Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Stable mixing ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

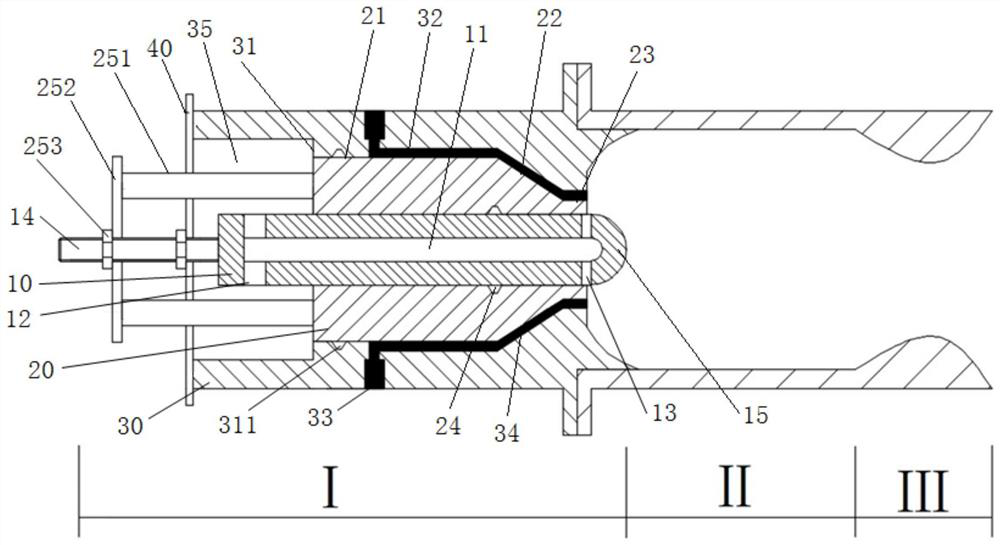

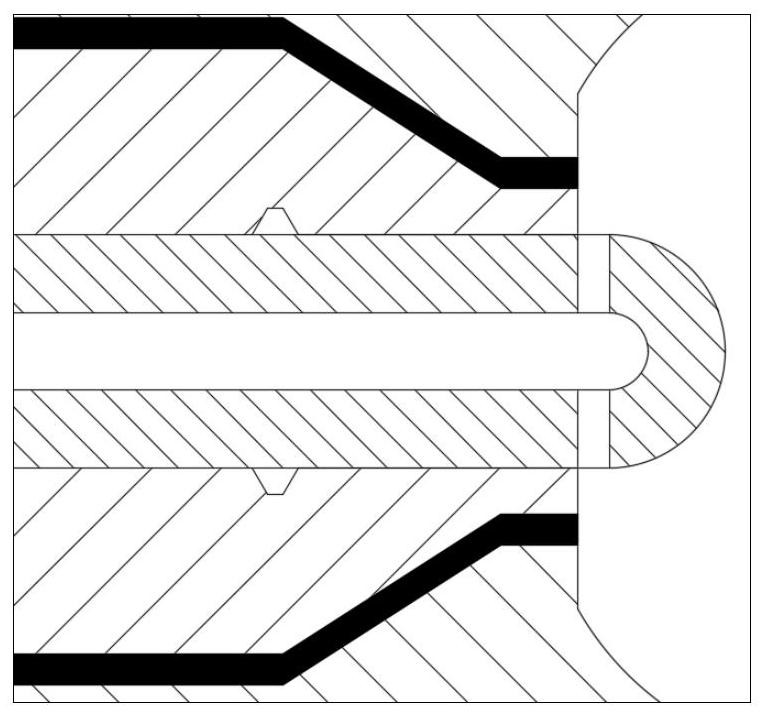

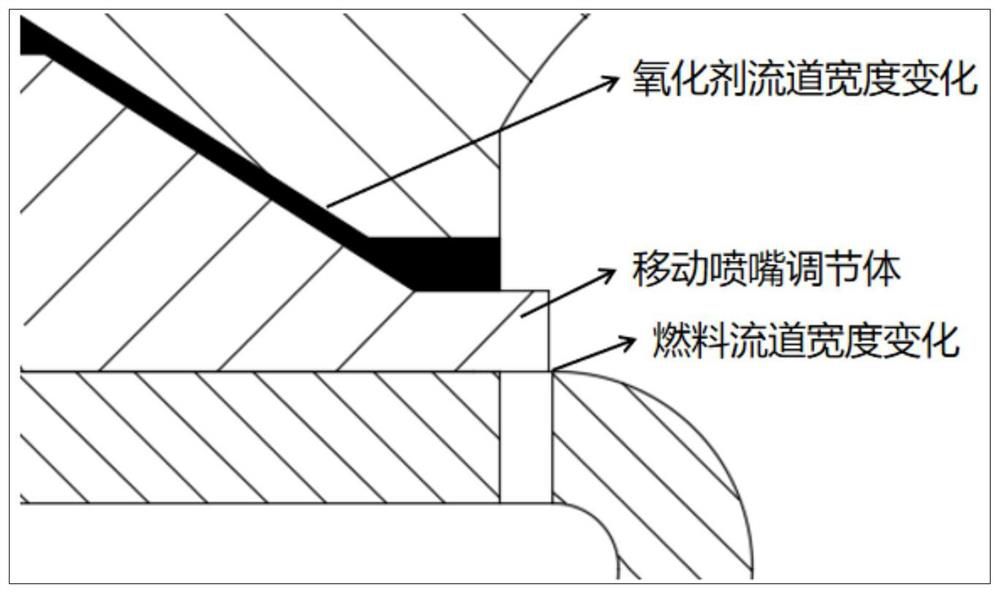

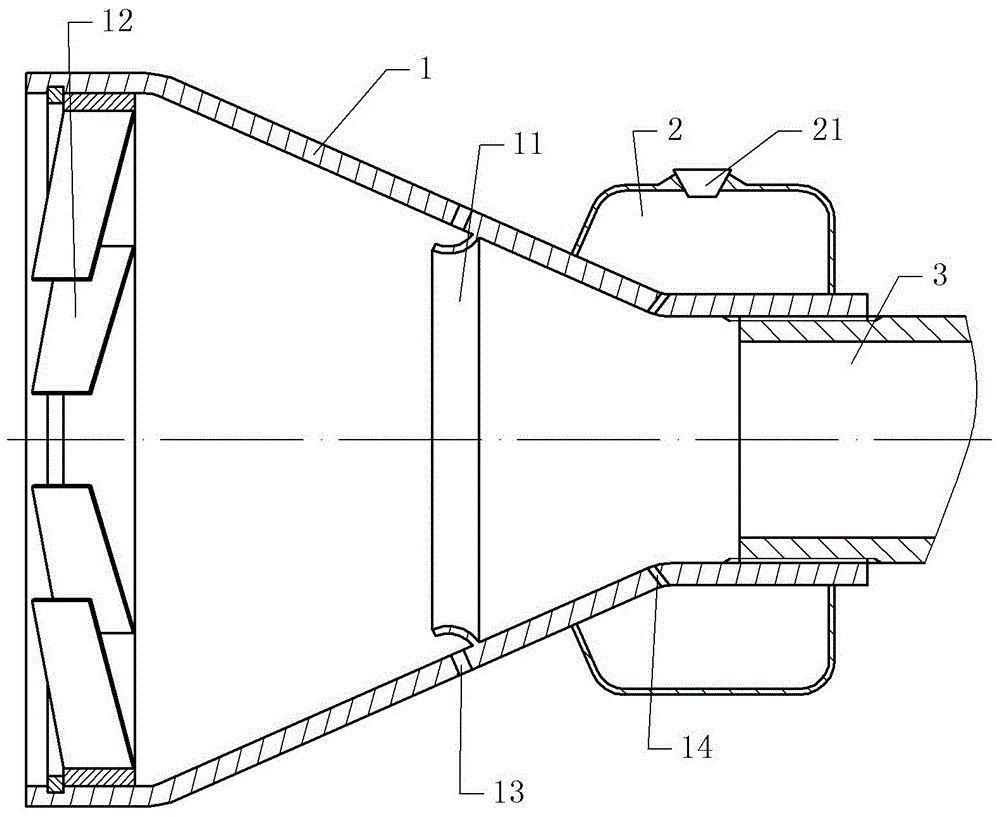

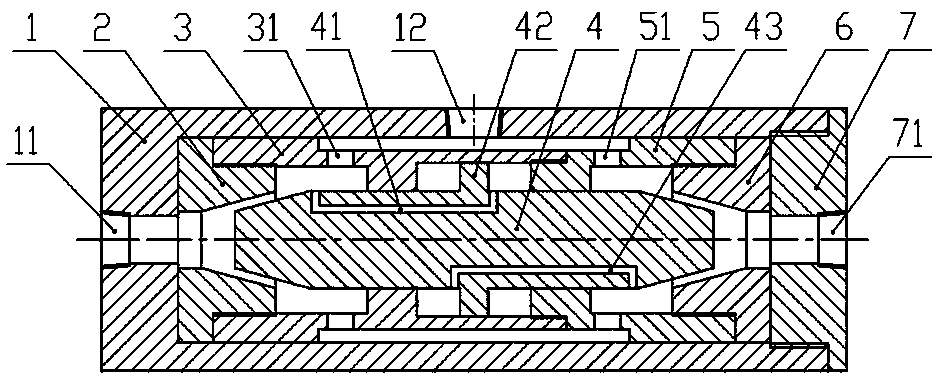

Two-component variable-thrust rotary detonation rocket engine based on pintle injector

ActiveCN113294264AStable mixing ratioReduce wasteRocket engine plantsCombustion chamberEquivalence ratio

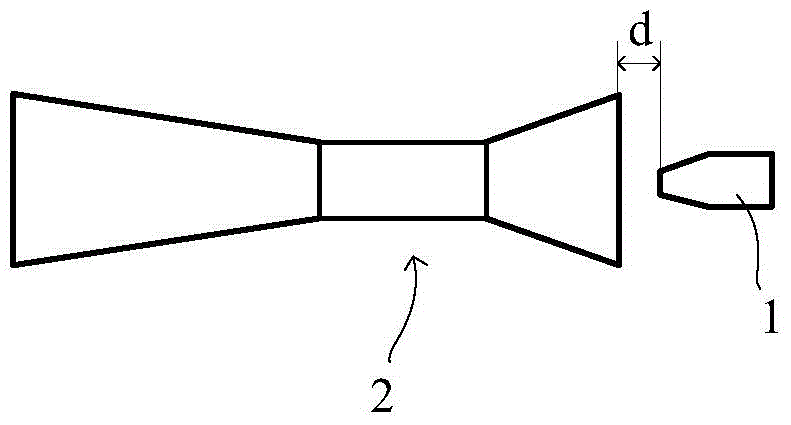

The invention discloses a two-component variable-thrust rotary detonation rocket engine based on a pintle injector. The two-component variable-thrust rotary detonation rocket engine based on the pintle injector comprises the pintle injector, a rotary detonation combustion chamber and an exhaust nozzle which are sequentially and coaxially arranged in the axial direction; the pintle injector comprises a center rod inner nozzle, a nozzle adjusting body and an injector shell which are sequentially and coaxially arranged from inside to outside in a sleeving mode; a fuel injection runner is arranged in the center of the center rod inner nozzle, a plurality of fuel injection openings are formed in the head of the center rod inner nozzle in the circumferential direction, and a broken-line-shaped oxidizing agent runner is formed between the outer wall face of the inner side of the nozzle adjusting body and the inner wall face of the injector shell; and the nozzle adjusting body can slide in the axial direction, and therefore the injection area of the fuel injection openings and the sectional area of the oxidizing agent runner are adjusted. According to the two-component variable-thrust rotary detonation rocket engine based on the pintle injector, under the condition that the equivalence ratio is not changed, the flow of a two-component propellant can be changed, thrust can be generated and changed, a fuel flowing area can be stabilized and the combustion rate of fuel can be increased by effectively utilizing a backflow area at the head of a pintle, fuel waste is reduced, and the propellant is saved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Manufacturing method for polyacrylic acid (salt) -based water-absorbent resin powder

