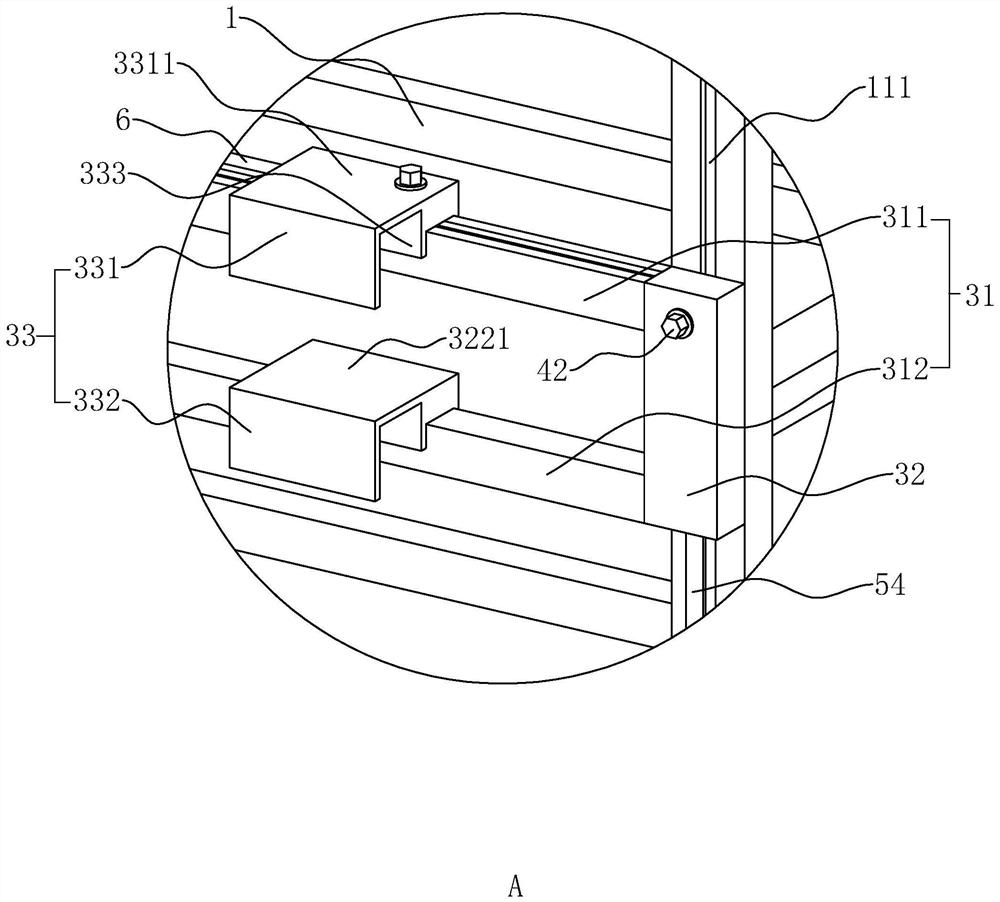

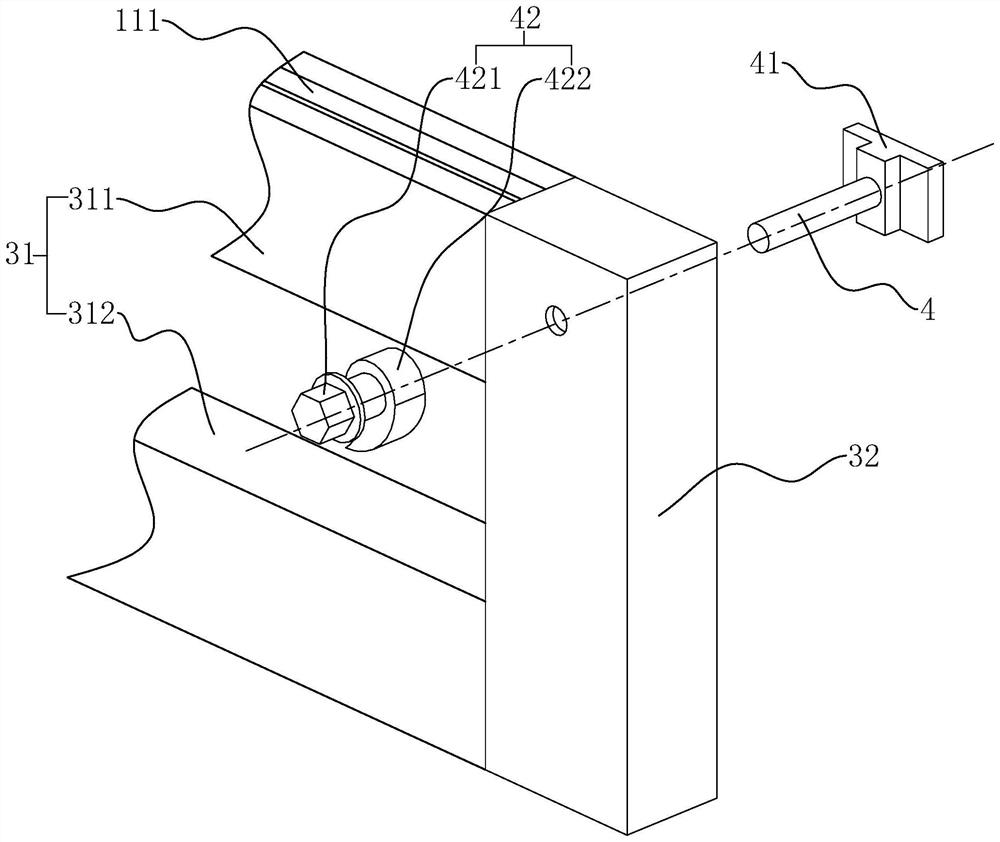

ActiveCN111292629BIncrease or decrease quantityGood orientationIdentification meansEngineeringMechanical engineering

