Intelligent full-synchronized pattern sewing machine

A pattern sewing machine and fully synchronous technology, applied in the field of sewing machines, can solve problems such as non-conformity to requirements, low product qualification rate, inability to rotate needle bars and shuttle beds, etc. The effect of sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The best example of the intelligent fully synchronous pattern sewing machine described in the present invention below does not limit the scope of protection of the present invention.

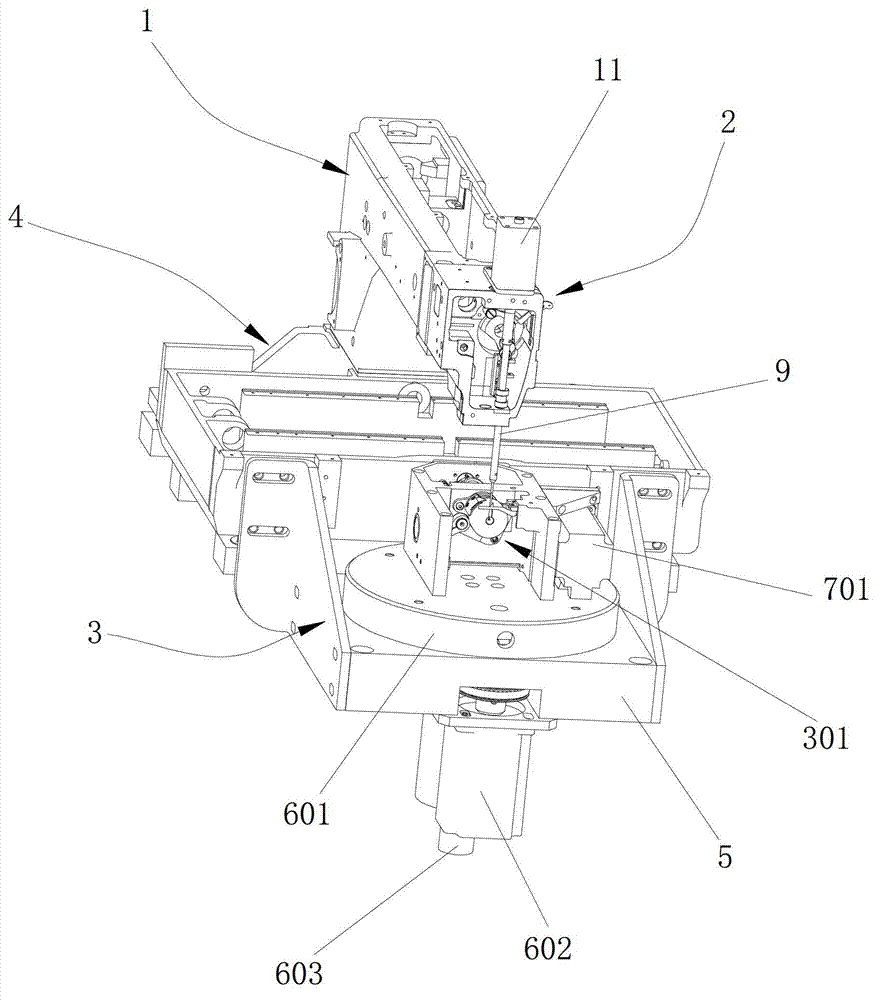

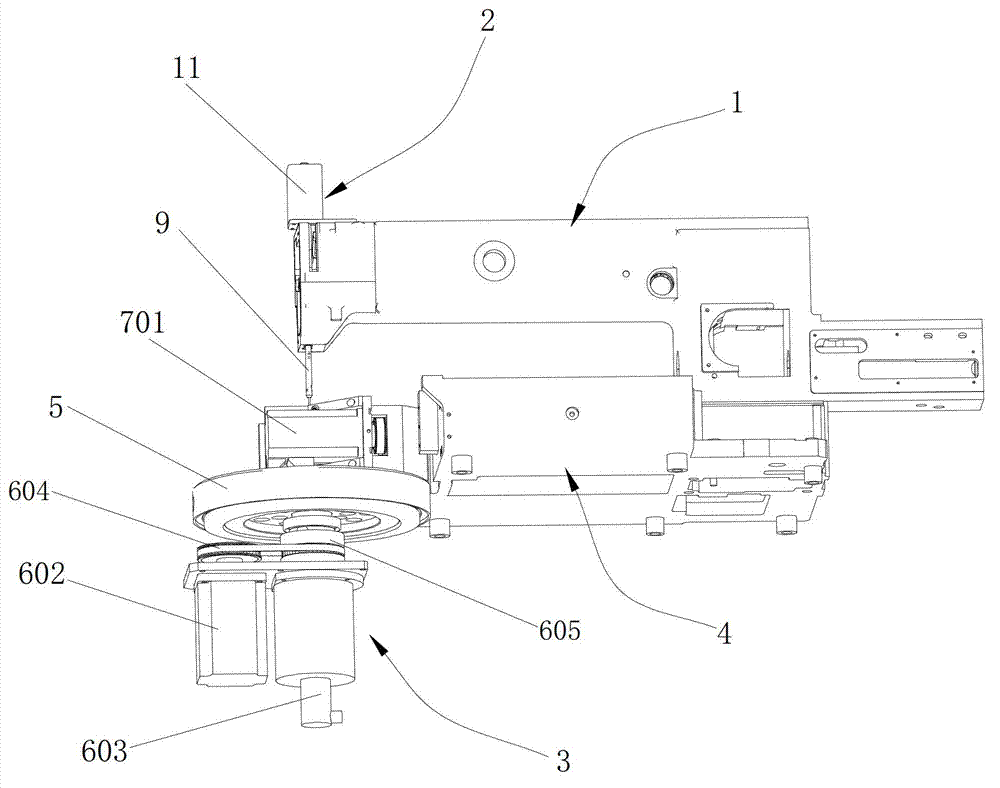

[0025] refer to Figure 1 to Figure 11 , providing an intelligent fully synchronous pattern sewing machine, including an upper casing 1, a needle bar synchronous rotation mechanism 2 installed at one end of the upper casing 1, and a needle bar synchronous rotation mechanism 2 installed under the needle bar synchronous rotation mechanism 2 and connected with the needle bar The shuttle bed synchronous rotation mechanism 3 that the synchronous rotation mechanism 2 rotates synchronously, under the synchronous rotation of the needle bar synchronous rotation mechanism 2 and the shuttle bed synchronous rotation mechanism 3, effectively avoids the thrust produced by the feeding mechanism when feeding the upper thread and The bottom thread is twisted to ensure the force balance between the upper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com