Owner:NIPPON SHOKUBAI CO LTD

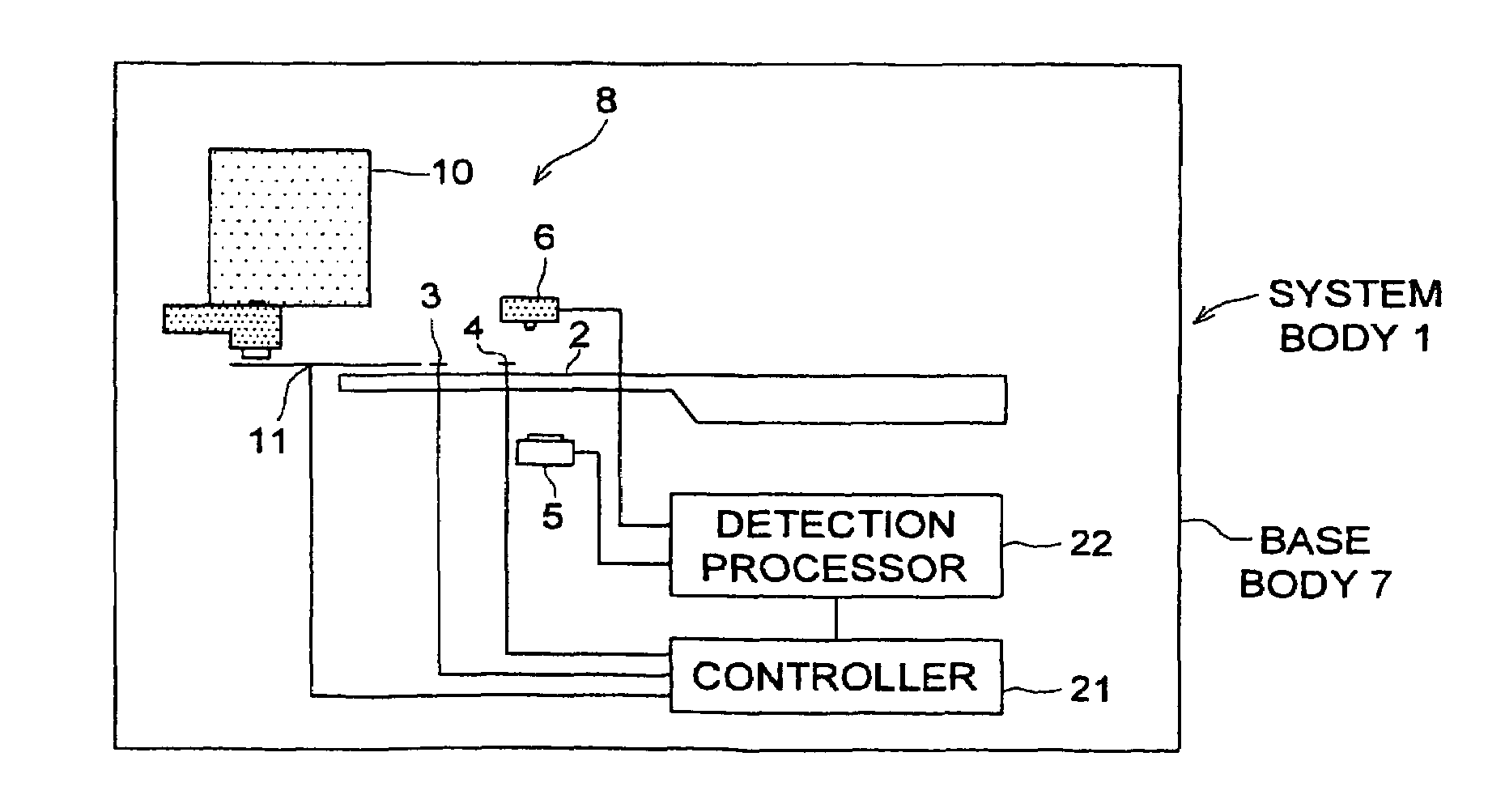

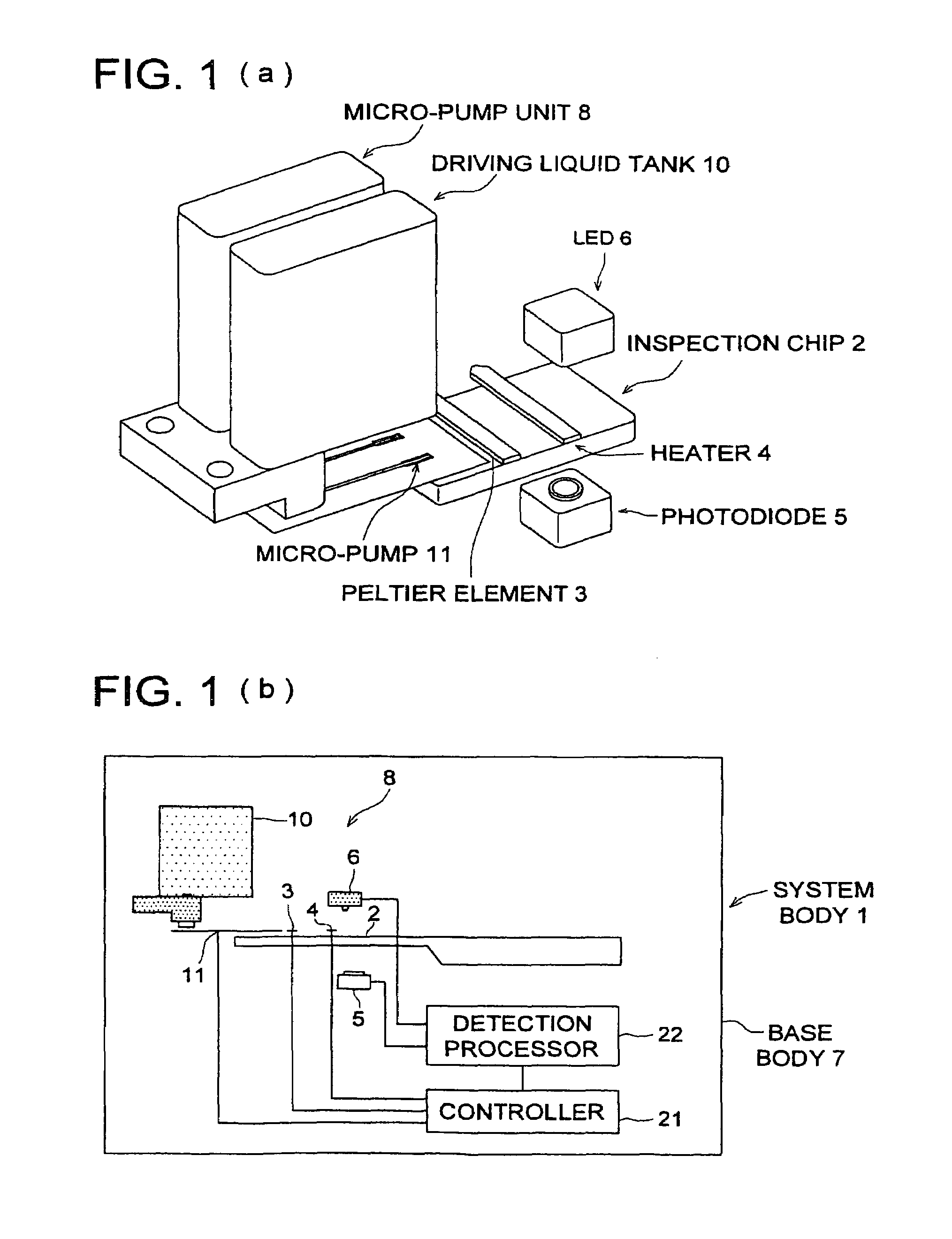

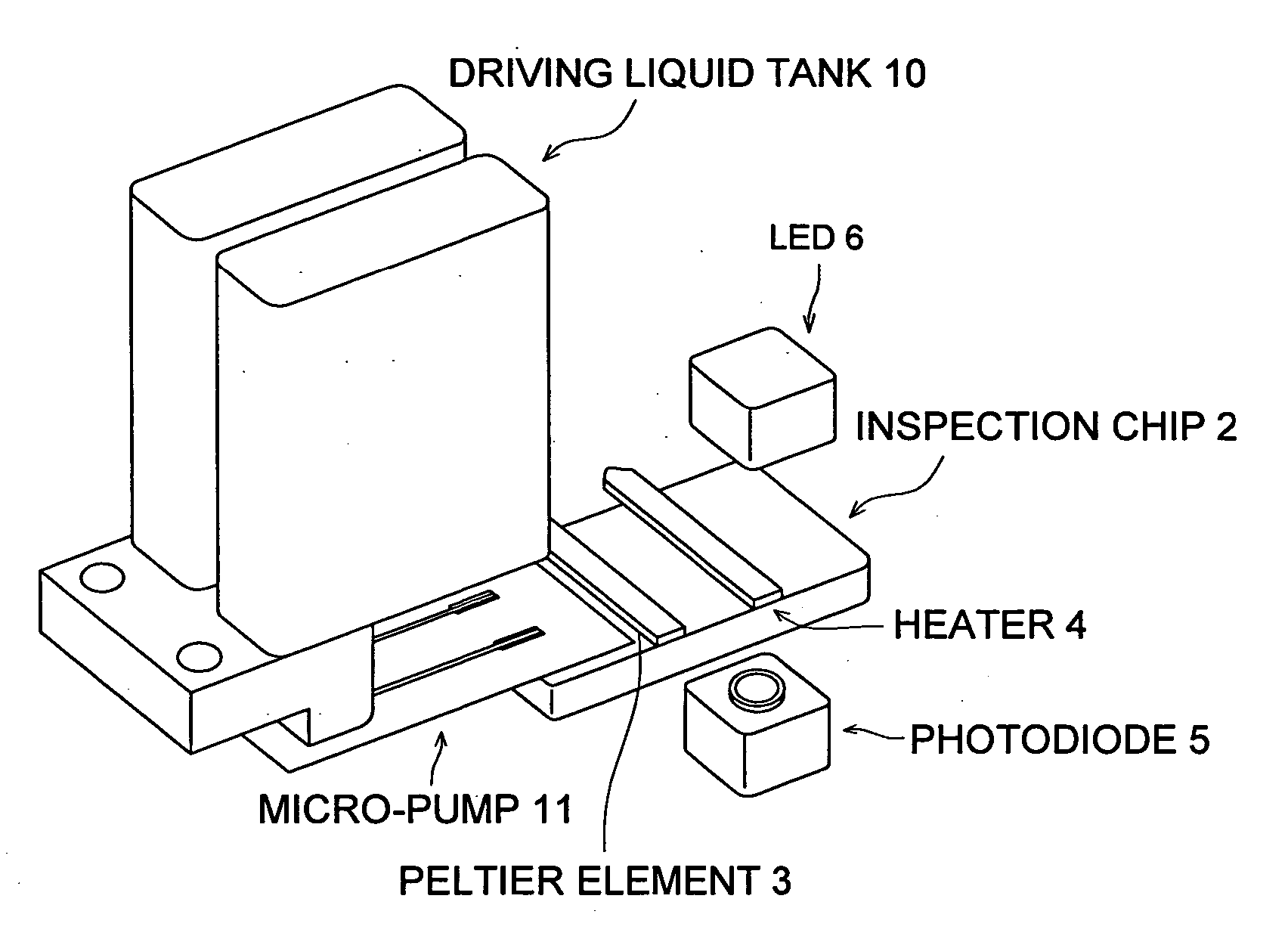

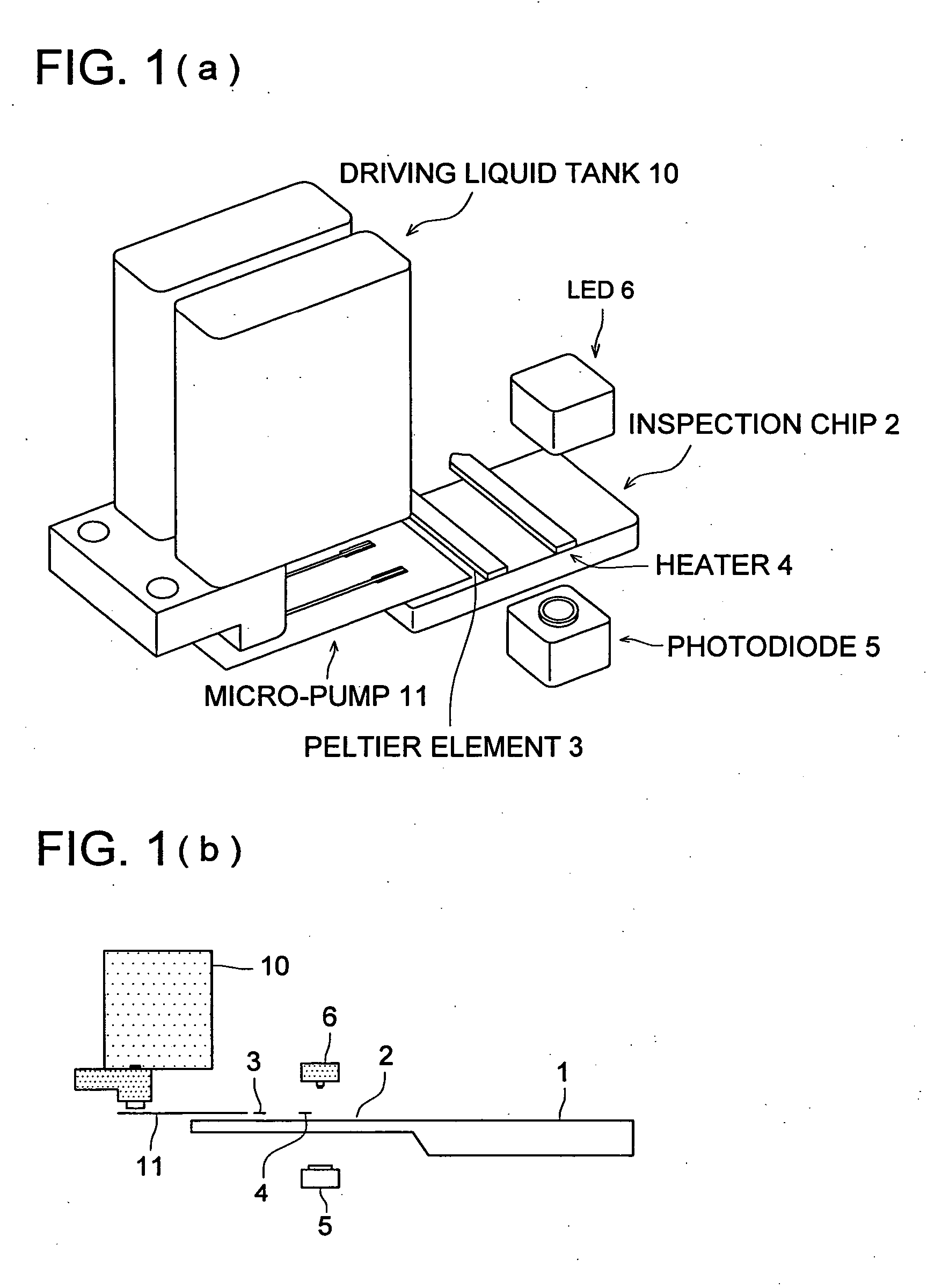

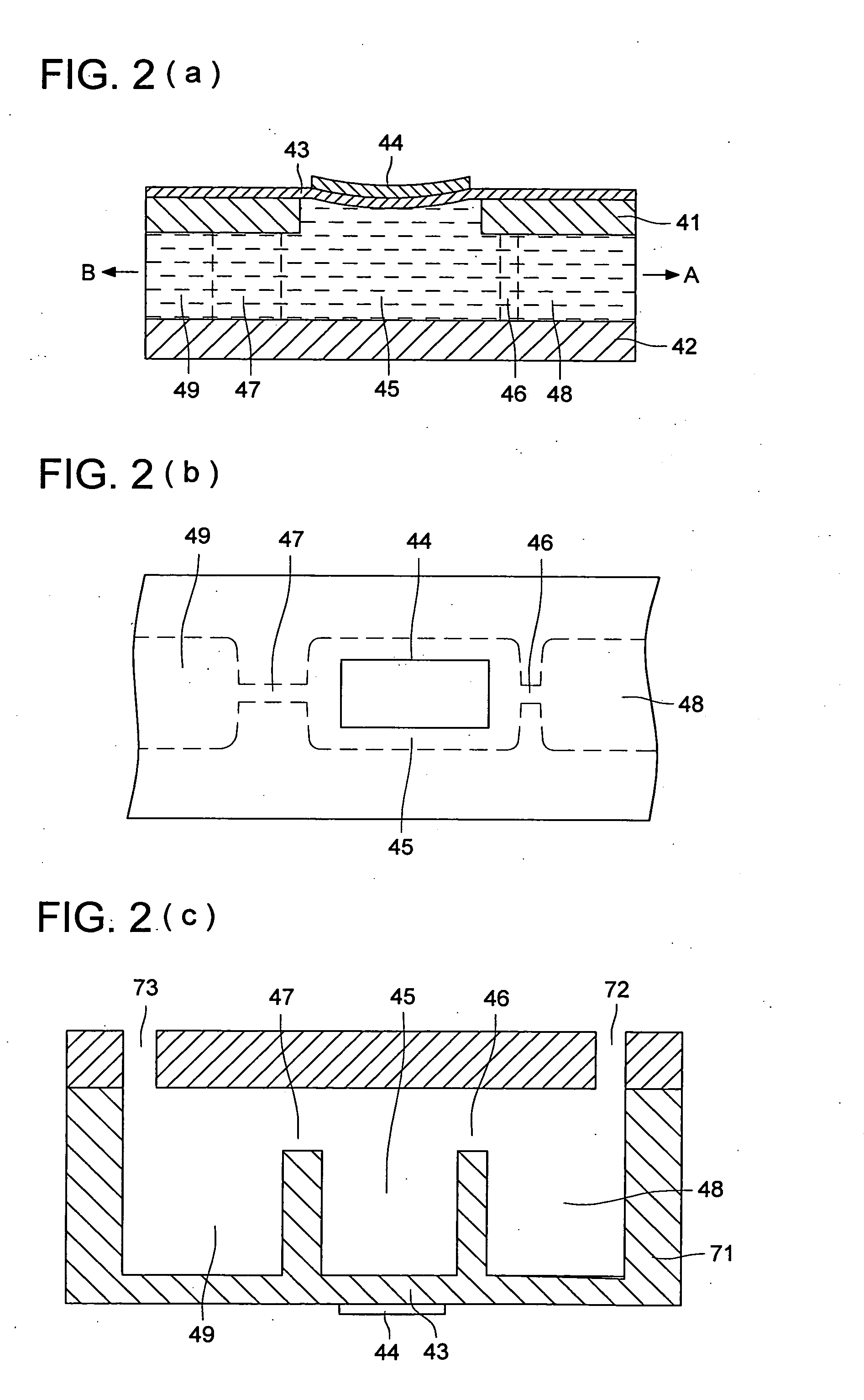

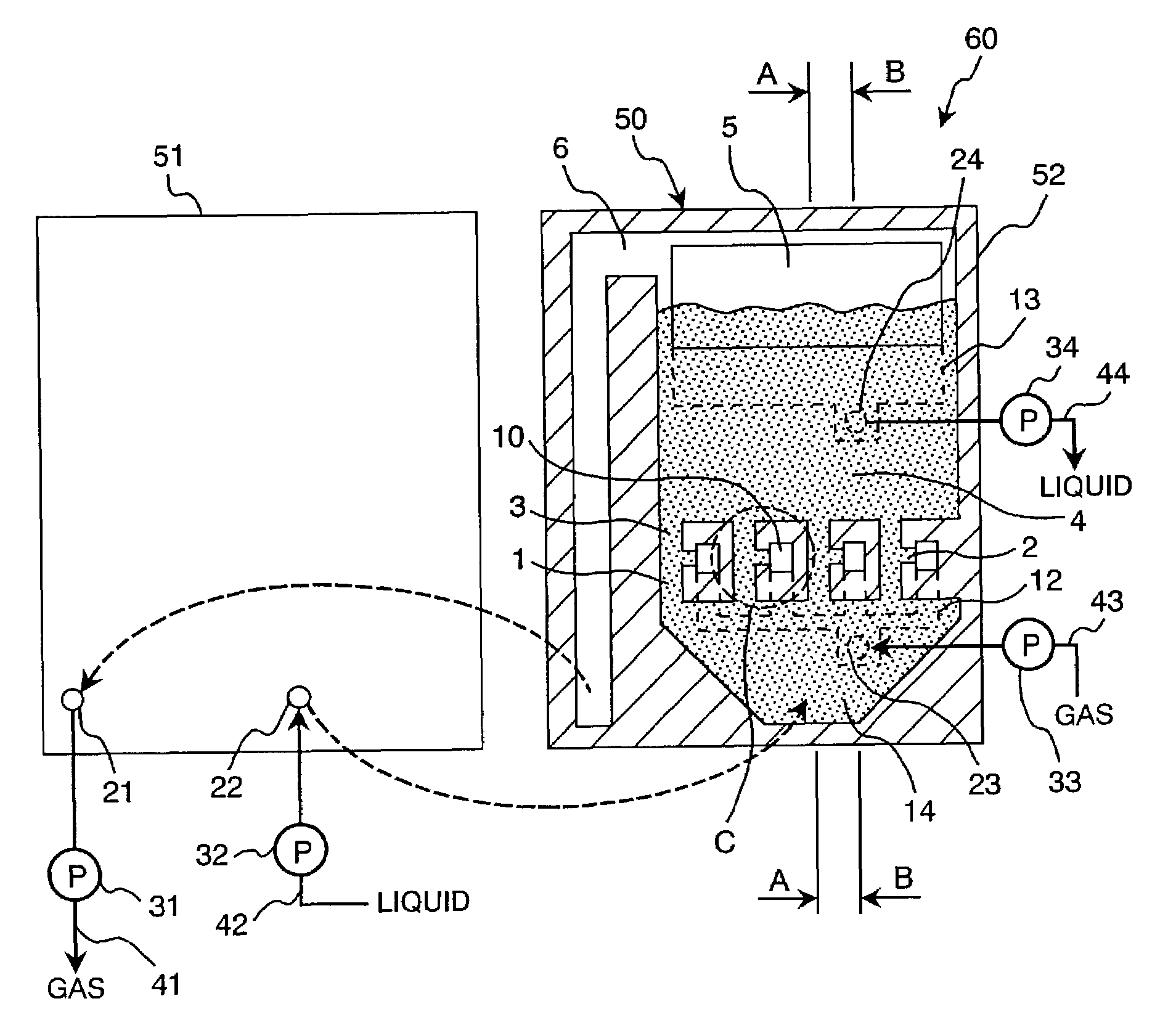

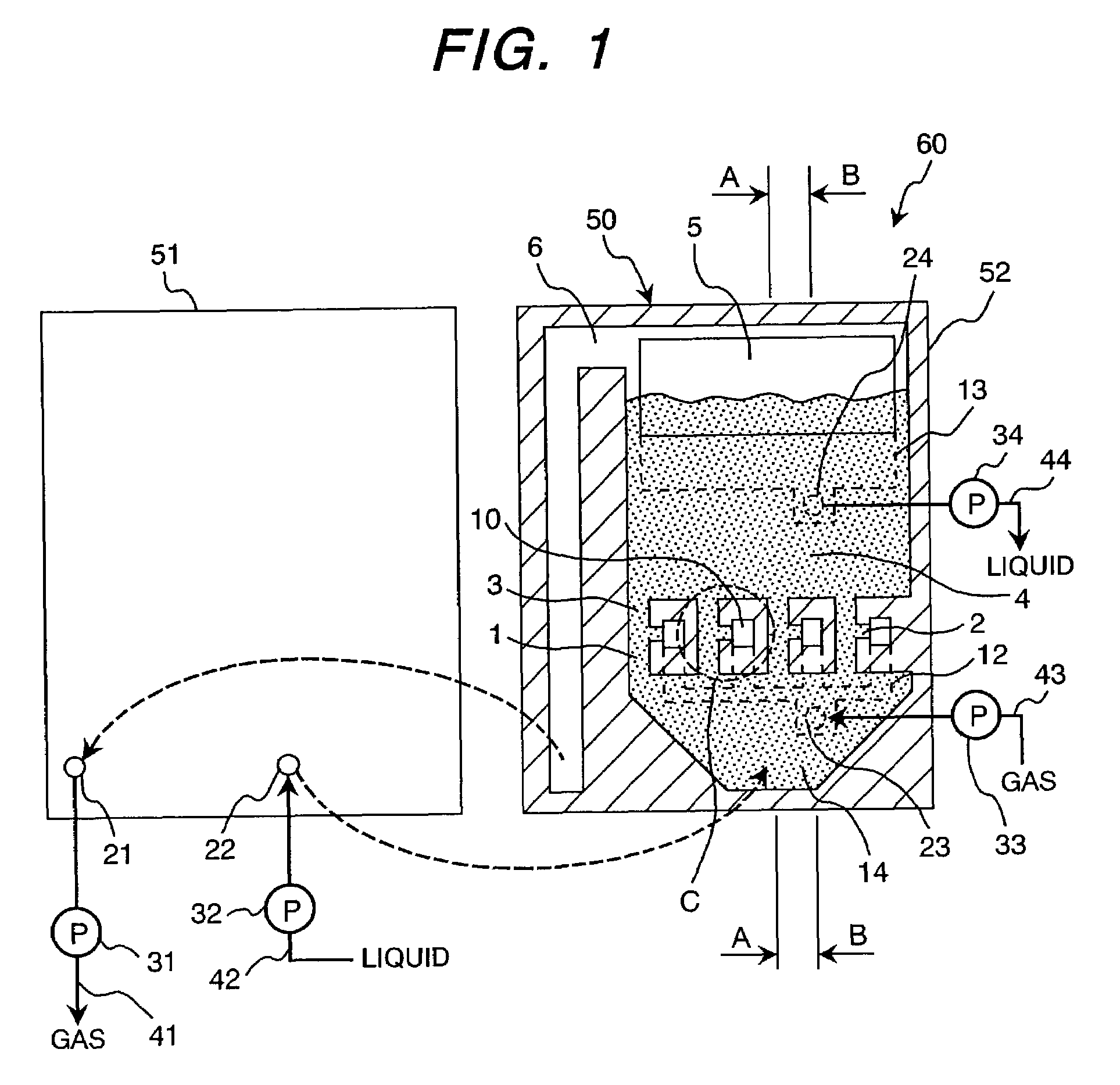

Micro total analysis system

ActiveUS7727478B2Easy to controlStable mixing ratioShaking/oscillating/vibrating mixersIon-exchanger regenerationEngineeringMixing ratio

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

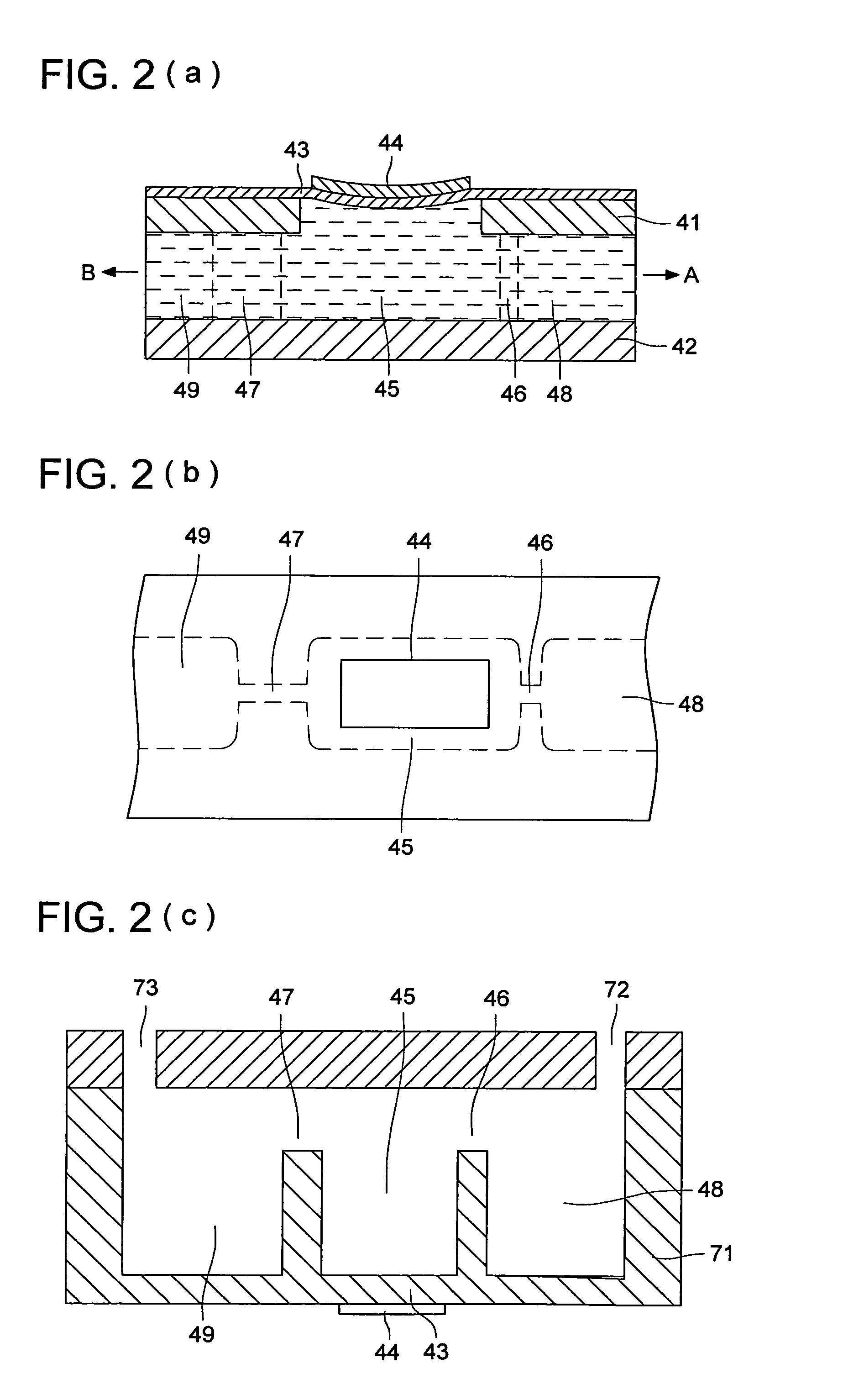

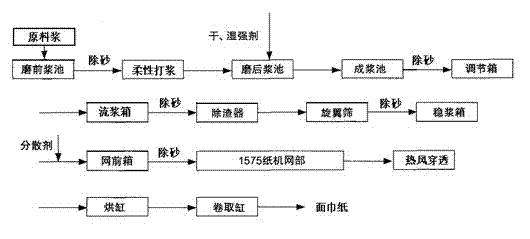

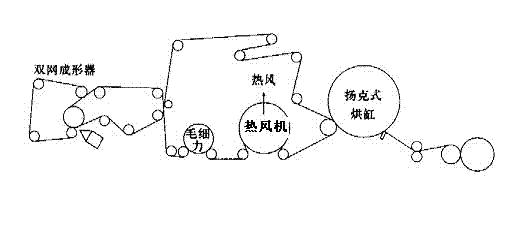

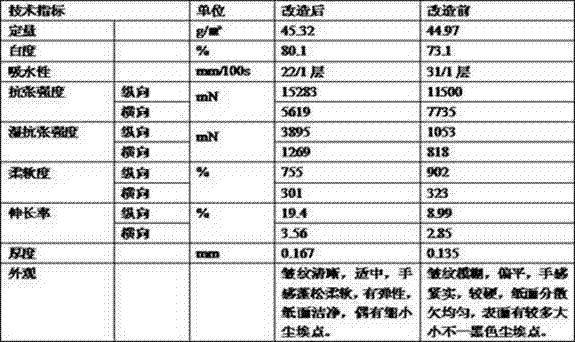

Production method of soft and fluffy facial tissue

ActiveCN103696318AImprove excessive tightness and insufficient bulkinessHigh speedPulp beating methodsDryer sectionPapermakingToughness

The invention relates to a papermaking method, and particularly relates to a method for producing household paper facial tissue by taking bagasse as a main raw material. The technical scheme is as follows: the bagasse pulp and a small amount of wood pulp at a high ratio are used as main raw materials, wherein the weight ratio of the bagasse pulp to the wood pulp is (65-75):(25-35); five grit removal processes are adopted to adjust the previous and later paper pulp concentration of each piece of equipment; a flexible beating process for fibrillation is adopted; a process of high-speed hot air penetrating through paper sheets is adopted to produce the soft and fluffy facial tissue with high toughness and low cost and meeting the health standard.

Owner:GUANGXI TIANLIFENG ECOLOGICAL MATERIAL

Micro total analysis system

ActiveUS20060239861A1Easy to controlStable mixing ratioShaking/oscillating/vibrating mixersIon-exchanger regenerationEngineeringMixing ratio

A system including an inspection chip equipped with at least a pump connection having a flow path opening for interconnecting to a micro-pump, a flow path through which a fluid flows, and a fluid mixing section for joining and mixing two or more fluids, and including a system body equipped with at least a base body, a chip connection having a flow path opening for interconnecting to the inspection chip, a micro-pump unit in the base body including micro-pumps in substantially the same shape, a detection processor and a controller for controlling at least the functions of the micro-pump unit and the detection processor, and the joining amount ratio is adjusted to set the mixing ratio of two fluids to be joined in the fluid mixing section to be approximately m:n (not 1:1) by making the drive voltages of the micro-pumps substantially equal to each other.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