The invention relates to a multi-screen combined electronic display screen. The multi-screen combined electronic display screen comprises a mounting frame and screen modules, a connecting mechanism for connecting the screen modules is arranged on the mounting frame; a longitudinal guide rod is arranged on the mounting frame; the connecting mechanism comprises a plurality of transverse guide beamsarranged on the longitudinal guide rod in a sliding mode in the vertical direction and a plurality of connecting assemblies arranged on the transverse guide beams in a sliding mode, and the screen modules are fixedly connected with the connecting assemblies in a one-to-one correspondence mode. A double-axis plane coordinate system is formed by the longitudinal guide rods and the transverse guide beams; position adjustment is conducted on the connecting assemblies connected to the transverse guide beams in a sliding mode, so adjustment and positioning the screen modules are achieved. The sliding connection mode facilitates position change, guidance quality and adjustment precision are higher, and after the number of the screen modules is increased or decreased, the position of the display screen can be quickly adjusted to be in the middle or located at the needed position.

Owner:温州速维网络科技有限公司

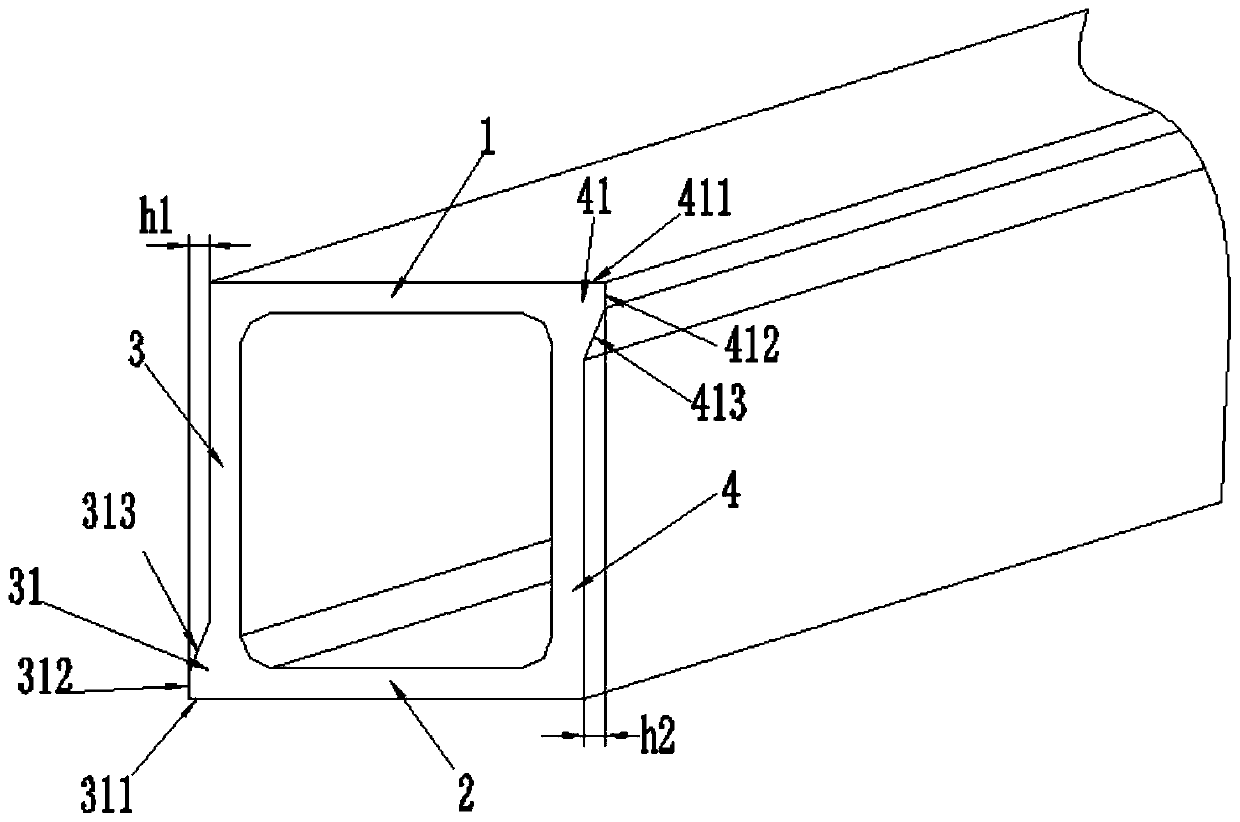

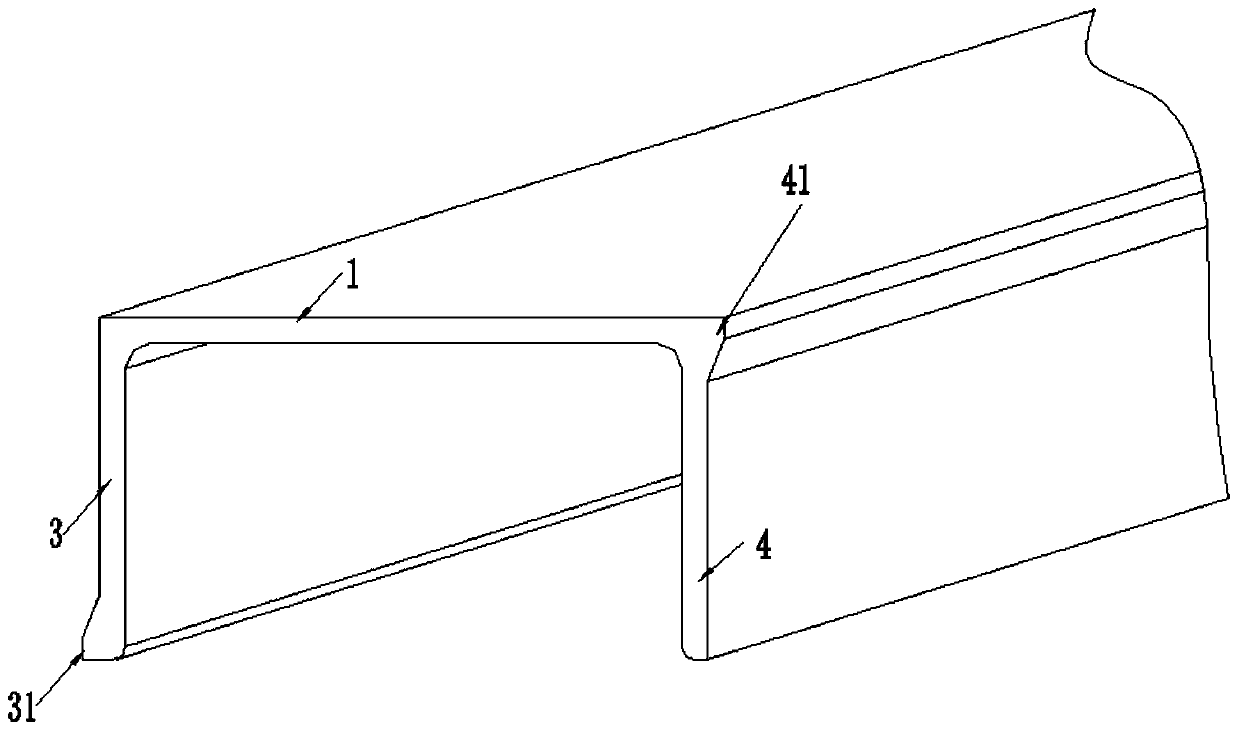

Sectional material and formwork structure

PendingCN111335621AEasy to installEffortless disassemblyForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringMechanical engineering

The invention provides a sectional material and a formwork structure. The sectional material is of a closed structure formed by sequentially connecting a working edge, a first splicing edge, a structural edge and a second splicing edge end to end, or the sectional material is of an open structure formed by the working edge, the first splicing edge and the second splicing edge. When the sectional material is of the open structure, the first splicing edge and the second splicing edge are connected to the two ends of the working edge respectively. The outer surface of the tail end or near-tail end, away from the working edge, of the first splicing edge is provided with a first splicing rib formed by protruding in the length direction, the outer surface of the tail end or near-tail end, closeto the working edge, of the second splicing edge is provided with a second splicing rib formed by protruding in the length direction, and the protruding height h1 of the first splicing rib is equal tothe protruding height h2 of the second splicing rib. Compared with the related art, the sectional material can be easily spliced or disassembled under the effect of the splicing ribs, and as the contact area is reduced, sectional materials can be spliced more closely.

