Continuous and synchronous mixing equipment for modified resin

A technology of mixing equipment and modified resin, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as increased viscosity of rubber materials, unstable construction quality, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

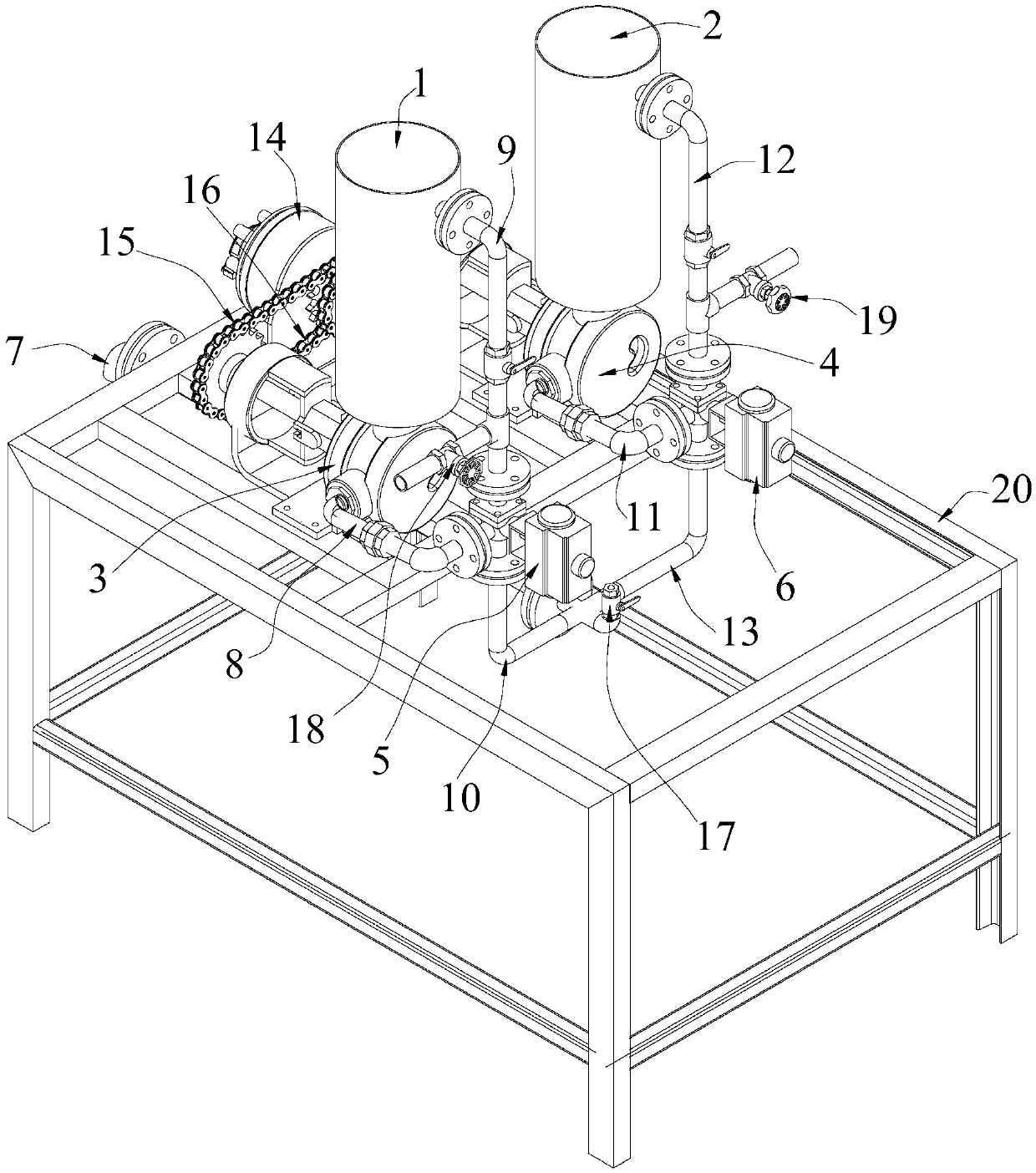

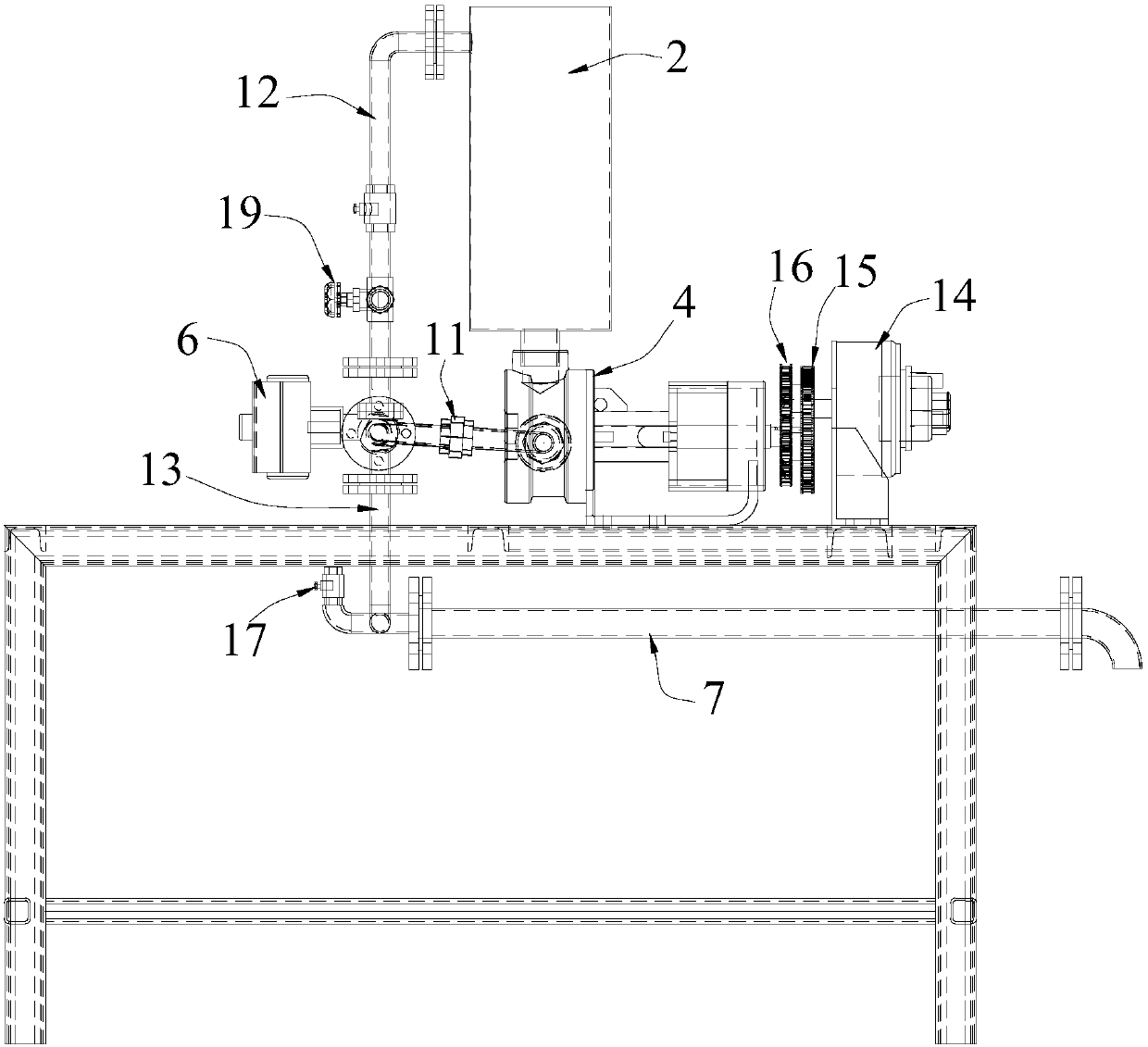

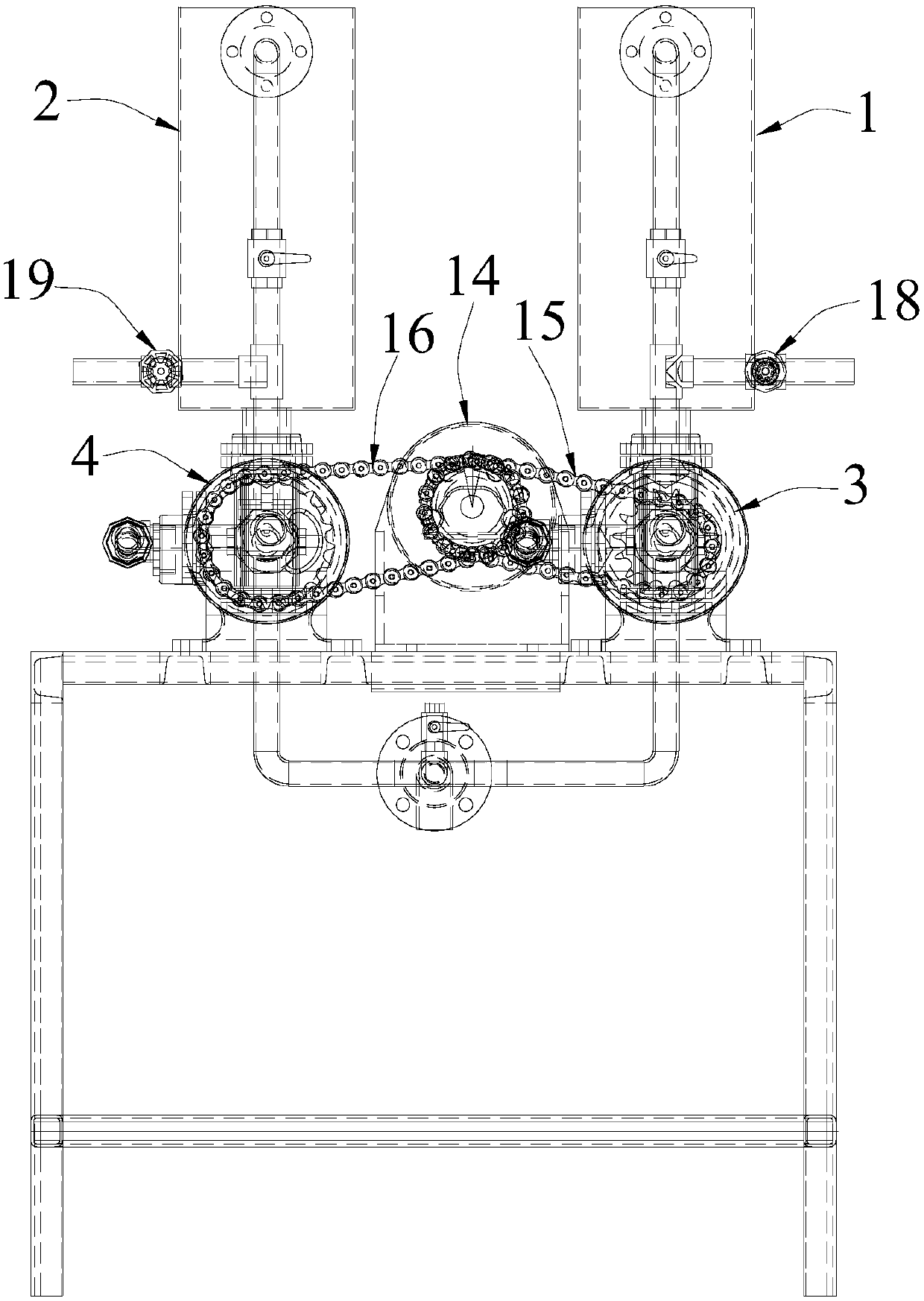

[0044] As a preferred embodiment of the present invention: the glue pump driving mechanism is composed of a motor 14, a resin gear chain transmission mechanism 15 and a curing agent gear chain transmission mechanism 16, and the motor 14 is relatively fixed with the resin glue pump 3 and the curing agent glue pump 4 The driving gears of the resin gear chain transmission mechanism 15 and the curing agent gear chain transmission mechanism 16 are all installed on the output shaft of the motor 14, and the driven gear of the resin gear chain transmission mechanism 15 is installed on the drive shaft of the resin pumping pump 3, The driven gear of the curing agent gear chain transmission mechanism 16 is installed on the drive shaft of the curing agent pumping pump 4 . Thereby, by selecting the number of teeth of the driving gear and the number of teeth of the driven gear of the resin gear chain transmission mechanism 15 and the curing agent gear chain transmission mechanism 16, the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com