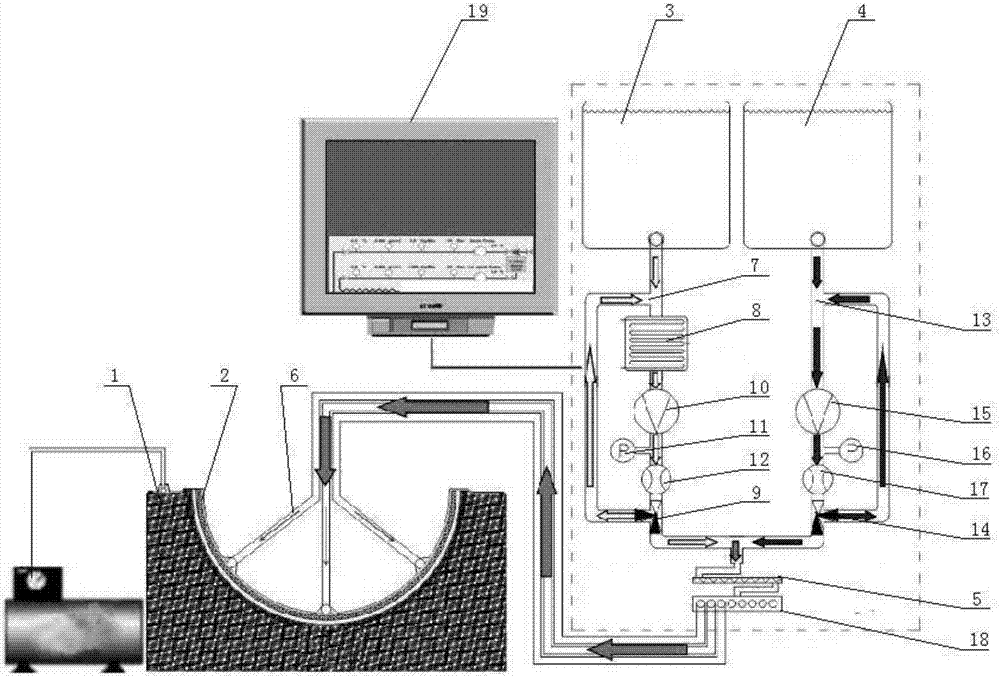

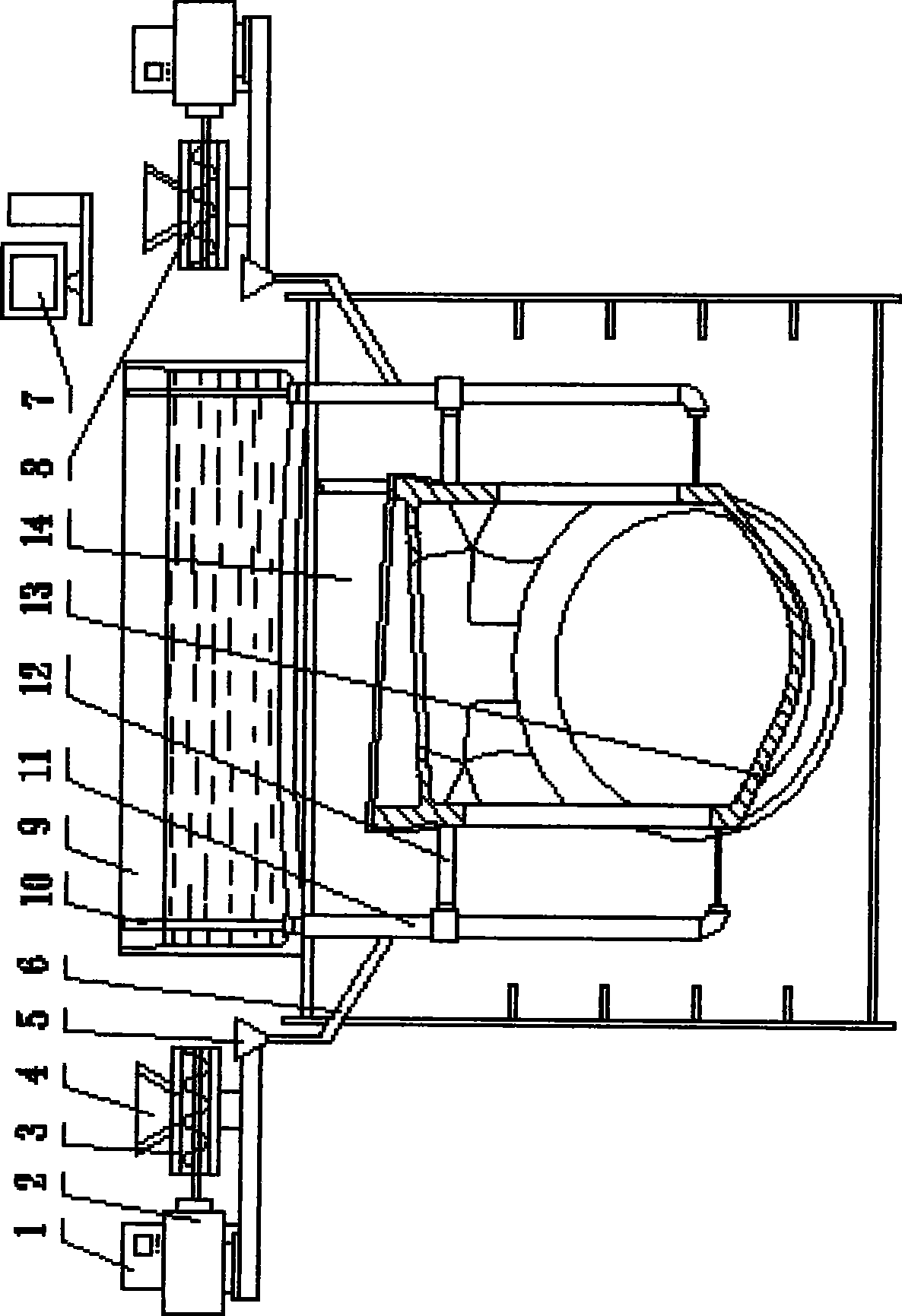

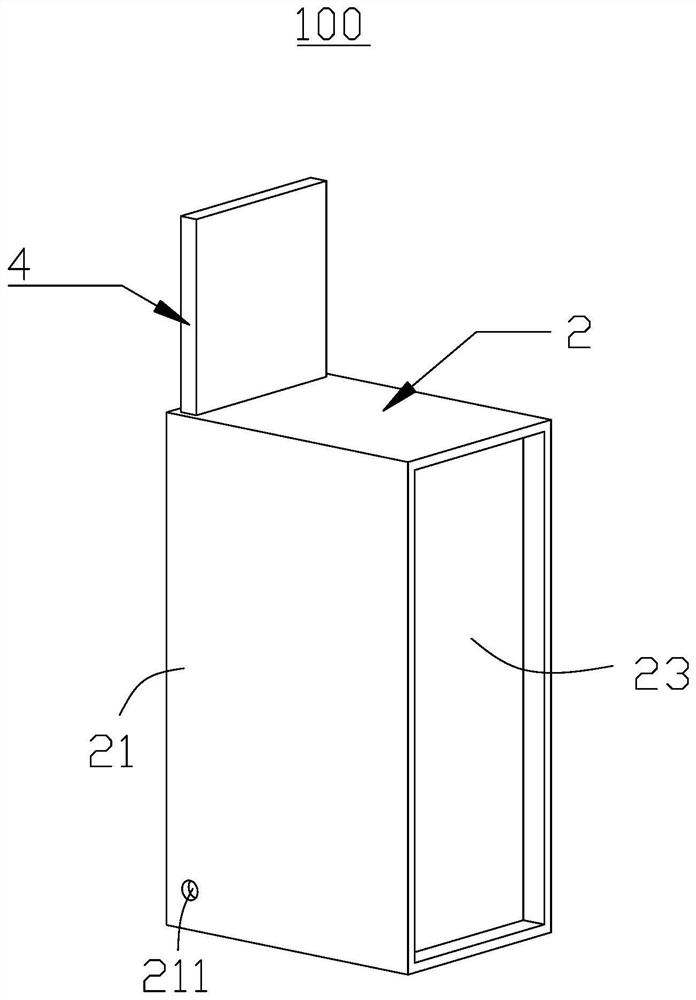

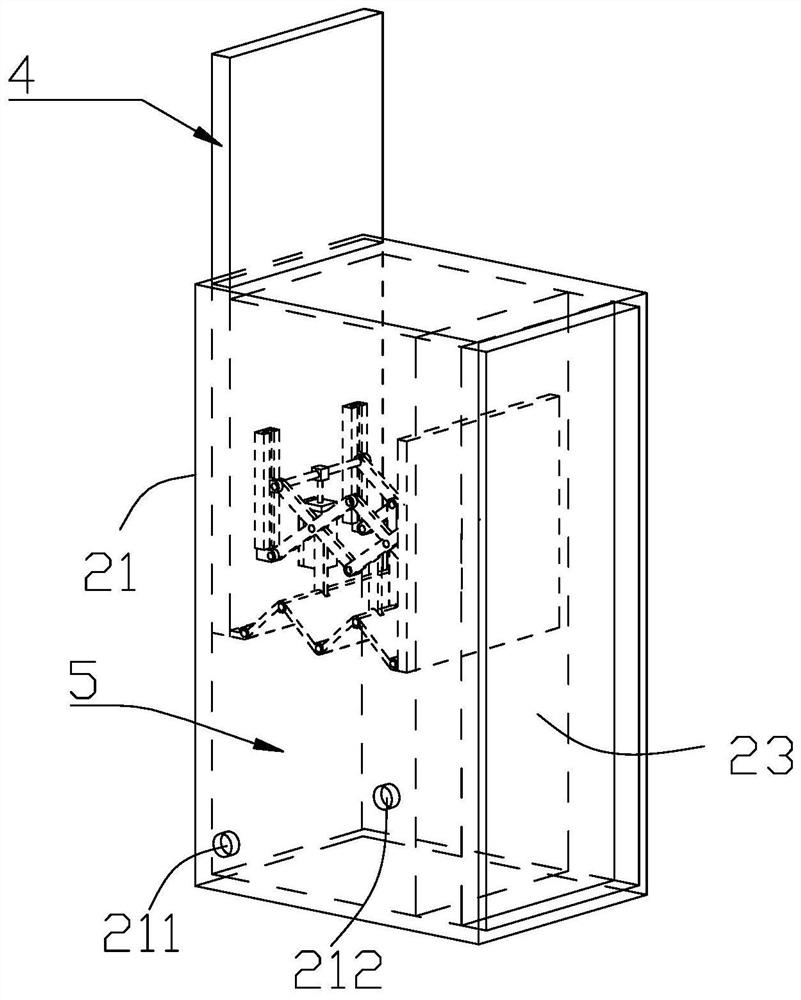

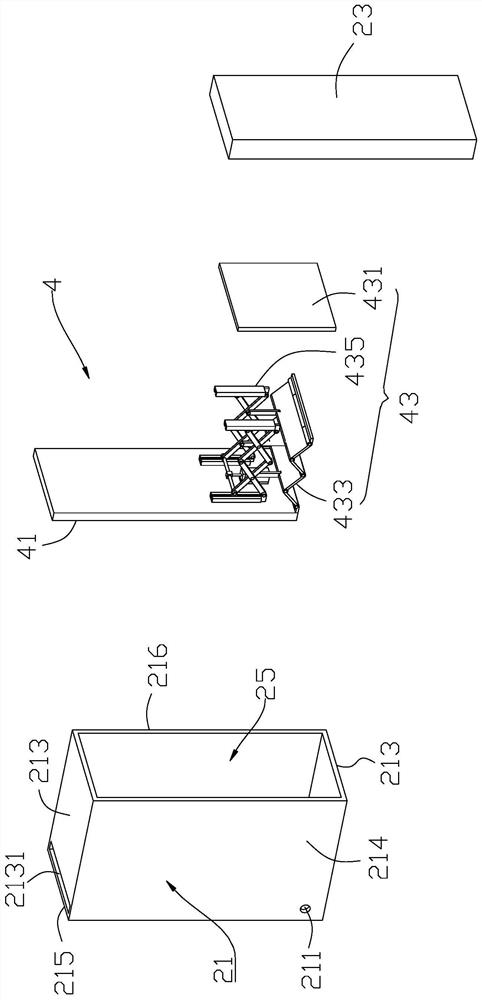

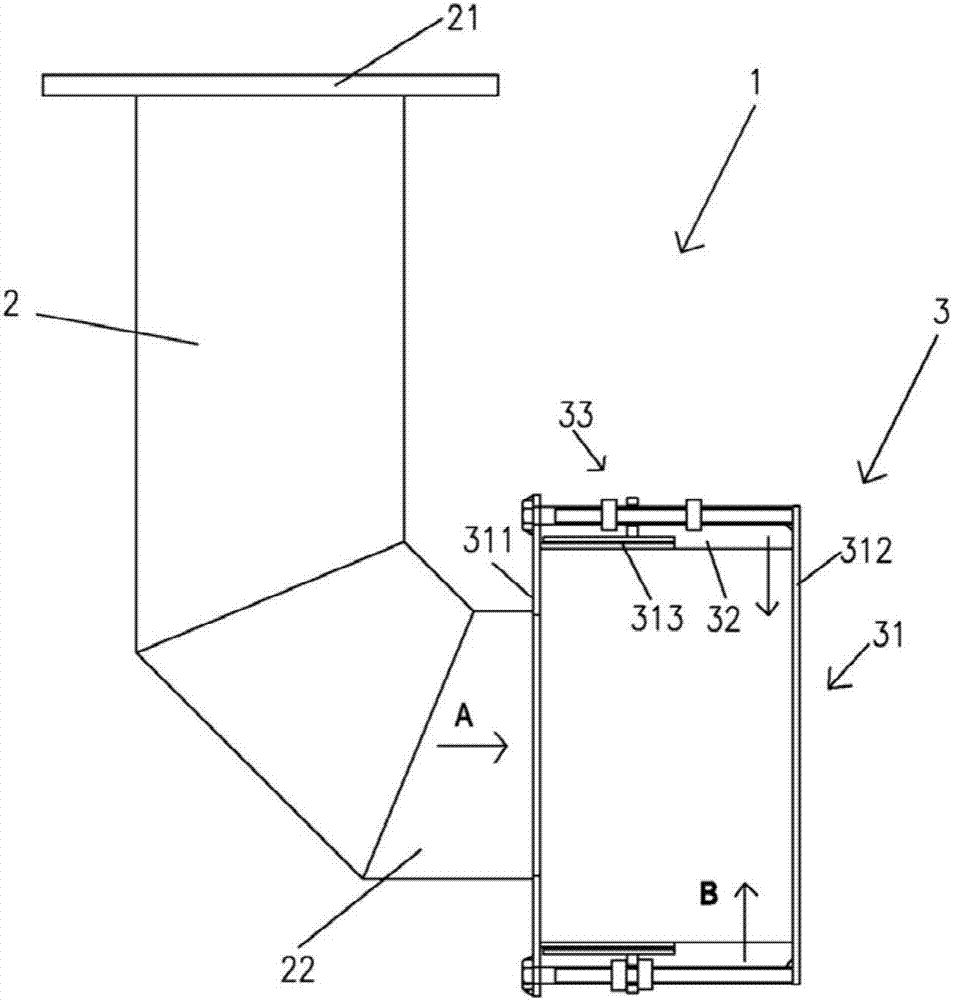

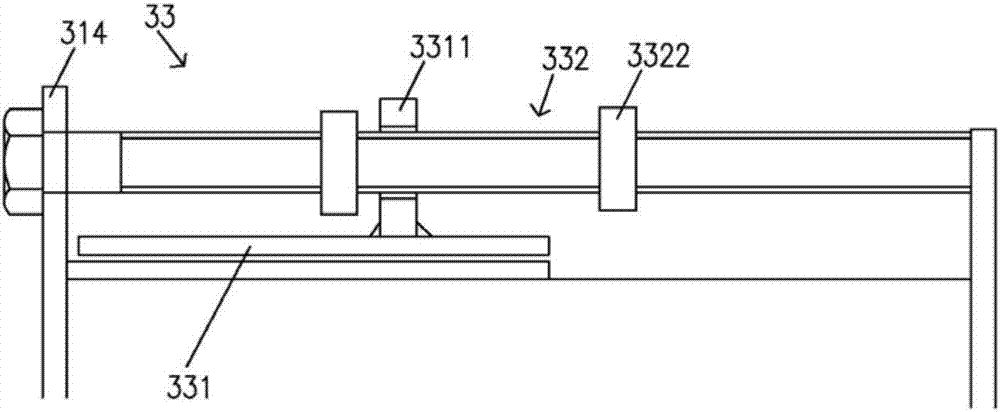

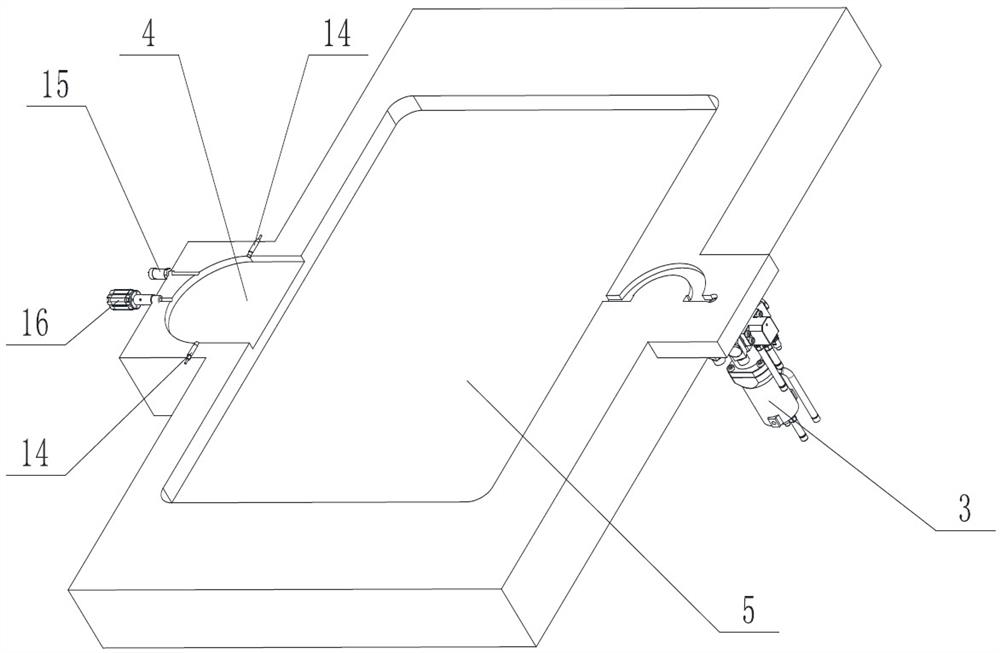

Vacuum pouring device for wind power blade molding

InactiveCN107953575AStable mixing ratioThe perfusion process is controllableDomestic articlesFiberElectricity

The invention discloses a vacuum pouring device for wind power blade molding, and mainly solves the problems that in an existing technology, an existing pouring process existing process is low in controllability, complex in process, overpowered in experientiality, easy to mix with bubbles, and bad in site environment. The vacuum pouring device for wind power blade molding includes a mould, a resinbarrel, a curing agent barrel, a curing agent quantitative output loop, and a performing body made of dry fiber reinforced materials and laid in the curing agent quantitative output loop. The resin barrel communicates a resin quantitative cycle output loop and a mixing device in sequence. The curing agent barrel communicates the curing agent quantitative output loop and the mixing device in sequence. The mixing device communicates multiple colloid injecting seats used for injecting colloid for the performing body. Through the scheme, the vacuum pouring device for wind power blade molding reaches the goal of being good in controllability and not easy to mix with bubbles, and has a high practical value and a high promotion value.

Owner:甘肃重通成飞新材料有限公司 +1

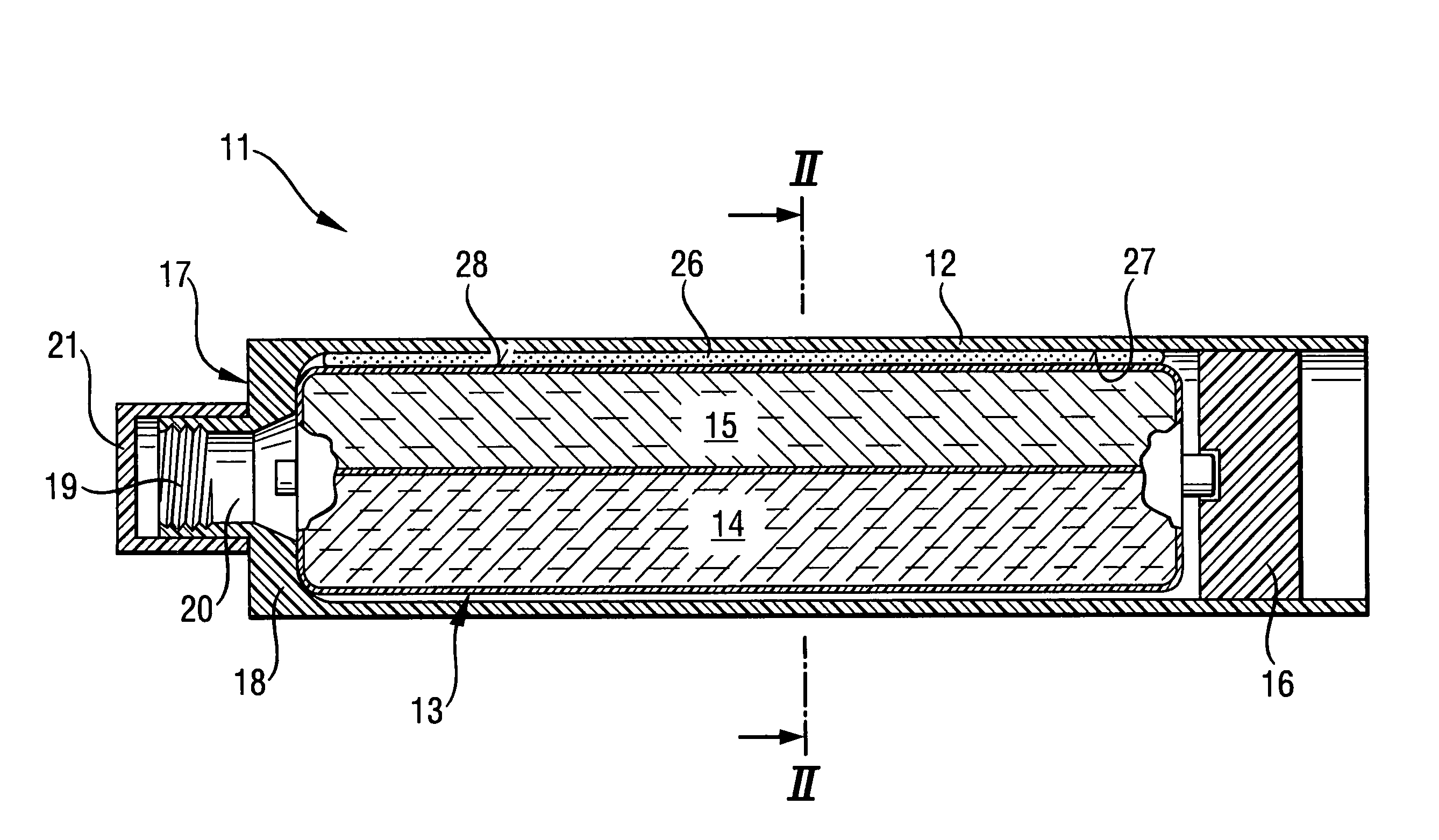

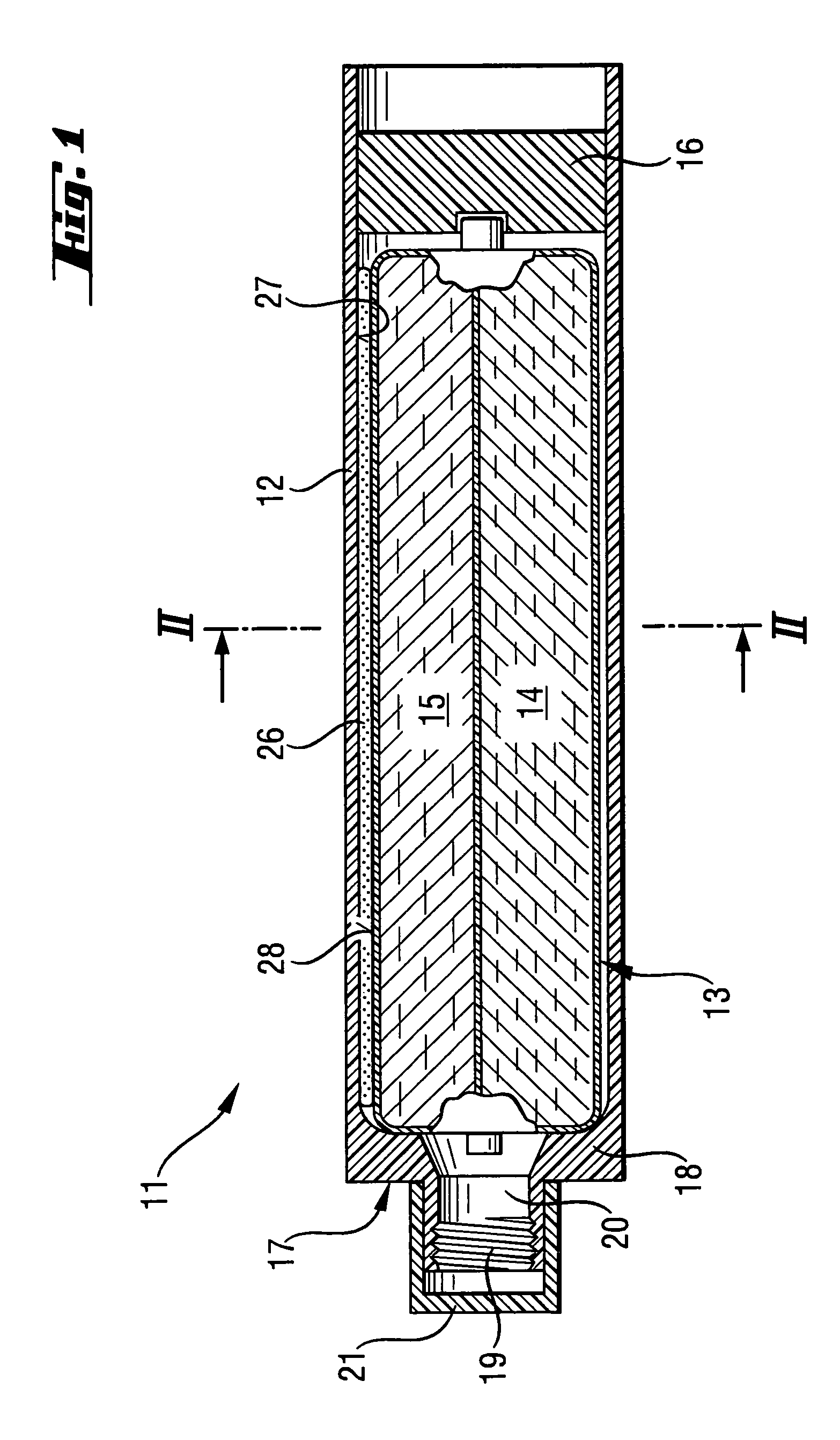

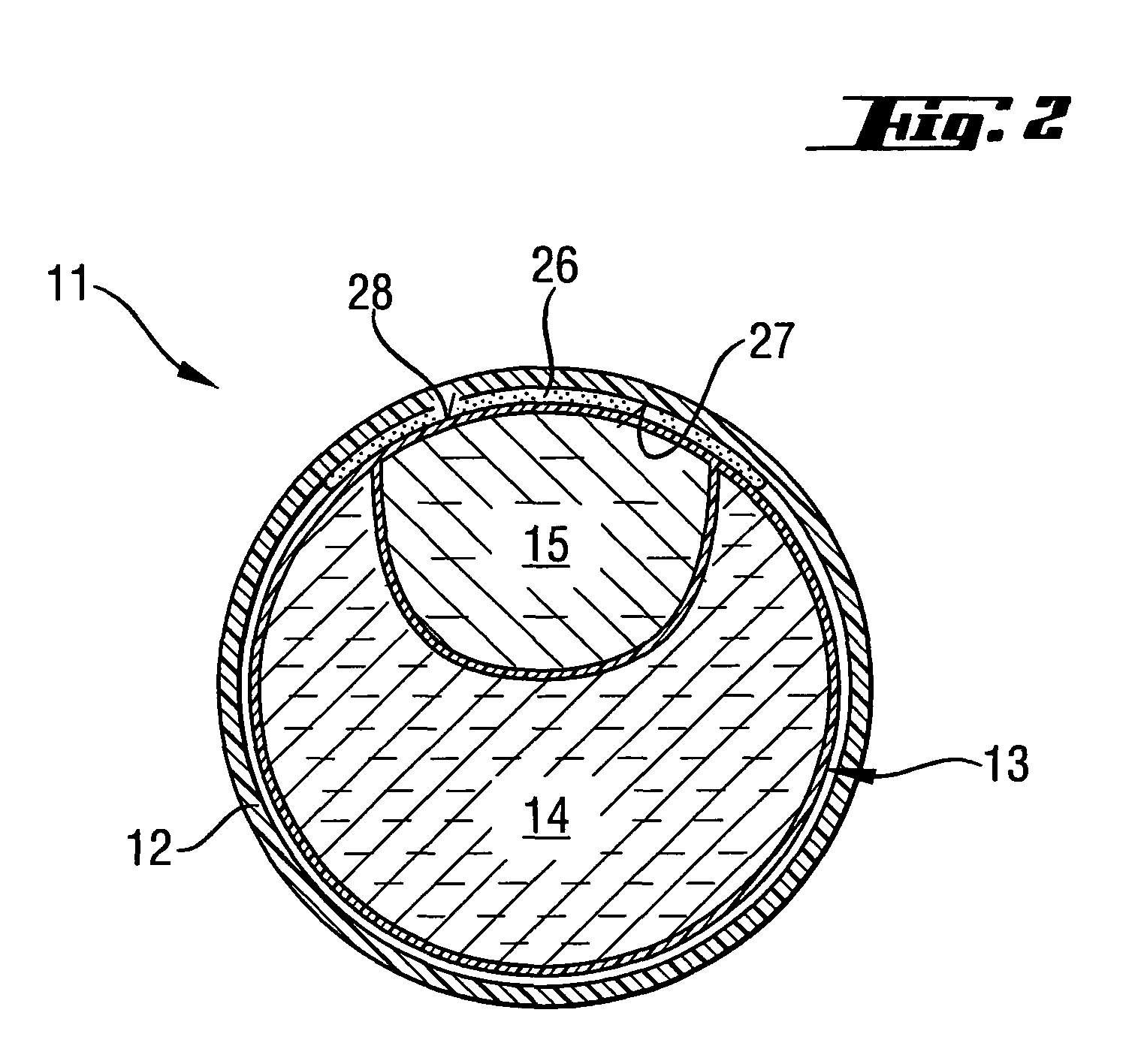

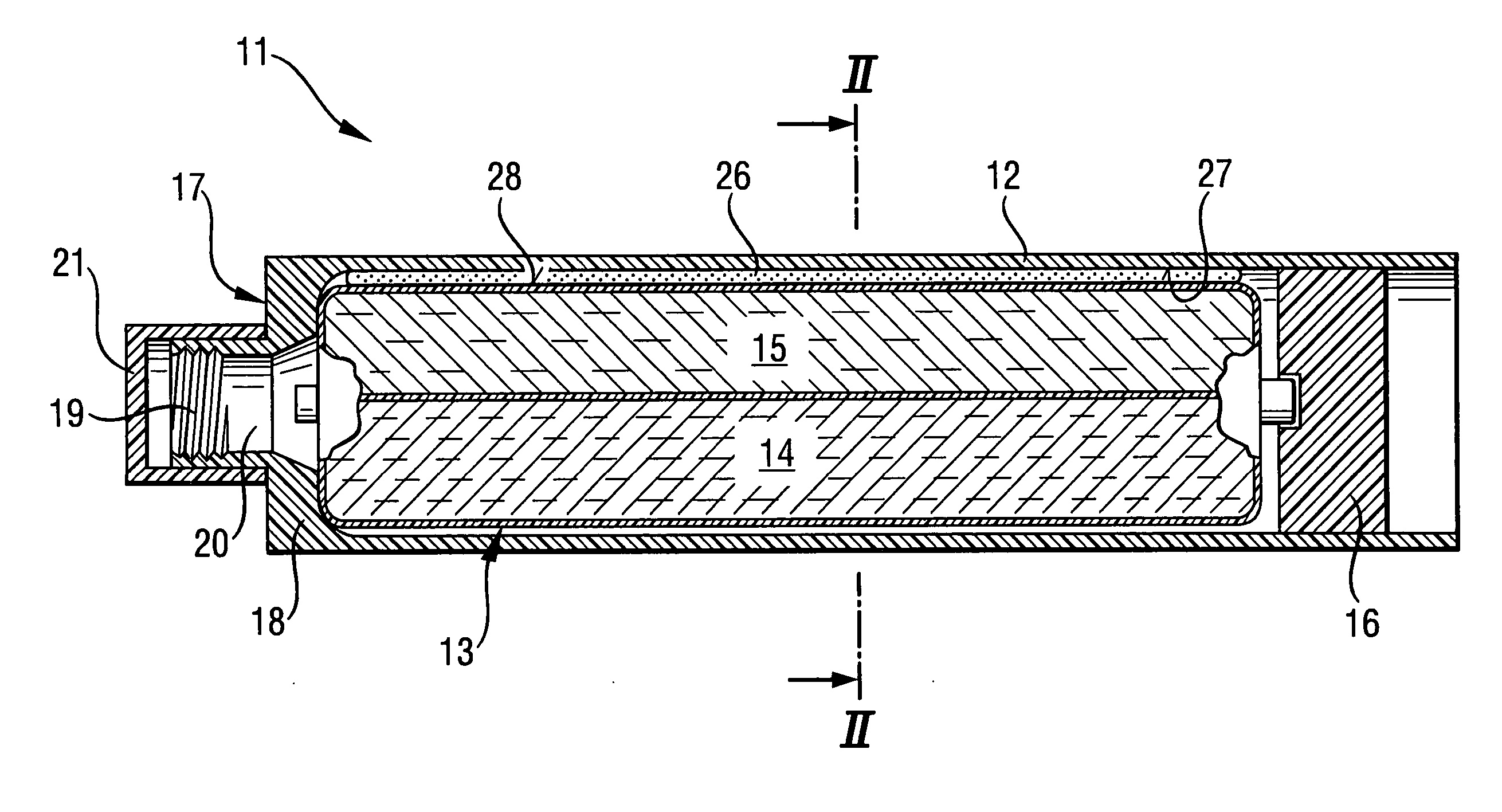

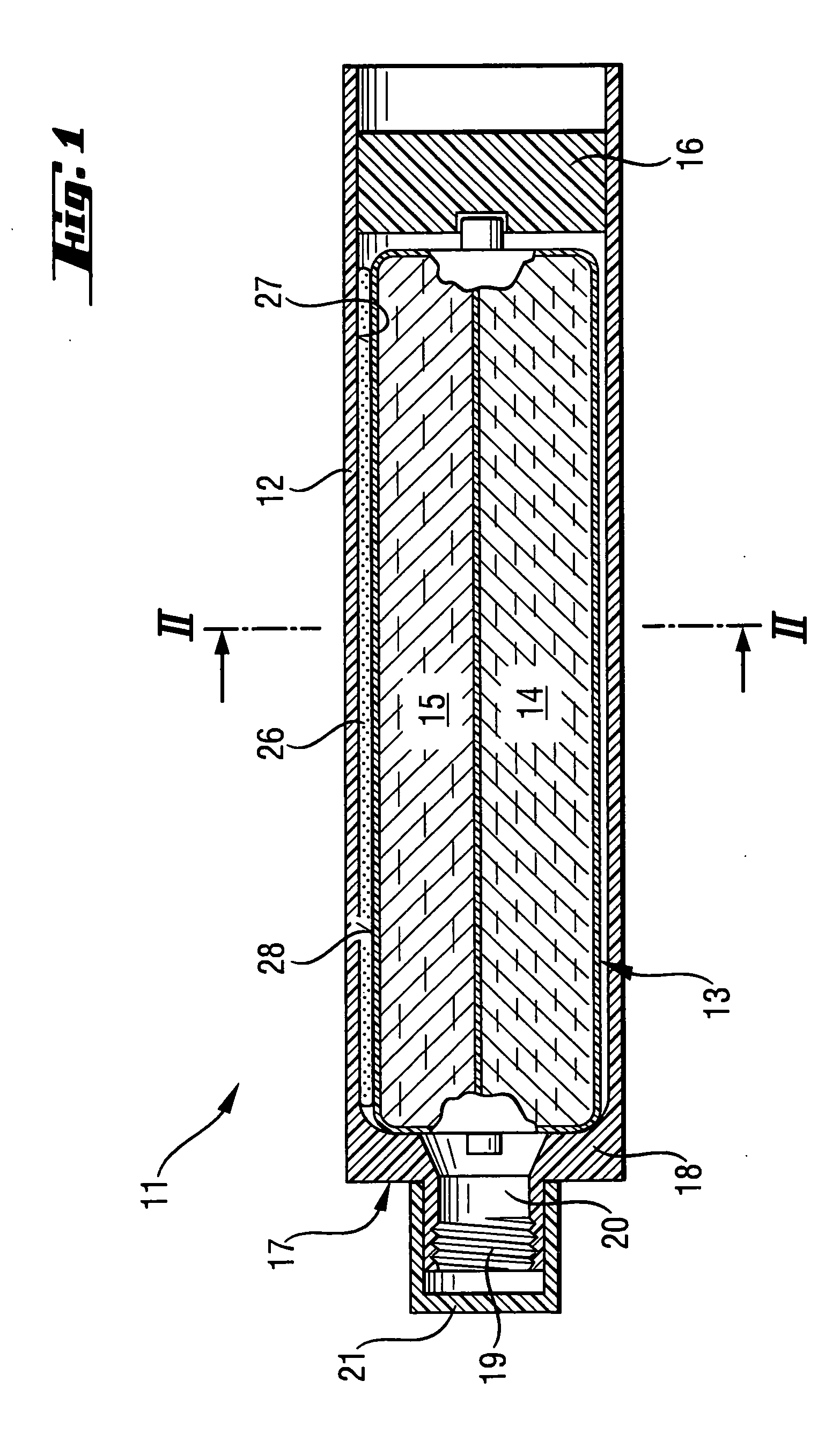

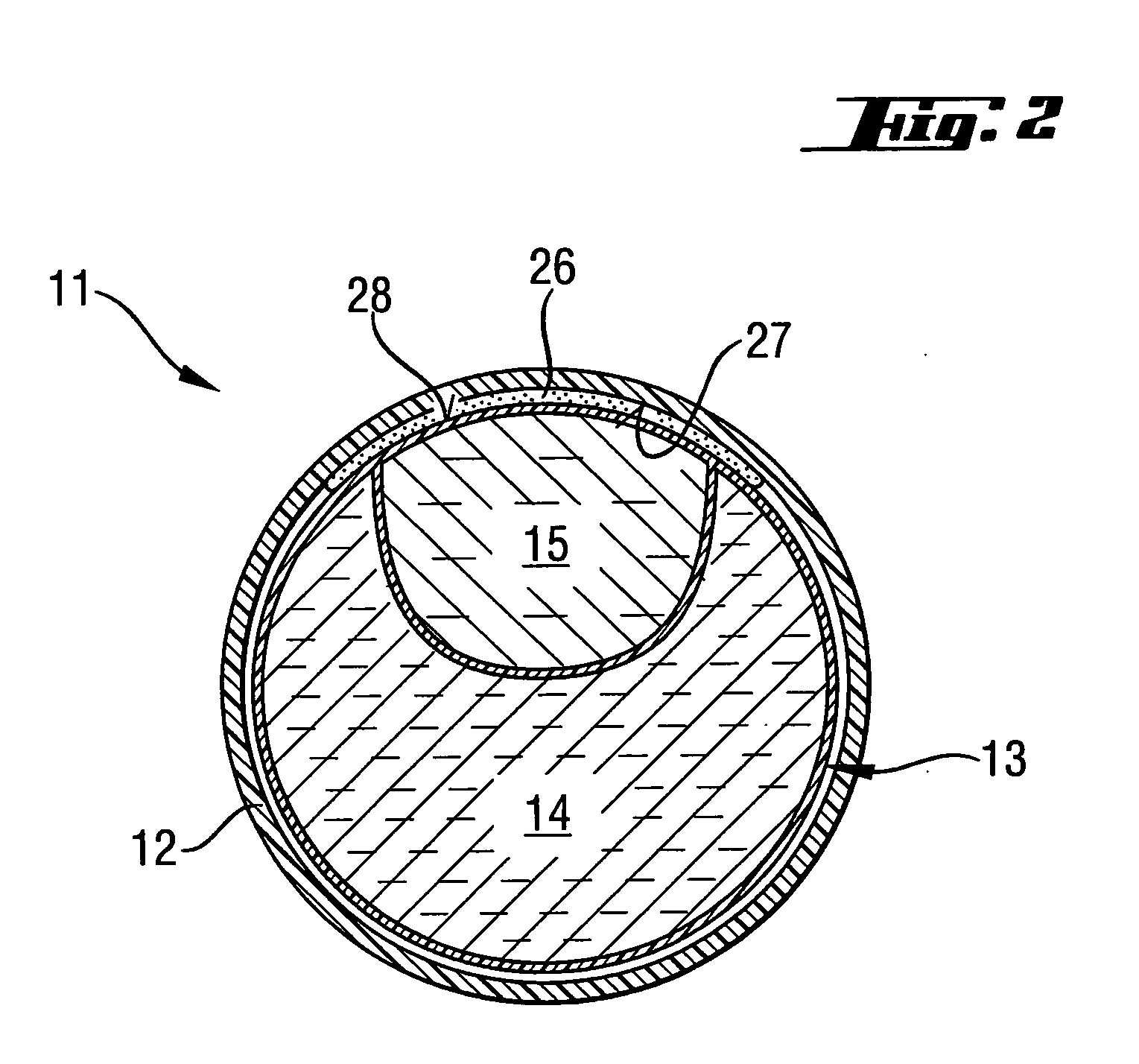

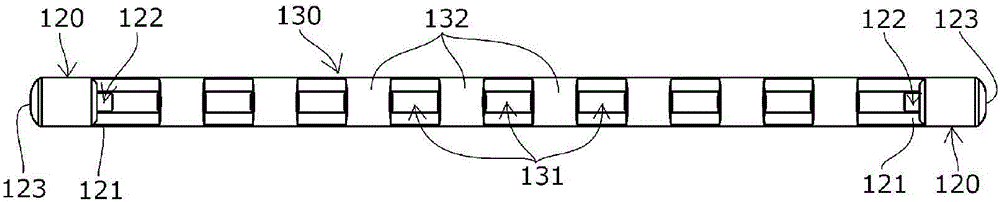

Cartridge for multicomponent masses

InactiveUS7913876B2Reduction in size and foldingIncrease reaction forceLarge containersLiquid transferring devicesEngineeringMechanical engineering

Cartridge for a multicomponent mass, has a housing (12) formed as a hollow profile and in which a multi-chamber pouch (13) having a plurality of chambers (14, 15) separated from each other in a longitudinal direction, is arranged and a large-surface connection region for releasably connecting the multi-chamber pouch (13) and the housing (12) and extending along a longitudinal extend of the multi-chamber pouch (13) and at least along a portion of the circumference of the multi-chamber pouch (13).