Owner:何其佳

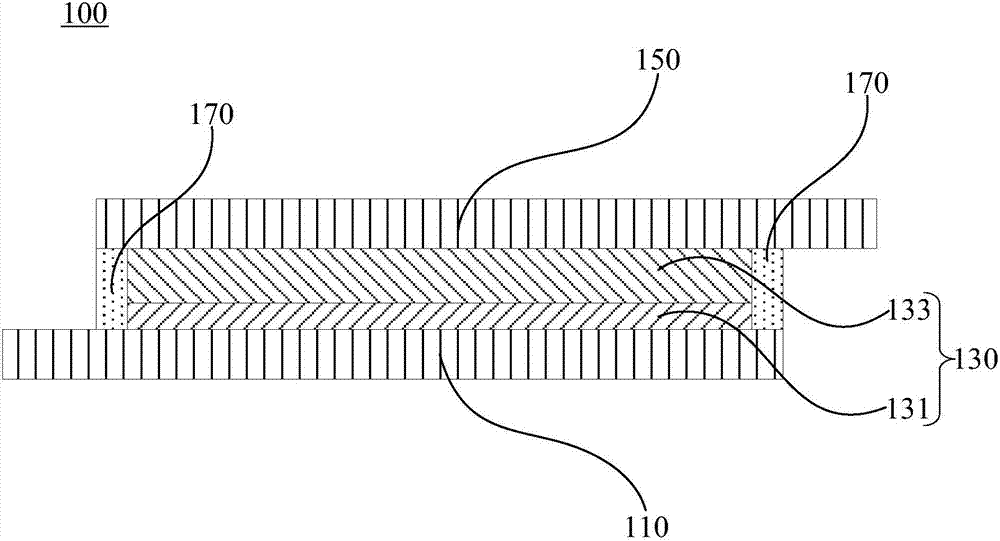

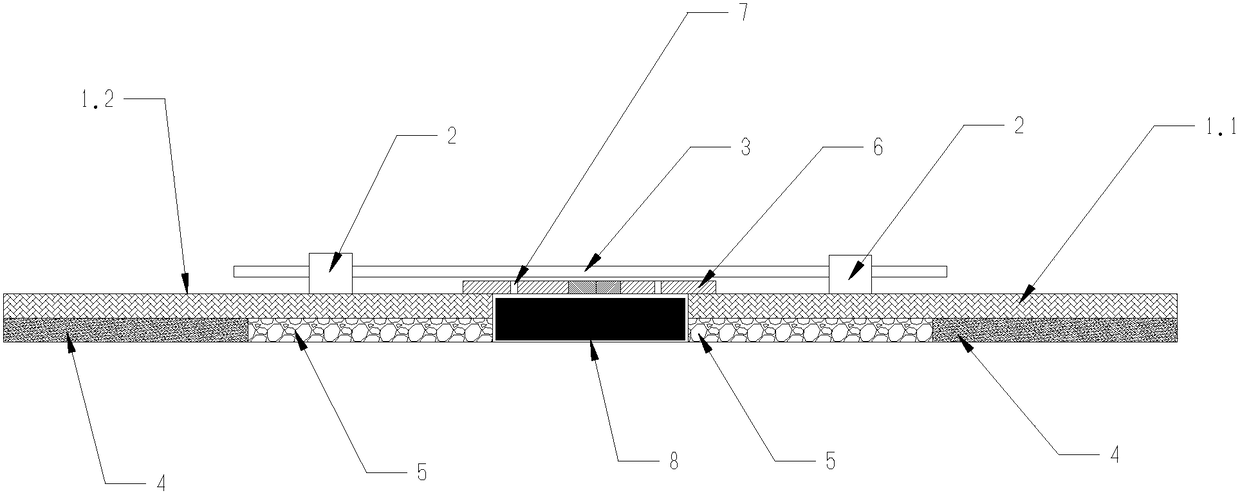

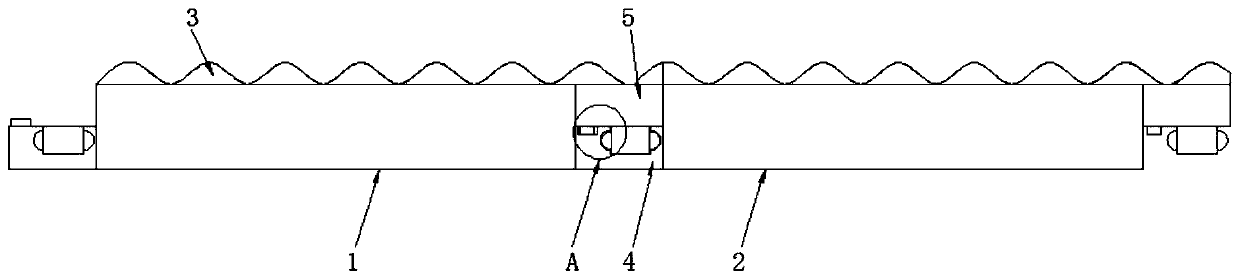

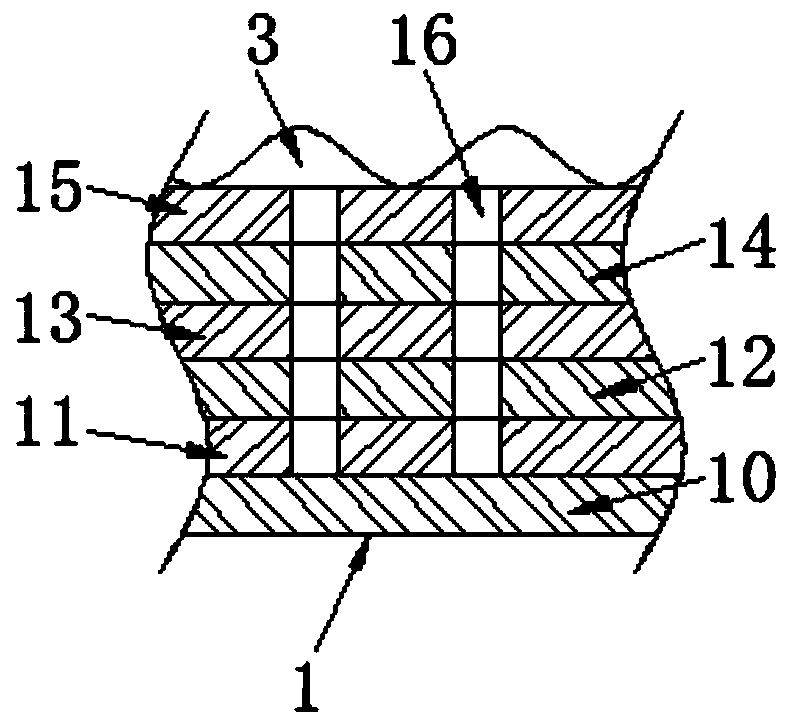

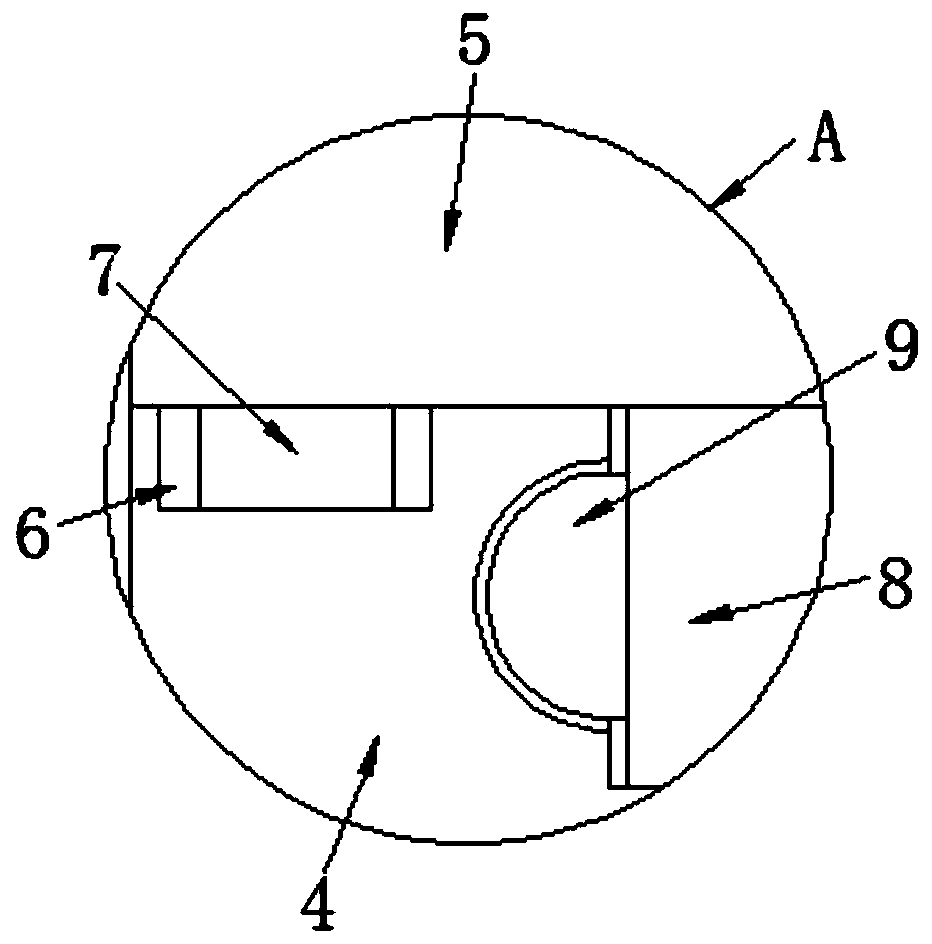

Solar panel and packaging method thereof

ActiveCN106898668AStitched tightlyReduce installation costsFinal product manufacturePhotovoltaic energy generationCells panelSingle support

The invention relates to a solar panel and a packaging method thereof. The solar panel includes a back plate having a plate-like structure; a cell module having a multilayer layered structure and being disposed on the back plate; and a cover plate having a plate-like structure and being disposed on the cell module. The cover plate, the cell module, and the back plate are sequentially laminated. The projection of the cover plate in the vertical direction is shifted from the back plate. The back plate of the solar panel is shifted from the cover plate so as to form a splicing structure among a plurality of solar panels. The plurality of solar panels are spliced to form a more tightly connected large-size cell panel. Meanwhile, the entire cell panel can be supported by a single support keel, and the installation cost is saved.

Owner:西安中易建科技集团有限公司

Wound closing device

InactiveCN108143454AConvenient careEasy to removeSuture equipmentsAnaesthesiaBandageBiomedical engineering

The invention discloses a wound closing device. A row of locking buttons for locking a bandage is fixed above each skin binding tape; one end of the bandage penetrates the locking buttons of the leftskin binding tape, and the other end of the bandage penetrates the locking buttons of the right skin binding tape; a zipper is connected between the left skin binding tape and the right skin binding tape, one side of the zipper is connected with the left skin binding tape, and the other side of the zipper is connected with the right skin binding tape. By means of the device, suture of irregular skin wounds and suture of skin wounds with different depths and different widths can be easily achieved, in the healing process of the wounds, it is convenient to apply medicine to the wounds for nursing, after healing, the device can be easily and quickly removed, and pains due to taking out stitches are avoided.

Owner:WUHAN HAOHONG TECH

LED (light emitting diode) lamp unit and LED combined lamp

InactiveCN101769465BMany changes in shapeEasy to combinePoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