Owner:HILTI AG

Instant inoculation method of large-section magnesium iron

The invention relates to an inoculation method for large-section ductile iron, which can accurately change the adding speed of inoculant according to different flow rates of molten iron during pouring. The method can be used for producing the large-section ductile iron with high performance requirement and capable of resisting low-temperature shock. The inoculation method for the large-section ductile iron is characterized in that the molten iron is poured into a straight pouring channel from a runner box, an automatic feeding device adds the inoculant into the straight pouring channel through a pipeline at the same time of pouring, the inoculant and the molten iron are in a half filling state in the straight pouring channel, mixed and then poured into a die cavity, and the automatic feeding device automatically adjusts the adding speed of the inoculant according to the flow change of the molten iron.

Owner:辽宁隆达集团百星达铸造有限责任公司

Cartridge for multicomponent masses

InactiveUS20060255062A1Reduction in size and foldingIncrease reaction forceLarge containersLiquid transferring devicesEngineeringMechanical engineering

Cartridge for a multicomponent mass, has a housing (12) formed as a hollow profile and in which a multi-chamber pouch (13) having a plurality of chambers (14, 15) separated from each other in a longitudinal direction, is arranged and a large-surface connection region for releasably connecting the multi-chamber pouch (13) and the housing (12) and extending along a longitudinal extend of the multi-chamber pouch (13) and at least along a portion of the circumference of the multi-chamber pouch (13).

Owner:HILTI AG

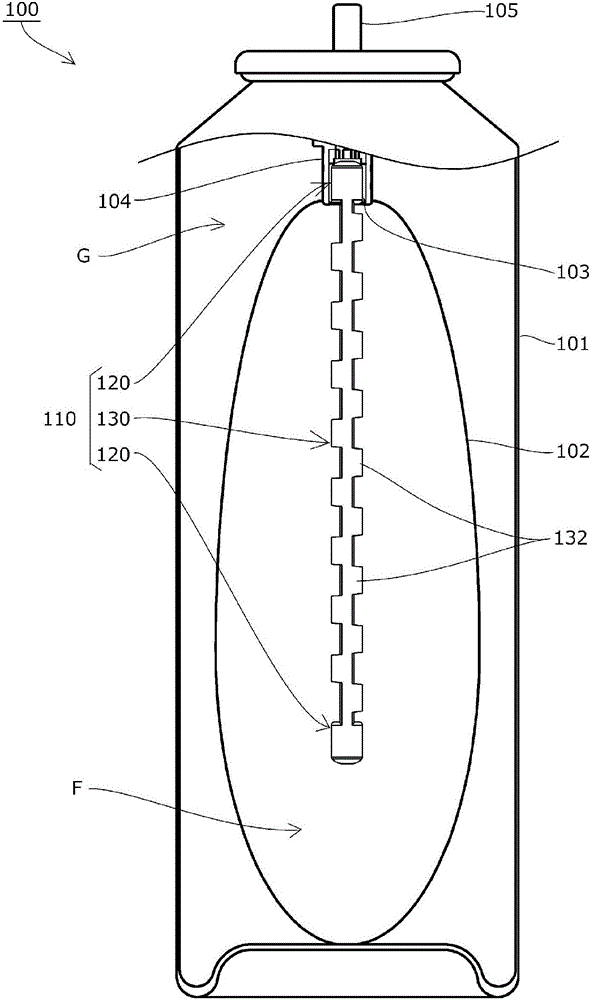

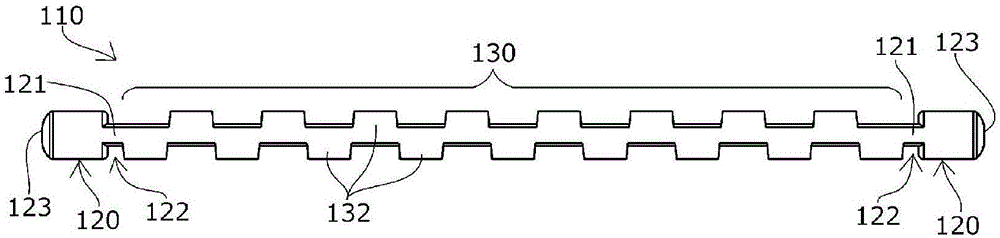

Residual quantity-reducing member

ActiveCN106660692AReduce the final remaining amountPrevent closed spacesLiquid dispensingRigid containersEngineeringMechanical engineering

The present invention provides a residual quantity-reducing member, which: reduces the final residual amount of contents to be discharged by preventing the occurrence of spaces, the perimeter of which is blocked by a pressurized fluid; stabilizes the amount of contents discharged per unit time; and makes it possible to discharge the contents smoothly to the end. Inside a flexible inner bag (102) that is disposed in an aerosol container (100), a residual quantity-reducing member (110) for reducing the final residual amount of contents (F) to be discharged is installed. The residual quantity-reducing member (110) is provided with a mounting part (120) that is mounted on an inflow port (103) of the inner bag (102) so as to allow inflow of the contents F, and a guide part (130) obtained by connecting multiple grooved blocks (132), which have a longitudinal guiding groove (131), in a row in the longitudinal direction.

Owner:TOYO AEROSOL IND CO LTD

Plastic cleaning device

InactiveCN105944855AEasy to cleanGood ability to carry dirtMovable spraying apparatusSpray nozzlesImpellerCarrying capacity

The invention discloses a plastic cleaning device, and relates to the field of plastic manufacturing. The plastic cleaning device comprises a conical guide cover; a small end of the guide cover is a connecting part matched with a high-pressure water pipe, and a large end of the guide cover is a liquid outlet end; a washing liquid accommodating cavity is formed out of the small end of the guide cover; multiple washing liquid inlets are formed in the side wall of the small end of the guide cover; multiple air inlets are formed in the side wall of the middle part of the guide cover; and an impeller rotationally connected with the guide cover is arranged in the large end of the guide cover. Washing liquid is uniformly distributed in mixed liquid formed in the plastic cleaning device; meanwhile, the mixed liquid contains multiple bubbles; and as the bubbles are larger in surface area, the dirt carrying capacity is better, and the plastic cleaning effect is enhanced.

Owner:重庆敏驰塑胶有限公司

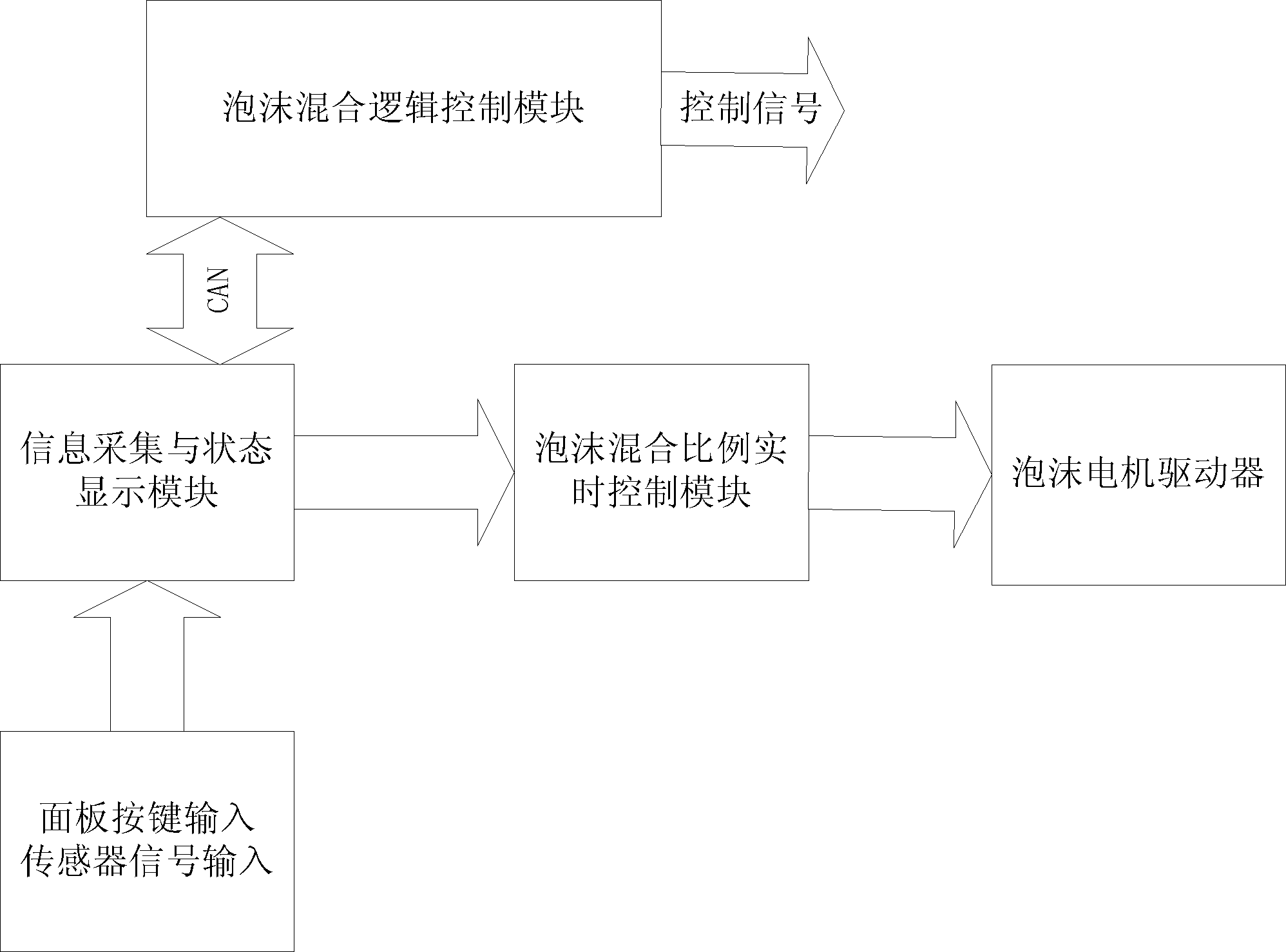

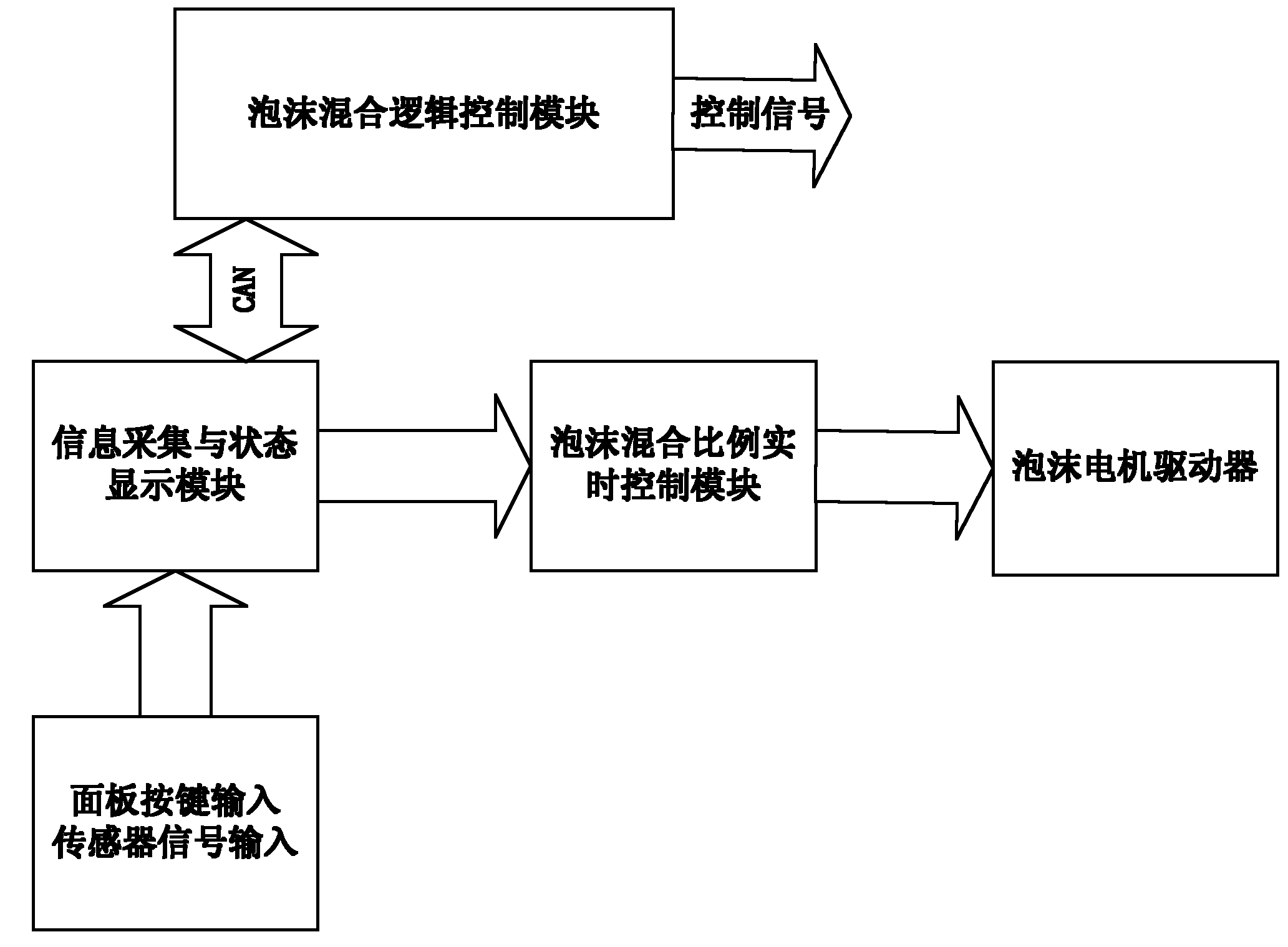

Compression air foam mixed control system of fire truck

ActiveCN102495644AStable mixing ratioAcquisition stableControlling ratio of multiple fluid flowsEngineeringCompressed air

The invention discloses a compression air foam mixing control system of a fire truck, which comprises an information collection and state display module, a foam mixing logical control module and a foam mixing proportion real-time control module. The foam mixing proportion real-time control module controls rotating speed of a foam mixing motor according to user panel key input signals transmitted by the information collection and state display module and current water flow and foam flow which are obtained by real-time collection through an internal digital PID controller to achieve the function of maintaining foam mixing proportion stability no matter how the water flow changes. The compression air foam mixing control system of the fire truck enables operation, information display, data collection, data analysis, data processing and data control of a whole machine to be more stable, simple, convenient and audio-visual through a highly integrated visual information system.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