Owner:CE LIGHTING

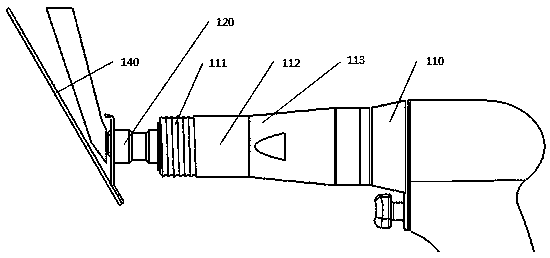

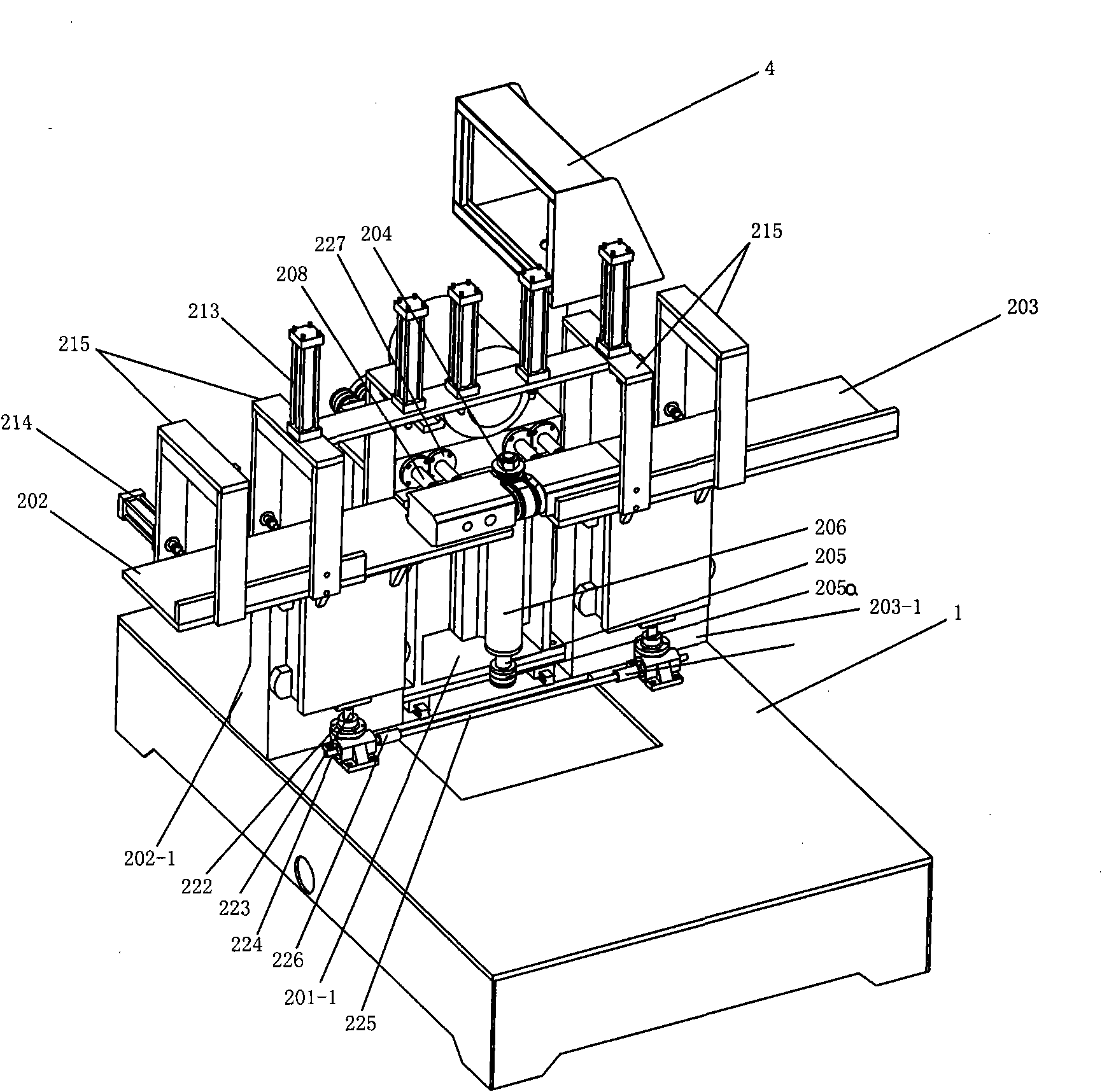

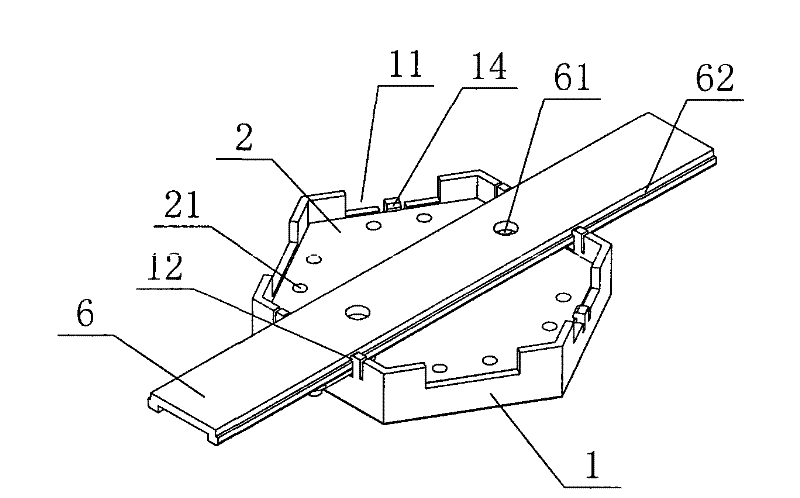

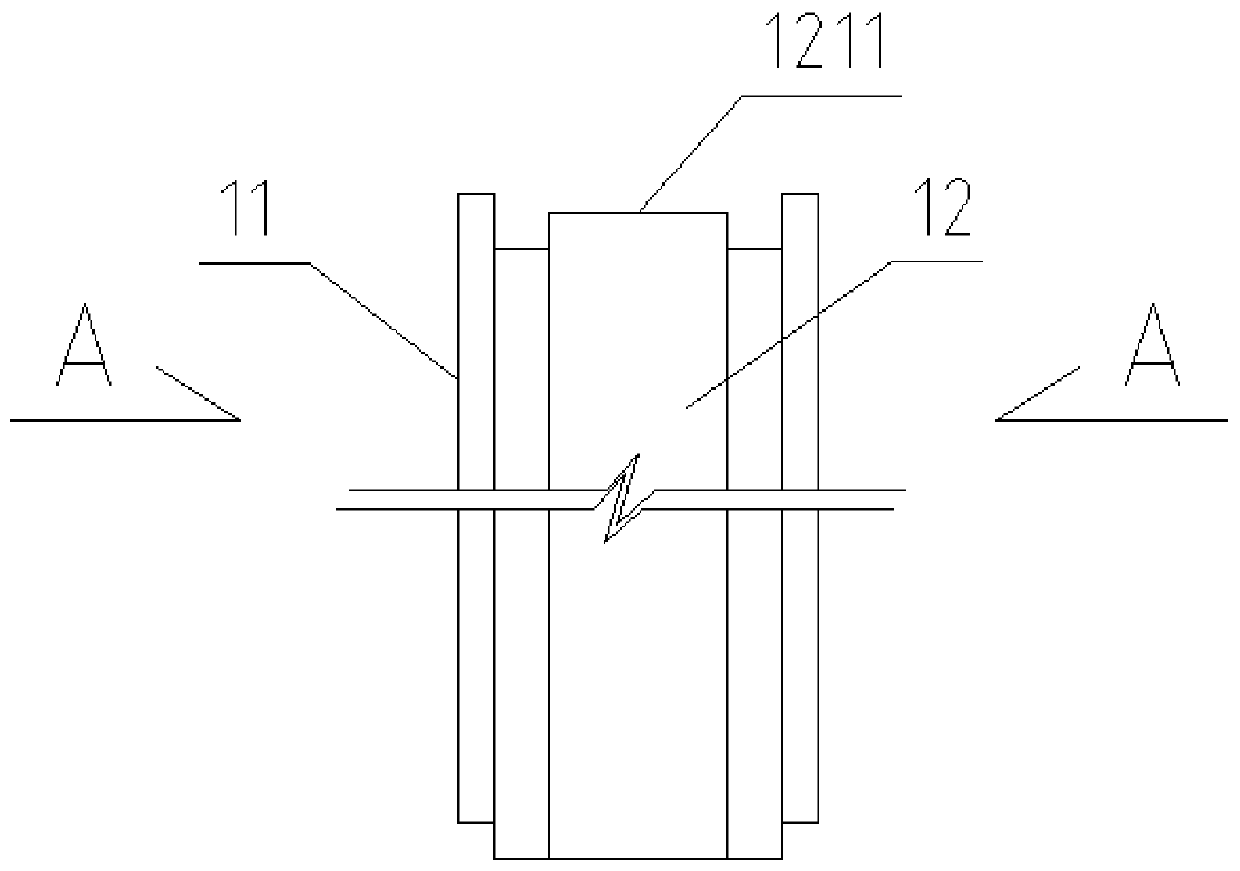

Intelligent full-synchronized pattern sewing machine

ActiveCN103194861AAvoid distortionStitched tightlyHem-stitch machinesNeedle barsEngineeringSewing needle

The invention discloses an intelligent full-synchronized pattern sewing machine. The sewing machine comprises an upper casing, a needle bar synchronous rotary mechanism and a shuttle race synchronous rotary mechanism. The needle bar synchronous rotary mechanism is arranged at one end of the upper casing, and the shuttle race synchronous rotary mechanism is mounted below the needle bar synchronous rotary mechanism and rotates synchronously with the needle bar synchronous rotary mechanism. When the intelligent full-synchronized pattern sewing machine performs sewing, the needle bar synchronous rotary mechanism and the shuttle race synchronous rotary mechanism can drive a needle bar and a shuttle race to rotate synchronously according to a line moving direction to enable the sewing direction of a sewing needle to be consistent with a set sewing line track, so that high-quality and perfect sewing is achieved, and the sewn line track has the advantages of being compact, orderly and uniform and identical with the set sewing line track; and the practicality is high, and wide industrial utilization values are provided.