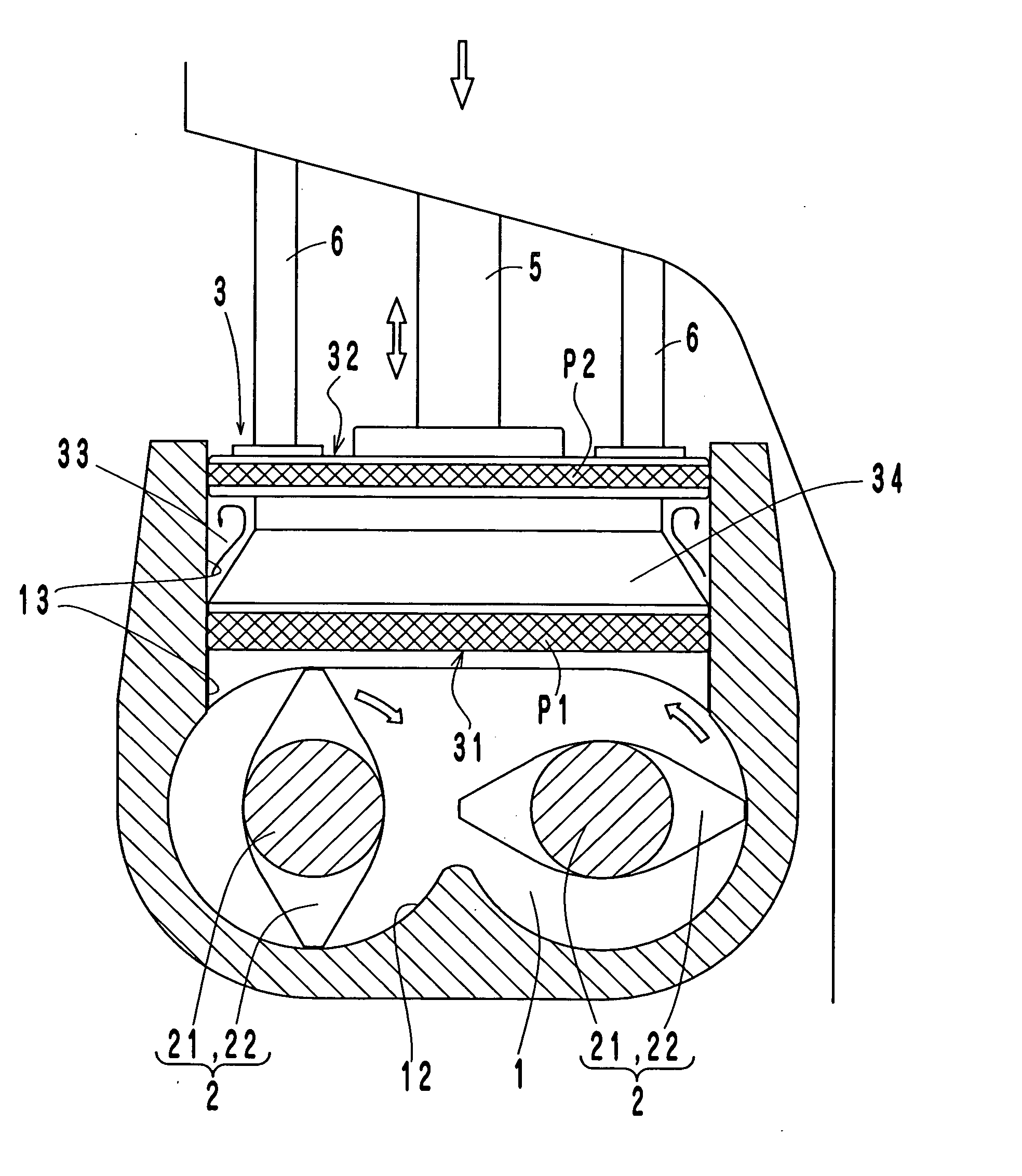

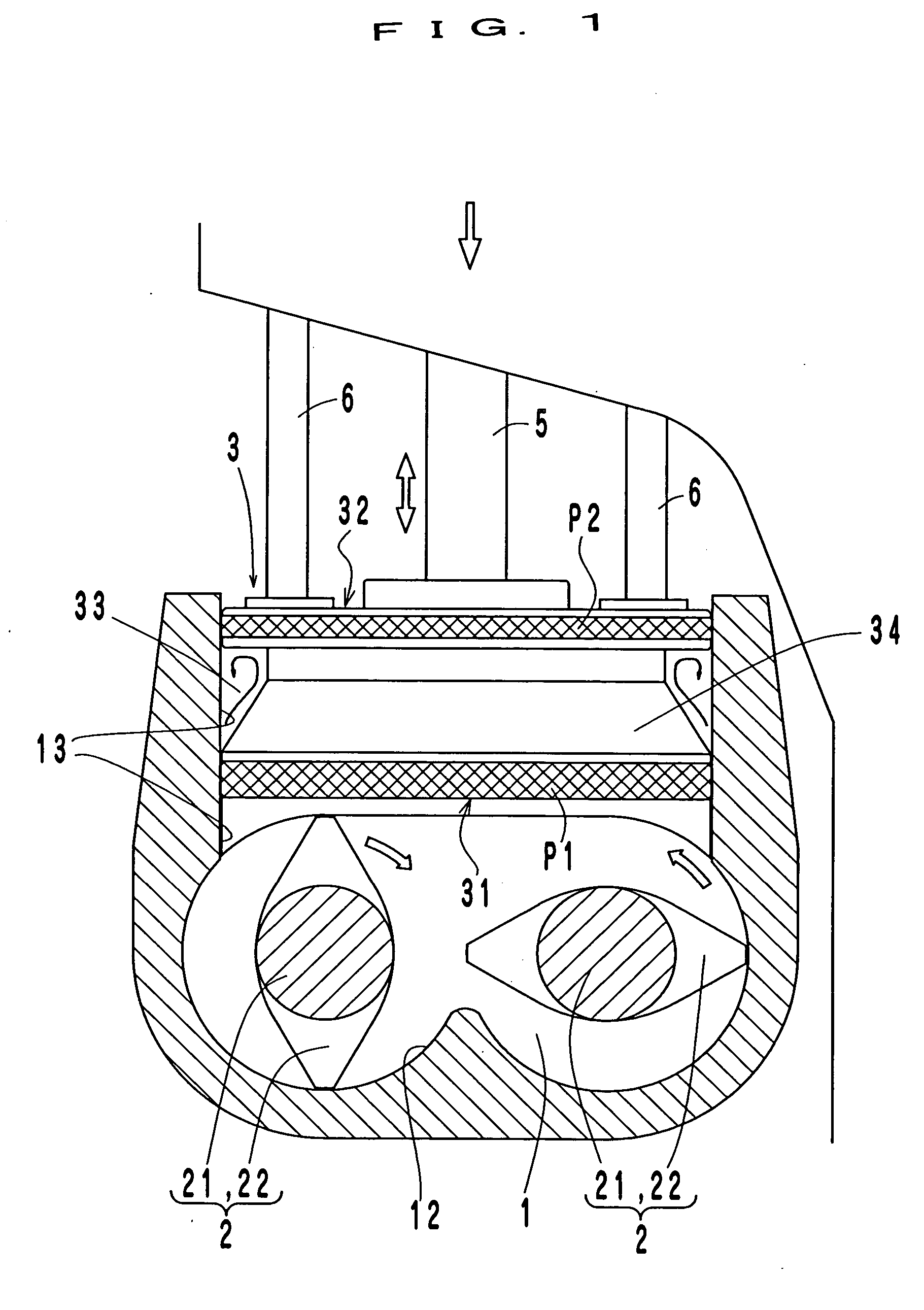

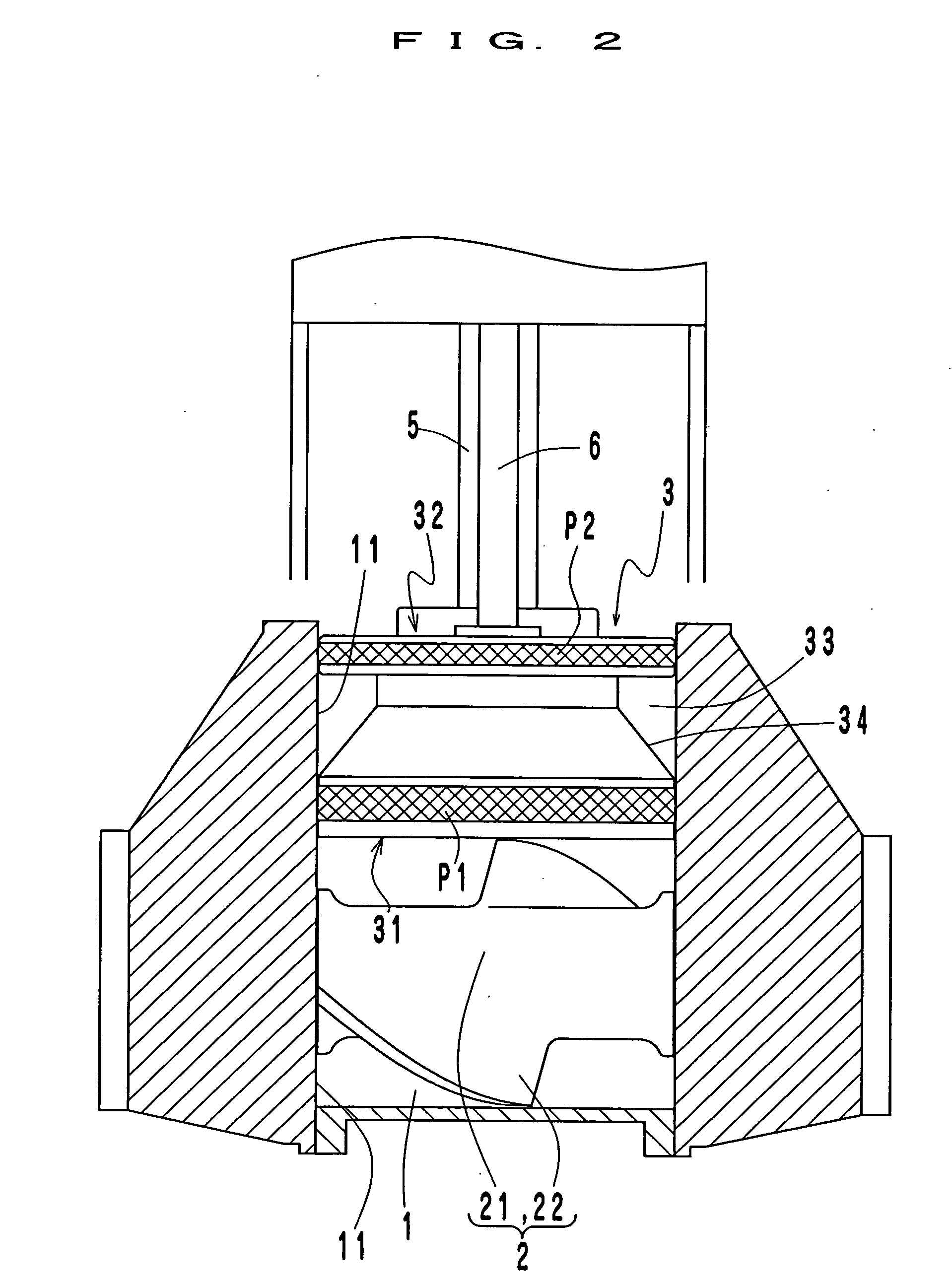

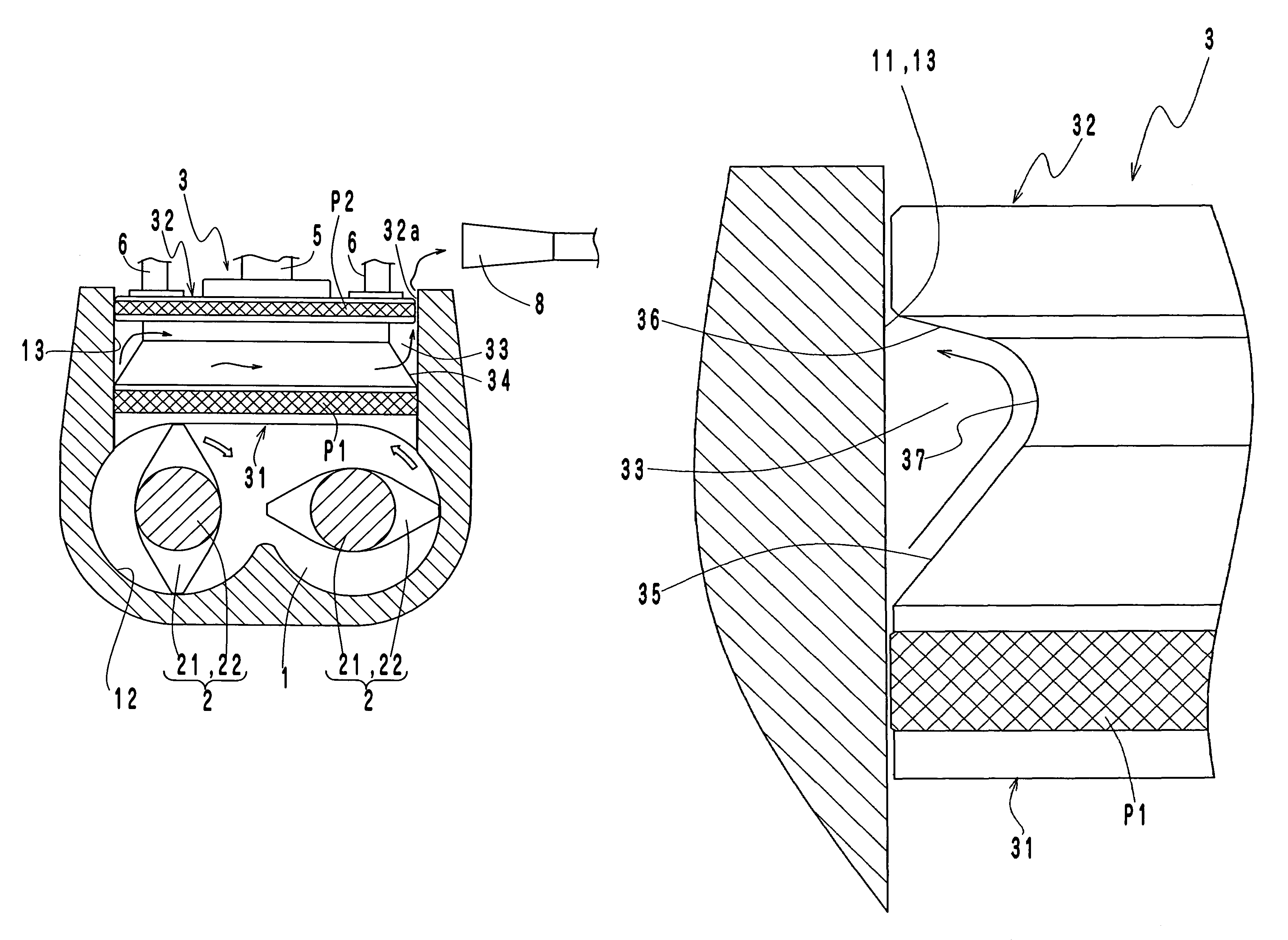

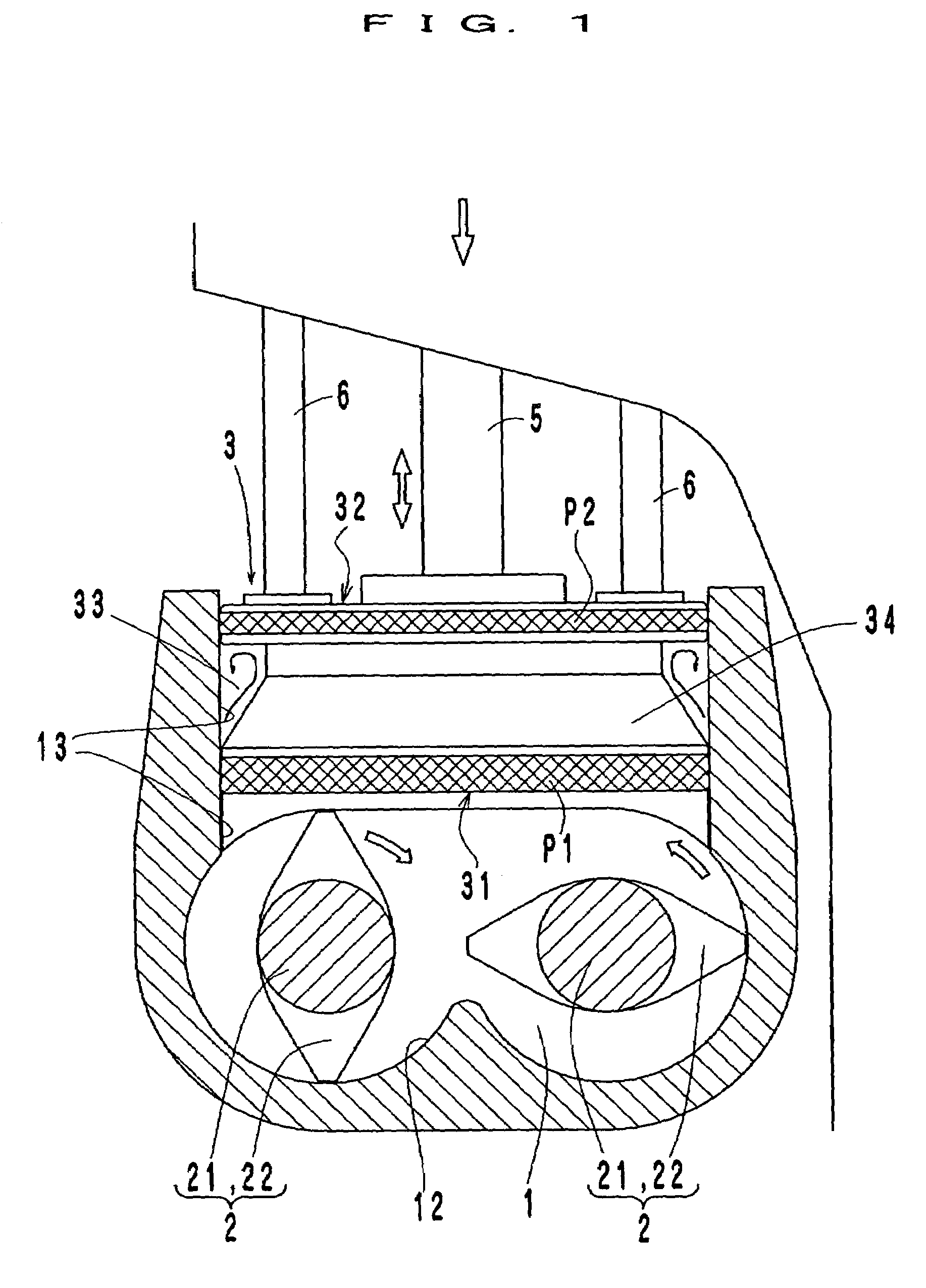

Kneader

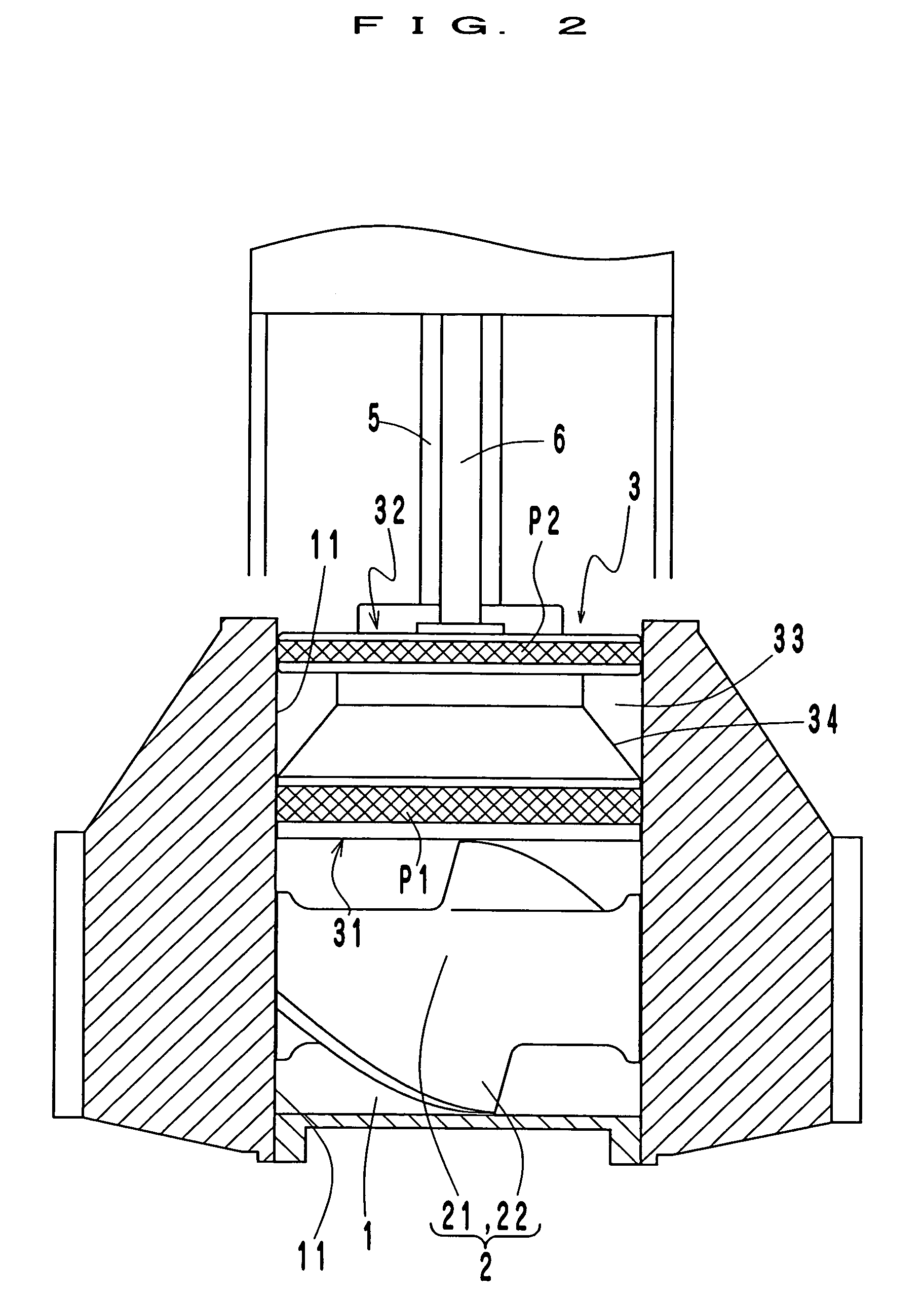

The present invention aims at providing a kneader capable of eliminating the cleaning process in the kneading process by preventing gushing of the filler through the clearance between the mixing tank and the pressurizing lid, stabilizing the blending ratio of the filler, and preventing defective dispersion due to fall and mixing of filler after the completion of kneading, for promoting improvement of dispersion and uniformity of kneaded materials such as rubber, plastics, etc. as well as stability of quality. In a kneader comprising a mixing tank 1 for storing the kneaded material, a pair of rotors 2, 2 disposed in parallel for kneading the kneaded material stored in the mixing tank 1, and a pressurizing lid 3 inserted slidably in the opening at the top of the mixing tank 1, the sliding portion of the pressurizing lid 3 against the mixing tank 1 is divided into a plurality of stages (upper, lower), packings P1, P2 are disposed for reducing the clearance between the respective pressurizing lids and the side wall of the mixing tank as much as possible, and an air reservoir 33 is formed between said upper and lower lids 31, 32.

Owner:MORIYAMA

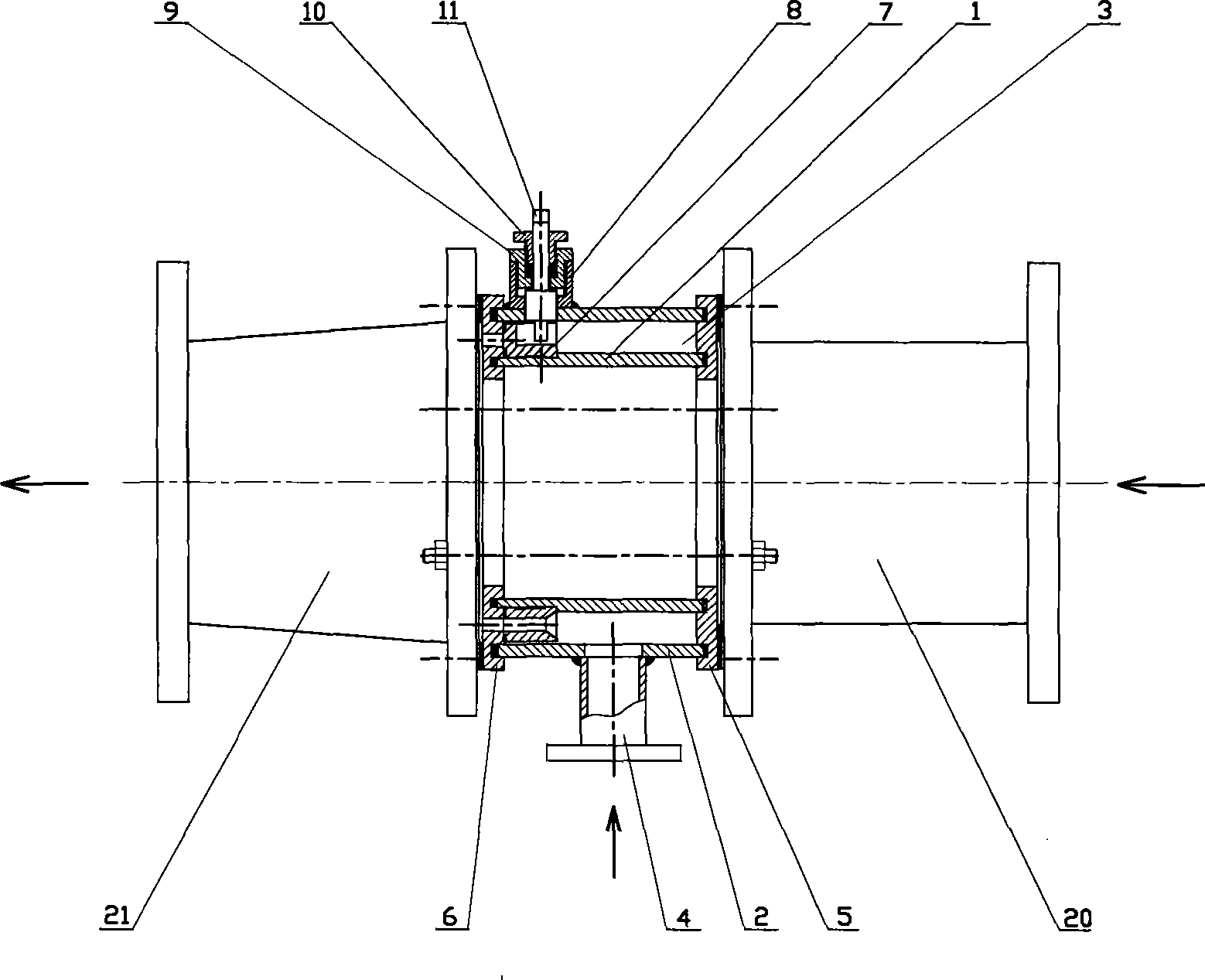

Regulation type proportional mixer

InactiveCN101251200AEasy to operateReduce labor intensityFire rescueMultiple way valvesFire controlEngineering

The invention discloses an adjusting proportioner with convenient operation, small labor intensity and excellent using effect. The adjusting proportioner comprises a runner pipe, wherein the outside of the runner pipe is provided with an outer thimble; a cavum is arranged between the runner pipe and the outer thimble; a foam concentrate pipe is arranged on the outer thimble; the foam concentrate pipe is communicated with the cavum; one end of the runner pipe and the outer thimble is provided with a closure plate closing a ring cavity formed by the end parts of the runner pipe and the outer thimble; the other end of the runner pipe and the outer thimble is provided with a pore plate provided with a plurality of holes communicated with the ring cavity formed by the runner pipe and the outer thimble; an adjusting ring is movably connected with one side of the pore plate; and the adjusting ring is provided with holes the amount of which is corresponding to the holes in the pore plate. The adjusting proportioner with convenient operation, small labor intensity and excellent using effect is applicable to proportioning for water and foam in a fire control foam extinguishing system.

Owner:KUAIDA FIRE SCI & TECH

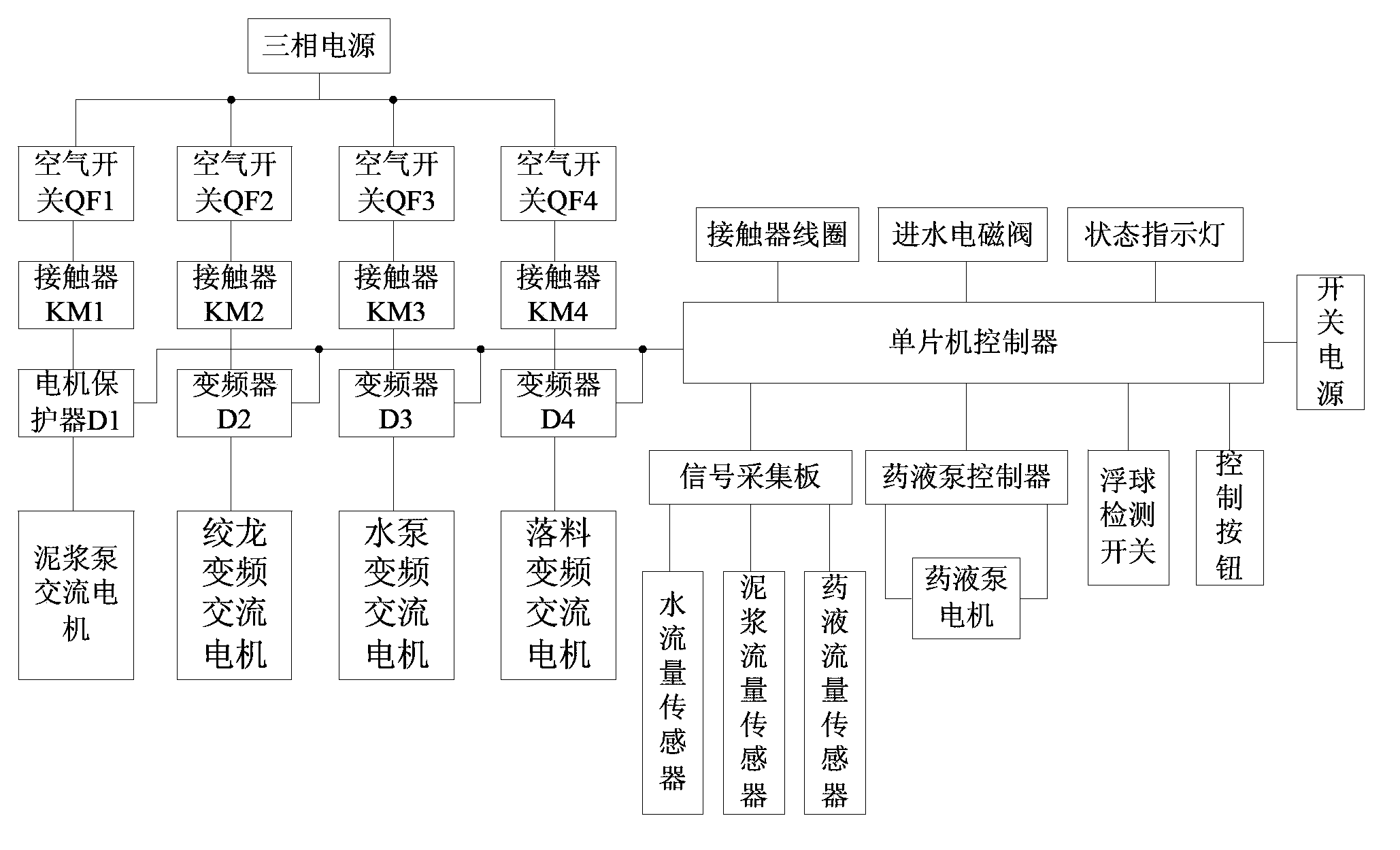

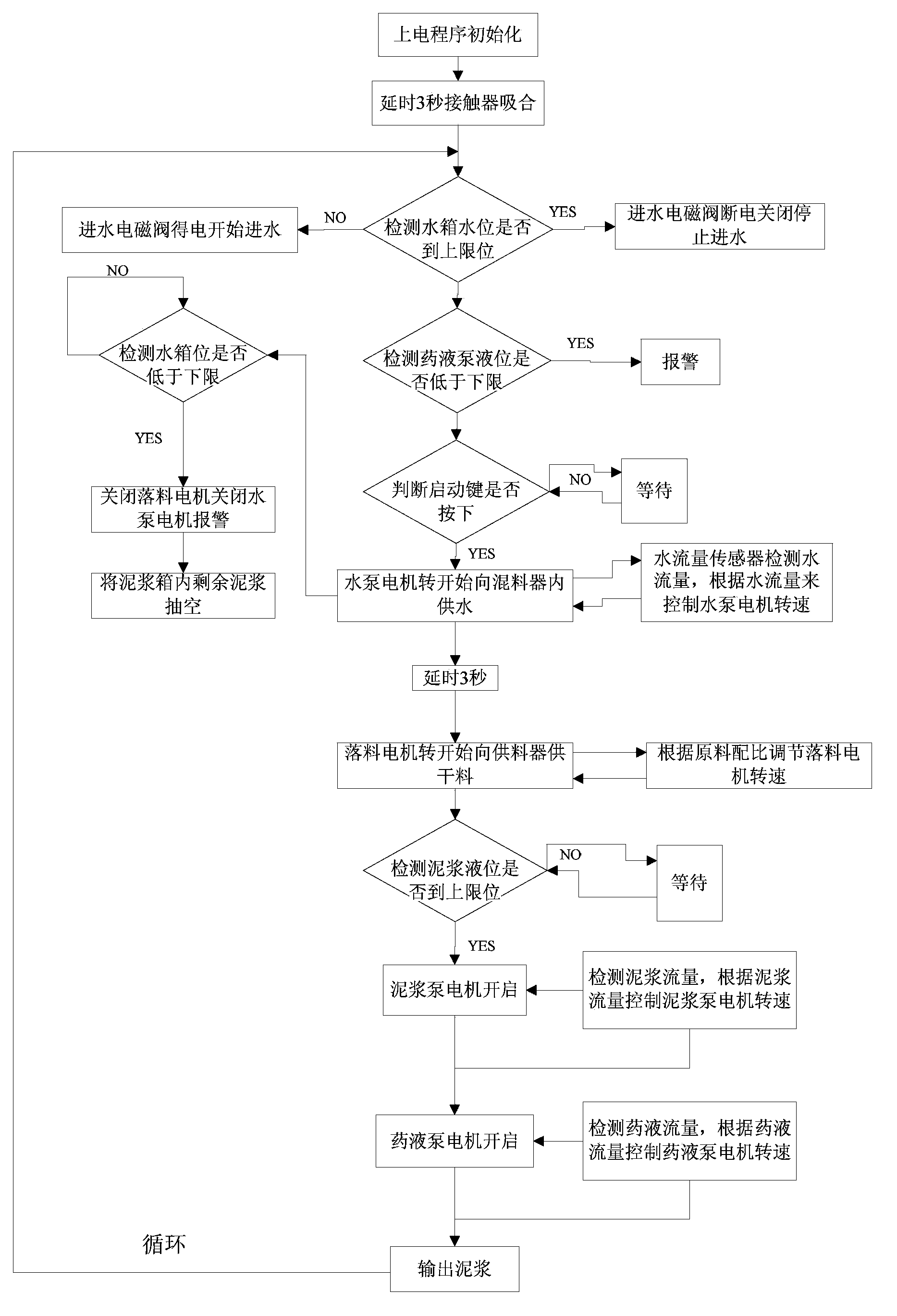

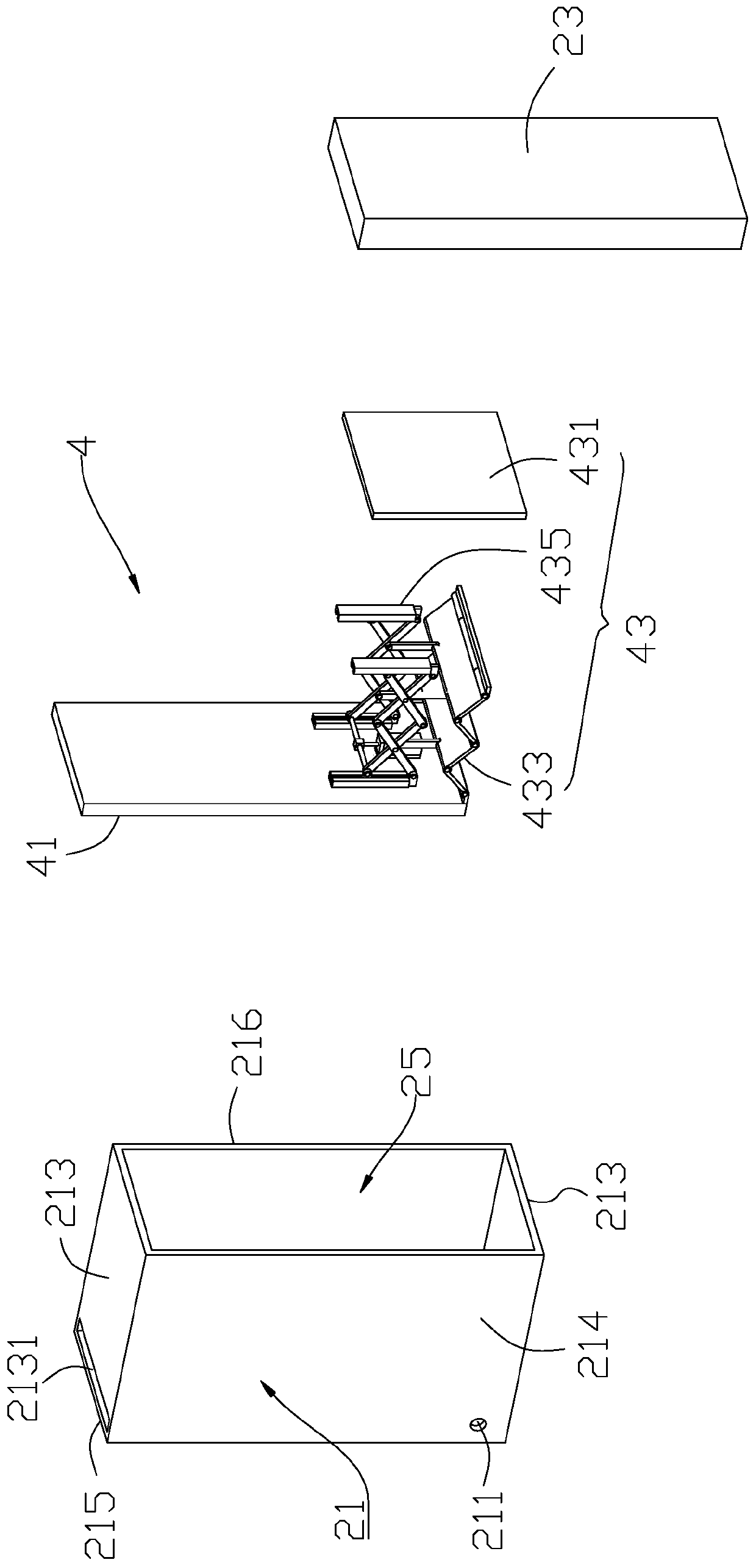

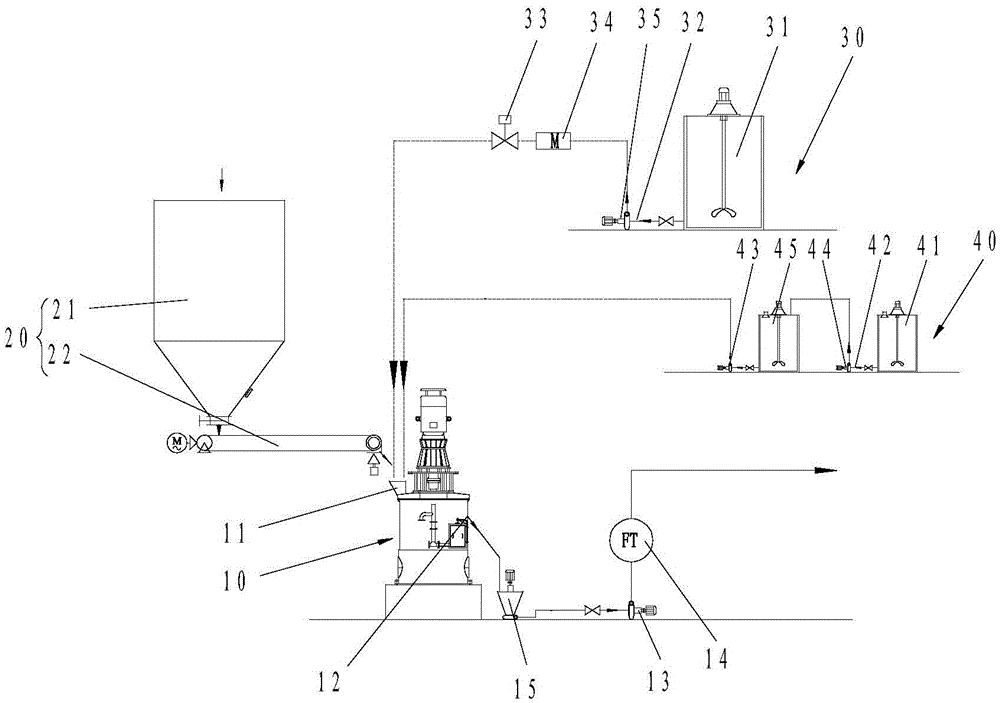

Method and device for dynamic and intelligent control of foamed concrete component proportional mixing

ActiveCN103878882AStable mixing ratioReduce labor intensityMixing operation control apparatusIngredients proportioning apparatusContactorSlurry flow

The invention relates to a method and a device for dynamic and intelligent control of foamed concrete component proportional mixing. A water flow sensor, a slurry flow sensor and an agent flow sensor are connected with a signal acquisition plate, and the signal acquisition plate is connected with a single-chip microcomputer controller; the single-chip microcomputer controller is also connected with a float detection switch for detecting liquid flow, an agent pump controller connected with an agent pump, a control button, a water inlet solenoid valve, and three frequency converters; the water inlet solenoid valve is connected with a water level upper limit float detection switch F5 in the float detection switch; the frequency converter is connected with a variable-frequency AC motor and a contactor, the other end of the contactor is connected with an air switch, and the other end of the air switch is connected with a three-phase power supply terminal; coils of a contactor KM1, a contactor KM2, a contactor KM3 and a contactor KM4 are connected with the single-chip microcomputer controller. According to the invention, the mixing proportions of various components of the slurry are stable, and do not change with the amount of the feed materials; the labor intensity of operators is reduced; the waste of dry materials, water, and agents is reduced; and the work efficiency is improved.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

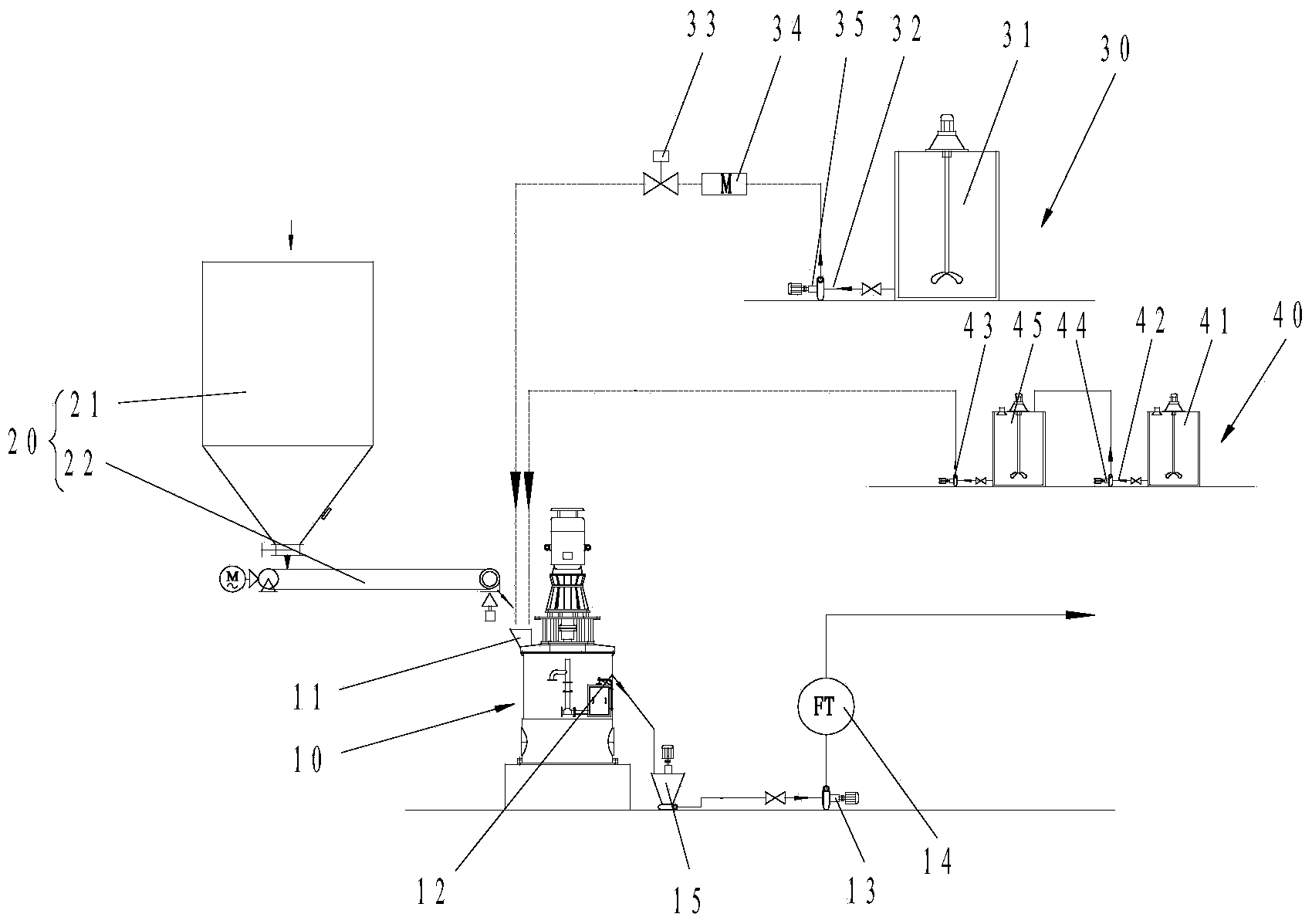

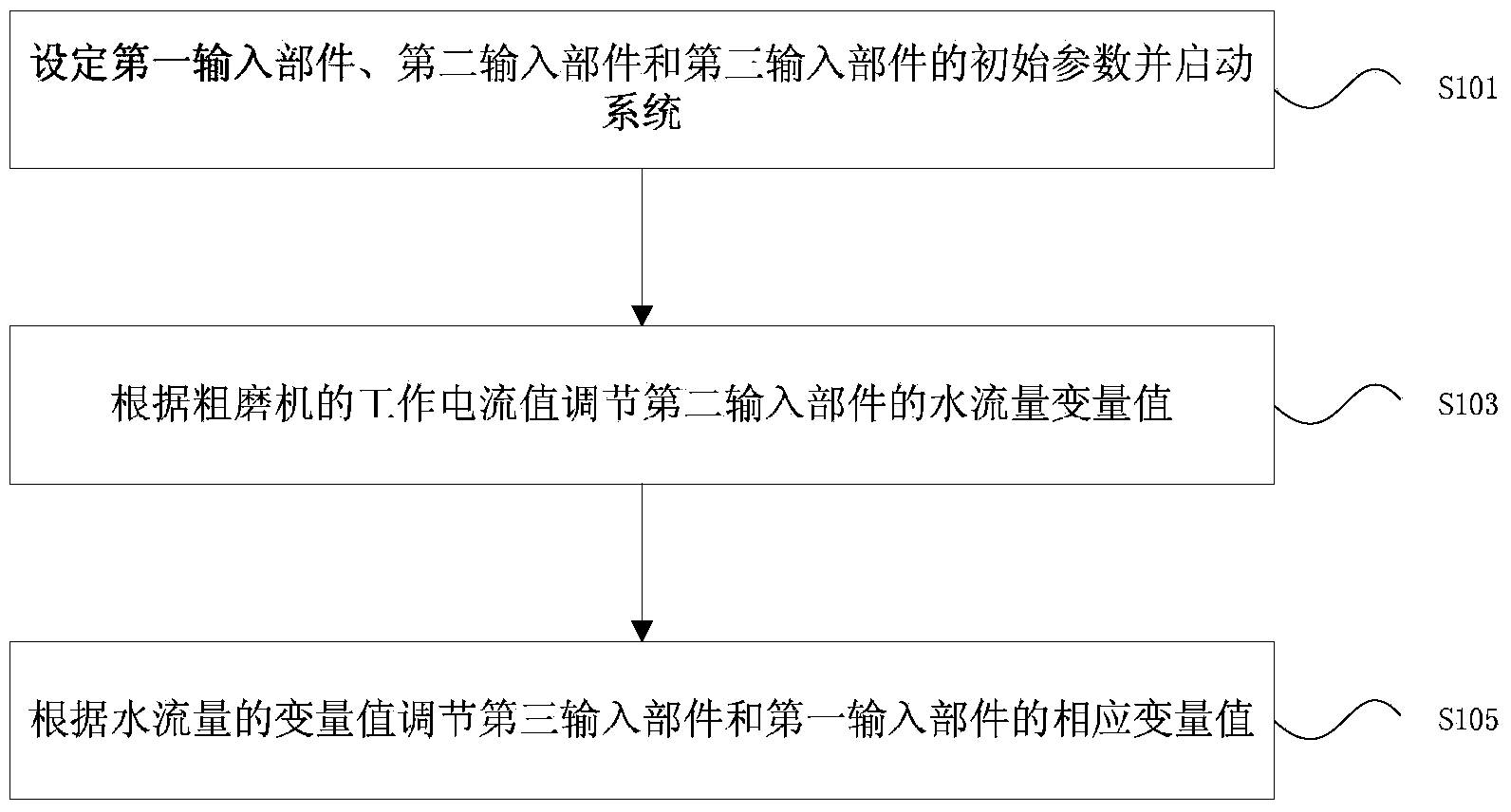

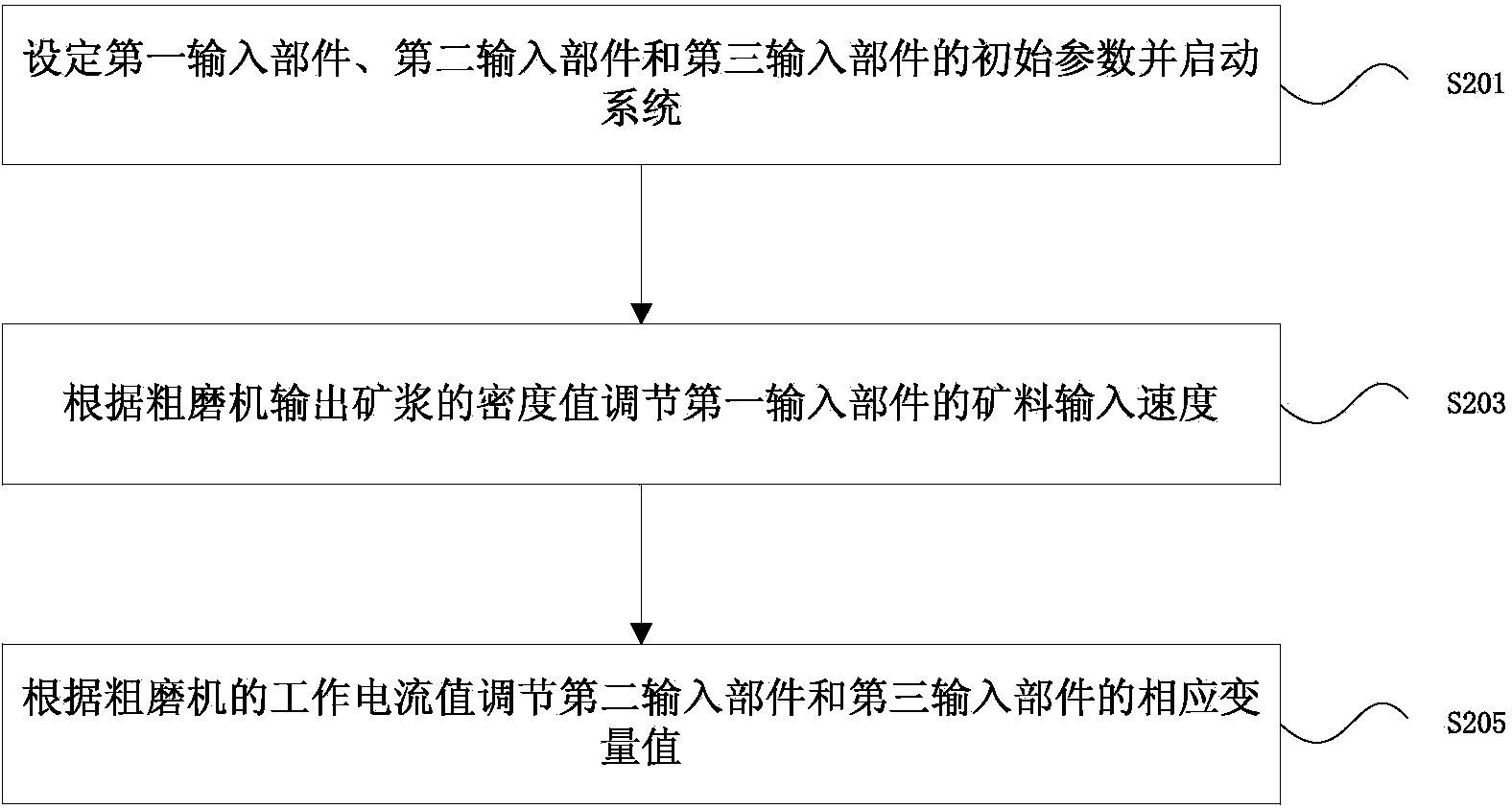

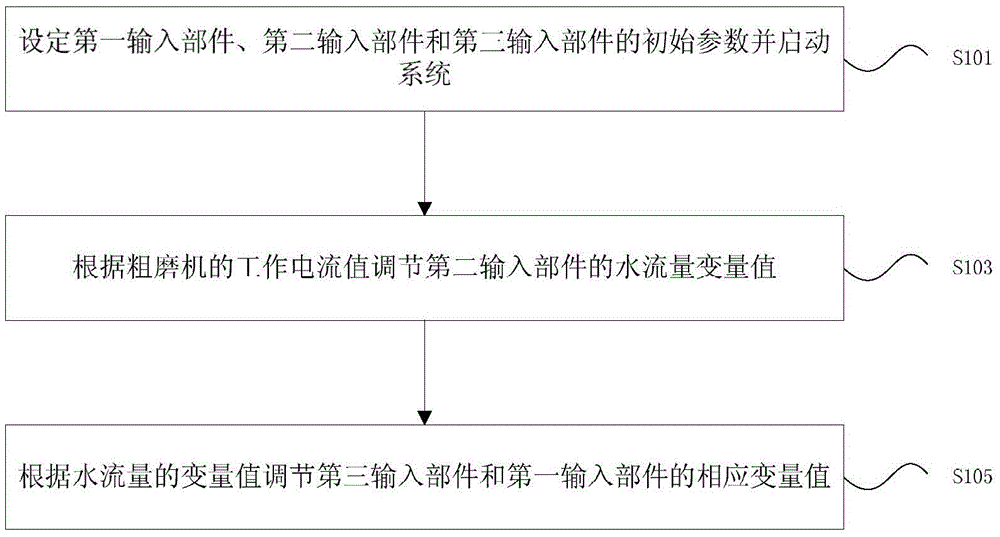

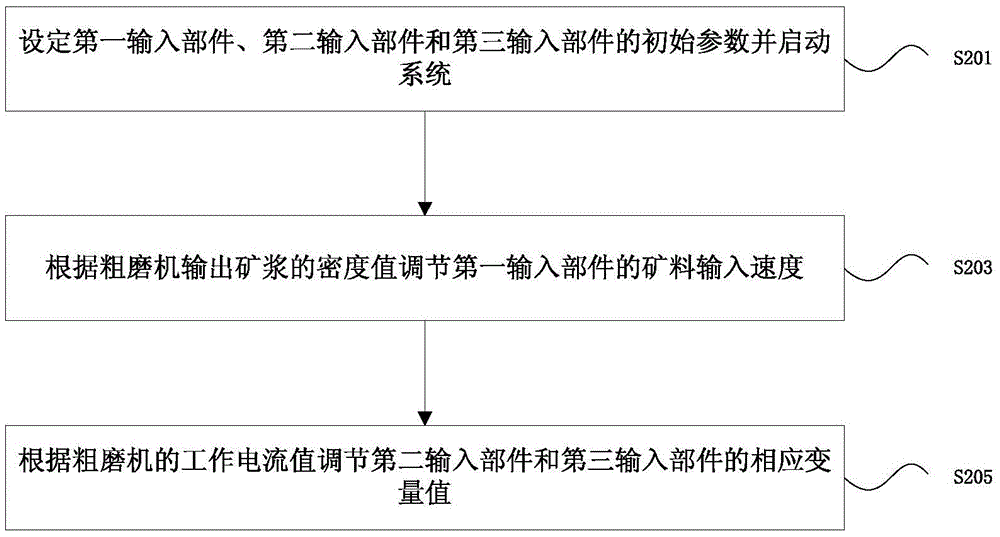

Automatic rough grinding and slurry mixing system and control method of system

ActiveCN104289303AImplement automatic importStable mixing ratioGrain treatmentsAutomatic controlEngineering

The invention discloses an automatic rough grinding and slurry mixing system and a control method of the system. The system comprises a rough grinding machine, wherein a material inlet and a slurry discharging hole are formed in the rough grinding machine; the material inlet is connected with a first input part used for introducing mineral material, a second input part used for introducing water and a third input part used for introducing a dispersing agent respectively; the system also comprises a processor and a detection sensor used for detecting parameter information of the rough grinding machine; the processor is used for controlling operation of the first input part, the second input part and the third input part according to the parameter information. According to the system, the first input part, the second input part and the third input part are respectively arranged on the rough grinding machine, the ore material, the water and the dispersing agent can be automatically introduced; and the processor is used for controlling the first input part, the second input part and the third input part; the feeding amount of each medium is automatically controlled; the stability of mixing ratio of the ore material, the water and the dispersing agent is ensured; the system is convenient to operate and has time-saving and labor-saving effects; and the quality of finished products is improved.

Owner:内蒙古超牌新材料股份有限公司

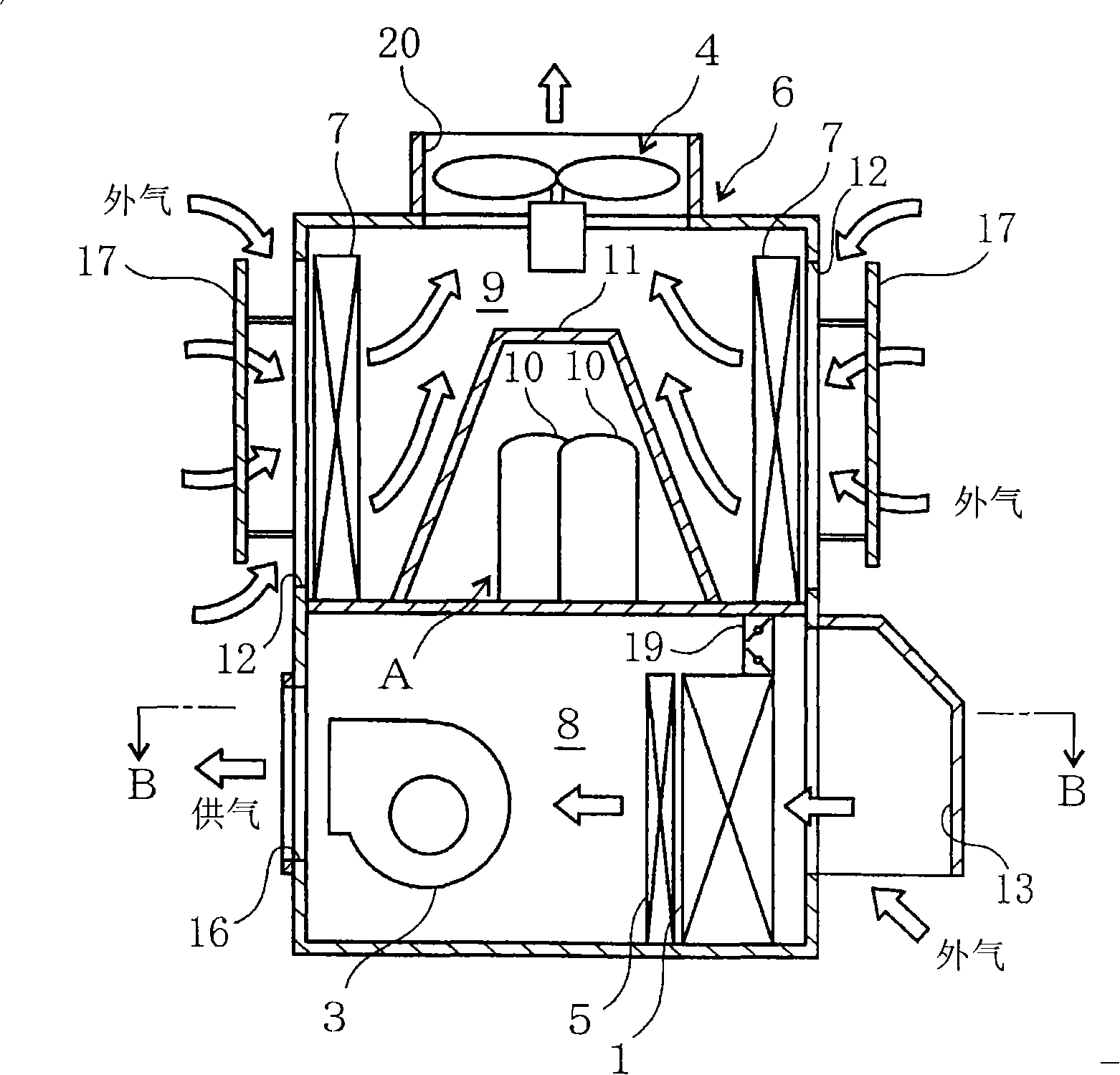

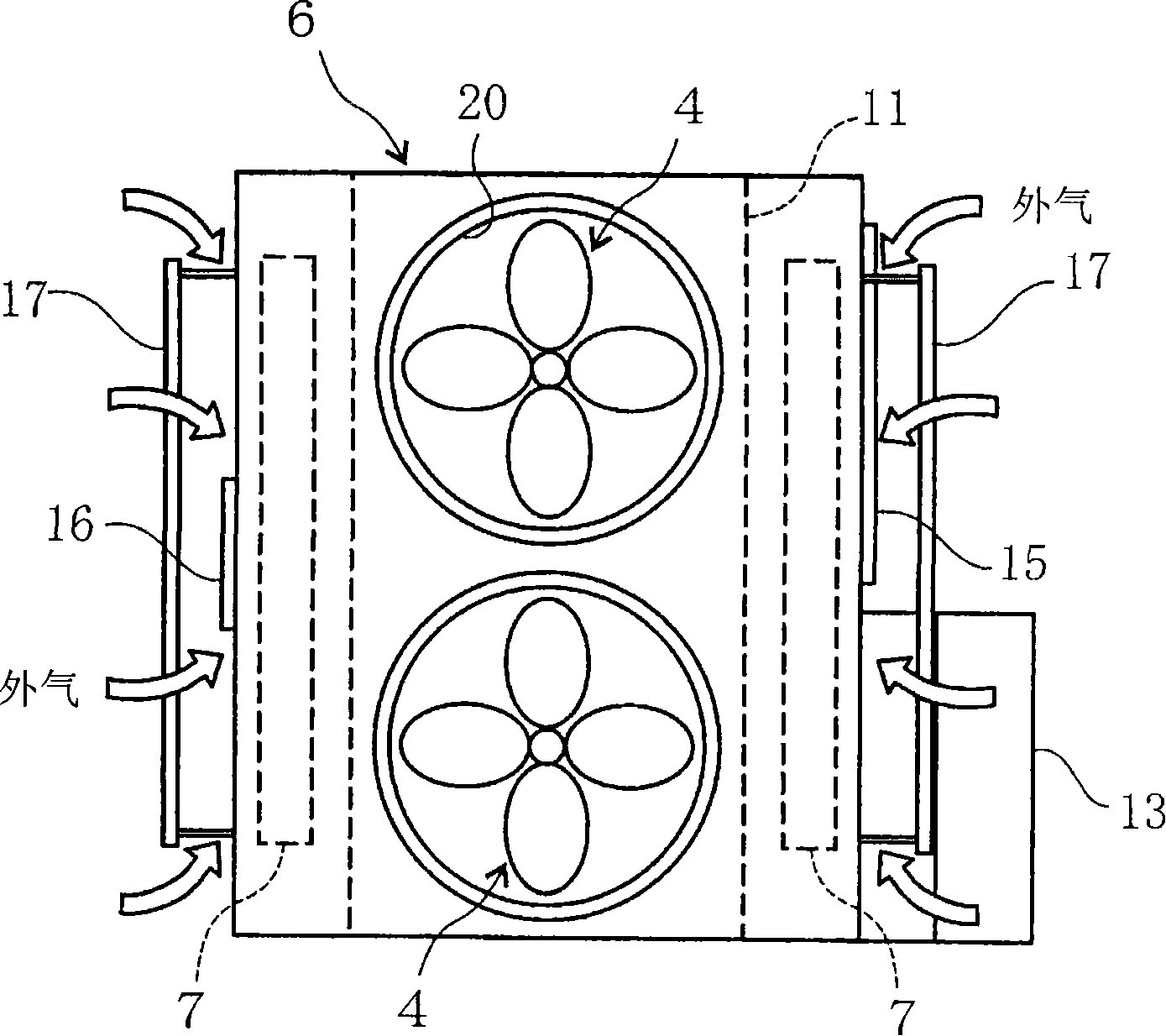

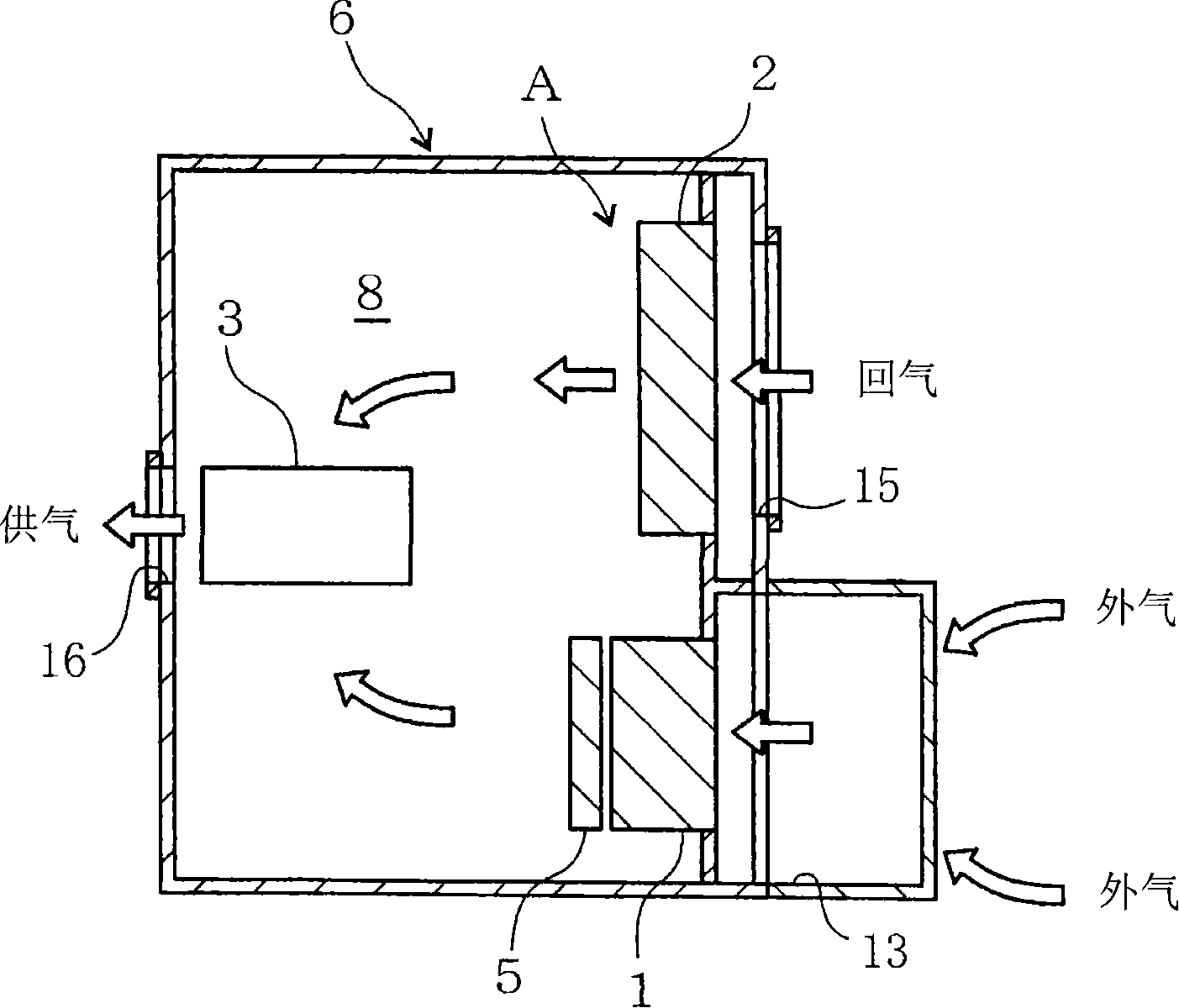

Air conditioner

InactiveCN101178227ASave energyLow running costEnergy recovery in ventilation and heatingCompression machines with reversible cycleWarm waterAir treatment

The invention provides an air conditioner, which respectively treats the outer air load and the indoor load without needing additional energy for cooling and reheating the returned air so as to save energy resource and reduce the operating cost; the air conditioner only utilizing thermal pump without using cold warm water pipe coil to control the temperature and the humidity of the supplied air, thereby realizing the reduction of the equipment cost and the operating cost. The air conditioner of the invention comprises: a first thermal pump A1 which can switch the cooled / heated outer air treatment adopted heat exchanger 1, a second thermal pump A2 which can switch the cooled / heated returned air treatment adopted heat exchanger 2, a humidifier 5 which humidifies to the outer air, and an air supply side ventilator which mixes the returned air of the returned air treatment adopted heat exchanger and the outer air of the outer air treatment adopted heat exchanger and the humidifier and then supplies air; after the mixing the outer air and the returned air, the outer air load and the indoor load can be respectively treated without cooling or heating.

Owner:KIMURA KOHKI CO LTD

Pressurizing lid structure of a kneader

ActiveUS7329036B2Exempt from cleaningStable mixing ratioPlungersTrunk pistonsMixing tankWaste management

In a kneader having a mixing tank 1 for storing the kneaded material, a pair of rotors, 2 disposed in parallel for kneading the kneaded material stored in the mixing tank 1, and a pressurizing lid 3 inserted slidably in the opening at the top of the mixing tank 1, the sliding portion of the pressurizing lid 3 against the mixing tank 1 is divided into a plurality of stages (upper, lower), packings P1, P2 are disposed for reducing the clearance between the respective pressurizing lids and the side wall of the mixing tank as much as possible, and an air reservoir 33 is formed between the upper and lower lids 31, 32.