Owner:ANHUI JIEYU SHOEMAKING MACHINERY TECH CO LTD +1

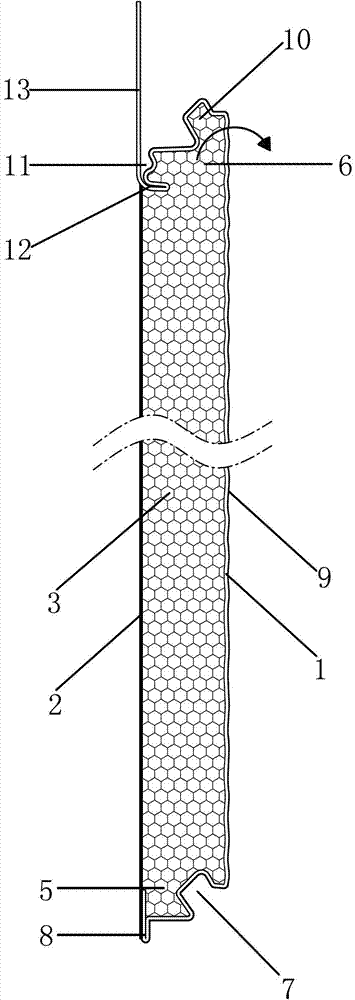

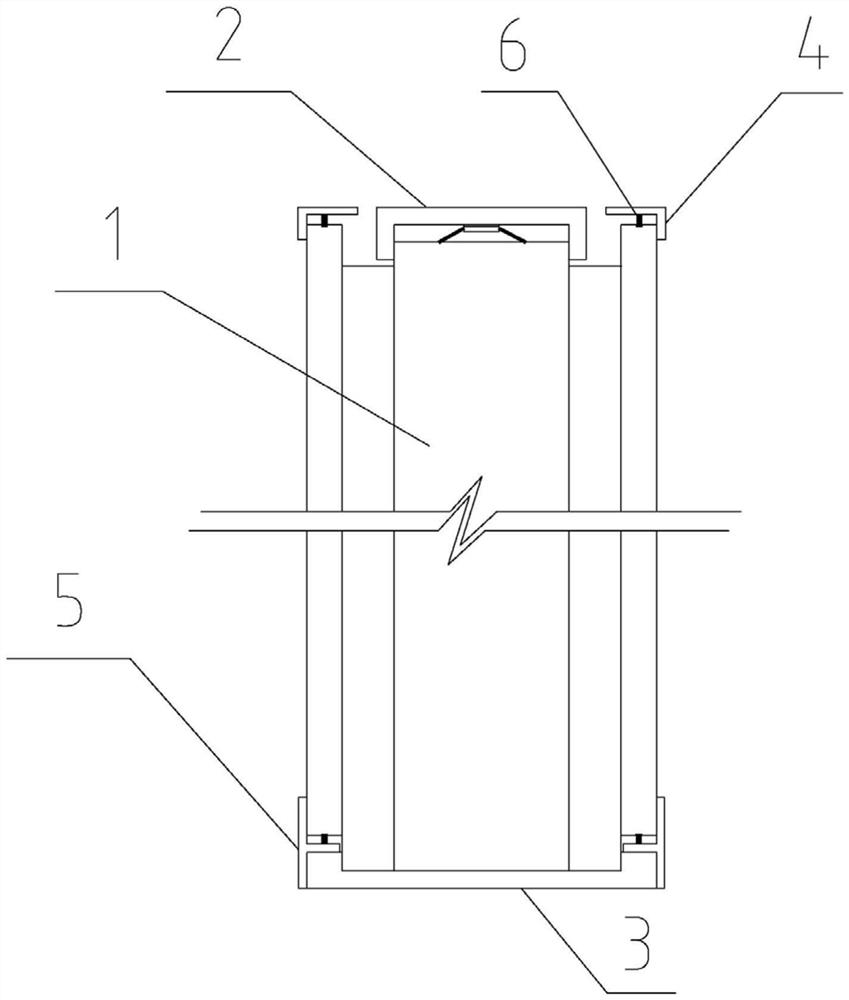

Partition wall plate with good anti-seismic performance

ActiveCN110761484AImprove seismic performanceIncrease stiffnessWallsProtective buildings/sheltersEarthquake resistanceClassical mechanics

The invention relates to a partition wall plate with good anti-seismic performance. The partition wall plate comprises walls, upper clamping grooves and lower guiding grooves, wherein the walls comprise decoration panels, structure bodies, filling bodies and suspension ropes; the structure bodies are each of a cylindrical structure and are sequentially spliced; cavities of the structure bodies arefilled with the filling bodies; the decoration panels are fixed to the outer side faces of the structure bodies; the suspension ropes are arranged at the tops of the structure bodies; the upper clamping grooves are clamped in the upper parts of the walls and provided with anti-seismic hooks, and the suspension ropes are suspended on the anti-seismic hooks; and the lower guiding grooves are clamped in the bottoms of the walls. The partition wall plate has many advantages of simple structure, convenient construction, good sound insulation performance, good anti-seismic performance and the like.

Owner:浙江华汇装饰工程股份有限公司 +1

Assembly type aluminum alloy form arranged at post-cast strip and construction joint positions

The invention relates to an assembly type aluminum alloy form arranged at post-cast strip and construction joint positions. The form comprises a surface rib form body, a web form body and a bottom ribform body which are all made of aluminum alloy materials, a plurality of lower U-shaped grooves with upward openings and allowing bottom ribs to penetrate are formed in the upper end of the bottom rib form body at intervals, the web form body is installed at the upper end of the bottom rib form body, a plurality of upper U-shaped grooves with downward openings and allowing surface ribs to penetrate are formed in the lower end of the surface rib form body at intervals, and the surface rib form body is installed at the upper end of the web form body. The aluminum alloy form has the advantages that 1, a material is recycled, the cost is saved, and the material-saving requirement is met; 2, manufacturing is conducted according to the steel bar spacing, the structural slab and the protective layer thickness, it is ensured that after pouring is completed, the steel bar spacing standard and the protective layer thickness of the post-cast strip and the construction joint meet the design requirement, and the structural durability is ensured; and 3, all components of the form are tightly spliced, so that concrete leakage is avoided as much as possible, and the forming quality is ensured.

Owner:THE FIRST CONSTR ENG COMPANY LTD OF CHINA CONSTR SECOND ENG BUREAU

Preparation method of imitated jade glass

The invention relates to a preparation method of imitated jade glass. The preparation method for imitated jade glass comprises the following steps of: polishing the both surfaces of plate glass, crushing the plate glass into blocks with sizes of 70-100 mm, cleaning and stacking in a trough layer by layer, then uniformly scattering bauxite, andalusite and silicon carbide reaction aids on the crushed glass, then heating the trough to 730-780 DEG C in 15-17 hours, insulating heat for 32-38 hours and then cooling to a normal temperature in 18-22 hours to obtain the product. The product has light-transmitting and lightproof effects, is of jade texture and many colours, is free of radioactivity of natural stone, as also has higher acid-base resistance, corrosion resistance, impact resistance and compressive strength than natural stone; the crushed particles are not sharp, cannot injury people, has good machining performance, good ageing resistance, does not absorb water, capable of persistently keeping a bright colour, and simple in installation method. The product is widely used in decoration for the interior and exterior walls, floors and furniture of buildings such as whole curtain walls, high-grade residences and clubs, is far superior to natural stone in both visual sense and tactile sense, noble and elegant in decoration effect, and is a new generation of environment-friendly decoration materials.

Owner:武卫兴

Novel cotton loop pile carpet

Owner:TIANJIN TIANRUI CARPET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com