Owner:MORIYAMA

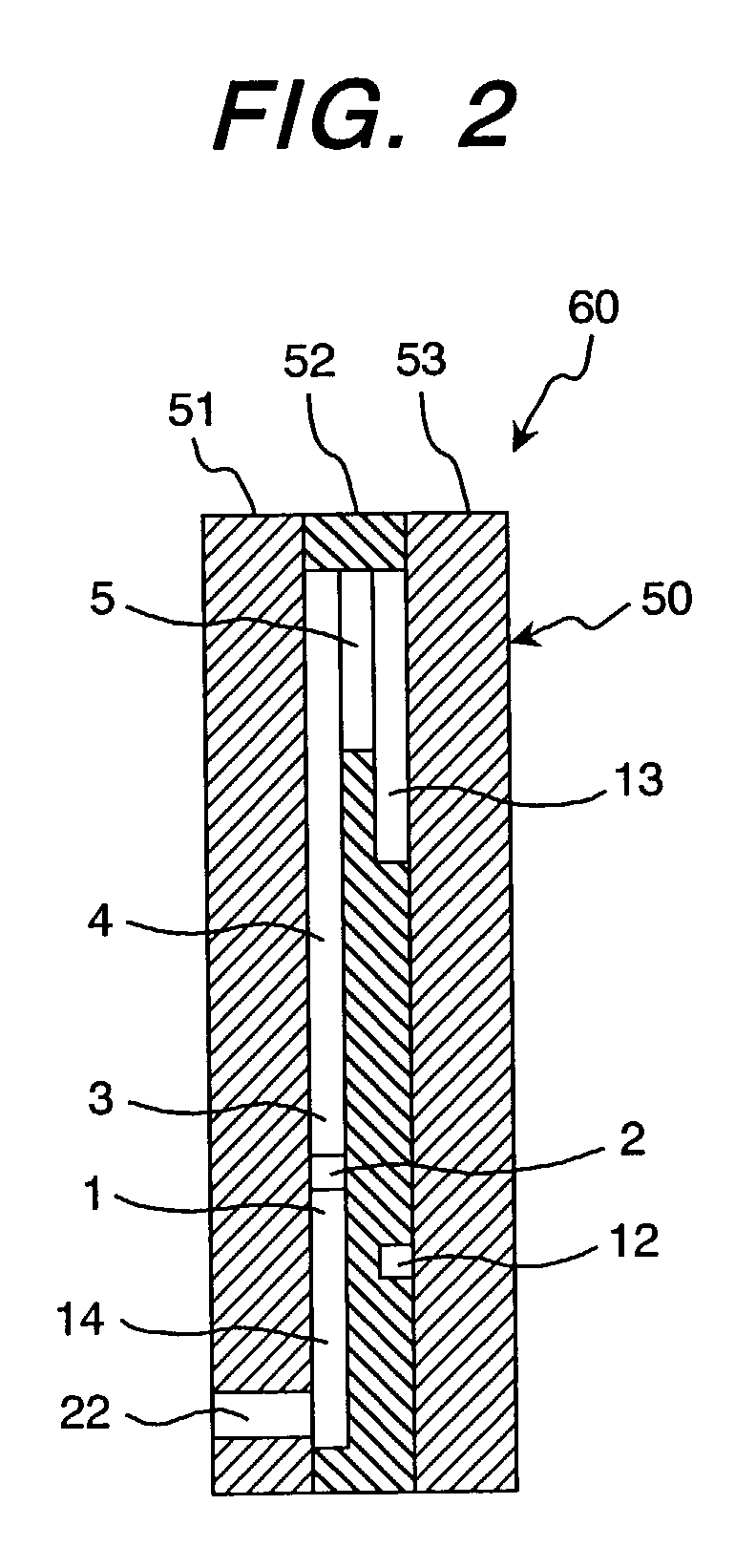

Reaction apparatus and mixing system

InactiveUS7413713B2Stable mixing ratioImprove reaction speedFlow mixersMixing methodsHybrid systemEngineering

A reaction apparatus comprises a first supply flow channel having a fine flow channel cross sectional area for a liquid pressurized by a pressurizing device, a gas supply flow channel having a fine flow channel cross sectional area for supplying a gas, a two-phase flow channel having a fine flow channel cross sectional area in communication with a joined portion for the first supply flow channel and the second supply flow channel for flowing a gas / liquid two-phase fluid, a gas bubble reaction flow channel in communication with the exit of the gas / liquid two-phase channel and having a flow channel cross sectional area larger than that of the gas / liquid two-phase flow channel, and a liquid discharge flow channel for discharging the liquid in the gas bubble reaction flow channel. Therefore, in the reaction apparatus, a stable mixing ratio of a gas to a liquid can be obtained and the mixing speed of the gas to the liquid is increased.

Owner:HITACHI LTD

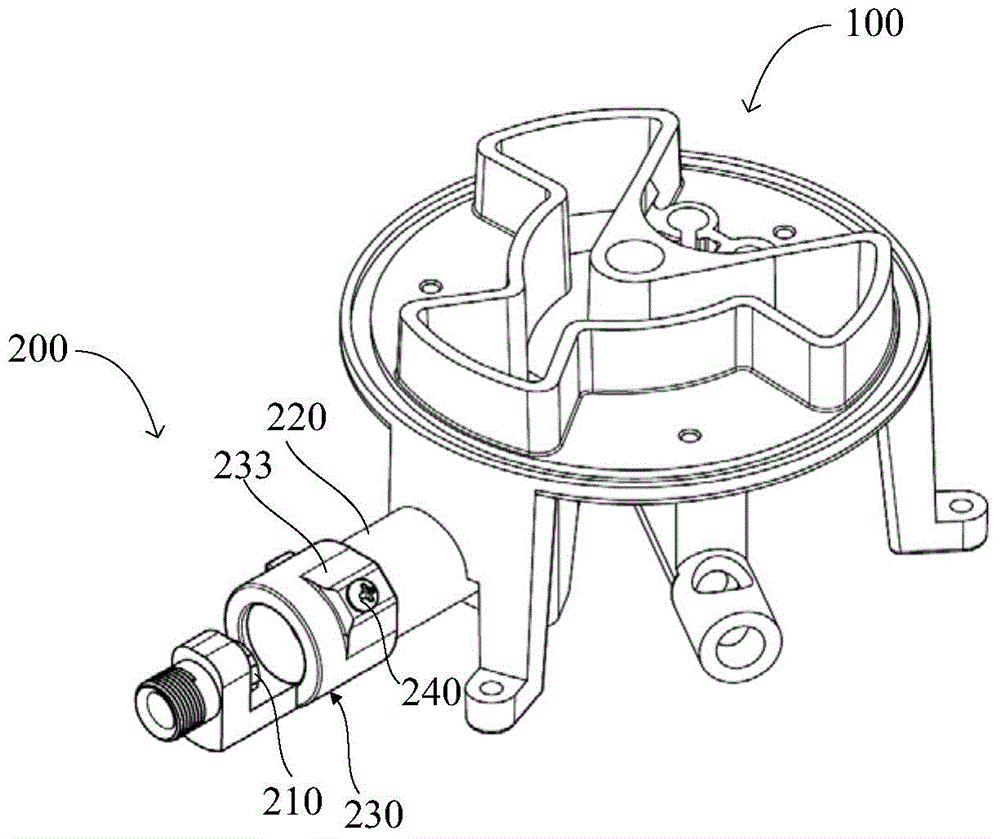

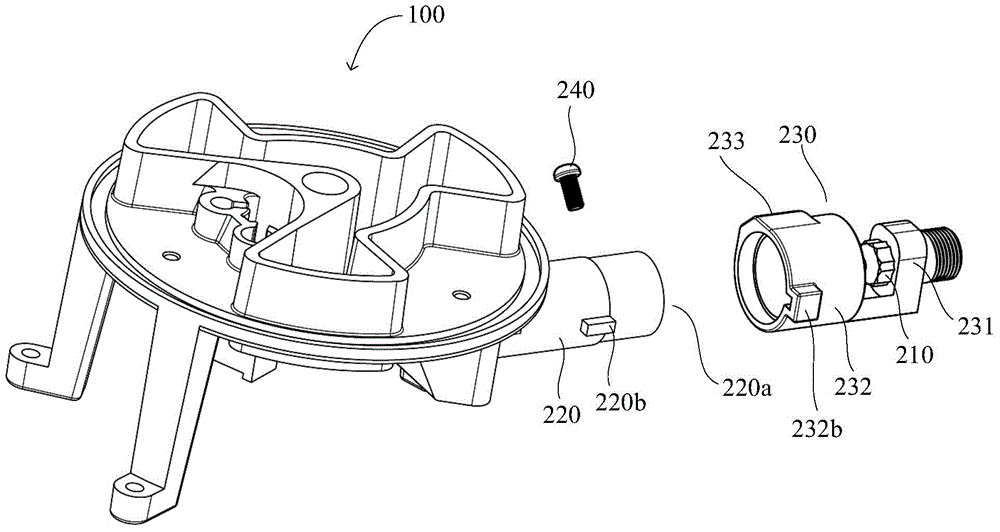

Burner for gas stove and gas stove

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

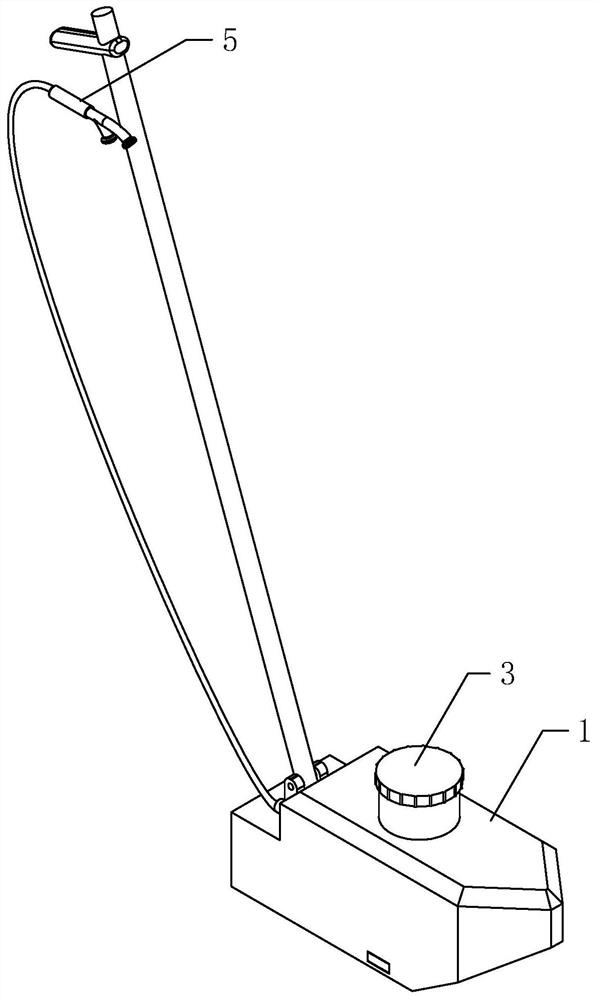

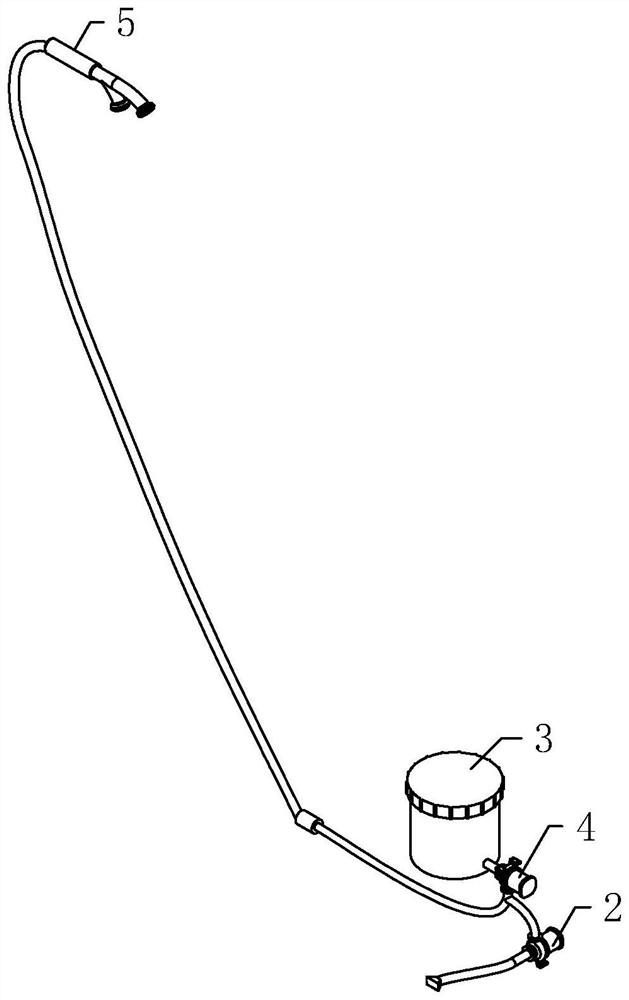

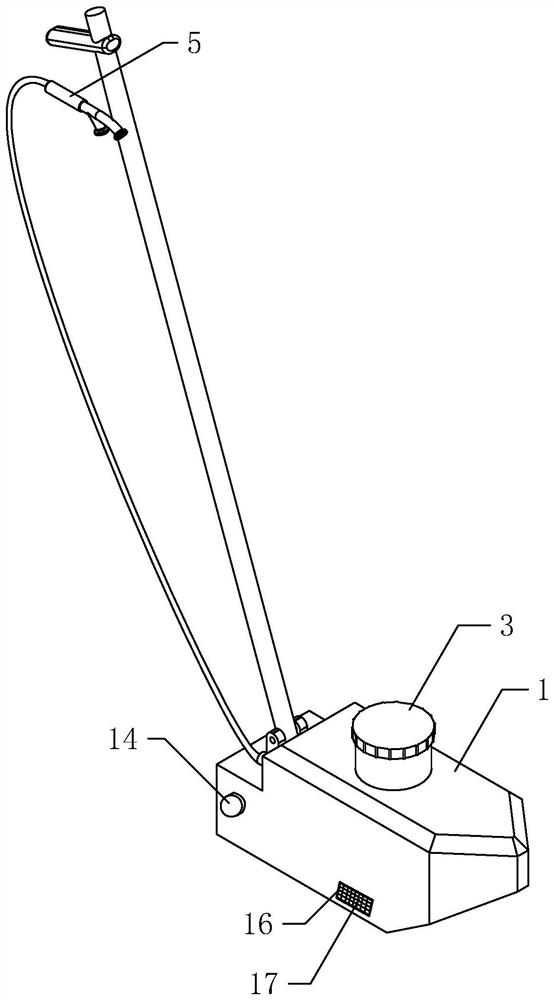

Sprayer for farmland

The invention discloses a sprayer for a farmland, and relates to novel farmland operation machinery. Key points of the technical scheme in the invention are as follows: the sprayer for the farmland comprises a sprayer body; the sprayer body is provided with a water suction pump, a medicine storage box, an infusion pump, a spray rod, a liquid mixing air pump and a pulse valve; the sprayer body is provided with a liquid mixing box; the sprayer body is provided with a pressure limiting device; the sprayer body is provided with a water inlet channel, a filter net and a hydraulic pressure box; a cavity and a barrier plate are arranged in the hydraulic pressure box; the barrier plate is provided with an adjusting spring; the barrier plate is provided with an adjusting rod; the infusion pump is provided with a communication pipeline; the communication pipeline is provided with a non-rising-stem valve; and the adjusting rod is provided with a driving mechanism. Due to arrangement of the mixingair pump and the liquid mixing box, medicine liquid is sufficiently mixed with a water body, so that the use effect of the medicine liquid is better; due to arrangement of the pressure limiting device, the amount of the medicine liquid sprayed by the sprayer is relatively steady; and, due to arrangement of the hydraulic pressure box, the adjusting rod and the driving mechanism, the mixing ratio of the medicine liquid to the water body can be relatively steady.

Owner:台州市绿蜻蜓喷雾器股份有限公司

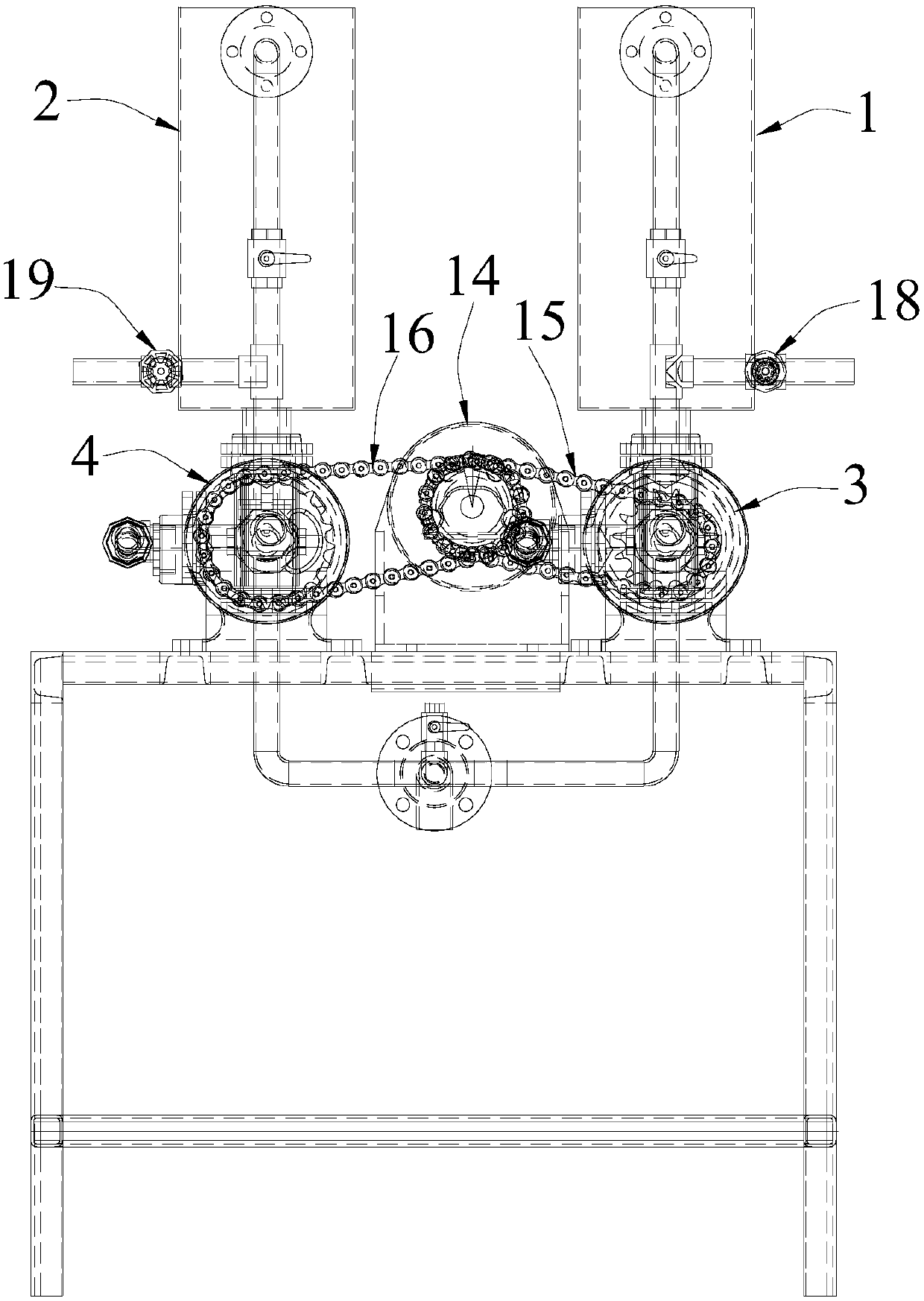

Liquid material output method adopting metering pumps

ActiveCN110397566AStable mixing ratioImprove pass ratePositive displacement pump componentsPump controlCylinder blockActuator

The invention provides a liquid material output method adopting metering pumps. The liquid material output method comprises the following steps that N metering pumps used for correspondingly conveyingN kinds of liquid materials are provided, wherein each metering pump comprises a cylinder body and a piston assembly, each cylinder body comprises a fixed cylinder and a cylinder body moving plate, and a cylinder body opening is formed in each fixed cylinder; each cylinder body moving plate is arranged at the corresponding cylinder body opening in a sliding mode, and a cylinder body space is defined by each cylinder body moving plate and the corresponding fixed cylinder; each piston assembly comprises an actuator plate and a piston telescopic part, each actuator plate is arranged on the corresponding fixed cylinder in a sliding mode, each piston telescopic part is connected to the corresponding actuator plate and is in sliding contact with the corresponding fixed cylinder and the corresponding cylinder body moving plate so as to form a closed space for accommodating the liquid material in the cylinder body space; the cross sectional area of the corresponding closed space is adjusted through the movement of the cylinder body moving plates and the stretching of the piston telescopic parts; and the actuator plates of the N metering pumps are driven to synchronously move, and the liquid feeding amount of each liquid material is the product of the cross sectional area of the corresponding closed space and the movement distance of the corresponding actuator plate. The liquid material output method can ensure that the mixed proportion of various liquid materials is stable.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH +1

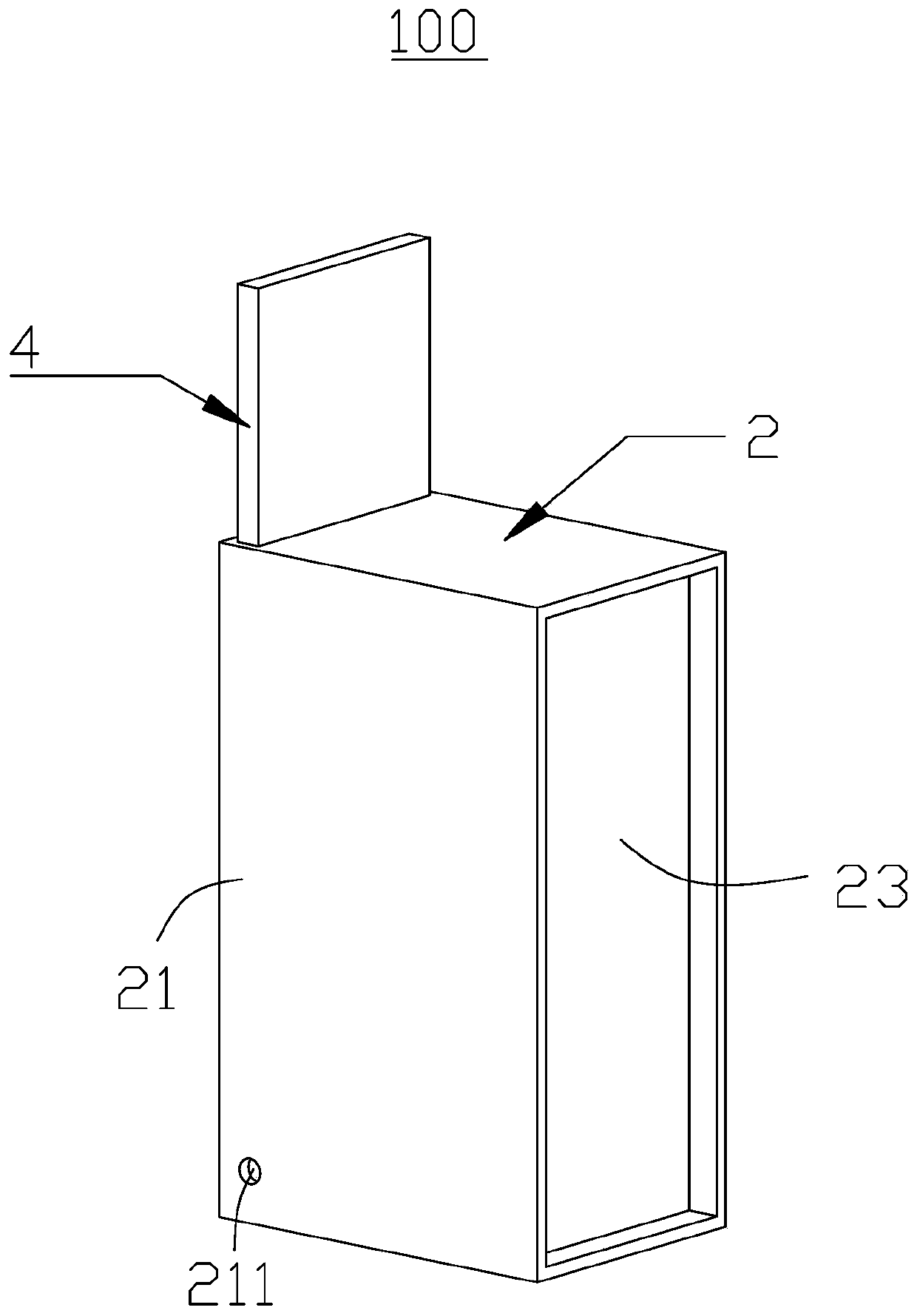

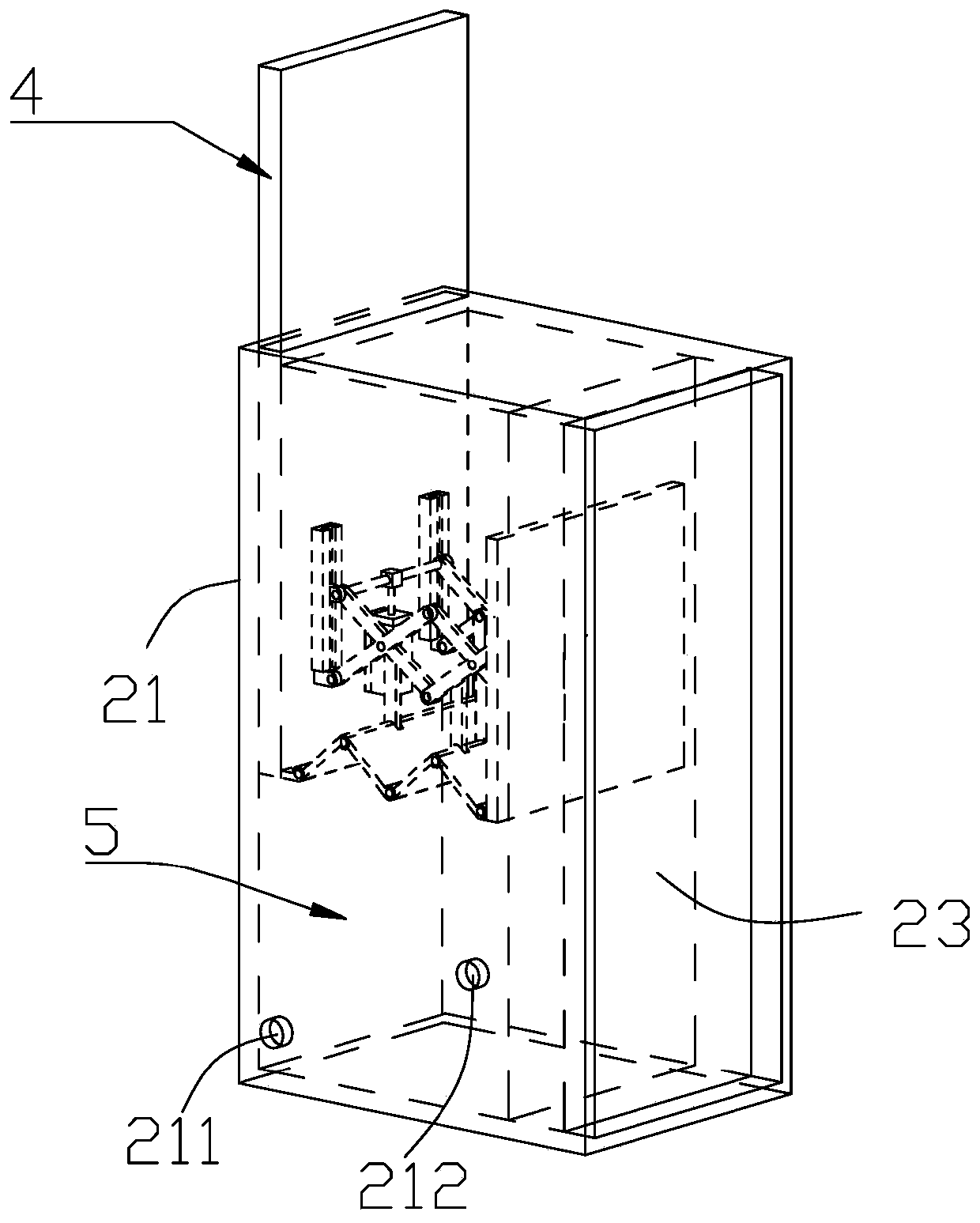

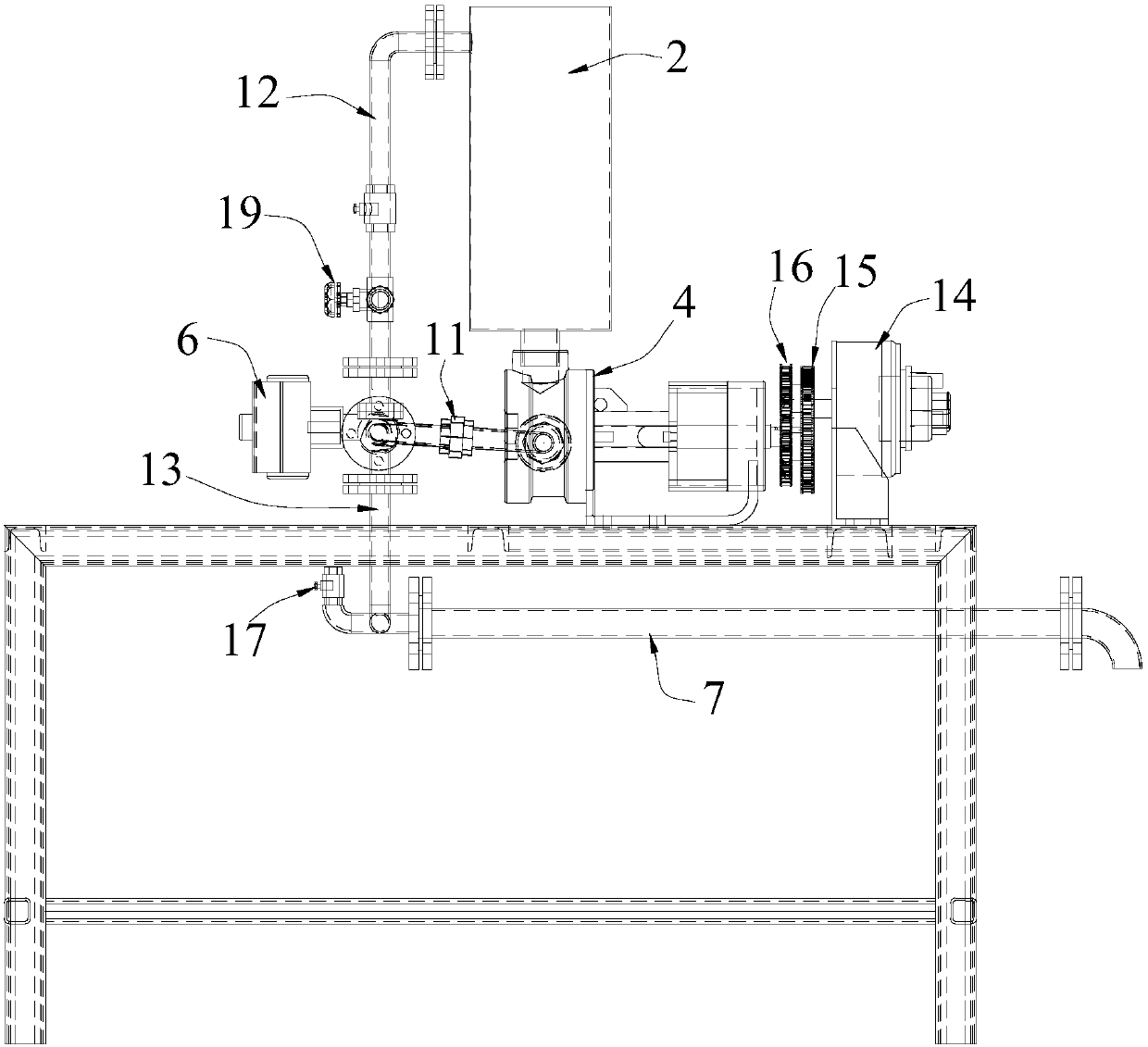

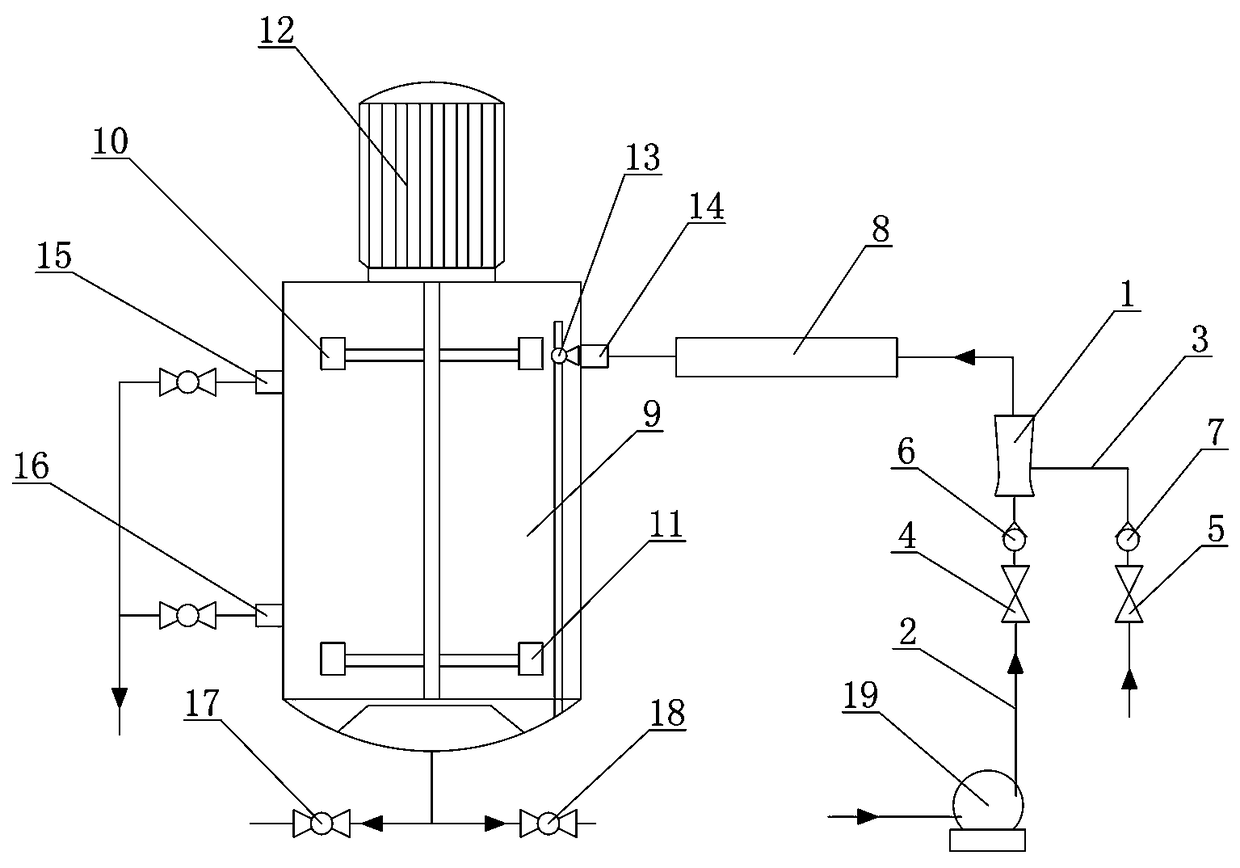

Continuous and synchronous mixing equipment for modified resin

InactiveCN107696316AThe output mixing ratio is accurateAccurate outputHollow article cleaningEngineeringStatic mixer

The invention discloses continuous and synchronous mixing equipment for modified resin. The continuous and synchronous mixing equipment for modified resin is provided with a resin storage tank, a curing agent storage tank, a resin pump, a curing agent pump, a resin three-way valve, a curing agent three-way valve, a static mixer and a pump driving mechanism. The continuous and synchronous mixing equipment can operate in an internal circulation state and a glue mixing state by controlling the resin three-way valve and the curing agent three-way valve. According to the continuous and synchronousmixing equipment, epoxy resin and a curing agent can be continuously mixed in an accurate and stable mixing proportion, the mixing proportion of the epoxy resin and the curing agent can be kept accurate and stable when the cemented epoxy resin is switch to the output starting state from the output stopping state, the automatic mixing procedure of the epoxy resin and the curing agent is achieved, and the requirement for continuous construction of thin epoxy pavement layers can be met; and operation is easy, the labor intensity is greatly lowered, the construction efficiency is improved, and thecontinuous and synchronous mixing equipment can be widely applied to pavement projects of thin epoxy of various pavements and bridges such as highways and roads in cities and towns.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

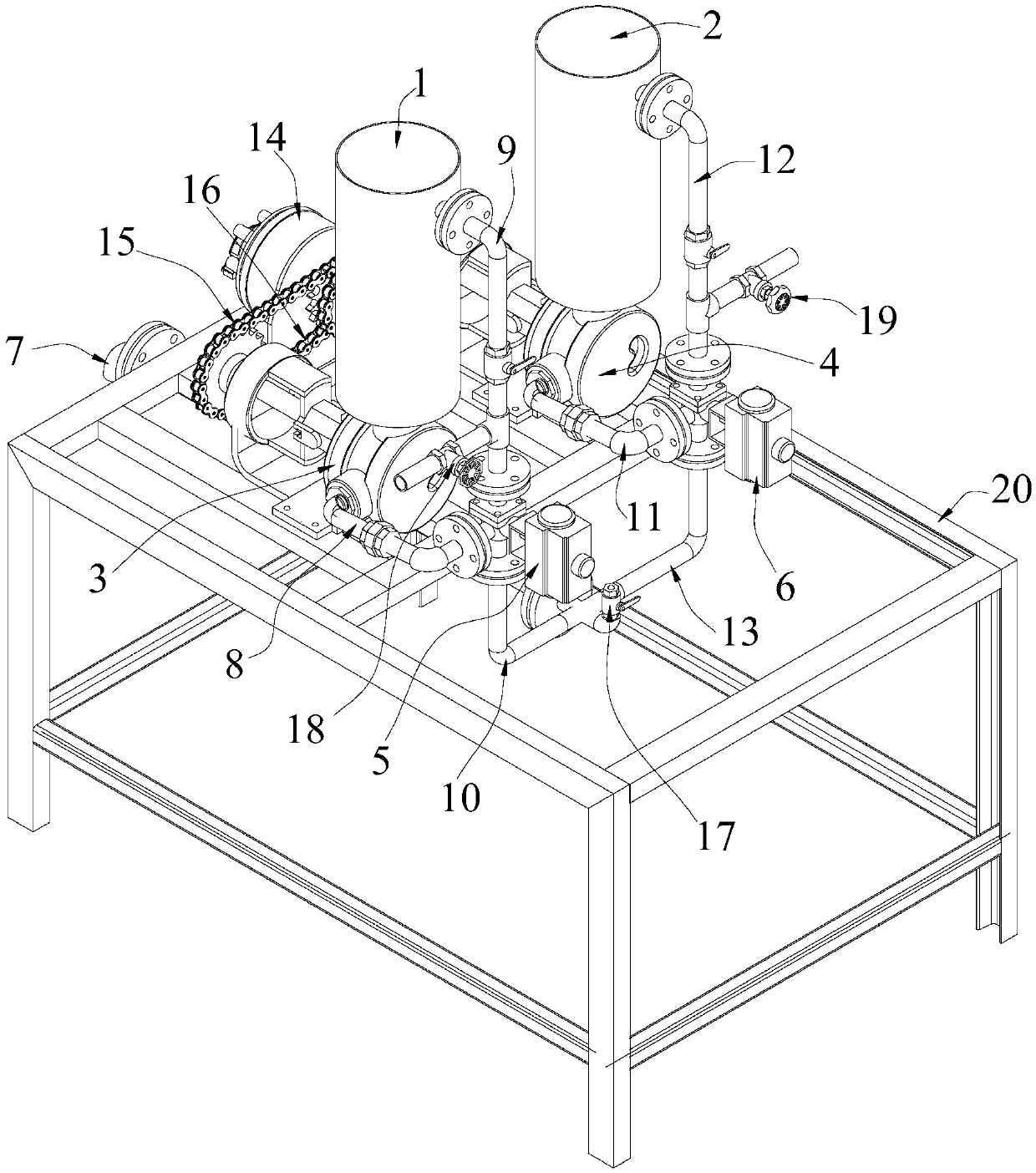

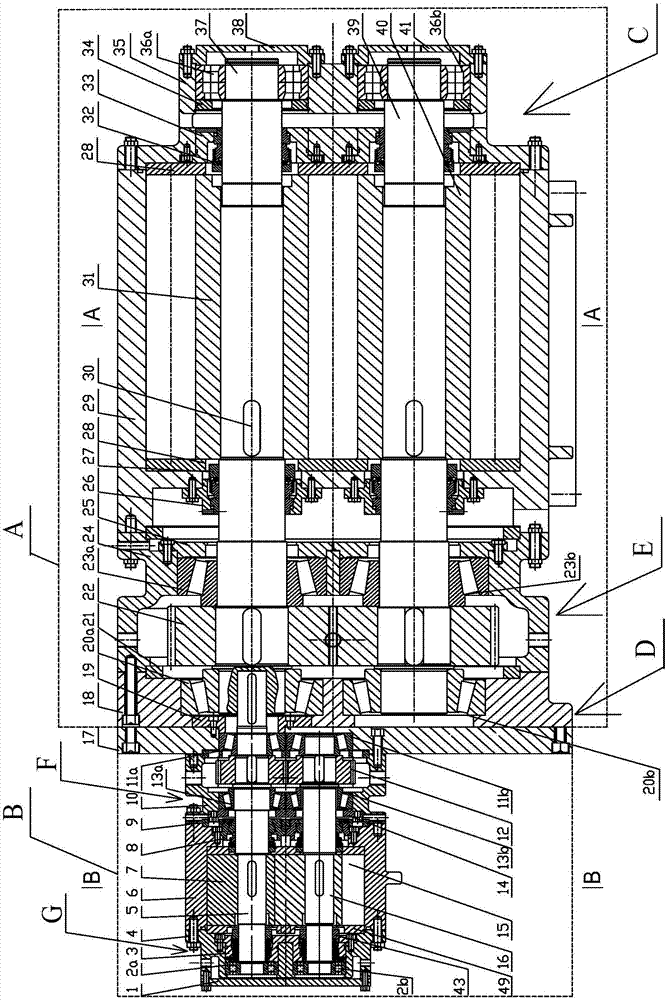

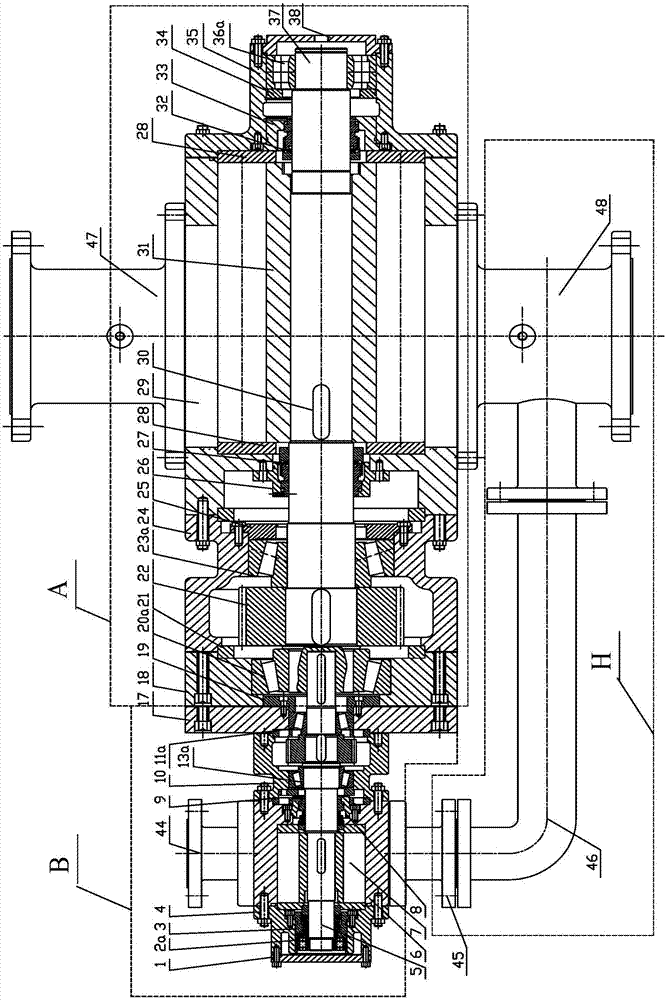

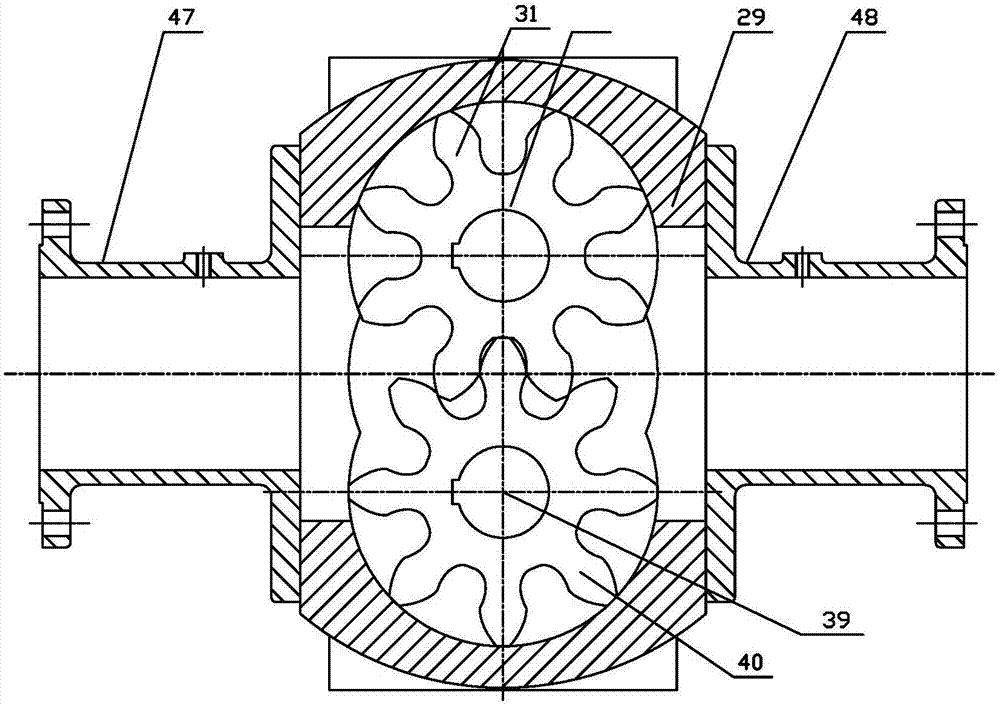

Gear machine pumping-in type foam proportional mixing device

InactiveCN107281670ALow cleanliness requirementsReduce backlashFire rescueGear wheelHydraulic turbines

The invention discloses a gear machine pumping-in type foam proportional mixing device. The gear machine pumping-in type foam proportional mixing device includes a hydraulic driving gear-type water turbine, a foam rotor pump which is connected with a driving output shaft of the hydraulic driving gear-type water turbine through an intermediate bearing mechanism, and a fire protection mixed liquor leading-out mechanism which is connected with a water outlet of the hydraulic driving gear-type water turbine and a liquor outlet of the foam rotor pump. The hydraulic driving gear-type water turbine is of a master-slave double-gear structure, and a constant gap is set between two gears constituting the master-slave double-gear structure. The foam rotor pump is of a master-slave double-rotor structure, and a constant gap is set between two rotors constituting the master-slave double-rotor structure. A main rotating shaft connected with a driving gear in the hydraulic driving gear-type water turbine forms the driving output shaft to be connected with a main rotating shaft in the foam rotor pump. According to the gear machine pumping-in type foam proportional mixing device, the hydraulic driving gear-type water turbine and the foam rotor pump are designed into a whole, cost is low, the structure is compact, the size is small, using is convenient, and due to the high volume efficiency, the system can consume lower fire protection water pressure.

Owner:刘彤贤

Three-stage mixing device with hydrodynamic self-control

ActiveCN105688729BEnsure safetyHighlight substantive featuresTransportation and packagingMixer accessoriesThree levelMotor drive

Owner:HENAN VOCATIONAL COLLEGE OF APPLIED TECH

A liquid material output method using a metering pump

ActiveCN110397566BStable mixing ratioImprove pass ratePositive displacement pump componentsPump controlEngineeringCylinder block

The invention provides a liquid material output method adopting metering pumps. The liquid material output method comprises the following steps that N metering pumps used for correspondingly conveyingN kinds of liquid materials are provided, wherein each metering pump comprises a cylinder body and a piston assembly, each cylinder body comprises a fixed cylinder and a cylinder body moving plate, and a cylinder body opening is formed in each fixed cylinder; each cylinder body moving plate is arranged at the corresponding cylinder body opening in a sliding mode, and a cylinder body space is defined by each cylinder body moving plate and the corresponding fixed cylinder; each piston assembly comprises an actuator plate and a piston telescopic part, each actuator plate is arranged on the corresponding fixed cylinder in a sliding mode, each piston telescopic part is connected to the corresponding actuator plate and is in sliding contact with the corresponding fixed cylinder and the corresponding cylinder body moving plate so as to form a closed space for accommodating the liquid material in the cylinder body space; the cross sectional area of the corresponding closed space is adjusted through the movement of the cylinder body moving plates and the stretching of the piston telescopic parts; and the actuator plates of the N metering pumps are driven to synchronously move, and the liquid feeding amount of each liquid material is the product of the cross sectional area of the corresponding closed space and the movement distance of the corresponding actuator plate. The liquid material output method can ensure that the mixed proportion of various liquid materials is stable.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH +1

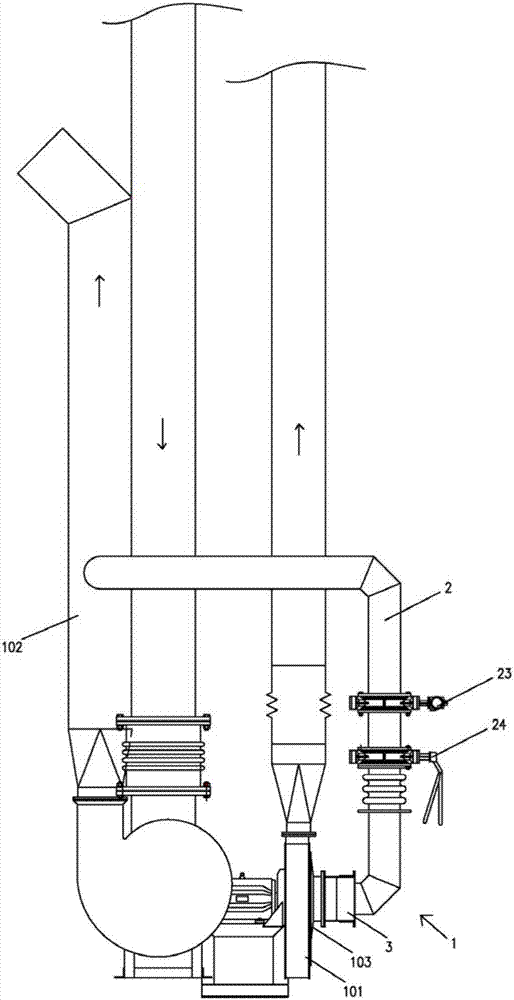

Smoke distributing device for heat accumulating type burning industrial furnace, smoke distributing assembly with smoke distributing device and industrial furnace

PendingCN107062918AReduce emissionsEasy to operate and manageCombustion apparatusWaste heat treatmentProcess engineeringSmoke exhaust ductwork

The invention provides a smoke distributing device and a smoke distributing assembly for reducing nitride emission of a heat accumulating type burning industrial furnace and the industrial furnace. The industrial furnace comprises a burner, a draught fan for supplying combustion air and a smoke discharging pipe; the draught fan is provided with a draught fan inlet connected with the smoke distributing device; the smoke distributing device comprises a barrel-shaped body, a plurality of air inlets and an adjusting device, the barrel-shaped body has a first end used for being connected with a smoke backflow pipe, a second end connected to the draught fan inlet and a side wall between the first end and the second end, a smoke backflow pipe guides smoke in the smoke discharging pipe to flow back to the draught fan; the multiple air inlets are formed in the side wall for guiding in external air; the adjusting device is used for adjusting the air inlet areas of the multiple air inlets so as to allocate the mixing ratio of smoke and air in advance; and when the smoke backflow pipe and the smoke distributing device are connected to the industrial furnace, the backflow smoke and introduced air are mixed into combustion air by means of the negative pressure of the draught fan inlet before introduced into the draught fan inlet. By means of the smoke distributing device, the smoke distributing assembly and the industrial furnace, the nitride in discharged smoke is greatly reduced.

Owner:重庆沃克斯博能科技有限公司

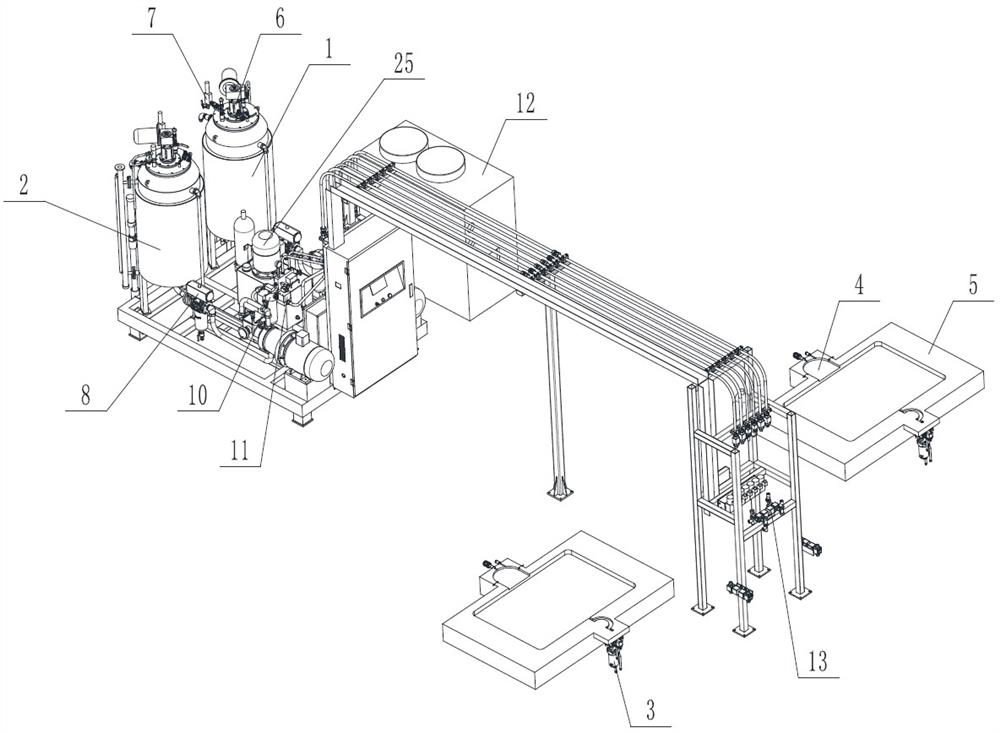

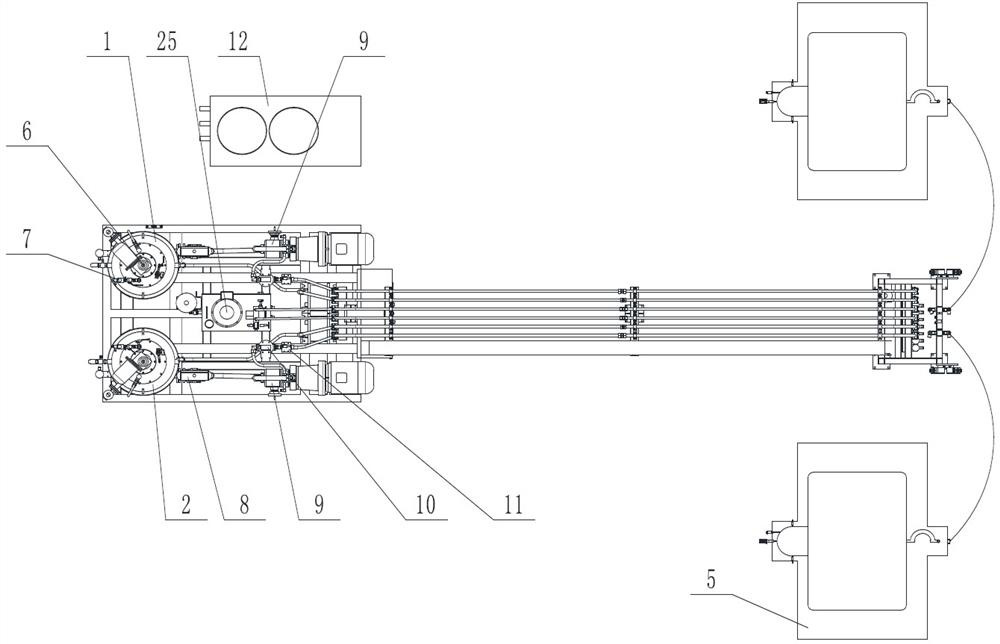

Reaction Injection Molding System Based on Dicyclopentadiene

The invention discloses a reaction injection molding system based on dicyclopentadiene, which includes a first material tank and a second material tank, and the first raw material and the second material are transported from the first material tank and the second material tank to the Mixing head; also includes the mold that is used for dicyclopentadiene reaction injection molding, and the overflow bag that communicates with mold cavity inside is arranged on described mold, and described mixing head, overflow bag are arranged on the relative both sides of mould, and mixing head It is used for pouring mixed raw materials into the mould, and a liquid level sensor is set in the overflow bag or the mould; it also includes a vacuum extraction device for vacuuming the mould. The present invention is used to solve the above-mentioned problems caused by the lack of production equipment dedicated to dicyclopentadiene injection products in the prior art, realize the production and preparation of dicyclopentadiene injection products through a special system, realize intelligent control of the injection process, and improve product quality. The purpose of quality, so that the technology can be widely used.

Owner:成都东日瑞姆机械有限公司

A Two-Phase Flow Constant Ratio Mixing Valve

ActiveCN109899575BRealize automatic adjustmentStable mixing ratioOperating means/releasing devices for valvesEqualizing valvesEngineeringCounterbore

The invention relates to a two-phase flow ratio mixed transportation valve for constant ratio mixed transportation of two-phase flow in therefining and chemical field. The invention solves the problemof unstable mixed ratio of two-phase flow, wherein the inner cavity of an outer shell is arranged as a counterbore, the left end of the outer shell is provided with a flow inlet hole a, and a mixed transportation hole is formed in the middle of the outer shell; the right end of the outer shell is connected with a cover sealing thread; a flow inlet hole b is formed in the middle of a sealing cover; the inner cavity of a taper sleeve a arranged as a conical hole; the inner cavity of the taper sleeve b is arranged as a conical hole; the taper sleeve a is in threaded connection with the left endof an inner cylinder a; the taper sleeve b is in threaded connection with the right end of an inner cylinder b; and the right end of an inner cylinder is in threaded connection with the left end of aninner cylinder b; a valve core is placed in the inner cavities of the inner cylinder a and the inner cylinder b, and a boss in the middle of the outer circumference of the valve core is positioned between a convex step in the middle of the inner cavity of the inner cylinder a and the convex step of the left end of the inner cavity of the inner cylinder b. The valve provided by the invention can balance the mixed ratio automatically by using the pressure of the two-phase flow, has a simple structure, and is suitable for complicated and variable working conditions.

Owner:山东宇生文化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com